Rolling bearing esp. for dynamo

A technology of bearing device and bearing raceway, which is applied in the field of motors, and can solve the problems of reducing the life of the bearing frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

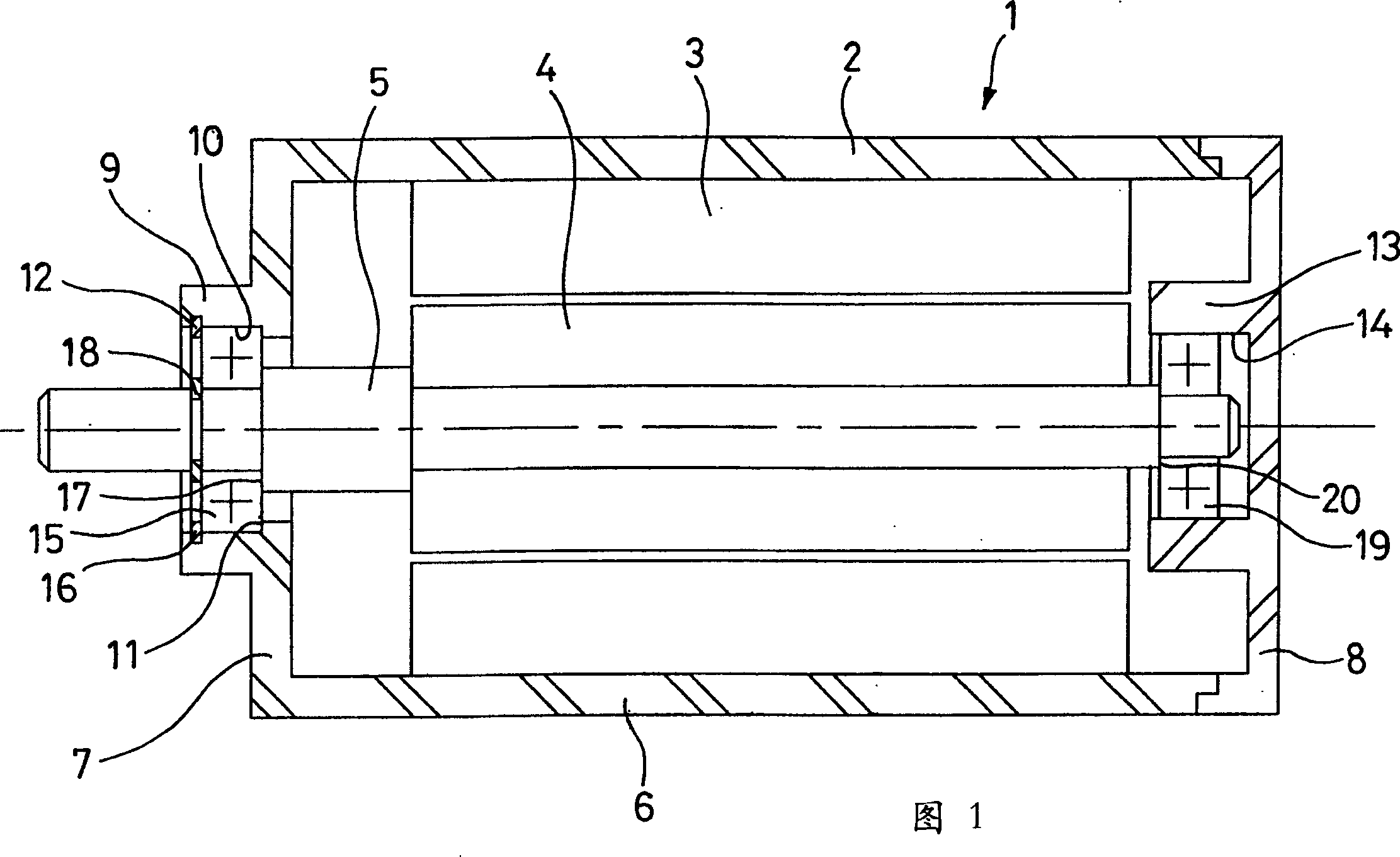

[0040] It can be seen from Fig. 1 that the motor 1 includes a housing 2 made of light alloy, a stator 3 integrated with the housing 2, a rotor 4 and a shaft 5 on which the rotor 4 is mounted. The housing 2 includes a substantially cylindrical part 6, a radial ring part 7 positioned at one end of the cylindrical part 6, and a radial part 8 positioned at the opposite end and having an annular shape.

[0041] The axial part 9 with the cylindrical bore 10, the shoulder 11 adjacent to the bore 10 and the groove 12 arranged along the bore 10 relative to the shoulder 11 are integrated with the radial annular part 7. The axial portion 13 with the cylindrical bore 14 is integrated with the radial annular portion 8 and extends axially toward the inside of the motor 1. A conventional type of bearing 15 is installed in the bore 10 of the axial flange 9 through its outer ring, and is axially fixed by a shoulder 11 and a circlip 16 provided in the groove 12. The bearing 15 is mounted on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com