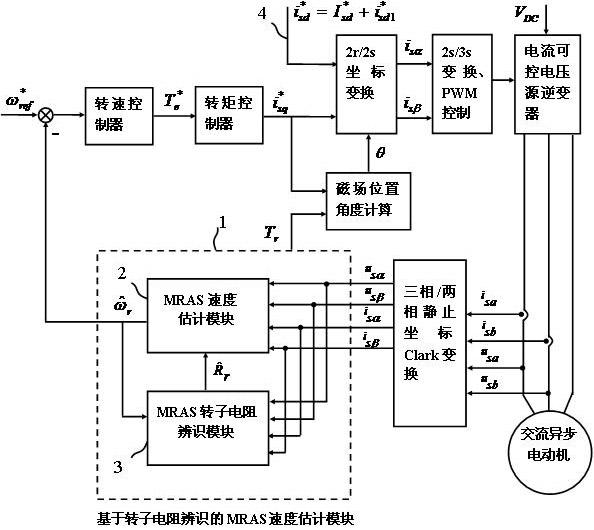

Electromotor dynamic/stable stage parameter identification method based on stator resistance observer

A stator resistance and motor technology, applied in electronic commutation motor control, motor generator control, control generator and other directions, can solve the problems of voltage model error, reduced estimation accuracy, rotor speed and rotor resistance identification difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

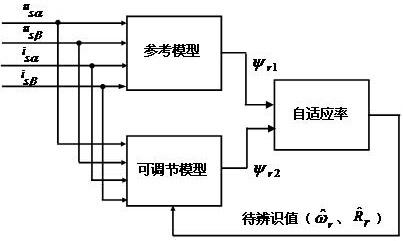

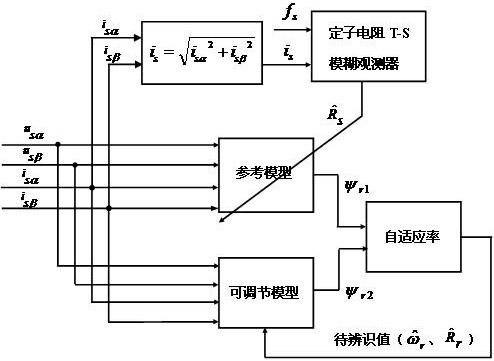

Method used

Image

Examples

Embodiment

[0155] In order to verify the effect brought by the present invention, the motors using the existing method and the method of the present invention were compared experimentally at different given rotational speed values. The experiments were performed at a load of 12 N . m (approximately 85.7% of the rated value), the speed setting is low speed, that is, it is carried out under the condition that the speed setting changes suddenly between 80~30rpm / min. The parameters of the induction motor used in the experiment are as follows: rated power , rated voltage , rated current ,Rated speed , stator resistance , rotor resistance , stator inductance , rotor inductance , mutual inductance , rated torque ,Number of pole pairs ,Moment of inertia .

[0156] attached Figure 13 is the motor speed value obtained according to the existing identification method, the dotted line in the figure is the given speed value, and the solid line is the actual speed value. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com