Manufacturing method of high-Te-content CuCr contact

A content and contact technology, which is applied in the field of preparation of CuCr contacts with high Te content, can solve the problems such as the failure of contact fusion welding, metallographic inclusion of contact materials, and increase in production costs, so as to reduce crucible scouring and reduce Inclusions in metallographic phase and the effect of reducing volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

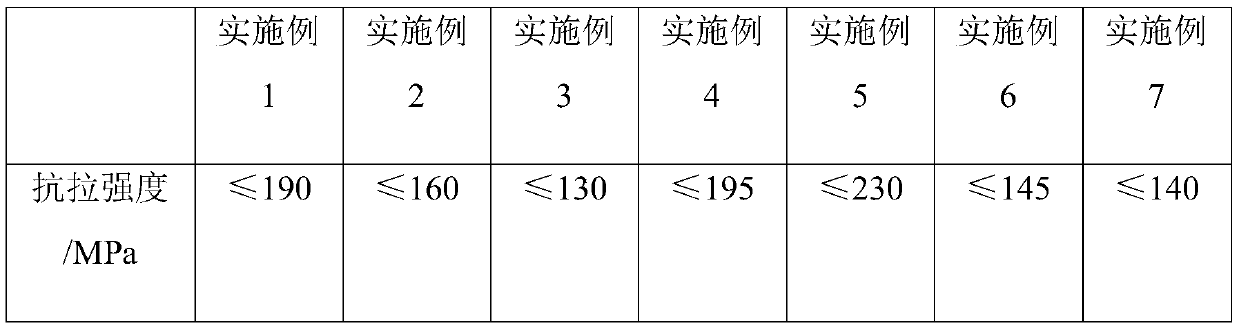

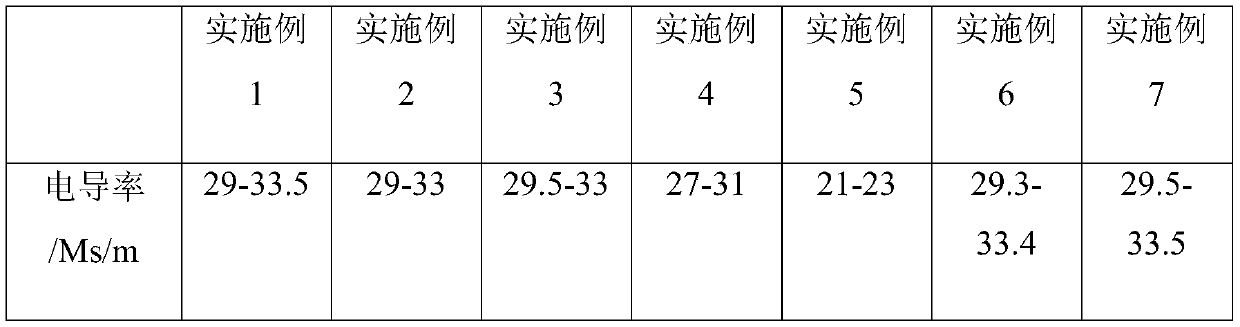

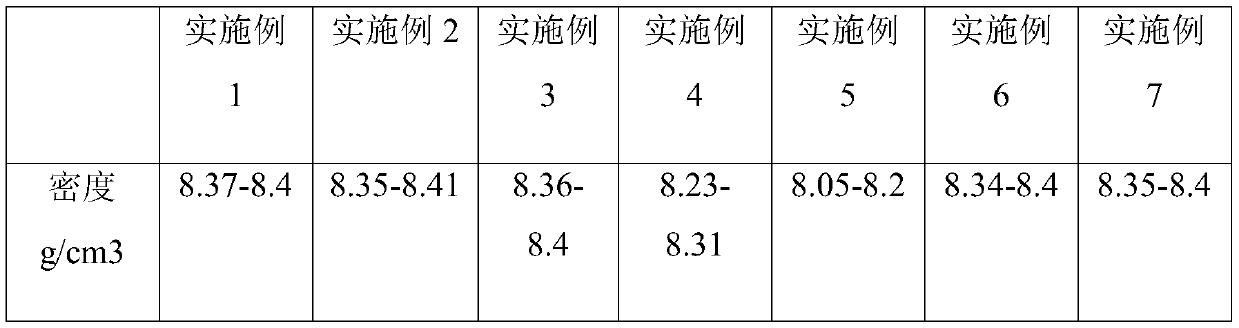

Embodiment 1

[0034] A method for preparing a CuCr contact with high Te content, mainly comprising the following steps:

[0035] S1 ingredients, CuCr (25 ~ 50) alloy block, Cu block, CuTe (10 ~ 50) alloy block ratio to reach a Cr content of 25%, and a Te addition of 0.3% for use; the intermediate alloy CuCr (25 ~ 50) alloy is used Block and CuTe (10-50) blocks are added, which reduces the melting temperature, ensures the uniformity and yield of Te addition, reduces crucible scour, reduces inclusions in the metallographic phase, and controls the amount of Te addition at 0.3-1%. Effectively reduce the tensile strength of the contact;

[0036] S2 Furnace loading: Use a suitable ceramic crucible, put the CuCr (25-50) alloy block and Cu block that have been proportioned into the crucible, put the CuTe (10-50) alloy block into the secondary feeding device, and then turn it on vacuum system;

[0037] S3 induction heating: when the vacuum is pumped to 10 -1 stage, carry out gradient heating, wai...

Embodiment 2

[0043] A method for preparing a CuCr contact with high Te content, mainly comprising the following steps:

[0044] S1 ingredients, CuCr (25 ~ 50) alloy block, Cu block, CuTe (10 ~ 50) alloy block ratio to reach a Cr content of 25%, and a Te addition of 0.6% for use; the intermediate alloy CuCr (25 ~ 50) alloy is used Block and CuTe (10-50) blocks are added, which reduces the melting temperature, ensures the uniformity and yield of Te addition, reduces crucible scour, reduces inclusions in the metallographic phase, and controls the amount of Te addition at 0.3-1%. Effectively reduce the tensile strength of the contact;

[0045] S2 Furnace loading: Use a suitable ceramic crucible, put the CuCr (25-50) alloy block and Cu block that have been proportioned into the crucible, put the CuTe (10-50) alloy block into the secondary feeding device, and then turn it on vacuum system;

[0046] S3 induction heating: when the vacuum is pumped to 10 -1 stage, carry out gradient heating, wai...

Embodiment 3

[0052] A method for preparing a CuCr contact with high Te content, mainly comprising the following steps:

[0053] S1 ingredients, CuCr (25 ~ 50) alloy block, Cu block, CuTe (10 ~ 50) alloy block ratio to reach a Cr content of 25%, and a Te addition of 0.9% for use; the intermediate alloy CuCr (25 ~ 50) alloy is used Block and CuTe (10-50) blocks are added, which reduces the melting temperature, ensures the uniformity and yield of Te addition, reduces crucible scour, reduces inclusions in the metallographic phase, and controls the amount of Te addition at 0.3-1%. Effectively reduce the tensile strength of the contact;

[0054] S2 Furnace loading: Use a suitable ceramic crucible, put the CuCr (25-50) alloy block and Cu block that have been proportioned into the crucible, put the CuTe (10-50) alloy block into the secondary feeding device, and then turn it on vacuum system;

[0055] S3 induction heating: when the vacuum is pumped to 10 -1 stage, carry out gradient heating, wai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com