Patents

Literature

160 results about "Blowoff valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A blow-off valve (BOV), dump valve or compressor bypass valve (CBV), is a pressure release system present in most turbocharged engines. Its main purpose is to take the load off the turbocharger when the throttle is suddenly closed.

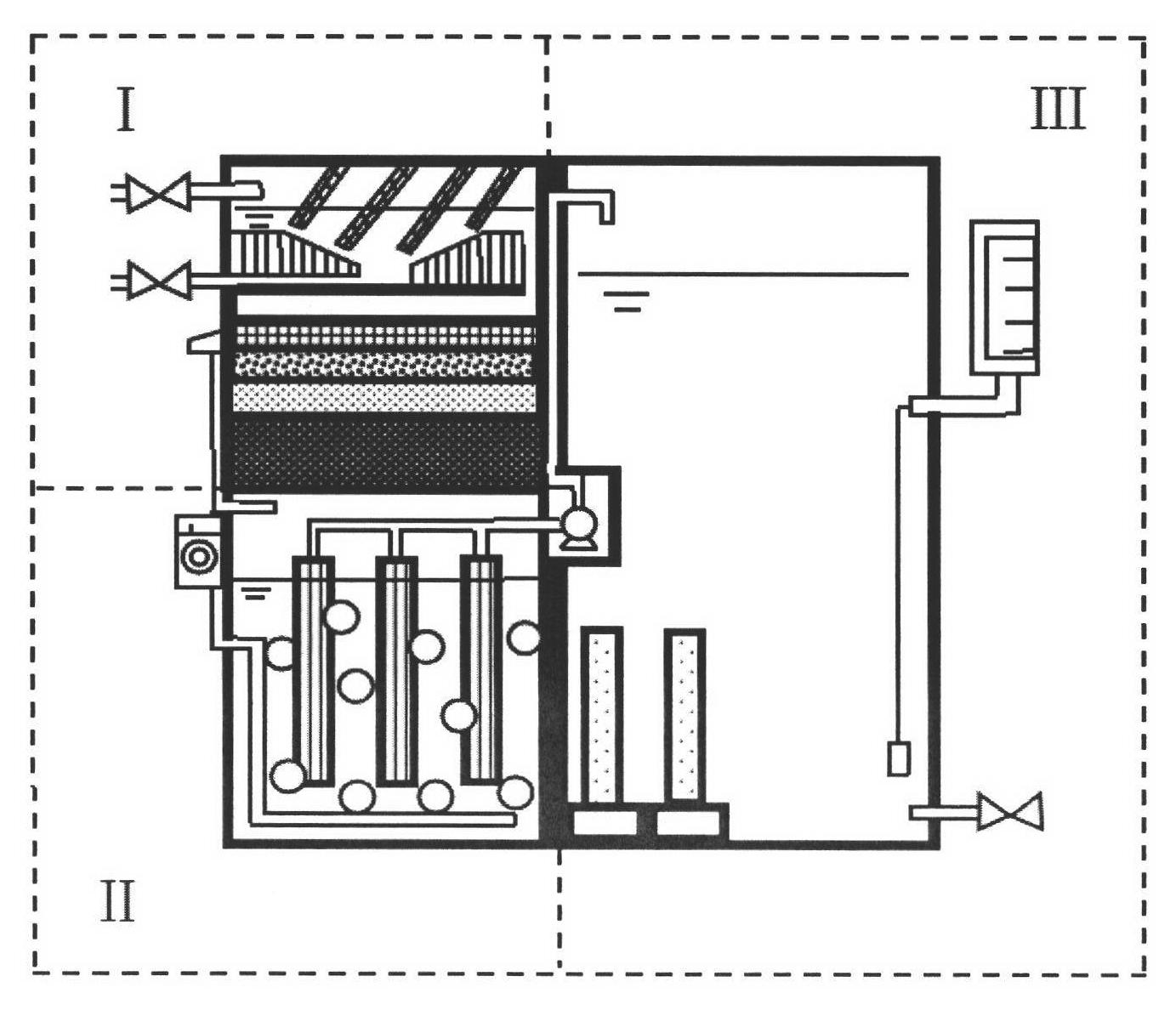

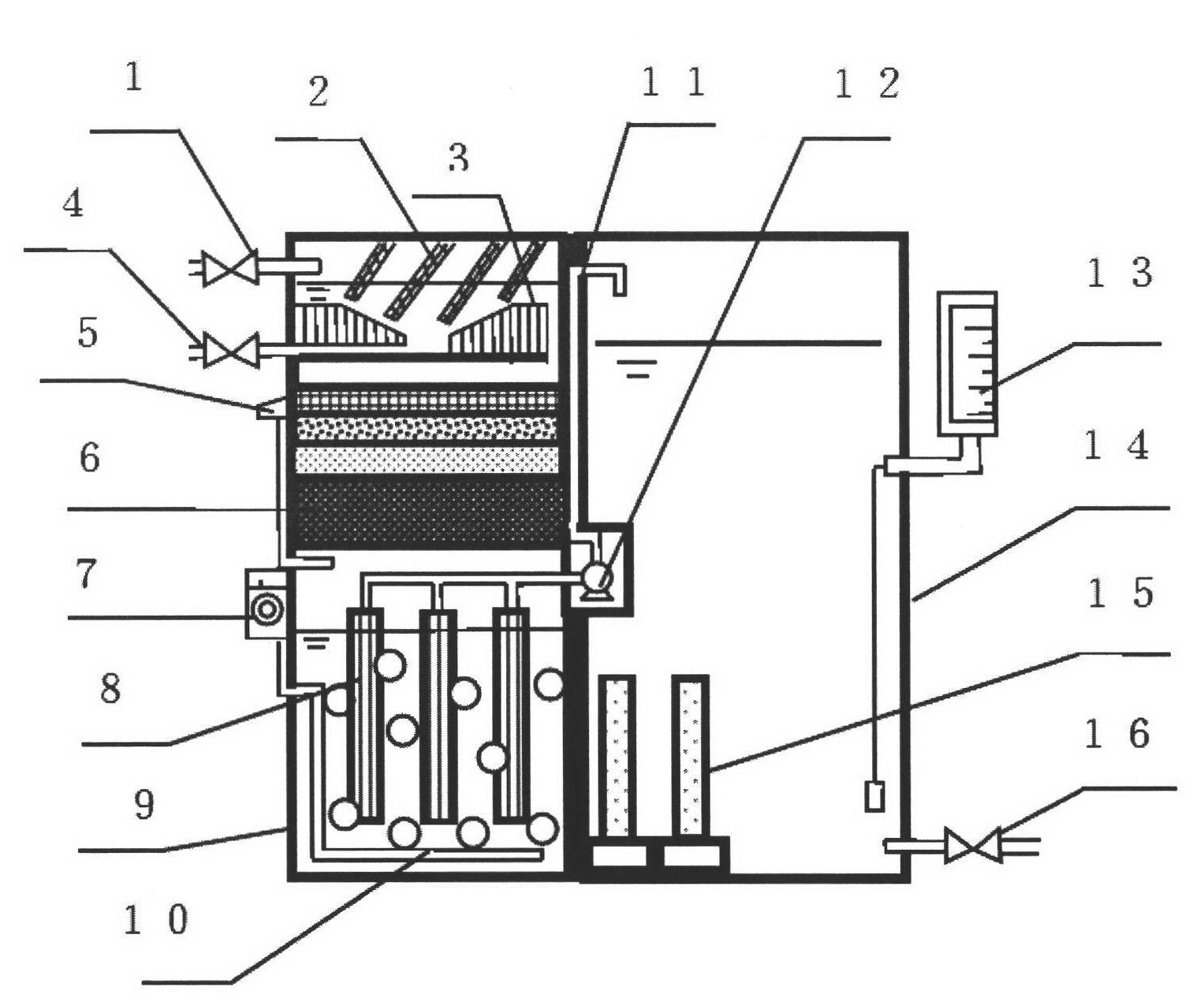

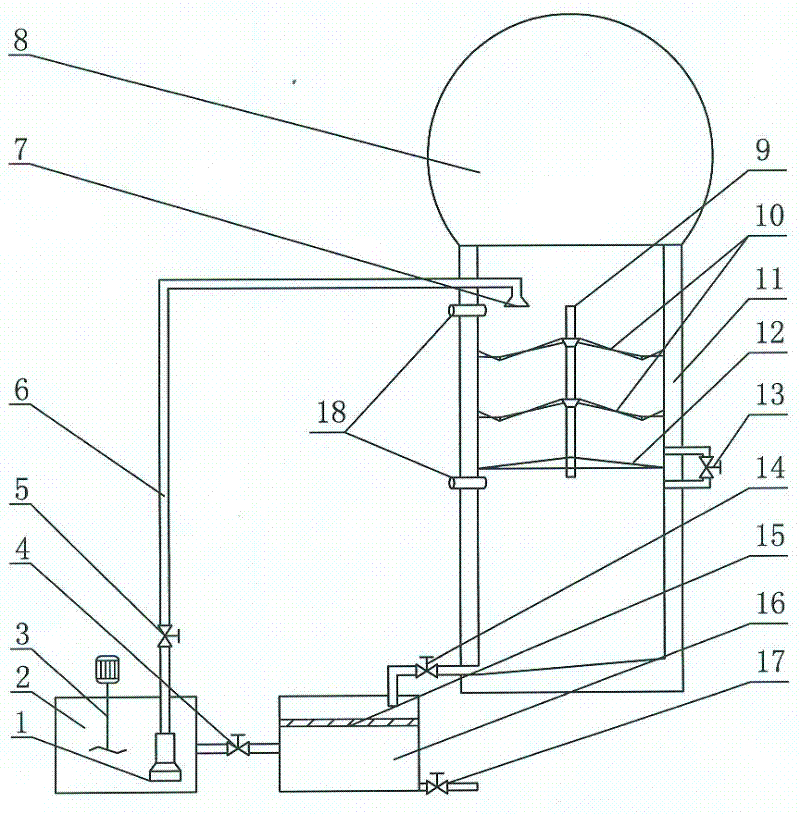

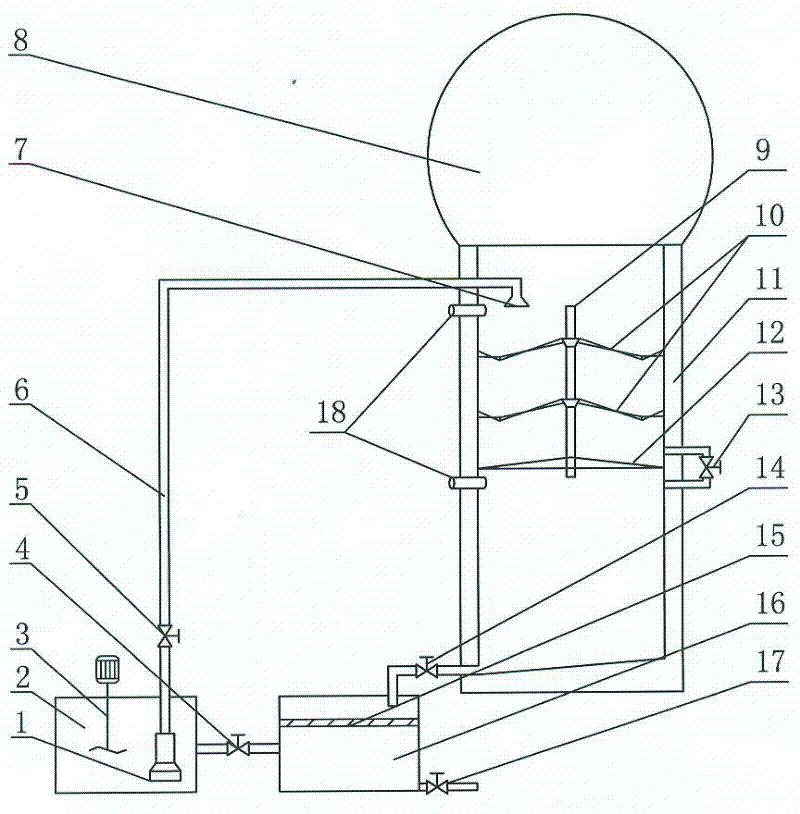

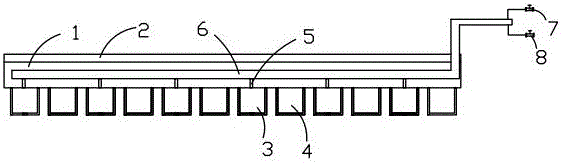

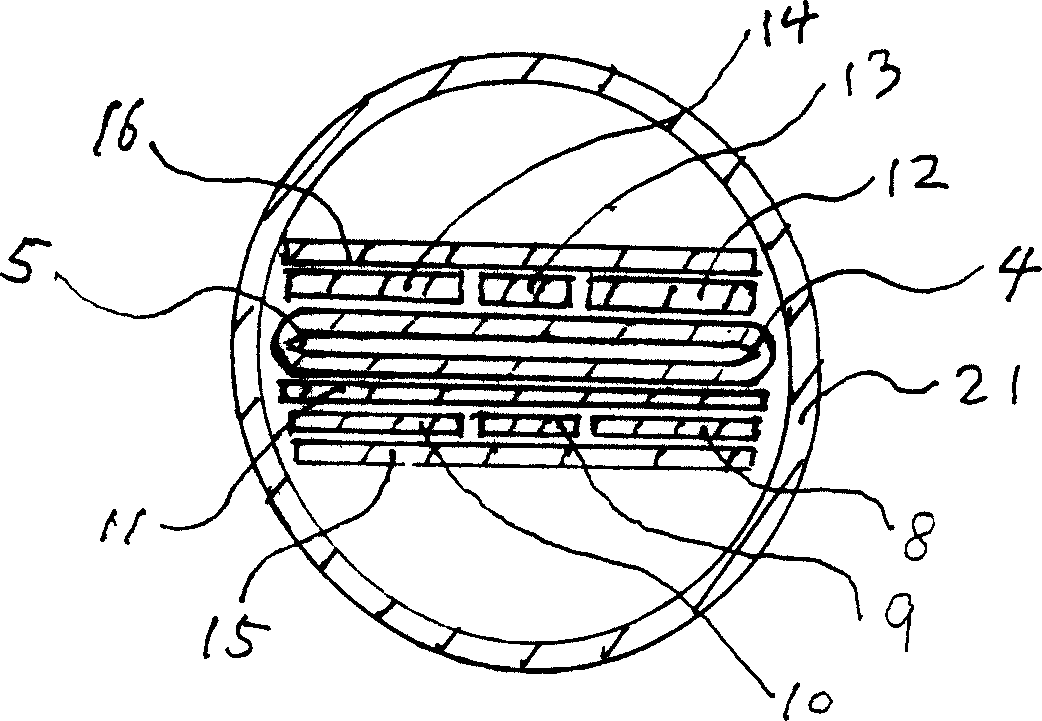

Household sewage treatment equipment

InactiveCN102674637AReduce turbidityReduce processing costsWater/sewage treatment by irradiationMultistage water/sewage treatmentFiberHollow fibre

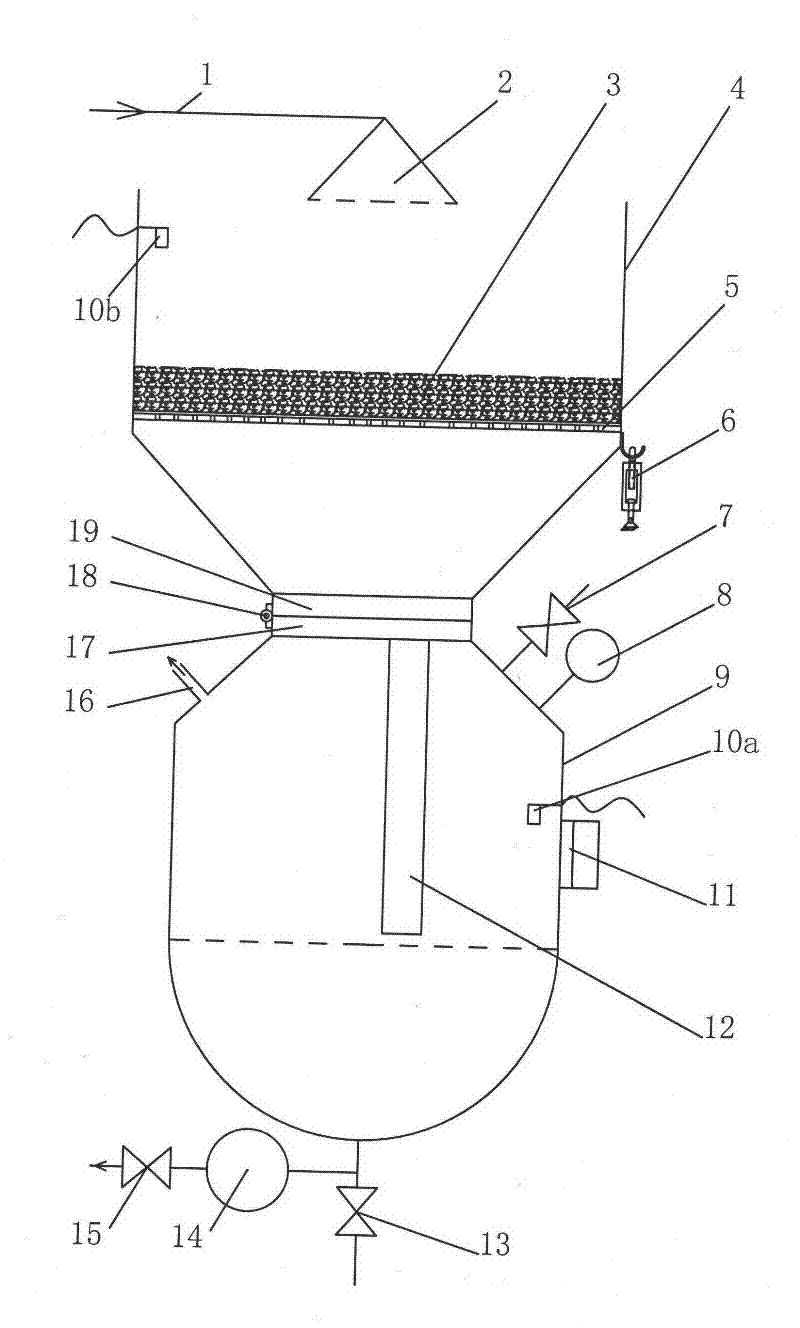

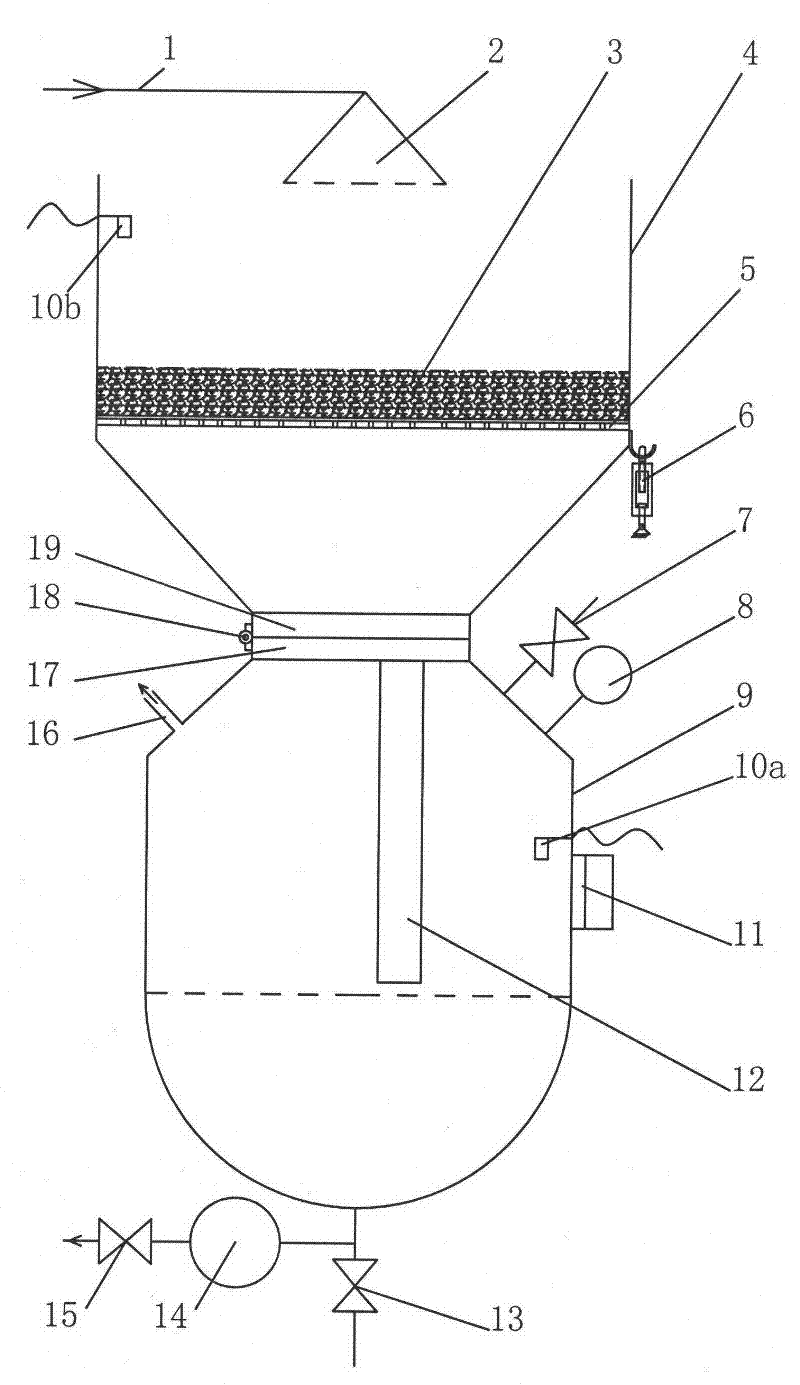

The invention relates to a piece of novel household sewage treatment equipment which is characterized by comprising a water inlet valve 1, a separation net 2, a clapboard 3, a blowoff valve 4, an exhaust valve 5, a filter layer 6, an air pump 7, a hollow fiber ultrafiltration membrane component 8, a membrane bioreactor 9, an air guide pipe 10, a water guide pipe 11, a water pump 12, a water level gauge 13, a water storage tank shell 14, an ultraviolet disinfection lamp 15, a water outlet valve 16, a sponge layer 17, a modified coal cinder layer 18, a quartz sand layer 19 and an active carbon layer 20. The household sewage treatment equipment uses the membrane bioreactor to treat sewage, pollutants are degraded in the membrane bioreactor to remove most of CODCr, BOD5, turbidity, NH3-N, total phosphorus and the like after passing through a filter (I) and a membrane bioreaction tank (II), and then the sewage is disinfected by the ultraviolet disinfection lamp so as to be stored in a recycled water reuse tank (III) to be used as household reuse water.

Owner:汪硕

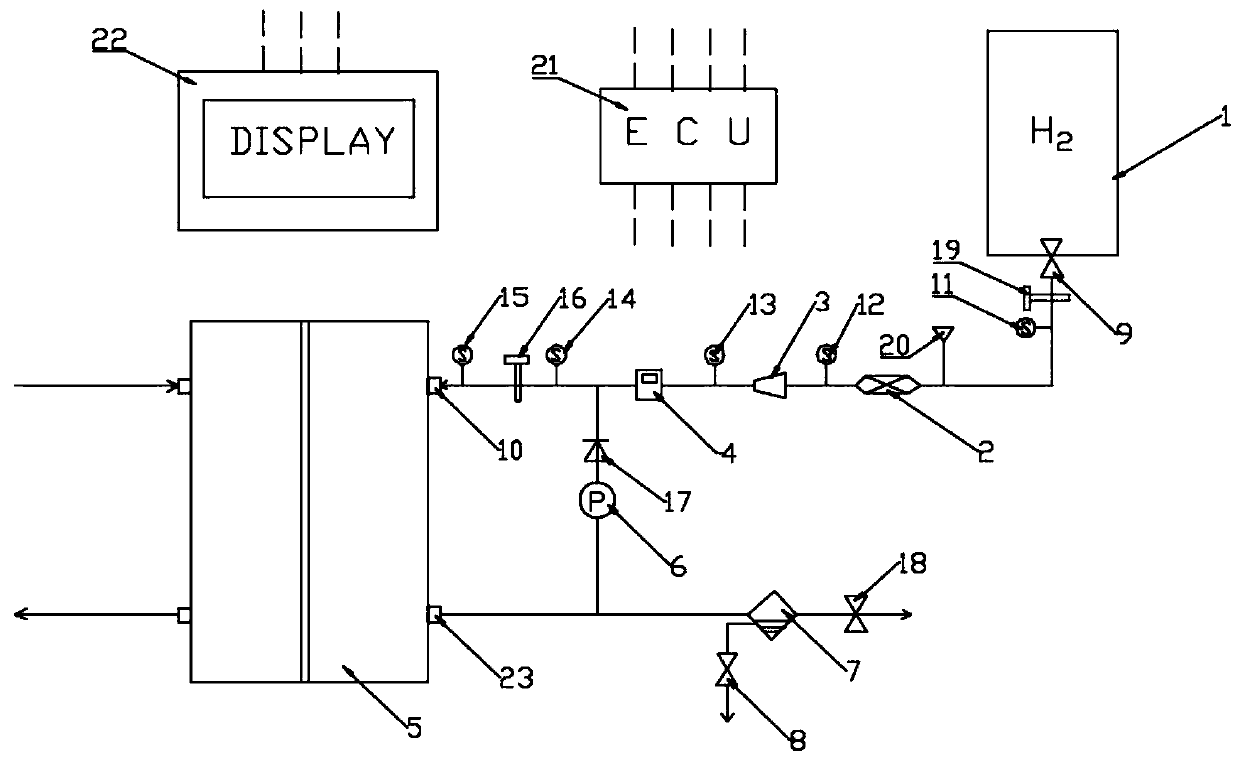

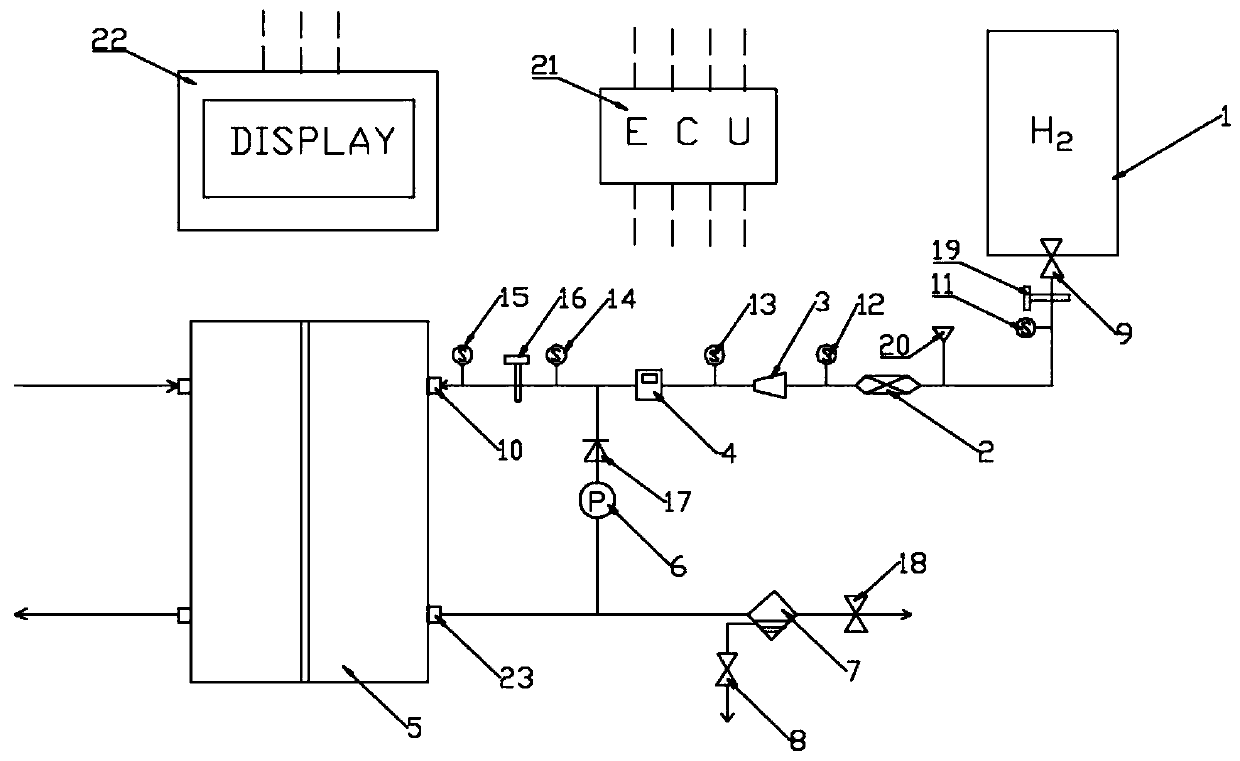

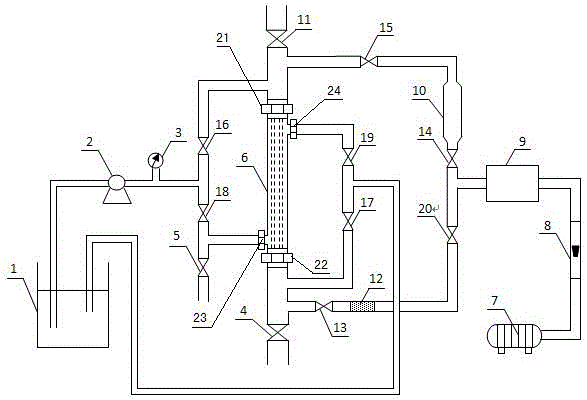

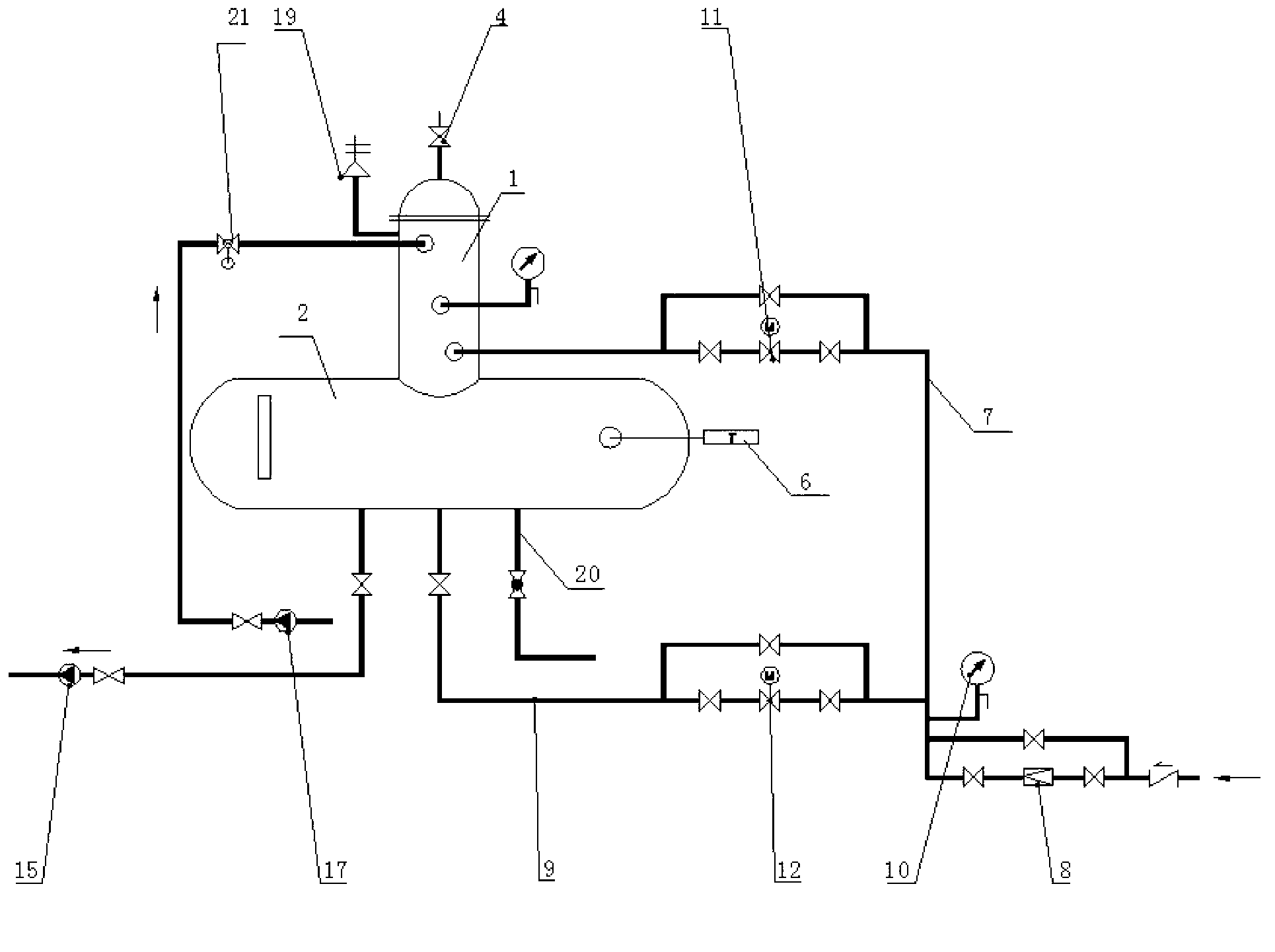

Hydrogen supply system for rapidly judging hydrogen leakage part

PendingCN109860663ASatisfy the needs of safe useReal-time monitoring of working statusFuel cellsBlowoff valveExhaust valve

The invention discloses a hydrogen supply system for rapidly judging a hydrogen leakage part. The hydrogen supply system for rapidly judging the hydrogen leakage part mainly comprises a hydrogen storage tank, an overflowing valve, a pressure reducing valve, an electromagnetic valve, a fuel cell stack, a hydrogen circulating pump, a moisture separator, a drainage valve, a high pressure cylinder valve, a hydrogen inlet, a hydrogen outlet, pressure sensors, a low pressure stop valve, a one-way valve, an exhaust valve, a high pressure stop valve, a blowoff valve, a vehicle-mounted computer, a hydrogen supply system state display and the like. According to the hydrogen supply system for rapidly judging the hydrogen leakage part, a self-inspection state when the system is started can be comparedwith a signal and a safety value of the vehicle-mounted computer fed back by the pressure sensors during normal work to judge whether hydrogen leaks or not, and assemblies with the problem can be rapidly positioned according to the sensors with abnormal pressure. The hydrogen supply system for rapidly judging the hydrogen leakage part is applied to hydrogen fuel cell passenger vehicles and hydrogen fuel cell commercial vehicles, a working state of the hydrogen supply system can be monitored in real time and the problem assemblies can be rapidly positioned, and the safety of the vehicles in the use process is improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

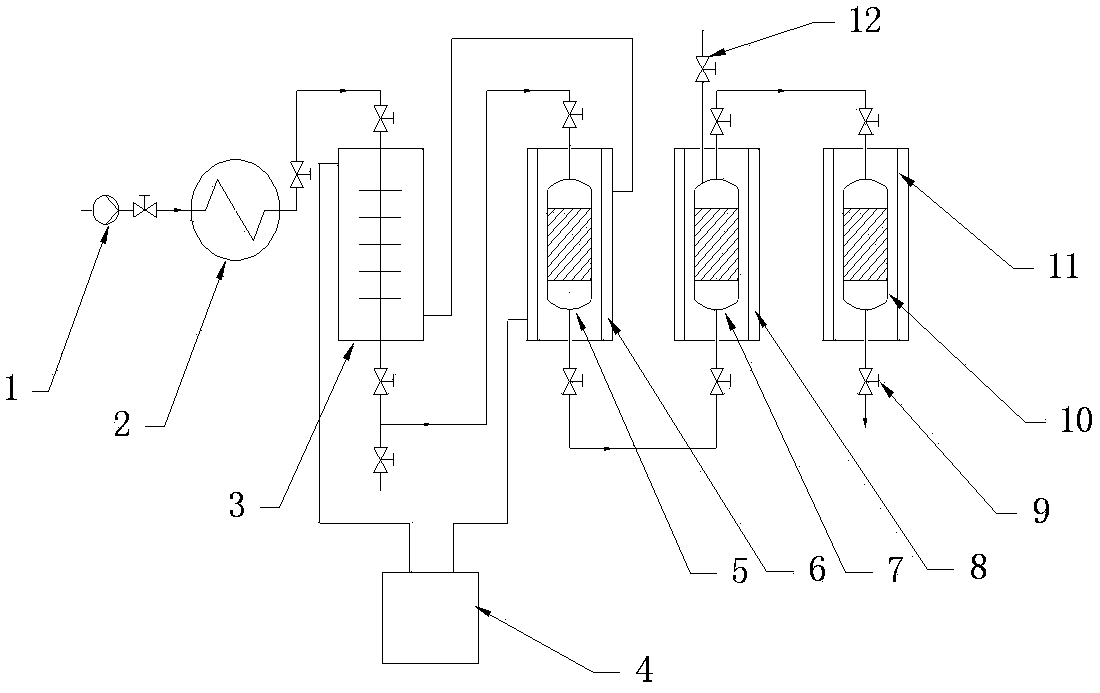

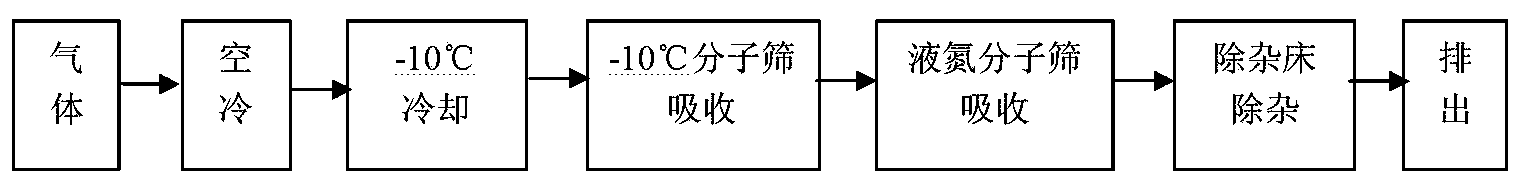

Tritium water collecting device

InactiveCN104167233AExtend your lifeReduce poisoning damageRadioactive decontaminationBlowoff valveSorbent

The invention provides a tritium water collecting device. According to the tritium water collecting device, a vacuum booster pump, an air cooling coil, a cold trap cooler, a molecular sieve absorber, a liquid nitrogen temperature molecular sieve absorber, a cleaning bed and a control panel are connected through a pipeline. According to the working procedure, the vacuum booster pump presses tritium gas into the air cooling coil, the tritium gas is cooled into the temperature about 40 DEG C and then enters the cold trap cooler to be cooled, tritium water is absorbed by a molecular sieve, the tritium water is absorbed by the molecular sieve under the liquid nitrogen temperature, and the left tritium gas is exhausted to a tritium purifying system through a blowoff valve. By means of the tritium water collecting device, the service life of an alloy hydrogen absorption bed and a catalytic oxidation bed of the tritium purifying system can be prolonged by about 50 percent, the using efficiency can be improved by more than 50 percent, and the radioactive waste of the produced molecular sieve dry adsorbent can be reduced by more than 80 percent. The tritium water collecting device can be applied to nuclear emergency work of high-radiation tritium gas of nuclear facilities.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

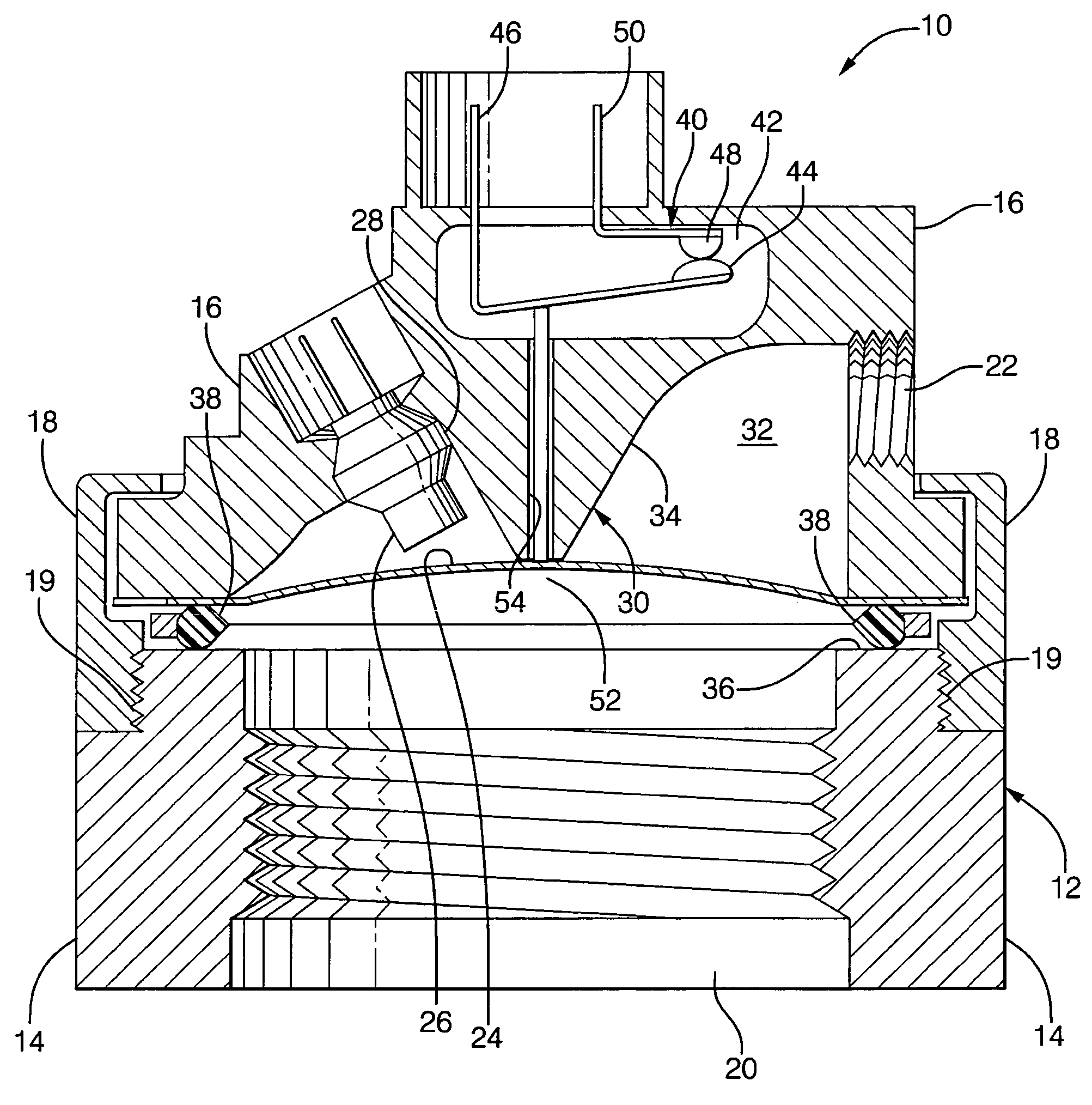

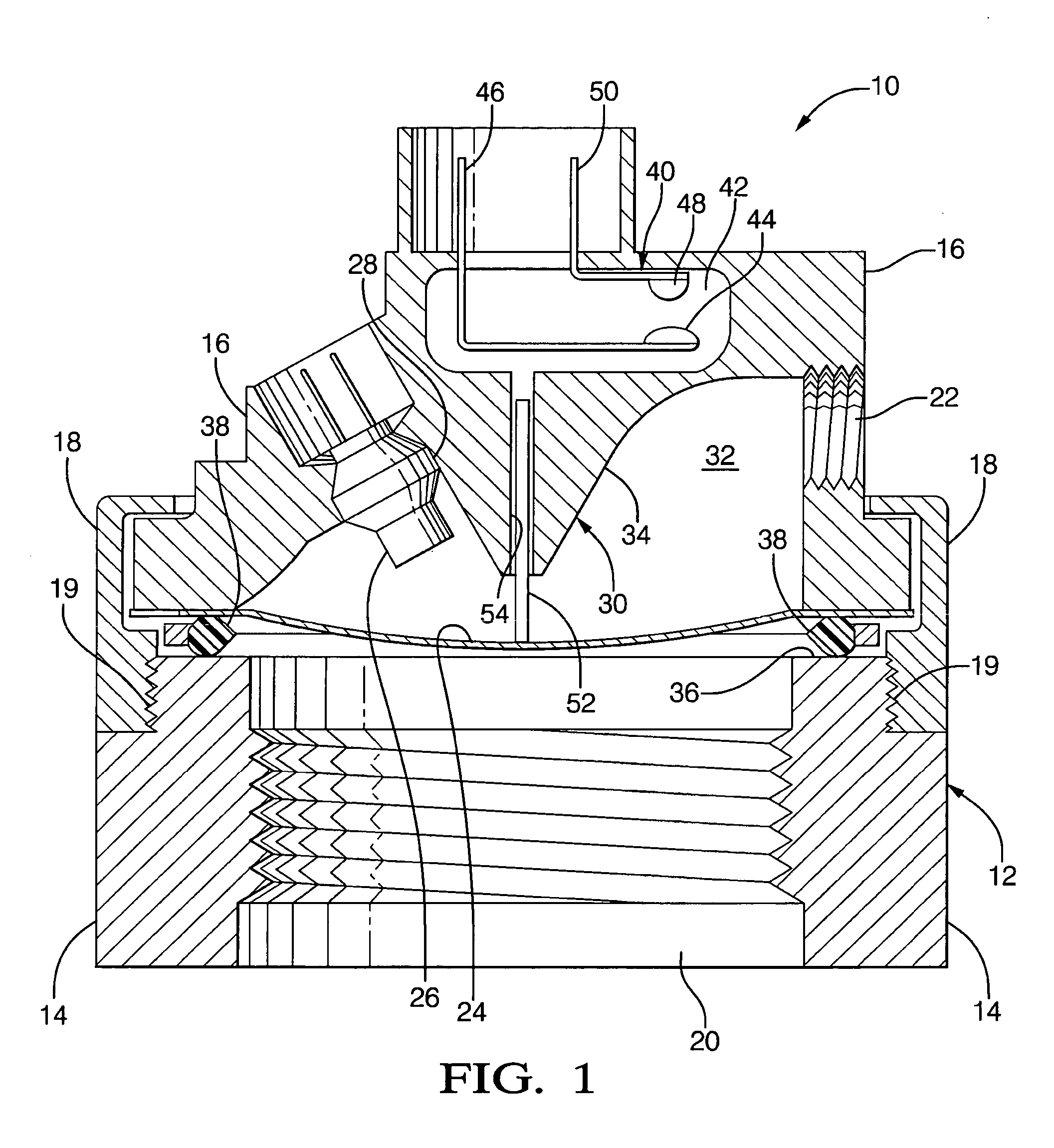

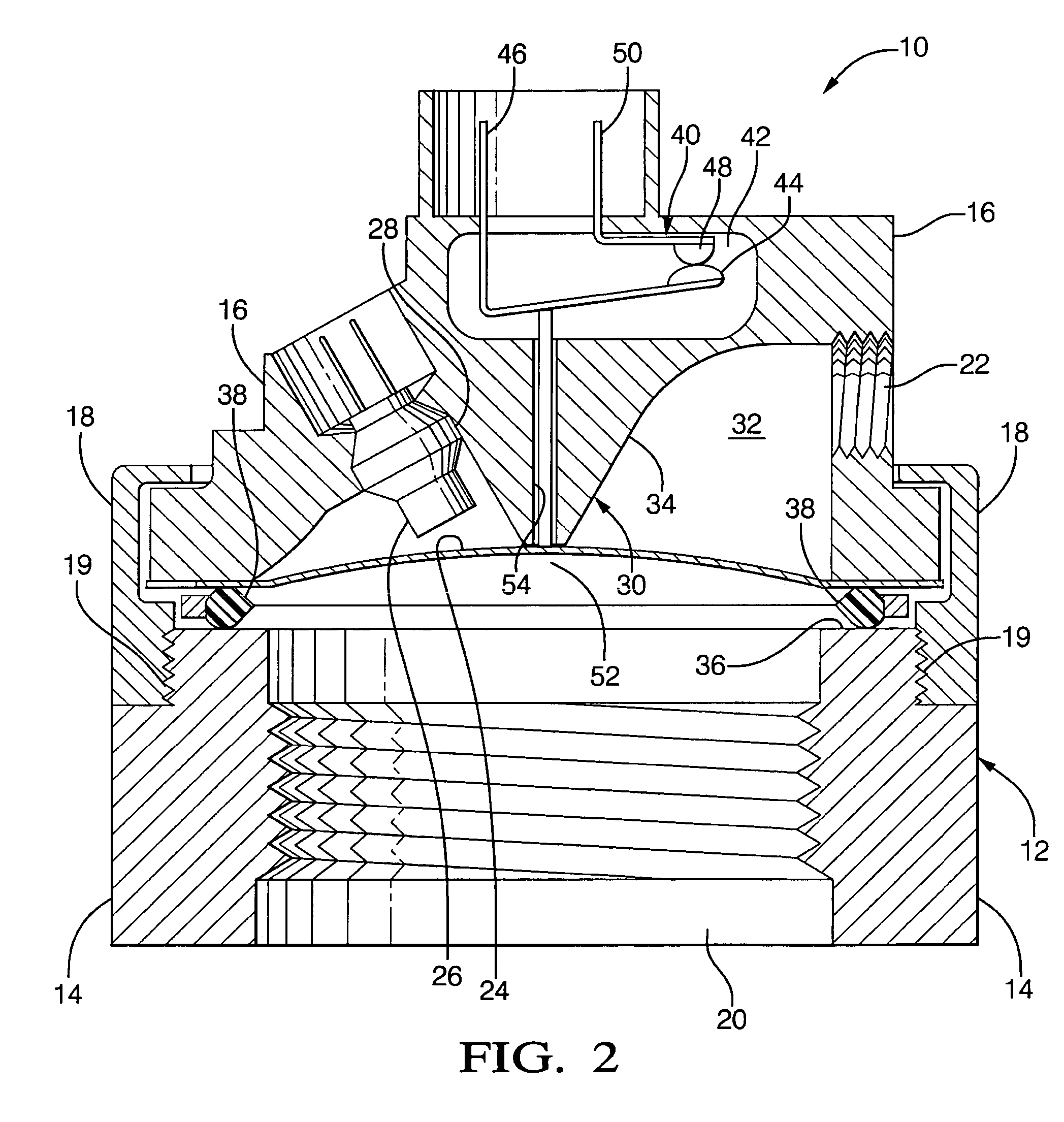

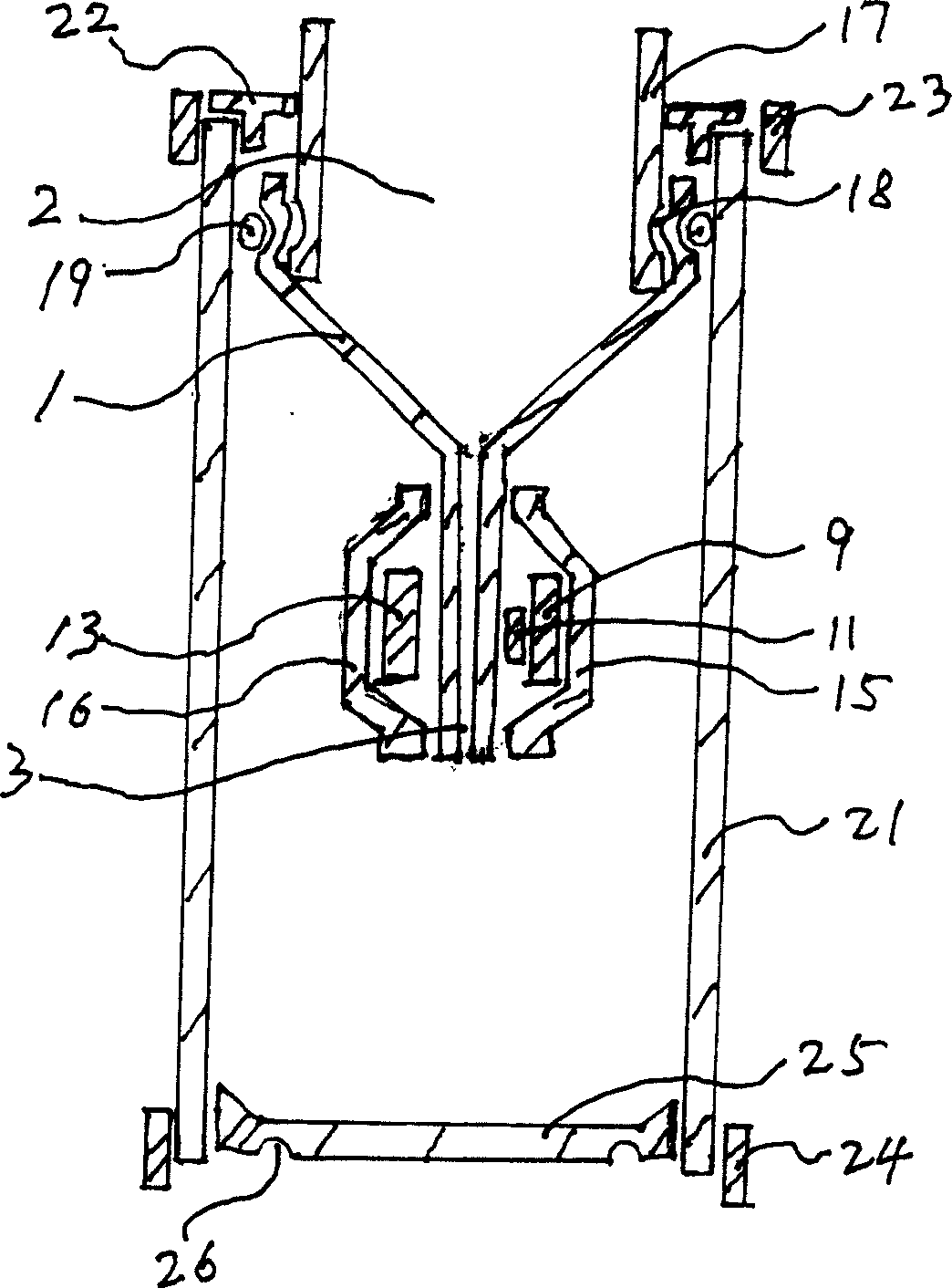

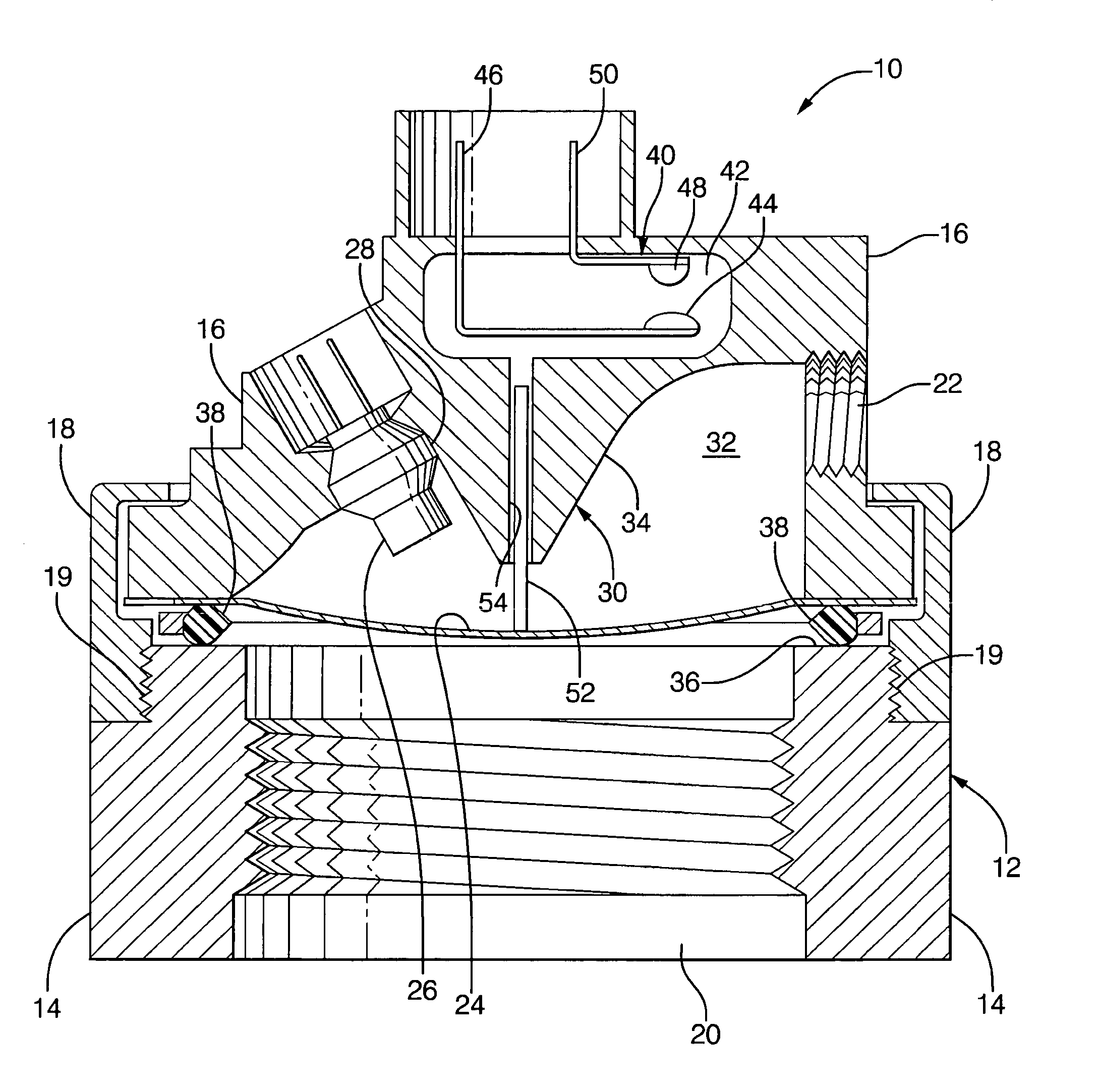

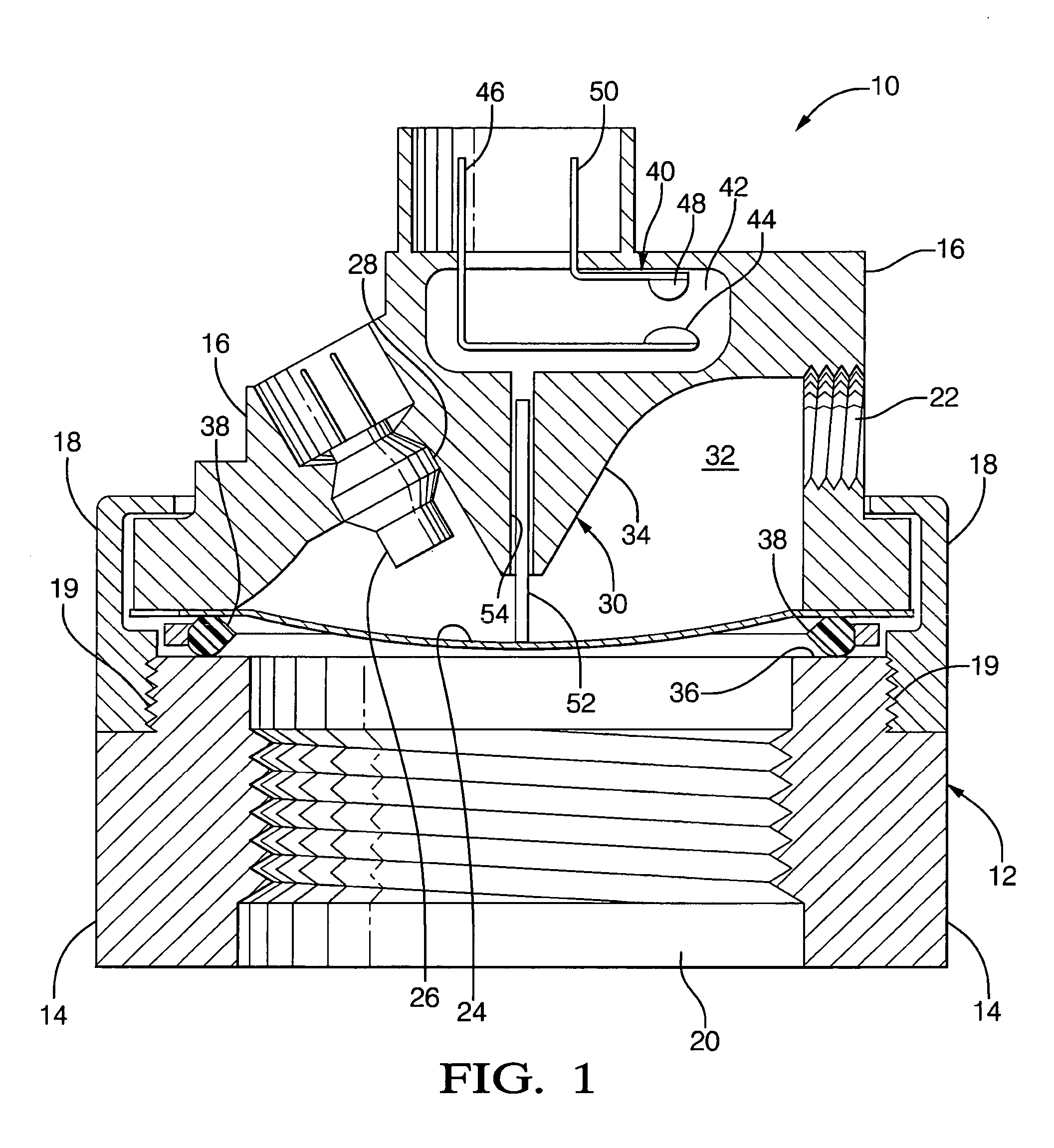

Blowoff valve assembly with integrated pressure switch

A blowoff valve assembly includes a diaphragm separating a refrigerant connection from an ambient port open to the atmosphere. The refrigerant connection is preferably connected to air conditioning system such that the diaphragm is in contact with refrigerant from the system. The diaphragm is deflectable based on the pressure of the refrigerant and is operatively connected to a switch. When pressure of the refrigerant drops to a predetermined level, the diaphragm deflects to activate the switch. Additionally, the assembly also includes a detonable squib that explodes and ruptures the diaphragm, allowing the refrigerant to flow from the refrigerant connection to the atmosphere. Additional features, such as sensors for detecting refrigerant outside of the system, a collision subsystem, and an associated controller are also disclosed.

Owner:DELPHI TECH INC

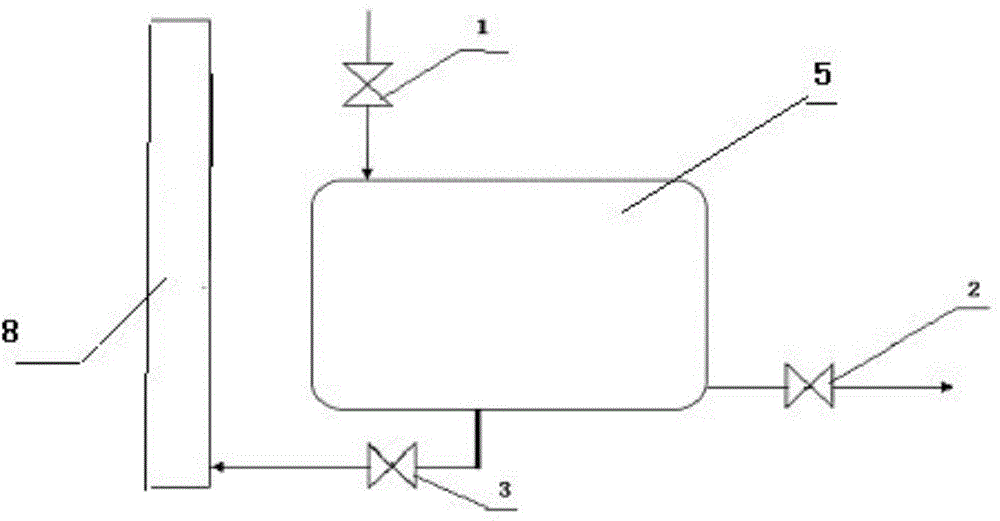

Solid phase and liquid phase integrated methane fermenting device

InactiveCN102212462ASimple structureEasy to operateGas production bioreactorsWaste based fuelBlowoff valveSludge

The invention relates to a solid phase and liquid phase integrated methane fermenting device. In the solid phase and liquid phase integrated methane fermenting device, a fermenting tank is divided into an upper part solid phase methane fermenting region and a lower part liquid phase methane fermenting region; substances of the two phases are separated by a solid phase bottom board; degraded sludge in the solid phase methane fermenting region enters the liquid phase region along with methane liquid through a drain valve; a methane liquid and methane communicating pipe is vertically arranged on the solid phase bottom board; and the methane liquid and methane communicating pipe is connected with the wall of the fermenting tank through two layers of shell-breaking cutting arms which are welded relatively interlacedly. According to the structure, shells can be broken automatically; the strength of the solid phase bottom board can be improved; raw materials are injected into the fermenting tank through a feeding slot and a slurry pump; methane slag and methane liquid are separated by a sieve plate; the slurry in the methane liquid is discharged from a blowoff valve at the bottom; and clear liquid is injected into the feeding slot through a connected valve. The solid phase and liquid phase integrated methane fermenting device has a simple structure, is convenient to operate and can be operated continuously; the shells can be broken automatically by utilizing lifting of liquid level, the solid phase and the liquid phase are fermented respectively, and degradation is performed completely; the fermenting raw materials, the methane slag and the methane liquid can realize double phase separation without power; and the methane liquid is recycled, so that blowdown load can be reduced.

Owner:SHENYANG AGRI UNIV

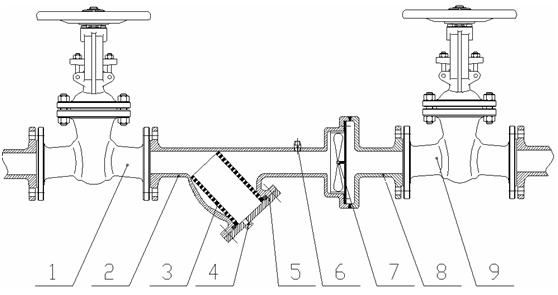

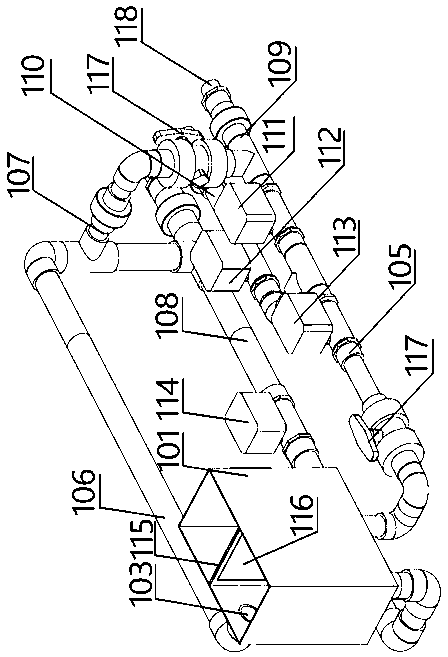

Repeated foaming device for gathering and delivering pipeline of foam drainage gas-production well

The invention relates to a repeated foaming device for a gathering and delivering pipeline of a foam drainage gas-production well in the natural gas gathering and delivering process. The repeated foaming device can solve the difficulty that natural production of a gas well is influenced by liquid accumulation, even blockage of the gathering and delivering pipeline, caused by foam burst and gas-liquid layering in the the gathering and delivering pipeline of the foam drainage gas-production well. A technical scheme of the invention is that an inlet gate valve is connected with an upstream gathering and delivering pipeline; the other end of the inlet gate valve is connected with a device housing A; a flange cover is arranged below the device housing A; a blowoff valve is arranged on the cover; one end of a filter cartridge is connected with an inlet of the device housing A while the other end thereof is connected with the blowoff valve; a hydraulic quick joint is mounted above the device housing A; a stirring blade is mounted on an outlet of the device housing A; an inlet end of a device housing B is connected with an outlet end of the device housing A; an outlet end of the device housing B is connected with an outlet gate valve; and the other end of the outlet gate valve is connected with a downstream gathering and delivering pipeline. By using the invention, a foaming agent can be injected into the gathering and delivering pipeline so that the accumulated liquid in the pipeline can foam again; moreover, solid-phase impurities in the pipeline is filtered to be removed so as to avoid gas-liquid layering and pipeline blockage.

Owner:SOUTHWEST PETROLEUM UNIV

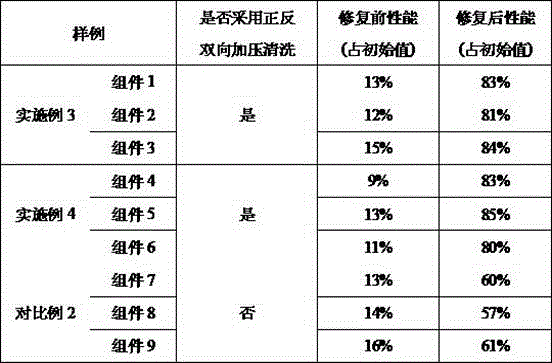

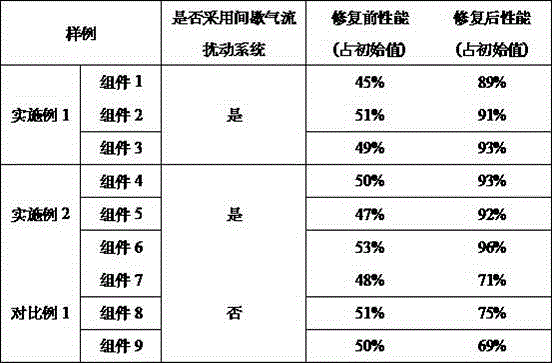

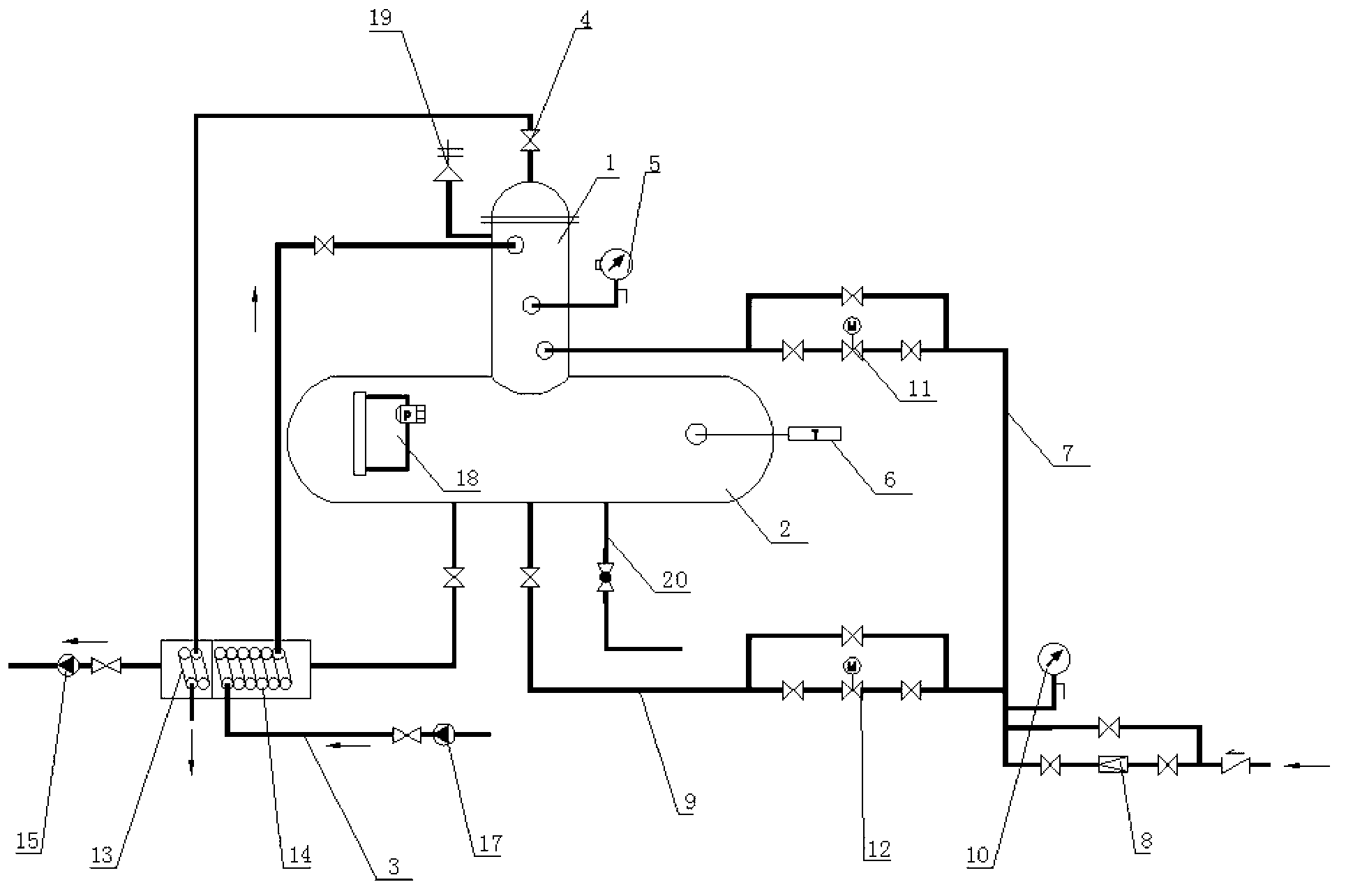

Cleaning device and method for hollow fiber gas separation membrane module

ActiveCN106621822APerformance fixesEasy to cleanSemi-permeable membranesDispersed particle filtrationBlowoff valveFiber

The invention discloses a cleaning device and method for a hollow fiber gas separation membrane module. The cleaning device is formed by the membrane module, a positive and negative bidirectional cleaning system, a ladder temperature purge system and an intermittent flow disturbance system. The positive and negative bidirectional cleaning system consists of a cleaning fluid tank, a cleaning pump, a pressure gauge, a positive and negative bidirectional cleaning pipeline and a blowoff valve. The ladder temperature purge system consists of an air compressor, a flowmeter, a control system, a heater, a purge pipeline and a blowoff valve. The intermittent flow disturbance system consists of an air compressor, a flowmeter, a control system, a disturbance gas flow generator, a check valve and a gas escape valve. The device disclosed by the invention can clean membrane modules in different pollution conditions; by a comprehensive cleaning effect of the intermittent flow disturbance system, the positive and negative bidirectional cleaning system and the ladder temperature purge system, performance of the membrane module is entirely repaired. The cleaning device and method are high in cleaning efficiency for the membrane module, good in effect, low in cost, simple in process and convenient to operate, and save enormous cost of replacing the membrane module.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

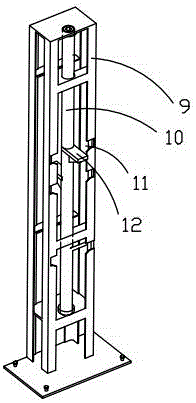

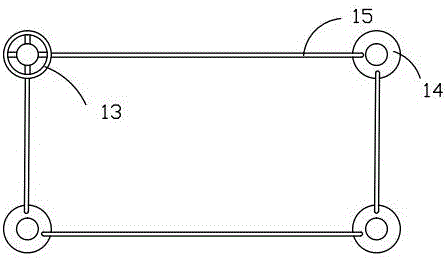

Water lift platform

The invention provides a water lift platform which comprises two bearing beams, a support frame arranged at two ends of the bearing beams and used for supporting the same, panels fixedly arranged on the upper surfaces of the bearing beams and a plurality of buoyancy boxes fixedly arranged at bottoms of the bearing beams, the buoyancy boxes include opening buoyancy boxes and sealed buoyancy boxes, the bottom of each opening buoyancy boxes is provided with an opening while the top of each opening buoyancy boxes is provided with an inflation pipeline, the inflation pipelines are communicated with a main gas supply pipeline, one end of the main gas supply pipeline is closed while the other end is connected with a blowoff valve or an inflation valve, compressed air is sealed in the sealed buoyancy boxes, the inflation valve is communicated with a compressed air supply, the support frame comprises an upright, a rotating shaft rotatably arranged in the upright, a plurality of notches formed in the upright and a plurality of support plates fixedly arranged on the rotating shaft, and the support plates are in one-to-one correspondence with the notches. The water lift platform is simple in structure and convenient in adjustment.

Owner:江阴四方游泳康复产业股份有限公司

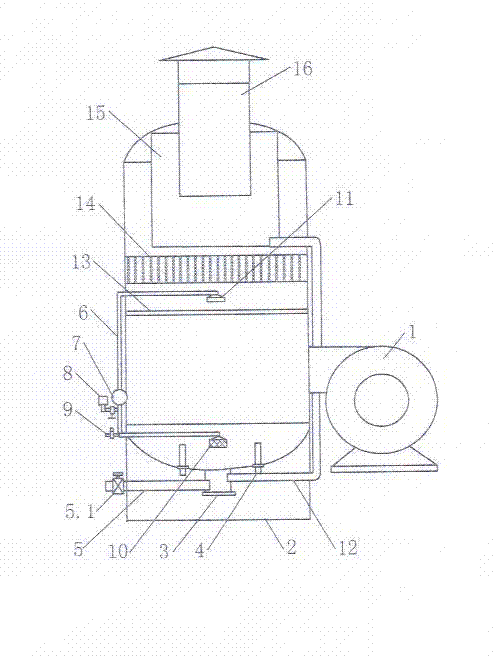

Paint mist purification treatment device

InactiveCN102772972AReduce pollution damageReduce harmCombination devicesBlowoff valveSolenoid valve

The invention provides a paint mist purification treatment device. A drain outlet is formed on the lower part of a purifier, and an exhaust pipe is arranged on the upper part of the purifier; a fan is arranged on one side of a purifier shell; one side of the drain outlet is connected with a sewage backflow pipe, and the upper end of the sewage backflow pipe is communicated with a dustiness separator; a discharge pipe provided with a blowoff valve is connected to the other side of the drain outlet; an additive tank is connected with a water supply pipe; a water supplement solenoid valve, the additive tank and a circulating water pump are arranged on the water supply pipe; a water inlet filtering net and a spray header are respectively communicated with the water supply pipe through a pipeline; a heater and a filtering net are arranged in the purifier shell; a steam-water mixer and the dustiness separator are arranged on the upper part of the spray header; and the dustiness separator is communicated with an exhaust port. The paint mist purification treatment device has the characteristics of being high in working efficiency and good in treatment effect, protecting the environment and preventing personal injury, and is suitable to be applied to the process of purifying paint spraying dust and paint mist in the utensil painting industry.

Owner:葫芦岛市滨海宇通自动化控制有限公司

Heat filler type deaerator with stable deaerating function and atomizing function

InactiveCN103292311AConstant and reliable water levelEnsure water qualityLiquid degasificationBlowoff valveDifferential pressure

The invention discloses a heat filler type deaerator with a stable deaerating function and an atomizing function. The heat filler type deaerator is characterized in that a heat-side inlet of an exhaust heat exchanger is communicated with a blowoff valve through a pipeline, a cold-side inlet of the exhaust heat exchanger is communicated with a deaerator water supply pipe, a cold-side water outlet of the exhaust heat exchanger is communicated with a deaerator water supply inlet through a pipeline, a heat-side inlet of a water outlet heat exchanger is communicated with a deaerator water outlet, a boiler water supply pump is connected to a heat-side outlet pipeline, a cold-side water inlet of the water outlet heat exchanger is communicated with the deaerator water supply pipe, a water supply pump is arranged on the deaerator water supply pipe, a differential pressure transmitter is arranged in a deaerator water tank, detected water level signals in the deaerator water tank are transmitted to a controller through the differential pressure transmitter, the controller transmits signals to a frequency converter, the frequency converter controls rotation speed of the water pump to adjust water supply, a pressure control gauge transmits pressure signals to the controller which controls opening of preheating pipeline electromagnetic valves, a temperature sensor transmits temperature signals to the controller, and then the controller controls opening of reheating steam electromagnetic valves.

Owner:JIHUA 3539 SHOE MAKING

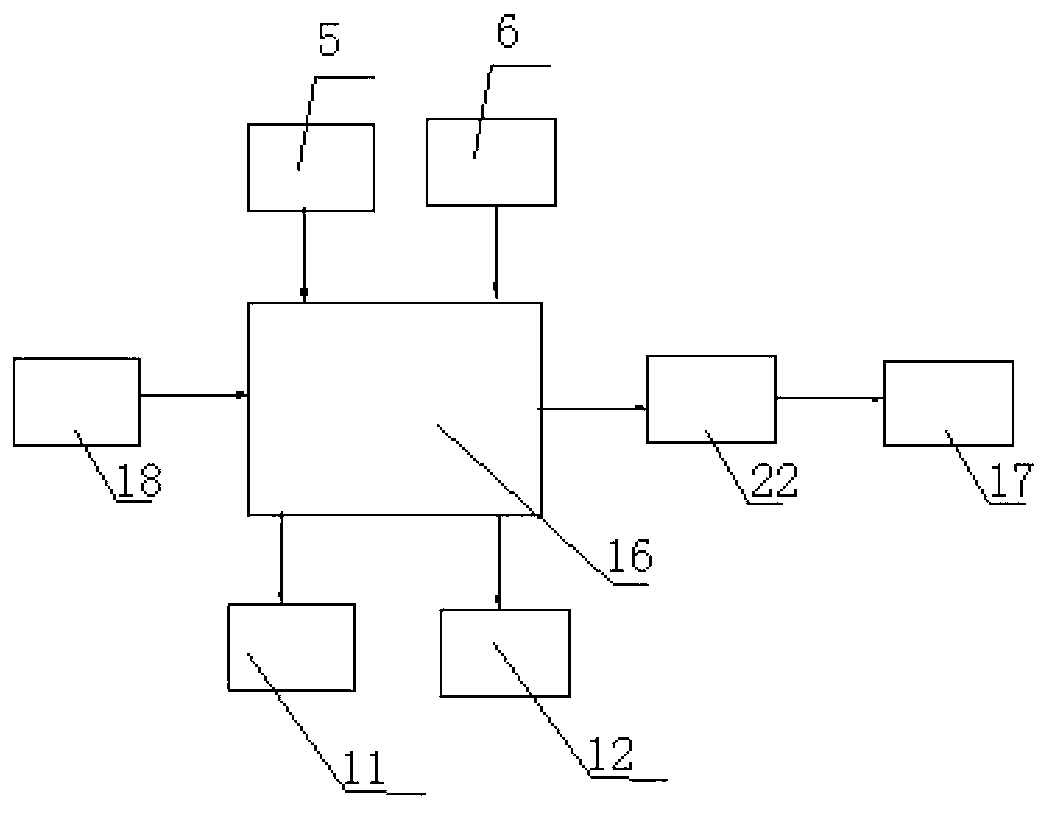

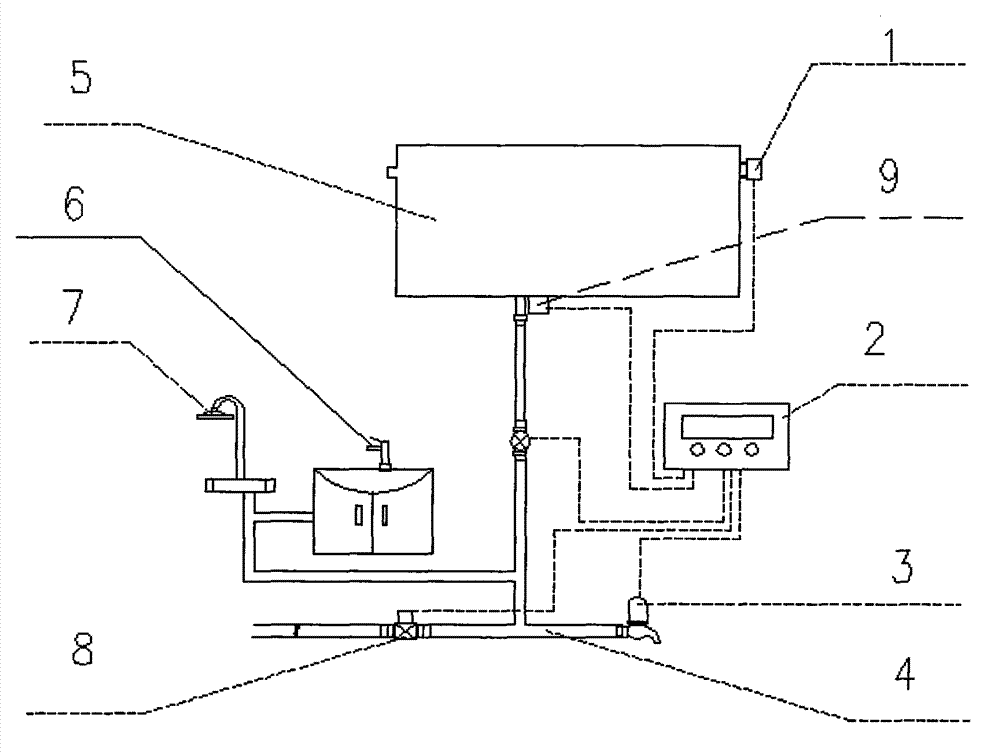

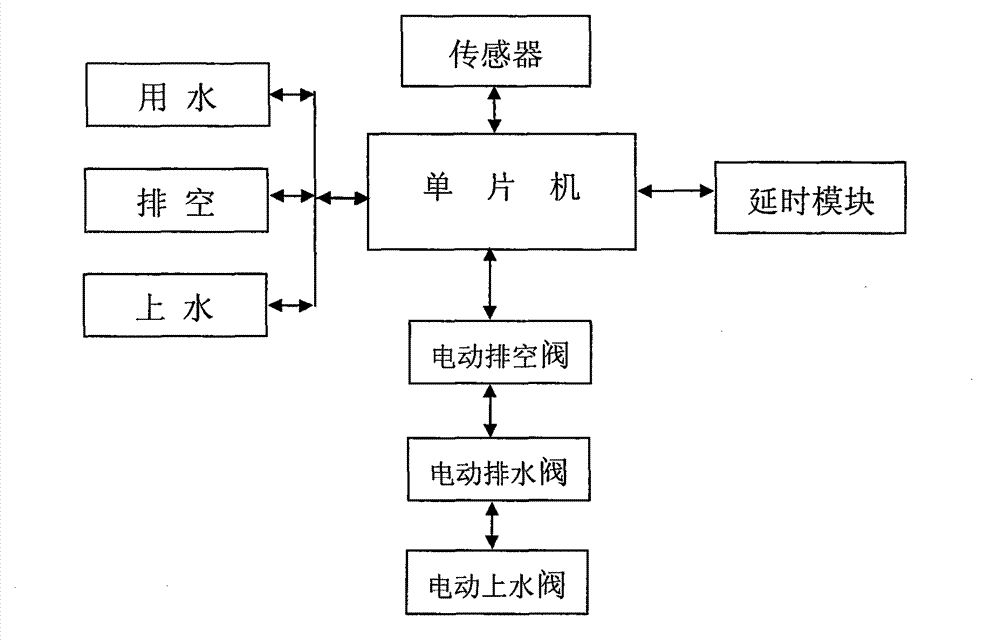

Full-automatic pipeline emptying and antifreezing system and control method

InactiveCN102967066AAvoid influenceGuaranteed uptimeSolar heat devicesSolar thermal energy generationMicrocontrollerBlowoff valve

The invention relates to a pipeline emptying and antifreezing system and a control method in the field of solar water heaters, and in particular to a full-automatic pipeline emptying and antifreezing system and a control method. The technical scheme is that the system comprises a water tank of a water heater, a water pipeline, a control instrument, an electric blowoff valve, an electric drain valve, an electric water filling valve, a sensor, a water faucet, a shower nozzle and the like, wherein the system is controlled through a singlechip program and is alternately switched on and off to be delayed for more than 3 seconds, and when water is used, the indoor electric drain valve is closed after being delayed for more than 10 seconds at least. The control method is that when the front end of the electric drain valve is bent to form a 'U' shape, air in the pipeline is smoothly discharged, so that the influence which is caused by the 'U'-shaped bending to the system is basically solved, the technical bottleneck which influences pipeline emptying and antifreezing all the time is broken through, automatic control is realized, and the purposes of convenience in use and high reliability are realized.

Owner:江苏晓红太阳能科技有限公司 +2

Recovery system of mould corrosive wash solution, namely sodium hydroxide

InactiveCN107055573ALow production costImprove etching efficiencyAlkali metal oxides/hydroxidesBlowoff valveSludge

The invention discloses a recovery system of a mould corrosive wash solution, namely sodium hydroxide. The system comprises a storage container, a mould boiling container and a reaction tank. A blowoff valve is arranged on the bottom of one side of the storage container, the other side of the storage container is connected with a liquid inlet of the mould boiling container through a pipe line I, an air discharging pipe is arranged on a top cover of the mould boiling container, the reaction tank is of a hollow structure with an opening in the top, stirring blades are arranged in the reaction tank, a liquid inlet in one side of the reaction tank is connected with a liquid outlet of the mould boiling container through a pipeline II, a conveying pump I is arranged on the pipeline II, an air inlet pipe is located at the position, above the pipeline II, of the reaction tank, a liquid outlet in the other side of the reaction tank is connected with a liquid inlet in the top of the storage container through a pipeline III, and a conveying pump II is arranged on the pipeline III. According to the recovery system, the sodium hydroxide solution containing NaAlO2 is converted into a sodium hydroxide solution which can be utilized again and dry sludge obtained through aluminum hydroxide sedimentation, the system saves more energy and is more environmentally friendly, and the corrosive wash efficiency of an extrusion mould is effectively improved.

Owner:JIANGSU JIALV IND

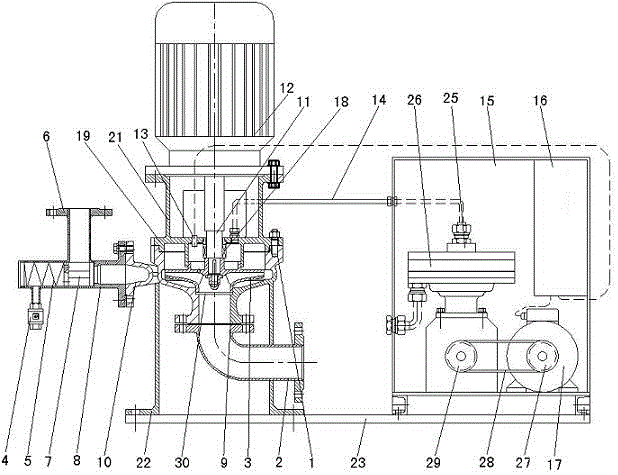

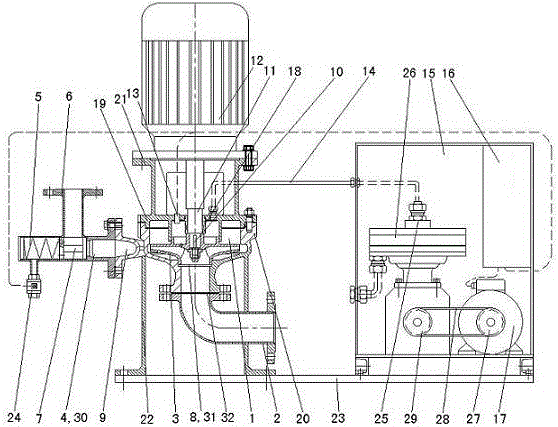

Automatic control type efficient self sucking pump

InactiveCN105736388ARapid positioningShort self-priming timePump componentsPriming pumpBlowoff valveElectricity

The invention relates to an automatic control type efficient self sucking pump. The automatic control type efficient self sucking pump comprises a pump body, a motor, an automatic exhausting and vacuumizing device and an intelligent control box; a liquid inlet is formed in the bottom of the pump body and is connected to an inlet elbow, a liquid outlet is formed in the side surface of the pump body and is connected to an automatic blowoff valve, an outlet stand pipe is arranged on the top of a valve body of the automatic blowoff valve, and the bottom of the valve body of the automatic blowoff valve is connected to a return pipeline through a return valve; a rotation shaft of the motor is connected to a pump shaft through a coupling, a pump cover is arranged between the pump body and the motor, a cavity formed by the pump body and the pump cover is a pump cavity, and an impeller is arranged inside the pump cavity; the pump cover is provided with an inductive probe and a vacuumizing and exhausting hole, an exhausting pipeline is installed on the vacuumizing and exhausting hole, the automatic exhausting and vacuumizing device communicates with the pump cavity through the exhausting pipeline, and the motor, the inductive probe and the automatic exhausting and vacuumizing device are electrically connected to the intelligent control box through signal cables. The automatic control type efficient self sucking pump is simple and compact in structure, the self sucking function is realized by the automatic exhausting and vacuumizing device, and the hydraulic efficiency is high.

Owner:蒋燕群

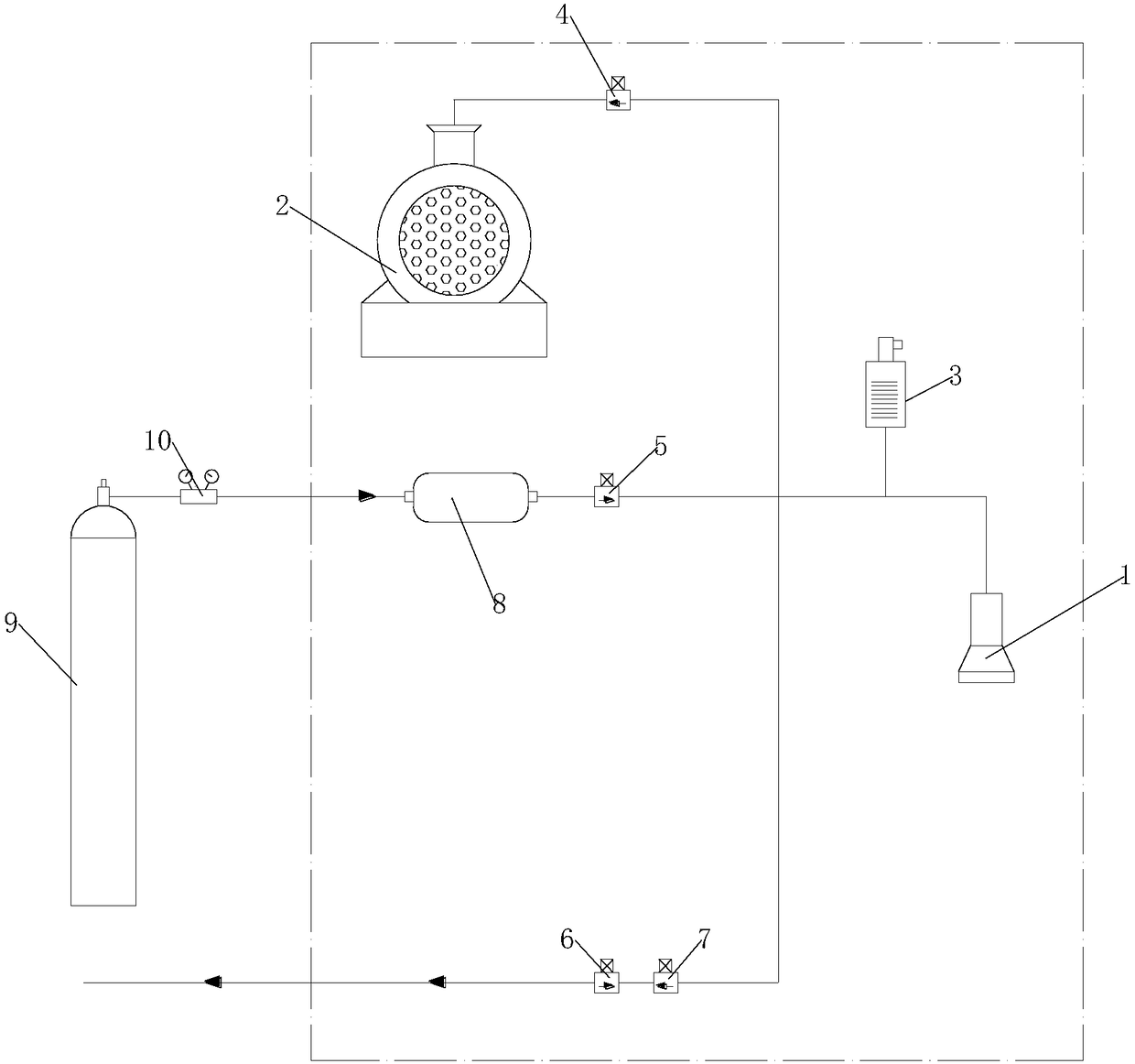

Automatic evacuation filling machine for nitrogen and hydrogen filling and leak detection

InactiveCN108488624AReduce gas costNo pollutionPipeline systemsFluid-tightness measurement using fluid/vacuumBlowoff valveGas cylinder

The invention discloses an automatic evacuation filling machine for nitrogen and hydrogen filling and leak detection. The filling machine comprises a gas cylinder, a vacuum pump and a filter, and thevacuum pump is connected a four-way connection through a link pipe; the part, between the vacuum pump and the four-way connection, of the link pipe is provided with an evacuation valve, and the four-way connection is connected to an evacuation and air charging connection through the link pipe; and the part, between the four-way connection and the evacuation and air charging connection, of the linkpipe is provided with a pressure sensor, and the four-way connection is connected to an exhaust port through an exhaust pipe which is provided with a first blowoff valve and a second blowoff valve separately. The nitrogen and hydrogen mixed trace gas comprises 95% of nitrogen and 5% of hydrogen, and the detectable leak rate of the trace gas can also reach 1*10<-7> mbarl / s; moreover, the mixed gasis not explosive, safe and low in cost of gas sources, and the emission of the mixed gas does not cause environmental pollution; the filling machine integrates three processes of evacuation, fillingand discharge, and is high in degree of automation; and the filling machine is used for leak detection through cooperation of customers, and the working efficiency is improved greatly.

Owner:顾晓航

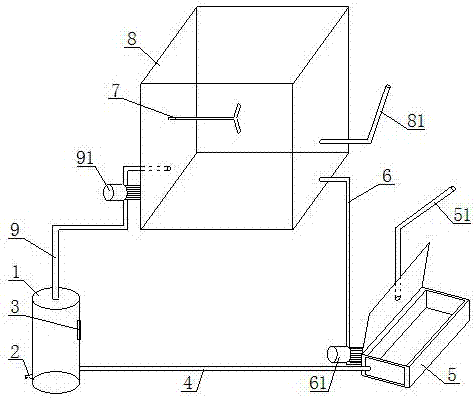

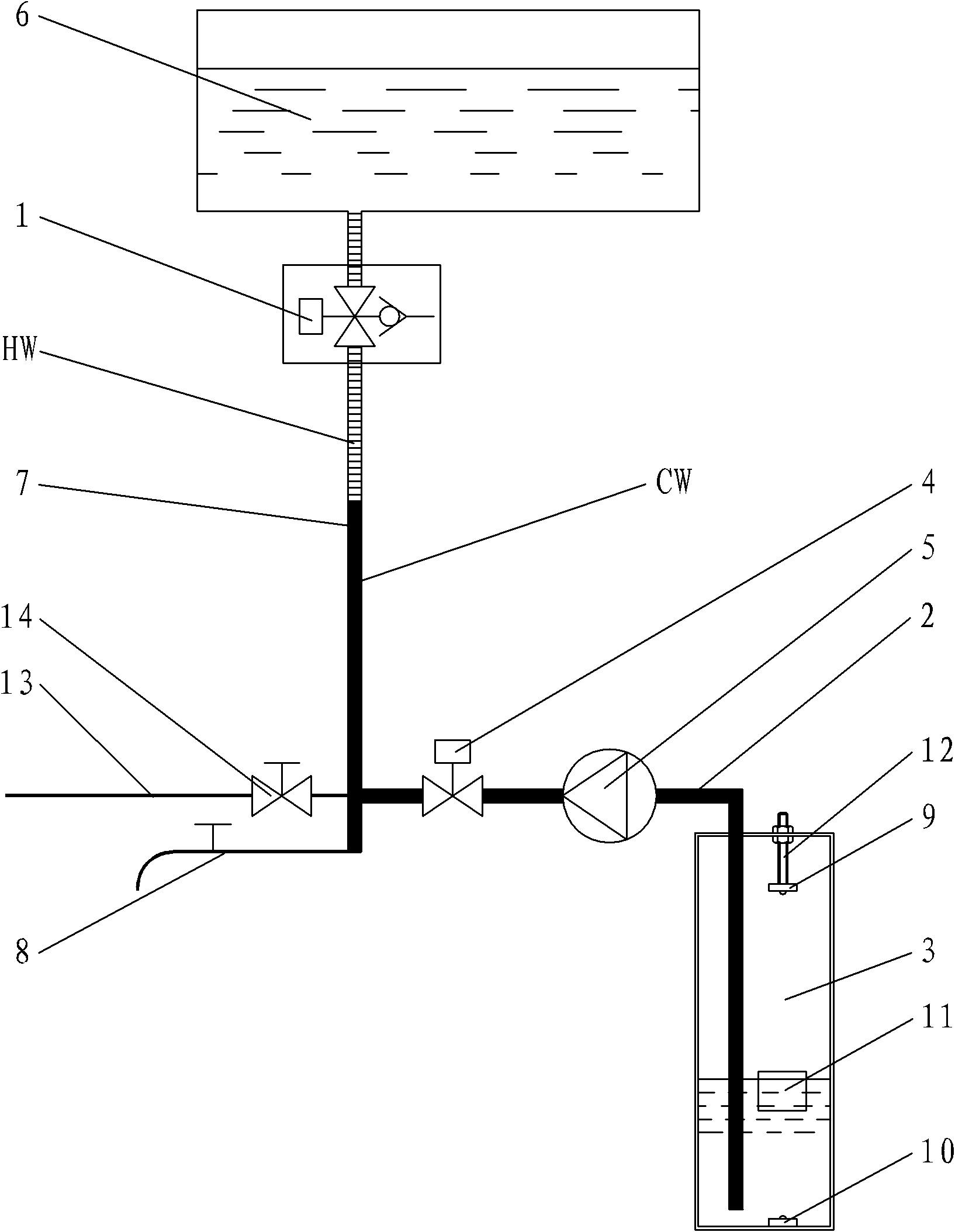

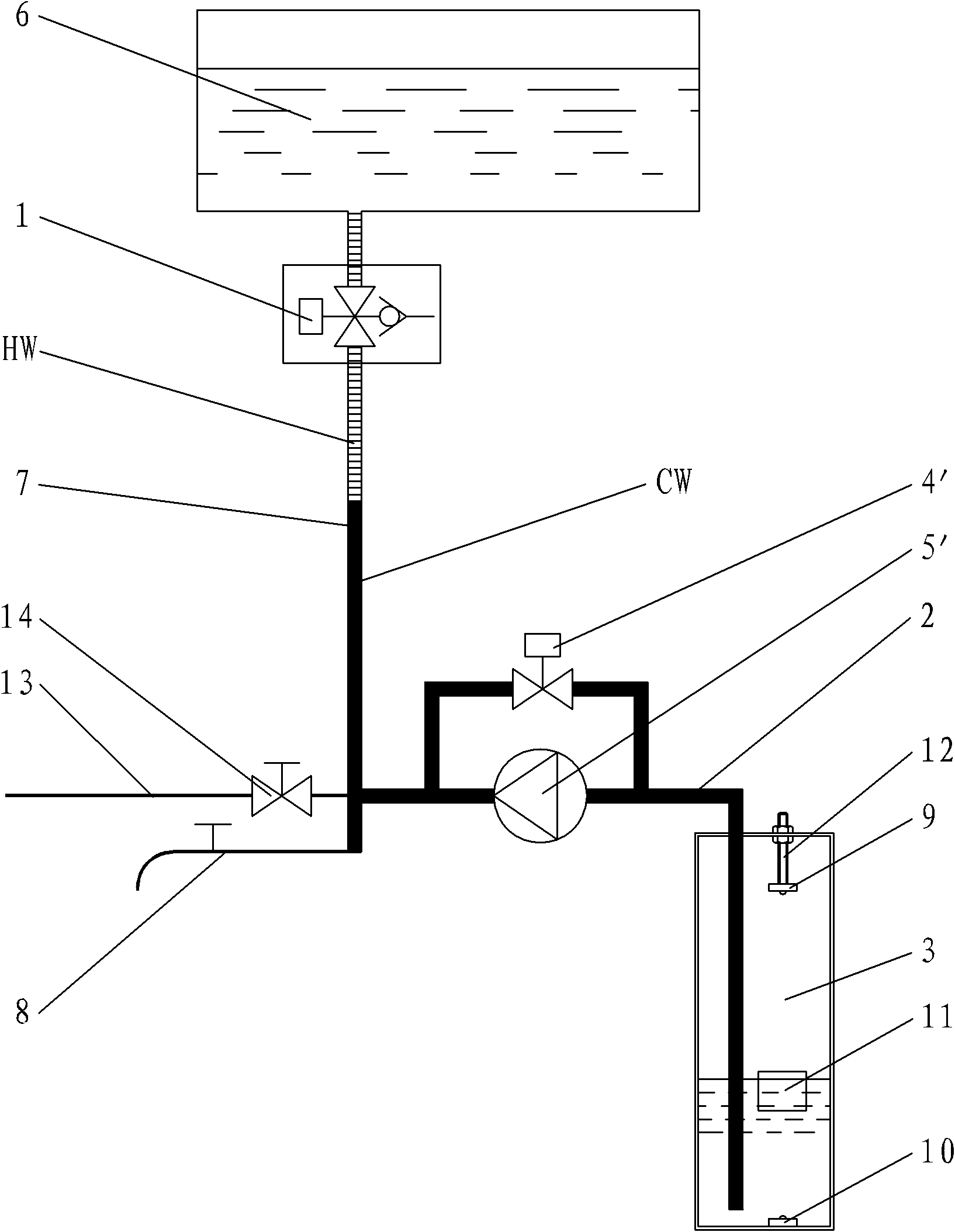

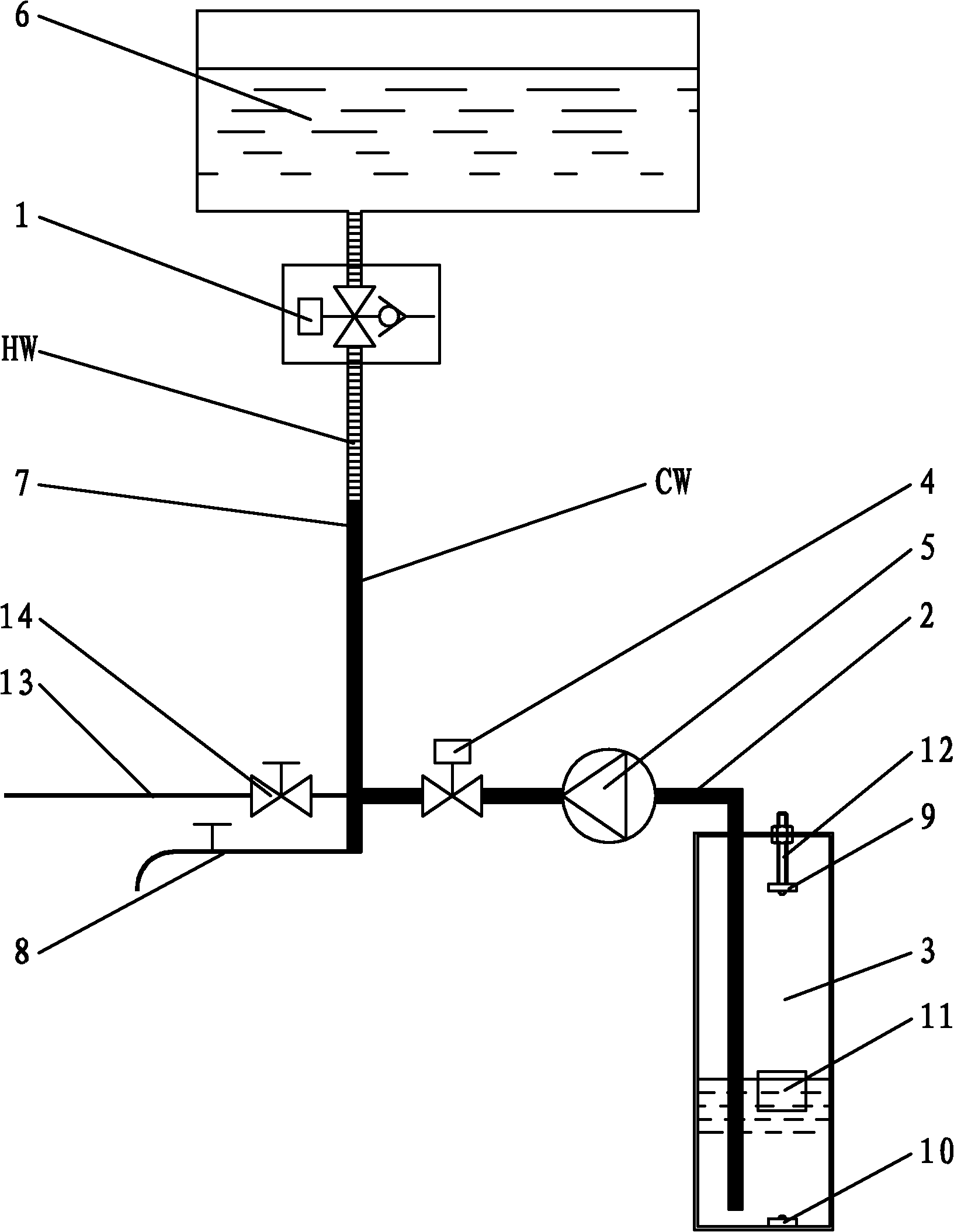

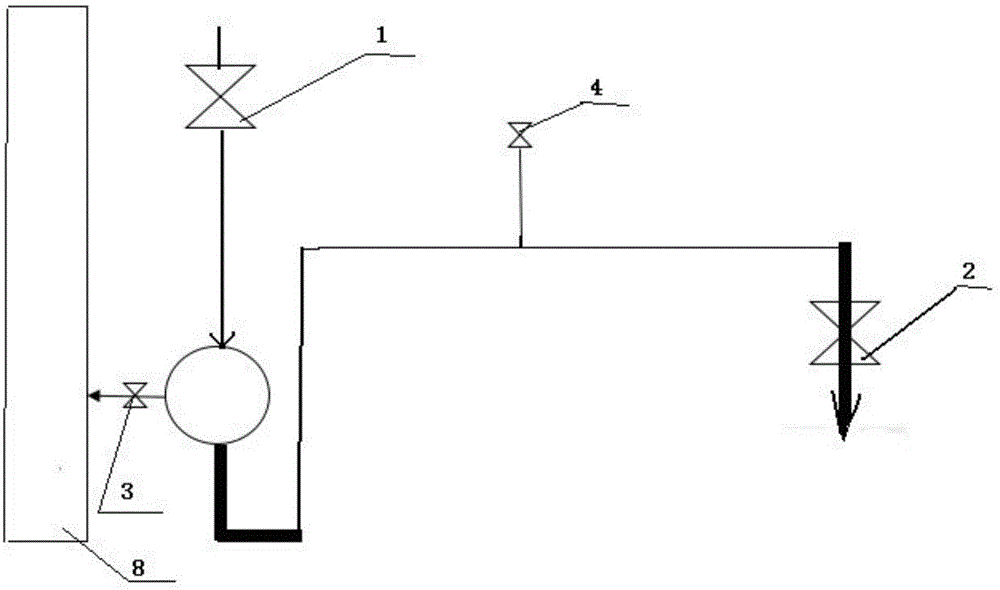

Hydraulic pressure type hot water recovery unit

InactiveCN101915471AAvoid wastingPrevent frost crackingSolar heat devicesSolar thermal energy generationWater savingBlowoff valve

The invention discloses a hydraulic pressure type hot water recovery unit, relating to a water-saving frost crack resistant device and aiming at providing a hydraulic pressure type hot water recovery unit which has simple structure, saves water and energy and can prevent pipelines from frost crack. The recovery unit is composed of a blowoff valve, a cold water pipe, a cold water tank, a cold water valve and a water pump, wherein the blowoff valve comprises three working holes, the first working hole is communicated with a hot water tank, the second working hole is communicated with an outlet valve via a hot water pipe, and the third working hole is communicated with external air; one end of the cold water pipe is connected on the junction of the hot water pipe and the outlet valve, and the other end thereof is arranged in the cold water tank; the water pump and the cold water valve are arranged on the cold water pipe; and the cold water tank is internally provided with a water level sensing device. When the outlet valve is opened, the first working hole and the second working hole of the blowoff valve are communicated, and the cold water valve and the water pump are closed; when the outlet valve is closed, the cold water valve is opened, and the water pump is started; and when the water level sensing device senses a low water level, the water pump is closed, and the second working hole and the third working hole are communicated.

Owner:施成福

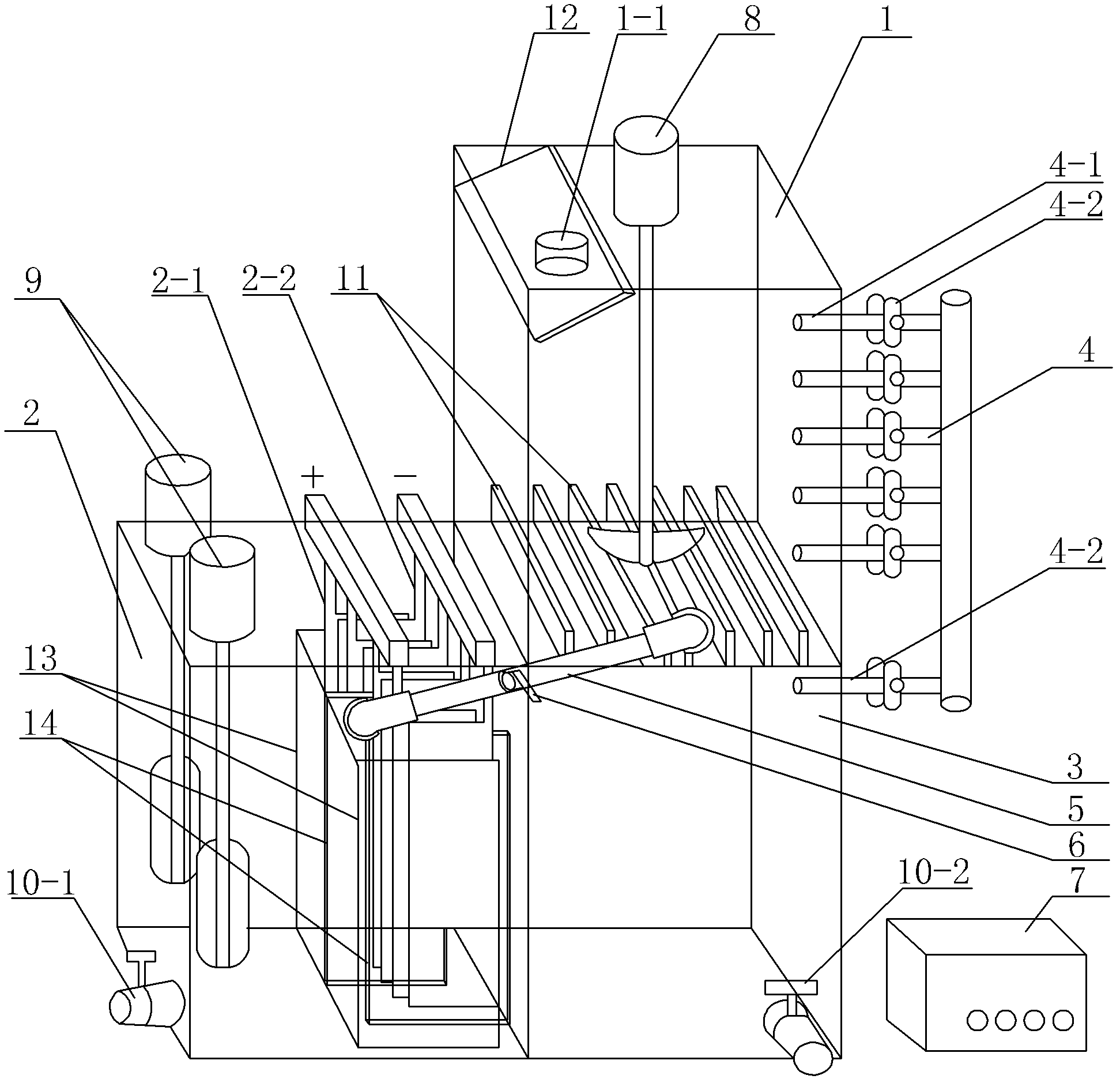

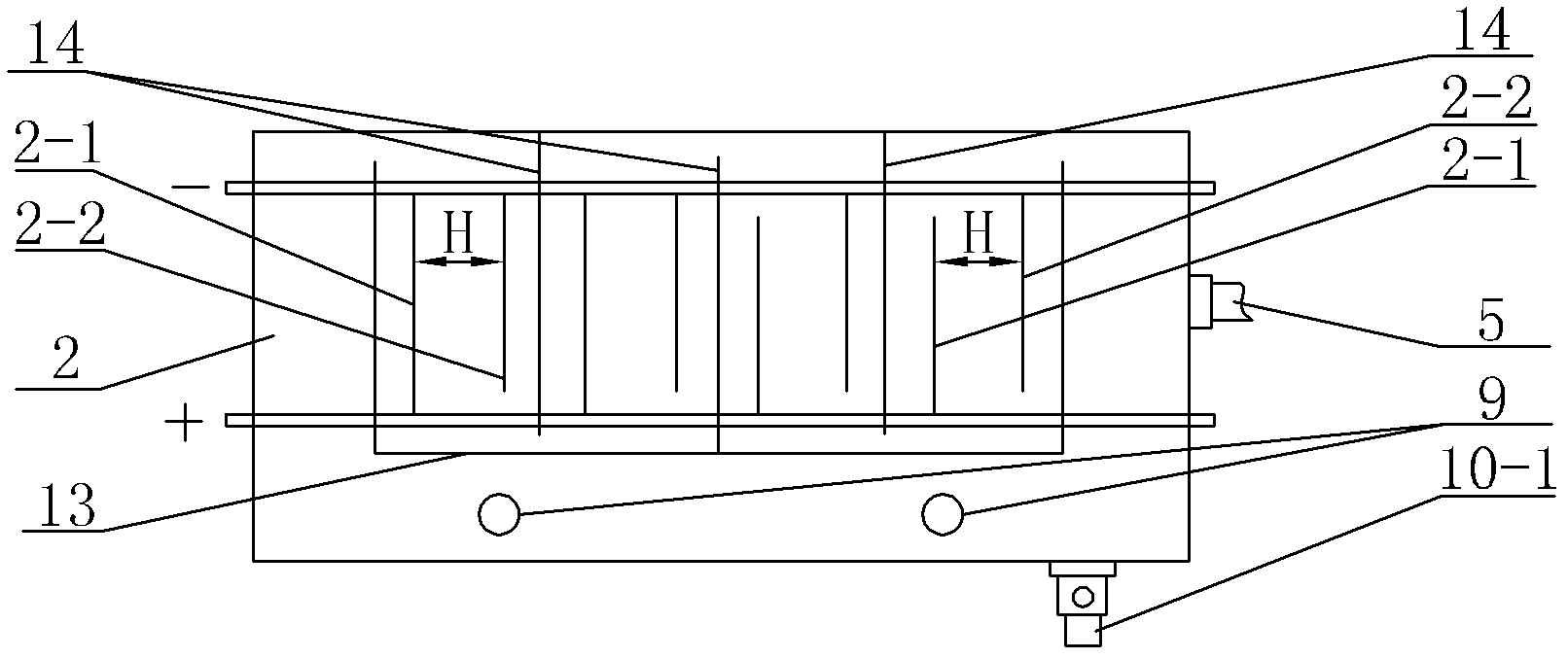

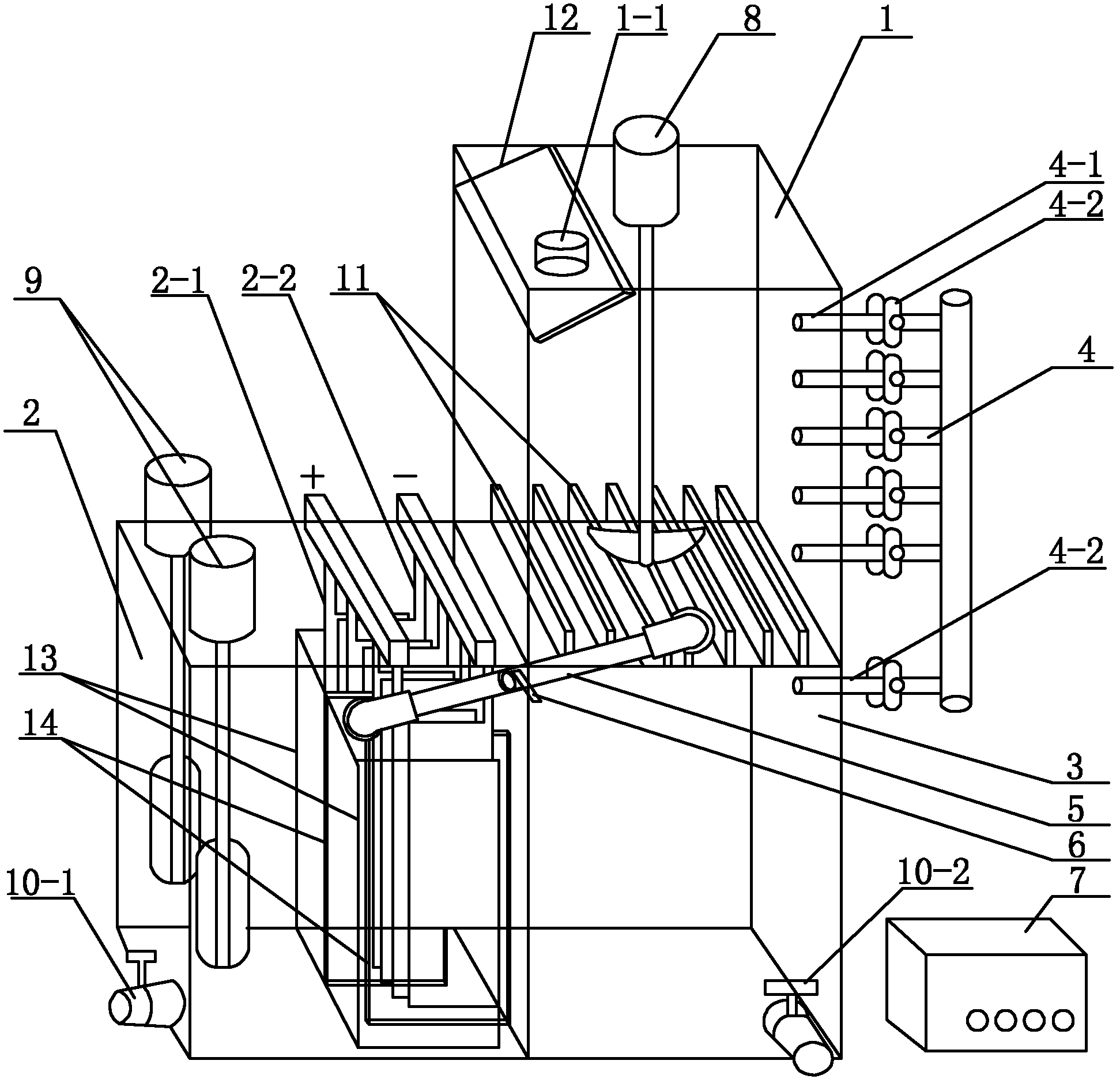

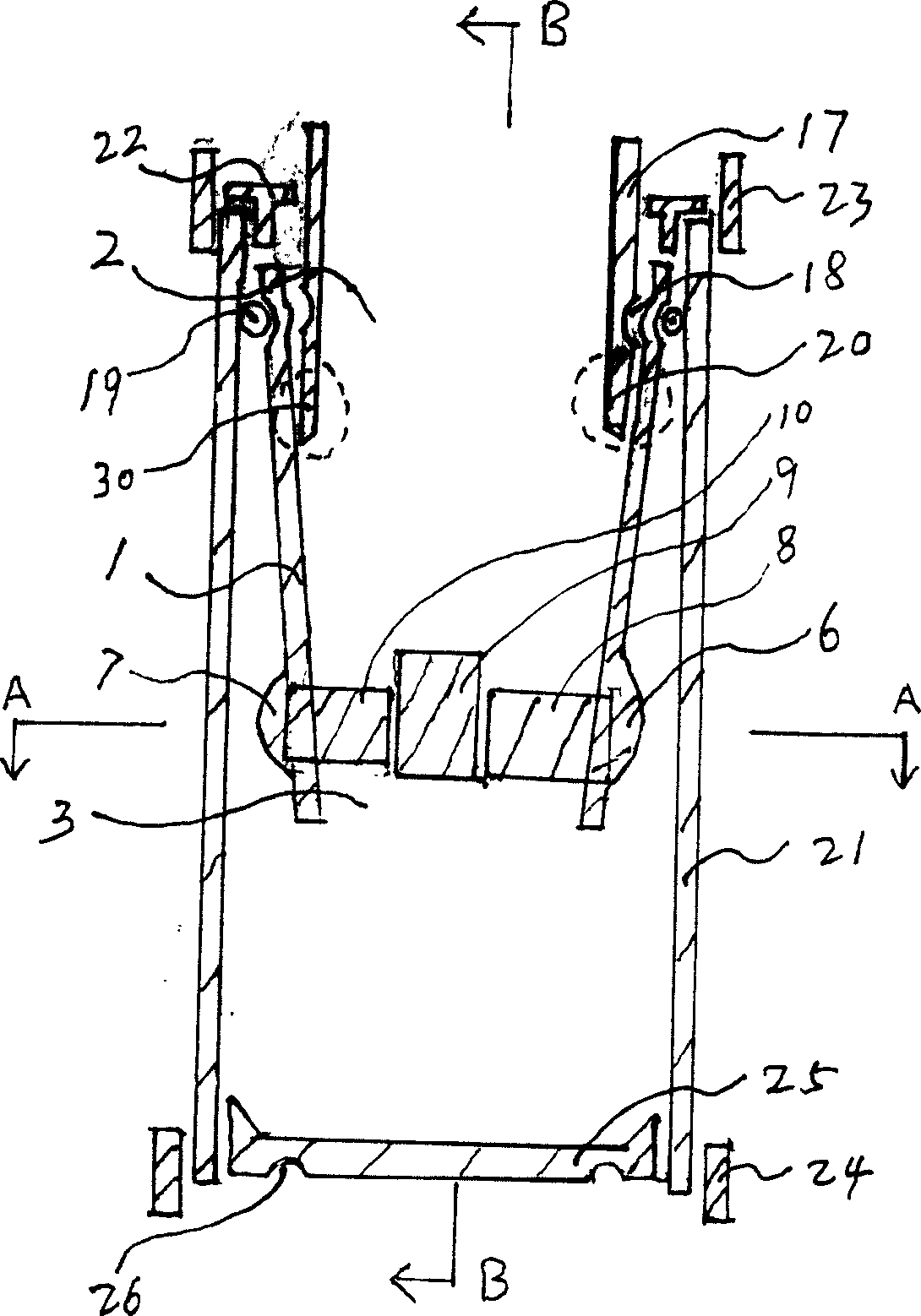

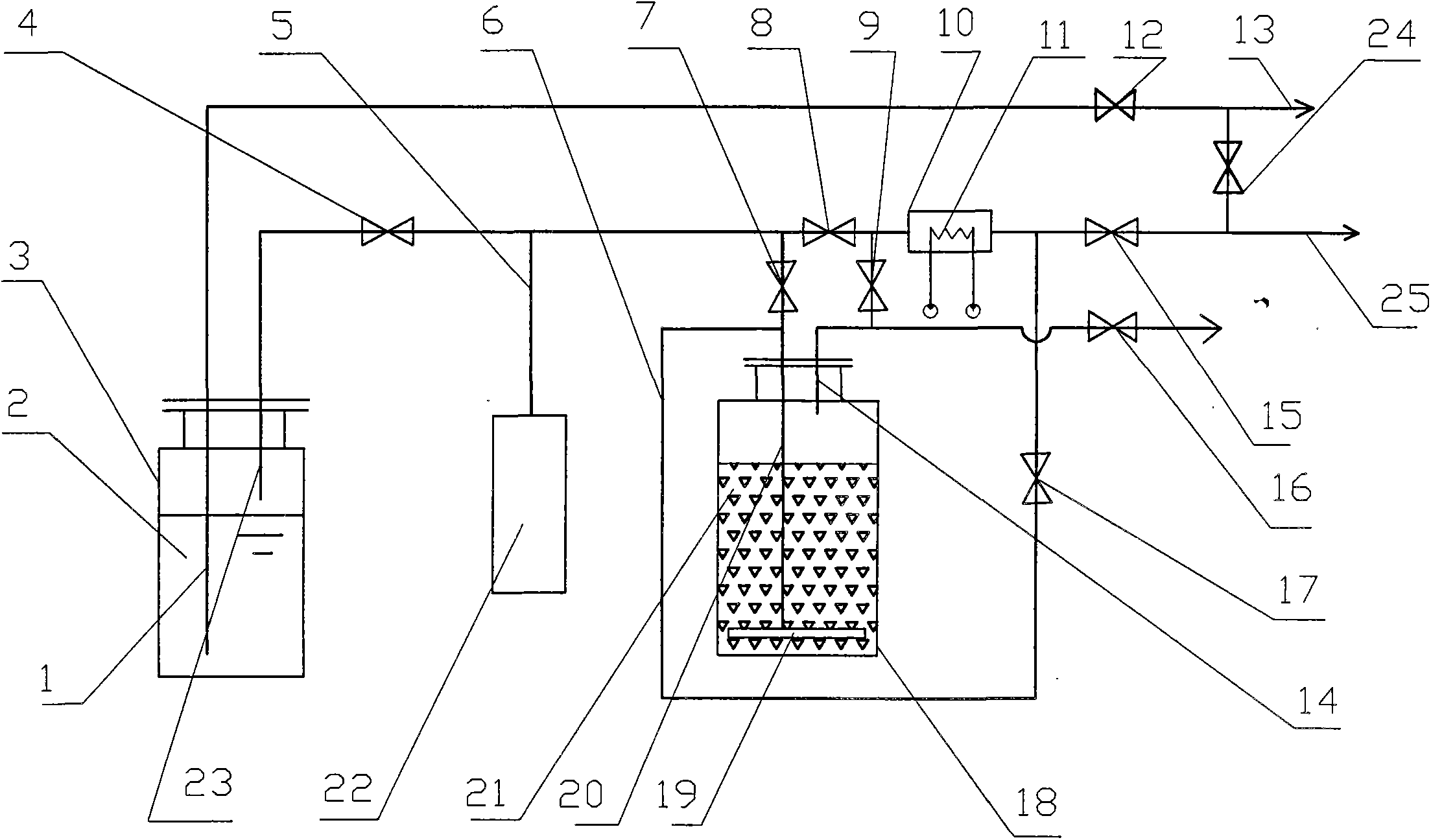

Silver recovery device for silver-containing waste liquor

ActiveCN102560537AReduce churnReduce pollutionPhotography auxillary processesBlowoff valveLiquid waste

The invention provides a silver recovery device for silver-containing waste liquor, relates to a silver recovery device, and specifically relates to a silver recovery device for laboratory and industrial silver-containing waste liquor. The silver recovery device is used for solving the problems of the prior art during the whole process from reaction to silver electrolysis that devices are scattered, the operation is complecated, the concentration polarization phenomenon is obvious, the electrolysis efficiency is low and the silver yield is low. The silver recovery device comprises a reaction tank, an electrolytic tank, a waste liquor tank, a liquid-draining pipe component, a liquid guide pipe, a switch valve, a first blowoff valve, a second blowoff valve, at least one first electric stirrer and at least two second electric stirrers, wherein the reaction tank, the electrolytic tank and the waste liquor tank are integrally manufactured; the electrolytic tank and the waste liquor tank are adjacent to each other; the reaction tank is arranged on the upper end face of the waste liquor tank; a liquid inlet is arranged on the upper end face of the reaction tank; the at least one first electric stirrer is arranged on the reaction tank; an anode of the electrolytic tank is composed of a plurality of first polar plates arranged in parallel; and a cathode of the electrolytic tank is composed of a plurality of second polar plates arranged in parallel. The silver recovery device is used for recovering the silver from the silver-containing waste liquor.

Owner:ERDOS ANXINTAI ENVIRONMENTAL PROTECTION TECH

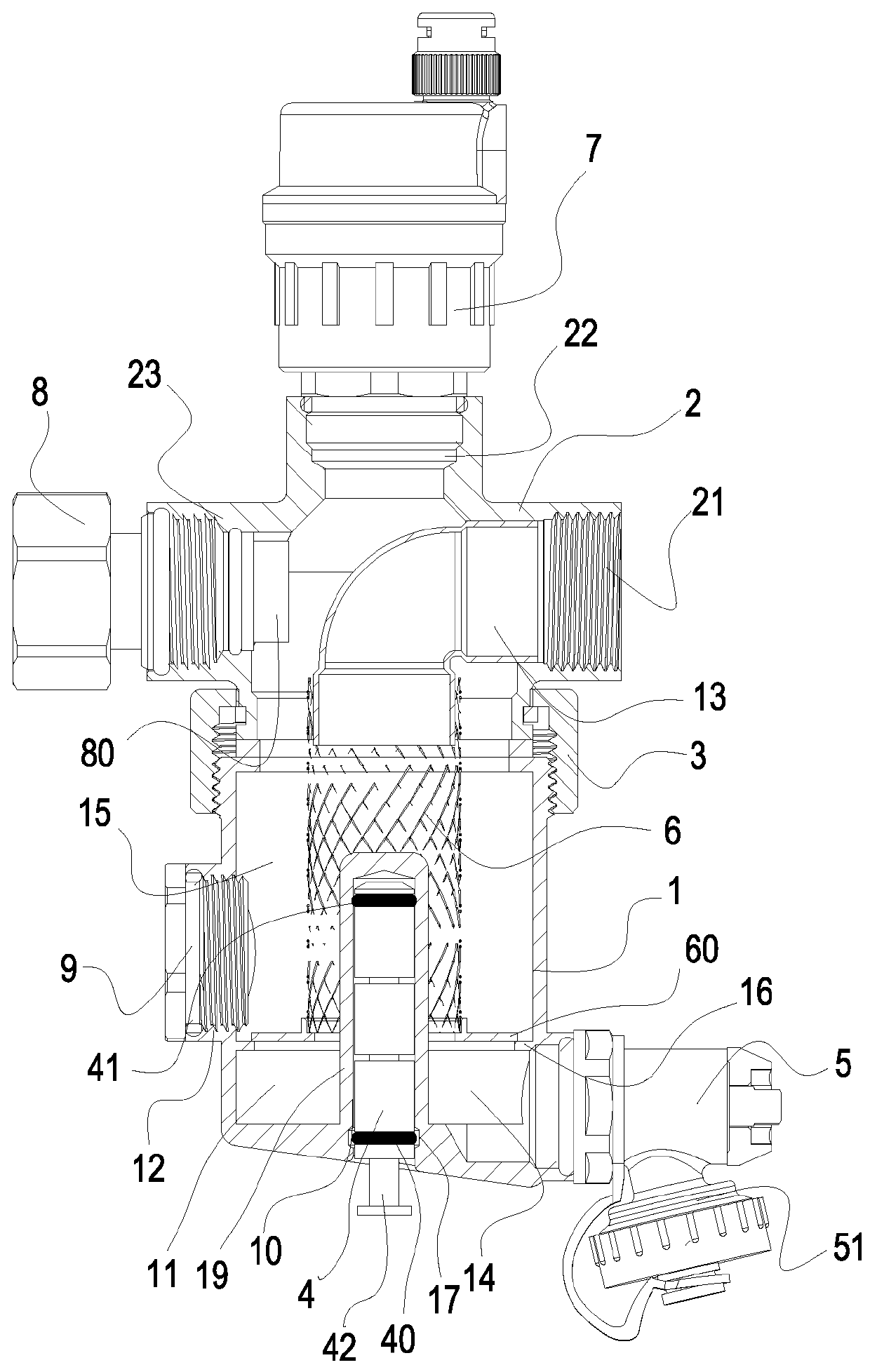

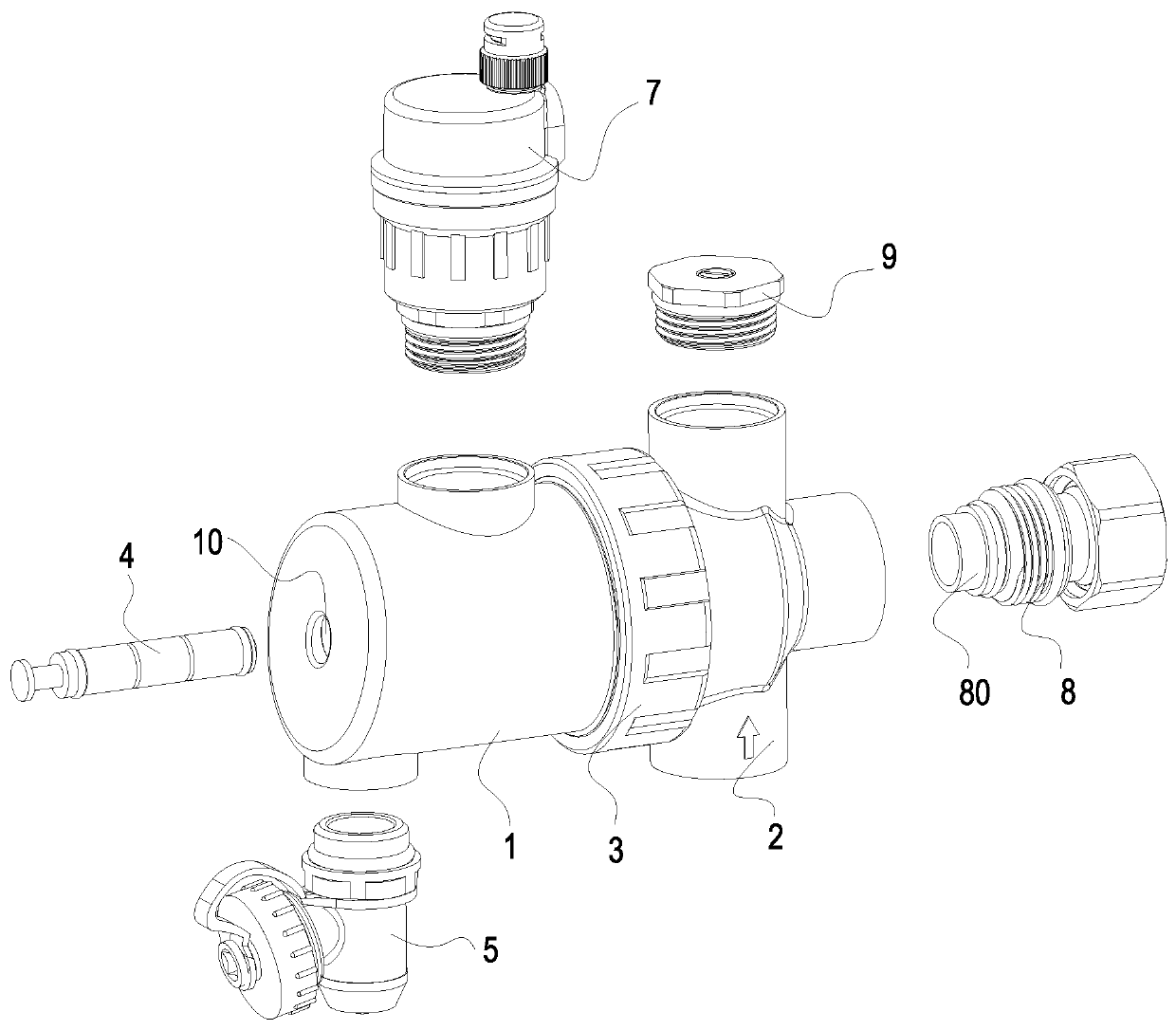

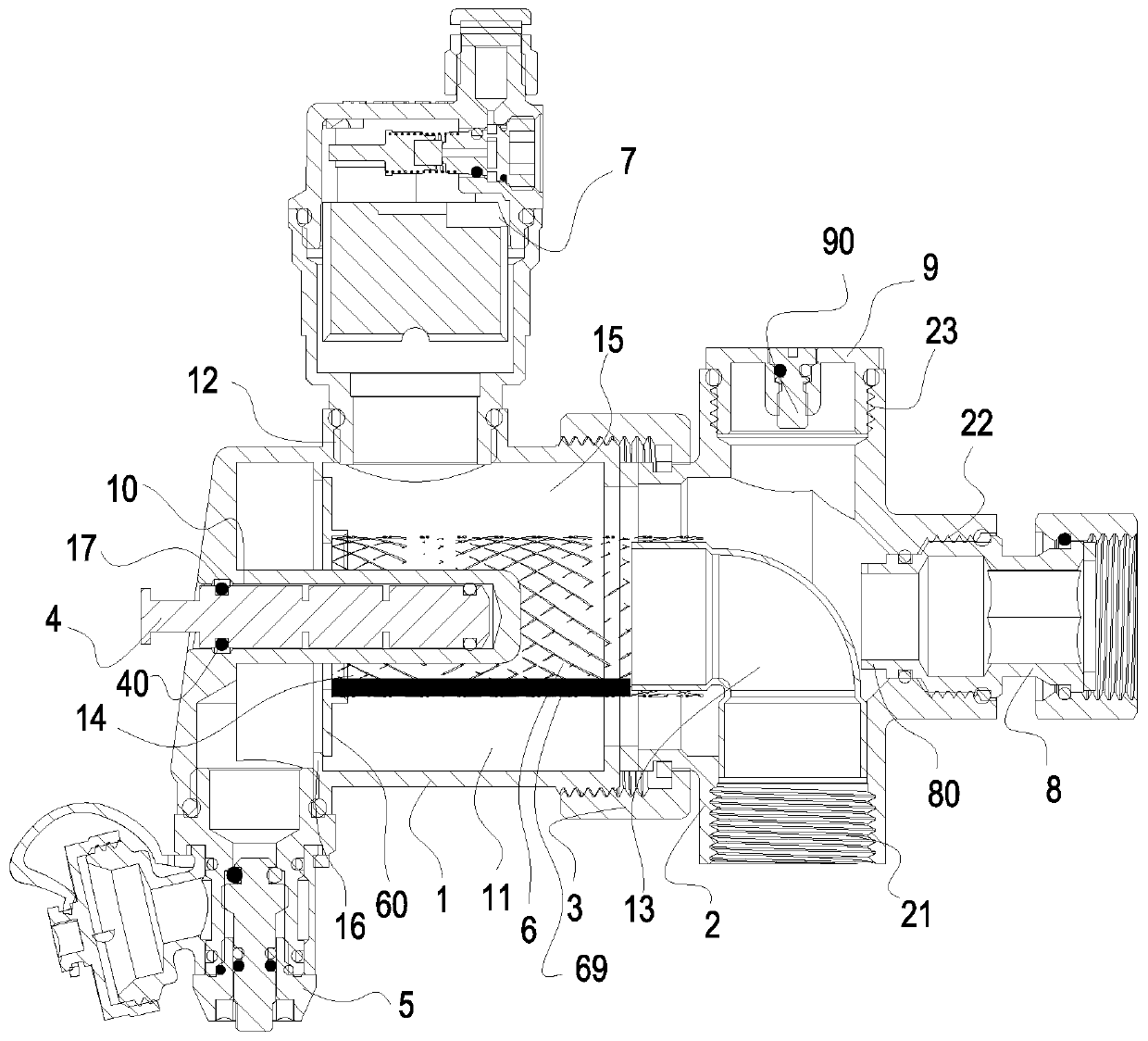

Multifunctional filter unit

ActiveCN110002660ASimple structureFlexible adjustmentTreatment involving filtrationMultistage water/sewage treatmentBlowoff valveBiochemical engineering

The invention relates to a filter unit, specifically to a filter unit for separating magnetic impurities, particle impurities and gases from a fluid. The filter unit is especially applicable to heating pipelines or air-conditioning systems. A multifunctional filter unit comprises a main body, a water inlet cover, and a locking cap which is clamped on the water inlet cover and tightens up the mainbody. A blind hole cavity used for planting a magnetic strip is arranged at the lower end of the main body. A blowoff valve is arranged at the lateral side of the bottom of the cavity of the main body. A fixed through hole is arranged at the opposite side of the blowoff valve. The upper end of the water inlet cover is equipped with a first fixed hole, a second fixed hole and a third fixed hole. The first fixed hole and the third fixed hole are horizontally and coaxially arranged. In the cavity of the main body, one end of a bend channel is connected with the first fixed hole, and the other endof the bend channel is connected with a cylindrical filter screen. The filter unit of the invention can meet access requirement of pipelines from multi-directions and multi-angles. The filter unit ofthe invention has a simple structure, is flexible to adjust, has high adaptability, and has market competitiveness.

Owner:TAIZHOU BANCHENG HVAC TECH CO LTD

Efficient intelligent self-control self-sucking pump

InactiveCN105756948ARapid positioningShort self-priming timeSpecific fluid pumpsPump componentsBlowoff valveImpeller

The invention relates to an efficient intelligent self-control self-sucking pump which comprises a pump body, a frequency conversion motor, an automatic exhaust device and an intelligent control box.The intelligent control box is arranged on the automatic exhaust device.A liquid inlet is formed in the bottom of the pump body.A liquid outlet is formed in the side face of the pump body.An inlet bent pipe is flange connection with the liquid inlet.A flow guiding pipe is in flange connection with the liquid outlet.An automatic blowoff valve is arranged on the flow guiding pipe.A pump cover is arranged between the pump body and the frequency conversion motor.An inner cavity formed by the pump body and the pump cover is a pump cavity.A centrifugal impeller is arranged in the pump cavity.The pump cover is provided with an induction probe and a vaccumizing exhaust hole.An exhaust pipeline is arranged on the vacuumizing exhaust hole.The automatic exhaust device is communicated with the pump cavity through the exhaust pipeline.The frequency conversion motor, the automatic blowoff valve, the induction probe and the automatic exhaust device are electrically connected with the intelligent control box through signal lines.The efficient intelligent self-control self-sucking pump is simple and compact in structure and high in intelligent degree, the self-sucking function is completed through the independent automatic exhaust device, and therefore the hydraulic efficiency is effectively improved.

Owner:蒋燕群

Filter-cone-type vacuum filtration waste oil device

InactiveCN102350109ALow filter oil temperatureEasy to operateGravity filtersStationary filtering element filtersElectricityBlowoff valve

The invention discloses a filter-cone-type vacuum filtration waste oil device, and relates to a vacuum oil filter. The device is characterized in that the upper opening on a filter cone is provided with a spray head which is communicated with an oil inlet pipe; a filter plate is arranged in the filter cone; a filter medium is arranged on the filter plate; the lower opening of the filter cone is connected with a vacuum tank; a vacuum connection opening, a vacuum pressure gage and a vacuum pressure regulating valve are arranged at the upper part of the vacuum tank; the waist part of the vacuum tank is provided with an observation window; an oil outlet pump, an oil outlet valve and a blowoff valve are arranged at the external part of the bottom of the vacuum tank; and an oil leakage pipe is arranged in the vacuum tank. The filter-cone-type vacuum filtration waste oil device provided by the invention is lower in filter oil temperature, simple in filtering operation, good in filter medium effect, extremely high in filtered oil cleanness, low in filter cost and low in manufacturing cost, can save electricity, is convenient in arrangement, use and maintenance, and has promotional value; and the filter oil is difficult to oxidize.

Owner:豆远奎

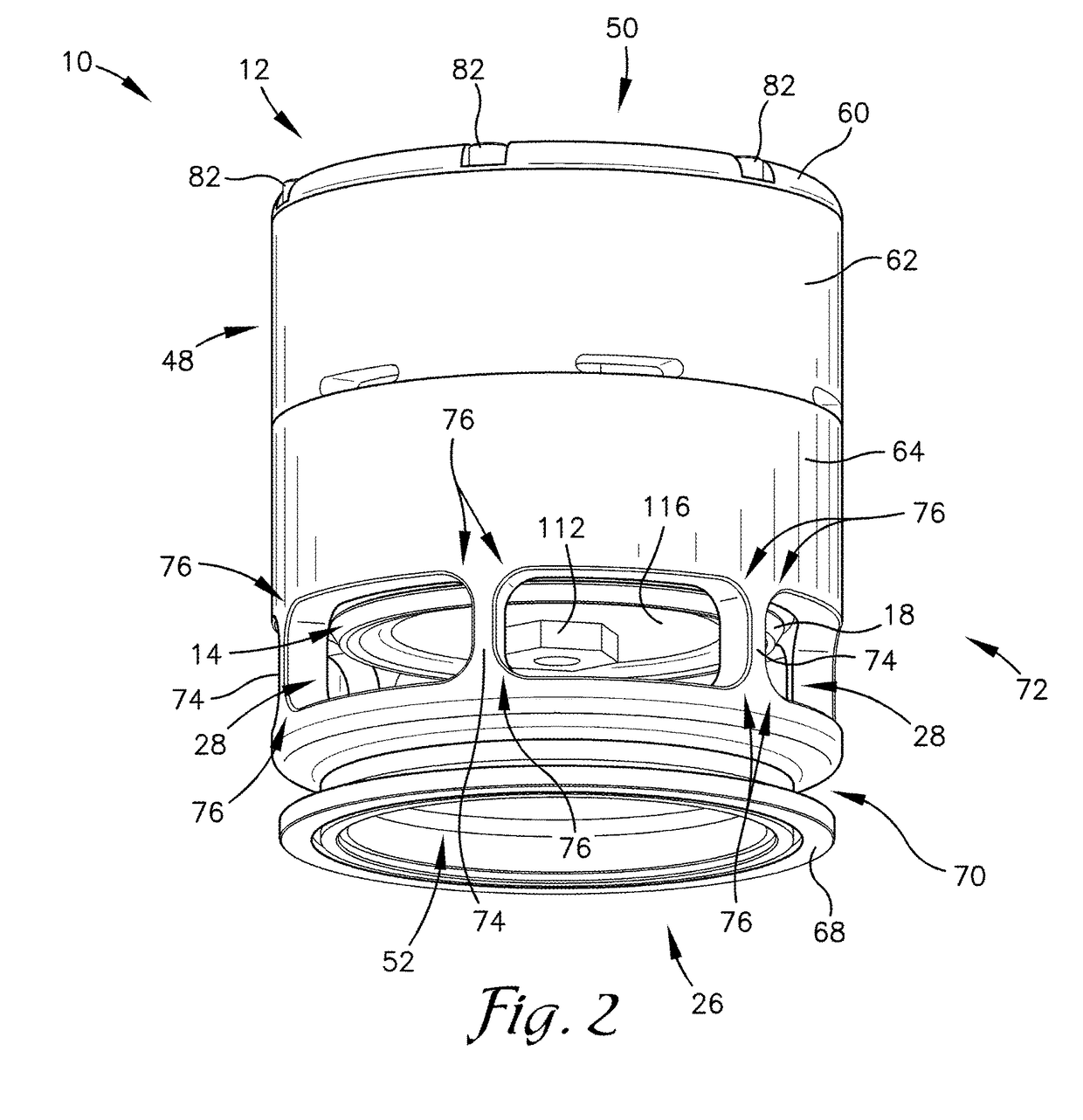

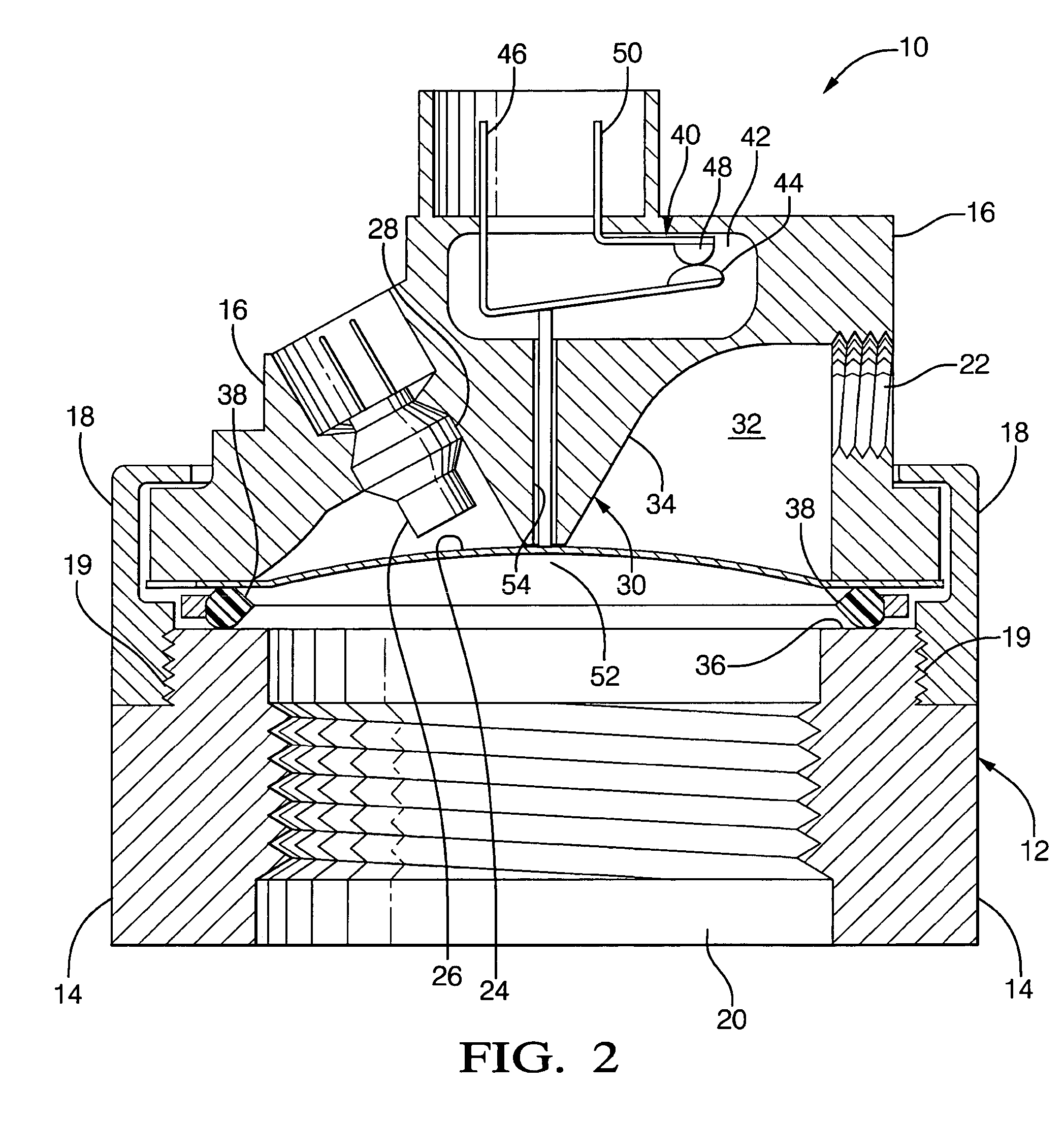

Multi-chamber blowoff valve

InactiveUS20170328316A1Small volumeReduce the cross-sectional areaOperating means/releasing devices for valvesInternal combustion piston enginesBlowoff valveExhaust valve

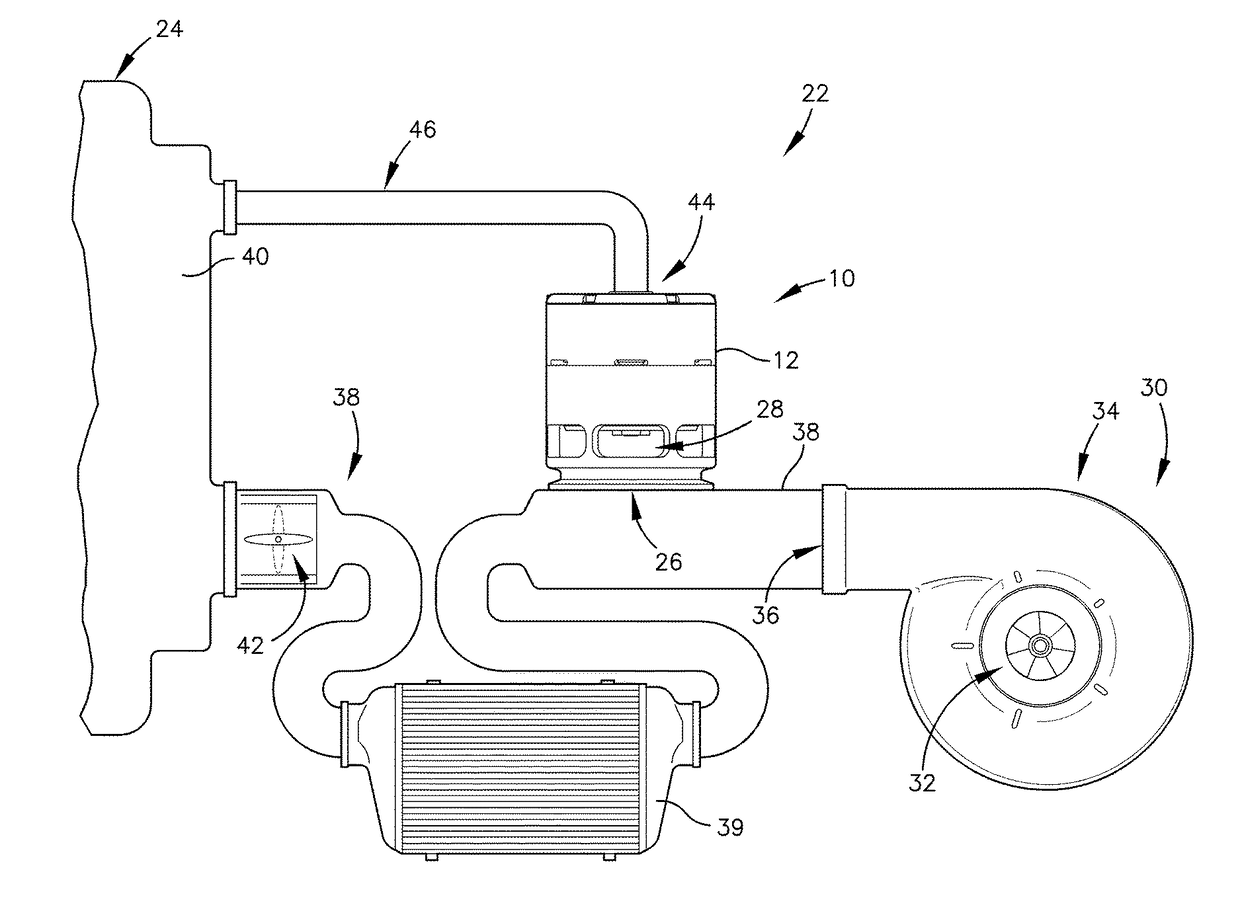

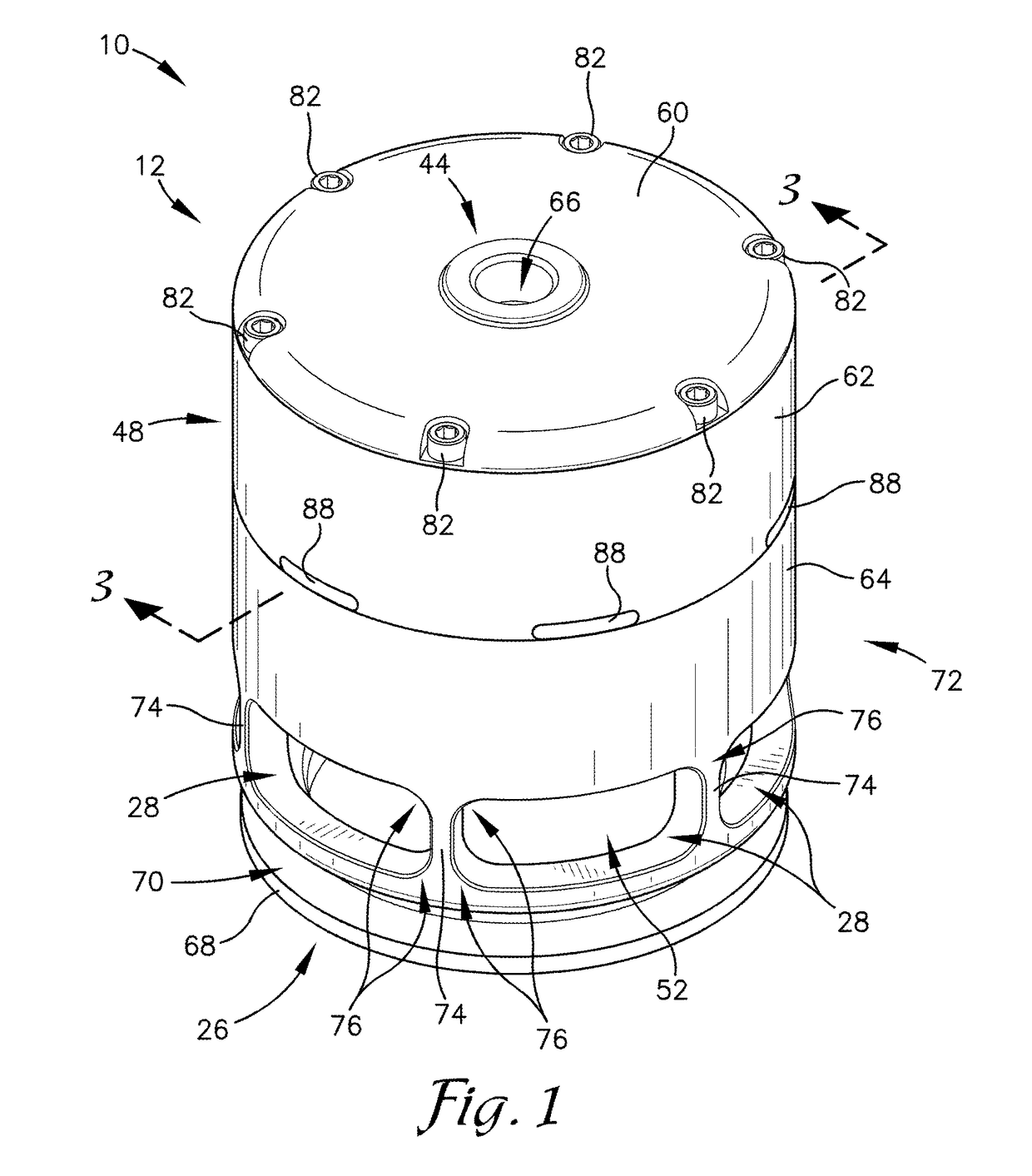

A multi-chamber blowoff valve is provided for releasing excess air pressure from a duct system associated with a vehicle. The blowoff valve has a valve housing, an engine-air interface, and a multiple piston assembly. The valve housing is configured to secure to the duct system at a duct-air interface. The engine-air interface is configured to allow air in and out of the valve housing. The multiple piston assembly is disposed within the valve housing and includes an upper piston and a lower piston that move in unison. The multiple piston assembly is configured to be in a closed position while a pressure differential is above a certain threshold and to be in an open position while the pressure differential is below said certain threshold. While in the open position, a portion of the air in the duct system is released.

Owner:ACCESSIBLE TECHONOLOGIES

Pulse type blow off valve

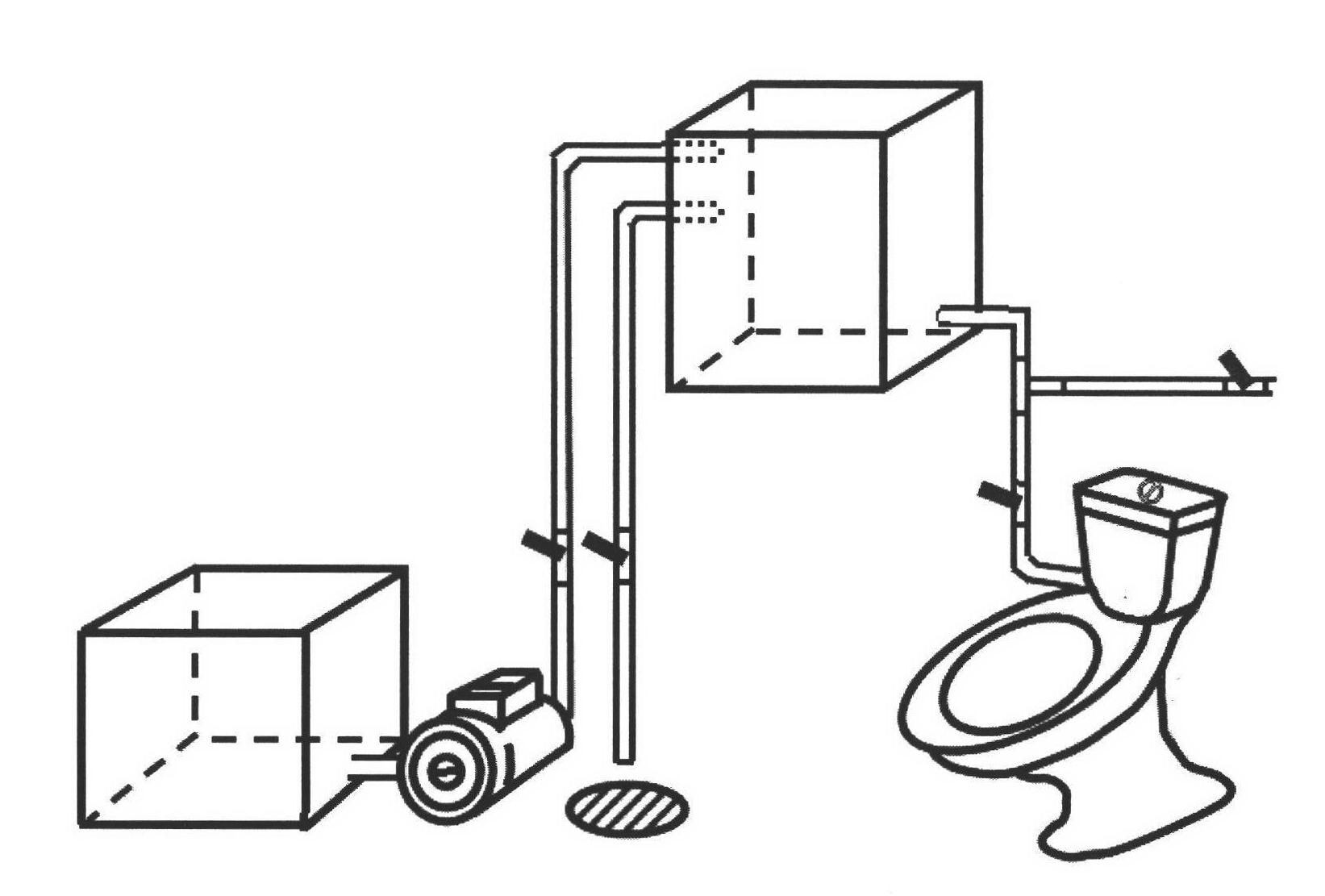

InactiveCN1916302AAvoid breedingPrevent diseaseWater closetsDomestic plumbingBlowoff valveFlush toilet

The present invention relates to a pulse blowoff valve for flush toilet or sewer. It includes a discharge tube, one end of said discharge tube is connected with discharge outlet of flush toilet, it another end is connected with exterior sewer pipe, said sewer pipe can be used as discharge channel of water and wastes. It also has a permanent magnet clamping device for closing discharge tube.

Owner:魏富儒

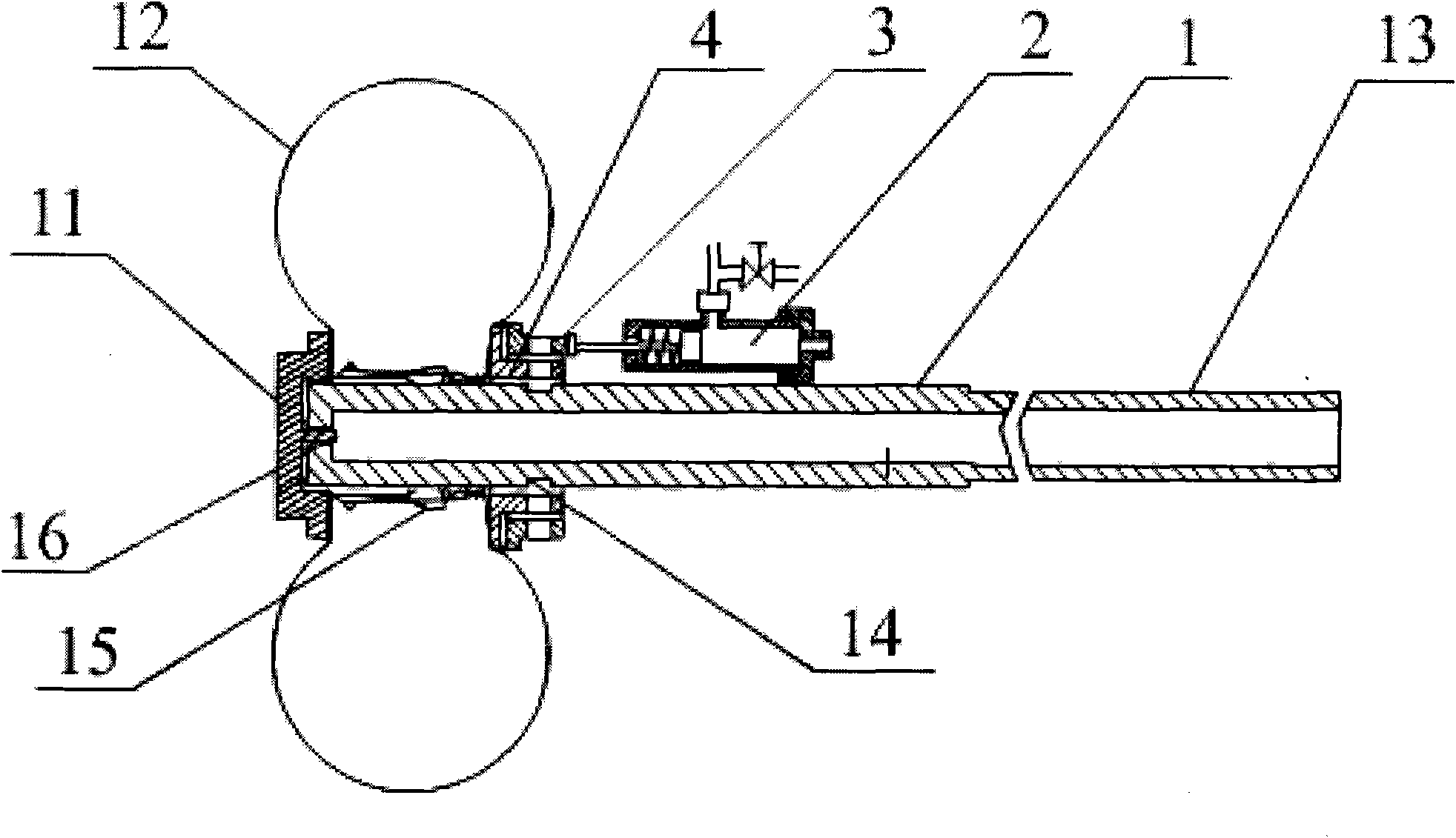

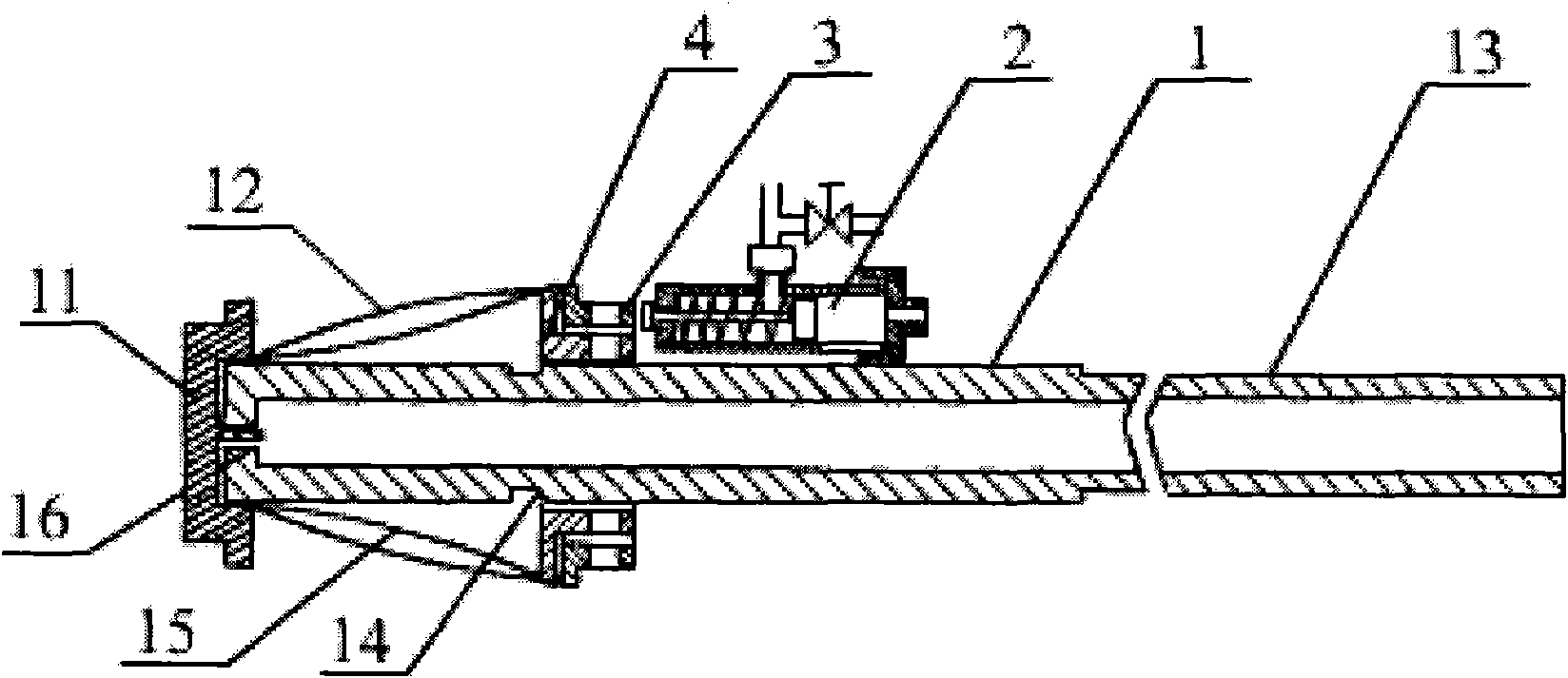

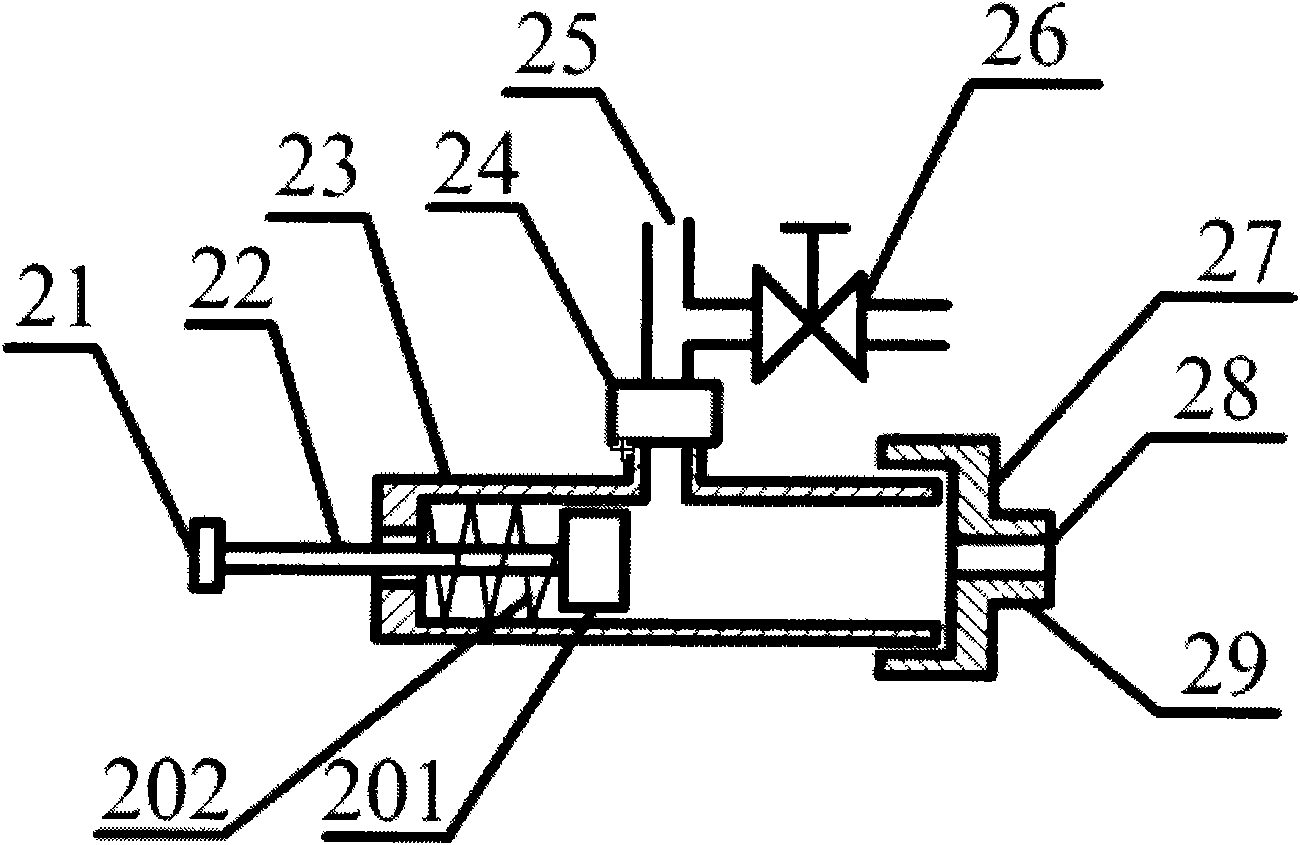

Outboard inflatable plugging air bag

The invention relates to an outboard inflatable plugging air bag, which consists of a master rod kit, a high-pressure air controller, an air bag seat, an air bag, a positioning pin, a supporting device and a high-pressure air container, wherein the master rod kit consists of a master rod and an end cover; the master rod is a pipe fitting with a sealed end, and the center of the sealing end is provided with a screw hole; the high-pressure air controller consists of a body, a top rod system, a check valve, a blowoff valve and a stuffy cover; the air bag seat consists of a master piece of the airbag seat and an accessory of the air bag seat, and the air bag seat is sleeved on the master rod and can make axial movement on the master rod; the air bag is divided into an inner layer and an outerlayer; when not being inflated, the air bag is in a cylindrical shape, and a sealing air bag space is formed between the two layers; the positioning pin consists of a positioning pin tongue, a positioning pin seat, a positioning pin spring, a positioning pin pull ring and a positioning pin substrate; and the supporting device consists of a handle, a supporting rod, a cross rod and a chuck. The outboard inflatable plugging air bag is suitable for the plugging after various ships are damaged, and thus, the outboard inflatable plugging air bag can support the ships reliably after the ships are plugged.

Owner:王晓勇

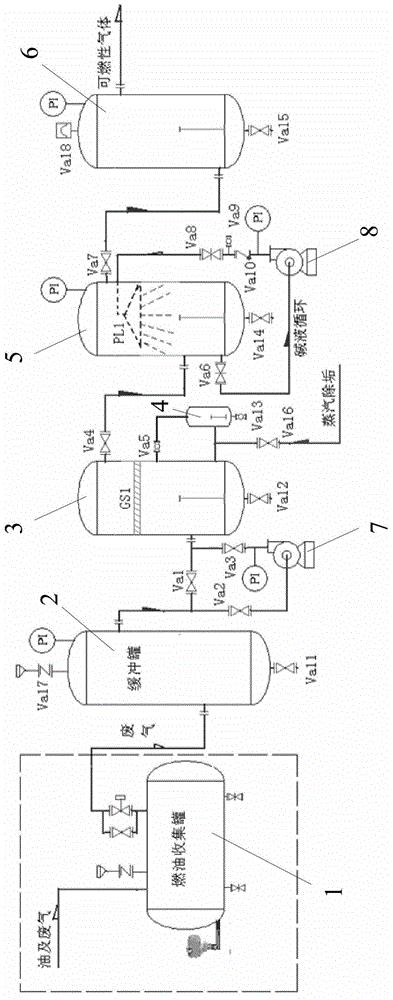

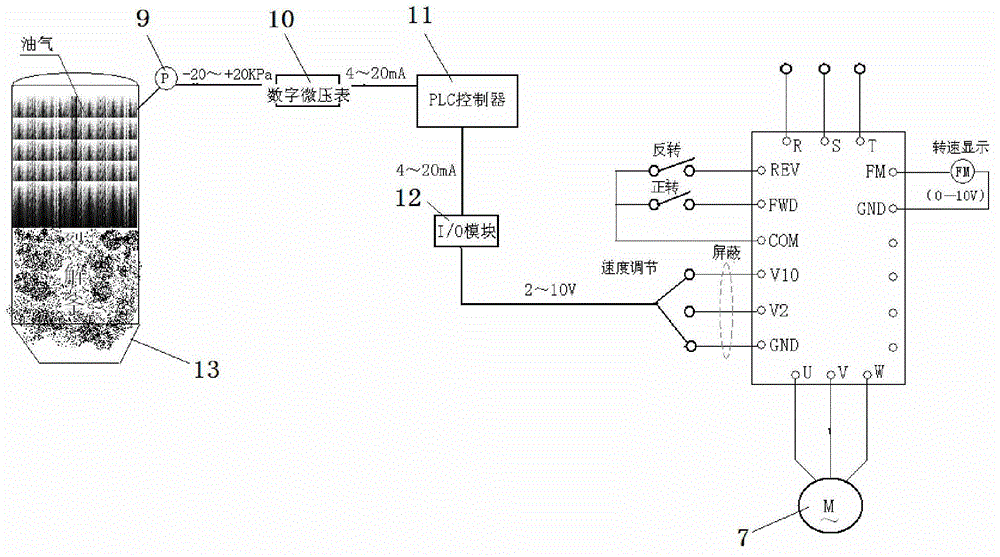

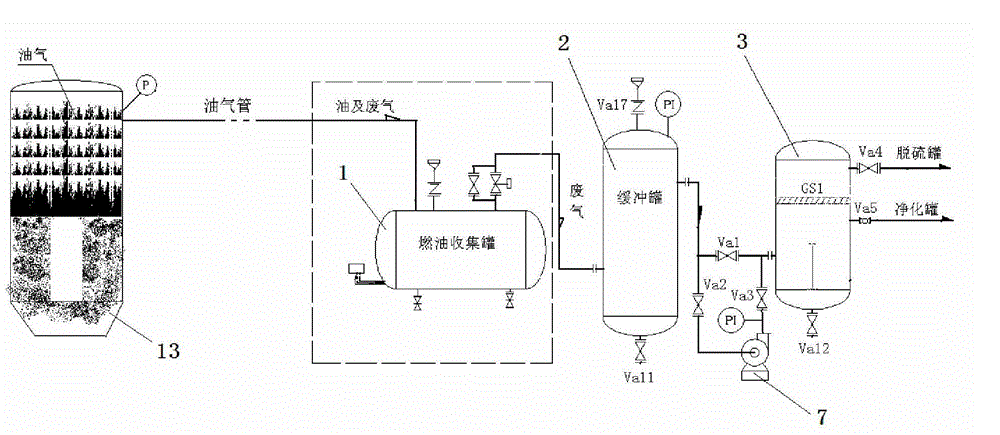

Treating device and treating process for waste gas produced in pyrolysis of waste rubber and plastics

The invention discloses a treating device and a treating process for waste gas produced in pyrolysis of waste rubber and plastics, belonging to the field of environmental protection. The device comprises a buffer tank, a liquid separating tank, a purification tank, a desulfurization tank, a safety tank, a vacuum pump, a corrosion-resistant pump, second to eighth stop valves, a ball valve, a gate valve, first to fifth blowoff valves, a steam valve, a gas respirator and an explosion-proof means. According to embodiments of the invention, by using the device composed of the buffer tank, the liquid separating tank, the purification tank, the desulfurization tank, the safety tank, the vacuum pump, the corrosion-resistant pumps and various control valves, solid dust, floating oil fumes and harmful gases like sulfur dioxide and hydrogen sulfide in waste gas can be effectively treated under the premise of safety and environmental protection so as to obtain an effective energy of combustible gas for a pyrolysis apparatus, and waste gas is thus completely recycled; not only the problem of environmental pollution caused by disordered emission of waste gas is overcome, but also a great amount of renewable energy is recycled and consumption of plenty of fuel oil or coal resources needed in pyrolysis is reduced.

Owner:深圳市华镛环境工程有限公司

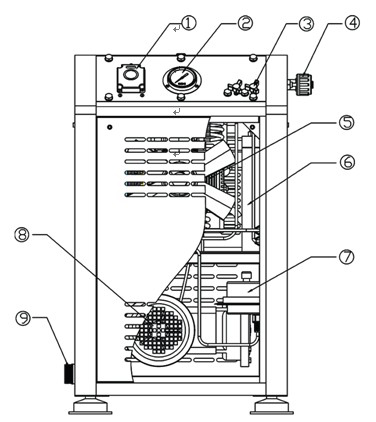

Compact-type natural gas compressor

InactiveCN102155382AIncrease exhaust pressureConvenient and flexible "in-place" inflation featurePositive displacement pump componentsMulti-stage pumpsLow noiseBlowoff valve

The invention relates to a compact-type natural gas compressor, wherein the outer wall of a machine box is provided with a blowoff valve (3), a disconnecting valve (4), a power supply connection (9), an inflation inlet (10), an air inlet (11) and a blowoff pipe (14), wherein the machine box is provided with a machine head (5), a filtering drum (6), an explosion-proof motor and an oil-water separator (12) internally. Efficient four-stage compression and two-stage filtration are adopted, the compressor has a convenient and flexible 'in-situ' inflation property, CNG (compressed natural gas) gas of 25MPa output pressure can be provided, the compressor has functions of automatic stop and blowoff valve simultaneously, a compressed air source is not required to be taken care and cleaned, the device has small volume, low noise, high gas exhaust pressure and long service life, and is mainly used for natural gas air cylinder fueling and natural gas fueling of a fuel gas automobile.

Owner:龚玉华

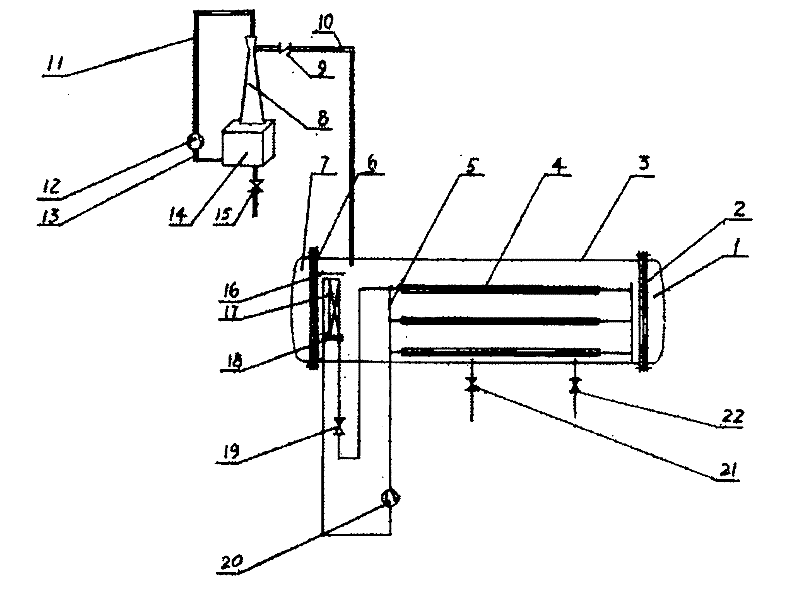

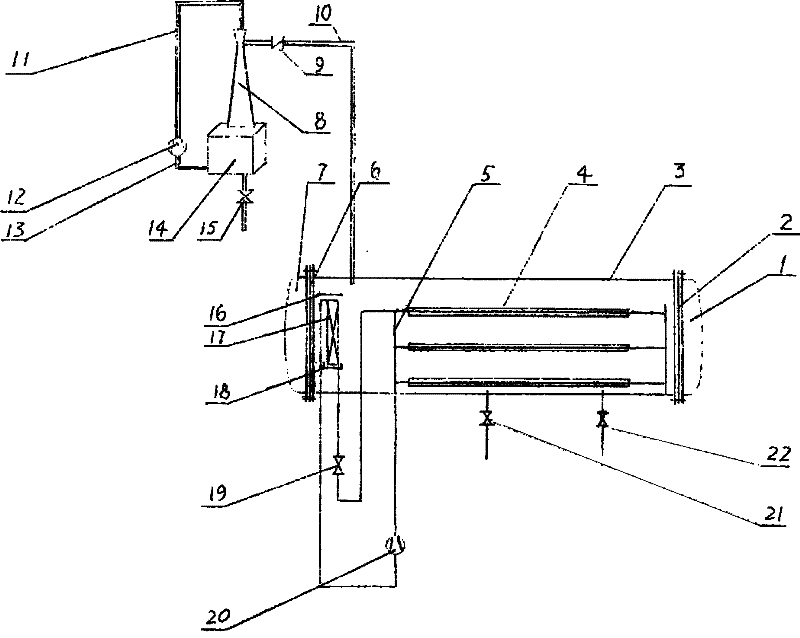

Liquid nitrogen air minimally invasive cold knife cold and heat source system

InactiveCN103829999ASurgical instruments for heatingSurgical instruments for coolingLiquid nitrogen containerBlowoff valve

The invention relates to a liquid nitrogen air minimally invasive cold knife cold and heat source system, and belongs to the field of medical equipment. The system comprises a liquid nitrogen suction pipe (1), liquid nitrogen (2), a liquid nitrogen container (3), a liquid nitrogen container air pressurization valve (4), an air pipe (5), a hot air pipe (6), a wet air valve (7), a by-pass valve (8), a dry air valve (9), an electric heater (10), a resistance heating wire (11), a liquid nitrogen valve (12), a liquid nitrogen supply pipe (13), a dry air pipe (14), a dry hot air valve (15), a blowoff valve (16), a hot air regeneration valve (17), an air drying tank (18), a wet air ejection ring (19), a moisture input pipe (20), drying agents (21), an air compressor (22), a pressure air pipe (23), a cold and heat source communication valve (24) and a hot air supply pipe (25). Accordingly, what is only needed is to conduct filling with the liquid nitrogen and the drying agents and shut down the corresponding valves, the resistance heating wire and the air compressor, the liquid nitrogen at the temperature of 196 DEG C below zero can be sent to nidus so that the nidus can be frozen, and then hot air at the temperature of 40 DEG C can be sent out, so that focus tissue is rapidly reheated. Thus, the steps are repeated for several times, and all nidus cells can be ruptured and necrotic.

Owner:李鑫

Vacuum heat pump drying device

InactiveCN102226633AIncrease vacuumReduce pollutionDrying using combination processesDrying machines with local agitationBlowoff valveChemical industry

The invention relates to a vacuum heat pump drying device, comprising a drying box body, wherein the left end and the right end of the drying box body are respectively provided with a left end cover and a right end cover as well as a left sealing strip and a right sealing strip, the box body is internally provided with a condenser coil pipe and an evaporator coil pipe lifting frame, the evaporator coil pipe lifting frame is provided with an evaporator coil pipe and a water receiving tray; the box body is externally provided with a compressor and a throttle, the inlet and the outlet of the compressor are respectively communicated with the outlet of the evaporator coil pipe and the inlet of the condenser coil pipe as well as the inlet and the outlet of the throttle are respectively communicated with the outlet of the condenser coil pipe and the inlet of the evaporator coil pipe; and a condenser coil pipe bracket is arranged on the inner side wall of the box body. The vacuum heat pump drying device is characterized in that a water ejector is arranged, the throat part of the water ejector is communicated with the box body by virtue of a check valve and a pipeline, the inlet of the water ejector is connected with the outlet of a high pressure water pump by virtue of a high pressure water pipeline, the inlet of the high pressure water pump is communicated with the lower part of a water tank by virtue of a water pipe, the lower part of the water tank is provided with a water escape valve, and the exterior below the drying box body is provided with a blowoff valve and an air intake valve. The vacuum heat pump drying device provided by the invention can be widely applied to industries requiring low temperature drying such as food industry, pharmaceutical industry, chemical industry and building material industry.

Owner:胡日生

Blowoff valve assembly with integrated pressure switch

A blowoff valve assembly includes a diaphragm separating a refrigerant connection from an ambient port open to the atmosphere. The refrigerant connection is preferably connected to air conditioning system such that the diaphragm is in contact with refrigerant from the system. The diaphragm is deflectable based on the pressure of the refrigerant and is operatively connected to a switch. When pressure of the refrigerant drops to a predetermined level, the diaphragm deflects to activate the switch. Additionally, the assembly also includes a detonable squib that explodes and ruptures the diaphragm, allowing the refrigerant to flow from the refrigerant connection to the atmosphere. Additional features, such as sensors for detecting refrigerant outside of the system, a collision subsystem, and an associated controller are also disclosed.

Owner:DELPHI TECH INC

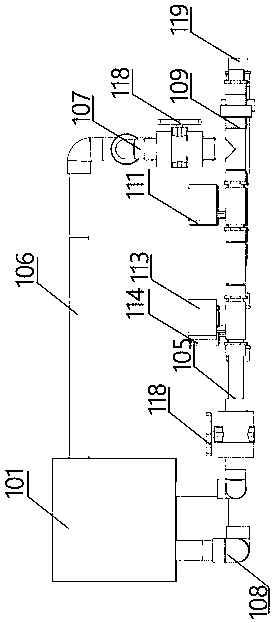

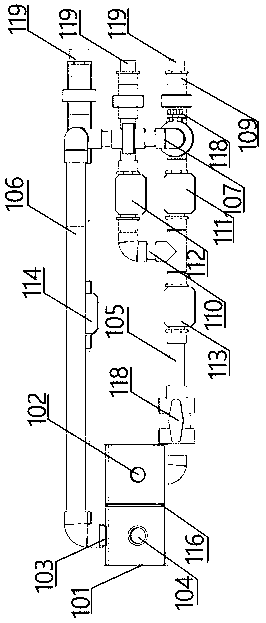

Water sampling and sample mixing system for outdoor water quality automatic monitoring station and method thereof

PendingCN108827713AImprove representationReflect the overall situationWithdrawing sample devicesPreparing sample for investigationBlowoff valveInlet valve

The invention provides a water sampling and sample mixing system for an outdoor water quality automatic monitoring station. The system comprises: a sample mixing cup, a water acquisition pipeline anda timer, wherein the sample mixing cup is provided with a water inlet, an overflow port and a water outlet; the water acquisition pipeline comprises a front pipeline, a sampling pipe, an overflow pipe, a breather pipe and an exhaust pipe; and the timer is connected to a water inlet valve, a recoil valve, a sampling valve and a blowoff valve, and is used for controlling the opening cycle and opening times of the water inlet valve, the recoil valve, the sampling valve and the blowoff valve. Through the technical scheme of the invention, each monitoring object is a mixed water sample in two watersampling monitoring interval times, which can reflect the comprehensive situation of water quality in the monitoring blank time period to some extent.

Owner:郑州富铭科技股份有限公司

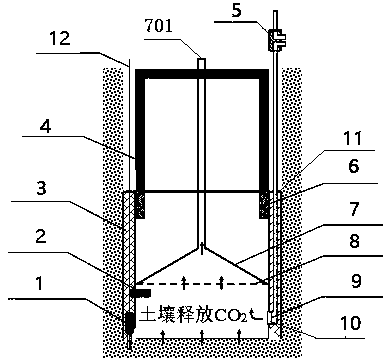

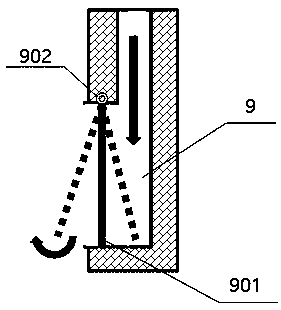

Gas production column for monitoring gas injection driving oil well field aeration zone soil carbon dioxide flux

ActiveCN108871876AThe deviation of monitoring results is smallHigh precisionWithdrawing sample devicesEarth material testingBlowoff valvePressure generation

The invention provides a gas production column for monitoring gas injection driving oil well field aeration zone soil carbon dioxide flux. The gas production column comprises a soil moisture sensor, atemperature sensor, a dynamic gas production box, a depth location rod, a blowoff valve, a gas collecting hood, a perforated plate, a pressure balance valve and a recording module, wherein the upperend of the dynamic gas production box is connected with the depth location rod, the gas collecting hood and the perforated plate are arranged at the lower part of the inner side of the dynamic gas production box, the perforated plate is arranged under the gas collecting hood, the soil moisture sensor, the temperature sensor and the pressure balance valve are all arranged at the lower part of the gas collecting hood, the upper end of the pressure balance valve is connected with the blowoff valve through a pipeline, and the soil moisture sensor and the temperature sensor are connected with the recording module through cables. As the pressure balance valve is arranged in the dynamic gas production box, negative pressure generation in a gas collecting process for measuring carbon dioxide fluxis avoided, and monitoring accuracy is improved; furthermore, temperature and soil moisture information of a target point position can be synchronously measured.

Owner:PETROCHINA CO LTD

Open fire maintenance method for liquid ammonia pipeline or equipment

Provided is an open fire maintenance method for a liquid ammonia pipeline or equipment. The method is characterized by comprising the following steps that (1), an inlet valve and an outlet valve of the equipment are closed, and a blowoff valve is opened; (2), a short connection pipe is manufactured, and the other end of a valve is connected with inert gas, wherein the inner diameter of the short connection pipe can be determined in the way that the short connection pipe covers a leakage point, and the short connection pipe is connected with the valve; (3), when the pressure of the pipeline or the equipment is close to the atmospheric pressure, the manufactured short connection pipe buckles the leakage point; (4), the inert gas is started to be continuously supplied to the pipeline or the equipment via the short connection pipe, and positive pressure is kept to open fire to weld the short connection pipe and the leakage point; (5), after the short connection pipe and the leakage point are welded, the inert gas continues to blow for a period to cool a welded point; (6), the inert gas is moved off, the valve of the short connection pipe is closed, and flaw detection and leakage test pressure testing are carried out on the welded point; (7), after the welded point passes the flaw detection and leakage test pressure testing, the open fire maintenance is finished. The open fire maintenance method for the liquid ammonia pipeline or equipment is applied to the field of liquid ammonia conveying.

Owner:WENGFU (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com