Concentrated supplementary food capable of improving palatability and resisting diseases for calves, as well as preparation method and application of concentrated supplementary food

A technology for intensive feeding and disease resistance, which is applied in the field of intensive feeding for calves and its preparation, can solve the problems of delayed mating date of bred cattle, low feed intake of mature cows, impact on economic benefits, etc. morbidity, increased calf feed intake, and increased fiber digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

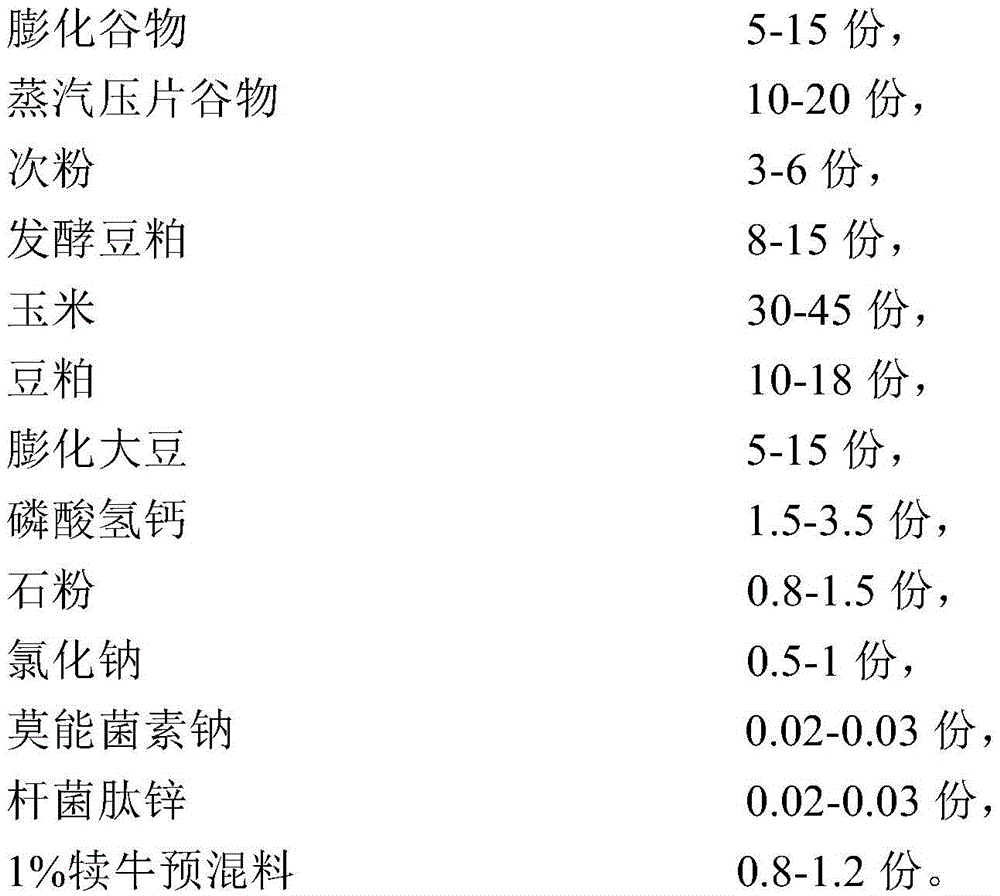

[0050] A kind of fine feed for calves with improved palatability and anti-disease, its formula is, by weight fraction:

[0051]

[0052] The preparation method is as follows:

[0053] a. Granulation process: This method includes: proportioning raw materials according to the following parts by weight, crushing and mixing the following raw materials through a sieve of 2.0-3.0mm, and preparing and granulating to obtain granule A, and the preparation temperature is 40-60°C , the modulation time is 30-40s;

[0054] According to the ratio of parts by weight, the raw materials are 5 parts of secondary powder, 32.25 parts of corn, 17 parts of soybean meal, 10 parts of fermented soybean meal, 5 parts of puffed soybean, 2 parts of calcium hydrogen phosphate, 1 part of stone powder, 0.7 part of sodium chloride, Mo 0.025 parts of nermycin sodium, 0.025 parts of bacitracin zinc, and 1 part of 1% calf premix.

[0055] b. Mixing process: 12 parts by weight of puffed corn and 14 parts of...

Embodiment 2

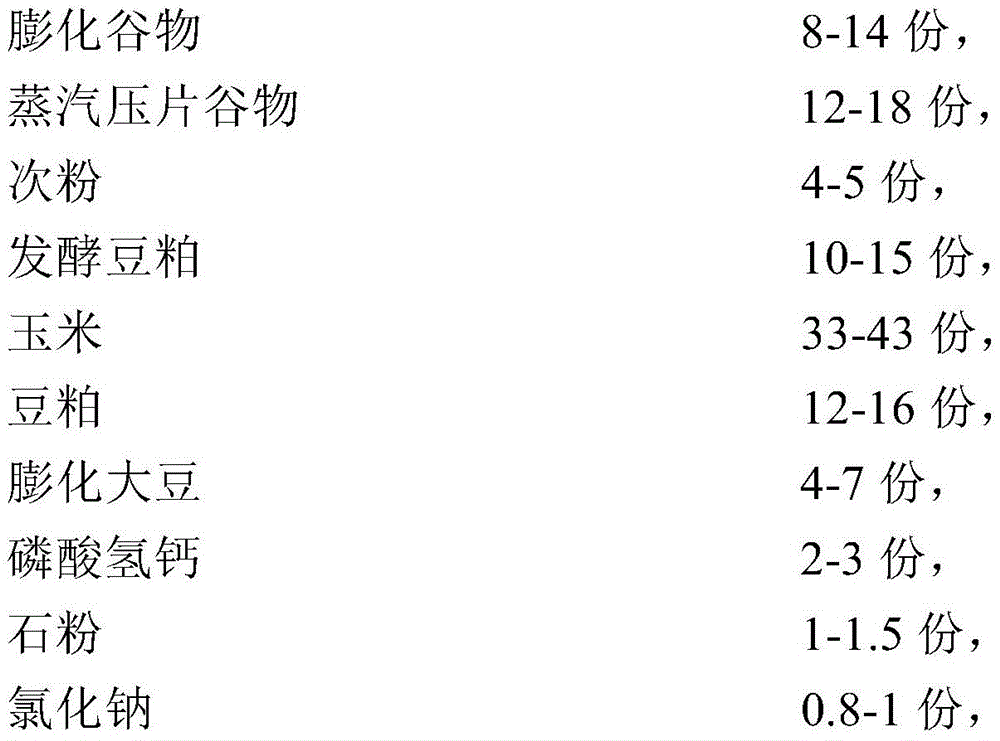

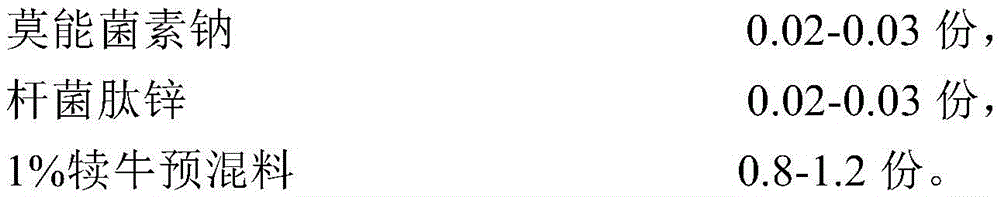

[0060] A calf concentrate for improving palatability and disease resistance, the formula of which is:

[0061]

[0062] The preparation method is as follows:

[0063] a. Granulation process: This method includes: proportioning raw materials according to the following parts by weight, crushing and mixing the following raw materials through a sieve of 2.0-3.0mm, and preparing and granulating to obtain granule A, and the preparation temperature is 40-60°C , the modulation time is 30-40s;

[0064] The raw materials are 4 parts by weight, 32.05 parts of corn, 12 parts of soybean meal, 12 parts of fermented soybean meal, 8 parts of puffed soybean, 2.2 parts of calcium hydrogen phosphate, 1 part of stone powder, 0.7 part of sodium chloride, 1 part of Mo 0.025 parts of nermycin sodium, 0.025 parts of bacitracin zinc, and 1 part of 1% calf premix.

[0065] b. Mixing process: 12 parts of puffed corn and 15 parts of steam-flaked corn were mixed with granular material A to obtain the...

Embodiment 3

[0070] A calf concentrate for improving palatability and disease resistance, the formula of which is:

[0071]

[0072]

[0073] The preparation method is as follows:

[0074] a. Granulation process: This method includes: proportioning raw materials according to the following parts by weight, crushing and mixing the following raw materials through a sieve of 2.0-3.0mm, and preparing and granulating to obtain granule A, and the preparation temperature is 40-60°C , the modulation time is 30-40s;

[0075] The raw materials are 4.5 parts by weight of secondary powder, 34.76 parts of corn, 15 parts of soybean meal, 12 parts of fermented soybean meal, 6 parts of puffed soybean, 2 parts of calcium hydrogen phosphate, 1 part of stone powder, 0.7 part of sodium chloride, molybdenum 0.02 part of nermycin sodium, 0.02 part of bacitracin zinc, and 1 part of 1% calf premix.

[0076] b. Mixing process: Mix 7 parts of puffed corn, 16 parts of steam-flaked corn with granular material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com