Solid insulating vacuum ring network cabinet

A solid insulation, ring network cabinet technology, applied in the substation/switchgear board/panel/desk, switchgear, configuration/arrangement of fuses, etc. High, complex processing technology and other issues, to reduce maintenance, improve environmental protection, improve safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

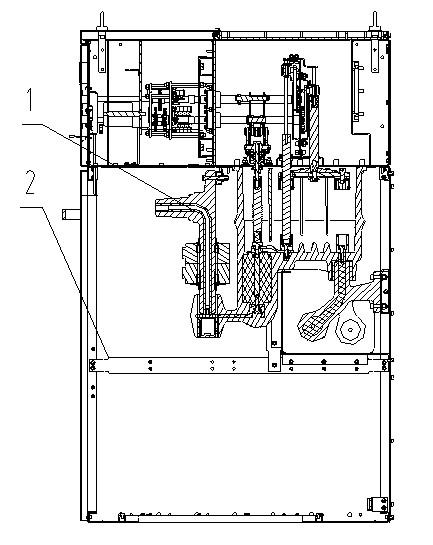

[0012] Control attached figure 1 , the structure of the incoming line ring network cabinet is that the vacuum switch unit 1 is installed on the cabinet body 2 through screws to form the entire incoming line ring network cabinet.

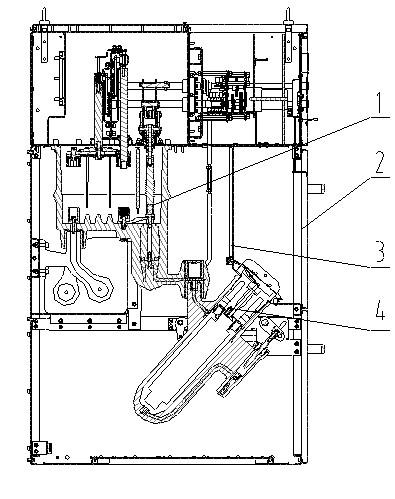

[0013] Control attached figure 2 , the structure of the outlet ring network cabinet is to include a vacuum switch unit 1, a cabinet body 2, a fuse trip interlock device 3, and a fuse barrel assembly 4, wherein the vacuum switch unit 1 and the fuse trip interlock device 3 are installed in the cabinet by screws On the body 2, the fuse cartridge assembly 4 is installed in the vacuum switch unit 1 at the position where the plug was originally installed on the solid-sealed pole.

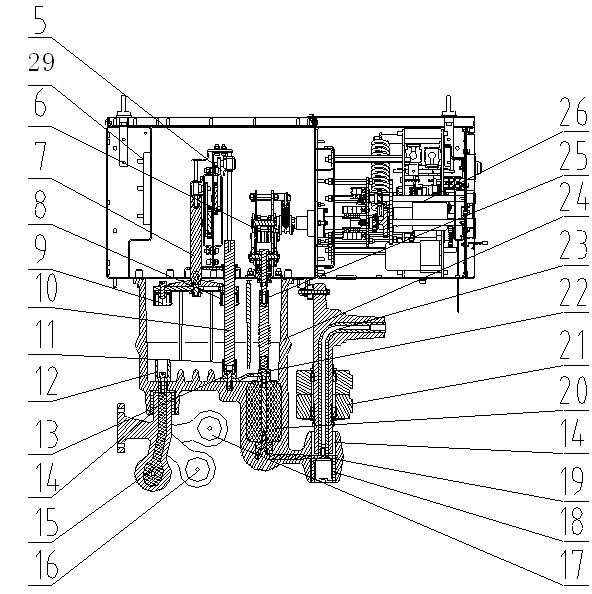

[0014] Control attached image 3 The structure of the vacuum switch unit 1 used for the incoming line ring network cabinet includes two parts: the solid-sealed pole 24 and the operating mechanism chamber 26. The solid-sealed pole 24 is installed on the operating mechanism by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com