Patents

Literature

1098 results about "Vacuum switch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prior to effective engine control unit computers, engine vacuum was used for many functions in an automobile. Vacuum switches were employed to regulate this flow. For instance a dual port vacuum switch located in a port on the intake manifold monitored the coolant temperature in the coolant crossover. It received vacuum (port E on the switch) from the carburetor. The vacuum flowed through the switch to a vacuum solenoid (such as a heat riser, used to restrict exhaust allowing the engine to heat up faster). When the coolant heated to operating temperature the vacuum switch closed off the port (port S on the vacuum switch) turning off the vacuum to the heat riser. The result is to clear the exhaust restriction. The switch monitored the temperature and when conditions were right it performed its designed function.

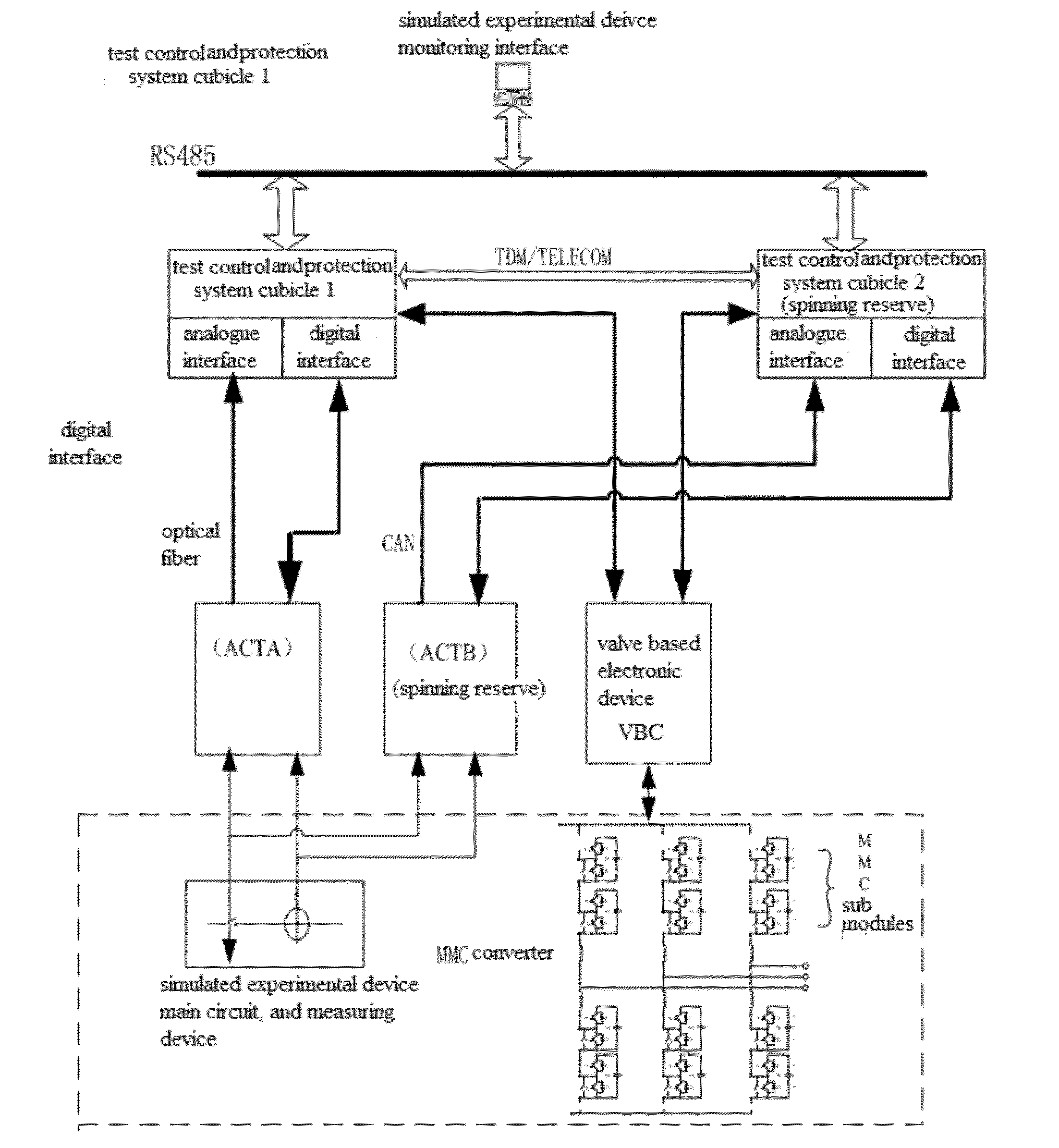

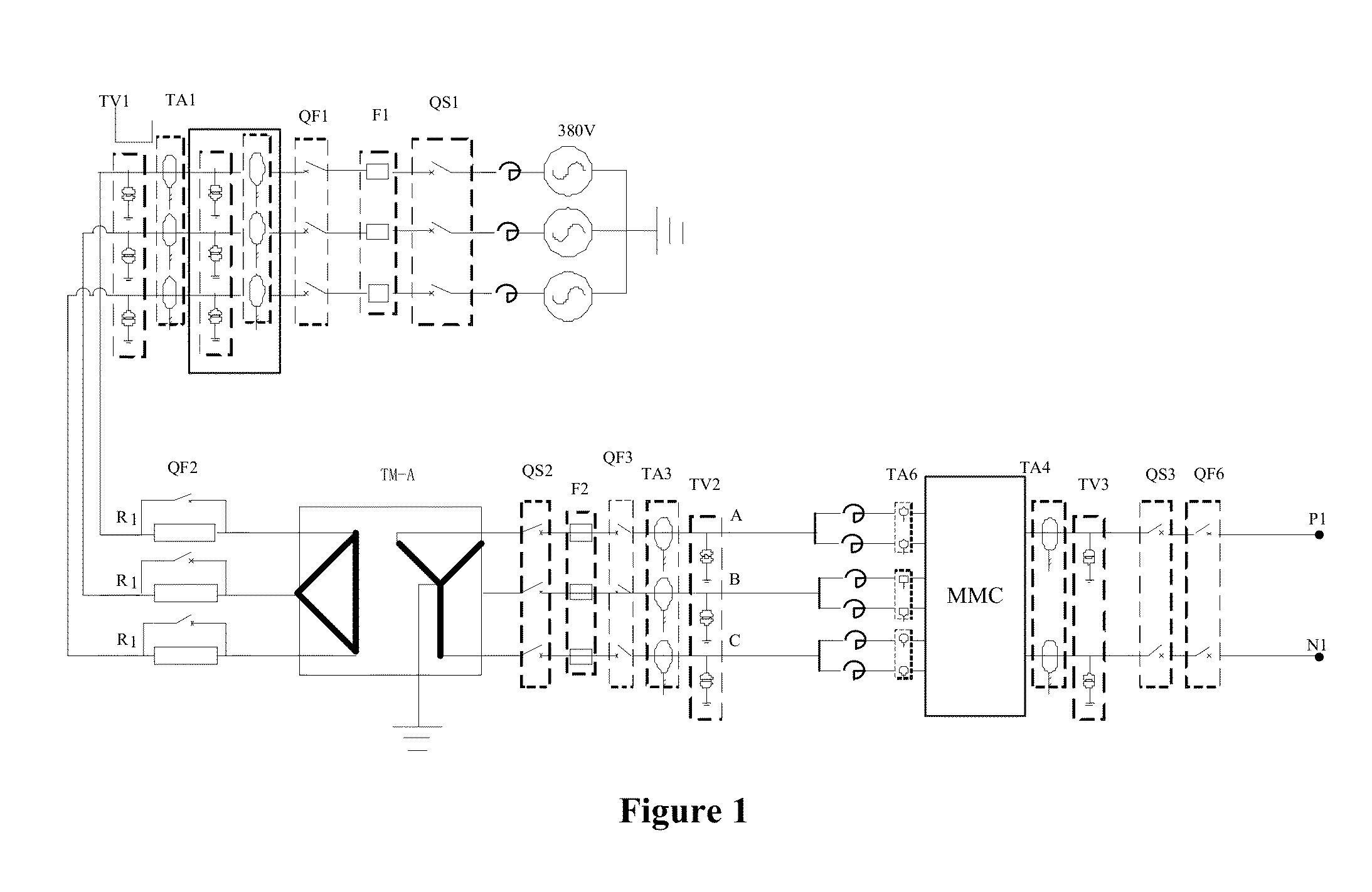

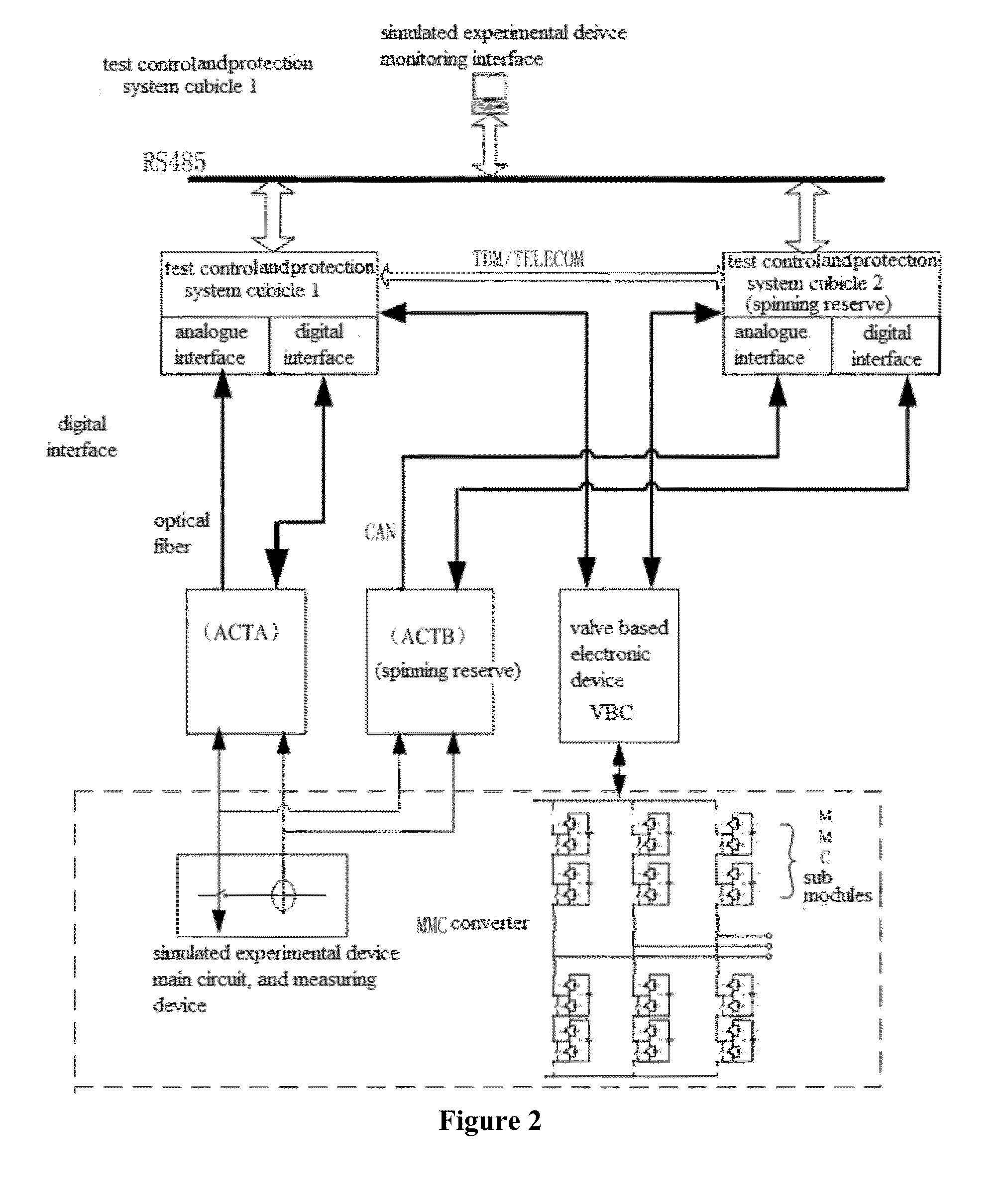

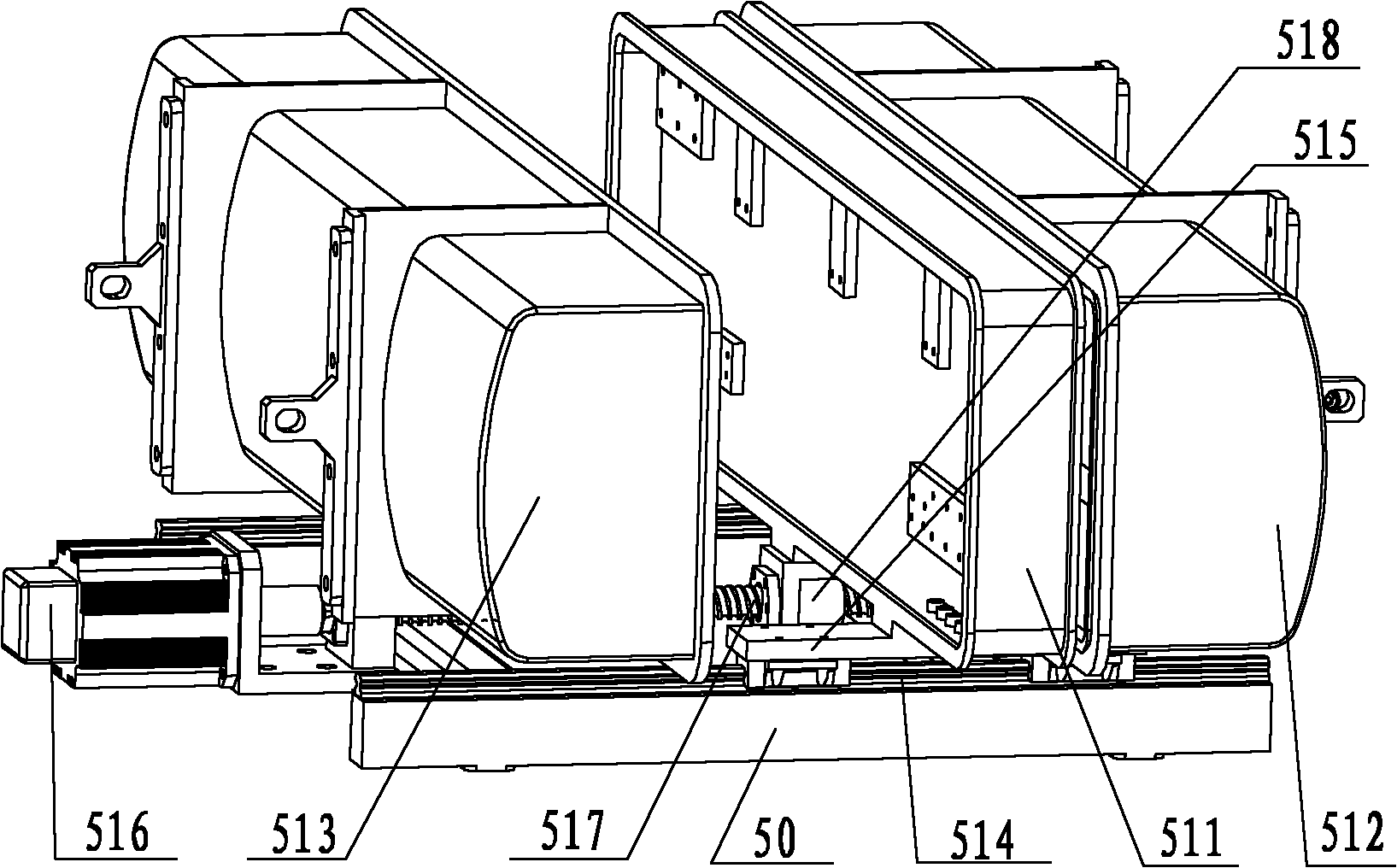

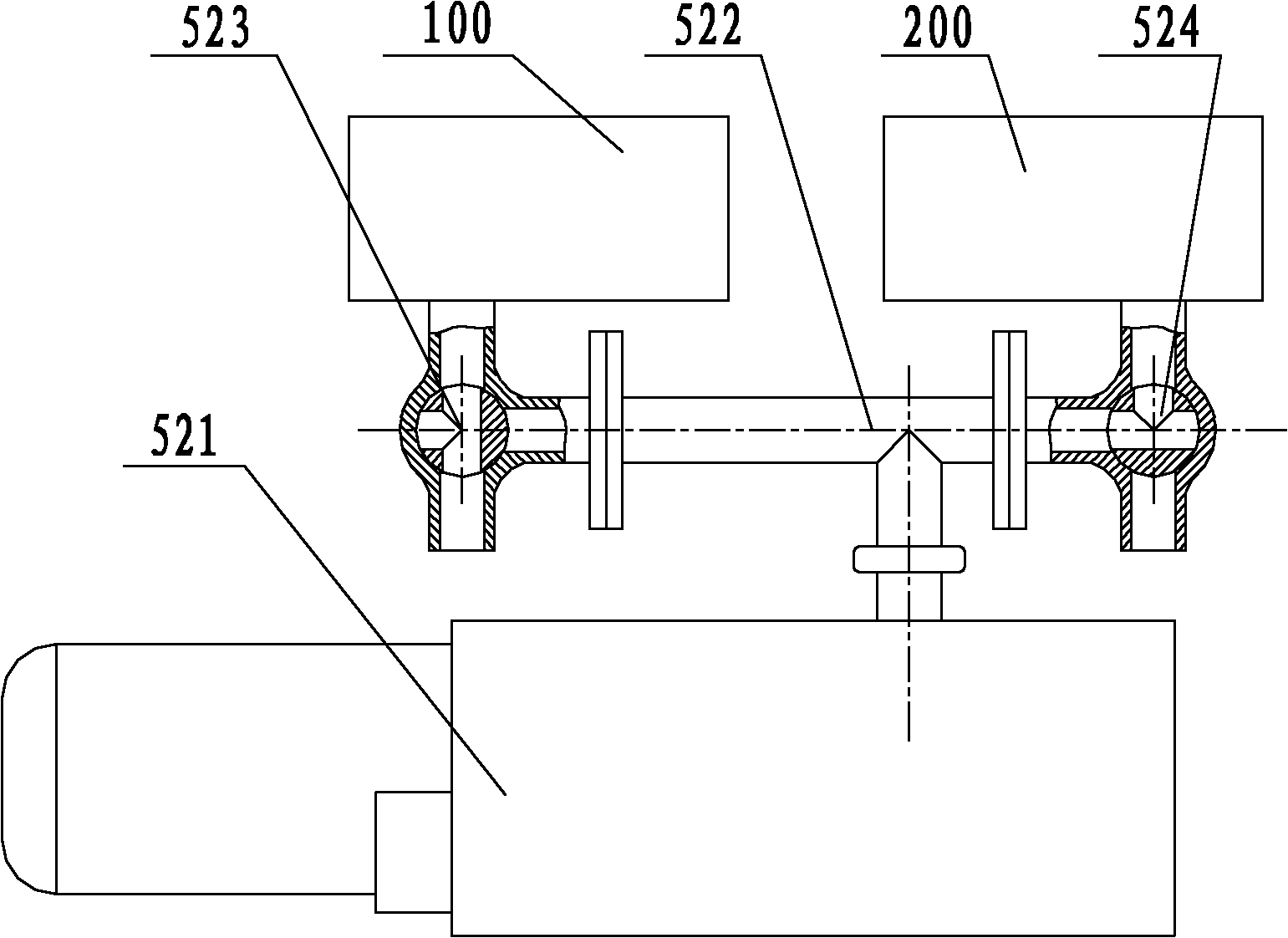

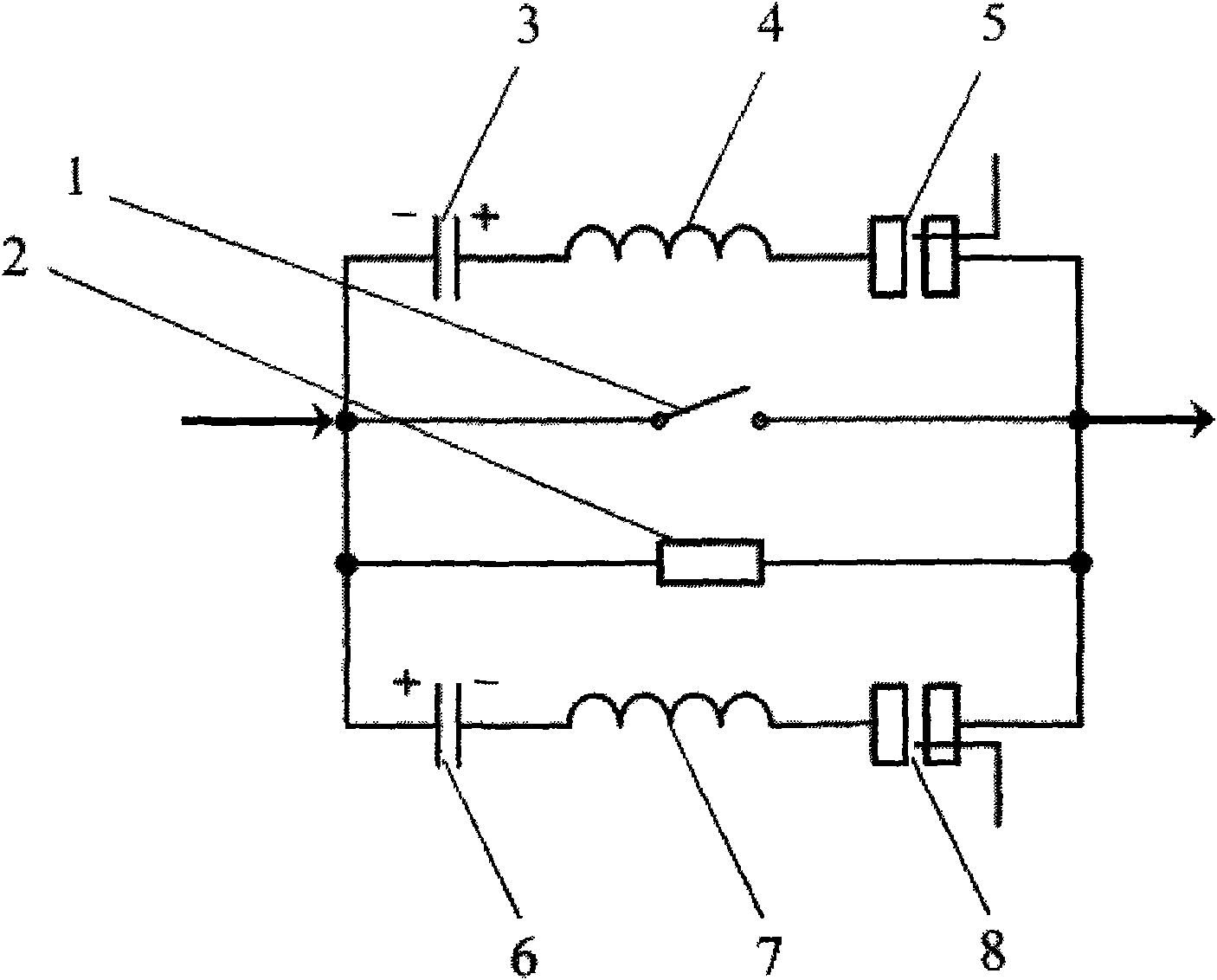

Real time dynamic physics simulation device of flexible DC transmission system

ActiveUS20140129195A1Accurately understand operation characteristicAccurate understandingFault location by conductor typesComputation using non-denominational number representationControl systemTransformer

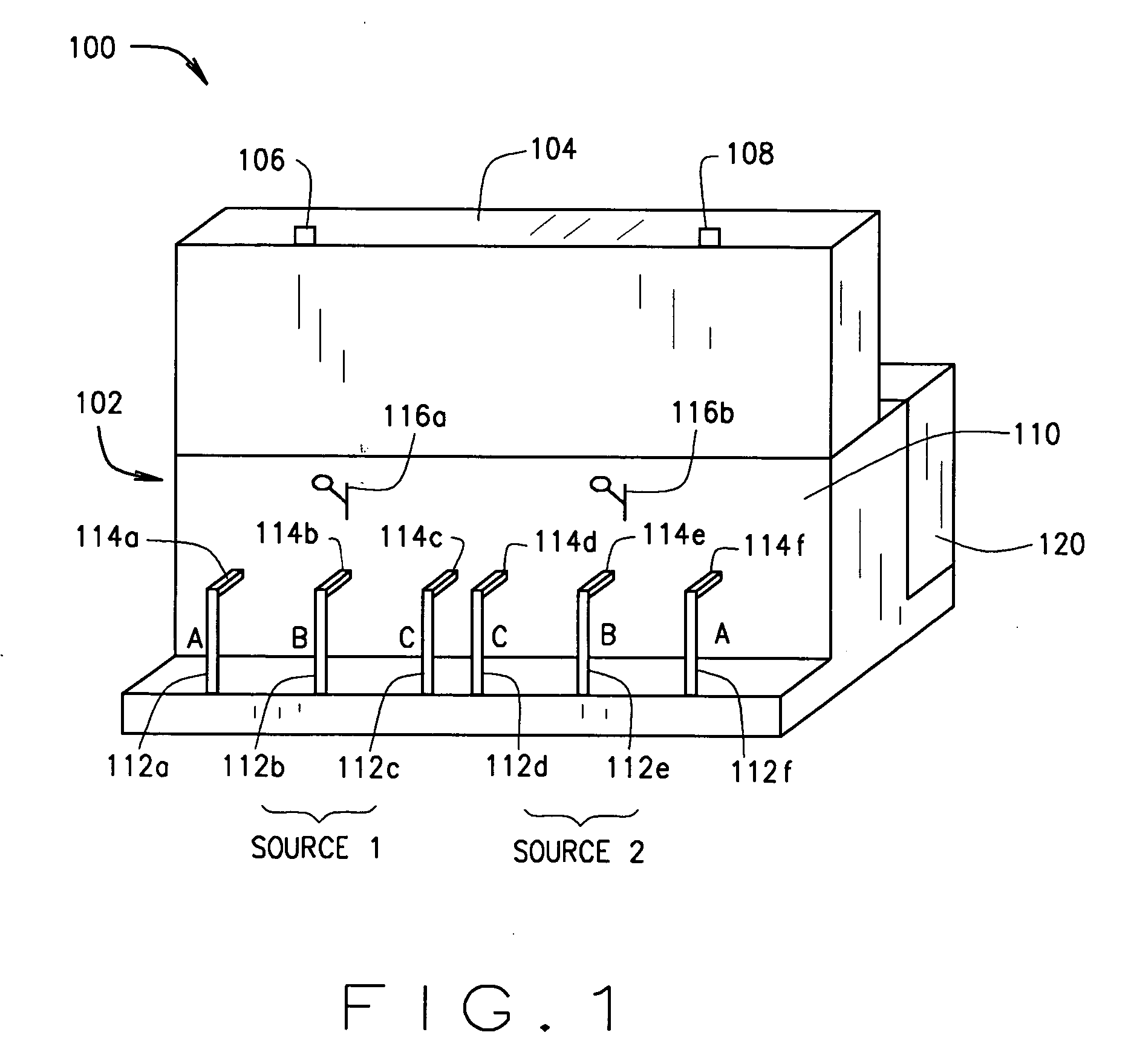

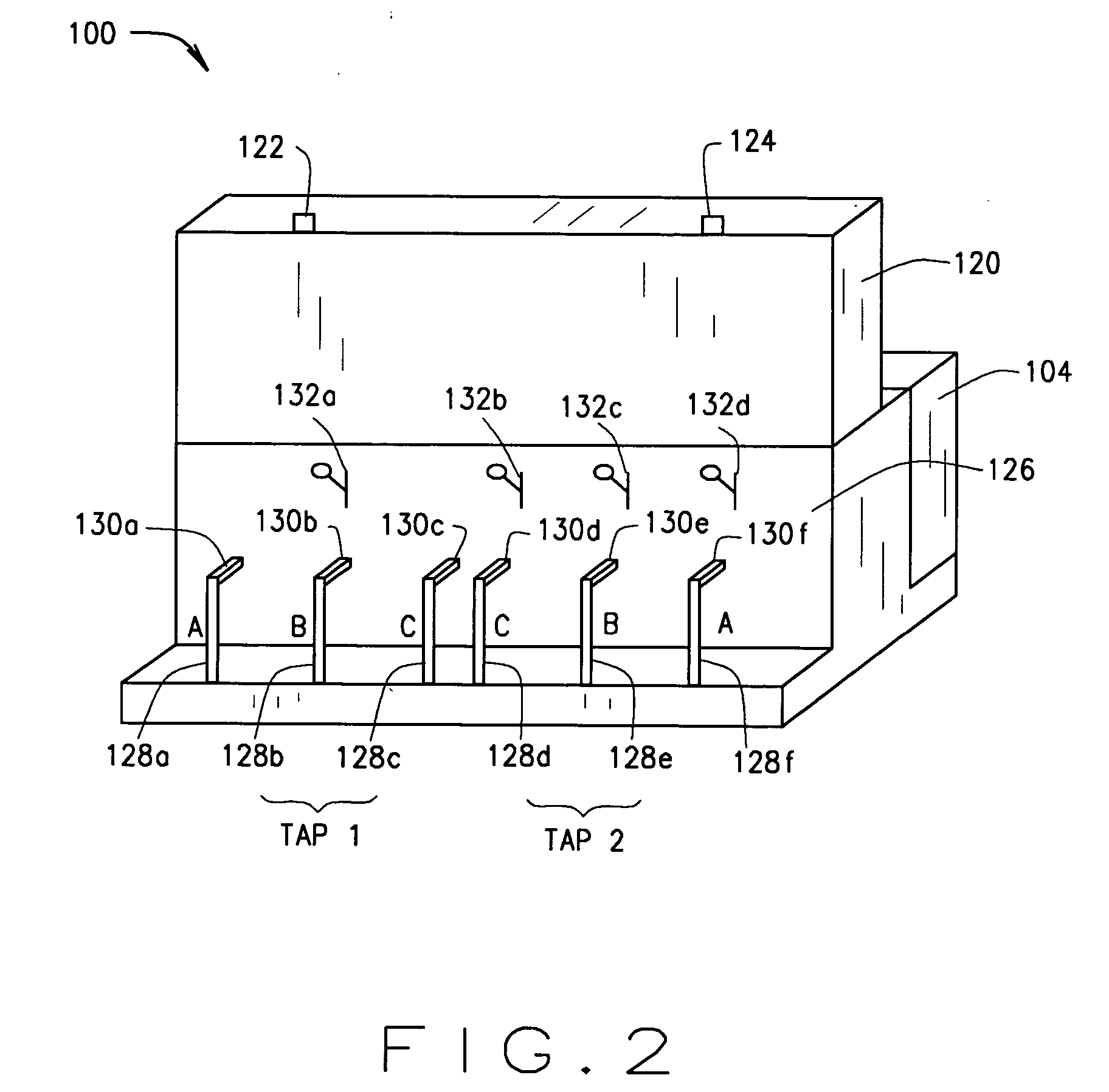

The present invention relates to a real time dynamic physics simulation device of flexible DC transmission system. The device includes simulated converter transformer, simulated AC field, simulated DC field, simulated converter reactor, simulated converter, and measurement and control cabinet chassis; the simulated AC field includes the vacuum switch I, the contactor I, resistors and the vacuum switch II connected orderly; the simulated DC field includes successively connected the vacuum switch contactor III and II; the simulated AC field is connected with said measurement and control cabinet chassis; Said converter transformer is set between said resistors and said vacuum switch II; Said simulated converter reactors and said simulated converter connected are set between the vacuum switch II and the vacuum switch III. The present invention can accurately simulate different voltage level flexible DC transmission system based on modular multilevel converter (MMC-HVDC), able to accurately understand the operation characteristics of MMC-HVDC and the dynamic responds to the instruction of the control system.

Owner:STATE GRID CORP OF CHINA +1

Vacuum switchgear assembly, system and method

Insulated vacuum switchgear and active switchgear elements therefor are provided with a rigid support structure mechanically isolating a vacuum insulator from axial loads in use without reinforcing or insulating encapsulations. At least one of the elastomeric insulating housing and the support structure directly contacts an outer surface of the insulator. Systems and methods for assembling the switchgear are also provided.

Owner:EATON INTELLIGENT POWER LIMITED

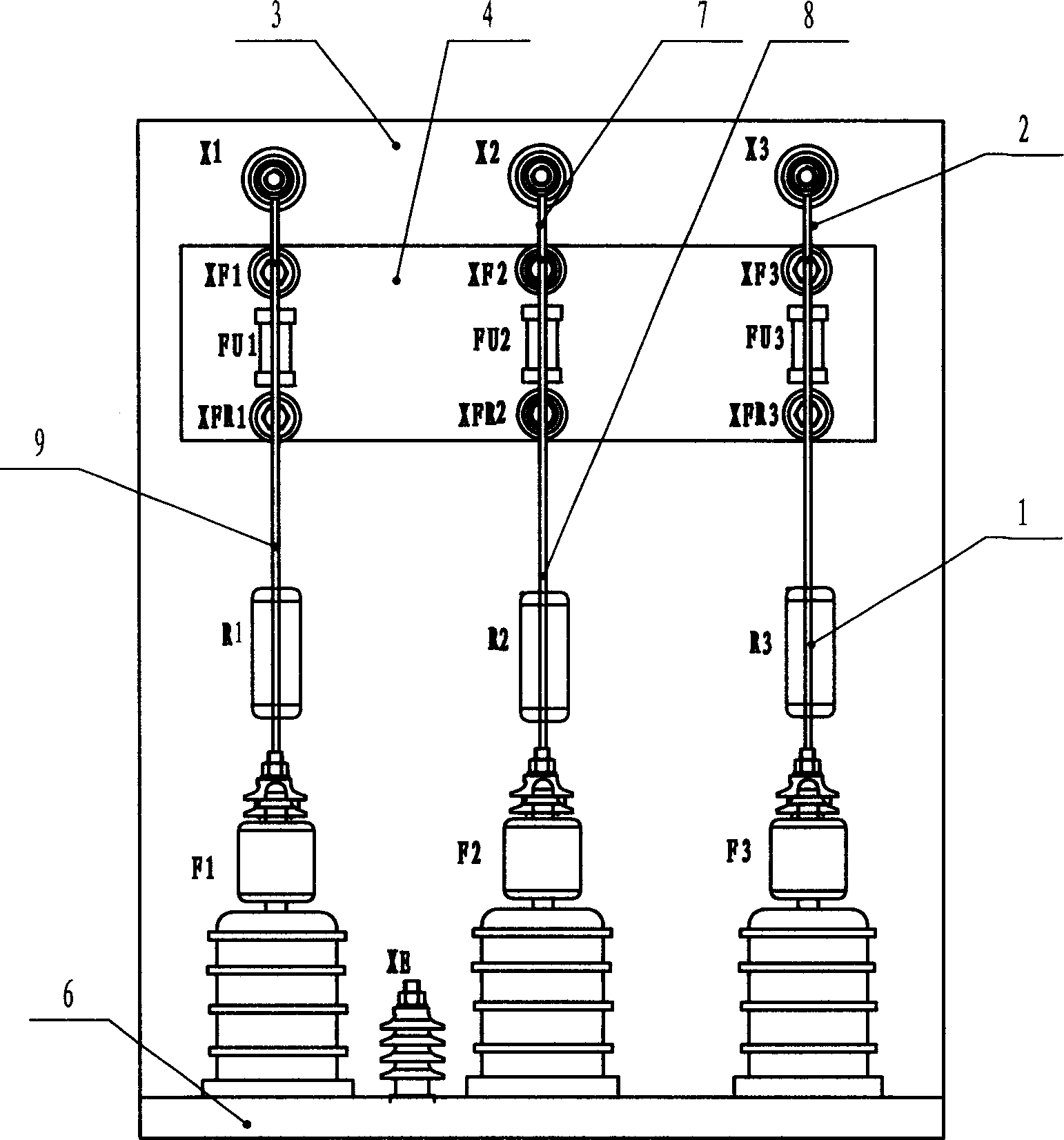

Three-station vacuum switch tube

ActiveCN102157297AAdvanced technologyReasonable designHigh-tension/heavy-dress switchesAir-break switchesElectricityGround contact

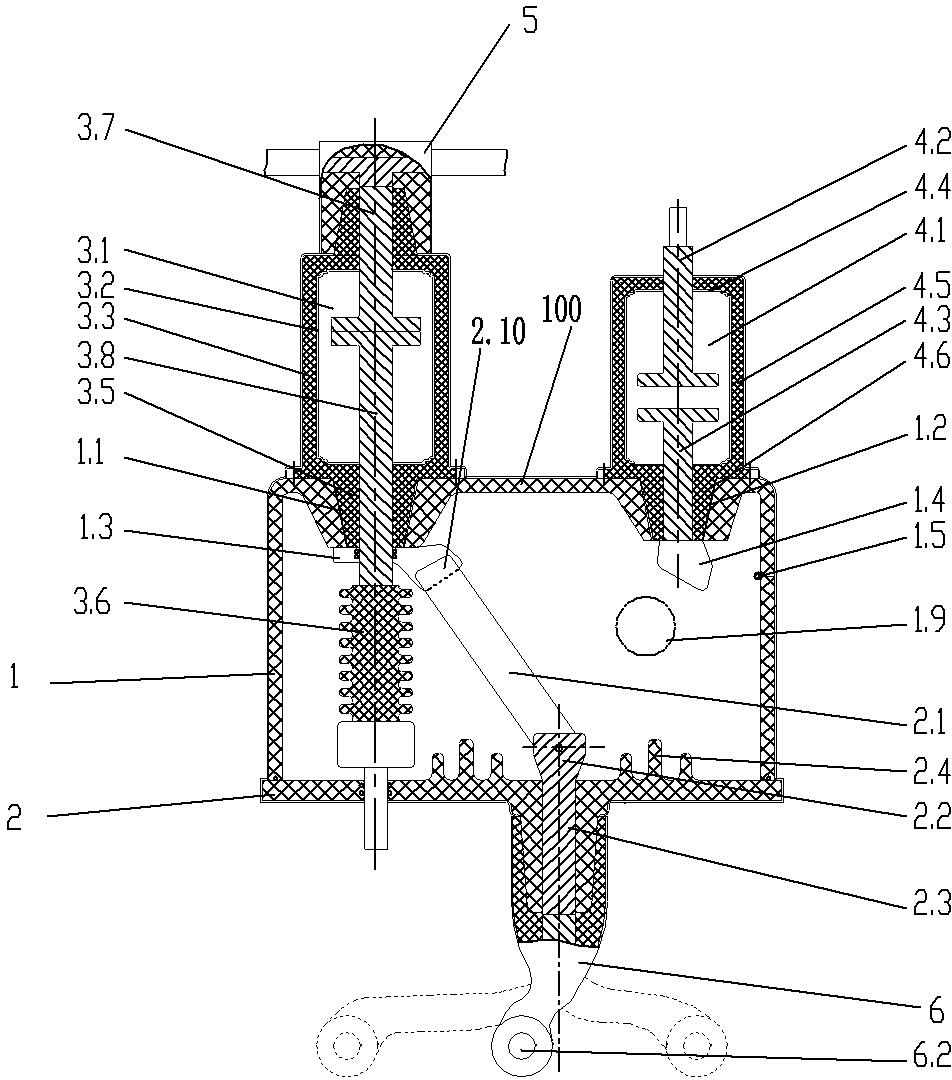

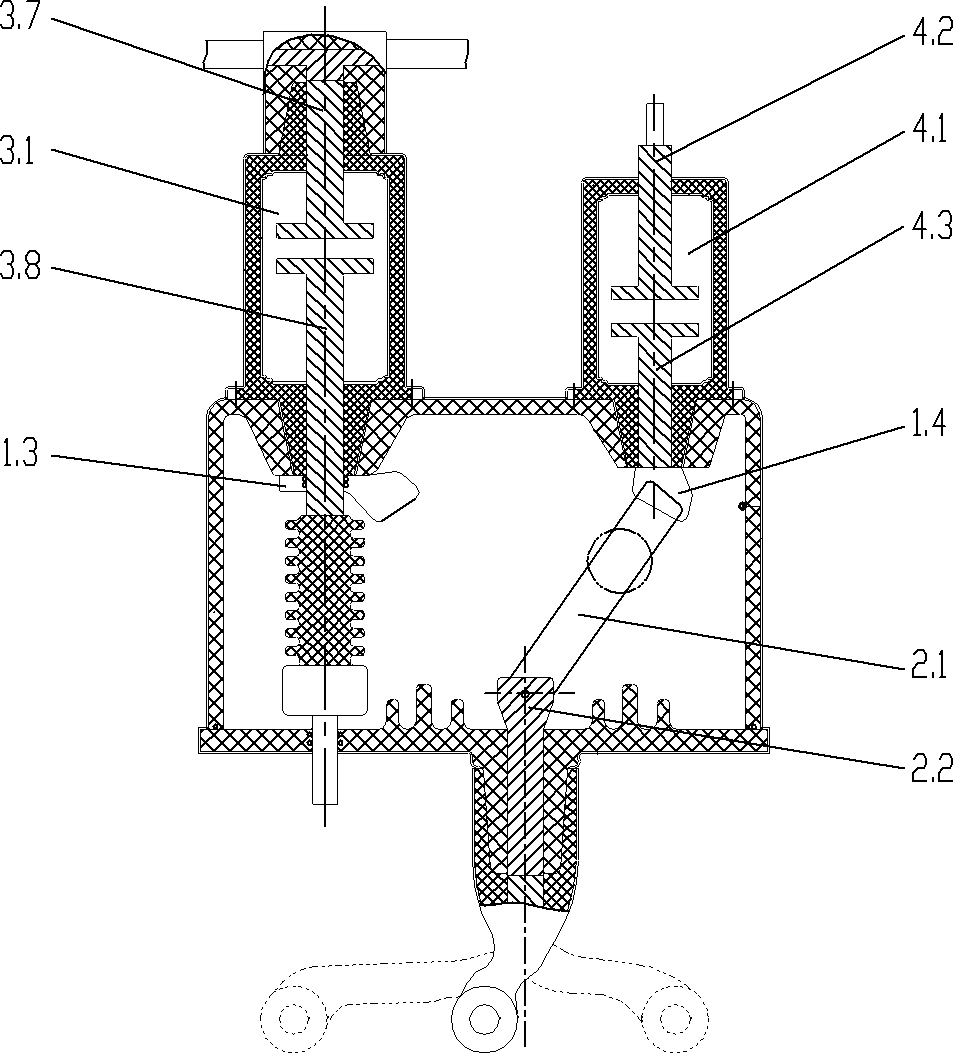

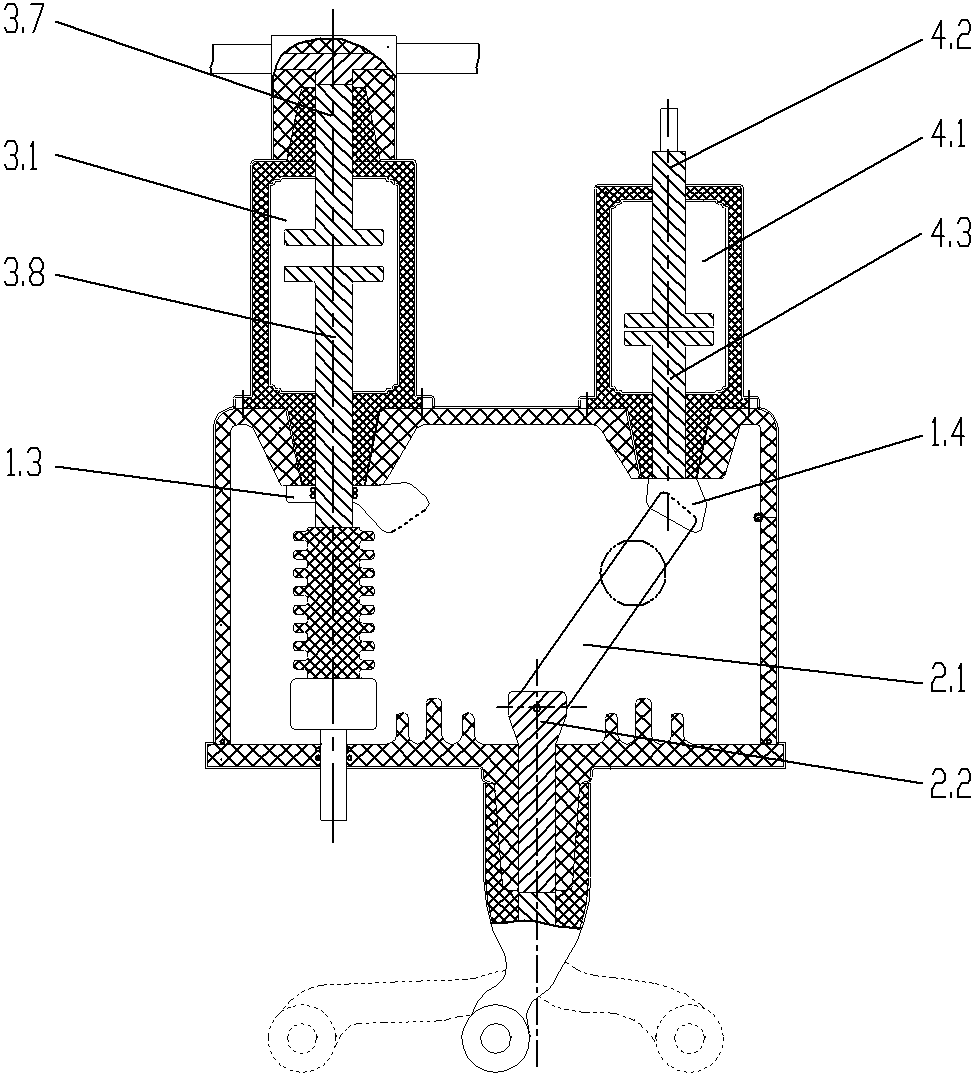

The invention discloses a three-station vacuum switch tube comprising a vacuum chamber, a fixed contact assembly, a moving contact assembly and a grounding contact, wherein the grounding contact comprises a grounding contact ring and a grounding terminal, wherein the grounding terminal is electrically connected with the grounding contact ring, and a moving contact is driven by an operating mechanism to take linear back-and-forth movement between a fixed contact and the grounding contact ring; and when the moving contact, the fixed contact and the grounding contact ring are all in off states, the tolerance electric field intensity between the moving contact and the fixed contact is higher than that between the moving contact or the fixed contact and the grounding contact ring. The invention realizes the switch-on, isolation and grounding three-station functions, also not only has the advantages of compact structure, reasonable design, advanced technology, current relative standard accordance, long electrical life and mechanical life, wide application range, high safety and reliability, and the like, but also realizes that electric breakdown firstly generates between a loading terminal and a grounding terminal once vacuum degree is reduced, enables the leakage currents and the short-circuit currents to flow into earth and ensures the safety of maintenance personnel who possibly mistakenly contact the loading terminal.

Owner:西安森源开关技术研究所有限公司

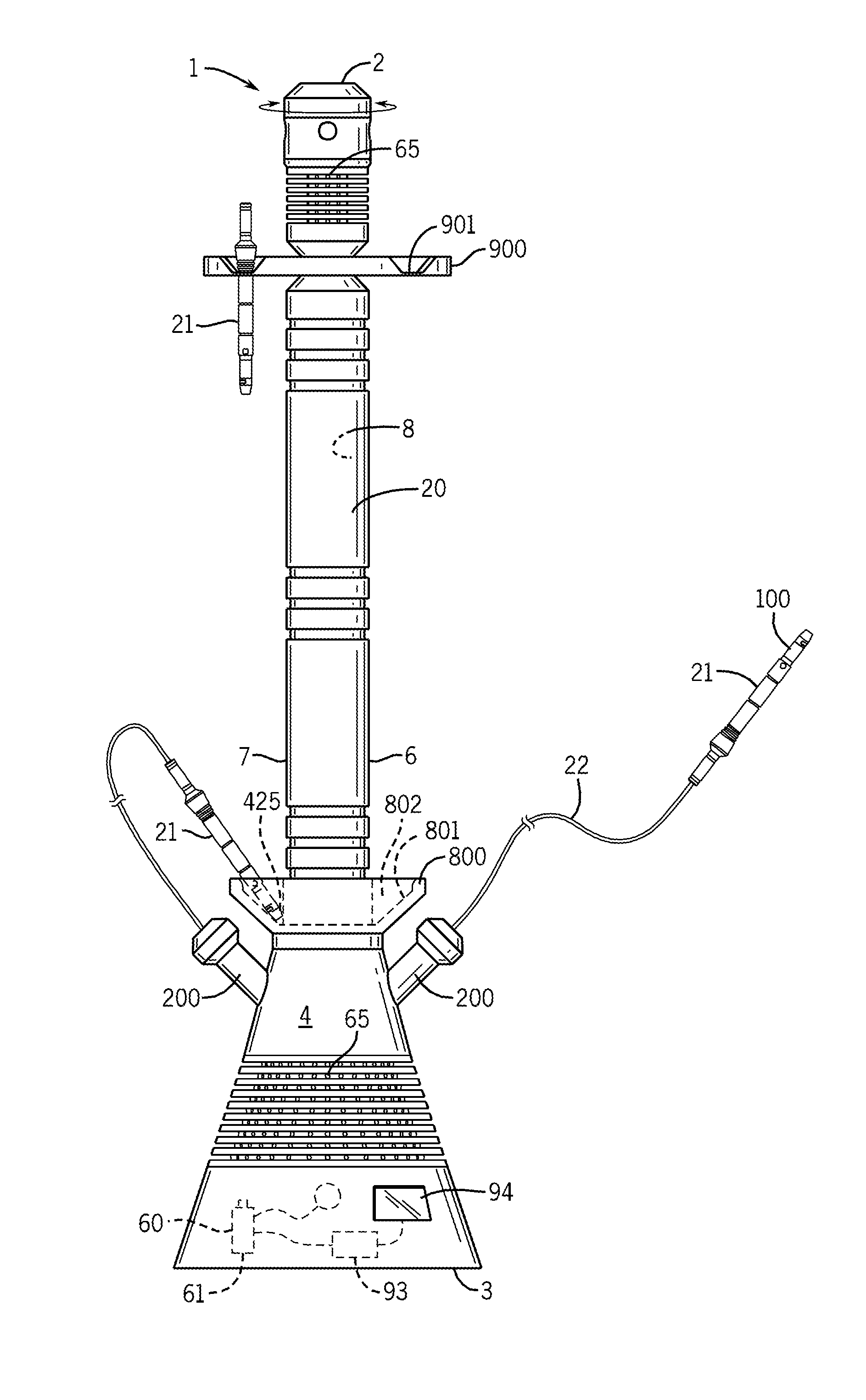

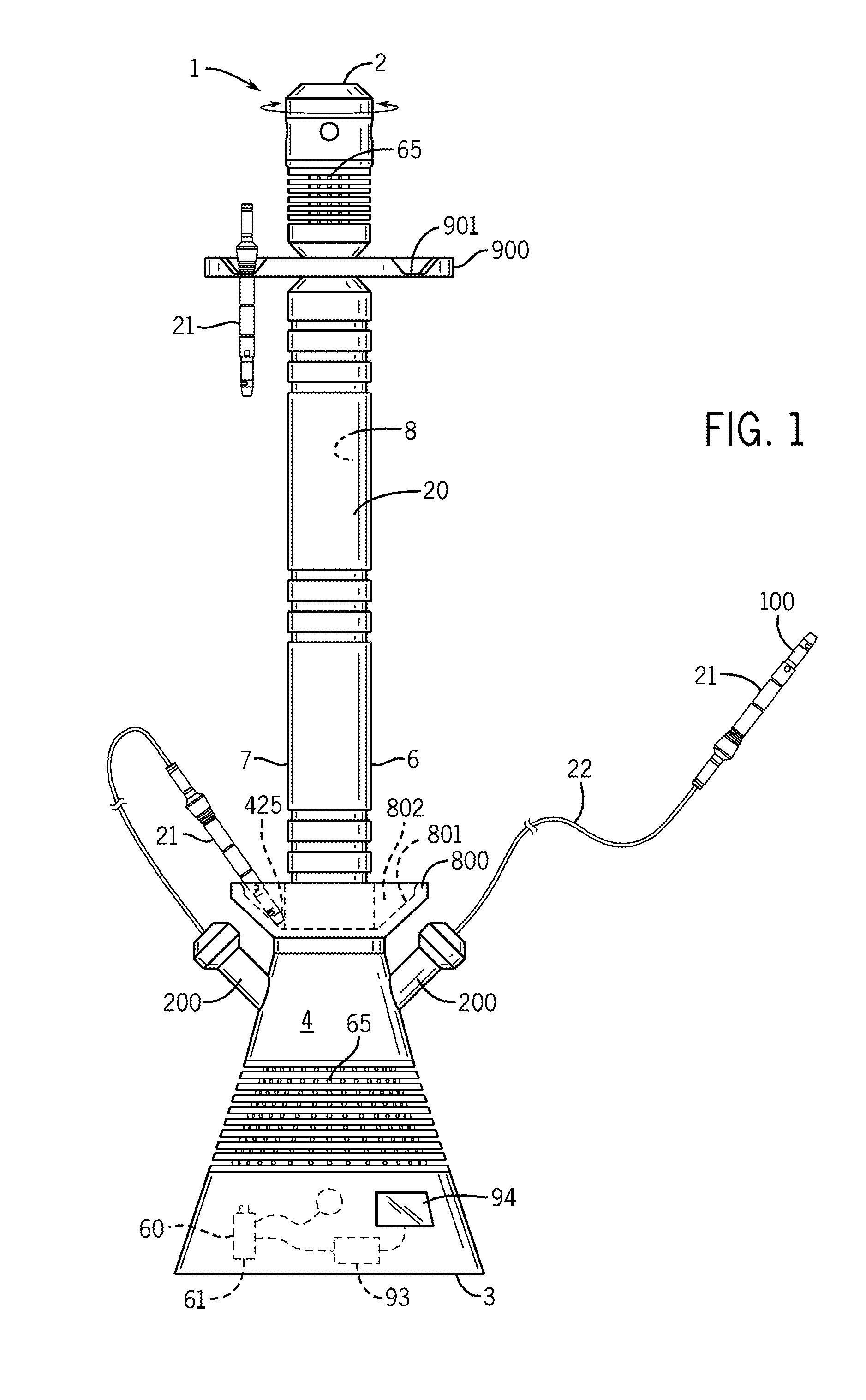

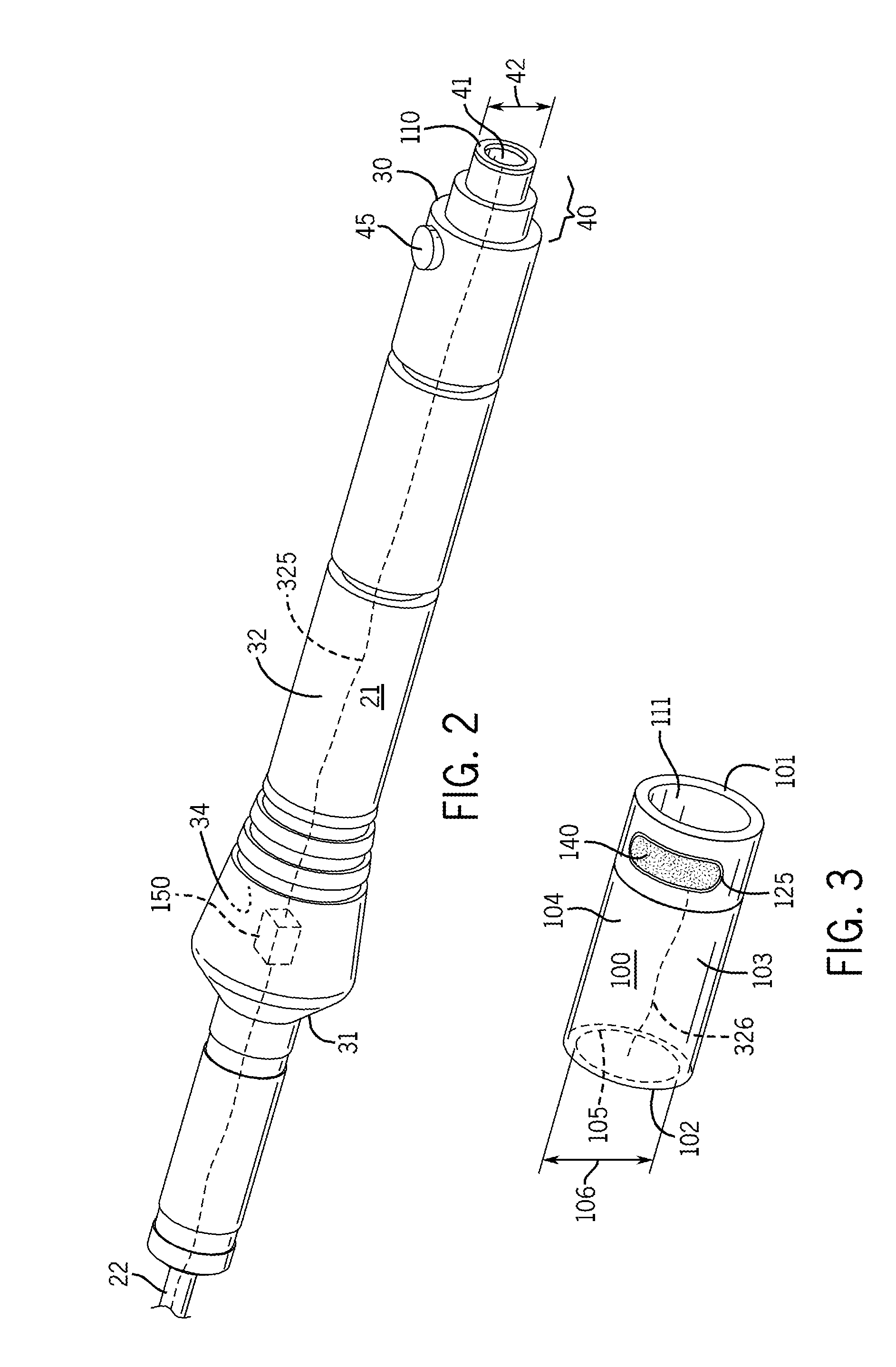

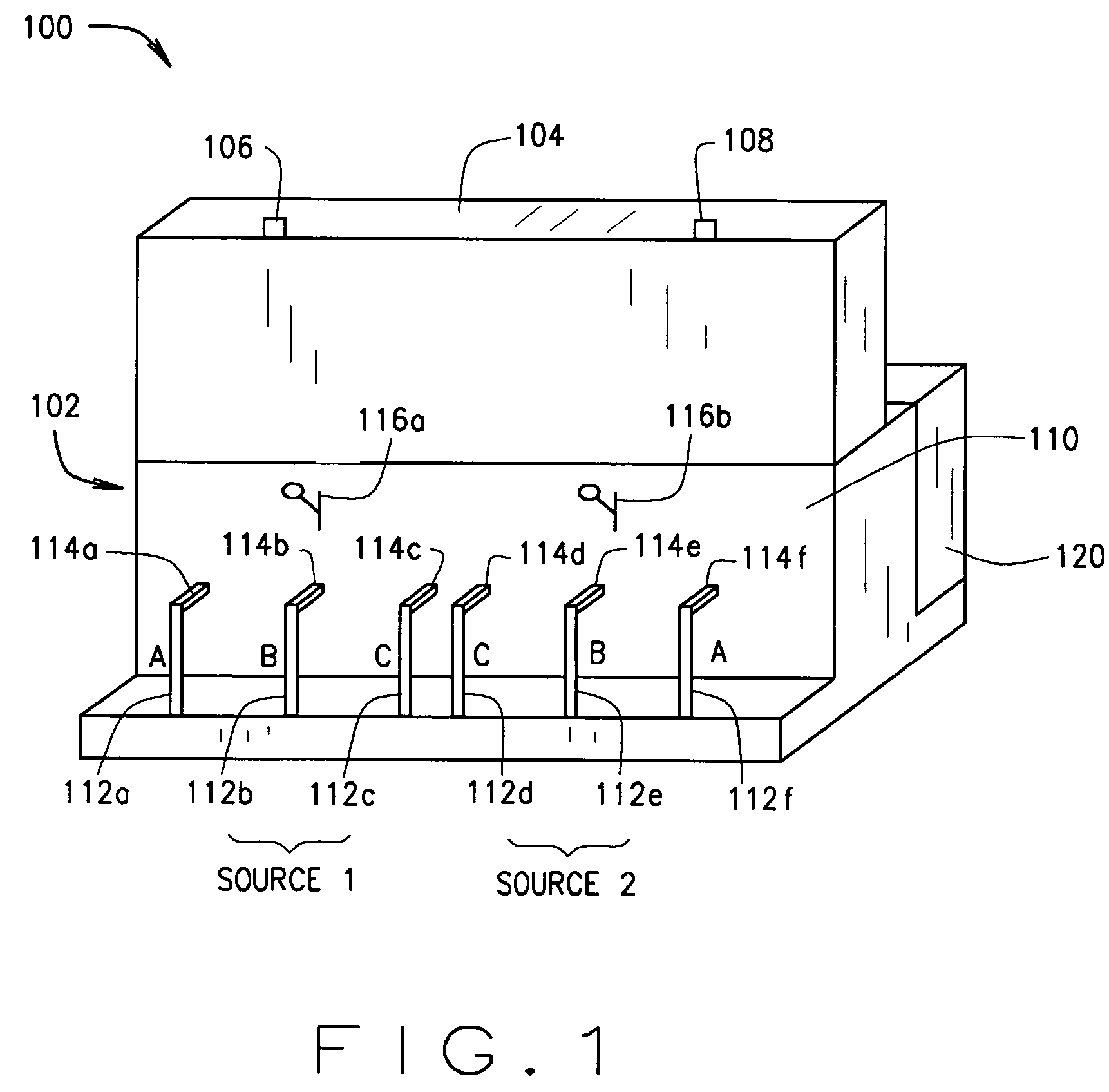

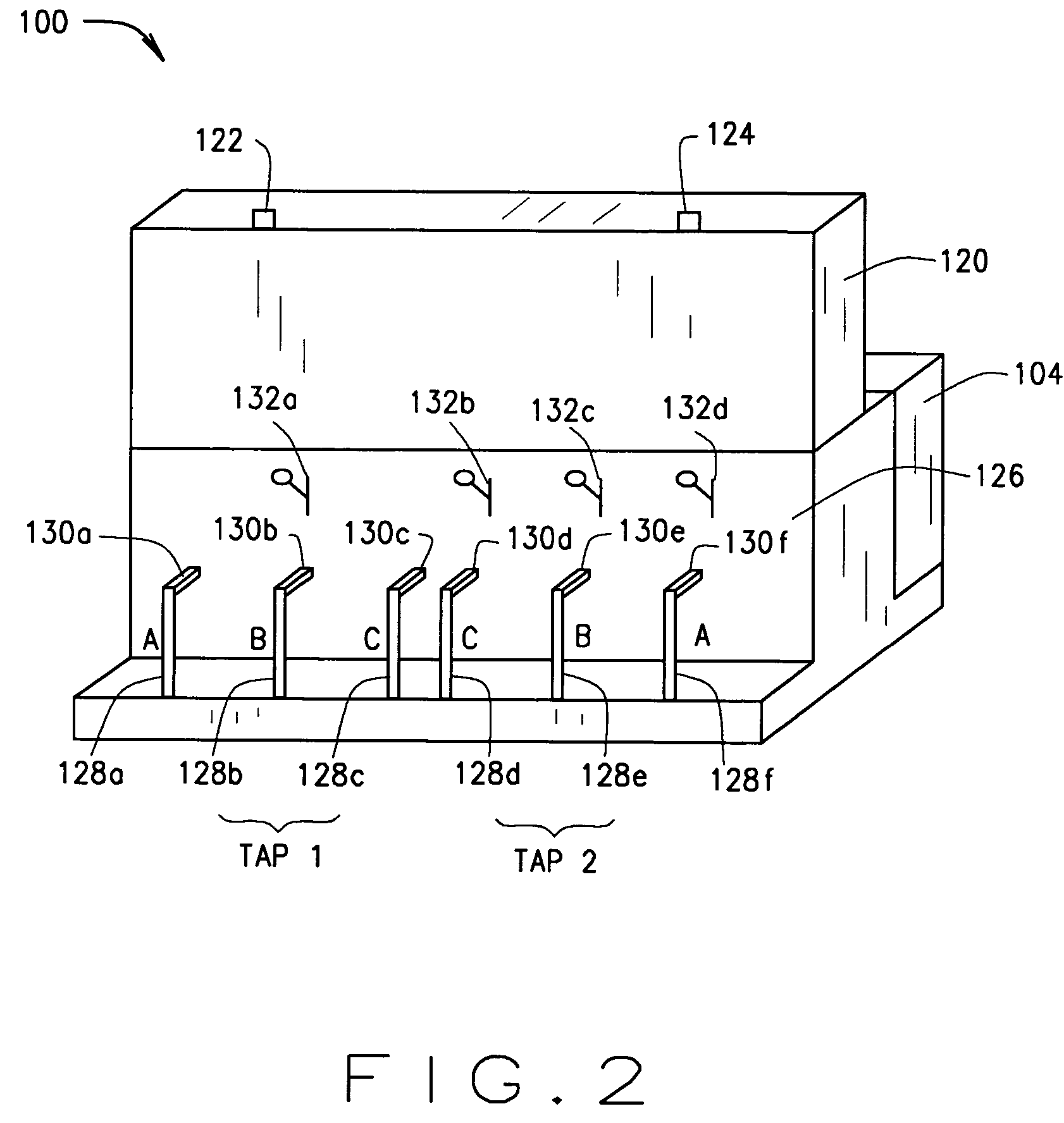

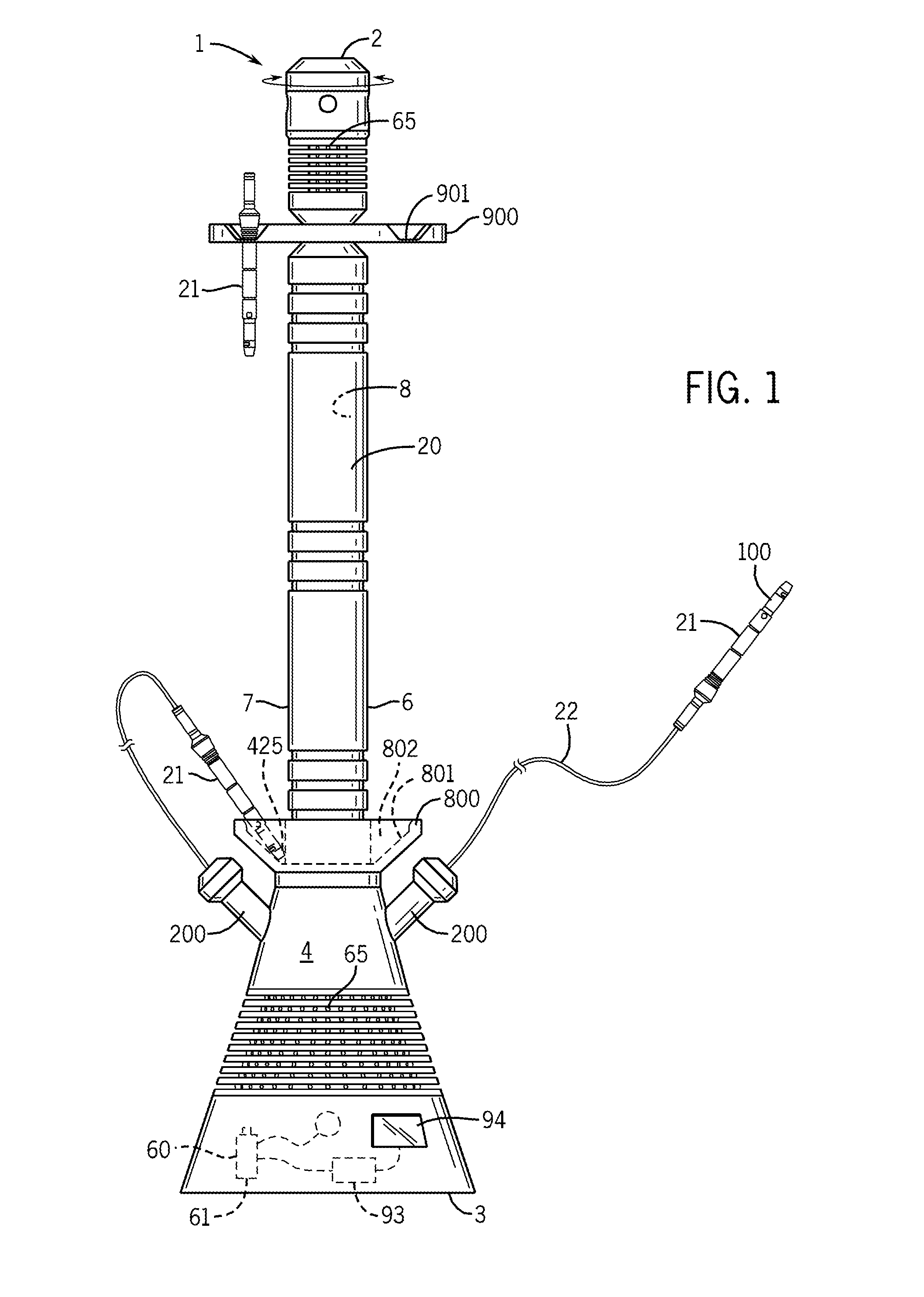

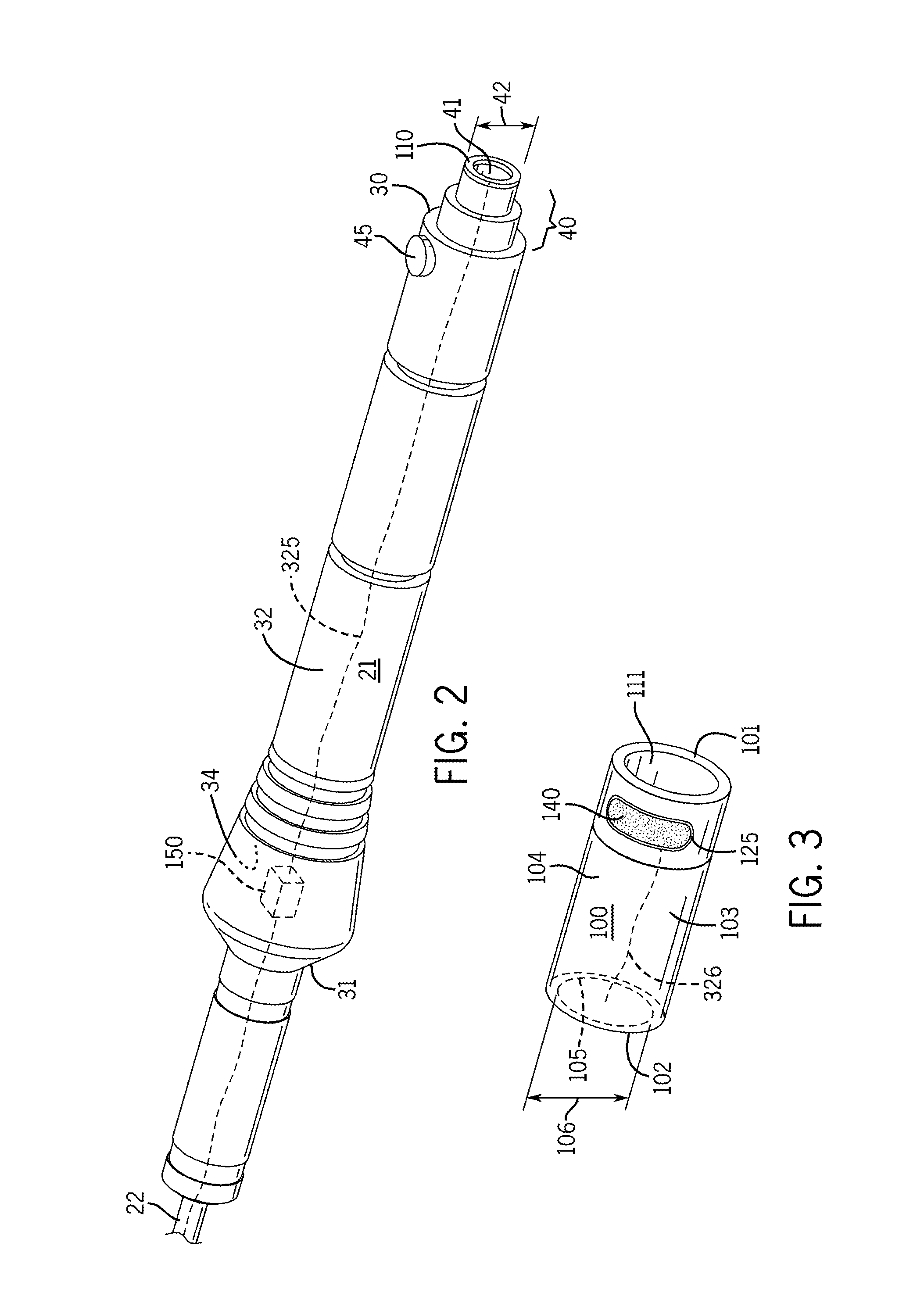

Waterless electronic hookah machine

InactiveUS20140083441A1Easy to switchDifferent flavorsTobacco pipesTobacco devicesElectricityEngineering

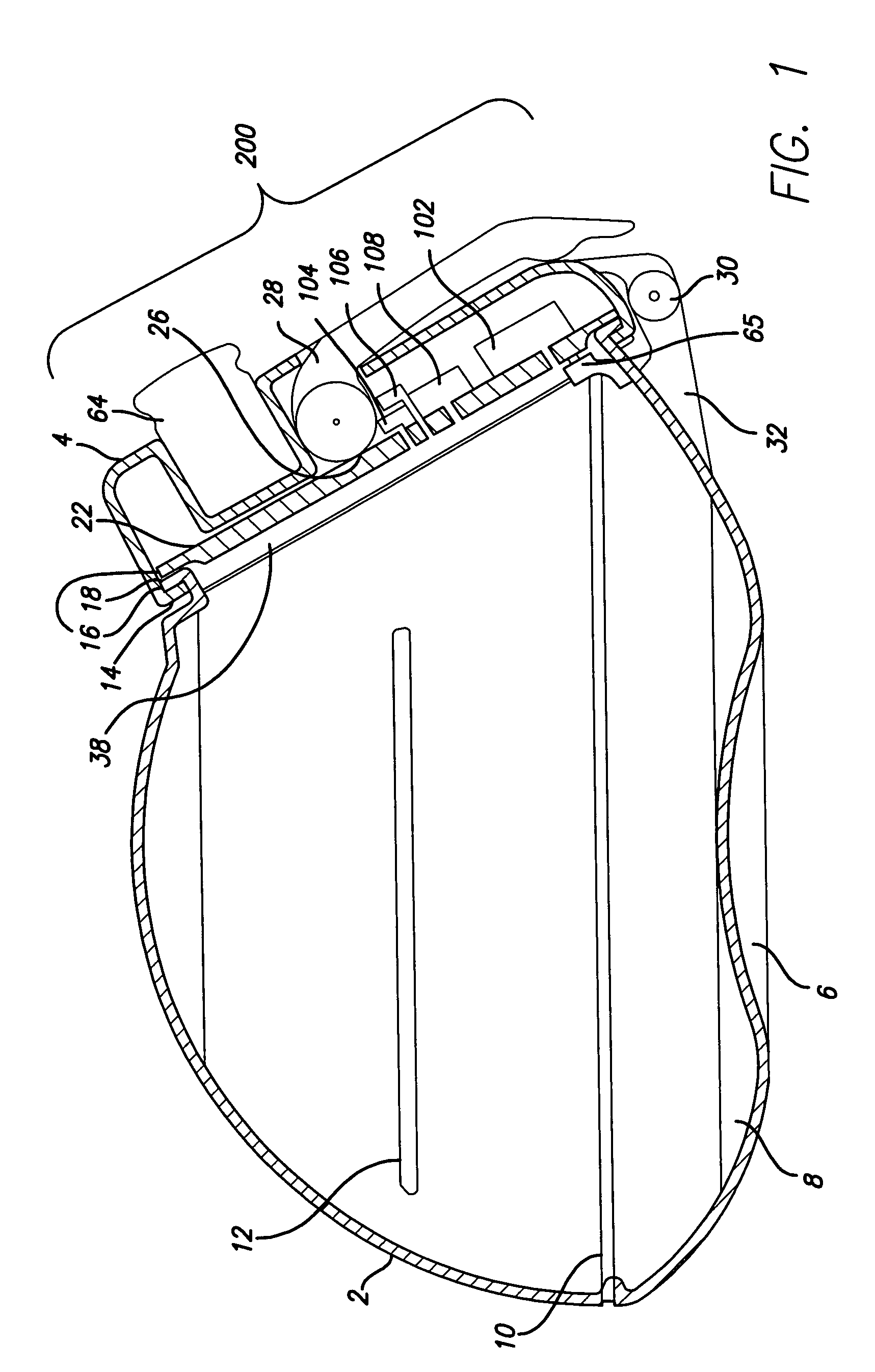

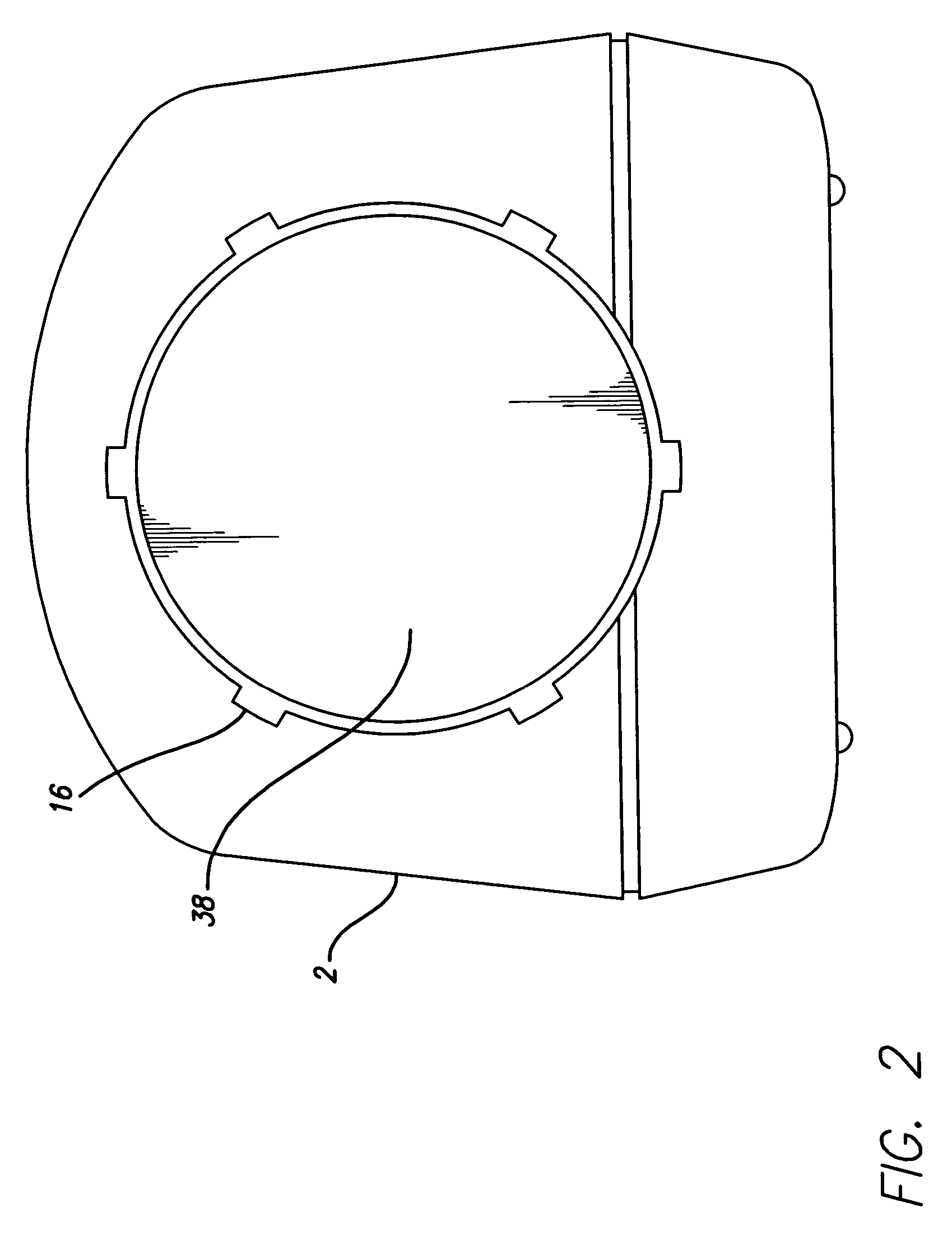

The present device generally relates to a waterless electronic hookah machine. The waterless electronic hookah machine has a main body portion, a handle section and a flexible wire cable (or “connector”). The flexible wire cable electrically connects the main body portion with the handle section. The handle section has a removable mouthpiece containing a cartridge having a liquid. When a user activates a push button or vacuum switch on the handle section, a power source in the main body portion sends power through the flexible wire cable to an atomizer located in the handle section which then heats the liquid in the cartridge of the mouthpiece and a vapor is created for the user to inhale. The device allows multiple users (generally up to six) to use the device at the same time wherein each user may experience a different flavor smoke. Flavors may be easily switched without the need to rinse out the electronic hookah machine. The user is able to adjust the voltage going to the handle.

Owner:KAPLANI FIRAS

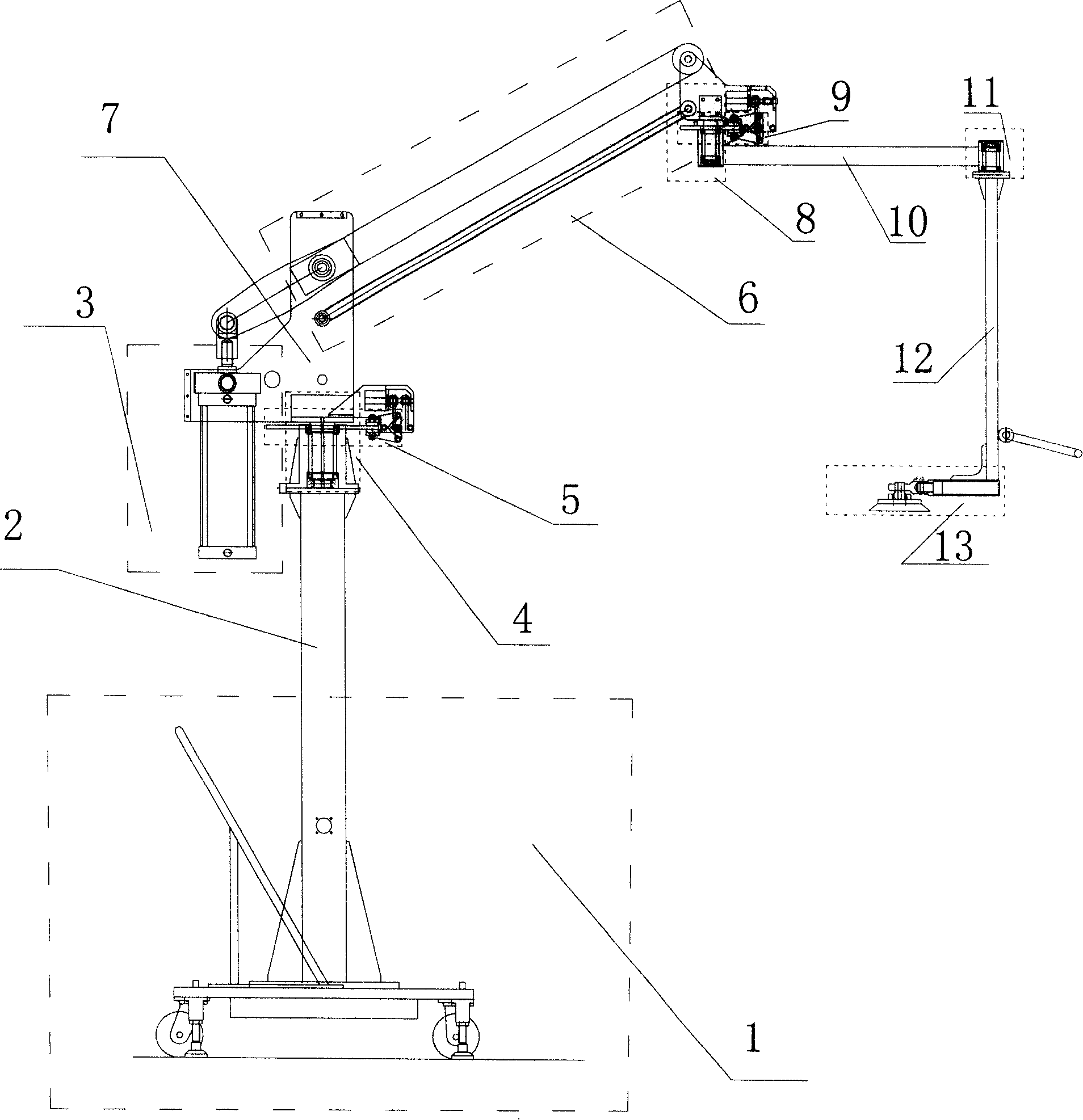

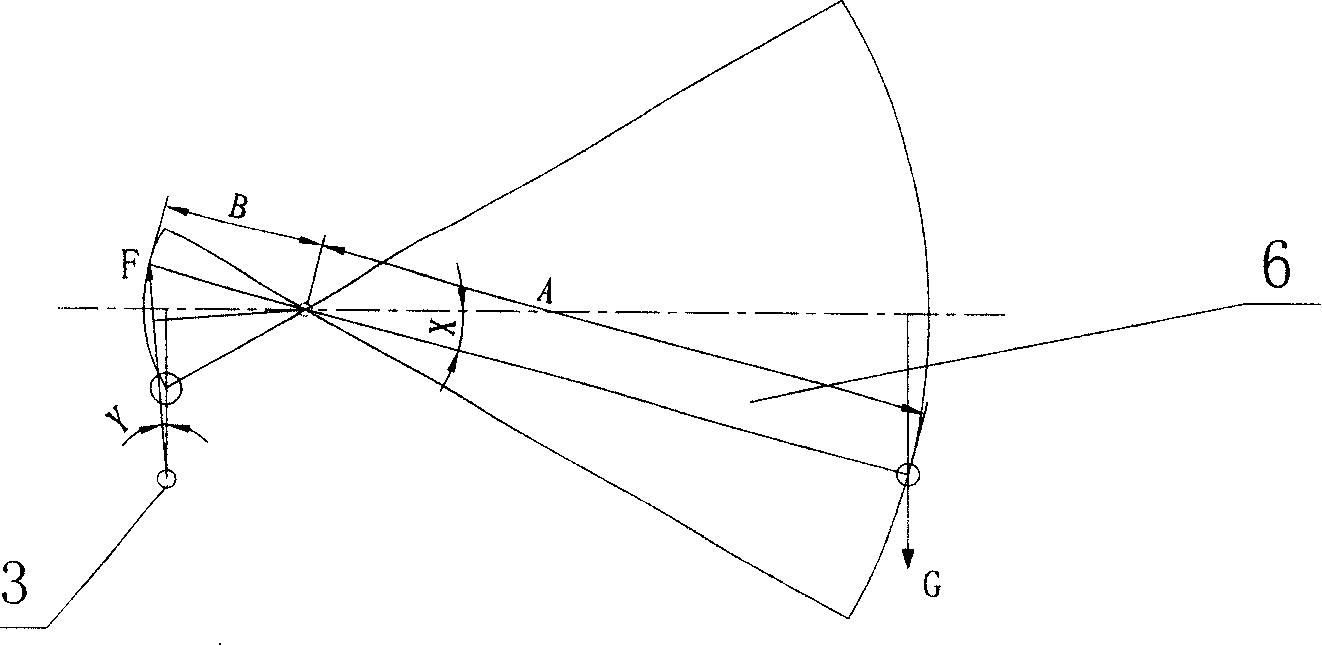

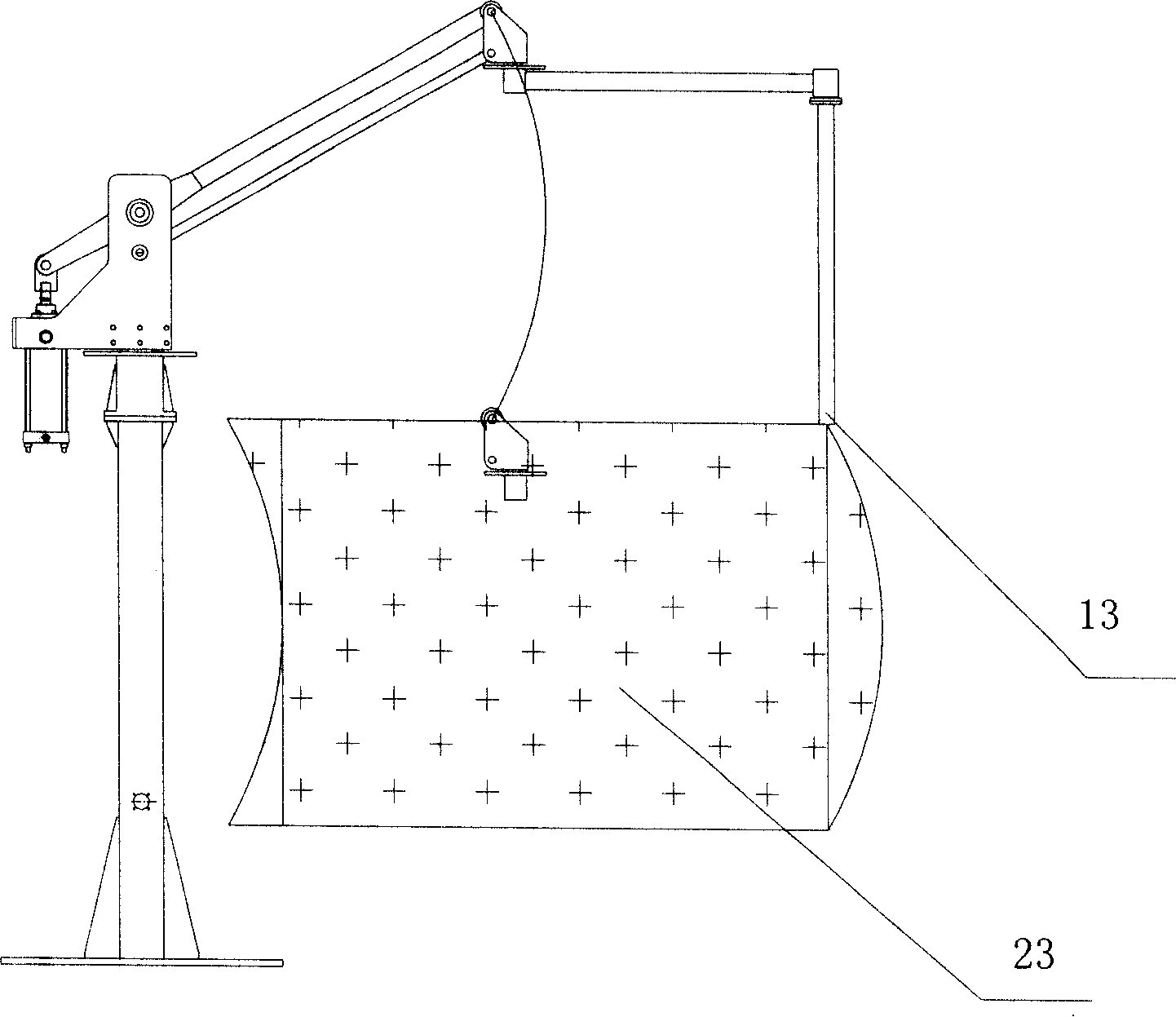

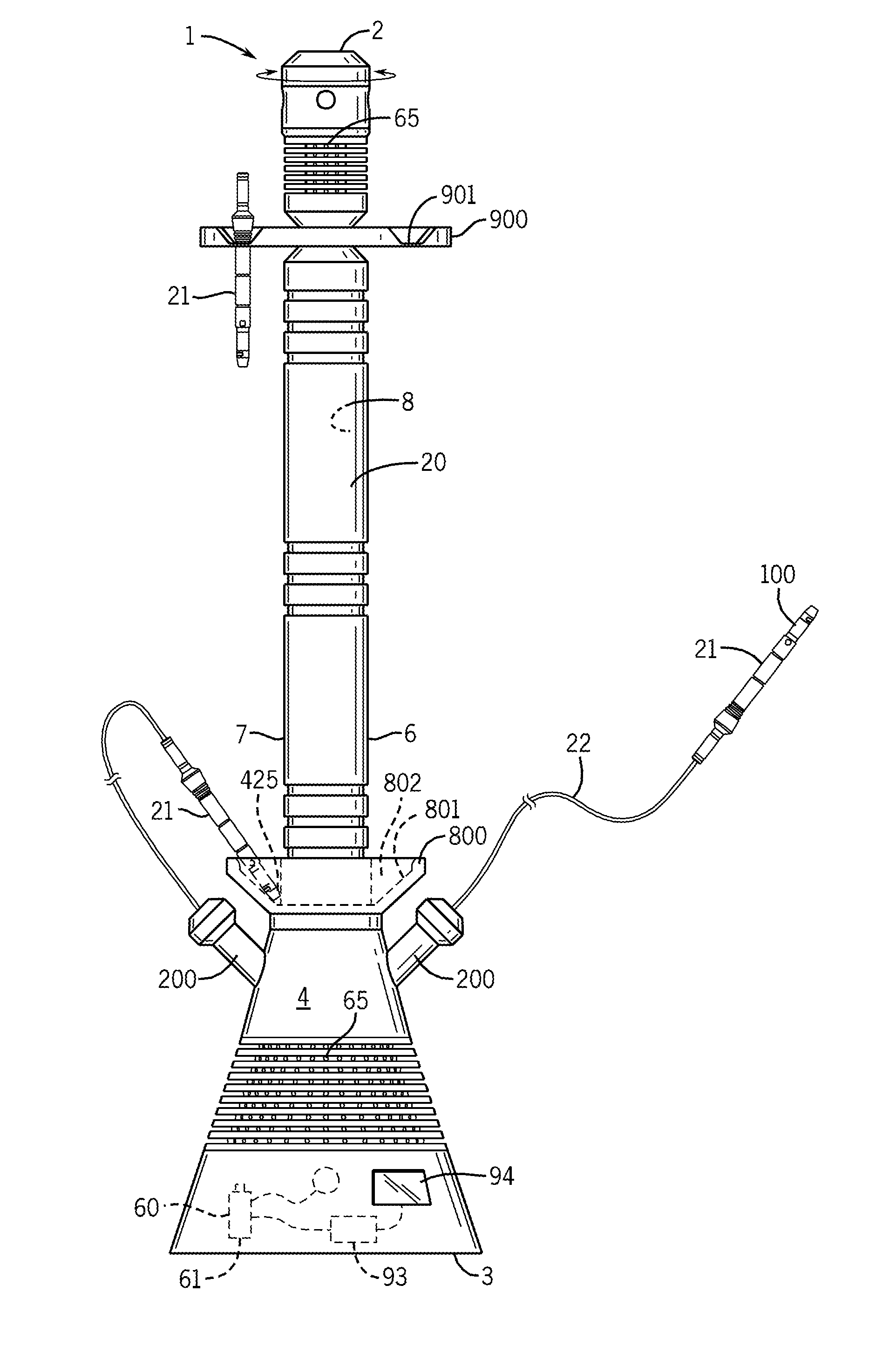

Pneumatic balancing mechanical arm

The invention provides an air balanced manipulator and an air control system of the manipulator, which comprises a base, a pillar, a rotator, an operating arm and a fixture. The manipulator also comprises a main cylinder, a brake cylinder, a rotary joint, parallel four connecting rods of organizations, a rotary arm, a dead point braking mechanism and a pneumatic control system. The air control system comprises a gas source, an airway, a vacuum switch and a vacuum generator. The manipulator can balance the carried articles at any position of the movable and solid space and meet the demand of accurate and rapid assembly, with a portable and free operation. The air control system can control the movement of the manipulator by controlling the movement of the main cylinder and the brake cylinder, ensure that the manipulator does not drop to pose a risk when the gas source stops supplying gas for accidents and avoid that the carried articles drop for misoperation, thereby ensuring the safety of operators and products in maximum.

Owner:胡青

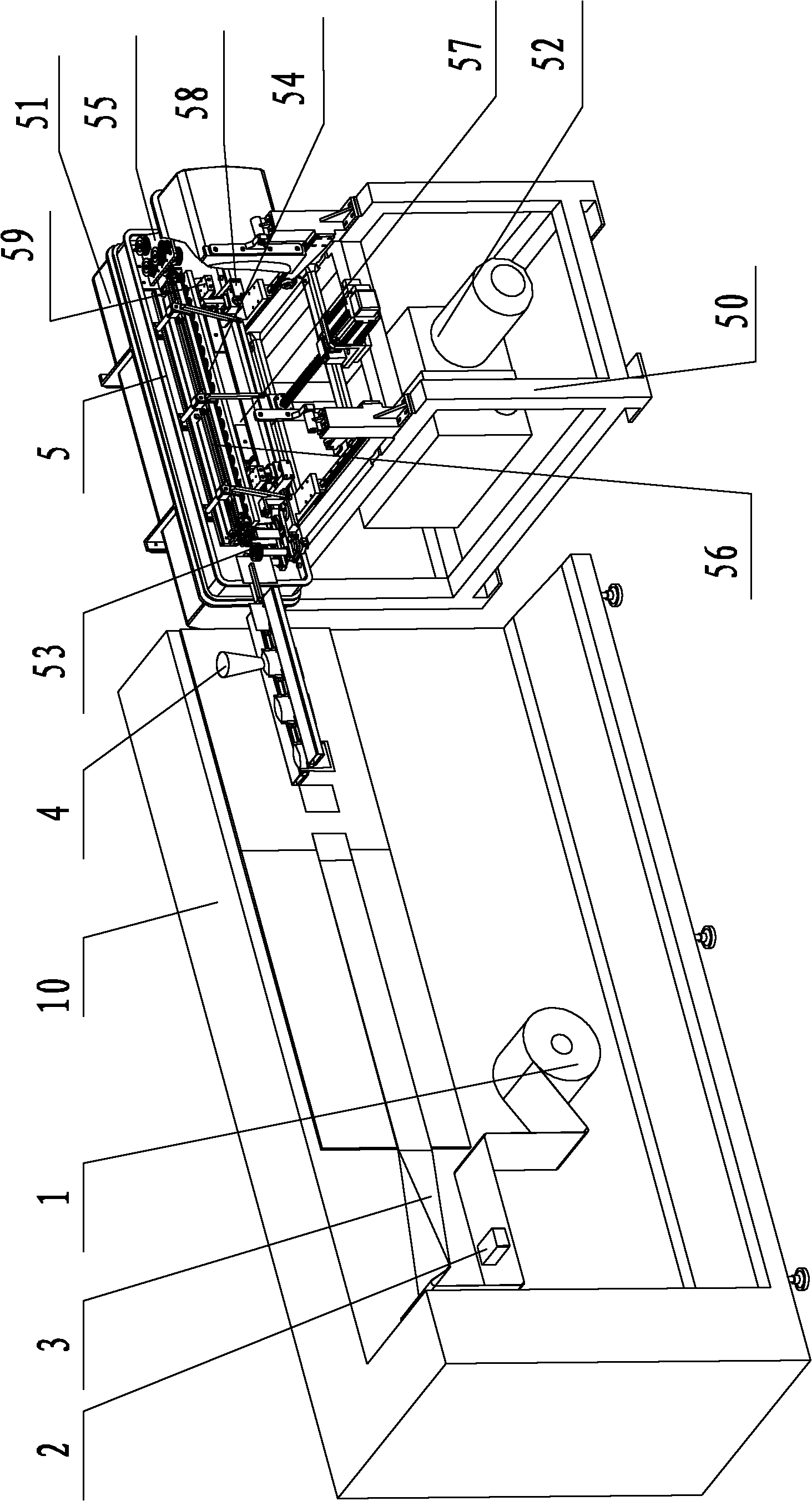

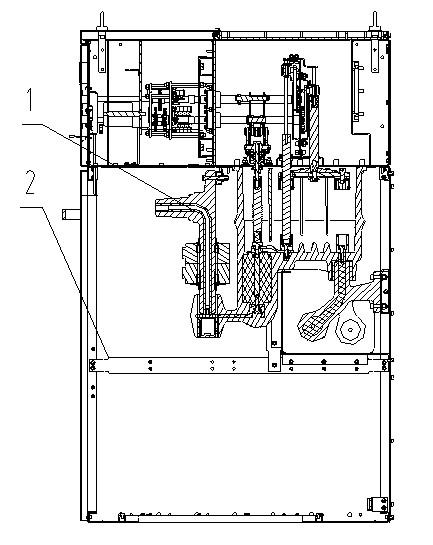

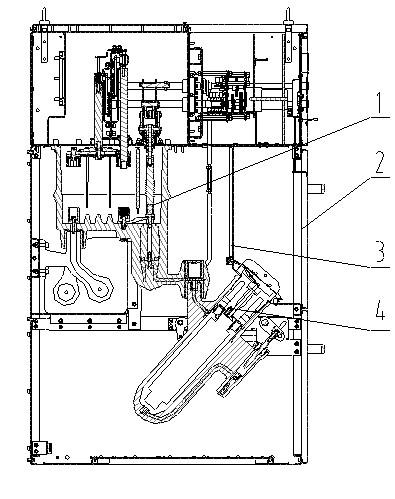

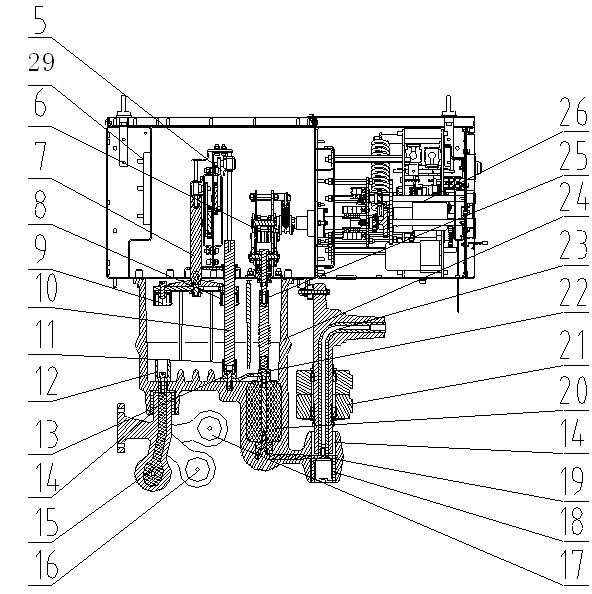

Full-automatic vacuum packaging machine

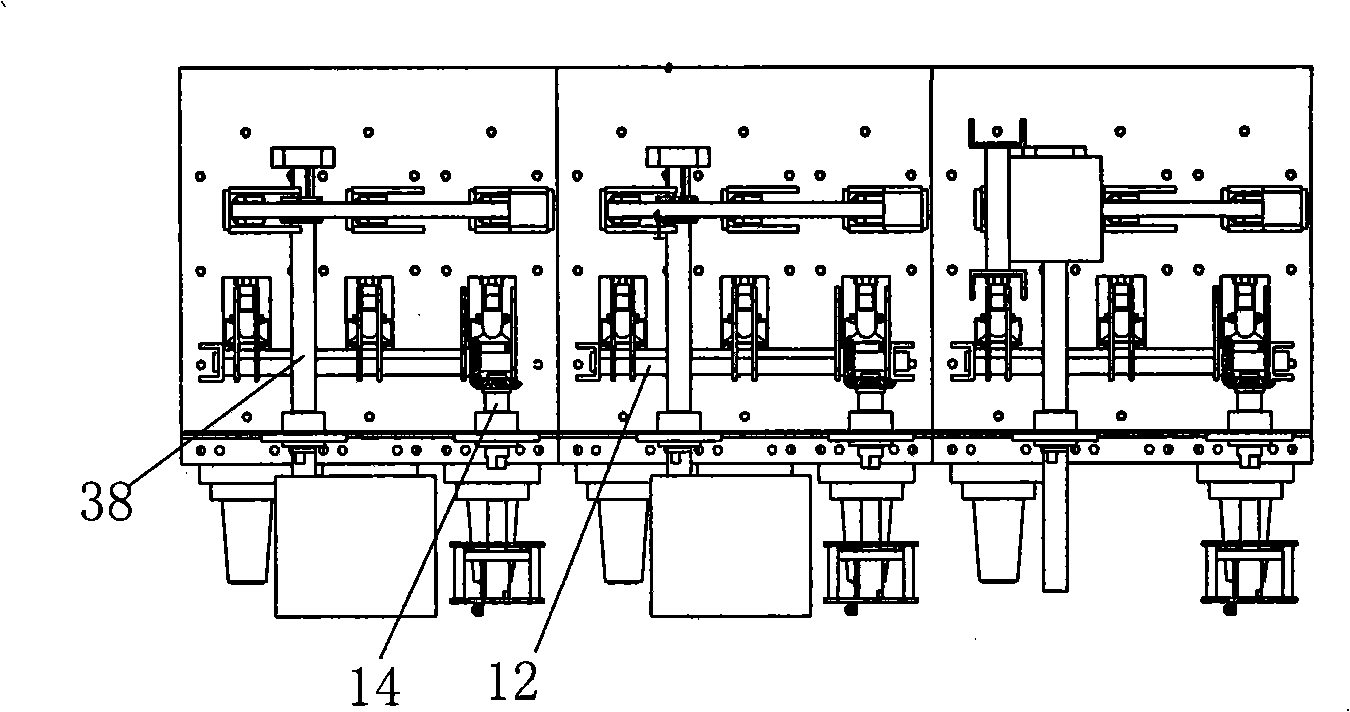

InactiveCN101973406AImprove work efficiencyPackaging under vacuum/special atmosphereWrapper twisting/gatheringEngineeringVacuum switch

The invention discloses a full-automatic vacuum packaging machine which comprises a membrane releasing device, a printing device, a bag making device, a feeding device and a vacuum and sealing device connected in sequence. The vacuum and sealing device comprises a vacuum reciprocating mechanism, a vacuum switching mechanism, a bag receiving mechanism, a bag delivery mechanism, a traction mechanism, a sealing mechanism, a bag pressing and shaping mechanism, a bag clamp adjusting mechanism and a transfer belt separating mechanism. The vacuum reciprocating mechanism comprises a main box body capable of laterally moving and fixed side box bodies located on both sides of the main box body, and the main box body laterally moves to be combined with one side box body to form a vacuum chamber and simultaneously to be separated from another side box body to form an opened sealing station. The vacuum switching mechanism is used for vacuumizing and relieving the vacuum of the vacuum chamber and the sealing station. The bag receiving mechanism, the bag delivery mechanism, the traction mechanism, the sealing mechanism, the bag pressing and shaping mechanism, the bag clamp adjusting mechanism and the transfer belt separating mechanism are respectively located on both sides of the main box body. Packaging, inputting and outputting can be carried out at the same time, so that the efficiency is greatly increased.

Owner:上海嘉迪机械有限公司

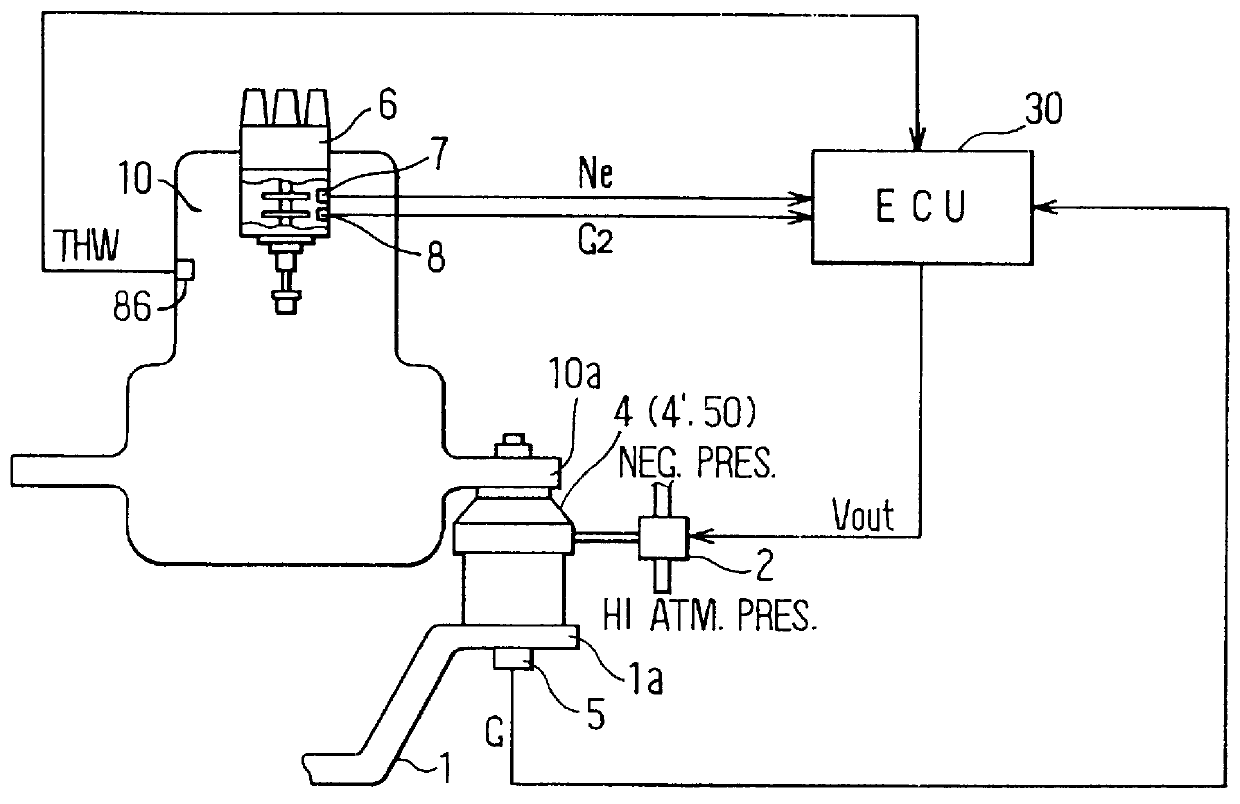

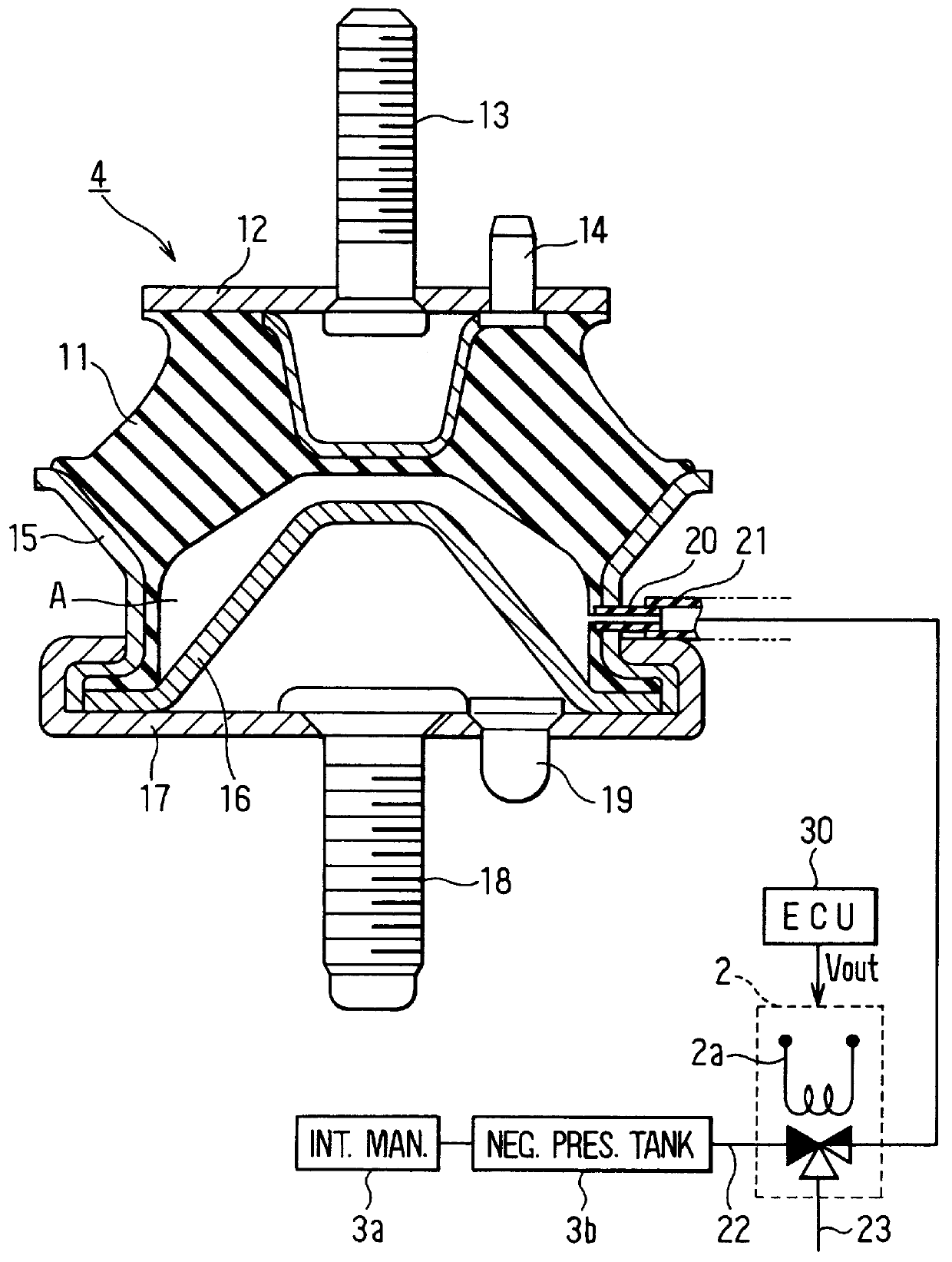

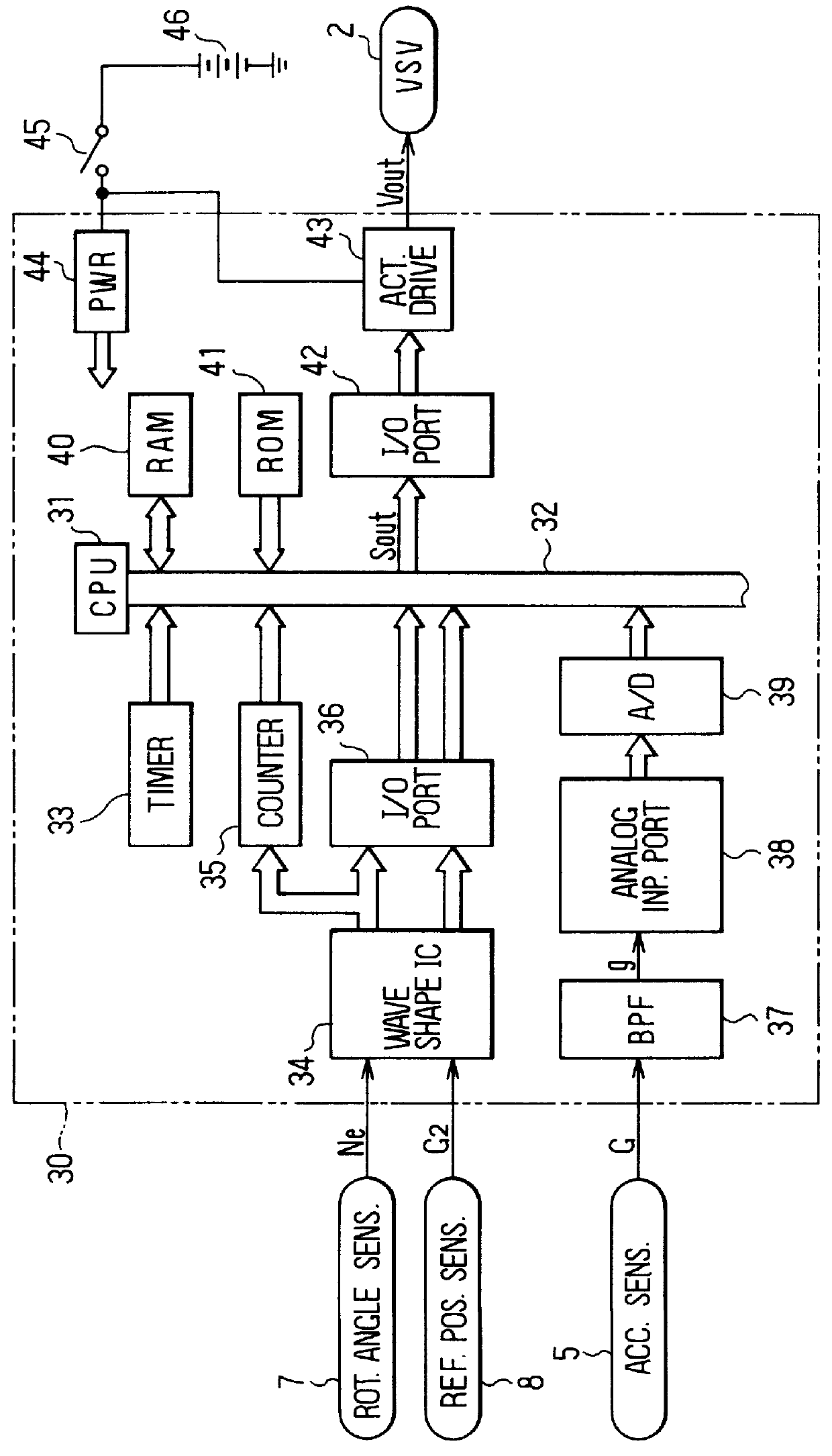

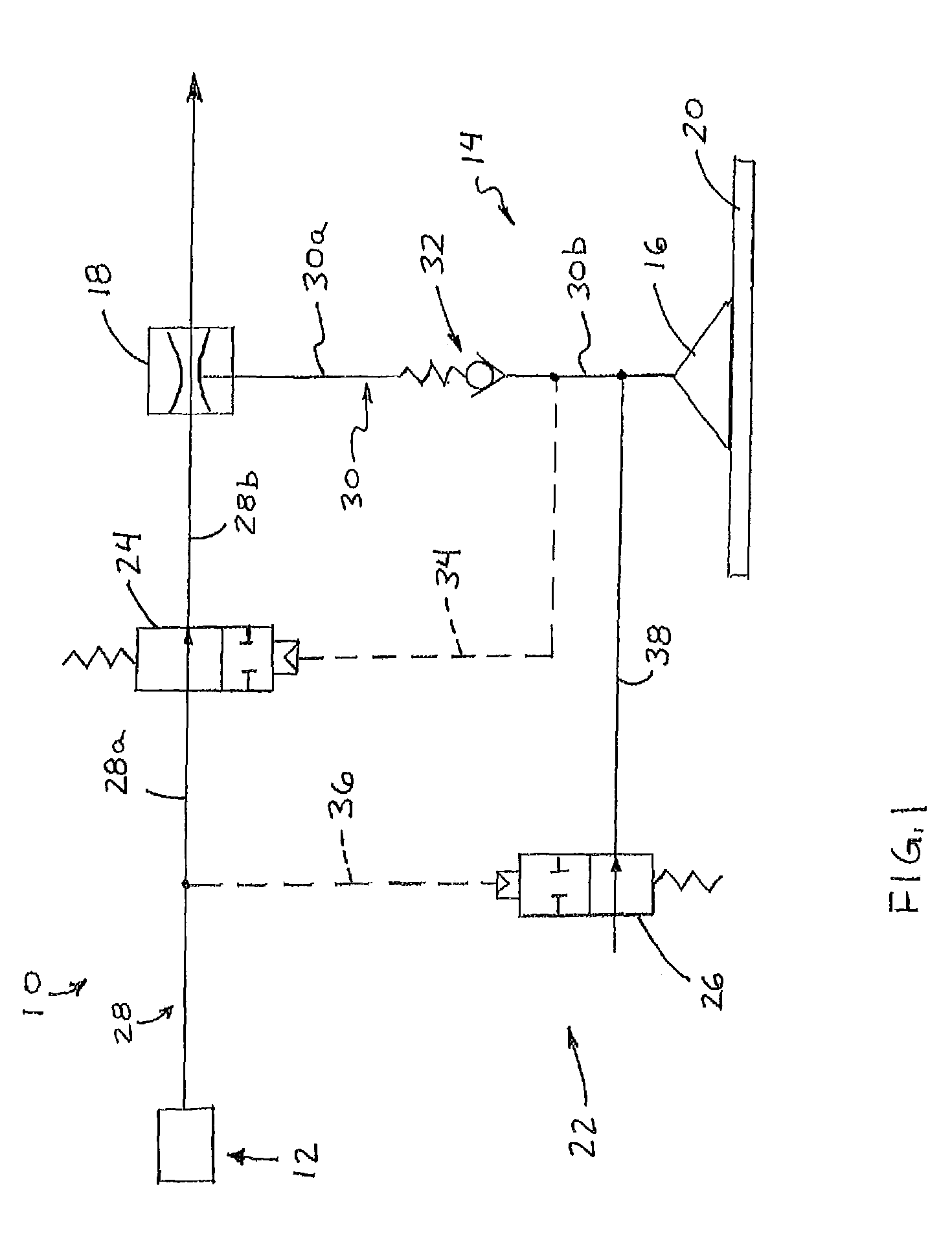

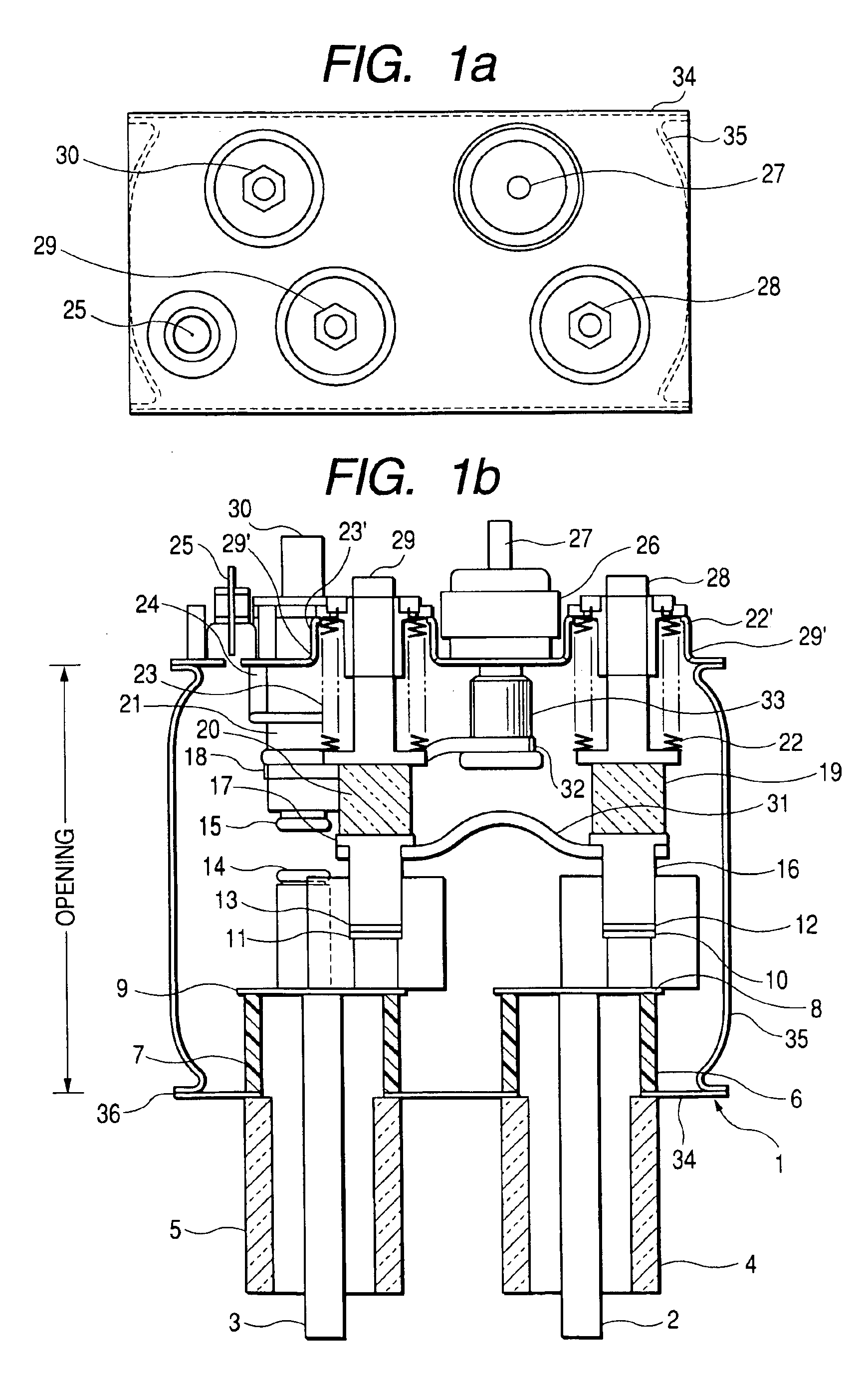

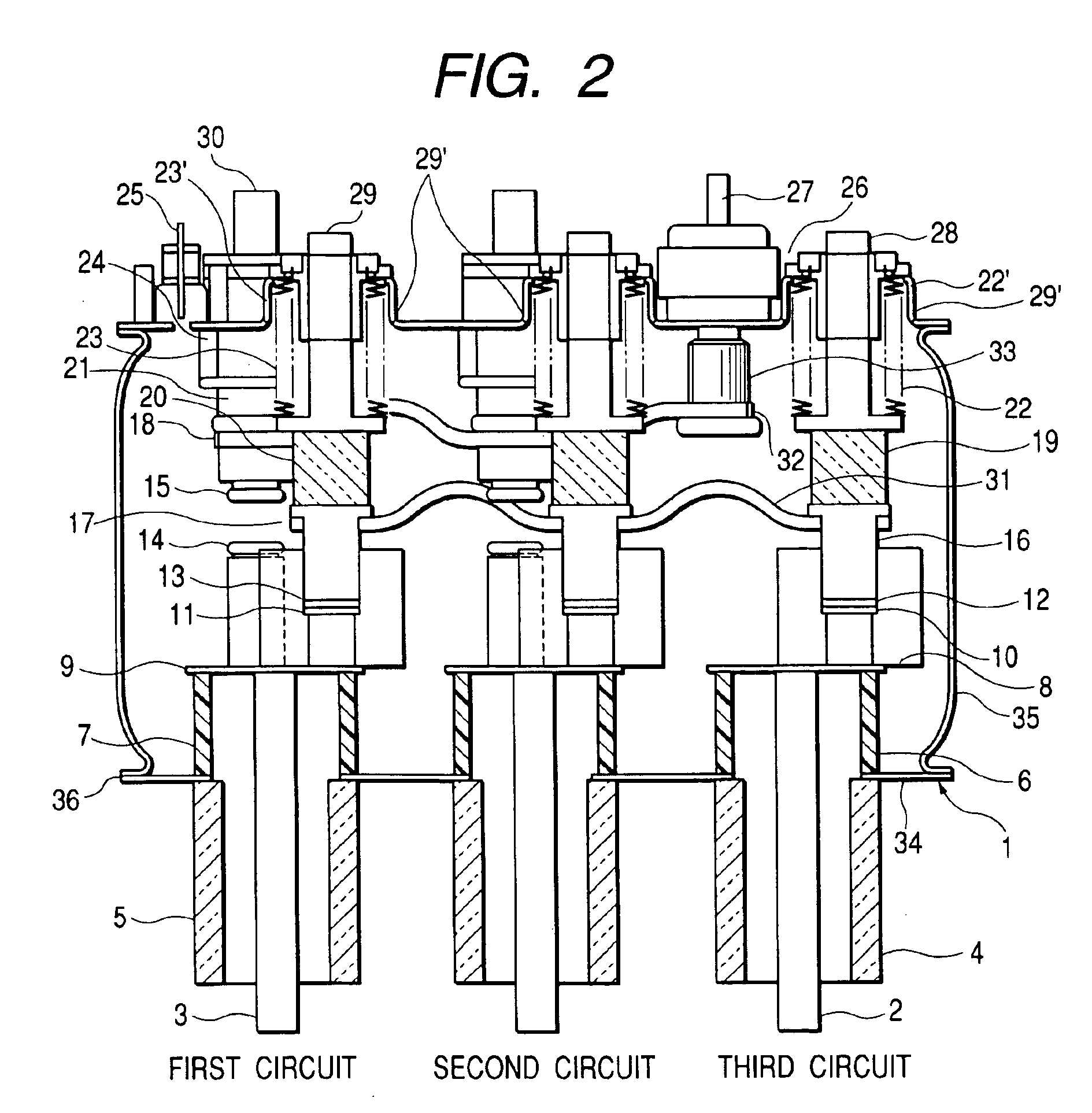

Electronically controlled engine mount

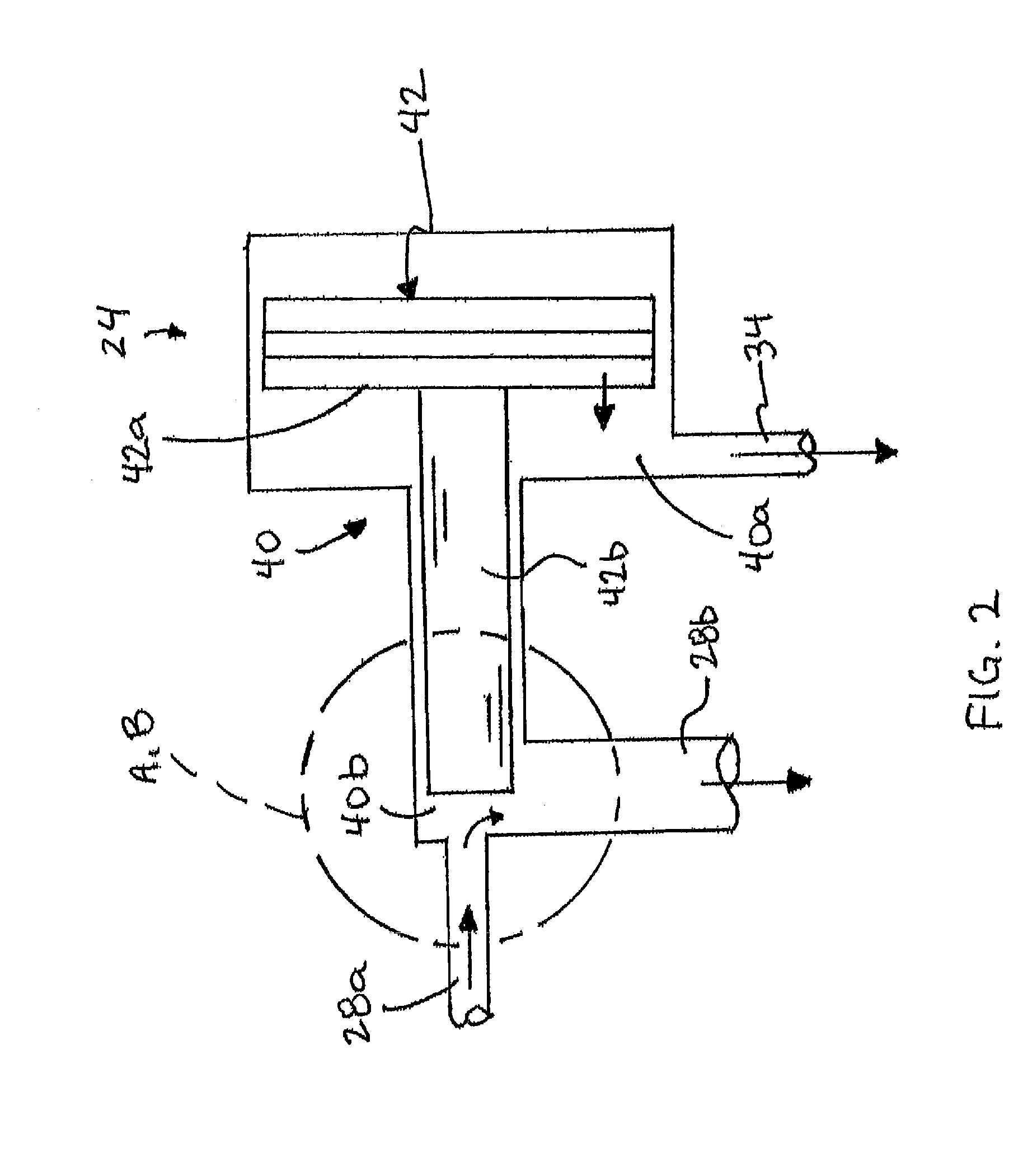

InactiveUS6120012AReduce vibrationSufficient characteristicMachine framesLiquid springsEngineeringVibration transmission

An engine mount which is capable of changing its vibration transmission characteristics with a simple structure using an inexpensive actuator is provided. A partition is inserted to a side member to which a mount rubber (rubber vibration isolator) of the engine mount is spliced to close a space between the mount rubber and to create an air chamber. An air duct pipe which communicates with the air chamber is connected to the side member and is connected to a VSV (vacuum switching valve) via a connection pipe. The VSV is controlled to ON / OFF states based on a driving voltage Vout from an ECU which corresponds to explosive vibrations of the engine to switch pressure within the air chamber to negative pressure of a vacuum tank in which negative pressure of an intake manifold is accumulated or to atmospheric pressure, interlocking with the vibration of the engine. Thereby, the vibration transmission characteristics of the engine mount may be adequately changed and the vehicular vibration may be reduced significantly.

Owner:DENSO CORP

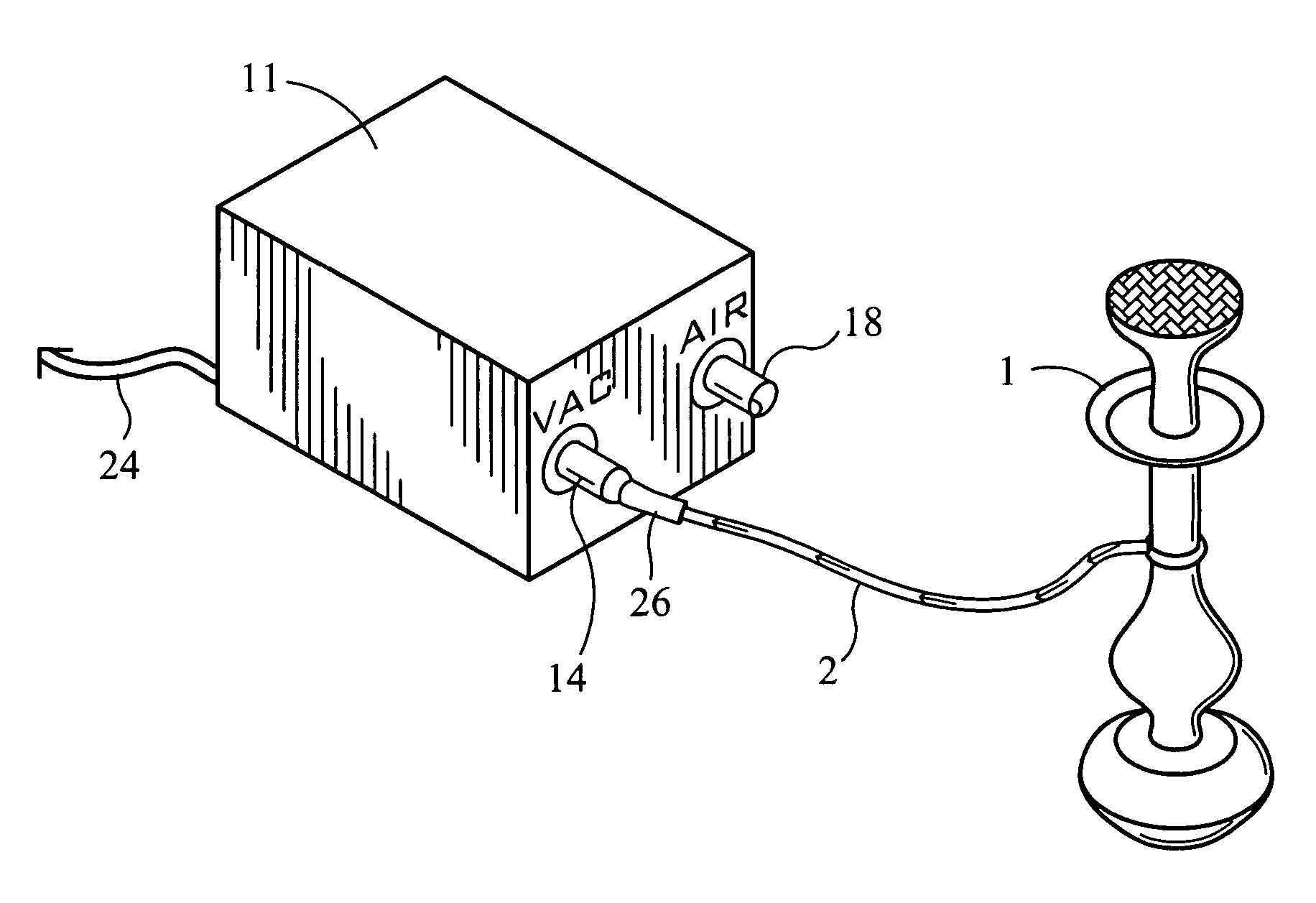

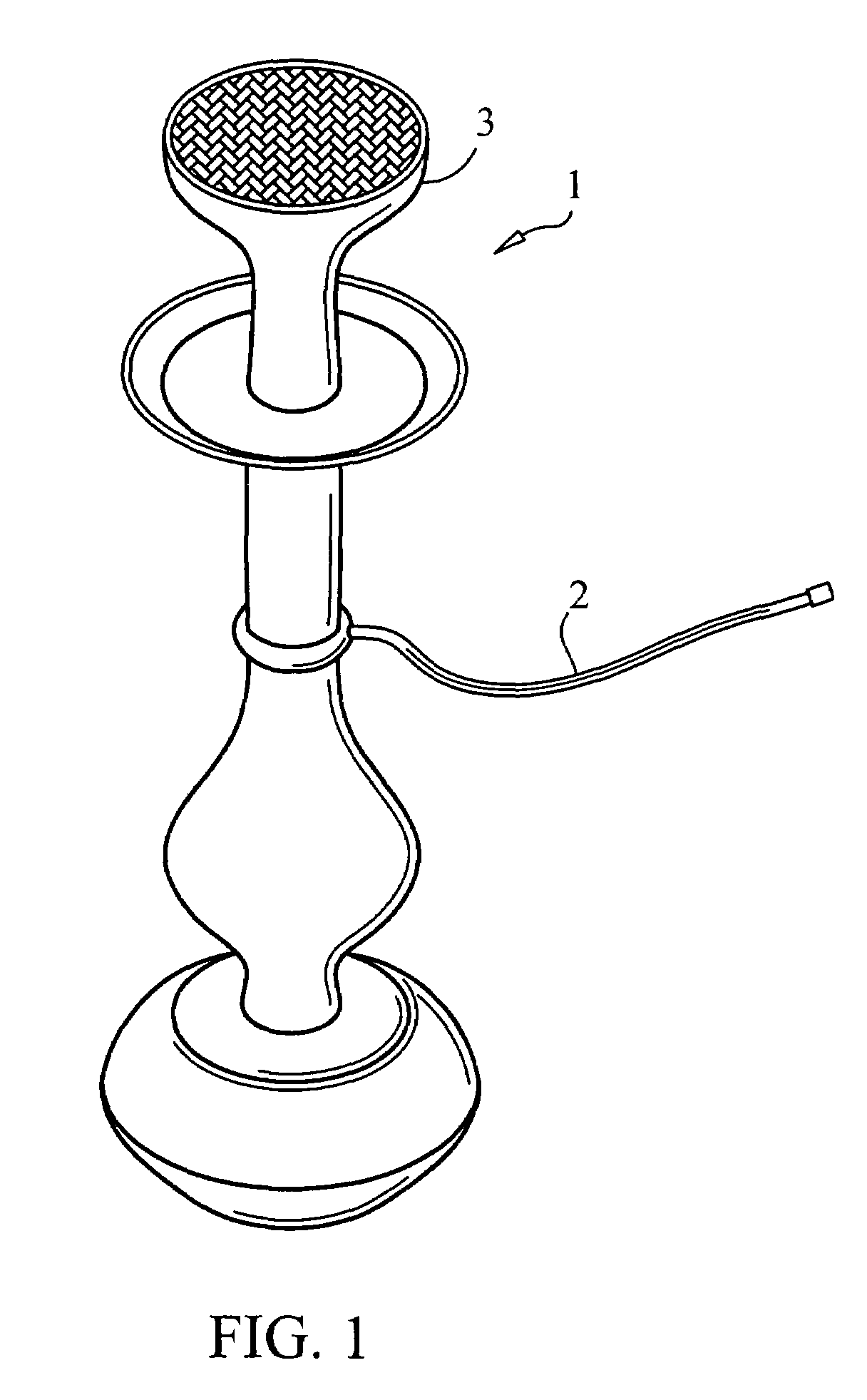

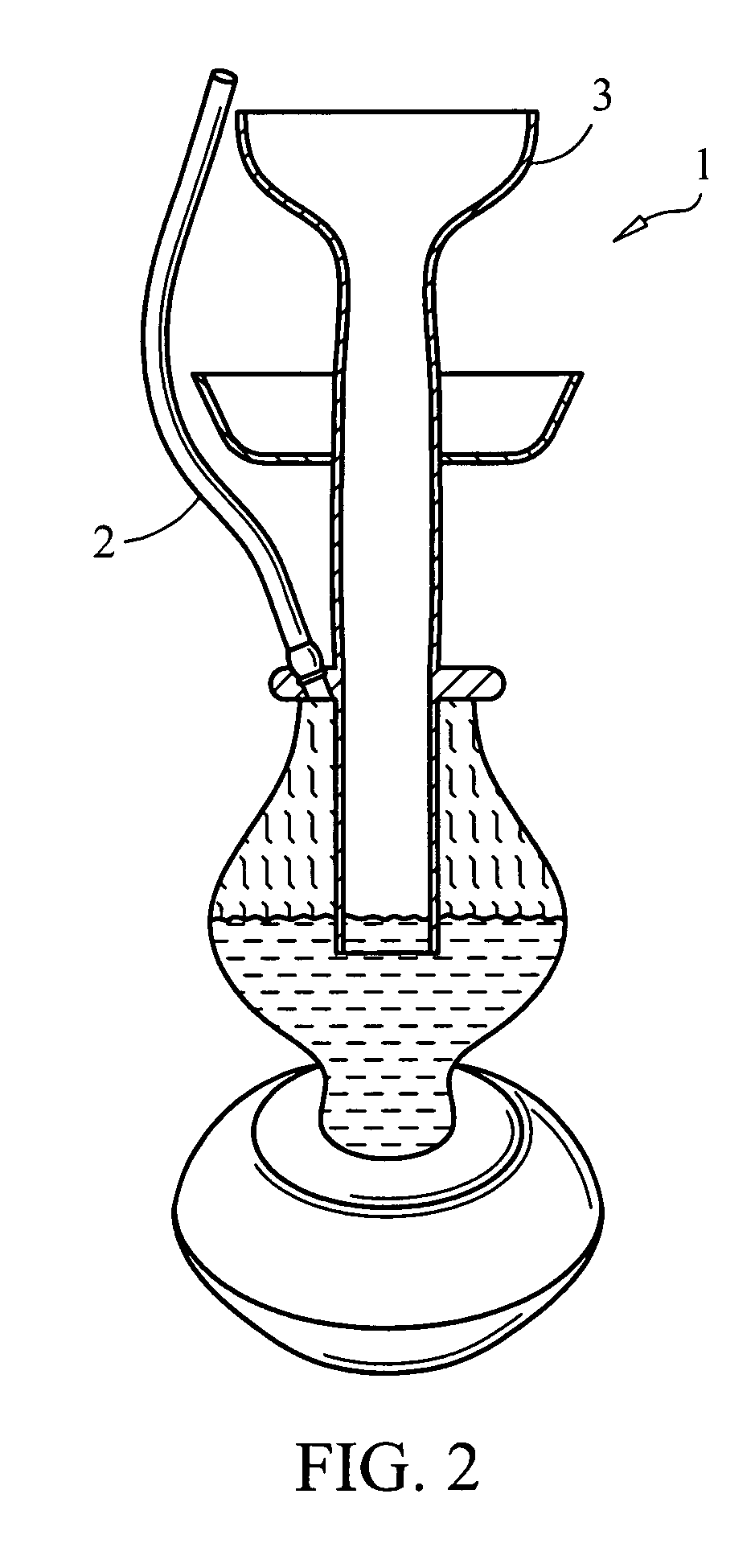

Water pipe starter and cleaning device

InactiveUS7690076B2Easy to igniteRemove particulateMechanical cleaningPressure cleaningMotor driveSuction force

A hookah accessory comprising a motor driven vacuum secured in a housing, vacuum port, filter between the vacuum port and vacuum used to apply a suction force used to ignite and start a hookah, blower port in pneumatic communication with the output / return port of the vacuum to provide a blow force used to clean hoses, switches in the vacuum and air pressure ports to automatically turn on the accessory when inserting a hose and fixed resistors in series with the switches for setting the vacuum at two constant speeds for a set suction force and set air pressure force. Alternatively, the accessory may have a variable resistor (rheostat) to adjust the speed of the motor, which adjusts the suction and blowing forces. The filter is in line with the vacuum port and vacuum to capture debris before it reaches the vacuum or vacuum motor. The vacuum and blower ports securely receive and hold different sized hoses and, or hose tips in a manner that creates a substantial airtight seal.

Owner:TANNOUS BISHARA

Vacuum switchgear assembly, system and method

Insulated vacuum switchgear and active switchgear elements therefor are provided with a rigid support structure mechanically isolating a vacuum insulator from axial loads in use without reinforcing or insulating encapsulations. At least one of the elastomeric insulating housing and the support structure directly contacts an outer surface of the insulator. Systems and methods for assembling the switchgear are also provided.

Owner:EATON INTELLIGENT POWER LTD

Waterless electronic hookah machine

The present device generally relates to a waterless electronic hookah machine. The waterless electronic hookah machine has a main body portion, a handle section and a flexible wire cable (or “connector”). The flexible wire cable electrically connects the main body portion with the handle section. The handle section has a removable mouthpiece containing a cartridge having a liquid. When a user activates a push button or vacuum switch on the handle section, a power source in the main body portion sends power through the flexible wire cable to an atomizer located in the handle section which then heats the liquid in the cartridge of the mouthpiece and a vapor is created for the user to inhale. The device allows multiple users (generally up to six) to use the device at the same time wherein each user may experience a different flavor smoke. Flavors may be easily switched without the need to rinse out the electronic hookah machine. The user is able to adjust the voltage going to the handle.

Owner:KAPLANI FIRAS

Solid insulating fully enclosed looped network cabinet

ActiveCN101340066AImprove the level ofExtended service lifeSubstation/switching arrangement casingsHigh-tension/heavy-dress switchesEngineeringHigh pressure

The invention discloses a solid insulated totally-enclosed ring main unit, which comprises at least a line of leading-in unit and at least a line of leading-out unit, and each line of switch comprises a 3-phase high-voltage vacuum switch unit. The high-voltage vacuum switch consists of a housing fixed inside a box body, and a main switch and an isolator arranged in the housing, wherein, the housing is made of epoxy resin, and a copper joint pin of the main switch and the outside of a busbar connected with the copper joint pin are coated with silicon rubber layers. The ring main unit of the invention adopts a totally enclosed design, which causes the ring main unit to have a smaller volume and compact structure, and to be safe and reliable; the probability of leakage and discharge is low, thus improving the insulation class, and the ring main unit has obvious effect on saving energy and materials; air, moisture, dust and hot and cool air sources are isolated, which effectively retards the corrosion of a power source body, stabilizes the output of source voltage, decreases the times of the device maintenance, reduces expense cost and prolongs the service life of the ring main unit.

Owner:BEIJING SOJO ELECTRIC

Turnable vacuum disc suction machine for duct piece

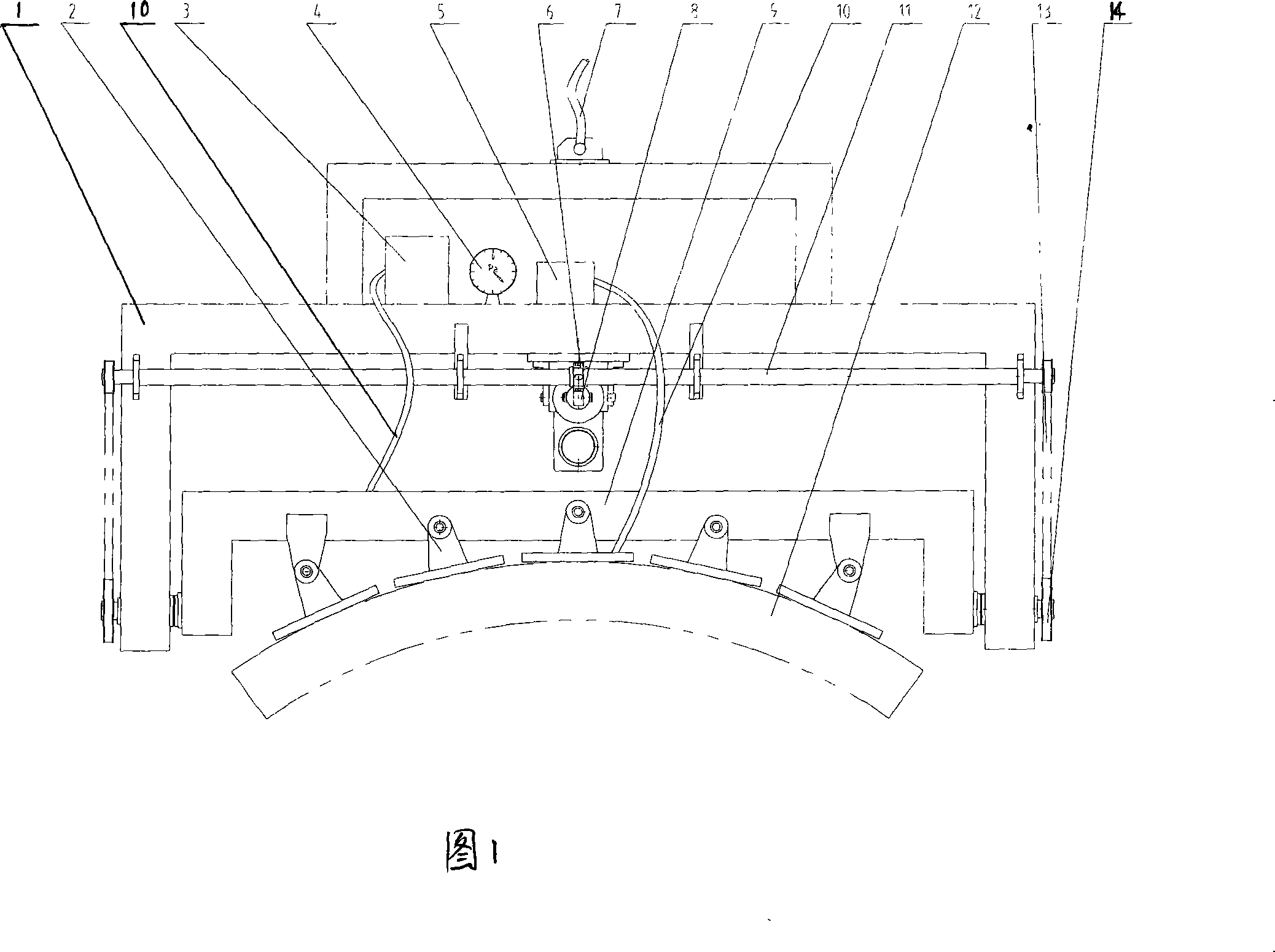

InactiveCN101229899ASmooth flipStrong suctionConveyor partsLoad-engaging elementsRotational axisTransfer system

The invention relates to a turnable vacuum chuck machine for lifting concrete segment and steel segment, which consists of a support bracket, a vacuum pump, a vacuum gauge, an electromagnetic valve, a turnable hollow sealing beam used as a gasholder and a plurality of vacuum chucks which are arranged on different positions of the hollow sealing beam with a hinge. When working, the whole chuck machine is hooked on a corresponding hoisting device through a wire rope and is attached to an external surface (which can be a plane surface or an arc surface) of the segment of the lifted object depending on the self gravity. The vacuum pump exhausts air in the hollow sealing beam driven by a self-bring motor through the electromagnetic valve to cause the sealing beam to generate certain vacuum; when operates the vacuum switch, the vacuum switch can be caused to be communicated with the vacuum in the hollow sealing beam through a gas source pipeline; the segment can be lifted by the negative difference of the vacuum and atmospheric pressure in the hollow sealing beam. When the lifted object segment needs to be turned, through a power transfer system which consists of a rack, a gear and a driving shaft driven by another motor, the lifted segment can wind around a rotational axis along the hollow sealing beam and arbitrarily turn in a required angle under the support bracket so as to be in favor of the storage and arrangement of the lifted segment. The turnable segment chuck machine adopts purely mechanical structure and has reliable suction crane as well as turns steadily. The invention can turn and stop in any angle with simple and flexible operation as well as convenient maintenance.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Auto-release venturi with vacuum switch

ActiveUS8096598B2Efficient use ofMaintain standardGripping headsWork holdersHandling systemVacuum switch

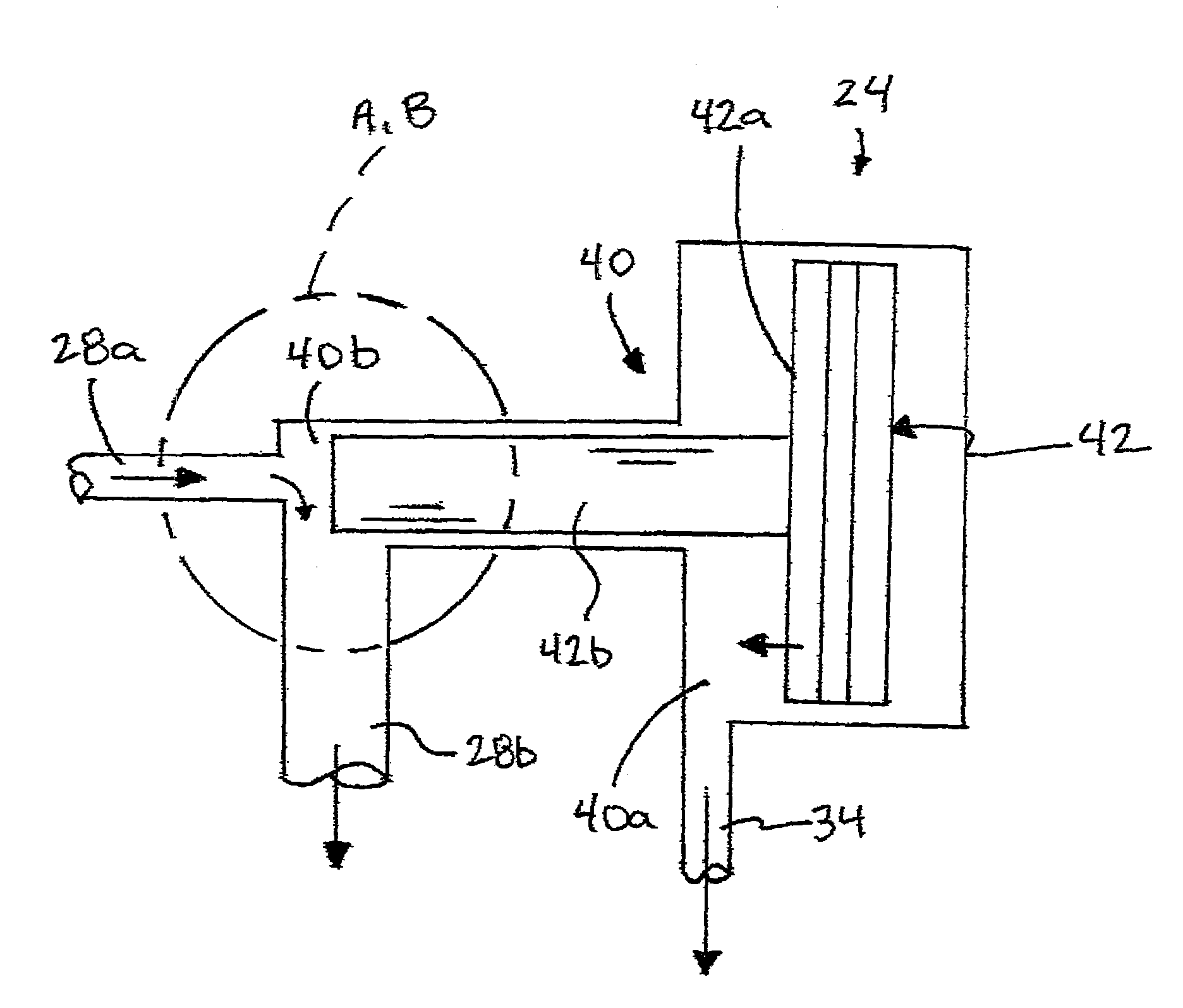

A material handling system has a vacuum cup assembly engagable with an object and movable to move the object using a pressurized air source, a vacuum cup, a venturi device and a vacuum valve and auto-release valve. The venturi device is in fluid communication with the vacuum cup and connected to the supply line so that pressurized air can be supplied to and through said venturi device to generate a partial vacuum when the perimeter seal of the vacuum cup is engaged with the object surface. The vacuum valve may open and close the supply line at a location upstream of the venturi device in response to a pressure level at the vacuum cup cavity. The auto-release valve may vent the vacuum cup cavity to atmosphere in response to reduced pressure in the supply line at a location upstream from the vacuum valve.

Owner:DELAWARE CAPITAL FORMATION INC

Solid insulation ring main unit

ActiveCN103368096AReduce control precision requirementsGuaranteed to workSwitchgear arrangementsHigh-tension/heavy-dress switchesEngineeringVacuum switch

The invention discloses a solid insulation ring main unit, comprising a high-voltage switch unit; the high-voltage switch unit comprises a vacuum arc-extinguishing chamber and an isolation grounding switch device comprising an insulation cavity body; a line outlet end, a grounding end and a line inlet end electrically connected with a conductive rod are arranged on the insulation cavity body; a vacuum switch tube for grounding is fixedly arranged inside or outside the insulation cavity body; the static contact of the vacuum switch tube for grounding is electrically connected with the grounding end while the movable contact is provided with a grounding wiring part; the movable contact of the vacuum switch tube for grounding is in transmission connection with a grounding operative mechanism; an isolation disconnecting link is arranged in the insulation cavity body; one end of the isolation disconnecting link is a hinging end hinged to the line outlet end while the other end is a contact end; and a driving mechanism is connected onto the isolation disconnecting link in a transmission way. The isolation grounding switch is positioned in different work conditions by controlling the swinging of the isolation disconnecting link and the connecting / disconnecting states of the static and movable contacts in the vacuum switch tube.

Owner:STATE GRID CORP OF CHINA +2

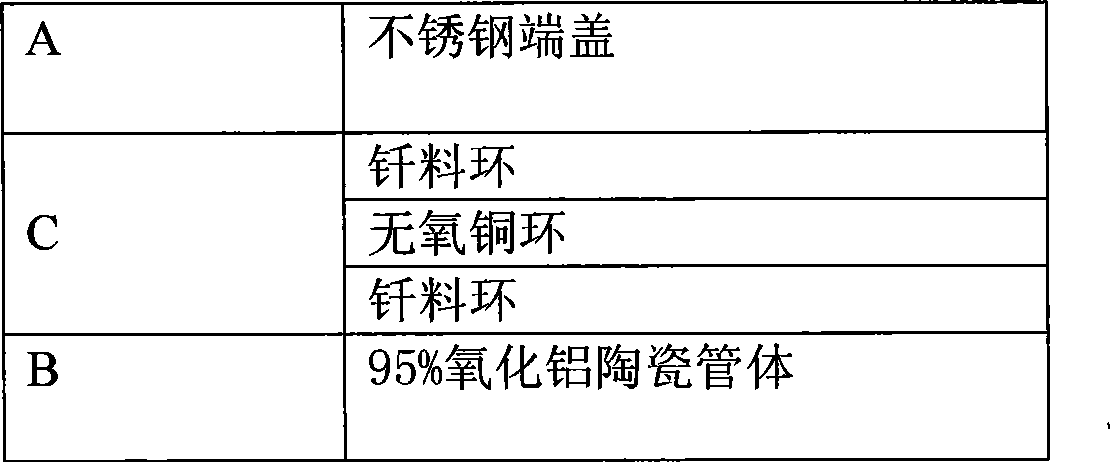

Stainless steel / alumina ceramic low stress hermetic seal solder

InactiveCN101475395AStrong stress absorption effectWelding/cutting media/materialsSoldering mediaAlloy compositeComposite solder

The invention relates to a silver alloy composite solder strip for a vacuum switch tube stainless steel and 95 percent alumina ceramic low-stress hermetic seal joint. The cross section of the composite solder strip has a three-layer overlapping structure of a solder alloy layer, a copper core layer and a solder alloy layer, wherein solder in the composite solder comprises the following compositions in percentage by mass: 55 to 72 percent of silver, 19.0 to 43.0 percent of copper and 0.50 to 4.50 percent of nickel; the melting temperature of the solder is between 780 and 835 DEG C, and the hermetic seal temperature is between 820 and 850 DEG C; the unilateral thickness of the solder alloy layer in the composite solder is between 0.08 and 0.20 millimeter; the copper core layer in the composite solder is copper with the purity of more than or equal to 99.95 percent or oxygen free copper; the interlayer composite proportion of the composite solder, namely the thickness of the solder layer to the thickness of the copper core layer to the thickness of the solder layer, is 1:X:1 (wherein, X is between 1.8 and 3.5); and firm metallurgical combination is formed between various layers. The intensity of the vacuum switch tube stainless steel and 95 percent alumina ceramic joint is more than or equal to 90 MPa, and the leakage rate of the joint is less than or equal to 1*10Pa.m / s.

Owner:SINO PLATINUM METALS CO LTD

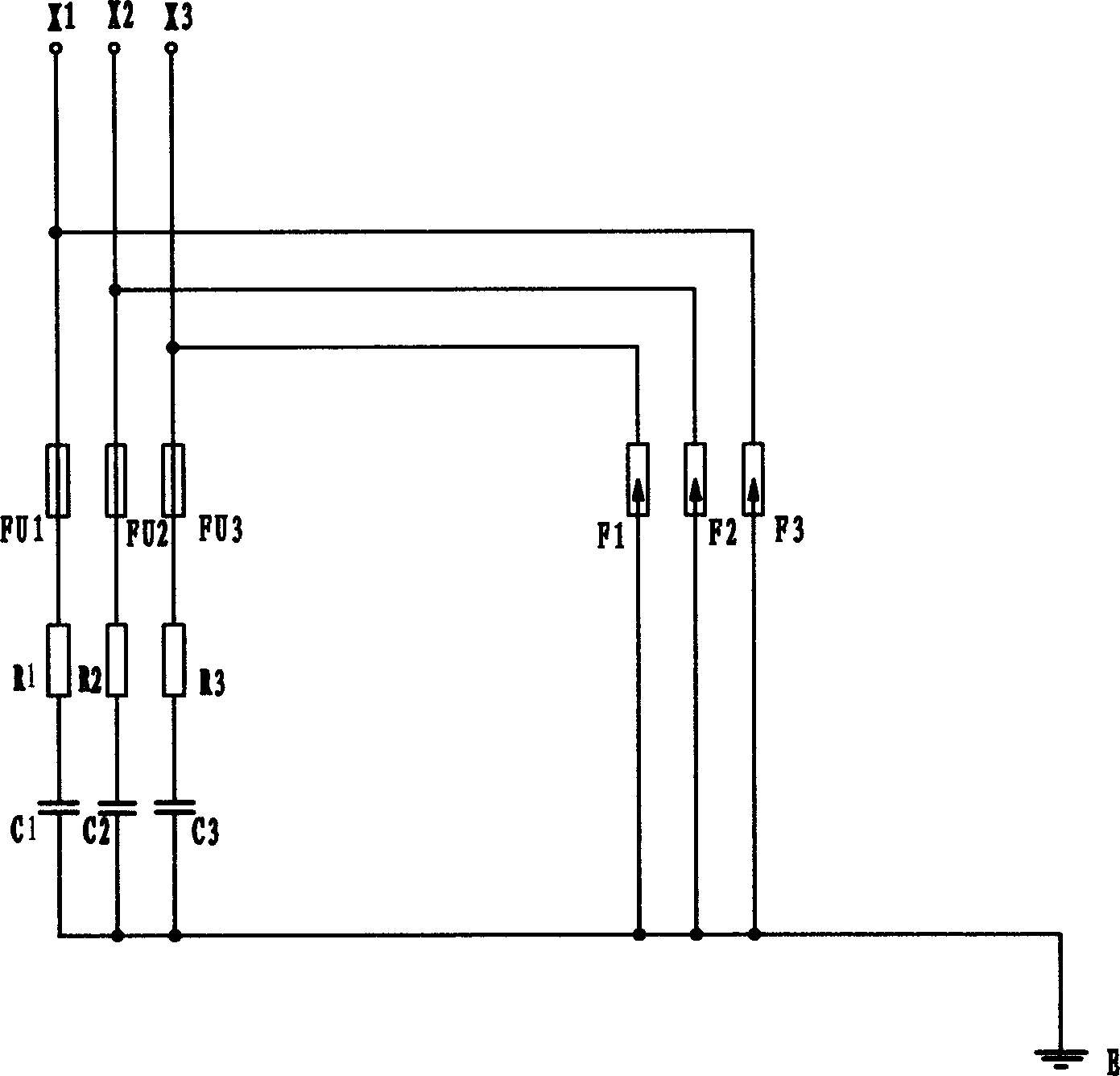

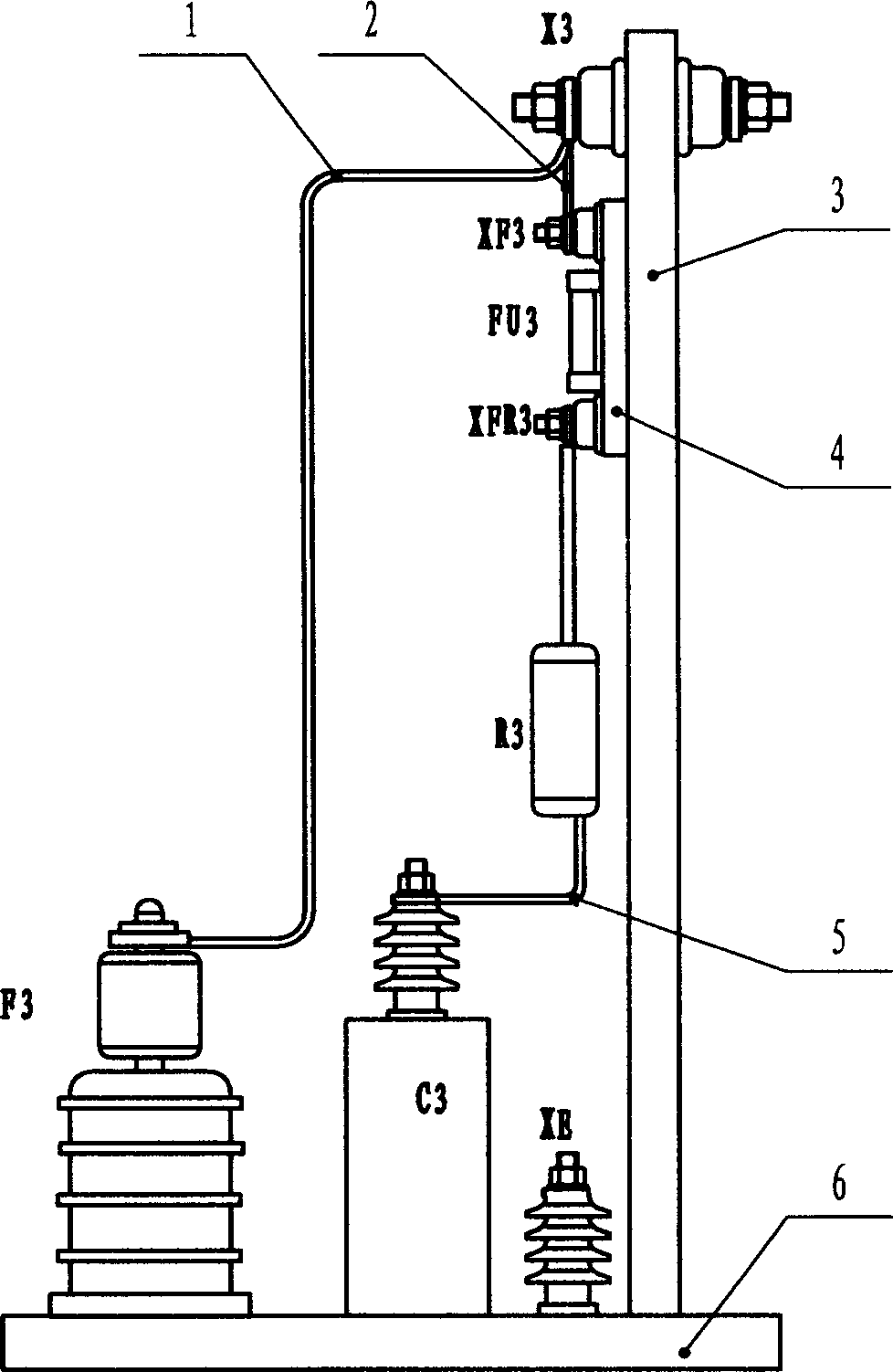

High power motor over-voltage protection device

InactiveCN1885660AEffective protectionReduce damage rateEmergency protective circuit arrangementsTransformerThree-phase

The related over-voltage protector for high-power motor comprises: three ZnO arresters with cathode paralleled together and connected to ground terminal and anode connected to three-phase terminal, three groups of R-C devices with two ends connected to ground terminal and arrester another end respectively. This invention can reduce damage rate of high-power motor and transformer to 2%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

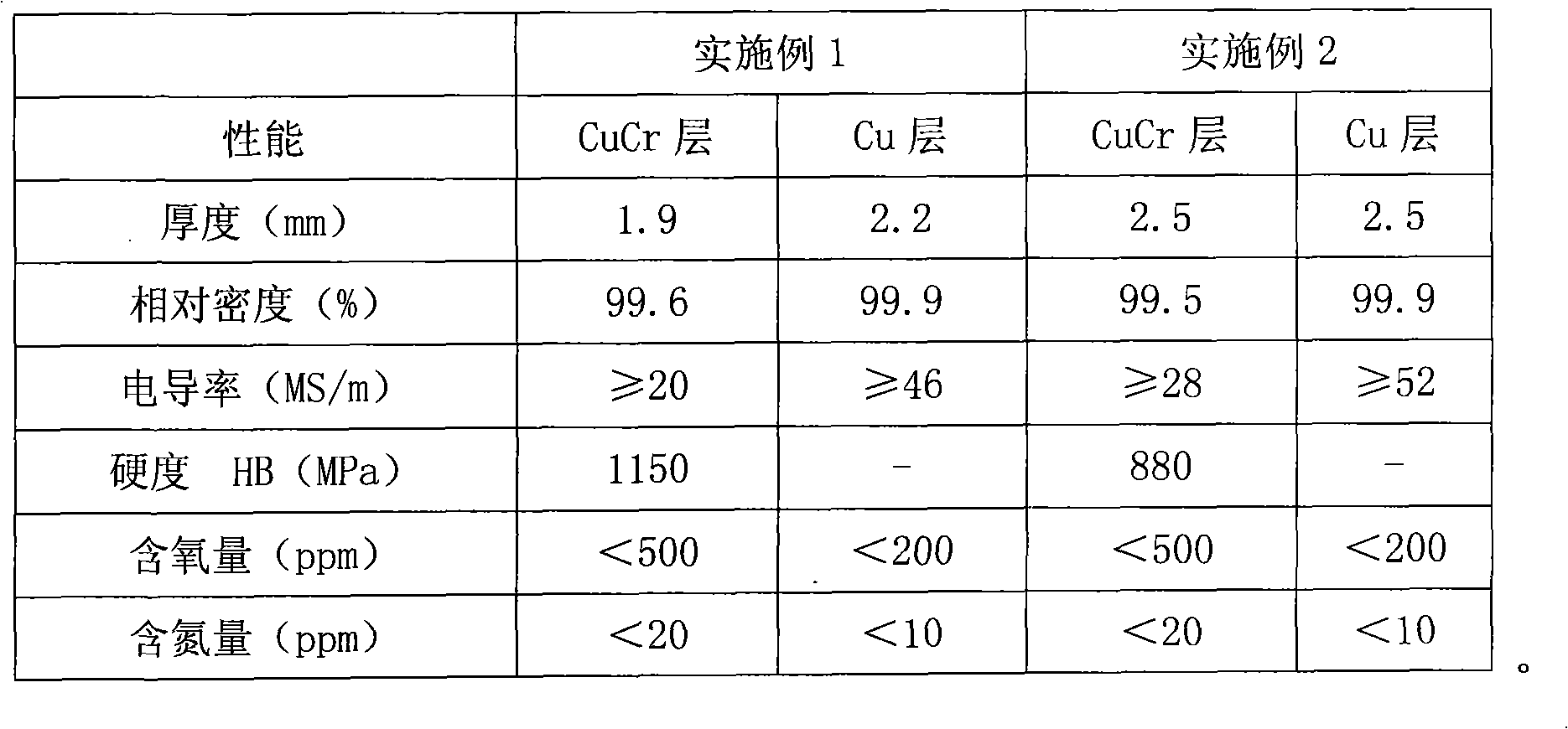

Cuprum chromium-cuprum composite contact material and manufacturing method thereof

ActiveCN101350255AReduce dosageReduce thicknessContactsElectrical resistance and conductanceTotal thickness

The invention relates to a cu-cr-copper composite contact material and the method for making the material, the cu-cr-copper composite contact material mainly comprises a cu-cr layer, a layer of copper is compounded on at least one surface of the cu-cr layer, and the thickness of the cu-cr layer is 1.5-2.5mm, the thickness of the copper layer is 1.5-4.5mm, and the total thickness of the cu-cr layer and the copper layer can be arbitrarily controlled between 3.0-7.0mm according to the requirements. The making method comprises the following steps: firstly, preparing powder materials of the cu-cr layer, secondly, preparing powder materials for the copper layer, thirdly, pressing composite materials, fourthly, carrying out the sintering, the repressing and the after-burning. The manufacturing method has the following technical effects: firstly, the thickness of the cu-cr layer is greatly reduced, the inner electric resistance of the contact material is effectively reduced, and the performance of a vacuum switch tube is improved, secondly, the difficulty of the welding technique of the copper layer and a conducting bar is reduced, the welding is easy and the quality is reliable, thirdly, the dosage of chromium is reduced, thereby the cost of raw materials for manufacturing the contact materials is reduced, fourthly, common silver-copper solder can be directly used, one time sealing and exhausting can be realized and the manufacturing cost of the vacuum switch tube can be greatly reduced.

Owner:ZHEJIANG YATONG METAL CERAMICS +1

Food preservation container

InactiveUS7040356B2Life is preservedEliminate accumulationFruit and vegetables preservationPackaging by pressurising/gasifyingOzone generatorSolenoid valve

Food Preservation Container with a main container body and a circular lid. The lid has a built in on-off switch, air pump, ozone generator, timing circuit, pressure switch, vacuum switch, solenoid valve, power indicator light, vacuum indicator light, pressure indicator light and power supply. The container has a circular opening. The opening has a plurality of outwardly facing tabs about its circumference. The lid has a plurality of mating inwardly facing tabs that can interface with said outwardly facing tabs. The lid has a secondary floating inner lid, said inner lid having a soft rubber gasket attached to its perimeter, said inner lid capable of being forced toward the lip of said container opening by a cam attached to a hinged lever located on the front of said circular lid. The components contained within said lid arranged in such a way that said air pump automatically turns on when the user twists said lid onto said container opening thereby activating said on-off switch which turns on said pump. Said pump being automatically turned off when a predetermined pressure or vacuum is reached by means of said pressure switch or said vacuum switch. Said ozone generator is automatically turned on for a predetermined period of time and turned automatically turned off by means of said timing circuit. The air in said container is capable of being periodically released by said solenoid valve that is controlled by said timing circuit.

Owner:TARLOW KENNETH A

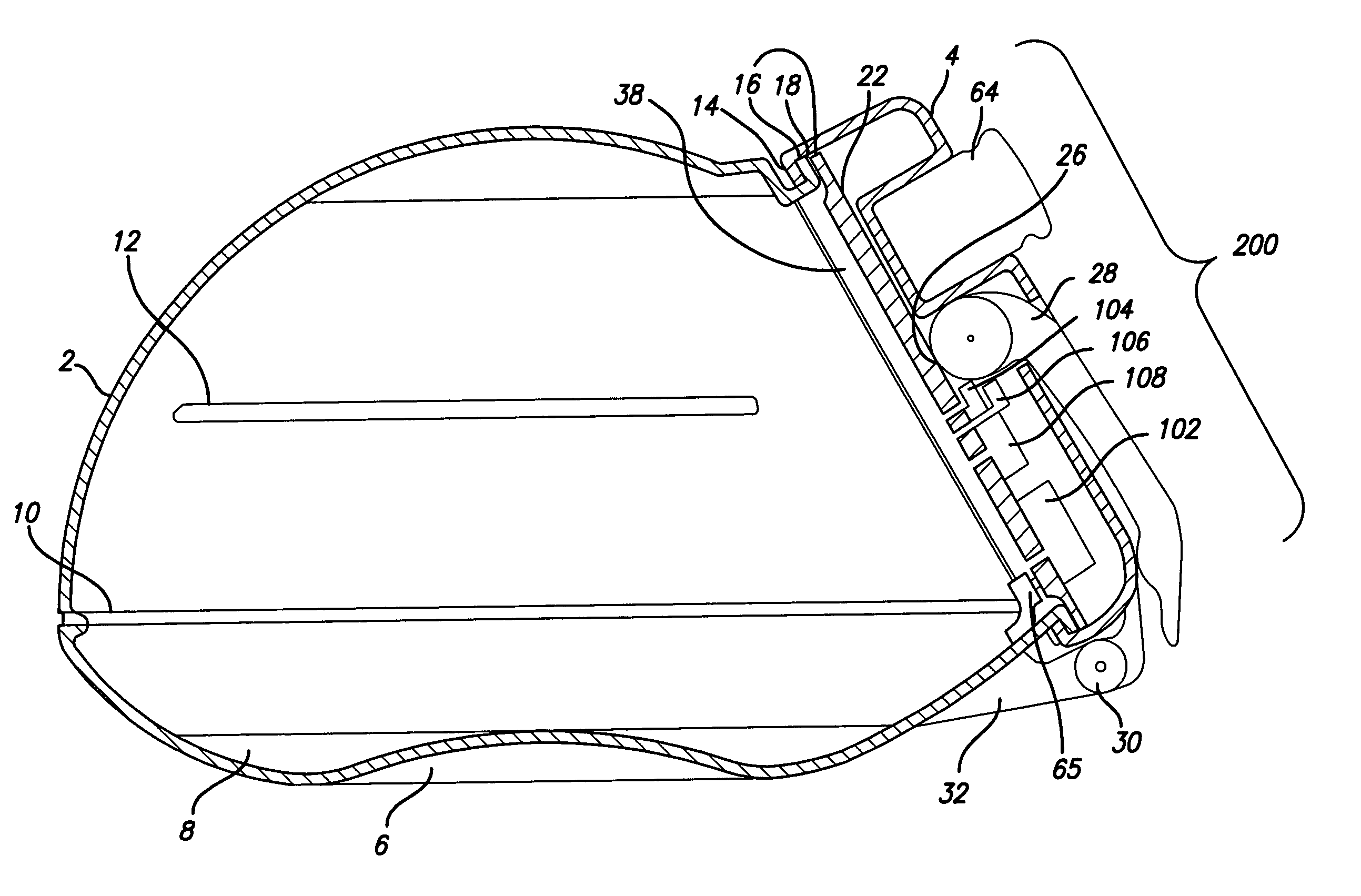

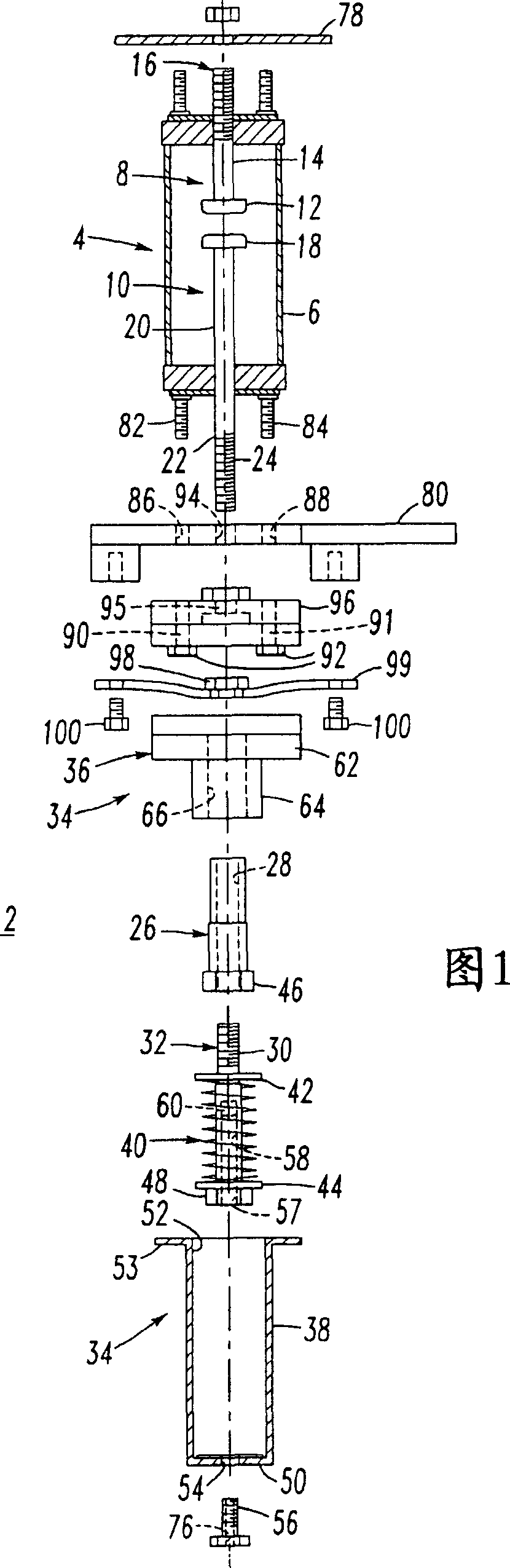

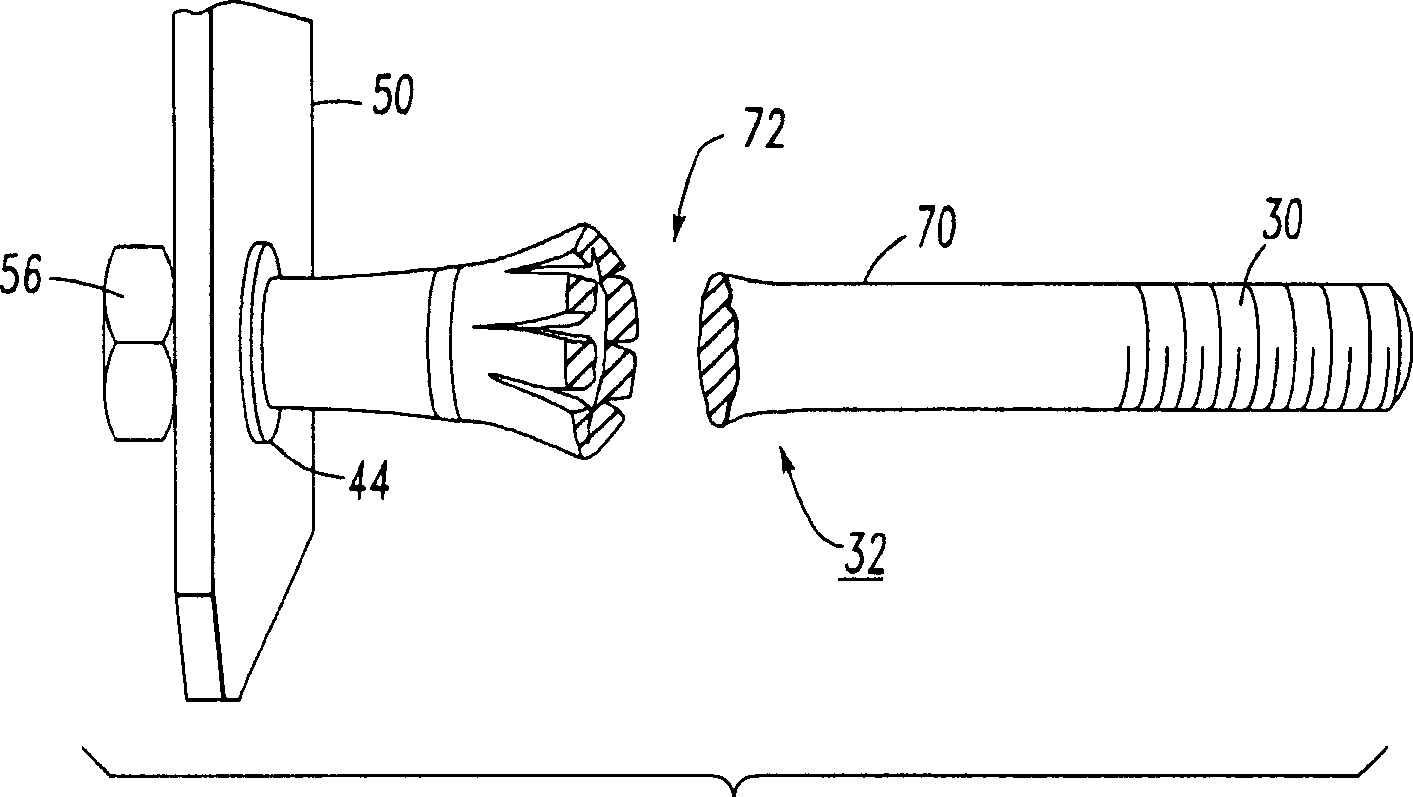

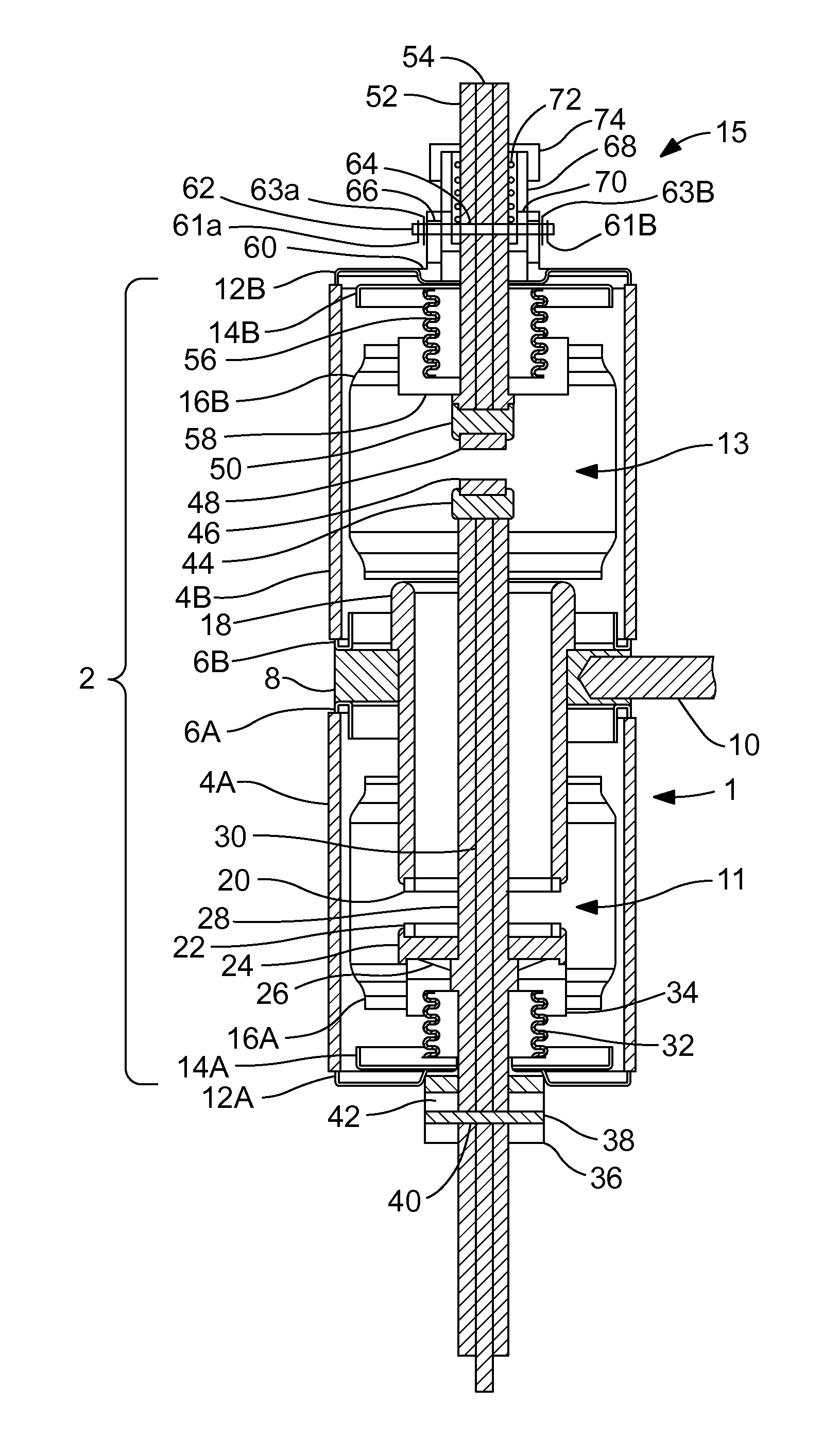

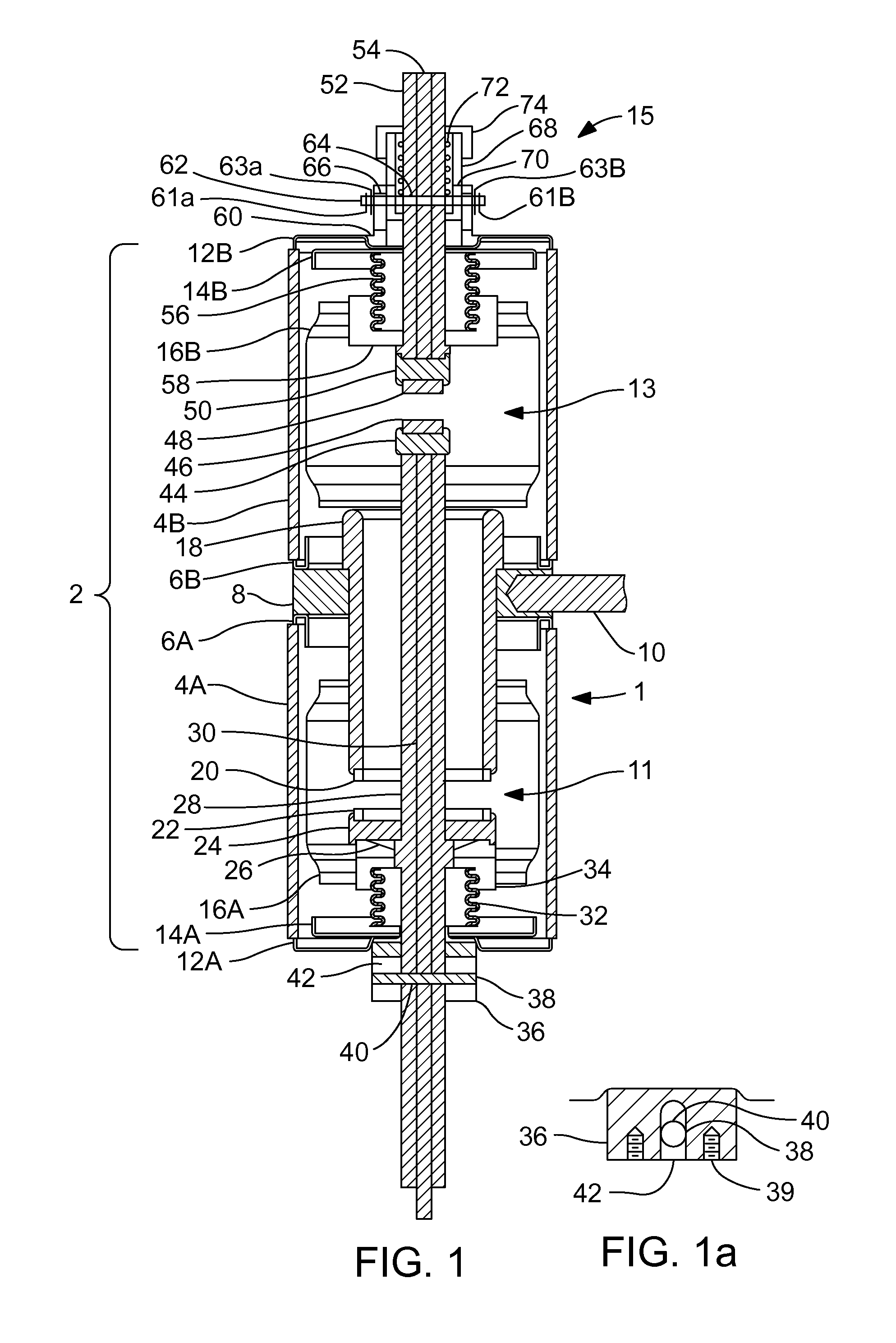

Shorting switch and system to eliminate arcing faults in power distribution equipment

InactiveCN1672228ASwitch power arrangementsEmergency protective arrangement detailsElectricityEngineering

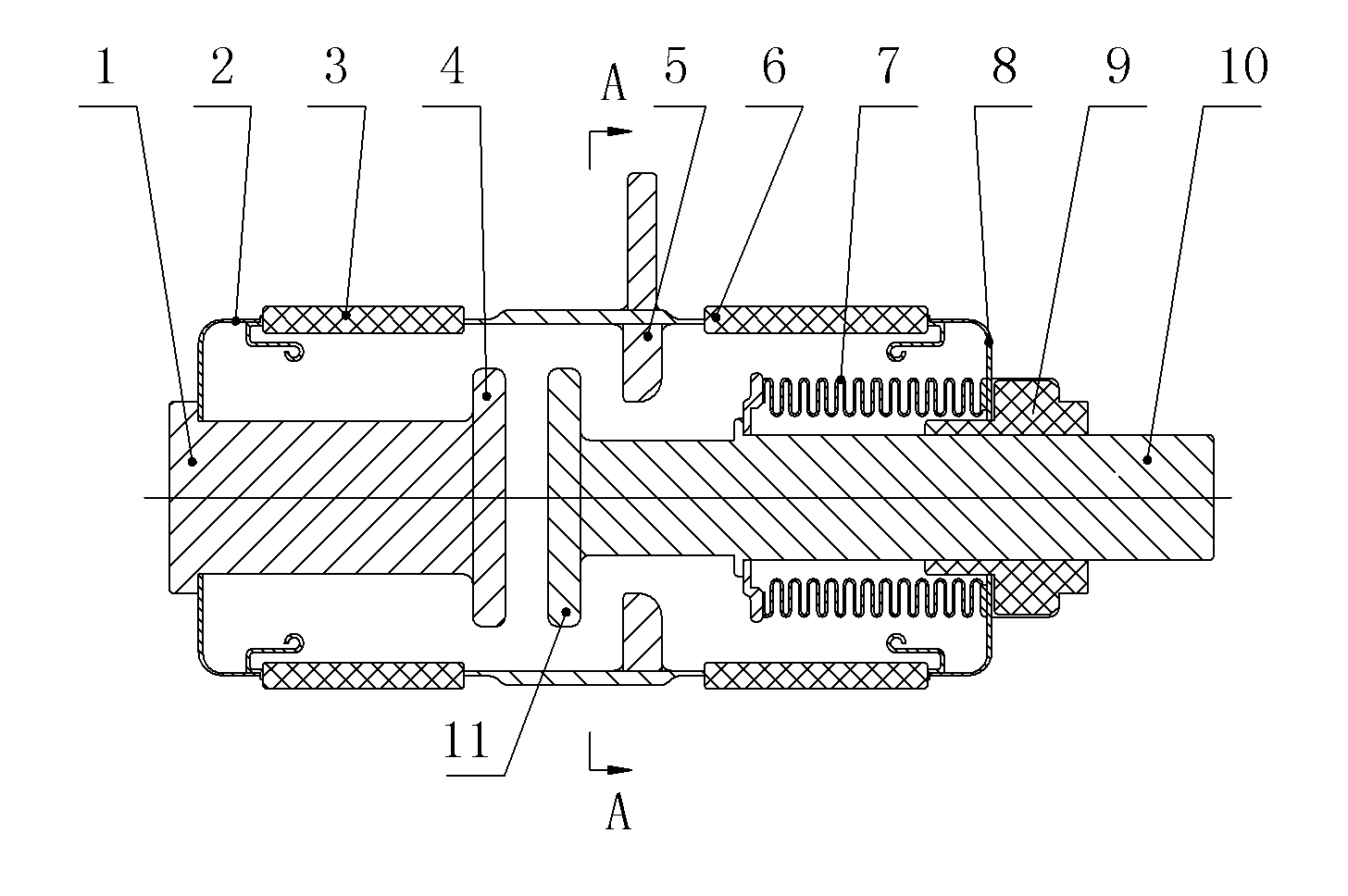

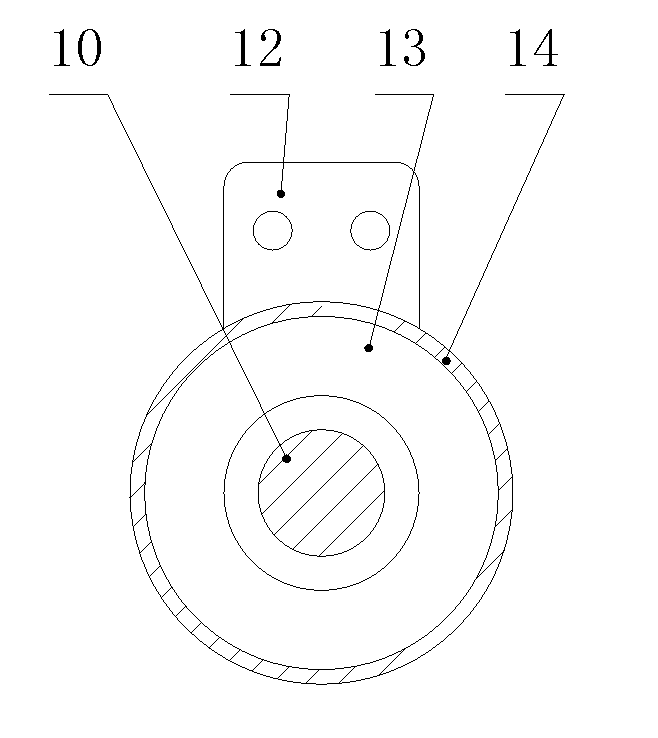

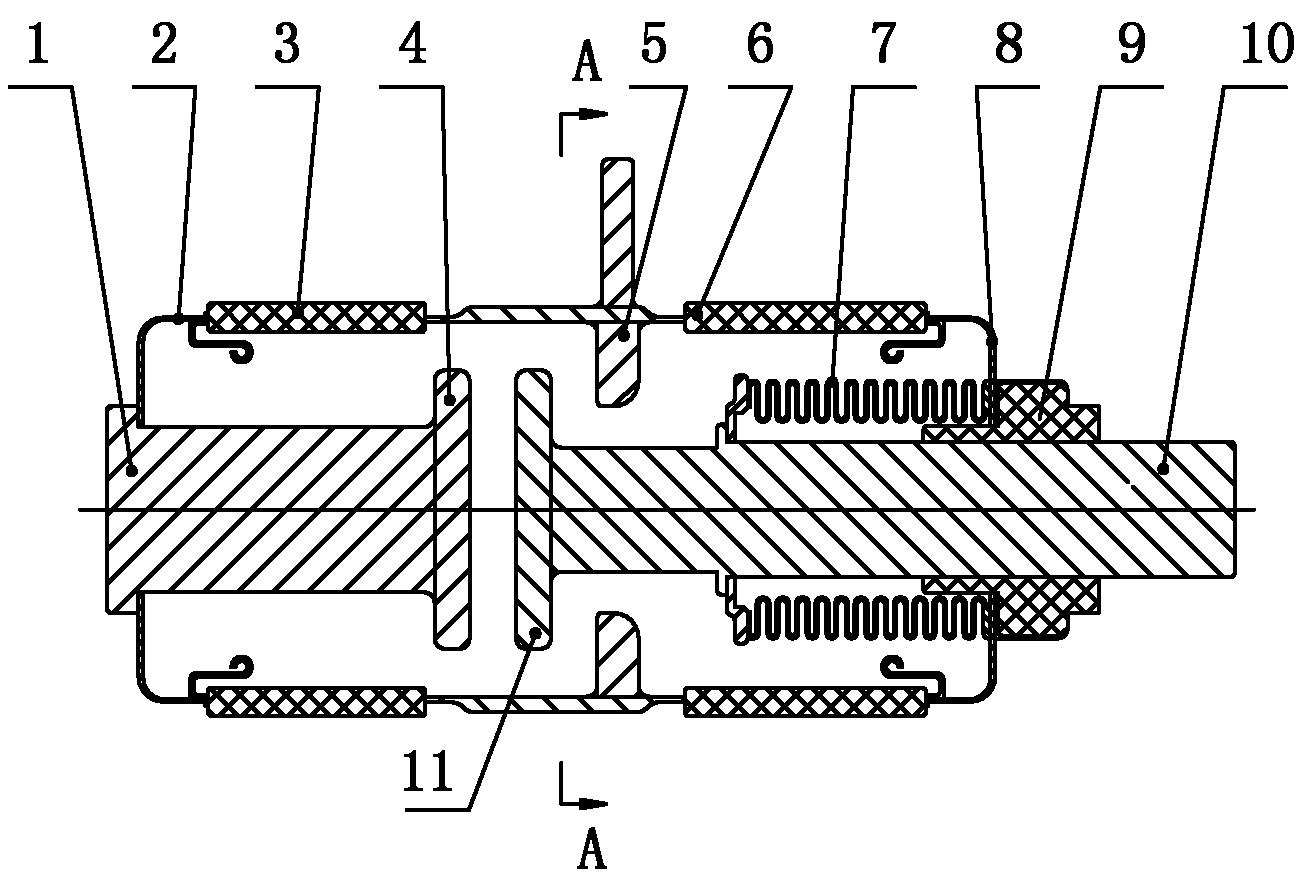

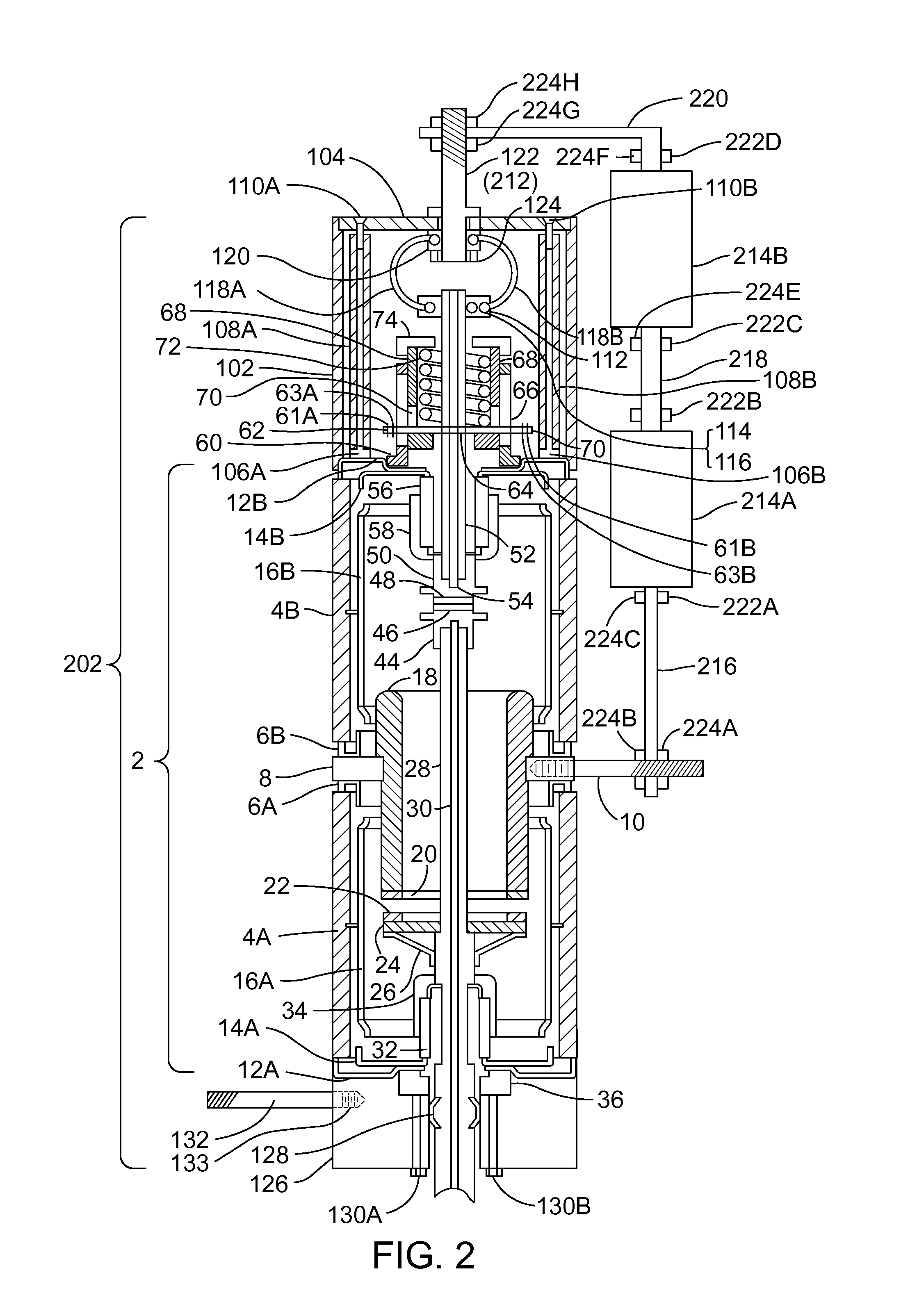

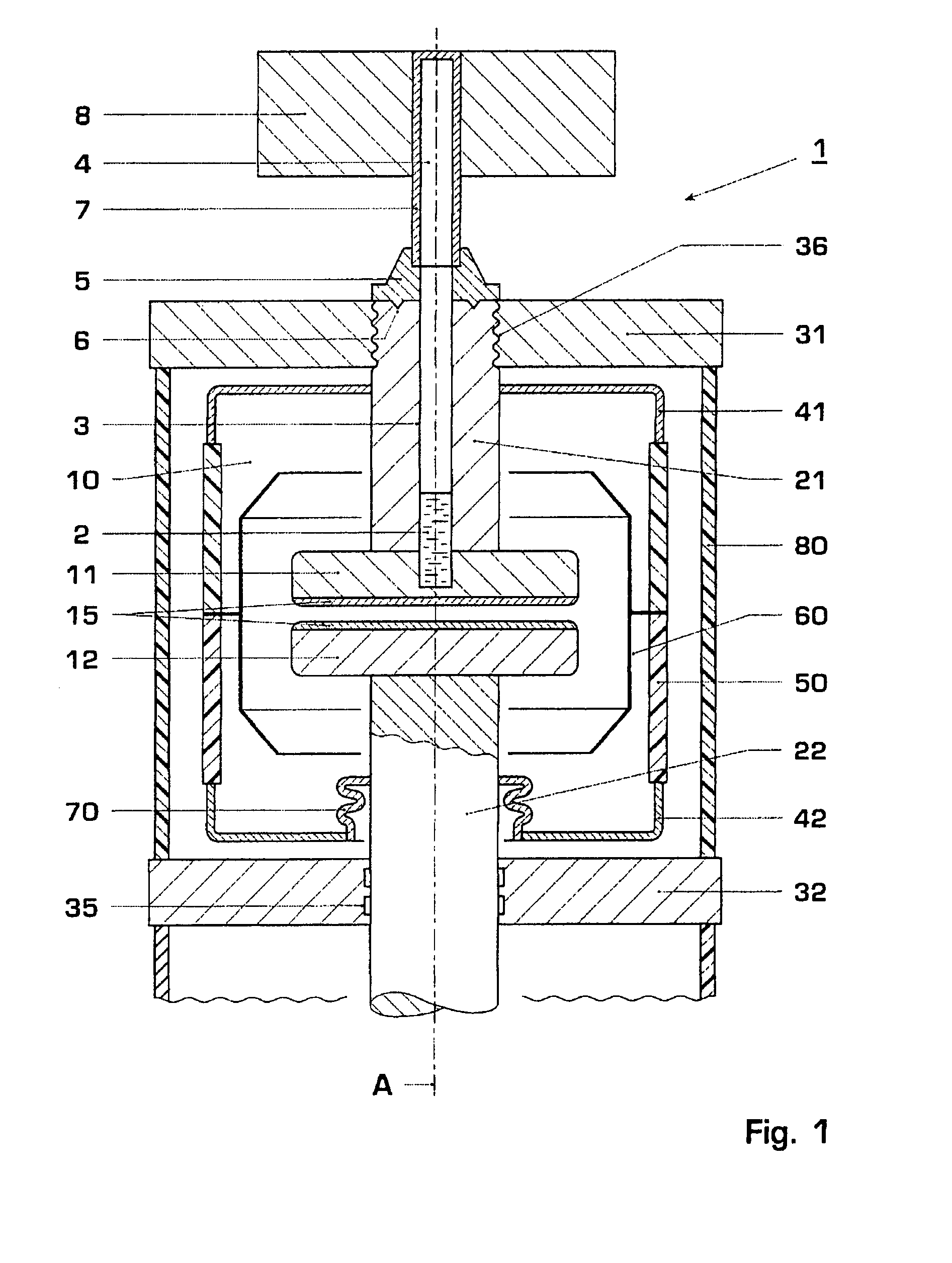

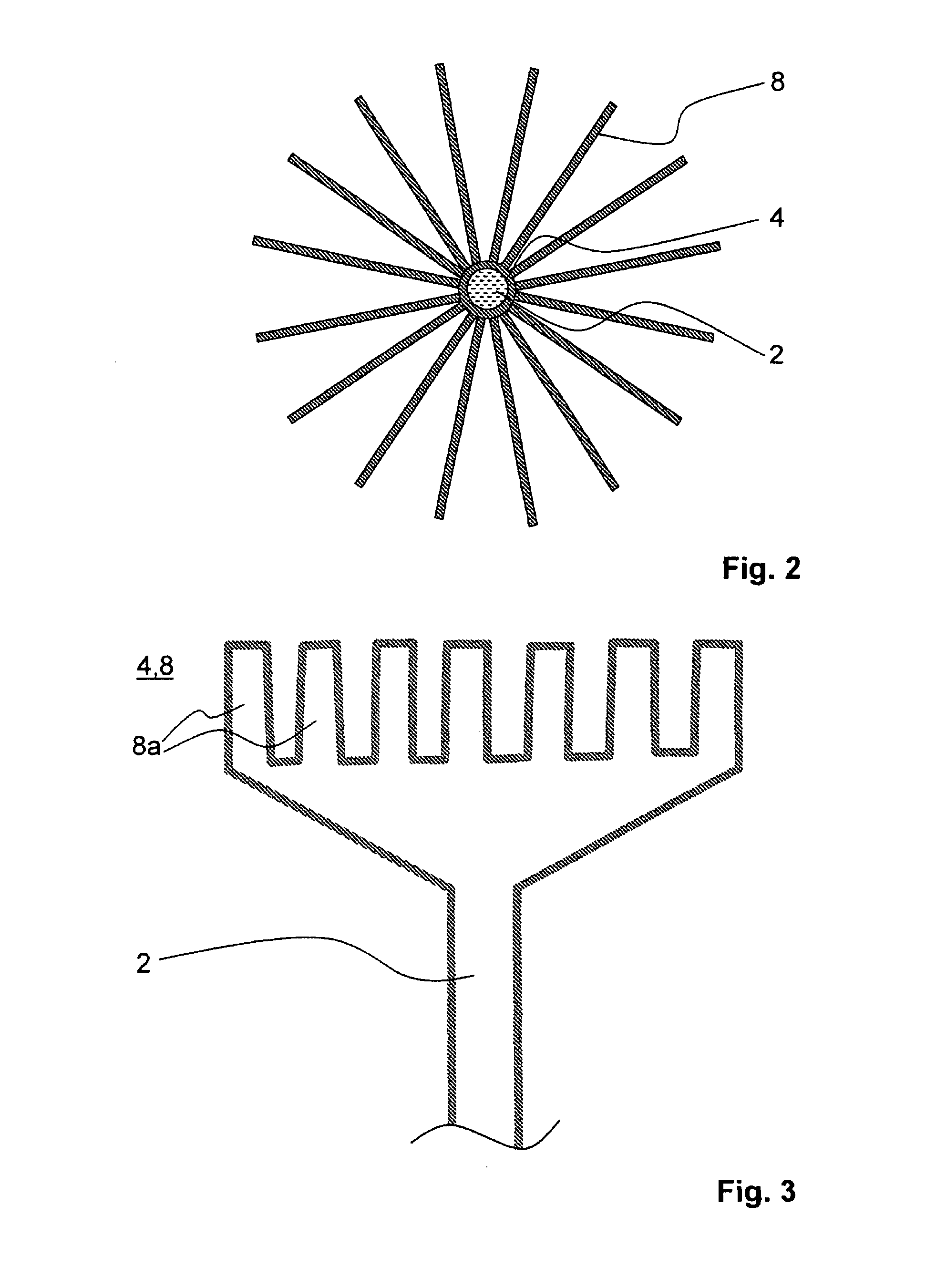

A shorting switch (2) includes a vacuum switch (4) having fixed and movable contact assemblies (8, 10) and a driven member (26). A spring cover tube (38) and bushing (36) mount the driven member (26) for linear movement along a path substantially parallel to a longitudinal axis of the movable contact assembly (10). The driven member (26) moves the movable contact assembly (10) between open and closed circuit positions. A compression spring (40) has a compressed state and a released state, which moves the driven member (26) and movable contact assembly (10) to the closed circuit position. A release bolt (32) has an opening (68) therein and is coupled to the driven member (26) to normally maintain the compression spring (40) in the compressed state. A charge (60) is disposed in the opening of the release bolt (32) and is actuated to fracture the release bolt and release the compression spring (40) to the released state. First and second terminals (16, 22) are respectively electrically interconnected with the fixed and movable contact assemblies (8, 10).

Owner:EATON CORP

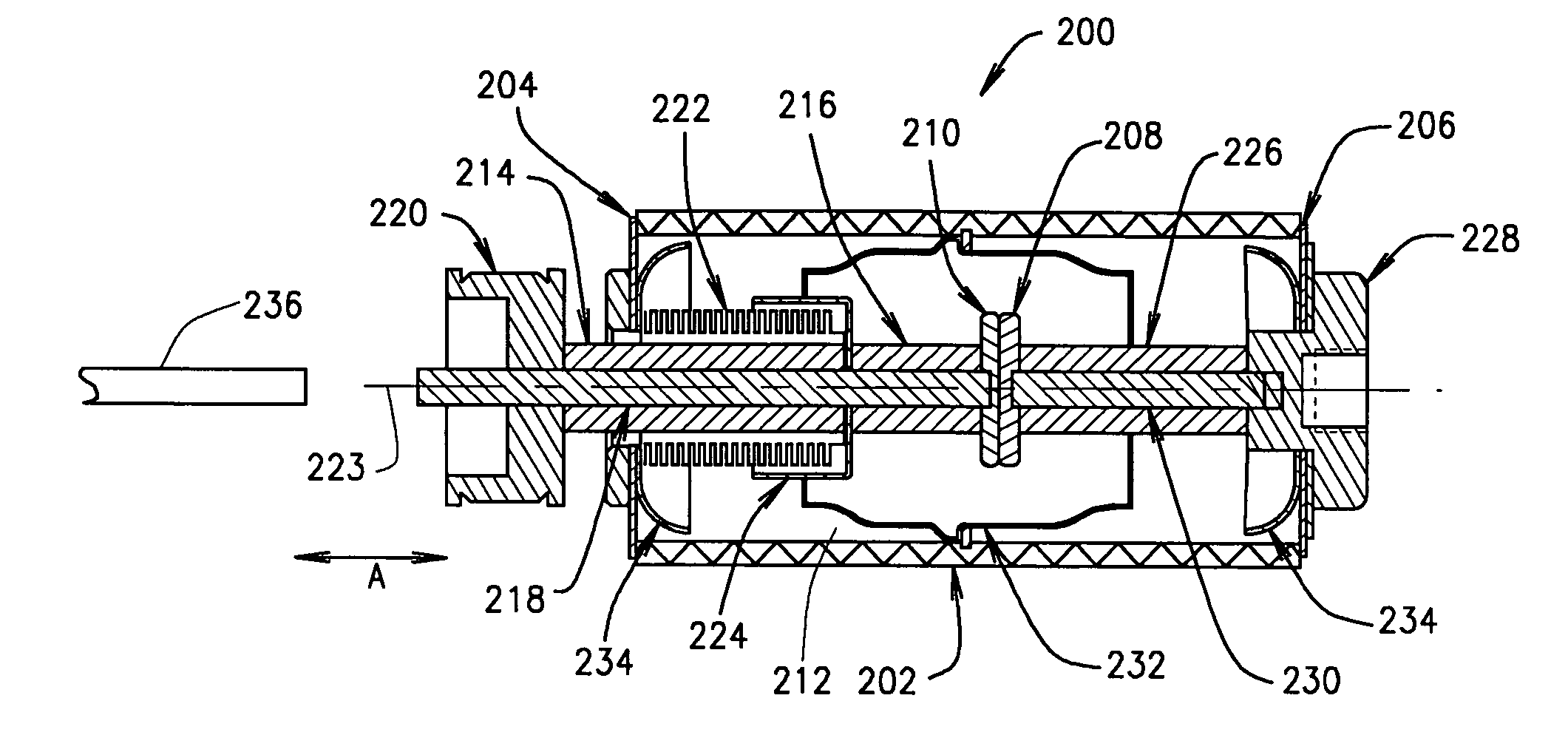

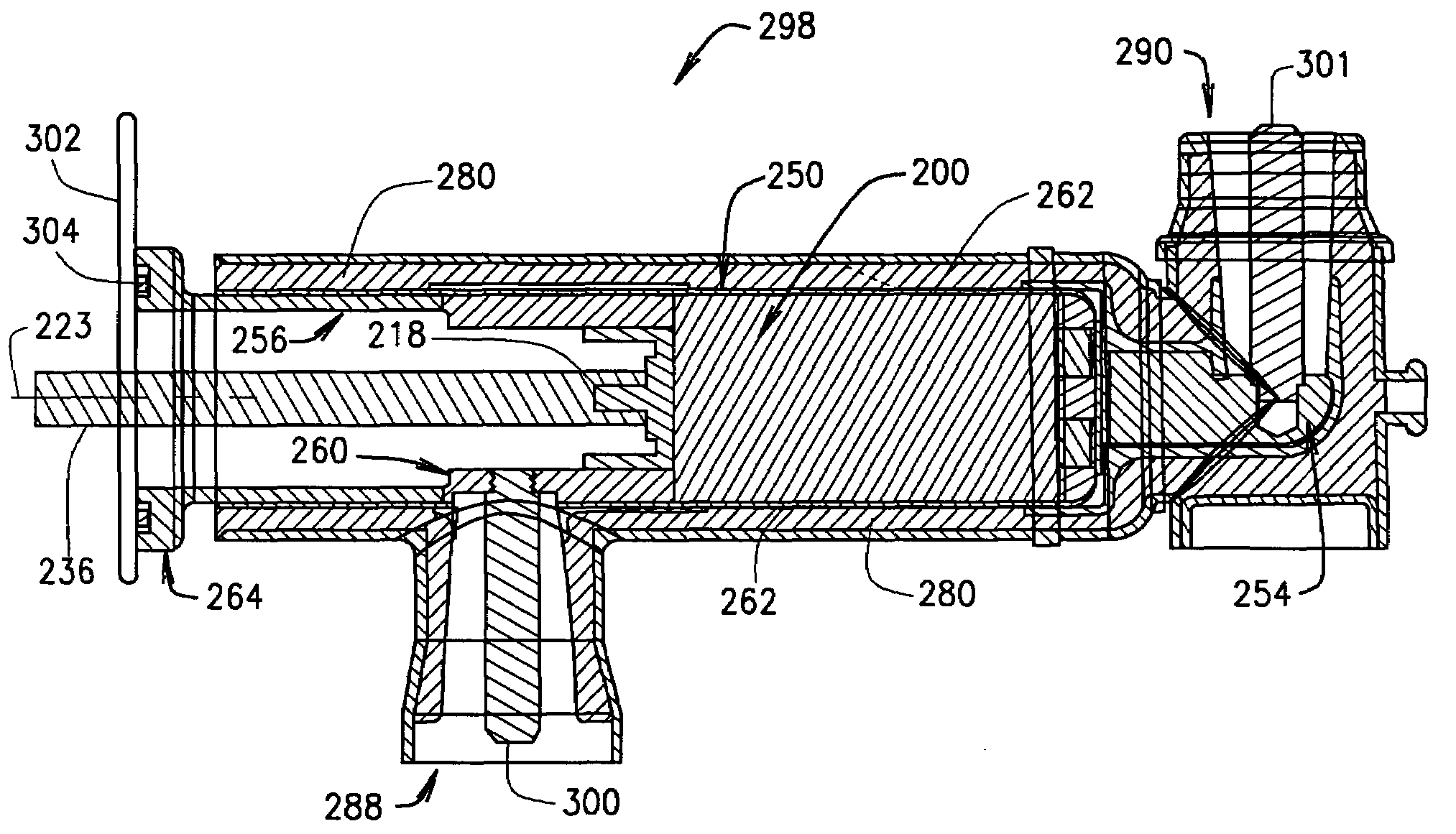

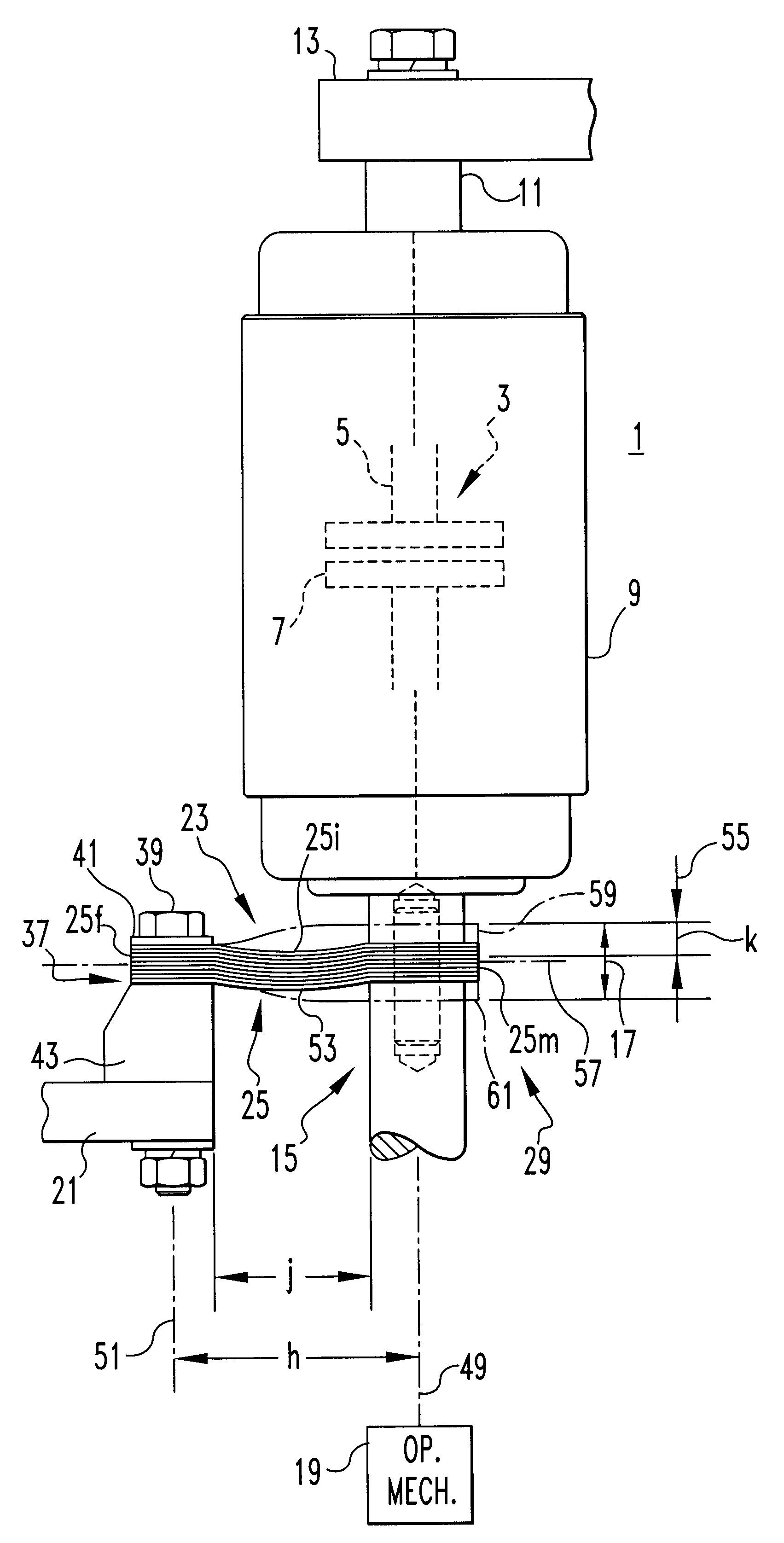

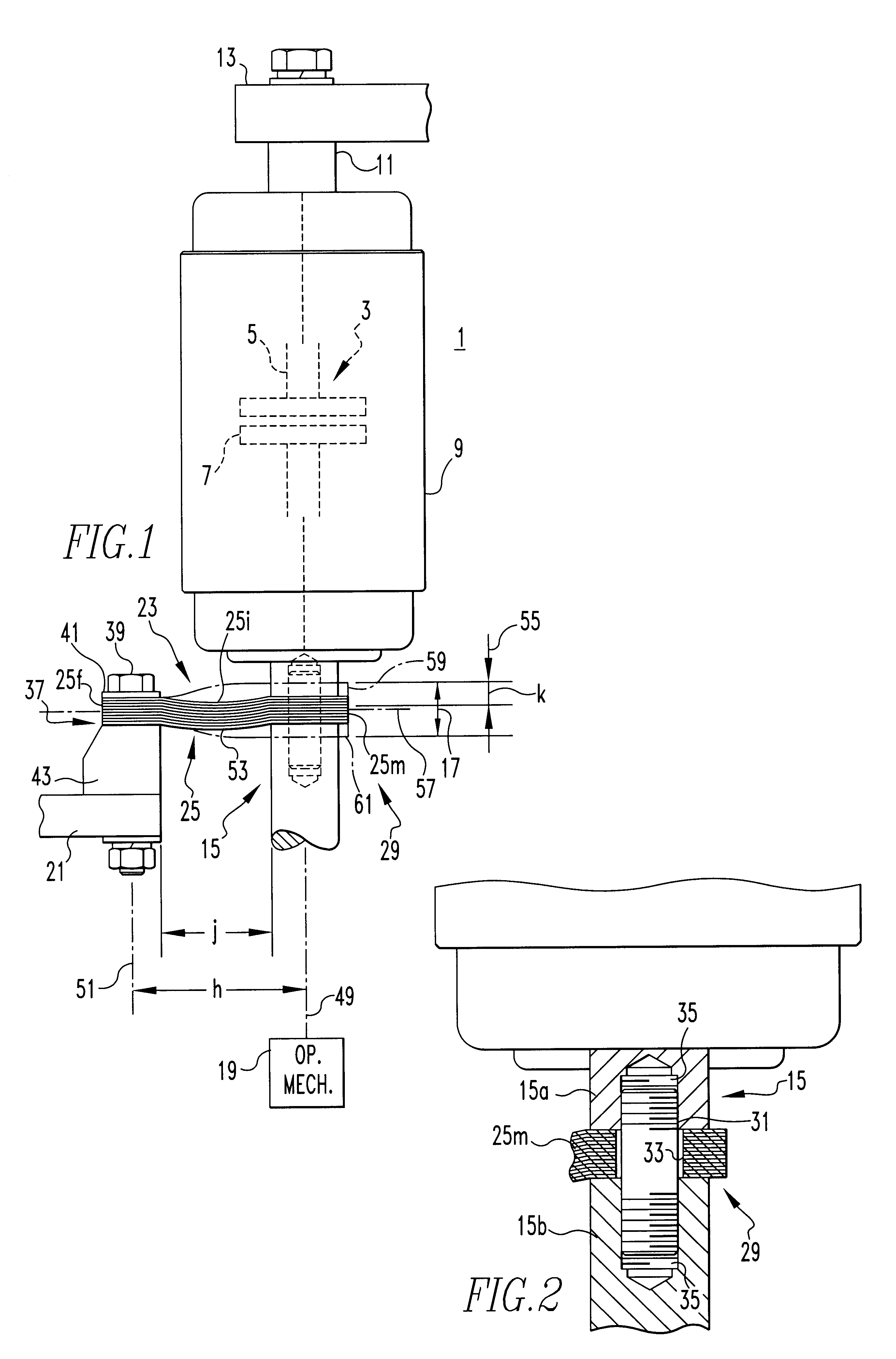

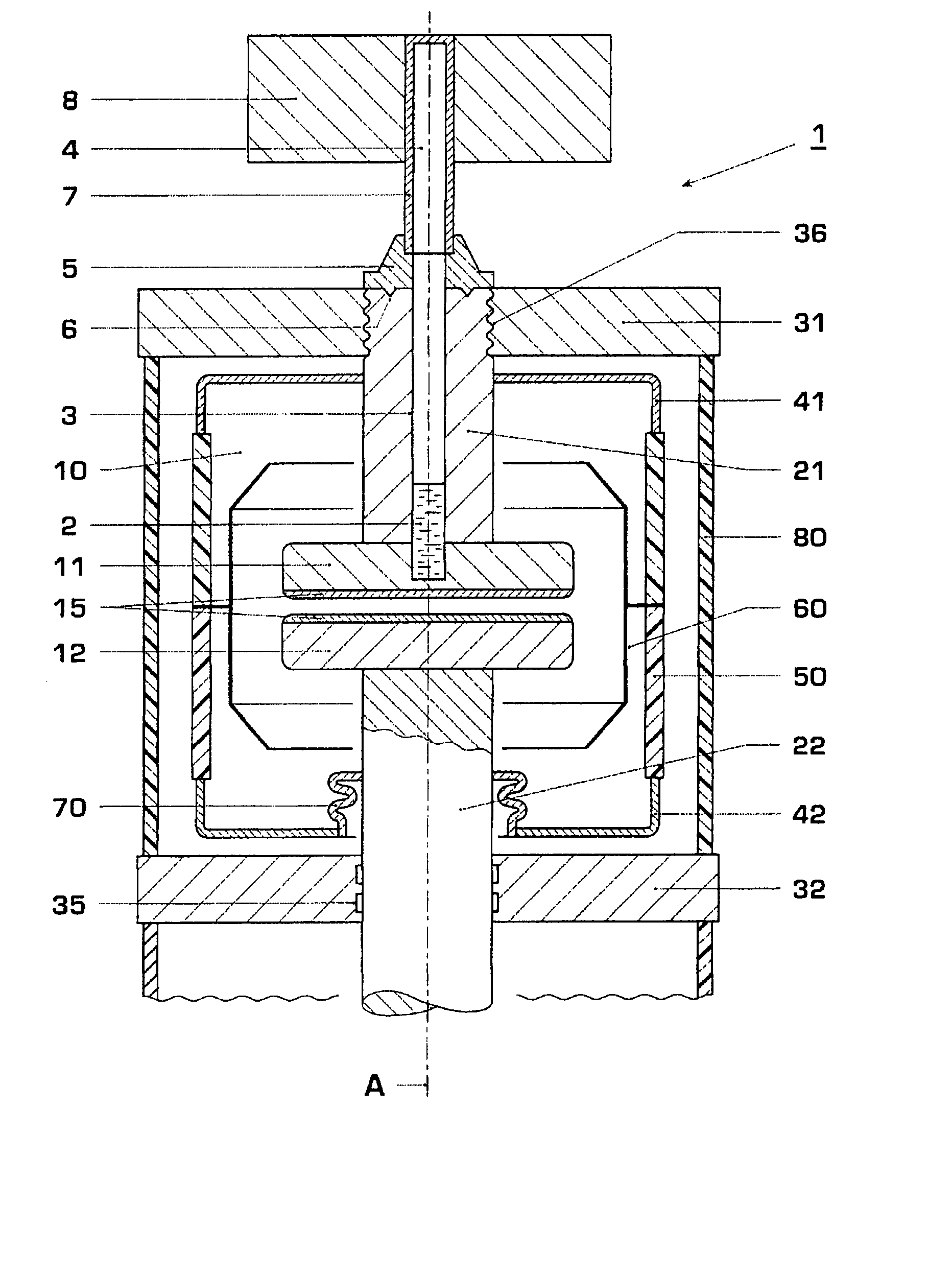

Vacuum switch operating mechanism including laminated flexible shunt connector

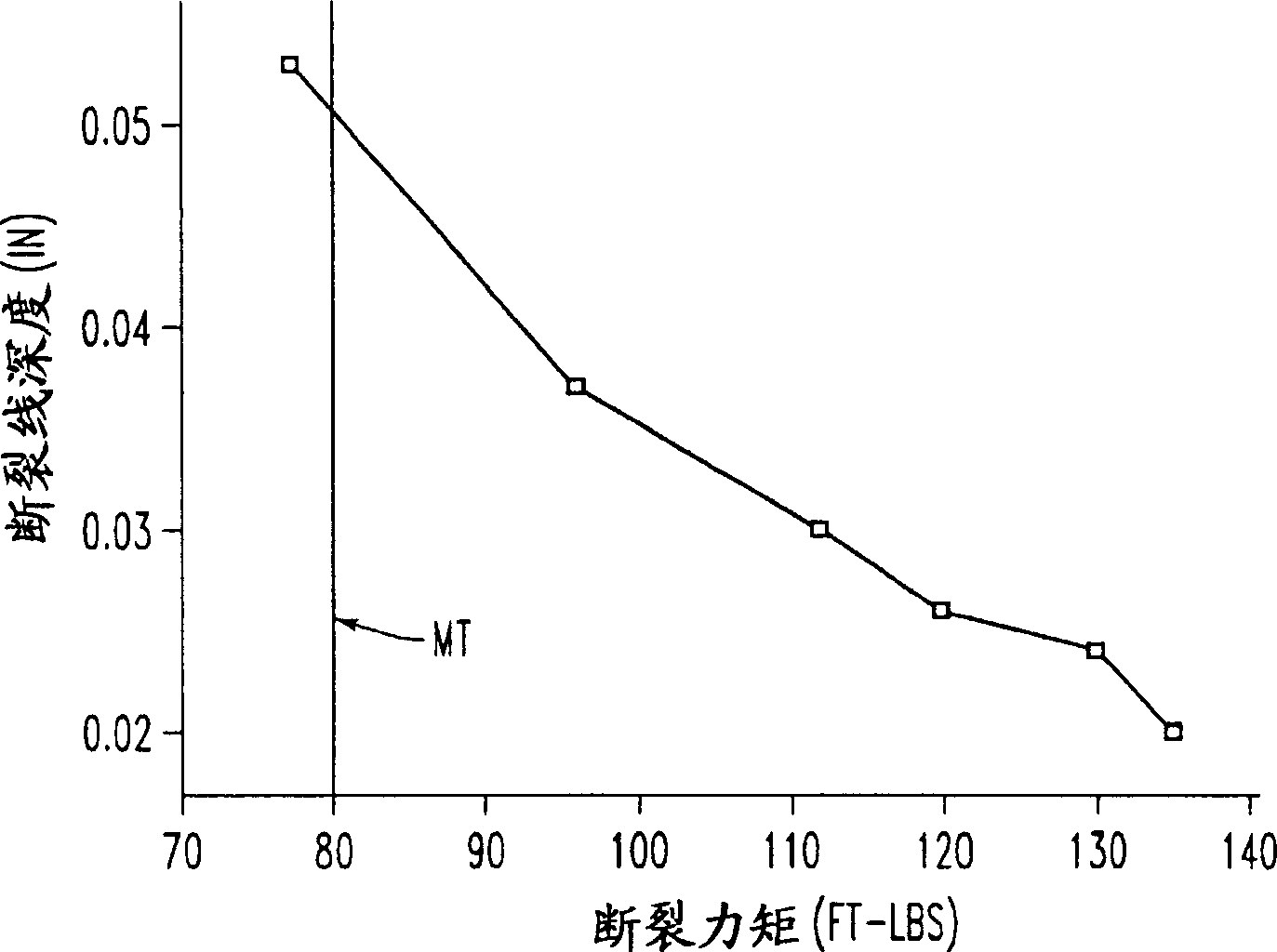

InactiveUS6444939B1Contact mechanismsHigh-tension/heavy-dress switchesElectrical conductorOffset distance

A flexible shunt in the form of a flexible member made up of a stack of electrically conductive laminations each of a thickness of no more than about 0.002 inch (0.051 mm) has a moveable end secured by a moveable mount to a moveable contact support of an electric power switch for movement along a linear path. A fixed mount secures the fixed end of the flexible member to a fixed conductor termination spaced laterally from the moveable end along a neutral axis perpendicular to the linear path of the moveable end by an offset distance such that the installed length of the intermediate section between the fixed and moveable ends is less than the free length of the intermediate section. With this arrangement the stroke of the moveable end along the linear path can be up to at least ⅓ and even ½ of the free length of the intermediate section of the flexible member and with very low operating forces.

Owner:EATON INTELLIGENT POWER LIMITED

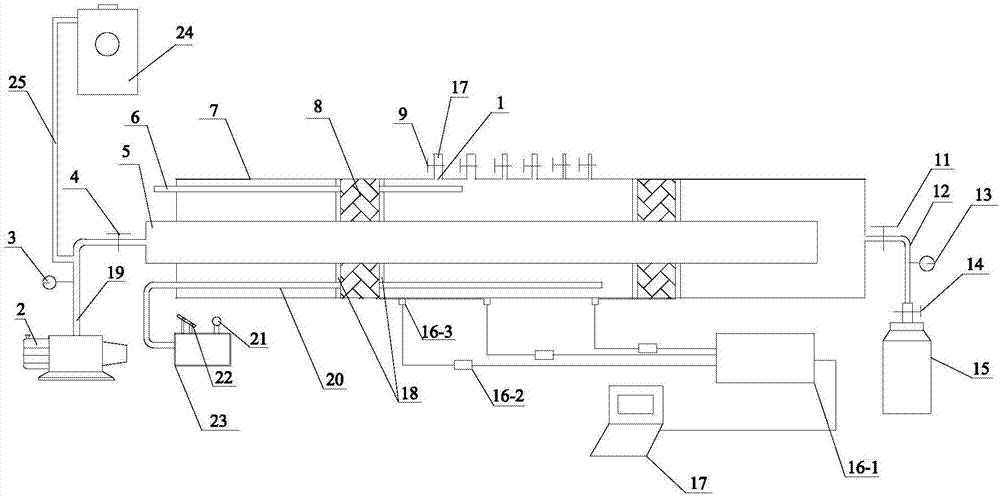

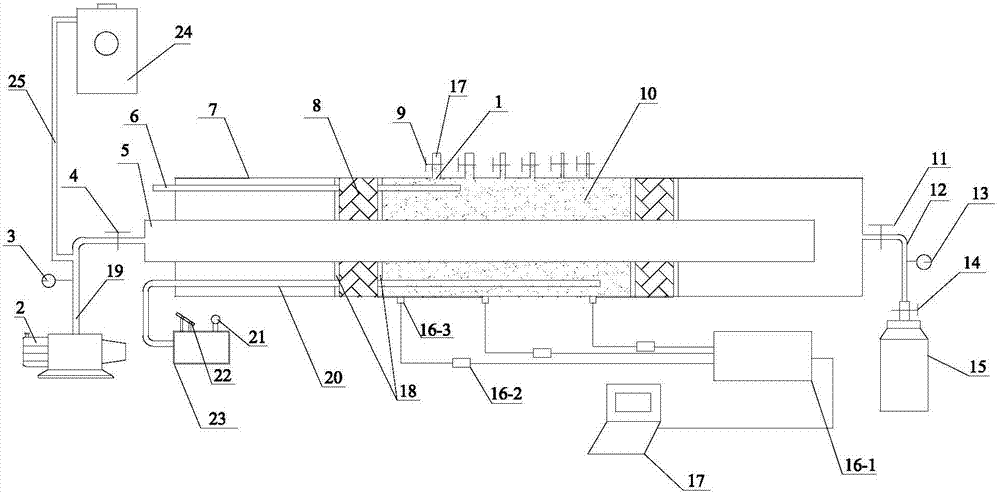

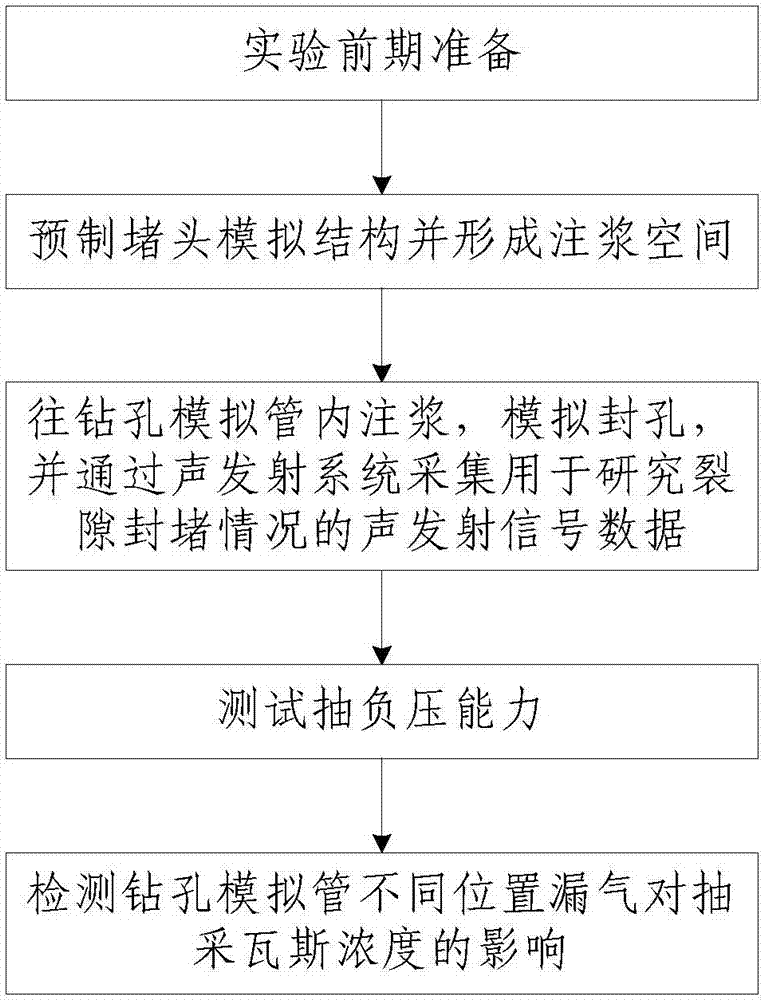

Drill hole gas extraction laboratory simulation system and method

ActiveCN107542486ASimple structureNovel and reasonable designSurveyMining devicesVacuum pressureDrill hole

The invention discloses a drill hole gas extraction laboratory simulation system which comprises a drill hole simulation pipe, a hole sealing slip casting system, a gas pressure simulation loading system, a gas detector, a sound emission system and a computer; the two ends inside the drill hole simulation pipe are provided with plug simulation structures, a plurality of crack simulation holes areformed in the wall of the drill hole simulation pipe, a crack simulation pipe is connected to each crack simulation hole, and a gas leakage detection switch is connected to each crack simulation pipe;the hole sealing slip casting system comprises a slip casting pipe, a slip returning pipe, a slip casting handle and a slip casting pressure gauge; the gas pressure simulation loading system comprises a vacuum pump, a gas tank, a vacuum pressure gauge, a vacuumizing switch, a gas tank switch, a gas pressure gauge and a gas extraction switch. The invention further discloses a drill hole gas extraction laboratory simulation method and a hole sealing material sealing performance testing method. The on-site situation can be truly simulated, little manpower and material resources consumed by experiments are consumed, the experiment effect is good, the experiment result accuracy is high, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

Intelligent integrated medium-voltage AC vacuum switchgear based on flexible switching-closing technology

ActiveCN104701064AAccurately reflect sports parametersImprove opening and closing performanceEmergency actuatorsHigh-tension/heavy-dress switchesSmart gridPower grid

The invention discloses an intelligent integrated medium-voltage AC vacuum switchgear based on a flexible switching-closing technology. The switchgear comprises a controller, and a vacuum switching tube, an insulator and a switching-closing mechanism connecting piece, all of which are orderly connected; a microprocessor is arranged in an intelligent circuit; a travel sensor is fixed on a movable contact connecting rod and used for directly detecting the state of motion of a movable contact and obtaining the accurate motion parameters of the movable contact; switching-closing operating parameters are comprehensively calculated according to arc light intensity detected by an arc light transducer and a temperature measured by an infrared temperature measuring transducer, so that the switching-closing performance of switching on and switching off the medium-voltage power grid can be greatly improved, the switching-closing time points are accurately controllable and flexible switching-closing can be realized; an over travel spring arranged in the insulator is capable of providing enough high pressure between the movable contact and the fixed contact of the vacuum switching tube during closing and capable of realizing bounce-free quick switching during switching; in the switching and closing processes, the harmful impact on the power grid, the loads and the switch is quite small and the demand on constructing a strong intelligent power grid can be satisfied.

Owner:JIANGSU MODERN POWER CAPACITOR

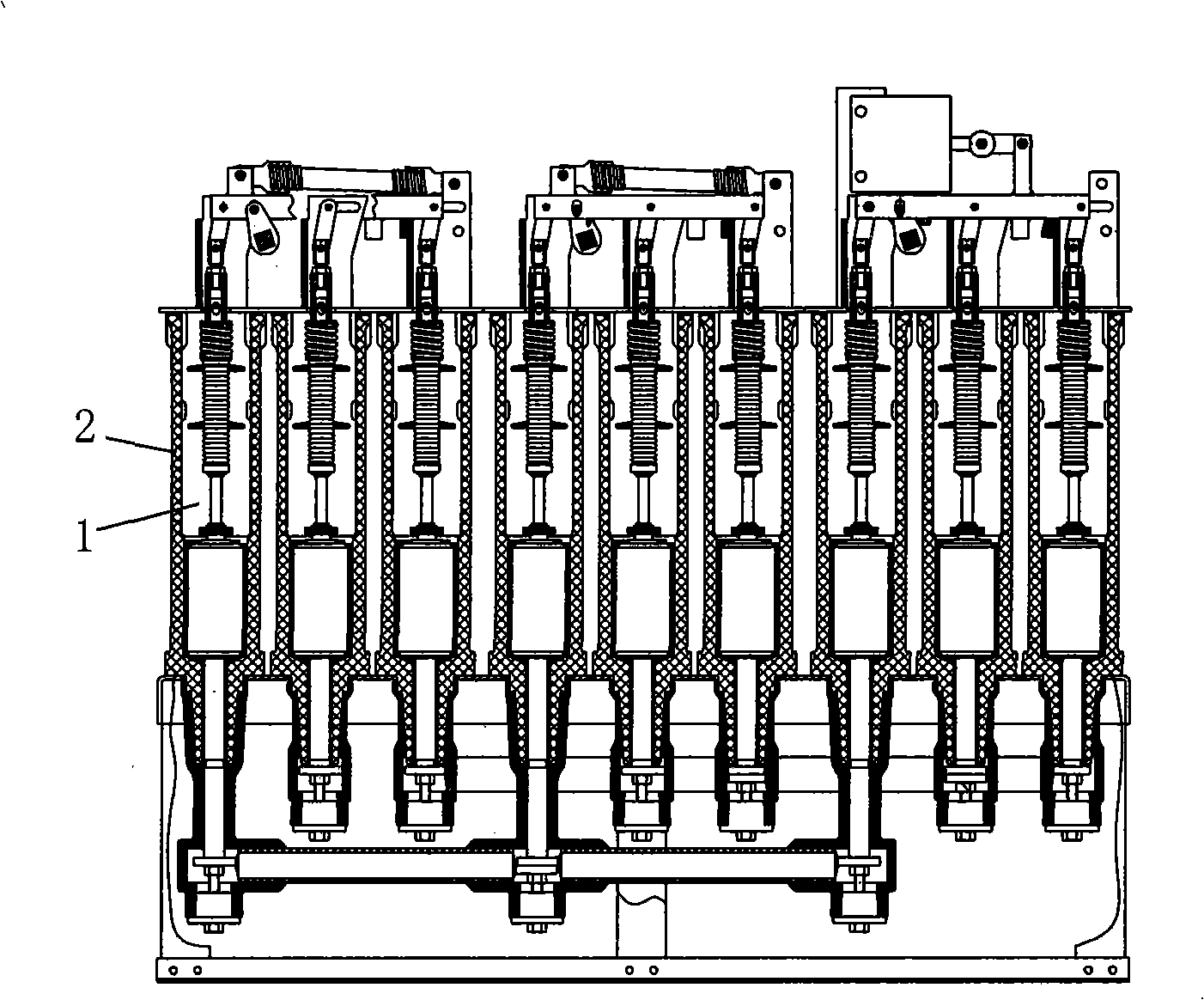

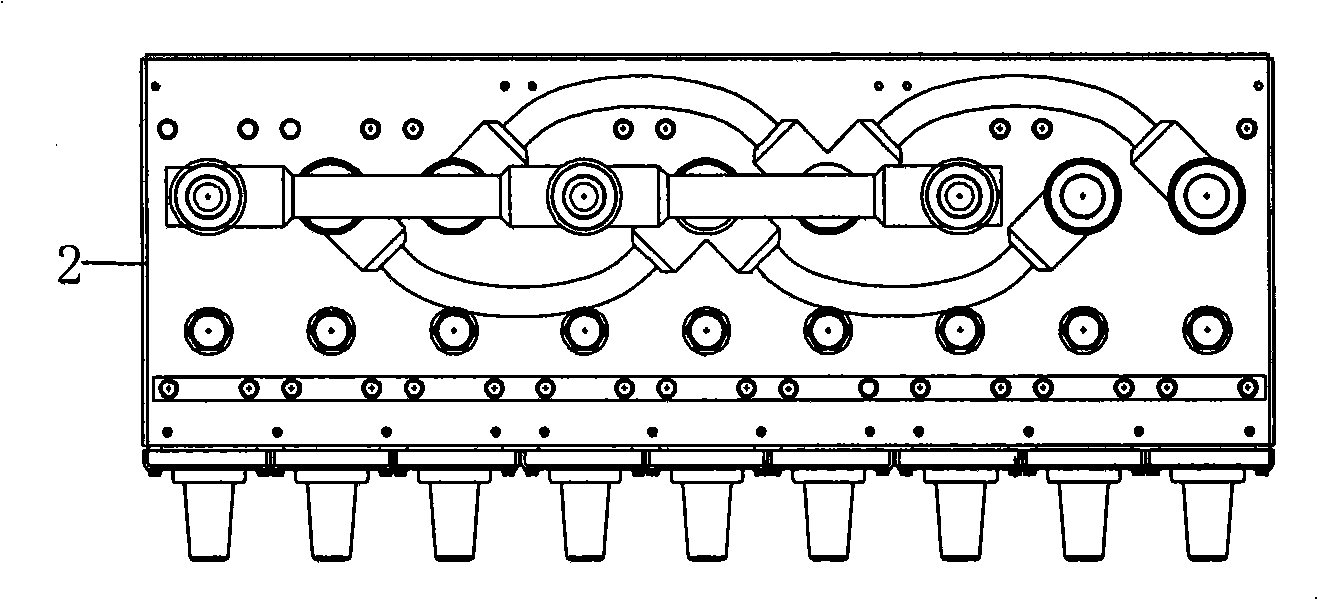

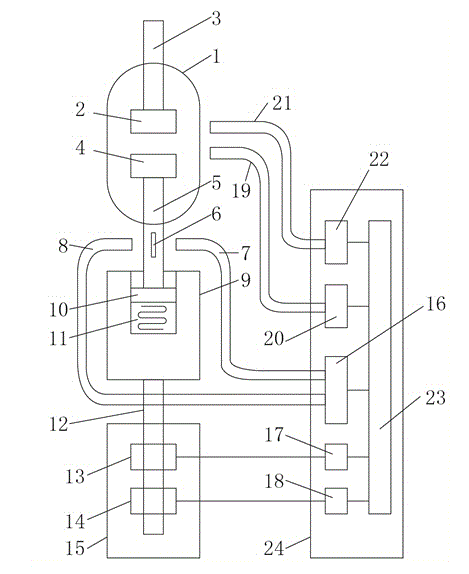

Fault current limiter based on fast switch and triggered vacuum switch

ActiveCN101604835ATrigger fastInhibit short circuit currentArrangements responsive to excess currentCapacitanceEngineering

A fault current limiter based on a fast switch and a triggered vacuum switch is disclosed, which comprises a fast switch (1) and a current limiting resistor (2) which are connected in parallel, wherein, a first pulse capacitor (3), a first inductor (4) and a first triggered vacuum switch (5) are connected in series between two ends of the fast switch (1); a second pulse capacitor (6), a second inductor (7) and a second triggered vacuum switch (8) are connected in series between two ends of the current limiting resistor (2). The invention: 1) enables short circuit current to be incapable of reaching a first current peak value in a state of infinite current; 2) causes arc current of the fast switch to achieve fast zero crossing and then arc blowout; 3) can pass through large pulse current at high triggering speed and can achieve arc blowout at the time of the zero crossing of the pulse current; 4) can rapidly inhibit the short circuit current; 5) and automatically limits current subsequent to the short circuit of a system to ensure quality of power supply and save establishment expenditure of network.

Owner:STATE GRID CORP OF CHINA +2

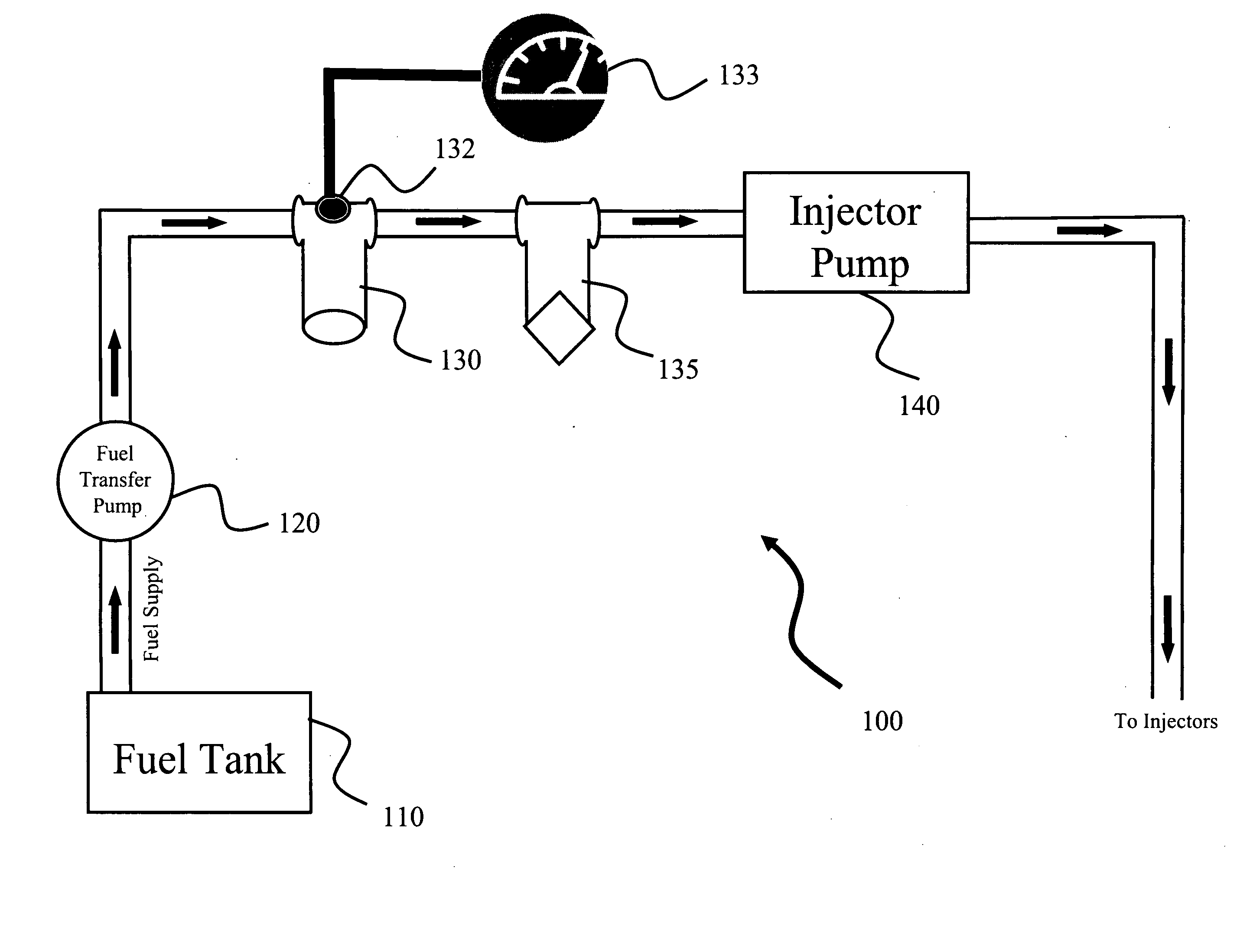

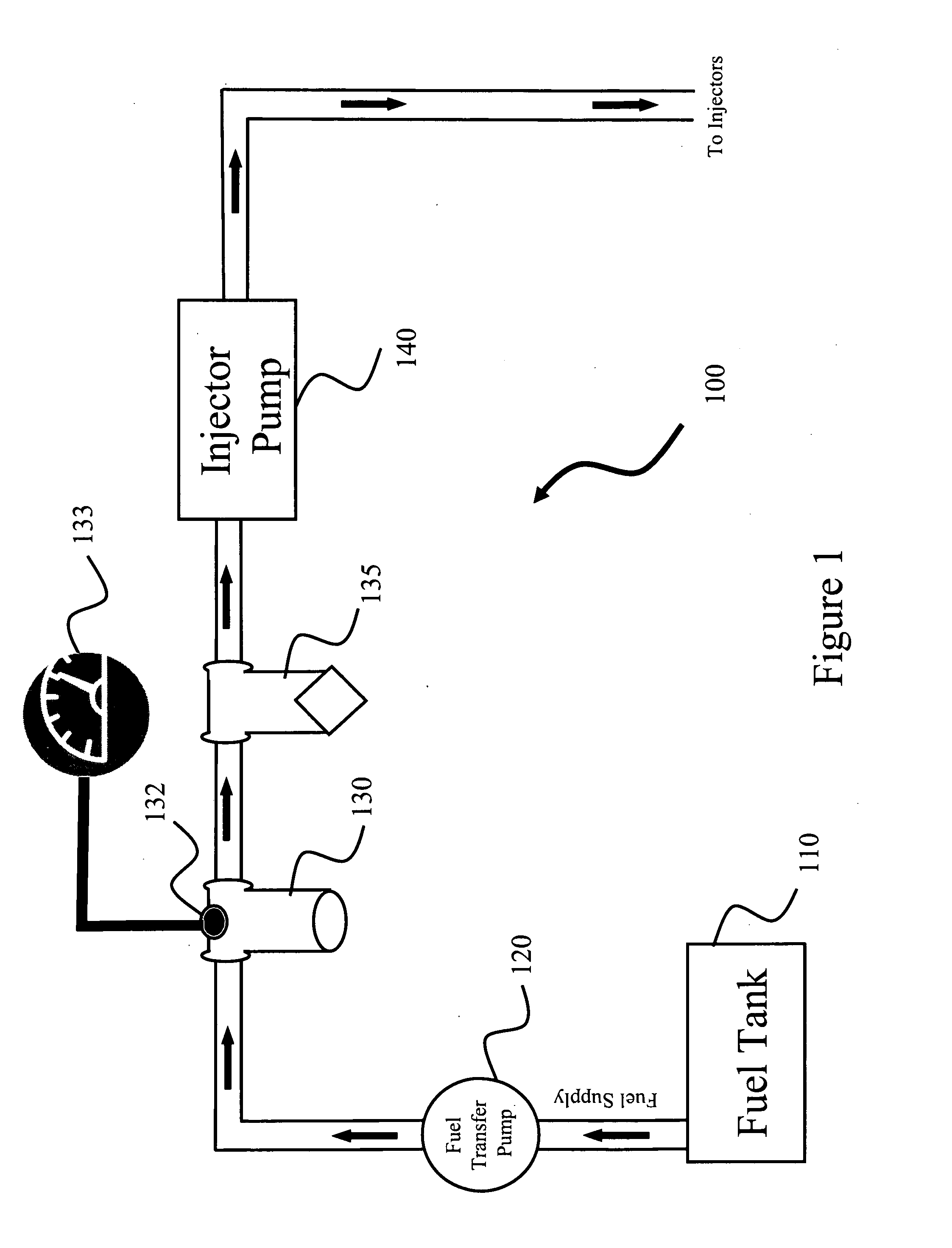

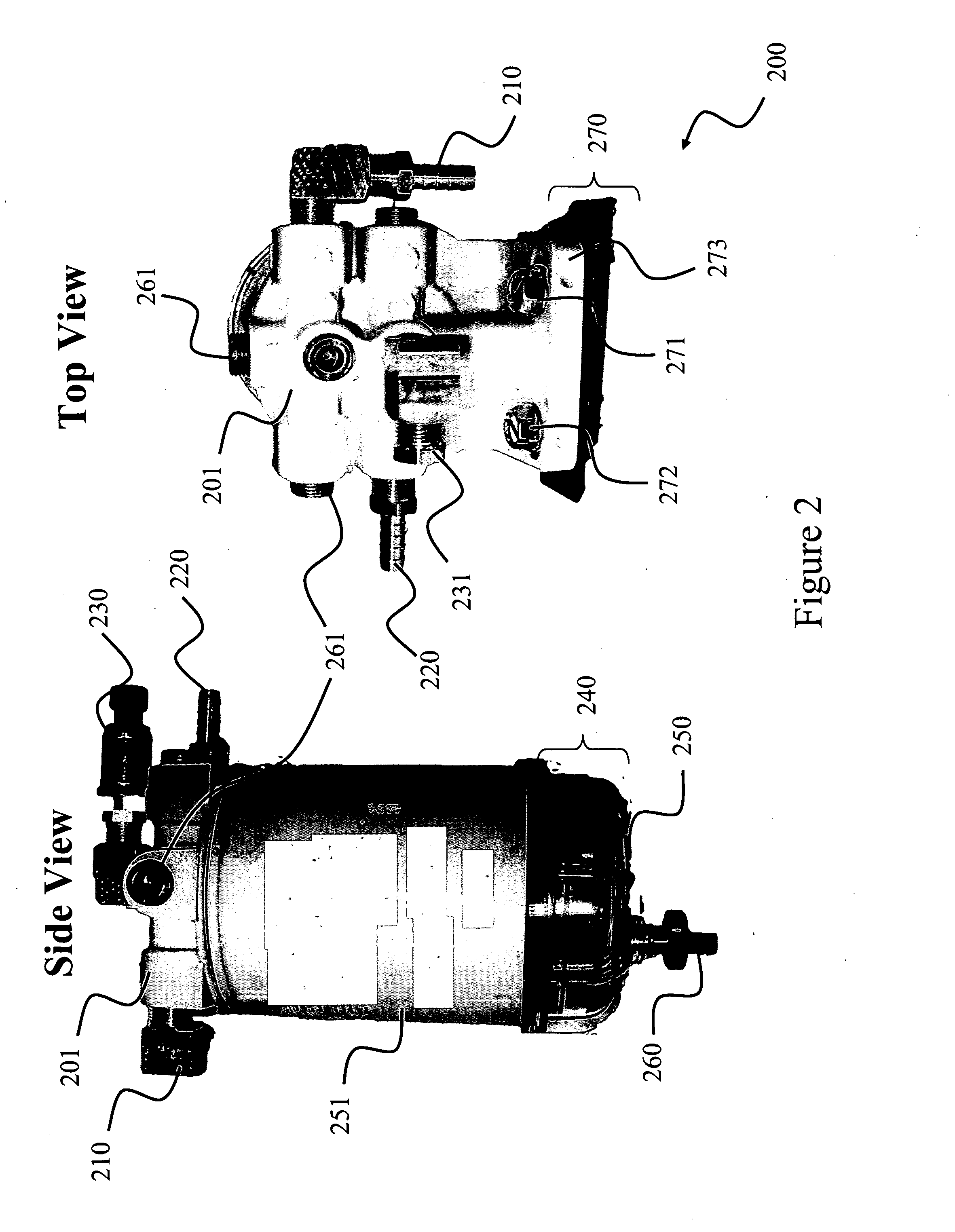

Fuel filter assembly with pressure sending unit

A fuel filter assembly having a pressure sending unit for filtering and monitoring fuel and fuel pressure for diesel engines and the like comprising a filter head, a spin-on element and collection bowl. The filter head is fastened to an engine or other suitable structure by flange, bolts and supports the fuel filter assembly by monitoring fuel pressure by utilizing a pressure sending unit in fluid communication with an outlet port on the filter head. Preferably, filter head is a die cast head and includes therein typical inlet port, outlet port, and connected respectively thereto, inlet chamber and outlet chamber. Filter head is a generally circular structure having a flat annular mounting surface. The filter head may further comprises vent ports, vacuum switch ports or both, which are in fluid communication with outlet ports and return check valve ports that are in fluid communication with inlet ports. Still further, filter head is in fluid communication with a pressure sending unit, which is in electrical communication with a pressure monitoring device or similar warning system.

Owner:WILLISON WILLIAM L

Solid insulating vacuum ring network cabinet

ActiveCN102222868AElectrical performance impactPromote environmental protectionBus-bar/wiring layoutsSwitchgear arrangementsEpoxyHazardous substance

The invention provides a solid insulating vacuum ring network cabinet comprising at least one wire inlet ring network cabinet and at least one wire outlet ring network cabinet, wherein the wire inlet ring network cabinet is assembled on a cabinet body by a vacuum switch unit through screws so as to form the whole wire inlet ring main unit; the wire outlet ring network cabinet is formed by assembling the vacuum switch unit and a fuse tripping interlocking device on the cabinet body through screws; a fuse cylinder component is arranged at the position in the vacuum switch unit at which a polar column assembling plug is securely sealed. The solid insulating vacuum ring network cabinet has the advantages that harmful substances are not generated during the working process; furthermore, all parts can be reclaimed after achieving the service life; and the environment-friendly requirement is adapted. All charged bodies are placed or arranged in epoxy resin; the electric performance of the ring network cabinet is not affected by external environments such as vapor, dust and the like; and the maintenance quantity is little and the service life is long. As charged bodies are all arranged inthe epoxy resin, semiconductor substance is sprayed outside the epoxy resin; and the induction voltage is grounded; therefore, even when a user contacts with the ring network cabinet, the electric shock accident does not occur, and the safety of equipment is improved.

Owner:SHANGHAI THEHAO ELECTRIC POWER TECH

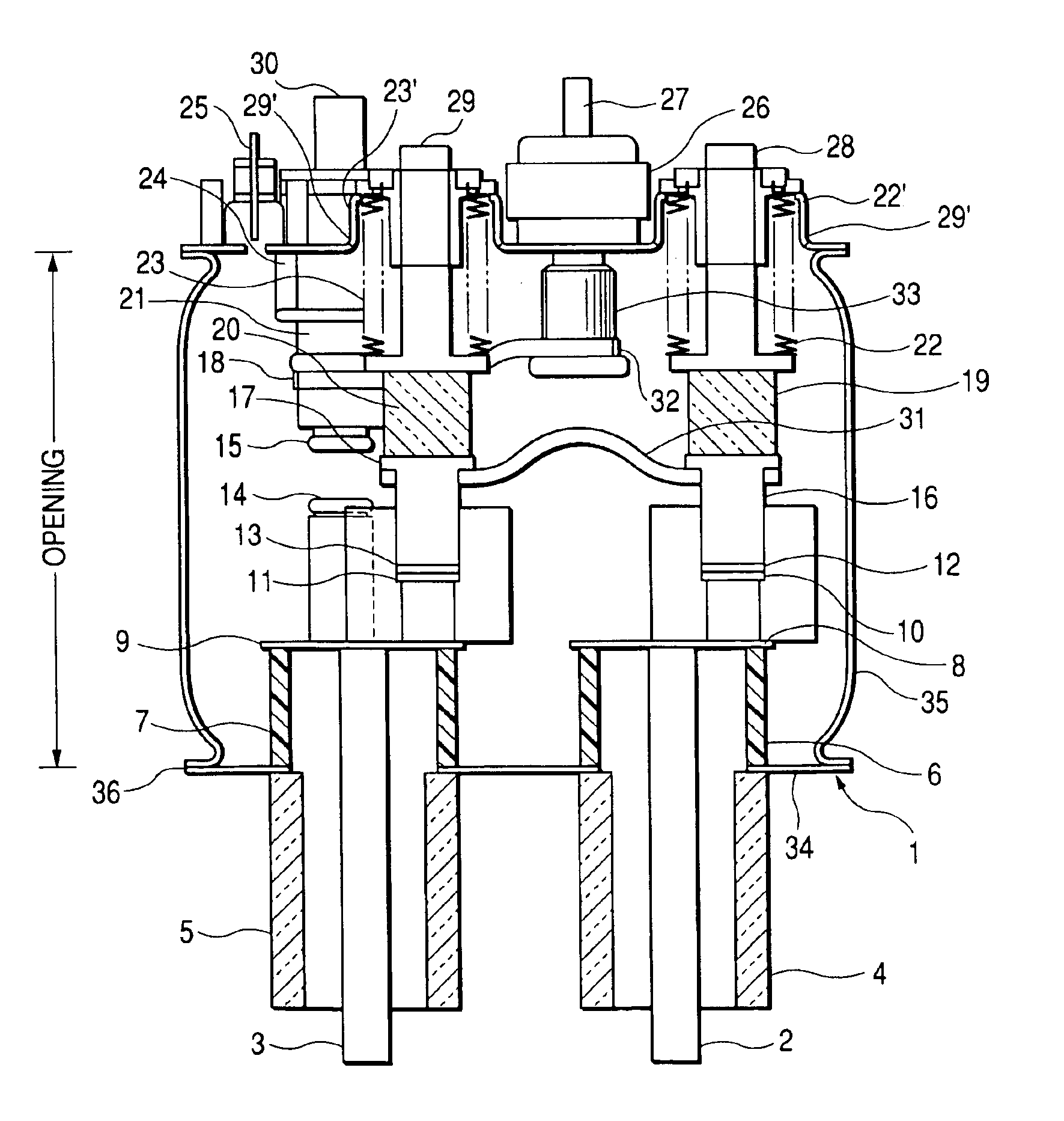

Vacuum switchgear

InactiveUS6881917B2Simple configurationLow costContact mechanismsHigh-tension/heavy-dress switchesElectrical conductorSwitchgear

Disclosed is a vacuum switchgear wherein a ground switch, a load switch, and an external connecting conductor to be electrically connected with the inside and outside of the vacuum container are provided in a vacuum container; the ground switch and the external connecting conductor are electrically connected in the vacuum container; and the vacuum container has a joint construction of a body portion having openings on both ends thereof, and a lid joined to the opening of the body.

Owner:HITACHI LTD

Vacuum Switch With Pre-Insertion Contact

ActiveUS20120175347A1Improve energy consumptionContact mechanismsHigh-tension/heavy-dress switchesPower flowEngineering

A vacuum switching device with pre-insertion contact arrangement is disclosed. The vacuum switch includes first and second contact systems. The first contact system includes an annular stationary contact and an annular moving contact retained on a moving contact drive rod. A second contact system includes a moving contact retained on an end of the moving contact drive rod and a floating contact retained along the same axis as the second moving contact. Both contact systems are enclosed in a vacuum envelope. A mechanical adjustment system is provided for the floating contact, which allows it to be positioned so that the secondary moving contact and floating moving contact may engage at a set interval before the annular moving contact engages the annular stationary contact. A resistor or inductor is connected between the second contact system and a load to prevent a current in-rush into the load.

Owner:GLASER MICHAEL DAVID

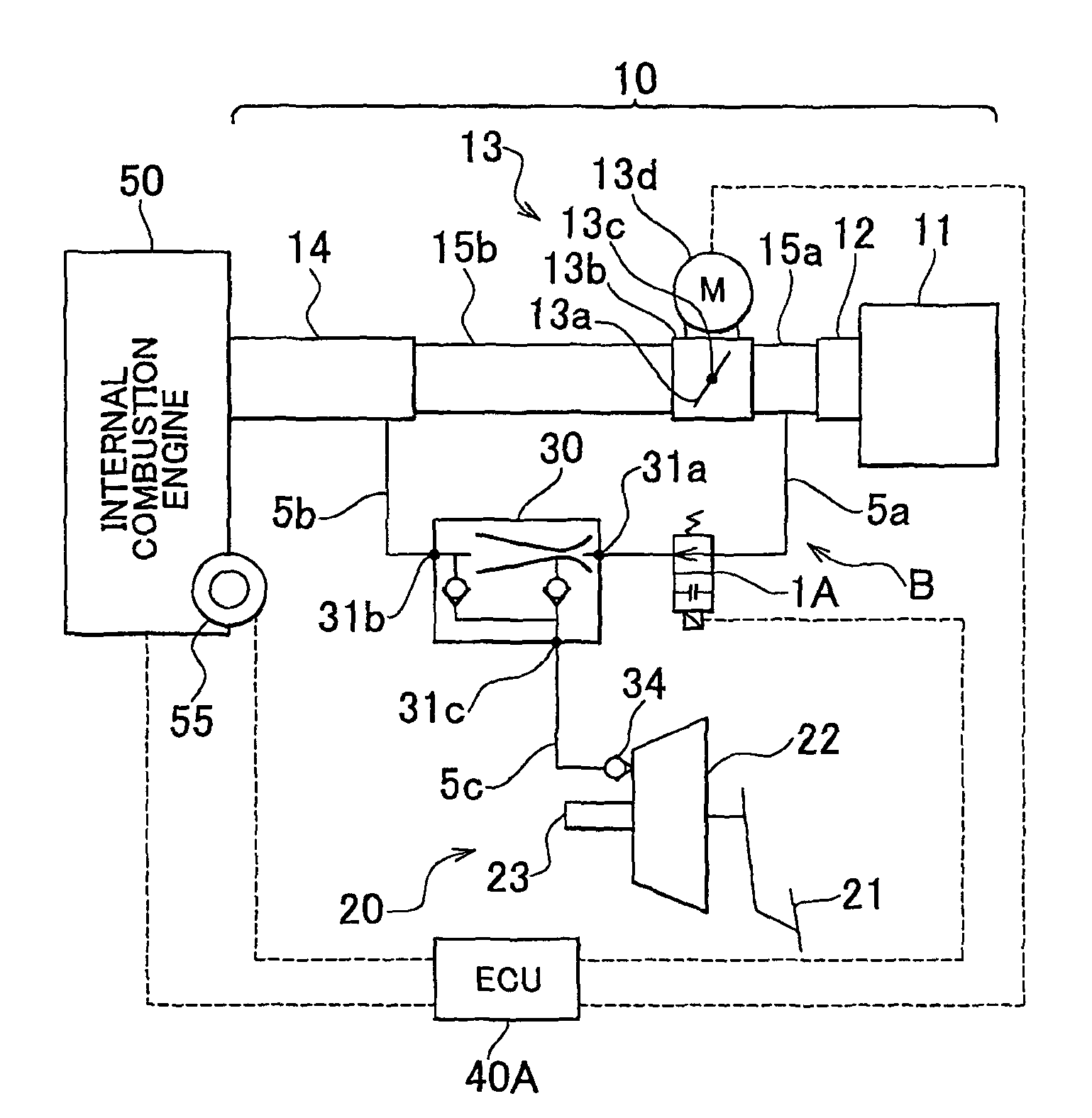

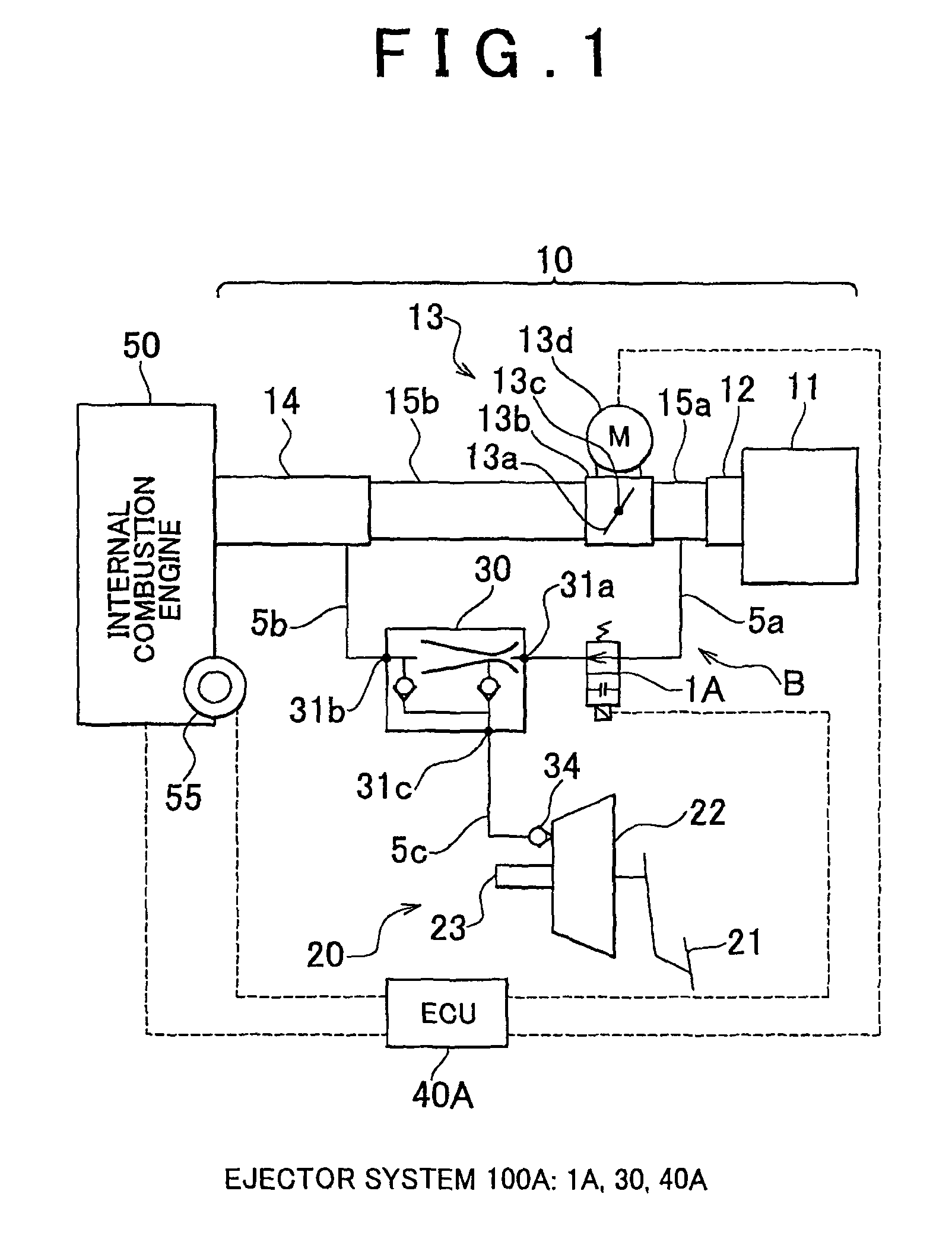

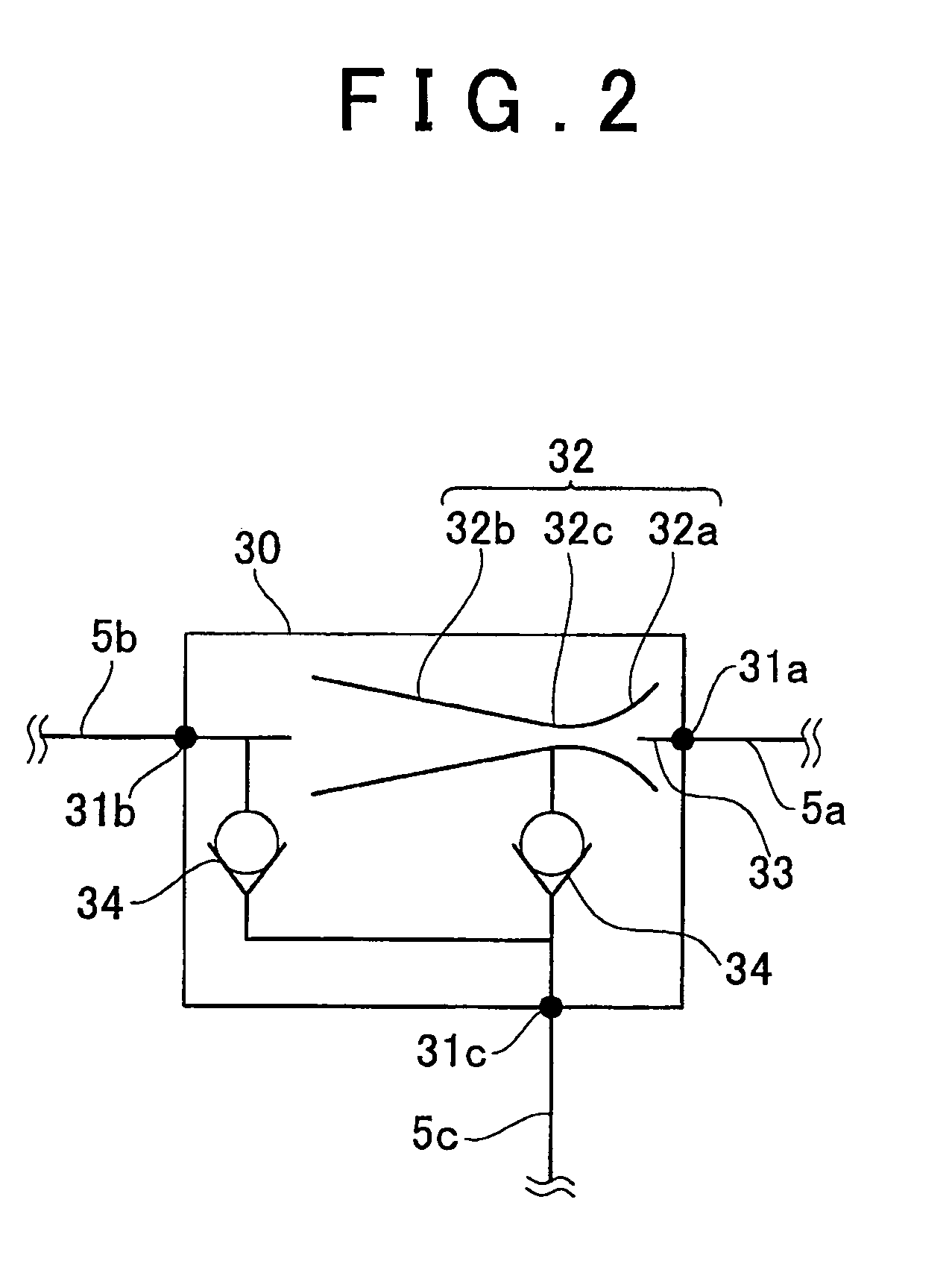

Ejector system for vehicle

InactiveUS7650221B2Suppress fluctuationsSuppress fluctuation in idle speedAnalogue computers for vehiclesElectrical controlIdle speedControl valves

An ejector system controls the idle speed of an internal combustion engine by controlling an electric throttle valve system that adjusts the flow-rate of the intake air to be supplied to the internal combustion engine, and includes an ejector which generates a negative pressure of which the absolute value is larger than the absolute value of a negative pressure to be introduced from an intake manifold, a vacuum control valve which causes the ejector to operate or causes the ejector to stop operating, and an ECU that controls the vacuum switching valve. With the ejector system, even if the ejector is caused to operate or caused to stop operating, it is possible to appropriately suppress fluctuations in the idle speed, and appropriately obtain a negative pressure.

Owner:TOYOTA JIDOSHA KK

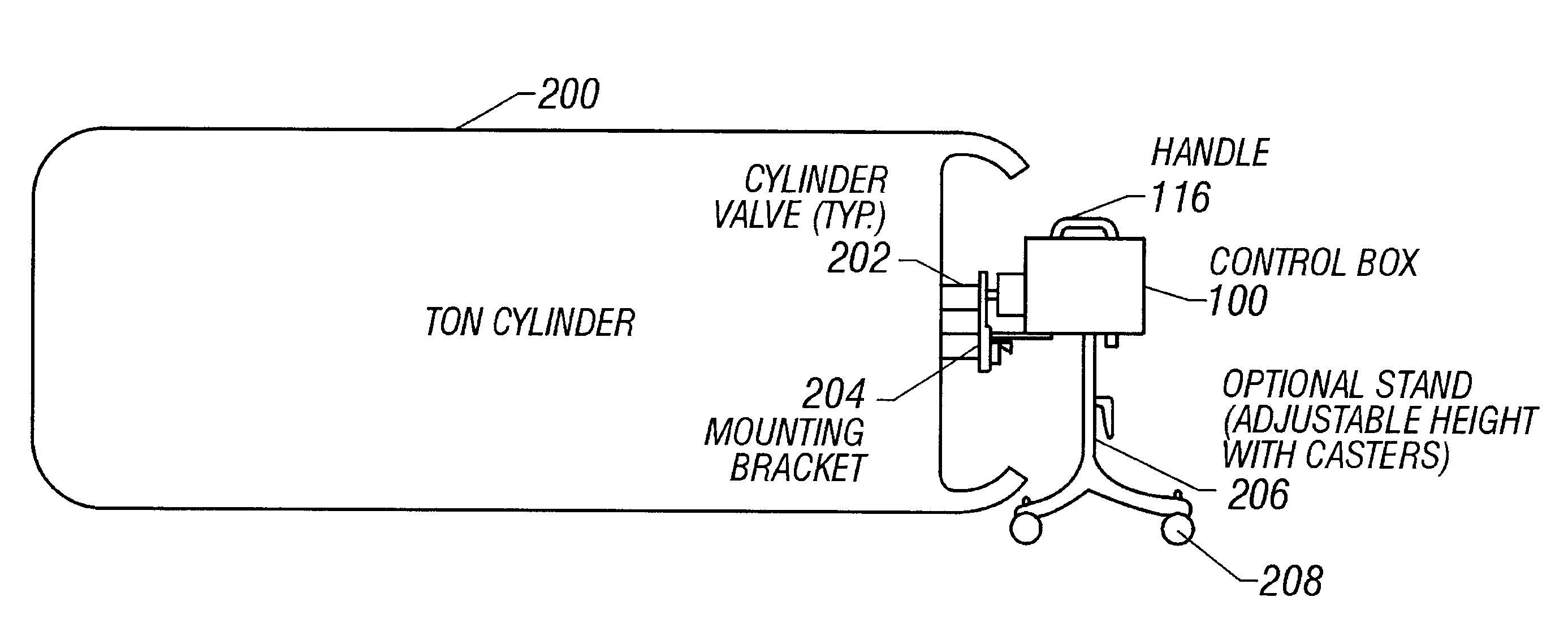

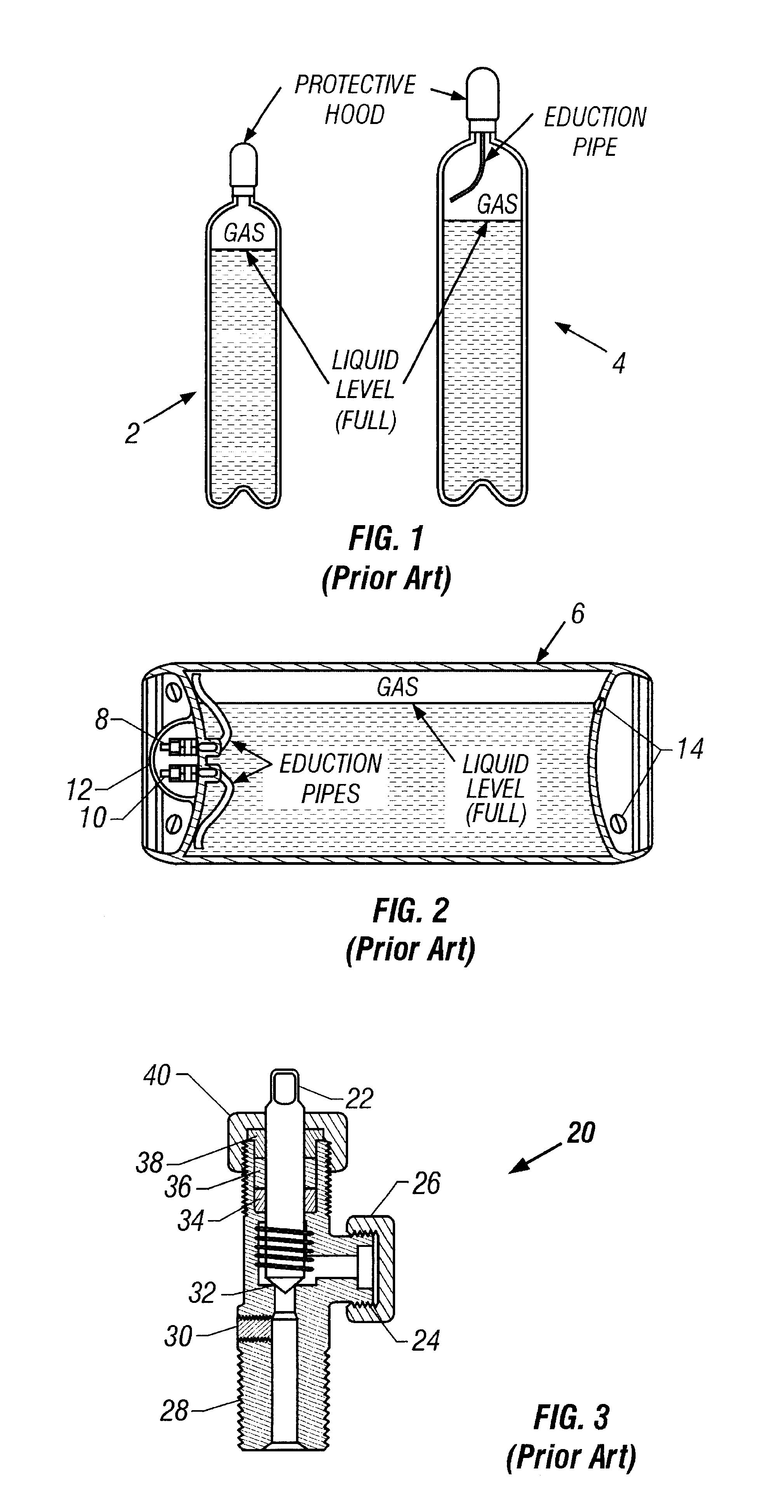

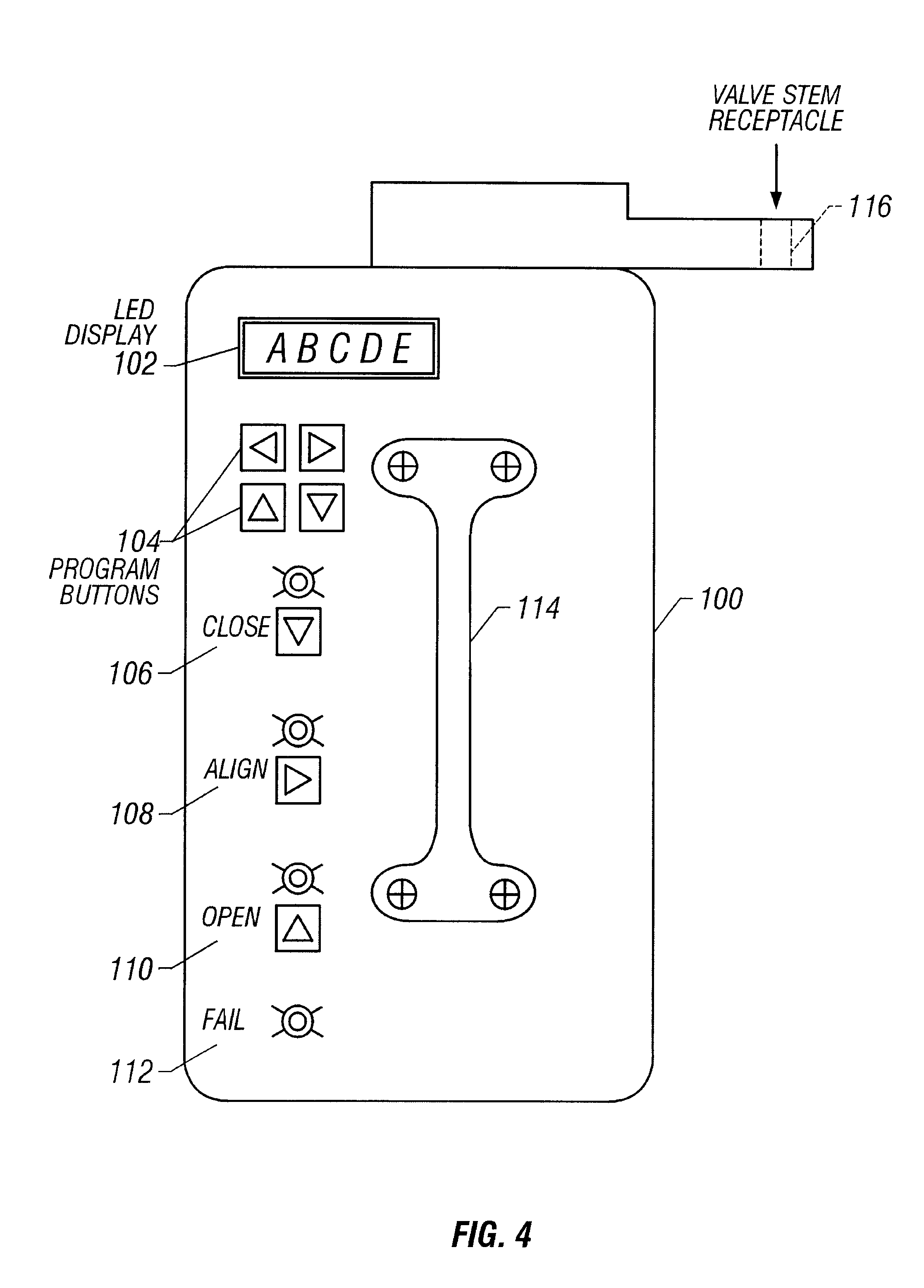

Automatic actuator system

InactiveUS6328053B1Operating means/releasing devices for valvesOther washing machinesGas cylinderOn board

A system for filing or discharging compressed gas or liquid cylinders mounted on the cylinder. An automatic system for filing or discharging a compressed gas cylinder, specifically chlorine, sulfur dioxide, or ammonia cylinders. The system includes an electric motor that rotates the cylinder valve system toward open or closed position without interfering with or requiring additional adapters for the filing or discharge hardware. The motor, gears, and controls are assembled as one unit to eliminate the necessity for a separate control panel or interconnecting control wires. The system has the capabilities for integral leak detection with automatic shutdown, battery backup in the event of power failure, remote control by leak detector, remote control panic button, remote low weight transmitter, remote vacuum switch for automatic switch-over systems and other remote digital signals. The system requires only a flexible power cord for trickle charge of the battery backup, which makes the assembly totally portable when not in use. Placement of the system container can be accomplished by connection to the cylinder valve, a permanent stand, or a movable stand on casters. Motor and controls are accomplished through an on-board microprocessor with integral LED displays for "C<SMALLCAPS>LOSED< / SMALLCAPS>," "A<SMALLCAPS>LIGN< / SMALLCAPS>," and "O<SMALLCAPS>PEN< / SMALLCAPS>" indicators. Programming is accomplished through an integral keypad. Actual valve position is transmitted to the microprocessor from a direct-coupled potentiometer.

Owner:WHITMORE BRIAN SCOTT SR

Vacuum circuit breaker having a high current-carrying capacity

InactiveUS20080000879A1Effective coolingImprove current carrying capacityIndirect heat exchangersHigh-tension/heavy-dress switchesCarrying capacityEngineering

The vacuum switching chamber has two contact pieces and is provided with at least one heat pipe for dissipating heat. The heat pipe contains a working medium for dissipating the heat by evaporating the working medium in a section, referred to as the evaporator, of the heat pipe and condensing the working medium in a section, referred to as the condenser, of the heat pipe. Advantageously, the evaporator is in close thermal contact with at least one contact piece, and, in particular, at least part of the evaporator is integrated in the first contact piece or the second contact piece. Advantageously, the condenser has a cooling rib arrangement.

Owner:ABB RES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com