Coating type multi-layer composite high-barrier film as well as preparation method and application thereof

A high-barrier film, multi-layer composite technology, applied in the field of material processing, can solve the problems of decreased barrier performance, easy water absorption of the film, and inability to melt processing, etc. Effect of Chemical Auxiliary Migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

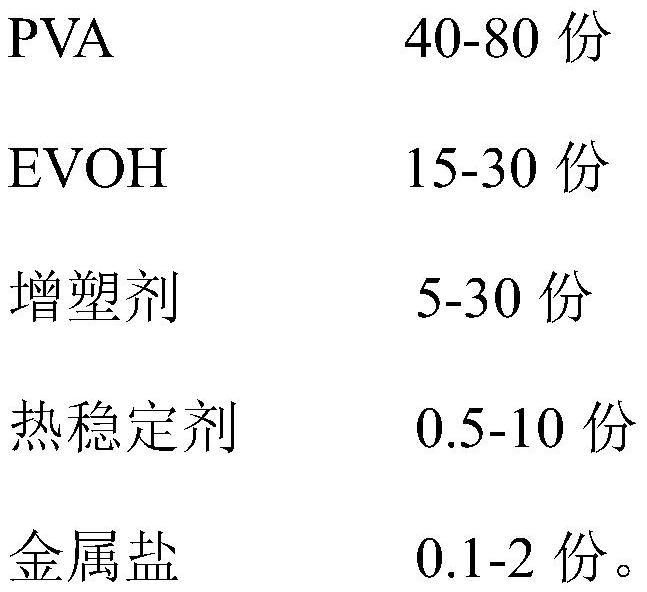

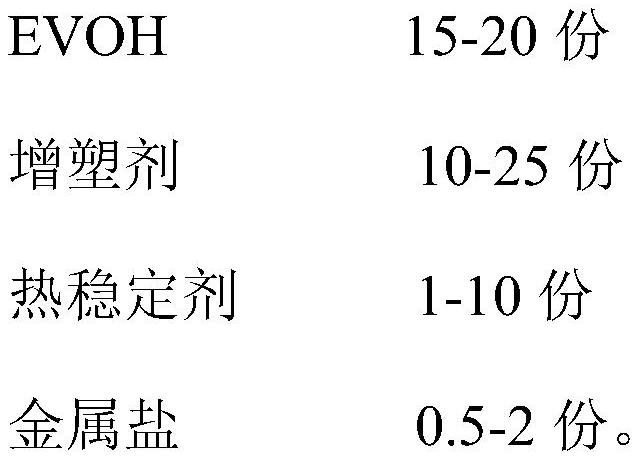

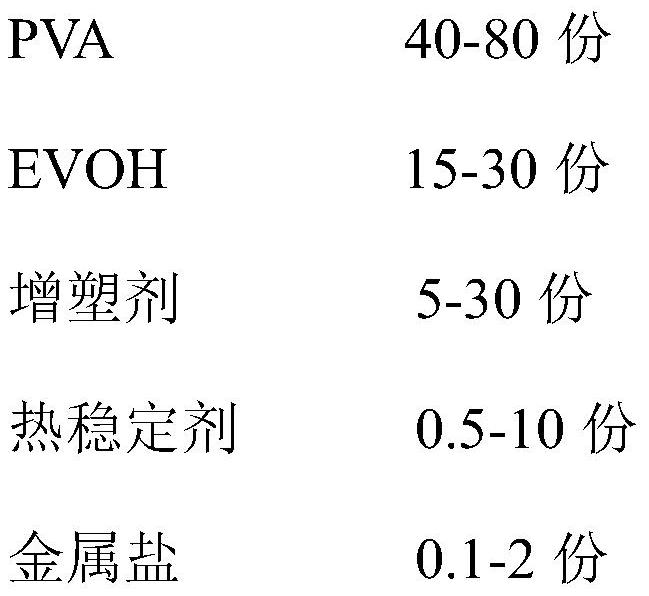

Method used

Image

Examples

Embodiment 1

[0038] Weigh 45 parts by weight of polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd., brand 1799), 5 parts by weight of polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd., brand 1099), polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd. company, trade mark 1799) 5 weight parts, 15 weight parts of sorbitol, 10 weight parts of diglycerin, 5 weight parts of tannic acid, 1 weight part of calcium chloride add in the blender, fully mix, make premix; Then Then the premix was plasticized in an oven at 60° C. for 3 hours; finally the plasticized premix was mixed with 20 parts by weight of ethylene / vinyl alcohol copolymer (Changchun Petrochemical Co., Ltd., brand EV4405, ethylene content 44mol%) ) mixed, put into a single-screw extruder for granulation, and obtained PVA-EVOH barrier layer resin 1 .

Embodiment 2

[0040]Weigh 45 parts by weight of polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd., brand 1799), 5 parts by weight of polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd., brand 1099), polyvinyl alcohol (Sinopec Great Wall Energy and Chemical Ningxia Co., Ltd. company, trade mark 1799) 5 weight parts, 15 weight parts of sorbitol, 10 weight parts of diglycerin, 5 weight parts of tannic acid, 1 weight part of calcium chloride add in the blender, fully mix, make premix; Then Then the premix was plasticized in an oven at 60°C for 3 hours; finally the plasticized premix and ethylene / vinyl alcohol copolymer (Changchun Petrochemical Co., Ltd., brand EV3801, ethylene content 38mol%) 20% by weight Parts are mixed and put into a single-screw extruder for granulation to obtain PVA-EVOH barrier layer resin 2 .

Embodiment 3

[0041] The structural formula of embodiment 3 composite film is expressed as follows:

[0042] PE / PVA-EVOH / clay coating solution 1 / adh / PE,

[0043] Introduce 3% Na-montmorillonite PVA-EVOH barrier layer resin 1 preparation in solution PVA-EVOH / clay coating Liquid 1 ;

[0044] will modify PVA-EVOH / clay coating solution 1 Directly coated on the surface of the PE substrate film surface treated by corona (2000W), after drying, it will be treated by electron beam crosslinking (electron beam energy 800Kev);

[0045] A water-based polyurethane adhesive containing 7% modified montmorillonite is coated on one side of the surface PE substrate, and after drying, it is compounded with the above-mentioned electron beam cross-linked film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com