Solar energy photovoltaic component seal gum and synthesis method thereof

A solar photovoltaic and sealant technology, which is applied in the field of sealants, can solve problems such as imperfect sealing performance and metal corrosion, and achieve the effects of high ultraviolet resistance, good weather resistance and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Solar photovoltaic module sealant, which is made of the following raw materials in weight percentage: polyisobutylene 50%, light calcium carbonate 30%, heavy calcium carbonate 10%, carbon five resin 3%, butyl rubber 6.7%, anti-oxidation Agent PL-100.3%.

[0036] The synthetic method of solar photovoltaic module sealant comprises the following steps: get 50kg of polyisobutylene with a molecular weight of 3W and put it into a vacuum kneader, heat up to 150 degrees; stir under 0.09Mpa vacuum condition for 0.5 hour; then add 3kg of carbon five resin Stir with 0.3kg of antioxidant PL-10 for 0.3 hours; then add 6.7kg of butyl rubber and stir for 0.3 hours; finally drop in 30kg of light calcium carbonate and 10kg of heavy calcium carbonate; mix the above under 0.09Mpa vacuum conditions Stir and knead for 1 hour to obtain the finished product. The performance test of the finished product is as follows:

[0037] Table 1: Physical data indicators of the solar photovoltaic modul...

Embodiment 2

Embodiment 3

1.08

weight per gallon

9lb / gallon

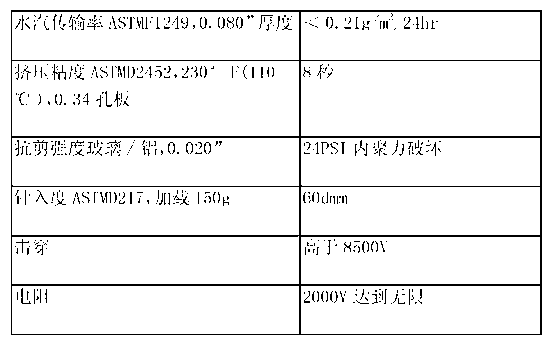

[0056] Table 2: Typical performance indicators of the solar photovoltaic module sealant prepared in Example 1

Water Vapor Transmission ASTM F1249, 0.080" Thickness

2 / 24hr

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com