A kind of granulation method of titanium concentrate

A technology of titanium concentrate and granulation, applied in the field of metallurgy, can solve the problems of reducing the quality of pellets, increasing the molding cost, and large size of the titanium concentrate pellets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Add titanium concentrate and strengthening agent according to the mass ratio of titanium concentrate dry weight to strengthening agent 100:1.8 and mix well to obtain a mixture. The final moisture content of the mixture is 11.8%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 20:5:75;

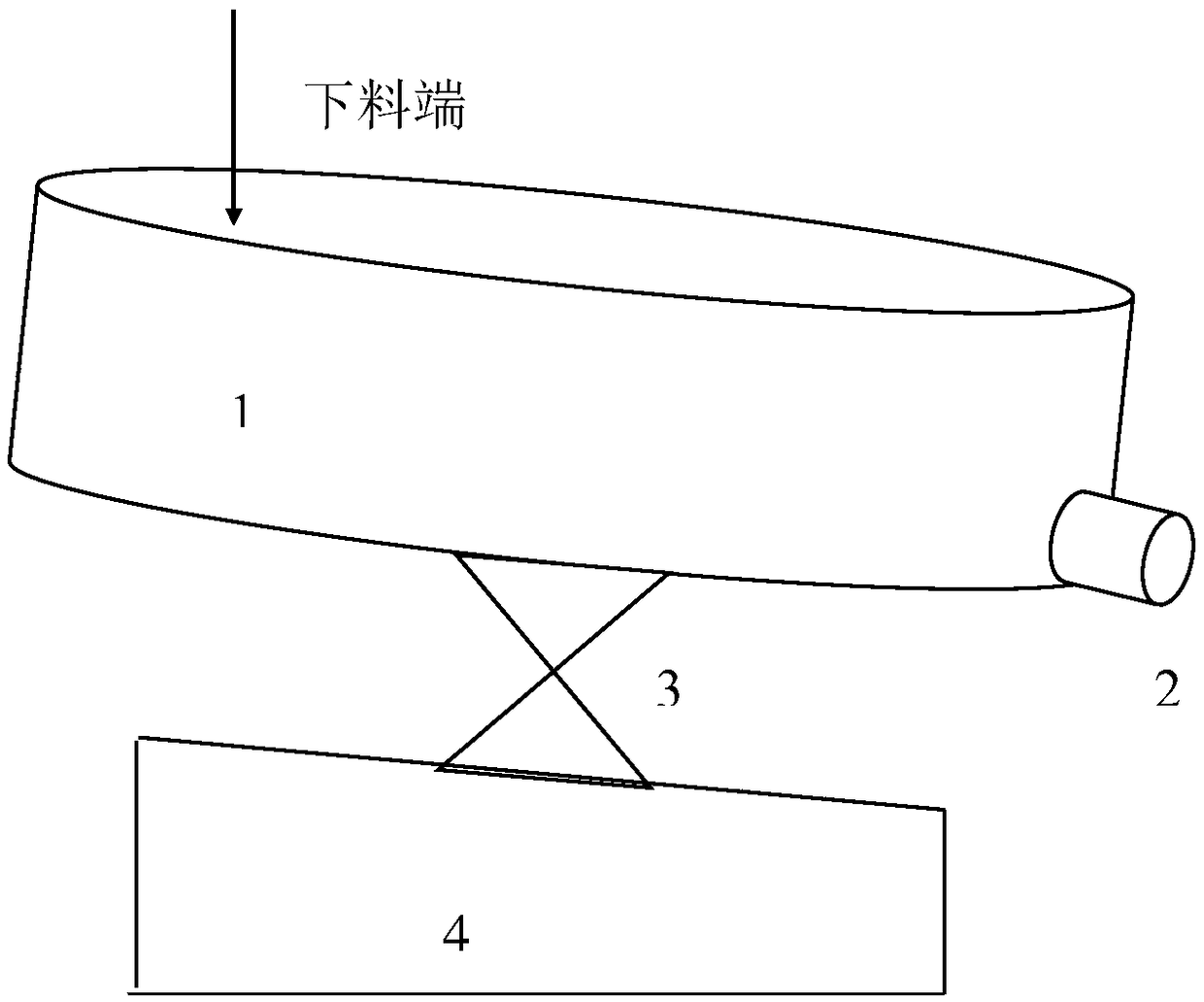

[0038] The above-mentioned mixture is granulated in an oscillating forming device with an inclination angle of 1° to obtain titanium concentrate forming wet granules; the vibration amplitude of the oscillating forming device is ±2cm, and the frequency is 12 times / s;

[0039] Pass the formed wet granules of titanium concentrate into a rotary kiln for drying at 100°C with flue gas, and finally obtain granulated dry particles of titanium concentrate with a mass ratio of 95.6% in the particle size range of 3 mm to 8 mm and an average drop strength of 8.4 times / m.

Embodiment 2

[0041] Add titanium concentrate and strengthening agent according to the ratio of titanium concentrate dry weight to strengthening agent mass ratio of 100:1.3 and mix well to obtain a mixture. The final moisture content of the mixture is 13.4%. The strengthening agent is composed of polyvinyl alcohol: medium temperature Asphalt powder: plant adhesive = 60:10:30;

[0042] The above-mentioned mixture is granulated in an oscillating forming device with an inclination angle of 2.5° to obtain titanium concentrate forming wet granules; the vibration amplitude of the oscillating forming device is ±7cm, and the frequency is 5 times / s;

[0043] Pass the ilmenite concentrate shaped wet granules into the rotary kiln for flue gas drying at 220°C, and finally get the ilmenite concentrate granulated dry granules, the mass proportion of which is within the range of 3 mm to 8 mm in particle size reaches 91%, and the average drop strength is 5.4 times / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com