Automatic single and double-reel take-up device

A wire take-up device and single-reel technology, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of reducing product production efficiency, unable to automate unmanned production, etc., and achieve the effect of improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

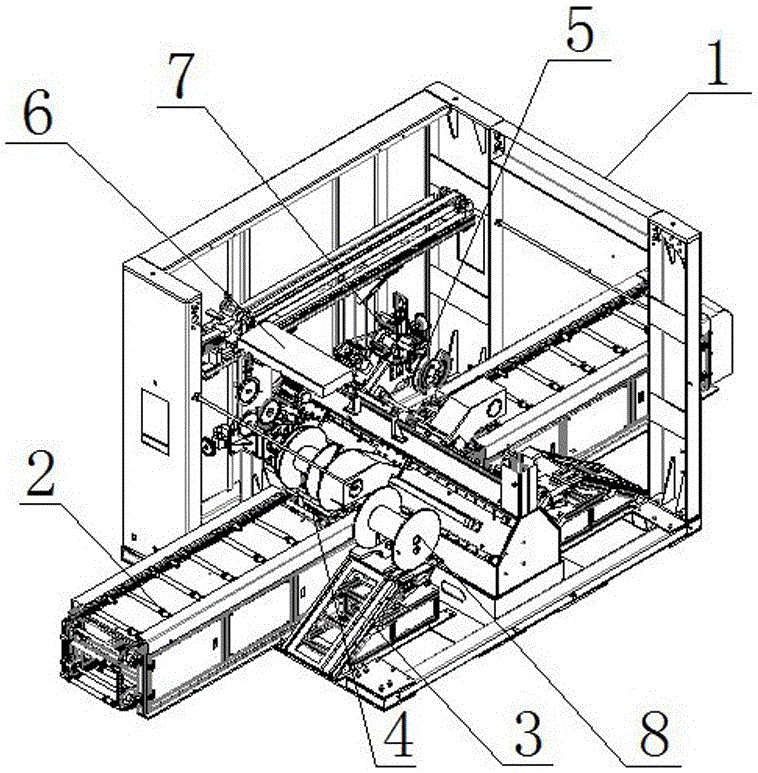

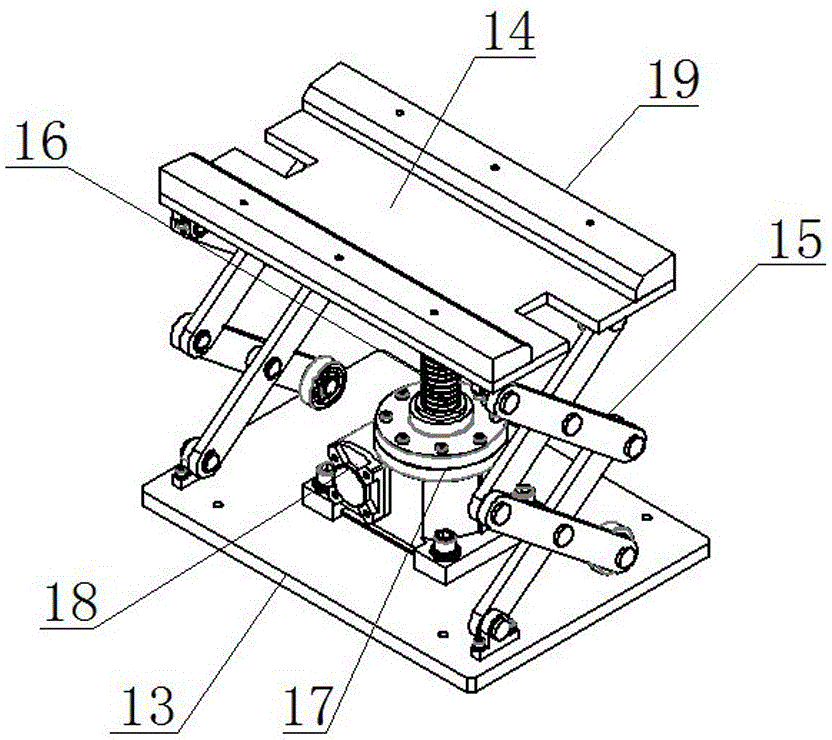

[0027] As shown in the figure, an automatic single-reel wire take-up device of the present invention includes a frame 1, a reel-feeding mechanism 2, a reel-out mechanism 3, a lifting mechanism 4, a wire reel clamping and rotating mechanism 5, a horizontal wire arranging mechanism 6 and The thread trimming mechanism 7 and the lifting mechanism 4 are arranged at one end of the reel feeding mechanism 2 and below the wire reel clamping and rotating mechanism 5. To the wire reel clamping and rotating mechanism 5, the wire reel clamping and rotating mechanism 5 clamps the wire reel 8 and drives the wire reel 8 to rotate and wind, and the horizontal wire arrangement mechanism 6 is arranged above the wire winding clamping and rotating mechanism 5 for lateral movement Make the winding uniform, the thread trimming mechanism 7 is arranged on the side of the wire reel clamping rotating mechanism 5 for winding and completing the thread trimming, and the reel-out mechanism 3 is arranged on t...

Embodiment 2

[0036] An automatic double-reel take-up device, including a frame 1 and two sets of reel-feeding mechanisms 2, a reel-out mechanism 3, a lifting mechanism 4, a reel clamping and rotating mechanism 5, and a horizontal cable arrangement mechanism arranged symmetrically on both sides of the frame 6 and thread trimming mechanism 7.

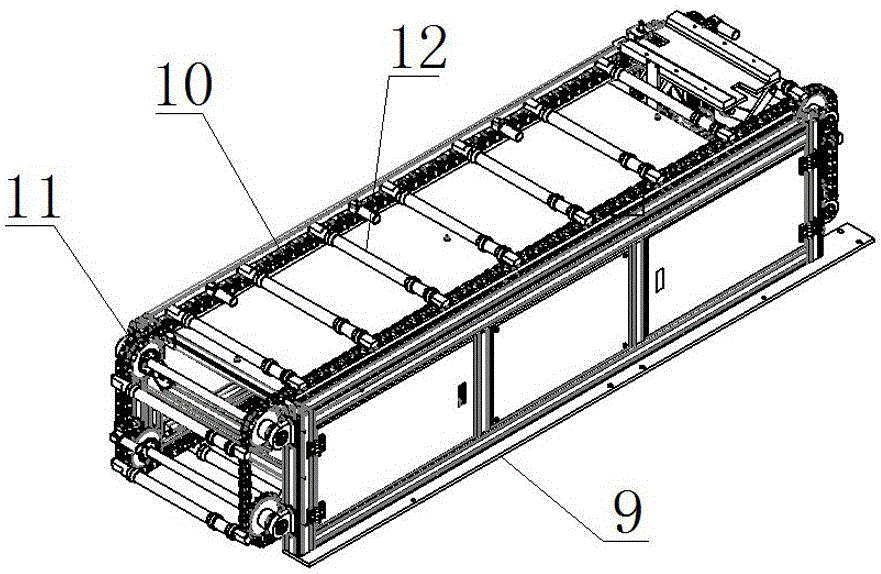

[0037] The disc delivery mechanism 2 includes a disc delivery bracket 9, a chain 10, a sprocket 11, and a transverse roller shaft 12. The eight sprockets 11 are divided into two groups and arranged on both sides of the disc delivery bracket 9, and each group of four sprockets 11 is respectively rotated and set. At the four corners of the side of the tray support 9, two chains 10 are respectively arranged on two groups of sprockets 11 and driven by the sprockets 11. The sprockets 11 are driven to rotate by the sprocket drive motor, and the two ends of the transverse roller shaft 12 are fixed on On the chains 10 on both sides, several transverse rollers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com