Patents

Literature

997results about How to "Guaranteed alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of drilling a hole through Co2 laser directly

InactiveCN1761378AHigh precisionGuaranteed alignmentConductive material chemical/electrolytical removalLaser beam welding apparatusEtchingCopper foil

Drilling method of carbon dioxide laser includes steps: preparing locating point on layer next to the outer layer; before pressfitting added layer, browning oxidizing surface of target bonding pad; after pressfitting added layer, milling location hole / polishing edge, washing surface under high pressure; browning front surface of copper, thinning and coursing the surface before drilling hole by layer; first time to drill hole by laser; positioning film perforation by using plate location hole in original etching method for making window of copper, burning through copper foil and resin above the locating point on layer next to the outer layer so as to expose the locating point; second time to drill hole by laser; using the exposed locating point as position fixing to make micro hole inplate; washing surface under high pressure to remove browning layer after drill hole. The invention saves dry film and etching liquid, and raises process precision.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

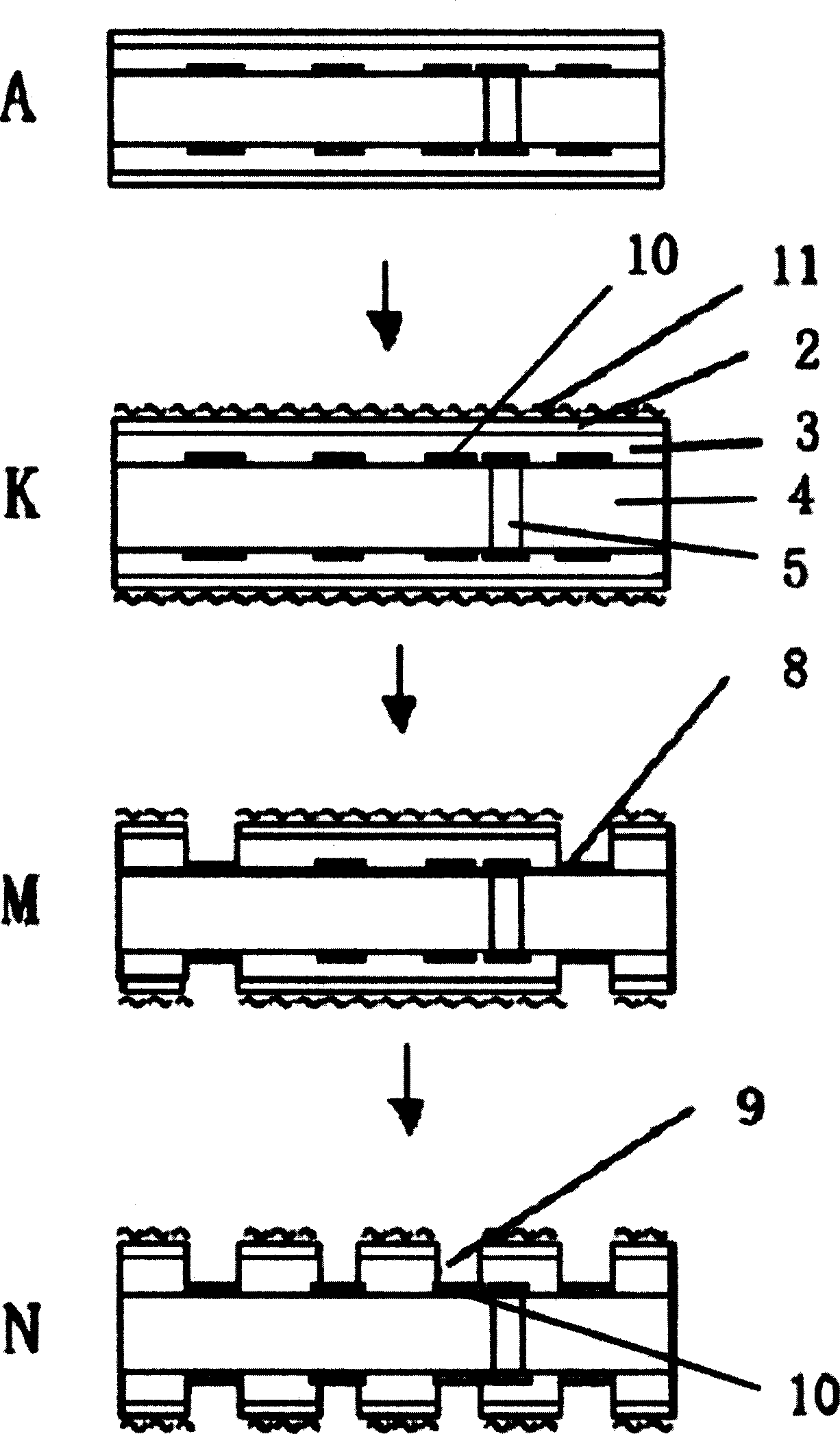

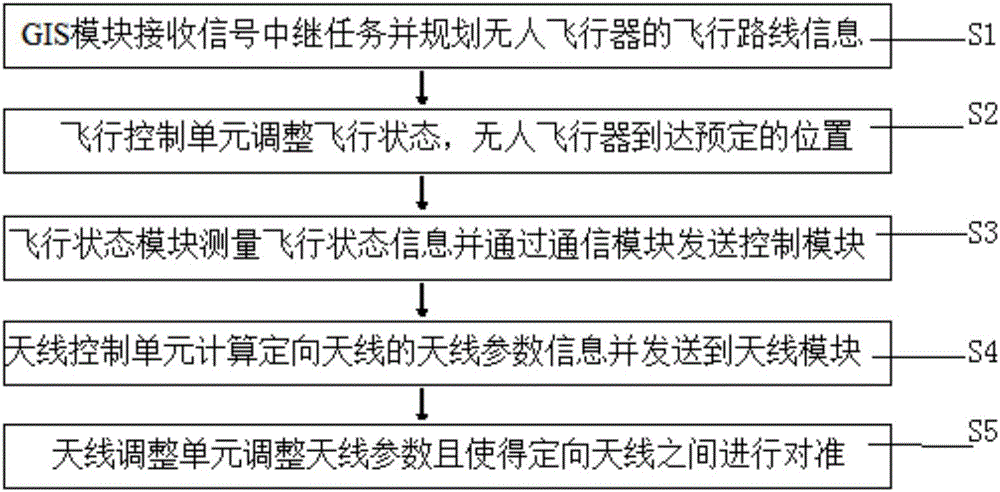

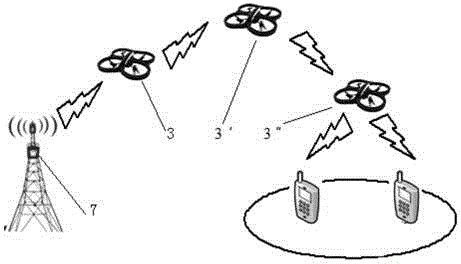

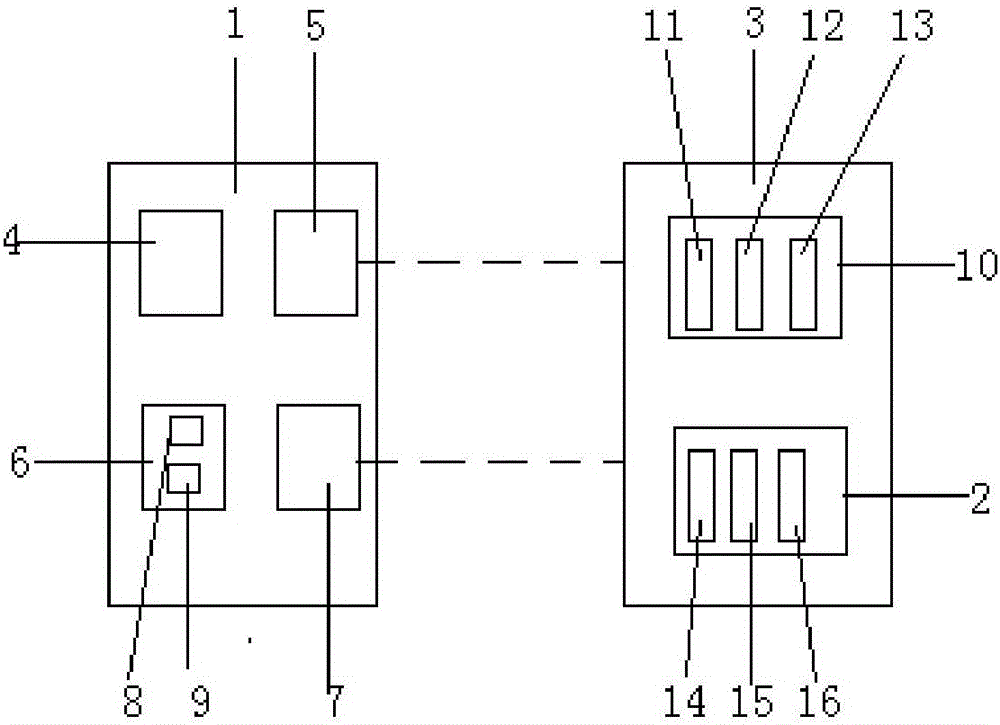

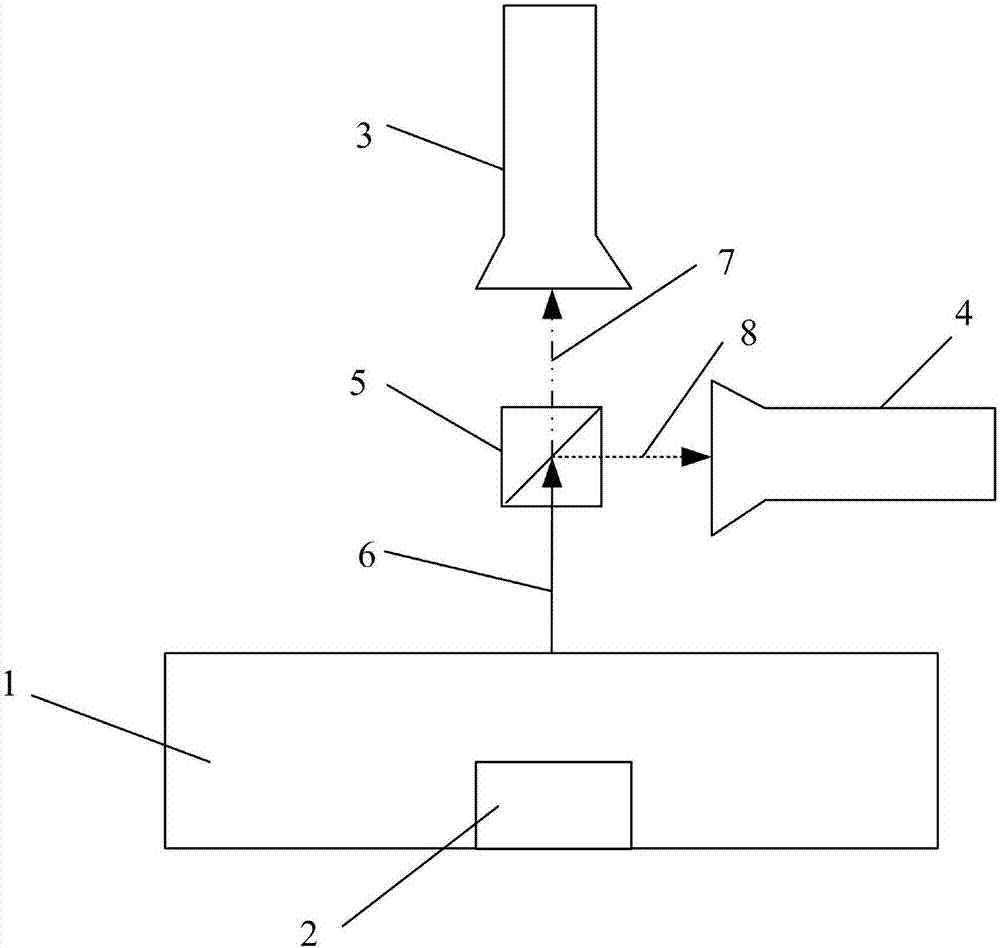

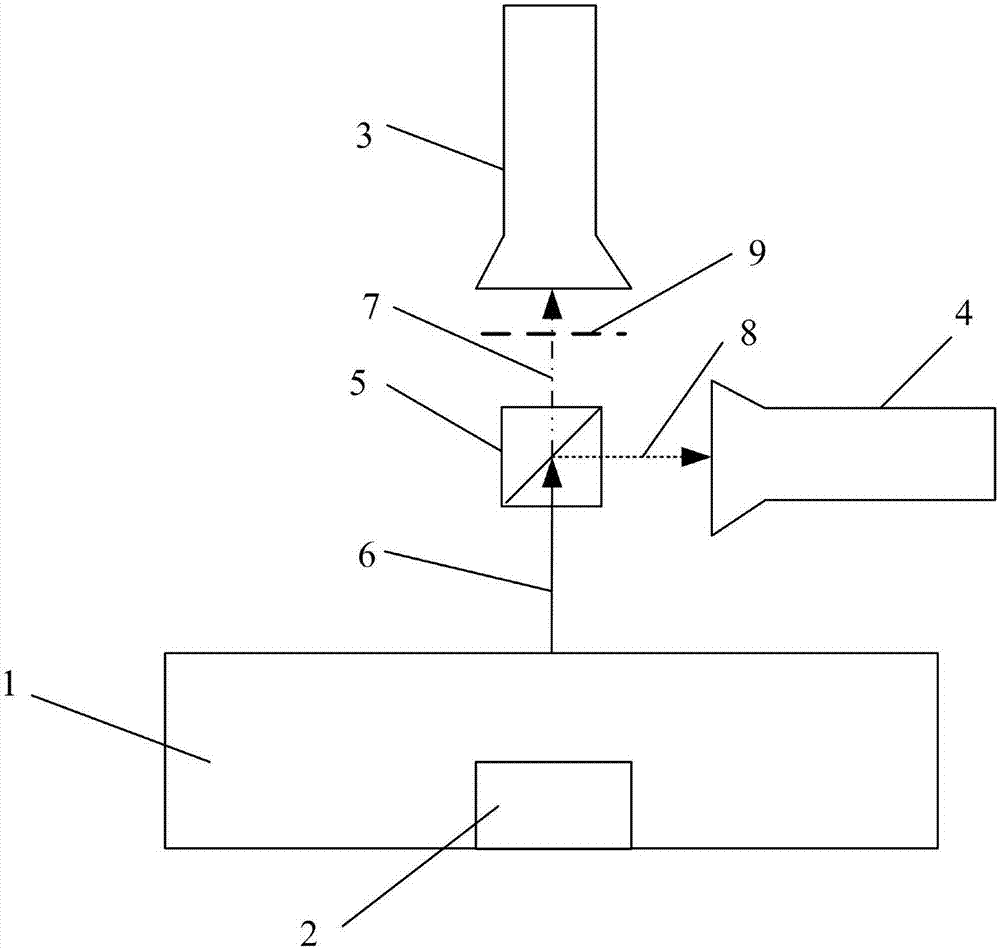

Signal relay system based on unmanned aircraft, and signal relay method thereof

ActiveCN105119650AGuaranteed alignmentEasy to adjustRadio transmissionDirectional antennaUnmanned air vehicle

Provided is a signal relay system based on an unmanned aircraft, and a signal relay method thereof. The system comprises a ground control device (1) and at least one unmanned aircraft (3). According to the flight state information of the unmanned aircraft (3) received by a communication module (5), an antenna control unit (9) calculates the antenna parameter information between a relay signal emitter (7) and the unmanned aircraft (3), and sends the antenna parameter information to an antenna module (2); a flight state module (10) measures the flight state information of the unmanned aircraft (3) through an electronic compass (11), an alleviator (12) and a GPS module (13), and sends the flight state information of the unmanned aircraft (3) to a control module (6) through the communication module (5); an antenna adjusting unit (16) adjusts antenna parameters according to the antenna parameter information sent by the communication module (5), and aligns directional antennas (15).

Owner:杨珊珊

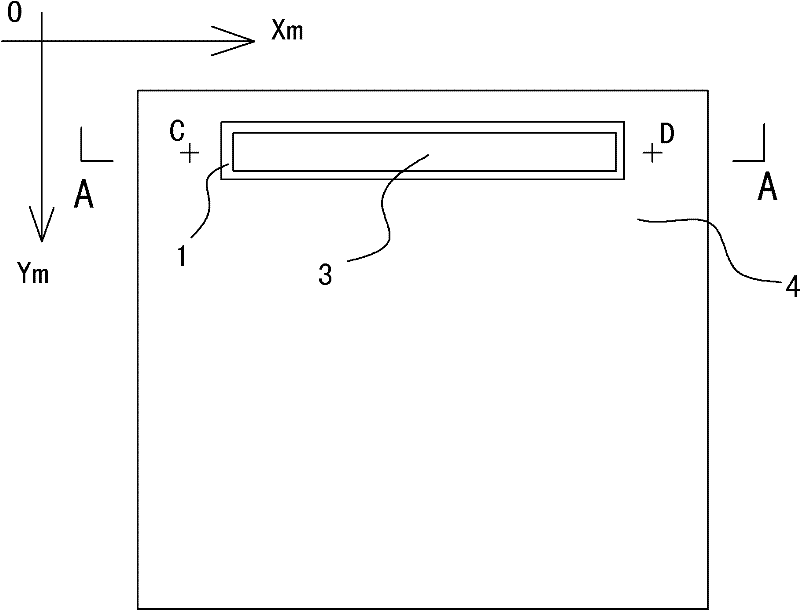

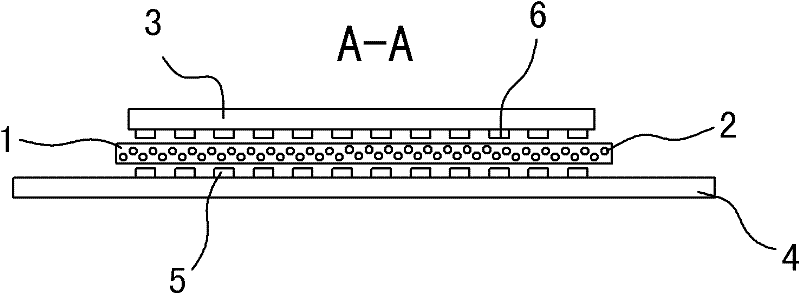

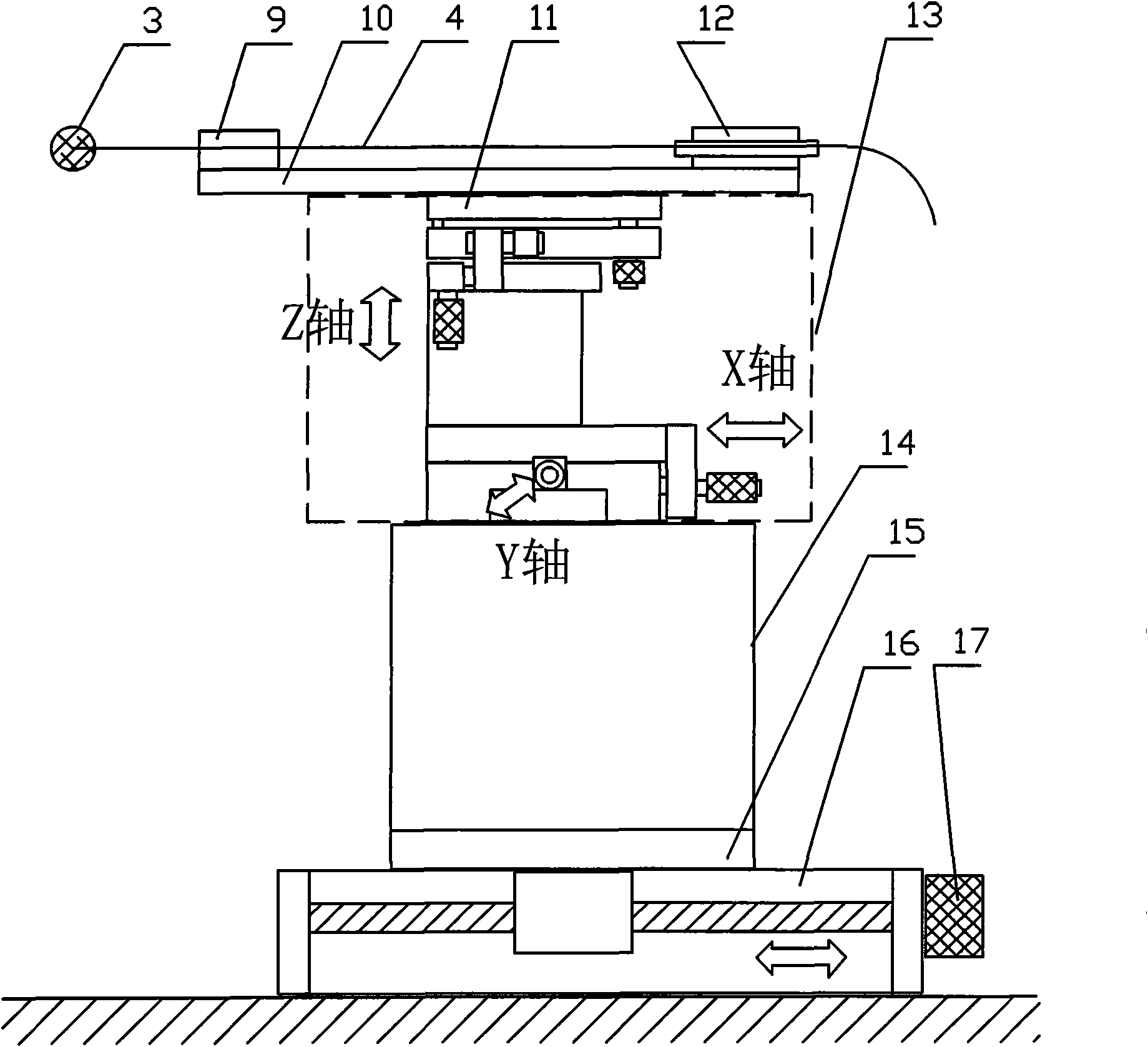

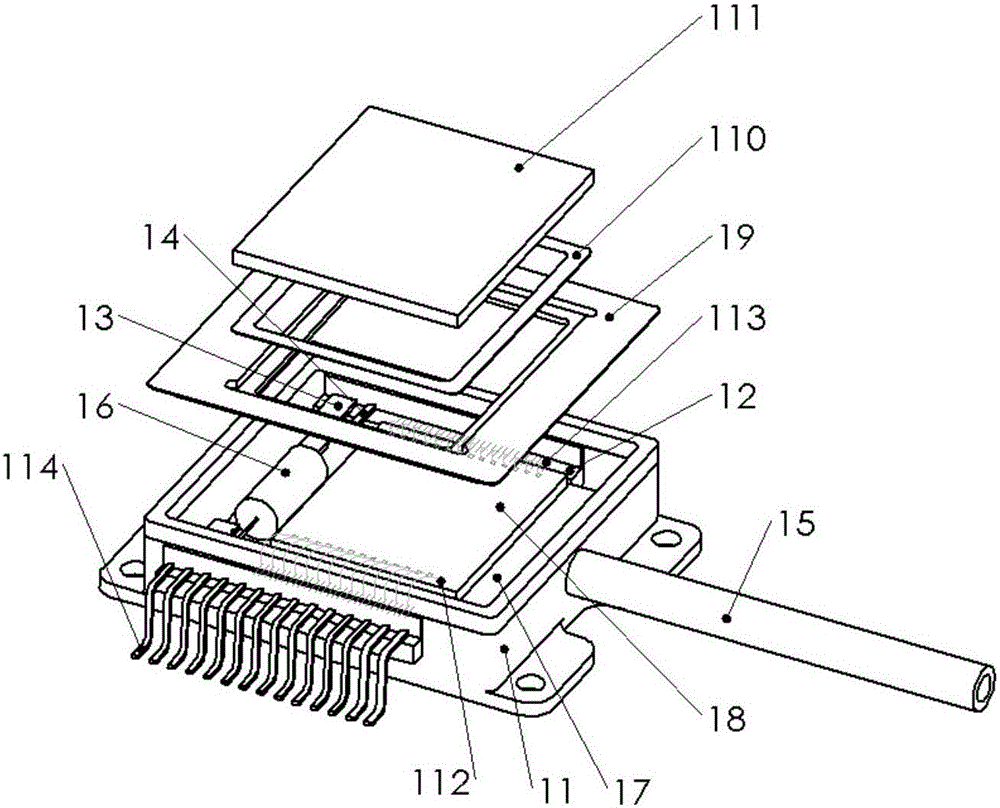

Alignment method for attaching chip or flexible circuit board to circuit substrate

ActiveCN102164460AImprove alignment accuracyGuaranteed alignmentPrinted circuit assemblingSemiconductor/solid-state device testing/measurementChip on filmImaging processing

The invention discloses an alignment method for attaching a chip or a flexible circuit board to a circuit substrate, which is characterized by comprising the following steps of: designing two identification points on the circuit substrate in advance; after the circuit substrate is transferred to a framing table board and positioned, shooting images of the two identification points by using a camera, converting the images of the two identification points into position coordinates of an image coordinate system by using an image processing system; converting image coordinates of the two identification points into mechanical coordinate values of a mechanical coordinate system by using a relationship between the image coordinate system and the mechanical coordinate system; finding out an X-directional offset, a Y-directional offset and a deflection angle around a Z axis between the actual positions of the two identification points and a target position through calculation; and finally adjusting the two identification points to the target position by using an X-directional movement mechanism, a Y-directional movement mechanism and a rotating mechanism around the Z axis, so that the chip or the flexible circuit board is aligned with a conducting terminal of the circuit substrate. By the invention, the alignment precision of a chip on glass (COG), a film on glass (FOG) and a chip on film (COF) is greatly improved.

Owner:苏州凯蒂亚半导体制造设备有限公司

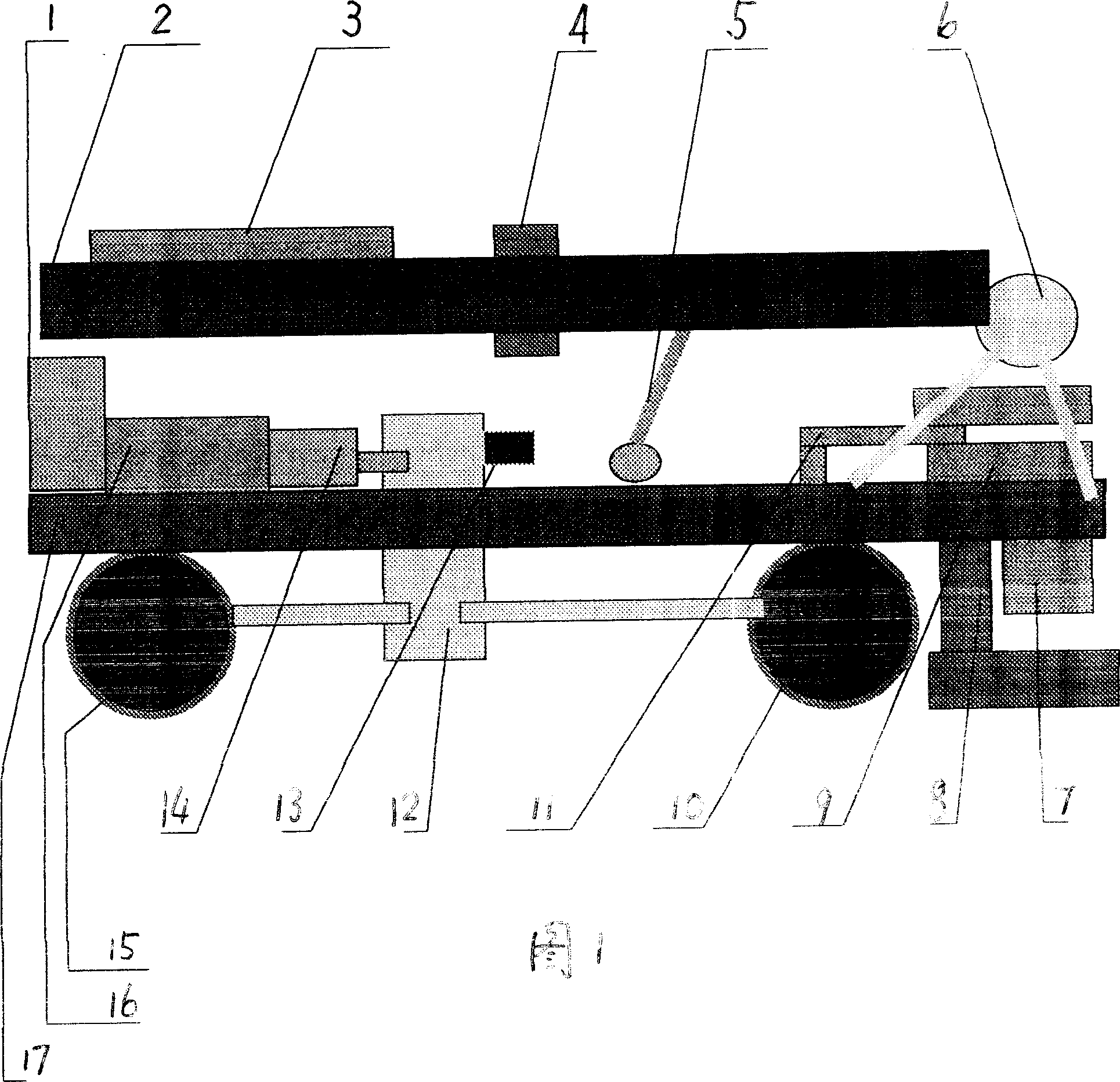

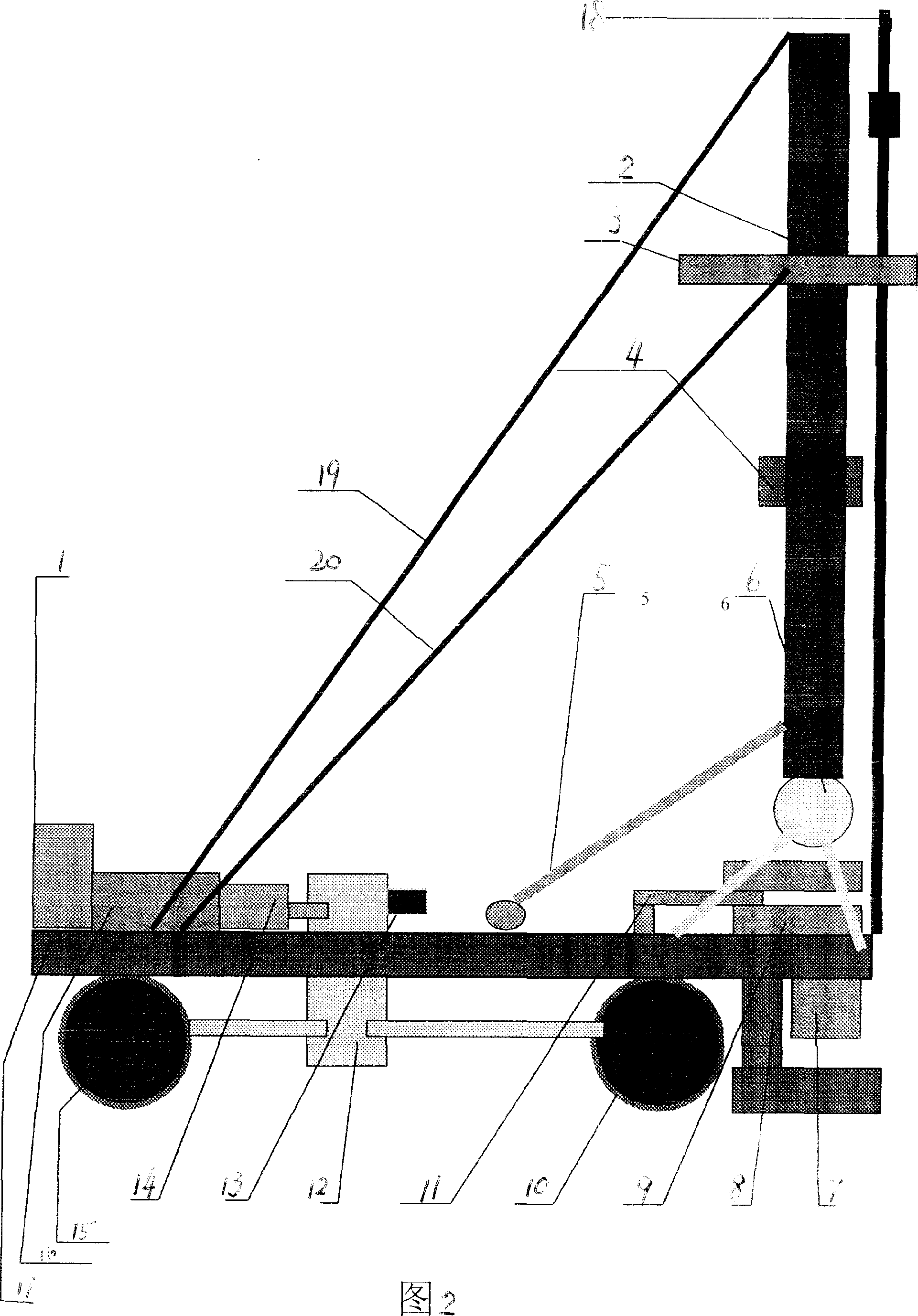

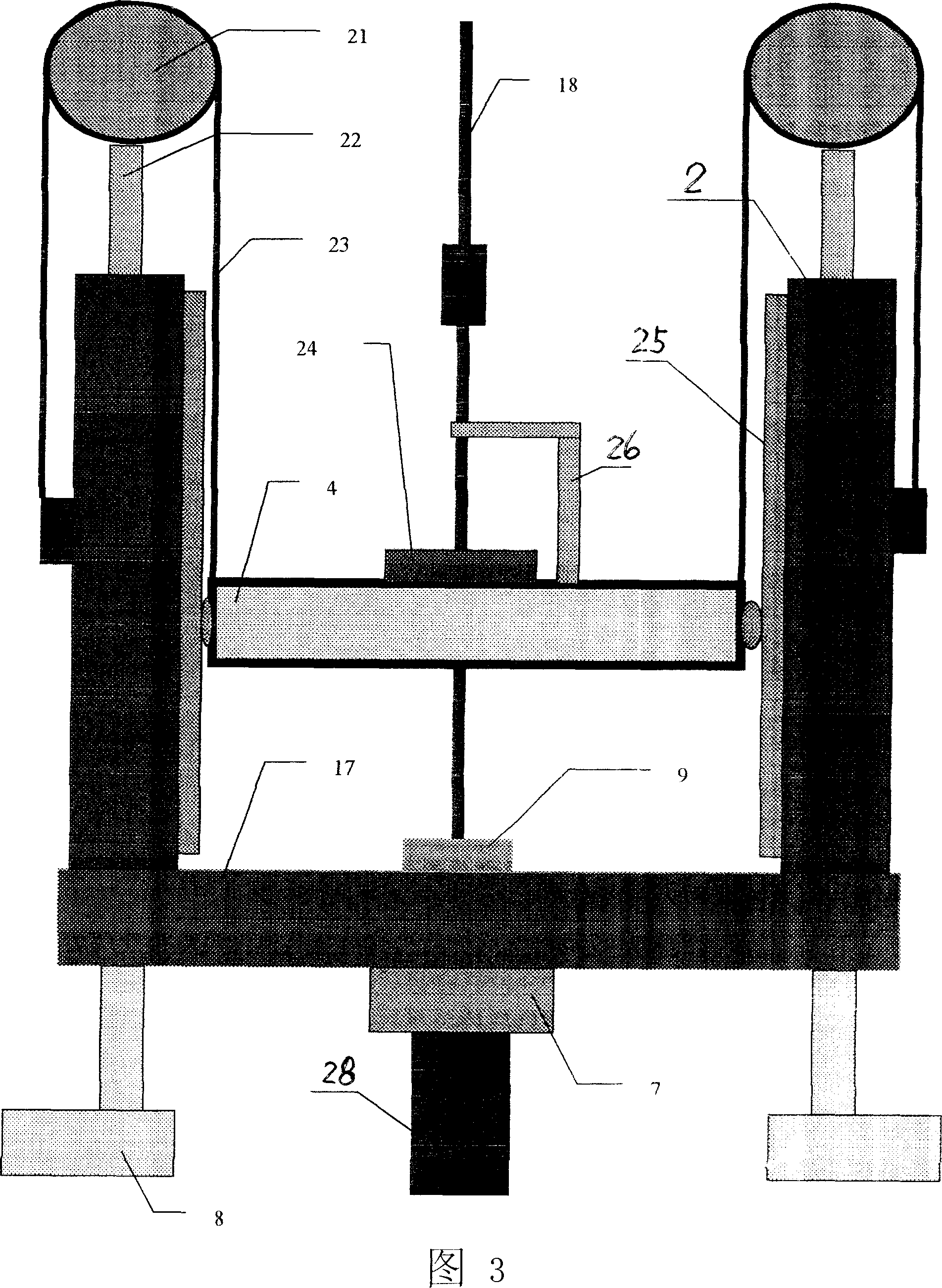

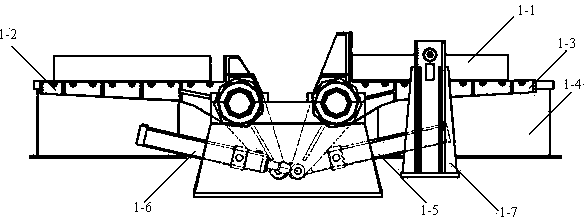

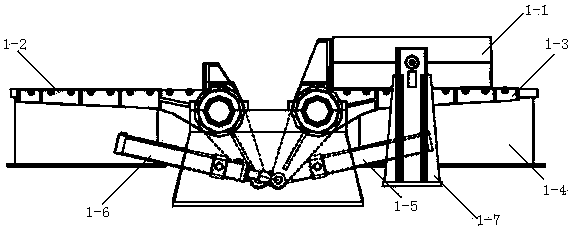

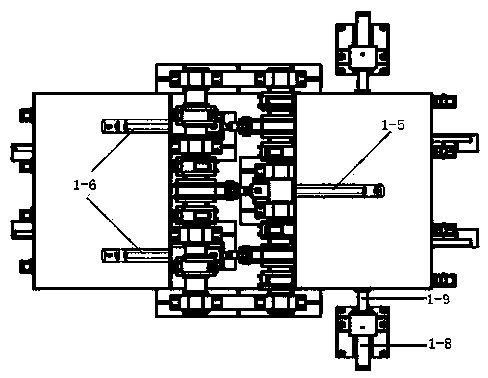

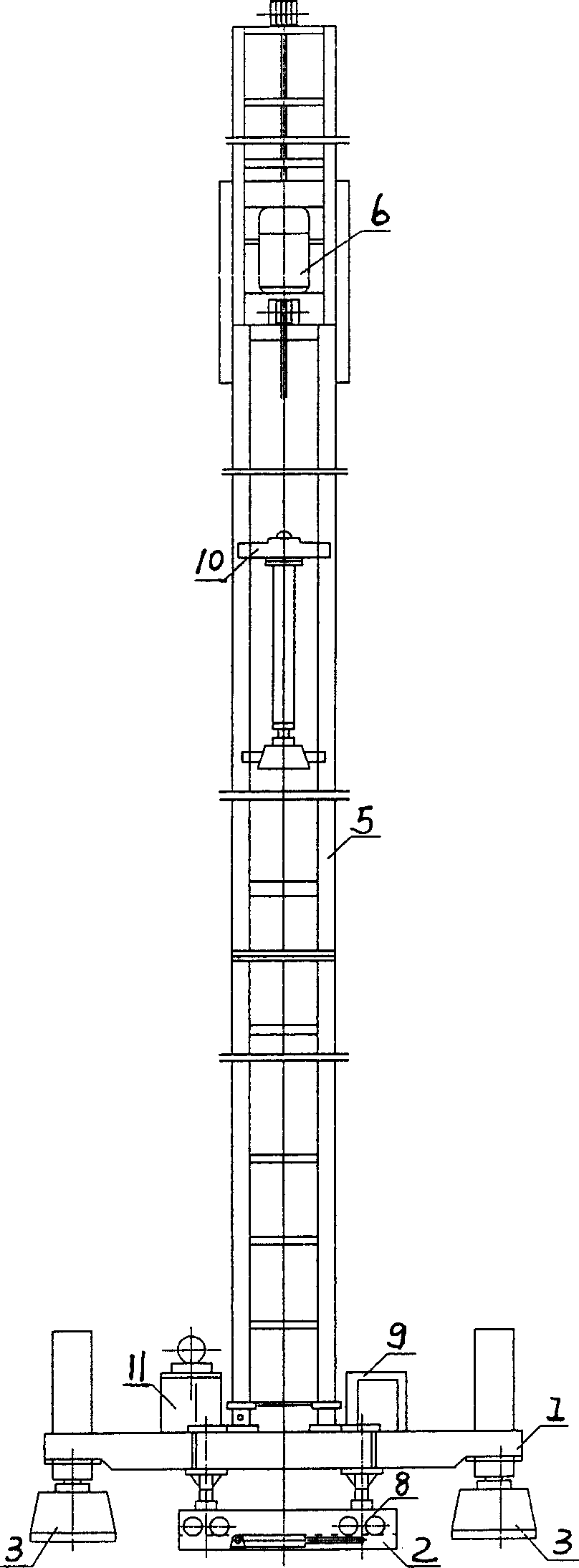

Drill floor well repairing machine without manual operation in well mouth

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

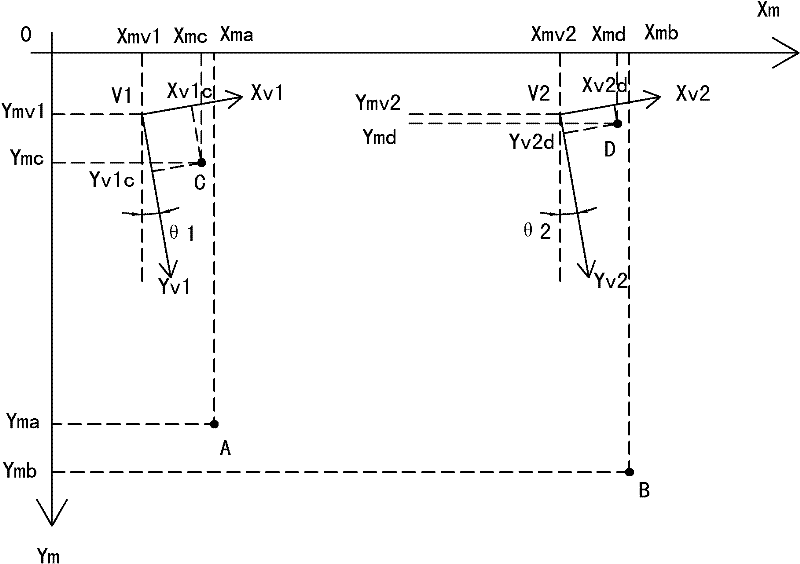

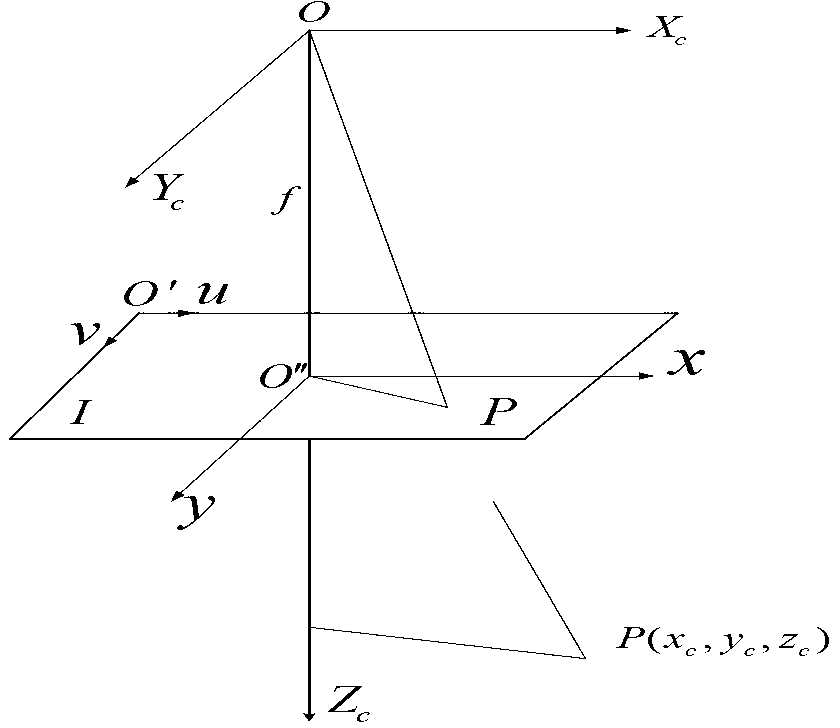

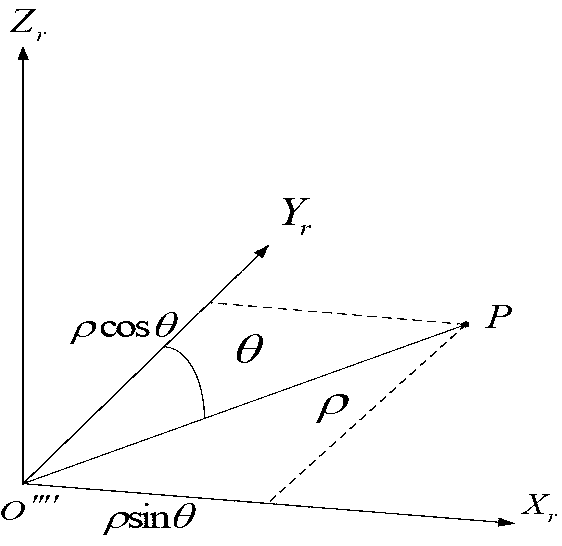

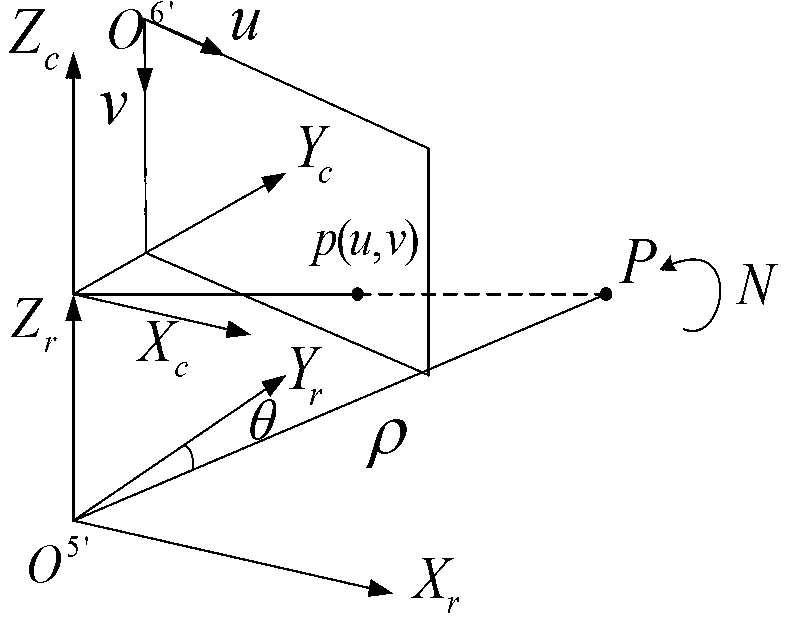

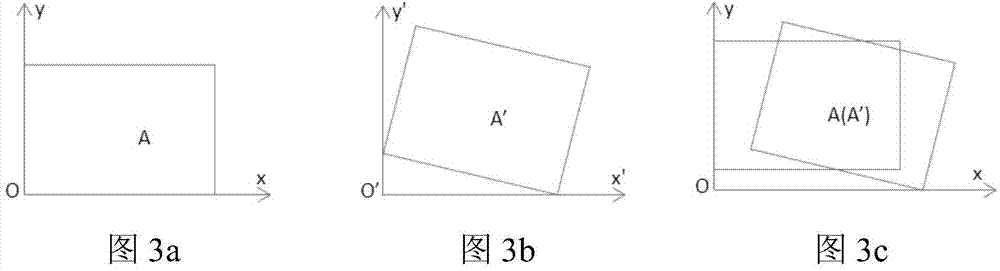

Subsection space aligning method based on homography transformational matrix

The invention discloses a subsection space aligning method based on a homography transformational matrix. According to the subsection space aligning method based on the homography transformational matrix, large marked distance is sectioned, the homography transformational matrix between a camera coordinate system and a millimeter-wave radar coordinate system of each subsection is acquired, errors caused by using a same homography transformational matrix to represent coordinate relations of two sensors in the prior art are avoided, and space aligning of target detection of the large marked distance can be achieved. Relations of different coordinate systems between the camera and the millimeter-wave radar are deduced and represented, and finally the relations of the coordinate systems between the camera and the millimeter-wave radar are represented by the homography transformational matrix N. The two sensors are used for obtaining target data and solving the homography transformational matrix N, and a camera internal parameter matrix and a rotation matrix which are composed of solving scaling factors, focal distance and the like are avoided and a camera external parameter matrix composed of translation vectors is avoided. Therefore, operation process is greatly simplified and operation time is saved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of super-thick alloy steel plate

ActiveCN103692166AShorten welding timeAvoid Crack SensitivityWelding/cutting auxillary devicesAuxillary welding devicesMetallurgyWelding joint

The invention belongs to the technical field of metallurgy and particularly relates to a preparation method of a super-thick alloy steel plate. The preparation method comprises steps that surface treatment is performed on two alloy steel continuous casting slabs matched in length and width dimension; the alloy steel continuous casting slabs are overlapped on a steel feeding swing arm of a tilting gear and align to each other; the alloy steel continuous casting slabs are fed into a vacuum chamber and welded through a structure with two electronic guns; when carbon equivalent of the continuous casting slabs to be compounded is smaller than 0.3%, a front electronic gun begins to perform welding from ends of the alloy steel continuous casting slabs, and a rear electronic gun begins to perform welding from middles of the alloy steel continuous casting slabs; when carbon equivalent of the continuous casting slabs to be compounded is higher than or equal to 0.3%, the distance between the two electronic guns is shortened, an electron beam of the front electronic gun is regulated into a defocusing mode, the front electronic gun preheats welding joints, and the rear electronic gun performs welding soon afterwards; heating rolling is performed on the welded slabs to obtain the super-thick alloy steel plate. By means of the technical scheme, compound interfaces between the continuous casting slabs to be compounded completely align, and yield of the super-thick alloy steel plate is increased.

Owner:沈阳科安捷材料技术有限公司

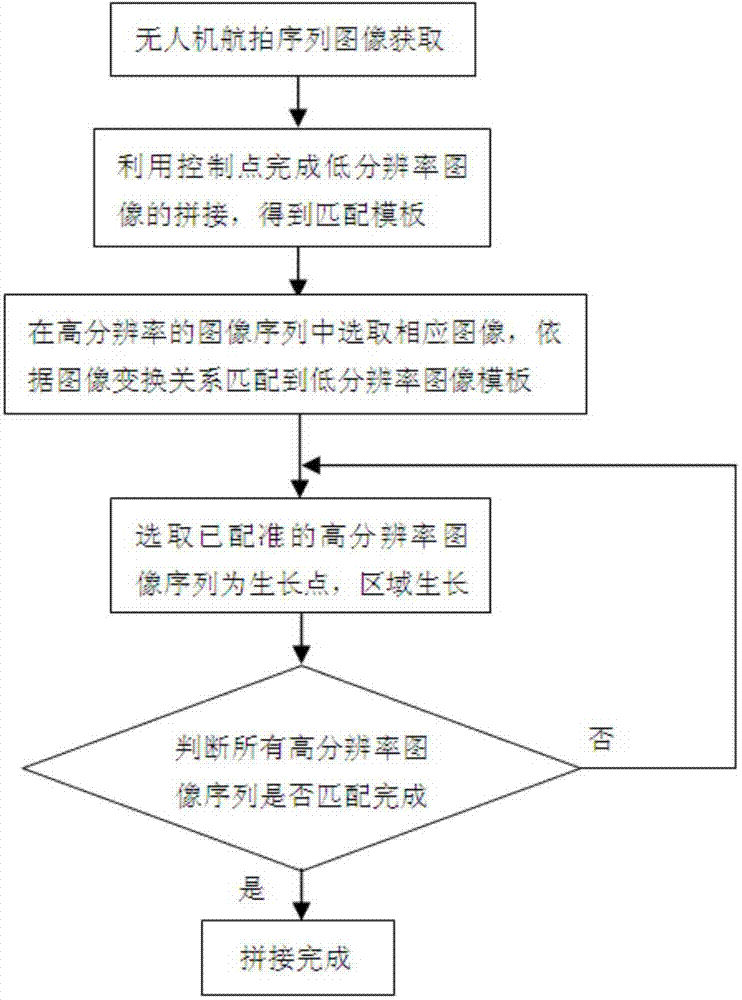

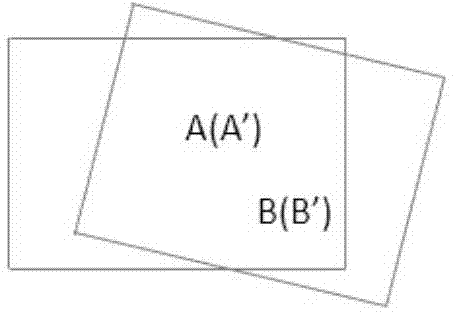

Multi-resolution image stitching method based on control points

InactiveCN104732482ARealize real-time stitchingAvoid accumulationImage enhancementGeometric image transformationImage resolutionHigh resolution image

The invention discloses a multi-resolution image stitching method based on control points. The multi-resolution image stitching method includes the steps that 1, unmanned-aerial-vehicle aerial photography sequence images are obtained, wherein rotation and transverse-movement transformation relations of the images are obtained through two sets of ground control point pairs in overlapped areas of the adjacent frames of low-resolution images, and finally the low-resolution sequence images are stitched and fused; 2, the stitching result of the low-resolution sequence images serves as a high-accuracy matching template, and final integral image matching is completed from coarse to fine; 3, the high-resolution sequence images matched to the template serve as growing points, the high-resolution sequence images of four adjacent regions of the growing points are stitched and fused through region growing, and the corresponding low-resolution images are replaced; then the high-resolution images of four adjacent regions serve as new region growing points for continuous growing till all the sequence images are matched to the template. By means of the multi-resolution image stitching method, the technical problems that in the existing image stitching technology, the image matching efficiency is low, and the aerial photography sequence images can not be stitched in real time are solved.

Owner:NO 63655 TROOPS OF THE CHINESE PEOPLES LIBERATION ARMY

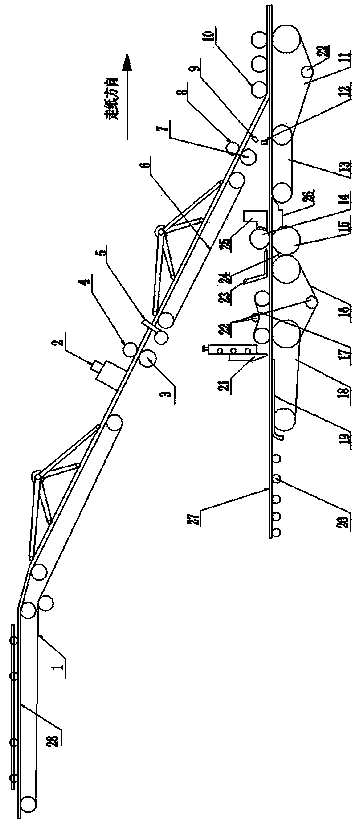

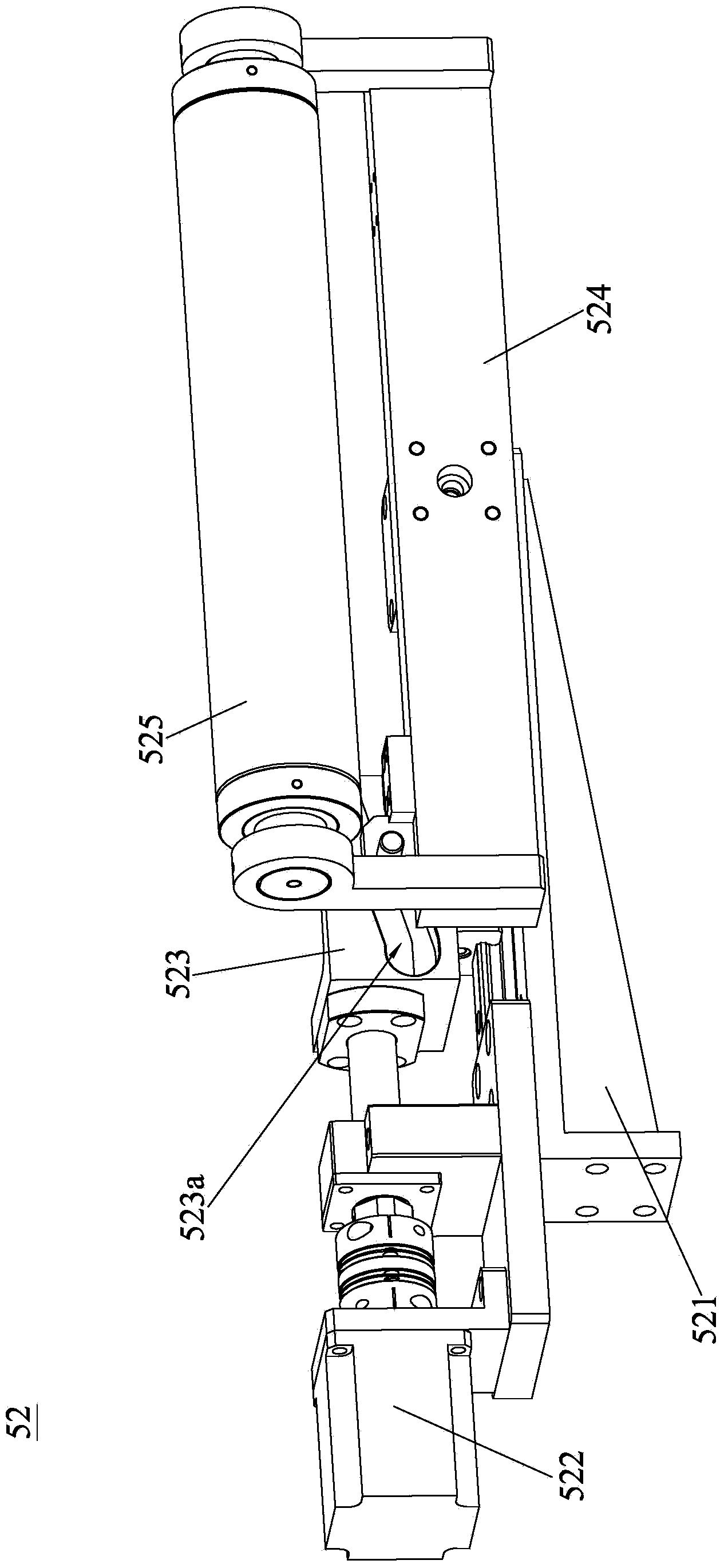

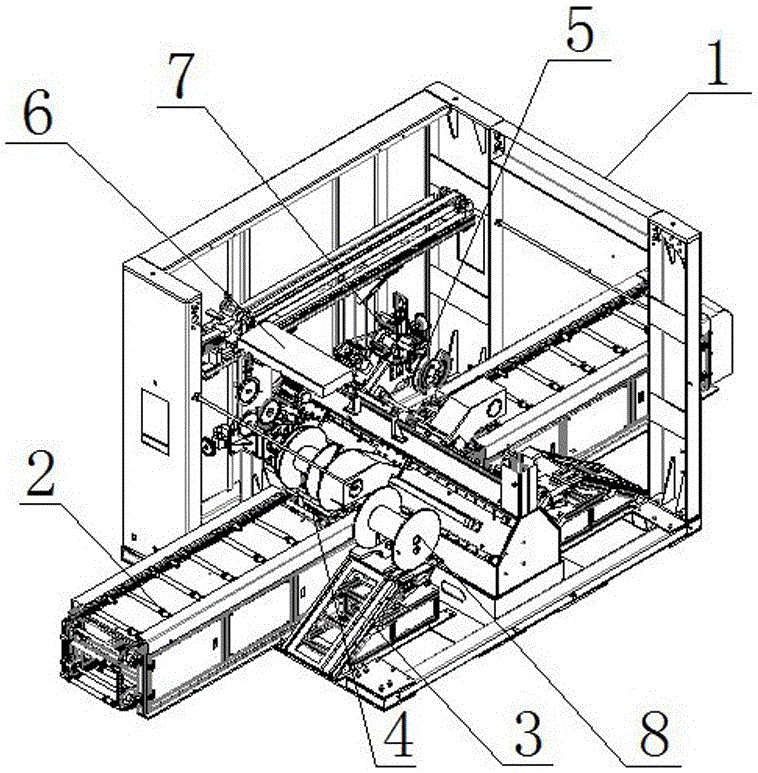

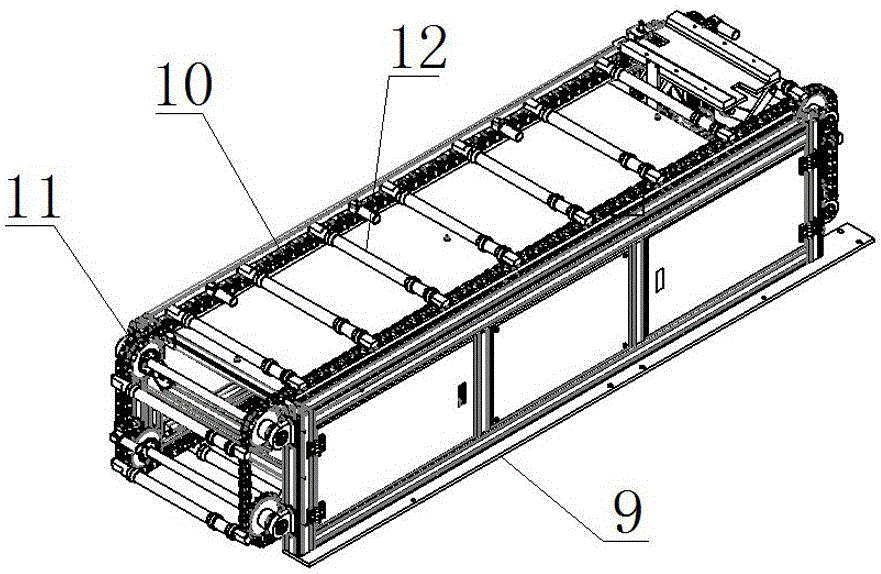

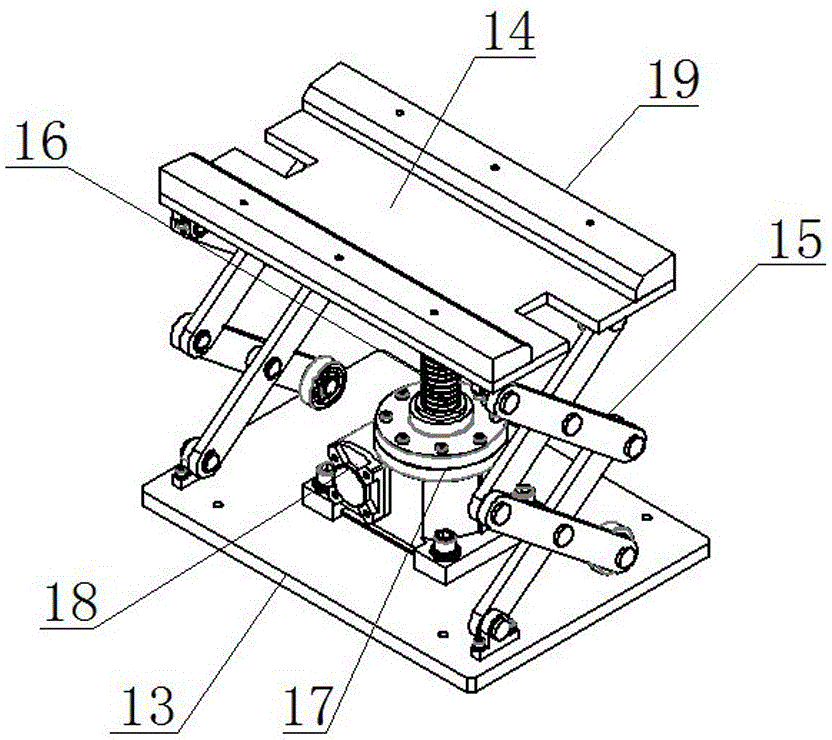

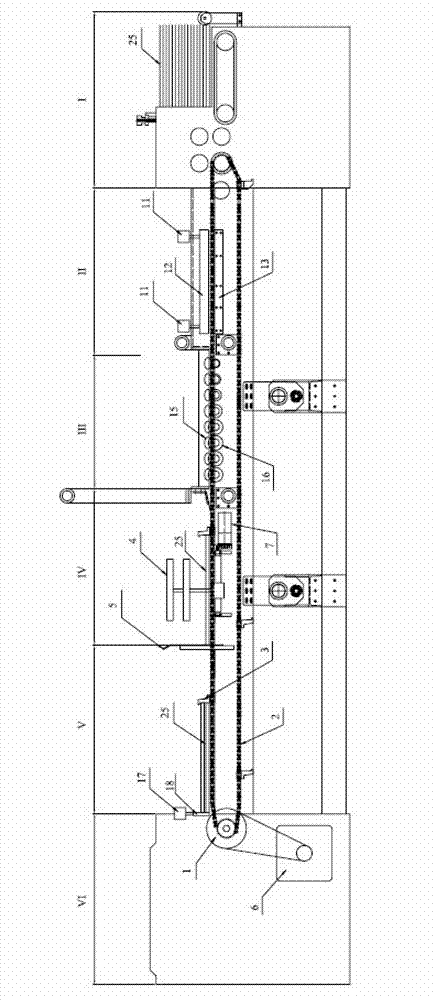

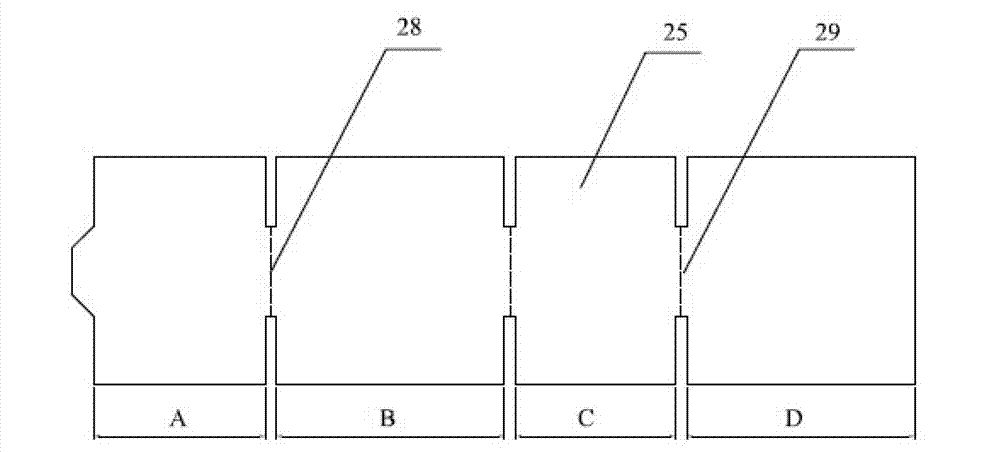

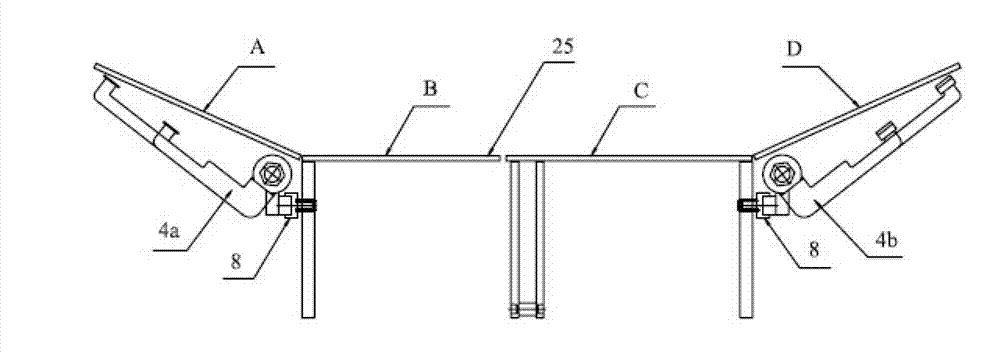

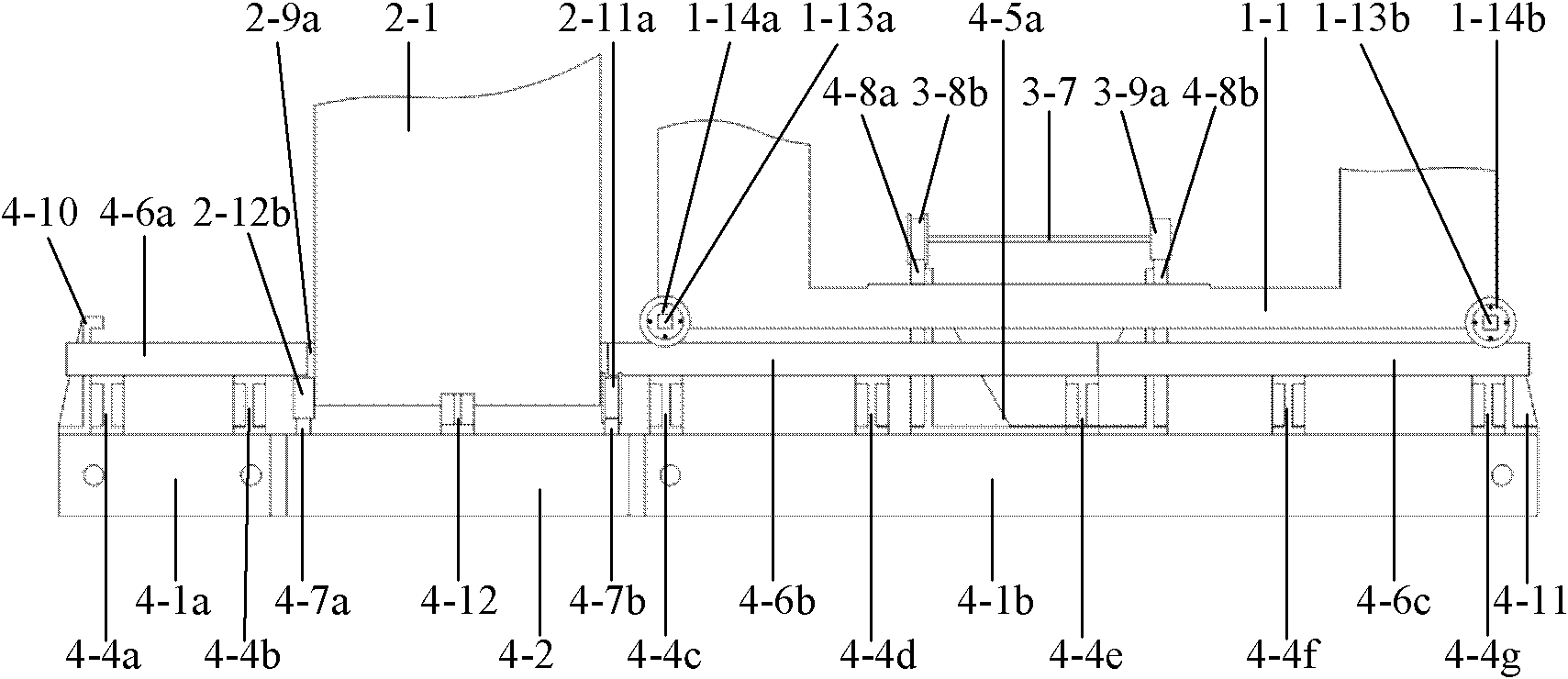

Synchronous body paper and face paper feeding device and control method

ActiveCN104340703ARealize synchronous high-speed paper feedingRealize functionArticle feedersWebs handlingMotor driveLow speed

The invention provides a synchronous body paper and face paper feeding device and a control method. The device is characterized in that a face paper front lay gauge, a face paper pressing wheel, a face paper side lay gauge, a body paper front lay gauge and a body paper lifting plate assembly are configured with cam mechanisms respectively and are driven by the respective cam mechanisms; a face paper motor drives a low-speed face paper feeding belt assembly, a body paper induced draft air distribution valve, a face paper side pull gauge and cam mechanisms thereof through a synchronous toothed belt or a roller chain; a paper injection driving roller, an upper pressing driving roller, a paper feeding driving roller, a high-speed face paper injection wheel and a high-speed face paper conveying belt assembly are driven by a body paper motor at the same speed. The distance between the face paper front lay gauge and a laminating roller is equal to the distance between the body paper front lay gauge and the laminating roller, so that body paper and face paper reach a converging point at the same time, and surface lamination is completed. The functions of synchronously feeding the body paper and the face paper at a high speed and automatically aligning the body paper with the face paper can be realized, the use of the motors is reduced, and the phenomenon that the motors are frequently started is avoided. The working efficiency is improved, and the manufacturing cost is reduced.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

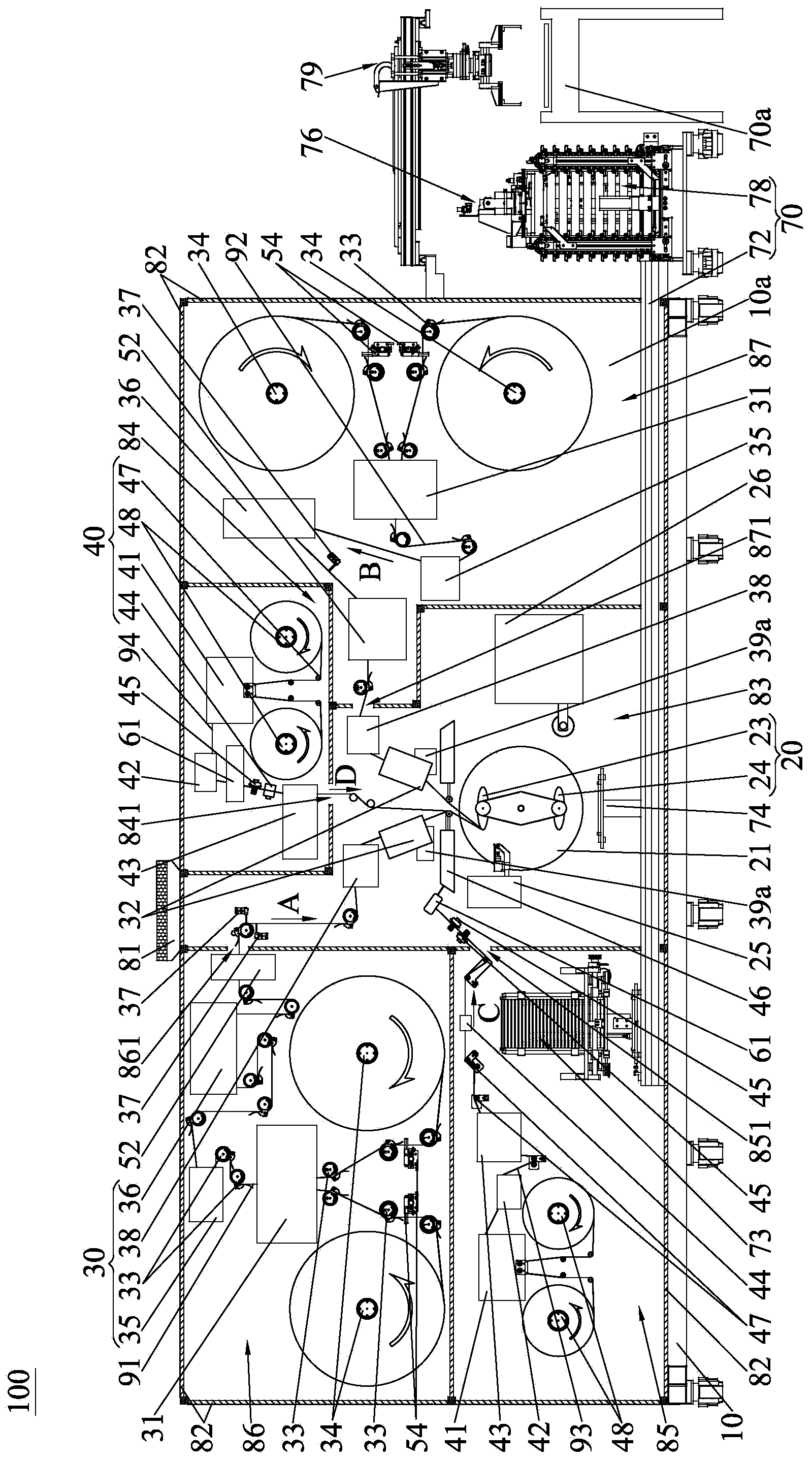

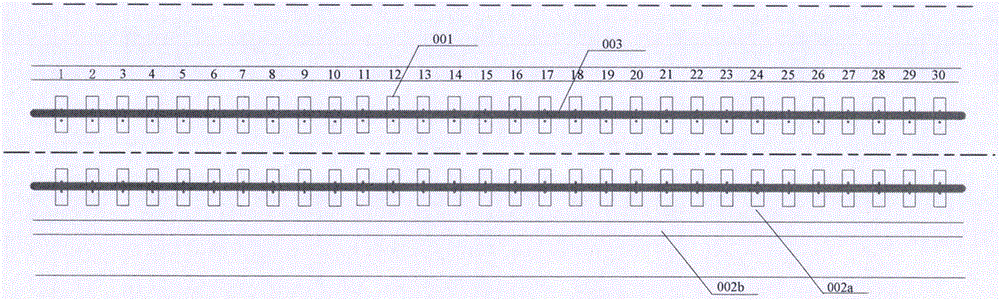

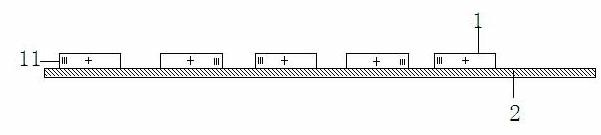

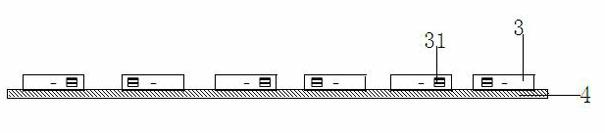

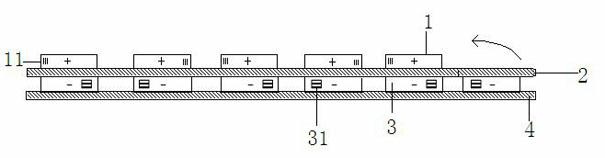

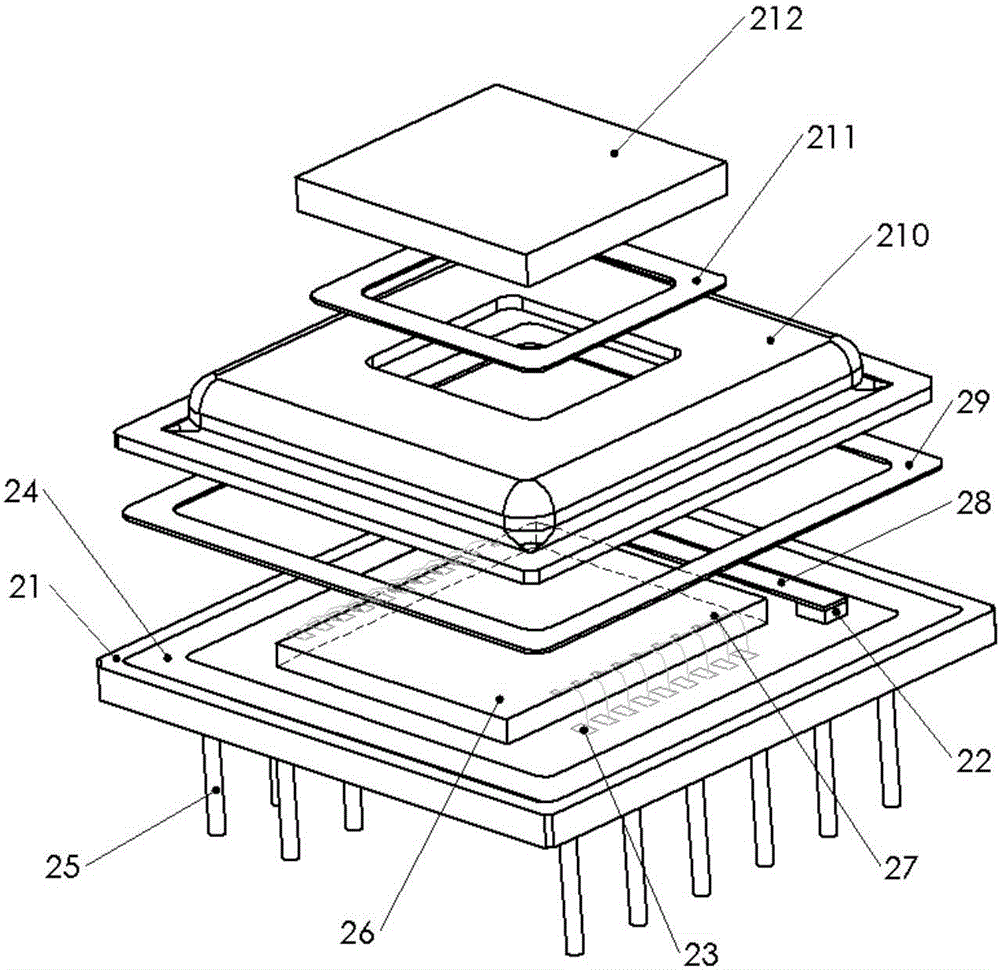

Battery winder

ActiveCN103915654ASimple structureImprove job stabilityMeasurement devicesAssembling battery machinesEngineeringPole piece

The invention discloses a battery winder which comprises a rack, an installation base board, a winding device, a delivery mechanism of two pole pieces and a delivery mechanism of two membranes, wherein the installation base board is arranged on the rack along the vertical direction, the winding device is arranged on the installation base board, a positive pole piece and a negative pole piece are respectively delivered to the winding device by virtue of the delivery mechanism of the two pole piece, a left membrane and a right membrane are respectively delivered to the winding device by the delivery mechanism of the two membranes, the left membrane, the positive pole piece, the right membrane and the negative pole piece which are successively superposed are wound and formed, so as to obtain a cell, a pole piece edge detection device and a pole piece centring device are arranged on the pole piece delivery mechanism, the pole piece edge detection device is used for detecting the edge of the positive pole piece or the negative pole piece in real time, the pole piece centring device is used for rectifying a deviation for the positive pole piece or the negative pole piece in real time according to the detection data of the pole piece edge detection device, a membrane edge detection device and a membrane centring device are arranged on the membrane delivery mechanism, the membrane edge detection device is used for detecting the edge of the left membrane or the right membrane in real time, and the membrane centring device is used for rectifying a deviation for the left membrane or the right membrane in real time according to the detection data of the membrane edge detection device.

Owner:东莞市博拓锂电科技有限公司

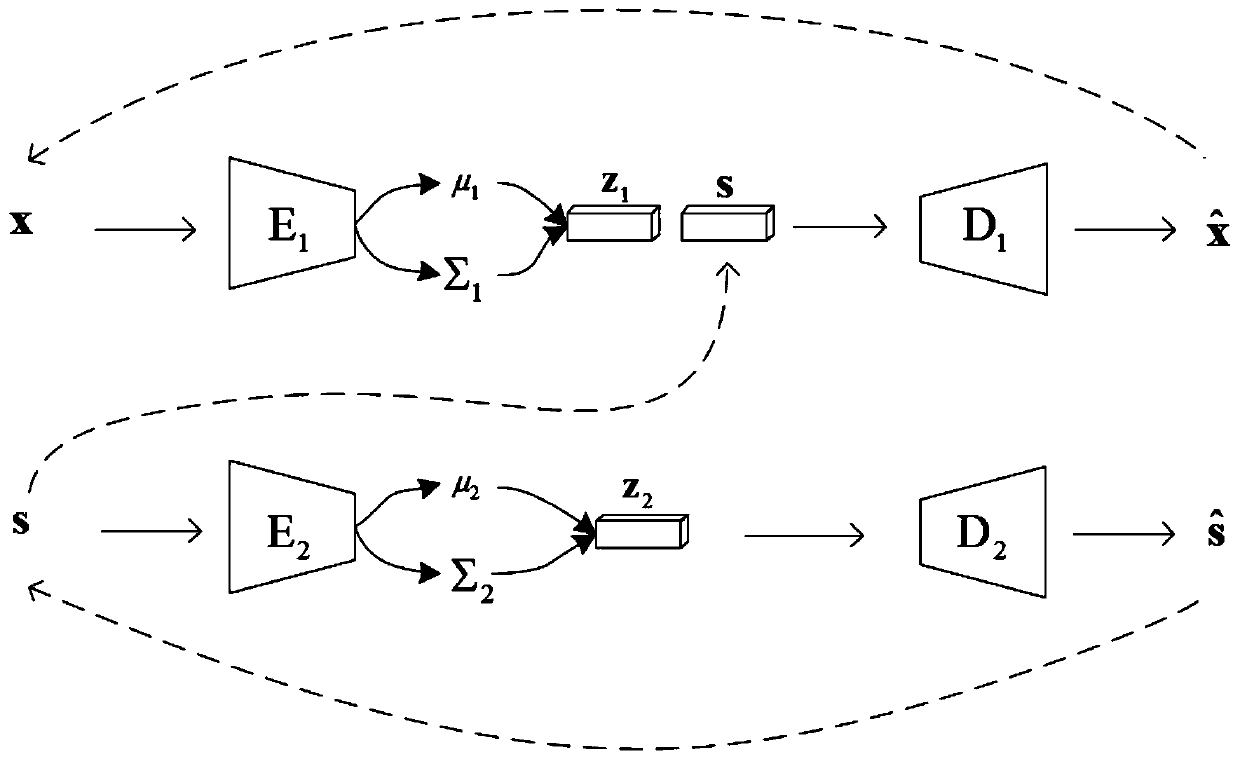

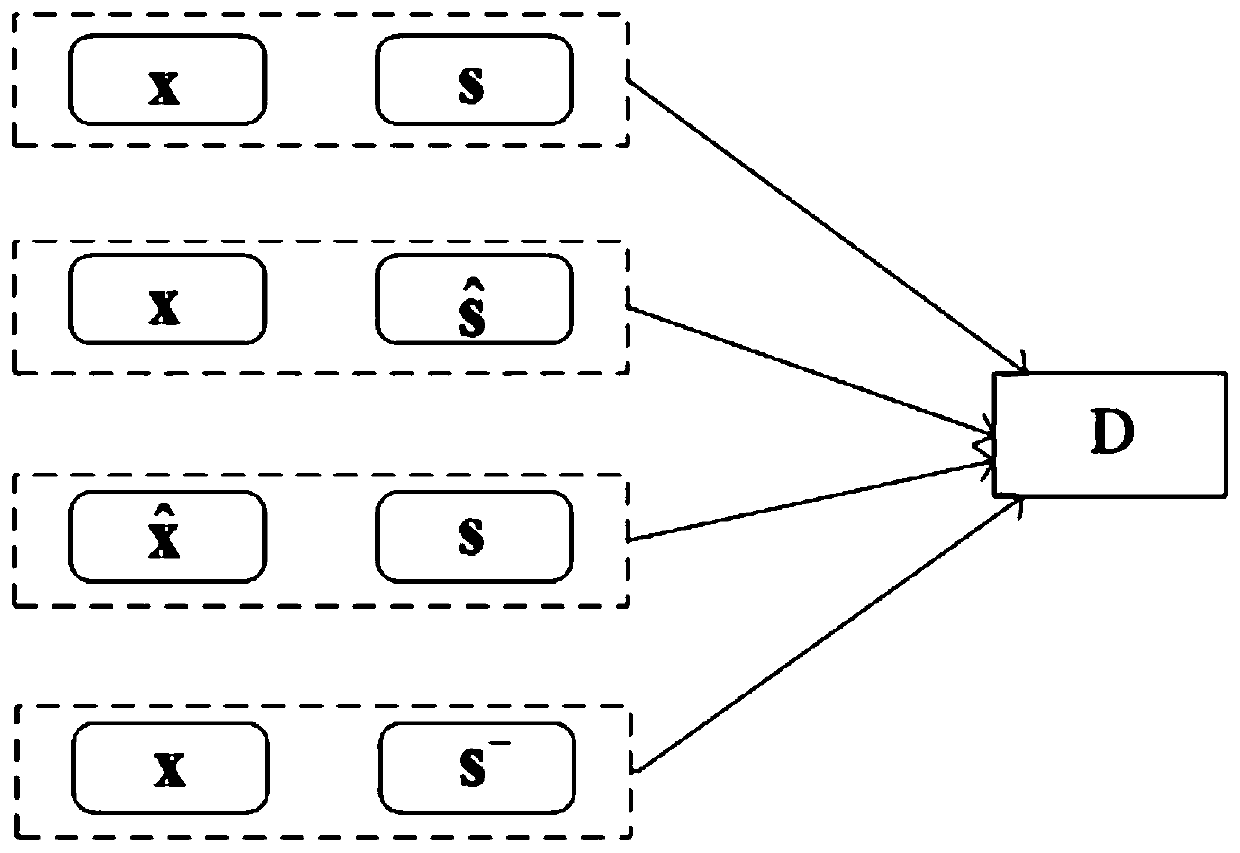

Zero-sample image classification method based on variational self-coding adversarial network

ActiveCN110580501AMitigating Domain Drift ProblemsGuaranteed alignmentCharacter and pattern recognitionClassification methodsSample image

The invention discloses a zero-sample image classification method based on a variational self-coding adversarial network. Two variational auto-encoders of a visual mode and a semantic mode are constructed, and visual features and semantic features are respectively and correspondingly used as inputs of the two variational auto-encoders; pseudo visual features and semantic features are generated, finally, the true visual features and the generated semantic features are input into a discriminator, and the adversarial process is completed through a metric learning method. Then starting to train asoftmax classifier, inputting the visual features of the non-visible class images into a variational auto-encoder of a visual mode, and training the classifier by utilizing the generated pseudo visualfeatures and corresponding labels; during testing, the real visual features of the non-visible class samples are input into the classifier for classification, and a zero-sample image classification task is realized. The method can achieve the classification task in a more real scene, facilitates the promotion of the application of zero-sample learning to the production and living reality, and accelerates the practical development of a deep learning algorithm.

Owner:TIANJIN UNIV

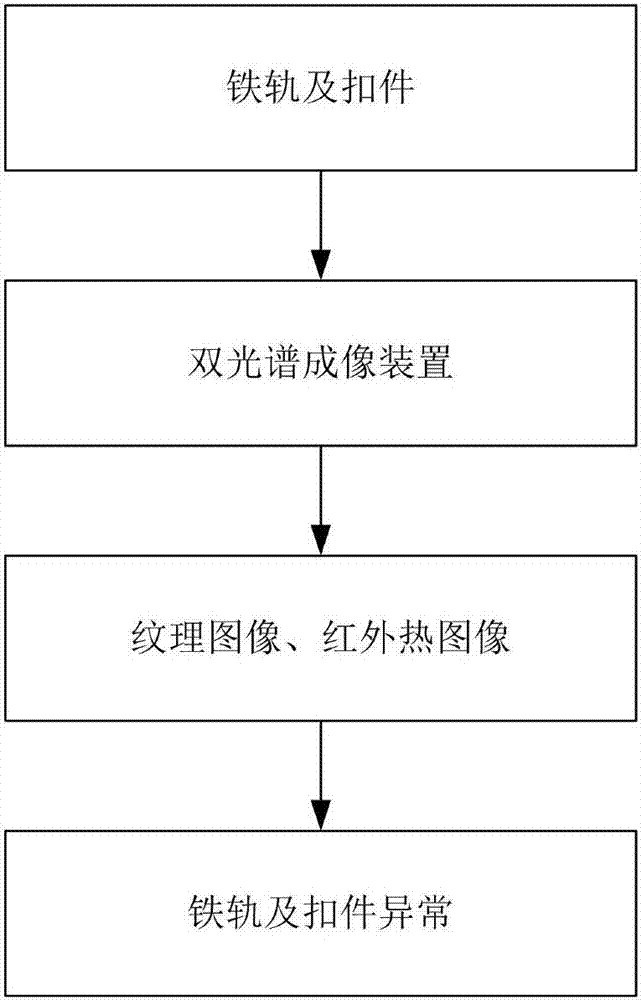

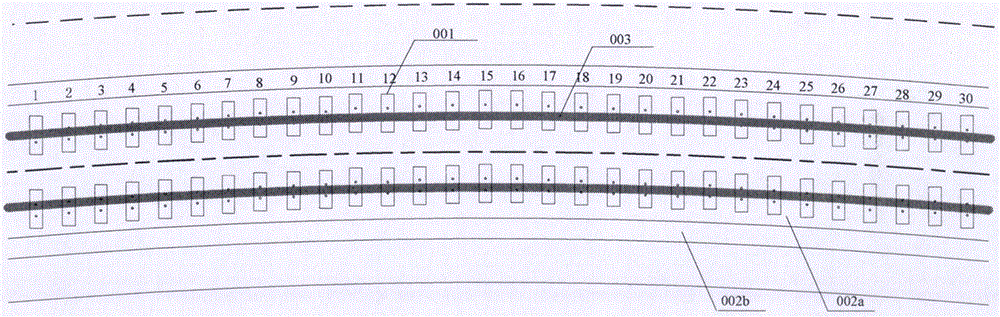

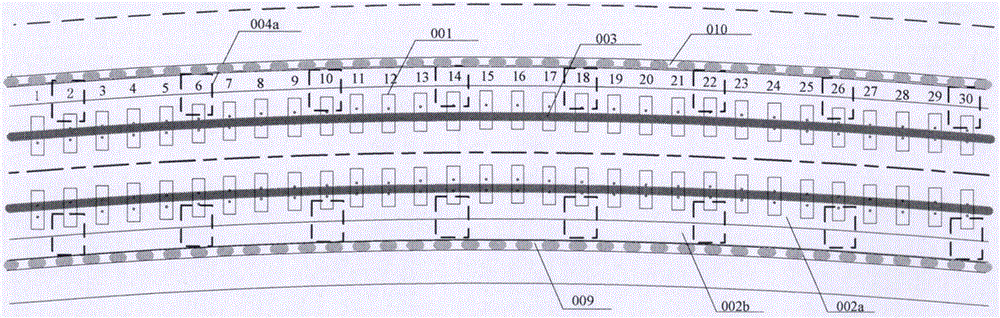

Method for detecting abnormal conditions of rails and fasteners through double-spectrum imaging

PendingCN107576666AImprove damage detection capabilitiesRefined comparative analysisOptically investigating flaws/contaminationRailway auxillary equipmentPattern recognitionRail transit

The invention discloses a method for detecting abnormal conditions of rails and fasteners through double-spectrum imaging, which belongs to the technical field of rail transport safety detection, andis used for solving the problem of difficulty in detecting the abnormal conditions of rails and fasteners in the prior art. According to the method, a visible light camera and an infrared camera forma double-spectrum imaging device for performing double-spectrum imaging on the rail and fastener areas and respectively acquiring the texture images and infrared thermal images of the rails and the fasteners; the texture images are adopted for positioning the rails and fasteners in the infrared thermal images; the background model comparison is adopted for detecting the abnormal conditions of missing, loosening and breaking of the fasteners; the texture images and the infrared thermal images are jointly used for detecting the rail peeling, scratching, corrugation and cracks. According to the method disclosed by the invention, the abnormal detection efficiency for the rails and the fasteners is effectively promoted and the rail transit safety is guaranteed.

Owner:成都精工华耀科技有限公司

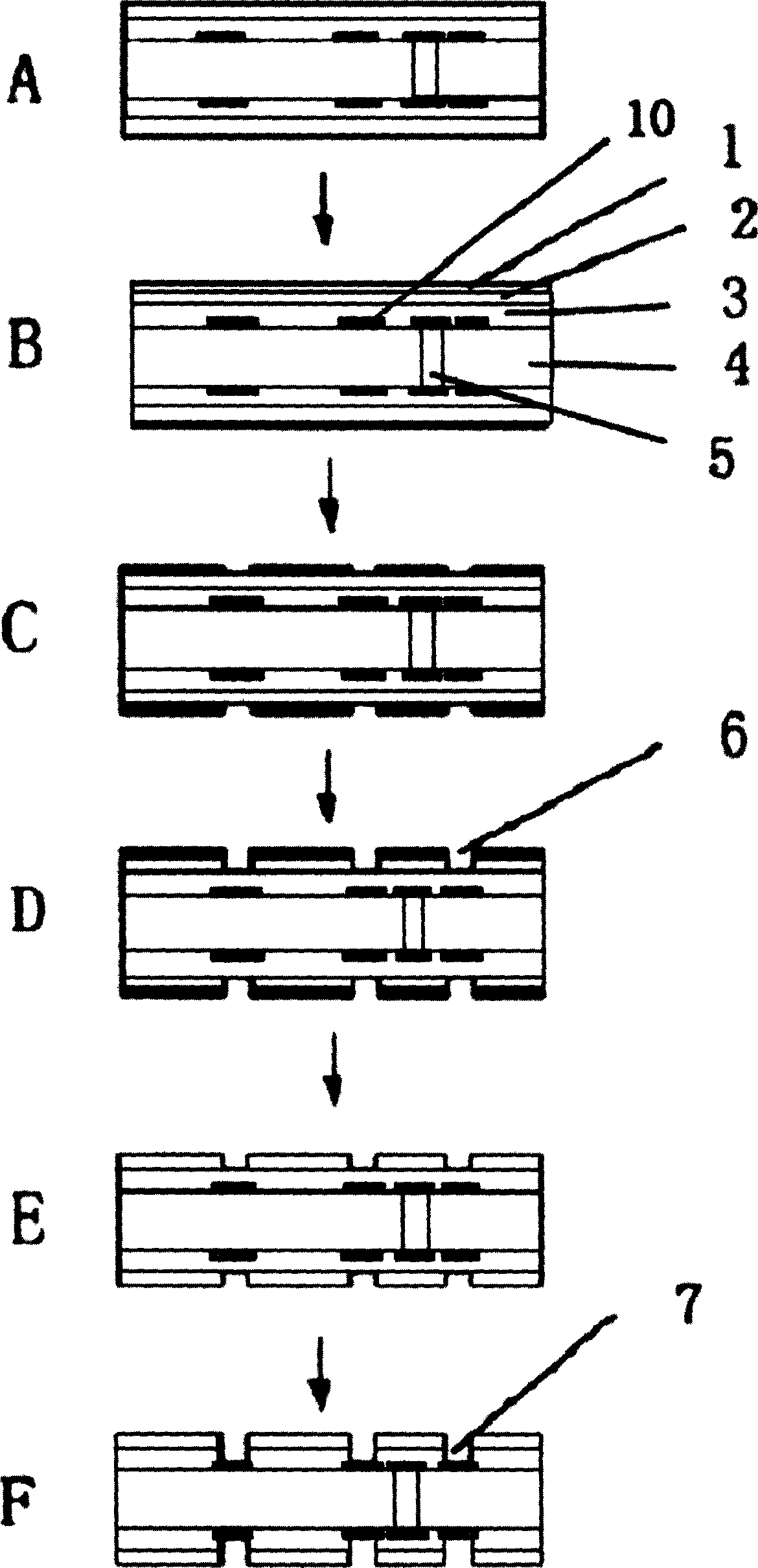

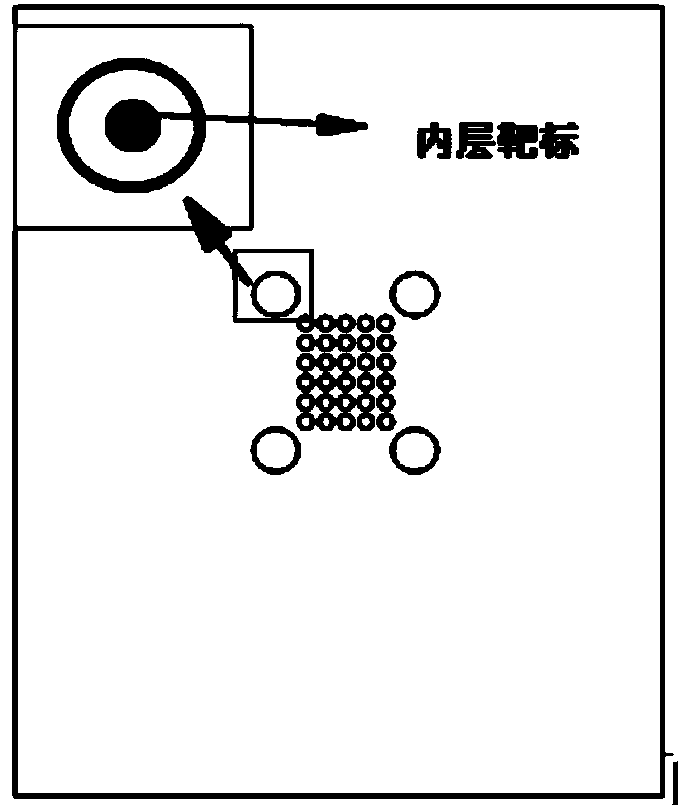

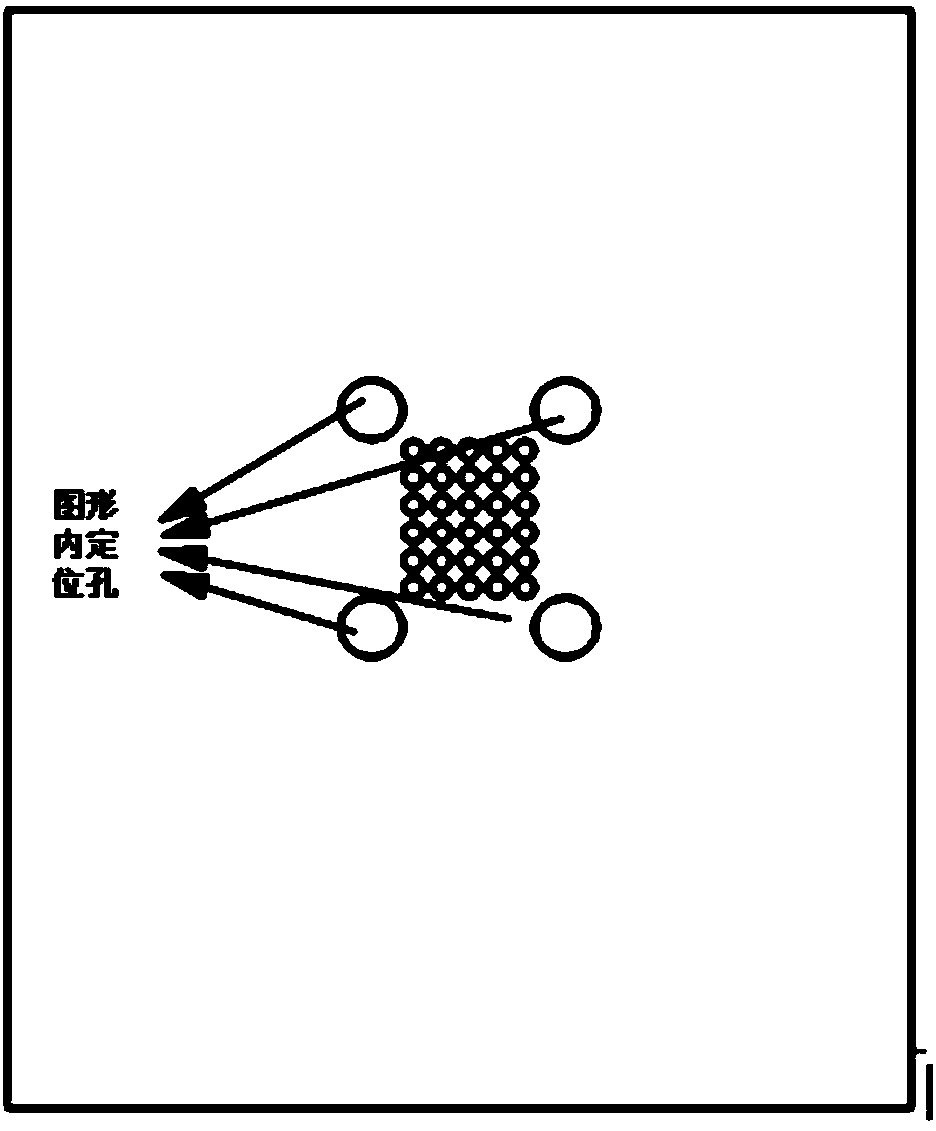

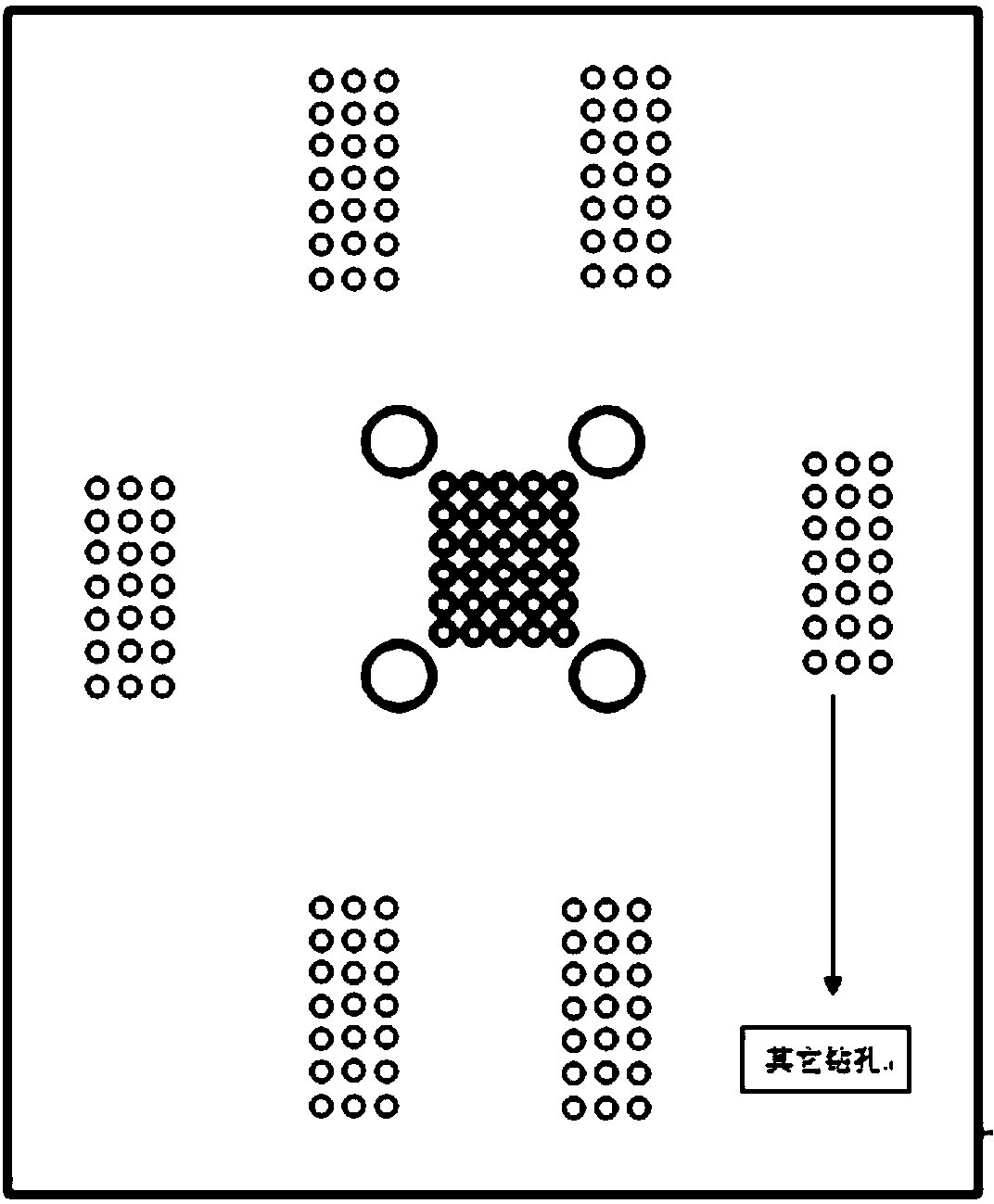

Local high-precision printed circuit board and manufacturing method thereof

ActiveCN104270889AImprove drilling alignment accuracyReduce the scrap rate of drilling deviationPCB positioning during processingElectrical connection printed elementsEngineeringPrinted circuit board

The invention discloses a local high-precision printed circuit board and a manufacturing method thereof. The whole printed circuit board is divided into a high-precision graphic area and a common graphic area. The manufacturing method comprises the steps of inner-layer graph manufacturing, press-fitting, drilling, outer-layer film drying and follow-up procedures. According to the press-fitting step, the Pin-Lam technology is adopted for conducting manufacturing; after the press-fitting step is executed, a graphic inner positioning hole is punched, so that a local expansion coefficient of the high-precision graphic area is calculated. According to the drilling step, a local drilling file is set according to the local expansion coefficient, meanwhile, an LDI datum hole is formed, drilling is carried out on the high-precision graphic area, and the datum hole is drilled; then drilling is carried out on the common graphic area through the whole board expansion coefficient. According to the outer-layer film drying step, the LDI technology is adopted. According to the manufacturing method, the drilling alignment precision of the local high-precision printed circuit board can be effectively improved, highly-difficult drilling can be carried out, the drilling misregistration scrap rate is greatly reduced, and the process is simple.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

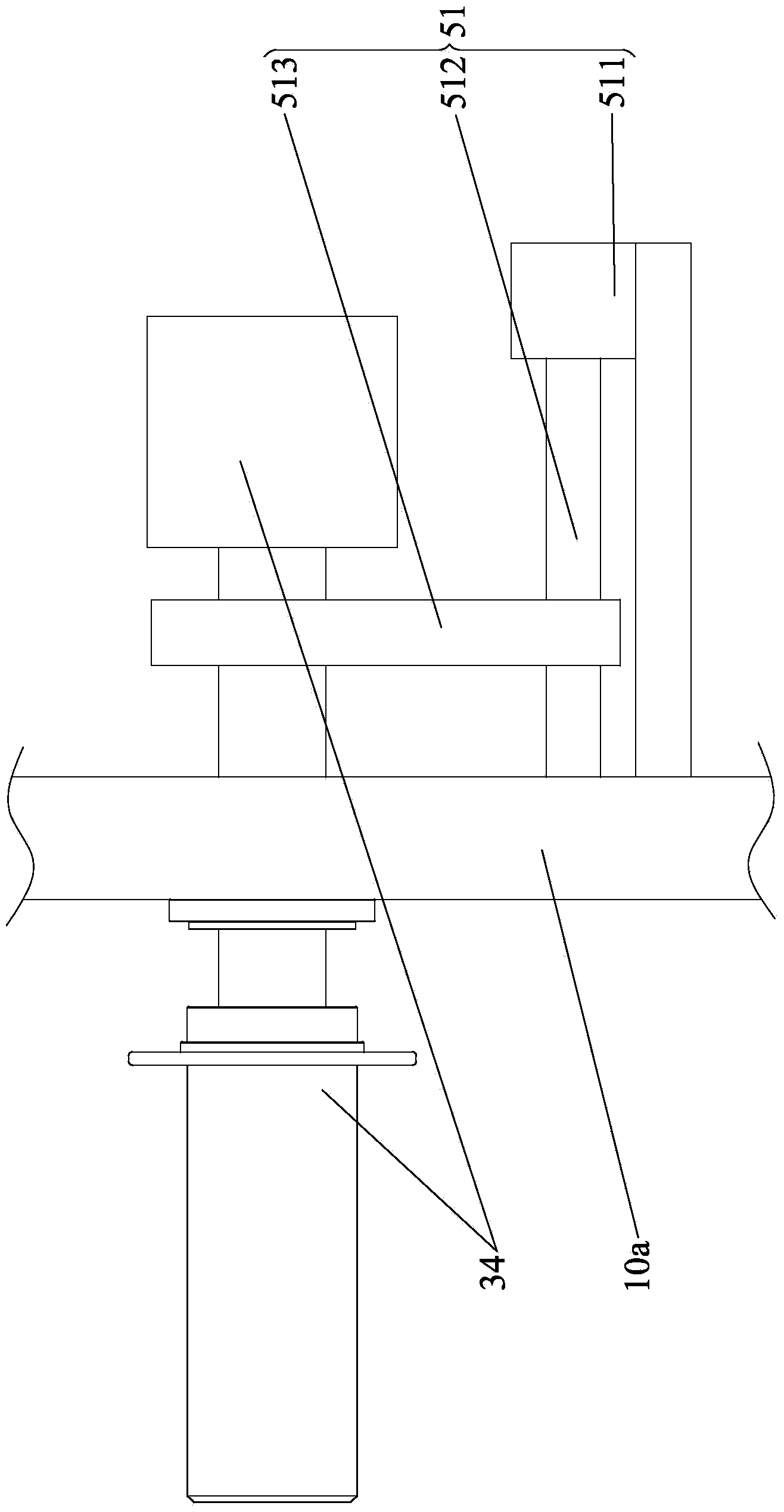

Automatic single and double-reel take-up device

ActiveCN106115368AGuaranteed alignmentGuaranteed centering; ensure the docking of the plate through the lifting system when the plate is releasedFilament handlingEngineeringAutomatic testing

Owner:中天智能装备有限公司

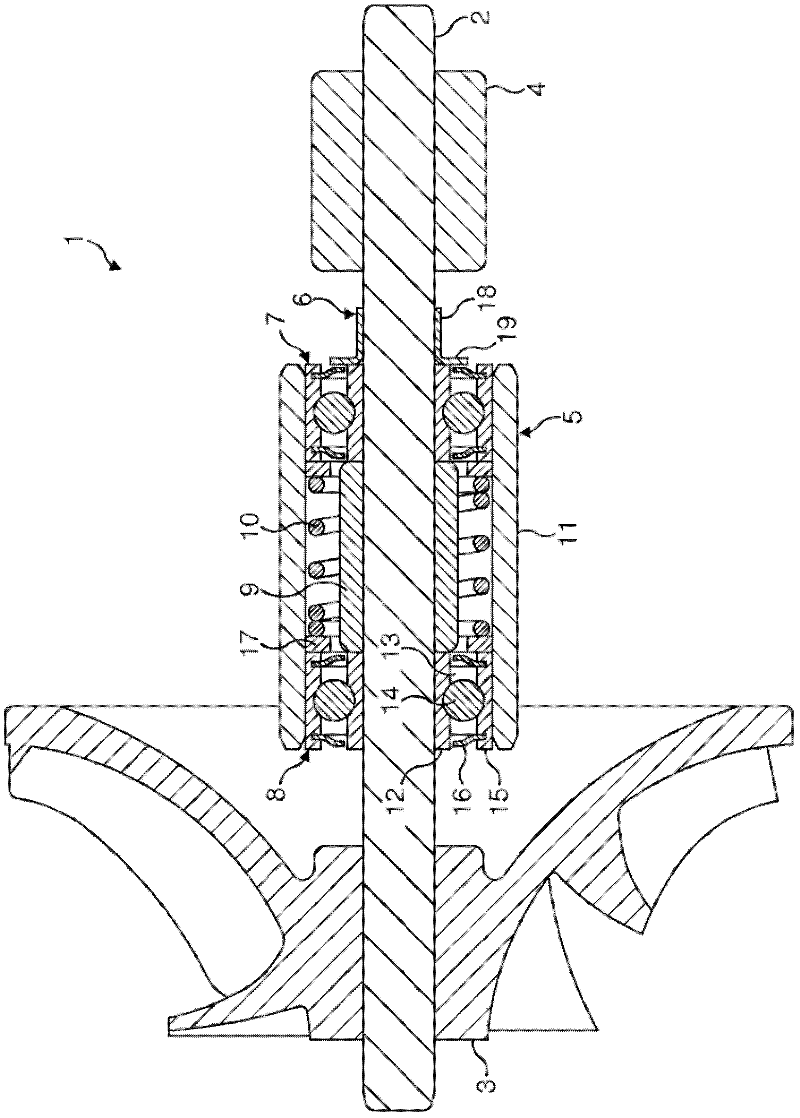

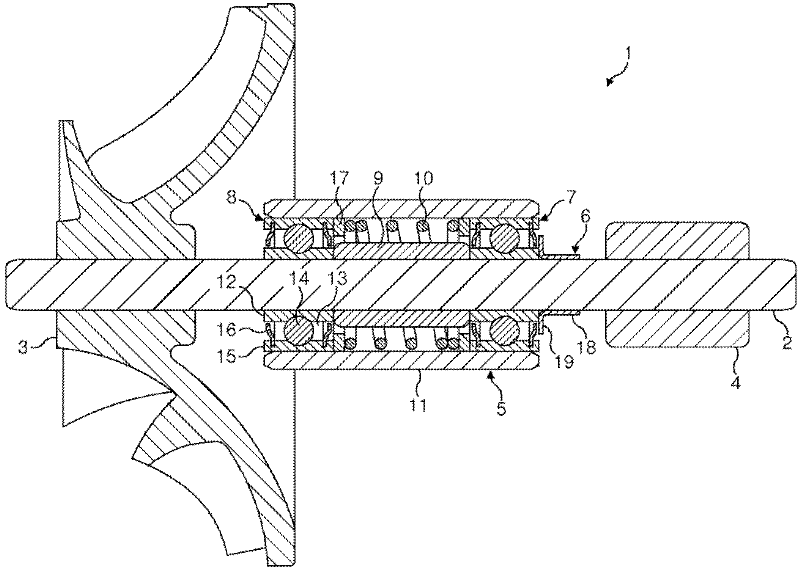

Rotor assembly

Owner:DYSON TECH LTD

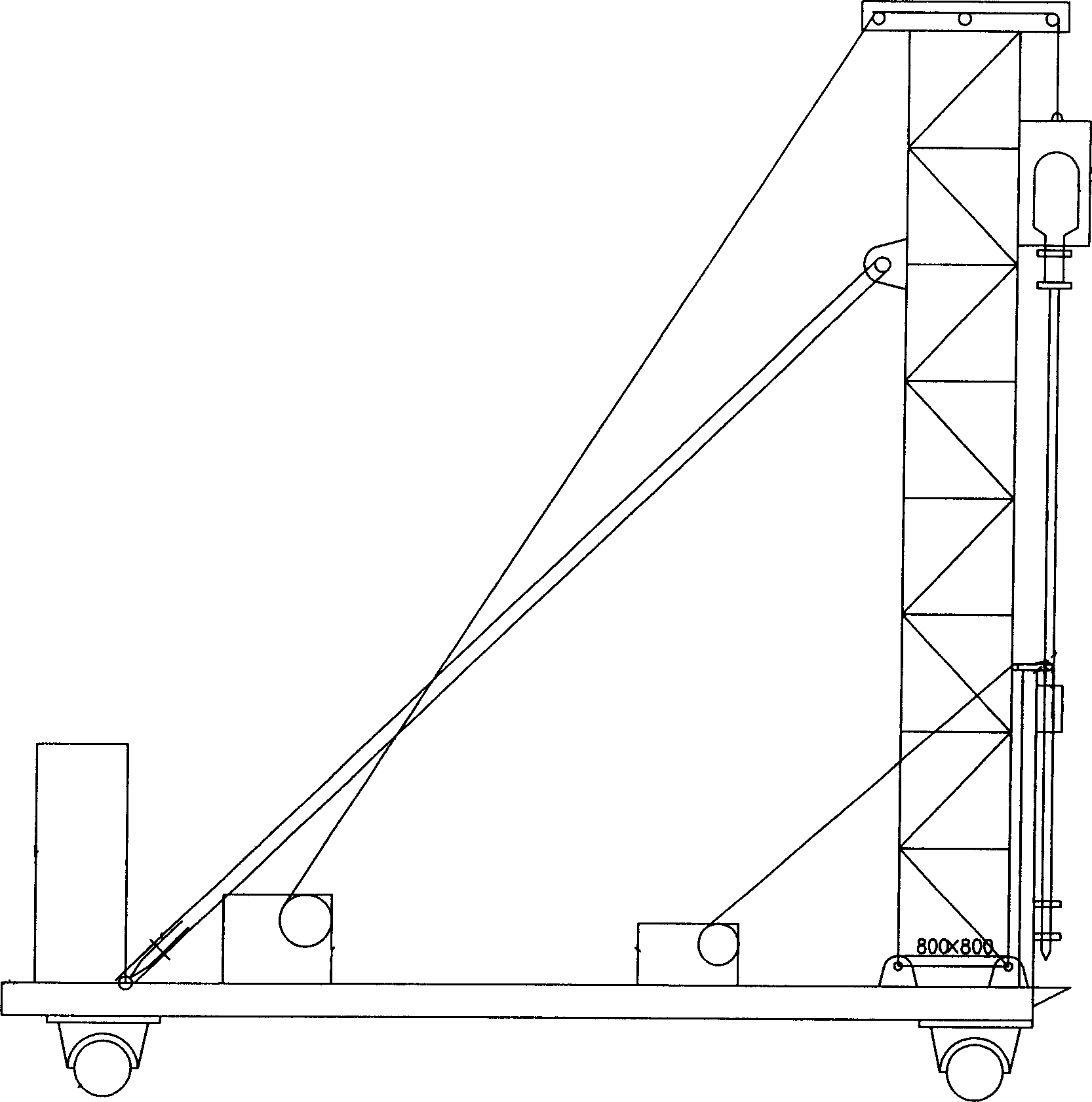

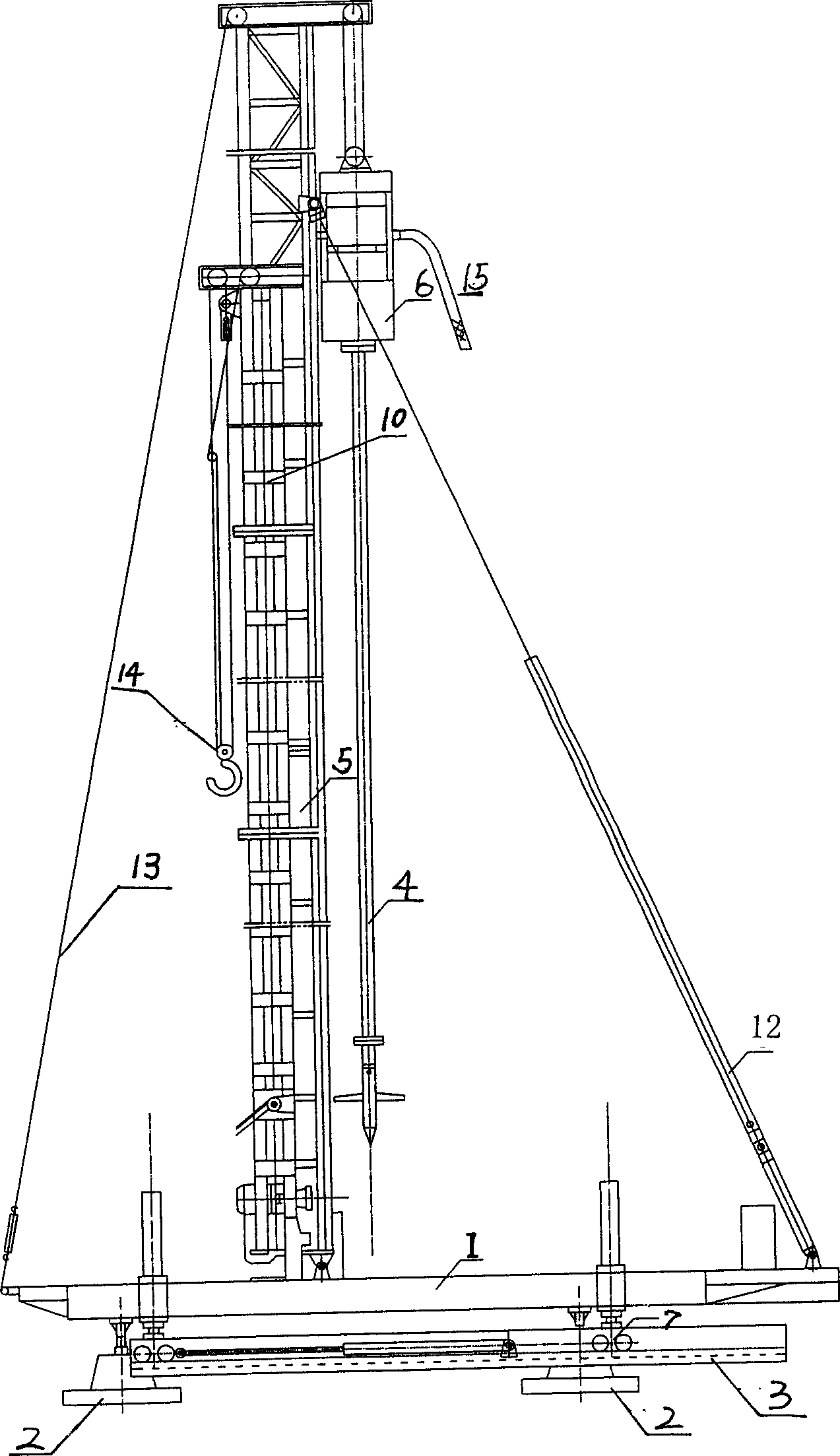

Concrete core cement soil stirring pile machine and its construction technological method

InactiveCN1718938AAvoid Weaknesses of Poor Fighting AbilityGuaranteed alignmentBulkheads/pilesHydraulic pumpArchitectural engineering

The present invention discloses a concrete core cement earth stirring pile machine and its construction process and method. The bottom portion of said pile machine is equipped with hydraulic walking system, including machine frame, base seat, hydraulic pump station, longitudinal and transverse moving beams, longitudinal and transverse roller supporting frames, guideway, deep stirring machine head, drilling machine, drill bit, slurry pump, distribution box and hydraulic pile-pressing system.

Owner:NANJING UNIV

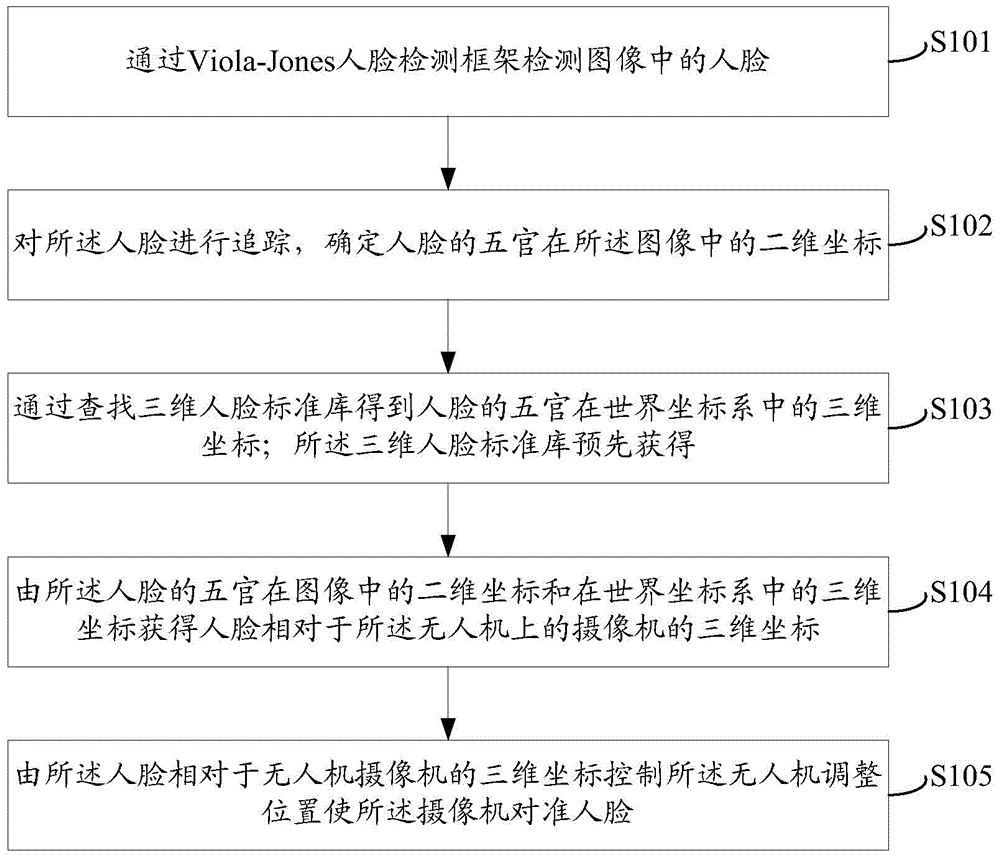

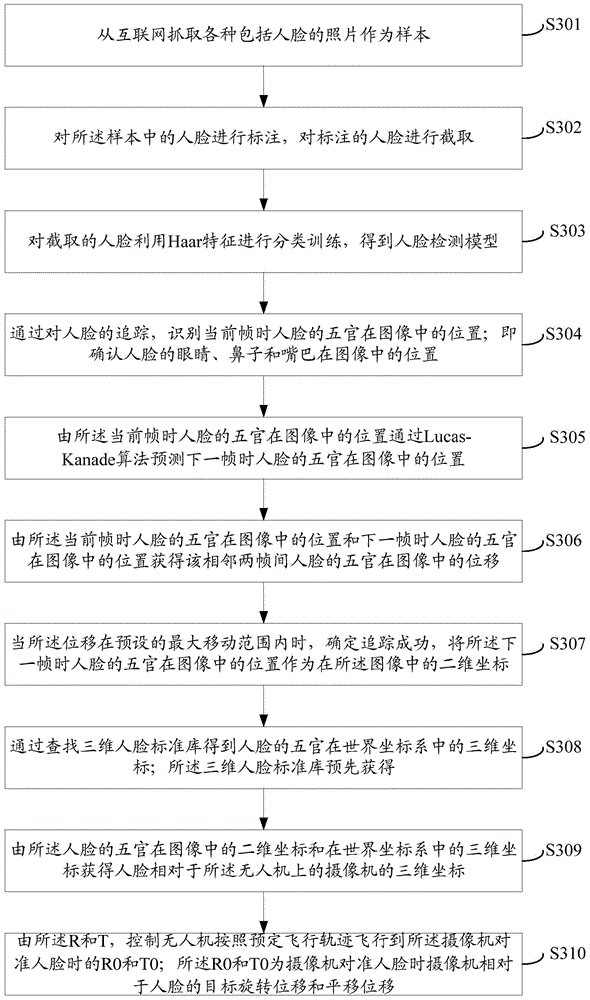

Method and device for controlling unmanned aerial vehicle to rotate along with face

InactiveCN105117022AGuaranteed alignmentInput/output for user-computer interactionAircraft controlFace detectionCamera lens

The invention provides a method and device for controlling an unmanned aerial vehicle to rotate along with the face. A camera is arranged on the unmanned aerial vehicle. The method includes the steps that the face in an image is detected through a Viola-Jones face detection framework; the face is tracked, and two-dimensional coordinates of the five sense organs of the face in the image are determined; a three-dimensional face standard library is searched for three-dimensional coordinates of the five sense organs of the face in a world coordinate system; the three-dimensional face standard library is obtained in advance; three-dimensional coordinates of the face relative to the camera on the unmanned aerial vehicle are obtained according to the two-dimensional coordinates of the five sense organs of the face in the image and the three-dimensional coordinates of the five sense organs of the face in the world coordinate system; the unmanned aerial vehicle is controlled for position adjustment to enable the camera to be aligned with the face through the three-dimensional coordinates of the face relative to the camera of the unmanned aerial vehicle. When the unmanned aerial vehicle tracks a user to take pictures or record videos, the unmanned aerial vehicle can move along with rotation of the face, and it is guaranteed that a camera lens of the camera on the unmanned aerial vehicle is always aligned with the face of the user.

Owner:BEIJING ZERO ZERO INFINITY TECH

Carton manufacturing device

ActiveCN103029323APrevent crashPrevent overrunningBox making operationsPaper-makingProduction lineCardboard

The invention relates to a carton manufacturing device. A chain driving shaft and a manipulator are respectively controlled by different servo motors, and a line pressing part and an extrusion part are added to carry out secondary line pressing and extrusion processing on cardboards; and meanwhile, a gap adjusting part is added and comprises a carton aligning device for carrying out alignment processing on the cardboards, and a nail wire conveying mechanism is added in a box nailing and sticking part. According to the device, the cost of the whole production line is greatly reduced, so that the device is suitable for being installed and used by small-and-medium-sized enterprises; and the control accuracy is high, so that the pass rate of the manufactured carton is greatly increased, and the quality of the carton is strictly ensured.

Owner:无锡唐诚机械有限公司

Center line deviation rectifying method for ballastless track of high-speed railway of roadbed segment

ActiveCN106049193AGuaranteed alignmentGuaranteed smoothnessBallastwayTrack maintainenceMiddle lineFastener

The invention provides a center line deviation rectifying method for a ballastless track of a high-speed railway of a roadbed segment. The method includes the following steps that the center line deviation amount and settling amount of a ballastless track line are measured; measured data are analyzed, and in combination of the track structure characteristics, lifting points and jacking points are arranged at the lower portion and the side face of a whole roadbed of a ballastless track structure; lifting devices are installed on the lifting points, the whole roadbed of the ballastless track and an upper structure are finely lifted, after an interface between the whole roadbed and graded gravel is jacked to be loosened, the lifting devices are unloaded, and the whole roadbed falls back; jacking devices are installed on the jacking points, and through grouped loading and level-by-level jacking, the ballastless track line is rectified to a designed position; and after line center line deviation rectification is finished, line restoration operation is conducted, a gap in the lower portion of the whole roadbed of the ballastless track is filled with polymer cement mortar, and line smoothness is restored through a fine adjustment fastener system. By the adoption of the method, the problem of center line deviation of the ballastless track line of the roadbed segment can be safely, rapidly and effectively solved within a skylight time, and line smoothness is restored.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +3

Lithium ion battery cell and preparation method thereof

InactiveCN102683742ALower internal impedanceReduce polarizationFinal product manufactureSecondary cellsInternal resistanceLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and in particular relates to a lithium ion battery cell which comprises at least two positive electrode plates, at least two negative electrode plates, a first wound membrane and a second wound membrane, wherein the positive electrode plates and the negative electrode plates are mutually overlapped, and the difference of the number of the positive electrode plates and the number of the negative electrode plates is one; the positive electrode plates are arranged at the same side of the first membrane; the negative electrode plates are arranged at the same side of the second membrane; and at the direction from the innermost circle to the outermost circle of the battery cell, the first membrane and the second membrane are alternatively arranged between the adjacent positive electrode plates and the negative electrode plates at intervals. Compared with the prior art, the lithium ion battery cell has the advantages that the parallel connection multiple layers of electrode plates provided by the invention can be used for reducing the internal resistance of the battery cell, thus the polarization is reduced, and the discharging platform is improved; the parallel connection of the electrode plates can be used for improving the high-multiplying-power charging and discharging capability of the battery cell; and because the electrode plates of the battery cell provided by the invention are stacked together, the internal structure is unified, the stress is distributed uniformly, the possibility of deformation is small. In addition, the invention also discloses a preparation method of the battery cell.

Owner:DONGGUAN AMPEREX TECH +1

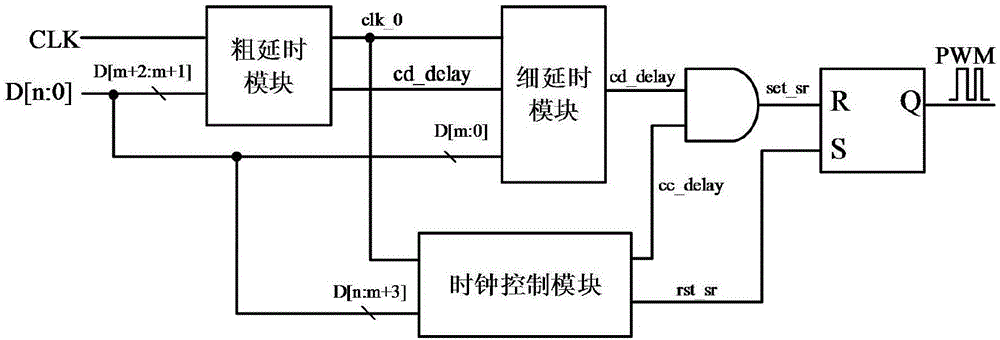

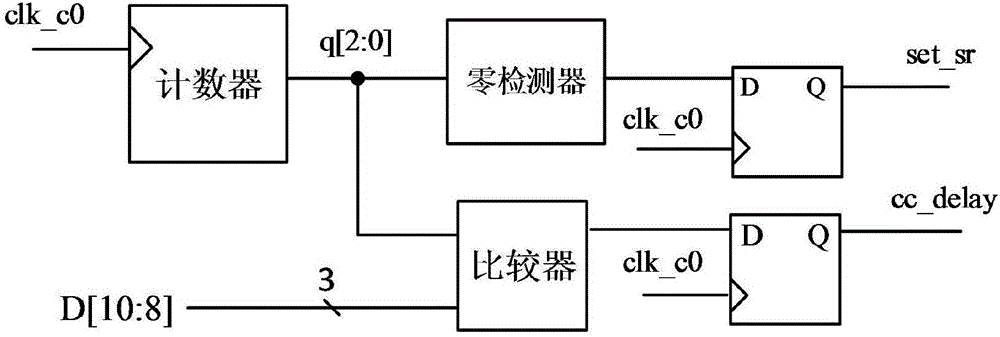

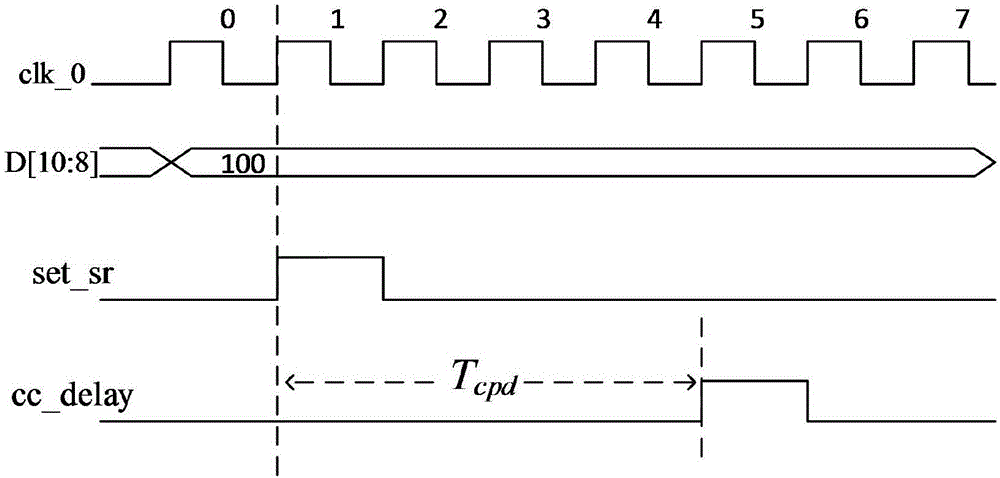

DPWM module for synchronous segmentation delay chain based on FPGA

ActiveCN106533401AImprove stabilityImprove linearityPulse automatic controlContinuous to patterned pulse manipulationDc dc converterTemporal resolution

The invention discloses a DPWM module for a synchronous segmentation delay chain based on an FPGA. The DPWM module is characterized by comprising a clock control module, a coarse delay module, a fine delay module, an AND gate and an RS latch, wherein the clock control module is based on a counter; the coarse delay module is based on a phase-locked loop; and the fine delay module is based on an adder chain. According to the DPWM module for the synchronous segmentation delay chain based on the FPGA disclosed by the invention, the temporal resolution, the duty ratio linearity and the stability of a pulse width modulator are improved, and the robustness of the pulse width modulator is reinforced; and thus, the ripples and the stabilization time of a DC-DC converter are shortened, and the overshoot and the ringing occurred in a modulation process are suppressed and are weakened.

Owner:HEFEI UNIV OF TECH

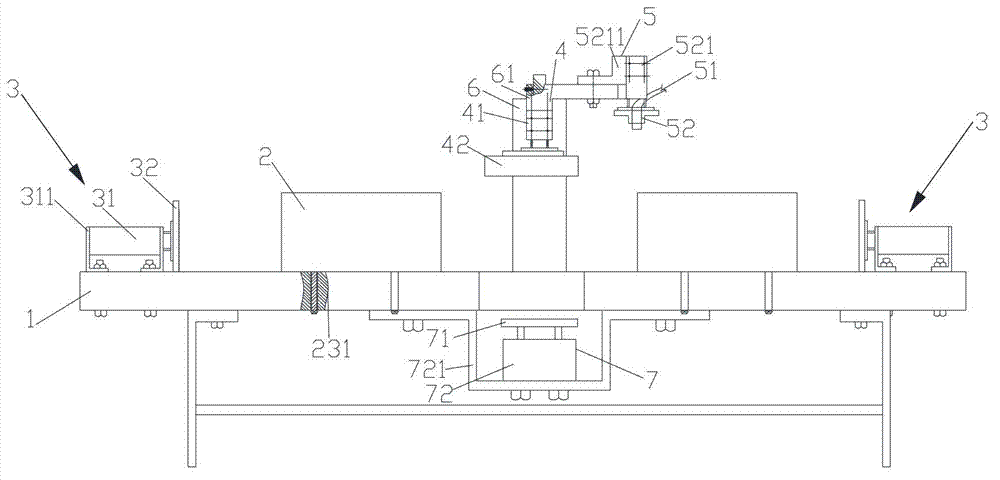

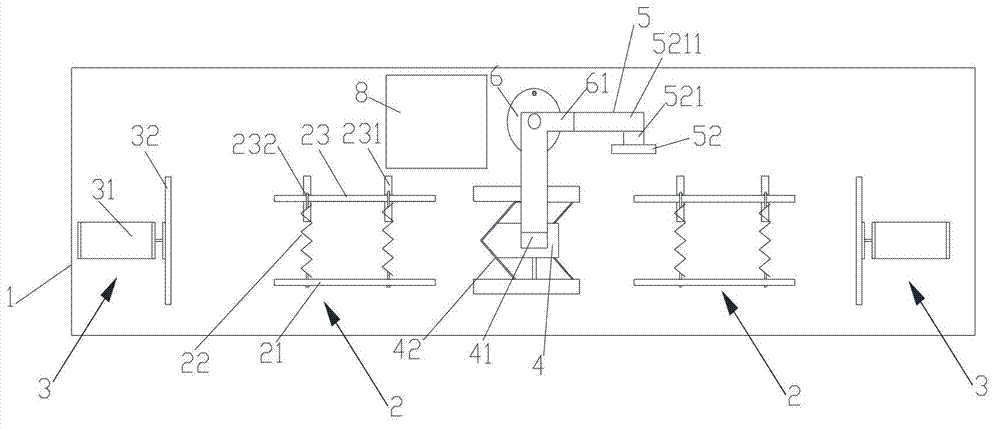

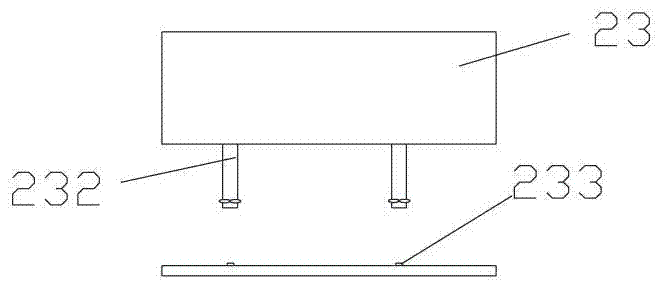

Seedling grafting machine and grafting method of seedling grafting machine

The invention belongs to the field of planting machinery and provides a grafting machine, which consists of a work table, a cutting engagement device and a seedling positioning device. The invention also provides a grafting method adopting the grafting machine. The seedling grafting machine has the beneficial effects that 1, the grafting mechanization is realized, and the problems of high work intensity and low work efficiency of artificial grafting are solved; 2, when the grafting machine provided by the invention is adopted, the cutting surfaces of stocks and cions are precisely aligned, at least one side of the forming layer is aligned, and the grafting survival rate is high; and 3, a wax coating mode is adopted for fixing the cutting surface combining part of the stocks and the cions, the wound infection is avoided, in addition, the seedling thickness increase is not influenced, and the binding rope unlocking treatment after the traditional grafting is omitted.

Owner:CHINA AGRI UNIV

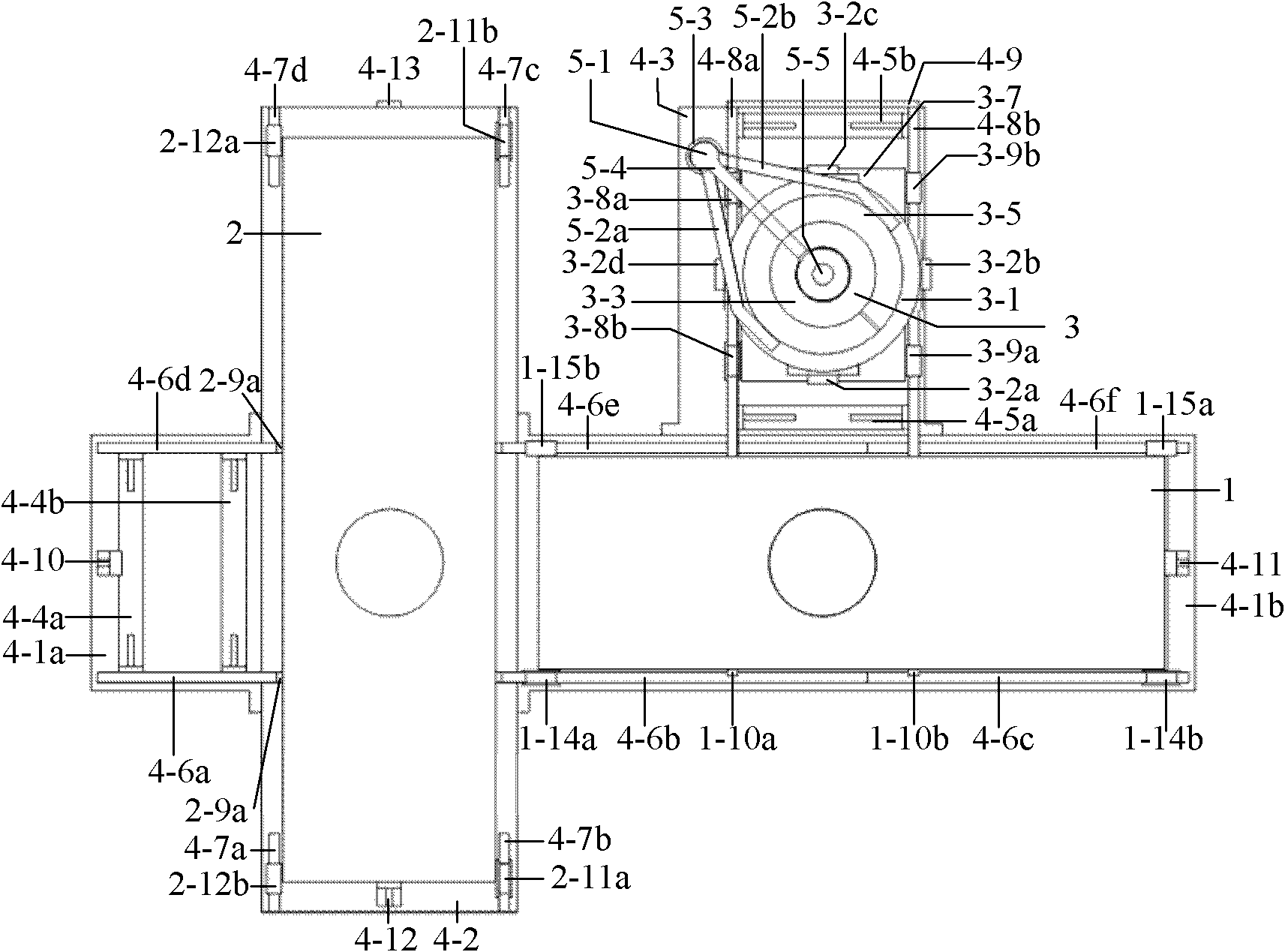

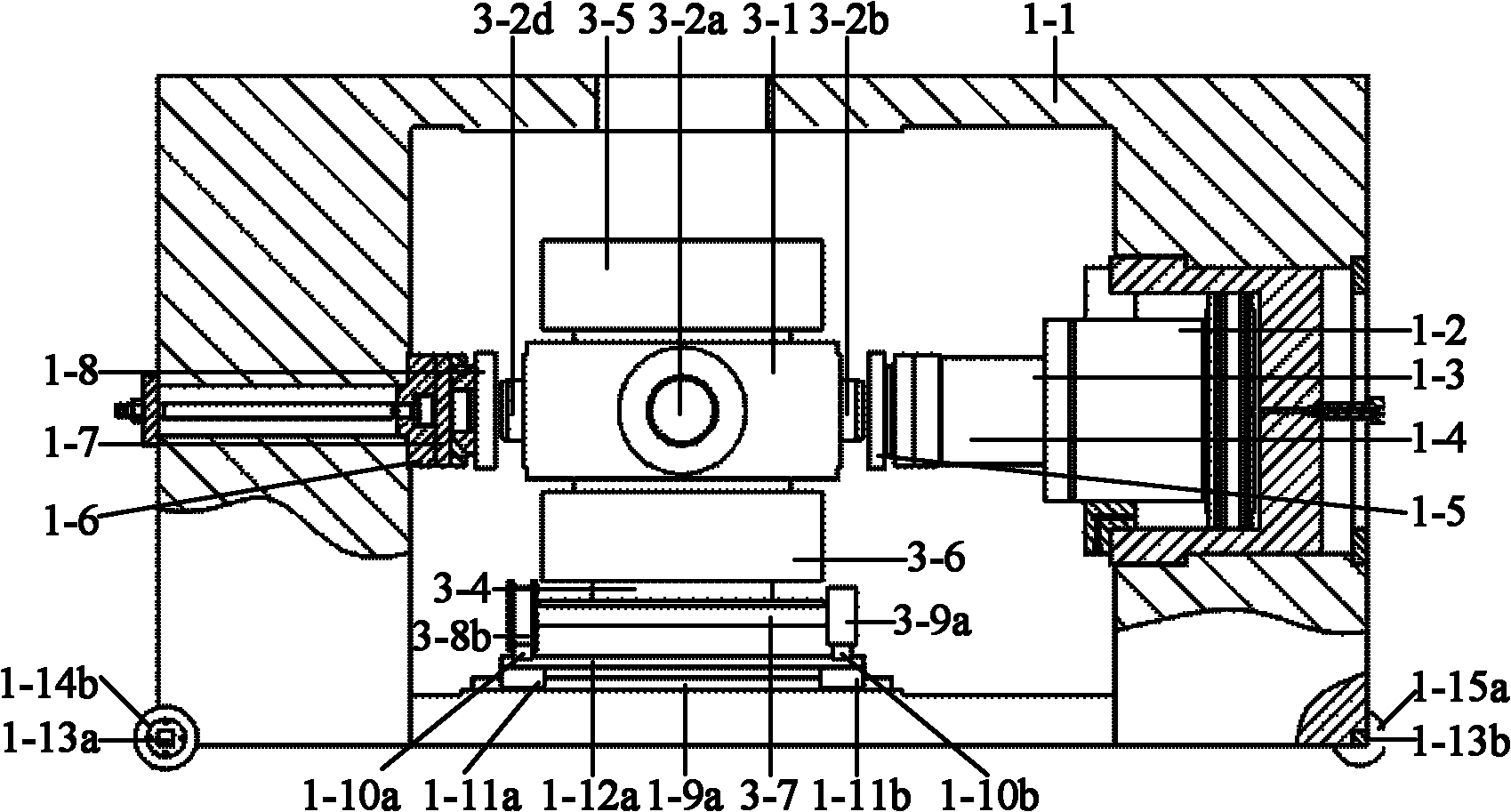

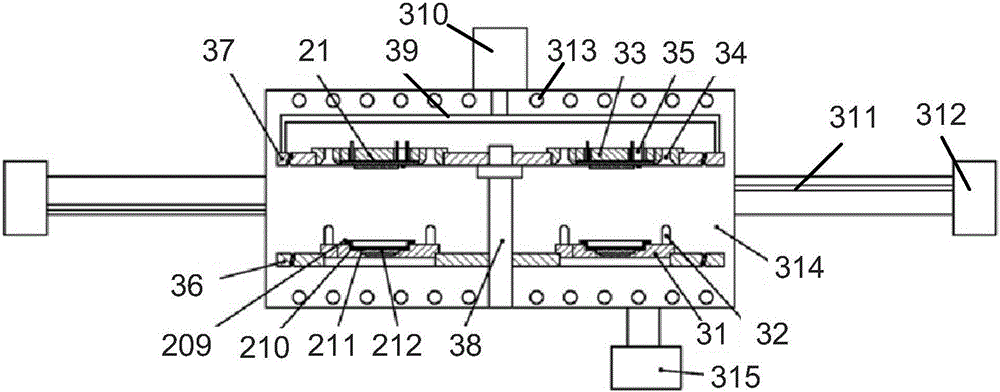

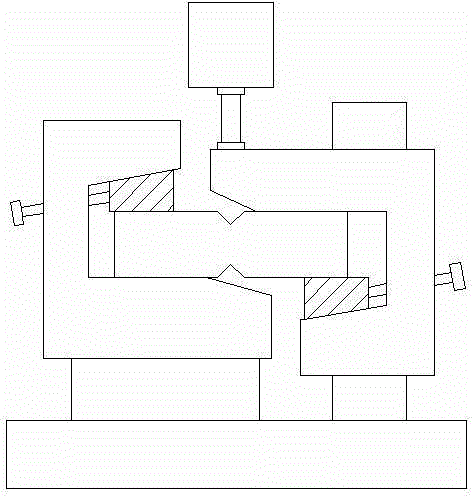

High pressure true triaxial test system

InactiveCN102323154ASimple designThe influence of self-weight is smallMaterial strength using tensile/compressive forcesTest sampleEngineering

The invention discloses a high pressure true triaxial test system which comprises a first loading device, a second loading device, a true triaxial pressure chamber, a base and a lifting part. The base is provided with a plurality of stages of rails. The first loading device, the second loading device and the true triaxial pressure chamber which are positioned on a plurality of stages of rails canrelatively move on the corresponding rails. One sides of the inner walls of the first loading device and the second loading device are provided with loading devices and the other sides of the inner walls of the first loading device and the second loading device are provided with counterforce devices. The true triaxial pressure chamber can be opened and closed by the lifting part. In the invention, the multistage rail design is adopted; the first loading device, the second loading device and the true triaxial pressure chamber in the system can relatively move; the high pressure true triaxial test system is convenient to install a test sample and a sensor; the influence of the dead weight of a frame on the high pressure true triaxial test system is low; the high pressure true triaxial test system is convenient for the design of the high-load high-rigidity frame; and when a double-axis oil-pressure-free experiment is carried out, real-time observation can be carried out.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

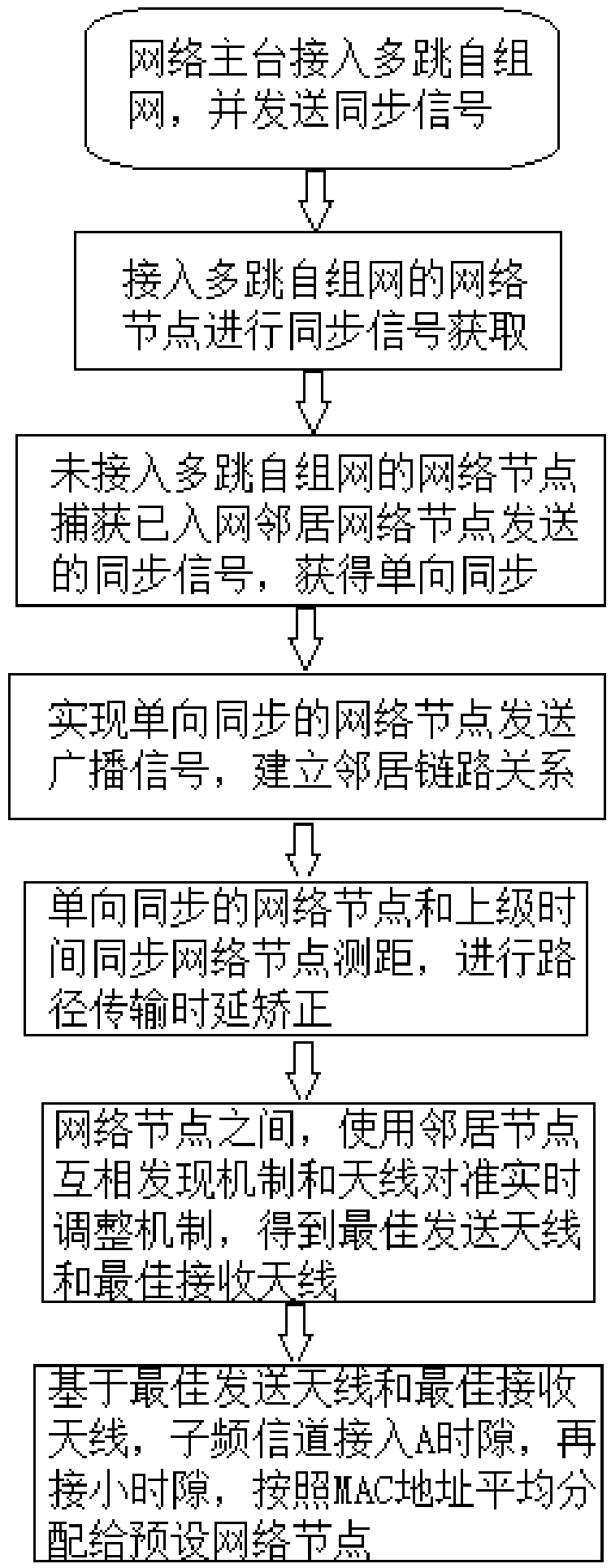

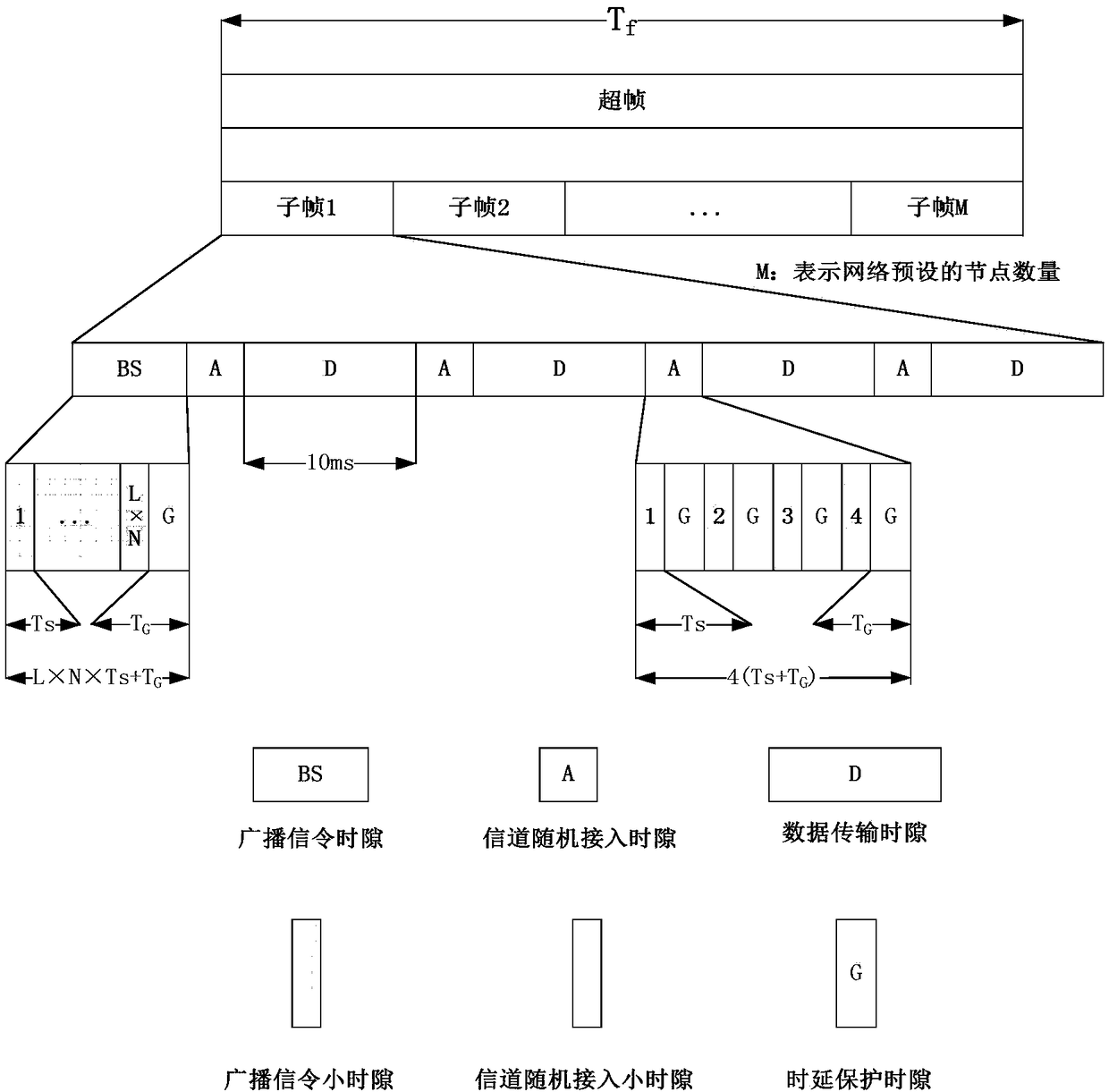

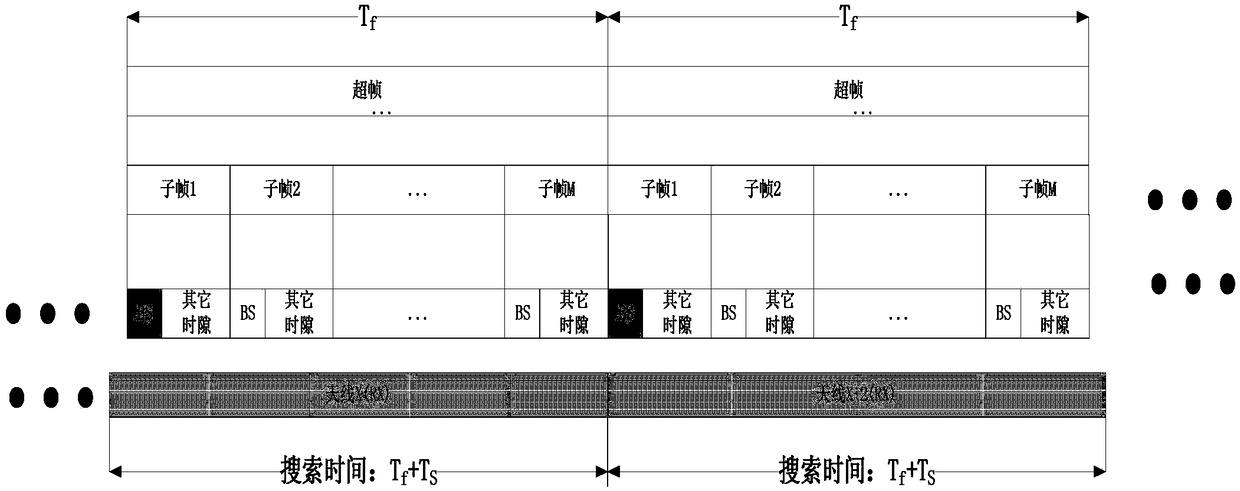

Microwave network channel accessing method based on narrowband wave beam directional antenna and system thereof

ActiveCN108934020AGuaranteed alignmentGuaranteed adjustabilitySynchronisation arrangementAssess restrictionDirectional antennaVIT signals

The invention discloses a microwave network channel accessing method based on a narrowband wave beam directional antenna. The method comprises the following steps of accessing a superframe structure multi-hop Ad Hoc network by a network main station, using the multi-hop Ad Hoc network operation time as a reference, and transmitting a synchronizing signal; capturing the synchronizing signal by other network nodes; if capturing succeeds, acquiring unidirectional synchronization; transmitting a broadcast signal according to an MAC address by means of a broadcast signaling time slot, performing searching on other network node broadcast signaling time slots, and establishing a neighboring link relation; performing distance measuring and performing path transmission time delay correction; performing neighbor discovering and antenna adjustment, and obtaining an optimal transmitting and receiving antenna; randomly accessing a time slot A by a sub-frequency channel, and accessing a small time slot by the channel of each time slot; and in a period, accessing the small time slot by M channels, and performing average distribution according to the MAC address. The microwave network channel accessing method is based on the microwave network and the distributed narrowband wave beam direction antenna and has advantages of realizing reliable and stable transmission in a high-mobility scene, quick real-time adjustment of the directional antenna, and effectively improving comprehensive communication performance of the network.

Owner:GUANGZHOU HAIGE COMM GRP INC

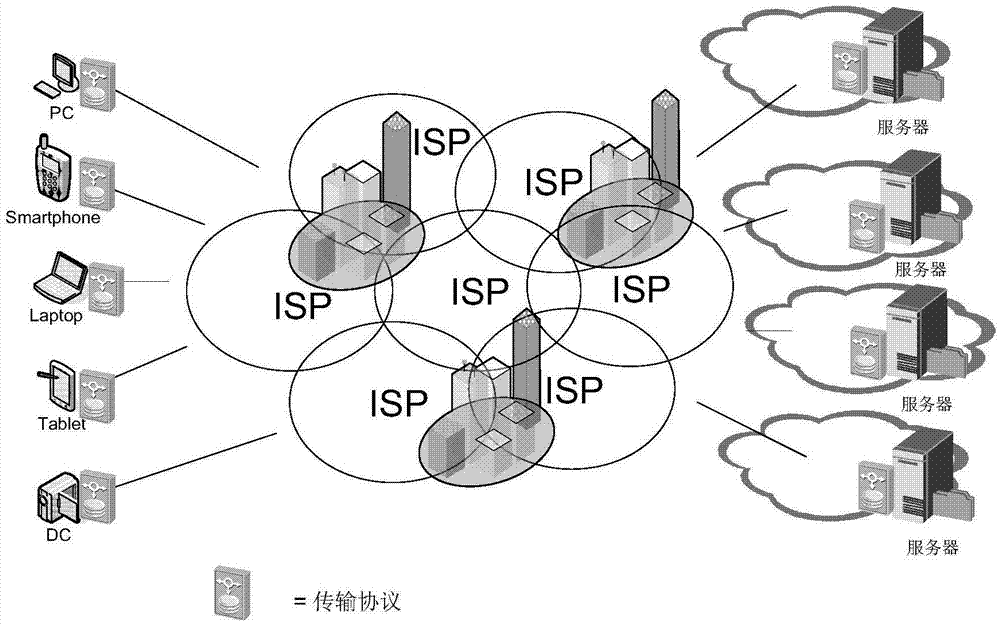

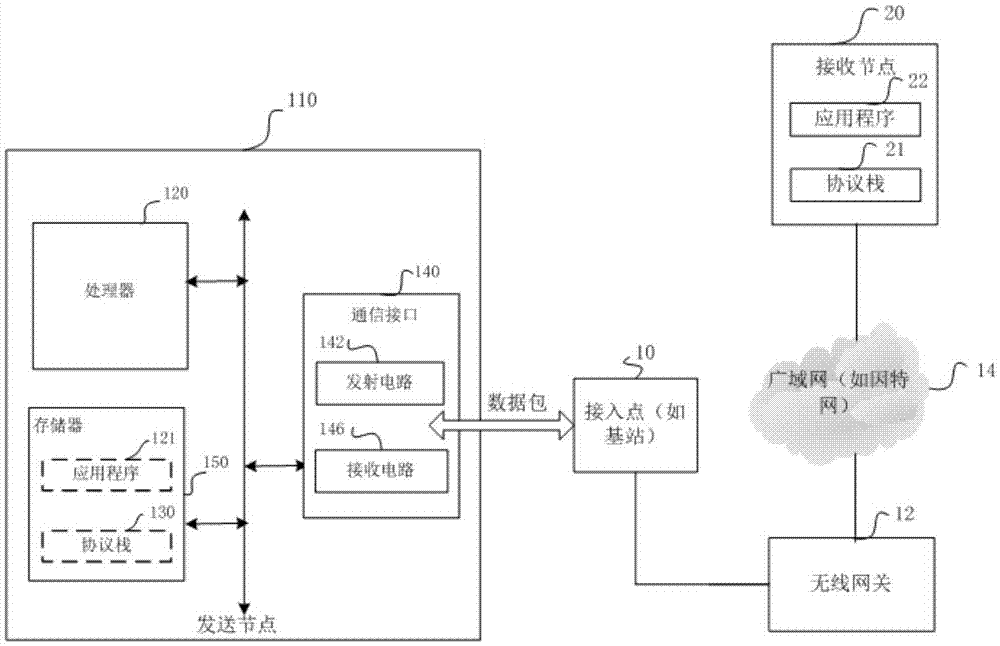

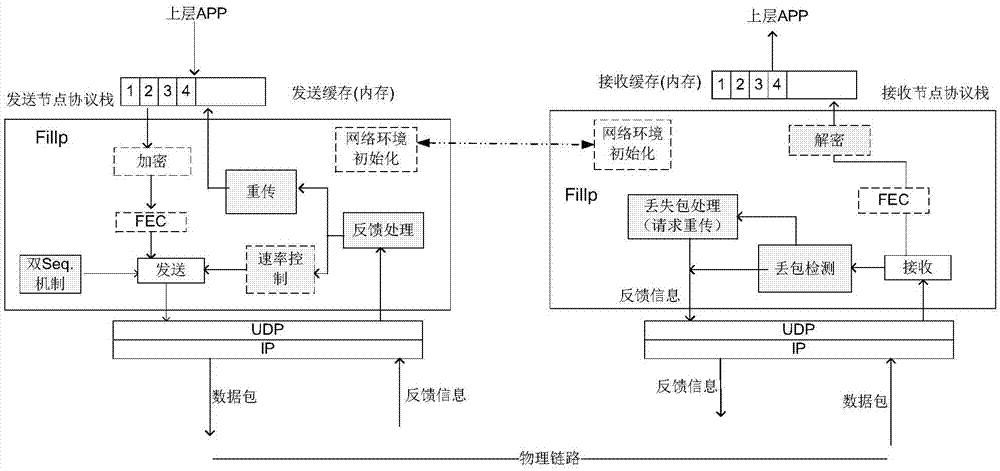

Data transmission method, transmission node, receiving node and data transmission system

ActiveCN106878191AIncrease throughput/transfer rateGuaranteed alignmentError prevention/detection by using return channelSignal allocationPacket lossSerial code

The invention discloses a data transmission acceleration method and related device and system. The method includes that the transmission node transmits data packets to the receiving node at a specific rate, wherein each data packet carries a random serial number and a rolling serial number related to the packet transmission sequence; the receiving node receives the two serial numbers of the data packets, determines lost data packets quickly and feeds serial number information of the lost packets back to the transmission node so as to indicate the transmission node to retransmit the lost data packets. By adopting the scheme provided by the invention, network throughput rate / transmission rate can be improved in a network with high delay and high packet loss probability and acute change of the high throughput rate / transmission rate due to network jitter is avoided.

Owner:HUAWEI TECH CO LTD

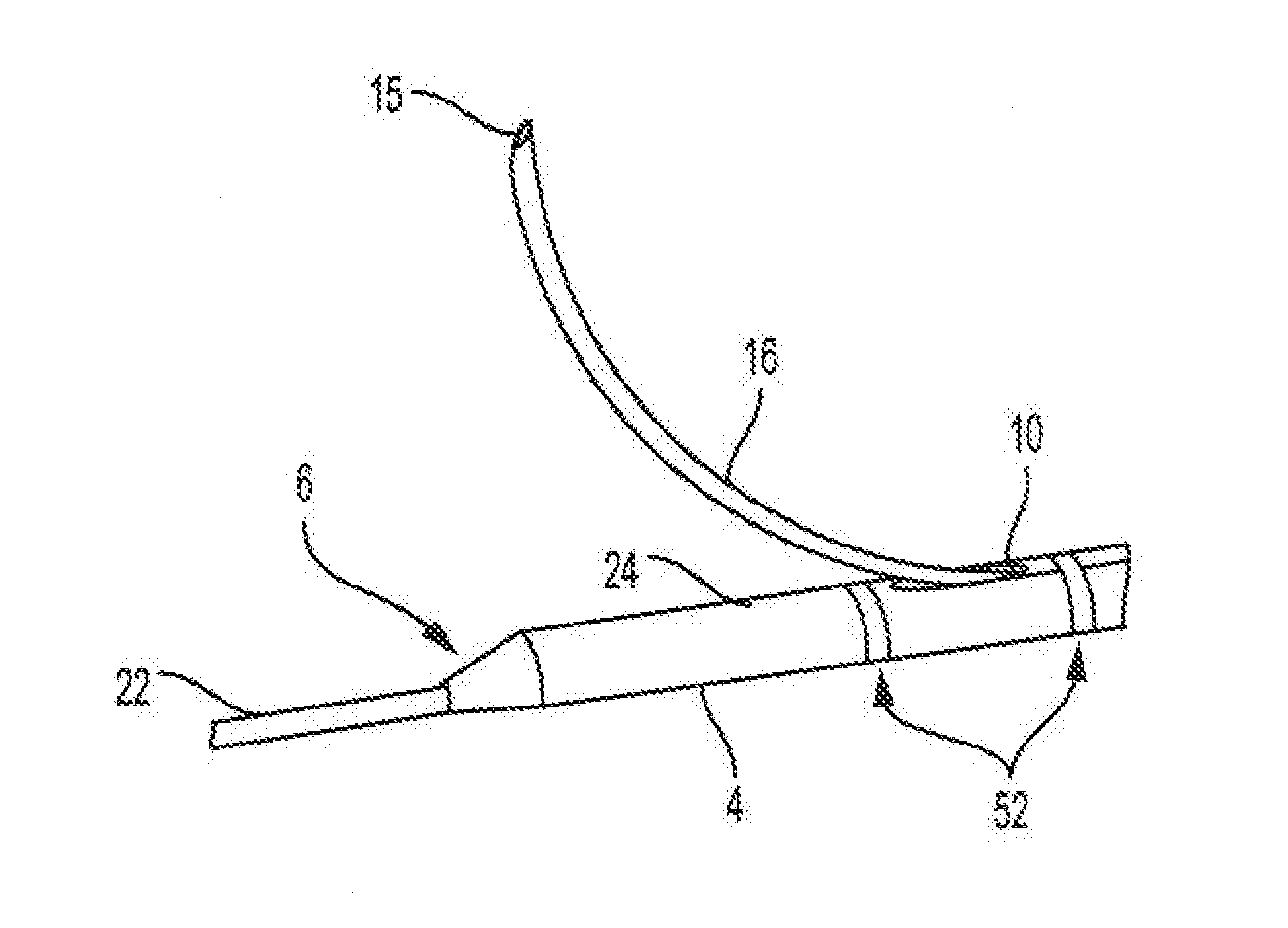

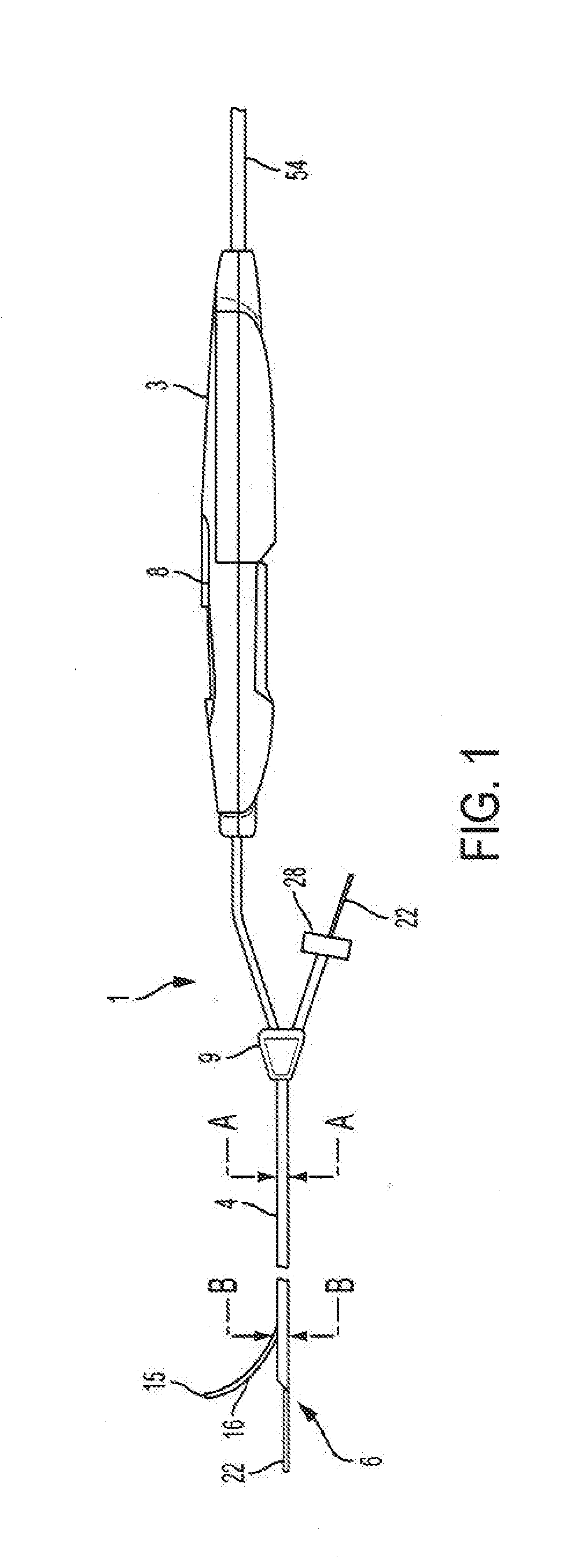

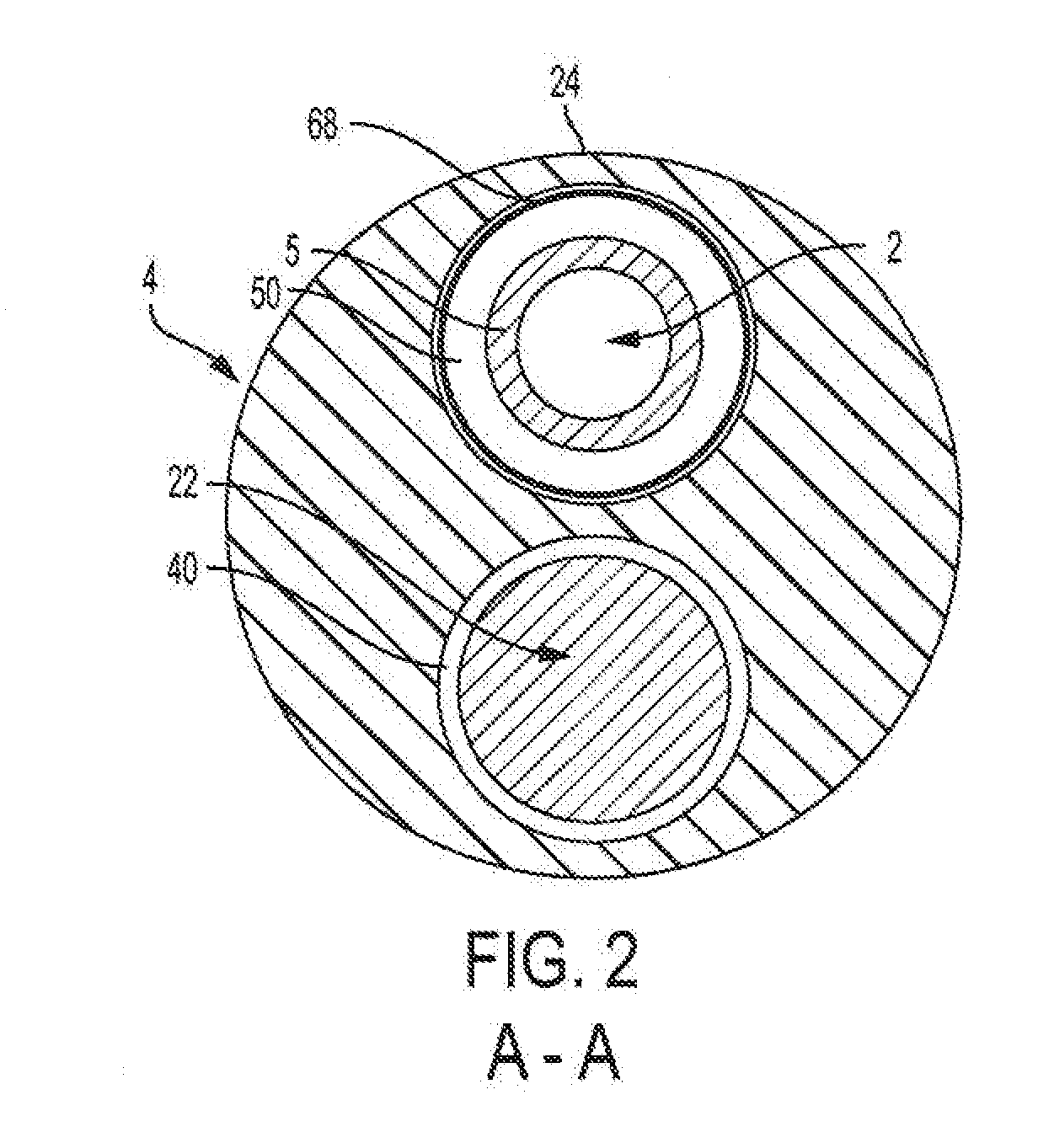

Endoluminal fluid delivery device and method

InactiveUS20170035990A1Minimize the numberImprove drug deliveryGuide needlesCatheterBiomedical engineering

A device and method for delivering a drug from inside a body lumen to tissue surrounding the body lumen. An endoluminal drug delivery device is connectable to a drug source and includes a dual-lumen catheter, including a treatment device lumen for housing a guidewire and / or a treatment device and a needle lumen for housing a retractable needle. The guidewire exits the catheter through an opening at the distal end, and the needle exits the catheter through an exit port in the outer wall of the catheter.

Owner:SWIFT KEVIN

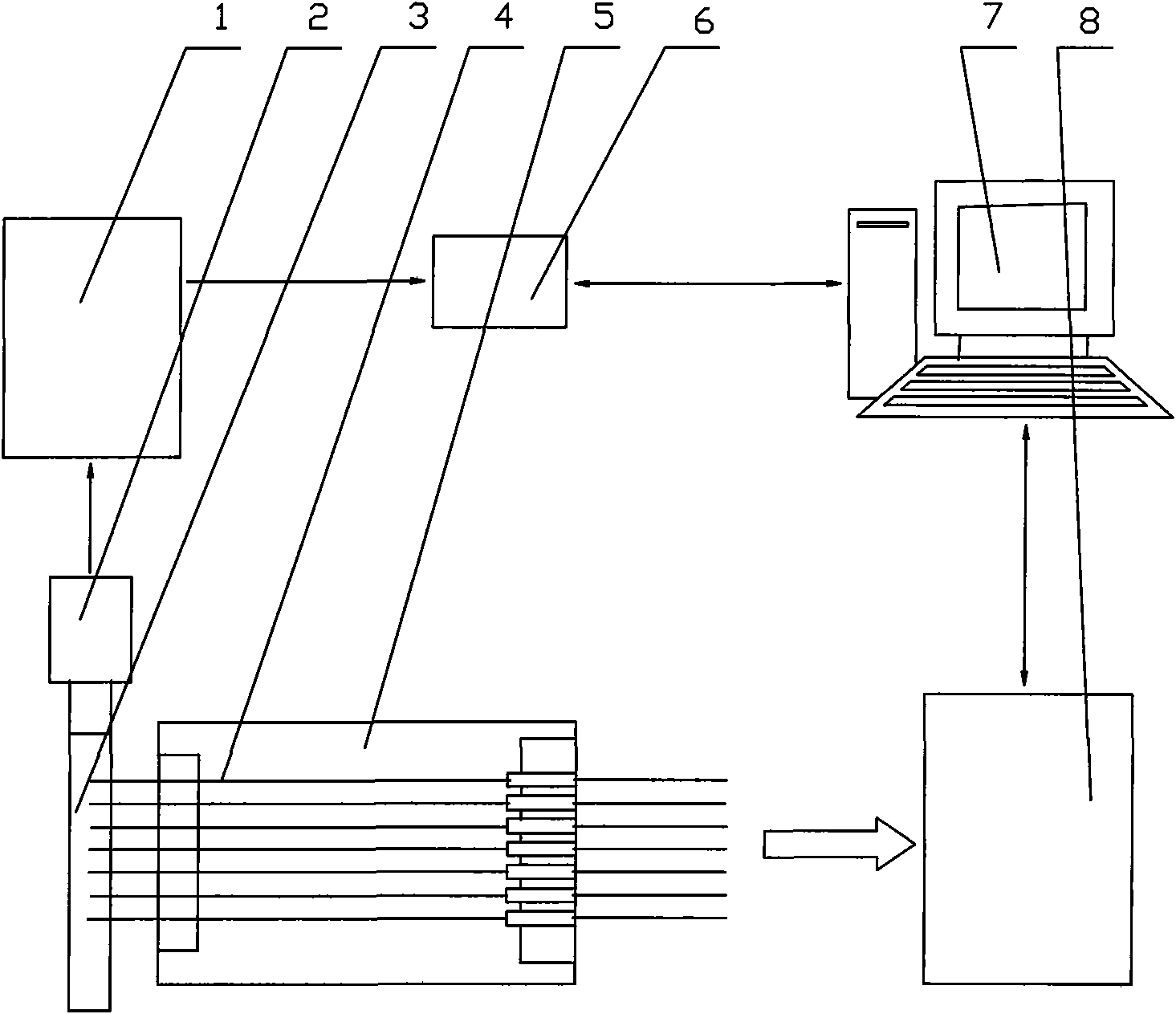

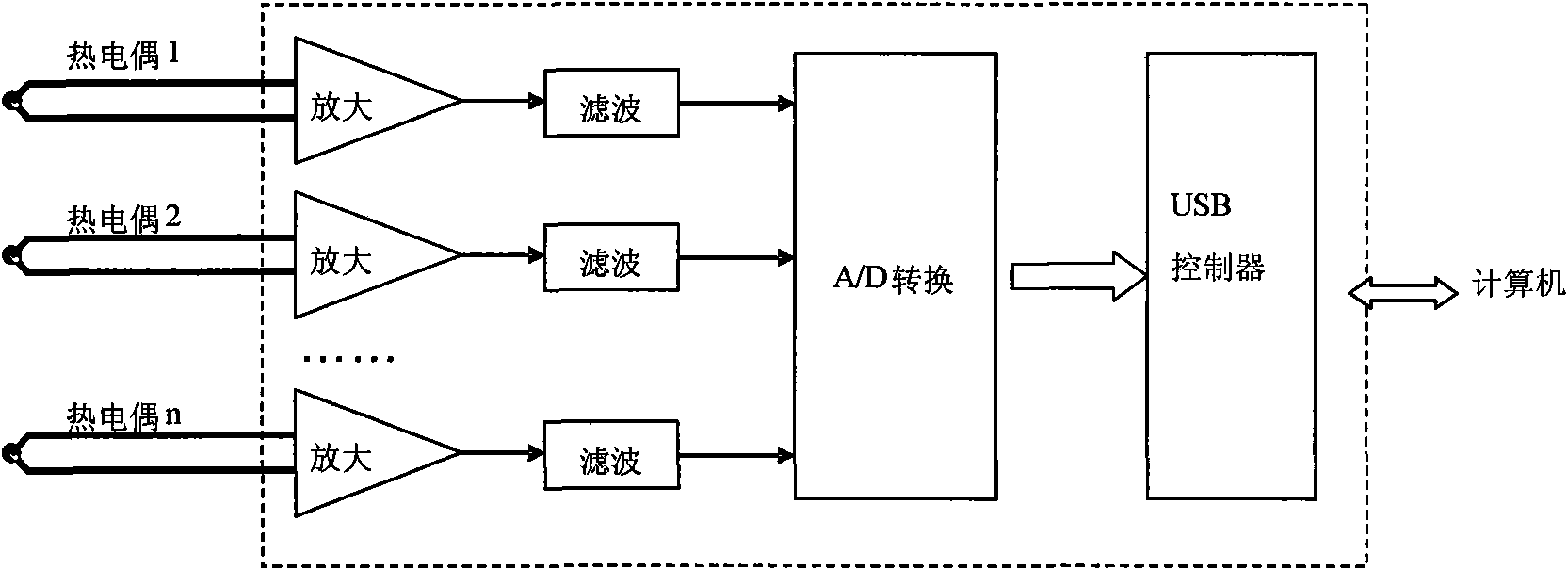

Device and method for measuring gas phase temperature of a cigarette combustion cone

InactiveCN101922979AGuaranteed alignmentEasy to operateThermometer detailsThermometers using electric/magnetic elementsMeasurement deviceGas phase

The invention discloses a device and a method for measuring the gas phase temperature of a cigarette combustion cone, which belong to the technical field of cigarette tests. The device is provided with a synchronous triggering device and a data acquisition card; a suction signal indication output end of a smoking machine is connected with an input end of the synchronous triggering device, and an output end of the synchronous triggering device is connected with a computer control system through an RS232 interface; and an output end of a thermocouple temperature measuring system provided with agroup of thermocouples is connected with an input end of the data acquisition card, and an output end of the data acquisition card is connected with the computer control system through a USB interface. The method for measuring the gas phase temperature of the cigarette combustion cone realizes automatical acquisition in synchronization with suction and realizes that software starts to acquire temperature data automatically at the same time of lighting the cigarette. Data of each independent experiment are ensured to be aligned on a time axis, and an automatic stop function of setting the acquisition time is realized. The instrumental automatic level is improved.

Owner:HUBEI CHINA TOBACCO IND +1

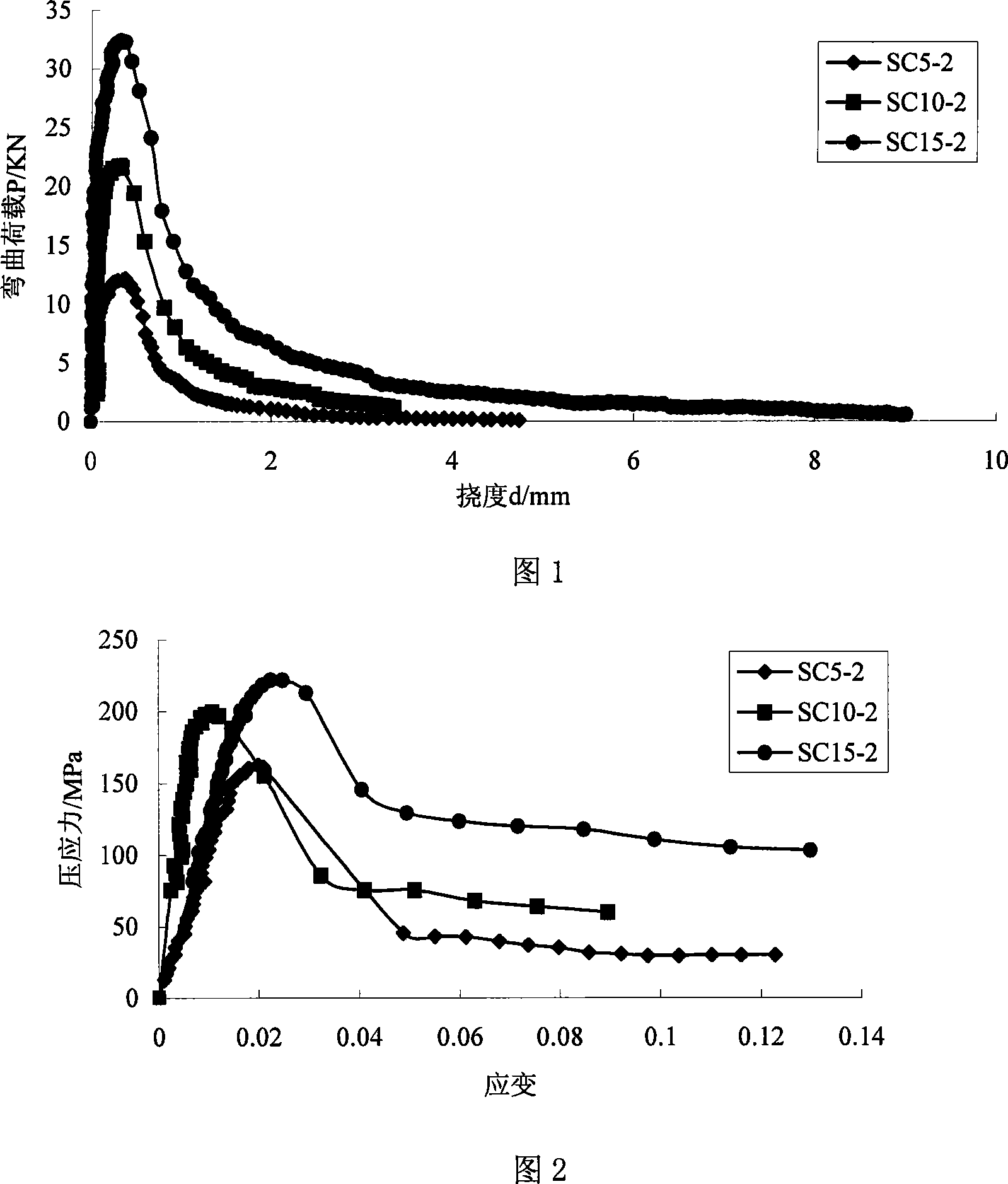

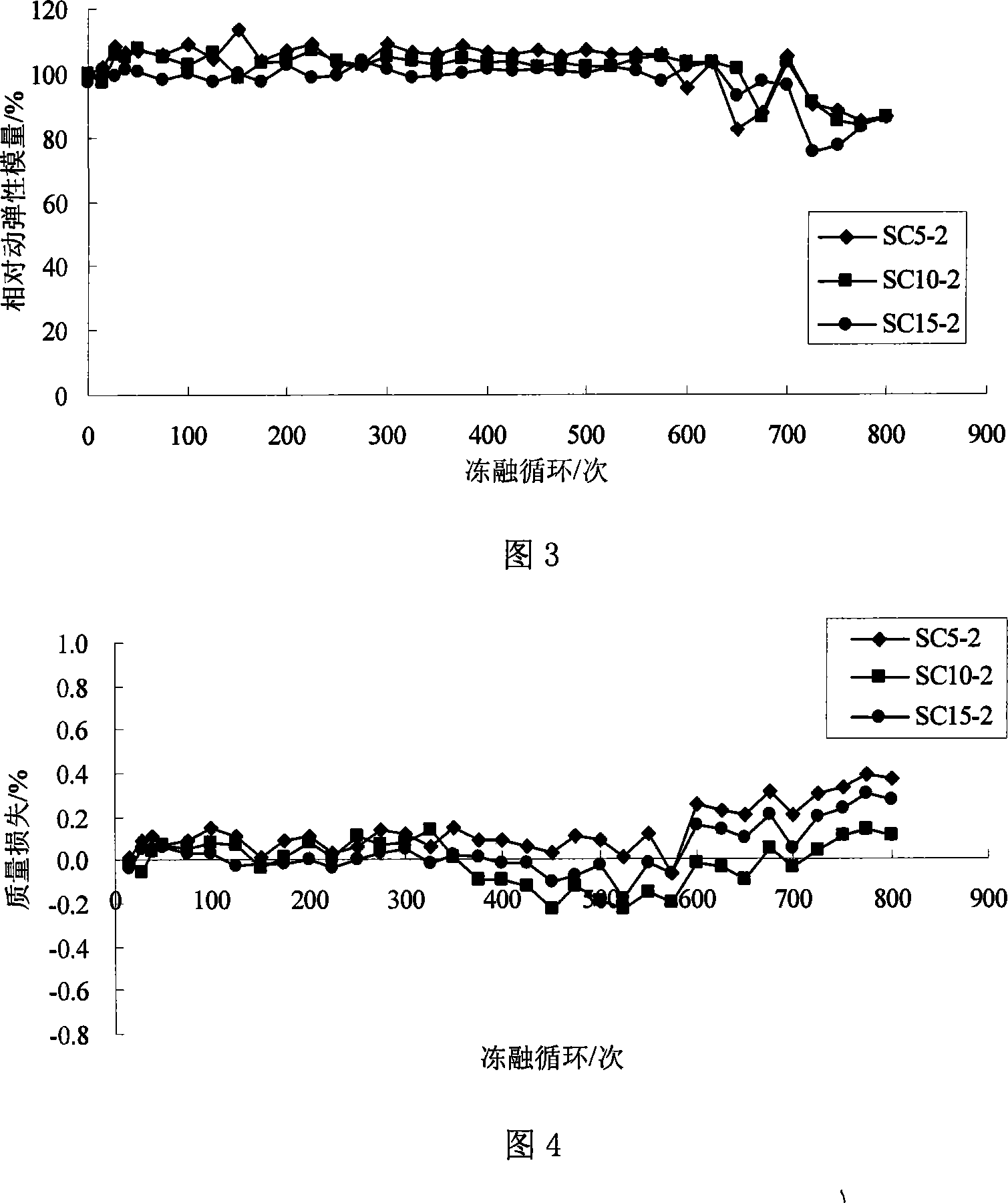

Three-dimensional orientation fibre-reinforced cement base composite material

InactiveCN101172824AImprove the effective coefficient of directionIncrease heightSolid waste managementSlagSuperplasticizer

The invention relates to three-dimensional oriented fibre reinforced cement base composite material which belongs to the field of concrete of building material. The composite material comprises gelled material, fine aggregate, water, three-dimensional oriented fibre and superplasticizer, wherein, the proportion by weight of the gelled material, the fine aggregate, the water and the superplasticizer is 1:(1 to 2.5):(0.13 to 0.35):(0.01 to 0.03). The gelled material component comprises cement and mineral additive, and the proportion by weight of the cement and the mineral additive is (0.4 to 0.9):(0.1 to 0.6), or the gelled material component comprises the cement , the mineral addition and expansion agent, the proportion by weight of the three is (0.35 to 0.85):(0.1 to 0.5):(0.05 to 0.15), the mineral additive is one of fly ash, slag, siliceous dust and metakaolin, the volume of the three-dimensional oriented fibre is 5 percent to 35 percent of the whole volume after all components are mixed, and the three-dimensional oriented fibre can choose a three-dimensional steel fibre net rack which is made of shortly-cut steel fibre and steel wires and a three-dimensional assorted fibre net rack which is made of steel wires and high performance organic base fibre. The invention ensures that the fibre is directionally arrayed at the high performance oriented fibre reinforced cement base composite material. Through utilizing the fly ash, the slag, the siliceous dust and the metakaolin as raw materials, the invention which can protect the environment and reduce the cost has the advantages of high strength, good toughness and high durability.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Vacuum packaging structure, packaging method thereof, and vacuum packaging device

ActiveCN106847759AReduce volumeGuaranteed performanceSemiconductor/solid-state device detailsSolid-state devicesLight filterMaterials science

A vacuum packaging structure, a packaging method thereof, and a vacuum packaging device are provided. The vacuum packaging structure comprises: a base; a cover cap having an opening at the top, wherein the opening is covered with an infrared filter, and the cover cap, the infrared filter and the base form a vacuum chamber; an infrared detector chip positioned in the vacuum chamber and adhering to the surface of the base; and a getter layer located within the vacuum chamber and having both ends welded to the base surface. The vacuum packaging structure requires no exhaust pipe, simplifies components, and significantly reduces the volume of an infrared detector. Moreover, the infrared detector chip completely fits with the base, and a chip base material has good temperature uniformity and effectively guarantees detector performance.

Owner:ZHEJIANG DALI TECH +1

Shearing testing device and operation method thereof

ActiveCN104677750ANeutral goodSimple structureMaterial strength using steady shearing forcesEngineeringTest element

The invention discloses a shearing testing device and an operation method thereof. The shearing testing device comprises a fixture base, guide rails, a movable fixture, a fixed fixture, a center-aligning block, a first aligning plate, a second aligning plate, a wedge-shaped block, a first compressing block, a second compressing block and a fixture leveling plate, wherein the two guide rails are longitudinally fixed on the fixture base side by side; symmetrical bosses are arranged at two sides of the movable fixture, and are provided with through holes; the movable fixture sleeves the guide rails via the through holes; the top of the center-aligning block is provided with a bulge matched with a V-shaped notch of a test element; the first aligning block and the second aligning block are both hexahedron square blocks with bulged steps; the first compressing block is positioned below the upper clamping surface of the fixed fixture and is connected with the upper clamping surface; the second compression block is positioned below the upper clamping surface of the movable fixture and is connected with the upper clamping surface. According to the invention, the precise alignment of the shearing test element at the thickness direction and length direction can be ensured, and the clamping operation is very convenient.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

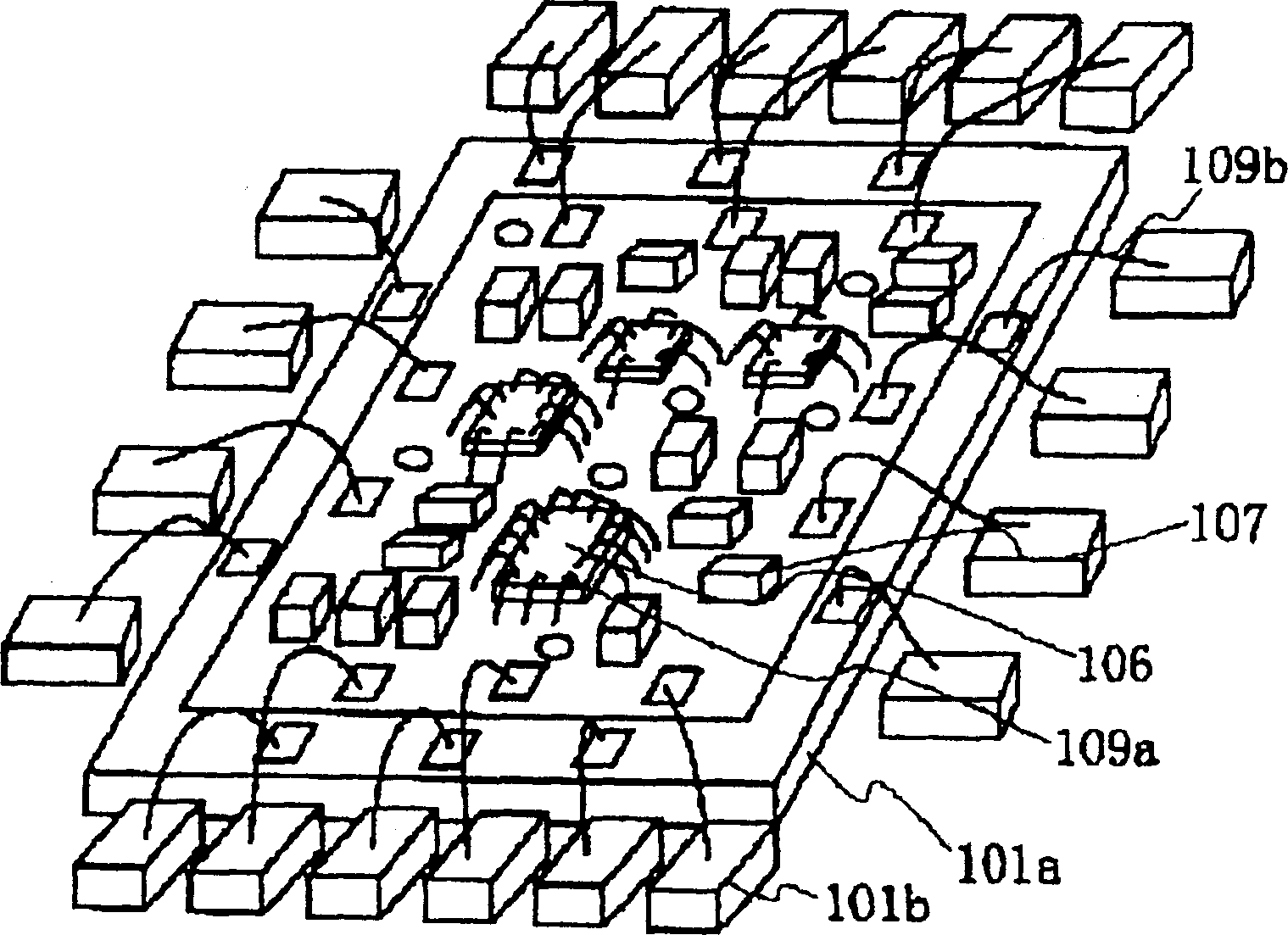

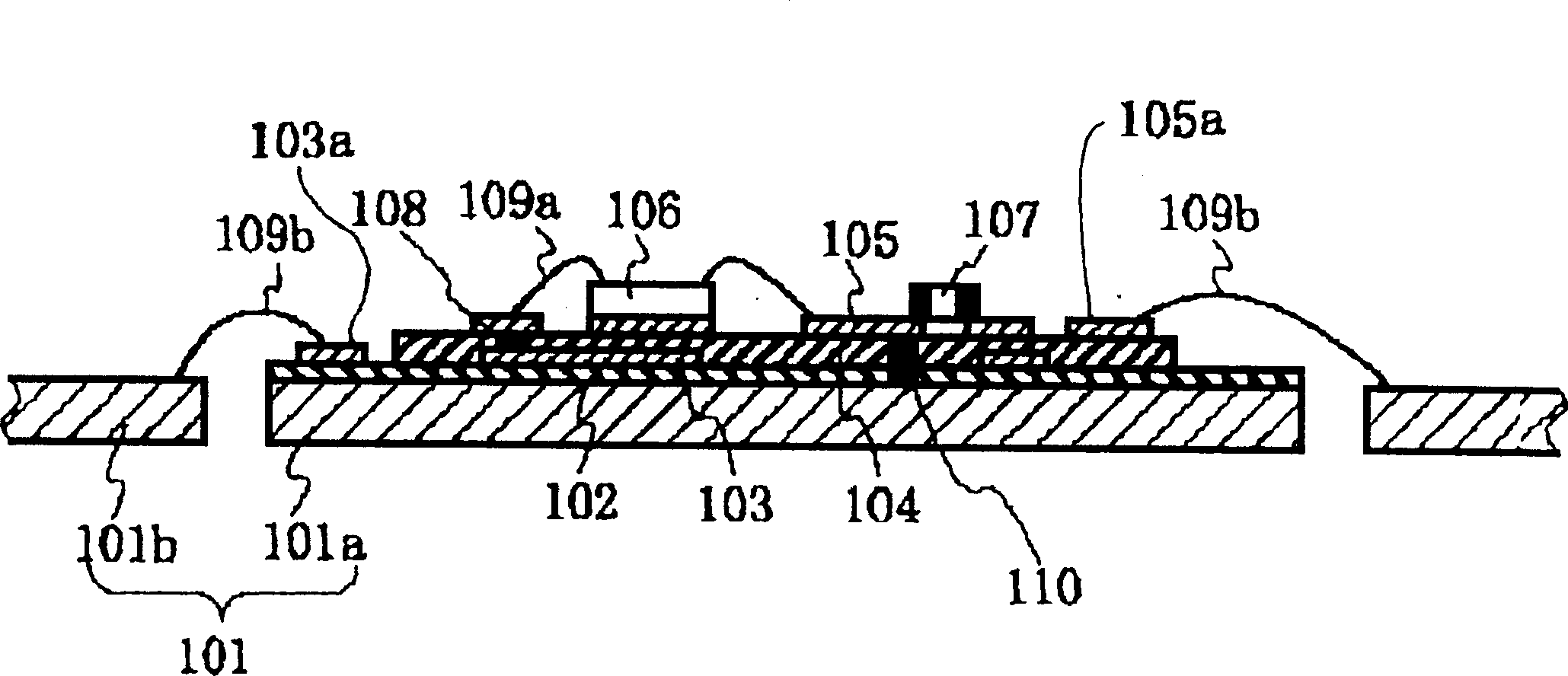

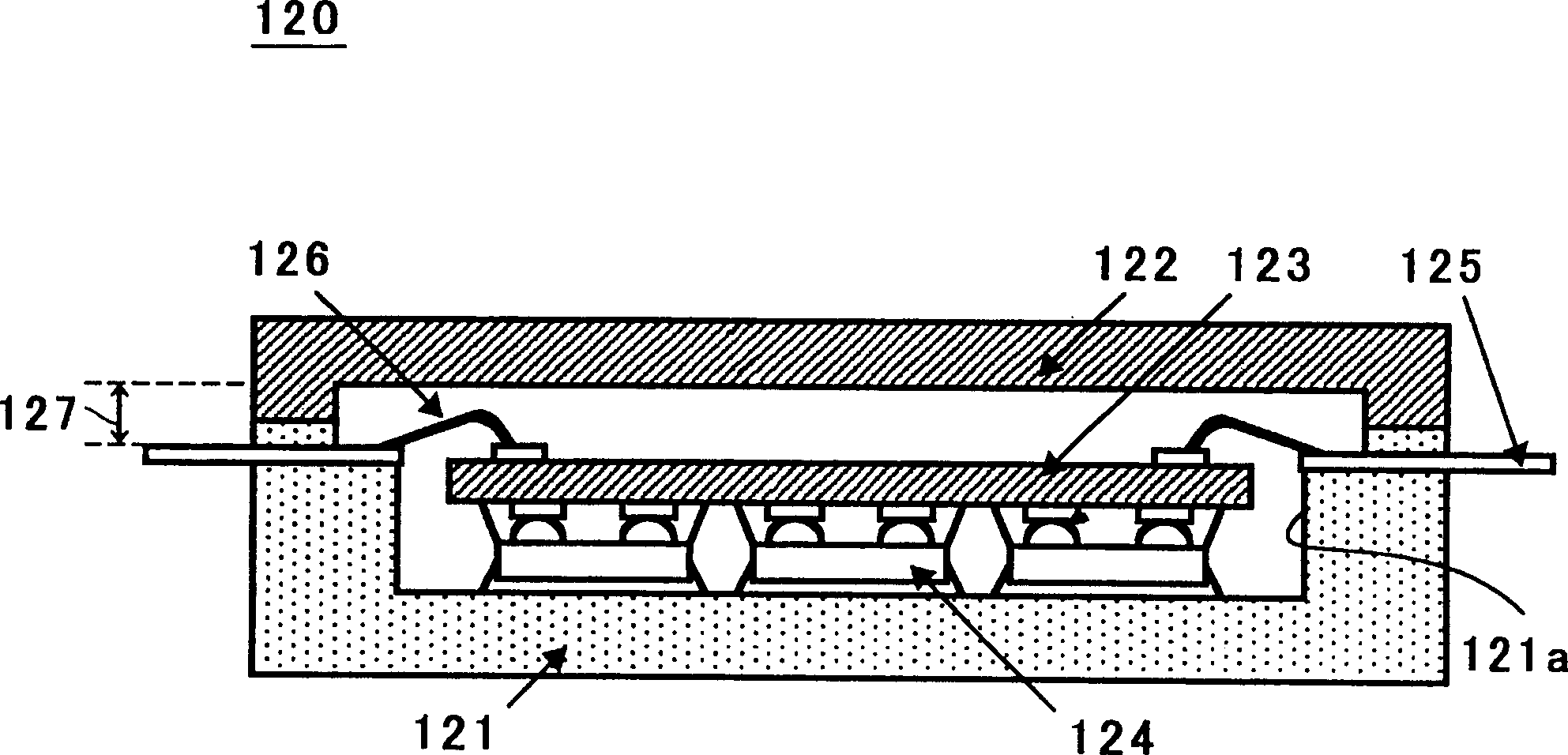

Semiconductor device and producing method thereof

InactiveCN1453858AShield electromagnetic wavesSmall sizeSemiconductor/solid-state device detailsSolid-state devicesDirect couplingEngineering

An electronic device (10) comprising: (a) a first wiring substrate (11) comprising a metal region (111) formed with a groove (15) extending to the metal region (111); and (b) The second wiring substrate (12) includes a ground electrode. When connected to the first wiring substrate (11), the grounding electrode is formed in the groove (15) and the area outside the signal transmission channel around the groove (15). pole; further comprising at least one first electronic component (14) mounted thereon. The first and second wiring substrates (11, 12) are directly coupled to each other such that the first electronic component (14) is placed within the recess (15).

Owner:NEC COMPOUND SEMICON DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com