Three-dimensional orientation fibre-reinforced cement base composite material

A fiber-reinforced cement and composite material technology, which is applied in the field of building materials, can solve the problems of uneven stress and easy lamination of materials, and achieve increased reinforcement and toughening effects, excellent tensile strength, and reduced average fiber spacing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

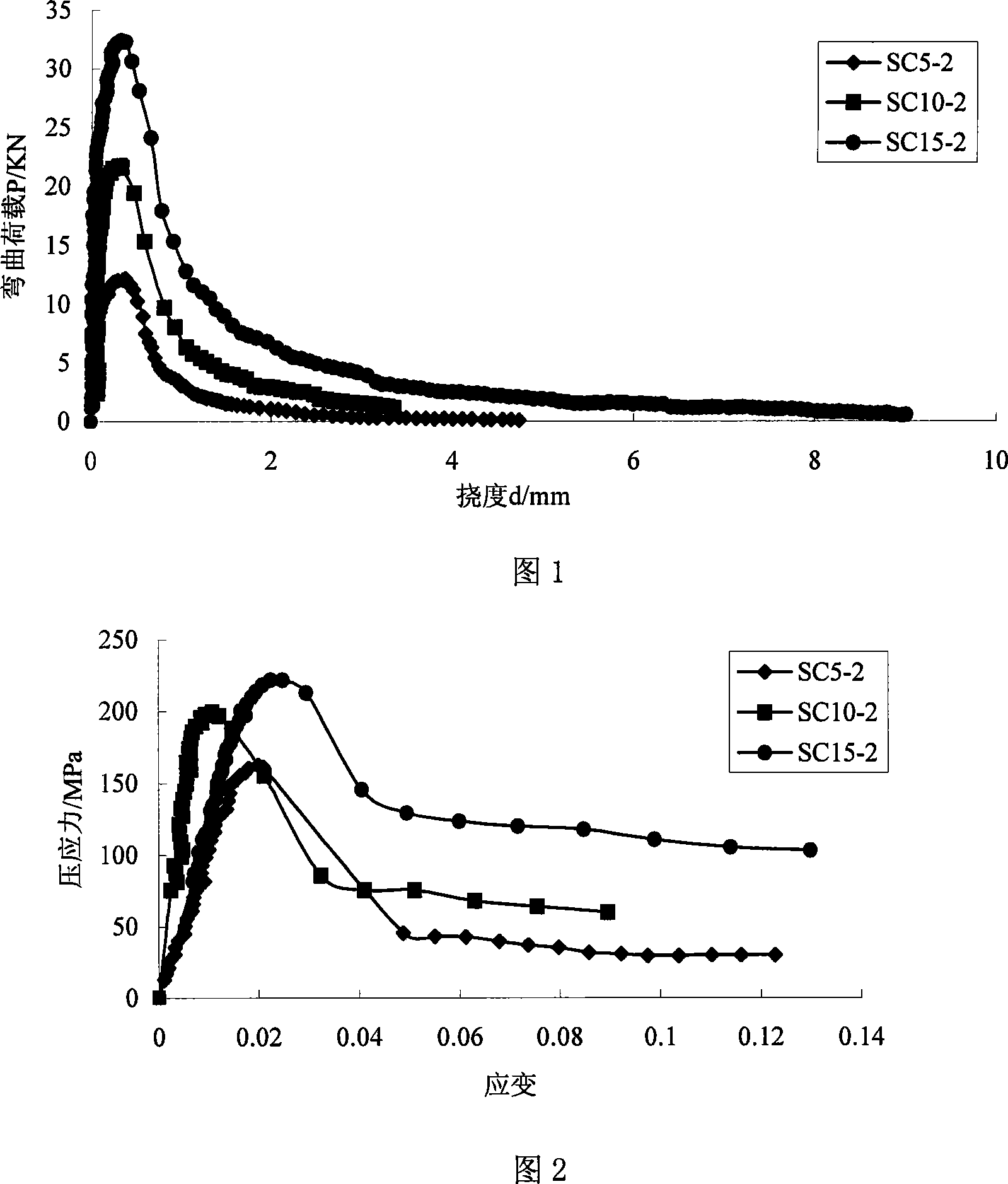

[0013] Use P.II 52.5R Portland cement, I-class fly ash, S95-class slag, silica fume (SiO2 content above 92%), low-alkali U-shaped concrete expansion agent (UEA-N), shield bell-shaped steel fiber ( The fiber equivalent diameter is 0.73mm, the fiber length is 25mm, the aspect ratio is 34.2, and the fiber tensile strength is above 900MPa), HP400R retarding superplasticizer (polycarboxylate superplasticizer) and ordinary yellow sand ( Fineness modulus 2.28) as raw material, the weight ratio of cementitious material components is: cement: fly ash: slag: silica fume: expansion agent = 0.6: 0.1: 0.1: 0.1: 0.1, cementitious material components and fine The weight ratio of aggregate, water and superplasticizer is: cementitious material component: fine aggregate: water: superplasticizer=1: 1: 0.24: 0.0195, and the volume of steel fiber is the total after all components are mixed. 5% of the volume. The 40mm×40mm×160mm specimen was molded with fiber-soaked slurry, and the steel fibers sh...

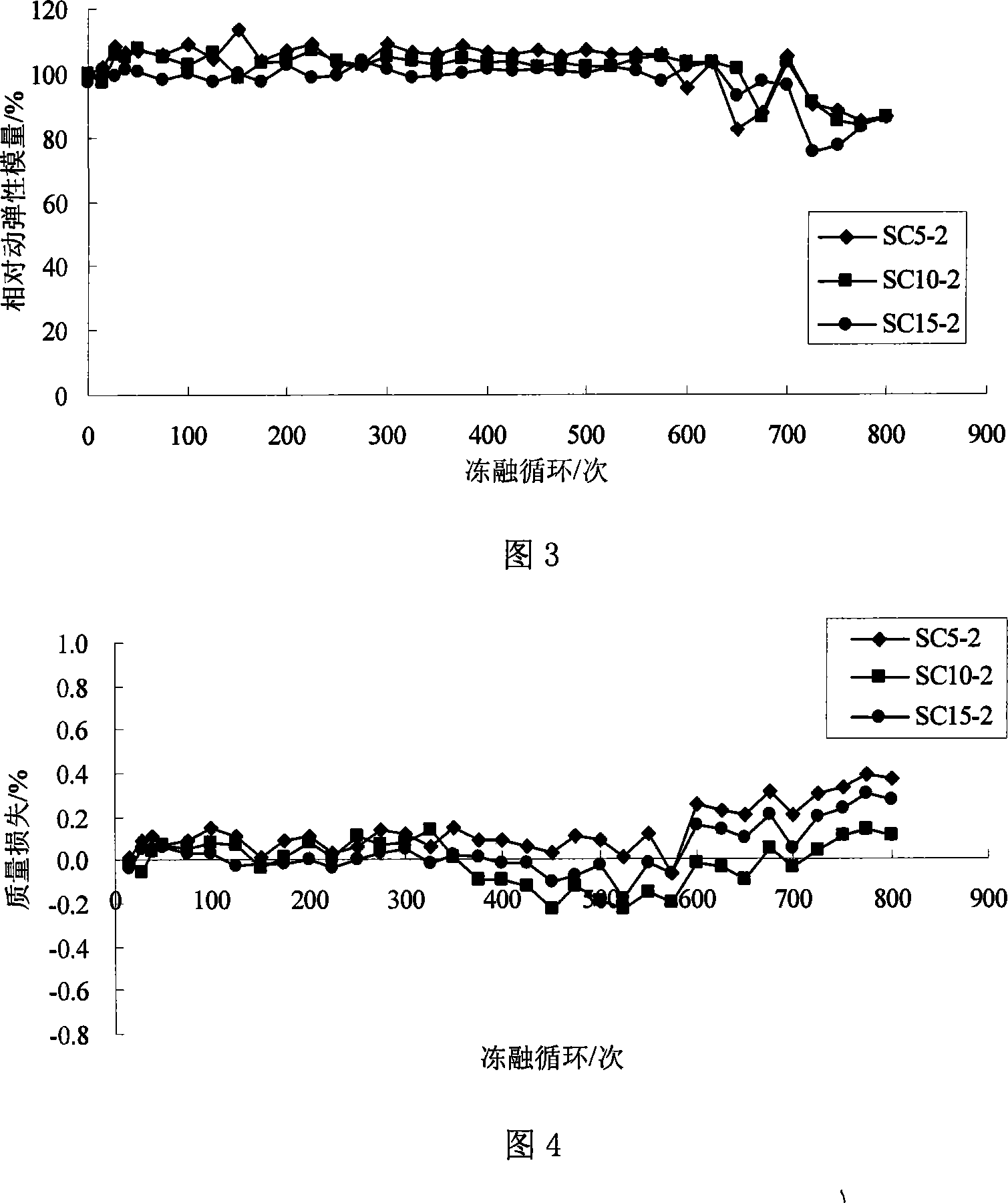

Embodiment 2

[0015] Using the same raw materials, mixing ratio, molding process and curing method as in Example 1, a 40mm×40mm×160mm high-performance directional fiber reinforced cement-based composite material specimen was made, and only the volume content of the steel fiber was increased to the entire composition 10% of the total volume after mixing. The physical and mechanical properties and frost resistance of the specimen were measured when the standard curing age reached 50 days. The results are as follows: the compressive strength of the three-dimensional oriented fiber reinforced cement-based composite material is 206.8 MPa, and the characteristic point compressive toughness index of 15.5 times the initial cracking strain The flexural strength is 15.43, the flexural strength is 52.0MPa, the flexural toughness is 26.91N m, the flexural toughness index of the characteristic point of 15.5 times the first crack deflection is 28.33, the splitting tensile strength is 23.29MPa, at -(17±2)℃...

Embodiment 3

[0017] Using the same raw materials, mixing ratio, molding process and curing method as in Example 1, a 40mm×40mm×160mm high-performance directional fiber reinforced cement-based composite material specimen was made, and only the volume content of the steel fiber was increased to the entire composition 15% of the total volume after mixing. The physical and mechanical properties and frost resistance of the specimen were measured when the standard curing age reached 50 days. The results are as follows: the compressive strength of the three-dimensional oriented fiber reinforced cement-based composite material is 222.8MPa, and the characteristic point compressive toughness index of 15.5 times the initial cracking strain The flexural strength is 31.52, the flexural strength is 69.1MPa, the flexural toughness is 42.73N m, the flexural toughness index of the characteristic point of 15.5 times the first crack deflection is 20.45, and the splitting tensile strength is 31.27MPa. After 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com