Patents

Literature

598results about How to "Solve process problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

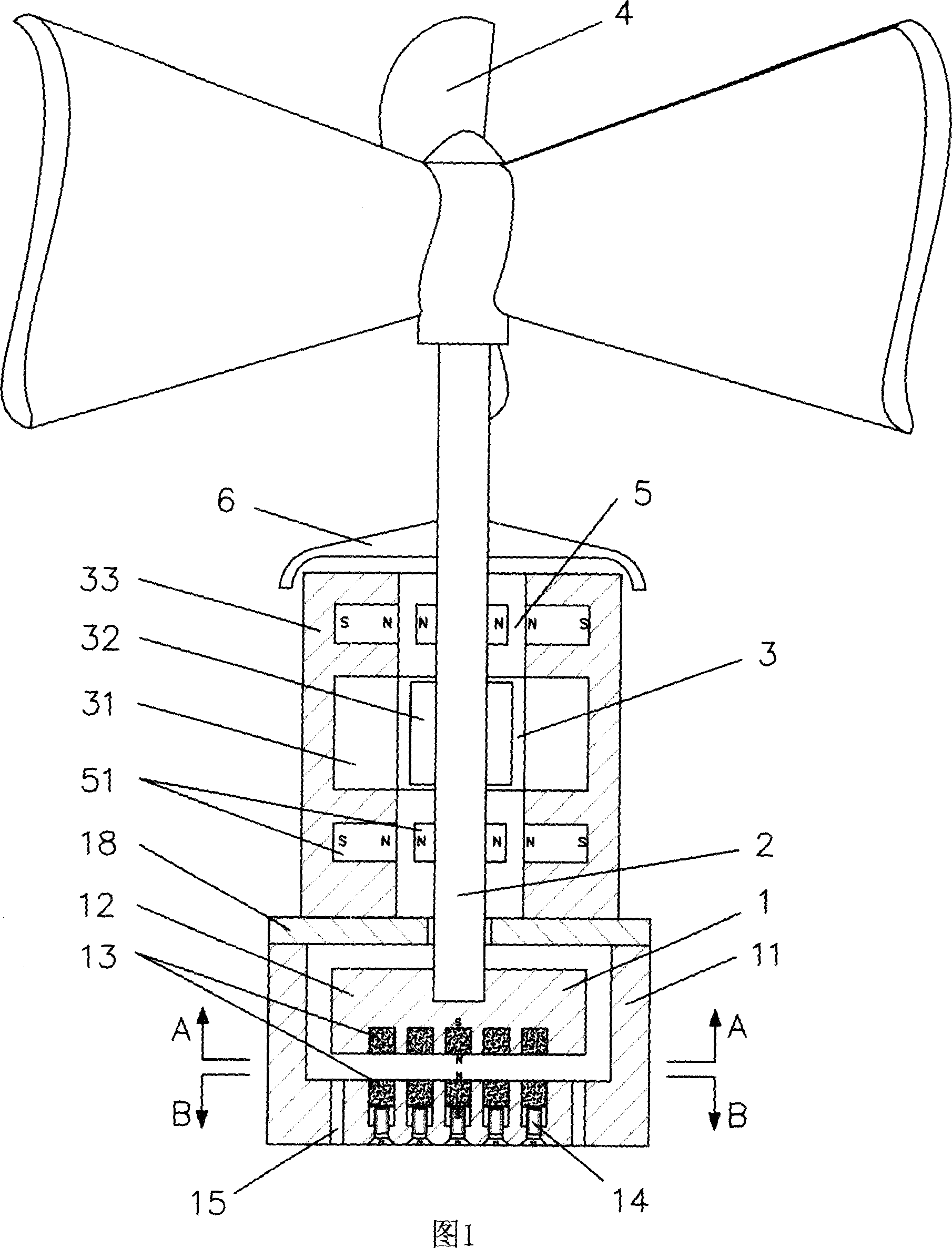

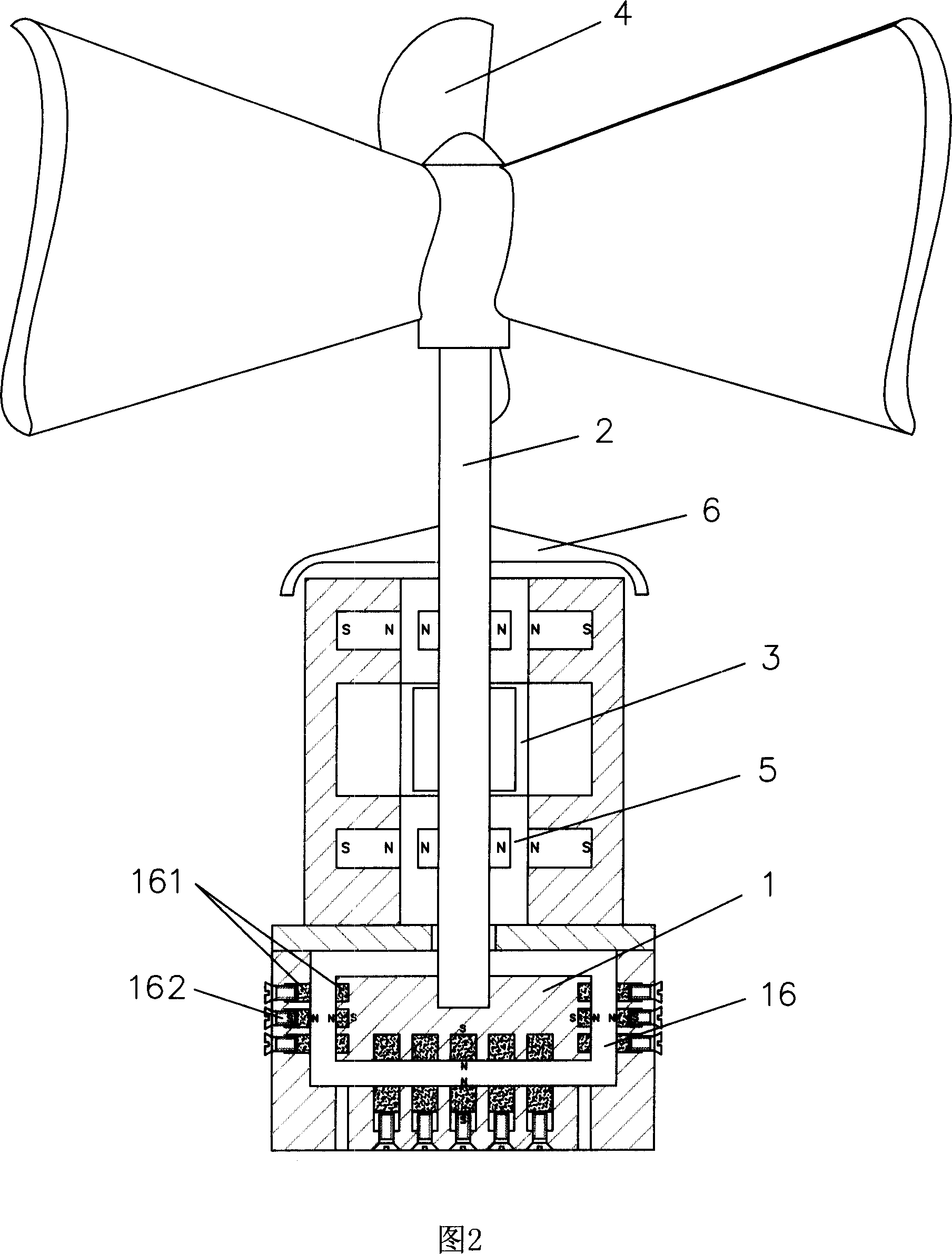

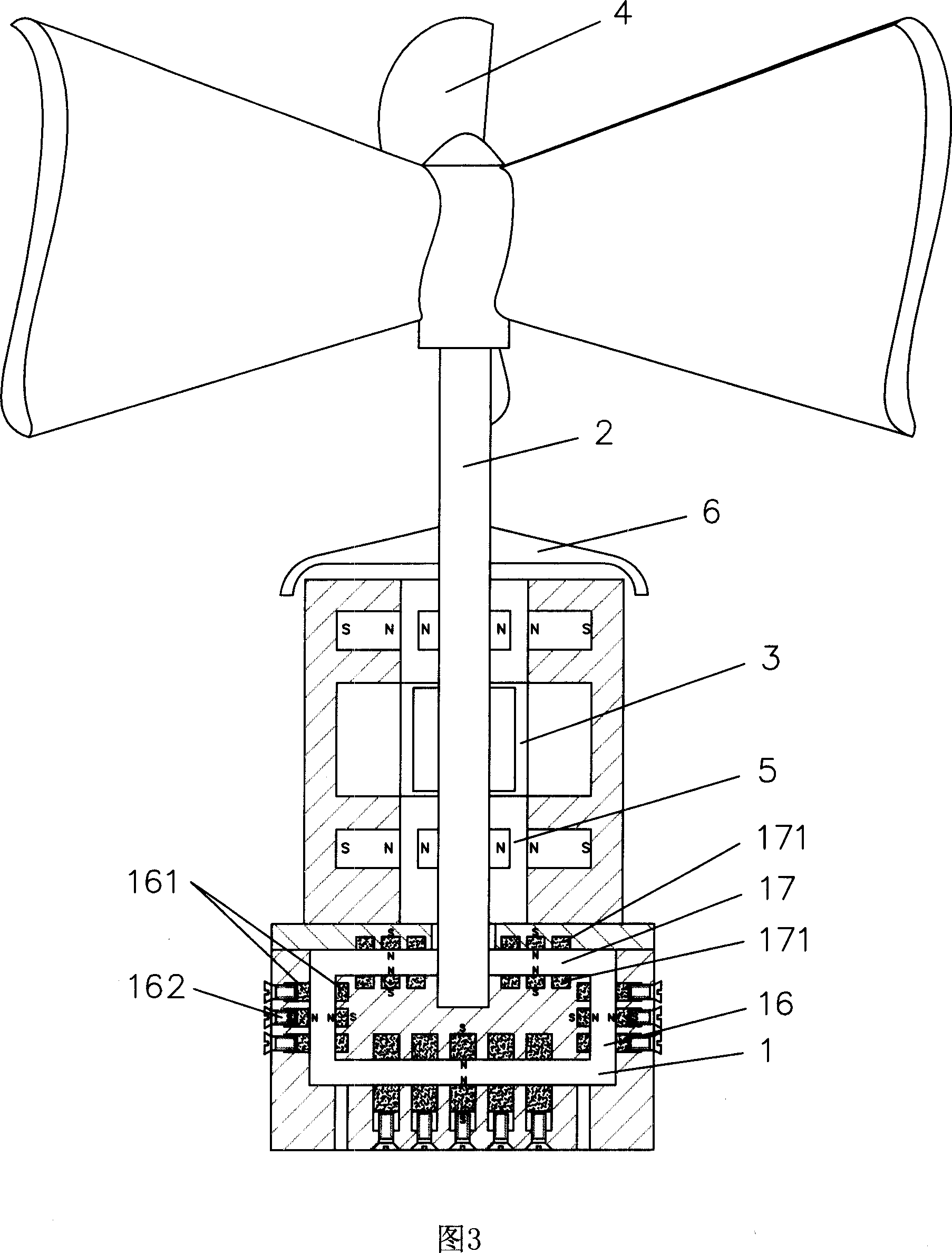

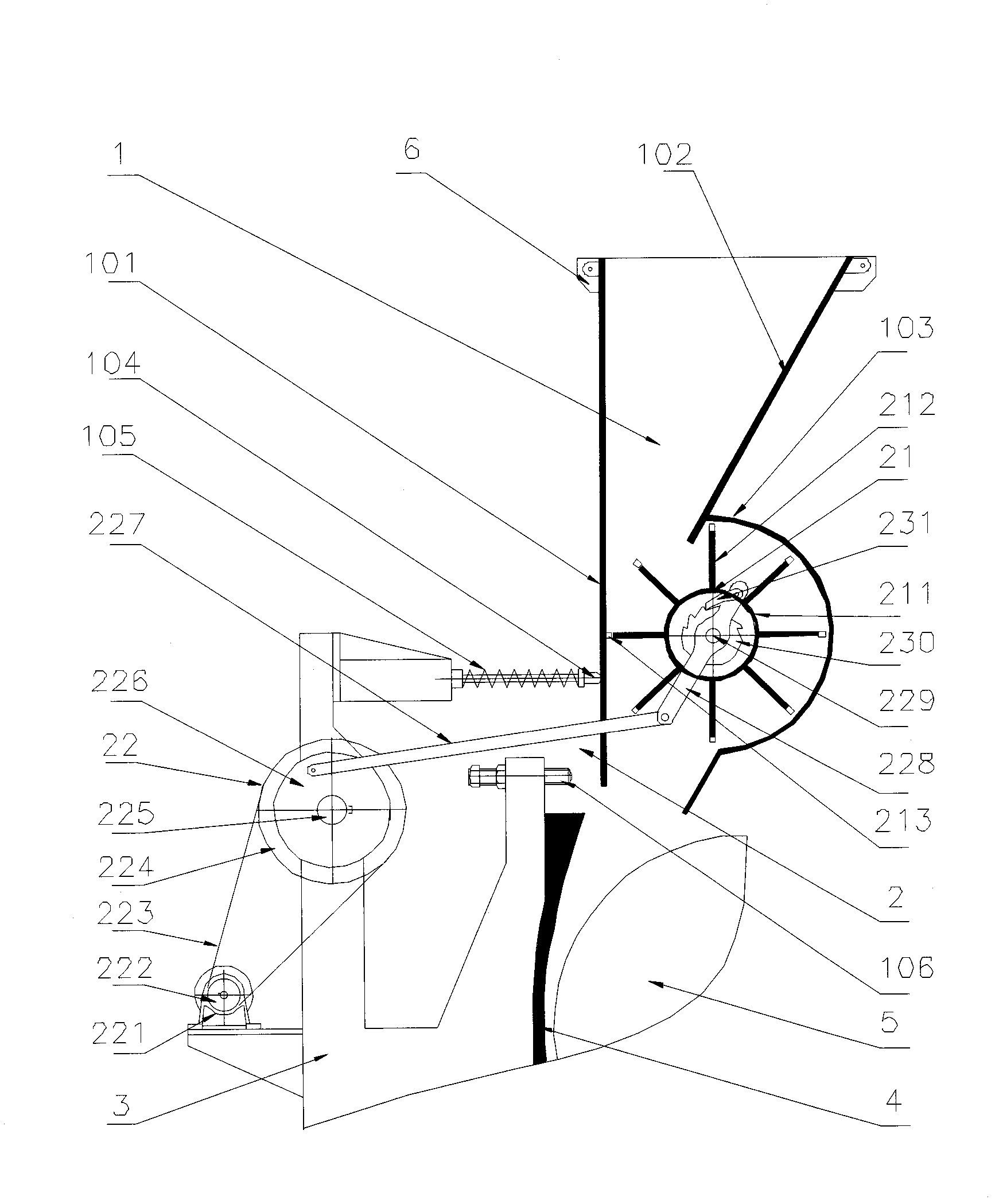

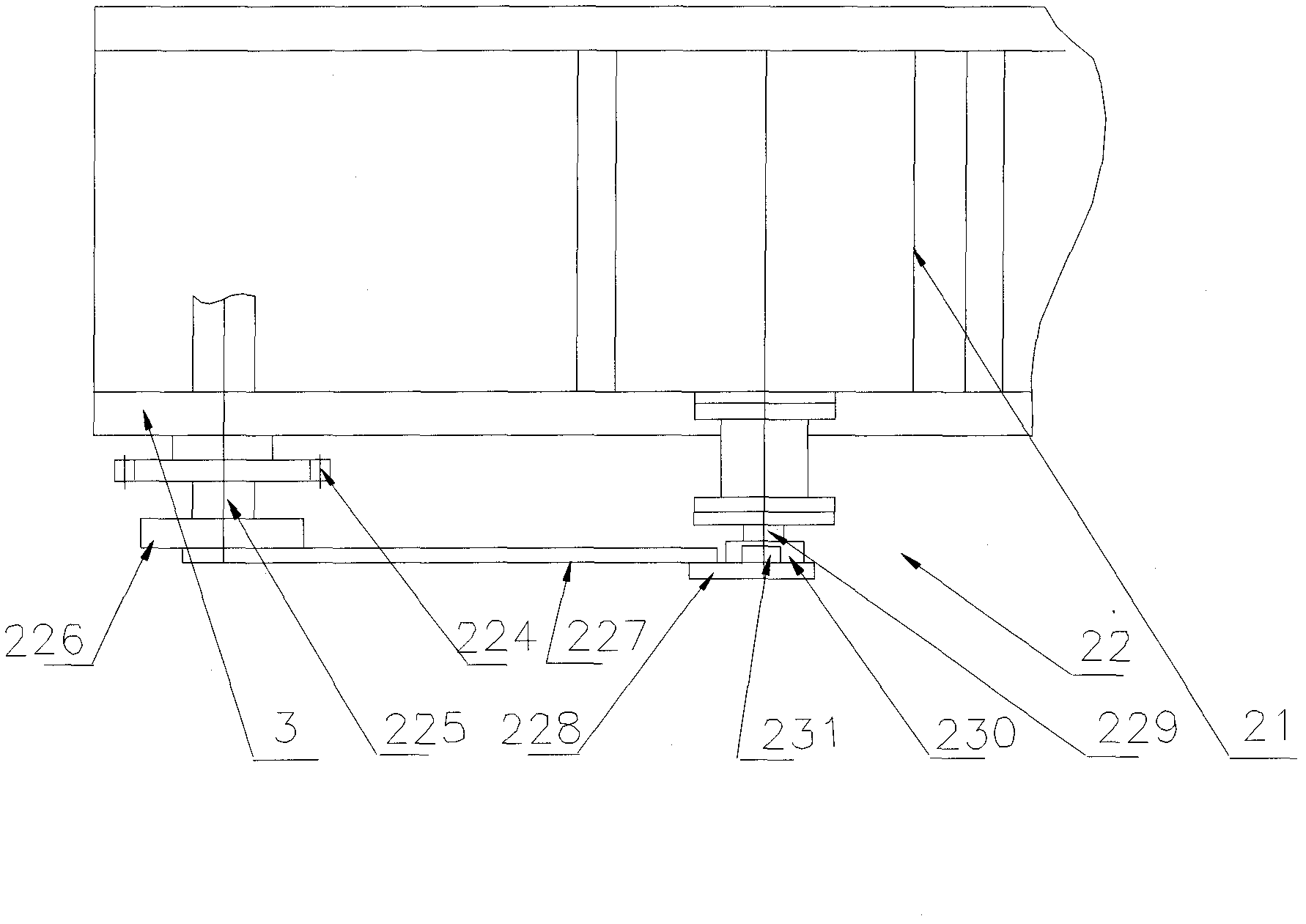

Vertical full magnetic suspension wind force power generator

InactiveCN1948746AEasy maintenanceEasy to replaceShaftsWind motor supports/mountsWind drivenDrive shaft

A vertical full-magnetic suspension wind-driven generator consists of a magnetic-suspension loading platform, a driving shaft, a generator, blades and a radial magnetic-suspension bearing. The magnetic-suspension loading platform is used for carrying the dead weight of the generator rotor, the driving shaft and the blades. The radial magnetic-suspension bearing is used, so the whole rotating part of the wind-driven magneto generator realize the magnetic suspension completely.

Owner:刘骁

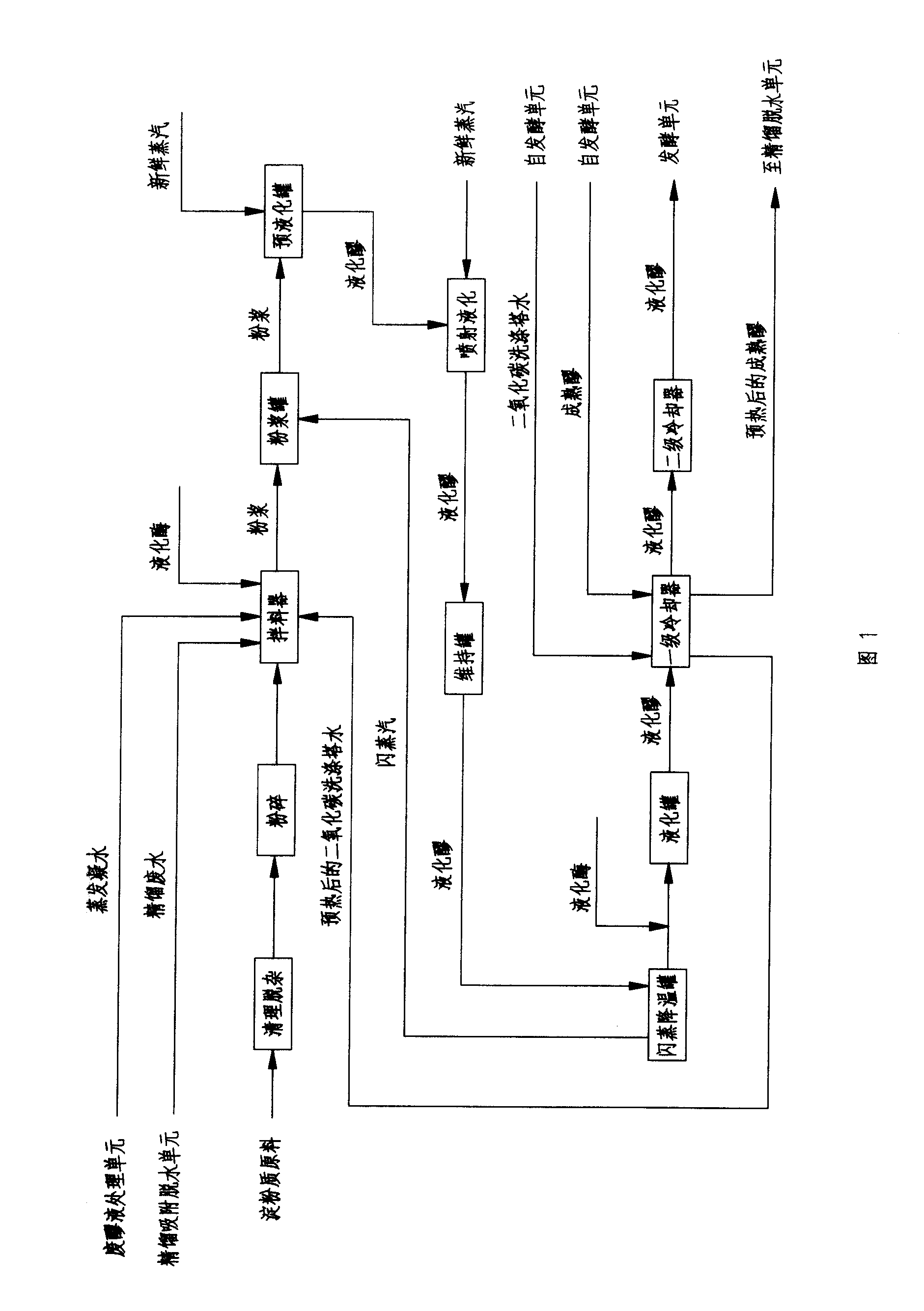

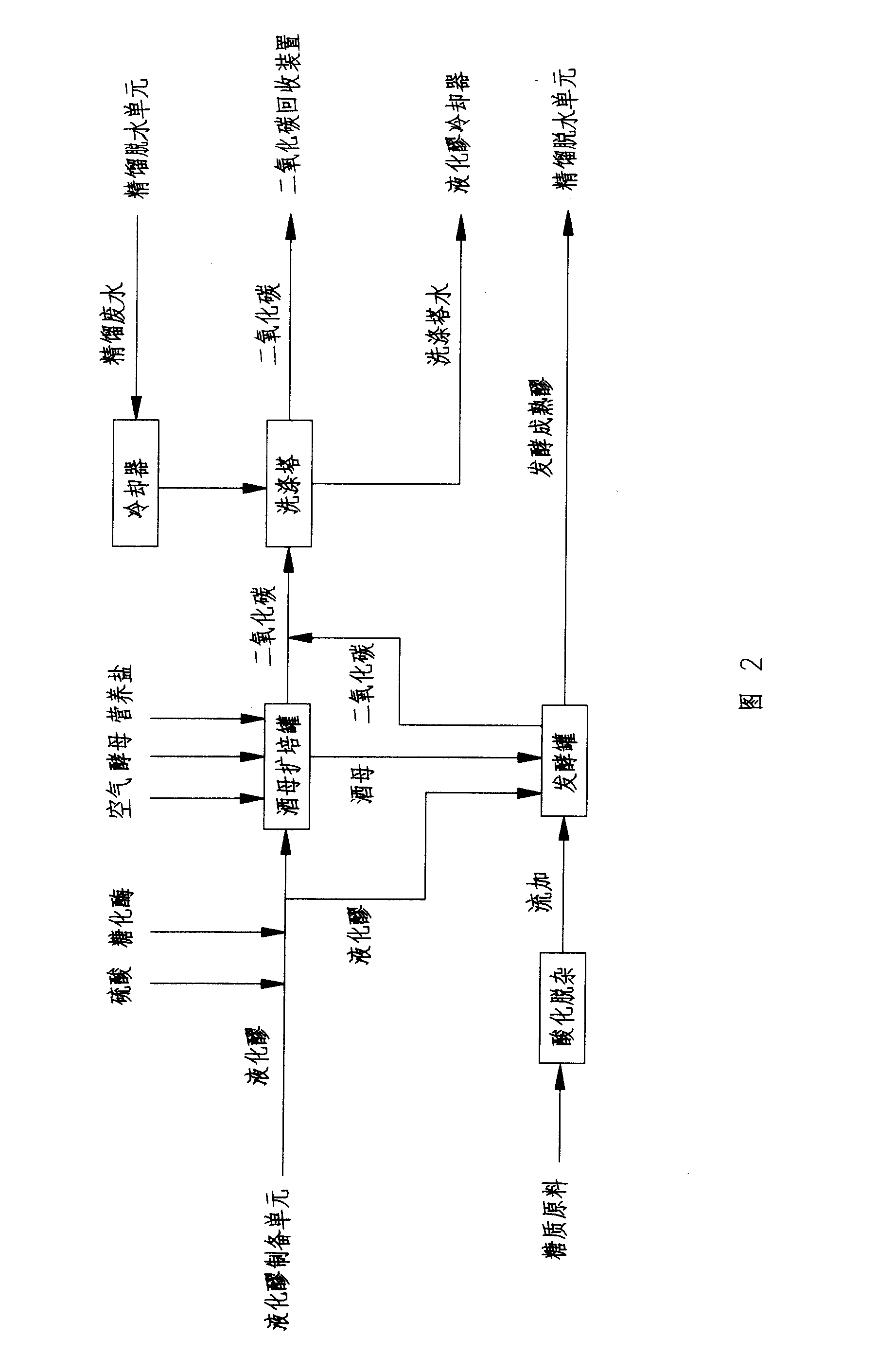

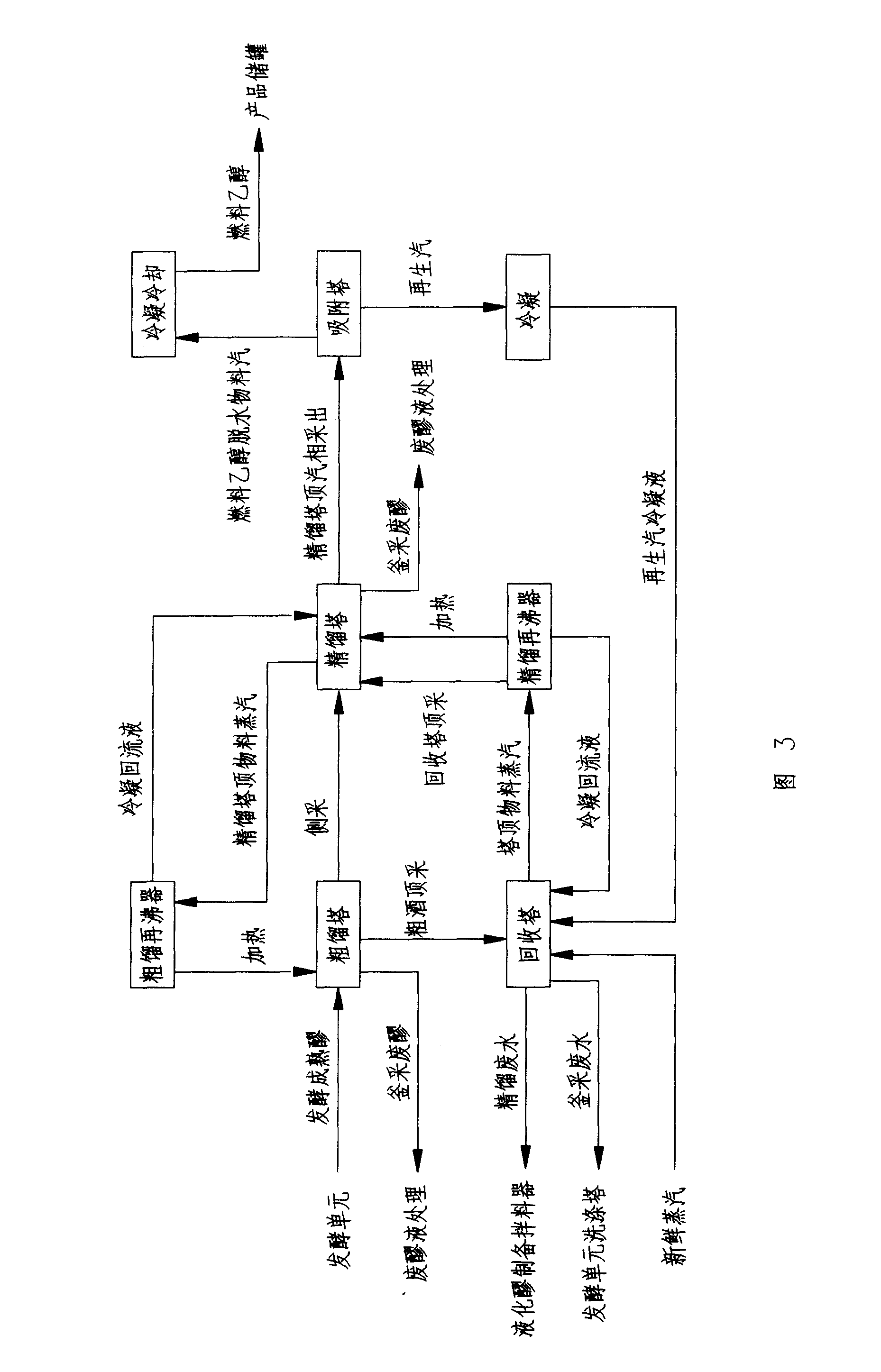

Fuel ethanol production equipment and method

InactiveCN101157890ASolve process problemsSolve problems such as large emissionsBioreactor/fermenter combinationsBiological substance pretreatmentsUltrafiltrationAlcohol production process

The invention relates to a novel equipment and a method of ethanol fuel production. The water resource in a preparation unit of liquefied wort is the washing water in a CO2 washing tower. A recovery tower pot collects waste water and a portion of liquor condensate by vaporing when waste water is dealt with to send to a mixing machine of the preparation unit of liquefied wort. And the consumption of fresh water is zero. The process of rectification and dehydration adopts technology of multieffect thermal coupling rectification. Only when the recovery tower pot uses fresh vapor to heat, the energy consumption of the process of rectification and dehydration is reduced largely. The waste wort solution produced by the alcohol production process which is dealt with by the device for pneumatic drying, multieffect evaporation of clear liquid, being anaerobic and oxygen consumption of the vapored condensate liquor and purifying by using ultrafiltration membrane etc, can be recovered with the valuable product. The reasonable treatment plan realizes zero discharge of technique waste water when in the ethanol fuel production.

Owner:TIANJIN UNIV

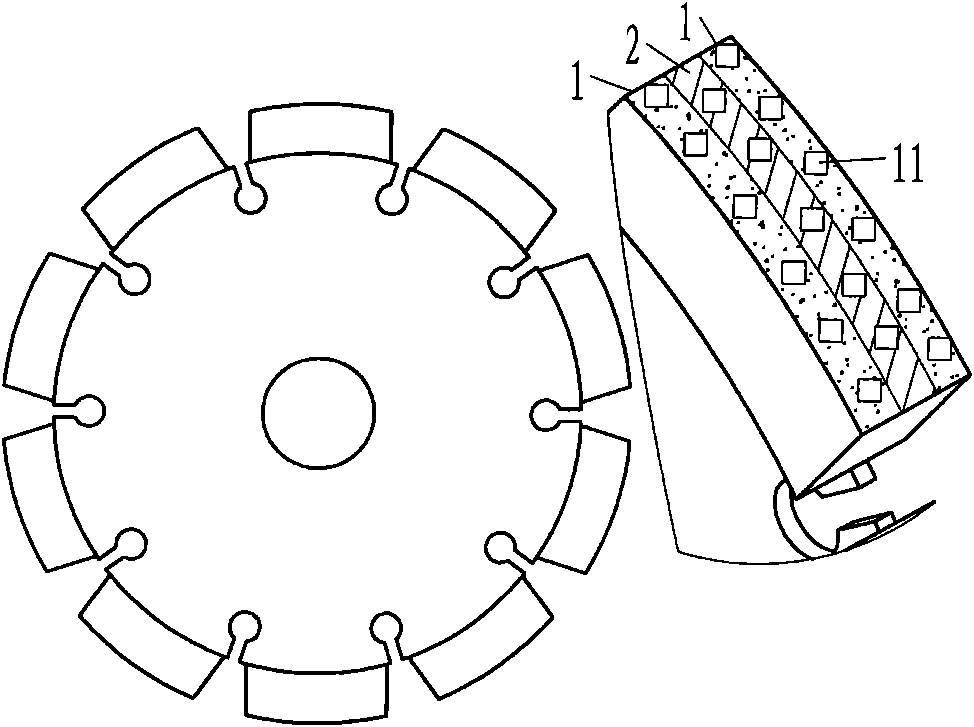

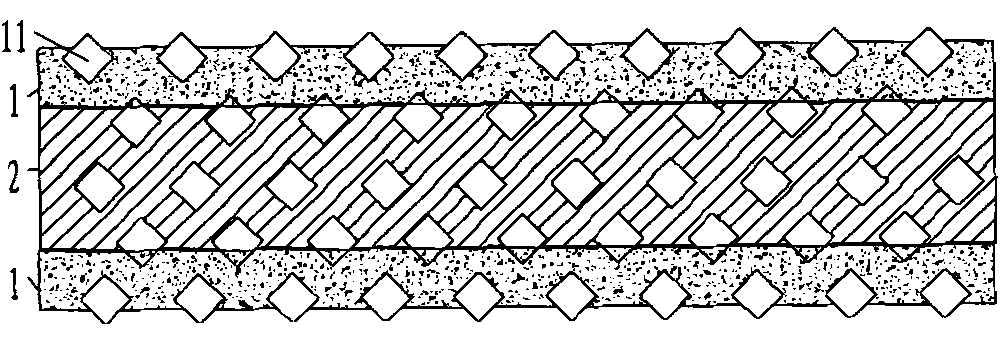

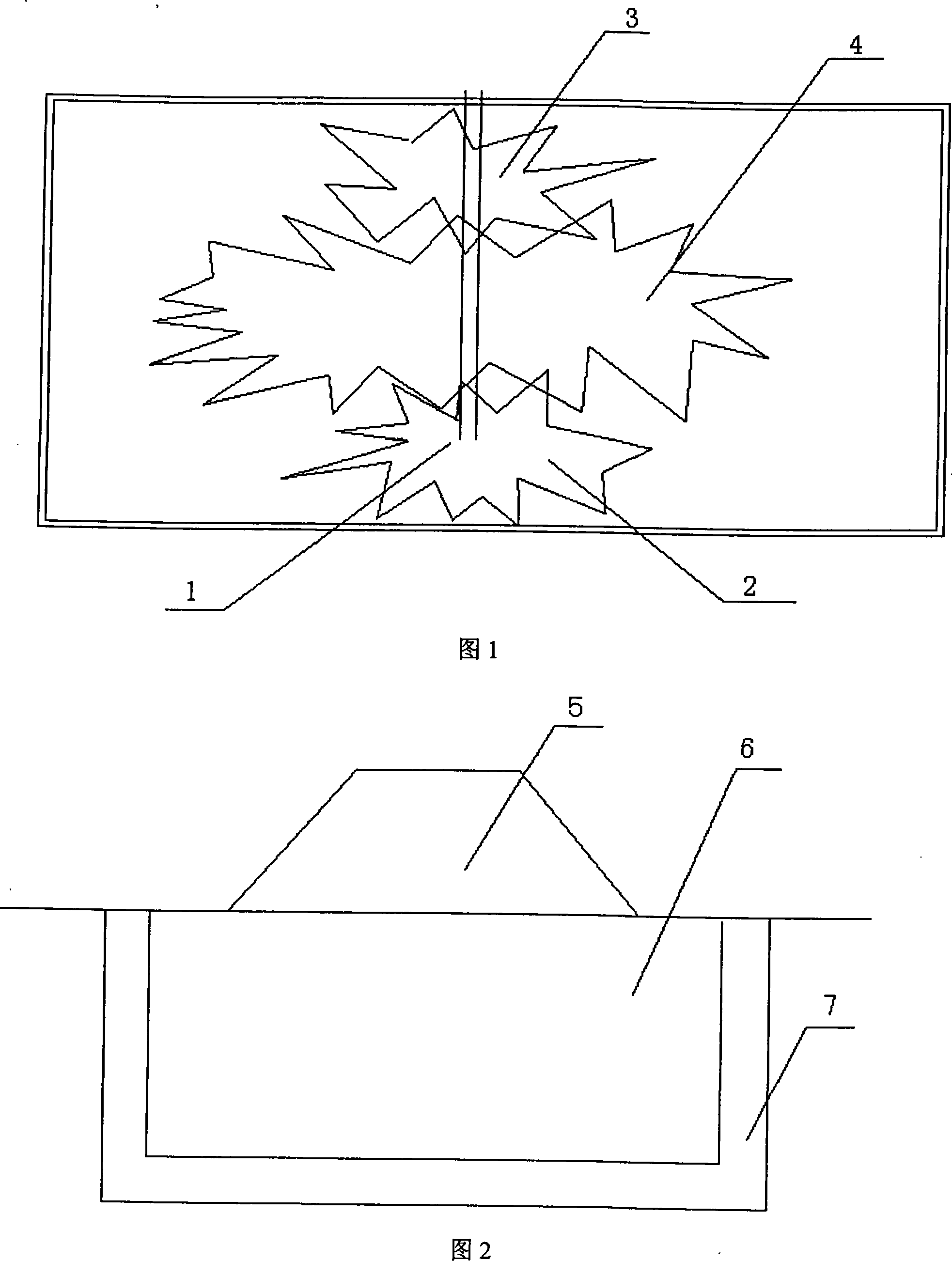

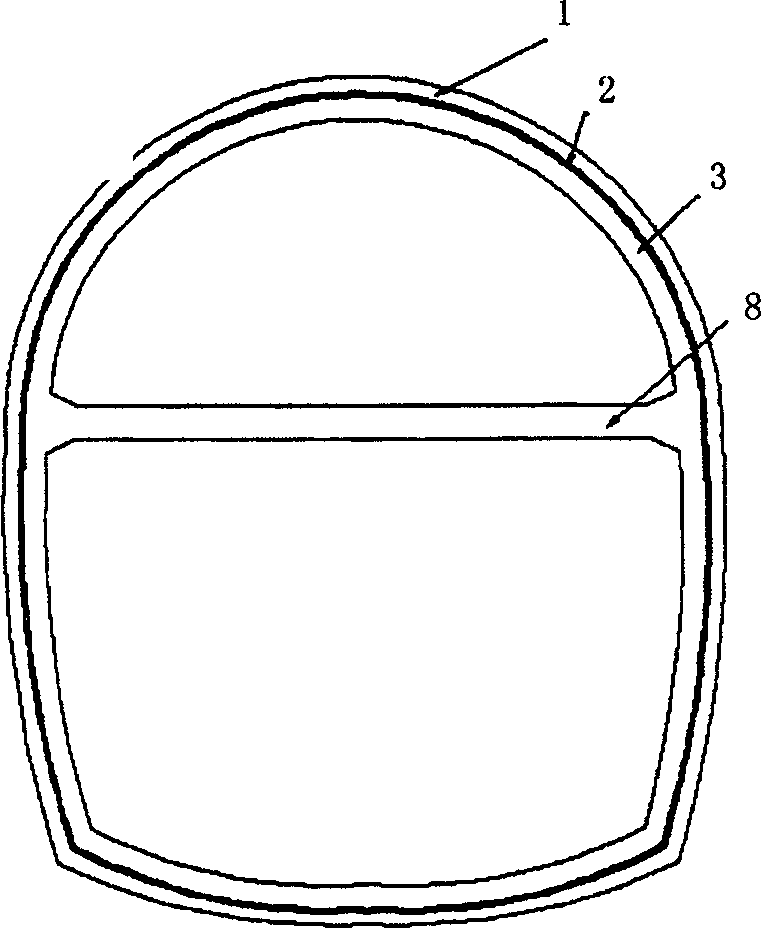

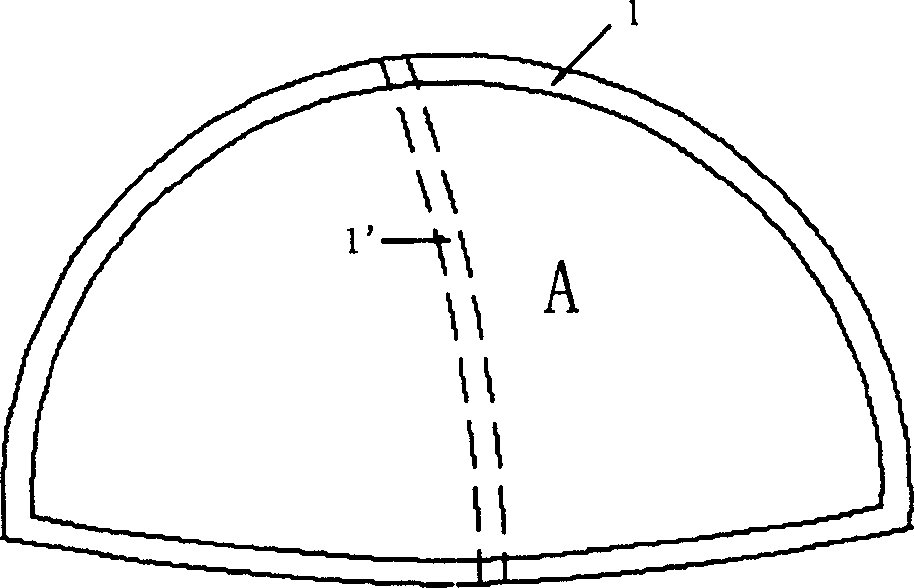

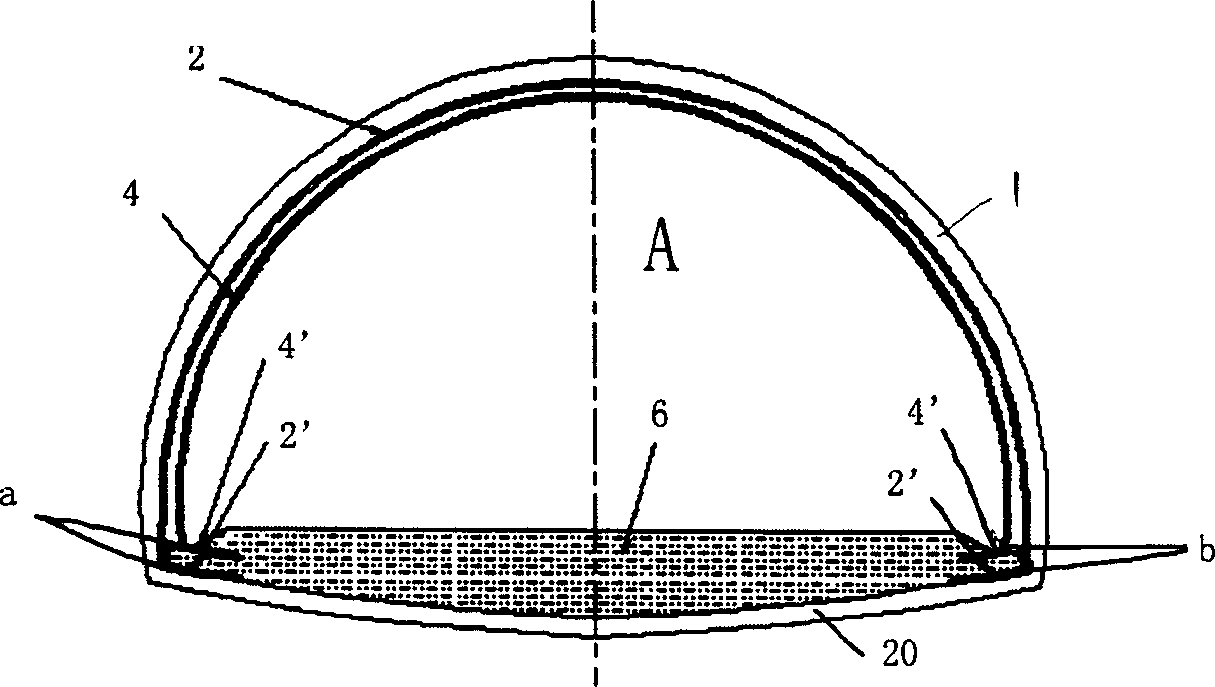

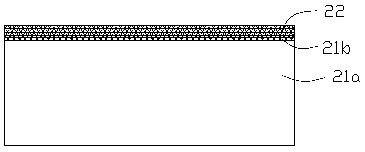

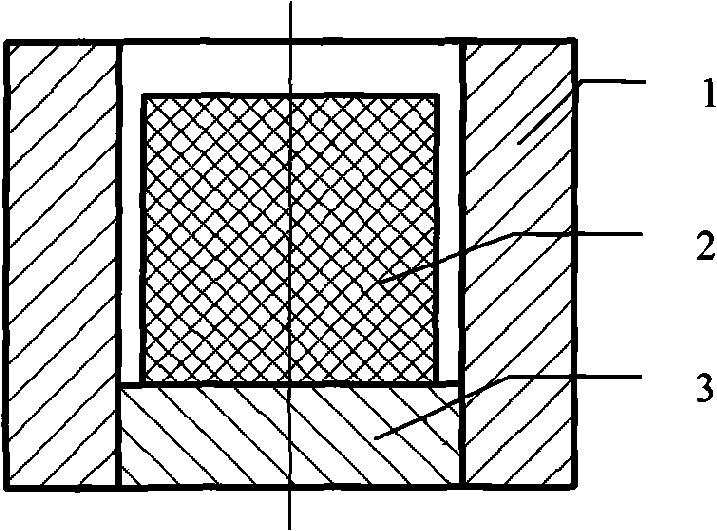

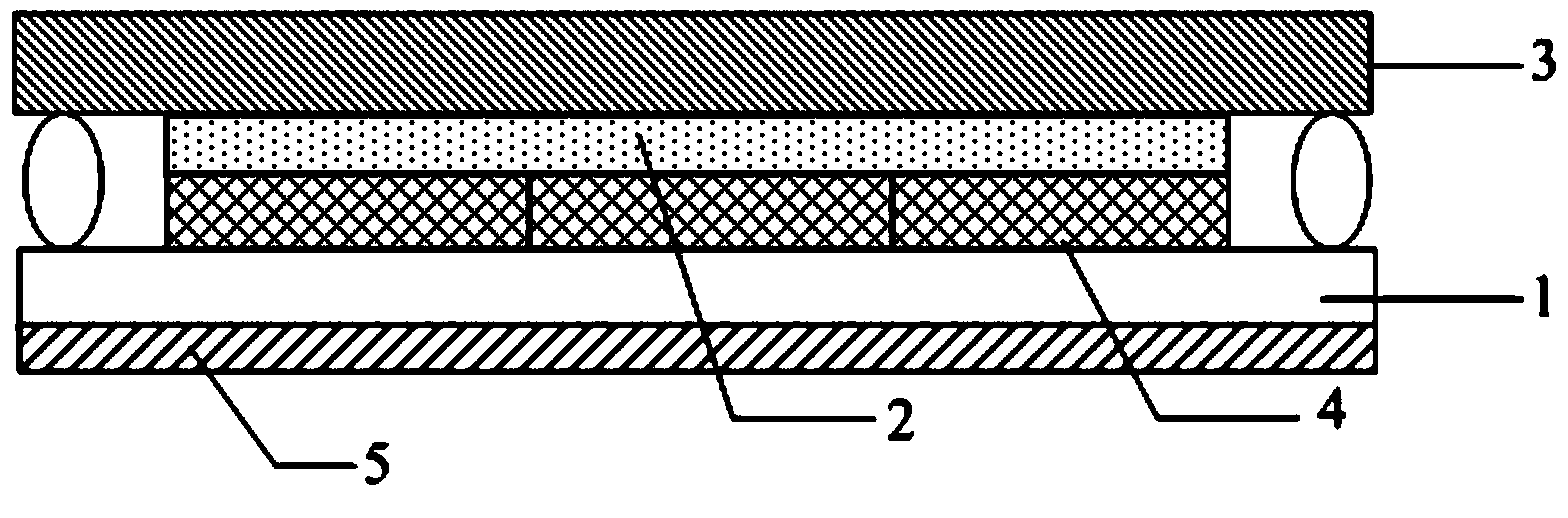

Brazing-hot pressing diamond tool and manufacturing method thereof

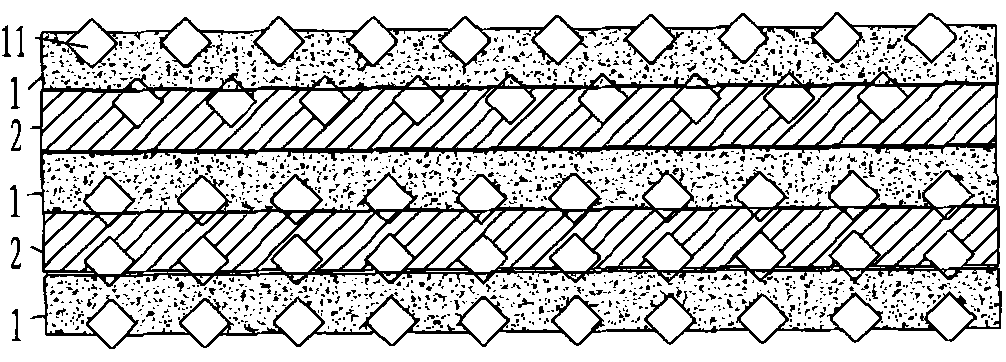

The invention relates to a grinding tool, in particular to a brazing-hot pressing diamond tool. The diamond tool consists of a steel matrix and a diamond tool bit, wherein the diamond tool bit consists of a plurality of alloy layers which are vertical to a working surface of the tool bit; the alloy layers are prepared from two alloy matrixes with different formulas by a vacuum hot pressing method; a prearranged diamond abrasive particle layer is arranged inside each alloy matrix layer; outer layers on two sides of the tool bit are brazing alloy matrix layers (1); a single-layer prearranged diamond abrasive particle layer is arranged inside each brazing alloy matrix layer (1); an intermediate layer of the tool bit is a pre-alloying matrix layer (2); and a single-layer or multi-layer prearranged diamond abrasive particle layer is arranged inside the pre-alloying matrix layer (2). The brazing-hot pressing diamond tool solves the problem that a multi-layer brazing tool is covered by a thick solder layer so as to cause low exposure effect and also solves the problem that a sintered diamond tool is insufficient in diamond holding force so as to make the diamond fall off too early. Therefore, the service life of the diamond tool is greatly prolonged and the processing efficiency thereof is greatly improved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

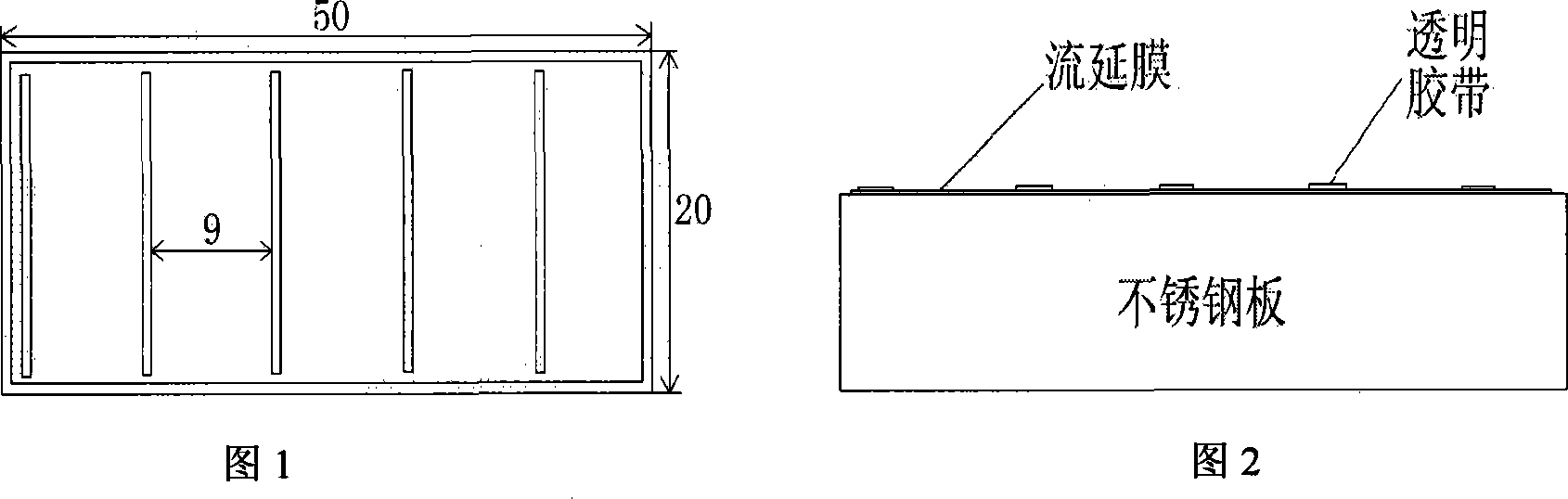

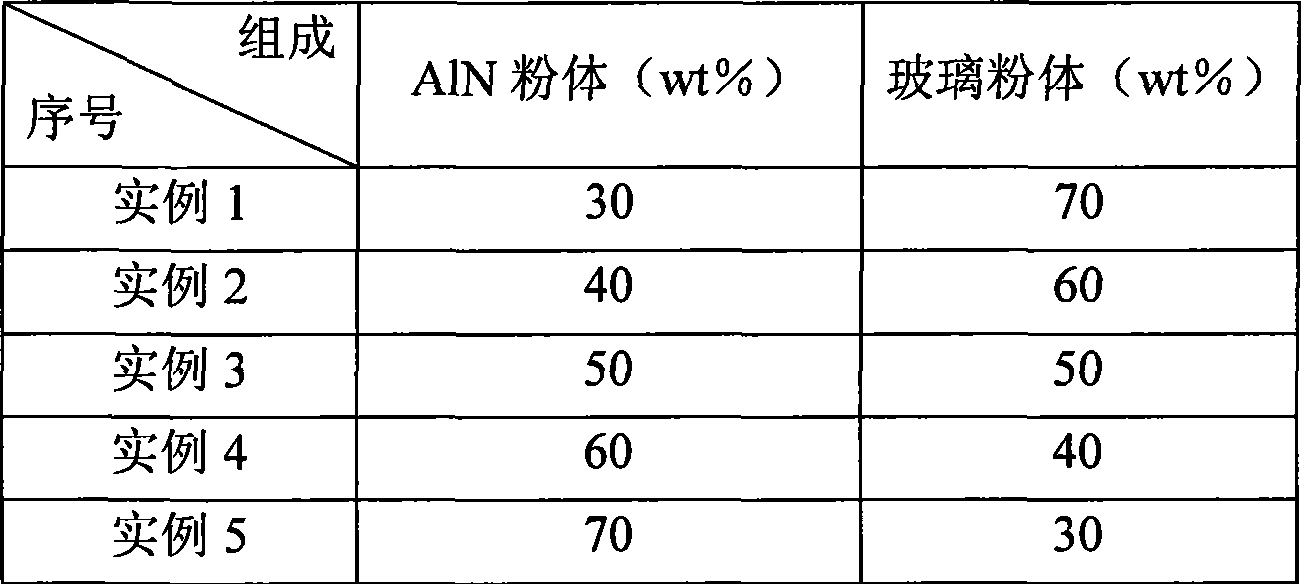

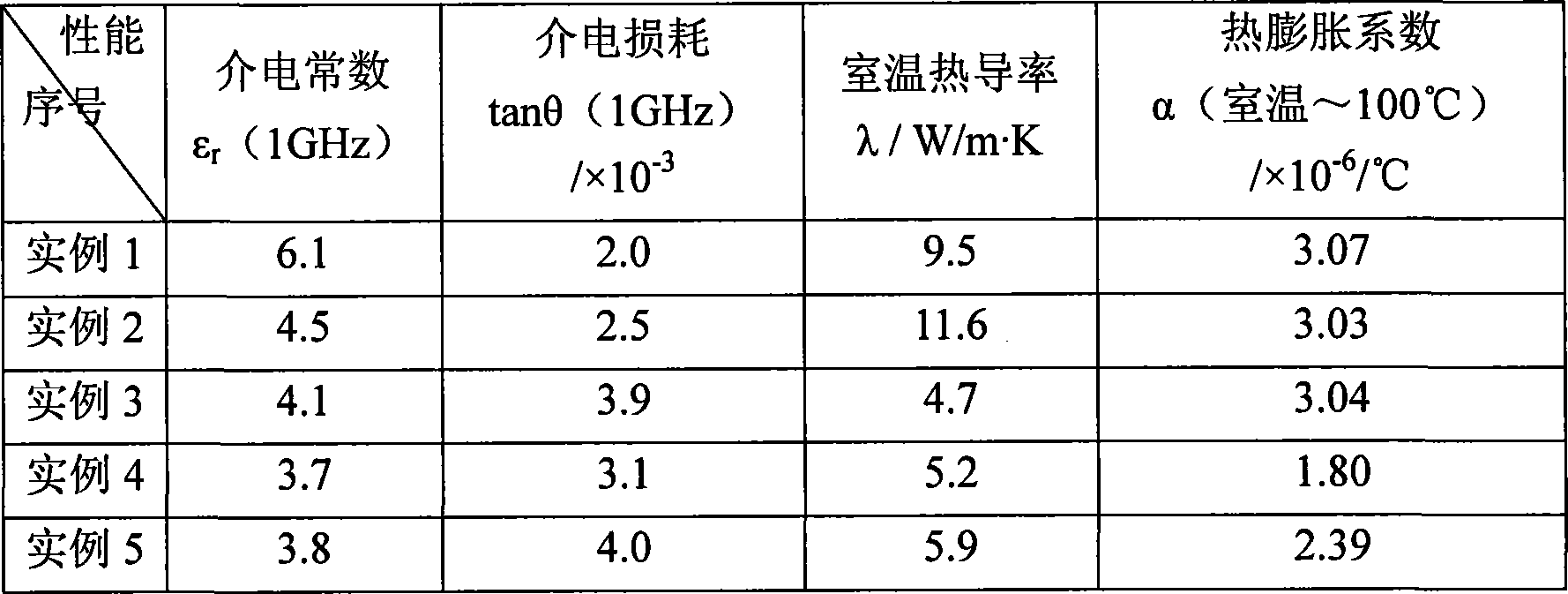

Aluminum nitride/borosilicate glass low-temperature co-fired ceramic substrate material and preparation method thereof

ActiveCN101100367AImprove performanceImprove thermal conductivityCircuit susbtrate materialsCo-fired ceramicProcess conditions

This invention relates to electronic baseplate by low-temperature co-sintering of aluminium nitride / borosilicate glass. This baseplate is composed of: AlN 30-70%; oxides 30-70%. Said oxides are then composed (by mol percentages) of: SiO2 8-12%, B203 18-24%, ZnO 45-60%, Al203 3-8%, Li20 3-8%. This inventive product has excellent comprehensive properties, its heat conductivity is increased from that of prior art product 2-5 W / m.K to 10W / m.K. It can be used in more greater power devices with excellent dielectric property. This invention has also advantages of: easily available raw materials, low cost, simple process.

Owner:TSINGHUA UNIV

Preparation method of oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in aqueous solution

PendingCN105536726ARaw materials are easy to obtainLow costOther chemical processesAlkali metal oxides/hydroxidesPeristaltic pumpFreeze-drying

The invention provides a preparation method of an oxidized graphene and sodium alginate composite absorbing material capable of removing ciprofloxacin in an aqueous solution. The preparation method comprises the following steps: dispersing a certain amount of oxidized graphene samples in deionized water, putting the oxidized graphene samples into an ultrasonic cleaner, and performing ultrasonic treatment for 6-10 hours; dissolving a certain amount of sodium alginate into an oxidized graphene solution subjected to ultrasonic treatment, and performing ultrasonic treatment for 20 minutes; dropewise adding the mixed solution into a 0.2mol / L calcium chloride solution by virtue of a peristaltic pump, soaking for 1-3 days, and cleaning with deionized water for 3-4 times, thereby obtaining a sodium alginate and oxidized graphene sphere hydrogel material; and freeze-drying, thereby obtaining oxidized graphene and sodium alginate sphere aerogel. The preparation method is performed under a relatively mild condition, and oxidized graphene is packaged in a sodium alginate network structure by an ion bridge method, so that the nano toxicity of graphene powder is avoided, and a new nano material capable of efficiently absorbing ciprofloxacin antibiotics in the aqueous solution is prepared. The preparation process is simple, easily controllable in condition, low in cost and suitable for large-scale batch production.

Owner:SHANGHAI INST OF TECH

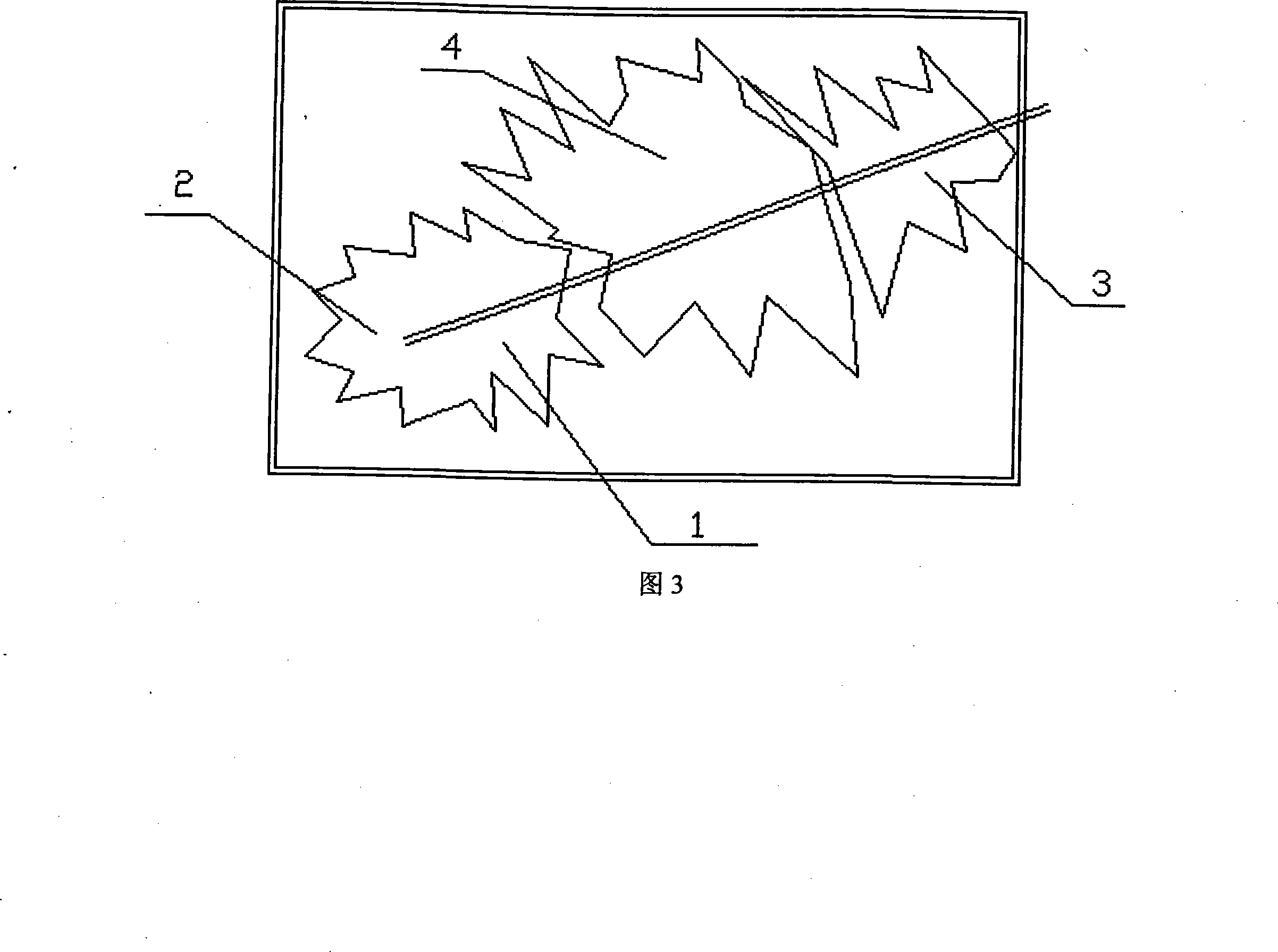

Layered multitime pressure regulating pulp conditioning casting method

The invention relates to a layered multiple pressure regulating grouting method which comprises the processing sequence: (1) a reinforced area is set up; the location and the depth of a grout stopping belt are determined; (2) the grouting soil distribution is determined according to different geological conditions, engineering features in the axial direction of a grouting hole; (3) a vary number of grouting pipes with different length are buried in the axial direction of a grouting hole according to different artesian conditions to cause grout to be spread in the designed different location; (4) a signal pole or soil sequencing holes of the reinforced area are repeatedly grouted. The invention has the characteristics of tangibility and strong pertinence, especially provides an efficient base process method for running grout, leaping grout caused by using a traditional grouting method in the geological conditions such as karst areas, large poriness when the fixing area is grouted and reinforced, and solves the deficiencies and shortcomings of the original construction technique through improving the techniques such as the grouting techniques, grouting materials, etc.

Owner:山东省交通厅公路局 +1

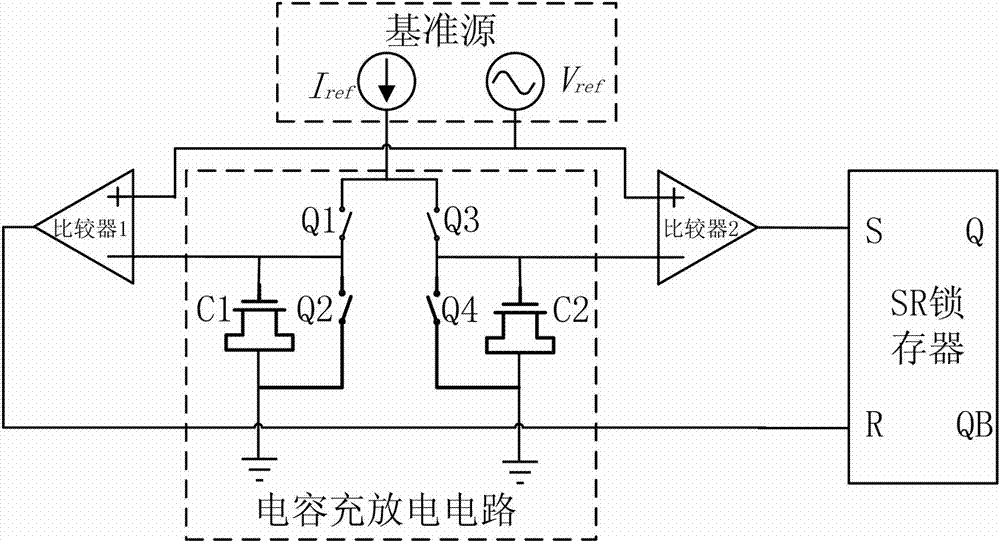

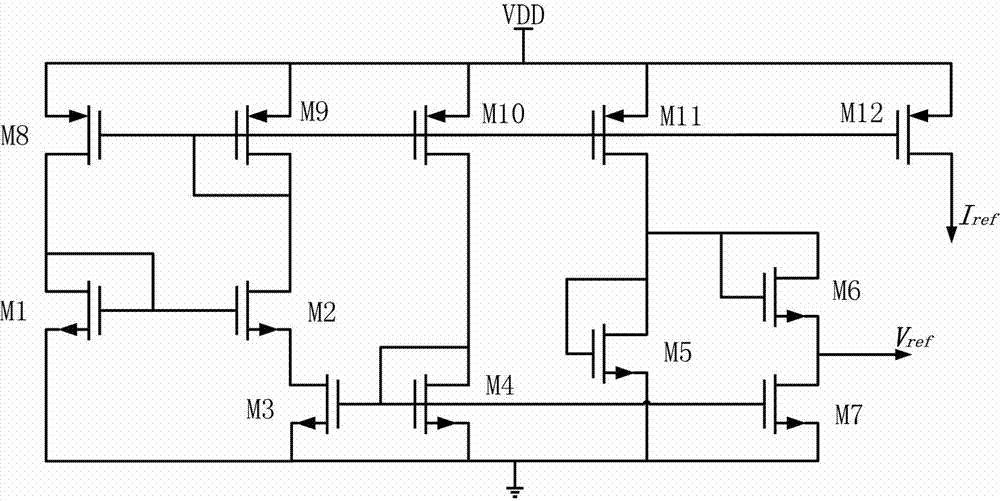

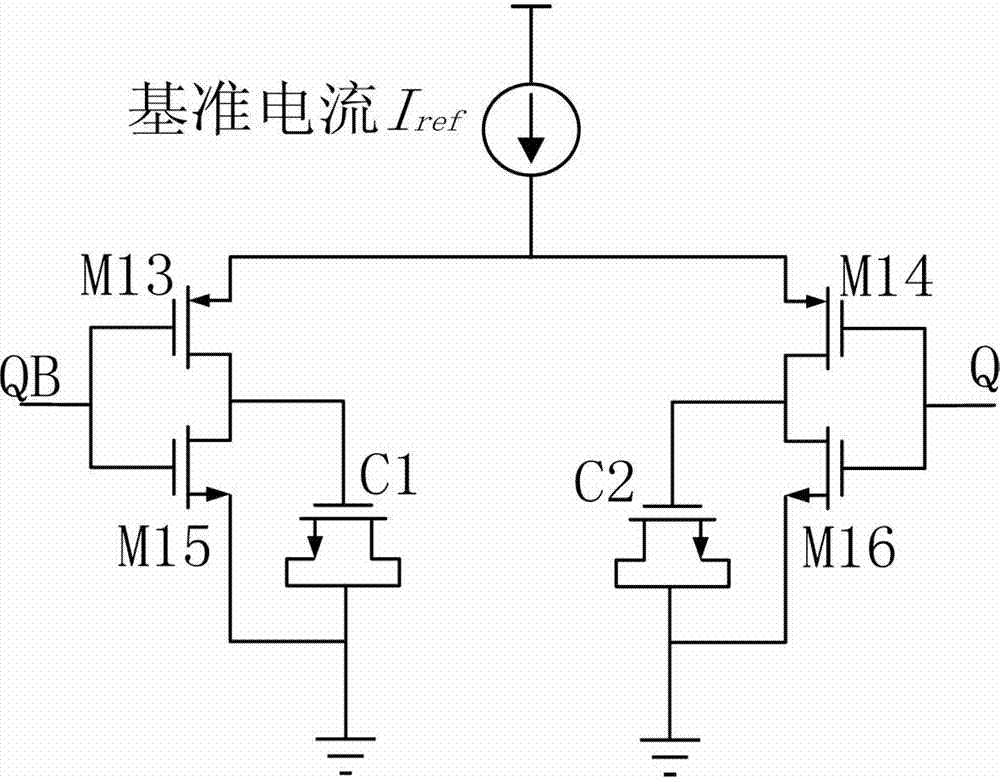

CMOS (complementary metal oxide semiconductor) relaxation oscillator with temperature and process self-compensating characteristics

ActiveCN103701411ASolve temperature problemsSolve process problemsOscillations generatorsCapacitanceProcess deviations

The invention discloses a CMOS (complementary metal oxide semiconductor) relaxation oscillator with temperature and process self-compensating characteristics. The CMOS relaxation oscillator comprises a reference source, a capacitor charge and discharge circuit, a first comparator, a second comparator and an SR (set reset) latch, wherein the reference current of the reference source is connected with the capacitor charge and discharge circuit, the reference voltage of the reference source is respectively connected with the same-phase input end of the first comparator and the same-phase input end of the second comparator, the reverse-phase input end of the first comparator and the reverse-phase input end of the second comparator are respectively connected with the capacitor charge and discharge circuit, the output end of the first comparator is connected with the R end of the SR latch, and the output end of the second comparator is connected with the S end of the SR latch. The CMOS relaxation oscillator with temperature and process self-compensating characteristics can overcome the defects of high cost, low reliability, great process deviation and the like in the prior art for realizing the advantages of low cost, high reliability and small process deviation.

Owner:四川电子科技大学教育发展基金会

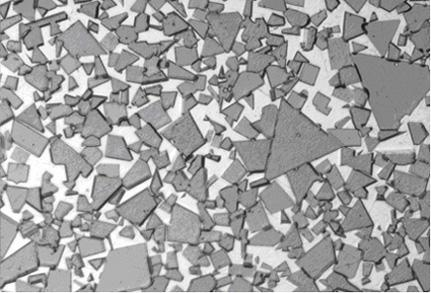

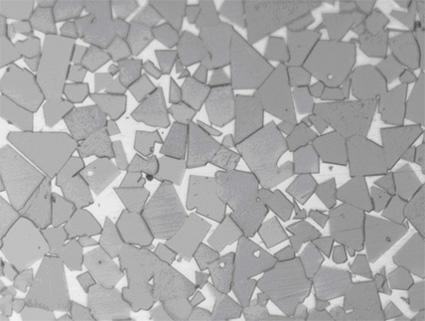

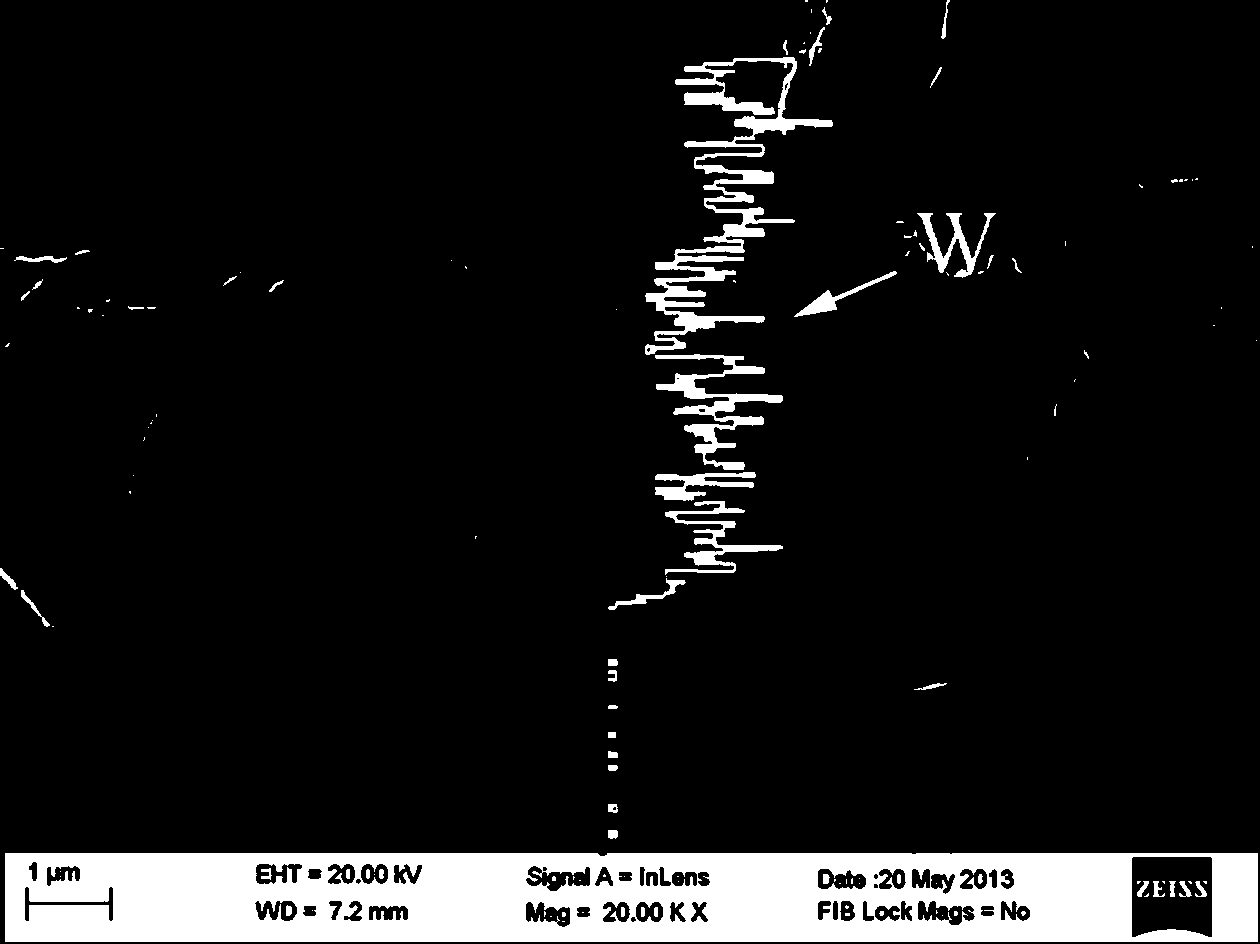

Ultra-thick hard alloy, and preparation method and application thereof

The invention discloses an ultra-thick hard alloy, a preparation method and application thereof. The raw material of the ultra-thick hard alloy comprises the following components in percentage by weight: 10.0-10.5% of Co and the balance of WC. The preparation method comprises the following steps of pretreatment, raw material preparation, wet grinding, spray drying, compression moulding and sintering. According to the invention, technical conditions of each component and technical conditions of each step are selected preferentially, and common technical problems in the preparation of ultra-thick ally in China, such as non-even grains, poor anti-impact toughness and thermal fatigue resistance and too many pores. The ultra-thick hard ally has excellent thermal conductivity, impact toughness and thermal fatigue resistance, cross breaking strength is larger than or equal to 3,100Mpa, the hardness is 86-87HRA, the coercive force is 3.0-4.0KA / m, and WC average grain size is 5-6 microns.

Owner:赣州海盛钨业股份有限公司

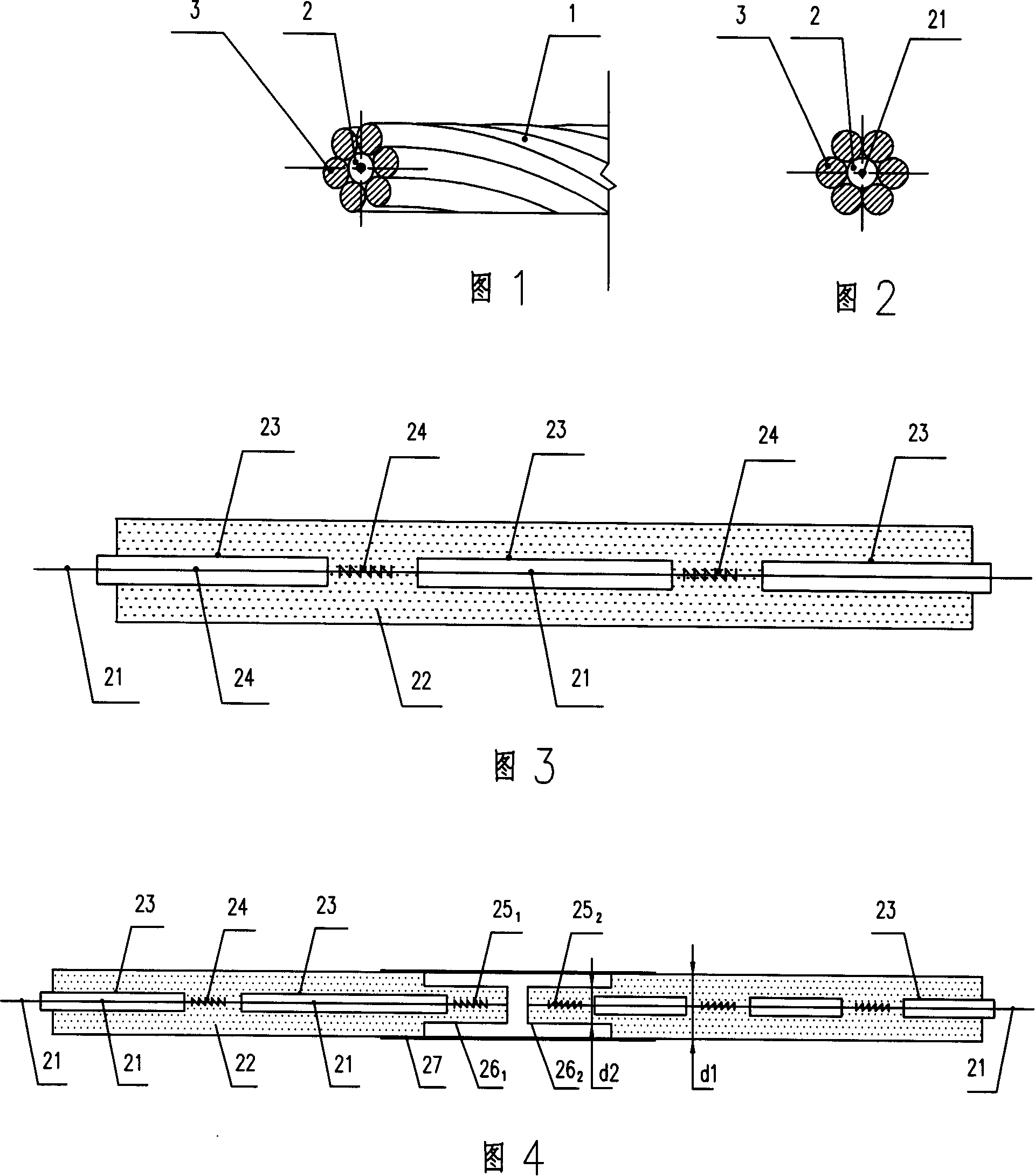

Optical fiber grating intelligent steel strand and its manufacture method

ActiveCN101210983AEffective protectionSo as not to damageForce measurement by measuring optical property variationCoupling light guidesGratingStress conditions

An intellectual steel strand for fiber lattice, which is molded by the stranding of central wire and wires around the central wire, the central wire is the enhanced composite intellectual rib of fiber lattice of a fiber lattice sensor; the intellectual rid comprises a fiber enhanced rid and fiber distributed along the lengthwise direction of the fiber enhanced rib, the fiber lattice sensor; a plastic sleeve is sleeved around the fiber without lattice, separates from the fiber and is connected with the fiber enhanced rib; the fiber transmitted by the fiber lattice sensor is led out from the head of the steel strand; a preparation method of the steel strand comprises the following steps of: firstly preparing the fiber lattice fiber enhanced composite intellectual rib; scattering stranding machines with the same length with the intellectual rib and substituting the central wire of the steel strand with fiber lattice fiber enhanced composite intellectual rib and finally molding the wire through stranding. The invented intellectual steel strand has self sensing property with all the advantages of fiber lattice, which can easily grasp the stress condition of the steel strand in the construction and service periods and instruct the tensioning of initial stress and the construction.

Owner:LIUZHOU OVM MASCH CO LTD

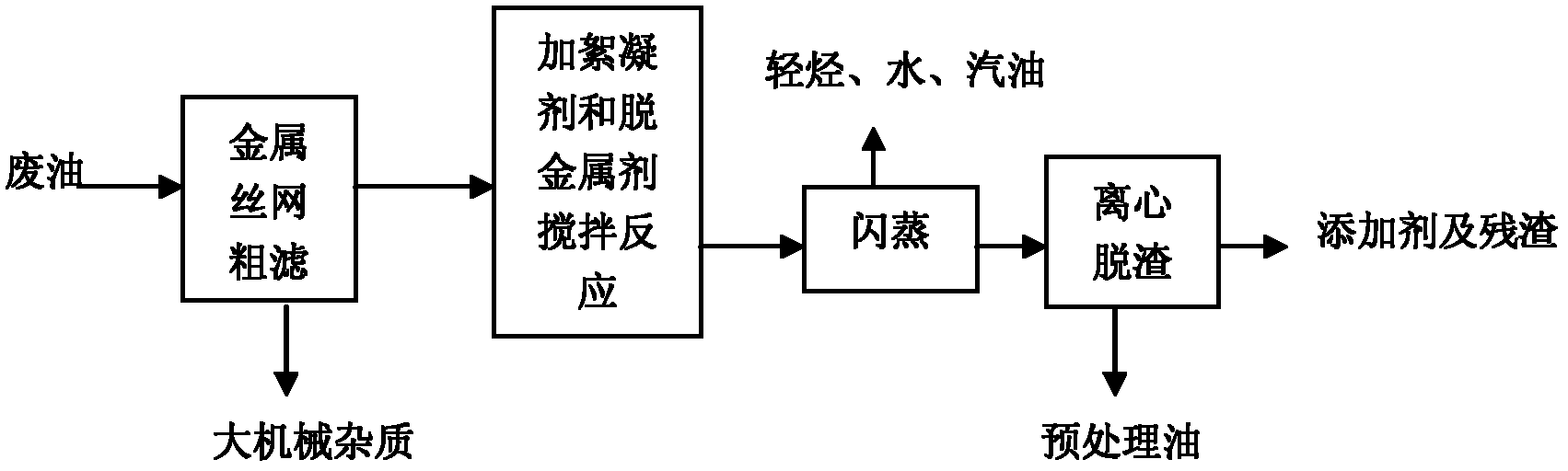

Waste lubricating oil pretreatment method

The invention relates to a waste lubricating oil pretreatment technique, belonging to pretreatment of waste lubricating oil before refinement. The invention aims to remove nonideal components (such as light hydrocarbons, moisture, gasoline, metal particles, carbon granules, dust, oil sludge, additives, residue asphalt, mechanical impurities and the like) in the waste oil to obtain the pretreated oil without impurities. The technique is characterized by comprising the following steps: 1) filtering the waste oil to remove large mechanical impurities; 2) adding 0.5-3.0% of pretreating agent, and stirring to react at the constant temperature of 30 DEG C for 20-60 minutes, wherein the pretreating agent is a mixture of organic flocculent and demetallizing agent in a ratio of (0.5-1.5):1 (m / m); 3) carrying out atmospheric flash evaporation on the reaction product in a distillation kettle, gradually heating in a nitrogen atmosphere to sequentially distil out light hydrocarbons, water and gasoline, and finally controlling the kettle temperature at less than 200 DEG C to remove the light hydrocarbons, moisture and gasoline; and 4) carrying out centrifugal slag removal treatment to obtain the pretreated oil.

Owner:PETROCHINA CO LTD

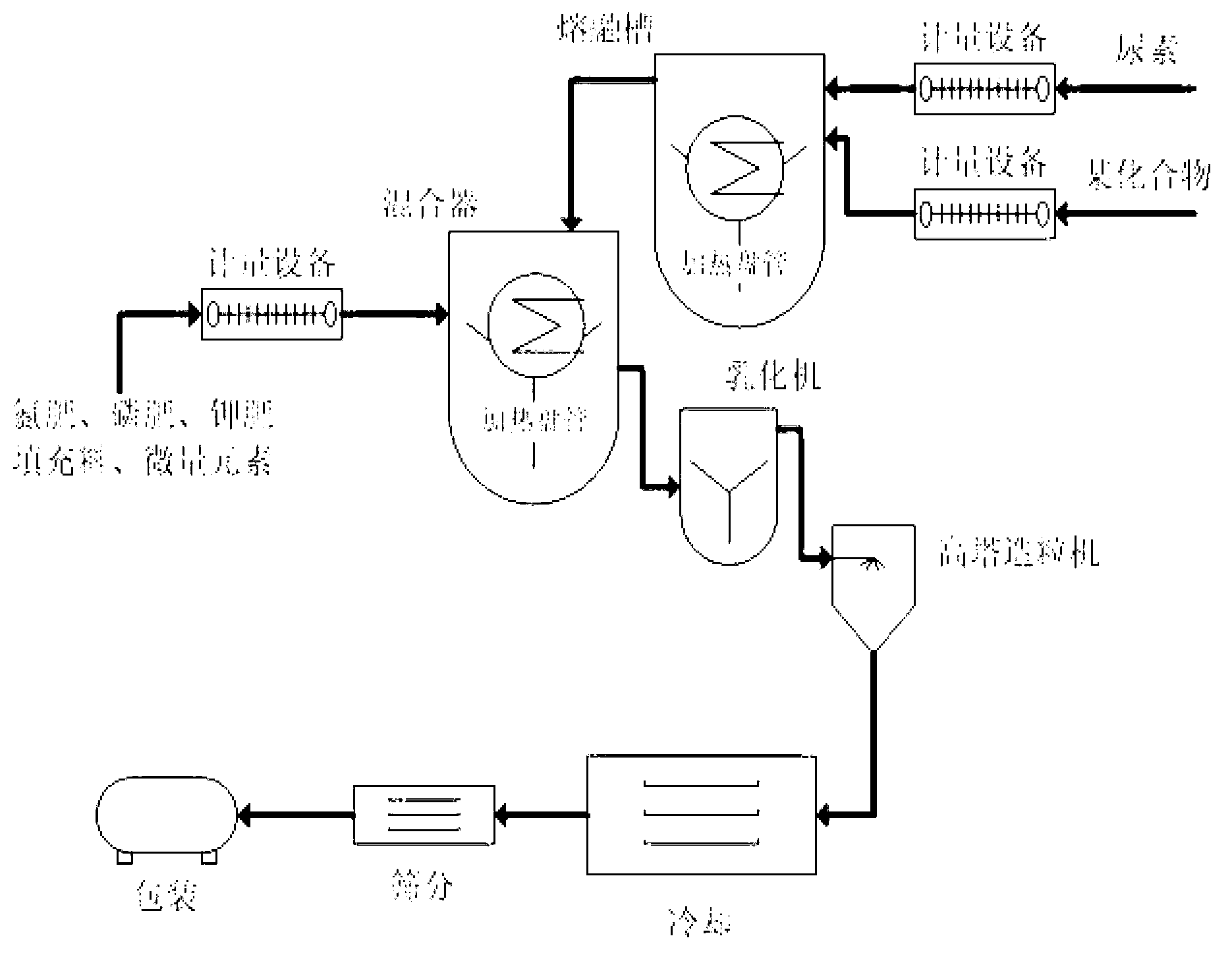

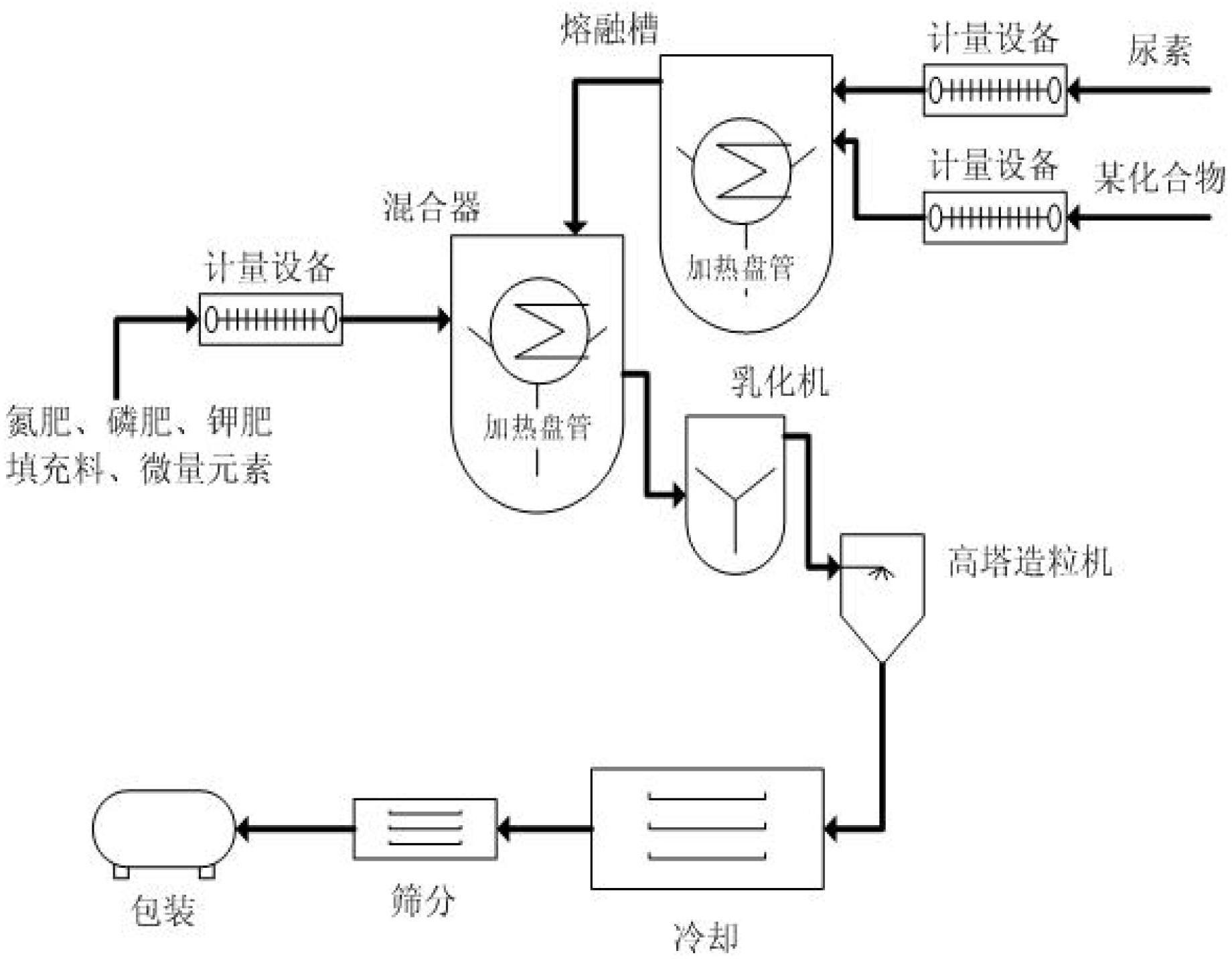

Method for controlling content of biuret in compound fertilizers for melt granulation in prilling tower

InactiveCN102701846AReduce generationReduce production energy consumptionUrea compound fertilisersFertilizer mixturesMelting tankPrill

The invention provides a method for controlling the content of biuret in compound fertilizers for melt granulation in a prilling tower. A low melting point mixture is formed by urea and compounds in a melting tank, and is melted completely at the temperature ranging from 104 to 114 DEG C; nitrogen fertilizers, phosphate fertilizers, potash fertilizers, fillers and trace elements are used for melting urine and production compound fertilizers and are added in a mixer according to product demand ratios, are premixed rapidly under the temperature condition ranging from 90 to 110 DEG C, then are mixed through a slurry emulsifying machine at a high speed so as to form emulsified slurry, and then are processed through the procedures such as granulation, cooling sieving and the like in the prilling tower so as to produce the granular compound fertilizers with low content of biuret; in addition, the content of biuret in the compound fertilizers that are produced by adopting the method is less than 0.6 percent, the quality is safe, and fertilizer damages cannot be caused. The method belongs to a novel environment-friendly production method with low consumption, which can produce the granular compound fertilizers on the basis of urea-based prilling tower melt granulation technology.

Owner:徐州市芭田生态有限公司

Dormant digging and separating construction method for underground two layers and multilayer composite lining structure

This is an underground hidden digging separated working method it is double layers or multiple layers complex lining brick structure. It contains: Use the existing shallow bury hidden digging technology to finish the lining bricks structure upper parts, and use the routine technology to finish the original support and protection. After finished the original protection and support of vault part, to spread out the water-proof plate and finish the middle separated plate to use the ground model, and pouring cement slurry to make the upper part structure. Under the protected of middle separated plate, then to make the structure under the middle separated plate, to finish the whole working process finally.

Owner:刘昌用

Capacitive pressure sensor and manufacturing method thereof

InactiveCN103257005AResolution timeSolve process problemsForce measurementFluid pressure measurement using capacitance variationCapacitive pressure sensorGas phase

The invention discloses a capacitive pressure sensor used for measuring pressure and a manufacturing method of the capacitive pressure sensor. According to the manufacturing method, by utilization of a surface silicon micro-machining technology, a silicon oxide sacrificial layer is deposited on a silicon substrate, and then a polycrystalline silicon film is deposited on the sacrificial layer to serve as a pressure sensitive film. The sacrificial layer is partially corroded to form a capacitance gap through sacrificial layer release holes formed in the polycrystalline silicon sensitive film. The sacrificial layer release holes in the polycrystalline silicon sensitive film are further filled through another deposition of a polycrystalline silicon film, and thus a sealed cavity is formed. At last, a gas vent hole is corroded in the polycrystalline silicon sensitive film again and sealed through metal with a physical vapor deposition (PVD) method, and thus a vacuum is formed in the sealed cavity.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

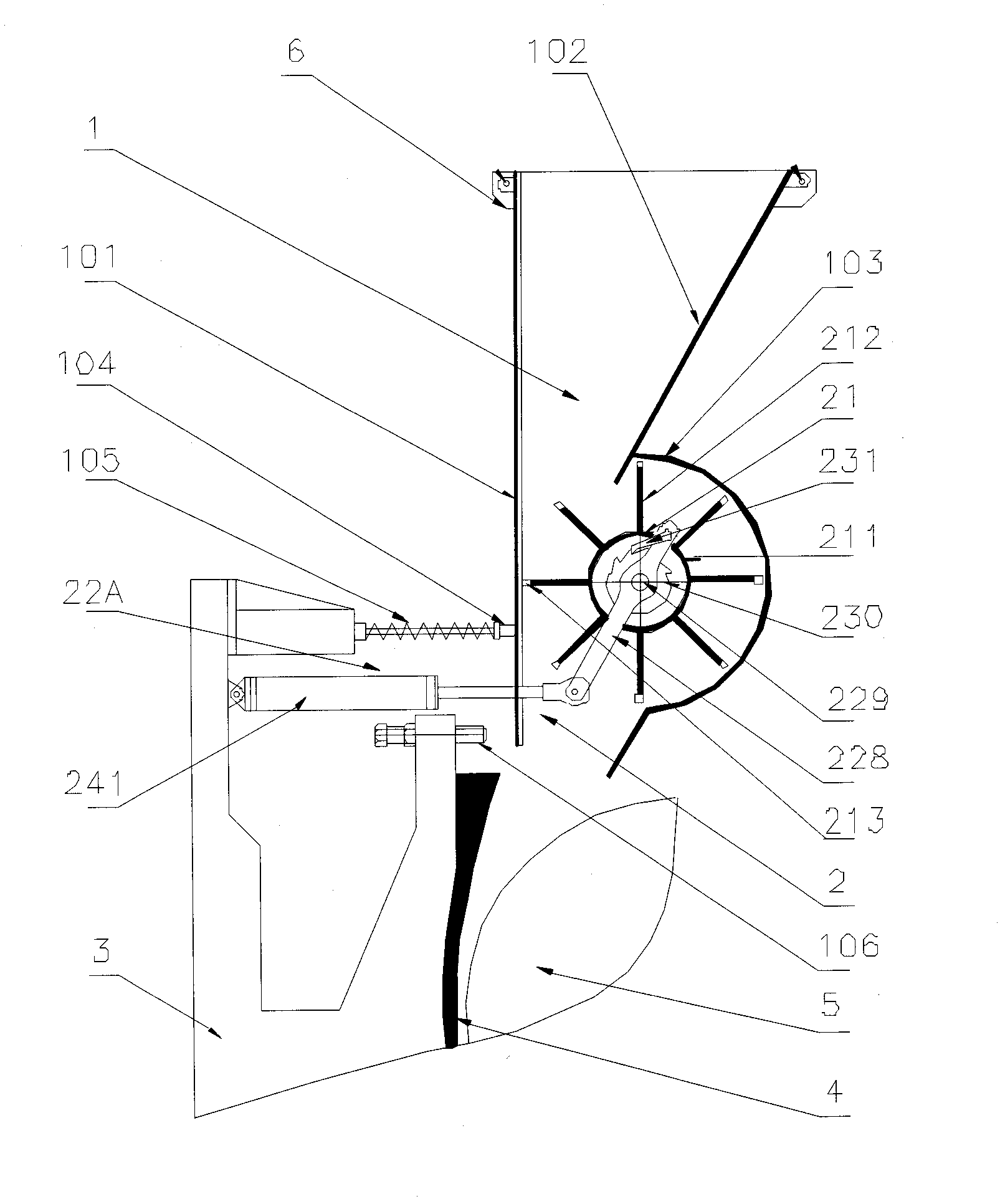

Feeding device of material crushing apparatus

A feeding device of a material crushing apparatus comprises a deformed bunker and an intermittent feeding mechanism, wherein one side of the deformed bunker is provided with a pendulous movable straight plate, the upper end of the movable straight plate is hinged to a fixed hopper lower edge, the other side of the deformed bunker is provided with a fixed semicircular plate and a movable inclined plate, the fixed semicircular plate makes a semicircular cavity, the upper end of the movable inclined plate is hinged to the fixed hopper lower edge, the lower end of the movable inclined plate is laid on the upper edge of the fixed semicircular plate in an inclined manner, and the outside of the movable straight plate is provided with a bunker plate resetting device; and the intermittent feeding mechanism comprises a uniform feeder and a stepping driving part, the uniform feeder is positioned in the cavity of the fixed semicircular plate and comprises a central ring and a plurality of separation plates fixed on the central ring in an equant manner, the central ring is arranged on the wheel shaft of a frame, the length of each of the separation plates can realize a case that the outer ends of the separation plates can successively move the movable inclined plate and the movable straight plate in the rotation of the separation plates, the outer end of the one of the separation plates props against the movable straight plate in the pause of the separation plates, and the stepping driving part intermittently pushes the uniform feeder to rotate. The feeding device realizes the uniform and quantitative feeding and the smooth production, and is suitable for the feeding of large-granule materials.

Owner:卢小平 +1

Soft-magnetic composite material and process for making magnetic conduction component by using same

InactiveCN1700368AWiden your optionsLow costInorganic material magnetismInductances/transformers/magnets manufactureLubricationCalcium carbonate

This invention relates to soft magnetic compound materials, which are characterized by the following: the said materials comprise iron material, isolation agent and lubrication agent with their weight percentage as 92-99 úÑ, 0.5-5 úÑ , 0.5-3 úÑ; the said iron material is powder material, which comprise deoxidized powder, atomized iron powder, hydroxide powder and iron alloy with iron of 80-99.8úÑ; Particle distribution of 20-500; the said isolation agent adopts nanometer calcium carbonate powder or ceramics powder or magnetic oxidation power; the said lubrication is micro powder. The process comprises the following steps: mixing, shaping, solidifying and stainless processing.

Owner:罗计添 +2

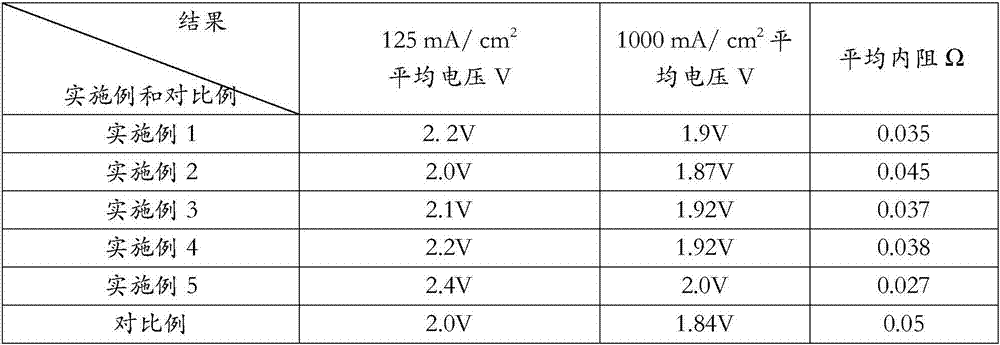

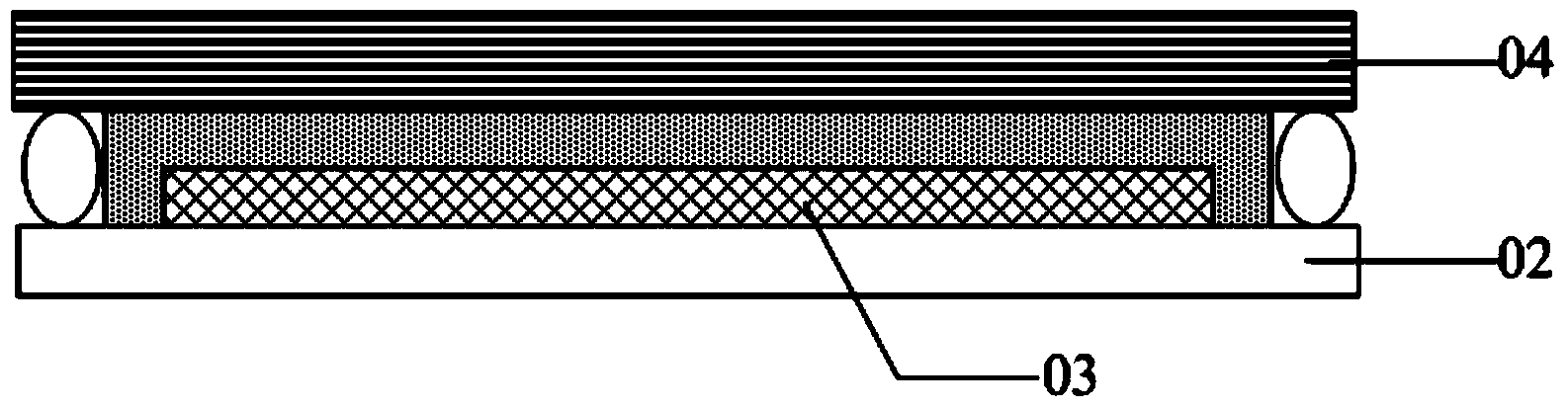

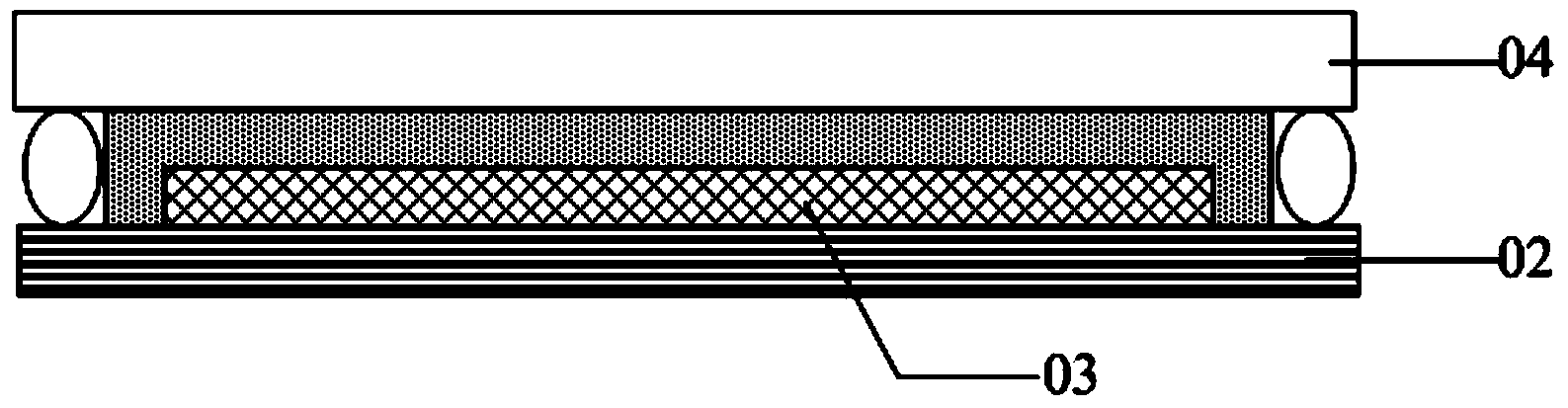

Method for preparing thin single cell thermal battery in laminated mode based on molten salt thermal spraying technology and thin single cell thermal battery

ActiveCN107394224AImprove discharge performanceSolve the inability to achieve thinningPrimary cell manufactureDeferred-action cellsLithiumThermal spraying

The invention discloses a method for preparing a thin single cell thermal battery in a laminated mode based on a molten salt thermal spraying technology and the thin single cell thermal battery, belonging to the field of battery preparation technology. The method comprises the following steps: (1) preparing positive molten salt, and spraying the positive molten salt on a collector plate to form a positive electrode layer; (2) preparing electrolyte molten salt, and spraying the electrolyte molten salt on the positive electrode layer to form an electrolyte layer; (3) preparing negative molten salt, and spraying the negative molten salt on the electrolyte layer to form a negative electrode layer; or, setting a lithium-boron alloy negative plate on the electrolyte layer; and (4) setting the collector plate on the negative electrode layer or the lithium-boron alloy negative plate, and performing compression moulding to obtain the thin single cell thermal battery. The preparation method disclosed by the invention is simple, and can be used for improving the discharge capacity and stability of the battery.

Owner:西科微纳(重庆)新能源技术研究院有限公司

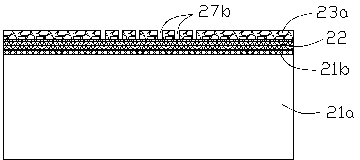

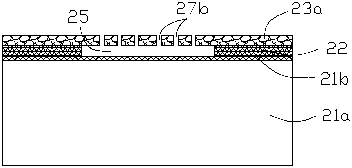

Method for manufacturing CEM (Composite Epoxy Material Grade)-3 copper-clad plate with high dielectric constant and low loss

ActiveCN103101252ASmall dielectric lossSimple processSynthetic resin layered productsLaminationDielectricFirming agent

The invention provides a method for manufacturing a CEM (Composite Epoxy Material Grade)-3 copper-clad plate with a high dielectric constant and low loss. The method for manufacturing the CEM-3 copper-clad plate with the high dielectric constant and the low loss comprises the following steps of: firstly, preparing epoxy resin liquid; carrying out surface treatment on composite fillers; preparing composite resin liquid; preparing a bonding sheet; and finally, pressing a lamination plate. The method provided by the invention uses bisphenol A epoxy resin with low cost, good manufacturability and good dielectric properties as main resin, and the problems of the cost and the manufacturability of a product can be solved; the high-dielectric fillers are partially composited by using a special curing agent, so that a curing article has a high dielectric constant, low loss, good thermal resistance, and high mechanical strength; and the CEM-3 copper-clad plate manufactured by the method disclosed by the invention has the advantages of simple process, low cost and good properties.

Owner:SHAANXI SHENGYI TECH

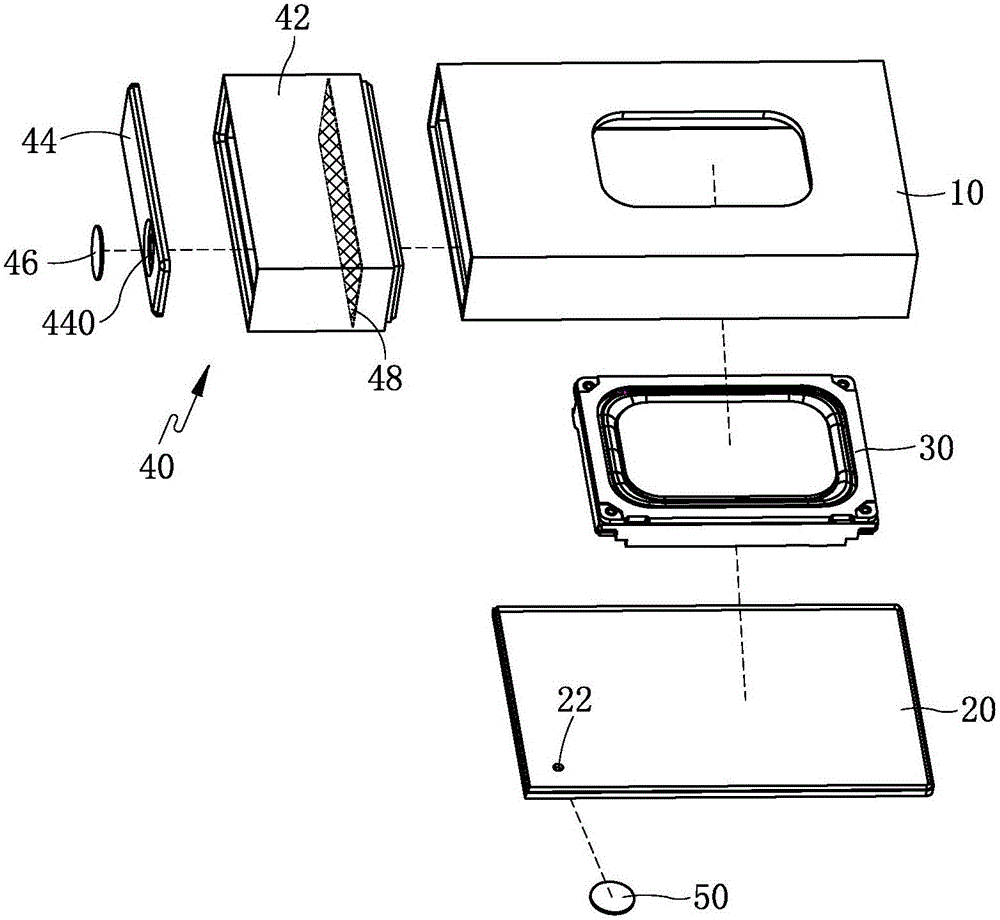

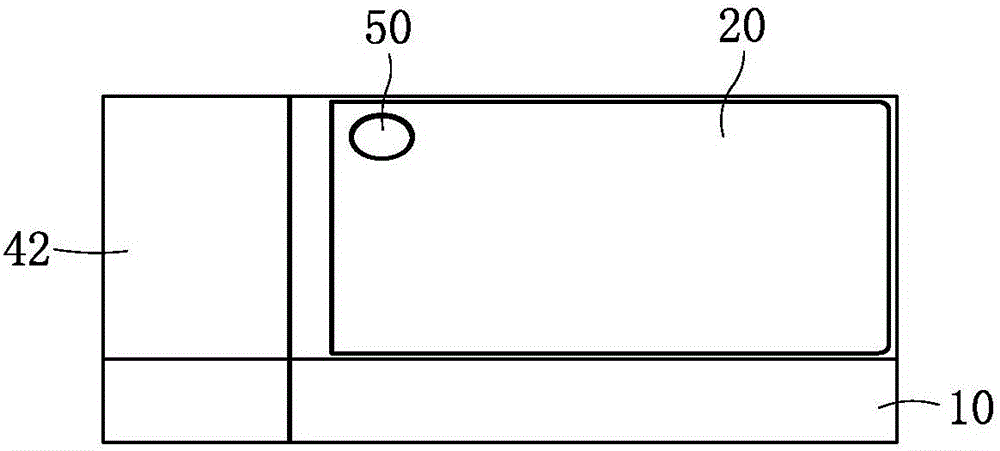

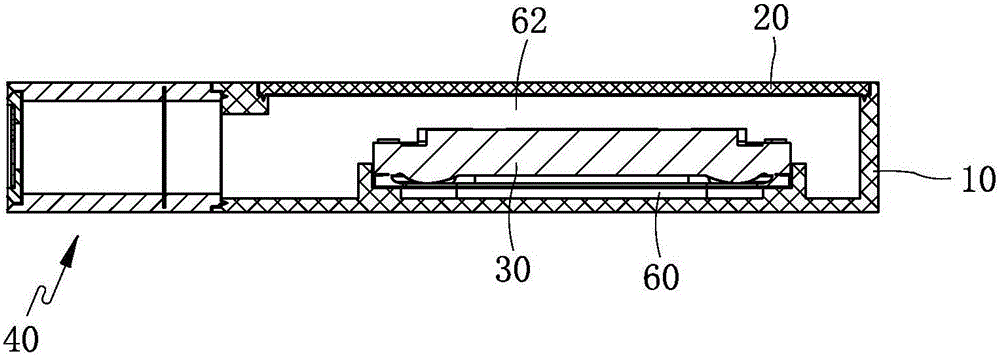

Loudspeaker module

ActiveCN105872917ALower F0Improve acoustic performanceElectrical transducersEngineeringSound quality

The invention discloses a loudspeaker module, and relates to the technical field of an electroacoustic product. The loudspeaker module comprises a module housing; a loudspeaker monomer is accommodated in the module housing; the loudspeaker monomer divides an integral module inner cavity into two cavities, i.e. a front sound cavity and a rear sound cavity; the rear sound cavity comprises an accommodating cavity and a sound adsorption cavity which are communicated; the loudspeaker monomer is positioned in the accommodating cavity; the sound adsorption cavity is filled with sound adsorption particles; the accommodating cavity is formed by the surrounding of the module housing; the sound adsorption cavity is formed by the surrounding of a sound adsorption cavity housing; the sound adsorption cavity housing is combined with the module housing; and a netted isolation part is arranged between the sound adsorption cavity and the accommodating cavity. The sound adsorption particles of the loudspeaker module disclosed by the invention cannot be influenced by a module production assembling process, and have a good sound adsorption effect; acoustic performance of the module is obviously improved; sound quality is higher; and meanwhile, the loudspeaker module is low in assembling difficulty and high in production efficiency.

Owner:GOERTEK INC

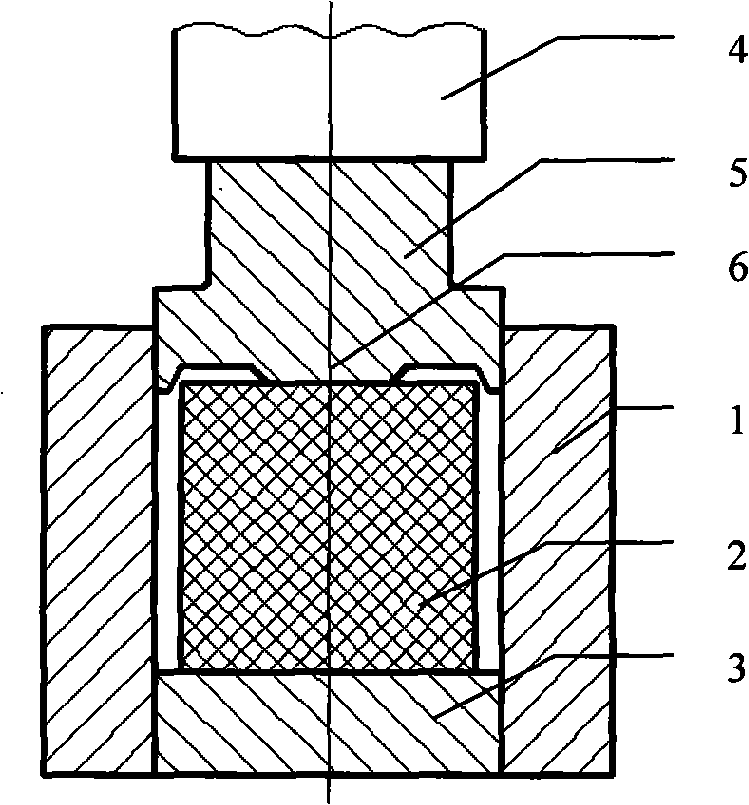

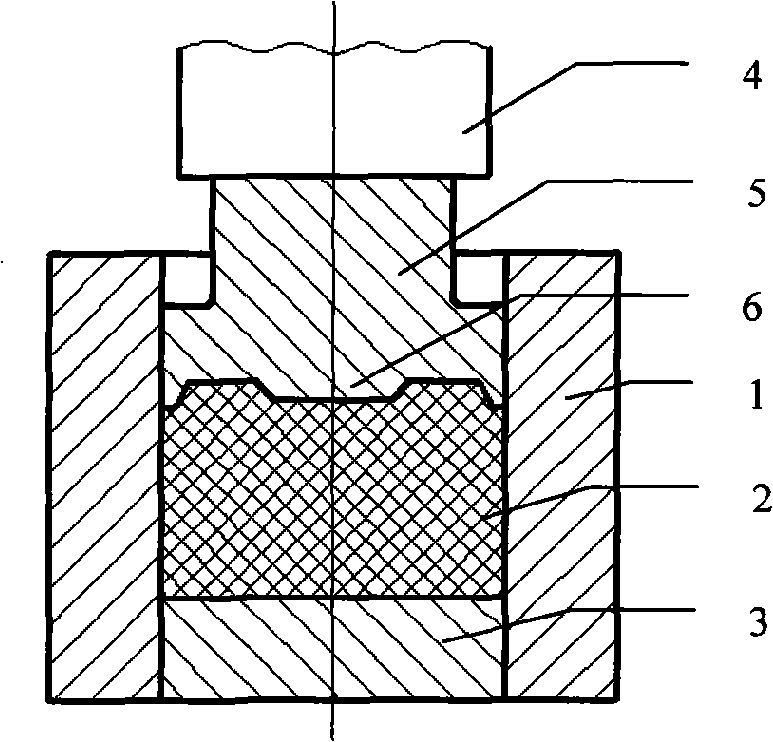

Hot impact extrusion process and device for large annular barrel type forged piece

ActiveCN101537438ASolve process problemsImprove uniformityExtrusion containersRams/plungersImpact extrusionLubricant

The invention relates to a hot impact extrusion process and a device for a large annular barrel type forged piece, which belongs to the technical field of hot forming of a large hollow forged piece. The process comprises the following steps: firstly, an extrusion cushion is placed on a press platform; secondly, the blanks to be heated are put on the extrusion cushion; thirdly, an extrusion cylinder is sleeved on the extrusion cushion; fourthly, a profiling punch is applied with force so that a mold cavity is filled with the blanks; fifthly, the lubricant is added; sixthly, a solid punch is applied with force so that the blanks are extruded to the set position of the process; seventhly, a hollow punch is sleeved on the solid punch and applied with pressure, so that the blanks are extruded to the set positioned of the process; eighthly, the extrusion cushion is taken out and a bottom flushing drain cap is replaced; and ninthly, the core material at the bottom is flushed out through the hollow punch. The devices required for finishing the process comprise an extrusion cylinder, an extrusion cushion, a profiling punch, a solid punch, a hollow punch, a solid extension rod, a hollow extension rod and a bottom flushing drain cap. The invention solves the difficult problems existing in the large annular barrel forged piece of long process flow of free forging, more forging times and large reverse extrusion molding for die forging and improves the utilization ratio of the material and the molding quality of the forged piece.

Owner:NANJING DEV ADVANCED MFG

OLED and display equipment

ActiveCN103682156AAvoid the problem of thickening in thickness, causing difficulty in curlingImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPolarizerOptical thin film

The invention discloses an OLED and display equipment. According to the OLED, an optical thin film laminate serves as a substrate or packaging cover plate of the OLED, wherein the optical thin film laminate comprises a circular polarizer film, a water and oxygen resistance film and a color resistance film, and the circular polarizer film, the water and oxygen resistance film and the color resistance film are located on a supporting substrate. In this way, the OLED has an anti-reflection function, good water and oxygen resistance performance and a full-color display function, and the problems that processes are tedious and cost is increased due to film pasting of the OLED are solved; in addition, the problem that curling is difficult to carry out because a flexible OLED is thickened due to film pasting is also avoided; meanwhile, the OLED has the advantages of being lighter, thinner, better in display effect and the like.

Owner:BOE TECH GRP CO LTD

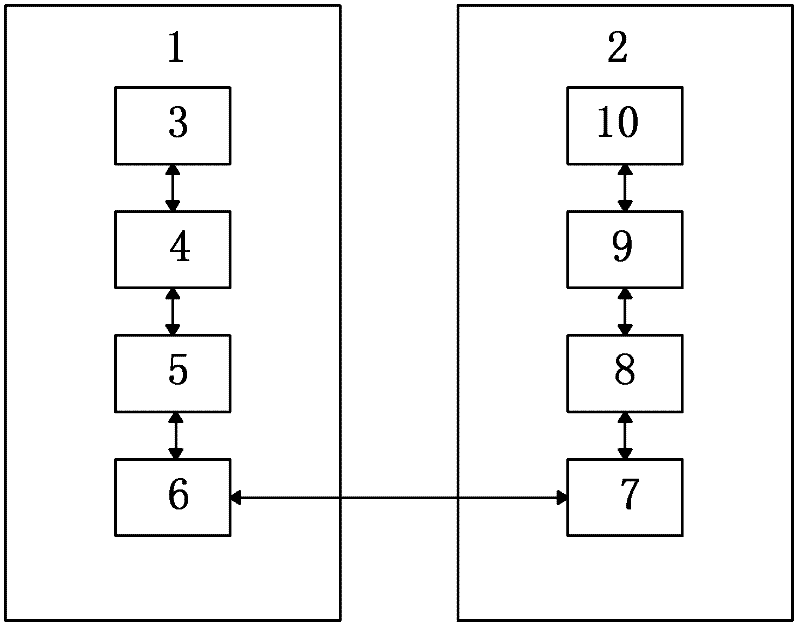

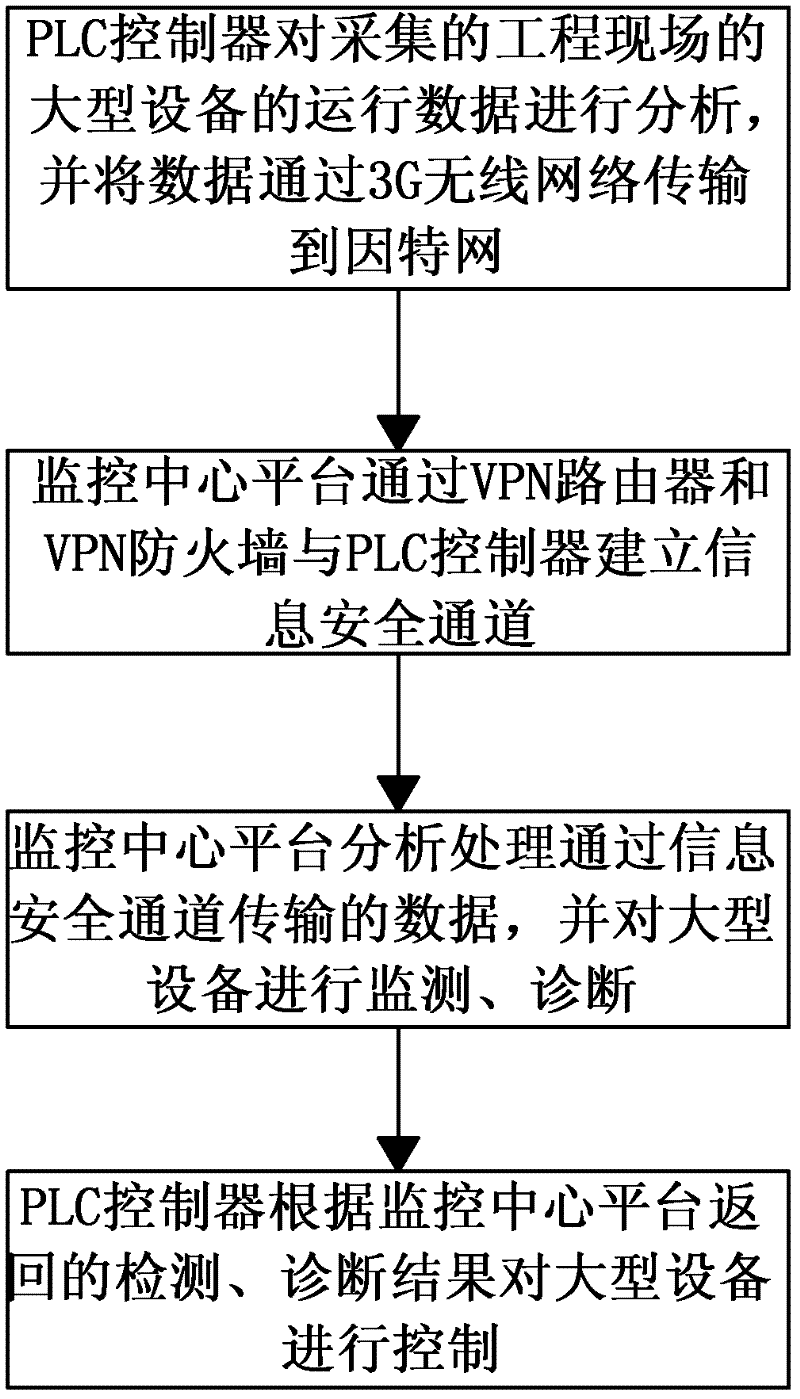

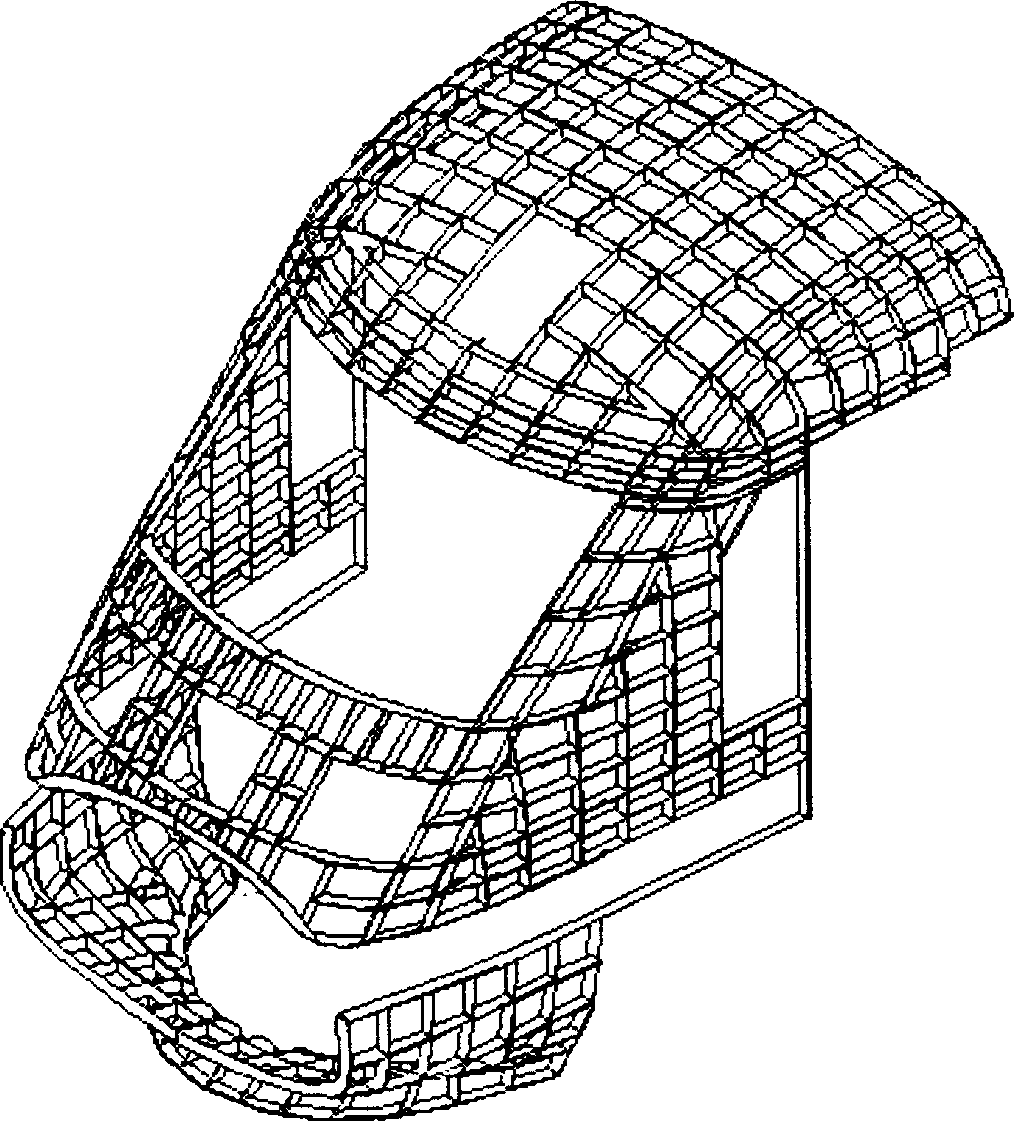

Method and system for monitoring and diagnosing large scale equipment remotely

InactiveCN102393715ASolve the speed problemSolve process problemsProgramme total factory controlPrivate networkProgrammable logic controller

The invention discloses a method and a system for monitoring and diagnosing large scale equipment remotely. The method comprises the steps as follows: firstly, a PLC (Programmable Logic Controller) analyzes collected running data of the large scale equipment on an engineering site, and transmits the data to an internet by a 3G (the third generation telecommunication) wireless network; secondly, a monitoring center platform builds a safe information channel with the PLC by a VPN (Virtual Private Network) router and a VPN fire bulkhead; thirdly, the monitoring center platform analyzes and processes data passing by the safe information channel, and monitors and diagnoses the large scale equipment; and fourthly, the PLC controls the large scale equipment according to the detection and diagnosis results sent back by the monitoring center platform. The method and the system can enhance the data transmission rate and improves the data transmission safety.

Owner:HUADIAN HEAVY IND CO LTD

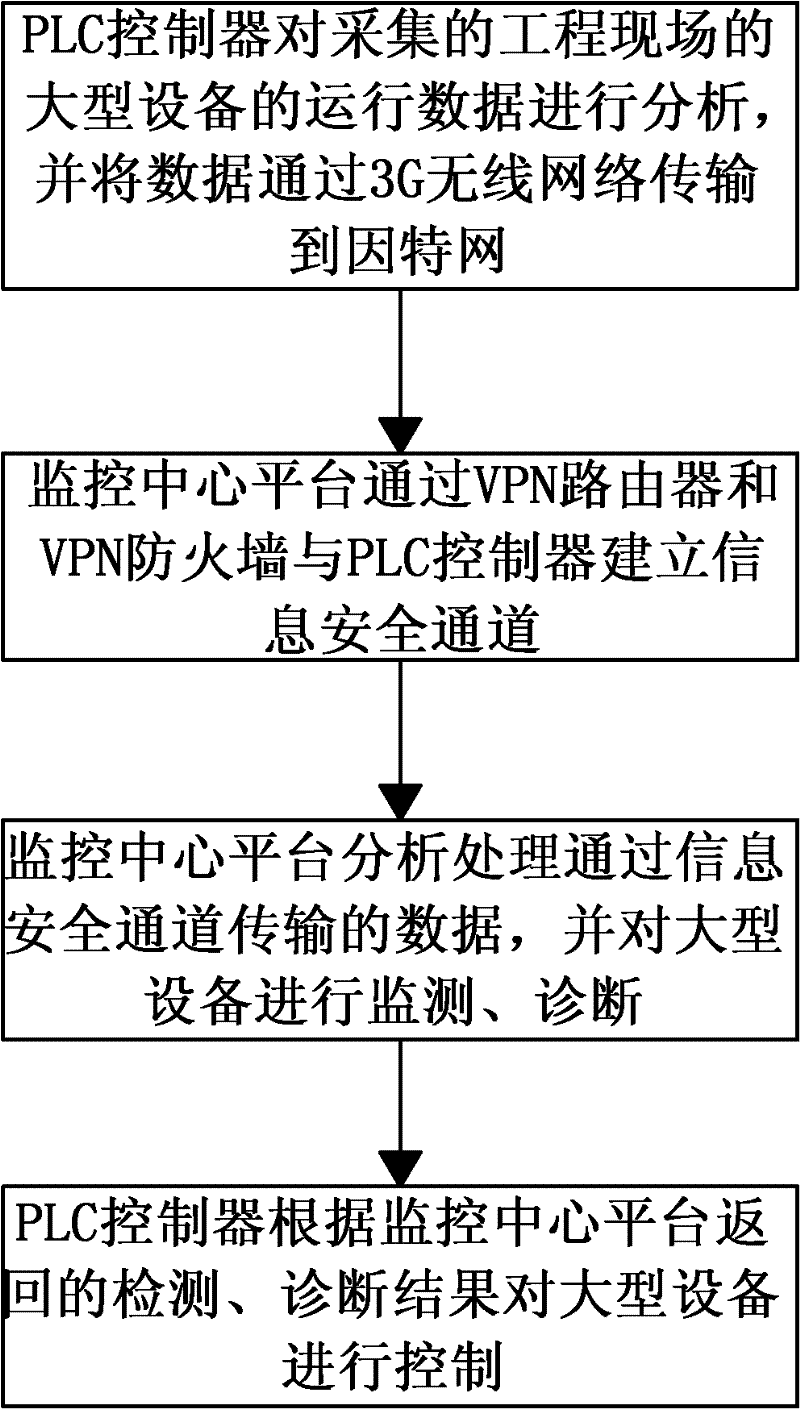

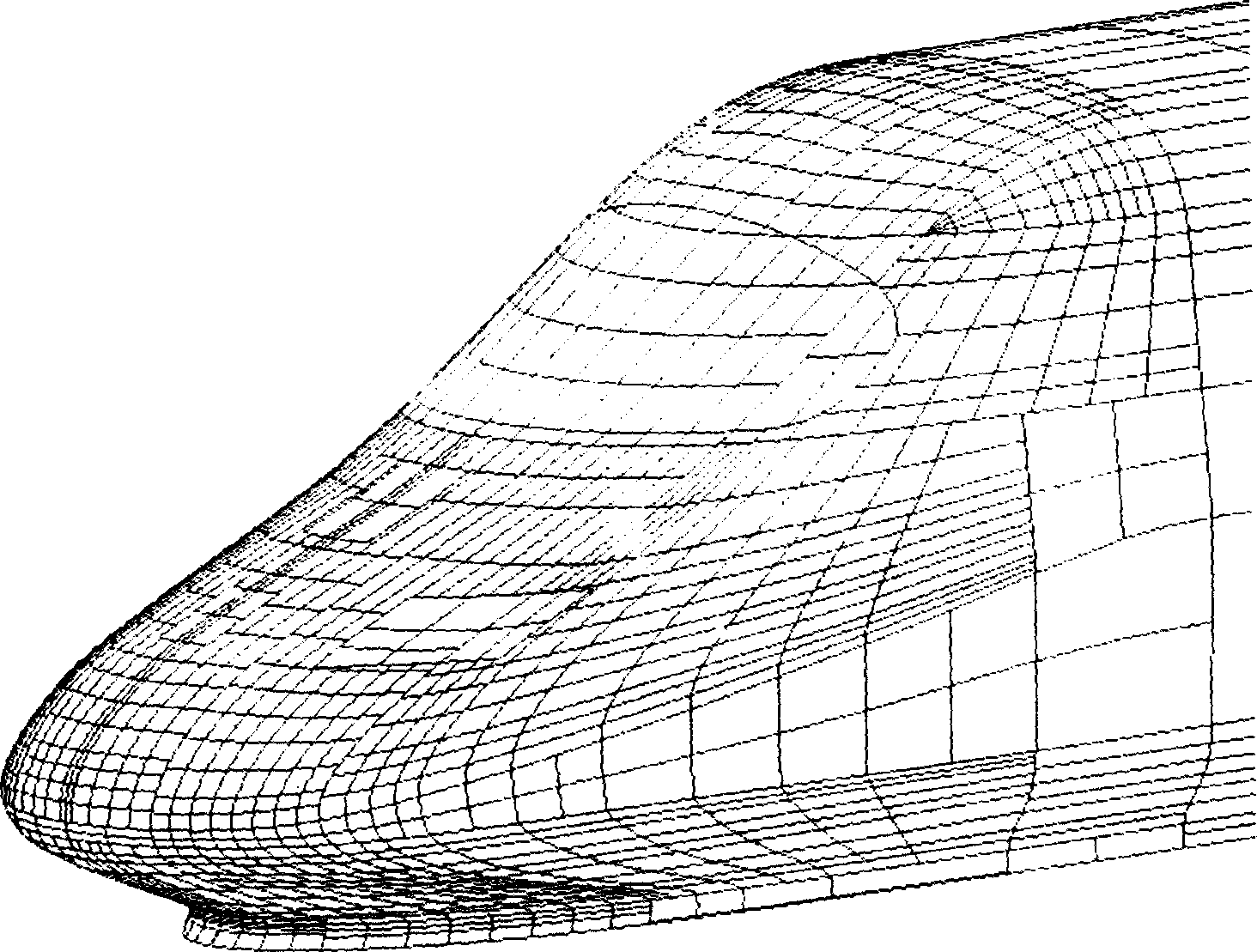

Design and process method for profile and structure of streamline locomotive

InactiveCN1634735AReduce labor intensityRealize shape designRailway transportAxle-box lubricationIntermediate typeCoating

This invention relates to train body parts kinds in railway trains and especially to streamline trains, which comprises railway speeding train, speeding gas train set and speeding automobiles or high speed magnetic floating train head part or structure design. The invention is characterized by the following: the streamline train head is composed of multiple NUBRS curved pieces to form the train head outline through dynamic automatic generation or piece adjusting; then welding the space net structure plane of the head structure with the coating iron into the streamline train head.

Owner:CENT SOUTH UNIV

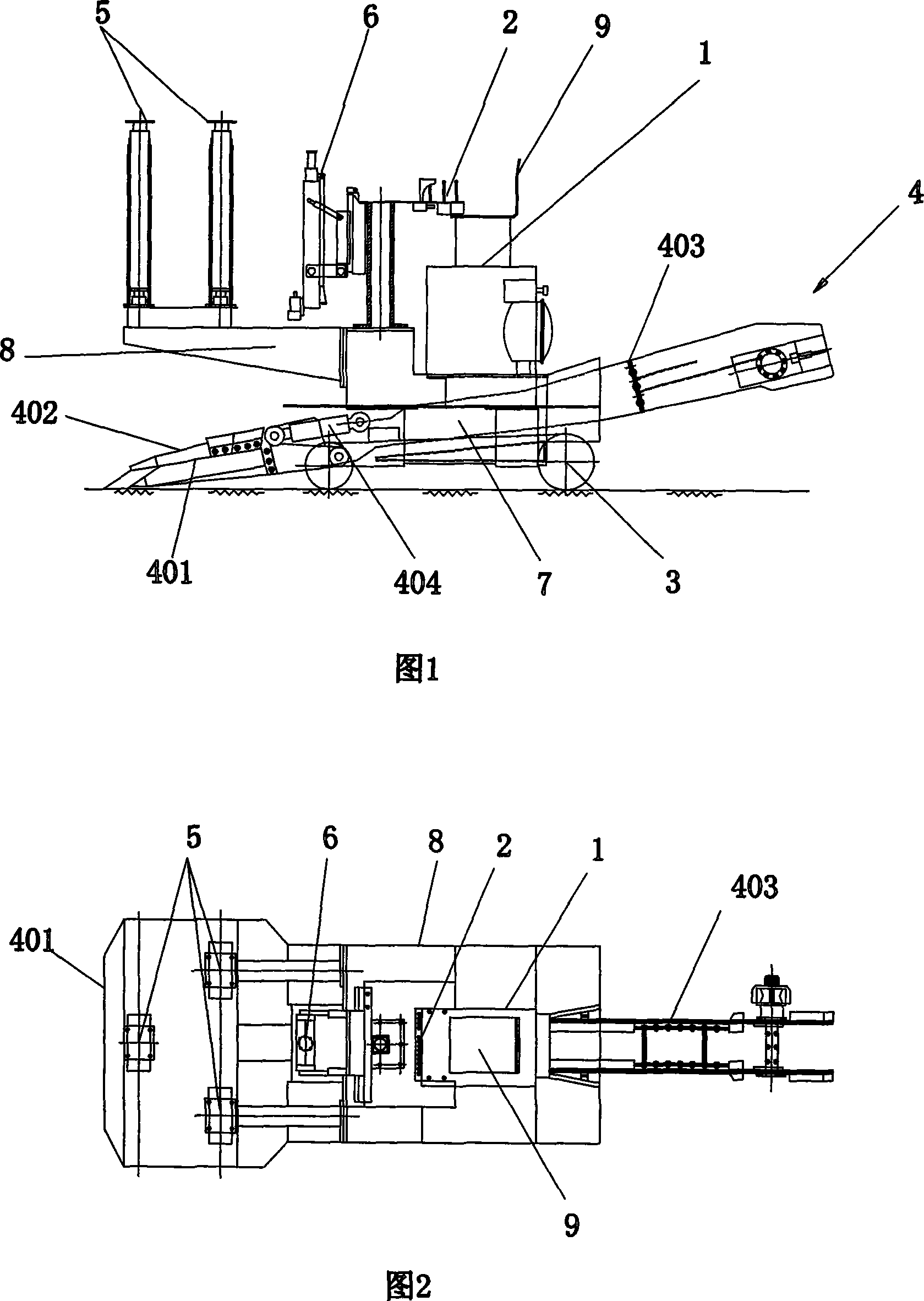

Explosion coal-falling, coal-loading, coal-conveying and anchor-rod supporting mechanism integration operation method and apparatus

InactiveCN101025086AIncrease the speed of excavationExcavation section is largeUnderground miningSurface miningResource recoveryEngineering

The invention provides a blast-winning, coal loading, coal conveying and anchor rod-timbering mechanical integrated operating method and device. And the device mainly comprises: hydraulic system, hydraulic control table, track walking part, coal loading and conveying part, timbering part, and hydraulic anchor rod machine, and the method uses integrated device, scraper conveyor and gate coal conveyor; and its drivage circulating speed is 1m to 1.5 m, blast-winning and after the fumes have settled, making the integrated device enter into the operating site, and after completing coal loading and conveying, making anchor rod timbering; after completing the anchor rod timbering operation, making the integrated device exit the operating site and over 20 meters distant from the operating site, and then making drilling and blasting operation. And it improves explosion level of blast winning and resources recovery, and reduces operators.

Owner:闫振东

Method for extracting uranium from uranium-contained niobium-tantalum leached tailings

ActiveCN102312094AReduce consumptionReduce energy consumptionProcess efficiency improvementNiobiumEnergy consumption

The invention relates to a method for extracting uranium from uranium-contained niobium-tantalum leached tailings, which comprises the steps of sulfuric acid leaching, extraction, back extraction, purification, extraction and purification, back extraction and the like. Compared with the prior art, the method for extracting the uranium from the uranium-contained niobium-tantalum leached tailings is capable of reducing the raw material consumption; pretreatment processes of exploitation, mineral separation and the like are not needed; and in a practical process, energy consumption is reduced, the process problem of extracting the uranium from complicated substrates is solved, and a qualified uranium product is successfully manufactured.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Antibacterial comfortable anti-static compound function fabric and manufacturing process thereof

The invention relates to an antibacterial comfortable anti-static compound function fabric. The fabric is formed by interweaving warp and weft and implanting electric conduction filaments. The warp and the weft are blended yarn composed of antibacterial modified polyester fiber and cotton fiber, wherein the weight content of the antibacterial modified polyester fiber in the blended yarn ranges from 60% to 65%, and the weight content of the cotton fiber ranges from 35% to 40%. The production technology process includes the steps of material and fiber compatibility portion determining, spinning, beaming, slashing, drafting and sleying, weaving, mending and managing, dyeing, after finishing and finished product detecting. The antibacterial modified polyester fiber, face cotton and the electric conduction filaments are used as main raw materials, fabric weave, the looming process and the dyeing and after finishing technical processes are reasonably designed, the process problems in weaving and after finishing of yarn are solved, and the antibacterial comfortable anti-static compound function fabric can meet the design and use requirements.

Owner:SWOTO PROTECTION & TECH CO LTD +1

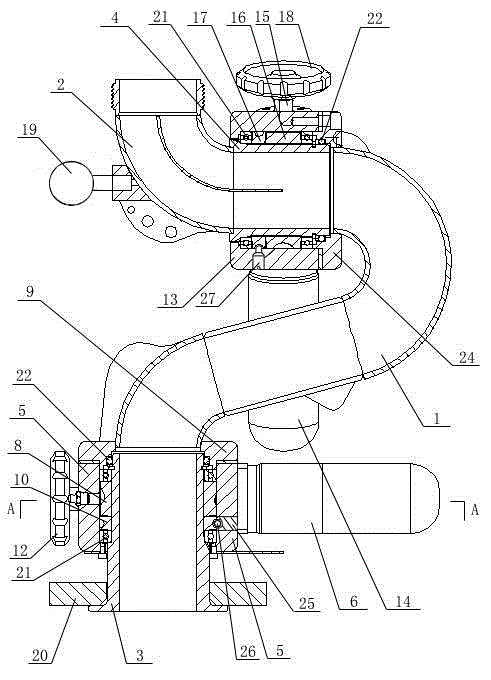

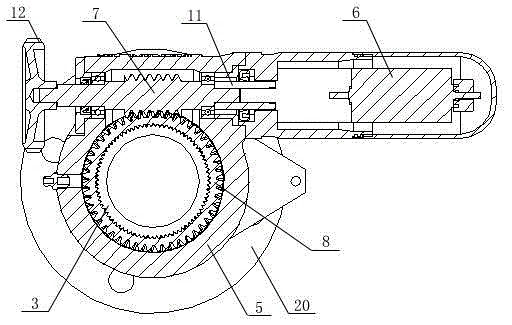

Servo control fire-fighting monitor

ActiveCN102940946ASolve process problemsSolve rigid problemsFire rescueElectric controlControl theory

The invention discloses a servo control fire-fighting monitor. The servo control fire-fighting monitor comprises a monitor body and a monitor head, a water inlet end of the monitor body is communicated with an entrance worm-wheel shaft through a horizontal servo control mechanism, a water outlet end is communicated with an exit worm-wheel shaft through a vertical servo control mechanism, and the exit worm-wheel shaft is fixedly connected with the monitor head. According to the servo control fire-fighting monitor, by means of the electric control, action commands are issued to servo motors in the horizontal and vertical directions respectively, the water outlet of the monitor head can perform corresponding angle adjustment, and due to the structural design of the horizontal servo control mechanism and the vertical servo control mechanism, the problems that in the existing fire-fighting monitor structure, the structural processability and rigidity are poor and the rotation accuracy is low when the monitor body rotates along the horizontal plane and rotates in a direction perpendicular to the horizontal plane are effectively solved.

Owner:VITALONG FIRE SAFETY GRP

Method for producing chromium-based iron alloys through cutting wastes by crystalline silicon

The invention belongs to the metallurgical field, and concretely relates to a new method for directly producing chromium-based iron alloy products in a metallurgical furnace by using a special furnace charge prepared through cutting wastes and chromium concentrate powder by monocrystalline or polycrystalline silicon. The method comprises the following steps: adding a certain amount of monocrystalline or polycrystalline silicon cutting waste powder to the chromium concentrate powder, processing through using a ball press or a disc pelletizer to prepare the spherical or block metallurgic furnace charge, and smelting in an induction furnace or an electric furnace to obtain medium-and-low-carbon ferrochrome, silicon-chromium-iron alloy and other chromium-based iron alloy products. The method reasonably and efficiently utilizes metallic silicon, silicon carbide and other high-quality high temperature metallurgical reducing agents contained in photovoltaic cutting wastes, directly uses the chromium concentrate powder, and adopts an electric-silicothermic metallurgy process through a one step technology. Compared with traditional methods, the method has the advantages of energy consumption saving, and solving of the pollution of solid wastes formed in the photovoltaic industry to the environment.

Owner:UNIV OF SCI & TECH BEIJING

Method and inhibitor capable of inhibiting foaming of ceramic tile polishing waste in high-temperature sintering

InactiveCN106220017AInhibition of foaming during high-temperature sinteringSolve process problemsCeramic materials productionClaywaresScrapCeramic tiles

The invention discloses a method and an inhibitor capable of inhibiting foaming of ceramic tile polishing waste in high-temperature sintering. The inhibitor refers to at least one of quartz and aluminum hydroxide and contains at least one of wollastonite and borax. The method includes: mixing, by mass, 10-20% of the inhibitor, 10-20% of the ceramic tile polishing waste and 60-70% of common ceramic tile blank materials; moulding the mixture to obtain blanks; finally performing high-temperature sintering to obtain smooth and compact ceramic products. The method and the inhibitor have advantages that by adoption of quartz and aluminum hydroxide as the inhibitor, high inhibition efficiency, easiness in control and wide application range are realized; the problem of high technique implementation and control difficulty in ceramic tile polishing waste based ceramic tile production is solved; efficient recycling of the ceramic tile polishing waste is realized, structural and appearance quality of ceramic tiles can be improved, production material cost is reduced, and high utilization rate and reduction of emission pollution of waste residues and materials are realized; technical simplicity in preparation, easiness in control, wide applicability and convenience in implementation and popularization are realized.

Owner:FOSHAN DONGPENG CERAMIC +3

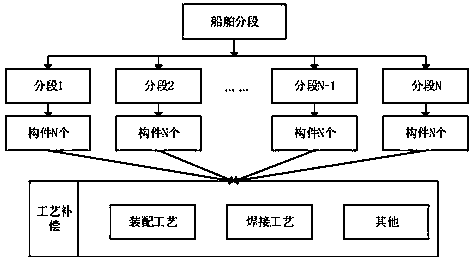

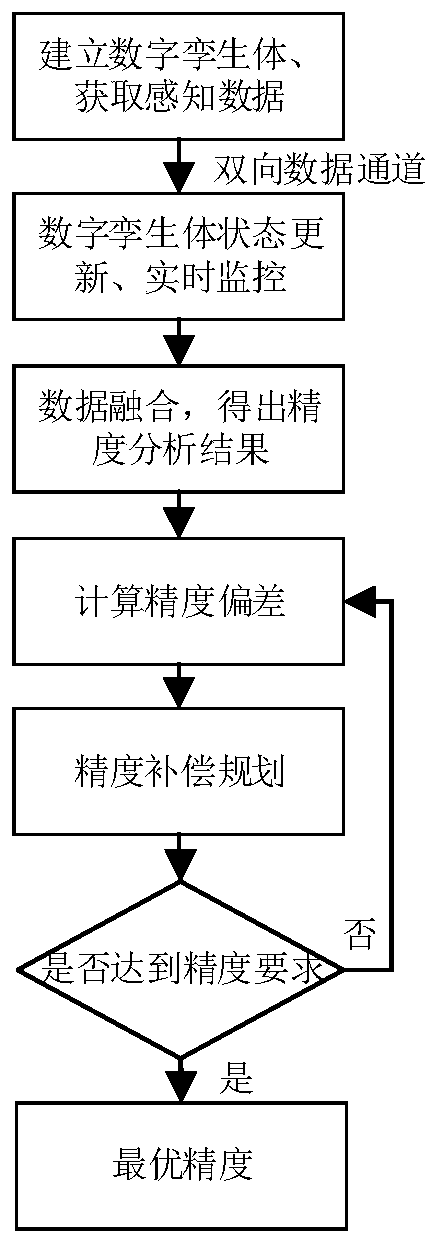

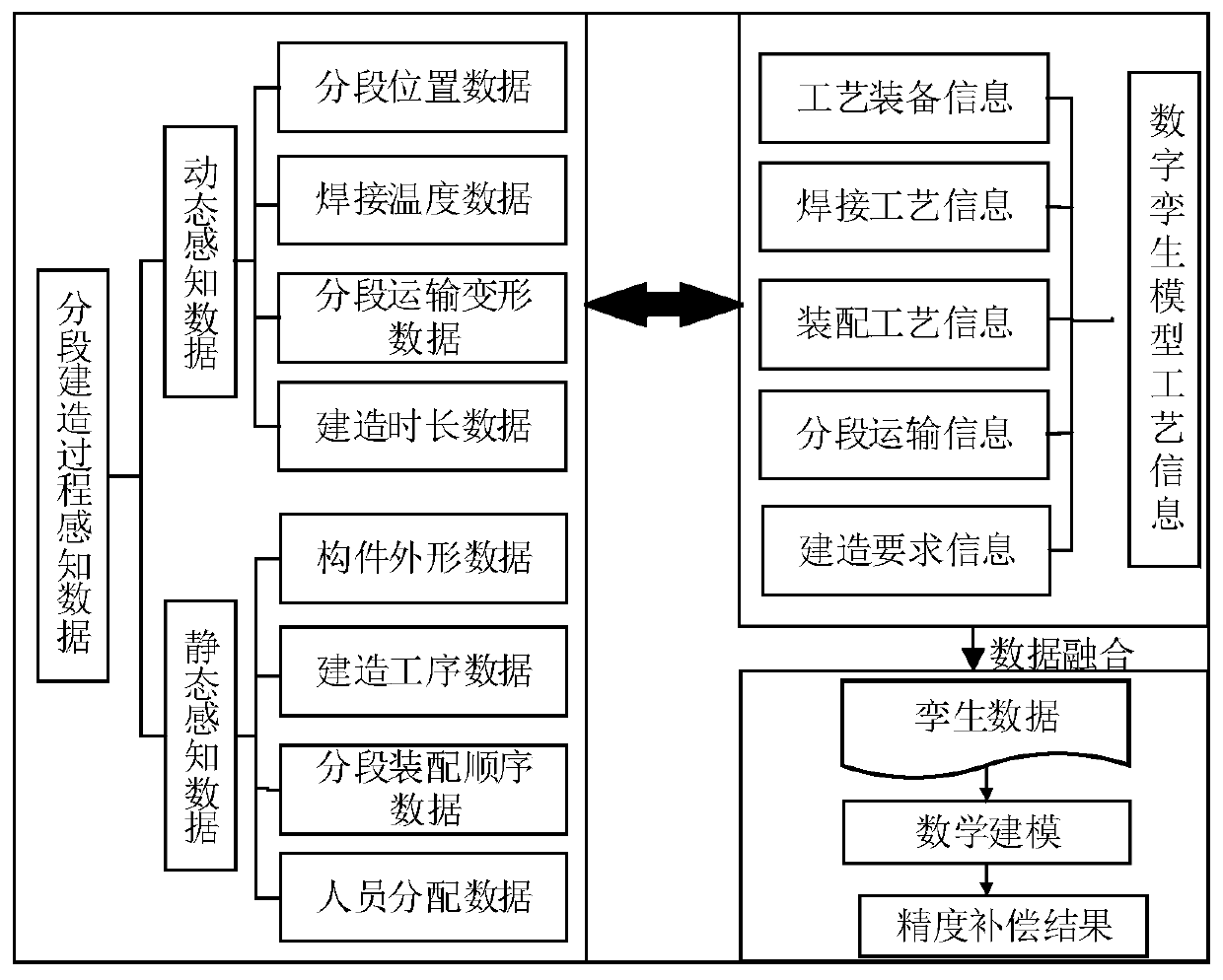

Ship segment construction precision control method based on digital twin

InactiveCN109866876ASolve collaboration problemsSolve process problemsVessel partsReal-time simulationBuilding construction

The invention discloses a ship segment construction precision control method based on the digital twin. The ship segment construction precision control method comprises the following steps of 1) constructing a ship segment digital twin body; 2) collecting sensory data of ship segments in the construction process, sending the sensory data to the digital twin body, and conducting updating; 3) fusingthe sensory data with technology information in the construction process to form twin data, and calculating the segment accuracy of all ship segments; 4) calculating a deviation between the total accuracy in the actual construction process and the accuracy in the theoretical construction process; 5) conducting accuracy compensation according to the above deviation; and 6) judging whether the accuracy requirement is met or not. By utilizing the digital twin technology, a segmented digital twin model of the ship segment construction process is constructed, real-time simulation and monitoring ofthe ship segment construction process are achieved, the problem about synergy between the technology and the accuracy in the ship segment construction process is well solved, and the quality of shipsegment construction is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Method for welding CVD diamond thick film and hard alloy

ActiveCN103894695AImprove surface wettabilityHigh bonding strengthSoldering apparatusChemical LinkageMetal device

The invention relates to a method for welding a CVD diamond thick film and hard alloy. The method comprises the steps that firstly, a double-glow plasma diffusion metal device metallizes a growth face of the CVD diamond thick film, and secondly, the double-glow plasma diffusion metal device is used for welding the metallized face and a hard alloy substrate in a brazing mode. According to the method, metal atoms are evenly diffused on the surface of the growth face of the diamond thick film according to the double-glow plasma diffusion metal technology, metal carbide is formed by the metal atoms and the diamond thick film, and superior bonding strength between a metal layer and the diamond thick film is guaranteed through chemical bonding. The metallized diamond thick film has good ground surface wettability, and a welding connector with high bonding strength can be formed through the metallized diamond thick film and the hard alloy under the heating action of plasma. The surface metallization of the diamond thick film and brazing can be finished through the same device, manufacturing production cost is greatly reduced, and industrialization can be achieved.

Owner:山西新碳超硬材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com