Patents

Literature

445 results about "Fiber-reinforced concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiber-reinforced concrete (FRC) is concrete containing fibrous material which increases its structural integrity. It contains short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers – each of which lend varying properties to the concrete. In addition, the character of fiber-reinforced concrete changes with varying concretes, fiber materials, geometries, distribution, orientation, and densities.

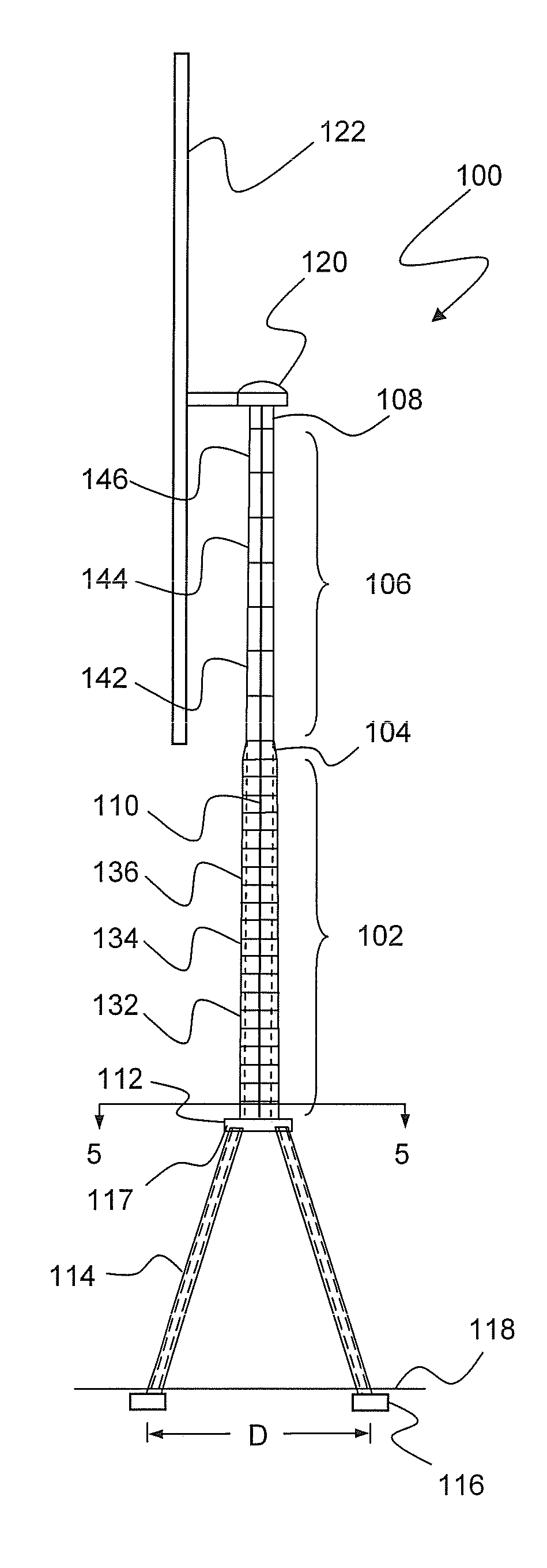

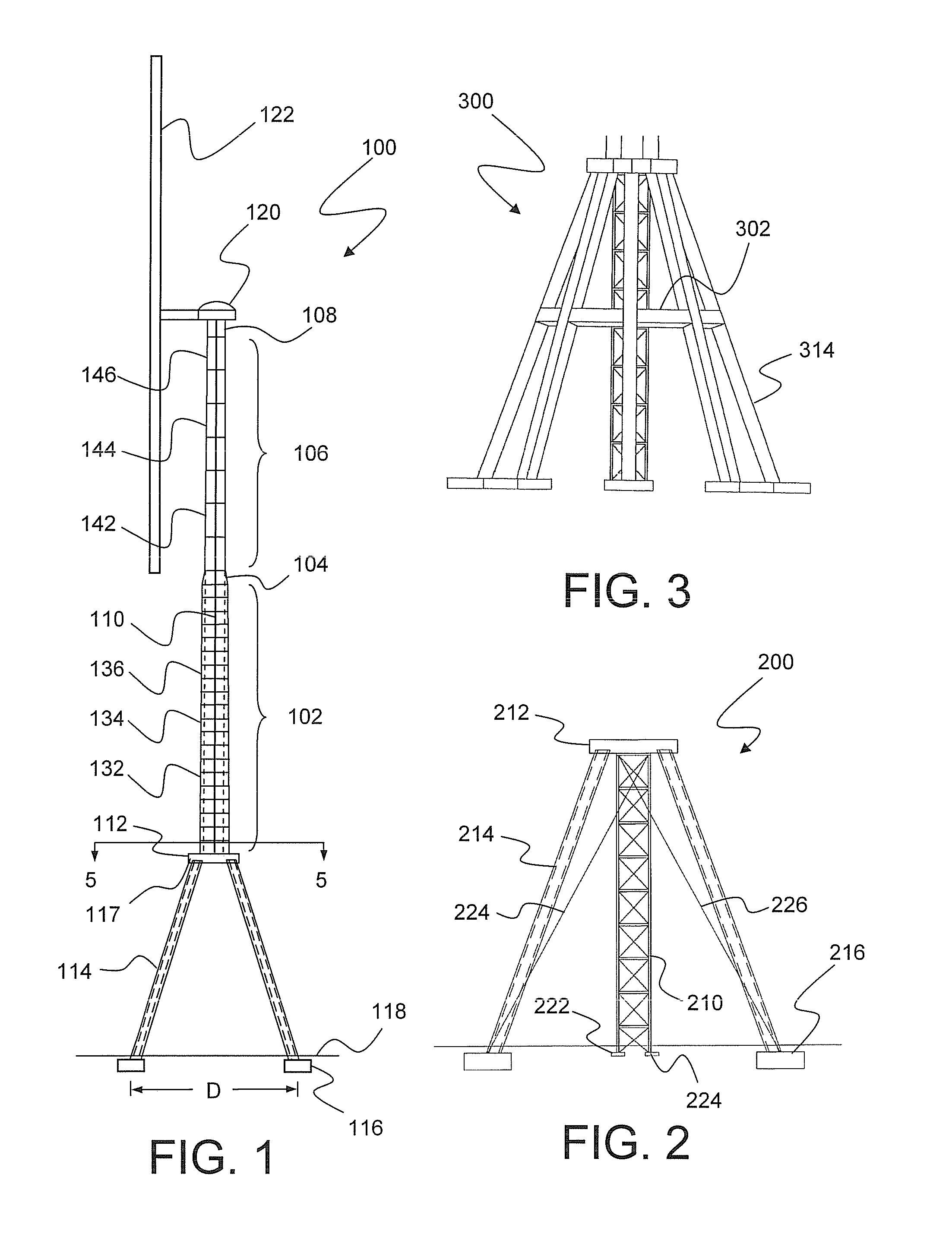

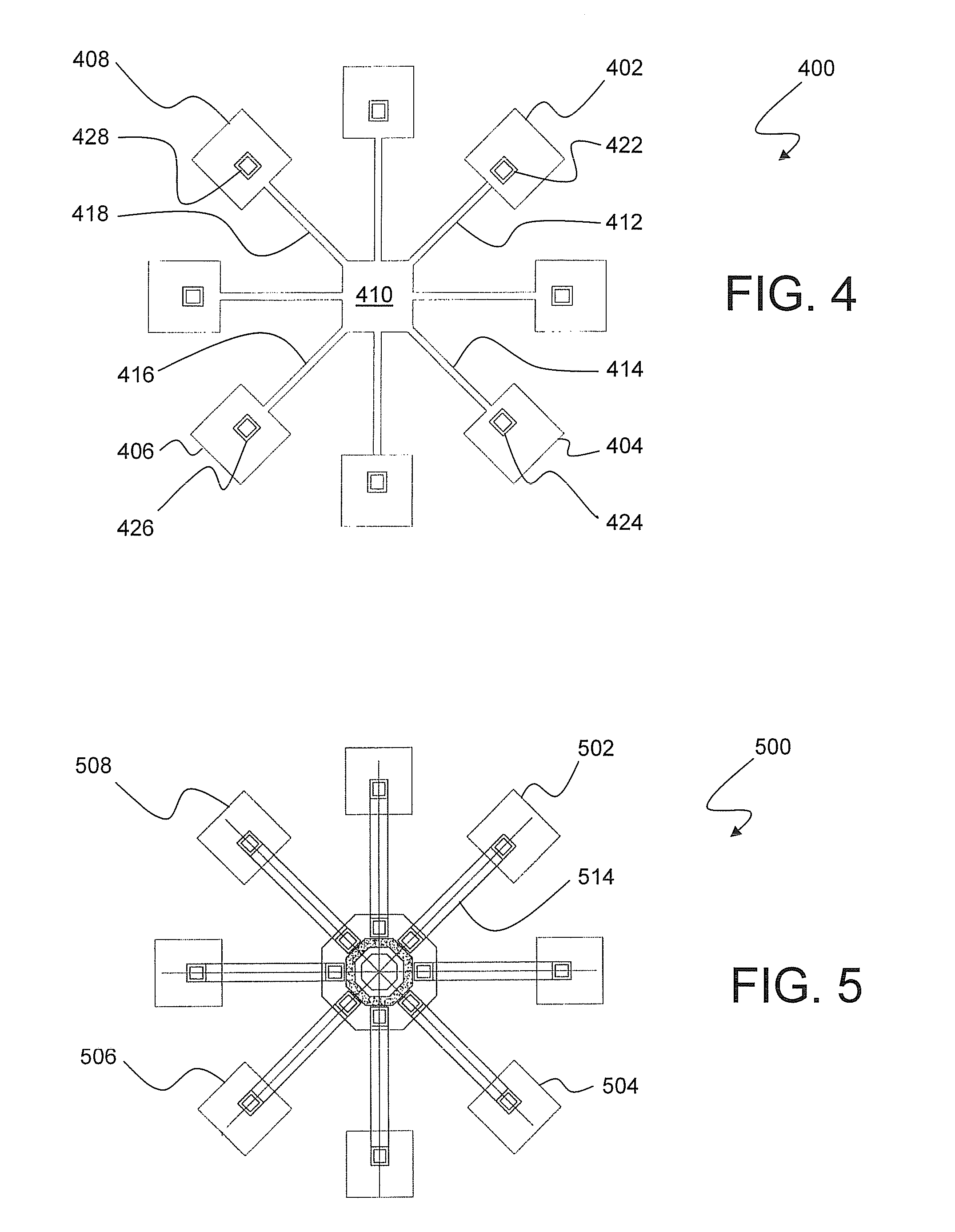

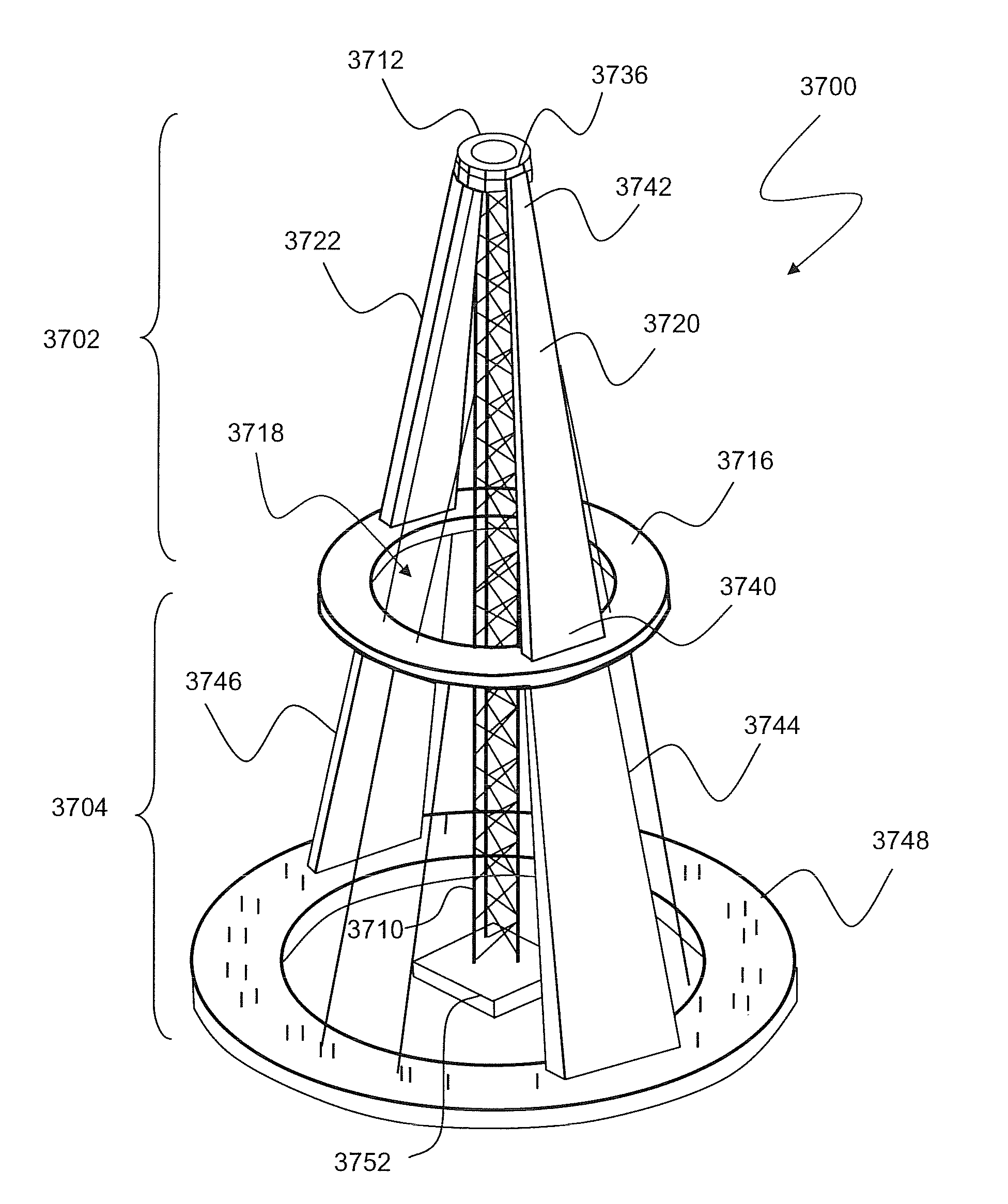

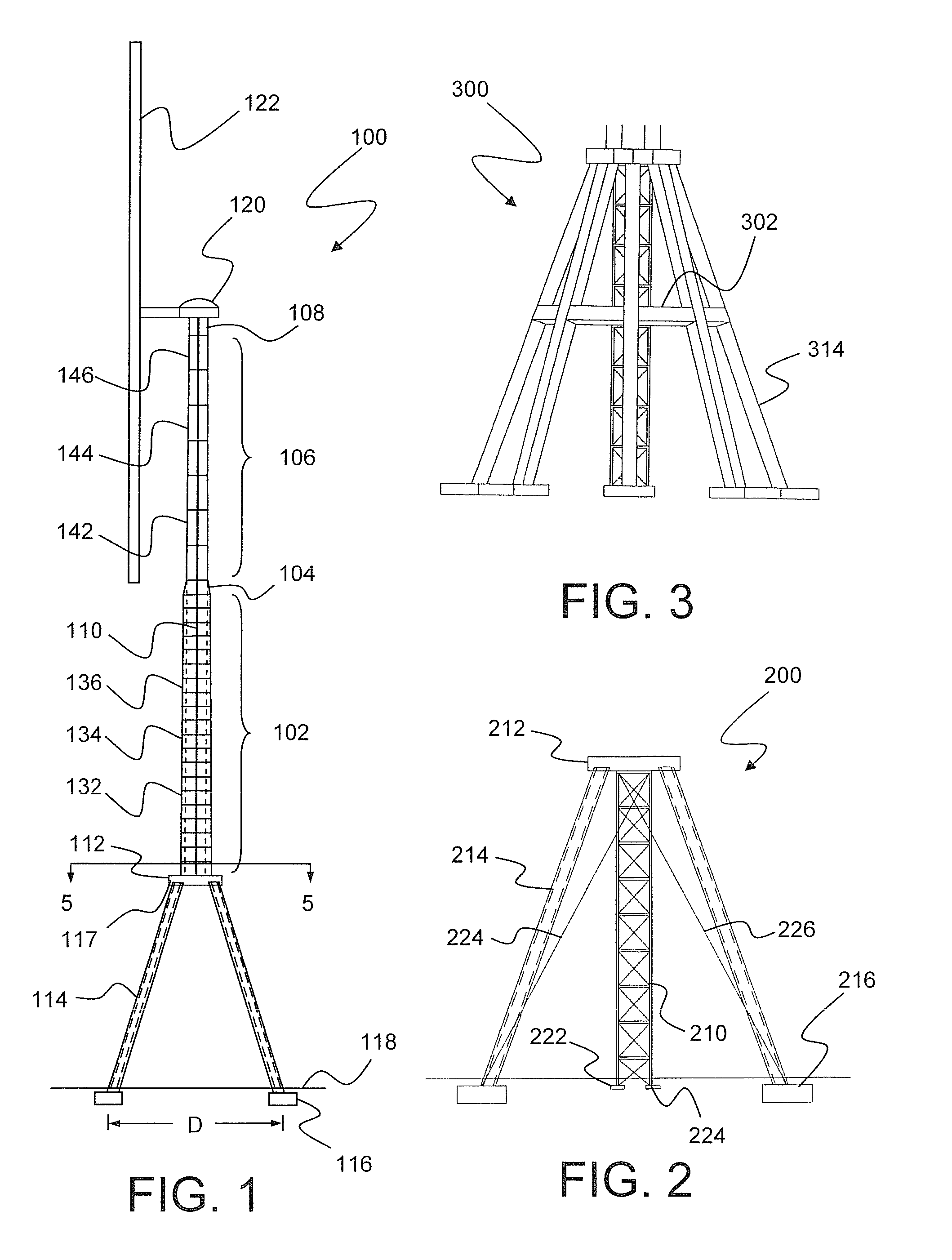

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

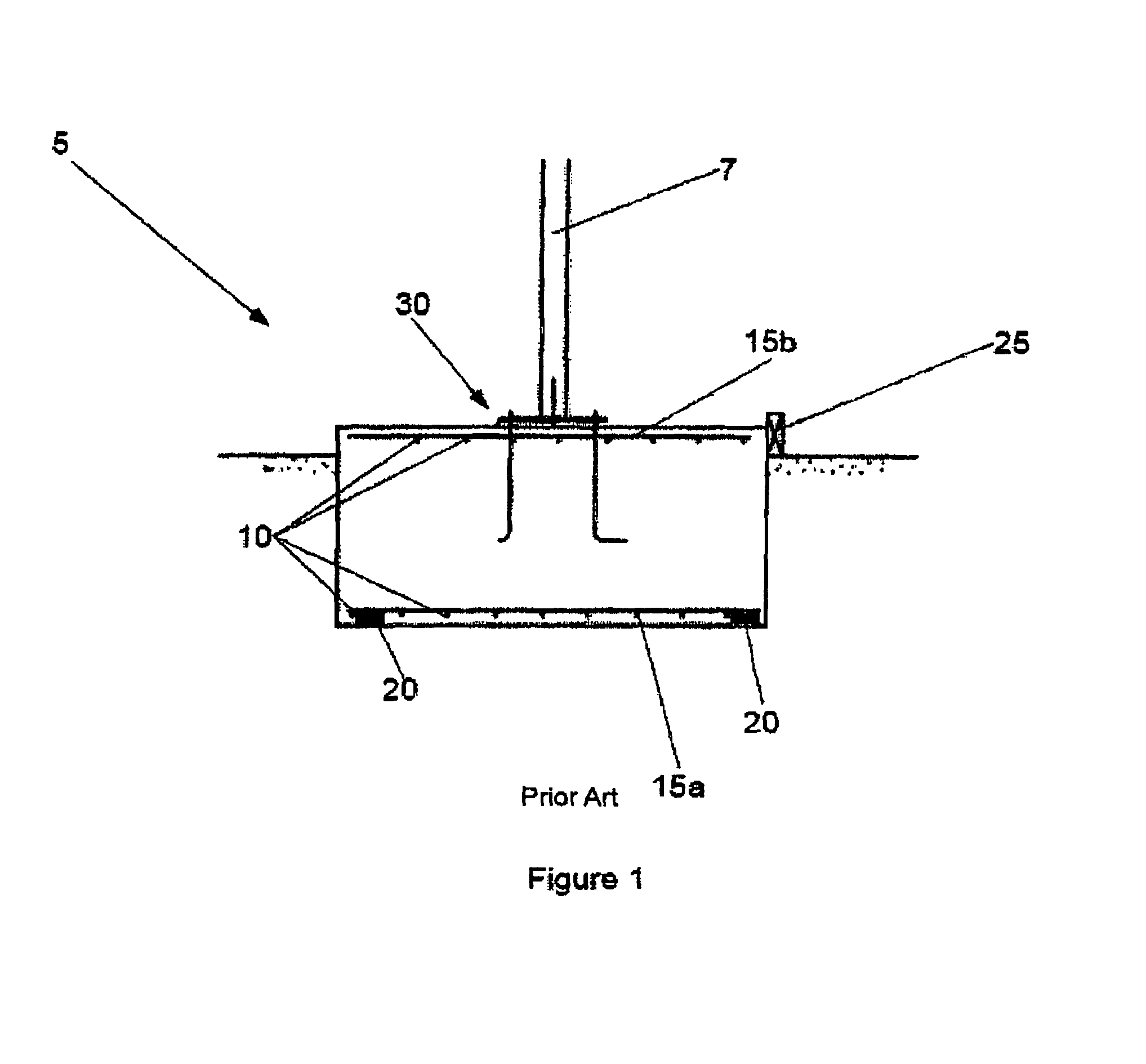

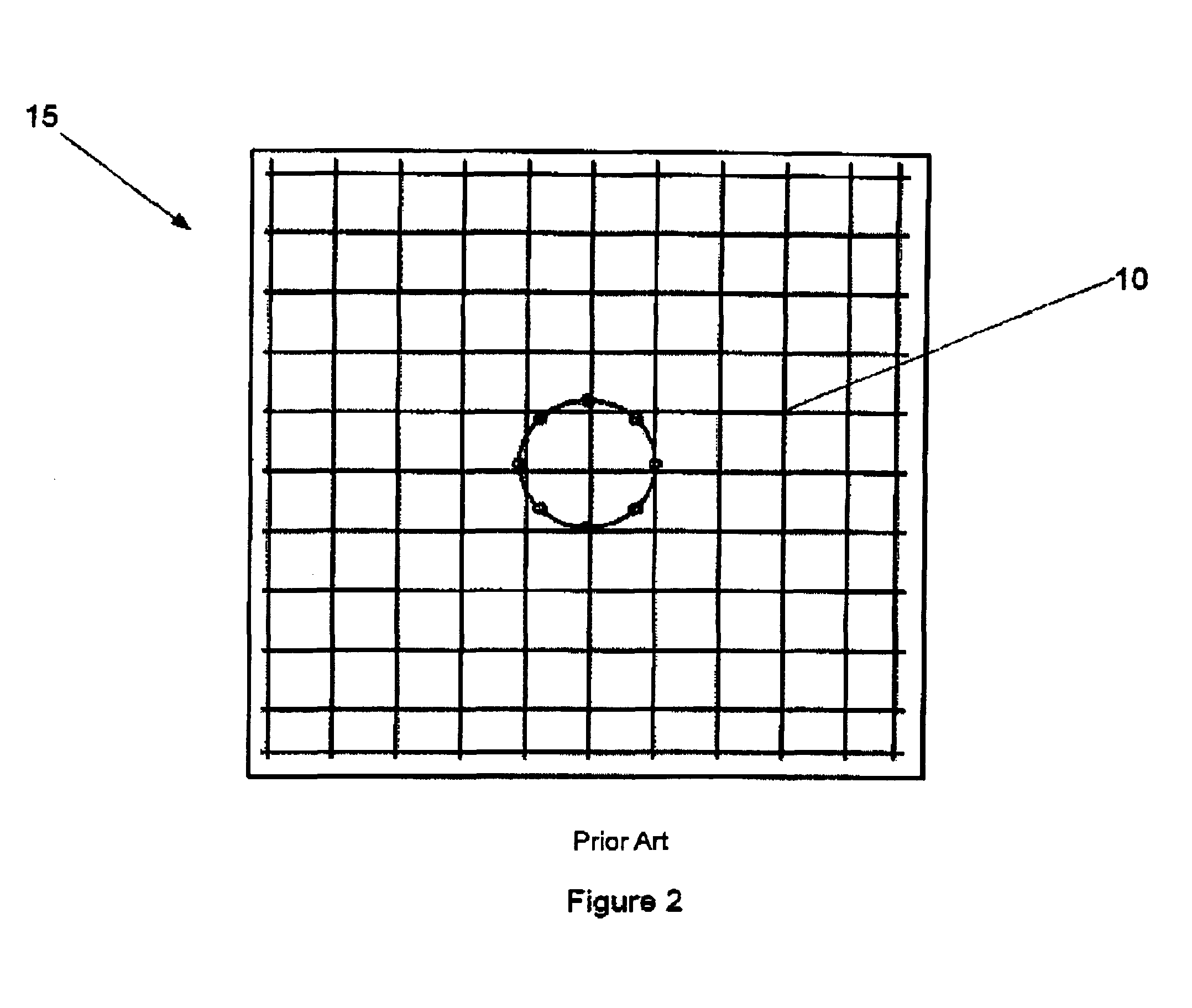

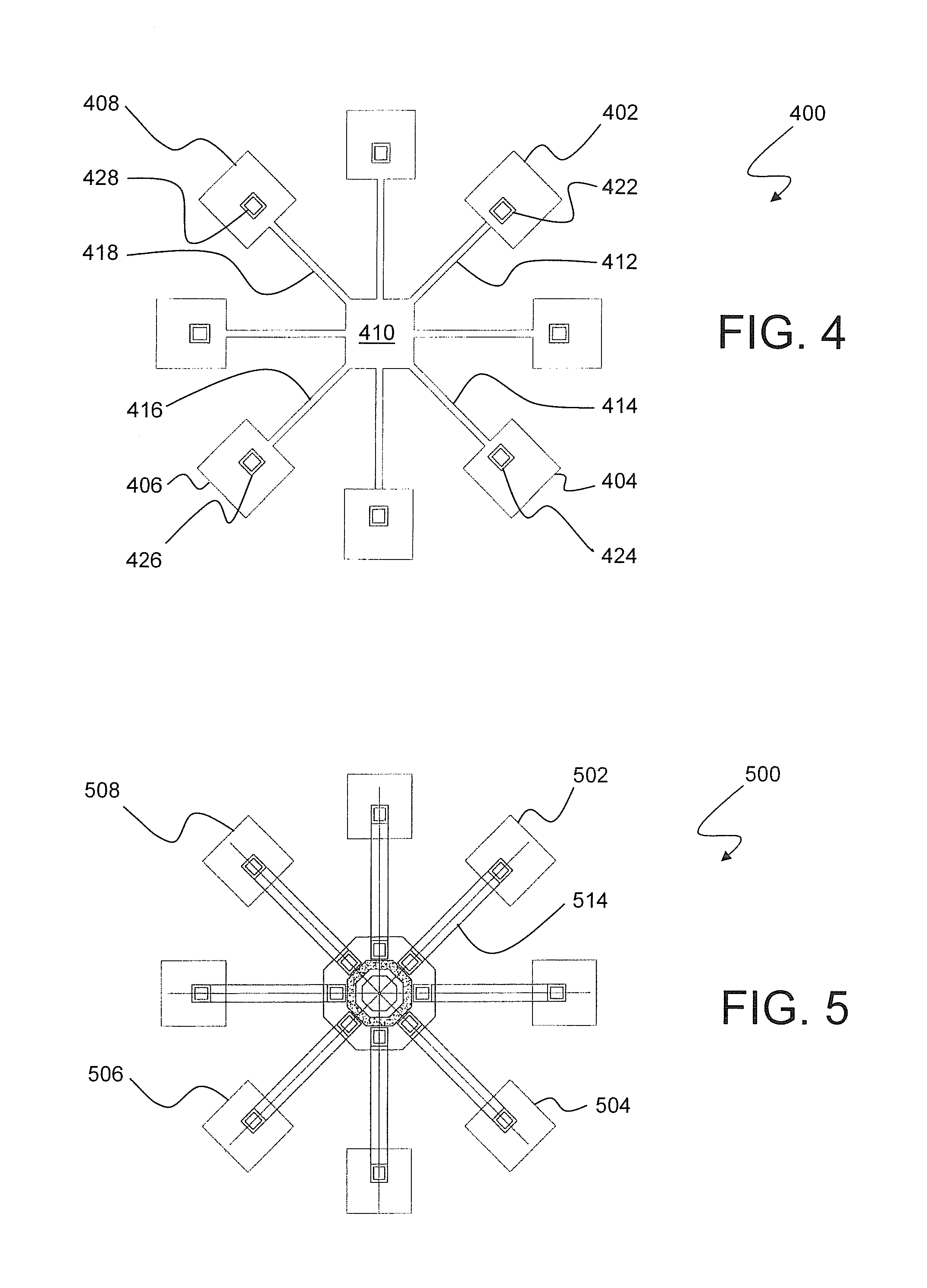

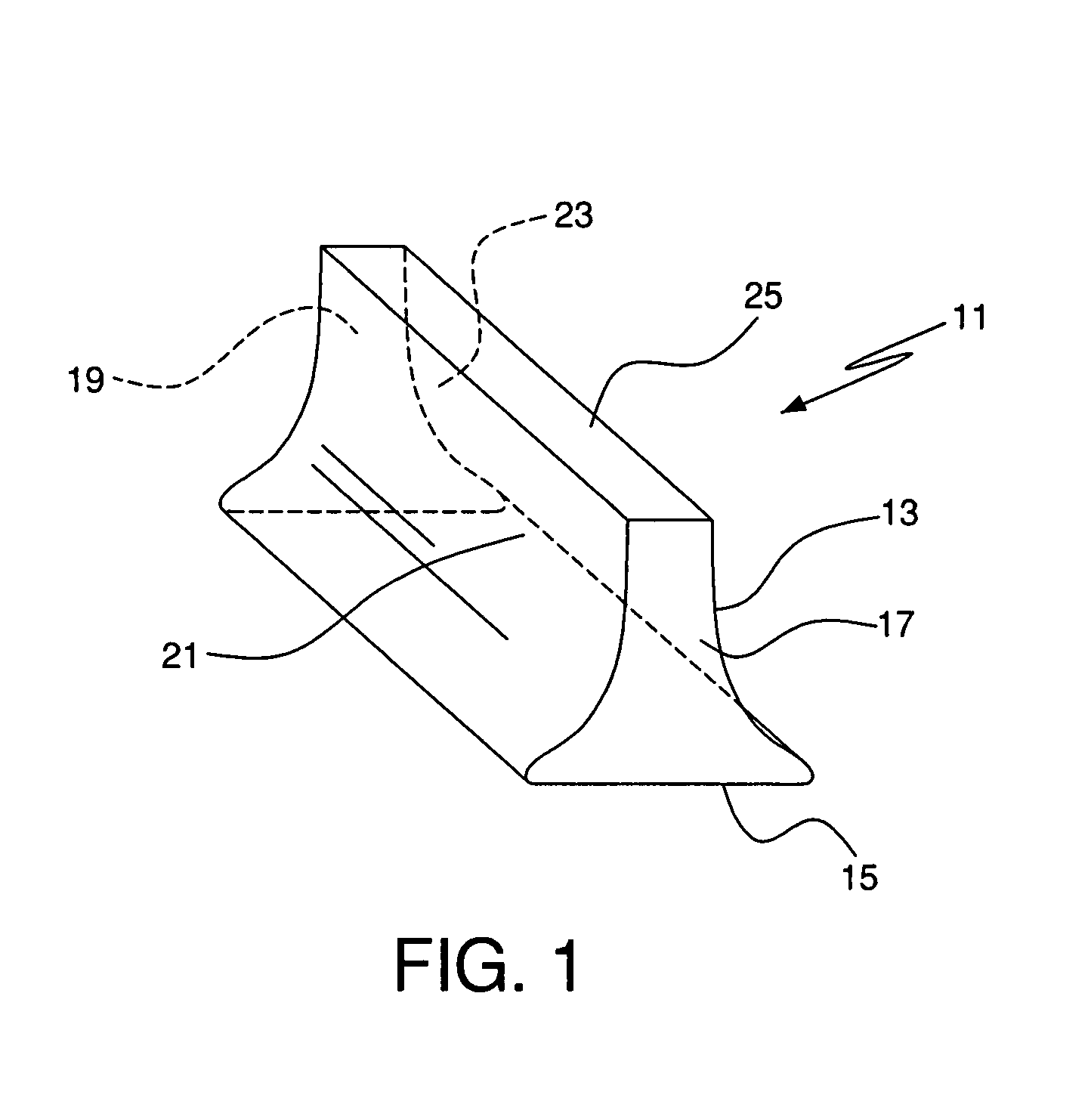

Foundation for monopole wind turbine tower

ActiveUS8161698B2Easy to useReduce laborWind motor supports/mountsFoundation engineeringEngineeringTower

An innovation is disclosed which relates to a wind turbine foundation. A circular foundation using fiber reinforced concrete has optional circular reinforcement rods. The foundation includes a vertical stanchion that rests in the bottom of an excavated hole and supports anchor bolts and reinforcement bars in a predetermined configuration while concrete is poured into the hole. All the necessary foundation materials can be combined in a simple and compact kit which can be shipped to a customer.

Owner:ANEMERGONICS

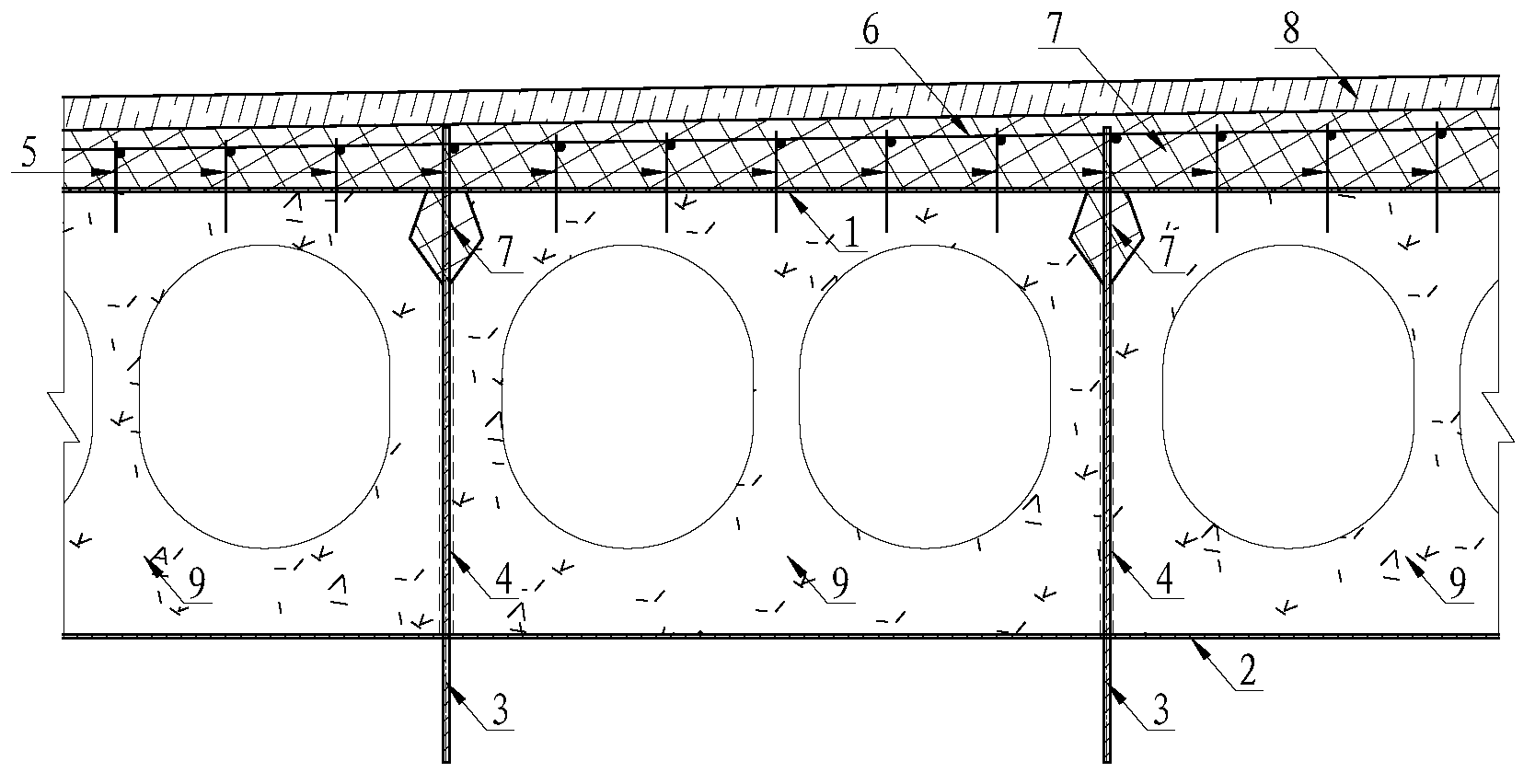

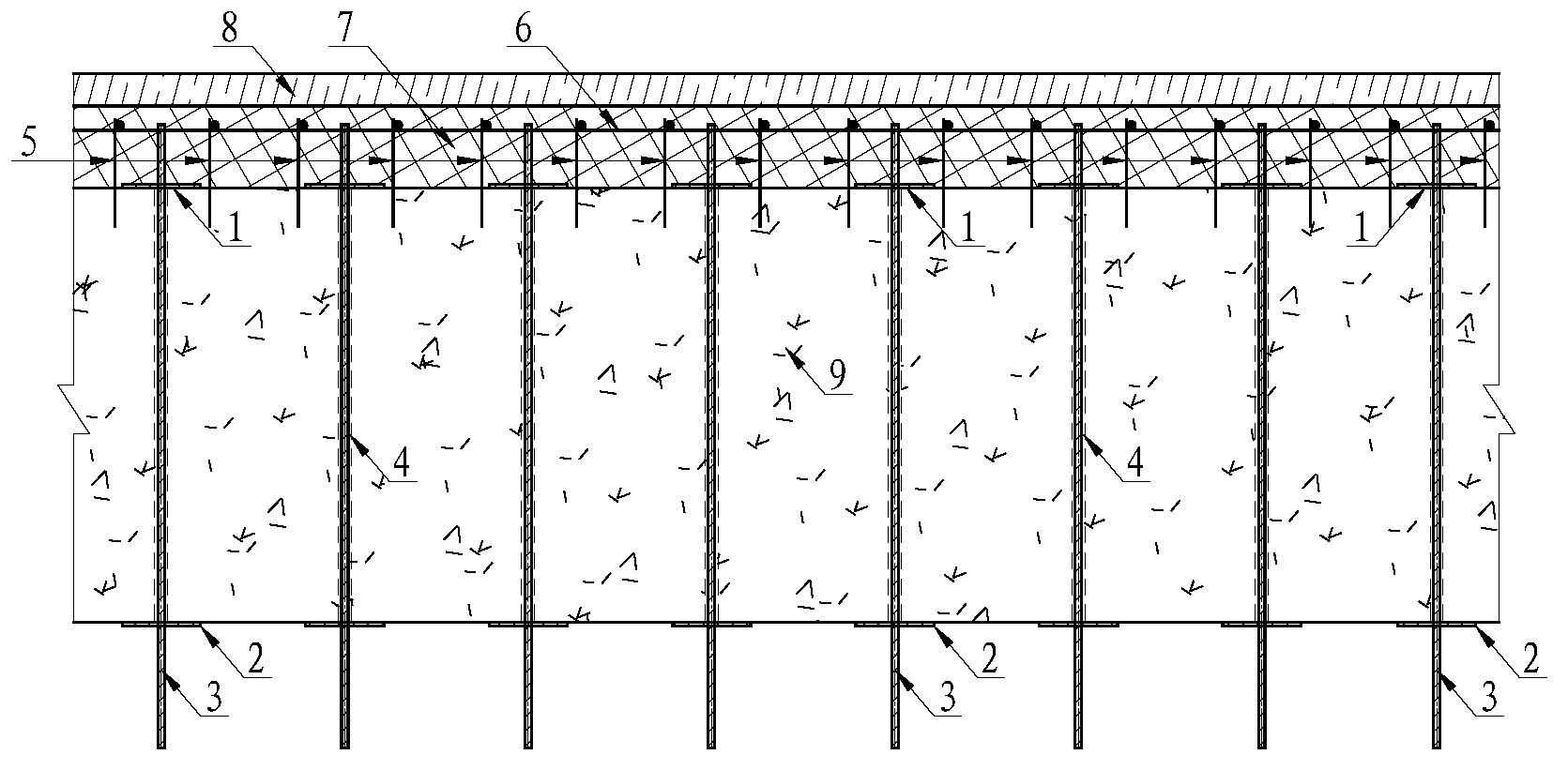

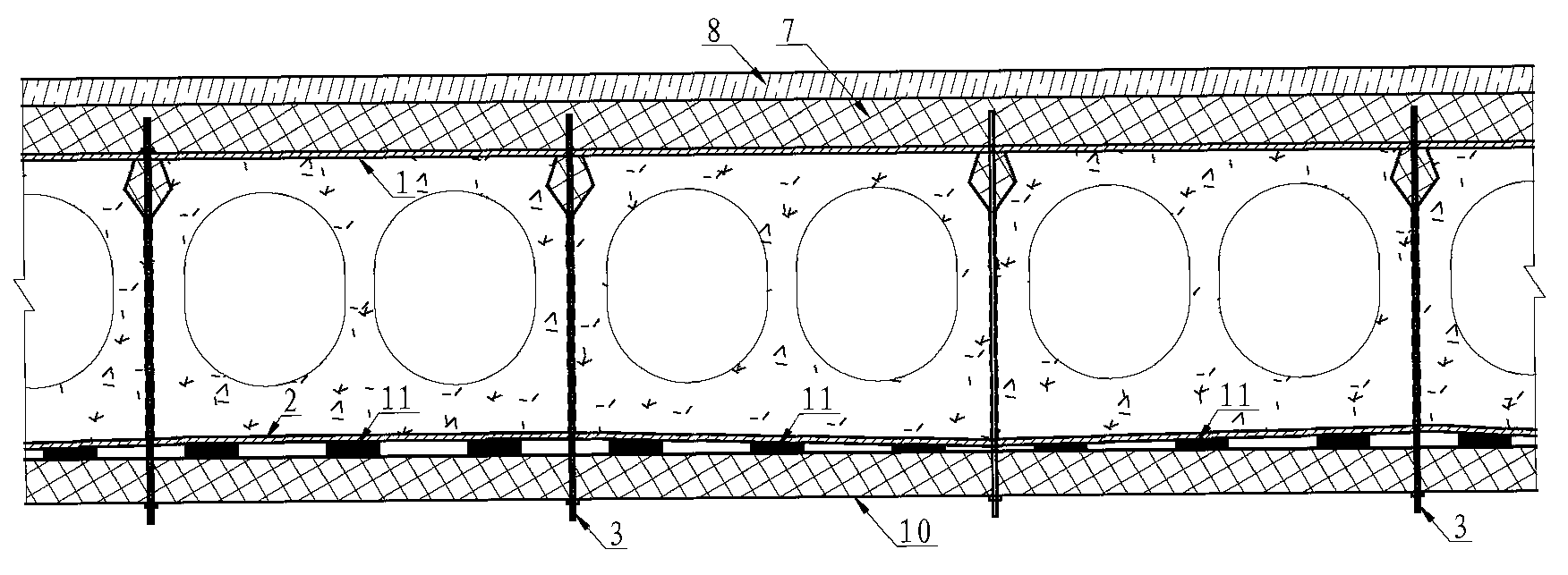

Single plate force-bearing reinforcing method of hollow slab bridge

InactiveCN103061271AAvoid destructionImprove reliabilityBridge erection/assemblyBridge strengtheningWhole bodyBridge deck

The invention relates to a single plate force-bearing reinforcing method of a hollow slab bridge. The single plate force-bearing reinforcing method includes that the original bridge deck pavement is shoveled, hinge joint concrete is removed, defects and cracks of the original hollow slab bridge beam body are processed, strip-shaped steel plates are transversely pasted on the upper surface and the lower surface of the hollow slab bridge in the longitudinal bridge direction at certain intervals, split screws penetrate through drilled holes at the hinge joint position, a counter-force frame is arranged, a wedge-shaped block is embedded between the counter-force frame and the steel plates, and the steel plates are pressurized and pasted in sealing mode and then are positioned and fixed; the counter-force frame is demounted after sticky steel glue is cured; cavities in beam joints are subjected to pressure grouting, shear reinforcements are placed into the top surface of a hollow slab, a reinforcement mesh is reconstructed, and the bridge deck reinforcement mesh and the implanted reinforcements are connected in binding or point welding mode to form a whole body; steel fiber reinforced concrete is poured and waterproof coatings are sprayed; and bituminous concrete is paved. The single plate force-bearing reinforcing method improves transverse load distribution, steel plate pasting reliability and bridge integral force-bearing performance on the premise of preventing hollow slab beam body damage, not changing a structural force-bearing system and not interrupting the traffic.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

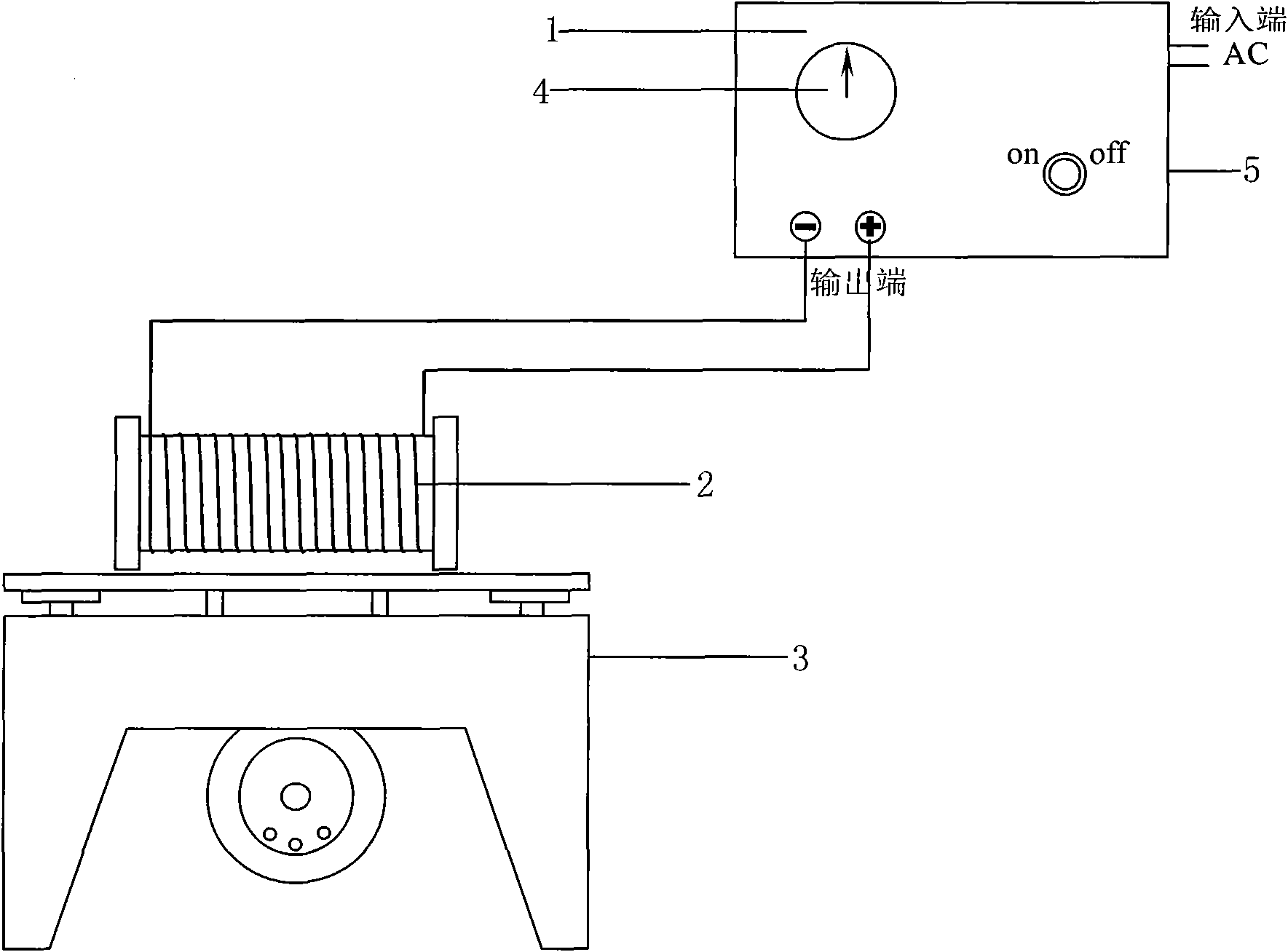

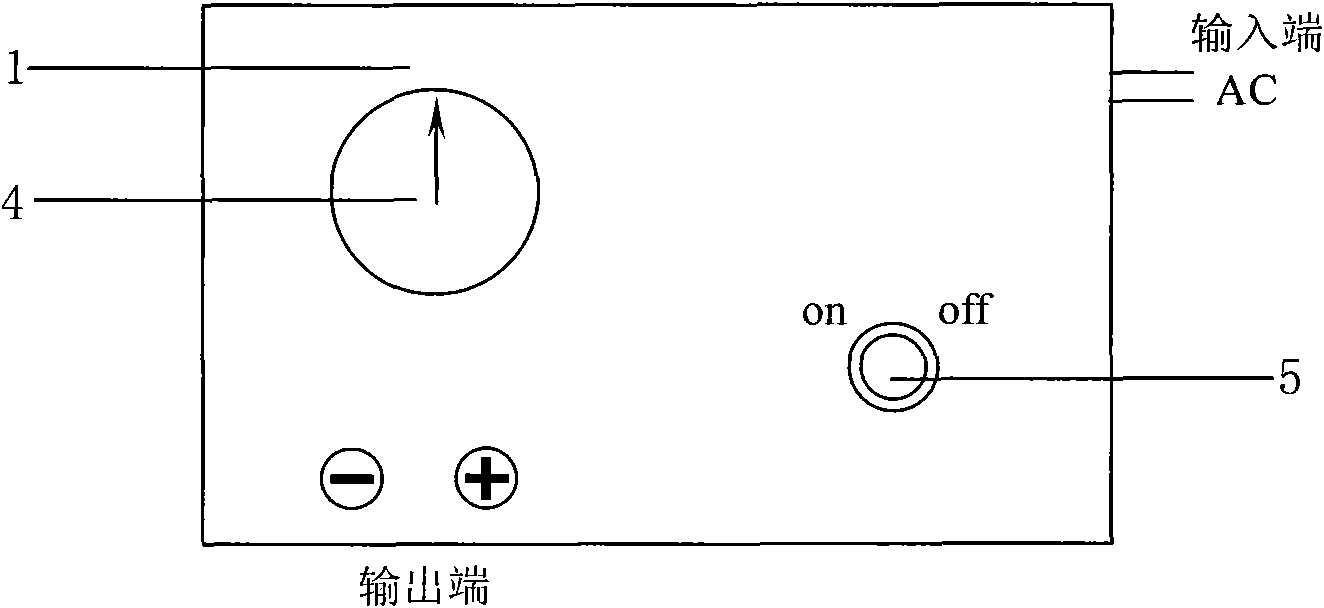

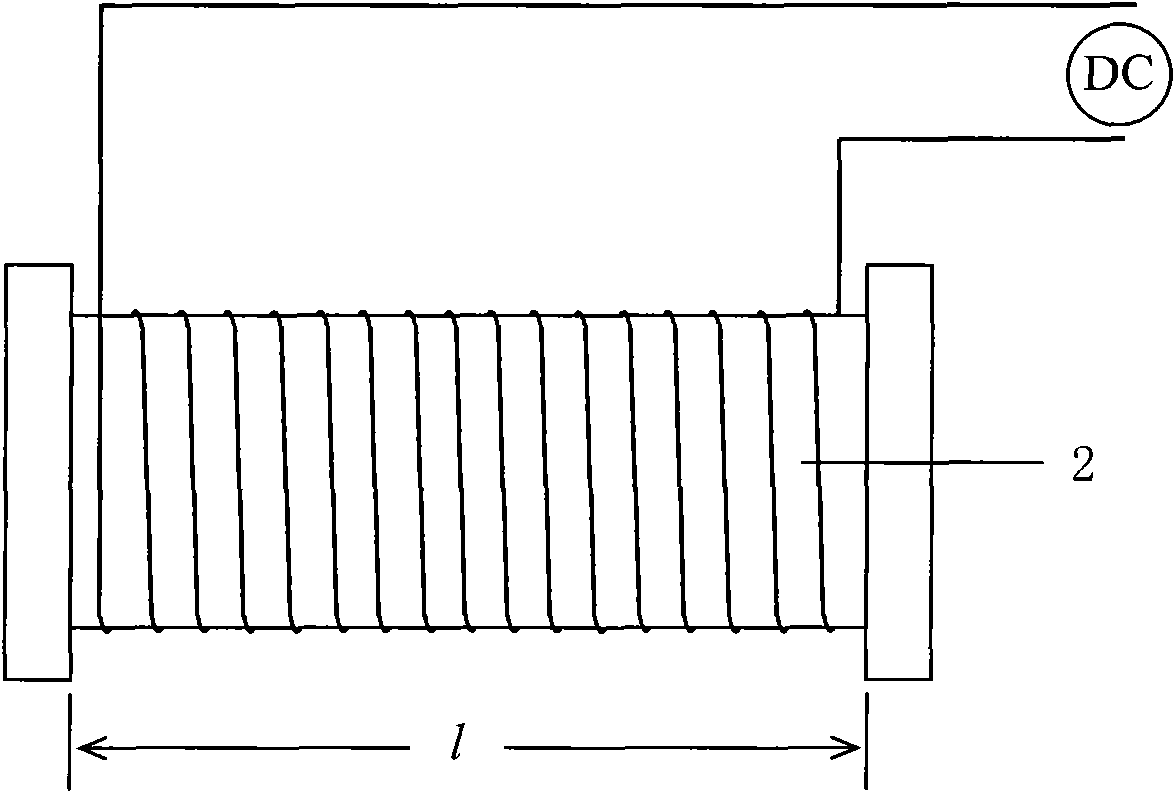

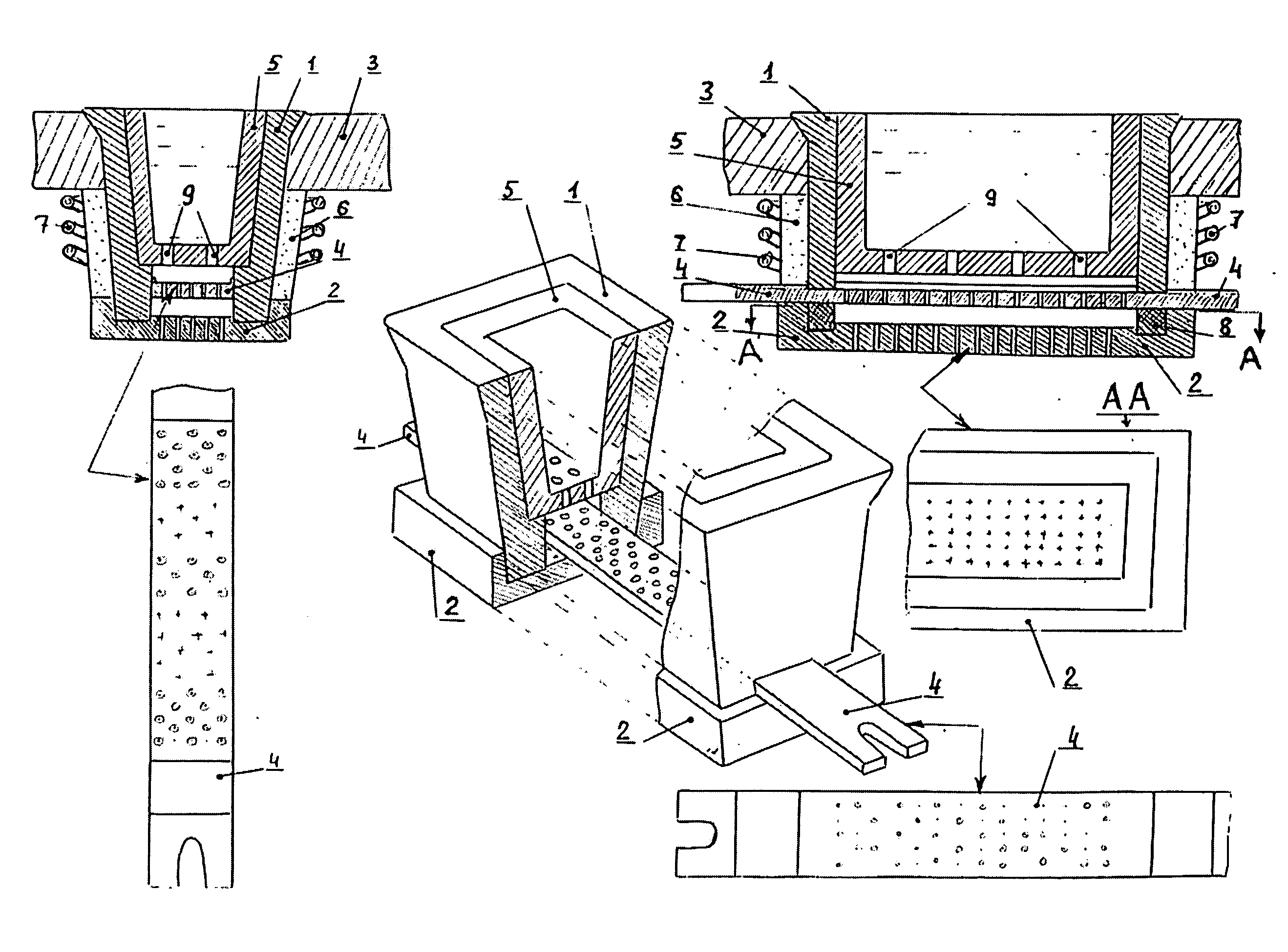

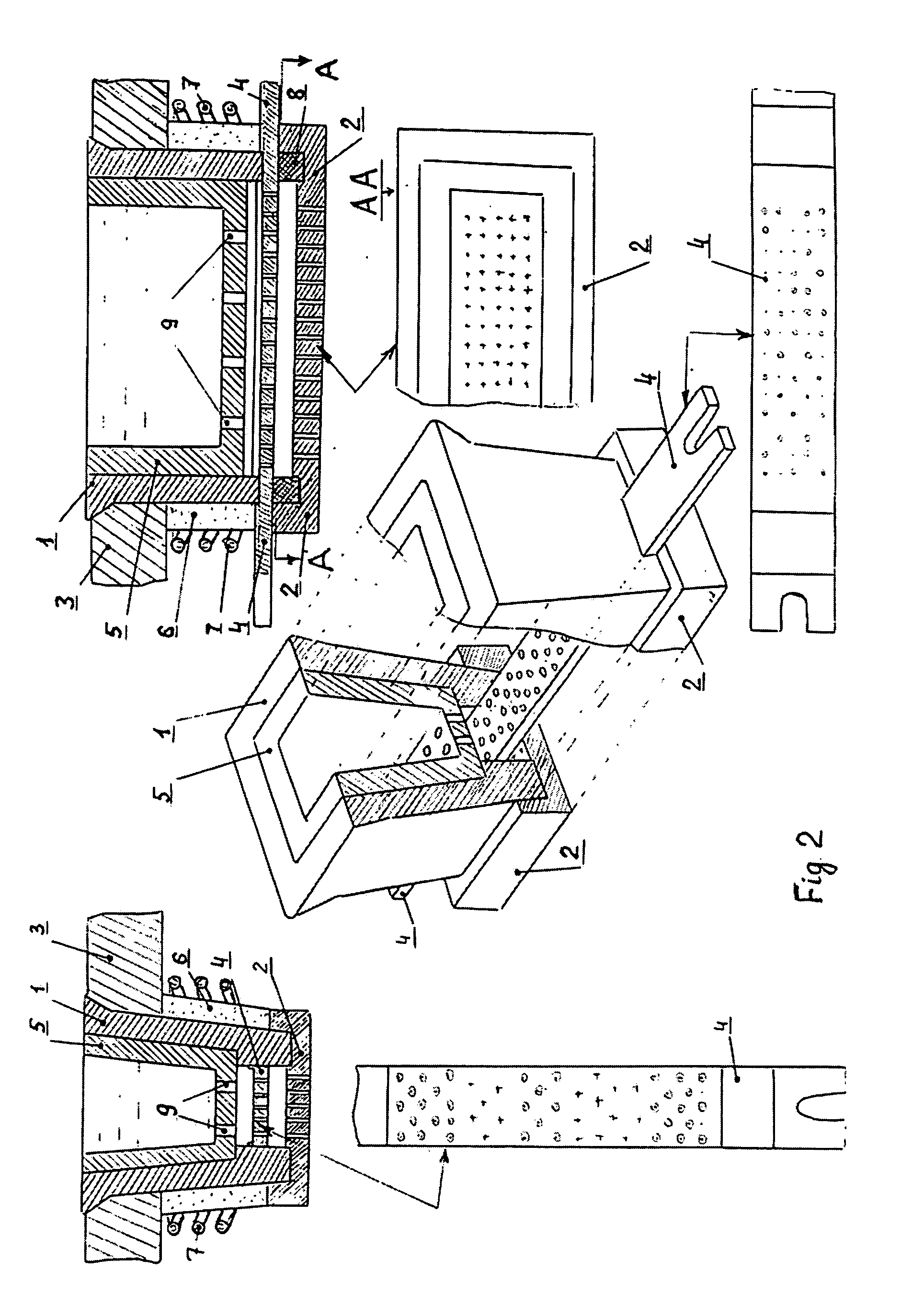

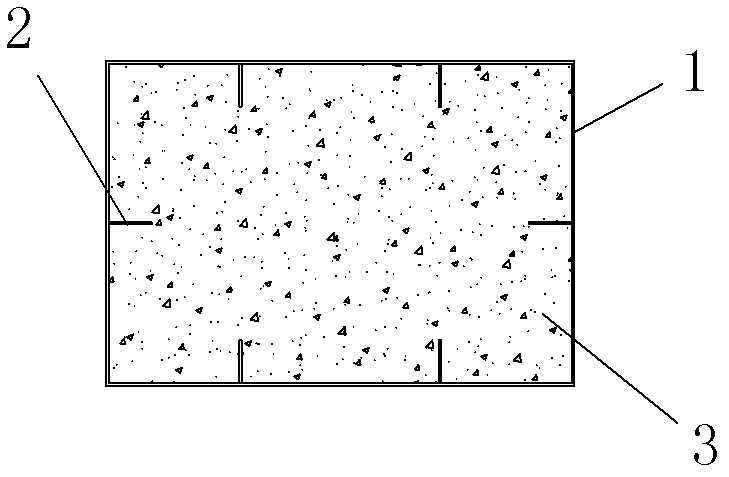

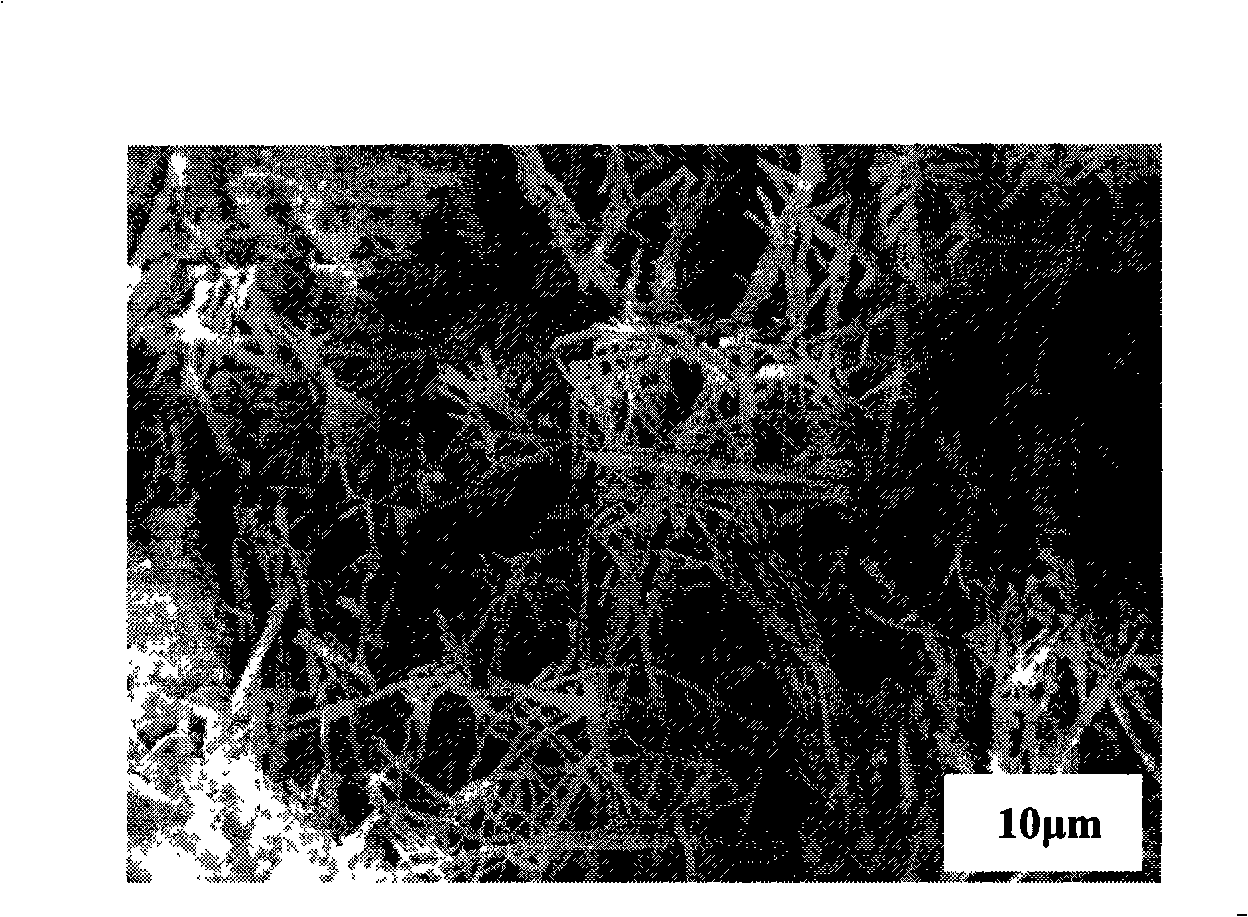

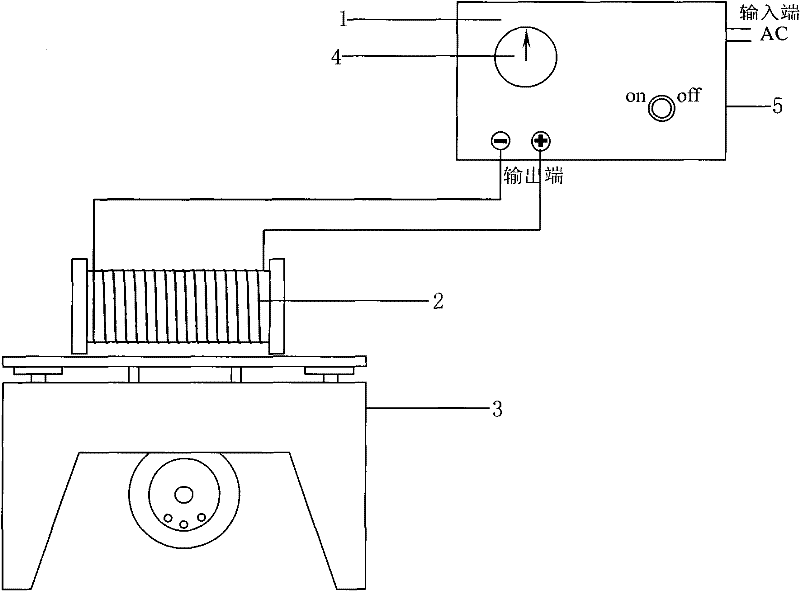

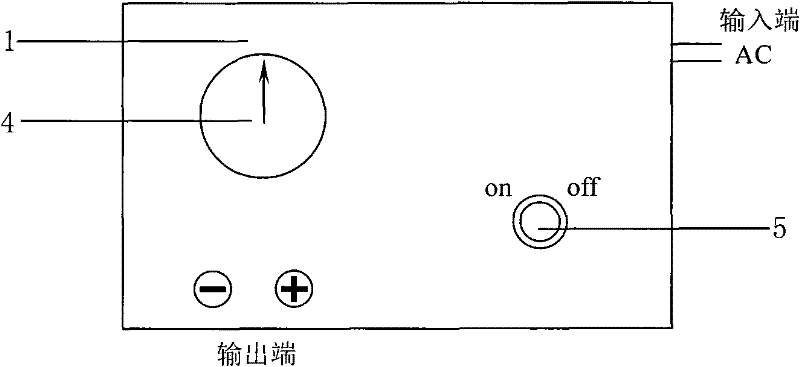

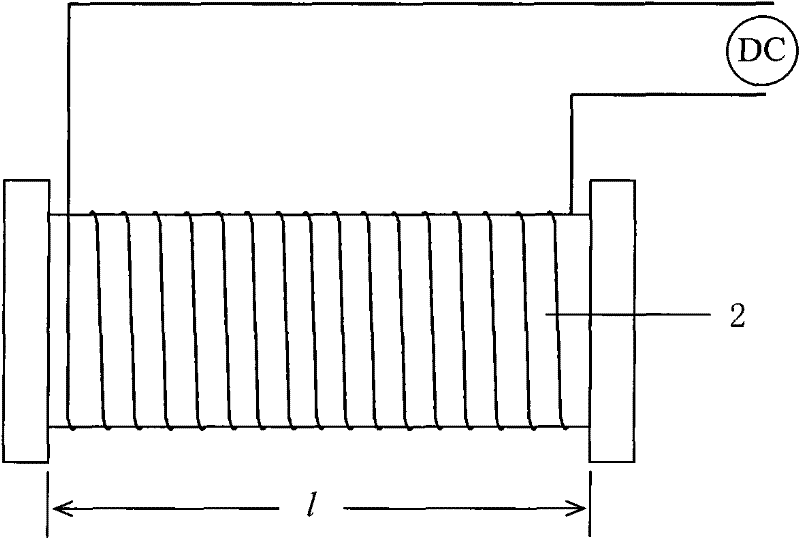

Method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete

ActiveCN101913188AHighlight substantiveReduce dosageCeramic shaping apparatusBreaking strengthUltimate tensile strength

The invention discloses a method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete and relates to fiber reinforced concrete. The method comprises the following key steps of: pouring a prepared steel fiber concrete mixture into a nonmetallic test mold and putting the test mold into a cavity in a framework of a coil of the special equipment for preparing the unidirectionally-distributed steel fiber reinforced concrete; putting the coil and the test mold on a vibrating table of the special equipment; switching on a direct current power supply of the special equipment to electrify the coil so as to form a magnetic field; applying the magnetic field to the prepared steel fiber concrete mixture so as to orient steel fiber; and keeping the direction of the magnetic field accordant with that of pulling stress during test piece testing or in a working state, wherein the special equipment consists of the vibrating table, the coil and the direct current power supply. Compared with steel fiber reinforced concrete prepared by the conventional method, the unidirectionally-distributed steel fiber reinforced concrete prepared by the method and the special equipment of the invention has breaking strength increased by 25 to 100 percent or saves the steel fiber by 25 to 60 percent.

Owner:HEBEI UNIV OF TECH

Reinforced concrete containing antimicrobial-enhanced fibers

InactiveUS6162845AReduce sensitivityReduce odorBiocideAntifouling/underwater paintsShrinkage crackingFlexural strength

A fiber-reinforced concrete-like material product includes a plurality of fibers containing an effective amount of at least one antimicrobial agent to inhibit organisms and protect the concrete from biological attack. Preferably, the antimicrobial agents are added to the fibers prior to the fibers being dispersed in the concrete. Such a concrete product containing antimicrobial-enhanced fibers simultaneously inhibits organisms from biological attack, reduces plastic shrinkage cracking of the concrete and improve post-peak flexural strength of the concrete.

Owner:PROPEX OPERATING

Apparatus integrated with ceramic bushing for manufacturing mineral/basalt fibers

ActiveUS20060218972A1Low costImprove stabilityGlass furnace apparatusRotary drum furnacesComposite applicationMicrometer

The apparatus integrated with ceramic bushing / s for manufacturing mineral / basalt fibers from natural basalt rocks is disclosed. The apparatus and the ceramic bushing / s are integrated into one unit capable provide all operations which are needed: melt basalt rock materials, homogenize basalt glass body suitable for forming fibers to be drawn / attenuated into continuous fibers and gathered into a strand of elemental fibers from 7 to 20 micrometers (μm) in diameter. Also the coarse fibers at the diameters from 20 μm to 100 micrometers (μm) having amorphous structural state which exhibit ductile / flexible properties. The ceramic bushing / s are designed to eliminate precious Pt, Rd metals using instead corrosion resistant ceramic materials to reduce basalt fiber products cost and to increase its commercial compatibility when compared to the other fibers currently been on the market in reinforced concrete / composite applications, including Three Dimension Fiber Reinforced Concrete-3D FRC.

Owner:BLACKBULL IND INC +1

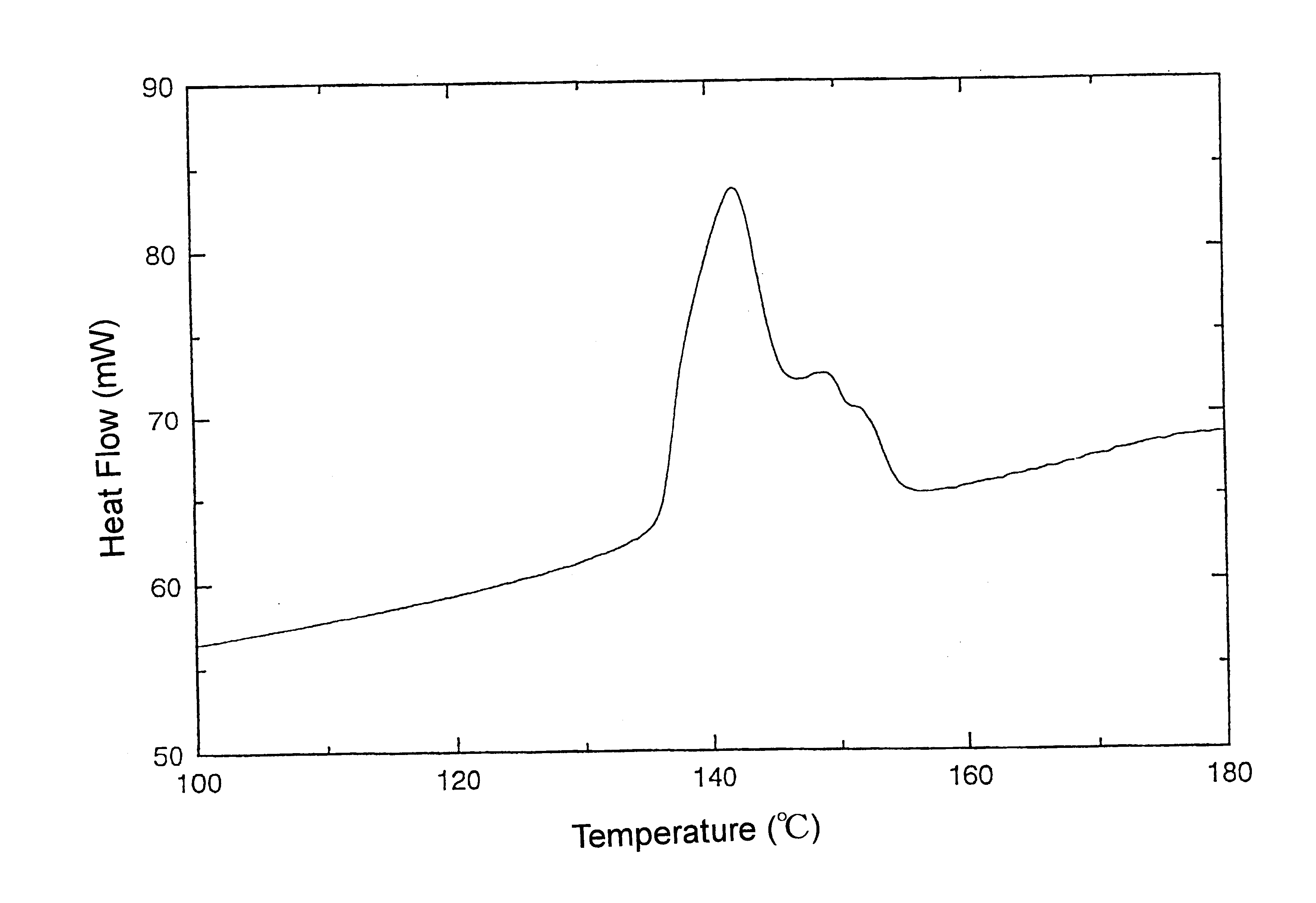

High strength polyethylene fibers and their applications

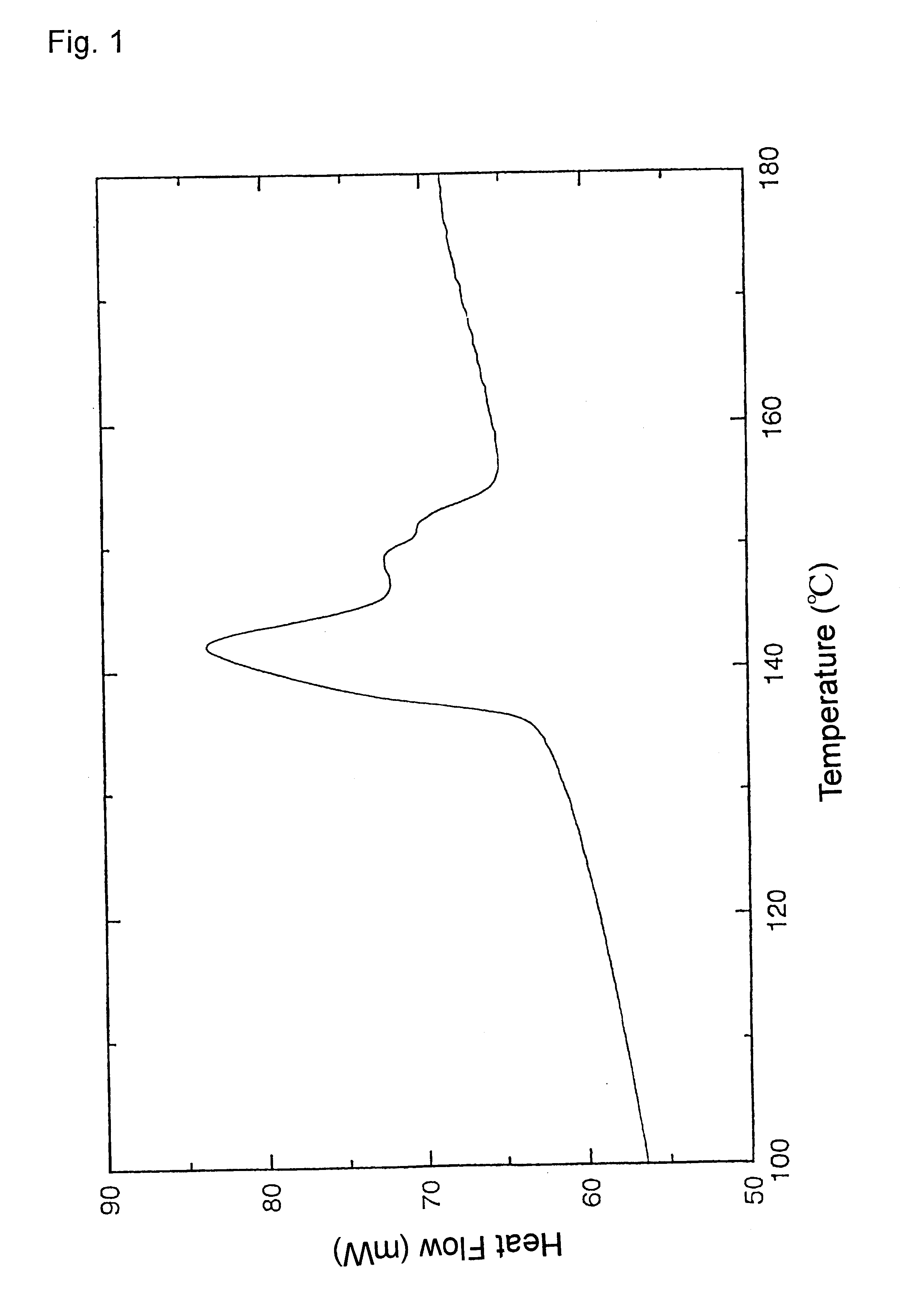

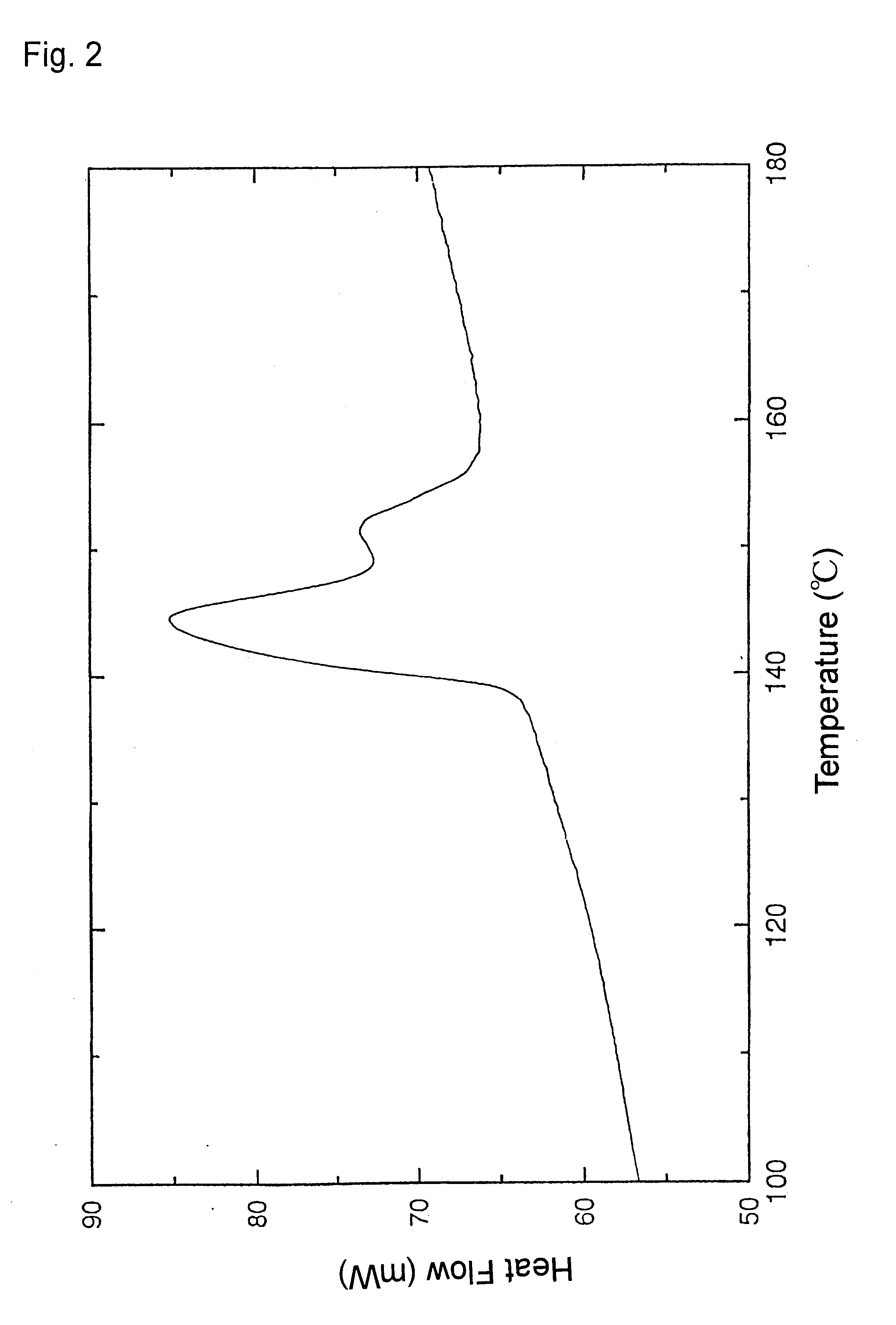

High strength polyethylene fibers and their applications, for example, chopped fibers, ropes, nets, ballistic materials or items, protective gloves, fiber reinforced concrete products, helmets, and other products obtained therefrom, in which the fiber is characterized in that: it contains a high molecular weight polyethylene consisting essentially of a repeating unit of ethylene; it has an intrinsic viscosity number of 5 or larger and an average strength of 22 cN / dtex or higher; and the measurement of the fiber by differential scanning calorimetry (DSC) exhibits a temperature-increasing DCS curve having at least one endothermic peak over a temperature region of 140° C. to 148° C. (on the low temperature side) and at least one endothermic peak over a temperature region of 148° C. or higher (on the high temperature side) or the number of frictions until the fiber is broken in an abrasion test according to method B for measuring abrasion resistance in the Testing Methods for Spun Yarn (JIS L 1095) is 100,000 or larger.

Owner:TOYOBO CO LTD

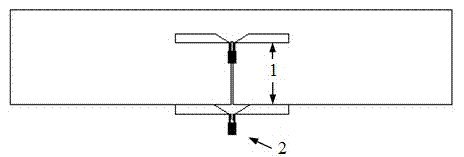

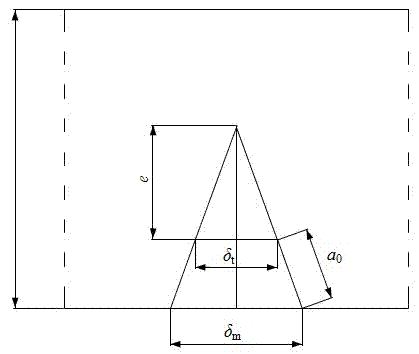

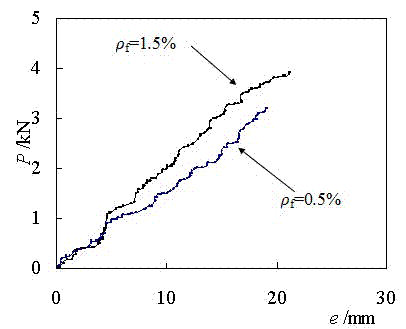

Testing method of steel fiber reinforced concrete fracture test crack initiation load

ActiveCN103760036AReduce test costsLower requirementMaterial strength using steady bending forcesStress intensity factorClassical mechanics

The invention relates to a testing method of steel fiber reinforced concrete fracture test crack initiation load, and belongs to the technical field of concrete cracking parameter testing. The testing method provided by the invention is characterized in that when a steel fiber reinforced concrete coped beam specimen cracks, a stress intensity factor of a prefabrication crack front edge achieves concrete fracture toughness, and the steel fibre blocking action is not exerted; the stress intensity factor generated by external load and concrete cracking toughness(i)K( / i) IC are equal, the external load value which is corresponding to a numerical value (i)K( / i)IC of the stress intensity factor generated by the external load can be used for determining the crack initiation load according to the curve relation graph of the external load and the stress intensity factor (i)K generated by the external load (img file='2014100081259100004dest_path_image002.TIF'wi='8'he='21' / )( / i)-(i)P( / i) curve relational graph. The testing method provided by the invenytion has the advantages that the required equipment, analyzing and processing method are simple, the cost is low, and the precision is high.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

Polypropylene coarse fiber for concrete and method for preparing same

Owner:JIANGSU SOBUTE NEW MATERIALS

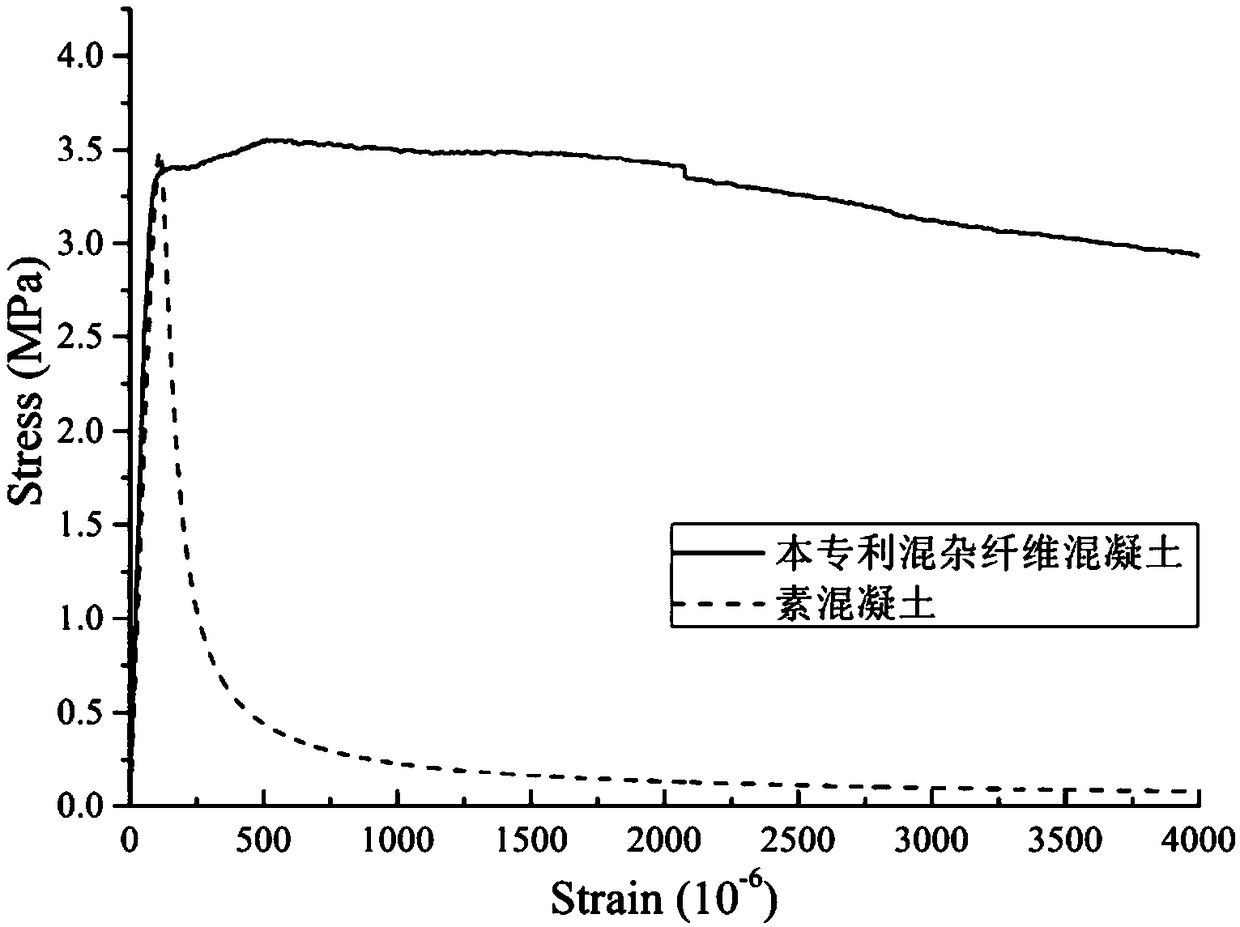

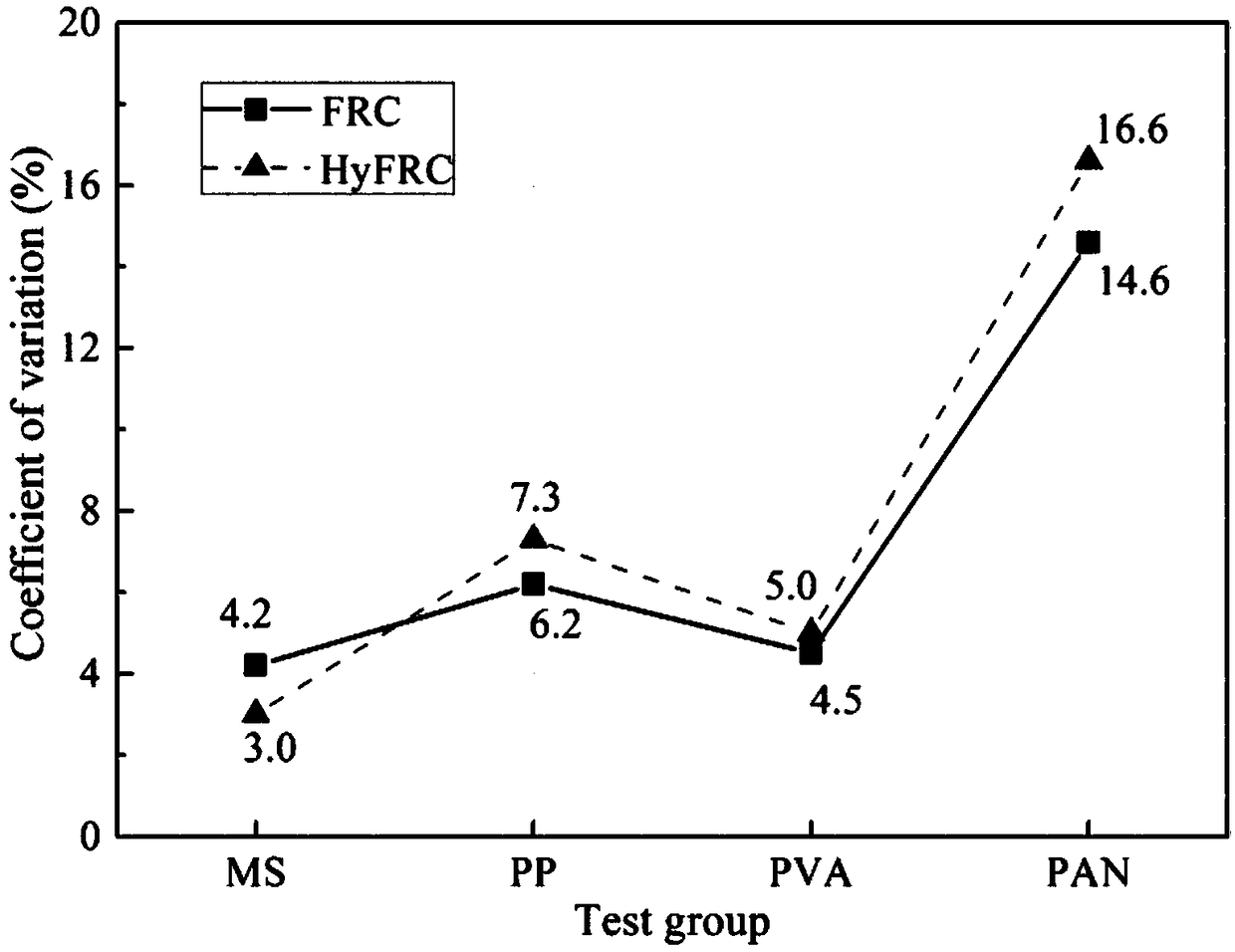

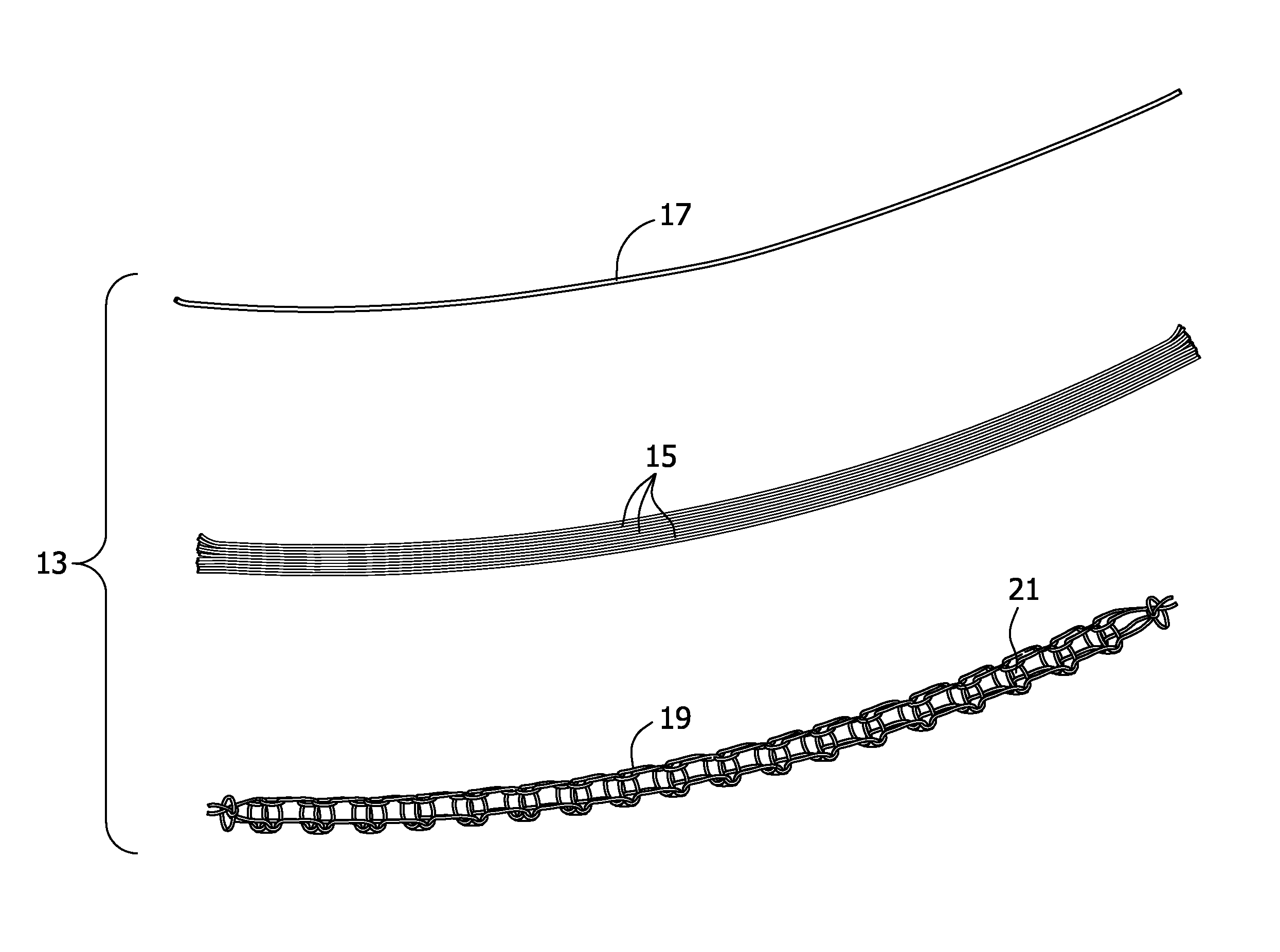

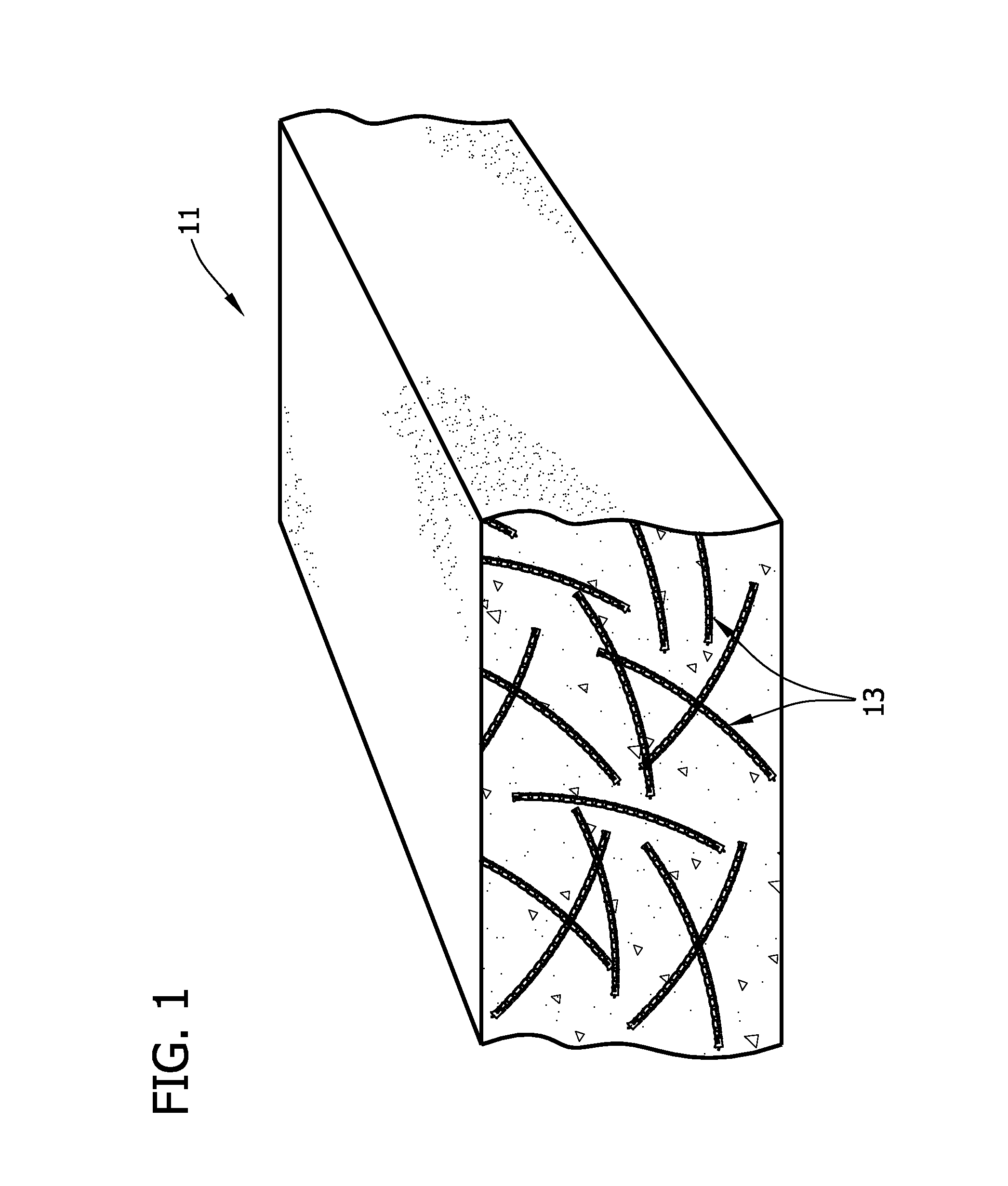

High performance concrete reinforced by assorted fiber

The present invention relates to a high-performance mixed fibre reinforced concrete, its composition includes (by volume %) high elastic modulas fibre 1%-5%, low elastic modulus fibre 0.2%-3% and the rest general concrete, the described high elastic modulus fibre is one of steel fibre, carbon fibre and glass fibre, and the described low elastic modulus fibre is one of vinylon fibre, polypropylene fibre, acrylic fibre, nylon fibre and polyethylene fibre. Said invention can be used for making manhole cover which not only has higher strength, but also has higher impact resistance.

Owner:SHANGHAI JIAO TONG UNIV

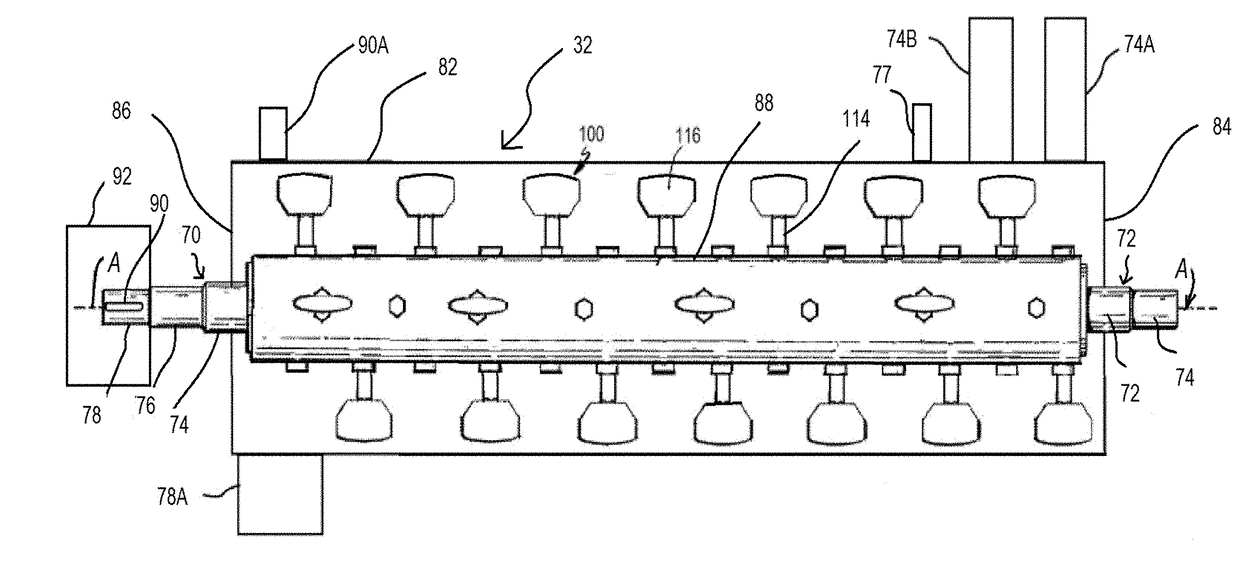

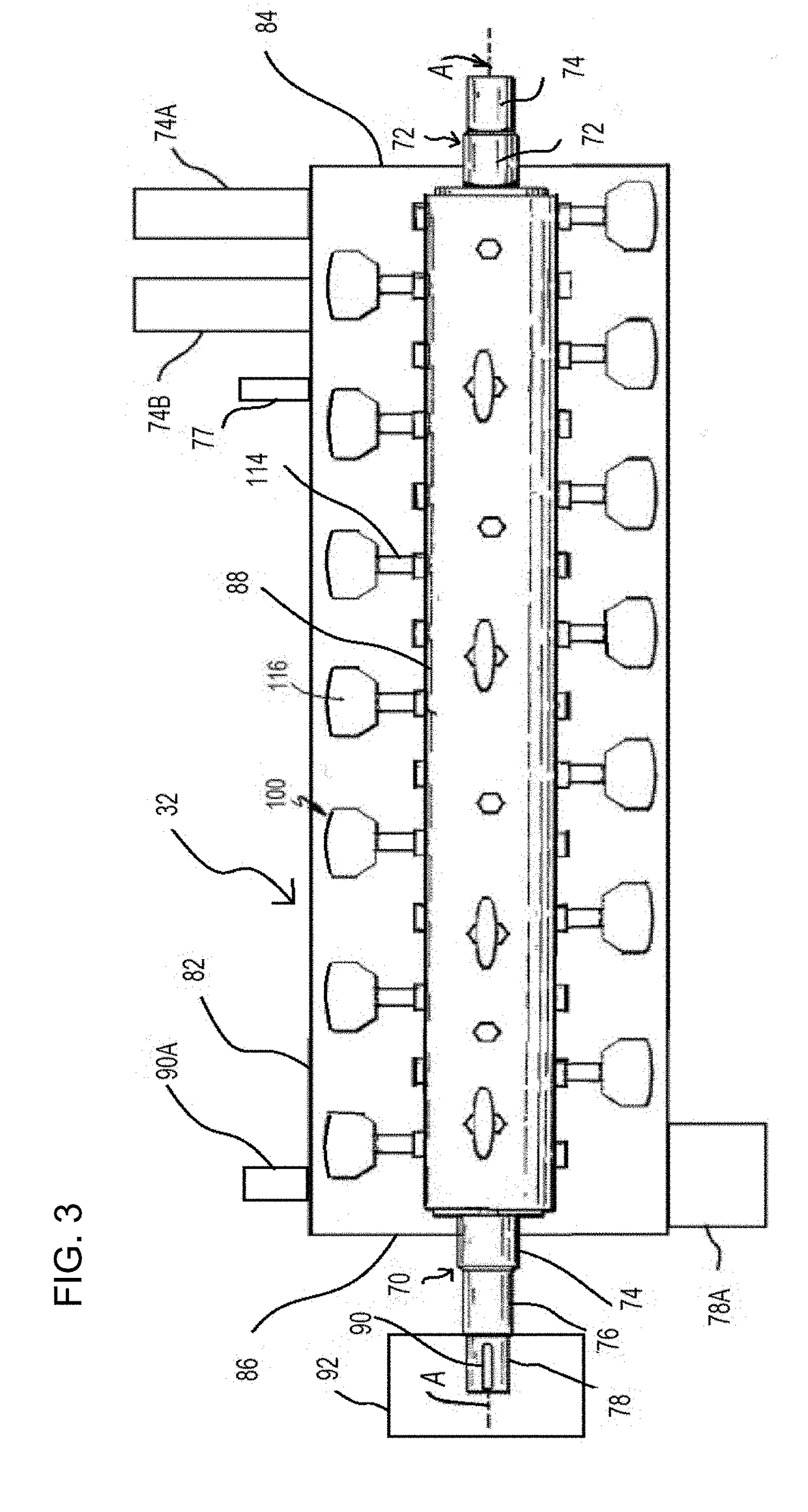

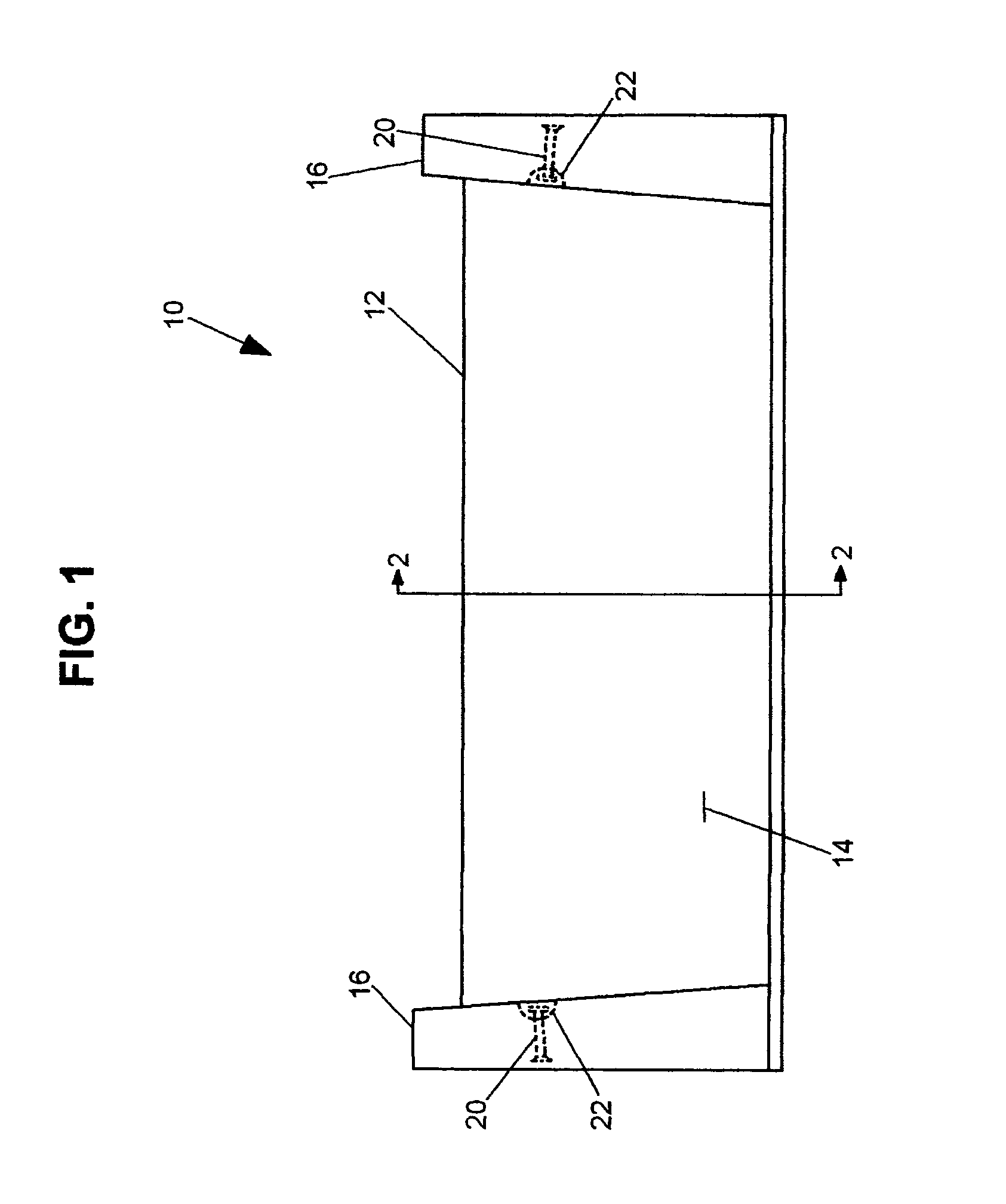

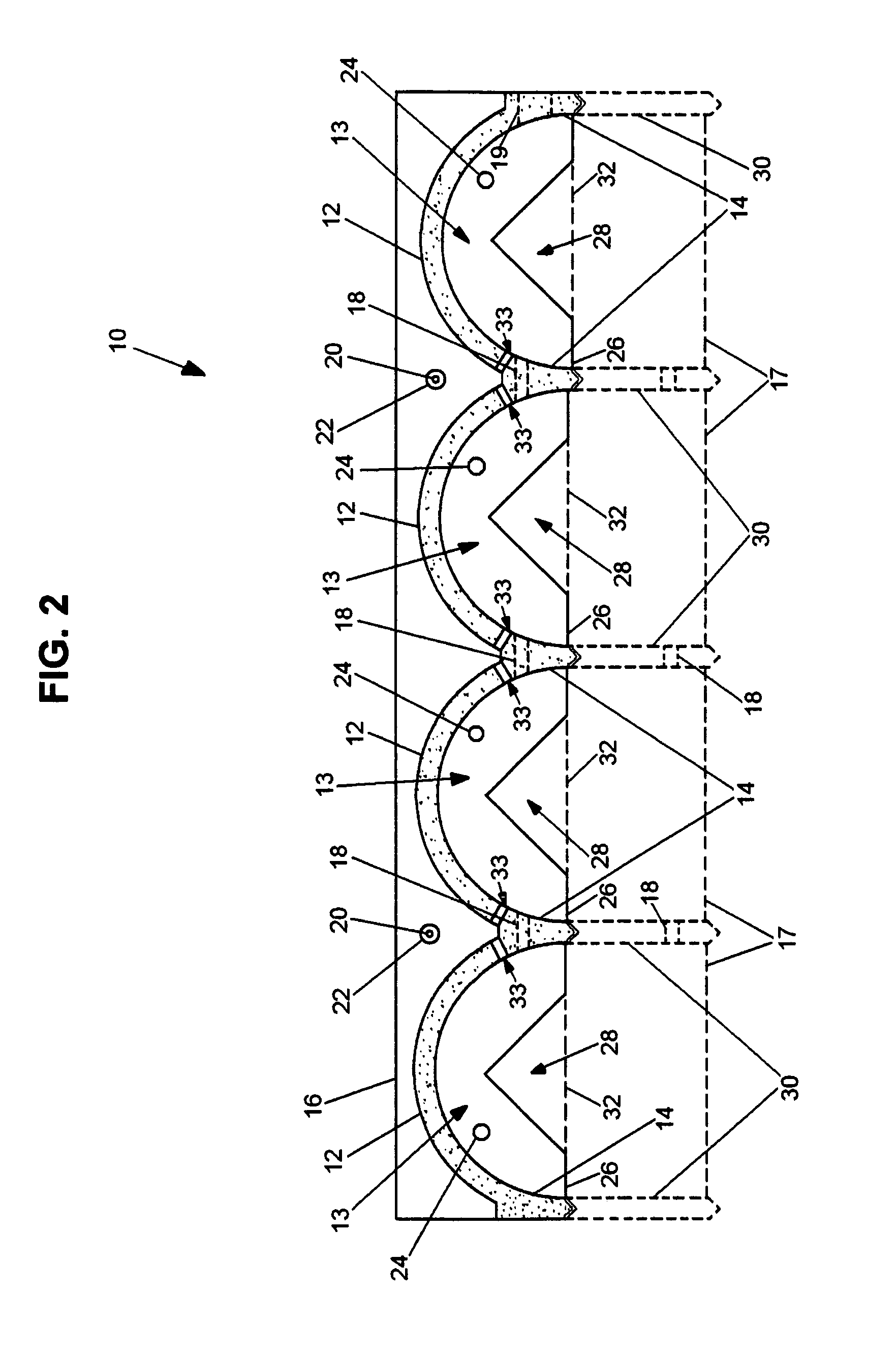

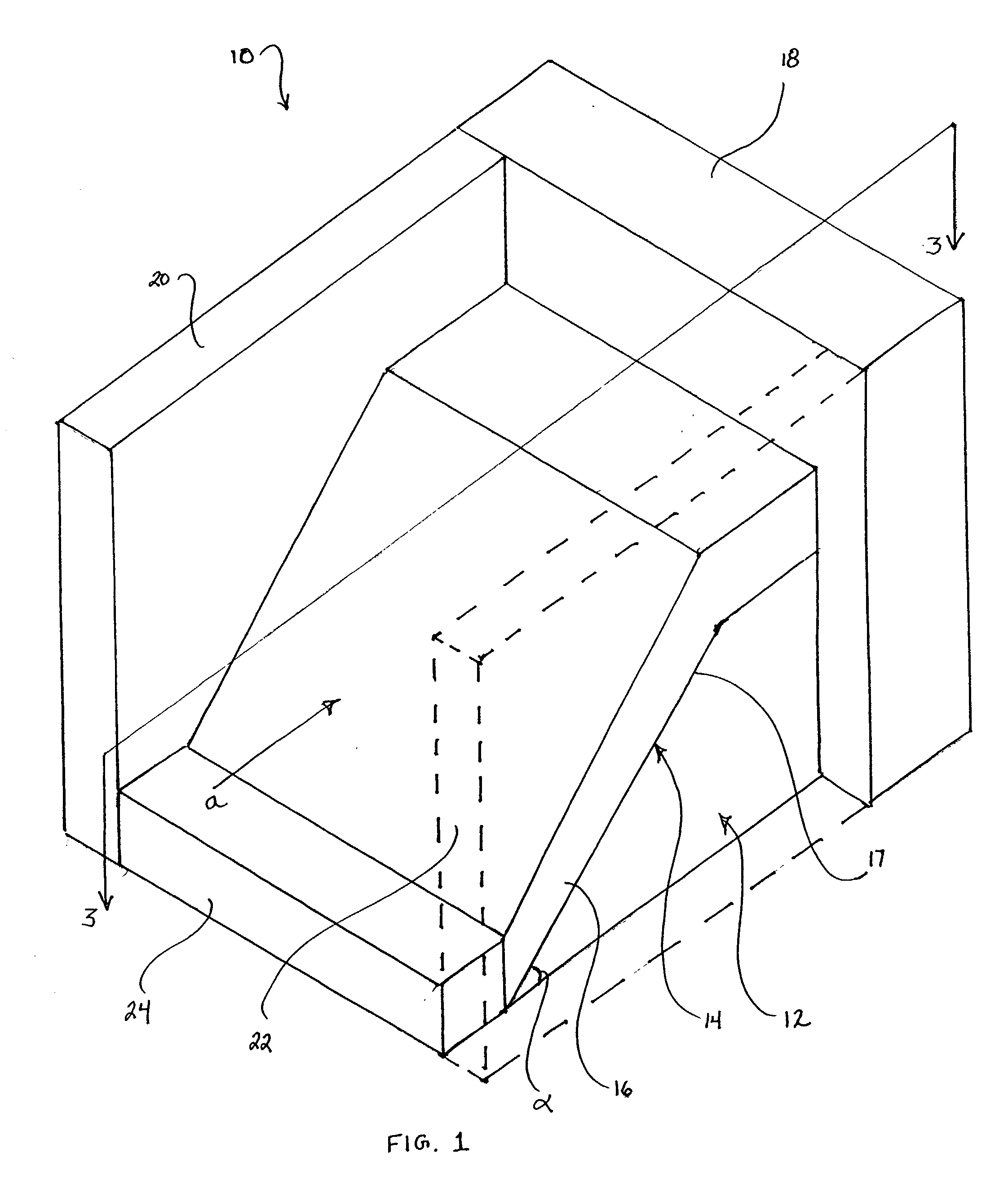

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

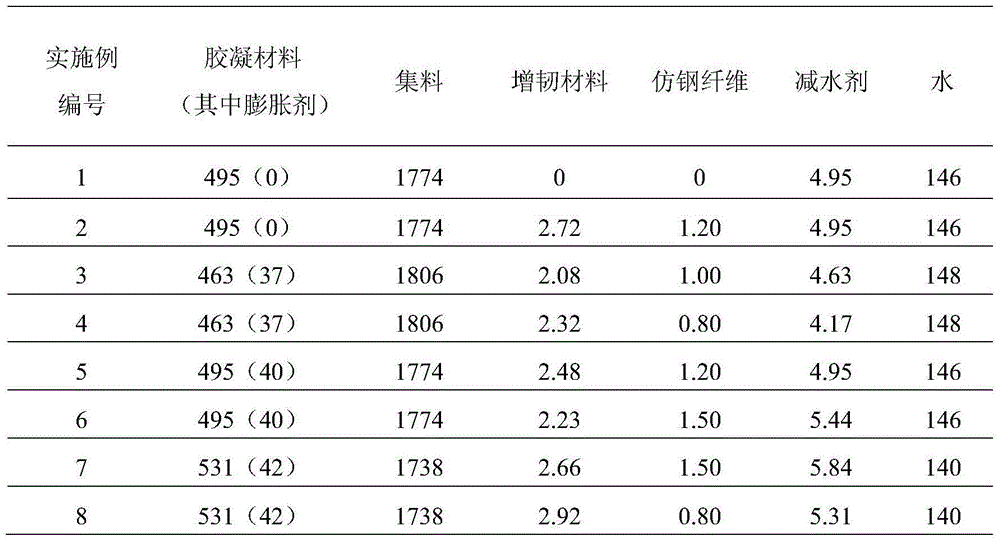

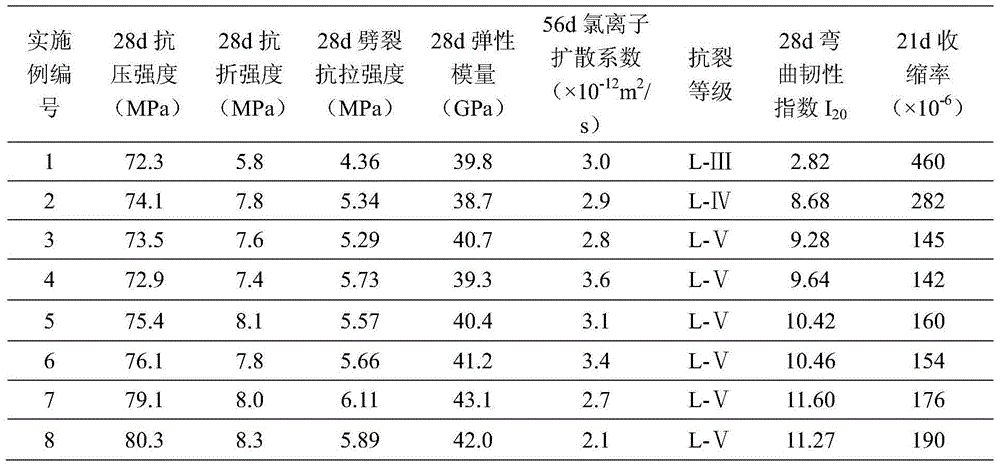

Micro-expansion fiber reinforced concrete and preparation method thereof

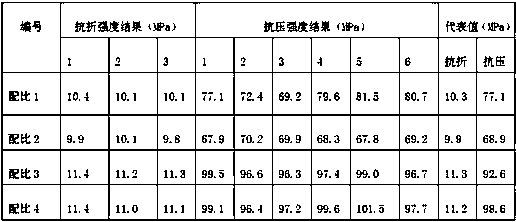

The invention discloses micro-expansion fiber reinforced concrete for a steel-concrete combined beam bridge panel wet joint and a preparation method of the micro-expansion fiber reinforced concrete, and relates to the preparation field of the micro-expansion fiber reinforced concrete. The micro-expansion fiber reinforced concrete comprises gel materials (cement, coal ash, slag powder and an expanding agent), aggregate, reinforcing materials, imitated steel fibers, a water reducer and water, wherein the 28 compressive strength of the micro-expansion fiber reinforced concrete is not lower than 69.0MPa, the 28d breaking strength of the micro-expansion fiber reinforced concrete is not lower than 7.0 MPa, the 28d splitting tensile strength of the micro-expansion fiber reinforced concrete is not lower than 5.0 MPa, the 28d elasticity modulus of the micro-expansion fiber reinforced concrete is not lower than 36.0 GPa, the cracking resistance level of the micro-expansion fiber reinforced concrete reaches L-IV level, the 28d bending toughness index I20 of the micro-expansion fiber reinforced concrete is not lower than 8, the 56d chlorine ion diffusion coefficient of the micro-expansion fiber reinforced concrete is lower than 4.0*10<-12>m<2> / s, the 21d shrinkage percentage of the micro-expansion fiber reinforced concrete is lower than 200*10<-6>. By using the preparation method, the shrinkage cracking of the micro-expansion fiber reinforced concrete can be effectively avoided, so that the reinforced concrete is relatively compact. The micro-expansion fiber reinforced concrete disclosed by the invention is relatively high in strength, relatively low in shrinkage percentage, good in bending toughness and durability, relatively low in cost and conveniently to widely use.

Owner:THE 2ND ENG CO LTD MBEC +1

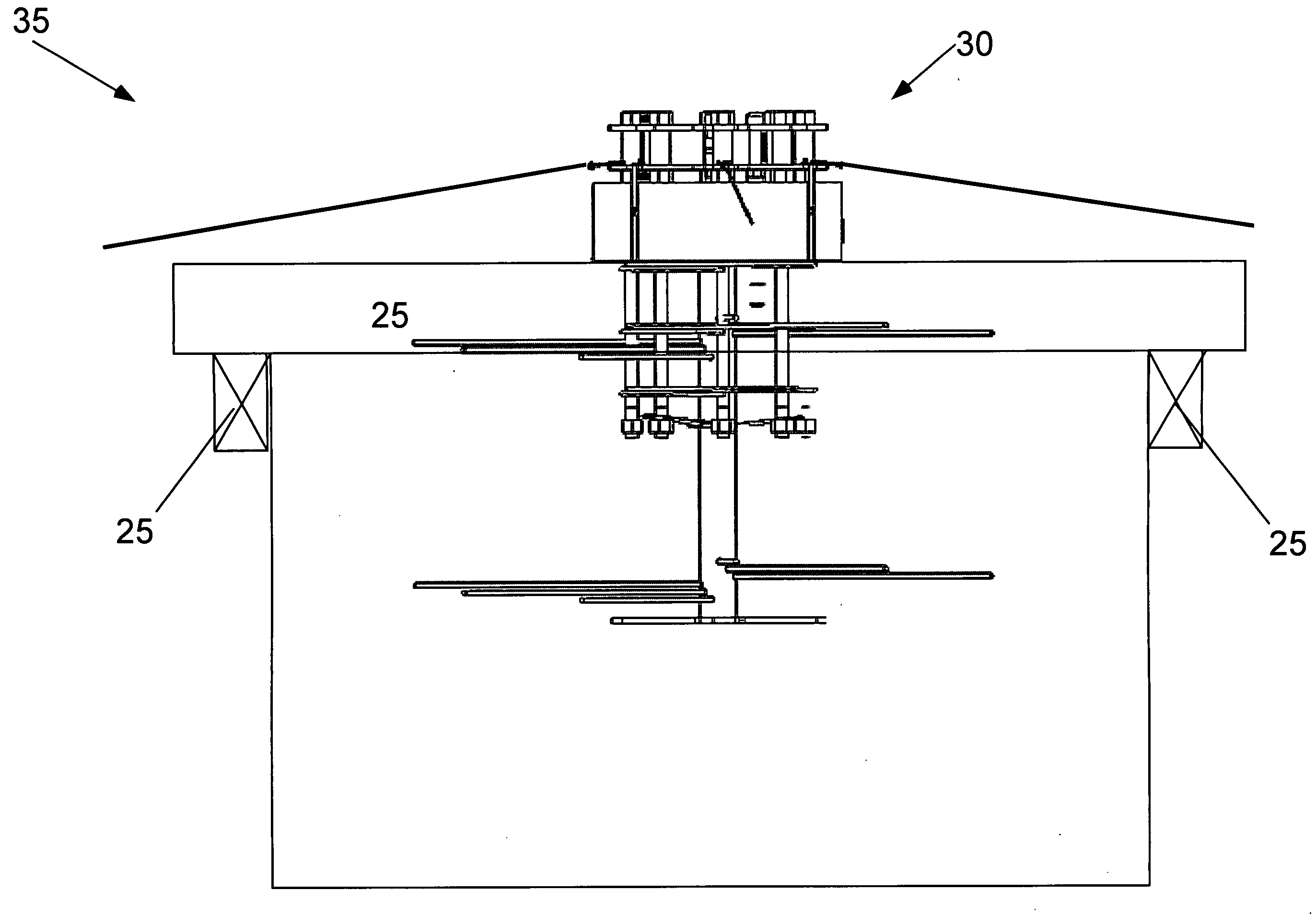

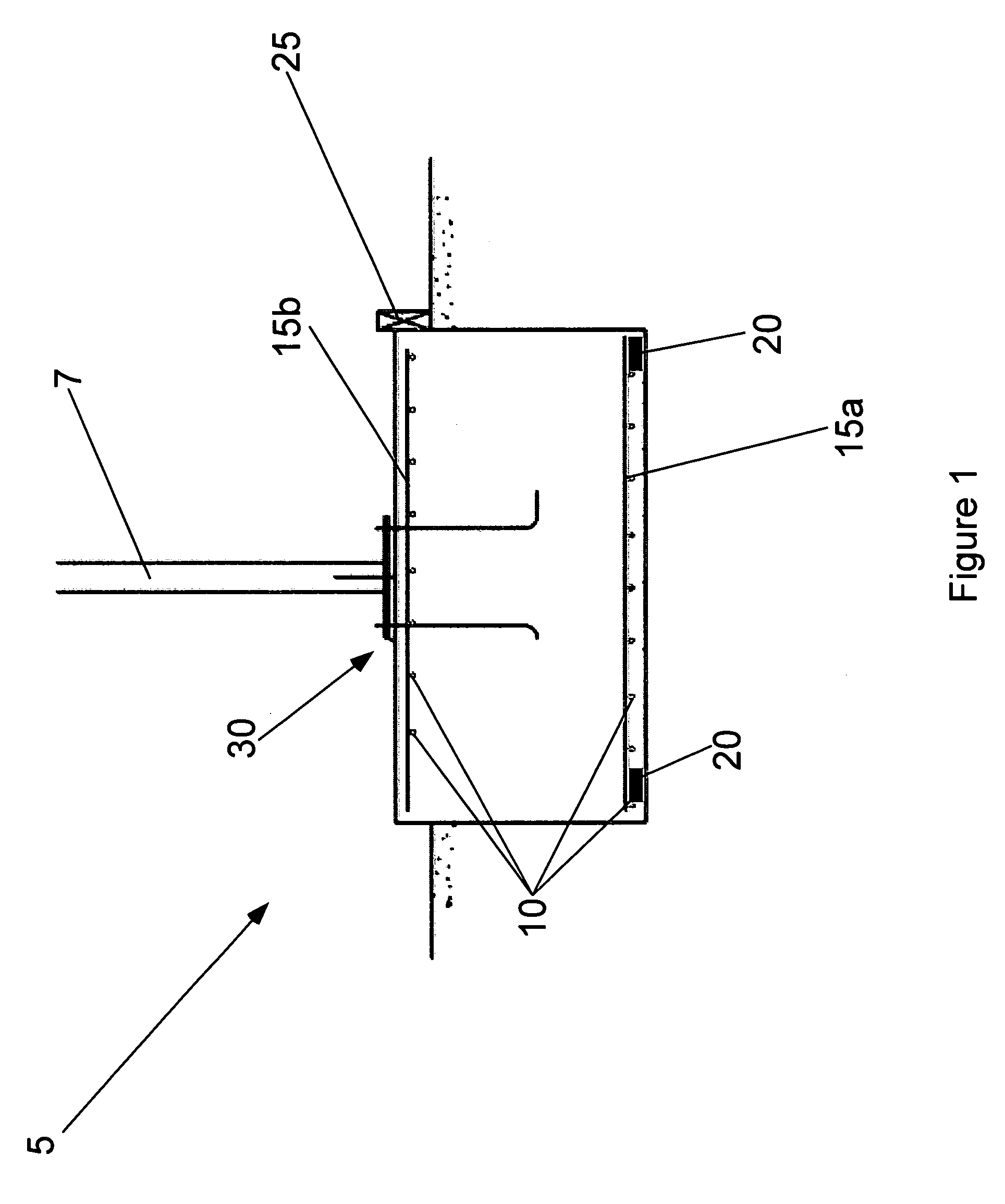

Foundation for monopole wind turbine tower

ActiveUS20080190058A1Reduce material costsReduction of construction laborWind motor supports/mountsFoundation engineeringEngineeringRebar

An innovation is disclosed which relates to a wind turbine foundation. A circular foundation using fiber reinforced concrete has optional circular reinforcement rods. The foundation includes a vertical stanchion that rests in the bottom of an excavated hole and supports anchor bolts and reinforcement bars in a predetermined configuration while concrete is poured into the hole. All the necessary foundation materials can be combined in a simple and compact kit which can be shipped to a customer.

Owner:ANEMERGONICS

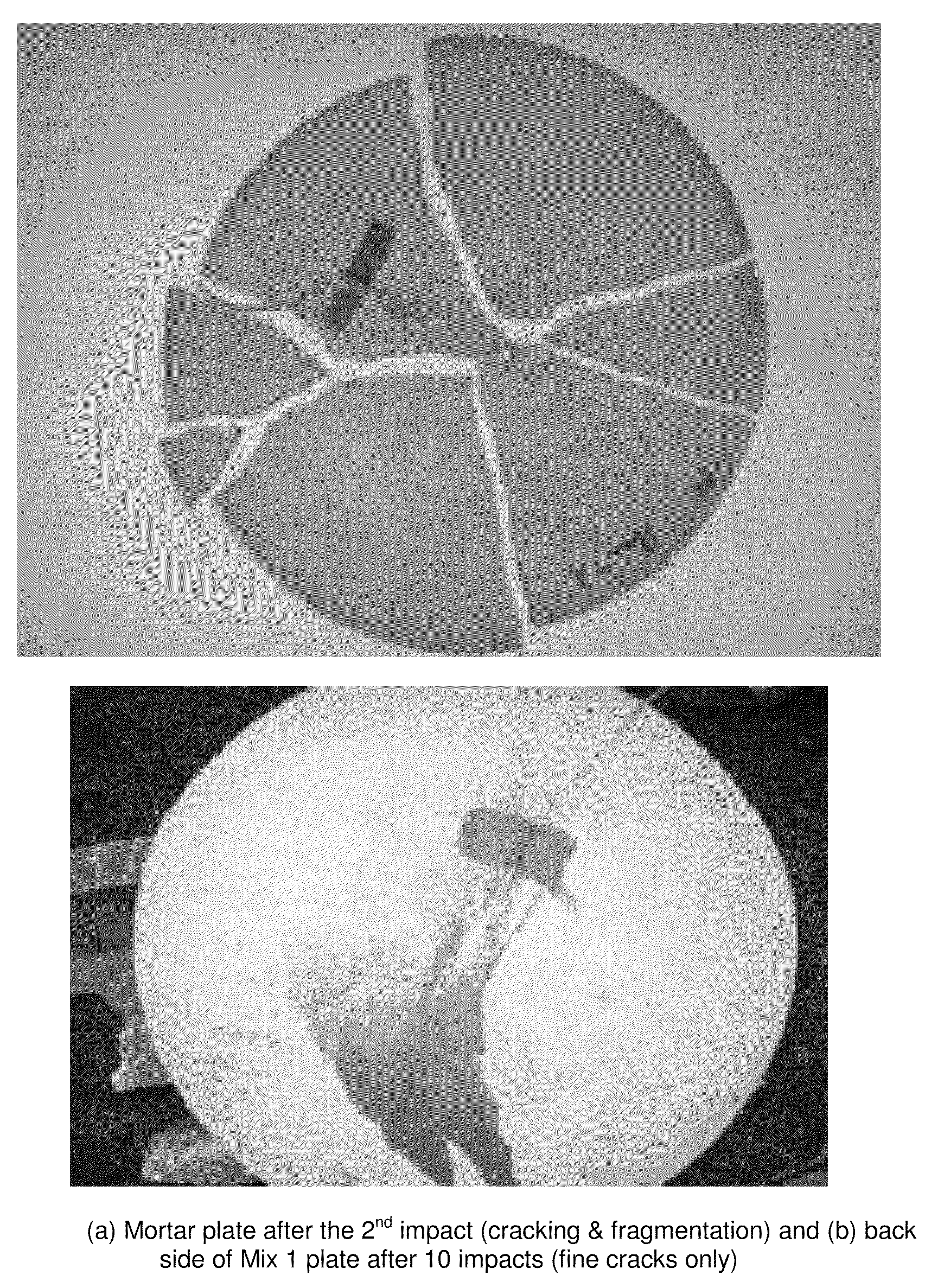

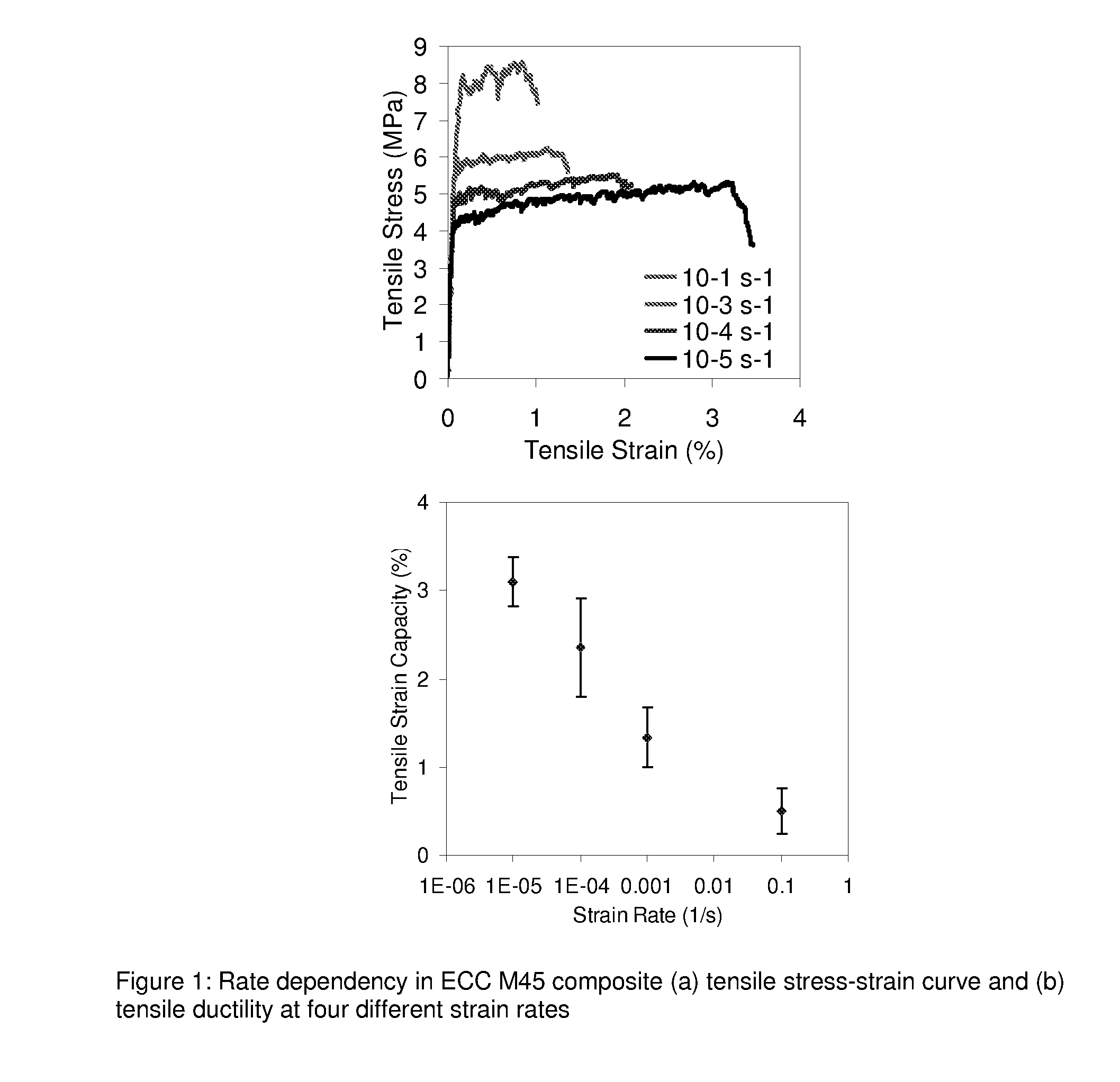

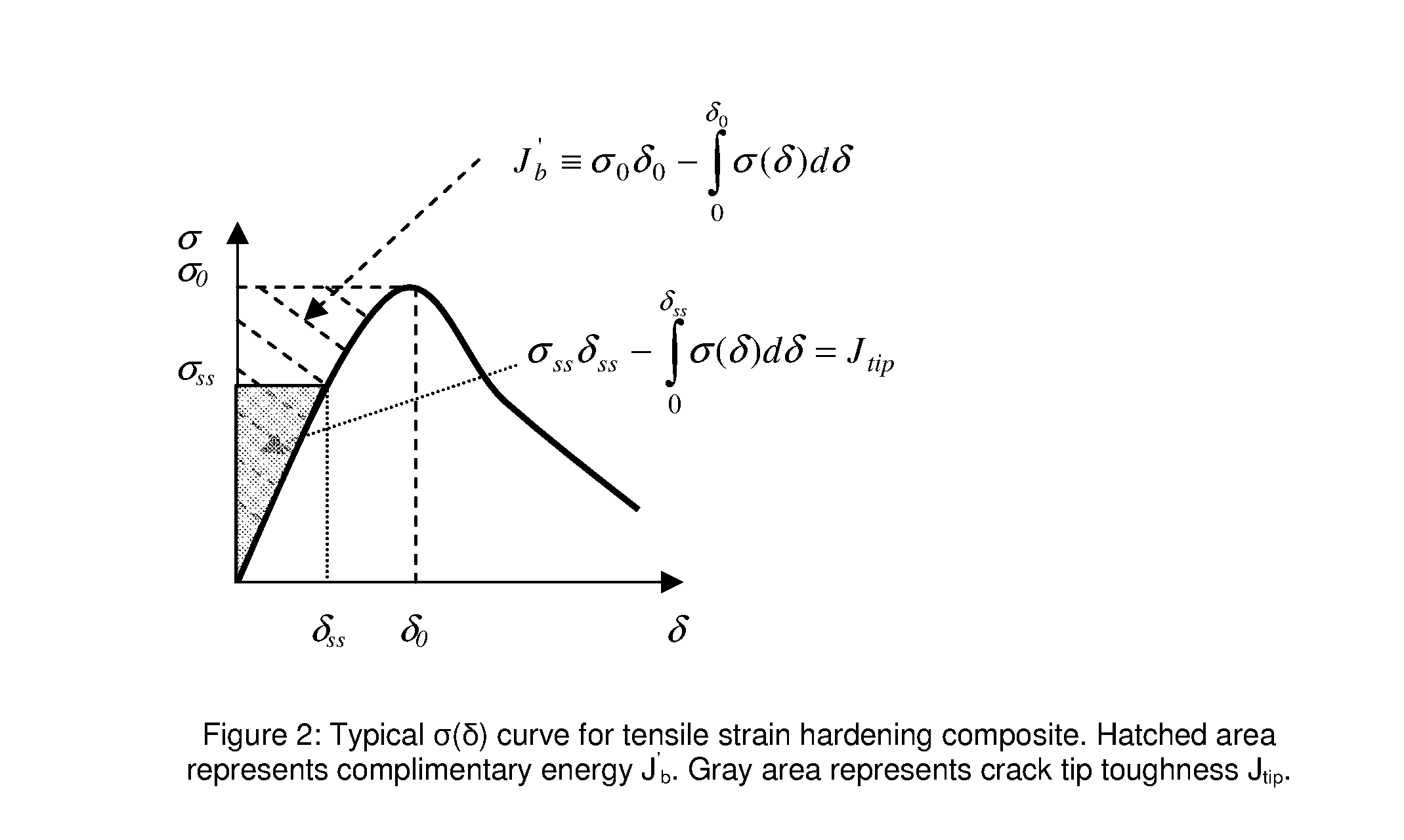

Impact resistant strain hardening brittle matrix composite for protective structures

InactiveUS20090075076A1Good tensile strain capacitySuppress localized brittle fractureSolid waste managementLayered productsResistant strainEngineered cementitious composite

An extremely ductile fiber reinforced brittle matrix composite is of great value to protective structures that may be subjected to dynamic and / or impact loading. Infrastructures such as homes, buildings, and bridges may experience such loads due to hurricane lifted objects, bombs, and other projectiles. Compared to normal concrete and fiber reinforced concrete, the invented composite has substantially improved tensile strain capacity with strain hardening behavior, several hundred times higher than that of conventional concrete and fiber reinforced concrete even when subjected to impact loading. The brittle matrix may be a hydraulic cement or an inorganic polymer. In an exemplary embodiment of the teachings, the composites are prepared by incorporating pozzolanic admixtures, lightweight filler, and fine aggregates in Engineered Cementitious Composite fresh mixture, to form the resulting mixtures, then placing the resulting mixtures into molds, and curing the resulting mixtures.

Owner:RGT UNIV OF MICHIGAN

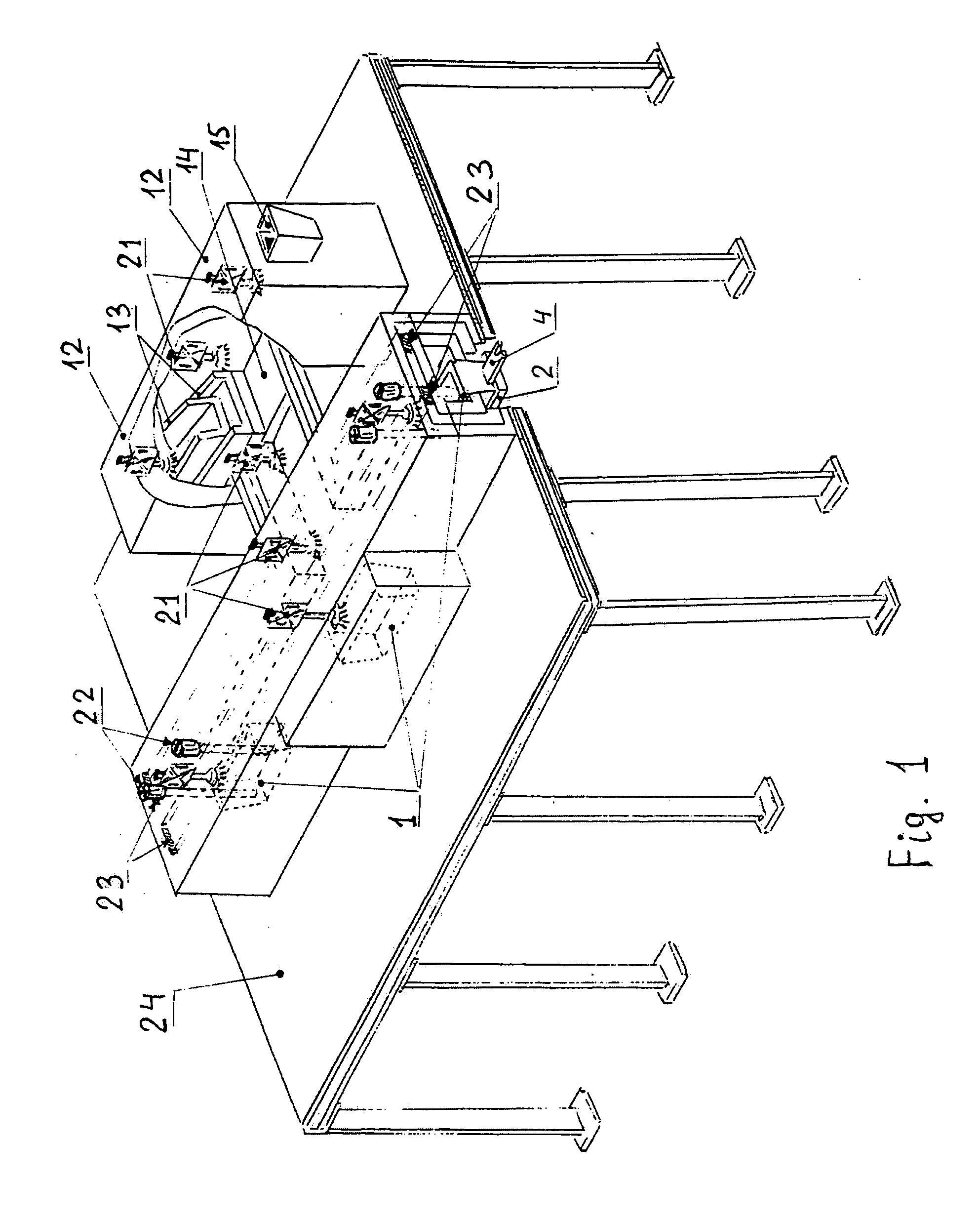

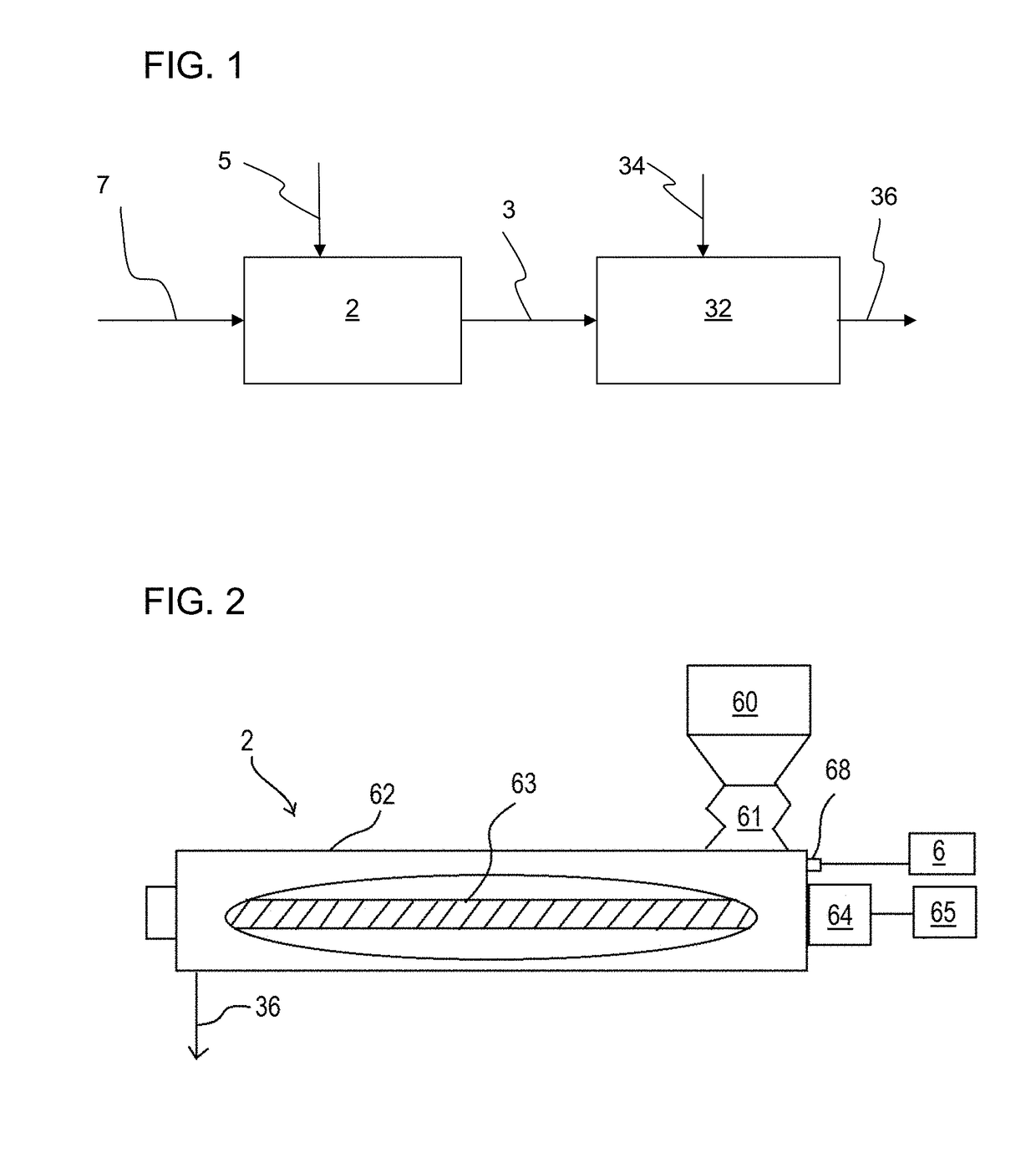

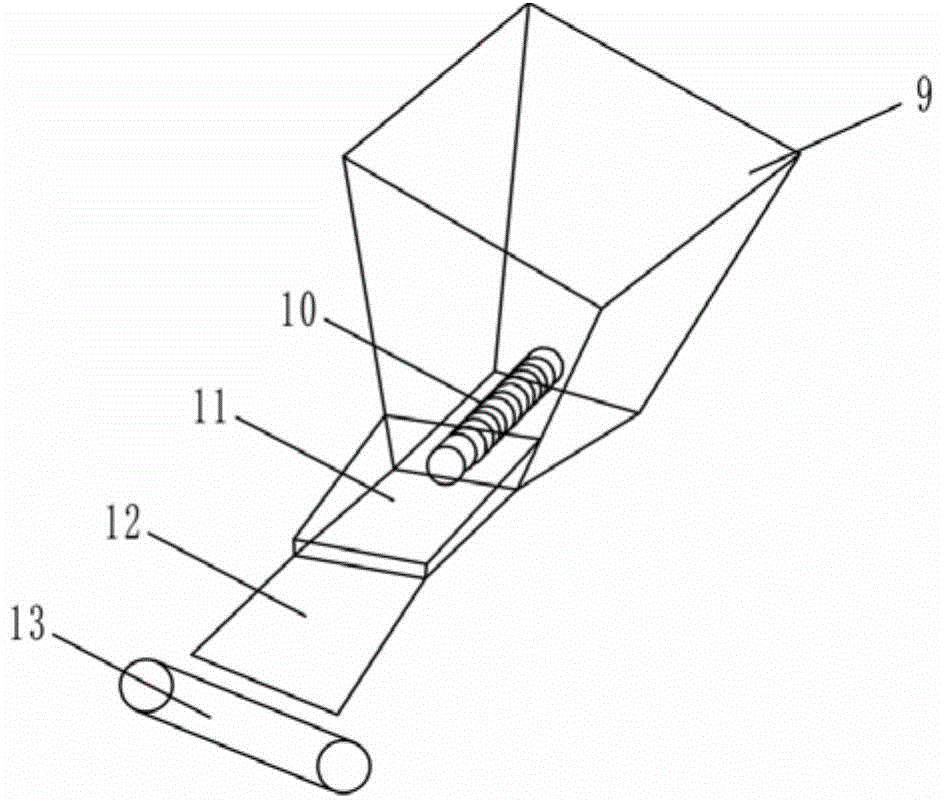

Continuous methods of making fiber reinforced concrete panels

ActiveUS20180036912A1Promote formationEasy to processLiquid surface applicatorsRotary stirring mixersStructural engineeringSlurry

Continuous method including:mixing water and cementitous powder to form slurry;mixing the slurry and reinforcement fibers in a single pass horizontal continuous mixer to form fiber-slurry mixture,the mixer includingan elongated mixing chamber having a reinforcement fiber inlet port, andupstream of the fiber inlet port is an inlet port to introduce water and cementitous powder together as one stream or at least two inlet ports to introduce water and dry cementitous powder separately as separate streams into the chamber,a rotating horizontal shaft / s within the chamber,part of the chamber for mixing the fibers and slurry and moving the fiber-slurry mixture to a mixture outlet;discharging the fiber-slurry mixture from the mixer outlet;forming and setting the fiber-slurry mixture on a moving surface;cutting the set mixture into fiber reinforced concrete panels and removing the panels from the moving surface.

Owner:UNITED STATES GYPSUM CO

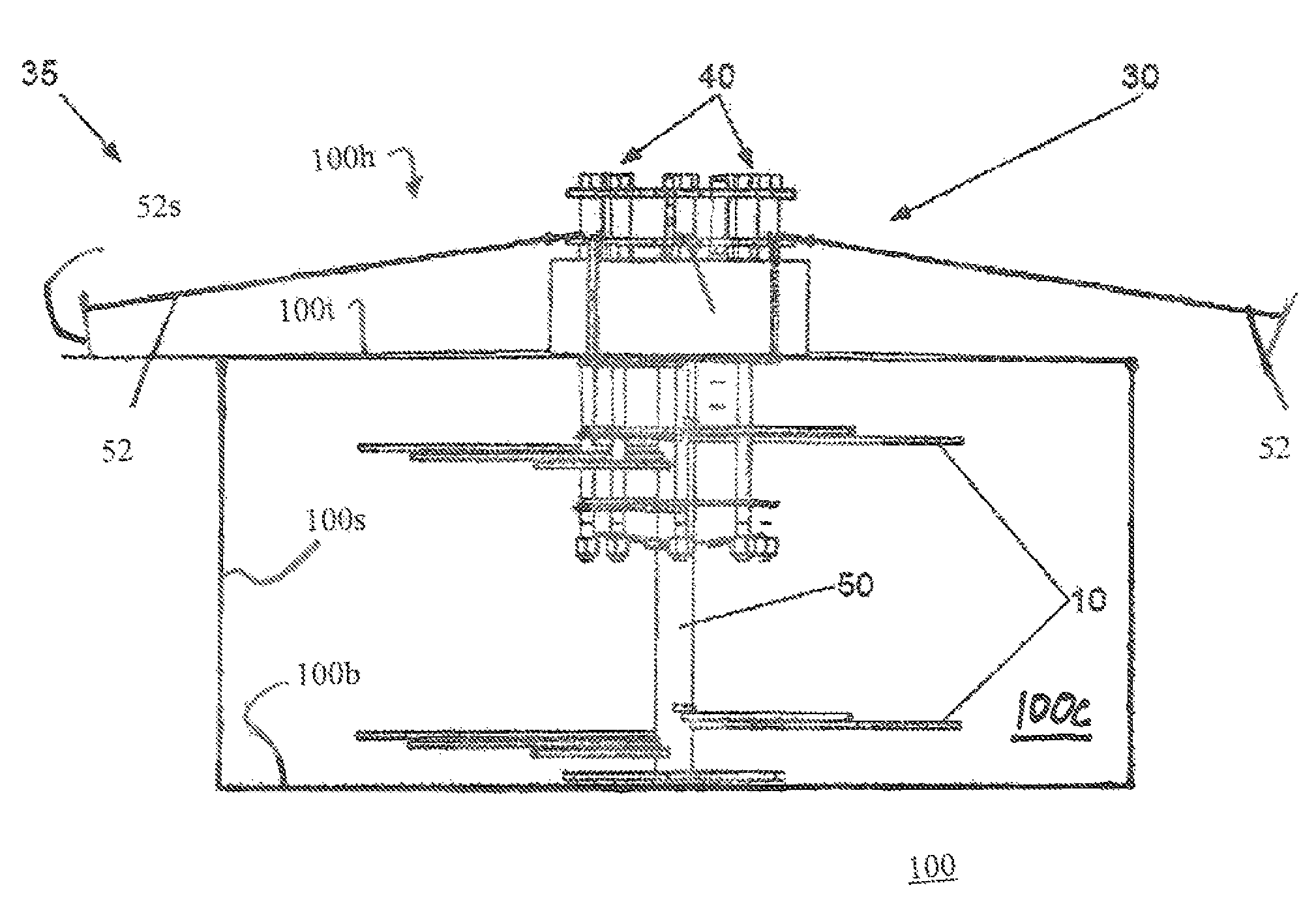

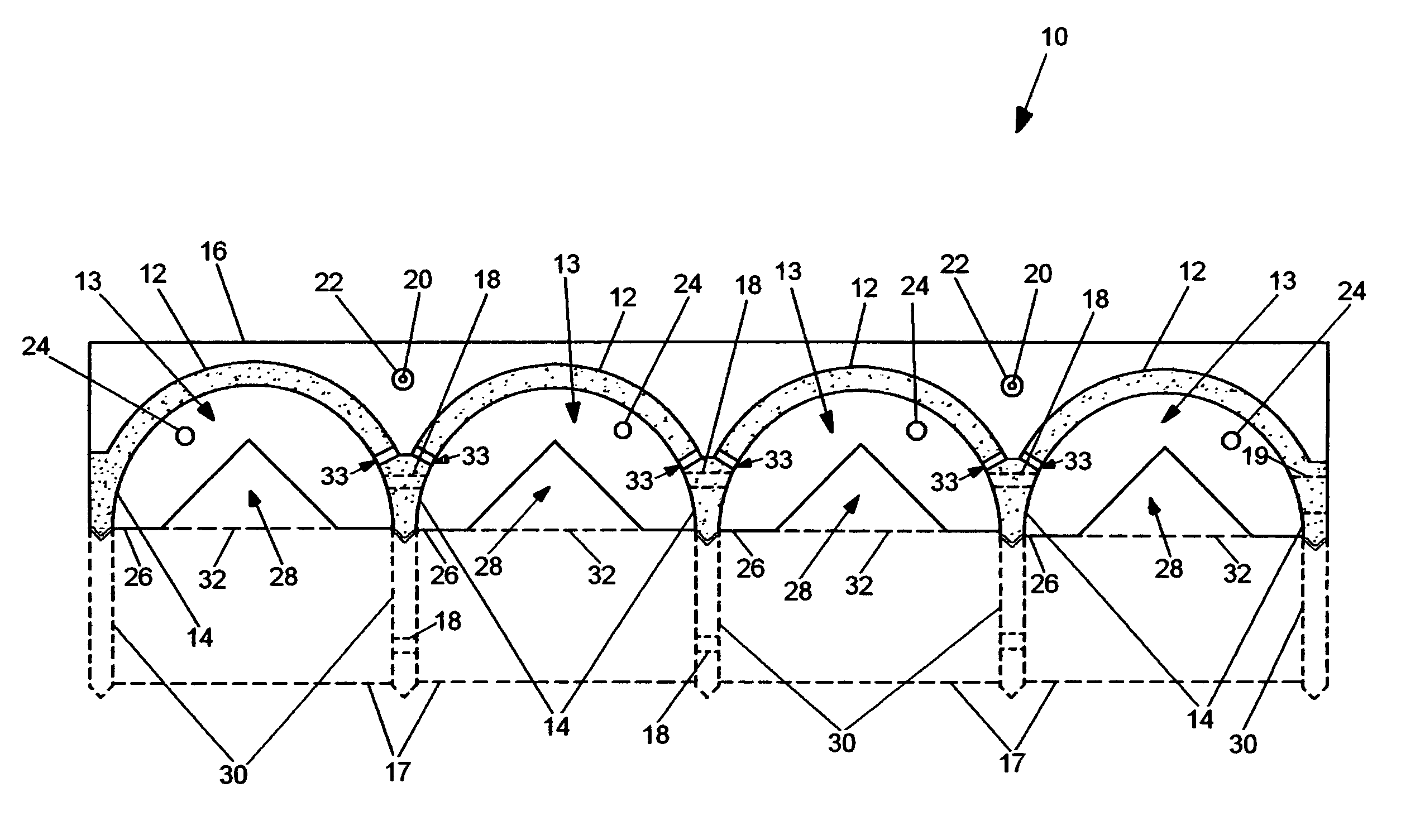

Stormwater capture module

ActiveUS7798747B1Improve life expectancyEliminates potential of corrosionGround-workSewage drainingParking areaRebar

The apparatus is an underground reservoir to capture and slowly release stormwater runoff from impervious surfaces such as roads, rooftops, and parking areas. The structure is assembled from one or more modules comprising at least two side by side precast fiber reinforced concrete vaulted shaped chambers, each with side walls and an arch top. The side by side chambers have common walls with openings in the walls. Modules placed end to end are mated at reinforced concrete end walls that include lifting pins for moving the module. Ends of the chambers are closed, but the end walls have openings for feeding stormwater in and venting air out.

Owner:TERRE HILL SILO

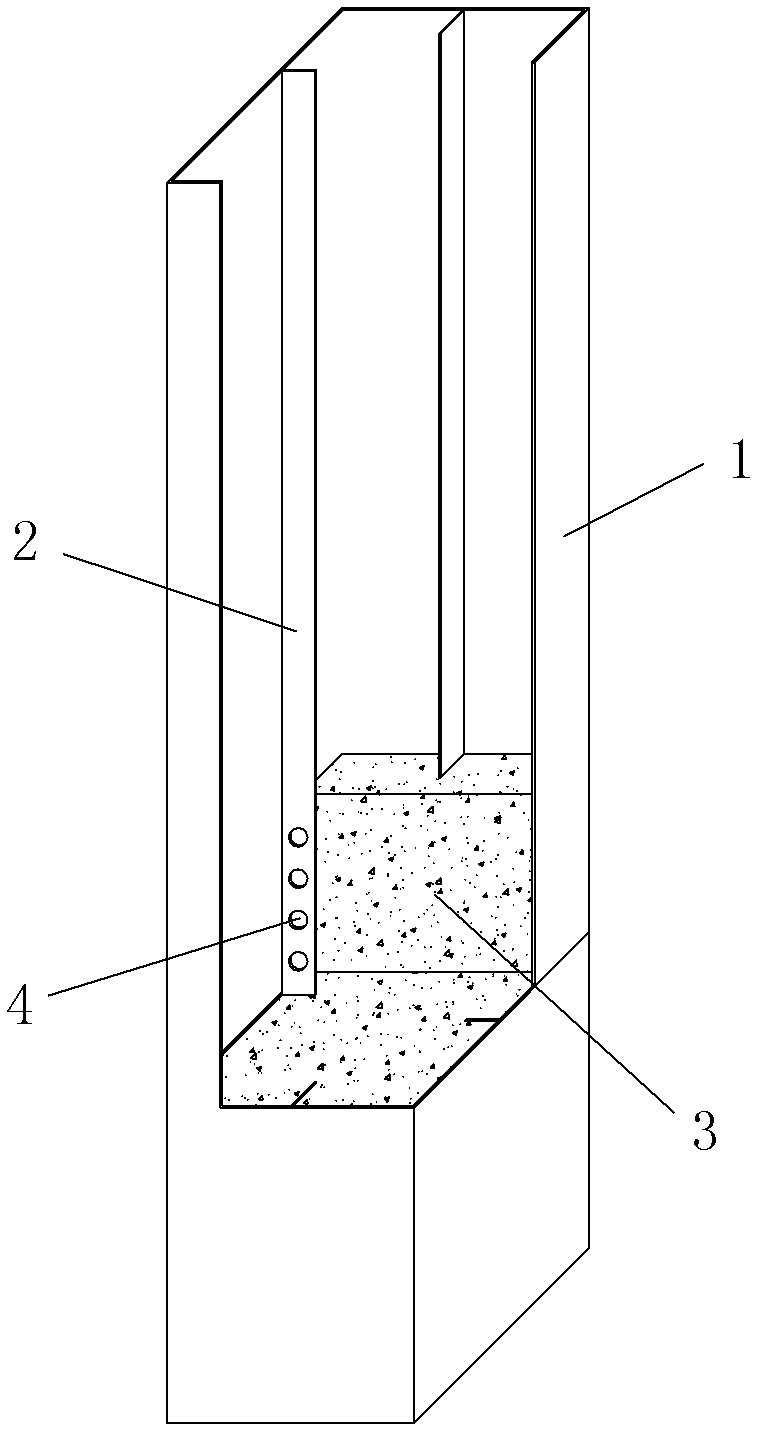

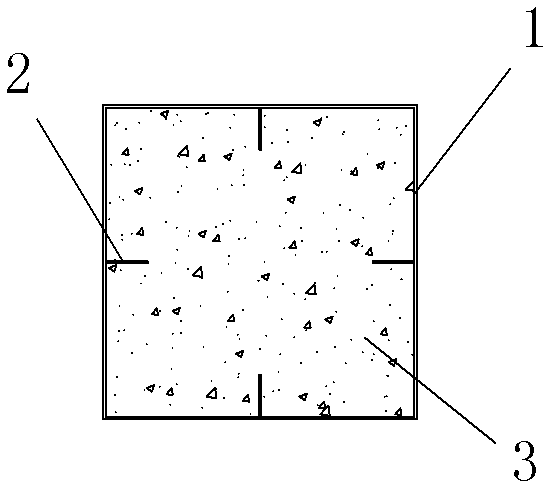

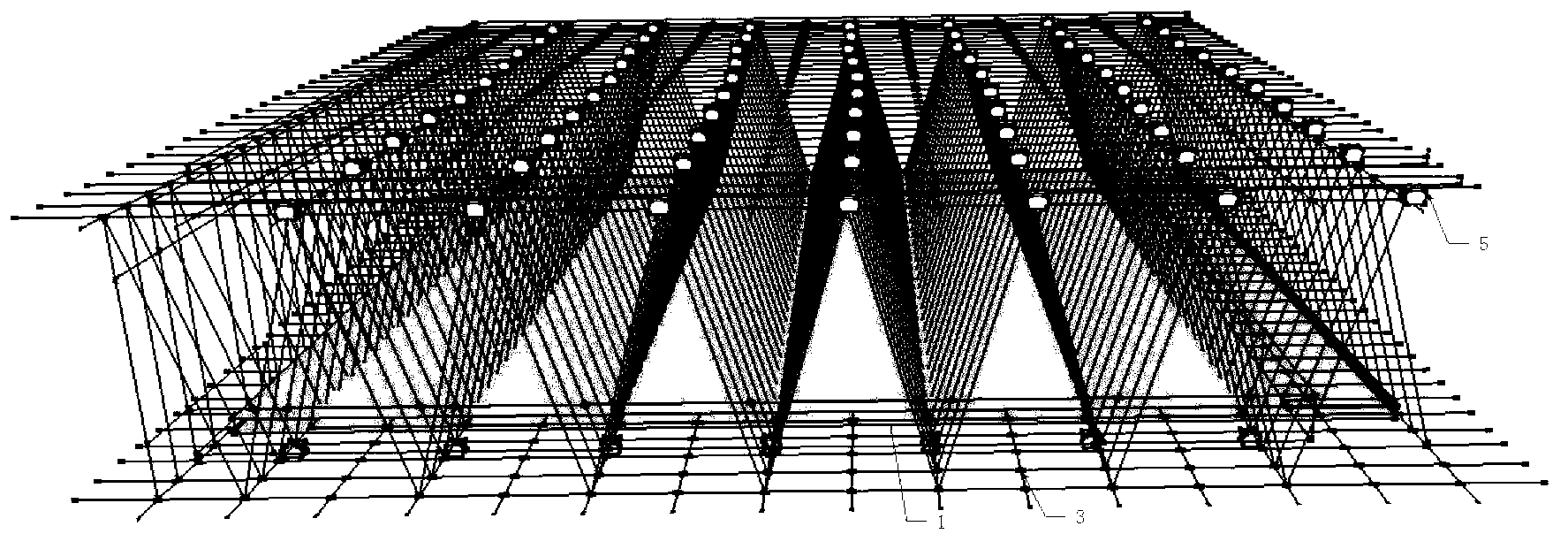

Cylindrical construction part provided with holed stiffening ribs and filled with steel fiber reinforced concrete

The invention discloses a cylindrical construction part provided with stiffening ribs and filled with steel fiber reinforced concrete. The cylindrical construction part comprises a square steel pipe which is vertically arranged, multiple vertical stiffening ribs which are respectively arranged on four side walls of the square steel pipe and a steel fiber reinforced concrete pillar which is formed through pouring steel fiber reinforced concrete filled in the lower part of the inner side of the square steel pipe, wherein the multiple vertical stiffening ribs are same in structure and size and are arranged in the same horizontal plane; and the vertical height of the multiple vertical stiffening ribs and the vertical height of a hollow steel pipe are same, the lower part of each vertical stiffening rib is a holed section with multiple through holes, the vertical height of the holed sections and the vertical height of the steel fiber reinforced concrete pillar are same, and the multiple through holes are arranged in a same vertical line from top to bottom. The cylindrical construction part provided by the invention has the advantages of simple structure, reasonable design and simpleness in construction, good stressing performance, and can overcome the problems of the conventional steel pipe concrete, such as large self weight, poor cohesive force between a steel pipe and concrete and poor structural integrity; moreover, the seismic performance of the integral structure is improved.

Owner:CHANGAN UNIV

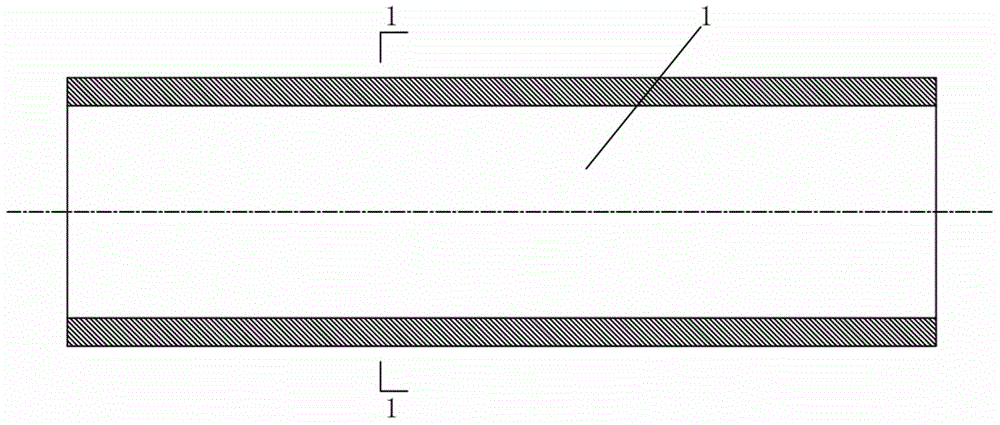

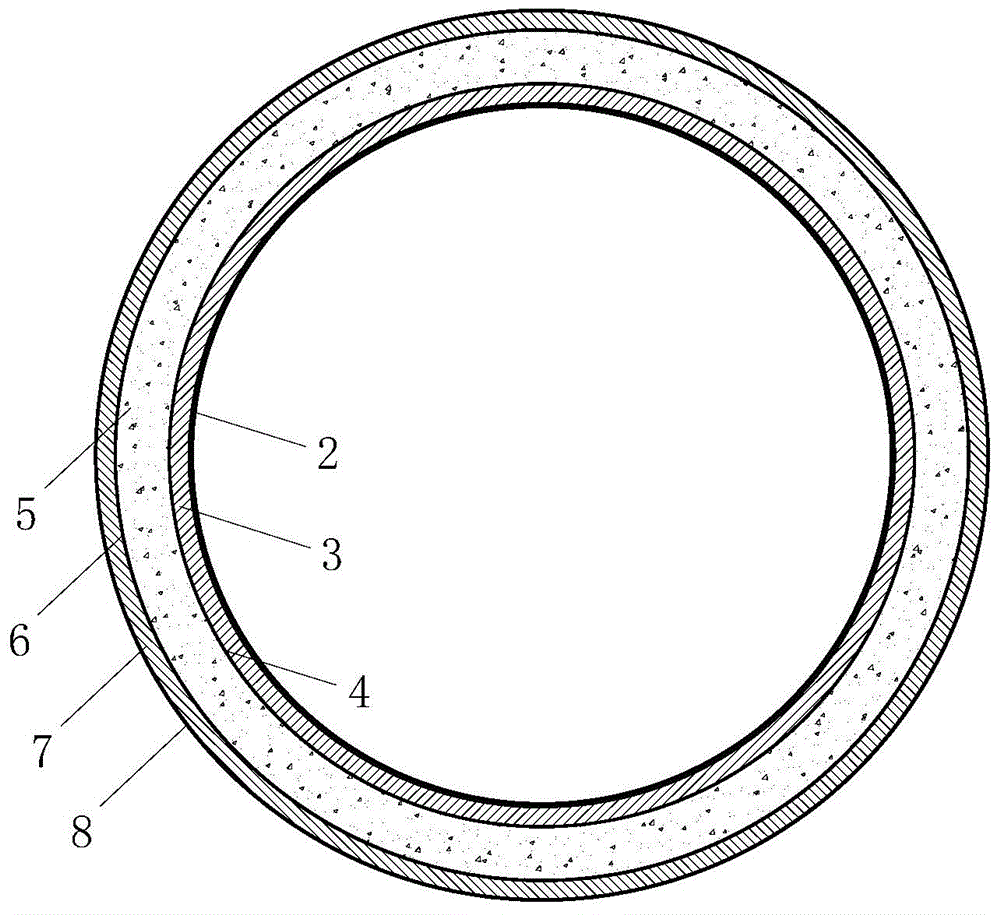

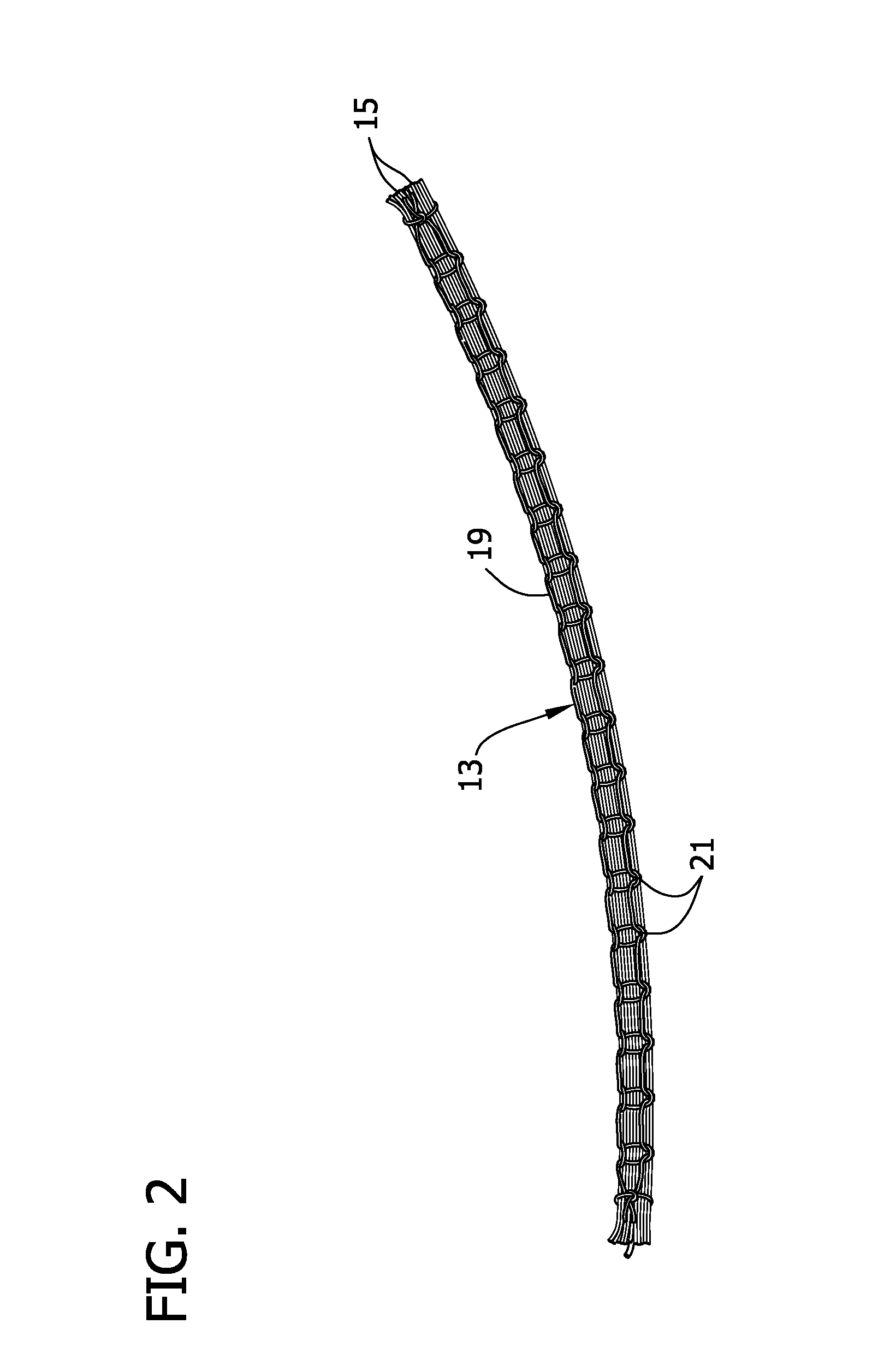

High-stiffness composite tube formed through fixed length winding and manufacturing method thereof

ActiveCN103557378AIncrease stiffnessHigh strengthCeramic shaping apparatusGlass/slag layered productsResin matrixEngineering

The invention discloses a high-stiffness composite tube formed through fixed length winding. The tube wall of the composite tube structurally and sequentially comprises an inside liner, an inner structure layer, an interface adaptation layer, an intermediate structure layer, an interface adaptation layer, an outer structure layer and an outer protective layer from inside to outside, wherein the inside liner, the inner structure layer, the outer structure layer and the outer protective layer are made of resin matrix composites, and the resin matrix composite is made of glass fibers and fabrics thereof, and resin; the intermediate structure layer is made of fiber reinforced concrete cement-based composite material; the interface adaptation layers are made of the mixture of organic bonding material and quartz sand. The prepared composite tube has the advantages that the stiffness of the composite tube is more than ten times of that of a commonly used glass steel tube at present, the weight of the composite tube is one third of that of a normal concrete pipe, the defects that the glass steel tube is low in stiffness and the concrete pipe is heavy are overcome, the cost of the composite tube is between the costs of the glass steel tube and the concrete pipe, and the composite tube is good in economic performance.

Owner:WUHAN UNIV OF TECH +1

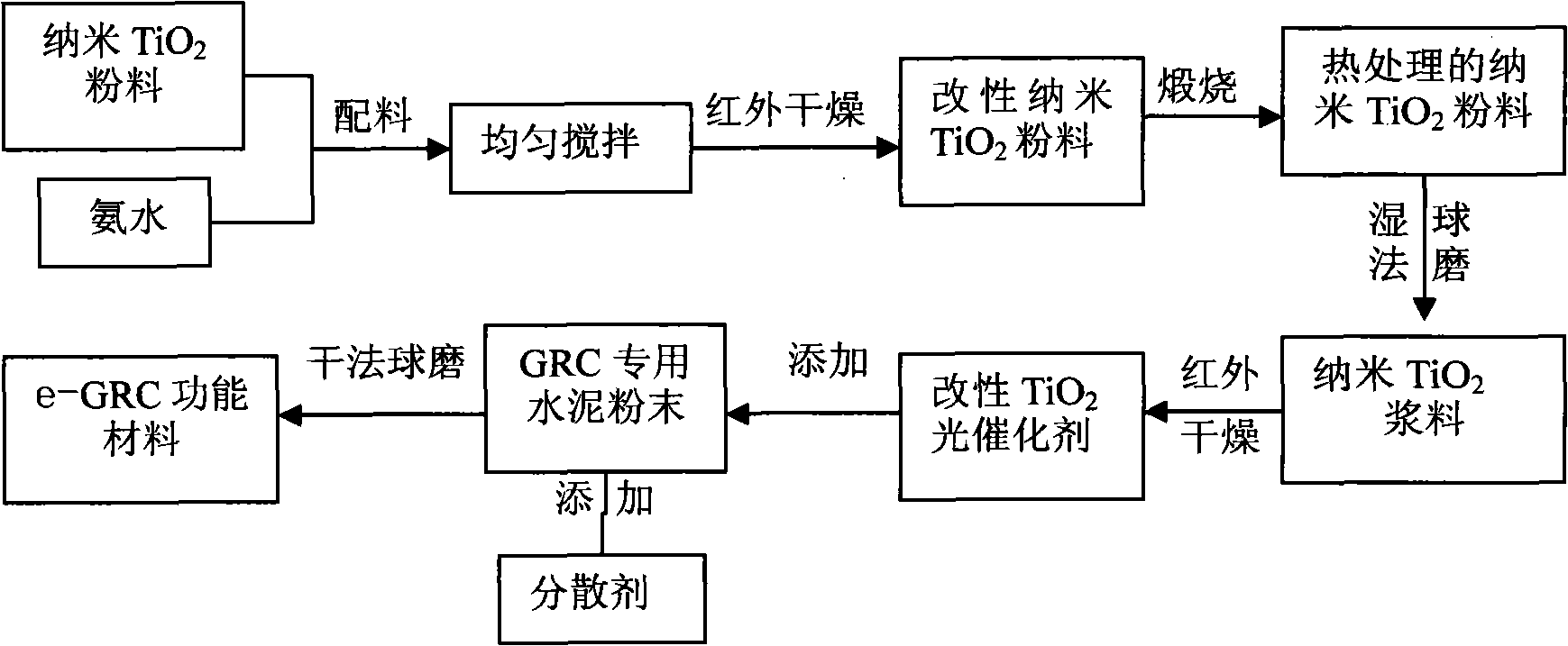

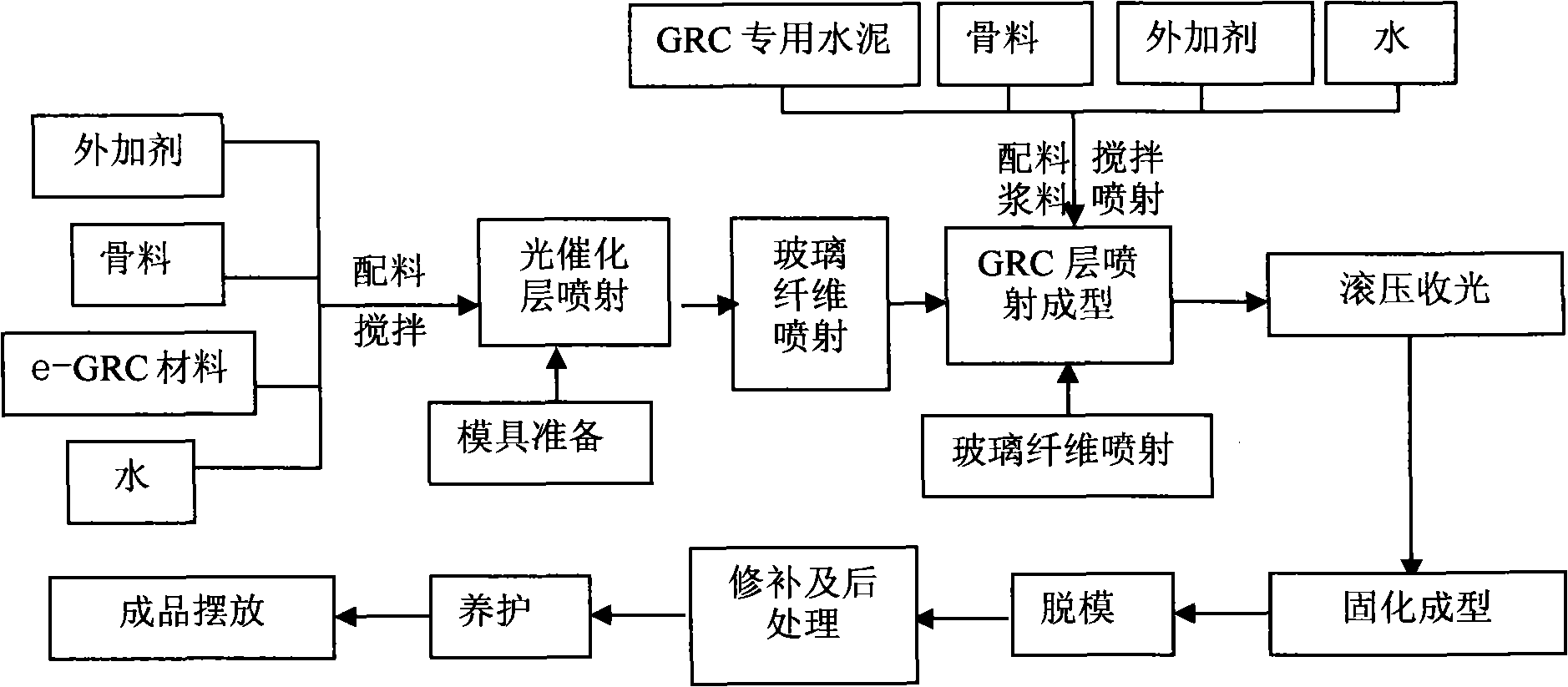

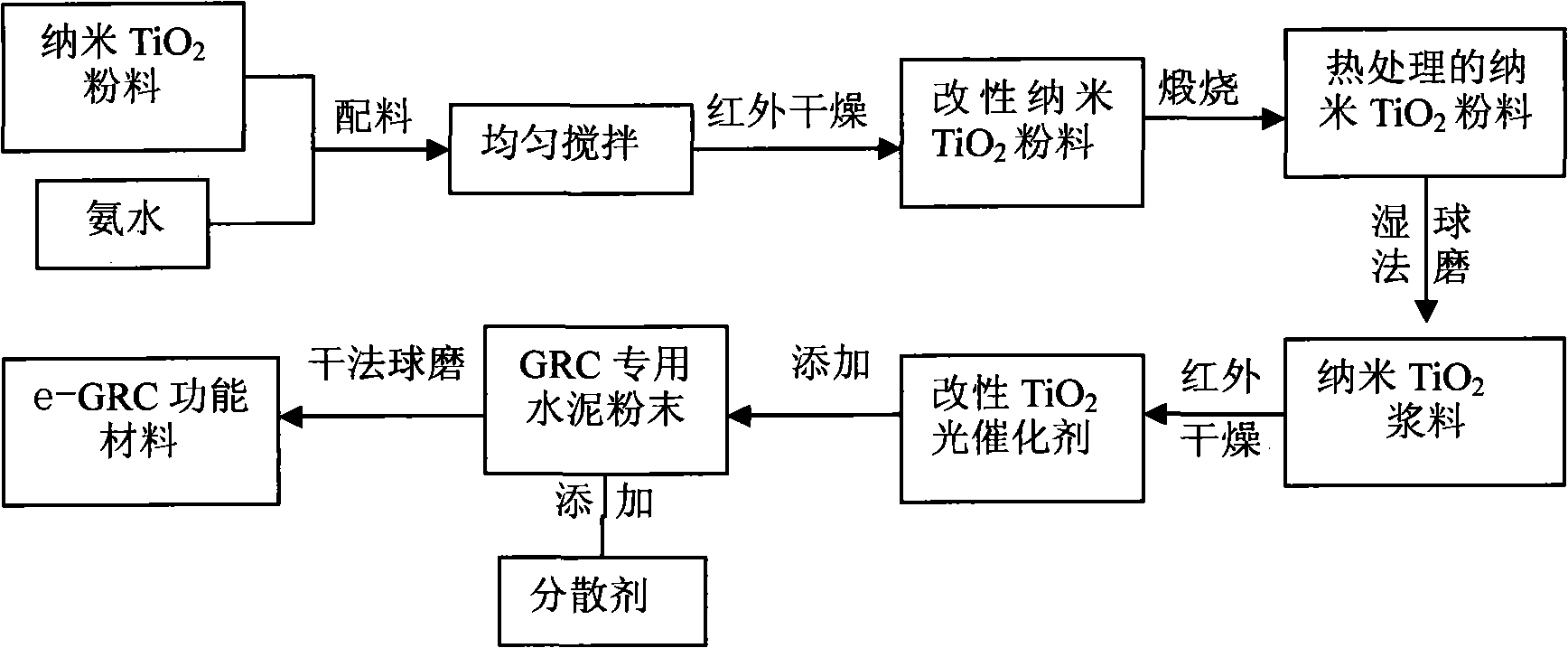

Preparation method and application of nano glass fiber reinforced concrete material

InactiveCN102167535AMeet molding needsMeet the requirements of building environmental protection and energy savingGlass fiberSurface layer

The invention discloses a preparation method and application of a nano glass fiber reinforced concrete material (e-GRC functional material). In the invention, a GRC material is used a photocatalysis carrier; TiO2 is used in glass fiber reinforced concrete; nano titanium dioxide is formed by mixing rutile and anatase at a ratio of (20:80)-(25:75); a multi-stage dispersion process is used; and fineglass fibers are substituted for steel bars in the traditional precast concrete, thus obtaining the nano glass fiber reinforced concrete material. The nano glass fiber reinforced concrete material has the self-cleaning function, can prevent and control air pollution, and is economical and practical. When being used in a building, the nano glass fiber reinforced concrete material can form a thin e-GRC coating on the surface layer of the building, thereby achieving the purposes of environment protection and energy saving.

Owner:NANJING BEILIDA NEW MATERIAL SYST ENG

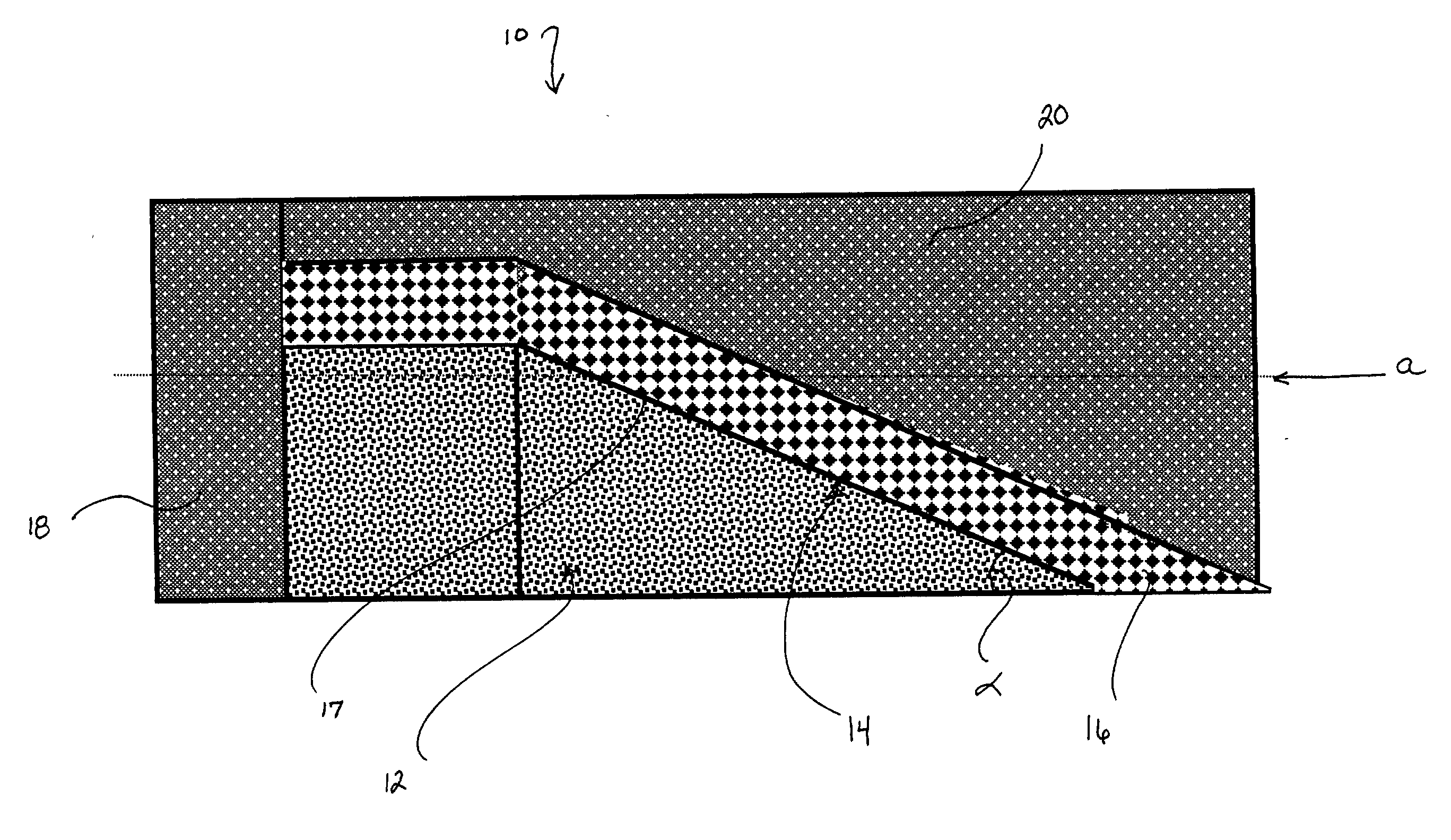

Bullet trapping medium and system

A backstop for decelerating and trapping projectiles generally includes a support structure having an inclined surface and a projectile trapping medium disposed on the inclined surface. The projectile trapping medium may be either a resilient granular ballistic medium or a combination of a ballistic medium with a hydrated super absorbent polymer (SAP) gel. Preferably, the support structure is made of a shock absorbing, foamed, fiber-reinforced concrete, such as SACON(R). In embodiments, the support structure also includes an enclosure. Additives may also be mixed into the projectile trapping medium to control alkalinity and prevent leaching of heavy metals.

Owner:ARMY UNITED STATES GOVERNMENT AS REPRESENTED BY THE SEC OF THE

Fiber reinforced concrete/cement products and method of preparation

InactiveUS7285167B2Improve propertiesHigh strengthSolid waste managementPolymer scienceCarbon fibers

Concrete and / or cement products and mixes with reinforcing carbon graphite fibers having a length of about 2½ inches to about 3½ inches, and / or nano and / or micron sized carbon fibers, and a method of reinforcing concrete.

Owner:OGDEN TECH

Method for preparing conductive fiber reinforced concrete base functional composite material

InactiveCN101269940AGood dispersionWon't breakFunctional compositeElectrical resistivity and conductivity

The present invention relates to a method for producing conductive-fiber cement-function-improved composite material, which resolves the problems of the prior art that the produced conductive-fiber cement-function-improved composite material has unfavorable disperse effect of the fiber, the fiber is easy to break, the electric conductivity is low and the function is poor. The preparation method comprises the steps: firstly, preparing the conductive fiber dispersion phase solution; secondly, preparing the cement pulp substrate; thirdly, adding the conductive fiber dispersion phase solution into the cement pulp substrate; fourthly, repeating the step two and the step three, and a billet with cement substrate being distributed with the conductive fiber at intervals is obtained, and the cement pulp substrate is poured on the upper surface of the billet; fifthly, after the poured cement pulp substrate is solidified, the die is removed, and the conductive-fiber cement-function-improved composite material can be obtained after the maintenance. The disperse effect of the fiber is good, and the fiber is free from being broken, and the conductivity is good, and the function of the material is favorable.

Owner:HARBIN INST OF TECH

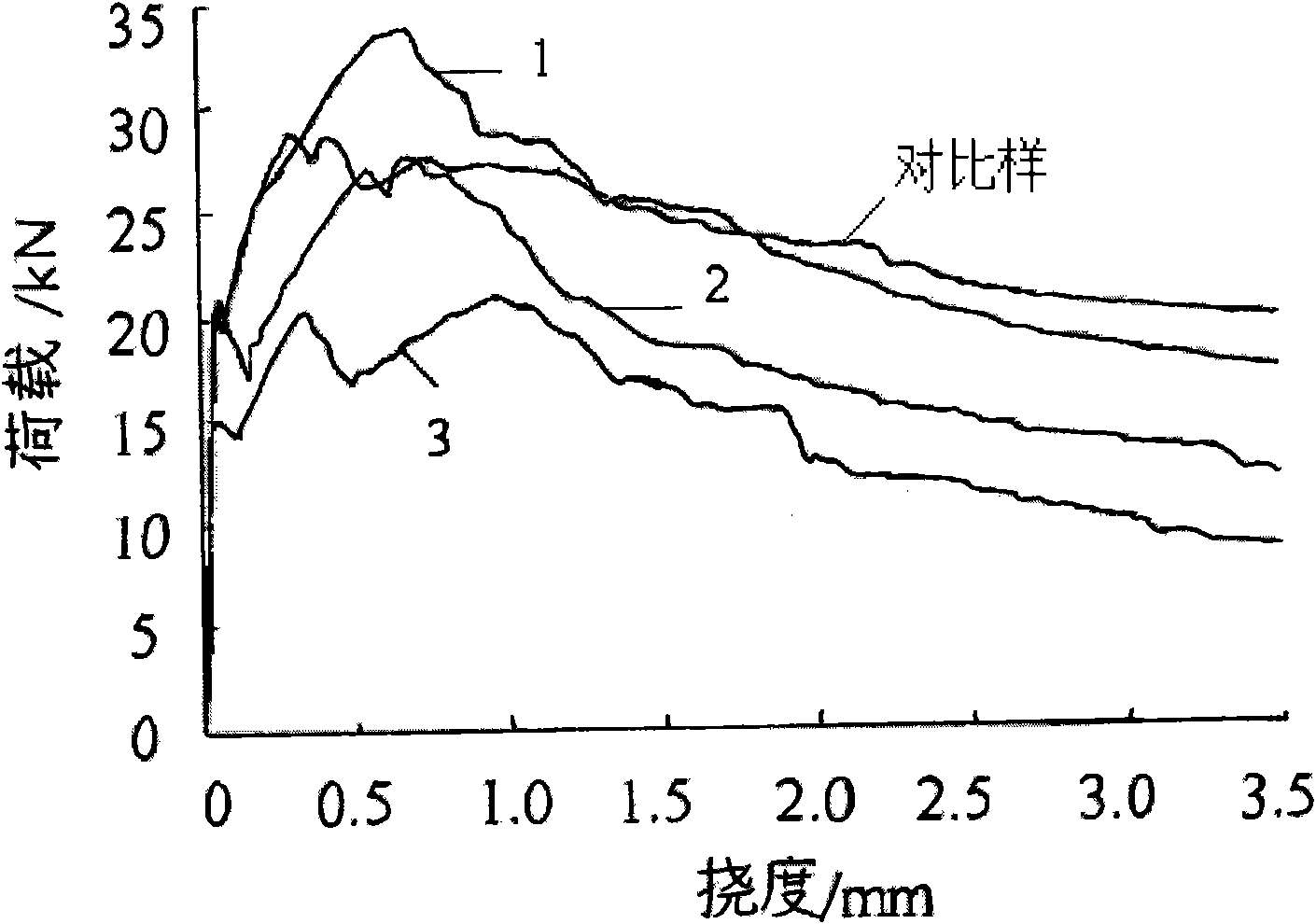

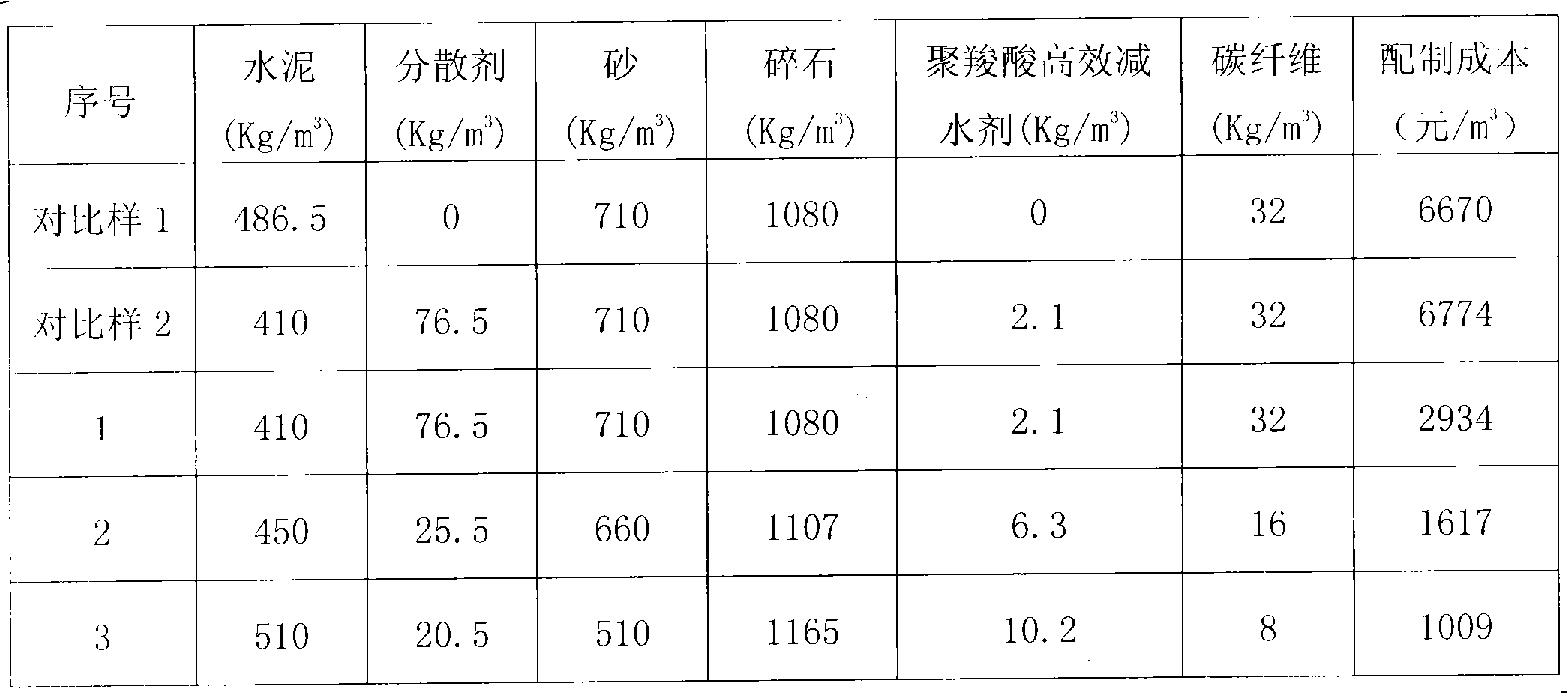

Low-cost carbon fiber reinforced concrete and preparation method and application thereof

Owner:CHINA BUILDING MATERIALS ACAD

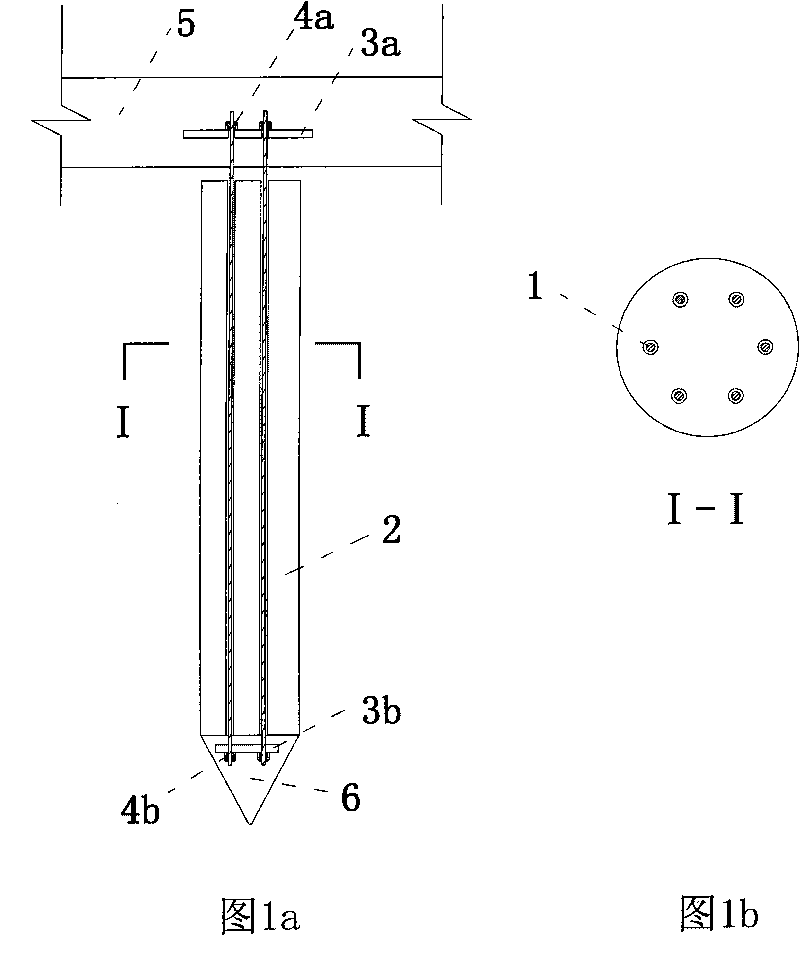

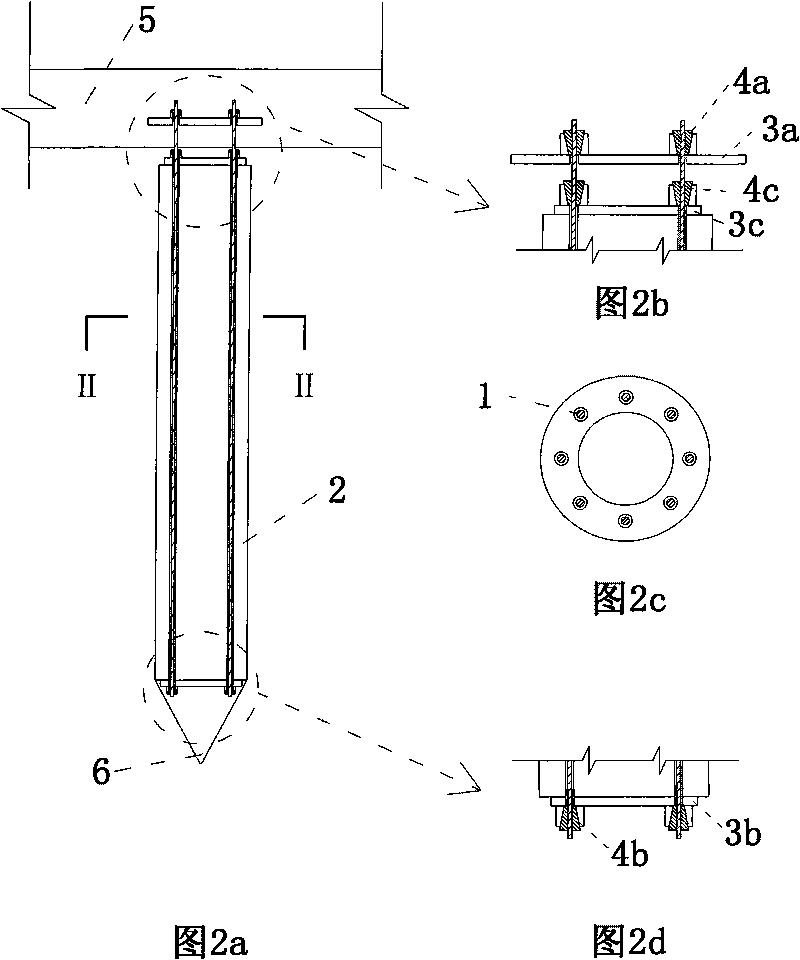

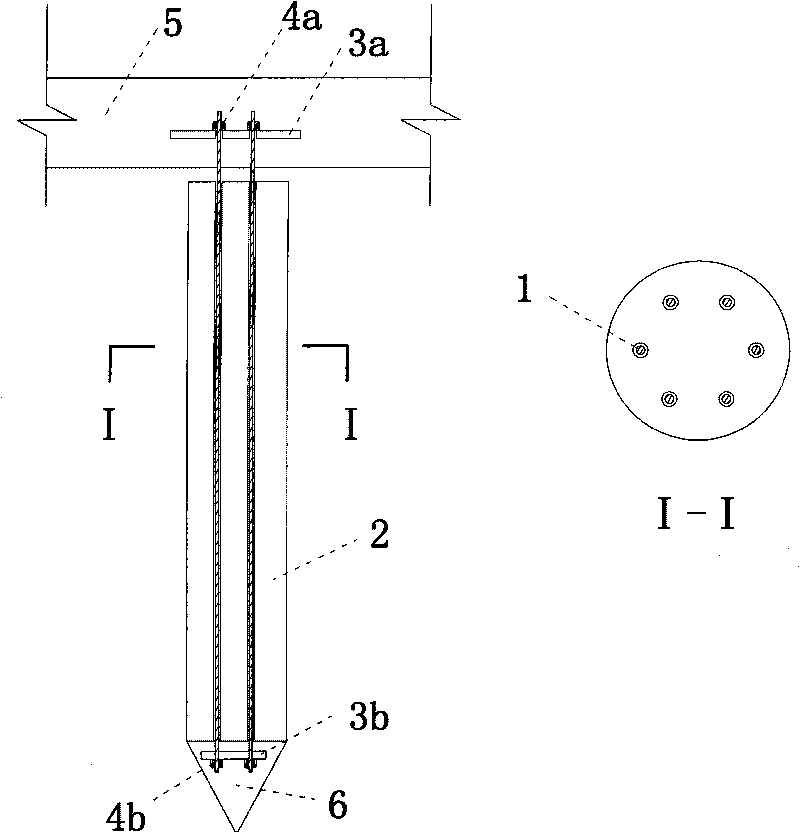

Fiber reinforced concrete uplift pile

InactiveCN101761089AInhibition of upward movementNo tensile cracksBulkheads/pilesPre stressFiber-reinforced concrete

The invention relates to a fiber reinforced concrete uplift pile which comprises a concrete pile body. A pile head is arranged at one end part of the concrete pile body; a FRP fiber reinforcement externally sleeved by a sleeve is arranged in the concrete pile body, one end thereof extends into the pile head, and the other end thereof reversely extends out of the concrete pile body; a second supporting plate is arranged in the pile head; one end of the FRP fiber reinforcement positioned in the pile head is fixed on a second supporting plate by a second anchorage device; a first supporting plate is sleeved at the other end of the FRP fiber reinforcement, and the other end of the FRP fiber reinforcement is fixed on the first supporting plate by a first anchorage device. Prestressing force is not applied to the FRP fiber reinforcement, the sleeve is enwrapped on the periphery of the FRP fiber reinforcement and is not bonded with concrete; and relative slide can be generated between the sleeve and the concrete. The lower end of the FRP fiber reinforcement is tensioned by the supporting plates at the bottom part of the pile and the anchorage devices, and the upper end of the RP fiber reinforcement is fixed in a bearing platform by the supporting plates in the bearing platform and the anchorage devices; and the bearing platform is completely separated with the concrete of the pile body.

Owner:NANCHANG CONSTR ENG GROUP

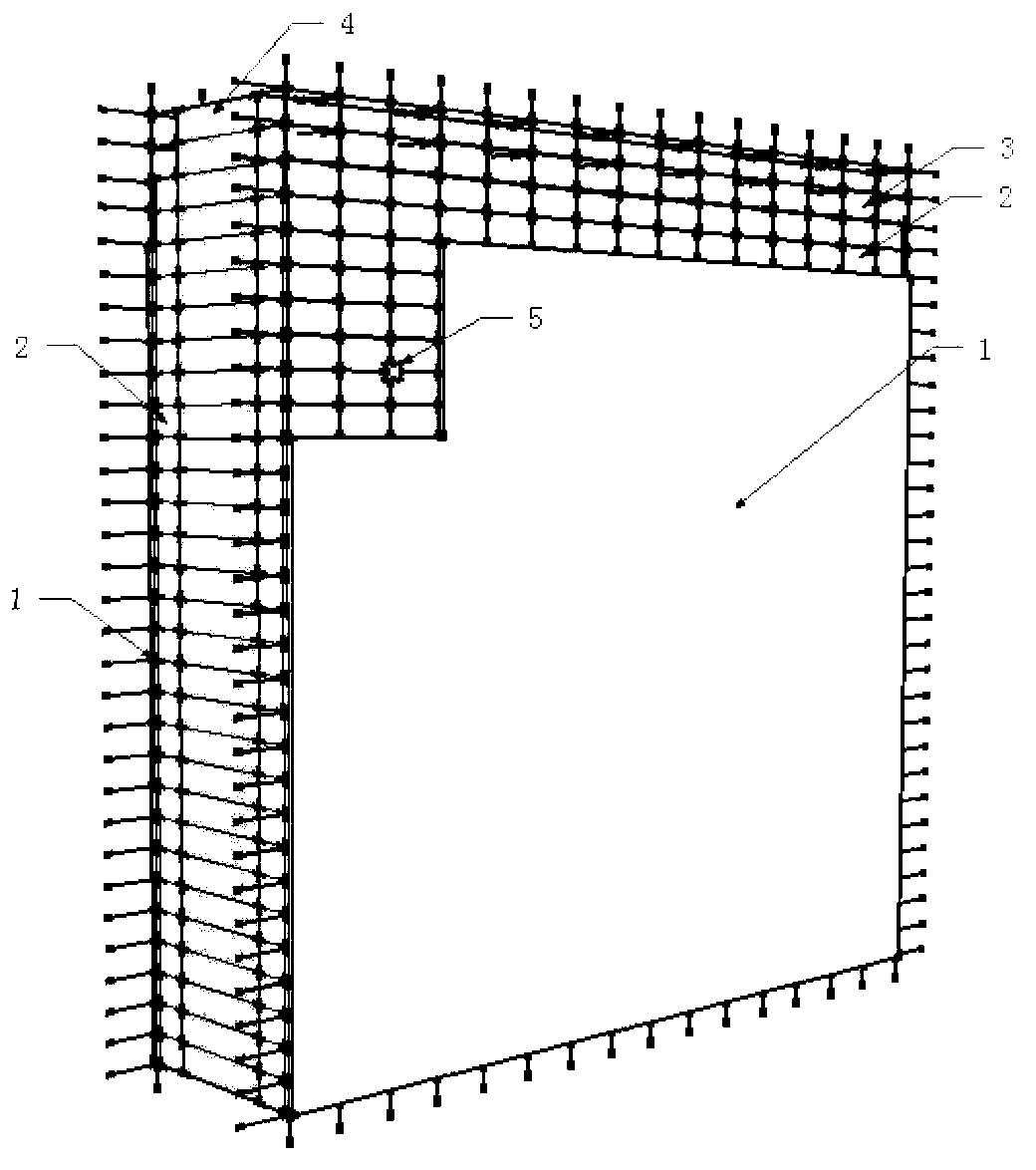

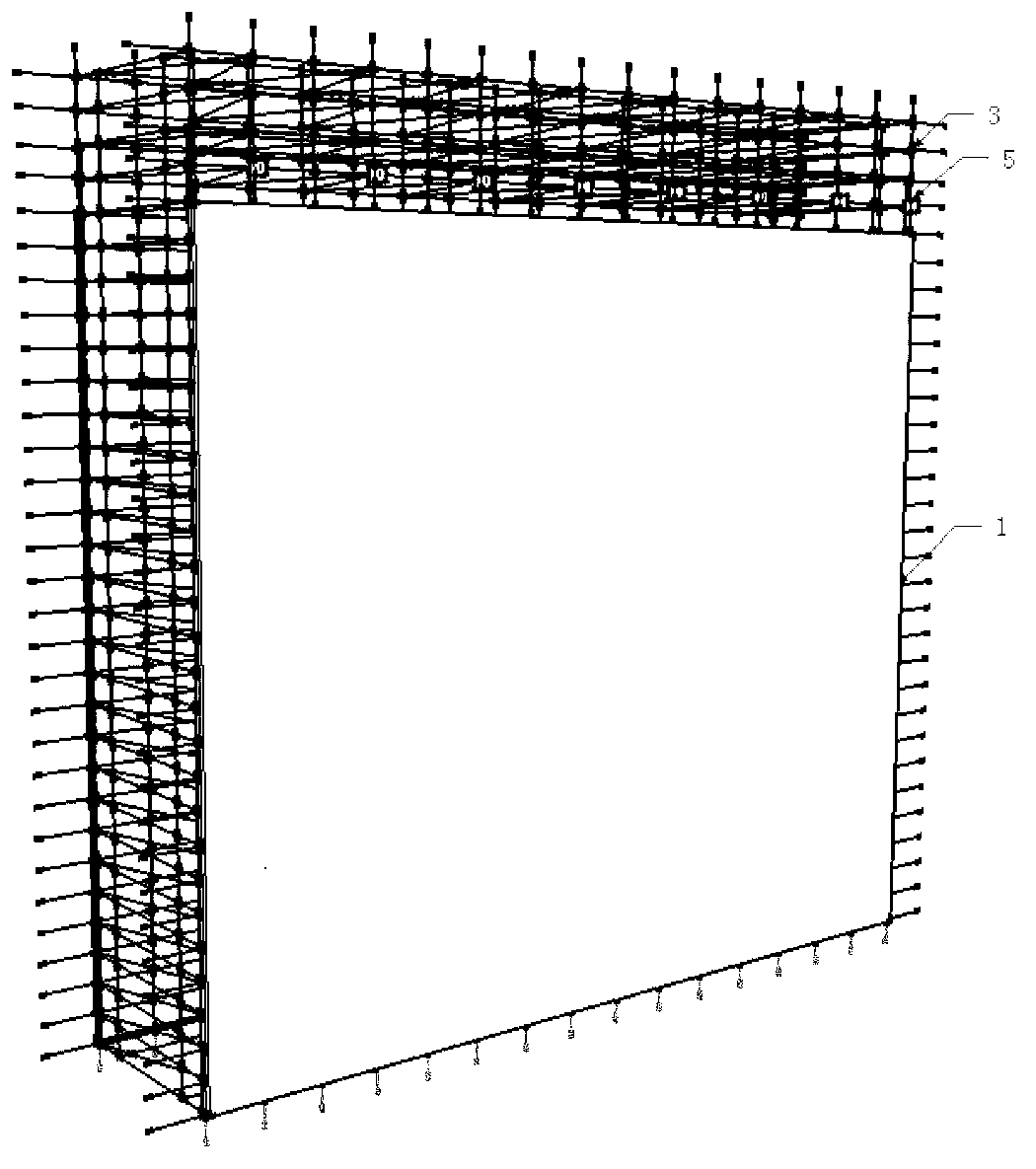

On-site concrete shear wall structure with permanent heat insulation formwork and construction process of on-site concrete shear wall structure

The invention discloses an on-site concrete shear wall structure with a permanent heat insulation formwork and a construction process of the on-site concrete shear wall structure. The cross section of the shear wall structure comprises an inner side permanent heat insulation formwork layer, an outer side permanent heat insulation formwork layer and a reinforced concrete structure layer; and the permanent heat insulation formwork is composed of a high-performance fiber reinforced concrete layer and a light concrete heat insulation layer. The construction process includes precasting a welding steel rack with the permanent heat insulation formwork, mounting on site, pouring concrete and constructing the heat insulation layers and the shear wall structure synchronously. The permanent heat insulation formwork plays the role of both the heat insulation layer and the formwork, is taken as one part of the structure to work with the others, and is beneficial to saving of a large quantity of construction formworks; construction efficiency is improved; and the on-site concrete shear wall structure is a novel assembly integrated structure with combination of structure, heat insulation and formworks. By the technical scheme, service life of the structure is as the same as that of building heat insulation; problems of firmness and durability of the connection between the heat insulation layers and the structure are completely achieved; the structure is beneficial to engineering quality guaranteeing, construction period saving and construction cost reducing; and development in building industry is promoted.

Owner:YANCHENG INST OF TECH +1

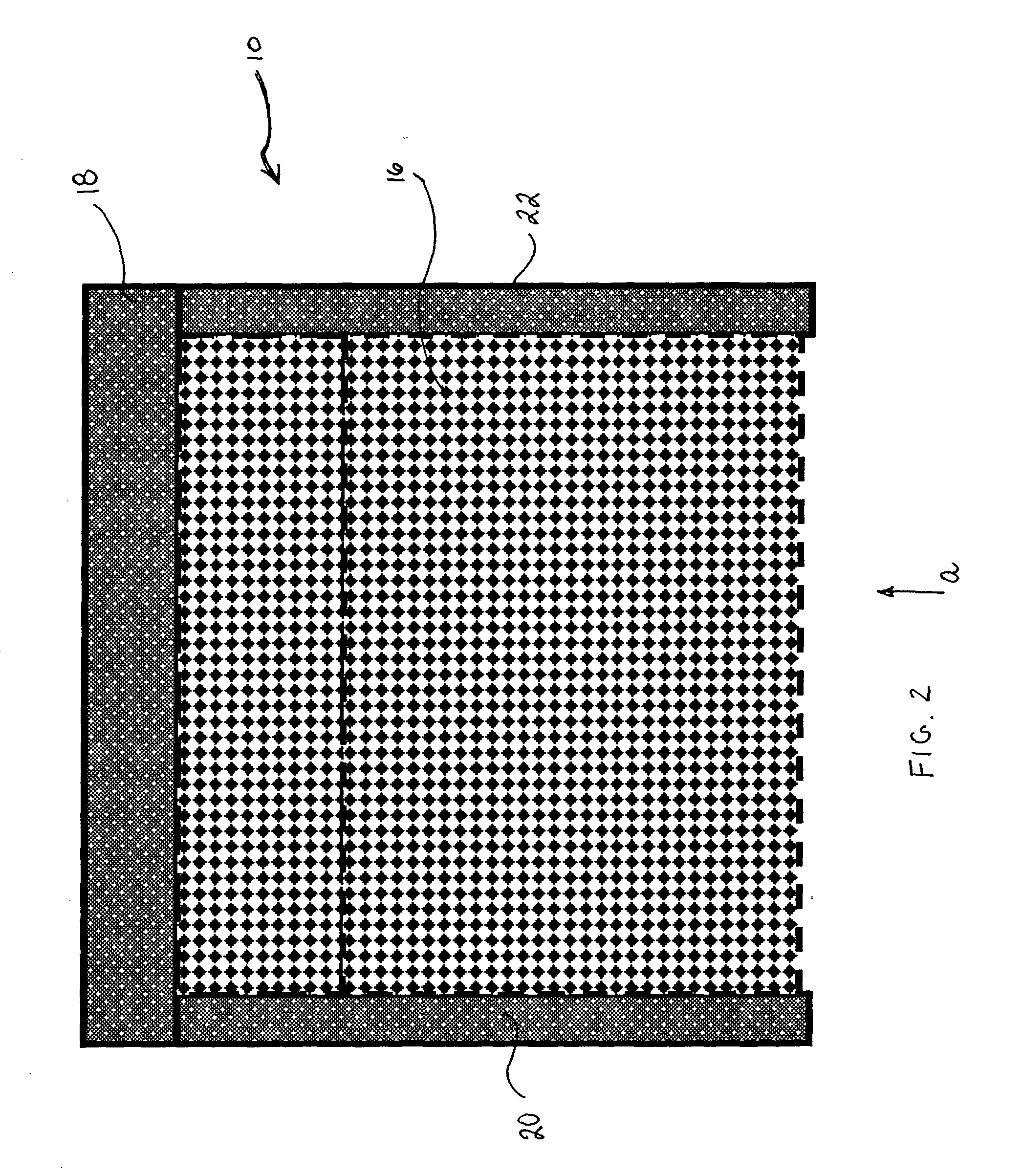

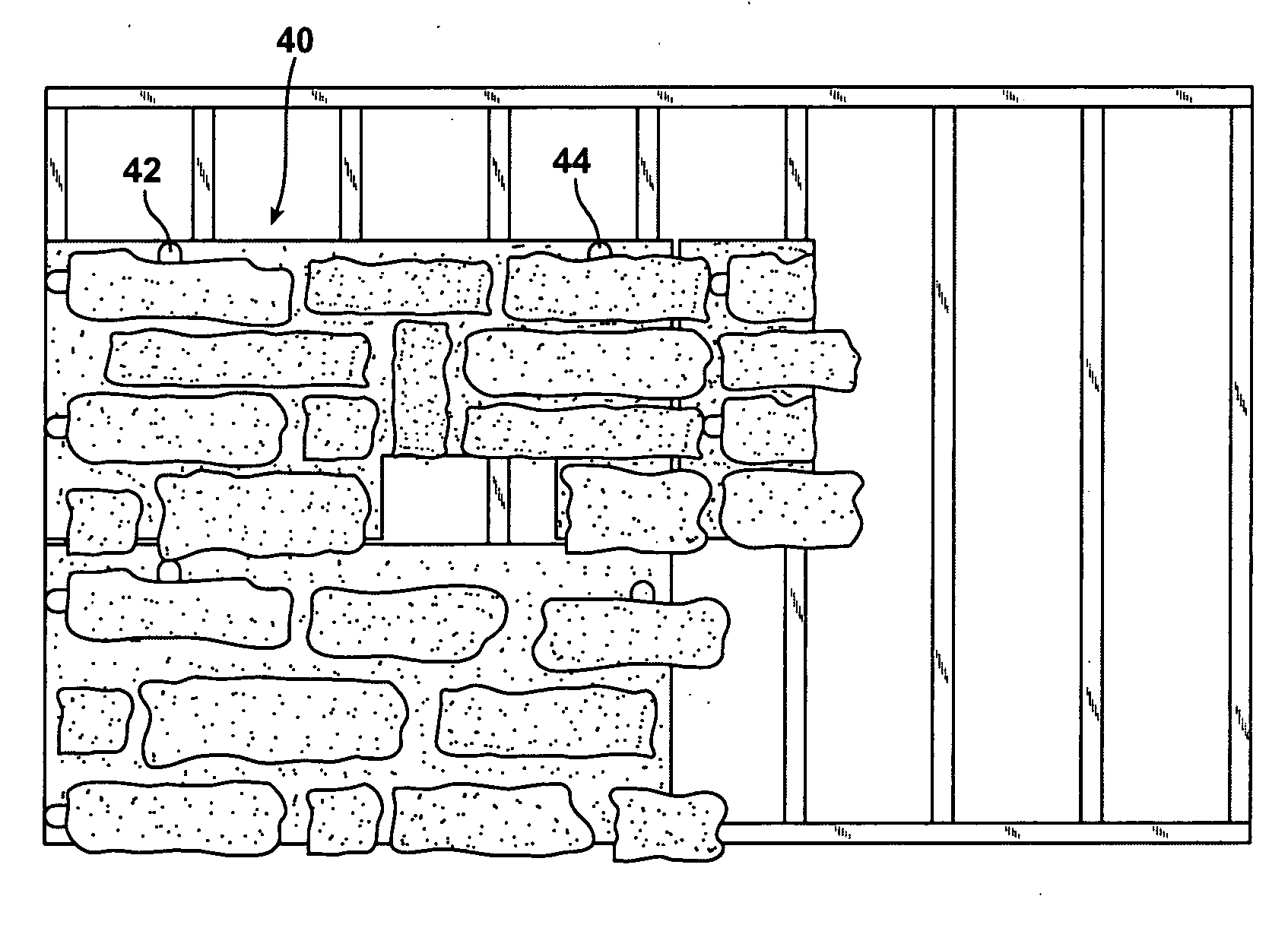

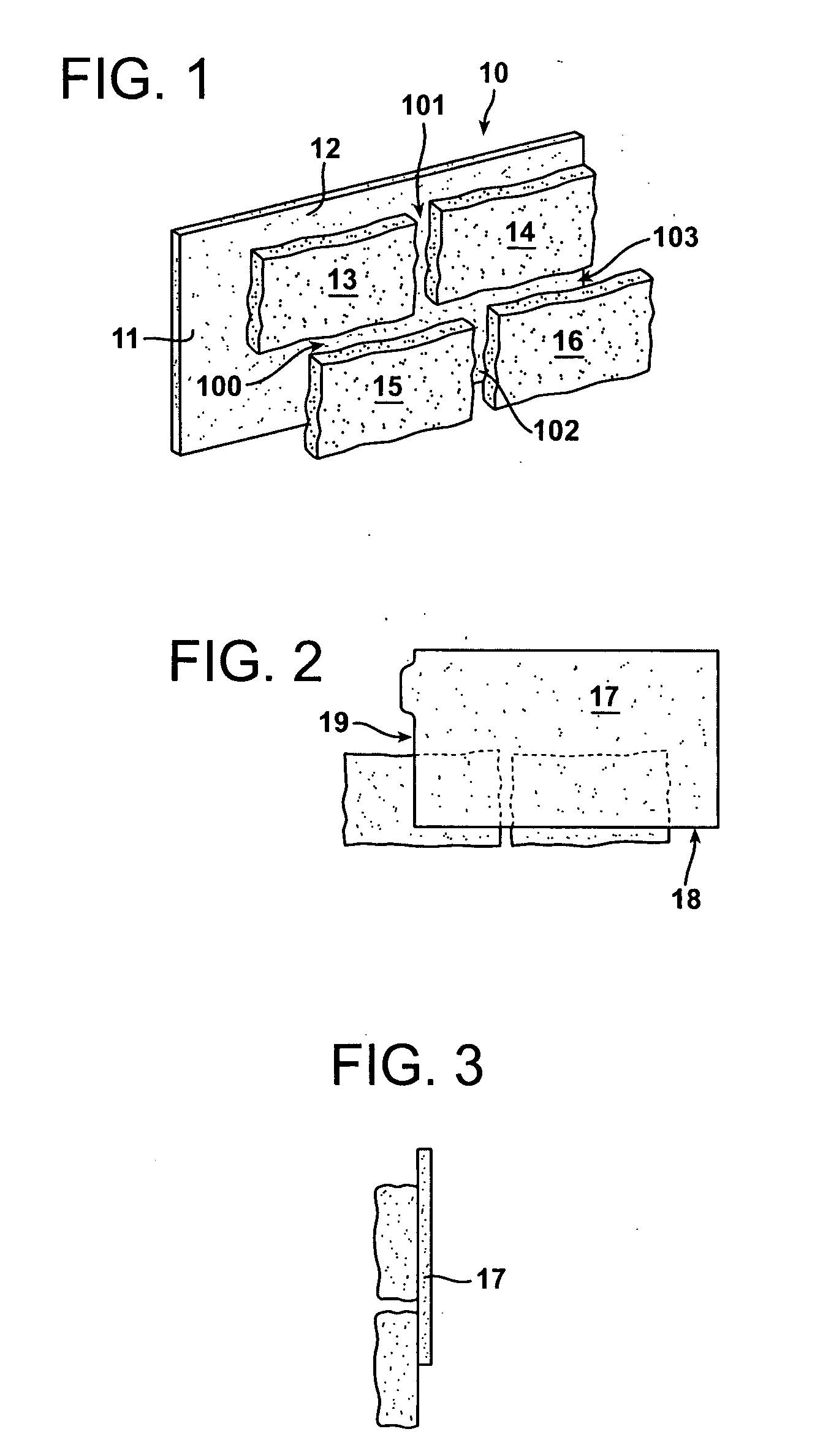

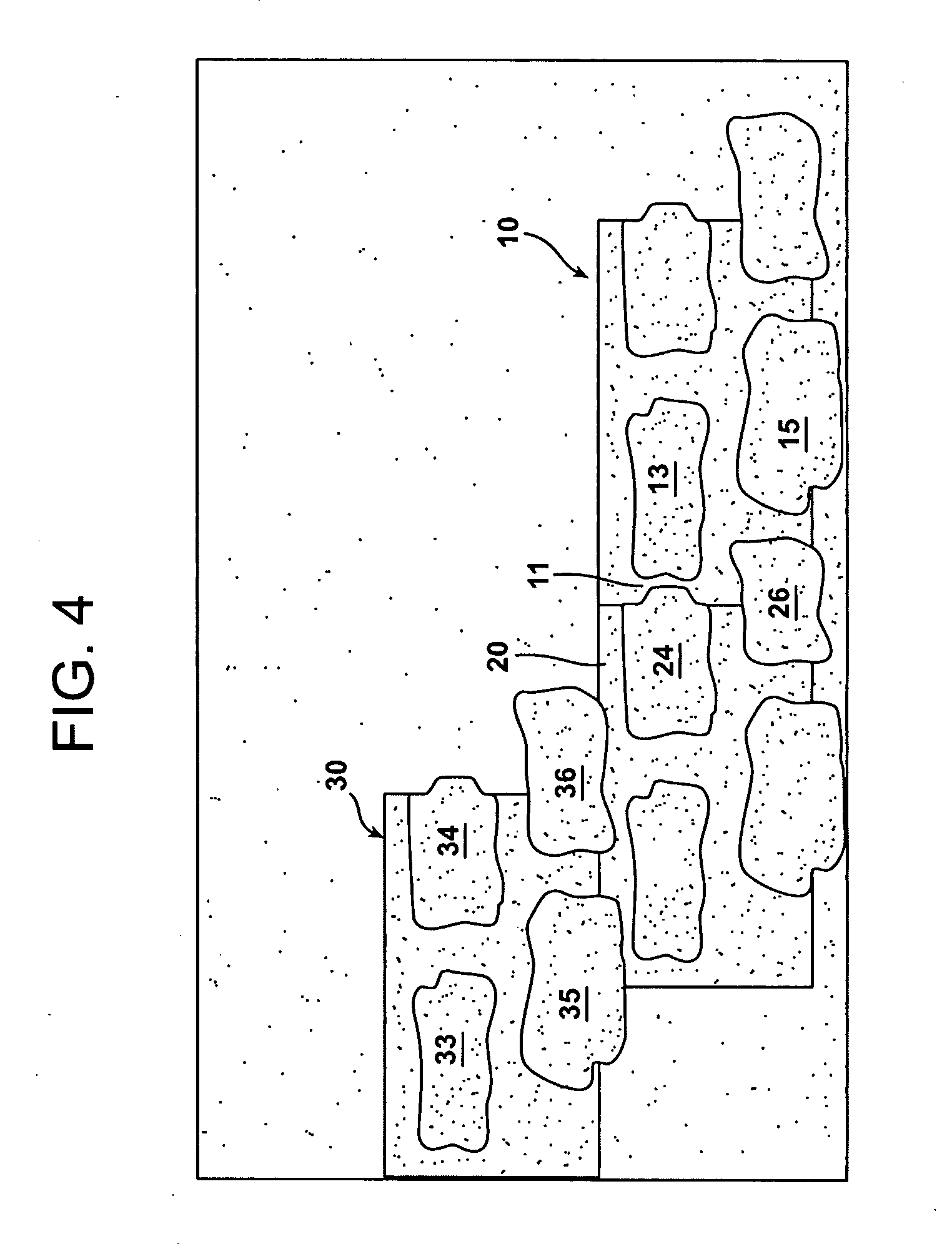

Fiber reinforced concrete stone panel system

InactiveUS20080155938A1Avoid swingingLess-costly to constructCeilingsConstruction materialRepeat patternStructural engineering

A method of forming an exterior wall of a building, including the wall, includes the step of mounting a fiber-reinforced panel to the building. The panel has a plurality of masonry units protruding from the face thereof that are spaced from one another with a groove between each of the masonry units. The method includes mounting a second, similar panel to the building spaced from the first panel with a groove therebetween, and injecting mortar into the grooves between the masonry units and the groove between the panels. The mortar covers the grooves between masonry units and the groove between panels to look the same, thereby making it difficult to distinguish the repeat pattern.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

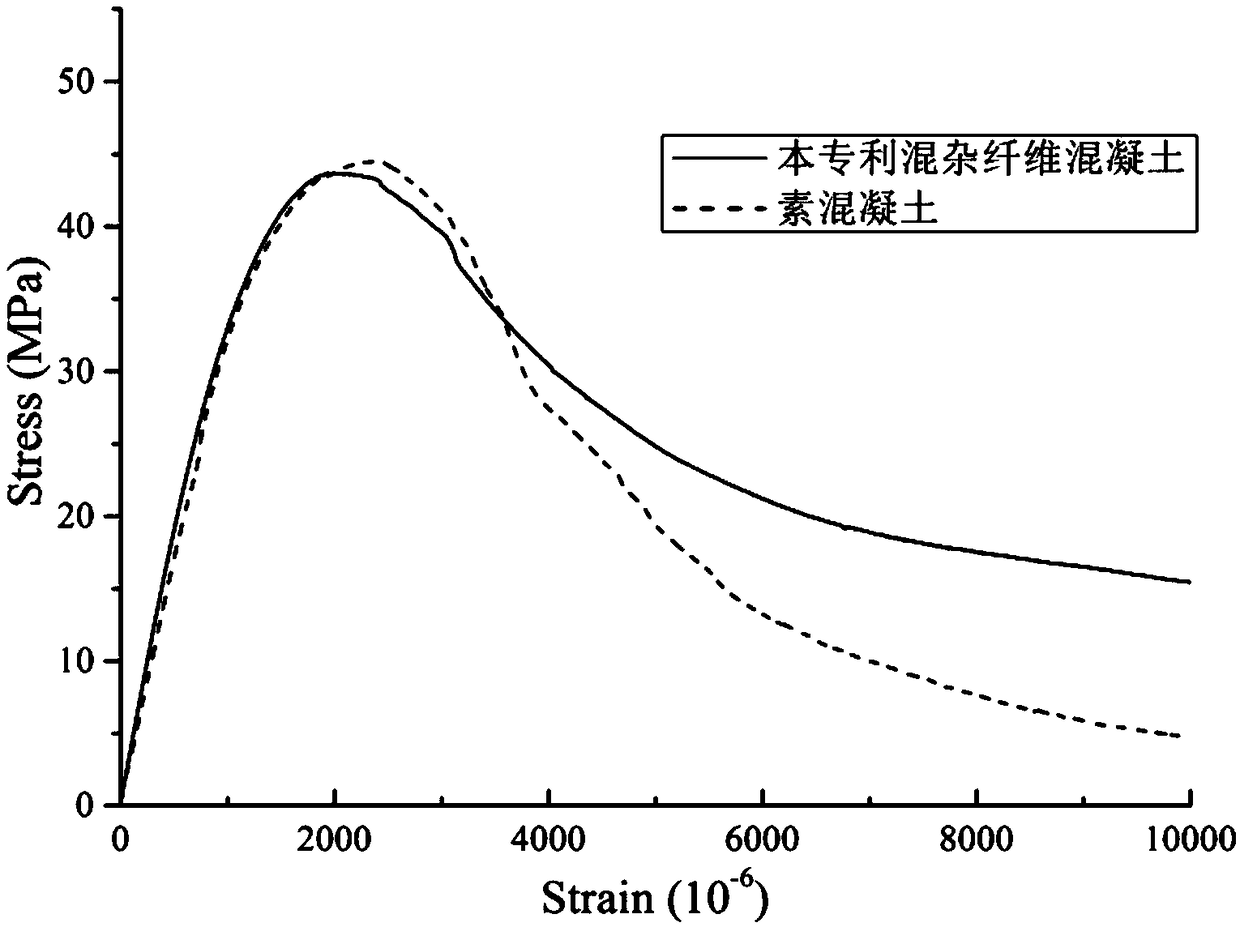

Hybrid fiber reinforced concrete, and preparation method and application thereof

The invention provides hybrid fiber reinforced concrete, and a preparation method and an application thereof. The hybrid fiber reinforced concrete comprises cement, a coarse aggregate, a fine aggregate, steel fibers, polyvinyl alcohol fibers, a water reducer and water. The preparation method comprises the following steps: adding the steel fibers into the coarse aggregate to obtain a first mixed material; adding the fine aggregate and cement into the first mixed material to obtain a second mixed material; adding the polyvinyl alcohol fibers into the second mixed material to obtain a third mixedmaterial; and mixing the water and the water reducer to obtain a mixed solution, and adding the mixed solution into the third mixed material to obtain the hybrid fiber reinforced concrete. The invention provides the most optimum criterion of parameters at multi-performance target, and establishes the optimum scoring system of parameters. The optimum fiber combination and doping amount are screened according to the system, that is, 1.3% by volume of steel fibers and 0.2% by volume of polyvinyl alcohol fibers are compounded. Compared with plain concrete with a same basic mix proportion, the mechanical property of the hybrid fiber reinforced concrete is enhanced obviously.

Owner:TONGJI UNIV

Fiber Reinforced Concrete

InactiveUS20140060392A1Prevent slippingSolid waste managementBuilding reinforcementsEngineeringFiber-reinforced concrete

Owner:PRO PERMA ENGINEERED COATINGS

Method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete

ActiveCN101913188BHighlight substantiveControlling Magnetic InductionCeramic shaping apparatusBreaking strengthUltimate tensile strength

The invention discloses a method and special equipment for preparing unidirectionally-distributed steel fiber reinforced concrete and relates to fiber reinforced concrete. The method comprises the following key steps of: pouring a prepared steel fiber concrete mixture into a nonmetallic test mold and putting the test mold into a cavity in a framework of a coil of the special equipment for preparing the unidirectionally-distributed steel fiber reinforced concrete; putting the coil and the test mold on a vibrating table of the special equipment; switching on a direct current power supply of thespecial equipment to electrify the coil so as to form a magnetic field; applying the magnetic field to the prepared steel fiber concrete mixture so as to orient steel fiber; and keeping the directionof the magnetic field accordant with that of pulling stress during test piece testing or in a working state, wherein the special equipment consists of the vibrating table, the coil and the direct current power supply. Compared with steel fiber reinforced concrete prepared by the conventional method, the unidirectionally-distributed steel fiber reinforced concrete prepared by the method and the special equipment of the invention has breaking strength increased by 25 to 100 percent or saves the steel fiber by 25 to 60 percent.

Owner:HEBEI UNIV OF TECH

Epoxy resin fiber reinforced concrete for repair and preparation method thereof

The invention relates to an epoxy resin fiber reinforced concrete for repair and preparation and application methods thereof. The epoxy resin fiber reinforced concrete is prepared from the following raw materials in percentage by weight: 55-70% of refined quartz sands, 33-17% of epoxy resin, 11-9% of curing agent and 1-4% of basalt fiber chopped strands. The preparation method comprises the following the following steps: by using the refined quartz sands as aggregates and epoxy resin as a gel material, adding the basalt fiber chopped strands; and mixing according to an appointed proportion. The product provided by the invention is extremely high in viscosity, can be well combined with defected concrete of a base layer and is not easy to peel and bulge. The strength can reach the strength grade of concrete C50. The concrete is simple to manufacture, can be prepared on site and needs not to be heated on site. Epoxy resin needs not to be diluted, and the construction steps are saved and the concrete is convenient to use while no diluents are introduced. The product is short in curing time, and comes into use in 24 hours after repair. The concrete is strong in adaptability, can be suitable for repairing defects of thick and thin layers of a terrace at the same time and can be used for repairing various defects of terrace such as pits formed by collision or high-low difference due to differential settlement of the concrete terrace.

Owner:北京金港建设股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com