Patents

Literature

88results about How to "Fast attachment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic oil spraying device and method

ActiveCN103657941ARealize automatic separationPrevent rustLiquid surface applicatorsLiquid spraying apparatusControl systemElectromagnetic valve

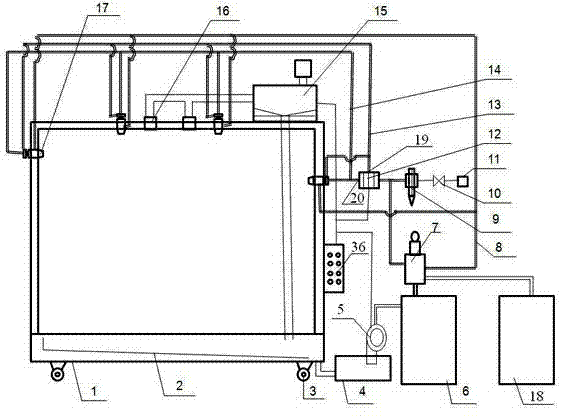

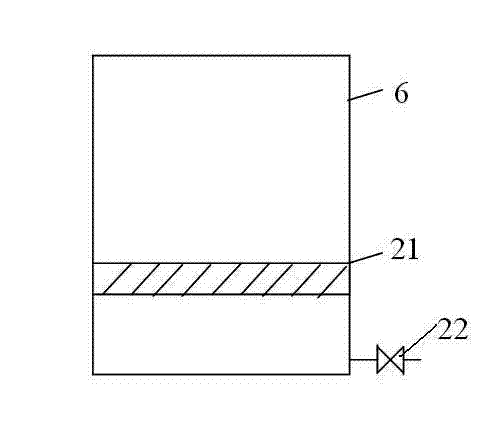

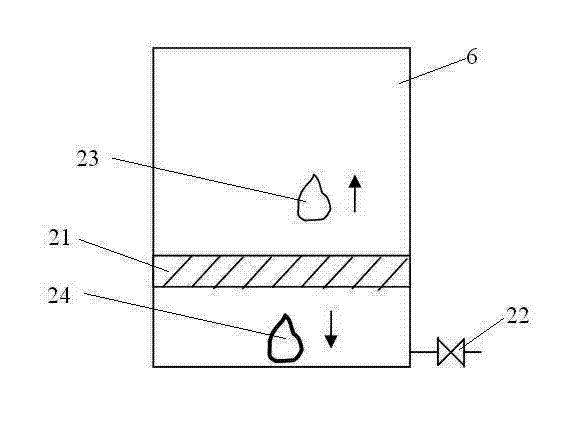

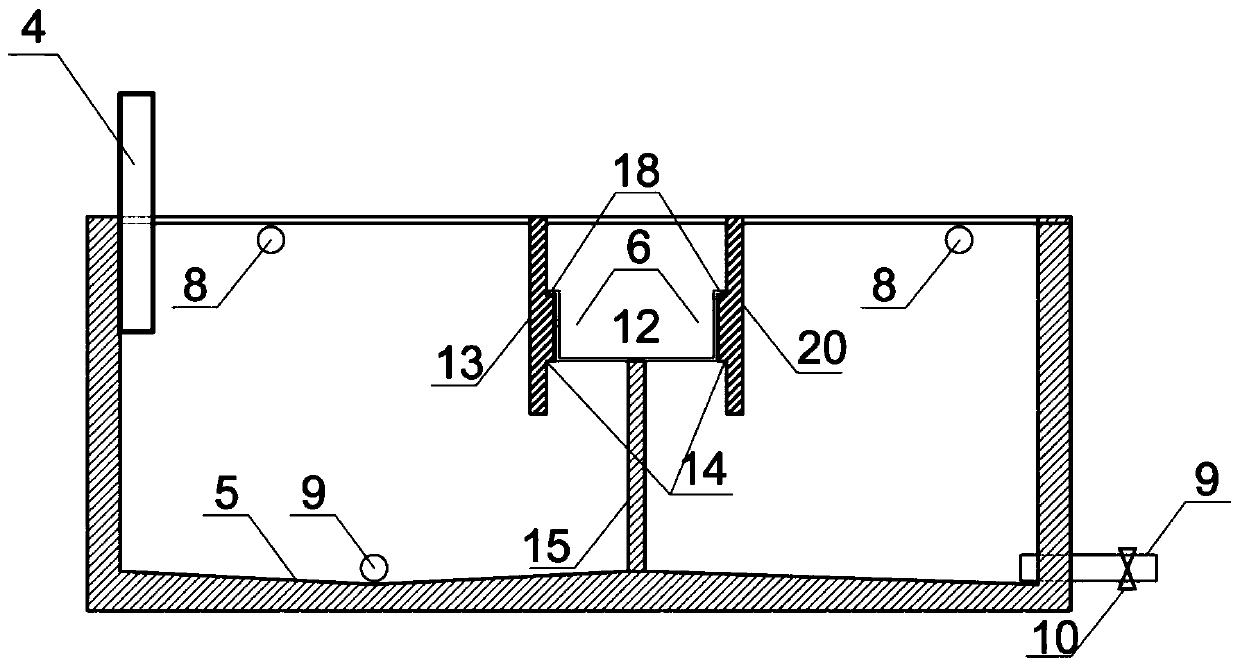

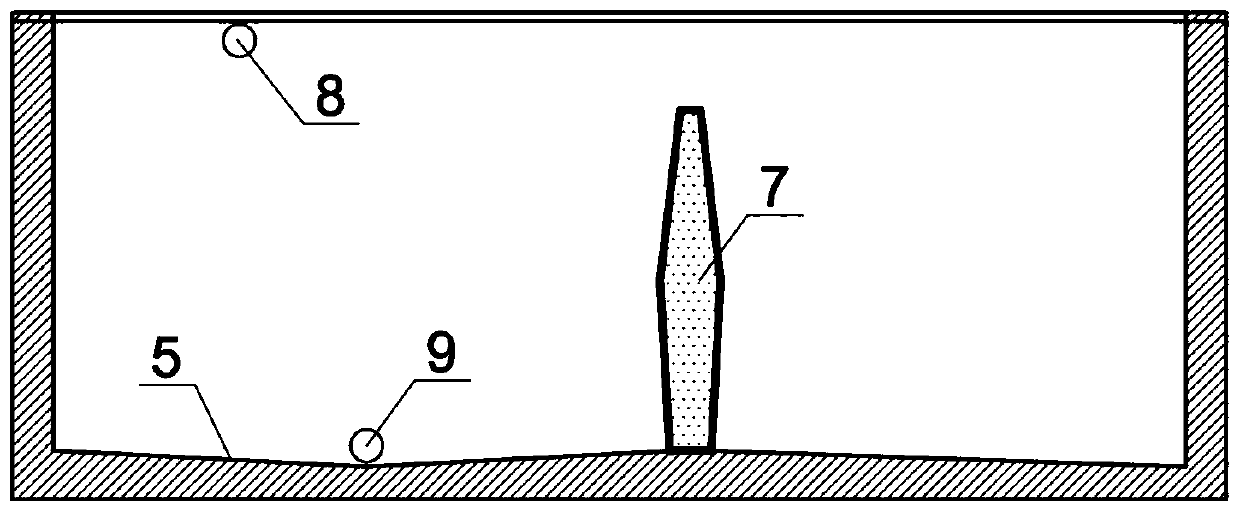

The invention discloses an automatic oil spraying device which comprises a closed oil spraying room, a fog spraying system, an oil recycling system and a control system. The fog spraying system comprises a main air source, a pressurizing mechanism, an oil drum, an electromagnetic valve and fog spraying valves, wherein the main air source is connected with the pressurizing mechanism, and the oil drum, the pressurizing mechanism and the fog spraying valves are sequentially connected through oil pipes. The electromagnetic valve comprises an air inlet, a first air outlet and a second air outlet, wherein the air inlet is connected with the main air source through a pipe, the first air outlet is connected with the fog spraying valves through a driving air source pipe, and the second air outlet is connected with the fog spraying valves through an atomization air source pipe. The driving air source pipe and the atomization air source pipe are provided with a first pressure adjustment mechanism and a second pressure adjustment mechanism respectively. The electromagnetic valve and the oil recycling system are respectively connected with the control system, and the oil recycling system is connected with the closed oil spraying room. The invention further discloses an automatic oil spraying method achieved through the automatic oil spraying device. By means of the automatic oil spraying device and the automatic oil spraying method, rapid and safe rust prevention processing on a large number of plates can be achieved, operation risks to persons are reduced, and waste oil can be recycled.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

Gypsum earth vegetation constructional materials and construction method thereof

The invention relates to a gypsum soil plant building material and construction method thereof, wherein the gypsum soil plant building material comprises two constituents of base material and straw seeds, and the base material mainly comprises gypsum, soil, coal ash, plant fiber, fertilizer, water-loss reducer and water.

Owner:CHONGQING UNIV

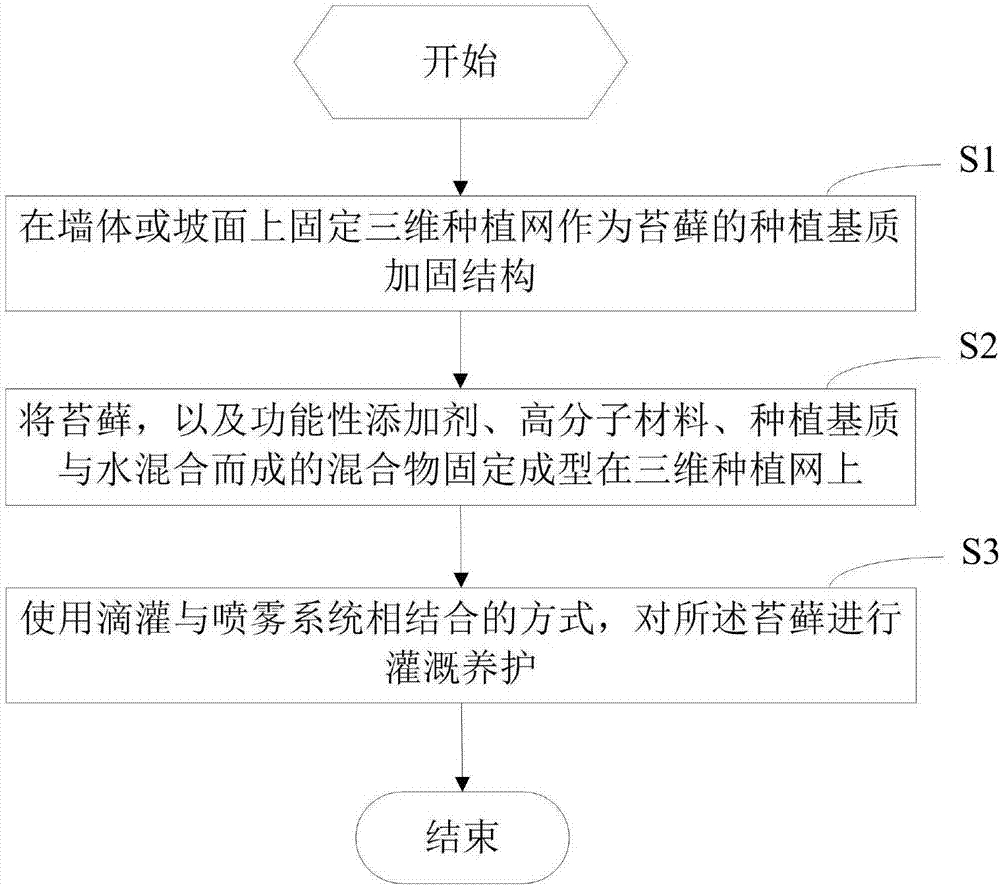

Moss stereoscopic greening process

InactiveCN107231959ALess prone to pestsFacilitate on-site construction workCultivating equipmentsHorticulture methodsGreeningHigh polymer

The invention provides a moss stereoscopic greening process. The process includes the steps that a three-dimensional planting net is fixed to a wall or slope to serve as a planting matrix reinforcing structure of moss; a mixture which has mechanical properties and is of a porous sponge structure is fixedly formed on the three-dimensional planting net, wherein the mixture is formed by mixing the moss, a functional additive, a high polymer material, a planting matrix and water; the moss is subjected to irrigation conservation in a drip irrigation and spray system combined mode. By means of the moss stereoscopic greening process, the moss can be rapidly attached to the wall or slope, and a good growth environment can be created for the moss.

Owner:深圳市道和生物海绵科技有限公司

Tin oxide modified carbon cloth base lithium and sodium metal negative electrode and preparation method thereof

InactiveCN108470882AIncrease the reaction areaIncrease contact areaNon-aqueous electrolyte accumulator electrodesCyclic processPorous carbon

The invention discloses a tin oxide modified carbon cloth base lithium and sodium metal negative electrode. The tin oxide modified carbon cloth base lithium and sodium metal negative electrode comprises carbon cloth used as a base, and tin oxide, lithium metal or sodium metal, wherein the mass ratio of carbon cloth to tin oxide to lithium metal is 1:0.048-0.065:1.2-1.8; the mass ratio of carbon cloth to tin oxide to sodium metal is 1:0.048-0.065:2.2-3.2; specifically, flexible porous carbon cloth is used as the support base; tin oxide is attached to the surface of the carbon cloth; and lithiumor sodium metal is adsorbed on the surface or holes of the tin oxide modified carbon cloth base. The invention also discloses a preparation method of the tin oxide modified carbon cloth based lithiumand sodium metal negative electrode. By virtue of the three-dimensional porous base, the reaction area of the battery negative electrode can be enlarged, and generation of dendritic crystal can be suppressed; the hole structure can be used for accommodating lithium or sodium deposition, and slowing down volume change of the lithium metal negative electrode or the sodium metal negative electrode in the charging-discharging cyclic process; and therefore, the voltage distribution curve can be more stable, and the negative electrode can be applied to a flexible energy storage device.

Owner:JIANGHAN UNIVERSITY

A liquid-state protective hands mask and preparation method thereof

ActiveCN1879593AReduce dosageDry fastCosmetic preparationsToilet preparationsOrganic solventAdjuvant

The invention relates to a liquid protection hand film and method for making same, wherein the raw material comprises the following constituents (by weight ratio): film-forming agent 10-15, film-forming adjuvant 8-14, emollient 1-4, auxiliary solvent 1-2, solvent 38-82, and preservative agent 0.01-0.05.

Owner:BEIJING XINLI MACHINERY

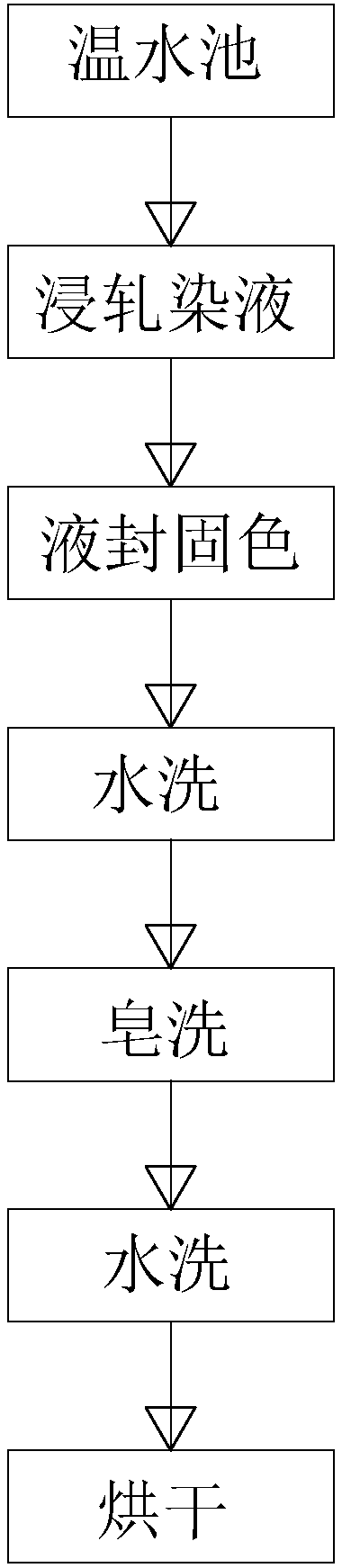

Vat dyes dyeing method of polyester cotton fiber cheese

The invention relates to a vat dyes dyeing method of polyester cotton fiber cheese, in particular relates to a dyeing method of the blend fiber cheese, and especially relates to a three-in-one dyeing method of blend fiber cheese, aiming at solving the problems that dyeing time is long, energy consumption is high, productivity is lower, more sewage is discharged, etc in the traditional dyeing method of the blend fiber cheese. The method comprises the steps of loosening yarns, dyeing and carrying out postprocessing, and is characterized in that in the step of loosening yarns, a digital winding way is adopted, and drum loosing is carried out on the blend fiber yarn; the dyeing comprises the steps of adding disperse dye, mixed alkali and an oxidizing agent at the room temperature; heating and carrying out heat preservation twice, and directly cooling the mixture; then, adding active dye and anhydrous sodium sulphate into the mixture, carrying out heat preservation, and directly discharging residual liquid; putting the product into water, heating and carrying out heat preservation, and then discharging; adding a certain weight of soaping agent for soaping, carrying out heat preservation, and then discharging; adding clear water and washing one time; softening and discharging; carrying out dehydration; drying by a variable frequency dryer; separating a drum for warping, or spooling to obtain the finished yarn product. After the three-in-one dyeing method is adopted, the dyeing process of the blend fiber cheese is greatly reduced, and the dyeing time and the dyeing process are greatly shortened.

Owner:ZHEJIANG SAINTYEAR TEXTILE

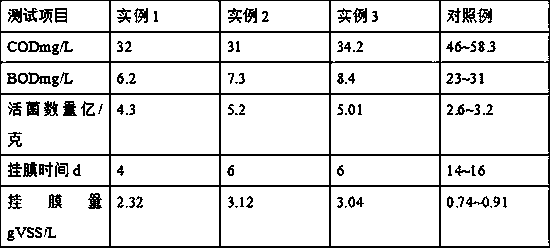

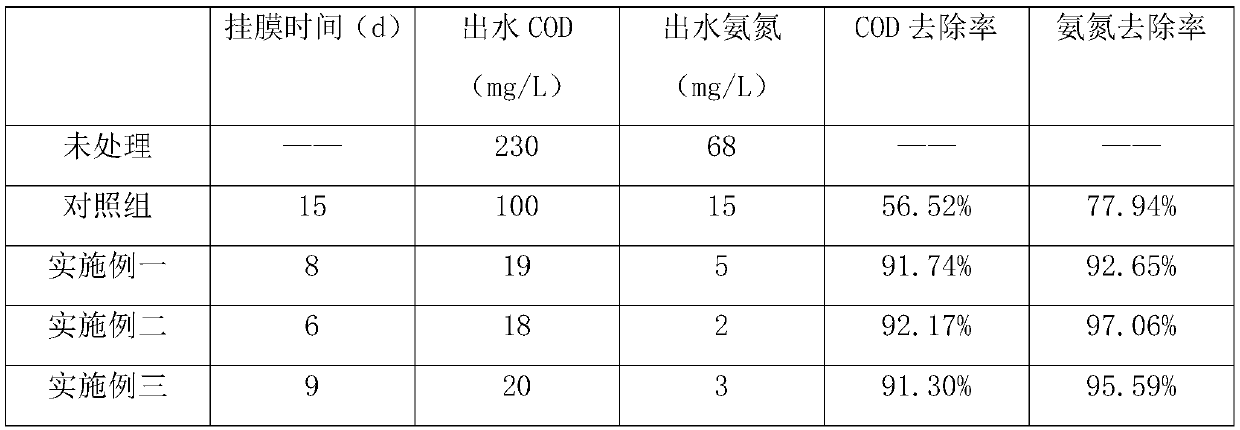

Preparation method of loofah sponge bio-filler for wastewater treatment

InactiveCN107686161ANon-toxicFast attachmentBiological water/sewage treatmentWastewaterSewage treatment

The invention discloses a preparation method of a loofah sponge bio-filler for wastewater treatment and belongs to the field of water treatment. Loofah sponge is used as a raw material having good mass transfer performance; the loofah sponge can be combined with a macromolecular material to facilitate quick attachment of microbes; microbial membrane carrier material is subjected to loading modification, and the novel filler is prepared by grafting a photocatalyst to the loofah sponge; the carrier function of the filler is enhanced; the bio-filler having high film-forming speed and high bioactivity is formed. A catalyzing enzyme is extracted from Penicillium simplicissimum; the catalyzing enzyme can be combined with a biological material to provide microbes with mass surface area suitable for rest and beneficial environments, the quantity of microbes in a bioreactor is quickly increased, and wastewater treatment efficiency is improved. The problem is solved that existing bio-fillers areunable to retain bioactivity and provide quick and effective enrichment of microbes due to the absence of affinity with microbes during wastewater treatment.

Owner:张芸

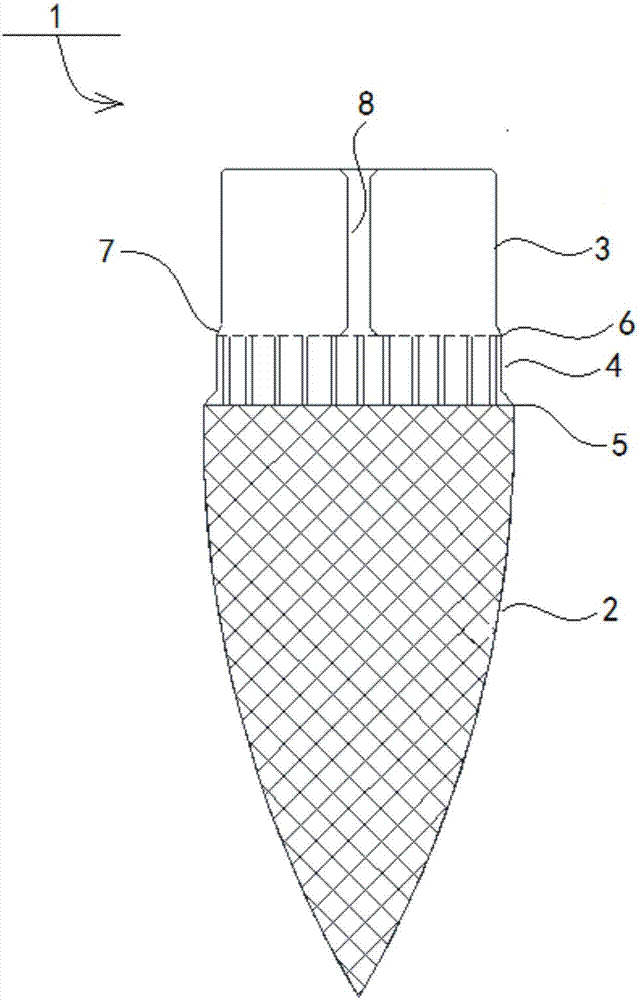

3D (three-dimensional) printing bionic dental implant and manufacturing method thereof

InactiveCN107260342AOvercoming difficulties in initial wound closureOvercome stabilityDental implantsAdditive manufacturing apparatusTooth neckDrug biological activity

The invention provides a 3D (three-dimensional) printing bionic dental implant and a manufacturing method thereof and belongs to the field of dental implants. Easy loosing and falling of an implant caused by relatively large difference between the elasticity modulus of the implant and the elasticity modulus of sclerotin can be avoided by the dental implant, the biological activity is relatively strong, and bone healing time can be greatly shortened. The 3D printing bionic dental implant comprises an implant body and also comprises a chitosan nanometer coating which is combined with the outer surface of the implant body into a whole. The implant body comprises a tooth neck base station and a tooth root which is positioned below the tooth neck base station and is integrally connected with the tooth neck base station, wherein the tooth root is of an all-layer three-dimensional network structure. The 3D printing bionic dental implant provided by the invention can be applied to immediate implantation of the dental implant.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

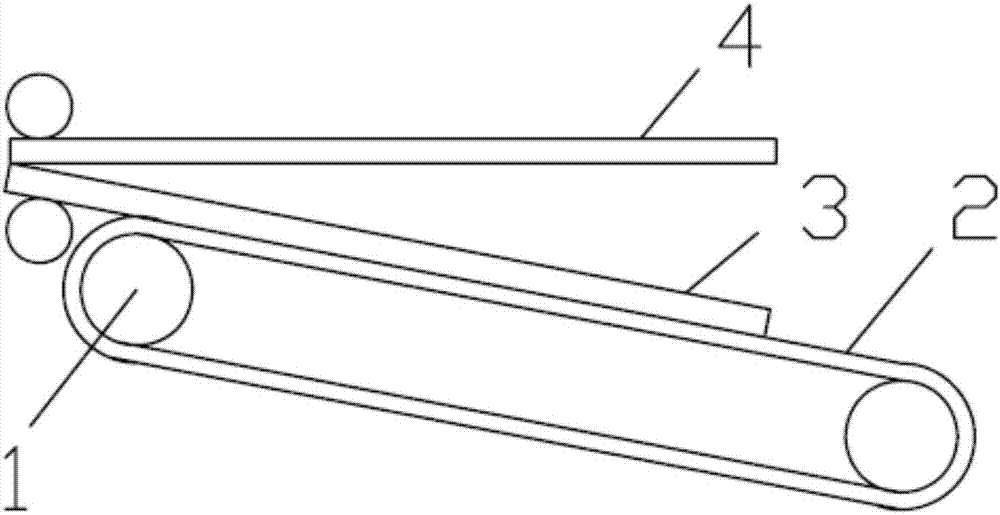

Dyeing process of suit fabric

ActiveCN110373845AFast attachmentFast dryingSucessive textile treatmentsSevering textilesYarnEngineering

The invention discloses a dyeing process of suit fabric. The dyeing process comprises steps as follows: cleaning of the suit fabric, burr removal, dyeing and drying and winding. A cutting blade is used for cutting two sides of the suit fabric to remove burrs, and the quality of the dyed suit fabric is guaranteed; a movable roller is arranged on the suit fabric to press the suit fabric, so that thesuit fabric is kept in a tensioned state during dyeing, yarn of the suit fabric is in an open state to facilitate penetration of dye, and the dyeing effect is improved; an electric hot plate heats the dye in a dye tank, control of temperature of the dye is facilitated, the best dyeing temperature is mastered, and the dyeing effect is guaranteed; the suit fabric passes below a drying mechanism, anair knife above the suit fabric dries the dyed suit fabric, the drying speed is high, the dye can quickly adhere to the suit fabric, and the working efficiency is high.

Owner:安徽弋尚纺织科技有限公司

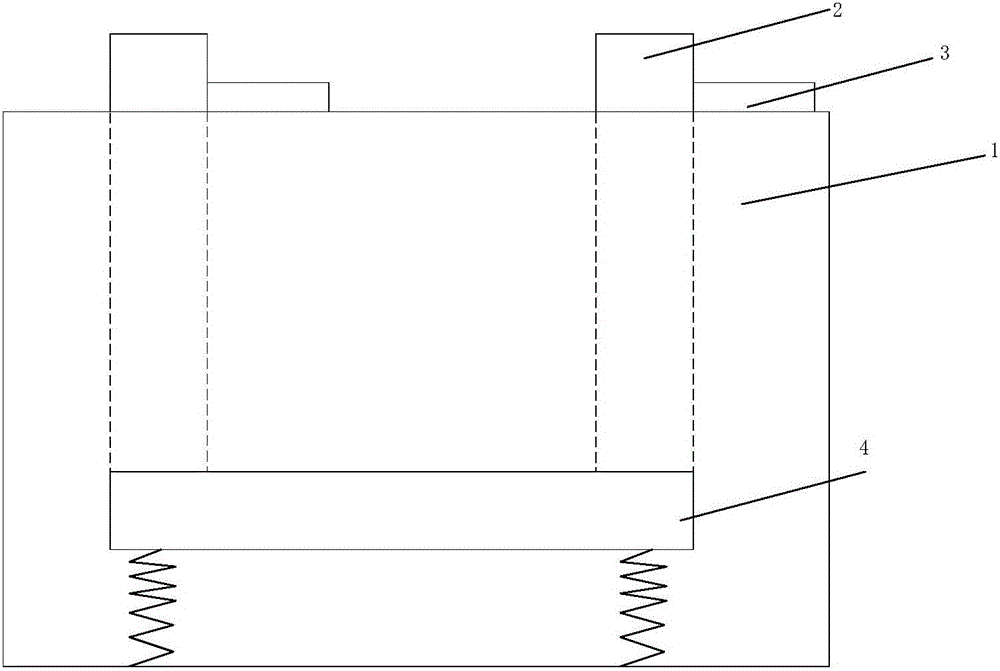

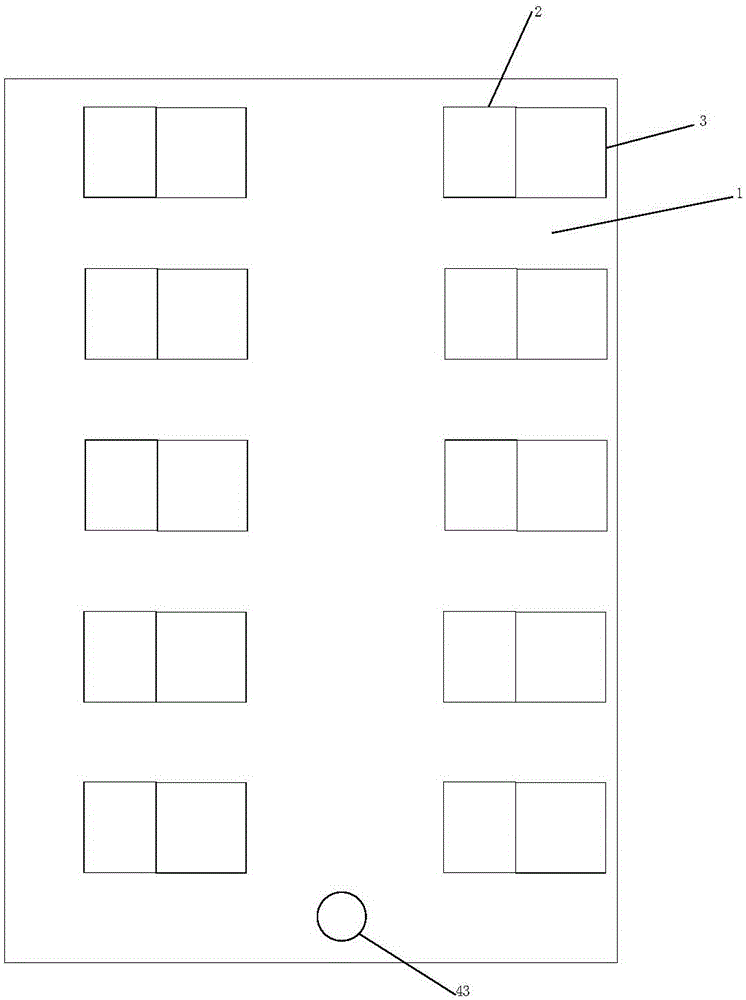

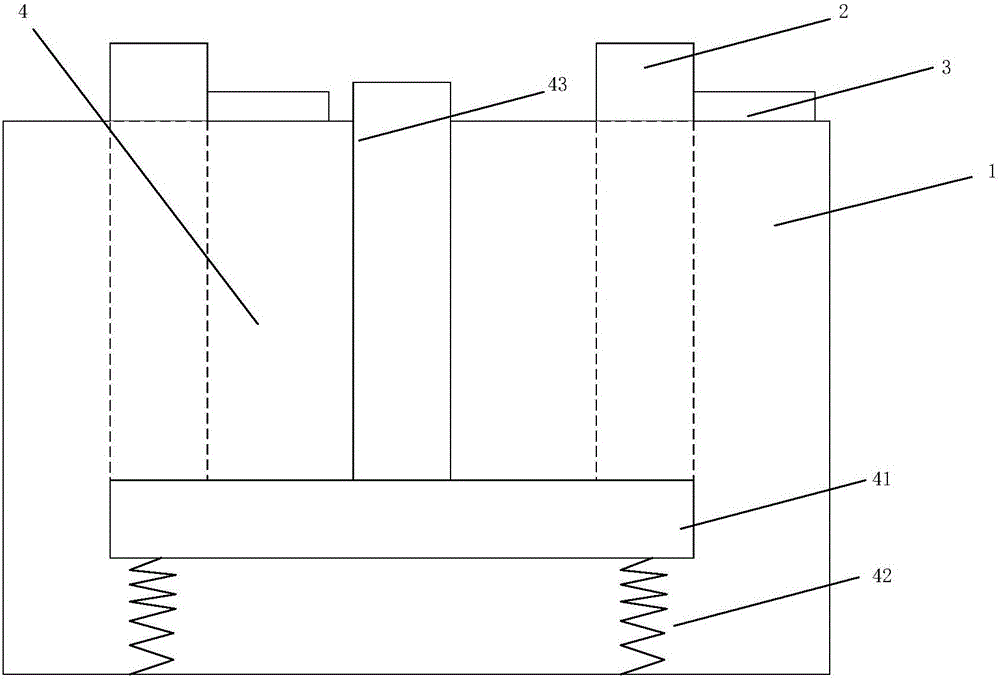

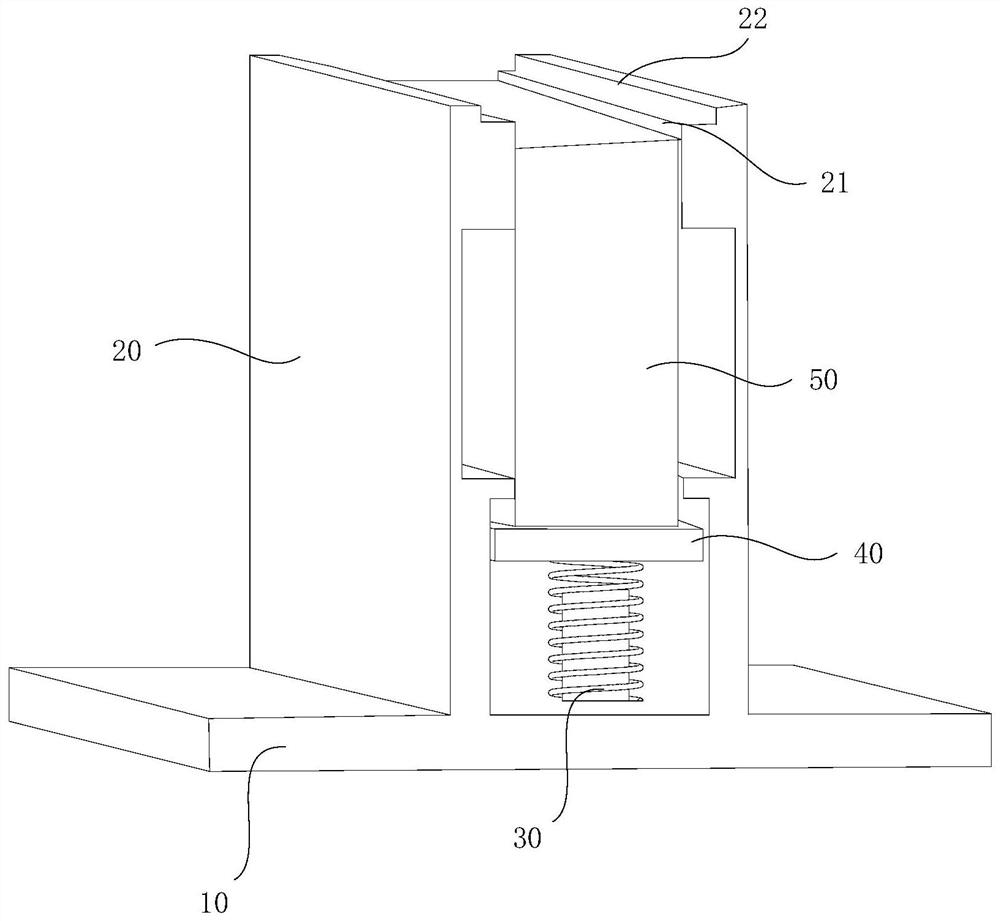

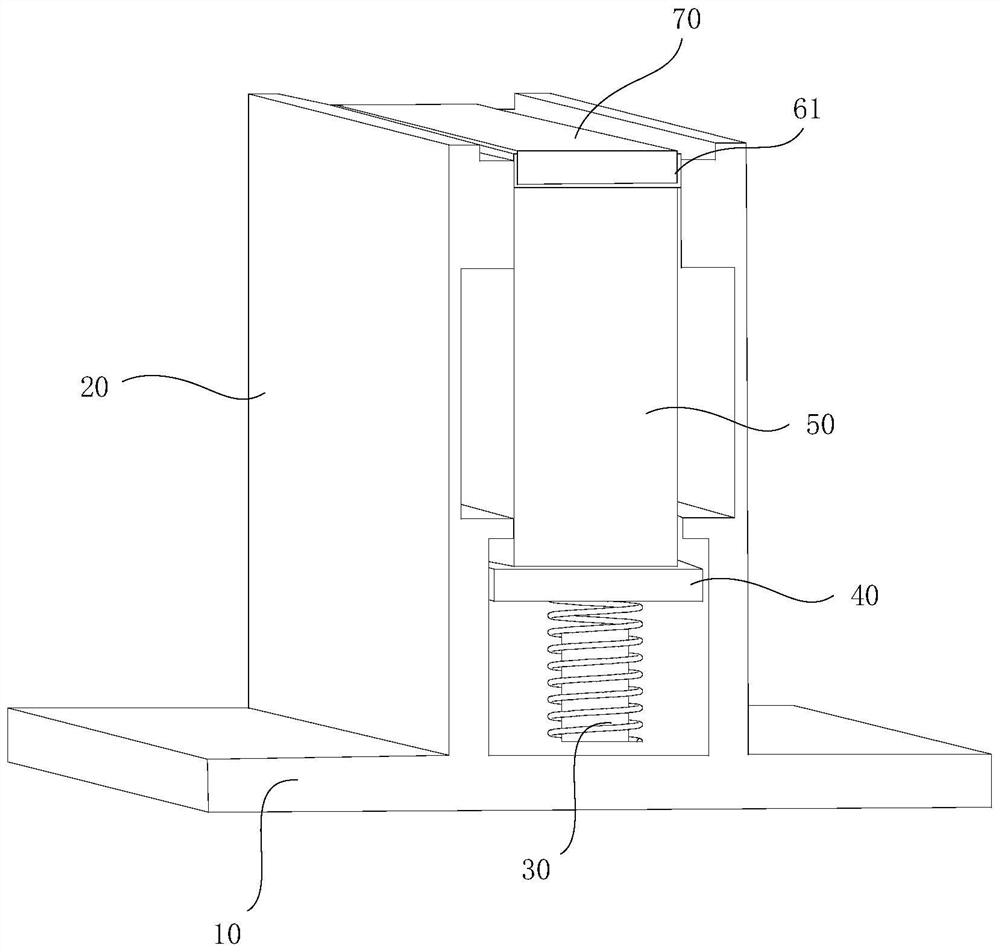

Anisotropic conductive adhesive attachment carrier device and anisotropic conductive adhesive attachment method

ActiveCN105093586ASolve the alignment accuracyFast attachmentNon-linear opticsAnisotropic conductive adhesiveFlexible circuits

The invention discloses an anisotropic conductive adhesive attachment carrier device and an anisotropic conductive adhesive attachment method. The device comprises a carrier body. A plurality of areas where flexible circuit boards are to be placed are arranged on the carrier body. At least one lifting baffle corresponding to the areas where flexible circuit boards are to be placed is arranged on the carrier body. The lifting baffles are flush with the set edges of the areas where flexible circuit boards are to be placed. The lifting baffles extend out of the upper surface of the carrier body before the flexible circuit boards are aligned. The lifting baffles retract to the upper surface of the carrier body after the flexible circuit boards are aligned. The lifting baffles are designed on a vacuum adsorption carrier, the FPCs can be directly supported by the lateral sides of the baffles to be aligned without being corrected through human eyes for a long time, the problem of the alignment accuracy of AFC can be effectively solved, and the overall ACF attachment speed can be effectively increased. The anisotropic conductive adhesive attachment carrier device and the anisotropic conductive adhesive attachment method are simple, practical, easy to operate, and capable of reducing raw material waste and saving cost.

Owner:BOE TECH GRP CO LTD +1

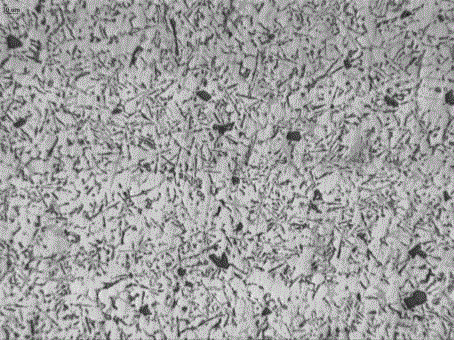

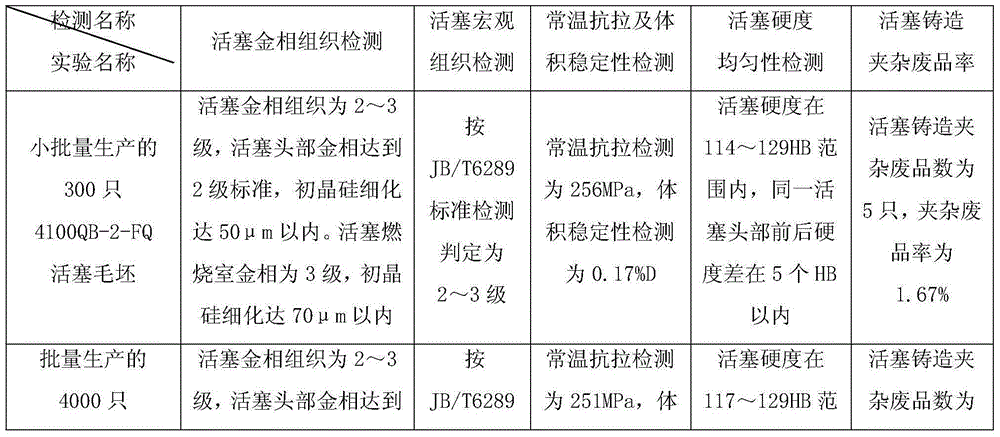

Method for casting high-quality aluminum part through chips of aluminum-silicon pistons

The invention discloses a method for casting a high-quality aluminum part through chips of aluminum-silicon pistons. The method includes the following steps that firstly, embracing and fusion are performed, wherein the machined chips of the aluminum-silicon pistons are recycled, dried and magnetically separated and are then added to a natural gas reverberatory furnace so as to be embraced and fused; secondly, high-temperature standing is performed, wherein the temperature of the natural gas reverberatory furnace is increased to 850 DEG C to 930 DEG C and kept for 50 min to 90 min, and molten aluminum is generated; thirdly, component detection is performed, wherein after slag of the molten aluminum is filtered out, magnesium is pressed to the bottom of the molten aluminum, after the molten aluminum stands still for 5 min to 9 min, a sample is obtained and analyzed, and the molten aluminum is adjusted till the content of each component in the molten aluminum meets the requirement; fourthly, refining and metamorphism are performed, wherein refining is performed before metamorphism; and fifthly, the aluminum part is cast, wherein when the temperature of the refined and metamorphosed molten aluminum ranges from 750 DEG C to 790 DEG C, the molten aluminum is treated through a degassing machine, stands still and is cast into the aluminum part. By the adoption of the method, complex equipment does not need to be invested, operation is easy, secondary aluminum burning losses can be reduced, energy is saved, consumption is reduced, the casting cost of the aluminum part is reduced, the waste aluminum chips are recycled, and the method is suitable for industrial large-scale production.

Owner:CHENGDU GALAXY POWER CO LTD

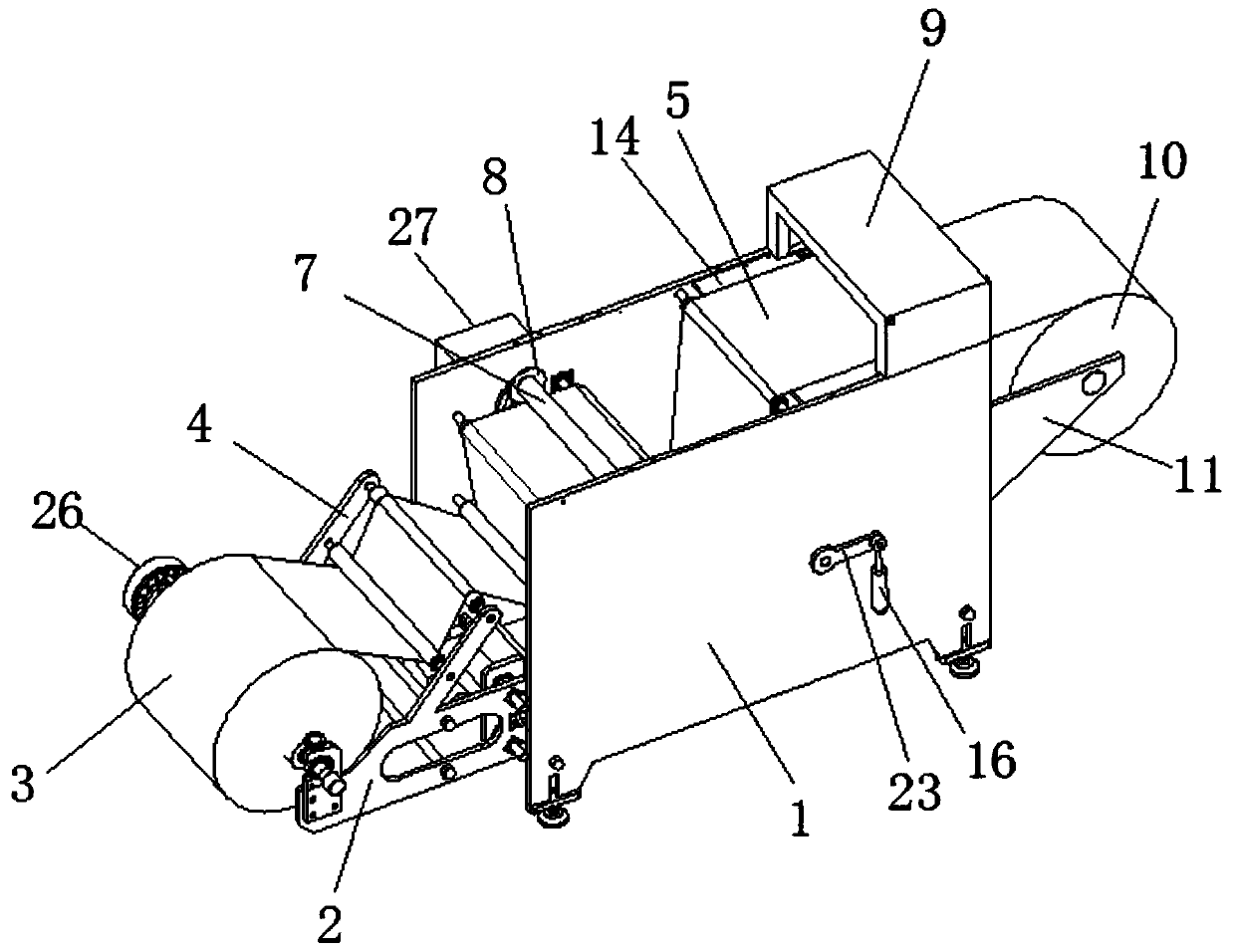

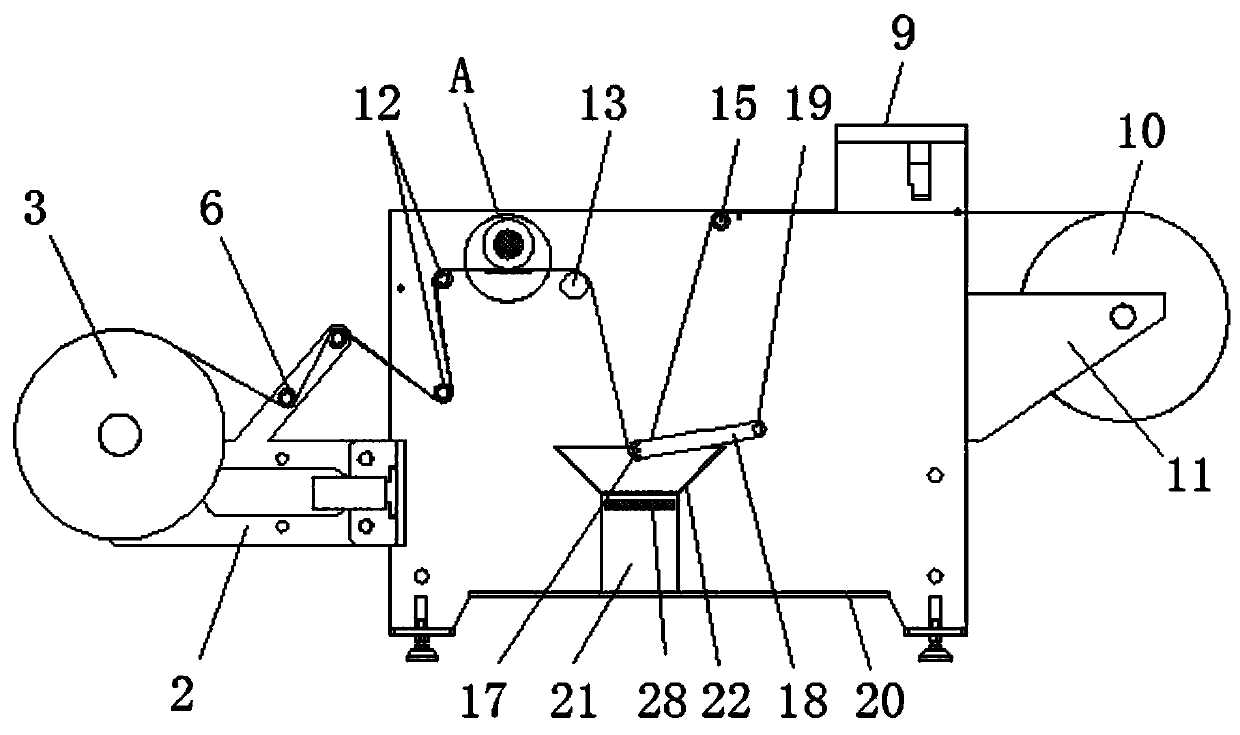

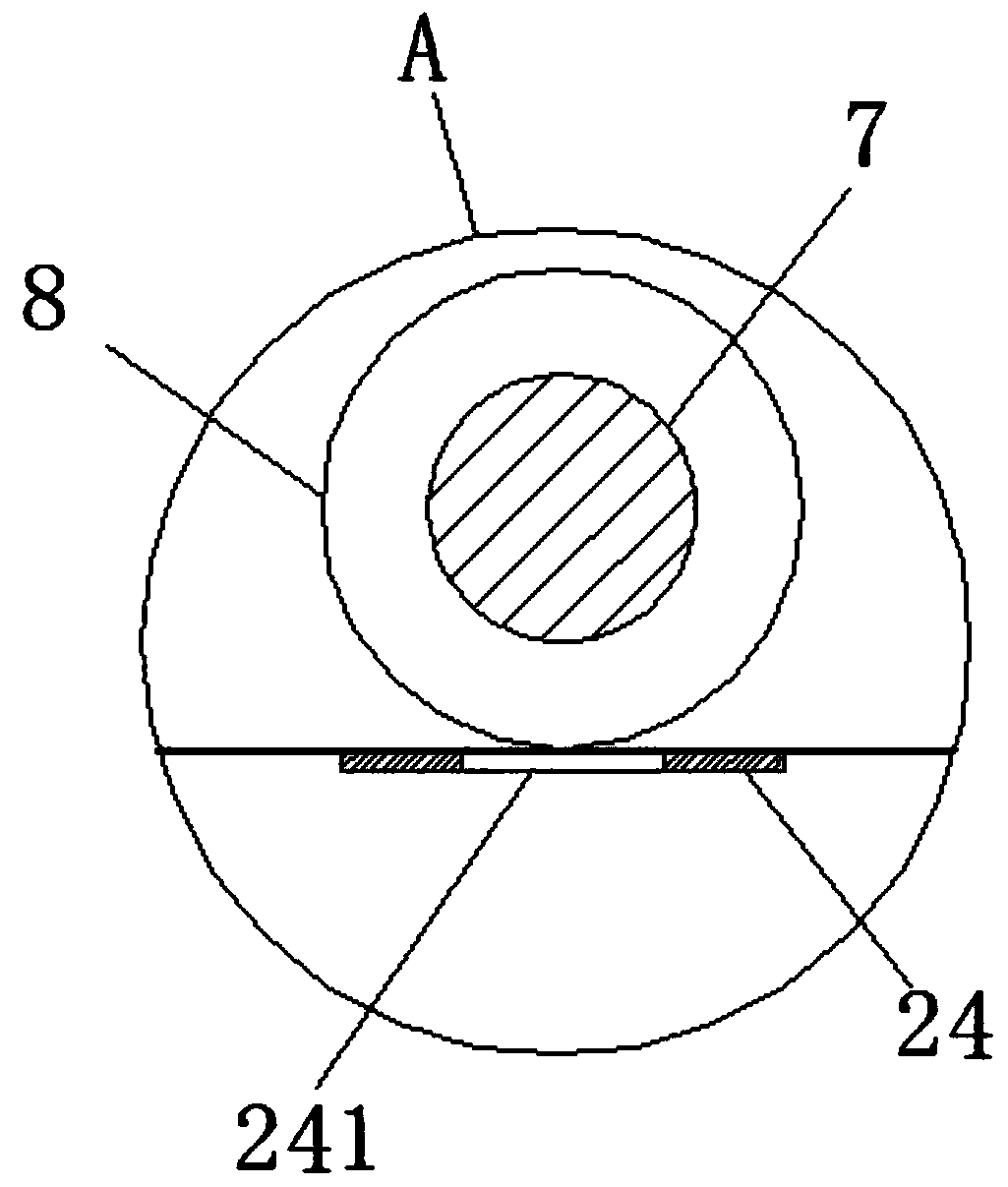

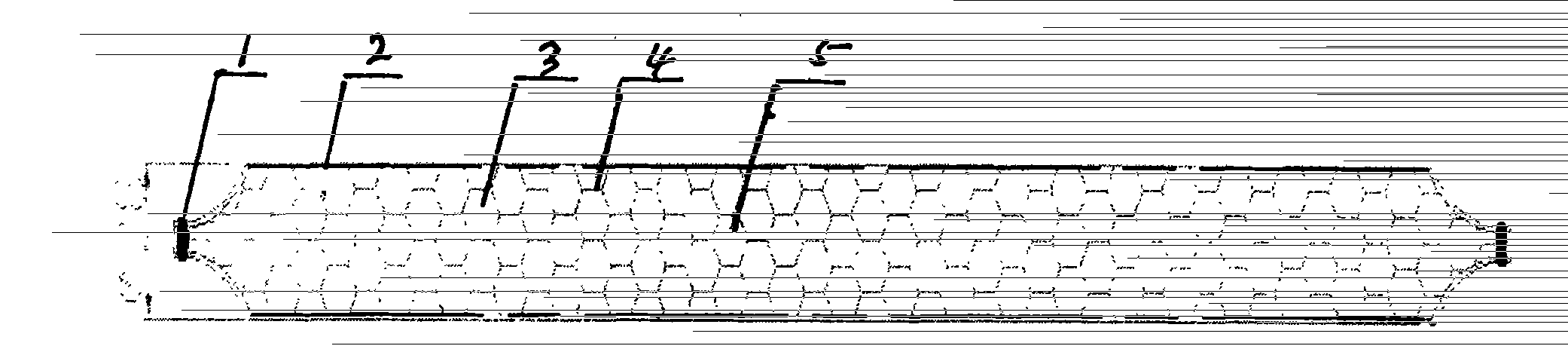

Novel quick blasthole sealant

The invention discloses a novel quick blasthole sealant, which solves the problems of long breeching time, high unexploded charge rate and big trouble in processing the unexploded charge of the traditional clay stemming. The novel quick blasthole sealant is characterized in that composite membrane materials are adopted; a cylindrical blasthole sealing shell 2 of which the diameter is 28mm and the length is 400mm is arranged; a fire retardant 3, a dust suppressant 4 and a binder 5 are filled into the cylindrical blasthole sealing shell 2; and two ends of the cylindrical blasthole sealing shell 2 are sealed by aluminum clip materials to form cones 2. The novel quick blasthole sealant has the advantages that gun dust after blasting is effectively lowered, the gun dust is quickly adhered, the construction time is shortened, the construction efficiency is improved, the open fire is inhibited, and the gas accident is reduced. The novel quick blasthole sealant is suitable for underground mining blasthole sealing.

Owner:YANGQUAN MINING CHEM

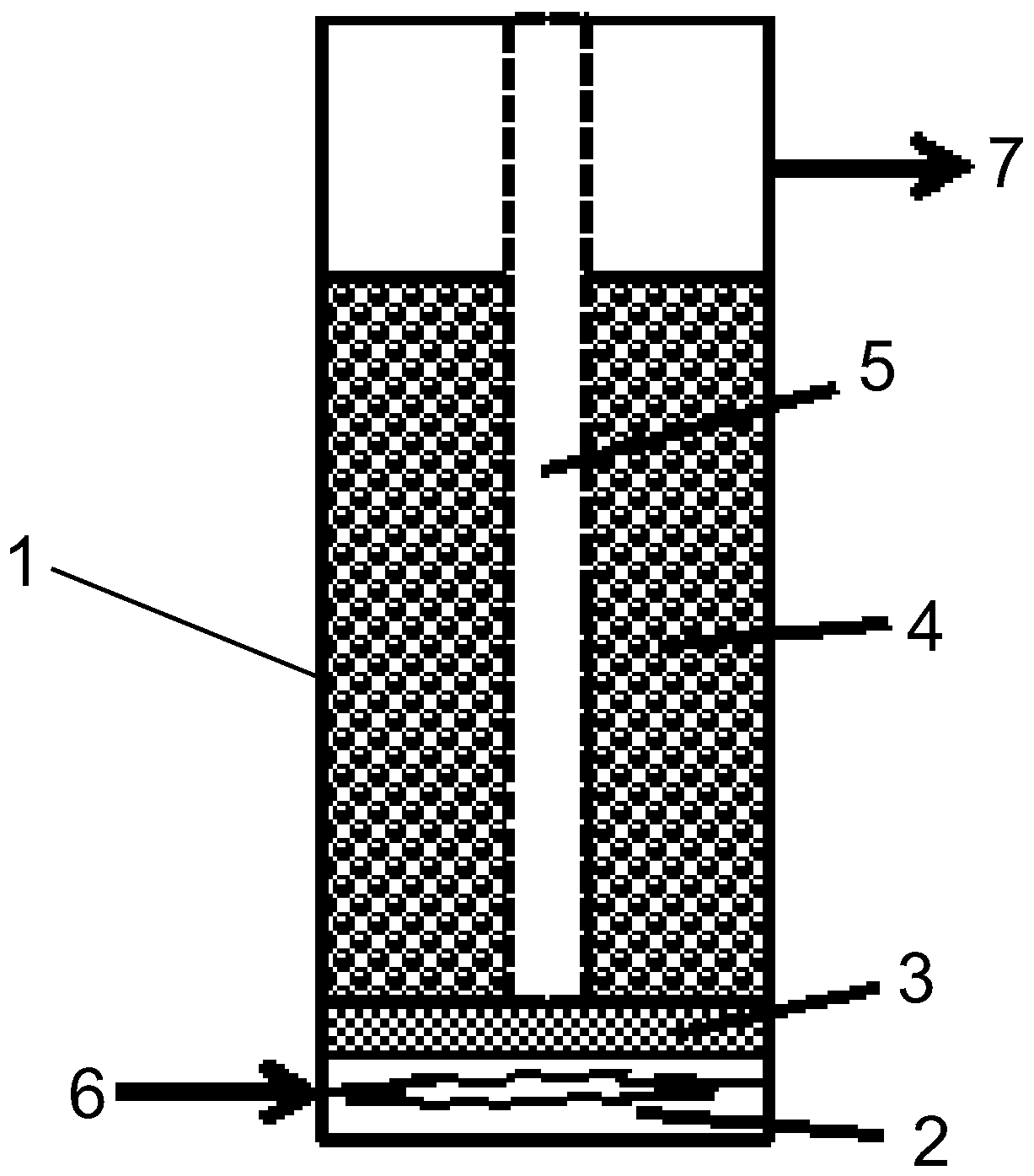

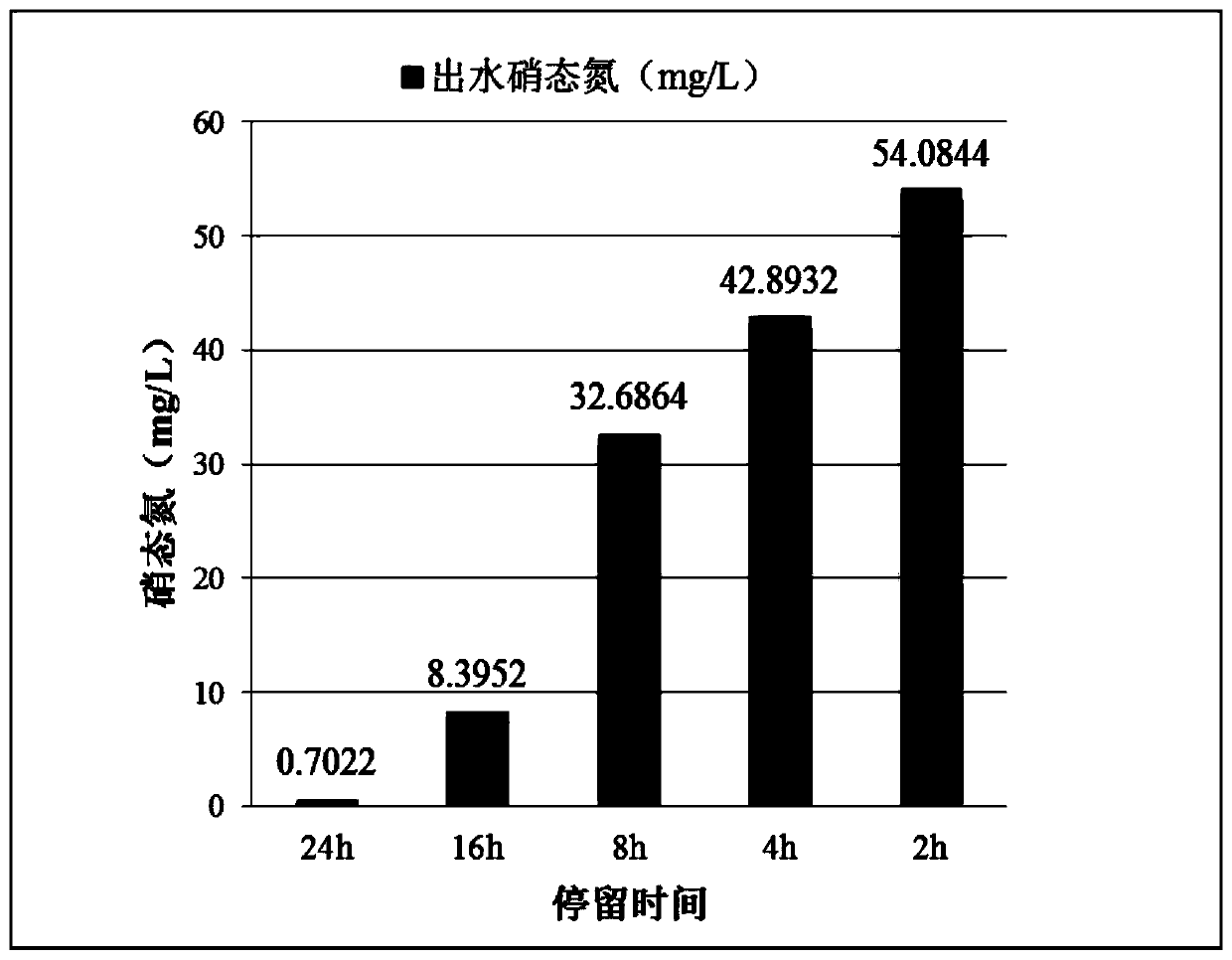

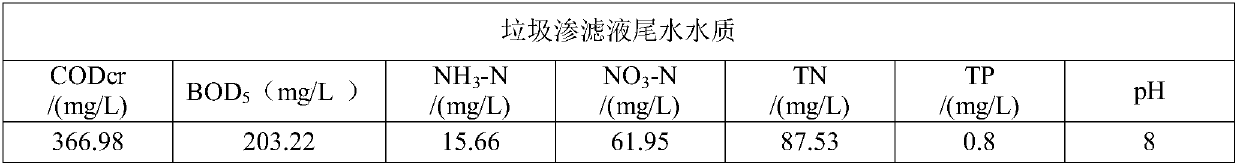

Rapid biological denitrification method for biochemical effluent of landfill leachate

ActiveCN110357271AActivate denitrification activityFast attachmentWater treatment parameter controlWater treatment compoundsDenitrifying bacteriaBacillus pumilus

The invention discloses a rapid biological denitrification method for biochemical effluent of landfill leachate, belonging to the field of water treatment. The rapid biological denitrification methodcomprises the following steps: 1) selecting Bacillus pumilus AD 0599 as a denitrifying strain; 2) subjecting the denitrifying strain to multiplication culture obtain bacteria, and mixing the obtainedbacteria with anaerobic sludge at the biochemical front end of the landfill leachate to obtain a seed strain; 3) placing the seed strain at the bottom of a denitrification filter, loading granular activated carbon, and introducing activated wastewater into the denitrification filter for activation; and 4) stopping the introduction of the activated wastewater, adding a carbon source, and then introducing the landfill leachate for denitrification. The method of the invention can directly perform rapid biological denitrification on the low-carbon-nitrogen-ratio biochemical effluent of the landfill leachate. The Bacillus pumilus is selected and used, and nitrate nitrogen in the biochemical effluent can be quickly denitrified and removed by adding only a small amount of the carbon source; at the same time, the CODcr of the effluent can be further reduced, so pressure on subsequent membrane separation can be alleviated.

Owner:HANGZHOU XIUCHUAN TECH CO LTD

Dyeing wet steaming process

The invention discloses a dyeing wet steaming process, some unnecessary processing steps in the traditional process can be reduced by the dyeing wet steaming process, the dyeing wet steaming process reduces energy consumption and pollution, improves the production efficiency of a fabric and reduces the use of labor; through control of temperature of the dyeing wet steaming process and addition ofadditives, the quality of the produced fabric can be ensured.

Owner:SHAOXING FEIYA DYEINGANDPRINTING CO LTD

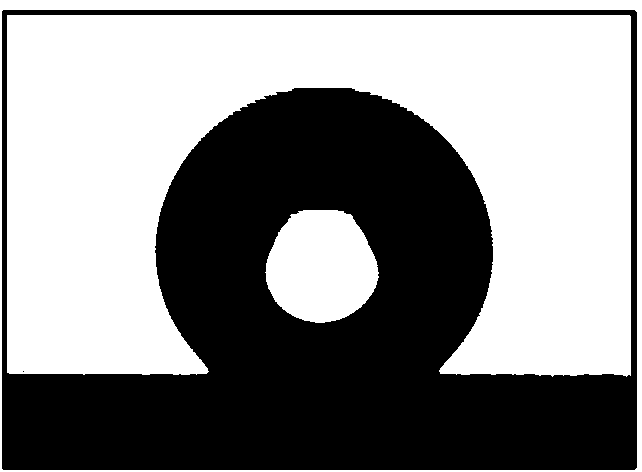

Sterilization method for improving synostosis of SLA implant

ActiveCN104353092ATo achieve the purpose of sterilizationImprove wettabilityHeatDrug biological activityBone cell

The invention discloses a sterilization method for improving synostosis of an SLA implant. The sterilization method comprises the following steps: putting the SLA implant into a sealed container, adding water or an aqueous solution serving as a sterilization medium, enabling the water or the aqueous solution to immerse the implant, packaging an aluminum foil on the surface of a cover when the cover of the container is approximately sealed, then putting the container in a pressure steam sterilization device for sterilization, sealing the cover of the container in the pressure steam sterilization device after the sterilization, and taking out the container. The sterilization method has the advantages that the purpose of sterilizing the SLA implant is fulfilled, the wettability of the implant is improved, the mutual action of the implant material and a cell is improved, then the bone cell is more rapidly adhered, spread, propagated, proliferated and differentiated on the surface of the implant, so that the surface energy and the biological activity of the SLA implant are improved, and the bonding strength between the implant and the natural bone is improved. Meanwhile, the method is simple to operate, conventional sterilizing installation is used, the processing cycle is short, and the method is suitable for clinical application.

Owner:JIANGSU UNIV OF SCI & TECH

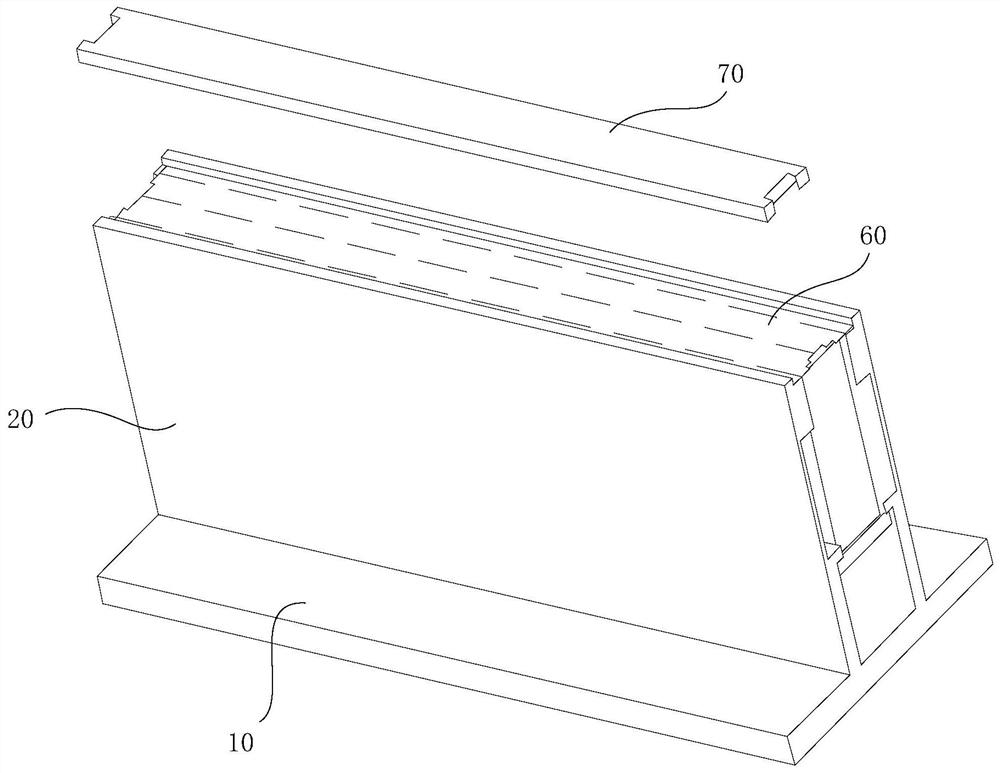

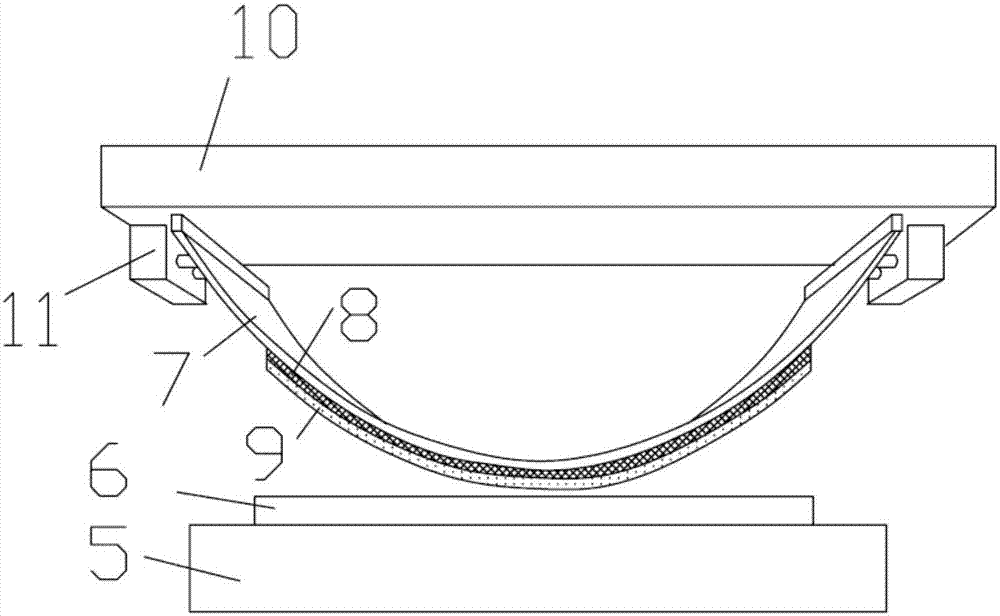

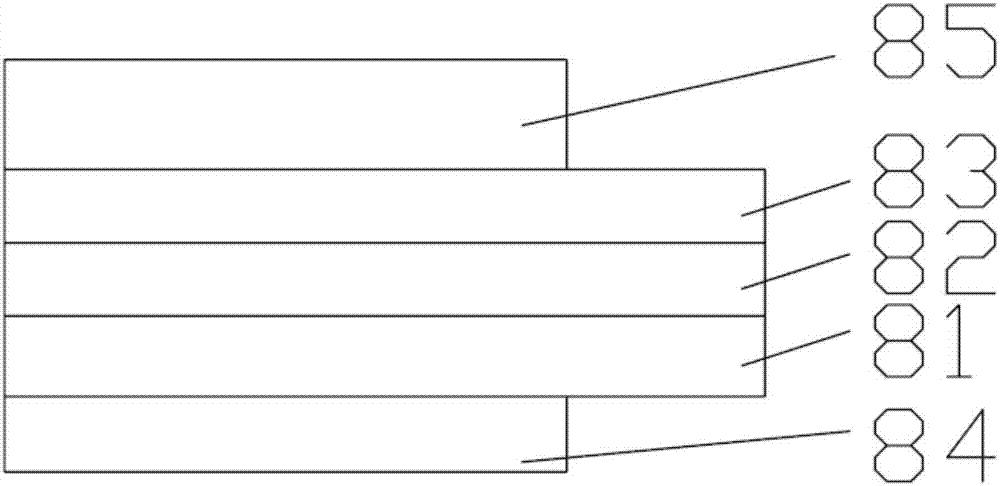

Attaching jig and attaching method for light guide plate and reflector plate, and backlight module

PendingCN112505822AGuaranteed full attachmentImprove reliabilityOptical light guidesLight guideEngineering

The invention discloses an attaching jig and an attaching method for a light guide plate and a reflector plate, and a backlight module. The attaching jig comprises a jig body, the jig body is providedwith a forming part and a supporting part, the supporting part is arranged above the forming part, the size of the supporting part is larger than that of the forming part, the size of the forming part is matched with that of a light guide plate, and the size of the supporting part is matched with the size of a preformed reflector plate. When the light guide plate and the preformed reflector plateare stacked on the supporting part, the light guide plate and the preformed reflector plate are pressed to the forming part from the supporting part by pressing the light guide plate or the preformedreflector plate, and the preformed reflector plate is formed into a formed reflector plate and attached to the light guide plate. The attaching jig is adopted for attaching the light guide plate andthe reflector plate, accurate attaching can be achieved, it is guaranteed that the light guide plate and the reflector plate are completely attached, the reliability of the backlight module is improved, the attaching speed is high, the production efficiency is improved, and manpower waste is reduced.

Owner:深圳市隆利光电科技发展有限公司

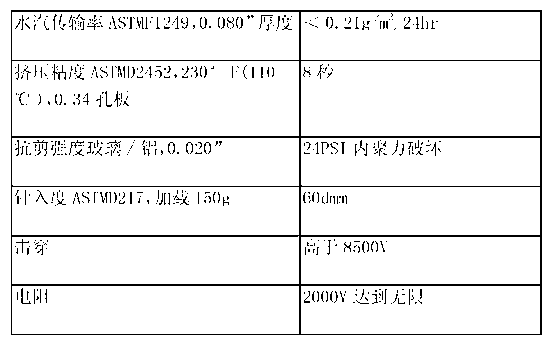

Solar energy photovoltaic component seal gum and synthesis method thereof

ActiveCN101735745BEasy to operateIncrease productivityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesWeather resistanceSolar lamp

The invention relates to a seal gum, in particular to a seal gum for binding and sealing a solar energy photovoltaic component or a solar lamp. The invention provides an improvement of a solar energy photovoltaic component seal gum. The seal gum is characterized by good sealing performance, fast curing speed, high weather resistance and convenient operation. The other aim of the invention is to provide a synthesis method of the solar energy photovoltaic component seal gum. The synthesis method is characterized by simple technological process and high yield. The technical scheme provided by the invention is that the solar energy photovoltaic component seal gum is characterized in that the seal gum is prepared from the following raw materials by weight percent: 50-75% of polyisobutylene, 10-30% of light calcium carbonate, 5-10% of heavy calcium carbonate, 2-5% of C5 resin, 5-10% of butyl rubber and 0.1-0.3% of antioxidant.

Owner:ZHEJIANG SHUNDA NEW MATERIAL

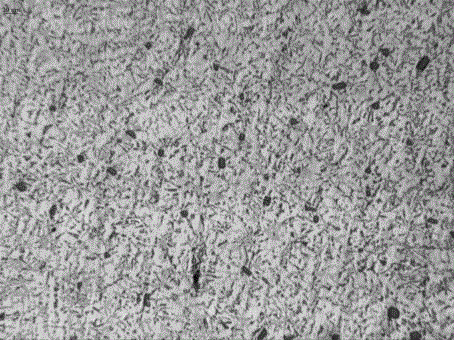

Nitrogen removal and phosphorus removal active biological carrier for sewage treatment, and preparation method thereof

ActiveCN110407332AHigh activityReduce releaseWater contaminantsBiological treatment apparatusMicrosphereNitrogen gas

The invention relates to the technical field of sewage treatment, particularly to a nitrogen removal and phosphorus removal active biological carrier for sewage treatment, and a preparation method thereof, wherein the biological carrier comprises the following raw materials by weight: 65-75 parts of high-density polyethylene, 0.08-0.12 part of polyhydroxyl fatty amide, 0.5-0.9 part of compound enzyme, 5-15 parts of iron rust, 20-30 parts of modified Retinervus Luffae Fructus, and 8-12 parts of shell powder / zinc oxide hollow microspheres, wherein the preparation method of the shell powder / zincoxide hollow microspheres comprises: carrying out a microwave reaction on calcined shell powder and a metal zinc salt in a nitrogen atmosphere, spraying the obtained material into liquid nitrogen, andsolidifying. According to the present invention, the nitrogen removal and phosphorus removal effect is enhanced by using the modified Retinervus Luffae Fructus and the shell powder / zinc oxide hollowmicrospheres, and the surface is subjected to plasma treatment and immersion hydrophilic treatment, such that the product has characteristics of rapid film forming, good hydrophilicity, high biological activity and long service life.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

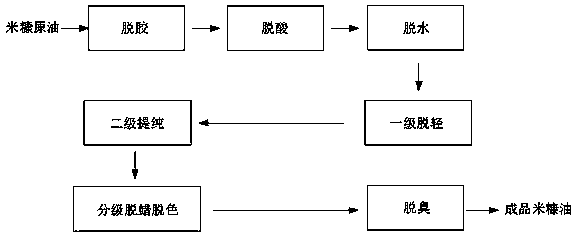

Rice bran oil refining method

ActiveCN109161438AFast attachmentIncrease contentFatty-oils/fats refiningFatty substance recoveryDistillationRice Bran Extract

The invention discloses a rice bran oil refining method. The method comprises the steps for processing of rice bran crude oil as follows: pretreatment and graded dewaxing and deodorization to obtain finished rice bran oil. Compared with the prior art, the process comprises the multistage dewaxing and decolorization steps, the content of octacosanol reserved in the rice bran oil product can be significantly increased, and the refining efficiency and the product quality can be improved. Besides, light components are removed with a molecular distillation technology, purification is performed through high-pressure steam, impurities in the rice bran crude oil are removed more sufficiently, and the refining degree and the quality of the rice bran oil product are improved.

Owner:SHANDONG SANXING CORN IND SCI CO LTD

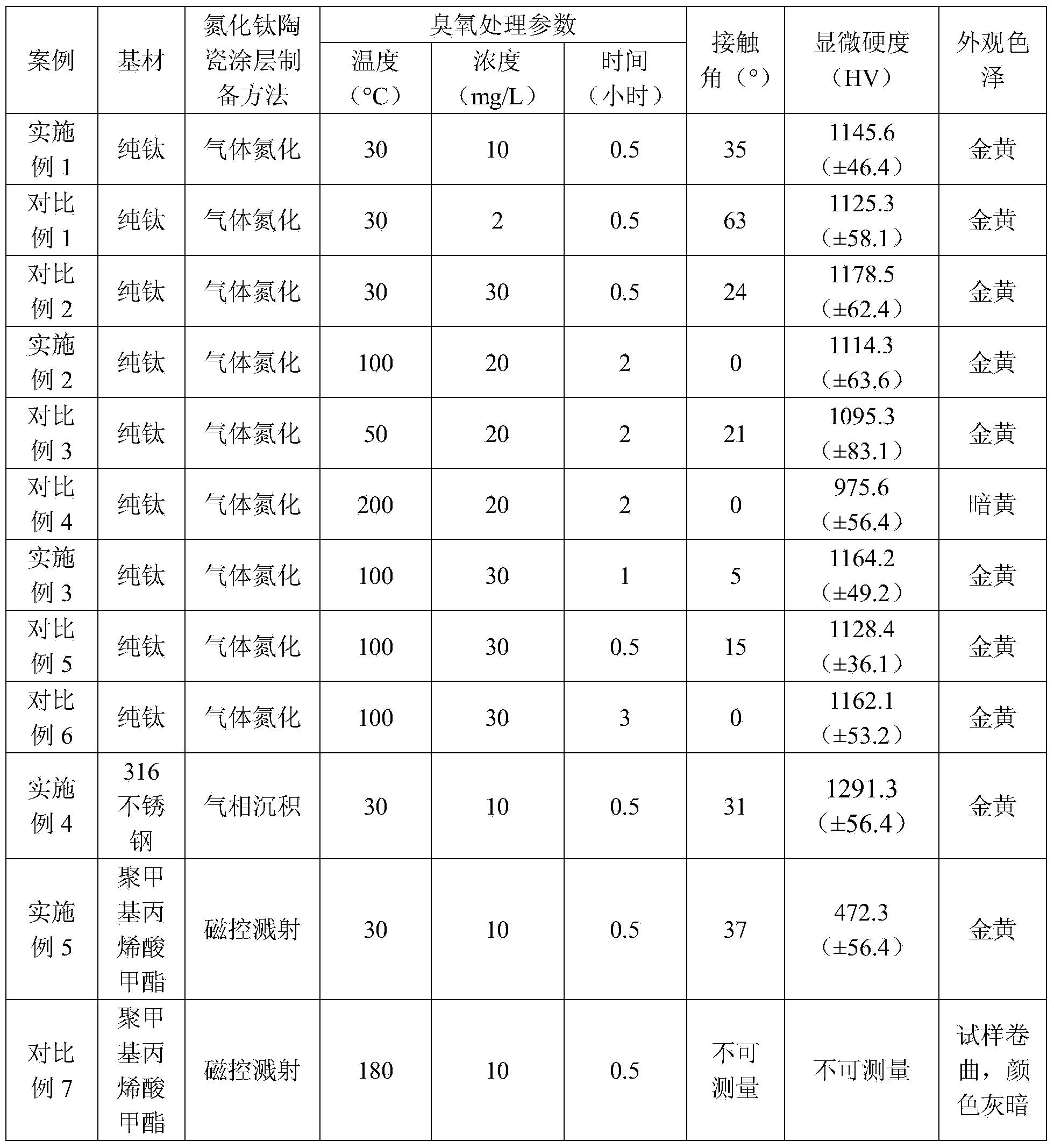

Method for improving biological activity of titanium nitride ceramic coating by ozone treatment

The invention discloses a method for improving the biological activity of a titanium nitride ceramic coating by ozone treatment. The method comprises the following steps: loading a sample with the titanium nitride ceramic coating into an inorganic tube; heating the inorganic tube till the temperature is 30-150 DEG C; charging ozone, wherein the concentration of the ozone is 10-30 mg / L, the working pressure intensity is 0.1 MPa, and the gas supply time is 0.5-6 hours; after reaction is completed, taking the sample out, and storing the sample in a sealed utensil made of an inorganic material. The method has the advantages that the surface of the titanium nitride ceramic coating is decontaminated and oxidized by utilizing the ozone, and the color, the microstructure, the hardness and the wear resistance of the titanium nitride ceramic coating are kept; meanwhile, the wetting performance of the surface of the titanium nitride ceramic coating is further obviously improved, so that interaction between cells and implant materials is improved, and bone cells can be more quickly attached, spread, proliferated and differentiated on the surface of an implant body. Therefore, the biocompatibility and the biological activity of the titanium nitride ceramic coating can be improved by virtue of an ozone treatment method provided by the invention.

Owner:JIANGSU UNIV OF SCI & TECH

Attaching device

Owner:BOE TECH GRP CO LTD +1

Preparation method of bone scaffold having anti-infection characteristic

InactiveCN110025822AAnti-infectionReduce or avoid secondary infectionAdditive manufacturing apparatusTissue regenerationBiocompatibility TestingHydroxylapatite

The invention provides a preparation method of a bone scaffold having an anti-infection characteristic. Mesoporous nanometer hydroxylapatite is used as a carrier of vancomycin, high vancomycin load capacity of the mesoporous nanometer hydroxylapatite and functions of the vancomycin for restraining bacterium growth and preventing infection are utilized, anti-infection effects of carboxymethyl chitosan and nanometer silver in various degrees are combined, vancomycin-loaded mesoporous nanometer hydroxylapatite and silver-carboxymethyl chitosan mixed powder is used as a base material, and the bonescaffold having the anti-infection characteristic is prepared through a three-dimensional printed quick shaping technique; and in the preparation course, the scaffold is modified through Type I collagen, and the biocompatibility of the scaffold is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

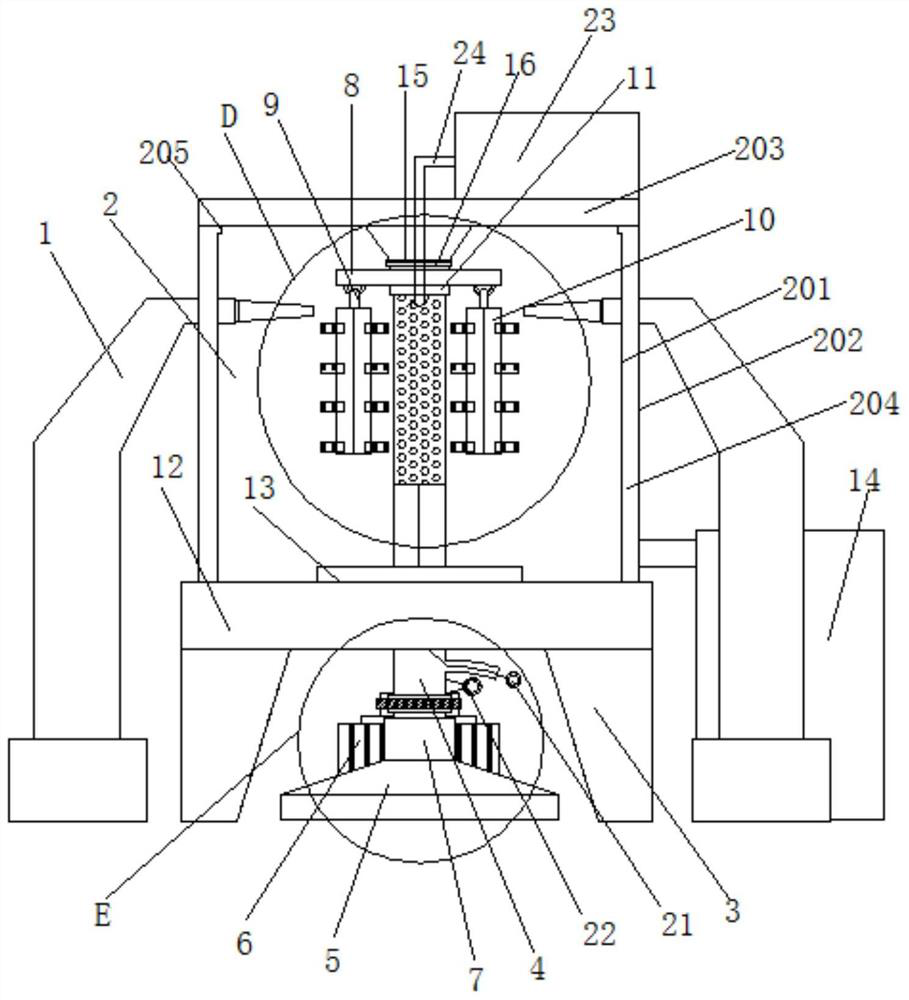

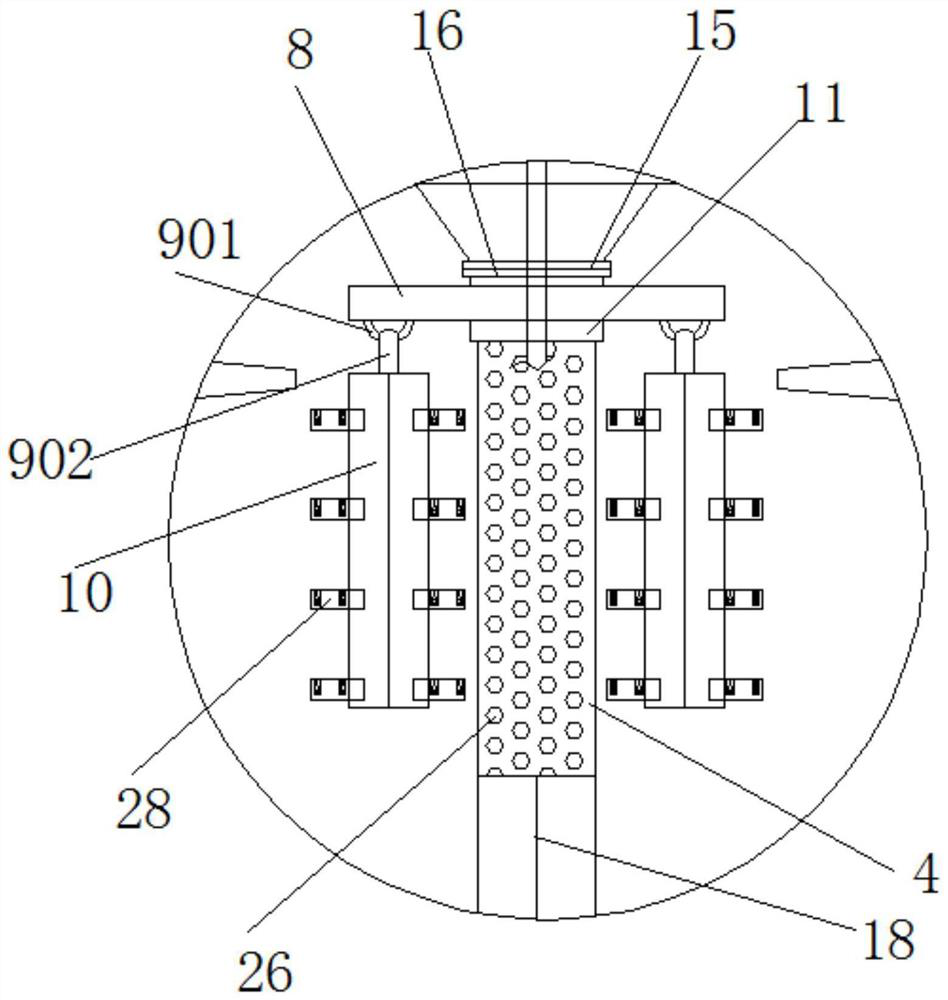

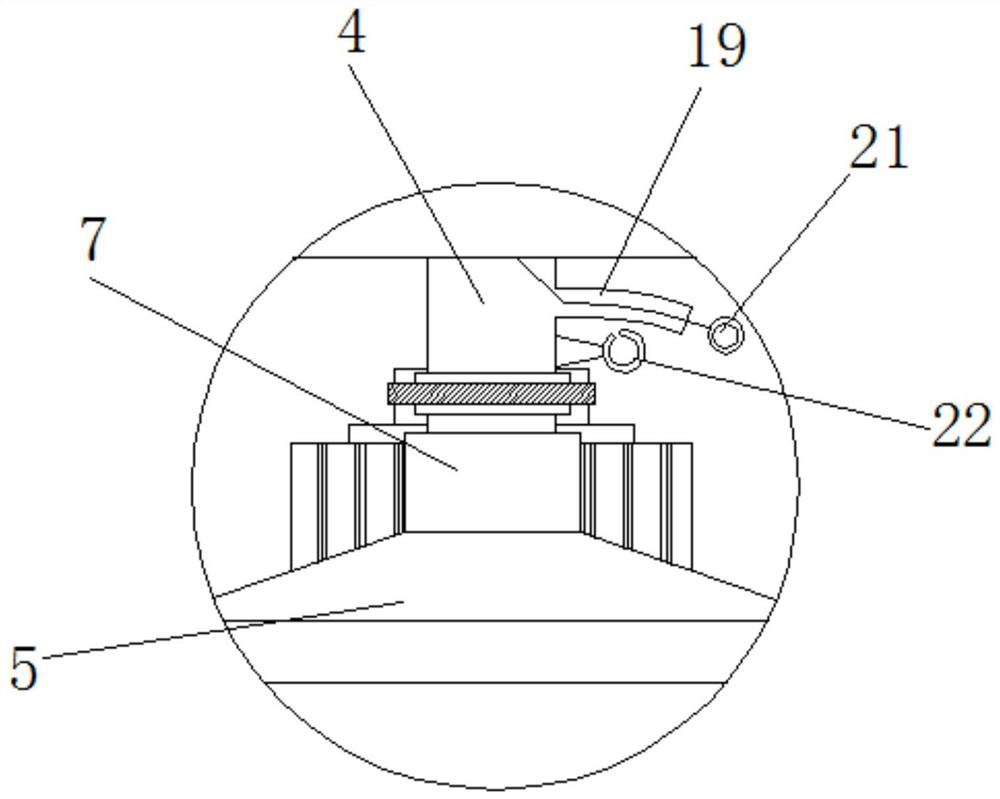

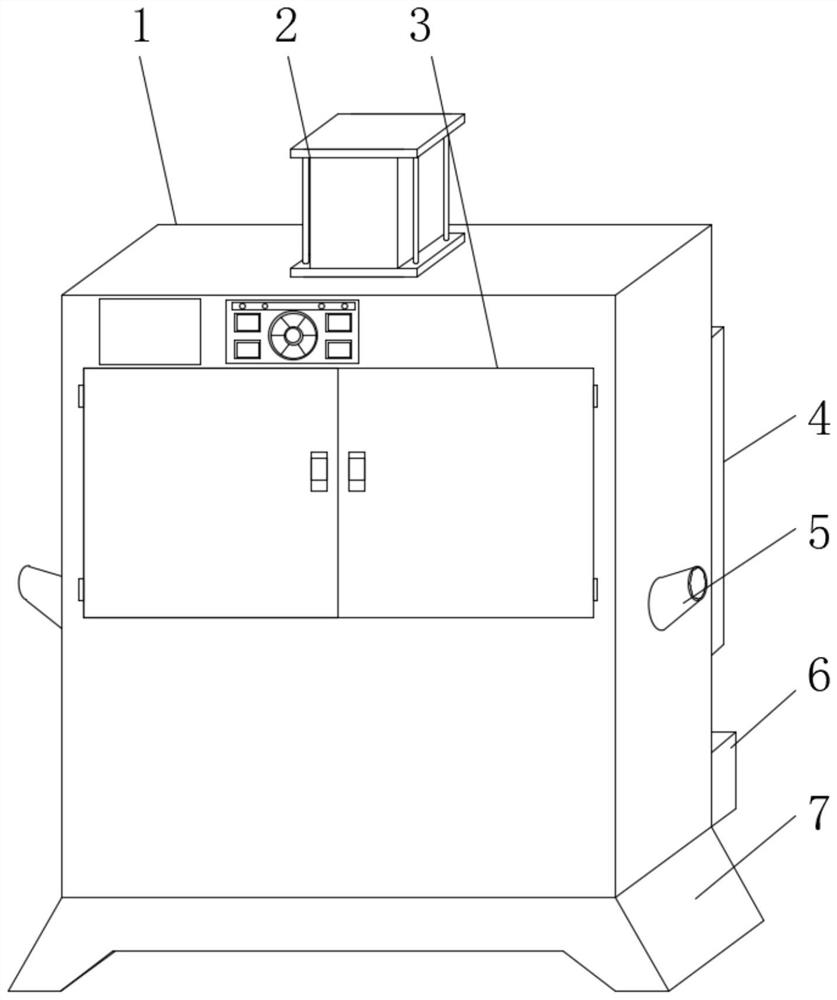

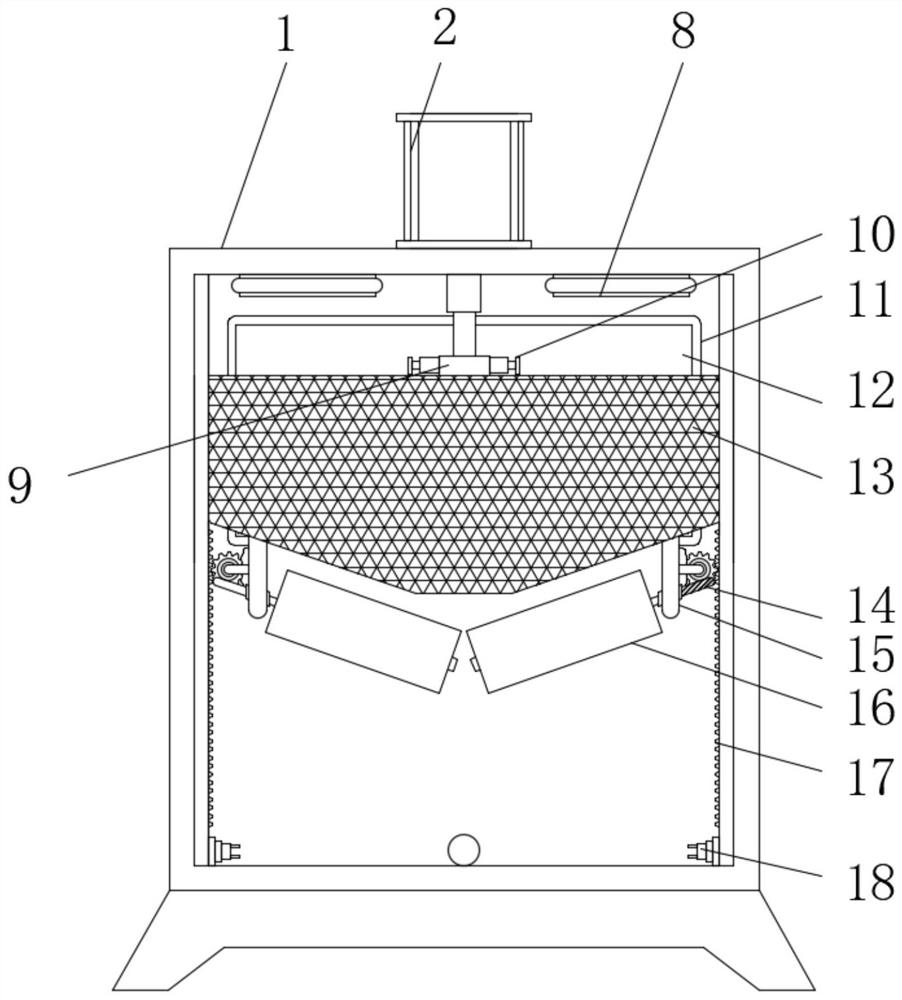

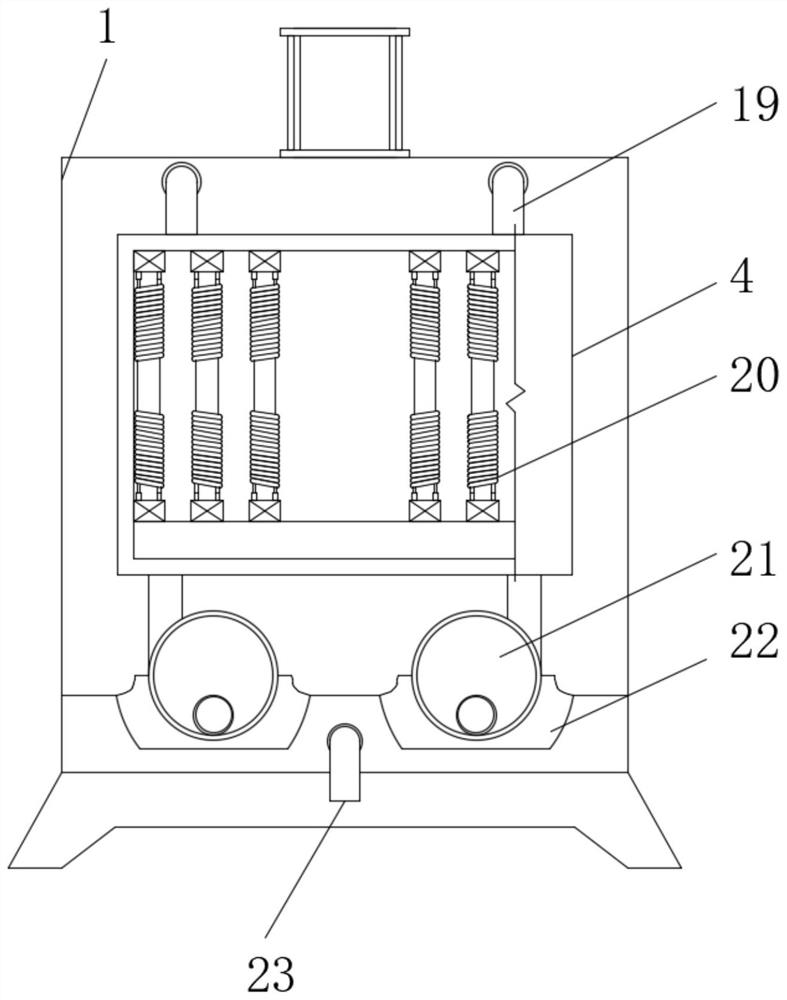

Environment-friendly automatic paint spraying equipment for automobile parts

PendingCN112295808ALabor savingImprove painting efficiencyPretreated surfacesCoatingsEngineeringSpray painting

The invention relates to environment-friendly automatic paint spraying equipment for automobile parts. The equipment comprises at least one mechanical arm spray gun and further comprises a hollow cylindrical closed paint spraying chamber, a base, a paint mist removing system, an accessory clamping device and a water collecting device arranged between the base and the cylindrical closed paint spraying chamber. According to the automatic paint spraying equipment, and the problems that respiratory tracts are hurt and the working efficiency is low due to manual paint spraying one by one are solvedthrough the arrangement of the manipulator spray guns and a rotatable adjustable clamp; a cylindrical paint mist removing system is adopted to form a water curtain paint mist absorbing system with the closed periphery, the problem that an existing single-face water wall cannot thoroughly and rapidly absorb paint mist is solved, and the environment-friendly effect is good; and by the adoption of adrying system, the problem that existing automobile parts cannot be dried and cured in time after being painted is solved, and the purpose of rapid attachment of paint molecules is guaranteed throughthe arrangement of the drying system.

Owner:YANGZHOU POLYTECHNIC INST

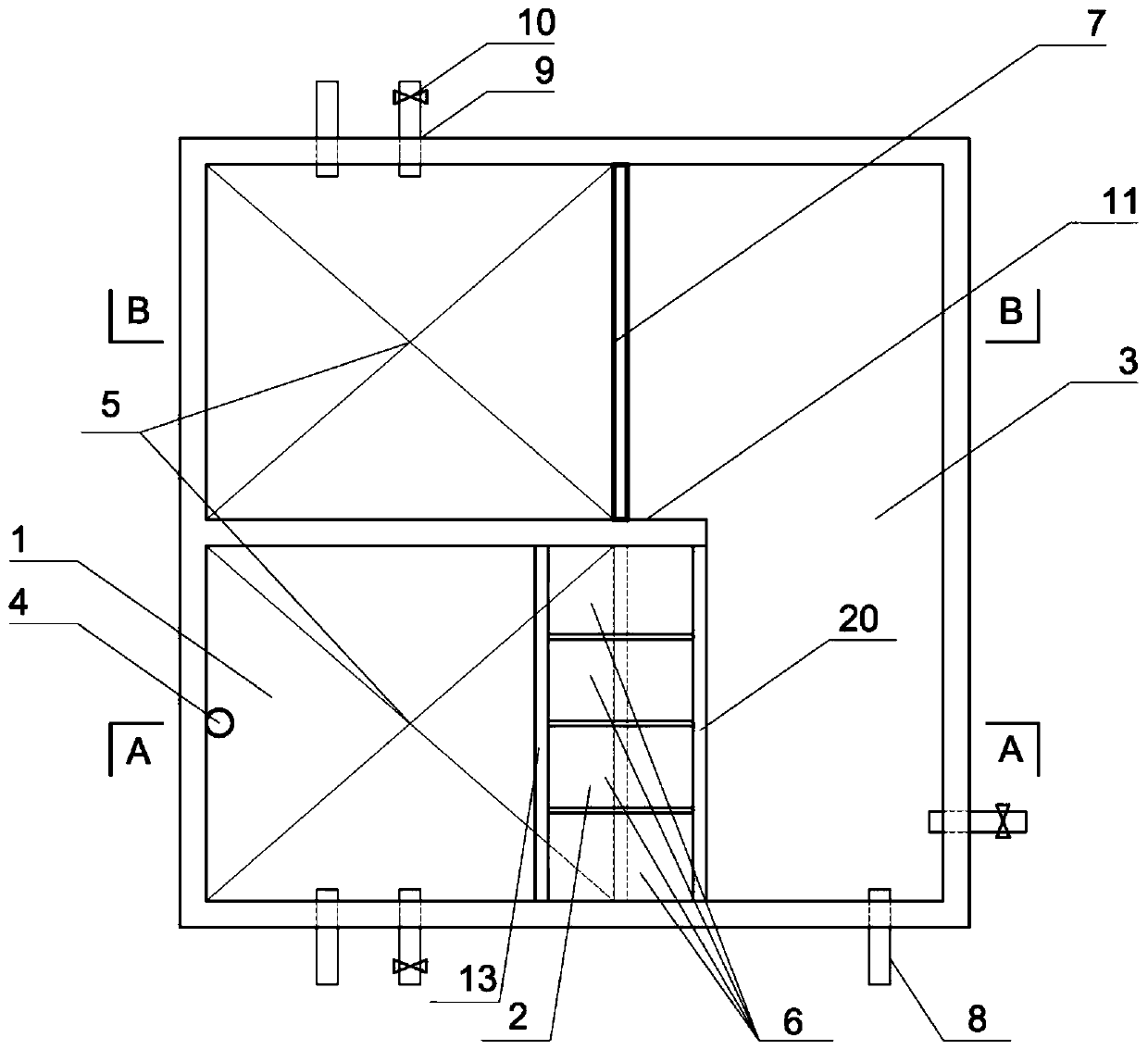

Highway bridge deck runoff purification emergency system

ActiveCN110847332AAchieve purificationTo achieve intensive utilizationFatty/oily/floating substances removal devicesSewerage structuresFiltrationBridge deck

The invention relates to a highway bridge deck runoff rainwater flood purification utilization and environmental risk emergency system, in particular to a highway bridge deck runoff purification emergency system with a floating oil removal function. The highway bridge deck runoff purification emergency system is divided into a pre-precipitation area, an oil removal area and a deep purification area through a partition wall, a first oil removal partition wall and a second oil removal partition wall, wherein the pre-precipitation area plays a main precipitation effect on suspended matters such as sediment in the rainwater runoff, the oil removal area is provided with a floating oil remover, special pollutants such as petroleum in the bridge deck runoff can be directionally removed, the deeppurification area realizes overall purification of runoff through a comprehensive process such as baffling precipitation, self-adsorption filtration and microbial decomposition, the discharged water can be used for the reuse function of greening irrigation and the like, and the intensive utilization of rainwater flood resource is realized.

Owner:CHINA ACAD OF TRANSPORTATION SCI

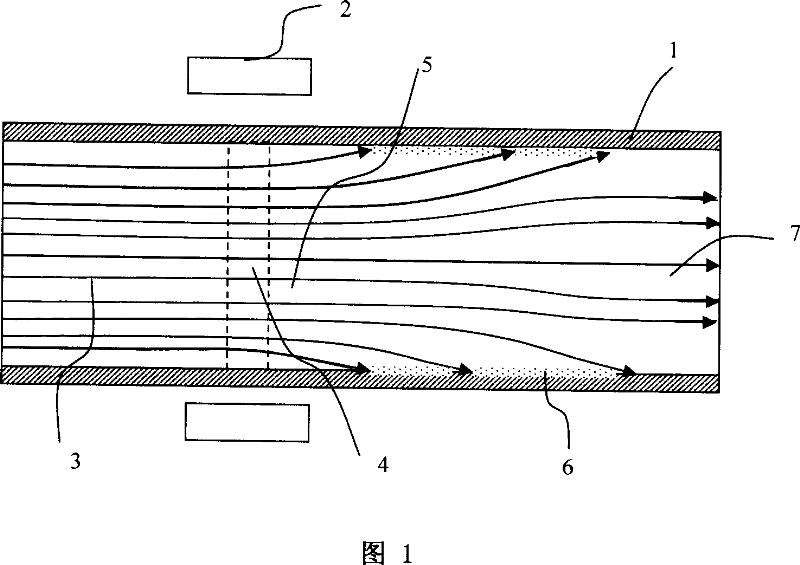

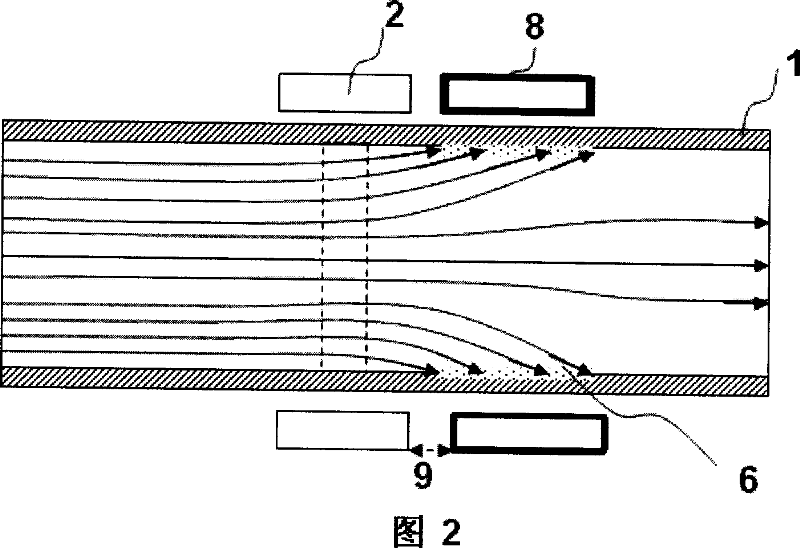

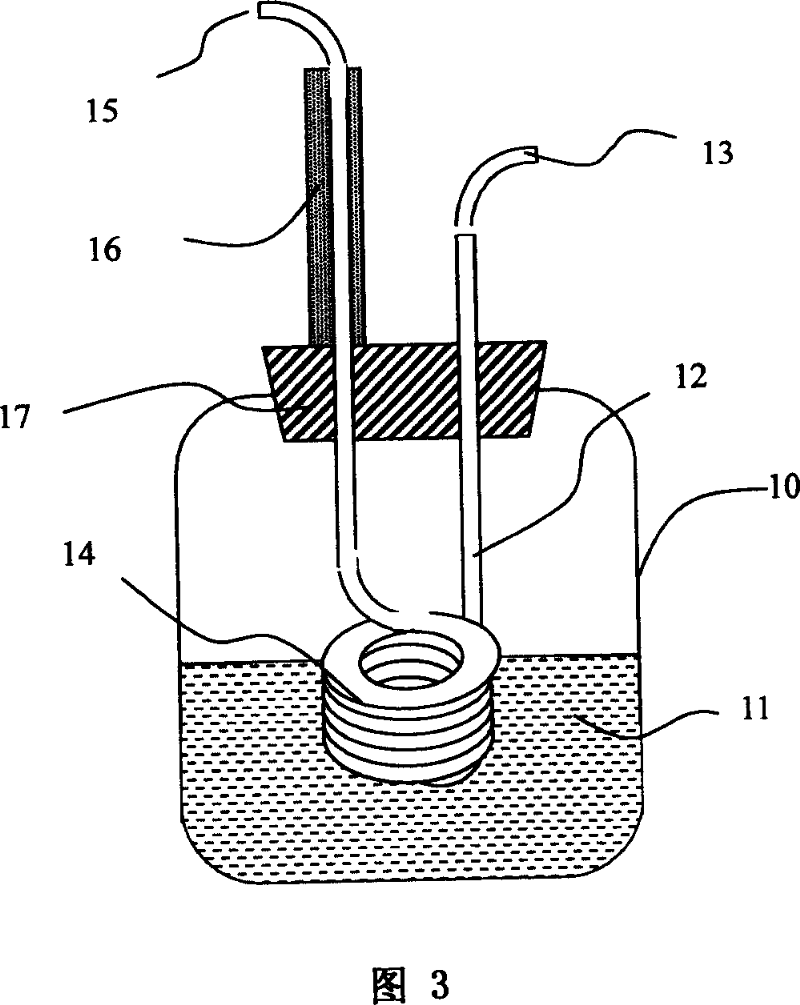

Method and device for improving MCVD deposition efficiency and quality of low-temperature refrigeration

InactiveCN101041550AEasy to operateMaximum cooling temperatureGlass deposition burnersGlass productionAudio power amplifierEngineering

The invention discloses an increasing method of MCVD depositing efficiency and quality through low-temperature gas refrigerant and device, which comprises the following steps: proceeding low-temperature cool for refrigerant gas; leading the cool gas through jet blast cold device; decreasing temperature of depositing tube heat-reacting area during MCVD depositing course; changing adventitious deposit course of reaction product particle in the tube; increasing depositing efficiency; improving quality of outgrowth particle adhesive layer at the same time.

Owner:BEIJING JIAOTONG UNIV

Manufacturing method of high-Te-content CuCr contact

The invention discloses a manufacturing method of a high-Te-content CuCr contact. The manufacturing method of the high-Te-content CuCr contact mainly comprises the following steps that S1, CuCr(25-50)alloy blocks, Cu blocks and CuTe(10-50) alloy blocks are prepared and selected to be reserved; S2, the matched CuCr(25-50) alloy blocks and the matched Cu blocks are put into a crucible, the CuTe(10-50) alloy blocks are put into a secondary feeding device, and then a vacuum system is opened; S3, gradient heating operation is conducted until the Cu blocks begin to melt, the vacuum system is closed, and argon is fed into the crucible; S4, the situation that the CuCr(25-50) alloy blocks and the Cu blocks completely melt is observed, molten alloy liquid is evenly stirred, and then the CuTe(10-50)alloy blocks are put into the molten alloy liquid; S5, the molten alloy liquid can flow to a crucible opening, and the temperature of the crucible opening is increased; S6, casting operation is conducted so that the molten alloy liquid can flow into a water-cooled copper mold; and S7, machining operation is conducted according to the drawing requirement. According to the manufacturing method of the high-Te-content CuCr contact, the intermediate alloy block addition mode is adopted by the technology, the smelting temperature is reduced, the Te addition uniformity and the Te addition yield areguaranteed, the crucible washing frequency is reduced, and the number of metallographical inclusions is reduced.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Nickel-gold-tin automatic production line for surface treatment of precision connector

PendingCN112708923AImprove surface qualityQuick spoilerCellsDrying solid materials without heatElectric heatingSurface processing

The invention discloses a nickel-gold-tin automatic production line for surface treatment of a precision connector, and belongs to the technical field of surface treatment. The nickel-gold-tin automatic production line comprises a casing, an electric heating shell, a screen frame, a driving assembly and a top plate, and an electric push rod is fixedly mounted at the top of the casing. According to the nickel-gold-tin automatic production line, by installing the lifting type screen frame, when a metal product is usually galvanized, the electric push rod can be directly started to control the screen frame to ascend and descend so that the metal product in the screen frame is stably removed from surface treatment liquid, and when the screen frame ascends and descends, a transmission gear of the driving assembly can be effectively engaged with an internal tooth sliding strip to rotate so that amounting shaft drives a transmission worm gear to rotate, the transmission worm gear can drive a transmission worm with stirring blades to rotate, the metal product is immersed in the surface treatment liquid, the surface treatment liquid is effectively stirred and quickly disturbed, the surface treatment liquid can be effectively and rapidly attached to the outer surface of the metal product, the omnibearing surface treatment effect is achieved, and the surface treatment quality of the product is improved.

Owner:SUZHOU PLATER ELECTRONICS CO LTD

Dyeing method of polyester-cotton fiber cheese with vat dyes

The invention relates to a vat dyes dyeing method of polyester cotton fiber cheese, in particular relates to a dyeing method of the blend fiber cheese, and especially relates to a three-in-one dyeing method of blend fiber cheese, aiming at solving the problems that dyeing time is long, energy consumption is high, productivity is lower, more sewage is discharged, etc in the traditional dyeing method of the blend fiber cheese. The method comprises the steps of loosening yarns, dyeing and carrying out postprocessing, and is characterized in that in the step of loosening yarns, a digital winding way is adopted, and drum loosing is carried out on the blend fiber yarn; the dyeing comprises the steps of adding disperse dye, mixed alkali and an oxidizing agent at the room temperature; heating and carrying out heat preservation twice, and directly cooling the mixture; then, adding active dye and anhydrous sodium sulphate into the mixture, carrying out heat preservation, and directly discharging residual liquid; putting the product into water, heating and carrying out heat preservation, and then discharging; adding a certain weight of soaping agent for soaping, carrying out heat preservation, and then discharging; adding clear water and washing one time; softening and discharging; carrying out dehydration; drying by a variable frequency dryer; separating a drum for warping, or spooling to obtain the finished yarn product. After the three-in-one dyeing method is adopted, the dyeing process of the blend fiber cheese is greatly reduced, and the dyeing time and the dyeing process are greatly shortened.

Owner:ZHEJIANG SAINTYEAR TEXTILE

Fragrance-retaining bead and preparation method thereof

PendingCN113913250AImprove adhesionFast attachmentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsFiberPolymer science

The invention discloses a fragrance-retaining bead and a preparation method thereof. The fragrance-retaining bead comprises the following raw materials in parts by weight: 35-50 parts of polyethylene glycol, 20-30 parts of a water-soluble inorganic compound, 5-15 parts of modified starch, 0.5-3 parts of essence microcapsules and 1-3 parts of essence, wherein the modified starch comprises sodium carboxymethyl starch and oxidized starch. The fragrance-retaining bead can be dissolved more rapidly in water, and after the fragrance-retaining bead is dissolved, the essence can be better attached to the surface of fabric fibers, so that the essence is slowly released at a certain speed, the purpose that the essence is more effectively attached to clothes for a long time is achieved, and the fragrance-retaining bead has the advantages of being rapid in dissolution and lasting in fragrance retention.

Owner:宁波洁品坊日化科技有限公司 +1

Color-increased treatment technology for black wool fabric

InactiveCN109457480AFast attachmentImprove adhesionAbrasion resistant fibresAnimal fibresCross-linkRefractive index

The invention discloses a color-increased treatment technology for black wool fabric. The technology comprises two steps of preparing first color-increased finishing liquid and second color-increasedfinishing liquid, and performing color-increased treatment. The color-increased treatment technology for the black wool fabric adopts padding finishing of fluorine-containing resin and polyurethane resin with two low refractive indexes. A penetrant is helpful to the resin to be rapidly adhered on the surface of wool fibers even between wool scales, and a cross-linking agent is helpful to increasean adhesive force of the resin and the wool fibers, water washing resistance and friction and peeling resistance of a resin layer are improved.

Owner:JIANGSU EAST CHINA TEXTILE PROD TESTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com