On-site concrete shear wall structure with permanent heat insulation formwork and construction process of on-site concrete shear wall structure

A technology of concrete shear wall and thermal insulation formwork, applied in thermal insulation, wall, building components and other directions, can solve the problems of difficult control of construction quality, limited external surface layer, long construction period, etc., to achieve the same life span of structure and thermal insulation, The quality of the project is easy to ensure and the effect of reducing the amount of formwork works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

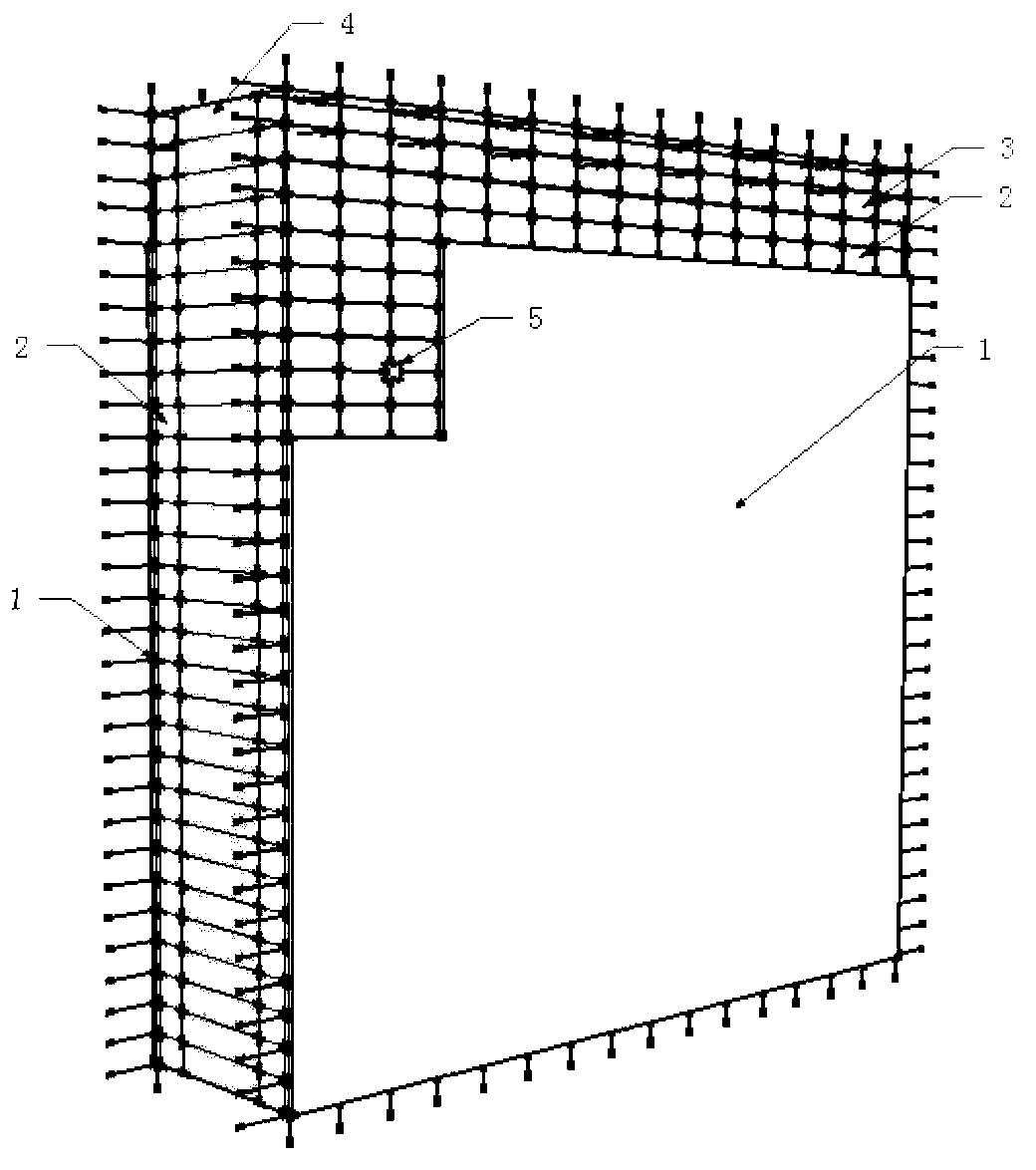

[0029] Embodiment 1 is an external thermal insulation structure of the external wall. The storey height and the thickness of the thermal insulation layer are determined according to the architectural design, and the stressed welded steel grid frame 3 is determined according to the structural design.

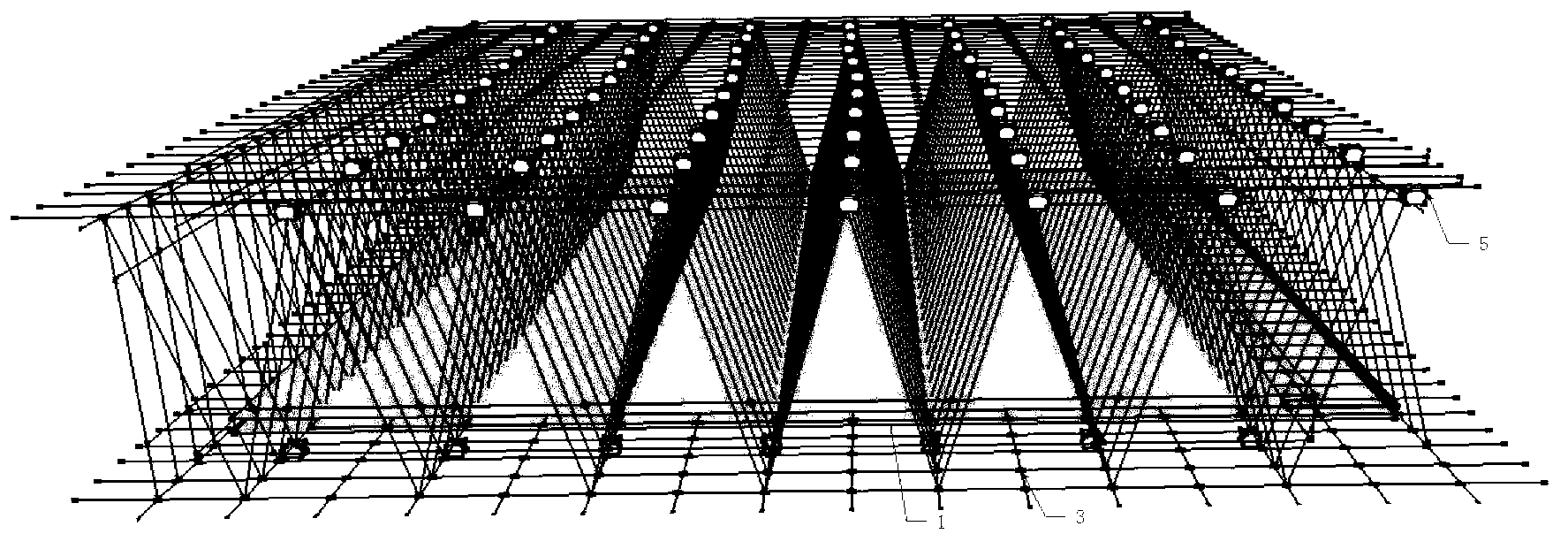

[0030] In the factory, weld the steel grid frame 3 according to the structural design requirements (see Figure 4 ), binding the prefabricated concrete protective layer block 5; paving high-performance concrete in the mold, then laying steel wire mesh or fiber mesh, and scraping to make fiber-reinforced high-performance concrete layer 1, that is, the inner permanent non-insulation formwork; welding The reinforced grid frame 3 is pressed into the inner permanent non-insulation formwork (see figure 2 ), conservation. Make a fiber-reinforced high-performance concrete layer 1 on the bottom of another mold, and then make a lightweight concrete insulation layer 2 on the upper side of...

Embodiment 2

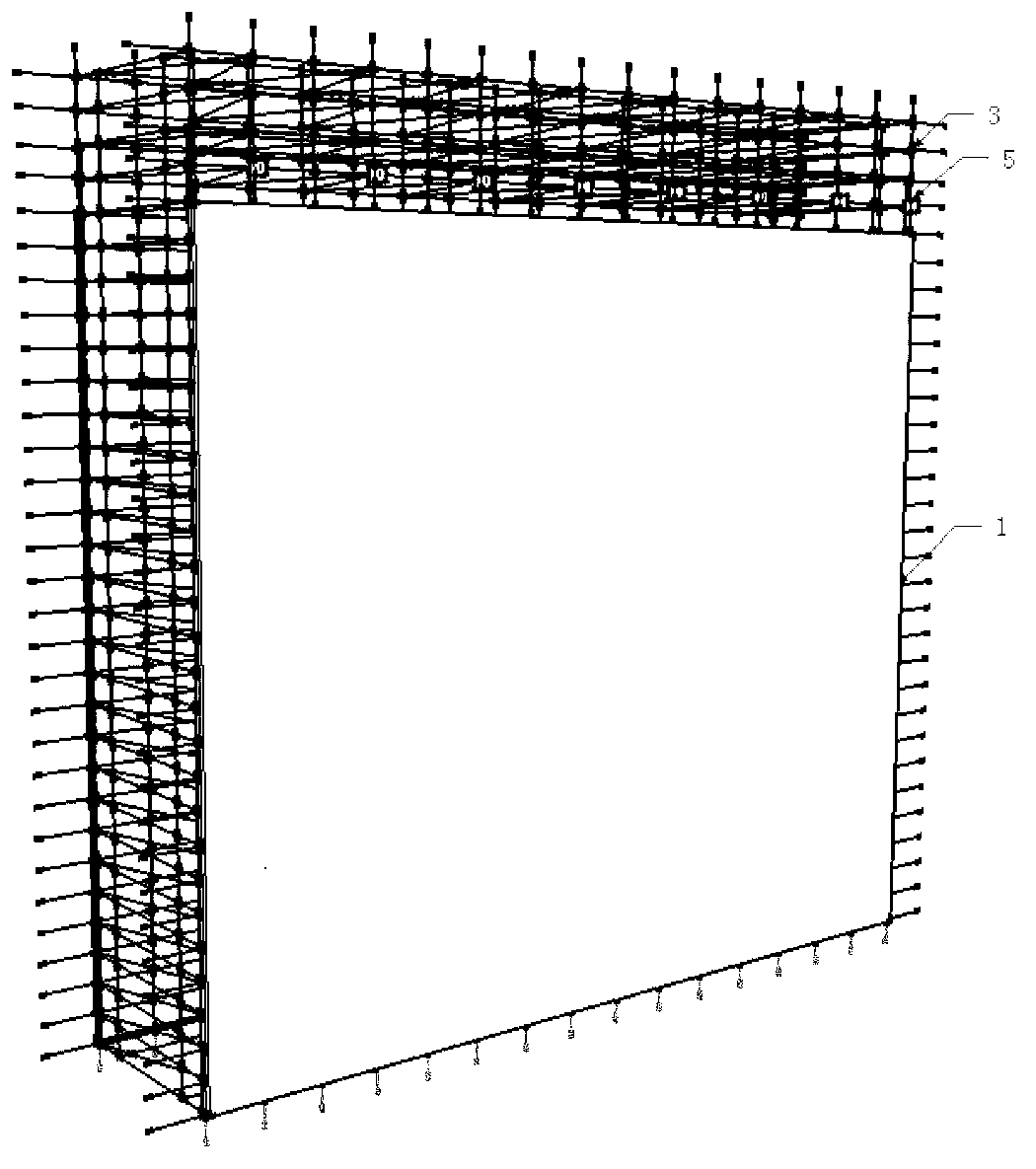

[0032] Example 2 is a double-sided thermal insulation structure for internal and external walls. The storey height and the thickness of the thermal insulation layer are determined according to the architectural design, and the stressed welded steel grid frame is determined according to the structural design.

[0033] In the factory, weld the steel grid frame 3 according to the structural design requirements (see Figure 4 ), binding the prefabricated concrete protective layer block 5; paving high-performance concrete in the mold, and then laying steel wire mesh or fiber mesh, and scraping to make a fiber-reinforced high-performance concrete layer 1, and then on the upper side of the high-performance concrete layer Make the lightweight concrete insulation layer 2, and make the outer permanent thermal insulation template; press the welded steel grid frame 3 into the outer permanent thermal insulation template (see image 3 ), maintenance. Make the inner permanent thermal insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com