Silver recovery device for silver-containing waste liquor

A technology for recovering devices and waste liquids, which is applied in photographic technology, instruments, and photographic auxiliary processes, etc. It can solve the problems of low electrolysis efficiency, cumbersome operation, scattered devices, etc., and achieve high electrolysis efficiency, increased surface area, and increased fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

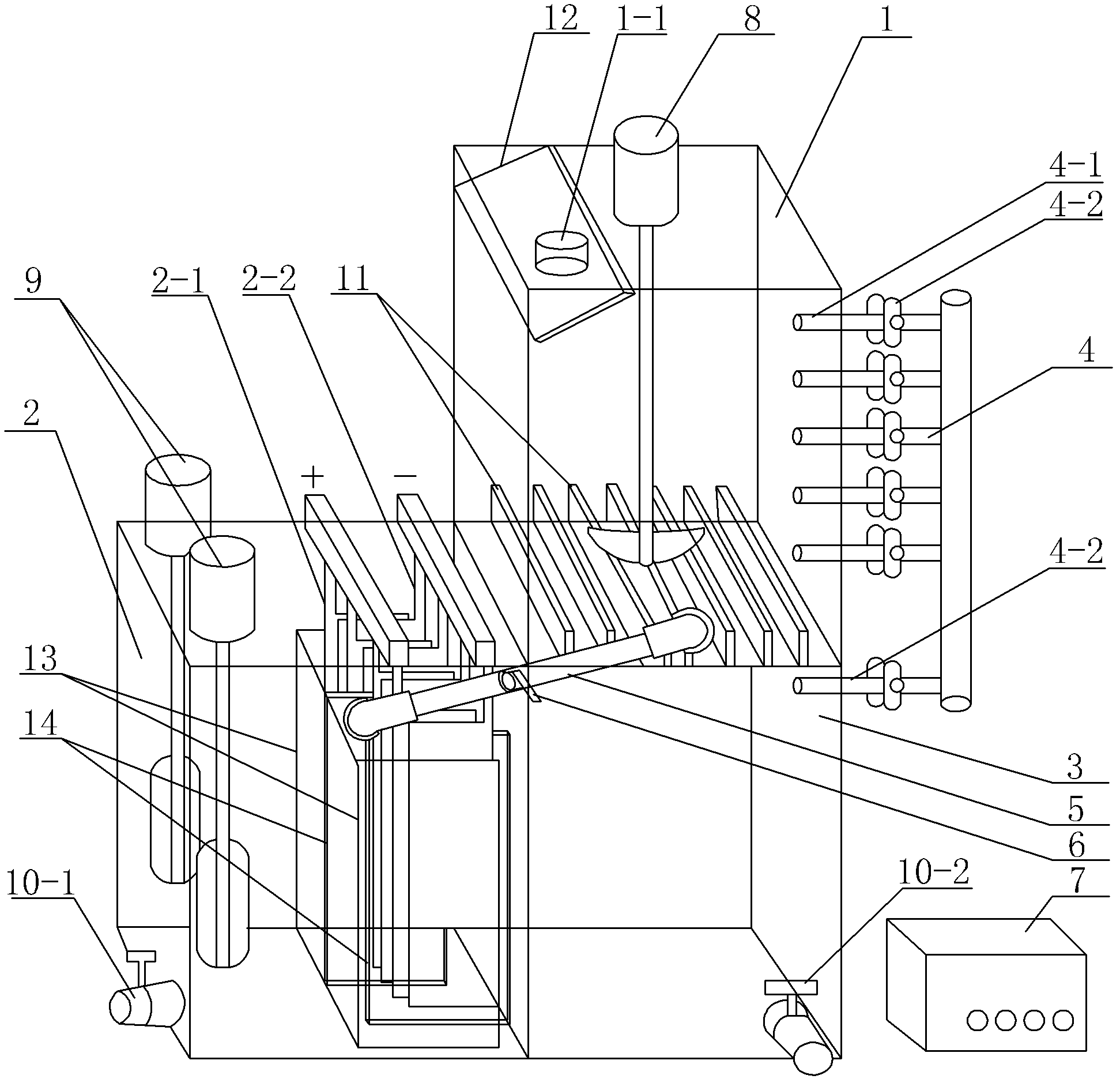

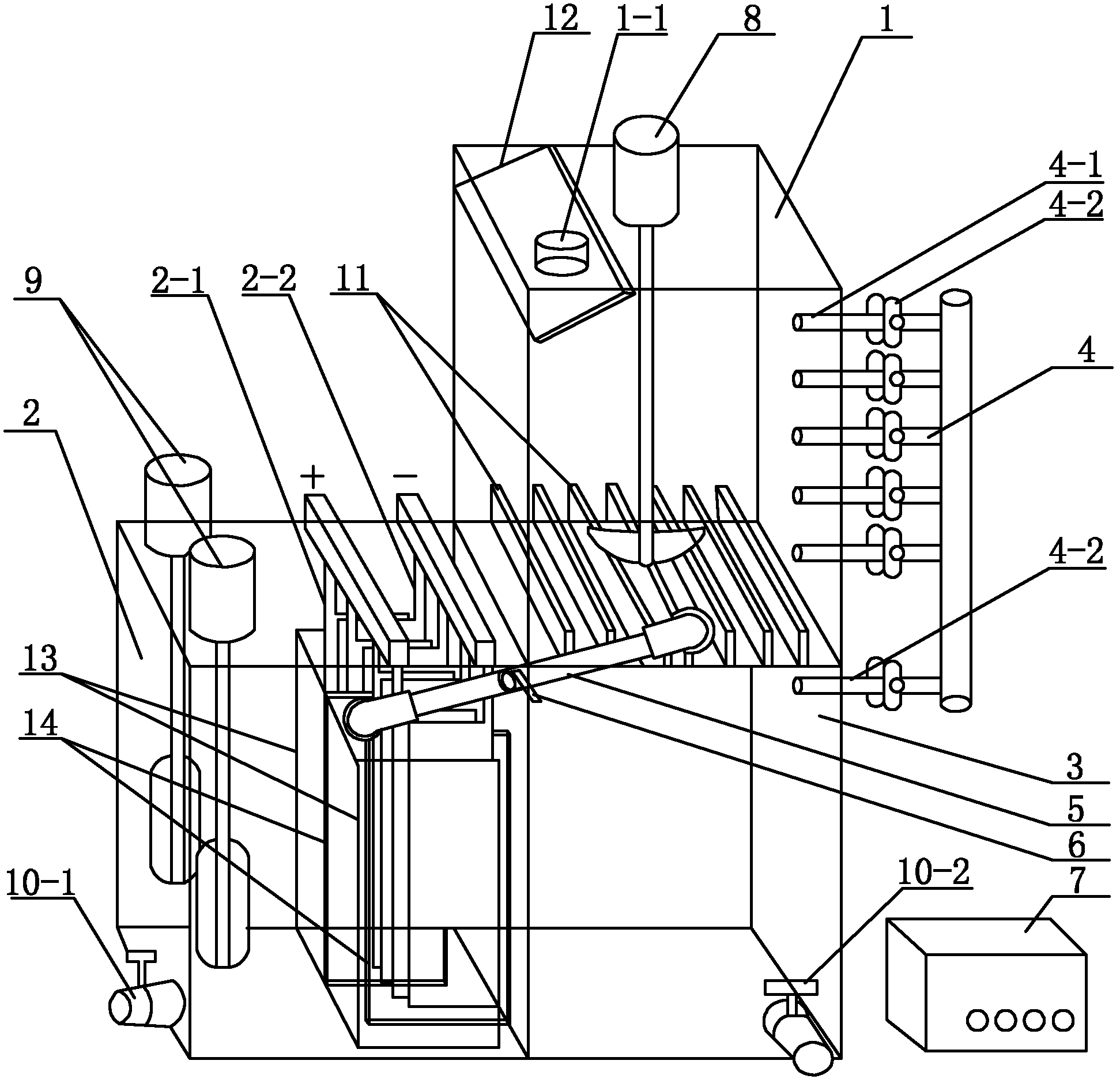

[0007] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the silver recovery device for silver-containing waste liquid described in this embodiment includes a reaction cell 1, an electrolytic cell 2, a waste liquid pool 3, a drain pipe assembly 4, a catheter 5, an on-off valve 6, a first Sewage valve 10-1, second blowdown valve 10-2, at least one first electric agitator 8 and at least two second electric agitators 9, the reaction pool 1, electrolytic cell 2 and waste liquid pool 3 are integrated The electrolytic cell 2 is arranged adjacent to the waste liquid pool 3, the upper end surface of the waste liquid pool 3 is provided with a reaction pool 1, the upper end face of the reaction pool 1 is provided with a liquid inlet 1-1, and the reaction pool 1 is provided with at least A first electric agitator 8, one end of the drain pipe assembly 4 communicates with the reaction pool 1, and the other end of the drain pipe assembly 4 comm...

specific Embodiment approach 2

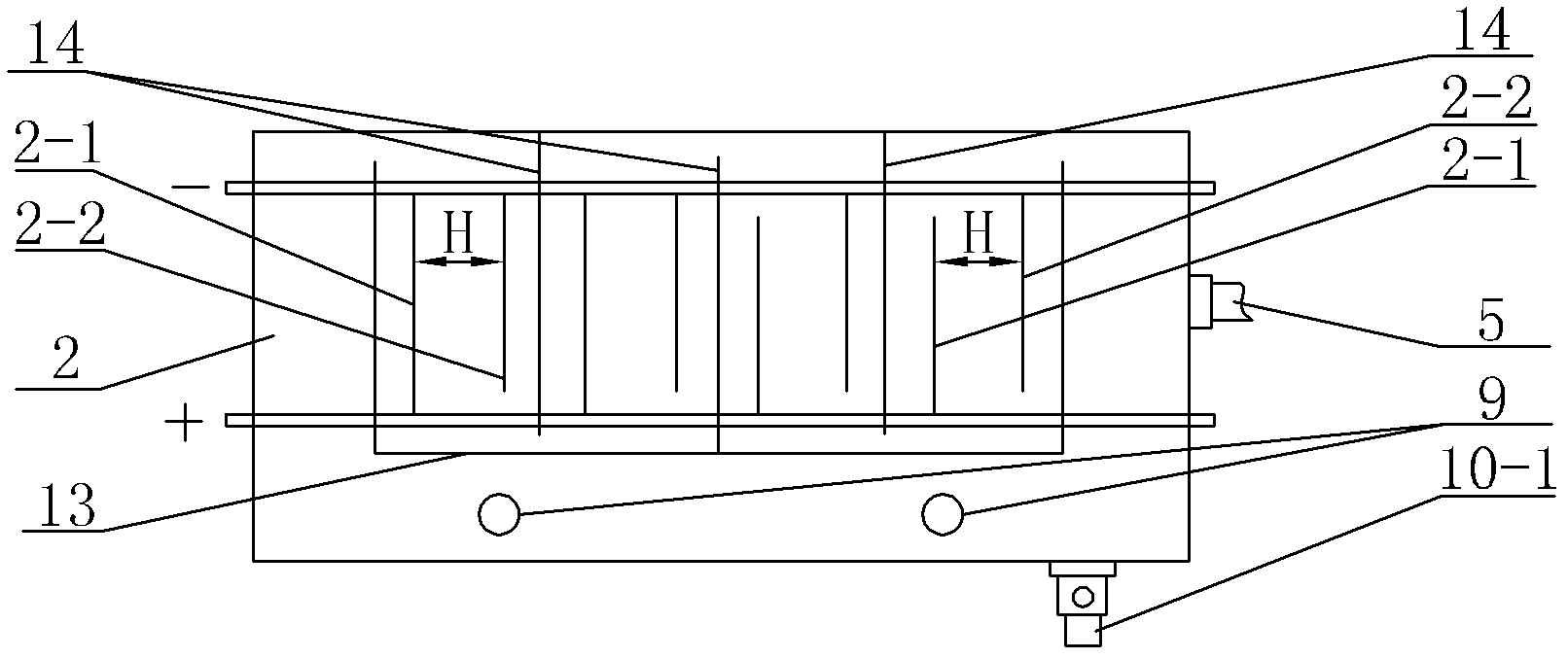

[0008] Specific implementation mode two: combination figure 2 To describe this embodiment, the distance H between two adjacent first pole plates 2 - 1 and second pole plates 2 - 2 in this embodiment is 1 cm to 2 cm. In this way, the silver quality obtained when the distance between the pole plates is within the range of 1cm to 2cm is good, and the silver yield is high. The silver production rate of this embodiment can be increased by more than 20%, and the pole plate area can reach 0.91dm 2 , the current density can reach 0.1A / dm 2 , the larger the spacing, the lower the output, and the smaller the spacing, the silver is easily oxidized, and the quality of the silver obtained is not high. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. The voltage of the DC power supply of the electrolytic cell 2 according to the present embodiment is 0.9V to 1.1V. If set in this way, the electrolytic voltage is in the range of 0.9V to 1.1V, the quality of the obtained silver is good, and the silver yield is high, and the silver yield can be increased by more than 20%. If the voltage is too high, the silver will easily turn black. If the voltage is too low, The efficiency of silver production is reduced. Others are the same as in the first or second embodiment.

[0010] Specific implementation mode four: combination figure 1 To illustrate this embodiment, the reaction cell 1 , electrolytic cell 2 and waste liquid cell 3 described in this embodiment are all made of organic glass. With such arrangement, the anti-corrosion performance is good, the manufacturing cost is low, and the use and installation are convenient. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com