Patents

Literature

567results about "Catheters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

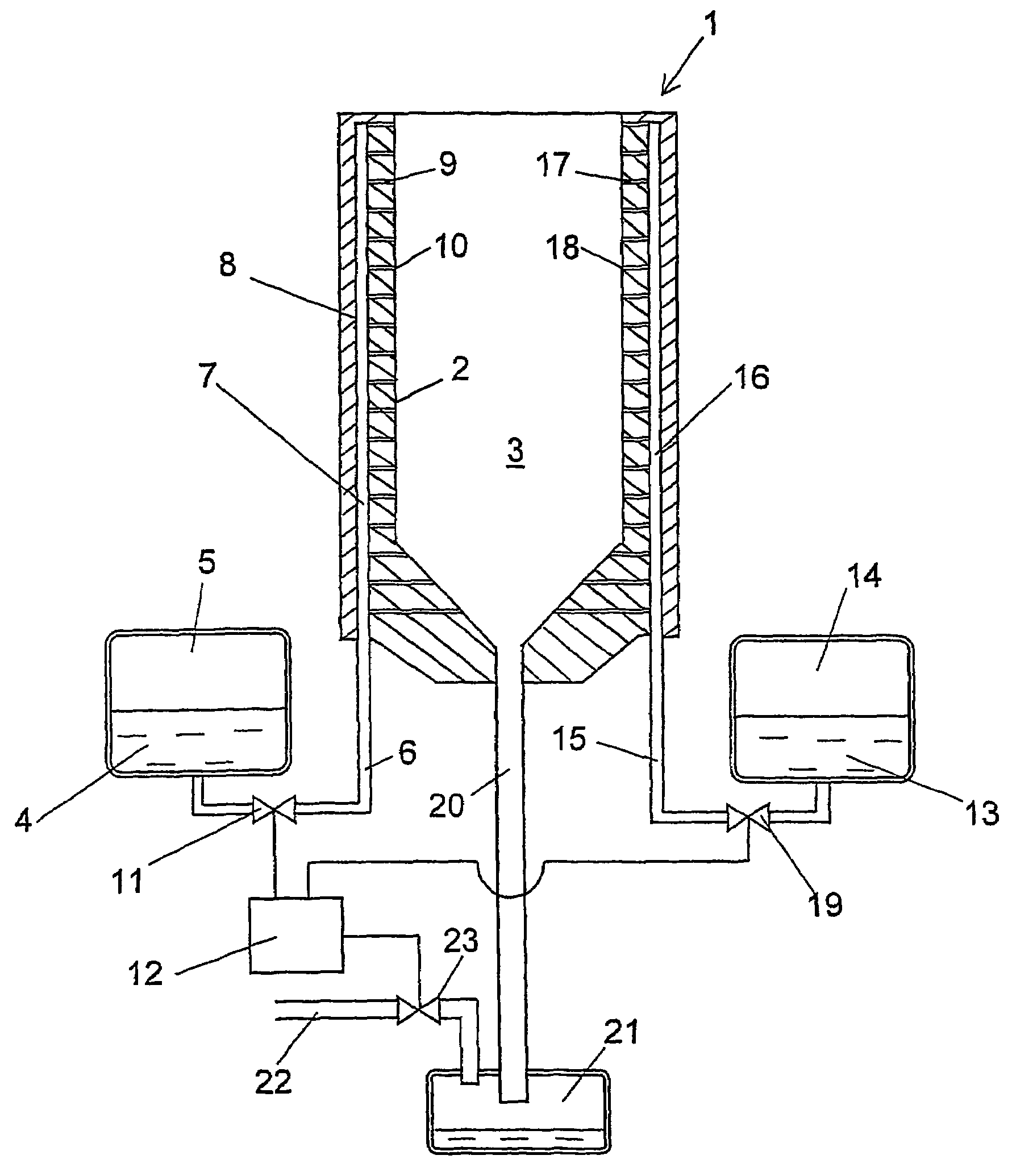

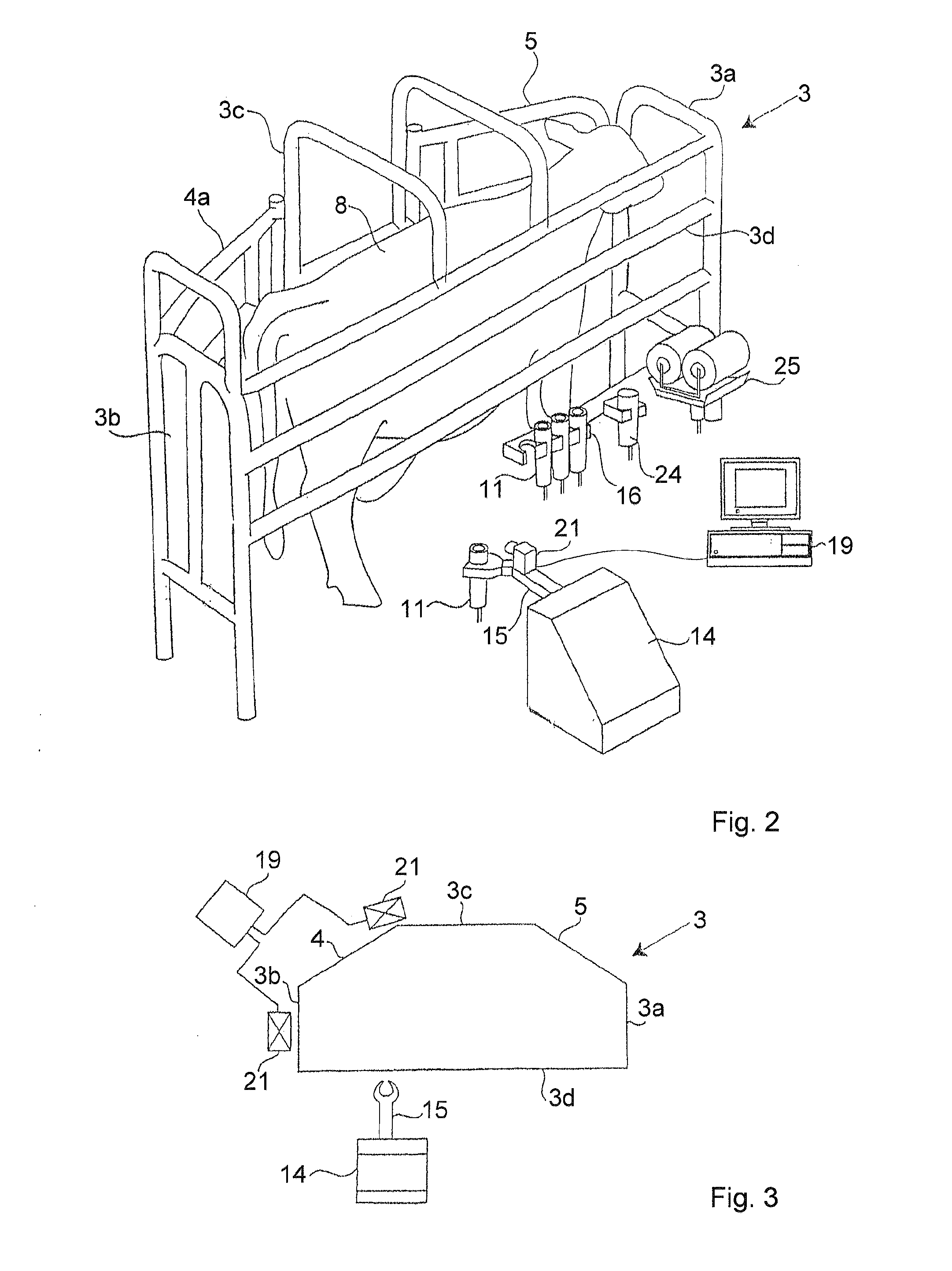

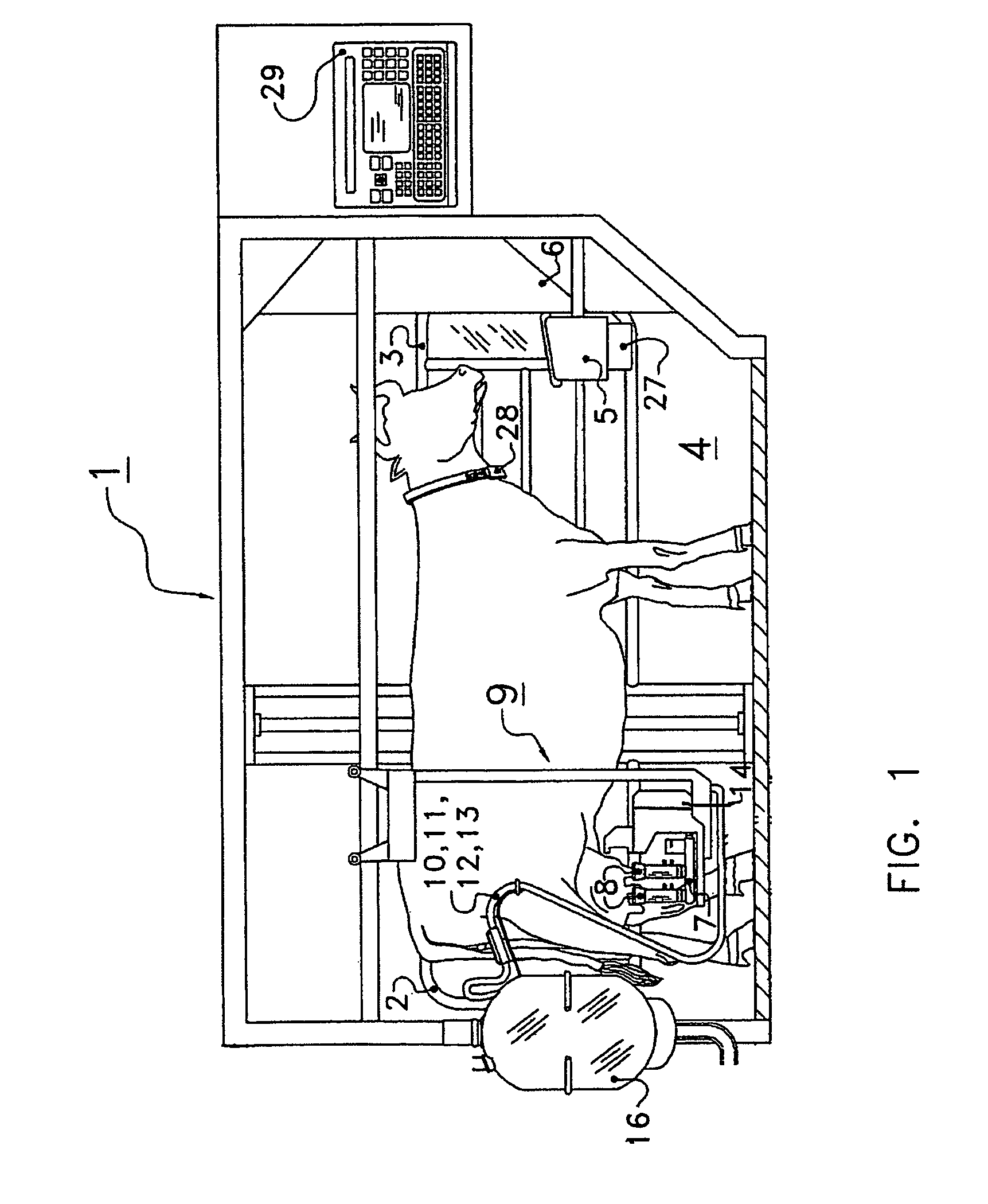

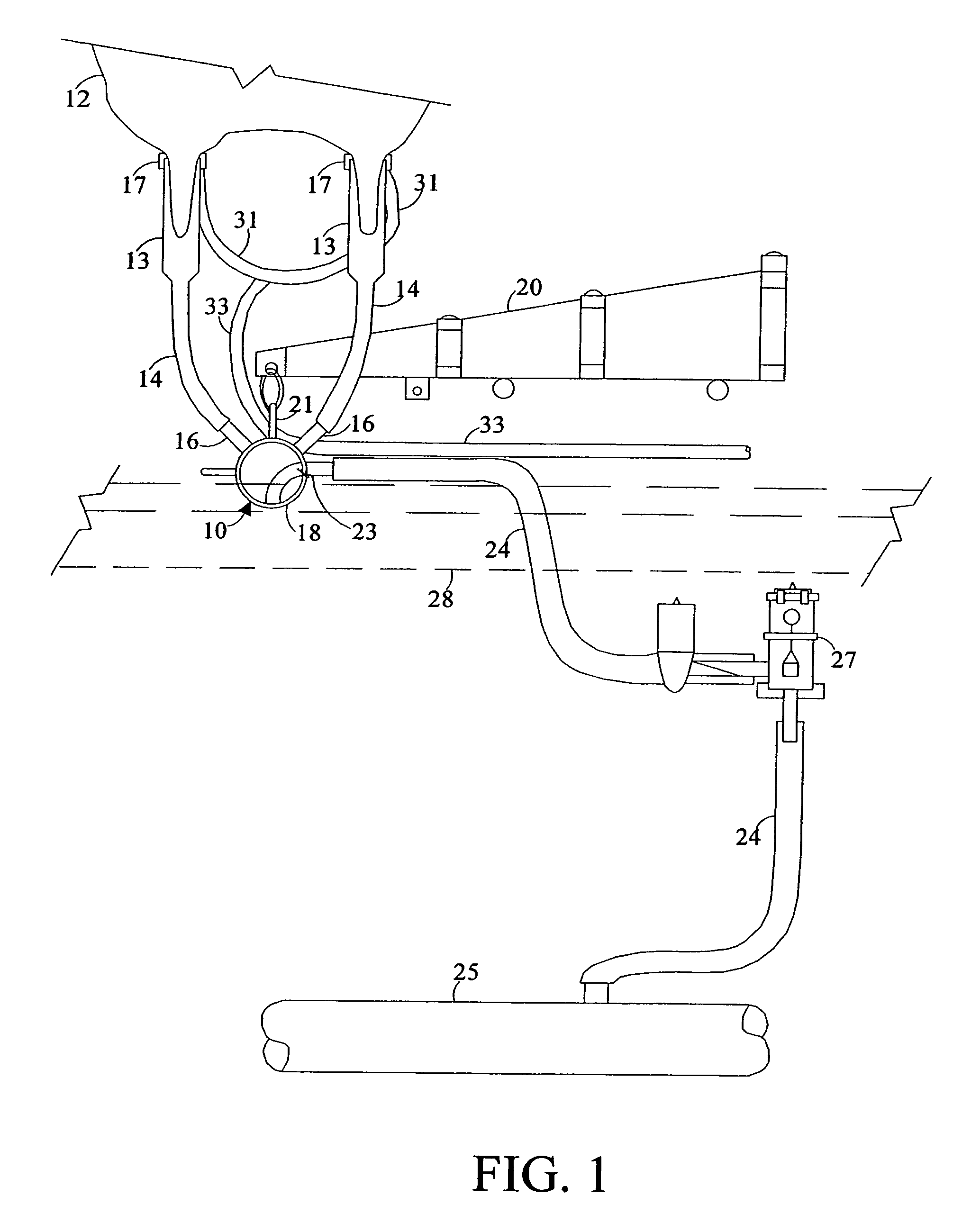

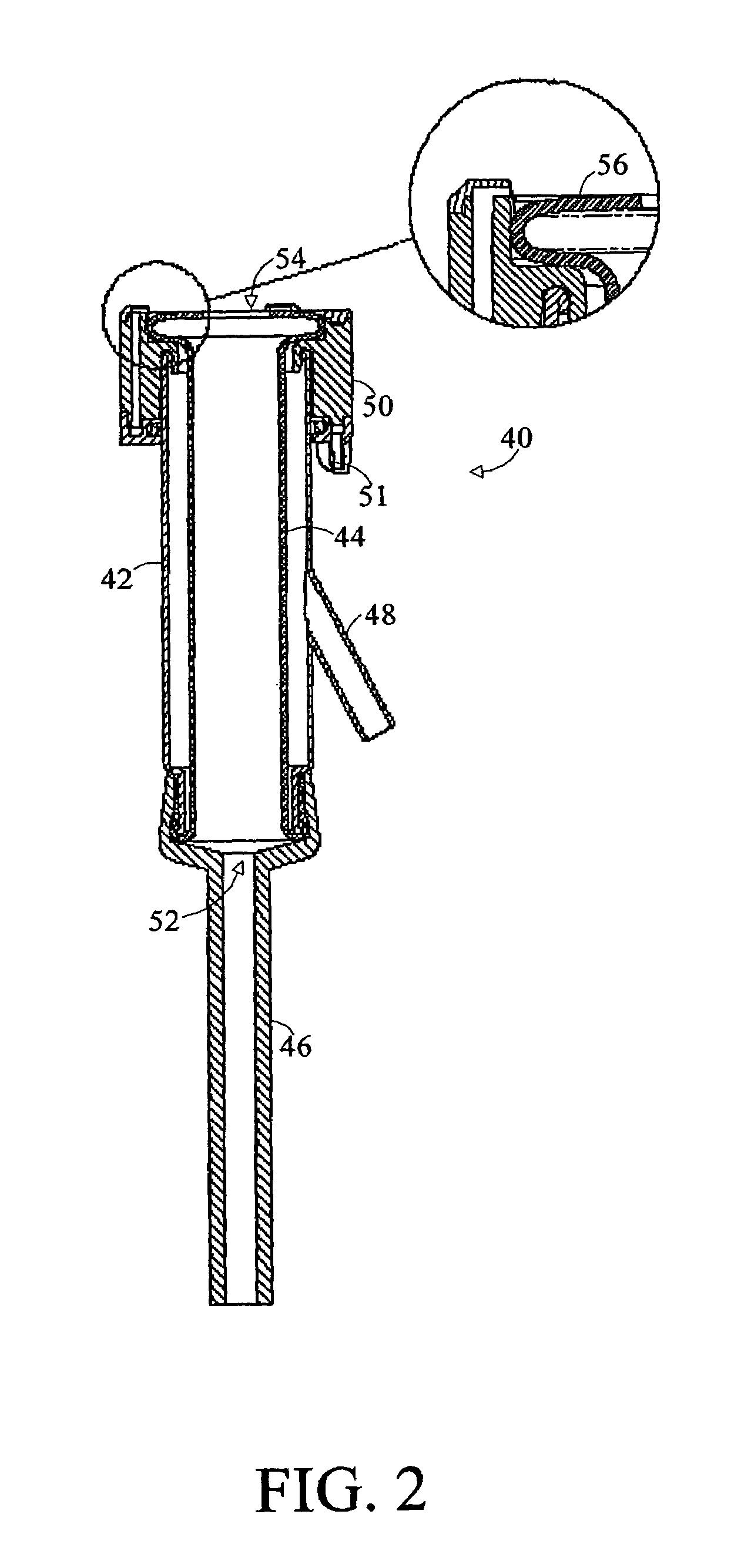

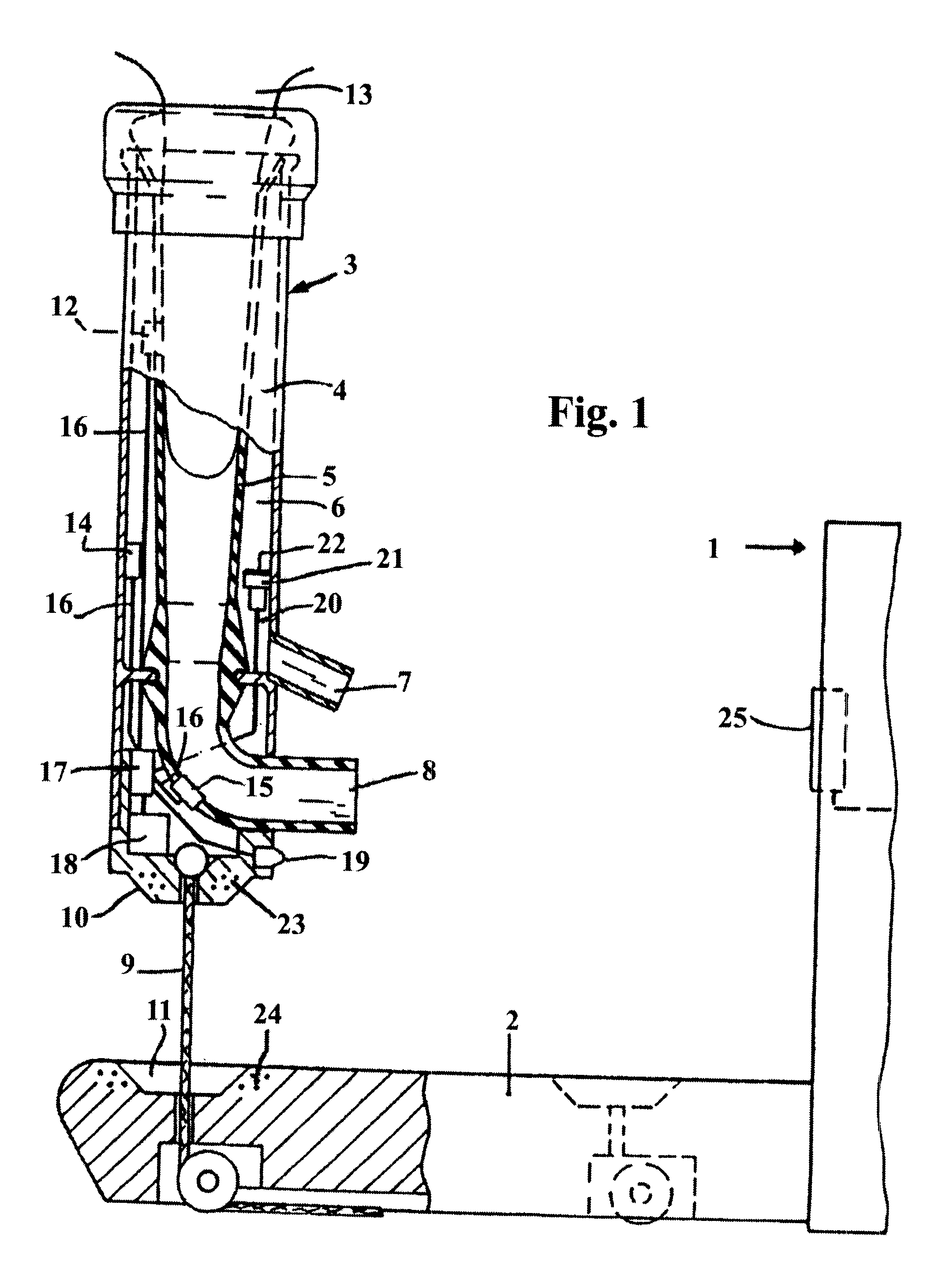

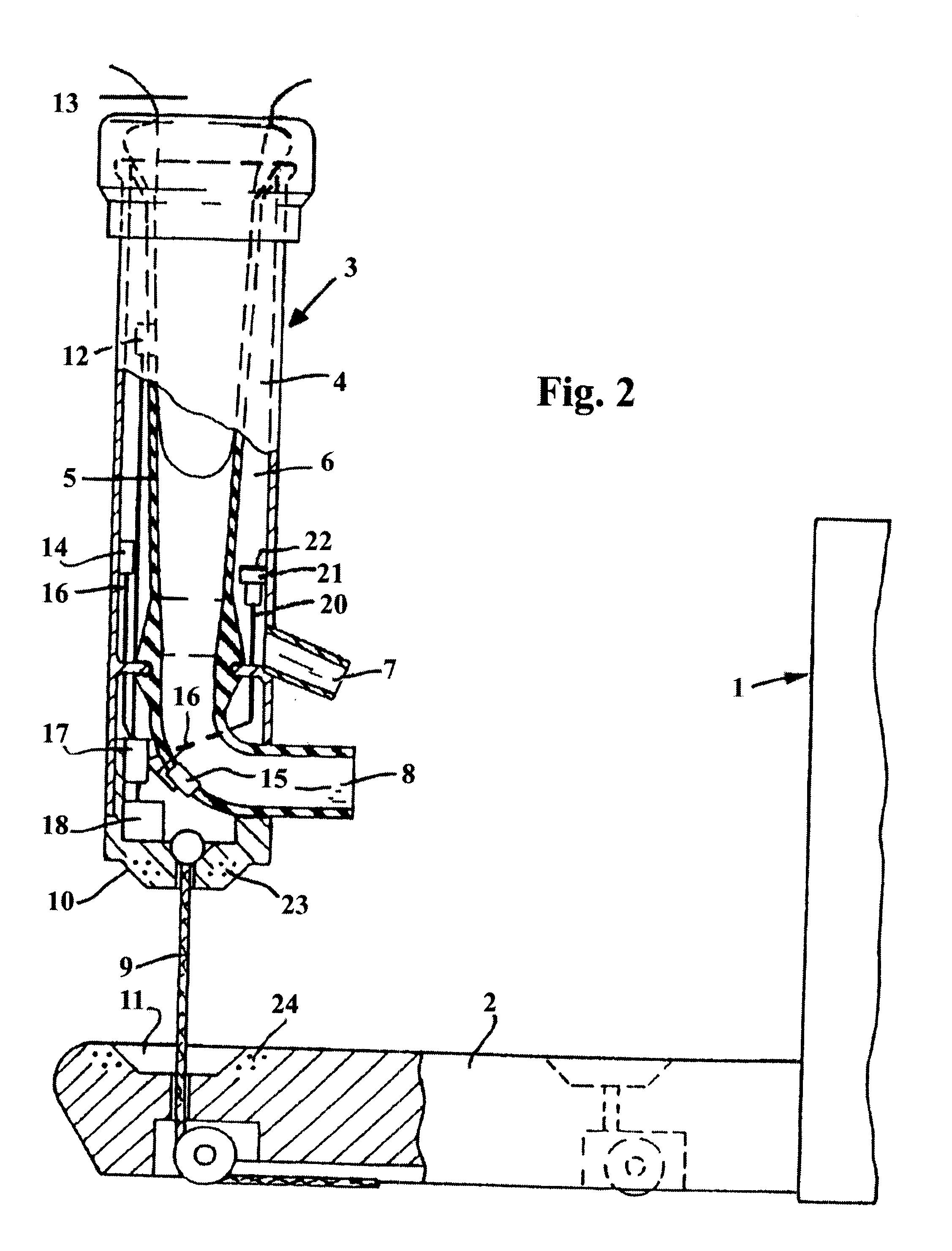

Combined cleaning and pre-milking device

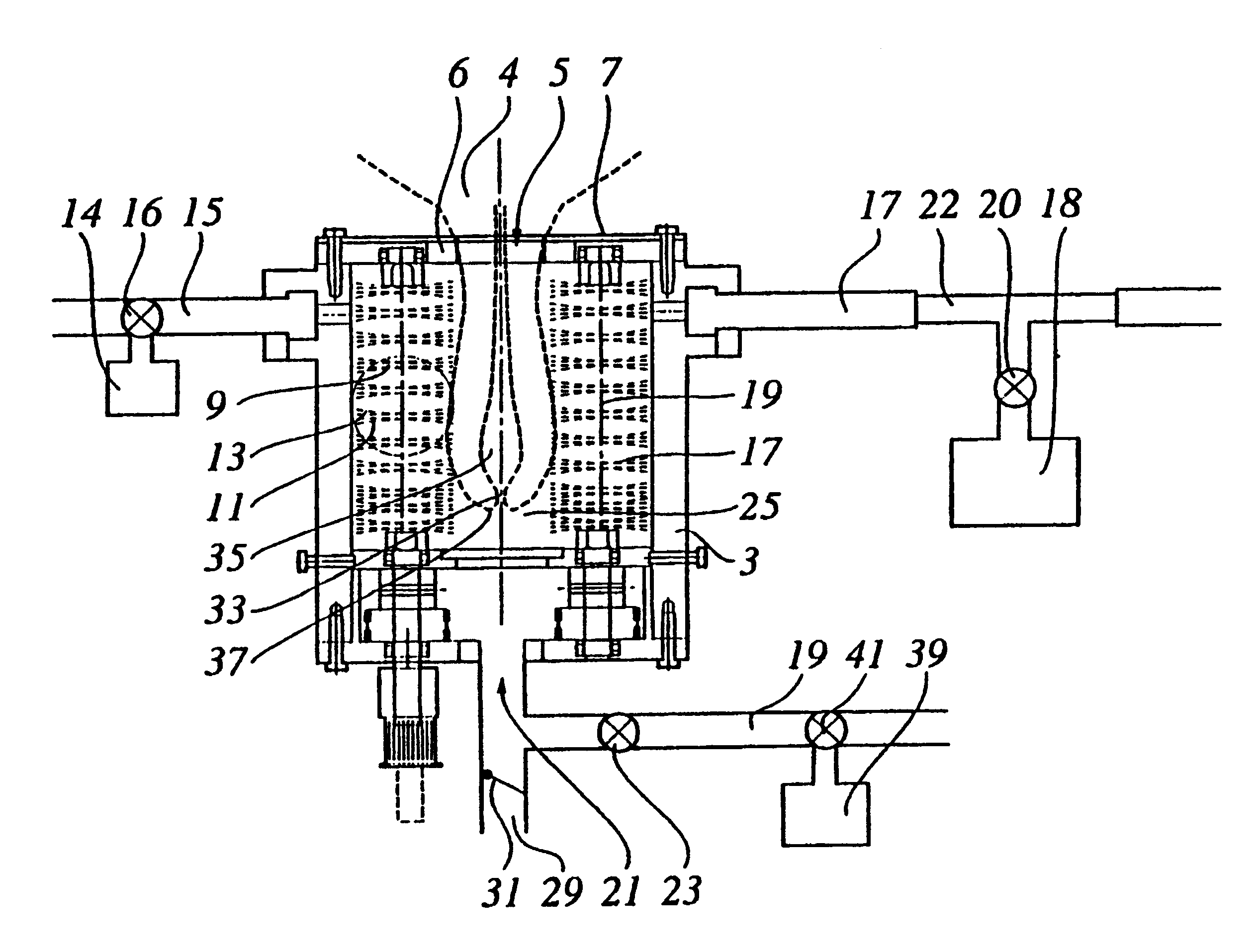

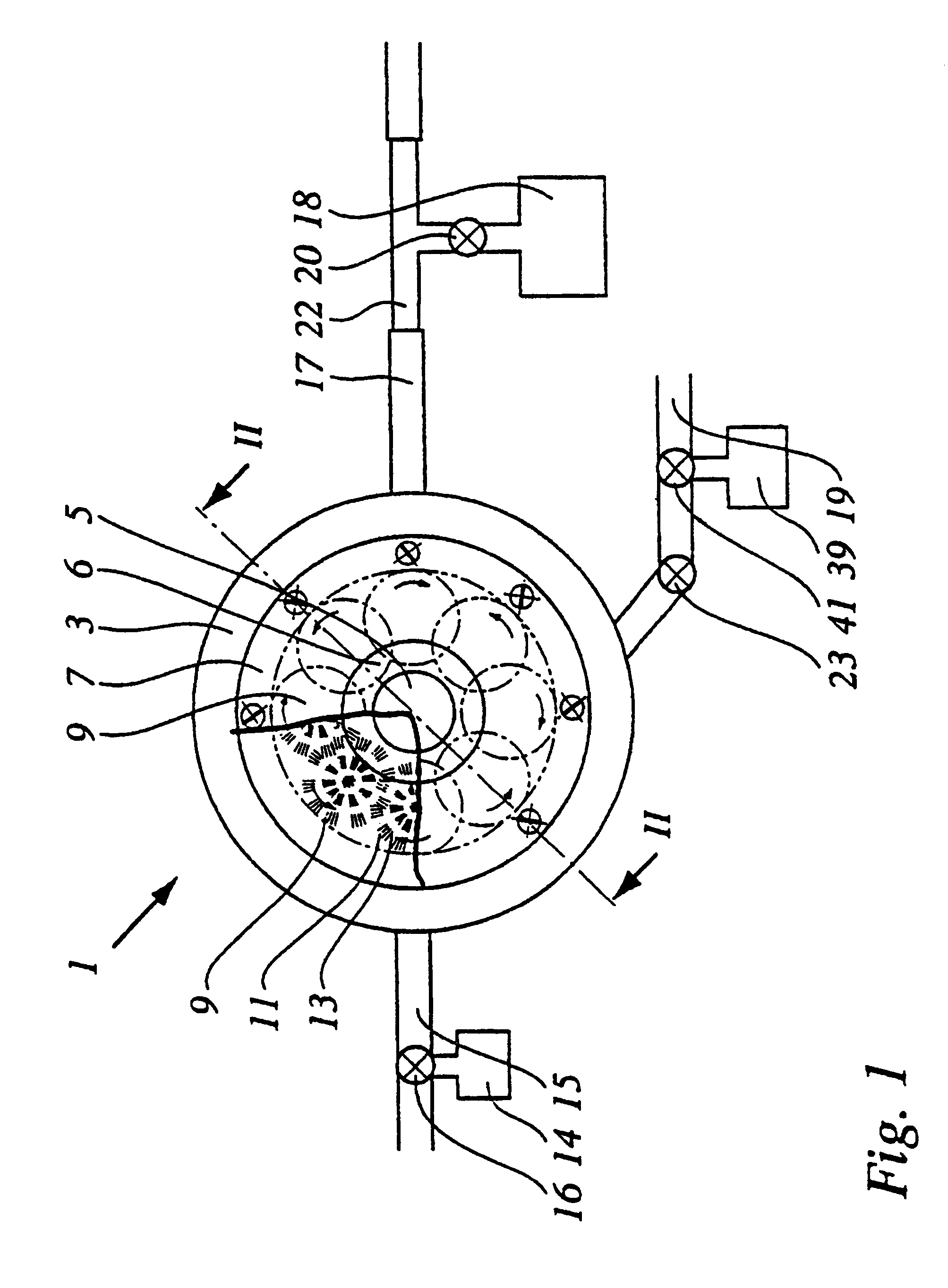

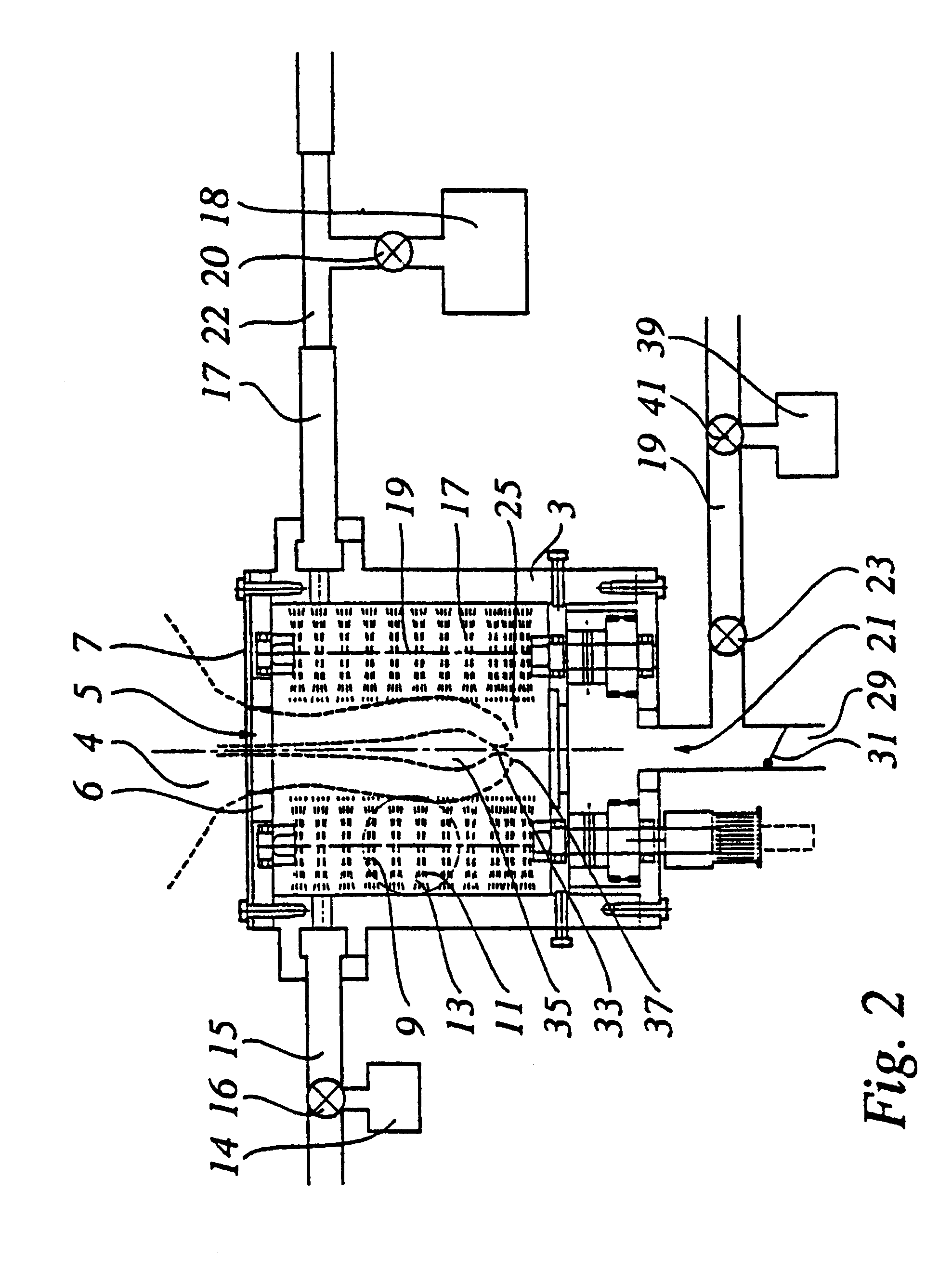

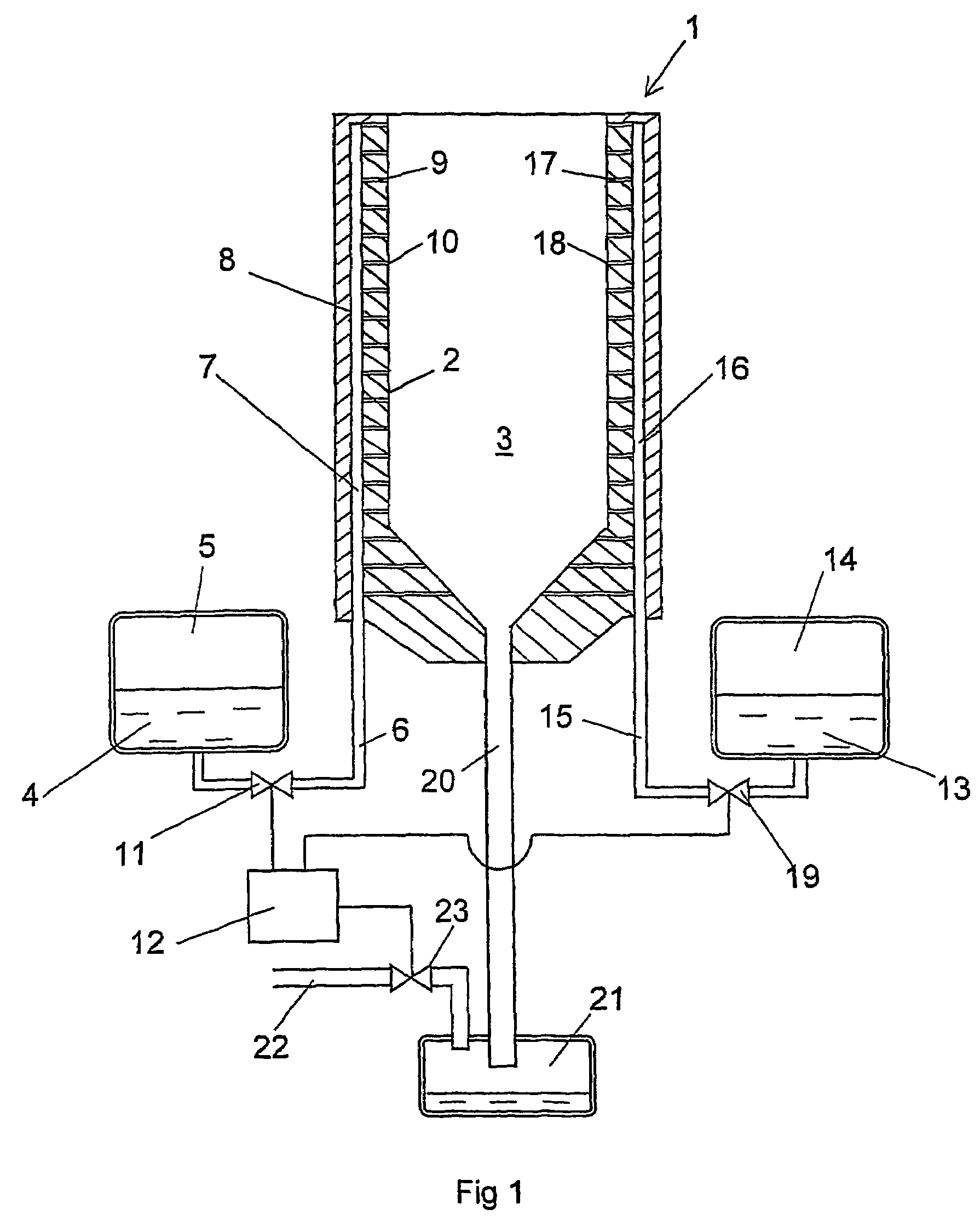

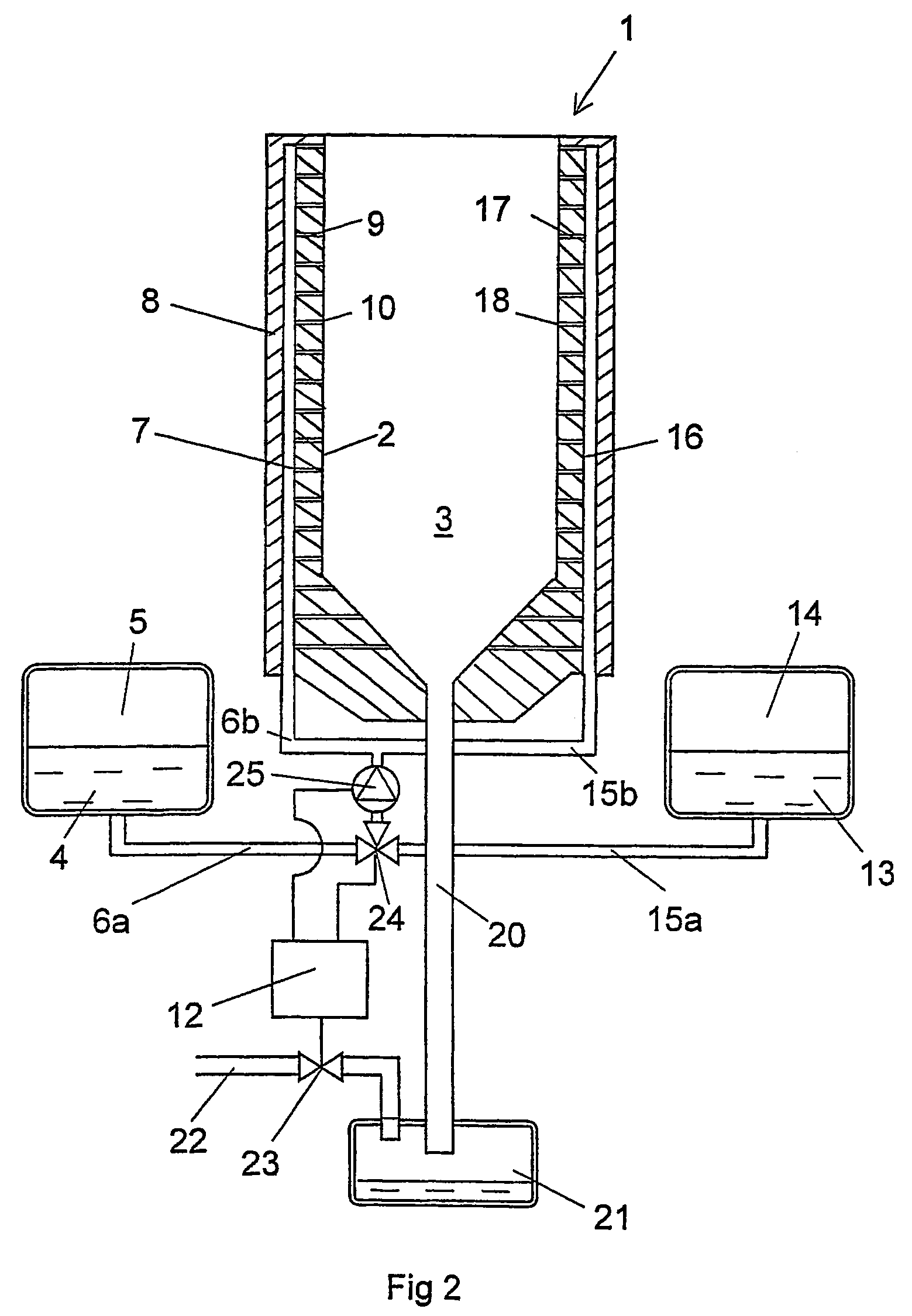

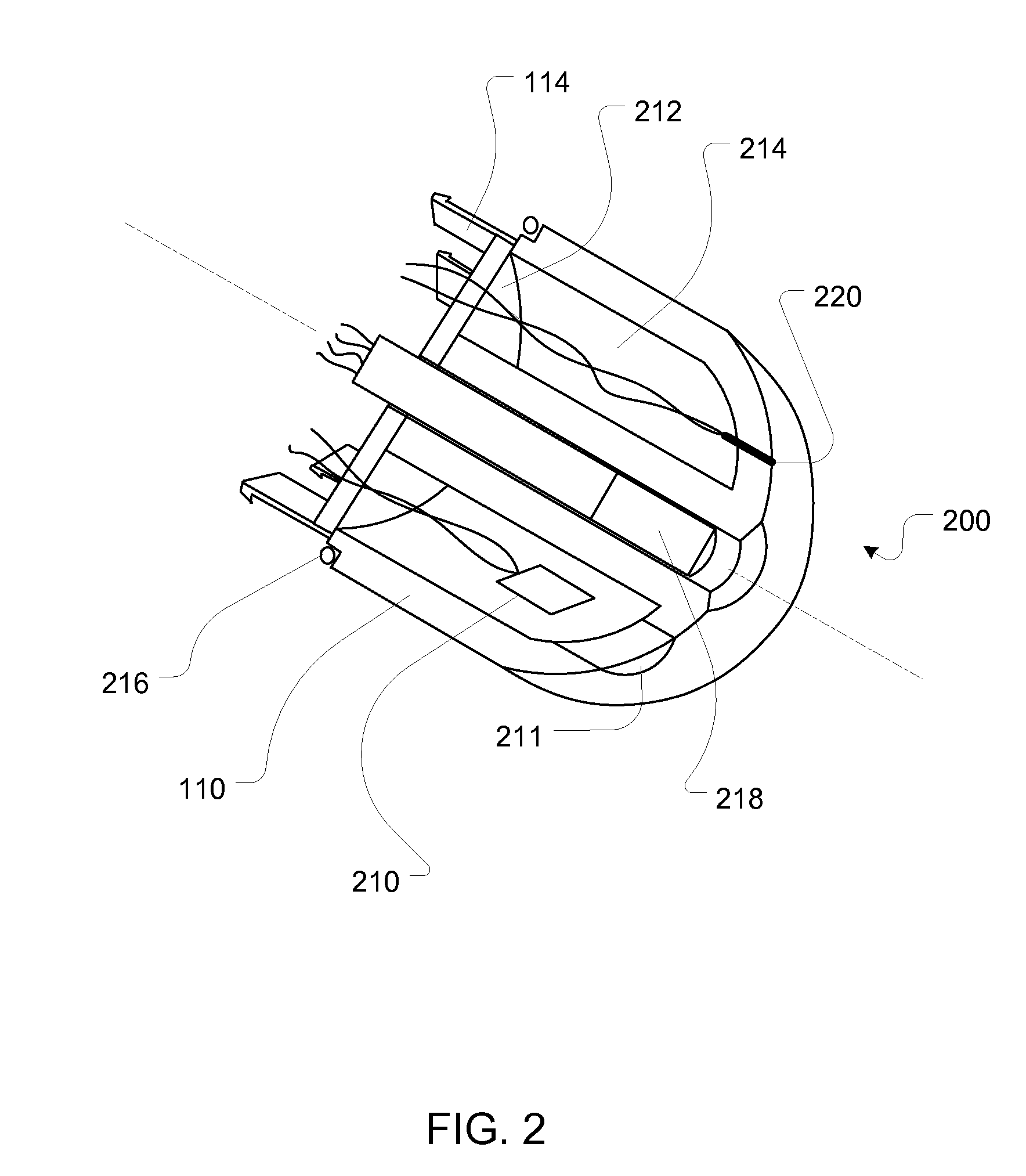

The present invention relates to a device and method for cleaning and pre-milking teats. The device comprises a teat receiving means (3, 53) having a teat receiving opening (5, 55) and cleaning means (9, 59), and it further comprises vacuum-supplying means (19, 69) and teat receiving opening sealing means (6, 56). Means (14, 16, 18, 20, 22) for sterilising teats may also be provided.

Owner:DELAVAL HLDG AB

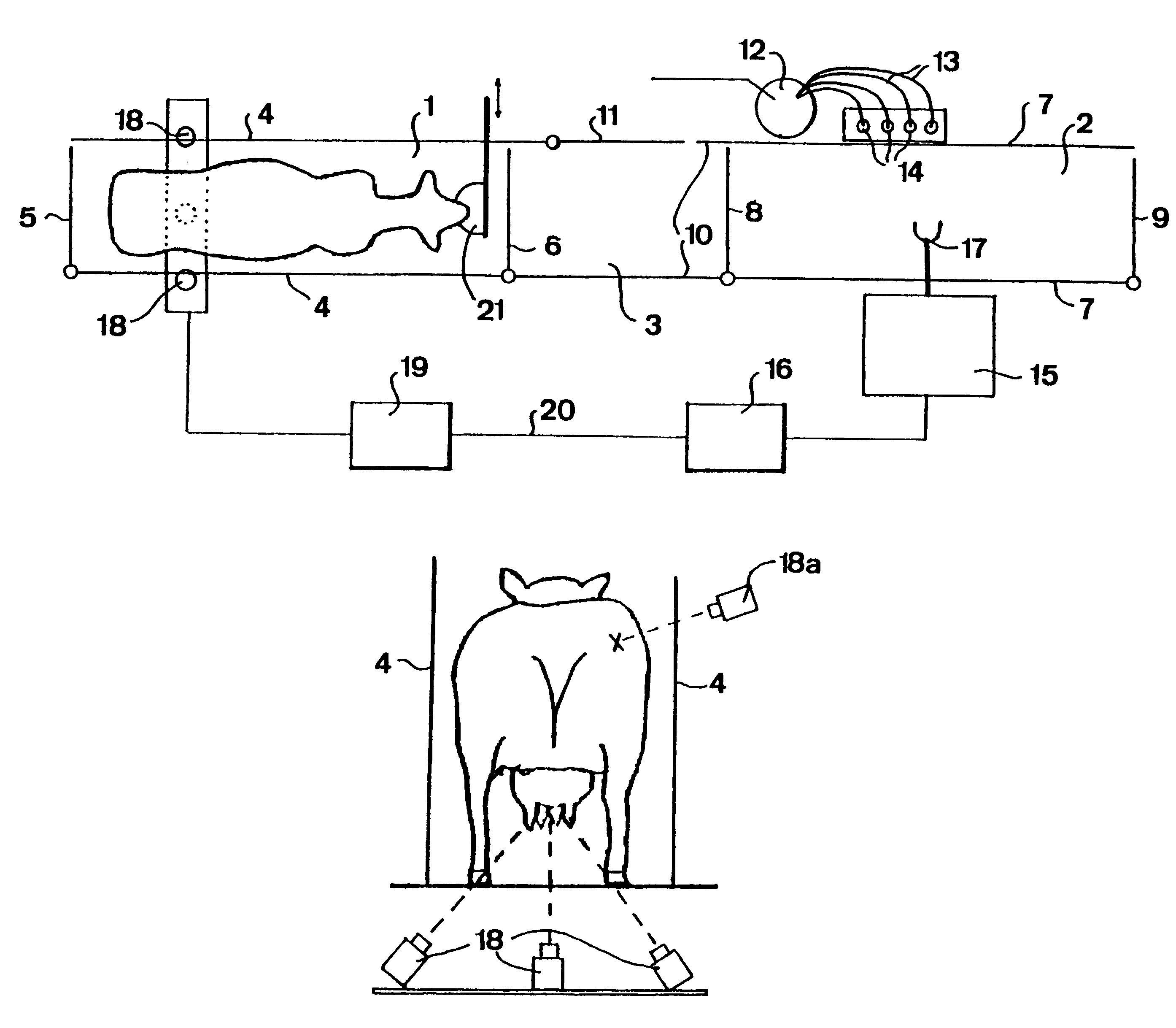

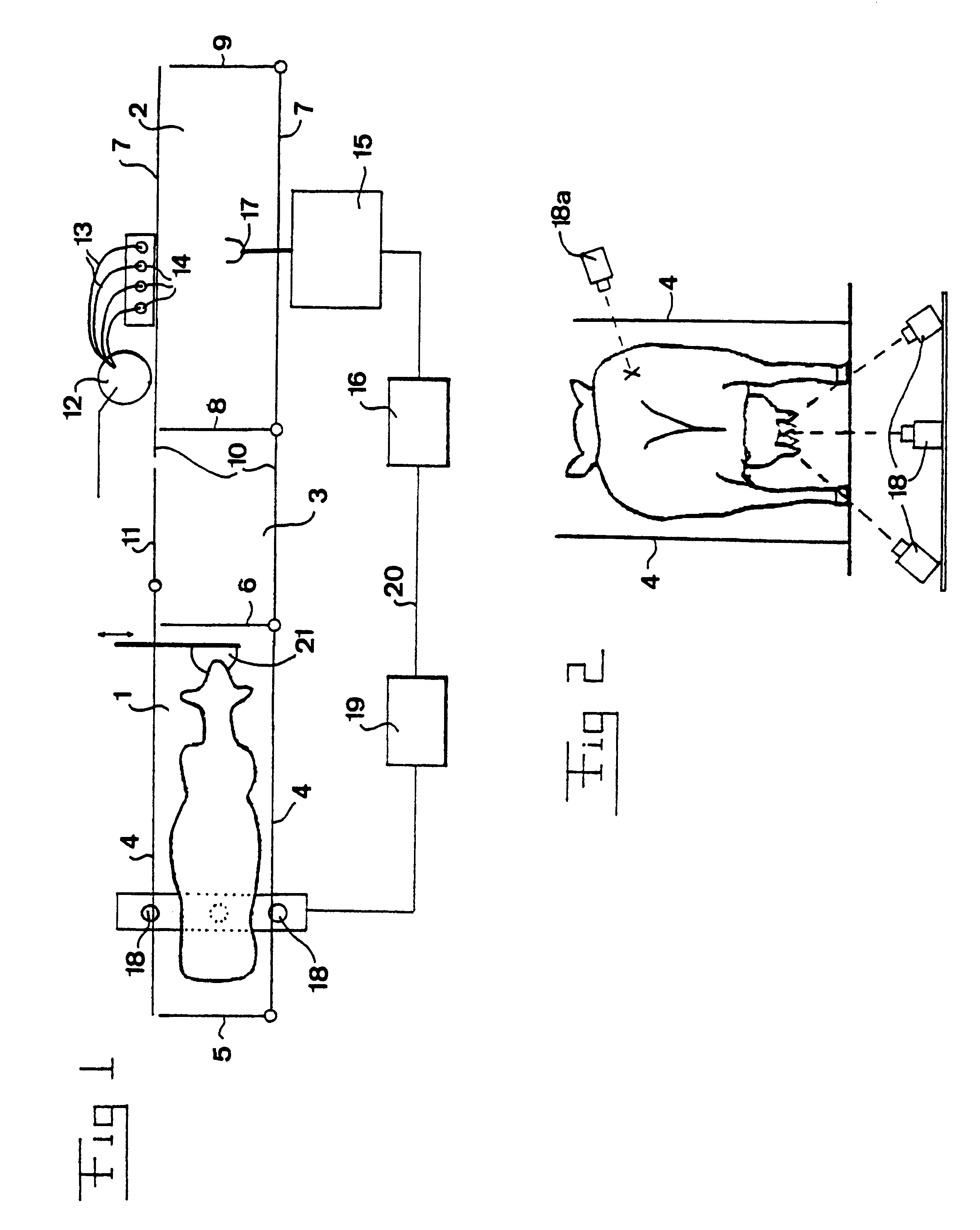

Apparatus for and a method of performing an animal-related action regarding at least a part of the body of an animal

Owner:DELAVAL HLDG AB

Apparatus and method for recognizing and determining the position of a part of an animal

InactiveUS6234109B1Easy to separateEasy to distinguishImage analysisCathetersComputer scienceImage capture

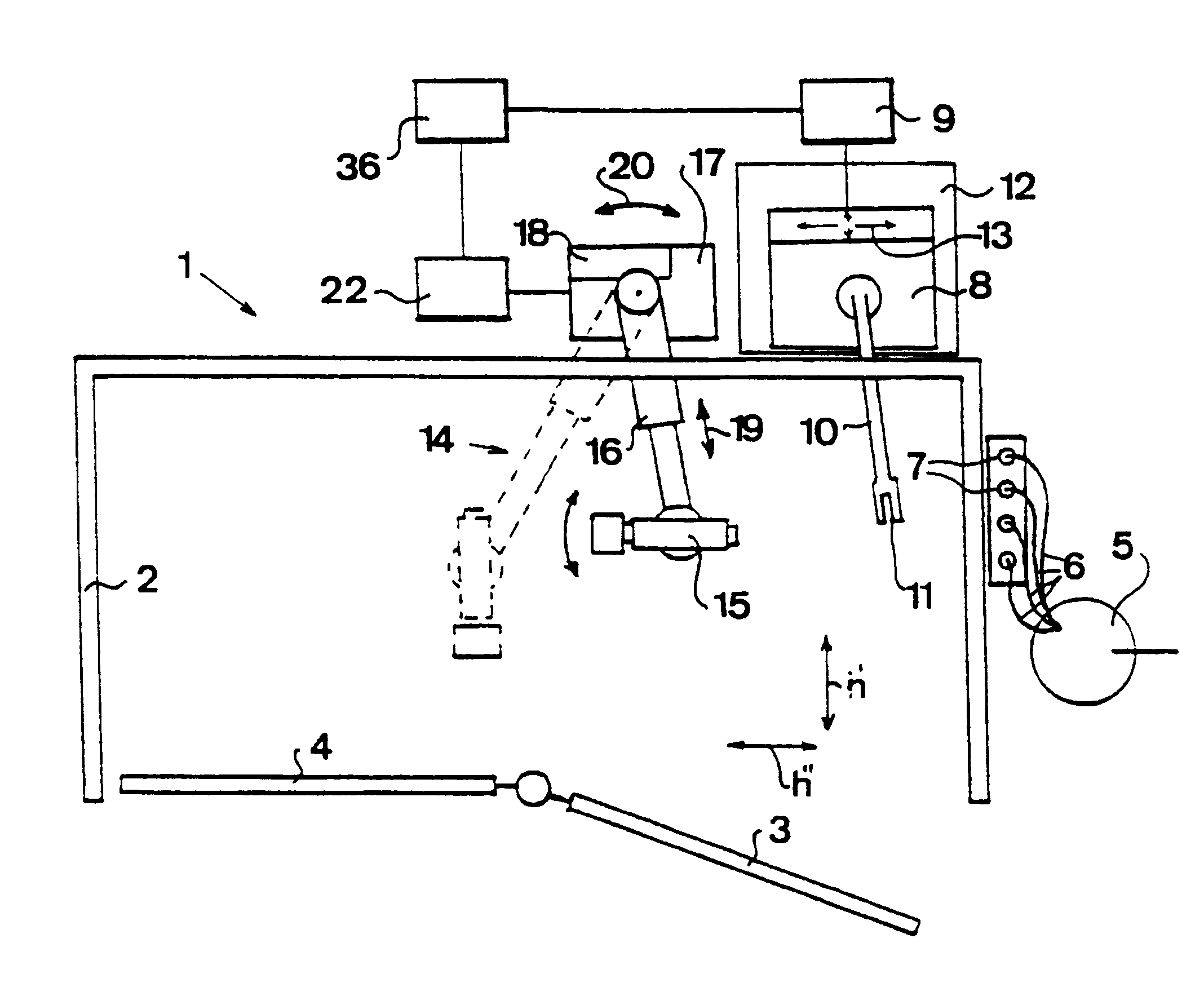

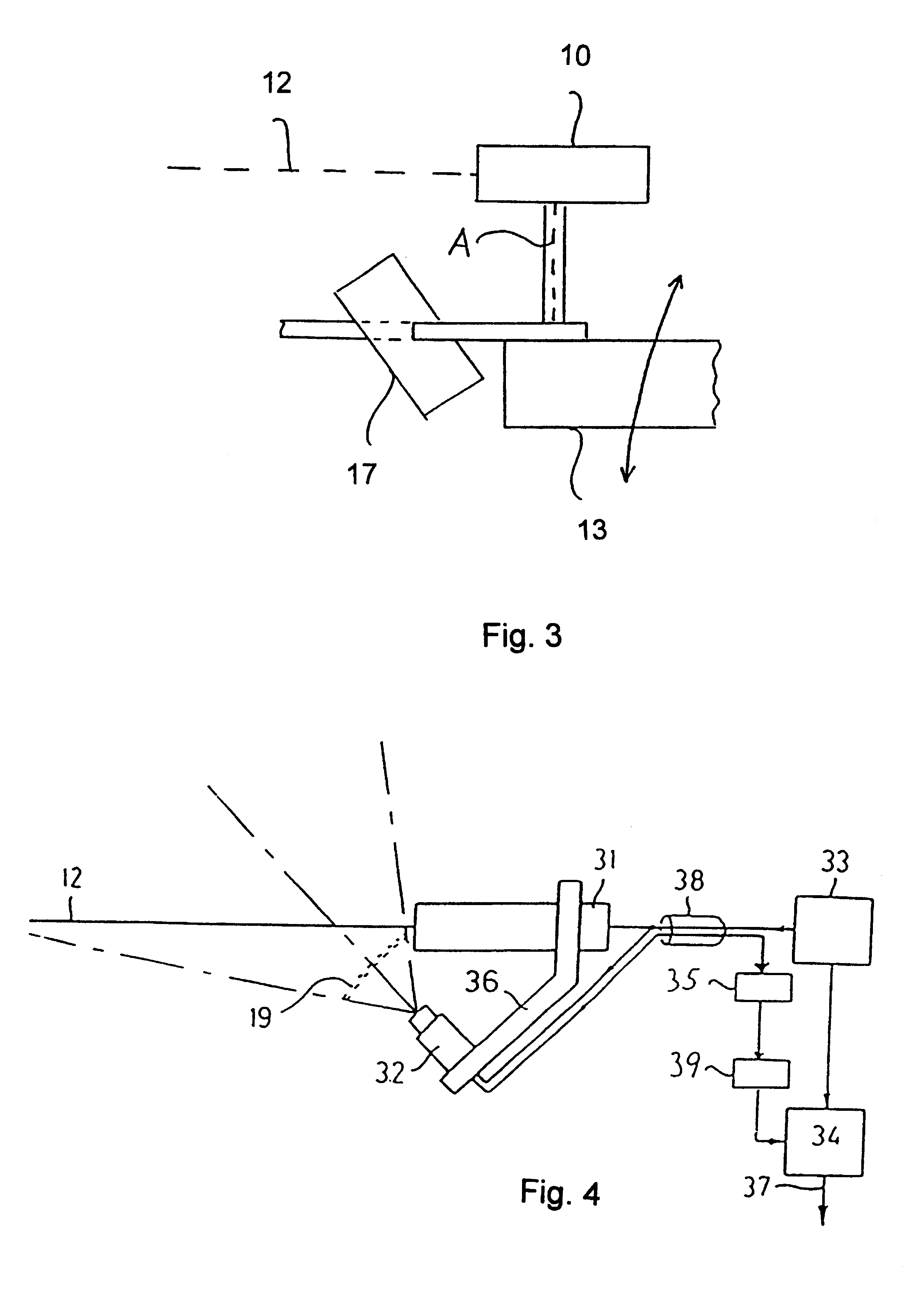

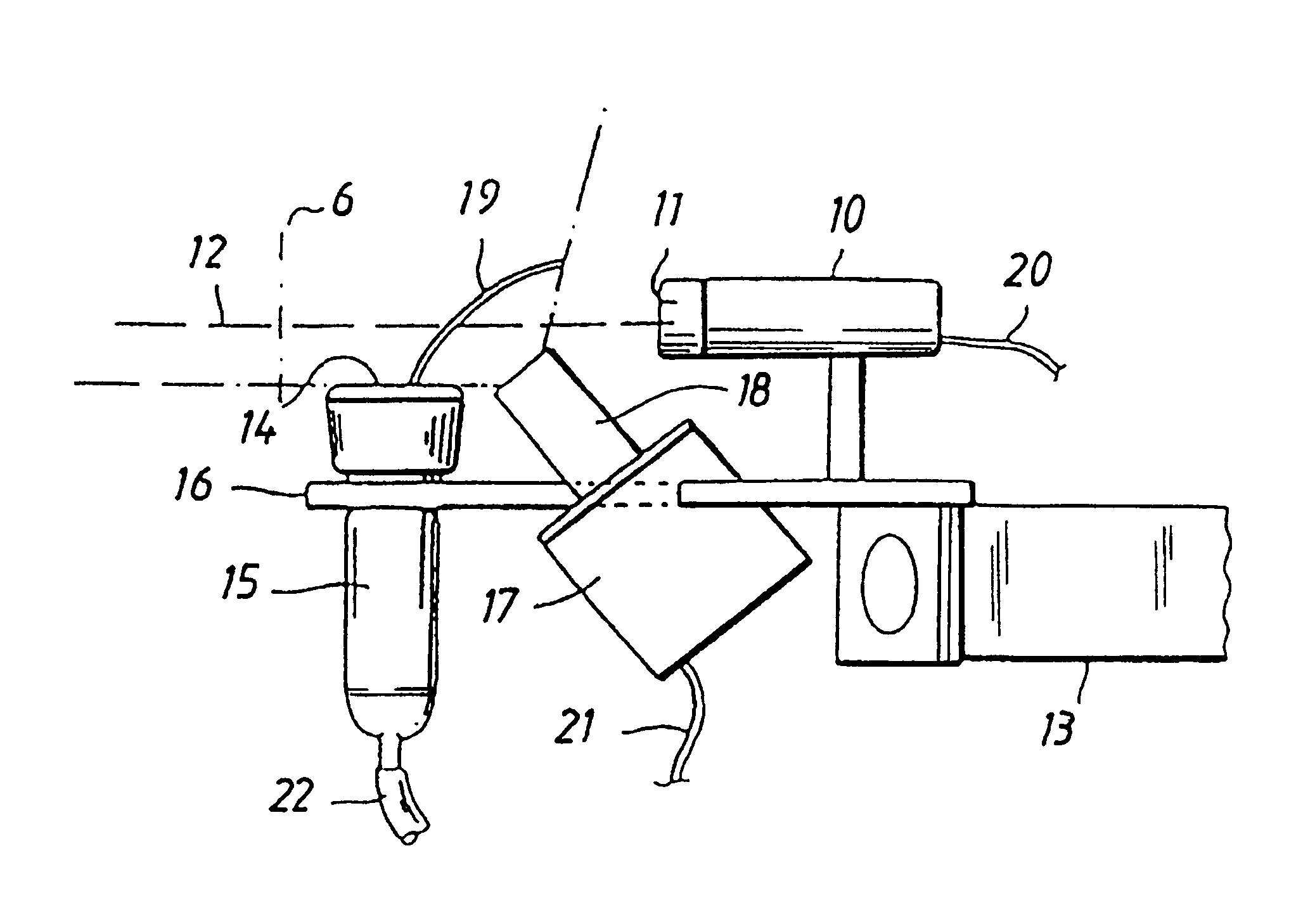

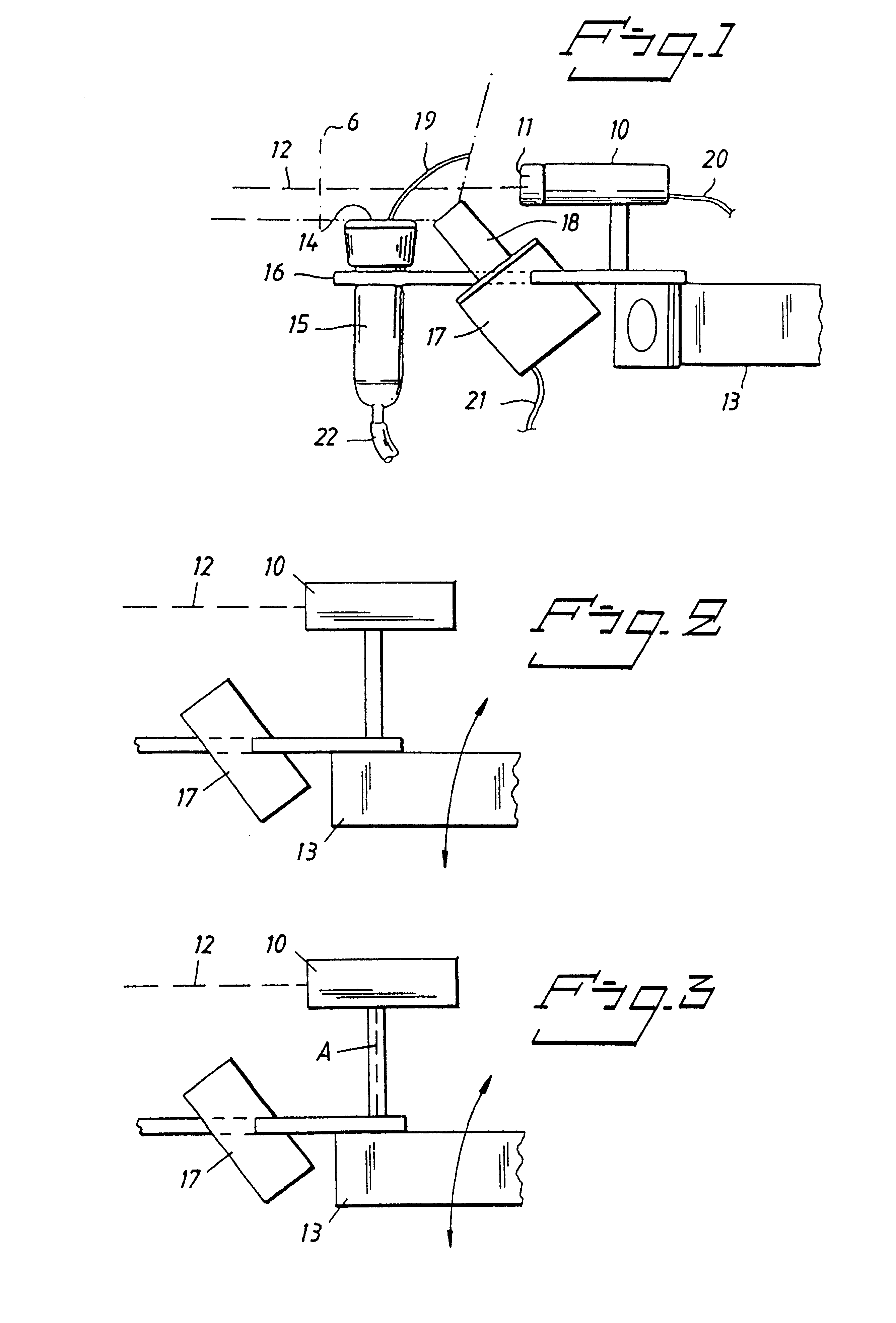

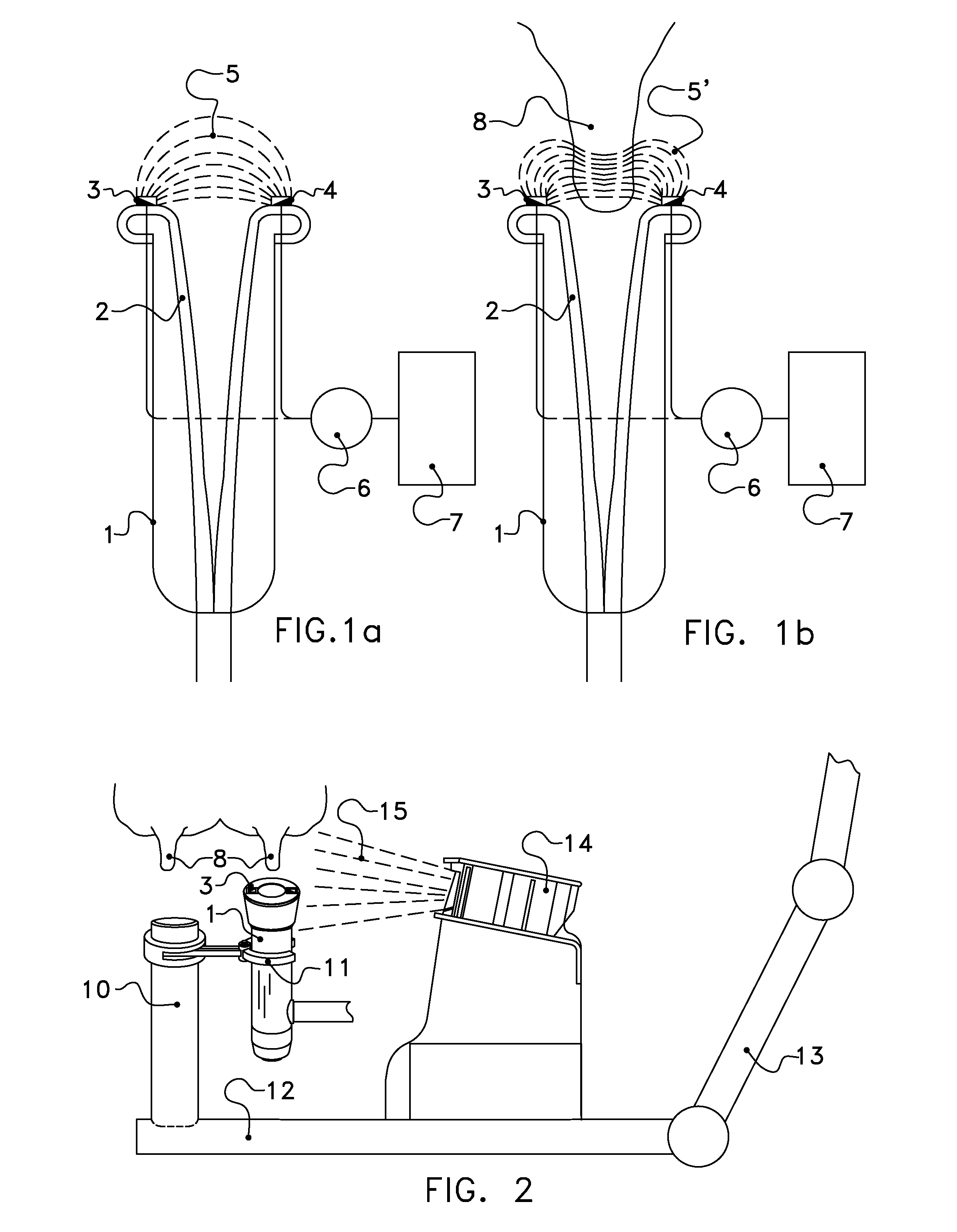

The present invention relates to an apparatus and a method for recognizing and determining the position of a part of an animal. The apparatus comprises a source of structured light for illuminating a region expected to contain at least one of the part in such a way that an object illuminated by the light will have at least one illuminated area with a very distinct outline in at least one direction, an image capture and processor device arranged to capture and process the at least one image formed by the light and a control device to determine if the illuminated object is the part by comparing the image of the illuminated object to reference criteria defining different objects, and if the illuminated object is established to be the part of the animal, the position thereof is established, and animal related device and a device to guide the animal related device towards position of the part are provided.

Owner:DELAVAL HLDG AB

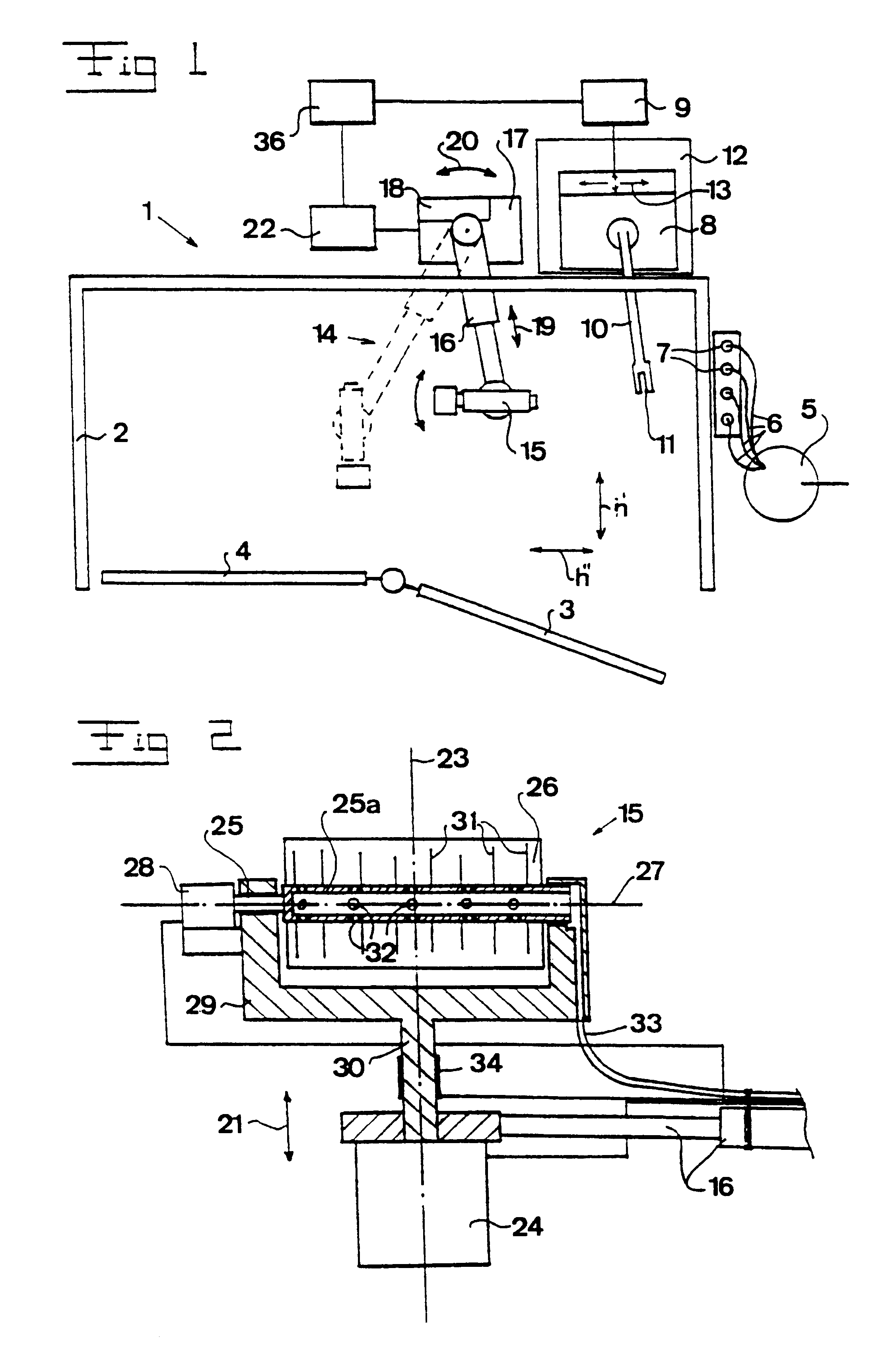

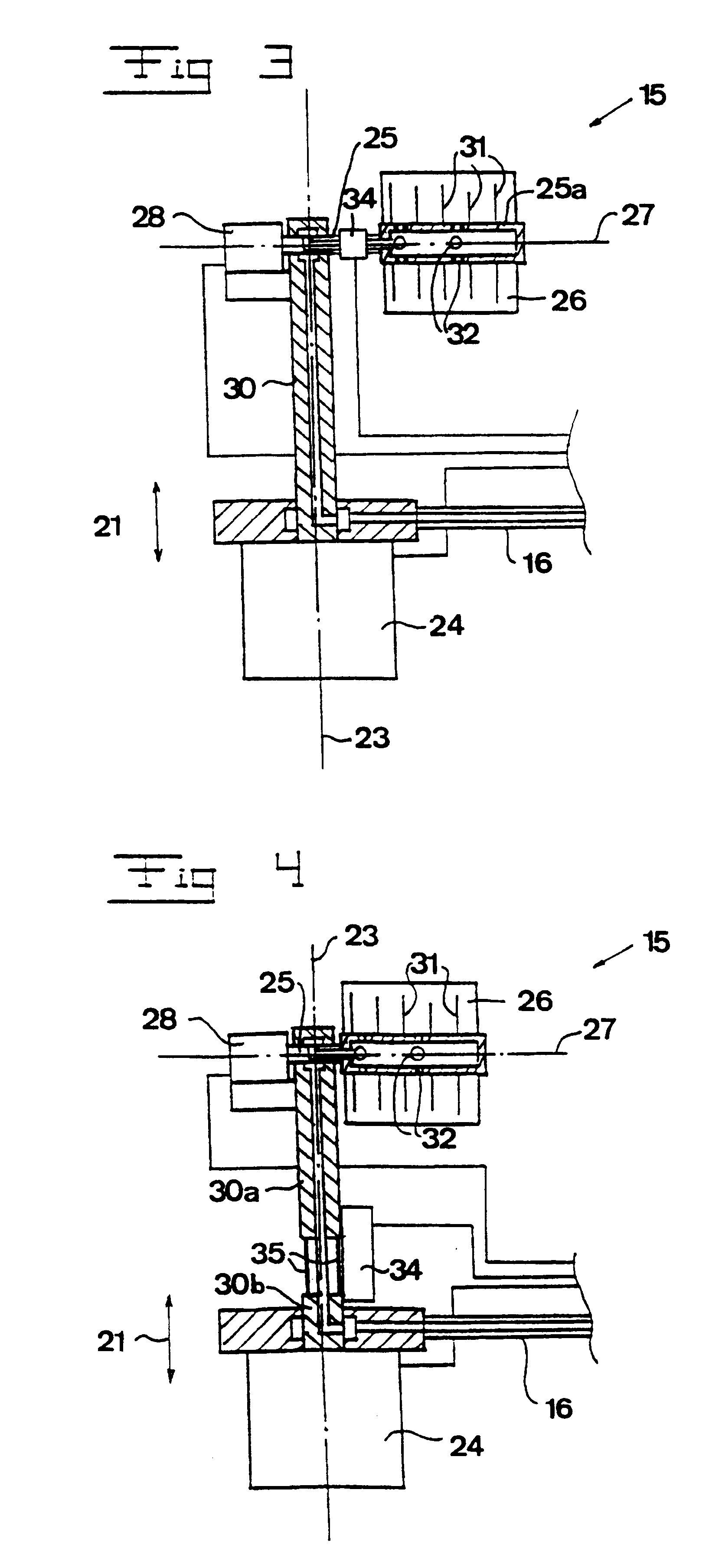

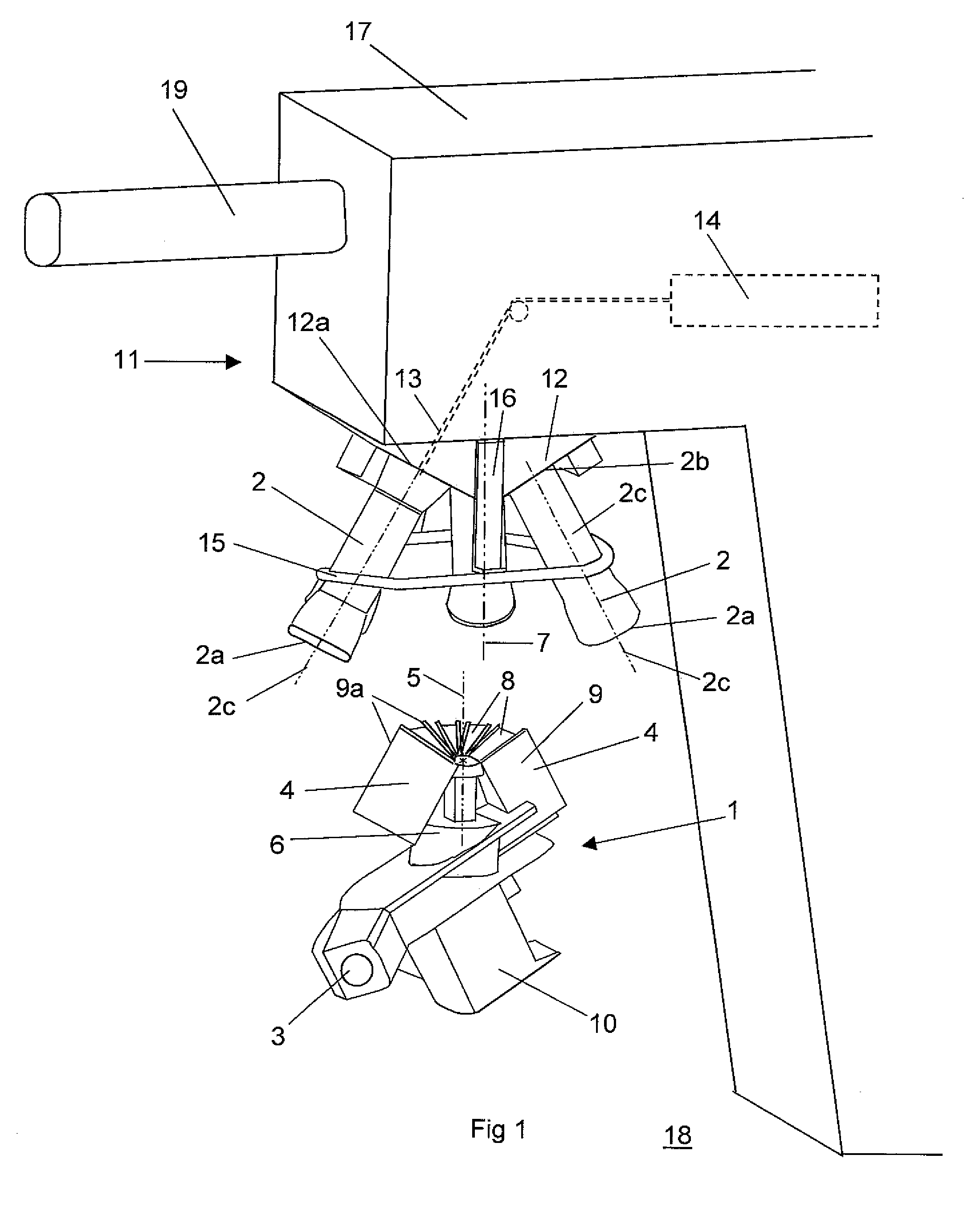

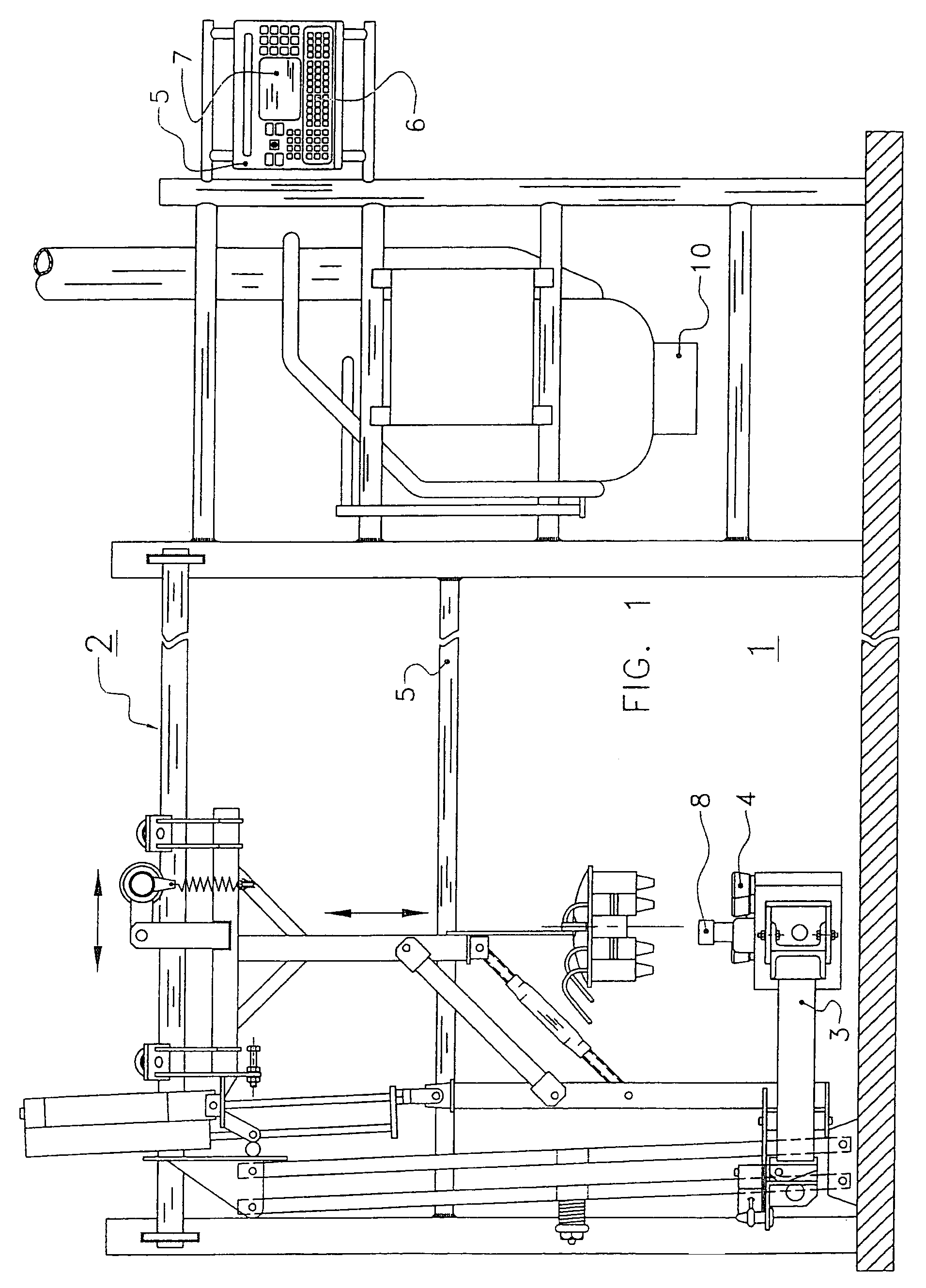

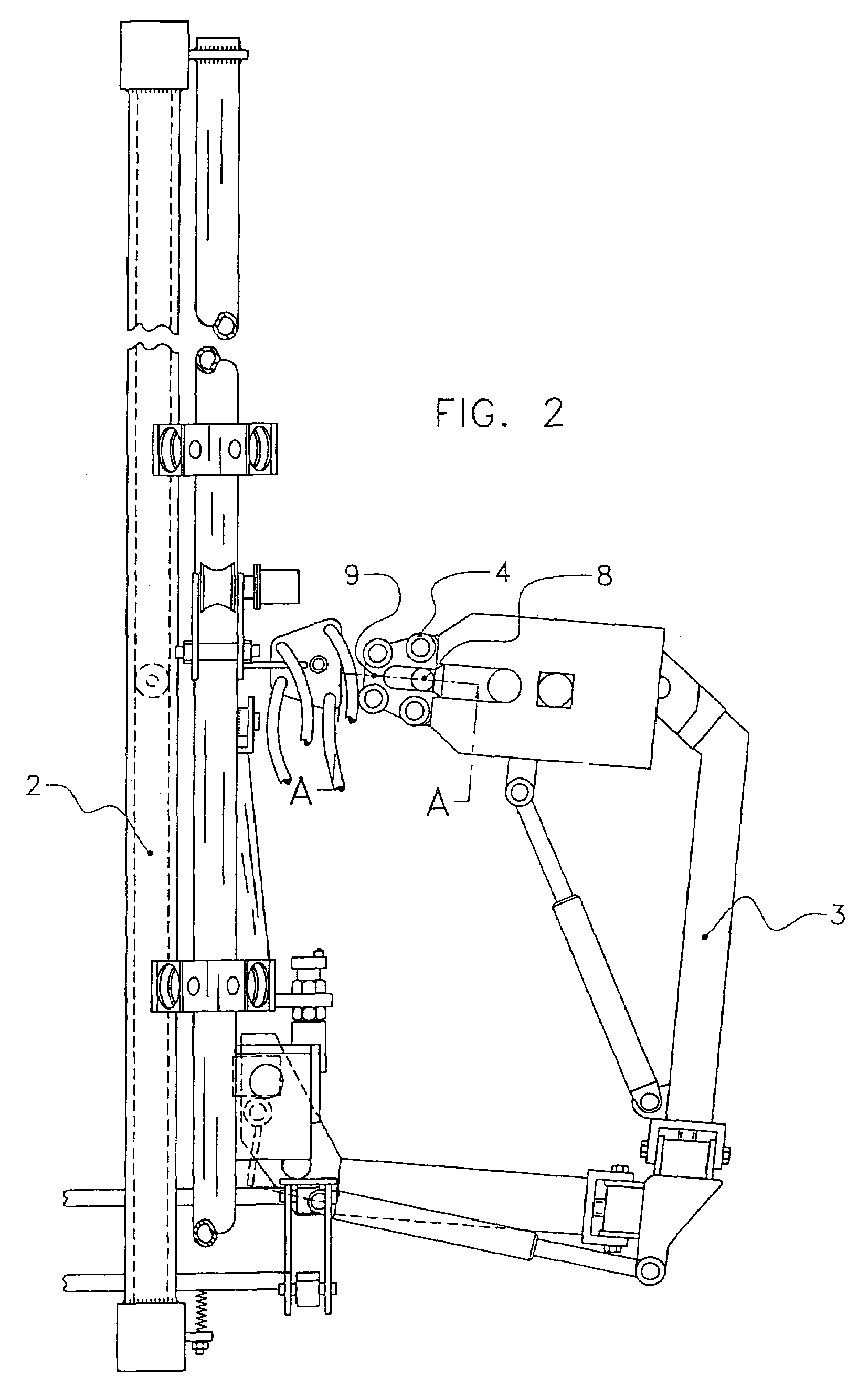

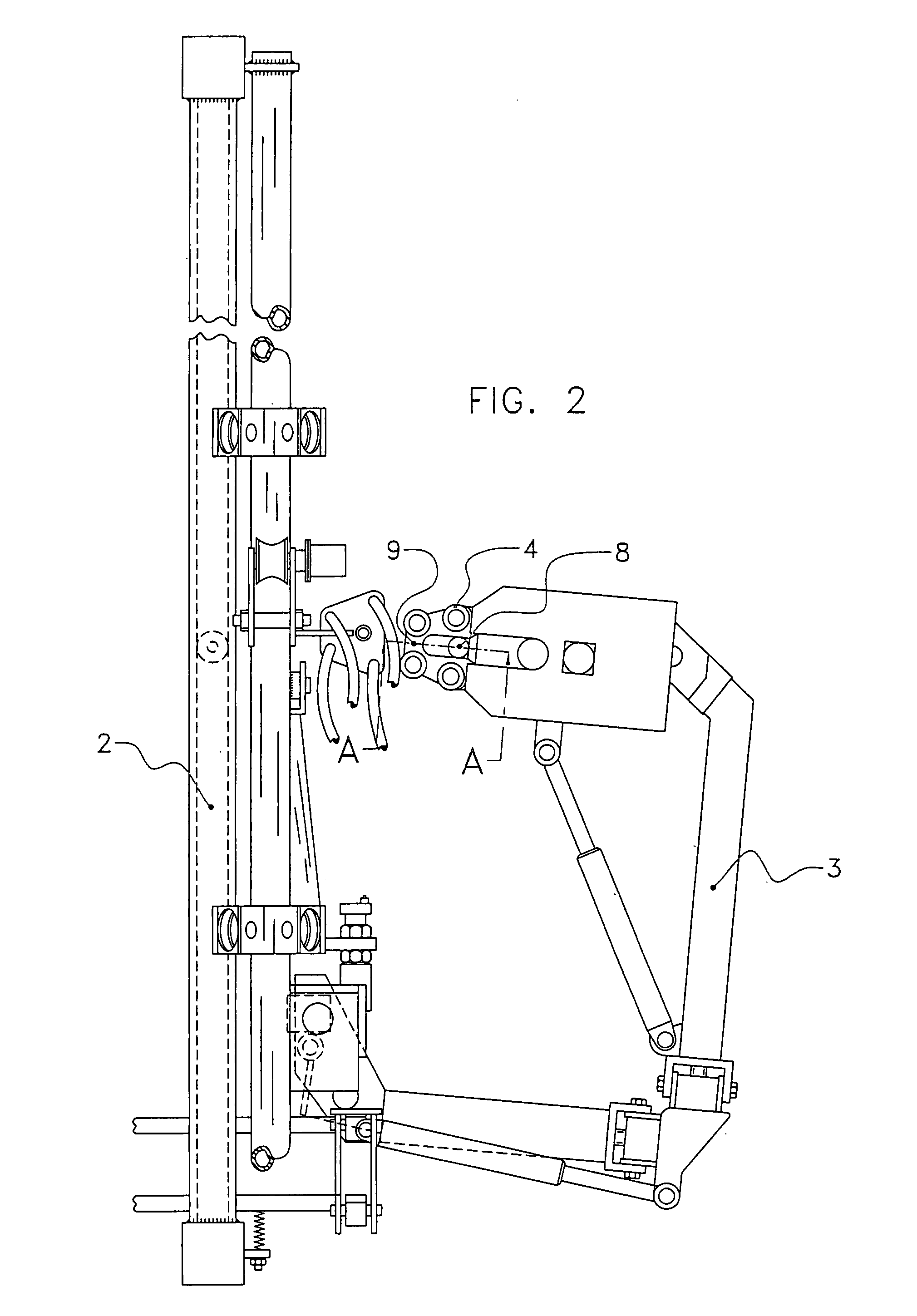

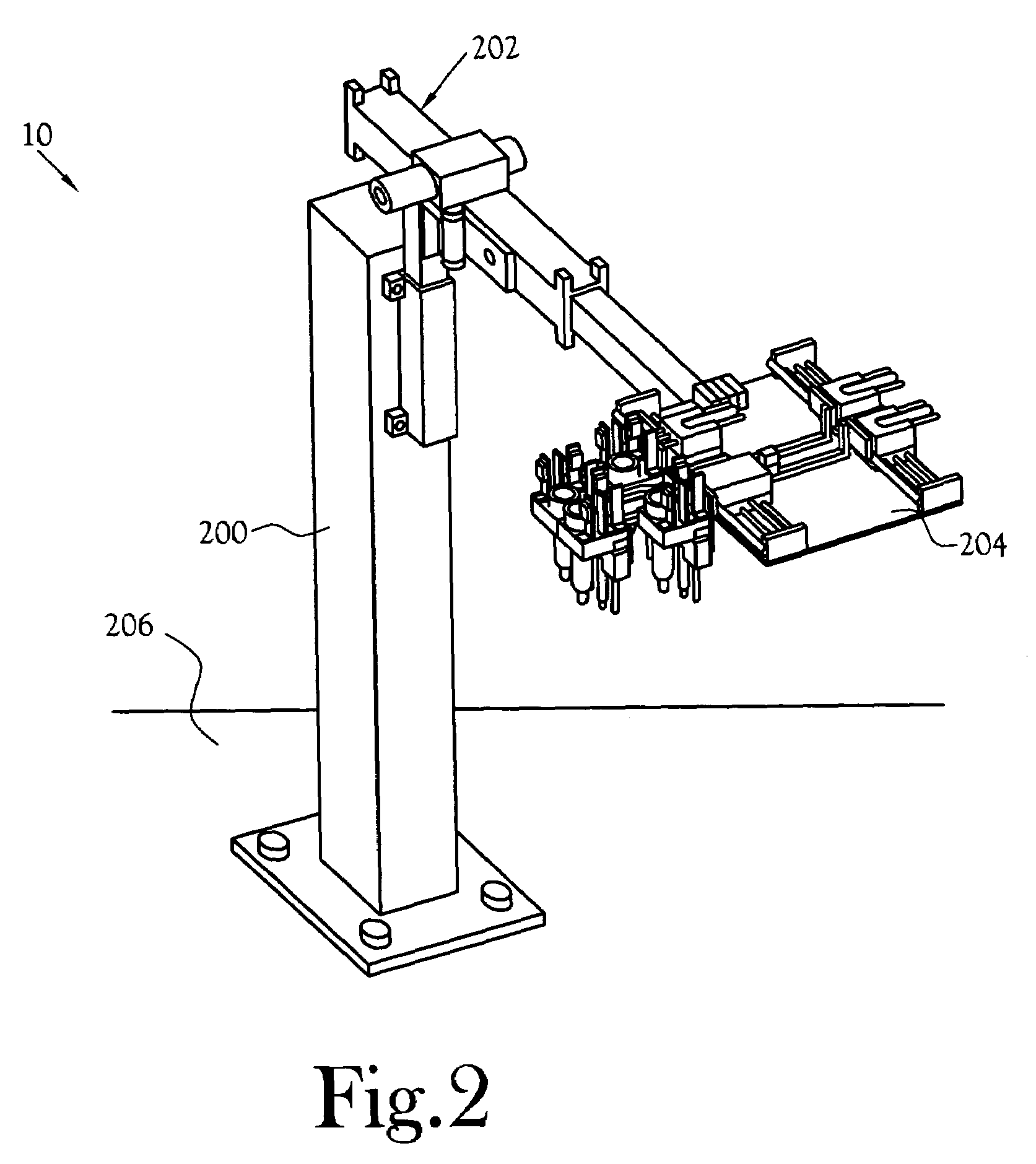

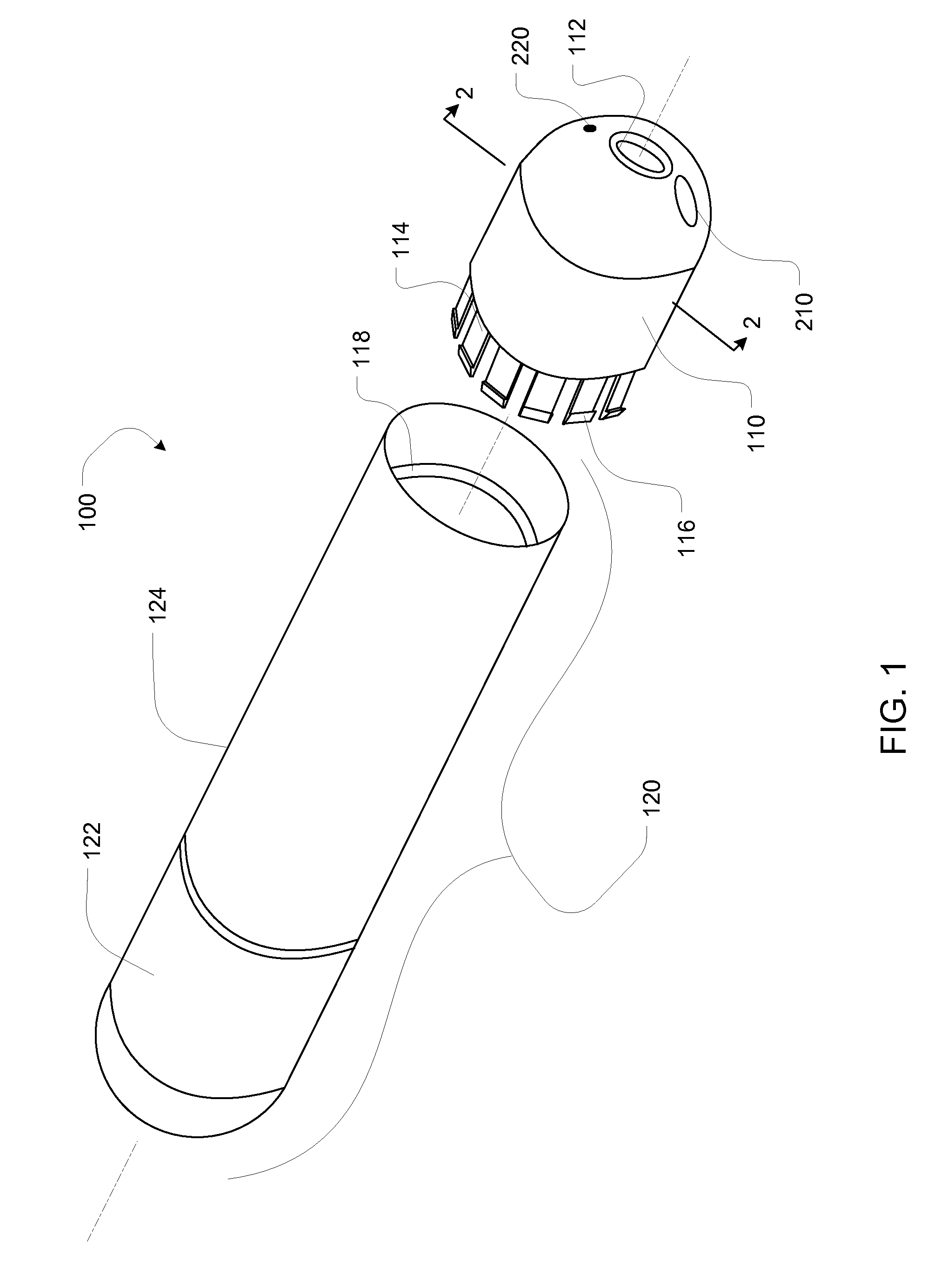

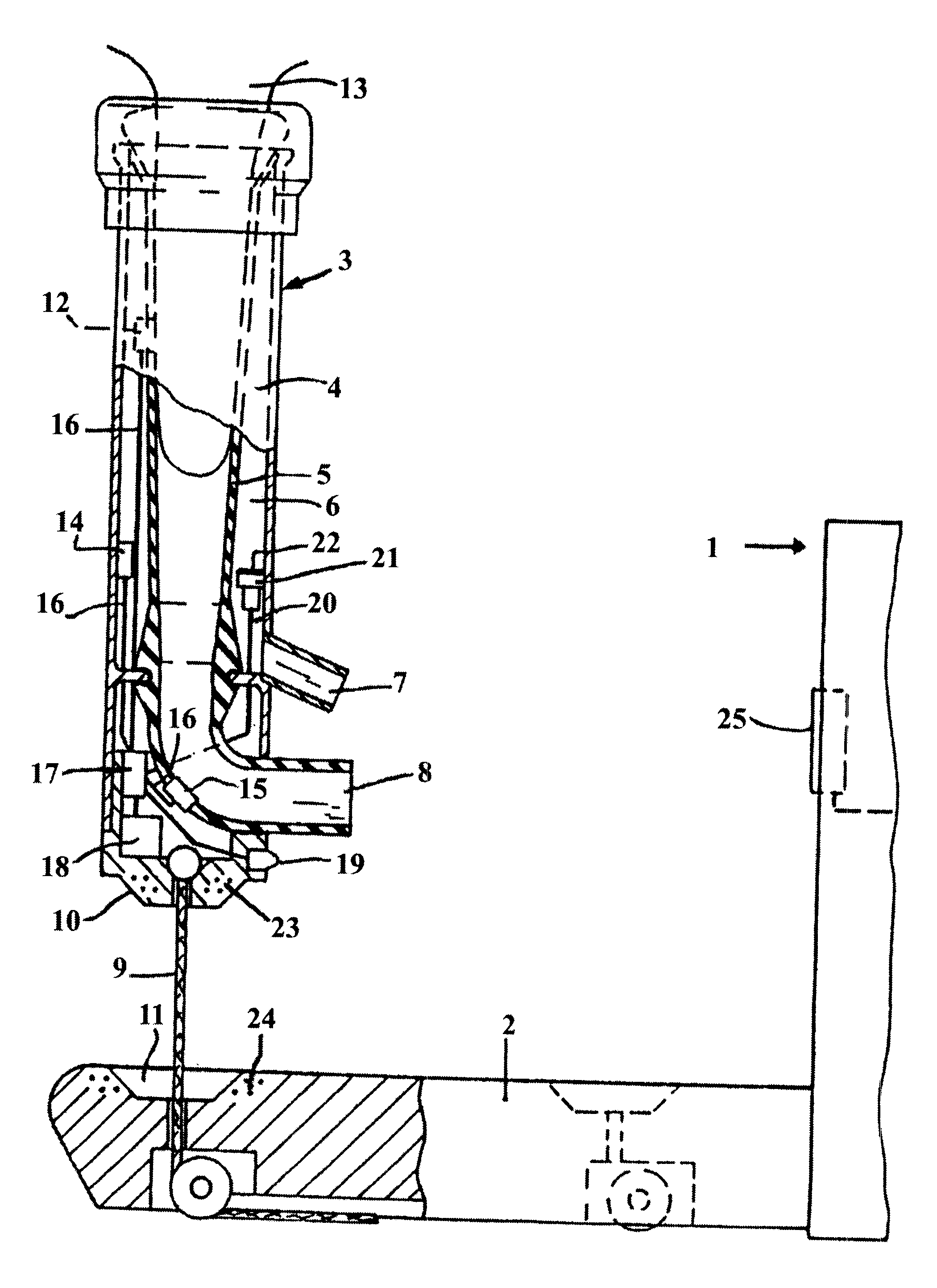

Method and apparatus for recognizing and determining a position and robot including such an apparatus

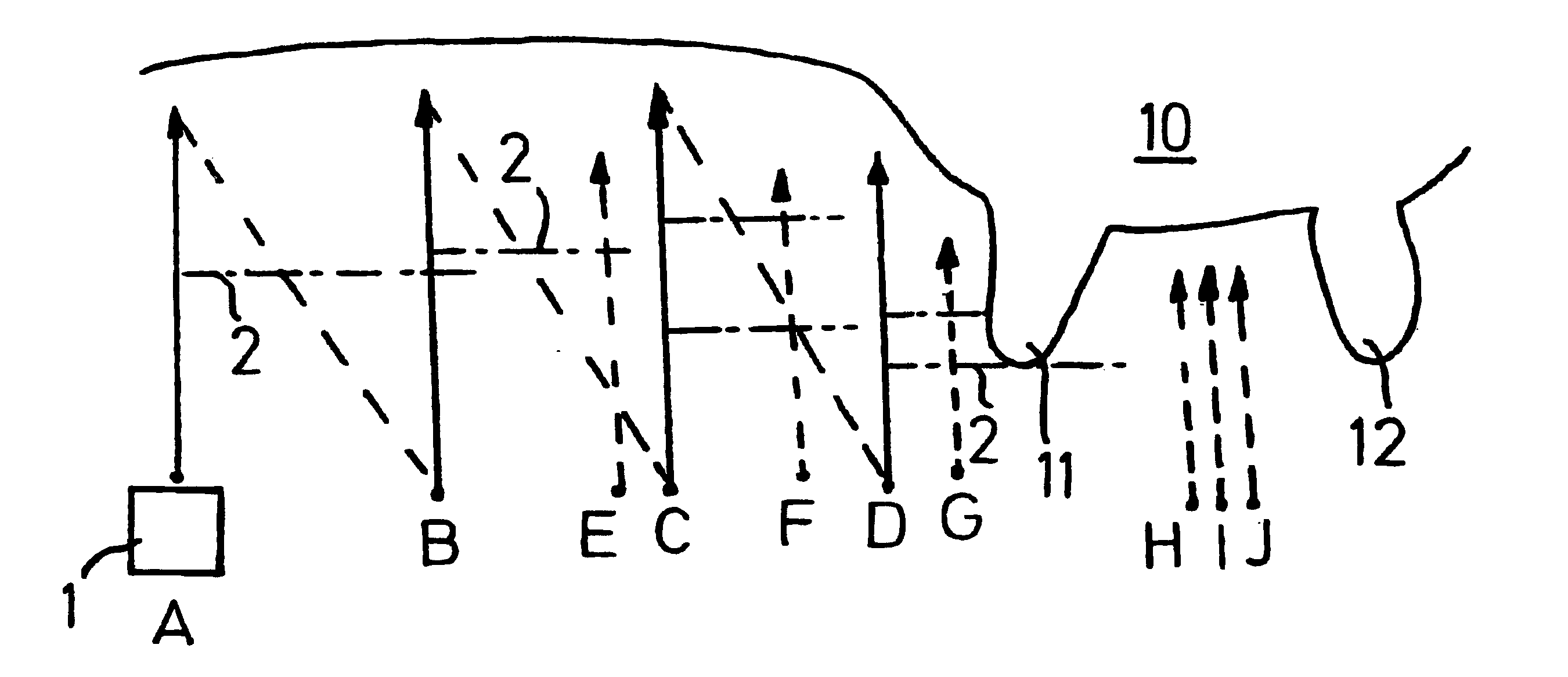

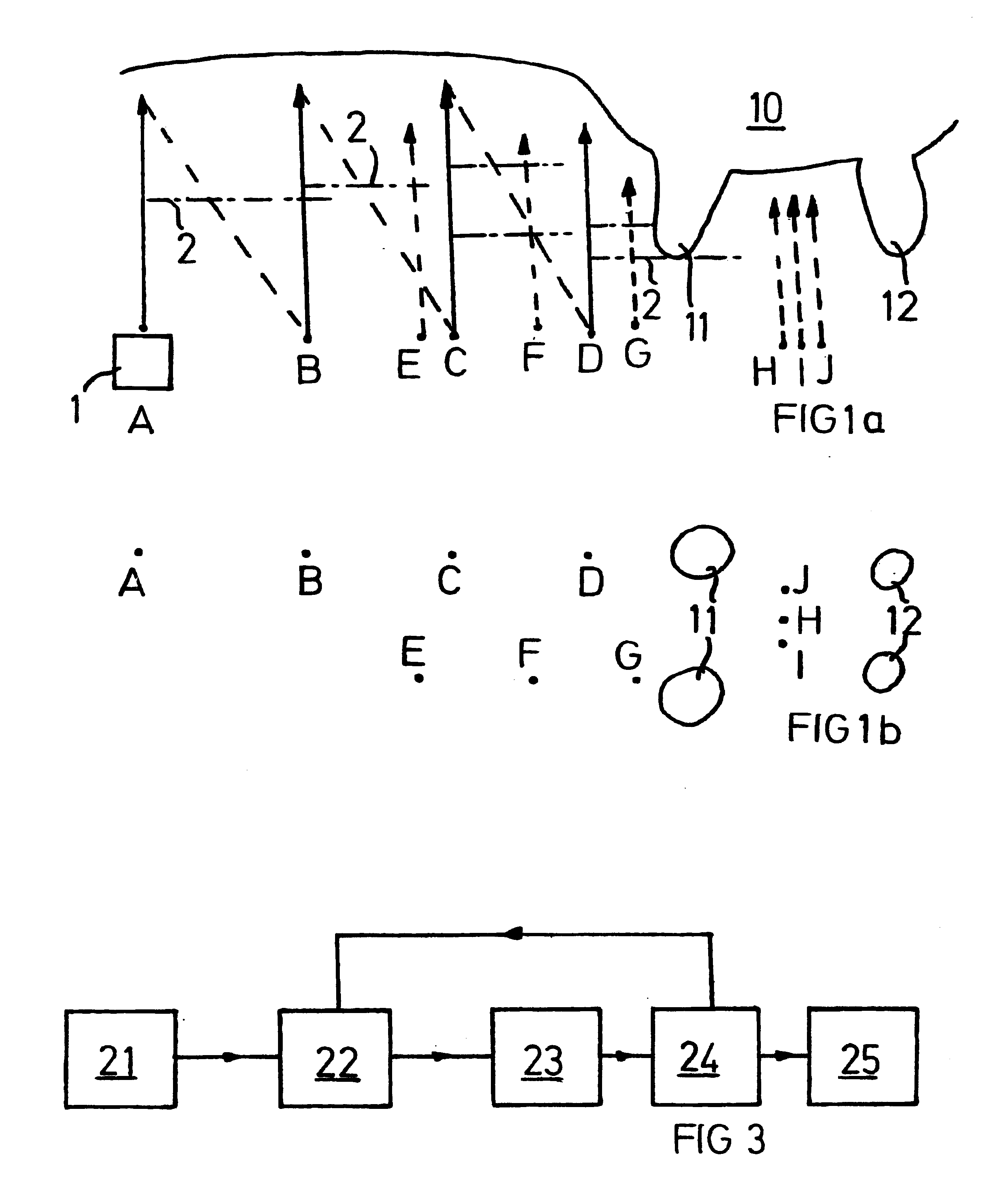

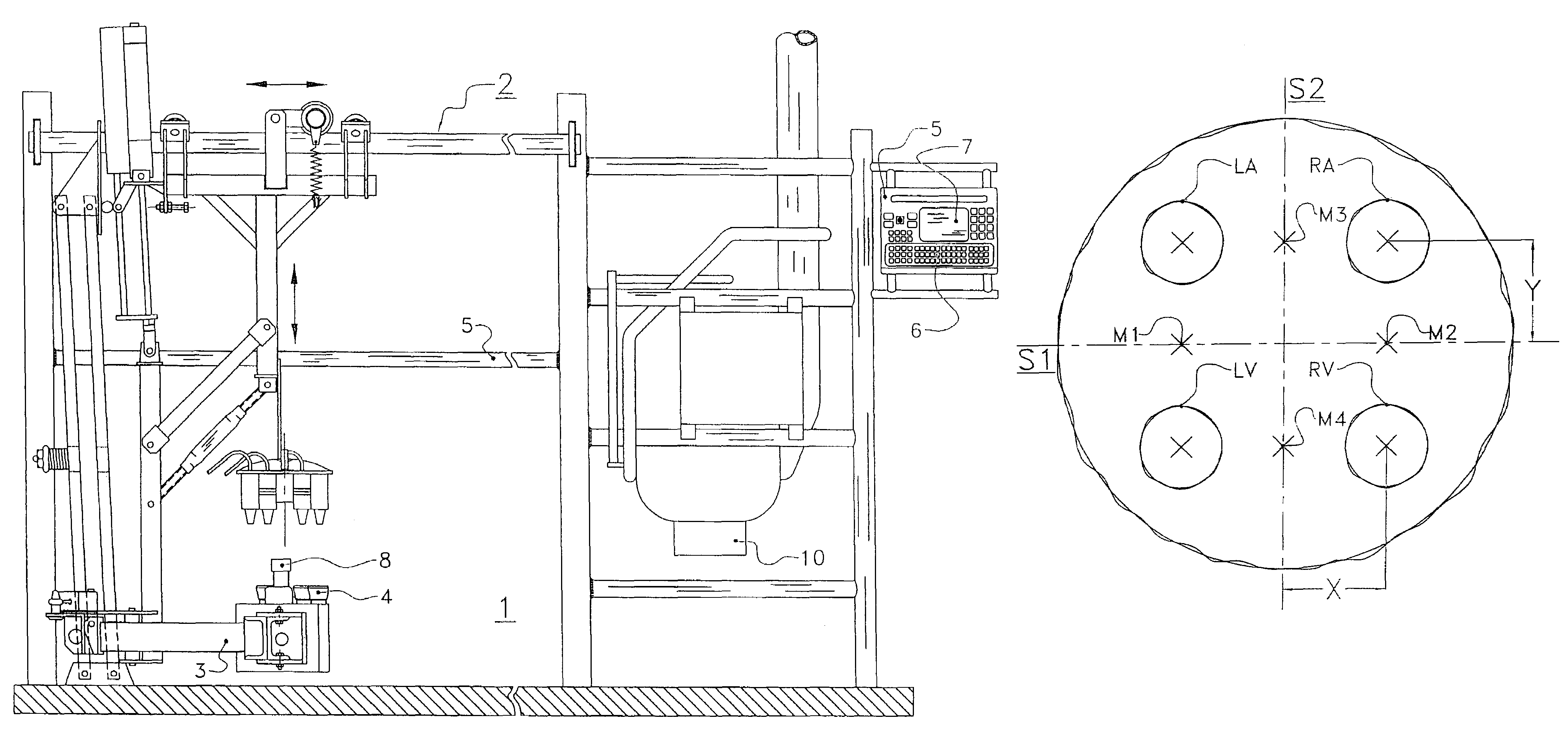

A method for recognizing and determining the position of at least one teat of a milking animal, including the steps: moving a scanning head including a light source to a region containing the teat or teats, capturing at least one image formed by said light, evaluating the image or images so as to determine if each image describes said teat or teats. The scanning head (1) is moved to a fixed initial position (A) in the room which is under the animal and clearly in front of an udder and thereby the teats of all known relevant animals, thereafter the scanning head is moved in determined steps (A-J) under the animal: upwards towards the animal, downwards, backwards towards the udder, upwards, downwards etc., while carrying out the scanning procedure. The invention also concerns an apparatus carrying out the process and a milking robot including such an apparatus.

Owner:DELAVAL HLDG AB

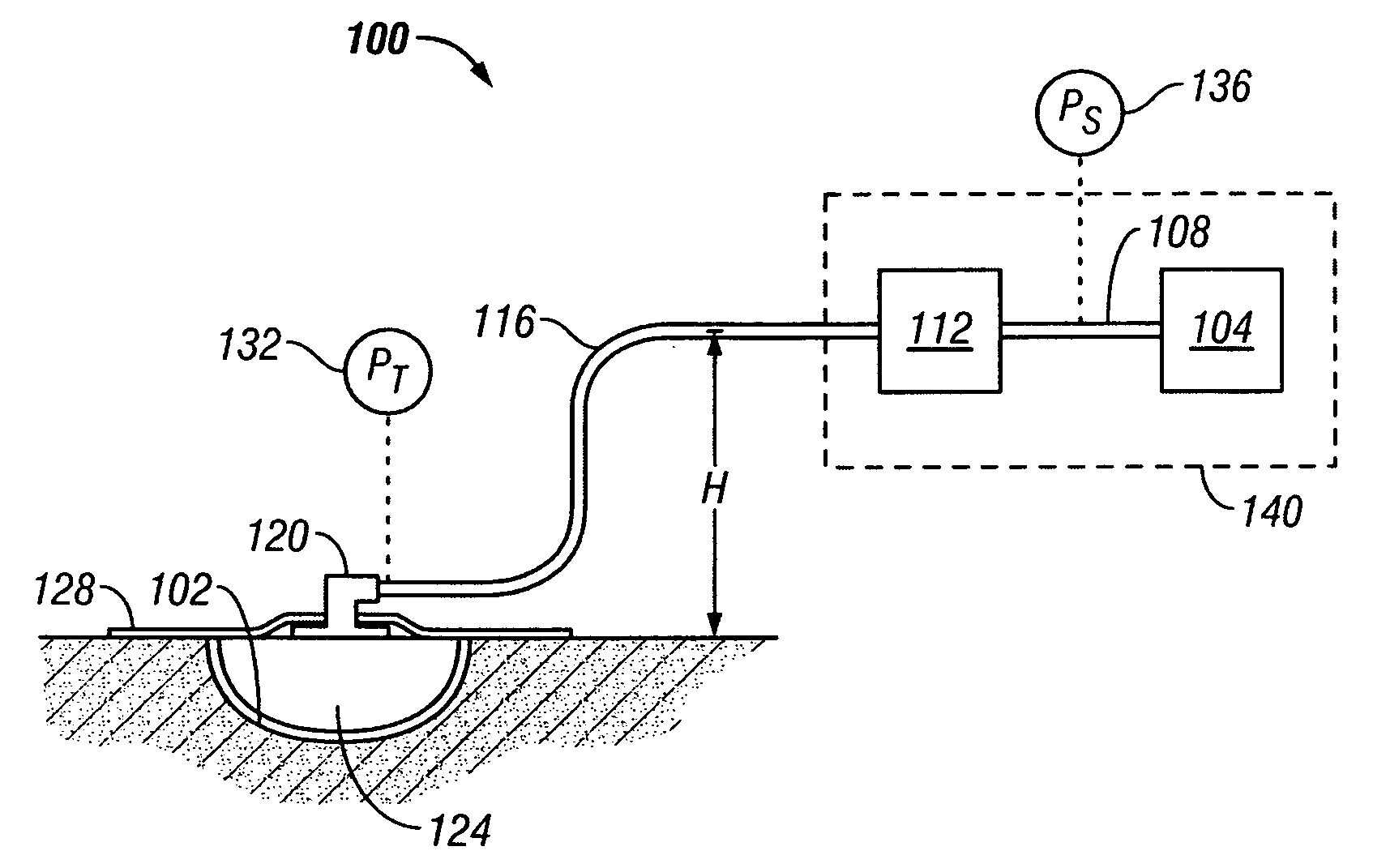

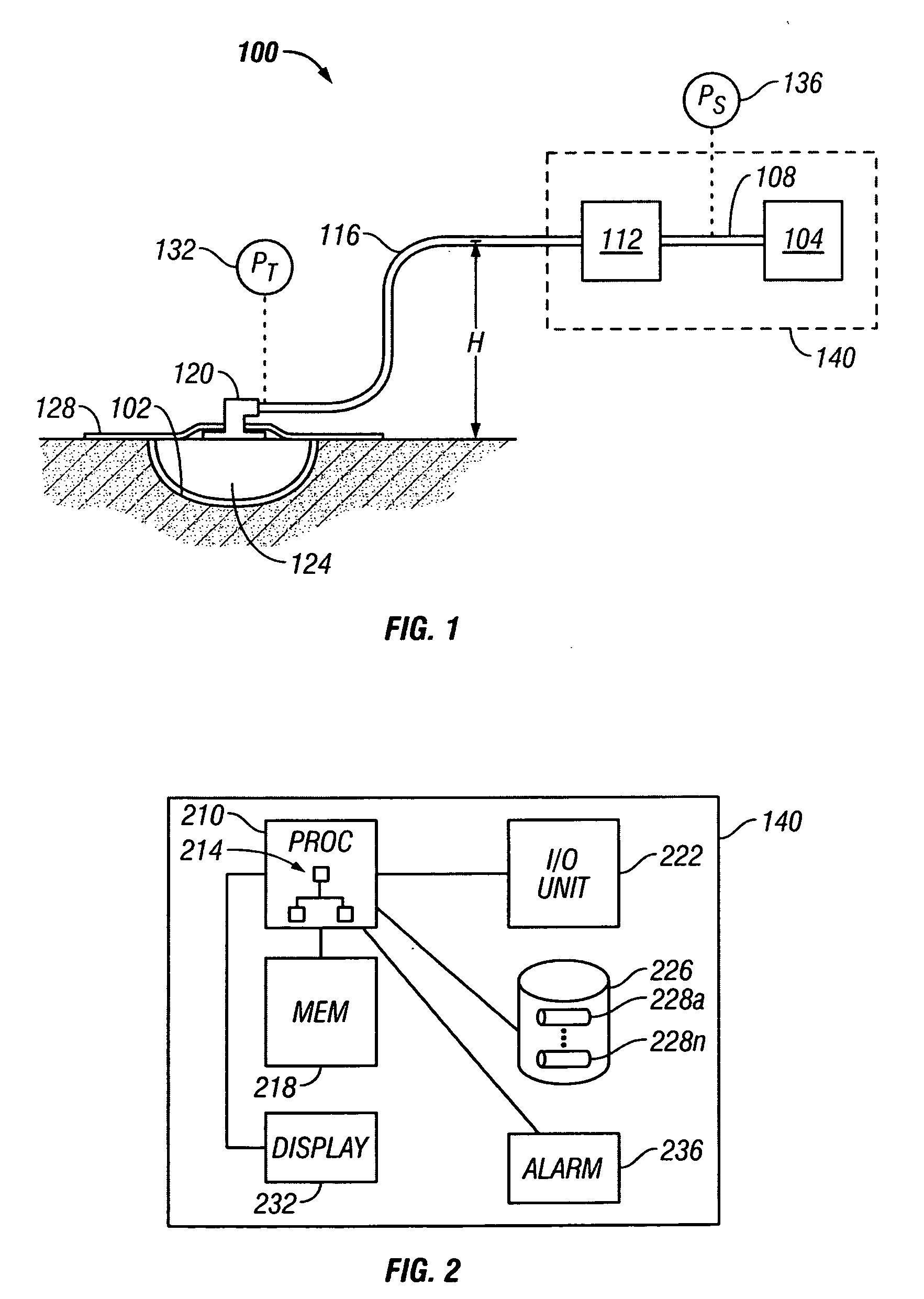

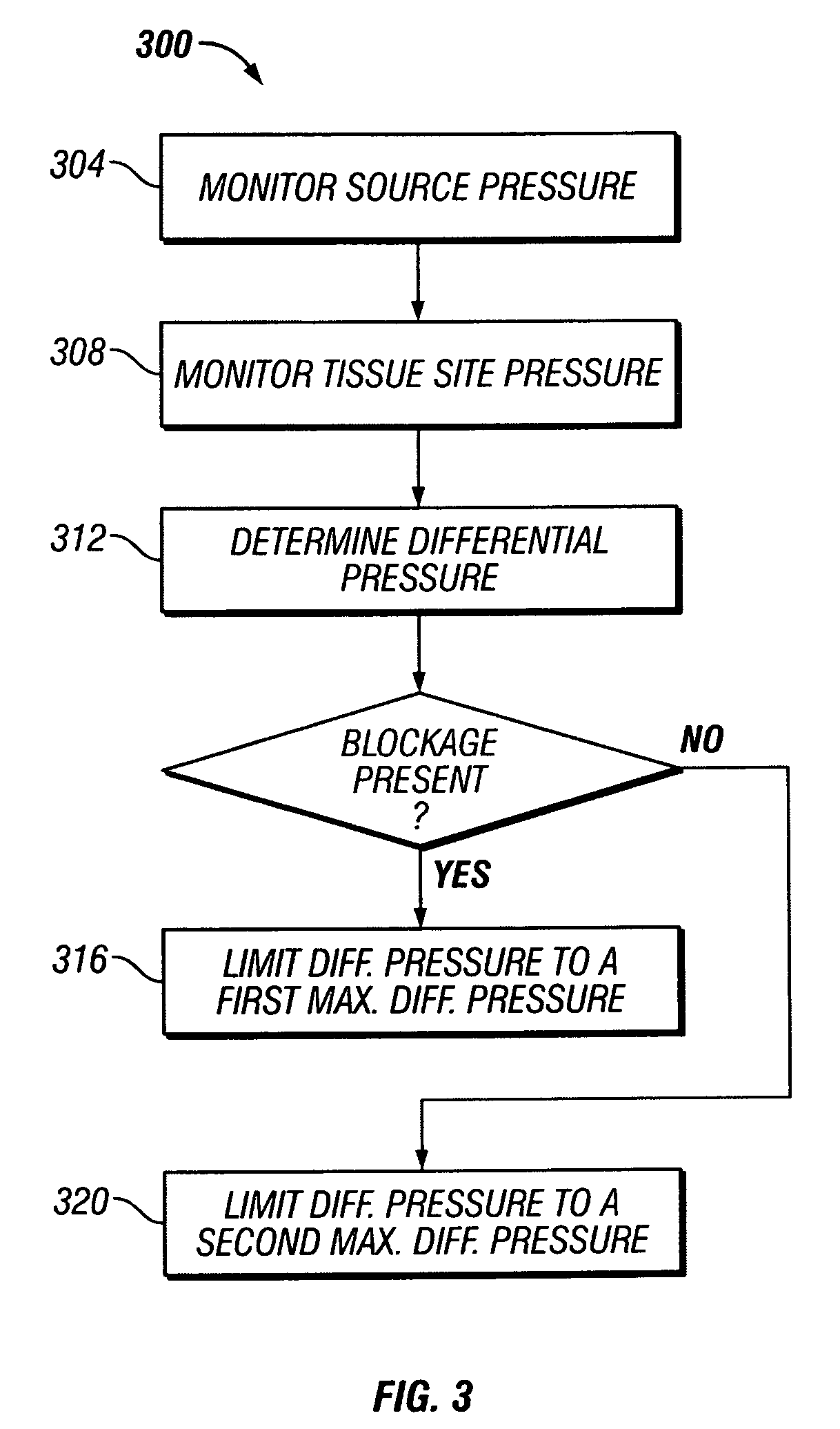

Reduced pressure treatment system having blockage clearing and dual-zone pressure protection capabilities

A method of treating a tissue site is provided. The method includes applying a reduced pressure to a tissue site with a reduced pressure source. A source pressure is monitored at the reduced pressure source, and a differential pressure is determined between the source pressure and the desired tissue site pressure. If a blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a first maximum differential pressure. If no blockage is present between the reduced pressure source and the tissue site, the differential pressure is limited to a second maximum differential pressure.

Owner:3M INNOVATIVE PROPERTIES CO

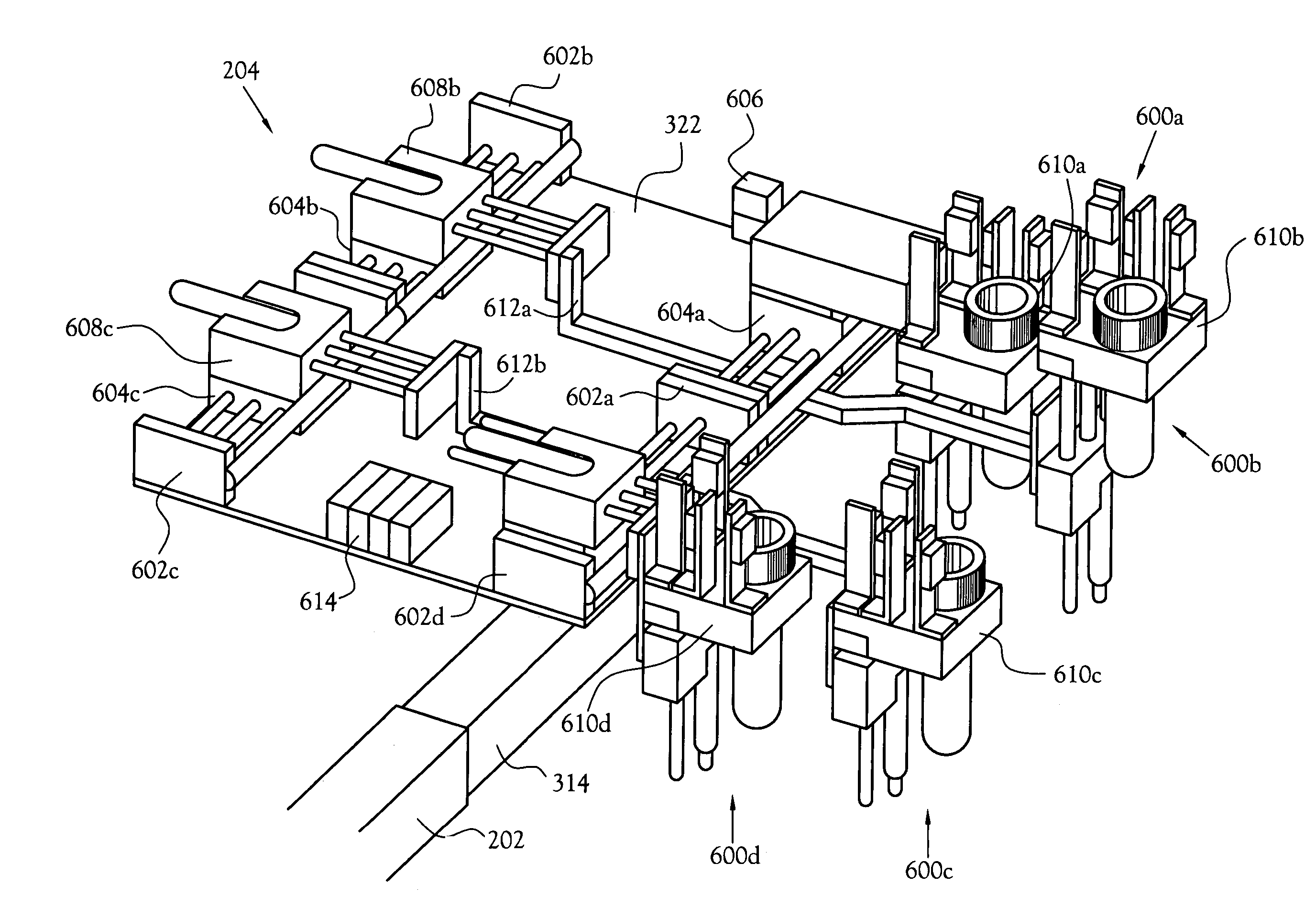

Device and a method for allowing performance of several separate treatments of a teat of an animal

InactiveUS7128020B2Quality improvementTreated differentlyCathetersOther apparatusInterior spaceEngineering

Owner:DELAVAL HLDG AB

Arrangement and a method of performing an animal-related action

InactiveUS6167839B1Improve performanceEfficient use ofCathetersAnimal housingEngineeringLocation determination

An arrangement for performing an animal-related action on an animal includes a position determining component having a detector and a processing unit for determining the position of an animal part to be subjected to the animal-related action, and a performance component such as an animal handling unit or milking robot for performing the animal-related action. The position determining component is located at a first location including a station for housing an animal and the performance component is located at a second location including a station for housing an animal at a distance from the first location. A signal line is provided for transferring the coordinates of the position determined at the first location to the performance component at the second location in order to enable the performance of the action with regard to the animal part.

Owner:DELAVAL INT

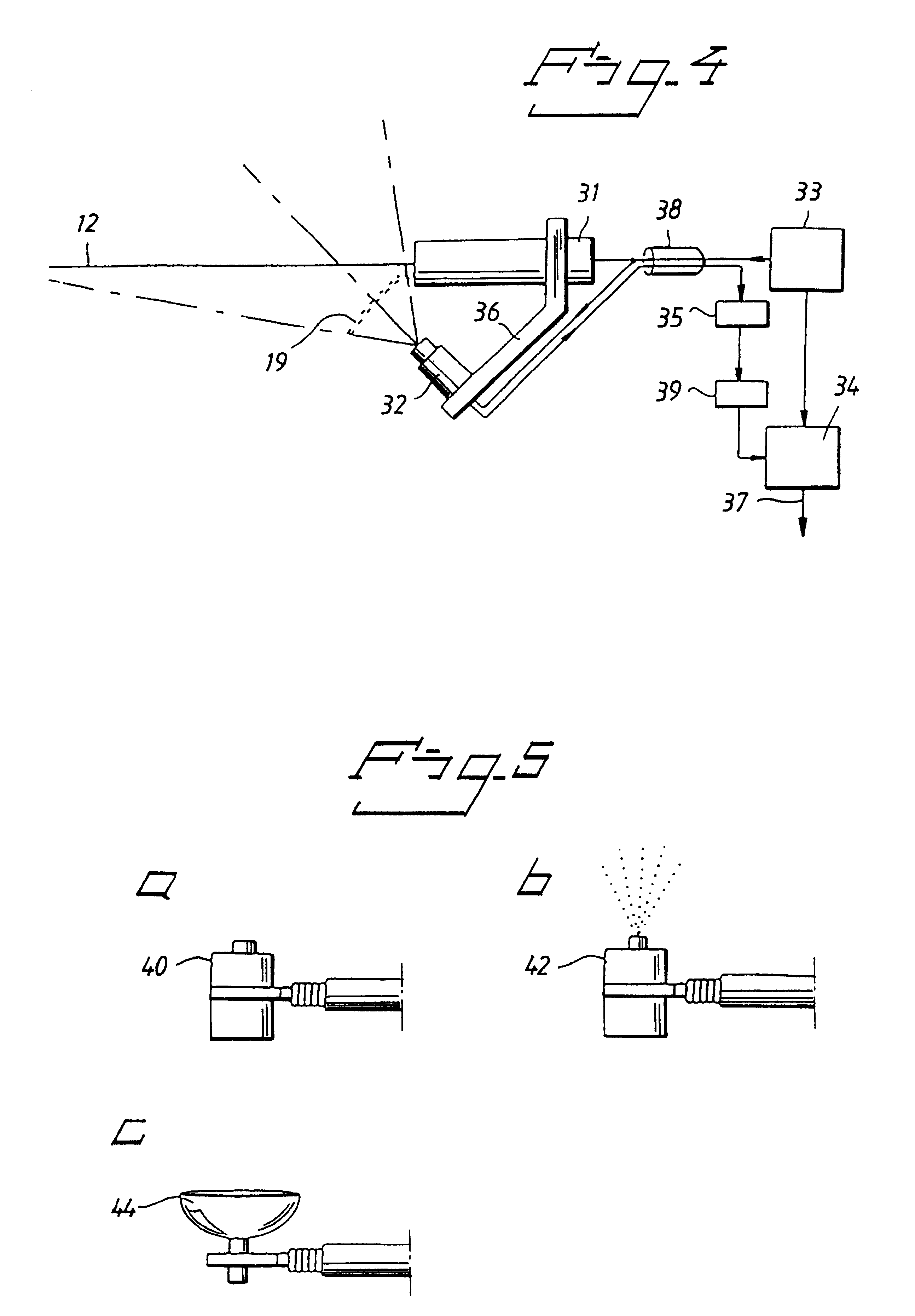

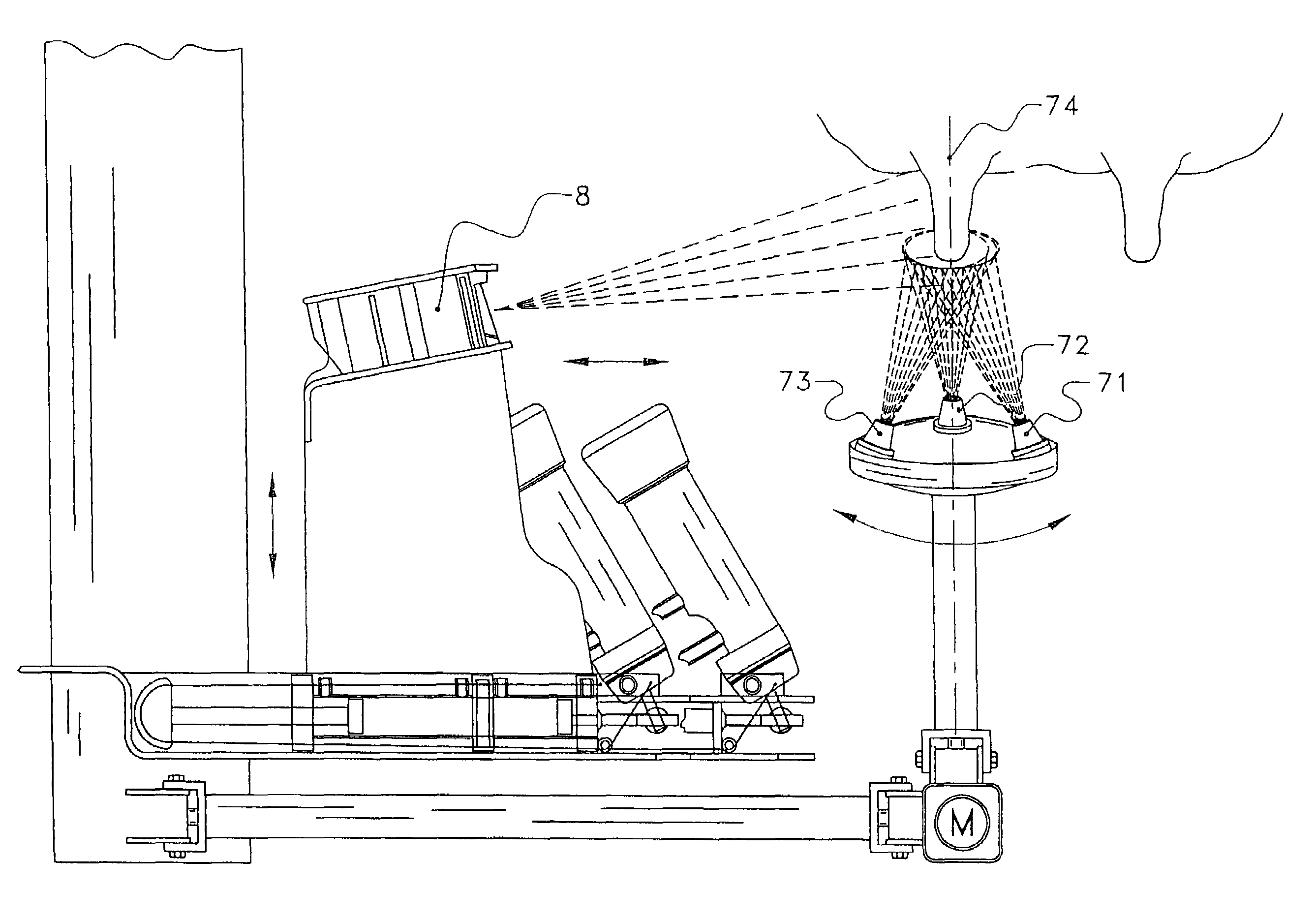

Method and apparatus for treating the teats of an animal

InactiveUS7377232B2Good choiceImprove versatilityLiquid surface applicatorsCathetersAnimal scienceMedicine

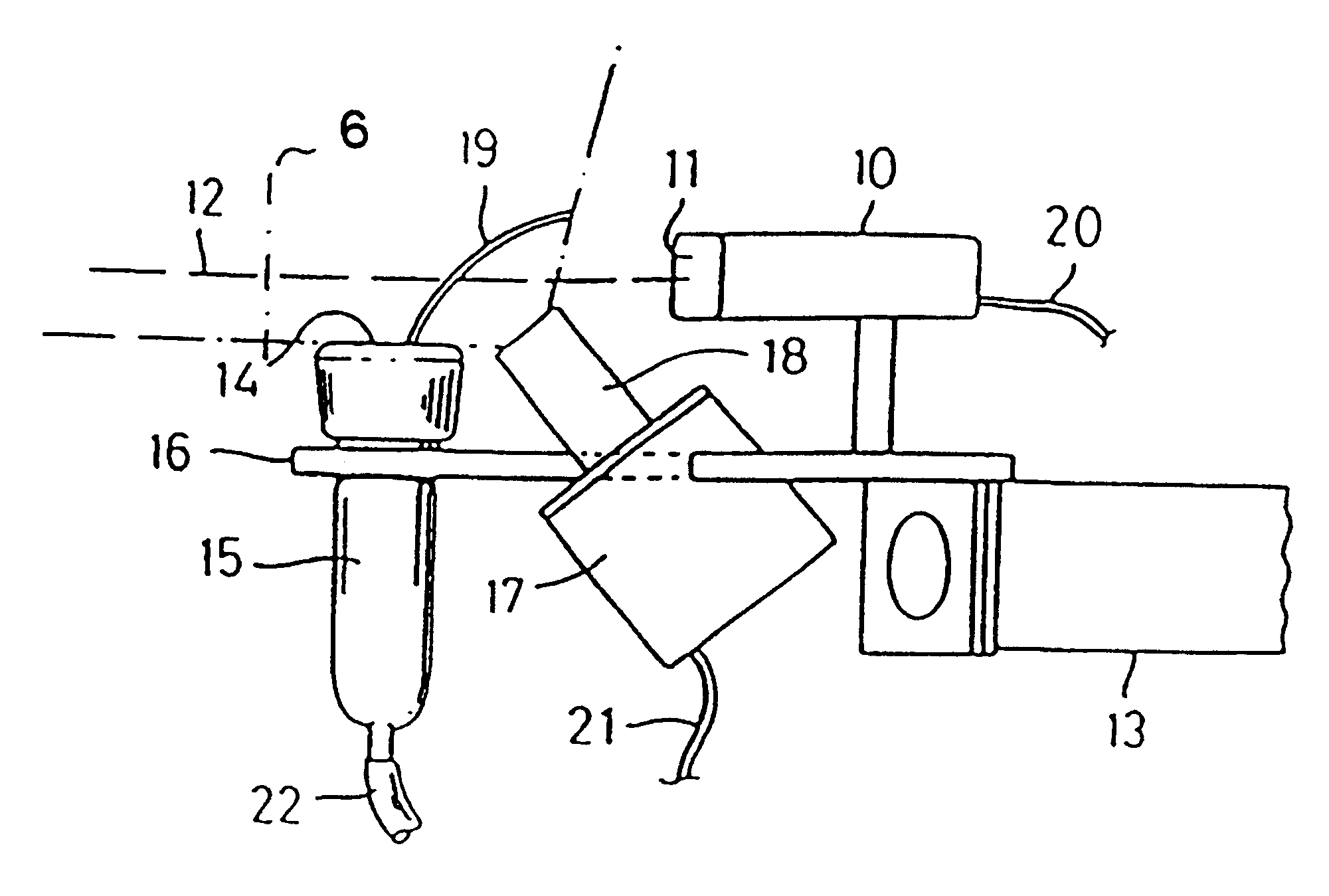

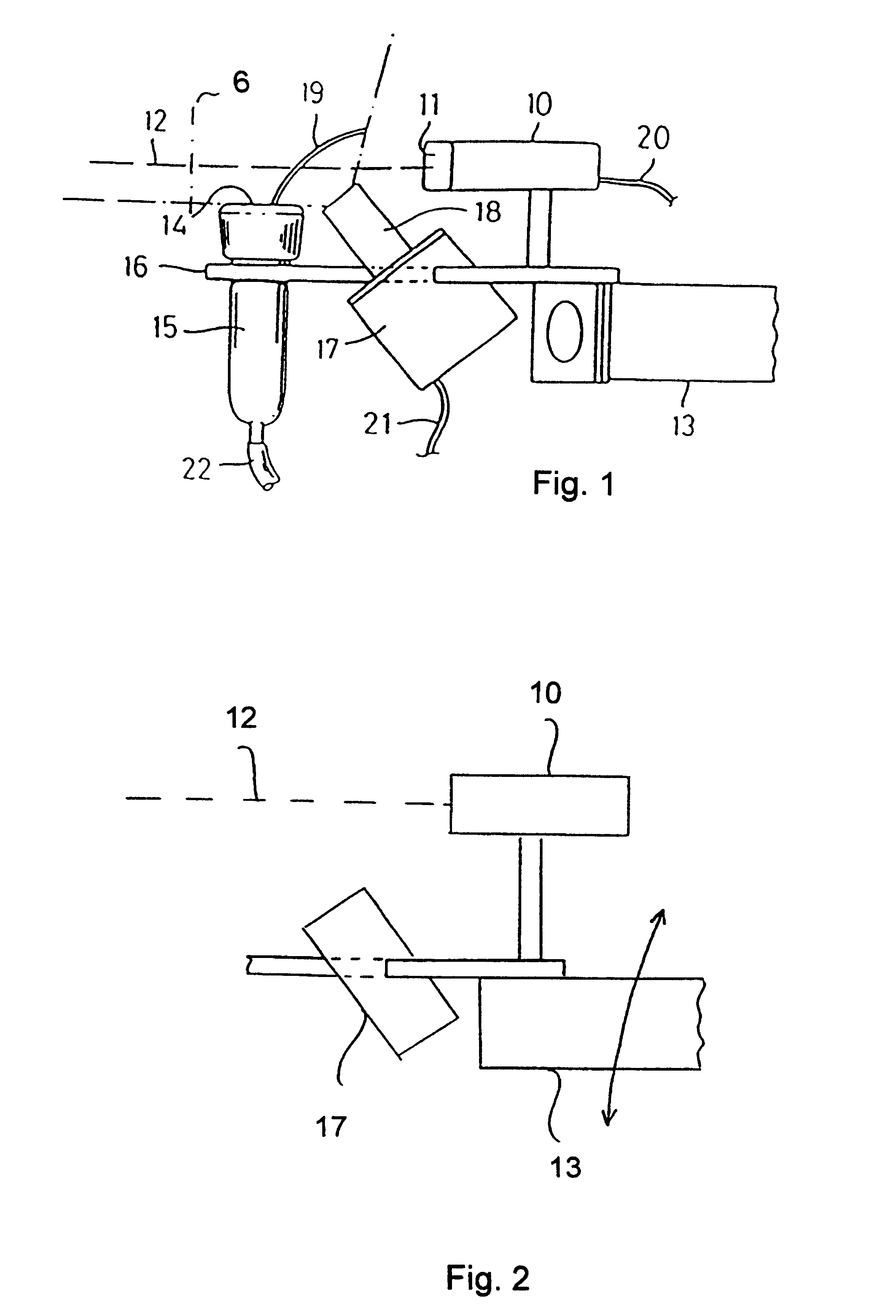

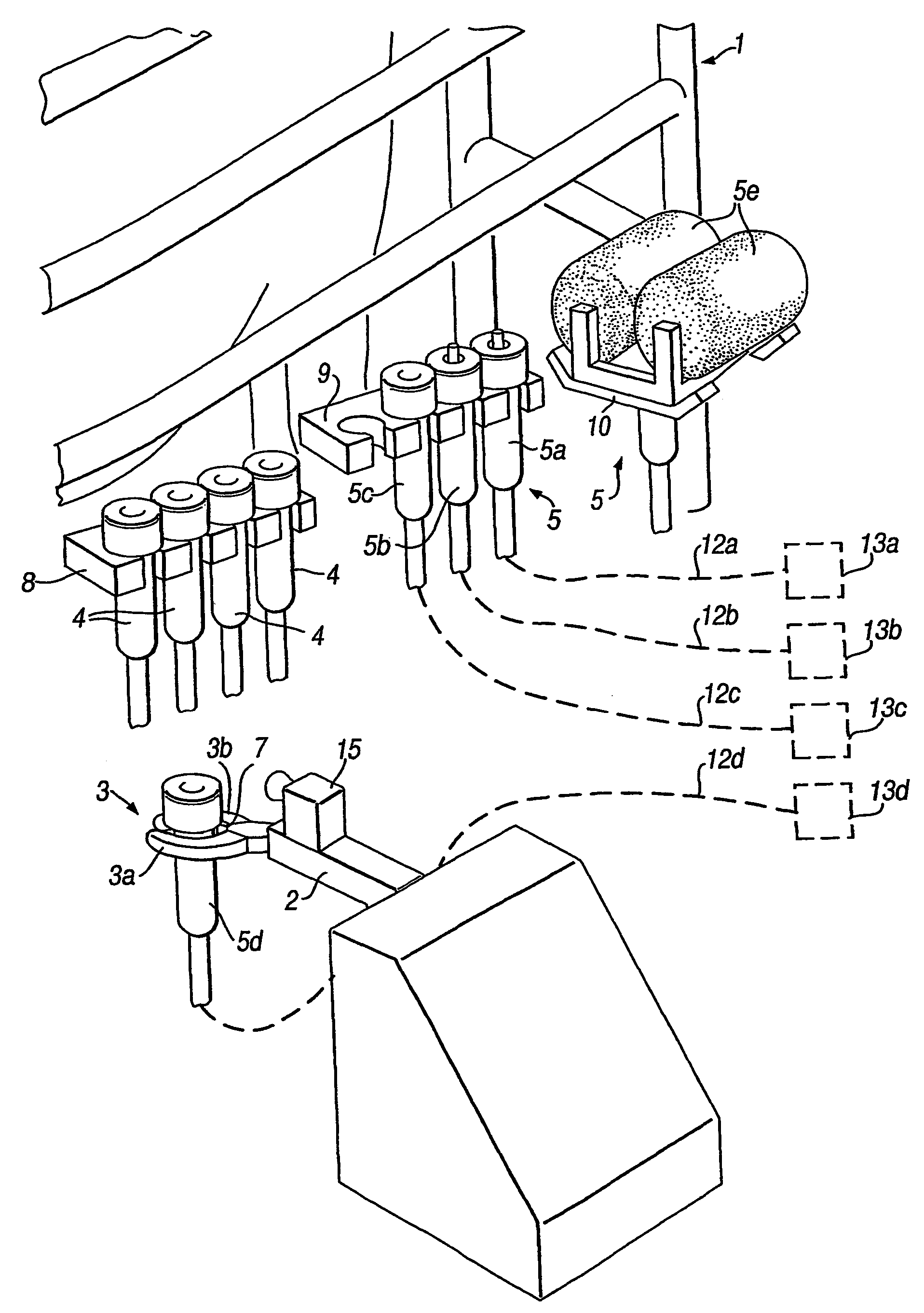

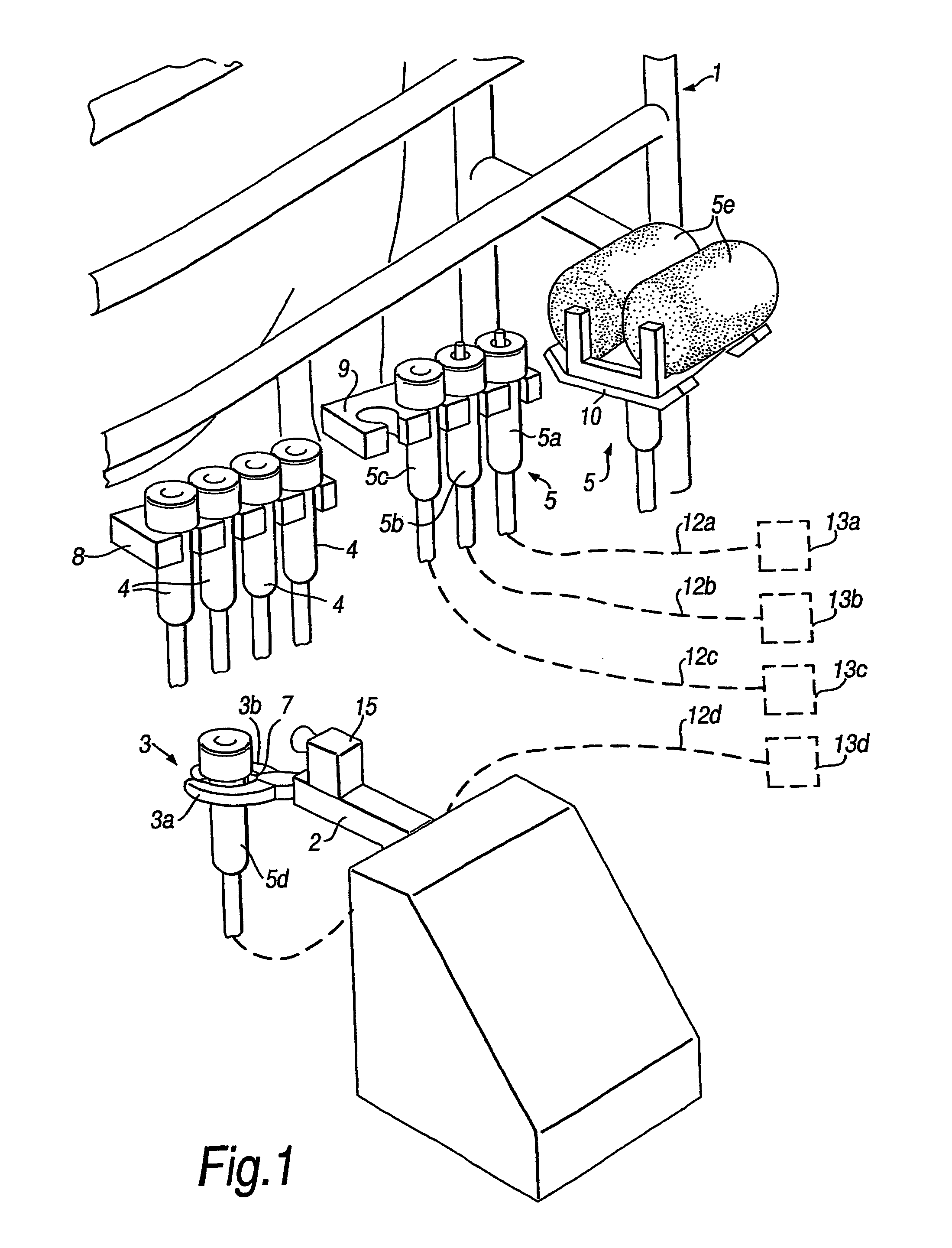

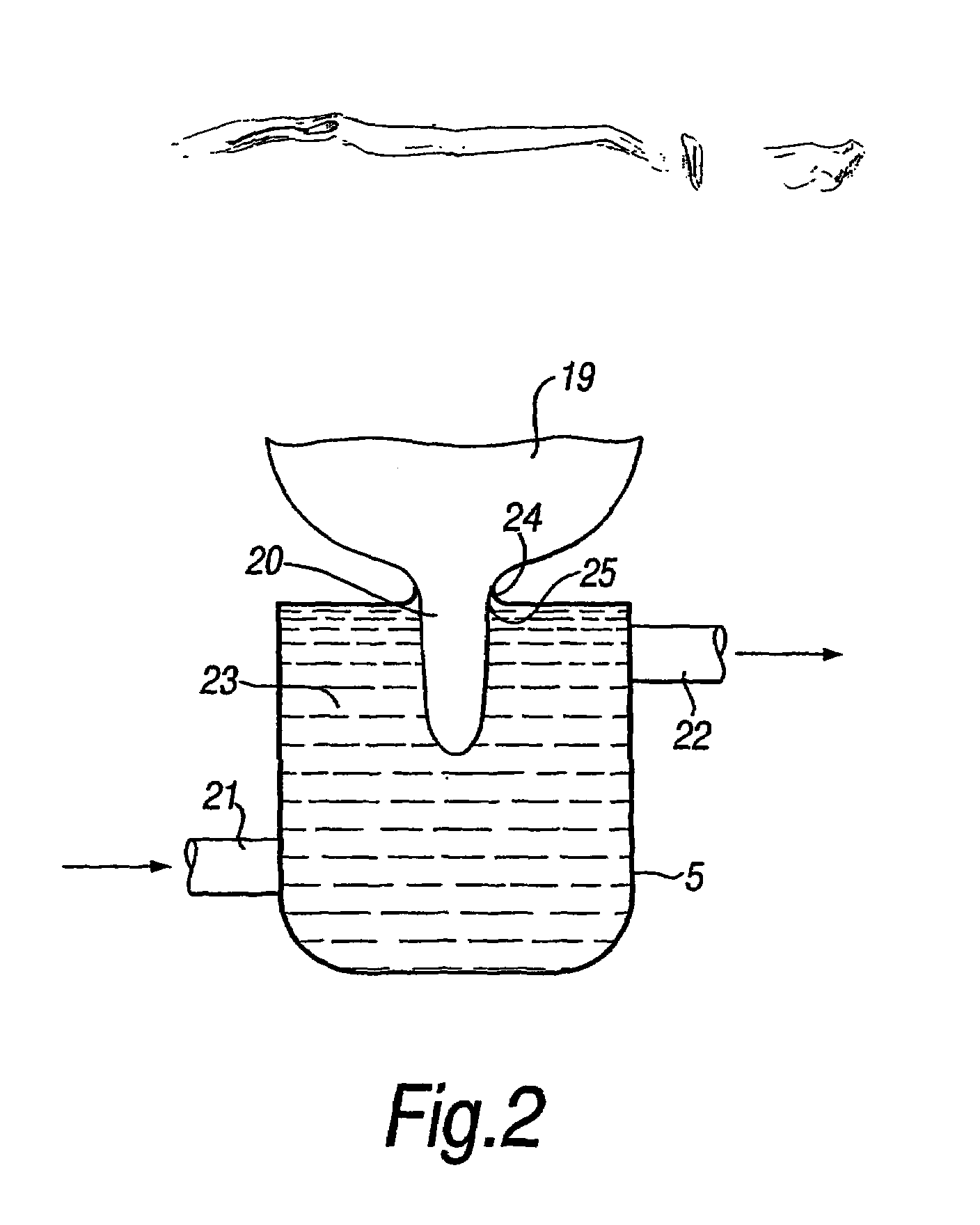

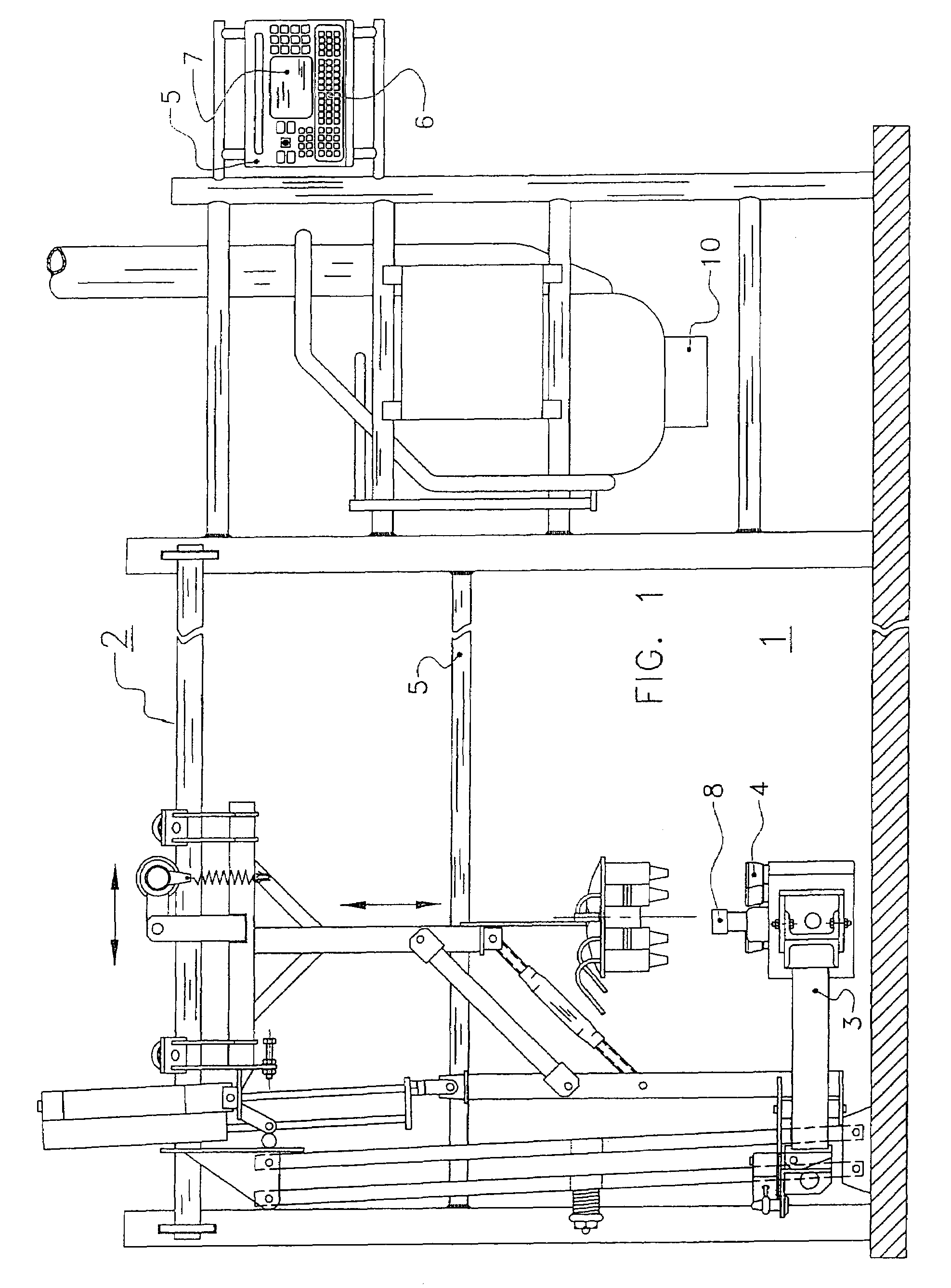

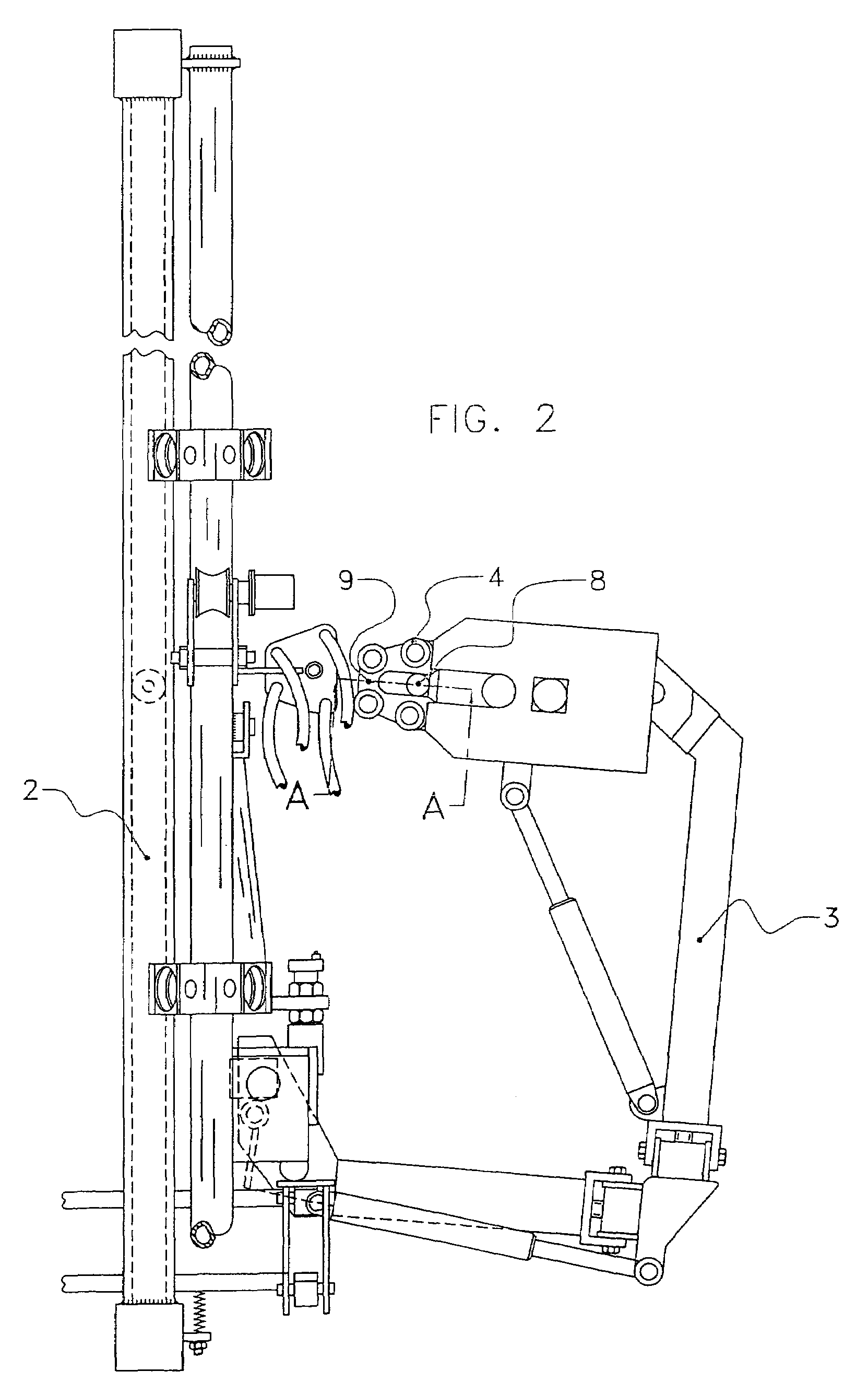

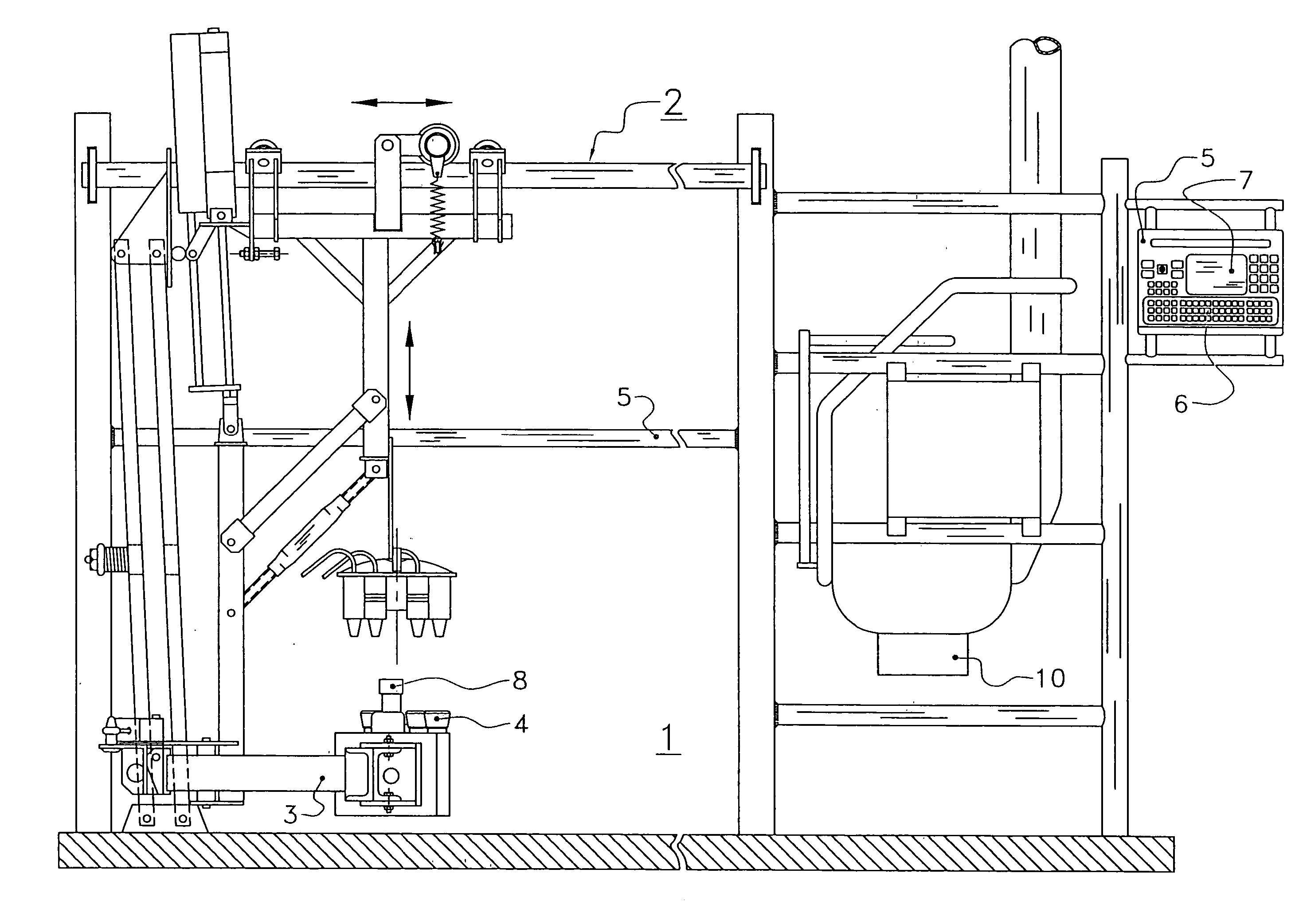

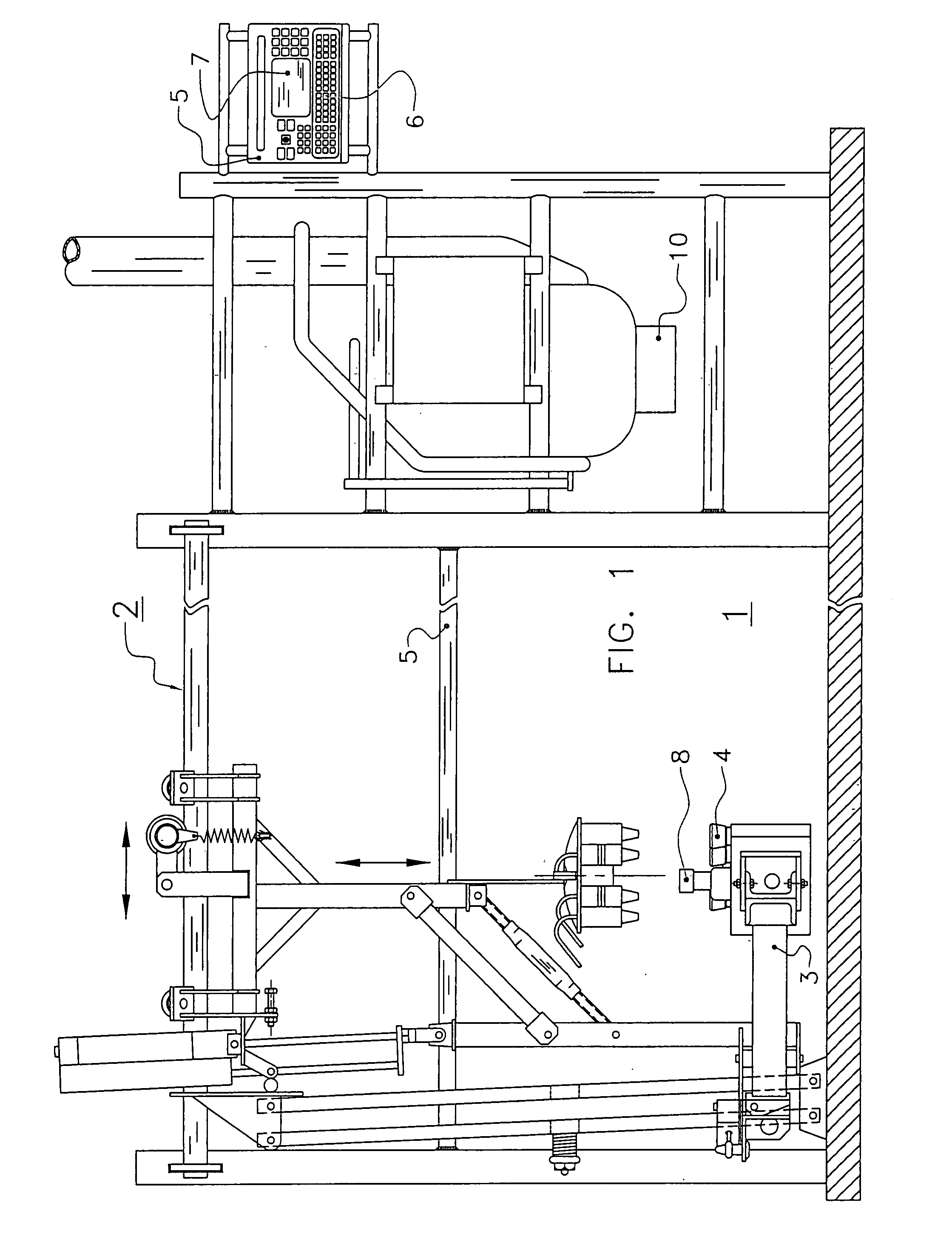

In an automatic milking installation including a robot arm (2) with a gripper (3) for attaching teat cups (4) to the teats of an animal, e.g. a cow, to be milked, for applying a teat dip to the teats after milking different members, such as spray nozzles (5a, 5b), dipping cups (5c, 5d) and sponge or cloth rollers (5e), are provided for applying different teat dip compositions. Under the control of a computer, the robot arm collects the member (5) appropriate for supplying the selected composition and takes it to a position appropriate for application of that composition. The selection can e effected in dependence upon the teat skin condition, e.g. detected by a camera (15) and / or environmental conditions.

Owner:DELAVAL HLDG AB

Device and method for determining teat positions

A device for determining the teat positions of a dairy animal after milking. The device is provided with at least one position-measuring device for determining a position of a teat prior to the milking of the dairy animal and for emitting a position signal corresponding to the teat position. The position-measuring device generates individual teat position signals and a control unit determines on the basis of the teat position signals determined before the milking, planes of symmetry extending substantially parallel to the teats. The expected positions are calculated with respect to the planes of symmetry.

Owner:LELY ENTERPRISES

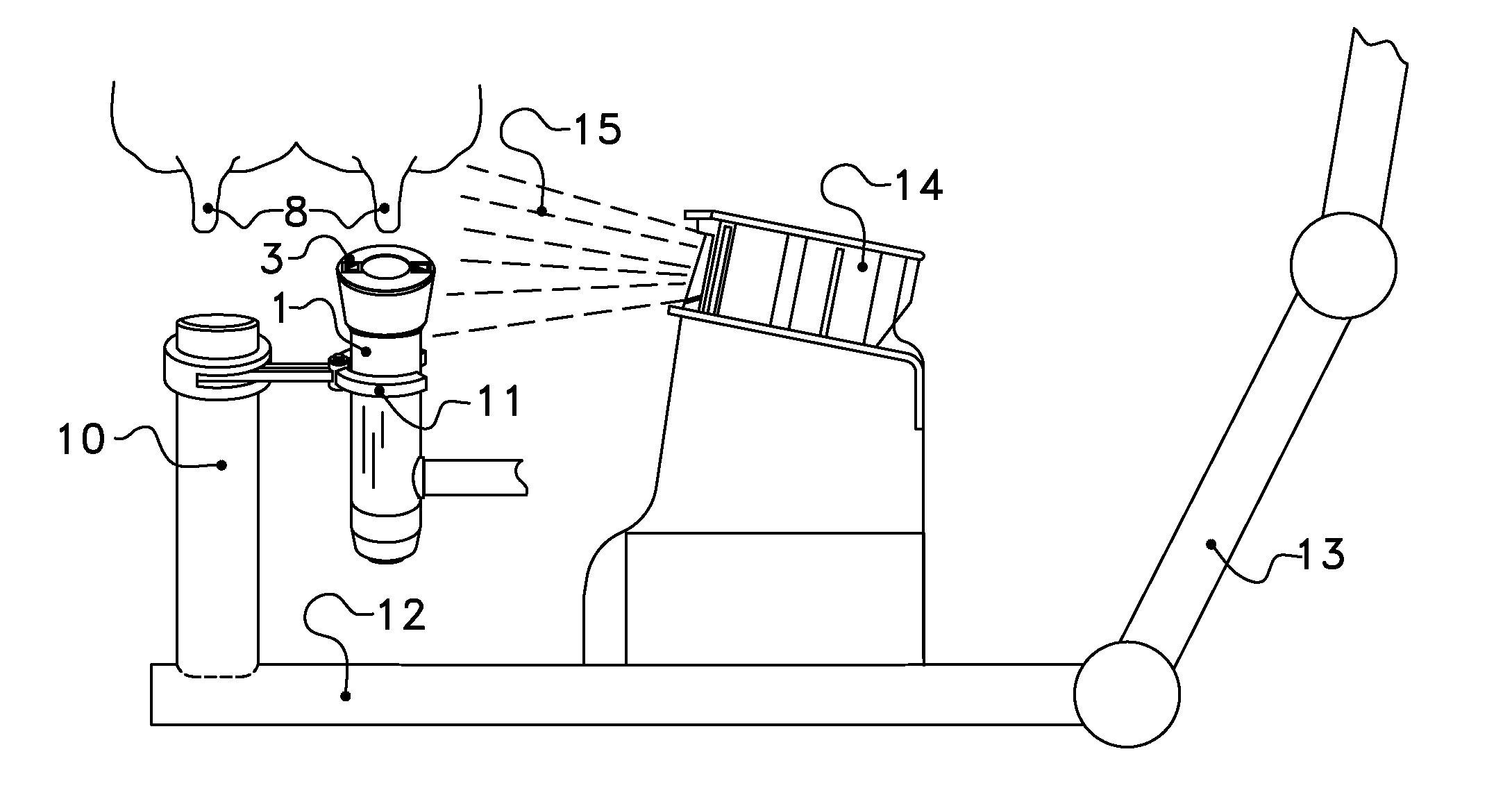

Apparatus and method for recognizing and determining the position of a part of an animal

InactiveUS6227142B1Easy to identifyQuality improvementCathetersUsing optical meansImage signalSignal processing

The present invention relates to an apparatus and a method for recognizing and determining the position of a part of an animal. The apparatus comprises a source of structured light for illuminating a region expected to contain at least one part in such a way that an object illuminated by the light simultaneously or discrete in time is partitioned into at least two illuminated areas, where each two illuminated areas are separated by a not illuminated area, an image capture device arranged to capture at least one image formed by the light and provide an image signal, the apparatus further comprising image signal processing device to respond to the captured image signal and a control device to determine if the illuminated object is the part by comparing the image of the illuminated object to reference criteria defining different objects, and if the illuminated object is established to be the part of the animal, the position thereof is established, an animal related device and the device to guide the animal related device towards to the position of the part.

Owner:DELAVAL HLDG AB

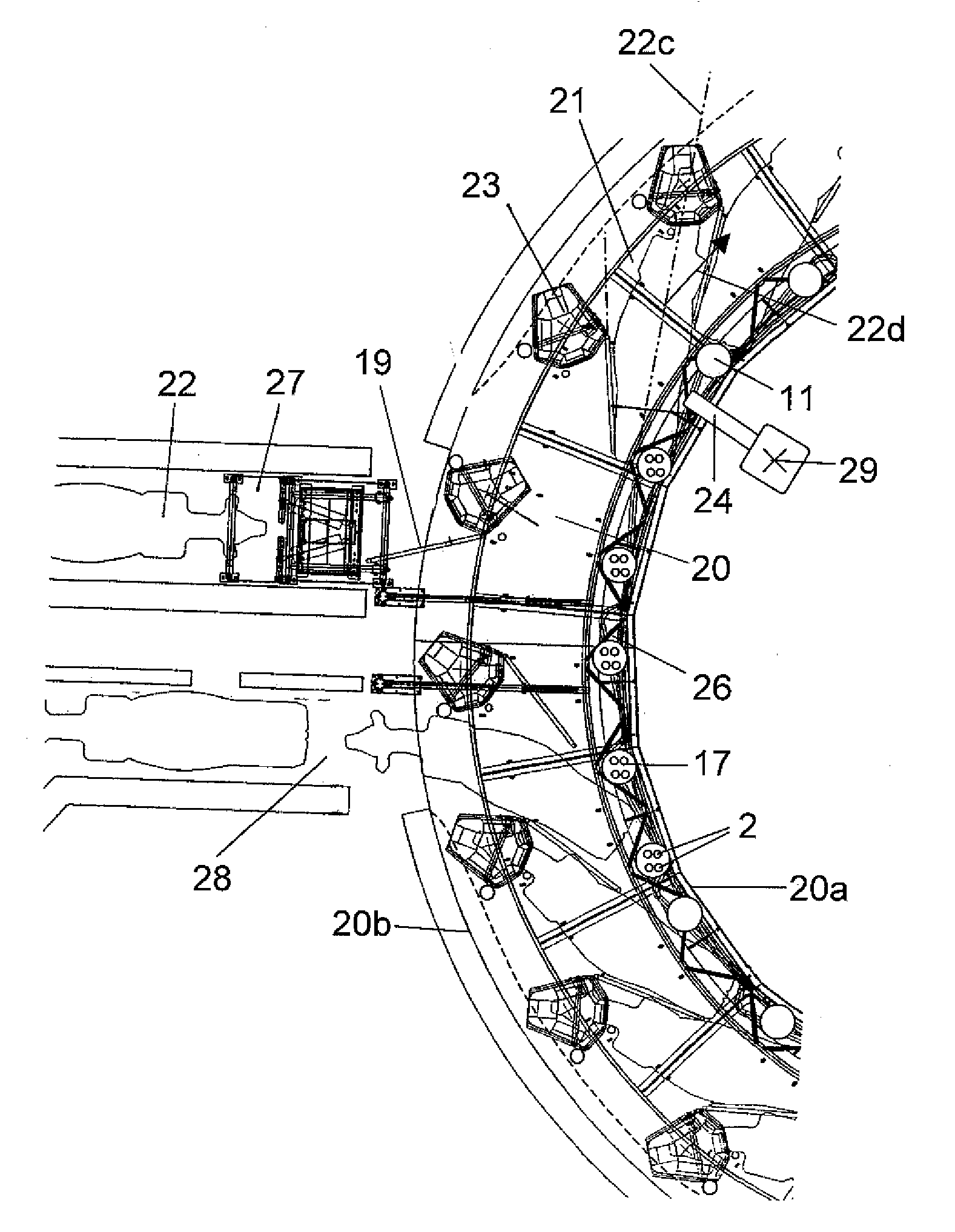

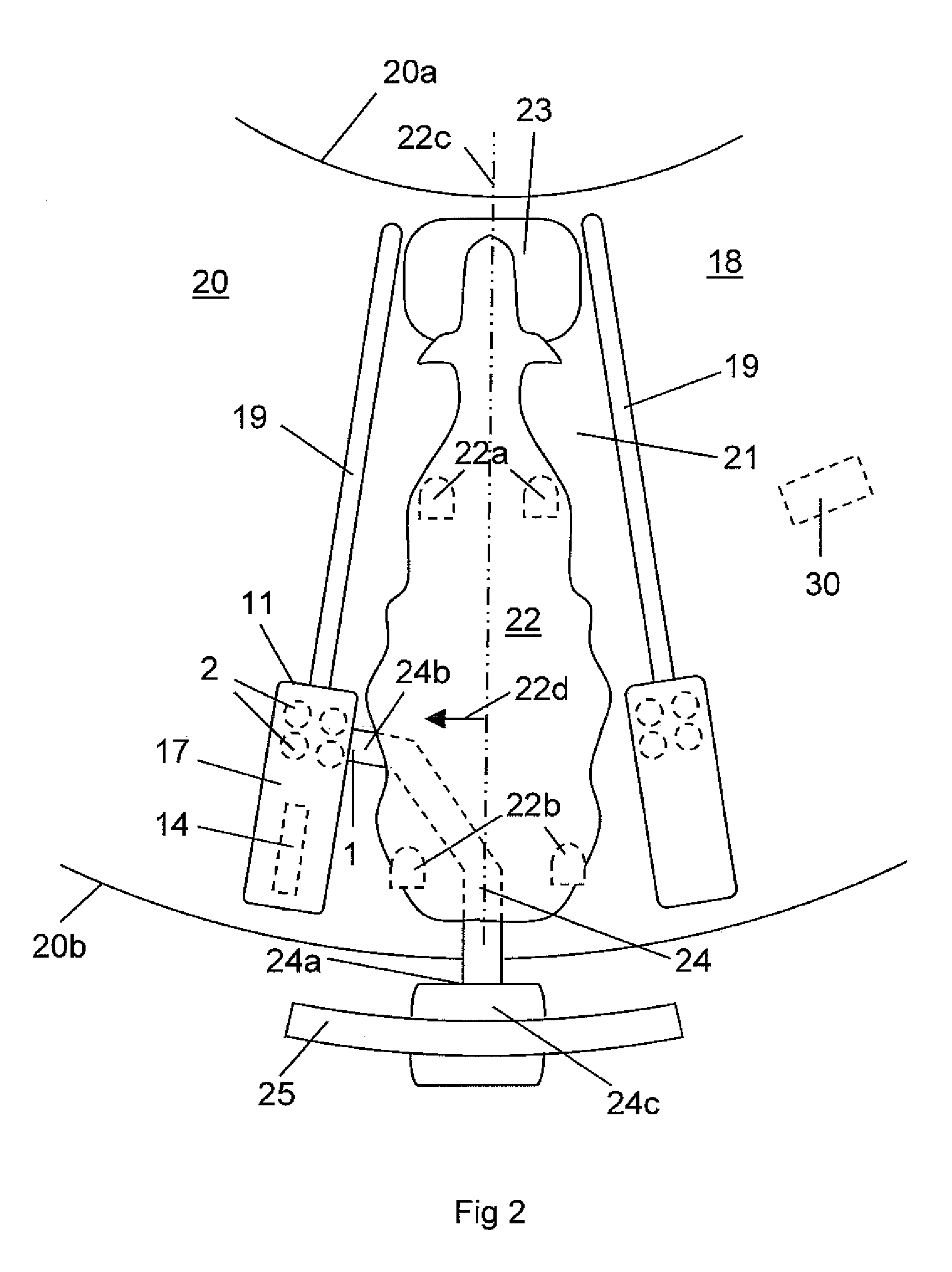

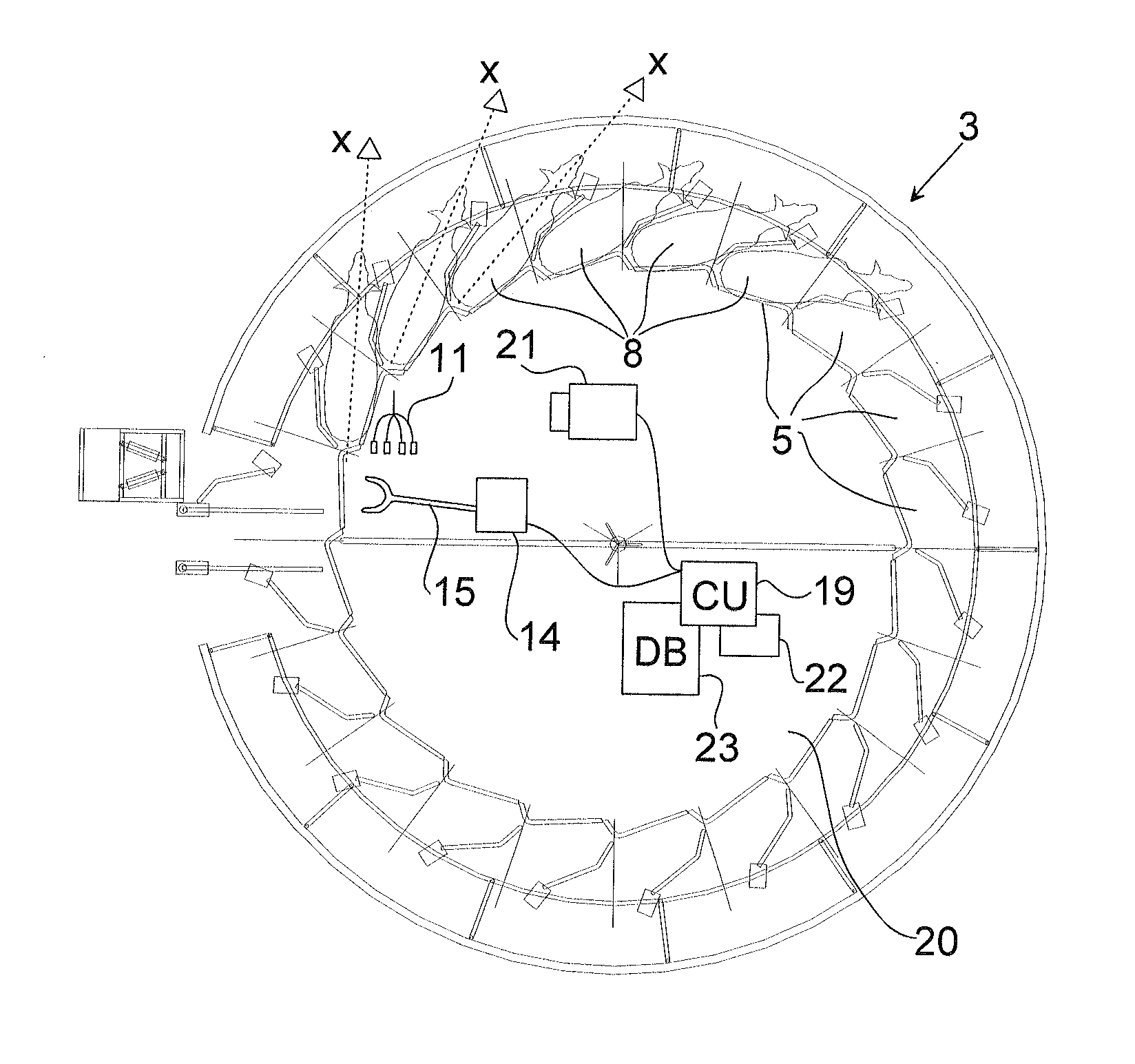

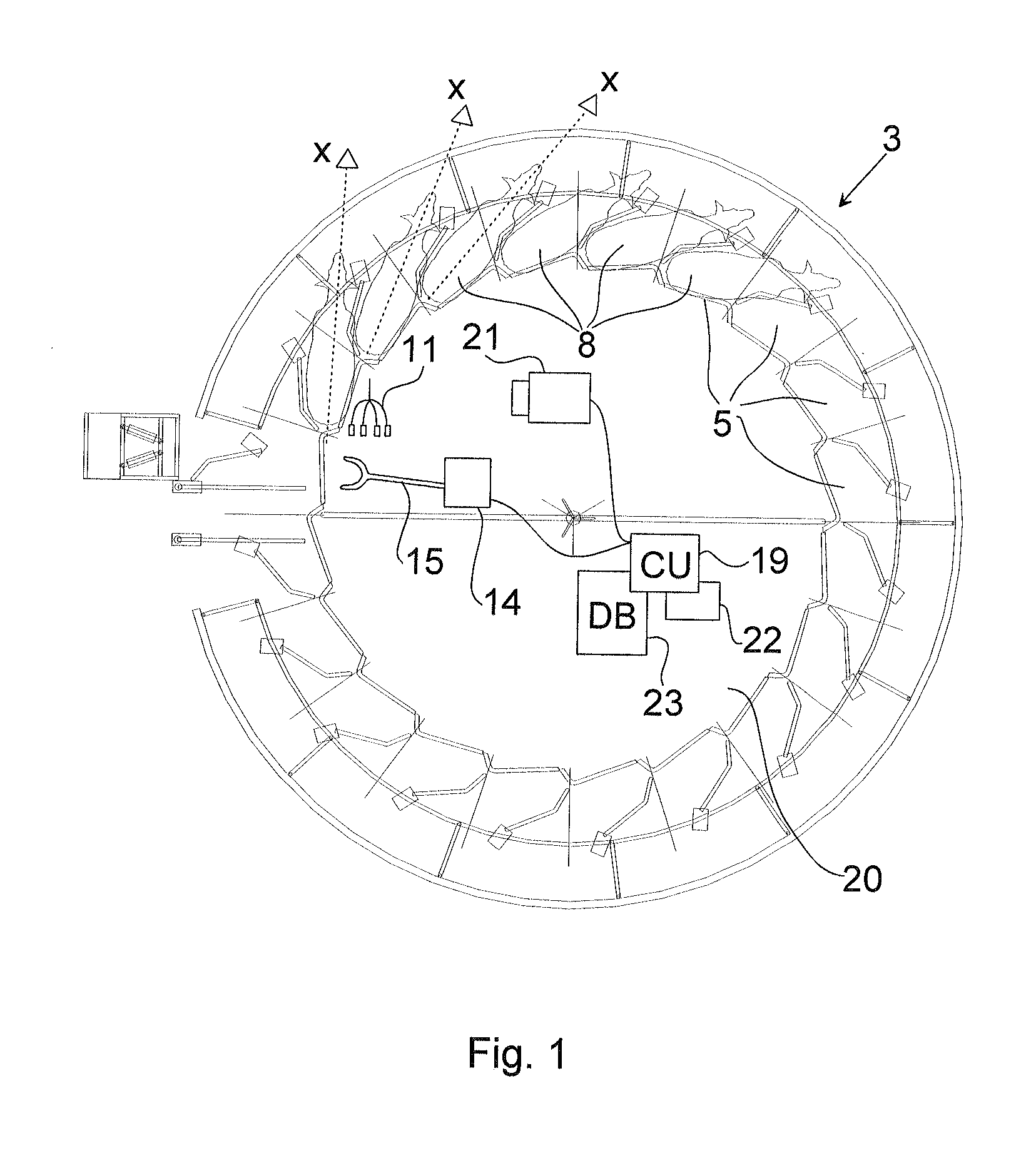

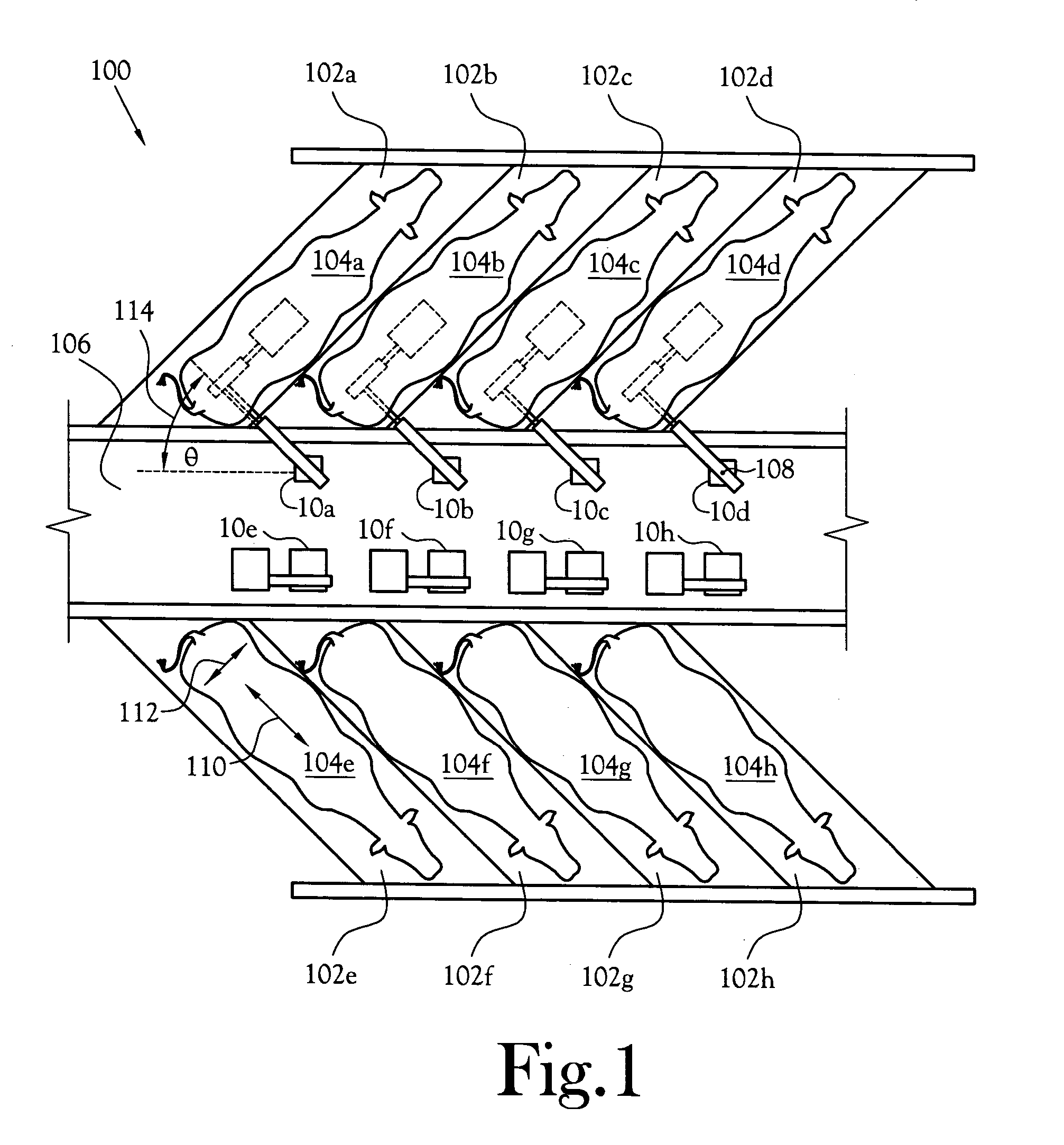

Rotary parlour for automatic milking of animals and a method for attaching teat cups to milking animals on a rotary platform

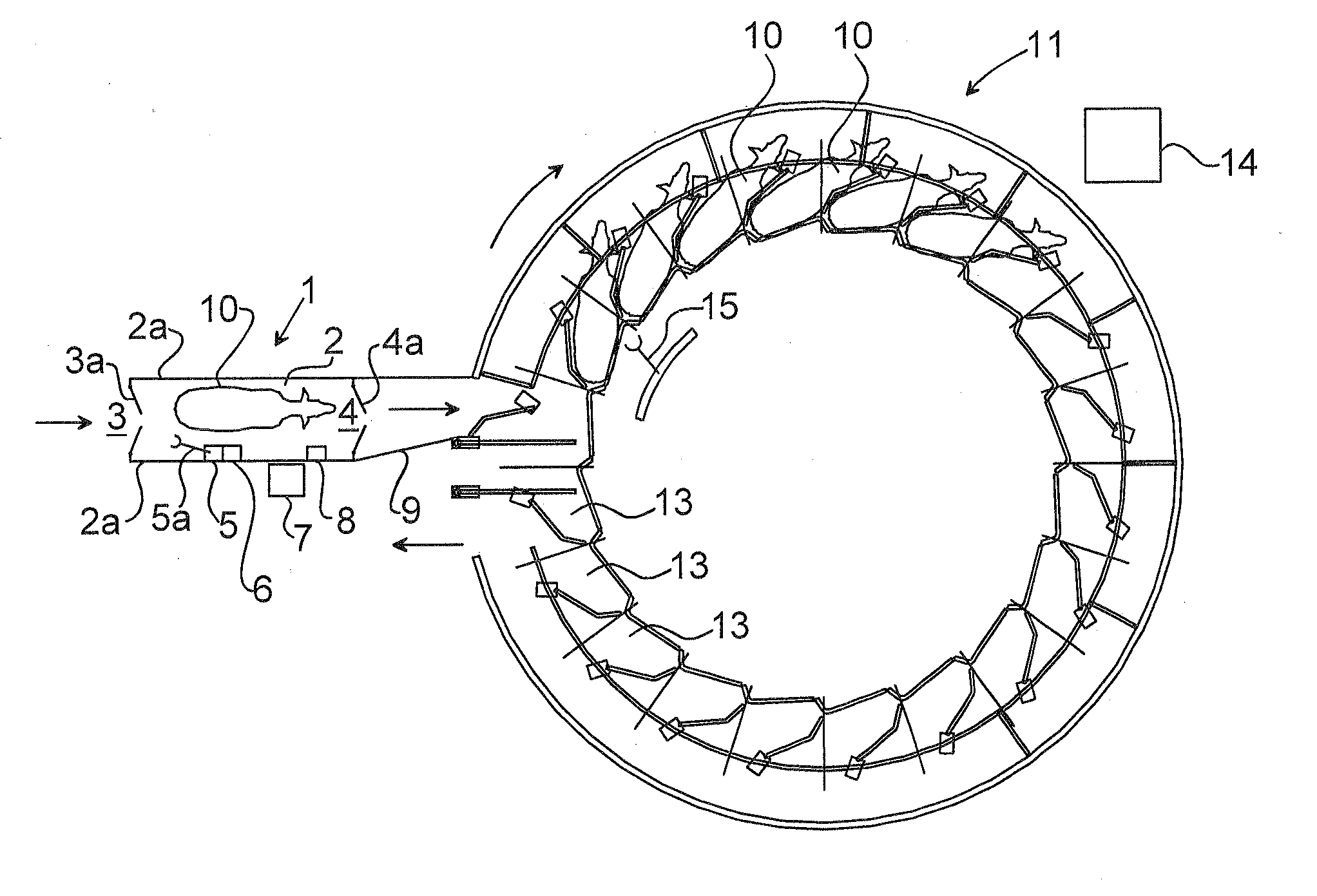

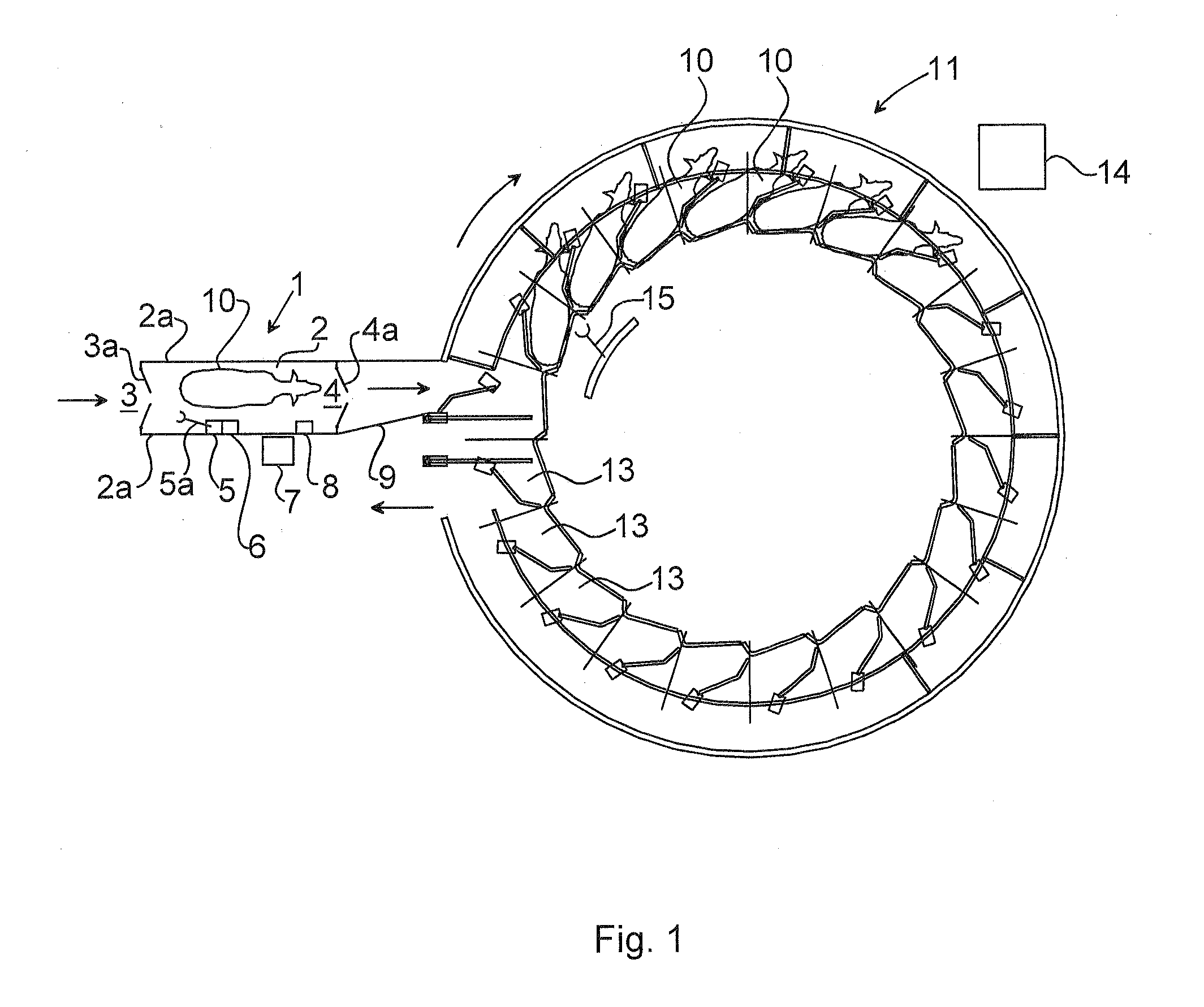

ActiveUS20100031889A1Fast attachmentEliminate needCathetersAnimal housingEngineeringAutomatic milking

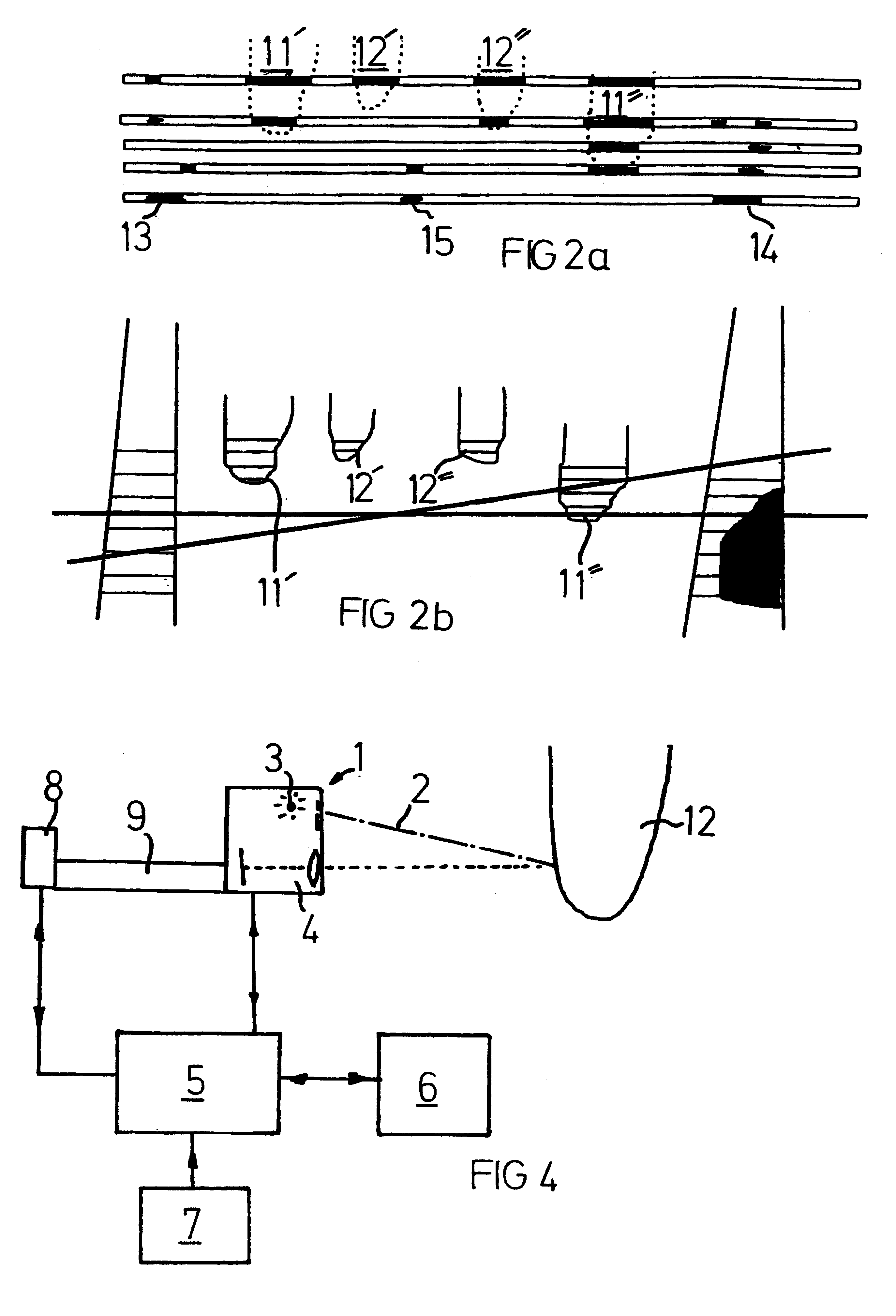

A rotary parlour for milking of animals includes an annular rotary platform (20) adapted to form a support surface (18) for the animals (22), positioning elements (19, 23) for arranging the animals (1) in milking positions on the platform (20), a drive mechanism (30) adapted to supply a rotational motion to the platform (20), and teat cup storing devices (11) for holding parked teat cups (2, 2′) in predetermined storing positions. The teat cup storing devices (11) are mounted in positions such that the teat cups (2, 2′) are located vertically above the platform (20) in their storing positions.

Owner:DELAVAL HLDG AB

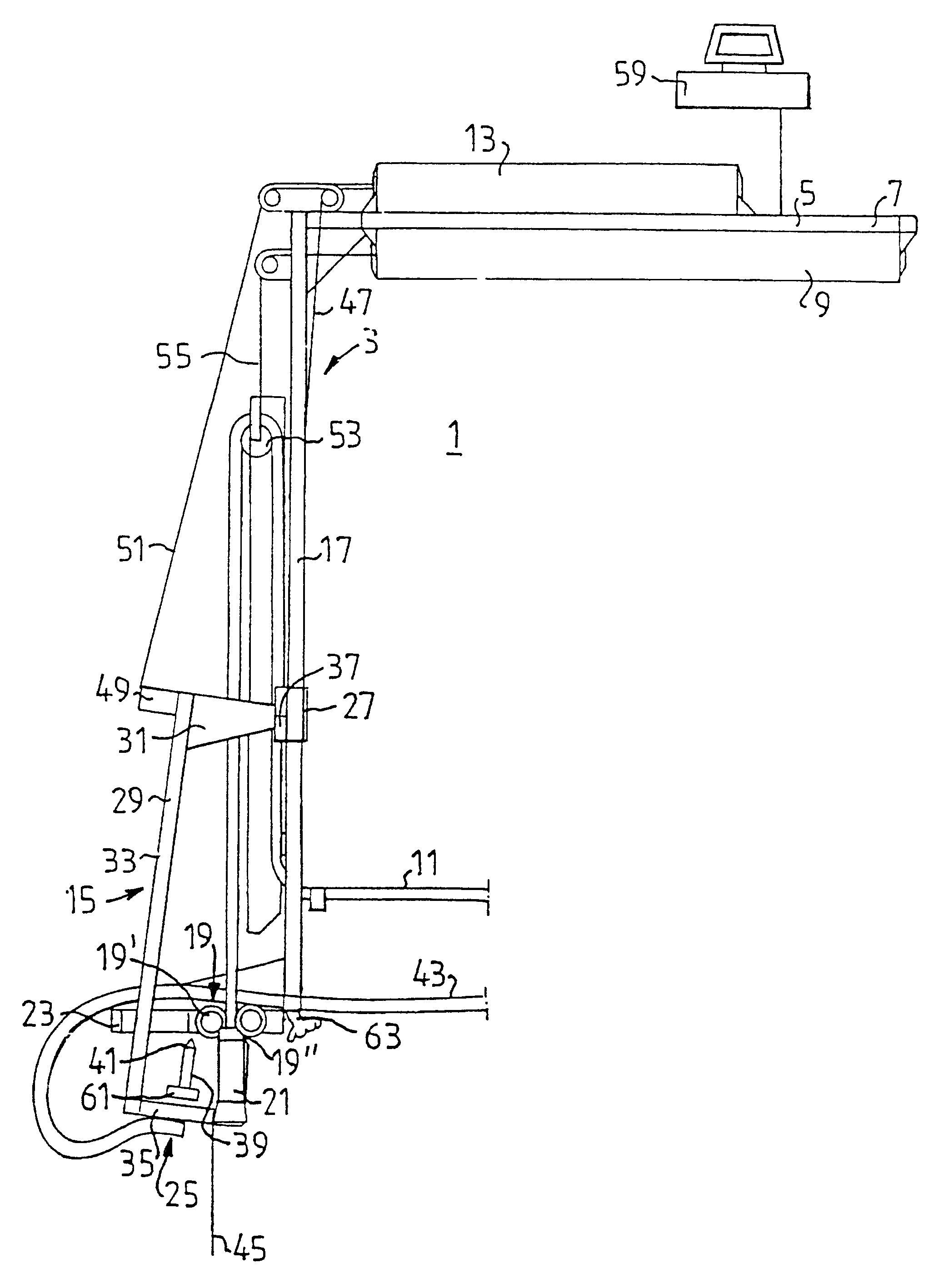

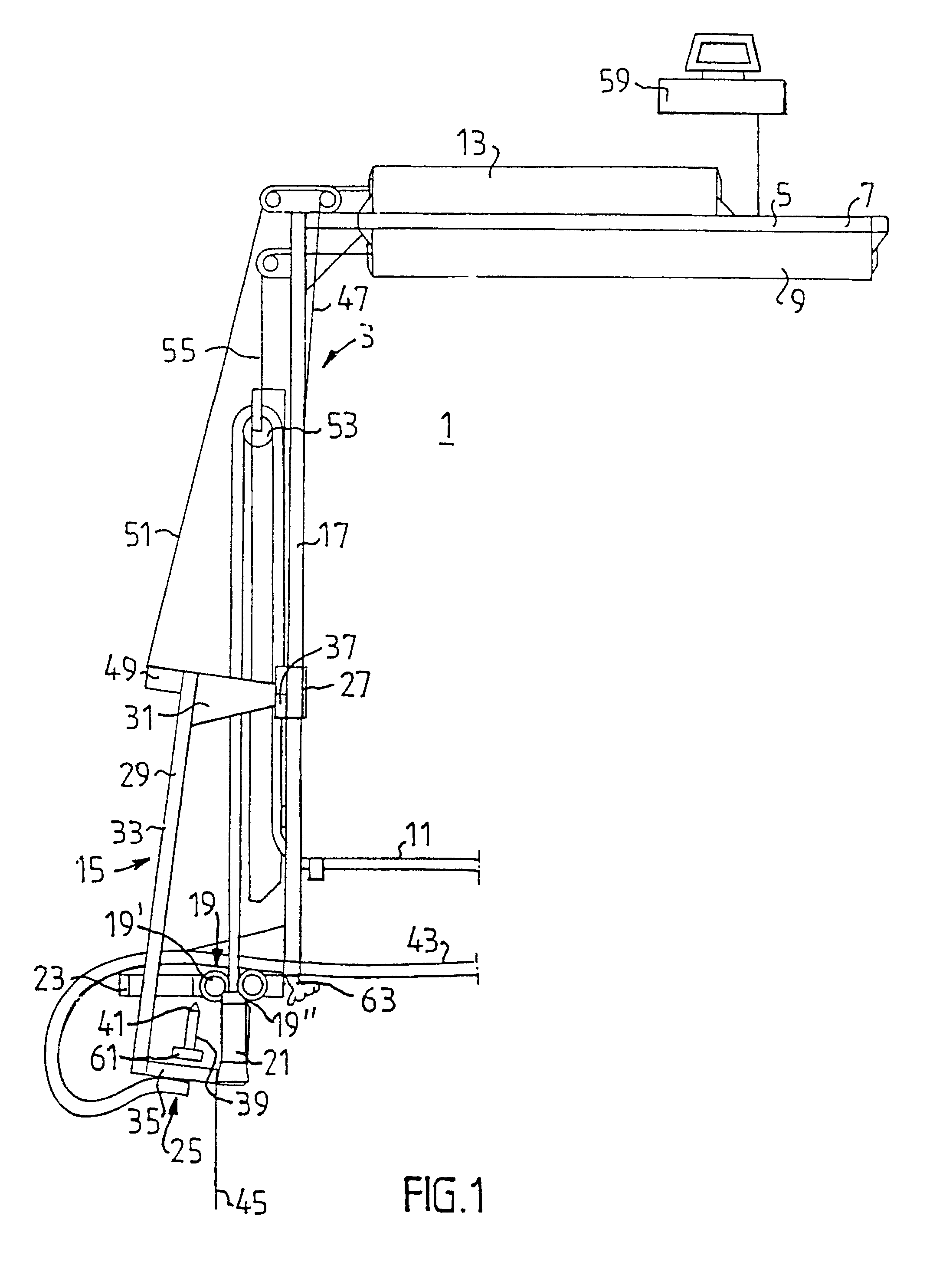

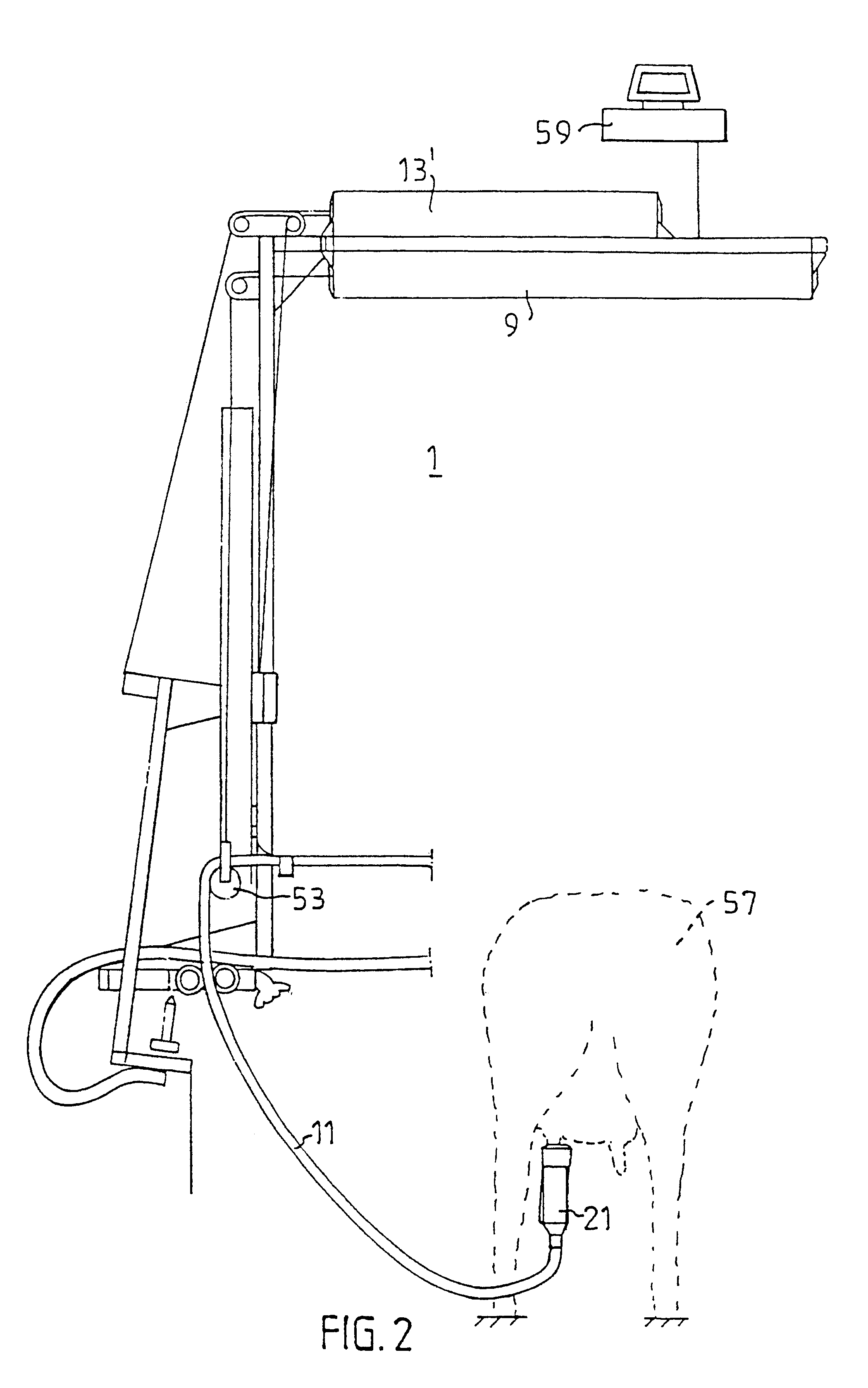

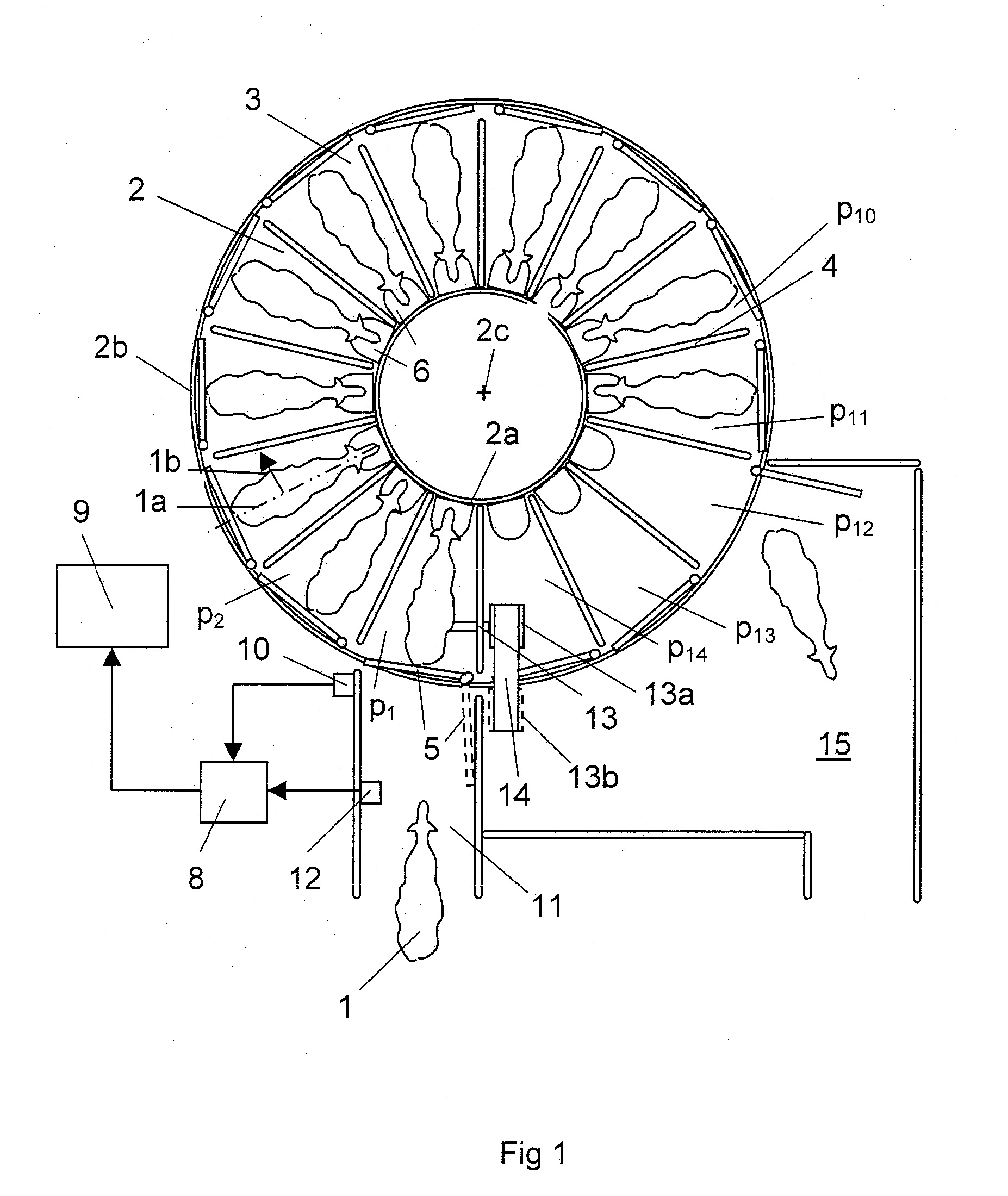

Teat cup holder rack

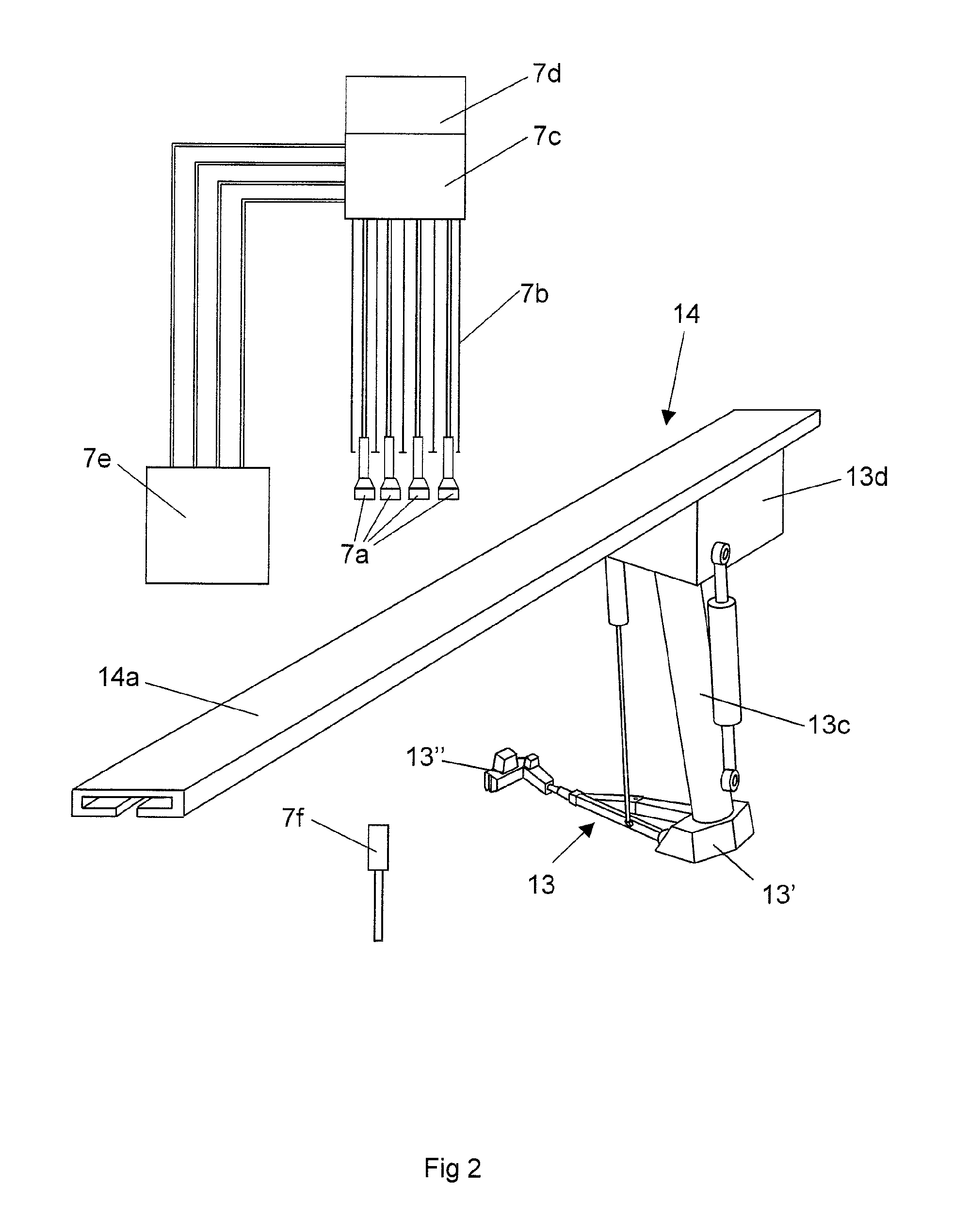

The present invention relates to a device and a method for cleaning teat cups (21) in a milking machine. It comprises a teat cup holding rack (1) having a teat cup (21) connected to a milk line (11), teat cup cleaning device (25) with cleaning fluid supply device such as a nozzle (41) and teat cup storing (19', 19''), milk line actuator (9, 53, 55) for retracting the milk line (11) until the teat cup (21) is positioned upside down and in contact with the teat cup storing device (19', 19''); and teat cup cleaning driver actuator (13'') for moving the cleaning fluid supply device (41) from a position not underneath said teat cup (21) to a position substantially vertically below the teat cup (21).

Owner:DELAVAL HLDG AB

Implement for automatically milking a dairy animal

ActiveUS20100186675A1High resolutionMaximum of constructive simplicityCathetersRobotPhase differenceMilk cow's

An implement for automatically milking a dairy animal, such as a cow, comprises a milking parlour, a sensor for observing a teat, and a milking robot for automatically attaching a teat cup to the teat. The milking robot comprises a robot control that is connected to the sensor. The sensor comprises a radiation source for emitting light, a receiver for receiving electromagnetic radiation reflected from the dairy animal, a lens, and sensor control unit. The sensor comprises a matrix with a plurality of rows and a plurality of columns of receivers. The sensor control unit is designed to determine for each of the receivers a phase difference between the emitted and the reflected electromagnetic radiation in order to calculate the distance from the sensor to a plurality of points on the part to be observed of the dairy animal.

Owner:MAASLAND

Arrangement and Method for Determining Positions of the Teats of A Milking Animal

ActiveUS20100289649A1Determination of the positions of the teats of an animalRapid determinationCathetersPosition fixationImaging processingEngineering

An arrangement is provided for attaching teat cups to teats of a milking animal in a rotary milking system having a milking stall for housing the milking animal during milking. The arrangement comprises a three-dimensional camera configured to be directed towards the udder of the milking animal in the milking stall and to repeatedly record three-dimensional images of the udder of the milking animal in real time. The three-dimensional camera is further configured to be directed towards the teat cups located in a magazine and to repeatedly record three-dimensional images of the teat cups in real time. The arrangement also includes an image processing device configured to repeatedly detect the teats of the milking animal and determine the positions of the teats in three spatial dimensions based on said repeatedly recorded three-dimensional images of the teats. The image processing device is also configured to repeatedly detect the plurality of teat cups and determine the positions of the teat cups in three spatial dimensions based on said repeatedly recorded three-dimensional images of the teat cups located in the magazine. The arrangement also includes a control device configured to control a robot arm, based on the determined positions of the teats of the milking animal and the determined positions of the teat cups, to automatically attach at least one teat cup to at least one teat of the milking animal in the milking stall.

Owner:DELAVAL HLDG AB

Fluid-applying device and a method of applying a fluid to a teat of a dairy animal

A fluid-applying device for applying a fluid to a teat of a dairy animal. The fluid-applying device comprises a fluid detector for determining a fluid application pattern of the fluid on the teat of the dairy animal. The fluid detector comprises a computer loaded with comparing software for comparing the determined fluid application pattern with a previously stored reference criterion, for emitting a comparison signal which is indicative of the comparison result, and for determining the teat length, the tip of the teat, and the fluid application distance, measured from the tip of the teat, over which the fluid has been applied to the teat, and for emitting a fluid signal comprising data in relation to the determined fluid application distance. The reference criterion may be a threshold distance with which the determined fluid application distance is compared.

Owner:LELY ENTERPRISES

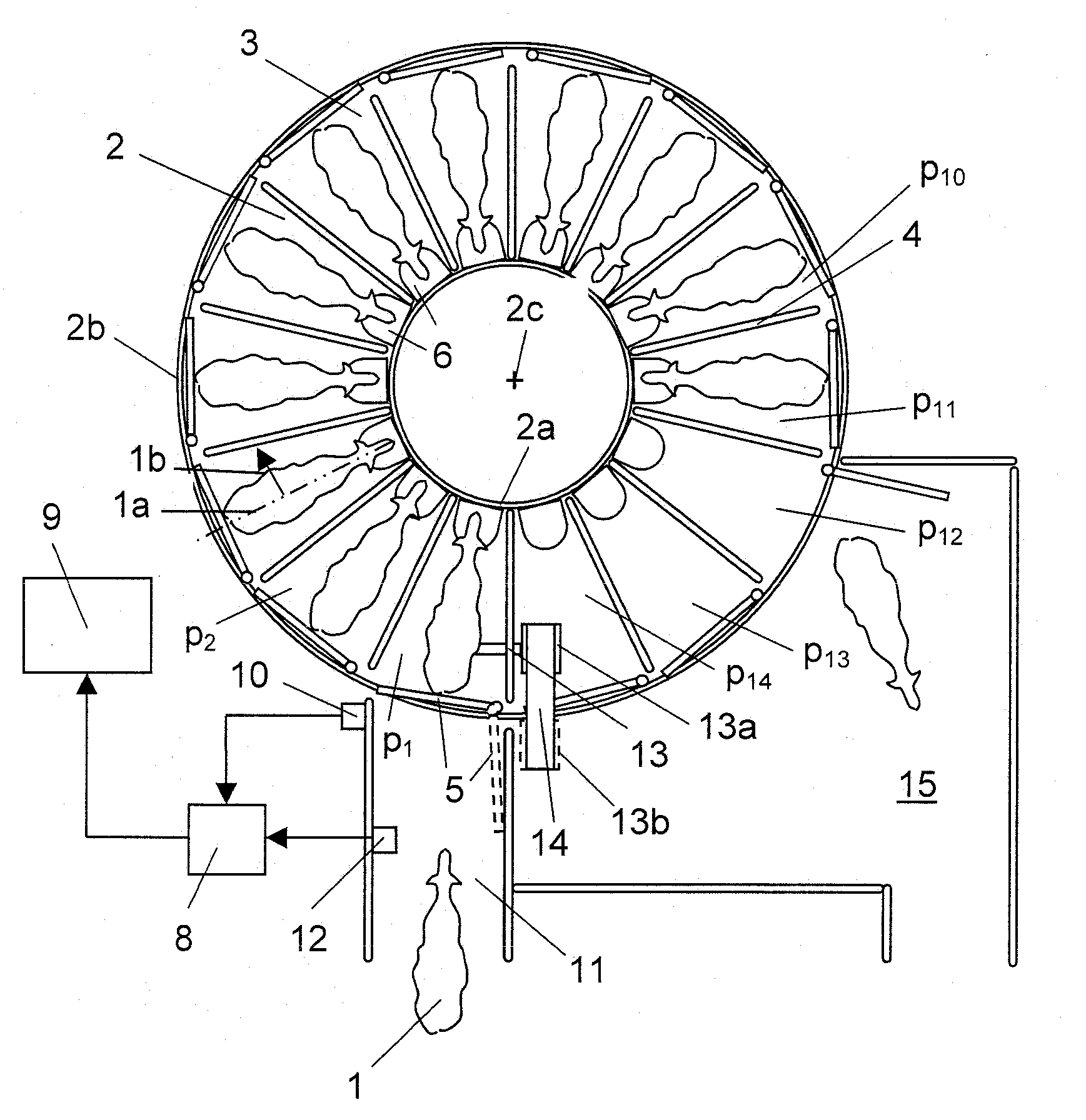

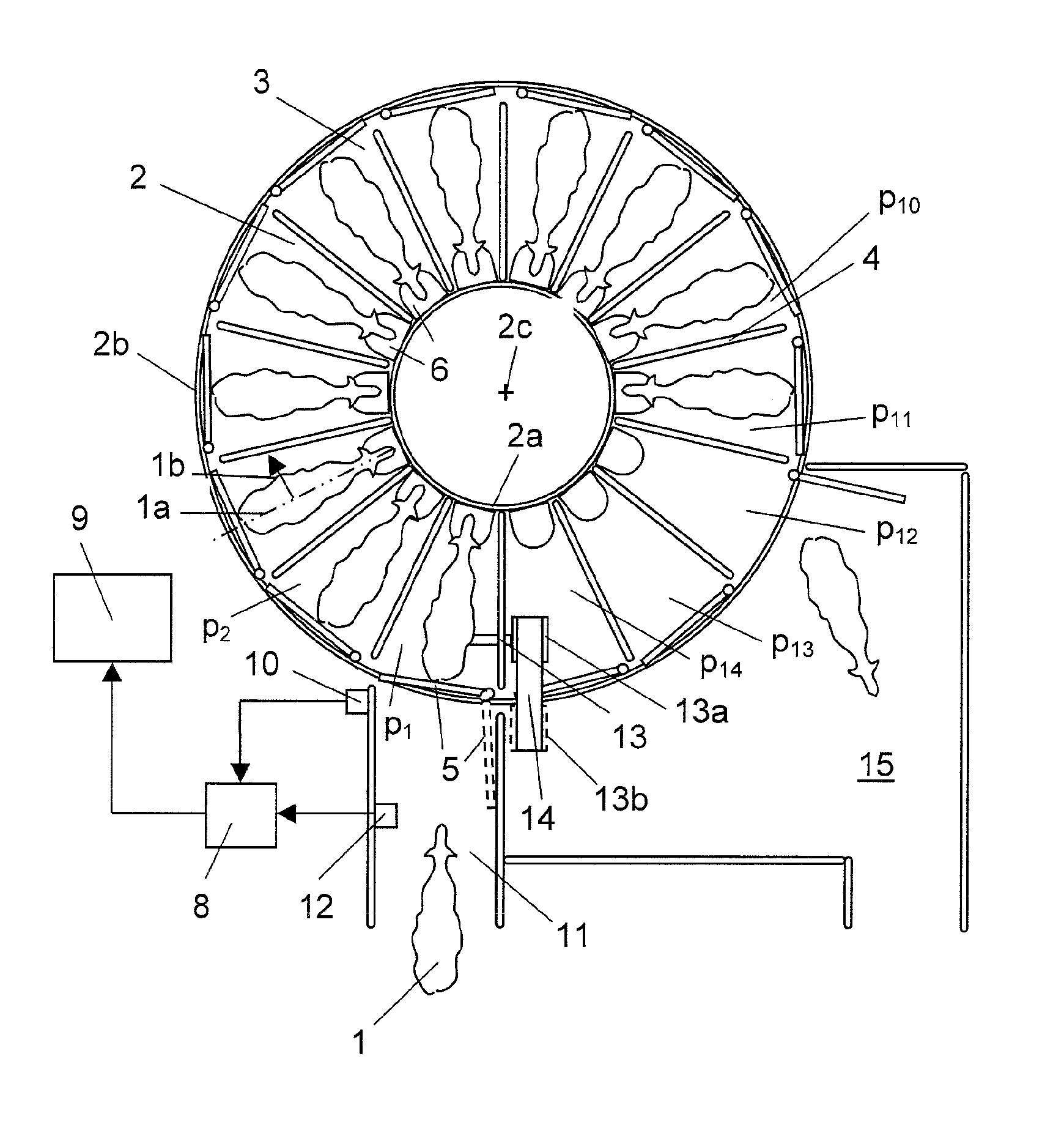

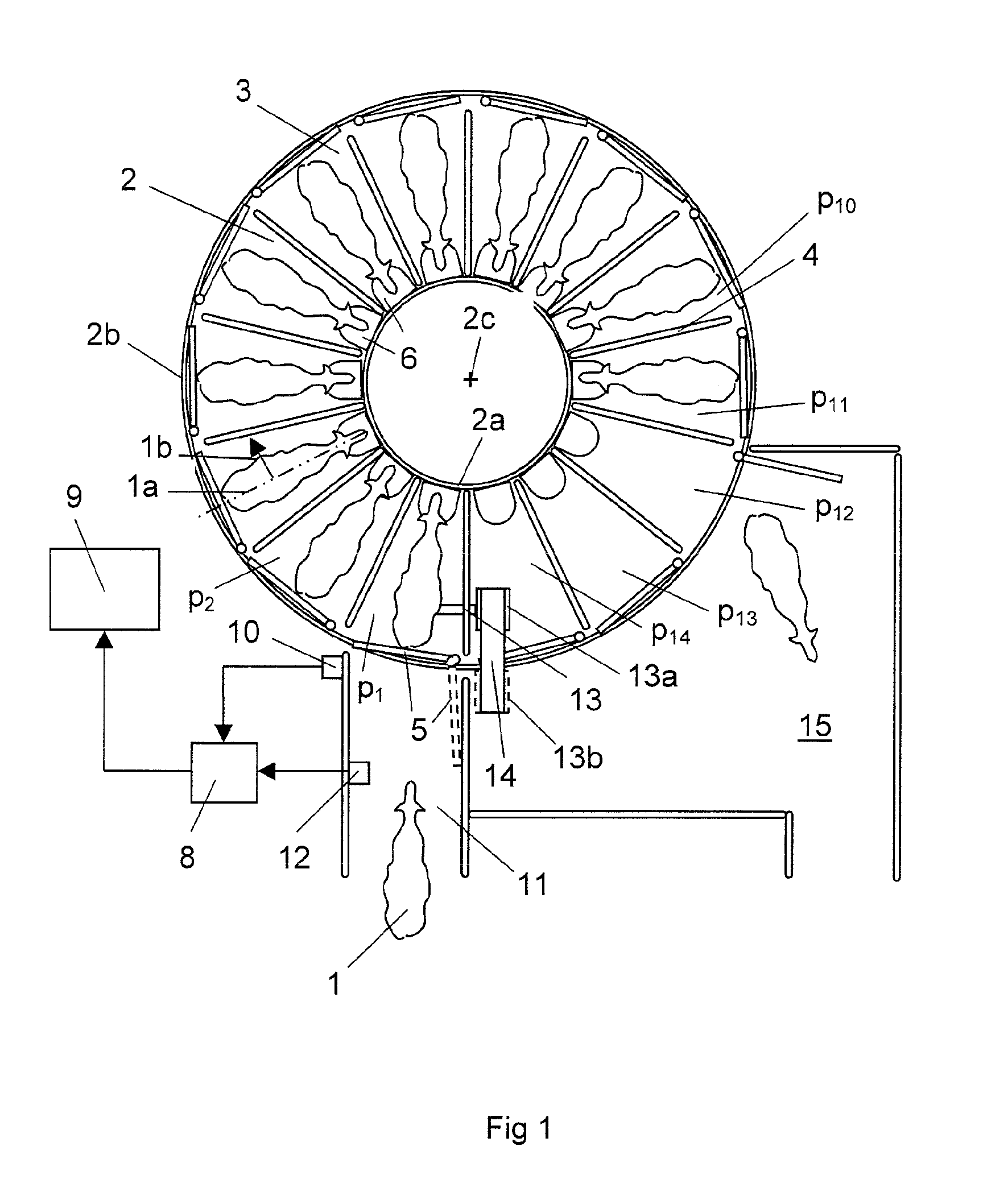

Rotary parlour for automatic milking of animals

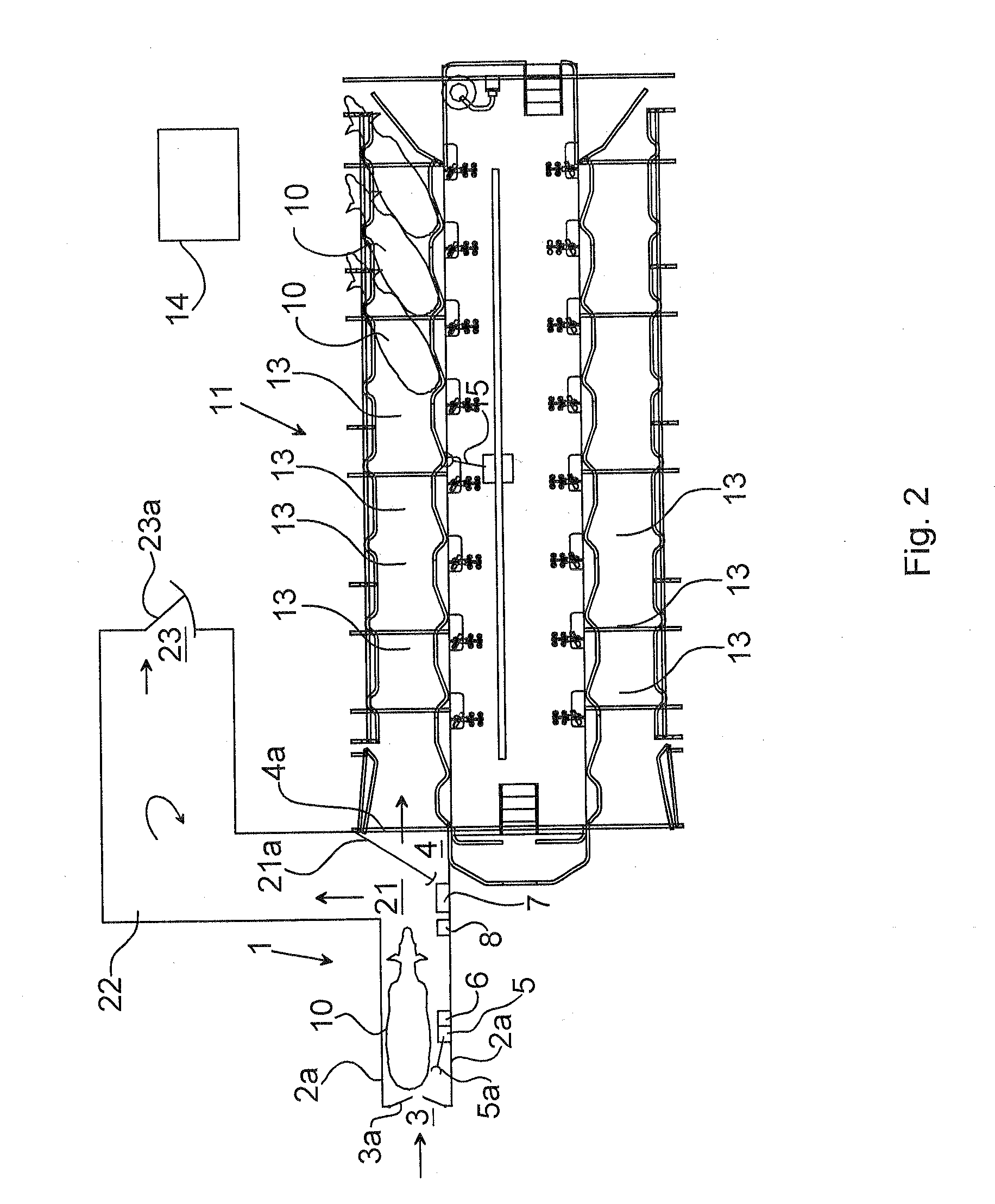

A rotary parlour for automatic milking of animals includes an annular rotary platform (2) adapted to form a support surface for the animals (1), driving element (9) for supplying a rotary motion to the platform (2), positioning element for arranging the animals in predetermined milking positions (3) on the platform, in which an longitudinal axis (1a) of the animals forms an angle to the direction of motion (1b) of the animals standing on the rotary platform (2), and a robot arm (13) adapted to attach teat cups (7a) to the teats of an animal (1) which has entered a milking position (3) on the platform (2). The entire robot arm (13) is located in a working position vertically above or on the platform (2) when it attaches the teat cups to the teats of the animals (1).

Owner:DELAVAL HLDG AB

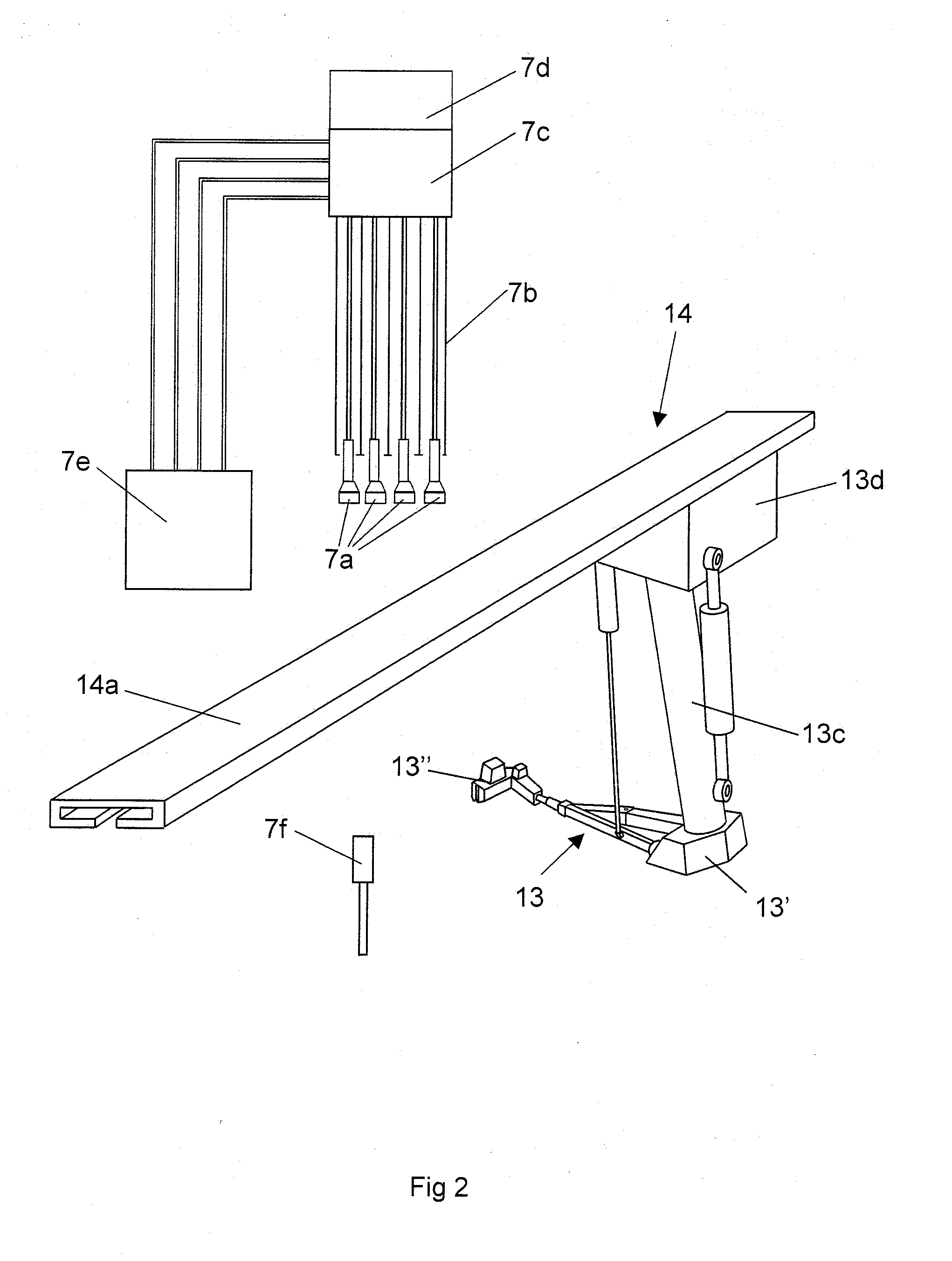

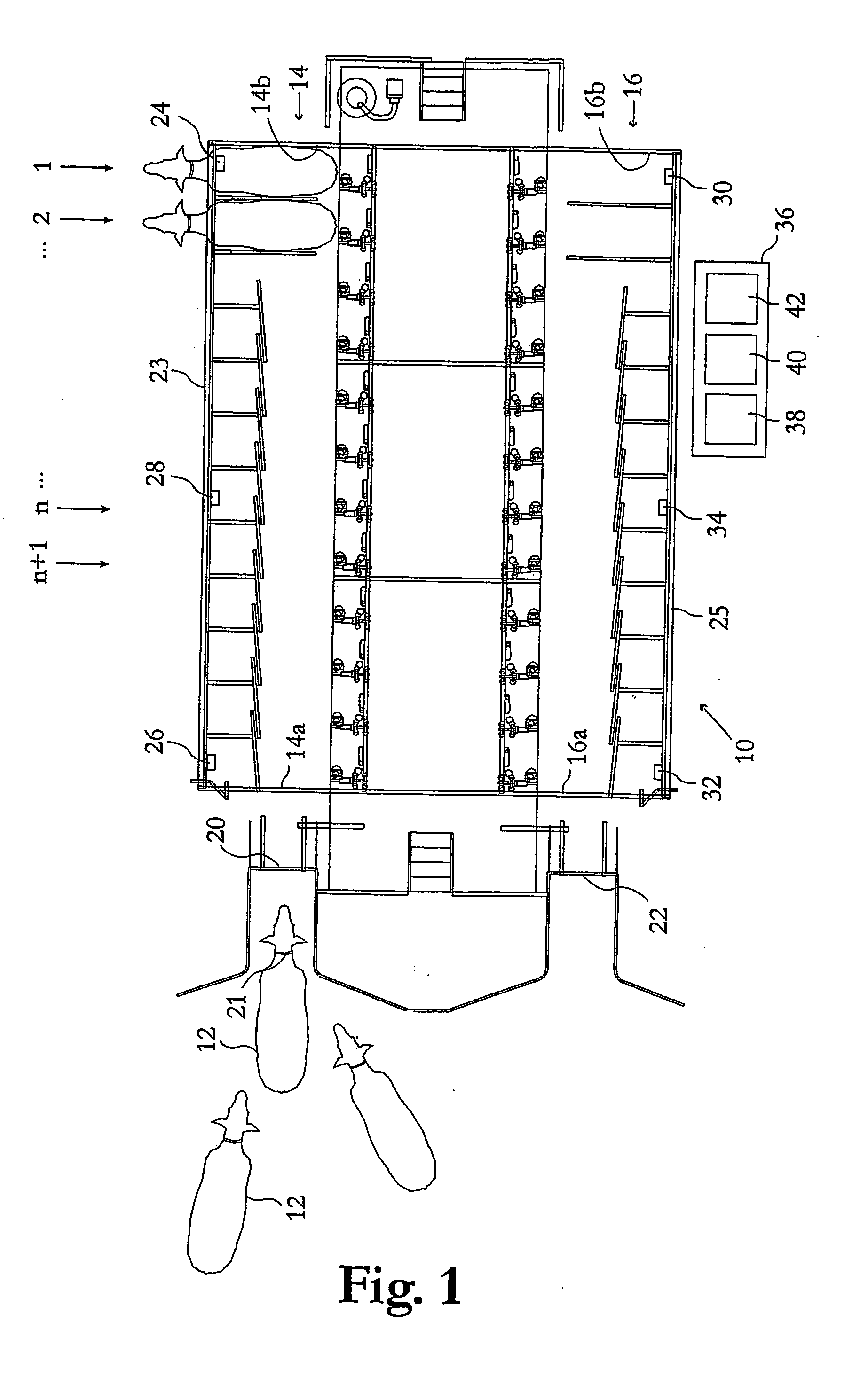

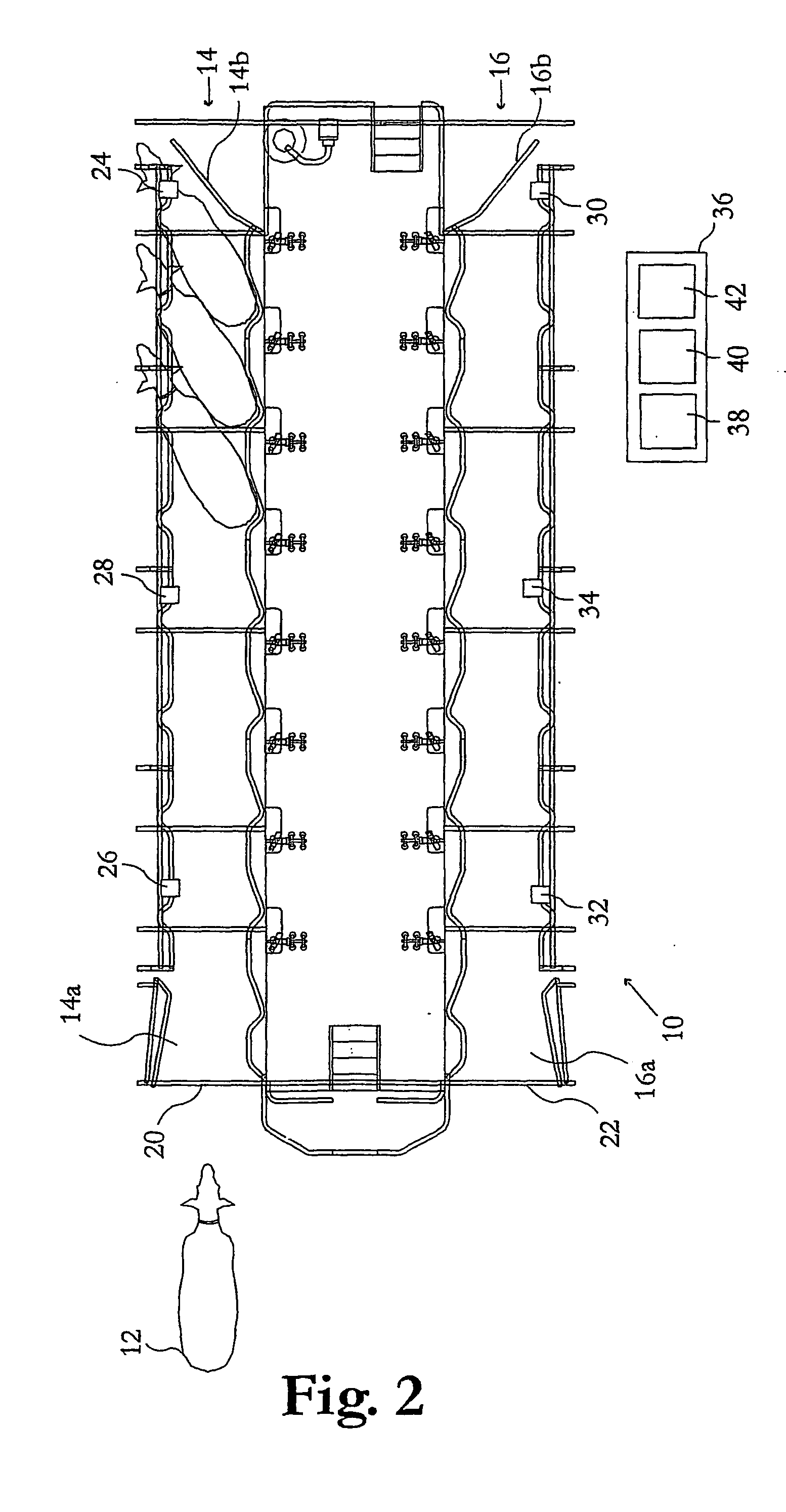

Method and arrangement for automatically verifying identities of milk producing animals

InactiveUS20050223997A1The process is simple and effectiveCathetersAnimal housingAnimal useEngineering

A milking parlor (10) comprises a row of stalls (14) accessible to milk producing animals (12) from a front end (14a) thereof, and adapted for milking the animals; and an identification station (20) arranged in the front end for identifying the animals when entering the parlor. A method of verifying the identities of the animals in the row comprises: (i) identifying the animals in the stall located at the far end (14b) of the row, in the stall located at the front end (14a) of the row, and in a stall located there in between by first, second and third identification members (24, 26, 28); (ii) comparing the identifications of the first, second, and third identification members (24, 26, 28) with the first, last and n'th identifications from the identification station (20), where the stall located between the far and front ends is the n'th stall as counted from the far end (14b); and (iii) depending on the comparison verifying the identities of at least some of the animals (12) in the row (14).

Owner:DELAVAL HLDG AB

Rotary parlour for automatic milking of animals

Owner:DELAVAL HLDG AB

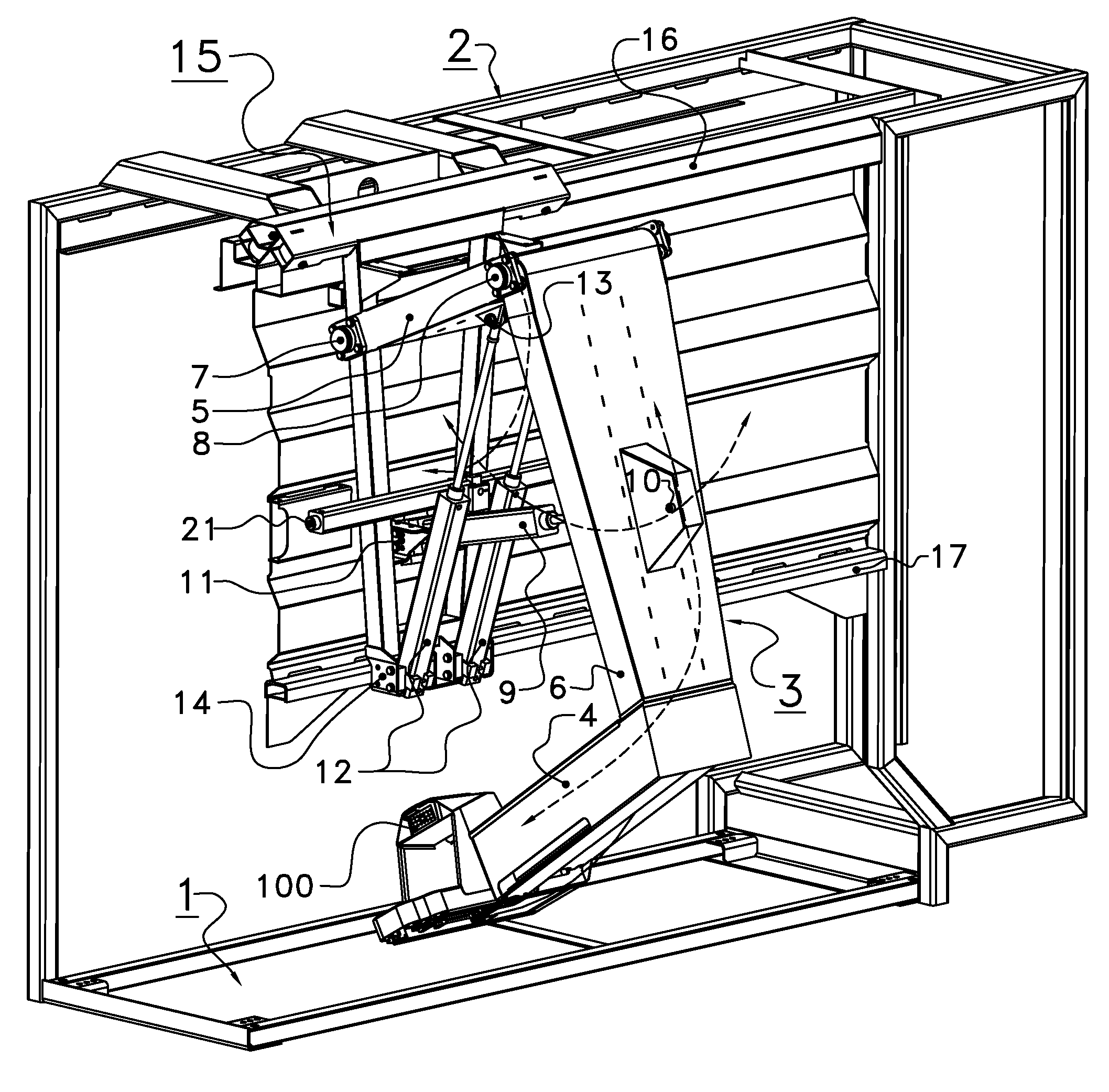

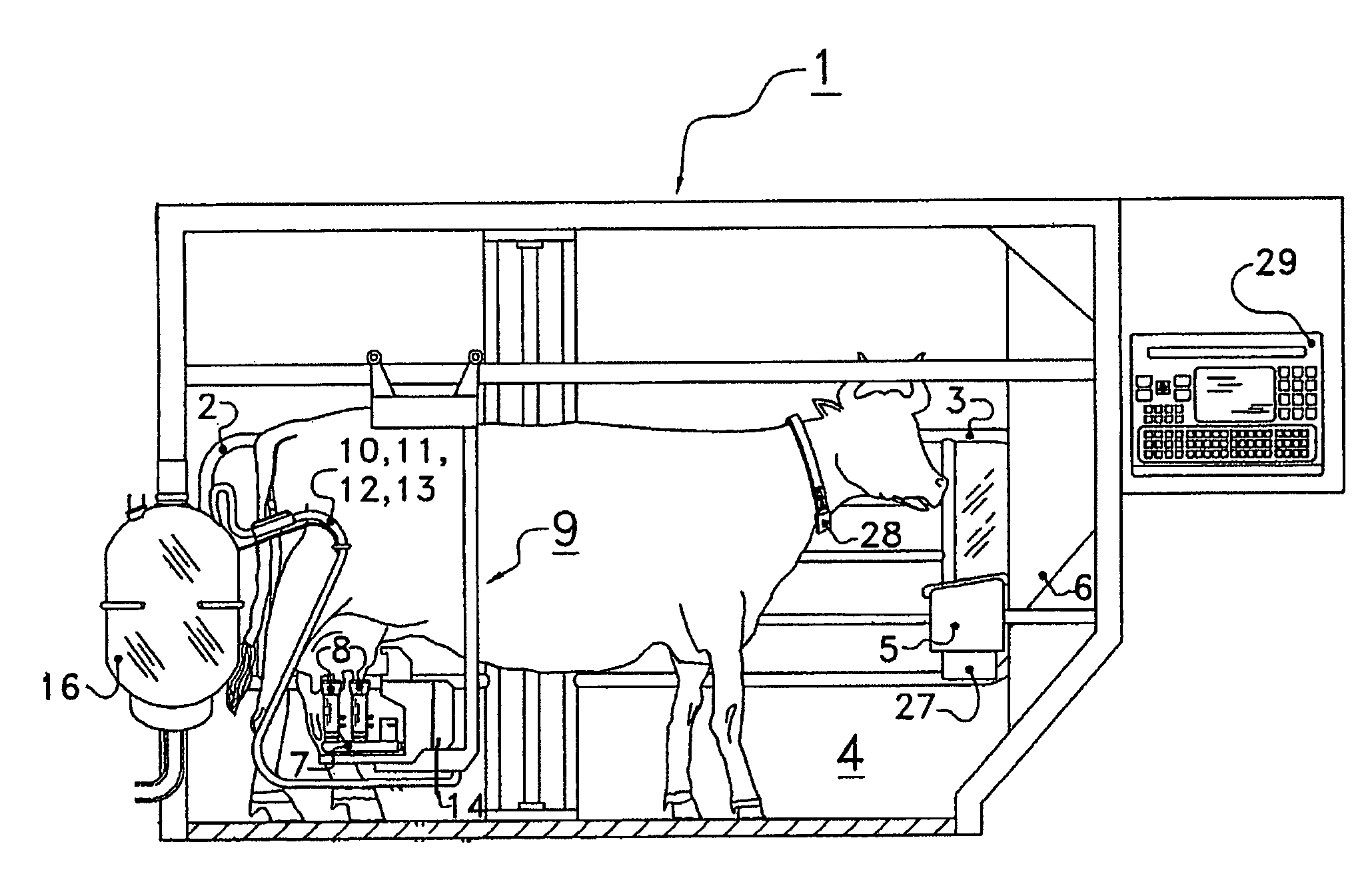

Teat preparation station and method for teat preparation

InactiveUS20100282172A1Flexible milking animal management arrangementImprove throughputCathetersAnimal housingAnimal scienceEngineering

A teat preparation station(1) for preparation of teats of milking animals prior to being milked in a milking system (11) equipped with at least one milking stall(13) is provided. The teat preparation station (1) includes a teat preparation area (2) housing at least one milking animal at a time; an exit (4) leading to the milking system; pre-milking equipment (5) provided for automatically pre-milking milking animals in the teat preparation area; and milk quality analyzing equipment (6) provided for automatically analyzing pre-milk from the milking animals.

Owner:DELAVAL HLDG AB

Method and device for controlling animal feeding when milking dairy animals

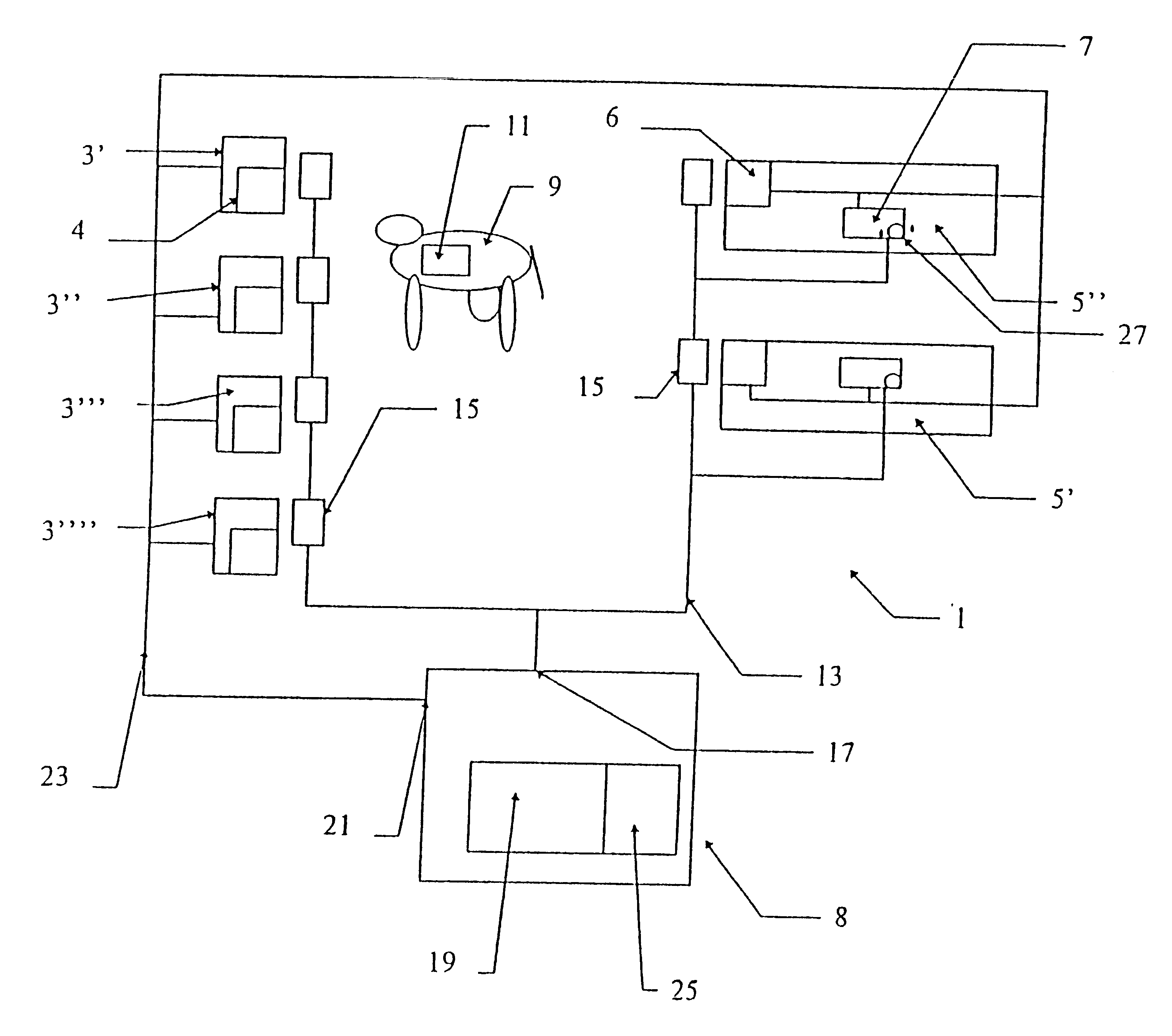

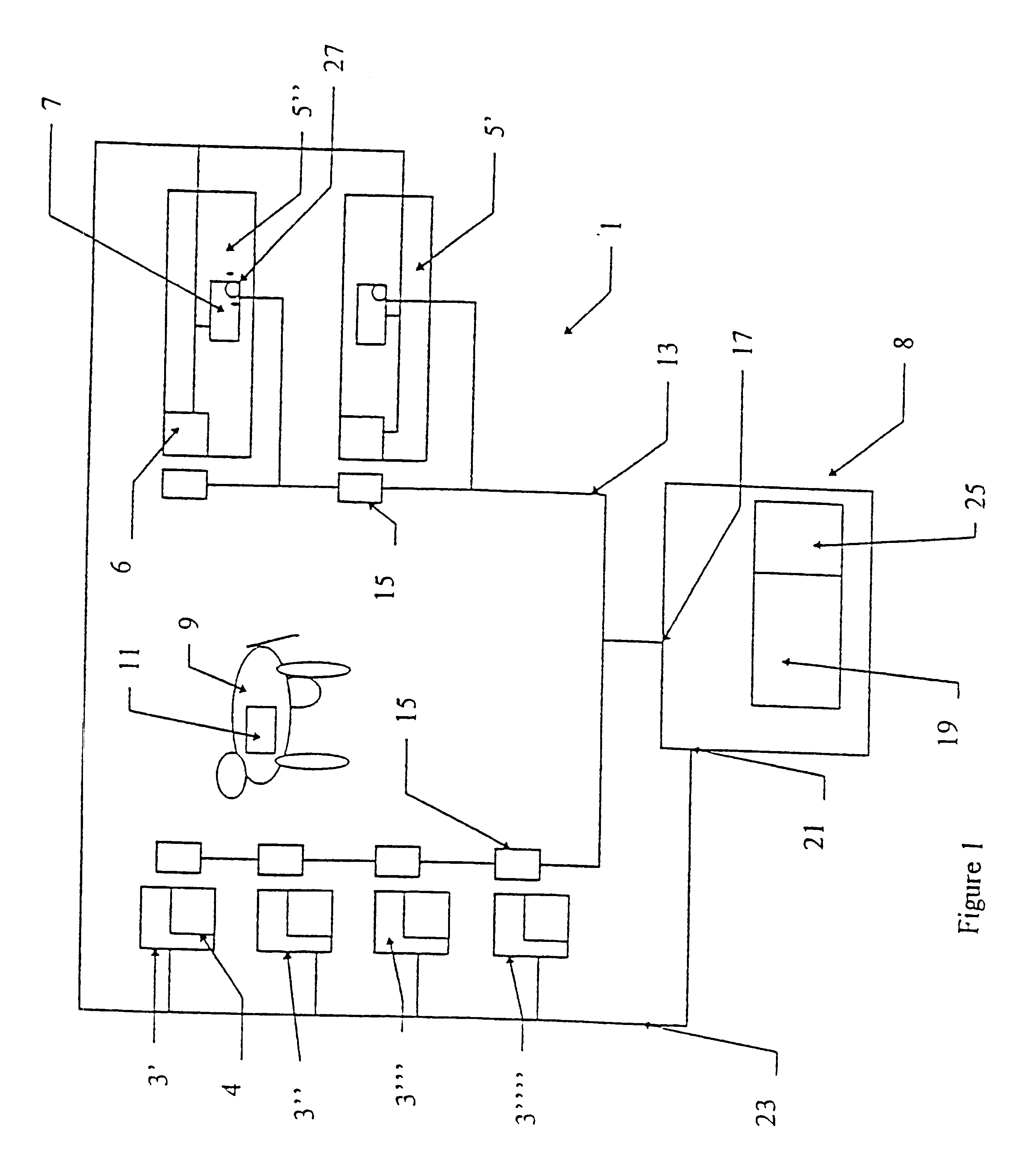

The present invention relates to a device and method for the milking of dairy animals (9), comprising individual identifiers (11) attachable to each individual diary animal (9); simple feeding station (3'-3''''), provided with food dispenser (4) for dispensing fodder and sensor (15) for sensing the individual identifiers (11); combined feeding and milking stations (5', 5''), provided with food dispensers (6) for dispensing fodder, milking apparatus (7) for milking animals (9) and sensors (15) for sensing the individual identifiers (11); and control device (8, 19) for controlling the simple feeding stations (3', 3'''') and combined feeding and milking stations (5', 5''), wherein the control device (8, 19) comprises determining apparatus (19) for determining a time for the next milking of said individual animal (9); and output apparatus (21) for commanding the single feeding stations (3',3'''') to stop dispensing food to the individual animal (9) if the actual time is after the time for the next milking of the animal (9).

Owner:DELAVAL HLDG AB

Device and method for determining teat positions

InactiveUS20070245964A1Improve accuracyEasy to detectCathetersPosition/course control in three dimensionsEngineeringControl unit

A device for determining the teat positions of a dairy animal after milking. The device is provided with at least one position-measuring device for determining a position of a teat prior to the milking of the dairy animal and for emitting a position signal corresponding to the teat position. The position-measuring device generates individual teat position signals and a control unit determines on the basis of the teat position signals determined before the milking, planes of symmetry extending substantially parallel to the teats. The expected positions are calculated with respect to the planes of symmetry.

Owner:LELY ENTERPRISES

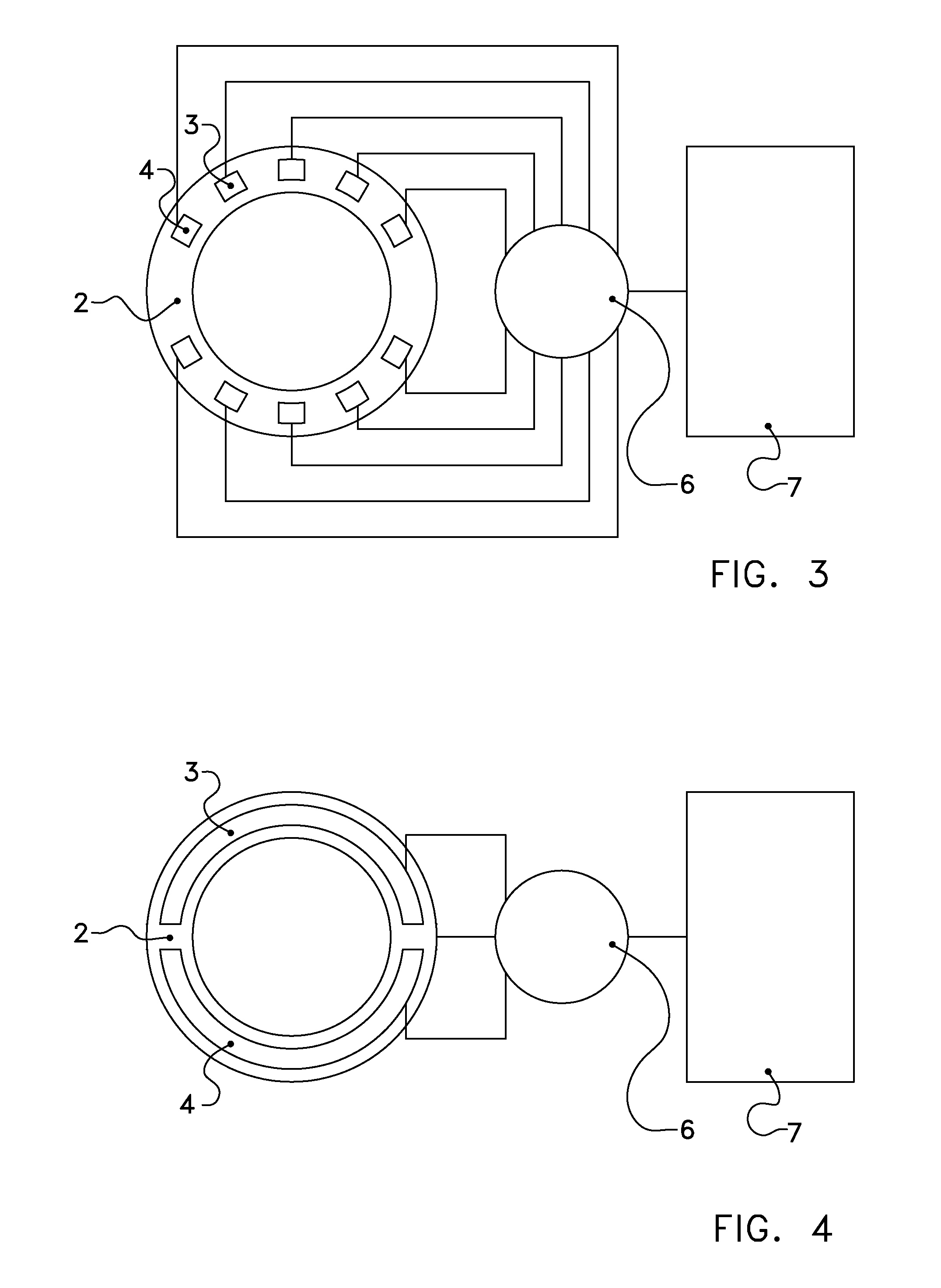

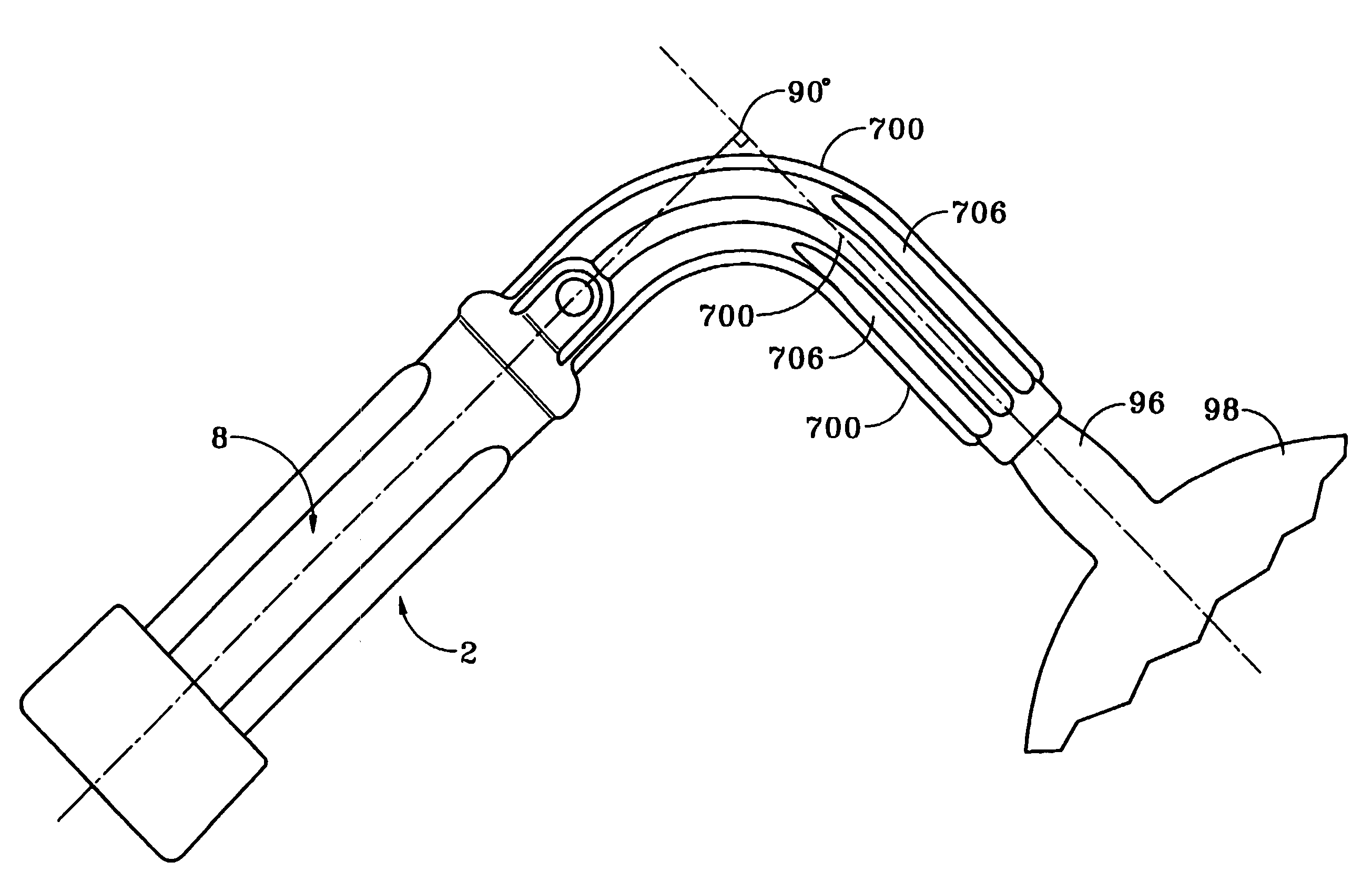

System for connecting a teat cup to a teat

The invention provides a system for connecting a teat cup to a teat, including a teat cup with an opening for receiving a teat, a robot arm for moving the teat cup, a teat cup positioning system with a 3D-sensor and a sensor device for measuring a control quantity, and for connecting the teat cup under the control of the 3D-camera and the control quantity. The sensor device includes at least two electrodes around the opening and a capacitive sensor configured to measure a quantity connected with the capacitance between the electrodes, in particular the capacitance between two electrodes. This system provides a reliable positioning with respect to a teat by, for example, maximization of the measured capacitance. The positioning system supports an optical 3D-sensor for the first, global positioning.

Owner:LELY PATENT

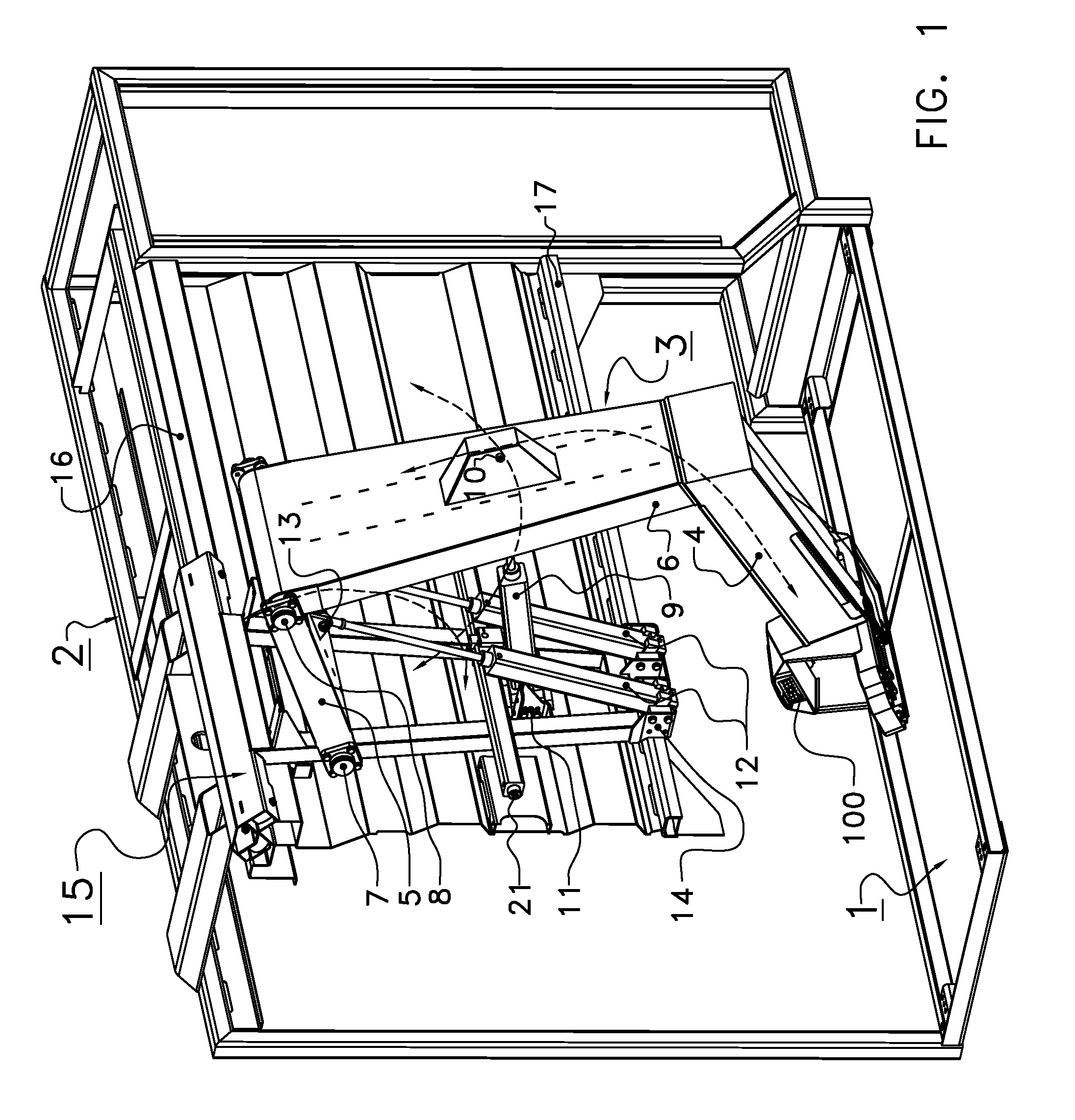

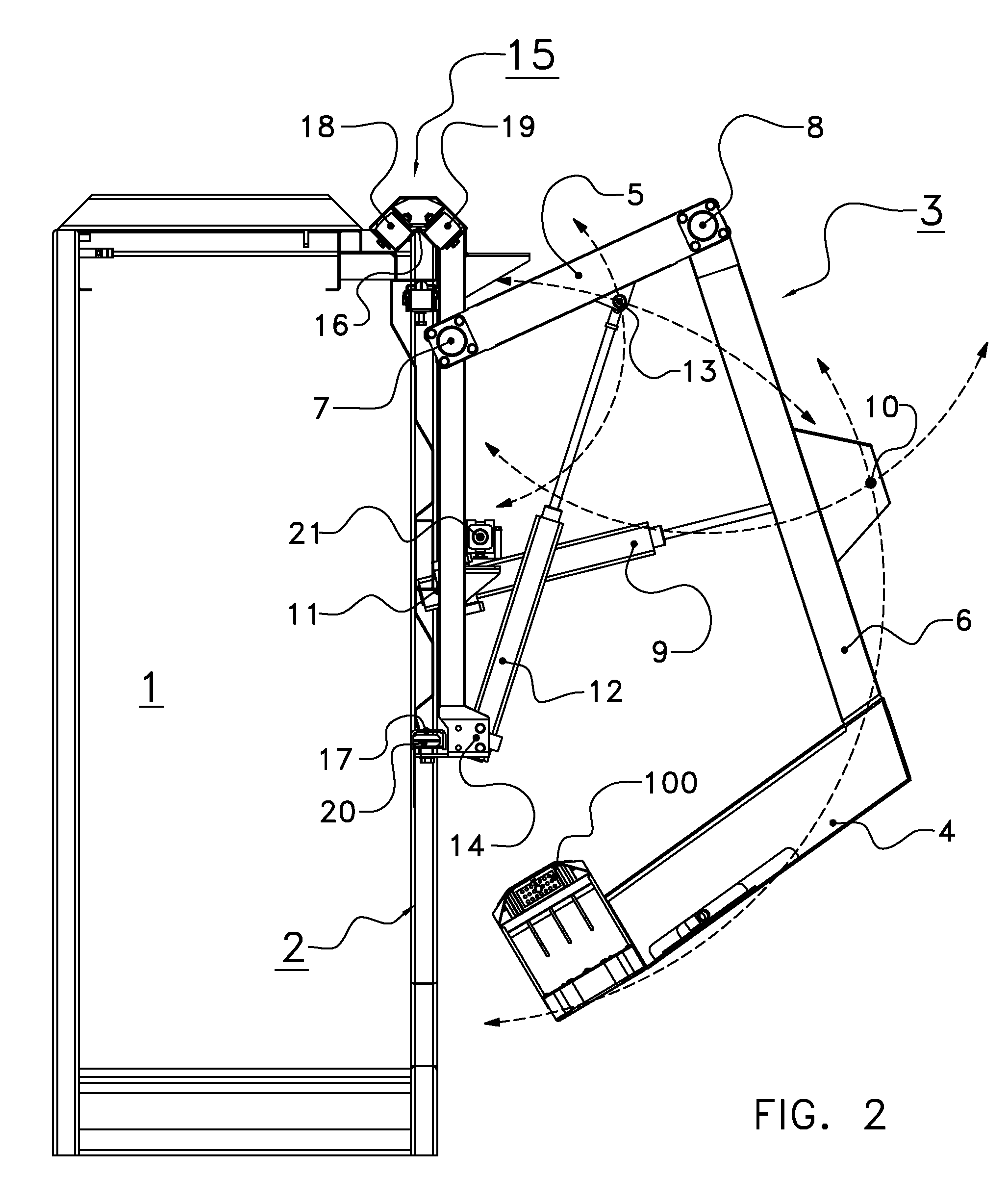

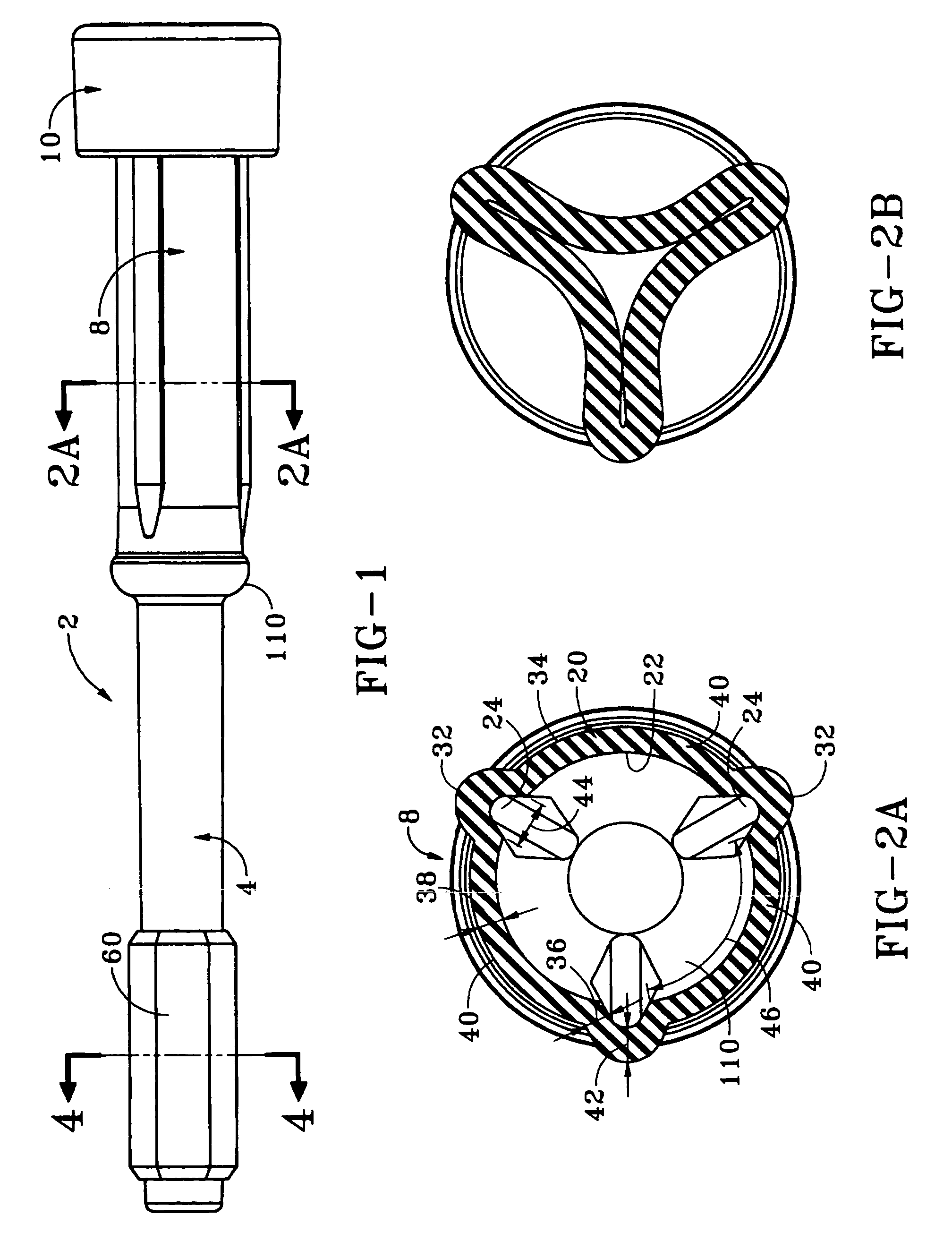

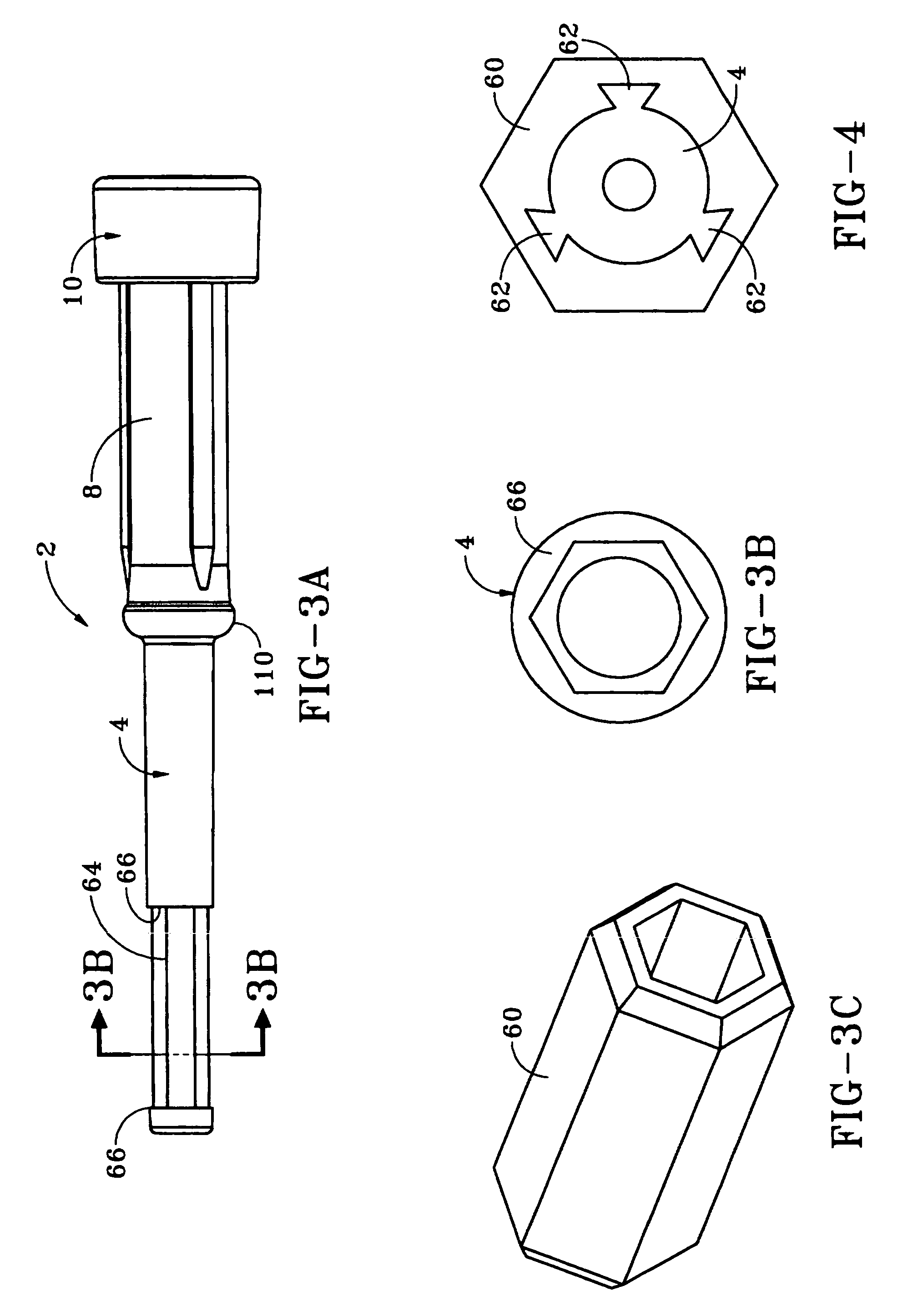

Live capture automated milking apparatus and method

A method and apparatus for the automated milking of dairy cattle employing live capture of the teats of a dairy cow without requiring identification of a particular dairy cow or the prior knowledge of the location of the individual teats. The live capture milking apparatus locates the individual teats of a dairy cow and attaches a teatcup to the teat without the need for human intervention. After the milking operation is completed, the live capture milking apparatus returns to a home position where cleaning and sanitization the milking equipment occurs.

Owner:INNOVATIVE AUTOMATION

Milking box expulsion system

A method of milking an animal involves admitting the animal into a milking box and expelling the animal from the milking box, the milking box comprising a connecting device, such as a robot arm, for automatically connecting a teat cup to a teat of the animal. The step of expelling the animal from the milking box is carried out using the robot arm. An installation for milking an animal is also described, the installation being provided with a milking box for the animal; a robot arm for automatically connecting a teat cup to a teat of the animal; and a device for expelling the animal from the milking box. The device for expelling the animal from the milking box comprises part of the robot arm.

Owner:MAASLAND

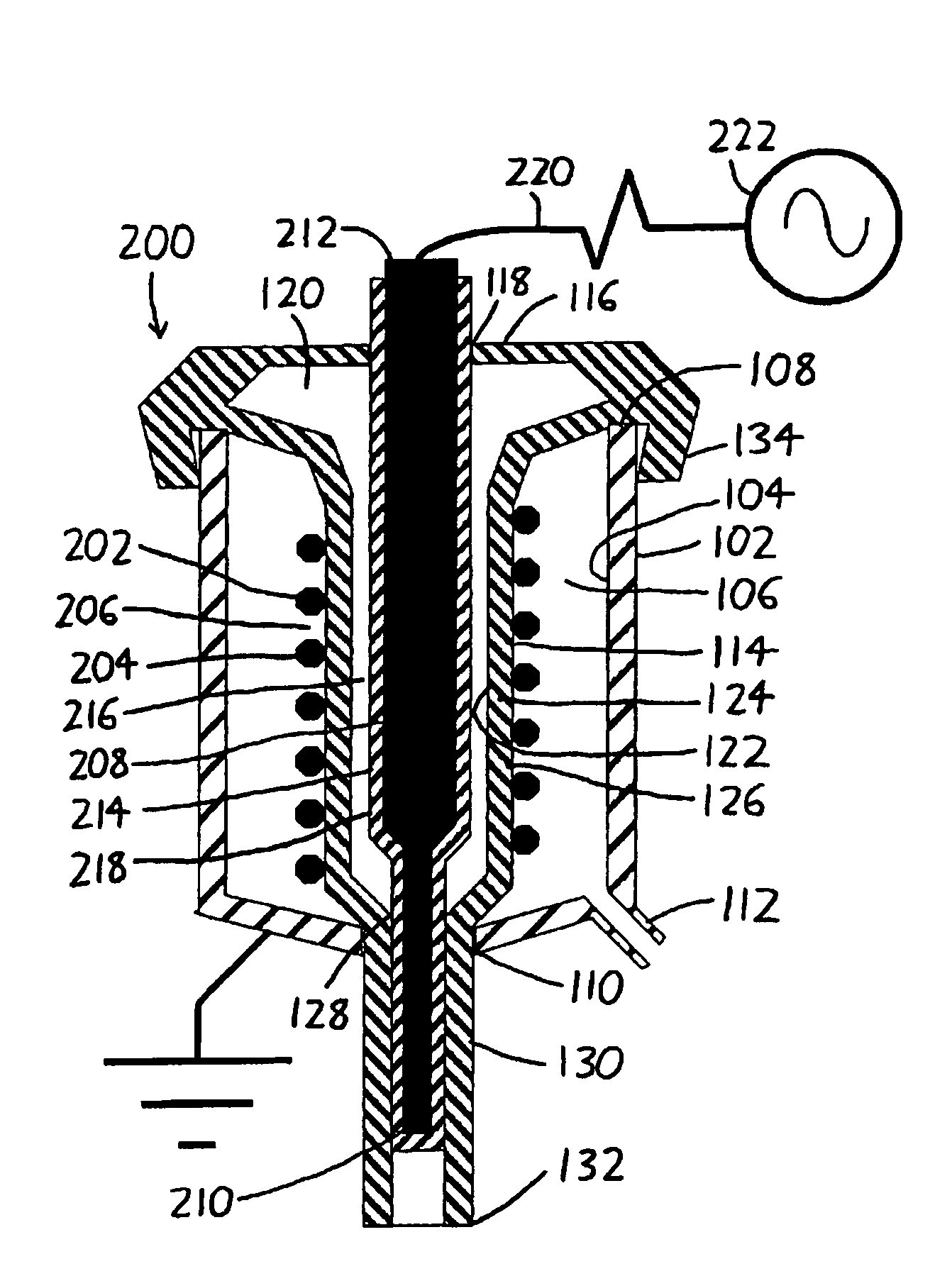

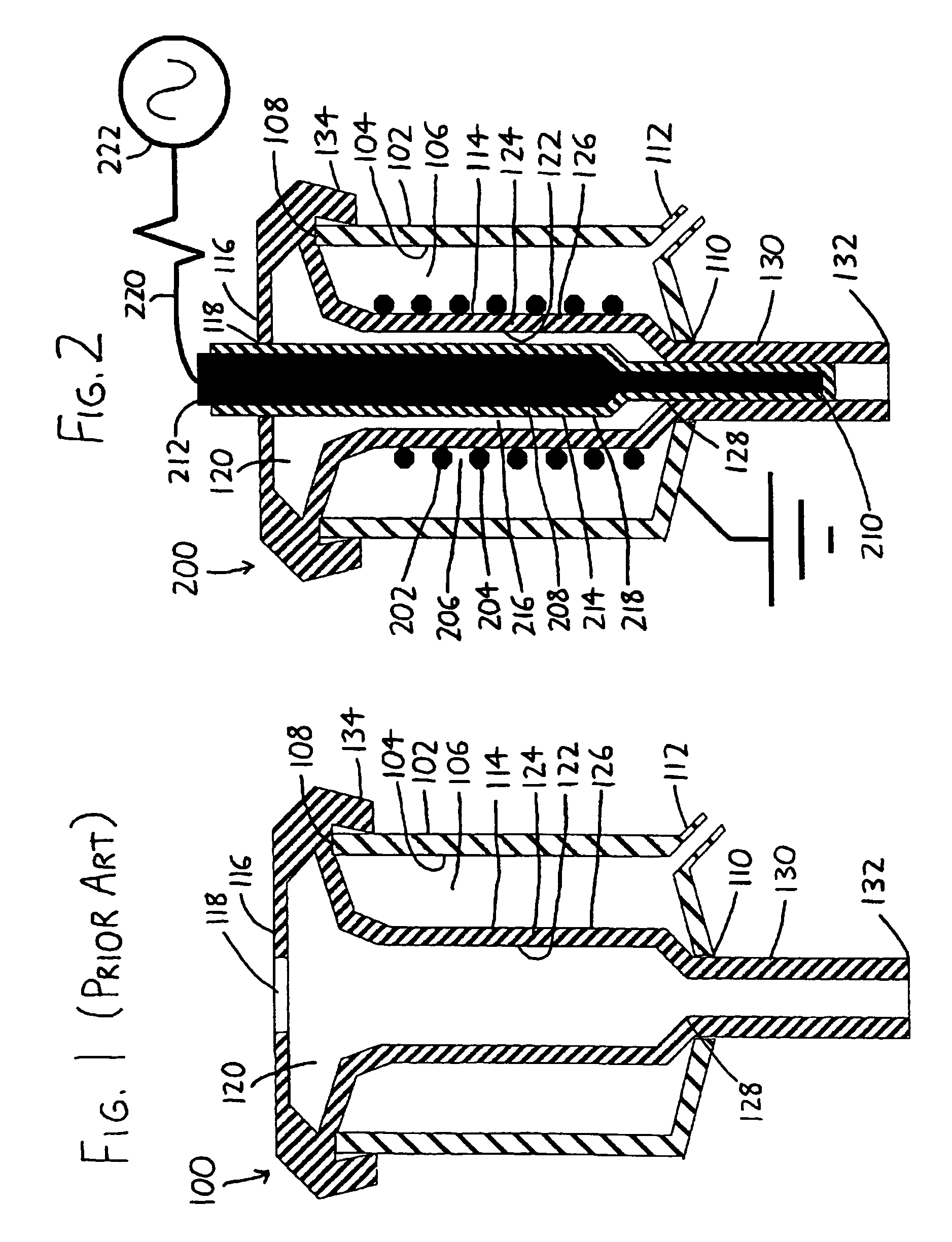

Plasma-assisted disinfection of milking machines

Owner:WISCONSIN ALUMNI RES FOUND

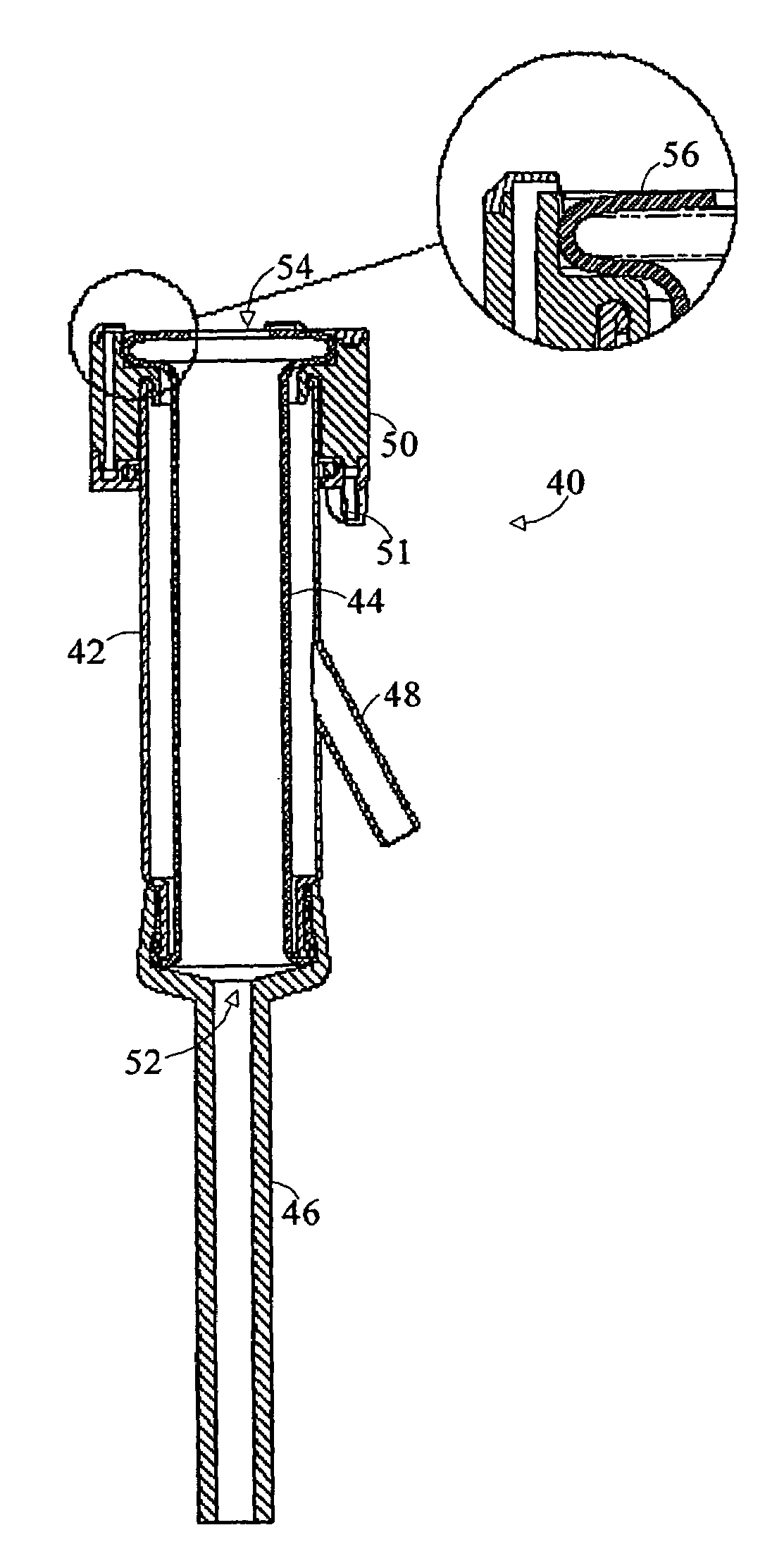

Milking and application teat cup, system, and method

Owner:DELAVAL INC

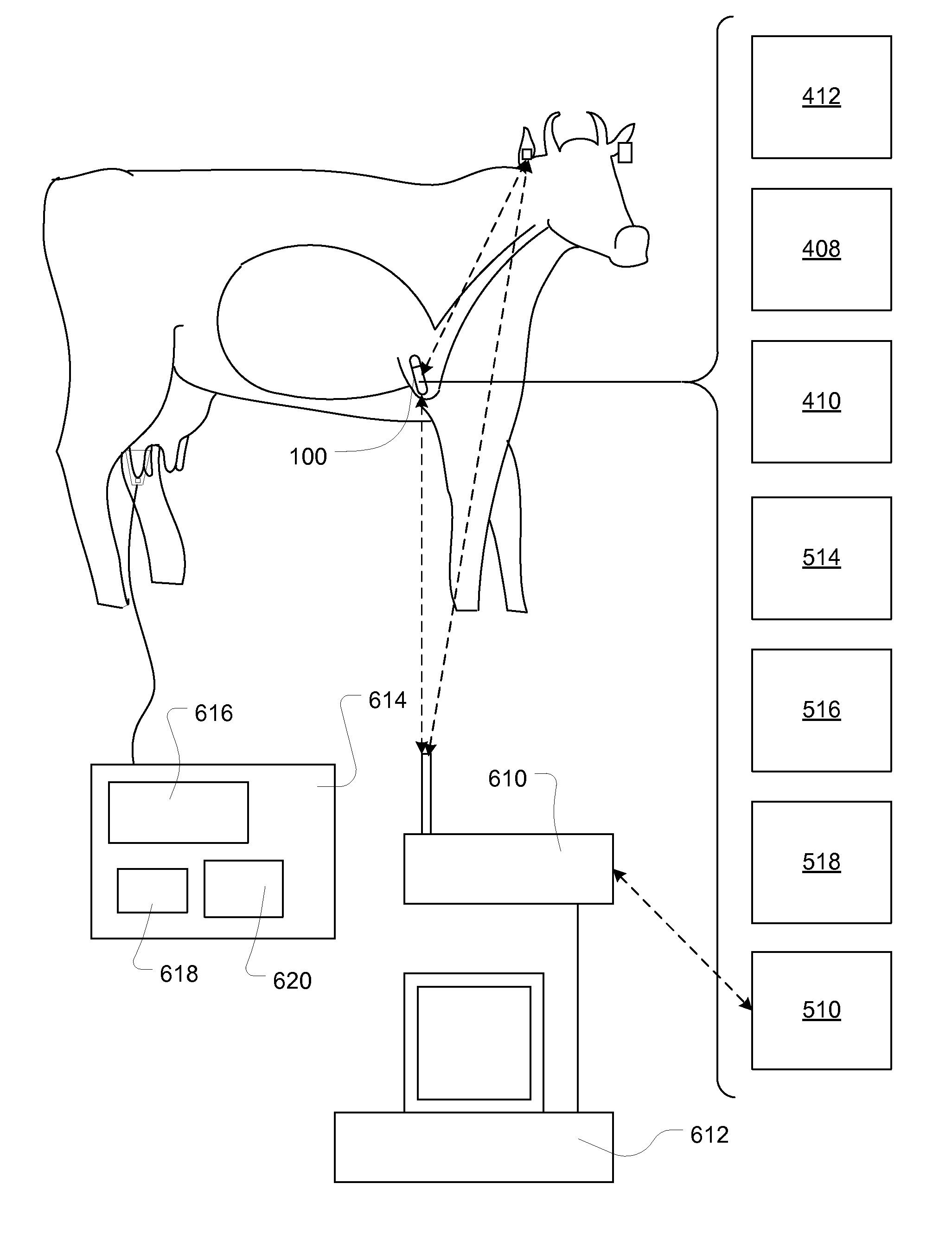

Apparatus, system, and method for animal monitor

InactiveUS20080236500A1Reduce manufacturing costPromote recoveryAnimal reproductionCathetersRuminant animalReticulorumen

An apparatus, system, and method enable monitoring of one or more physiological conditions in an animal including pH. A monitor may take the form of a bolus that may be installed in a stomach of an animal such as in a reticulorumen of a ruminant animal. The monitor may include sensors for detecting one or more of the pH, temperature, pressure, and position. The monitor includes a power source and electronics for processing, storing, and transmitting signals representing the physiological conditions detected by the sensor(s). The monitor may include first and second portions that are releasably joined, and that may support respective components for ease of assembly during manufacture and servicing. The monitor may form part of a system having a receiver for receiving and interpreting the signals from the monitor. The method includes installing the monitor in an animal and monitoring the animal by detecting physiological characteristics.

Owner:HODTERRY E +1

Milking liner

Owner:LAUREN AGRISYST

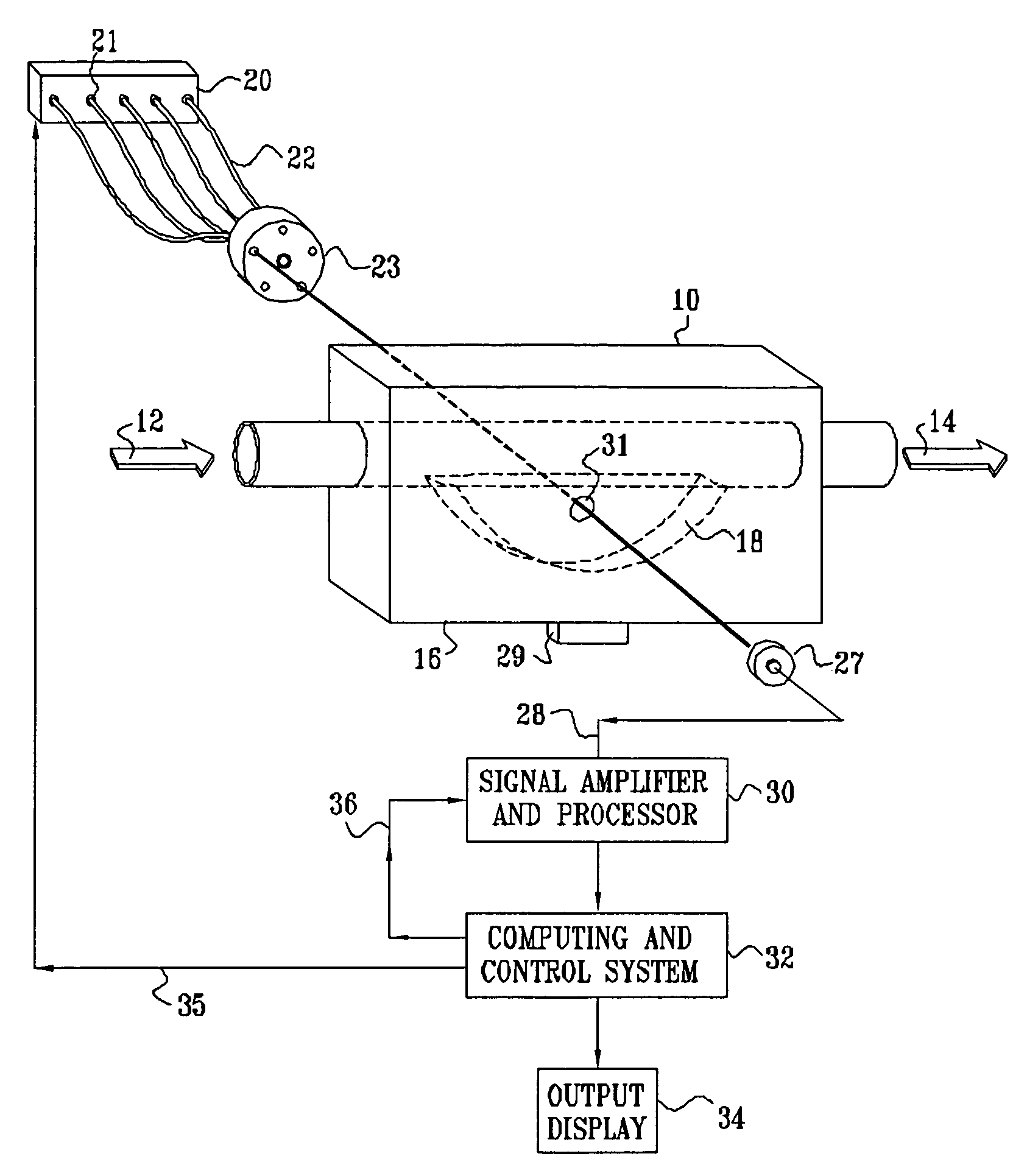

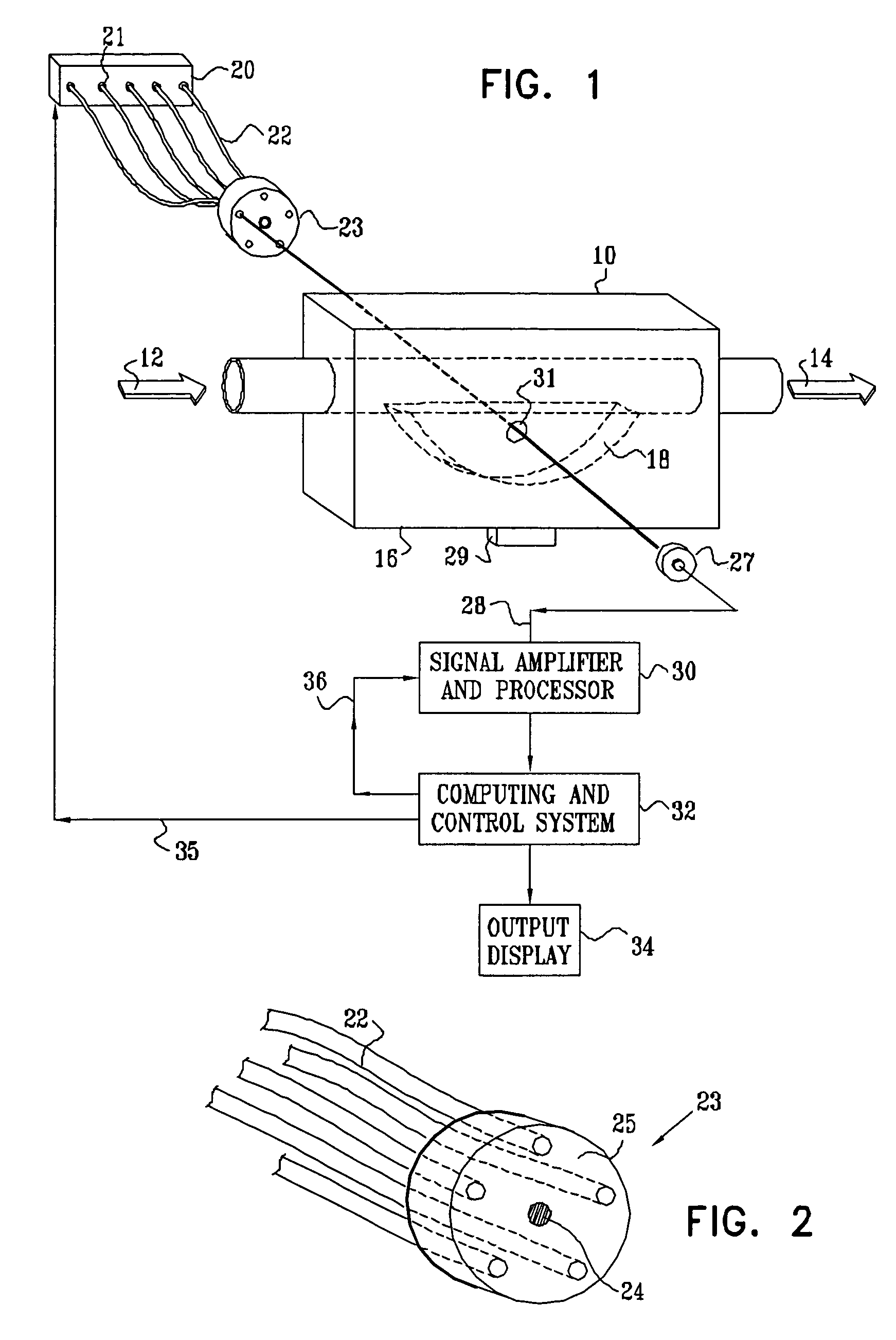

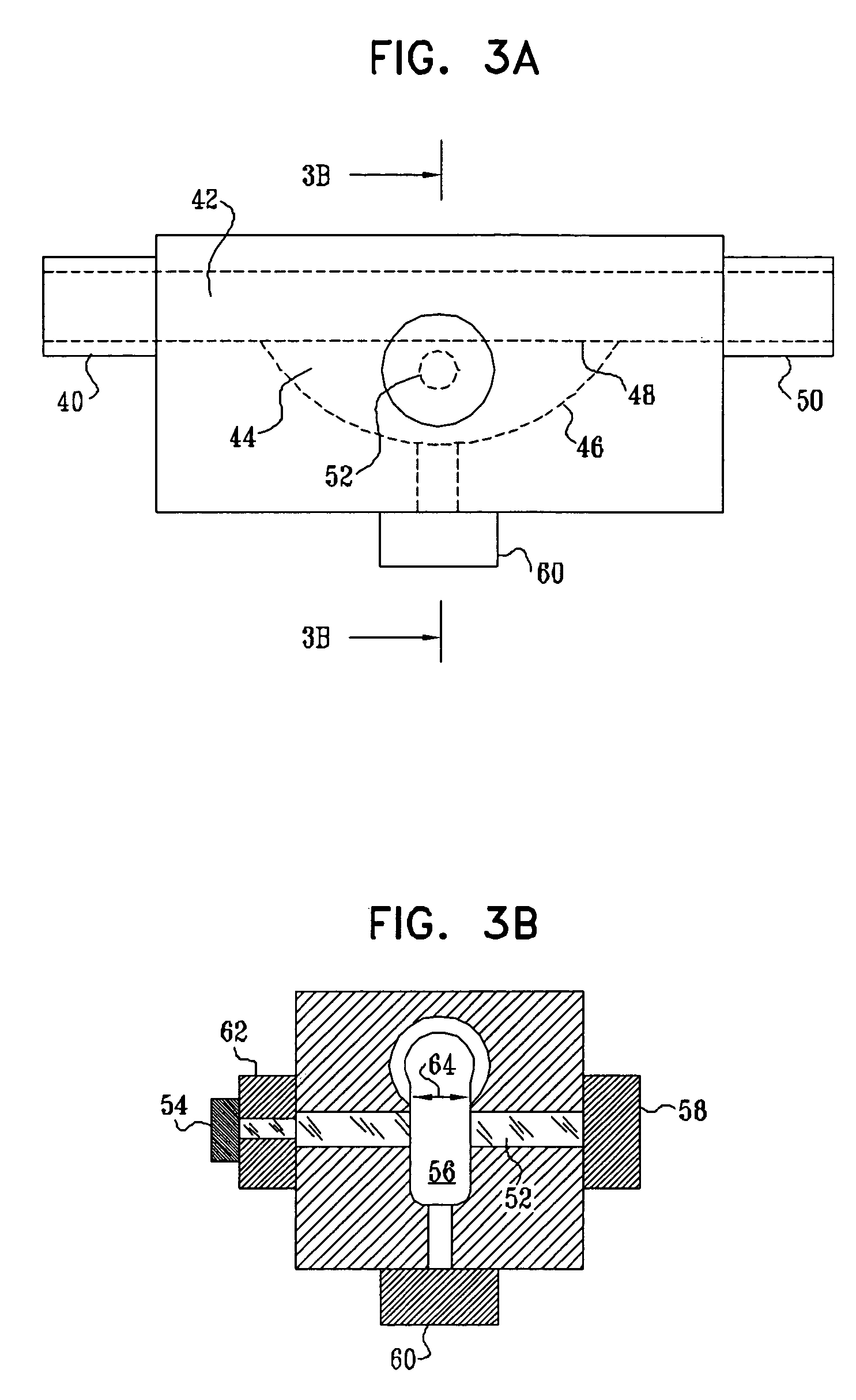

Spectroscopic fluid analyzer

InactiveUS7236237B2Readily availableEasy to applyRadiation pyrometryWithdrawing sample devicesPhotodetectorStatistical analysis

An NIR spectroscopy fluid analyzing system using a series of LED's, each having its own preselected center wavelength, as illumination sources. These wavelengths have overlapping spectral widths, such that the measurement covers a broad spectrum. The LED's illuminate the fluid sample sequentially, and subsequently the transmission absorbance through the sample and the reflectance or scattering from the sample is measured for the wavelength range of each LED. The measurements are performed using photodetectors. The concentrations of component parts of the fluid are expressed in the form of a polynomial, which is a function of the measured transmitted and / or reflected intensities, and of empirical coefficients, which are extracted by prior statistical analysis on measured intensities obtained from a large number of test samples having known concentrations of the component. A novel sample chamber, capable of performing optical absorption measurements on a flowing sample of fluid, is described.

Owner:AFIMILK AGRI COOP

Implement for milking animals, such as cows

This invention relates to an Apparatus for milking animals, such as cows, and comprising a milking machine with teat cups and sensors which govern the milking process, examine the milk obtained and the physical condition of the animal being milked. The apparatus also includes a processing unit such as a computer for processing signals received from the sensors. The signals from the sensors are wirelessly transmitted via a transmitter to the processing unit. The sensors may be incorporated in each teat cup or only one teat cup. Energy for the sensors is generated by movements of magnets in coils, which are incorporated in each teat cup or in at least one of the feed cups, the movements of the magnets being provided by vacuum pulsations on each teat cup or one of the teat cups, or from another energy sources such as solar cells.

Owner:LELY ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com