Patents

Literature

1758 results about "External wall insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An external wall insulation system (or EWIS) is a thermally insulated, protective, decorative exterior cladding procedure involving the use of expanded polystyrene, mineral wool, polyurethane foam or phenolic foam, topped off with a reinforced cement based, mineral or synthetic finish and plaster.

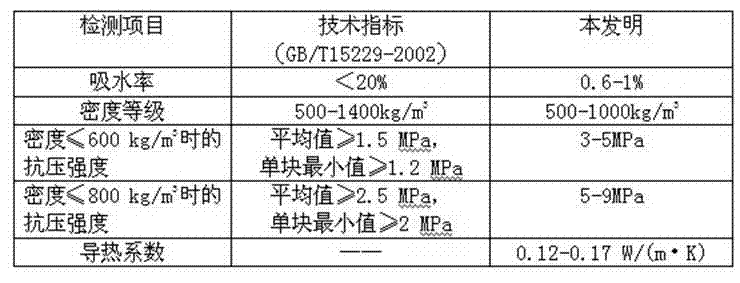

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

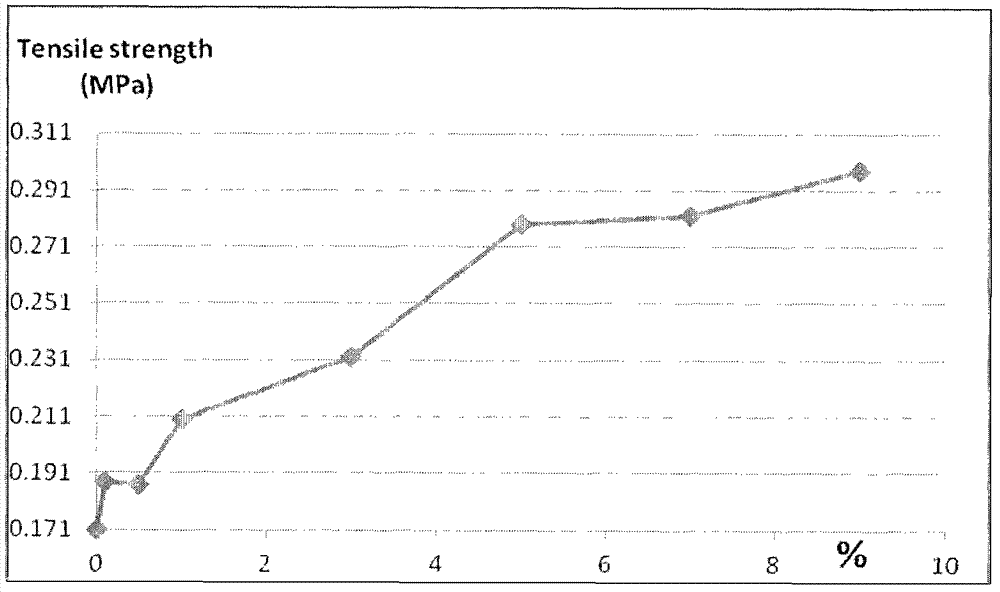

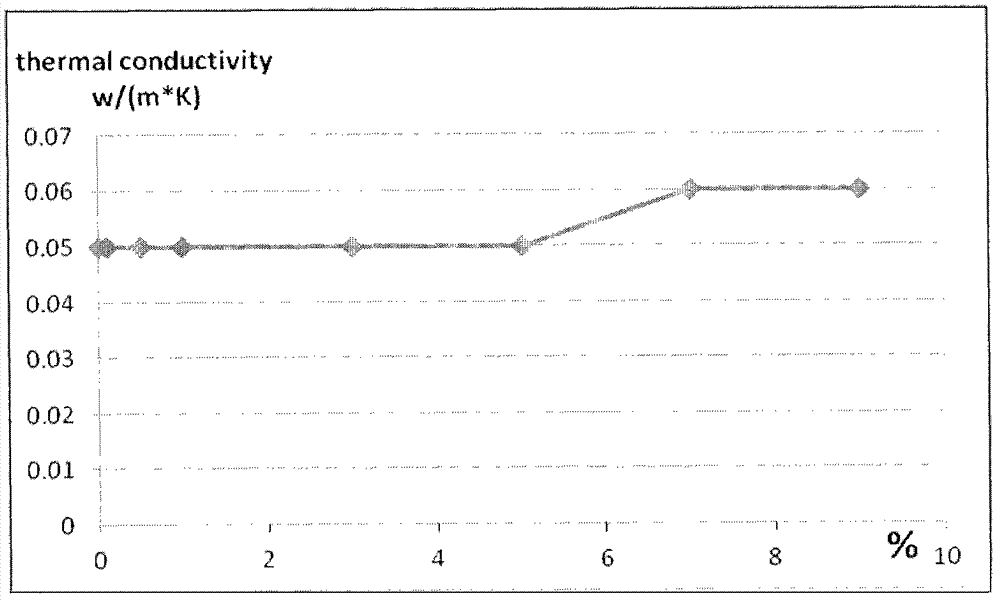

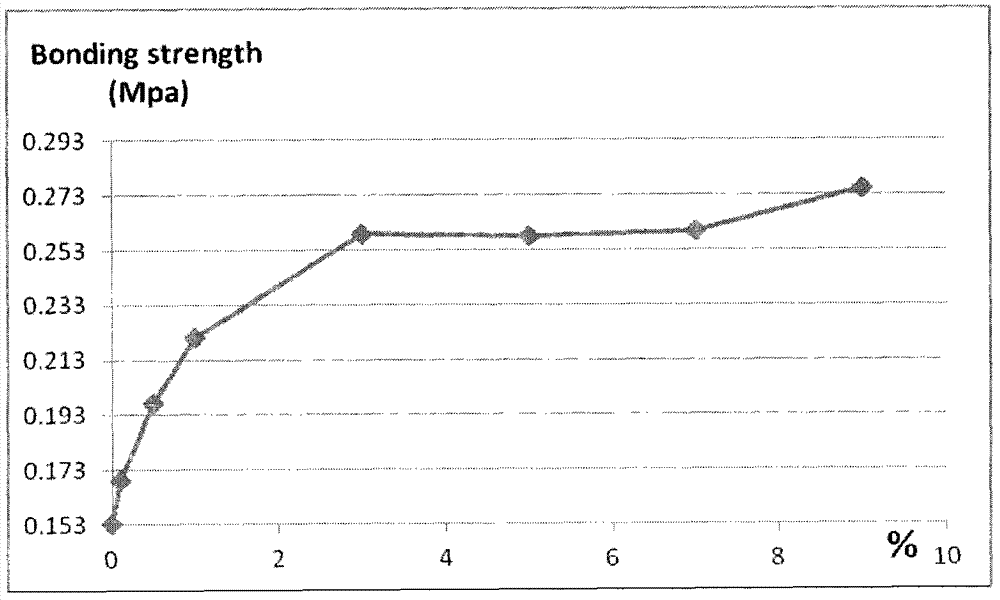

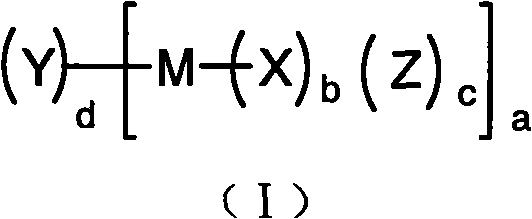

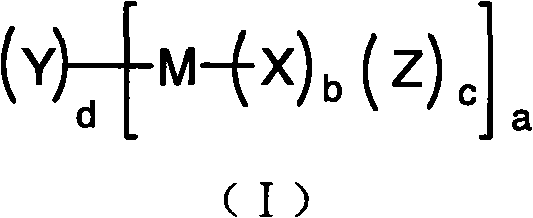

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

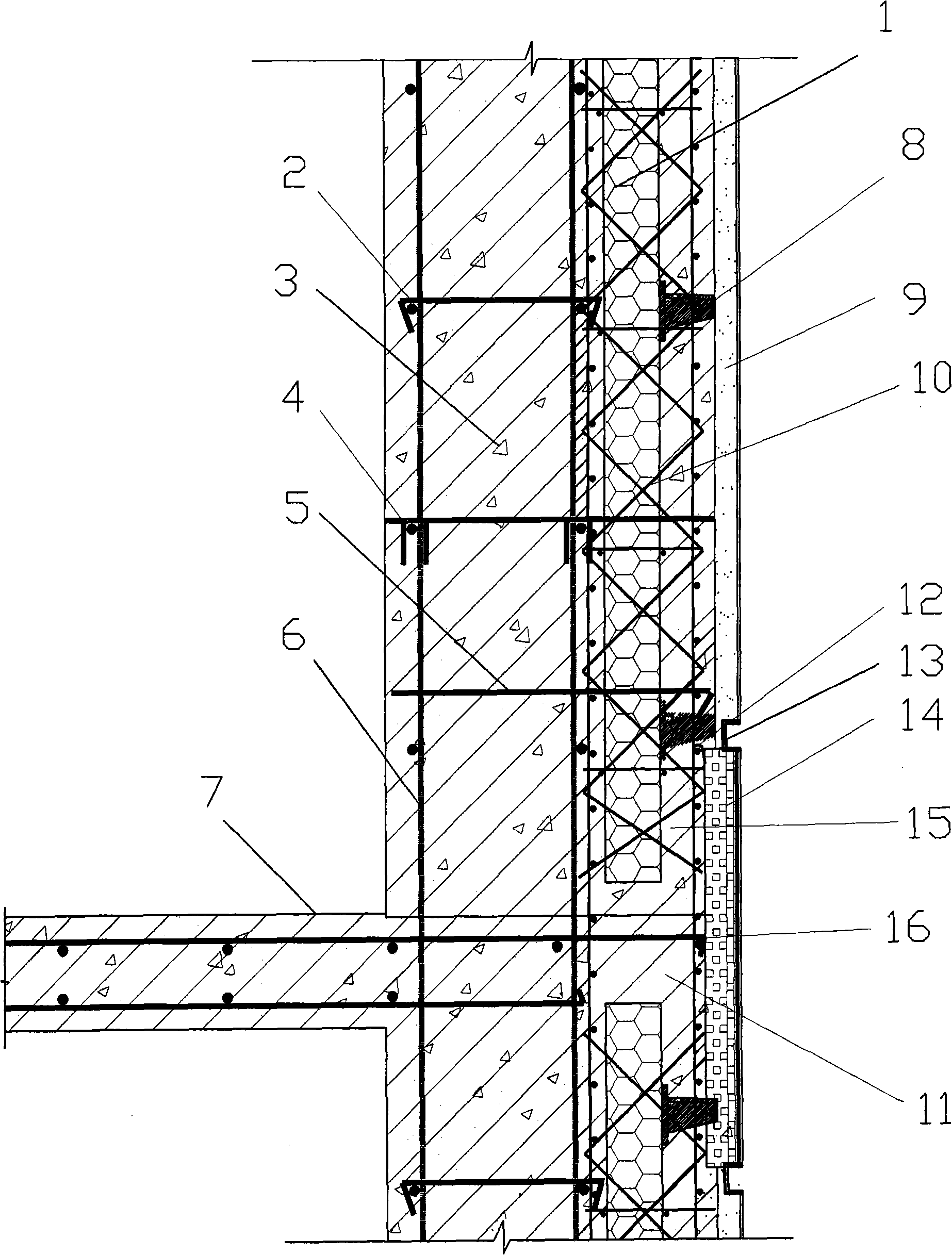

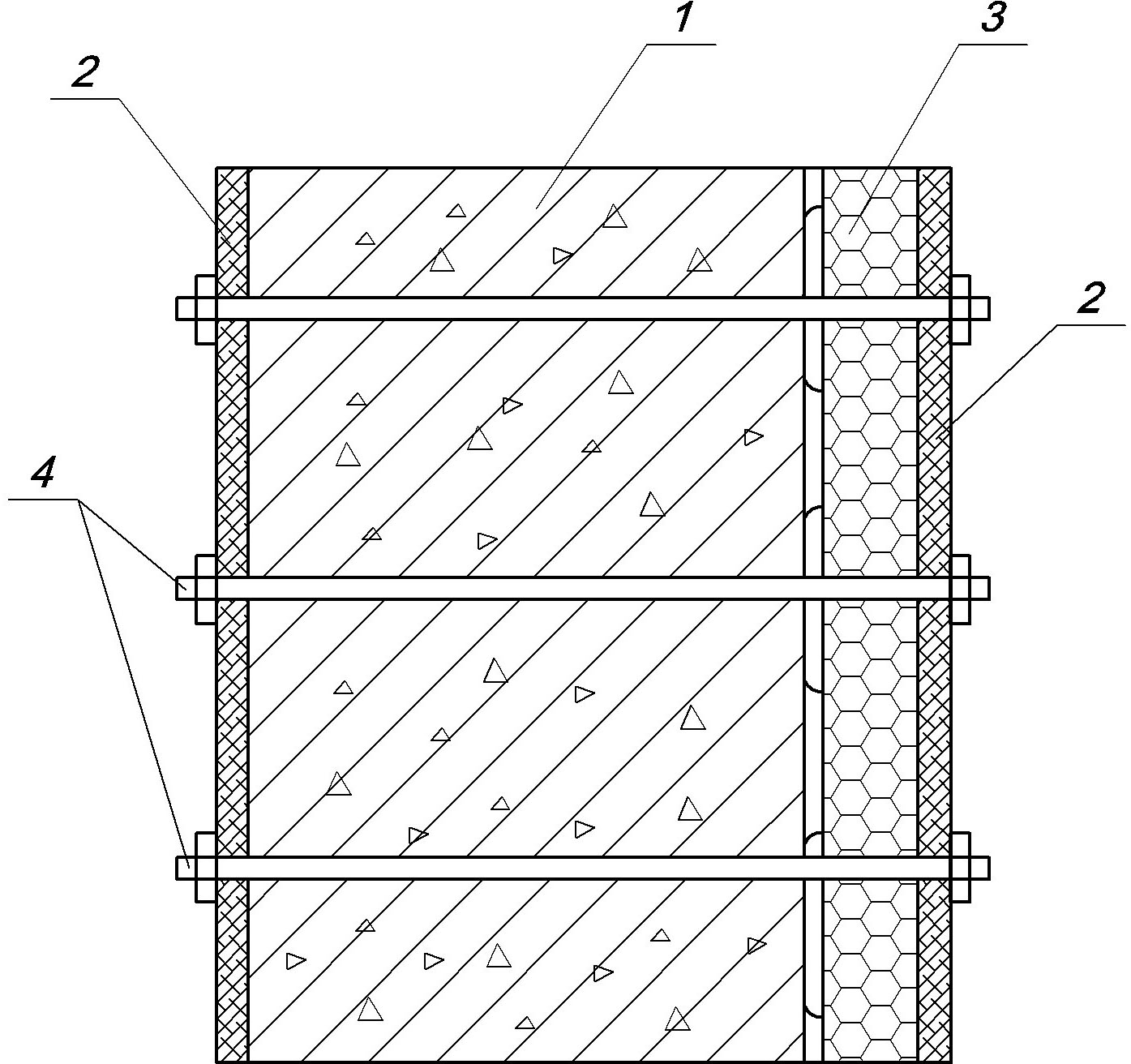

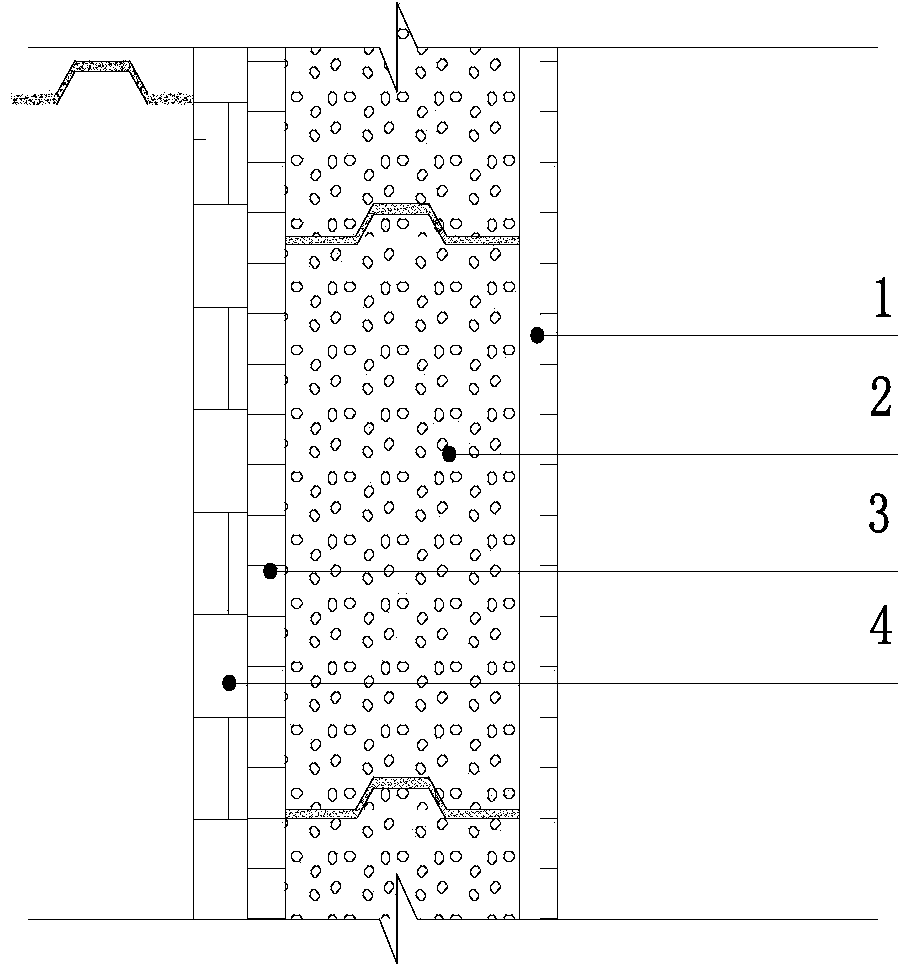

Externally reinforced concrete irrigated and heat preservation wall structure embedded energy-saving system and its construction method

ActiveCN101319525ANovel structureImprove thermal insulation performanceWallsClimate change adaptationInsulation layerSteel bar

The invention relates to an energy-saving system for a reinforced concrete outer-casting built-in heat insulation wall body structure and a construction method thereof, which can effectively solve the problems of external wall heat insulation of a high-rise building with high heat insulation requirement and cracking and falling of a heat insulation layer. The system is produced by a wall body and reinforcing steel bars in the wall body which are cast by concrete. The method comprises the following steps that: a reinforcing steel bar frame of the wall body is produced and arranged, namely parallel vertical reinforcing steel bars and indoor floor-connecting board tie bars perpendicular to the parallel vertical reinforcing steel bars are bound together, a grid board is hoisted and externally suspended outside the vertical reinforcing steel bars of the wall body, and is bound with the vertical reinforcing steel bars of the wall body by hooked bars and binding steel bars as well as framework positioning bearing bars, then a framework is arranged on the framework positioning bearing bars and is firmly bound with reinforcing steel bars of beams and boards of a floor, lapping bars are reserved, a heat insulation grid board is firstly arranged, then reinforcing steel bars of corbel brackets of a balcony and an air conditioning board external wall are bound, finally the concrete is cast, the curing is performed, and the framework is removed to repair the structure. The system has good heat insulation effect, energy conservation, environmental protection, simple method, and huge economic benefit and social benefit.

Owner:HENAN JINYUAN CONSTR

Foamed ceramics energy saving and heat preservation decorative wall brick and manufacture method thereof

InactiveCN101560111ALow thermal conductivityLow densityCeramic materials productionCeramicwareBrickSlurry

The invention discloses a foamed ceramics energy saving and heat preservation decorative wall brick and a manufacture method thereof, including the steps of conducting ball milling on 15-65 percent wt of industrial residues, 10-45 percent wt of plastic clay, 15-60 percent wt of solvent, 10-45 percent wt of pore-forming agent with the fineness being 1-100mum and proper amount of water to form slurry; spray drying or dehydration and clay preparation, and forming powder material or clay segment through staleness; and implementing pressure forming to make billet which is burned under heat preservation at temperature of 1140-1240 DEG C to finally form the foamed ceramics wall brick. The wall brick can be used not only for the heat preservation and decoration of external walls, but also for indoor heat preservation and decoration, and the external wall and the indoor space can realize the organic combination of uniform heat preservation and decoration, which agrees with the development direction of heat preservation material industry of external walls. The wall brick has the advantages of: I. high temperature resistance, acid and alkali-resistance, good chemical stability, no ageing, strong durability, long service life, no generation of heat channel and good adhesive fixity; and II. difficult water seepage and crack, strong anti-corrosion capacity, uneasy deformation and damage, simplification of mounting, laying and sticking procedures, convenience for construction, relief of labor intensity and decrease of material consumption quantity.

Owner:吴汉阳

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

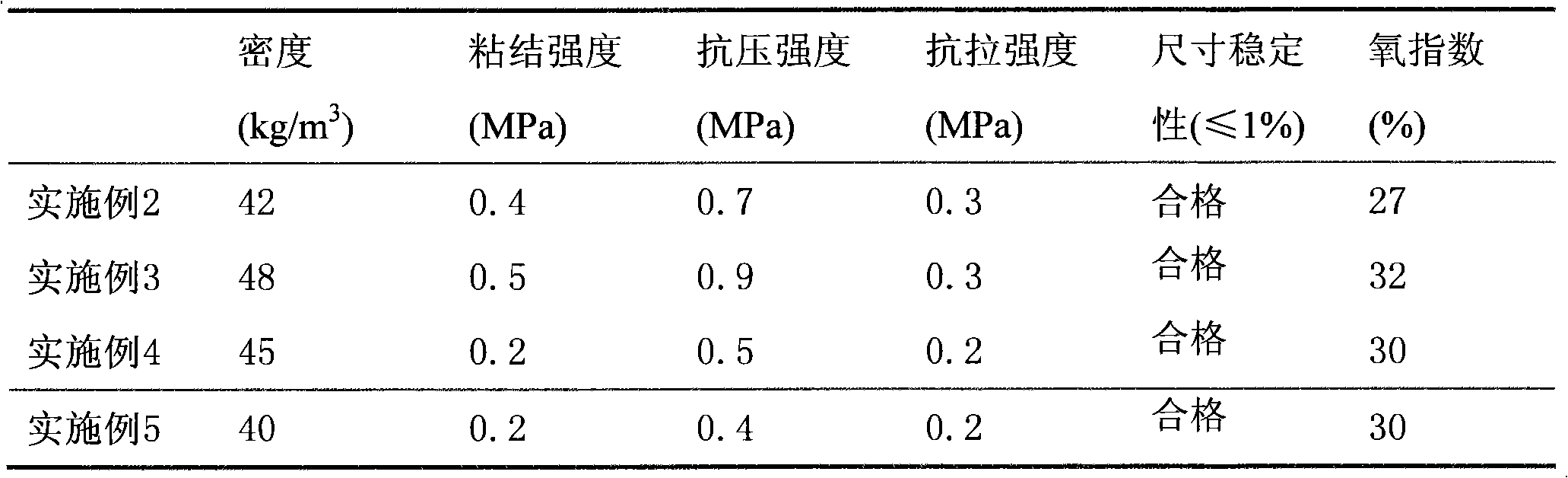

Polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and preparation method thereof

InactiveCN101831168AImprove flame retardant performanceImprove mechanical propertiesEpoxyFire retardant

The invention provides a polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy and a preparation method thereof. The polyurethane rigid foam exterior wall thermal insulation material with high flame retardancy comprises a component A and a component B, wherein the component A consists of phenolic resin, brominated epoxy resin, phosphorated flame retardant polyether polyol, organosilicon foam stabilizer, catalyst dimethylethanolamine, catalyst dibutyltin dilaurate, flame retardant and foaming agent 1,1-dichloro-1-fluoroethane, and the component B is flame retardant polyisocyanate curing agent. The invention also provides a preparation method of the exterior wall thermal insulation material. The polyurethane rigid foam exterior wall thermal insulation material has excellent mechanical property and high flame retardancy, overcomes the problem that the fireproof flame retardancy and the mechanical property of the traditional polyurethane rigid foam thermal insulation materials are mutually in contradiction and is suitable for exterior wall thermal construction of a building with higher fireproof level requirement.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD

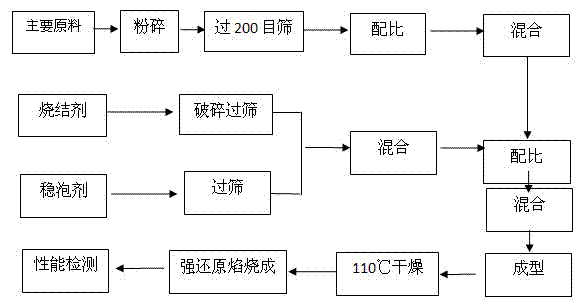

Method for preparing foam ceramic self-insulation wall material by utilizing solid wastes

InactiveCN103396150AReduce manufacturing costRealize comprehensive utilizationSolid waste disposalCeramicwareChromium sesquioxideInsulation layer

The invention relates to a method for preparing a foam ceramic self-insulation wall material by utilizing solid wastes. The wall material comprises a main material and an admixture. The main material is prepared from the following components in proportion: 25% to 35% of chromium slags, 19% to 27% of coal gangue, 20% to 26% of waste ceramic polishing residues, 17% to 25% of albite and 1% to 6% of bentonite. The method comprises the following steps of: adding 16 to 20g of the admixture into every 200g of the main material; evenly mixing and screening the mixture; putting the mixture into a die; molding the mixture in a pressing manner and drying; sintering the mixture under a strong reducing atmosphere at the temperature of 1120-1180 DEG C, thereby obtaining the foam ceramic self-insulation wall material. The carbon in the coal gangue can serve as a foaming agent or a reducing agent, so that hexavalent chromium is reduced into chromium sesquioxide at the high temperature and under the strong reducing atmosphere. Thus, the toxicity of the chromium slags is eliminated. The prepared foam ceramic self-insulation wall material is low in pyroconductivity, small in density and low in water absorption rate; the usage temperature can reach 900 DEG C. In addition, the foam ceramic self-insulation wall material is complete in fire resistance, high in strength and long in service life, and can be used for replacing the existing wall materials and flammable insulation materials. The wall material integrates protection and thermal insulation functions; an exterior wall insulating layer is not required. Thus, the construction cost is lowered.

Owner:HENAN COAL CHEM IND GROUP INST +1

Explosion-proof heat-preservation multifunctional sheet material of foaming concrete sandwich and preparation method of material

InactiveCN102747789AWith anti-knock abilityStrong anti-knock abilityHeat proofingWater-setting substance layered productFoam concreteUltimate tensile strength

The invention discloses an explosion-proof heat-preservation multifunctional sheet material of a foaming concrete sandwich and a preparation method of the material. The sheet material comprises an outer wall heat-preservation sheet material core body; and explosion-proof light mortar outer protection plates are respectively spliced on the surfaces of the two sides of the outer wall heat-preservation sheet material core body. The explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich has stronger explosion-proof capability and can be used for protecting the safety and stability of a main body structure of a building under the effect of protecting an explosive load; and the heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products. The method comprises the following steps of: A, preparing an explosion-proof and light-weight mortar outer protection plate; and B, preparing a foaming concrete core body. The heat-preservation, heat-insulation, fireproof, environmentally-friendly performances and the like of the explosion-proof heat-preservation multifunctional sheet material are better than those of like products and the construction process is simple. Panels on the two sides of the explosion-proof heat-preservation multifunctional sheet material of the foaming concrete sandwich are made of high-strength and light-weight mortar and the strength of the panels is higher. When the panels are cast and molded, a metal grid reinforcing layer is additionally arranged so that the panels have stronger anti-explosion capability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

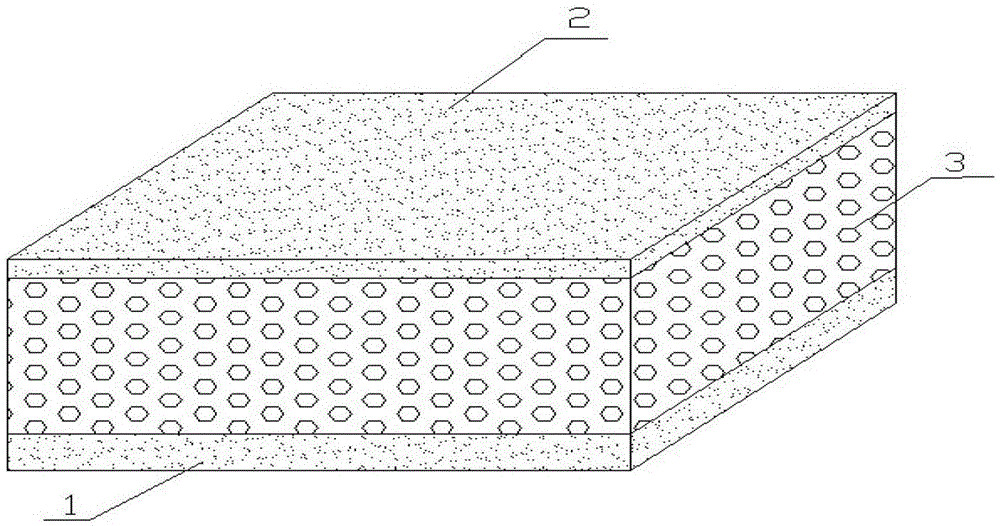

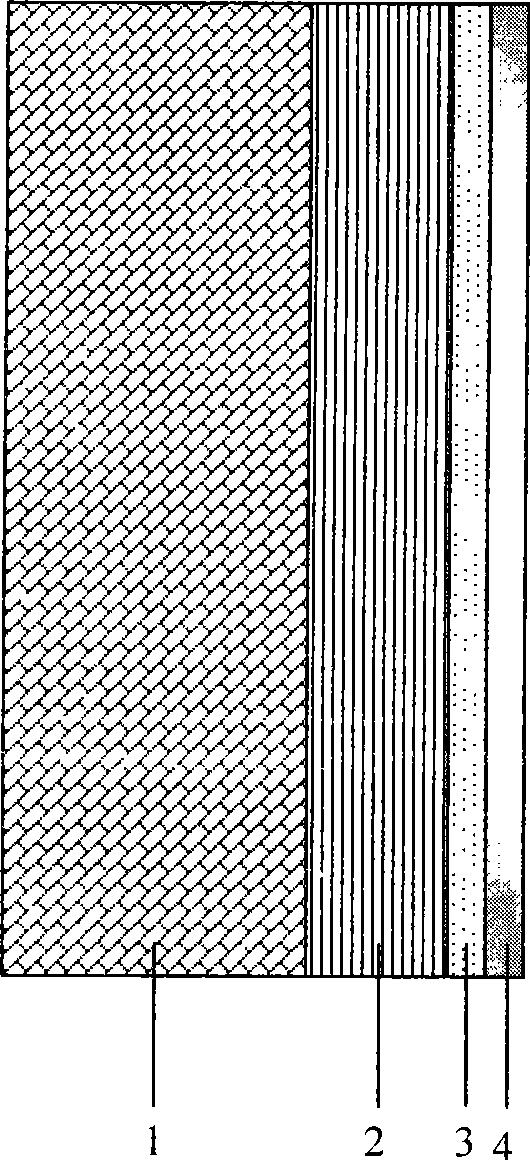

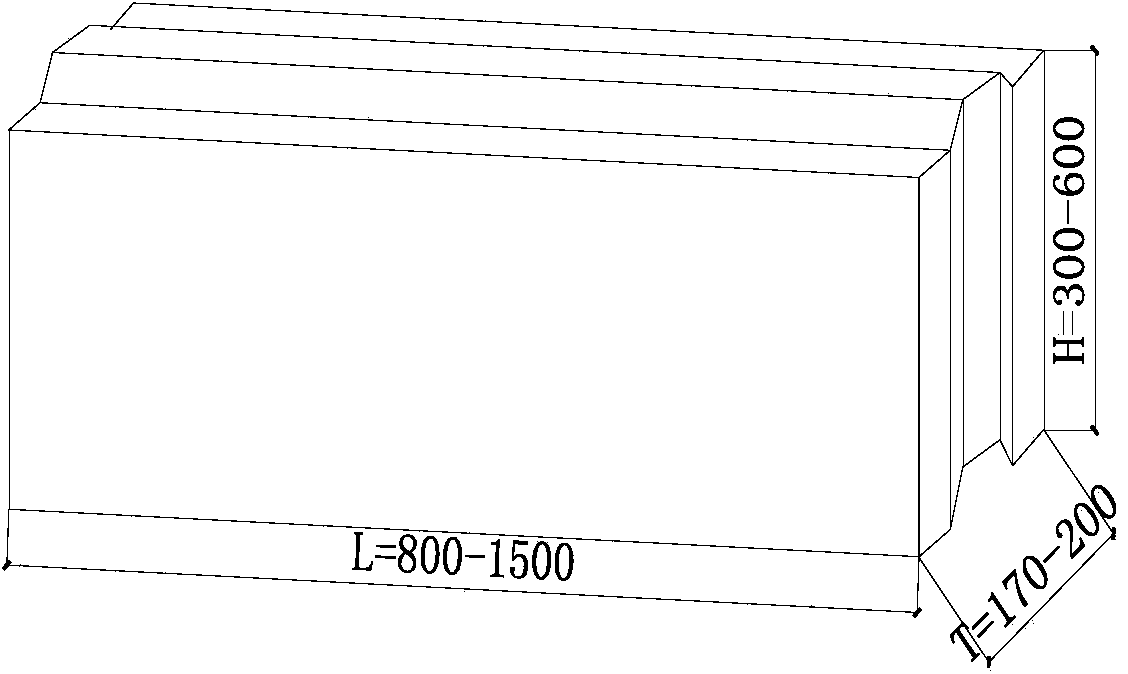

Insulating decoration integral board for building exterior wall

InactiveCN101205753AAdequate bond strengthImprove crack resistanceCovering/liningsSolid waste managementEngineeringEnergy consumption

The invention relates to a constructional material, in particular to a heat preservation and decoration board for a building exterior wall. The invention has a structure that the board mainly comprises three layers; an inner layer serves as an insulating course, an outer layer serves as a decorative layer and a middle layer serves as a binding course; wherein, the insulating course has a polyphenyl board or a plastic extrusion plate or a polyurethane board; the decorative board has various exterior wall facing dopes or a decorative plate; the binding course is the polymer caking agent layer, the insulating course and the decorative layer are stuck into a whole by the cementing action of the polymer caking agent. The invention has convenient construction, easy manipulation, low cost, good heat prevention effect and strong suitability, thereby contributing to the quick popularization of energy consumption of a building.

Owner:李旭东

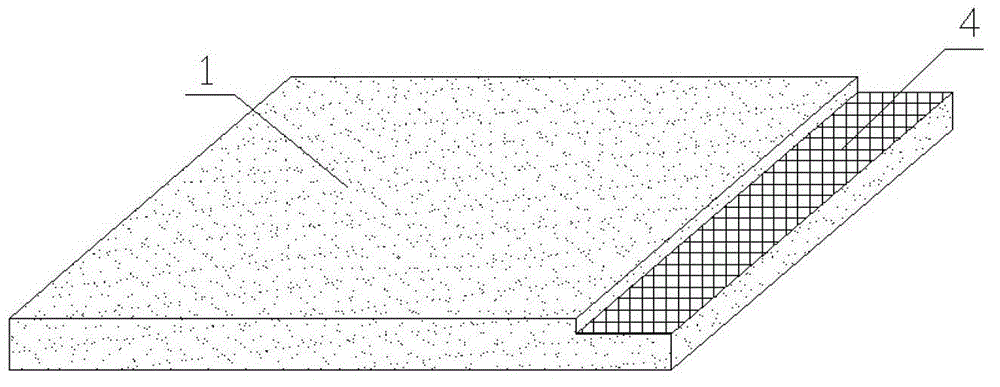

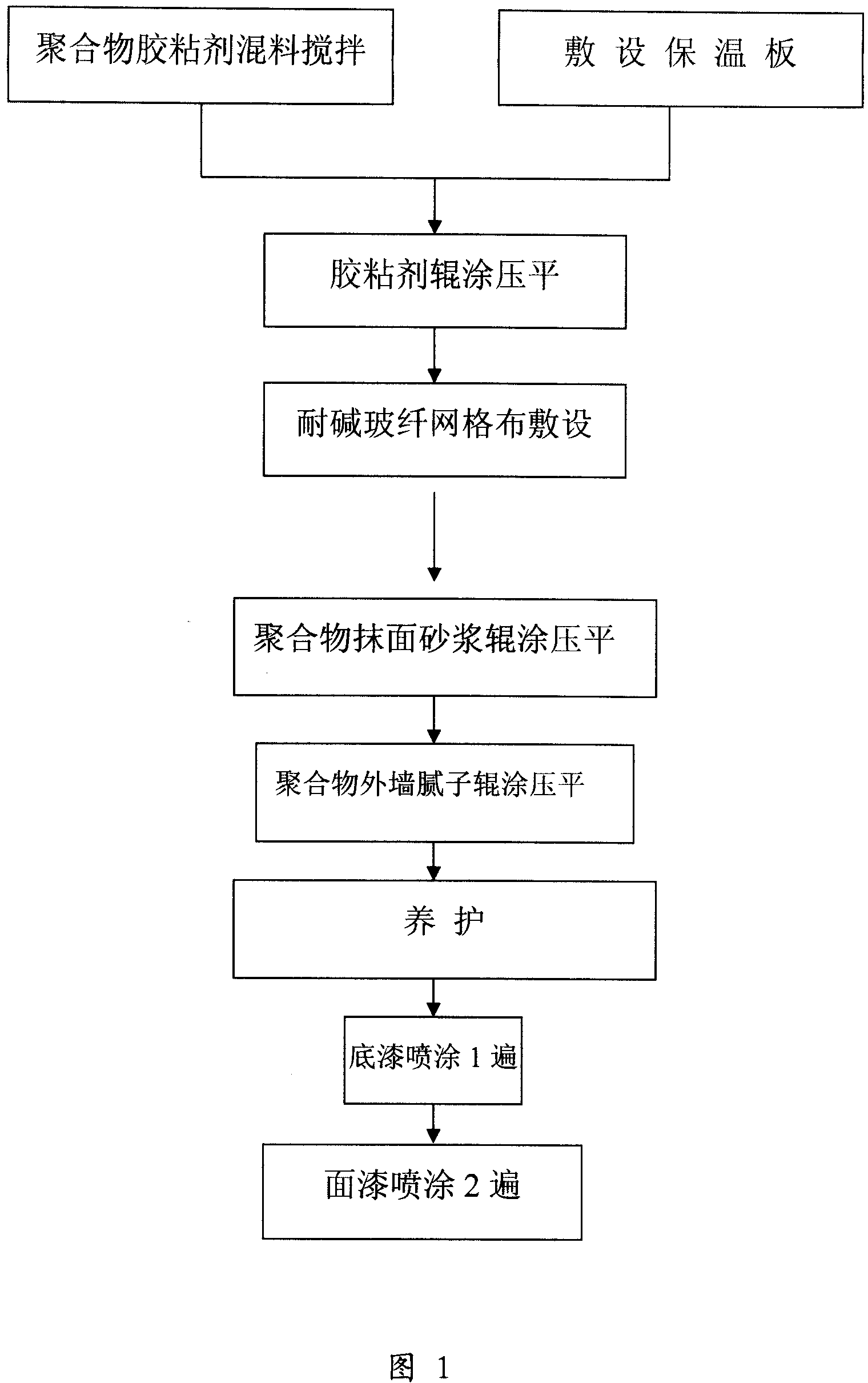

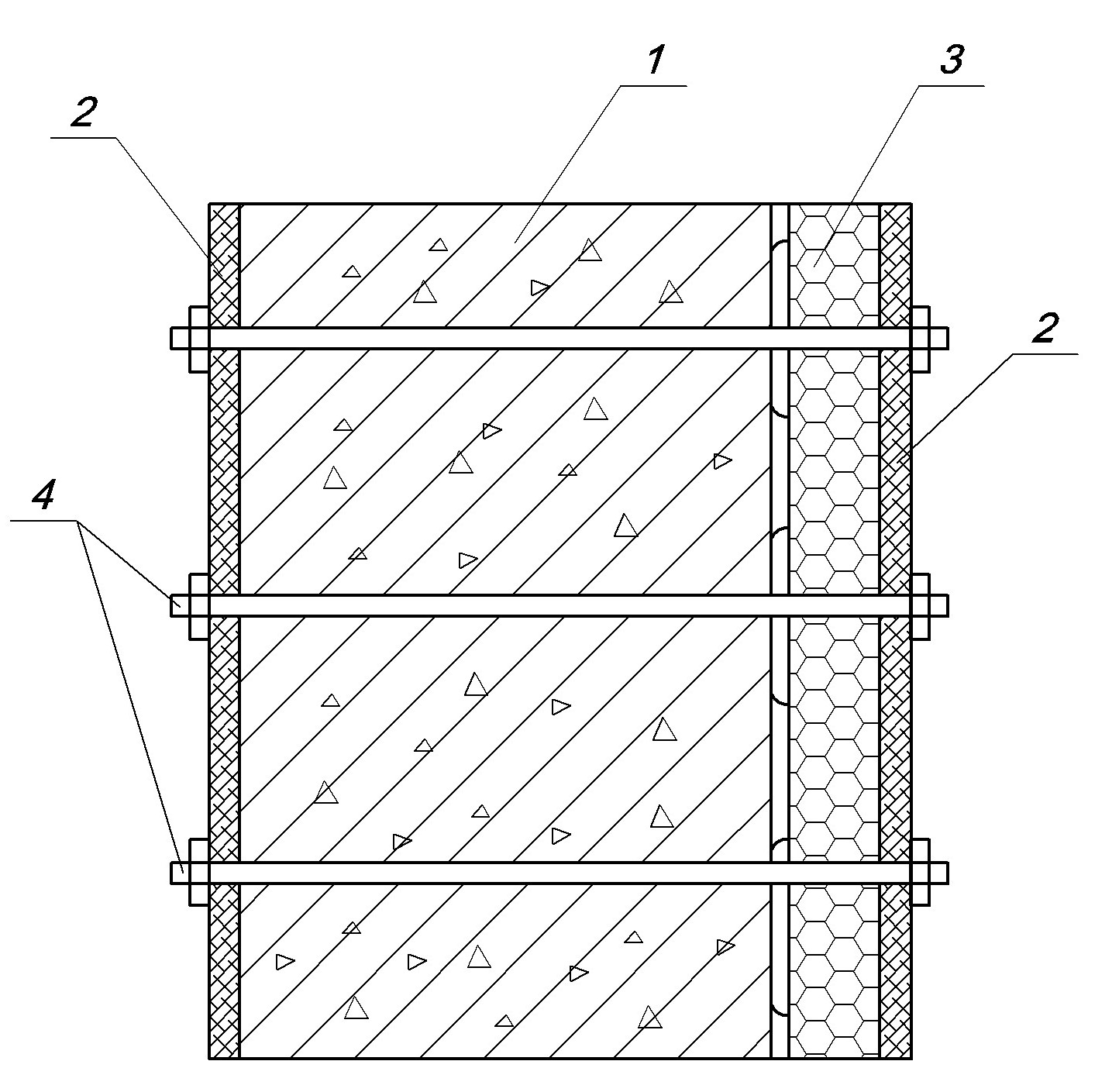

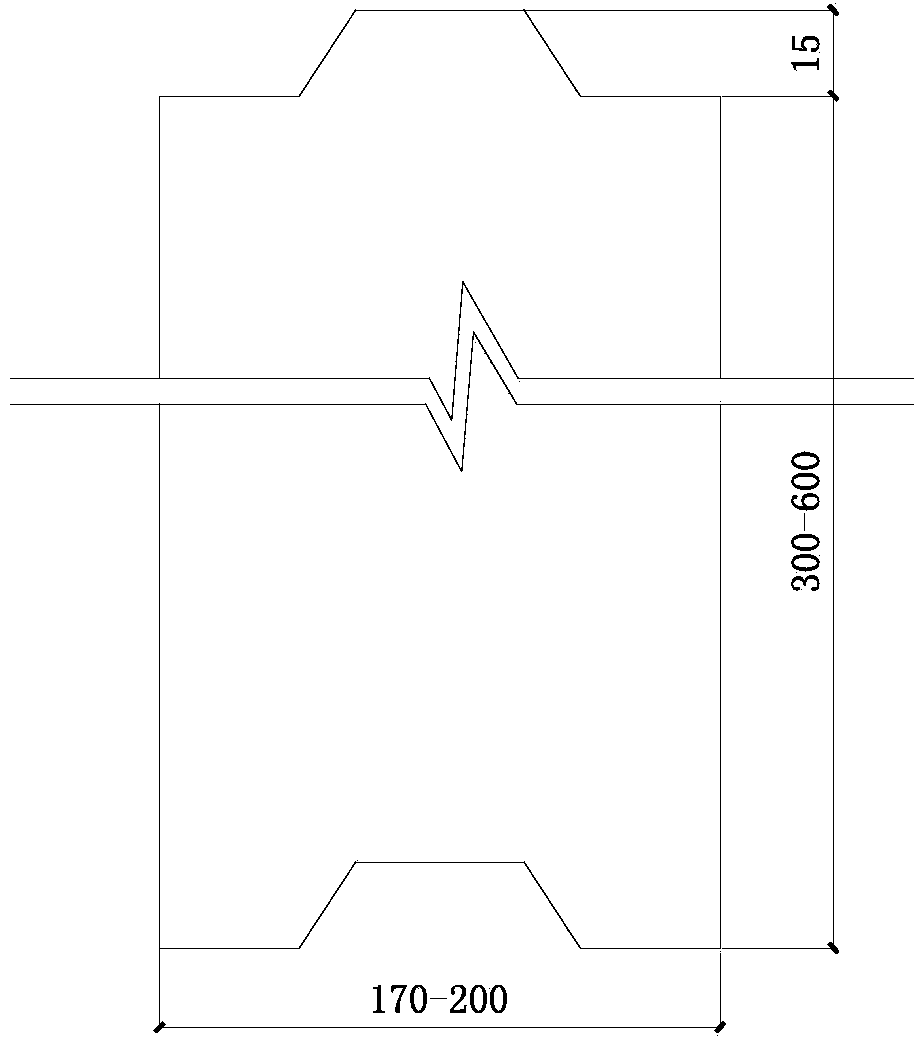

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

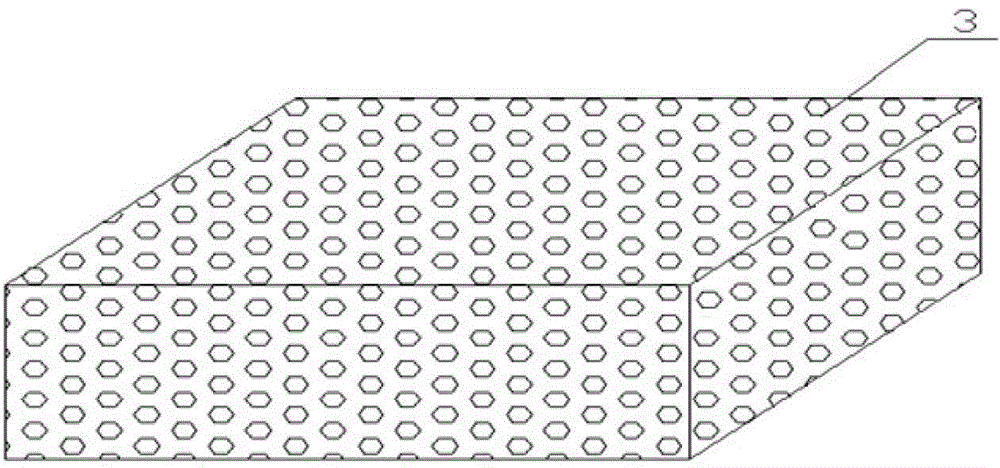

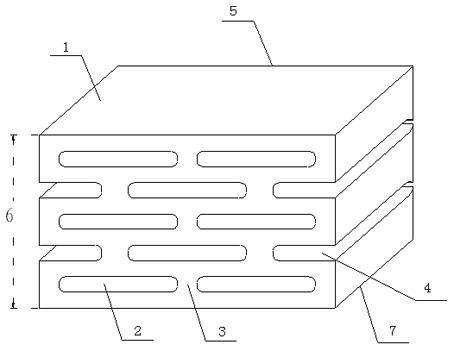

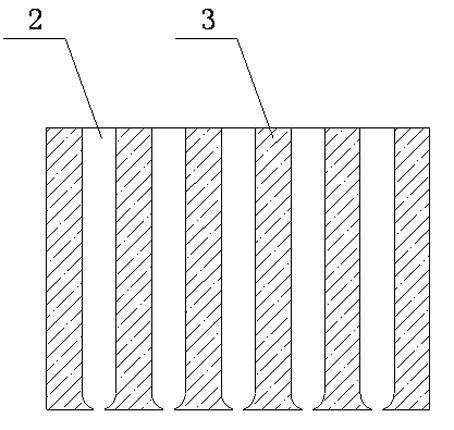

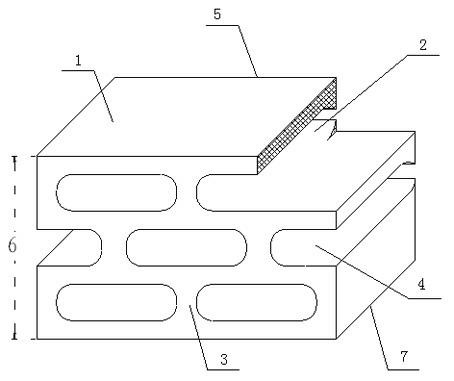

Light fly ash multi-row hole self-thermal insulation building block

InactiveCN102320799AIncrease thermal resistanceReduce usageClimate change adaptationPassive housesSlagAdhesive

The invention relates to a building material, and particularly relates to a light fly ash multi-row hole self-thermal insulation building block. The technical scheme is that: according to the light fly ash multi-row hole self-thermal insulation building block, through holes are uniformly distributed on a cuboid light fly ash building block. The light fly ash building block is prepared by adopting portland cement as a gelling material, adopting fly ash, crude ash, ceramsite or slag, pumice, perlite or vermiculite, sawdust, polyphenyl particles, building adhesives, humectants and additives as filling materials, diluting and dissolving the mixture with water, mixing, stirring, extruding, and curing; the cross sections of the through holes are rectangular, and the arrangement form of the through holes is multi-section, multi-layer, parallel, and interactive. With the combination of the structure of the multi-row hole self-thermal insulation building block and the light composite fly ash material, the performance of the building block such as heat preservation, light weight, thermal insulation, sound insulation, fire prevention, durability, and the like is greatly improved; traditional clay bricks, aerated blocks and traditional outer wall insulation methods are substituted; and national requirements for building energy saving are fully met.

Owner:王长河

Preparation method for warm-keeping mortar

A preparation method for warm-keeping mortar is disclosed. The mortar is characterized by comprising, in parts by weight, 500-1000 parts of cement, 0-200 parts of mineral powder, 0-150 parts of fly ash, 0-100 parts of talcum powder, 0-100 parts of heavy calcium powder, 0-50 parts of silica fume, 0-100 parts of an expanding agent, 0-1 part of an early strength agent, 0-2 parts of PP fiber, 0-2 parts of wood fiber, 0-30 parts of latex powder, 0.5-8 parts of cellulose ether, 0-3 parts of a water repellent, 0.001-0.2 part of an air entraining agent, 1-4 parts of a water reducer, 0-2 parts of starch ether, 0-2 parts of a retarder, 2-500 parts of a lightweight particle, and 400-1000 parts of water. The warm-keeping mortar possesses good fluidity and fluidity maintenance property, good wrapping property, good durability and high strength. The product can be produced as dry-mixed mortar, also can be produced as wet-mixed mortar in a wet-mixed mortar production line or a concrete stirring station, is used by being transported to a building site by utilizing a tank car, and accords with the current-stage environment protection requirements of saving energy and reducing emission and preventing dust. The mortar is good in plasticity, is applicable to exterior-wall warm insulation, indoor baffle walls, roofs and the like, and is wide in application scope and low in cost.

Owner:潍坊德霖建材科技有限公司

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

Building exterior wall thermal insulation material and preparation process thereof

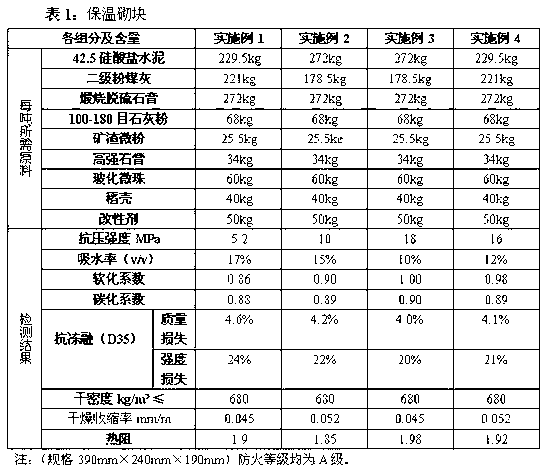

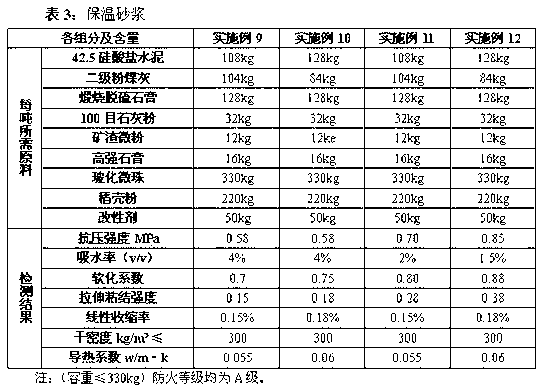

The invention discloses a building exterior wall thermal insulation material. The building exterior wall thermal insulation material is formed by mixing a binding material, thermal insulation lightweight aggregate and a property-modifying additive according to the weight ratio of (40-85): (10-55):5. The building exterior wall thermal insulation material disclosed by the invention can be manufactured into wall thermal insulation mortar, thermal insulation blocks and thermal insulation boards, can be applied to different parts of a building, so as to ensure that the energy conservation index of the building meets the national mandatory standard, the fire rating can reach level A, and the drying shrinkage is low. A preparation process of the building exterior wall thermal insulation material is energy-saving, meanwhile, the recycling problem of industrial waste gypsum is solved, and the pollution of the industrial waste gypsum to the environment is avoided.

Owner:李奕

A kind of foam concrete and preparation method thereof

The invention relates to a foamed concrete and a preparation method thereof. The foamed concrete adopts a chemical foaming method, and a foam stabilizer, an early strength agent, and a water reducer are respectively added to ordinary Portland cement slurry and stirred evenly, and then chemical foaming agent is added. The foaming agent is fully stirred evenly, then injection molded, cured at room temperature, and hardened. The dry apparent density range of the foamed concrete prepared by this method is 150-300kg / m3, the corresponding compressive strength is 0.10-0.50MPa, and the thermal conductivity is lower than 0.10W / mK. It can be used as roof insulation project, floor heating project, light Cushion material, especially suitable for external wall insulation system, energy-saving composite panels, etc. used in building energy-saving projects.

Owner:NANJING UNIV OF TECH

Lightweight concrete exterior wall insulation building block and production method thereof

The invention discloses a lightweight concrete exterior wall insulation building block and a production method thereof. The lightweight concrete exterior wall insulation building block is prepared by mixing the following raw material components in proportion by weight: 20-50 of cement, 20-40 of fly ash, 8-20 of fine sand, 1-8 of calcareous material, 5-16 of plant filler, 0.2-0.5 of adjuvant, 8-15 of water and 0.3-0.7 of foaming agent. The production method of the lightweight concrete exterior wall insulation building block comprises the following steps of: forming raw material slurry by uniformly mixing production raw materials in mixing proportion; adding the water to the foaming agent, and generating uniform and stable bubbles by using a foaming device; mixing the bubbles with the raw material slurry so as to prepare bubble concrete slurry; and casting the bubble concrete slurry into a mold and curing. According to the lightweight concrete exterior wall insulation building block and the production method of the lightweight concrete exterior wall insulation building block, the plant filler, such as sawdust or crop straw powder, is mixed, so that the weight is reduced, the flexibility is improved, and the improvement on the strength of a finished product and the cracking prevention are favored; and the bubbles are enabled to be uniformly distributed in the raw material slurry by adding the foaming agent, so that not only is the weight of the building block reduced, but also the heat preservation and heat insulation effects are improved.

Owner:郑小东

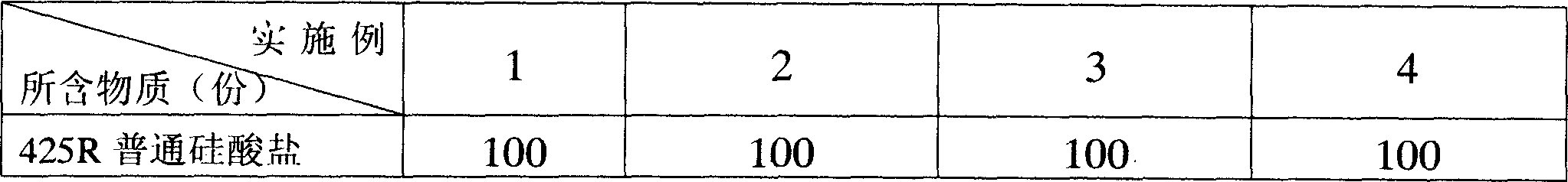

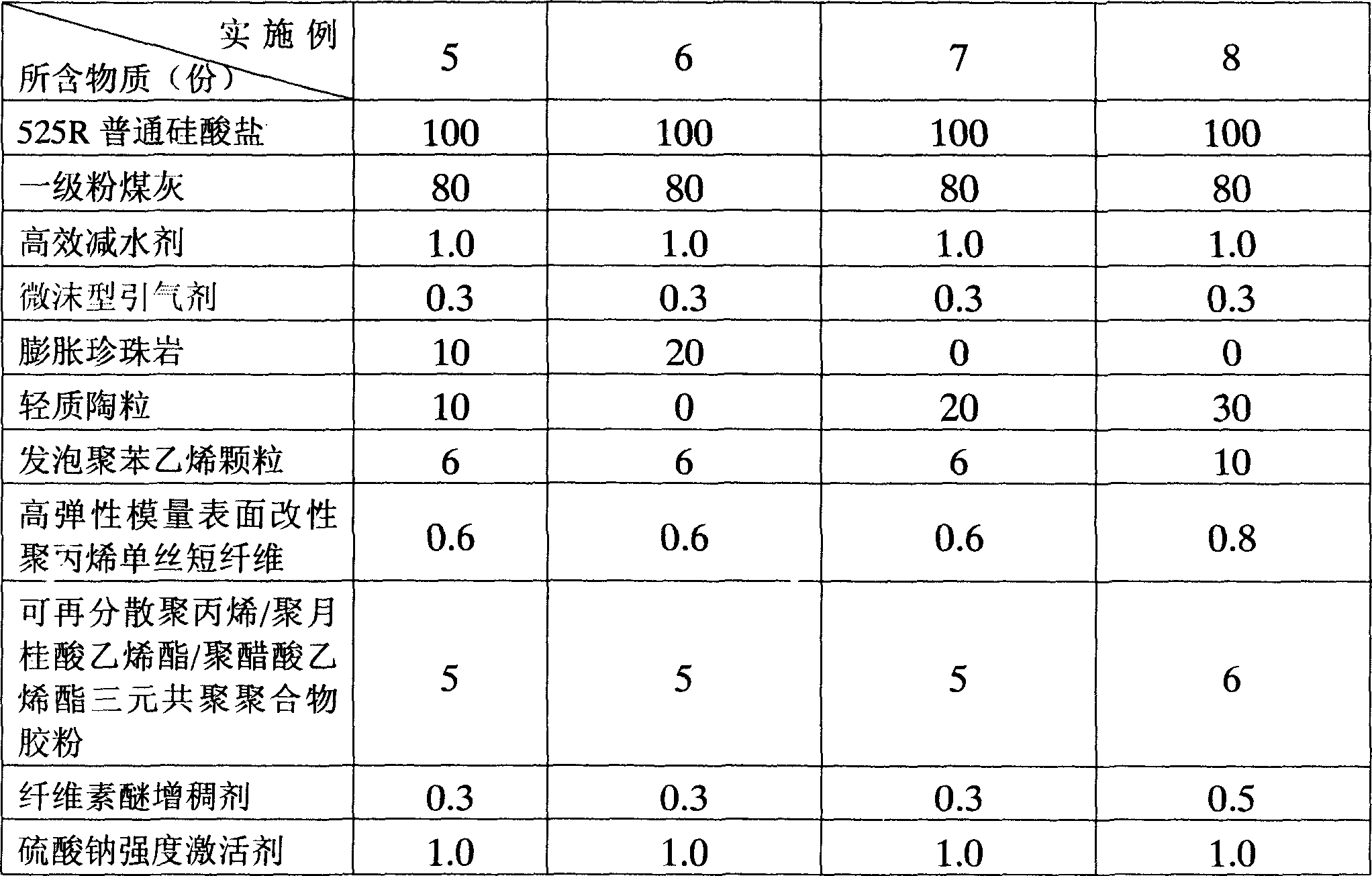

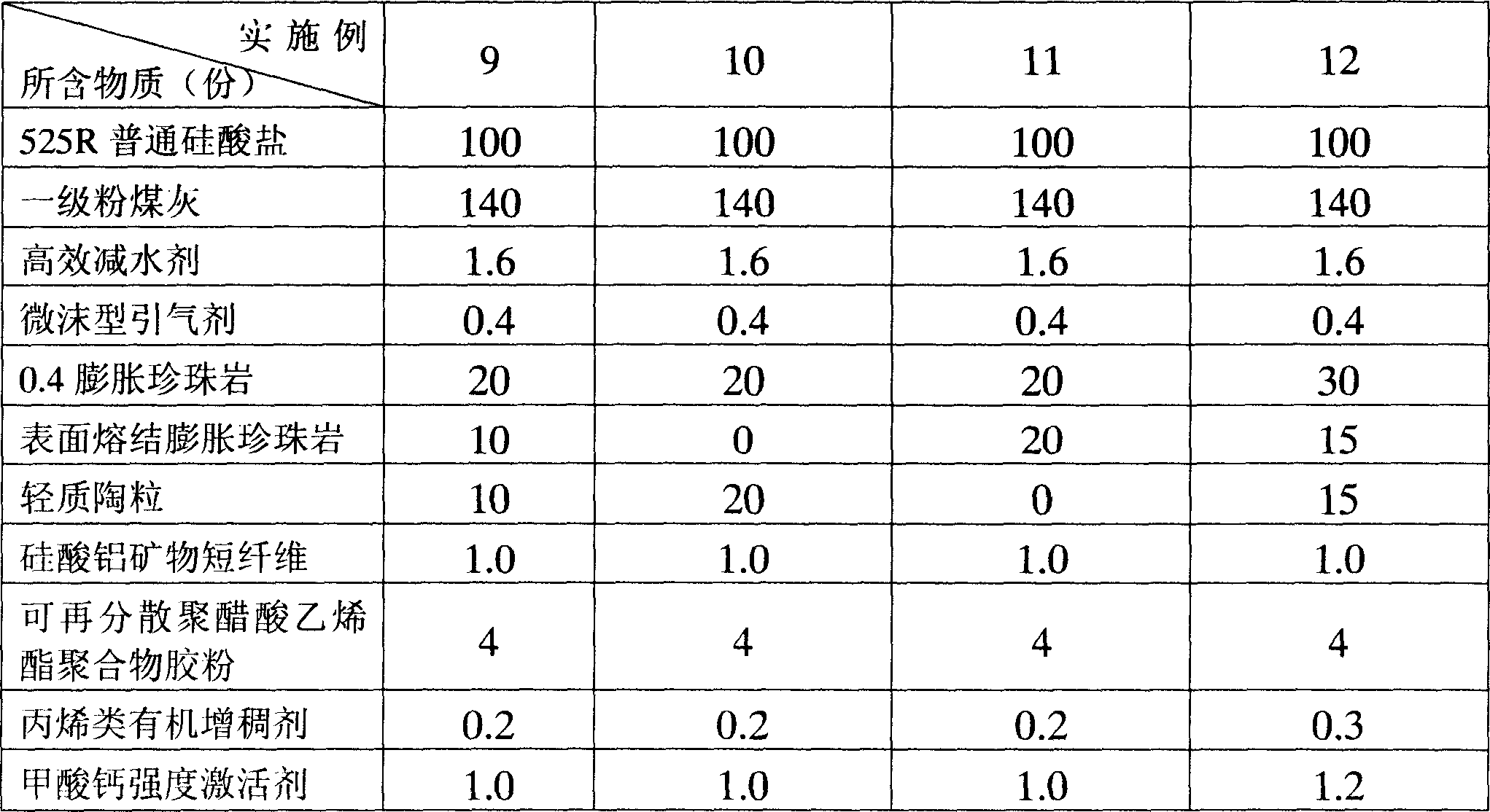

Heat-insulating mortar for external wall of building

InactiveCN1690008APrevent shrinkage crackingPrevent moisture absorptionSolid waste managementPolymer modifiedPolymer science

The heat insulating mortar for outer building wall consists of hydraulic Portland cement, flyash, high efficiency water reducing agent, compound heat isolating aggregate, short fiber, re-dispersible polymer adhesive powder, and strength activator. It is prepared by means of fiber reinforcing technology, polymer modification technology and comprehensive flyash utilizing technology. It forms heat insulating system for outer building wall has the advantages of excellent heat insulating performance, no cracking, being hydrophobic, high wall adhering strength, excellent construction performance, etc.

Owner:宁波荣山新型材料有限公司

Ultra-low-density foam concrete and preparation method thereof

InactiveCN102153363ALow densityConvenient construction requirementsCeramic shaping apparatusCeramicwareFoam concreteApparent density

The invention relates to ultra-low-density foam concrete and a preparation method thereof. The foam concrete is formed by mixing cement, a chemical foaming agent, a foam stabilizer and water in a mass ratio of (130-180):(10.3-15.2):(0.1-1.8):(60-90). The ultra-low-density foam concrete is prepared in a chemical foaming manner by the steps of: adding the foam stabilizer into sulfate aluminum cement slurry, stirring the slurry uniformly, then adding the chemical foaming agent, fully stirring the slurry and performing injection molding and natural curing. The dry apparent density of the ultra-low-density foam concrete prepared with the method is 130 to 150kg / m<3>, the compressive strength is more than 0.10MPa, and the heat conduction coefficient is less than 0.10W / mK; and the ultra-low-density foam concrete can be used as a material for roof heat preservation engineering, floor heating engineering and lightweight cushion layers, and is particularly suitable for an outer wall heat preservation system, an energy-saving composite board and the like.

Owner:NANJING UNIV OF TECH

Fire-proof type exterior wall composite thermal insulation decorative board and manufacture method thereof

The invention belongs to the technical field of building materials and particularly relates to a fireproof composite thermal-insulation decorative board for an exterior wall and a preparation method thereof. The fireproof composite thermal-insulation decorative board for the exterior wall is characterized in that the fireproof composite thermal-insulation decorative board for the exterior wall comprises a fireproof thermal insulation layer, a strengthening layer and a decoration layer. The thickness of the fireproof thermal insulation layer is between 30 and 80mm, and the fireproof thermal insulation layer consists of rock wool and a calcium silicate board, or mineral cotton and the calcium silicate board, or a rock wool board and the calcium silicate board, or a mineral cotton board and the calcium silicate board, or one of the mineral cotton board and the rock wool board, wherein the rock wool, the mineral cotton, the rock wool board, and the mineral cotton board are all subjected to hydrophobic treatment by organic silicon. The thickness of the strengthening layer is between 3 and 8mm, and the strengthening layer is polymer mortar or the calcium silicate board. The decoration layer is fluorobcarbon coating, metallic paint, stone like coating or crylic acid emulsion paint. The thermal insulation board is arranged on the wall surface through a mode with the combination of adhesion and anchorage. The invention can prevent the thermal-insulation decorative board for the exterior wall from being burnt and destroyed too early during fire hazards, protect the safety of personal life of personnel and properties in buildings during the fire hazards, and has the advantages of controllable quality of prefabricated forming, assembled construction, and integrated decoration and thermal insulation functions.

Owner:武汉科华高新材料发展有限公司

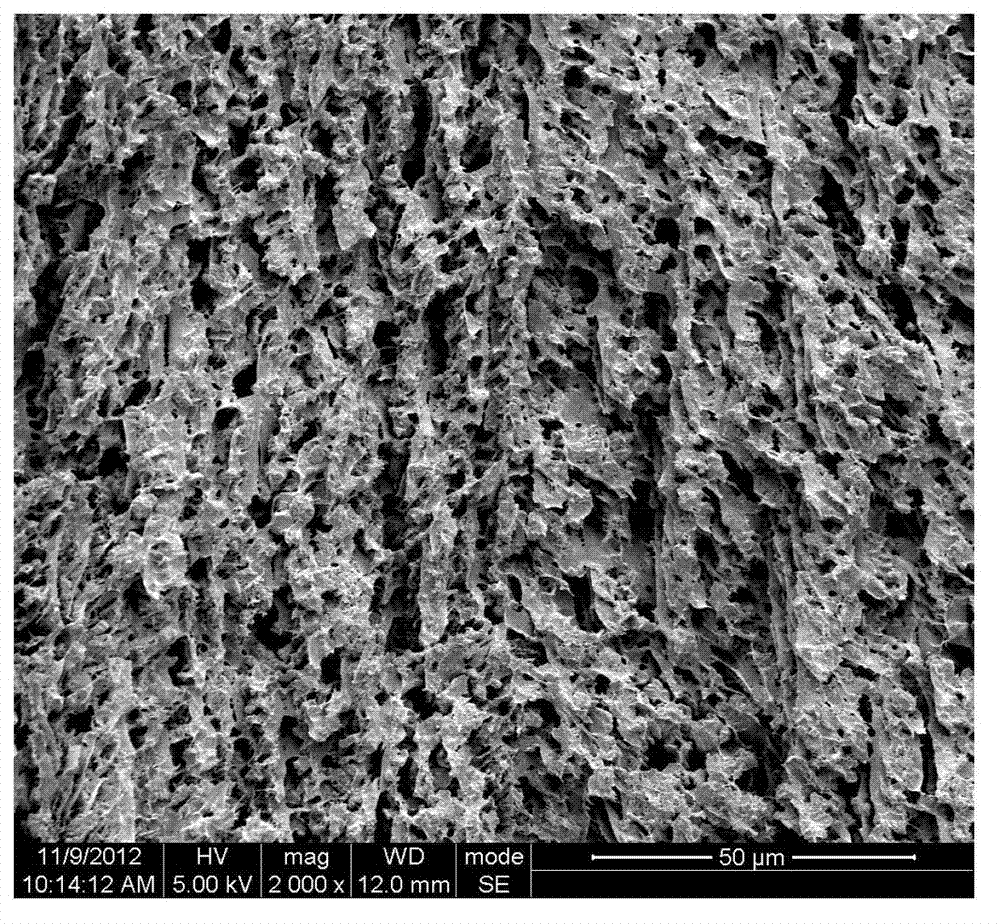

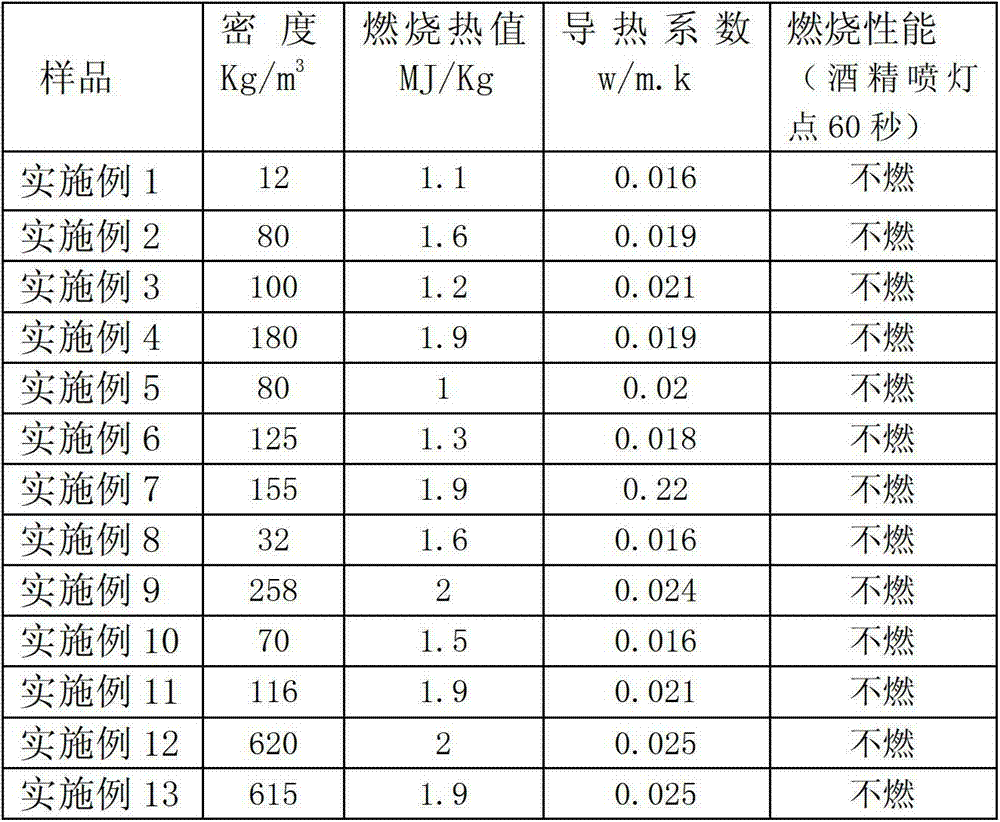

Inorganic micro/nanoparticle/polymer composite building thermal-insulation aerogel material and preparation method thereof

The invention discloses an inorganic micro / nanoparticle / polymer composite building thermal-insulation aerogel material which is compounded from the following components in parts by weight: 0.5-50 parts of inorganic micro / nanoparticle, 0.1-5 parts of polymer, 0-10 parts of crosslinkable polymer, 0.5-20 parts of reinforcing fiber, 0.1-5 parts of defoaming agent and 100 parts of water. The density of the material is 12-620 Kg / m<3>, the heat conductivity coefficient is 0.016-0.025 w / m.k, and the combustion heat value is 1.1-2.0 MJ / Kg. The invention also provides a preparation method of the aerogel material. The aerogel material disclosed by the invention has the advantages of low density, light weight, favorable mechanical strength and low heat conductivity coefficient, and is beneficial to energy saving and consumption reduction. The combustion heat value is lower than 2.0 MJ / Kg, and thus, the aerogel material satisfies the flame-retardant requirements for Grade-A building thermal-insulation materials. The aerogel material is an ideal building flame-retardant thermal-insulation material, and can be widely used in external-wall thermal-insulation occasions.

Owner:SICHUAN UNIV

Novel composite insulating thin-wall external wall board and manufacturing method thereof

InactiveCN102733536ACorrosion resistanceImprove bearing capacityClimate change adaptationBuilding reinforcementsFiberReinforced concrete

The invention provides a novel composite insulating thin-wall external wall board. The novel composite insulating thin-wall external wall board mainly comprises the components of fiber-woven-mesh reinforced concrete and an insulating-wall-body material, wherein the fiber-woven-mesh reinforced concrete consists of the components of high-performance fine concrete and a fiber woven mesh; the fiber woven mesh is used as a reinforced material; the insulating-wall-body material comprises one or all of a cement-based material insulating board and insulating material powder. The invention also provides a preparation method of the novel composite insulating thin-wall external wall board. The external wall board provided by the invention integrates the advantages of being long in service life, having a light-weight thin wall, capacity of heat insulation, sound insulation, vibration resistance, impact resistance, fire resistance, and water resistance, being simple in installation and surface decoration processes and the like, is applicable to outer-wall insulation of buildings and is a novel composite insulating building outer-wall structure with a wide application prospect.

Owner:浙江固邦新材料有限公司

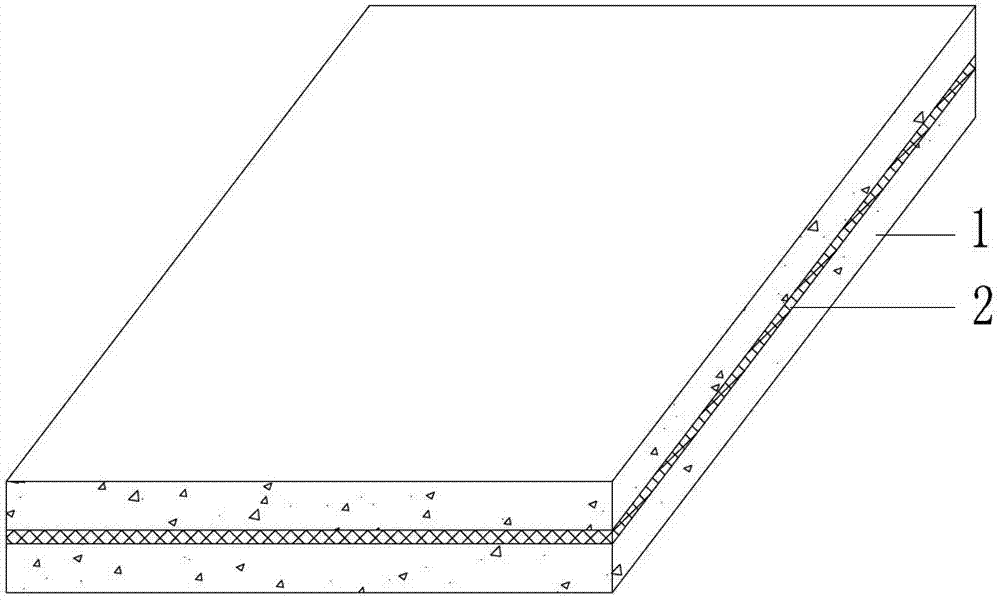

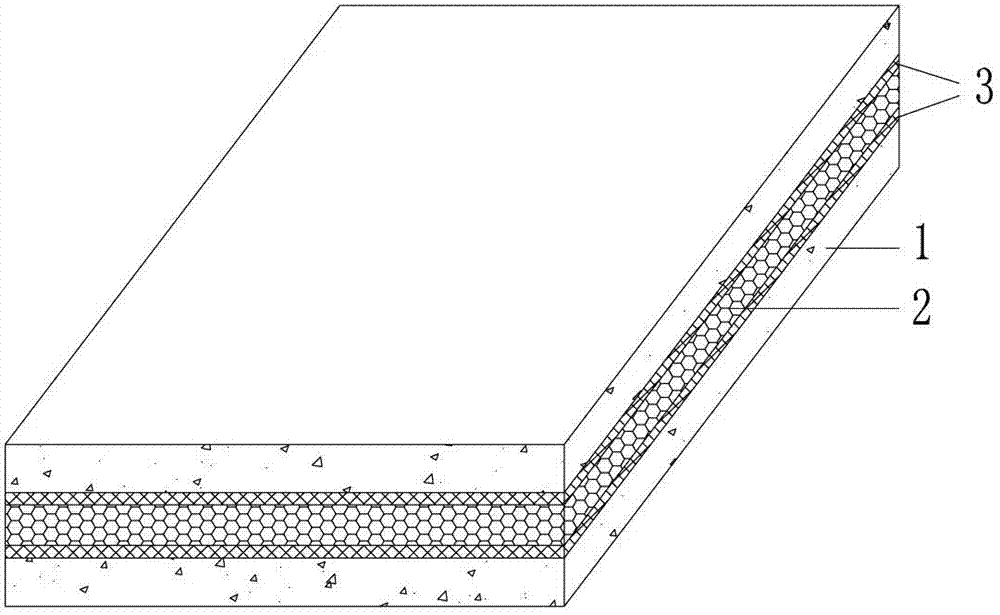

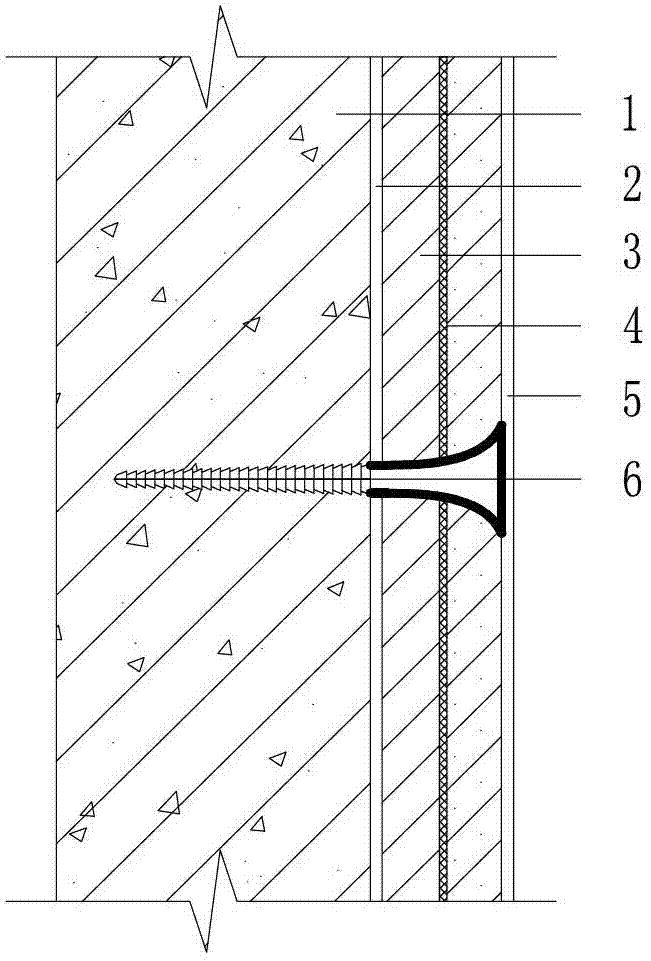

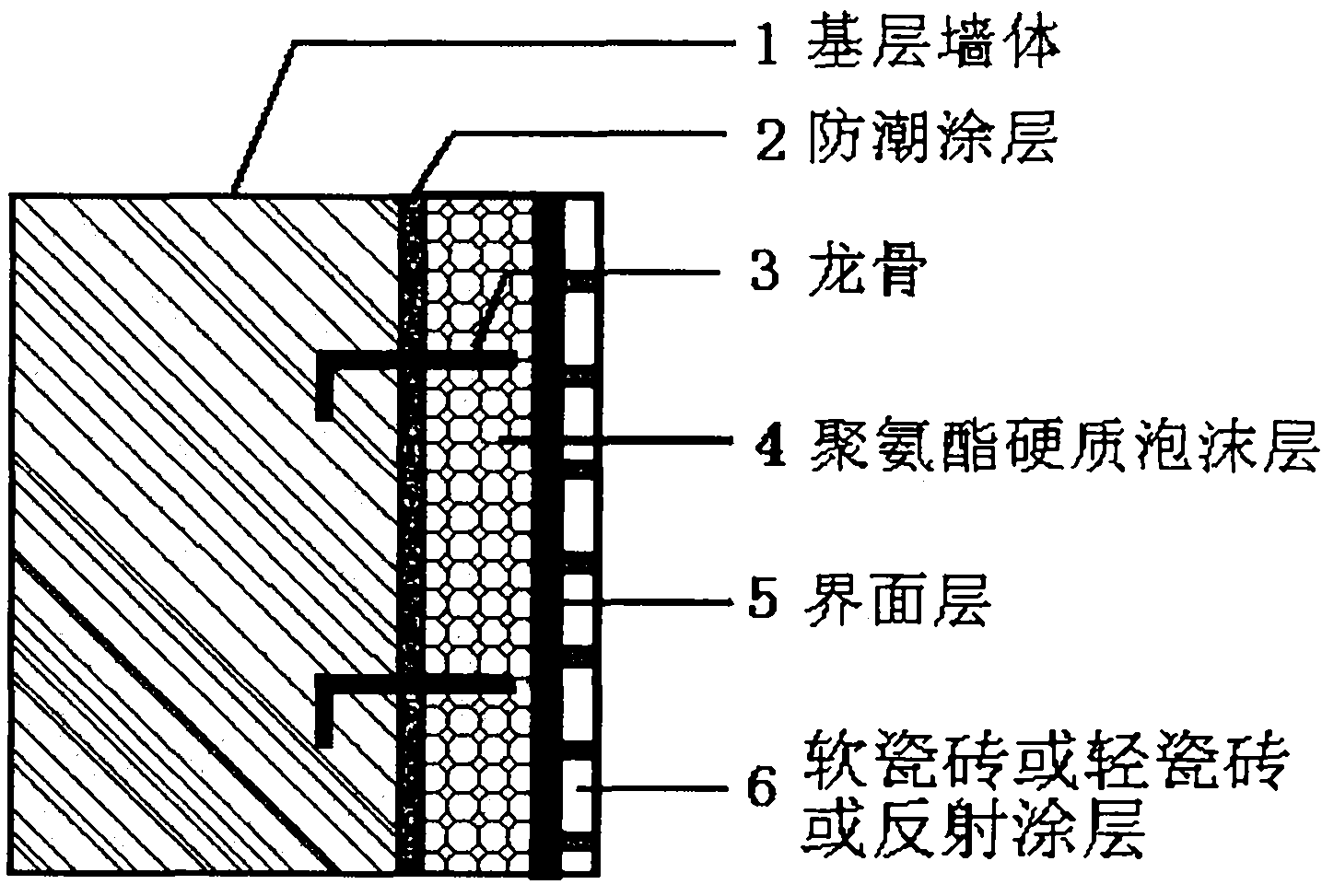

High flame retardant polyurethane rigid foam outer wall thermal insulation system

ActiveCN101956429AMeet the needs of beautificationImprove the problem of shrinkage and collapseHeat proofingBuilding material handlingWet bondingKeel

The invention discloses a high flame retardant polyurethane rigid foam outer wall thermal insulation system. From a basic unit wall provided with a keel and connecting pieces, a prime coat thickening layer, a polyurethane rigid foam layer, an interface layer, and soft tiles, light tiles or a reflective coating are arranged in turn. In the system, the prime coat thickening layer has high adhesion and good wet bonding strength for the basic unit wall and the polyurethane rigid foam; and the high flame retardant polyurethane rigid foam outer wall thermal insulation system is foamed by pure water, and is halogen-free, flame retardant, safe and environment-friendly. The vertical face of the wall is successfully foamed on site, and the polyurethane rigid foam can be directly sprayed and foamed on the basic unit wall which is treated by the prime coat thickening layer, can reach high adhesion to the basic unit wall after 24 to 48 hours, and has the coefficient of thermal conductivity of less than 0.03W / (m.K), the vertical burning reaching V-0 level, and the water absorption of less than 2.5 percent.

Owner:海聚高分子材料科技(广州)有限公司

Outer wall structure and construction and installation method

InactiveCN104018598AComplete and reliable quality assuranceSolve common quality problemsCovering/liningsSolid waste managementWater leakageArchitectural engineering

The invention relates to a building outer wall structure, in particular to an outer wall structure and a construction and installation method. The outer wall structure is sequentially provided with an inner decorative layer, a structural layer, a waterproof layer and an outer decorative layer from inside to outside. The construction and installation method of the outer wall structure includes the steps that wall battens and doors and windows are installed; the waterproof layer is constructed; construction and installation method of the outer wall structure are finished after the inner wall face and the outer wall face are decorated. The common quality problems such as empty drums, deformation, cracks and water seepage caused by thermal insulation construction on the outer wall are solved by using a self-heat-preservation system for the outer wall, so that an integral and reliable quality guarantee is provided for an outer wall engineering system; all the adopted materials are common combinations with light inorganic materials as carriers and are good in cosolvency, usability, cohesiveness, ageing resistance and the like; the construction procedure of outer wall engineering is simplified, construction period is shortened, unified management on construction sites is facilitated, management cost is lowered, and project management efficiency is improved; the self-heat-preservation function of the wall is achieved, and the problem that the outer wall is prone to water seepage or water leakage is solved.

Owner:江西昌南建设集团有限公司

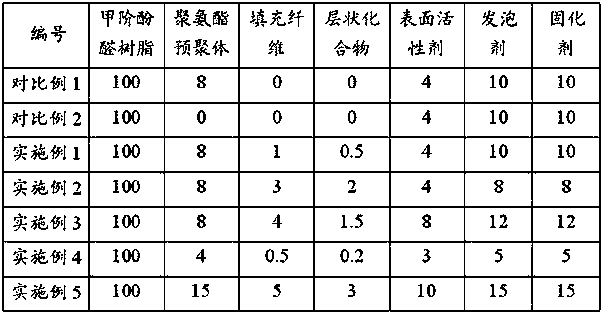

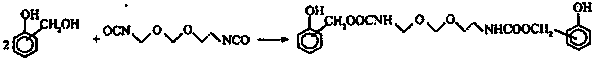

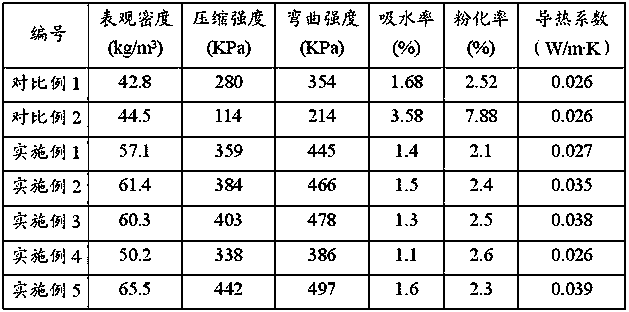

Modified phenolic foam and preparation method thereof

The invention discloses a modified phenolic foam and a preparation method thereof. The modified phenolic foam is prepared from the following components by weight: 100 parts of a resol resin, 3 to 15 parts of a toughening modifier, 5 to 15 parts of a foaming agent, 3 to 10 parts of a surfactant, 5 to 15 parts of a curing agent, 0.5 to 5 parts of a glass fiber and 0.2 to 3 parts of a lamellar compound which is preferably organically modified montmorillonite. According to the invention, a polyurethane performed polymer is used as the toughening modifier, the glass fiber and the lamellar compound are introduced for modification of phenolic foam, so toughness of the phenolic foam is improved, and the disadvantages of easy efflorescence and scaling-off, fragility, small strength, no ductility and high water absorption of the phenolic foam are overcome; thermal stability and flame retardation of the phenolic foam are improved; and thus, the modified phenolic foam is an upgrading product for external wall insulation materials. Moreover, toughening of the polyurethane performed polymer and phenolic foaming and curing are carried out at the same time, operation is simple and easily practicable, so the method is suitable for large-scale production.

Owner:HEFEI GENIUS NEW MATERIALS

Coal gangue-fly ash foam concrete

InactiveCN101182175AEfficient use ofLow costSolid waste managementCeramicwareFoam concreteInsulation layer

A coal gangue-fly ash foam concrete relates to lightweight foam concrete. The invention is composed of coal gangue, fly ash, cement, lime, gypsum, filler and foaming agent. The invention utilizes coal gangue and fly ash industrial waste, which not only reduces product cost but also saves natural resources, and its product also has low cost, high strength, low thermal conductivity, good heat insulation performance, and can be directly plastered after masonry, etc. features. Therefore, the product of the present invention can be widely used in the single thermal insulation wall body (body of wall self-insulation and heat insulation) of outer wall, the internal and external partition wall of frame structure, the rear board wall of large closet; Inner wall of cold storage; thermal insulation layer of floor and roof; thermal insulation board.

Owner:CHONGQING UNIV

Phosphorus slag powder doped dry powdered anti-crack mortar

Owner:TONGJI UNIV

White finishing mortar composition

The invention provides a white surface mortar compound which comprises the following components of parts by weight: 400 to 600pbw of white cement, 50 to 100pbw of semi-water gypsum, 50 to 100pbw of calcium hydroxide, 200 to 400pbw of modified fiber light calcium, 30 to 50pbw of latex powder which can be dispersed again, 2 to 4pbw of cellulose ether, 1 to 3pbw calcium chloride, 1 to 3pbw of calcium formate, 1 to 3pbw of aluminum potassium sulfate, 1 to 5pbw of polypropylene fiber and 250pbw of water. The surface mortar compound of the invention can be hydrated with cement and other components to form fine, dense and good finish surface to be applied for painting a wall body with different color surfaces, and the cost is reduced while the construction efficiency is enhanced. The compound is particularly applicable to an insulation system of the external wall of a civil building and an office building, which is economic and can be used as the surface mortar and internal dope of other wall bodies.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Double-foaming cellular concrete and production method thereof

The invention discloses double-foaming cellular concrete and a site production construction method thereof. The volume weight of the double-foaming cellular concrete ranges from 100 KG / M<3> to 400 KG / M<3>; the heat conduction coefficient is as little as 0.020 W / M.DEG C, and the intensity is up to 5 MPa. The double-foaming cellular concrete can be widely applied to the production of light-weight heat preservation materials such as roof heat preservation materials and external wall heat preservation materials and hanging pieces such as light-weight building hanging beams, and has the purposes of the filling of light-weight hollow bricks and hollow building covers; more importantly, the double-foaming cellular concrete can be applied to the construction of underwater facilities. The site production construction method for the double-foaming cellular concrete is simple in technology and simple and convenient to operate; by special equipment, full-automatic integrated productions, such as automatic foaming, metering and proportioning, are effectively realized; upon automatic control, the production construction of the double-foaming cellular concrete is finished highly efficiently at low cost.

Owner:河南华泰新材科技股份有限公司

Man-made vitreous fibres

Man-made vitreous fibers have a solubility of pH 4.5 of at least 20 nm per day and a melt viscosity of 10 to 70 poise at 1400° C. Novel fibers contain at least 18% Al2O3. Particular products include external wall insulation or cladding and pipe sections. A composition for making suitable fibres may be selected by determining solubility at pH 4.5 or in macrophage.

Owner:ROCKWOOL INT AS

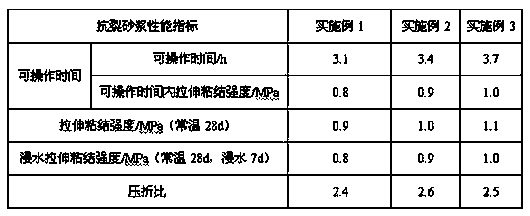

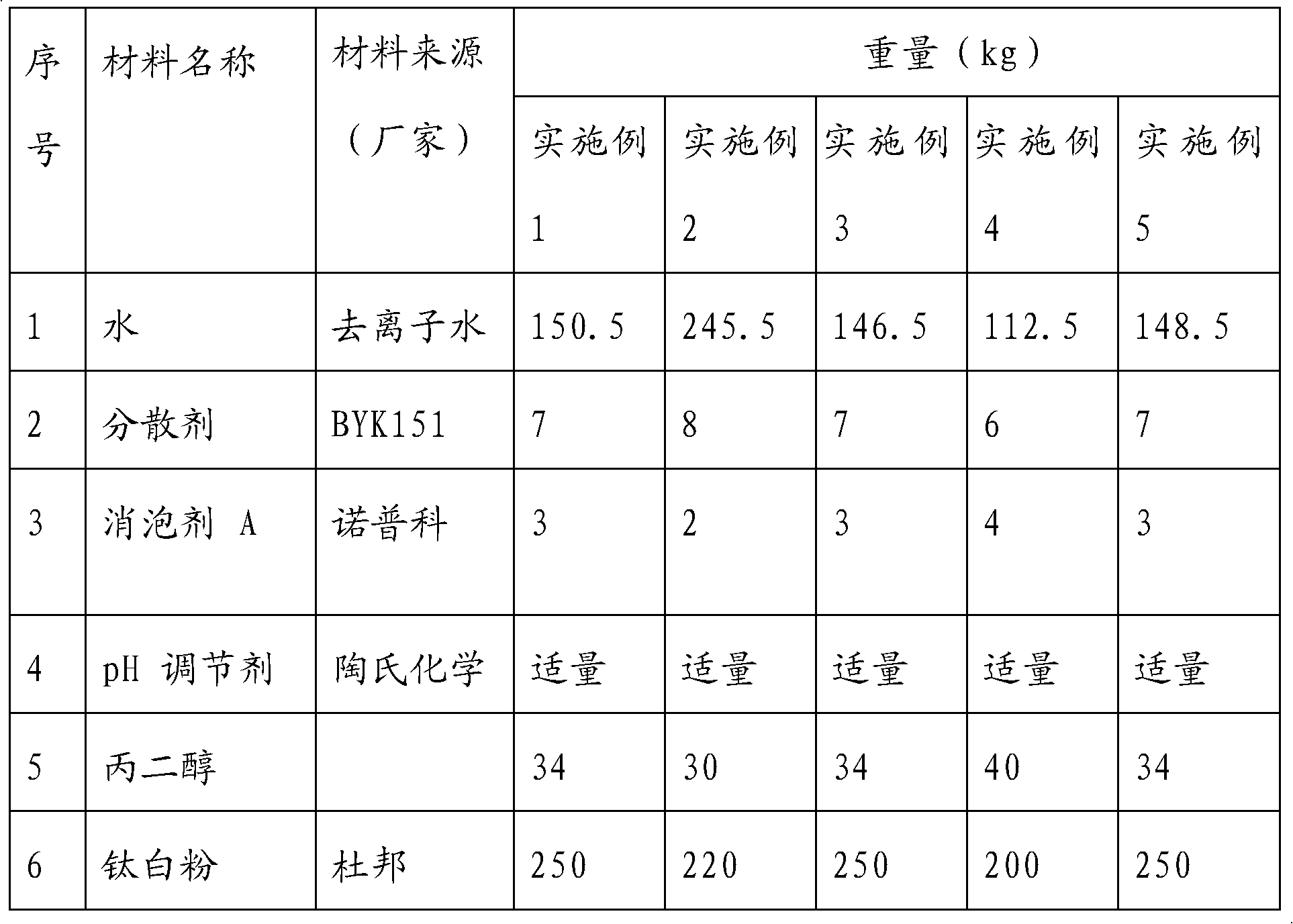

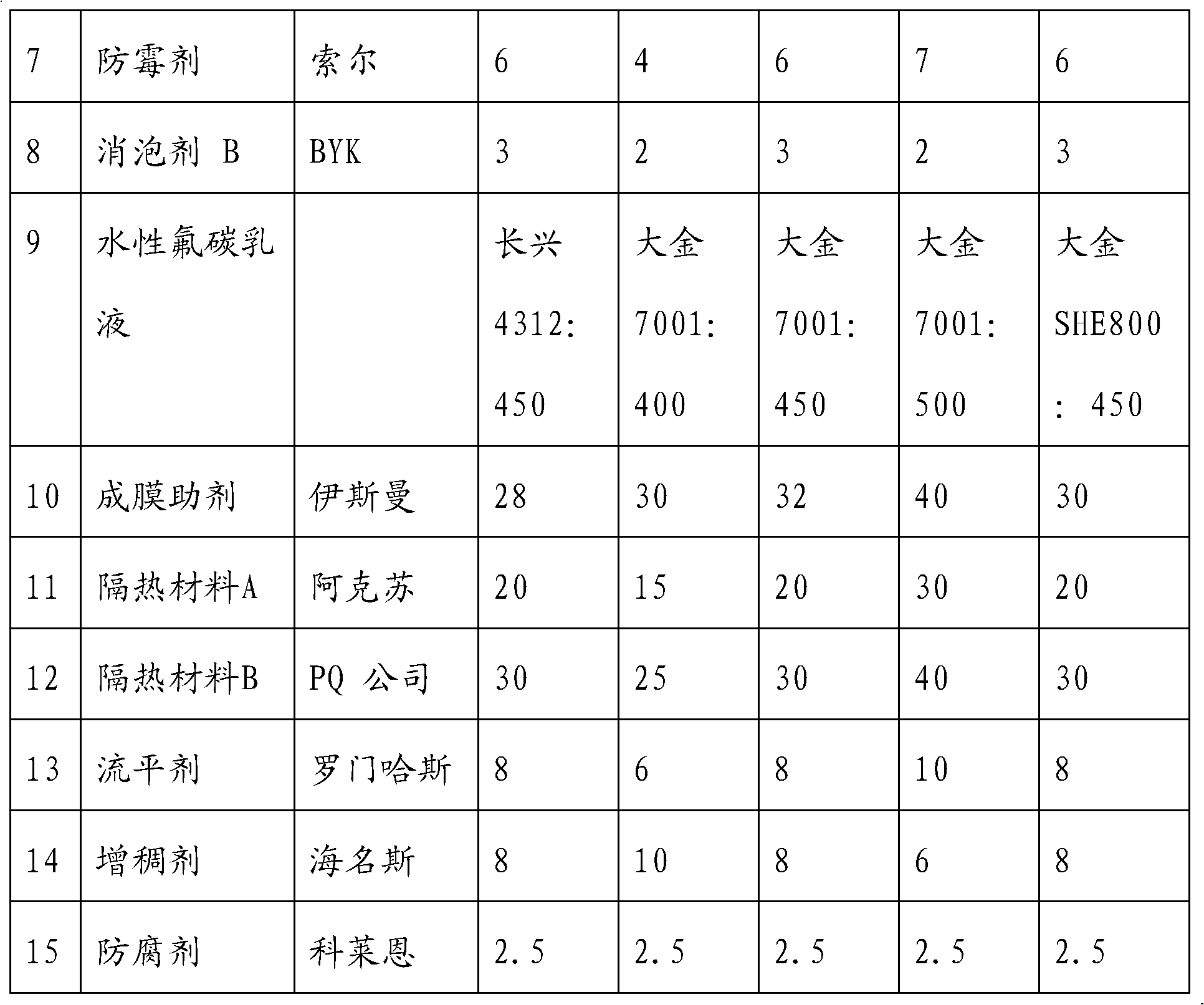

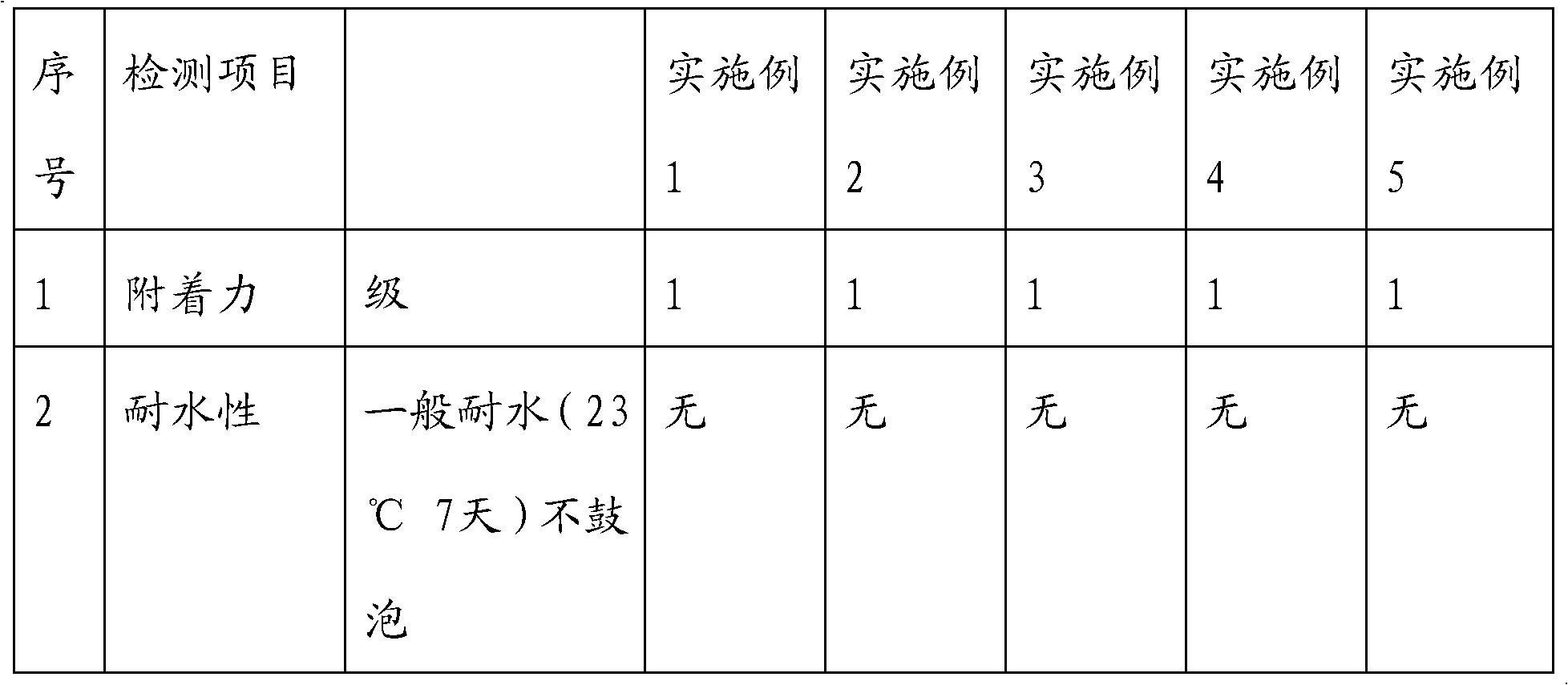

Water-based fluorocarbon heat insulation coating and preparation method

InactiveCN102585626AImprove reflectivityLow thermal conductivityReflecting/signal paintsWater basedInsulation system

A water-based fluorocarbon heat insulation coating is prepared by the following components by weight: 100 to 250 parts of water, 6 to 8 parts of dispersing agent, 2 to 4 parts of defoamer A, pH regulators of right amount, 30 to 40 parts of propylene glycol, 200 to 250 parts of titanium dioxide powder, 4 to 7 parts of mildew preventive, 2 to 4 parts of defoamer B, 400 to 500 parts of water-based fluorocarbon emulsion, 28 to 40 parts of film-forming assistant, 15 to 30 parts of heat insulation material A, 25 to 40 parts of heat insulation material B, 6 to 10 parts of flatting agent, 6 to 10 parts of thickening agent and 2.5 parts of preservative. A product of the water-based fluorocarbon heat insulation coating has various performances, can achieve the effect of oil-based fluorocarbon coating, can overcome the shortcomings of the oil-based fluorocarbon coating, and can meet requirements of an external wall heat insulation system in addition.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Preparation of Foam Concrete by a Chemical Foaming Method

The invention discloses a chemical foaming method for preparing foamed concrete, which belongs to the technical field of building thermal insulation materials. The raw material composition and weight percentage of foam concrete are: cement 20-80wt%, ore powder 1-5wt%, fly ash 5-30wt%, foaming agent 1-6wt%, water 10-70wt%, modifier 0.2- 1.5wt%, fiber 0.2-1wt%, auxiliary material 1-8wt%. Its preparation method is to pour water into the container first, then put a certain amount of cement, ore powder, fly ash, and additives into the water, stir evenly with a stirrer, pour in foaming agent to mix and stir, and then quickly transfer After leaving the mixer, the foaming is completed within 30 minutes, and the strength is reached after 24 hours, and the formed foam concrete is obtained after 28 days of curing. The foamed concrete obtained by the invention has good water resistance, low thermal conductivity, low dry density, high strength, strong durability, simple formula and convenient construction; it can partially replace polystyrene board, extruded plastic board and rubber powder in the external wall insulation system Polystyrene particles and other organic insulation materials.

Owner:北京翰高兄弟科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com