Preparation method of winding-structure lithium ion battery

A technology of lithium-ion batteries and positive plates, which is applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of rapid drop of battery discharge platform, improve product competitiveness, improve rate performance and cycle life, and reduce production capacity. The effect of air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

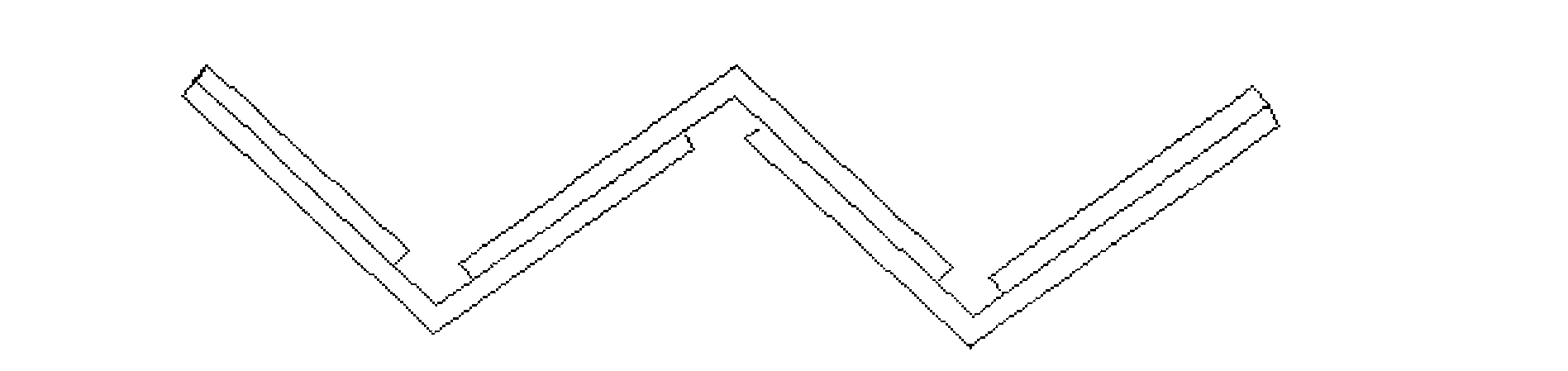

[0040] The following is an example of bending once along the center line of the length of the pole piece (that is, only one V shape is provided on the positive pole piece 10 and the negative pole piece 20) to illustrate the specific process:

[0041] Preparation of positive electrode sheet 10:

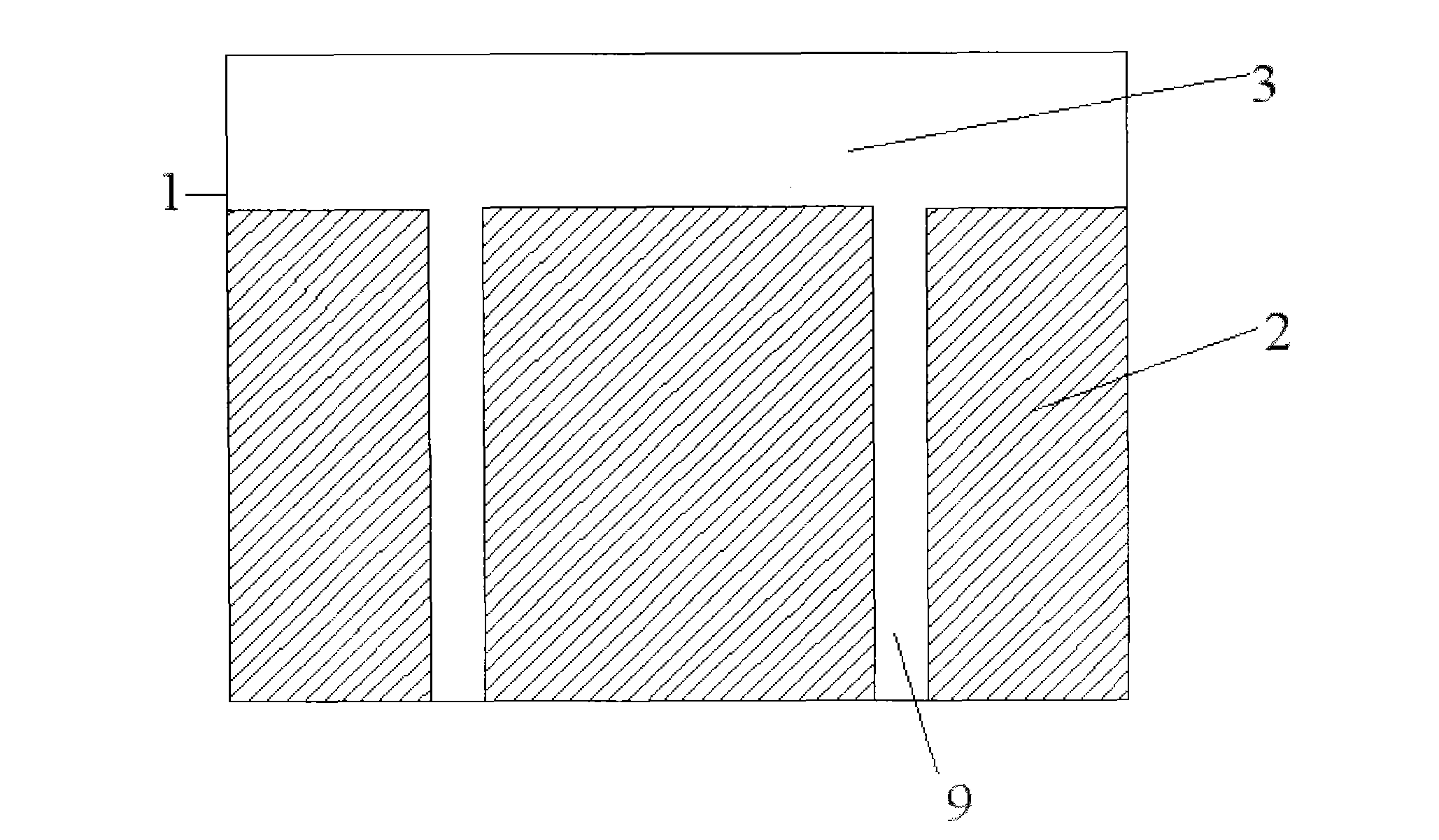

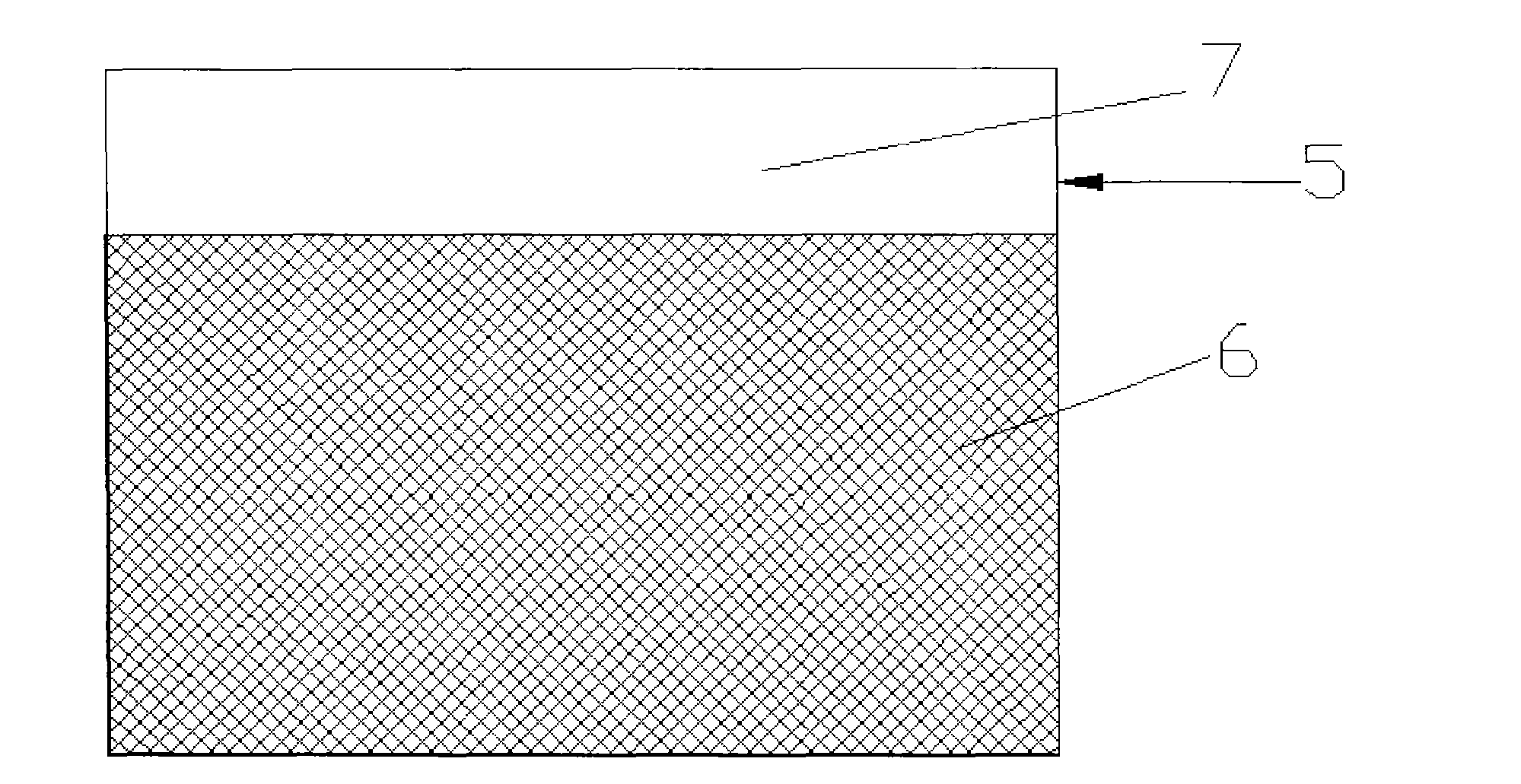

[0042] LiCoO 2 (Lithium cobaltate), Super-P (conductive carbon black), PVDF (polyvinylidene fluoride) and NMP (N,N-dimethylpyrrolidone) in a mass ratio of 95:2:3 were mixed and stirred evenly to obtain positive electrode slurry material. Viscosity was adjusted by NMP during stirring. Then the slurry is evenly coated on both sides of the 14 micron thick positive electrode current collector 1 (aluminum foil) according to a certain width, and the coating adopts interval coating instead of continuous coating. Reserve a blank area 3 for the positive electrode sheet on both sides (such as figure 1 As shown), a horizontal blank area 9 is reserved in the width direction of one side of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com