Patents

Literature

592results about How to "Effective bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

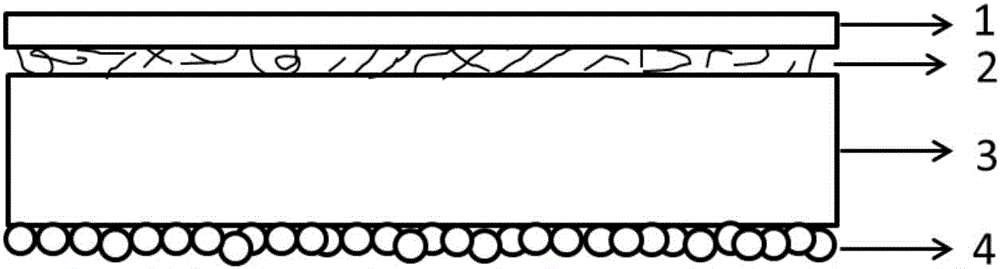

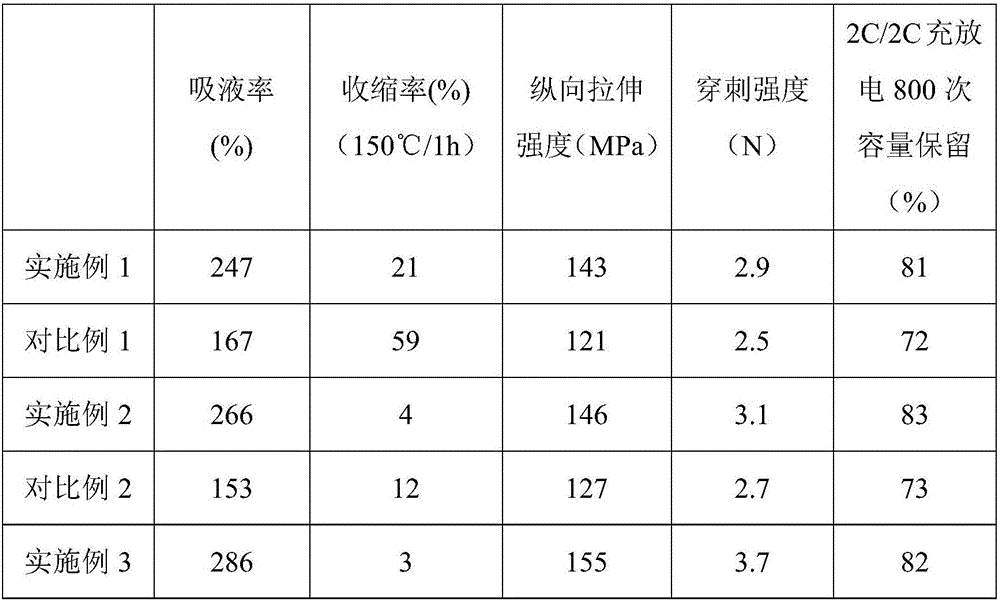

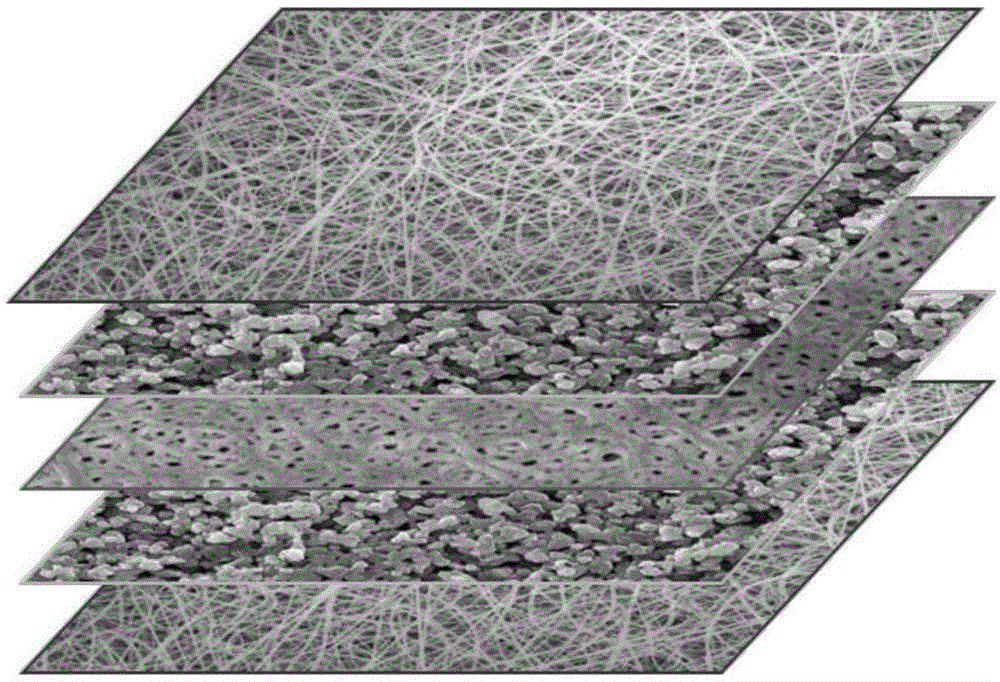

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

ActiveCN106252565ATight bondIncrease volumetric energy densityFireproof paintsCell component detailsLithium-ion batteryAramid

The invention discloses a lithium-ion battery separator subjected to composite coating treatment and a preparation method thereof. The lithium-ion battery separator comprises a basement membrane, a polymer coating coated at one side of the basement membrane, and an inorganic particle coating coated at the other side of the basement membrane; the polymer coating is composed of an aramid coating coated on the basement membrane and a polyvinylidene fluoride coating coated on the aramid coating, and the thickness of the polymer coating is 0.3 to 5 [mu] m; and the inorganic particle coating is composed of inorganic particles of different particle sizes and a binding agent, and the thickness of the inorganic particle coating is s 0.5 to 5 [mu] m. The lithium-ion battery separator provided by the invention has the characteristics of being excellent in mechanical property and heat resistant property, having good wettability and solution preserving property to electrolyte, and excellent in cycle performance and high in safety performance.

Owner:深圳市鼎泰祥新能源科技有限公司

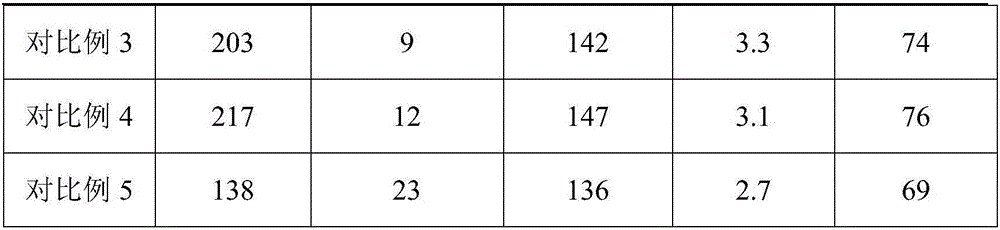

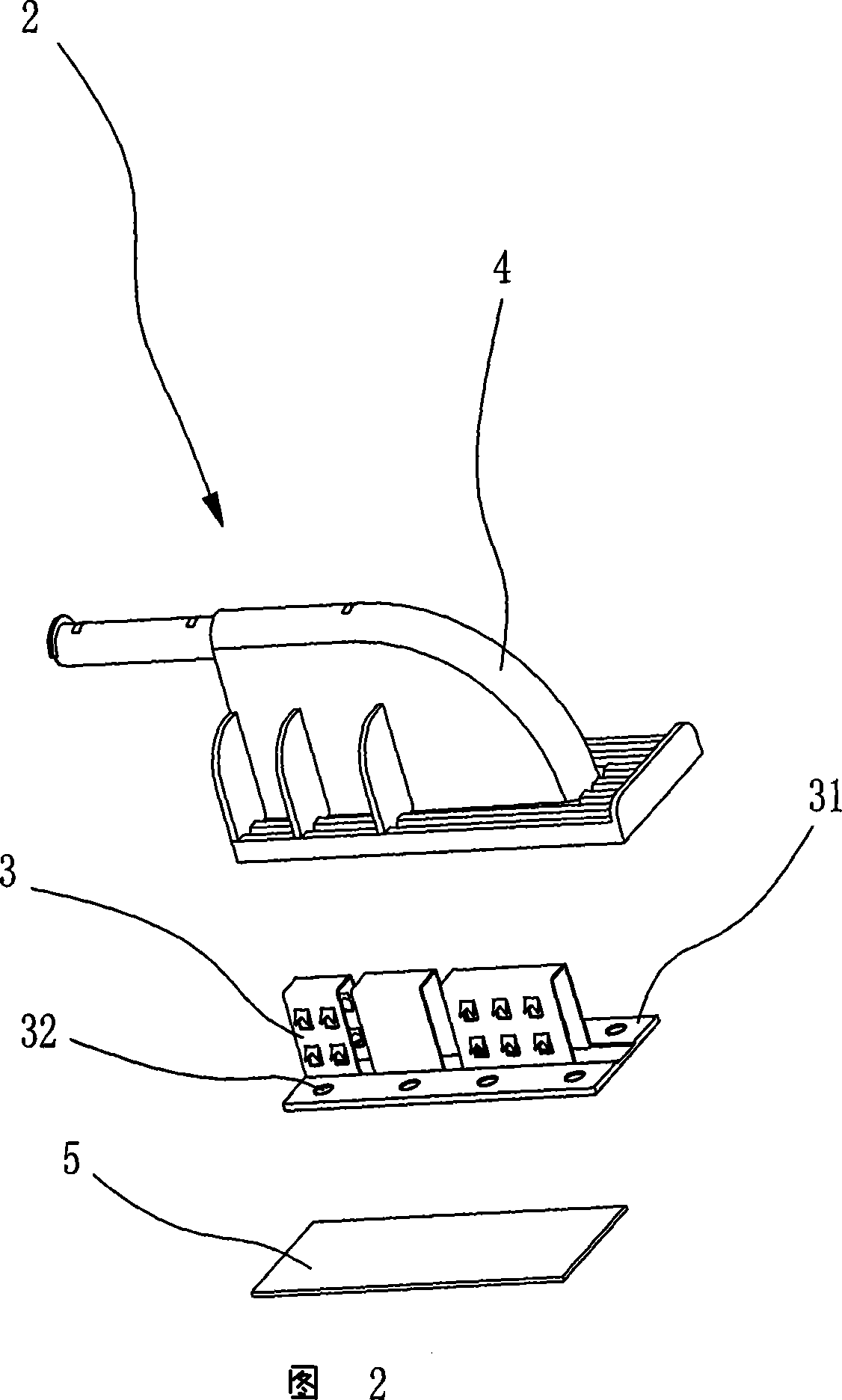

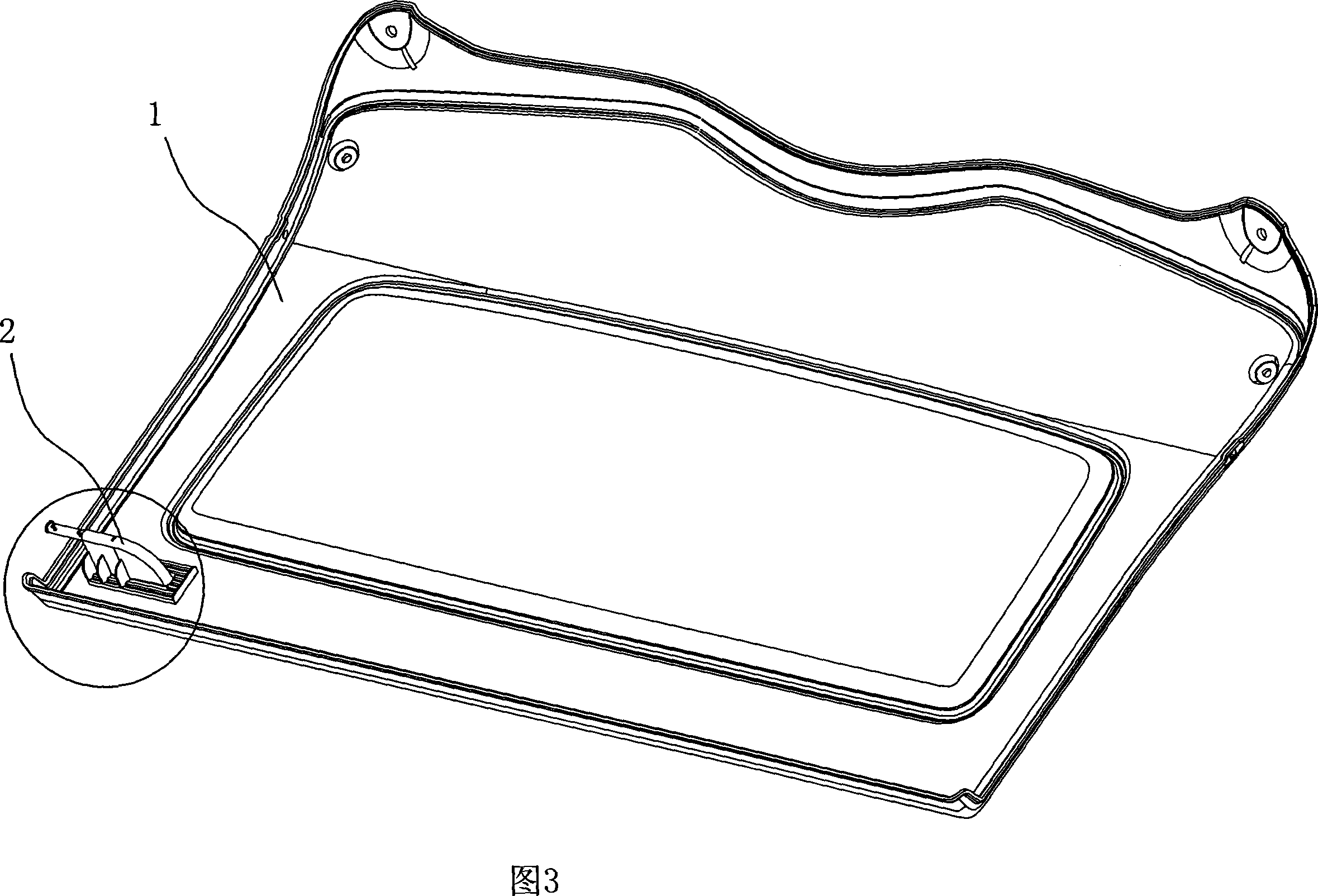

Automobile internal decorative piece and making method

InactiveCN101024387ASolve the problem of not being able to bond effectivelyEffective bondingSheet joiningSuperstructure subunitsFrame basedPolypropylene

The invention discloses a vehicle inner ornament and the manufacturing method. It is made up of frame base material and fixed a buckle that includes bottom board. The feature is that the frame base material compounding or polypropylene included woodflour board including polypropylene board, and the bottom board of fixed buckle is connected on the polypropylene board or the woodflour board. The method includes the following steps: softening frame base material and polypropylene board or woodflour board, putting fixed buckle into mold and locating the polypropylene board or woodflour board and base material into mold, and ensuring the polypropylene board and woodflour board is located between bottom board and frame base material; taking pressure forming. The bond strength between buckle and frame base material could reach 420N, and it is low cost. It is convenient to produce and has high efficiency.

Owner:宁波拓普隔音系统有限公司

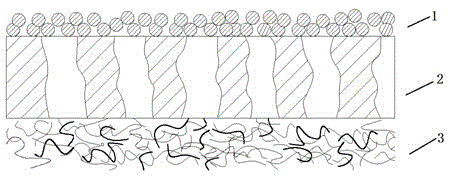

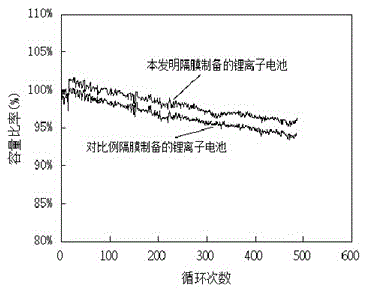

Composite coating lithium-ion battery separator and preparation method thereof

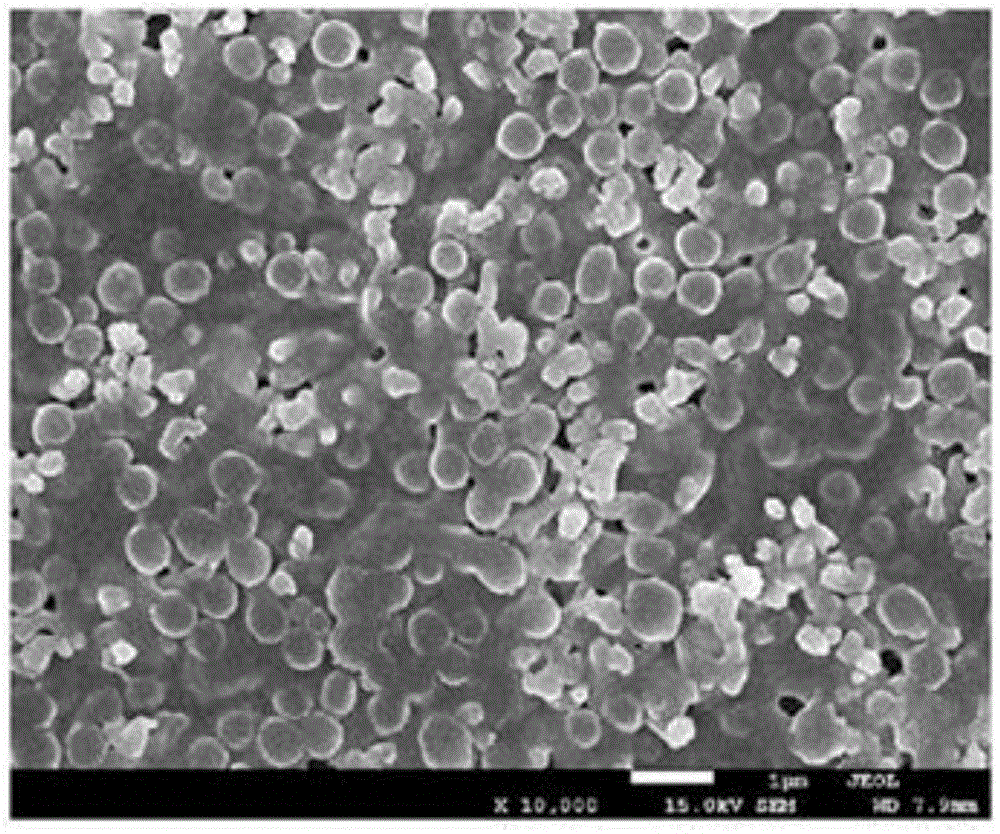

ActiveCN105552284AImprove thermal performanceImprove mechanical propertiesCell component detailsWater basedPole piece

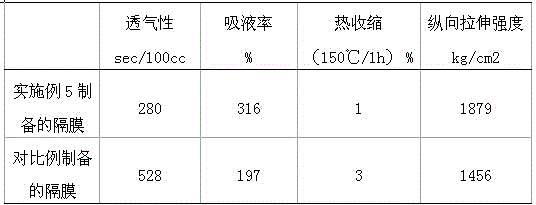

The invention relates to a composite coating lithium-ion battery separator. The composite coating lithium-ion battery separator is composed of a base film, an aramid fiber coating coated on one side of the base film and a PVDF coating coated on the other side of the base film; the aramid fiber coating is obtained by an aramid fiber sizing agent after coating, soaking and drying, and the thickness of the coating is 0.5-4 microns; the PVDF coating is obtained by a water-based PVDF sizing agent after coating and drying, and the thickness of the coating is 0.1-2 microns. The invention also provides a preparation method of the separator. According to the composite coating lithium-ion battery separator and the preparation method thereof, the separator has the characteristics that the aramid fiber coating is good in thermal performance and mechanical performance and the PVDF coating has good wettability and liquid retention property for electrolytes, can effectively adhere batteries and pole pieces and is little in environmental pollution, and is beneficial for preparing lithium-ion batteries with longer cycle life and higher safety. Tests indicate that the separator has good air permeability, liquid absorption rate, thermal contraction and tensile strength, so that the cycle life of the batteries can be obviously prolonged by using the lithium-ion batteries prepared by the separator.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

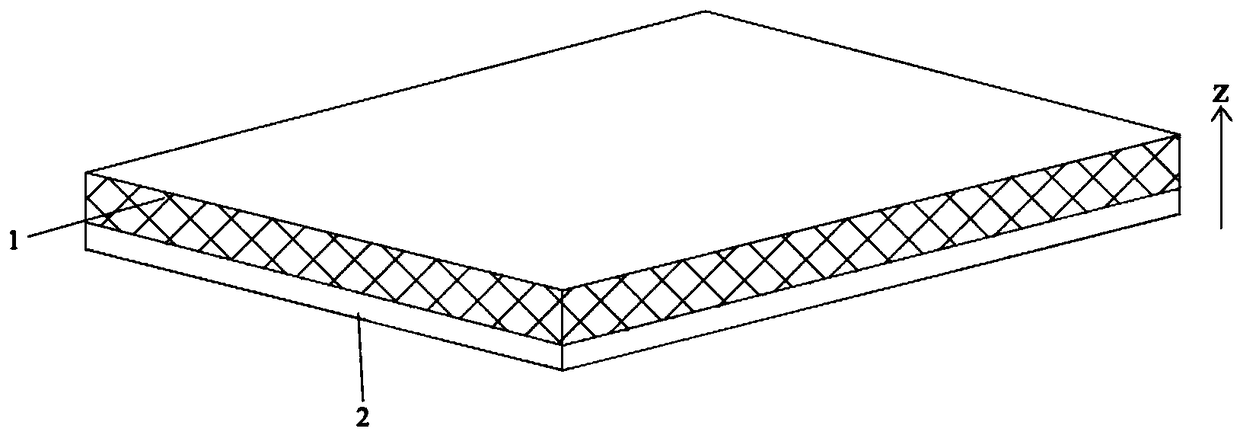

Composite board based on mixed waste polymers and preparation method thereof

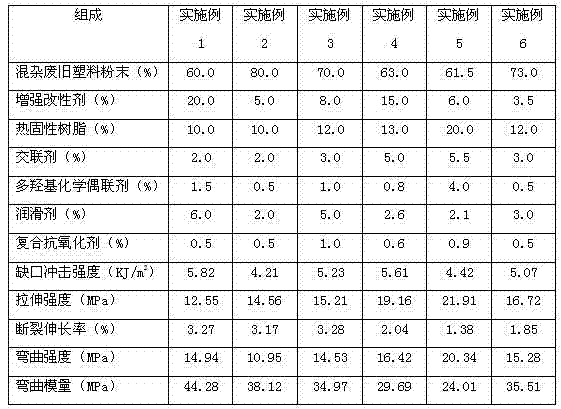

The present invention discloses a composite board based on mixed waste polymers and a preparation method thereof. The preparation method of the composite board based on the mixed waste polymers is characterized by comprising the following steps of: (1) weighing the raw materials according to a certain proportion, adding the raw materials to a high-speed mixer, mixing at the temperature of 40-60 DEG C and the rotation speed of 800-2000 rpm for 20-30 minutes, cooling to room temperature and discharging; and (2) adding the mixed material to a mold, vulcanizing at the temperature of 150-180 DEG C and the pressure of 10-15 MPa for 10-20 minutes, cooling and relieving pressure. The composite board based on the mixed waste polymers provided by the invention does not need to consider the complex compatibility and plasticizing problems of multiple polymers, effectively solves the problems that the existing mixed waste polymers can not be classified and are discarded, and can be used as the substitute for wood to be applied in the tray manufacturing field and other fields. The production process provided by the invention is simple, uses existing equipment and is suitable for mass production.

Owner:佛山市南海承骏科技有限公司 +1

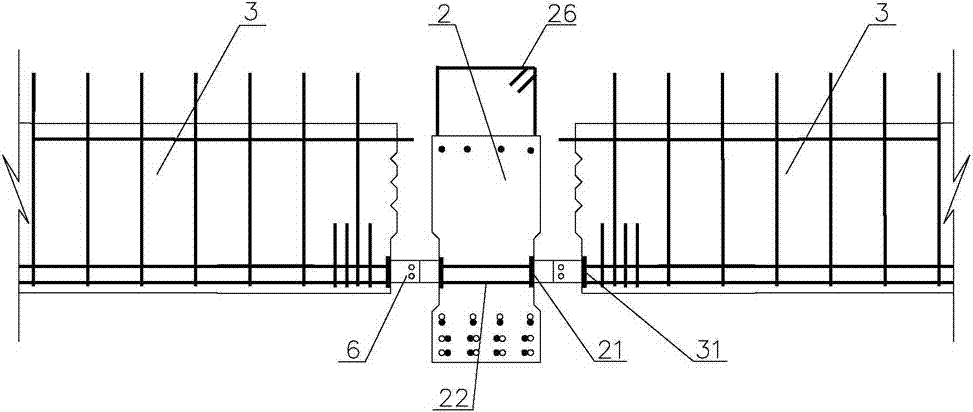

Pre-tensioning prestressed composite beam structural system and construction method thereof

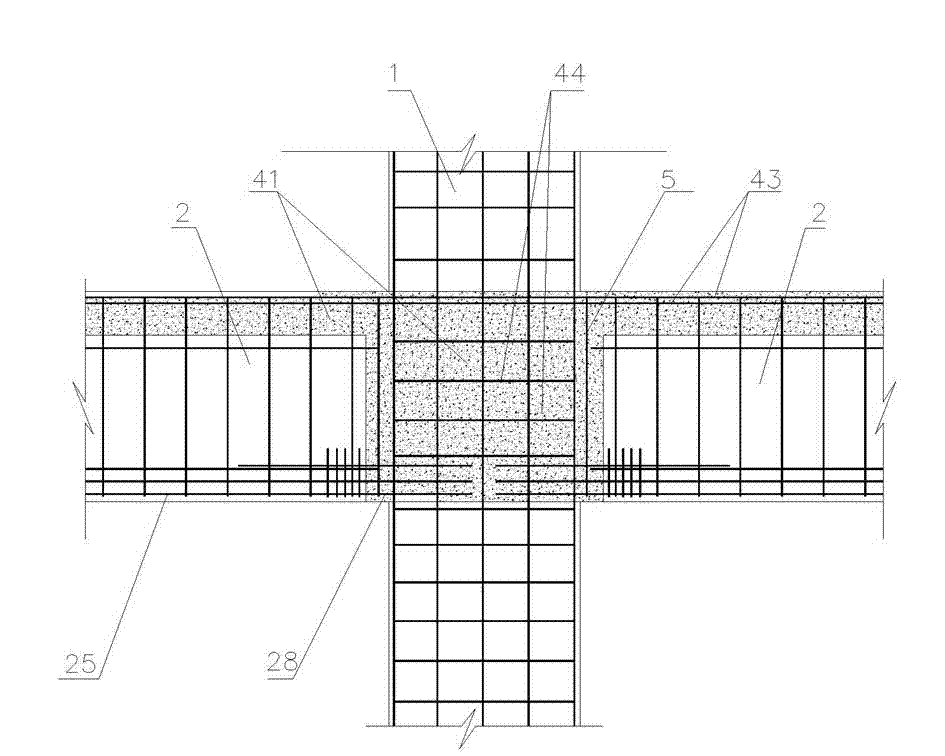

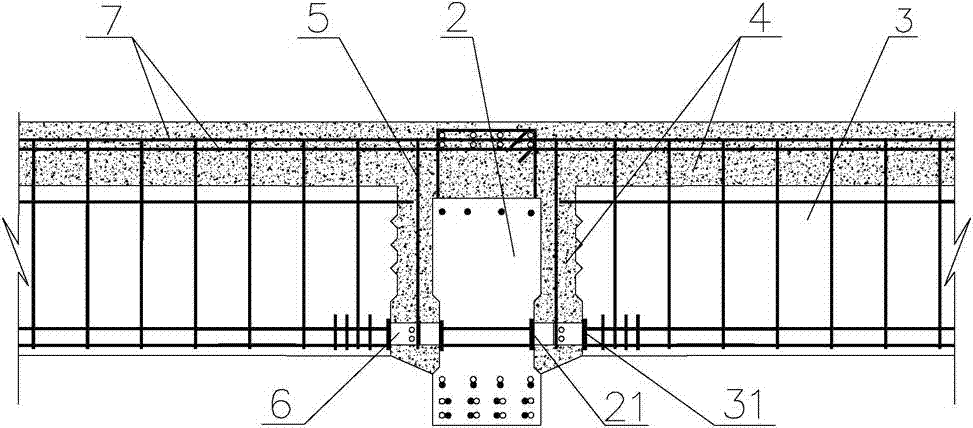

The invention relates to a pre-tensioning prestressed composite beam structural system and a construction method of the pre-tensioning prestressed composite beam structural system. Lower longitudinal reinforcements are bound and lapped on lower longitudinal prestress wires in composite frame beam prefabricated components; the lower longitudinal reinforcements are inserted into frame pillars; second pre-buried steel plates are buried in the lower end portions of the composite frame beam prefabricated components; lower portion longitudinal prestress wires are buried in the composite frame beam prefabricated components; secondary beam longitudinal reinforcements are lapped and bound on the lower portion longitudinal prestress wires; the second pre-buried steel plates are welded with the secondary beam longitudinal reinforcements; first pre-buried steel plates opposite to the second pre-buried steel plates are arranged on the composite frame beam prefabricated components; pitch point steel plates are respectively welded on the first pre-buried steel plates and the second pre-buried steel plates; and the pitch point steel plates are connected through bolts, which enables the composite frame beam prefabricated components to connect with composite secondary beam prefabricated components. Wires and longitudinal reinforcements are lapped to use in the pre-tensioning prestressed composite beam structural system, and therefore the connecting mode of the pre-tensioning prestressed composite beam structural system is scientific and reasonable, and quality is safe and reliable.

Owner:HUA HUI ENGINEERING DESIGN GROUP CO LTD

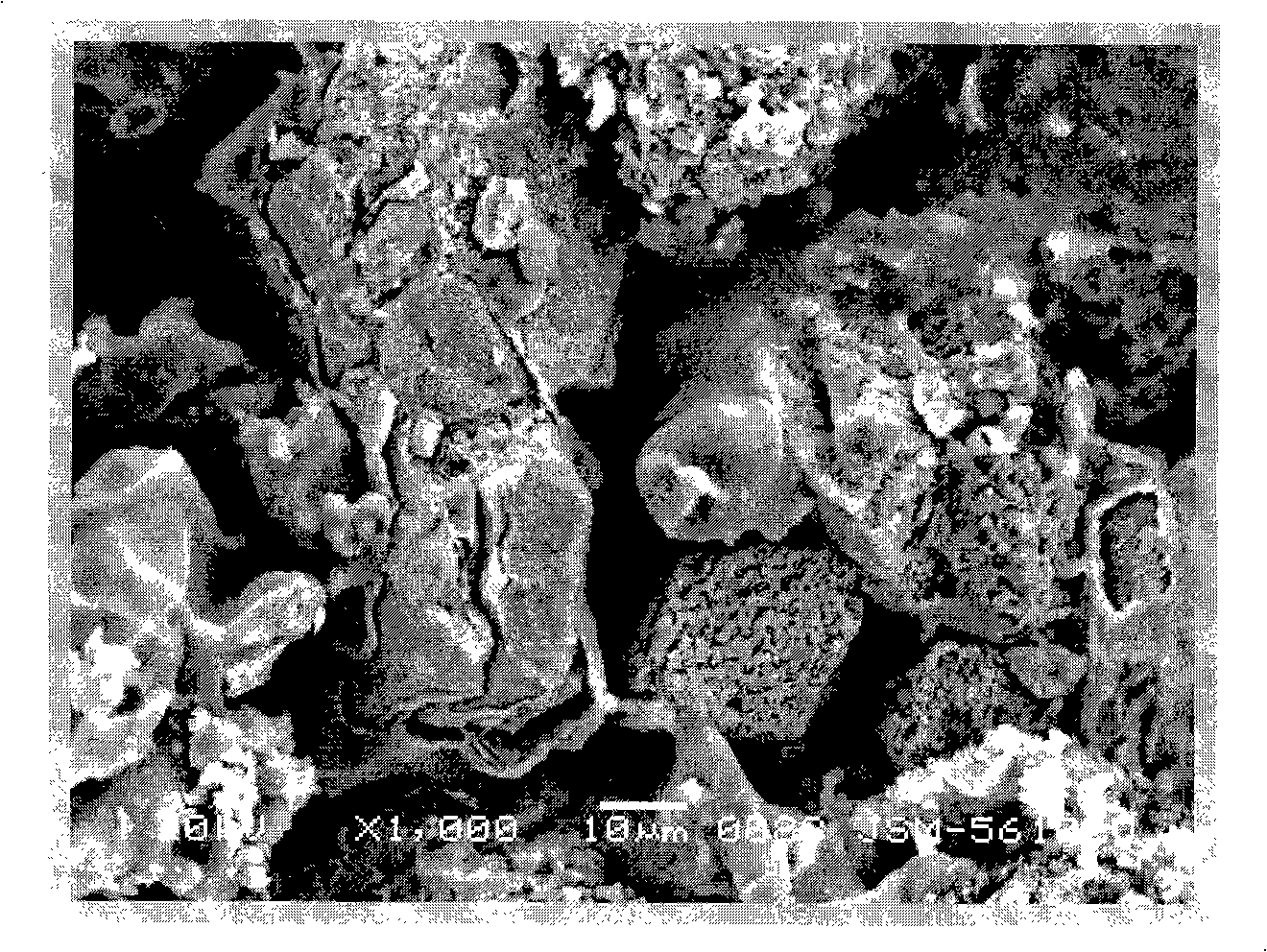

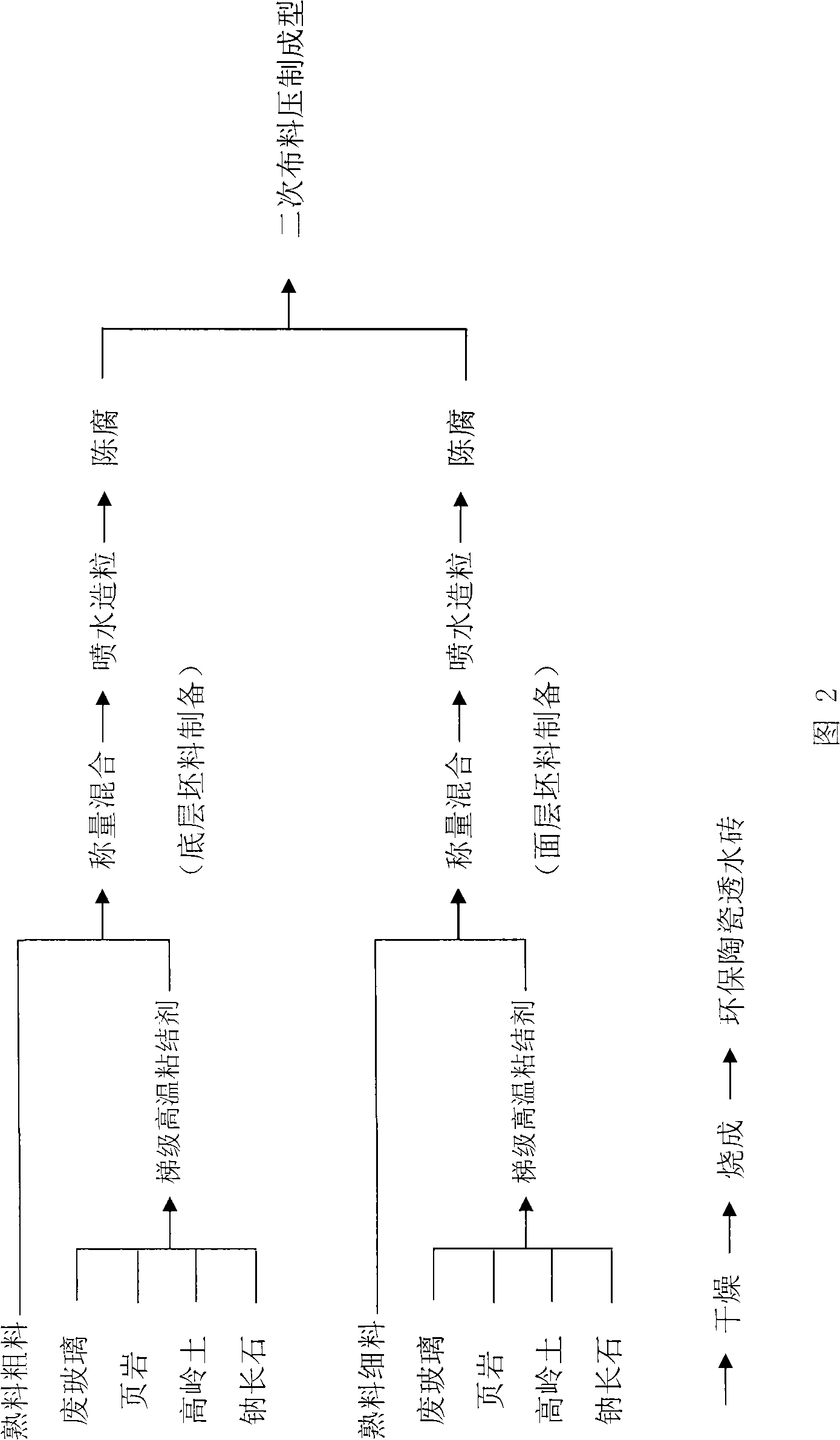

Preparation of enviroment protective ceramic water permeable brick

The invention belongs to the building material technology field, specially relates to a method for preparing a ceramic permeable brick comprising the following steps: 1) preparation of the bottom blank: crushing the solid waste clinkers and screening the same into coarse grains with a grain size of 2-3mm to get coarse grain solid waste clinkers, wherein the weight percentage of each component is as follows: 60-80% of coarse grain solid waste clinkers, 20-40% of cascade high temperature binders which pass through a 100 mesh screen; choosing the coarse grain solid waste clinkers and the cascade high temperature binders which pass through a 100 mesh screen for stand; sealing and staling the mixture by plastic clothing to get the bottom blank; 2) preparation of the surface course blank: crushing the solid waste clinkers, screening the same into fine grains with a grain size less than 2mm and more than or equal to 1mm; 3) moulding by means of hydraulic press machine of brick; 4) drying the permeable brick green body; 5) calcining the dried permeable brick green body by a silicon carbide bar furnace or a fuel gas shuttle kiln at 1100-1200 DEG C to get the environmental ceramic permeable brick products. The ceramic permeable brick has advantages of high intension and low cost.

Owner:WUHAN UNIV OF TECH +1

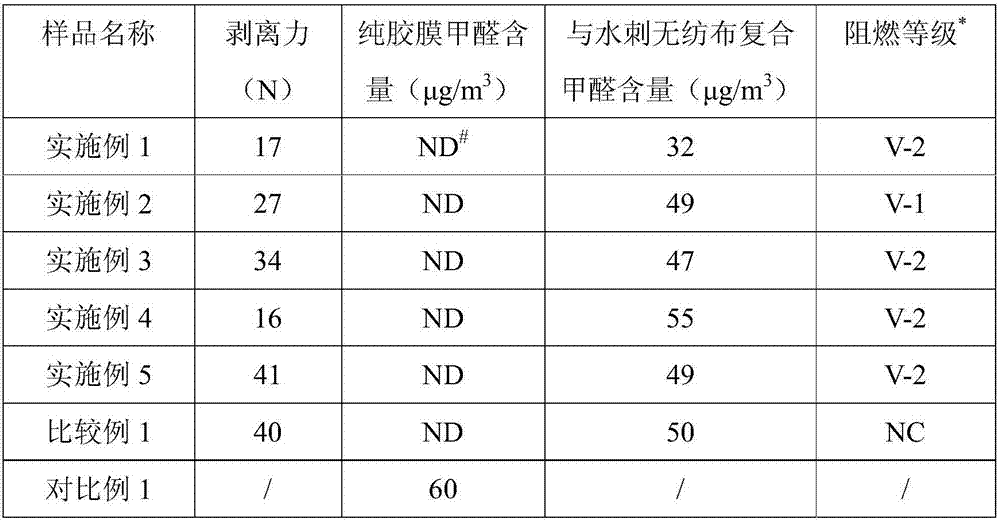

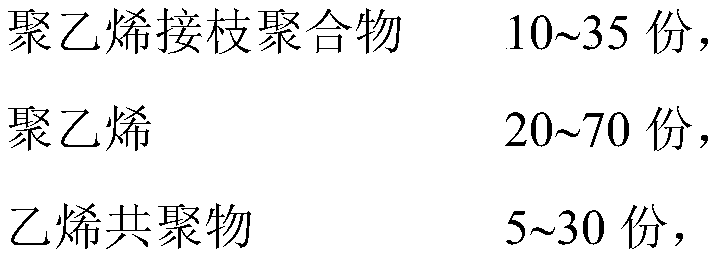

Environmentally friendly hot melt adhesive membrane for automotive interior products, preparation method and application

ActiveCN107151539AHigh strengthEffective bondingNon-macromolecular adhesive additivesFilm/foil adhesivesOrganic solventElastic component

The invention discloses an environmentally friendly hot melt adhesive membrane for automotive interior products, a preparation method and application. The environmentally friendly hot melt adhesive membrane for the automotive interior products comprises the following components in parts by mass: 100 parts of an elastic component, 0.1-50 parts of a non-elastic component and 0.1-20 parts of composite filler. The melt index of the elastic component is 0.9-30 g / 10 min (190 DEG C, 2.16 kg), the melt index of the non-elastic component is 0.2-10 g / 10 min (190 DEG C, 2.16 kg), and the melt index of the elastic component is greater than that of the non-elastic component. The composite filler comprises bamboo charcoal fibers and flame-retardant filler. The environmentally friendly hot melt adhesive membrane is used for adhesion of the automotive interior products, does not contain any organic solvents, does not produce toxic or harmful gas, and has antibacterial property and flame retardancy. Compared with a common antibacterial or flame-retardant product, the environmentally friendly hot melt adhesive membrane for the automotive interior products is simple and convenient to process.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

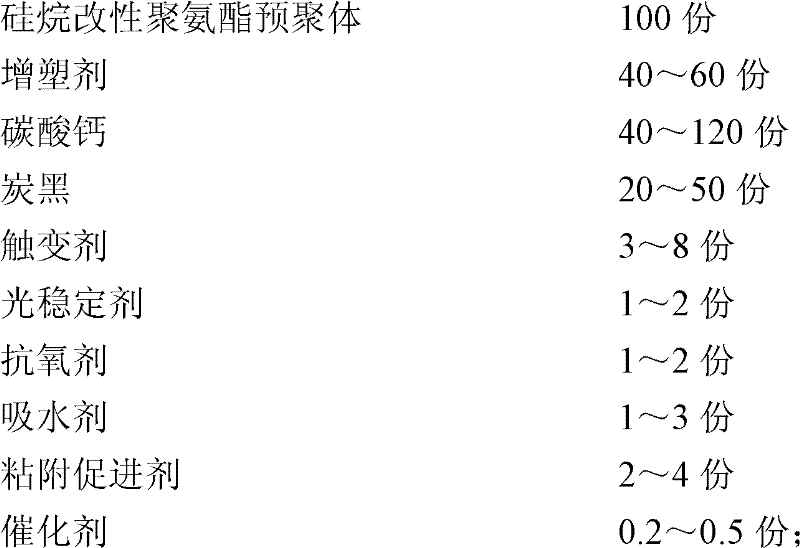

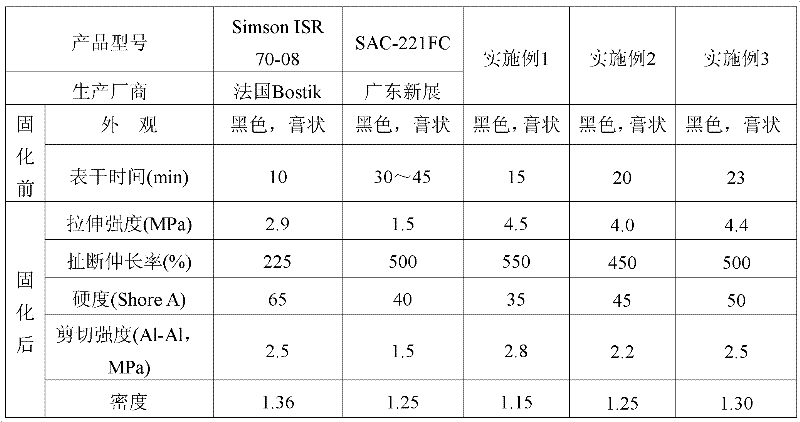

Silane modified polyurethane sealing glue with quick surface dry as well as preparation and application thereof

ActiveCN102504748AHigh mechanical strengthImprove sealingEngine sealsNon-macromolecular adhesive additivesSilanesAntioxidant

The invention discloses silane modified polyurethane sealing glue with quick surface dry as well as a preparation and an application thereof. The sealing glue is prepared from the following substances in parts by weight: 100 parts of silane modified polyurethane prepolymer, 40-60 parts of plasticizer, 40-120 parts of calcium carbonate, 20-50 parts of carbon black, 3-8 parts of thixotropic agent, 1-2 parts of light stabilizer, 1-2 parts of antioxidant, 1-3 parts of water absorbent, 2-4 parts of adhesion promoter and 0.2-0.5 part of catalyst. According to the invention, by dispersing the raw materials at a certain temperature and under vacuum conditions to prepare the silane modified polyurethane sealing glue product. The product is the single-component sealing glue cured at a room temperature and has a fast surface dry speed, and the surface dry time is 15-20 min; the sealing glue does not influence the assembling of parts so that the sealing glue can be applied to industrial fields including gluing, sealing and the like of automotive windscreens; the sealing glue does not need to be firstly coated in the construction process and has the advantages of higher temperature resistance, water resistance, ageing resistance and higher physical mechanics performances after being cured.

Owner:GUANGZHOU MECHANICAL ENG RES INST

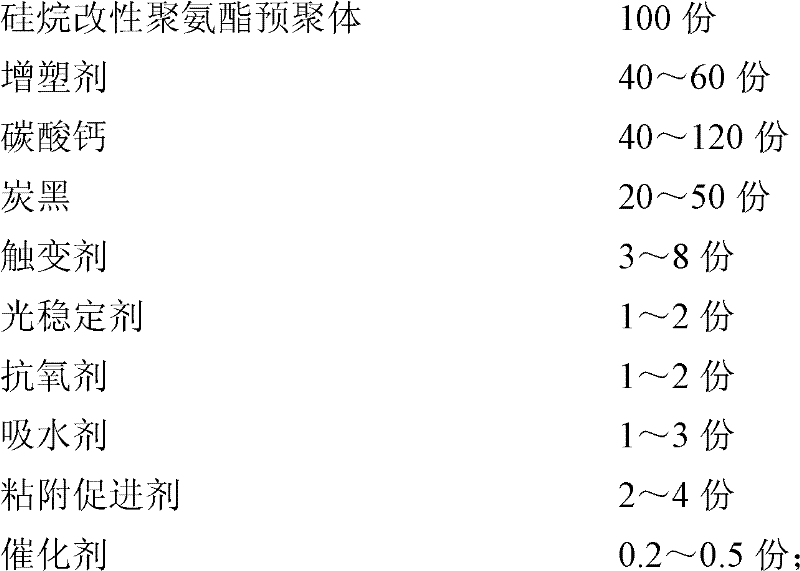

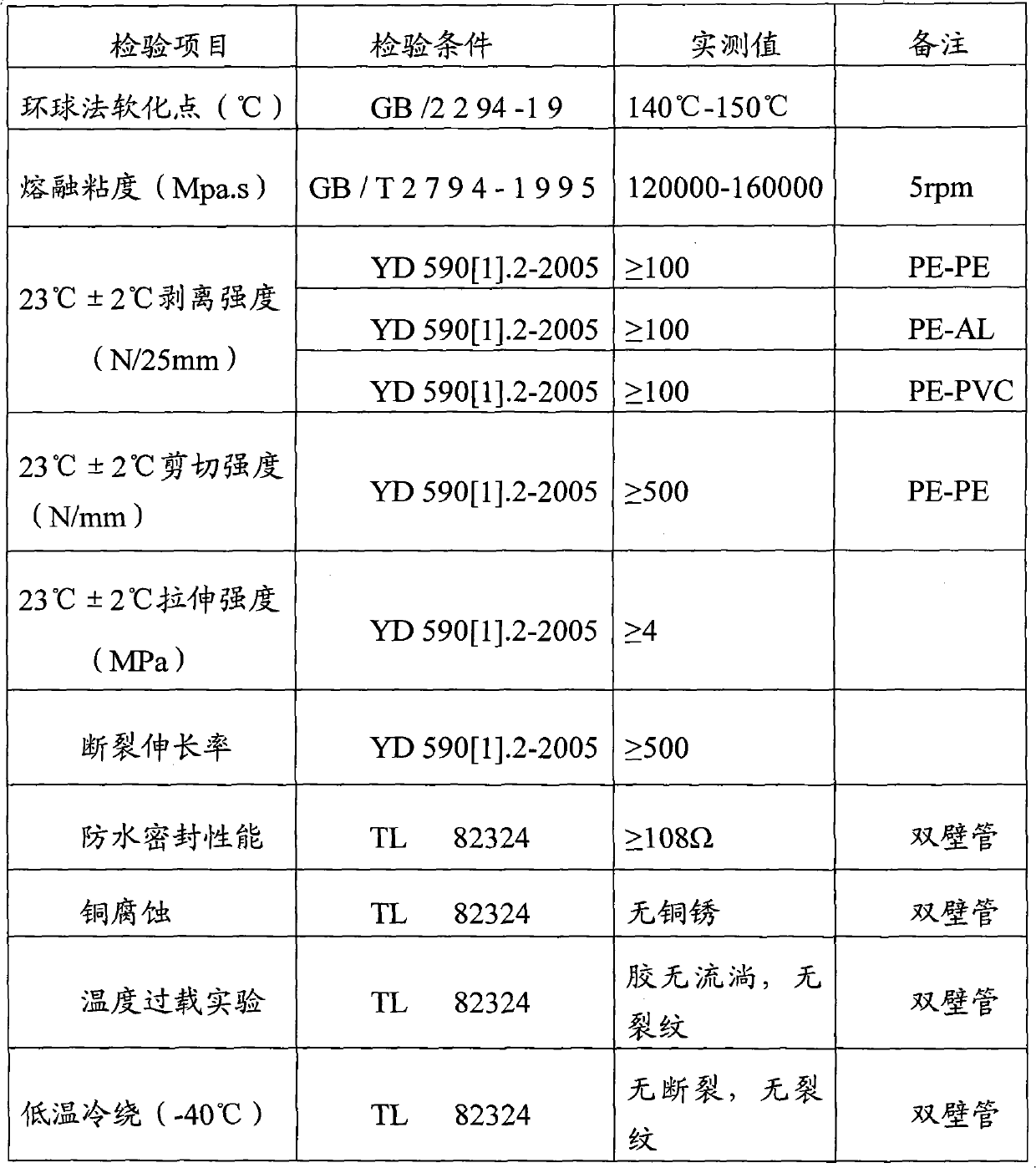

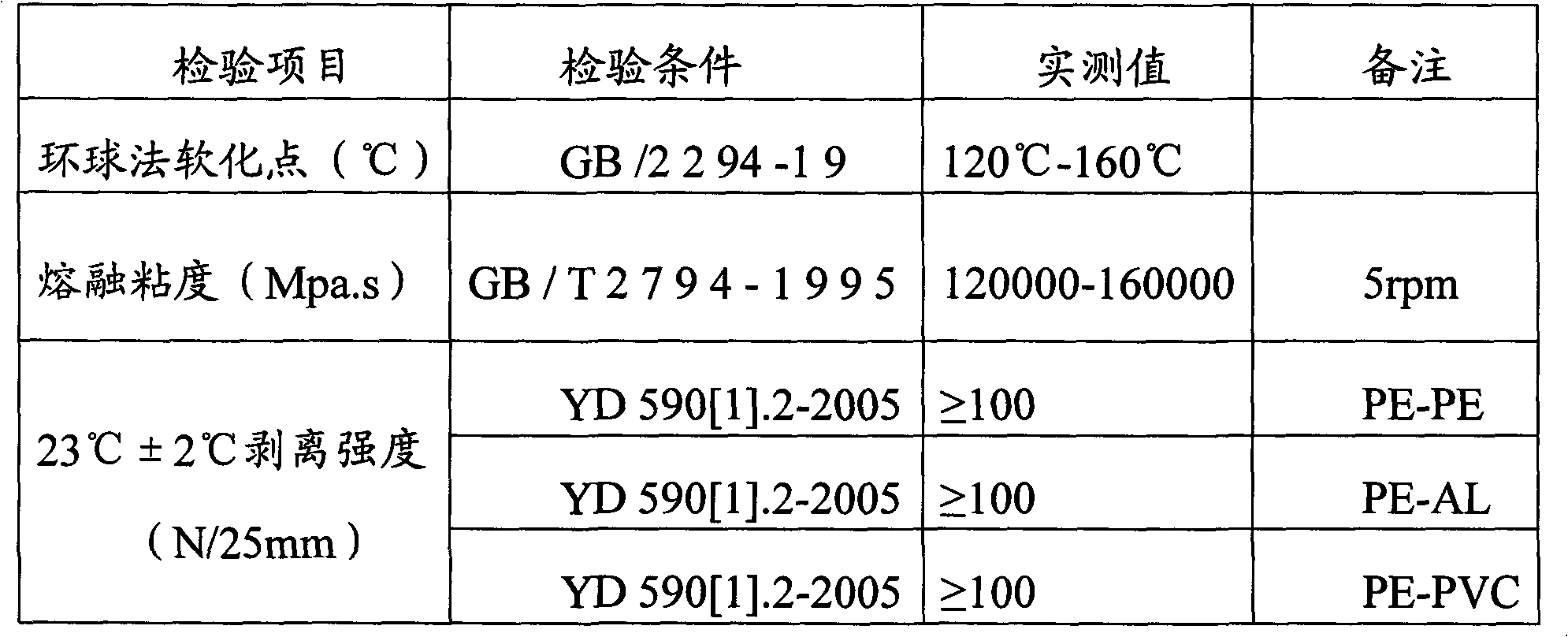

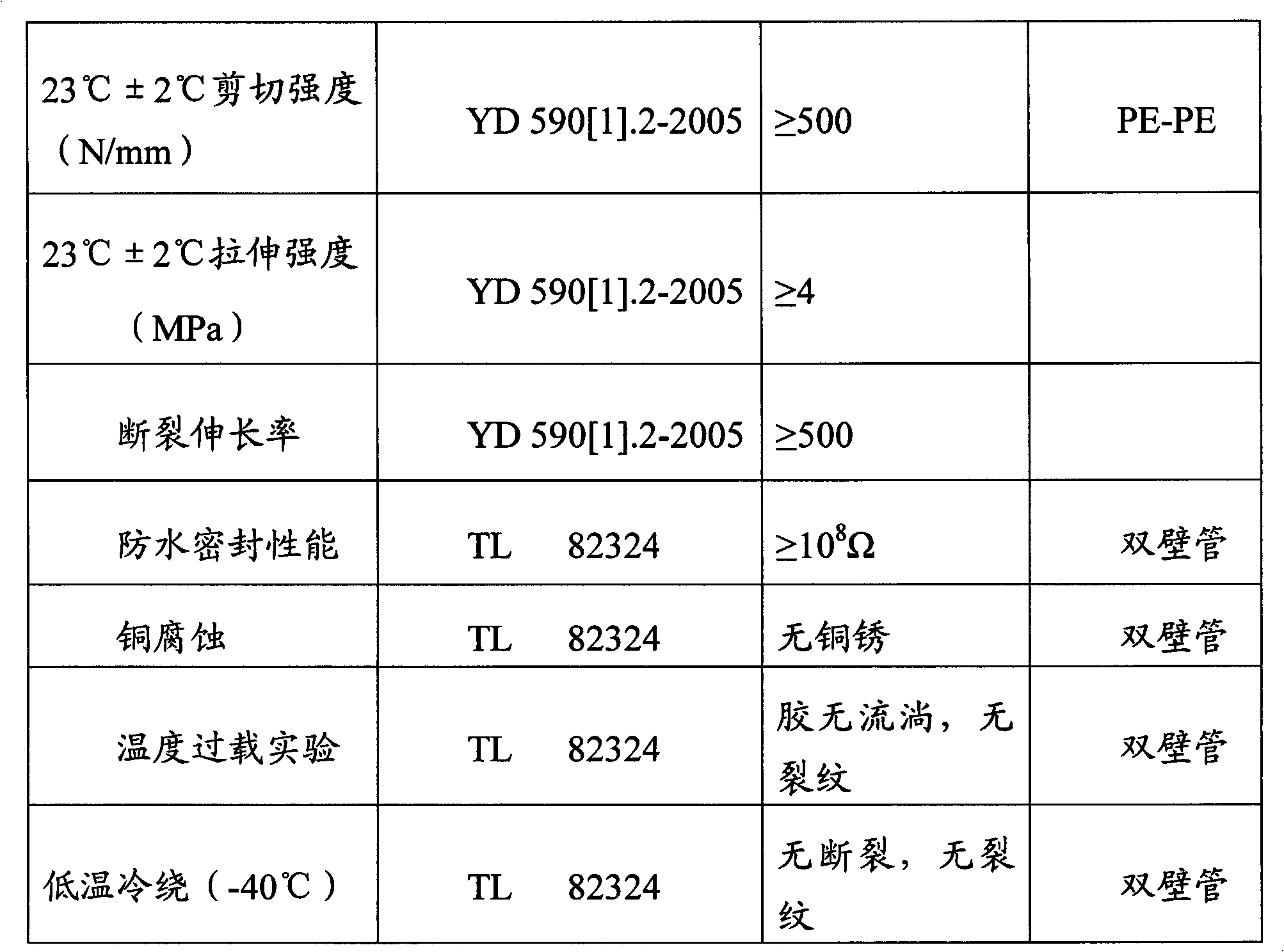

High temperature resistant hot melt adhesive and processing process thereof

The invention provides a formula of a high temperature resistant hot melt adhesive and a processing process of the hot melt adhesive. The formula comprises the following components: polyamide, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, a tackifier, an antioxidant and a modifier. The high temperature resistant hot melt adhesive is high in bonding strength, resistant to high temperature, excellent in insulating and sealing performance, resistant to a low temperature, environment-friendly, non-toxic, simple in production process and good in repeatability.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

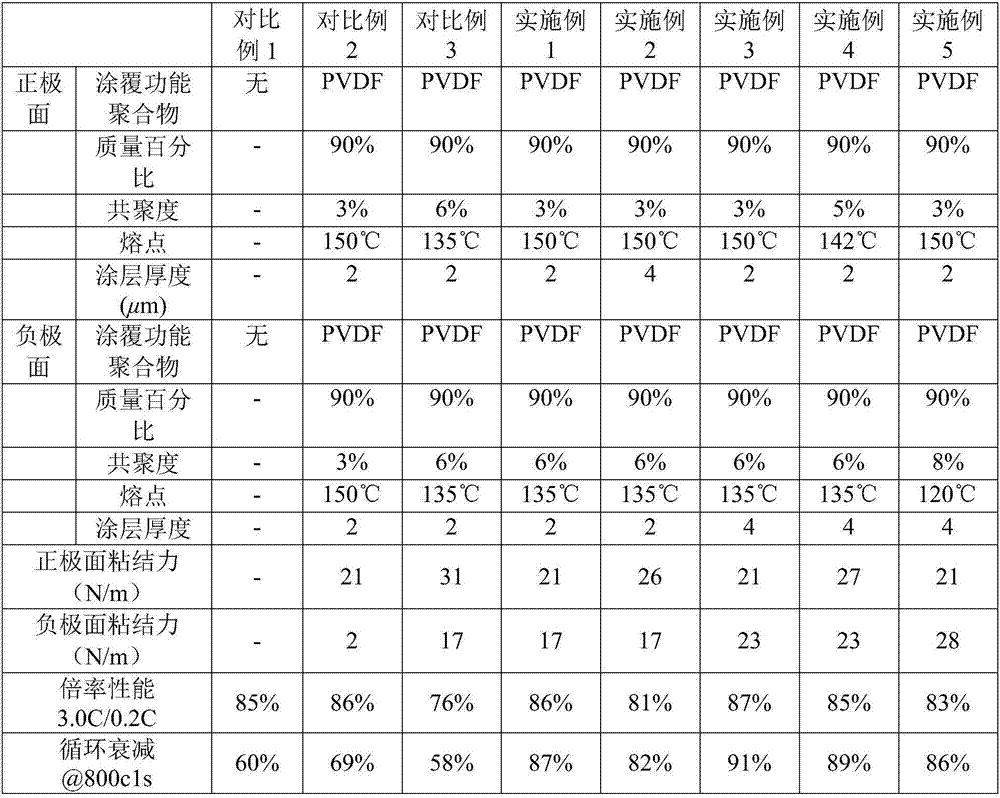

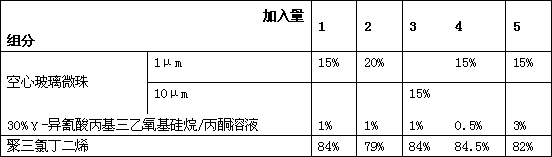

Organic functional porous isolating membrane, preparation method and lithium ion battery

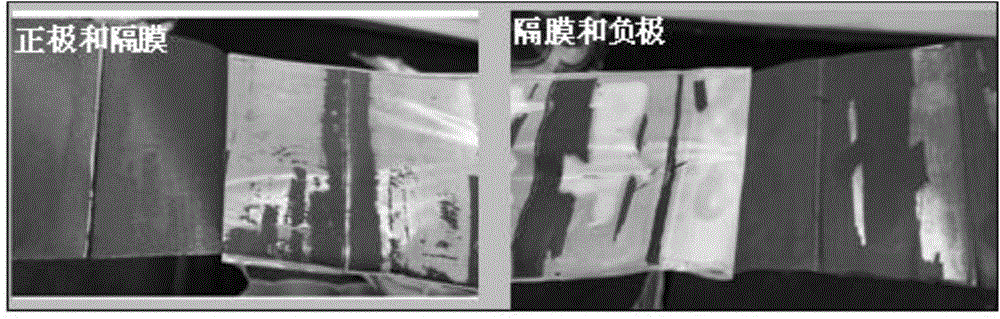

ActiveCN107123767AImprove adhesionExcellent rate performanceCell seperators/membranes/diaphragms/spacersSecondary cellsSodium-ion batteryLong term cycling

The invention discloses an organic functional porous isolating membrane, a preparation method and a lithium ion battery, and aims to the solve the problem that a function of a coating layer is influenced caused by different binding effects when the surfaces of two coating layers of the same specification of an isolating membrane are laminated and glued with positive and negative plates of different physical properties of a battery. According to the main points of the technical scheme, the organic functional porous isolating membrane comprises a porous base material and organic functional coating layers attached to two surfaces of the porous base material; and each organic functional coating layer comprises organic functional polymer polyvinylidene fluoride, an aqueous polymer thickening agent, and an aqueous polymer binder. According to the different characteristics of the positive and negative electrode materials of the lithium ion battery corresponding to the two surfaces of the porous base material, the organic functional polymer polyvinylidene fluoride with different copolymerization degrees and fusing temperatures can be selected on the surfaces of the isolating membranes of the corresponding positive and negative electrodes, so that the safety performance and the long-term cycling stability of the battery can be improved.

Owner:深圳市旭然电子有限公司

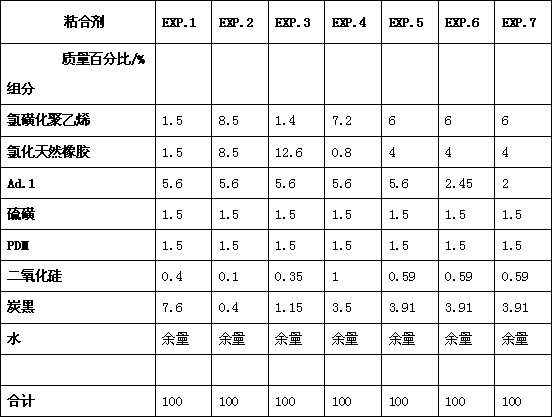

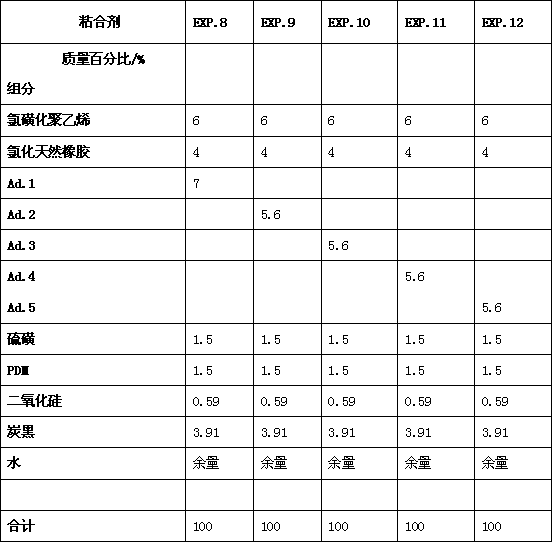

Adhesion promoter for bonding elastomers and metals and adhesive composition

ActiveCN103074009AHigh bonding strengthImprove aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to an adhesion promoter for bonding elastomers and metals and an adhesive composition. The adhesion promoter is prepared by using a porous inorganic filler as a bracket, performing surface treatment on a silane coupling agent, and then performing polyolefin-supported. The adhesive composition composed of the adhesion promoter contains at least one halogenated polyolefin, the adhesion promoter, at least one vulcanizing agent and at least one inert inorganic filler. According to the invention, due to the presence of the adhesion promoter, the adhesive composition can effectively bond various elastomers and hard base materials, and form a moderately hard transition layer between the elastomers and the hard base materials, so that the adhesion of the adhesive composition for the elastomers is promoted, and the adhesive force of the adhesive composition for the hard base materials is increased.

Owner:安徽普力通新材料科技有限公司

High-looseness tobacco sheet applied to low-temperature cigarette and production process

The invention provides a high-looseness tobacco sheet applied to a low-temperature cigarette and a production process. The tobacco sheet comprises, by mass, 50-80% of tobacco raw material powder, 10-30% of atomizing agent, 0.5-10% of adhesive, 0.01-1% of leavening agent, 5-15% of tobacco essence perfume and 0-30% of water and is manufactured by means of a roll pressing production process. During manufacturing of the sheet, the production process is not changed, only the leavening agent is added to a raw material formula to loosen the sheet, and absorption of a large quantity of the atomizing agent and the external perfume is facilitated. When a consumer smokes the low-temperature cigarette prepared from the sheet, the obtained smoke amount is larger, and the obtained physiological satisfaction feeling is stronger. At the same time, the production process of the sheet is mature, simple and high in controllability, and the quality is stable.

Owner:HUBEI CHINA TOBACCO IND

Silicon rubber for large-scale injection moulding vulcanization and preparation method thereof

InactiveCN101724272AHigh tear strengthImprove appearance qualityRubber insulatorsVulcanizationPolymer science

The invention discloses silicon rubber for large-scale injection moulding vulcanization, which is characterized in that: the silicon rubber is prepared from the following raw materials in part by weight: 90 to 120 parts of silicon rubber, 20 to 50 parts of reinforcing agent, 1 to 8 parts of coupling agent, 0.05 to 0.5 part of vulcanizing agent, 1 to 3 parts of softening agent, 0.4 to 3.5 parts of active agent, 90 to 150 parts of flame retardant, and 1 to 3 parts of coloring agent. The method not only improves the mechanical strength of the heat vulcanized silicone rubber, but also improves all electric properties of the silicone rubber sheath and shed of a composite pillar insulator, and also improves the operational reliability of the composite pillar insulator.

Owner:CHINA XD ELECTRIC CO LTD

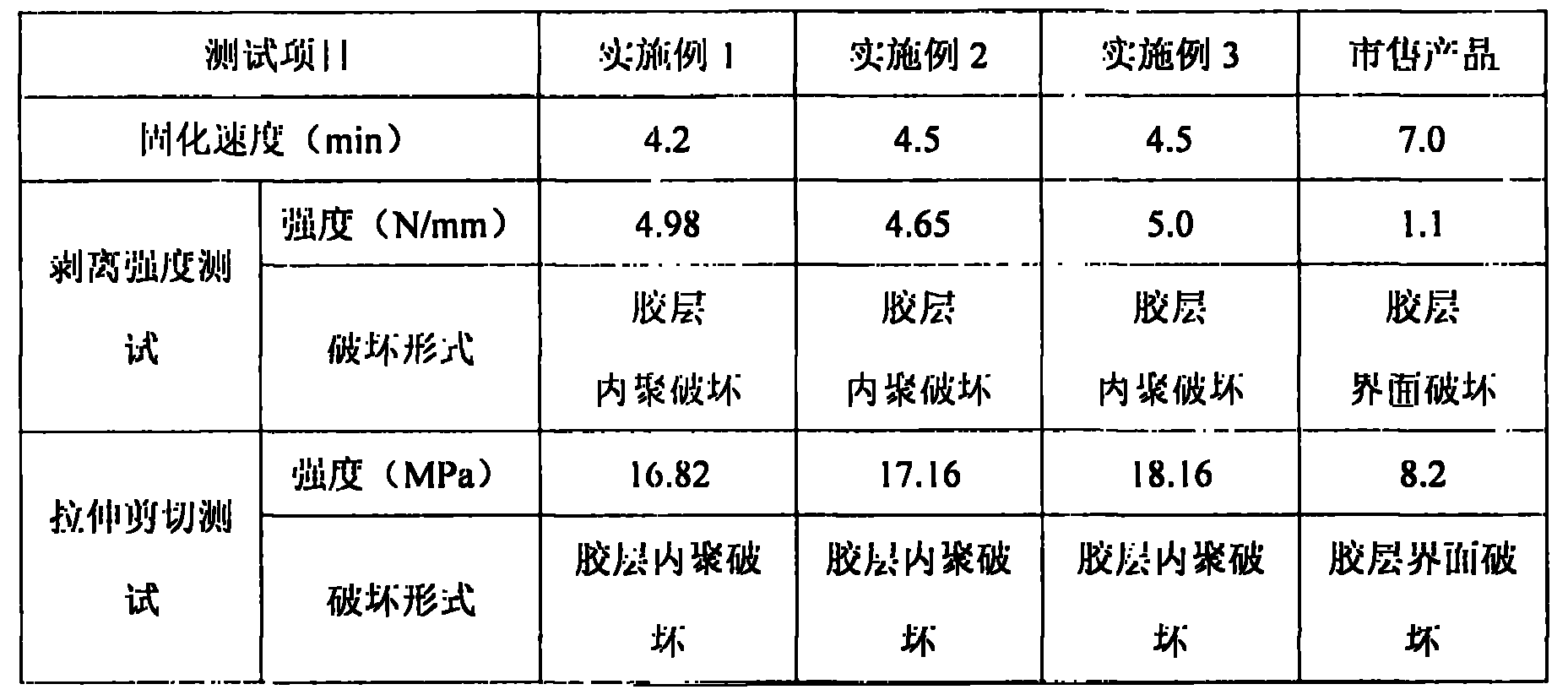

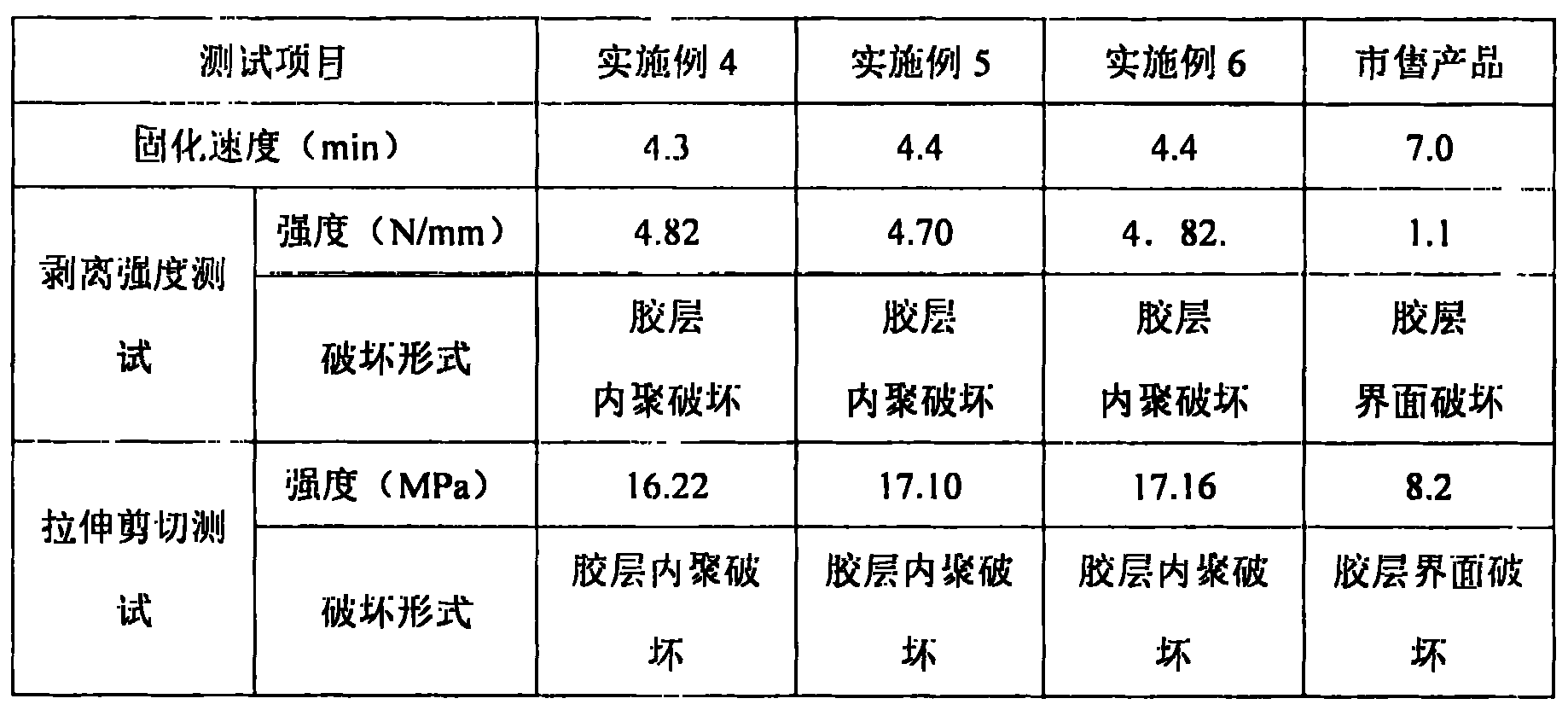

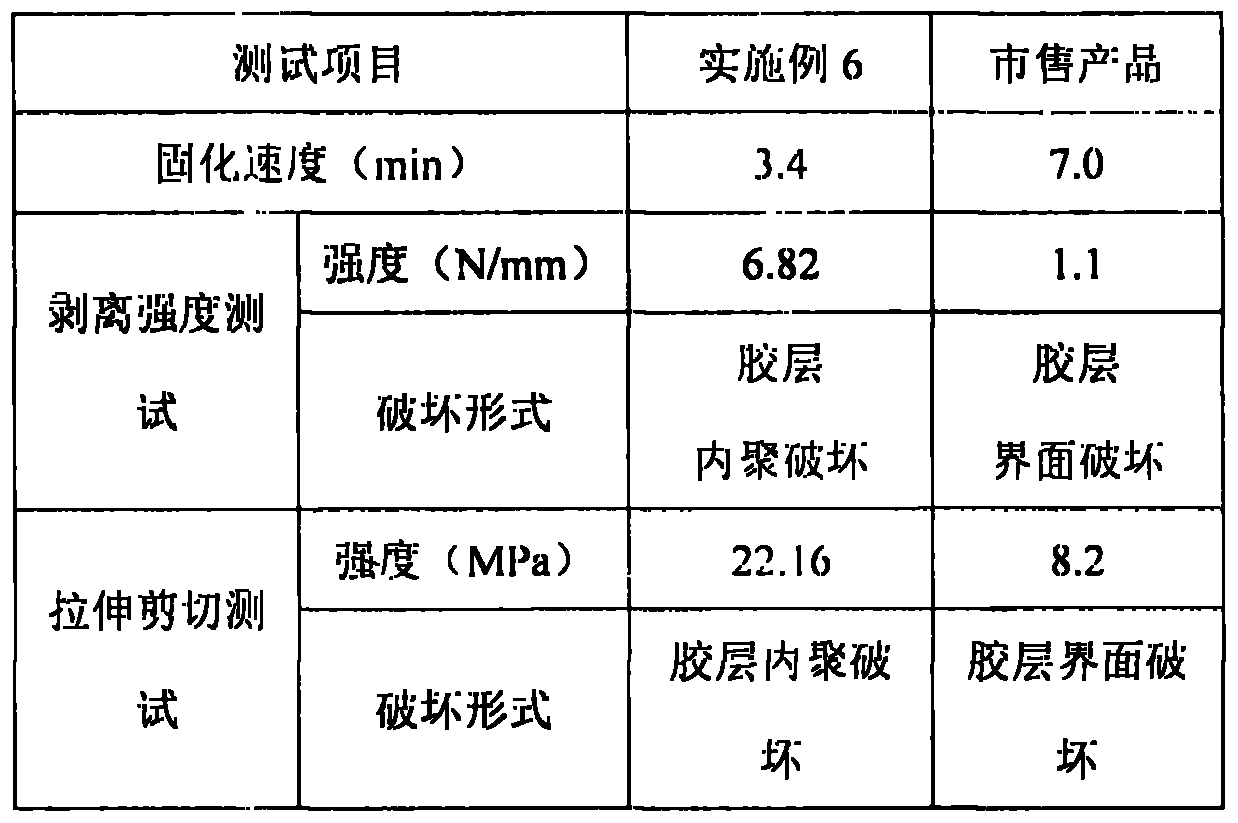

Double-component acrylate structure adhesive for bonding electrophoretic coating materials

ActiveCN104178075AImprove biteEffective bondingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAcrylic resinAdhesive

The invention discloses a double-component acrylate structure adhesive for bonding electrophoretic coating materials and a preparation method of the structure adhesive, belonging to the technical field of adhesives. The structure adhesive is prepared by mixing a component A with a component B according to a volume ratio of 10 : (0.1-2), wherein the component A comprises acrylate monomers, acrylic resin, strongly acidic monomers, non-polar rubber, flexible rubber, non-polar organic particles, an accelerator, a stabilizer and paraffin; the component B comprises an initiator, a plasticizer, a thickener and pigment. The structure adhesive can be used for effectively bonding and quickly curing electrophoretic coatings, is high in stripping strength and shear strength, and has the characteristics of being convenient to apply, good in room-temperature storage stability and the like; the bonding surface destruction form is cohesive failure of an adhesive layer.

Owner:TONSAN ADHESIVES INC

Low-temperature resistant hot melt adhesive and processing technology thereof

InactiveCN103173186AImprove low temperature resistanceNo changeMonocarboxylic acid ester polymer adhesivesWaxAntioxidant

The invention provides low-temperature resistant hot melt adhesive and a processing technology of the low-temperature resistant hot melt adhesive. The low-temperature resistant hot melt adhesive comprises the following components: polyamide, an ethylene vinyl acetate copolymer, an ethylene-acrylate-maleic anhydride terpolymer, wax, tackifying resin and an antioxidant. The low-temperature resistant hot melt adhesive is high in adhesive strength, excellent in insulating seal performance, environmentally-friendly, nontoxic, simple in production technology and high in repeatability, and is mainly applicable to places requiring high low-temperature performance.

Owner:HONGSHANG HEAT SHRINKABLE MATERIALS

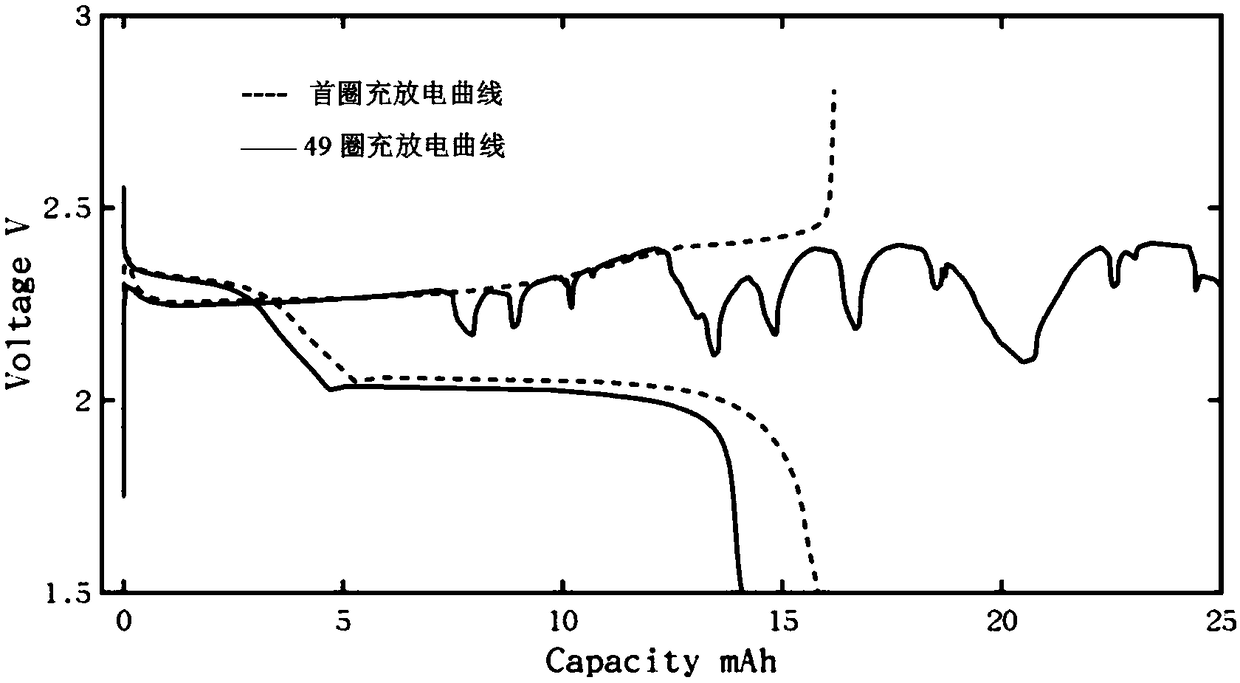

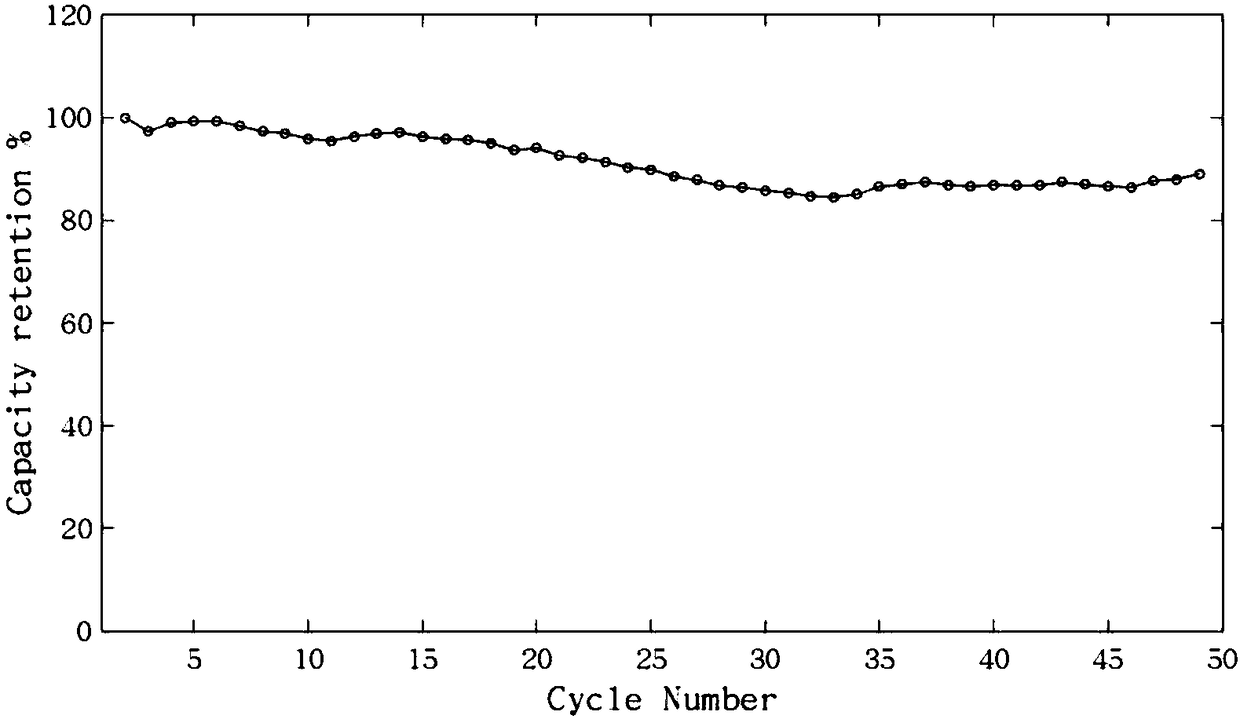

Lithium positive electrode surface protective coating and method for preparing same

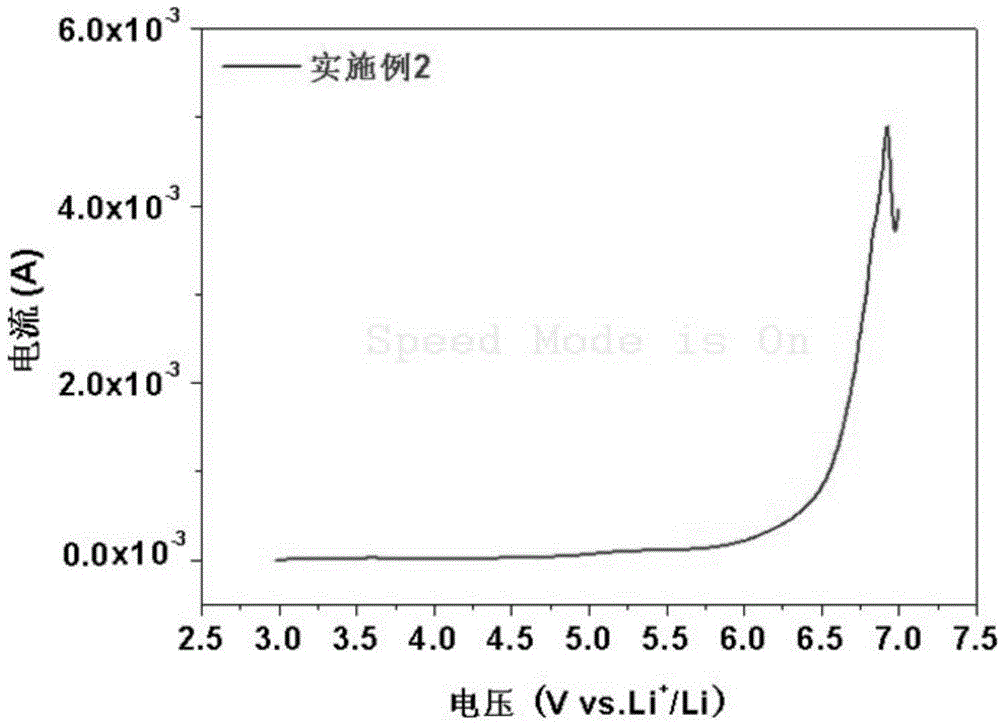

ActiveCN108376783AEasy to operateReduce processing costsCell electrodesFinal product manufactureSolid state electrolyteNanoparticle

The invention discloses a lithium positive electrode surface protective coating and a method for preparing the same. The lithium positive electrode surface protective coating is characterized in thata protective coating mainly comprises nanometer particles which are stacked, and stacked pores of the nanometer particles are filled with solid electrolytes; the protective coating is arranged betweena lithium positive electrode and a diaphragm. The lithium positive electrode surface protective coating and the method have the advantages that the nanometer particles are stacked to form the protective coating, growth of lithium dendrites on lithium metal pole plates can be effectively inhibited by stacked structures formed by the nanometer particles by means of stacking, and accordingly the problem of diaphragm piercing due to growth of existing lithium dendrites can be solved; the solid electrolytes in the stacked pores of the nanometer particles are high in lithium ionic conductivity, accordingly, the transmission rate of the lithium metal pole plates can be guaranteed, side reaction between lithium metal and electrolyte solution can be effectively isolated, the recycling service lives of the lithium metal pole plates can be greatly prolonged, and the safety of the lithium metal pole plates can be improved.

Owner:四川华昆能源有限责任公司

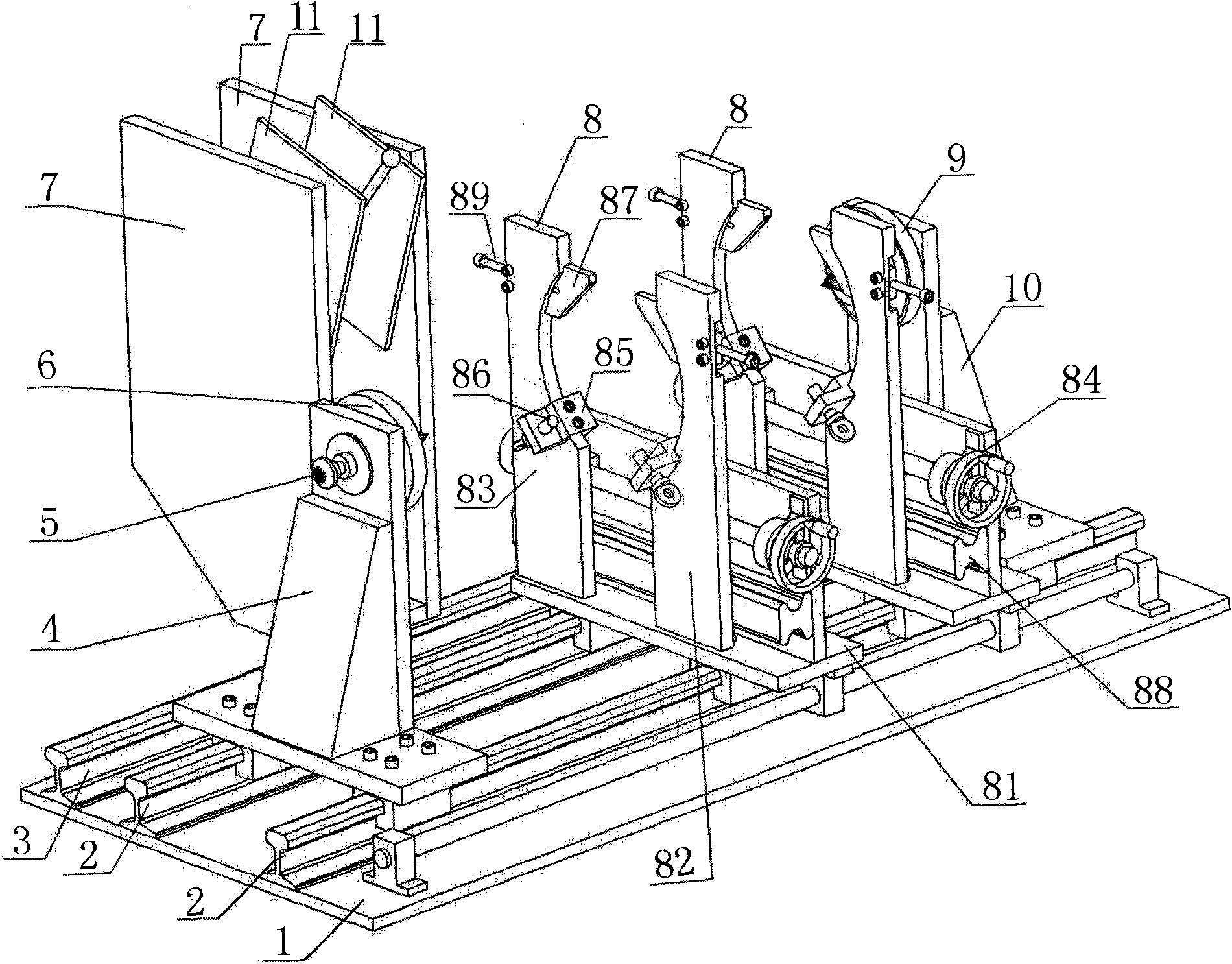

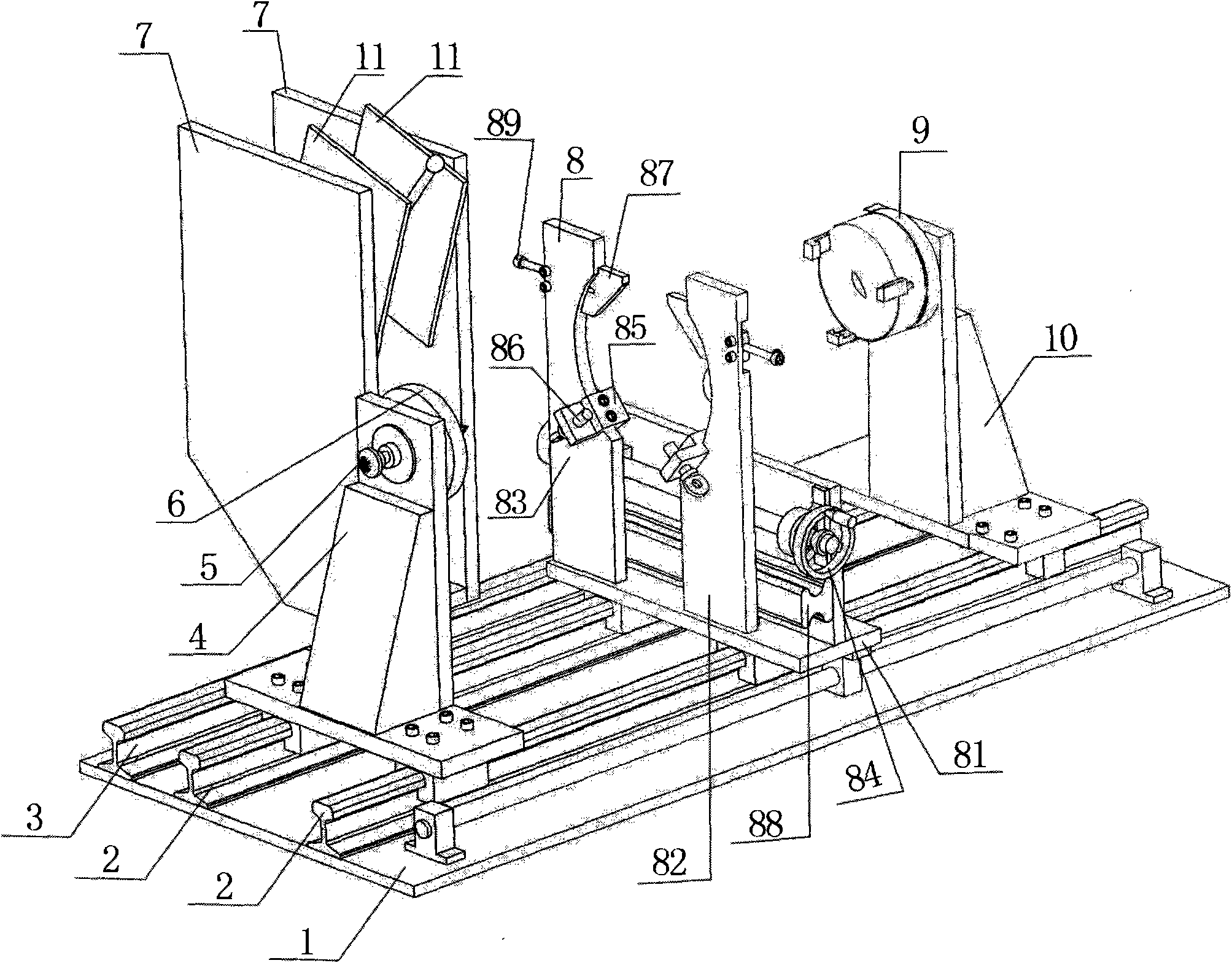

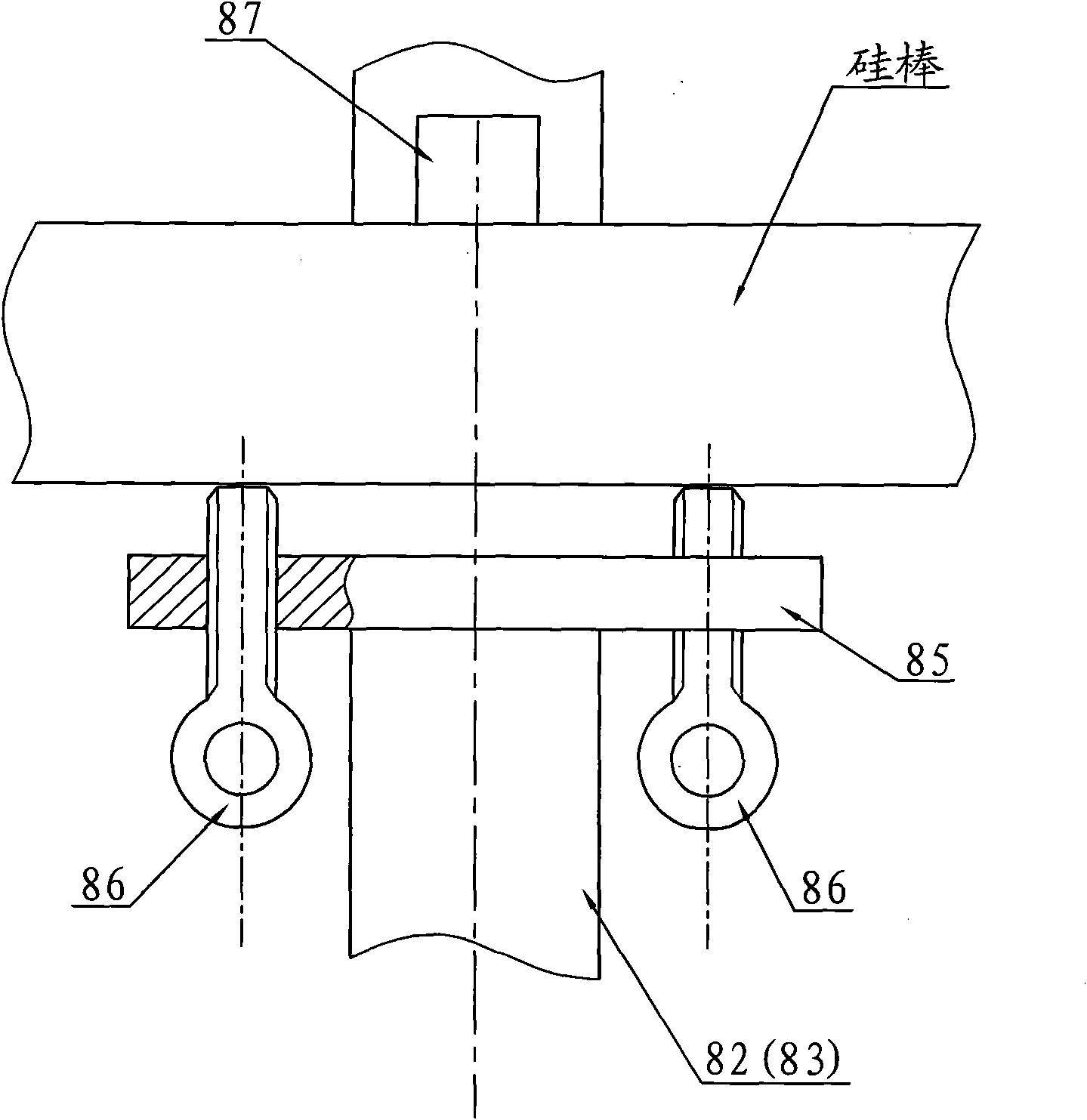

Silicon rod glue joint machine with single clamping bracket

InactiveCN101973074AReduced adjustment distanceSimple structureWorking accessoriesFine working devicesEngineeringCrystal base

The invention relates to a silicon rod glue joint machine with a single clamping bracket which comprises a silicon rod clamping mechanism. Two adjusting screws are symmetrically arranged on a locating block, and a distance between the two adjusting screws is 30-100cm. The silicon rod clamping mechanism can stably support a silicon rod only by placing the gravity center of the silicon rod to be adhered between the two adjusting screws. Compared with the prior art, an adjusting distance between a left slide carriage and a right slide carriage is further reduced only by the silicon rod clamping mechanism; and as long as the length of the silicon rod to be adhered can satisfy the clamping of a three jaw chuck and the silicon rod can be placed on the silicon rod clamping mechanism, the silicon rod can be effectively clamped, and adhesion of the silicon rod with a crystal base can be ensured. The silicon rod adhesive machine is enabled to have more compact structure, is more convenient to operate, and can effectively adhere the silicon rod with smaller liner dimension, and the silicon rod which cannot be subjected to normal cutting and slicing processing can be fully utilized.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

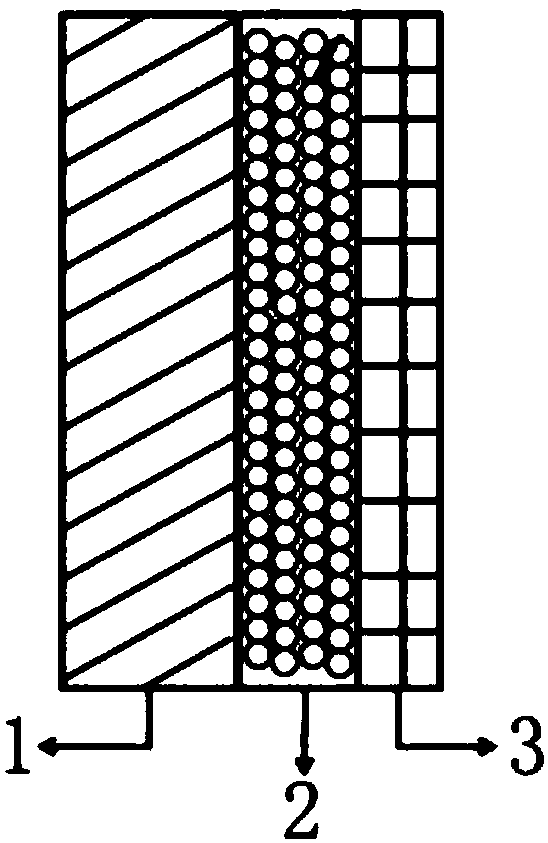

Polymer composite membrane, preparation method thereof, polymer composite membrane prepared by method, gel electrolyte and lithium ion battery

ActiveCN106159173AHigh porosityGuaranteed ionic conductivitySecondary cellsCell component detailsPorosityPolymer science

In order to solve the problem of poor cohesiveness of a fiber layer in a polymer composite membrane in the prior art, the invention provides a polymer composite membrane. The polymer composite membrane comprises a separator and a fiber layer, wherein the fiber layer is arranged on the separator, and the peel strength of the fiber layer is over 0.03kN / m. Meanwhile, the invention also discloses a preparation method of the abovementioned polymer composite membrane. Moreover, the invention also provides the polymer composite membrane obtained according to the abovementioned preparation method, a gel electrolyte comprising the abovementioned polymer composite membrane and a lithium ion battery applying the polymer composite membrane. In the polymer composite membrane provided by the invention, the fiber layer has favorable cohesiveness, particularly, the cohesiveness between filaments in the fiber layer is high, and a positive / negative electrode and the separator can be effectively bonded into a whole; high porosity of the fiber layer is beneficial for improving the ionic conductivity; and when the polymer composite membrane provided by the invention is used for the lithium ion battery, the rate performance, the cycle performance and the safety of the lithium ion battery are greatly improved, and the service lifetime of the lithium ion battery is long.

Owner:BYD CO LTD

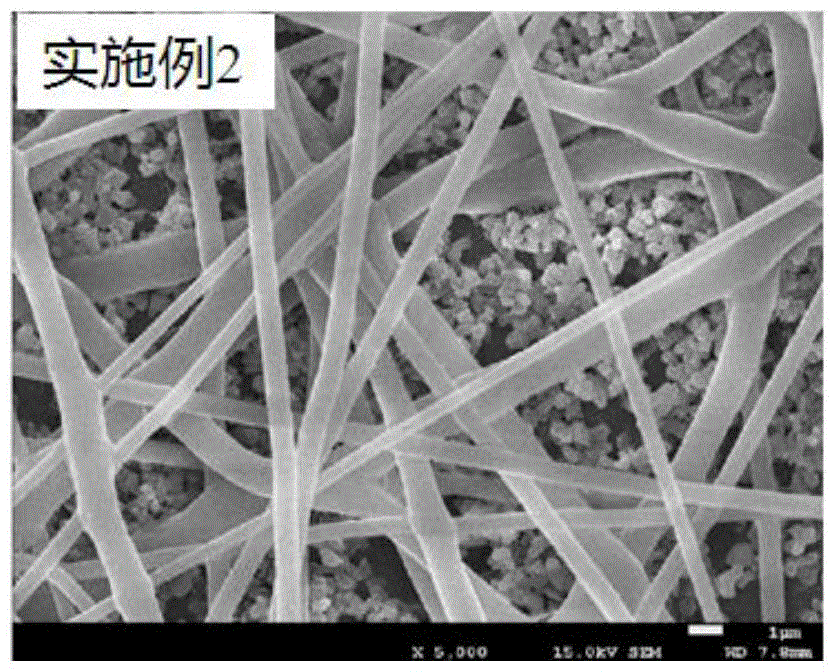

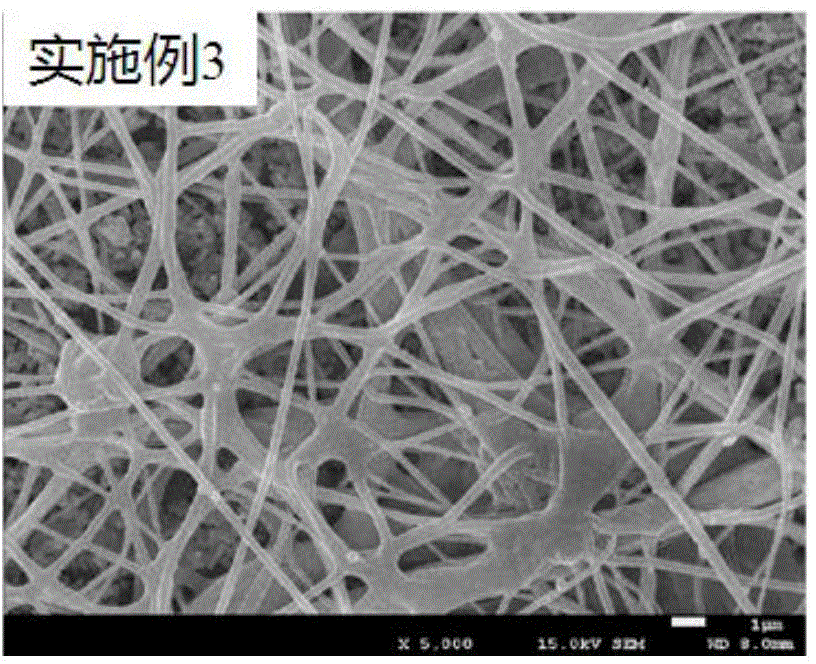

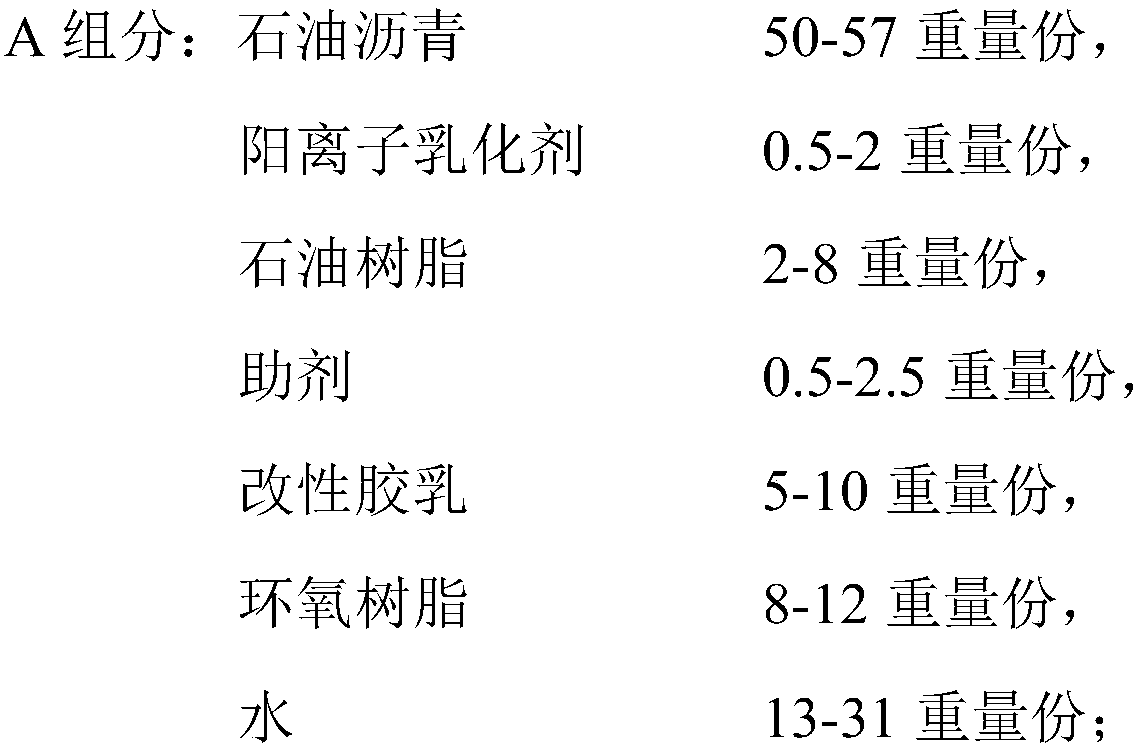

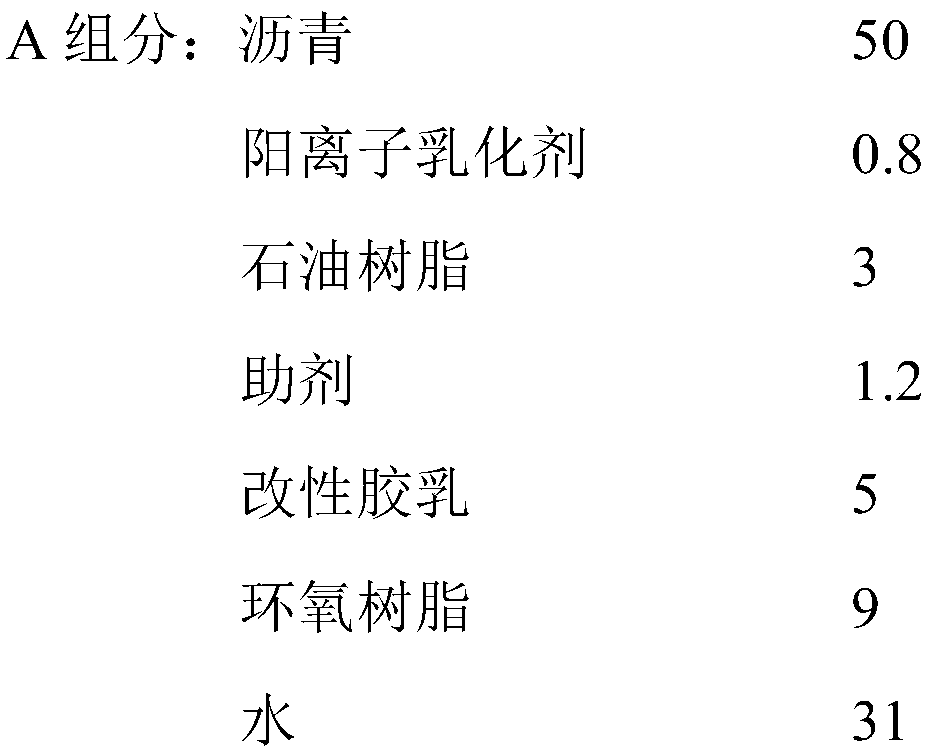

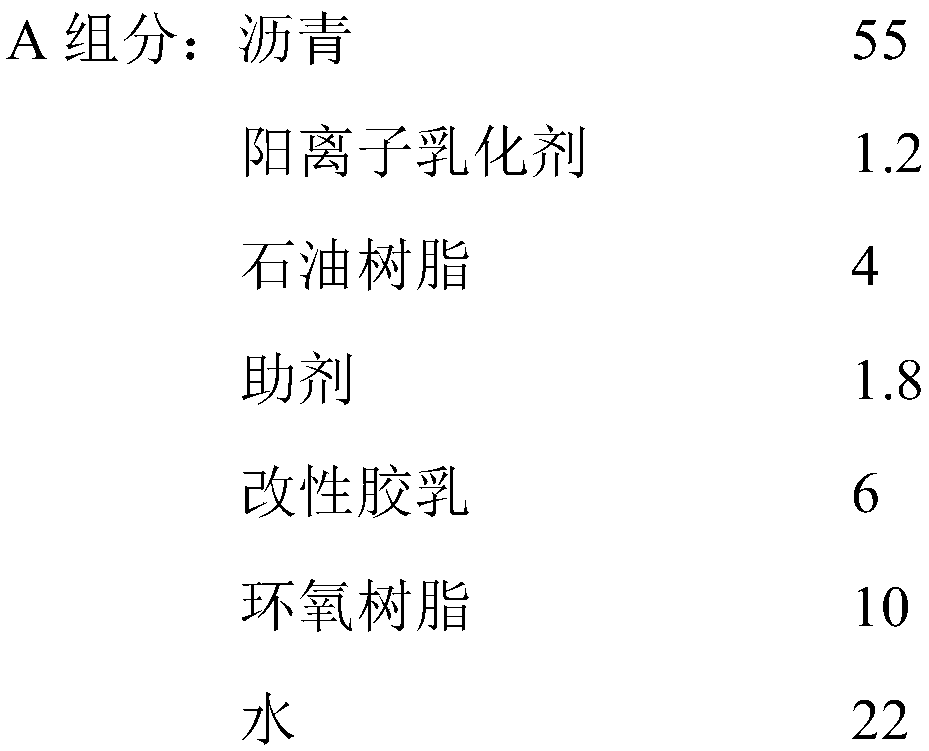

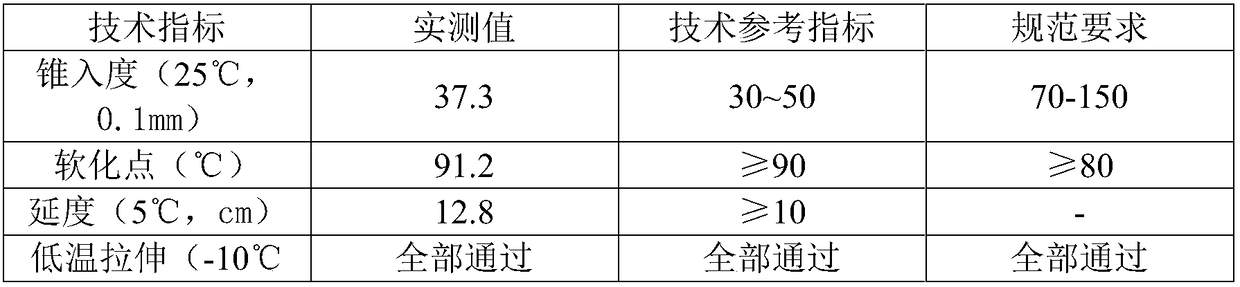

Aqueous emulsion type epoxy asphalt coating and preparation method thereof

ActiveCN109233636AHigh bonding strengthGood compatibilityEpoxy resin coatingsBituminous coatingsEpoxyEmulsion

The invention belongs to the field of waterproof coatings and relates to an aqueous emulsion type epoxy asphalt coating and a preparation method of the aqueous emulsion type epoxy asphalt coating. Theaqueous emulsion type epoxy asphalt coating comprises a component A and a component B, the component A comprises 40-55 parts by weight of petroleum asphalt, 0.5-2 parts by weight of a cationic emulsifier, 2-8 parts by weight of petroleum resin, 0.5-2.5 parts by weight of an additive, 5-10 parts by weight of modified latex, 8-12 parts by weight of epoxy resin, and 15-40 parts by weight of water; and the component B comprises a curing agent emulsion, and the mass ratio of the component A to the component B is (4-10):1. The aqueous emulsion type epoxy asphalt coating combines the advantages of emulsified asphalt and epoxy asphalt, has the advantages of high bonding strength, high compatibility with an asphalt roll, environment protection and the like, and is matched with a vertical face of aself-adhesive bituminous waterproof sheet material in the construction, and a composite waterproof layer formed after the construction is excellent in high-temperature and low-temperature weather fastness.

Owner:XUZHOU WONIUSHAN NEW WATERPROOF MATERIALS

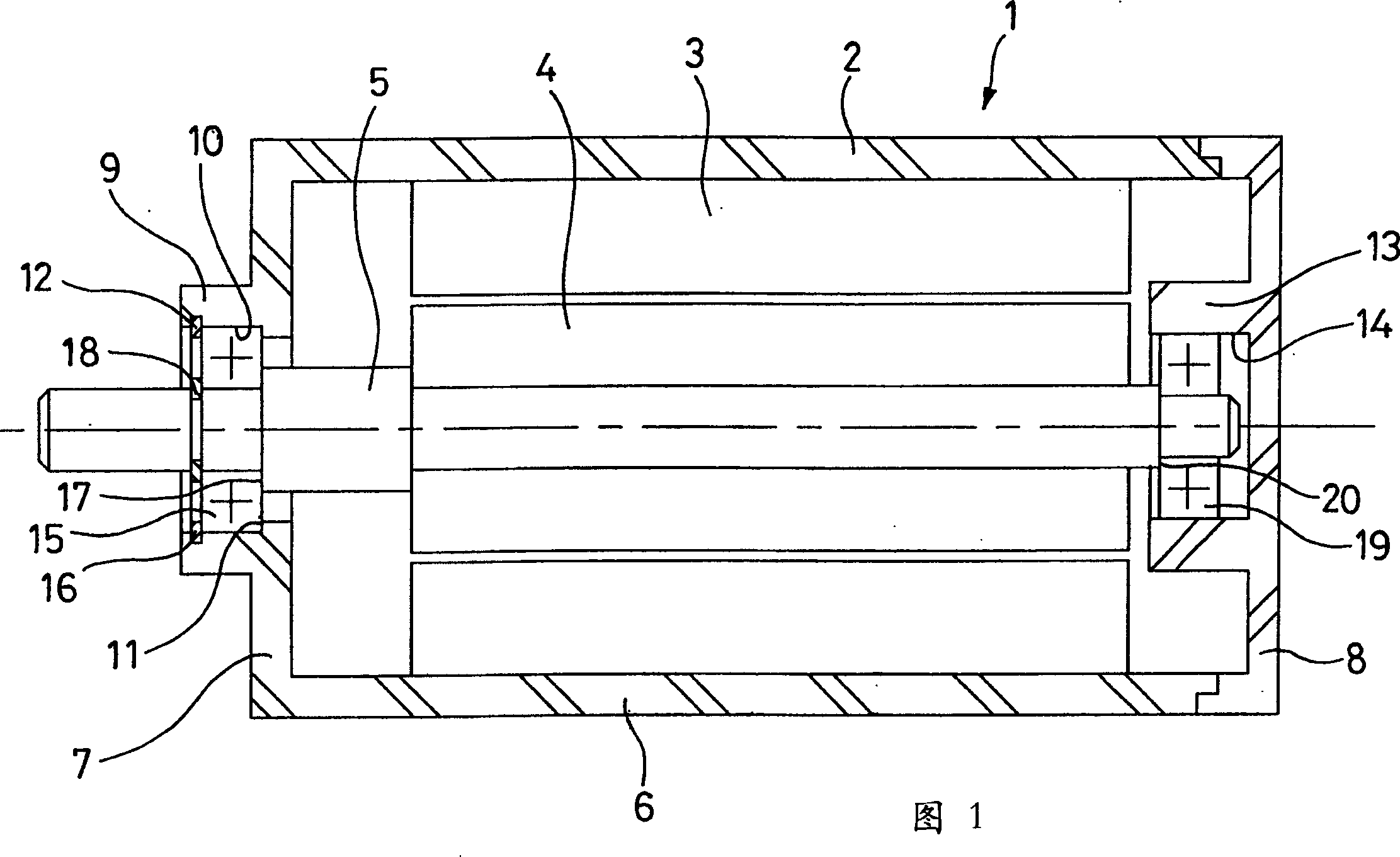

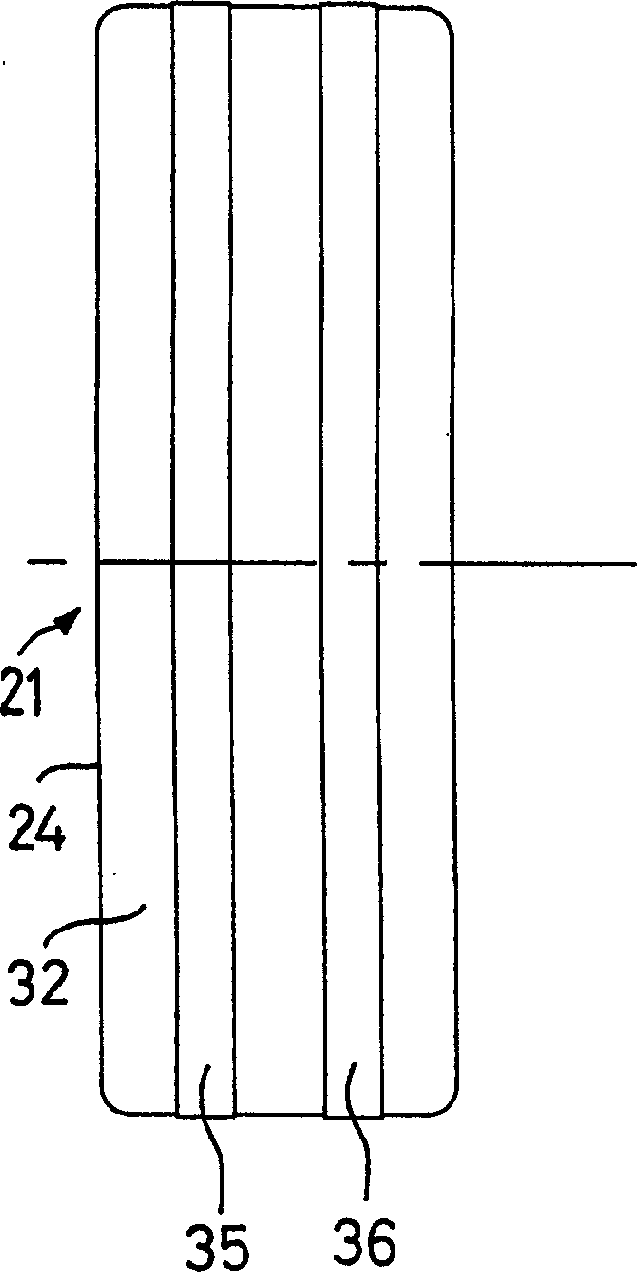

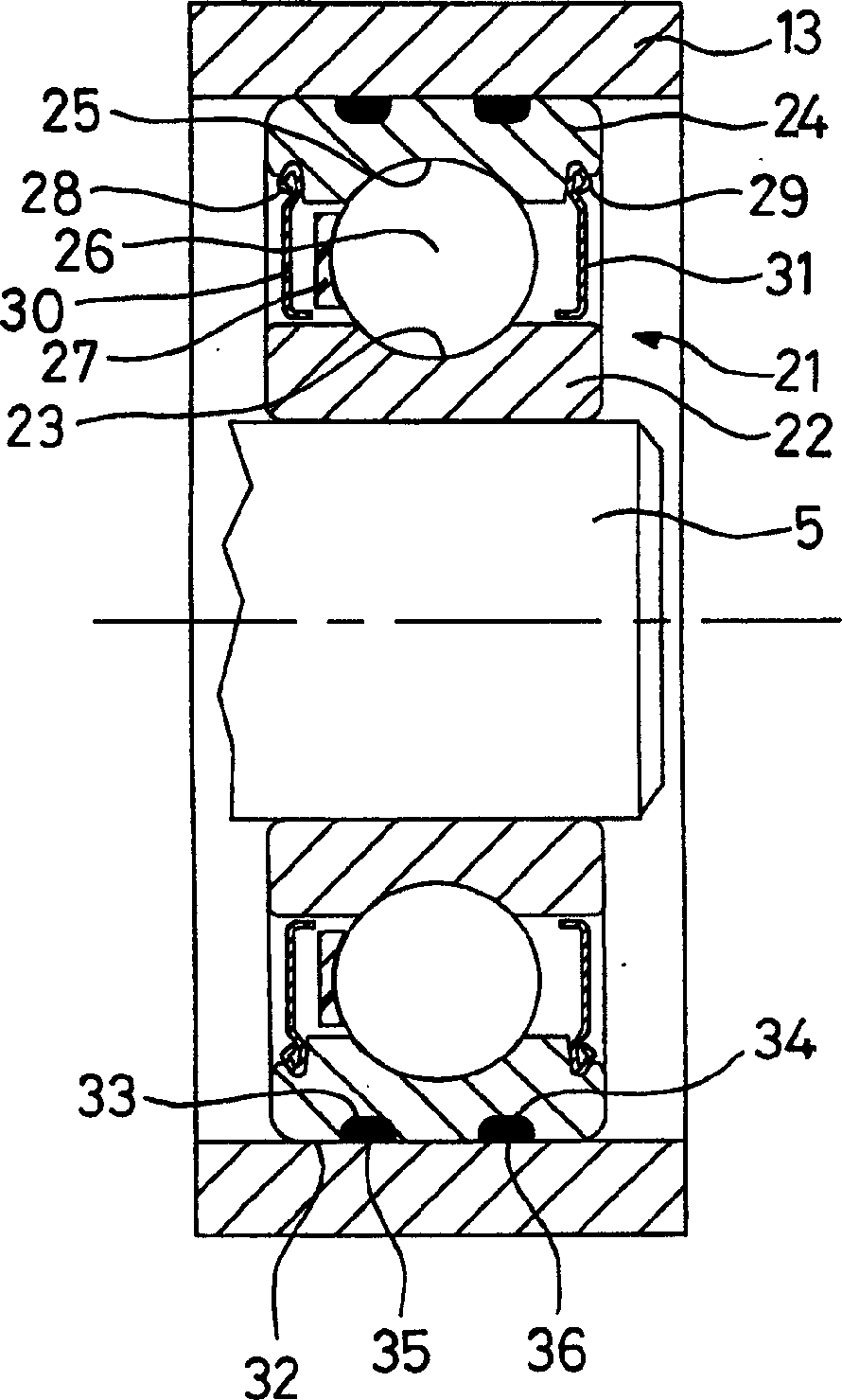

Rolling bearing esp. for dynamo

InactiveCN1447038APrevent rotationGuaranteed alignmentShaftsBall bearingsRolling-element bearingEngineering

A bearing assembly (21), comprises an outer race (24) adjusting in the cylindrical flute. The outer race (24) comprises a runner face in contact with several balls (26) etc., while at least one expansion compensating race (35) is located in an annular groove (33) in the cylindrical outer face of the outer race. The expansion compensating race is of material with a larger expansion coefficient than that of the outer race. The expansion compensating race has an outer diameter between the outer diameter of outer race, minus 50 microns, and the outer diameter of outer race, plus 20 microns.

Owner:AB SKF

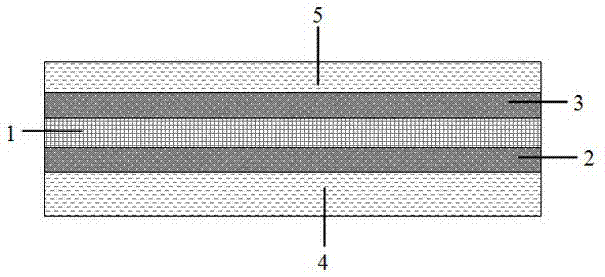

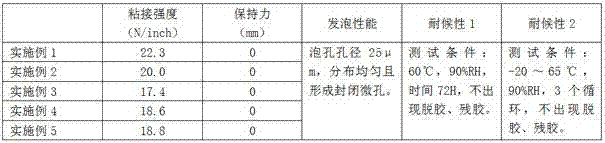

Novel thermally-bonded double-sided tape and making and use methods thereof

InactiveCN104263264AHigh bonding strengthIncreased durabilityNon-macromolecular adhesive additivesFilm/foil adhesivesFoaming agentSolvent

The invention discloses a novel thermally-bonded double-sided tape and a making method thereof. The novel thermally-bonded double-sided tape comprises a heating foamed adhesive layer and a pressure-sensitive adhesive layer coating the upper surface and the lower surface of a substrate layer respectively, wherein glue used in the heating foamed adhesive layer is obtained by mixing and baking the following components in parts by mass: 100 parts of a pressure-sensitive adhesive, 0.5-5 parts of a foaming agent, 0.5-5 parts of a foaming aid, 1-3 parts of a crosslinking agent and 10-30 parts of a solvent. The thermally-bonded double-sided tape made by adopting the making method has high bonding durability. Through transient heating and sticking of the thermally-bonded double-sided tape at the temperature of 90 DEG C and under the pressure of 200KPa for ten seconds, extremely high bonding strength can be achieved on surfaces such as concavo-convex surfaces, porous surfaces and oblique surfaces.

Owner:LONGCHANG YUXI NEW MATERIAL TECH

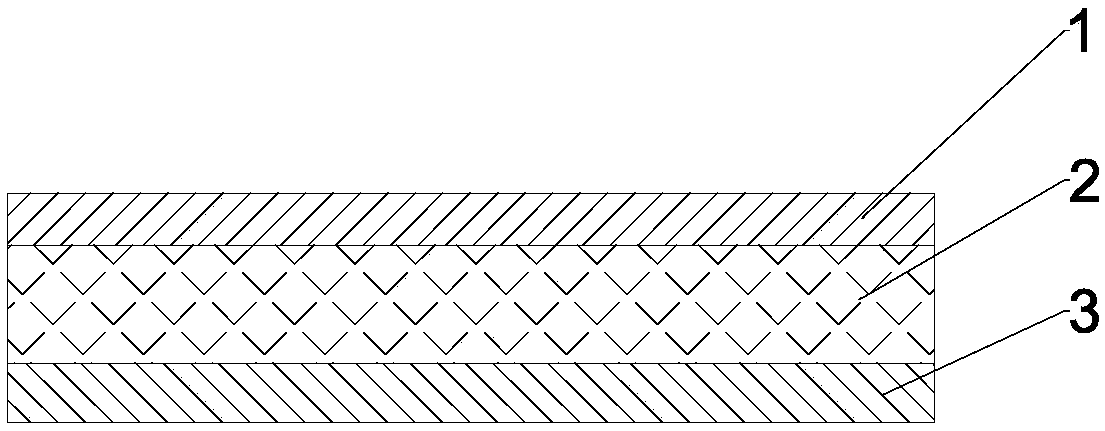

Three-layer composite hot melt adhesive film for bonding metal and polar functional plastic and processing technique thereof

InactiveCN109207073AHigh bond strengthEasy constructionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSteel platesChemistry

Disclosed are a three-layer composite hot melt adhesive film for bonding a metal and a polar functional plastic and a preparation process therefor, wherein the three-layer composite hot melt adhesivefilm comprises an inner layer adhesive bonded to the metal, an outer layer adhesive bonded to the polar functional plastic, and a transition adhesive connecting the inner layer adhesive and the outerlayer adhesive; the inner layer adhesive, the outer layer adhesive and the transition adhesive with different functionalities are modified and then compounded effectively by means of co-extrusion filmblowing or casting, the three-layer composite hot melt adhesive film is used for bonding polar functional materials with metals such as aluminum, galvanized steel plates and the like, and is high inbonding strength and convenient to construct, and can effectively solve the problems of low bonding strength or large odor, serious environmental pollution and the like of an adhesive used for bondingthe polar functional plastic and the metal at present. The three-layer composite hot melt adhesive film can effectively bond the metal and the polar functional plastic at a relatively low temperatureby means of a laminating machine or a stamping machine device, the bonding is convenient, and the plastic is not damaged.

Owner:SHANGHAI BANZAN MACROMOLECULE MATERIAL

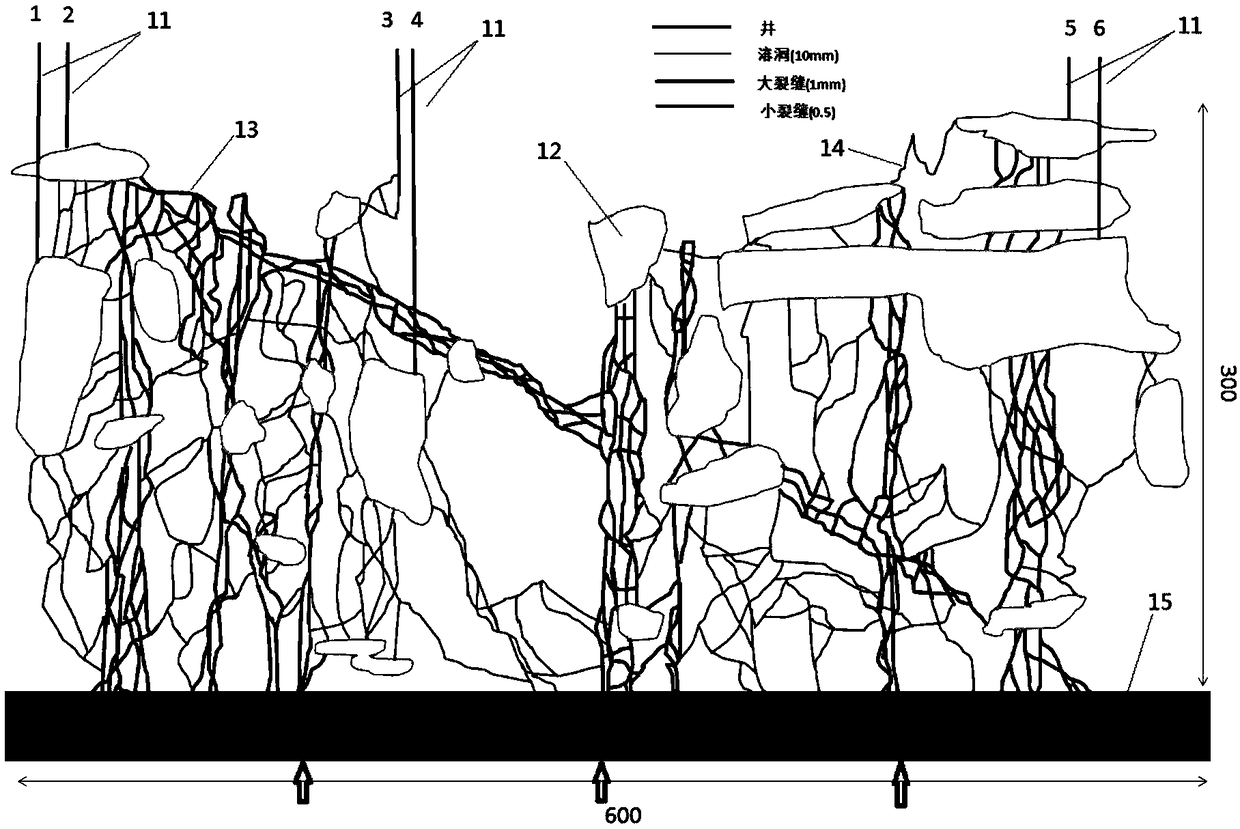

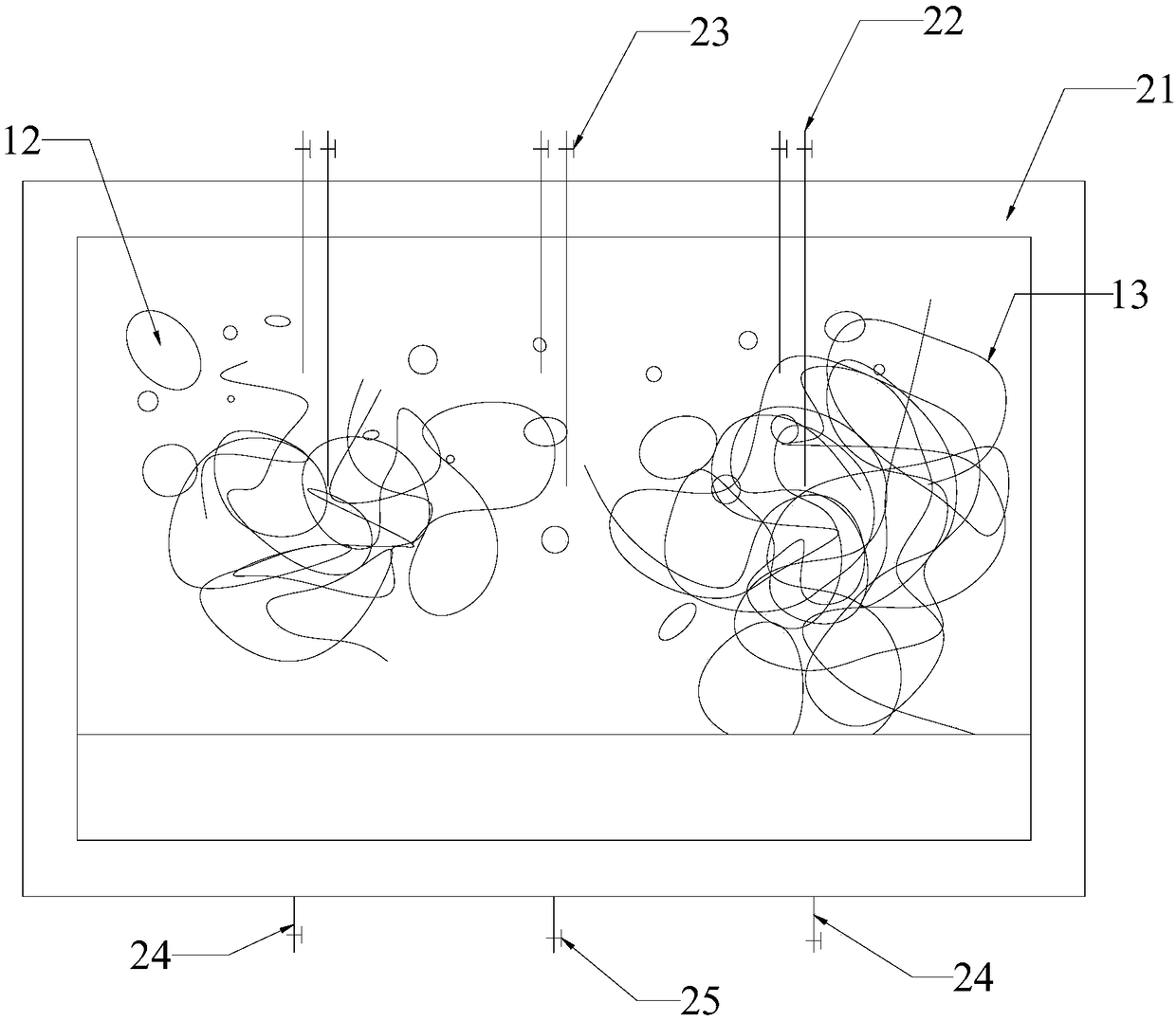

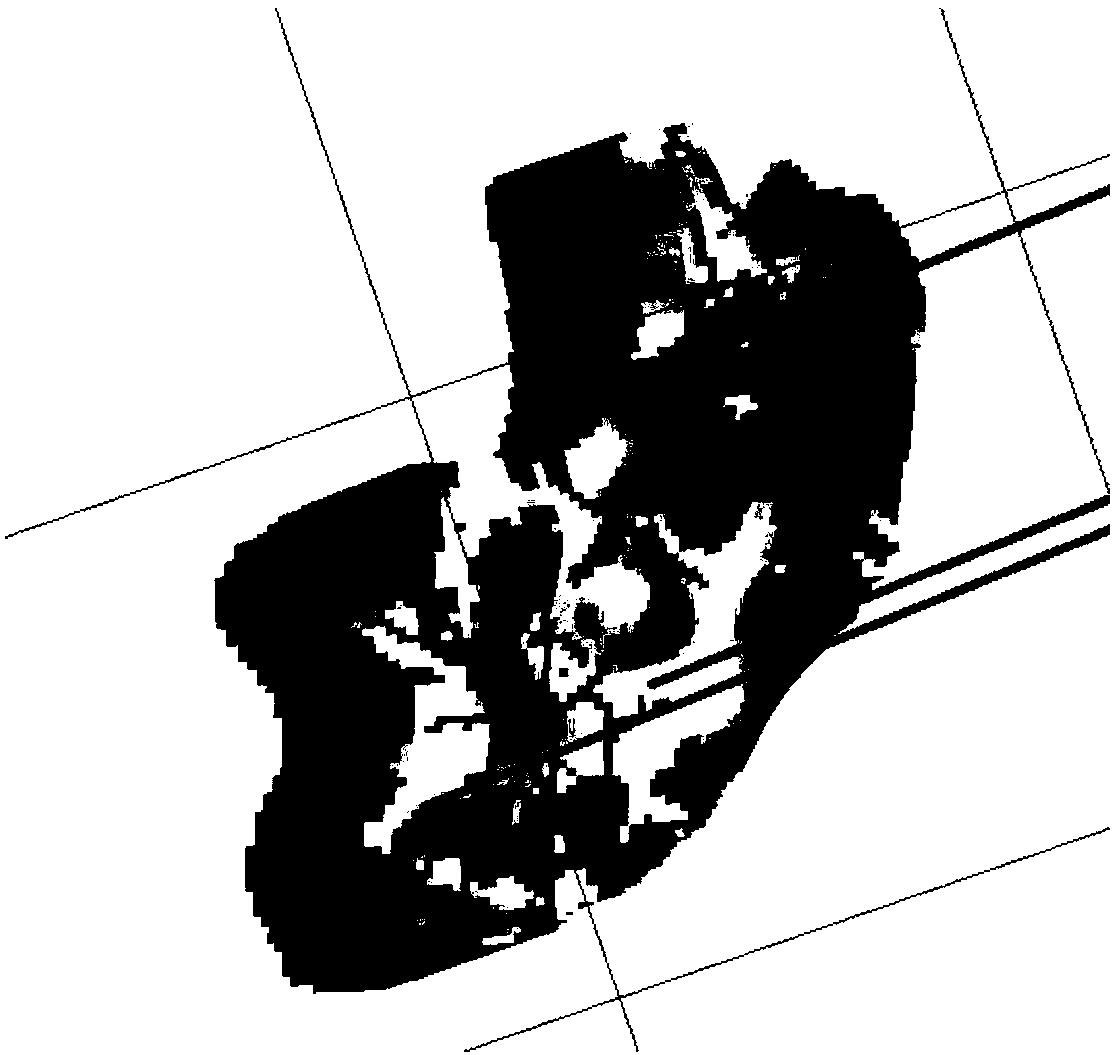

Establishment method for fracture-cave distribution diagram of fracture-cave carbonate reservoir, model and application

ActiveCN108875148AMeet filling requirementsFinely craftedGeometric CADConstructionsProfile diagramGeomorphology

The invention provides an establishment method for a fracture-cave distribution diagram of a fracture-cave carbonate reservoir, a model and an application. The method comprises the following steps ofbased on a built geological model of a target well group region, marking fractures, karst caves and underground rivers, and obtaining a three-dimensional profile structure diagram of the geological model of the target well group region; based on the three-dimensional profile structure diagram, performing layered display on the geological model, and selecting a most representative path between wells of the target well group region to perform two-dimensional cutting connection on the wells, thereby obtaining a two-dimensional profile diagram between the wells; based on the two-dimensional profile diagram, delineating regions of the karst caves and the underground rivers, taking a whole of the delineated closed region as the karst cave region, and obtaining a two-dimensional profile fracture-cave structure depiction diagram; and restoring middle-scale fractures around large-scale fractures in the two-dimensional profile fracture-cave structure depiction diagram, so as to obtain the fracture-cave distribution diagram of the fracture-cave carbonate reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

Copper-based oil bearing material and preparation method thereof

InactiveCN105689722APlay a lubricating roleHigh strengthTransportation and packagingMetal-working apparatusHeat conductingSolid solution strengthening

The invention discloses a graphene / copper oil bearing material and a preparation method thereof, and belongs to the field of graphene reinforced metal-matrix composites. Nickel powder, tin powder, copper powder and a dispersing agent are loaded on graphene according to a certain mass fraction for burdening, a planetary ball mill is used for mixing, and a graphene / copper-based oil bearing is obtained through pressing, sintering, oil immersing and die full shaping processes. The graphene is introduced by loading nickel particles on the graphene, and the purpose that graphene strengthening phases are evenly dispersed in a metal matrix to form strong interfacial chemical binding is achieved. On the other hand, copper and nickel form an infinite mutual-soluble solid solution, and the solid solution strengthening effect is achieved. The graphene / copper-based oil bearing manufactured through the method is even in structure and has good heat-conducting performance and high strength and abrasion resistance.

Owner:HEBEI UNIV OF ENG

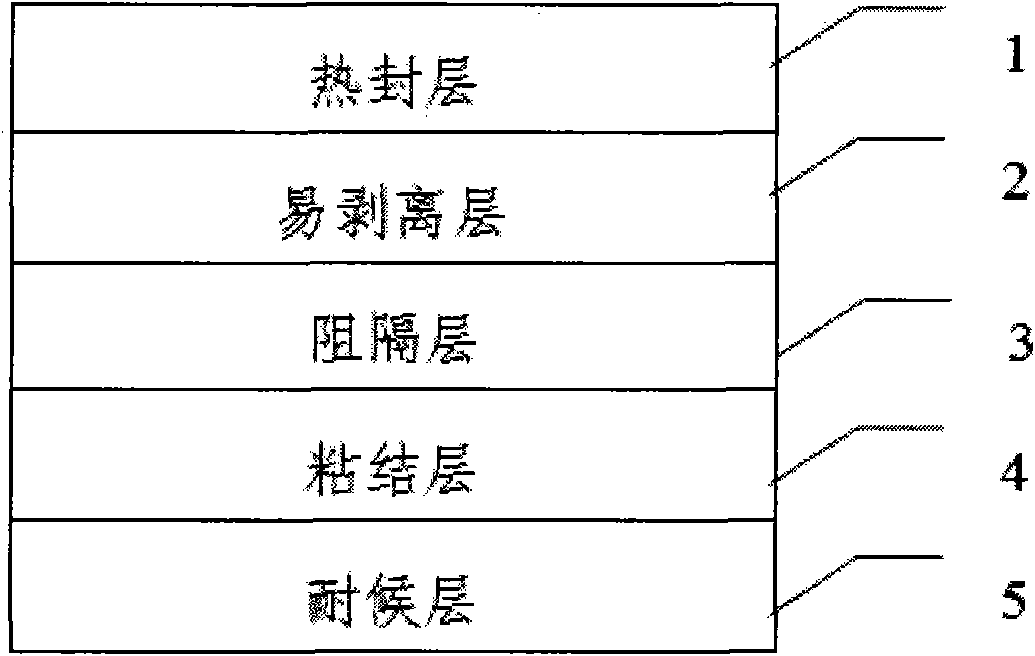

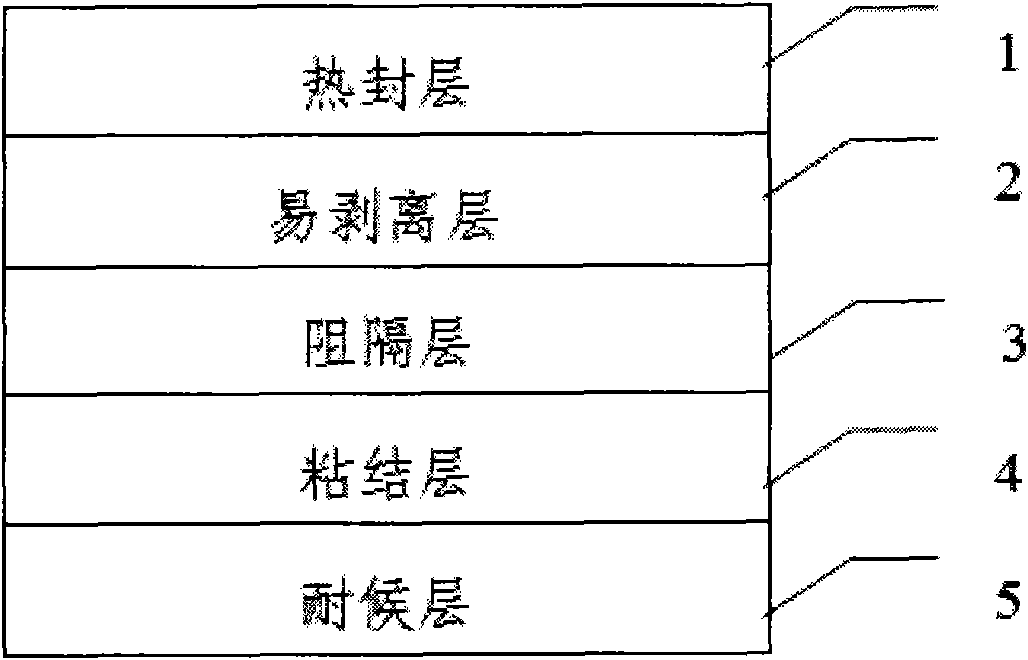

Easy-to-peel cover film

InactiveCN102380983AImproves stress cracking resistanceLow melting pointSynthetic resin layered productsSealingLow-density polyethylenePolyester

The invention discloses an easy-to-peel cover film, which comprises a hot sealing layer, an easy-to-peel layer, a blocking layer, a bonding layer and a weatherproof layer in sequence arrangement, wherein the hot sealing layer is an ethylene-vinyl acetate copolymer film layer modified by low-density polyethylene and metallocene low-density polyethylene, the easy-to-peel layer is a low-density polyethylene layer, the blocking layer is a soft-state aluminum foil layer, the bonding layer is a polyester type polyurethane layer, and the weatherproof layer is a polyester layer. The easy-to-peel cover film is an easy-to-peel cover film with the advantages that the integral performance is excellent, the easy-to-peel cover film is particularly suitable for various containers, and the easy-to-peel performance, the sealing performance and the ventilation performance are better.

Owner:SUZHOU HAISHUN PACKAGING MATERIAL

Turtle feed

InactiveCN104171267AEnsure normal food intakePromote growthAnimal feeding stuffAccessory food factorsBetaineAnimal science

A turtle feed comprises the following ingredients in percentage by weight: white fish meal, red fish meal, a starch, beer yeast, liver powder, hydrolyzed animal protein, calcium lactate, calcium dihydrogen phosphate, multi vitamins for turtle, multi minerals for turtle, betaine, choline chloride, Chinese wax gourd, carrot, and vitamins. The turtle feed has the following advantages that the white fish meal, red fish meal, a starch, beer yeast, liver powder, hydrolyzed animal protein, calcium lactate, calcium dihydrogen phosphate, multi vitamins for turtle, multi minerals for turtle, betaine, choline chloride, Chinese wax gourd, carrot, and vitamins are mixed, so as to effectively guarantee that turtle can normally eat the feed and grow well, the fat acids required by growth of turtle are provided, the ingredients are effectively adhered to facilitate that turtle can eat the feed in different environments, and various diseases of turtle during the growth process can be effectively avoided; dysplasia, loss of appetite, thin and fertility decline of turtle can be also voided, and the quality of turtle can be improved.

Owner:CHANGXING LONGQING SPECIAL AQUACULTURE

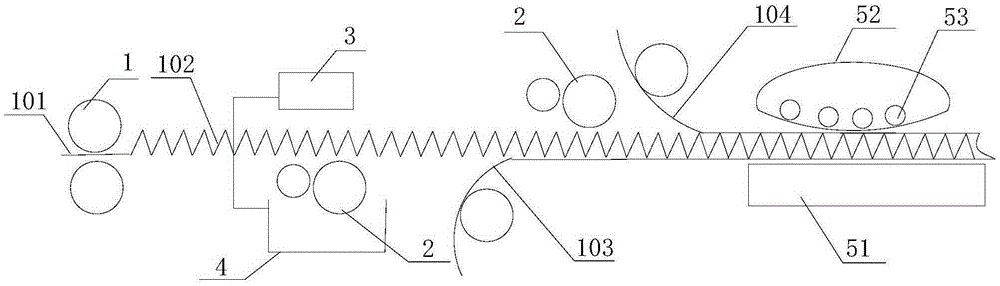

Corrugated board production method and apparatus thereof

InactiveCN105398180AEffective bondingAdhesive production is efficientLaminationLamination apparatusCardboardAdhesive

The invention discloses a corrugated board production method and an apparatus thereof. The production method comprises the following steps: coating corrugated paper with a heated adhesive at a low temperature, and bonding the coated corrugated paper with a cardboard to obtain a one-sided corrugated board. Traditional technologies and apparatuses for producing corrugated paper through a starch adhesive are subverted, a hot adhesive is applied in production of the corrugated paper, and the hot adhesive obtained after heating the adhesive can effectively bond paper with the corrugated paper without heating the paper, so the corrugated board can be produced at a low temperature, and heating is carried out in adhesive application and adhesive storage processes without heating a corrugation roller, thereby the energy consumption is greatly reduced.

Owner:薛敬哲

Gel tissue plugging material and preparation method thereof, and plugging product

ActiveCN109106974AImprove adhesionHigh strengthSurgical adhesivesOcculdersBiological bodyBursting strength

The invention provides a gel tissue plugging material and a preparation method thereof, and a plugging product. The gel tissue plugging material comprises: a matrix, wherein the matrix comprises a gellayer; and a wet-state adhesion layer on at least one surface of the matrix, wherein at least one surface of the matrix contacts an adhesion solution to obtain the wet-state adhesion layer, the adhesion solution contains an amino compound and a buffer liquid, and the amino compound is dissolved in the buffer liquid. According to the present invention, the gel tissue plugging material has advantages of excellent adhesion property, excellent bursting strength, suitable elongation at break and good elasticity, and can be effectively adhered to the surface of organisms or substantial organs so asto provide tissue plugging effect.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Polymer film and preparation method thereof, gel electrolyte and polymer battery

InactiveCN105529495AImprove breathabilityEffective bondingSecondary cellsPolymer electrolytesVitrification

The invention provides a polymer film to overcome the problem that a gel polymer electrolyte is relatively low in ionic conductivity in the prior art. The polymer film comprises a first polymer matrix, second polymer particles and inorganic particles, wherein the second polymer particles and the inorganic particles are distributed in the first polymer matrix; the glass-transition temperature of the first polymer matrix is lower than 40 DEG C; the glass-transition temperature of the second polymer particles is higher than 40 DEG C; the glass-transition temperature of the polymer film is 30-60 DEG C; and the air permeability is 150-600sec / 100mL. Meanwhile, the invention further discloses a preparation method of the polymer film and a gel electrolyte and a polymer battery comprising the polymer film. The gel electrolyte prepared by the polymer film provided by the invention has excellent ionic conducting properties.

Owner:BYD CO LTD

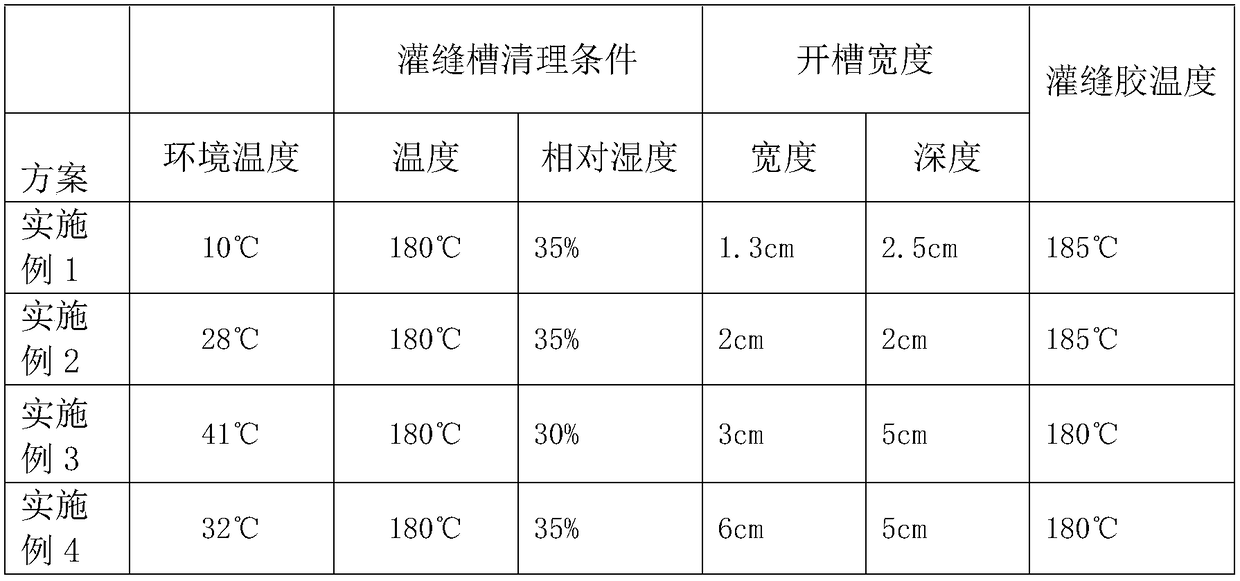

Road crack filling and repairing process

InactiveCN108118577AGuaranteed full integrationGuaranteed sealing effectPaving detailsRoads maintainenceFilling materialsHigh pressure

The invention discloses a road crack filling and repairing process. The key point of the technical scheme is as follows: the road crack filling and repairing process comprises the following steps: cutting and slotting, namely cutting and slotting a pavement according a standard operation for damaged cracks of the pavement, wherein the slot width is 1.3-3cm, the slot depth is smaller than 3cm, paving dry pebbles in the lower part of the pavement when the slot width is 3-6cm, and carrying out glue filling and cap sealing in 2cm in the upper part, wherein a dustproof operation is adopted in the process; filling crack cleaning, namely cleaning a filling slot by high pressure hot wind of a heat spray gun, wherein the temperature of the heat spray gun is set at 1500 DEG C, the pressure of an airsource is 0.2-0.5MPa, and the filling crack cleaning speed is 10m / min in summer and 5m / min in winter; carrying out crack filling operation, namely injecting filling glue into the filling slot througha filling machine, and controlling the height of the filling layer to be not lower than about 0.5cm of the pavement; and cooling and maintaining, namely after the filling operation, paving dry sand,lime powder and the like to the surface of the filling material during maintenance and vibrating, compacting and floating the pavement, wherein the road can come into use within about 10-20min. The road crack filling and repairing process can be used for repairing micro cracks of the pavement quickly, so that the service life of the road is prolonged, and the maintenance cost is lowered.

Owner:ZHONGSHAN YILUMEI ROAD MAINTENANCE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com