Patents

Literature

77results about How to "Electrical performance impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium-ion battery with high rate discharge performance

ActiveCN103730625AImprove rate discharge performanceImprove securitySecondary cellsCell component detailsHigh rateEngineering

The invention discloses a lithium-ion battery with high rate discharge performance. The lithium-ion battery comprises a cover, a battery core in the cover, an upper cover plate, and a lower cover plate, wherein the battery core is prepared either by winding or laminating a positive pole piece with a positive pole ear, a negative pole piece with a negative pole ear and a diaphragm. The lithium-ion battery is characterized in that a positive pole piece clamping mechanism and a negative pole piece clamping mechanism are also arranged; the positive pole ear is packed and fixed inside of the positive pole piece clamping mechanism and a positive pole stud is arranged on the outside of the positive pole piece clamping mechanism and is in detachable connection with the upper cover plate; the negative pole ear is packed and fixed inside of the negative pole piece clamping mechanism and a negative pole stud is arranged on the outside of the negative pole piece clamping mechanism and is in detachable connection with the lower cover plate. The lithium-ion battery is particularly applicable to the fields of electrical motorcycles, electrical taxies and electrical buses, and the like, and can meet the requirements for high rate discharge performance of batteries when the vehicles are in the bad circumstances such as climbing, instantaneous starting and instantaneous accelerating.

Owner:安徽金鑫宏运新能源科技有限公司

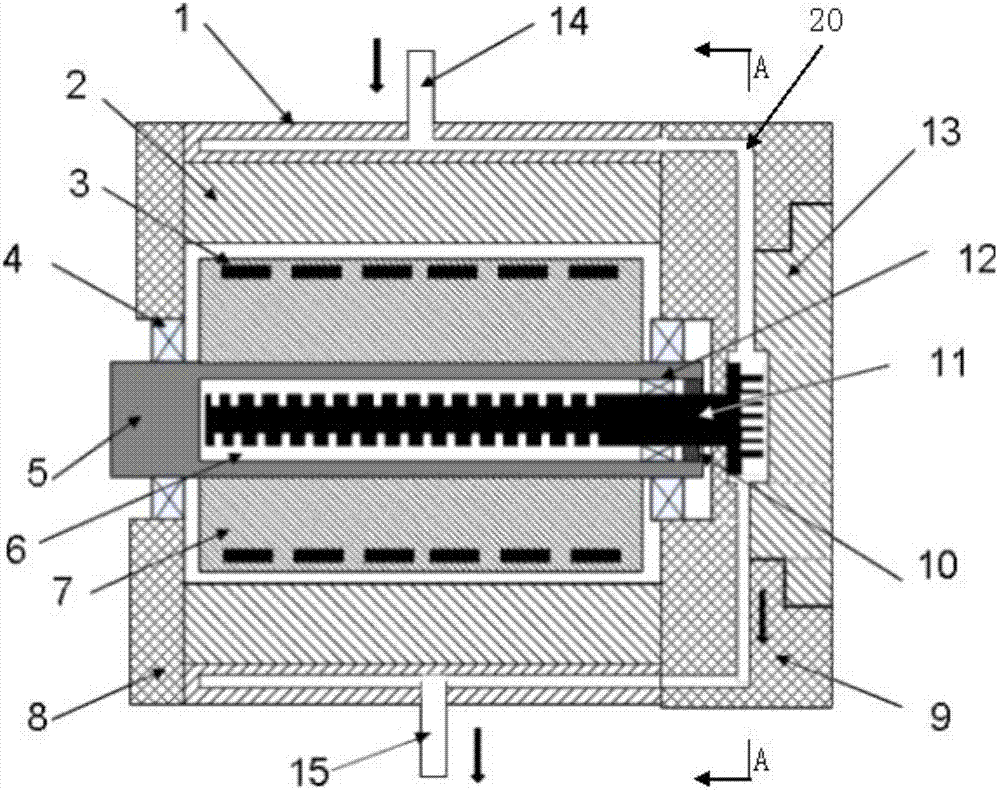

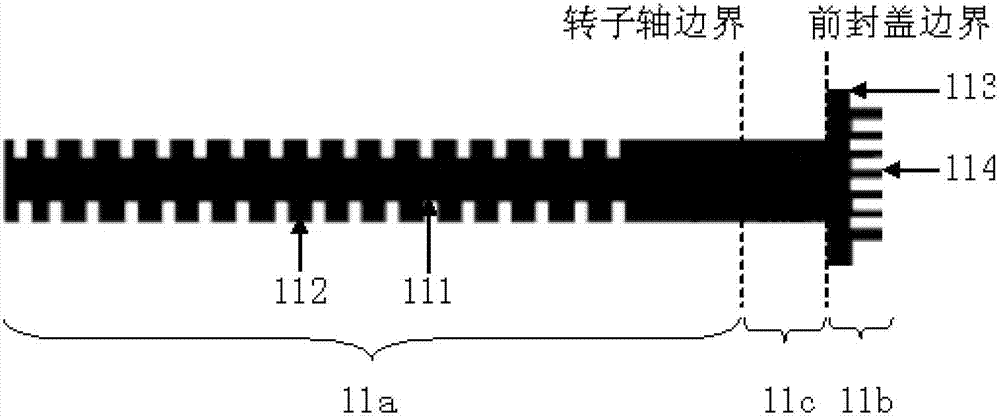

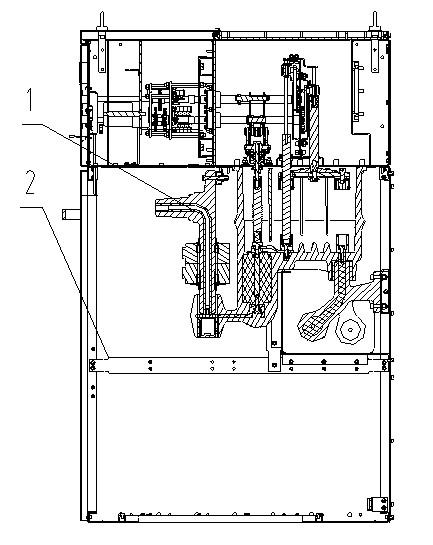

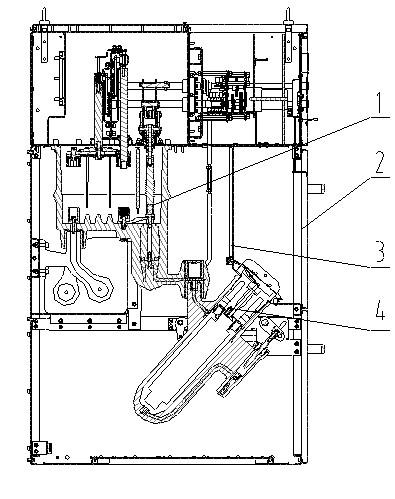

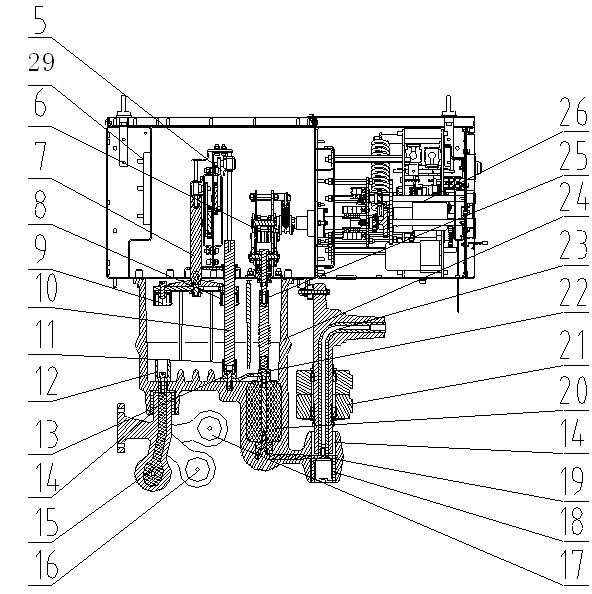

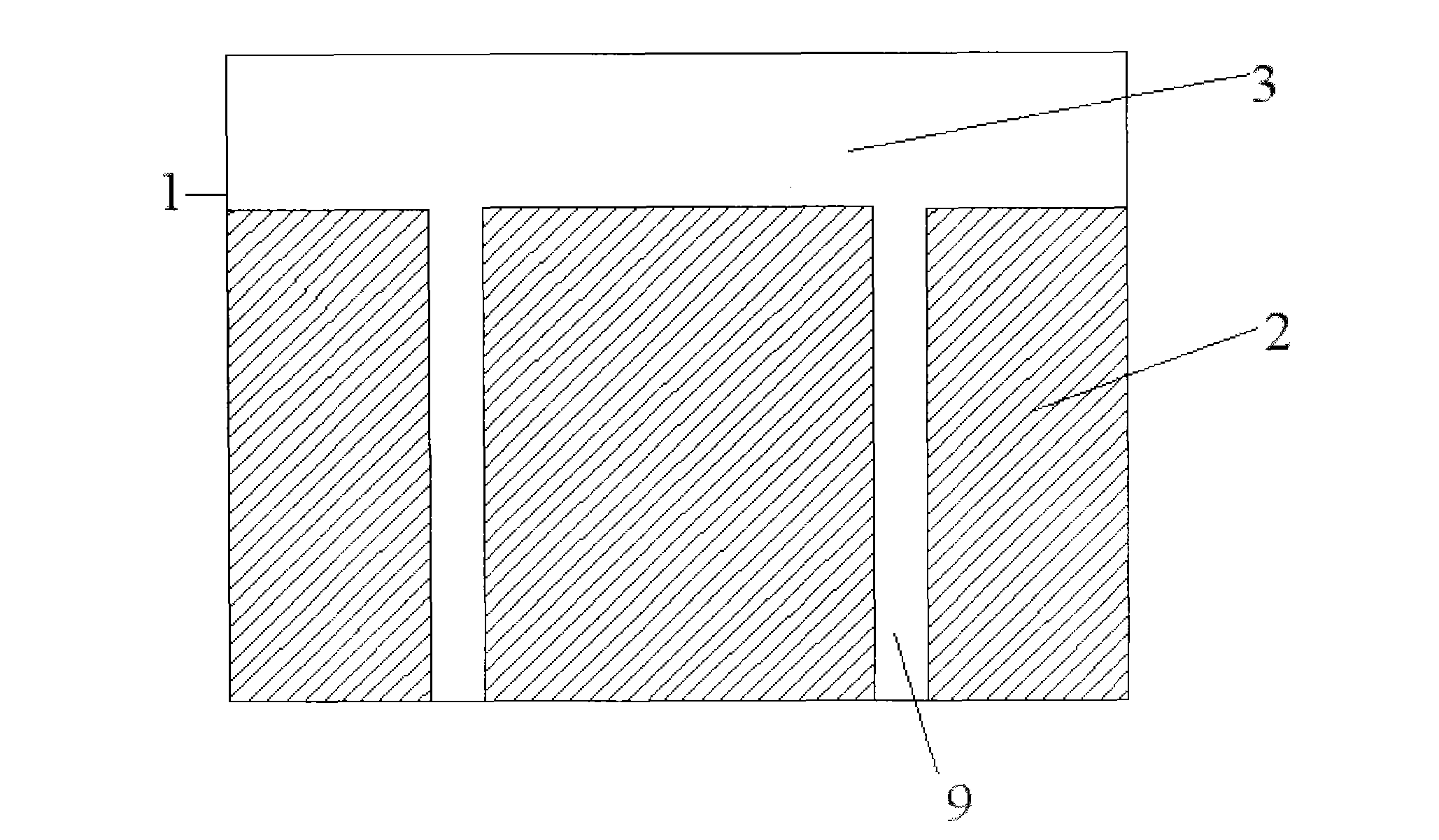

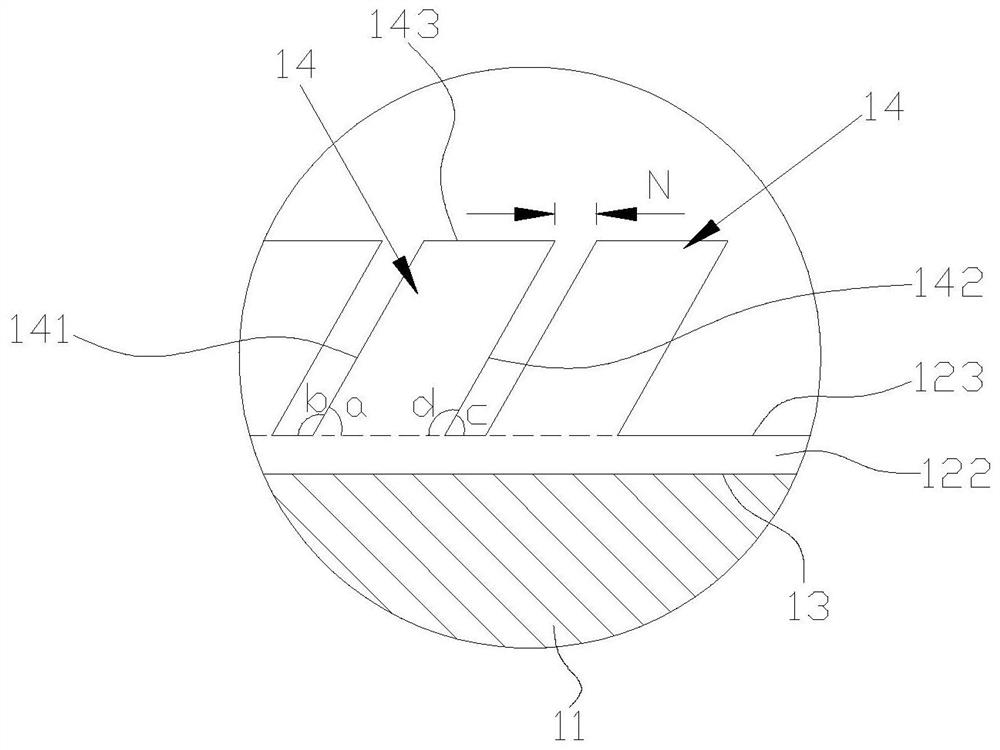

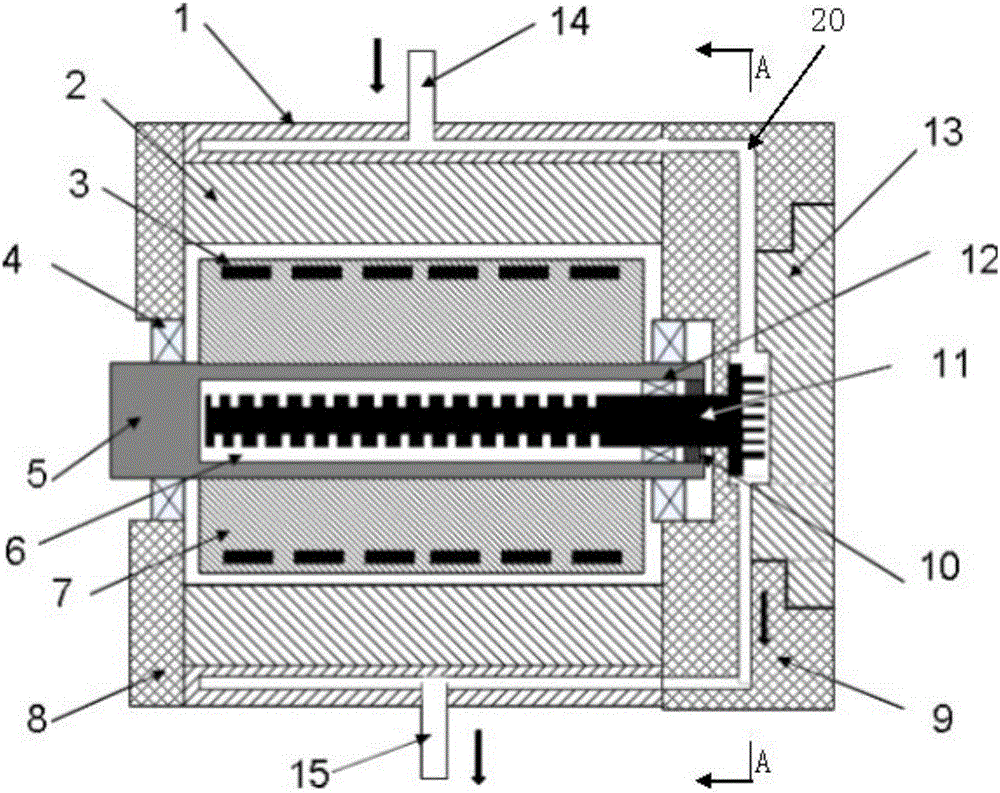

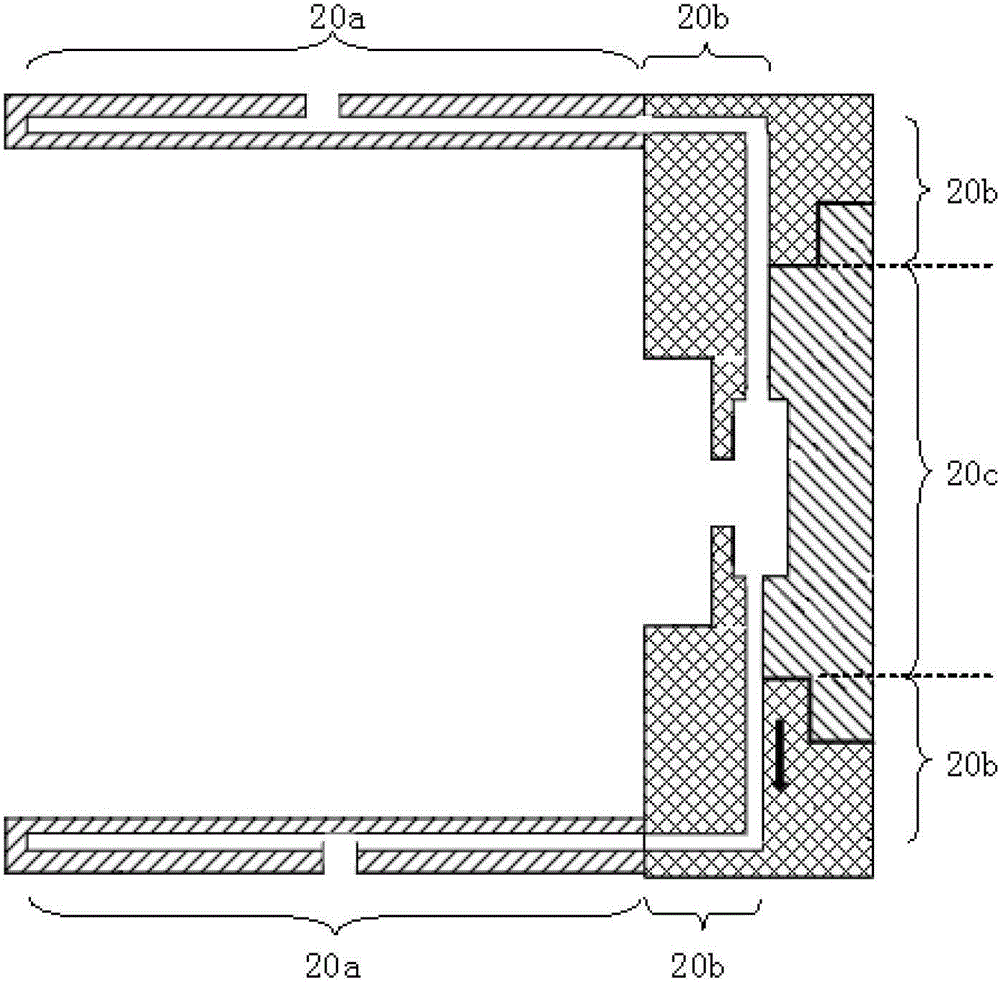

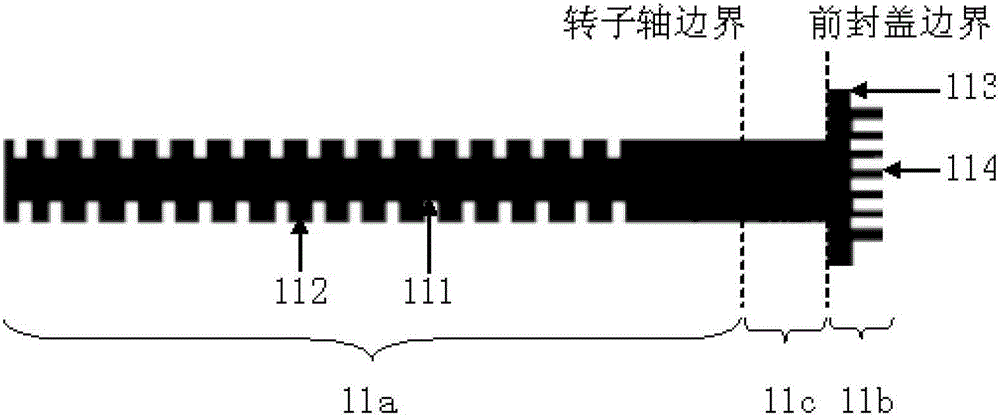

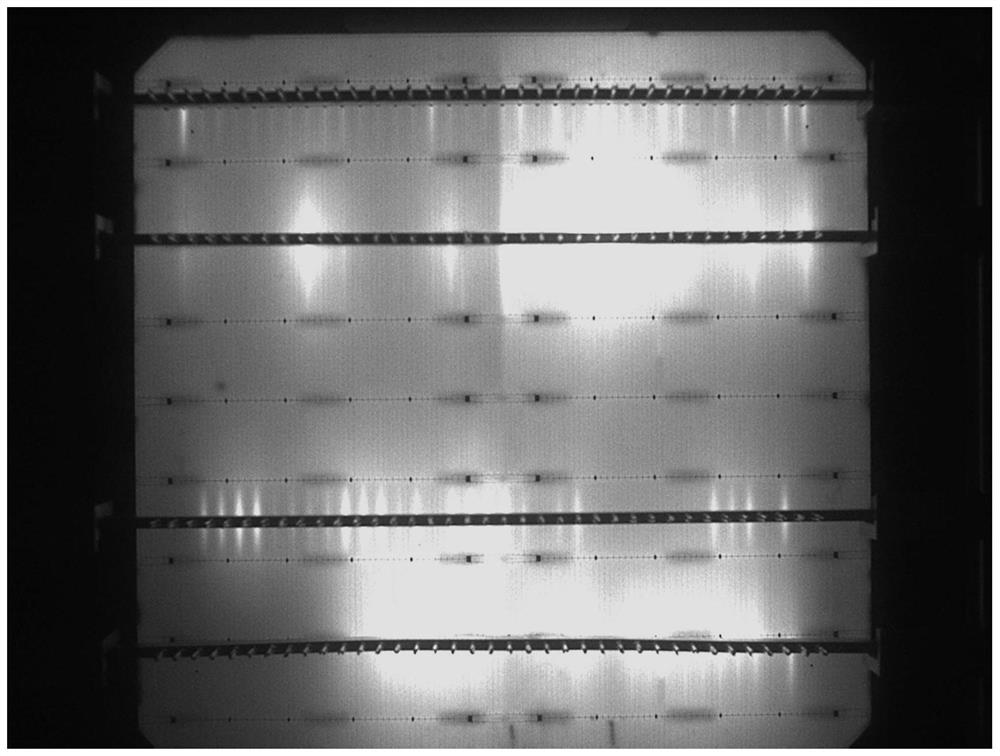

Cooling structure of inner rotor motor

ActiveCN102810943AElectrical performance impactImprove performanceMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringCooling medium

The invention discloses a cooling structure of an inner rotor motor. The inner rotor motor comprises a rotor shaft, a rotor section, a stator section, a front end cover and a seal cover. The cooling structure comprises a third cavity arranged between the front end cover and the seal cover, and the third cavity is used as one part of a cooling medium channel. The rotor shaft is internally provided with a heat conduction cavity, an opening of the heat conduction cavity is arranged at one side of the front end cover, and the inner part of the heat conduction cavity is provided with heat conduction media. The first end of a heat conduction rod is arranged in the heat conduction cavity and is contacted with the heat conduction media, the second end of the heat conduction rod is arranged in the third cavity and is contacted with cooling media, and the second end and the front end cover are sealed by adopting a static seal way. The rotor shaft and the heat conduction rod are sealed by adopting a dynamic seal way. The heat of the rotor section and the rotor shaft is transmitted from the first end of the heat conduction rod in the heat conduction cavity to the second end of the heat conduction rod and is dissipated through the cooling media in the third cavity. According to the cooling structure of an inner rotor motor, the good heat dissipating effects of the stator and the rotor are obtained, and meanwhile the strict requirements for insulation, seal and volume are satisfied.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

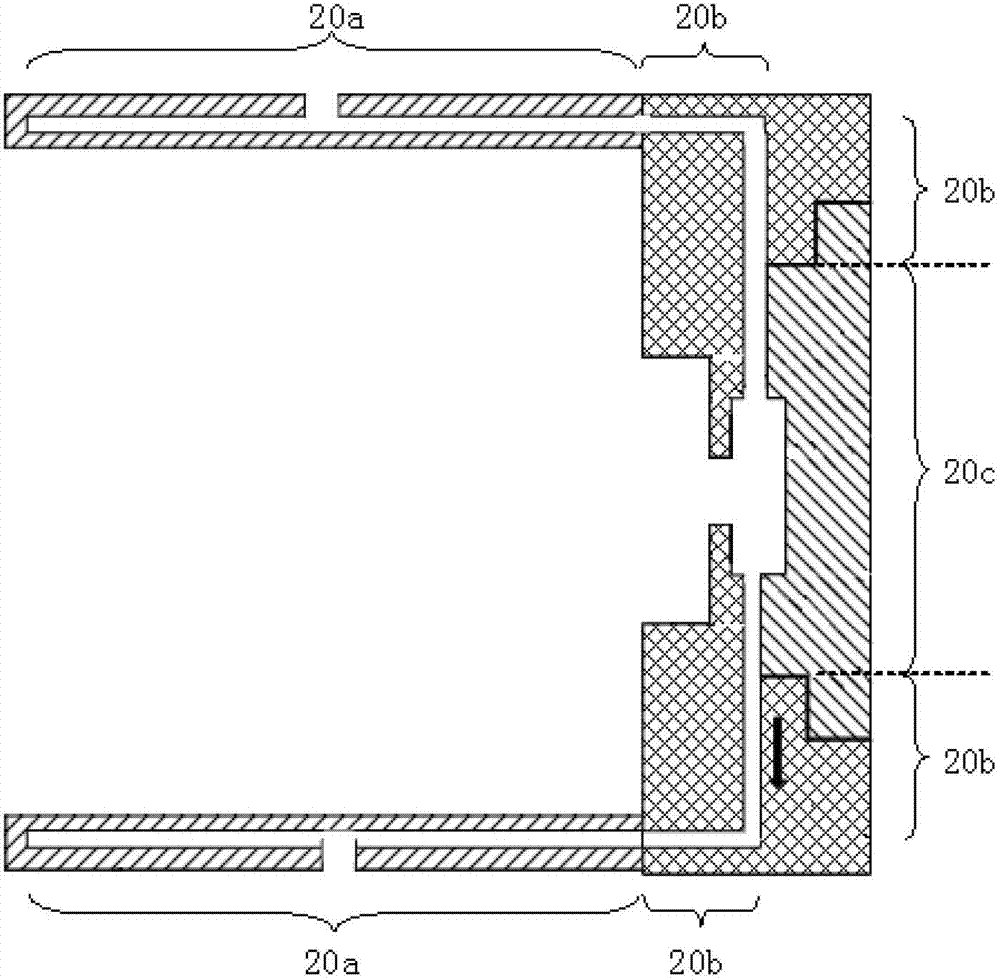

Solid insulating vacuum ring network cabinet

ActiveCN102222868AElectrical performance impactPromote environmental protectionBus-bar/wiring layoutsSwitchgear arrangementsEpoxyHazardous substance

The invention provides a solid insulating vacuum ring network cabinet comprising at least one wire inlet ring network cabinet and at least one wire outlet ring network cabinet, wherein the wire inlet ring network cabinet is assembled on a cabinet body by a vacuum switch unit through screws so as to form the whole wire inlet ring main unit; the wire outlet ring network cabinet is formed by assembling the vacuum switch unit and a fuse tripping interlocking device on the cabinet body through screws; a fuse cylinder component is arranged at the position in the vacuum switch unit at which a polar column assembling plug is securely sealed. The solid insulating vacuum ring network cabinet has the advantages that harmful substances are not generated during the working process; furthermore, all parts can be reclaimed after achieving the service life; and the environment-friendly requirement is adapted. All charged bodies are placed or arranged in epoxy resin; the electric performance of the ring network cabinet is not affected by external environments such as vapor, dust and the like; and the maintenance quantity is little and the service life is long. As charged bodies are all arranged inthe epoxy resin, semiconductor substance is sprayed outside the epoxy resin; and the induction voltage is grounded; therefore, even when a user contacts with the ring network cabinet, the electric shock accident does not occur, and the safety of equipment is improved.

Owner:SHANGHAI THEHAO ELECTRIC POWER TECH

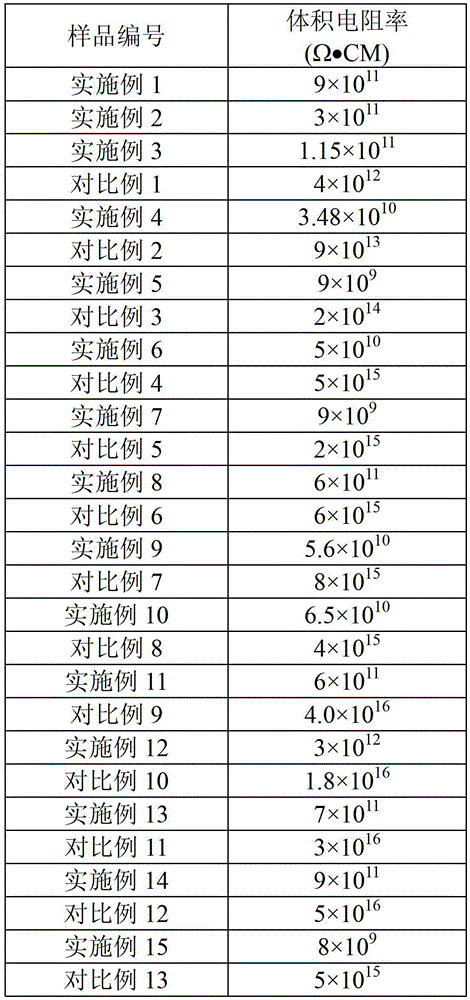

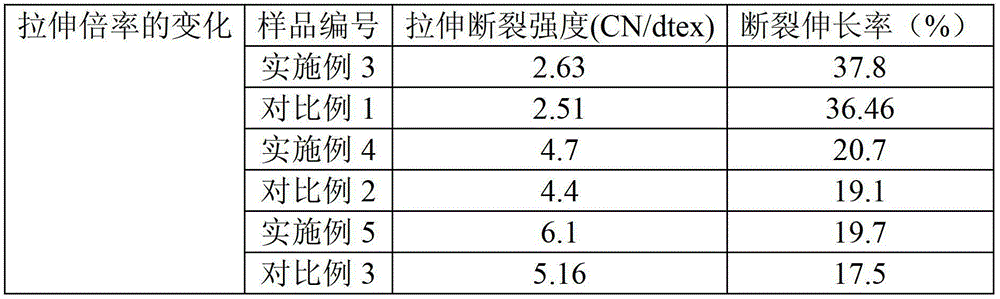

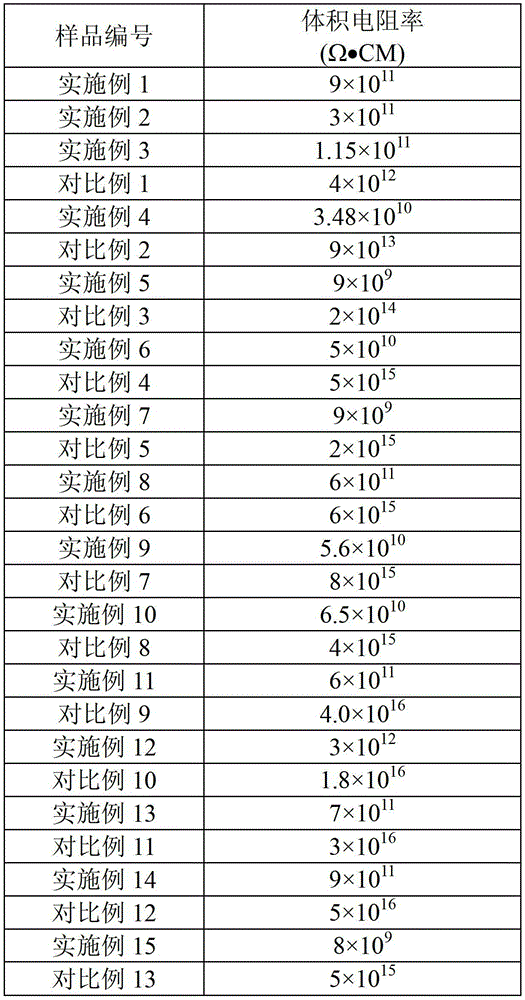

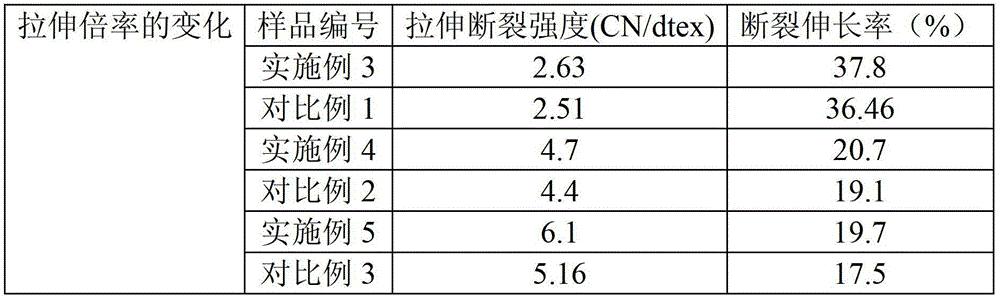

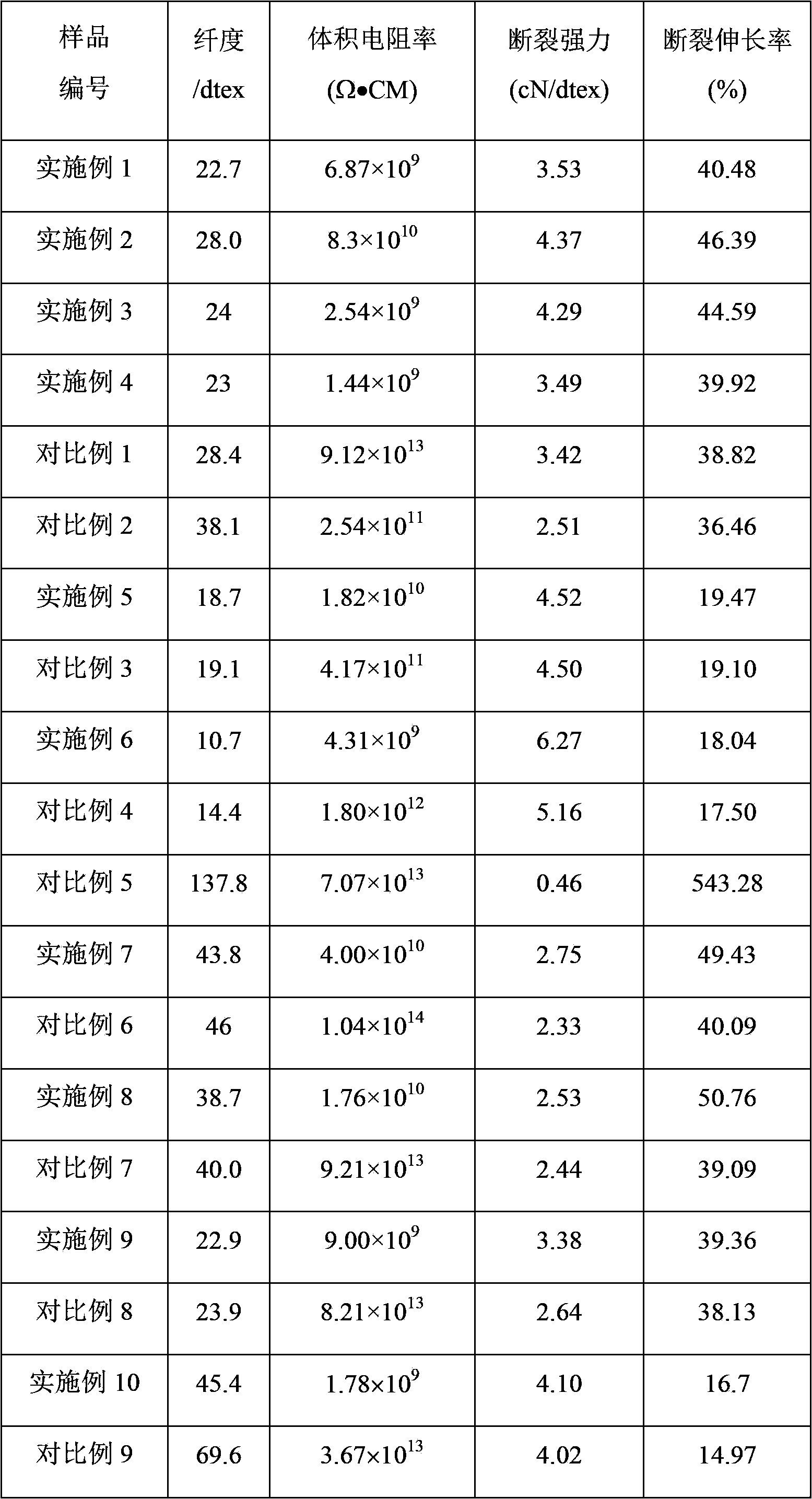

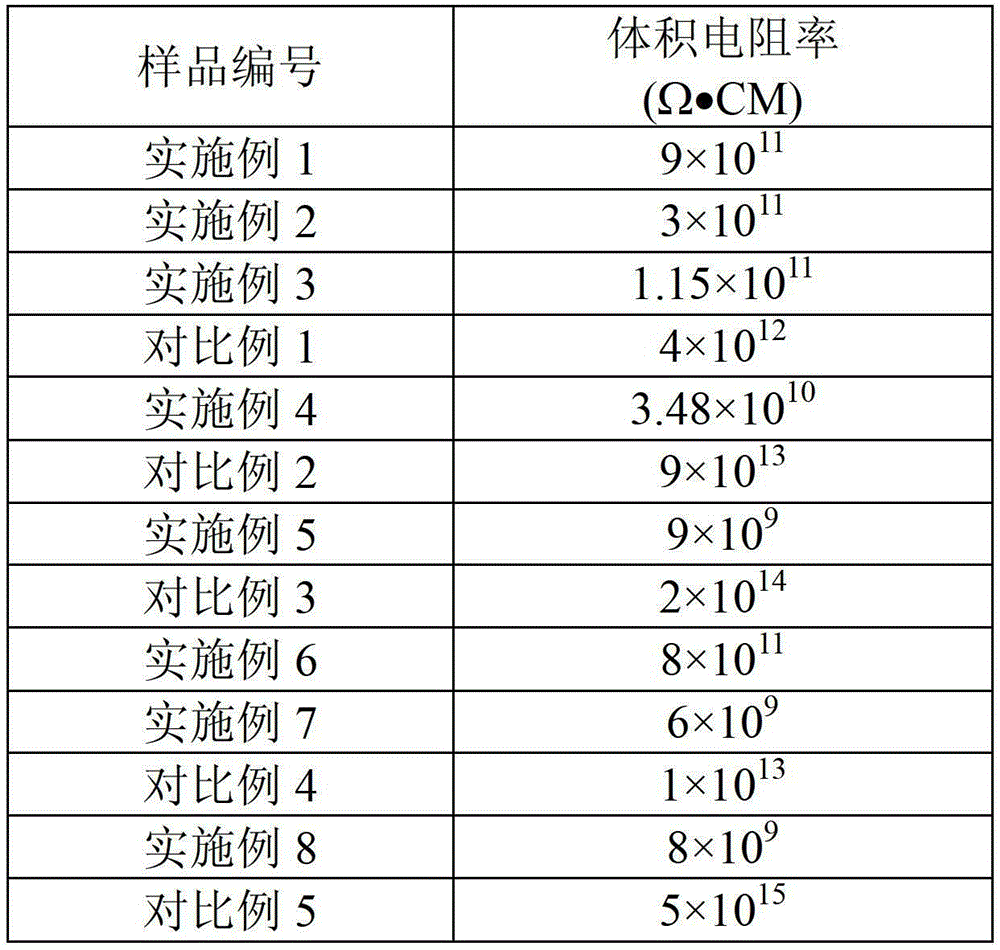

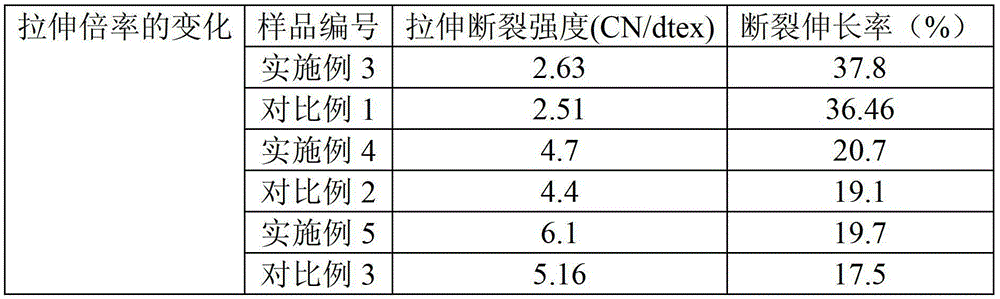

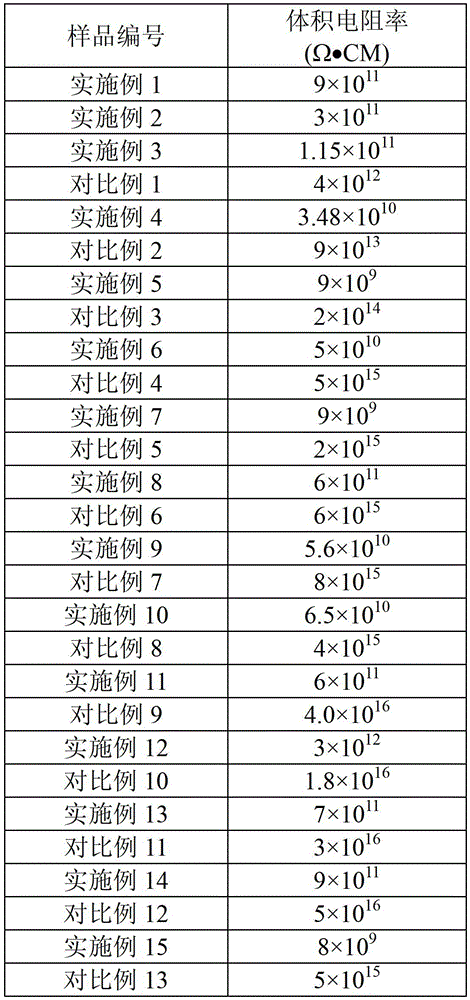

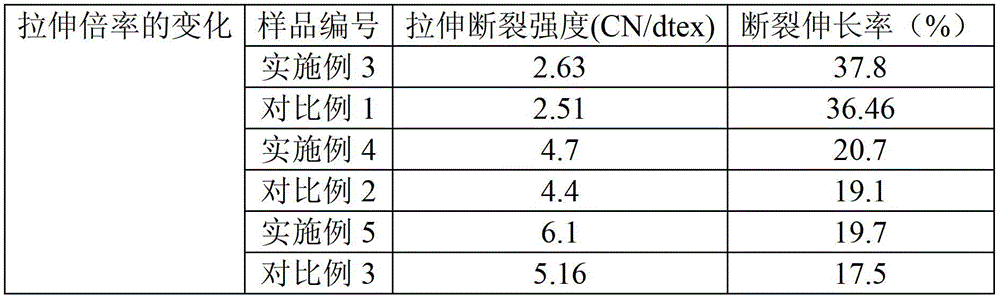

Polymer/filler/metal composite fiber and preparation method thereof

ActiveCN104099684AImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

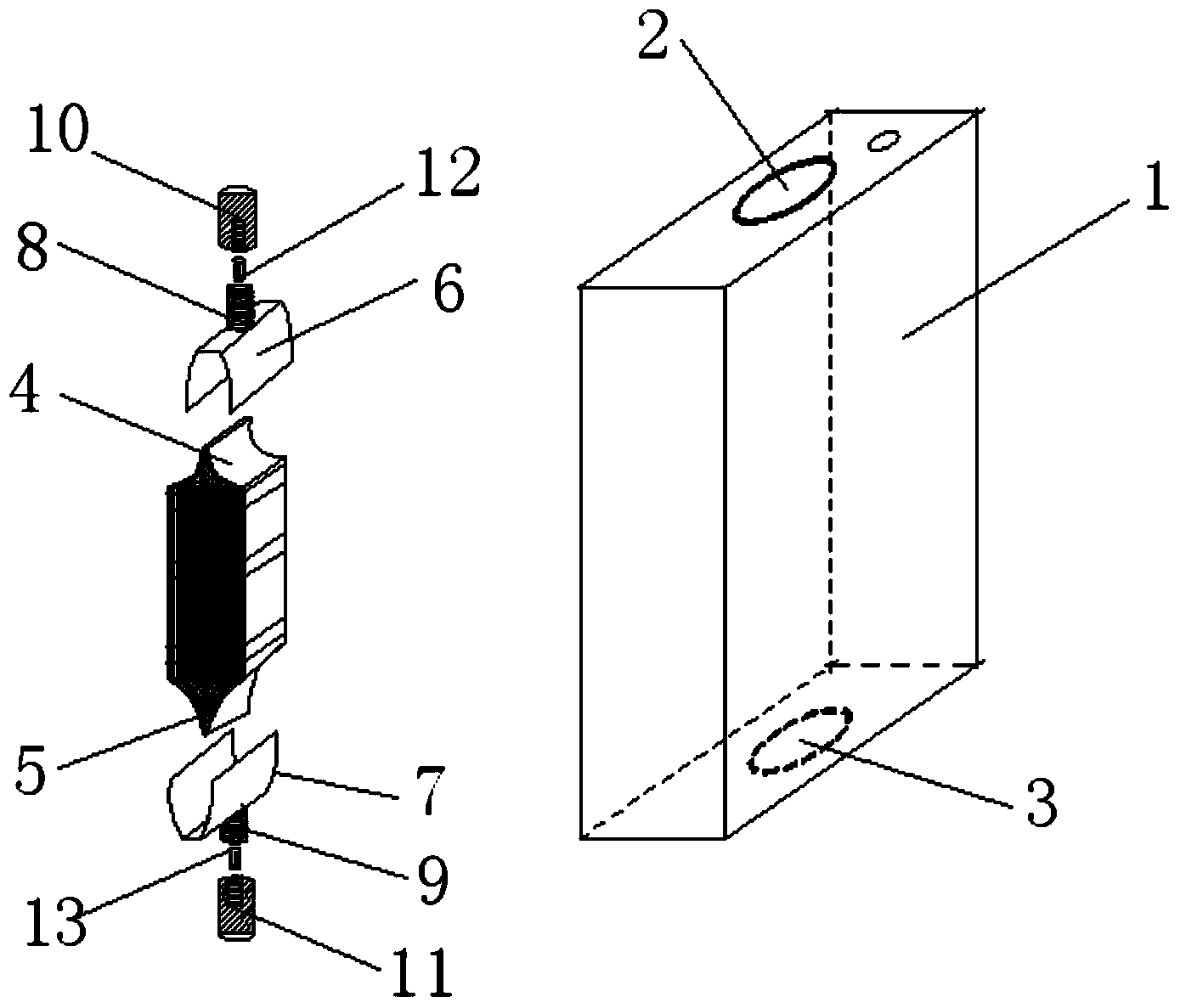

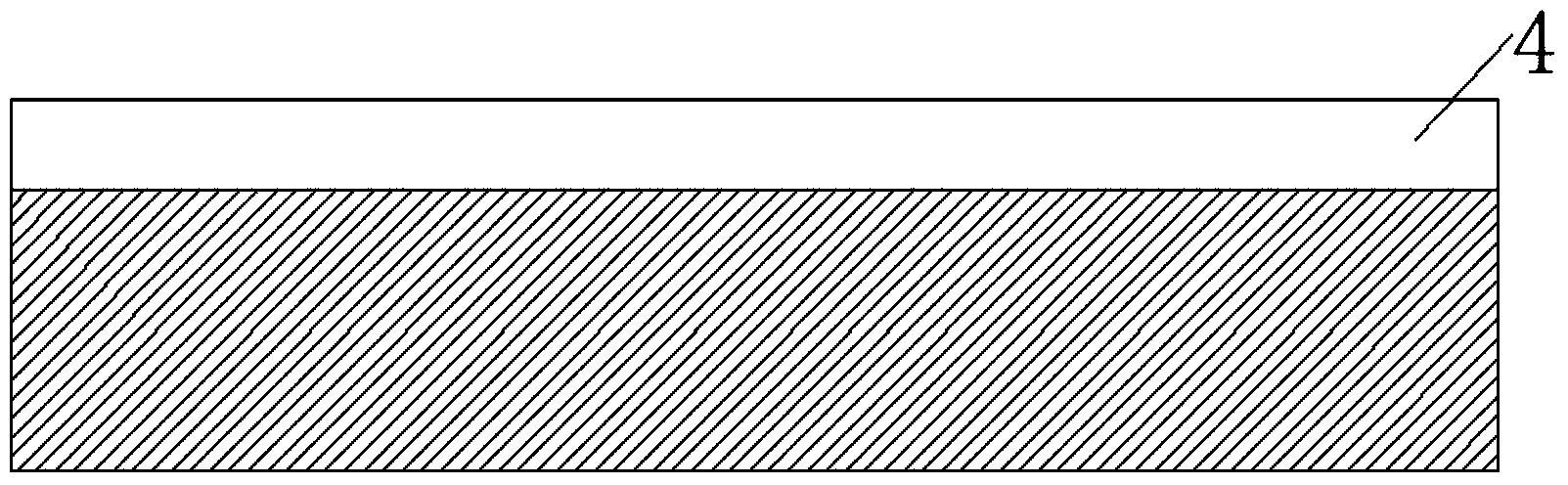

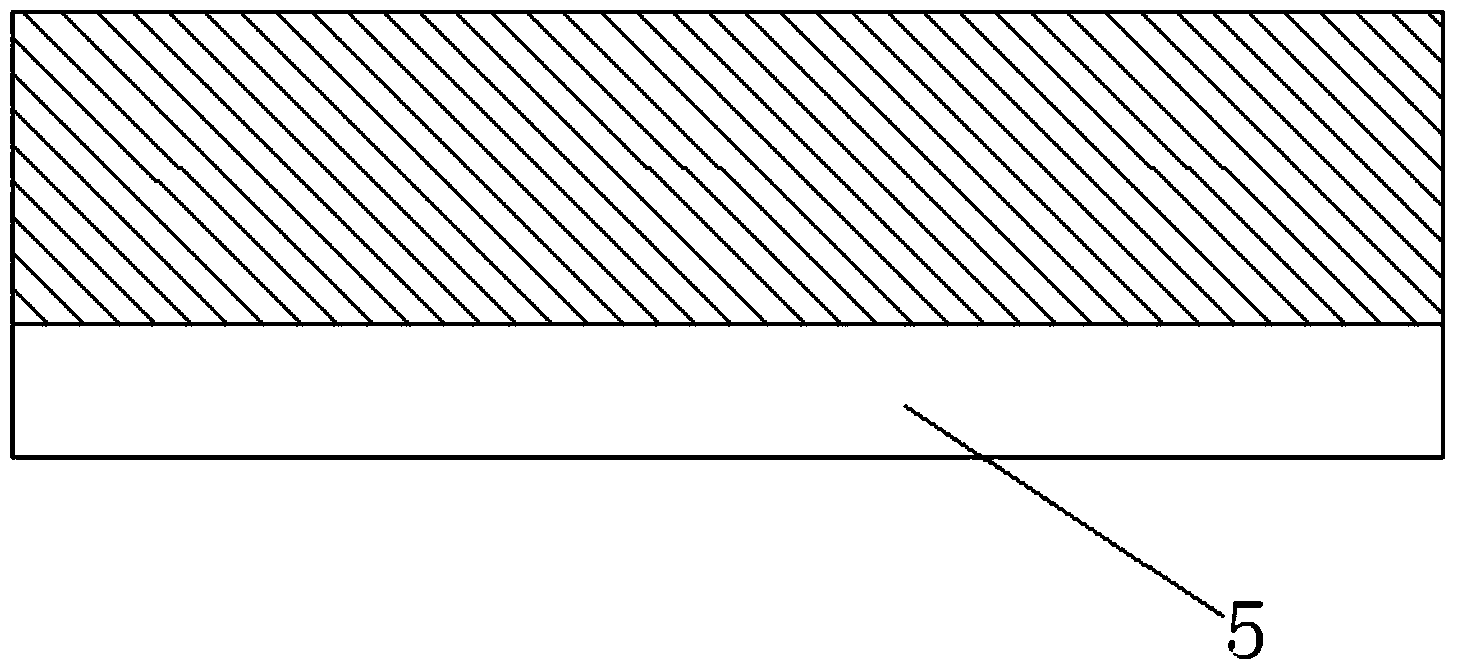

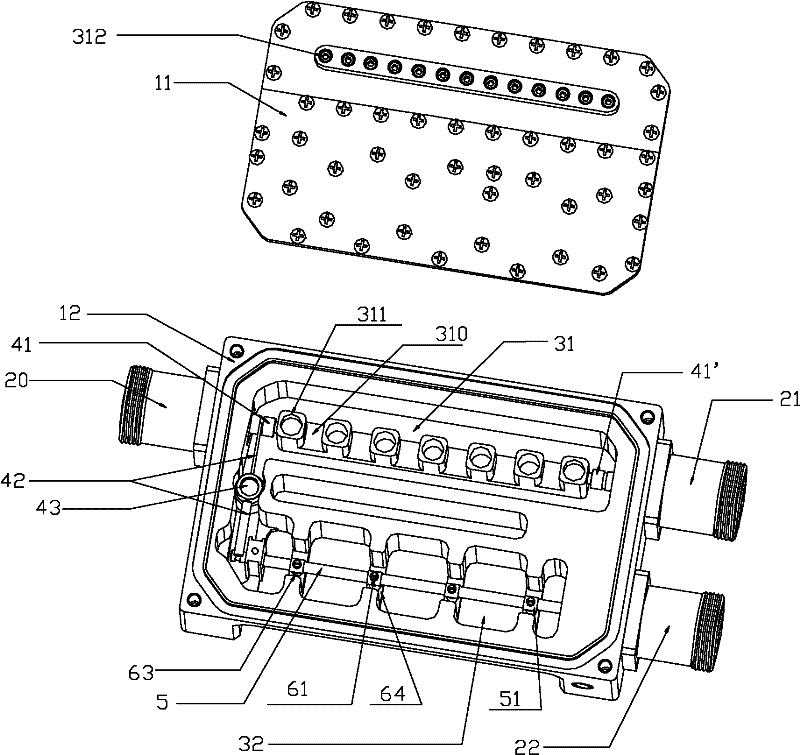

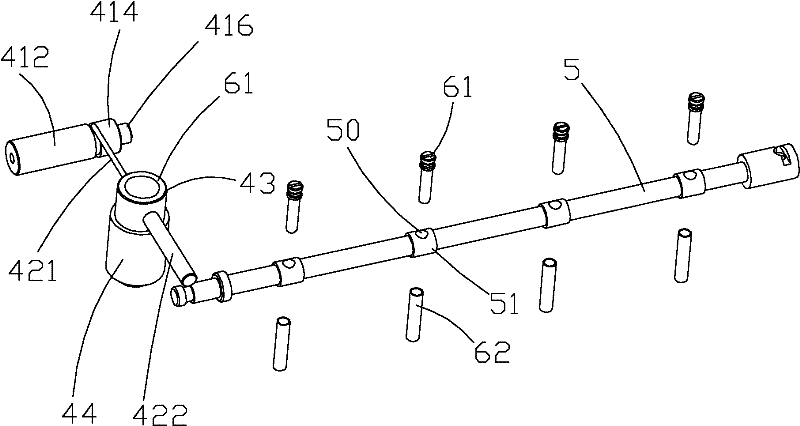

Communication cavity device and combining and distribution structure thereof

ActiveCN102386463ARealize functionElectrical performance impactWaveguide type devicesFrequency bandLine segment

The invention discloses a communication cavity device and a combining and distribution structure thereof. The combining and distribution structure comprises a connection piece, an impedance conversion transmission line, a resonant column and a media supporting piece. One end of the connection piece forms a public port, and the other end of the connection piece is used for being coupled with a first frequency band signal of the communication cavity device. One end of the impedance conversion transmission line is used for being connected with a second frequency band signal of the communication cavity device, the other end of the impedance conversion transmission line is connected with the connection piece, and the impedance conversion transmission line comprises at least two line sections with different impedance. The resonant column is connected with the middle of the impedance conversion transmission line in series. The media supporting piece is used for fixing the resonant column and enabling the resonant column to be insulated from a cavity of the communication cavity device. By means of the combining and distribution structure, the two frequency band signals can be well isolated to conduct combining and distribution. Further, combined with an elliptic function type low-pass filter with a specific structure, the communication cavity device can generate strong restraint out of band on the premise of guaranteeing high relative bandwidth, thereby meeting requirements of high isolation degree among communication systems.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

OLED display panel and touch panel

ActiveCN105528119AReduce reflected lightReduce blackening processInput/output processes for data processingPolarizerOptoelectronics

The invention provides an OLED display panel and a touch panel. The touch panel comprises a linear polarizer, a 1 / 2 wave plate layer, a 1 / 4 wave plate layer and a touch electrode layer, wherein the 1 / 2 wave plate layer is formed on one side of the linear polarizer, the 1 / 4 wave plate layer is formed on one side, away from the linear polarizer, of the 1 / 2 wave plate layer, the touch electrode layer is formed on one side, away from the linear polarizer, of the 1 / 4 wave plate layer and comprises a plurality of touch electrodes, and the touch electrodes are meshed metal grids. The OLED display panel and the touch panel have the advantages that panel reflectivity is reduced, and panel touch precision is increased at the same time.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

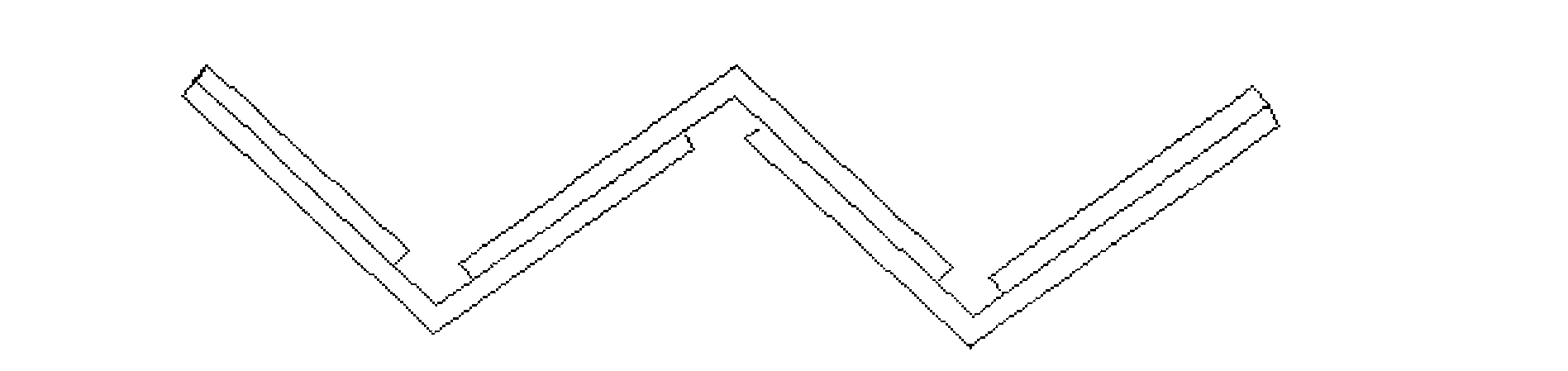

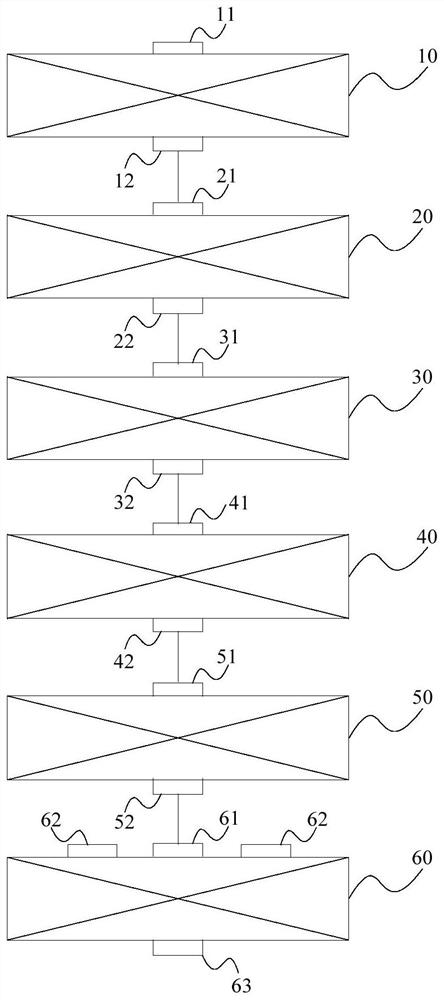

Preparation method of winding-structure lithium ion battery

ActiveCN102637906ALower resistanceReduce Ohmic PolarizationFinal product manufactureSecondary cellsCharge dischargeJoule

The invention belongs to the technical field of lithium ion batteries and particularly relates to a preparation method of a winding lithium ion battery. The preparation method comprises the following steps of: coating anode paste on an anode current collector, drying and then cold pressing the anode paste, and then bending an anode plate to be V-shaped; processing an cathode plate with the same steps, placing the bent anode plate and the bent cathode plate in a crossing way, placing a diaphragm between the anode plate and the cathode plate, welding and connecting the anode plate by virtue of an anode pole ear, and welding and connecting the cathode plate by virtue of a cathode pole ear, thus obtaining a pole plate group; winding the pole plate group to form a battery cell, placing the battery cell in a packaging bag, and performing injection and formation to obtain the lithium ion battery. Compared with the prior art, the preparation method decreases the resistance of the pole plates through bending the pole plates, thus reducing ohmic polarization in a charge-discharge process, improving the consistency of the battery, and obviously reducing the gas production speed of joule heat and side reaction in the charge-discharge process so as to improve the power multiplying performance and prolong the cycle life of the lithium battery and a lithium ion battery pack.

Owner:NINGDE AMPEREX TECH +1

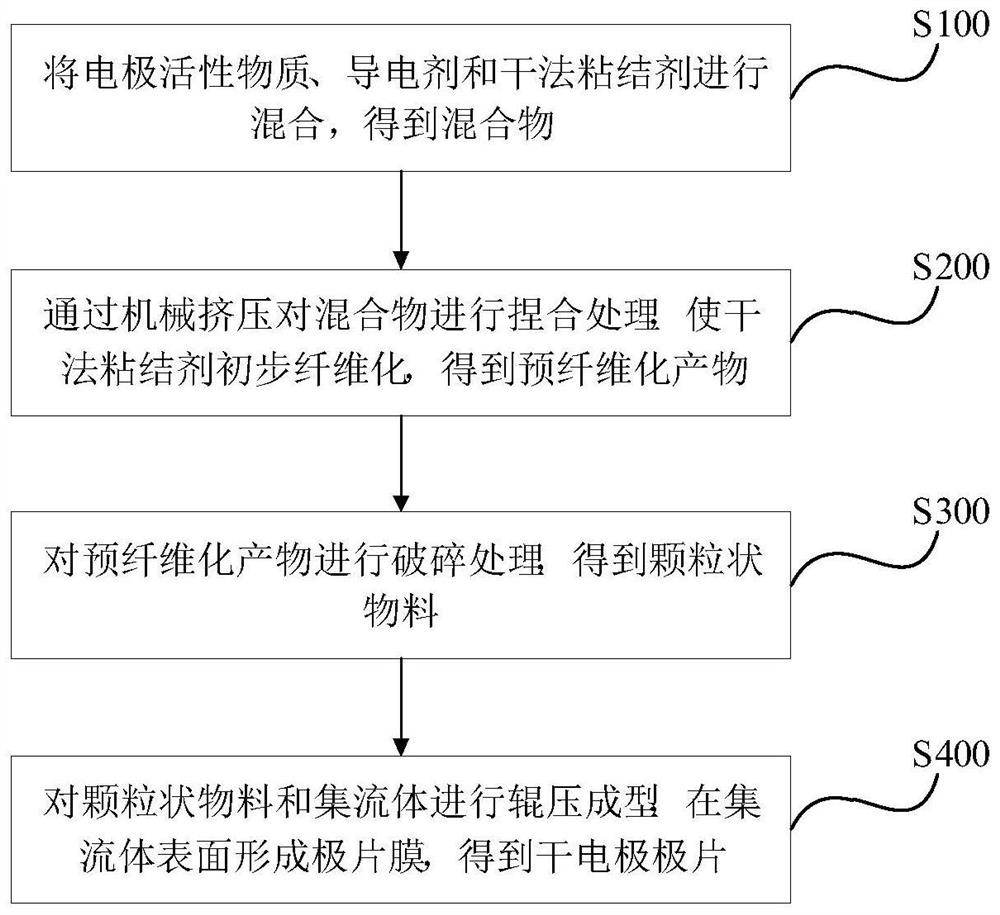

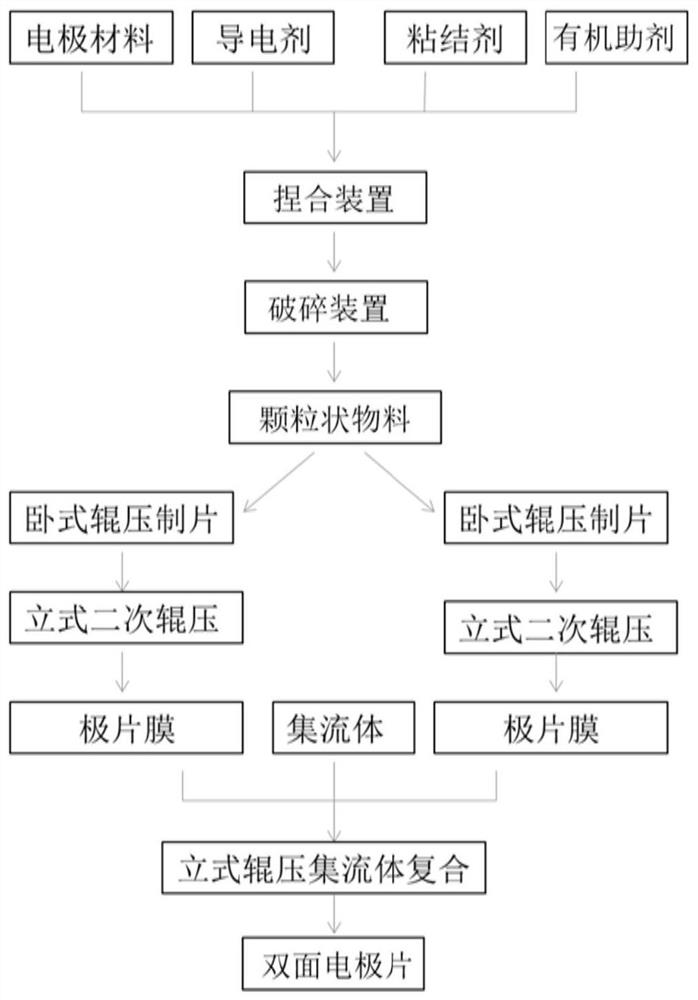

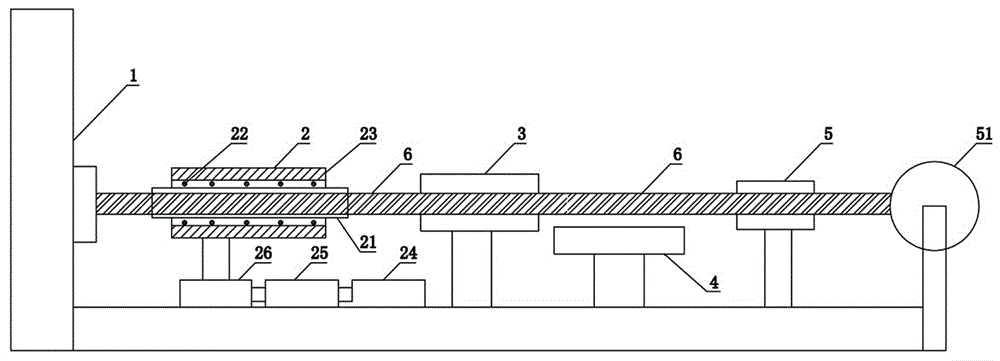

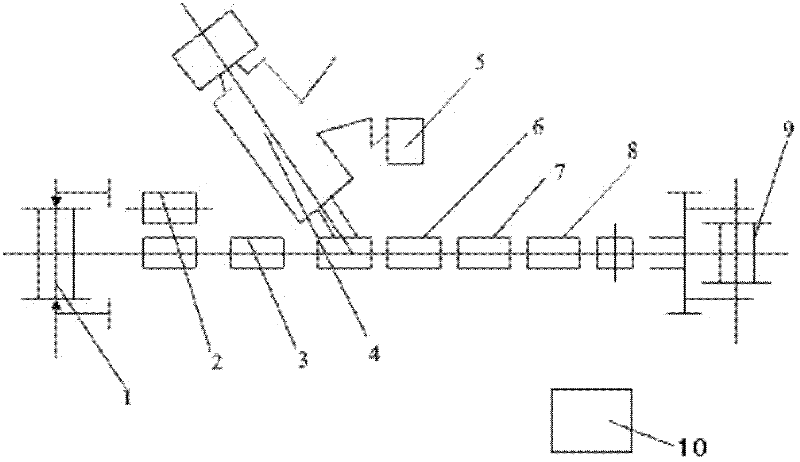

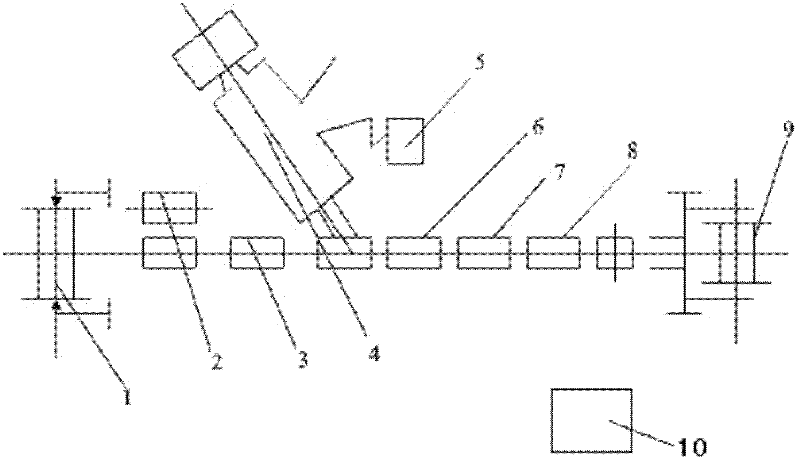

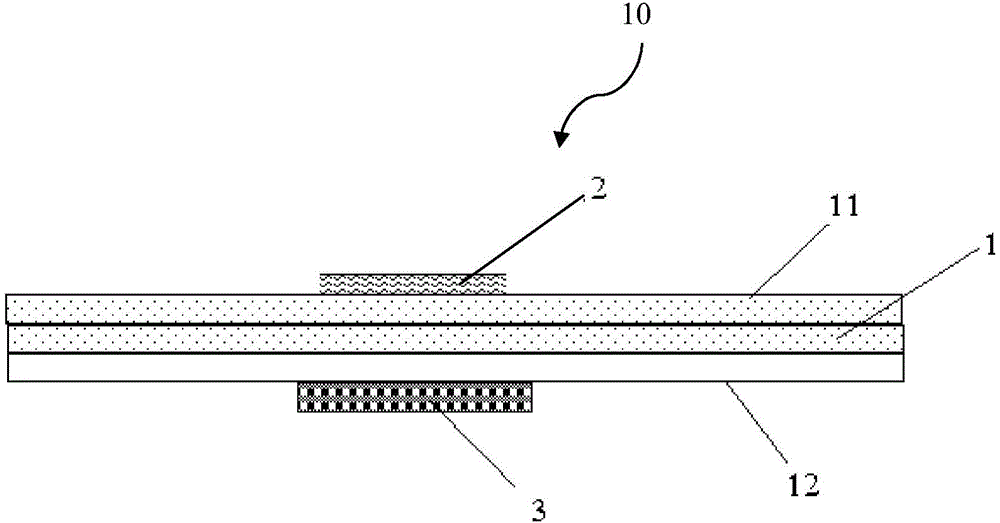

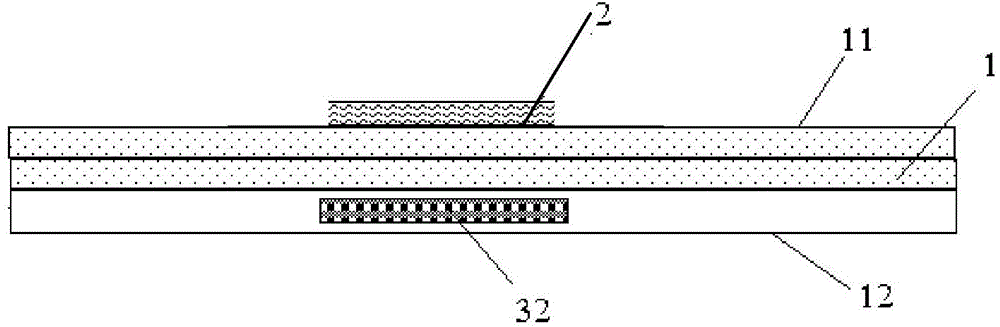

Method and system for preparing electrode plate by dry process, and application

PendingCN113675362AIncrease productivityAffect the electrochemical performanceElectrode rolling/calenderingHybrid/EDL manufactureNew energyProcess engineering

The invention discloses a method and a system for preparing an electrode plate by a dry process, and application. The method comprises the following steps: mixing an electrode active material, a conductive agent and a dry binder to obtain a mixture; carrying out kneading treatment on the mixture through mechanical extrusion so as to carry out preliminary fibration on the dry-method binder to obtain a blocky and / or flocculent pre-fibration product; carrying out crushing treatment on the pre-fibration product so as to obtain a granular material; and carrying out roll forming on the granular material and the current collector so as to form a pole piece film on the surface of the current collector, thereby obtaining the dry electrode plate. The method is simple and feasible, required equipment is simple, the problem that the electrode active material structure is damaged in the material crushing treatment process can be effectively solved, the production efficiency is higher, amplification is easy, the method is more suitable for large-scale mass production of the dry electrode technology, development of the new energy industry is promoted, and the method has wide application prospects.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

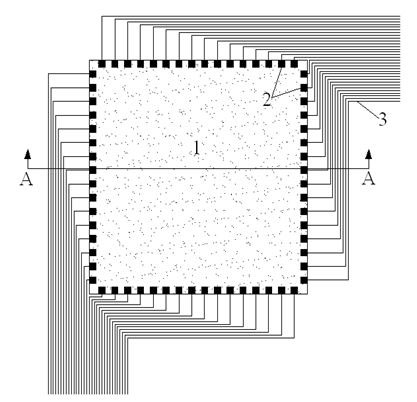

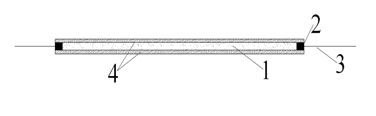

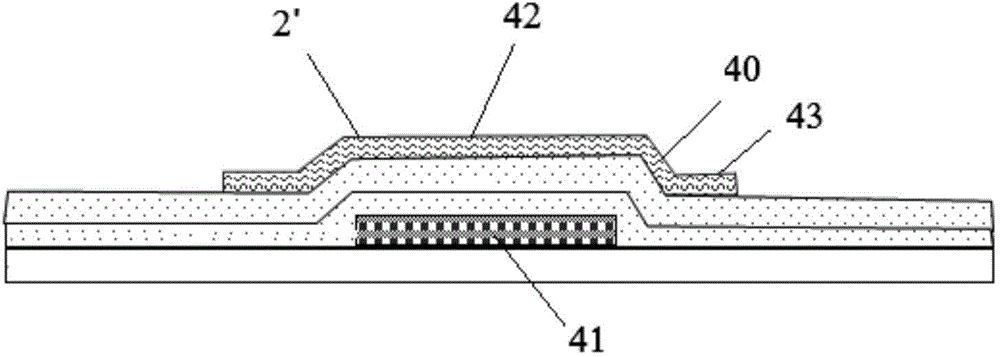

Surface deformation distribution test sensing element

InactiveCN102305587AAchieve ultra-thinStrain sensitiveElectrical/magnetic solid deformation measurementElectrical resistance and conductanceInsulation layer

The invention discloses a surface deformation distribution test sensing element which comprises a flexible sensing thin film, electrodes arranged at the periphery of the flexible sensing thin film uniformly at intervals, lead wires which are connected with the electrodes, an upper flexible insulation layer and a lower flexible insulation layer. Composite materials with strain sensitivity characteristics are utilized to prepare the flexible sensing thin film; and the electrodes and the lead wires are used for outputting specific resistivity information at different positions of the flexible sensing thin film. When in test, the lead wires and a testing instrument are connected; collection test and calculation are carried out by utilizing the electrical impedance imaging technology, the specific resistivity distribution at different positions of the flexible sensing thin film is obtained, and the strain size distribution is obtained through the specific relationship between the strain size of the sensing thin film and the size of the specific resistivity again. The test of two-dimensional deformation field quantity can be realized by the sensing element disclosed by the invention, and the sensing element has the characteristics of simple and ultrathin structure, flexibility, high resolution ratio and precision, great strain range and low cost.

Owner:CHINA UNIV OF MINING & TECH

Polymer/conductive filler/metal composite fiber and preparation method thereof

ActiveCN104099683AImprove breaking strengthImprove electrical performanceElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / conductive filler / metal composite fiber. The composite fiber comprises polymer fiber containing metal short fiber and a conductive filler, the metal short fiber is dispersed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber; the conductive filler is dispersed in the polymer fiber and distributed among the metal short fiber; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C to 480 DEG C and lower than a polymer processing temperature; the volume ratio of the metal short fiber to the polymer fiber is 0.01:100-20:100; and the weight ratio of the conductive filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

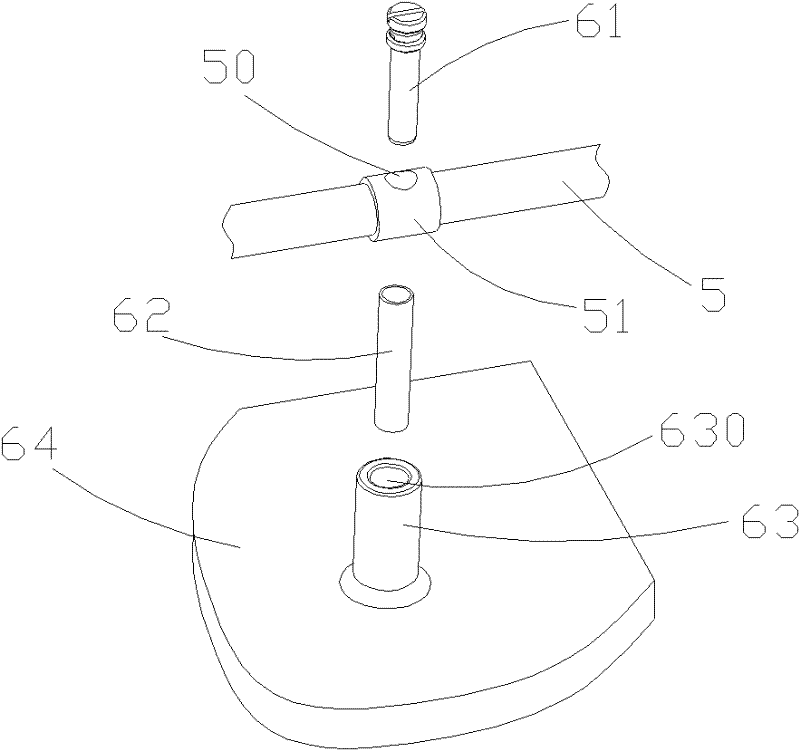

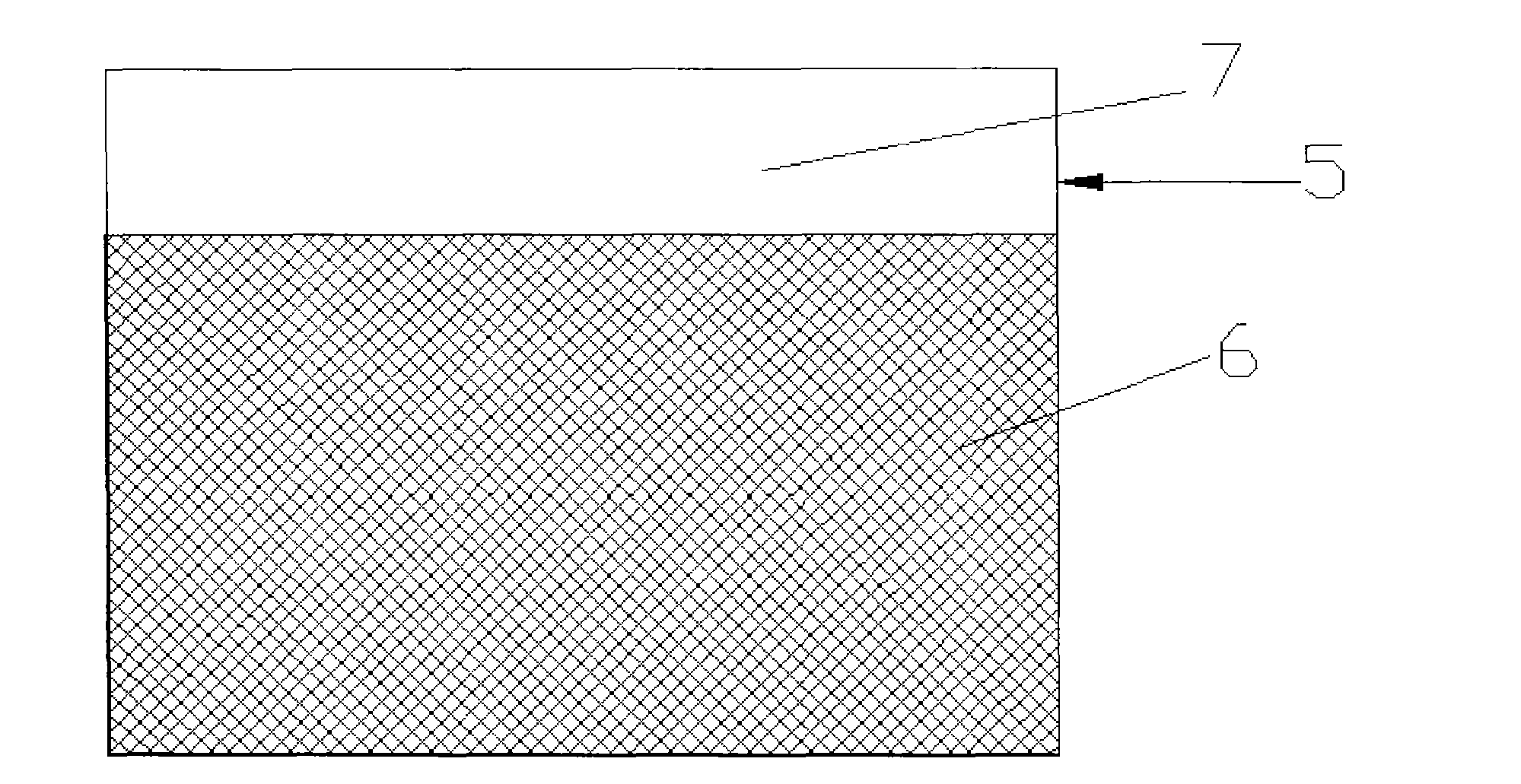

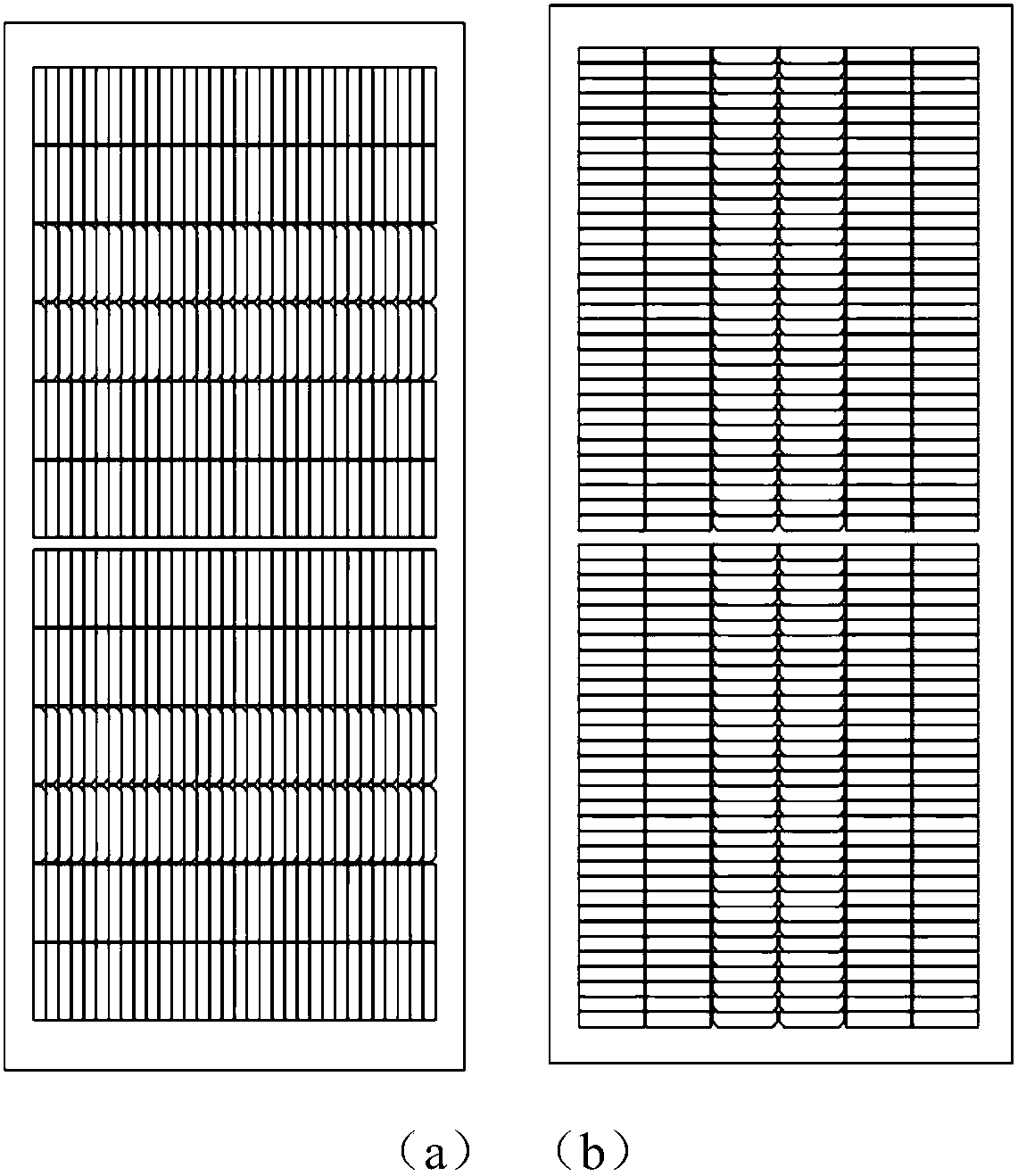

Solar cell grid line structure, solar cell sheet and solar laminate module

PendingCN108538948AElectrical performance impactImprove conductivityPhotovoltaic energy generationSemiconductor devicesConductive pasteElectricity

The invention provides a solar cell grid line structure, a solar cell sheet and a solar lamination module. The grid line structure comprises a plurality of sub grid lines arranged on a silicon wafer and a main grid line perpendicular to the sub grid lines. The main grid line is formed by a grid-like porous structure. When the main grid line is coated with a conductive paste, grid holes are filledwith a part of the conductive paste. Since the materials of the conductive paste and the main grid line have good electrical conductivity, when the above grid lines are sufficiently dense, the use ofa grid pattern instead of a solid pattern does not seriously affect the electrical performance of a module. The deformation of the conductive paste and the diffusion on a cell shell texture covered bysilicon nitride are limited by the grid pattern of the main grid line and are limited in the grid pattern, and thus paste overflow and bleeding are avoided.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

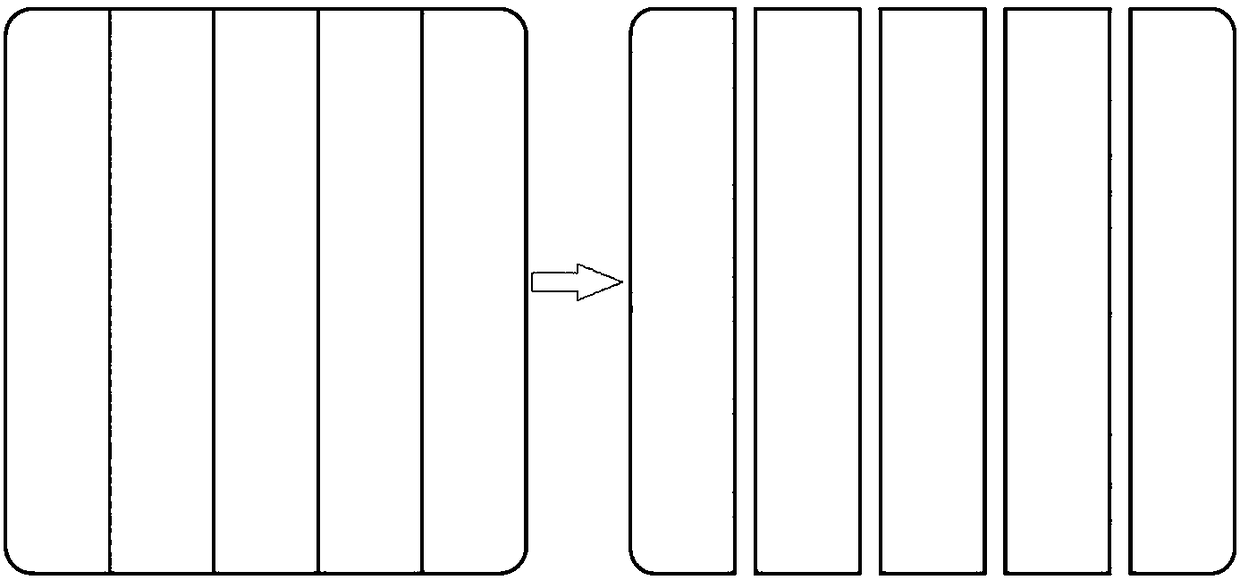

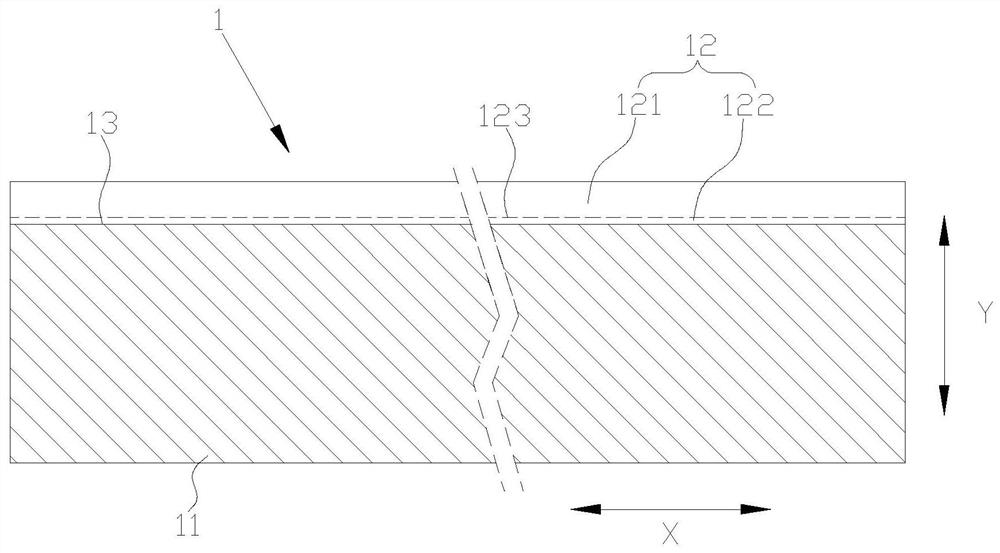

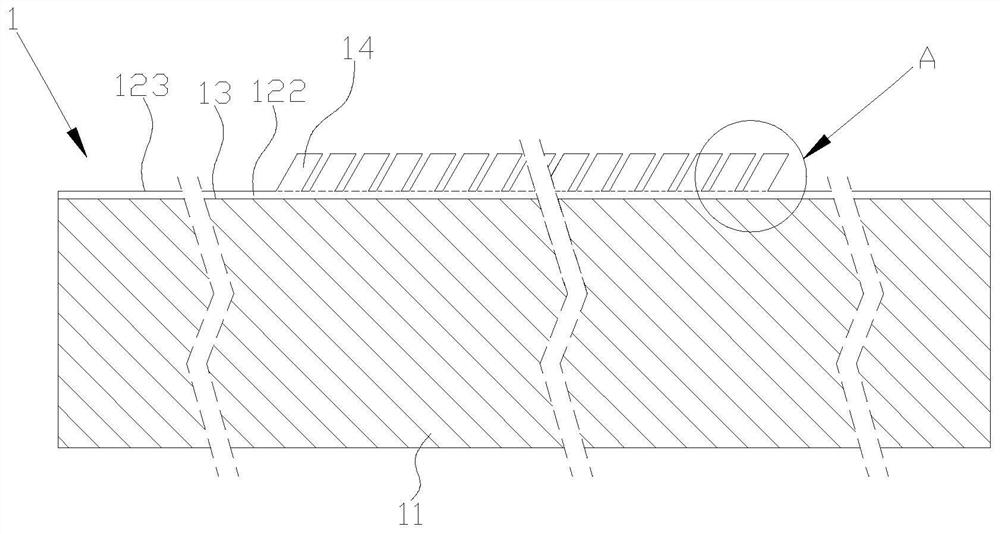

Tab pole piece and winding battery

ActiveCN113193165AReduce roll pressureAvoid deformationFinal product manufactureSecondary cellsAcute anglePole piece

The invention provides a tab pole piece, which comprises a coating area and an empty foil area positioned on one side of the coating area, the empty foil area comprises a cutting area and a retaining area, the retaining area is positioned between the coating area and the cutting area, the cutting area forms a plurality of tabs through cutting, the plurality of tabs are sequentially arranged in the length direction of the tab pole piece, and the ends, close to the coating area, of the plurality of tabs are connected into a whole through the reserving area; a parting line is formed at a position where the cutting area is connected with the reserving area, each tab comprises a first edge and a second edge which are opposite to each other, the first edge and the second edge intersect with the parting line, an included angle a is formed between the first edge and the parting line, the included angle a is located in the tab, and the included angle a is an acute angle. The invention also provides a wound battery.

Owner:MICROVAST POWER SYST CO LTD

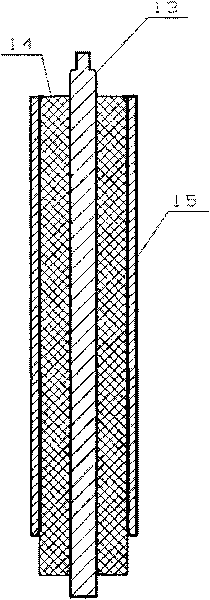

Online heat treatment device of cable stranding machine

InactiveCN105039659AElectrical performance recoveryElectrical performance impactFurnace typesCable/conductor manufactureElectricityElectrical conductor

The invention provides an online heat treatment device of a cable stranding machine. The online heat treatment device comprises a cable stranding machine body, an electromagnetic induction heating device, a cooling water tank, a drying device and a cable tractor, wherein the electromagnetic induction heating device comprises a heating pipe, an electromagnetic induction heating coil wound on the heating pipe, an insulation outer protective cover sleeving the electromagnetic induction heating coil, an electromagnetic controller and a power supply device; the electromagnetic induction heating coil is connected with the power supply device through the electromagnetic controller; an alternating / direct-current converter is arranged between the power supply device and the electromagnetic controller; the drying device comprises a blowing machine arranged in an outlet of the cooling water tank; and a cable winding wheel is arranged in an outlet of the cable tractor. The online heat treatment device of the cable stranding machine has the advantages of simple structure, strong practicability, reduction of production cost and stable electrical performance of produced conductors.

Owner:HENAN KAIQI POWER IND

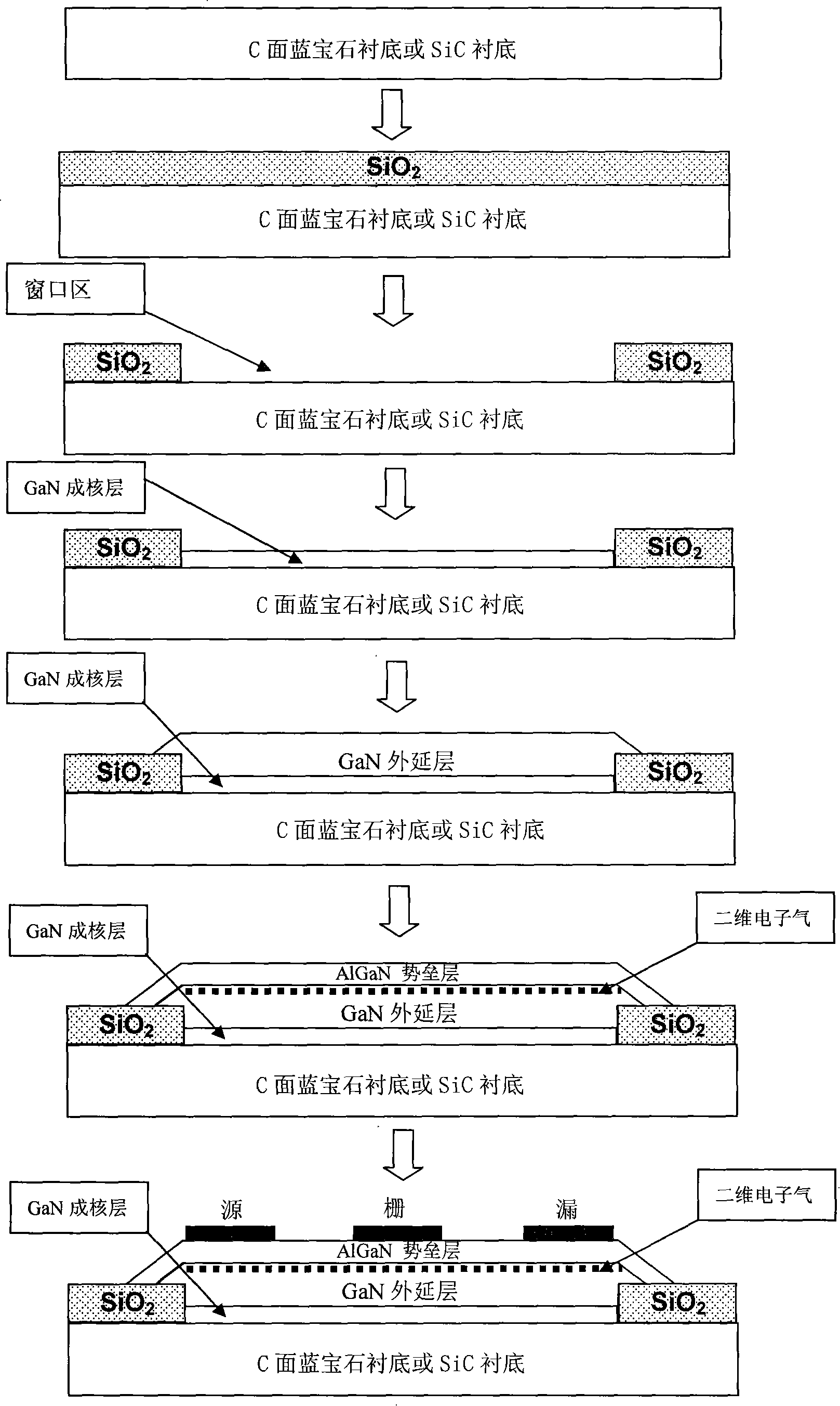

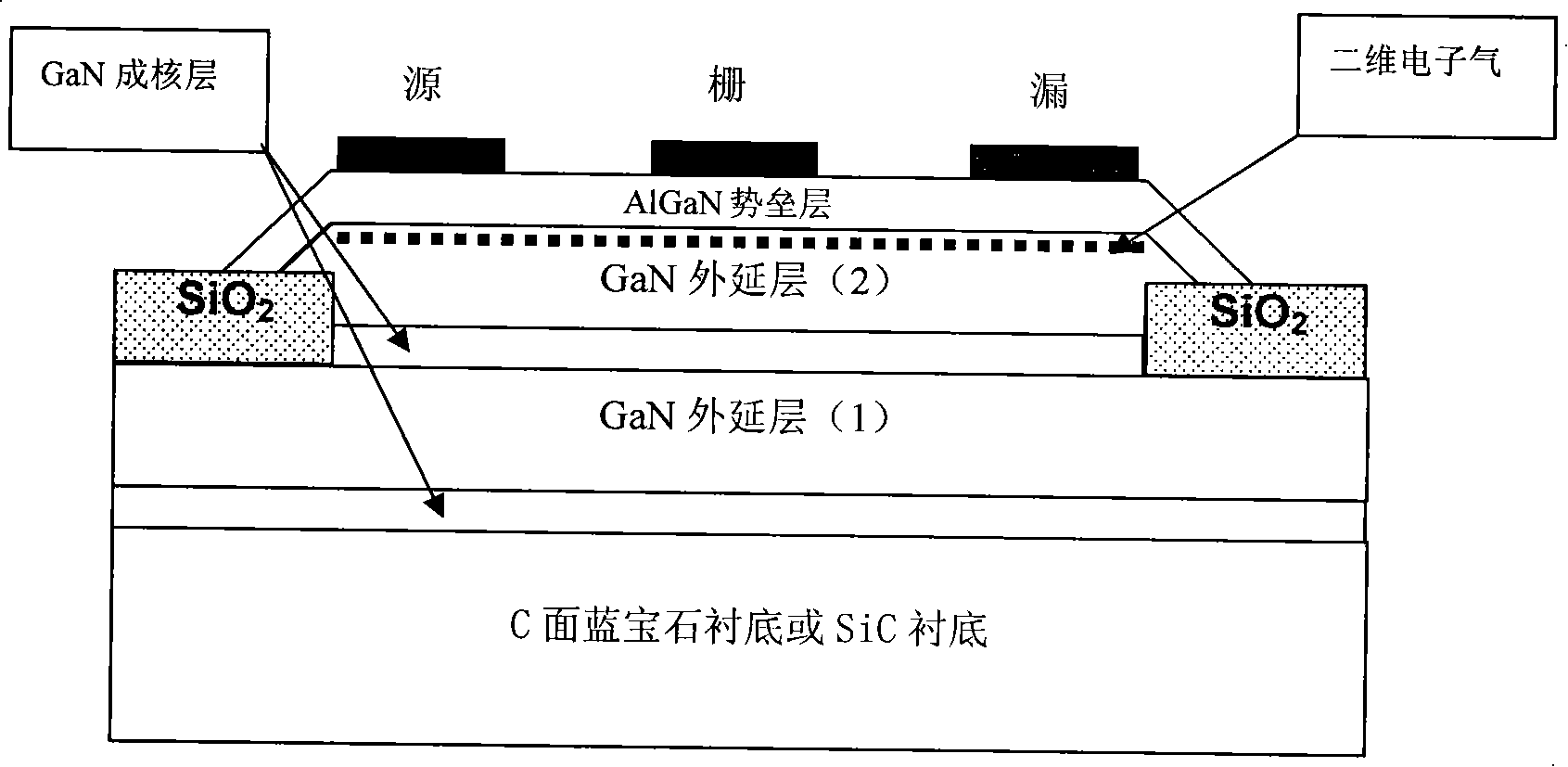

Method for insulating AlGaN / GaN HEMT device

InactiveCN101252100AElectrical performance impactAffect stabilitySemiconductor/solid-state device manufacturingSic substrateEngineering

The invention discloses an isolation method for an AlGaN / GaN HEMT device, belonging to the microelectronic technical field. The invention aims to avoid material damage in the isolation technology of the prior device by adoption of the method. The method is realized as follows: selective epitaxial growth GaN base materials are taken as the core; a spacer medium film is deposited on a sapphire or a Sic substrate at first; the spacer medium film is selectively etched according to a design mask, and areas of the medium film which are exposed out of the substrate surface are removed, namely a window area is an active area of the device and the spacer medium film is kept on the outside of the active area; growth of a GaN epitaxial layer and an AlGaN / GaN heterostructure is continued by adoption of the MOCVD technology; the AlGaN / GaN heterostructure only grows in the window area and the surface of a medium film area is only provided with GaN polycrystalline particles and AlGaN polycrystalline particles, thereby isolation of the active area is formed, namely isolation of the device and growth of the materials are completed simultaneously. The invention can be used for manufacturing high performance heterostructure devices, high-power devices and so on.

Owner:XIDIAN UNIV

Polymer/metal composite fibers and preparation method thereof

ActiveCN103789859AImprove spin performanceLow costElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberBreaking strength

The present invention provides polymer / metal composite fibers and a preparation method thereof. The composite fibers comprise polymer fibers containing metal staple fibers, wherein the metal staple fibers are adopted as the dispersed phase and are distributed in the polymer fibers in a parallel manner along the polymer fiber axis, the polymer is a thermoplastic resin, the metal is at least one selected from a single-component metal and a metal alloy, the melting point of the metal is 20-480 DEG C and is lower than the melting point of the polymer, a volume ratio of the metal staple fibers to the polymer fibers is 0.01:100-20:100, and the volume resistivity of the composite fibers is less than or equal to 1*10<11>[omega].CM. According to the present invention, the fibers are obtained by carrying out melt blending, spinning and heating stretching on the metal and the polymer; the antistatic property, the breaking strength, and the elongation at break of the composite fibers are concurrently increased, the size is reduced, the dyeability is good, and the antistatic property is lasting; and the preparation method is simple and is easily subjected to industrialized mass production.

Owner:CHINA PETROLEUM & CHEM CORP +1

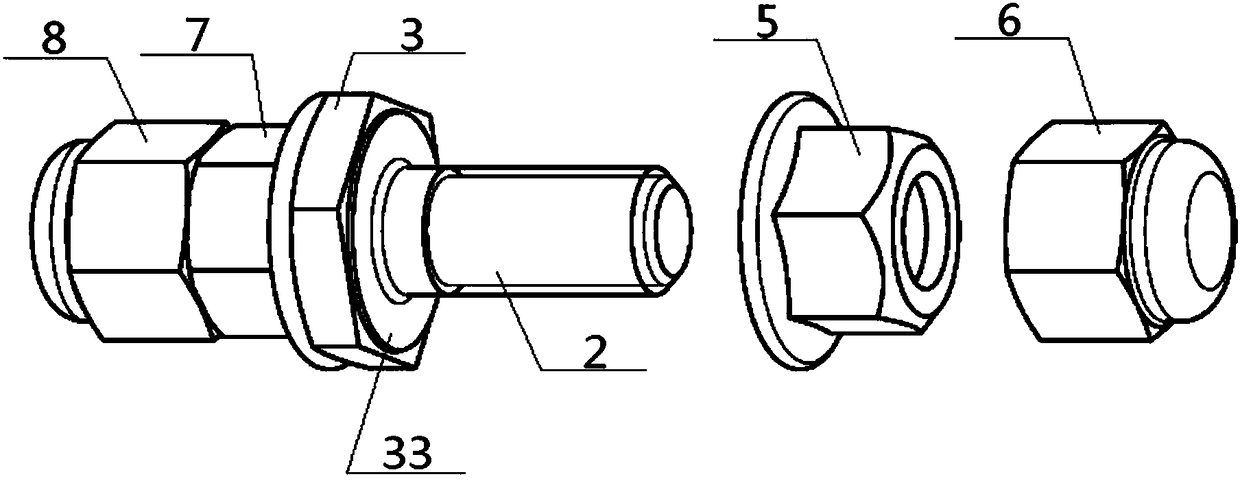

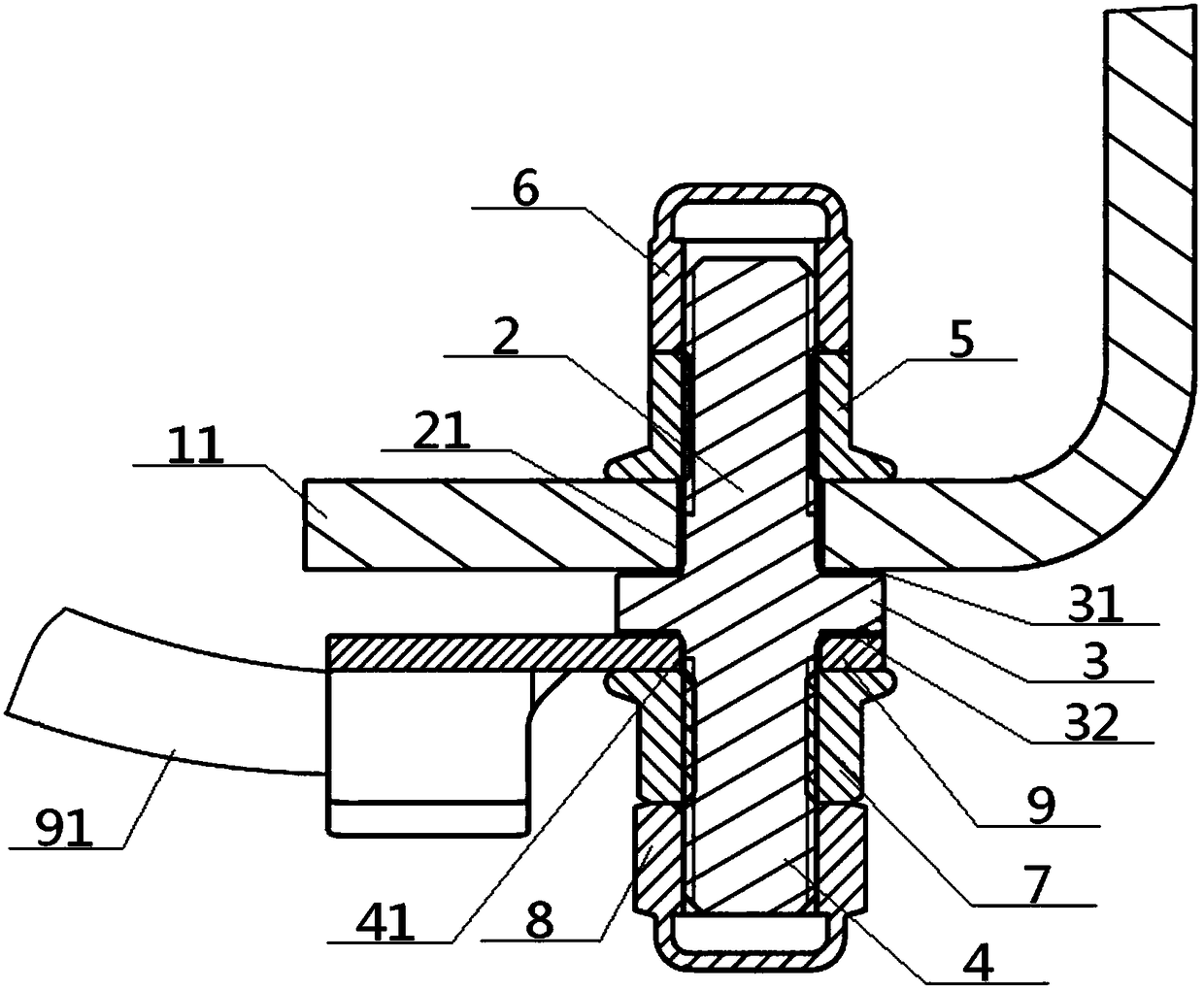

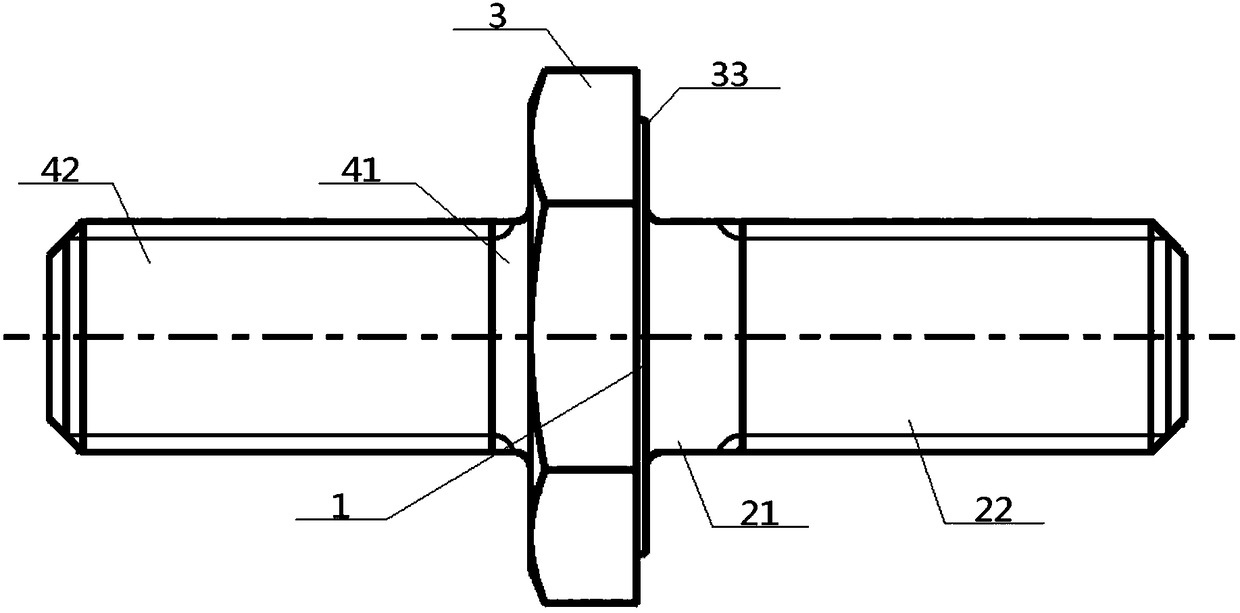

Common grounding structure and use method thereof

ActiveCN108155490AAvoid corrosionNot easy to corrodeLine/current collector detailsConnection contact member materialElectricityMechanical engineering

The invention relates to a common grounding structure. The structure comprises a mounting bolt, a mounting nut, a wiring bolt and a wiring nut, the mounting bolt and the wiring bolt are connected to form a double-head grounding bolt of an integrated structure through a boss, and the two side surfaces of the boss are a common conduction contact surface and a wiring conduction contact surface; the mounting nut and a mounting covering cap sleeve the periphery of the mounting bolt from inside to outside, the wiring nut and a wiring covering cap sleeve the periphery of the wiring bolt from inside to outside, and the diameter of the boss is larger than the diameters of the mounting bolt and the wiring bolt. According to the common grounding structure, it can be guaranteed that the conduction contact surfaces are not easily corroded, the electric performance is not easily aged and lowered, the technology is convenient and easy to implement, the anti-loosening and protection effects are extremely good, and the production cost is low.

Owner:DONGFENG COMML VEHICLE CO LTD

Manufacturing method of F-level electromagnetic wire

ActiveCN102412026AImprove corona resistanceImprove thermal conductivityInsulating conductors/cablesHeat resistanceCopper wire

The invention relates to a manufacturing method of a single-side reinforcement F-level electromagnetic wire, and the manufacturing method provided by the invention is lower in manufacturing cost, is suitable for energy conservation and emission reduction, and can be used for reducing the environmental pollution and ensuring the product performance to be higher. The manufacturing method comprises the following steps: adding a polyester resin into a nano material subjected to surface activation treatment and uniformly stirring to obtain an insulation resin for later use; delivering the insulation resin into an extruder hopper, enabling the insulation resin to be in a high-temperature viscous flow state by virtue of an extruder and continuously extruding the insulation resin from the die sleeve port of the extruder; meanwhile, aligning and preheating a bare copper wire, enabling the aligned and preheated bare copper wire to pass through a forming die of a machine head of the extruder, and packaging the insulation resin extruded from the die sleeve onto the bare copper wire; and cooling the bare copper wire covered with the insulation resin so as to obtain the F-level electromagnetic wire. The proportion of an inorganic nano material is suitable for improving the heat resistance of an insulating layer, and the manufactured electromagnetic wire can achieve F-level insulation; and the coefficient of heat conductivity achieves 0.55 W / Mk, and the thickness of the insulating layer is adjusted within a range of 0.15-1.4 mm ( bifacial thickness).

Owner:JIANGSU BINGCHENG HYDROGEN ENERGY TECH CO LTD

Soldering method of ABS (Acrylonitrile Butadiene Styrene) rectifier bridge

InactiveCN102513633AIncrease production speedIncrease productionSoldering apparatusSolder ballGraphite

The invention discloses a soldering method of an ABS (Acrylonitrile Butadiene Styrene) rectifier bridge. The method comprises the following steps of: filling a layer of core grains and a layer of soldering flakes in a first presoldering boat, wherein the core grains are arranged on the lower layer, the soldering flakes are arranged on the upper layer, the P surfaces of the core grains are upward, and a second presoldering boat is covered on the first presoldering boat after the core grains and the soldering flakes are filled; placing the two combined presoldering boats in a soldering furnace to heat, presoldering the soldering flakes and the core grains, fusing the soldering flakes after the soldering flakes are heated to form a solder ball shape, adsorbing the soldering flakes in centers of the core grains to form soldering points, and placing the core grains into a vessel for later use after the two combined presoldering boats are taken out of the furnace and cooled; fixing an upper material flake and a lower material flake on a locating plate, after dispensing solder glue on planes of the upper material flake and the lower material flake, prefixing the presoldered core grains after placing the presoldered core grains on surface points of the upper material flake and the lower material flake by using a pipette, and carrying out die assembly after moving the upper material flake and the lower material flake onto a graphite boat. According to the invention, the core grains are accurately located in a way of presoldering the single surface of each core grain, the deviation of core materials is avoided, and the electrical property of a soldered rectifier bridge is ensured.

Owner:CHANGZHOUSR SEA ELECTRONICS

Adhesive for gluing piezoelectric ceramic buzzing slice and preparation method

ActiveCN103122234AGood liquidityGood thixotropyNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyamideAdhesive

The invention discloses the production technology of a piezoelectric ceramic buzzing slice, and particularly discloses an adhesive for gluing the piezoelectric ceramic buzzing slice and a preparation method. The adhesive comprises the following components in parts by mass: 79 to 83 parts of EPE (Expand Aple Poly Ephylene) modified epoxy resin, 5 to 8.5 parts of 2-ethyl-4-methylimidazole, 2.5 to 5 parts of low-molecular polyamide, 1.2 to 1.8 parts of KH-550, 2.1 to 2.6 parts of KH-560 and 3 to 5 parts of nitrile rubber buna, wherein the EPE modified epoxy resin comprises the following components in parts by mass: 20 parts of epoxy resin E-51, 45 parts of epoxy resin E-42 and 35 parts of polyol glycidyl ethers. According to the adhesive, the technical defect that the existing adhesive for gluing the piezoelectric ceramic buzzing slice cannot resist the impact at the high temperature of 150 DEG C is solved. The adhesive disclosed by the invention has the advantages of capability of resisting the wave peak welding impact at the high temperature of 150 DEG C, and long service life and the like. The adhesive can realize the automatic production of the piezoelectric ceramic buzzing slice, and is safe and reliable.

Owner:NINGBO KEPO ELECTRONICS

Polymer/carbon nanotube/metal composite fiber and preparation method thereof

ActiveCN104099682AImprove spin performanceLow costMonocomponent polyolefin artificial filamentMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to polymer / carbon nanotube / metal composite fiber. The composite fiber comprises polymer fiber containing metal short fiber and carbon nanotube, the metal short fiber is dispersed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber; the carbon nanotube is dispersed in the polymer fiber and distributed among the metal short fiber; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C to 480 DEG C and lower than a polymer processing temperature; the volume ratio of the metal short fiber to the polymer fiber is 0.01:100-20:100; and the weight ratio of the carbon nanotube to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

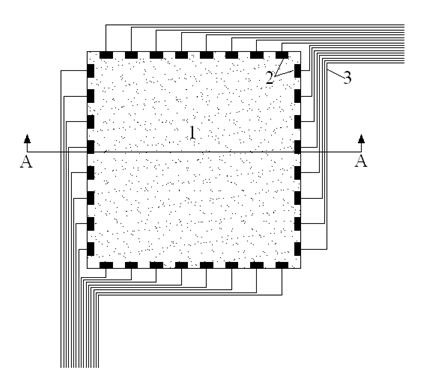

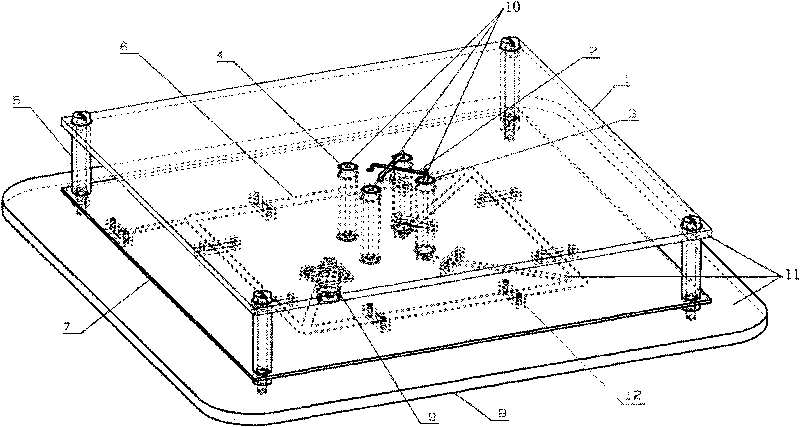

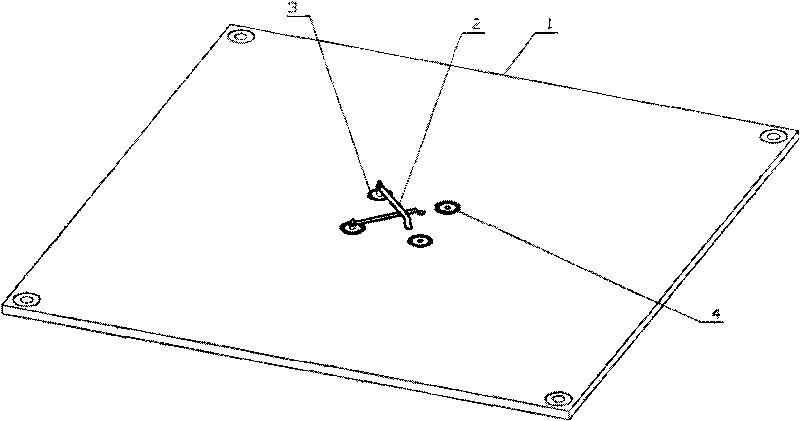

Embedded invisible circular polarized antenna

InactiveCN101707277ALow dielectric constantBandwidthAntenna supports/mountingsElectrical conductorCircularly polarized antenna

The invention provides an embedded invisible circular polarized antenna, aiming at providing the embedded invisible circular polarized antenna with wide wave beam coverage range and coverage area, which can bear high power, receive signals in a plurality of frequency segments, receive and transmit circular polarized electromagnetic wave within wide-angle range and realize wide-angle coverage. Theembedded invisible circular polarized antenna comprises a printed circuit board (1), a cable component (10), a strip line feed network (11), a high-frequency connector (9); the cable component is composed of two feed cables (3) and two balanced current cables (4) arranged on a printed board by a 2*2 rectangular array, wherein the two feed cables are connected with the port (20) and port (21) of a3dB directional coupler (6) in the strip line feed network, an outer conductor of the two balanced current cables is connected with the copper foil on the printed board, and the high-frequency signalcurrent of an outside signal source is fed into the 3dB directional coupler by the high-frequency connector and then is distributed to the cable component, then is fed into the printed board by crossfeed sheets (2) on the feed cables (3).

Owner:10TH RES INST OF CETC

Cooling structure of inner rotor motor

ActiveCN102810943BElectrical performance impactImprove performanceMagnetic circuit rotating partsCooling/ventillation arrangementEngineeringCooling medium

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

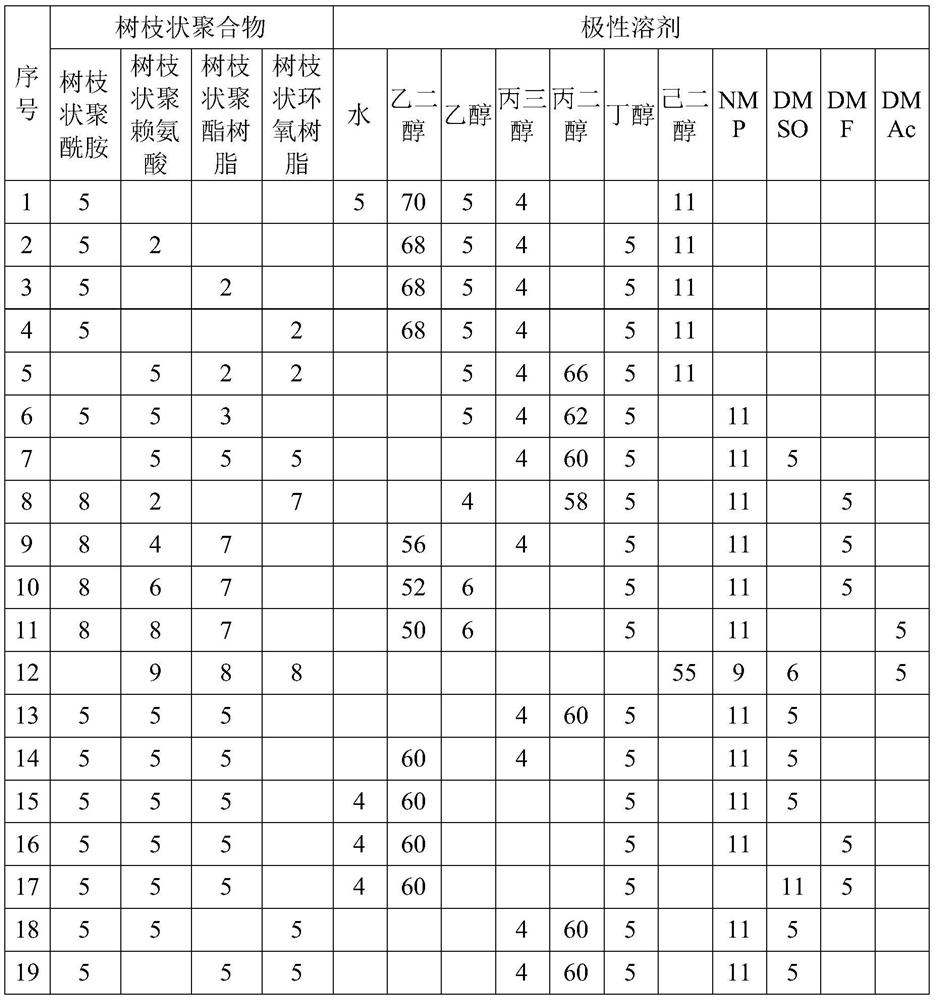

Solar cell conductive silver paste free of silicone oil and application thereof

ActiveCN113488223AElectrical performance impactImproved viscosity propertiesNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSilver pastePolymer science

The invention provides solar cell conductive silver paste free of silicone oil and application thereof. Raw materials of the conductive silver paste comprise silver powder, glass powder, an organic carrier and a polymer additive, and the polymer additive comprises a dendritic polymer and a polar solvent. The invention further provides a solar cell which comprises the solar cell conductive silver paste free of silicone oil. According to the conductive silver paste provided by the invention, silicone oil does not need to be added, and the problems that the silicone oil cannot be completely volatilized in the sintering process, silicon residues exist, the series resistance of a battery piece is increased, and sintering is poor in the front conductive silver paste containing the silicone oil are solved.

Owner:SUZHOU ISILVER MATERIALS

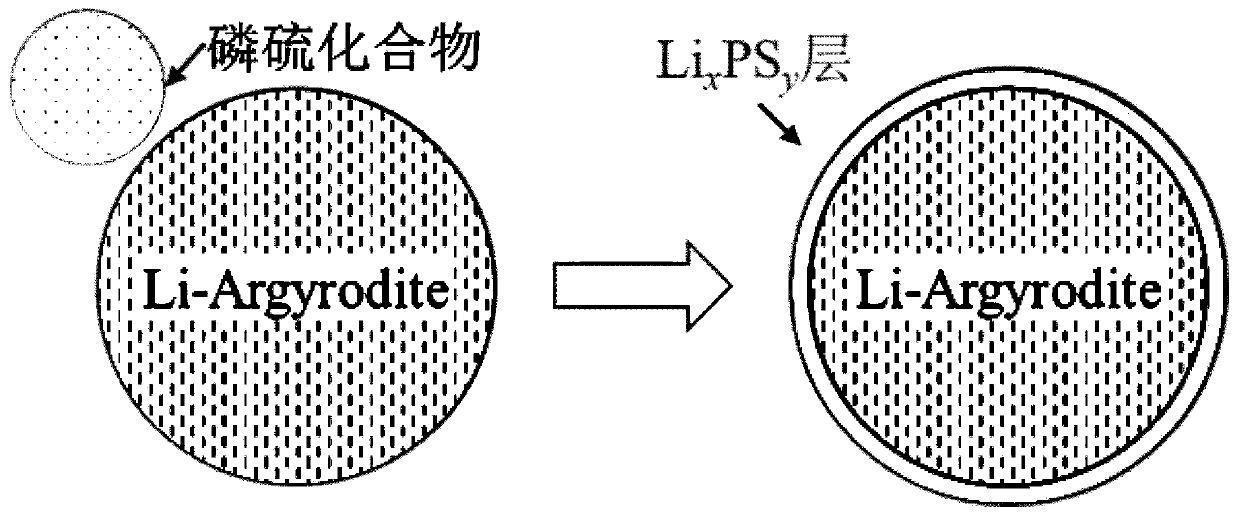

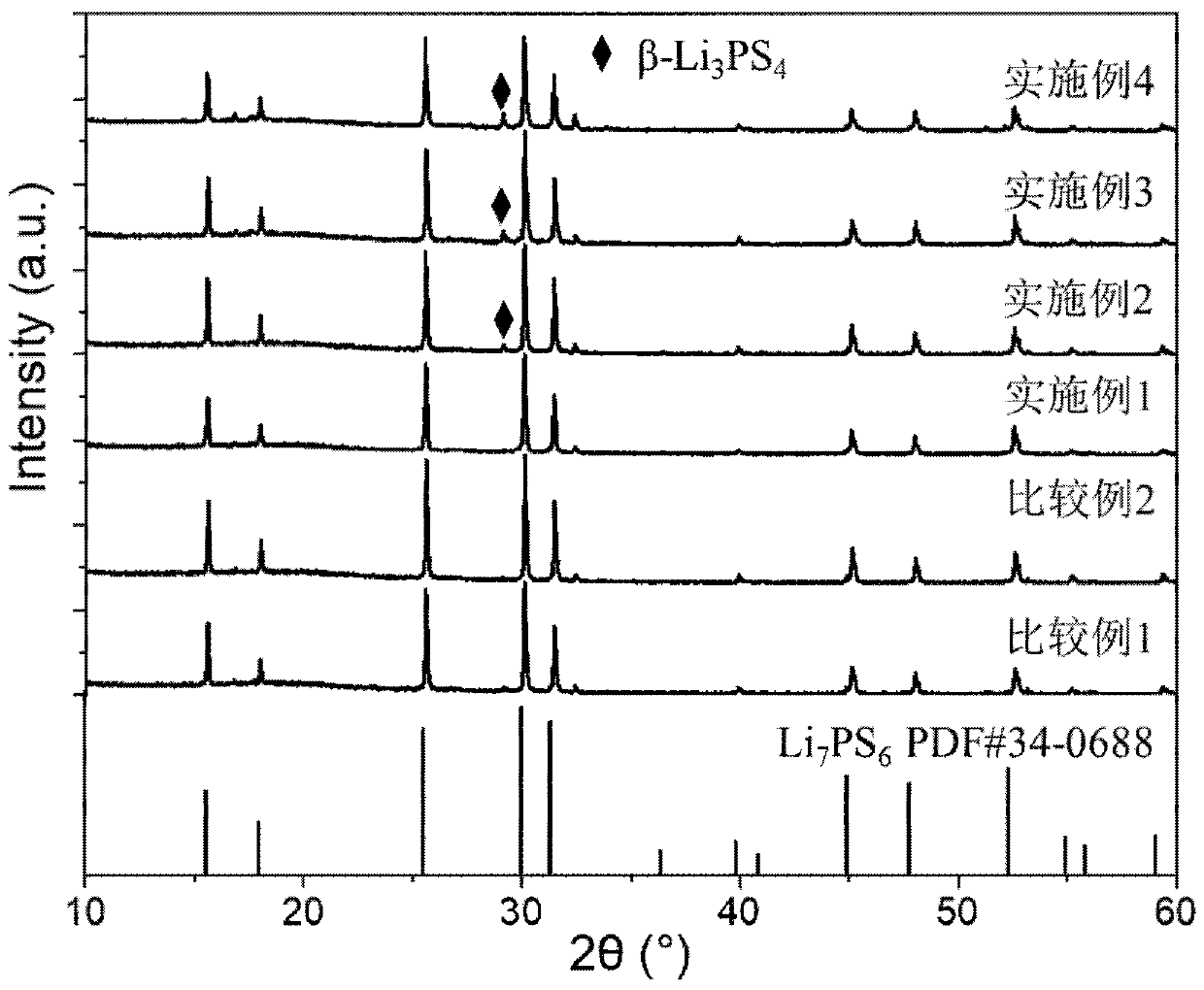

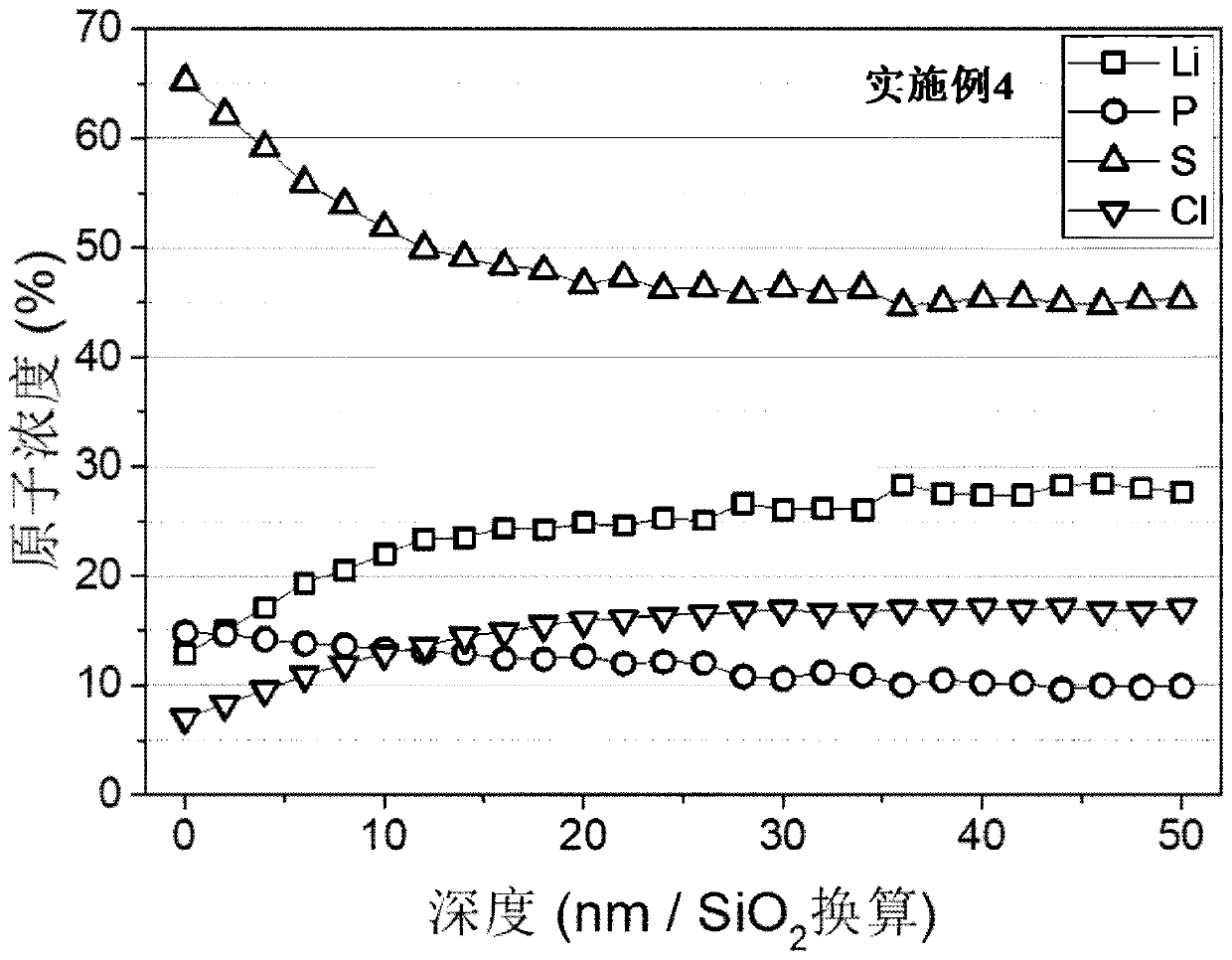

Sulfide solid electrolyte stable to lithium, preparation method thereof and solid-state battery with solid electrolyte

PendingCN110911733AImprove economic efficiencyElectrical performance impactSecondary cellsSolid-state batteryMetallic lithium

The invention discloses a sulfide solid electrolyte stable to lithium, and relates to the field of solid-state batteries, and the sulfide solid electrolyte takes argyrodite sulfide solid electrolyte as a core, and the surface of the argyrodite sulfide solid electrolyte is coated with a shell layer composed of Li-P-S compounds. By adopting the technical scheme, the Li-P-S compound shell component is generally Li <3>P<S4> or Li <3-x>P<S4-y> lithium-deficient sulfur-phosphorus compound. The compound is relatively stable when being in contact with lithium metal and dry air, so that the purpose ofprotecting the inner core of the argyrodite sulfide solid electrolyte is achieved.

Owner:ZHEJIANG FUNLITHIUM NEW ENERGY TECH CO LTD

Manufacturing method of H-level and 200-level electromagnetic wire

ActiveCN102412027AImprove corona resistanceImprove thermal conductivityInsulating conductors/cablesCopper wireHeat resistance

The invention relates to a manufacturing method of an H-level and 200-level electromagnetic wire, and the manufacturing method provided by the invention is lower in manufacturing cost, is suitable for energy conservation and emission reduction can be used for reducing the environmental pollution and ensuring the product performance to be higher. The manufacturing method comprises the following steps: adding a polyester resin into a nanometer material subjected to surface activation treatment, uniformly stirring and then delivering into an extruder hopper; the insulation resin to be in a high-temperature viscous flow state by virtue of an extruder and continuously extruding from a die sleeve port of the extruder; meanwhile, aligning and preheating a bare copper wire, enabling the aligned and preheated bare copper wire to pass through a forming die of a machine head of the extruder, and packaging the insulation resin extruded from the die sleeve onto the bare copper wire; and cooling the bare copper wire covered with the insulation resin so as to obtain the H-level and 200-level electromagnetic wire; the electromagnetic wire eliminates a gap at a joint seam of a pin hole and a rolling covered wire, thus the electrical insulation performance is improved; and meanwhile, an inorganic nanometer material with high corona resistance and high thermal conductivity is added into insulating layer, the heat resistance of the insulating layer is improved, and the heat-conduction coefficient can achieve 0.60 W / Mk.

Owner:江苏冰城氢能科技有限公司

Thin-film transistor and liquid crystal displayer

ActiveCN104810394AImprove performancePerformance impactSemiconductor/solid-state device detailsSolid-state devicesLiquid-crystal displayLiquid crystal

The invention relates to a thin-film transistor and a liquid crystal displayer. The thin-film transistor comprises a substrate, a conductive lamination layer which is arranged on the substrate, and a light shielding layer which is arranged on the substrate. The light shielding layer is arranged below the conductive lamination layer, and the positions of the light shielding layer and the conductive lamination layer are exactly opposite. The thin-film transistor is provided with the light shielding layer used for light shielding of the conductive lamination layer so that adverse influence of illumination on electrical properties of oxides can be effectively prevented, and thus the electrical properties of the thin-film transistor can be enhanced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD +1

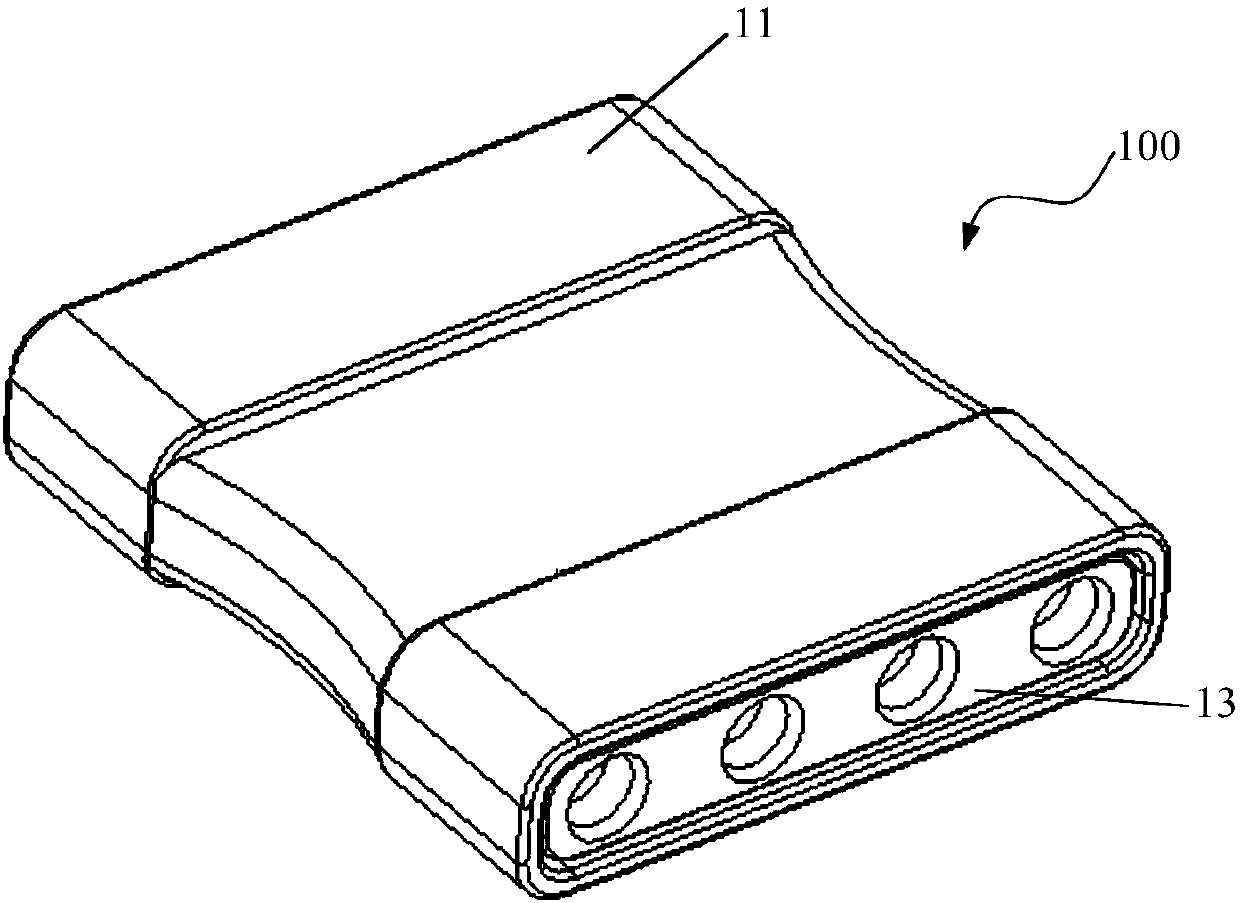

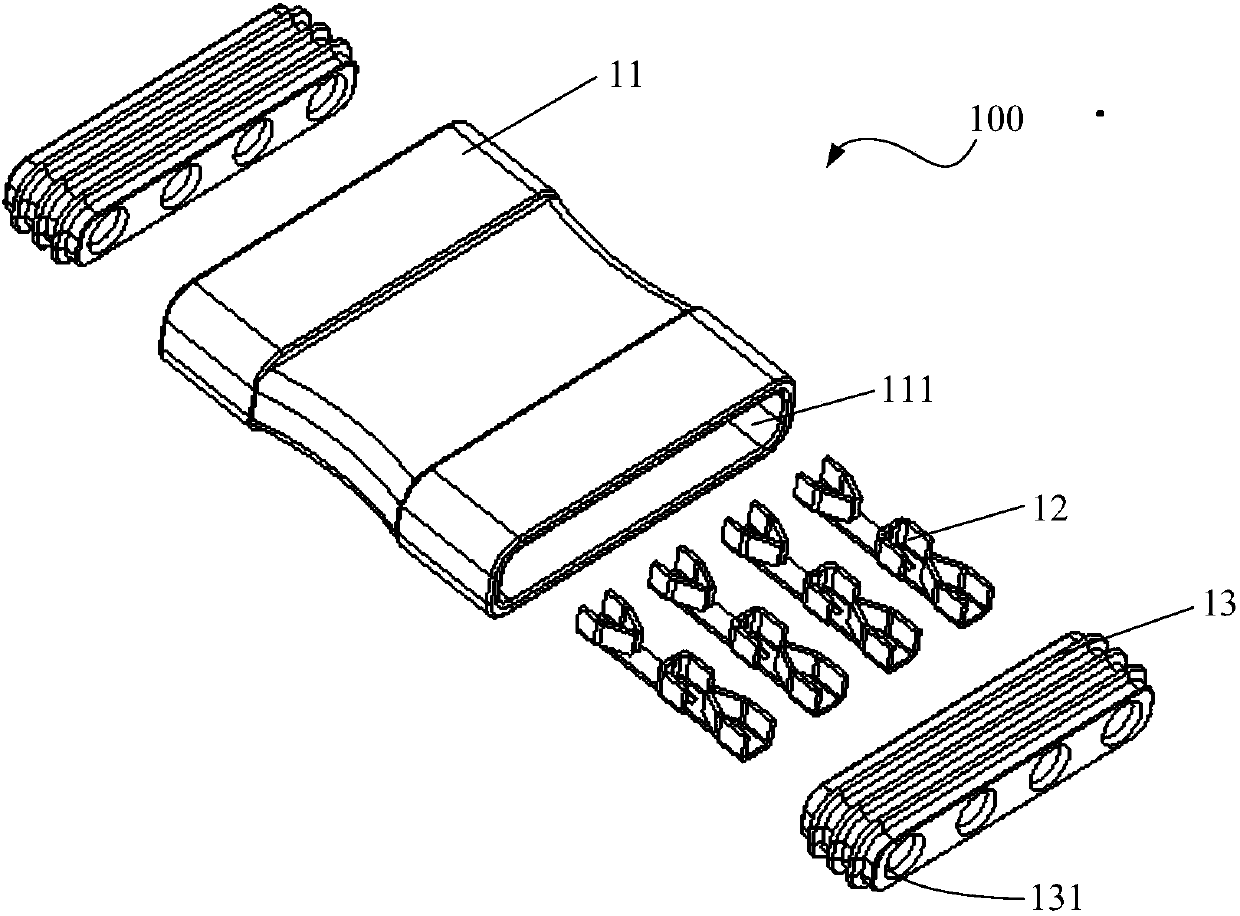

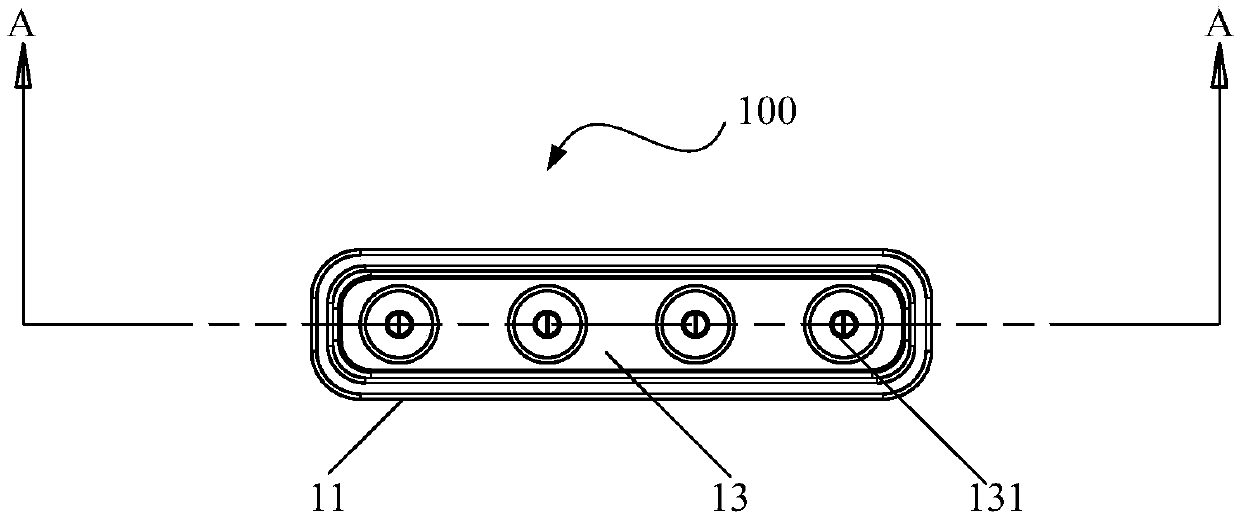

Plug-in type wire-to-wire connector

PendingCN110011110AElectrical performance impactAvoid enteringElectrically conductive connectionsDustproof/splashproof/drip-proof/waterproof/flameproof connectionElectrical connectionMoisture

The present invention discloses a plug-in type wire-to-wire connector comprises an insulating housing, at least one integral conductive terminal and two sealing members. At least one receiving passagepenetrating through the insulating housing in the insertion direction of a first wire or a second wire is formed in the insulating housing, and two ends of the receiving passage comprise a first socket and a second socket which allow the insertion of the first wire and the second wire. The at least one integral conductive terminal is received in the at least one receiving passage of the insulating housing and is used for achieving the electrical connection between the first wire and the second wire. The two sealing members are installed near the first socket and the second socket of the receiving passage, each of the sealing members is provided with at least one through hole which allows a wire to pass so as to prevent external moisture from entering the receiving channel from a socket. In the present invention, by setting the sealing members at the sockets of the receiving passage of the insulating housing, the connector has a waterproof function.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD

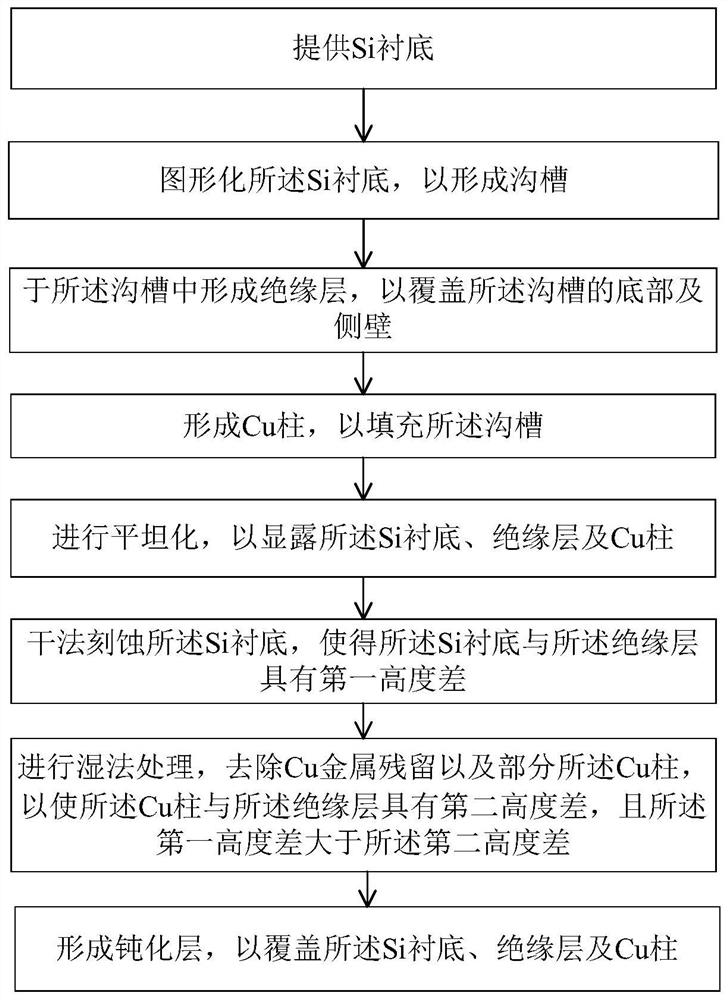

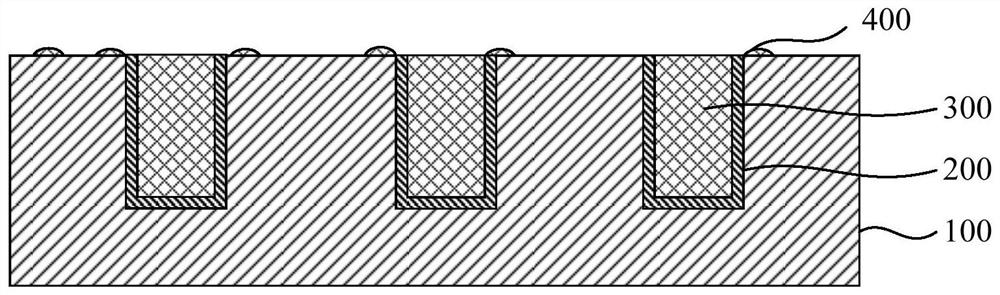

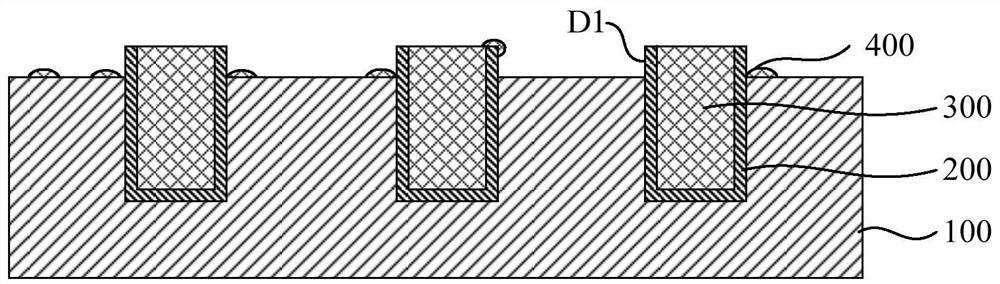

Semiconductor structure and preparation method thereof

PendingCN114141698AGood insulation effectAvoid affecting electrical performanceSemiconductor/solid-state device detailsSolid-state devicesPhysicsElectrically conductive

According to the semiconductor structure and the preparation method thereof provided by the invention, after planarization, the Si substrate is etched through a dry method, so that the first height difference exists between the Si substrate and the insulating layer, residual Cu metal near the edge of the Cu column can be effectively removed through wet processing, the second height difference exists between the Cu column and the insulating layer, and the first height difference is greater than the second height difference; therefore, connection of Cu metal on the inner side and the outer side of the insulating layer can be avoided, and influence on the electrical performance of the device is effectively avoided. Furthermore, through the passivation layer, the Si substrate can be effectively covered, and a conductive channel is prevented from being formed on the Si substrate in a subsequent process, so that a good insulation effect is achieved, and the influence on the electrical performance of the device can be further avoided.

Owner:SJ SEMICON JIANGYIN CORP

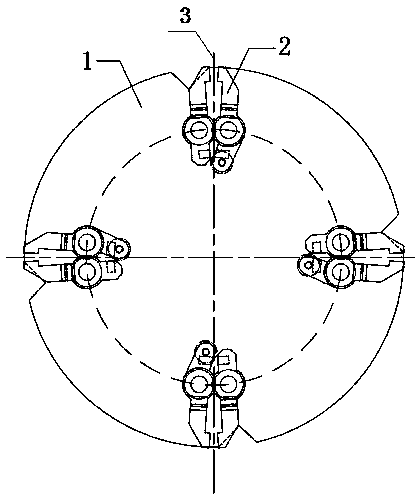

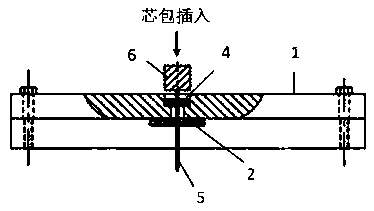

Integrated multi-station plate and automatic guide pin clamping device for assembling aluminum electrolytic capacitors

PendingCN108962603AReduce in quantitySimplify combination assembly proceduresCapacitor terminalsCapacitor manufactureManipulatorAluminum foil

The invention discloses an integrated multi-station plate and automatic guide pin clamping device for assembling aluminum electrolytic capacitors. According to the invention, multiple groups of guidepin clamping manipulators are arranged at equal intervals in the circumferential direction at the bottom of an integrated multi-station plate, the clamping end of each guide pin clamping manipulator is located at the edge of the multi-station plate, a rubber cover is arranged below the integrated multi-station plate and located at a position perpendicular to the clamping end, and a core cladding guide pin of the small aluminum electrolytic capacitor passes through the rubber cover and then clamped and fixed by the clamping end. The device disclosed by the invention enables the multi-station plate to be molded at one time by using an integrated multi-station technology, is convenient to assembly and easy to be in place accurately, and improves the working efficiency; and the automatic accurate positioning guide pin clamping device at the bottom of the multi-station plate enables a core cladding to move stably in the assembling process, thereby greatly reducing the possibility of damaging a riveting part between an aluminum foil and a guide pin of the core cladding.

Owner:SHENZHEN JIANGHAO ELECTRON

A kind of polymer/filler/metal composite fiber and its preparation method

ActiveCN104099684BImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com