Patents

Literature

7909 results about "Pole piece" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pole piece is a structure composed of material of high magnetic permeability that serves to direct the magnetic field produced by a magnet. A pole piece attaches to and in a sense extends a pole of the magnet, hence the name.

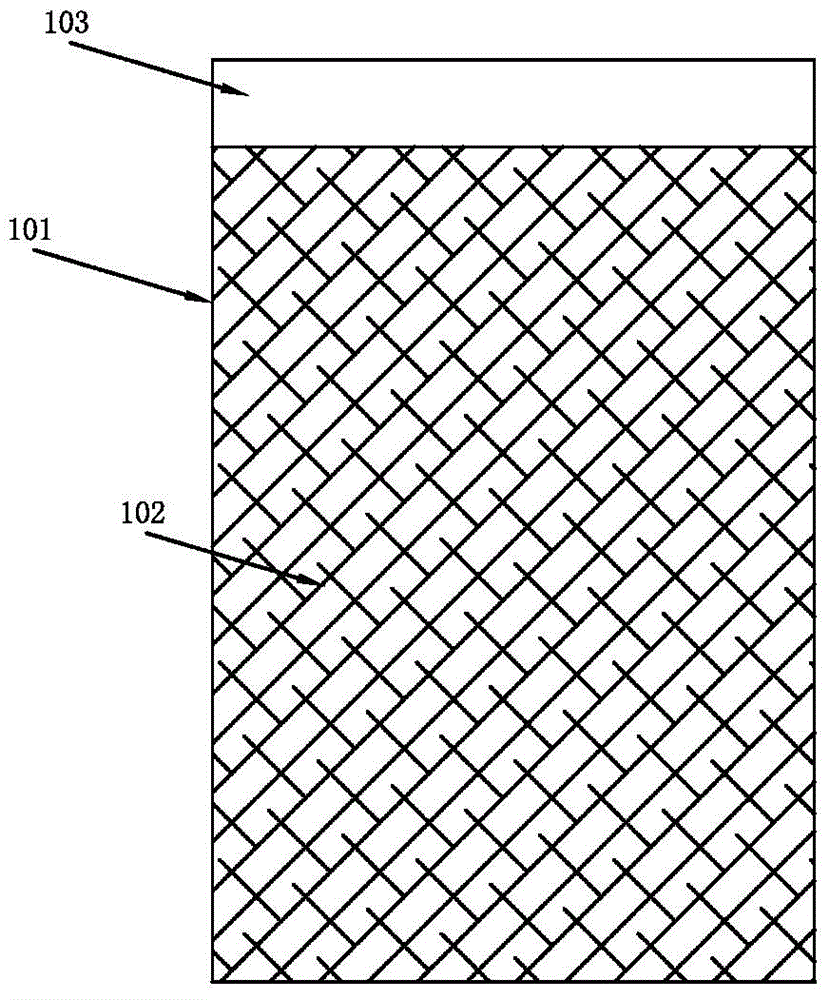

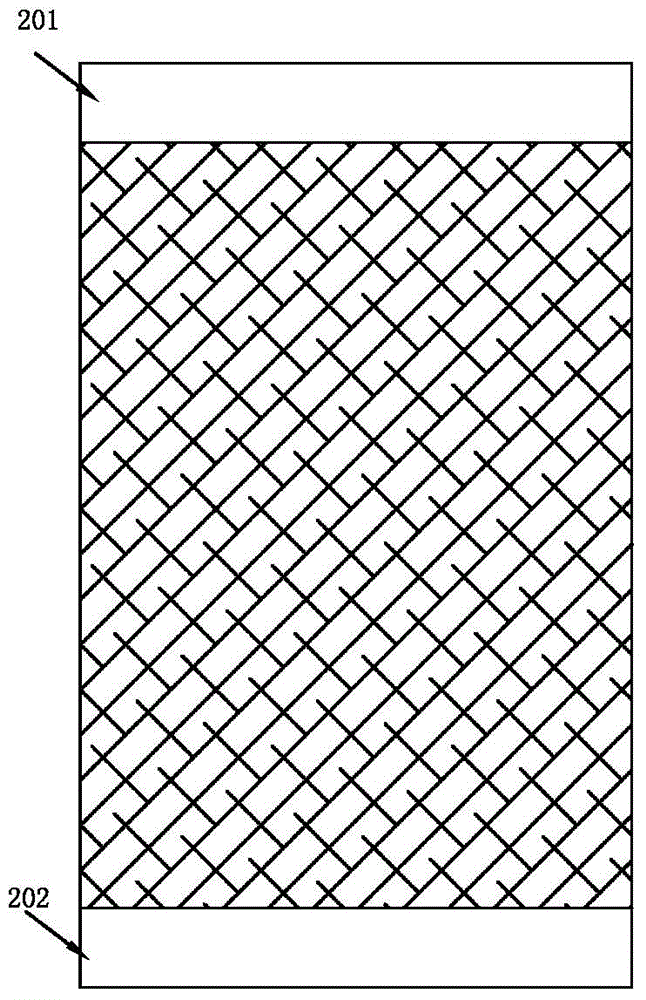

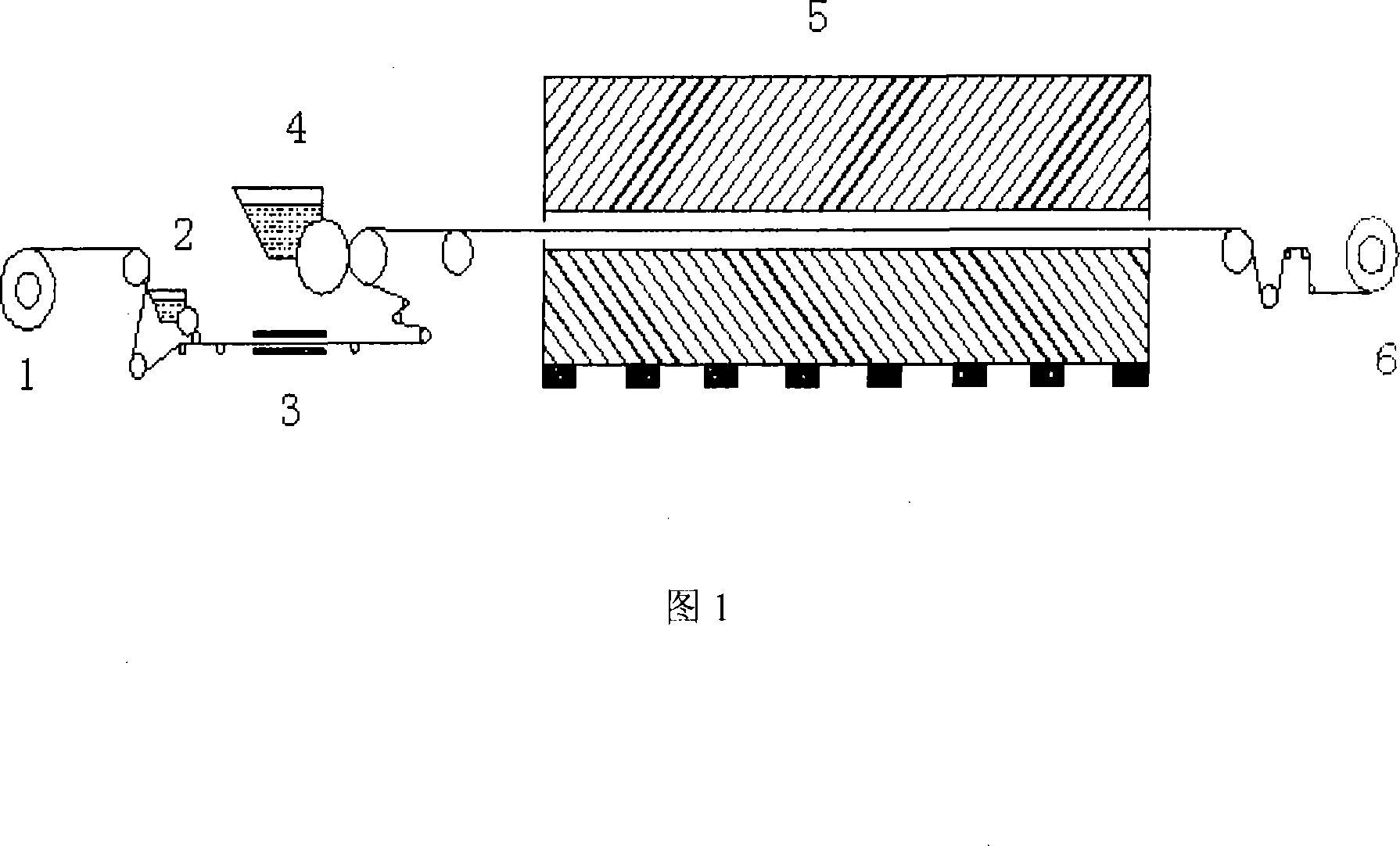

Laminated lithium ion battery, battery pack comprising same and pole piece of laminated lithium ion battery

InactiveCN104882635AImprove cooling effectReduce welding processFinal product manufactureElectrode carriers/collectorsInternal resistanceElectrical battery

Disclosed are a laminated lithium ion battery, a battery pack comprising the same and a pole piece of the laminated lithium ion battery. The pole piece comprises a current collector and an active material layer, wherein the current collector is coated with the active material layer. A section of continuous uncoated area is arranged at the tail end of a first width end portion of the pole piece, the top face and the bottom face of the uncoated area are not coated with the active material layer, the current collector is exposed in the uncoated area, and the exposed current collector serves as a pole lug of the pole piece. By the pole piece, internal resistance of the lithium ion battery is reduced and heat dissipation performance of the battery is improved.

Owner:SHENZHEN GREPOW BATTERY CO LTD

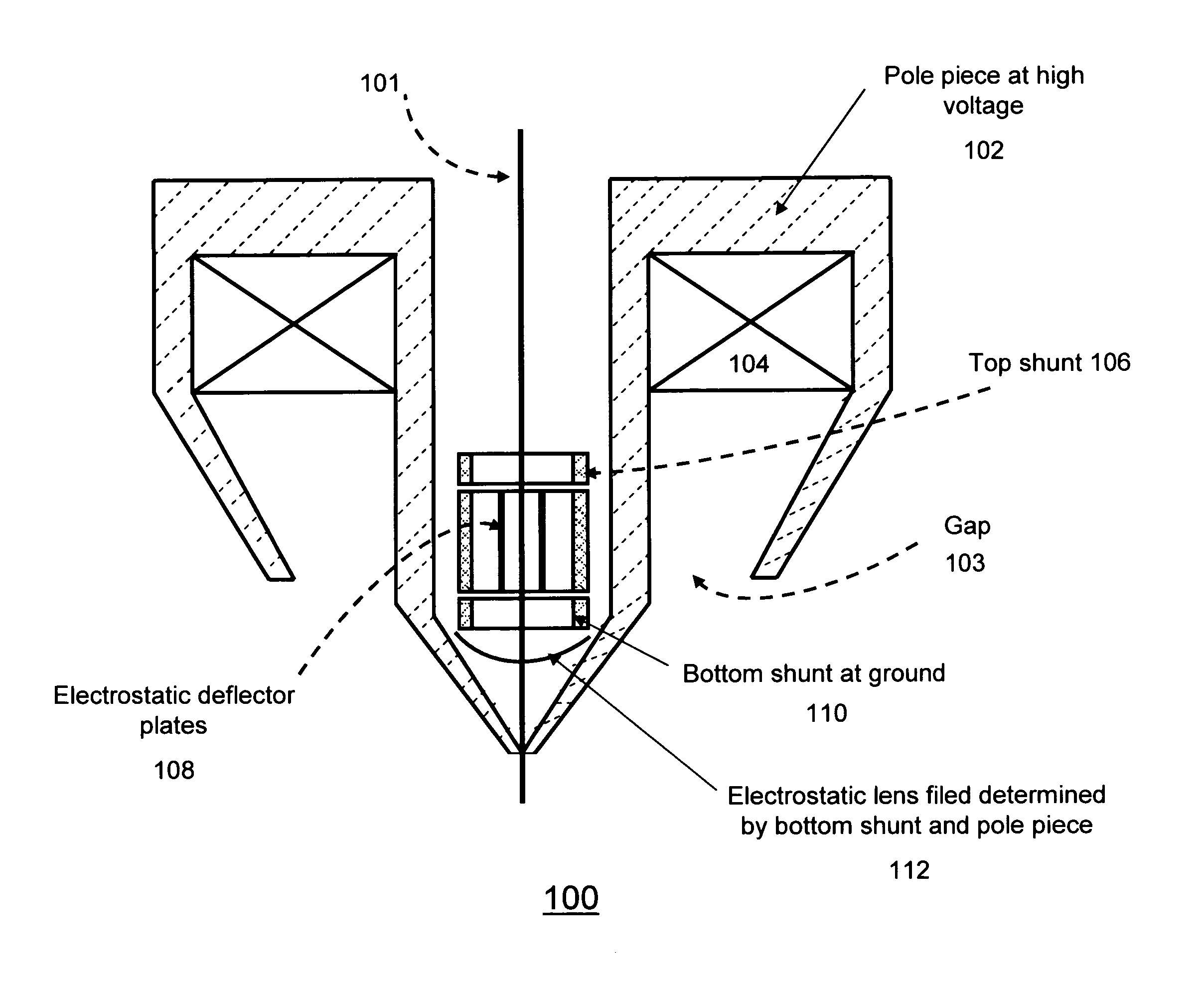

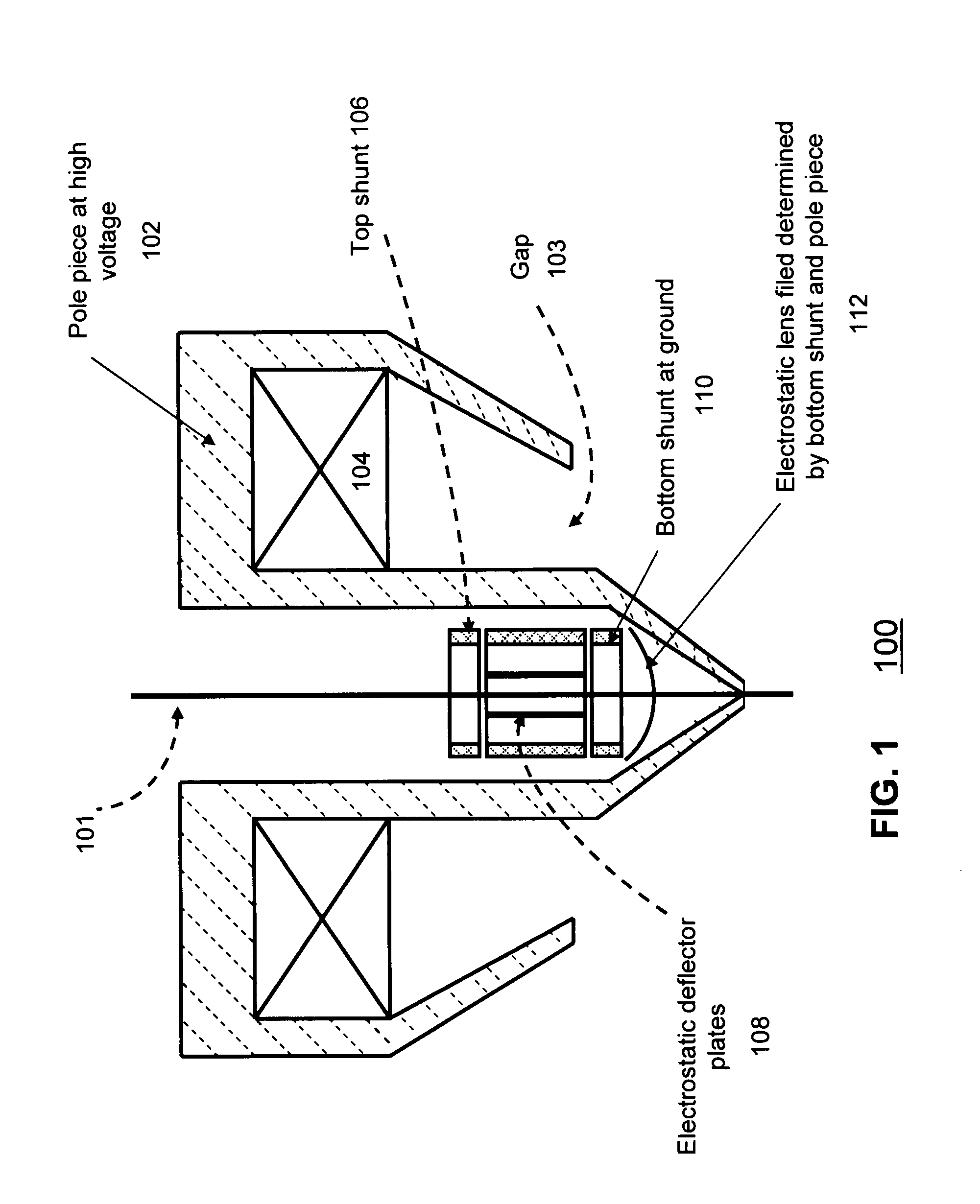

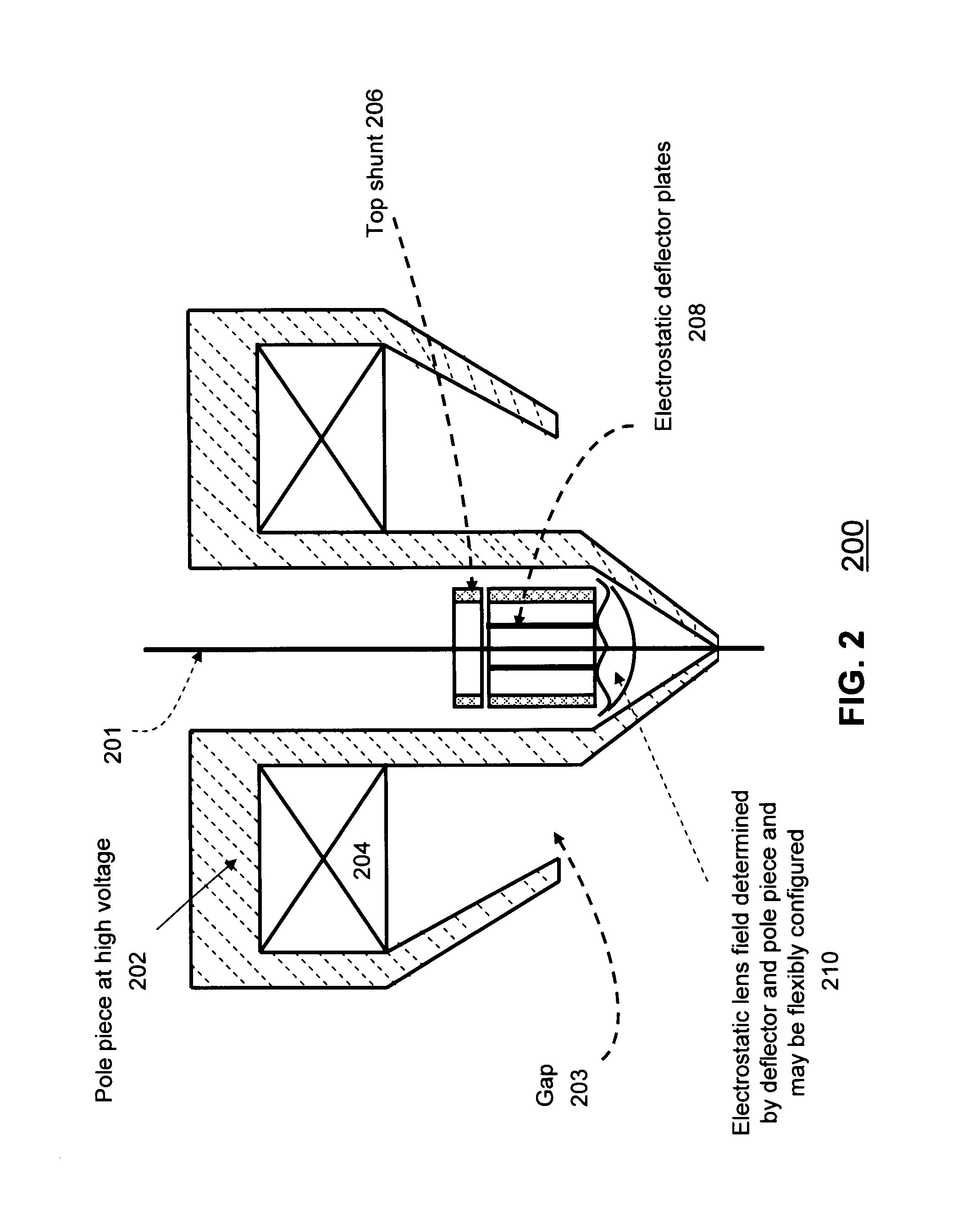

Objective lens with deflector plates immersed in electrostatic lens field

InactiveUS8698093B1Stability-of-path spectrometersBeam/ray focussing/reflecting arrangementsMagnetic polesPole piece

One embodiment relates to an objective lens utilizing magnetic and electrostatic fields which is configured to focus a primary electron beam onto a surface of a target substrate. The objective lens includes a magnetic pole piece and an electrostatic deflector configured within the pole piece. An electrostatic lens field is determined by the pole piece and the electrostatic deflector, and the electrostatic lens field is configured by adjusting offset voltages applied to plates of the electrostatic deflector. Other embodiments, aspects and features are also disclosed.

Owner:KLA TENCOR TECH CORP

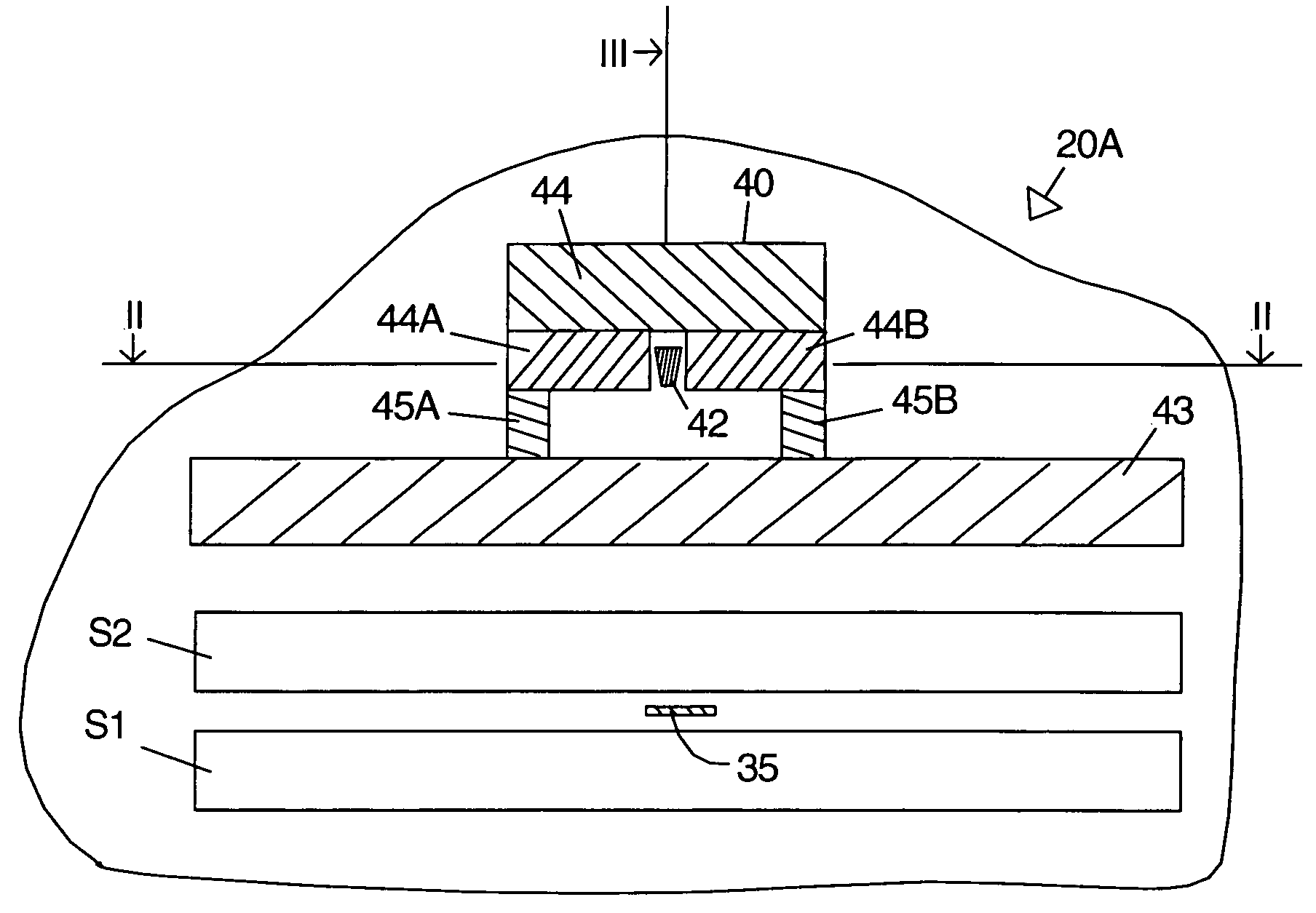

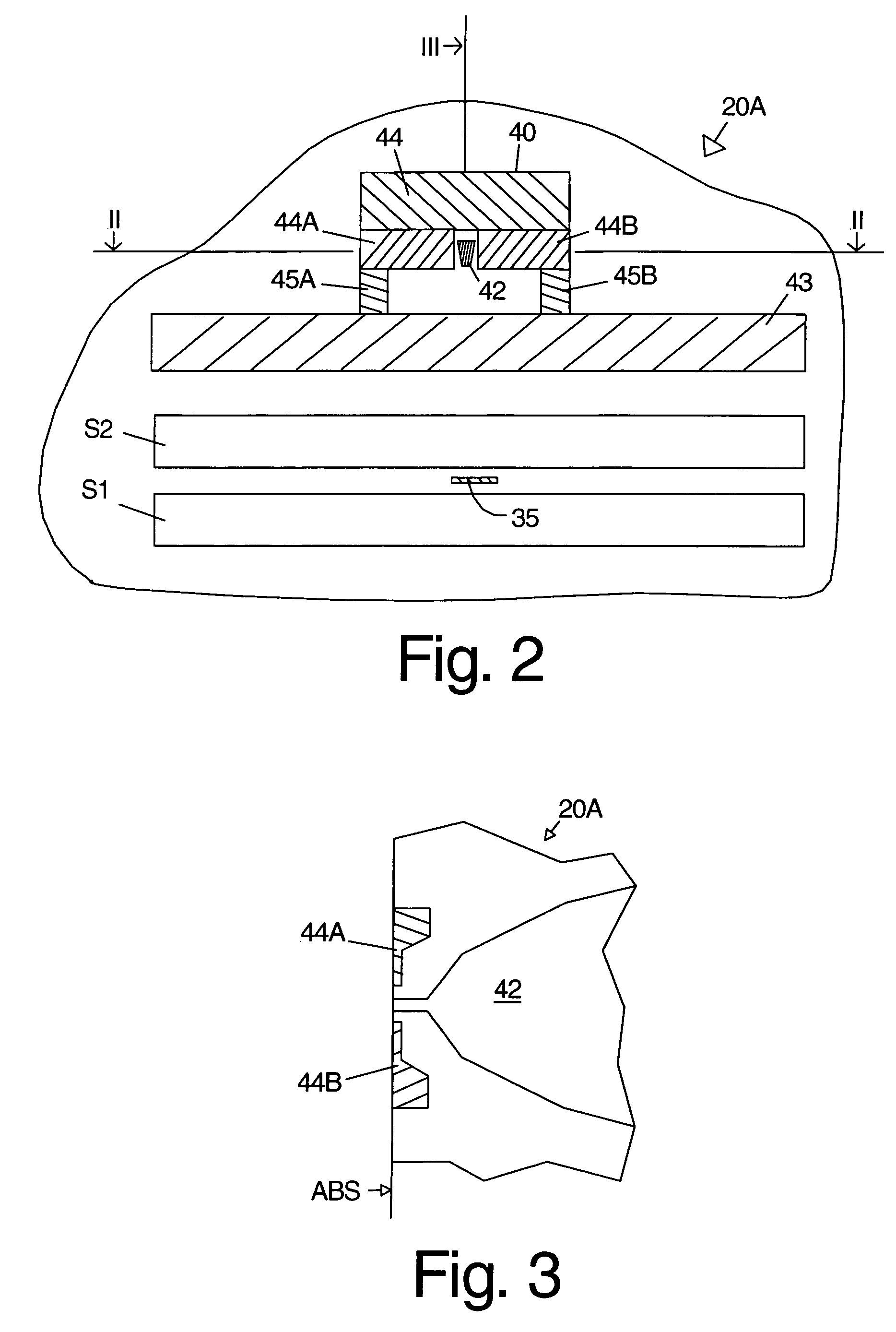

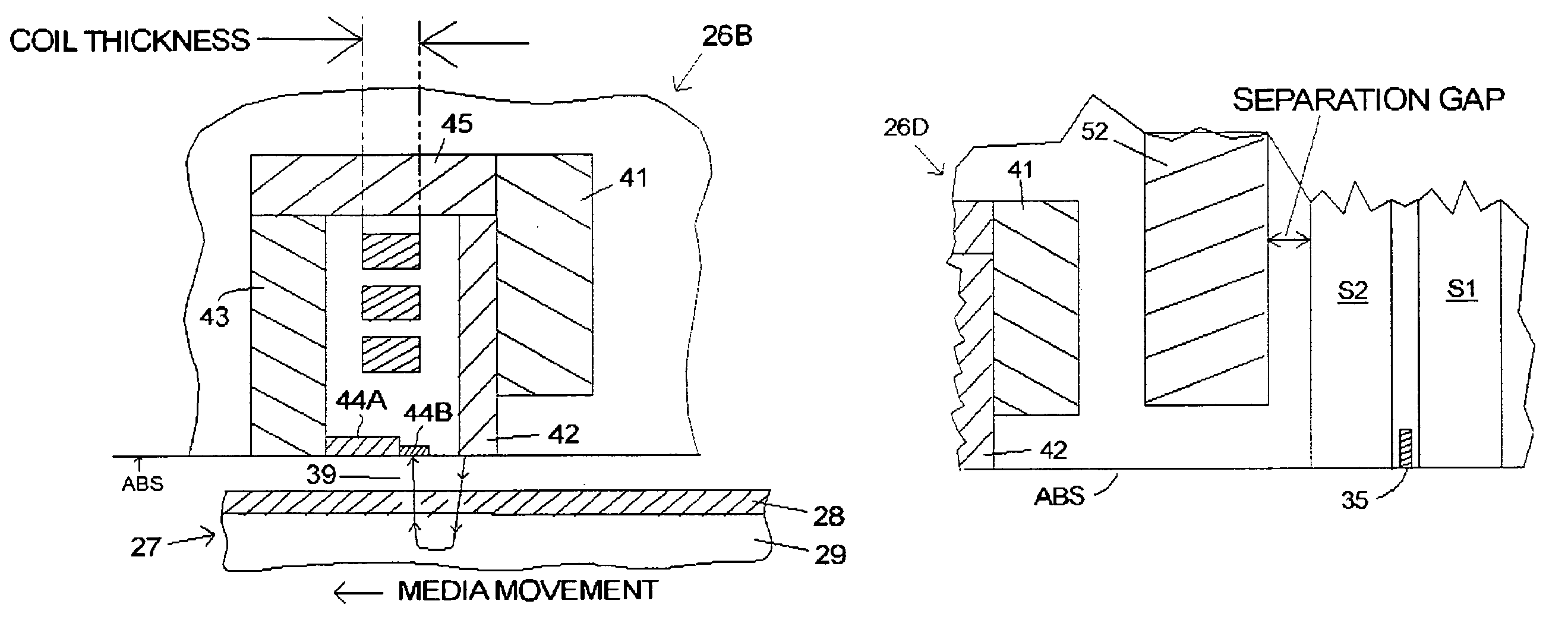

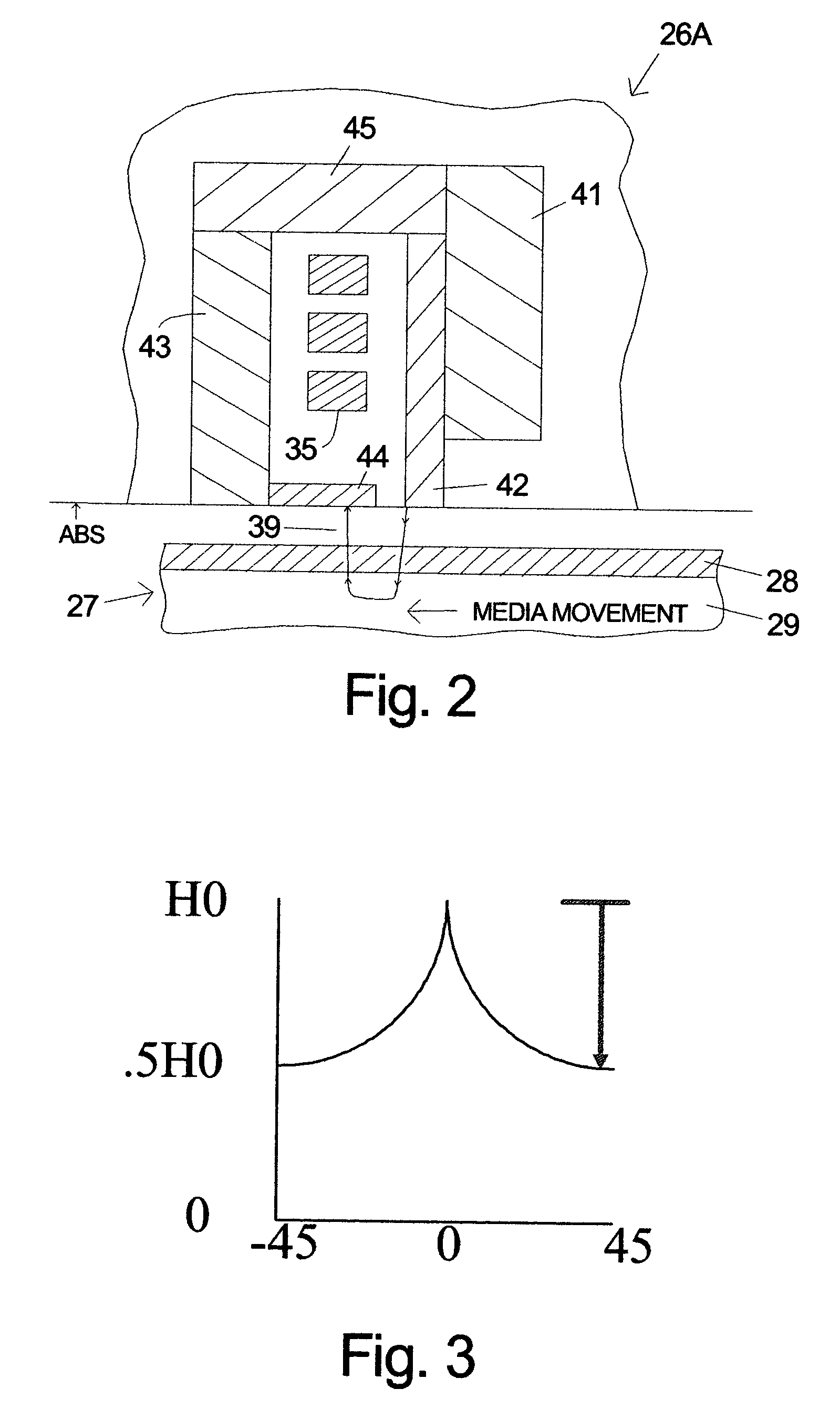

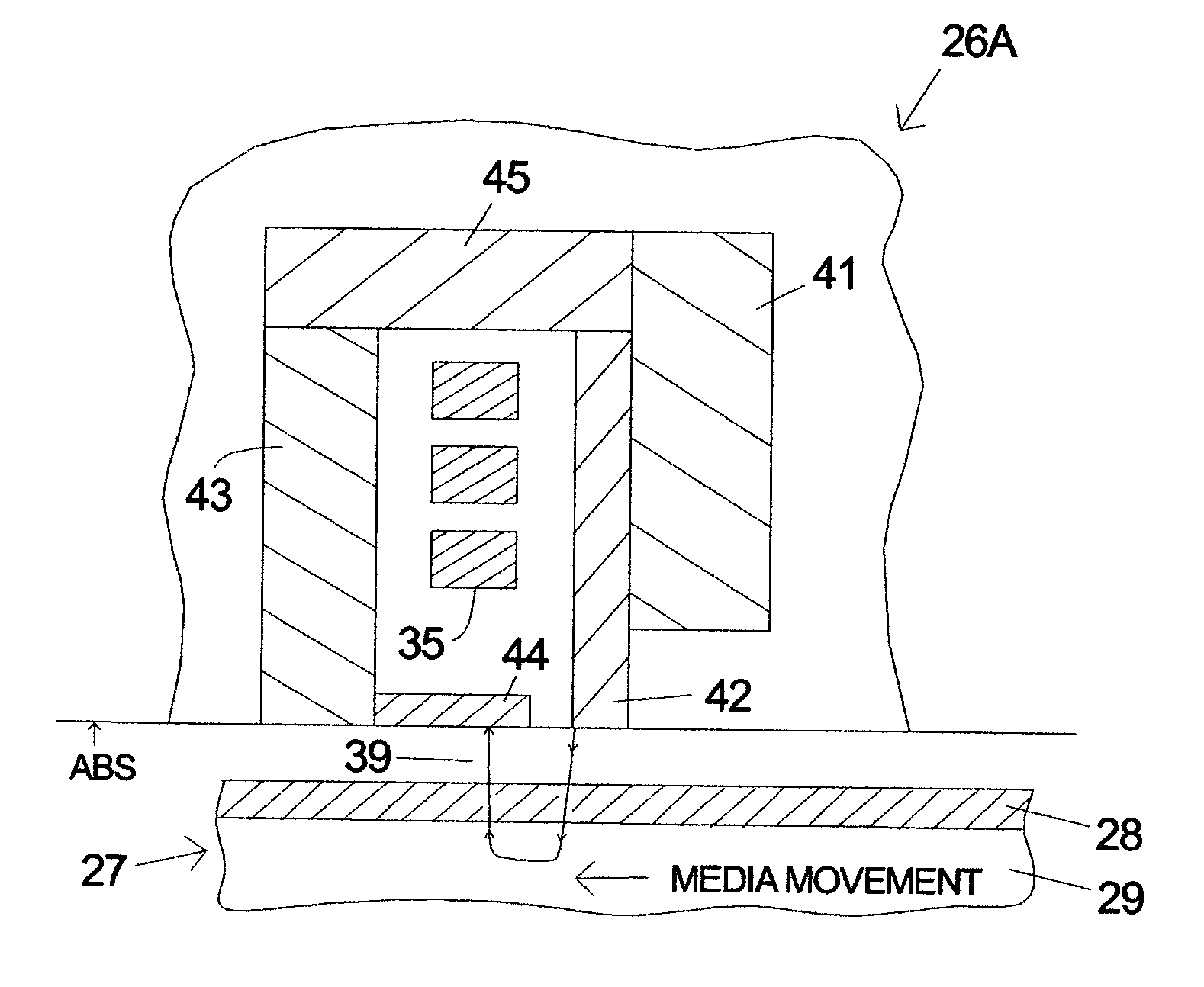

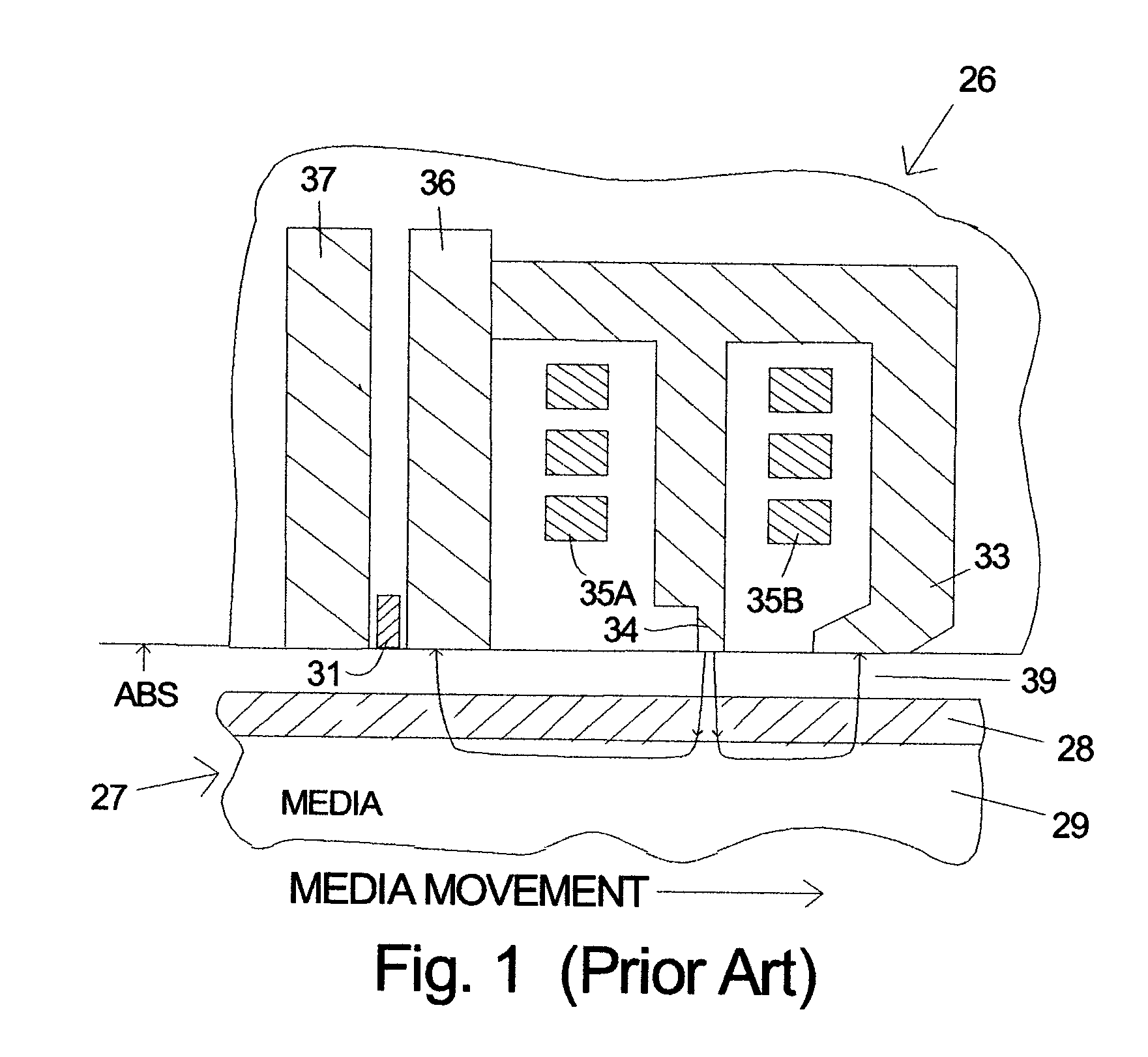

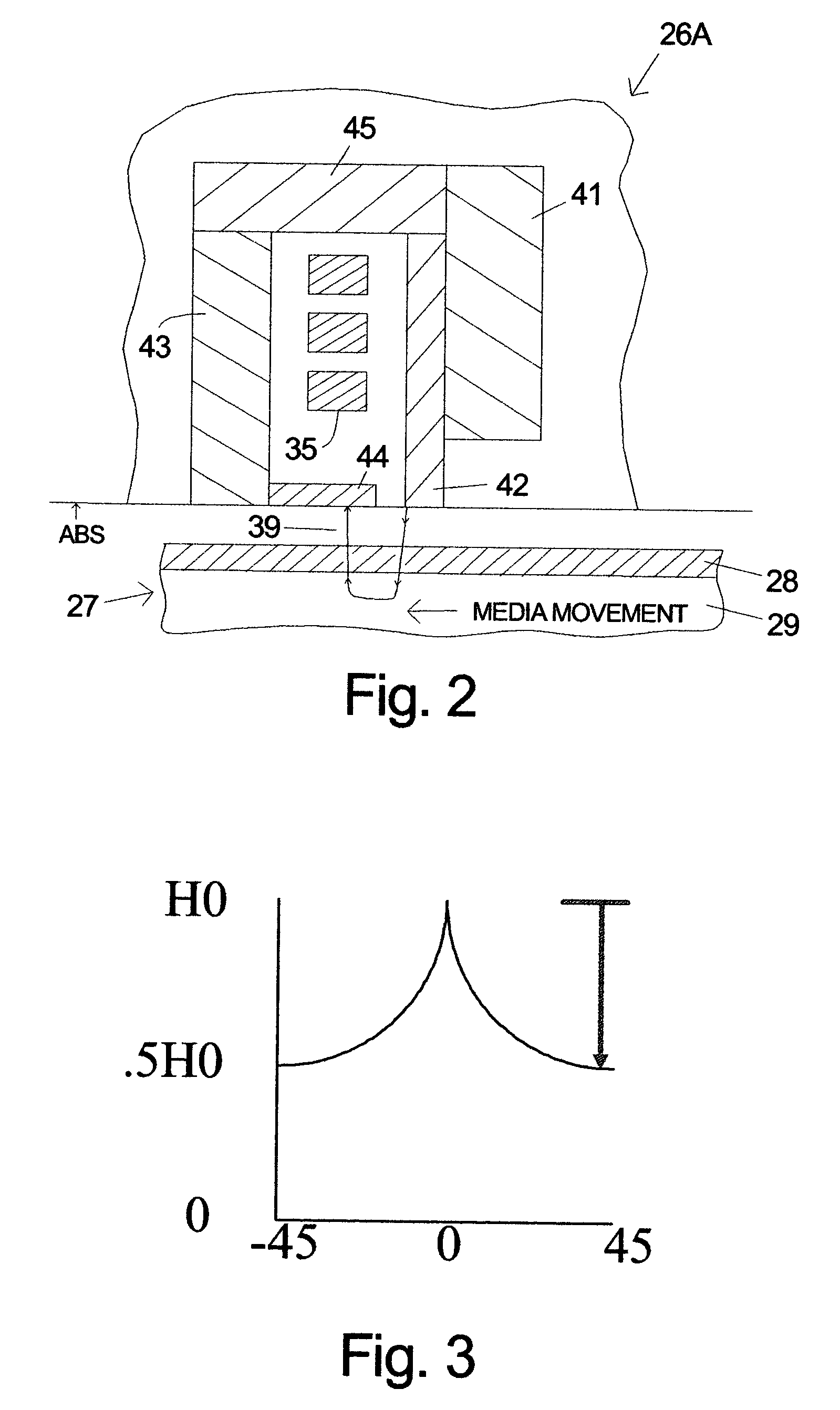

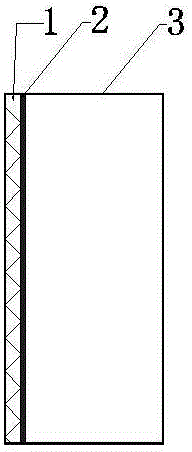

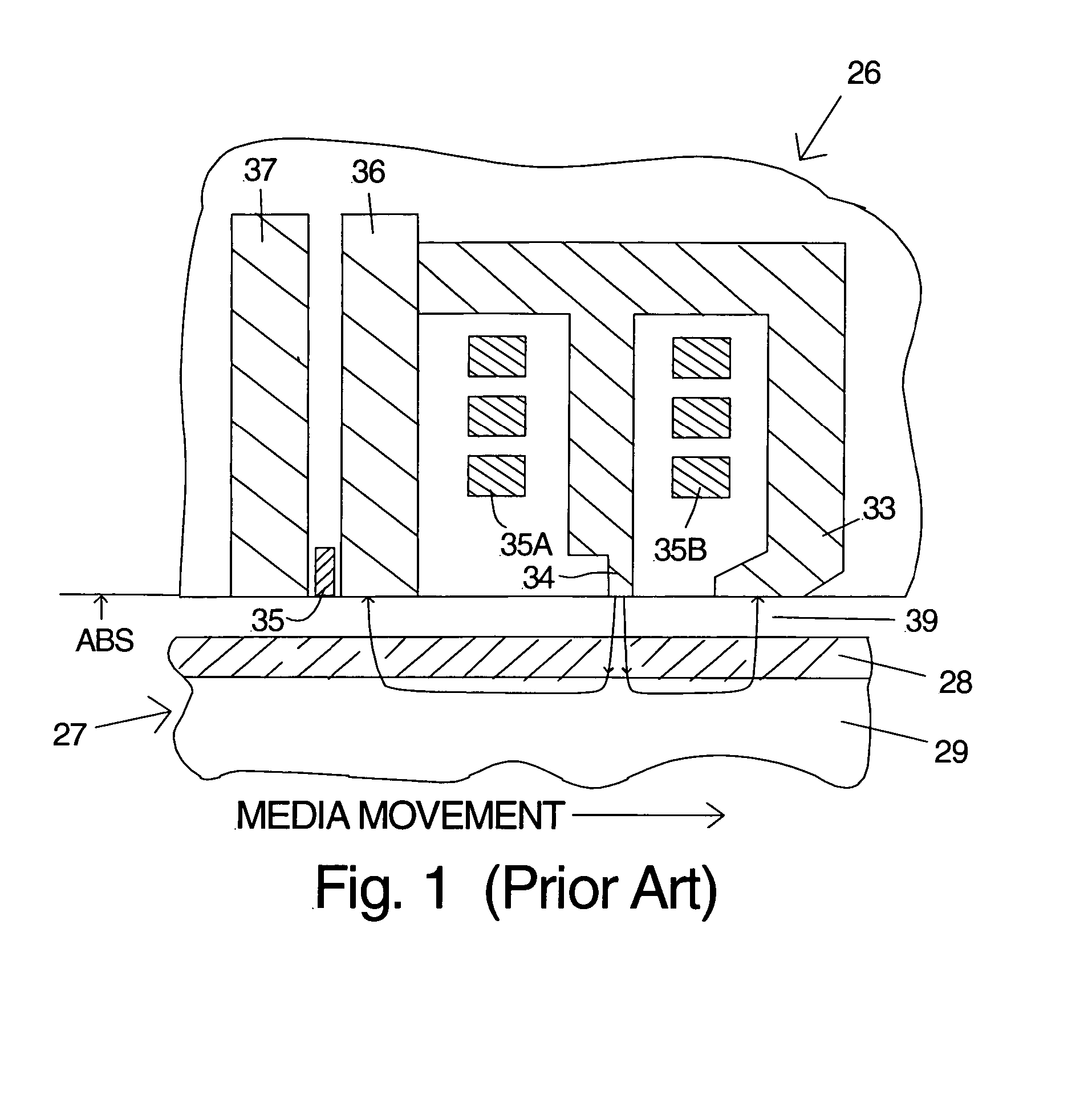

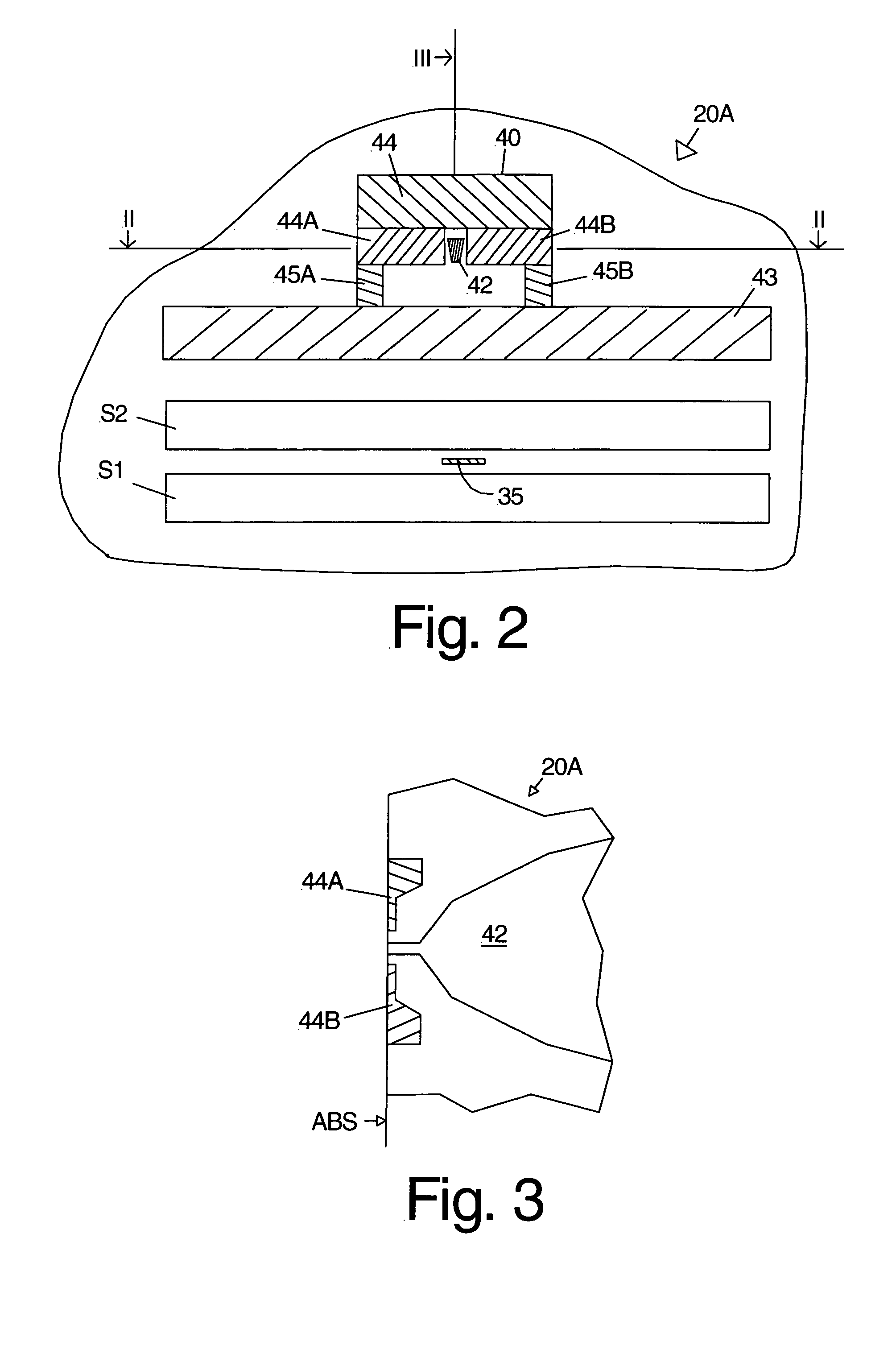

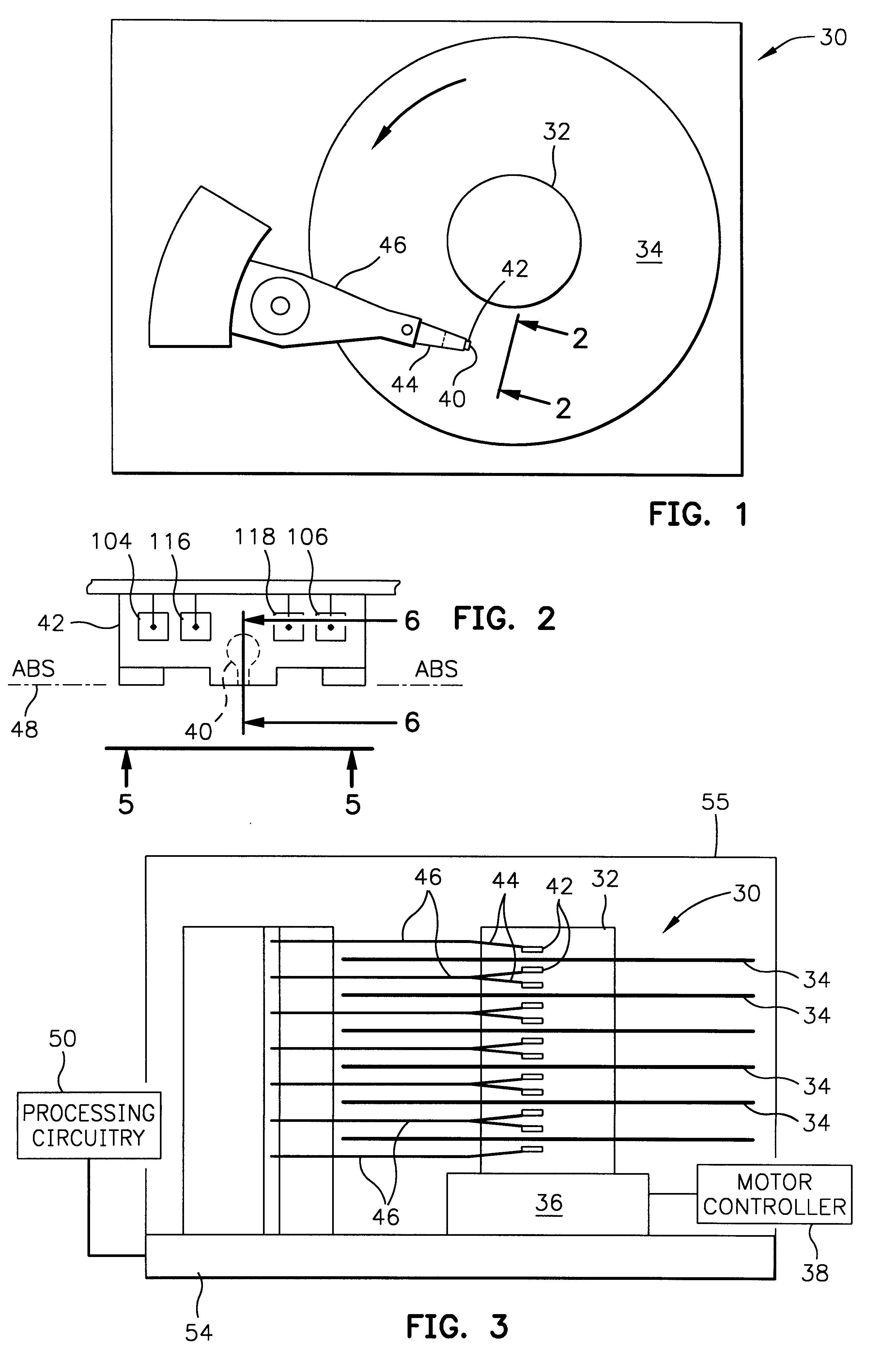

Head for perpendicular magnetic recording with a shield structure connected to the return pole piece

An embodiment of the invention is a head for perpendicular recording that has a trailing shield and side shields that are connected to the return pole piece by two studs of ferromagnetic material. The studs extend parallel to the track direction and are located a sufficient distance away from the main pole piece to reduce the flux flow from the main pole piece to the studs. Optionally the studs can be recessed behind the air-bearing surface. The preferred embodiment of the invention is a magnetic transducer with separated read and write heads for perpendicular recording.

Owner:WESTERN DIGITAL TECH INC

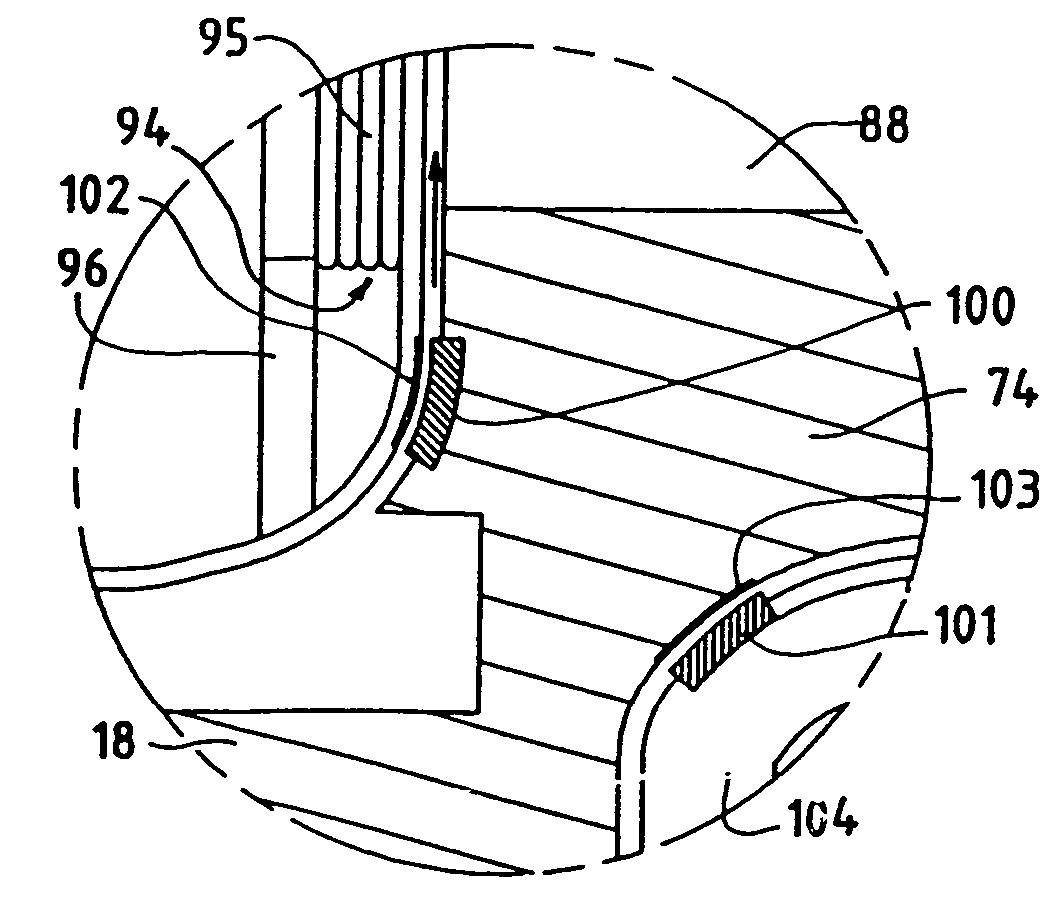

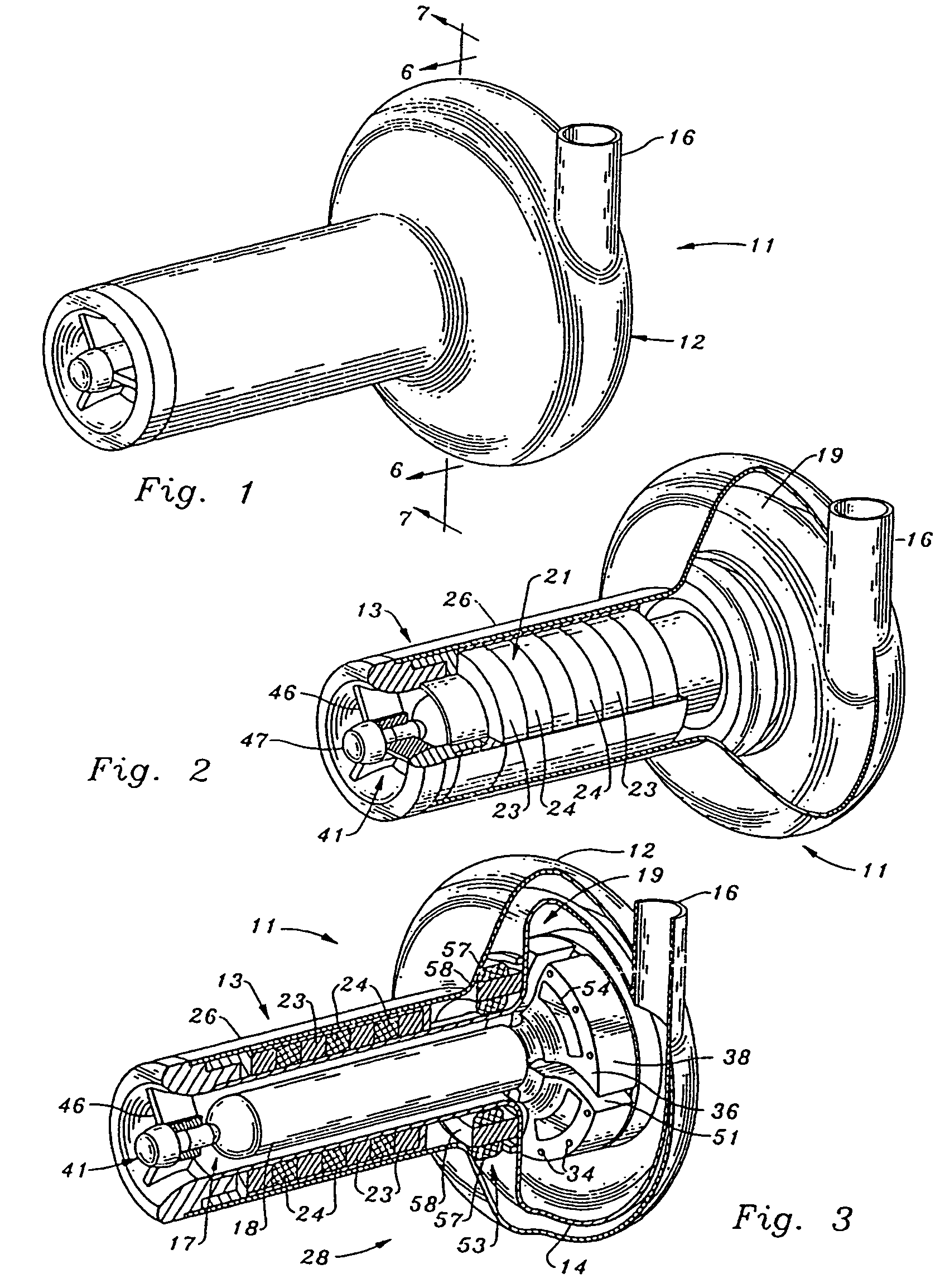

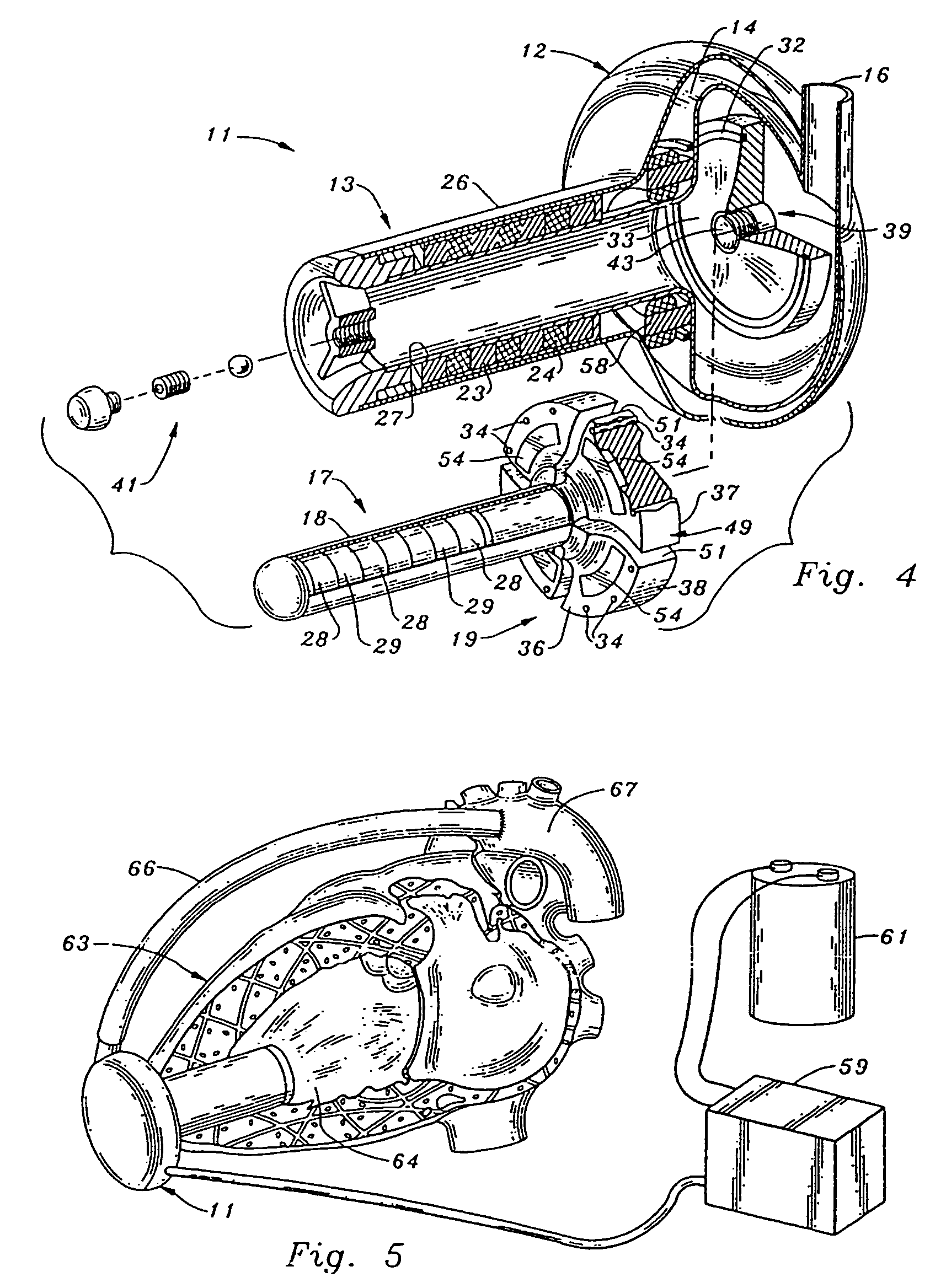

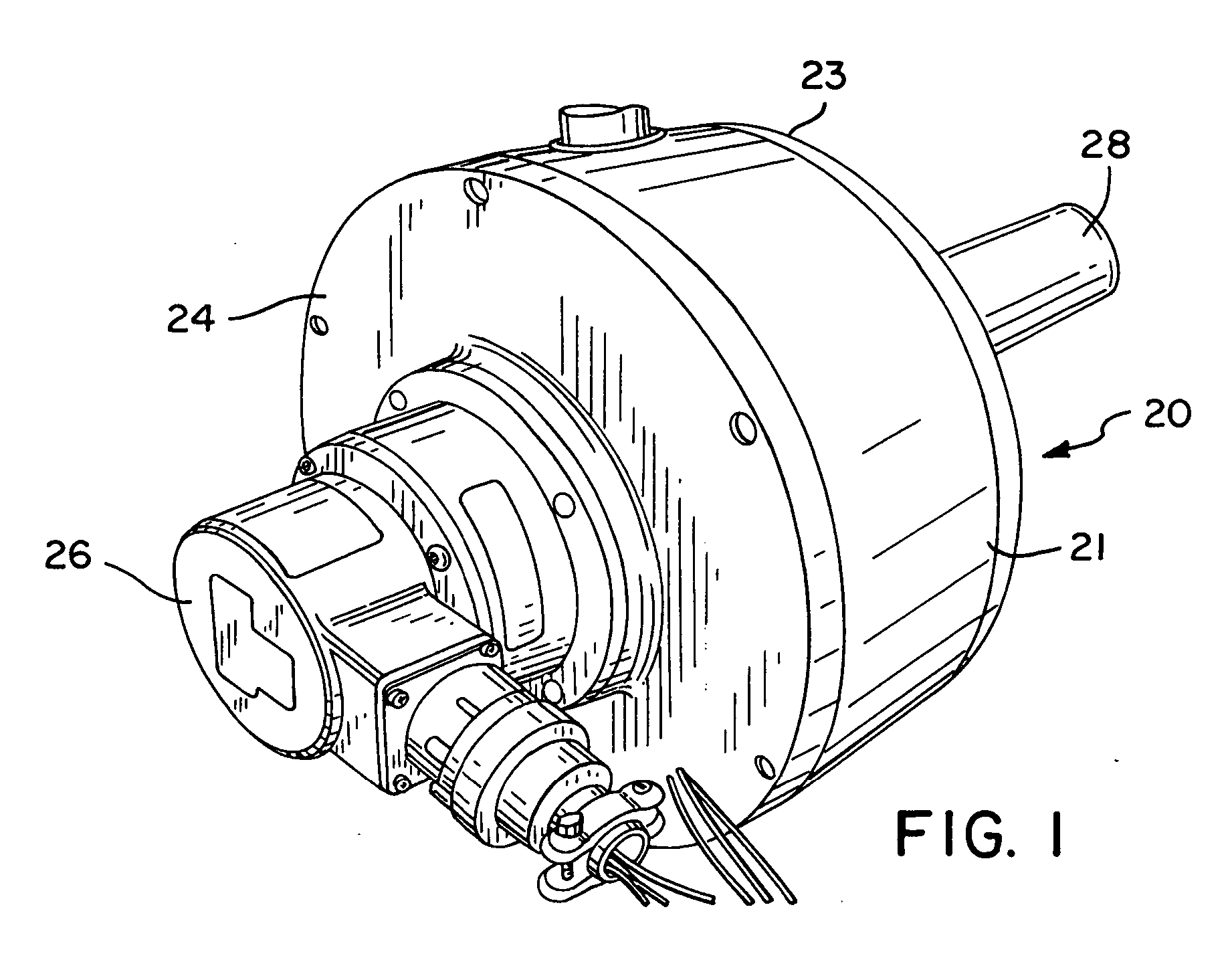

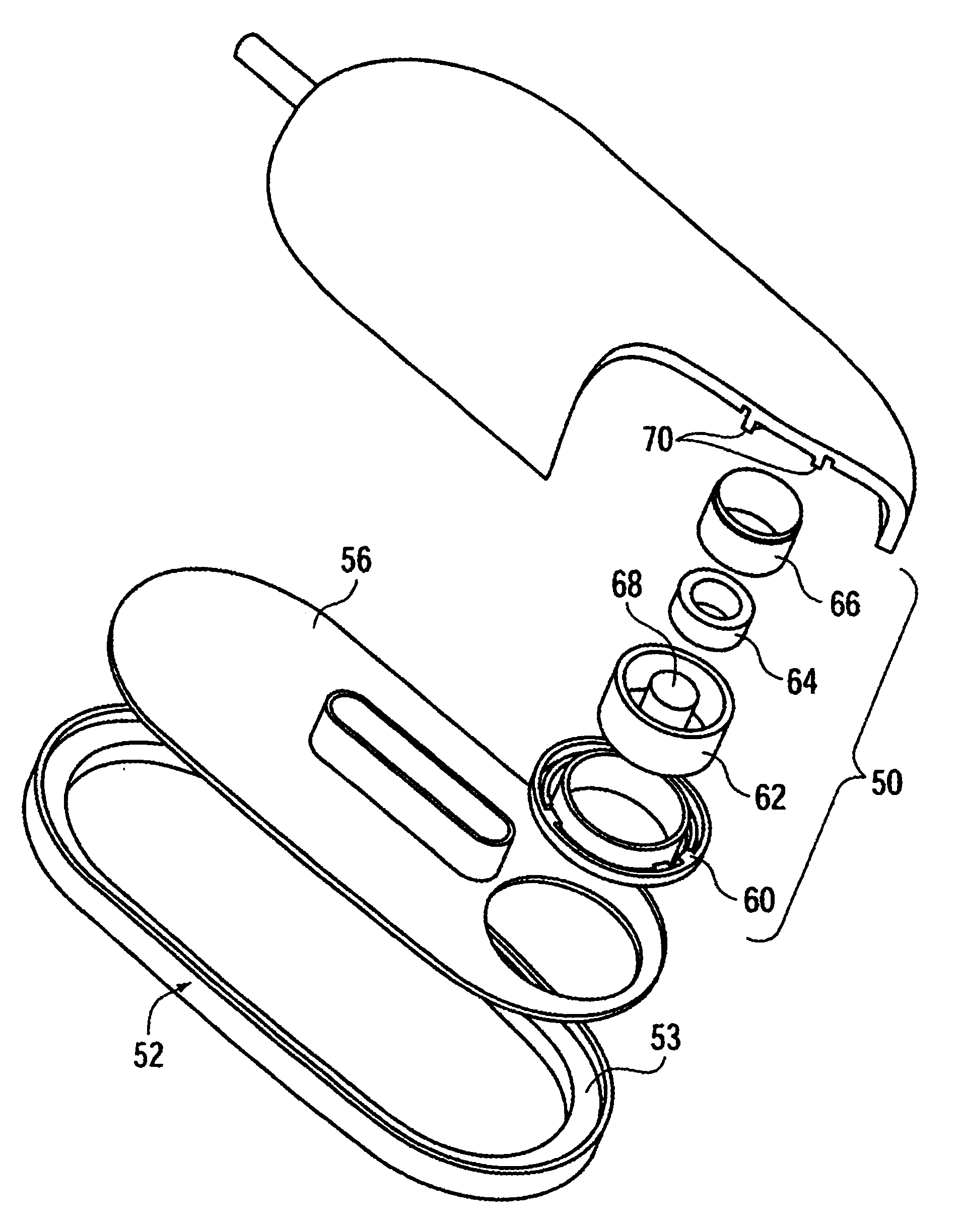

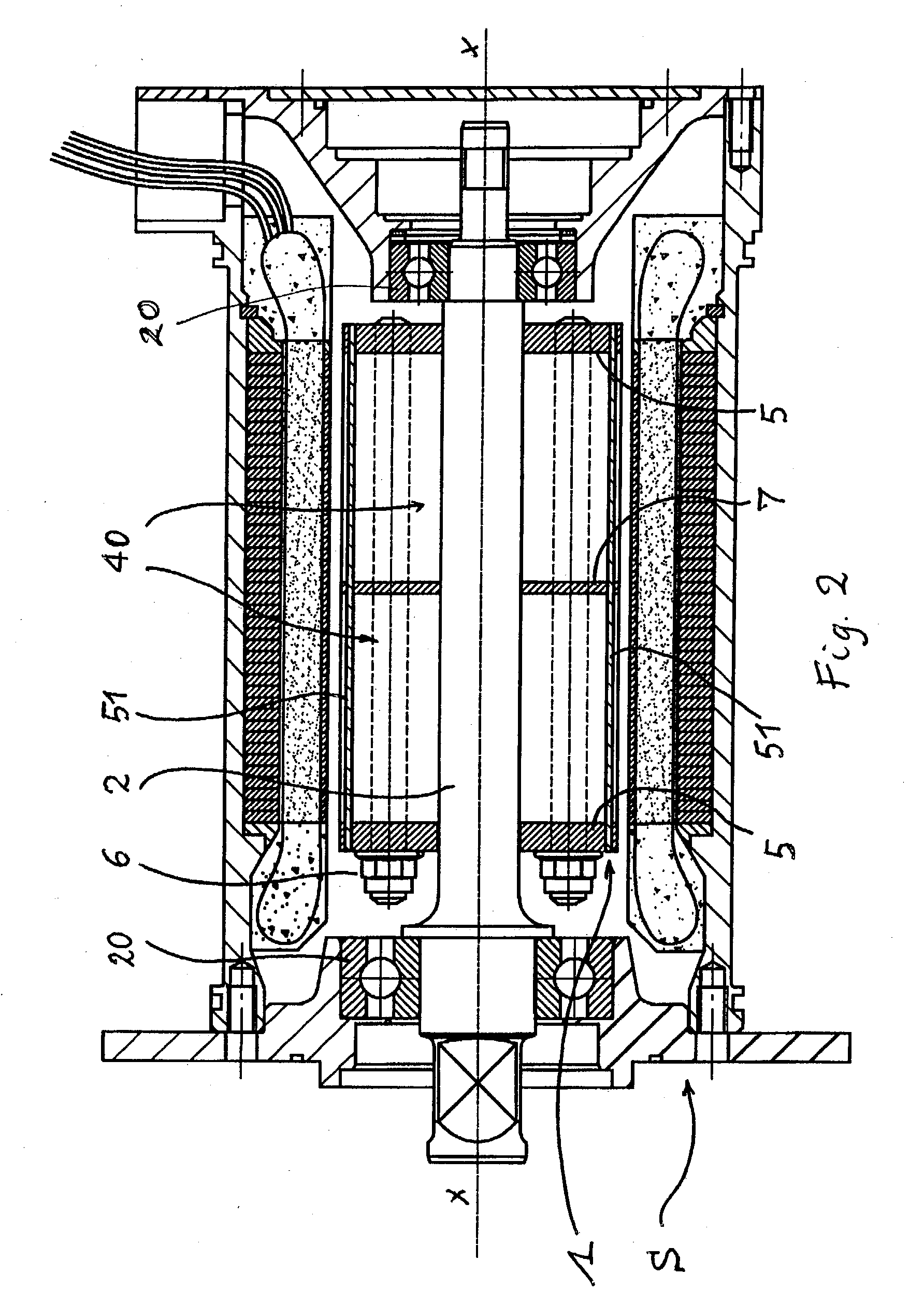

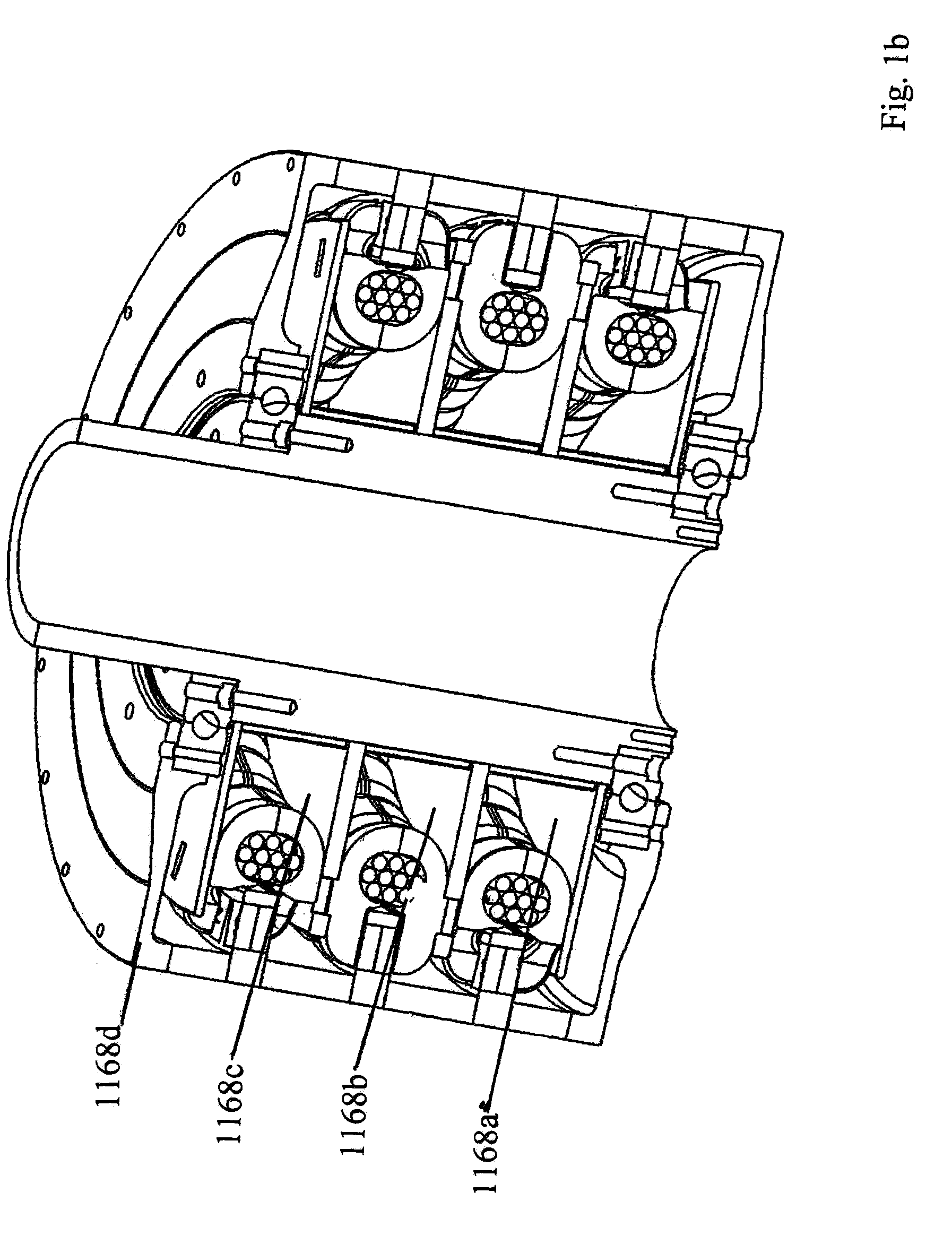

Sealless rotary blood pump

InactiveUS7575423B2Minimize the possibilityShortening its residence timePump componentsMedical devicesImpellerThrust bearing

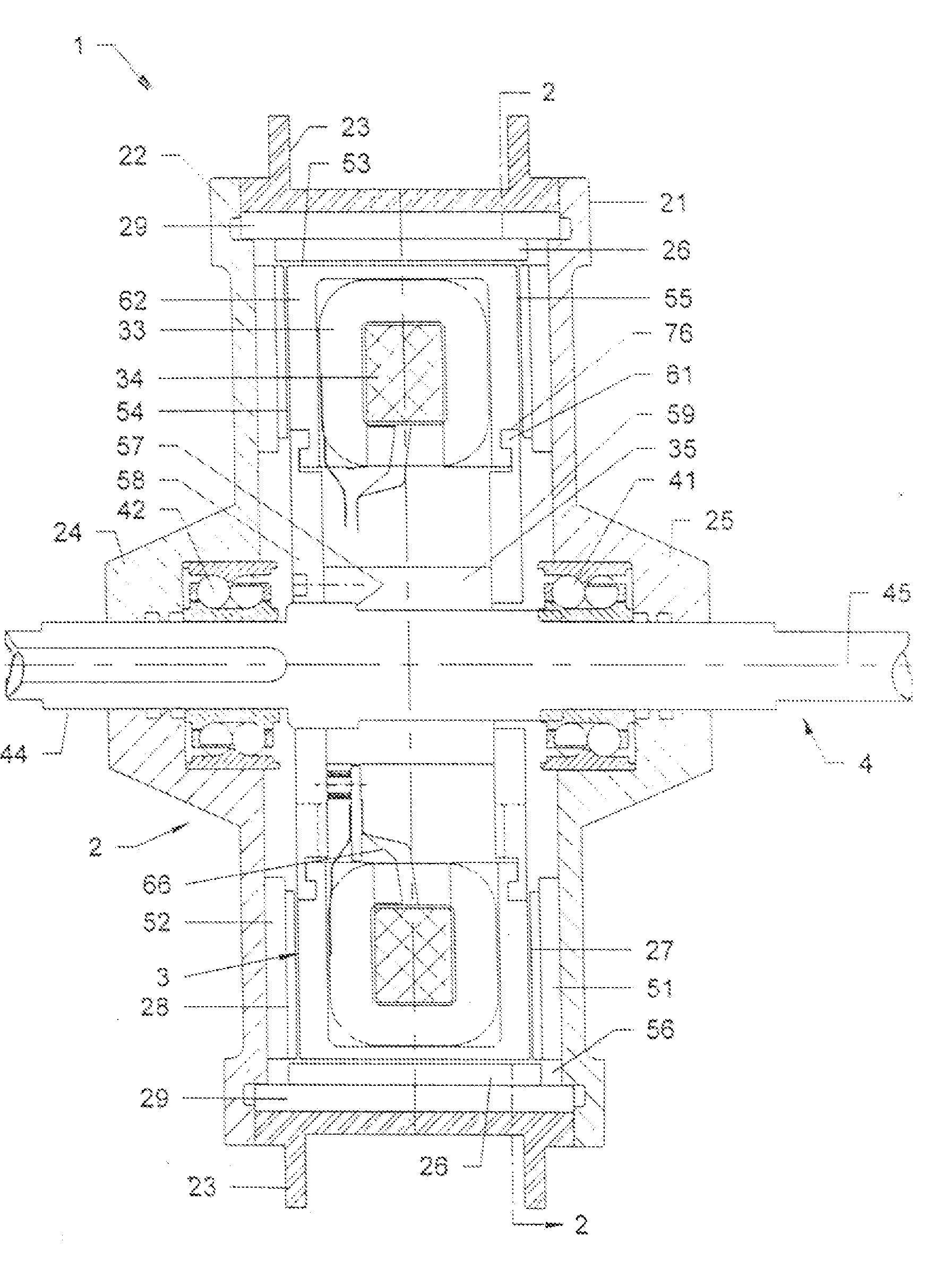

A rotary blood pump is provided which includes a pump housing and a rotor mounted for rotation with the housing. The rotor has an impeller. A rotor motor is provided including a plurality of permanent magnets carried by the impeller. A first motor stator is positioned on one side of the impeller and a second motor stator is positioned on an opposite side of the impeller. The motor stators each include a plurality of electrically conductive coils and pole pieces located within the housing. A plurality of wedge-shaped hydrodynamic thrust bearings are located outside of the axis of the rotor. During rotation of the impeller, the hydrodynamic bearings are separated from the housing by a fluid film and are not in direct mechanical contact with the housing.

Owner:THORATEC CORPORTION

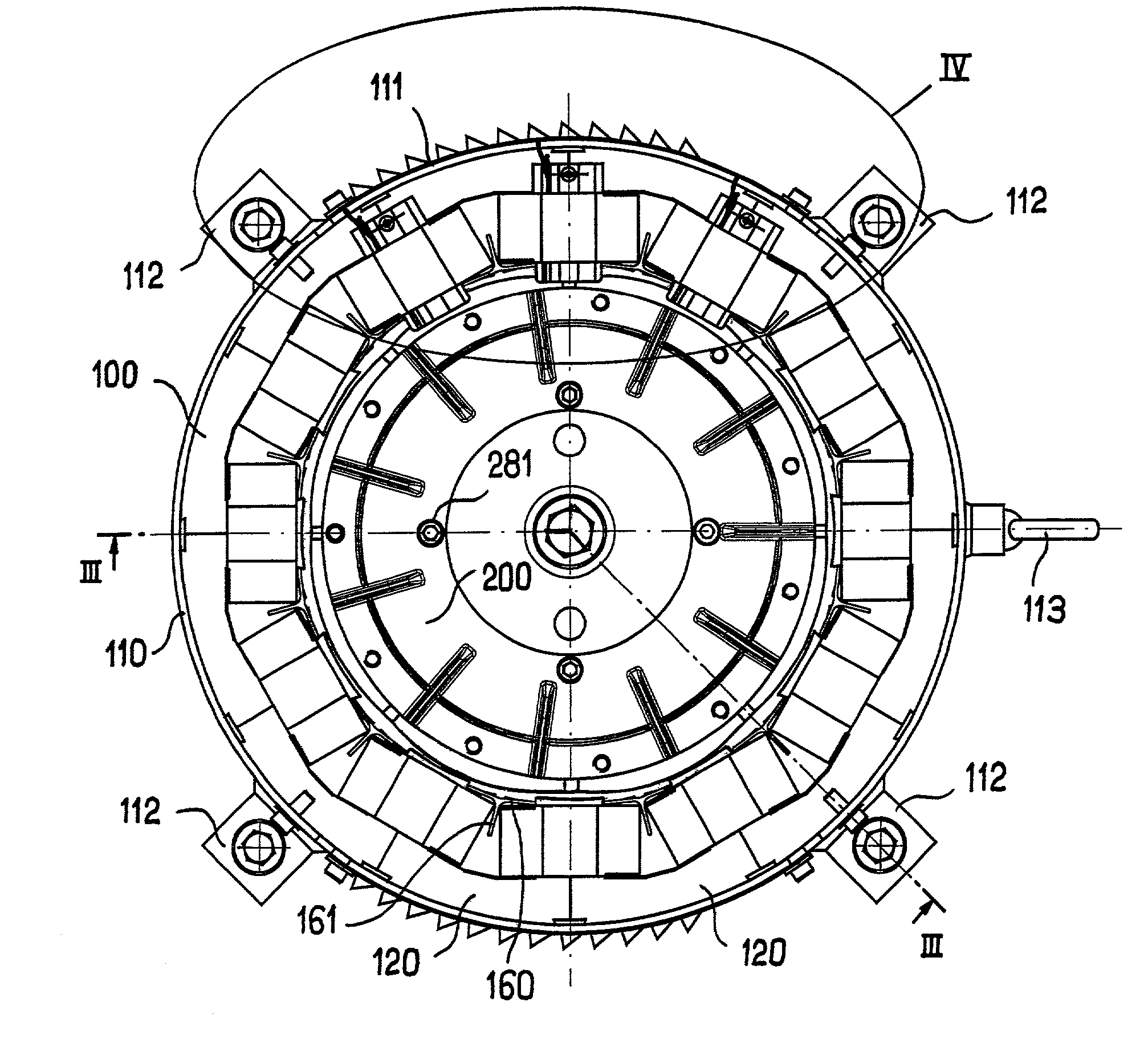

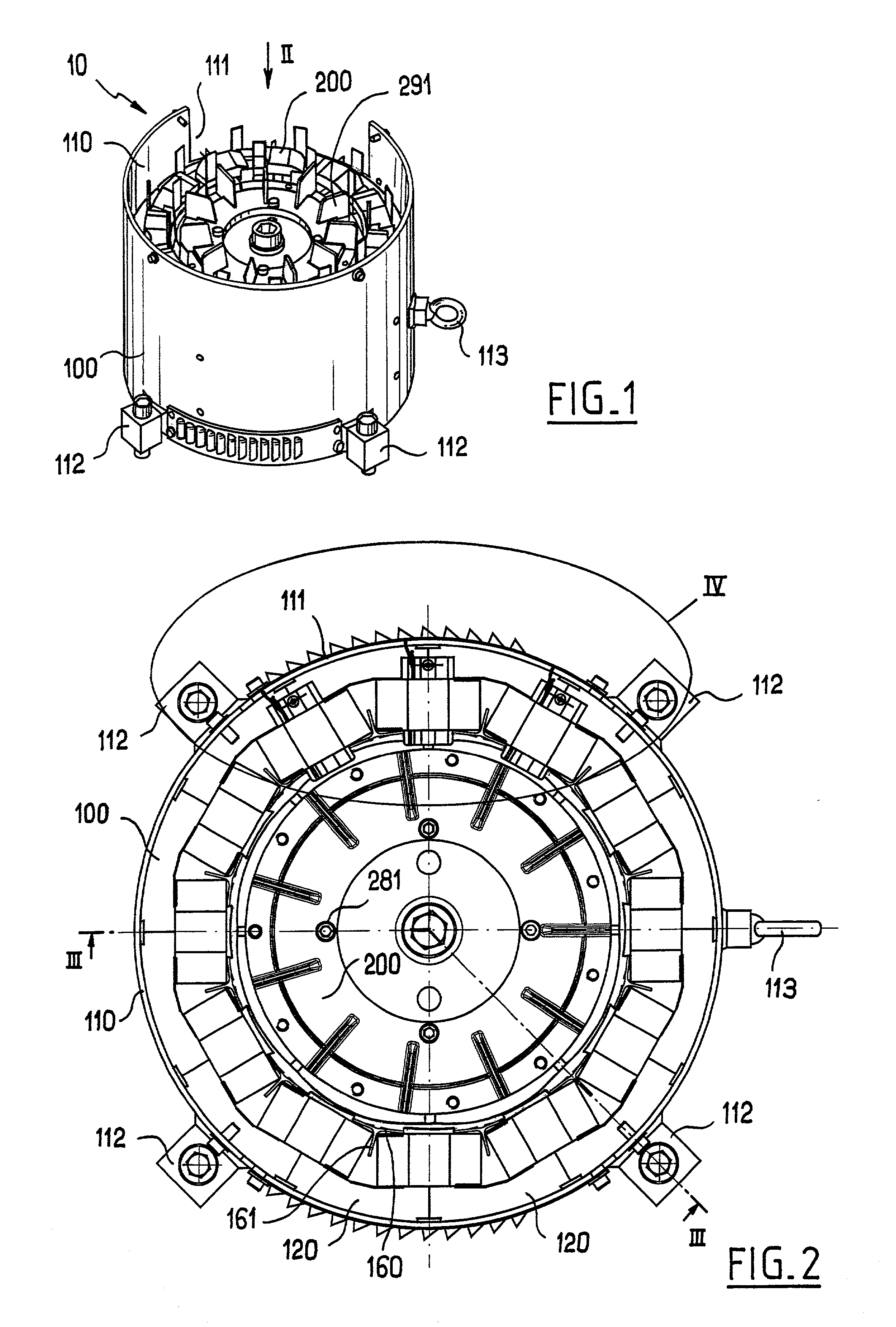

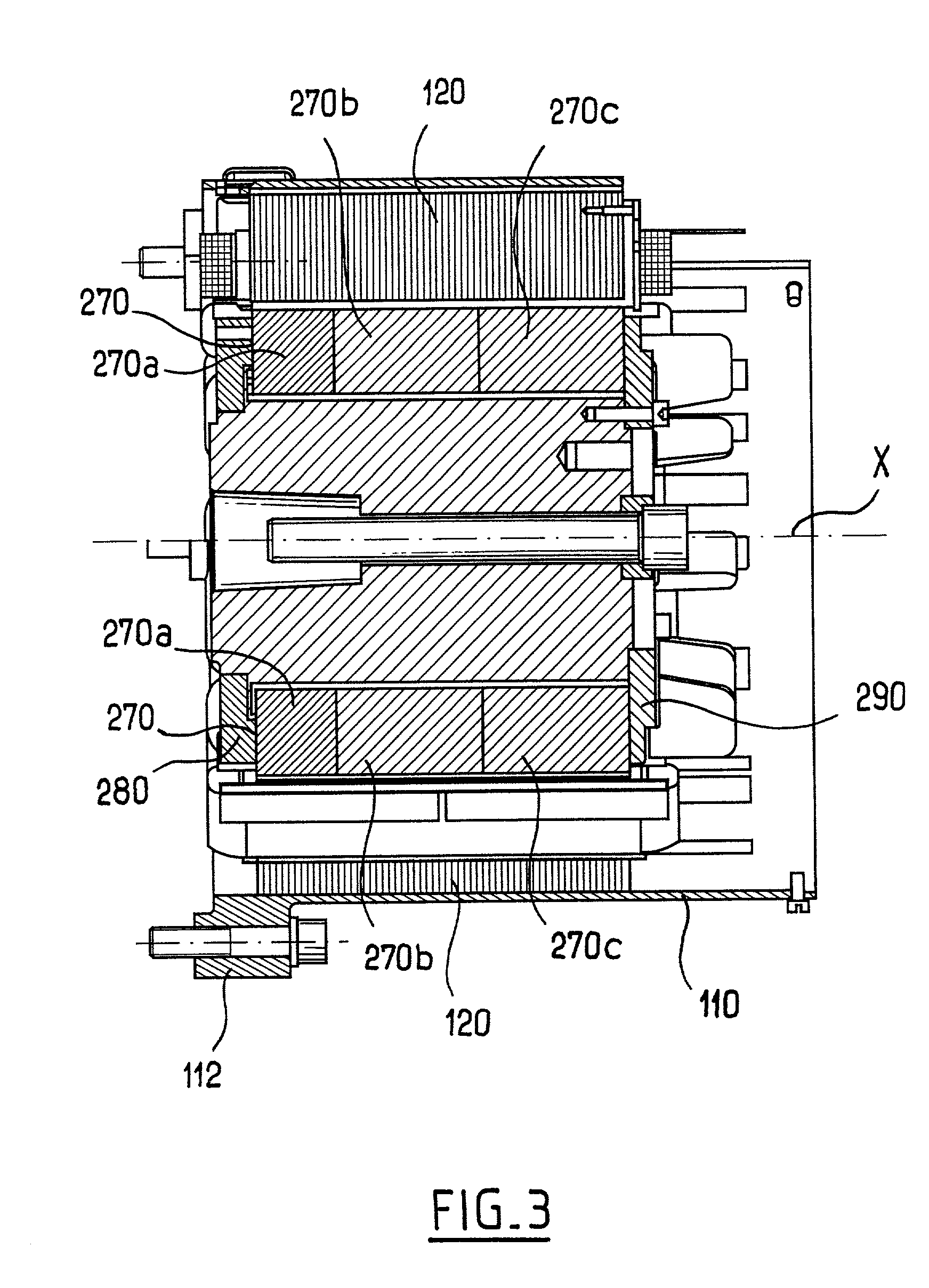

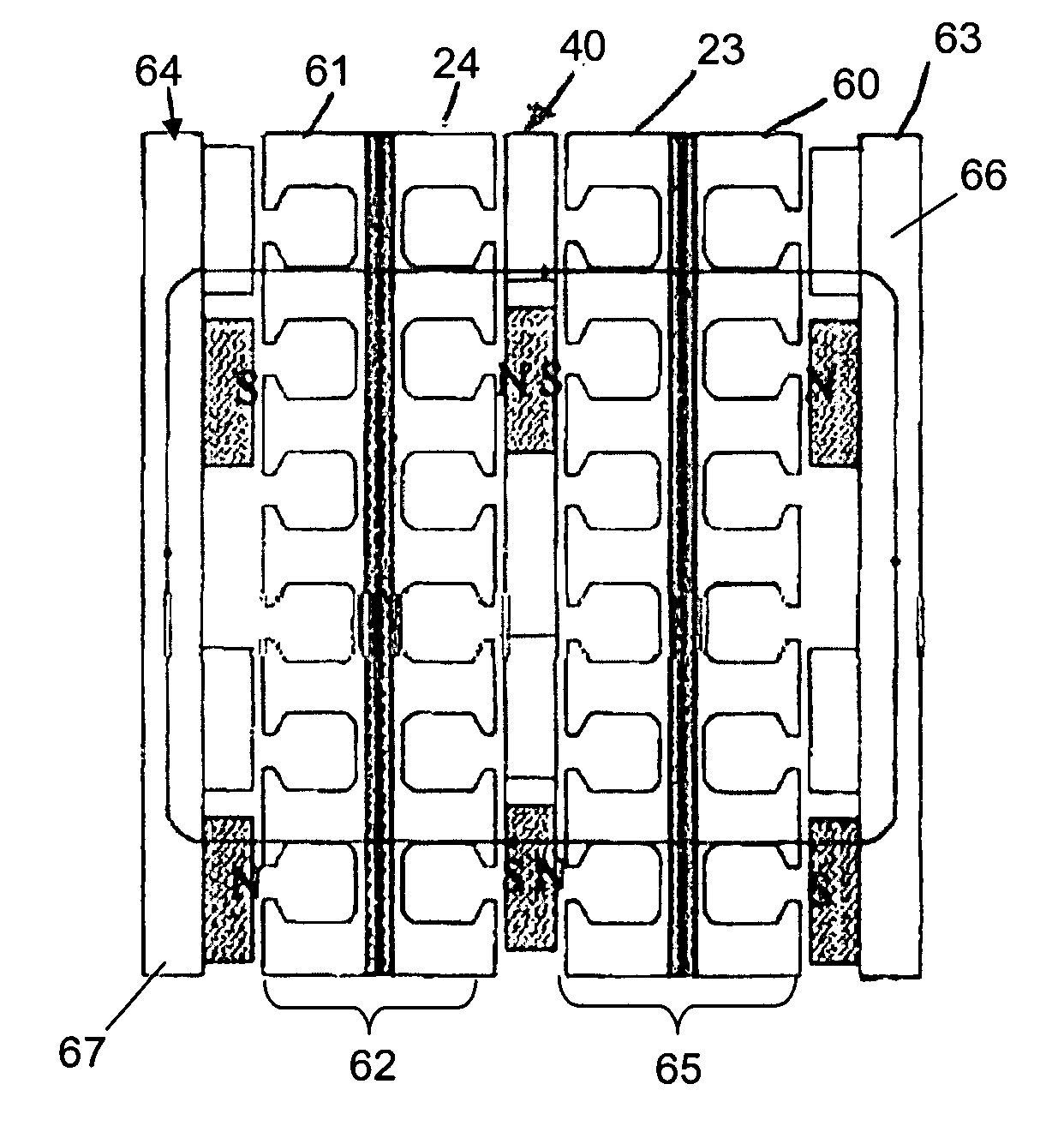

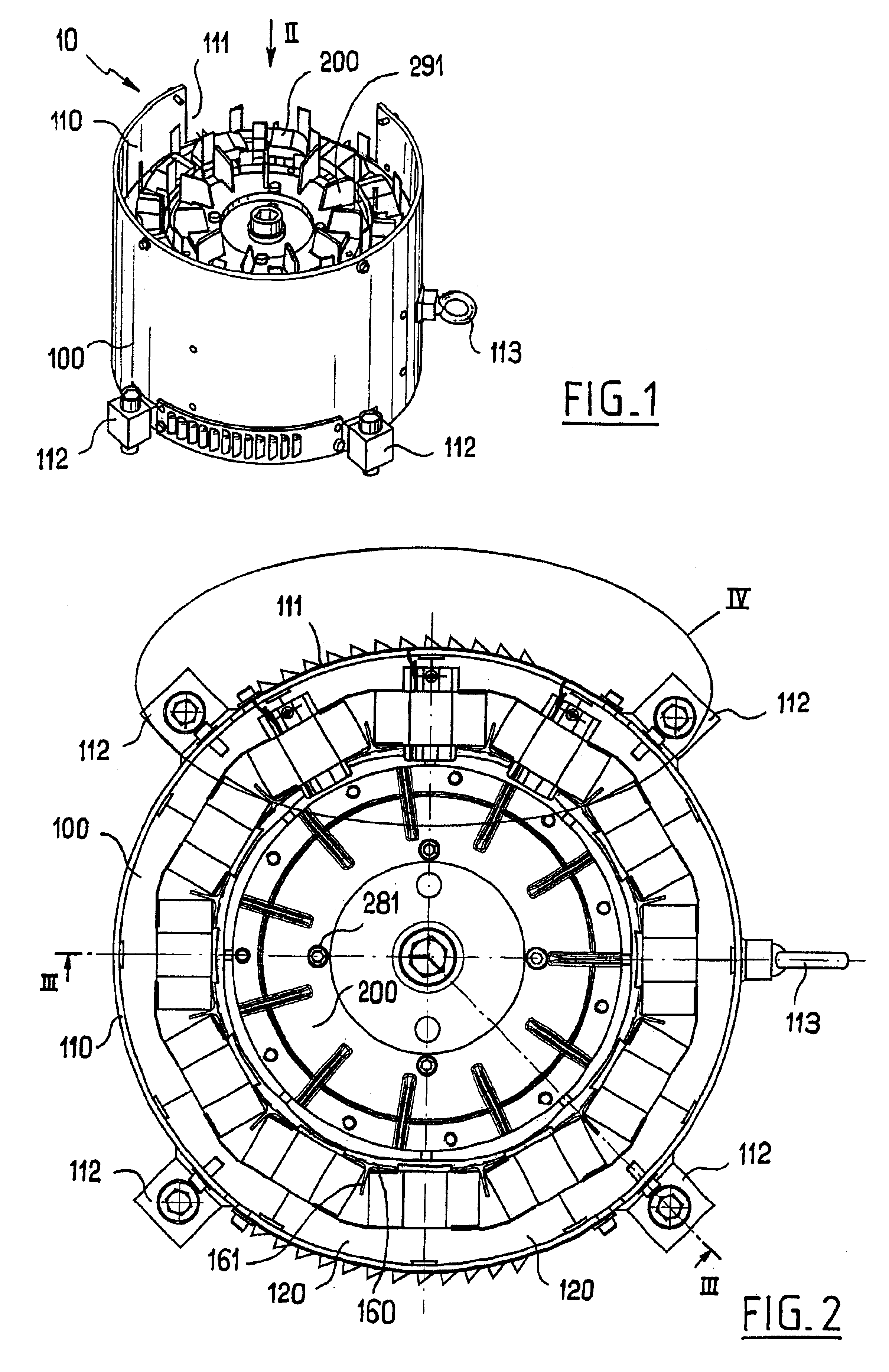

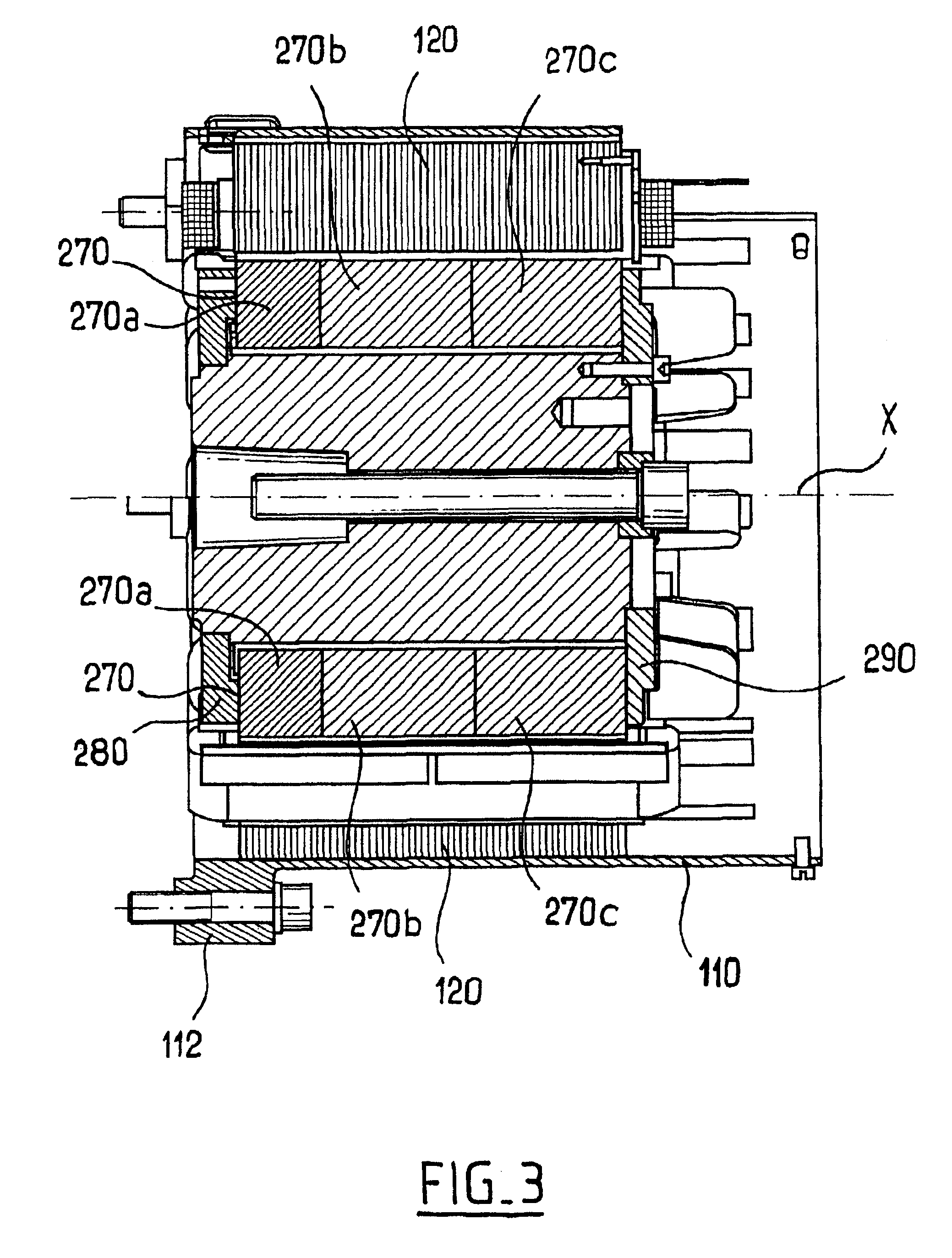

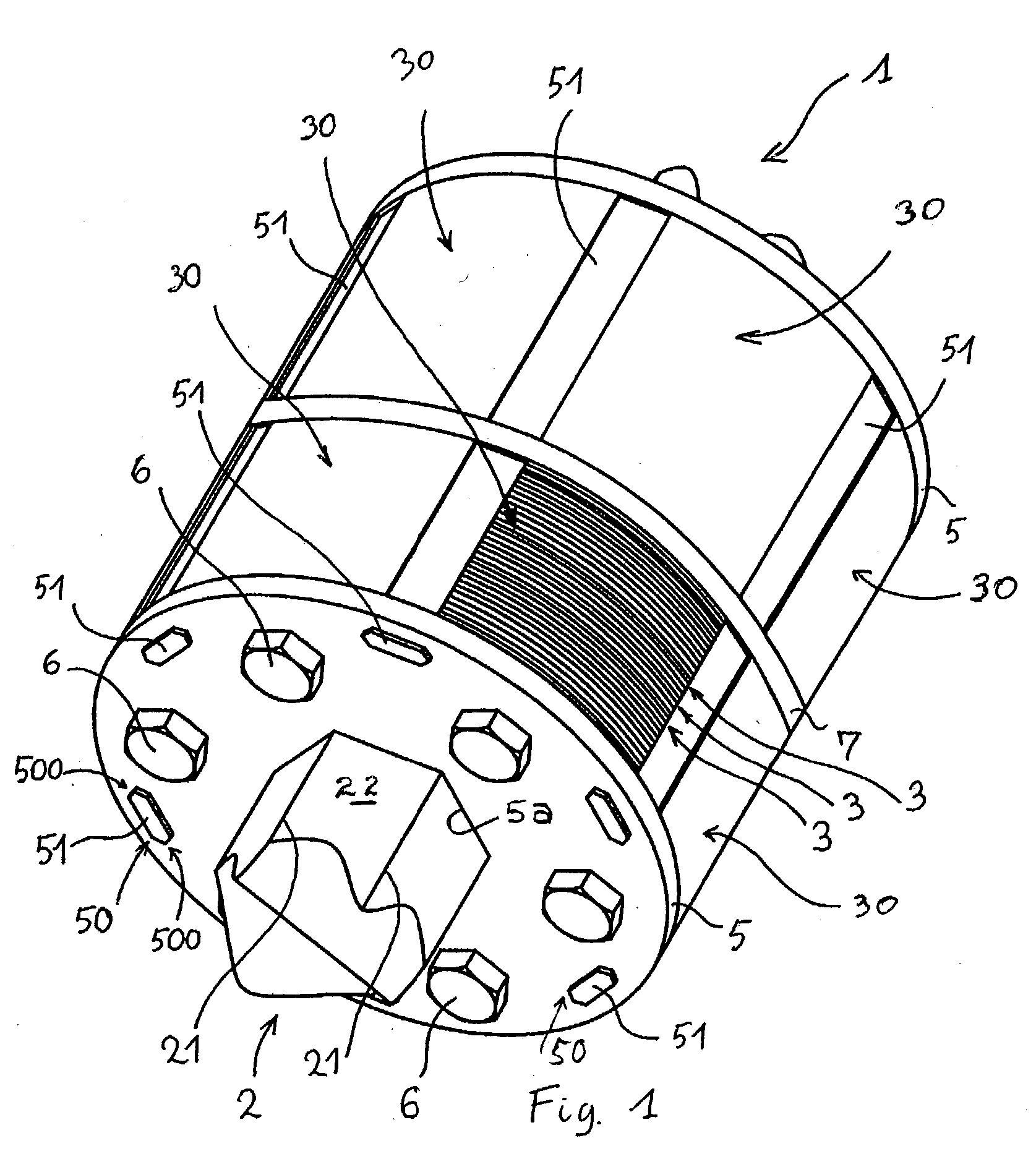

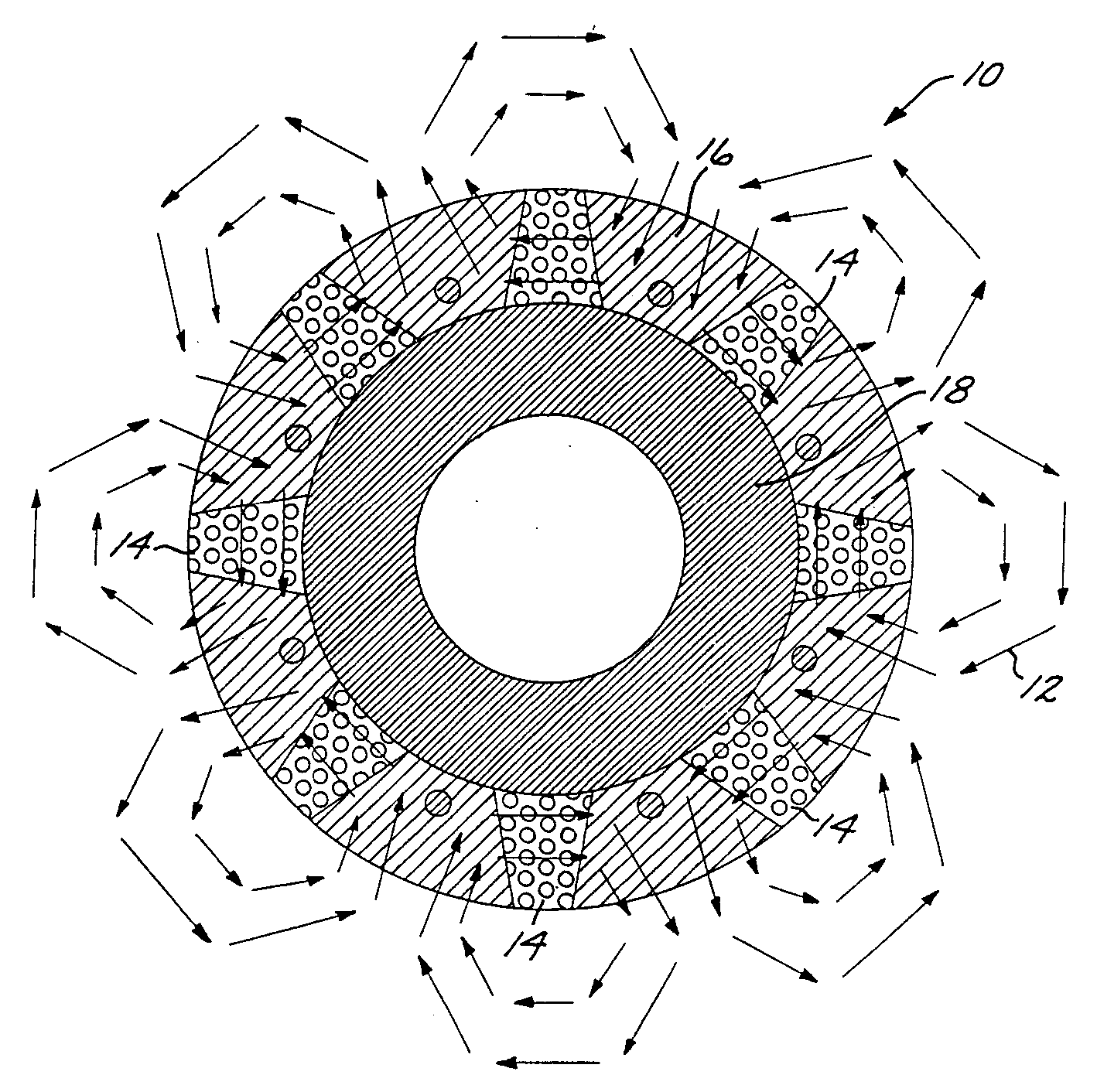

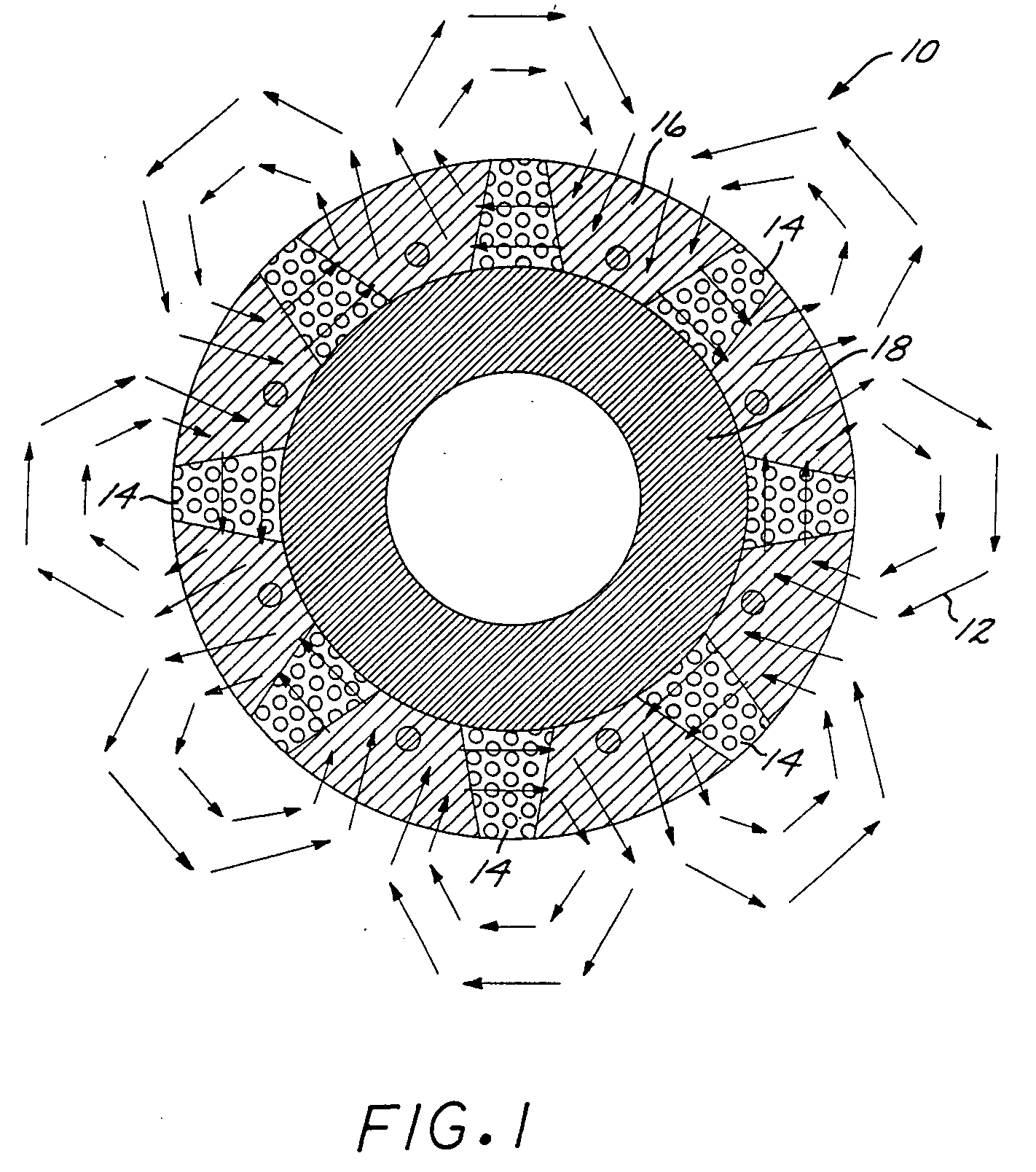

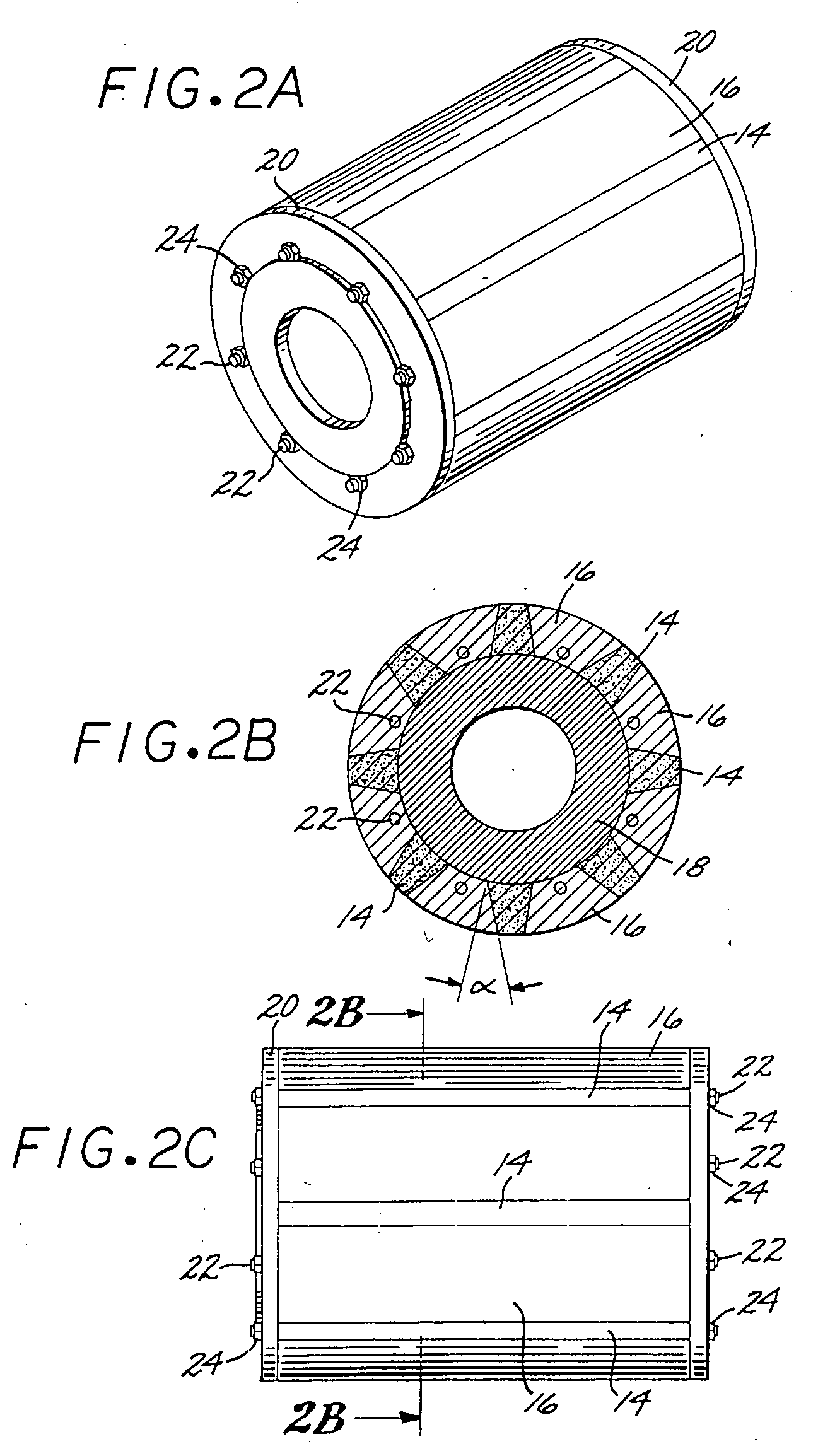

Rotary electric machine having a flux-concentrating rotor and a stator with windings on teeth

InactiveUS20020047425A1Increase powerReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePole piece

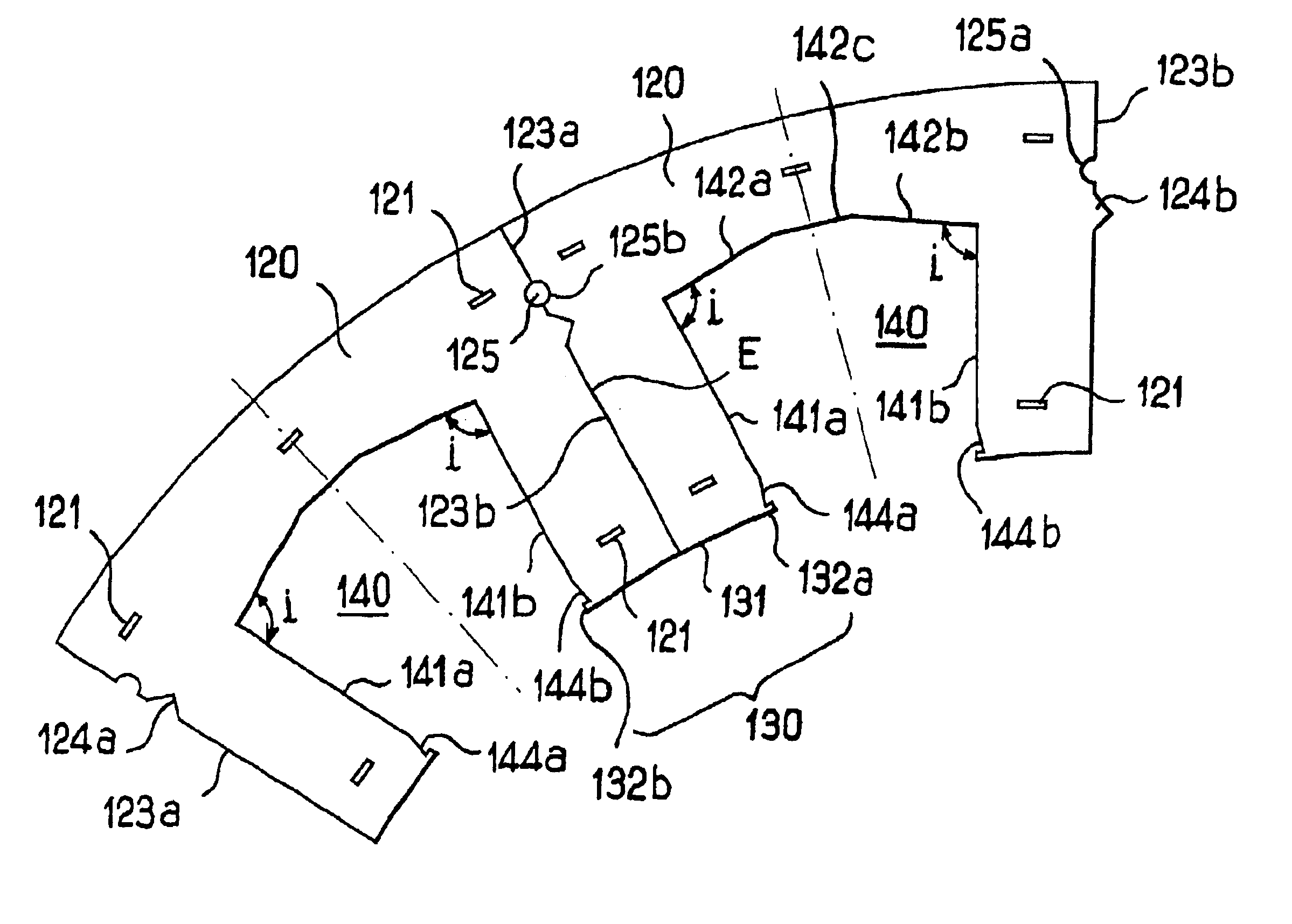

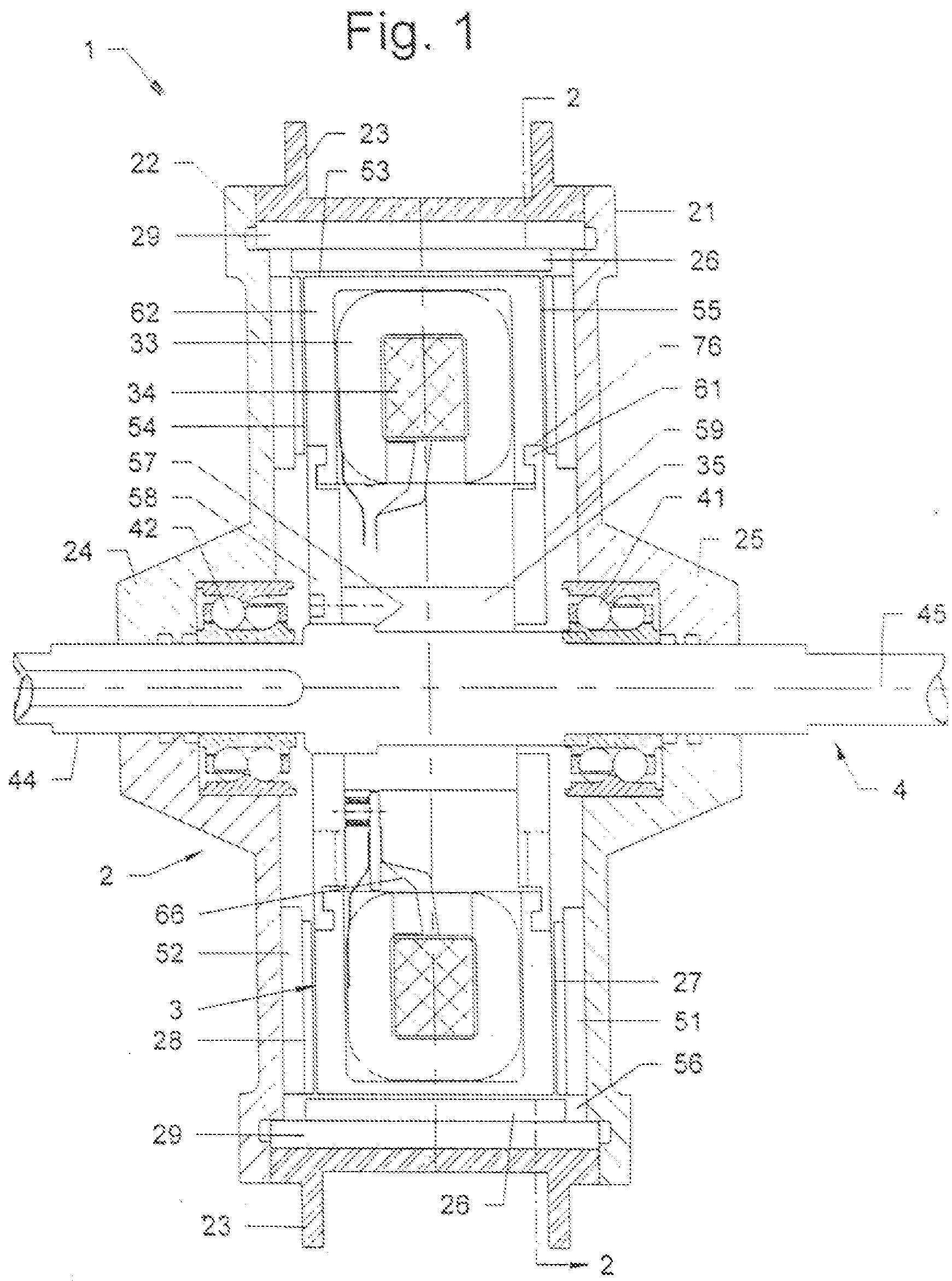

The invention relates to a rotary electric machine comprising a flux-concentrating rotor with permanent magnets disposed between pole pieces, and a stator with windings on teeth.

Owner:MOTEURS LEROY SOMER

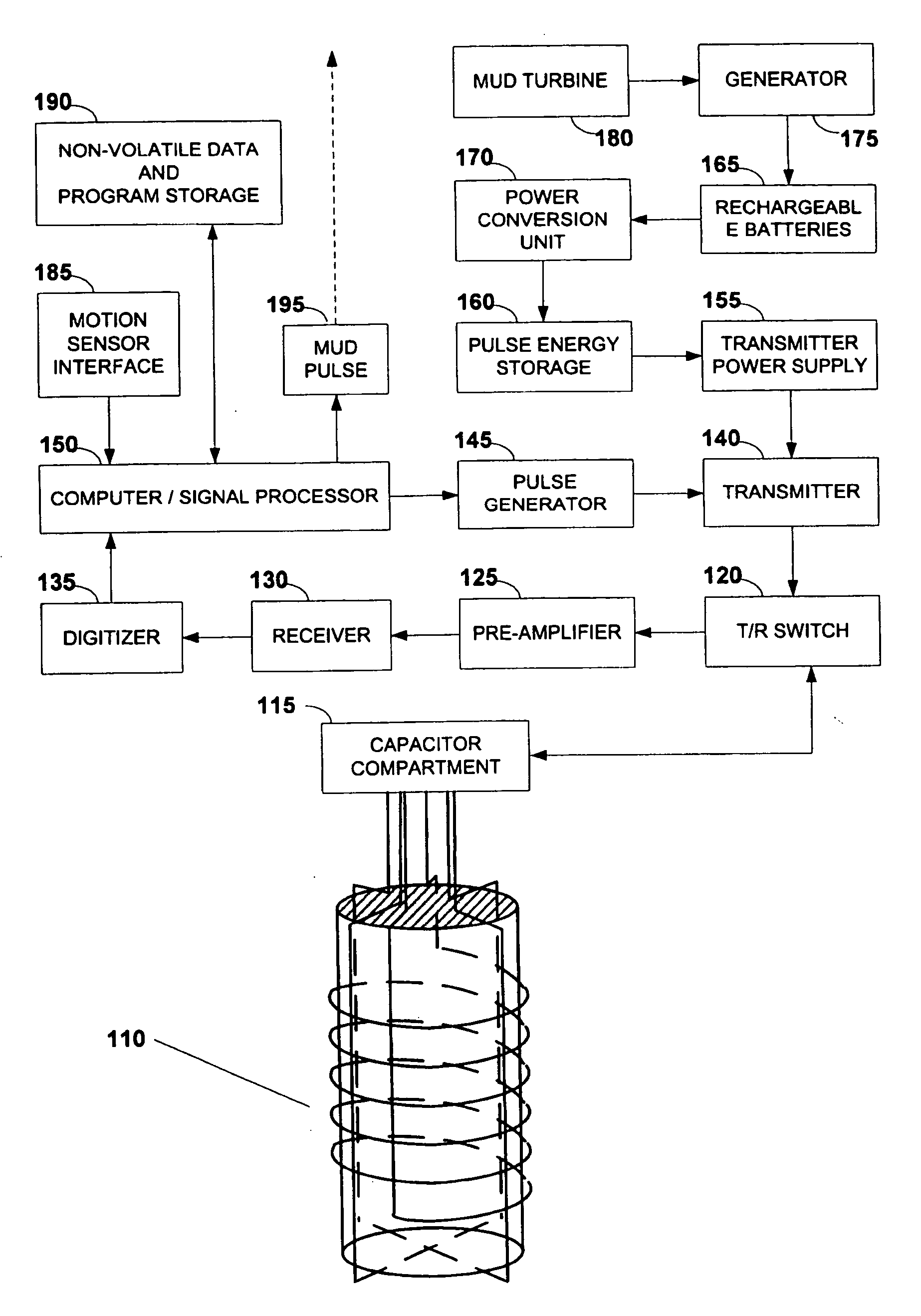

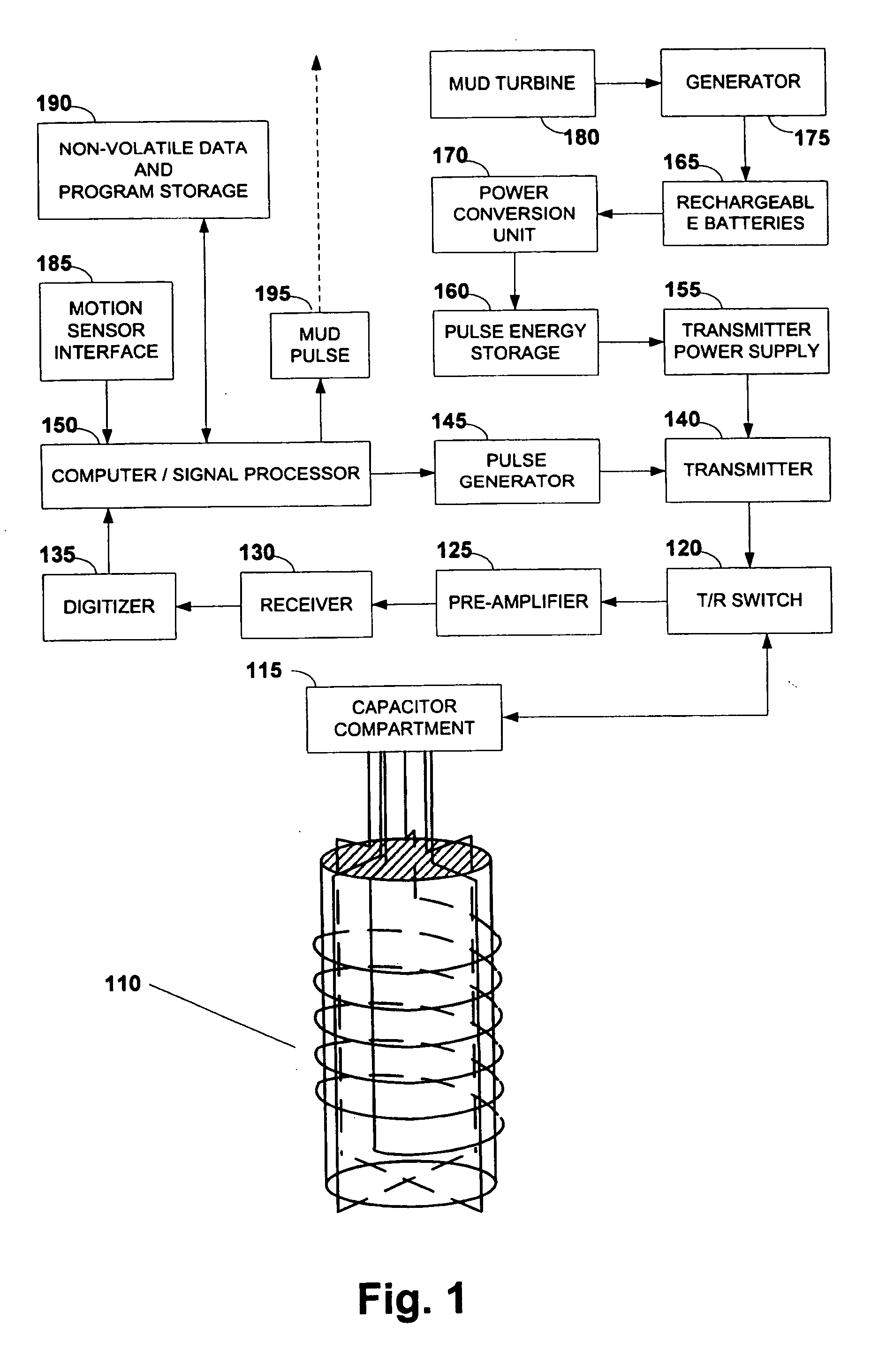

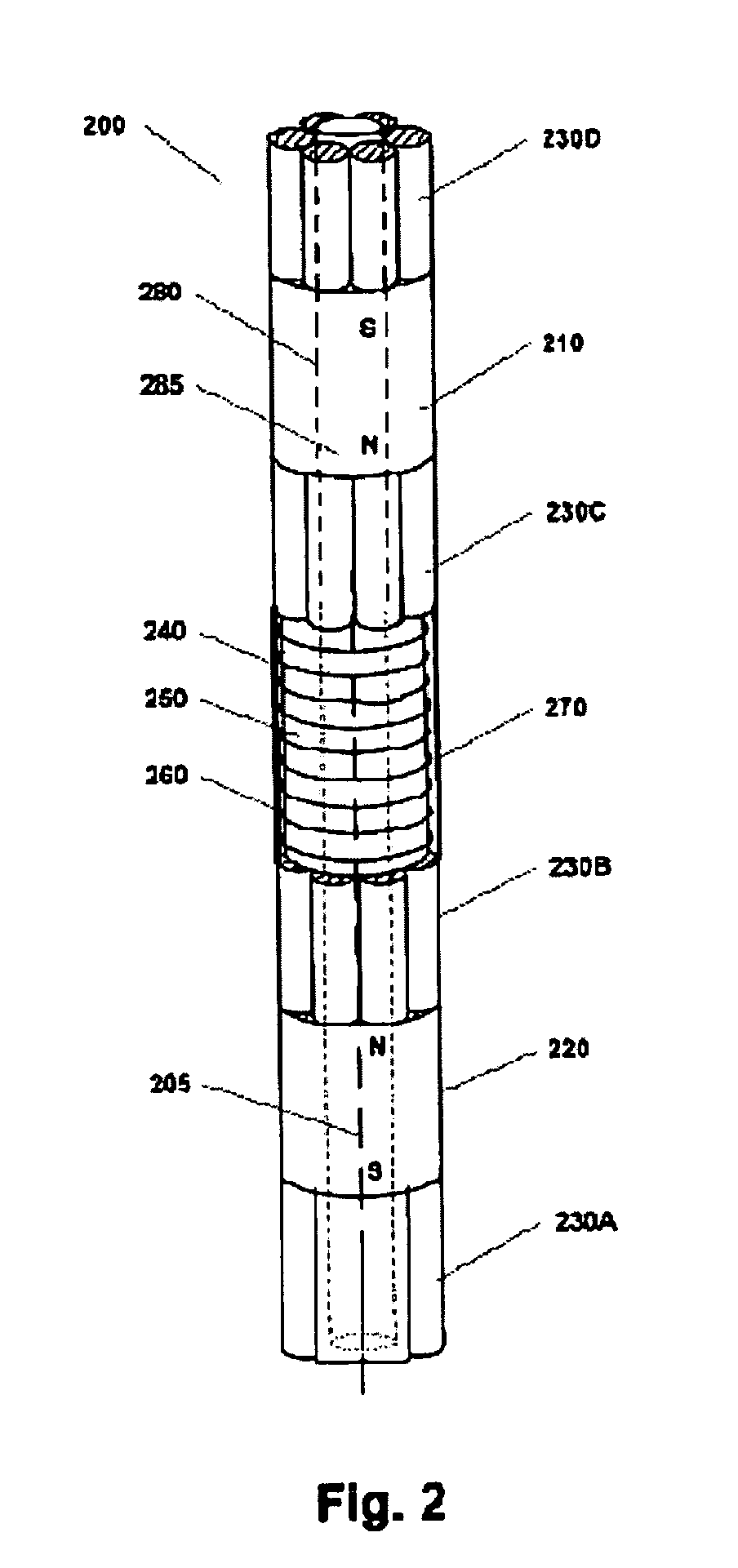

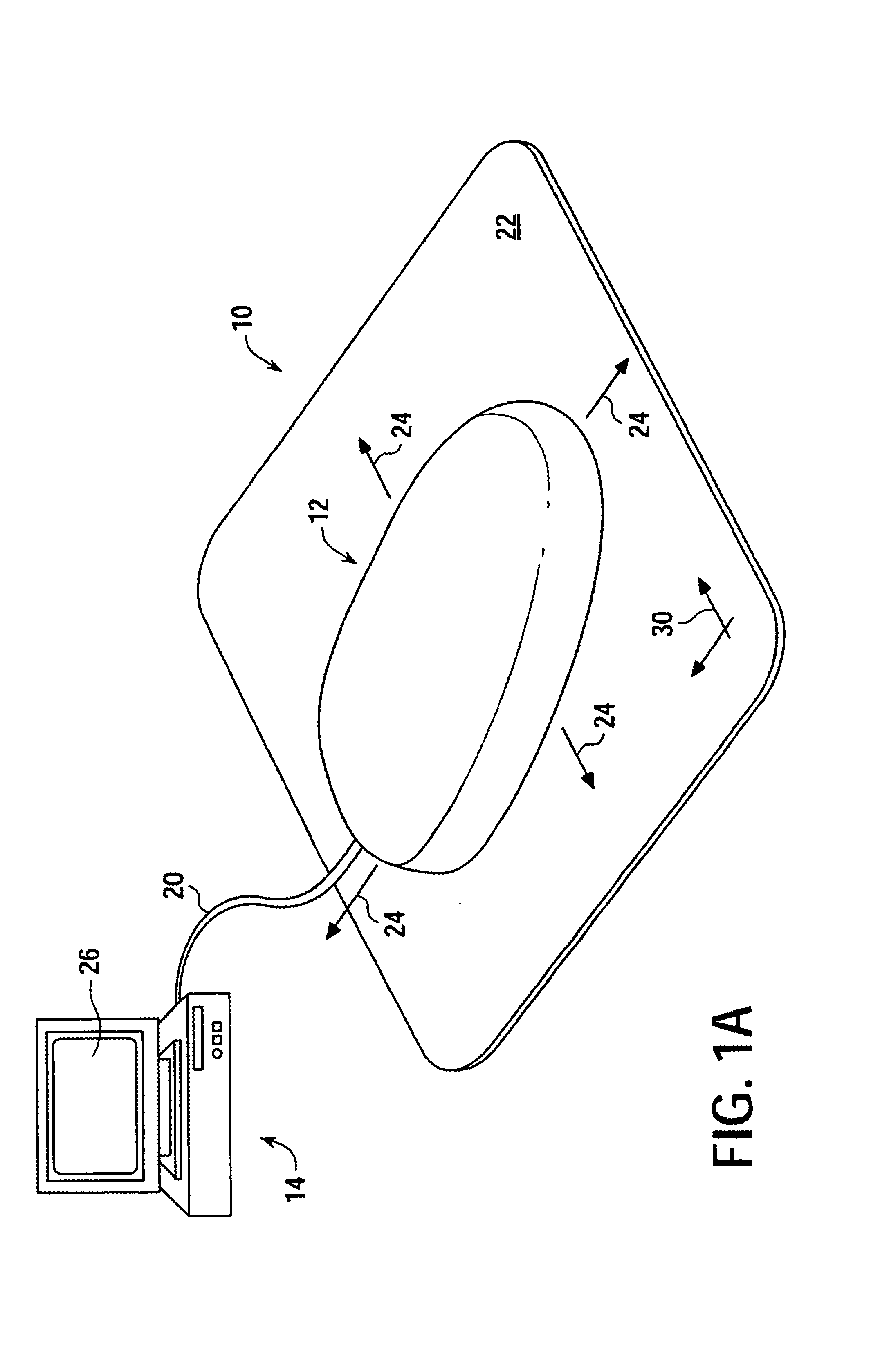

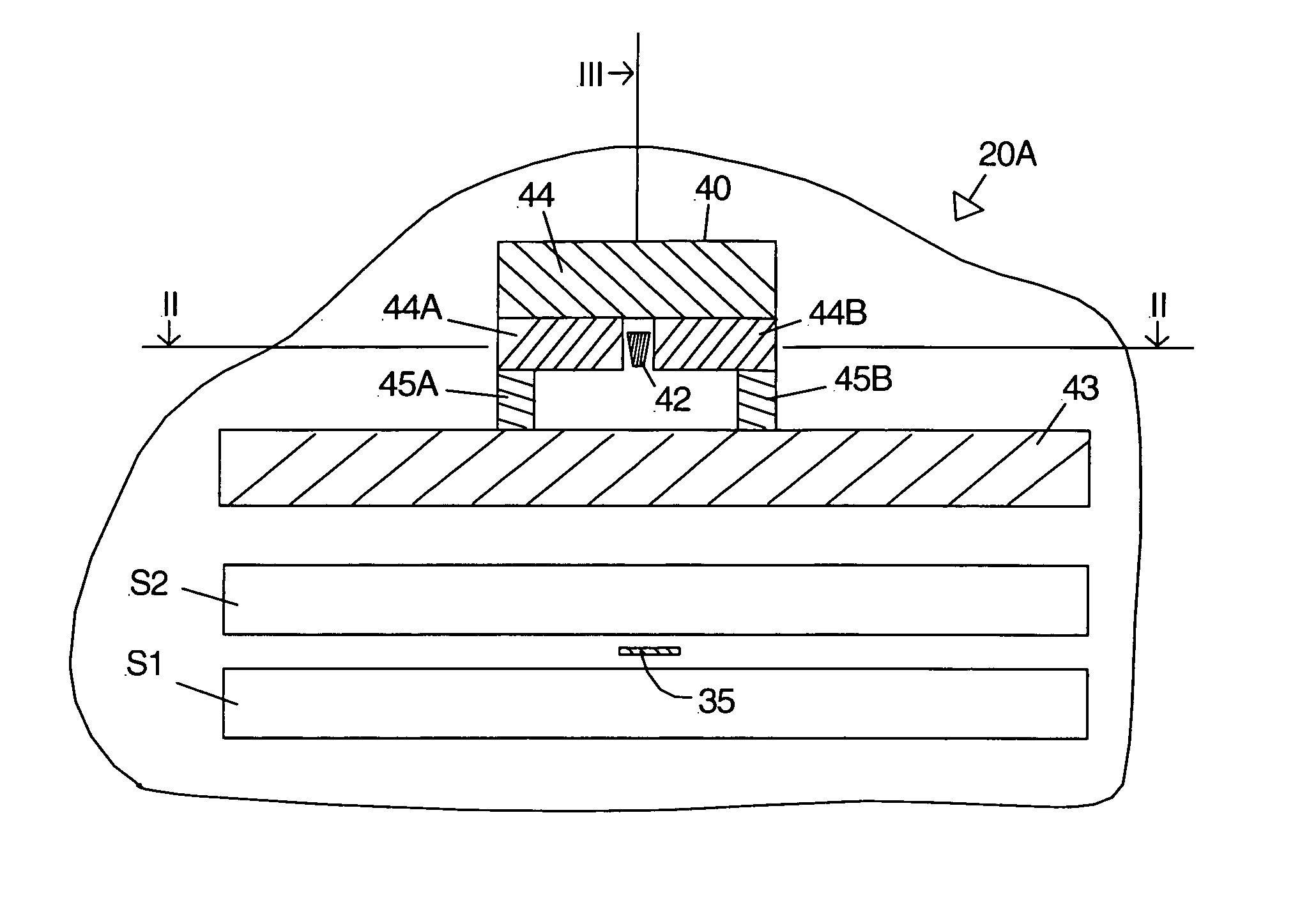

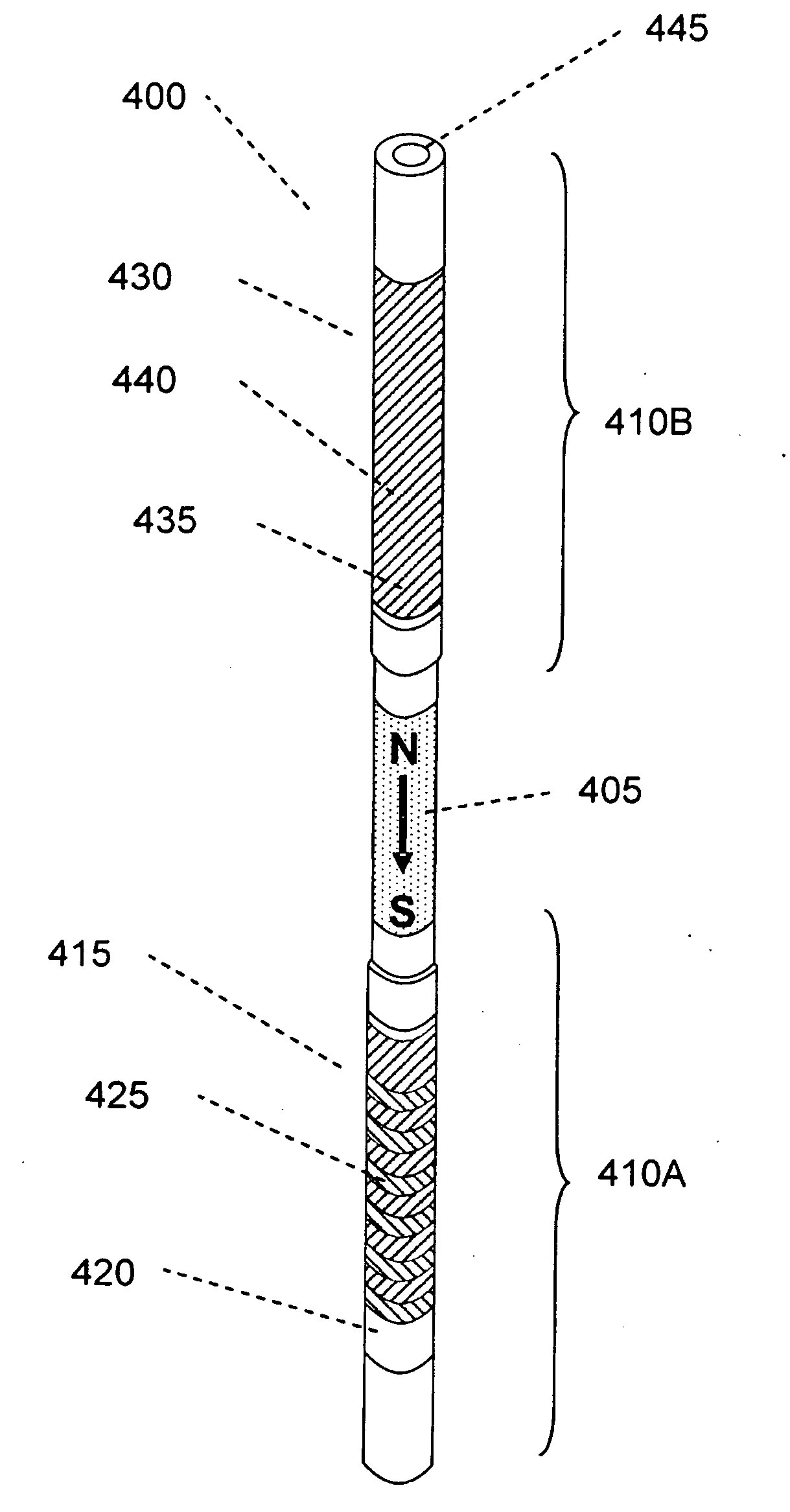

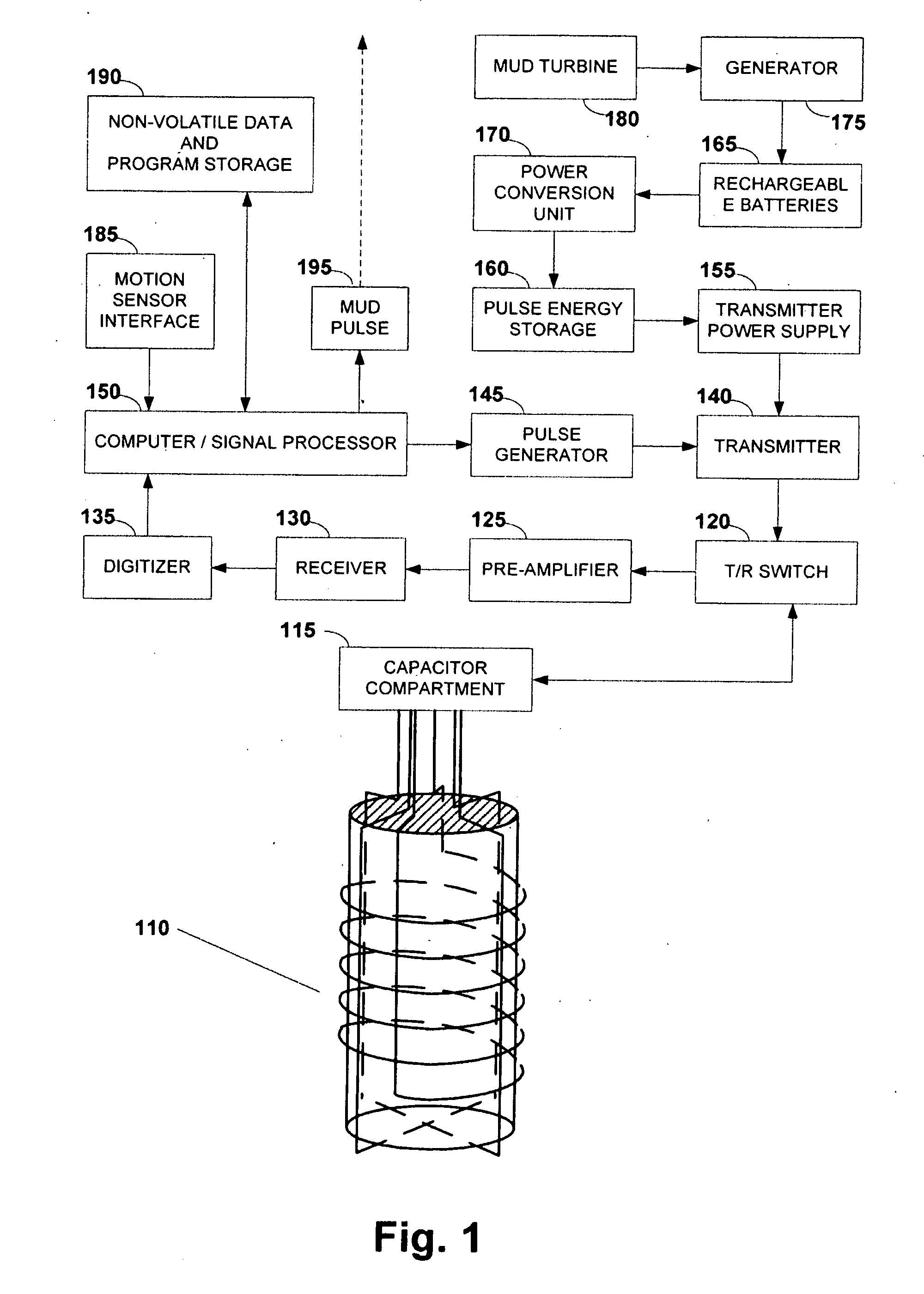

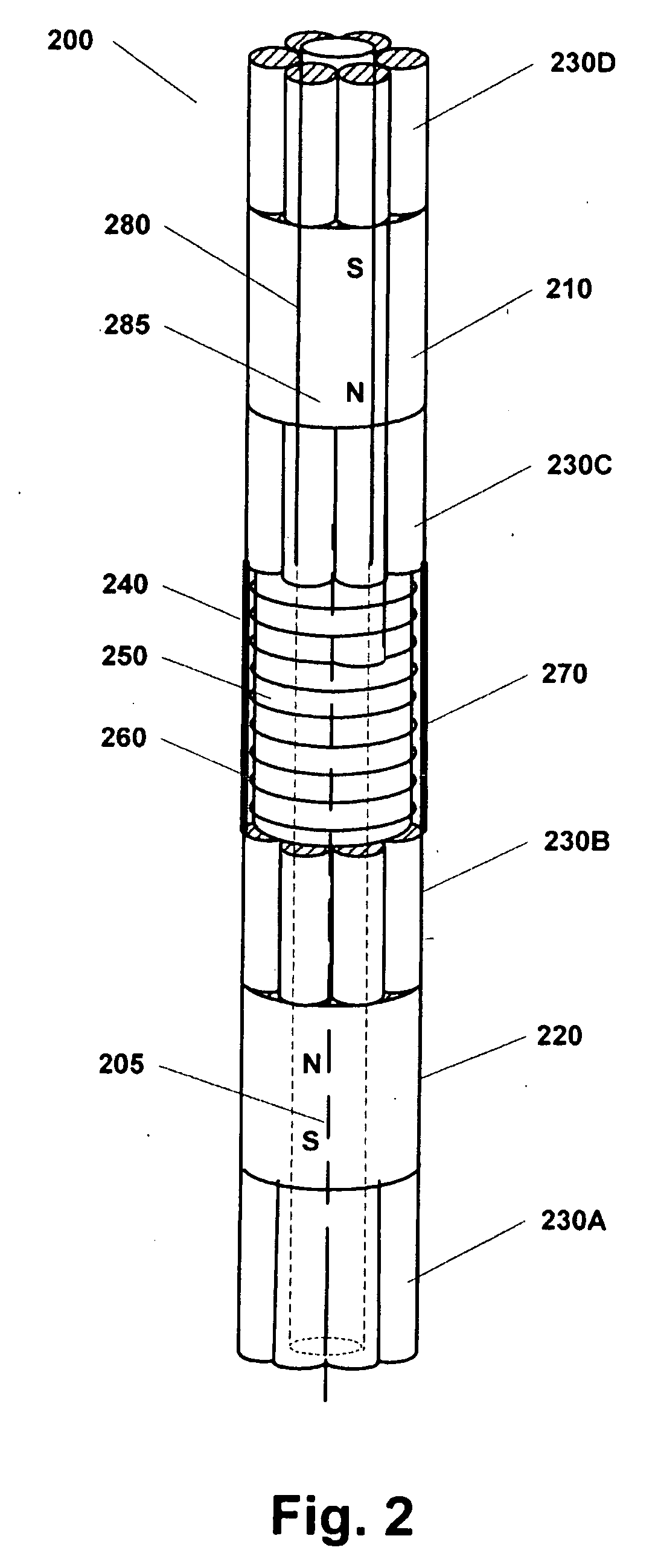

Systems and methods for NMR logging

ActiveUS20050030021A1Add depthAccurate estimateElectric/magnetic detection for well-loggingMaterial analysis by using resonanceEngineeringPole piece

An NMR logging tool for conducting NMR measurements in a plurality of sensitive volumes ranging up to a meter from the tool. The tool comprises a magnetic assembly using one or more permanent magnets and at least one pole piece for extending a magnet pole and shaping the magnetic field to simulate a magnetic monopole in a sensitive volume within the formation. Different embodiments of a segmented antenna enable directional NMR logging. The tool embodiments and methods of their use are suitable for wireline or LWD logging, and can be used for directional drilling.

Owner:HALLIBURTON ENERGY SERVICES INC

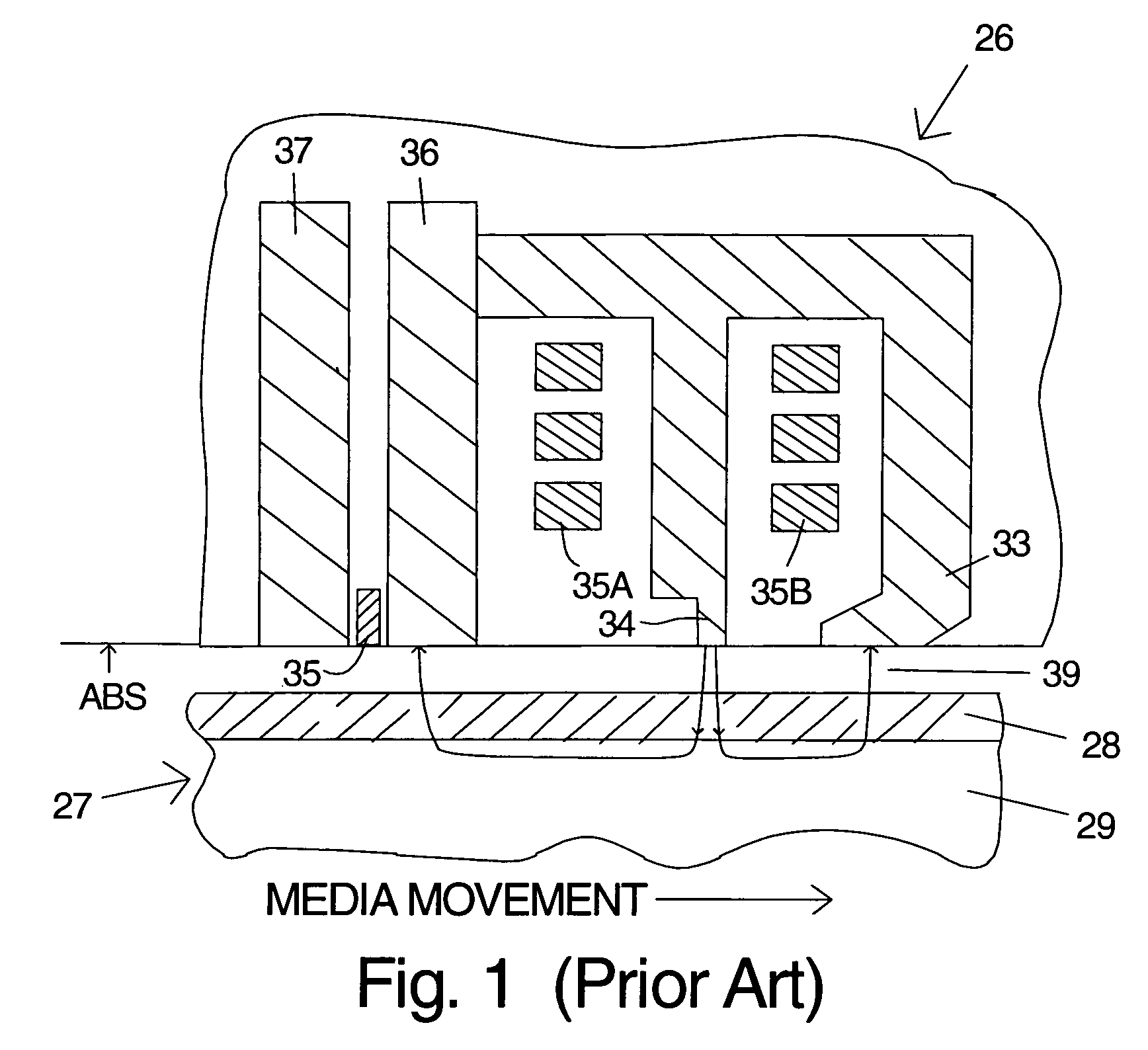

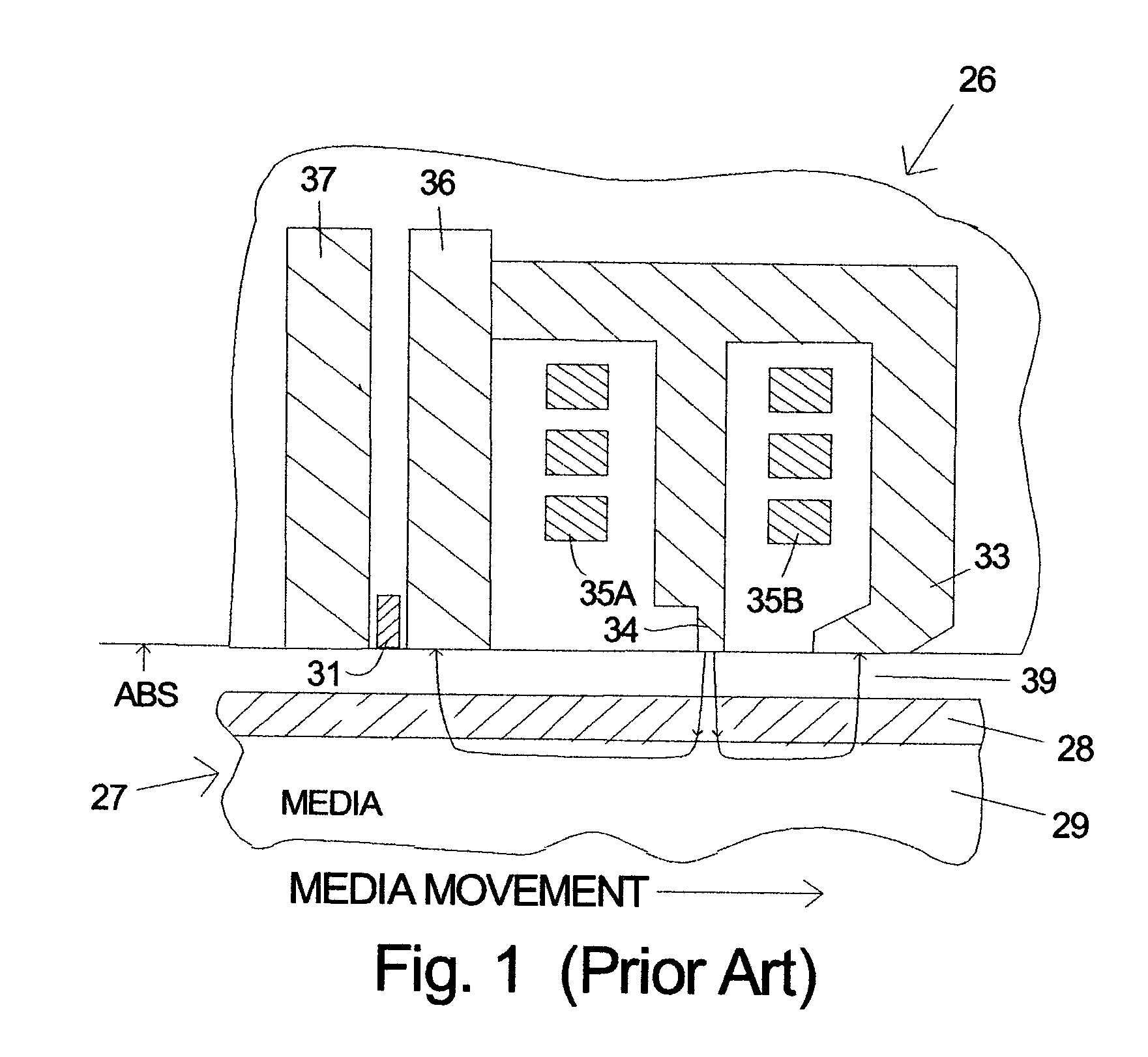

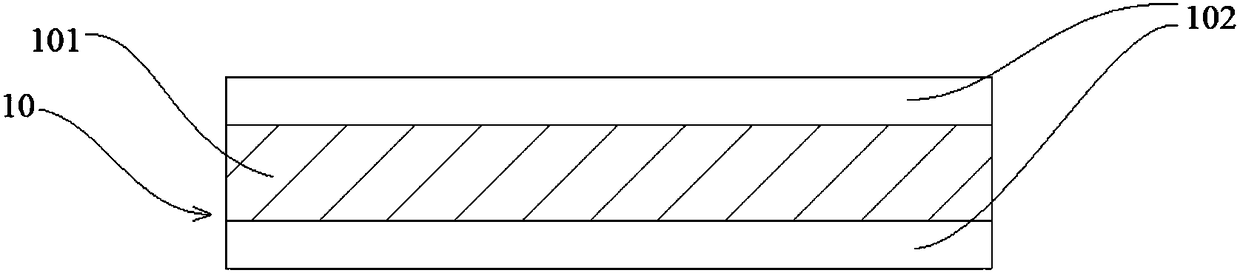

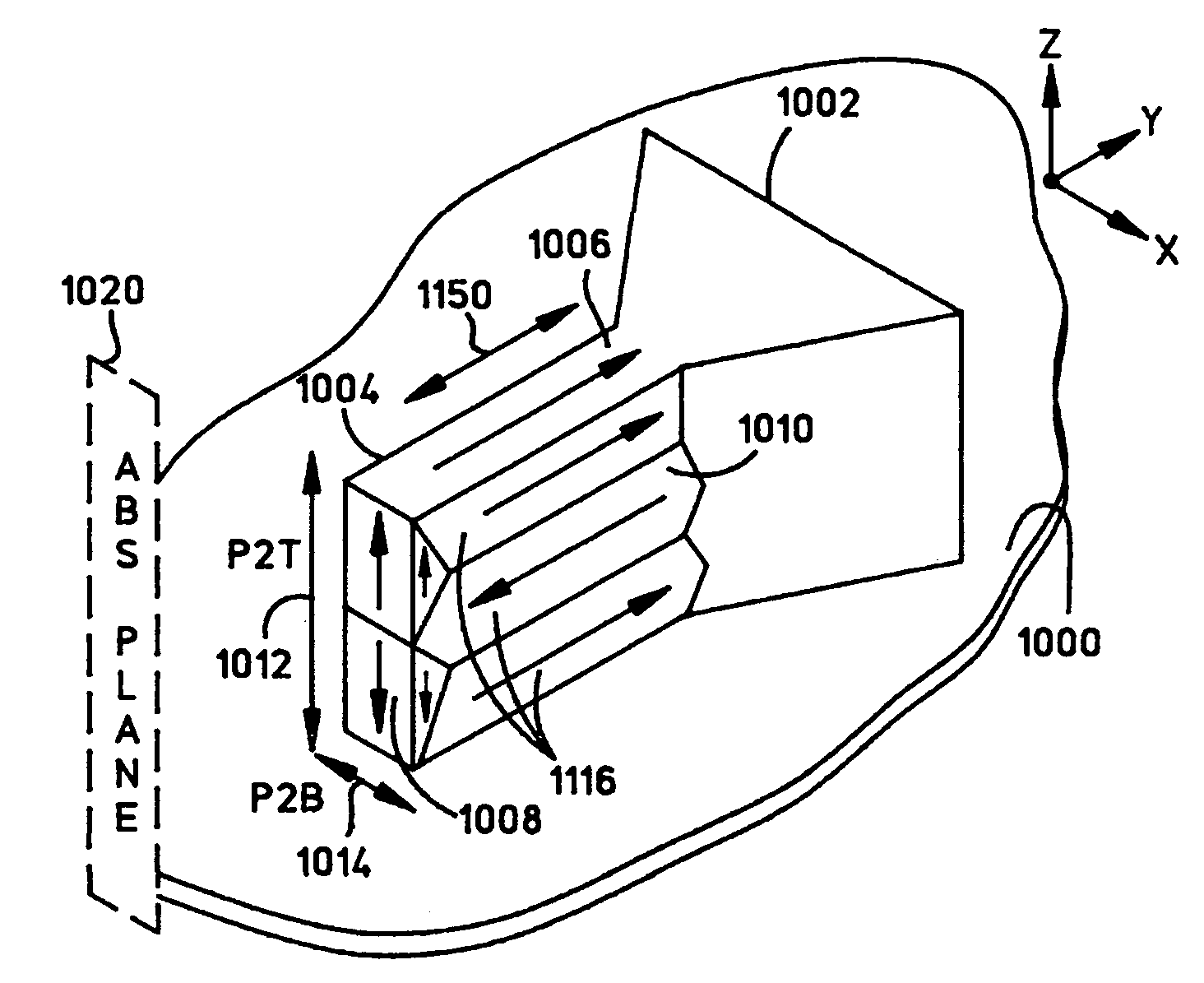

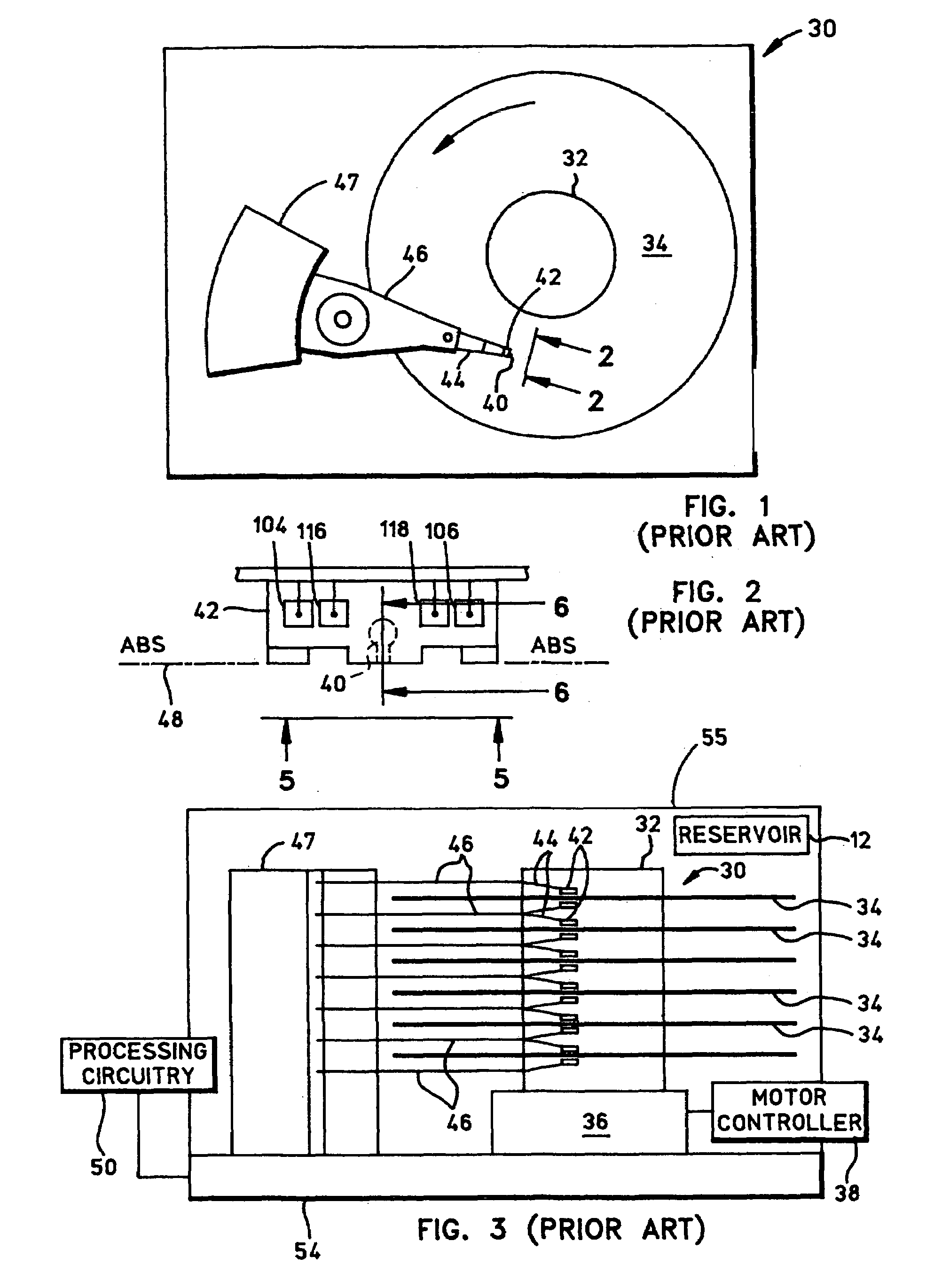

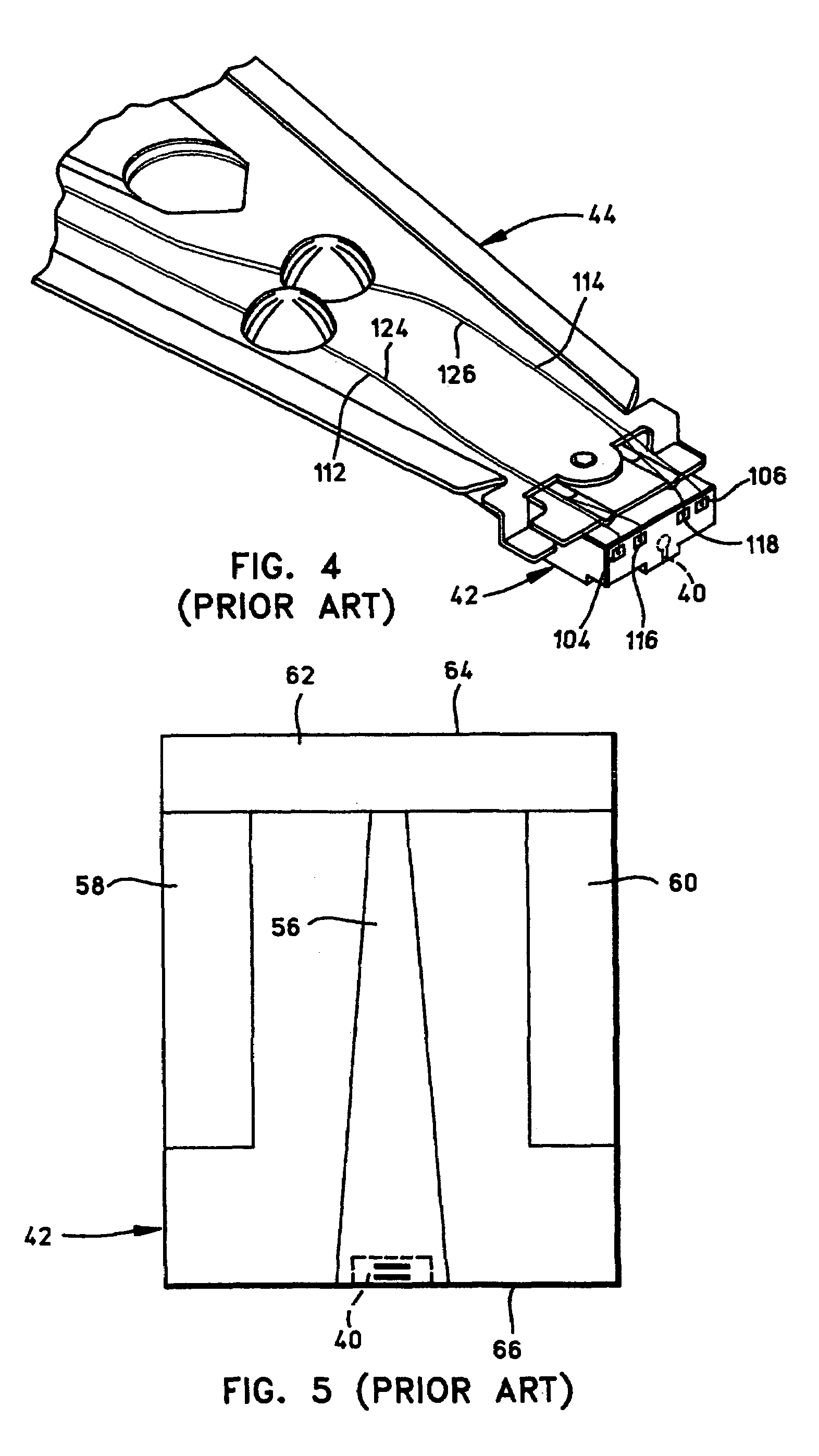

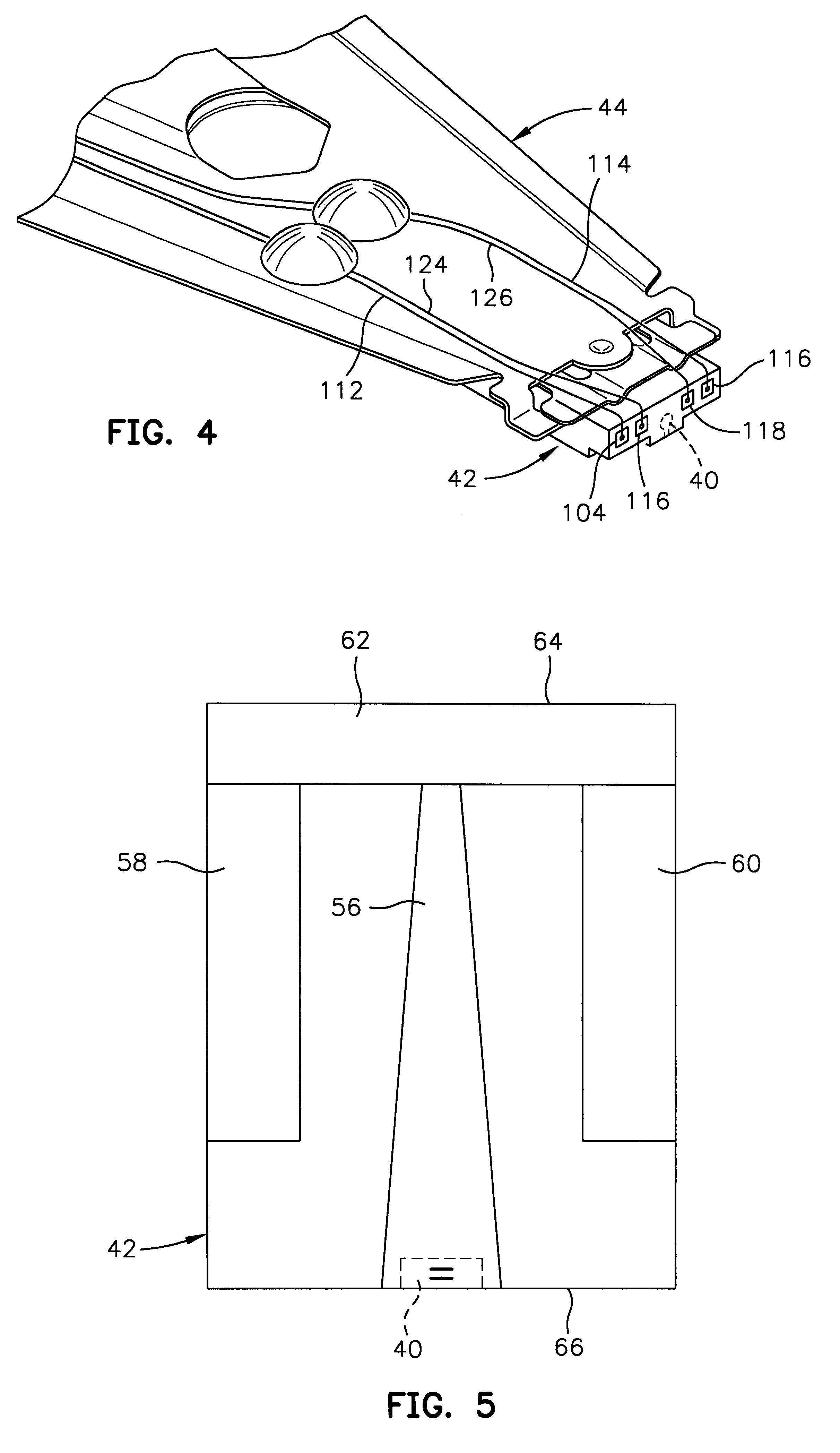

Magnetic transducer for perpendicular magnetic recording with single pole write head with trailing shield

The invention is a magnetic transducer with separated read and write heads for perpendicular recording. The write head has a trailing shield that extends from the return pole piece toward the main pole piece to form the write gap at the air-bearing surface. One embodiment of the trailing shield is a two part structure with a pedestal and a much smaller tip that confronts the main pole piece at the gap. In one embodiment a sink of non-magnetic, electrically conductive material is disposed in the separation gap between the read head and the flux bearing pole piece. The sink is preferably made of copper and does not extend to the ABS.

Owner:WESTERN DIGITAL TECH INC

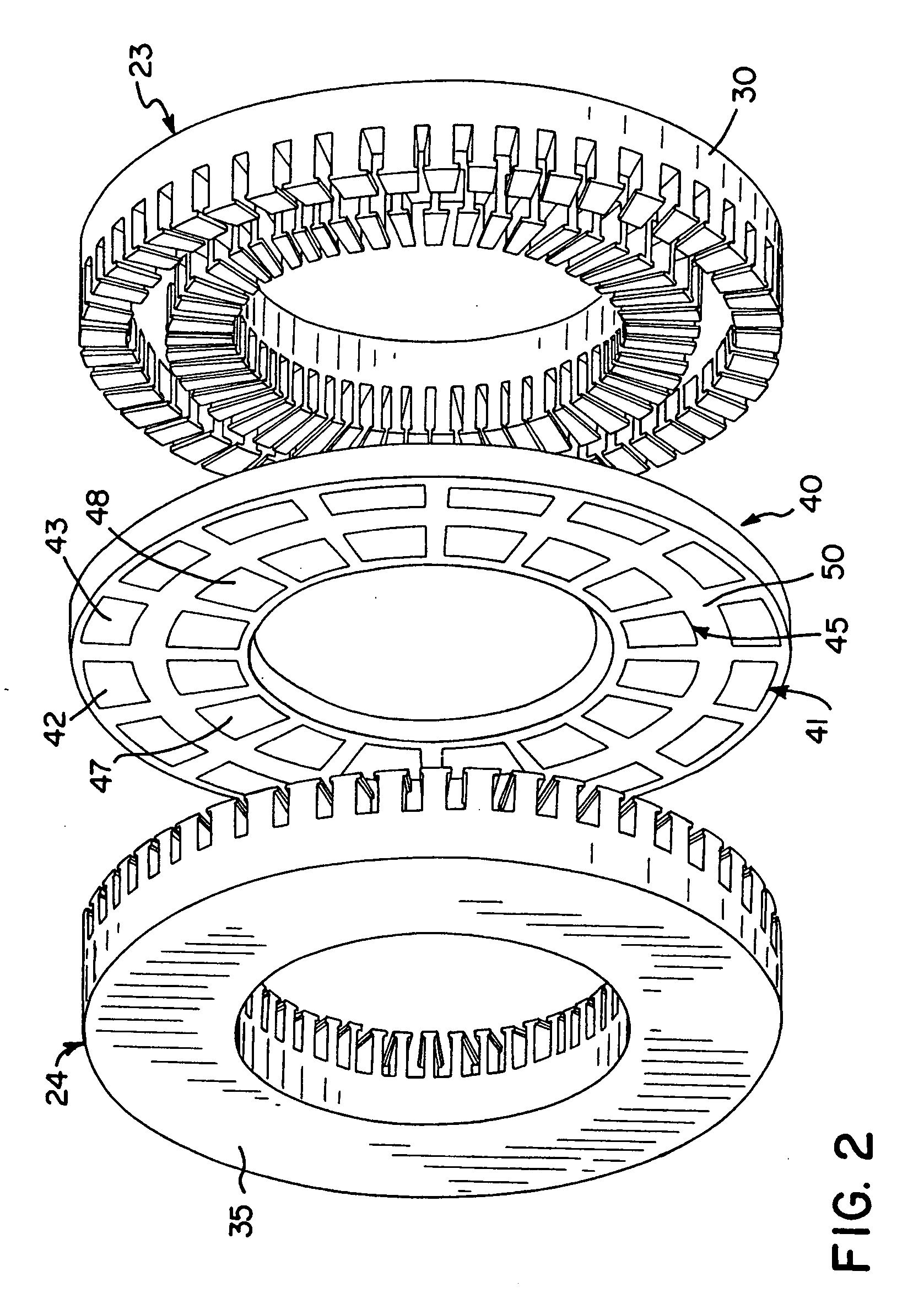

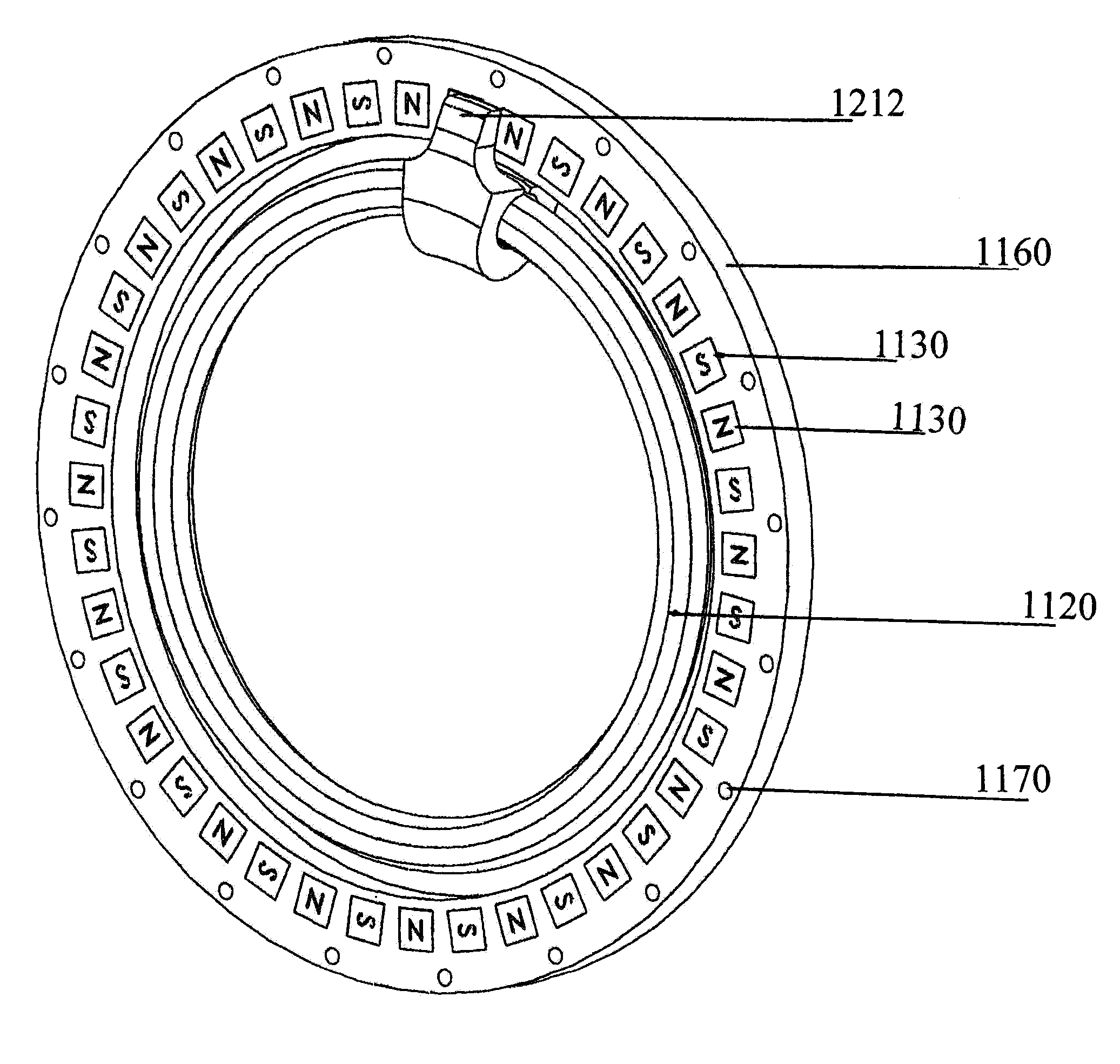

Field controlled axial flux permanent magnet electrical machine

ActiveUS20070046124A1Implementing controlLess expensiveMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsElectric machinePole piece

An electrical machine is provided. The machine includes at least one rotor mounted for rotation about a central axis and at least two stator sections mounted axially adjacent to and on opposite sides of the rotor. The rotor includes two circumferentially arrayed rows of alternating segments of permanent magnet and ferromagnetic pole pieces. One of the rows is spaced radially inwardly from the other row. The permanent magnet and ferromagnetic pole pieces are separated by a non-ferromagnetic material. The pole pieces are arranged so that the permanent magnet segments in the first row are radially adjacent to ferromagnetic segments in the second row so that the N-S magnetic fields of the permanent magnet segments are aligned axially. Each stator section includes a ferromagnetic stator frame, at least a first AC winding wound in circumferential slots in the stator frame, and a DC field winding wound on the stator frame.

Owner:WISCONSIN ALUMNI RES FOUND

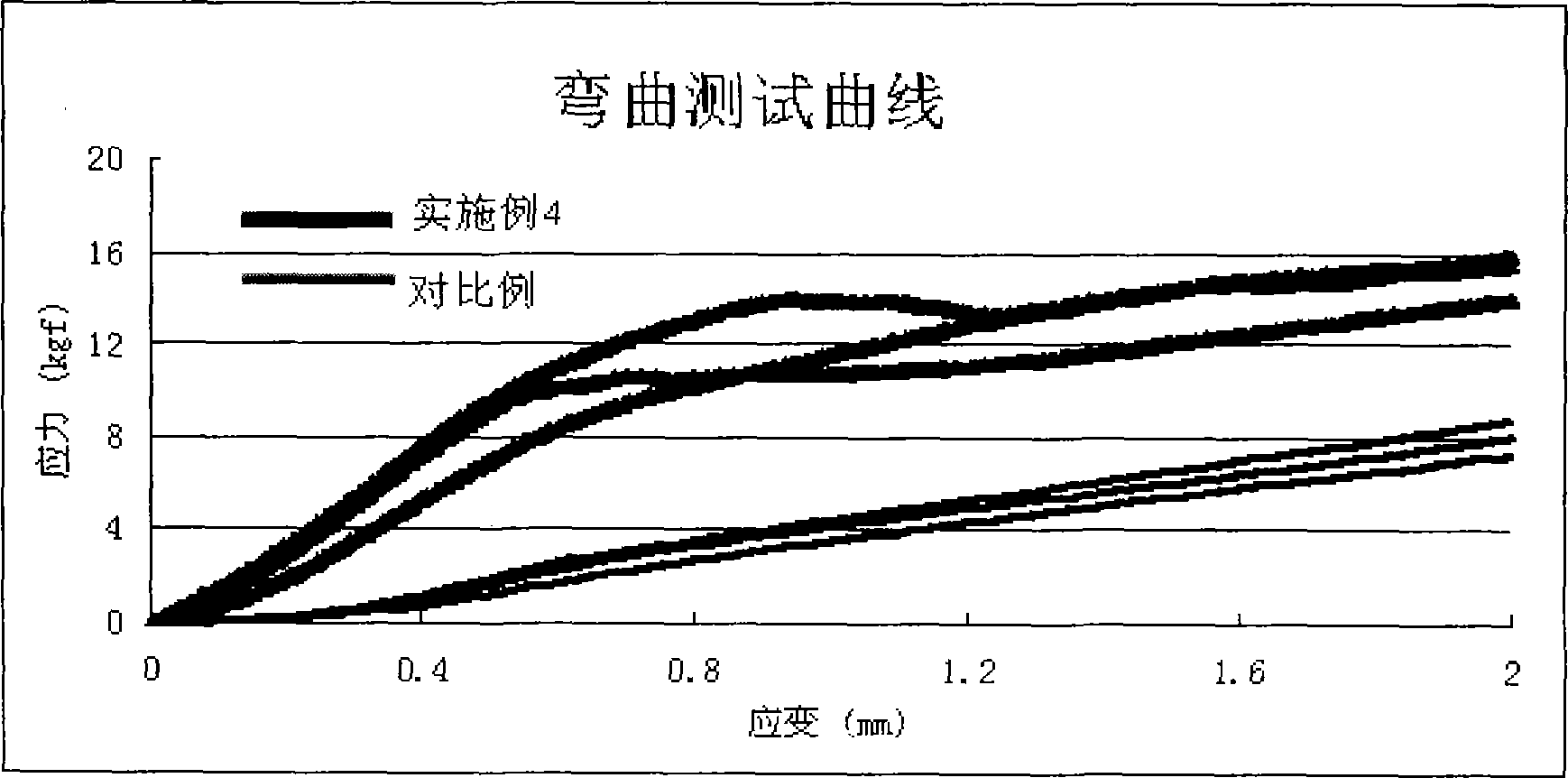

Anode or cathode pole piece of lithium ion battery and coating method thereof

InactiveCN101174685ALower surface energyLow densityElectrode manufacturing processesActive material electrodesCyclic processPole piece

The present invention relates to a lithium-ion battery anode or cathode pole piece and a spreading method of the anode pole piece or the cathode pole piece, wherein, the anode pole piece and the cathode pole piece consists of a foil, a conducting adhesive thin layer and an electrode active material layer in turn; the thickness of the conducting adhesive thin layer is five to ten microns. The electrode pole piece is made in the procedures that a layer of conducting adhesive thin layer in the thickness of five to ten microns are pre-coated on the surface of the foil before the sizing agent is spread, so that a conducting adhesive thin layer having good adhesive force, good conductivity and compact structure is formed on the surface of the foil. Then the electrode active material sizing agent is spread on the conducting adhesive thin layer, and is dried under an appropriate temperature to produce a required pole piece. The present invention can reduce the surface of the foil, and can improve the wetting quality of the sizing agent, thereby improving the adhesion performance of the anode material and the collecting body (aluminum foil) so as to reduce the powder-dropping of the battery during the cycling process, and to prolong the cycling service life of the battery; moreover, the present invention can reduce the content of the adhesive agent in the sizing agent, and improve the utilization rate of the active substance, and the method of the present invention does not produce negative influence on the performance of the battery.

Owner:CENT SOUTH UNIV

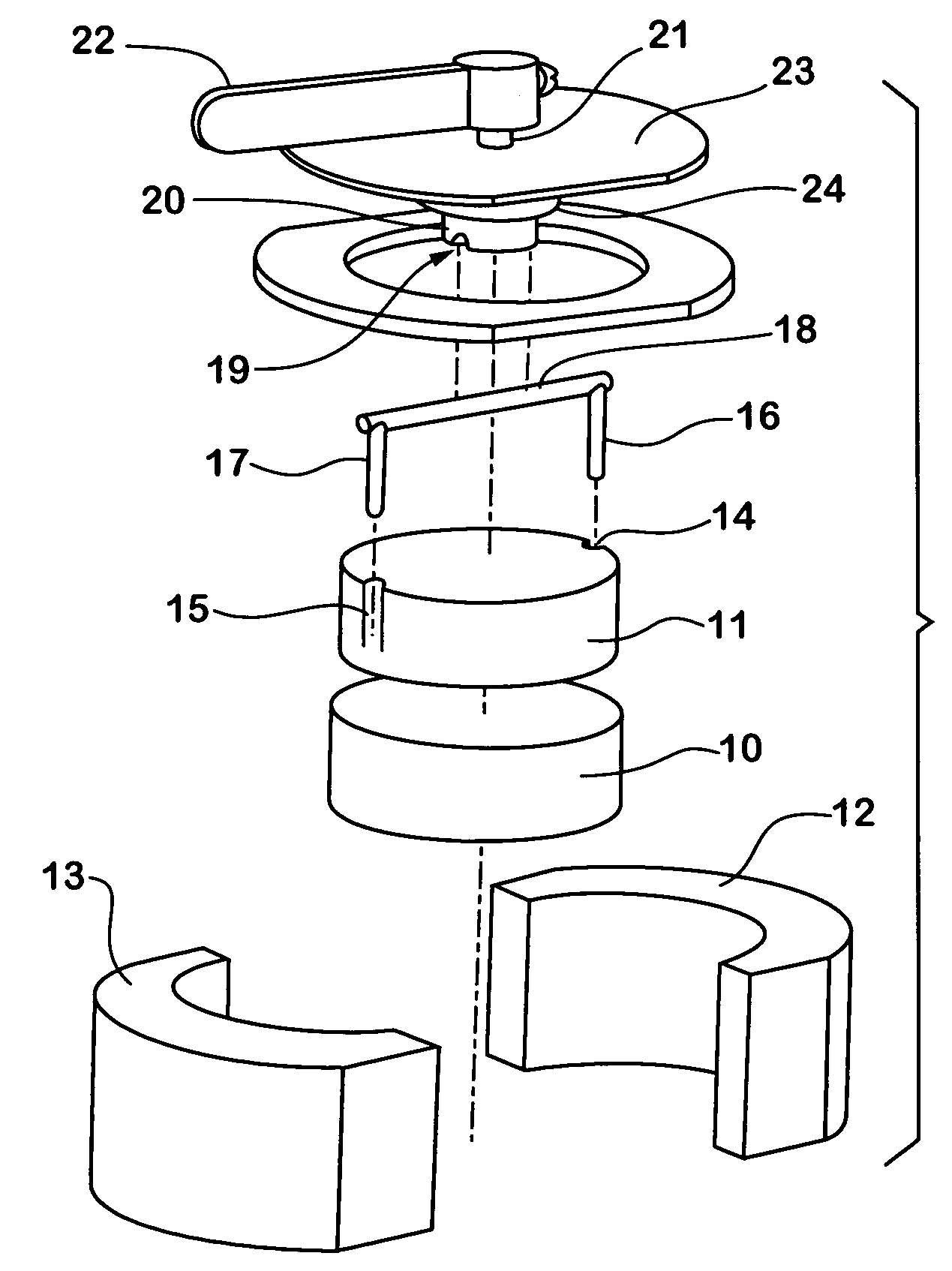

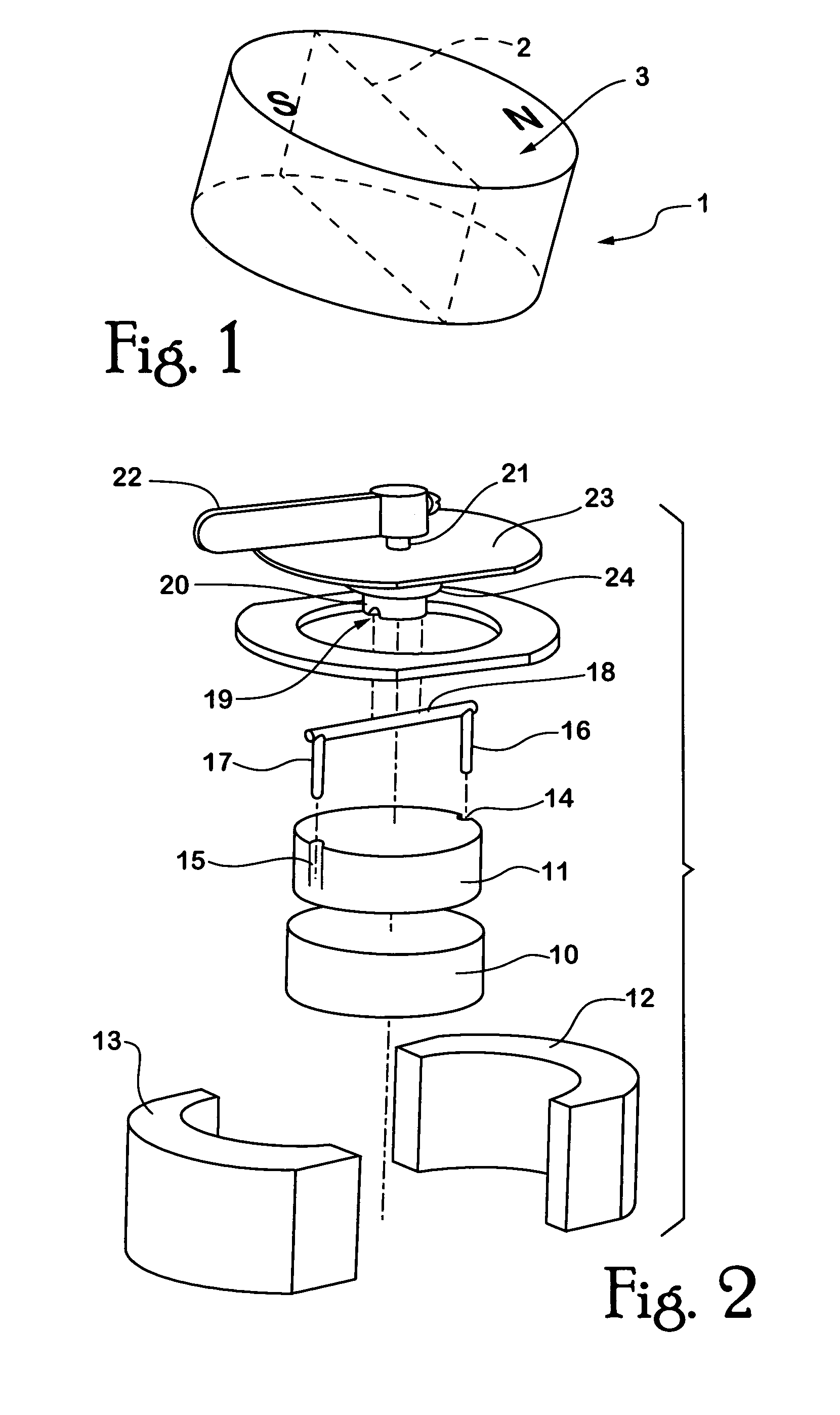

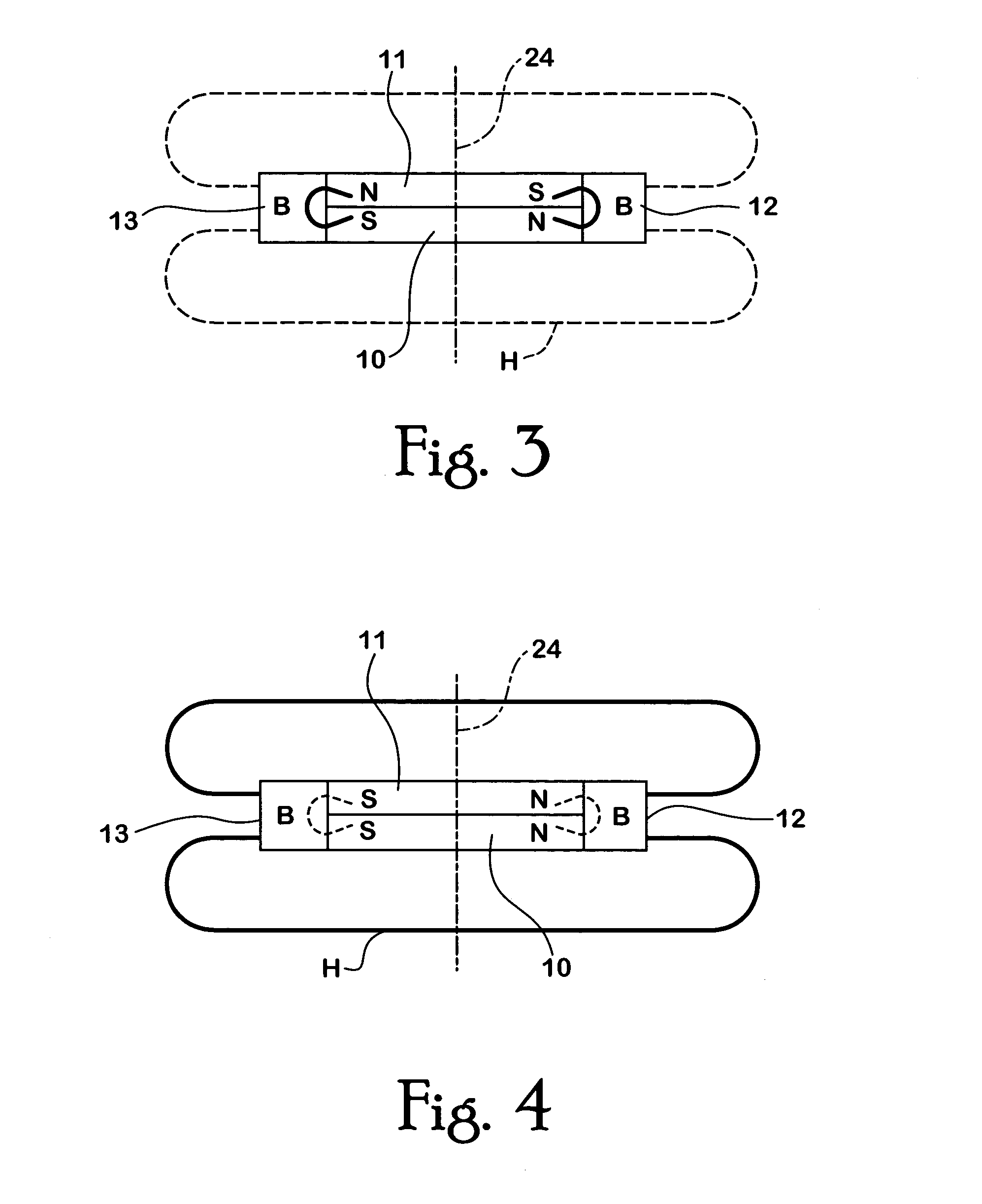

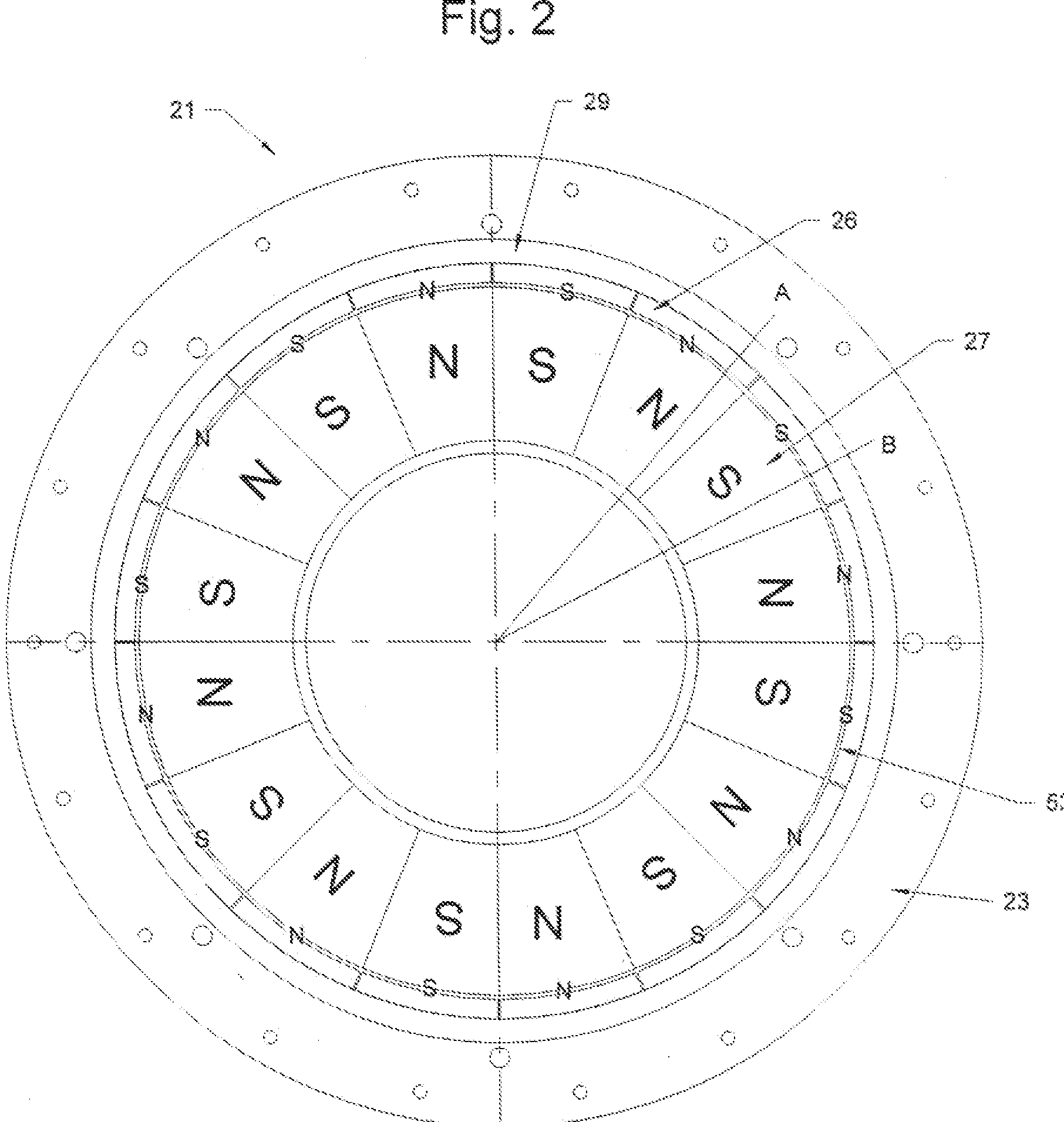

Switchable permanent magnetic device

InactiveUS7012495B2Improve propertiesMaximized strengthElectromagnets without armaturesPermanent magnetsPole pieceFerromagnetism

A switchable magnetic device includes a first magnet and a second magnet, both of which are essentially cylindrical. Magnets are housed in a housing made from pole pieces. Pole pieces are ferromagnetic. Lower magnet is fixedly mounted in the housing while upper magnet can rotate within the housing. Upper magnet is formed with notches or grooves along its vertical side walls. These notches or grooves receive downwardly depending arms of bar. Bar is received inside a groove formed on boss. Boss is connected to a short bar that, in turn, is fixedly connected to a handle or lever. By this means, rotation of handle or lever causes rotation of second magnet. When the upper magnet is positioned such that its north pole substantially overlies the south pole of lower magnet and the south pole of upper magnet substantially overlies the north pole of lower magnet, the first and second magnets act as an internal active magnetic shunt and as a result the external magnetic field strength from the device is quite low. Rotating the upper magnet 180° about its axis of rotation brings the magnets into alignment such that the respective north and south poles of the upper magnet substantially overlie respective north and south poles of lower magnet. In this alignment, the external magnet field from the device is quite strong and the device can be affixed to surfaces or objects.

Owner:MAGSWITCH TECH

Rotary electric machine having a flux-concentrating rotor and a stator with windings on teeth

InactiveUS6891299B2Increase powerReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePole piece

A rotary electric machine including a flux-concentrating rotor with permanent magnets disposed between pole pieces, and a stator with teeth having a free end deprived of pole swellings and a concentrated winding. The pole pieces and the magnets are configured so as to minimize the difference Ld−Lq where Ld is inductance on a forward axis and Lq is inductance on a quadrature axis.

Owner:MOTEURS LEROY SOMER

Magnetic transducer for perpendicular magnetic recording with single pole write head with trailing shield

ActiveUS20050068671A1Manufacture head surfacePrinted circuit detailsMagnetic transducersMagnetic poles

The invention is a magnetic transducer with separated read and write heads for perpendicular recording. The write head has a trailing shield that extends from the return pole piece toward the main pole piece to form the write gap at the air-bearing surface. One embodiment of the trailing shield is a two part structure with a pedestal and a much smaller tip that confronts the main pole piece at the gap. In one embodiment a sink of non-magnetic, electrically conductive material is disposed in the separation gap between the read head and the flux bearing pole piece. The sink is preferably made of copper and does not extend to the ABS.

Owner:WESTERN DIGITAL TECH INC

Current collector and application thereof, and pole piece and battery using same

ActiveCN108281662ANo fireThere will be no accidents such as explosionsElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceFilm resistance

The invention specifically relates to a current collector and application thereof, and a pole piece and a battery using the same, belonging to the field of batteries. The current collector of the invention comprises an insulating layer and a conducting layer, wherein the insulating layer is used for bearing the conducting layer; the conducting layer is used for bearing an electrode active materiallayer; and the normal-temperature film resistance Rs of the conducting layer is no less than 0.016 omega / sq and no more than 420 omega / sq. The current collector provided by the invention can greatlyincrease the short-circuit resistance of the battery in cases of abnormal conditions, allows short-circuit current to be greatly reduced, so heat produced by short circuits is greatly lowered, and heat produced at sites where internal short circuits occur can be totally absorbed by the battery; and thus, the influence of short-circuit damage to the battery is limited to certain points, only pointcircuit break occurs, and the normal operation of the battery in a short period of time is not affected.

Owner:CONTEMPORARY AMPEREX TECH CO

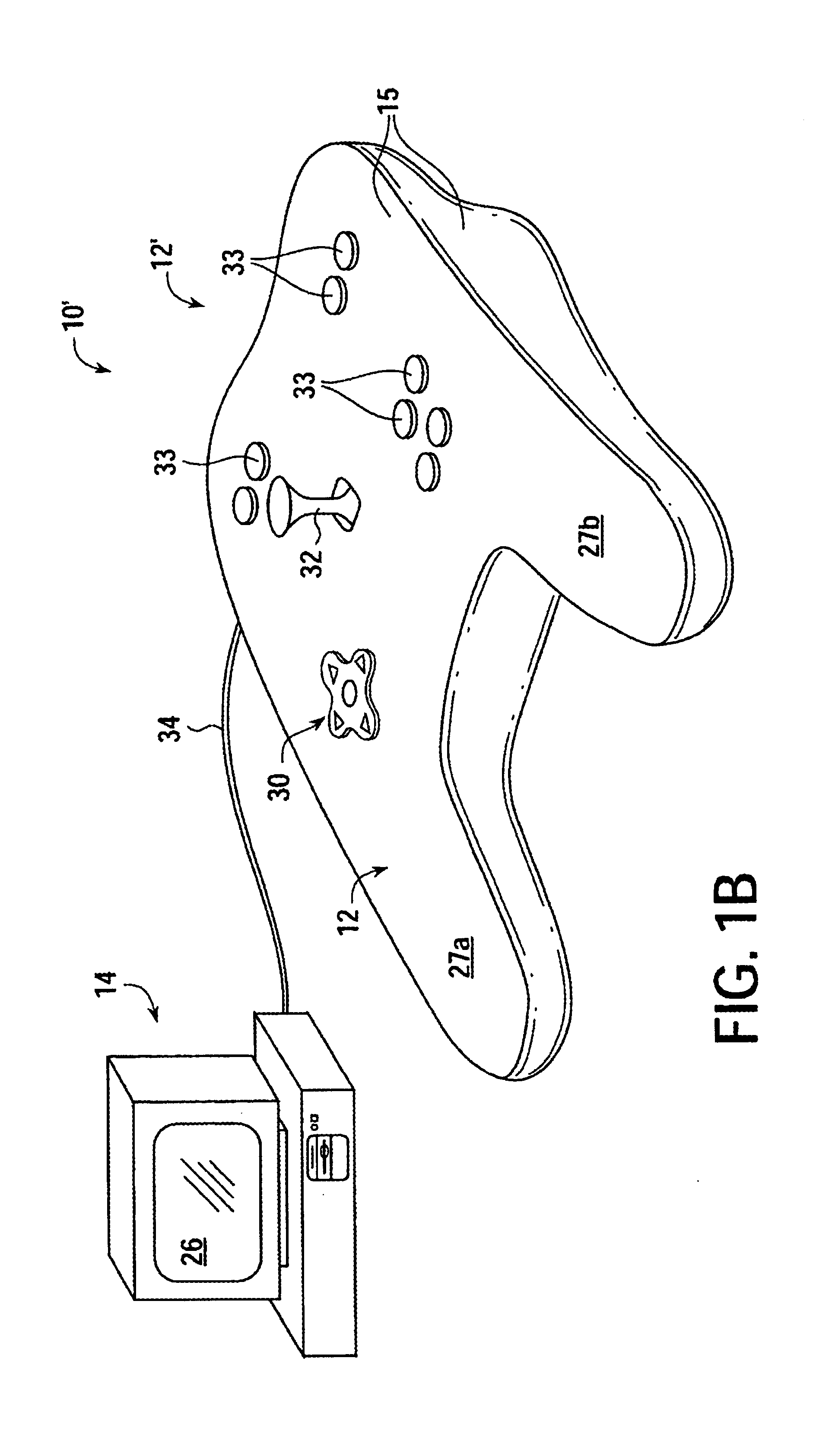

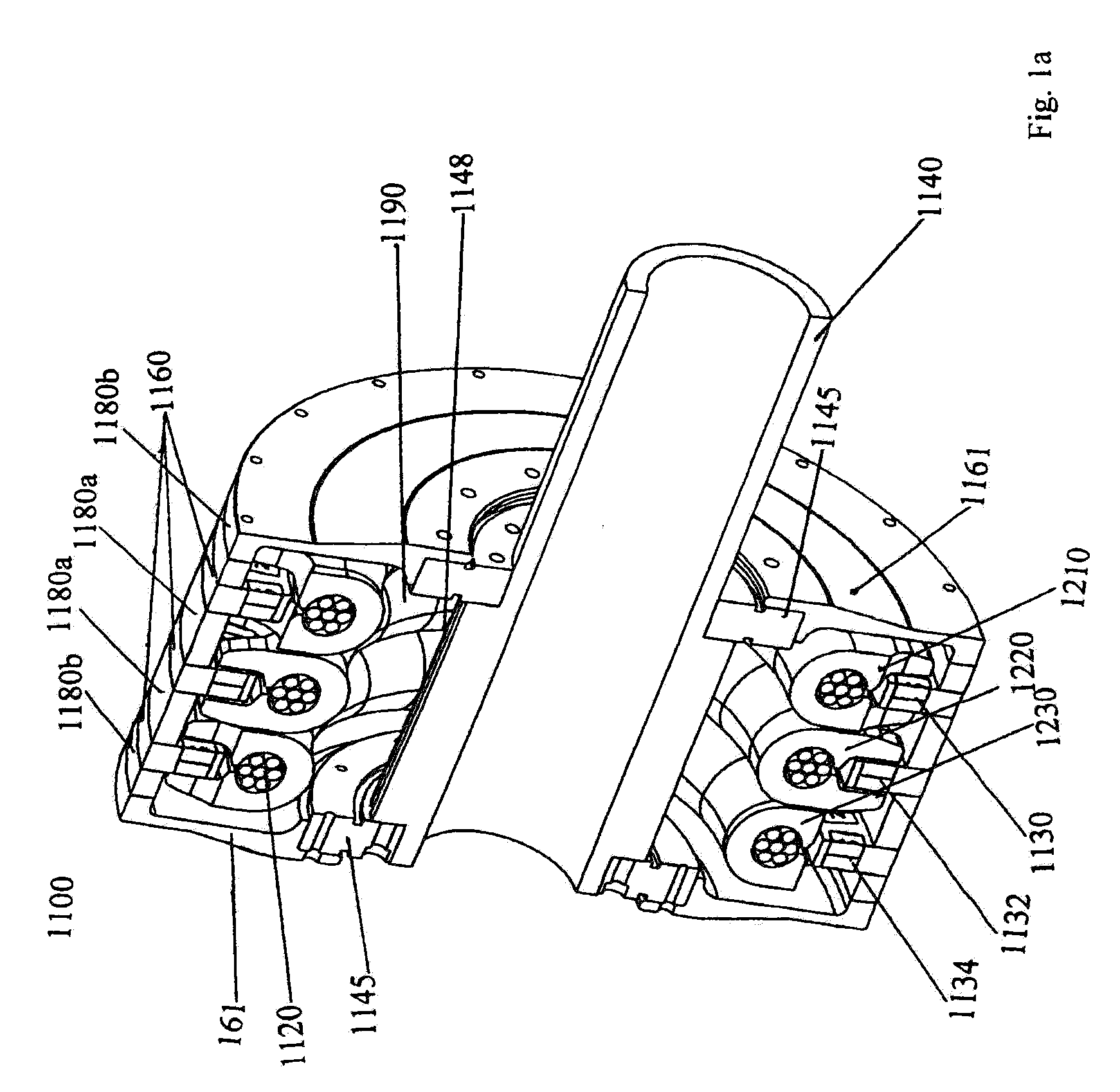

Actuator for providing tactile sensations and device for directional tactile sensations

InactiveUS7084854B1Low costInput/output for user-computer interactionCathode-ray tube indicatorsInertial massUser input

An interface device providing haptic feedback to a user is in communication with a host computer. The device includes a housing, at least one sensor for detecting user input, and an actuator assembly. The actuator assembly includes a grounded flexure suspension coupled to an inertial mass which moves when the actuator assembly is energized to cause inertial sensations. The inertial mass includes a pole piece surrounding a magnet, and a grounded coil between magnet and pole piece causes the motion of the inertial mass when current is flowed therethrough. Another embodiment provides directional haptic feedback to a user and includes at least two actuator assemblies oriented such that the inertial masses oscillate substantially orthogonally, and can be controlled to output the inertial sensations approximately along a single axis having a desired orientation.

Owner:IMMERSION CORPORATION

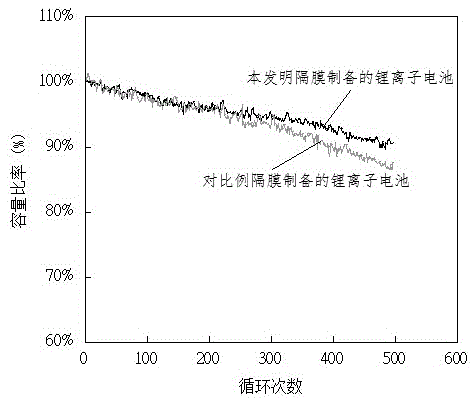

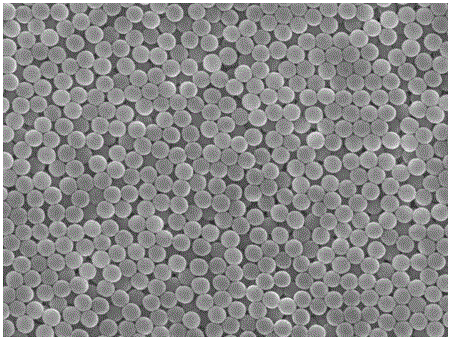

PVDF-coated lithium-ion battery separator and preparation method thereof

The invention provides a PVDF-coated lithium-ion battery separator and a preparation method thereof. The PVDF-coated lithium-ion battery separator comprises a base film and a coating, wherein the coating coats a single side or double sides of the base film; the coating is obtained by coating and drying slurry; and the coating is 0.1-0.5 micron in thickness and contains evenly arranged PVDF spherical particles. According to the PVDF-coated lithium-ion battery separator, a traditional technology that an existing PVDF-coated lithium-ion battery separator takes oil substances of acetone and the like as solvents is abandoned. Water is adopted as the solvent of a PVDF material; and no a thickening agent is added, so that the low-viscosity water-based PVDF coating slurry is obtained; an ultra-thin coating of which the PVDF particles are regularly arranged and which is relatively loose is obtained after the slurry is coated; the ultra-thin coating improves the hardness of a pole piece and the effective utilization space of the battery when effectively bonded to the lithium-ion battery separator and the pole piece; and the ventilation loss caused by the thickness of the coating is reduced.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

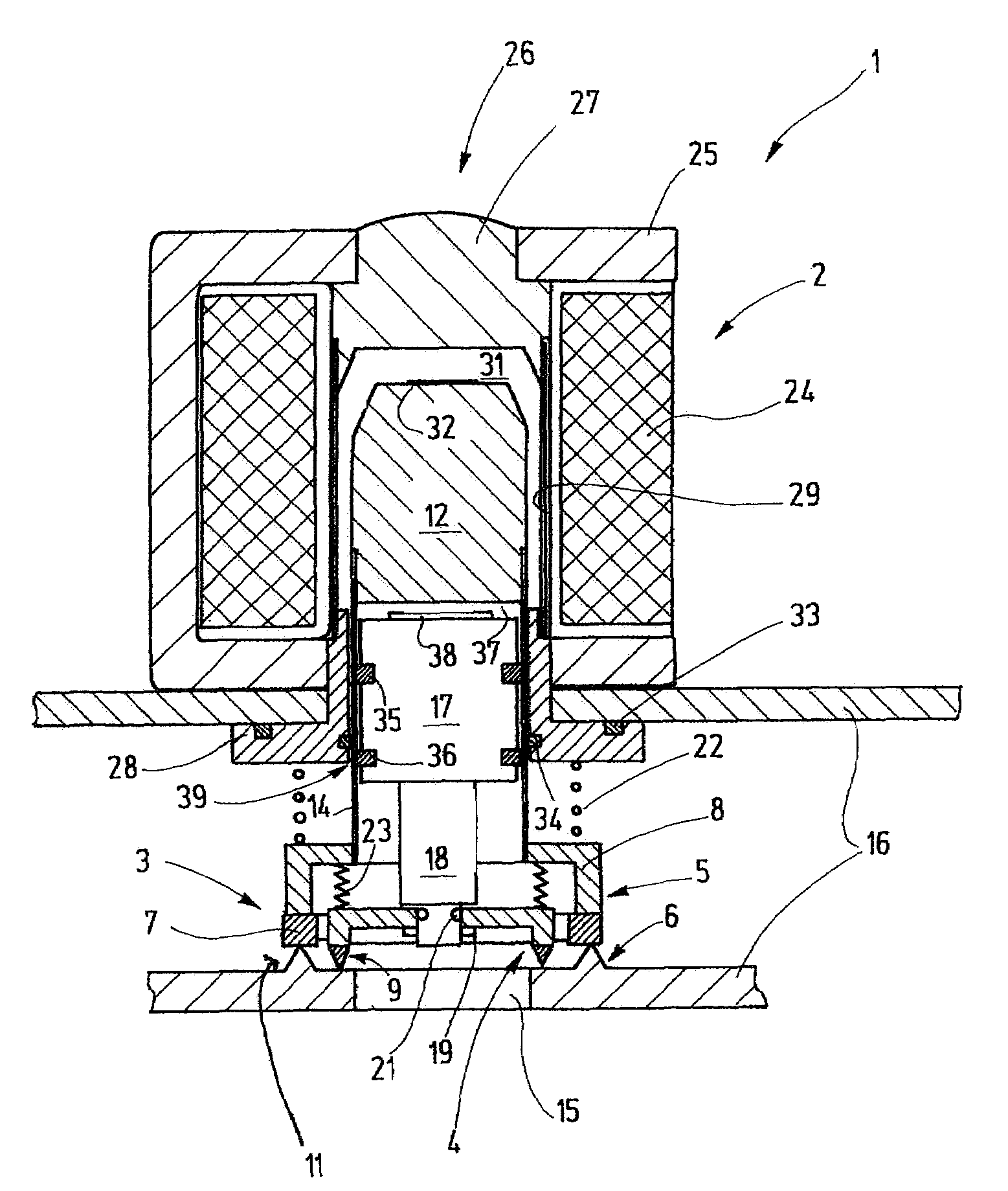

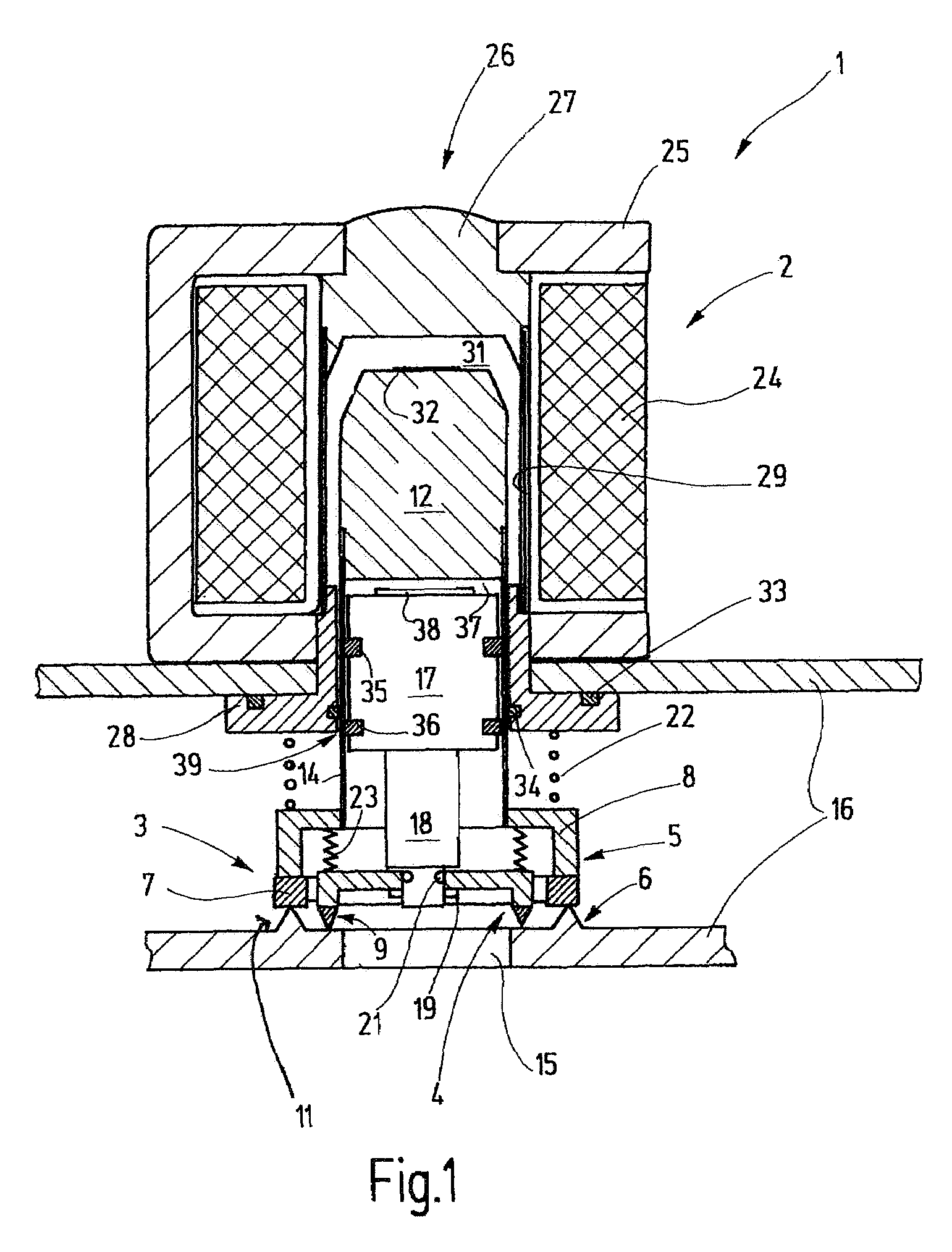

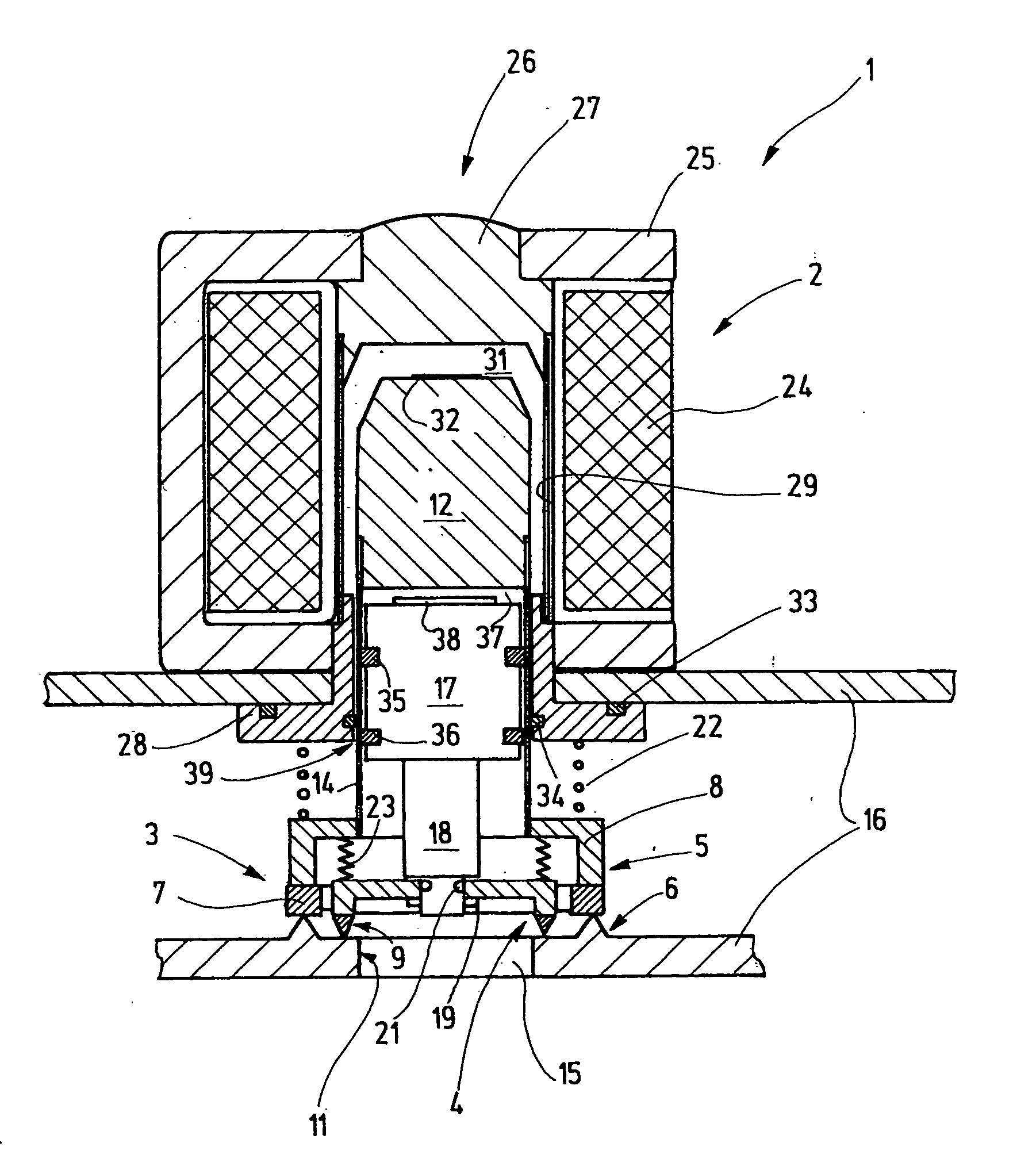

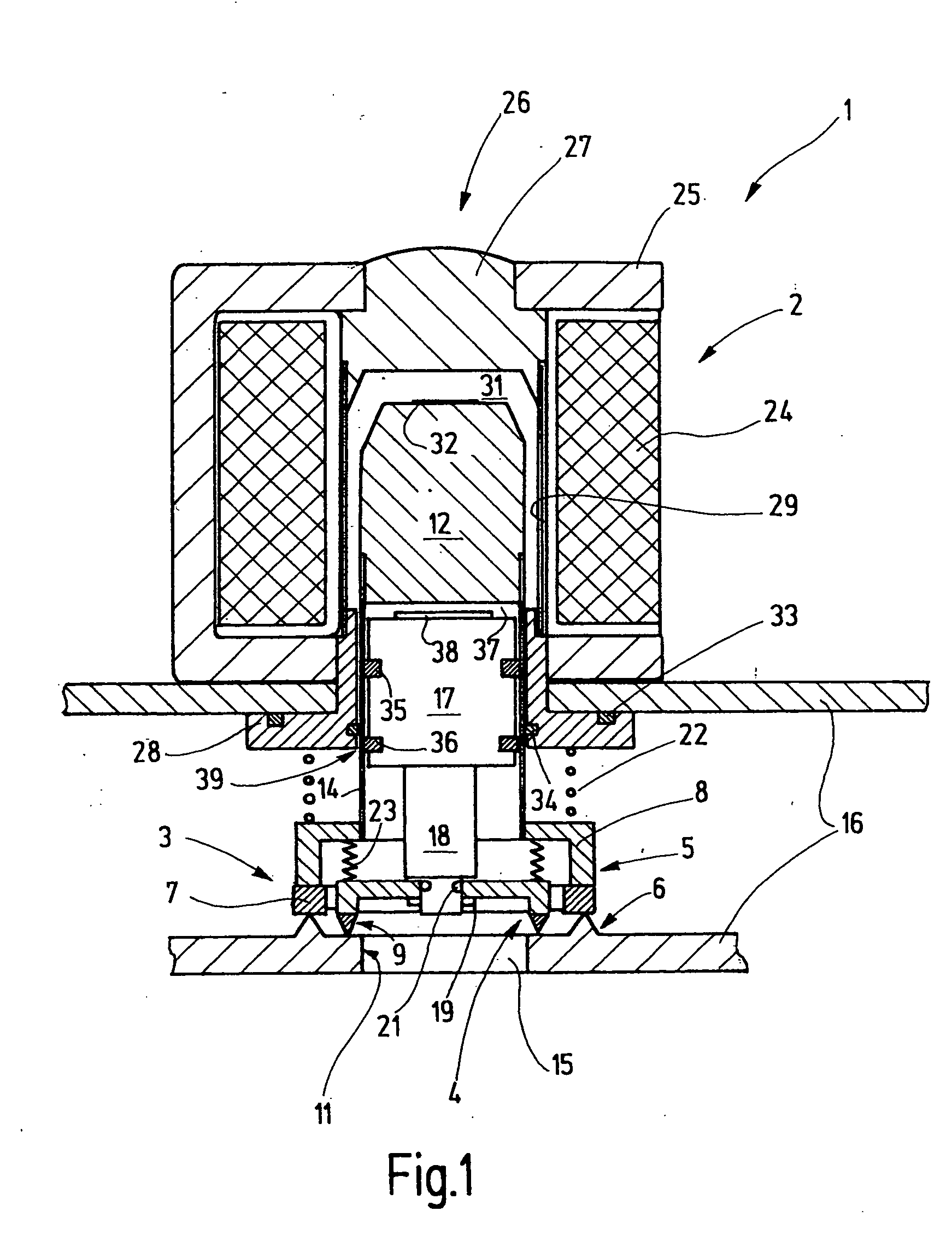

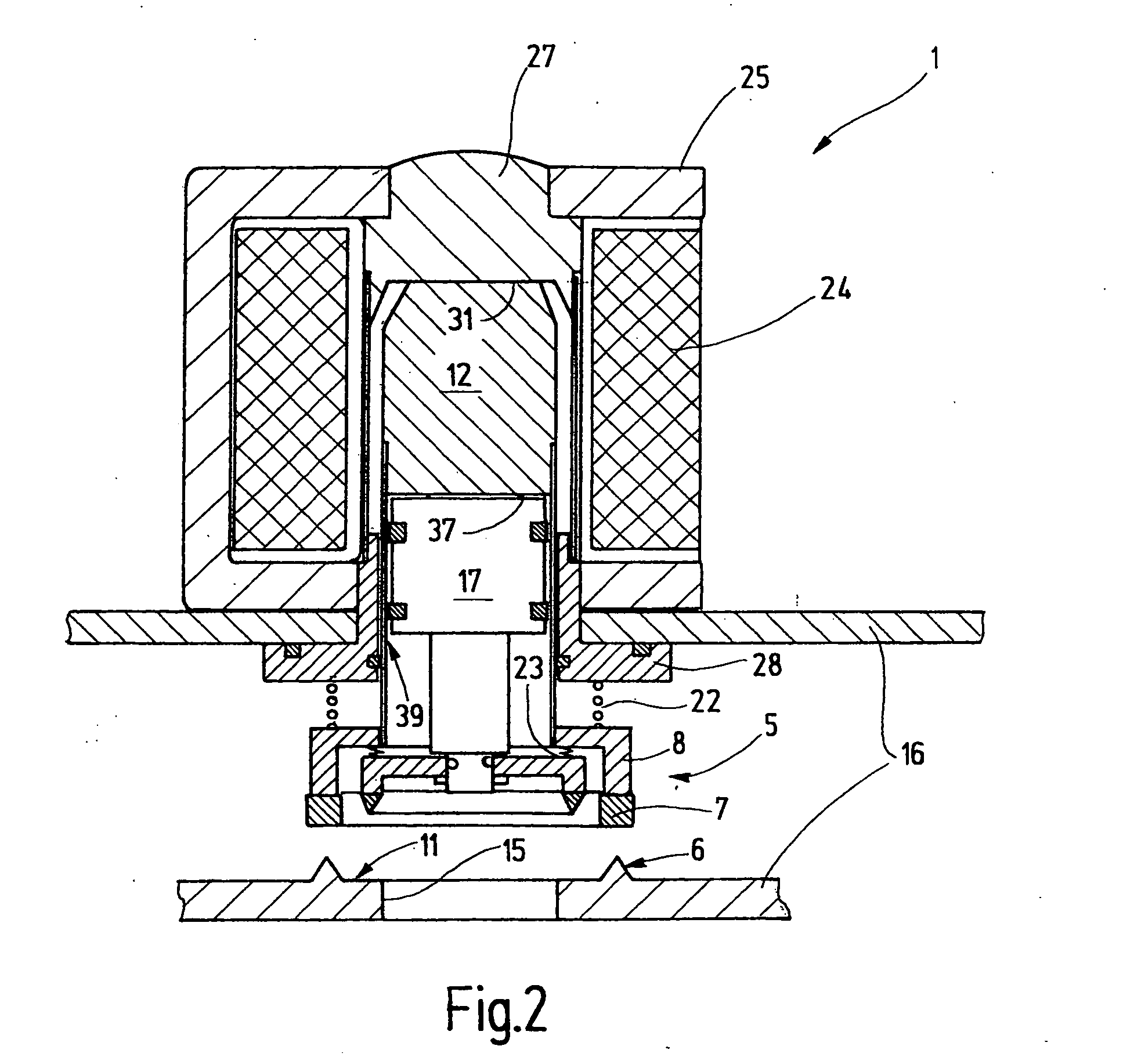

Solenoid valve

ActiveUS7347221B2Easy to moveMinimal gap widthFuel supply regulationGaseous fuel feeder/distributionPower flowSolenoid valve

A valve assembly comprises two valves and a single solenoid actuator with only one magnetizing coil that controls both valves. The corresponding magnetic circuit comprises a yoke with only two pole pieces. The valves are arranged concentric to one another. The valve closing element of the outer valve is connected to an armature by means of a sleeve. The cup thus formed receives the armature that is connected to the valve closing element of the inner valve. The pole piece and the armature form a transmission air gap through which the sleeve extends. A coupling air gap is formed between the armatures. The armature and the pole piece form a working air gap. The valves are opened collectively and are able to close independently of one another when the coil is rendered currentless.

Owner:KARL DUNGS

Preparation method of lithium ion battery pole piece containing PTC coating

InactiveCN104409681AImprove conductivityLow resistivityElectrode manufacturing processesBatteriesSlurryPole piece

The invention discloses a preparation method of a lithium ion battery pole piece containing a PTC (Positive Temperature Coefficient) coating. The pole piece prepared by the method is a multilayer coated pole piece. The method comprises the following steps: before coating slurry comprising an anode or a cathode active substance onto a current collector, coating the current collector with a precoated layer with the temperature sensitivity in advance, wherein the precoated layer with the temperature sensitivity comprises ingredients of a binding agent, a positive temperature material and a conductive agent; the weight ratio of the binding agent to the positive temperature material to the conductive agent is (2-8): (1-8): (0-7). The method provided by the invention is used for preparing the lithium ion battery pole piece containing the PTC coating; the battery using the pole piece has good safety characteristics against overcharge, short circuit, squeezing, needling and the like.

Owner:SHANGHAI AEROSPACE POWER TECH

Head for perpendicular magnetic recording with a shield structure connected to the return pole piece

An embodiment of the invention is a head for perpendicular recording that has a trailing shield and side shields that are connected to the return pole piece by two studs of ferromagnetic material. The studs extend parallel to the track direction and are located a sufficient distance away from the main pole piece to reduce the flux flow from the main pole piece to the studs. Optionally the studs can be recessed behind the air-bearing surface. The preferred embodiment of the invention is a magnetic transducer with separated read and write heads for perpendicular recording.

Owner:WESTERN DIGITAL TECH INC

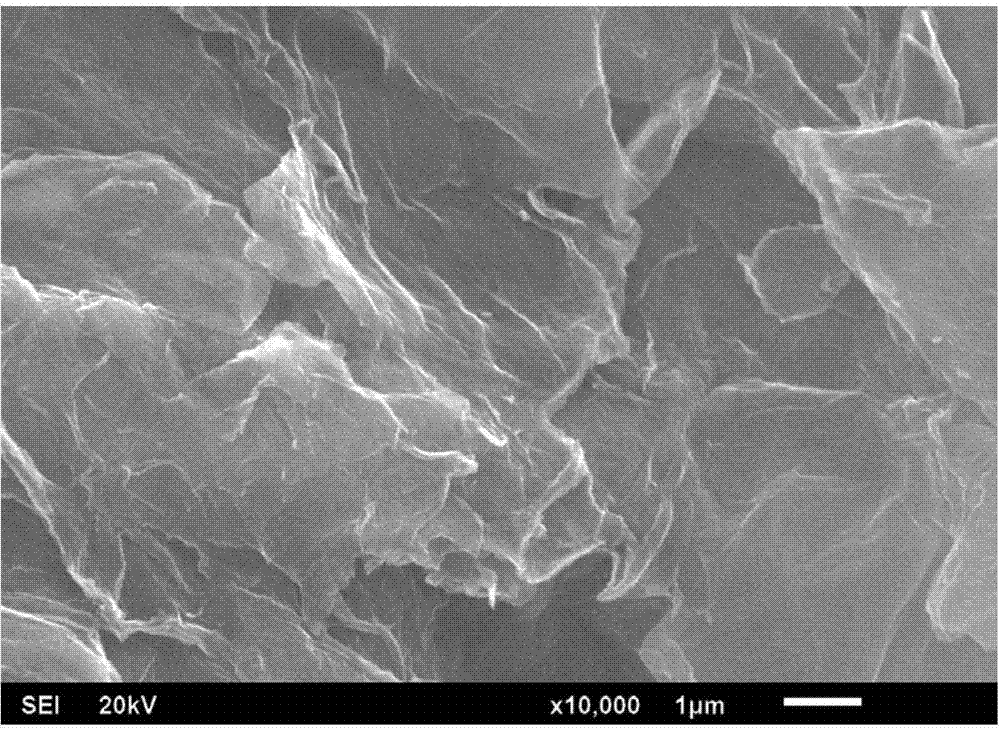

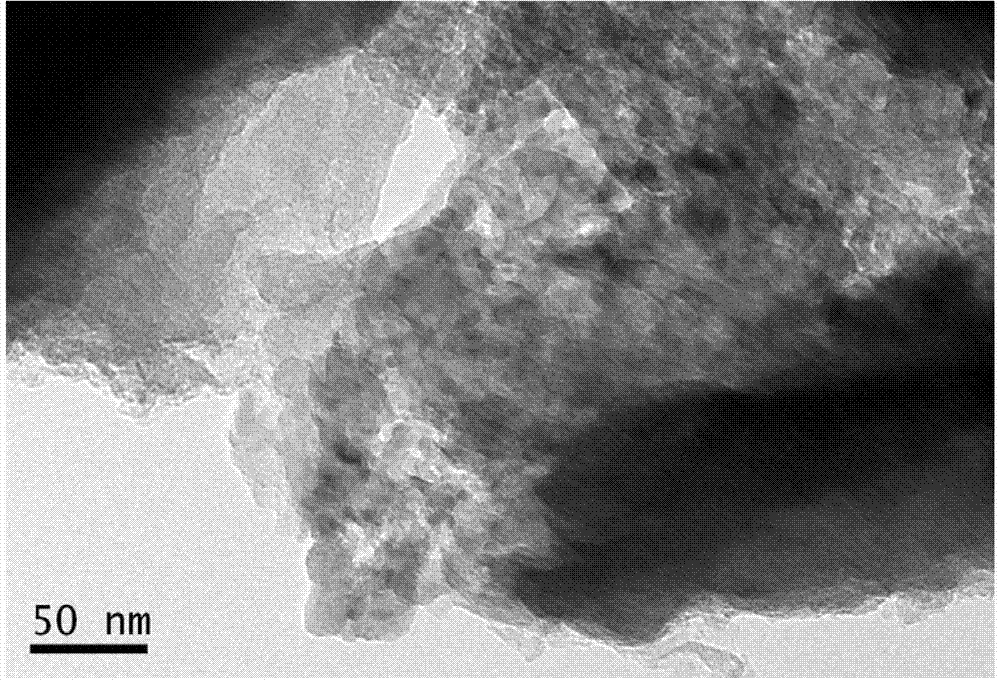

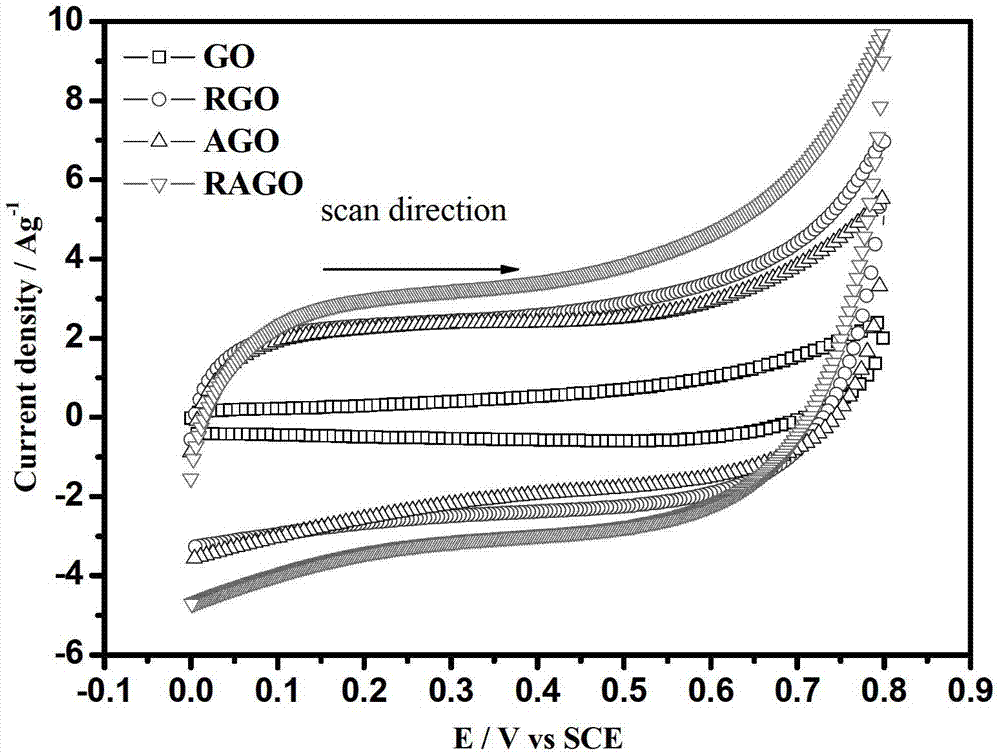

Preparation method for three-dimensional porous graphene for supercapacitor

InactiveCN102923698AReduce the degree of reunionChange surface structureGrapheneHybrid/EDL manufacturePorous grapheneAdhesive

The invention provides a preparation method for three-dimensional porous graphene for a supercapacitor. The preparation method comprises steps as follows: ultrasonically dispersing graphene oxide; fully mixing with a strong alkali solution; pre-drying until a surface is humidified; then activating at a vacuum environment at 120 to 180 DEG C or in protective gas atmosphere at 180 to 1200 DEG C under a high temperature; and etching the surface of the graphene to obtain a three-dimensional porous structure through high-temperature strong alkali and stream, so as to improve a specific surface area of a graphene material. According to the preparation method, activated graphene oxide is reduced through chemical reduction and high-temperature reduction methods, so as to improve a performance of activated graphene. The activated graphene and an adhesive are mixed to prepare into electrode paste based on a certain mass ratio, and the electrode paste is loaded on a conductive current collector to prepare into a supercapacitor electrode, so that a degree of agglomeration of the graphene on a pole piece can be further reduced, and a high electrochemical performance can be obtained.

Owner:CENT SOUTH UNIV +1

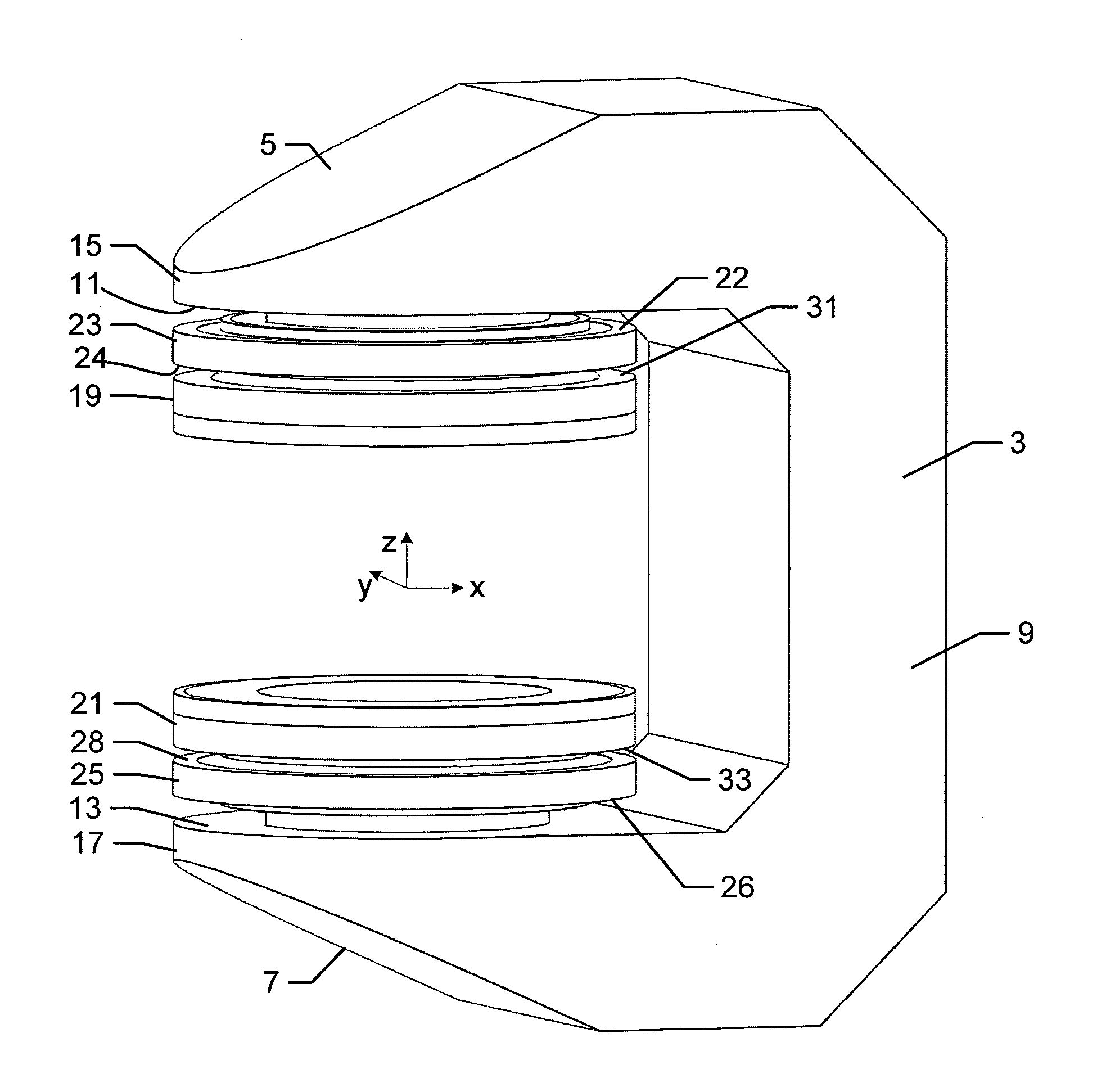

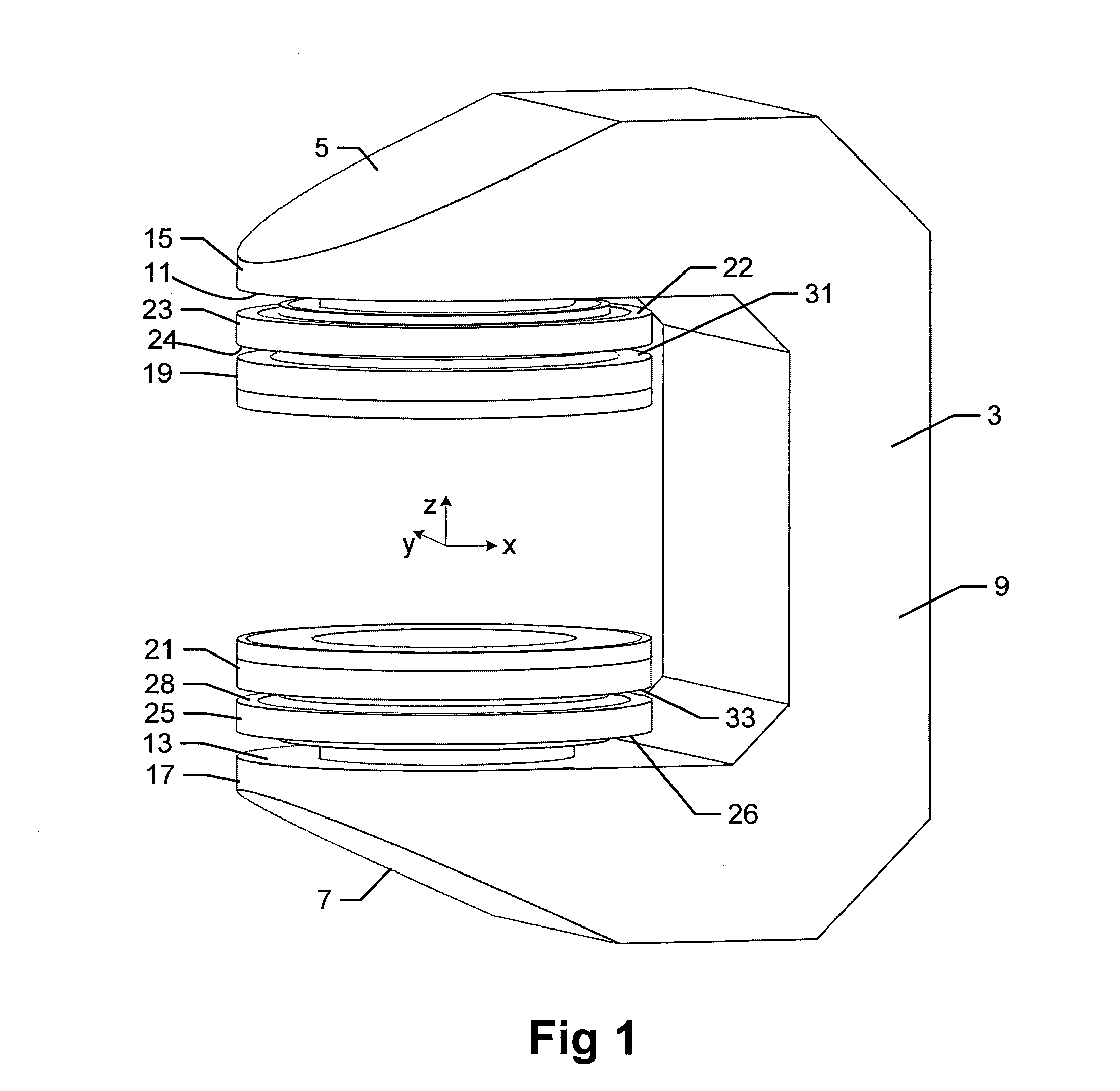

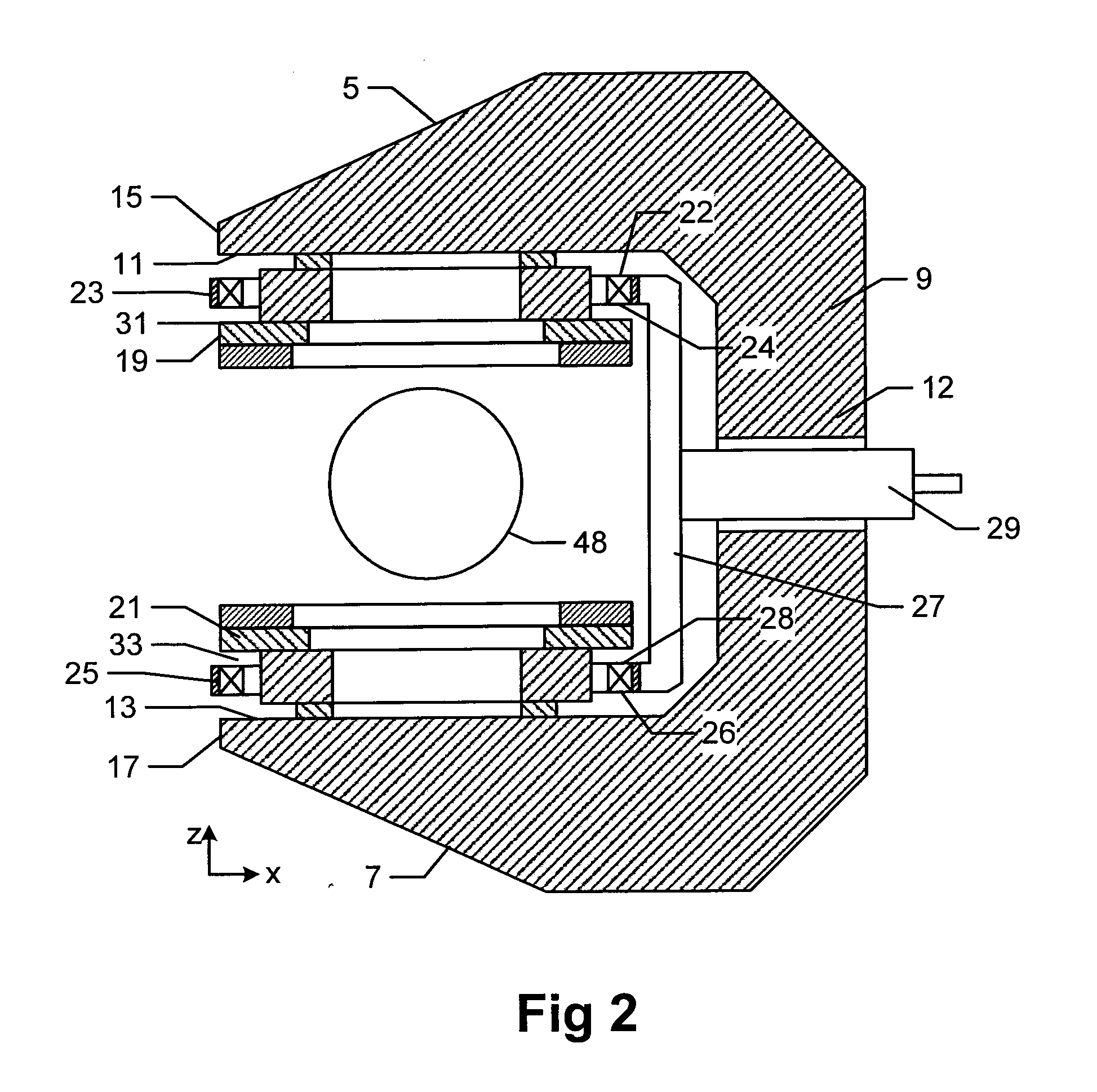

Magnet assembly

InactiveUS20100219833A1Maintain good propertiesPrecise positioningMagnetic materialsSuperconducting magnets/coilsEngineeringPole piece

An electromagnet comprising a ferromagnetic yoke which comprises a yoke. Mutually opposing first and second pole pieces are provided. The first pole piece is provided with a planar coil having a first side facing the yoke and a second side facing the yoke. A balancing member is arranged on the second side of the planar coil to counterbalance the attractive force between the planar coil and the yoke. The other pole piece may also be provided with a corresponding balancing member.

Owner:EMSCAN

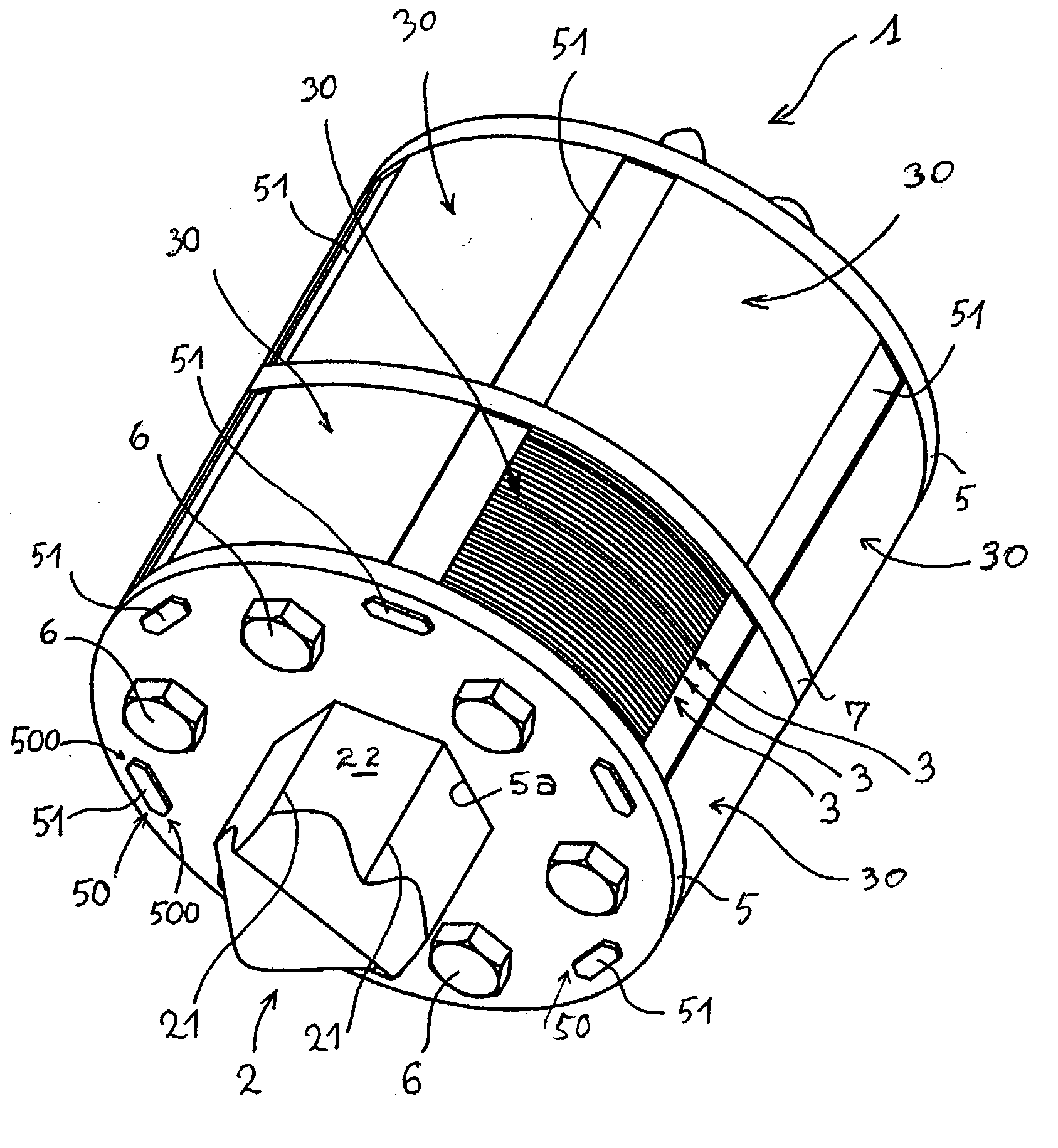

Three-gapped motor with outer rotor and stationary shaft

InactiveUS20070228860A1Magnetic circuit rotating partsAsynchronous induction motorsElectrical polarityEngineering

A motor with three gaps produces higher torque than existing one or two gap motors. The motor uses both one radial and two axial gaps to produce torque. A single stator is provided with an essentially “U” shaped rotor shell having permanent magnets with back iron. The stator has loops of coil windings separated by pole pieces. Current flowing in three segments of the coils interacts with the fields from the permanent magnets to produce more torque. The plane of the coils extends through the centerline of the stator. In a given plane through the motor axis, the same polarity of the magnets on the rotor face the stator.

Owner:PRECISION MAGNETIC BEARING SYST

Electrical machine having a rotor specially adapted to high speeds

InactiveUS20040004407A1Increase speedWindingsMagnetic circuit rotating partsElectric machinePole piece

An electrical rotating machine having a rotor comprising a shaft made from nonmagnetic material, a plurality of pole pieces made from magnetic material and surrounding the shaft, with permanent magnets fixed in receivers by wedges cooperating with the pole pieces to block radially outward movement of the magnets.

Owner:CONCEPTION & DEV MICHELIN SA

High-Efficiency Wheel-Motor Utilizing Molded Magnetic Flux Channels with Transverse-Flux Stator

InactiveUS20090322165A1Reducing hysteresis lossIncrease torqueMotor/generator/converter stoppersMotor control for very low speedsTransverse fluxEngineering

A motor including an outside rotor having a rotor disc with plural magnets alternating polarities flush mounted in the disc, an inside stator assembly with a ring of pole pieces forming a channel to house a transversely wound stator windings, and a controller coupled with feedback electronics for monitoring a timing, speed and direction and coupling a signal to a processing unit for adjusting the drive electronics driving the phase windings. A u-shaped gap above the channel to receive the rotor disc and focus the captured magnetic flux in the pole pieces toward the magnets. In an embodiment the molded magnetic flux channel pole pieces of the inside stator are sets of molded magnetic flux channel pole pieces, each set forming a channel and corresponding to one phase of the motor; and a section of each one of the transverse windings passing through one channel, the remaining section folding back outside the set in close proximity to the outer base of the set of molded magnetic flux channel pole pieces.

Owner:RITTENHOUSE NORMAN P

Methods of orienting an easy axis of a high-aspect ratio write head for improved writing efficiency

InactiveUS7237320B2Efficient switchingElectrical transducersRecord information storageIn planeEngineering

A pole piece of a magnetic write head is formed over a substrate and includes a pole tip having a width that is less than its height which is normal the substrate. Due to stress-anisotropy, the pole tip structure has an inherent easy-axis which is oriented in an unfavorable direction (i.e. perpendicular to the ABS and almost collinear with a driving field of the write head). To alleviate this problem, during electroplating or annealing of the pole piece a magnetic field is applied to the pole tip in a direction which is out-of-plane from the substrate but in-plane with a side wall of the pole tip which vertically projects from the substrate. By applying the magnetic field in this manner, the easy axis of the pole piece is oriented in the direction of the applied magnetic field to facilitate more efficient switching in the write head. Ideally, the angle θ is about 90° for Hexagonal-Closed Packed (HCP) materials or about 50° for Face-Centered Cubic or Body-Centered Cubic (BCC) materials (e.g. NiFe and CoFe).

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Sleeveless permanent magnet rotor construction

InactiveUS20050093391A1Magnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorMagnetic poles

Method and apparatus for containing and protecting the magnets of a permanent magnet rotor spinning at high speeds without the use of a sleeve and is applicable to all permanent magnet rotors with two or more poles. Magnetic pole pieces are used to mechanically retain the magnets as well as provide a low reluctance path for the magnetic field to travel. The pole pieces and magnets are oriented radially on a hub made of a non-magnetic material such that the flux path of the magnets to the rotor poles is not shorted through the hub or shaft. The rotor poles have a taper angle and are secured to the rotor hub; the pole taper angle trapping the magnets, which have a matching taper angle. End cap pieces are provided to retain the rotor poles and the permanent magnets as an integral magnets / poles subassembly for use in a motor or generator.

Owner:CALNETIX

Systems and methods for deep-looking nmr logging

ActiveUS20090072825A1Add depthAccurate estimateElectric/magnetic detection for well-loggingMaterial analysis by using resonanceNMR - Nuclear magnetic resonanceMagnetic poles

An NMR logging tool for conducting NMR measurements in a plurality of sensitive volumes ranging up to a meter from the tool. The tool comprises a magnetic assembly using one or more permanent magnets and at least one pole piece for extending a magnet pole and shaping the magnetic field to simulate a magnetic monopole in a sensitive volume within the formation. Different embodiments of a segmented antenna enable directional NMR logging. The tool embodiments and methods of their use are suitable for wireline or LWD logging, and can be used for directional drilling.

Owner:HALLIBURTON ENERGY SERVICES INC

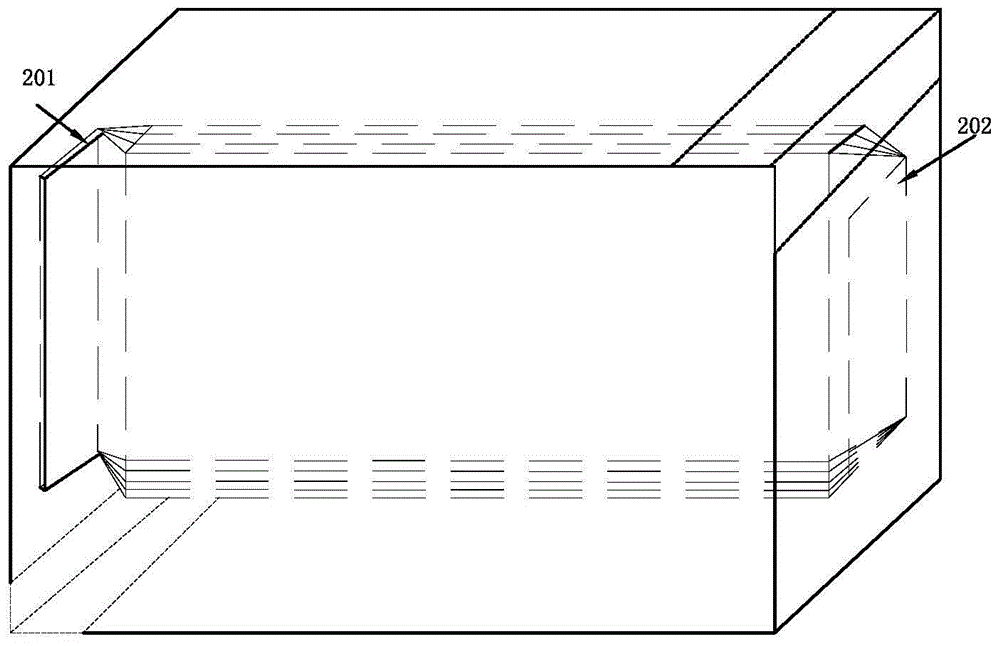

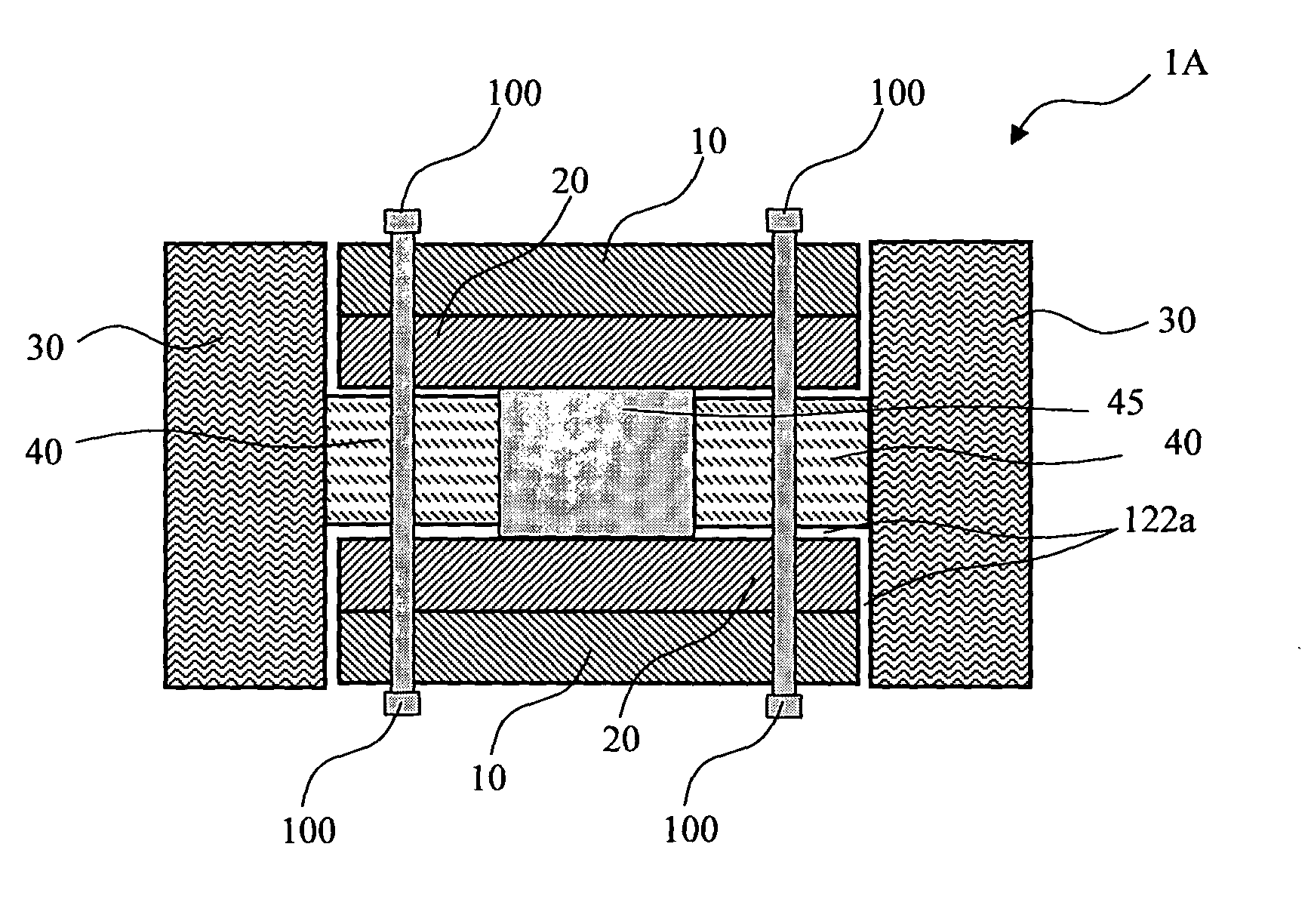

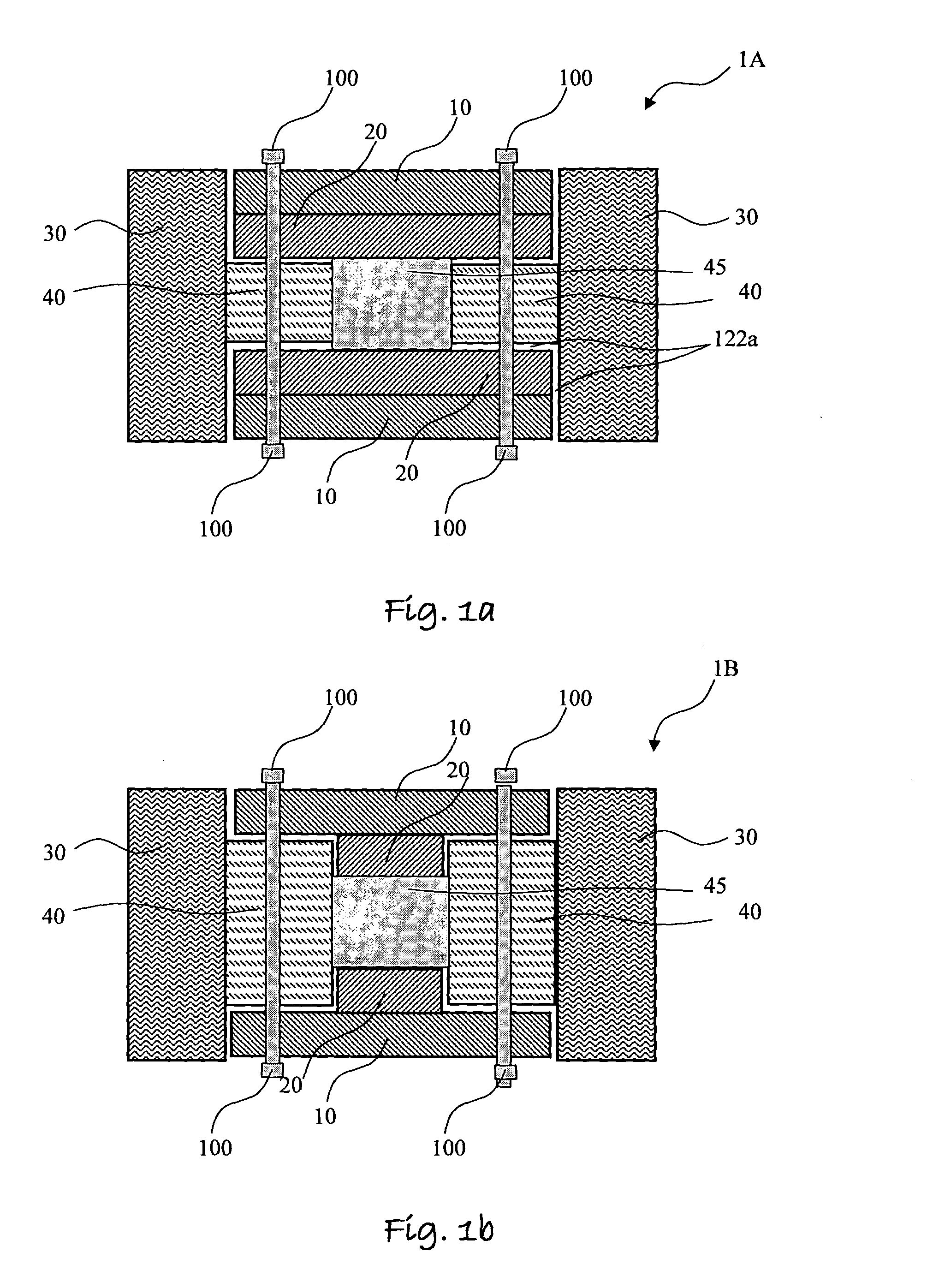

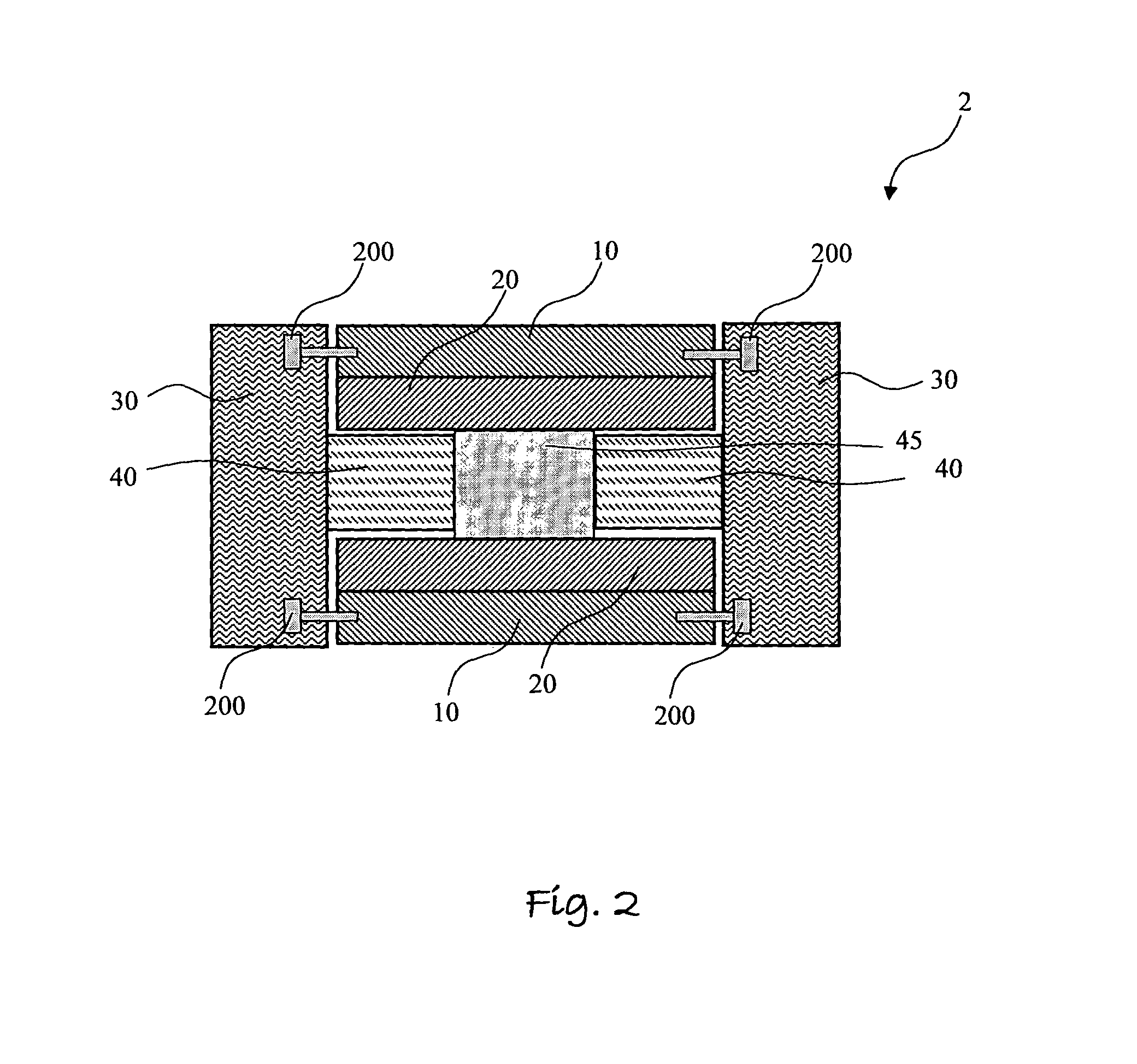

Cage in an MRD with a fastening/attenuating system

Methods of fastening a cage with a fastening system in an MRD. One method includes: assembling: a plurality of pole pieces; a plurality of side magnets, the side magnets substantially enclosing the pole pieces and thereby defining a magnetic envelope and enclosed volume therein; a plurality of side walls, the side walls substantially enclosing the side magnets; a plurality of face walls and a plurality of fastening rods; and passing a plurality of fastening rods through at least one of the side magnets and at least one of the pole pieces and fastening them in an effective measure, such that the rods physically interconnects at least one pair of side walls.

Owner:ASPECT IMAGING

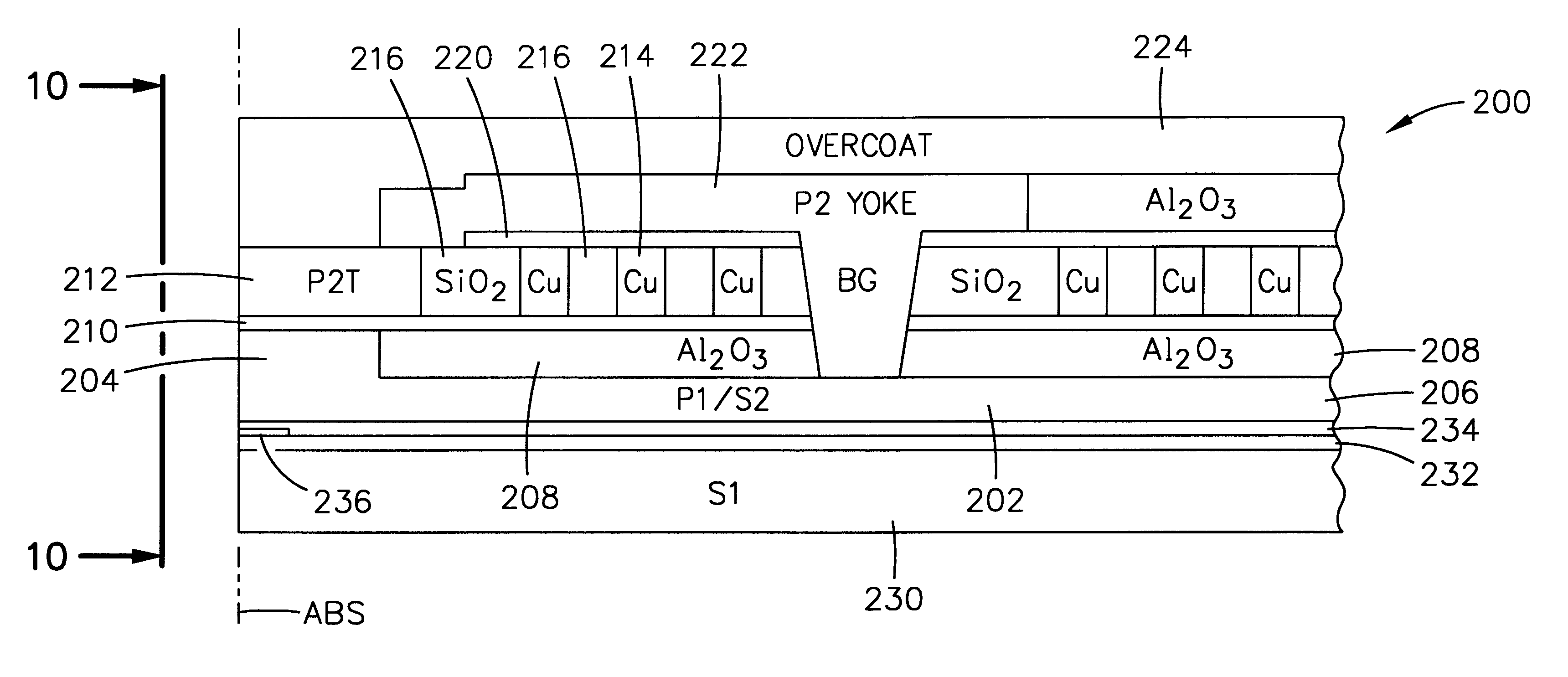

Planar stitched write head having write coil insulated with inorganic insulation

InactiveUS6226149B1Avoid layeringEliminate hard bakingConstruction of head windingsElectrical transducersInsulation layerEngineering

A write head has a second pole tip layer, a coil layer and a write coil insulation layer that are planarized at their top surfaces. A thin top insulation layer insulates the top of the coil layer from a yoke portion of the second pole piece which is connected to the second pole tip layer in the pole tip region and connected to a first pole piece layer in a back gap region. In a preferred embodiment the write gap layer extends throughout the yoke region and provides the only insulation between the first pole piece layer and the coil layer. Further, it is preferred that the write coil insulation layer be an inorganic material such as silicon dioxide (SiO2). Several embodiments of the write head are provided along with novel methods of making.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Solenoid valve

ActiveUS20050166979A1Easy to moveMinimal gap widthFuel supply regulationGaseous fuel feeder/distributionSolenoid valveEngineering

A valve assembly comprises two valves and a single solenoid actuator with only one magnetizing coil that controls both valves. The corresponding magnetic circuit comprises a yoke with only two pole pieces. The valves are arranged concentric to one another. The valve closing element of the outer valve is connected to an armature by means of a sleeve. The cup thus formed receives the armature that is connected to the valve closing element of the inner valve. The pole piece and the armature form a transmission air gap through which the sleeve extends. A coupling air gap is formed between the armatures. The armature and the pole piece form a working air gap. The valves are opened collectively and are able to close independently of one another when the coil is rendered currentless.

Owner:KARL DUNGS

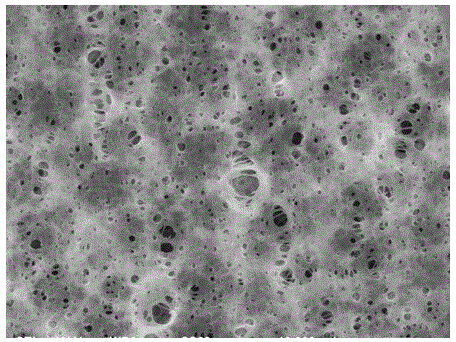

Polymer lithium ion battery and diaphragm thereof

ActiveCN102610773AImprove thermal stabilityImprove mechanical propertiesSecondary cellsCell component detailsCyclic processSwelling capacity

The invention belongs to the technical field of polymer lithium ion batteries, in particular to a diaphragm for the polymer lithium ion battery. The diaphragm comprises a multihole base material, wherein an inorganic substance coating layer and an organic substance coating layer are coated on at least one surface of the multihole base material; and the organic substance coating layer is in island-type and / or linear distribution and coated on the surface of the multihole base material and / or the inorganic substance coating layer. Compared with the prior art, due to the inorganic substance coating layer, the diaphragm can keep relatively high heat stability and mechanical performance, so that the lithium ion battery has high safety performance; the organic substance coating layer has high imbibition swelling capacity, and an interface has high stability, so that the manufactured lithium ion battery has perfect mechanical performance; due to the distribution characteristic of the organic substance coating layer, spaces are provided for charging and discharging processes of a pole piece and a circulation process; and the problem of deformation of the polymer lithium ion battery is well solved. Furthermore, the invention also discloses a polymer lithium ion batter with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com