Patents

Literature

30results about How to "Guaranteed granulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

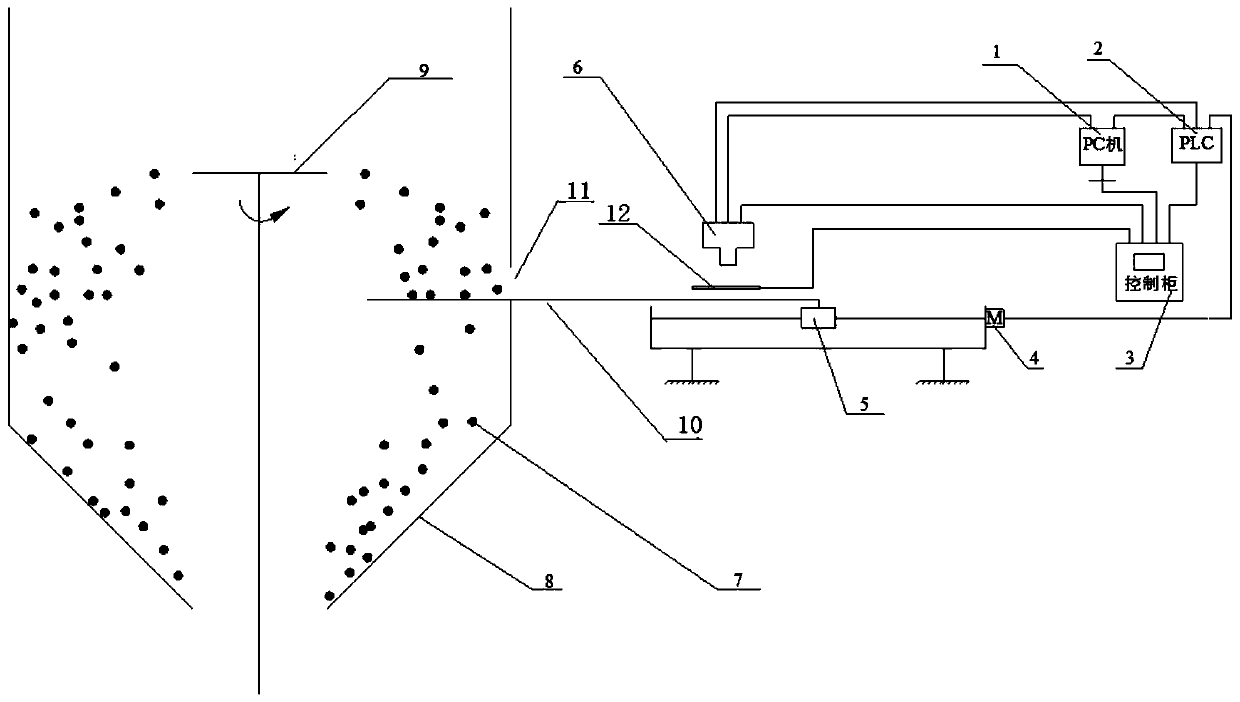

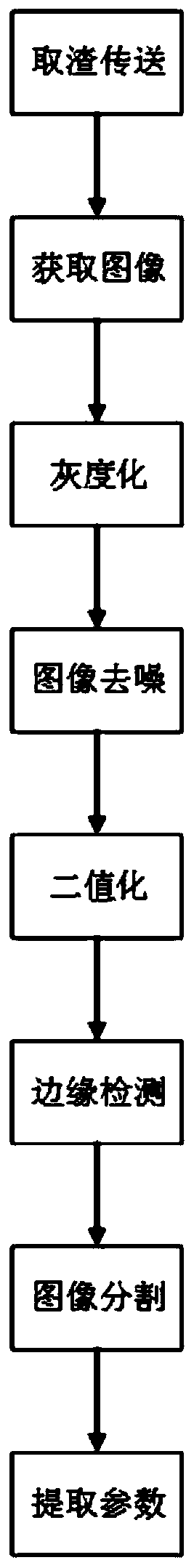

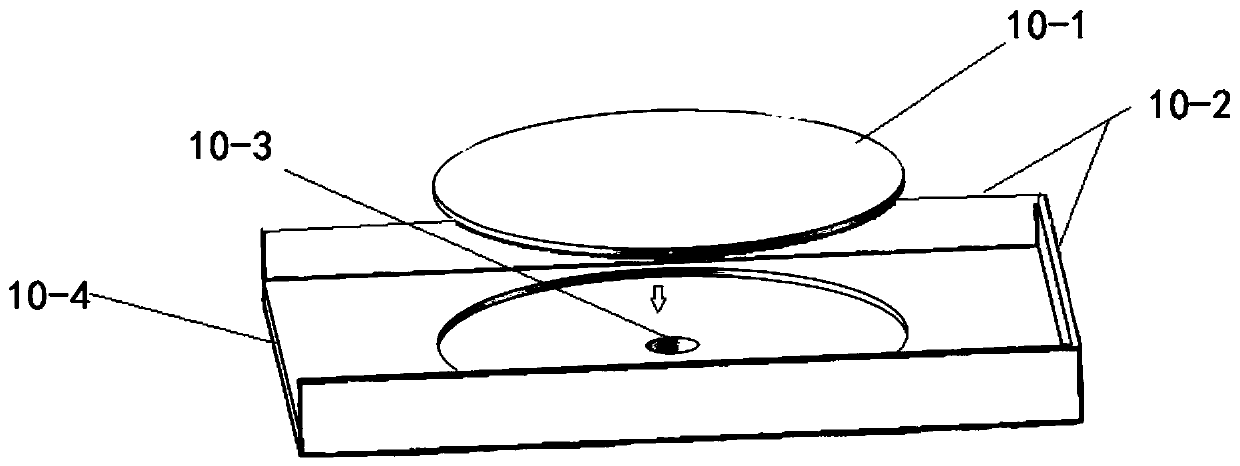

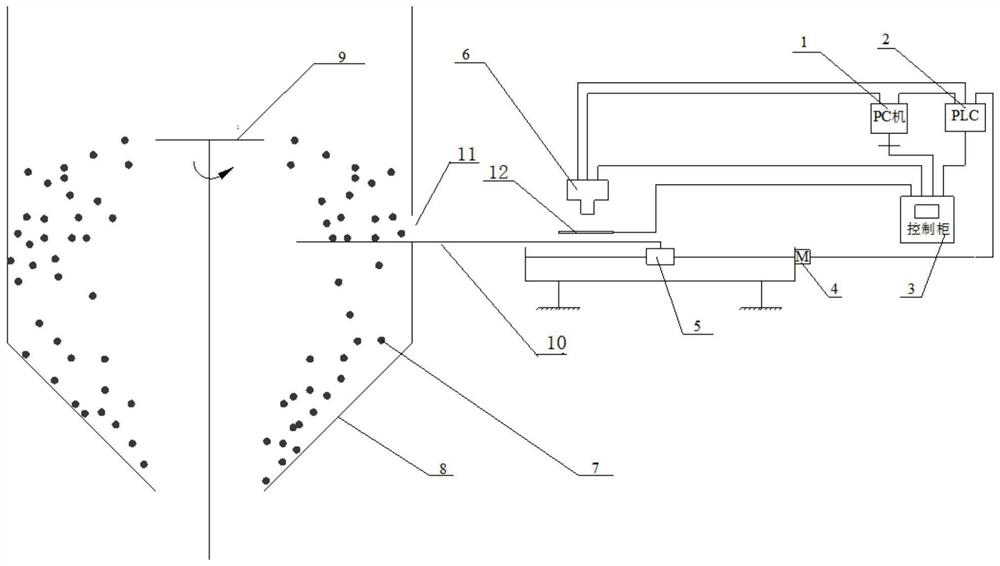

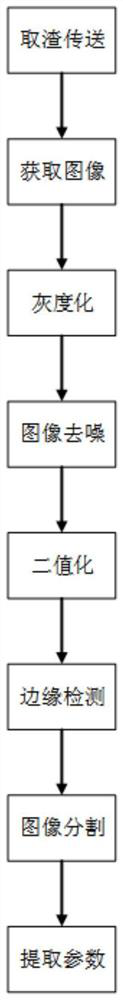

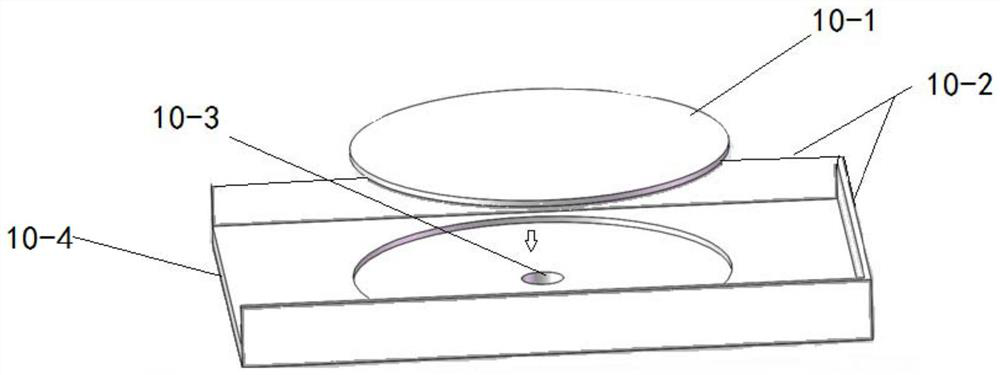

Blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition

InactiveCN110218824AControl diameterOvercome technical issues that cannot be measured in real timeCharacter and pattern recognitionParticle size analysisSlagParticle size measurement

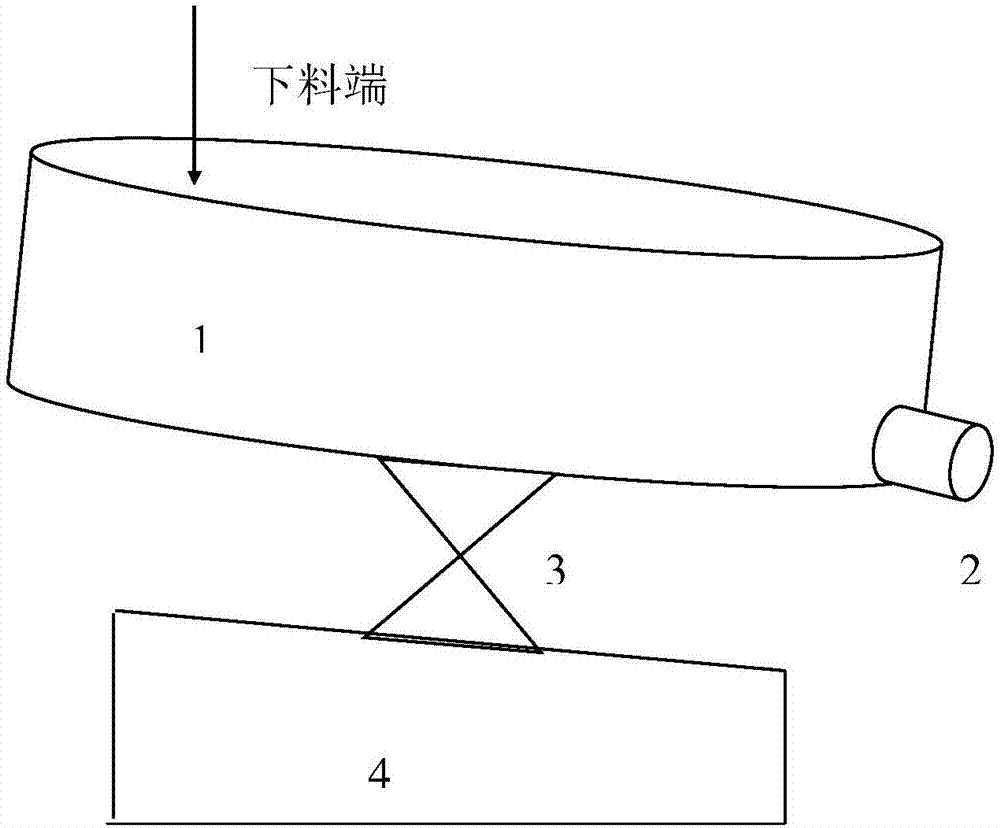

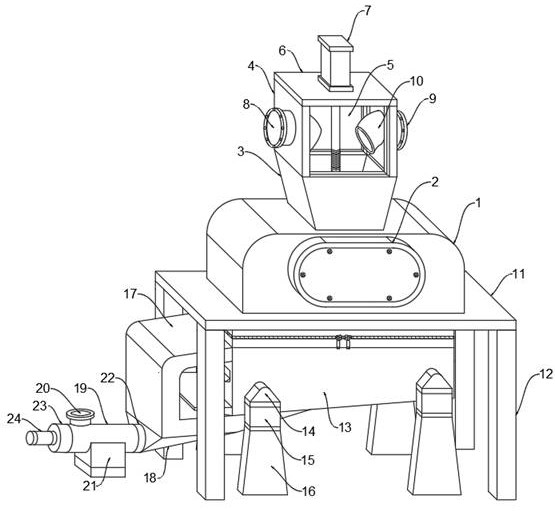

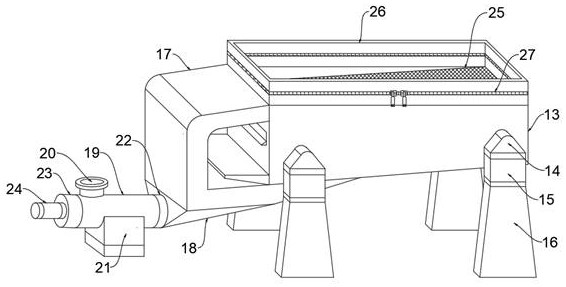

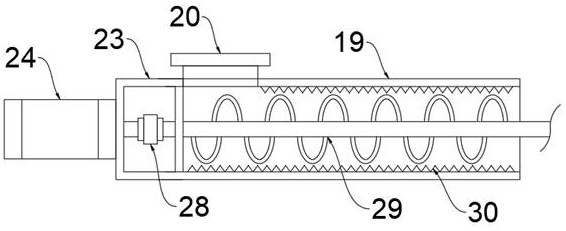

The invention discloses a blast furnace slag centrifuging and pelletizing particle size detecting system and method based on image recognition. The detecting system comprises a control unit, a slag taking device and an image acquisition unit, wherein the slag taking device carries out sampling on slag particles obtained after the blast furnace slag is centrifuged and pelletized; the image acquisition unit collects the images of the slag particles; the control unit detects and analyzes the sizes of the slag particles according to the collected images to obtain the detecting data of the sizes ofthe slag particles; and the control unit is connected with the slag taking device and the image acquisition unit. According to the detecting system, the image acquisition unit is arranged to collectthe images of the slag particles, the data of the size of the slag particles is obtained after image analysis, the soft measurement method is adopted to solve the technical problem that the particlesof the blast furnace slag cannot be measured in real time due to high temperature, and the real-time performance and the precision of blast furnace slag centrifuging and pelletizing particle size measurement are improved. A blast furnace slag pelletizing device can be adjusted and controlled in real time according to the size data of the slag particles to control the particle diameter in real timeand ensure the heat recovery efficiency of mechanical centrifuging and pelletizing of liquid-state slag.

Owner:QINGDAO UNIV

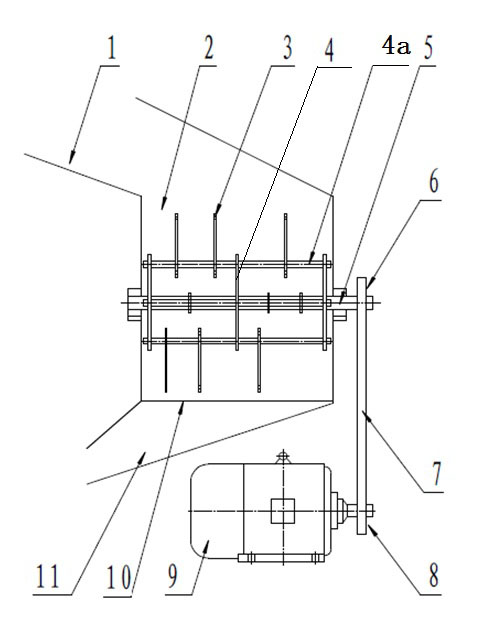

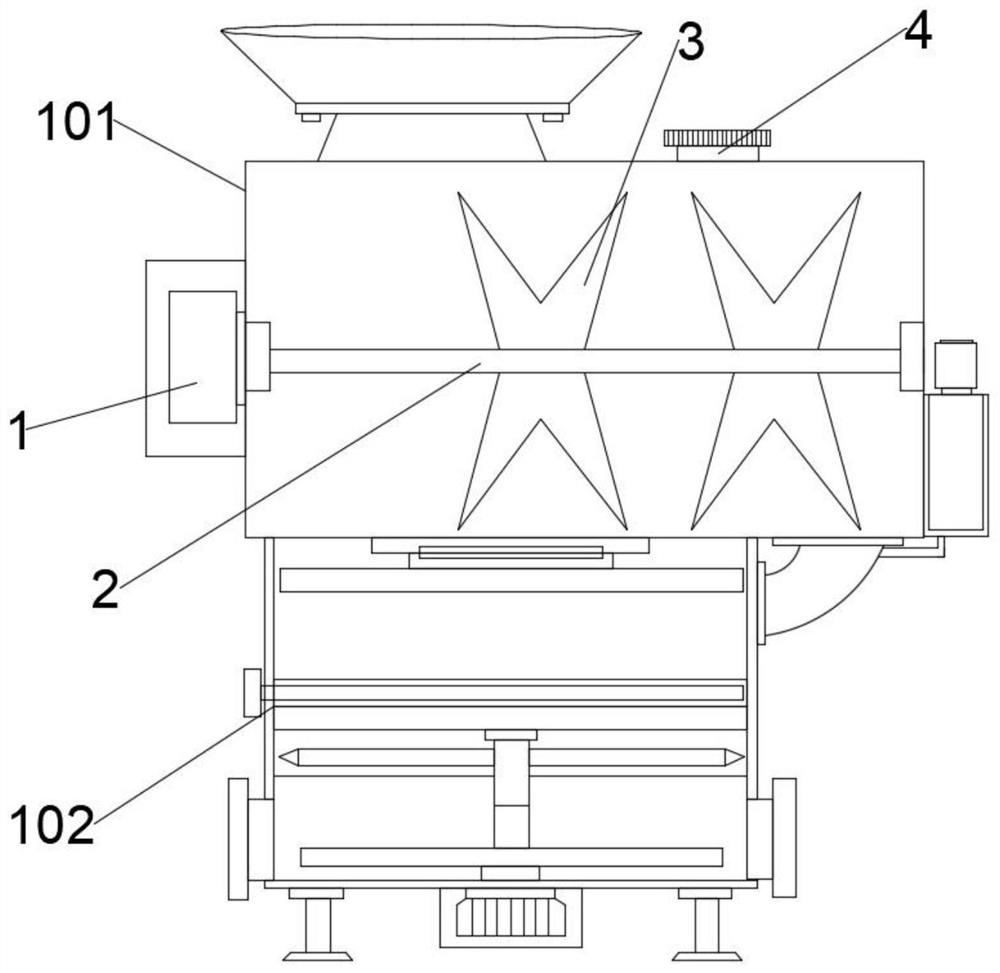

Hammer type shearing granulator

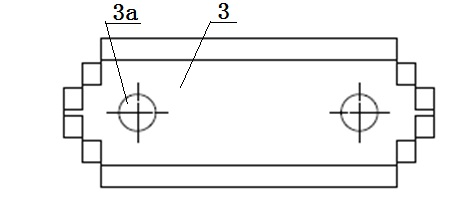

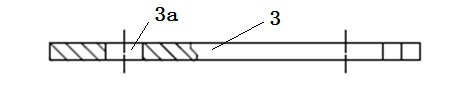

A hammer type shearing granulator comprises a granulating cabin (2) provided with a feeding port (1) and a discharging port (11), a blade support (4) and shearing blades (3) installed on the blade support, wherein the blade support (4) is installed in the granulating cabin and can rotate around a horizontal central shaft (5). The outer end of the central shaft of the blade support is connected with a power transmission device. The blade support is of a transversely arranged cylindrical-cage-shaped structure, cylindrical-cage-shaped strips (4a) are evenly distributed on the outer circumferential face of the blade support, each blade is of a structure with a single side or double sides provided with edges, installation holes (3a) capable of being freely sleeved on the cage strips (4a) are arranged at one ends or two ends of the blades, at least two blades are evenly installed on each cage strip, the blades on two adjacent cage strips are arranged in staggered mode, and a screen net (10) is arranged at the position of the discharging port of the granulating cabin. Expansion tobacco stalk granulation is performed by means of the hammer type shearing granulator, particle shape of ternary porous particles of expansion tobacco stalk is changed, production yield is improved, a product filling value is improved, and service life of the blades is prolonged.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Sludge freezing pelletizing method and device

ActiveCN107777858AReduce odorEasy to shapeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludge cakeMolding machine

The invention discloses a sludge freezing pelletizing method and device and belongs to the field of solid waste treatment. The sludge freezing pelletizing device comprises a roller press, a serrated knife molding machine and a stirring type drying machine from top to bottom in sequence, wherein sludge which is simply dried in air and disposed by precipitating is conveyed into the roller press to be frozen through a feeding machine and then is rolled into thin sludge cakes; the thin sludge cakes are then frozen and cut into bars by using the serrated knife molding machine; the sludge bars are broken into granules under the action of gravity; sludge granules are fed into the sealed stirring type drying machine and are heated and turned over for multiple times, then moisture of the sludge granules is sublimated and vaporized to an appointed range; and the sludge granules are further conveyed to an appointed position by a discharging machine, and then sludge freezing, drying and pelletizing are completed. By adopting rolling pelletizing and step-by-step treatment, the sludge freezing pelletizing method has relatively high energy utilization rate and relatively good drying effect.

Owner:SHENGHUO TECH HENAN

Continuous heat shrinkable material with low smoke, low halogen and high pressure resistance and manufacturing method thereof

InactiveCN102020797AImprove mechanical propertiesGuaranteed granulation effectChemical industryPolyolefin

The invention relates to a continuous heat shrinkable material with low smoke, low halogen and high pressure resistance and a manufacturing method thereof, and relates to the technical field of production processes of continuous heat shrinkable materials with low smoke, low halogen and high pressure resistance. The product consisting of 50 parts of polyolefin resin, 0.5-1 part of antioxidant, 4.5-9 parts of toughening agent, 28-48 parts of fire retardant, 1-4 parts of heat stabilizer, 1.5-3 parts of sensitizer, 3-5 parts of colored resin and 0.5-2 parts of novel coupling agent is formed by secondary pelleting, extruding, radiating and expanding; the continuous heat shrinkable material with low smoke, low halogen and high pressure resistance has an oxygen index of more than or equal to 28, a tensile strength of more than or equal 12MPa, and a breaking elongation rate of more than or equal to 500%; and the electrical performance can satisfy the corresponding high-pressure demand index, thus the material can be widely applied to the transformer substation bus insulating protection in a power supply system and the industries such as mining industry, chemical industry, petrifaction industry and the like.

Owner:扬州辐照中心

Method and device for carrying out drying treatment on sludge

PendingCN107814472AReduce moisture contentEasy to shapeSludge treatment by de-watering/drying/thickeningSludge cakeProcess engineering

The invention discloses a method and a device for carrying out drying treatment on sludge, and belongs to the field of solid waste treatment. The device comprises a heat source and a sludge drying treatment machine, wherein the sludge drying treatment machine comprises a roller press, a toothed blade forming machine and a stirring type drying machine in sequence from top to bottom. The method comprises the following steps: transporting sludge which is subjected to simple drying and precipitation treatment to the roller press through a feeding machine, and rolling the sludge into thin sludge cake; cutting the thin sludge cake into strips by the toothed blade forming machine; enabling sludge particles to enter the stirring type drying machine, and heating and overturning for many times, thusreducing the moisture content of the sludge particles to a designated range; transporting the sludge to a designated place through a discharging machine, and completing drying treatment of the sludge. According to the device and the method, disclosed by the invention, by adopting the modes of rolling the sludge into particles and gradually carrying out the drying treatment, the energy utilizationrate and a drying effect are better.

Owner:SHENGHUO TECH HENAN

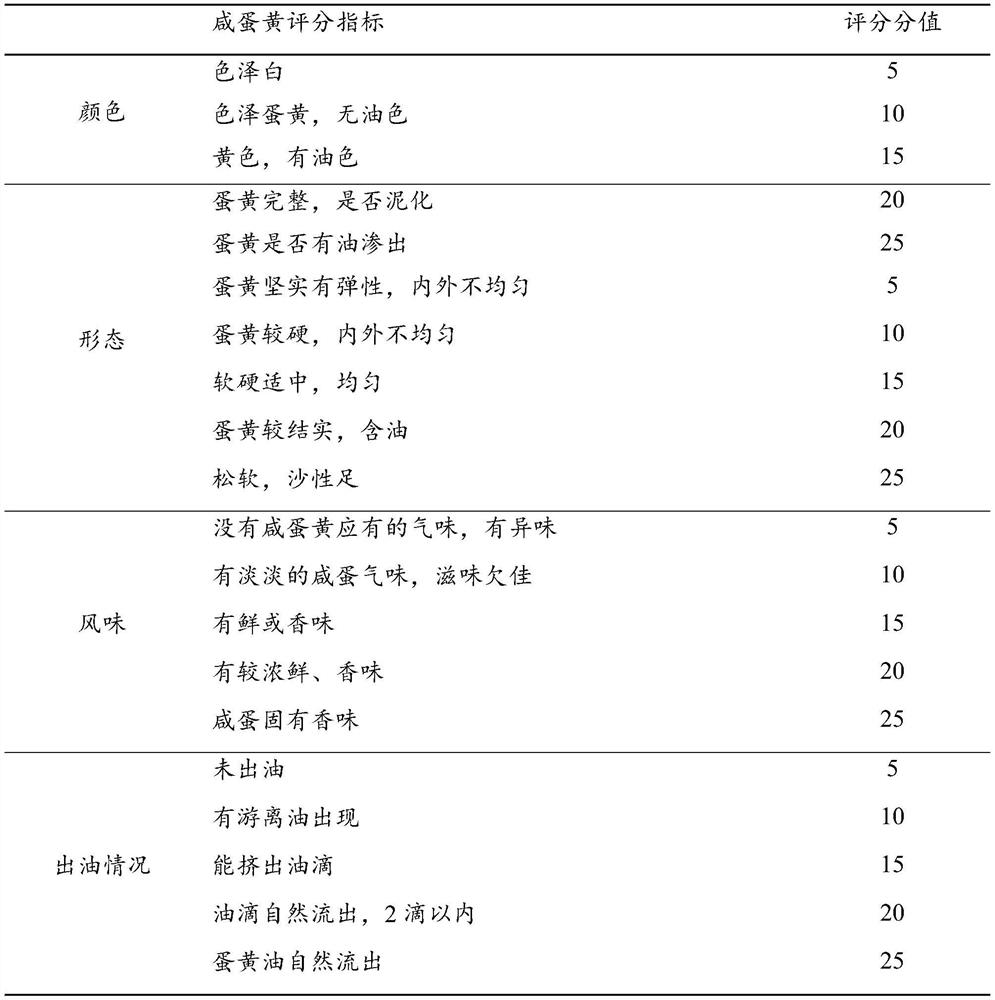

Concentrated supplementary food capable of improving palatability and resisting diseases for calves, as well as preparation method and application of concentrated supplementary food

InactiveCN106689705AGuaranteed granulation effectImproves fiber digestibilityFood processingAnimal feeding stuffFiberDisease

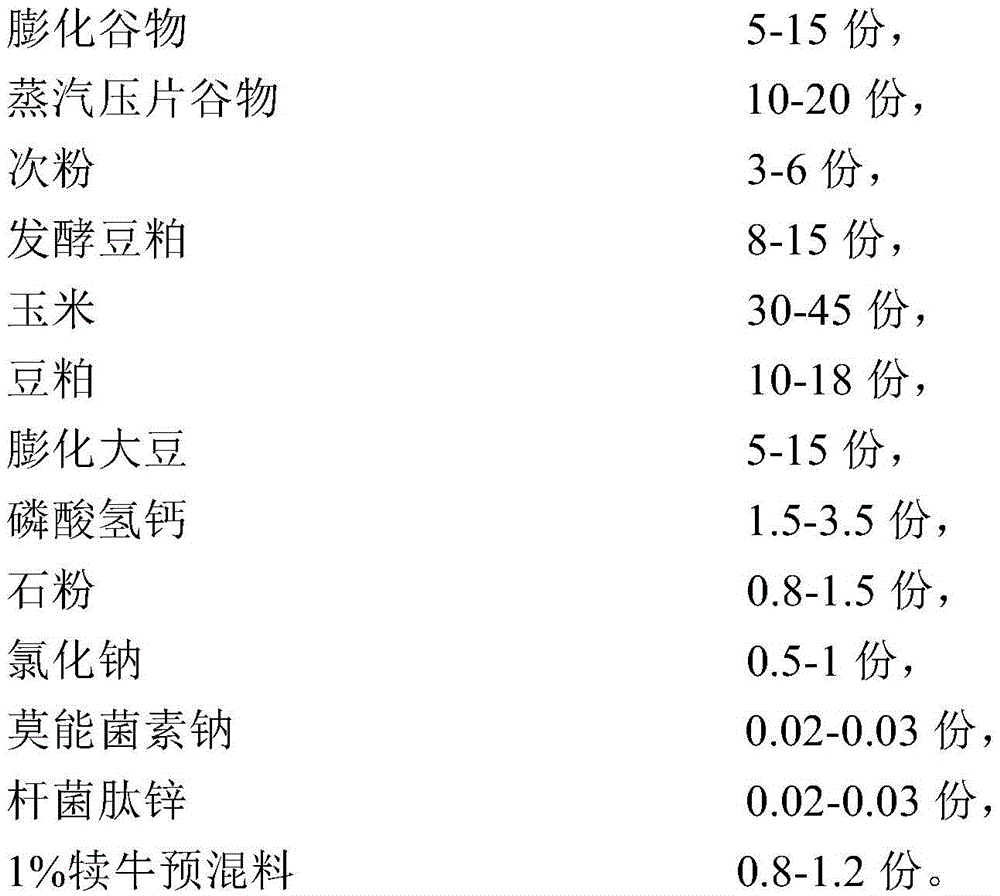

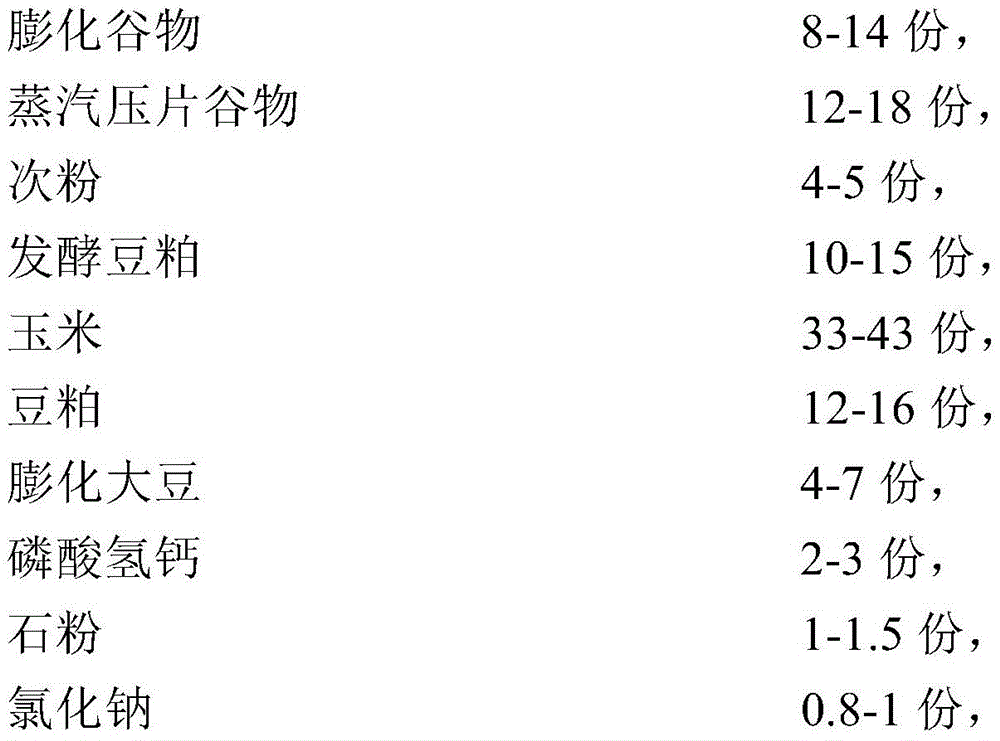

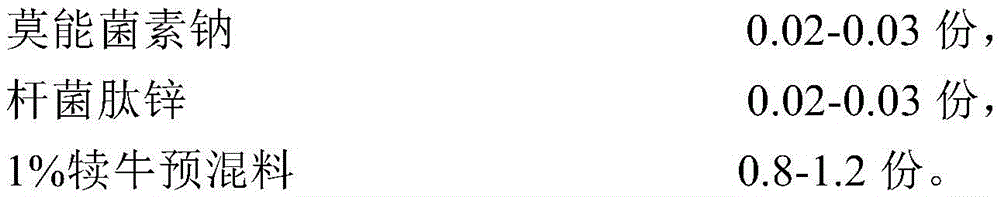

The invention discloses a concentrated supplementary food capable of improving palatability and resisting diseases for calves, as well as a preparation method and application of the concentrated supplementary food. A formula of the concentrated supplementary food comprises 5-15 parts of puffed cereals, 10-20 parts of steam tabletting cereals, 3-6 parts of middling, 8-15 parts of fermented soybean meal, 30-45 parts of corn, 10-18 parts of soybean meal, 5-15 parts of puffing soybeans, 1.5-3.5 parts of calcium hydrogen phosphate, 0.8-1.5 parts of stone powder, 0.5-1 part of sodium chloride, 0.02-0.03 part of monensin sodium, 0.02-0.03 part of zinc bacitracin and 0.8-1.2 parts of a 1% calf premix. According to the concentrated supplementary food and the preparation method and application thereof disclosed by the invention, raw materials which are high in the content of effective fibers and high in the content of digestible protein, such as the steam tabletting cereals, the puffed cereals and the fermented soybean meal are added, and the middling is added, so that the granular sensation of a feed is improved, the palatability of the calves is met, and minerals, trace elements and vitamins are strengthened; besides, a feed additive for enhancing immunity is added, so that the palatability can be improved, the development level of rumens can be increased, the food consumption and the daily gain of the calves are increased, the disease resistance of the calves can be enhanced, the feed cost can be reduced, the breeding period of replacement cattle can be shortened, the milk production of cows can be increased, and the economic benefits can be increased.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

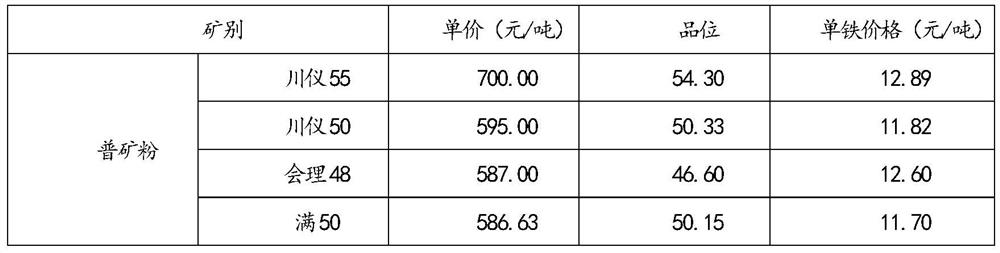

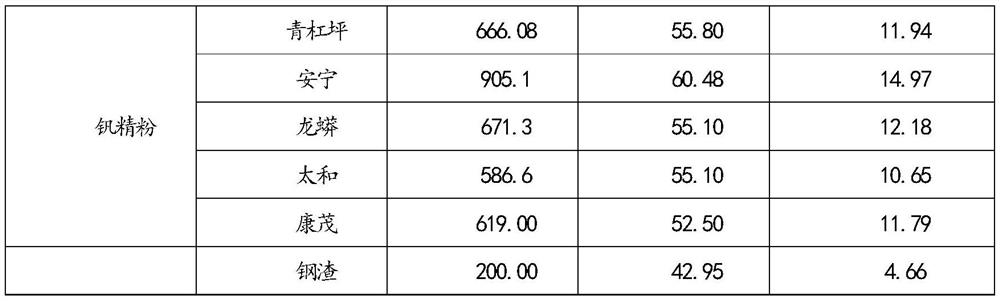

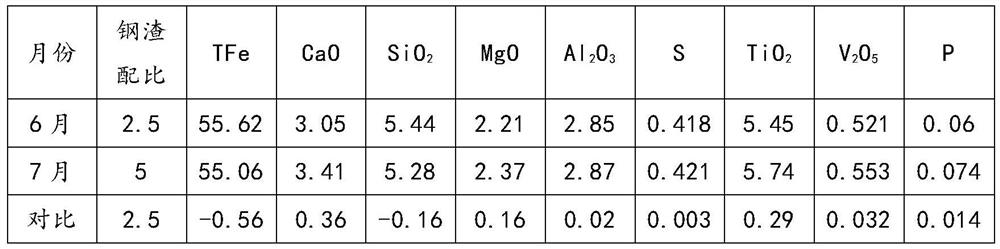

Method for improving proportion of steel slag in blended ore

PendingCN113930613AImprove the degree of mixingReduce ingredient costsMagnetic separationProcess efficiency improvementIron contentMagnetic separation

The invention discloses a method for improving the proportion of steel slag in blended ore. The method comprises the following four steps: (1), crushing the steel slag until the granularity of the crushed steel slag is less than or equal to 10 mm; (2), carrying out magnetic separation treatment on the steel slag, wherein the total iron content TFe of the steel slag after magnetic separation is greater than or equal to 18% and less than or equal to 23%; (3), and adjusting a batching structure participating in uniform ore blending according to the requirements of different types of steel for steelmaking smelting on the P content of molten iron; and (4), making a thick material layer and forming a low machine speed in the sintering mode of the uniformly mixed ore. The method solves the problems of resource occupation caused by steel slag accumulation and loss and waste of an iron element in steel slag takeout due to a low steel slag utilization rate.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

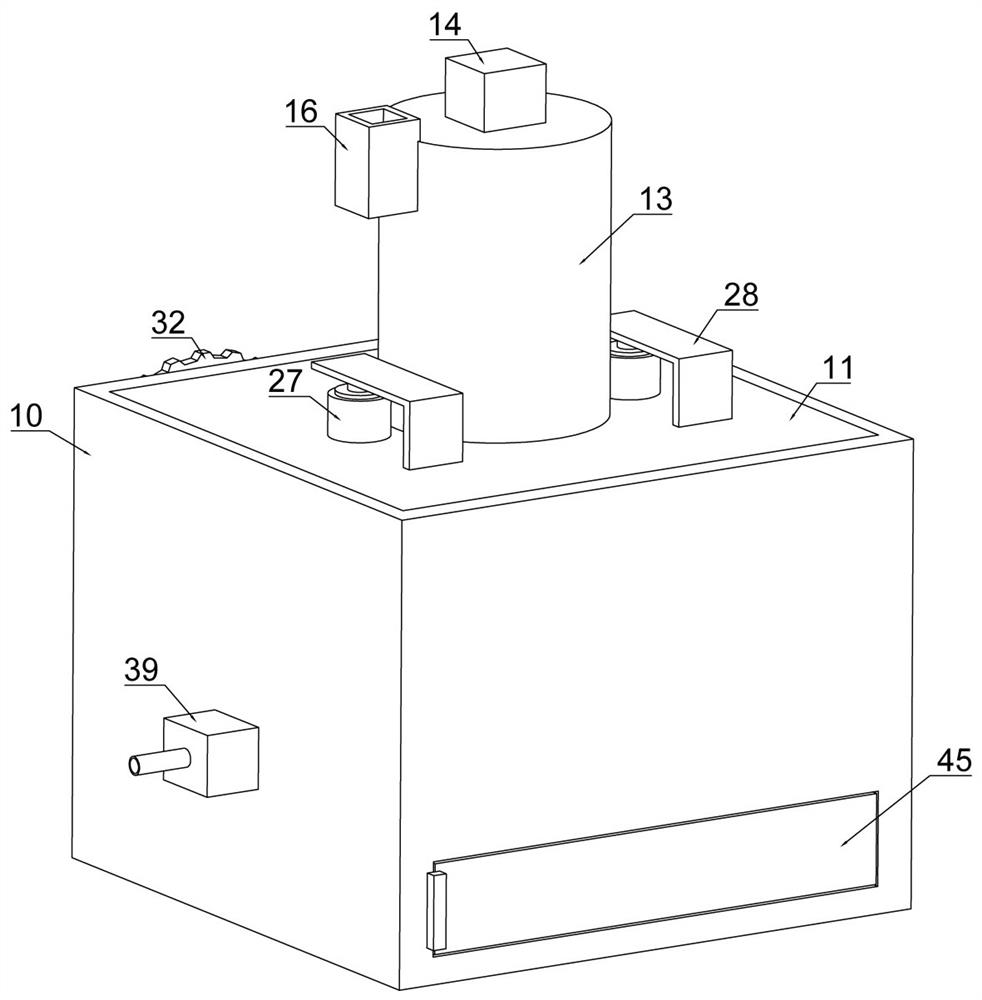

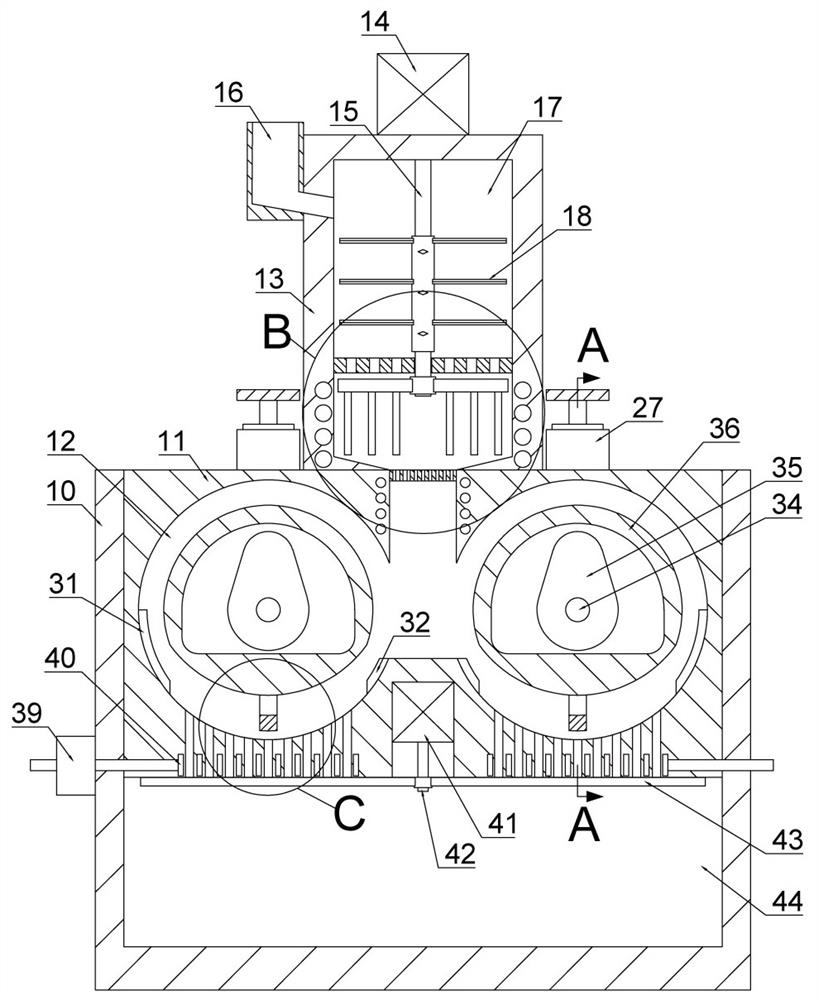

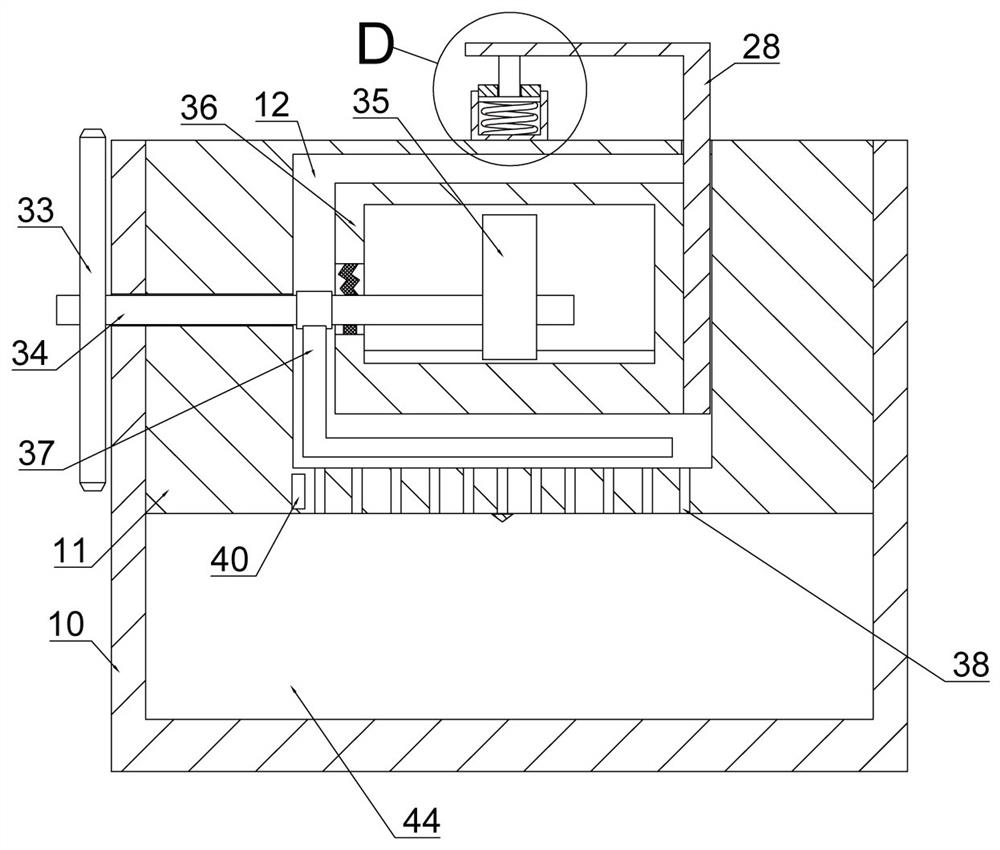

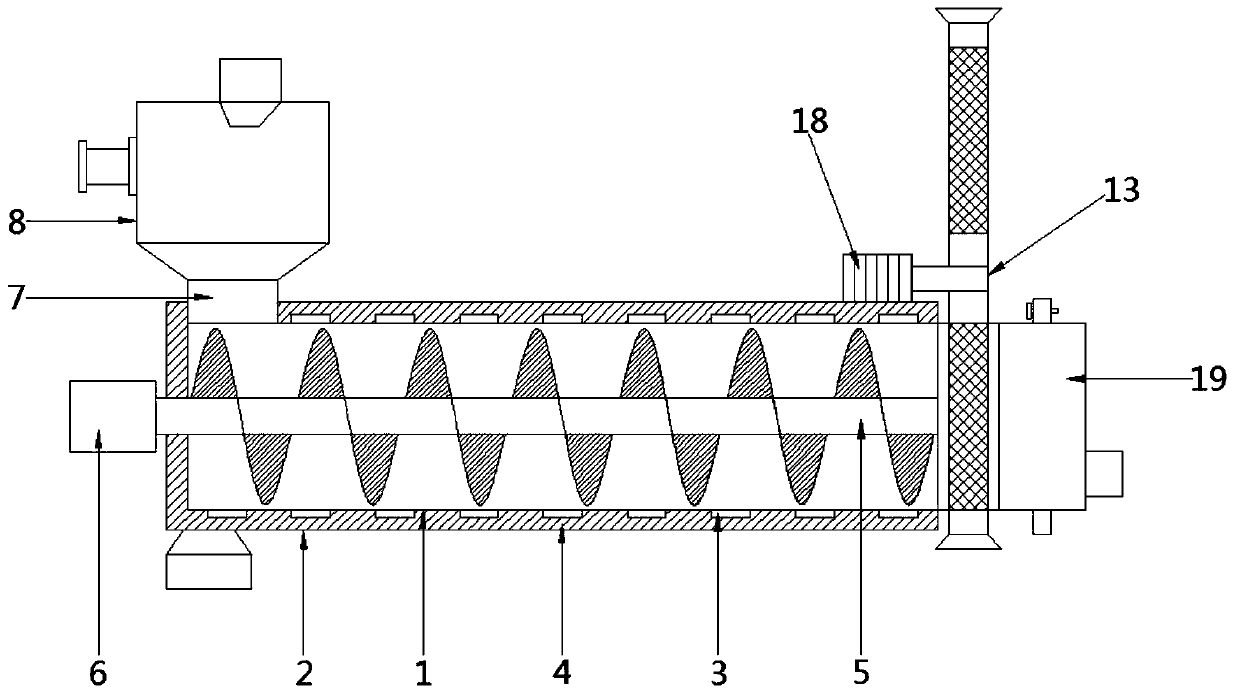

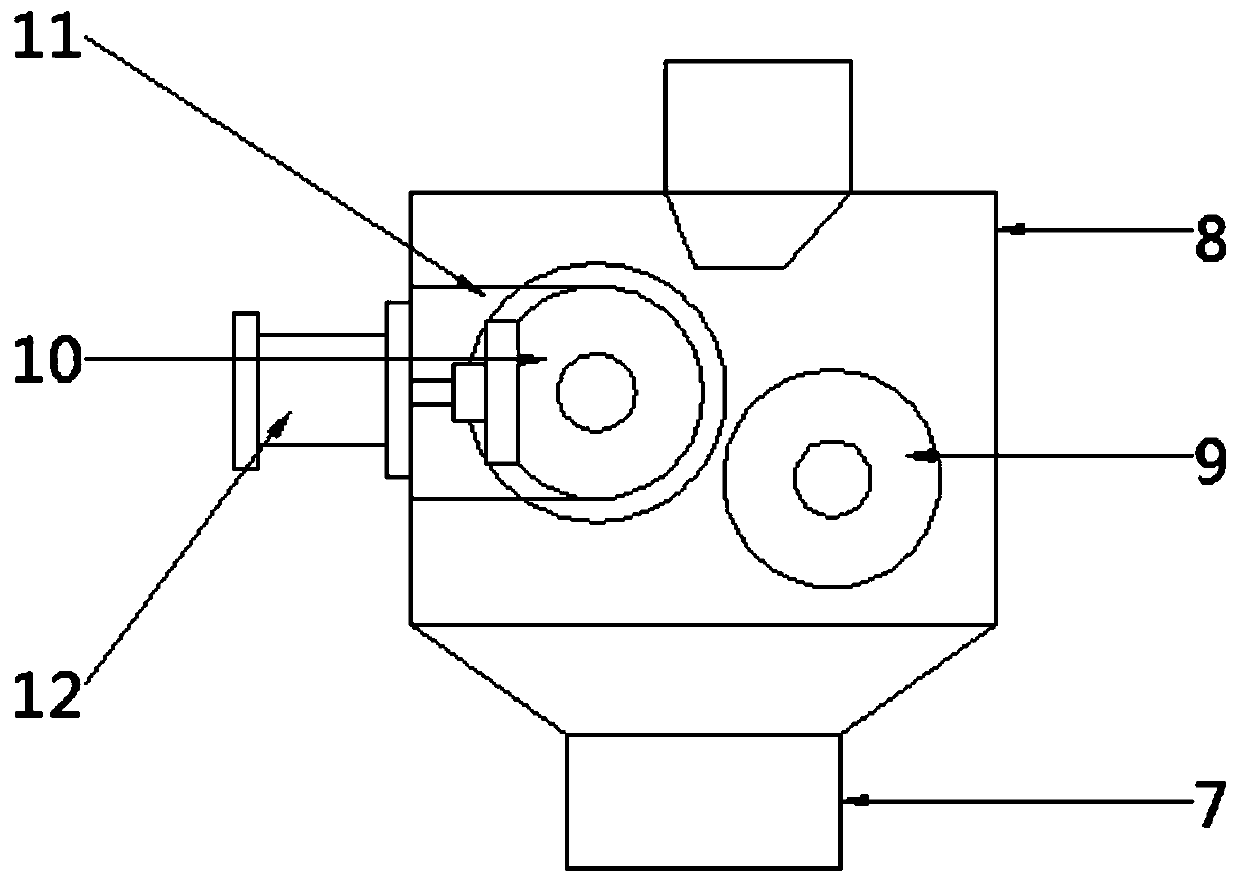

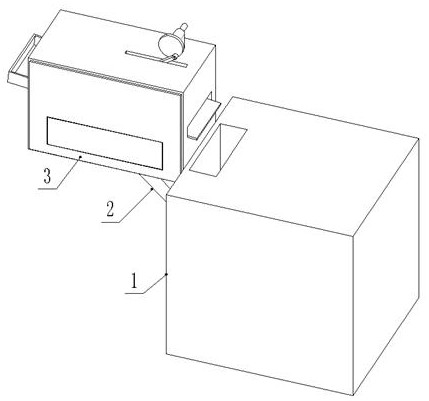

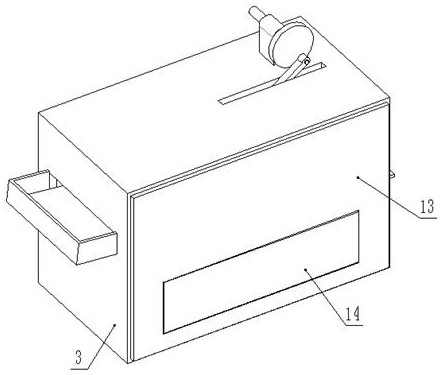

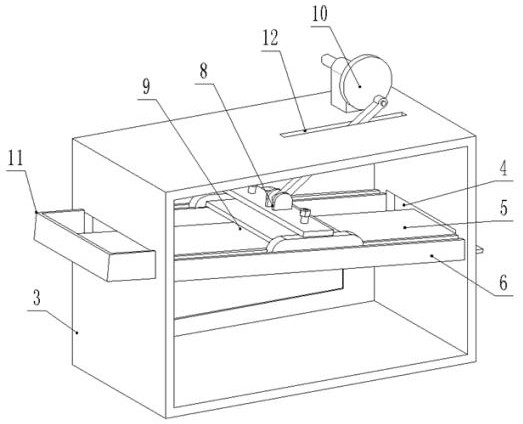

High polymer material continuous granulation equipment

InactiveCN114407226ARealize continuous granulationImprove the mixing effectPolymer sciencePolymer chemistry

The invention belongs to the technical field of material granulation, and relates to high polymer material continuous granulation equipment which comprises a shell, a smashing device, a melting and mixing device and a granulation device are arranged on the shell, the smashing device is used for smashing and preliminarily mixing high polymer material manufacturing raw materials, and the melting and mixing device is used for melting and mixing the high polymer material manufacturing raw materials. The melting and mixing device is used for melting and uniformly mixing the crushed raw materials, and the granulating device is used for continuously granulating the melted raw materials and ensuring uniform particle quality. The raw materials are rapidly melted under the cooperation of the crushing device and the melting and mixing device, the raw materials are uniformly heated, the quality of high polymer material particles is ensured, the raw materials are extruded and granulated every time the granulation shaft rotates by a circle through the continuous rotation of the granulation shaft under the work of the granulation device, and the production efficiency is improved. And continuous granulation of the conveyed materials is realized.

Owner:杭州凯喔斯科技有限公司

Durable granulator

InactiveCN106111016AGuaranteed granulation effectImprove granulation efficiencyGranulation by material expressionGranulation by pressingInsulation layerEngineering

The invention relates to the field of agricultural apparatuses, in particular to a durable granulator. The durable granulator is characterized in that a cover body of the durable granulator comprises a radiation plate, wherein the radiation plate comprises an air heat insulation layer, two layers of support plates positioned on the outer sides of the air heat insulation layer, heat insulation plates positioned on the outer sides of the two layers of support plates and made from a heat insulation material, and a connecting piece for connecting the air heat insulation layer, the support plates and the heat insulation plates; the connecting piece comprises an upright post and a plurality of condensing balls arranged on the upright post; undercut parts are arranged at the tail ends of the upright post; the apertures of the undercut parts are gradually increased in directions far away from the air heat insulation layer. According to the durable granulator, a material can be guided to a granulation position after entering the granulator, and uniformity in a transmission process of the material and high dustproof performance in a granulation process are achieved; an area covered by a dust removal device is large, so that the material is unlikely to be folded; temperature in the granulation process is not high, so that the granulator can be protected, and the service life can be prolonged.

Owner:安徽盛昌生物能源科技开发有限公司

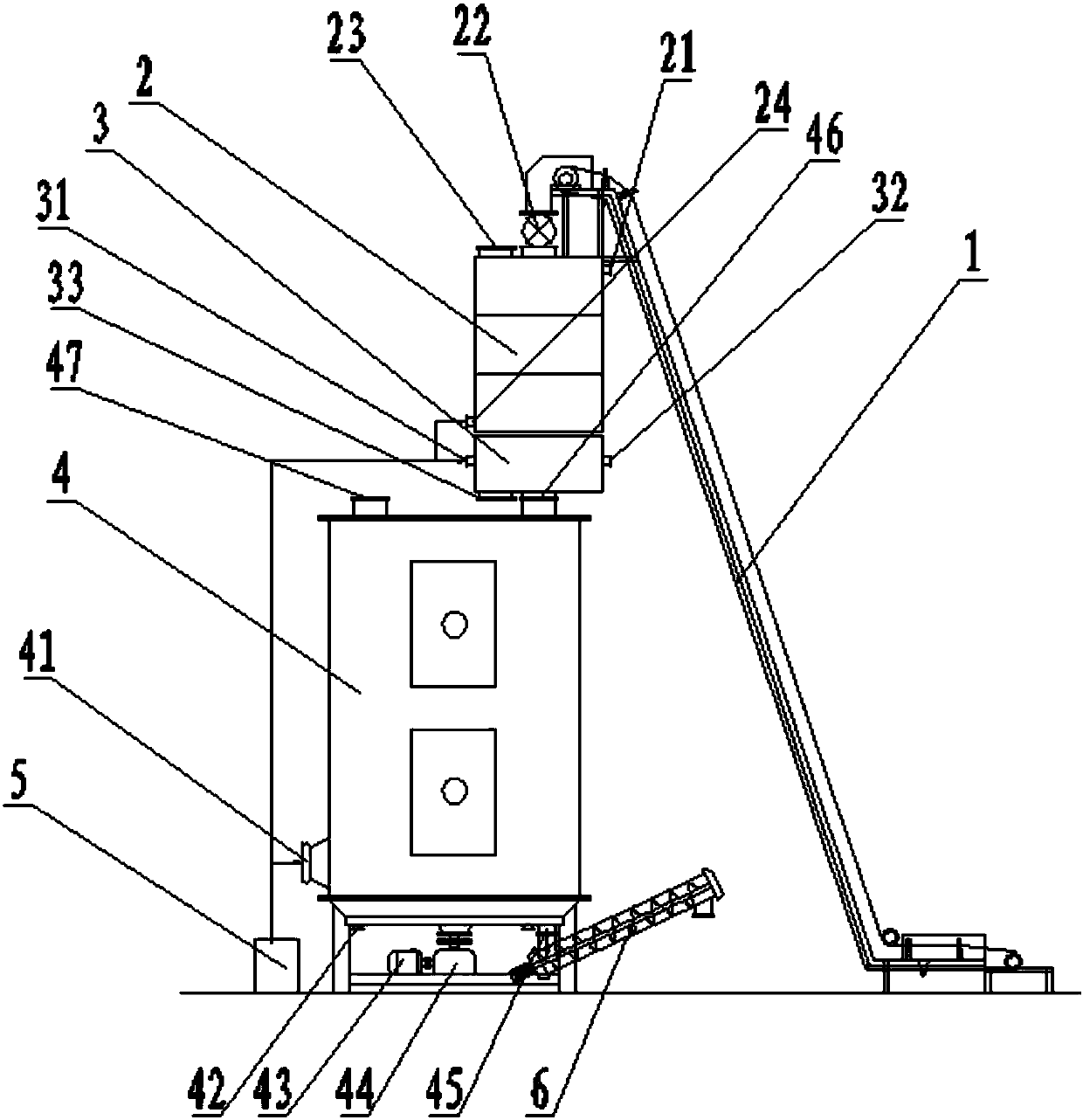

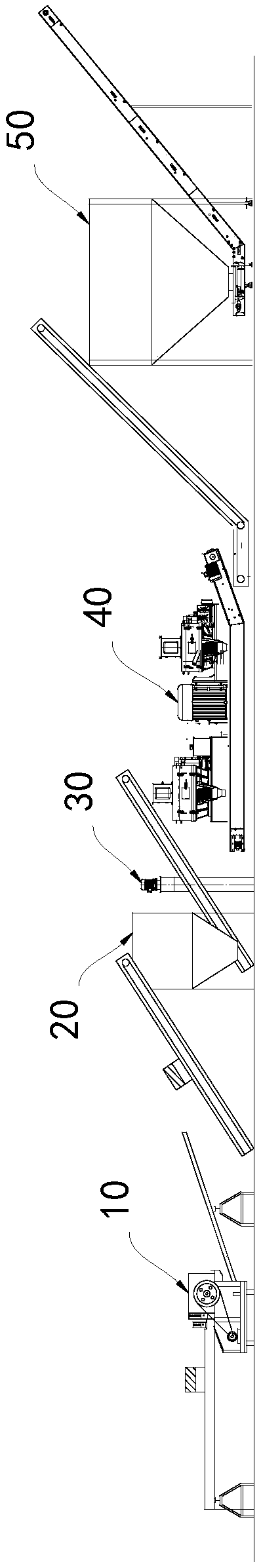

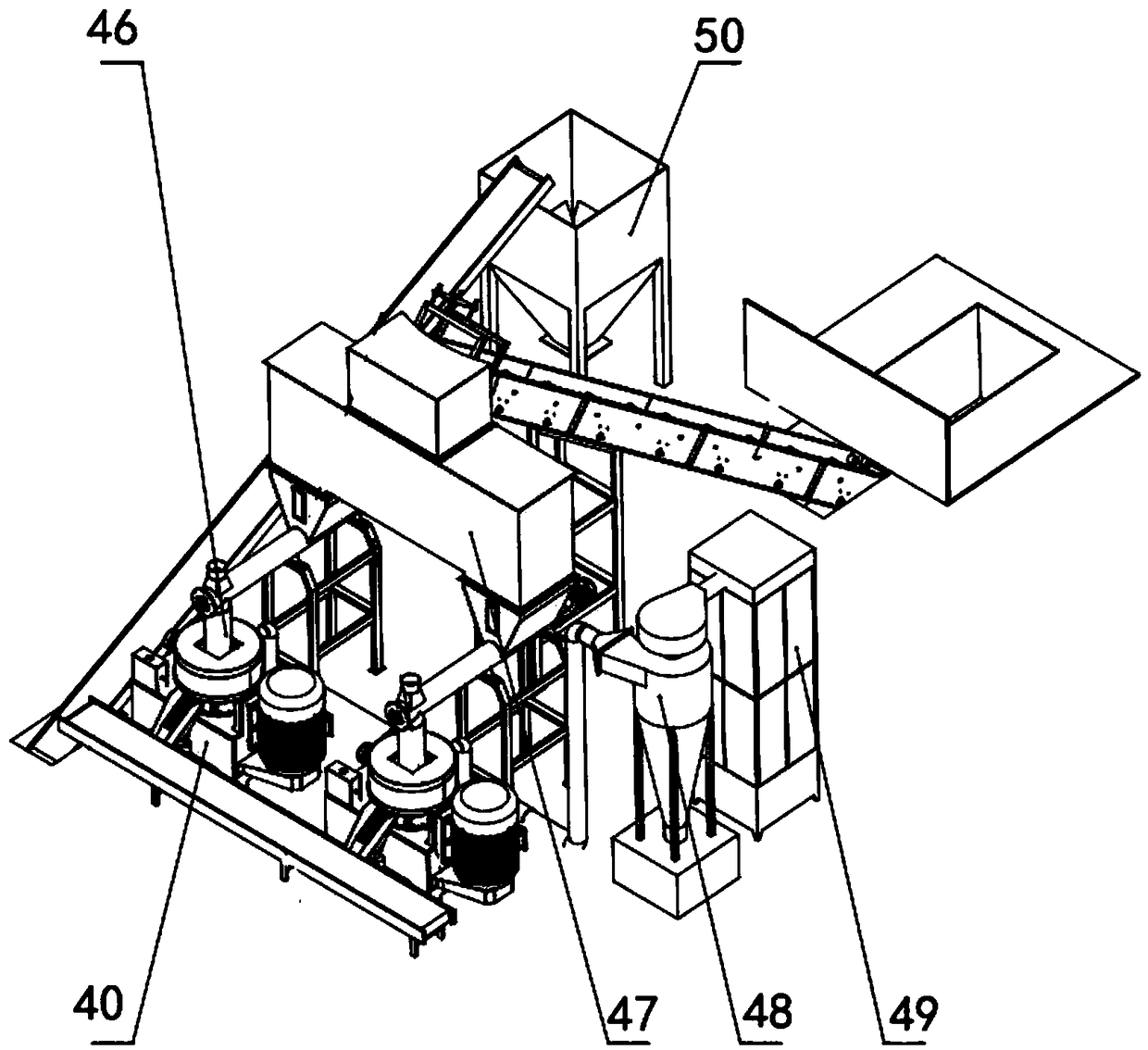

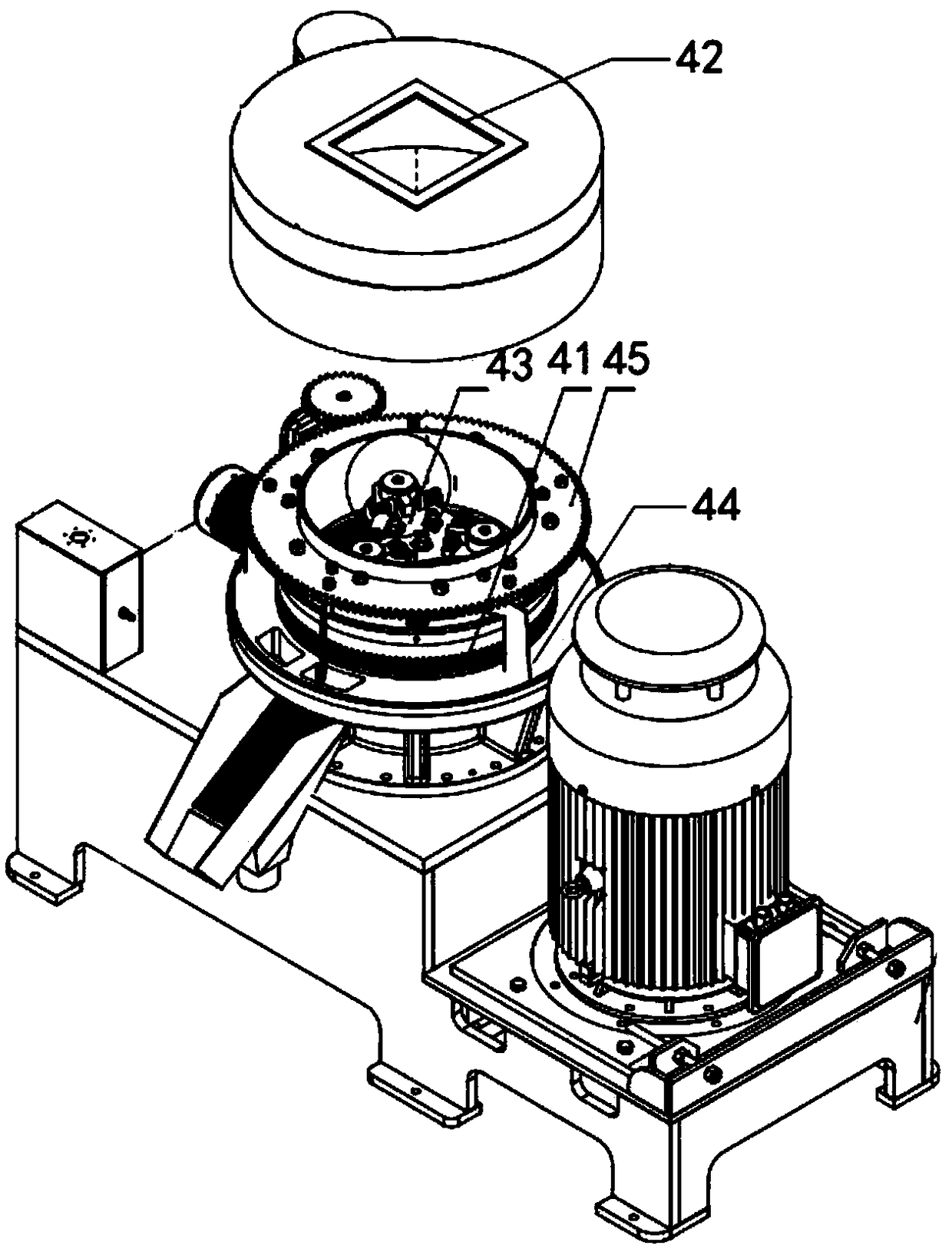

Production technology of waste cloth strip and sludge fuel particles and equipment thereof

The invention discloses a production technology of waste cloth strip and sludge fuel particles and equipment thereof. The technology comprises the following steps that 1, waste cloth strips are shredded to obtain shreds, and the shreds are transported to a quantitative material cylinder; 2, the shreds are evenly put onto a mixed conveyor belt by the quantitative material cylinder; 3, dried sludgeis put onto the mixed conveyor belt, on which the shreds are laid, through a packing auger; 4, the shreds and the sludge are mixed by a planetary rotation roller in a granulation device, a mixture issubjected to centrifugal extrusion to prepare the fuel particles, the fuel particles are compact in surface, and core portions are provided with air gaps. The production technology of the waste clothstrip and sludge fuel particles and the equipment thereof have the characteristics of high economic benefits and environmental friendliness.

Owner:湖州织里长和热电有限公司

Grain feed formula capable of accelerating weight increment of fattening beef cattle as well as preparation method and application of grain feed formula

InactiveCN108719615AHigh starch digestibilityImprove digestibilityFood processingAnimal feeding stuffChemistryCalcium

The invention provides a grain feed formula capable of accelerating weight increment of fattening beef cattle as well as a preparation method and application of the grain feed formula. The grain feedformula mainly consists of tabletted corn, barley, soybean meal (43%), rice bran meal, DDGS, puffed soybeans, calcium hydrogen phosphate, sodium chloride, baking soda and a beef cattle premix. The invention further provides the preparation method and application of the grain feed formula capable of accelerating weight increment of fattening beef cattle. The barley and the tabletted corn are used as main energy raw materials, and after the grain feed formula is adopted for the beef cattle of 15 months old for two months, the daily gain of the cattle can achieve 2.20 kilograms, and the fatteningeffect is notable.

Owner:INNER MONGOLIA UNIVERSITY

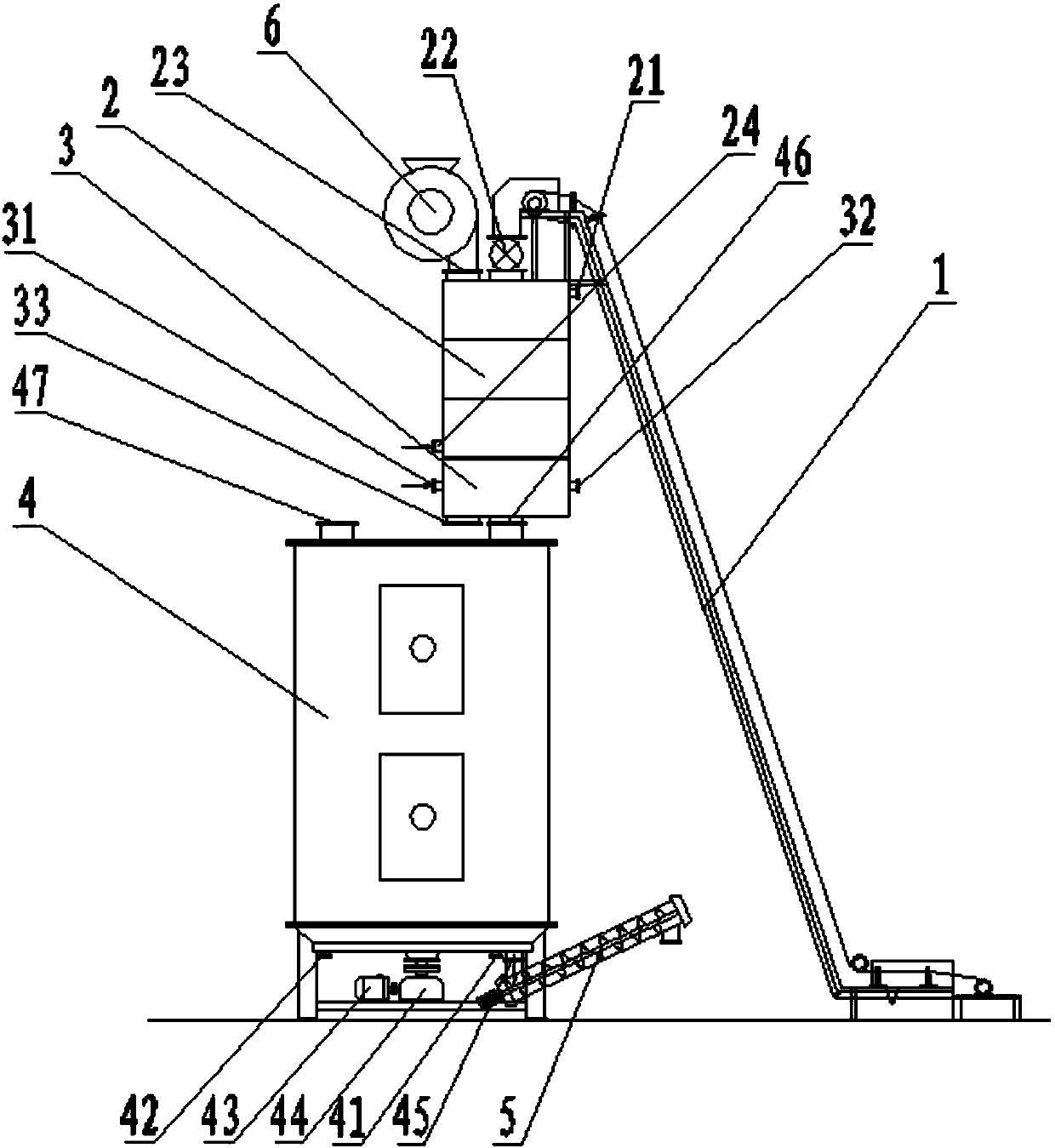

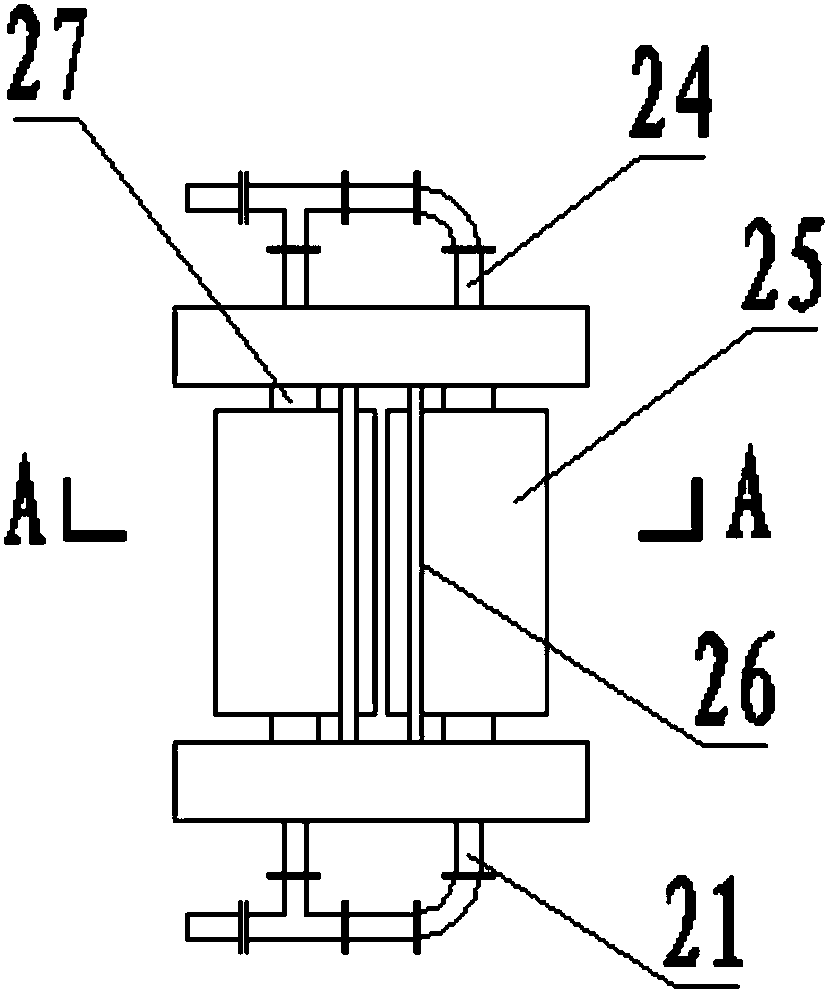

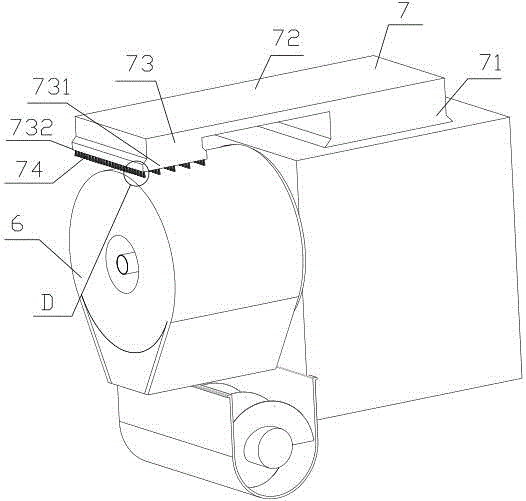

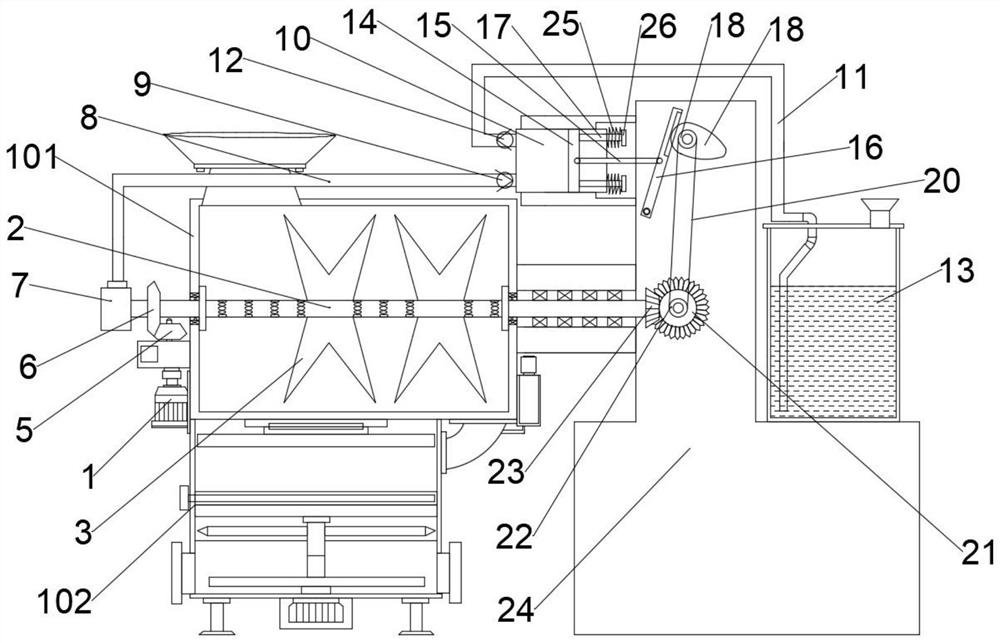

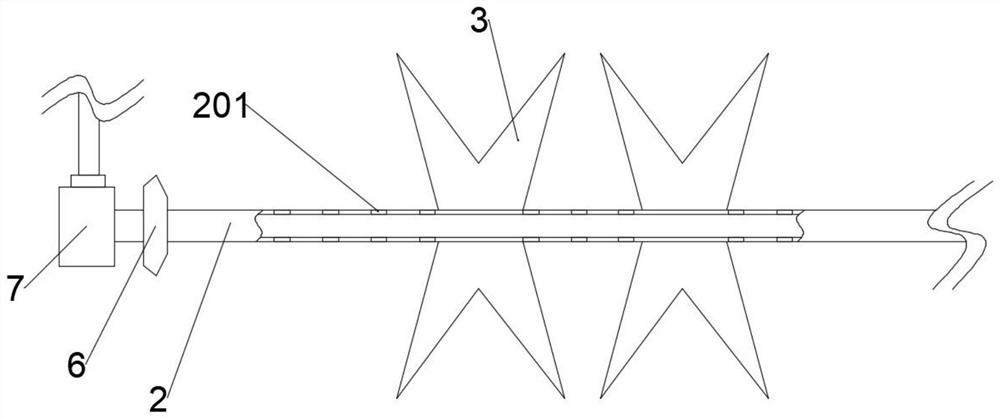

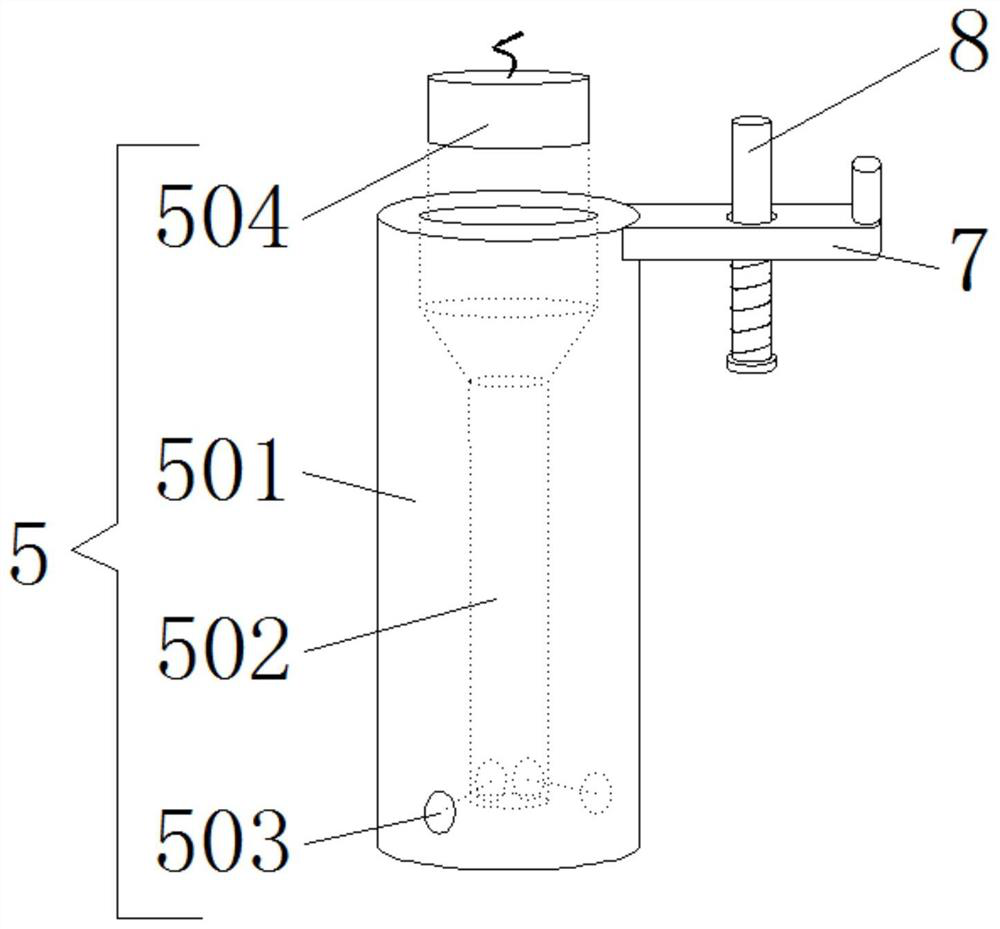

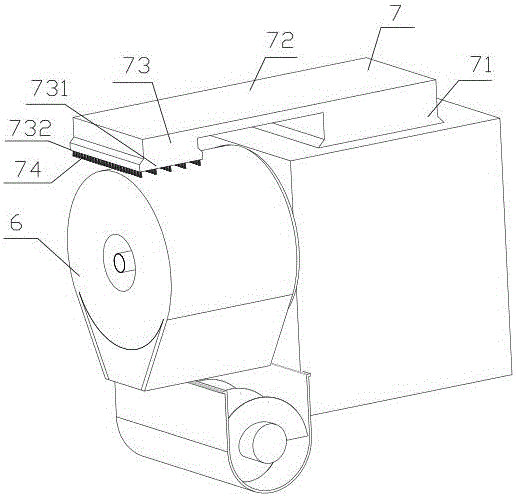

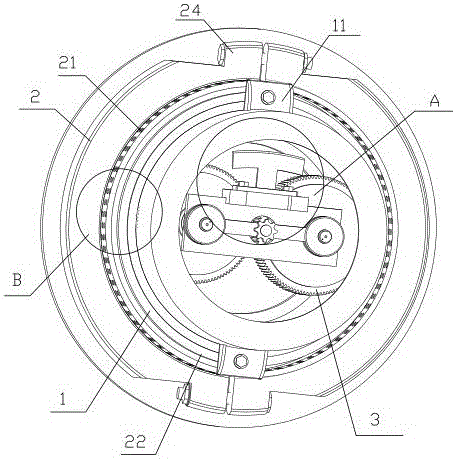

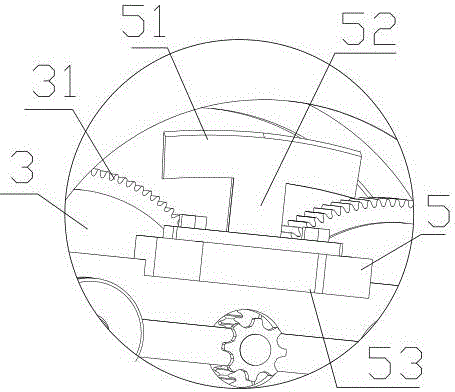

Special 520 type granulator for producing forage grass and biomass particles

PendingCN112007582AGuaranteed granulation effectSolve incomplete mixingTransportation and packagingRotary stirring mixersReduction driveGear wheel

The invention discloses a special granulator for producing pasture and biomass particles. The granulator comprises an upper feed mixing chamber, a lower granule granulating chamber, a stirring motor,a stirring shaft, a mixing blade, a solid material feeding hopper and a liquid supply tank; a liquid extraction pipe is led out from the liquid supply tank; the discharge end of a negative pressure pumping cylinder is communicated and butted with a liquid agent discharge pipe; the rod body of each supporting pressure rod is correspondingly sleeved with a reset pressure spring; a driven belt wheeland a driving belt wheel are connected together through a transmission belt; and a plurality of small release holes are evenly formed in the side wall face of a shaft body, located in the upper feed mixing chamber, of the stirring shaft, a driving gear is driven by a stirring motor to operate through a speed reducer, and the other end of the liquid agent discharging pipe is correspondingly communicated to the left end of the stirring shaft through a rotary connector. According to the invention, the problem of incomplete mixing in the prior art is solved, and the mixing degree of solid-liquid mixing is greatly improved.

Owner:溧阳市振和机械制造有限公司

An extraction device for rotary plant extraction

ActiveCN110339591BEasy to pressGuaranteed stabilityMaterial granulationSolid solvent extractionAgricultural engineeringMechanical engineering

The invention discloses a rotary extracting device for extracting plants, which comprises a frame, a sticking plate, a hook and a piston, an extraction tank is opened inside the frame, a pressure bar is fixed on the outer surface of the pressure wheel, and the A handle bar is installed on the outside of the top end of the connecting bracket, a mounting cover is connected to the outside of the connecting bracket, a feed inlet is provided in the left middle part of the frame, and the feed inlet includes an outer wall plate, a card seat and a connecting bump, The inner surface of the outer wall plate is respectively provided with a card seat and a connecting protrusion, the piston is installed at the bottom of the frame, and a liquid collection tank connected with the bottom end of the frame is arranged under the piston. The rotary extraction device for plant extraction is convenient for pressing plant samples, is beneficial to ensure the granulation effect, is convenient to ensure the stability of the injection of the extract solution, is conducive to stable adjustment, is convenient to ensure stability, and is convenient for disassembly and cleaning. It is convenient to ensure the effect of extraction and is beneficial to ensure the extraction rate.

Owner:陕西佰瑞衡健康科技有限公司

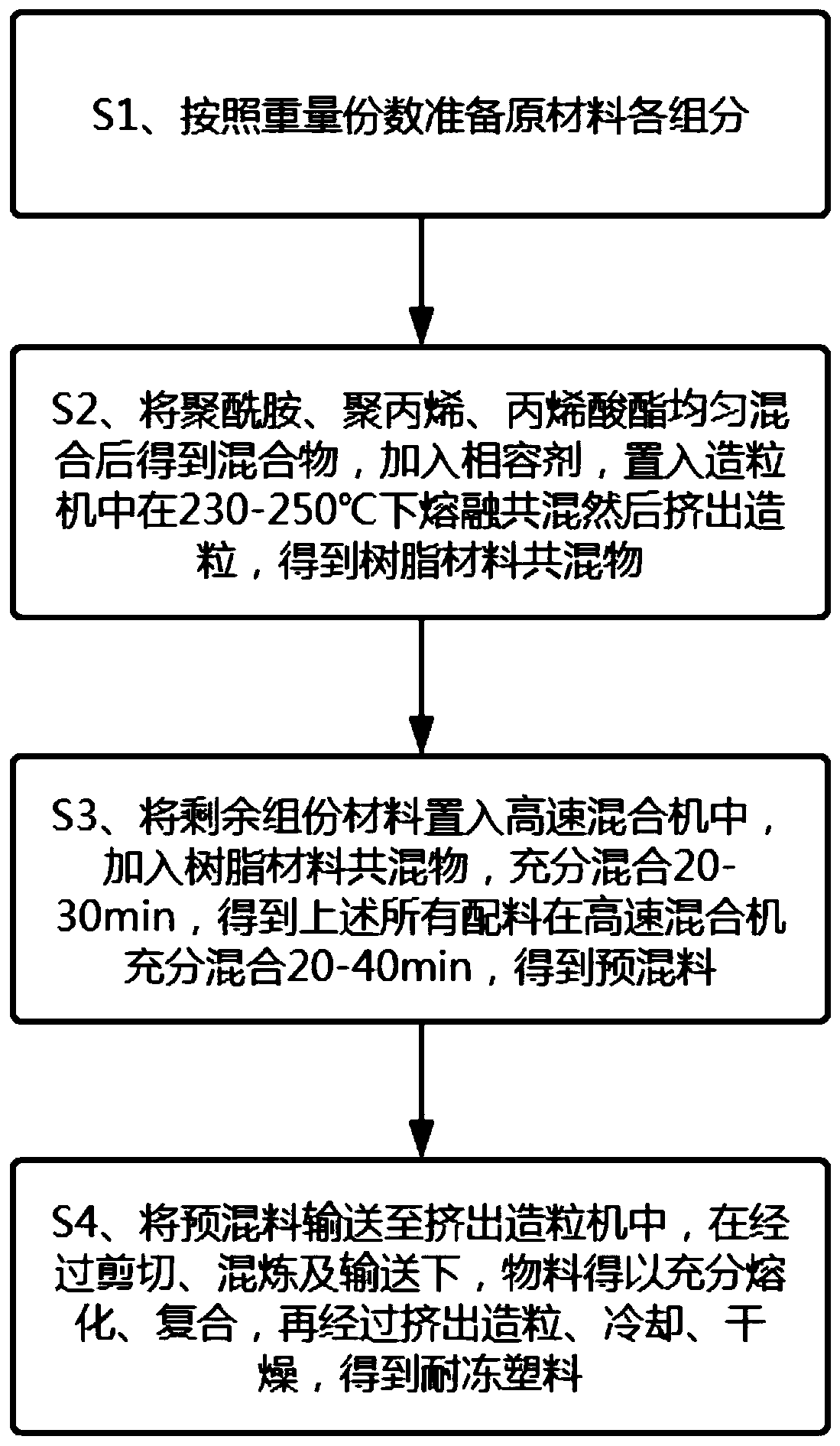

Freezing-resistant plastic used in extremely cold environment

InactiveCN111057366AImproved shock resistanceImprove low temperature resistanceCoatingsPolymer sciencePolystyrene

The invention discloses a freezing-resistant plastic used in an extremely cold environment, which belongs to the technical field of plastic products, and the freezing-resistant plastic comprises polyamide, polypropylene, polystyrene resin, diatomite, ultrafine calcium carbonate, silicon nitride, a composite flame retardant, a cold-resistant plasticizer, a weather-resistant agent, an anti-crackingagent, an antioxidant, an antibacterial agent and other components, and the preparation method comprises the following steps: preparing the raw material components according to parts by weight; preparing a resin material blend; fully mixing to obtain a premix; and conveying the premix into an extrusion granulator, and carrying out extrusion granulation, cooling and drying to obtain the freezing-resistant plastic. According to the freezing-resistant plastic disclosed by the invention, the polyamide, the polypropylene and the acrylate are used as main raw materials, the polyamide and the polypropylene have good low-temperature resistance, a compatilizer with specific components is added, so that the defect of poor solvent resistance of resin is overcome, and the low-temperature impact resistance of the modified plastic is greatly improved by introducing the polystyrene resin.

Owner:黄金平

A kind of strengthening agent for titanium concentrate granulation and a kind of granulation method of titanium concentrate

The invention provides a titanium concentrate prilling enhancer which comprises polyvinyl alcohol, pitch and a plant adhesive. The invention further provides a titanium concentrate prilling method. The titanium concentrate prilling method comprises the following steps that titanium concentrate and the enhancer are mixed to obtain an initial mixture; the enhancer comprises the polyvinyl alcohol, the pitch and the plant adhesive; the initial mixture is subject to prilling to obtain titanium concentrate molding wet particles; and the titanium concentrate molding wet particles are dried to obtain titanium concentrate molding dry particles. According to the dewatering characteristic of the titanium concentrate, the complete physical bonding organic molding enhancer is used for prilling, the proportion of the prepared titanium concentrate particles with the grain size ranging from 1 mm to 5 mm is larger than 90%, the falling strength is larger than 5 times per meter, the problem of raise dust in titanium concentrate transferring and electric furnace smelting process is effectively solved, the normal smelting rate is guaranteed, and the electric furnace equipment operation rate and the material yield are improved.

Owner:SICHUAN PAN YAN TECH

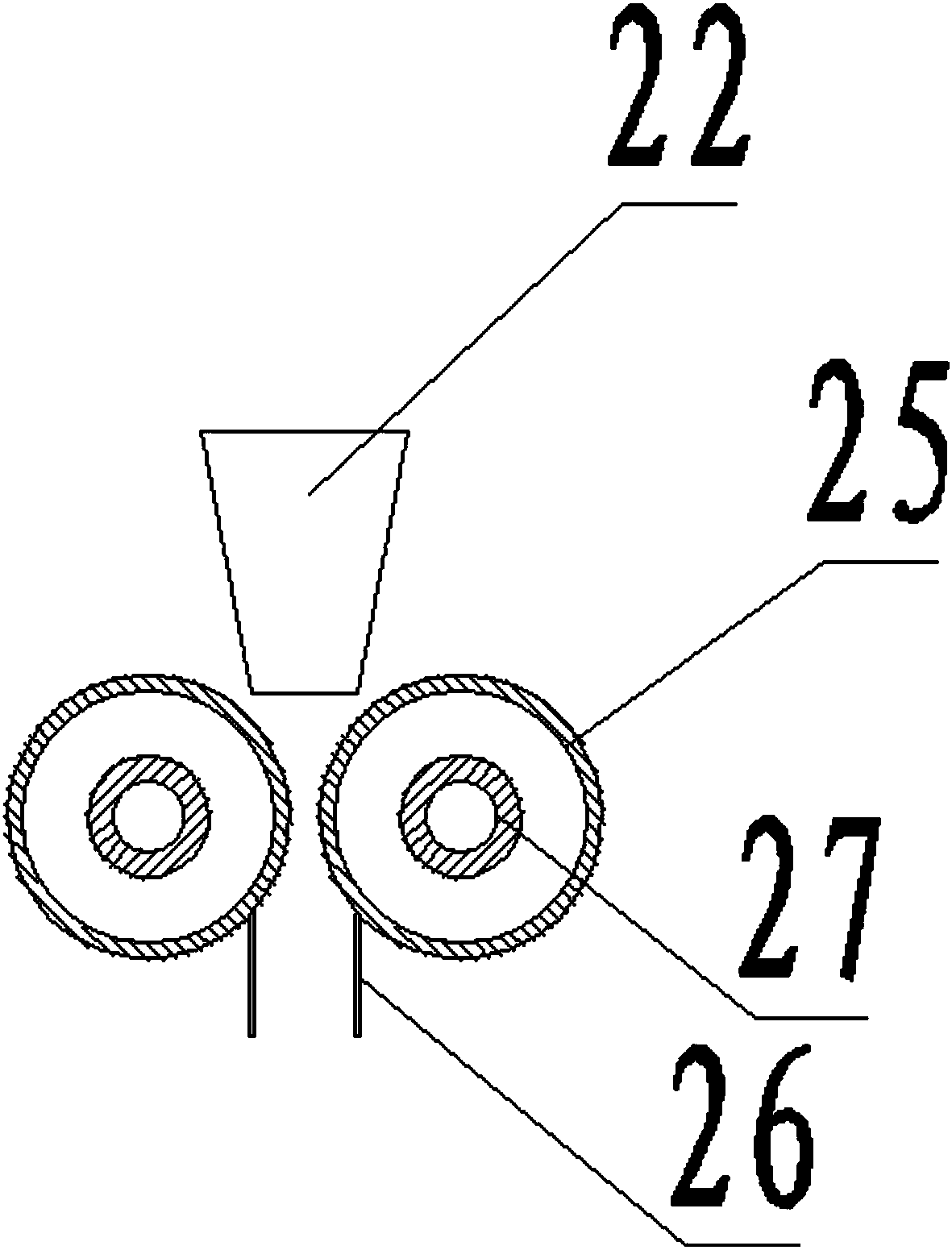

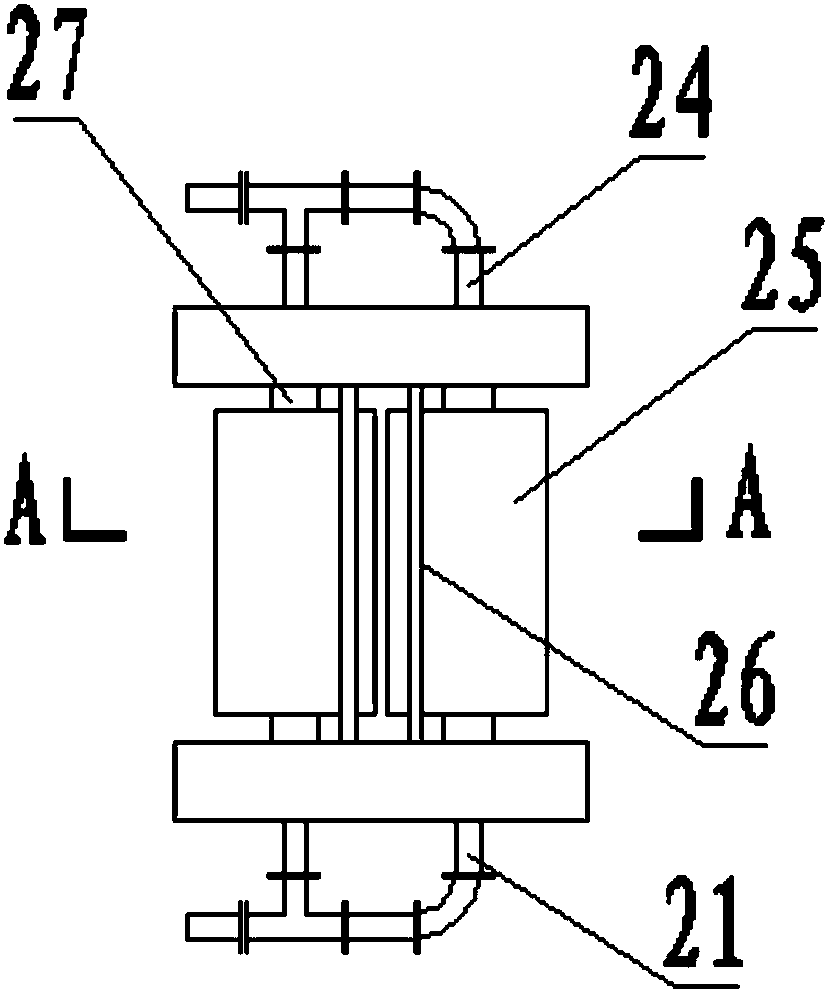

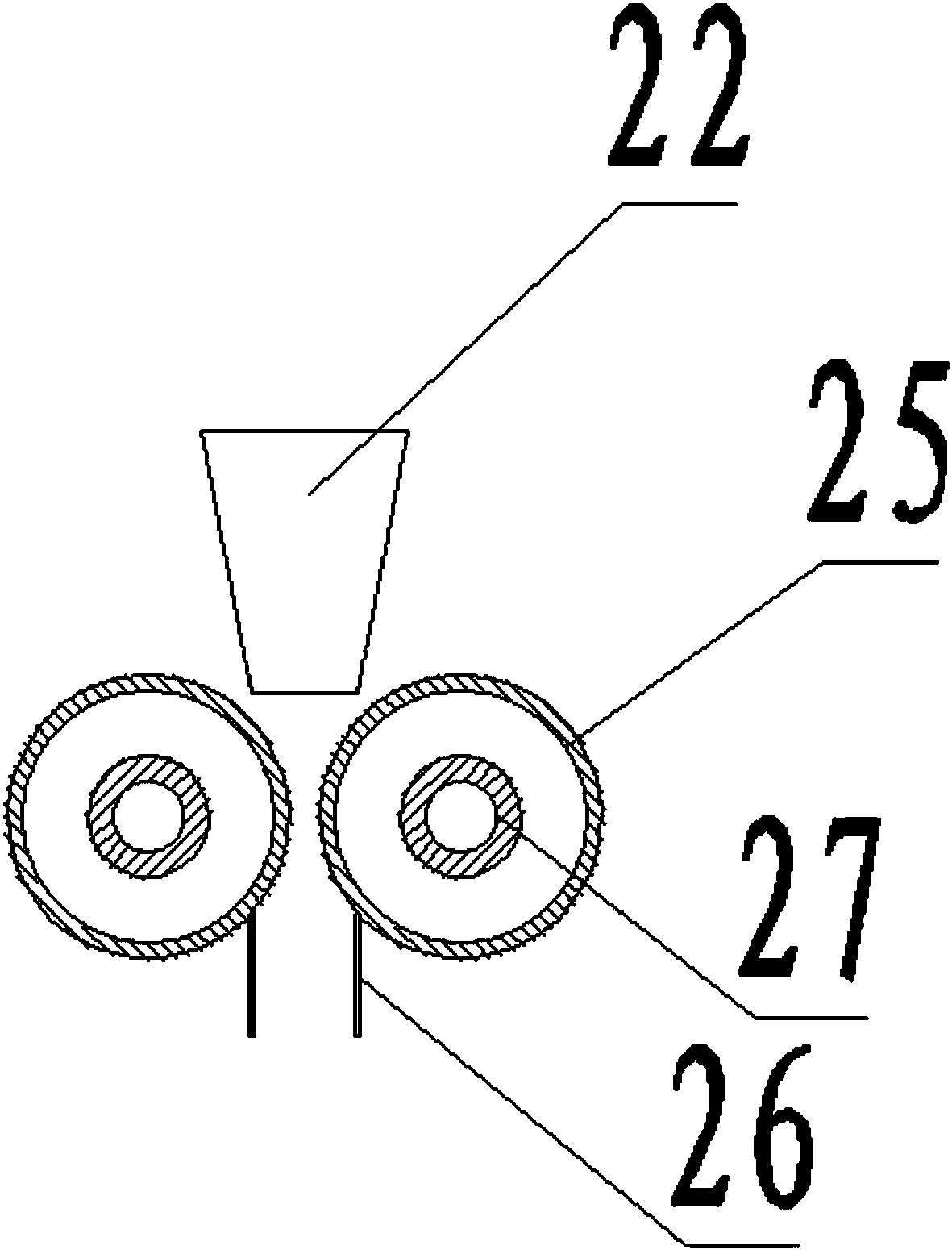

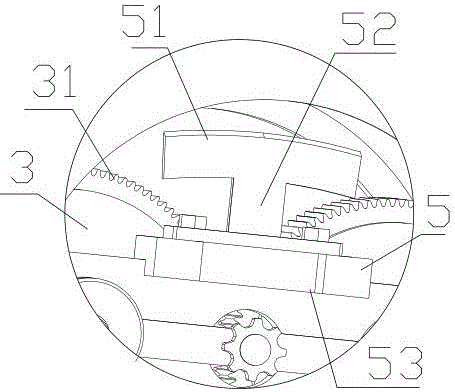

Granulator device for producing veterinary drugs

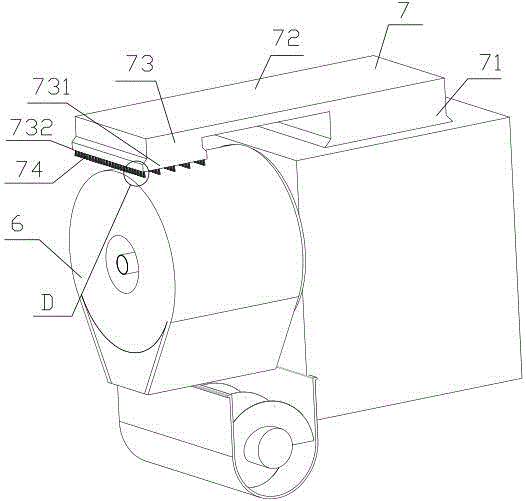

PendingCN113069994AEvenly distributedAdjustable blanking gapMaterial granulationOfficinalMechanical engineering

The invention discloses a granulator device for producing veterinary drugs, and relates to the technical field of veterinary drug production, the granulator device comprises a granulation mechanism and a support, the granulation mechanism is supported and fixed with a feeding box body through the support, an inclined guide plate is arranged in the feeding box body, two sides of the guide plate are fixedly connected with baffle plates, the baffle plates are slidably connected with a gap adjusting assembly, the gap adjusting assembly is parallel to the material guiding plate, a discharging gap is reserved between the gap adjusting assembly and the material guiding plate, and a driving mechanism is arranged on the feeding box body. Compared with the prior art, the device has the beneficial effects that the position of the pressing plate is adjusted through the adjusting bolt, the discharging gap can be adjusted, when powdery raw materials are conveyed downwards from the material guide plate, the gap adjusting assembly is driven by the driving mechanism to slide on the baffle plates in a reciprocating mode, the raw materials on the material guide plate can be bulldozed, and the raw materials falling into the granulator are uniformly distributed and thus the granulating effect is ensured.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Continuous heat shrinkable material with low smoke, low halogen and high pressure resistance and manufacturing method thereof

InactiveCN102020797BImprove mechanical propertiesGuaranteed granulation effectChemical industryPolyolefin

Owner:扬州辐照中心

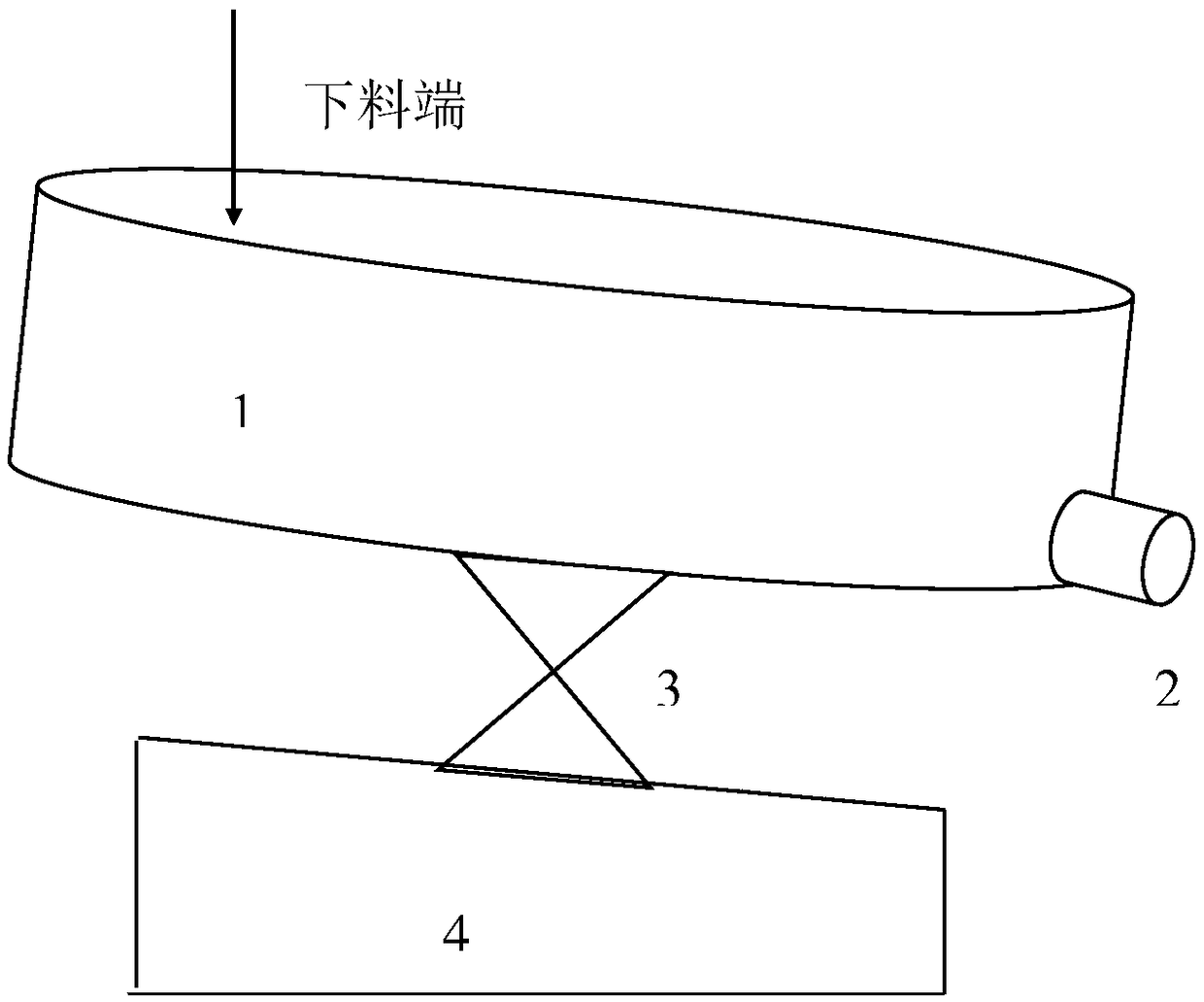

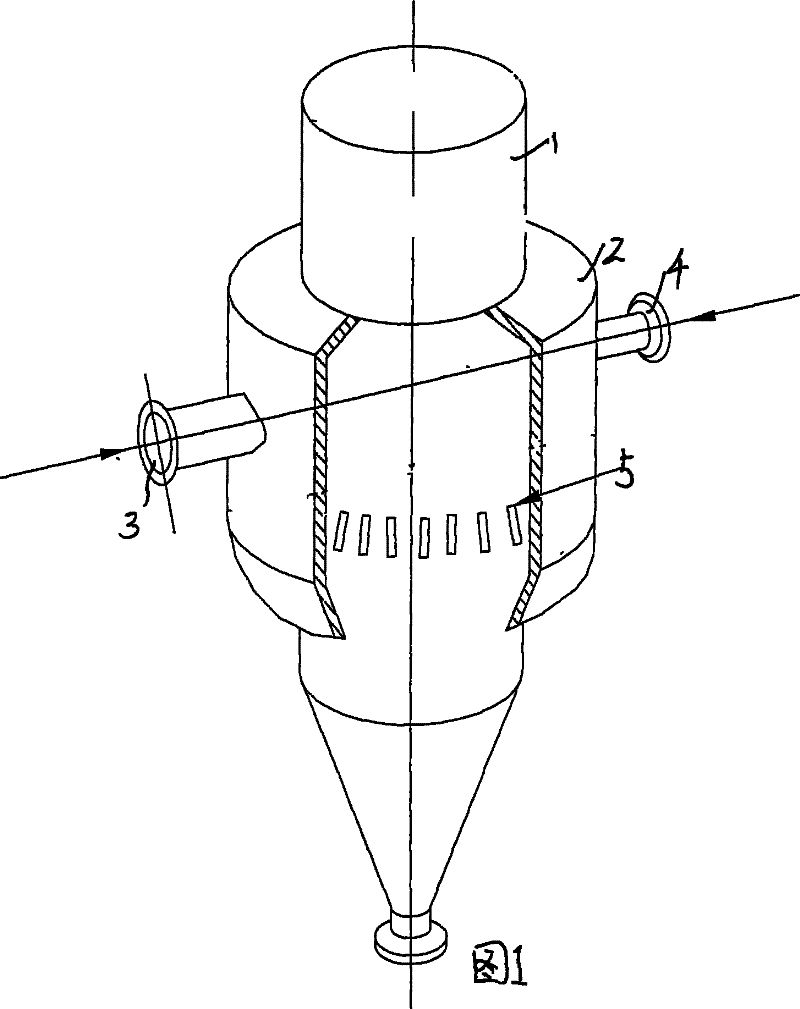

Pelletizing method of titanium concentrate

The invention provides a pelletizing method of titanium concentrate. The pelletizing method includes the following steps that the titanium concentrate and a reinforcer are mixed, and an initial mixture is obtained; the reinforcer is prepared from polyvinyl alcohol, pitch and a plant adhesive; the initial mixture is pelletized in an oscillatory type forming device, and titanium concentrate formed wet particles are obtained; and the titanium concentrate formed wet particles are dried, and titanium concentrate formed dry particles are obtained. According to the hydrophobic nature of the titanium concentrate, the organic forming reinforcer completely in physical adhesion is used for pelletizing, the percentage of the prepared titanium concentrate particles with the grain diameters ranging from 3 mm to 8 mm is larger than 90%, the drop strength is larger than 5 times per meter, the problem of flying dust generated in the titanium concentrate transferring and electric furnace smelting process is effectively solved, the normal smelting rate is guaranteed, and the electric furnace equipment operating rate and the material yield are increased.

Owner:SICHUAN PAN YAN TECH

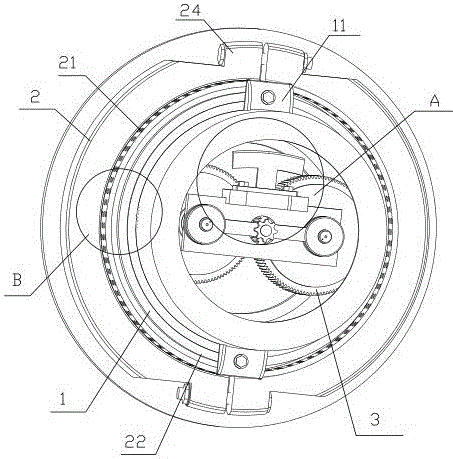

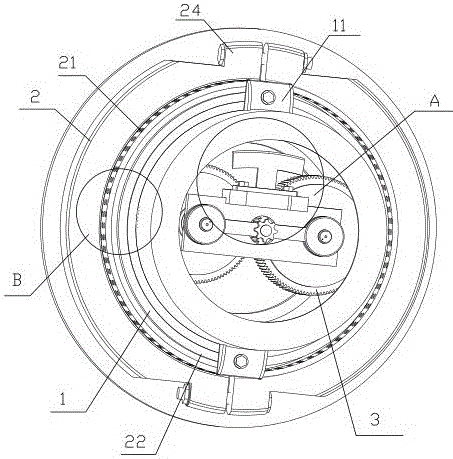

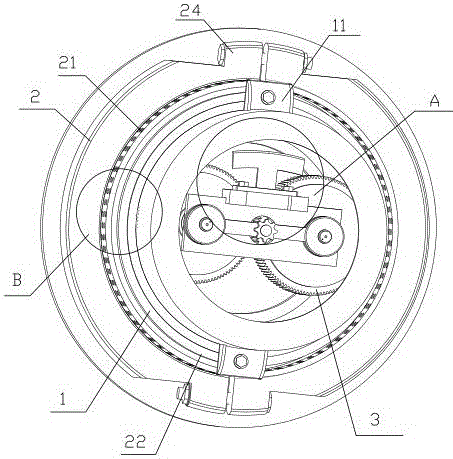

Automatic granulating machine

InactiveCN106215806AImprove granulation efficiencyReduce manual operationsGranulation by pressingMaterial transferEngineering

The present invention relates to the agricultural machinery field, and in particular relates to an automatic granulating machine. The automatic granulating machine comprises a cover body and an inner cavity arranged in the cover body, the automatic granulating machine includes pressing wheels arranged in the inner cavity, and also includes a housing, the upper surface of the housing is provided with an inlet, a blocking portion includes a base part and extending parts, the base part is located just above the inlet, the extending parts are located at the two ends of the base part, blocking pieces include external blocking pieces on the extending parts, each external blocking piece comprises a soft straight part and a hard bending part, the soft straight part is made of a soft material, and extends in vertical direction, the hard bending part is connected with the end of the soft straight part, and the hard bending part is bent in the way of gradually being away from the inlet along vertically-down direction. The purpose of this invention is to provide the automatic granulating machine, after a material enters the automatic granulating machine, the material is guided to a granulation position, the material transfer process is even, in the granulating process, dustproof performance is good, and a dust removal device has a large blocking area, and is not easy to break.

Owner:安徽盛昌生物能源科技开发有限公司

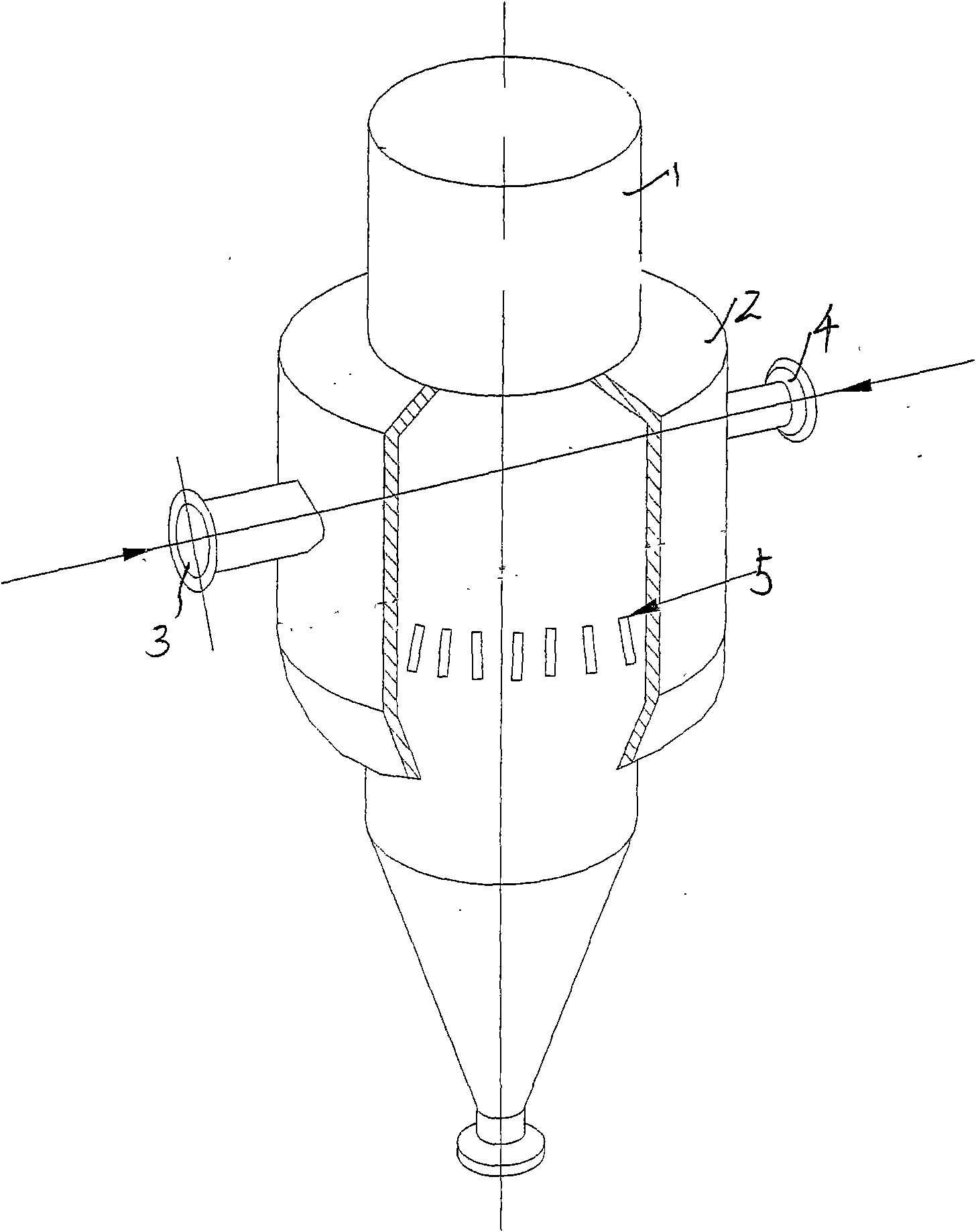

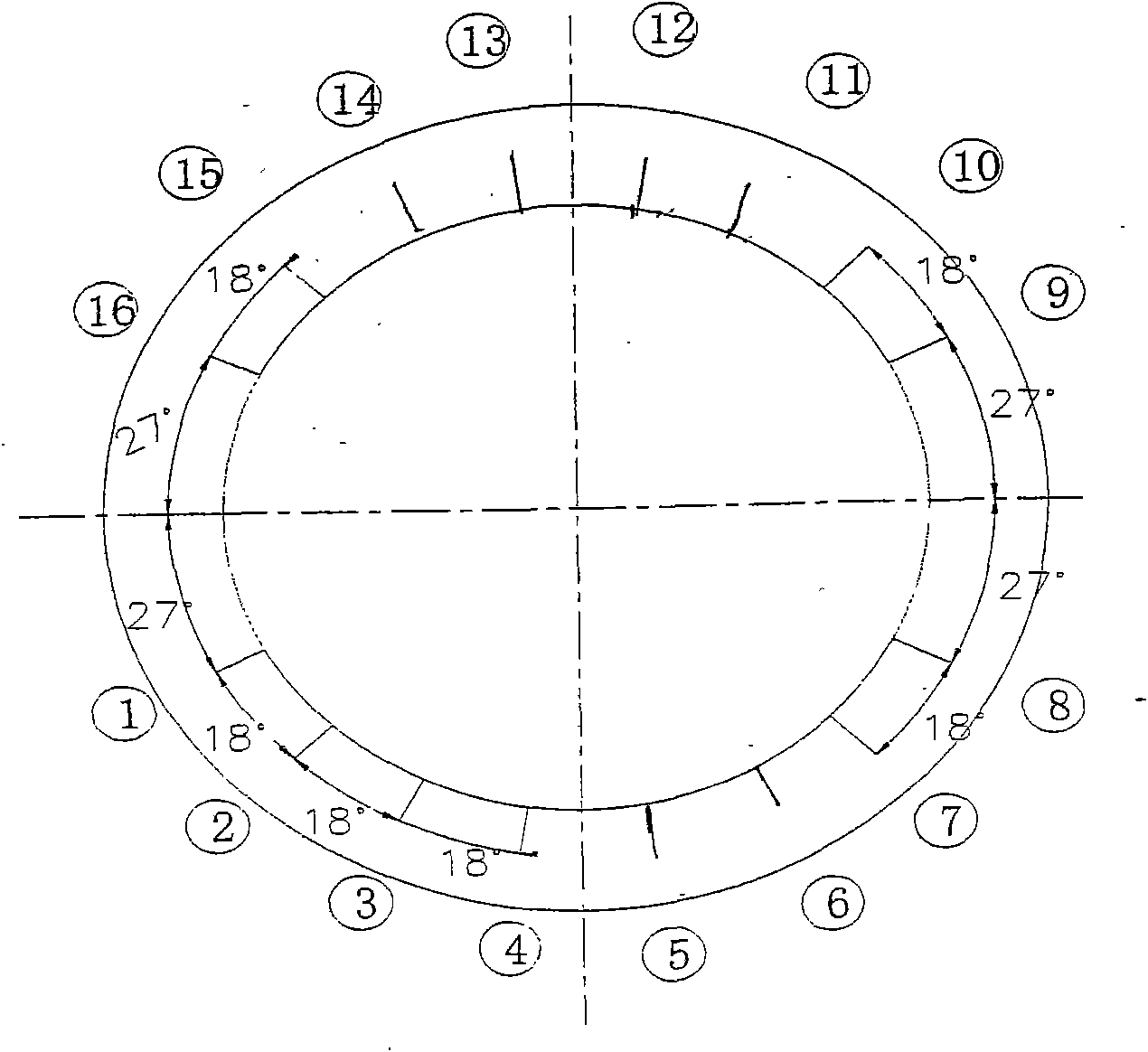

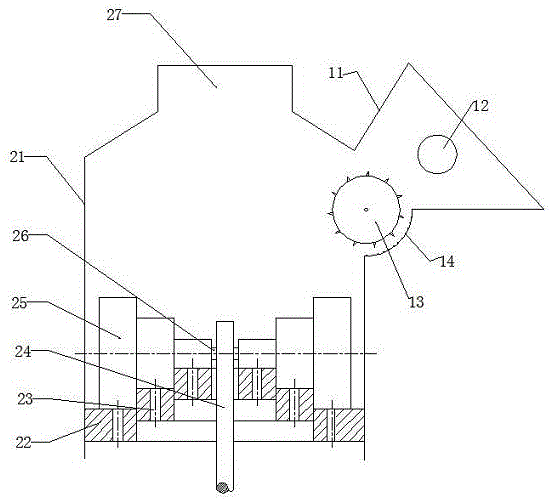

Bisphenol A production granulating system

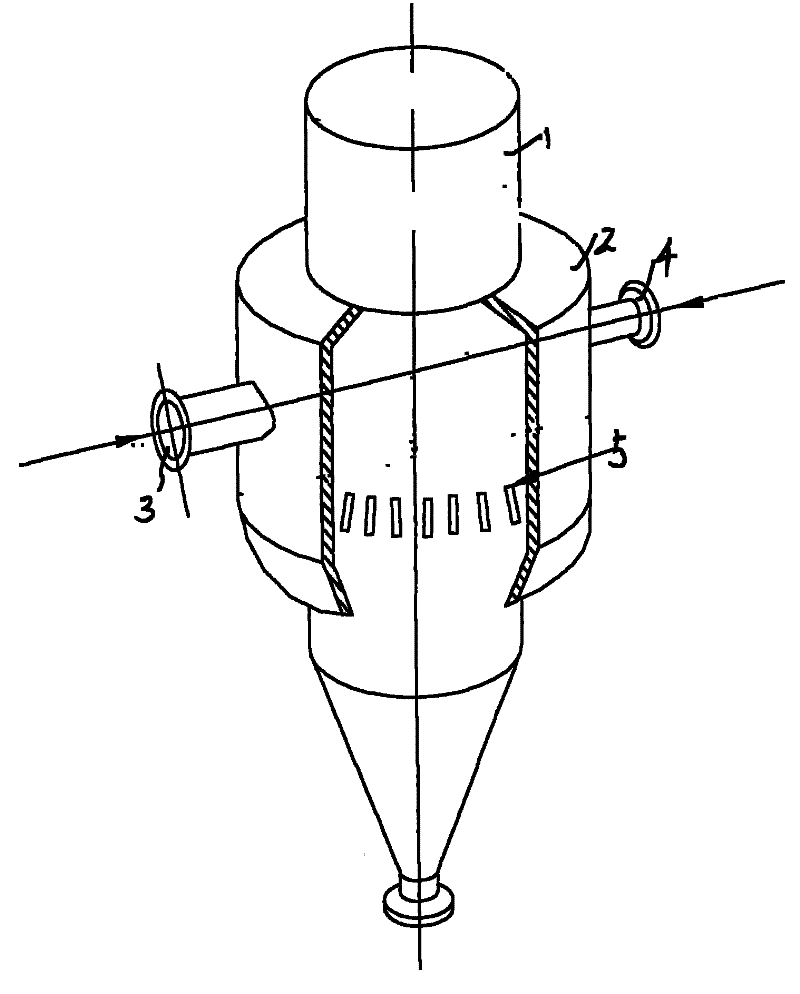

ActiveCN101549267AEvenly distributedUniform sizeOrganic chemistryGranulation by liquid drop formationEngineeringTower

The invention discloses a bisphenol A production granulating system, comprising a granulating tower. The granulating tower is provided with a granulating tower body; the lower part of the granulating tower body is provided with an outer sleeve; the upper end and the lower end of the outer sleeve are jointed with the granulating tower body in a sealing way; a nitrogen cavity is arranged between the outer sleeve and the granulating tower; an inlet for cooling nitrogen is arranged on the outer sleeve; and a plurality of nitrogen inlet holes are arranged at the same height with the granulating tower in the outer sleeve. The bisphenol A production granulating system has reasonable structure, can guarantee uniform distribution of rising nitrogen flow, finally achieve uniform size of granulated particles and meet the requirements of the expected value of the technique.

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

A kind of granulation method of titanium concentrate

The invention provides a pelletizing method of titanium concentrate. The pelletizing method includes the following steps that the titanium concentrate and a reinforcer are mixed, and an initial mixture is obtained; the reinforcer is prepared from polyvinyl alcohol, pitch and a plant adhesive; the initial mixture is pelletized in an oscillatory type forming device, and titanium concentrate formed wet particles are obtained; and the titanium concentrate formed wet particles are dried, and titanium concentrate formed dry particles are obtained. According to the hydrophobic nature of the titanium concentrate, the organic forming reinforcer completely in physical adhesion is used for pelletizing, the percentage of the prepared titanium concentrate particles with the grain diameters ranging from 3 mm to 8 mm is larger than 90%, the drop strength is larger than 5 times per meter, the problem of flying dust generated in the titanium concentrate transferring and electric furnace smelting process is effectively solved, the normal smelting rate is guaranteed, and the electric furnace equipment operating rate and the material yield are increased.

Owner:SICHUAN PAN YAN TECH

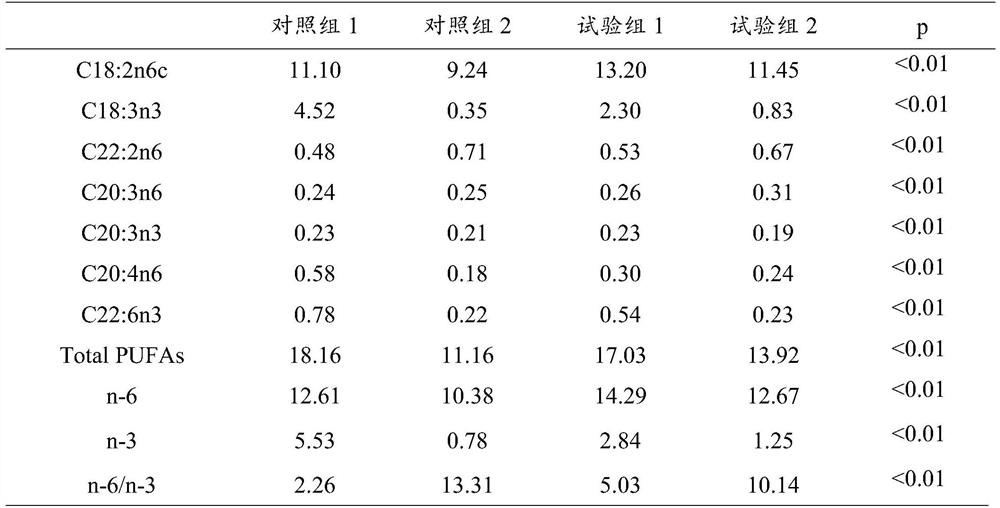

Feed for producing duck eggs rich in polyunsaturated fatty acids beneficial to human health and preparation method of feed

PendingCN114747691APromote absorptionEfficient use ofAnimal feeding stuffAccessory food factorsBiotechnologyAnimal science

The invention discloses a feed for producing duck eggs rich in polyunsaturated fatty acids beneficial to human health and a preparation method of the feed. Belongs to the technical field of feed. Each kilogram of the feed comprises 262.1 to 295.6 g of corn, 116.5 to 118.2 g of wheat, 263 to 284.2 g of wheat bran, 168.3 to 178.9 g of soybean meal, 5 to 25 g of flaxseeds, 18 to 22 g of soybean oil, 11 to 11.5 g of calcium hydrophosphate, 85 to 95 g of stone powder, 1.5 to 1.9 g of DL-methionine, 2.5 to 3 g of salt, 0.7 to 0.9 g of arginine, 1.4 to 1.5 g of lysine hydrochloride, 0.18 to 0.22 g of tryptophan, 0 to 0.1 g of threonine, 0.5 to 0.6 g of compound enzyme, 3 to 4 g of binding elements and 10 g of premix. The method is used for producing duck egg products which are good in taste and have polyunsaturated fatty acid with the proportion suitable for human body absorption, and technical support is provided for multifunctional food production.

Owner:ANIMAL SCI RES INST GUANGDONG ACADEMY OF AGRI SCI

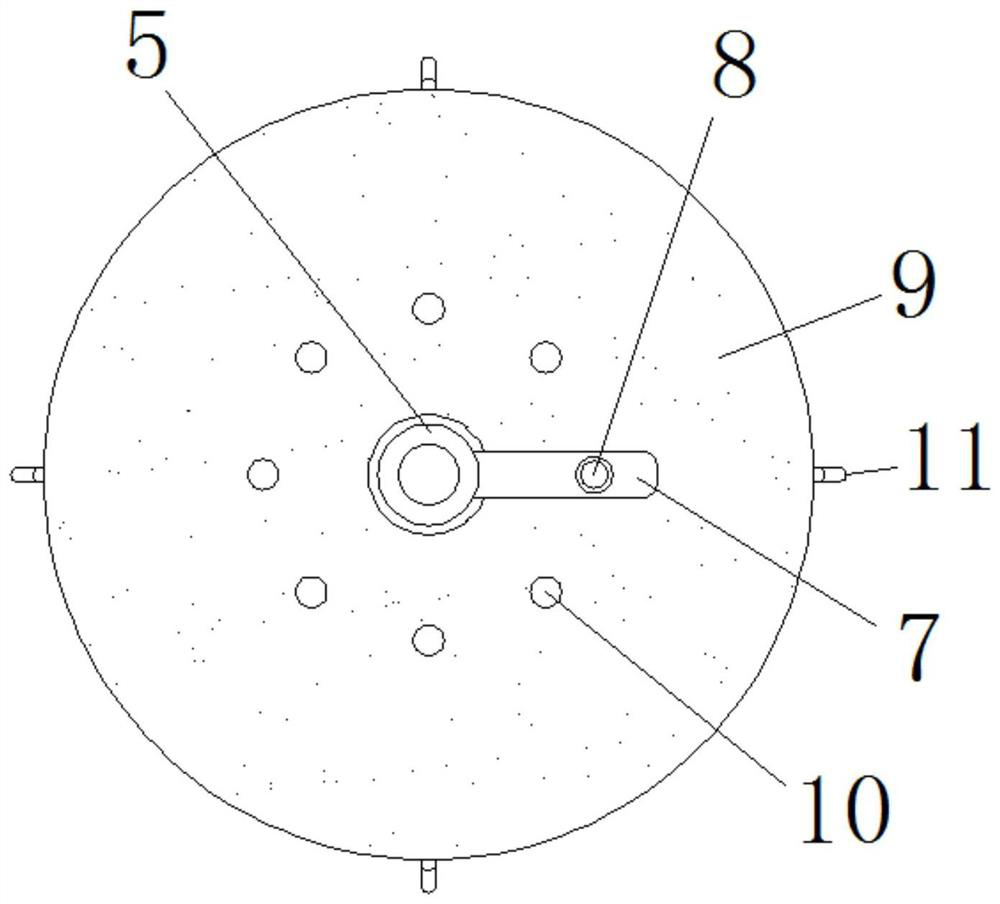

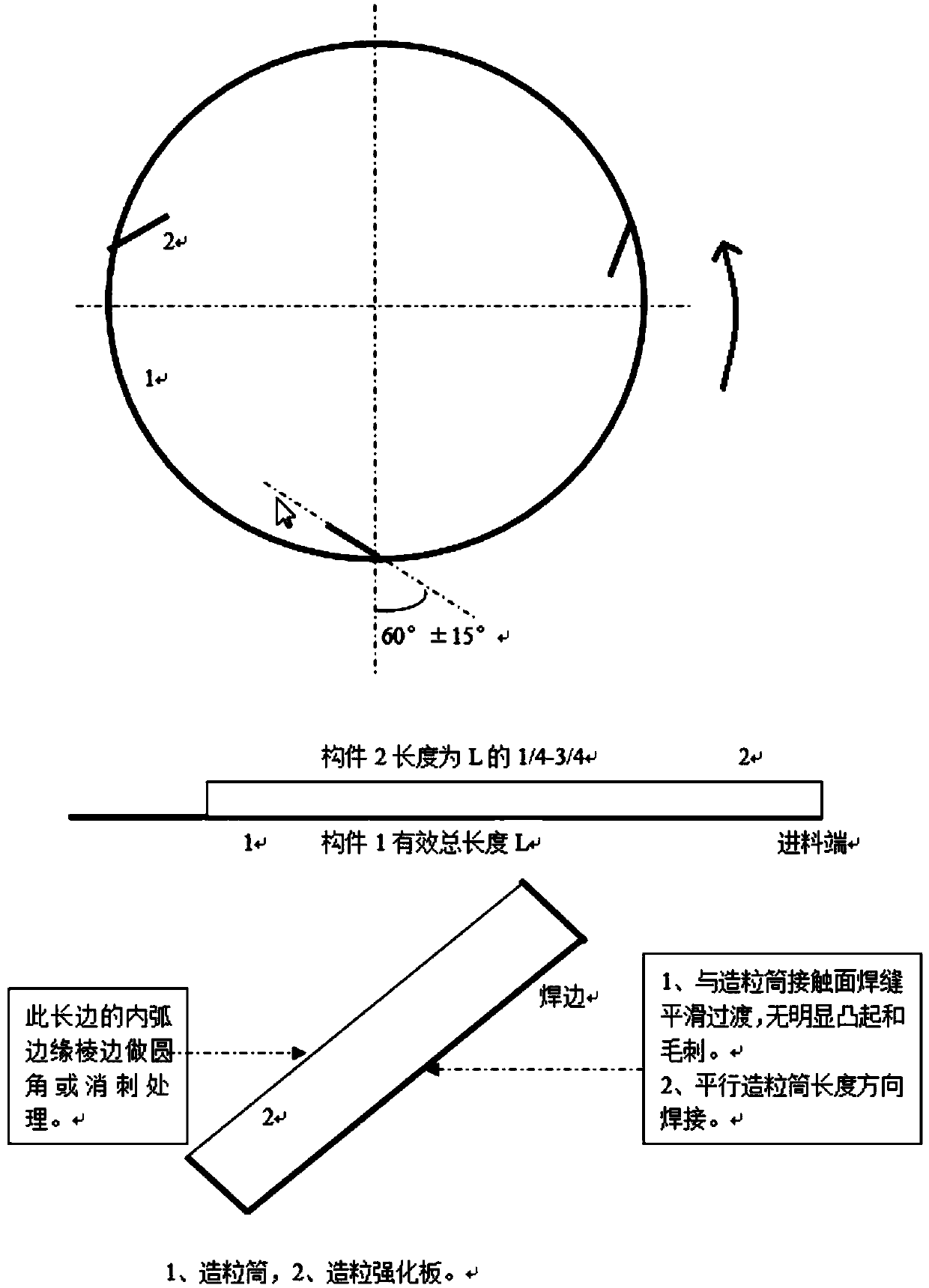

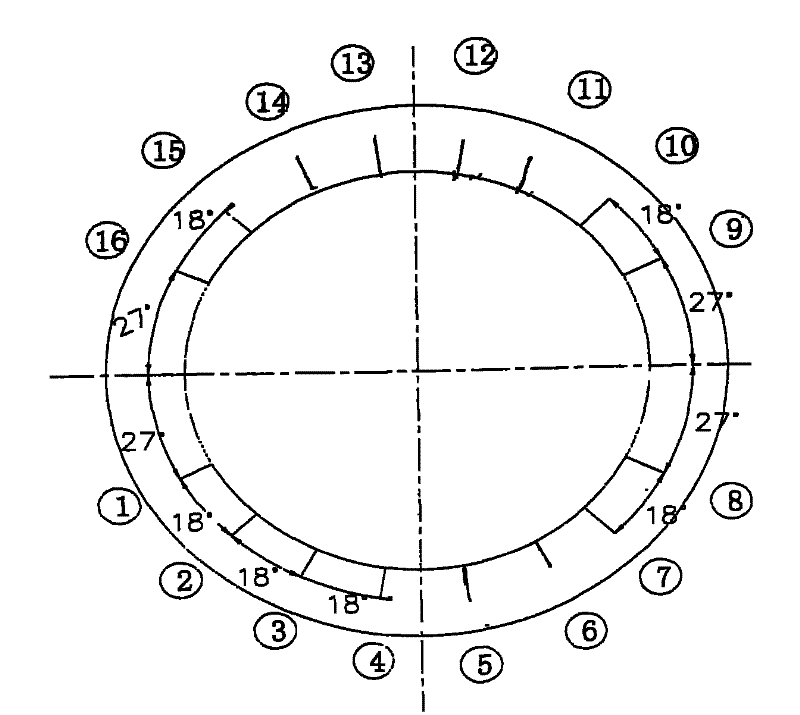

Stepped mold straw granulation device

InactiveCN104888662ALarge diameterIncrease line speedGranulation by pressingAngular velocityEngineering

The invention discloses a stepped mold straw granulation device. The device comprises a charging chamber, a molding mold located at the bottom of the charging chamber, a rotation shaft which vertically goes through the molding mold and is driven by a power mechanism, a transmission bar extending from the rotation shaft to outside, and a compression roller rotatingly connected to the transmission bar. The molding mold circumference where the compression roller carries out revolution along with the rotation shaft is provided with a molding hole. The upper surface of the molding mold is in a shape of a declining ladder from the circle center to the edge. The shape of the compression roller matches with the shape of the upper surface of the molding mold. The upper surface of the molding mold is in a shape of a declining ladder from the circle center to the edge and the shape of the compression roller matches with the shape of the upper surface of the molding mold so that the diameter of the outer side of the compression roller is increased. Under the condition of an invariant angular velocity, a compression roller outer side linear velocity is increased, sliding friction between the compression roller and the molding mold is greatly reduced, roller compression effects are ensured, a straw crushing degree is reduced, straw crushing energy consumption is reduced and a straw granulation cost is reduced.

Owner:HUAIAN HUADIAN ENVIRONMENTAL PROTECTION MACHINERY MFG

Bisphenol A production granulating system

ActiveCN101549267BEvenly distributedGuaranteed heat exchange effectOrganic chemistryGranulation by liquid drop formationEngineeringTower

Owner:NANTONG XINGCHEN SYNTHETIC MATERIAL

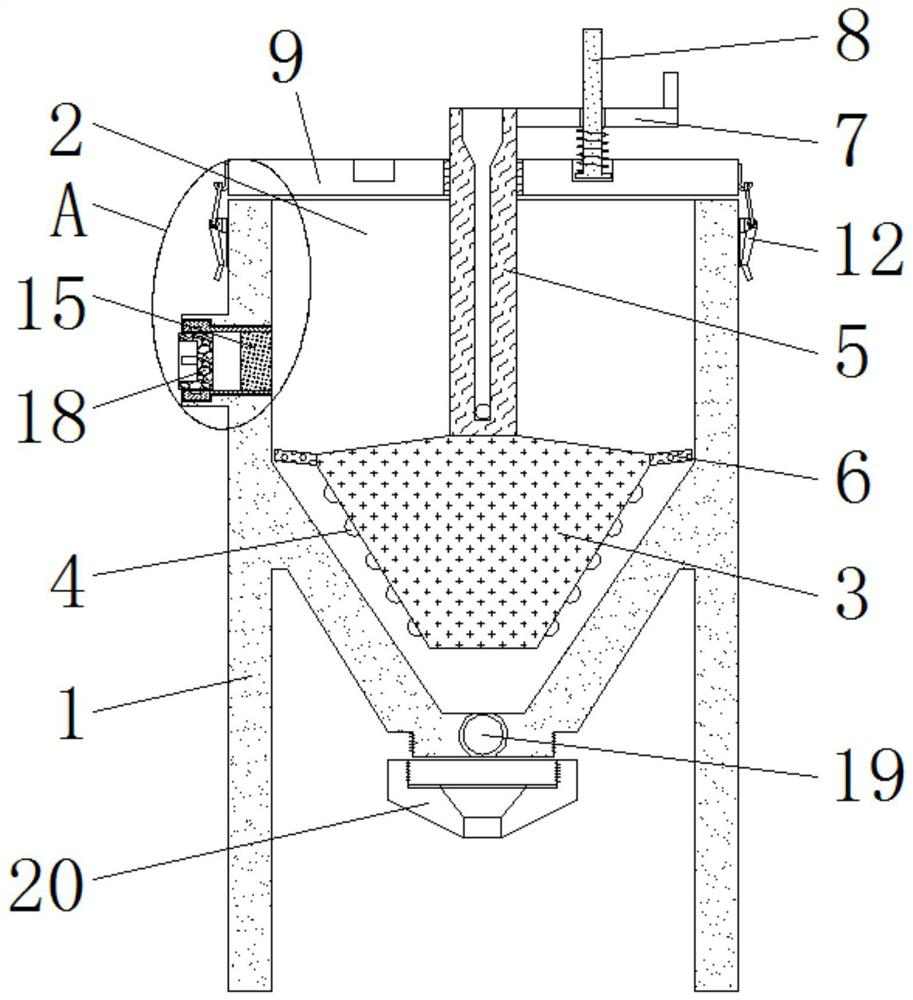

Granulating and screening integrated equipment for compound fertilizer production

InactiveCN113941287AAchieving an integrated processImprove work efficiencySievingGas current separationAgricultural scienceGear drive

The invention discloses granulation and screening integrated equipment for compound fertilizer production and belongs to the technical field of compound fertilizer production. Existing compound fertilizer granulation equipment and screening equipment are generally of an independent structure, more time is wasted when a compound fertilizer is transferred to the screening equipment after granulation is completed, and the production efficiency is affected. The invention just aims to solve the above problem. A feeding hopper is installed at the upper end of a granulation mechanism, material baffles are installed on the two sides of the connecting position of the feeding hopper and the granulation mechanism, a gear protective cover is installed on the front end face of the granulation mechanism, a belt protective cover is installed on the rear end face of the granulation mechanism, a third motor is installed at one end of the belt protective cover, granulation rollers are mounted on the two sides of the interior of the granulation mechanism, roller shafts at the front ends of the granulation rollers on the two sides penetrate through and extend into the gear protective cover and are in transmission connection through gears, and the roller shaft at the rear end of the granulation roller on one side penetrates through and extends into the belt protective cover and is in transmission connection with the output end of the third motor through a belt.

Owner:GARSONI FERTILIZER NINGLING

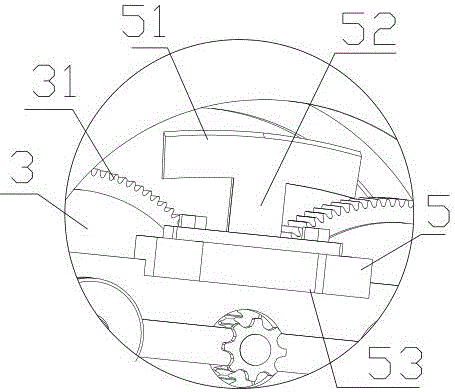

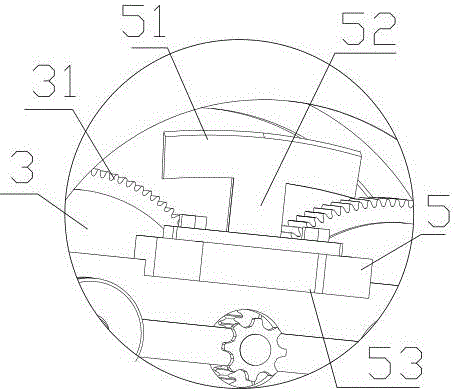

Precision granulator

InactiveCN106040096AGuaranteed granulation effectImprove granulation efficiencyGranulation by pressingEngineeringMechanical engineering

The invention relates to the field of agricultural machinery, in particular to a precision granulator, implemented through a following technical scheme: the precision granulator, comprising an enclosure and an inner cavity arranged in the enclosure, also comprising a press wheel arranged in the inner cavity and also comprising a shell; the upper surface of the shell is provided with an entry, a dust collector is arranged above the entry and comprises a fixed base, an elongation portion connected with the fixed base and a retaining portion connected to the tail end of the elongation portion, the retaining portion comprises a base portion positioned right above the entry and extension portions positioned at two ends of the base portion, and blocking parts on the base portion are more than those on the extension portions. The invention is intended to provide a precision granulator, after entering the granulator, material can be guided to a granulating station, the material is evenly conveyed, and dust prevention is good during granulating.

Owner:安徽盛昌生物能源科技开发有限公司

A particle size detection system and method for blast furnace slag centrifugal granulation based on image recognition

InactiveCN110218824BOvercome technical issues that cannot be measured in real timeReal-time regulationCharacter and pattern recognitionParticle size analysisControl cellEngineering

The disclosure proposes an image recognition-based blast furnace slag centrifugal granulation particle size detection system and method. The detection system includes a control unit, a slag extraction device, and an image acquisition unit. The image acquisition unit collects the image of the slag particles, and the control unit detects and analyzes the size of the slag particles according to the collected image to obtain the detection data of the slag particle size; the control unit is respectively connected with the slag extraction device and the image acquisition unit. The disclosure collects images of slag particles by setting an image acquisition device, and obtains the size data of slag particles after image analysis, adopts a soft measurement method to overcome the technical problem that blast furnace slag particles cannot be measured in real time due to high temperature, and improves the centrifugal force of blast furnace slag. Real-time and accuracy of particle size measurement. According to the data of slag particle size, the blast furnace slag granulation device can be regulated in real time to control the particle diameter in real time and ensure the heat recovery efficiency of liquid slag mechanical centrifugal granulation.

Owner:QINGDAO UNIV

Accurate guiding granulator

InactiveCN106111014AGuaranteed granulation effectImprove granulation efficiencyGranulation by pressingEngineeringPulp and paper industry

The invention relates to the field of agricultural apparatuses, in particular to an accurate guiding granulator. According to the technical scheme, a granule pressing machine of the granulator comprises a cover and an inner cavity formed in the cover, further comprises pressing wheels arranged in the inner cavity, and further comprises a shell; the shell comprises an extending part for extending into the inner cavity, a guiding part for guiding completely-granulated materials and a stirring device arranged on the extending part, and the stirring device comprises a rotating shaft and a plurality of stirring blades arranged on the rotating shaft; the guiding part comprises an aslant-arranged slant guiding wall and an outlet formed below the slant guiding wall. According to the accurate guiding granulator, the materials enter the device and can be guided to the granulating position, the material delivering process is even, granulating is full, and then the materials are successfully guided.

Owner:安徽盛昌生物能源科技开发有限公司

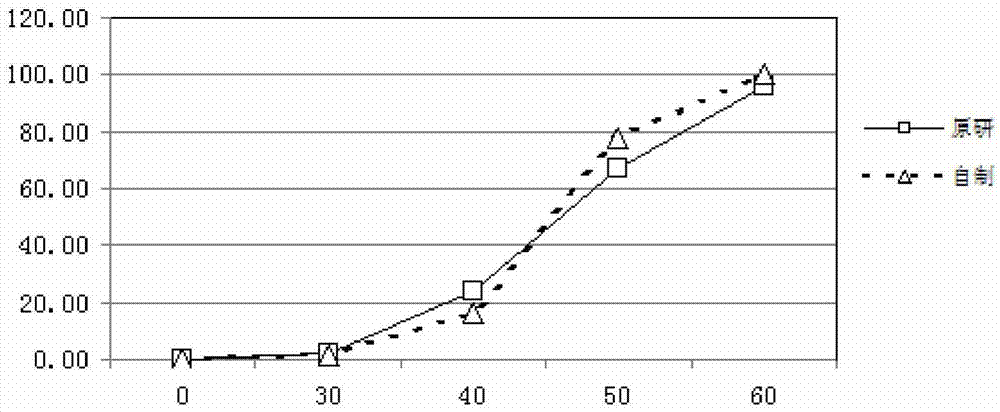

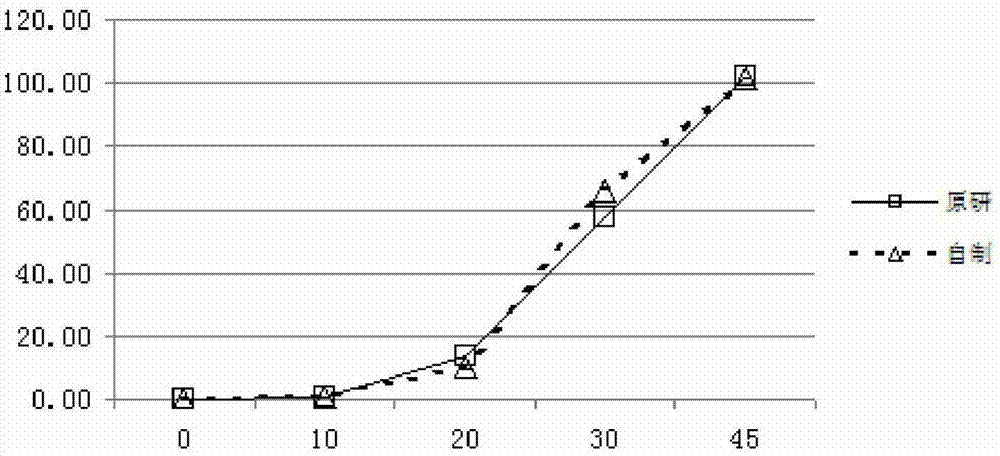

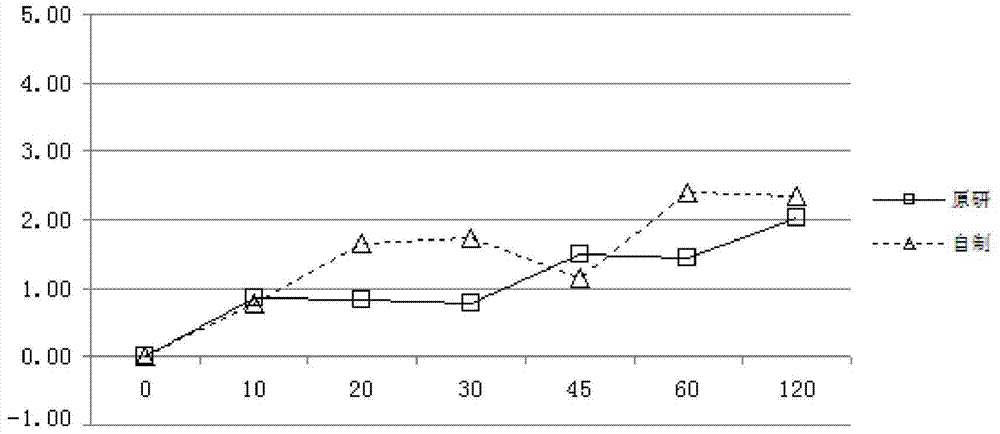

A kind of pantoprazole sodium enteric-coated tablet and preparation method thereof

ActiveCN104382875BCreativeMeet the requirements of consistency evaluationOrganic active ingredientsDigestive systemFiller ExcipientIsolation layer

Owner:HANGZHOU CONBA PHARMA

Preparation technology of spherical-like lithium cobalt material

The invention discloses a preparation technology of a spherical-like lithium cobalt material. The preparation technology comprises the following steps: proportioning of raw materials, and dry type mixing; preforming and pelletizing; primary roasting; crushing and mixing; secondary roasting; sieving, deironing and packaging. The materials subjected to dry type mixing are preformed and pelletized through a preforming machine, air in the materials is emitted under the extrusion of a roller, and materials are changed into dense from fluffy, so that the bulk density of the materials is improved. When the preformed materials are subjected to primary roasting and charging, the charging amount of the primary roasting can be increased, and under the same roasting condition, the output of the materials is also obviously increased. Through preforming and pelletizing, the productivity of lithium cobalt oxide can be increased, and the production cost can also be lowered.

Owner:NANTONG RESHINE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com