Patents

Literature

135results about How to "Reduce pulverization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pelletizing method of ilmenite concentrates and pellet binder

The invention discloses a pelletizing method of ilmenite concentrates and a pellet binder, wherein the method comprises the following steps: uniformly mixing the ilmenite concentrates, the binder anda carbonaceous reducing agent to obtain a mixed material; pressing the mixed material into green pellets; and drying the green pellets to obtain the dry green pellets.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +3

Modified phenolic foam and preparation method thereof

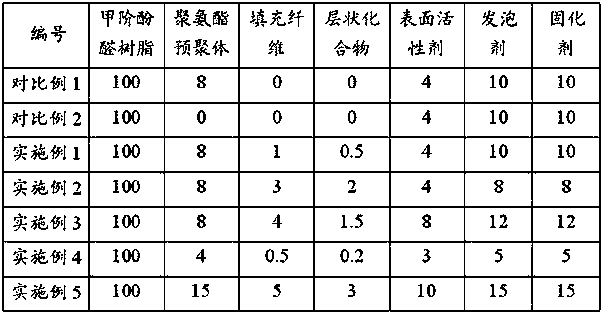

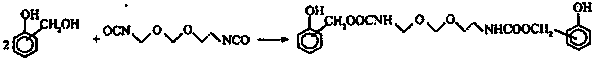

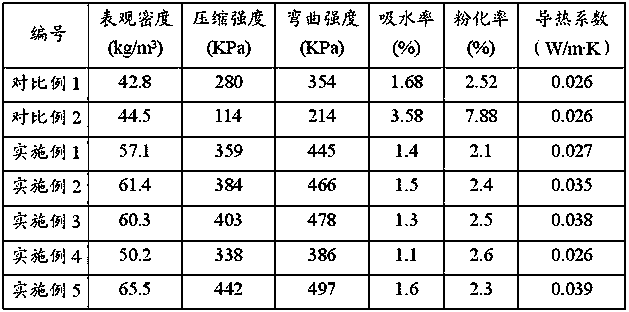

The invention discloses a modified phenolic foam and a preparation method thereof. The modified phenolic foam is prepared from the following components by weight: 100 parts of a resol resin, 3 to 15 parts of a toughening modifier, 5 to 15 parts of a foaming agent, 3 to 10 parts of a surfactant, 5 to 15 parts of a curing agent, 0.5 to 5 parts of a glass fiber and 0.2 to 3 parts of a lamellar compound which is preferably organically modified montmorillonite. According to the invention, a polyurethane performed polymer is used as the toughening modifier, the glass fiber and the lamellar compound are introduced for modification of phenolic foam, so toughness of the phenolic foam is improved, and the disadvantages of easy efflorescence and scaling-off, fragility, small strength, no ductility and high water absorption of the phenolic foam are overcome; thermal stability and flame retardation of the phenolic foam are improved; and thus, the modified phenolic foam is an upgrading product for external wall insulation materials. Moreover, toughening of the polyurethane performed polymer and phenolic foaming and curing are carried out at the same time, operation is simple and easily practicable, so the method is suitable for large-scale production.

Owner:HEFEI GENIUS NEW MATERIALS

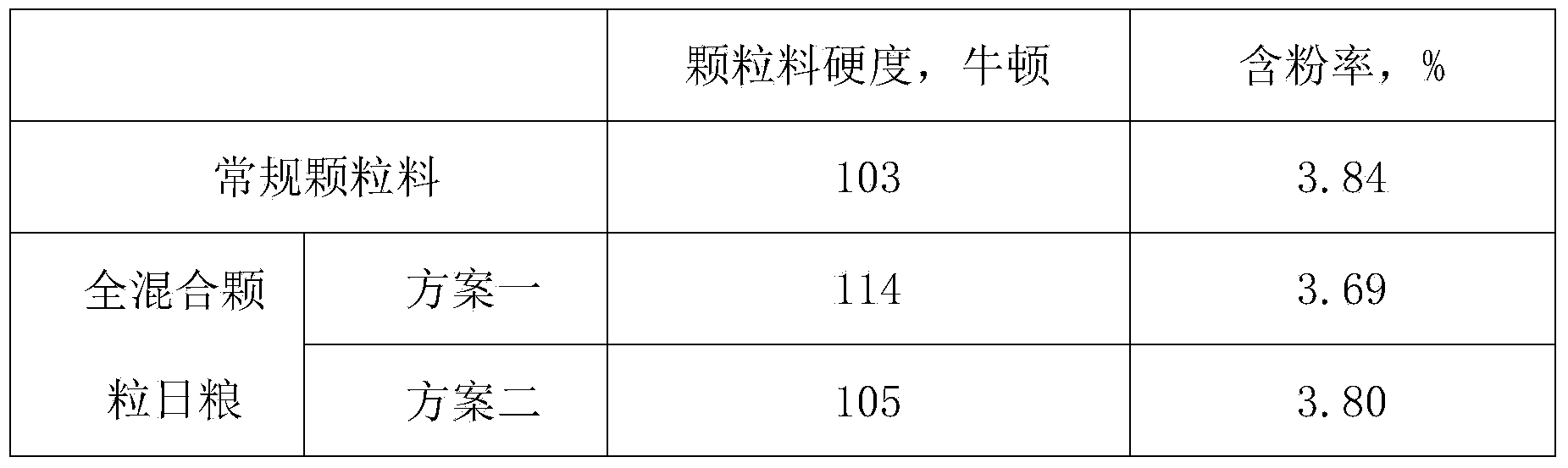

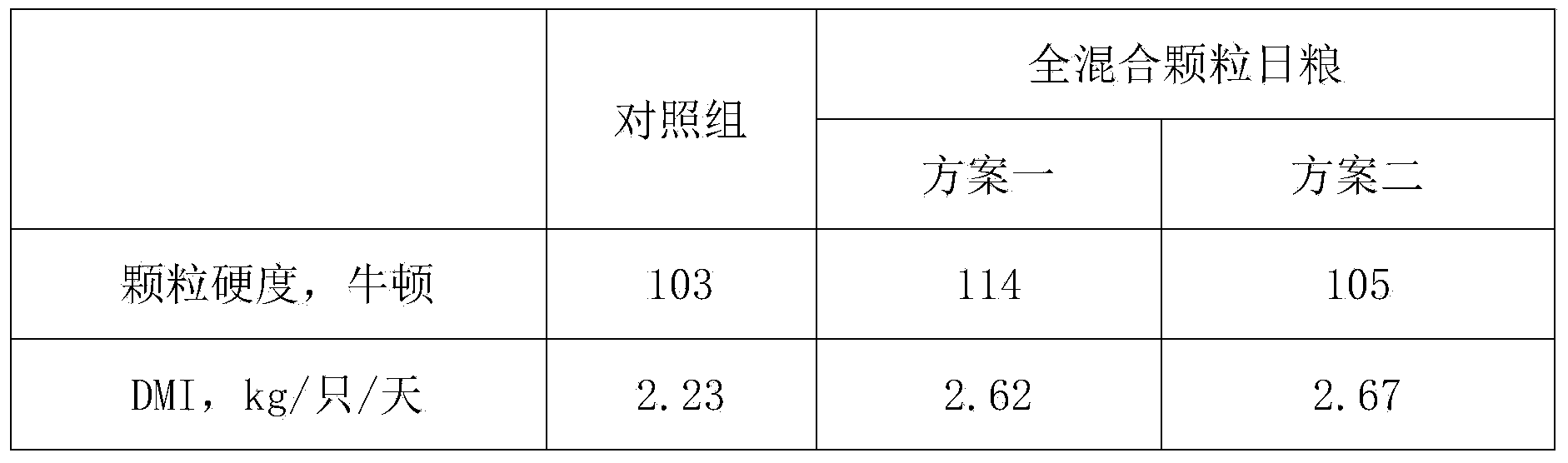

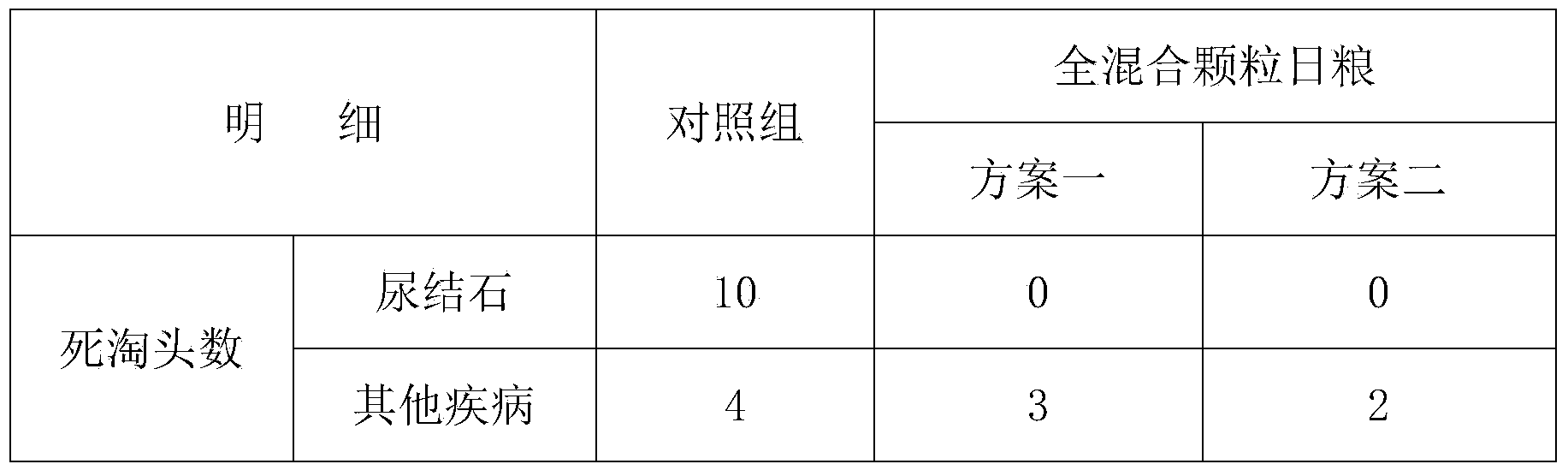

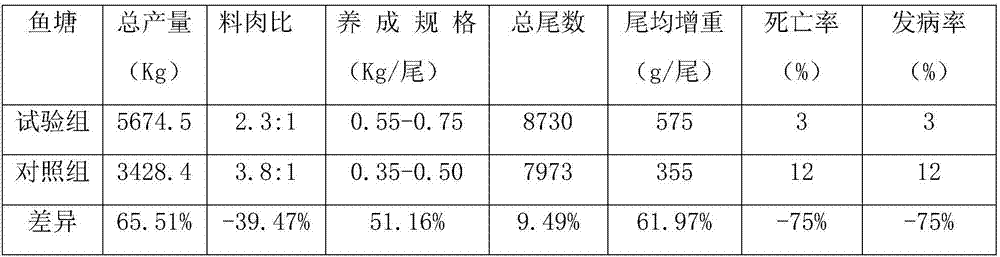

Granular total mixed ration for fattening meat sheep and processing process thereof

ActiveCN104304822AIncrease the rate of weight gainReduce feeding costsFood processingAnimal feeding stuffFiberAnimal science

A granular total mixed ration for fattening meat sheep is characterized by comprising 10-15% of corns, 5-8% of barley, 10-13% of corn bran, 5-6% of corn germ meal, 5-7% of DDGS (Distillers Dried Grains with Soluble), 4-7% of double-low rapeseed meal and 1.5-2.5% of mountain flour. The granular total mixed ration for fattening the meat sheep, provided by the invention, has the advantages that the palatability is good, the total mixed ration is rich in energy, crude protein, crude fiber, vitamins and trace elements, the weight increasing speed of the meat sheep can be effectively increased, the feeding cost is reduced and urinary stone in the fattening process is eliminated.

Owner:LIAONING WELLHOPE AGRI TECH

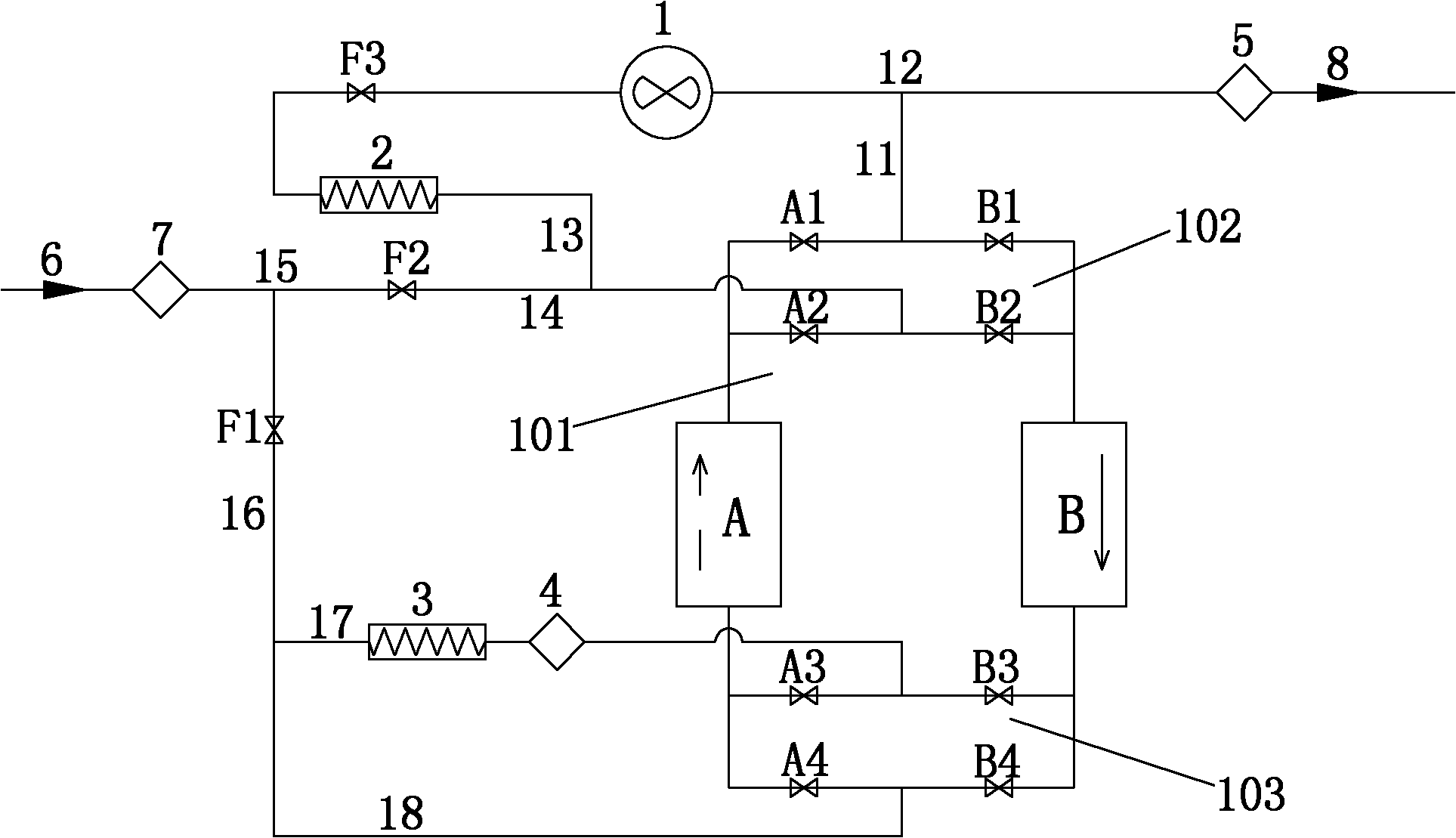

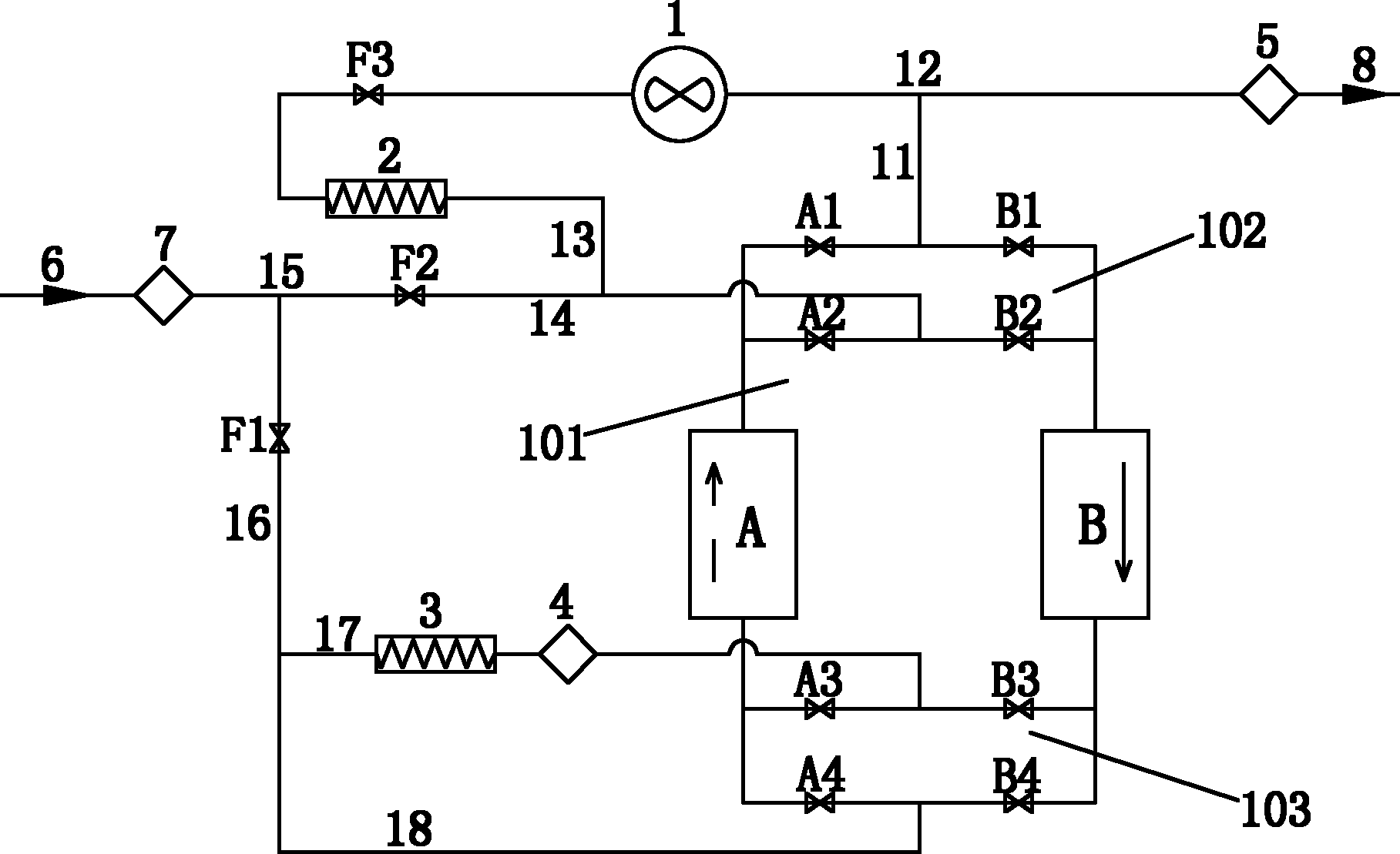

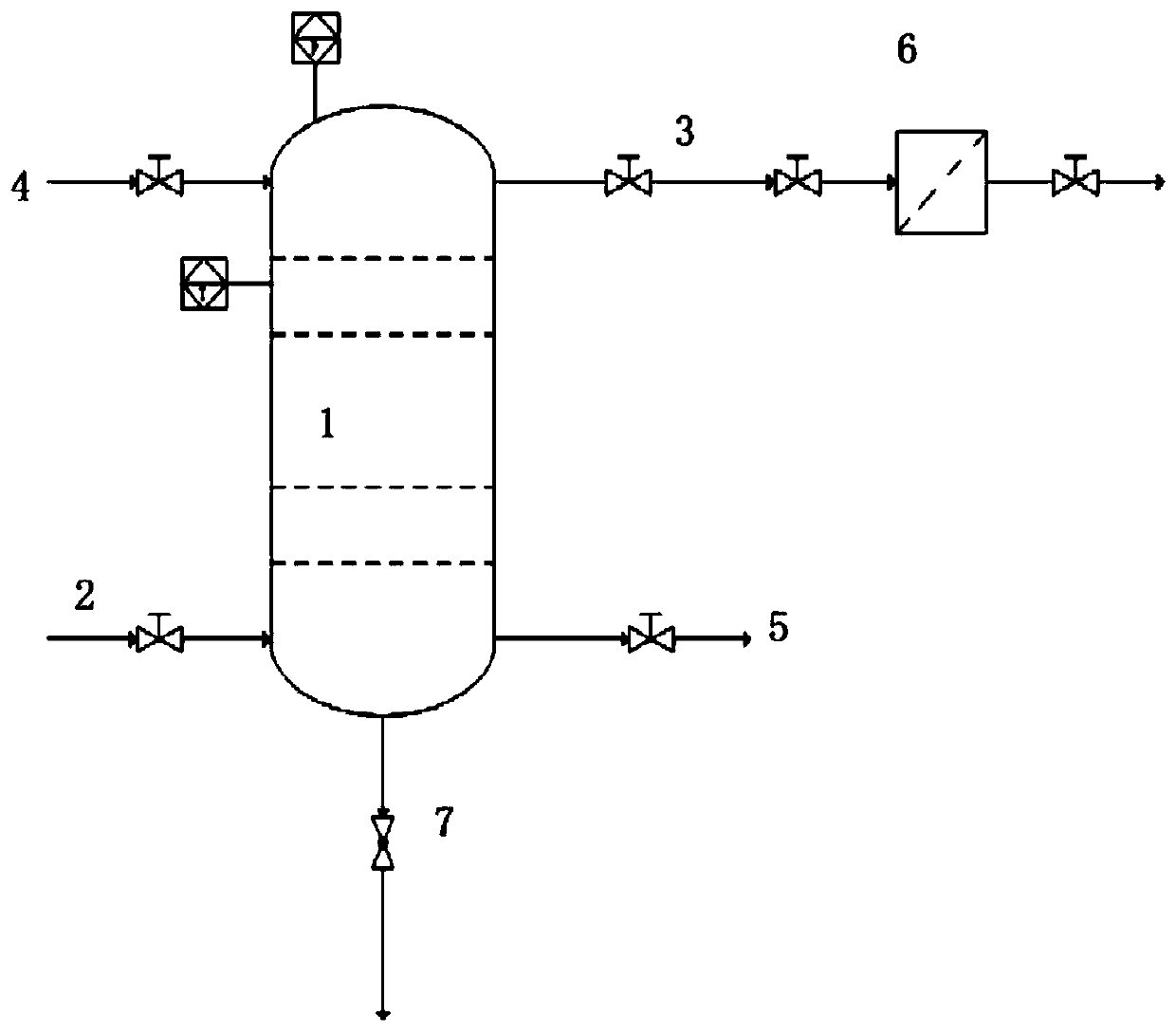

Process and device for drying adsorption type compressed gas regenerated by using compression heat

ActiveCN102101003ARemarkable effect of energy saving and consumption reductionAchieve regenerationGas treatmentDispersed particle separationEngineeringProcess engineering

Aiming at overcoming the defects of the traditional absorption drying method and a large adsorption type compressed air dryer, the invention provides a process and device being used for drying an adsorption type compressed gas regenerated by using compression heat, being capable of obtaining a drying gas with lower dew point and recycling a blast-cold gas. According to the invention, an exhaust and pressure-reduction process does not exist, the regenerated and heated blast-cold gas is recycled, the compressed air and the energy are saved, and the energy consumption is lowered.

Owner:XIAN UNIONFILTER PURIFICATION EQUIP

Soft-pellet creep feed and preparation method thereof

ActiveCN103416591AImprove palatabilityEliminate lossAnimal feeding stuffAdditive ingredientBlood plasma

The invention discloses a soft-pellet creep feed and a preparation method thereof, and belongs to the field of feed formulation design and feed processing techniques. The preparation method comprises the following steps: mixing and bacillus subtilis and pickled vegetables fermentation liquor, performing fermentation in sequence to form fermented soybean meal and rice which are taken as main raw materials; adding steam fish meal, blood plasma powder, soybean meal and the like in a matched manner; utilizing a soft pelletizer to prepare pellet materials through ultramicro smashing; utilizing a syrup spray device to uniformly spray syrup on the surfaces of the pellet materials. The creep feed provided by the invention is full and balanced in nutrition, is easy to digest and intake, has stable quality, and is subjected to multiple fermentation. Moreover, feed inducing performance, soft protection performance and nutrition full value performance are improved, as a process of combining a soft manufacturing system and the syrup spray system is adopted; the incidence of hardening of medium-sized pellet feed during the preservation process is reduced; compared with a dry pellet feed, the loss of nutritional ingredient during the granulating heating and drying process is avoided, and the palatability of soft pellet feed is kept well.

Owner:LIAONING WELLHOPE AGRI TECH

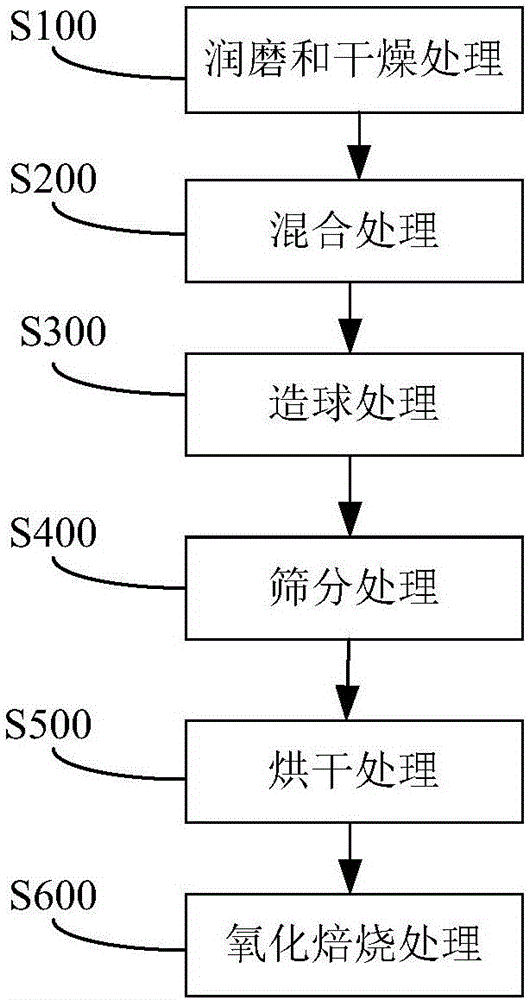

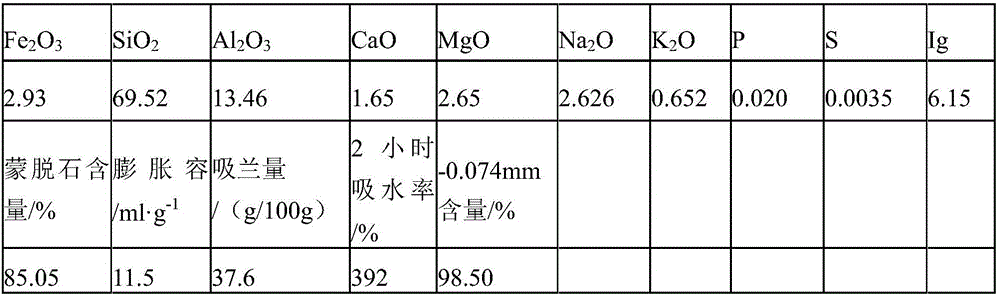

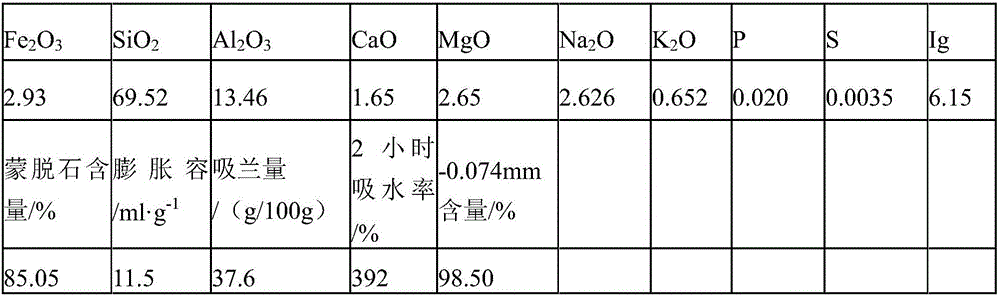

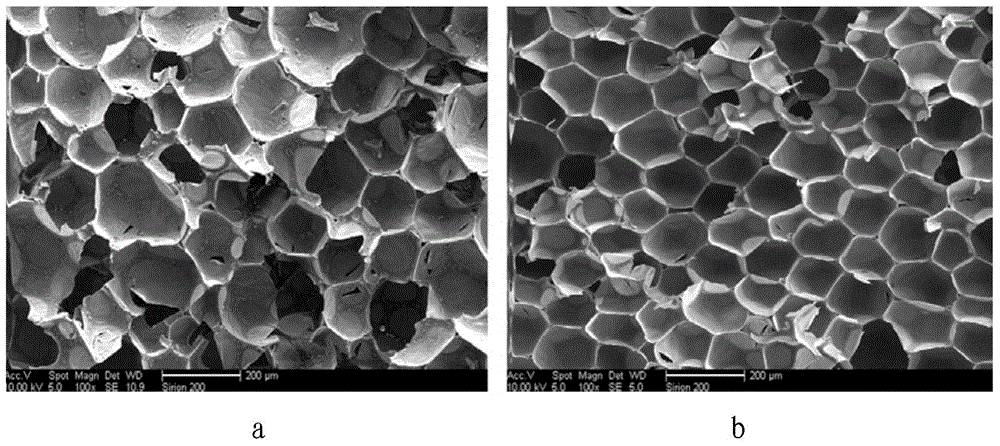

Method for preparing full-vanadium-titanium pellets

The invention discloses a method for preparing full-vanadium-titanium pellets. The method comprises the steps: carrying out wet grinding and drying treatment on vanadium titano-magnetite powder, so as to obtain dried vanadium titano-magnetite powder; carrying out dry mixing treatment on the dried vanadium titano-magnetite powder and a binder, so as to obtain a dry-mixed material; carrying out first wet-mixing treatment on one part of the dry-mixed material, so as to obtain a first wet-mixed material; carrying out second wet-mixing treatment on the other part of the dry-mixed material, so as to obtain a second wet-mixed material, wherein the moisture content of the second wet-mixed material is higher than that of the first wet-mixed material; carrying out first pelletizing treatment by using the first wet-mixed material, so as to obtain parent nuclei; carrying out second pelletizing treatment by using the parent nuclei and the second wet-mixed material, so as to obtain pellets; carrying out screening treatment on the pellets, so as to obtain screened pellets; carrying out drying treatment on the screened pellets, so as to obtain dried pellets; carrying out oxidizing roasting treatment on the dried pellets, thereby obtaining the full-vanadium-titanium pellets.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

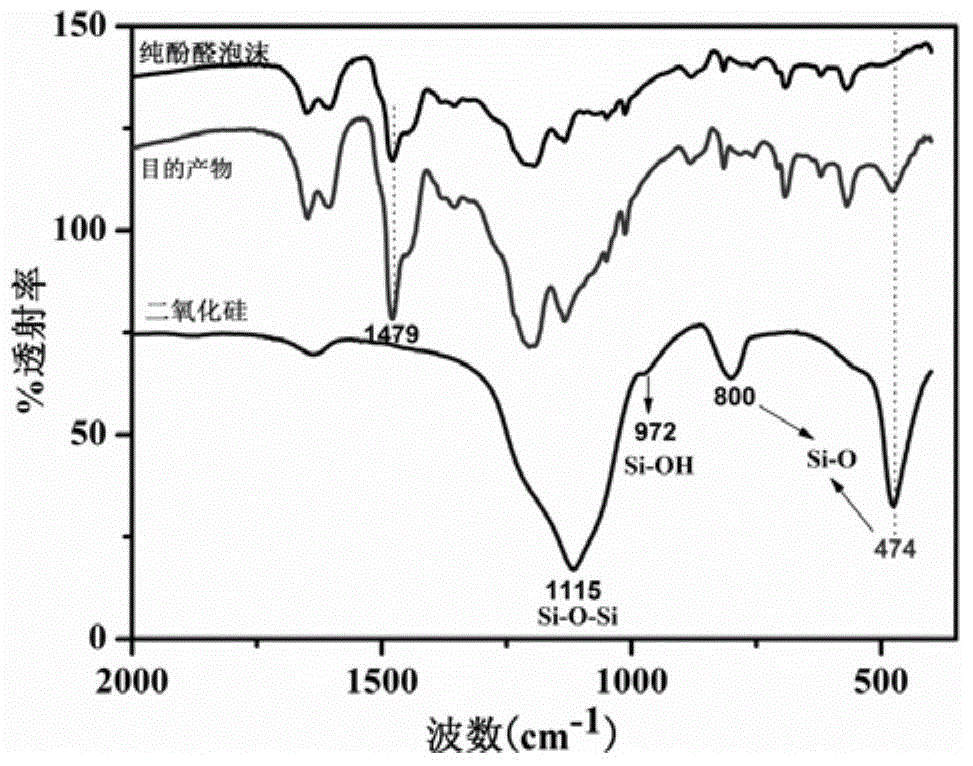

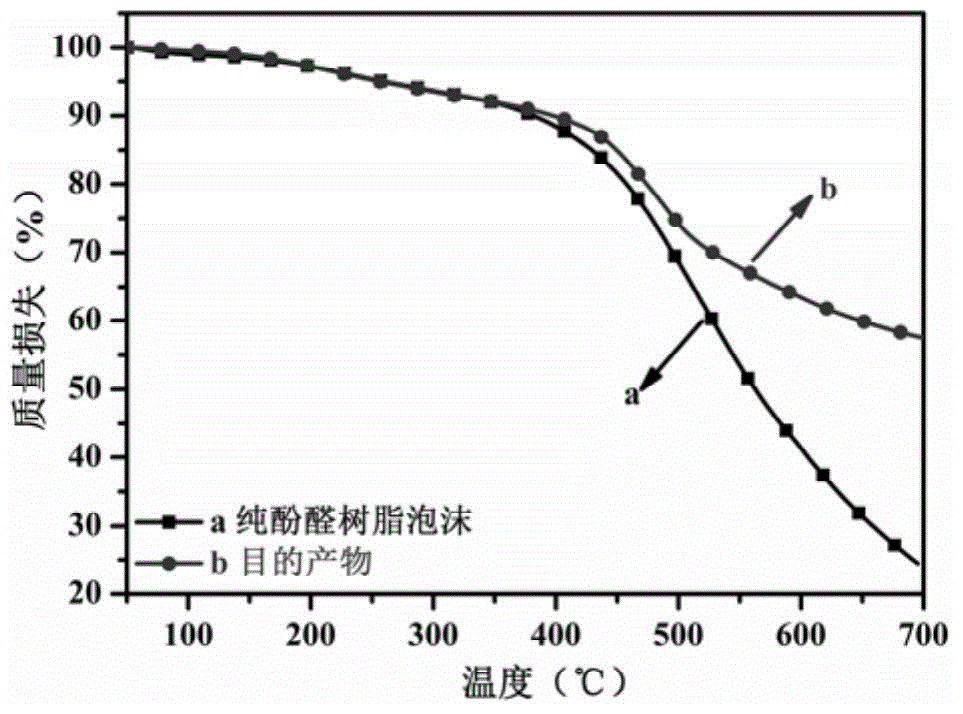

Nano carbon dioxide-phenolic resin composite foam material and preparation method thereof

The invention discloses a nano silicon dioxide-phenolic resin composite foam material and a preparation method thereof. The composite foam material is prepared from silicon dioxide nanoparticles, free phenol, free formaldehyde, a surfactant, a curing agent and sodium chloride as well as phenolic resin, wherein the silicon dioxide nanoparticles are bonded with phenolic resin by virtue of Si-O-C chemical bonds. The method comprises the following steps: firstly, ultrasonically dispersing a SiO2 sol in a formaldehyde solution or a mixed liquid of formaldehyde solution and paraformaldehyde to obtain a mixed solution; then, after mixing the mixed solution, phenol and an alkaline solution, and carrying out polymerization reaction to obtain resol in which the silicon dioxide nanoparticles are uniformly dispersed; then, firstly, carrying out acid neutralization and reduced pressure distillation on the resol; then, mixing and stirring the resol with a foaming agent and the surfactant to obtain mixed resin; and finally, adding the curing agent into the mixed resin and putting into a die to cure and foam to prepare a targeted product. The nano silicon dioxide-phenolic resin composite foam material disclosed by the invention can be widely applied to the fields such as building, aviation, refrigeration and the like commercially.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

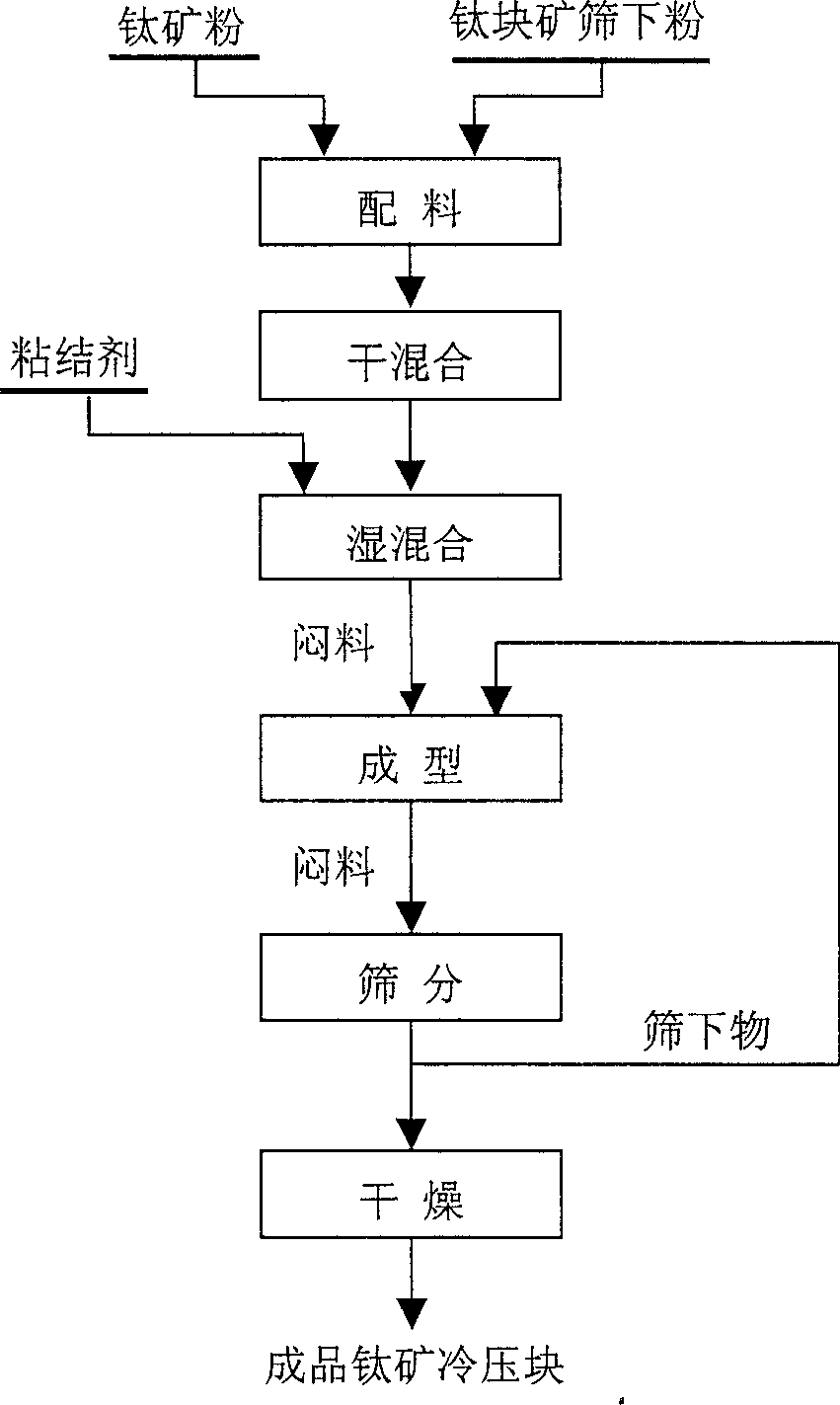

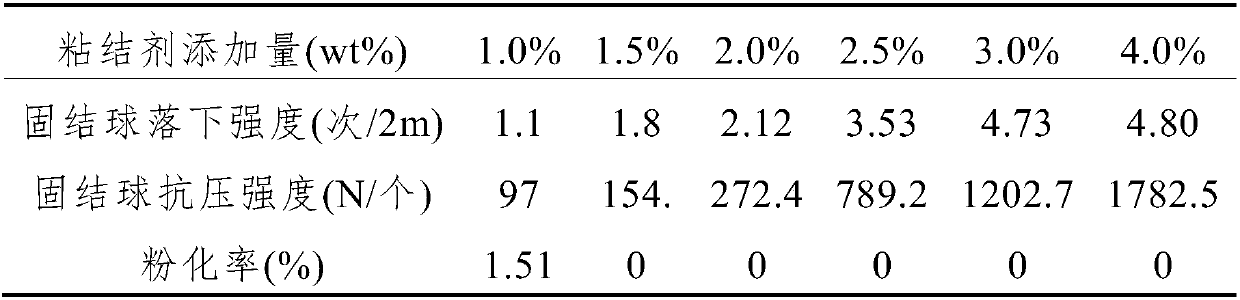

Titanium ore cold briquetting for protecting blast furnace and its production method

ActiveCN1766129AThe occurrence of powder rate is reducedHigh temperature strengthTop armouringsEpoxyCellulose

The chill-pressing titanium block to protect blast furnace comprises: 90~98% titanium powder, 2~10wt% composite adhesive composed of cement, polyvinyl alcohol and phosphodiester by proportion as 4~8:1~5:0~1; wherein, cement: cellulose is 5~10:1~5,epoxy resin:sodium humate is 8~10í†0~2, waste molasses liquid:lime hydrate is 7~10í†0~3, and waterglass:bentonite:silicasol is 7~10í†0~2í†0~1. The preparation method comprises: mixing material with adhesive, rolling, covering tightly the material, pressing to form; screening the crude block to re-press the powder less than 10mmm and form product. Compared with prior art, this invention increases mechanical strength, and reduces greatly the powder rate when screening powder.

Owner:BAOSHAN IRON & STEEL CO LTD +1

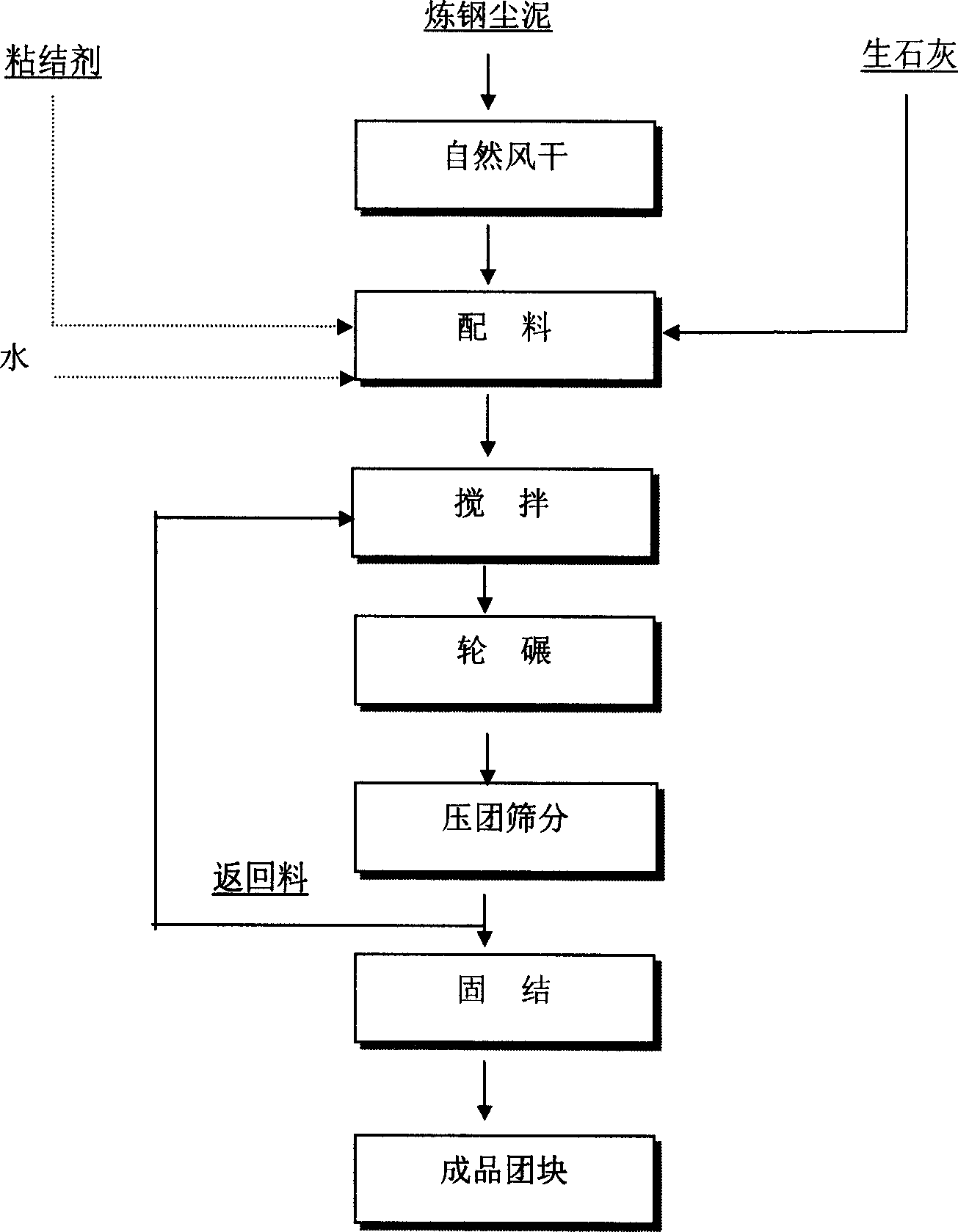

Process for preparing slag by pelletization of steel-making dust slime

InactiveCN1664120AHigh strengthIncreased degree of plastic deformationManufacturing convertersProcess efficiency improvementSteelmaking

The invention relates to a comprehensive utilization method of dust and mud in steelmaking process, which is specifically a spheroiditic slagging agent production process. The invention comprises the following steps: drying dust and mud in the open, adding 2-6% burnt lime and 0.5-1% adhensive to the mud to produce mixture, sending the mixture to agitator to intimate mixing, sending the mixture to roller to be pulverized fully, sending it to pelletizer to produce green-ball of phi20-phi30mm size by roll-type briquetting process in presure of 40-60KN, processing green-ball in jigging screen to get green-ball end product on sifter and sliver as return material under sifter and sending green-ball to tower furnace via charging system to be adglutinate and get end product.

Owner:张清学

Special binding agent for converter dedusting ash cold-pressed pellets

The invention relates to a special binding agent for converter dedusting ash cold-pressed pellets. The special binding agent comprises the following components including, by weight, 0.1-1.5 parts of syrup, 8-22 parts of carbonate, and 0.5-2.5 parts of sodium carboxymethylcellulose. When the special binding agent is used for preparing the cold-pressed pellets by converter dedusting ash, the strength of the converter dedusting ash cold-pressed pellets can be effectively improved, the pulverization rate is reduced, the utilization rate of the converter dedusting ash is fully increased, and the environmental pollution is reduced.

Owner:NORTHEASTERN UNIV LIAONING

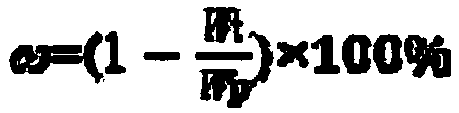

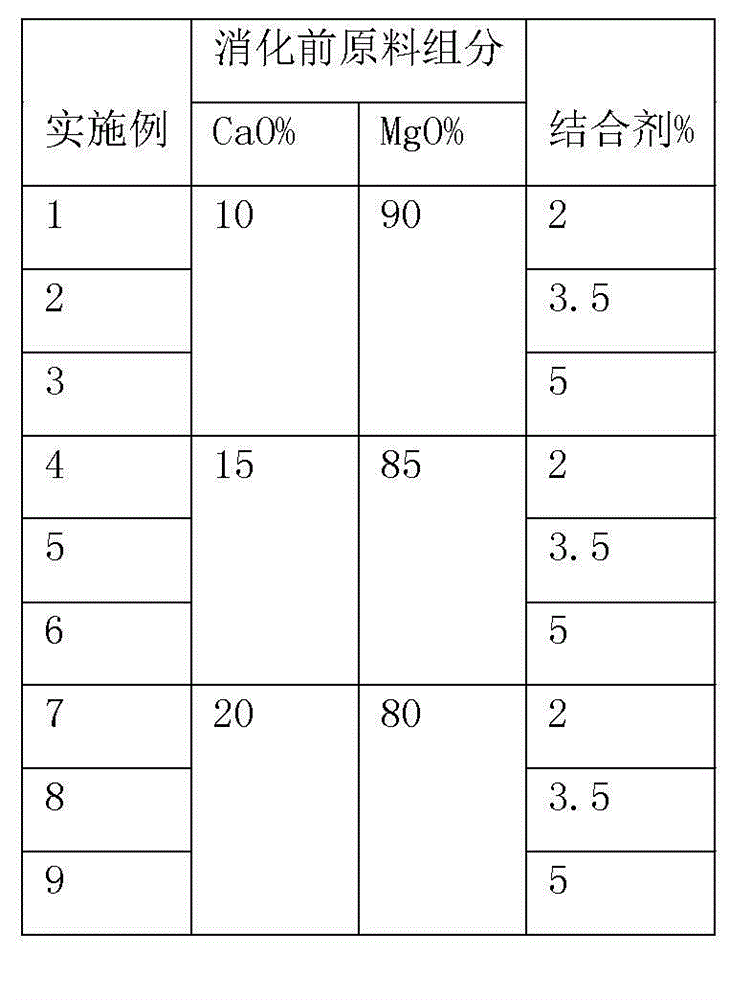

Method for preparing high-quality calcium magnesia by superhigh-temperature calcination

The invention relates to the field of preparation of refractory materials, particularly a method for preparing high-quality calcium magnesia by superhigh-temperature calcination, which is characterized by comprising the following steps: preparing dolomite and magnesite into a raw material in which the CaO content is 15-20 wt% and the MgO content is 80-85%; adding the raw material into a ball milling tank, grinding and mixing, and meanwhile, adding water to carry out slaking and slurrying; and drying the slurry, adding calcium lignosulphonate, evenly mixing, pressing into green bricks, and calcining. The calcination process comprises the following steps: heating to 1100 DEG C, keeping the temperature for 3-5 hours, heating to the final calcination temperature of 2000-2200 DEG C, keeping the temperature for 5-7 hours, vacuumizing, cooling with water to 1000 DEG C, introducing protective hydrogen, and continuing cooling with water to room temperature. Compared with the prior art, the calcium magnesia has the advantages of high hydration resistance and high corrosion resistance, thereby basically solving the problem of high hydration tendency in the magnesium-calcium refractory material, and facilitating the storage, transportation, building and the like in future.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Method for manufacturing stainless steel dedusting ash pressure ball

InactiveCN102212678AReduce the probability of burstingReduce pollutionPolyvinyl alcoholMixed materials

The invention relates to a method for manufacturing a stainless steel dedusting ash pressure ball, sequentially comprising the following steps of: 1, mixing the following raw materials including 10 parts of stainless steel dedusting ash and 0.8-1.2 parts of cement into a mixed material; 2, adding water and organic binder, mixing 0.2-0.3 part by weight of MgC12, 0.1-0.2 part by weight of polyvinyl alcohol and 1.3-1.8 parts by weight of water into glue, spraying the glue on the mixed material and uniformly mixing; 3, extruding and forming, conveying the mixed material in which the glue is added to a ball pressing machine, pressing into a block with the maximum outline size of 30-45 mm; 4, naturally drying and maintaining the extruded and formed block, wherein the intensity is 2100+ / -500N per one ball; and 5, drying the maintained ball in a dried ventilation region for 5+ / -1days, wherein after being dried, the water content of the ball is not more than 2.0%. When the pressure ball manufactured by using the method for manufacturing the stainless steel dedusting ash pressure ball is used for making steel in an electric furnace, the smoke level is reduced; and the environmental pollution is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

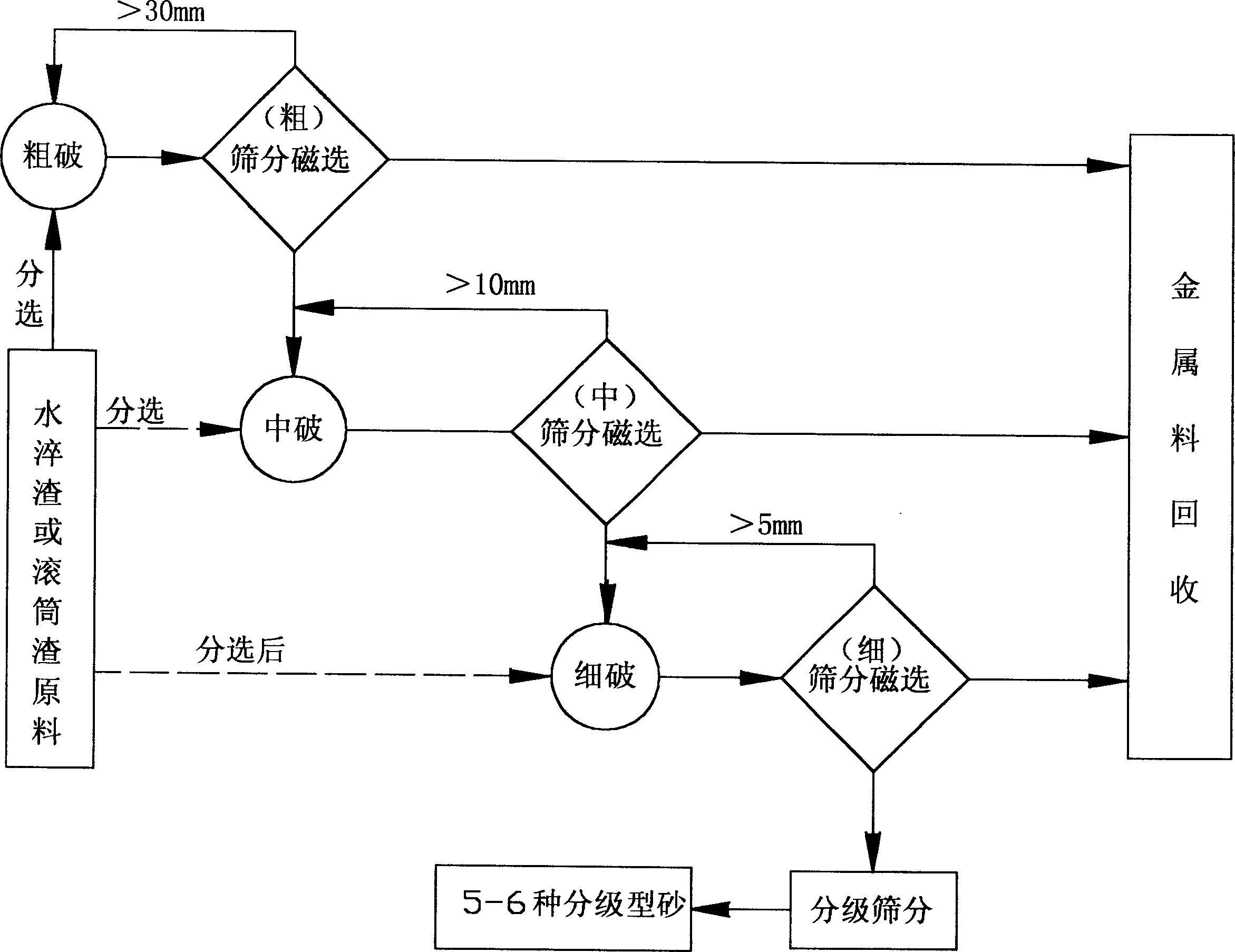

Preparation method of steel slag mould sand

InactiveCN1557970AEfficient use ofAchieve separationRecycling and recovery technologiesGranularitySlag

The present invention relates to the application of converter steel slag, and is especially the preparation process of steel slag molding sand. Steel slag is injected with water and quickly cooled to obtain water quenched steel slag or cylindrical slag, and the quenched steel slag or cylindrical slag is circularly crushed and sieved to for molding sand with granularity not greater than 5 mm and in different size. The molding sand has low free calcium oxide content, low metal iron content, low pulverization rate and other features, and may be used to replace quartz sand widely used as fine aggregate, sand blast, water filtering material, etc.

Owner:MCC BAOSTEEL TECH SERVICE

Foamed dephosphorization pellet and preparation method thereof

InactiveCN101818229ALess slagSolve the problem of moisture brought into molten steelProcess efficiency improvementElectric furnaceAdhesiveSulfur

The invention provides a foamed dephosphorization pellet and a preparation method thereof. The pellet consists of the following components: 15 to 40 percent of calcium oxide (CaO), 15 to 40 percent of carbon (C), 20 to 30 percent of ferric oxide (Fe2O3), 1 to 3 percent of sodium oxide (Na2O) and 20 to 40 percent of caustic soda. The preparation method for the pellet comprises the following steps of: preparing limestone, low-sulfur coal powder, iron oxide red and soda ash according to the component content of the foamed dephosphorization pellet, mixing the materials uniformly by using a mixer, then adding a little amount of adhesive into the mixture, and pelleting the mixture by using a disc pelleting machine. The dephosphorization pellet of the invention does not produce pollution to the environment, so the pellet is favorable for environmental protection; the pellet has good dephosphorization effect and is favorable for improving the quality of the steel; and the pellet has little corrosion to a furnace lining, can reduce the using amount of lime fed into the furnace so as to simplify the operation in front of the furnace, and has obvious comprehensive economic benefit.

Owner:ANGANG STEEL CO LTD

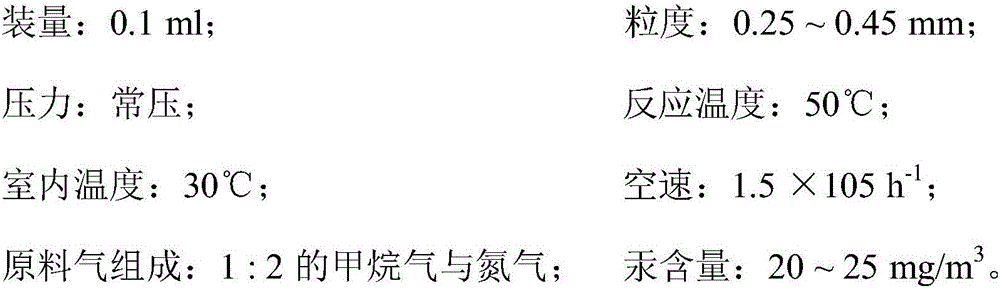

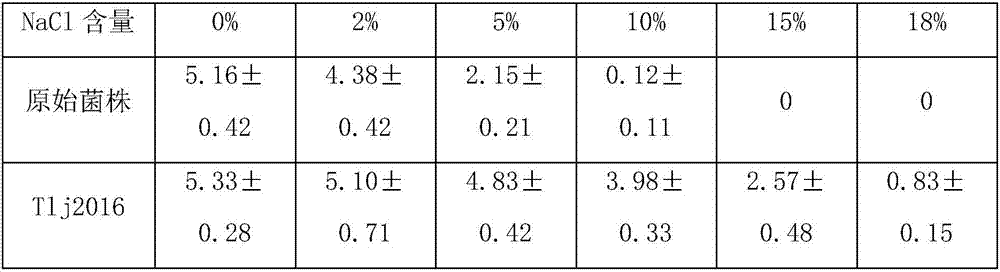

Mercury removal agent with copper sulfide and method for preparing mercury removal agent

InactiveCN106311279AHigh activityHigh precisionGaseous fuelsCatalyst activation/preparationMicro structureActive component

The invention belongs to the field of mercury removal agents, and particularly relates to a mercury removal agent with copper sulfide and a method for preparing the mercury removal agent. The mercury removal agent with the copper sulfide comprises, by weight, 10%-45% of the active copper sulfide, 0%-7% of structural auxiliaries, 50%-85% of carriers and 3%-12% of binders. The mercury removal agent and the method have the advantages that active components in the mercury removal agent with the copper sulfide are prepared by the aid of co-precipitation processes, and the copper sulfide is high in activity and is high in mercury capacity and mercury removal precision when used for removing mercury; the structural auxiliaries are added into the copper sulfide, accordingly, defect sites of copper sulfide crystals can be increased, the quantities of active S2- can be increased, and the mercury removal activity of the copper sulfide further can be improved; the silica sol binders are added into the copper sulfide, the strength of products can be greatly improved, collapse of micro-structures of catalysts can be prevented in service procedures, accordingly, the integrity of the integral structure of the mercury removal agent can be guaranteed, and the mercury removal agent is low in pulverization rate.

Owner:XIAN SUNWARD AEROSPACE MATERIAL CO LTD

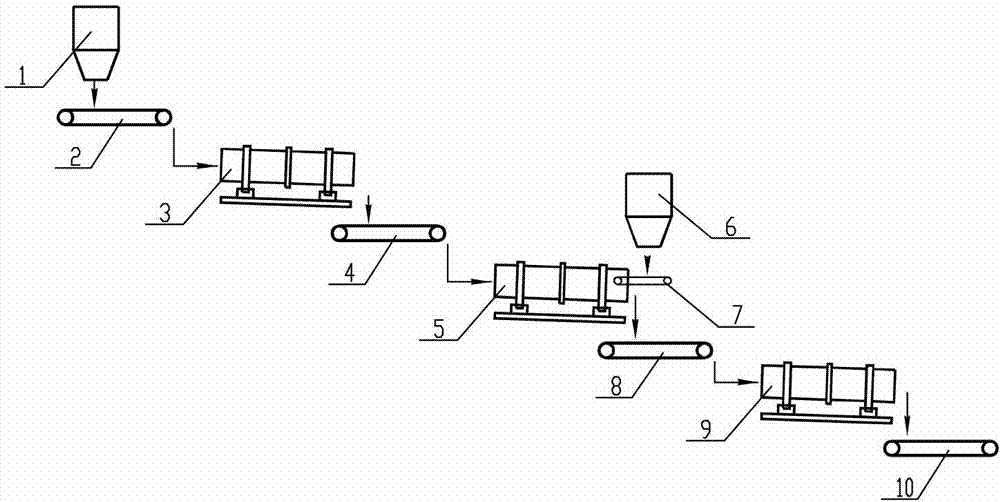

Process for mixing materials and making external-rolled coal through sintering machine

InactiveCN103498046AReduce consumptionHigh calcium oxide content on the surfaceSolid fuelEngineering

The invention relates to a process for mixing materials and making external-rolled coal through a sintering machine, wherein the process includes the steps of preparing materials, conducting mixing and making balls. The process is characterized in that a mixing and ball making technology combining internal matched solid fuel with externally-rolled fuel is adopted, the internal matched solid fuel which is 25wt% to 35wt% of the amount of the solid fuel added to the mixed raw material is added to the mixed raw material in a material preparing chamber fuel mine tank, mixing and ball making are conducted to make small balls which contain the internal matched solid fuel accounting for 50wt% to 60wt% of the total weight of balls and have the particle size ranging from 1mm to 3mm, the solid fuel which is 65wt% to 75wt% of the amount of the solid fuel added to the mixed raw material is used as externally-rolled fuel and added into the fuel material preparing tank, the mixture along with the made small balls are fed to a three-time feed belt machine through a constant weight feeder, then, the mixture and the small balls are sent to a coal rolling machine so that sinter of the externally-rolled fuel can be obtained, and the sinter is conveyed to a sintering chamber through a sealing-tape machine so that sintering can be conducted. The process for mixing the materials and making the external-rolled coal through the sintering machine has the advantages that the fuel is evenly distributed, the combustion condition of the fuel is improved, the sintering quality is improved, and meanwhile consumption of the solid fuel can be lowered.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

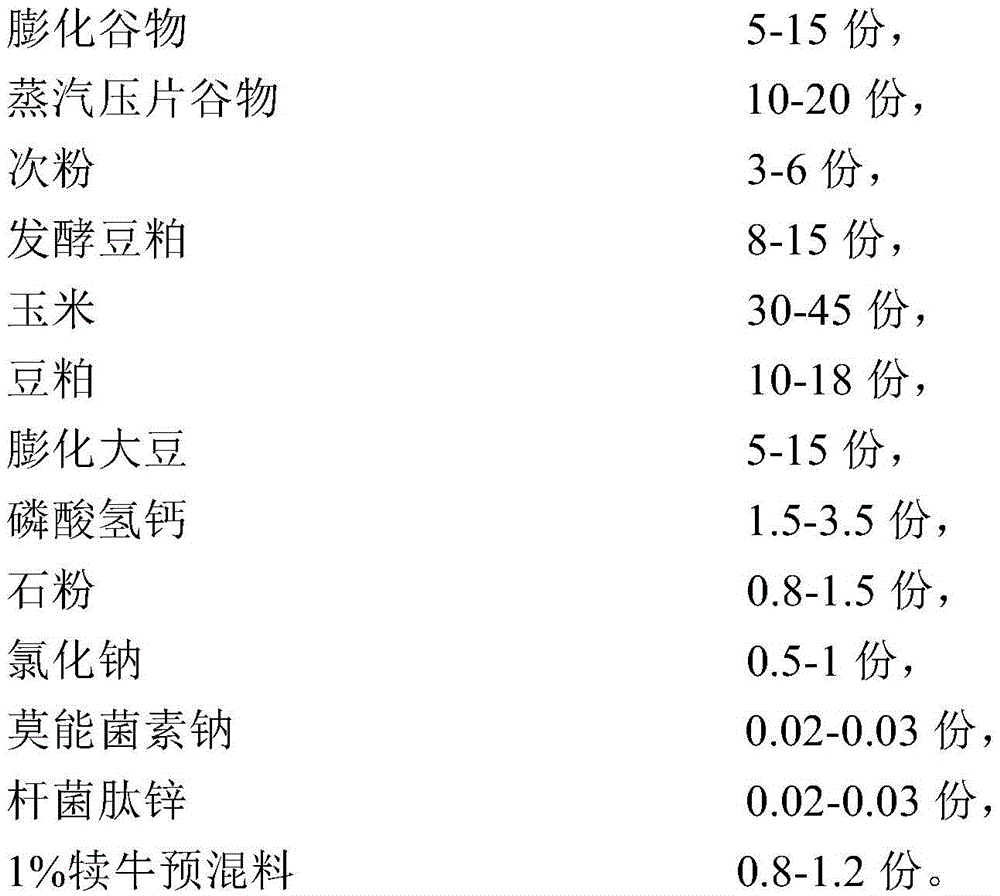

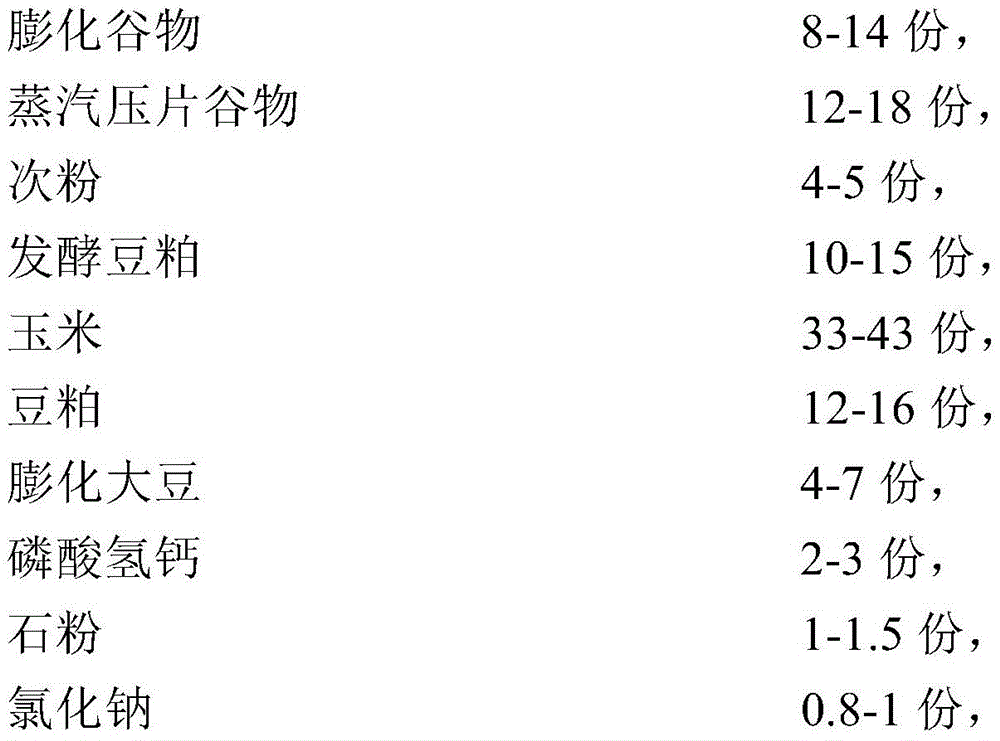

Concentrated supplementary food capable of improving palatability and resisting diseases for calves, as well as preparation method and application of concentrated supplementary food

InactiveCN106689705AGuaranteed granulation effectImproves fiber digestibilityFood processingAnimal feeding stuffFiberDisease

The invention discloses a concentrated supplementary food capable of improving palatability and resisting diseases for calves, as well as a preparation method and application of the concentrated supplementary food. A formula of the concentrated supplementary food comprises 5-15 parts of puffed cereals, 10-20 parts of steam tabletting cereals, 3-6 parts of middling, 8-15 parts of fermented soybean meal, 30-45 parts of corn, 10-18 parts of soybean meal, 5-15 parts of puffing soybeans, 1.5-3.5 parts of calcium hydrogen phosphate, 0.8-1.5 parts of stone powder, 0.5-1 part of sodium chloride, 0.02-0.03 part of monensin sodium, 0.02-0.03 part of zinc bacitracin and 0.8-1.2 parts of a 1% calf premix. According to the concentrated supplementary food and the preparation method and application thereof disclosed by the invention, raw materials which are high in the content of effective fibers and high in the content of digestible protein, such as the steam tabletting cereals, the puffed cereals and the fermented soybean meal are added, and the middling is added, so that the granular sensation of a feed is improved, the palatability of the calves is met, and minerals, trace elements and vitamins are strengthened; besides, a feed additive for enhancing immunity is added, so that the palatability can be improved, the development level of rumens can be increased, the food consumption and the daily gain of the calves are increased, the disease resistance of the calves can be enhanced, the feed cost can be reduced, the breeding period of replacement cattle can be shortened, the milk production of cows can be increased, and the economic benefits can be increased.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

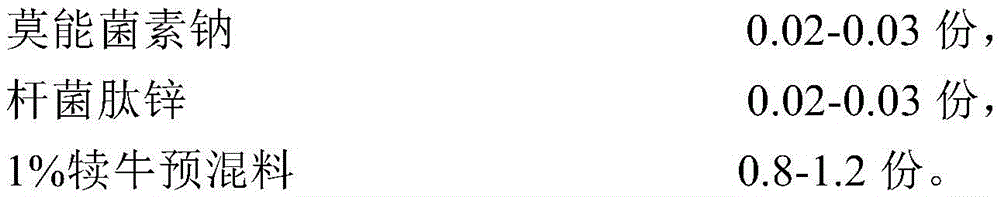

Method for preparing artificial rutile from titanium concentrate

The invention relates to a method for preparing artificial rutile. The method comprises the following steps: ilmenite classification, oxidizing roasting, reduction roasting, fluoride salt staging acidleaching impurity removal, water washing and calcination for obtaining high-grade artificial rutile. The problems of high calcium and magnesium content and low grade of artificial rutile are solved through hydrochloric acid leaching of redox-modified ilmenite, and fluoride salt staging acid leaching impurity removal adopted in the acid leaching process of the method enhances the impurity removalcapability, especially the calcium impurity removal capability, of individually used hydrochloric acid, so the prepared artificial rutile has a high grade and a low calcium and magnesium content, andcan be directly used as a raw material for a chlorination process. The method has the advantages of simple process and device, convenience in operation, low cost, and easiness in realization of industrial production. The grade of the artificial rutile obtained by the method is 90% or more, the impurity removal effect is good, and the total content of calcium and magnesium is 0.5% or less. The rawmaterial used in the invention is ilmenite from Panzhihua and Xichang regions in Sichuan.

Owner:LOMON BILLIONS GRP CO LTD

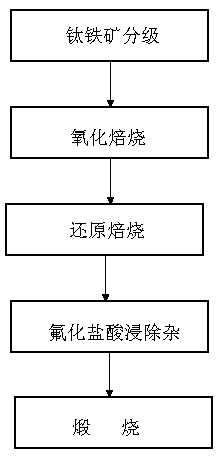

Method and system for reducing reduction degradation of vanadium-titanium magnet pellets

The invention discloses a method and system for reducing reduction degradation of vanadium-titanium magnet pellets. The method for reducing reduction degradation of the vanadium-titanium magnet pellets includes the following steps that firstly, vanadium-titanium magnetite is ground to be fine, and vanadium-titanium magnetite powder is obtained; secondly, the vanadium-titanium magnetite powder is mixed with bentonite, and a mixture is obtained; thirdly, the mixture is pelletized, and green pellets are obtained, wherein a boric acid water solution is added in the pelletizing process to serve as water for pellet pelletizing; and fourthly, the green pellets are roasted, and the vanadium-titanium magnet pellets are obtained. The invention further discloses a system implementing the method, and the system includes a fine grinding device, a material mixing device, a pelletizing device and a roasting device. According to the method and the device, in the pelletizing process, the boric acid water solution is evenly sprayed into the green pellets, the reduction degradation rate of the vanadium-titanium magnet pellets is effectively reduced, and the metallurgical performance in the pellet smelting reduction process is improved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

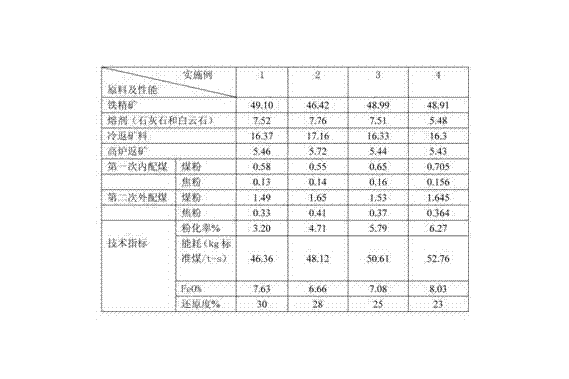

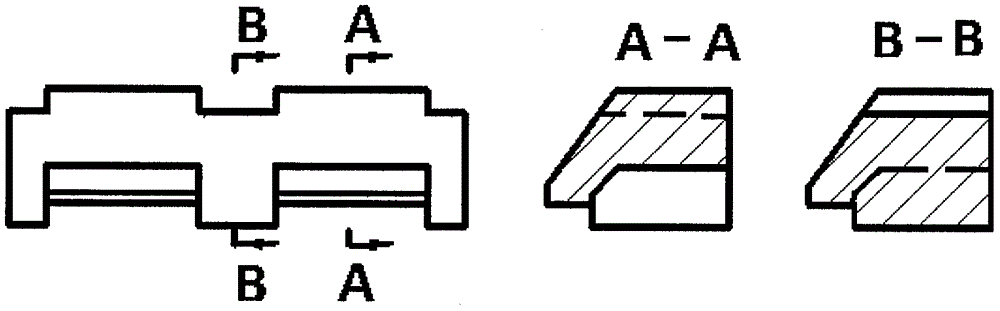

Sintering process for ferrochromium fine powder ore pellets

The invention discloses a sintering process for ferrochromium fine powder ore pellets. The sintering process is characterized by comprising the following steps: 1) carrying out ball-milling on ferrochromium fine powder ores by a ball mill; 2) screening cokes; 3) screening bentonite; 4) carrying out internal carbon distribution on the ferrochromium fine powder ores prepared in the step 1); 5) manufacturing green pellets in a first drum; 6) carrying out external carbon distribition on the green pellets prepared in the step 5) in a second drum, thus obtaining carbon proportioning green pellets; 7) carrying out material distribution in a sintering machine in a material distribution manner of distributing large pellets at the top and distributing small pellets at the bottom; 8) roasting and preheating a sintering cup by petroleum gas before sintering, and then carrying out draft sintering.

Owner:JILIN MECHANICAL & ELECTRICAL EQUIP

Method for preparing starch granules

The invention provides a method for preparing starch granules, which comprises the following steps: 1) uniformly mixing starch, water and an adhesive according to the weight ratio of 50-100:10-45:5-60 to prepare a mixed material; 2) adding the above mixed material in a wet type granulator to obtain starch granules, passing the starch granules through a microwave treatment section provided at an outlet of the wet type granulator, entering into a drying device to obtain the starch granules, wherein the granularity is 10-100 meshes and the packaging density is 1.05-1.15g / cm<3>. The method for preparing the starch granules is characterized in that the starch is prepared to starch granules, a process of microwave treatment is added after wet type granulation, the microwave heat-effect and microwave non-thermal effect can be enhanced so that the starch granules absorb microwave electromagnetic energy to generate collision, crushing and aggregation effects, the pulverization rate of starch granules can be reduced, and the uniform gelatinization effect of the starch granules can be enhanced. The provided method has the advantages of simple process, convenient operation, less investment and high efficiency, and the produced starch granules have the convenient eating and good mouthfeel.

Owner:HUBEI RSEN AGRI TECH DEV

Device and method for removing hydrogen fluoride in fluorine gas

InactiveCN111085081ASolve the problem of liquefactionLess likely to cause safety accidentsGas treatmentDispersed particle separationHydrogen fluorideChemical industry

The invention discloses a device and a method for removing hydrogen fluoride in fluorine gas, belonging to the technical field of fluorine chemical industry. The device comprises an alkali metal adsorption tower, an F2 gas inlet pipeline, an F2 gas outlet pipeline, a nitrogen back-blowing gas inlet pipeline, a nitrogen gas outlet pipeline, a filter and a blow-off pipeline. The method comprises thefollowing steps: step 1, preparing alkali metal adsorption balls; step 2, allowing HF-containing fluorine gas generated by electrolysis to enter an alkali metal adsorption tower and then to enter a filter, and allowing filtered gas to enter a subsequent pipeline so as to obtain purified F2 gas; and step 3, discharging liquid HF in the alkali metal adsorption tower through the blow-off pipeline. According to the invention, by using of cylindrical inner-framework adsorption ball with porous structure, the adsorption efficiency is improved, and the requirements of preparation of high-purity fluorine gas with a purity of 99.9% and high-purity fluorine gas mixed gas on HF indexes can be met; the service life of the alkali metal adsorption balls is prolonged; meanwhile, the problem of fluorineliquefaction caused by over-low temperature in the prior art is also solved.

Owner:PERIC SPECIAL GASES CO LTD

Silurus asotus feed phagostimulant and preparation method thereof

InactiveCN107348229AOptimized formulaImprove antioxidant capacityFood processingClimate change adaptationSoluble fiberArtemisia carvifolia

The present invention discloses a silurus asotus feed phagostimulant and a preparation method thereof, and belongs to the technical field of feed additive preparations. Based on nutritional requirements of silurus asotus and water body environment, and combining food intake characteristics, a formula of raw materials is optimized. The silurus asotus feed phagostimulant scientifically combines compound flavor peptides greatly improving palatability and feed utilization rate, having a relatively strong anti-oxidation effect and eliminating free radicals; an accharomyces cerevisiae culture having functional characteristics of being strong in nutrition, biological activity, oxidation resistance, etc.; a high-calcium cerasus humilis extract effectively supplementing calcium, iron and soluble fibers, having a strong embedding effect and prolonging a shelf life; artemisia carvifolia seed powder significantly improving antifreeze effects and stability, improving water resistance and gloss, and enhancing and promoting palatability; and wheat malt powder providing rich nutrients, bioactive substances and plant enzyme sources. Finally, the prepared silurus asotus feed phagostimulant is strong in phagostimulant and good in production performances.

Owner:田岗

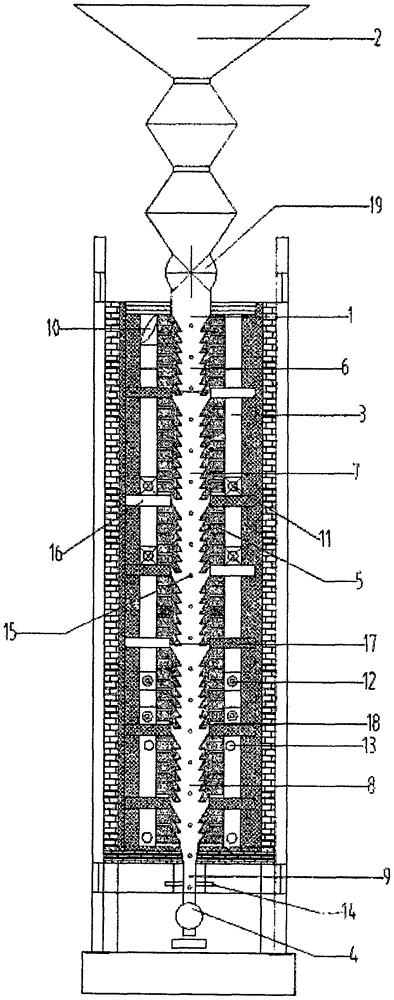

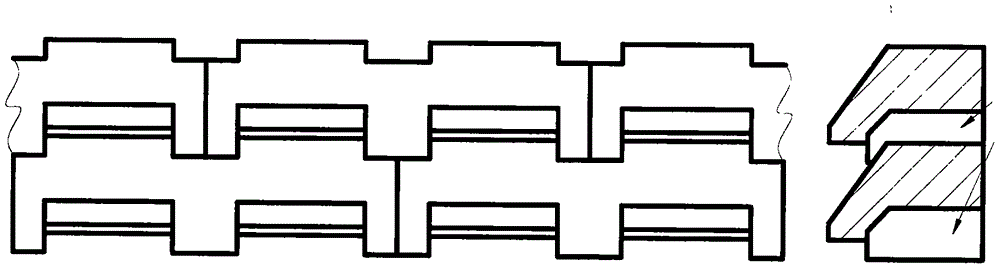

Carbonization and activation device for active coke production

The invention belongs to the field of chemical engineering devices and relates to a carbonization and activation device for active coke production. The device comprises a material channel and flues at two sides of the material channel. The device also comprises a preheating section, a carbonization section, an activation section and a cooling section and the sections are orderly arranged from top to bottom along a vertical direction. The flues in the carbonization and activation sections are respectively provided with gas burners. The flue in the activation section is provided with an activator inlet. The device realizes combination of carbonization and activation, has less processes, uniform and continuous reaction processes, a fast activation rate, a high raw material utilization rate and high production power, greatly reduces power and energy consumption and has a low cost and a high product yield.

Owner:赵英杰

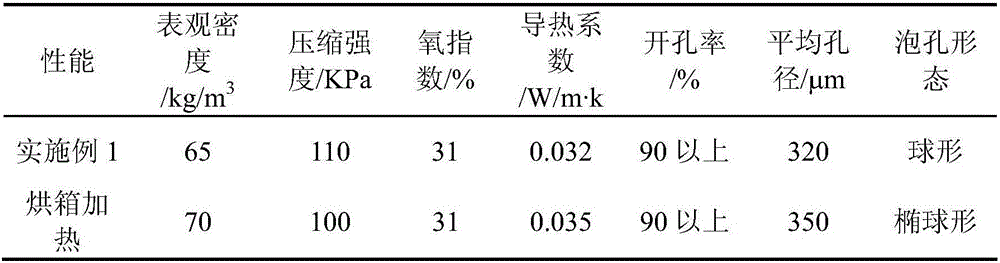

Urea resin foam material prepared by microwave foaming and preparation method of urea resin foam material

The invention relates to a foam material and a preparation method thereof, in particular to a urea resin foam material prepared by microwave foaming and a preparation method of the urea resin foam material. The urea resin foam material is prepared by three steps and prepared from, by weight, 100 parts of urea resin available for microwave foaming, 1-5 parts of a foaming agent, 2-7 parts of a surfactant and 0.1-3.5 parts of a curing agent. A microwave heating method is adopted and assisted by oven heating for forming. The urea resin foam material and the preparation method thereof have advantages of high foaming efficiency, high foaming ratio, technical simplicity, low cost, high flame retardation performance and low fire risk and can be widely applicable to the field of exterior insulation of buildings.

Owner:NORTHEAST FORESTRY UNIVERSITY

Slagging agent for iron and steel metallurgy

InactiveCN103484602AReduce pulverization rateEasy to transportProcess efficiency improvementOperating environmentMelting point

The invention provides a slagging agent for iron and steel metallurgy, and relates to the technical field of iron and steel smelting. The slagging agent comprises the following components, by weight, 48% of F6, 12% of A12, 4-29% of Na4, S < 0.05%, P < 0.05%, H2O <= 1% and Fe 2O3 <= 1%. Products are mechanically pressed and formed and are granulated, granularity ranges from 5mm to 40mm, the pulverulent ratio is low, and the products are convenient to transport and store; the melting point of lime can be effectively reduced, and therefore the effects of slagging and fluxing are achieved; the fluorine content of the slagging agent is lower than the fluorine content of fluorite, therefore, environmental pollution is small, and the operating environment of workers is improved; the slagging agent is better in slagging effect compared with fluorite, molten steel temperature drop is small in the slagging process, and the slagging agent has the obvious effects for improving the quality of molten steel, shortening refining time, and reducing steel-making cost.

Owner:天津驰宏冶金材料制造有限公司

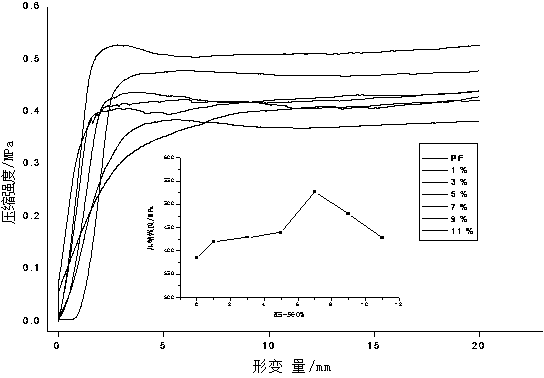

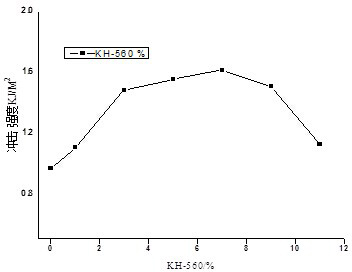

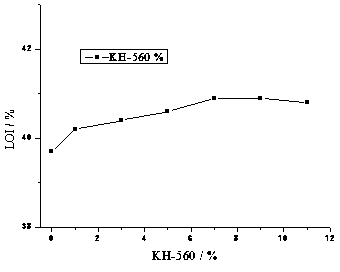

Preparation method of novel KH-560 modified phenolic foam

InactiveCN104004216AHigh mechanical strengthIncreased mechanical toughnessPhenolformaldehyde foamPhenolic aldehyde

The invention discloses a preparation method of novel KH-560 modified phenolic foam. The preparation method comprises the steps that the mole ratio of formaldehyde to phenol is 1.8:1, the temperature rises to 40 DEG C while a water bath is carried out in the 200rpm stirring state, pH is adjusted to range from 9 to 10, temperature continues to rise to 60 DEG C, and reaction is carried out for 30 min; a 7% silane coupling agent is added, a Tween-80, n-pentane and 50wt% sulfuric acid are then added, and foaming curing is carried out at the 70 DEG C. Medical strength and toughness of the obtained modified phenolic foam are remarkably improved. Compared with pure phenolic foam, compression strength of the modified phenolic foam is improved by 37%, impact strength of the modified phenolic foam is improved by 68%, the pulverization rate of the modified phenolic foam is reduced to 1.6%, and mechanical strength and toughness of the modified phenolic foam are remarkably improved. Meanwhile, according to thermogravimetric analysis, heat stability of the modified phenolic foam is only slightly reduced, the thermal weight loss rate of the modified phenolic foam is reduced by 1% to 3% compared with pure phenolic foam at the same temperature, and excellent heat stability and good fire resistance of the modified phenolic foam are still kept.

Owner:CHANGCHUN UNIV OF TECH

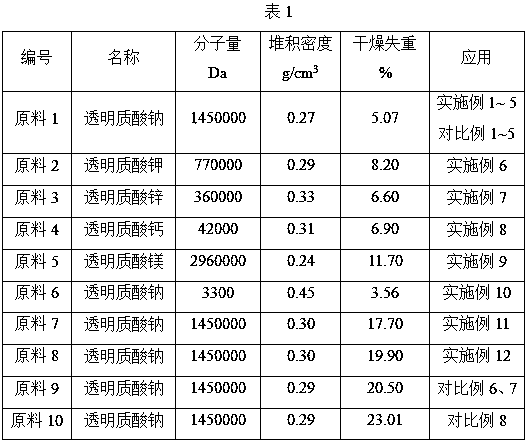

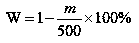

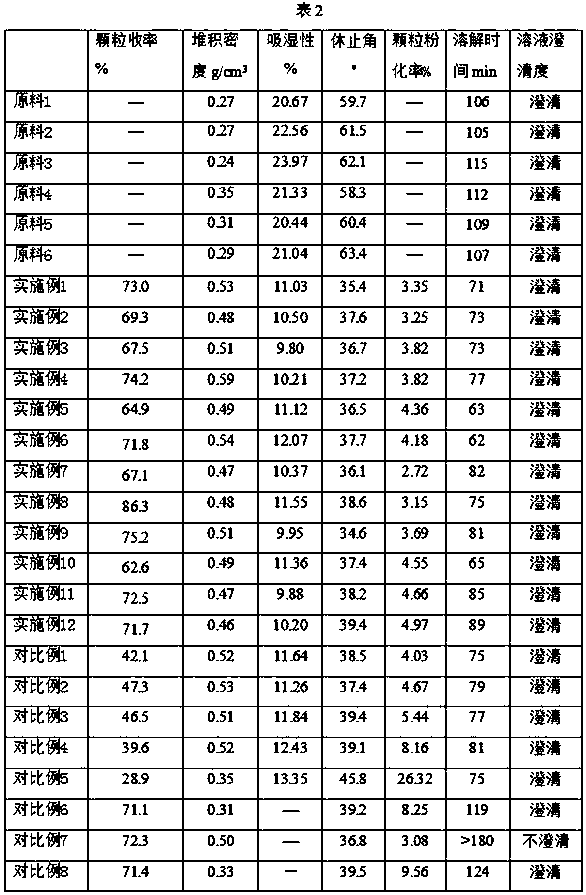

Preparing method for hyaluronic acid or salt particles of hyaluronic acid and obtained product

ActiveCN109531857AImprove pulverization rateReduce pulverization rateAdditive ingredientHyaluronic acid

The invention discloses a preparing method for hyaluronic acid or salt particles of the hyaluronic acid and an obtained product. The hyaluronic acid particle preparing method is a dry process granulation method, the hyaluronic acid or salt powder of the hyaluronic acid is subjected to rolling, pulverizing, fine granulating, screening and discharging through a dry process rolling and granulating method under the situation that a bonding agent is not used, and the hyaluronic acid or salt particles of the hyaluronic acid are obtained. The product has the characteristics of being high in stackingdensity, weak in hygroscopicity, good in mobility and stability and the like; and in the usage process, the advantages that dissolving is easy, adding is convenient, dust waste and pollution are reduced, long-term storage is achieved, and the transportation powdering ratio is low. According to the preparing method, operation is simple, little equipment is needed, a bonding agent and ingredients donot need to be added, influences on the structure and the property of the hyaluronic acid or the salt of the hyaluronic acid are avoided, and industrial production can be achieved.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

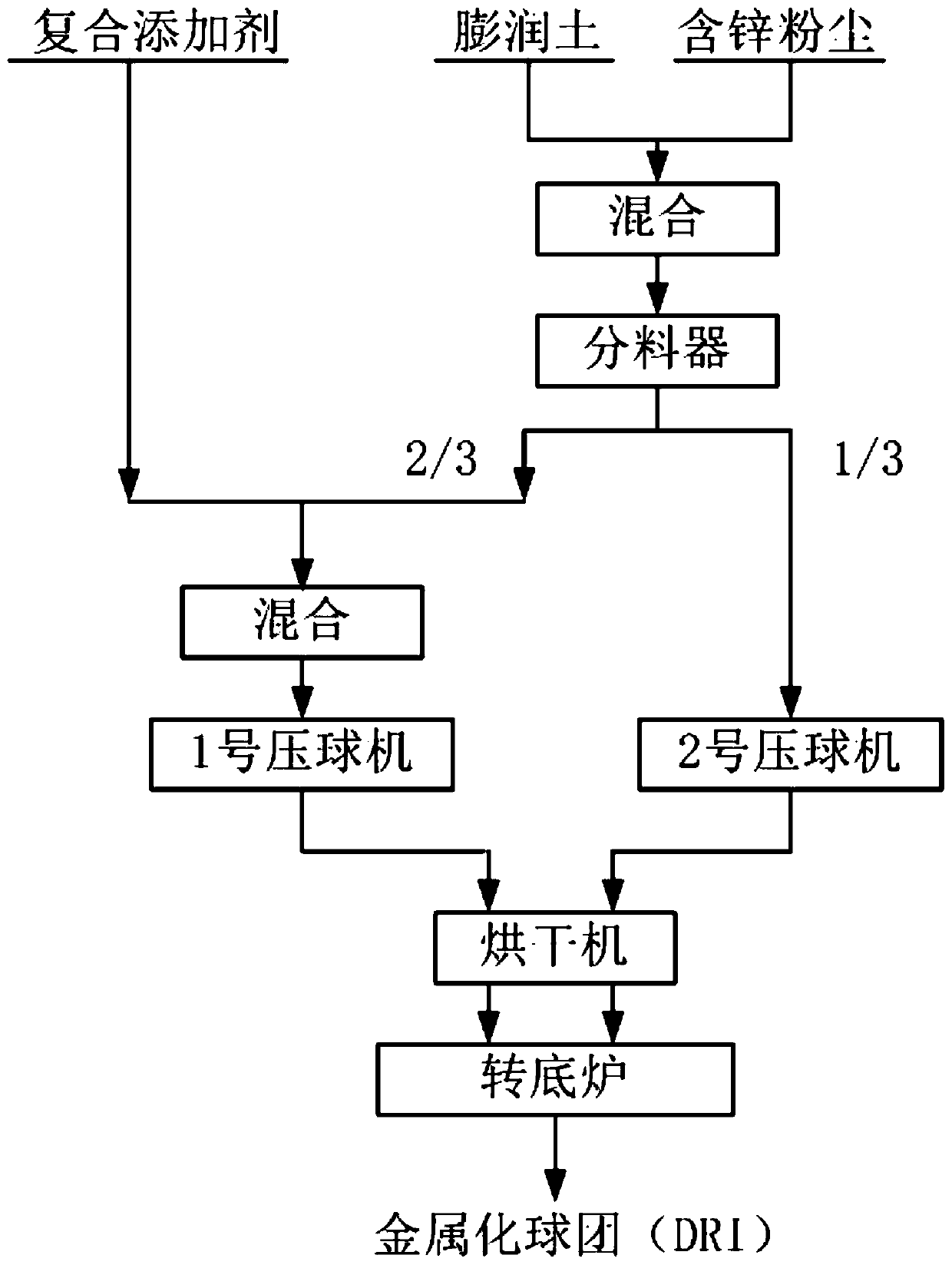

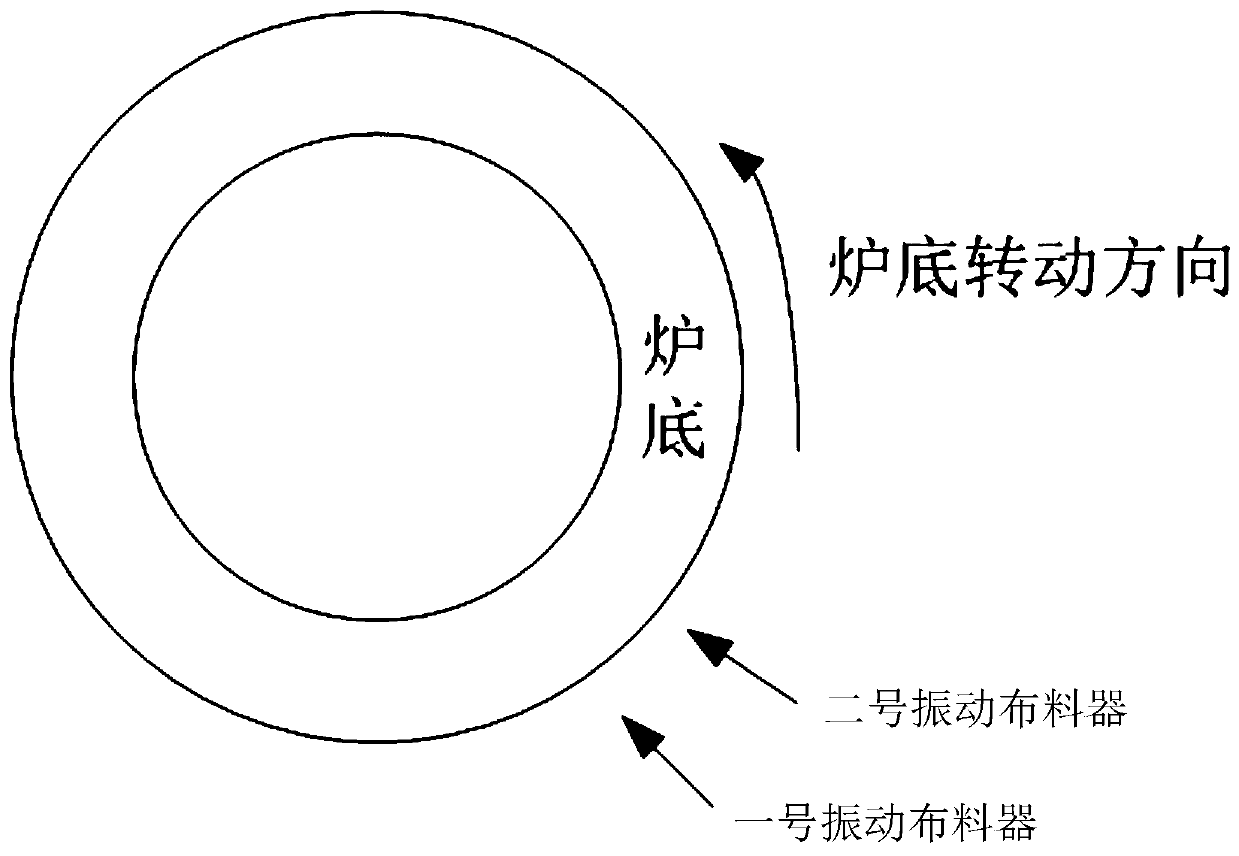

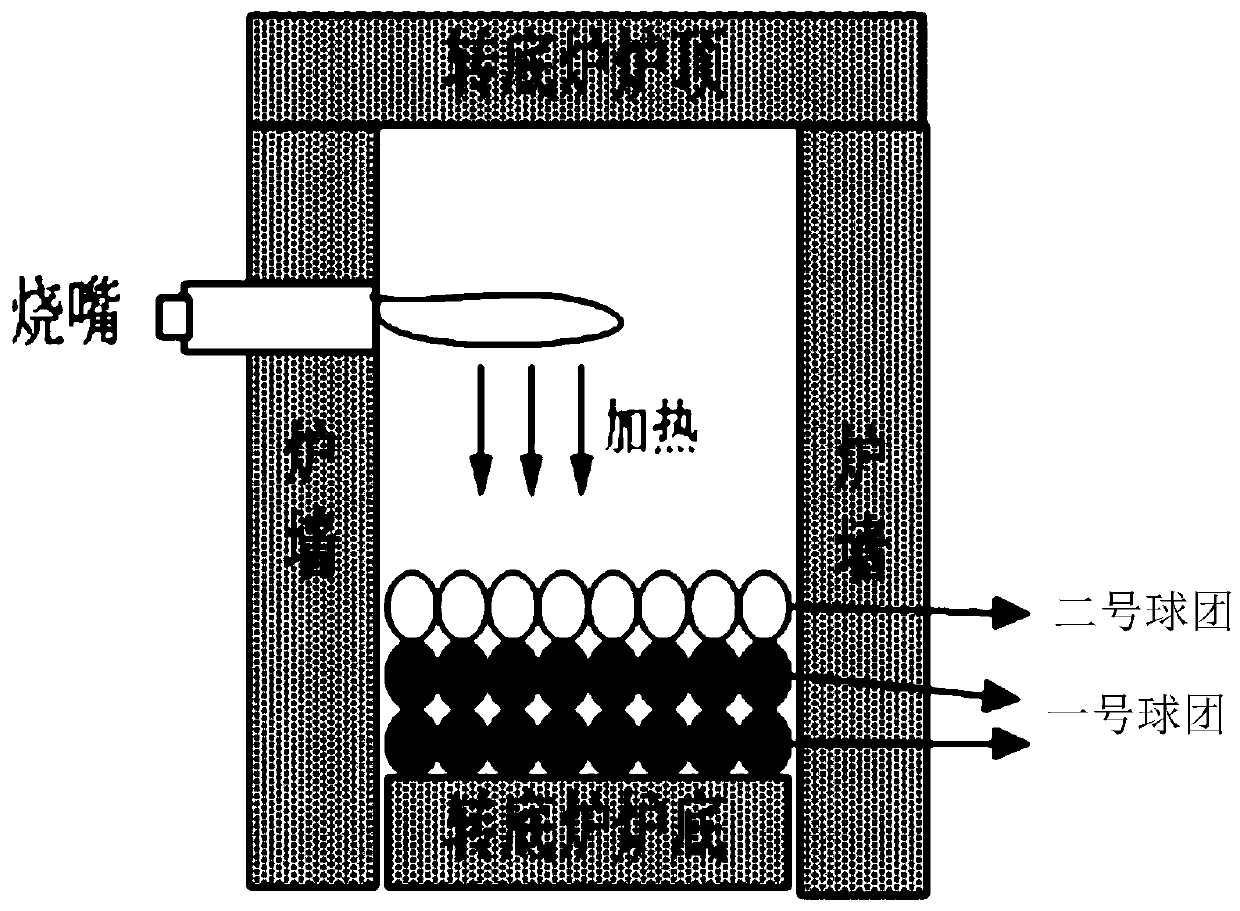

Method for inhibiting reduction degradation of zinc-containing dust pellets in rotary hearth furnace

ActiveCN110788113AReduce pulverization rateIncrease productivityTransportation and packagingSolid waste disposalZincManufacturing engineering

The invention discloses a method for inhibiting reduction degradation of zinc-containing dust pellets in a rotary hearth furnace. The method comprises the steps as follows: 1), zinc-containing dust and bentonite are pneumatically transported to a stock bin and mixed, and a mixture is formed and divided into two parts by a distributor; 2), after part of the mixture and a composite additive are mixed uniformly, the obtained mixture is fed into a No.1 ball press machine and pressed into No.1 pellets to be sent into a drier, and the dried No.1 pellets are distributed into the rotary hearth furnacethrough a No.1 vibrating distributor; 3), the other part of mixture is sent into a No.2 ball press machine and pressed into No.2 pellets to be sent into the drier, and the dried No.2 pellets are distributed into the rotary hearth furnace through a No.2 vibrating distributor; and 4), the reduction process of the pellets distributed at the bottom of the rotary hearth furnace is completed in the rotary hearth furnace. The problem about the reduction degradation of the zinc-containing dust in the rotary hearth furnace is thoroughly solved from the source.

Owner:宝武集团环境资源科技有限公司

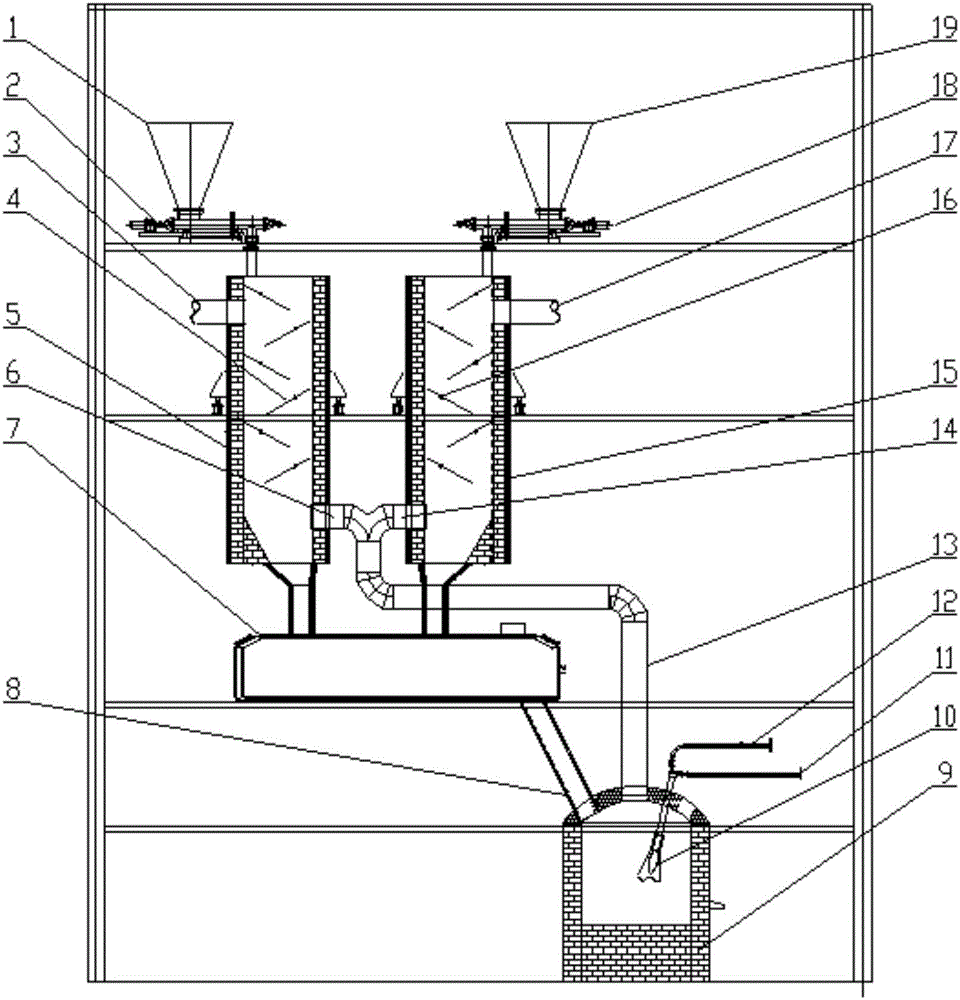

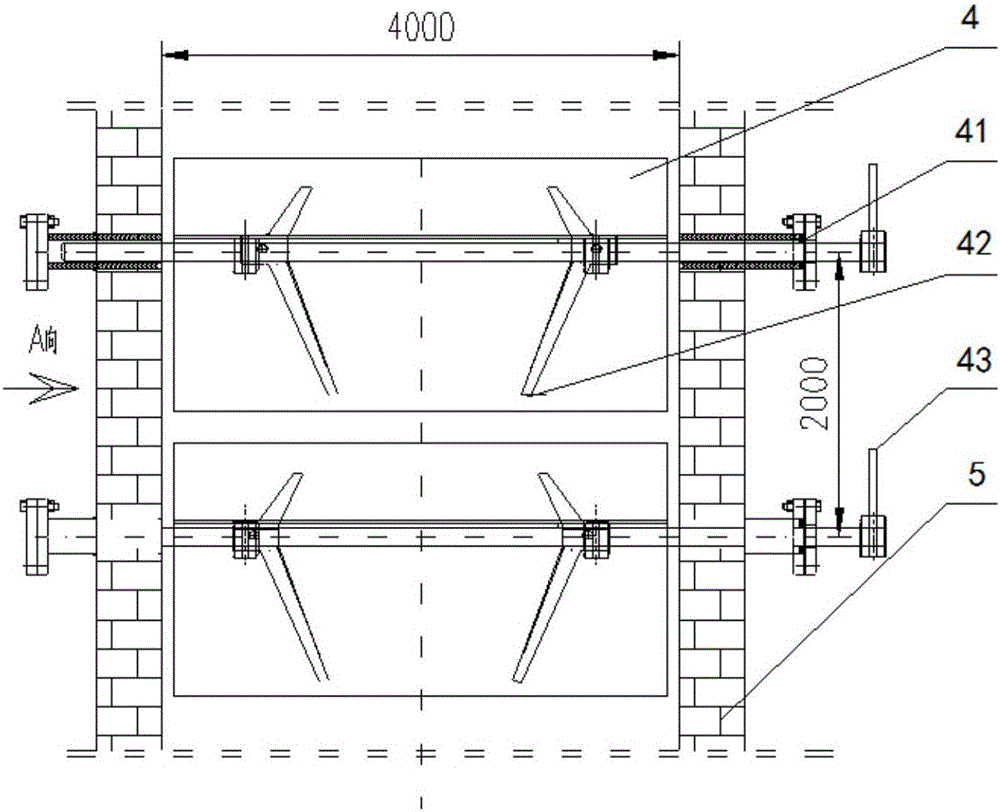

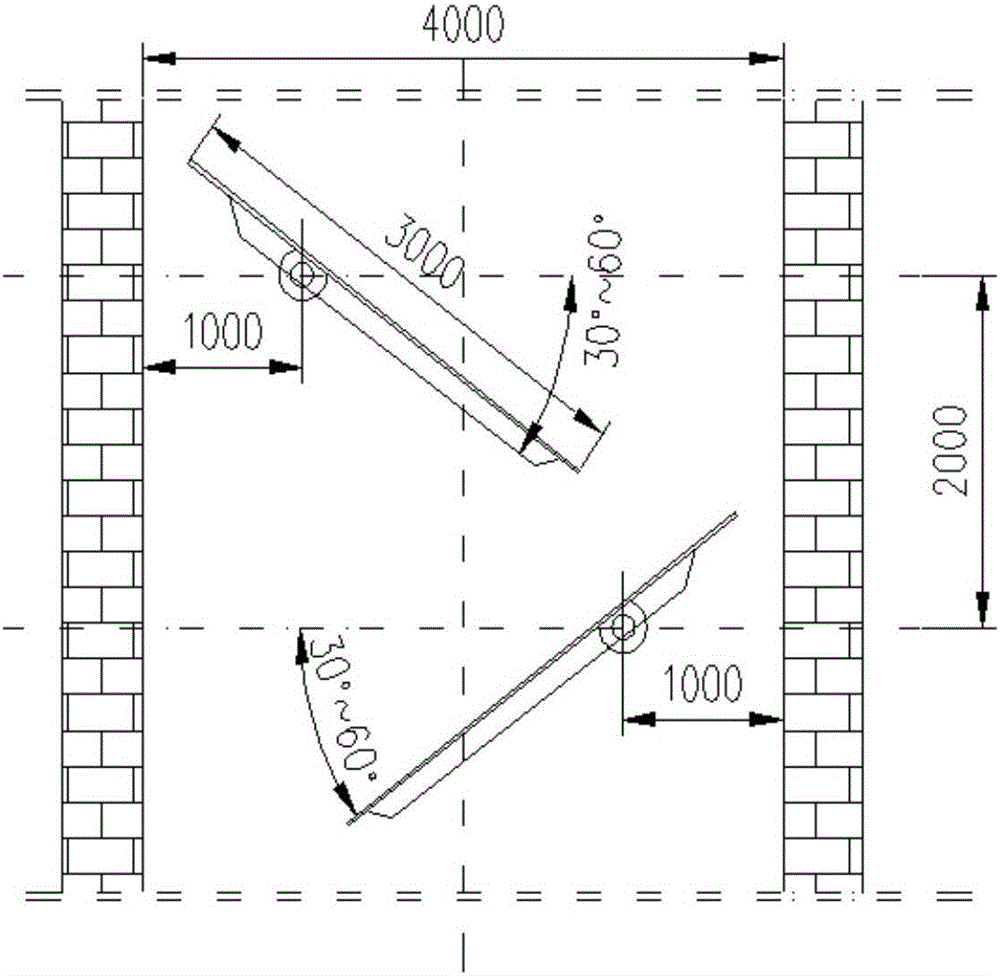

System and method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace

ActiveCN106082222ALow costReduce pulverization rateSpecial form destructive distillationShaft furnaceOxygen

The invention relates to a system and a method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace. The system comprises a vertical lime furnace, a high temperature pyrolyzing furnace, an oxygen thermal process calcium carbide furnace, a ball pressing machine and an oxygen coal gun, wherein the vertical lime furnace comprises a limestone flour inlet, a lime discharging opening and a vertical lime furnace smoke inlet; a baffle capable of adjusting inclining angle is arranged in a hearth of the vertical lime furnace; the high temperature pyrolyzing furnace comprises a coal dust feeding port, a carbon powder discharging opening, a carbon powder inlet and discharging opening; the baffle capable of adjusting inclining angle is arranged in the hearth of the high temperature pyrolyzing furnace; the ball pressing machine comprises a lime inlet, a carbon power inlet and discharging opening; the oxygen thermal process calcium carbide furnace comprises a lime feeding port, a carbon powder feeding port, a smoke outlet and a discharging opening; a spray gun of the oxygen coal gun is arranged in the oxygen thermal process calcium carbide furnace. According to the system and the method for producing calcium carbide through high-temperature ball-pressing double-vertical-furnace provided by the invention, the baffle capable of adjusting inclining angle is respectively arranged in the vertical lime furnace and the high temperature pyrolyzing furnace, so that the reaction and pyrolysis time of the materials in the furnace can be conveniently controlled and the reaction degree and efficiency of the materials can be ensured.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com