Automatic control type efficient self sucking pump

A self-priming pump, high-efficiency technology, applied in the field of self-priming pumps, high-efficiency self-control self-priming pumps, can solve the problems affecting the smoothness of the pump inlet, not paying attention to hydraulic efficiency, freezing and cracking of water tanks and pump casings, etc., to achieve the degree of automation High, simple and compact structure, anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

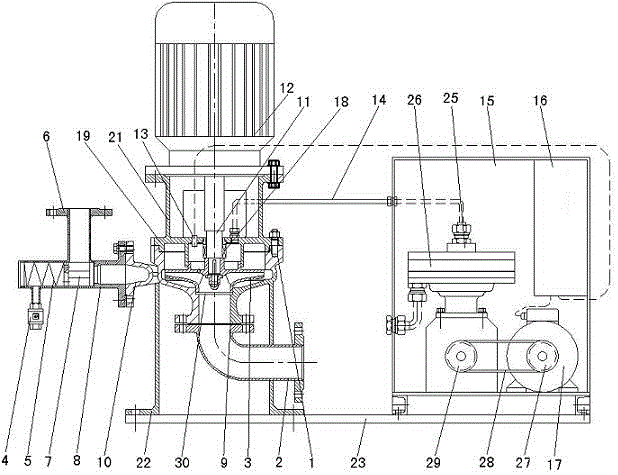

[0013] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, a self-controlled high-efficiency self-priming pump includes a pump body 1, a motor 12, an automatic exhaust and vacuum device 15 and an intelligent control box 16, and the pump body 1 is fixed on a base 23 through a pump bracket 22 at the bottom of the pump body 1 Above, the motor 12 is installed on the motor bracket 21 arranged on the upper end of the pump body 1, the automatic exhaust vacuum device 15 is fixedly installed on the base 23, and the intelligent control box 16 is arranged on the automatic exhaust vacuum device 15 on. A liquid inlet 9 is provided at the bottom of the pump body 1 , and a liquid outlet 10 is provided at the side of the pump body 1 , and an inlet elbow 2 is flanged on the liquid inlet 9 . The shape of the inlet el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com