Patents

Literature

171results about How to "High gas barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

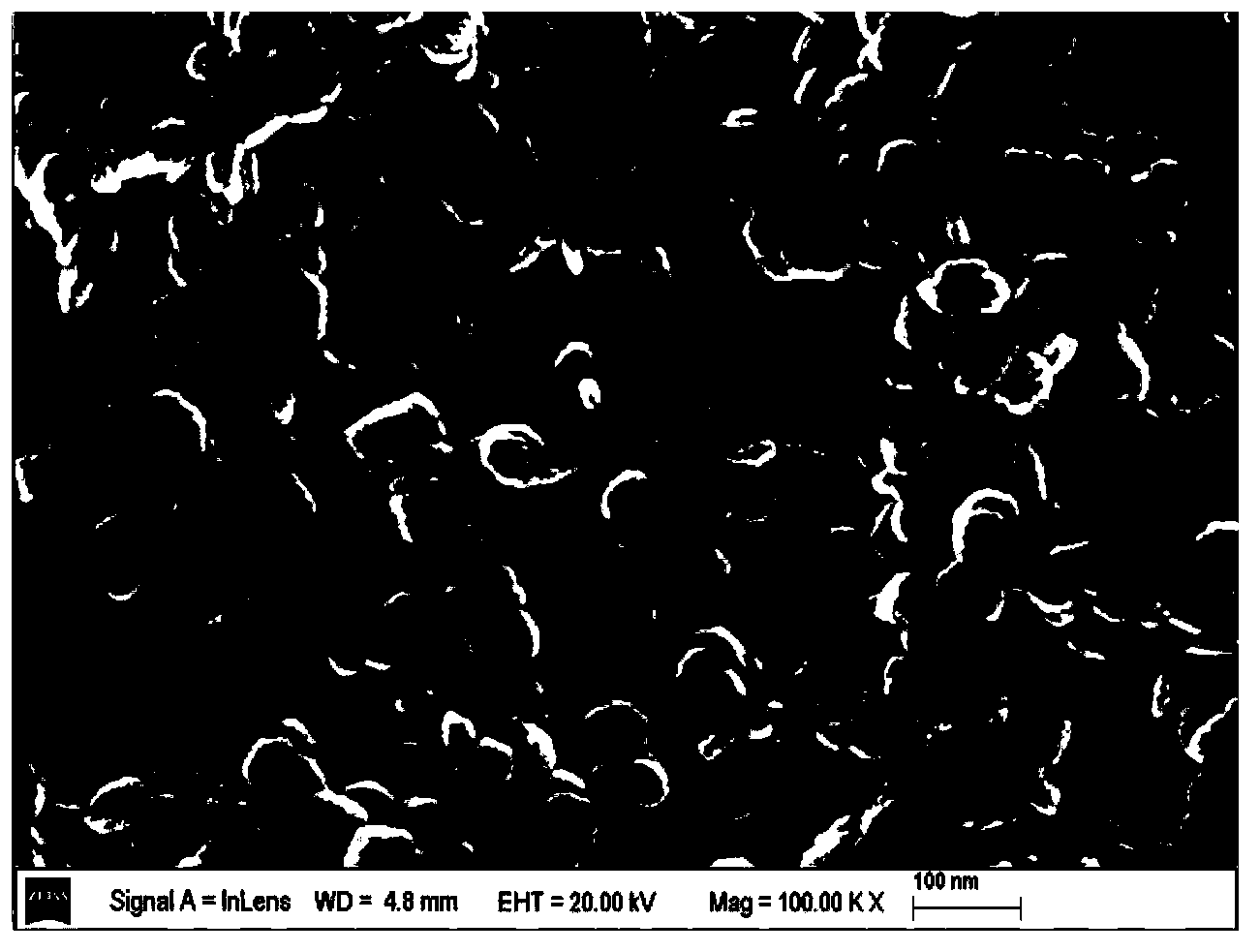

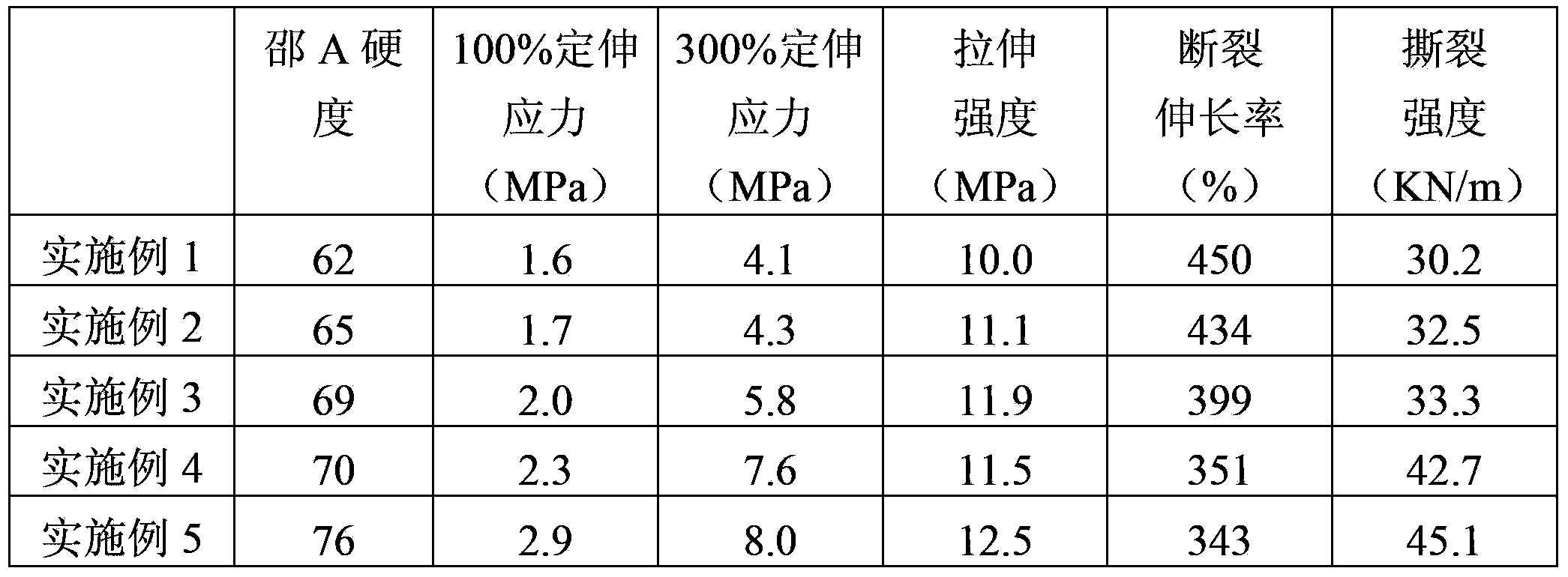

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

Light-emitting device

InactiveUS20030178937A1Increased durabilityImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesMetal foilThermal expansion

A light-emitting device comprising an anode, one or more organic compound layers containing at least a light-emitting layer, and a transparent cathode on a flexible support substrate having a linear thermal expansion coefficient of 20 ppm / ° C. or less, water permeability of 0.01 g / m<2>.day or less, and oxygen permeability of 0.01 cc / m<2>.day.atm or less. The flexible support substrate is constituted by a metal foil provided with an insulating layer on one or both surfaces thereof.

Owner:FUJIFILM CORP

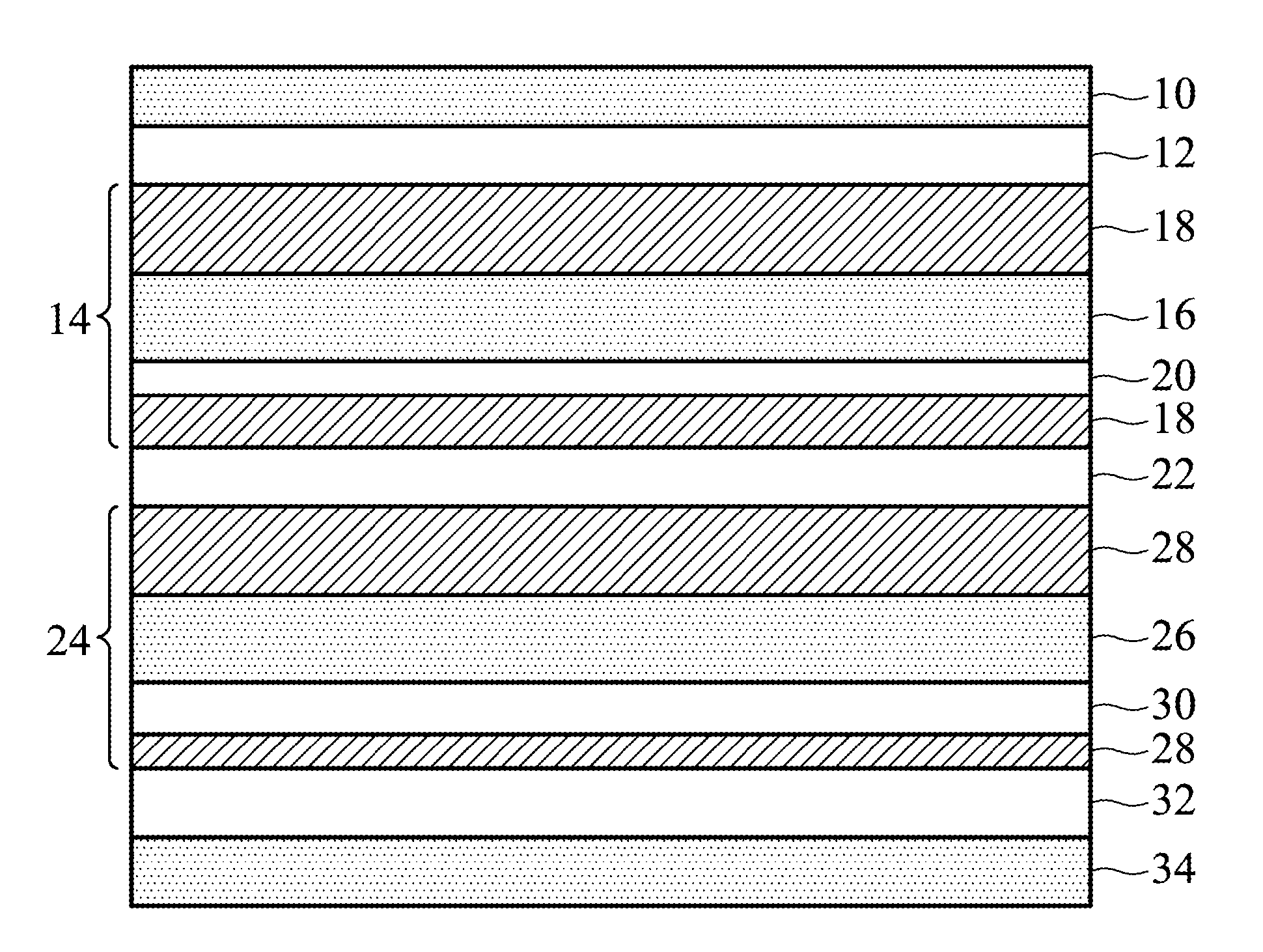

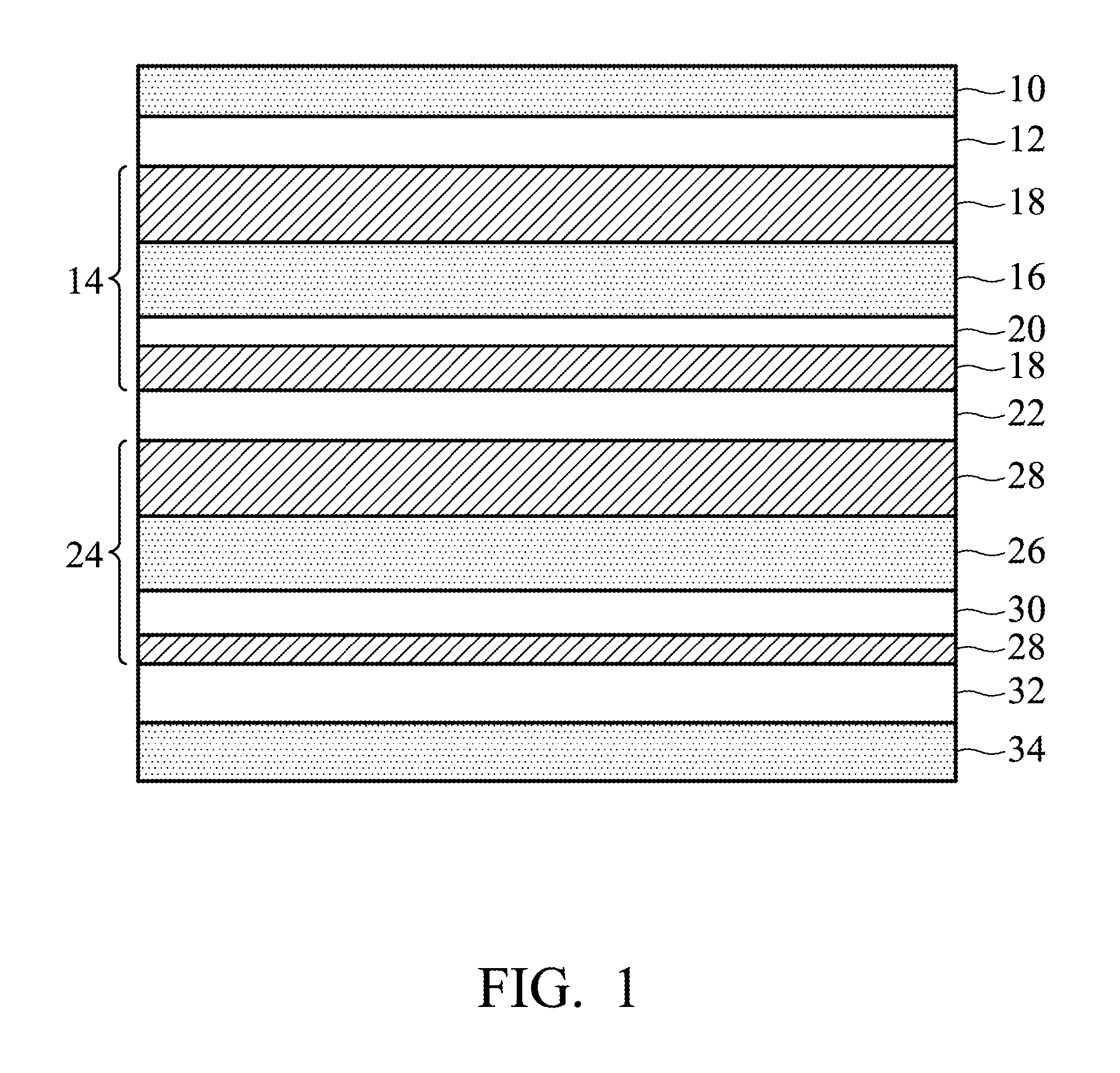

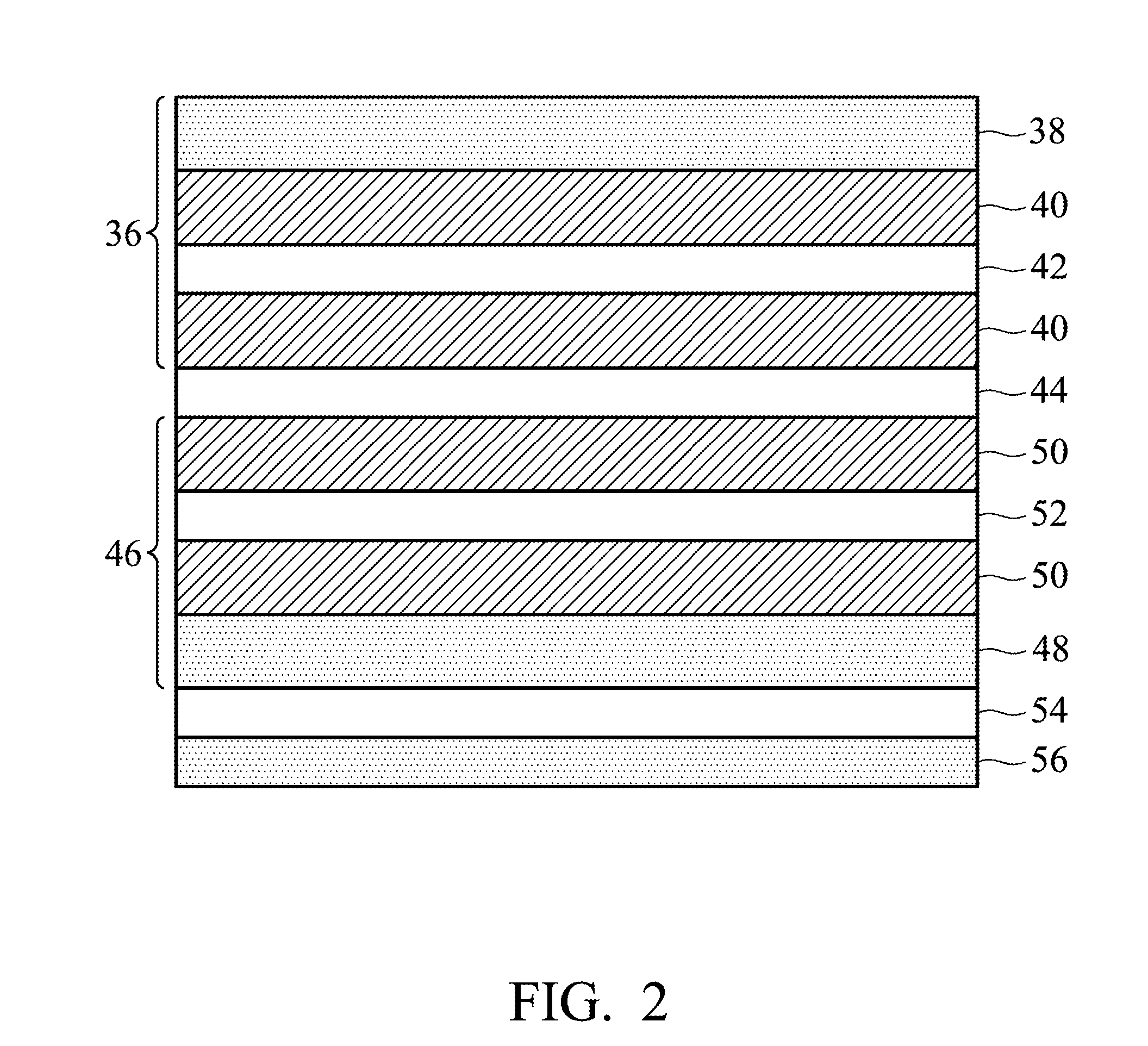

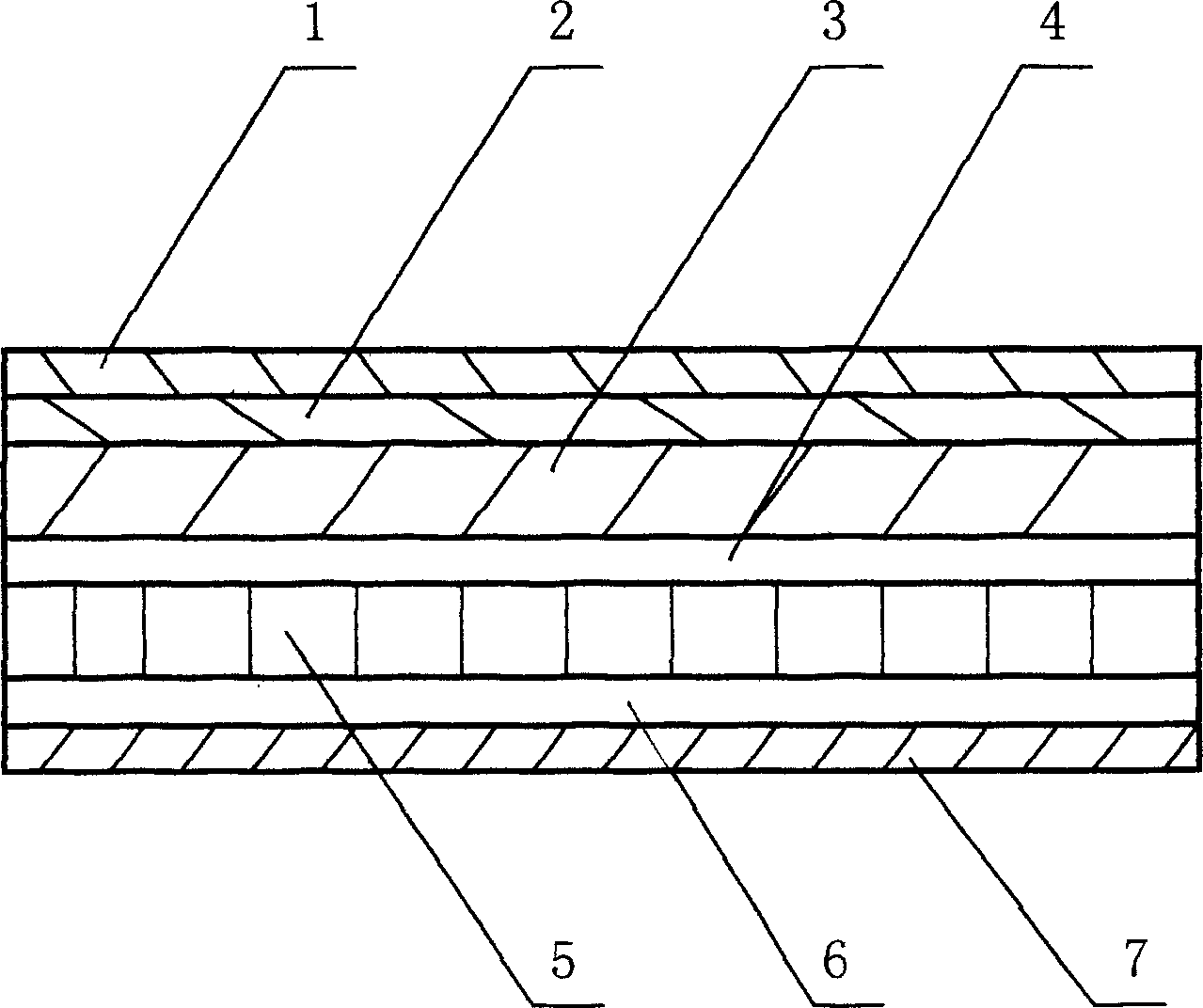

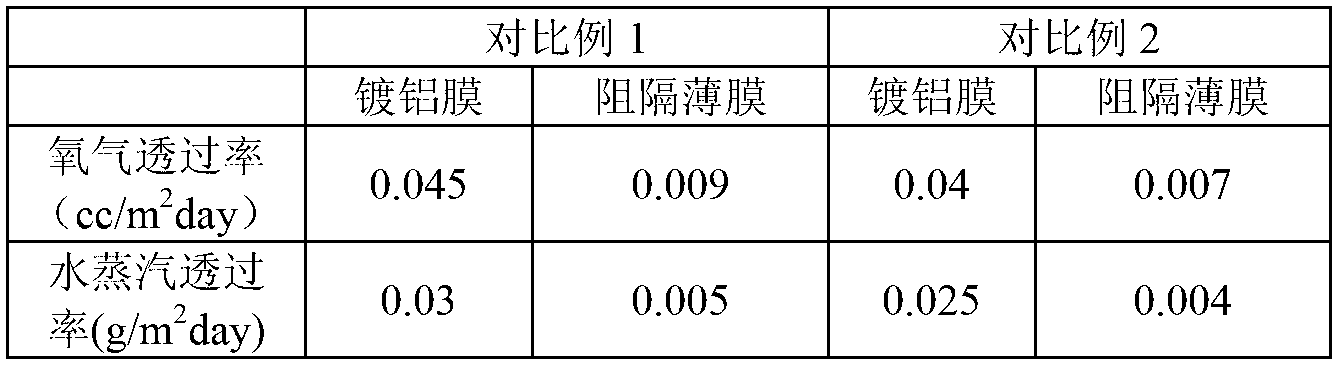

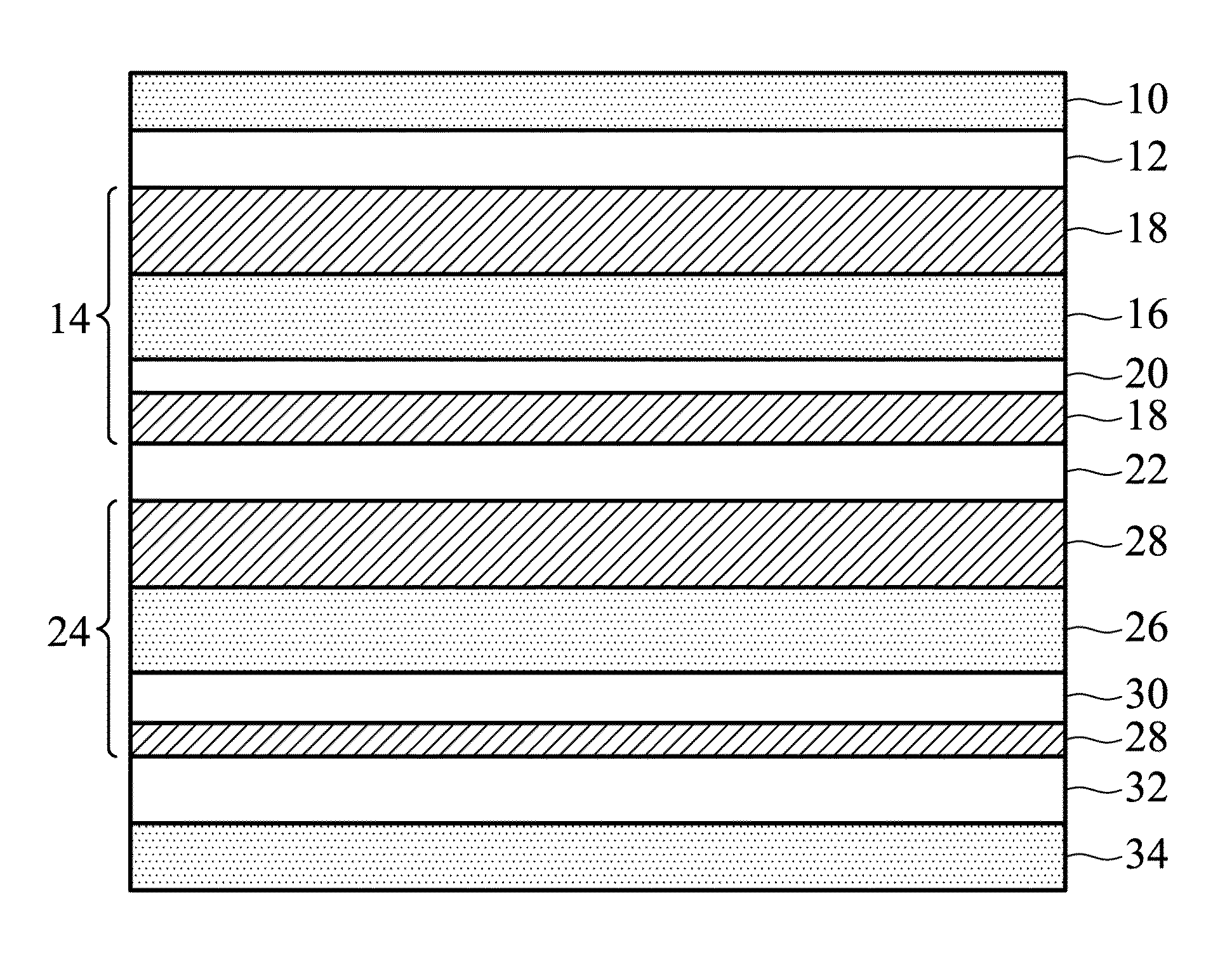

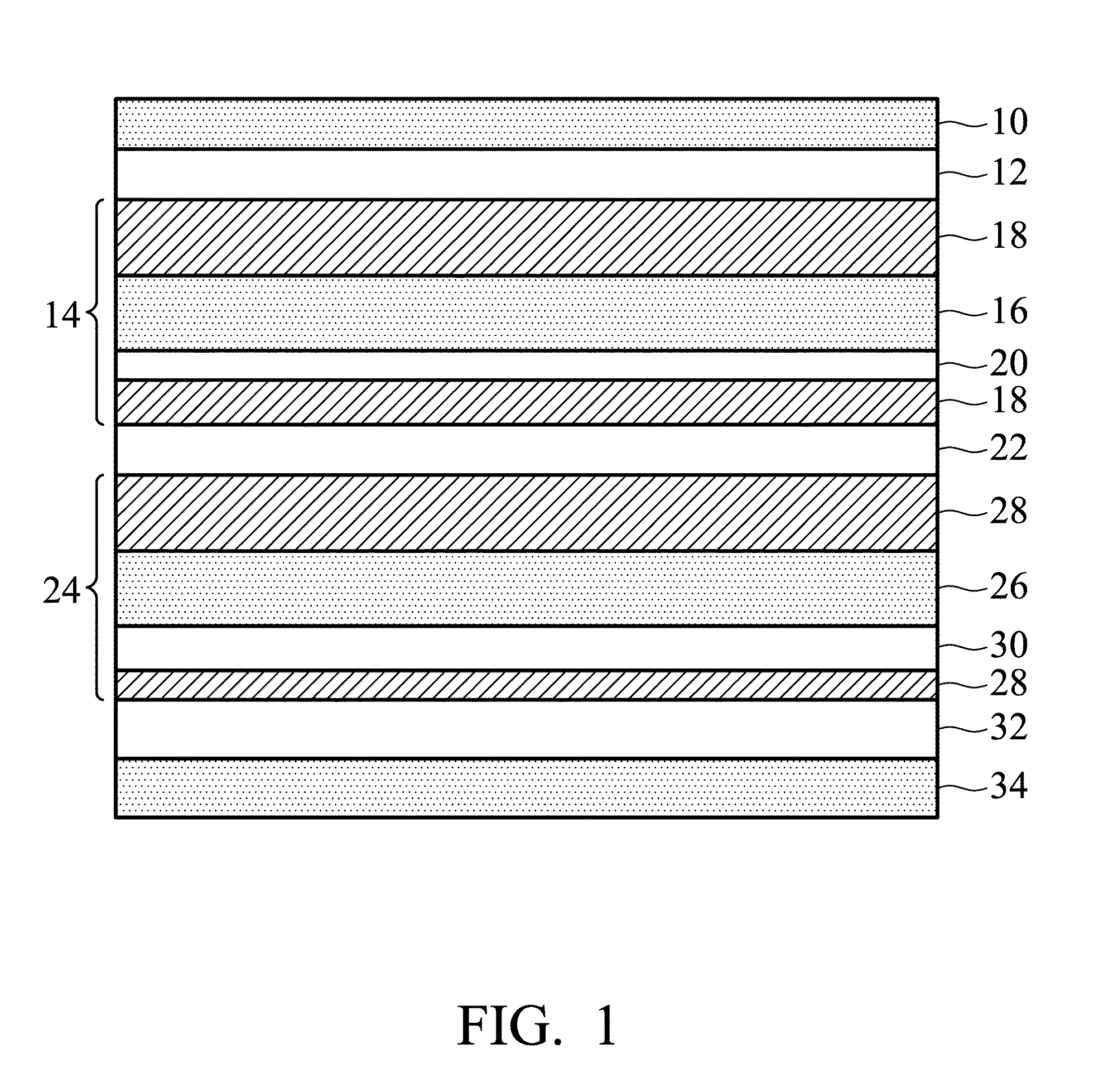

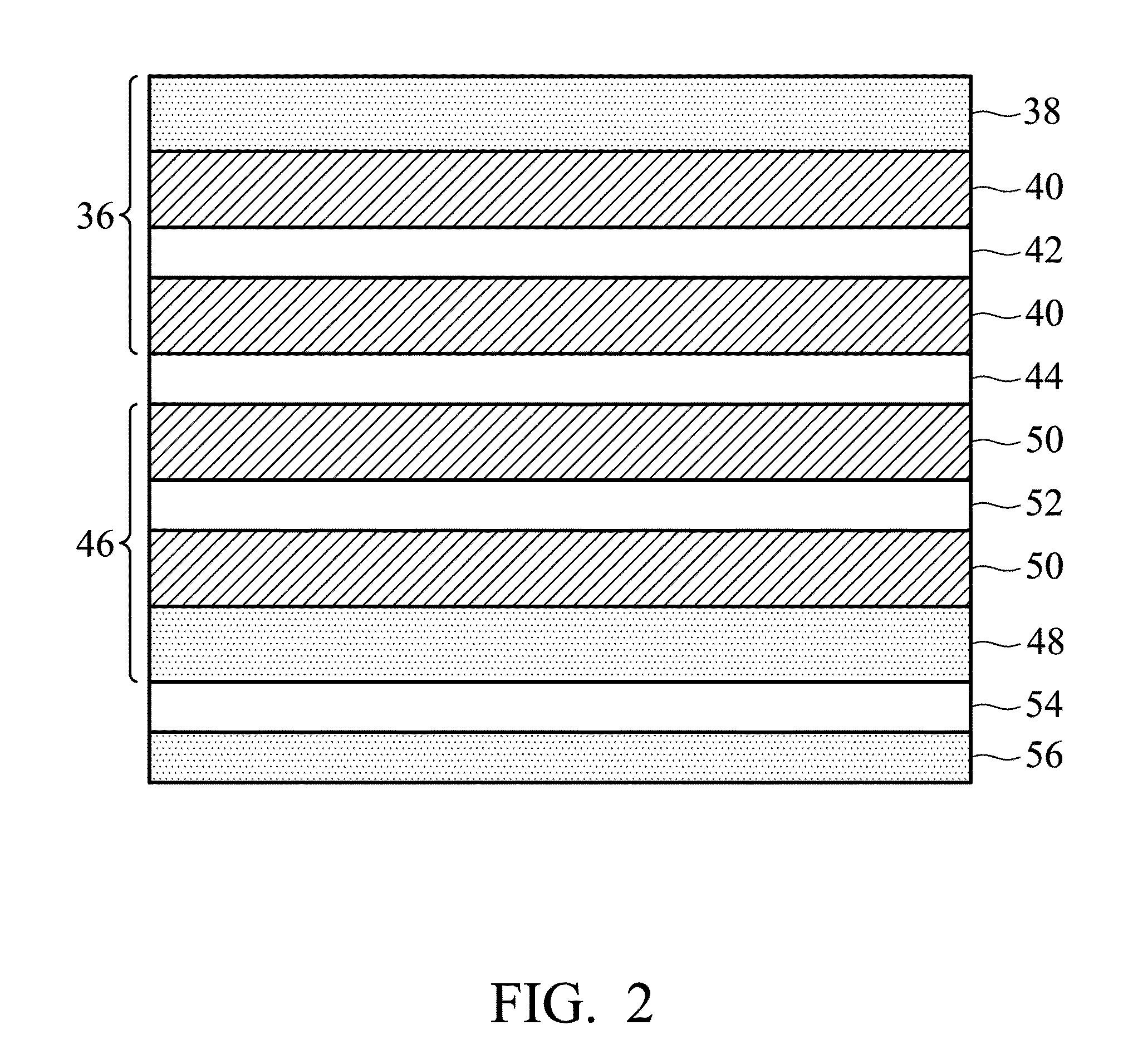

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

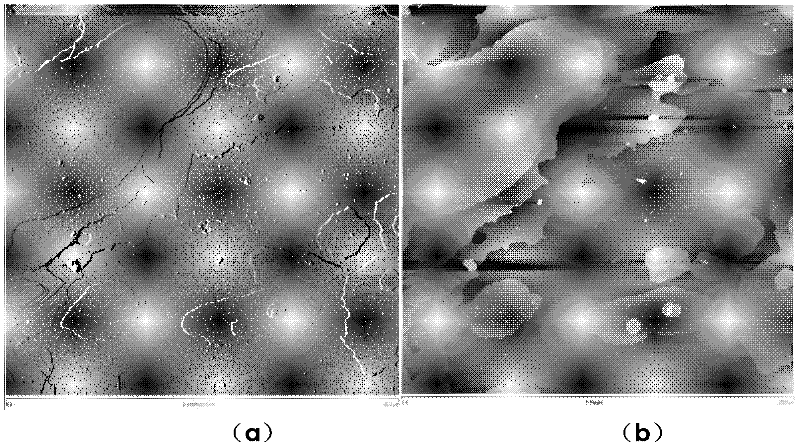

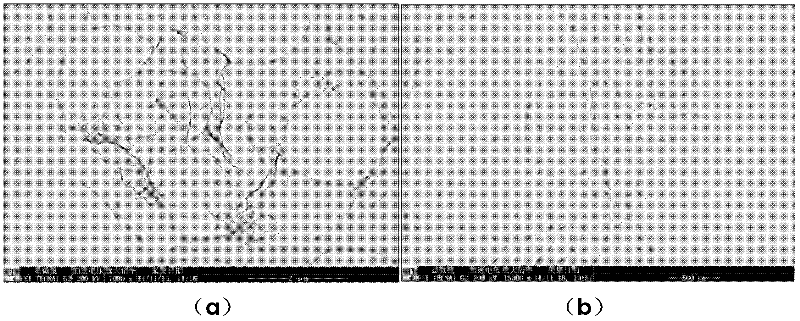

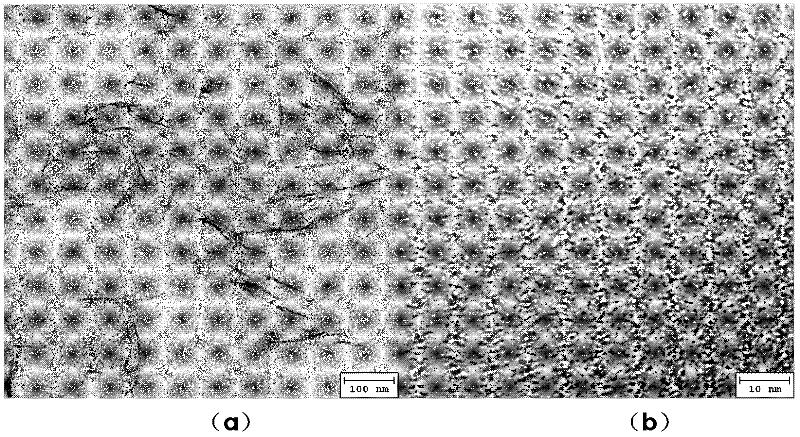

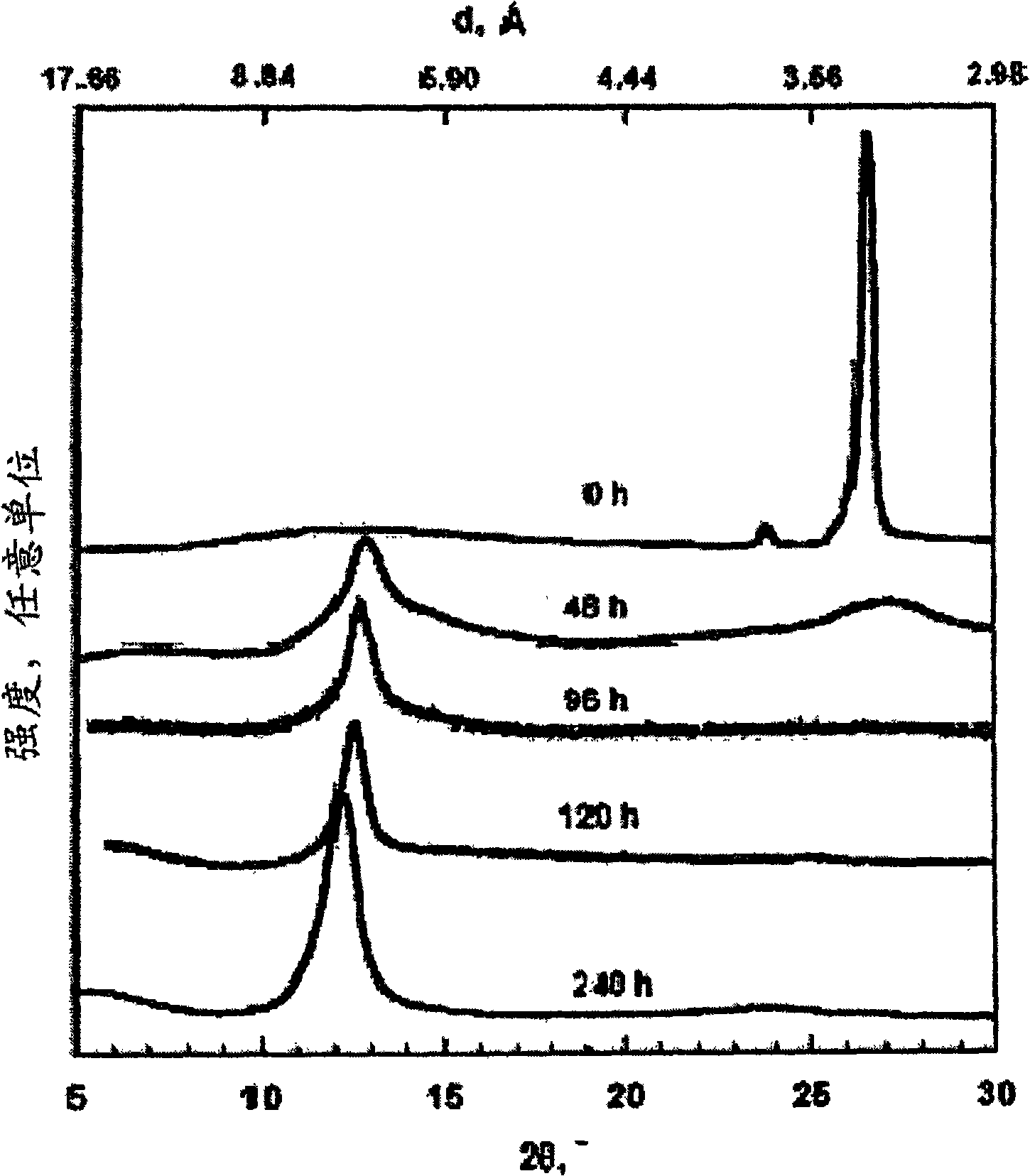

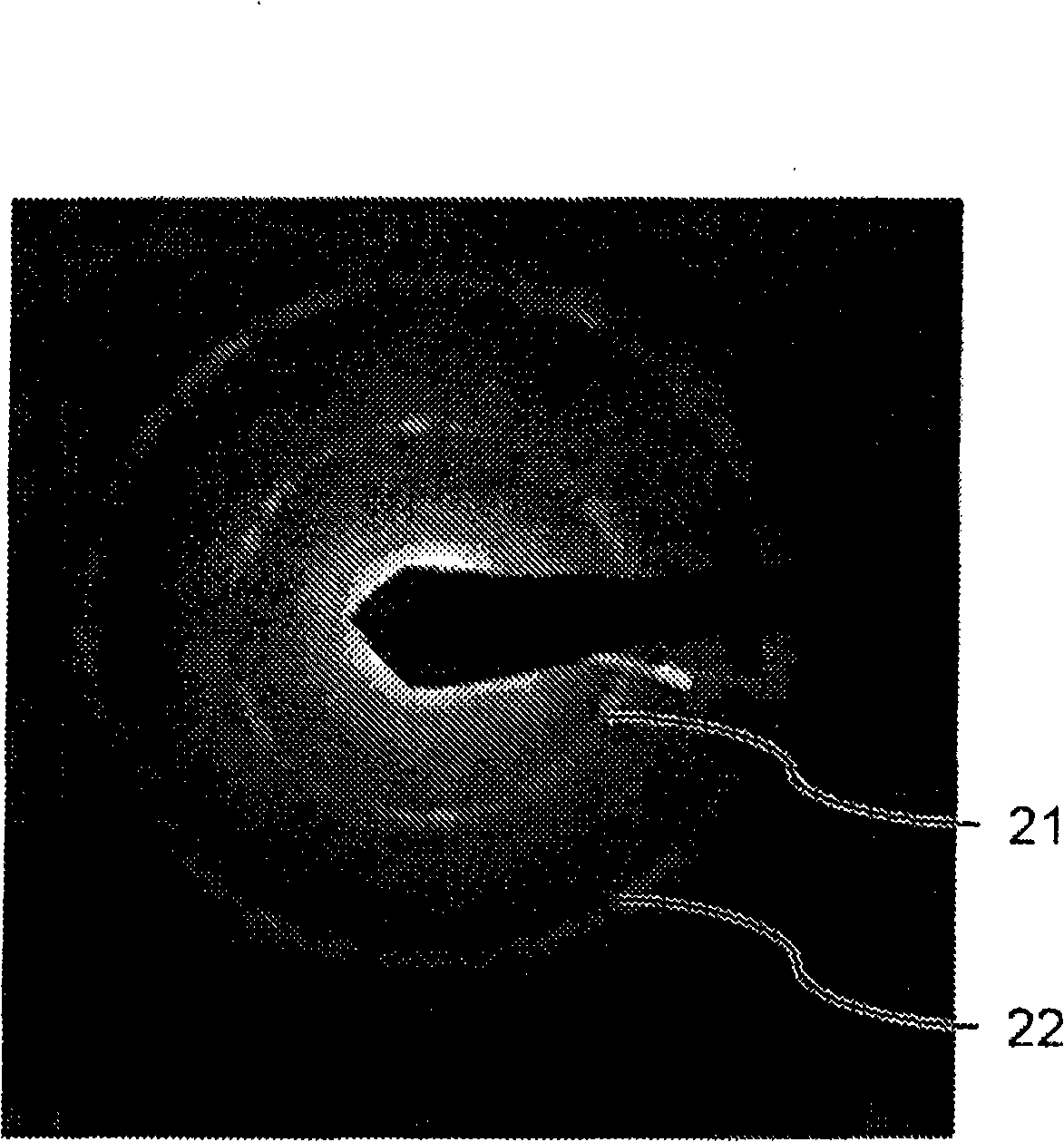

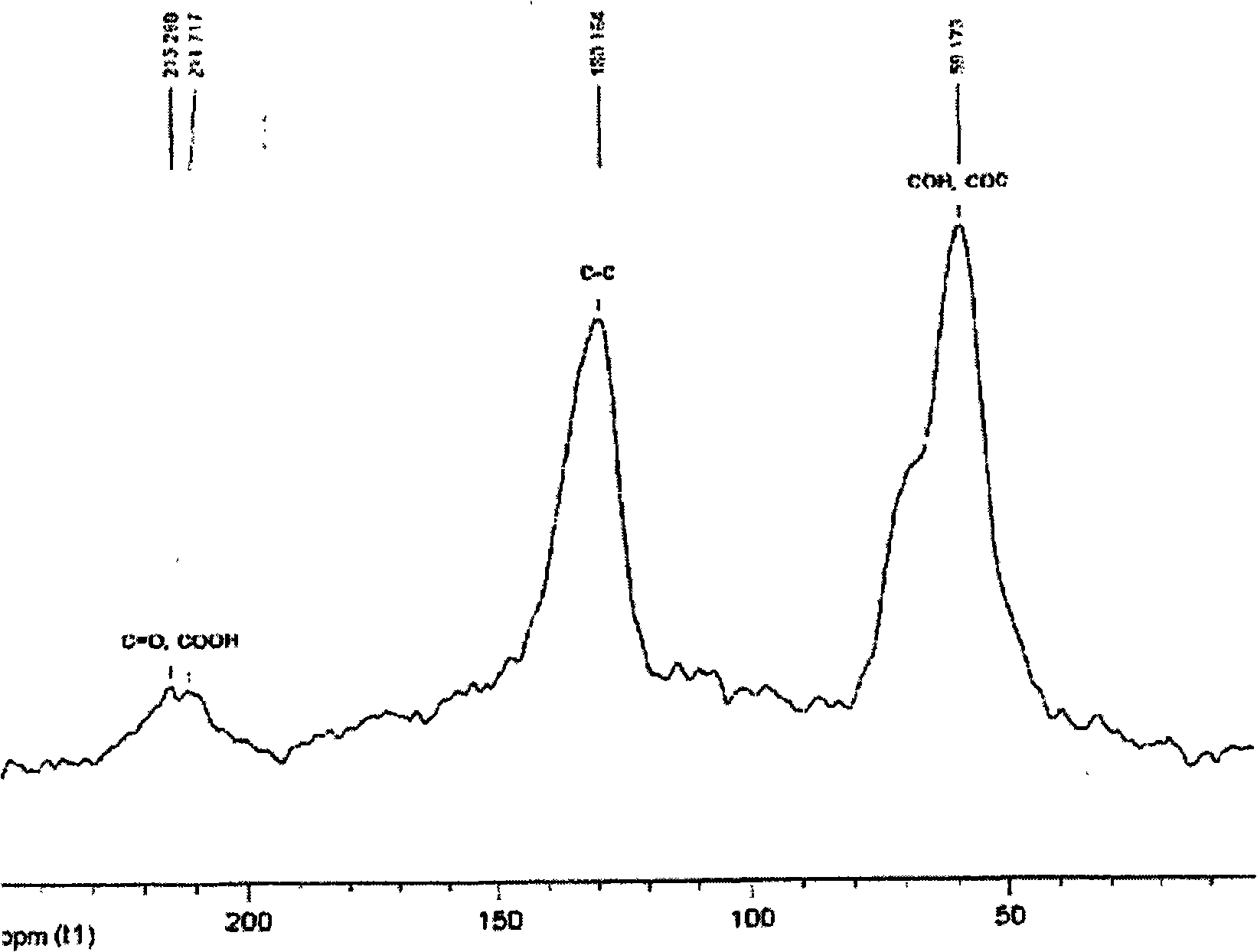

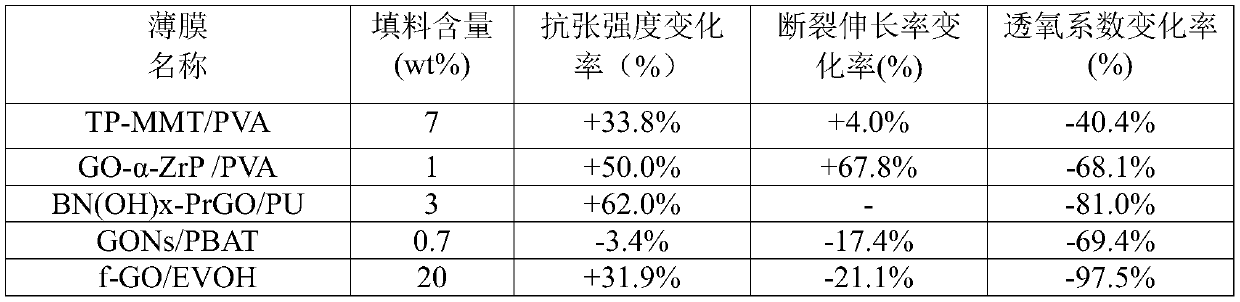

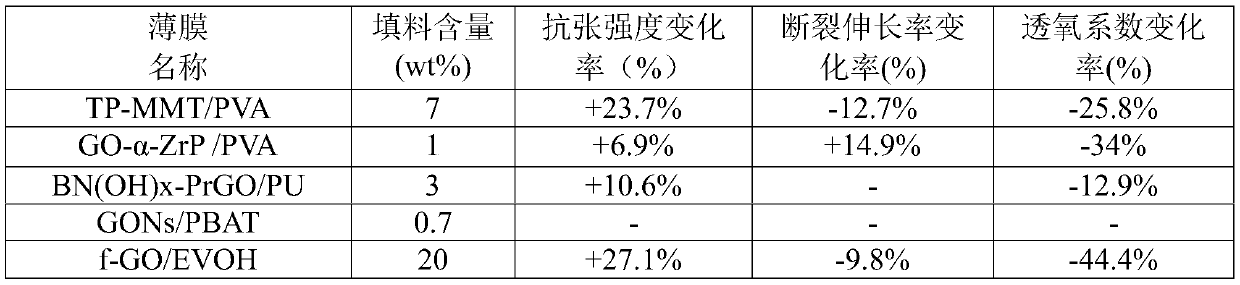

Functional graphene-polymer nanocomposites for gas barrier applications

InactiveCN101558457AHigh gas barrierImprove mechanical (strengthMaterial nanotechnologyGraphitePolymer scienceDiffusion barrier

Owner:THE TRUSTEES OF PRINCETON UNIV

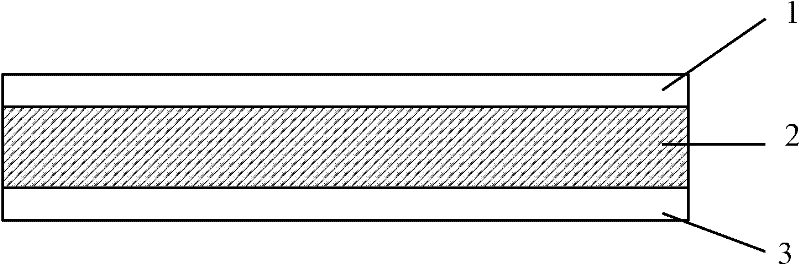

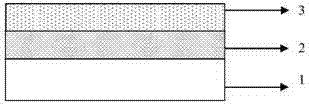

High-barrier polyester film and its preparation method

ActiveCN102225648AImprove barrier propertiesGood physical and mechanical propertiesSynthetic resin layered productsComposite constructionPolyester

The invention discloses a high-barrier polyester film, which has a three-layer composite construction, comprising a core layer, an upper cortex and a lower cortex. The core layer comprises the following components of: 60-100 wt% of PET polyester slices, 0-40 wt% of PEN polyester slices; the cortexes comprise the following components of: 92-98 wt% of PEN polyester slices, 0.2-2 wt% of a nucleating agent and 1-6 wt% of a nucleating modifier. The invention also discloses a coextruding-drawing preparation method of the above high-barrier polyester film. The invention has a simple preparation technology; in addition to excellent physical properties, the produced polyester film has better gas barrier property, heat resistance and radiation resistance performance, and can be applied in the fields of solar energy cell back-piece and the like.

Owner:JIANGSU YUXING FILM TECH

Silane coupling agent modified clay and butadiene styrene rubber nanometer composite material preparation method

InactiveCN1970607AImprove interface strengthImprove mechanical propertiesMaterials preparationPolymer science

The invention discloses a making method of clay modified by silane coupling agent with butadiene styrene rubber nanometer composite material, wherein the silane coupling agent is gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide, which comprises the following steps: making gamma-aminotriethylene silane modified clay liquid suspension under normal temperature; blending with butylbenzene rubber emulsion completely; flocculating; washing; drying; fusing; sulfurizing to obtain the product; adding di-(gamma-triethylene propyl) tetrasulfide to obtain the modified clay and butadiene styrene rubber nanometer composite material of gamma-aminotriethylene silane and di-(gamma-triethylene propyl) tetrasulfide.

Owner:BEIJING UNIV OF CHEM TECH

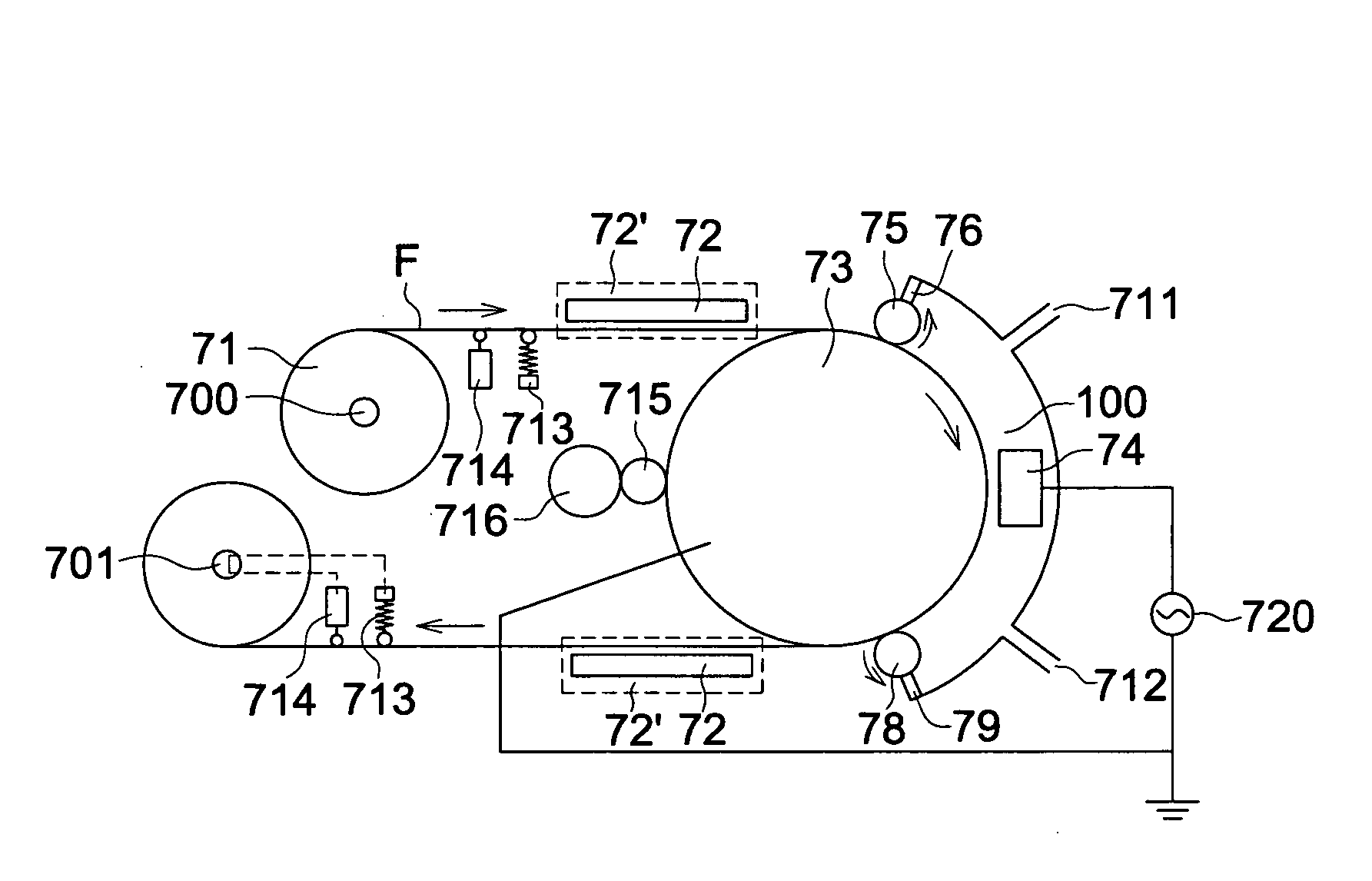

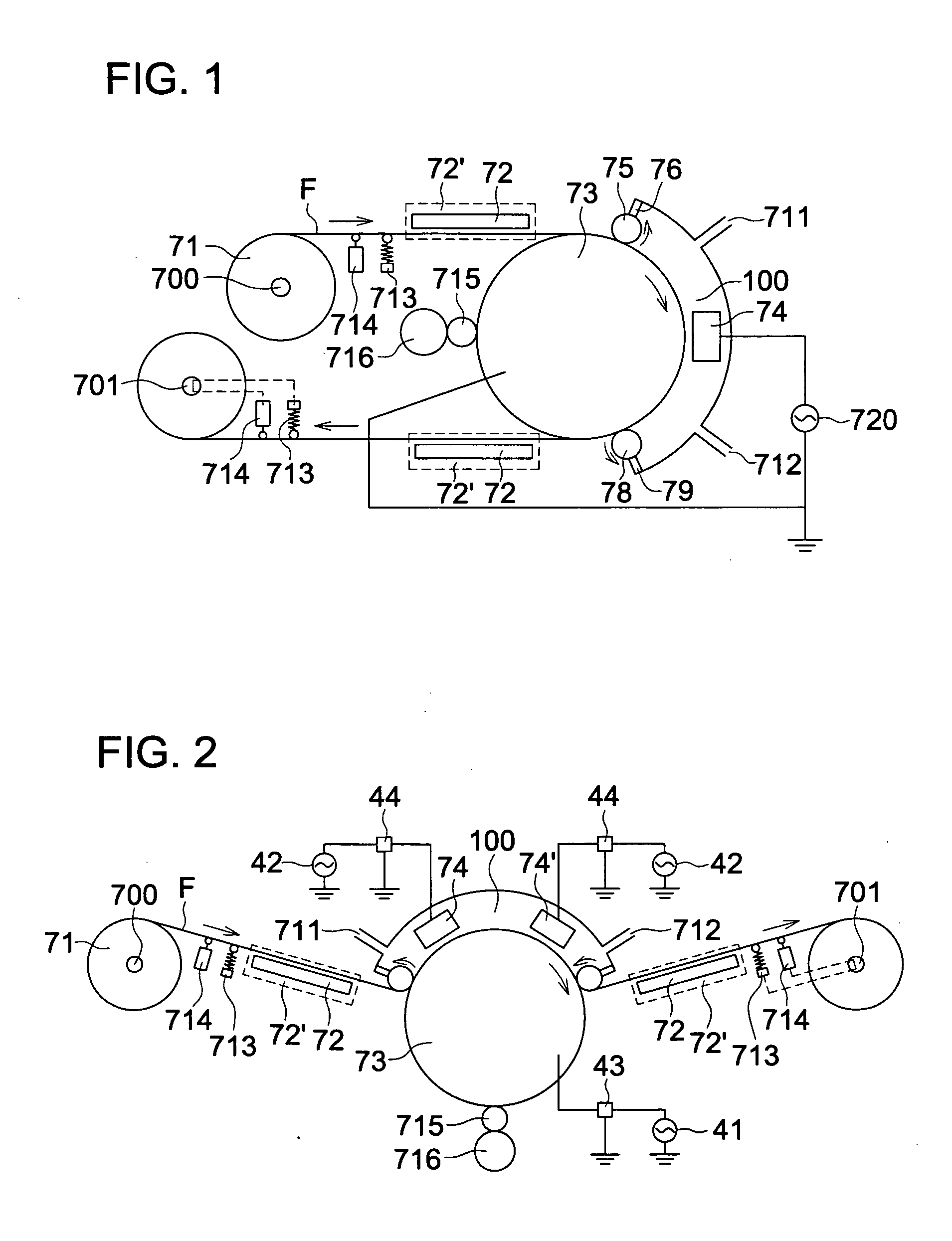

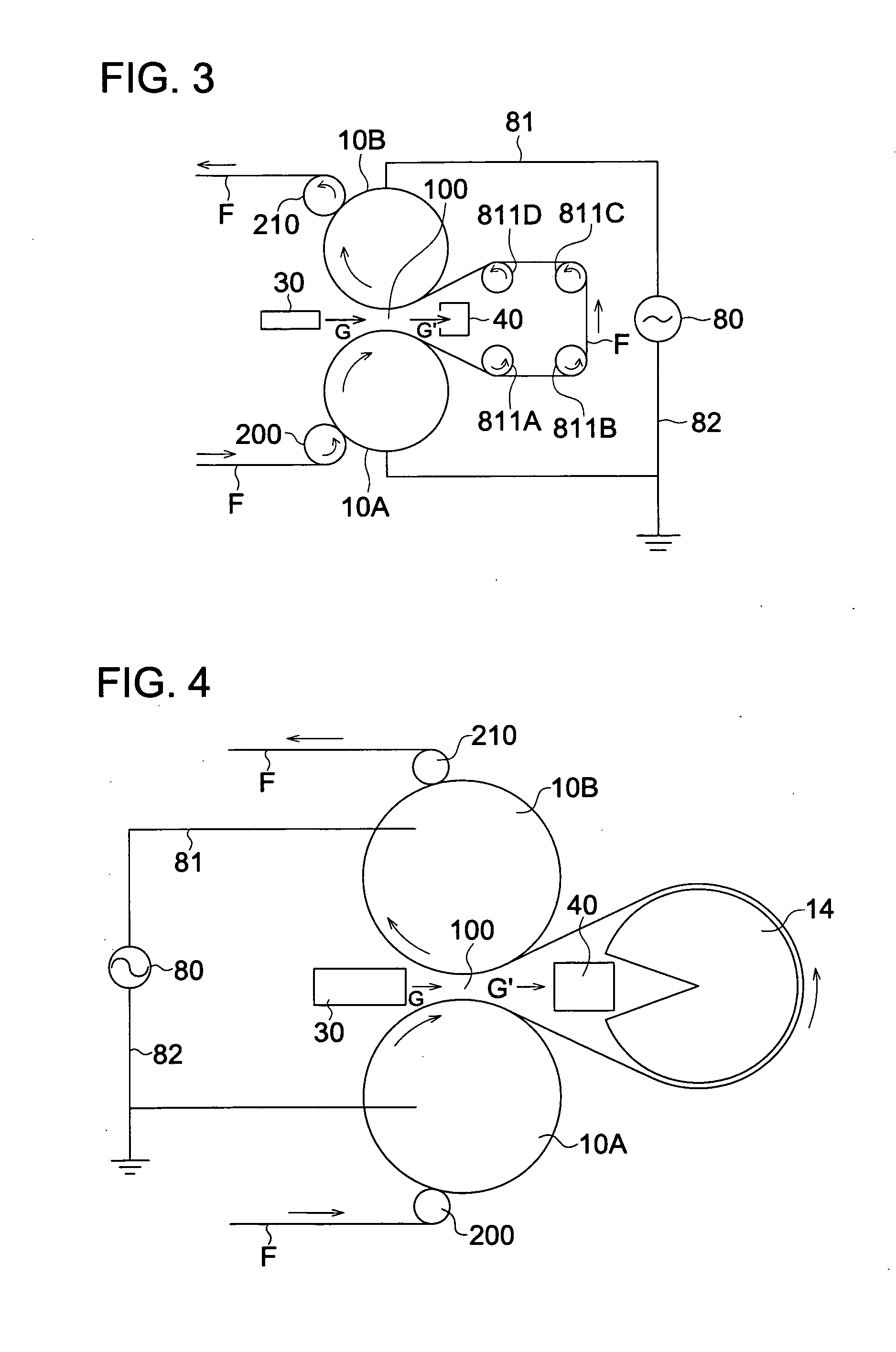

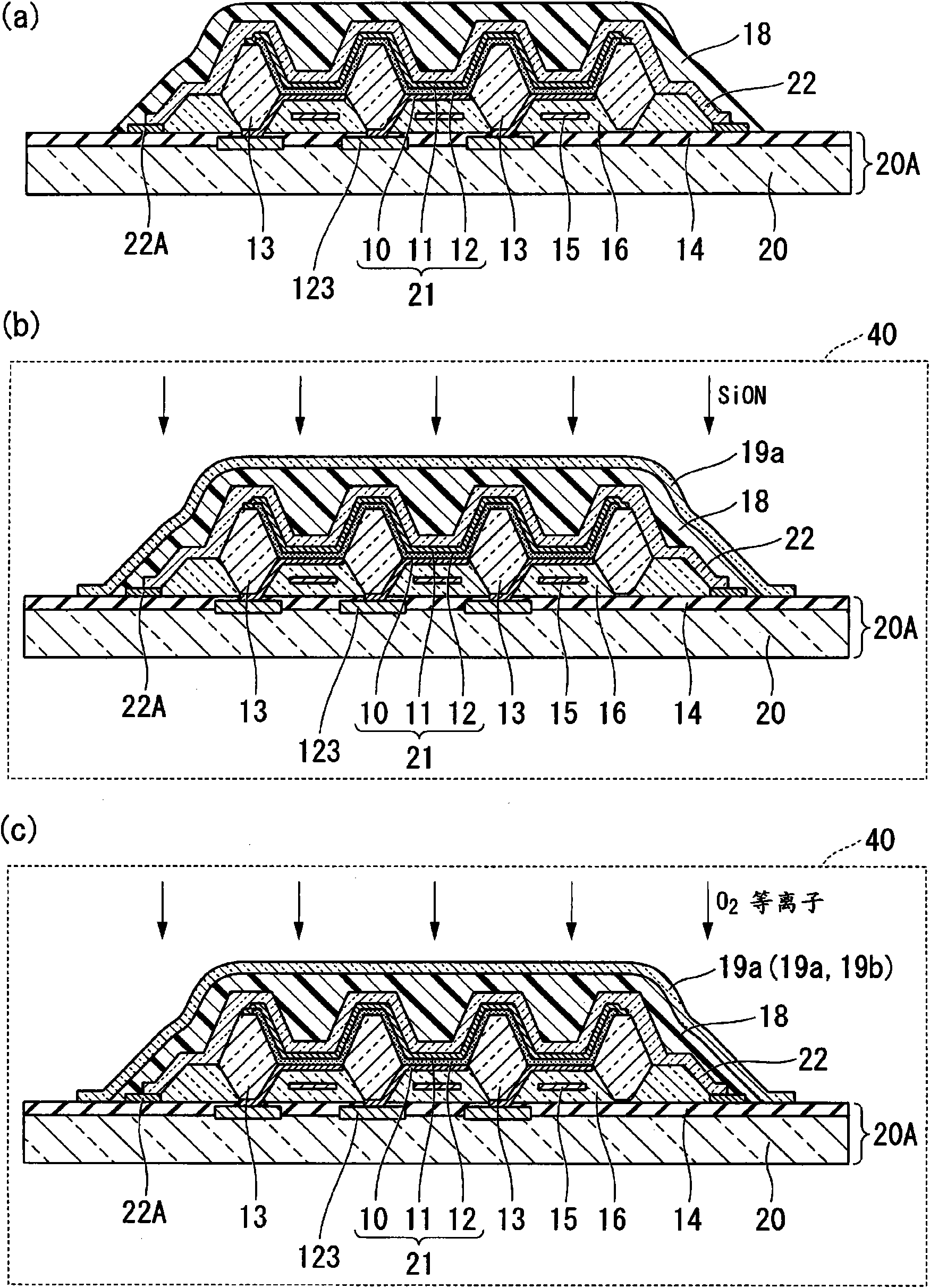

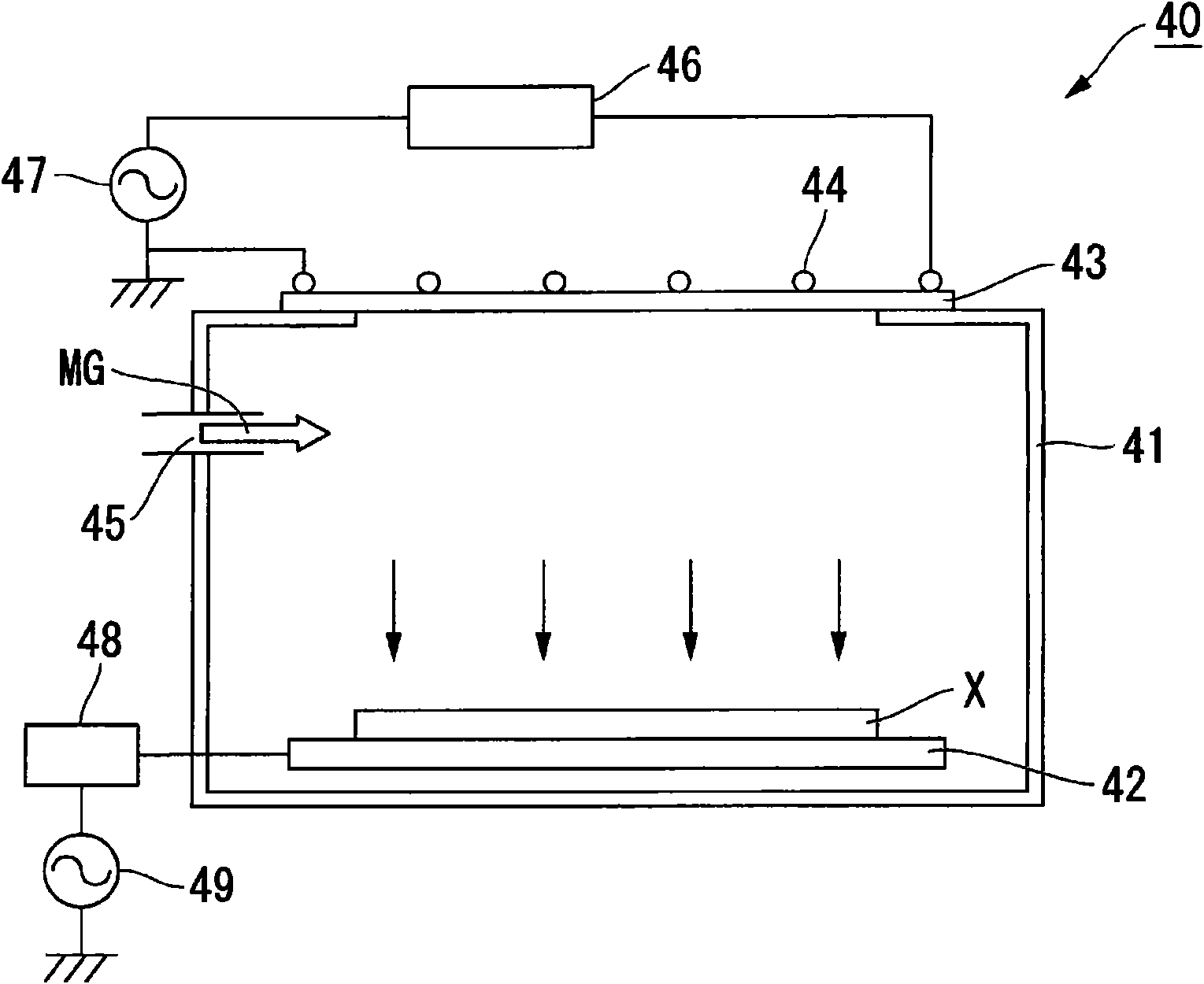

Plasma discharge treatment apparatus, and method of manufacturing gas barrier film

InactiveUS20090252893A1Increase productionMinimal numberElectric discharge tubesChemical vapor deposition coatingThin layerOptoelectronics

Provide is a method of preparing a highly-functional film capable of reducing surface failure and of improving the yield, and a manufacturing apparatus thereof. This is a plasma discharge treatment apparatus to plasma-discharge-treat for the surface of a substrate conveyed between a winder and an unwinder at atmospheric pressure or approximately atmospheric pressure, and is a plasma discharge treatment apparatus by which the substrate is conveyed with no contact by only nip roller separating the discharge section from outside. Provided is a method of preparing a gas barrier film exhibiting high gas barrier, together with reduction of surface failure (crack failure) during gas barrier thin layer formation. The surface on the gas barrier thin layer side of the gas barrier film has a curvature radius of at least 75 mm during conveyance, and the surface on the opposite side has a curvature radius of at least 37.5 mm.

Owner:KONICA MINOLTA INC

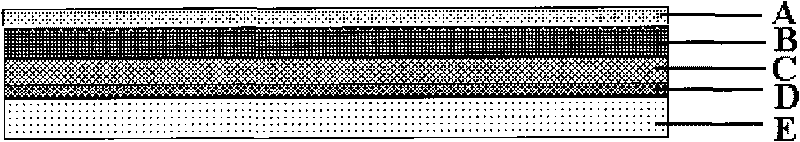

High barrier aluminum-plating composite film for packing liquid dairy product

InactiveCN1880182AHigh gas barrierImprove water resistanceFlexible coversWrappersComposite filmFolding endurance

The invention relates to a high insulated aluminum composite film used to pack liquid milk, wherein it has multilayer structure, from outer to inner, as printing layer, adhesive layer, aluminum layer, adhesive layer, baffle layer, adhesive layer and thermal sealing layer; the baffle layer is made from polyvinylidene chloride polymer or ethane-ethenol polymer. Compared with traditional plastic soft film, the invention avoids the carbon black layer and increases the aluminum layer and oxygen baffle layer, to obtain high waterproof ability and high insulated property, etc.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

Isolating polypropylene composite material and preparation method thereof

InactiveCN101633761AImprove toughnessHigh gas barrierWater vapor permeationEthylene vinyl alcohol copolymer

The invention discloses an isolating polypropylene composite material which is prepared from the following components in terms of parts by weight: 60-80 parts of polypropylene, 20-40 parts of ethylene-vinyl alcohol copolymer and 1-10 parts of compatilizer. Meanwhile, the invention also discloses a preparation method of the isolating polypropylene composite material. The isolating polypropylene composite material has high tenacity, and the impact strength thereof is as high as 210 J / m or so. In addition, the isolating polypropylene composite material has high gas isolation capability, and water vapor permeation speed can be approximately 2000 g*um / (m<2>*24h). The isolating polypropylene composite material has both high gas isolation capability and high tenacity, therefore when the isolating polypropylene composite material is used for preparing an isolating film, a traditional film making process can be adopted, wherein the process is relatively simple and the production cost is relatively low. The isolating polypropylene composite material has a prospect for generalized application.

Owner:洛阳石化吉润化工有限责任公司

Back film for solar module

ActiveCN101764163AHigh gas barrierGood mechanical strengthSynthetic resin layered productsPhotovoltaic energy generationChemistryWater vapor

The invention discloses a back film for a solar module; the back film comprises an outer surface fluoride containing layer, a middle layer and an inner surface ethylene- vinyl acetate copolymer layer; the middle layer comprises a polyester layer, an ethylene-vinyl alcohol copolymer layer and a bonding layer; the middle layer is prepared by co-extruding the polyester material layer, the ethylene-vinyl alcohol copolymer layer and the bonding layer; the outer surface fluoride containing layer is a fluoride containing film compounded on the polyester layer of the middle layer or the fluoride containing coating coated on the polyester layer of the middle layer; and the inner surface ethylene- vinyl acetate copolymer layer is applied on the bonding layer of the middle layer by curtain coating. The back film of the solar module provided by the invention has the advantages of low water vapor transmission rate and high insulation performance, not only has excellent barrier and insulation performance, but also has the packaging performance.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

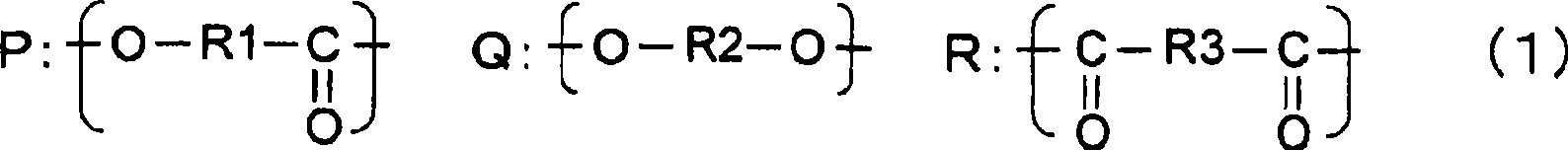

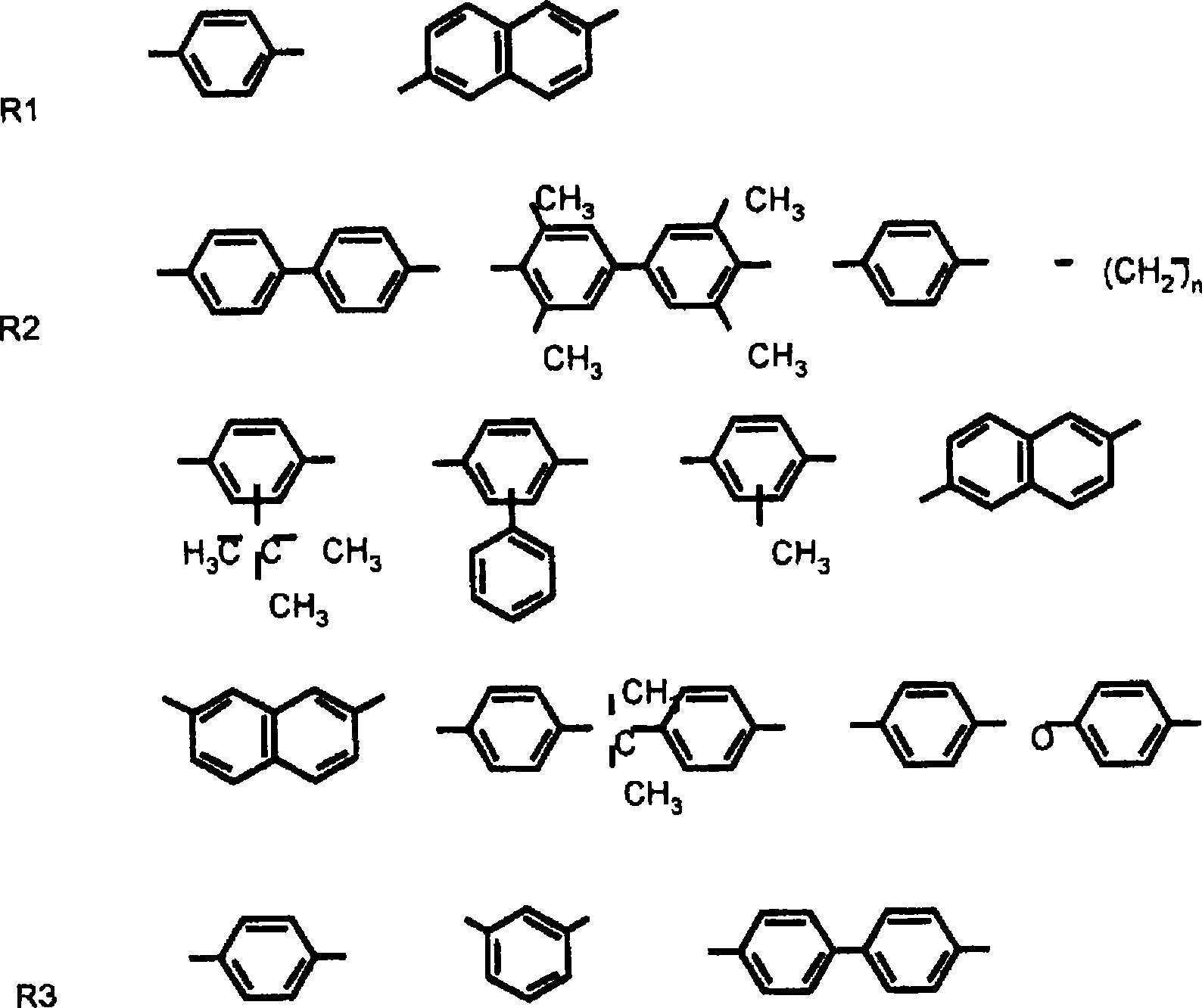

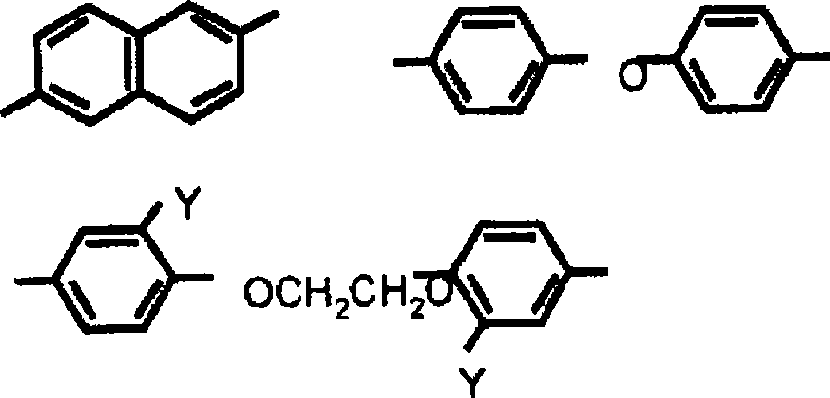

Dendritic polyester, method for producing the same, and thermoplastic resin composition

Disclosed is a dendritic polyester containing at least one constituent unit selected from an aromatic oxycarbonyl unit (P), an aromatic and / or aliphatic dioxy unit (Q) and an aromatic dicarboxy unit (R), and a tri- or more-functional organic residue (B). In this dendritic polyester, the content of (B) relative to the total monomers constituting the dendritic polyester is within the range of 7.5-50 mol%. When this dendritic polyester is blended in a thermoplastic resin, the resin can be remarkably improved in thin-wall fluidity, rigidity, gas barrier properties and the like. Also disclosed is a thermoplastic resin composition containing such a dendritic polyester.

Owner:TORAY IND INC

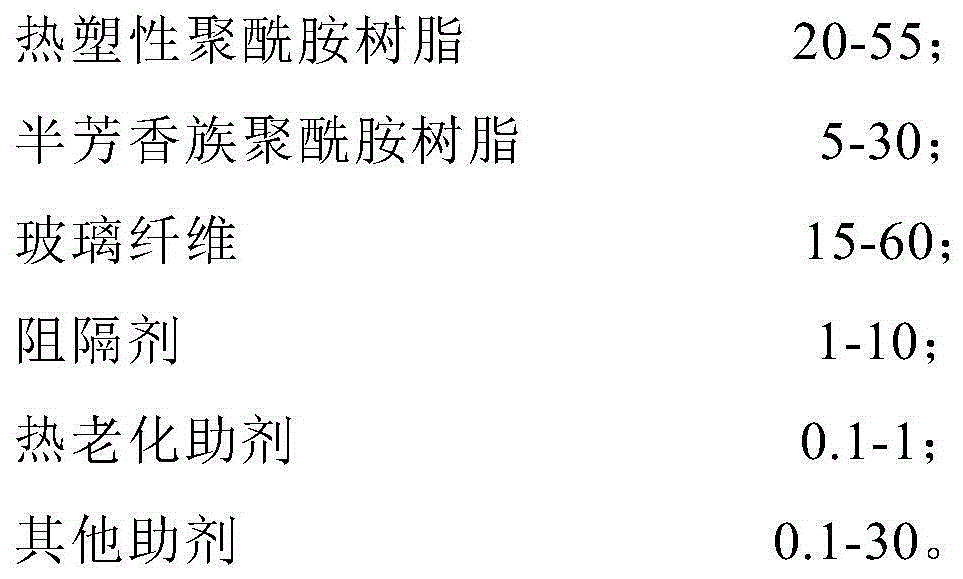

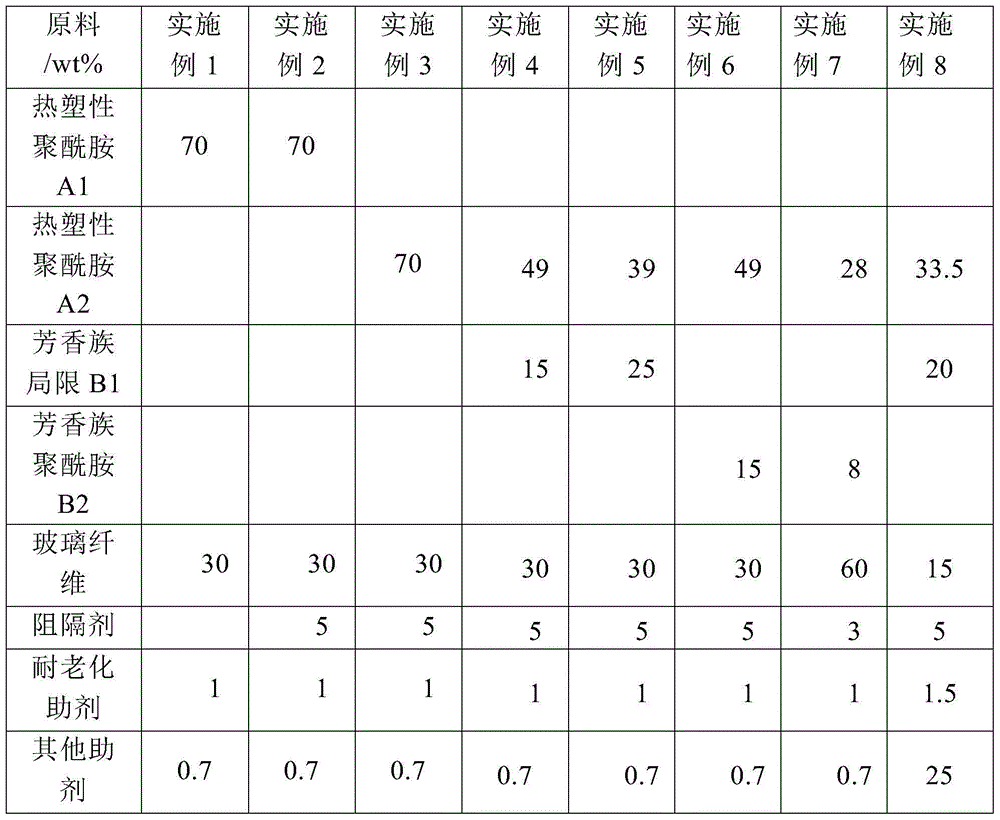

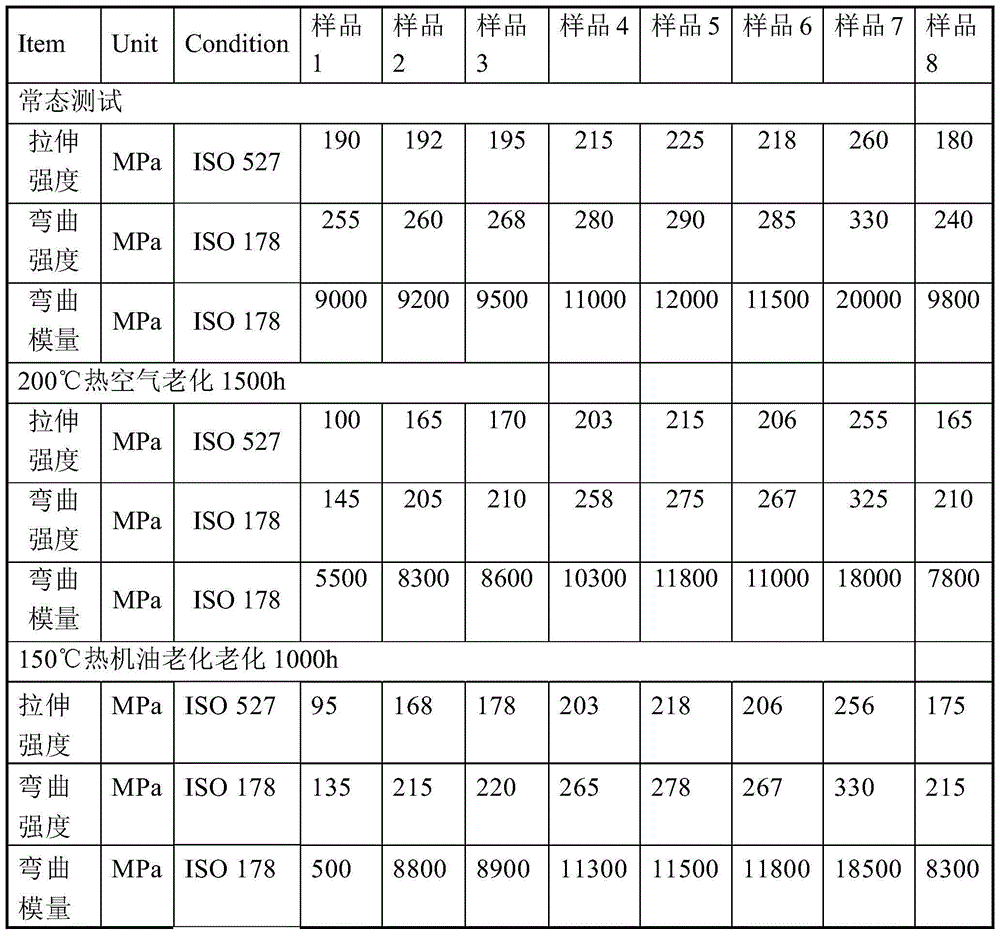

Low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and preparation method thereof

The invention relates to a low-moisture-absorption long-term heat-resistant aging-resistant polyamide composition and a preparation method thereof. The polyamide composition is prepared from the following raw materials in percentages by weight: 20-55% of thermoplastic polyamide resin, 5-30% of semi-aromatic polyamide resin, 15-60% of glass fiber, 1-10% of a blocker, 0.1-1% of a thermal aging additive and 0.1-30% of other additives. Compared with the prior art, the semi-aromatic polymer is added into the composite system, the moisture-absorption property of a matrix can be significantly decreased due to the high steric-hindrance effect of the composite system; in addition, because of the presence of benzene rings, characteristics of good barrier property and heat resistance and retention are achieved and the polyamide composition also has the advantages of low moisture absorption, very excellent mechanical strength, heat resistance, aging resistance and the like.

Owner:SHANGHAI SUNNY

High-performance graphene-containing water-based acrylate coating as well as preparation method and application thereof

InactiveCN105038459AImprove performanceHigh tensile strengthAnti-corrosive paintsWater basedDefoaming Agents

The invention discloses a high-performance graphene-containing water-based acrylate coating. The high-performance graphene-containing water-based acrylate coating contains pure acrylic and / or a styrene-acrylic emulsion, titanium dioxide, calcium carbonate, a dispersing agent, a defoaming agent, a film-forming agent, a flatting agent and sulfonated graphene. The invention further discloses a method for preparing the water-based acrylate coating. Compared with an existing water-based acrylate coating, by adding a minute quantity of sulfonated grapheme into the water-based acrylate coating, the comprehensive properties of the prepared coating are substantially improved, for instance, the tensile strength is increased by 20%-60%, the elongation at break is increased by 25%-70%, the thermal conductivity is increased by 20%-100%, the water resistance is obviously improved, the electrical conductivity is improved by an order of magnitude, and the gas barrier property is increased by 10%-80%. The high-performance graphene-containing water-based acrylate coating is easy to prepare, low in cost and convenient to use and can be applied to the various fields of toughening, heat conduction, corrosion prevention and the like of the water-based acrylate coating.

Owner:SUZHOU GRAPHENE NEW MATERIAL TECH

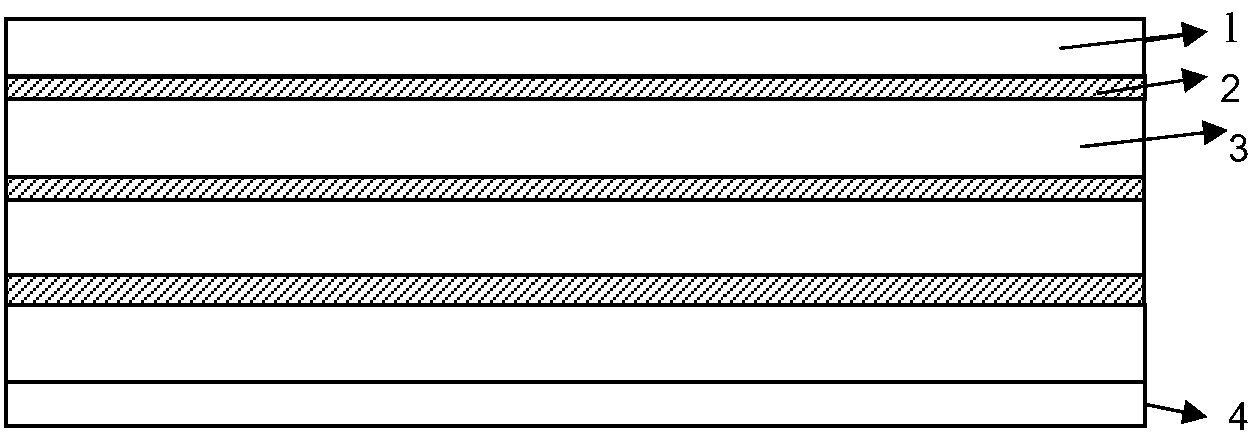

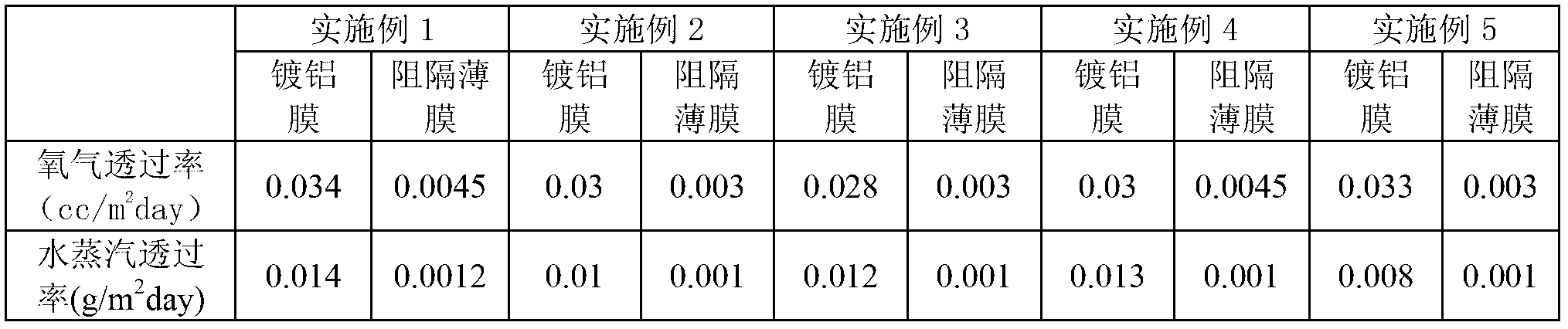

Barrier film and vacuum insulating board adopting same

ActiveCN103057212AHigh gas barrierHigh barrierVacuum evaporation coatingSputtering coatingPolyethylene terephthalateSurface layer

The invention provides a barrier film and a vacuum insulating board compounded by utilizing the barrier film. The barrier film is formed by adhering a surface layer, a gas barrier layer and a heat seal layer, wherein the gas barrier layer consists of at least one aluminum-plated polyethylene terephthalate (PET) film layer. The preparation process of the aluminum-plated PET film comprises the following of: (1) arranging a PET substrate film in an aluminum-plating chamber for performing vacuum aluminum plating, and forming an aluminum-plating layer on the surface of the PET substrate film; and (2) introducing nitrogen into the aluminum-plating chamber in stages after aluminum plating is ended, introducing the nitrogen until the nitrogen pressure is 800-1200pa at the first time, maintaining for 8-12 hours, introducing the nitrogen until the nitrogen pressure is 1300-1500pa, maintaining for at least 12 hours, and obtaining the aluminum-plated PET film. Compared with the conventional aluminum-plated film prepared by the prior art, the aluminum-plated film has the advantages that the overall barrier performance of the barrier film can be effectively improved, so that the requirements can be met in occasions with strict barrier performance requirement.

Owner:中亨新型材料科技有限公司

Aqueous ethylene/vinyl alcohol copolymer dispersion

ActiveCN101065439AGood storage stabilityHigh gas barrierSynthetic resin layered productsCoatingsPVA - Polyvinyl alcoholSaponification

An aqueous ethylene / vinyl alcohol copolymer dispersion which has excellent long-term storage stability, has excellent film-forming properties even when dried at a low temperature or in a short time or applied thick, and gives a film having high gas barrier performance. The aqueous ethylene / vinyl alcohol copolymer dispersion comprises (A) an ethylene / vinyl alcohol copolymer having an ethylene content of 15-65 mol% and a degree of saponification of 80 mol% or higher, (B) an ethylene / a,ss-unsaturated carboxylic acid copolymer neutralized with a base, and (C) polyvinyl alcohol having a degree of saponification of 75-100 mol% and a degree of polymerization of 100-3,500, the amount of the polyvinyl alcohol (C) being 0.5-100 parts by weight per 100 parts by weight of the ethylene / vinyl alcohol copolymer (A).

Owner:SUMITOMO SEIKA CHEM CO LTD +1

High-strength and high-toughness polylactic acid composite film with antimicrobial and barrier properties

ActiveCN105440611AFusion wellImprove flexibilitySynthetic resin layered productsLaminationGlycidyl methacrylateComposite film

The present invention relates to high-strength and high-toughness polylactic acid composite film with antimicrobial and barrier properties. Raw materials of the high-toughness polylactic acid composite film comprises polylactic acid, EVOH, polylactic acid grafted glycidyl methacrylate, ethylene-octene copolymer grafted glycidyl methacrylate, eight-arm maleic anhydride POSS, nano TiO2, an antioxidant, and an anti-UV agent. The composite film is formed through multilayer coextrusion. The composite film has excellent strength and toughness, a good oxygen barrier property to gas, and a good antimicrobial effect, and can be used in the field of the environmentally friendly packaging film.

Owner:HUNAN YIYONGFENG PRINGTING PACKAGING

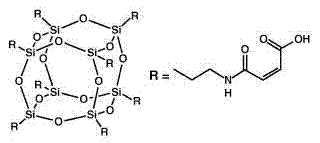

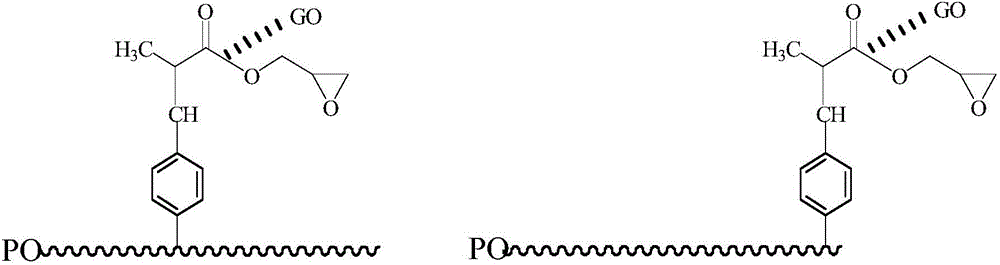

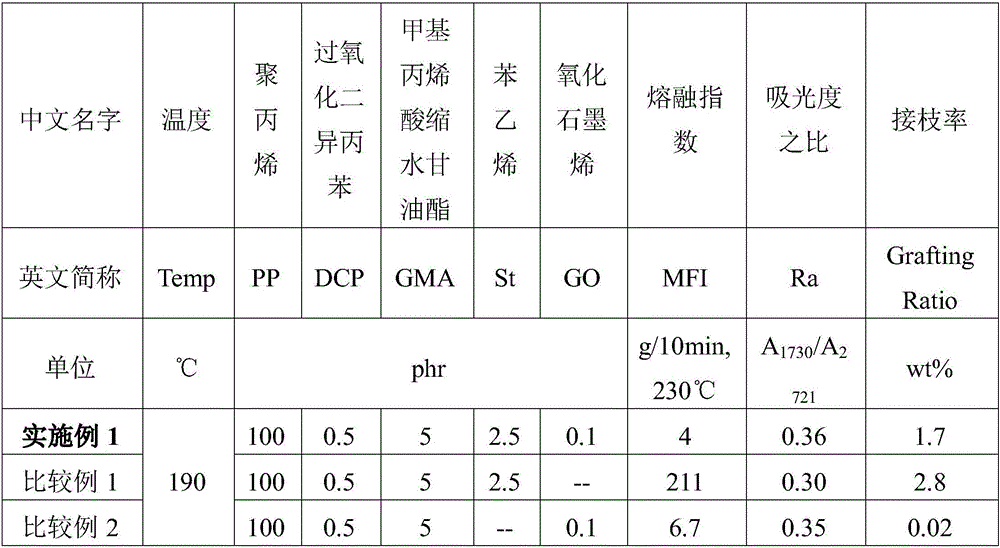

Preparation method of glycidyl methacrylate melt-grafted polyolefin material

The invention discloses a preparation method of a glycidyl methacrylate melt-grafted polyolefin material. The preparation method comprises the following steps: directly adding glycidyl methacrylate and graphene oxide onto polyolefin pellets or powder, uniformly mixing at normal temperature, and adding the physical mixture into reaction equipment; and uniformly mixing an initiator and a styrene liquid, adding the mixture into the above reaction equipment, and melt-blending at a certain temperature. The prepared glycidyl methacrylate grafted polyolefin has high grafting rate and high molecular weight or high grafting rate and low crosslinking degree.

Owner:HANGZHOU NORMAL UNIVERSITY

Transparent oxide film and process for producing same

ActiveCN103380229AHigh gas barrierHigh transparencyFinal product manufactureVacuum evaporation coatingComposite oxideOxide

Provided are: a zinc oxide-based transparent oxide film which has a low refractive index and good gas barrier properties; and a process for producing the same. This transparent oxide film is amorphous, and has a composition which contains, relative to the total amount of all the metal components, 0.9 to 20.0at% of Al and 25.5 to 68.0at% of Si with the balance consisting of Zn and unavoidable impurities. In this process, DC sputtering is conducted in an inert gas atmosphere that contains oxygen and / or under such conditions that the substrate is in a heated state, using a sputtering target consisting of a sintered oxide which has a composition that contains, relative to the total amount of all the metal components, 0.3 to 4.0wt% of Al and 6.0 to 14.5wt% of Si with the balance consisting of Zn and unavoidable impurities and in which both a composite oxide, Zn2SiO4, and ZnO are present in the structure.

Owner:MITSUBISHI MATERIALS CORP

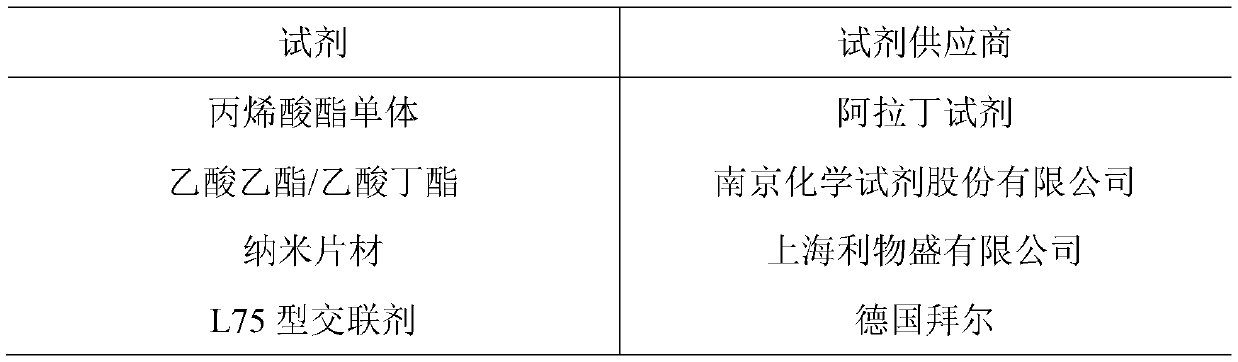

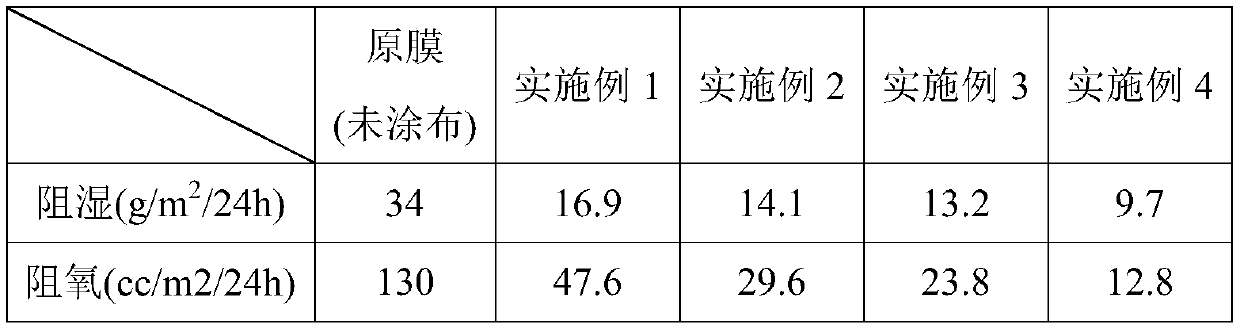

High barrier paint for bi-oriented polyester thin film and preparing method thereof

The invention discloses a high barrier paint for a bi-oriented polyester thin film and a preparing method thereof. The high barrier paint is prepared from, by mass, 20-40 parts of acrylate copolymers,2 parts of an isocyanate cross-linking agent, 0.001-0.1 part of a nanosheet material and the balance mixed solvent. According to the high barrier paint, gas molecules pass through the nanosheet material with difficulty, and cross linking makes the paint more compact; the compact high barrier resin is mixed with the nanosheet material, so that cross linking is further conducted to make most of oxygen and water blocked on the outer side, the contact with the interior of a package is reduced, and thus the purpose of prolonging the service life of a goods shelf is achieved.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

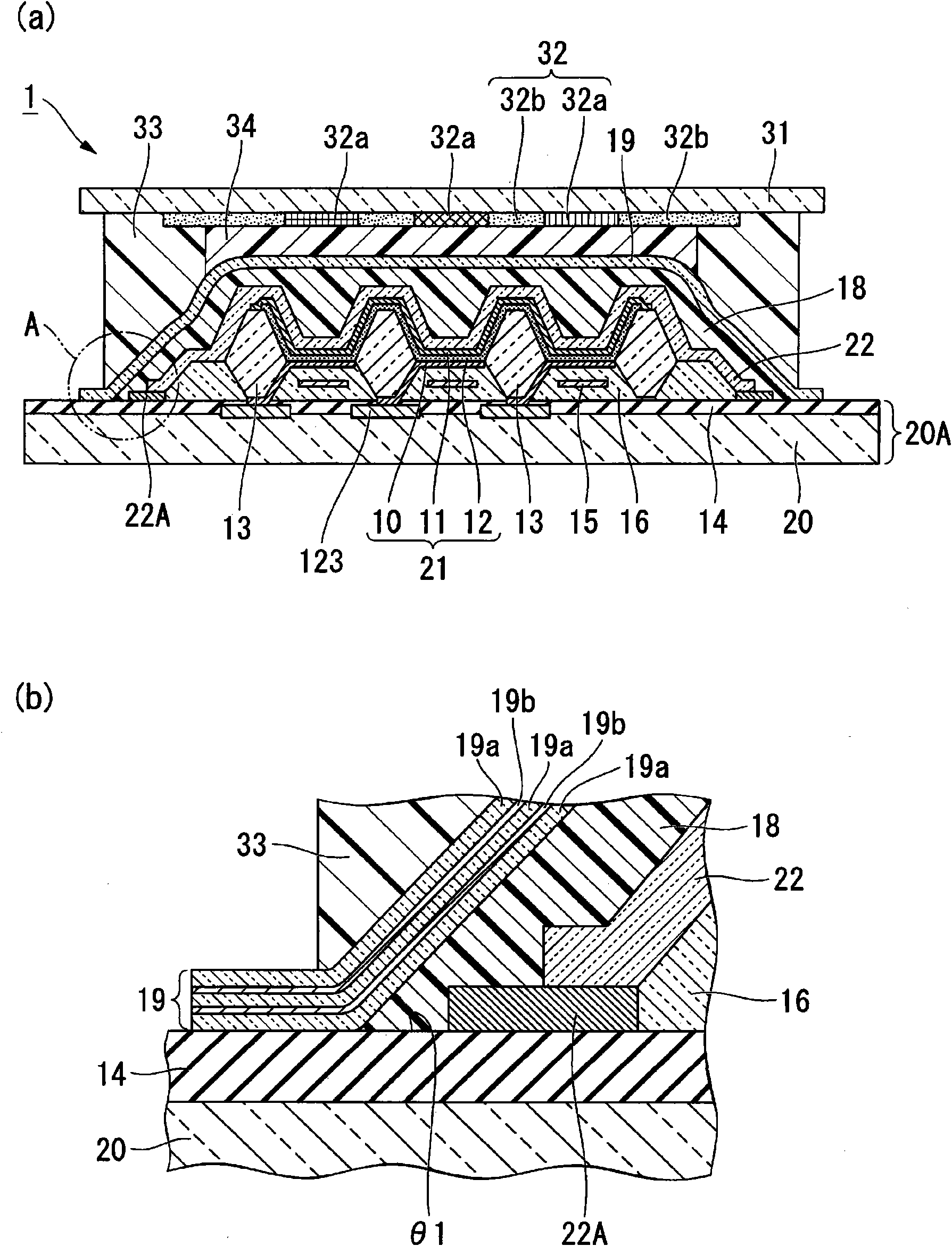

Organic electroluminescence device, process of producing organic electroluminescence device, and electronic apparatus

InactiveCN101635306AIncreased durabilityImprove reliabilitySemiconductor/solid-state device detailsElectroluminescent light sourcesNitrogenOrganic electroluminescence

An organic electroluminescence device includes a substrate, a plurality of light-emitting elements arranged on the substrate, each including a pair of electrodes and an organic light-emitting layer disposed between the electrodes, an organic buffer layer covering the plurality of light-emitting elements, and a gas barrier layer covering the organic buffer layer. The gas barrier layer has a structure wherein first inorganic films and second inorganic films are alternately stacked. The first inorganic films contain a silicon compound containing nitrogen, the second inorganic films contain an oxide of the formation material of the first inorganic films and each have a thickness smaller than that of each first inorganic film. The numbers of the first inorganic films and the second inorganic films are each at least two.

Owner:SEIKO EPSON CORP

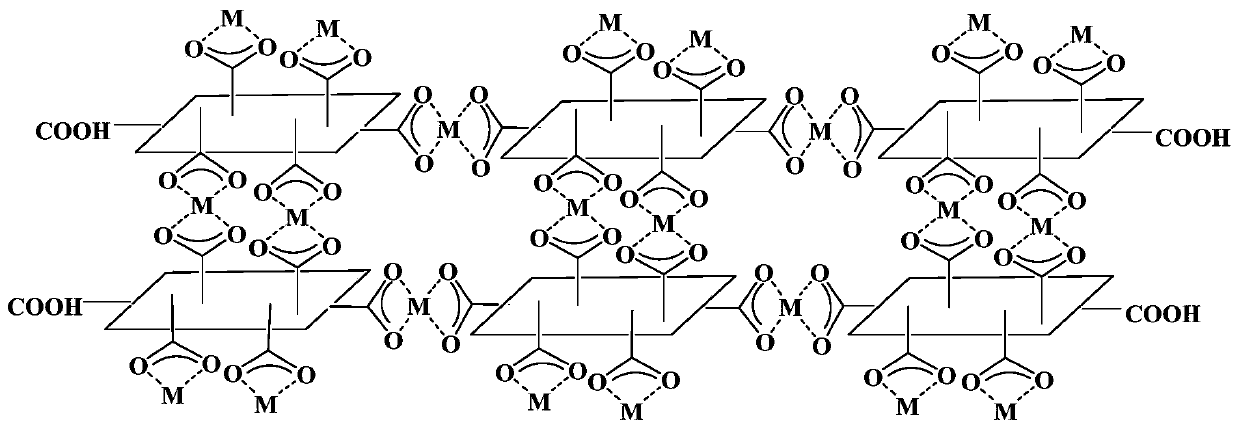

High-oxygen-resistance polymer nano-composite film and preparation method thereof

InactiveCN109880267AExcellent gas barrier propertiesHigh gas barrierMetal chlorideMechanical property

The invention discloses a high-oxygen-resistance nano-composite membrane and a preparation method thereof. The preparation method comprises the following steps: adding a filler dispersion liquid intoa first solution, conducting uniform stirring, dropwise adding a second solution, conducting uniform mixing under stirring, carrying out ultrasonic degassing treatment and standing, conducting tape-casting on the mixed liquid to enable the mixed liquid to enter a mold, and conducting drying and curing to obtain the high-oxygen-resistance nano-composite film. The lamellar nano-filler is controlledto account for 0.2-2 wt% of the total mass of the raw materials. The first solution is obtained by adding a hydrophilic polymer into deionized water and conducting heating and stirring to completely dissolve the hydrophilic polymer; the second solution is obtained by dissolving a metal chloride in deionized water to prepare a metal ion solution; and the uniform filler dispersion liquid is obtainedby adding a lamellar nano-filler into deionized water and conducting uniform stirring and mixing and ultrasonic treatment. The high-oxygen-resistance nano-composite membrane has the advantages of being excellent in oxygen barrier property, small in filler consumption, simple and convenient to operate, easy to process, biodegradable and excellent in comprehensive mechanical property.

Owner:SOUTH CHINA UNIV OF TECH

Adhesive for gas barrier laminates and laminated films

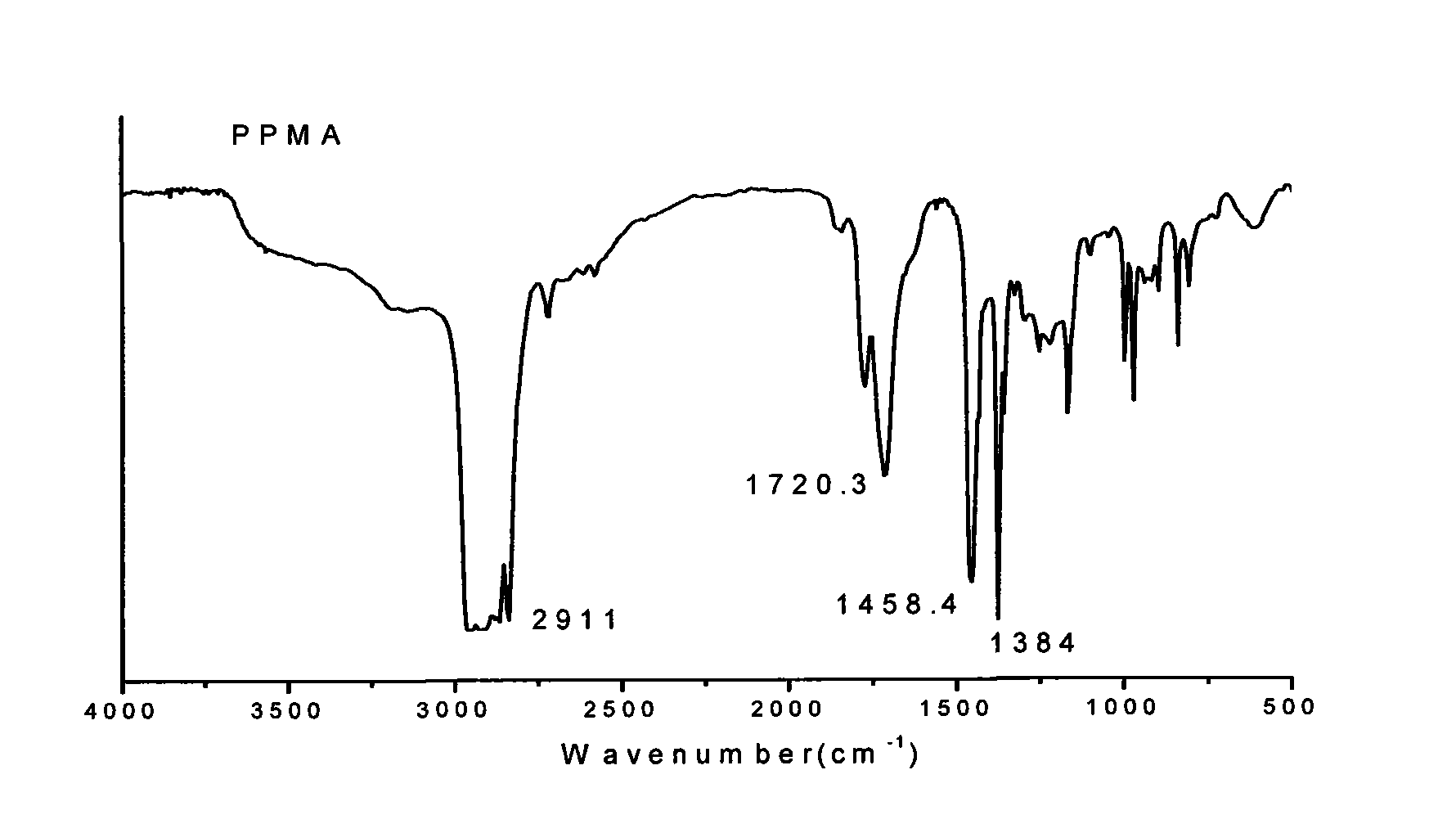

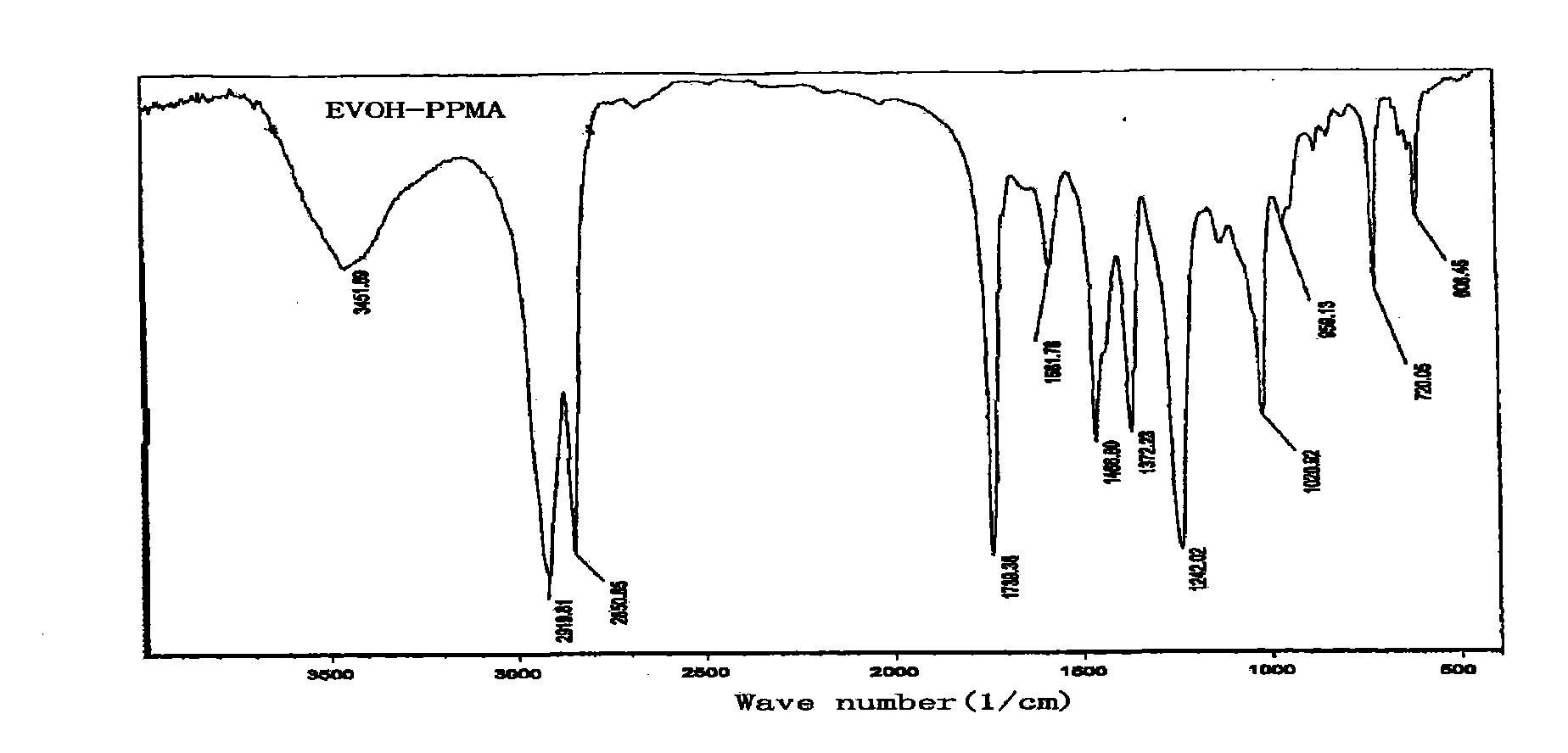

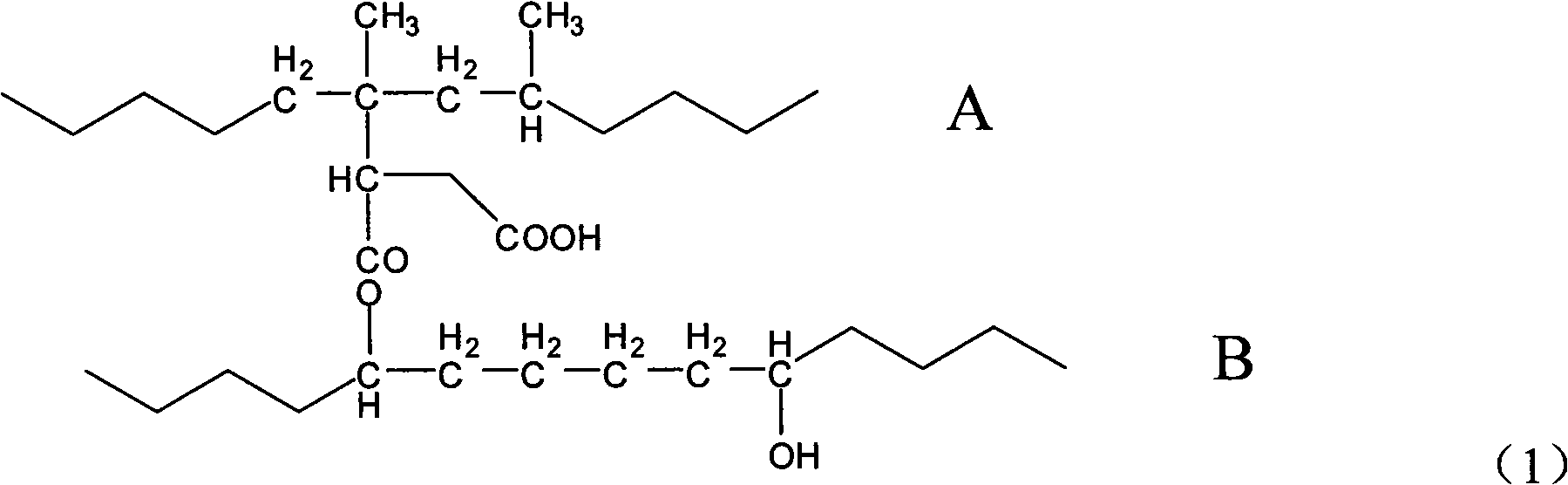

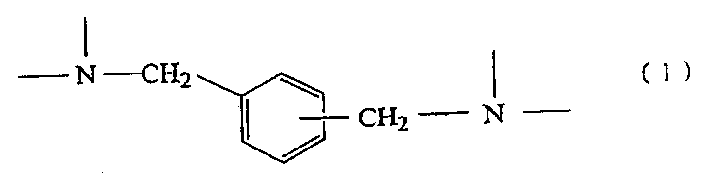

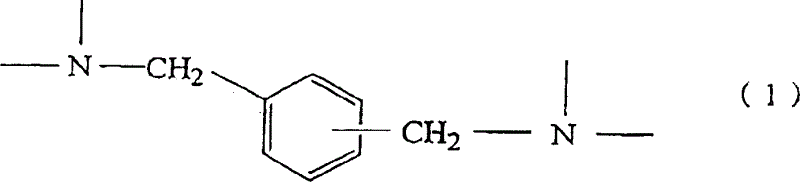

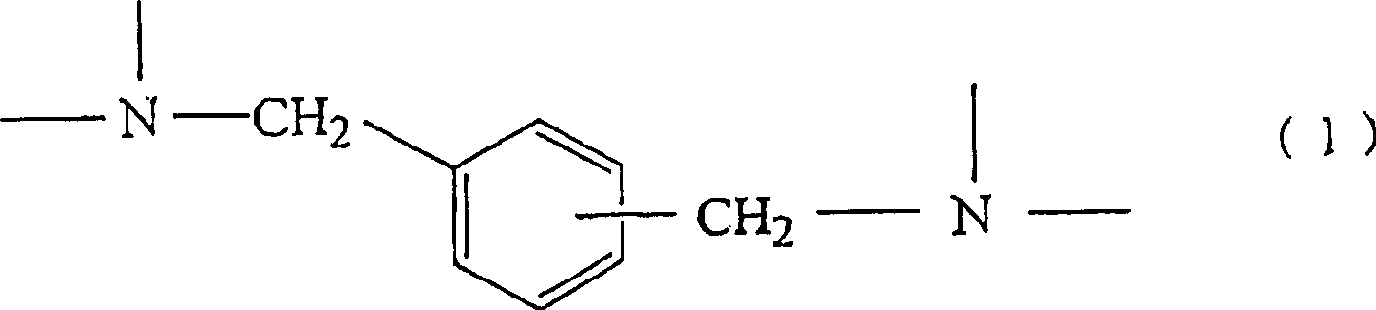

InactiveCN1551910ASuitable adhesionExcellent gas barrier propertiesSynthetic resin layered productsBagsPolymer scienceAdhesive

The present invention provides an adhesive for laminates containing, as a main component, an epoxy resin composition comprising an epoxy resin and an epoxy resin-curing agent, the epoxy resin composition being formed into an epoxy resin cured product containing a skeleton structure represented by the formula (1): in an amount of at least 40% by weight. Since the adhesive of the present invention reveals not only a suitable adhesion to various film materials but also a high gas-barrier property, only a single layer formed therefrom can realize both an excellent gas-barrier property and an excellent adhesion property in combination, so that it is possible to produce a high gas-barrier laminated film for a packaging material without forming a separate gas-barrier layer therein.

Owner:MITSUBISHI GAS CHEM CO INC

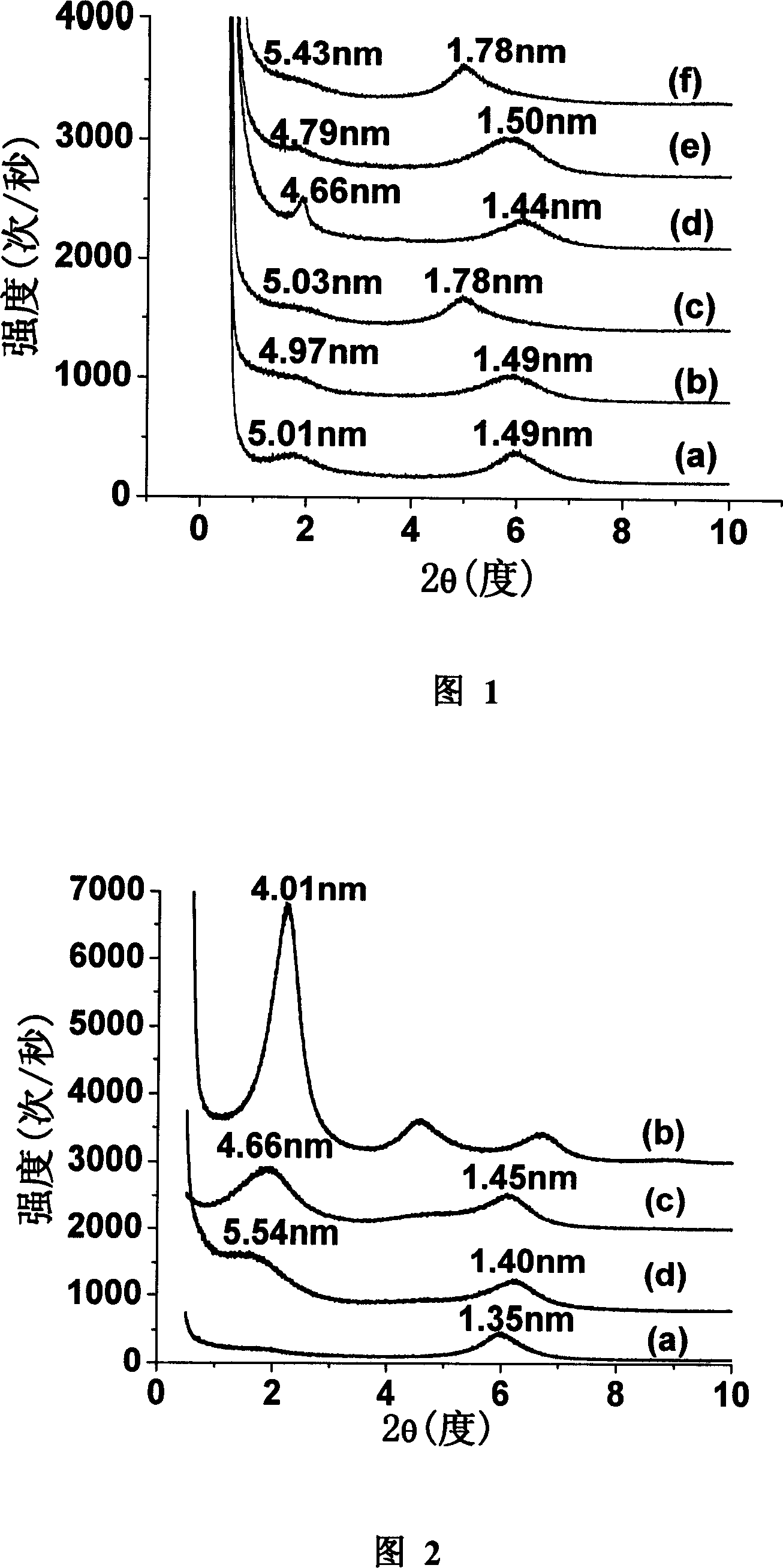

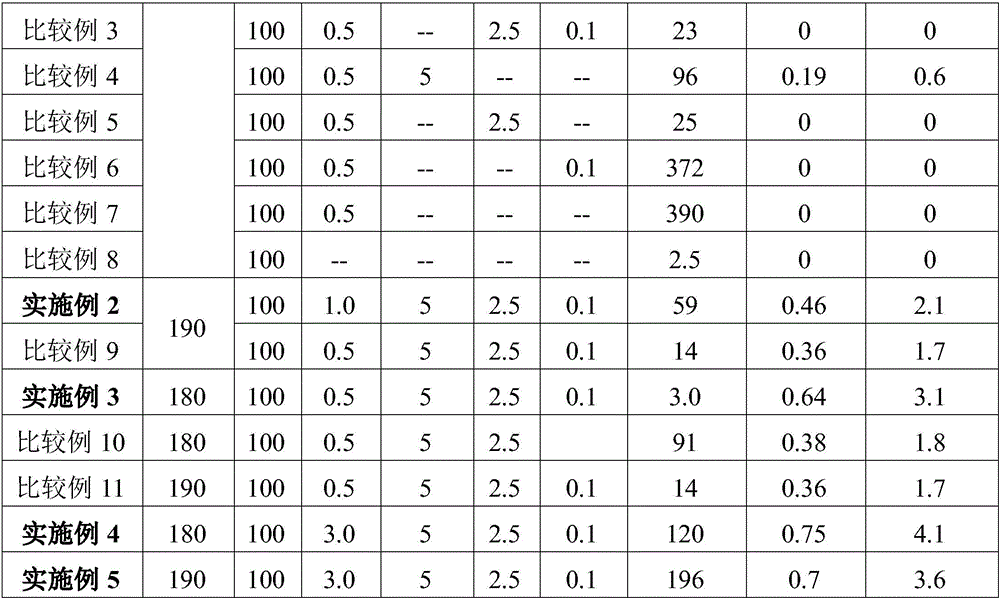

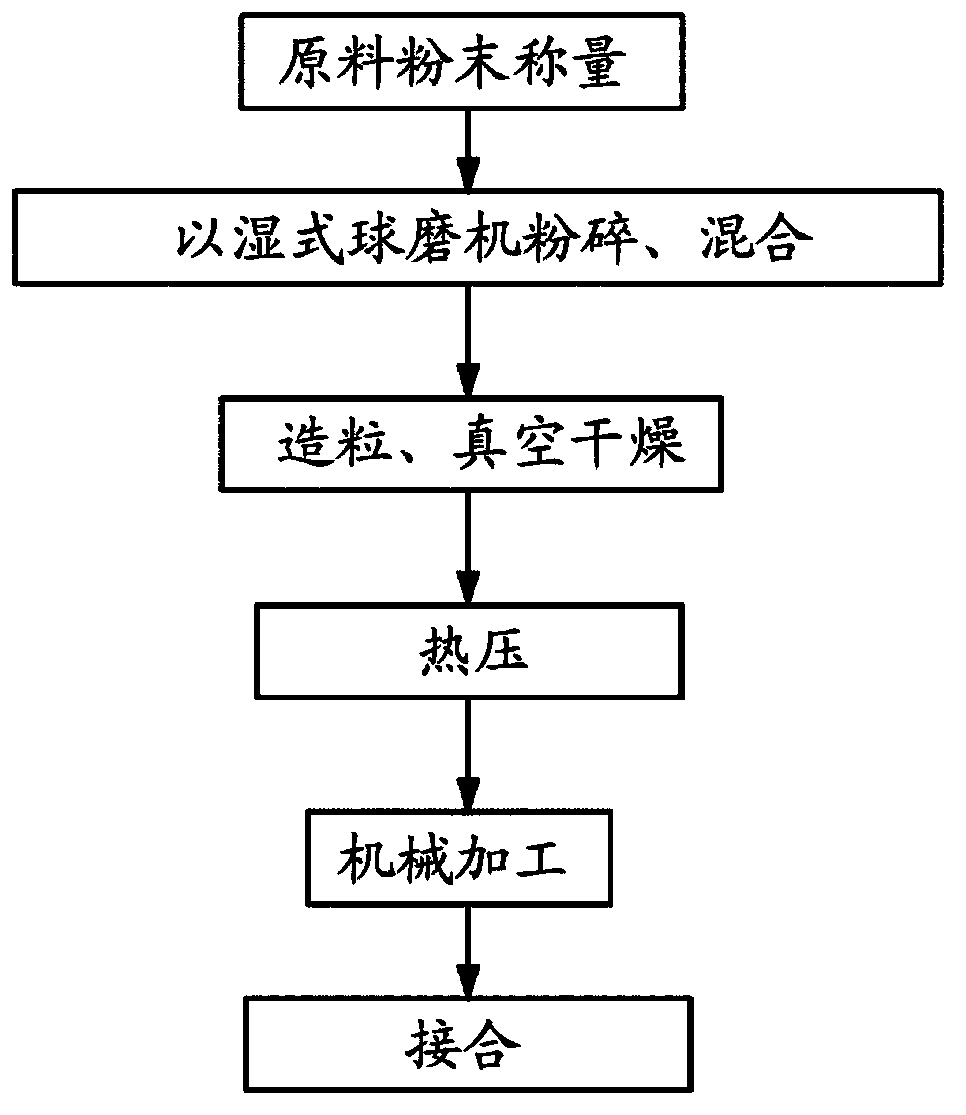

Preparation method of supermolecule/rubber airtight materials

The invention discloses a preparation method of supermolecule / rubber airtight materials, in order to provide a method for improving the rubber gas barrier property by utilizing supermolecule LDHs (layered double hydroxides). The method comprises the following steps of: adding LDHs as packing into rubber, and preparing a compound of LDHs and rubber by adopting an emulsion compounded method or a mechanical alloying method. The main components comprise 100 parts of base body rubber materials and 0.2-40 part of LDHs by mass; the base body rubber materials are rubber emulsion or solid rubber; the supermolecule LDHs is adopted. The compound material with excellent gas barrier property can be obtained through filling the LDHs into rubber.

Owner:BEIJING UNIV OF CHEM TECH

Bentonite/ starch composite degrading material produced by melt intercalation and preparation method

The invention discloses a bentonite / starch composite degrading material produced by melt intercalation and a preparation method. The bentonite / starch composite degrading material is prepared from the following raw materials in parts by weight: 10 to 90 parts of biodegradable polymer material, 10 to 90 parts of starch, 5 to 30 parts of plasticizer, 1 to 5 parts of internal / external lubricant, 1 to 5 parts of heat stabilizer, 0.5 to 2.5 parts of antioxidant, and 1 to 30 parts of bentonite. The preparation method comprises the steps of blending the compound materials; plasticizing; extruding; granulating to obtain the final product. The bentonite / starch composite degrading material produced by melt intercalation and the preparation method has the beneficial effects that (1) the bentonite added can improve the heat resistance and processing fluidity of starch and can be greatly intercalated or filled, so that the production cost is decreased; (2) the starch is easily plasticized through the plasticizer; (3) the starch strength is greatly improved after the plasticizing; (4) the biodegradation is completely done; the characteristics of being small in investment, fast to develop and simple in production method are achieved.

Owner:WEIFANG HUAWEI MATERIALS TECH CO LTD

Bag skin material and aerostat

InactiveCN105173052AHigh gas barrierExtended air timeSynthetic resin layered productsGas-bag arrangementsMontmorilloniteWeight-bearing

The invention provides a bag skin material and an aerostat. The bag skin material comprises a weather-proof layer, an air-blocking layer, a weight-bearing layer and a welding layer which are overlapped, wherein the air-blocking layer is organic polymer with montmorillonite dispersed. The montmorillonite is dispersed in the organic polymer to form the air-blocking layer. Due to the property that the montmorillonite is layered crystalline silicate clay ore, the air-blocking performance of the bag skin material is improved. Furthermore, leakage of air inside the aerostat or an airship is reduced, and the hang time of the aerostat or the airship is lengthened.

Owner:DONGGUAN FRONTIER TECH INST +1

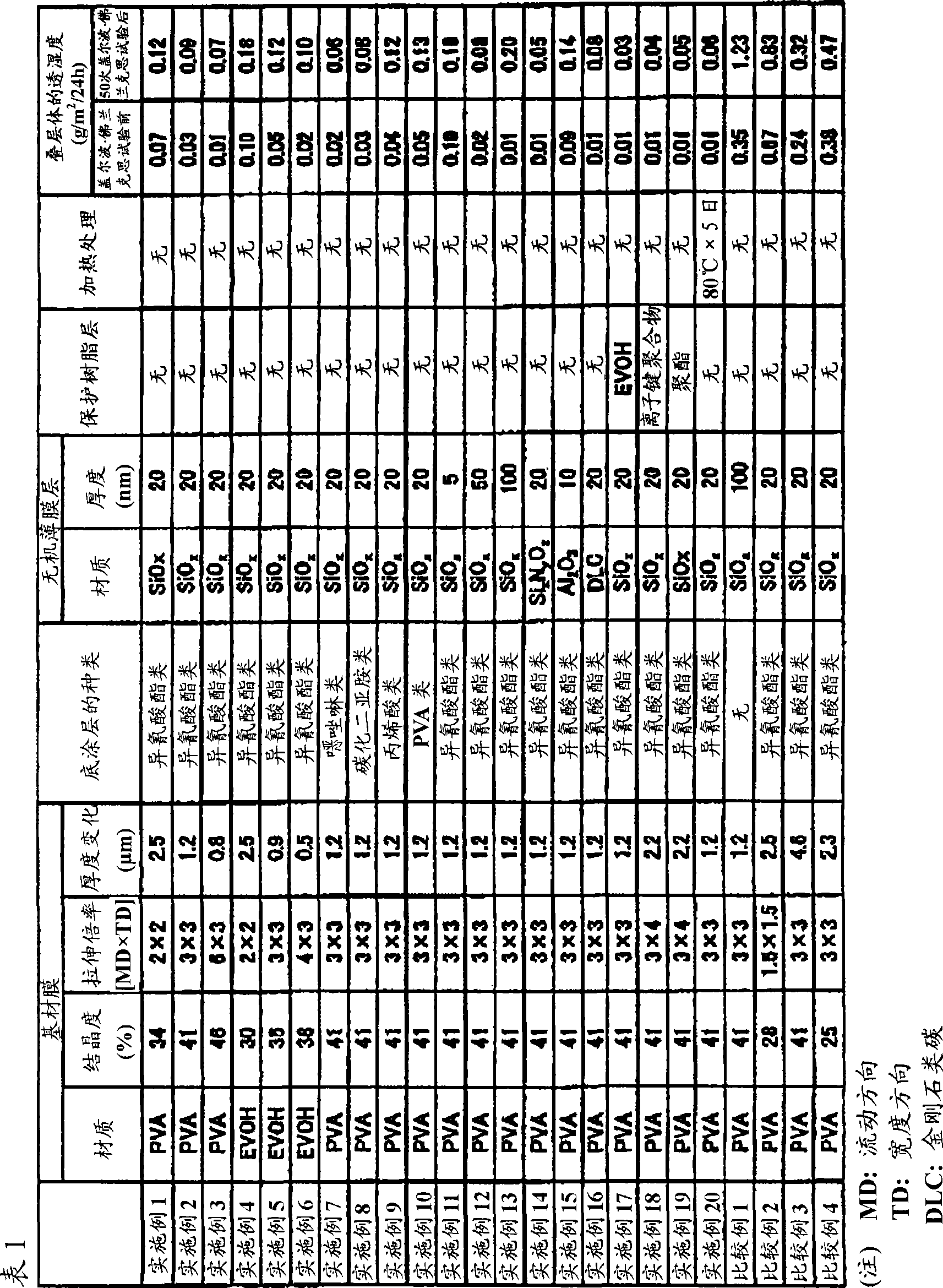

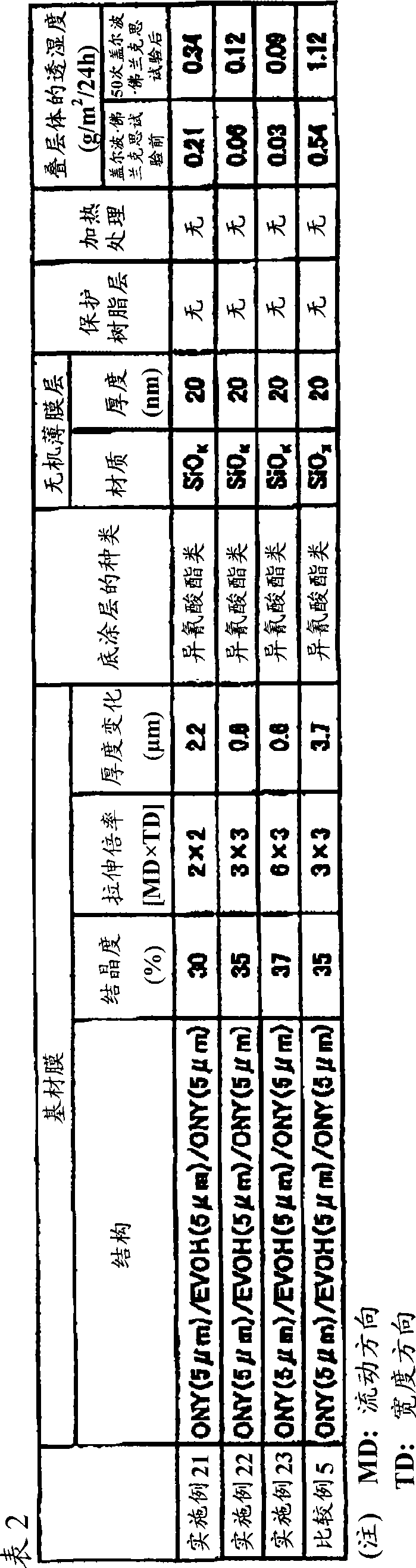

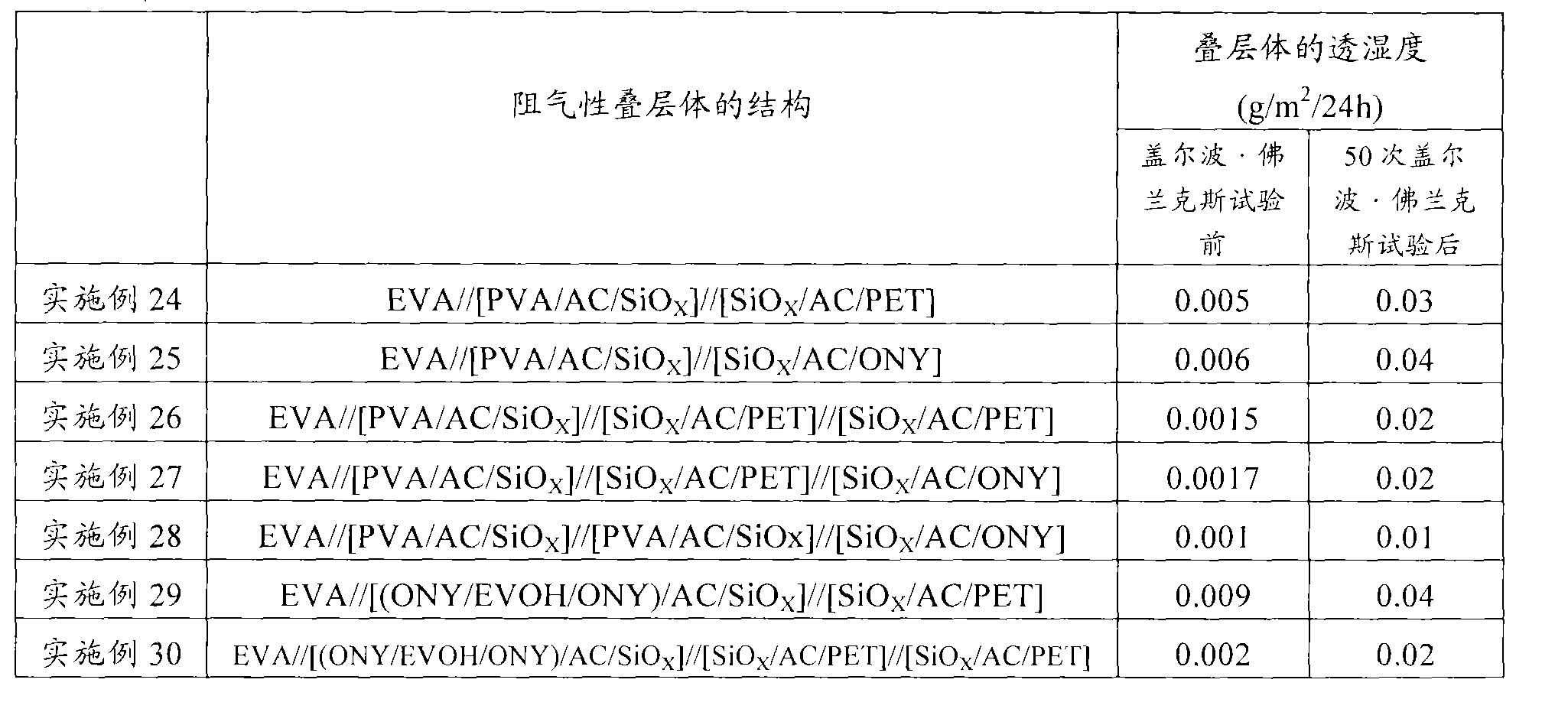

Gas barrier laminate

InactiveCN101421097AHigh gas barrierGalpo Franks Sex EnhancementFlexible coversWrappersPolyvinyl alcoholCrystallinity

There is provided a gas-barrier laminate composed of a base film and an inorganic thin film layer formed on the base film which considerably enhanced in gas-barrier property and gelbo flex resistance. The present invention relates to a gas-barrier laminate comprising a base film containing at least one compound selected from the group consisting of polyvinyl alcohol and an ethylene-vinyl alcohol copolymer, and an anchor coat layer and an inorganic thin film layer successively formed on one surface of the base film in this order, wherein the base film is in the form of a biaxially stretched film having a variation in thickness of 3.5 [mu]m or less and a crystallinity of 30% or more.

Owner:MITSUBISHI PLASTICS INC

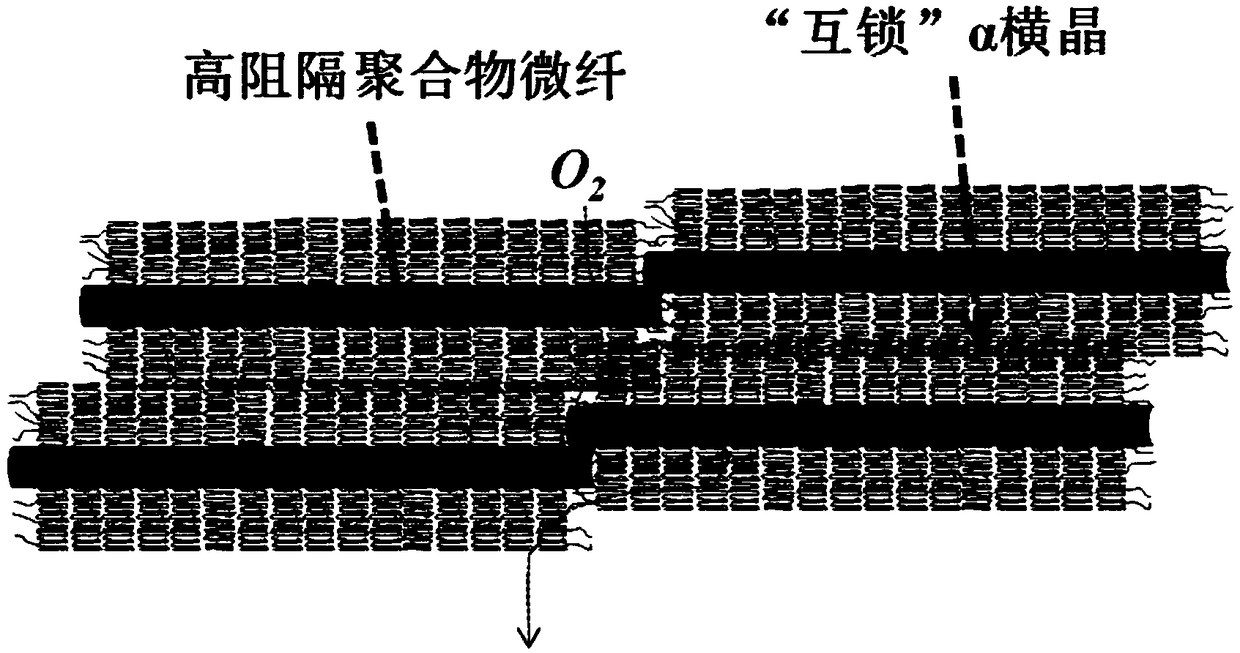

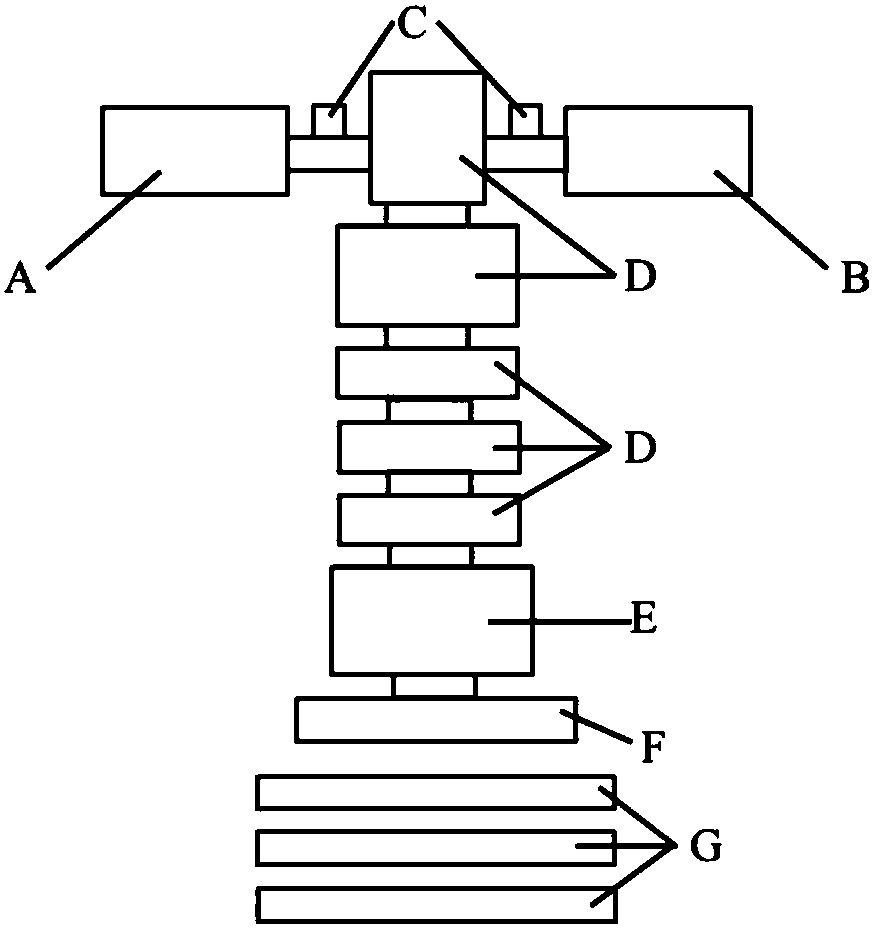

Method for preparing high-barrier polypropylene material through phase morphology and interface crystallization regulation

The invention discloses a method for preparing a high-barrier polypropylene material through phase morphology and interface crystallization regulation. The method is characterized in that a micro-nanolaminating co-extrusion device is utilized for in-situ micro-fibrillation of a high-barrier polymer containing an alpha nucleating agent in polypropylene; phase morphology regulation is organically combined with interface crystallization regulation, and a multi-layer microstructure of oriented microfibers and interlocking alpha transverse crystals is built in the polypropylene; the gas barrier property of the polypropylene is improved by using the multi-layer microstructure. According to the method, the interface structure of the high-barrier polymer and the polypropylene is optimized in an interface crystallization way under the condition without a compatilizer, and the problem is solved that in a common preparation technology, interactions between the interfaces of the high-barrier polymer and the polypropylene are weak, so that further improvement of the gas barrier property is restricted. The devices involved in the method are easy to operate, dies are easy to process, the manufacturing cost is low, continuous production is achieved, the production efficiency is high, and the method has good industrial application prospects.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

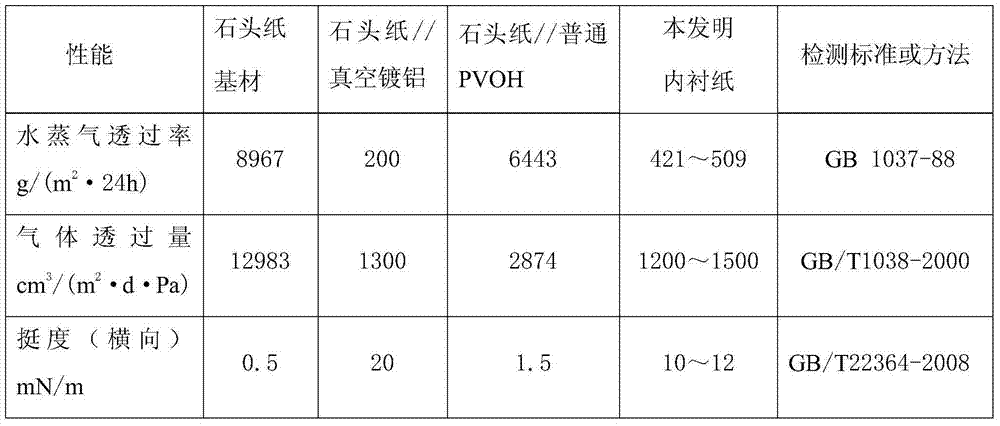

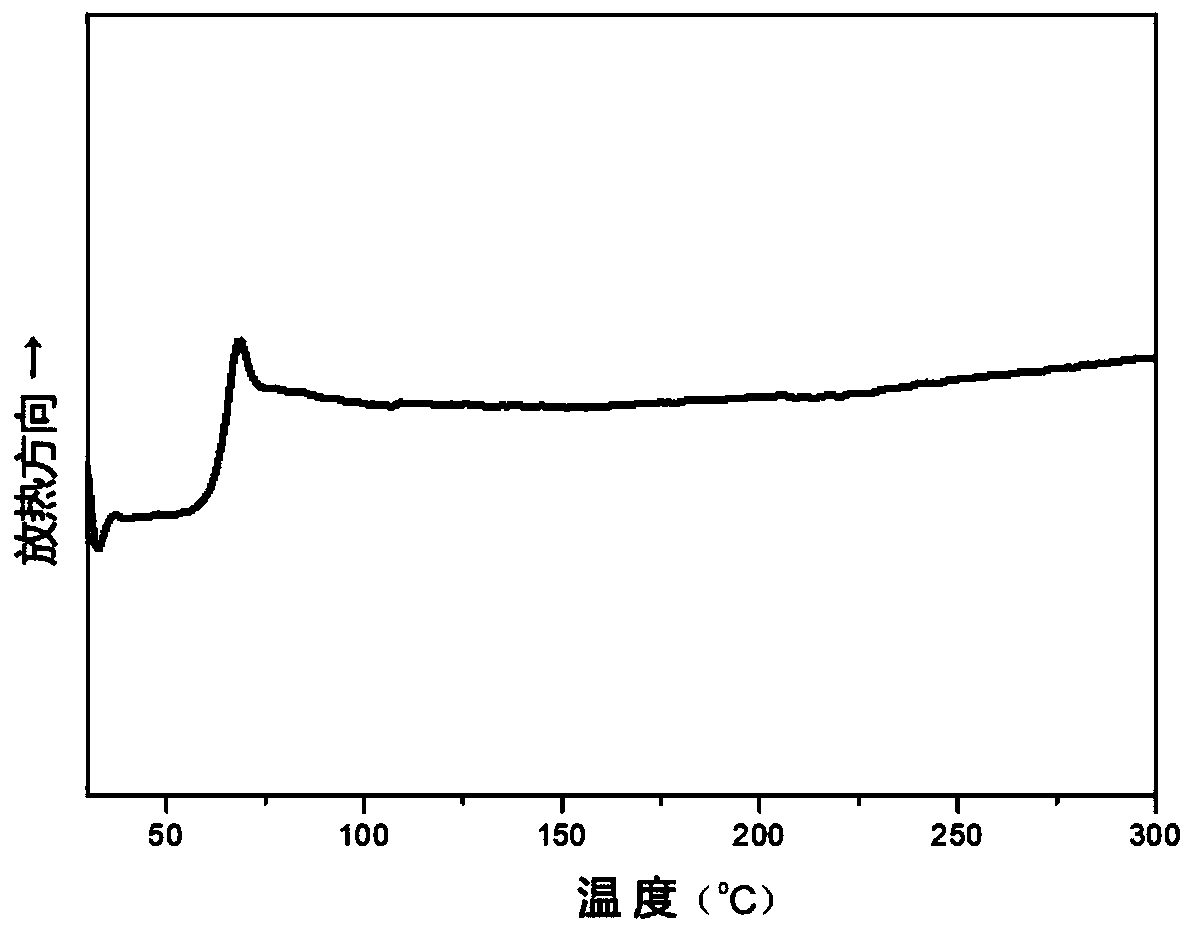

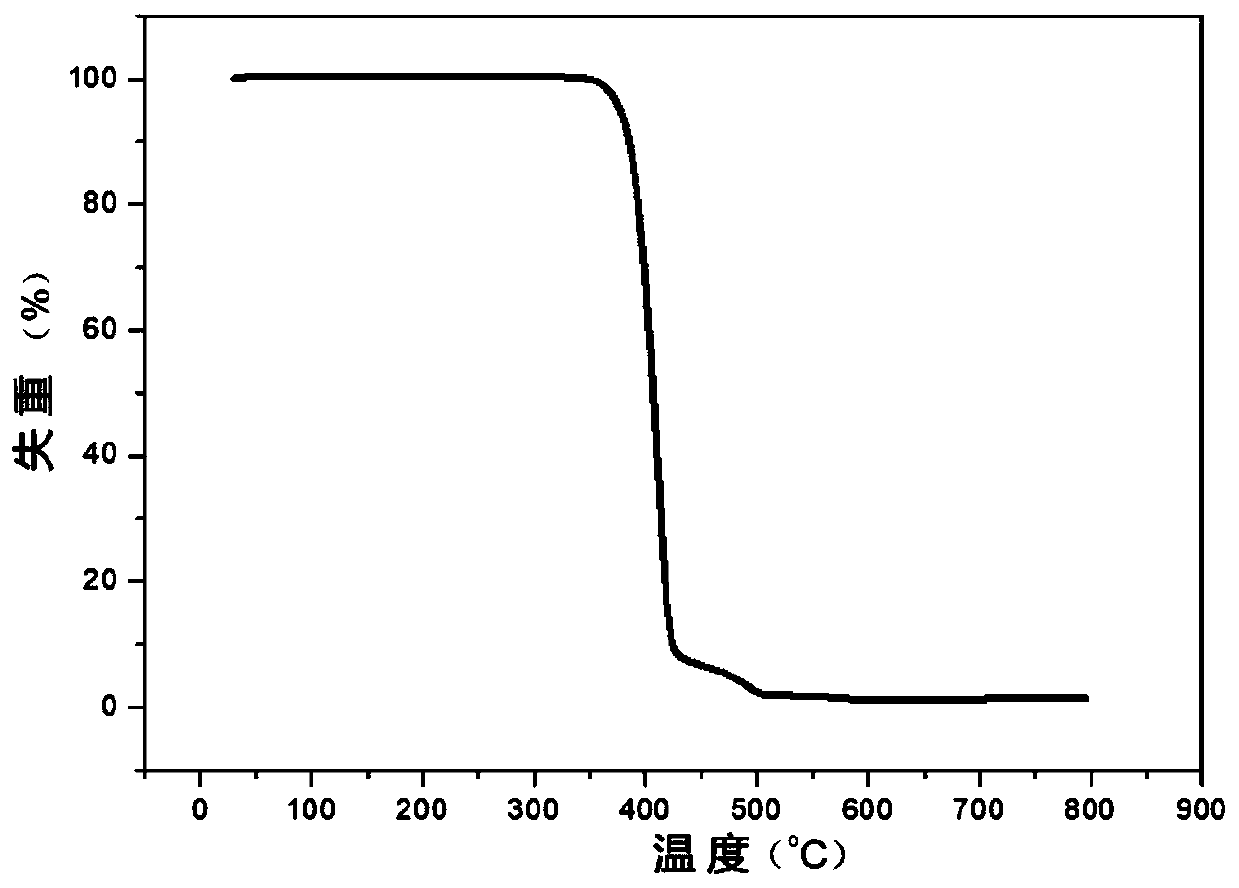

High-barrier environmental-friendly coating lined paper and manufacturing method thereof

ActiveCN104118156AHigh barrierImprove stiffnessLiquid surface applicatorsSynthetic resin layered productsPolyvinyl alcoholSoftened water

The invention relates to high-barrier environmental-friendly coating lined paper and a manufacturing method thereof. The lined paper comprises following three layers: a stone paper layer, an ink layer on the surface of the stone paper layer and a high-barrier layer on the surface of the ink layer. The gram weight of the stone paper base material is 55-80 g / m2. The ink layer is a coating formed by drying aqueous soybean ink. The barrier layer is a coating formed by coating base material paper with modified polyvinyl alcohol coating and drying. The modified polyvinyl alcohol coating is prepared by polymerization of following raw materials by weight: 4-7% of polyvinyl alcohol, 5-9% of carbon nanofiber, 3-6% of citronellal, 3-7% of a catalyst, 2-7% of a defoaming agent and 70-79% of softened water. The lined paper has characteristics of excellent barrier performance, good stiffness and strength, capability of environmental protection and low production cost, and can fully replace traditional composite lined paper or aluminized lined paper.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Novel thiophenedicarboxylic acid-based copolyester as well as preparation method and application thereof

The invention discloses novel thiophenedicarboxylic acid-based copolyester as well as a preparation method and application thereof. The novel thiophenedicarboxylic acid-based copolyester has a structure represented by the following formula: wherein m, n and x are all selected from 1-200, and R is an aliphatic chain or alicyclic ring with a C atom number of 2-20. The novel thiophenedicarboxylic acid copolyester provided by the invention has the characteristics of high visible light transmittance, low melt viscosity, good heat resistance, excellent mechanical property and gas barrier property and the like, and can be widely applied to the fields of barrier films, barrier bottles, fibers, engineering plastics and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS8747986B2High gas barrierImprove adhesionSynthetic resin layered productsCoatingsPolytetramethylene terephthalateComposite film

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com