Patents

Literature

101results about How to "Improve water and oxygen resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

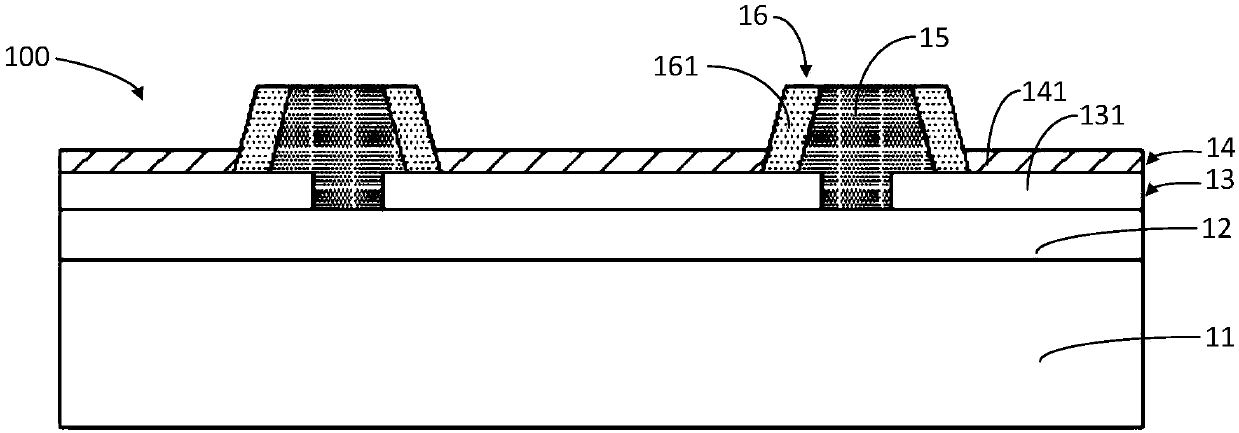

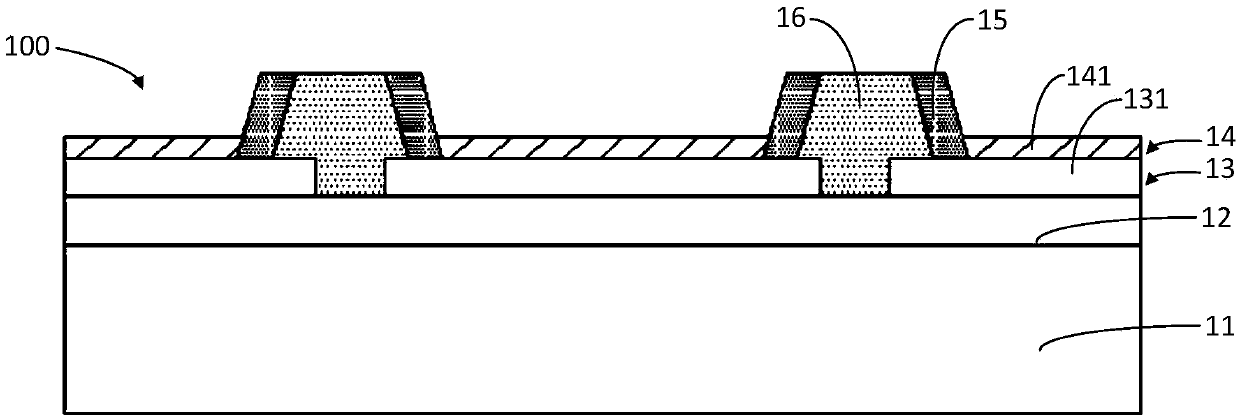

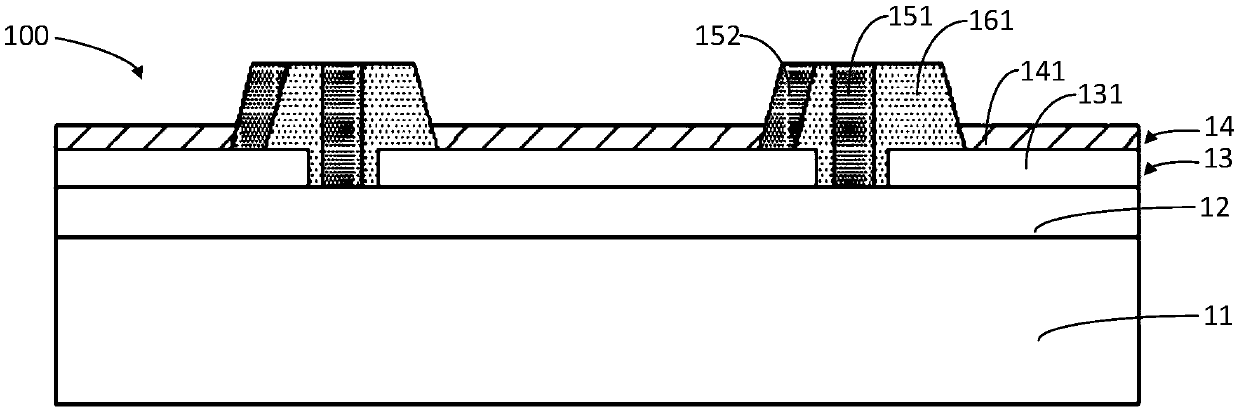

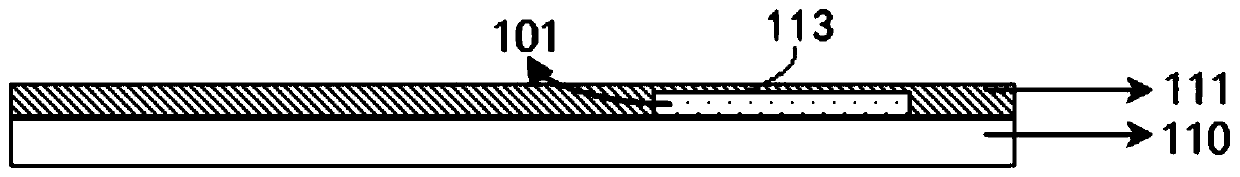

Preparation method of flexible substrate base plate and preparation method of flexible OLED (organic light emitting diode) display

InactiveCN106158740AImprove water and oxygen barrier performanceImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryDisplay device

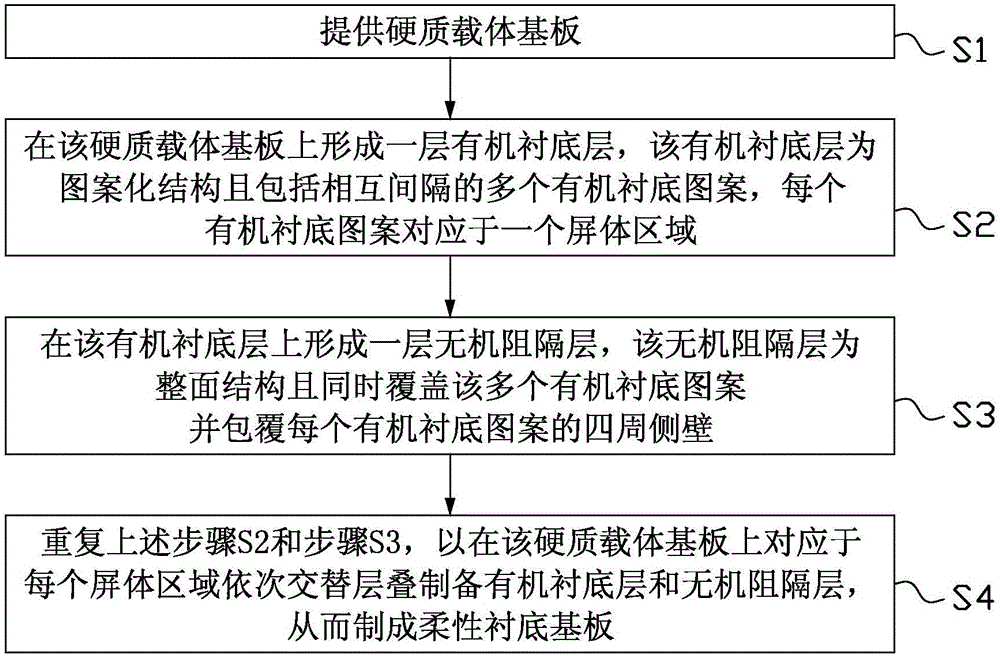

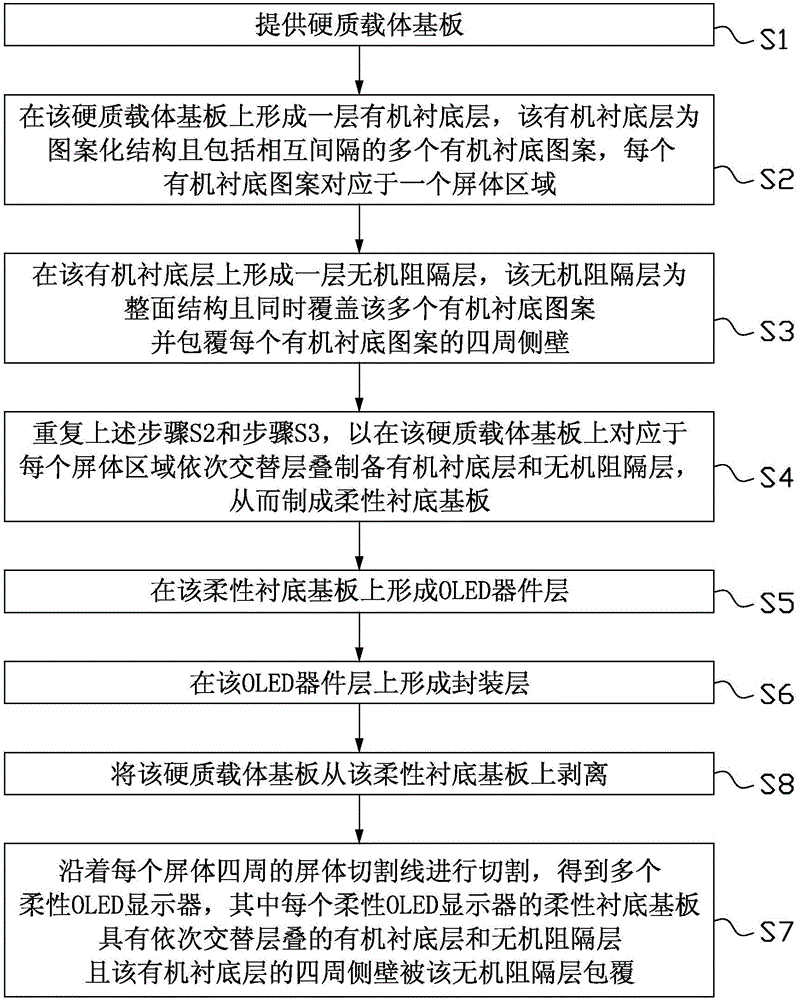

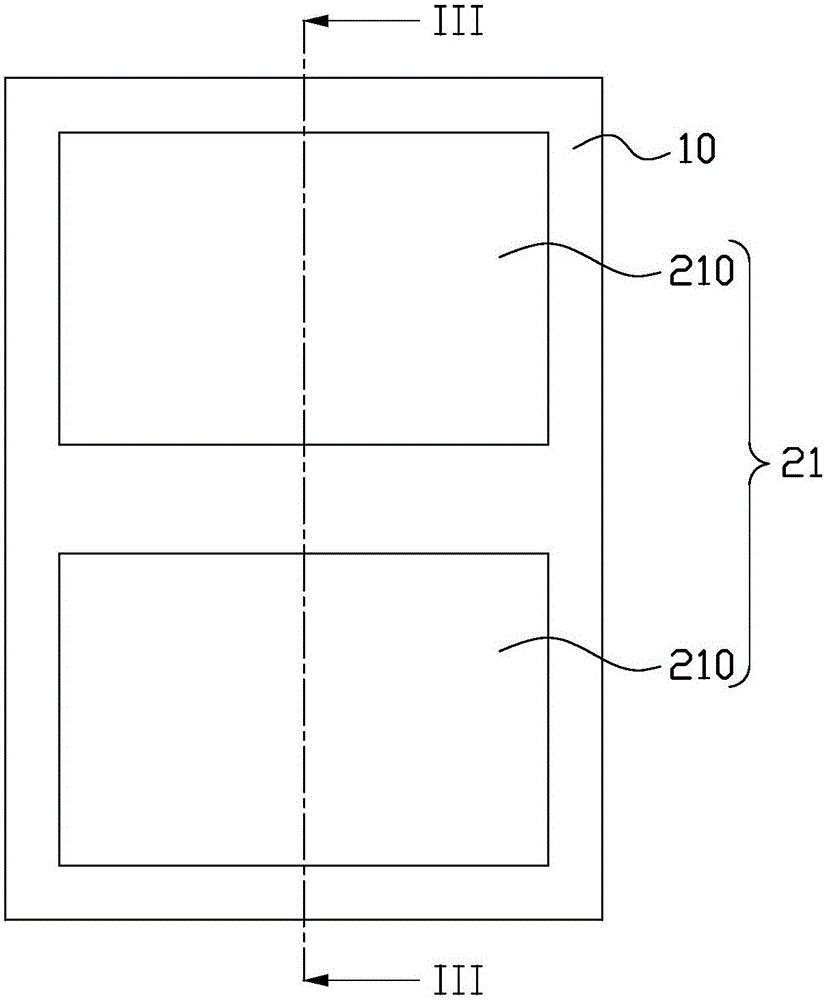

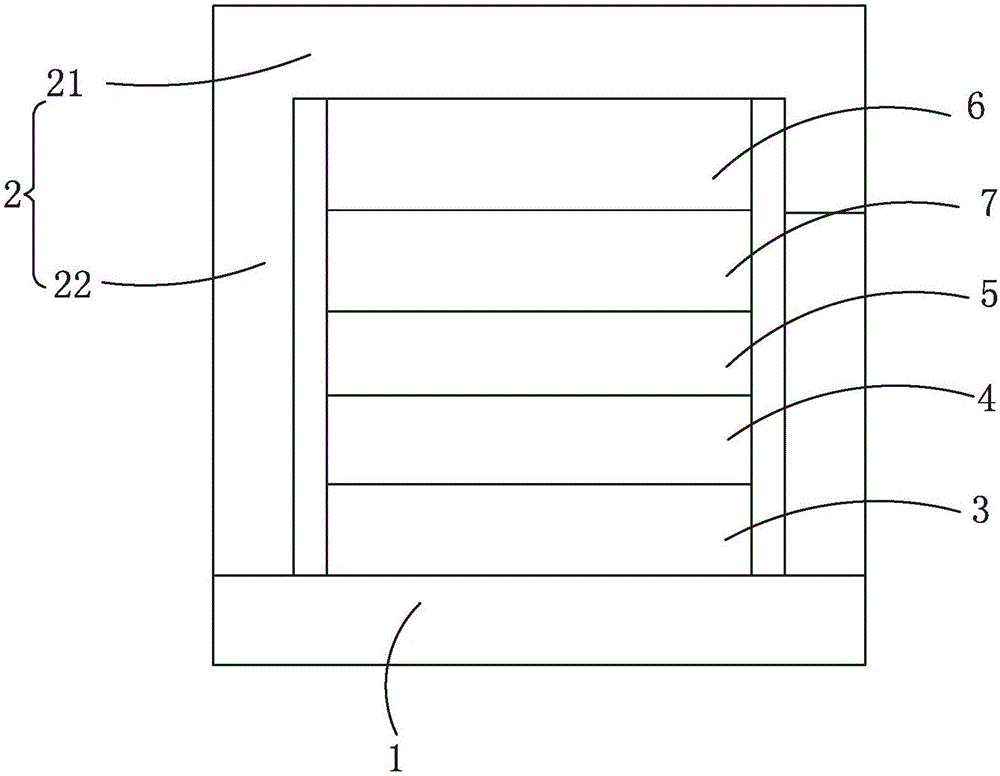

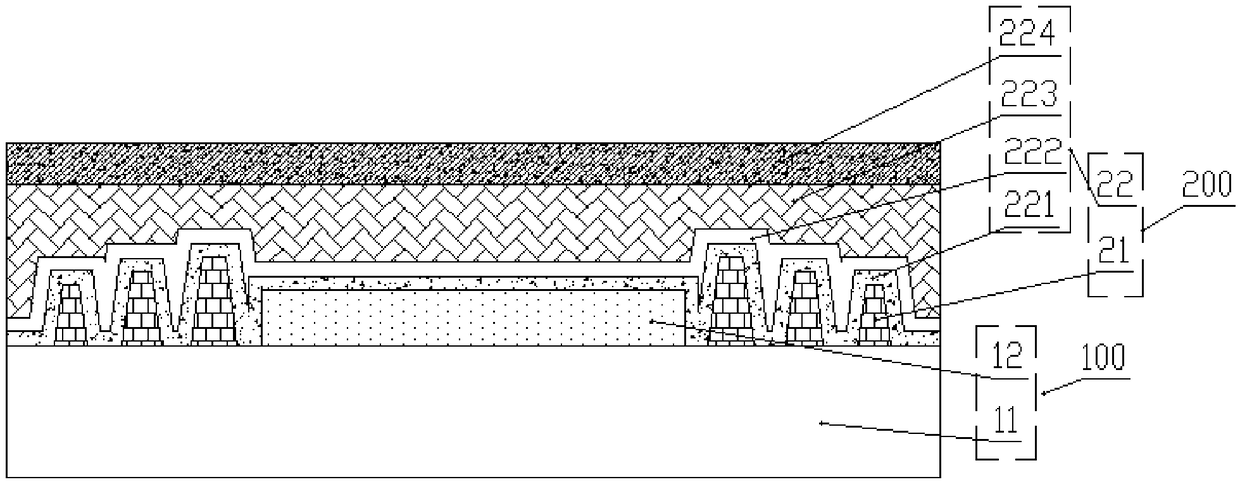

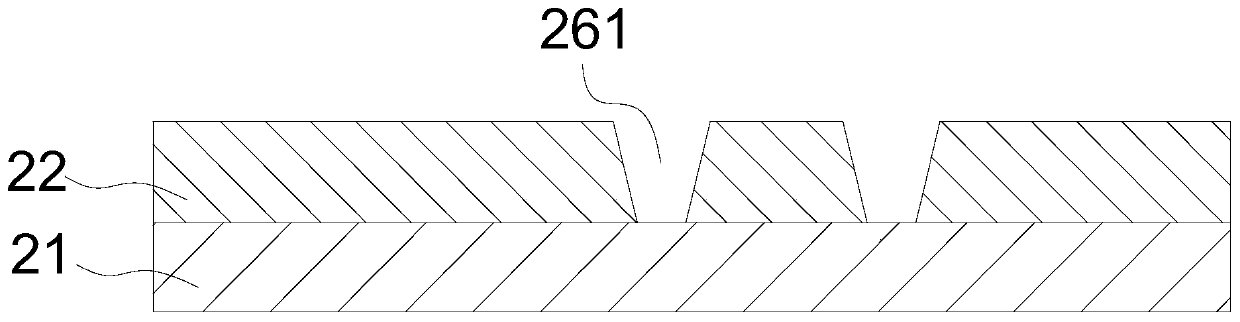

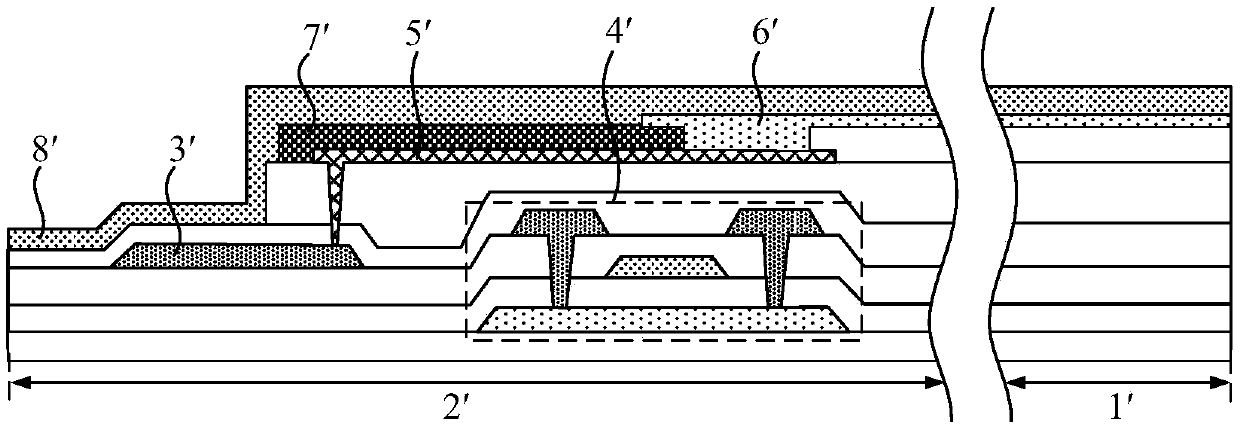

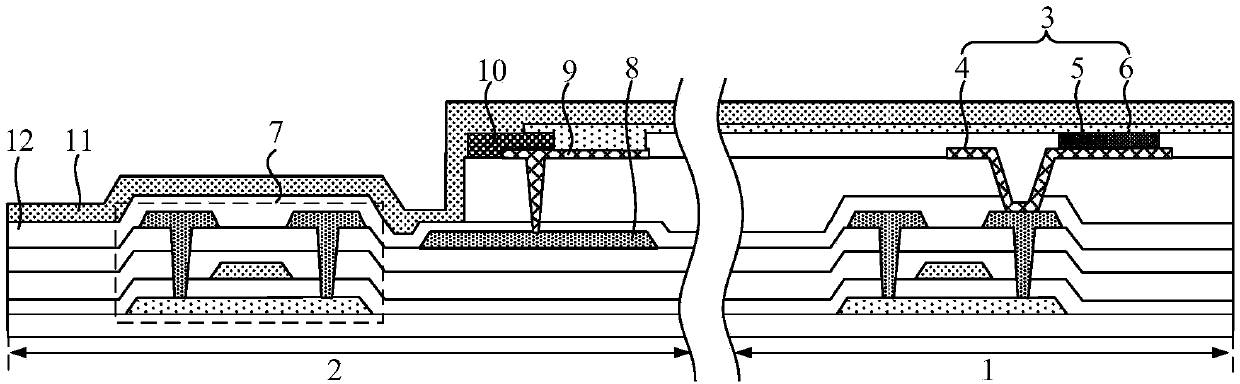

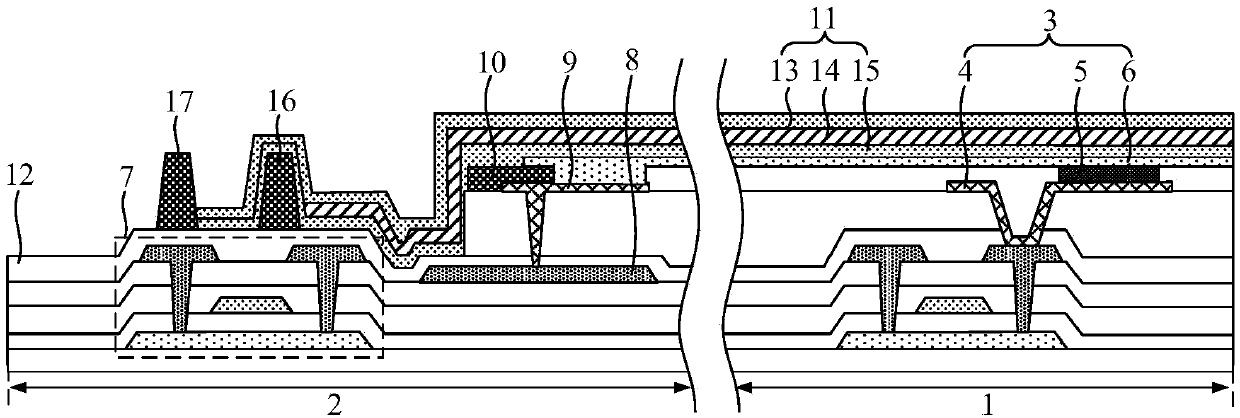

The invention relates to a preparation method of a flexible substrate base plate and a preparation method of a flexible OLED (organic light emitting diode) display, wherein the preparation method of the flexible substrate base plate comprises the following steps of providing a hard carrier base plate; forming an organic substrate layer on the hard carrier base plate, wherein the organic substrate layer is of a pattern structure and comprises a plurality of mutually separated organic substrate patterns, and each organic substrate pattern corresponds to one screen body region; forming an inorganic blocking layer on the organic substrate layer, wherein the inorganic blocking layer is of an integral surface structure, simultaneously covers the plurality of organic substrate patterns and covers the peripheral side walls of each organic substrate pattern, so that the flexible substrate base plate is prepared. In the preparation method of the flexible substrate base plate, the peripheral side wall of each organic substrate pattern (corresponding to each screen body) is covered by the inorganic blocking layer; the water and oxygen blocking capability of the front side and the lateral side of the flexible substrate base plate can be greatly improved; the water and oxygen blocking performance of the side surface of the flexible display screen body can be effectively improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

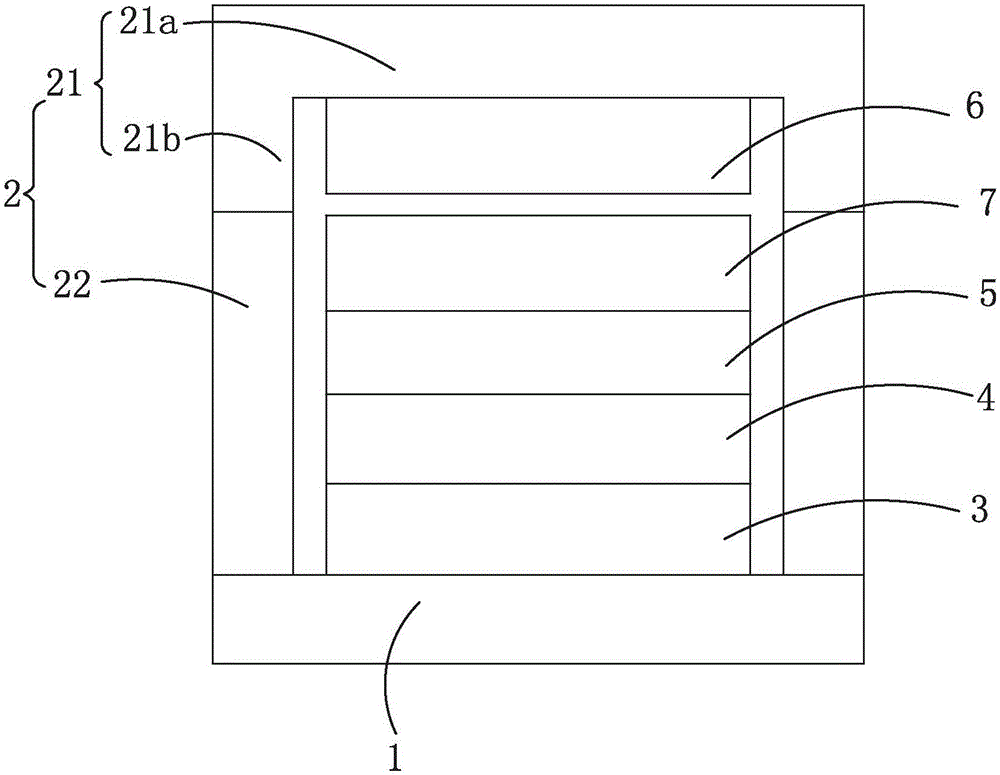

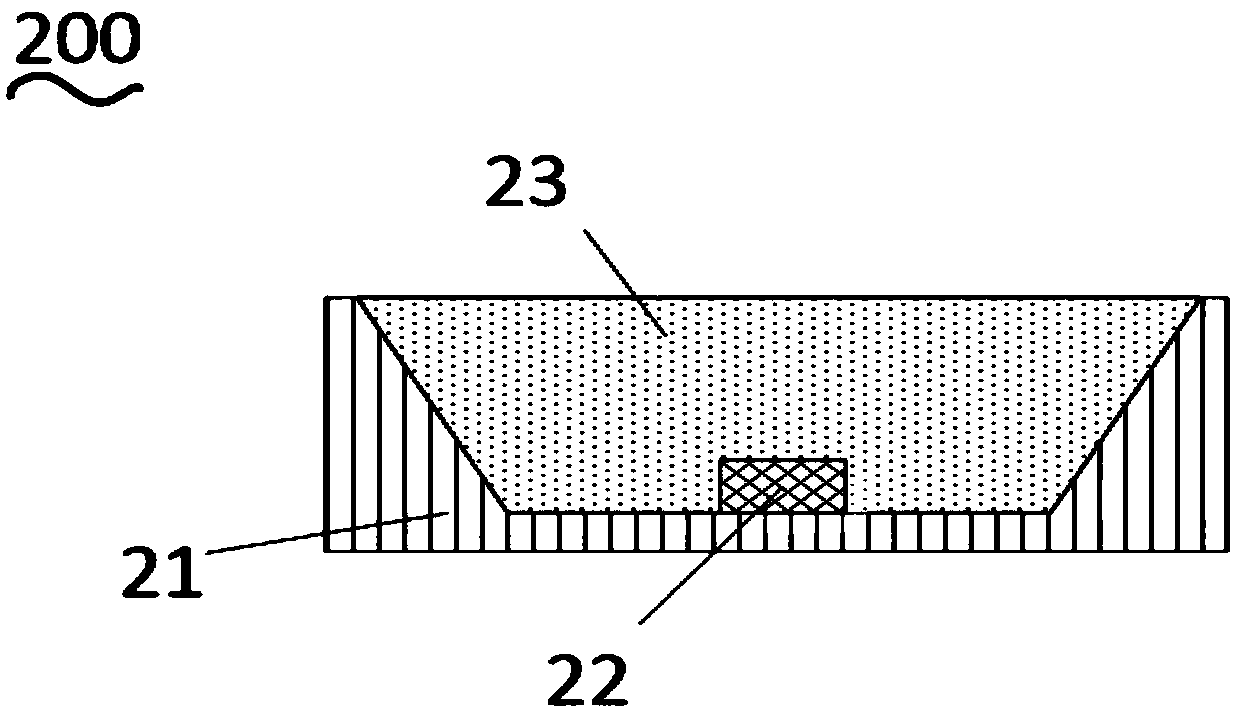

OLED and display equipment

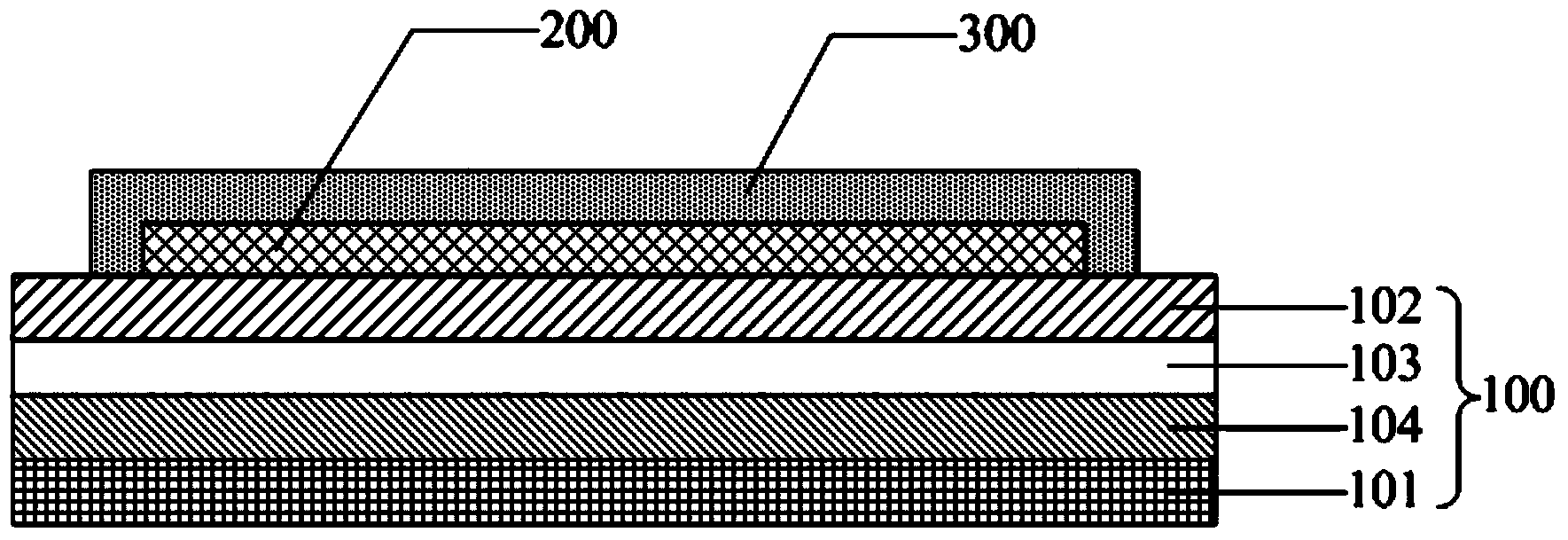

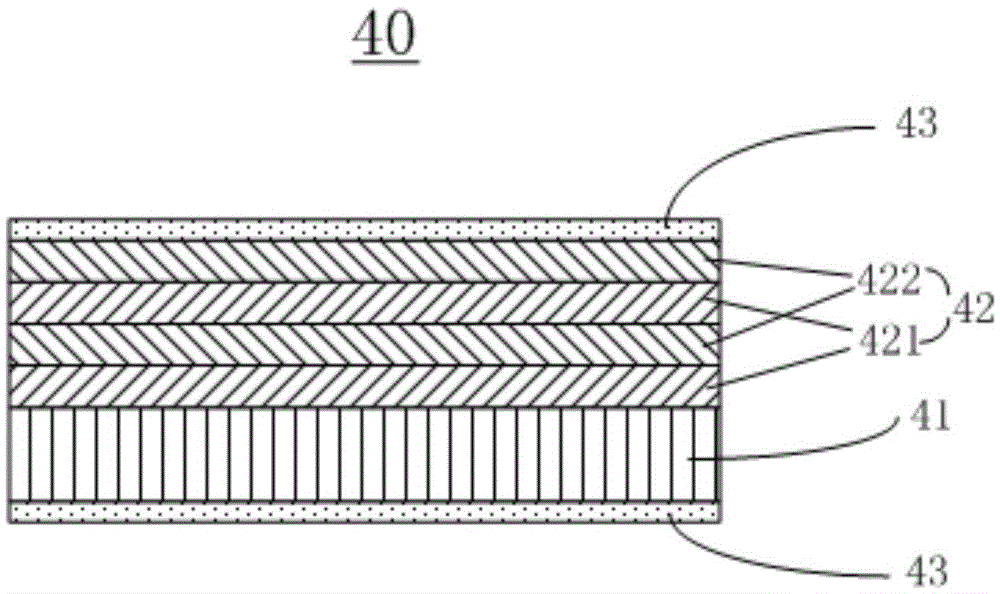

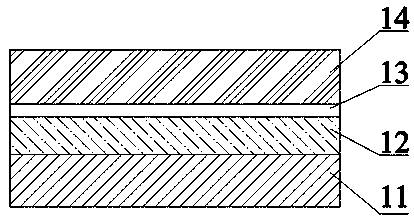

ActiveCN103682156AAvoid the problem of thickening in thickness, causing difficulty in curlingImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPolarizerOptical thin film

The invention discloses an OLED and display equipment. According to the OLED, an optical thin film laminate serves as a substrate or packaging cover plate of the OLED, wherein the optical thin film laminate comprises a circular polarizer film, a water and oxygen resistance film and a color resistance film, and the circular polarizer film, the water and oxygen resistance film and the color resistance film are located on a supporting substrate. In this way, the OLED has an anti-reflection function, good water and oxygen resistance performance and a full-color display function, and the problems that processes are tedious and cost is increased due to film pasting of the OLED are solved; in addition, the problem that curling is difficult to carry out because a flexible OLED is thickened due to film pasting is also avoided; meanwhile, the OLED has the advantages of being lighter, thinner, better in display effect and the like.

Owner:BOE TECH GRP CO LTD

White light OLED device

InactiveCN106848080AImprove lighting effectsThe overall thickness is thinSolid-state devicesSemiconductor/solid-state device manufacturingQuantum dotLight-emitting diode

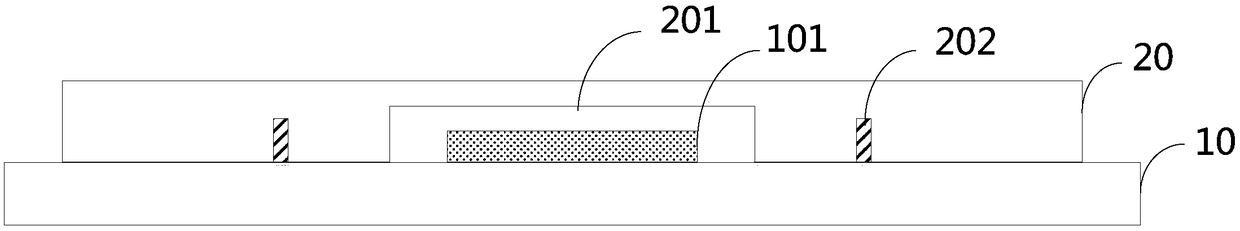

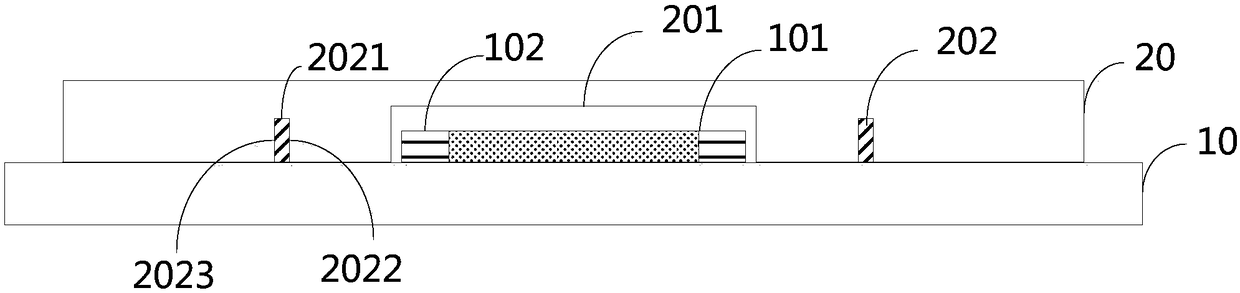

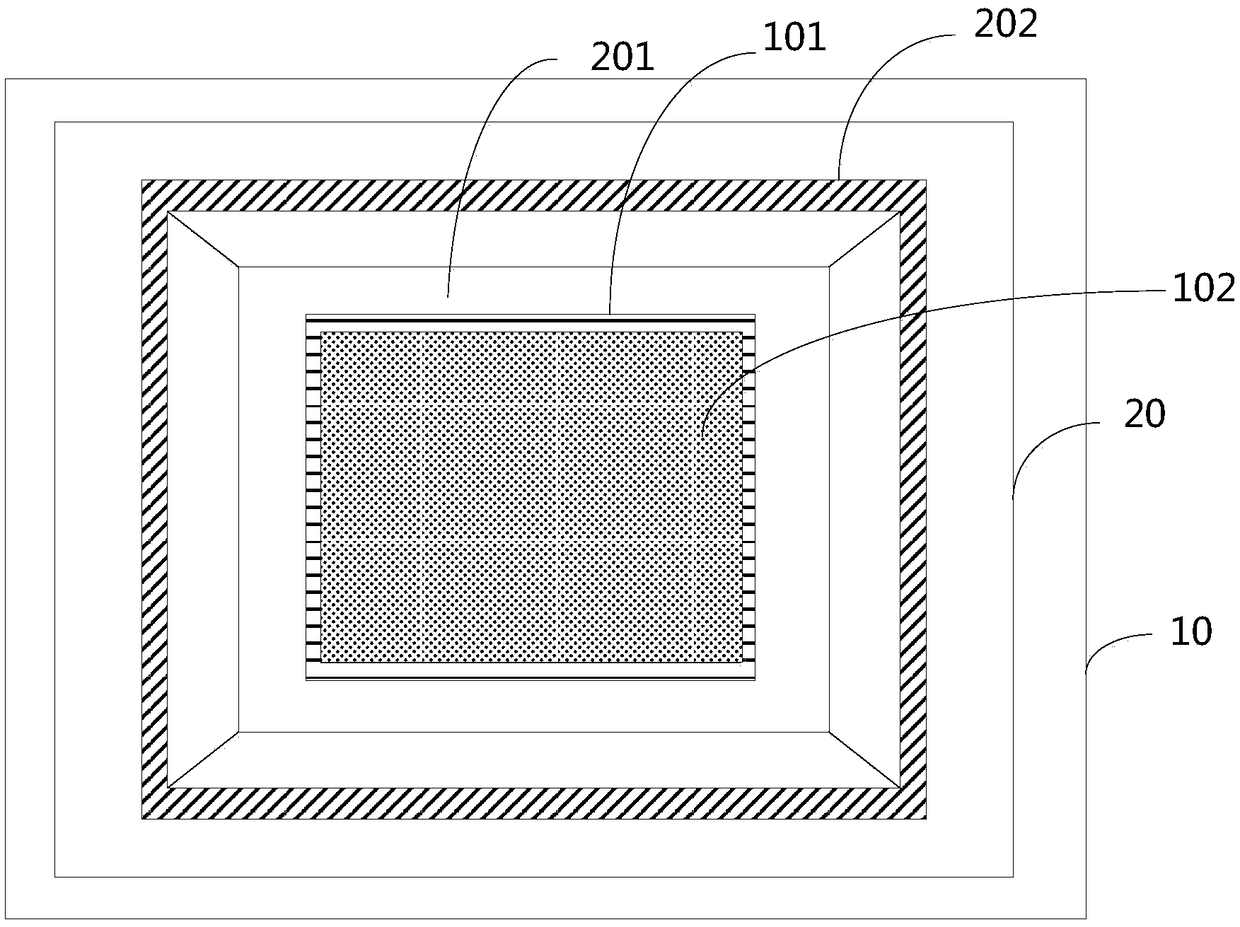

The invention relates to a white light OLED (Organic Light Emitting Diode) device. The structure includes a substrate, a packaging layer in sealed connection with the substrate so as to form a packaging space, and an anode conducting layer, a blue ray light emitting layer and a cathode conducting layer arranged in the packaging space and formed on the substrate successively. The white light OLED device also includes a quantum dot light emitting layer arranged between the packaging layer and the cathode conducting layer. The blue ray light emitting layer emits blue rays and excites the quantum dot light emitting layer to emit light. The blue rays and light emitted by the quantum dot light emitting layer are mixed into white light. In the scheme, by adopting the combination of the blue ray light emitting layer and the quantum dot light emitting layer, the OLED light color stability is improved and the OLED service lifetime is prolonged.

Owner:AAC MICROTECH CHANGZHOU

Organic electroluminescence display, optical thin film stacking body of organic electroluminescence display and preparing method of optical thin film stacking body

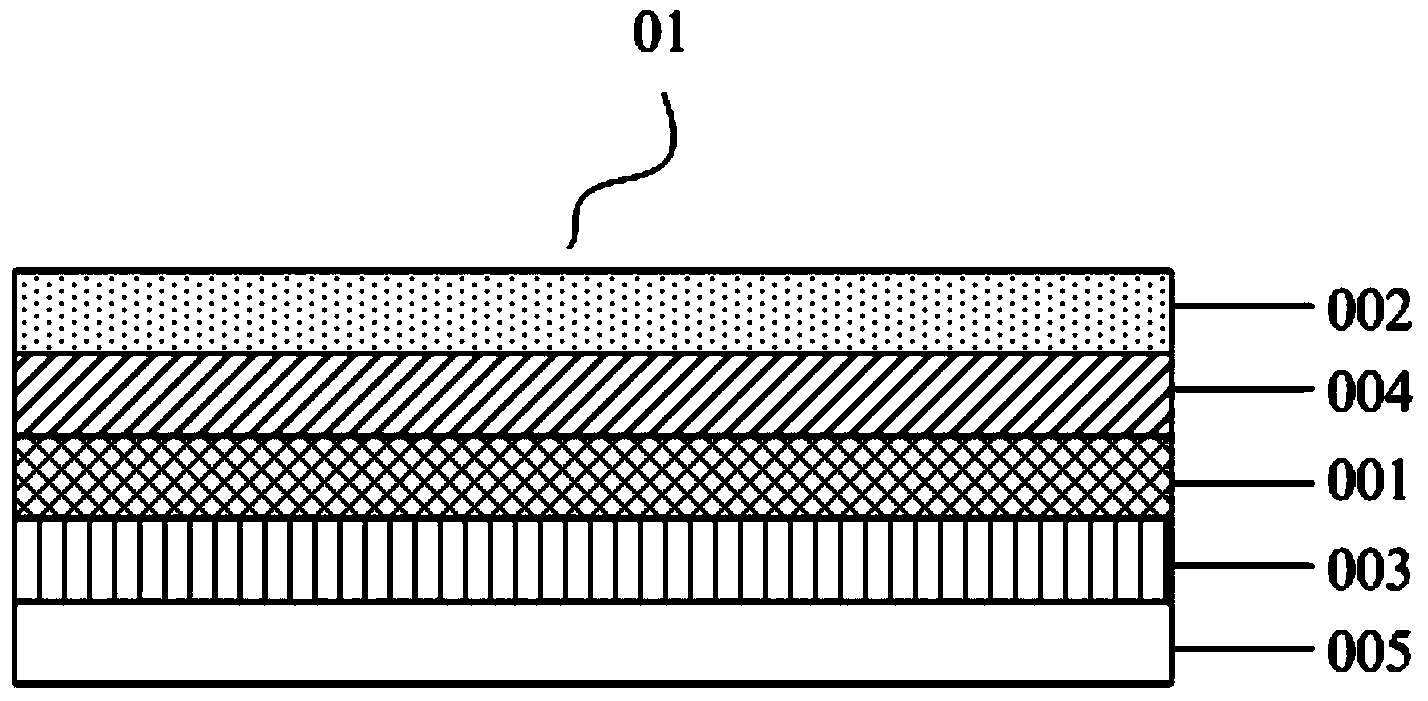

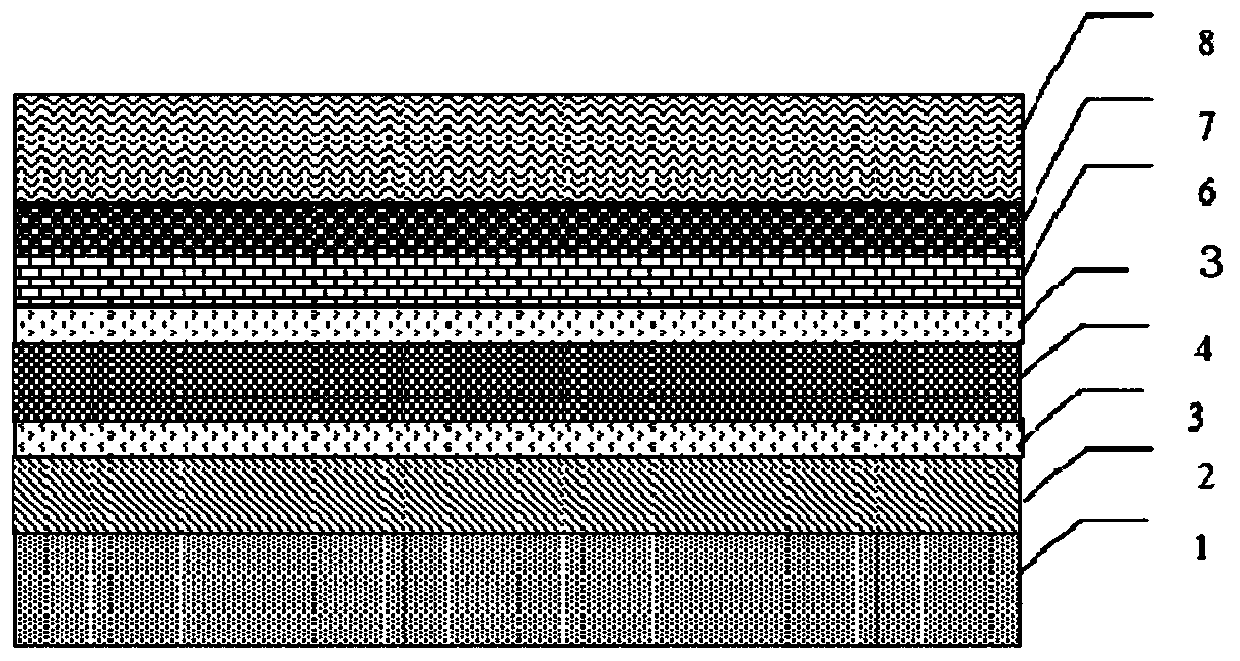

InactiveCN103682155AImprove the display effectSolve process problemsFinal product manufactureSolid-state devicesOptical thin filmWater block

The invention discloses an organic electroluminescence display, an optical thin film stacking body of the organic electroluminescence display and a preparing method of the optical thin film stacking body. The optical thin film stacking body comprises a circular polaroid film layer, a protection film layer located on the incident side of the circular polaroid film layer, a binding layer located on the light-emitting side of the circular polaroid film layer and a water blocking oxygen film layer. The water blocking oxygen film layer is located between the light-emitting side of the circular polaroid film layer and the binding layer, and / or located between the incident side of the circular polaroid film layer and the protection film layer. Due to the fact that the optical thin film stacking body comprises the circular polaroid film layer and the water blocking oxygen film layer, the optical thin film stacking body has the anti-reflection function and the good water blocking oxygen property. When the optical thin film stacking body with the double functions is applied to the OLED, the problems, caused by secondary pasting, of the complex technological process, high cost and soft OLED crimping difficulty and the like are solved, and meanwhile the OLED can have the advantages of being lighter, thinner, better in displaying effect and the like.

Owner:BOE TECH GRP CO LTD

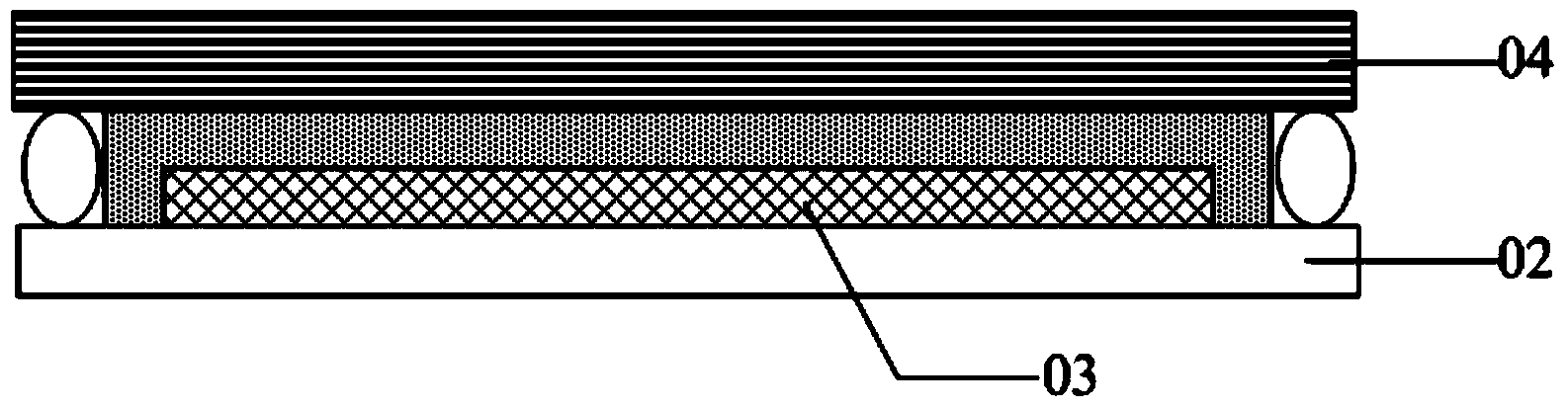

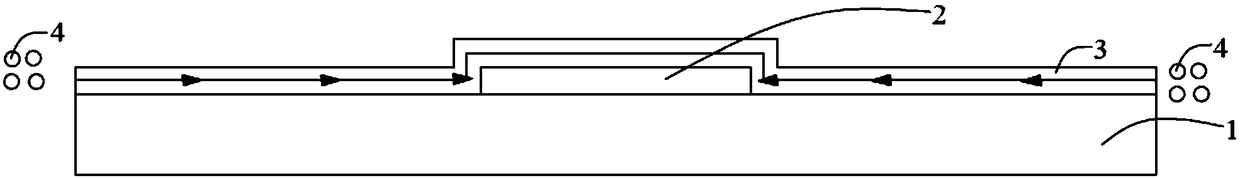

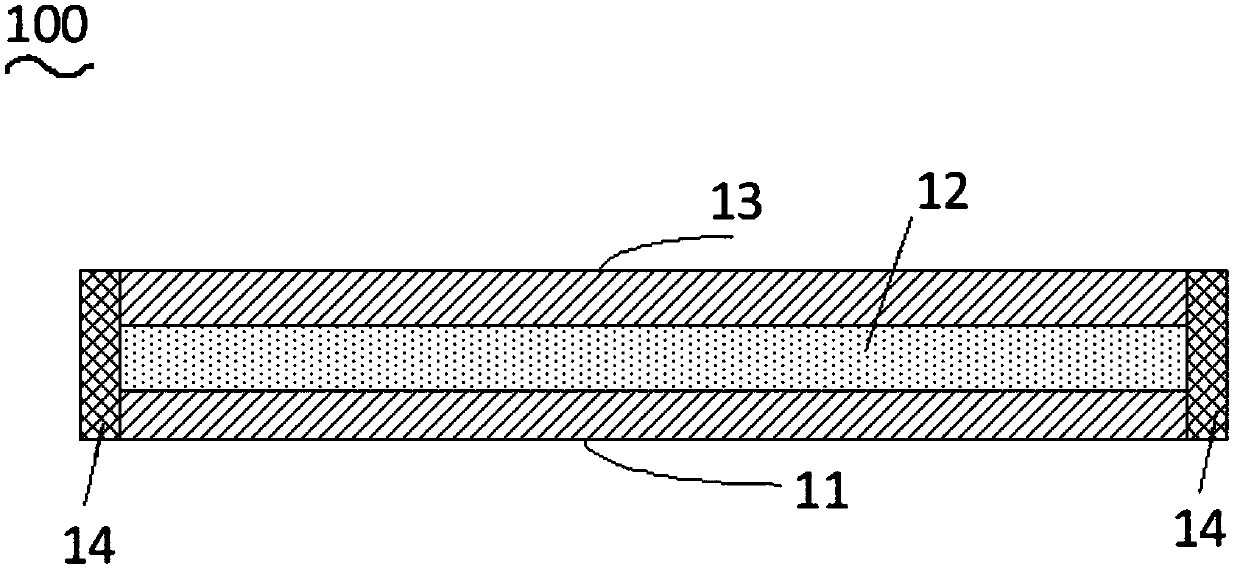

Transparent flexible encapsulation substrate and flexible OLED encapsulation method

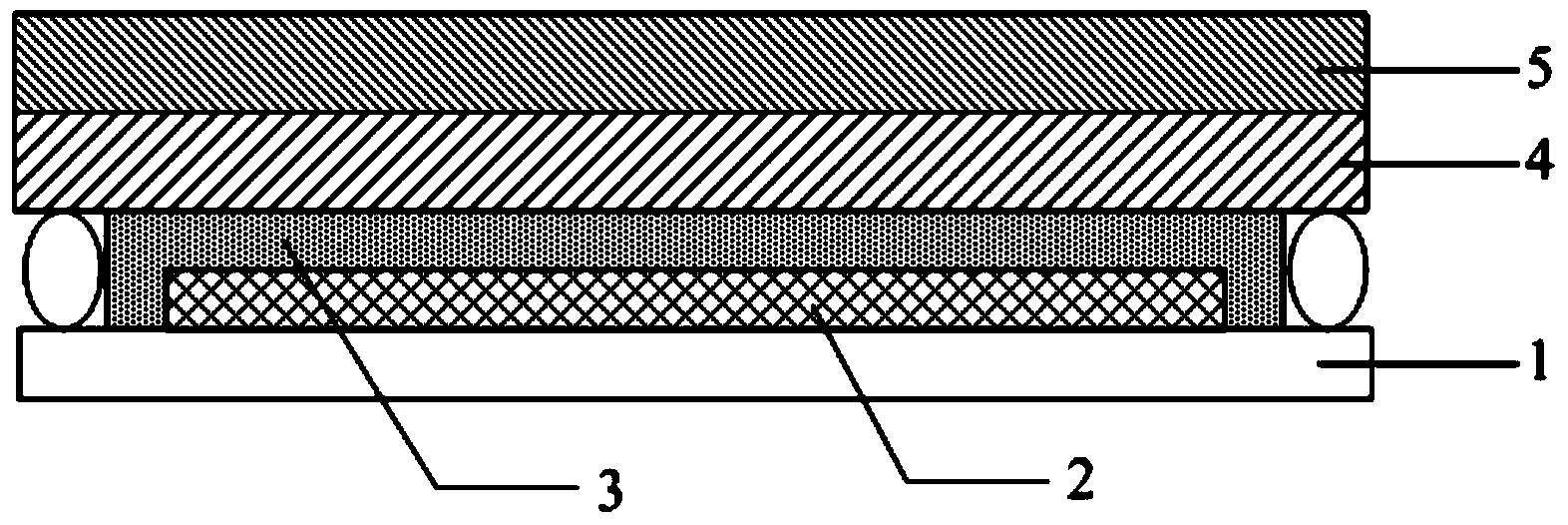

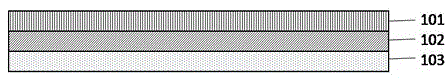

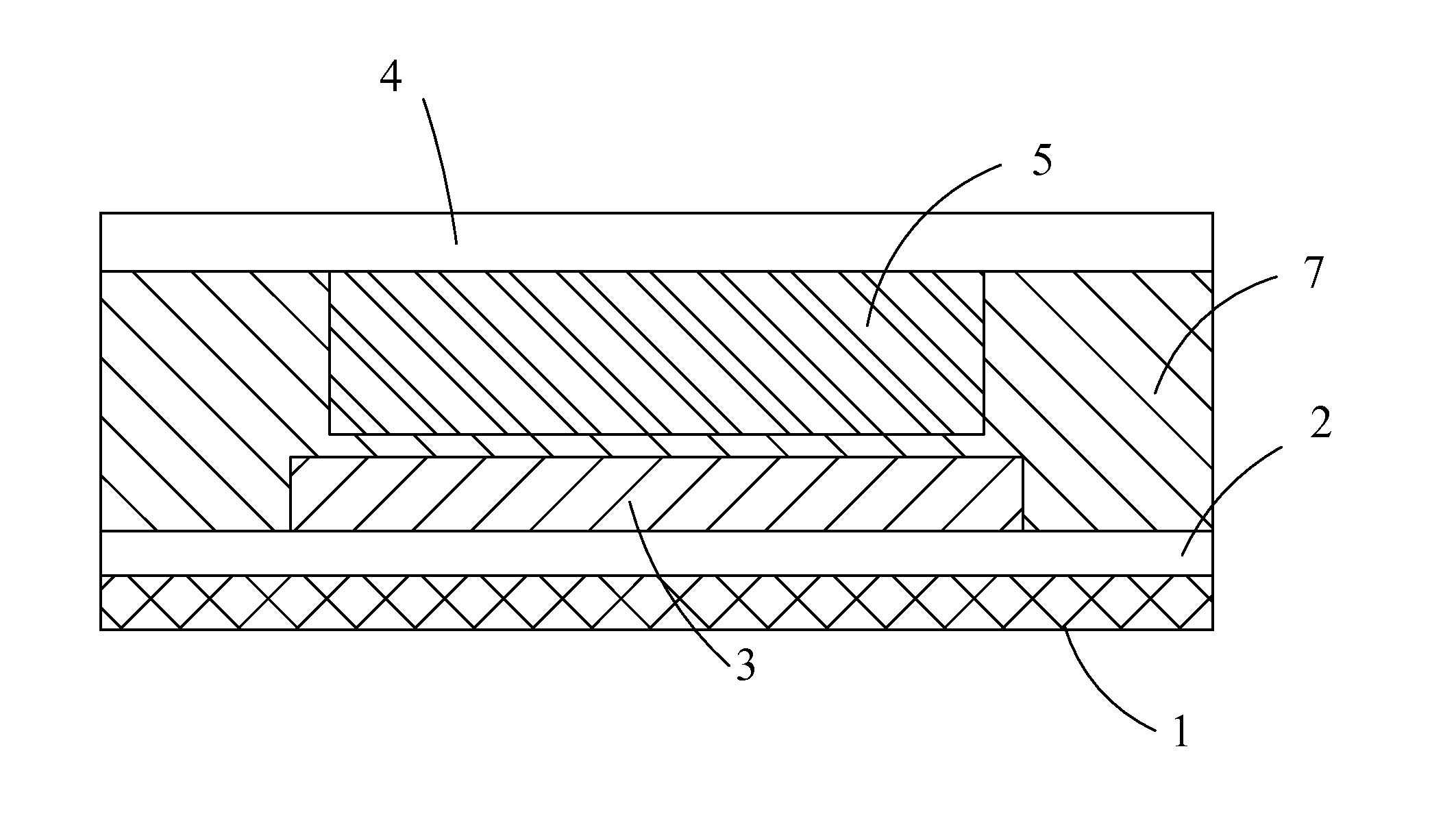

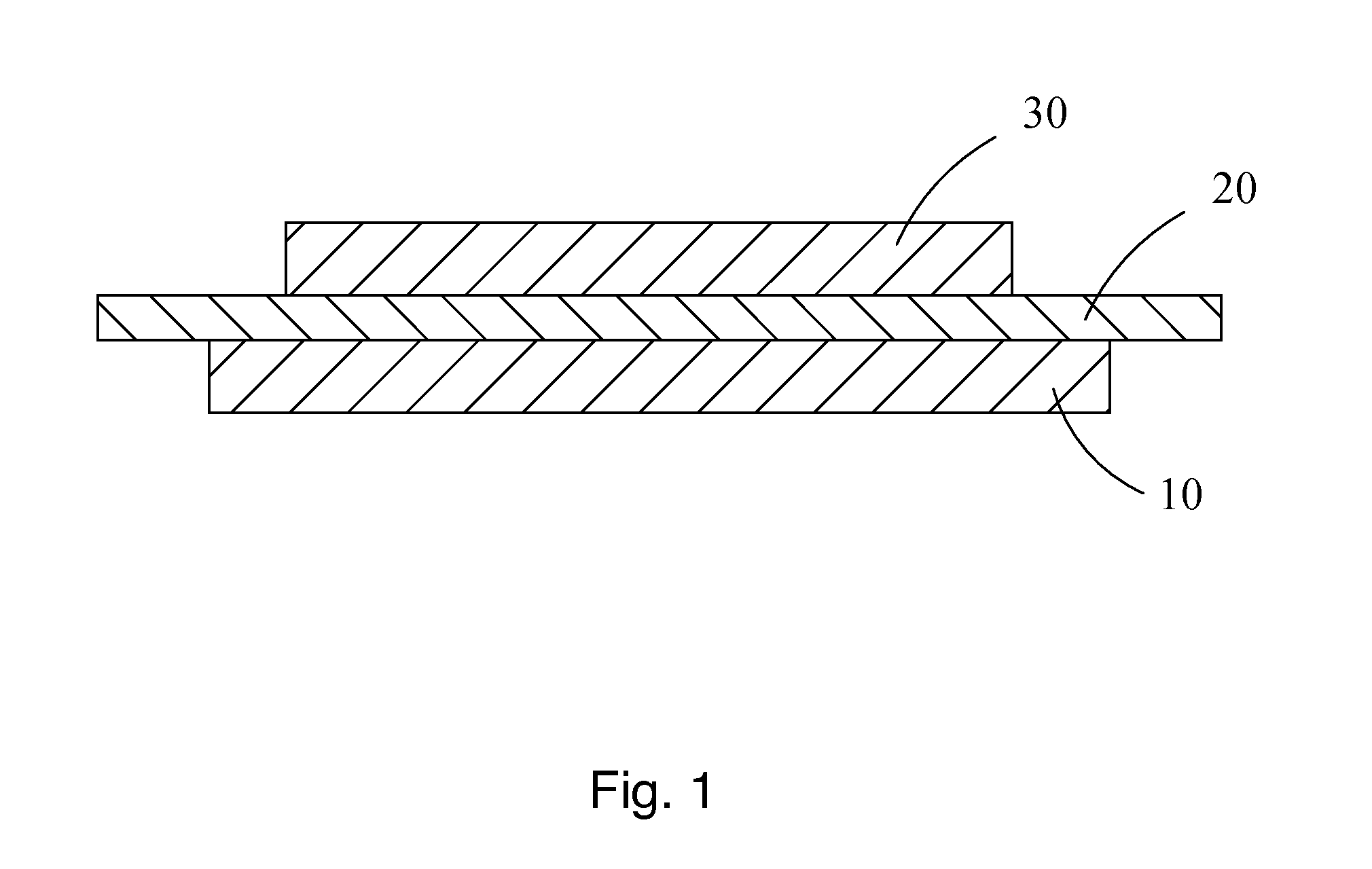

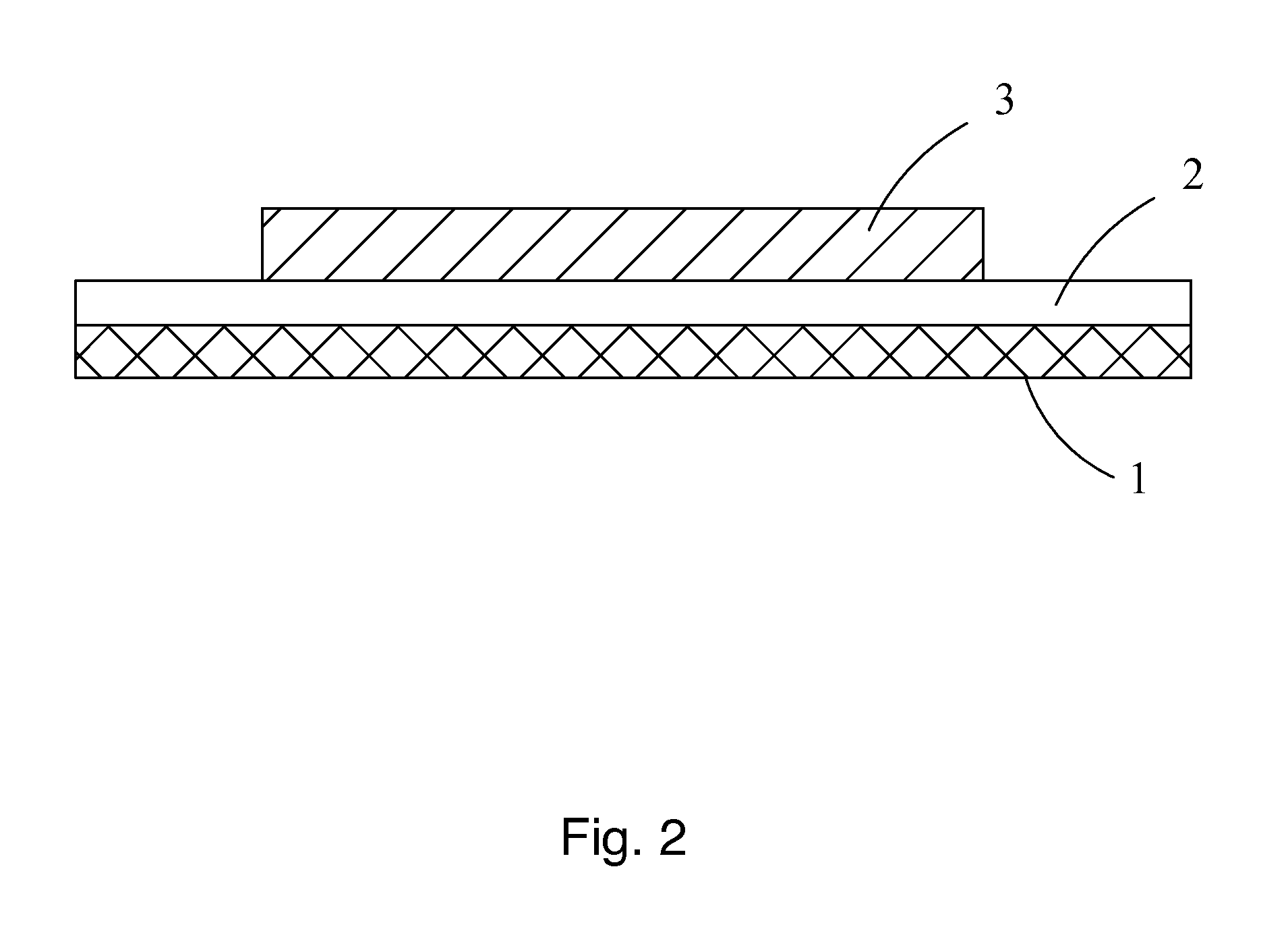

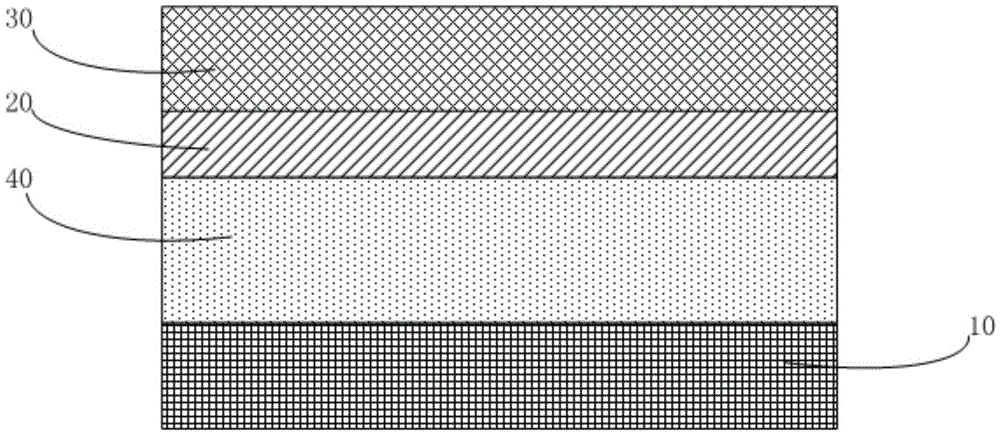

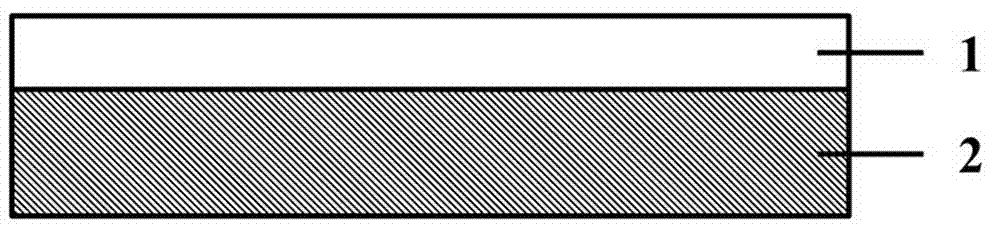

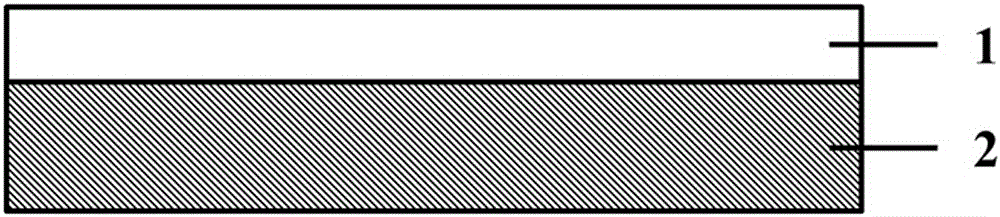

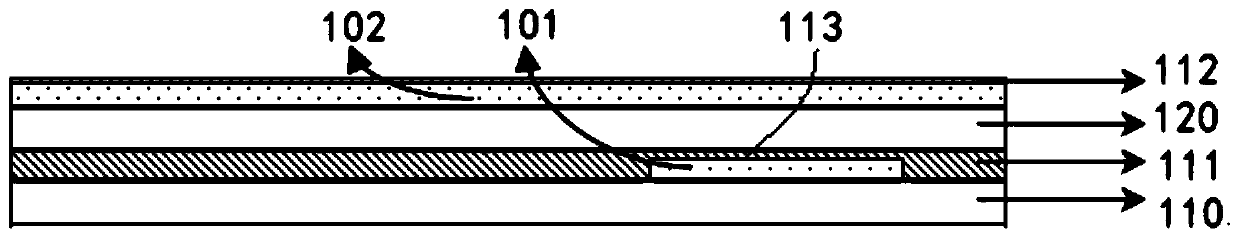

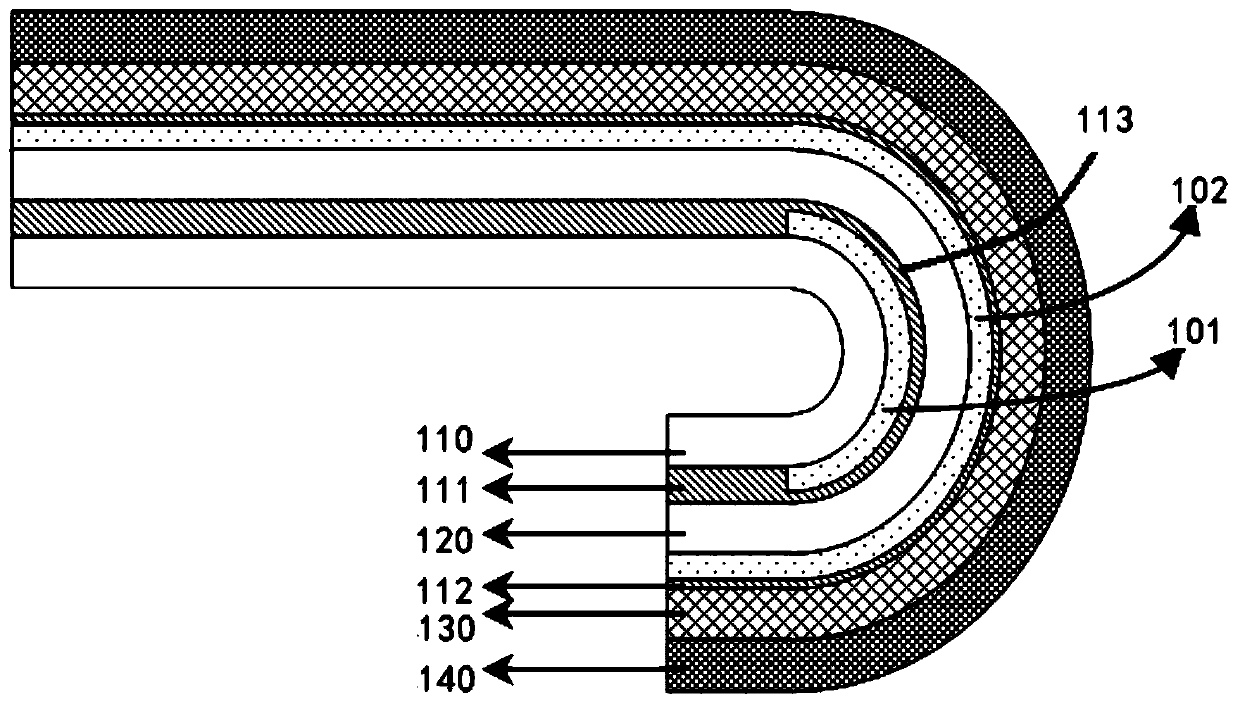

InactiveCN104576964AGood flexibilityImprove water and oxygen resistanceSynthetic resin layered productsSolid-state devicesRubber materialDisplay device

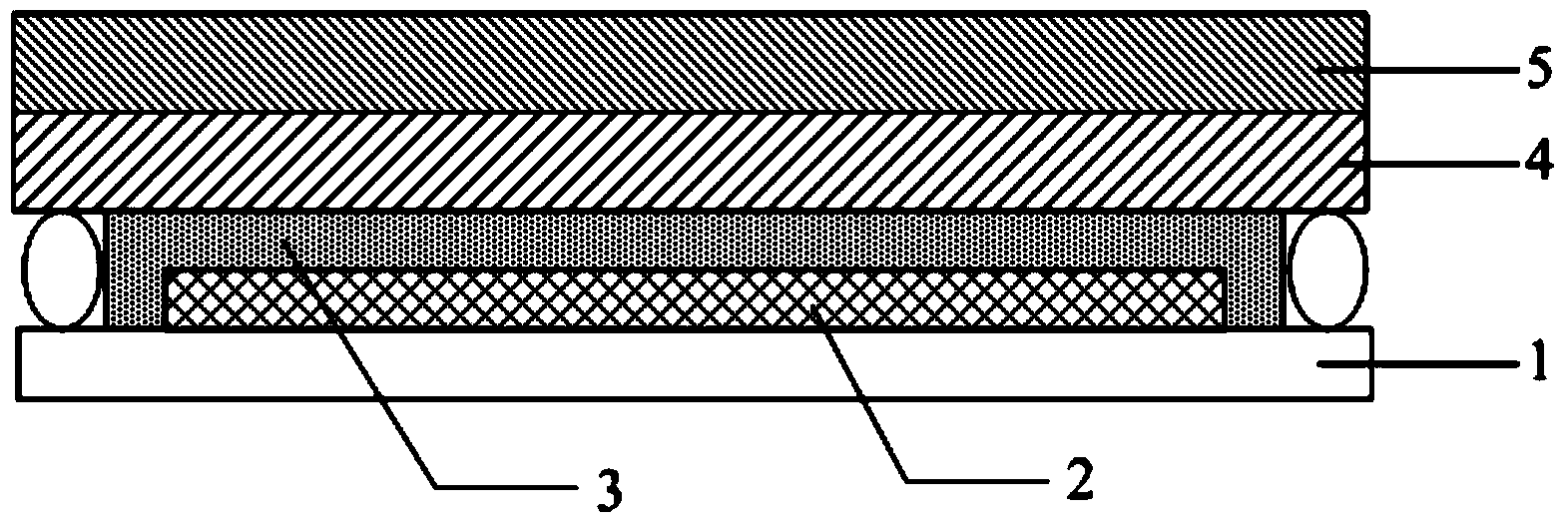

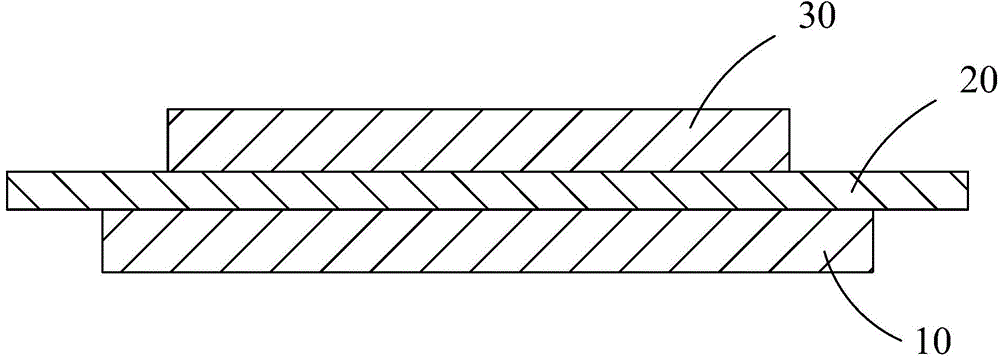

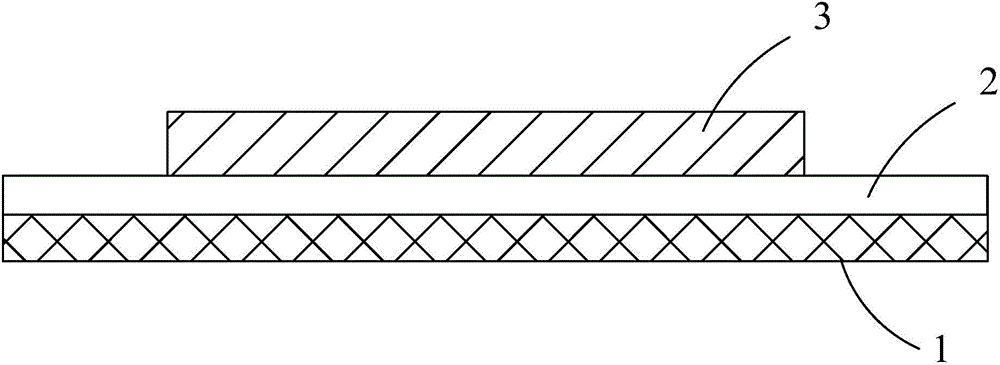

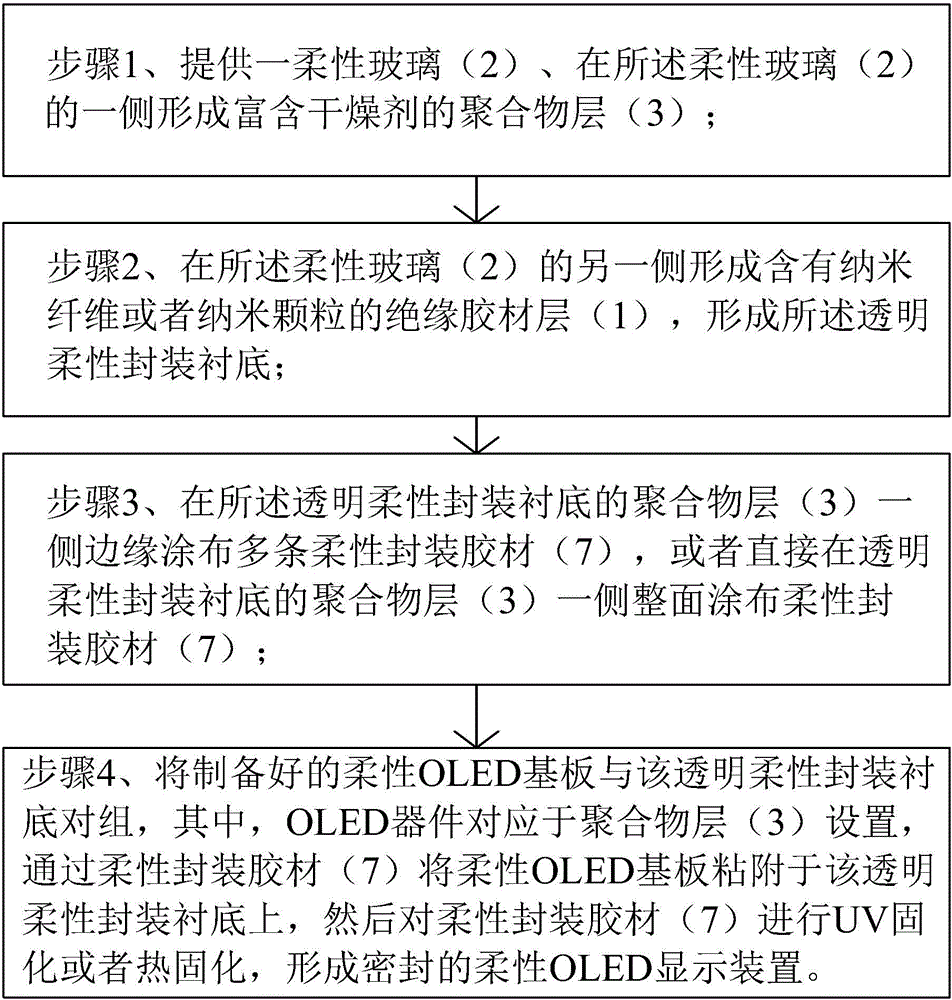

The invention provides a transparent flexible encapsulation substrate and a flexible OLED encapsulation method. The transparent flexible encapsulation substrate comprises flexible glass (2), an insulating rubber material layer (1) arranged on one side of the flexible glass (2) and a polymer layer (3) arranged on the other side of the flexible glass (2), wherein the surface size of the flexible glass (2) is larger than the surface size of the polymer layer (3); the surface size of the flexible glass (2) is smaller than or equal to the surface size of the insulating rubber material layer (1). The transparent flexible encapsulation substrate has excellent flexibility and water and oxygen blocking capability. The transparent flexible encapsulation substrate prepared from the flexible glass material is applied in a wide range and can be applied in the encapsulation of various OLED display devices.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

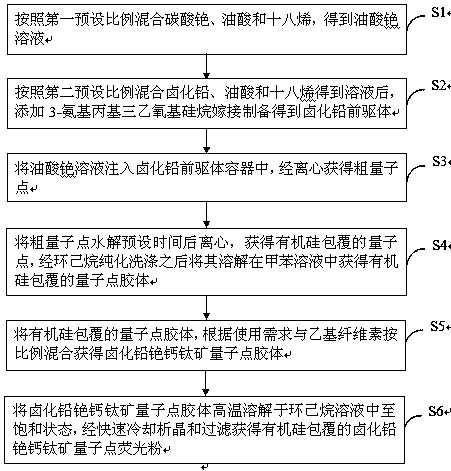

Preparation method for lead halide caesium perovskite quantum dot colloid and quantum dot fluorescent powder

ActiveCN109266343ASolve instabilityImprove luminous efficiencyLuminescent compositionsOrganosiliconQuantum dot

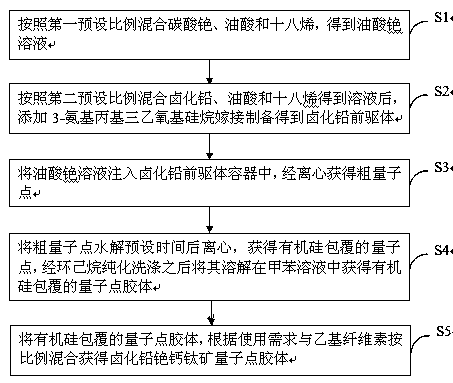

The invention discloses a preparation method for a lead halide caesium perovskite quantum dot colloid and a quantum dot fluorescent powder. The preparation method for the quantum dot colloid comprisesthe following steps: mixing cesium carbonate, oleic acid and octadecene at ratio, thereby acquiring a cesium oleate solution; mixing lead halide, oleic acid and octadecene at ratio, thereby acquiringa solution; adding 3-aminopropyl triethoxysilane into the solution and grafting, thereby acquiring a lead halide precursor; injecting the cesium oleate solution into a container containing the lead halide precursor and centrifuging, thereby acquiring a crude quantum dot; hydrolyzing the crude quantum dot for a preset period of time and then centrifuging, thereby acquiring an organic silicon coated quantum dot; washing with cyclohexane and then dissolving in a methylbenzene solution, thereby acquiring an organic silicon coated quantum dot colloid; mixing the organic silicon coated quantum dotcolloid with ethyecellulose at ratio according to the use requirement, thereby acquiring the lead halide caesium perovskite quantum dot colloid. 3-aminopropyl triethoxysilane and ethyecellulose double-layer chemical bonding coating is adopted, so that the lead halide caesium perovskite quantum dot colloid with high stability is acquired.

Owner:NANCHANG UNIV

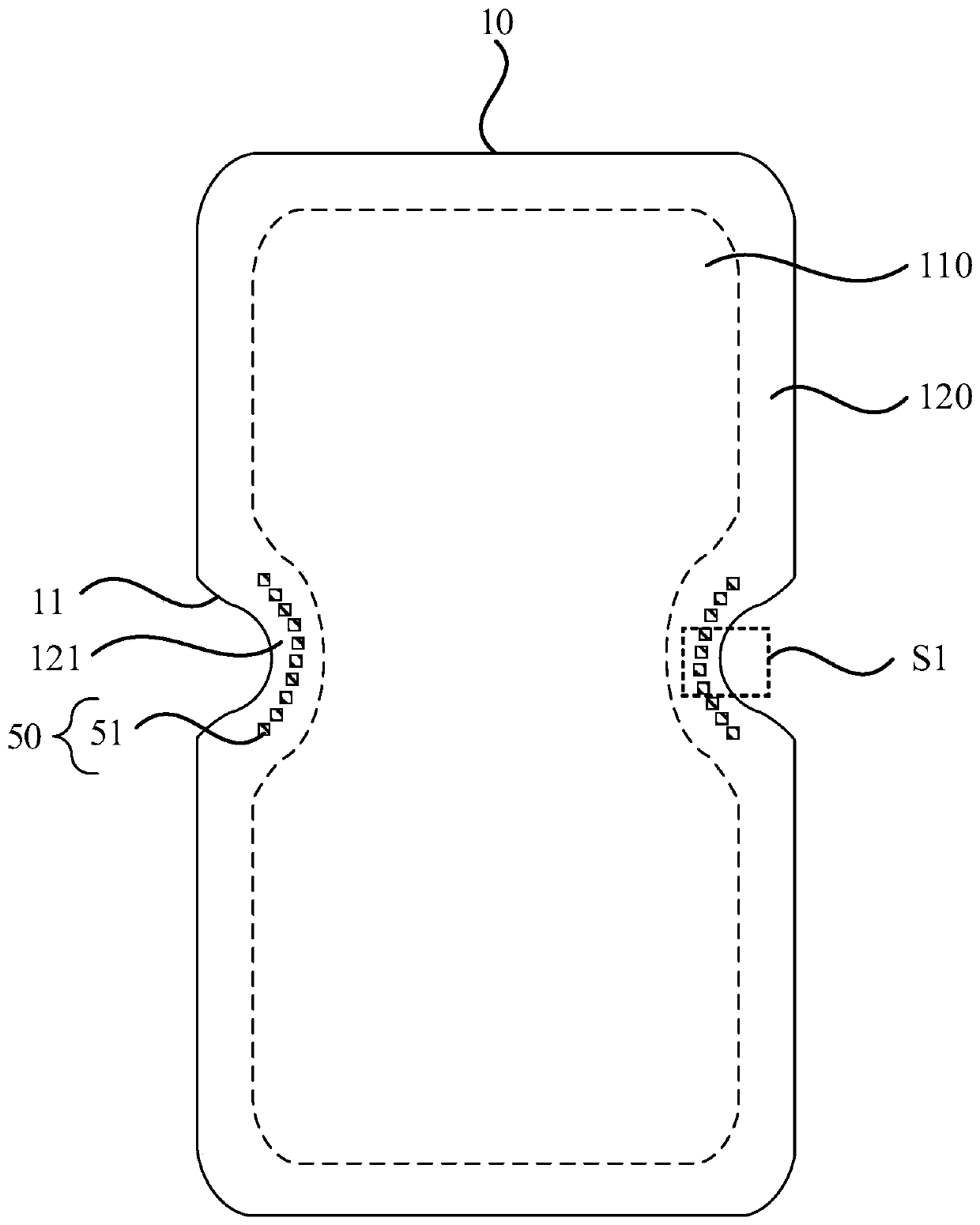

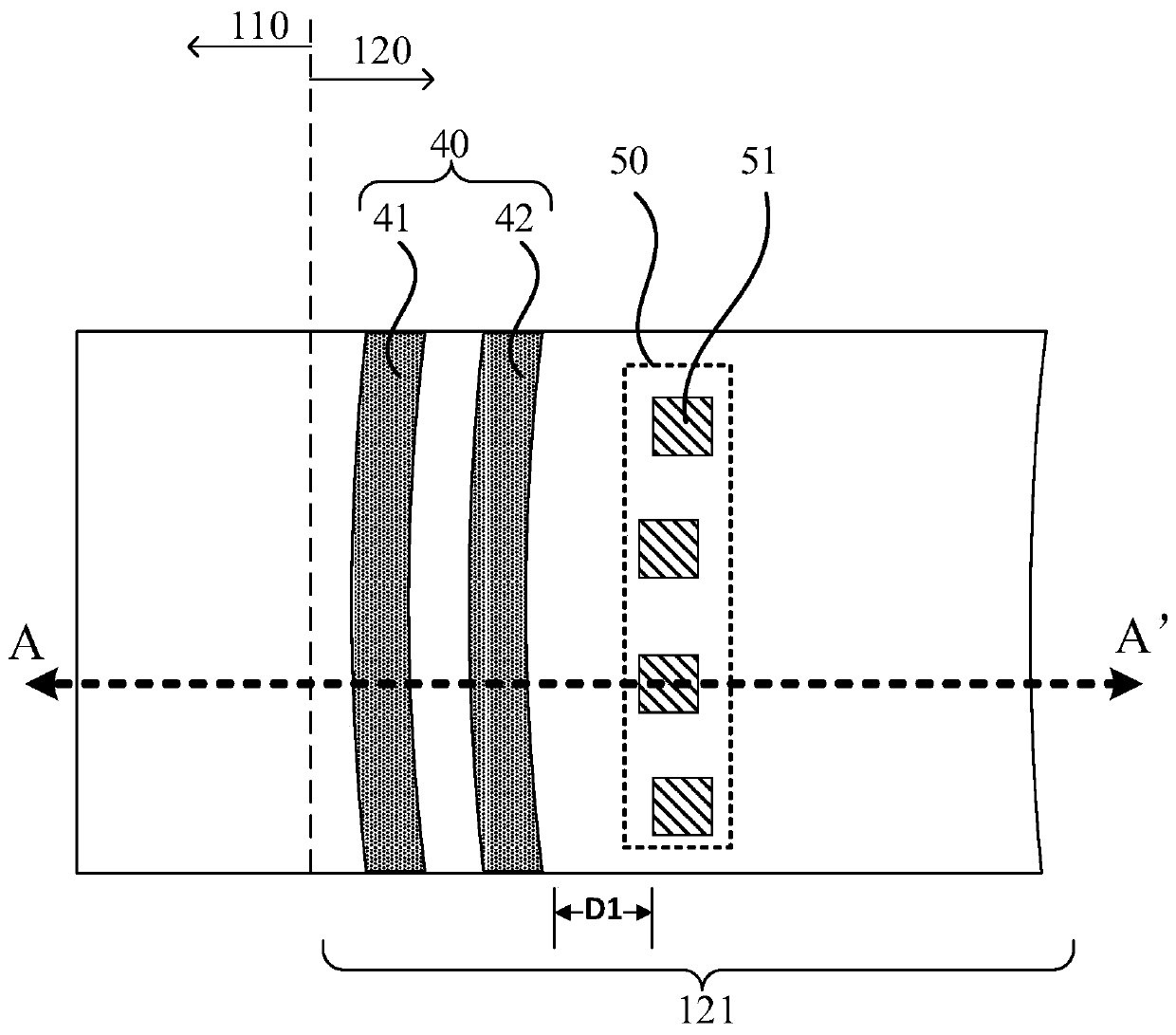

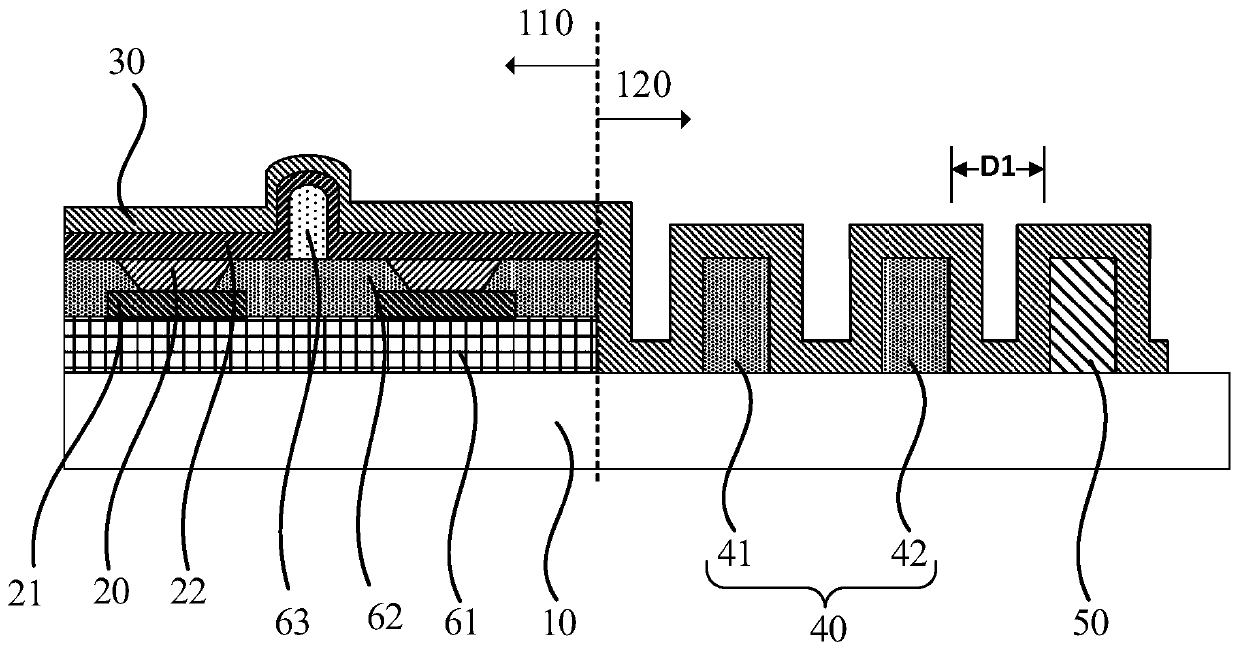

Organic light-emitting display panel and display device

ActiveCN110211998AReduce stressImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an organic light-emitting display panel and a display device. The organic light-emitting display panel comprises a substrate, an organic light-emitting structure layer, a thin film packaging layer, at least one retaining wall and at least one protective device, wherein the substrate comprises a display area, a non-display area, at least one special-shaped edge located in thenon-display area and at least one special-shaped area corresponding to the at least one special-shaped edge; the special-shaped area is an area in the non-display area adjacent to the special-shapededge on the substrate; the organic light-emitting structure layer is located on one side of the substrate and located in the display area; the thin film packaging layer is located on one side, far away from the substrate, of the organic light-emitting structure layer; the thin-film packaging layer comprises at least one inorganic layer; the inorganic layers in the thin film packaging layer cover the organic light-emitting structure layer in the display area and extend to cover part of the substrate in the non-display area; the at least one retaining wall is located in the non-display area; theinorganic layers cover the at least one retaining wall; and the at least one protective device is located in the special-shaped area and is located on one side, far away from the display area, of theat least one retaining wall. The water and oxygen resistance of the thin film packaging layer can be improved, so that the occurrence of package failure can be prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

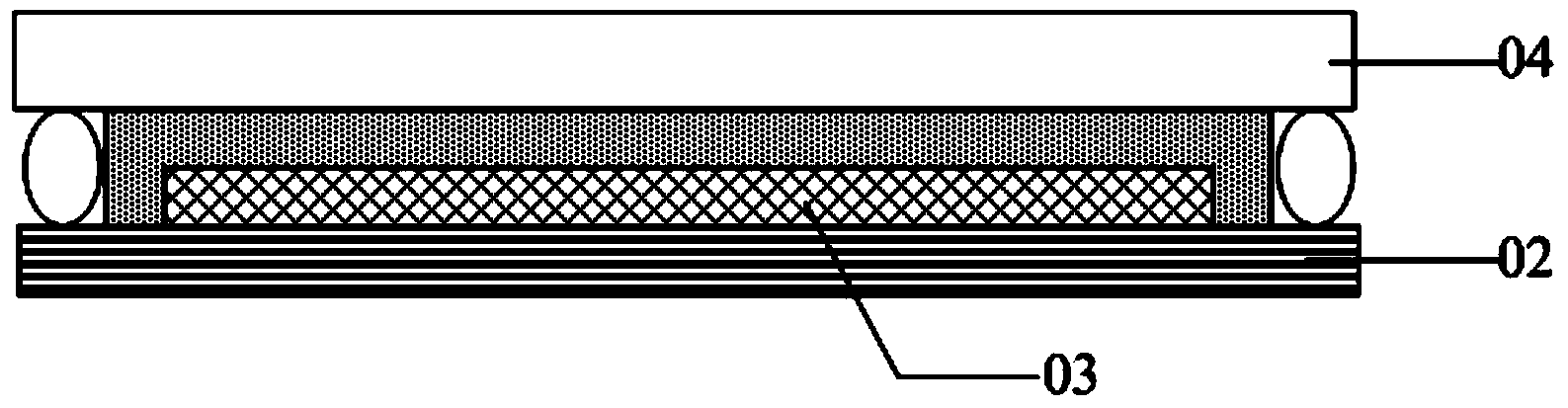

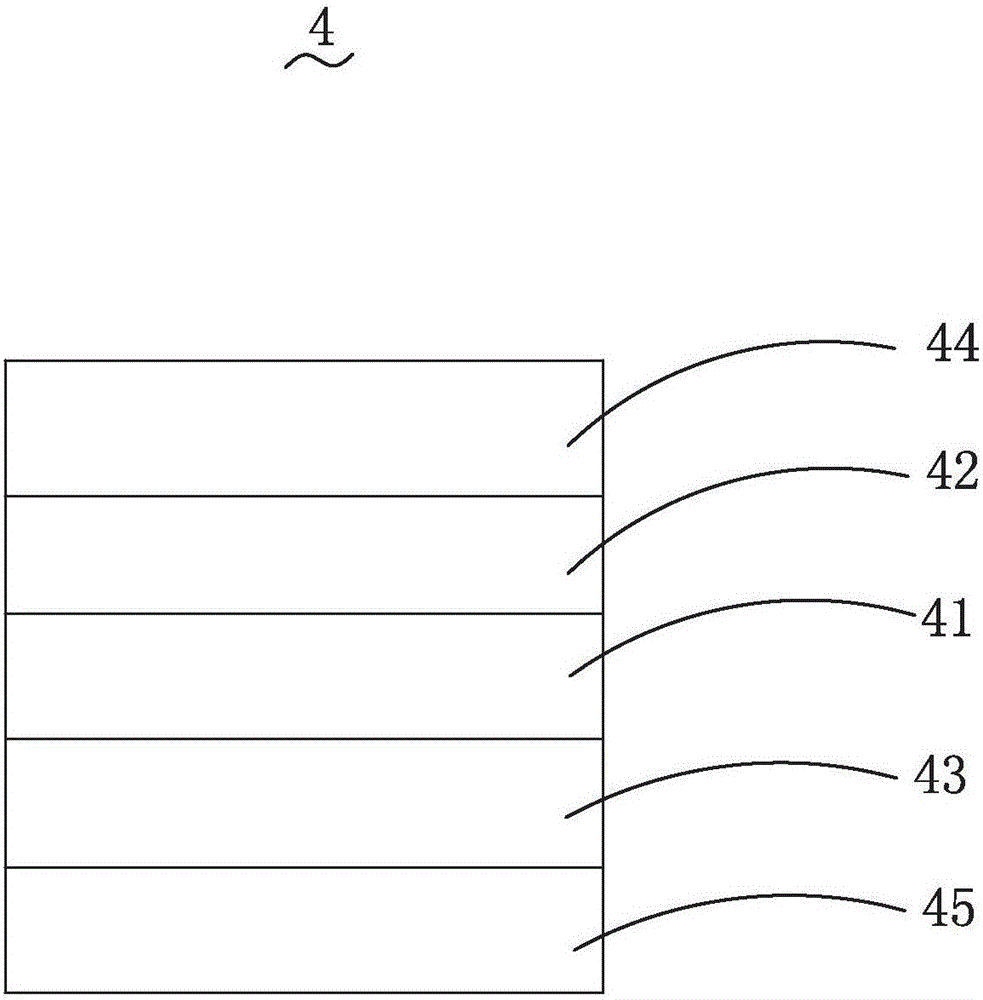

Organic electroluminescent display device and manufacturing method and display device thereof

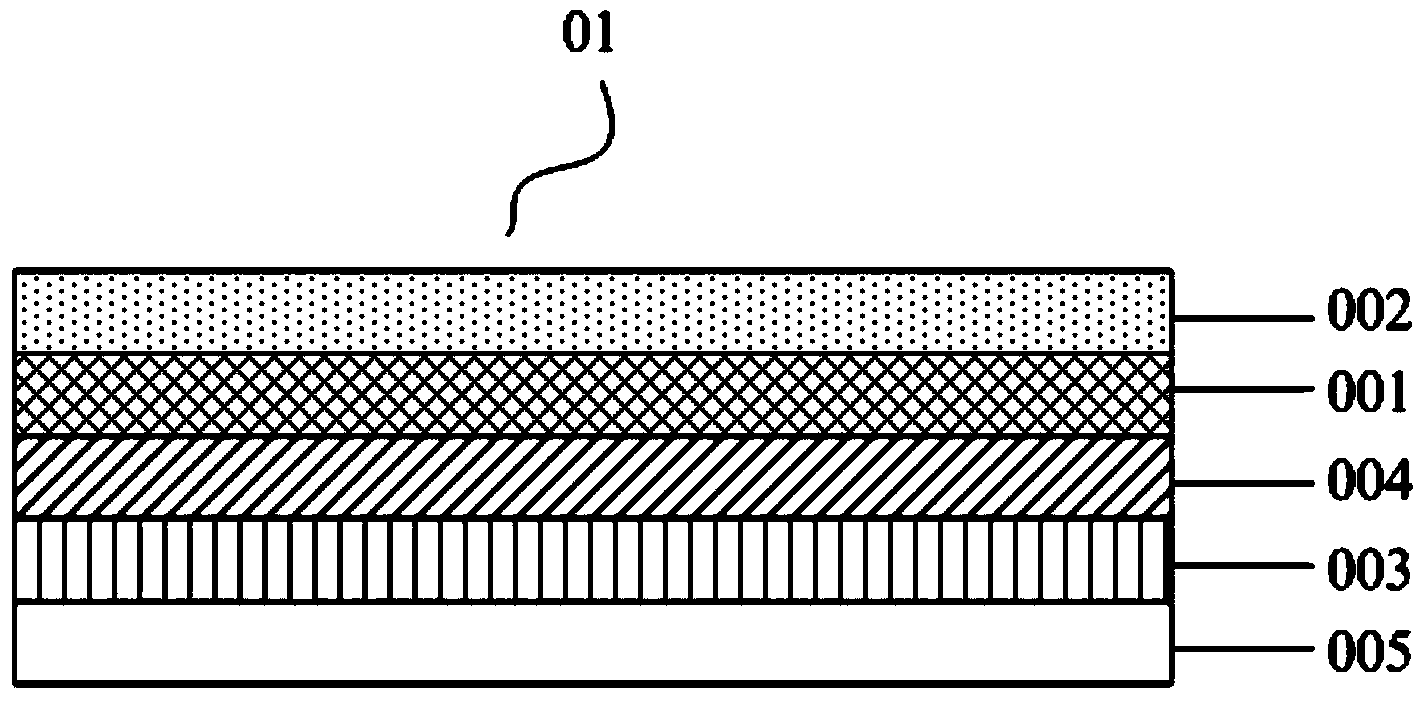

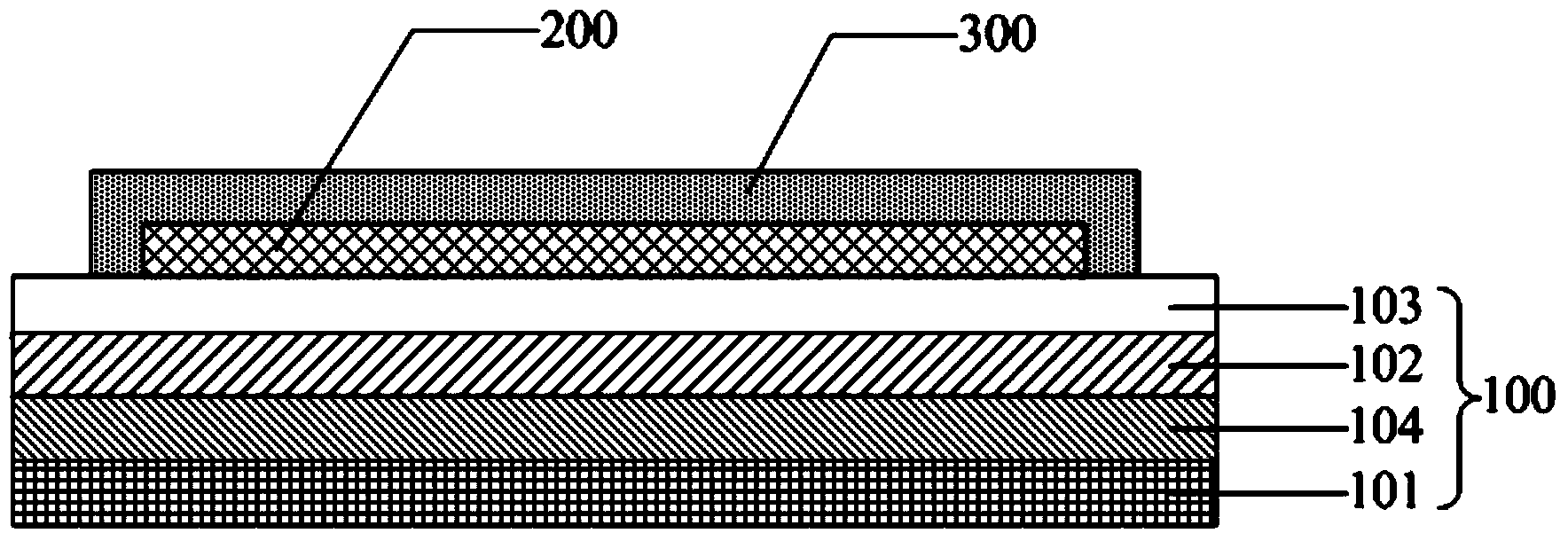

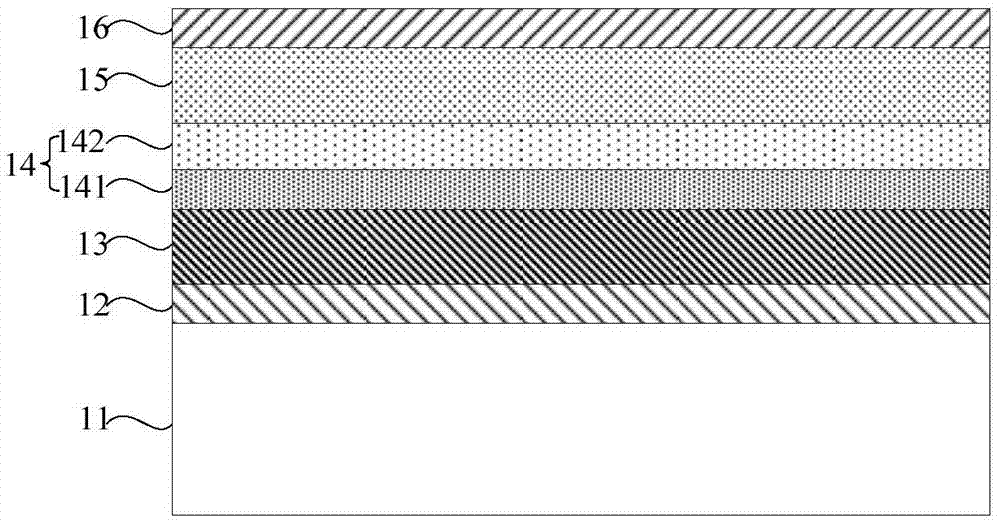

InactiveCN103682158AWith water and oxygen resistanceImprove water and oxygen resistanceFinal product manufactureSolid-state devicesComposite filmPhase difference

The invention discloses an organic electroluminescent display device and a manufacturing method and a display device of the organic electroluminescent display device. A multifunctional composite film layer is adopted for a substrate bearing an organic electroluminescent pixel array. The substrate comprises a body material film layer, a first phase difference film layer, a water blocking oxygen film layer and a polarized light function film layer, wherein the body material film layer, the first phase difference film layer, the water blocking oxygen film layer and the polarized light function film layer are arranged in a mutual stacking mode, the first phase difference film layer and the polarized light function film layer have the anti-reflection effect after being combined, and the water blocking oxygen film layer has the water blocking oxygen performance. Thus, the substrate can have both the anti-reflection effect and the good water blocking oxygen performance, the secondary film pasting technology for pasting circular polarizers and the water blocking oxygen film layer on the bottom-emission type organic electroluminescent display device manufactured on the substrate can be omitted, the manufacturing process is simplified, production cost is reduced, and meanwhile the curving difficulty problem caused by the situation that the flexible device is thickened because of secondary film pasting can be avoided.

Owner:BOE TECH GRP CO LTD

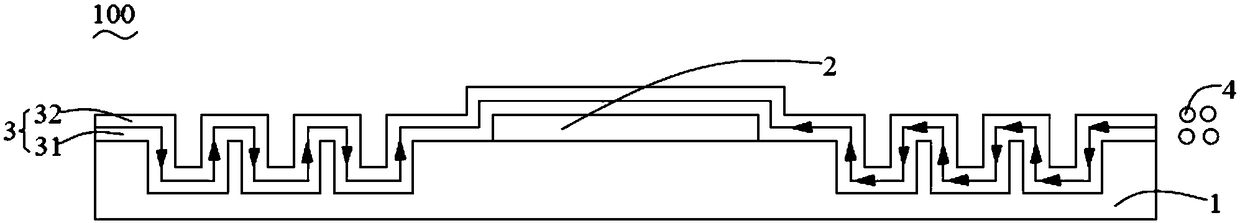

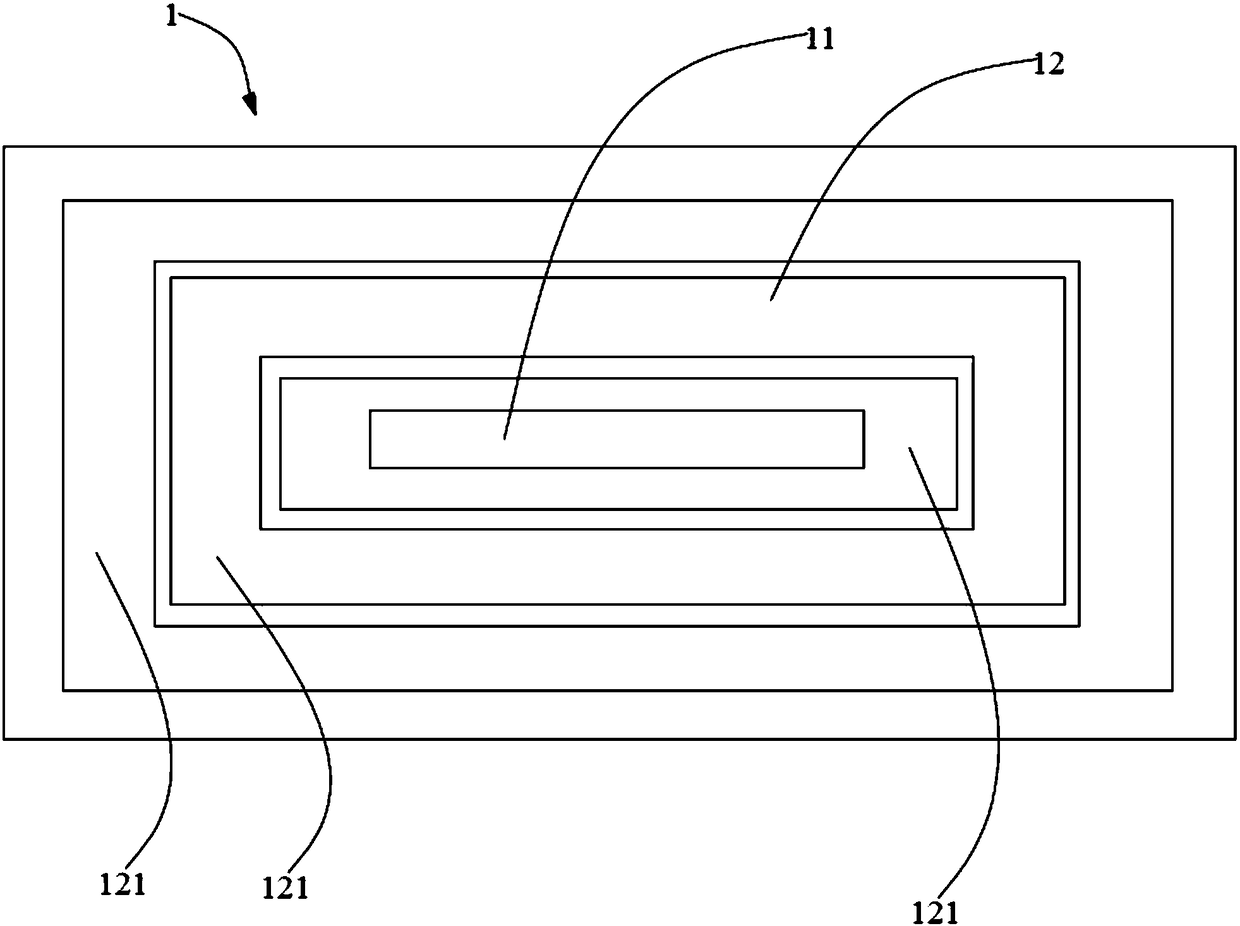

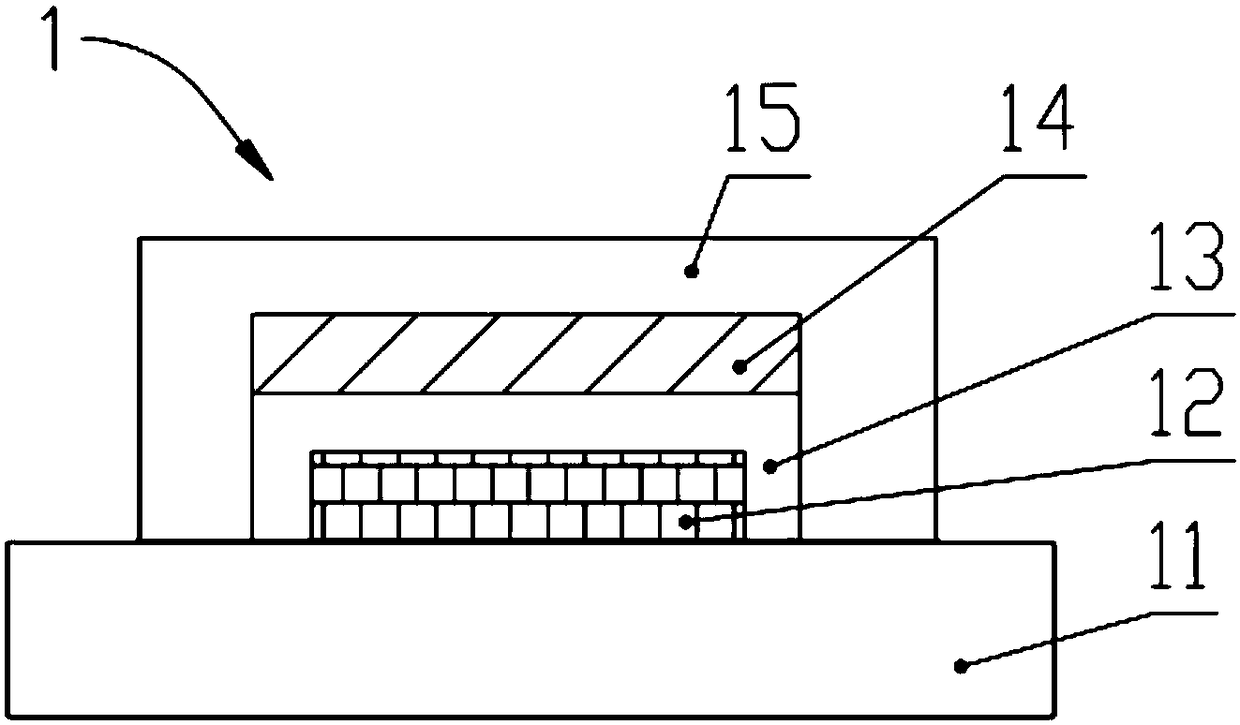

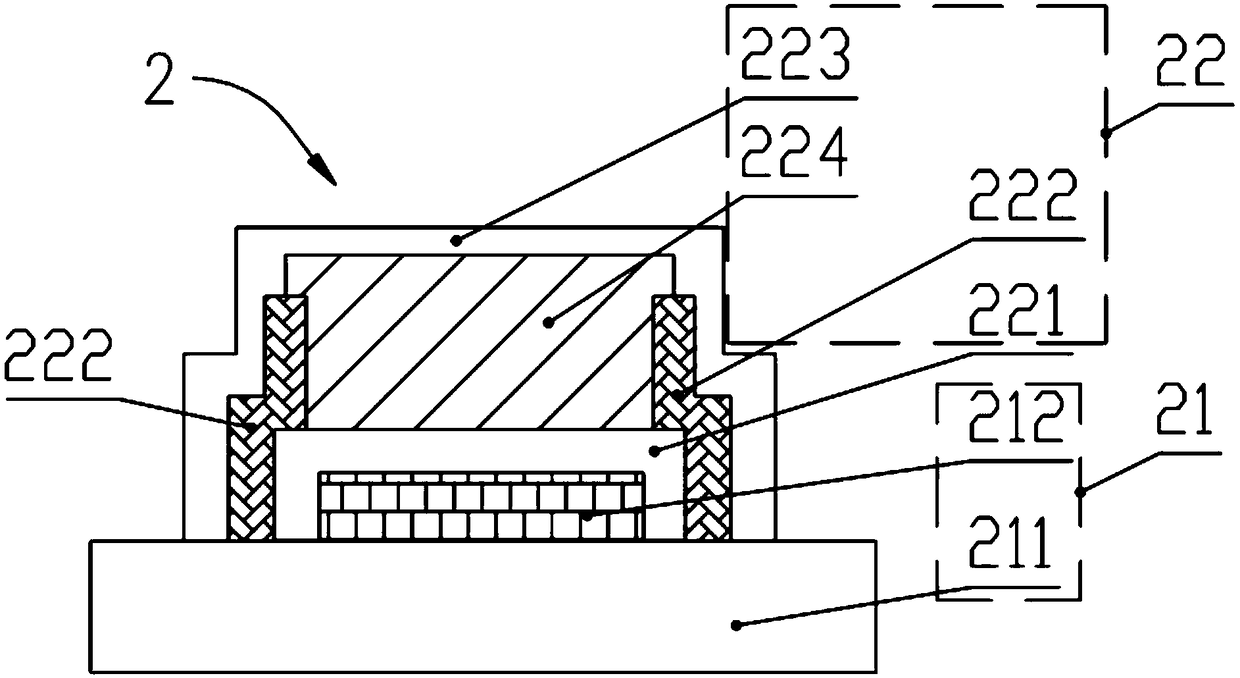

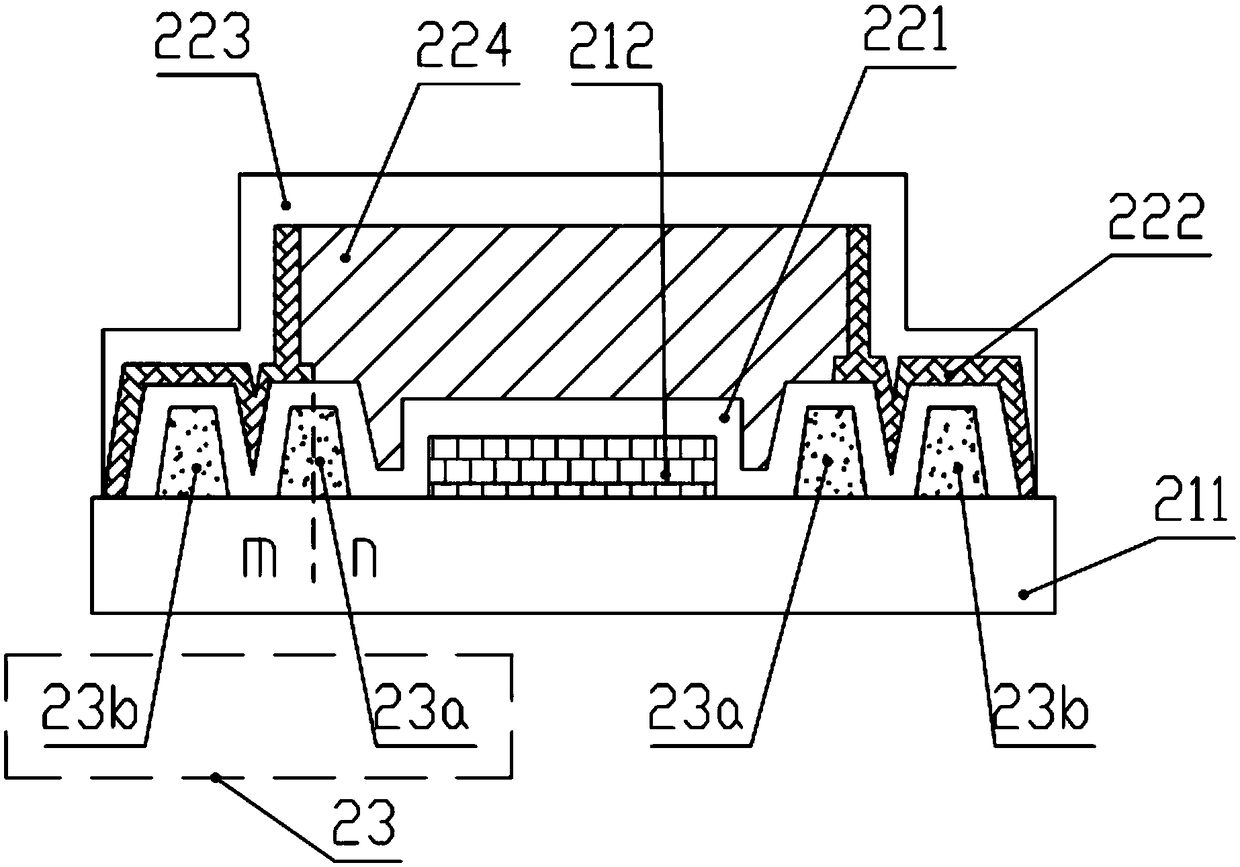

Miniature OLED display device and manufacturing method

InactiveCN108321173AImprove water and oxygen resistanceExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOxygen

The invention provides a miniature OLED display device. The device comprises a silicon substrate, an OLED device arranged on the silicon substrate and a film packaging layer used for packaging the OLED device. The silicon substrate comprises a display area corresponding to the orthographic projection of the OLED device and a packaging area located at the periphery of the display area. The packaging area has several grooves. The film packaging layer covers the several grooves. Through using the several grooves, the permeation paths of side surface water vapor and oxygen are prolonged, the waterprevention oxygen performance of the miniature OLED display device is increased, and the service life of the miniature OLED display device is prolonged. The invention also provides a method for manufacturing the miniature OLED display device, and a technology process is simple.

Owner:KUNSHAN FANTAVIEW ELECTRONICS TECH CO LTD

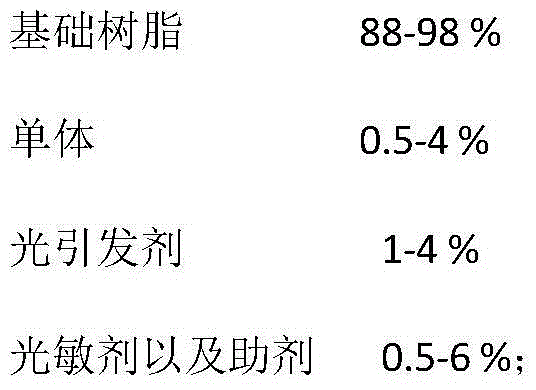

Resin composition, light conversion element and light source component

ActiveCN107760232AImprove water and oxygen resistanceImprove stabilityNon-macromolecular adhesive additivesSynthetic resin layered productsGas phaseQuantum dot

The invention provides a resin composition which is characterized by comprising the following components in percentage by weight: 60.00-95.00% of an organic resin, 0.01-5.00% of an initiator, 0.10-10.00% of hydrophobic fumed silica and 1.00-30.00% of obstruction particles which are uniformly dispersed in the organic resin. A light conversion element based on the resin composition is good in stability and long in service life, and the problems that a conventional quantum dot material is poor in stability and short in service life in the use process are effectively solved.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

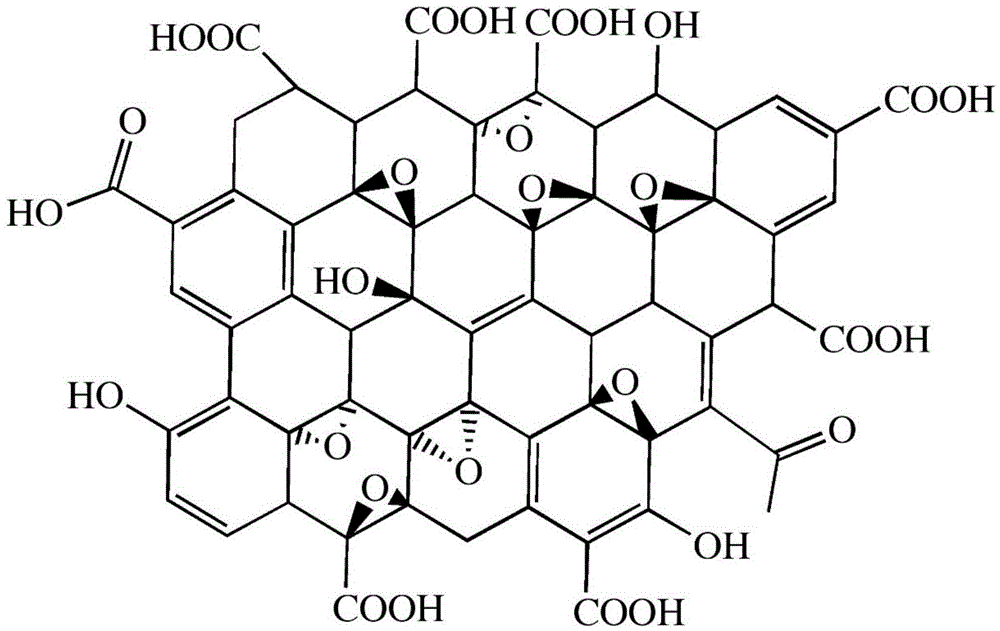

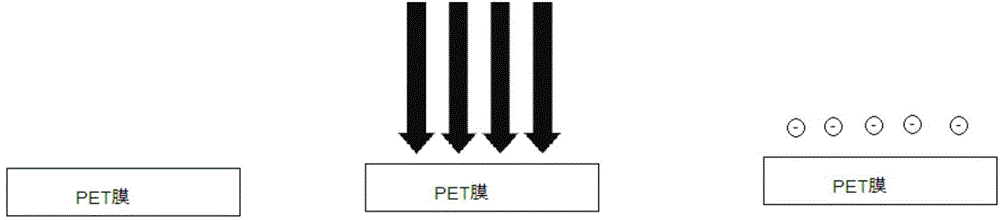

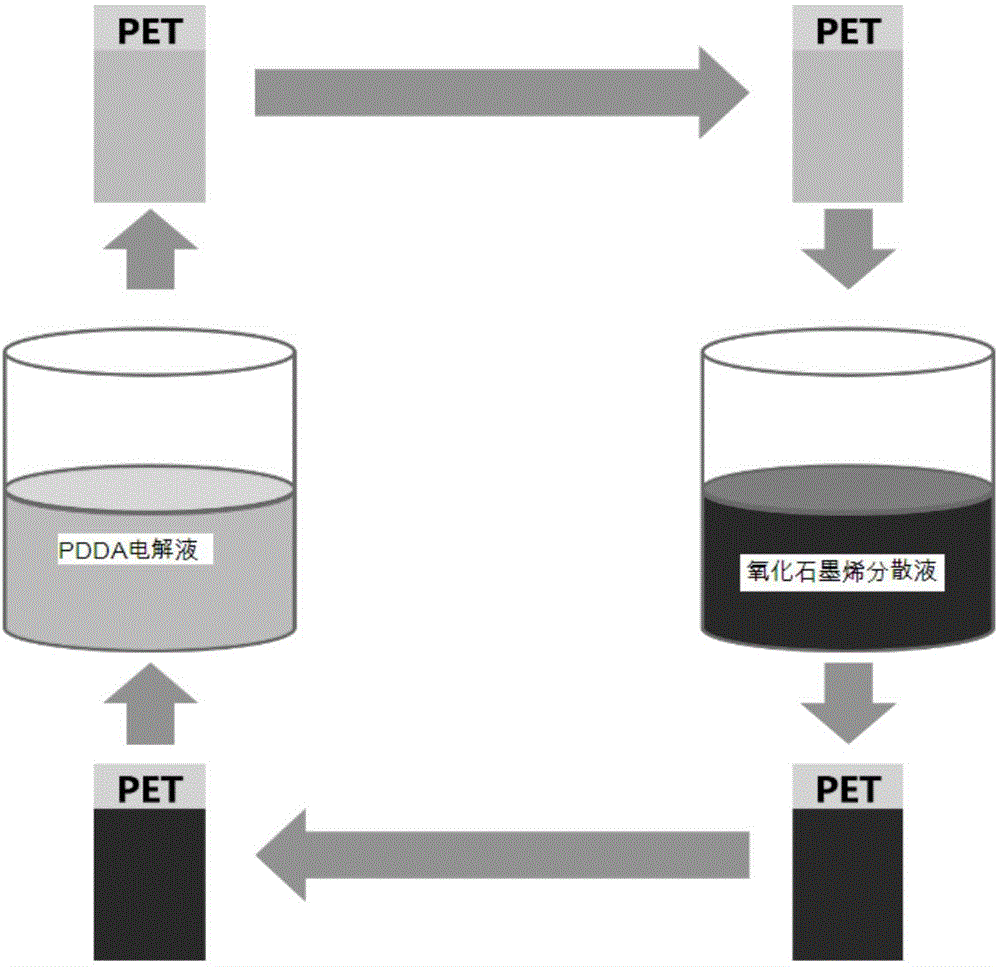

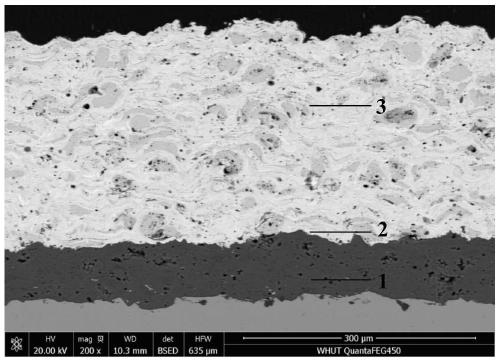

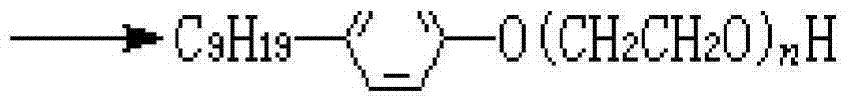

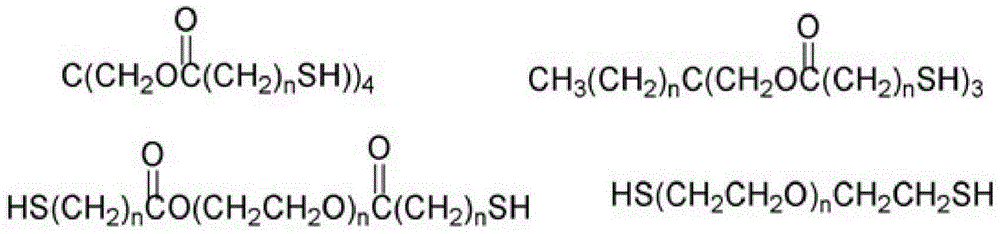

Composite thin film and manufacturing method, organic light emitting diode and packaging method

ActiveCN104966792AImprove transmittanceFirm packagingSolid-state devicesSemiconductor/solid-state device manufacturingComposite filmLight-emitting diode

The invention discloses a composite thin film and a manufacturing method, an organic light emitting diode and a packaging method. The composite thin film comprises a substrate film, a PDDA layer deposited on the first face of the substrate film, a graphene oxide layer deposited on the PDDA layer, and a monomolecular layer arranged on the surface of the graphene oxide layer in a self-assembly mode and composed of a compound as shown in a formula I. The composite thin film manufacturing method comprises a self-assembly step in which the substrate film deposited with the graphene oxide layer is placed in a solution of the compound as shown in the formula I for immersion, and the compound as shown in the formula I is arranged on the graphene oxide layer in a self-assembly mode. The organic light emitting diode is packaged by adopting the composite thin film of the invention. The organic light emitting diode packaging method comprises a polymer deposition step and a packaging step.

Owner:BOE TECH GRP CO LTD +1

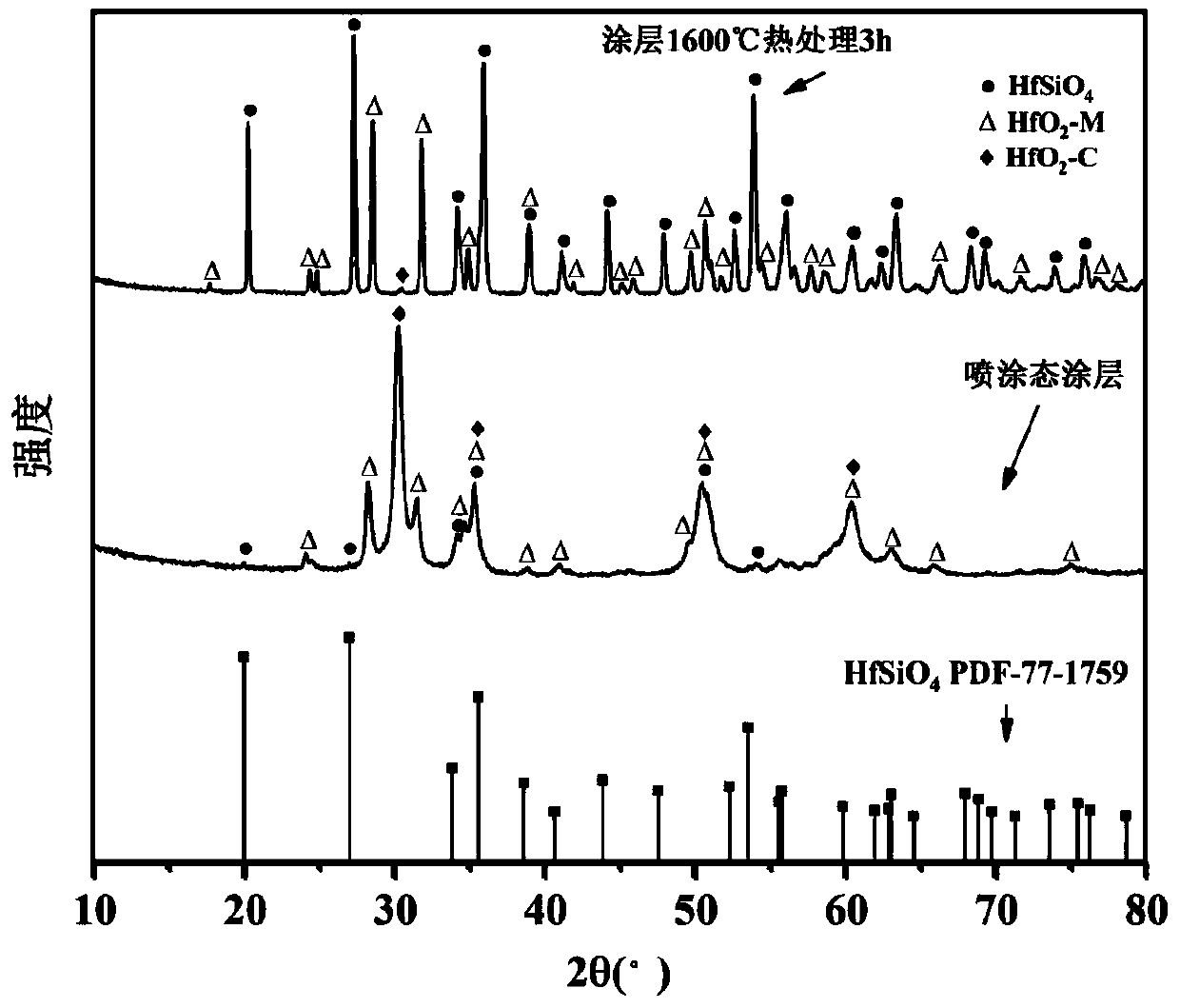

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

Display panel and display device

ActiveCN109671859APrevent proliferationImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides a display panel and a display device. The display panel comprises an array substrate, a planarization layer, an anode layer, a light-emitting device layer comprising light-emitting device units, pixel definition bodies arranged between adjacent light-emitting device units and retaining walls arranged between adjacent light-emitting device units and used for blocking water and oxygen. The retaining walls are in contact with at least one of the planarization layer and the anode layer. The upper surface of the retaining walls is not lower than the upper surface of the pixeldefinition bodies. According to the display panel, the retaining walls for blocking water and oxygen are additionally arranged between adjacent light-emitting device units, so that the water and oxygen are prevented from diffusing in the horizontal direction in the display panel. The water and oxygen resistance of the display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Solar cell packaging film

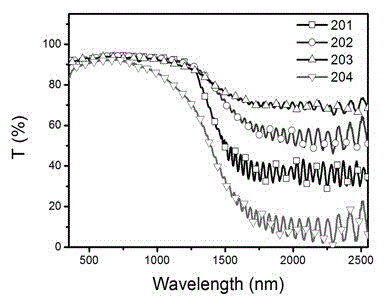

ActiveCN105161558ASimple structureHigh transparencyPhotovoltaic energy generationSemiconductor devicesSolar lightWater vapor

The invention discloses a solar cell packaging film. The solar cell packaging film comprises a transparent support wear-resistant filtering layer and a gas barrier layer. The optical transmittance of the packaging film is 80%-95%. The transmittance of the packaging film over solar light with the wavelength of 380-1200 nm is 90%-95%, the transmittance over the solar light with the wavelength of 1400-2500 nm is 30%-80%, and the water vapor transmittance is 1*10<-4>-1*10<-1> g / m2*day. According to the invention, the solar cell packaging film is simple in structure and convenient to produce and machine; the surface density is low, installation and transportation are facilitated; the water air barrier property and the weather fastness are good, and the lifetime requirement of more than 25 years is met for a solar cell; in addition, the solar cell packaging film is also provided with a wear-resistant function and an optical filtering function, so that the practical power generation capability of a packaged cell assembly is further improved.

Owner:LUCKY HUAGUANG GRAPHICS

OLED display panel and manufacturing method thereof

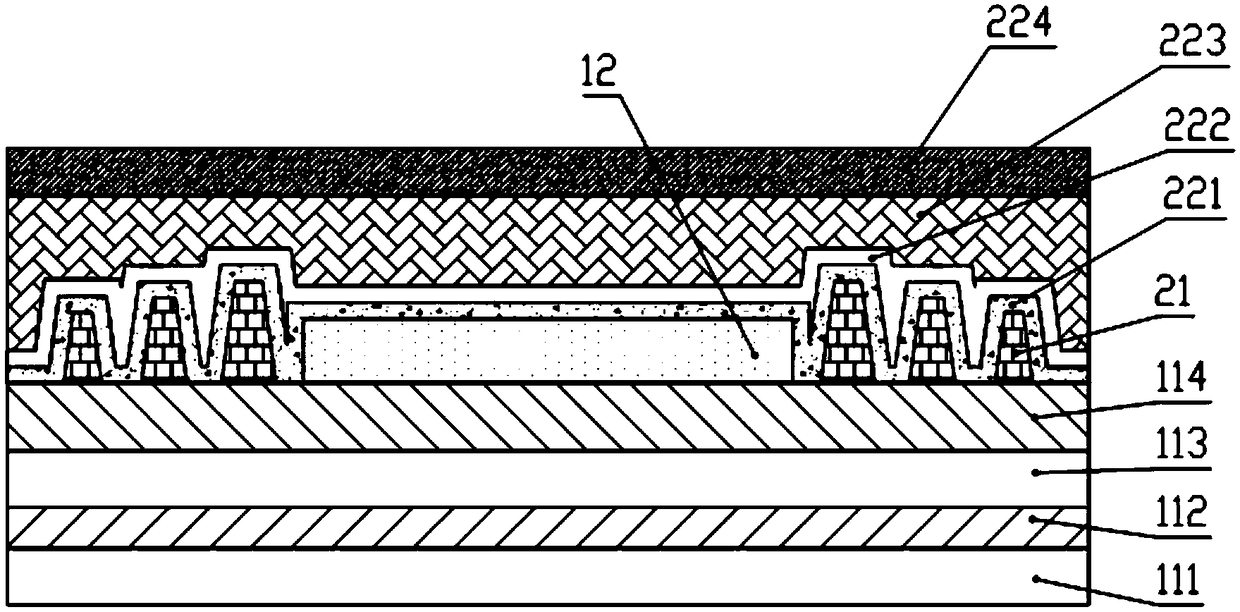

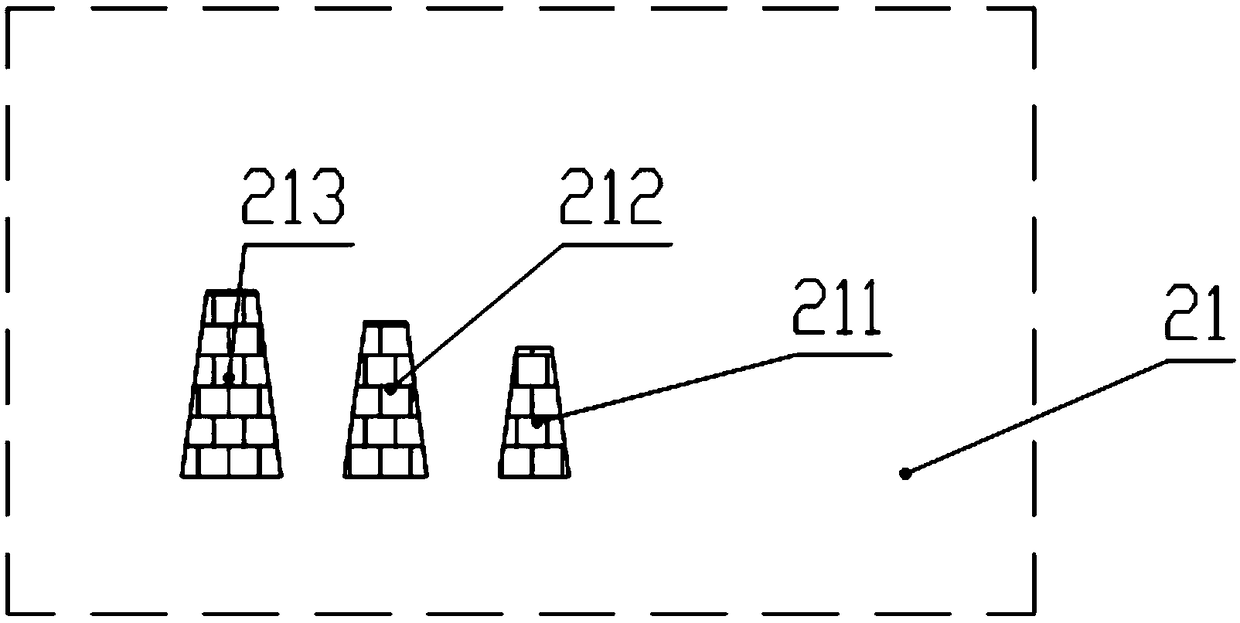

InactiveCN109037487AStrengthen the water and oxygen resistance of the sideSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention provides an OLED display panel and a manufacturing method thereof, comprising an OLED substrate and a packaging part arranged on the OLED substrate. The OLED substrate comprises a substrate and an OLED layer, wherein the substrate comprises a display area and an edge area surrounding the display area, and the OLED layer is arranged in the display area; The encapsulation part comprises a barrier body and an encapsulation layer. the barrier body is arranged in the edge region and comprises at least one coil of barrier ring. The barrier ring surrounds the OLED layer and spaced fromthe OLED. The encapsulation layer is arranged above the barrier body. By providing a barrier including at least one loop of barrier coils in an edge region of an OLED substrate, The barrier and the inorganic layer are combined to enhance the water-oxygen resistance of the side surface of the OLED display panel, thereby avoiding the multi-layer photomask manufacturing process and simplifying the manufacturing process of the OLED display panel on the basis of improving the water-oxygen resistance of the packaging structure omni-directionally.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

OLED display panel

ActiveCN109860238AReduce thicknessImprove bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLED displayPolarizer

The present invention provides an OLED display panel. The OLED display panel comprises a packaging layer, a polarizer, a touch function layer, optical glue and a cover window, and the polarizer is formed on the packaging layer. The touch function layer is formed on the polarizer. The optical glue is formed on the touch function layer. The cover window is arranged on the optical glue. The touch function layer comprises an inorganic protection sublayer, a first metal sublayer, a barrier sublayer and a second metal sublayer which are formed on the polarizer in order. The polarizer and the touch function layer are directly prepared on the packaging layer to reduce the thickness of the LED display panel and improve the bending resistance of the OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

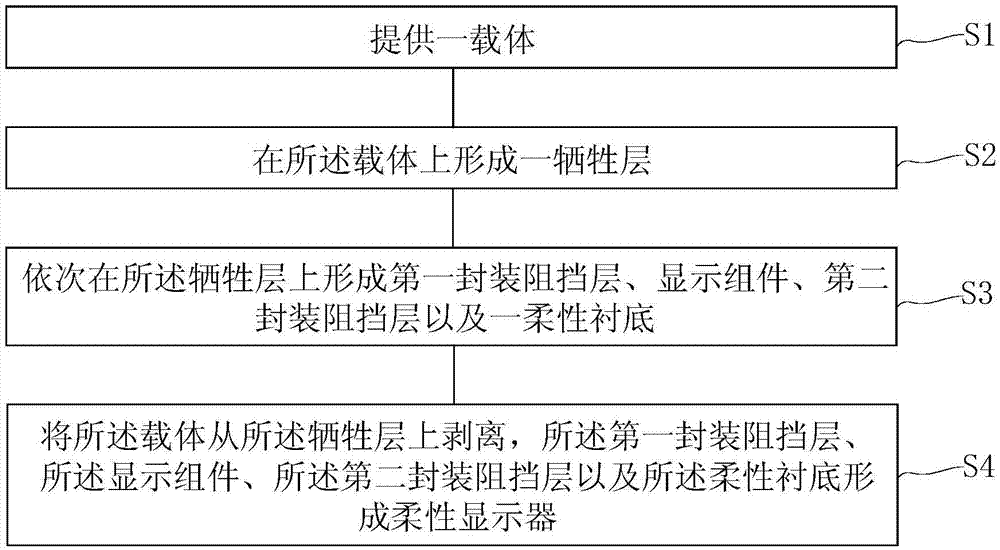

Preparation method for flexible display

InactiveCN106920813AImprove performanceImprove water and oxygen resistanceSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides a preparation method for a flexible display. The preparation method comprises the steps of providing a carrier; forming a sacrificial layer on the carrier; forming a first packaging barrier layer, a display assembly, a second packaging barrier layer and a flexible substrate on the sacrificial layer in sequence; and stripping the carrier from the sacrificial layer, wherein the first packaging barrier layer, the display assembly, the second packaging barrier layer and the flexible substrate form the flexible display. According to the flexible display formed in the invention, the flexible substrate is used as the carrier of the flexible display, and is positioned on the second packaging layer, so that the flexible substrate does not suffer from influence from a high-temperature process in the preparation of the display assembly; and material selection of the flexible substrate is higher in degree of freedom, so that the prepared flexible display can ensure flexibility of the flexible substrate as well as can ensure the water oxygen blocking capability of the first packaging barrier layer, thereby improving the performance of the flexible display.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT

Display panel and display device

ActiveCN109686771AReduce distanceIncrease distanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceNegative power

An embodiment of the invention provides a display panel and a display device, and relates to the technical field of display. The distance between an organic isolation layer and the edge of a thin filmpackaging layer is increased, and the water oxidation resistance of the display panel is improved. The display panel comprises a display area and a non-display area; a light-emitting element comprising an anode layer, a light-emitting layer and a cathode layer; a driving circuit located in the non-display area; a negative power signal line located between the driving circuit and the display area;a signal transmission line located between the driving circuit and the display area, wherein the signal transmission line is electrically connected to the negative power signal line and the cathode layer respectively; the organic isolation layer covering the area of the signal transmission line not in contact with the cathode layer; the thin film packaging layer covering the display area and thenon-display area.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

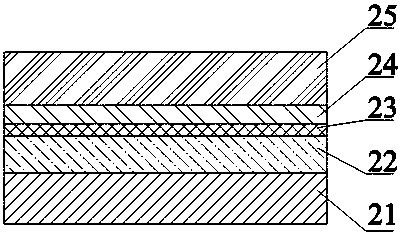

Flexible packaging adhesive film for flexible OLED device

PendingCN110828700AImprove thermal stabilityAvoid failureSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistryHeat stability

The invention relates to a flexible packaging adhesive film for a flexible OLED device. An organic planarization layer, an inorganic barrier layer, an organic water absorption layer, an inorganic barrier layer, a heat dissipation layer, a barrier pressure-sensitive adhesive layer and a release film are sequentially arranged on the packaging adhesive film on one side of a flexible transparent substrate from inside to outside. According to the flexible packaging adhesive film disclosed by the invention, the heat dissipation layer is introduced into the adhesive film; heat generated in the flexible OLED device is conducted out in time by utilizing the excellent heat conduction performance of the heat dissipation layer; the failure of the device, caused by temperature rise caused by heat accumulation in the device, is avoided; the thermal stability of the OLED device is remarkably improved; by adding barrier filling particles in the pressure-sensitive adhesive, the water and oxygen blocking performance of the adhesive layer is improved; the problem of side leakage of the flexible OLED packaged by the existing imprint lithography is solved; and the water and oxygen stability of the OLEDdevice is remarkably improved. The flexible packaging adhesive film is used for packaging the flexible OLED device, and has a simple process. Reel-to-reel transmission production can be achieved. Therequirements for flexibility and practicability are met. The service life of the packaged device is prolonged by about 40 times.

Owner:CHINA LUCKY FILM CORP

Coating type multi-layer composite high-barrier film as well as preparation method and application thereof

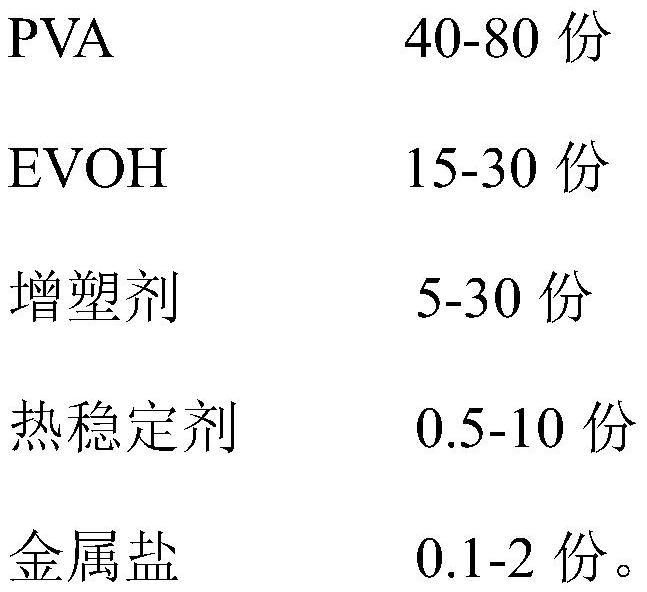

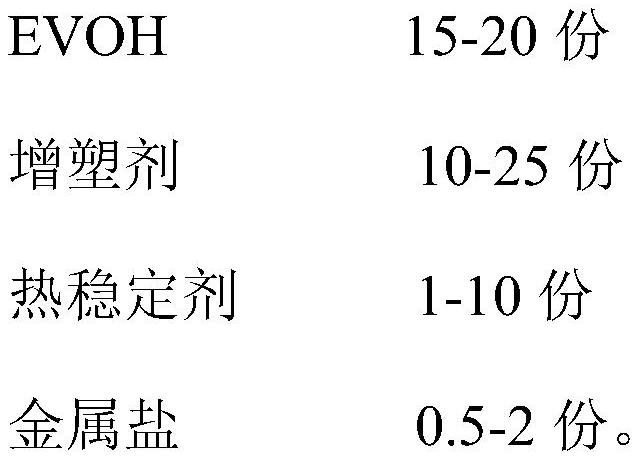

InactiveCN111703165AImprove barrier propertiesHigh gas barrierFlexible coversWrappersPolymer chemistryPlasticizer

The invention relates to a coating type multilayer composite high-barrier film, a preparation method and application thereof, wherein the coating type multilayer composite high-barrier film is formedby compounding multilayer polymers through a coating composite molding method; the structural expression is A / (adh / C)n / B / (adh / C)n / adh / A; in the formula, n is an integer greater than 0, the A represents a surface layer, the B represents a barrier layer, the adh represents an adhesive layer, and the C represents an additional layer. The barrier layer B is a PVA-EVOH composition which is prepared from the following raw materials in parts by weight: 40 to 80 parts of PVA, 15 to 30 parts of EVOH, 5 to 30 parts of plasticizer, 0.5 to 10 parts of heat stabilizer and 0.1 to 2 parts of metal salt; andthe surface layers A and C are thermoplastic high-molecular polymers. The film disclosed by the invention has excellent strength and oxygen-blocking and water-blocking properties, and can be applied to the field of packaging of various foods, medicines and the like.

Owner:JIANGNAN UNIV

Transparent flexible package substrate and flexible OLED package method

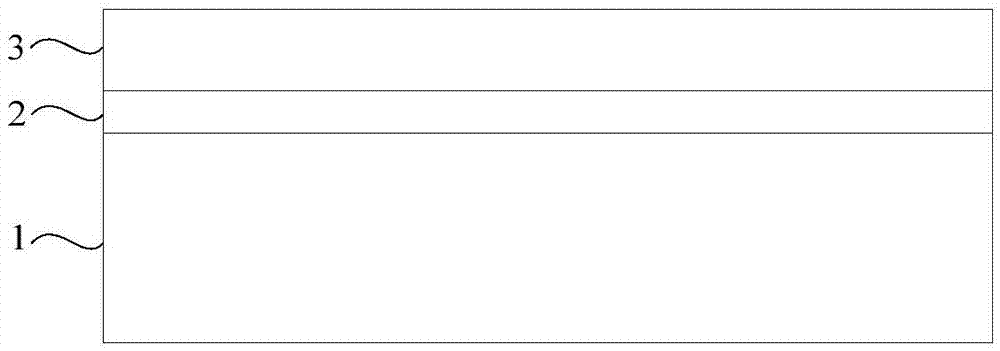

InactiveUS20160343993A1Good flexibilityImprove water and oxygen resistanceSynthetic resin layered productsSolid-state devicesDisplay deviceEngineering

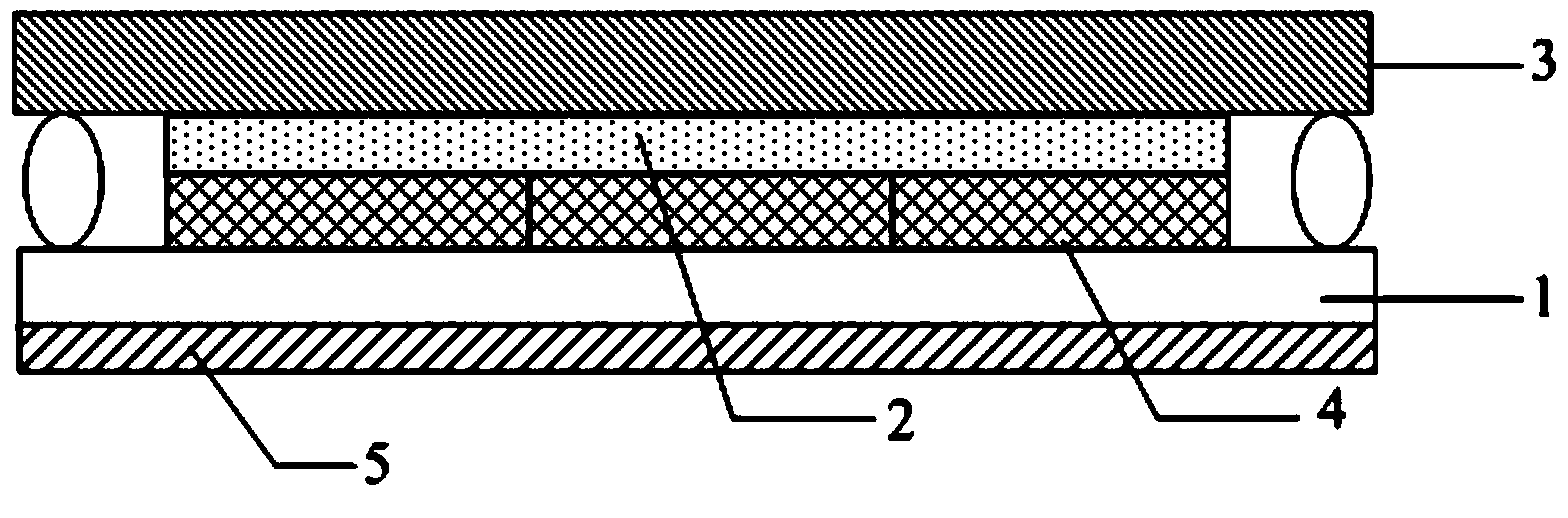

The present invention provides a transparent flexible package substrate and a flexible OLED package method, comprising: a flexible glass (2), an insulative glue layer (1) located at one side of the flexible glass (2), a polymer layer (3) located at the other side of the flexible glass (2); a surface dimension of the flexible glass (2) is larger than a surface dimension of the polymer layer (3); a surface dimension of the flexible glass (2) is smaller than or equal to a surface dimension of the insulative glue layer (1). The transparent flexible package substrate possesses well flexibility and properties of excellent anti-water, anti-oxygen abilities, and manufactured with flexible glass material, which is a transparent flexible package substrate capable of being widely utilized and applicable for packages of many kinds of OLED display elements.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

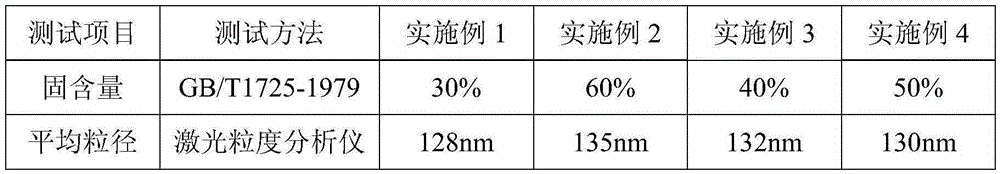

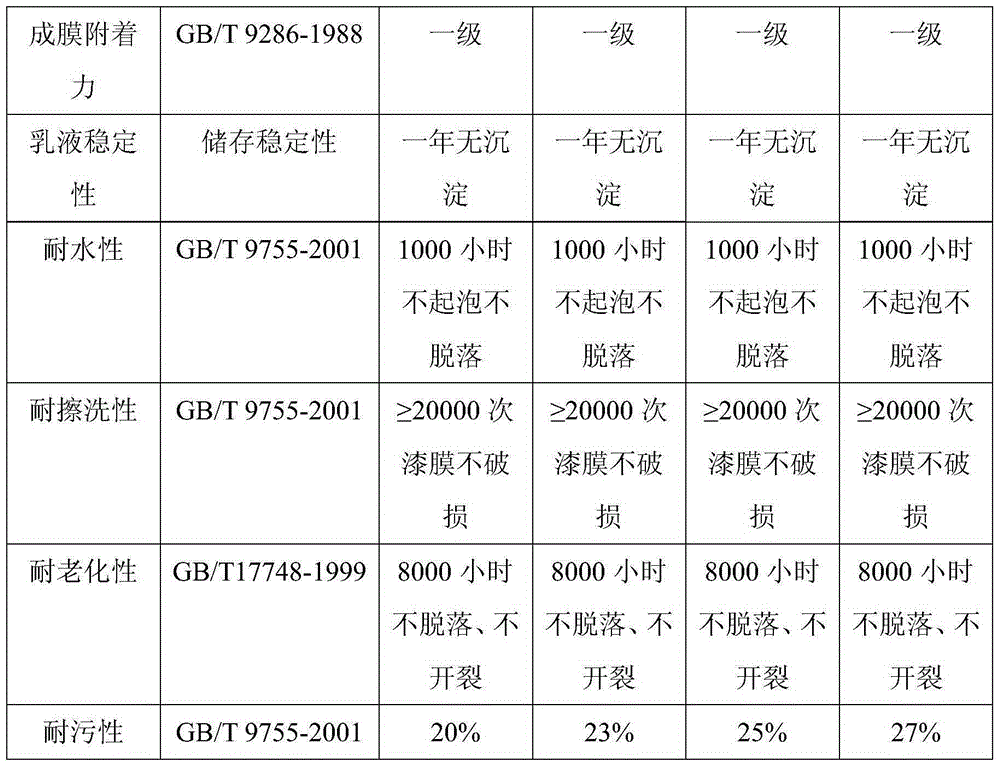

Preparation method of fluorine-containing polyvinylidene chloride emulsion for coating

ActiveCN105273121ASimple processReaction conditions are easy to controlCoatingsWeather resistanceEmulsion

The invention discloses a preparation method of a fluorine-containing polyvinylidene chloride emulsion for a coating. The preparation method comprises the following steps of (1) preparing for reaction raw materials for later use; (2) preparing a seed emulsion; (3) preparing a vinylidene chloride copolymer solution; and (4) preparing the fluorine-containing polyvinylidene chloride emulsion to obtain the fluorine-containing polyvinylidene chloride emulsion for the coating. The preparation method has the characteristics of simple process, easily-controlled reaction condition, good emulsion stability, environment friendliness and the like; and the obtained fluorine-containing polyvinylidene chloride emulsion has the advantages of good adhesive force, good oxygen and water resistance, good chemical stability and good stain resistance and is particularly suitable for outdoor high-grade building exterior wall coatings, wood coatings and the like with relatively high requirements for water resistance and weather resistance.

Owner:ELECTROCHEM PLANT OF ZHEJIANG JUHUA +1

A packaging structure of an OLED device and a display panel

InactiveCN109065745AImprove reliabilityImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingBiochemical engineeringAdhesive materials

The packaging structure of the OLED device provided by the invention comprises a substrate formed with the OLED device and a packaging cover plate arranged on the substrate; Wherein the package coverplate is provided with a first groove and a second groove, and the second groove is arranged around the first groove, the OLED device is arranged in the first groove, and the second groove is providedwith an adhesive material so that the package cover plate and the substrate formed with the OLED device are adhered and fixed. As that first groove and the second groove are arrange on the package cover plate, and the adhesive material is arrange in the second groove, the purpose of improving the reliability of the package of the OLED device is achieved, thus improving the water and oxygen resistance of the OLED device, and prolonging the service life of the OLED device.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Touch control type organic light-emitting display panel

ActiveCN105118849AReduce blue lightTo achieve the purpose of eye protectionSolid-state devicesOrganic semiconductor devicesProtecting eyeOxygen

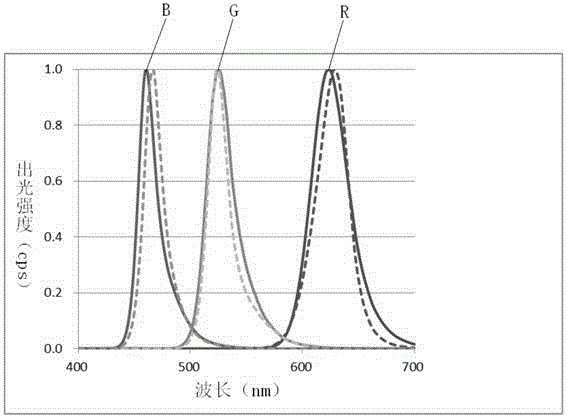

The invention relates to a touch control type organic light-emitting display panel. A dielectric layer with a specific Bragg reflector layer structure is disposed between a polaroid and an organic light-emitting diode device or between the polaroid and a touch control panel. In this way, 438nm blue light that is harmful to the eyes of people can be greatly reduced, and an eye protection purpose is achieved. Meanwhile, the inventor accidentally finds that the Bragg reflector layer structure plays a micro-cavity control effect, and can correspond to an organic optical micro-cavity in the device to form a resonator effect, so the spectrum of the display panel is controlled, and the purity is improved. Moreover, in terms of the outer dielectric layer attached to the device, different Bragg reflector layer structures can be designed on the basis of different devices and different demands, and thus a better eye protection effect is achieved. Furthermore, the Bragg reflector layer of the dielectric layer helps to improve the performance of water-resisting oxygen and improve the packaging effect.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Degradable substrate for flexible photoelectric device and production method of substrate

InactiveCN104733615AReduce crystallinityReduce scatterSolid-state devicesSemiconductor/solid-state device manufacturingCross-linkEpoxy

The invention discloses a degradable substrate for a flexible photoelectric device and a production method of the substrate. The substrate comprises a flexible substrate and a conductive layer, wherein the conductive layer is located on the flexible substrate, and the flexible substrate is shellac doped with ultraviolet-sensitive adhesive; the ultraviolet-sensitive adhesive comprises photosensitive polysiloxane, photoinitiator, thinner and promoter; the thinner comprises methylbenzene, xylene, active epoxy resin thinner, cyclic ether and vinyl ether monomer; the promoter comprises filler, stabilizer and cross-linking agent. The degradable substrate has the advantages that the light transmittance of the flexible substrate is increased by the cross-linking effect of the ultraviolet-sensitive adhesive, the toughness of the flexible substrate is increased, and the combining force of the conductive layer and the flexible substrate is strong at the same time; in addition, the substrate is biodegradable and is widely applicable to the field of flexible photoelectric devices.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Degradable substrate for flexible optoelectronic device and manufacture method thereof

InactiveCN104953034AReduce crystallinityReduce scatterSolid-state devicesSemiconductor/solid-state device manufacturingCross-linkEcological environment

The invention discloses a degradable substrate for a flexible optoelectronic device and a manufacture method thereof. The substrate comprises a flexible substrate and a conducting layer on the flexible substrate. The flexible substrate is made of shellac which is doped with ultraviolet-sensitive adhesive with the mass ratio of 0.3-6.5%. The ultraviolet-sensitive adhesive is a mixture of free-radical type ultraviolet-sensitive adhesive and cationic-type ultraviolet-sensitive adhesive. According to the invention, the light transmission performance of the substrate is improved through cross-linking reaction of the ultraviolet-sensitive adhesive, therefore increasing the performance of the optoelectronic device. Meanwhile, the flexibility and the water- and oxygen-resistant performance of the substrate are also greatly enhanced, and the conducting layer and the substrate are combined quite firmly. Furthermore, the shellac has the biodegradability which solves the problem of ecological environment pollution caused by electronic wastes, and can be widely applied in the environment-friendly flexible optoelectronic field in future.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Flexible touch screen base material and preparation method thereof

InactiveCN108373847AImprove water and oxygen resistanceImprove packaging effectEpoxy resin coatingsInput/output processes for data processingNano sio2Hardness

The invention relates to a flexible touch screen base material and a preparation method thereof. The flexible touch screen base material is characterized in that the flexible touch screen base material includes a nano material with a weight percentage being 0.1-80 wt% and a base material main body material; the base material main body material is one selected from transparency PI, acrylic materials or epoxy resin; and the nano material is one selected from nanometer silicon nitride, nanometer SiO2, nanometer Al2O3, nanometer aluminium nitride, nanometer TiO2, nanometer ZrO2, nanometer MgO, ornanometer HfO2. The invention also relates to a preparation method of the flexible touch screen base material and a display panel containing the flexible touch screen base material. Compared to the prior art, the flexible touch screen base material of the invention has performance of thin thickness, high hardness, friction resistance, and being soft and bendable.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

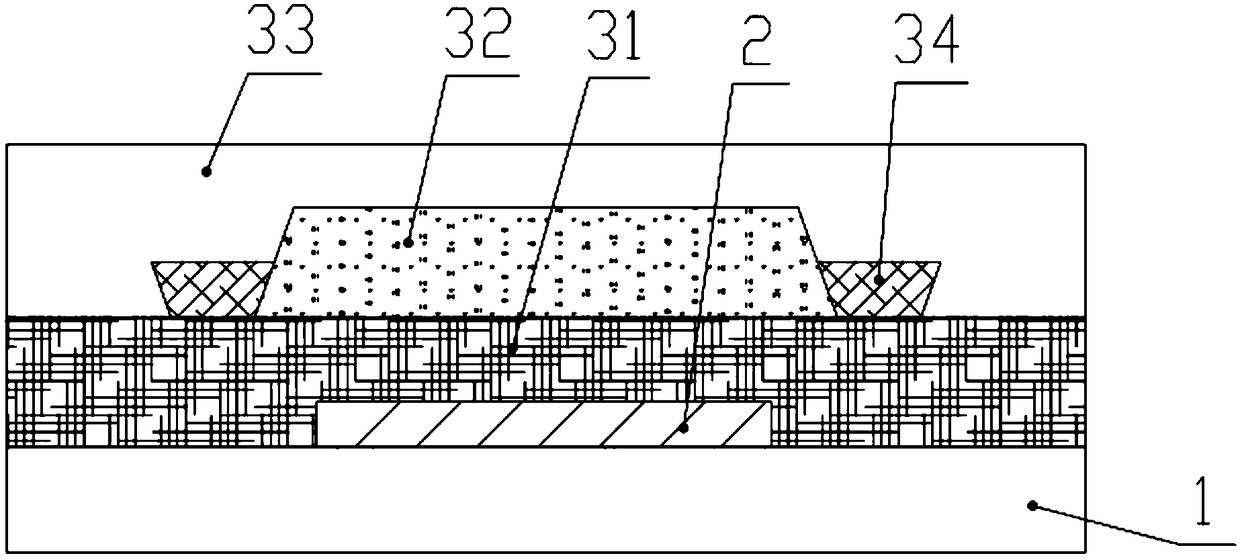

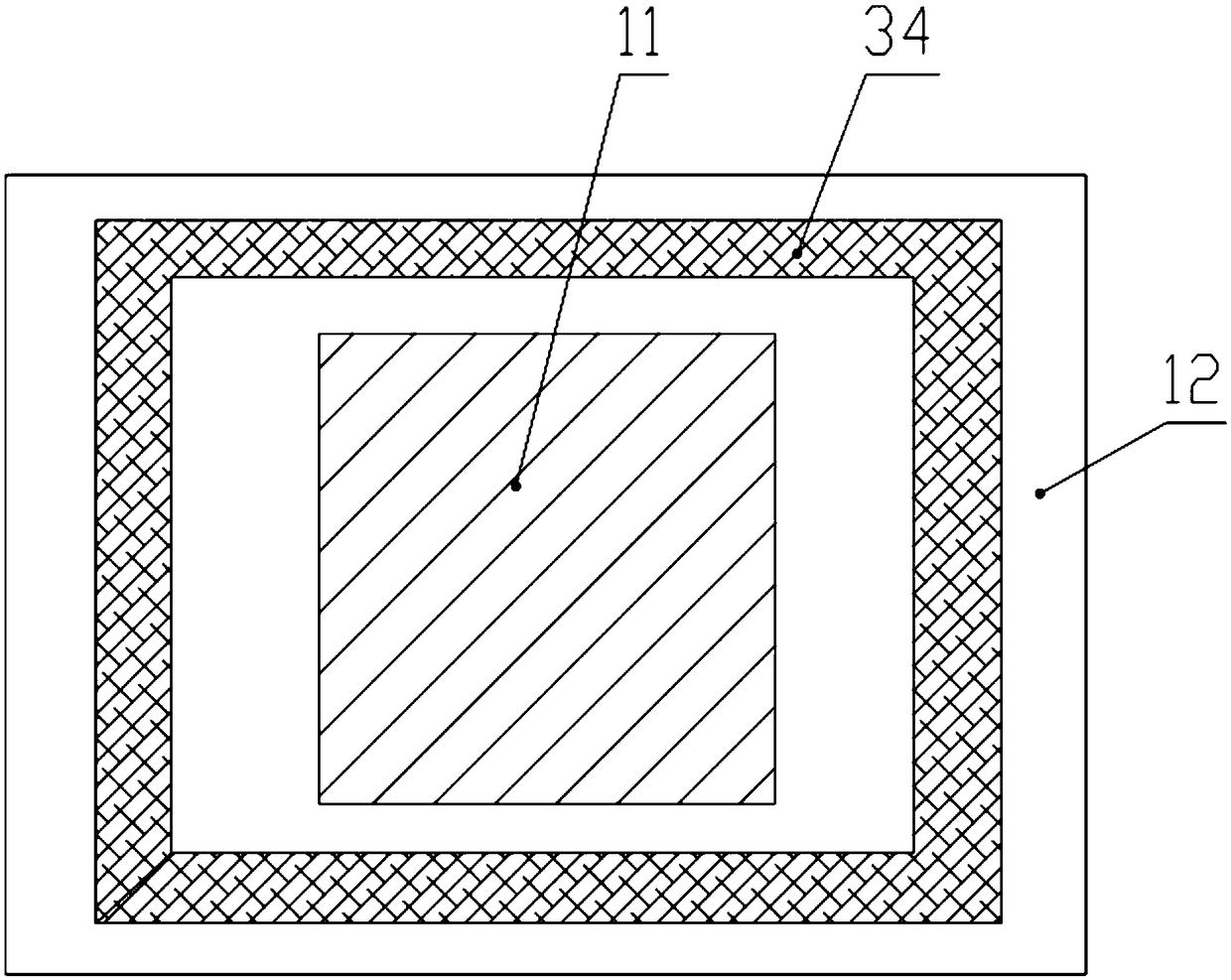

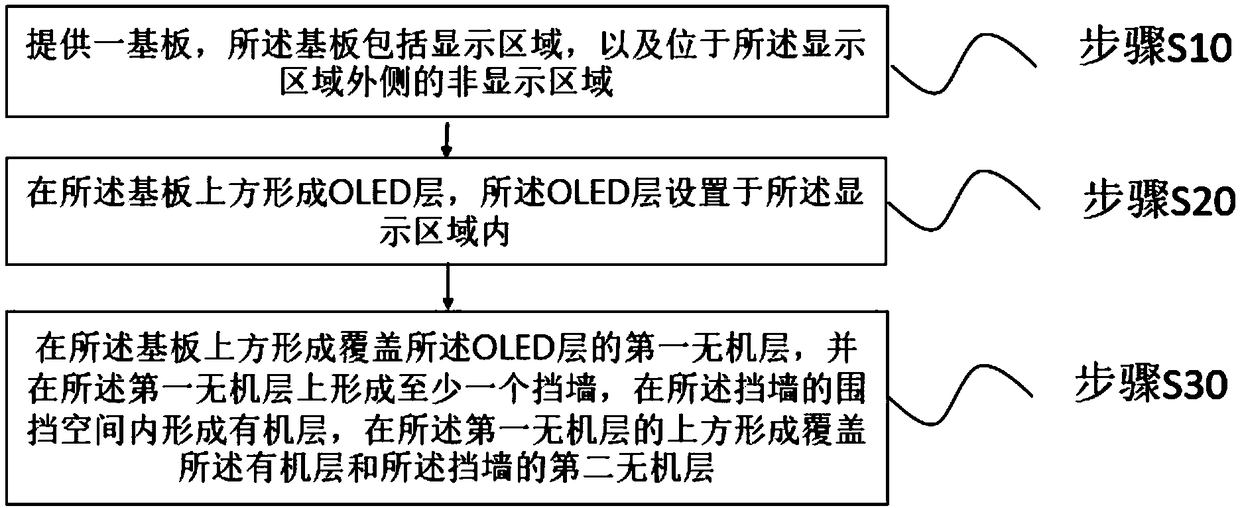

OLED display panel and manufacturing method thereof

InactiveCN109378400AHigh precisionImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringOxidation resistance

The present invention provides an OLED display panel and a manufacturing method thereof. The OLED display panel includes a substrate including a display area, and a non-display area located outside the display area; an OLED layer disposed in the display area of the substrate; a packaging portion disposed above the OLED layer and including an organic layer and at least one retaining wall disposed around the organic layer. The organic layer is located within the enclosure space of the retaining wall. By disposing the retaining wall for stopping the overflow of an organic solution above the substrate, the precision of the OLED display panel is improved, the water oxidation resistance of the OLED display panel is improved, and the quality of the OLED display panel is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

OLED display panel and manufacturing method thereof

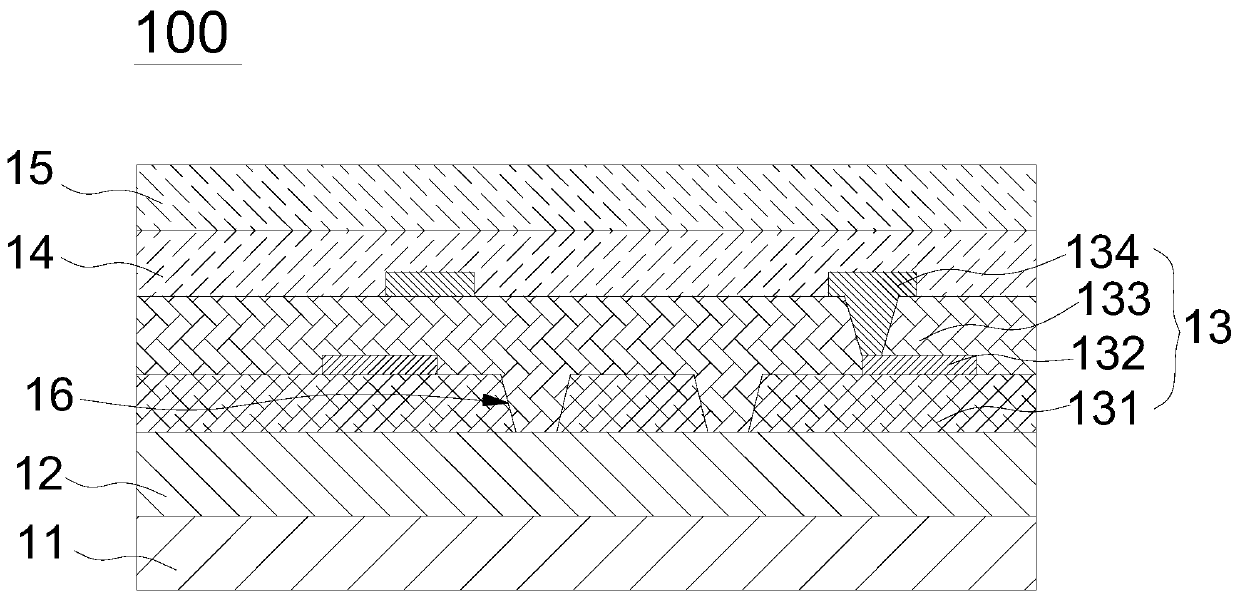

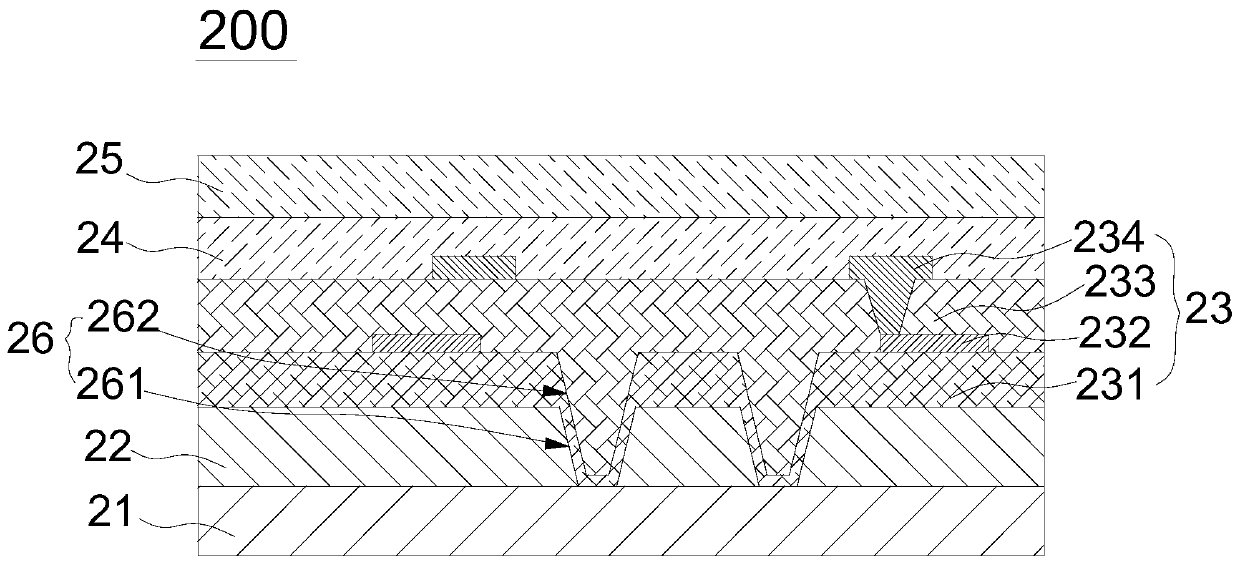

ActiveCN109148717AImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOxygen

The invention provides an OLED display panel and a manufacturing method thereof, comprising an OLED substrate and a packaging part arranged on the OLED substrate. The OLED substrate comprises an arraysubstrate and an OLED layer arranged on the array substrate. The packaging part comprises: a first inorganic layer arranged on the OLED substrate and covering the OLED layer; an organic layer disposed on the first inorganic layer; A second inorganic layer disposed on a side of the first inorganic layer; and a third inorganic layer disposed on the organic layer and covering the organic layer and the second inorganic layer. The invention has the beneficial effect that an inorganic layer with high water-oxygen resistance is added to the side part of the organic layer in the packaging part, so asto improve the water-oxygen resistance of the side area of the OLED display panel.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Flexible substrate and fabrication method thereof, and display panel

ActiveCN110071230AImprove water and oxygen resistanceImprove ductilityFinal product manufactureSolid-state devicesOxygenMaterials science

The invention discloses a flexible substrate and a fabrication method thereof, and a display panel. The flexible substrate comprises a first flexible layer comprising a bending area and a display area, a metal oxidation layer arranged on the display area of the first flexible layer, and a first metal layer arranged on the bending area of the first flexible layer, and the surface of the first metallayer is oxidized as the metal oxidation layer so that the flexible substrate has excellent water-oxygen blocking capability and bending resistance.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com