Patents

Literature

242 results about "Foam drainage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-gas-production solid-foam liquor drainage ball of watered gas well

ActiveCN101671553AImprove high temperature resistanceImprove high salt resistanceFluid removalDrilling compositionHalf-lifeFoam drainage

The invention relates to a self-gas-production solid-foam liquor drainage ball of a watered gas well, which is applied to the technical field of the foam drainage gas-production technique. The liquordrainage ball mainly consists of a ball A and a ball B and is characterized in that the ball A contains the components by the weight ratio: 100-150 parts of sodium nitrite and 10-30 parts of foaming agent; and the ball B contains the components by the weight ratio: 100-120 parts of ammonium chloride, 5-10 parts of foam stabilizer, 25-40 parts of catalyst and 5-10 parts of ethylene diamine tetraacetic acid (EDTA). The liquor drainage ball has the effects that the foaming capacity is very good, and the liquor in the gas well can produce the over ten times of foam after the liquor drainage ball is put into the well; in addition, the foam is steady, the half-life period is long, and the liquor carrying capacity is very good. Both the ball A and the ball B are non-toxic, and the inertia and non-toxic gas can be produced after reaction. Moreover, the special high-pressure injection equipment is not needed in the process of the oil field operation, therefore, the technique is simple, and theoperation is convenient.

Owner:PETROCHINA CO LTD

Foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance and preparation method

InactiveCN102851015AGood value for moneyNo smellDrilling compositionCocamidopropyl dimethylaminePhysical chemistry

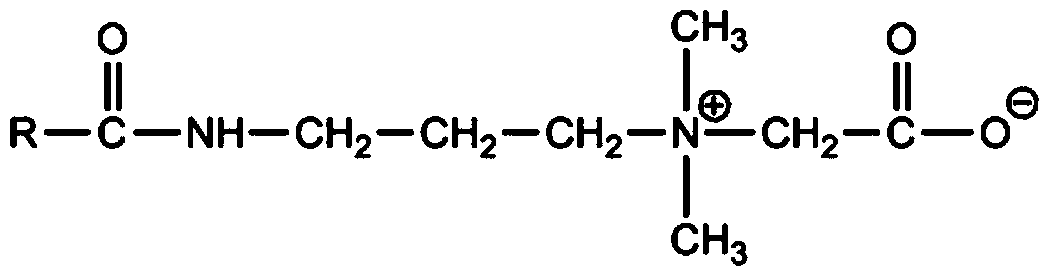

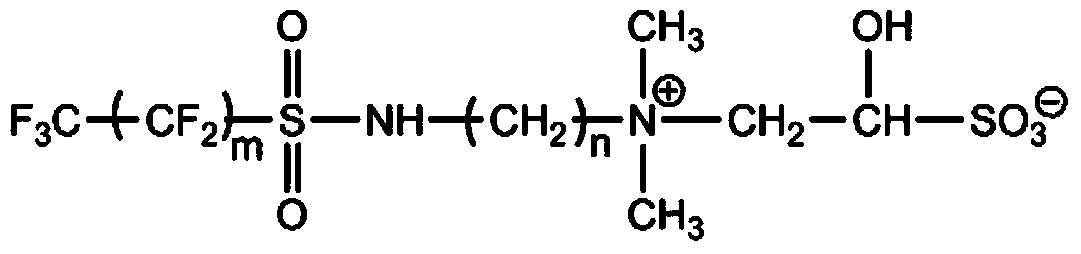

The invention relates to a foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance and a preparation method. The foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance comprises 60 percent to 40 percent of cocamidopropyl betaine, 40 percent to 20 percent of cocoamido propyl hydroxy sulfobetaine, 20 percent to 10 percent of cocamidopropyl dimethylamine oxide and 10 percent to 5 percent of water. The preparation method comprises the following steps of: respectively and sequentially adding the components into a reaction kettle in percentage by weight; and at normal temperature, stirring for 30 minutes and enabling the materials in the reaction kettle to sufficiently react with each other to obtain the foam drainage agent. The foam drainage agent discloses by the invention has the advantages of high temperature resistance, high condensate oil resistance, hypersalinity resistance, strong liquid carrying capacity and the like and is suitable for various water producing gas wells. The method disclosed by the invention has the characteristics of simplicity for operation, low equipment and environmental requirements, easiness for implementing the industrial production, high product cost performance and the like.

Owner:浙江仁智股份有限公司

Foam drainage gas recovery method for natural gas horizontal well

InactiveCN102587865AThe effect of drainage and gas recovery is obviousSimple and safe operationFluid removalDrilling compositionRecovery methodPolyethylene glycol

The invention relates to a foam drainage gas recovery method used for a natural gas horizontal well. The method is capable of injecting a foam scrubbing agent into the bottommost end of a gas well shaft, so that the whole shaft is filled with foam fluid and optimal drainage gas recovery effect is achieved. The technical scheme of the method comprises the following steps: firstly, manufacturing a dynamical underground foam scrubbing bar which consists of a gas nozzle, a tail wing, a boosting agent, a shell and a protection head sleeve, wherein the material for manufacturing the tail wing, the shell and the protection head sleeve is the solid foam scrubbing agent which consists of polyoxyethylene alkyl ethers, polyethylene glycol, urea, imidazoline, sodium dodecyl benzene sulfonate and saturated alcohol sulfate; and the boosting agent is one of dry ice, sodium hydride or potassium oxide; and secondly, throwing the dynamical underground foam scrubbing bar to the bottom of the well, wherein the boosting agent is in contact with water to generate a large amount of gas, so that the foam scrubbing bar is pushed to the bottommost end; and as the foam scrubbing agent is dissolved, a large amount of foam is formed to achieve the optimal effect of drainage gas recovery. The method disclosed by the invention has a wide application range without any wellhead equipment and energy, is simpleand safe in operation, low in cost and has no pollution to the environment.

Owner:SOUTHWEST PETROLEUM UNIV

Use of a betaine as a foam drainage reducing agent

InactiveUS20100140531A1Reduce the amount requiredEasy to obtainCosmetic preparationsOrganic detergent compounding agentsBetaineMedicine

The invention relates to the use of a betaine as a foam drainage reducing agent. The invention also relates to the use of betaine in processes involving foam.

Owner:RHODIA OPERATIONS SAS

Foam drainage agent for gas well drainage gas recovery

ActiveCN104140802AImprove stabilityGood water carrying effectDrilling compositionBond energyChemical agent

Belonging to the technical field of oil-gas field chemical agents, the invention relates to a foaming drainage agent for gas well drainage gas recovery. The foaming drainage agent for gas well drainage gas recovery is formed by mixing of a gemini surfactant, a zwitterionic surfactant, a high-bond energy surfactant and a macromolecular polymer. The foaming drainage agent provided by the invention has high temperature environment resistance (up to 180DEG C), suitability to environment with wide pH value (of 1-10), high mineralization degree resistance (greater than or equal to 320000mg / L), and resistance to hydrogen sulfide and carbon dioxide atmosphere (with the hydrogen sulfide partial pressure being greater than or equal to 25% and the carbon dioxide partial pressure being greater than or equal to 20%). And the foaming drainage agent also has the advantages of excellent foaming performance, good foam stability, good water-carrying effect, low surface tension, and foam volume mostly higher than 8 times.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas field foam drainage agent

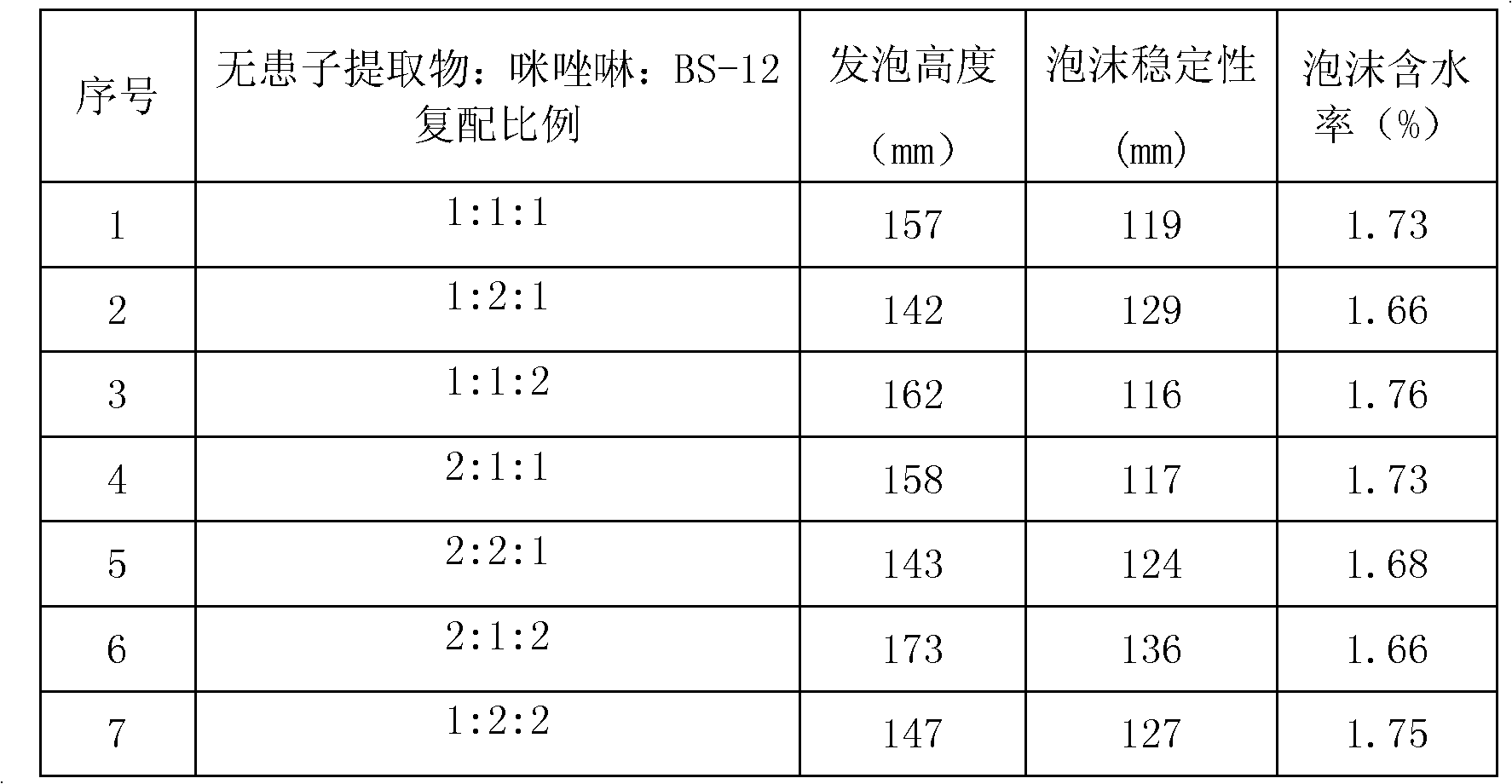

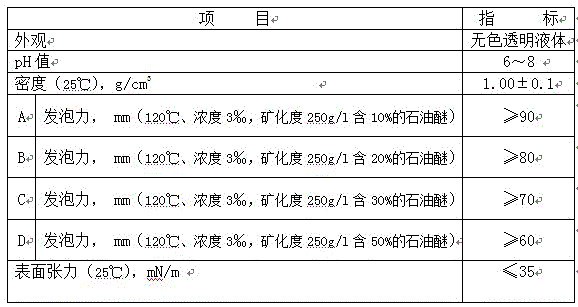

The invention discloses a gas field foam drainage agent which comprises the components in parts by weight: 95-105 parts of surface active agent, 3-7 parts of methyl cellulose and 5-10 parts of bubble control agent, wherein the surface active agent comprises soapberry extract, imidazoline, dodecyl dimethyl betaine according to the weight ratio of 1-2: 1-2: 1-2. The foam generated by the gas field foam drainage agent in water has good stability, and the stability of the foam reaches 141mm; the water content of the foam is less than or equal to 2.18%; and the mineralization resistance is 200000mg / L, the condensate oil resistance is 30%, the temperature resistance is more than 90 DEG C, and the optimal effective concentration is 3-5%. Furthermore, the gas field foam drainage agent is non-toxic, easily degraded and free from pollution to the environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance and preparation method

InactiveCN102851015BGood value for moneyNo smellDrilling compositionCocamidopropyl dimethylaminePhysical chemistry

The invention relates to a foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance and a preparation method. The foam drainage agent with high temperature resistance, high condensate oil resistance and hypersalinity resistance comprises 60 percent to 40 percent of cocamidopropyl betaine, 40 percent to 20 percent of cocoamido propyl hydroxy sulfobetaine, 20 percent to 10 percent of cocamidopropyl dimethylamine oxide and 10 percent to 5 percent of water. The preparation method comprises the following steps of: respectively and sequentially adding the components into a reaction kettle in percentage by weight; and at normal temperature, stirring for 30 minutes and enabling the materials in the reaction kettle to sufficiently react with each other to obtain the foam drainage agent. The foam drainage agent discloses by the invention has the advantages of high temperature resistance, high condensate oil resistance, hypersalinity resistance, strong liquid carrying capacity and the like and is suitable for various water producing gas wells. The method disclosed by the invention has the characteristics of simplicity for operation, low equipment and environmental requirements, easiness for implementing the industrial production, high product cost performance and the like.

Owner:浙江仁智股份有限公司

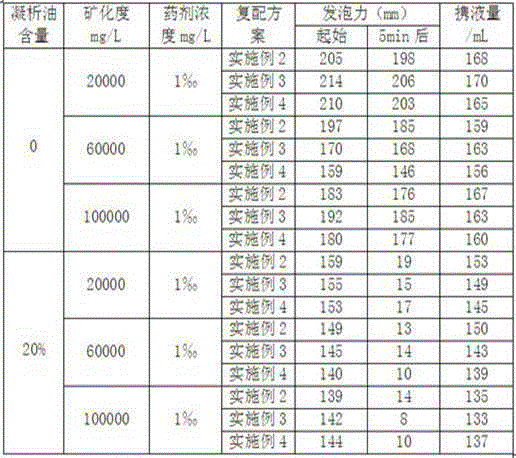

Foaming drainage agent resisting methanol, condensate oil and high salinity

ActiveCN104531121APromote degradationGood compatibilityDrilling compositionBetainePolyethylene glycol

The invention belongs to the technical field of oil-gas field chemical accessories, and in particular relates to a foaming drainage agent resisting methanol, condensate oil and high salinity. The foaming drainage agent is compounded from various nonionic surfactants, an anionic surfactant, an amphoteric surfactant, a drag reducer and pure water, wherein the various nonionic surfactants comprise polyether type surfactants including fatty alcohol-polyoxyethylene ether and alkyl alcohol ether carboxylate, the anionic surfactant comprises sodium lauryl alcohol sulfate and a Gemini cationic surfactant, the amphoteric surfactant is dodecyl dimethyl betaine, and the drag reducer is polyethylene glycol. The foaming drainage agent has relatively good biodegradability, and cannot be deposited and layered when in use. The foaming drainage agent provided by the invention is strong in foaming power, has rich and stable foams, is moderate in salt resistance, can be used in an oil-water-gas three-phase coproduction well containing condensate oil, has excellent foaming performance, is good in compatibility with various corrosion inhibitors, and also has good corrosion inhibiting ability.

Owner:PETROCHINA CO LTD

Environmental-friendly type foam water-draining agent and preparation method thereof

ActiveCN106244127AEasy to operateGood drainageDrilling compositionCocamidopropyl dimethylamineBetaine

The invention discloses an environmental-friendly type foam water-draining agent and a preparation method thereof. The environmental-friendly type foam water-draining agent adopts a biodegradable material; and the foam water drainage refers to discharging liquid accumulated at the bottom of a well out of the well by utilizing the water containing performance of foam and the own capability of the well bottom so as to realize the purpose of increasing the yield of the natural gas well. In a field experiment, the foam water-draining agent disclosed by the invention has the advantages that the foam water drainage gas producing process can be met by good foaming capability, foam stabilizing capability and liquid carrying capability, and the foam water-draining effect can be achieved. The environmental-friendly type foam water-draining agent is characterized by comprising the following components of: cocamidopropyl dimethylamine hydroxysultaine, dodecyl dimethyl betaine, alkyl glycoside, cocamidopropyl betaine, lauramidopropyl betaine, dodecyl dimethyl ammonium oxide, hexadecyl trimethyl ammonium chloride, fatty alcohol polyoxyethylene ether, urea and water.

Owner:北京众博达石油科技有限公司

Environmental-friendly foam drainage bar, and preparation method thereof

ActiveCN106244128AEasy to carrySimple filling processDrilling compositionSodium bicarbonatePolyethyleneglycol stearate

The invention discloses an environmental-friendly foam drainage bar, and a preparation method thereof. The environmental protection performance of the environmental-friendly foam drainage bar is used for referring that the environmental-friendly foam drainage bar is prepared from biodegradable raw materials. Foam drainage is used for referring discharging of well bottom accumulated water or accumulated liquid out of wells via utilization of water-containing or fluid-carrying capability of foam, so that gas recovery factor of gas wells is increased fully. The environmental-friendly foam drainage bar is capable of satisfying requirements of foam draining gas recovery and achieving excellent foam draining effect in field tests because of the excellent foaming ability, foam stabilizing ability, and liquid carrying capacity of the environmental-friendly foam drainage bar. The environmental-friendly foam drainage bar comprises following raw materials: cocamidopropyl betaine, sodium lauryl oxyethyl sulfonate, sodium lauroyl glutamate, fatty alcohol polyoxyethylene ether, polyethylene glycol monostearate, urea, citric acid, sodium bicarbonate, and sodium carbonate.

Owner:北京众博达石油科技有限公司

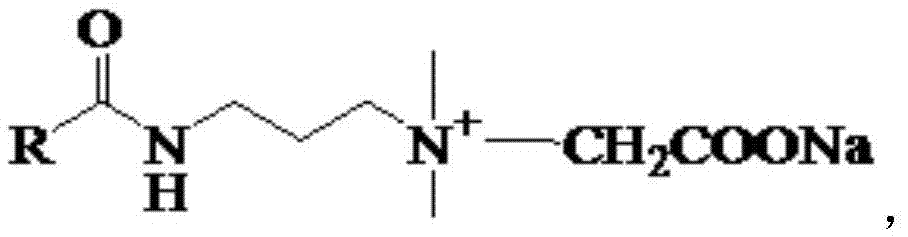

Fatty acid amide propyl betaine foam scrubbing agent as well as preparation method and application thereof

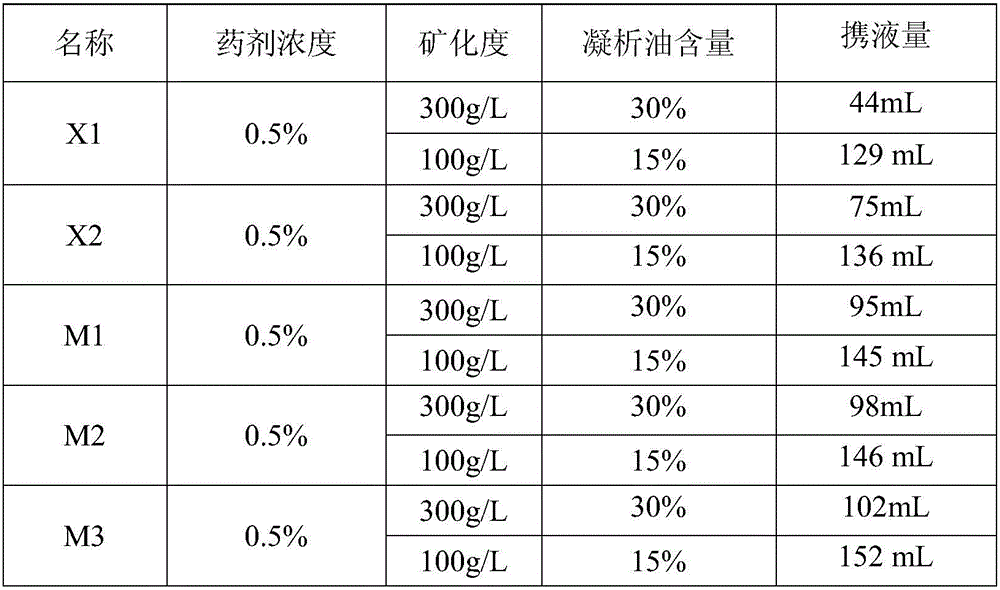

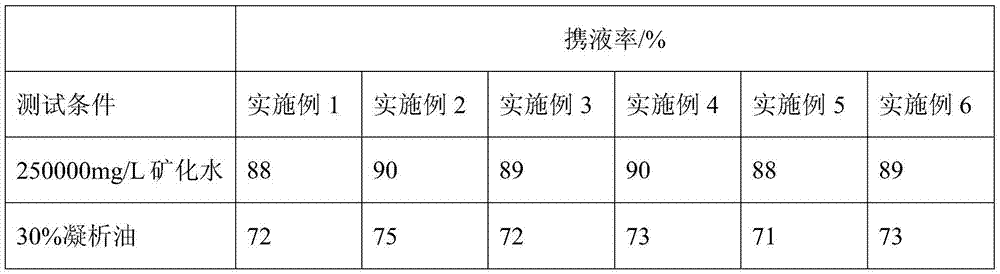

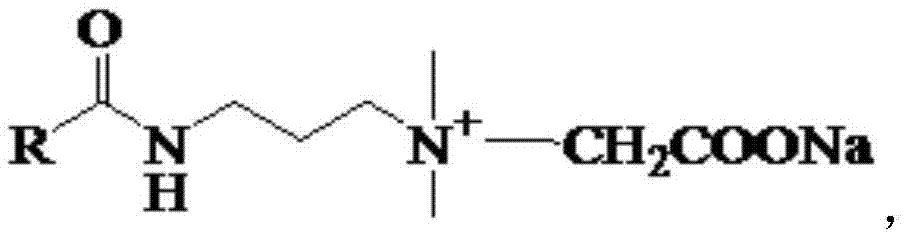

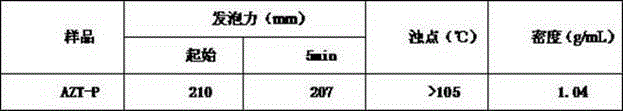

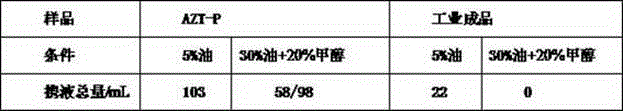

ActiveCN105439885AFine foamGood foam stabilization effectOrganic compound preparationFluid removalBetaineSodium chloroacetate

The invention relates to a foaming agent developed for foam drainage of a gas well, in particular to a fatty acid amide propyl betaine foam scrubbing agent as well as a preparation method and an application thereof. The fatty acid amide propyl betaine foam scrubbing agent is adaptable to the highly-mineralized and high-oil-bearing extreme environment with the mineralization degree higher than 25*10<4> mg / L and the content of condensate oil higher than 30%. According to the technical scheme, lauric acid, coconut fatty acid, oleic acid (cis-9-octadecenoic acid) and other fatty acids are added to a reactor in a certain mole ratio and have a condensation reaction with N,N-dimethyl-1,3-propane diamine at the temperature of 140-160 DEG C for 3-4 h, and an intermediate product, namely, long-chain alkyl tertiary amine, is obtained; the intermediate product and sodium chloroacetate have a nucleophilic substitution reaction at the temperature of 60-90 DEG C for 3-6 h, the content of free amine is tested to be smaller than 0.5%, fatty acid amide propyl betaine is obtained after the reaction, and fatty acid amide propyl betaine is a main agent of the foam scrubbing agent for the gas well. The prepared foam scrubbing agent has good foaming and foam stabilizing performance, foams carry a large quantity of liquids, and the foam scrubbing agent has excellent foam flooding performance in various extreme environments and has wide prospect.

Owner:西安长庆化工集团有限公司

Foam drainage agent resistant to gas condensate and mineralization degree and preparation method thereof

On the basis of analysis of a composition and physicochemical conditions of an accumulated fluid of a natural gas well, based on a synergistic effect between an anionic surfactant and a nonionic surfactant, through compounding of the anionic surfactant and the nonionic surfactant, and with supplement of modification of a foam stabilizer and an amphoteric surfactant, a foam drainage agent which is strong in fluid-carrying capability and can meet drainage and gas exploitation of the natural gas well containing more gas condensate and having relatively high alkaline earth metal ion concentration in the well cylinder accumulated fluid is obtained. The foam drainage agent is applicable for drainage and gas exploitation of the natural gas well, and especially for drainage and gas exploitation of the natural gas well having high gas condensate content and high alkaline earth metal ion concentration.

Owner:NINGXIA ZHONGKE KANGYU CHEM

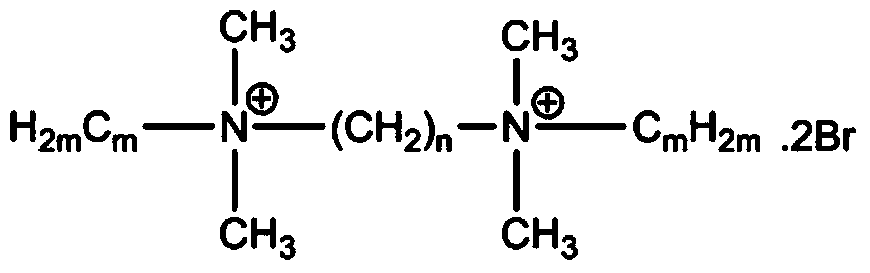

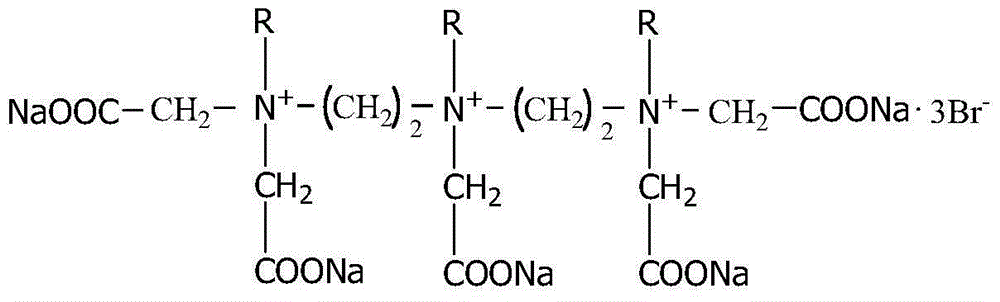

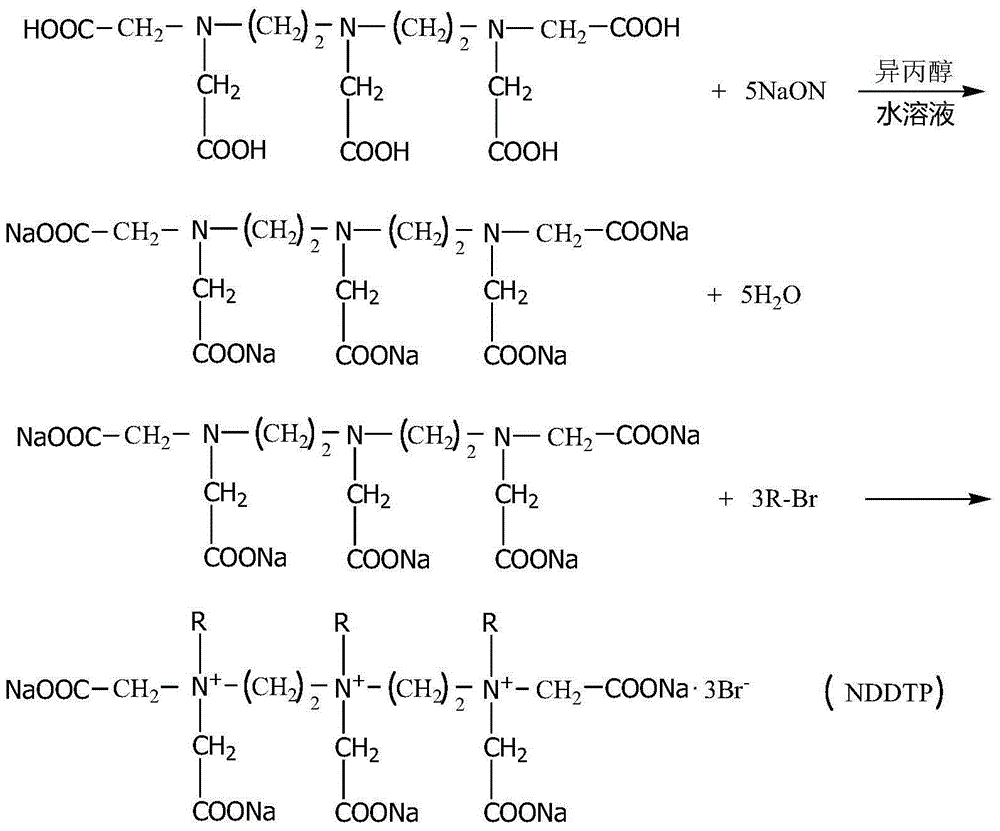

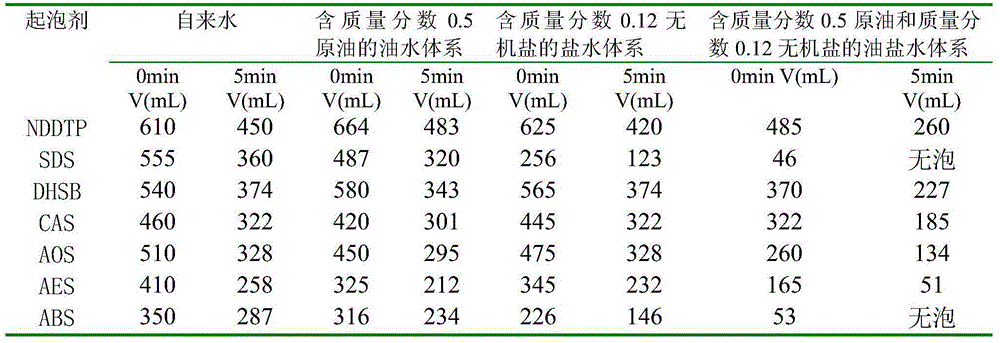

Oligomeric betanine type foam drainage agent and preparation method

InactiveCN105199700ALow costEasy to operateOrganic compound preparationAmino-carboxyl compound preparationDistillationDissolution

The invention relates to an oligomeric betanine type foam drainage agent for foam drainage gas recovery in the later period of oil and gas well development and a preparation method. The agent can improve the foaming performance and stability of a foaming agent in electrolytes and hydrocarbons. The technical scheme is as follows: the chemical name of the foam drainage agent is N,N,N''-alkyl sodium diethyletriaminepentaacetate named NDDTP; firstly, sodium hydroxide and an isopropyl alcohol aqueous solution are added to a three-neck bottle, and the solution is stirred for dissolution; then diethylenetriaminepentaacetic acid is added, the mixture reacts at the temperature of 65-75 DEG C for 15 min, and an intermediate product,namely, sodium diethylenetriaminepentaacetate, is obtained; then a bromoalkanol solution is added to the intermediate product solution while stirring, and the mixture reacts at the temperature of 75-85 DEG C for 6-8 h; finally, a coarse product is obtained through distillation of a reaction liquid, and a solid product is obtained through desalinzation with ethanol and recrystallization with acetone. A foam drainage solution is prepared through compound of the foam drainage agent and ethylene glycol, has good foaming performance and foam stability and is used for increasing gas recovery ratio.

Owner:SOUTHWEST PETROLEUM UNIV

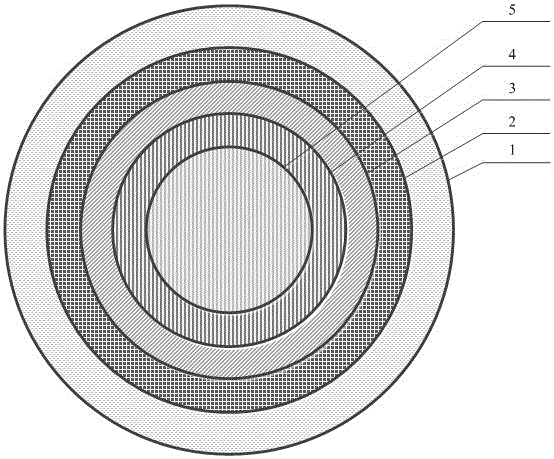

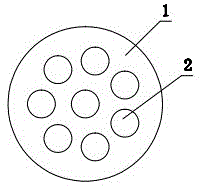

Spherical solid foam scrubbing agent for natural gas fluctuation horizontal well

ActiveCN106190080AEasy to manageGood effectFluid removalDrilling compositionSodium bicarbonateAutomatic control

The invention relates to a spherical solid foam scrubbing agent for a natural gas fluctuation horizontal well in gas field foam drainage gas recovery production. Lifting can be automatically controlled at a horizontal extension section of a horizontal well to improve the drainage gas recovery effect of the horizontal well. According to the technical scheme, the spherical solid foam scrubbing agent is a multi-layer concentric sphere and is prepared from 25-45% of sodium dodecyl sulfate, 10-35% of fatty alcohol-polyoxyethylene ether, 10-25% of acrylic resin, 0-40% of sodium bicarbonate and 5-10% of urea. The spherical solid foam scrubbing agent is composed of multiple foam scrubbing spheres, and foam scrubbing agents with different formulas and densities are adopted for manufacturing 3-9 layers to form a concentric sphere which is pressed and toasted to be dry to form the spherical solid foam scrubbing agent; the foam scrubbing agent is placed into the horizontal well, sunk and dissolved and ascends to the extension section of the whole horizontal well, and foam drainage gas recovery is achieved. By means of the spherical solid foam scrubbing agent, the drainage efficiency of the horizontal well is improved, accumulated liquid can be smoothly drained, and use is convenient, easy and economical.

Owner:SOUTHWEST PETROLEUM UNIV

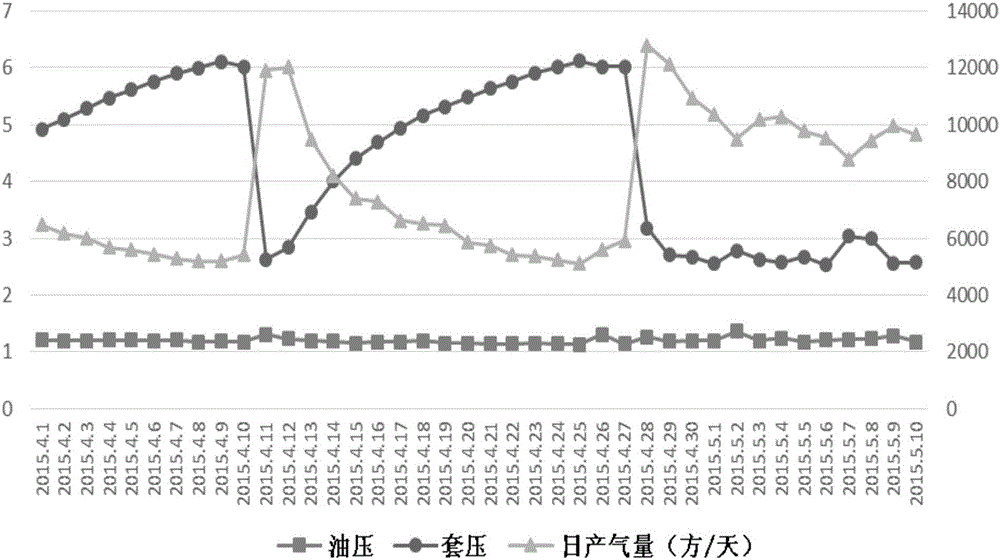

Method for removing gas well accumulated liquid by means of oil jacket pressure balancing method

InactiveCN104790916AReduce dosageThe technology is applicable to a wide range of well conditionsConstructionsFluid removalLiquid ratioFoaming agent

The invention belongs to the technical field of water drainage and gas recovery of a gas well, and particularly provides a method for removing gas well accumulated liquid by means of the oil jacket pressure balancing method. The method mainly comprises the steps of bottom hole accumulated liquid diagnosis, formation pressure prediction, flow inducing with the oil jacket balancing method, foam drainage and the like. The feasibility of the technique is determined through accumulated liquid diagnosis and formation pressure prediction. Liquid in a well and foaming agents can be well mixed through accumulated liquid flowing caused by the oil jacket balancing method, and liquid drainage effect is promoted cooperatively. The method is suitable for wells with certain stratum energy and reduced productivity due to liquid accumulation or dead wells. The method is not limited by well deflection, gas-liquid ratio, ground environment and the like and has the advantages of being simple, economical and practical.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

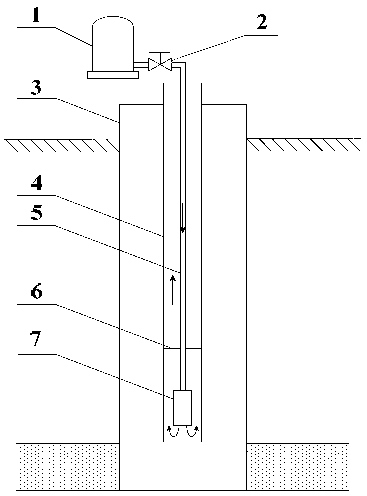

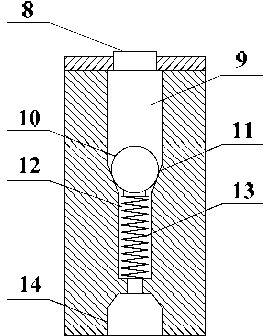

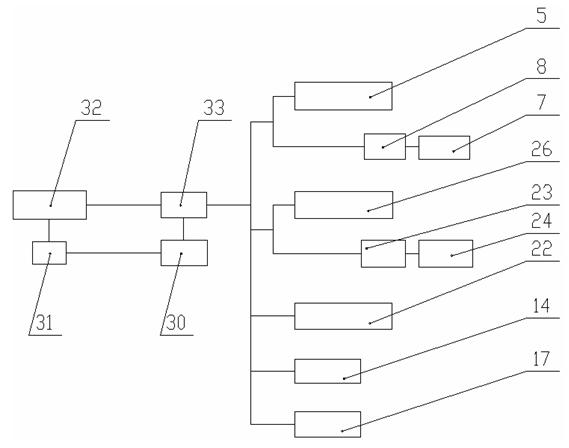

Automatic chemical feeding device and method in foam-drainage gas recovery well

InactiveCN103291266APrevent floodingExtend the stable production periodFluid removalChemical storageDifferential pressure

The invention relates to an automatic chemical feeding device and method in a foam-drainage gas recovery well. The automatic chemical feeding device mainly comprises a ground chemical storage tank, a thin pipe valve, a thin pipe, a pressure difference control valve, an oil pipe and a casing. The ground chemical storage tank, the thin pipe valve, the thin pipe and the pressure difference control valve form a chemical feeding channel, the thin pipe and the oil pipe form an annular liquid discharge channel, and the pressure difference control valve mainly comprises a chemical inlet, an upper cavity, a valve spool ball, a conical valve seat, a lower cavity, a spring and a chemical outlet. The upper end of the pressure difference control valve is stressed by chemical gravity (constant in pressure), and the lower end thereof is stressed by return pressure at bottom of the well. The more the accumulated liquid is, the higher the return pressure at the bottom of the well is and the lower the downward pressure difference stressed on the valve spool ball is, so that the spring can overcome the pressure difference to support the valve spool ball upwards and chemicals are begun to be added. After the accumulated liquid is discharged, the pressure difference is larger than elastic force of the spring and presses the valve spool ball to stop chemical feeding. The automatic chemical feeding device can automatically feed and stop feeding chemicals according to level of the accumulated liquid, and the chemicals and the accumulated liquid at the bottom can be guaranteed to be sufficiently mixed.

Owner:SOUTHWEST PETROLEUM UNIV

Special foam drainage method for low-gas-yield water-flooded well, foam drainage agent and foam drainage device

InactiveCN105525899AEfficient use ofContinuous gas recoveryFluid removalDrilling compositionUltrasound deviceFoaming agent

The invention relates to foam drainage gas production, in particular to a special foam drainage method for a low-gas-yield water-flooded well, a foam drainage agent and a foam drainage device. A chemical mode or / and a physical mode is / are adopted to stir accumulated liquid in the low-gas-yield water-flooded well and generate fluctuation, the fluctuating accumulated liquid makes the foam drainage agent put into the accumulated liquid mix with air water in the accumulated liquid to generate foam, and accordingly foam drainage gas production of the low-gas-yield water-flooded well is achieved. The foam drainage agent is prepared from, by weight percentage, 10-25% of non-ionic surfactant, 20-45% of zwitter-ion surfactant, 15-25% of anion surfactant and the balance a foaming agent. Ultrasonic equipment, a micro fan and carbon dioxide injection equipment are adopted as the foam drainage device. Due to the structure, the special foam drainage method for the low-gas-yield water-flooded well, the foam drainage agent and the foam drainage device have the advantage of breaking the technical bottleneck that the effective technology of foam drainage cannot be applied to the low-gas-yield water-flooded well.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

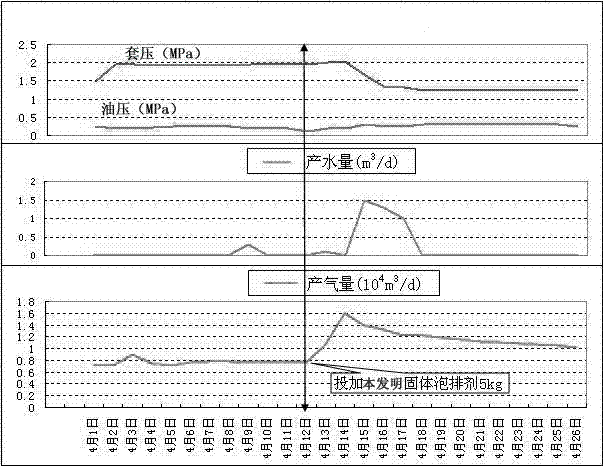

Solid foam drainage agent applied to gas field

ActiveCN104342097AIncrease moisture contentLarge liquid carrying capacityDrilling compositionField testsSalinity

The invention relates to a solid foam drainage agent, which is composed of the following raw materials in percentage by mass: 40-50% of surfactant, 5-20% of sodium carbonate and 40-55% of sodium dihydrogen phosphate. The solid foam drainage agent disclosed by the invention is strong in foaming capacity, rich in foam, high in foam moisture content and high liquid load, and is excellent in salt, methanol and oil resistance; the solid foam drainage agent shows good compatibility with underground auxiliaries and is quite stable in product performance; foam drainage success rate in a field test is quite high; and the solid foam drainage agent is applicable to shaft drainage in natural gas extraction, and in particular to gas wells of high temperature (100 DEG C), highly condensate oil (less than or equal to 50%), methanol resistance (less than or equal to 30%) and high salinity (less than or equal to 200000mg / L).

Owner:PETROCHINA CO LTD

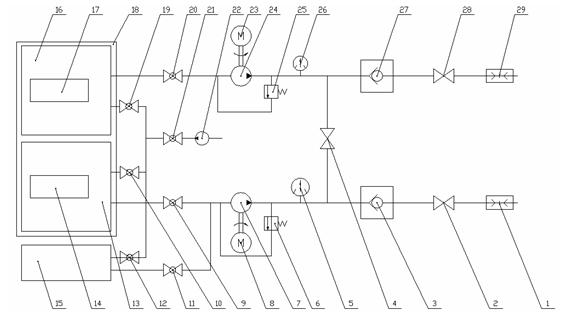

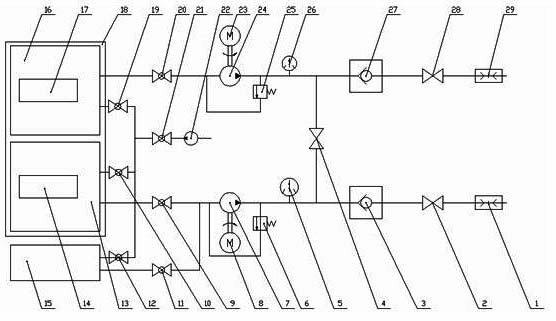

Injection device capable of adapting to low-temperature environment in foam drainage gas recovery

InactiveCN102162347AMeet the requirements of foam drainage and gas recovery operationsAchieve reuseFluid removalEngineeringElectric control

The invention discloses an injection device capable of adapting to a low-temperature environment in foam drainage gas recovery, which is applied to a water-bearing natural gas field and can overcome the difficulties of removing liquid accumulations of the well shaft in the gas well with accumulated liquids and removing foams in the produced fluids under the conditions of no commercial power supply and low ambient temperature. The technical scheme adopted in the invention is as follows: a liquid feeding pump is connected with ball valves through a pipe and then connected in parallel with a chemical tank I, a chemical tank II and an anti-freezing agent tank through the ball valves; heaters are arranged inside the chemical tanks; tail gas jackets are arranged at the periphery of the chemical tanks; a first quick-acting coupling is connected with a first cut-off valve and a first one-way valve through a pipe and then connected with a first electric contact pressure gauge, a first plunger pump and a first motor; the outlet end of the first plunger pump is connected with the ball valves respectively and then connected with the chemical tanks and the anti-freezing agent tank; a second quick-acting coupling is connected with a second cut-off valve and a second one-way valve through a pipe and then connected with a second electric contact pressure gauge, a second plunger pump and a second motor; the outlet end of the second plunger pump is connected with the chemical tanks; and an oil-fired generator and an electric control system form a circuit system. The injection device has compact structure, is convenient in transportation, is suitable for the actual environments in natural gas field production, and improves the drainage gas recovery effect.

Owner:SOUTHWEST PETROLEUM UNIV

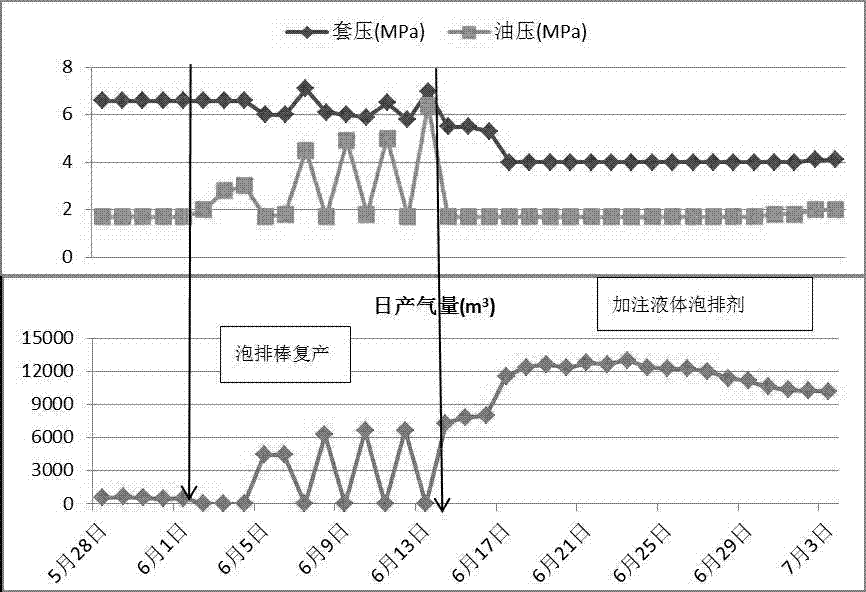

Energy increase type foam drainage gas recovery process

InactiveCN105114046AImprove recoveryRealize the revival of flooded wellsFluid removalDrilling compositionChemistryFoam drainage

The invention discloses an energy increase type foam drainage gas recovery process. Firstly, a reagent A is fed into accumulated liquid in a gas well, then a reagent B is fed into the accumulated liquid in the gas well, wherein the reagent A comprises sodium nitrite A1 and ammonium chloride A2, and the reagent B comprises a catalyst and a foaming agent. According to the invention, by injecting the chemical agents in the well in batches and through different channels, chemical agents are in chemical reaction in the well to generate lots of gases and foam, under the action of gases generated by chemical reaction, foam moves upwards to drain accumulated liquid in a wellbore, and thus a conventional foam drainage gas recovery process is expanded to peripheral wells and flooded out wells with extremely low yields, and the recovery percent of the gas well is increased further.

Owner:CHINA PETROLEUM & CHEM CORP +1

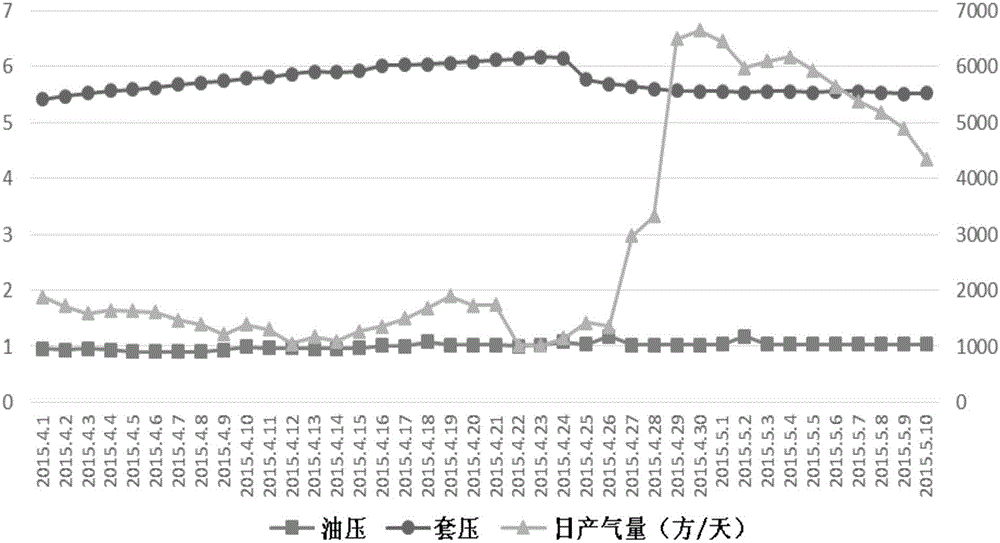

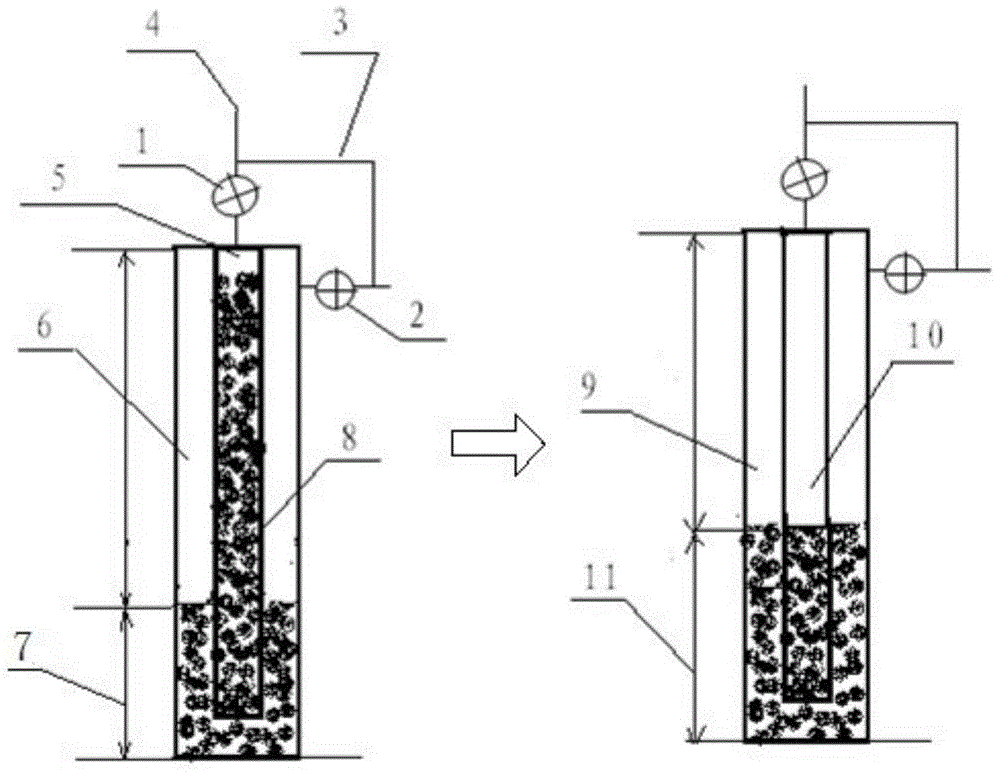

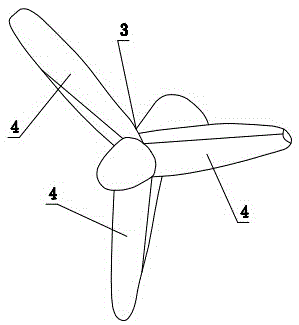

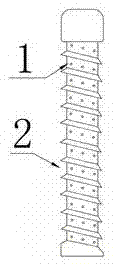

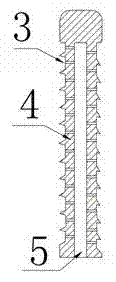

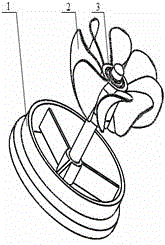

Integrated and combined gas production method based on plunger gas lifting and foam drainage

ActiveCN106869865ASimple stepsObvious effect of drainage and gas recoveryFluid removalDrilling compositionCarboxymethyl celluloseProduction effect

The invention relates to an integrated and combined gas production method of based on plunger gas lifting and foam drainage. The integrated and combined gas production method based on the plunger and the foam drainage solves the problems that the process existing of drainage gas production techniques is simplex and a multi-item dewatering and gas production technology under complicated changeable well condition is complex. According to technical scheme of the integrated and combined gas production method based on the plunger and the foam drainage includes the steps that a foam drainage rod is made firstly, the rod is a cylindrical plunger, a plunger main chamber is formed in the rod, trapezoidal grooves in spiral shapes are distributed on external surface of the main plunger body at equal intervals, fluid through holes are evenly distributed between the grooves, the plunger main chamber and the fluid through holes are connected through a small fluid channel; the main components of the foam drainage rod include polyethylene glycol, sodium dodecyl benzene sulfonate, imidazoline, polyoxyethylene alkyl ether and carboxymethyl cellulose; in the gas lifting and drainage stage of the plunger, the plunger lifts the liquid out of the well in a slugged mode; and the main plunger body is gradually dissolved, the foam drainage rod sinks to the bottom of the well, and dissolves to produces large amounts of foam, gas production is conducted through foam drainage. According to the gas production method, two drainage and gas production technologies are conducted spontaneously, the process is simple and the best drainage and gas production effect can be achieved.

Owner:SOUTHWEST PETROLEUM UNIV

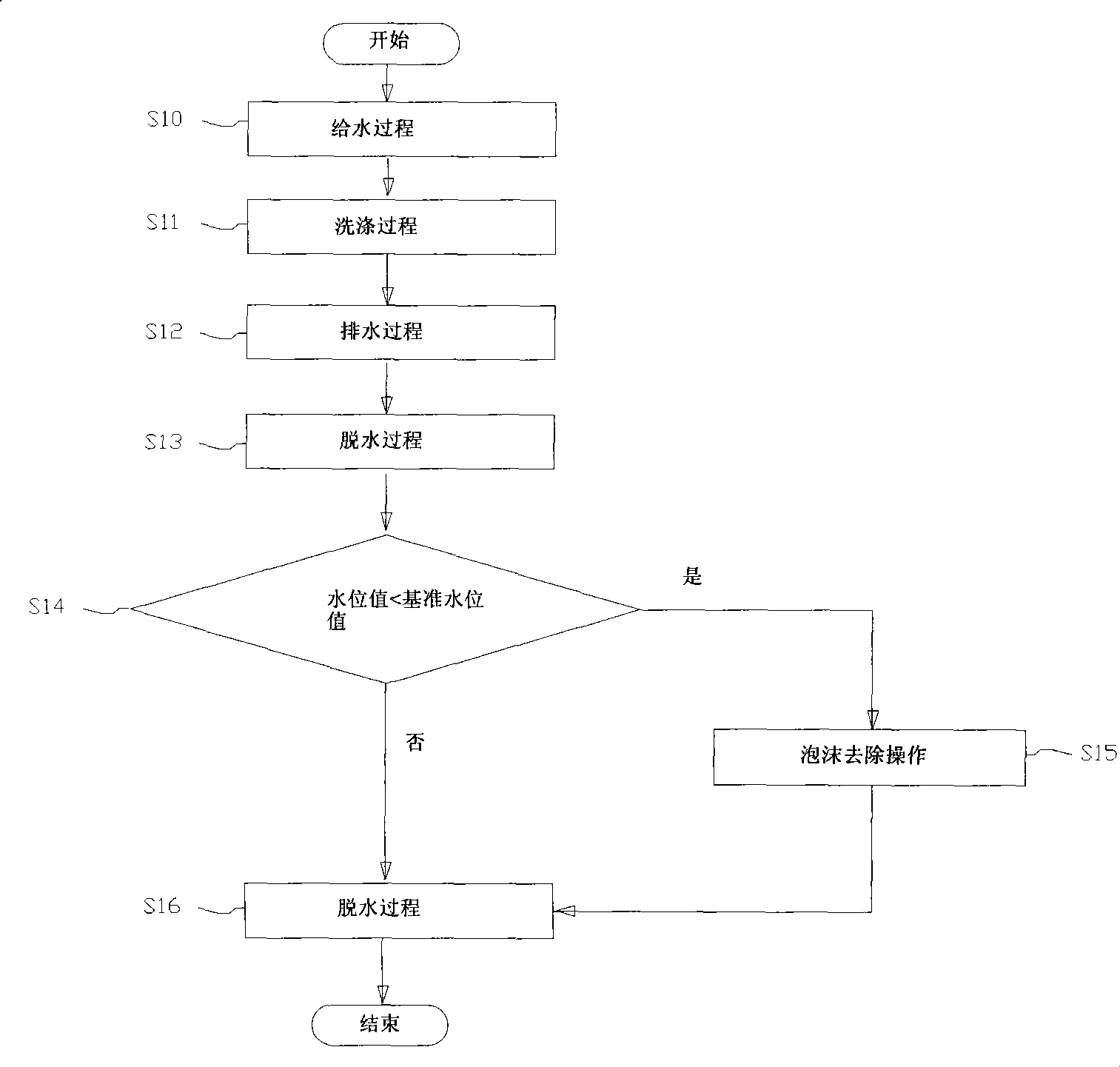

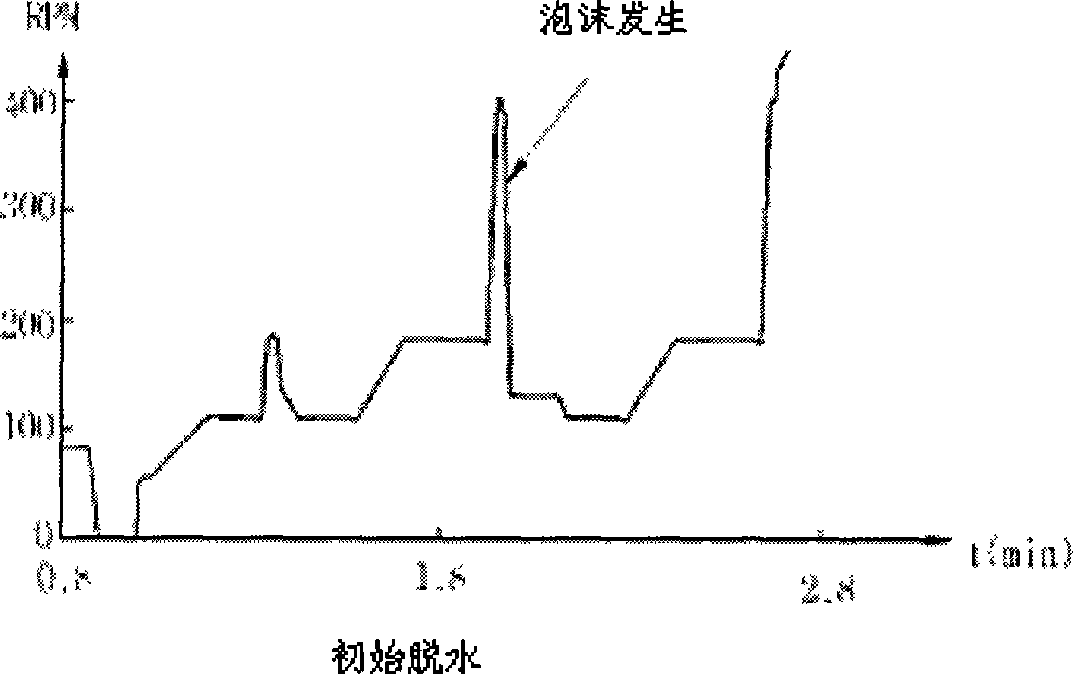

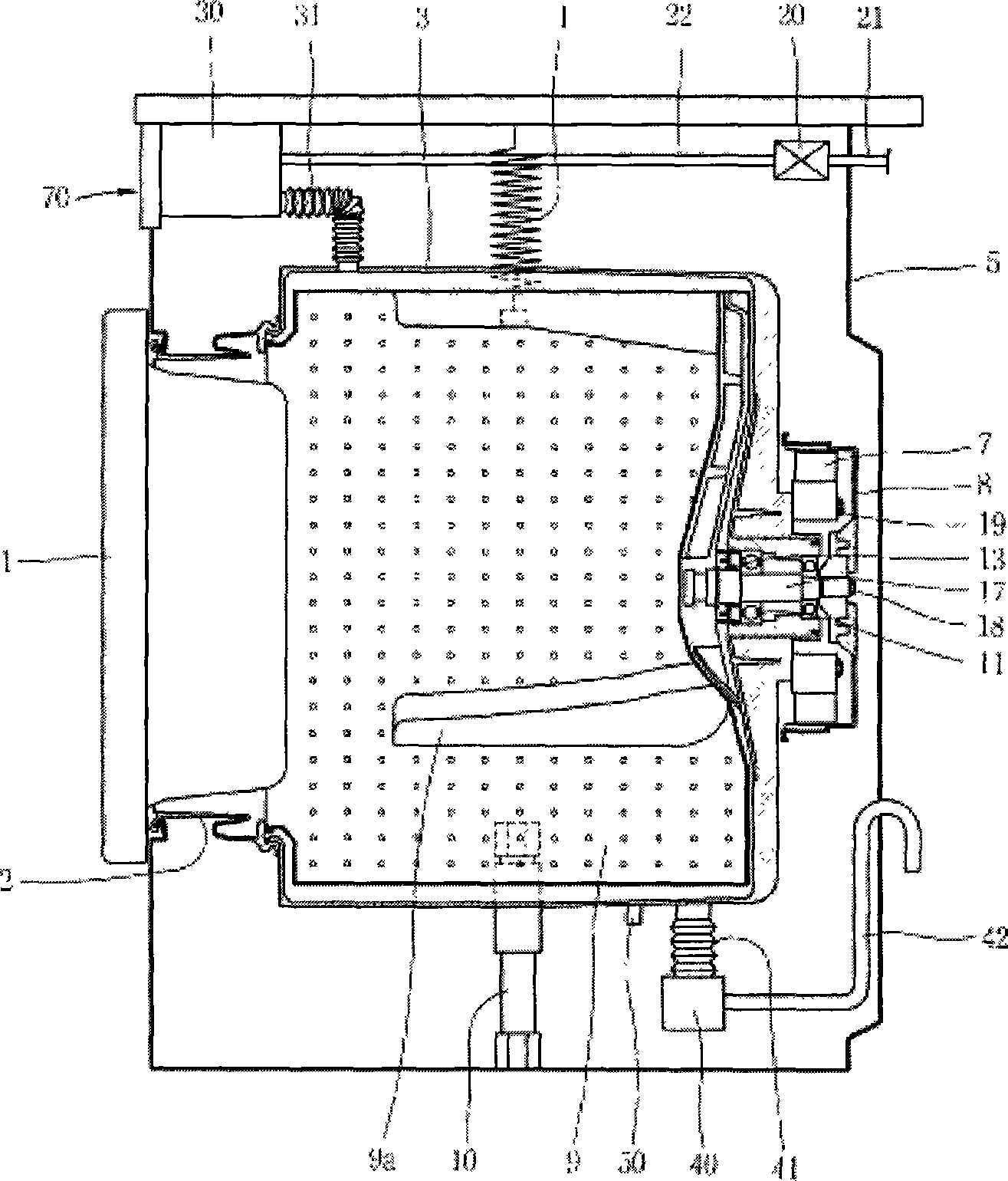

Foam detecting method of washing machine

InactiveCN101363181APrevent overflowPrevent slippingOther washing machinesControl devices for washing apparatusEngineeringDrainage time

The invention relates to a foam detecting method of a washing machine. The foam detecting method of a washing machine in the invention judges whether the foam is generated in the washing process after the unwatering process, rather than by comparing the drainage time and foam drainage time prior to the occurrence of the bubble to determine whether or not. Because of judging the emergence of the foam or not in advance in the course of draining off water, rather than judge in the unwatering process, and carrying out the foam to remove and operate according to judged result, thus the invention can avoid the adverse effect caused by happening in bubble.

Owner:NANJING LG PANDA APPLIANCES

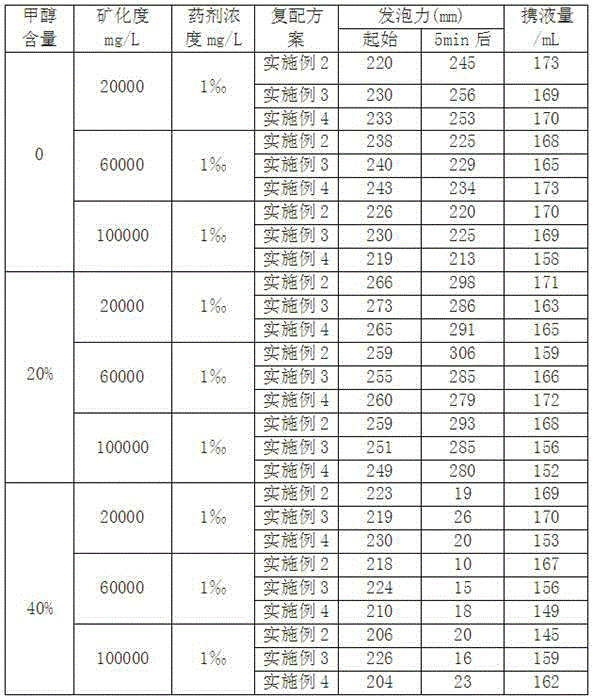

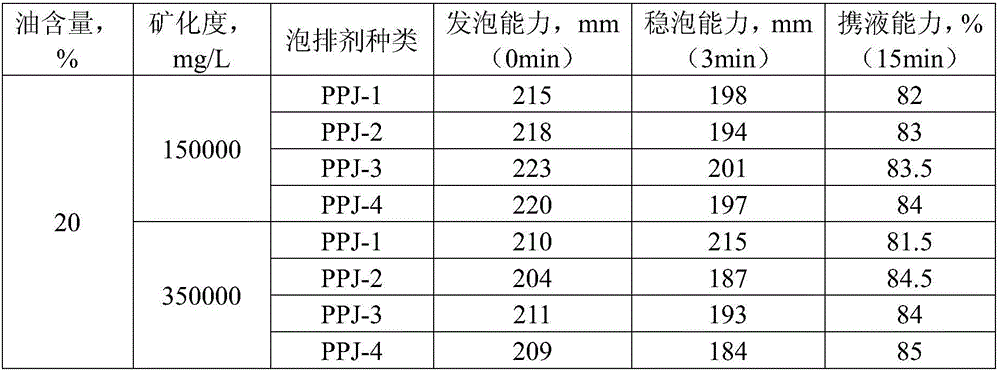

Foaming drainage agent, preparation method and application

InactiveCN106433597AImprove compactnessImprove stabilityFluid removalDrilling compositionBetaineFatty alcohol

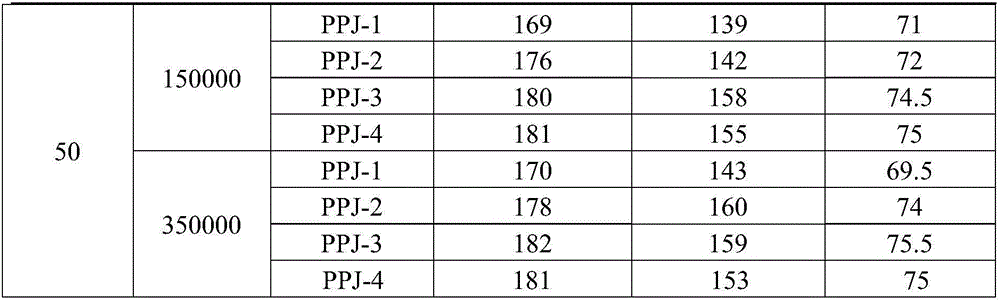

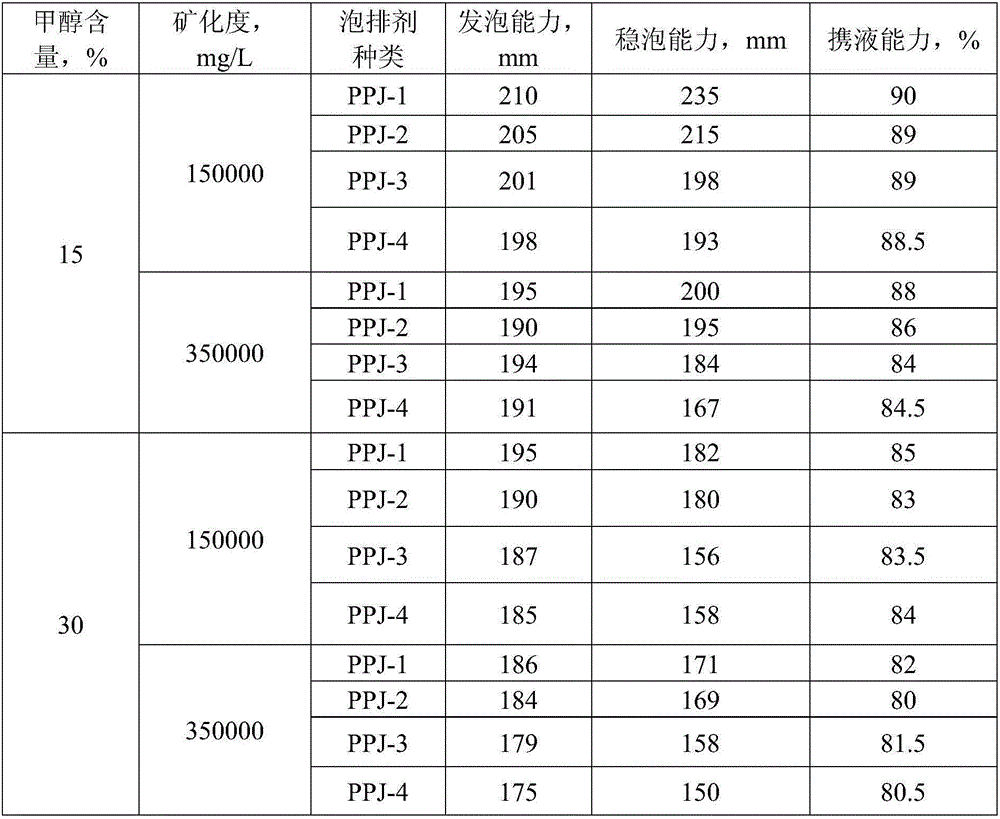

The invention provides a foaming drainage agent. The foaming drainage agent is prepared from components in percentage by mass as follows: 15%-30% of betaine, 25%-50% of amine oxide, 5%-15% of fatty alcohol polyoxyethylene ether sulfate, 1%-4% of alkyl glycoside and the balance of water. The invention further provides a preparation method and an application of the foaming drainage agent. Different types of surfactants with different functional group structures are compounded, so that a special synergistic effect is realized, compacter oriented molecule arrangement is formed, compactness and stability of foam are enhanced, foam performance is improved, condensate oil resistance is up to 50%, methyl alcohol resistance is up to 30%, mineralization resistance reaches 350,000 mg / L, liquid carrying capacity is 70% or higher, surface tension is 28 mN / m or lower, and the problems that a conventional foaming drainage agent is difficult to foam, the foam stability is poor and the liquid carrying amount is low in an extreme environment are solved.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

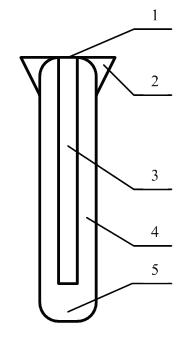

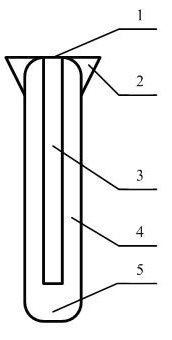

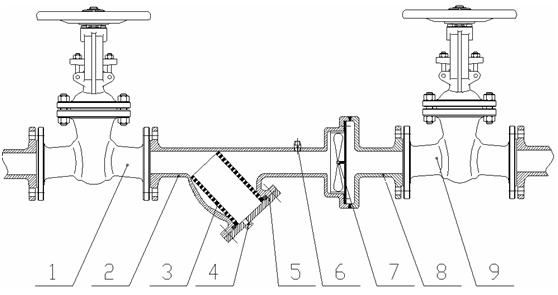

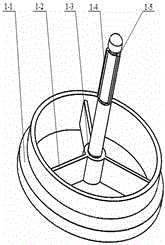

Repeated foaming device for gathering and delivering pipeline of foam drainage gas-production well

The invention relates to a repeated foaming device for a gathering and delivering pipeline of a foam drainage gas-production well in the natural gas gathering and delivering process. The repeated foaming device can solve the difficulty that natural production of a gas well is influenced by liquid accumulation, even blockage of the gathering and delivering pipeline, caused by foam burst and gas-liquid layering in the the gathering and delivering pipeline of the foam drainage gas-production well. A technical scheme of the invention is that an inlet gate valve is connected with an upstream gathering and delivering pipeline; the other end of the inlet gate valve is connected with a device housing A; a flange cover is arranged below the device housing A; a blowoff valve is arranged on the cover; one end of a filter cartridge is connected with an inlet of the device housing A while the other end thereof is connected with the blowoff valve; a hydraulic quick joint is mounted above the device housing A; a stirring blade is mounted on an outlet of the device housing A; an inlet end of a device housing B is connected with an outlet end of the device housing A; an outlet end of the device housing B is connected with an outlet gate valve; and the other end of the outlet gate valve is connected with a downstream gathering and delivering pipeline. By using the invention, a foaming agent can be injected into the gathering and delivering pipeline so that the accumulated liquid in the pipeline can foam again; moreover, solid-phase impurities in the pipeline is filtered to be removed so as to avoid gas-liquid layering and pipeline blockage.

Owner:SOUTHWEST PETROLEUM UNIV

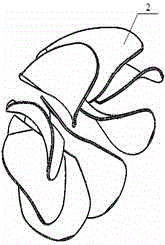

Cohesion-type foam drainage blender

InactiveCN104958934AReduce frictionHigh performance of liquid accumulationFluid removalFoam dispersion/preventionEngineeringFoam drainage

The invention provides a cohesion-type foam drainage blender. The cohesion-type foam drainage blender comprises a base with a support, rotation blades, and a blender main body with bearings fitting to a middle base. The top of the outer part of the base is provided with a chamfer matching with a tubing nipple. The base is provided with three support frames for fixing the support and is provided with a gas-liquid channel. One end of the support of the base is provided with three locking raised parts for adjusting the blender main body to a correct position. The blender main body is characterized in that the middle base between the bearings at two ends is positioned to and matches with the bearings by three cylindrical pins. The external diameter of the middle base is slightly smaller than those of the bearings. Two ends of the blender main body are positioned by fixing gaskets. The cohesion-type foam drainage blender does not influence the gas-liquid channel. Stratum gas drives the blender to rotate so that gas and liquid are concentrated to the middle part of a shaft, olisthy is reduced, a foaming amount is increased and foam drainage efficiency is improved.

Owner:SOUTHWEST PETROLEUM UNIV

Self-foaming-type foaming drainage agent and preparation method thereof

ActiveCN104498013AStrong foamingHigh liquid carrying rateDrilling compositionSodium bicarbonateWater block

The invention discloses a self-foaming-type foaming drainage agent. The self-foaming-type foaming drainage agent comprises, by weight, 20-40 parts of soapberry fruit saponin, 8-25 parts of sodium fatty acid methyl ester sulfonate, 8-25 parts of 1-hydroxyethylidene-1,1-diphosphonicacid, 10-30 parts of sodium bicarbonate and 10-30 parts of tartrate. The preparation method comprises the following steps of S1, weighing: weighing the raw materials according to the above ratio for next use, S2, drying: drying the weighed raw materials so that water content is less than 3%, and S3, pressing: adding all the dried raw materials into a mixer, carrying out stirring for 4-8min, transferring the mixture into a hydraulic press and carrying out processing to obtain round rod-shaped solids which are the self-foaming-type foaming drainage agents. The self-foaming-type foaming drainage agent realizes natural gas well foaming drainage of a water-blocked gas well or a natural gas well with a weak stratum capability, has dual effects of gaslifting and a foaming drainage agent, has a strong self-foaming capacity and a high liquid carrying rate and can produce effects fast. The preparation method has simple and convenient processes, has a low production cost, is environmentally friendly and is suitable for industrial large-scale production.

Owner:成都孚吉科技有限责任公司

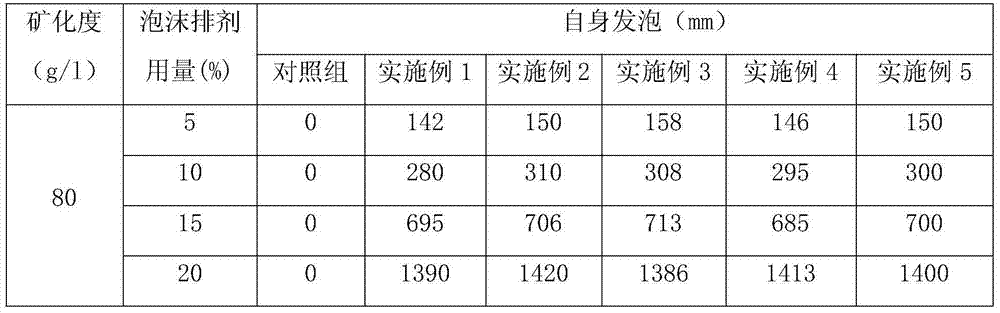

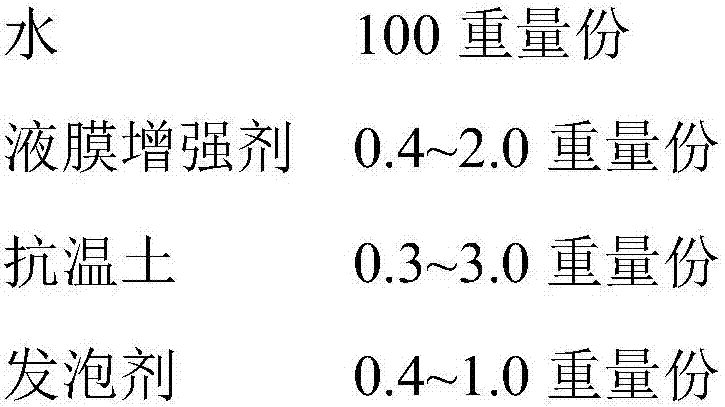

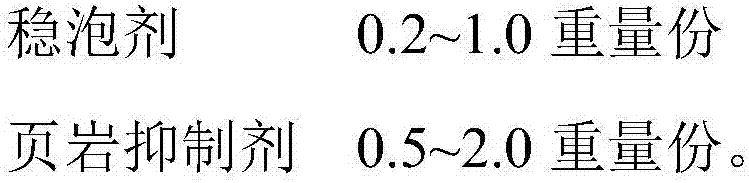

Low-solid-phase and high-temperature-resistant foam drilling fluid and preparation method thereof

The invention relates to low-solid-phase and high-temperature-resistant foam drilling fluid and preparation method thereof in the technical field of oilfield drilling fluids. The high-temperature-resistant foam drilling fluid with low solid phase is prepared from the following components in parts by weight: 100 parts of water, 0.1-3.0 parts of a liquid film reinforcing agent, 0.1-5.0 parts of temperature-resistant soil, 0.1-3.0 parts of a foaming agent, 0.1-4.0 parts of a foam stabilizer and 0.1-5.0 parts of a shale inhibitor. A foaming base fluid is re-stirred highly and foamed after being aged at the high temperature of 230 DEG C, the foam drainage half-life is equal to or longer than 9 minutes, the defect of poor temperature resistance of the existing foam drilling fluid is overcome, and requirements of geothermal wells with the temperature reaching 230 DEG C and low-pressure reservoirs for temperature resistance of the foam drilling fluid are met basically.

Owner:CHINA PETROLEUM & CHEM CORP +1

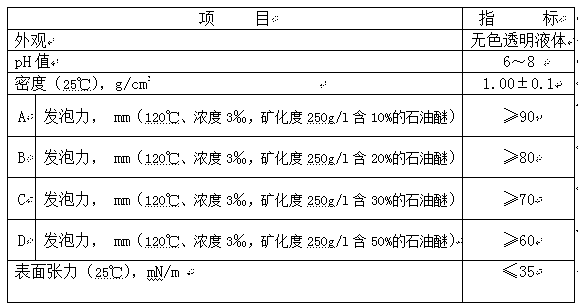

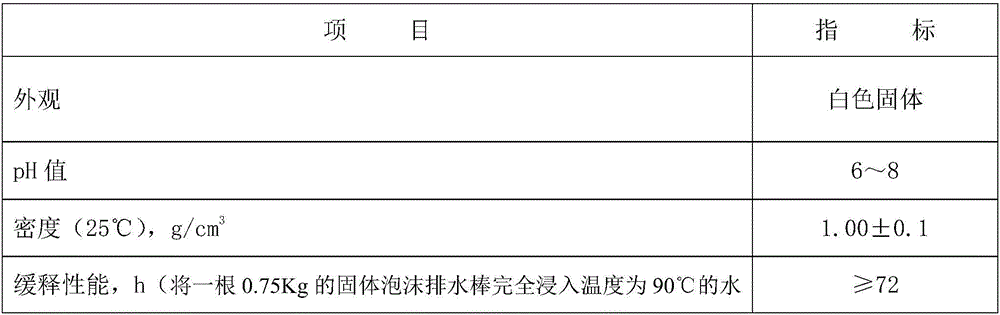

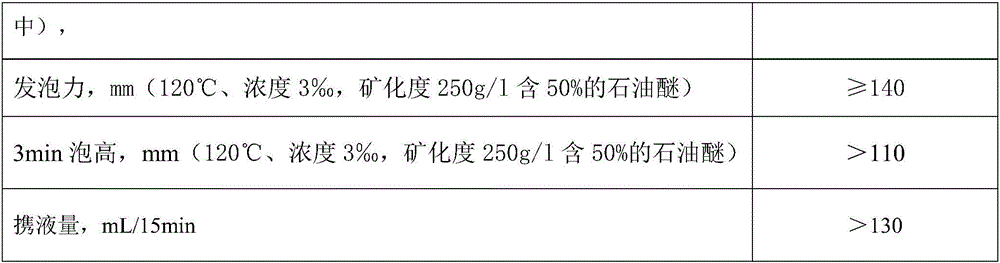

Oil-proof sustained-release solid foaming drainage agent used for gas wells, and preparation method and applications thereof

The invention discloses an oil-proof sustained-release solid foaming drainage agent used for gas wells, and a preparation method and applications thereof. The oil-proof sustained-release solid foaming drainage agent is mainly used for solving problems of conventional solid foaming drainage agents that high local concentration and waste are caused because of high dissolving speed, and preferable application is different to realize when gas well output water is high in gas condensate content, high in mineralization degree, and high in temperature. The dissolving time of the oil-proof sustained-release solid foaming drainage agent at 90 DEG C formation water condition is longer than 72h, and agent effect lasting time is long; the oil-proof sustained-release solid foaming drainage agent is capable of resisting gas condensate of 50% or higher, temperature of 120 DEG C or higher, and mineralization degree of 250000ppm; the foaming power is equal to or larger than 140mm; foam stabilizing time is long; and compatibility with agents such as methyl alcohol, corrosion inhibitors, and scale inhibitors is high. The preparation method is simple; no environment pollution is caused; no chemical reaction of products with gas and liquid ingredients is caused; equipment or pipeline corrosion is not caused; the prominent problems of gas wells are solved; and the oil-proof sustained-release solid foaming drainage agent is suitable for a plurality of water-producing gas wells.

Owner:四川锦盛油田技术服务有限公司

Gas field foam water drainage bar and preparation method thereof

The invention relates to a gas field foam water drainage bar and a preparation method thereof, in particular to an amphoteric foam water drainage bar resistant to mineralization, methyl alcohol and gas condensate. The gas field foam water drainage bar is suitable for foam water drainage of various gas wells and capable of effectively removing liquid accumulated at the bottom of a well and increasing the gas output. The gas field foam water drainage bar is prepared from a fatty acid glycine betaine derivative, polyvinyl alcohol, polyvinyl pyrrolidone, sodium carboxymethylcellulose and water. According to the gas field foam water drainage bar and the preparation method thereof, the problem that the foaming performance and liquid carrying performance of an existing foam drainage agent under complex conditions are greatly reduced or even can not meet field use is solved, the foaming effect is improved, the foam water drainage efficiency under high mineralization, methyl alcohol and gas condensate is improved, and the foam water drainage bar is high in foaming capability and is not influenced by high mineralization, methyl alcohol and gas condensate, and operation is easy and safe.

Owner:PETROCHINA CO LTD

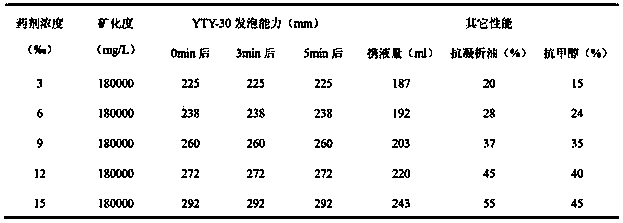

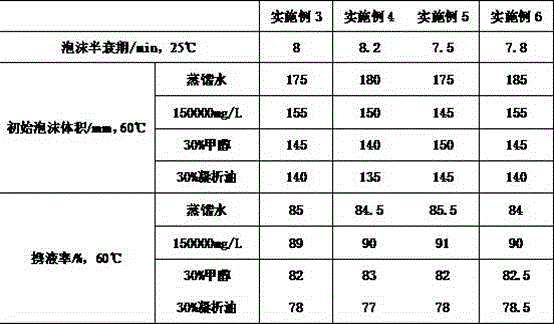

Solid foaming drainage agent composition as well as preparation method and application thereof

ActiveCN107573917AIncreased fluid carrying capacitySlow downDrilling compositionAdhesivePetrochemical

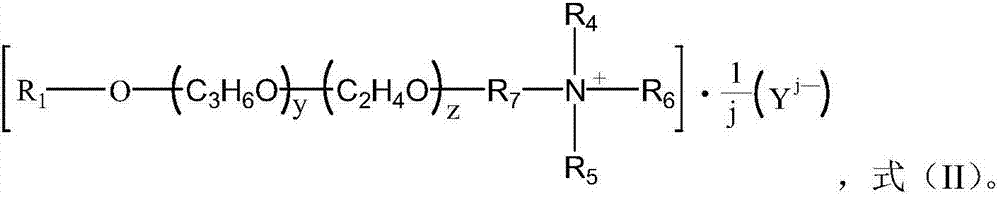

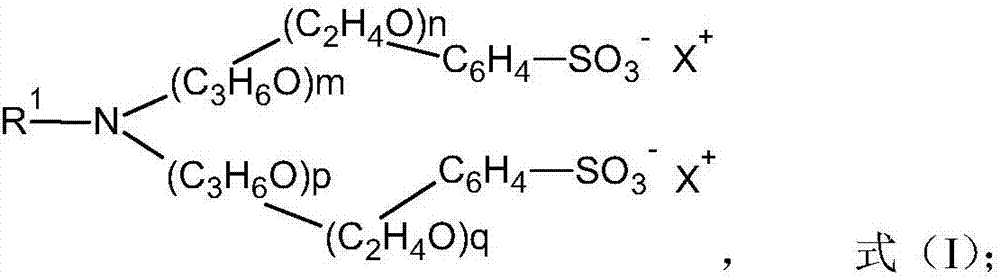

The invention relates to a solid foaming drainage agent composition as well as a preparation method and application thereof and belongs to the technical field of petrochemical engineering. The solid foaming drainage agent composition disclosed by the invention comprises the following components in parts by mass: 1 part of alkylamine polyether benzene sulfonate, 0.1-50 parts of long-chain polyethernitrogen-containing compounds, 0.2-100 parts of solid fillers and 0-0.5 part of an adhesive. By virtue of the technical scheme in the invention, the solid foaming drainage agent is subjected to foaming performance test according to SY / T 6465-2000 Foaming Agent Evaluation Method for Foaming Drainage Gas Recovery, the foaming height is more than 200mm in 0-200000 mg / L of salinity brine, the liquorcarrying capacity is more than 150mL, and when aged at a high temperature of 180 DEG C for 24 hours, the change ratio of the foaming height and drainage performance of the foam is less than 5%. The solid foaming drainage agent composition has excellent temperature resistance, salt resistance, foaming performance and liquor carrying capacity, and excellent technical effects are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com