Patents

Literature

216 results about "Water vapor permeation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biodegradable polymer films and sheets suitable for use as laminate coatings as well as wraps and other packaging materials

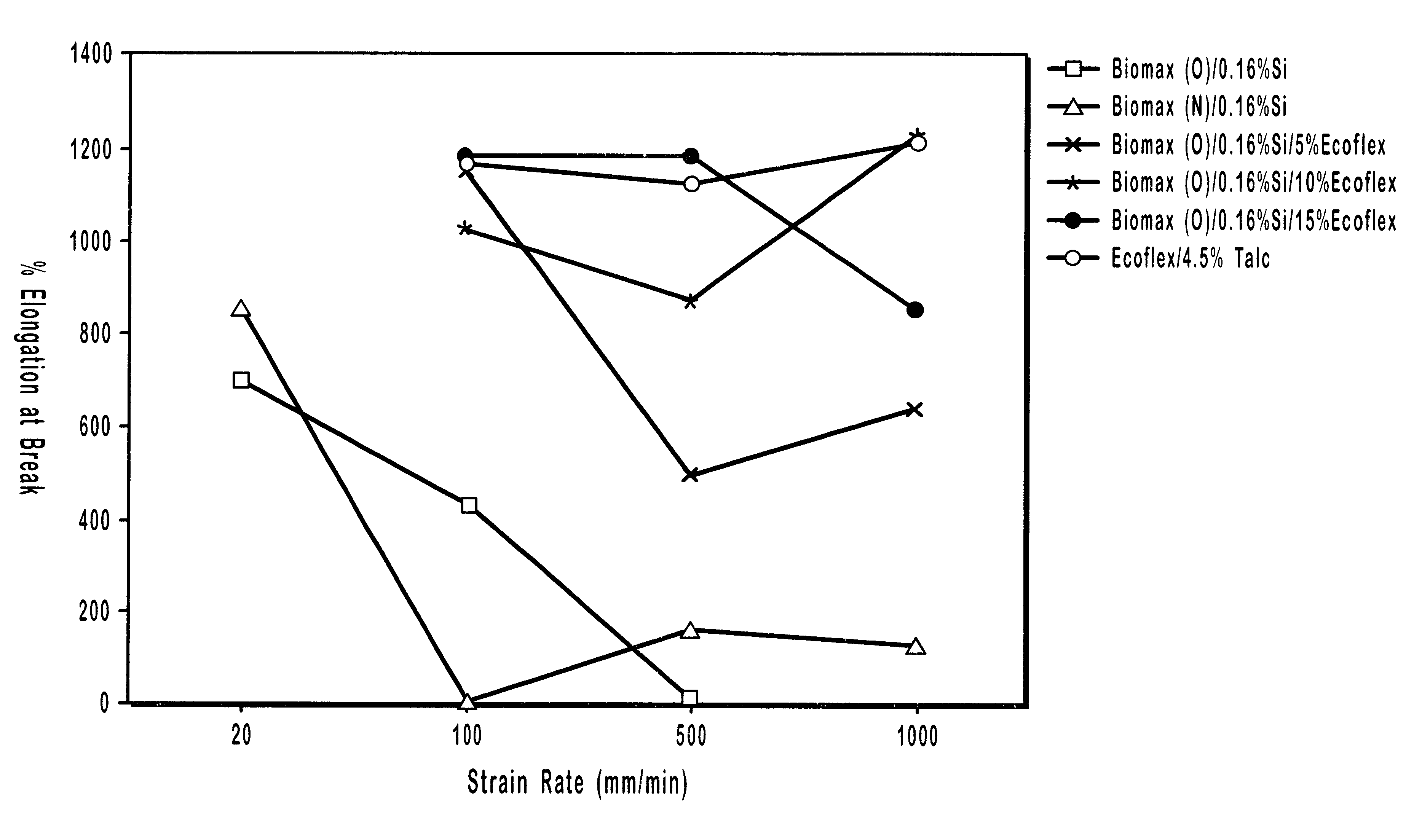

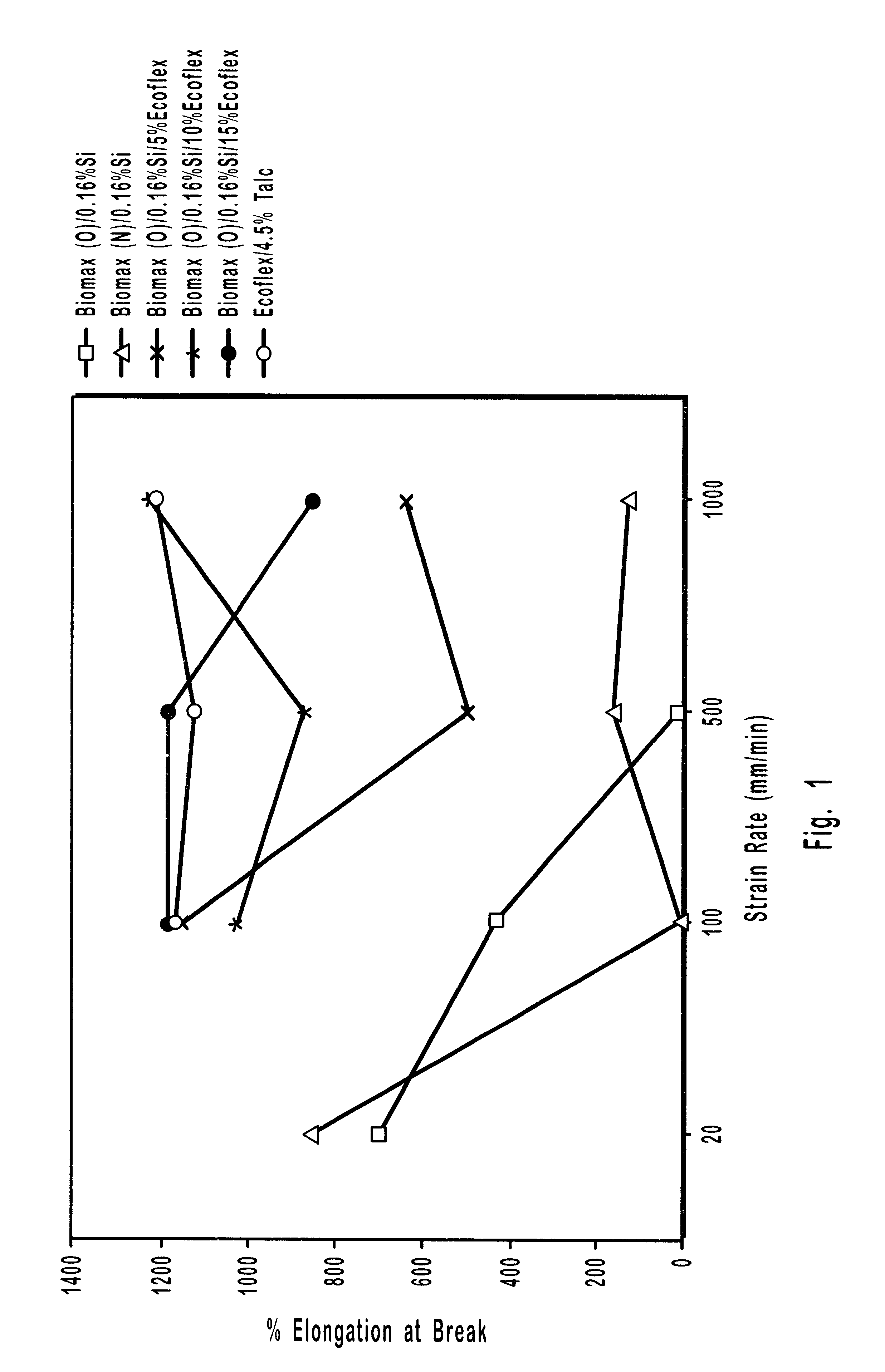

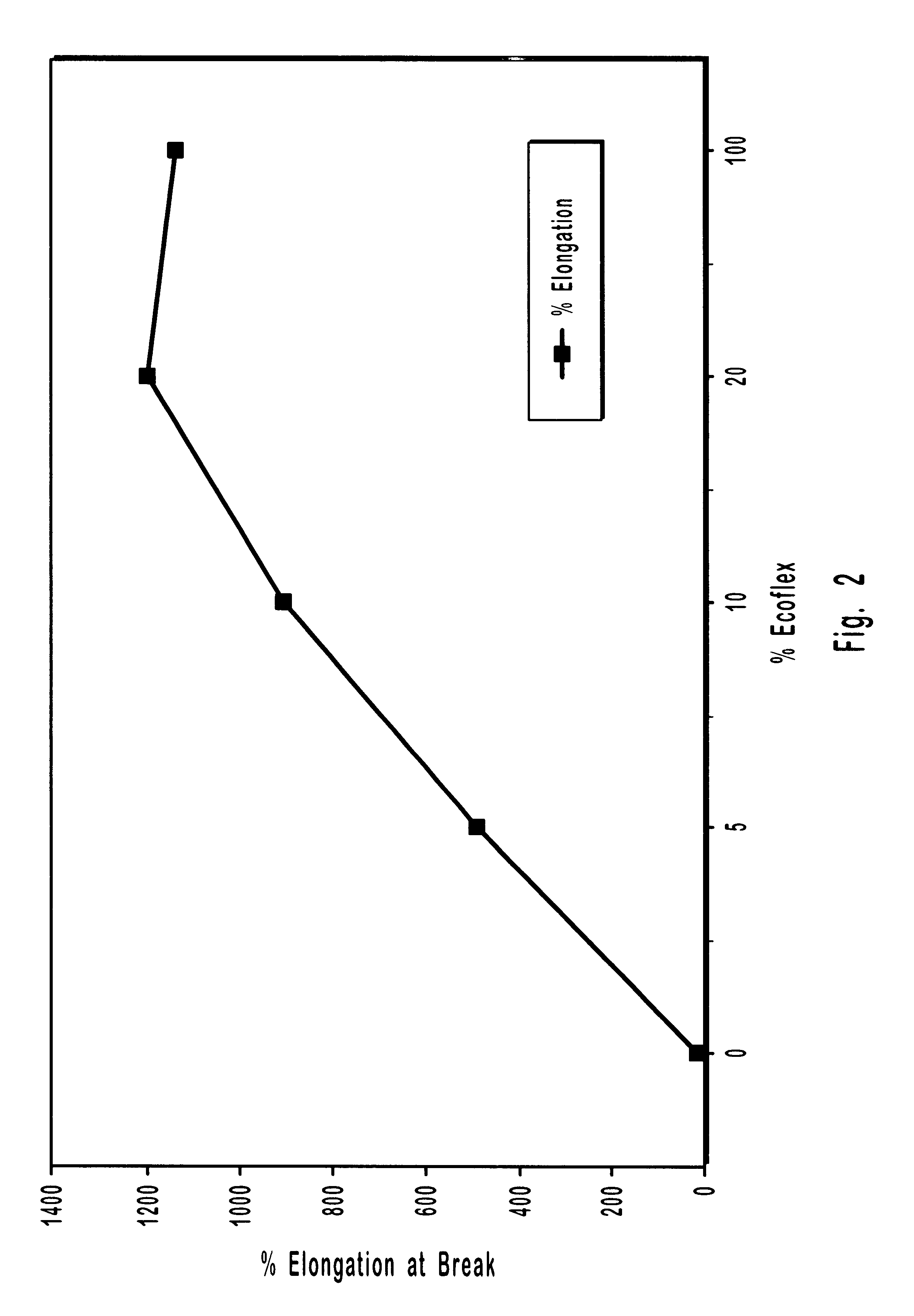

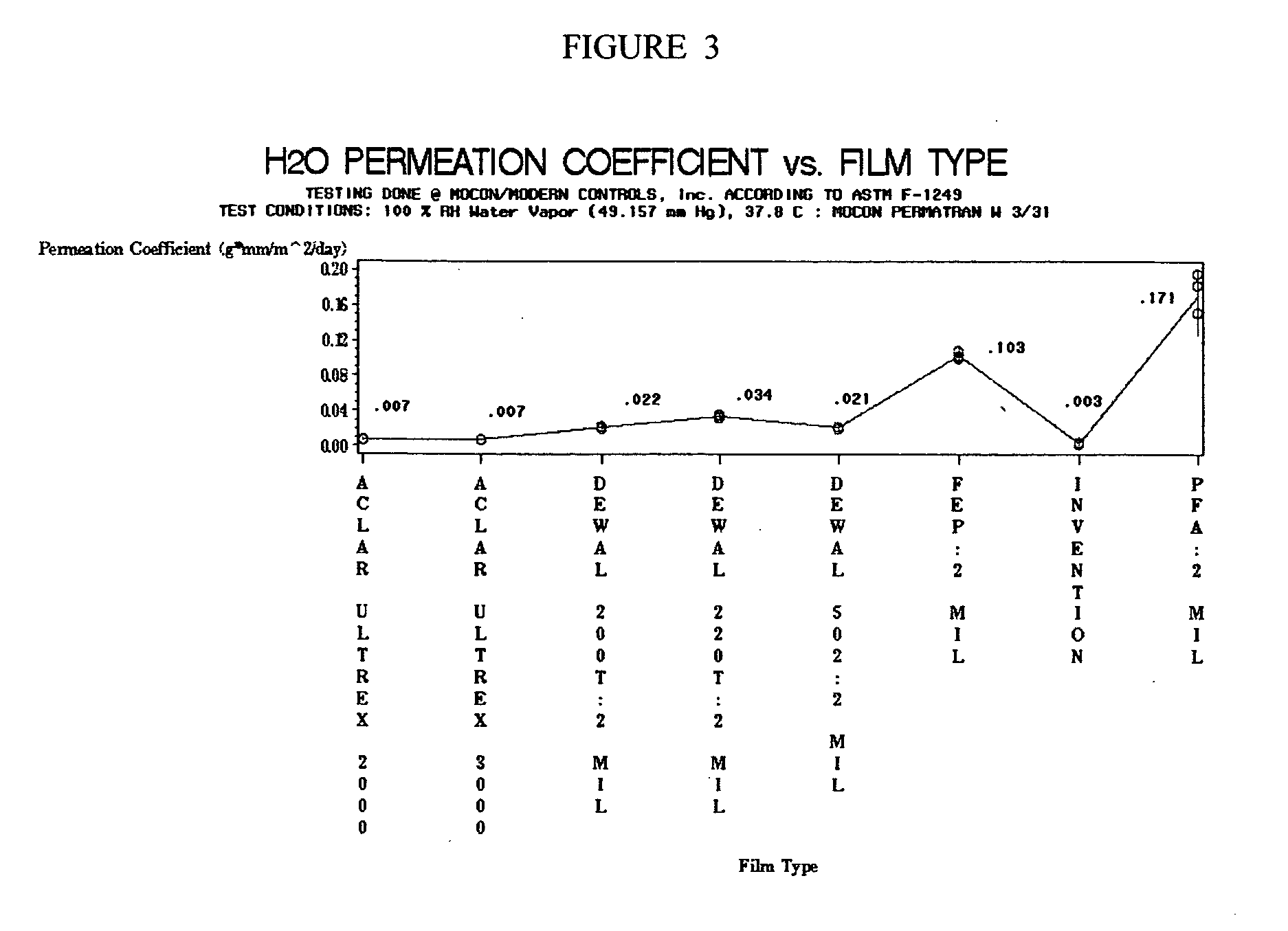

Biodegradable polymer blends suitable for laminate coatings, wraps and other packaging materials manufactured from at least one "hard" biopolymer and at least one "soft" biopolymer. "Hard" biopolymers tend to be more brittle and rigid and typically have a glass transition temperature greater than about 10° C. "Soft" biopolymers tend to be more flexible and pliable and typically have a glass transition temperature less than about 0° C. While hard and soft polymers each possess certain intrinsic benefits, certain blends of hard and soft polymers have been discovered which possess synergistic properties superior to those of either hard or soft polymers by themselves. Biodegradable polymers include polyesters, polyesteramides and thermoplastically processable starch. The polymer blends may optionally include an inorganic filler. Films and sheets made from the polymer blends may be textured so as to increase the bulk hand feel. Wraps will typically be manufactured so as to have good "dead-fold" properties so as to remain in a wrapped position and not spring back to an "unwrapped" and planar form. Laminate films will typically have good water vapor barrier properties as measured by the their Water Vapor Permeability Coefficient (WVPC).

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Fluoropolymer barrier material

InactiveUS7521010B2Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

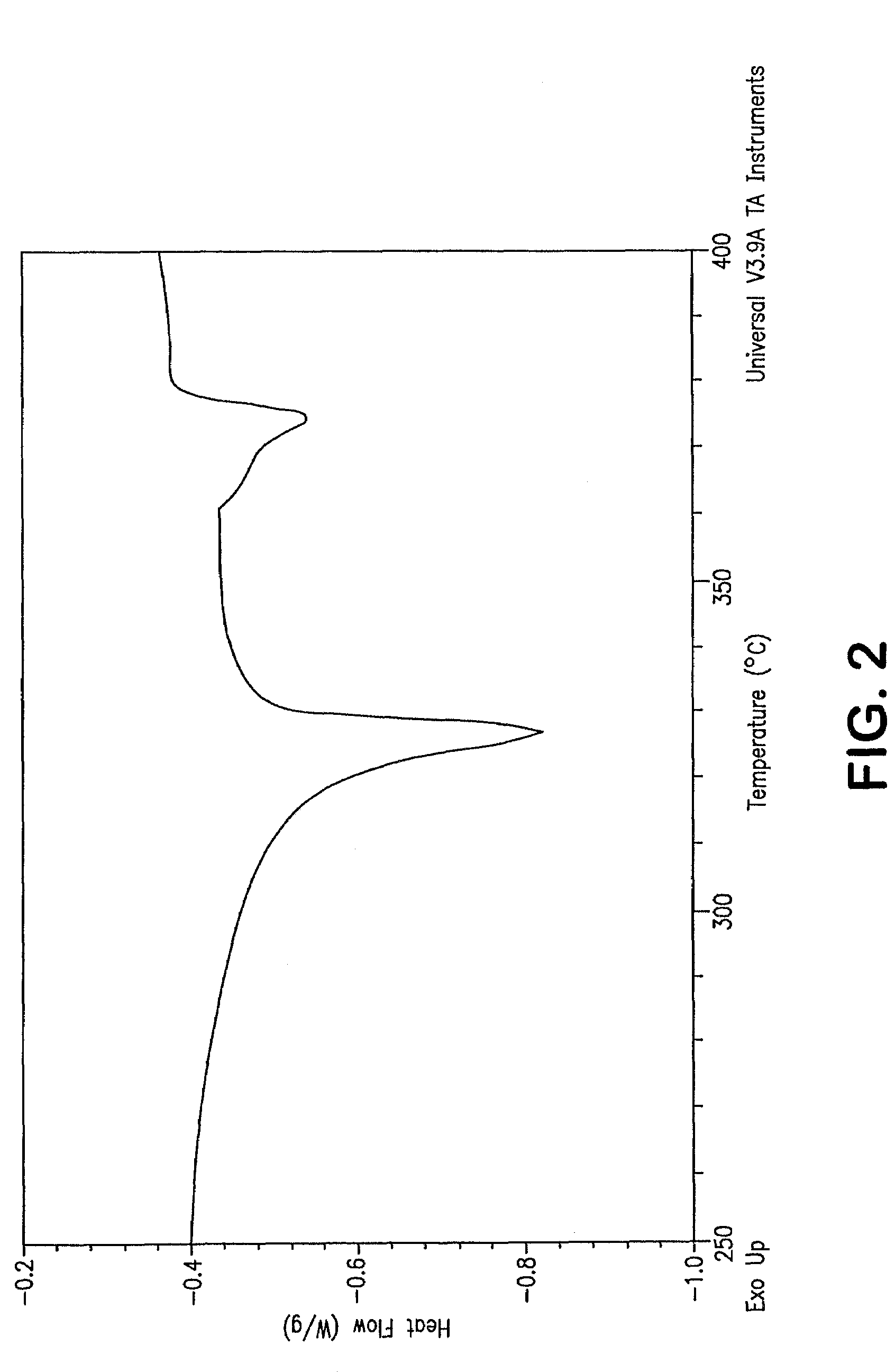

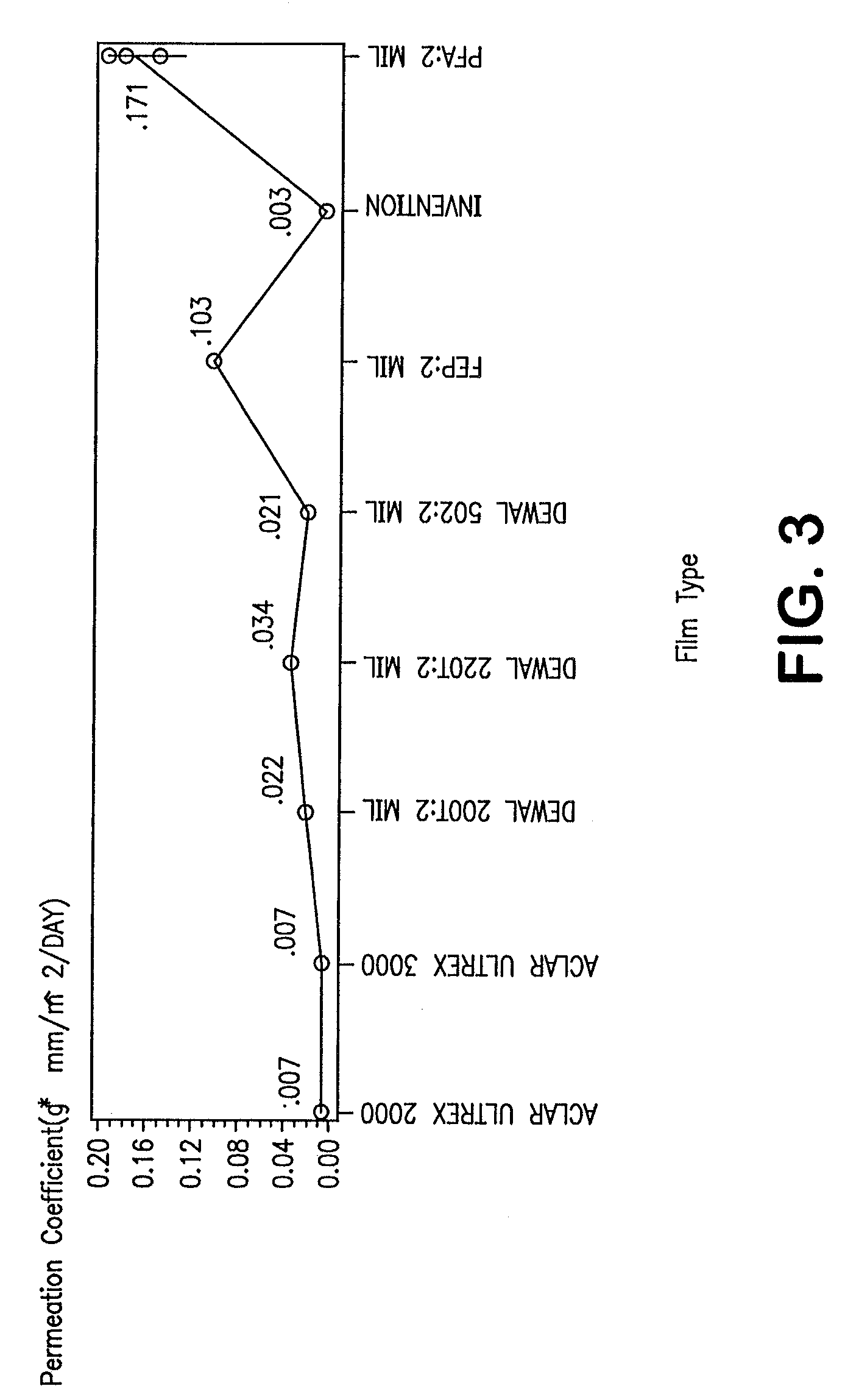

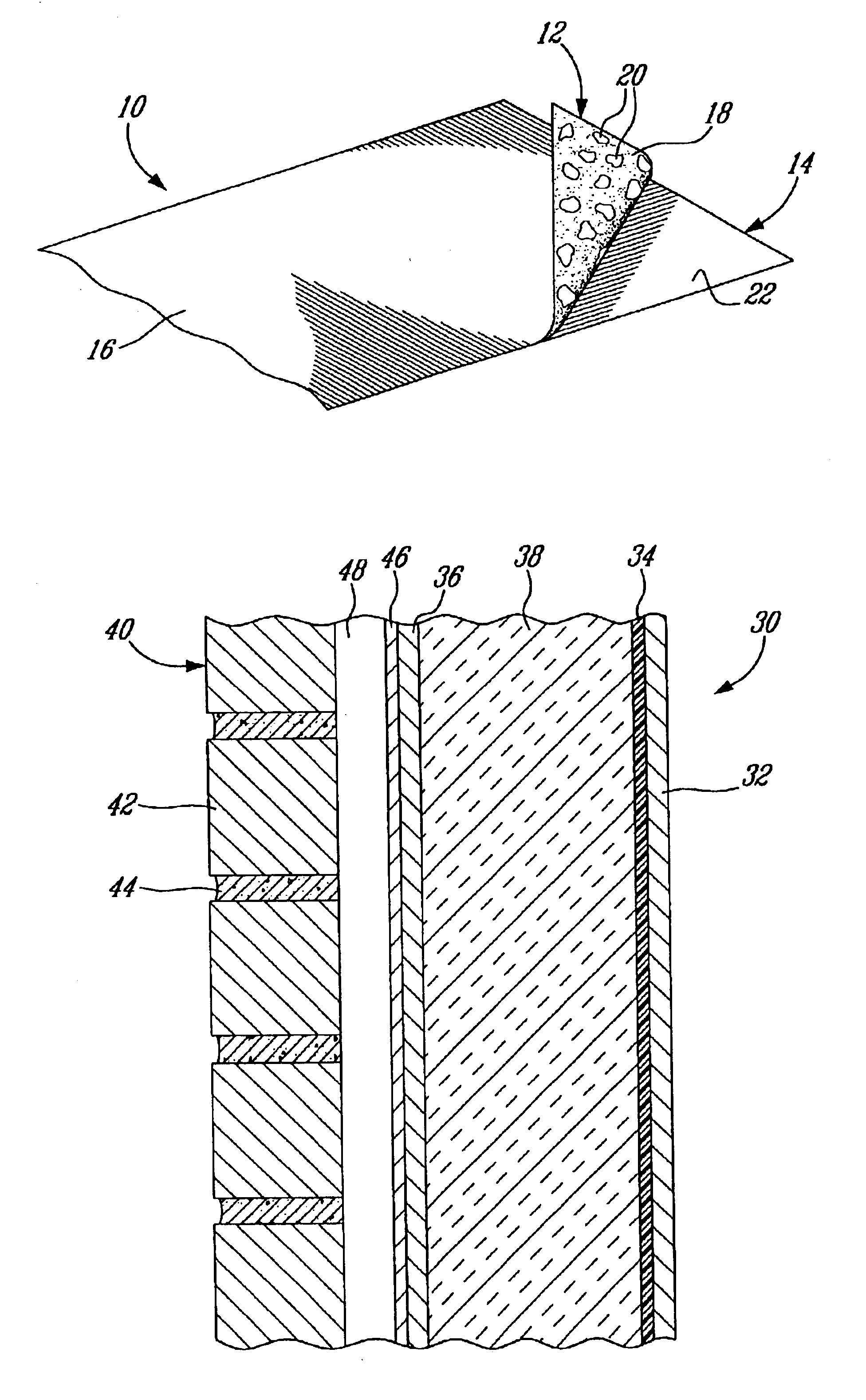

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Self-adhering vapor permeable air and moisture barrier membrane

InactiveUS6901712B2Prevent lateral movementEliminate channelingCovering/liningsWallsAdhesiveWater vapor

Owner:HENRY COMPANY CANADA

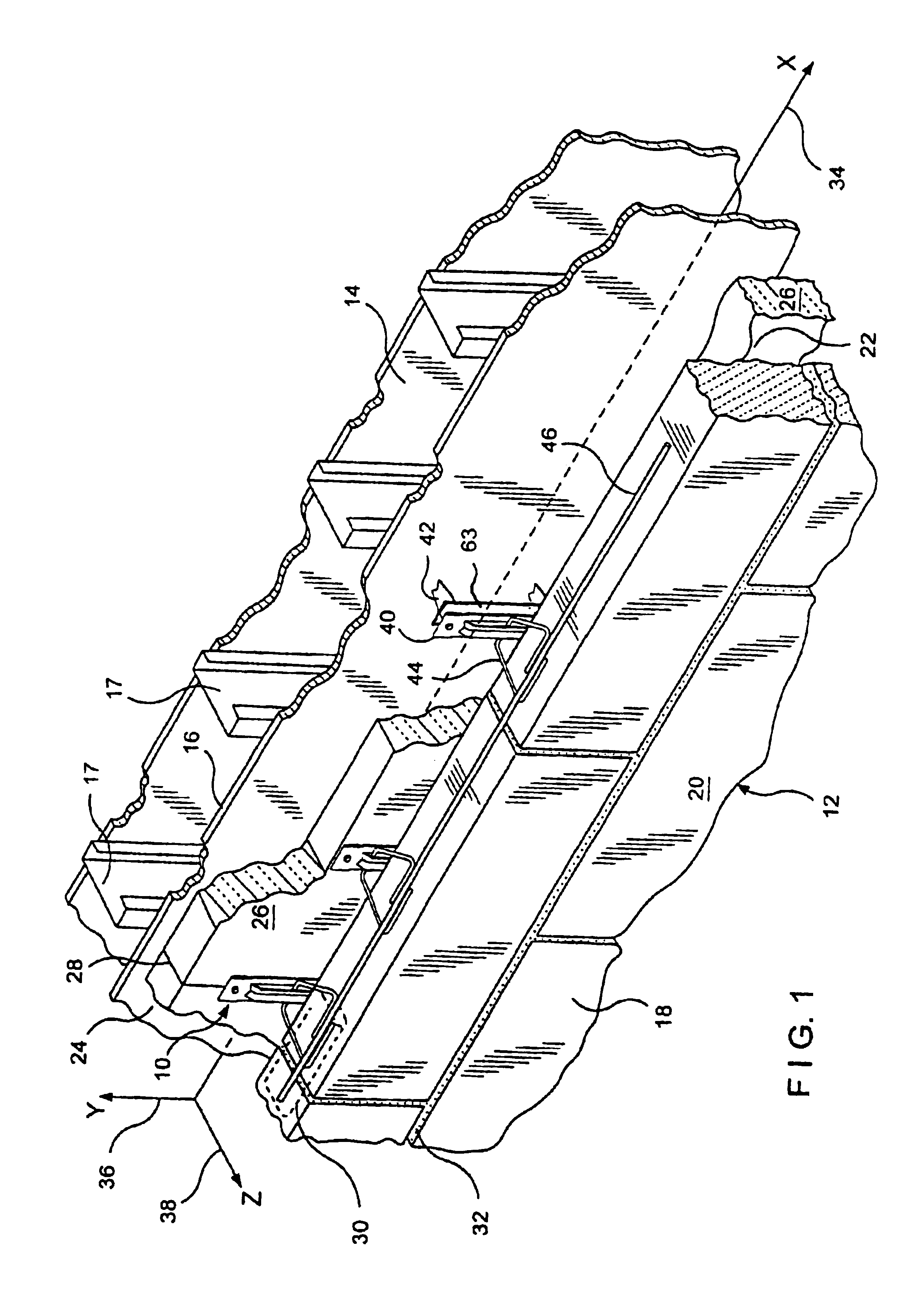

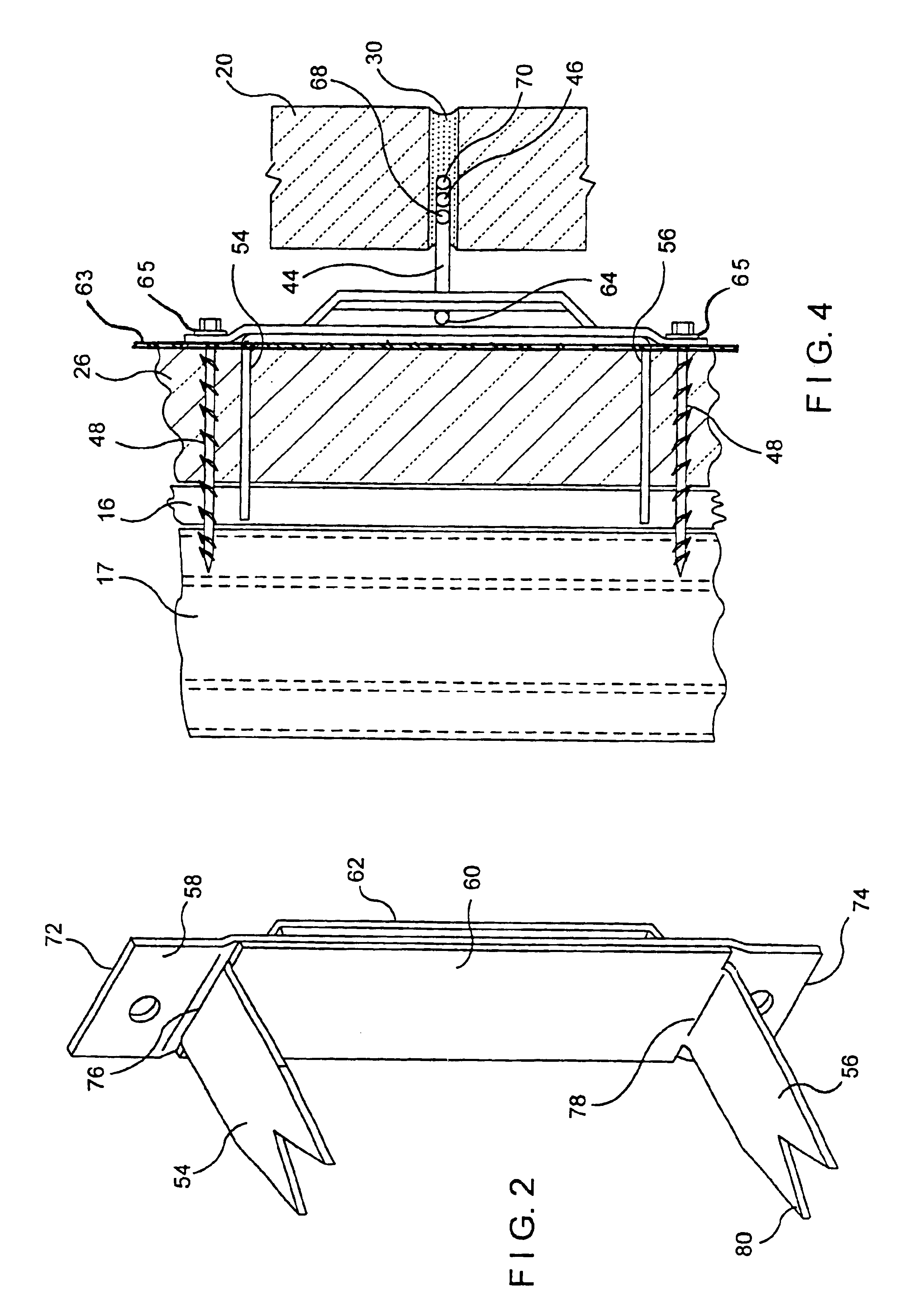

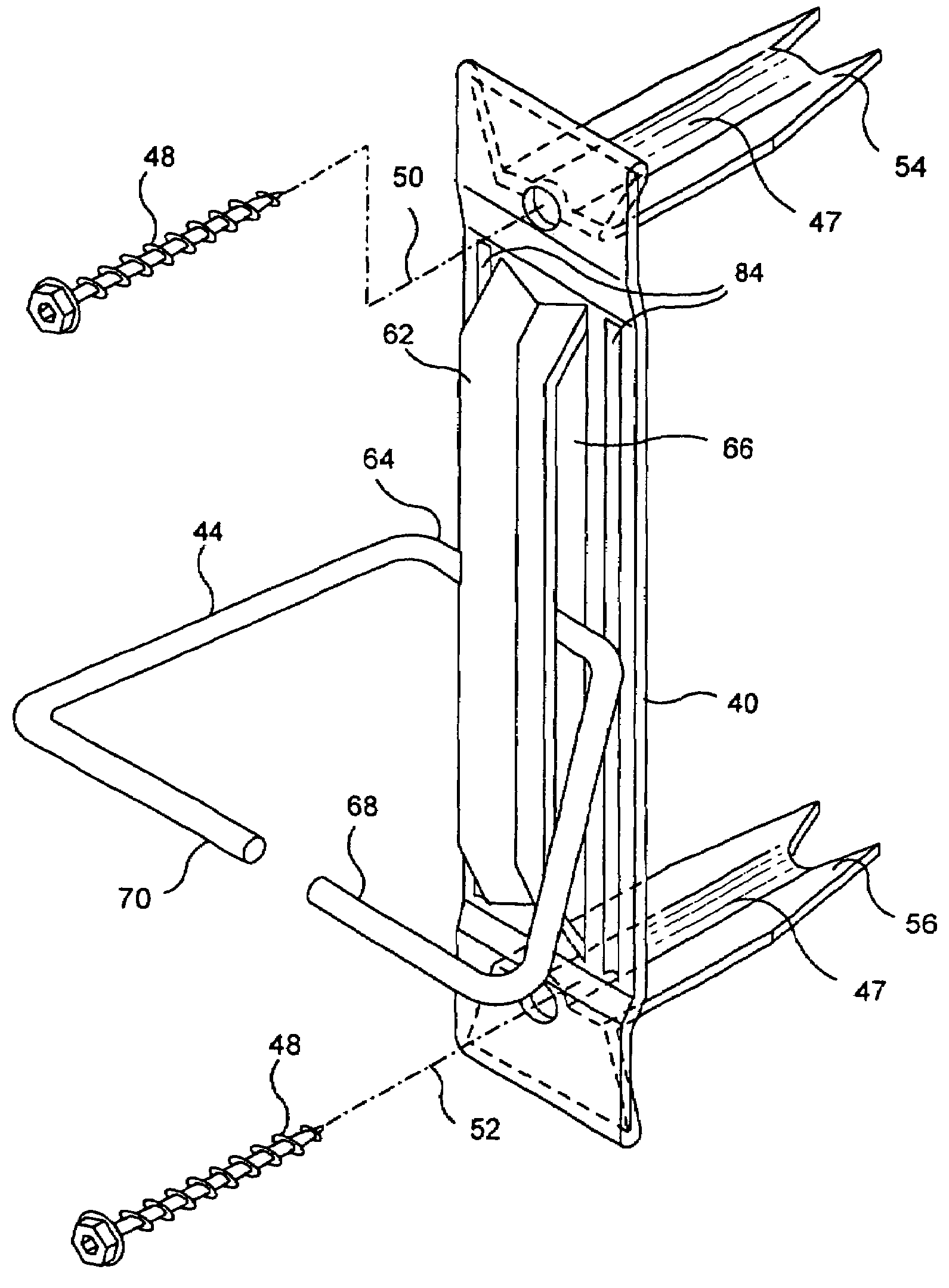

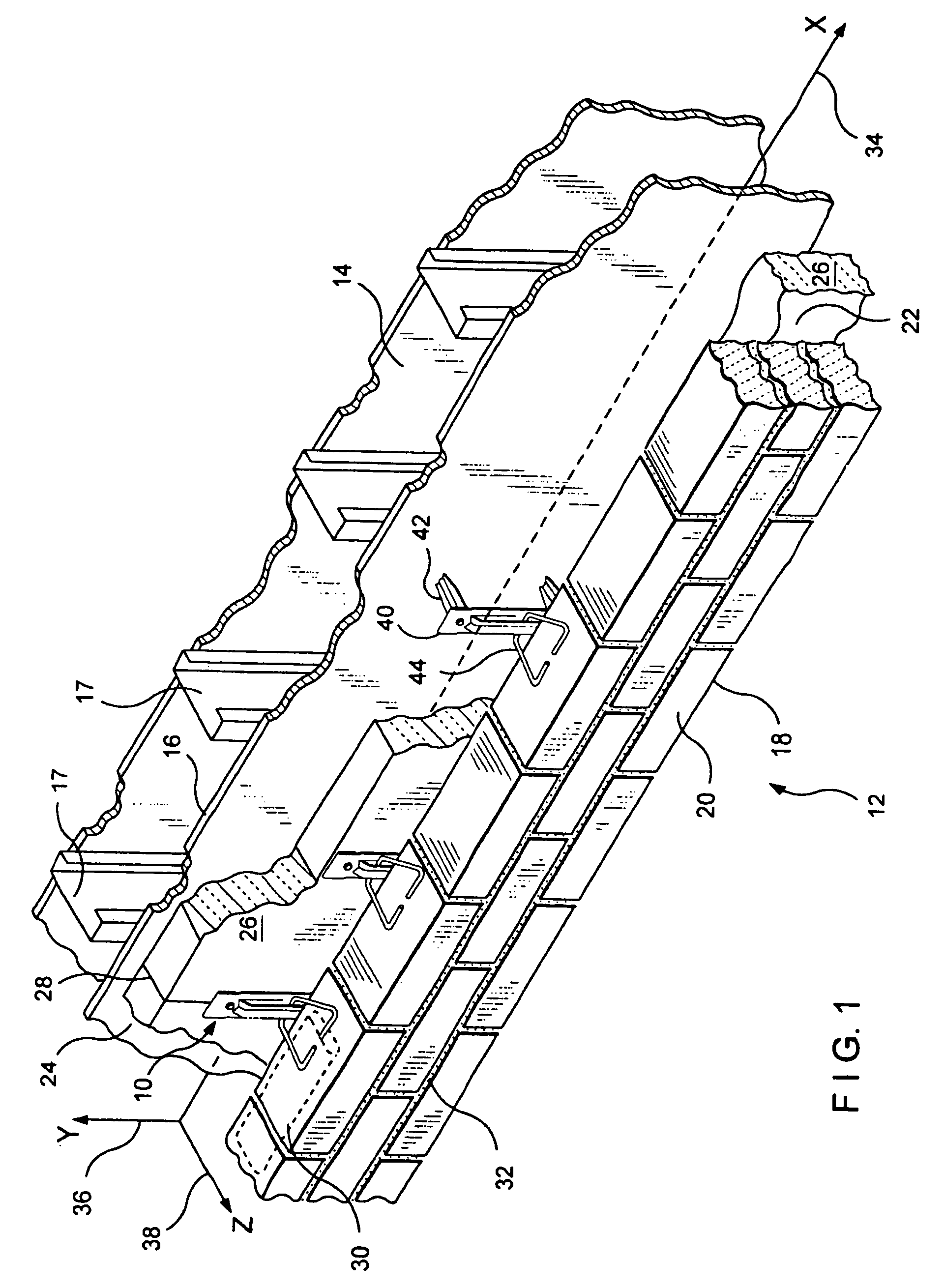

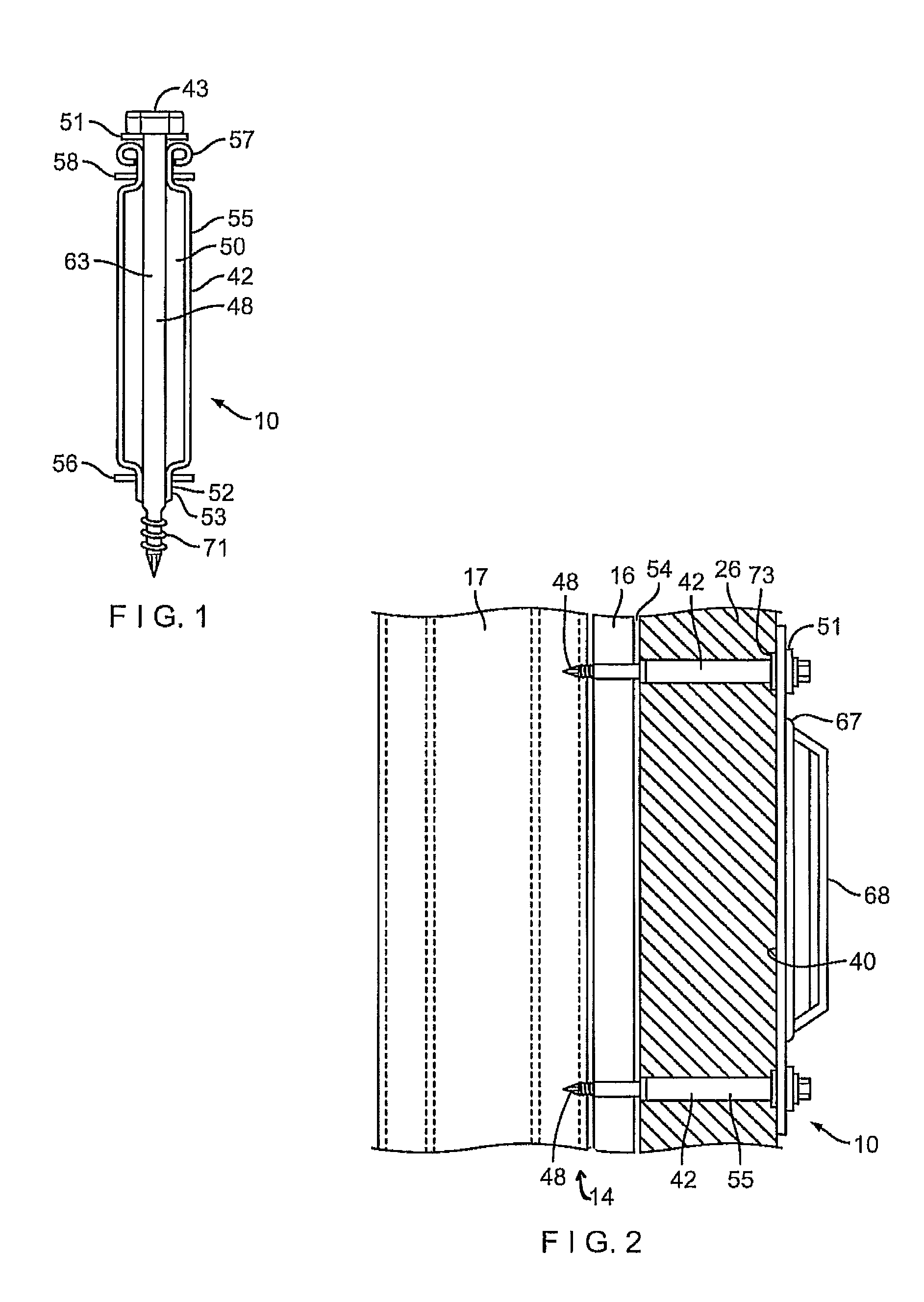

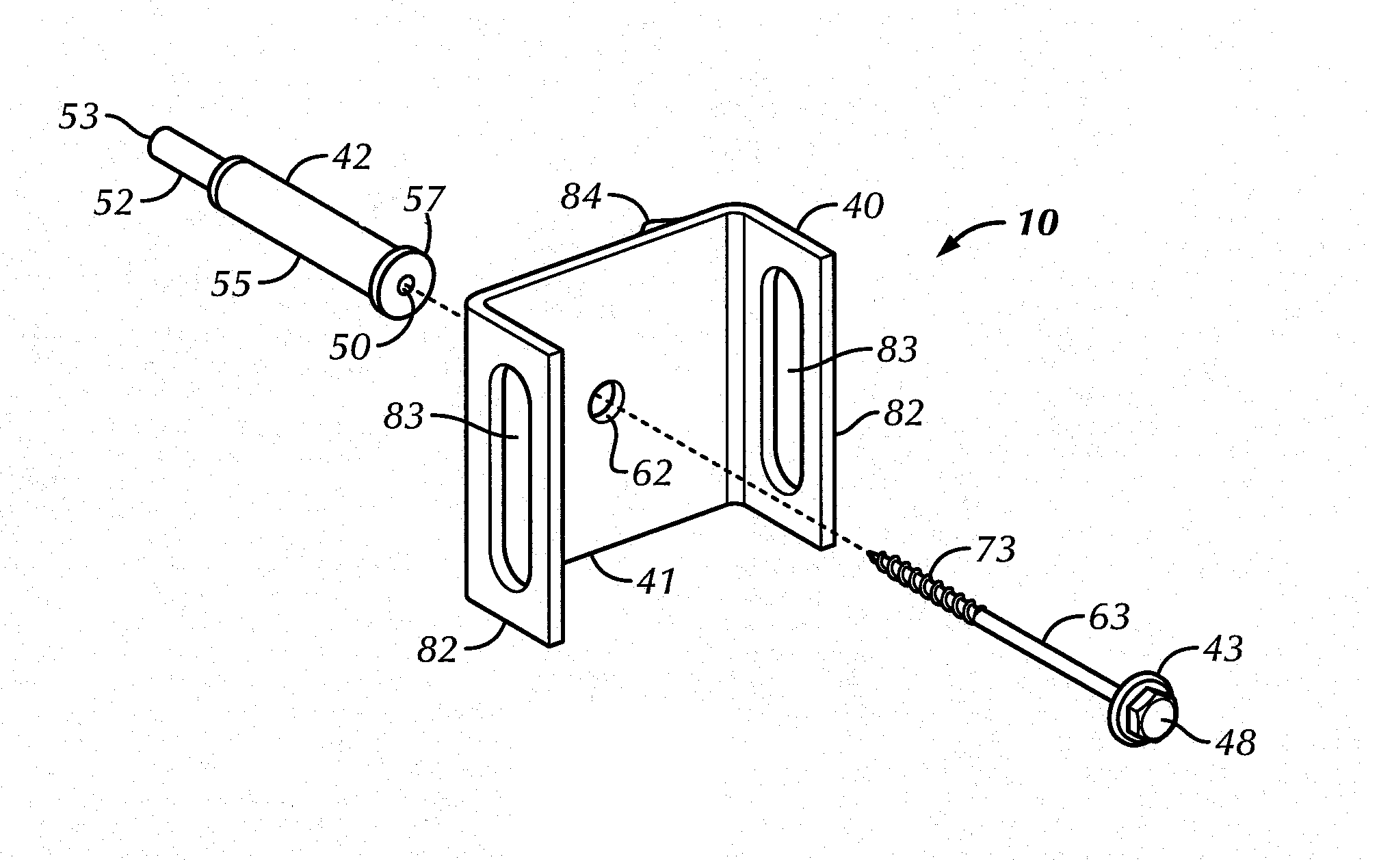

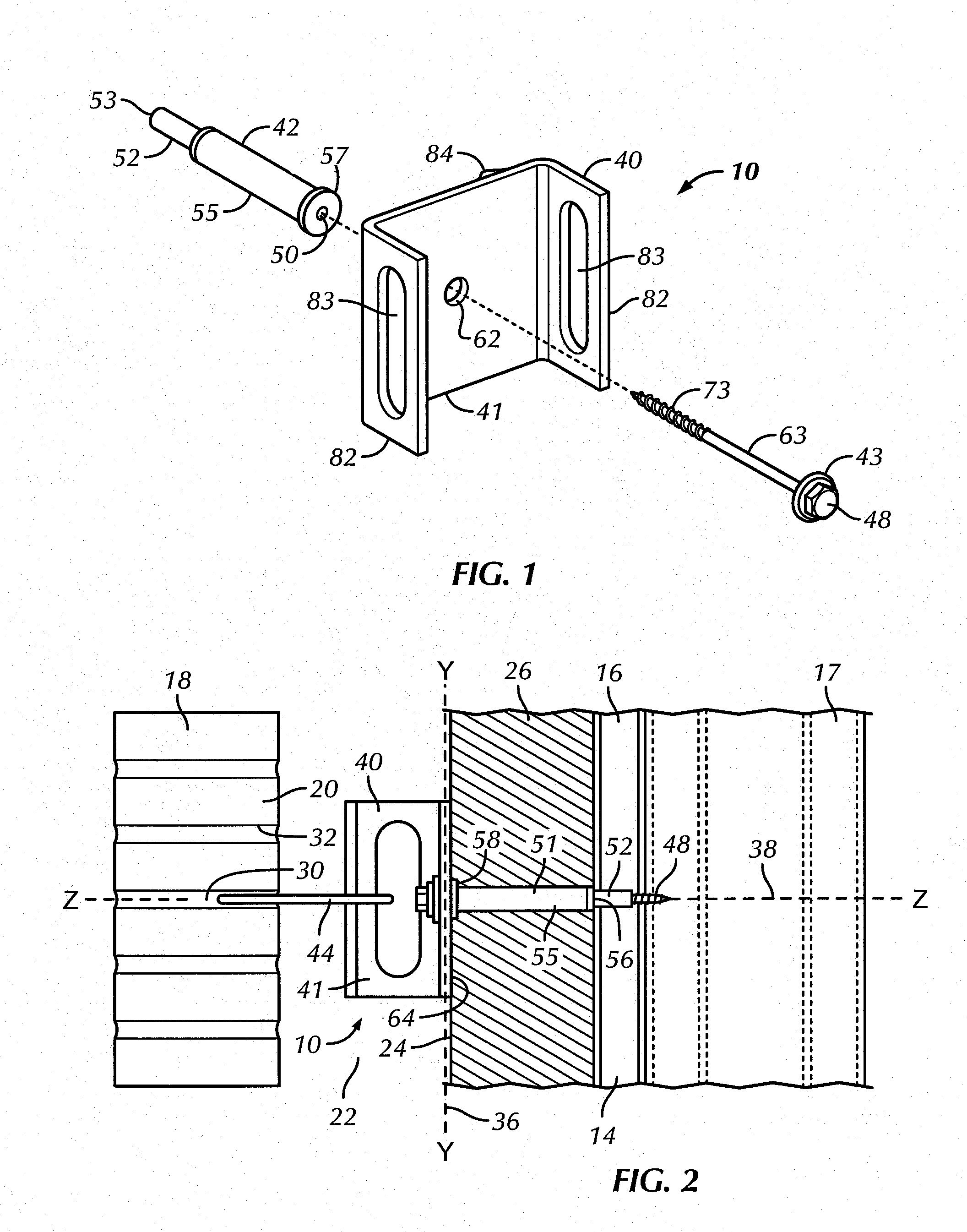

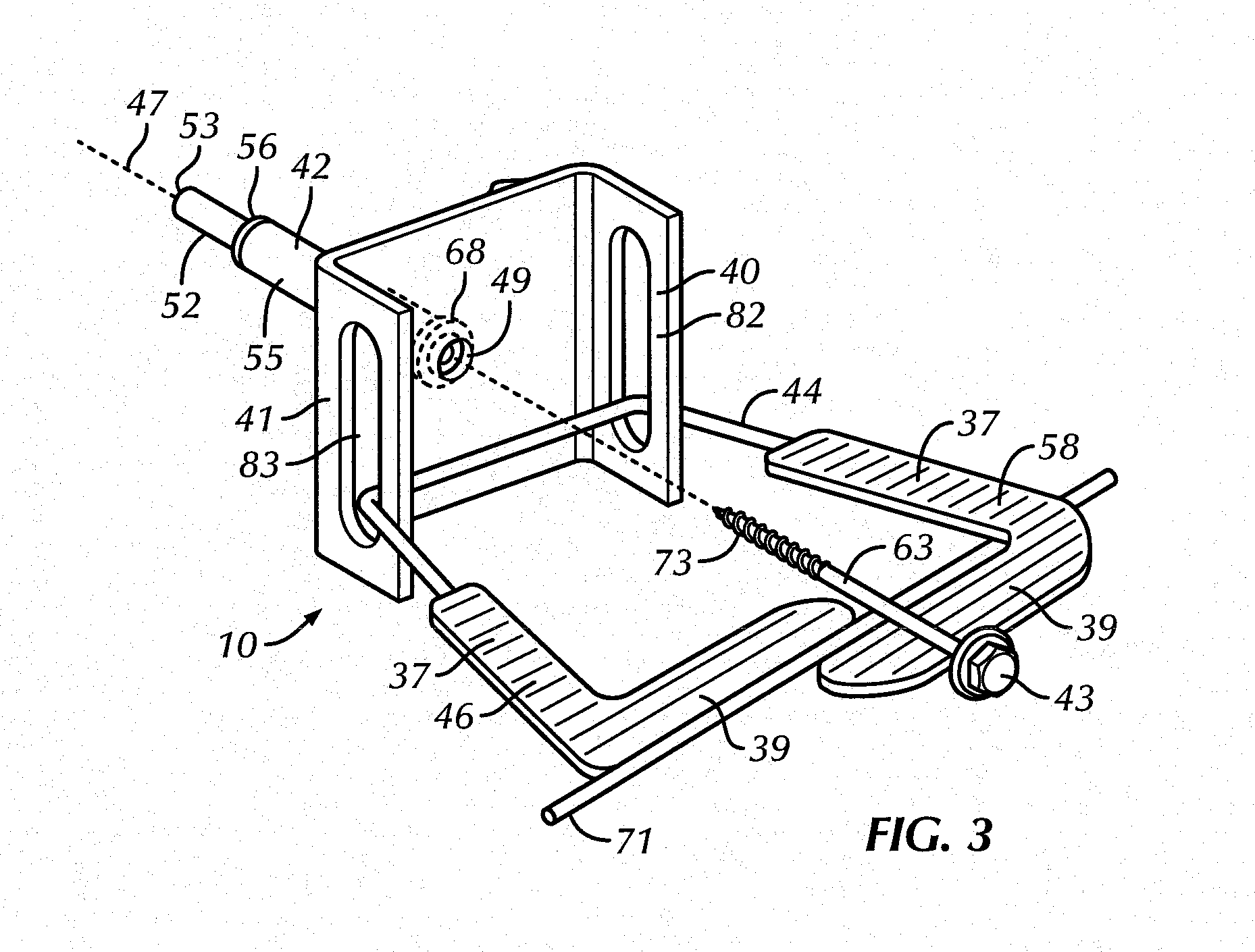

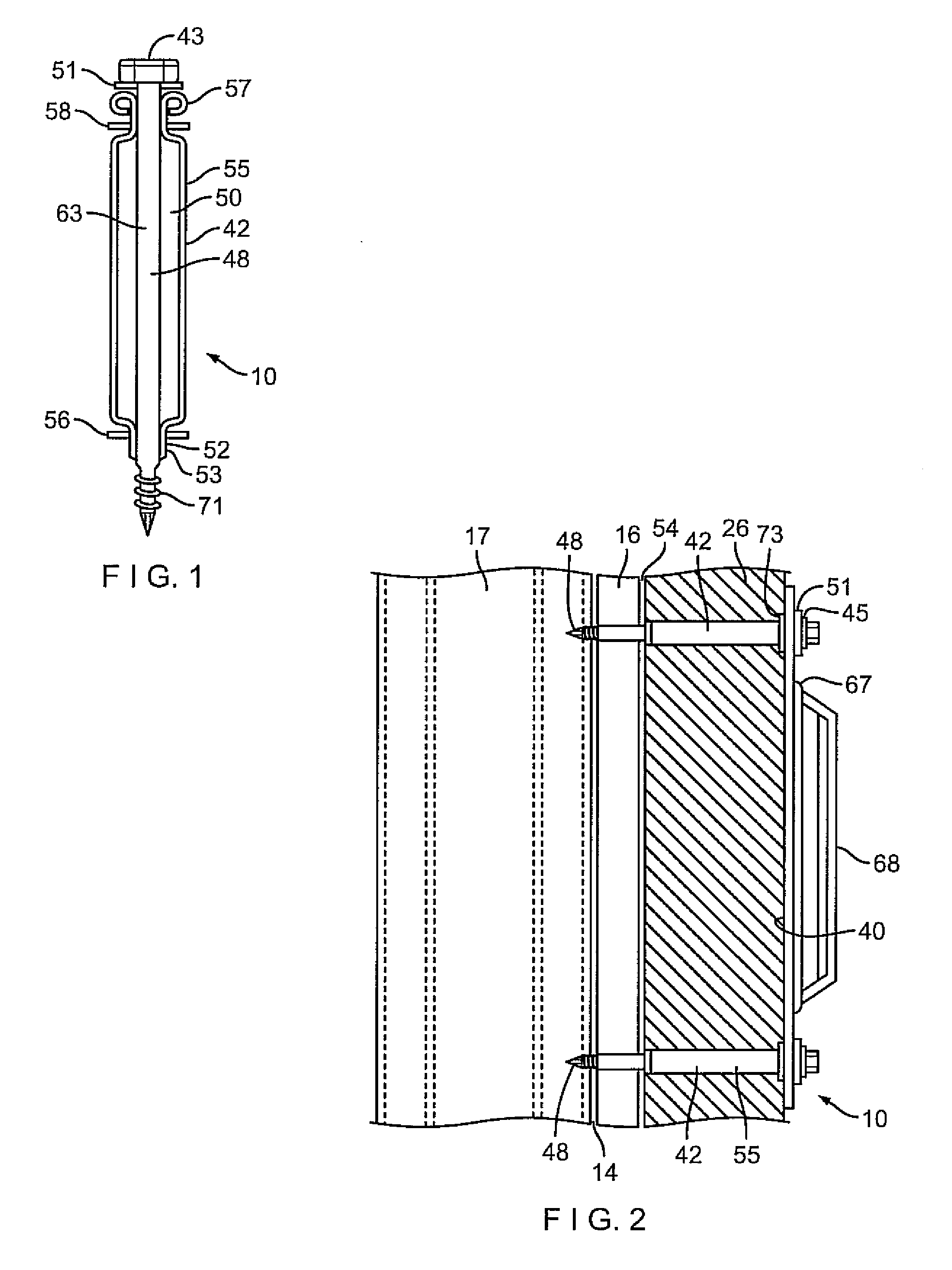

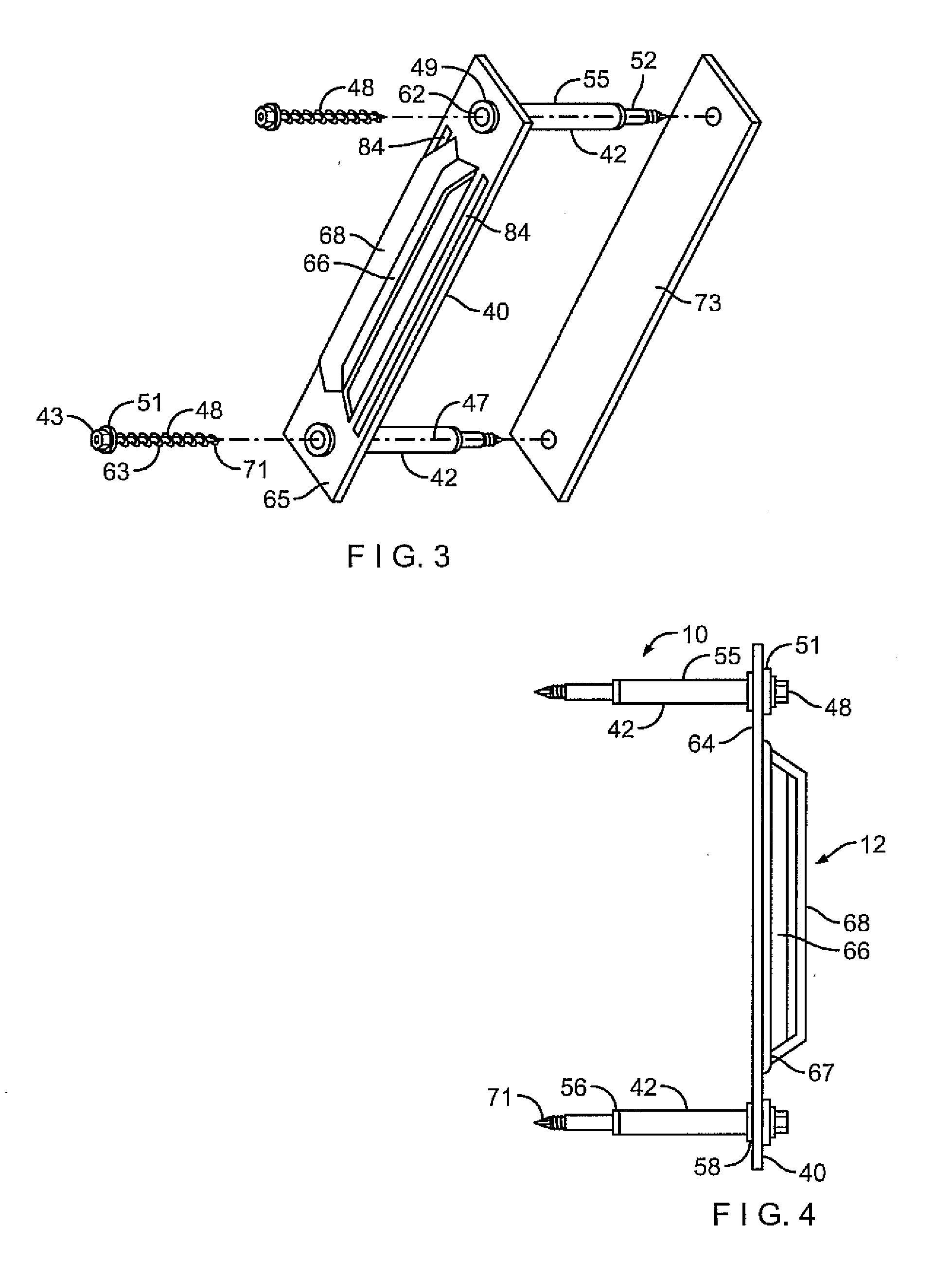

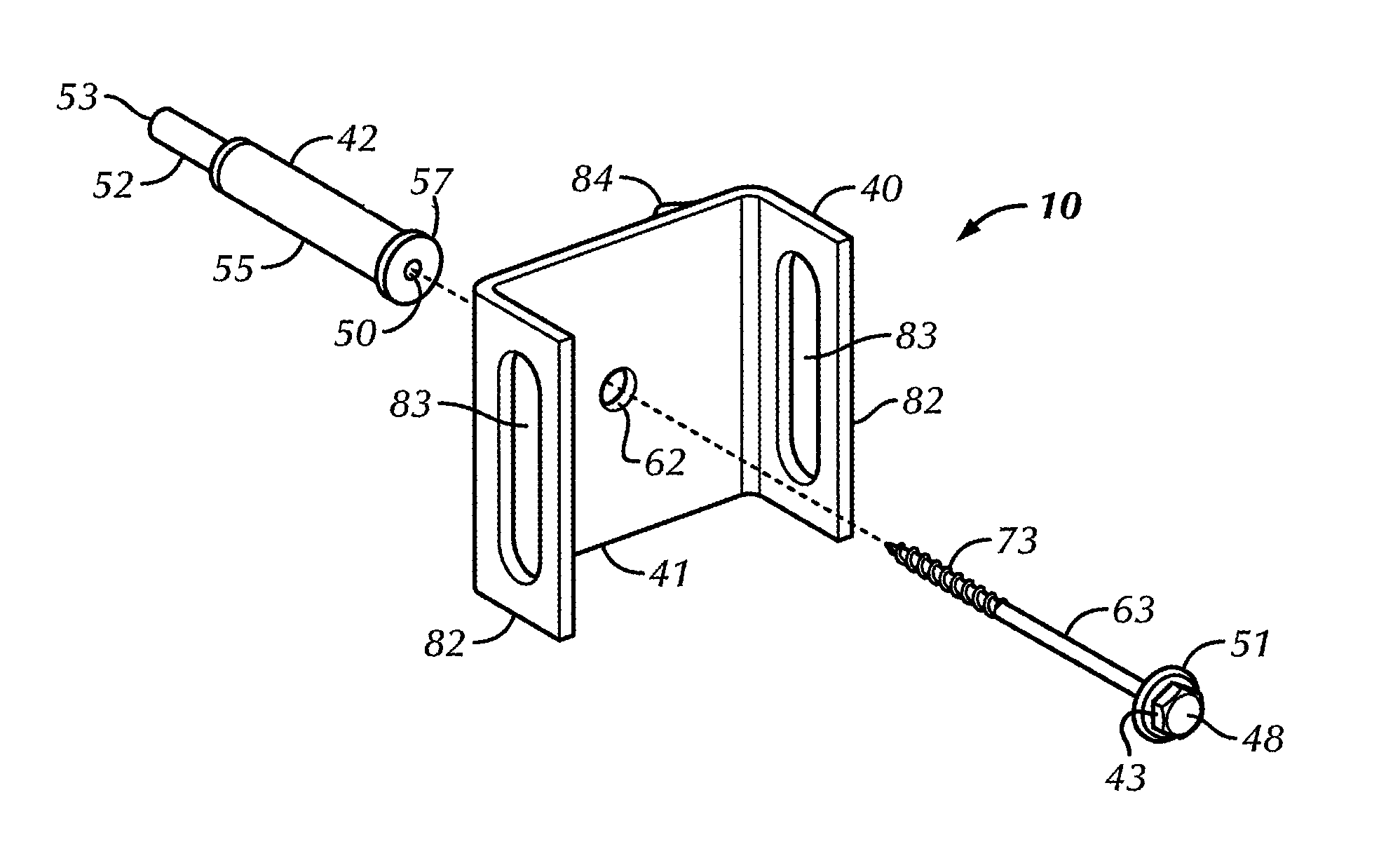

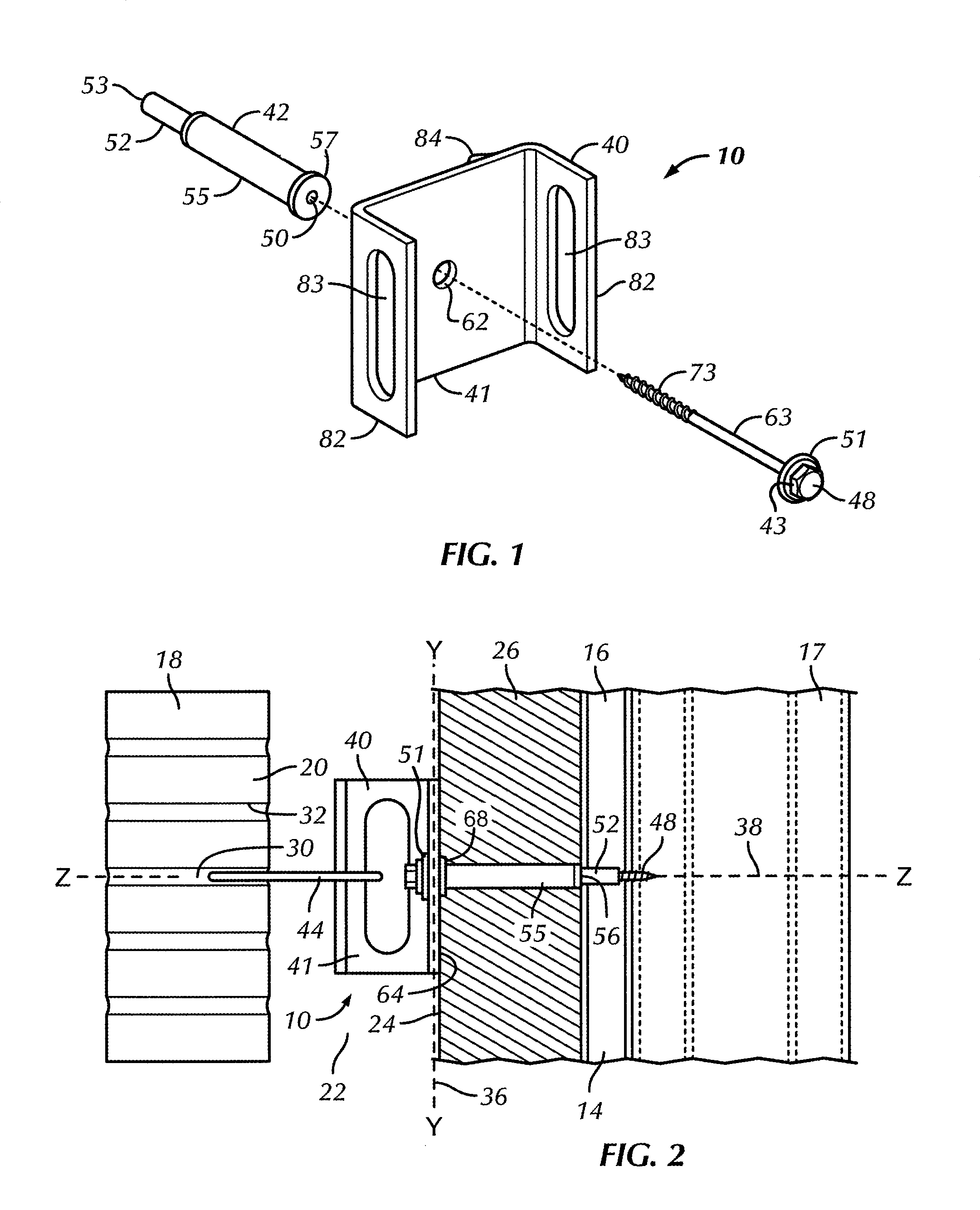

Wall anchor constructs and surface-mounted anchoring systems utilizing the same

Wall anchor constructs and anchoring systems employing the same are disclosed. Each anchor is a sheetmetal construct utilizable with various wire formative veneer ties. In the wall anchor structures, the junctures of the legs and the base of the wall anchor are located inboard from the periphery of the wall anchor base. With the surfaces of the leg base and the anchor base coplanar, the leg insertion point is, upon installation, sealed thereby. This sealing precludes penetration of air, Moisture, and water vapor into the wall structure. Various embodiments showing wall anchor configurations with suitable veneer ties are provided.

Owner:HOHMANN & BARNARD INC

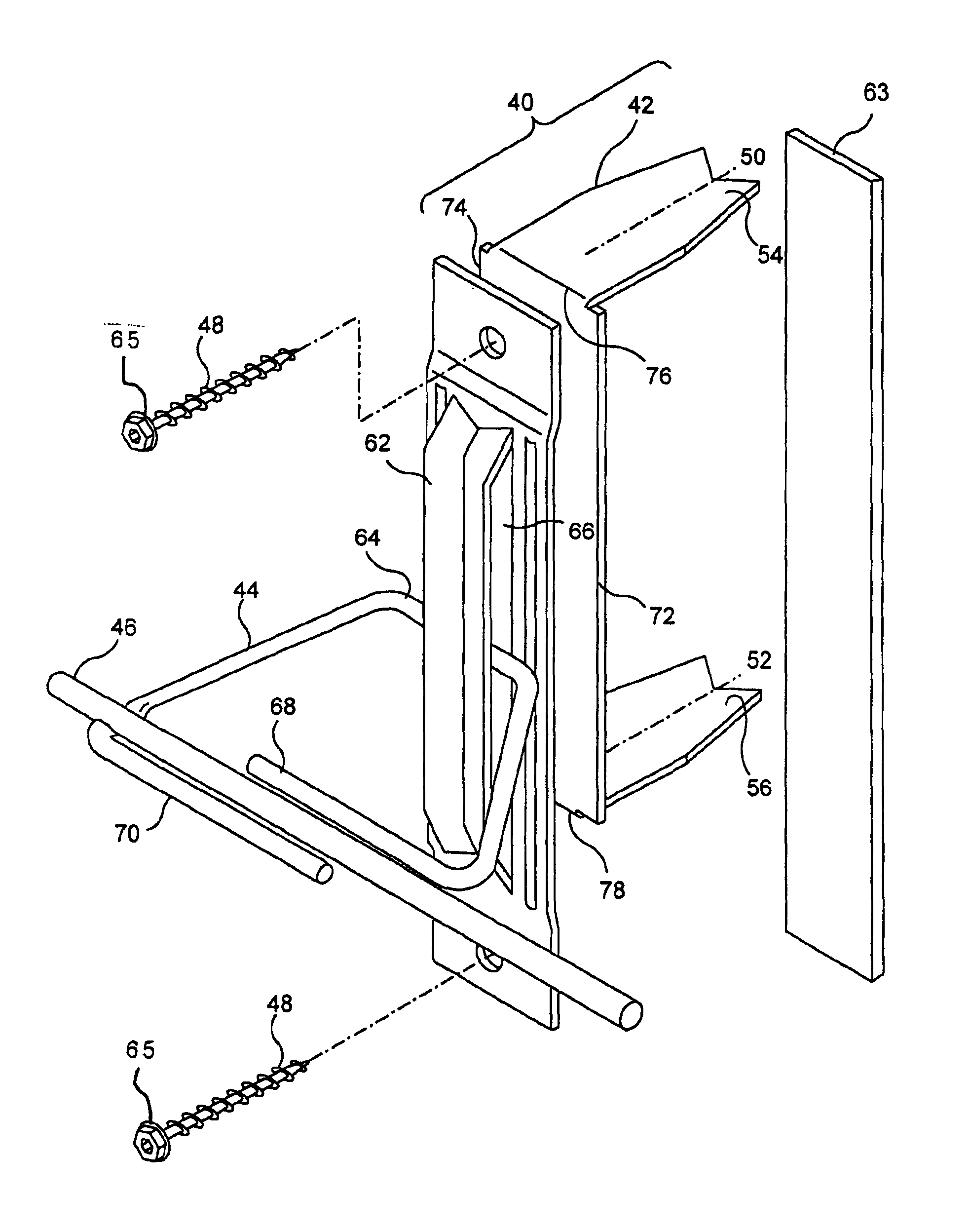

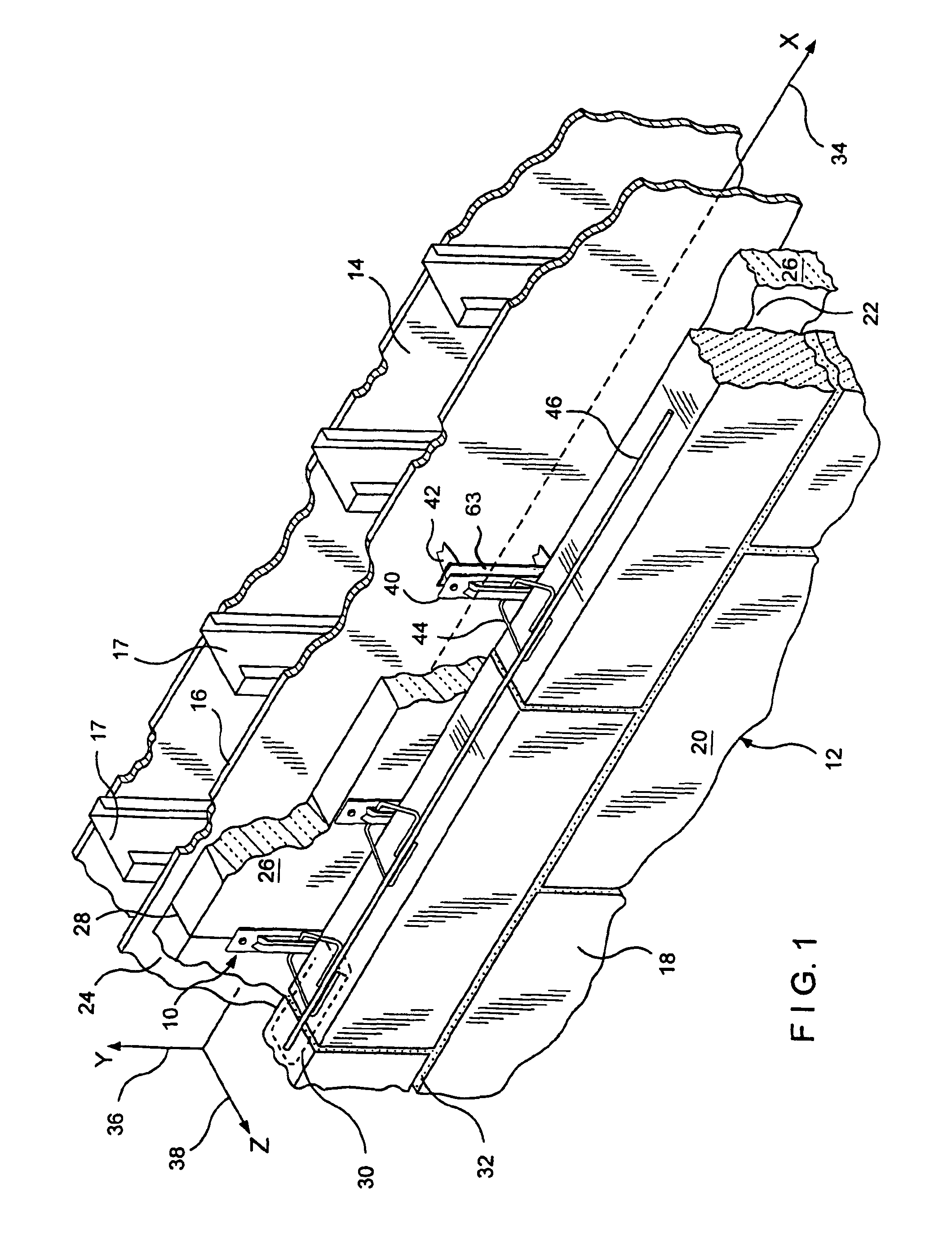

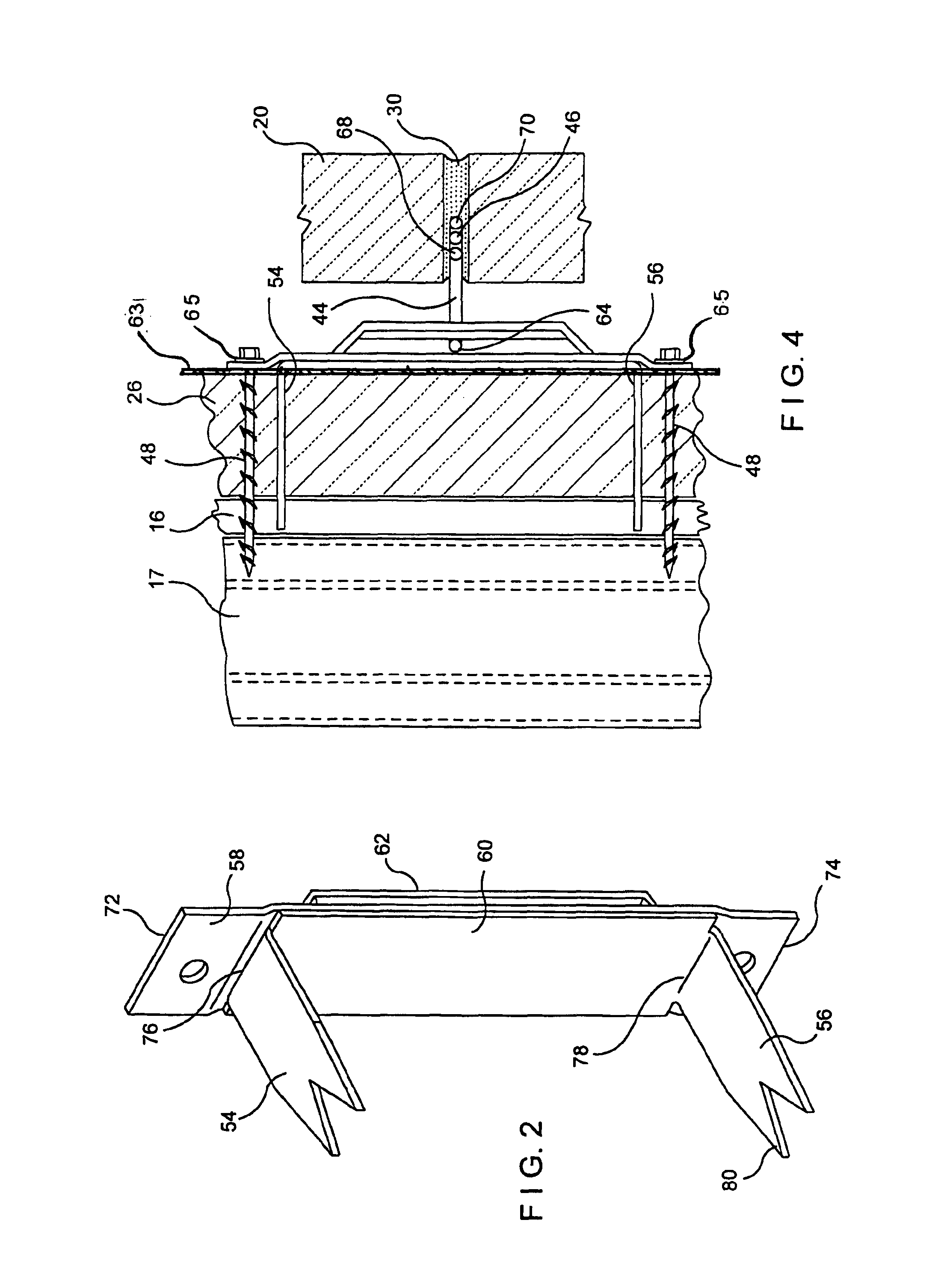

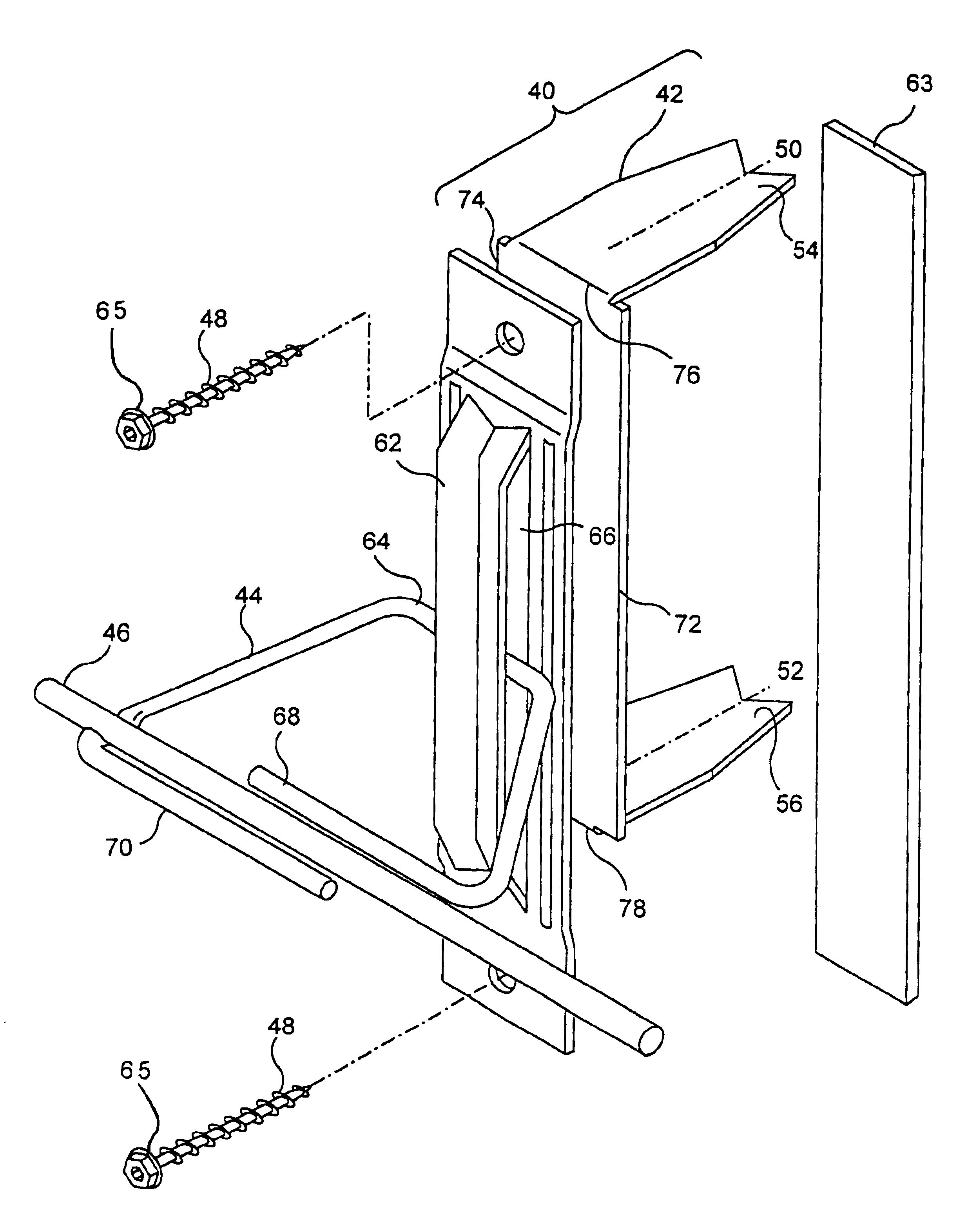

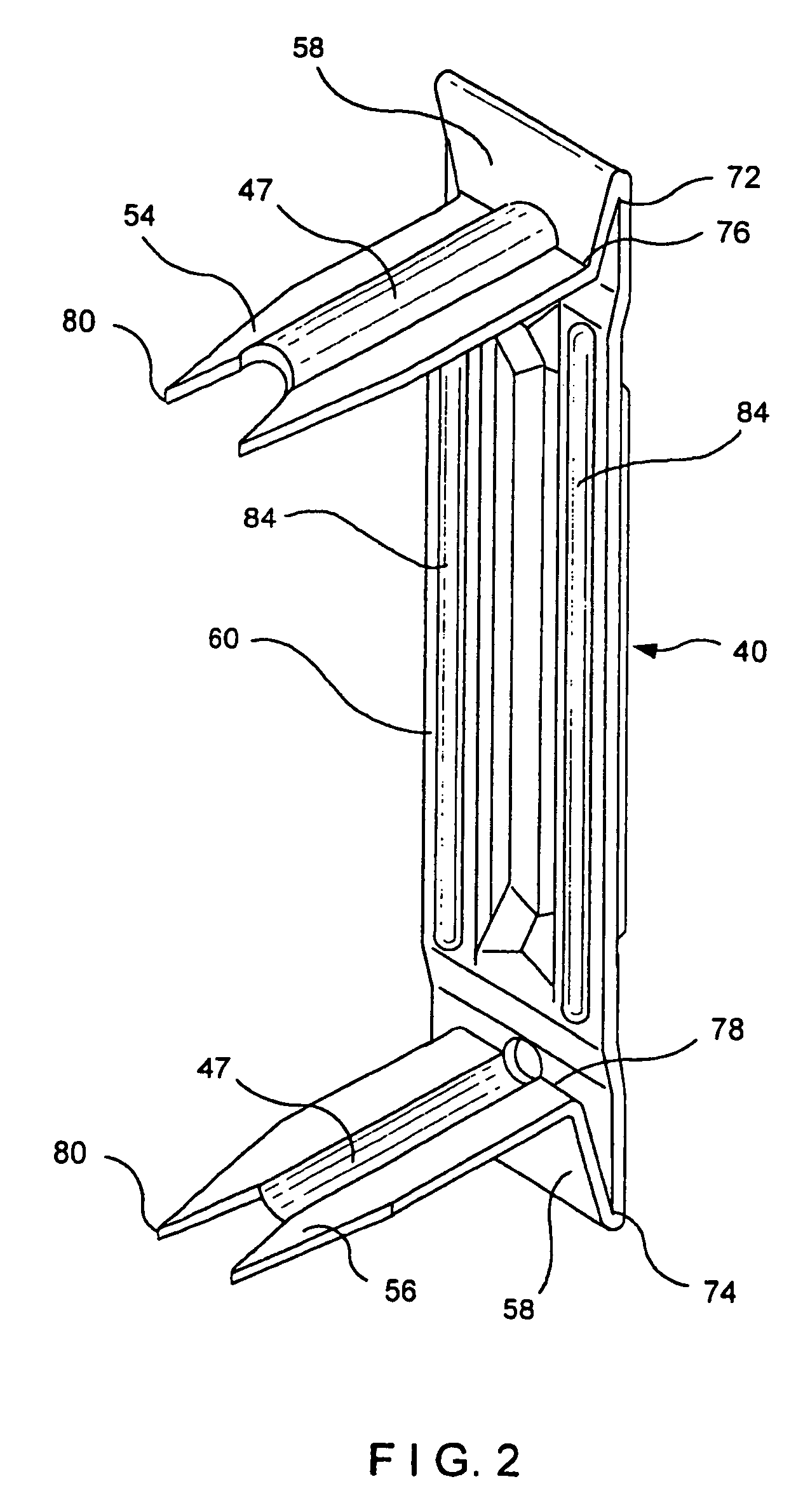

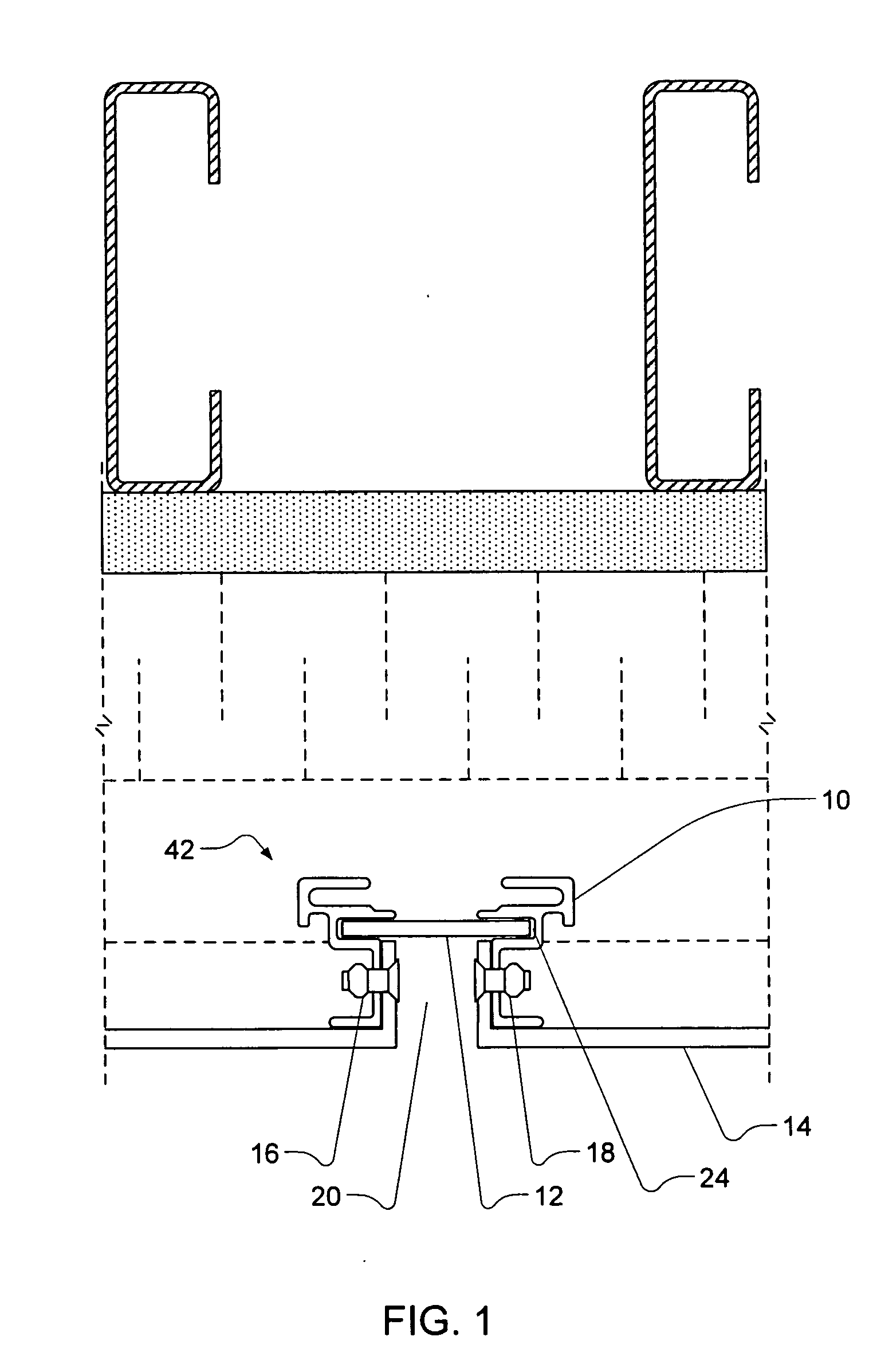

Folded wall anchor and surface-mounted anchoring

InactiveUS6925768B2Prevent disengagementCeilingsConstruction materialSurface mountingStructural engineering

A folded wall anchor and an anchoring system employing the same are disclosed. The anchor is a folded sheetmetal construct utilizable with various wire formative veneer ties. The folded wall tie enables the junctures of the legs and the base of the wall anchor to be located inboard from the periphery of the wall anchor. Upon installation with the surfaces of the enfolded leg and of the base coplanar, the leg insertion point is sealed thereby. This sealing precludes penetration of air, moisture, and water vapor into the wall structure. Various embodiments showing wall anchor configurations with suitable veneer ties are provided.

Owner:HOHMANN & BARNARD INC

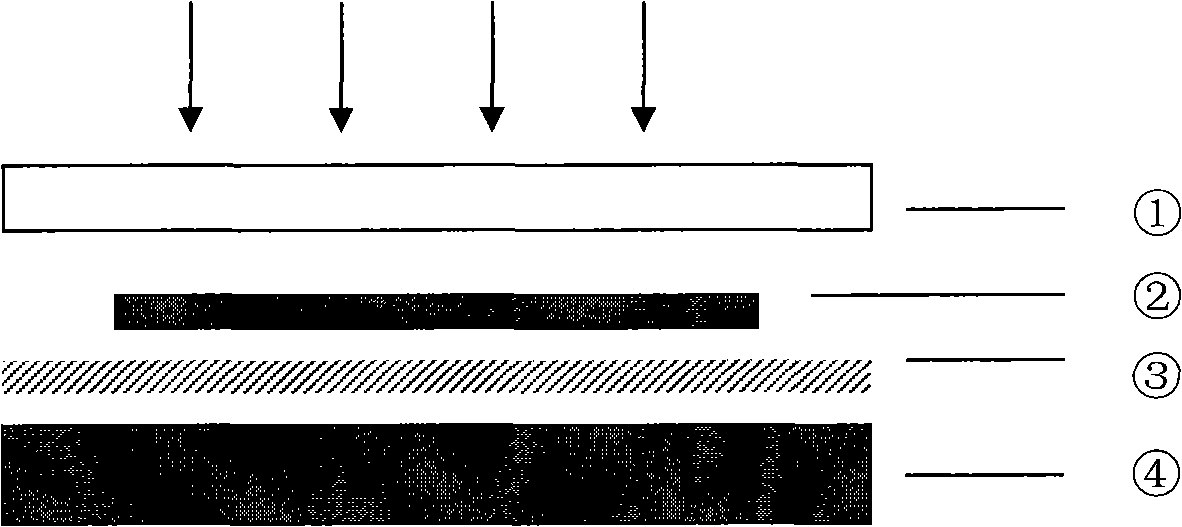

Back film of solar cell and preparing technique thereof

InactiveCN101290950AAvoid Bubble ProblemsAvoid stickingSynthetic resin layered productsPretreated surfacesWeather resistanceMass ratio

The invention discloses a solar panel back film and a technique for manufacturing the same. The back film comprises a PET film substrate with thickness of between 100 and 350 micrometers, wherein, fluoropolymer coatings with thickness of between 15 and 30 micrometers are coated on both sides of the substrate; an adhesive layer with thickness of between 0.5 and 5 micrometers is coated on the fluoropolymer coating on one side; the fluoropolymer coatings are obtained by direct coating of mixed latex which is obtained through mixture of various raw material compositions according to the mixture ratio and subsequent grinding treatment on the PET film substrate; the compositions by mass ratio of the raw materials of the fluoropolymer coatings are 30 to 55 percent of fluoride coating materials, 20 to 40 percent of solvent, 2 to 6 percent of cross-linking agent and curing agent and 15 to 40 percent of filling. The technique greatly improves the bonding strength between a back film layer and a layer, improves the ageing resistance, the weathering resistance of products, simultaneously improves the insulativity and the vapor permeability resistance due to the design of a multilayered structure and also can design and modify the performance and the appearance of the products as required.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS +2

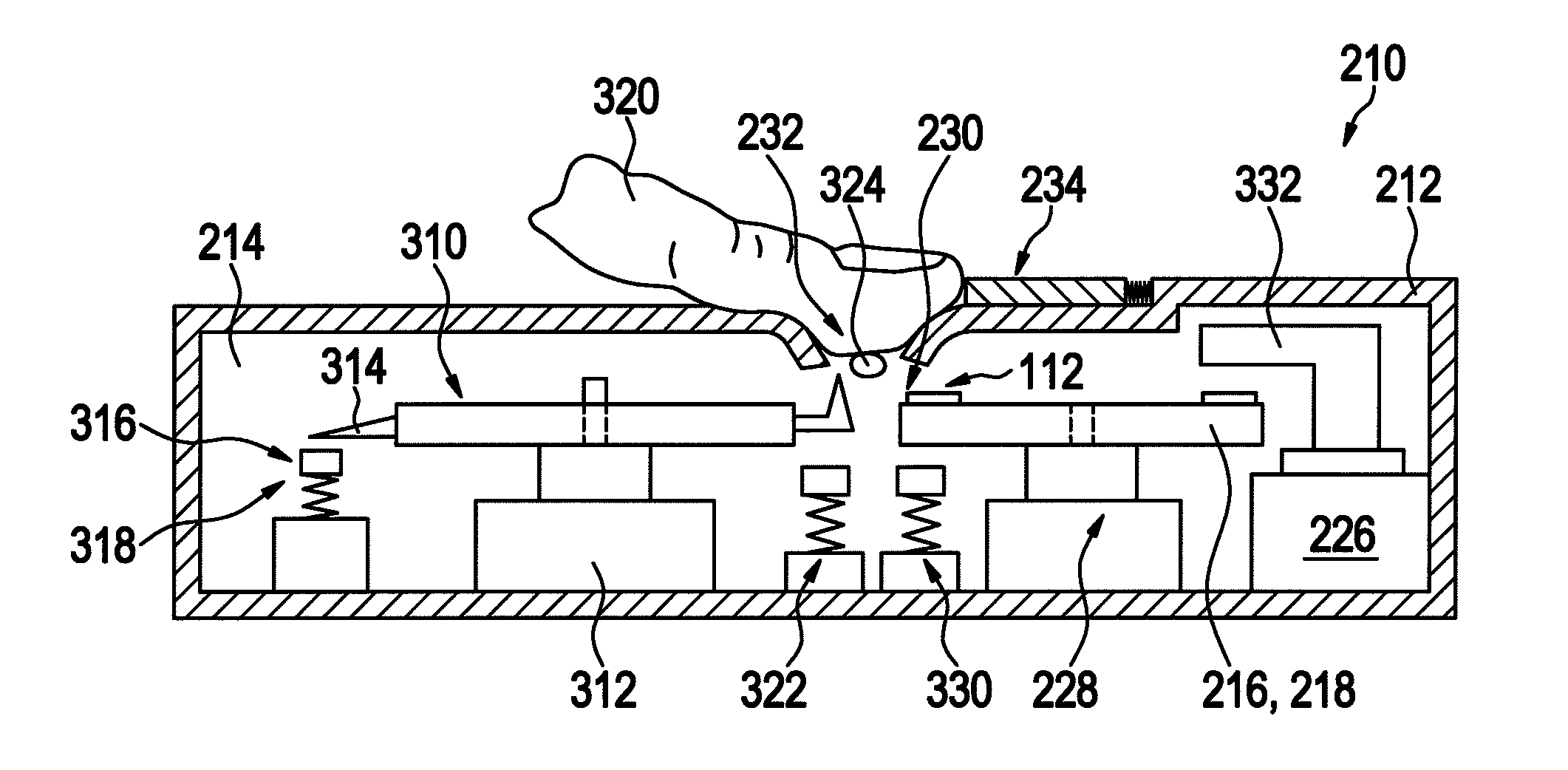

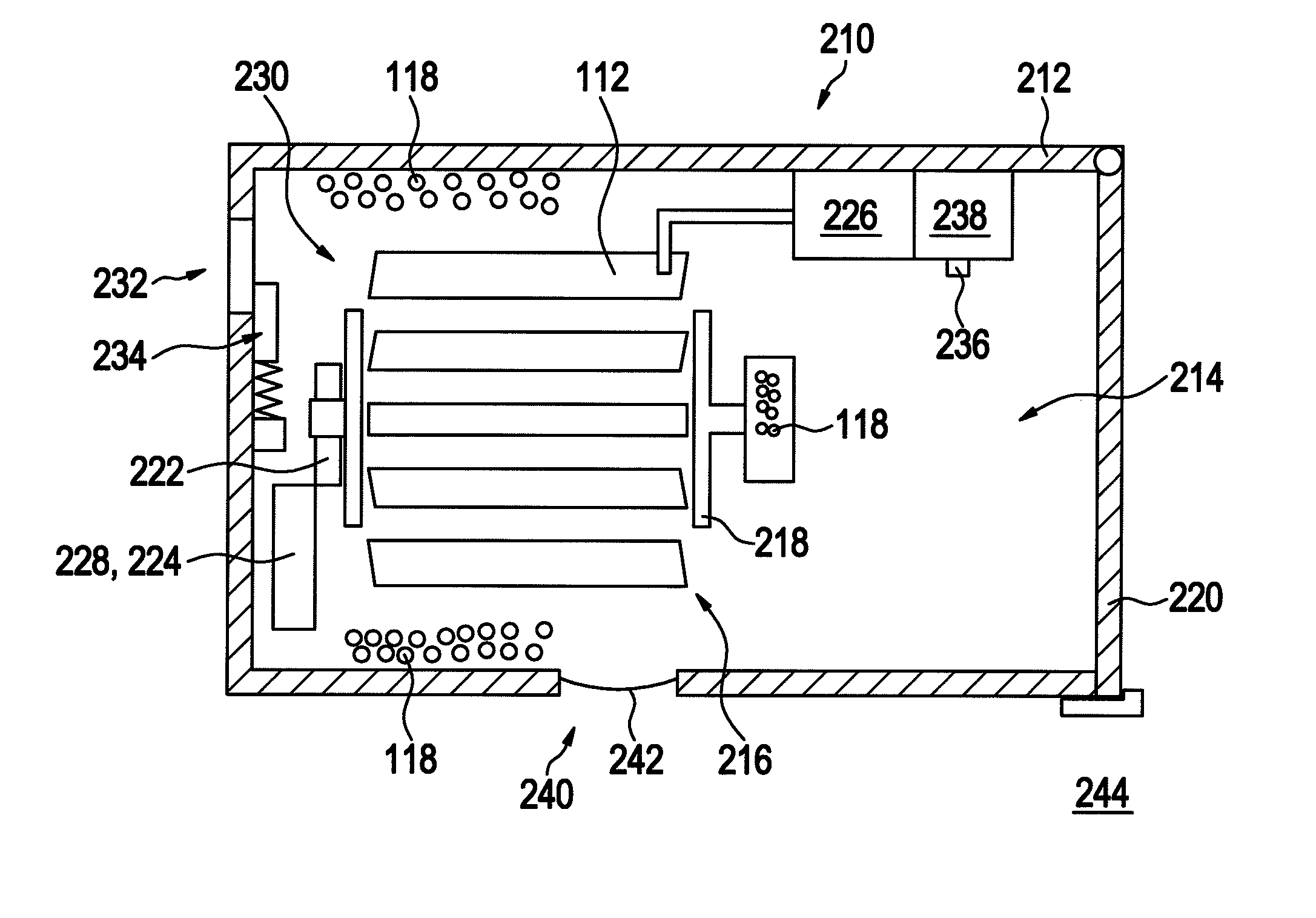

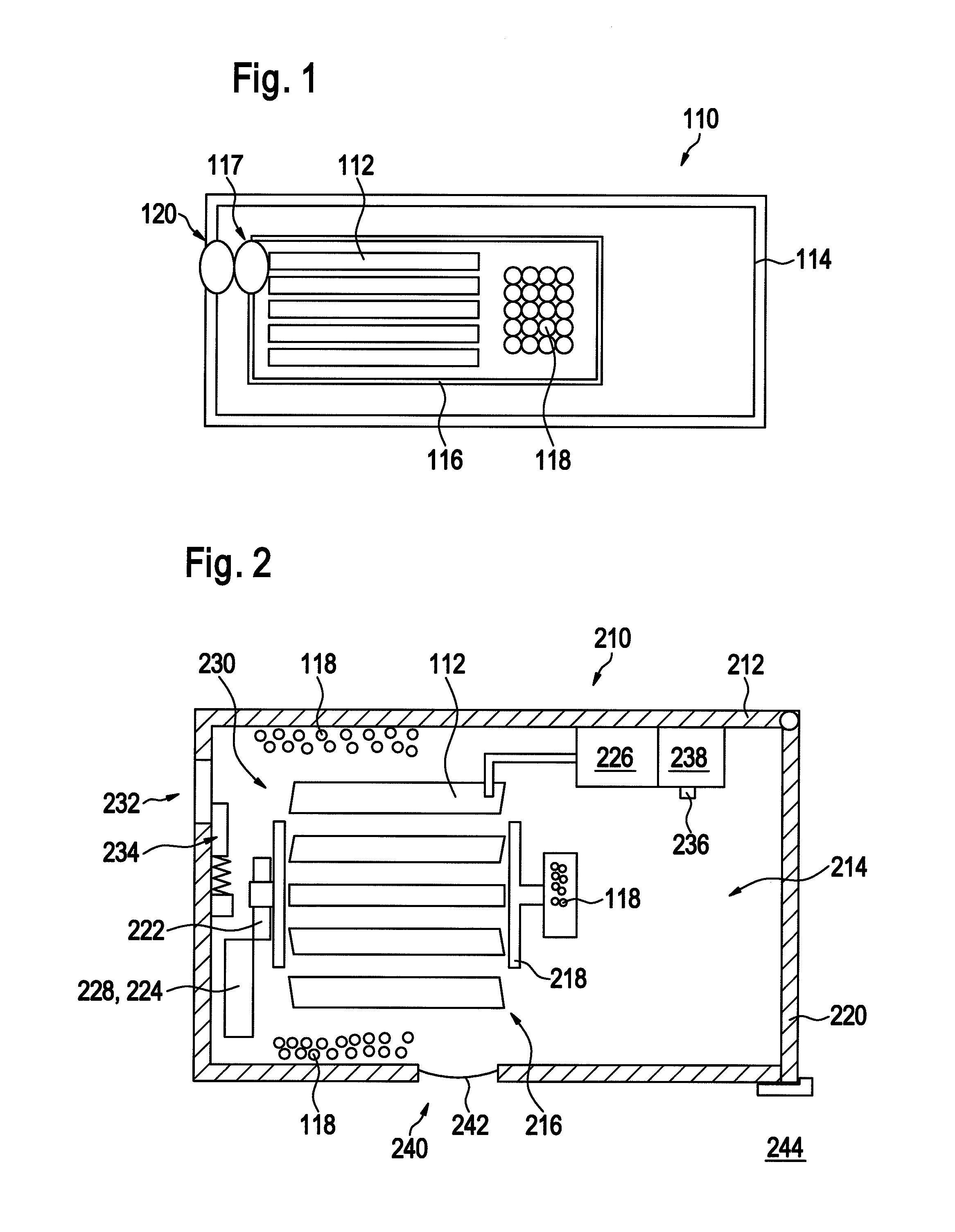

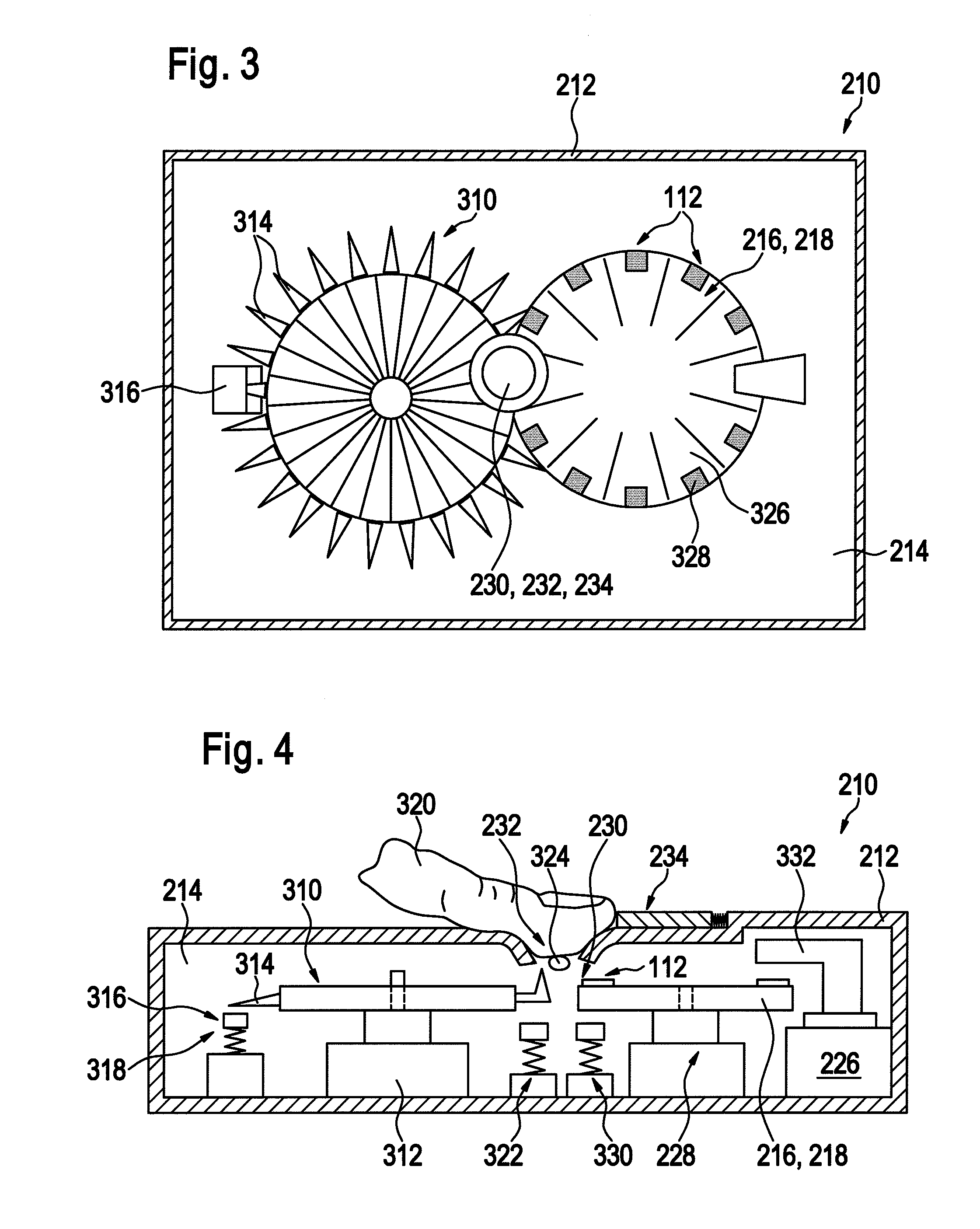

Portable measuring system having a moisture-proof assembly space

ActiveUS8231548B2Reduced assembly spaceImprove sealingCatheterDiagnostic recording/measuringAnalyteWater vapor

A portable measuring system which analyzes a liquid sample for at least one analyte. The portable measuring system has a substantially moisture-proof housing with an internal atmosphere. The housing prevents moisture from the air and water vapor from penetrating into the housing. The portable measuring system also has at least one test element support inserted into the internal atmosphere of the housing. The test element support is equipped with a retaining structure and a test element that is supported by the retaining structure. The test element support is designed such that, after insertion into the internal atmosphere, the test element is exposed to the internal atmosphere. A release mechanism is also provided which can convey at least one test element into an application position within the internal atmosphere of the housing. In this application position, the liquid sample can be applied to the test element.

Owner:ROCHE DIABETES CARE INC

High-strength surface-mounted anchors and wall anchor systems using the same

Owner:HOHMANN & BARNARD INC

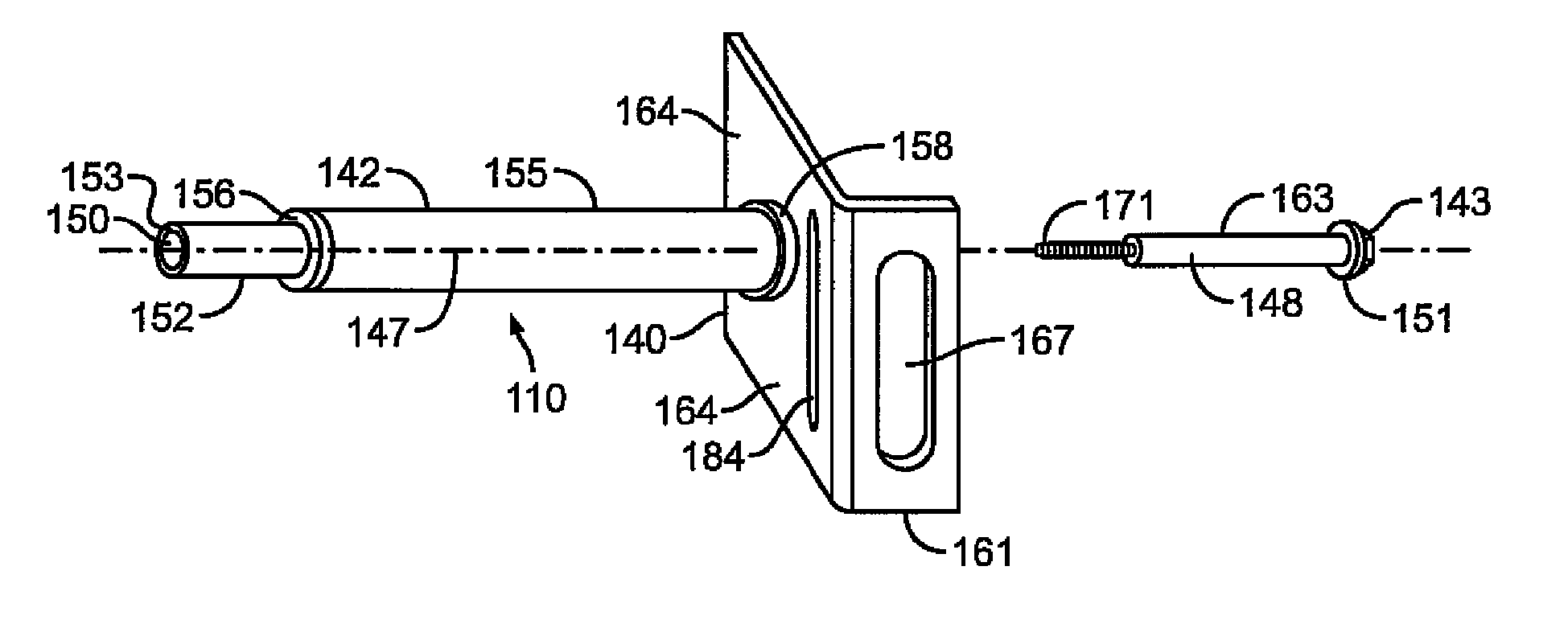

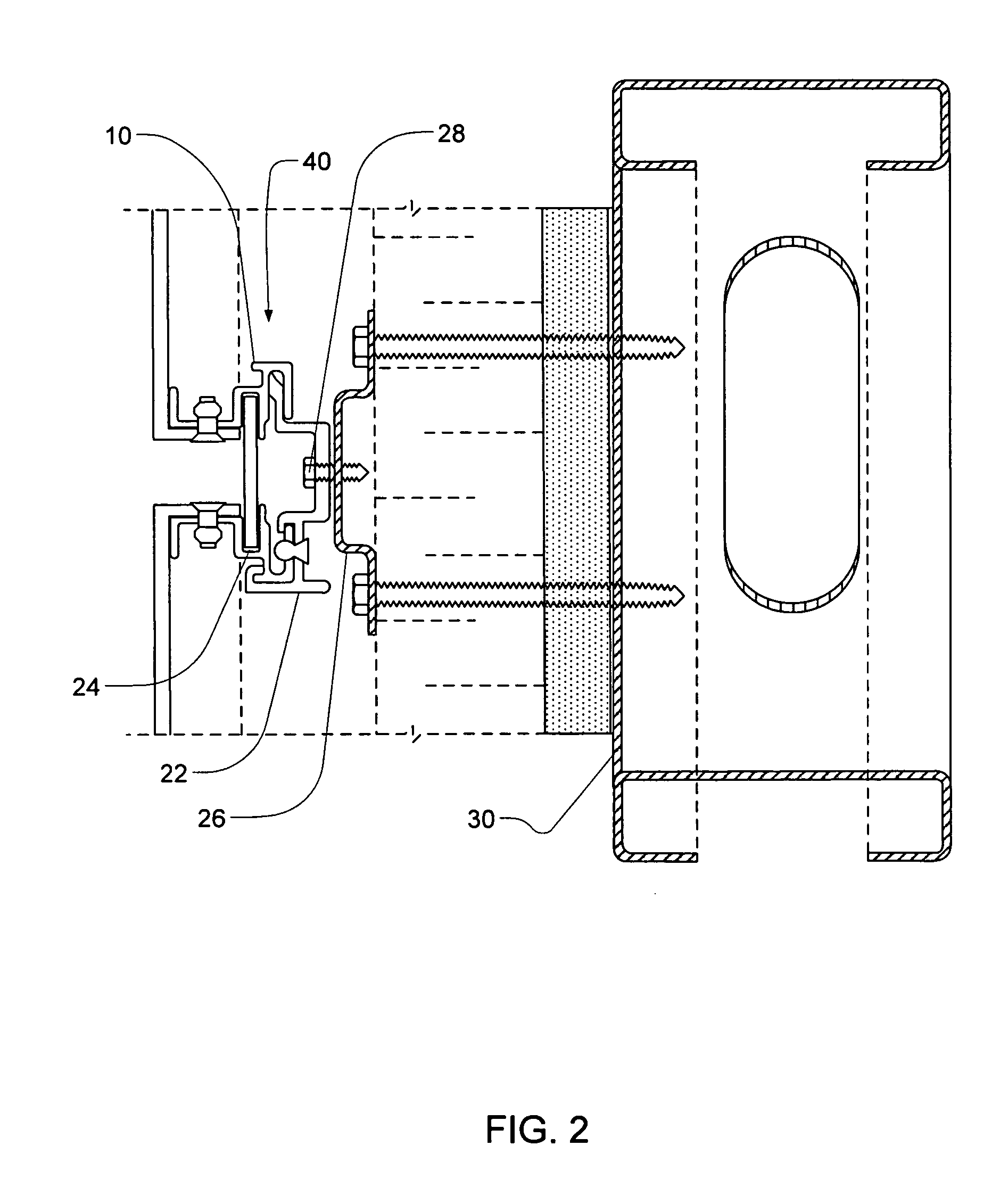

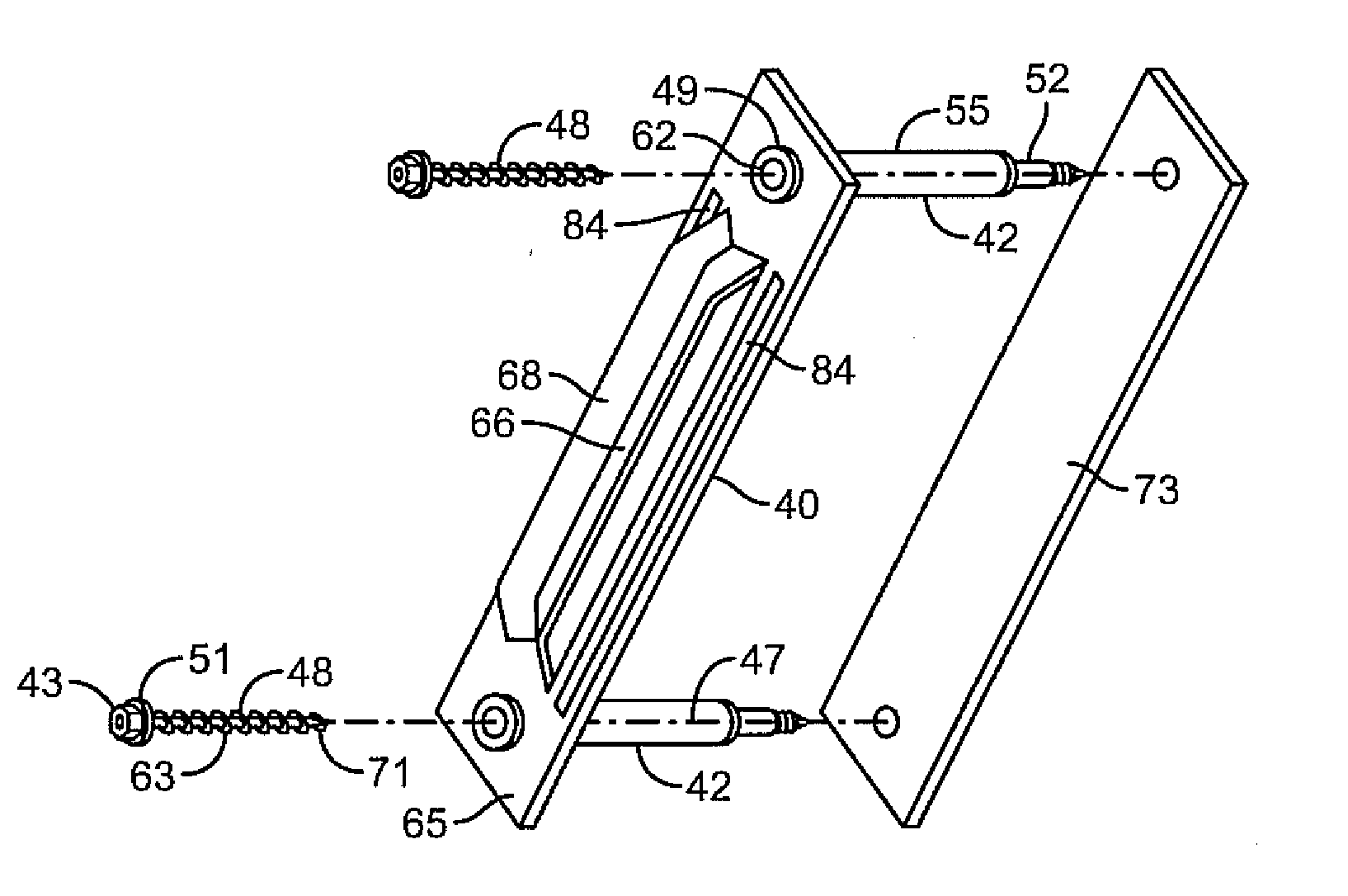

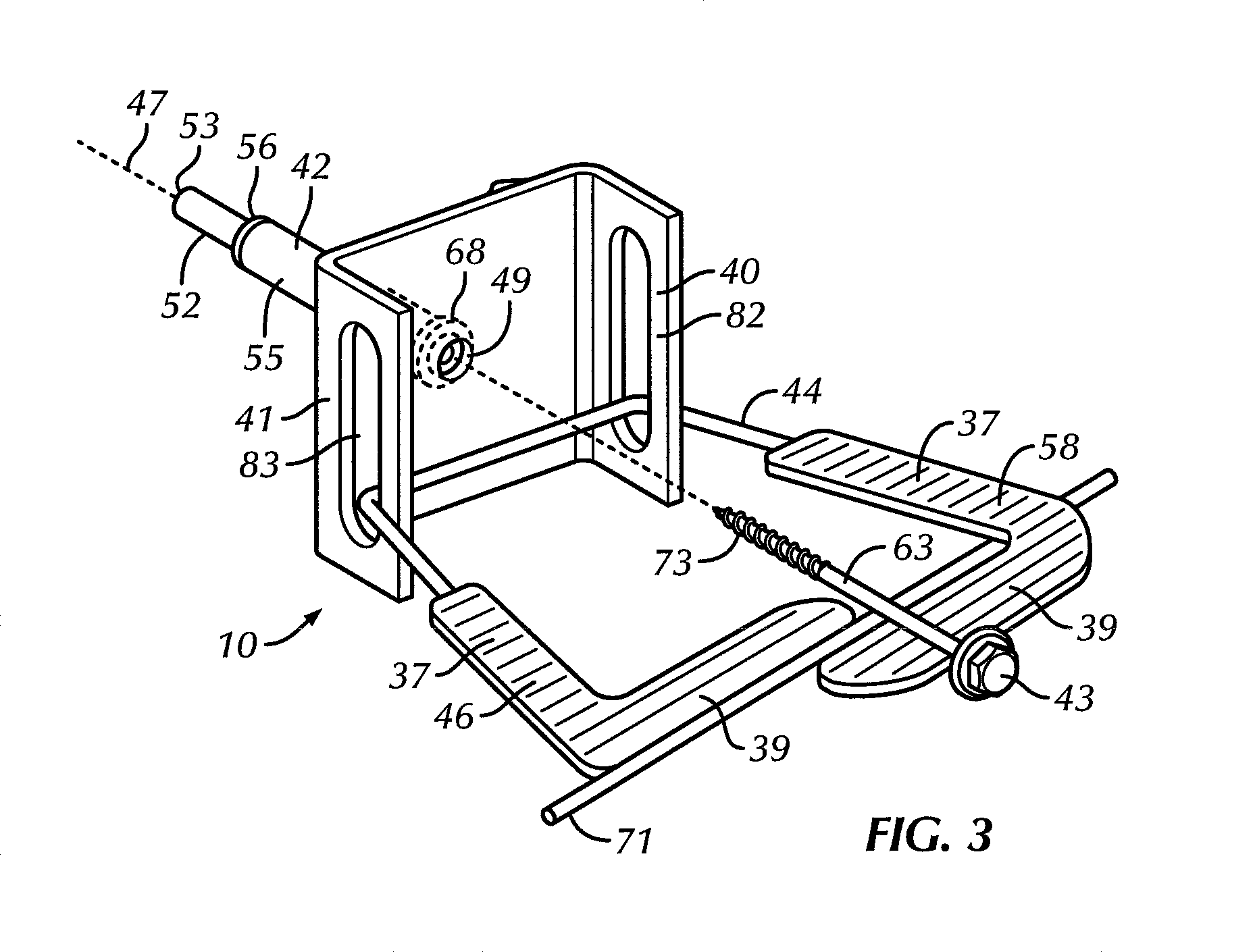

Thermally isolating tubule for wall anchor

ActiveUS8516763B2High levelPrevent disengagementCeilingsConstruction materialSurface mountingWater vapor

A tubule assembly for thermally isolating a surface-mounted wall anchor and an anchoring system employing the same are disclosed. The thermally-isolated tubule assembly is adaptable to varied anchor structures and for use with interlocking veneer ties and reinforcement wires to provide a high-strength surface mounted anchoring system for cavity walls. The stepped cylinders sheath the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The tubule assembly is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings and set within the perimeter of the anchor base. Seals are formed which preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

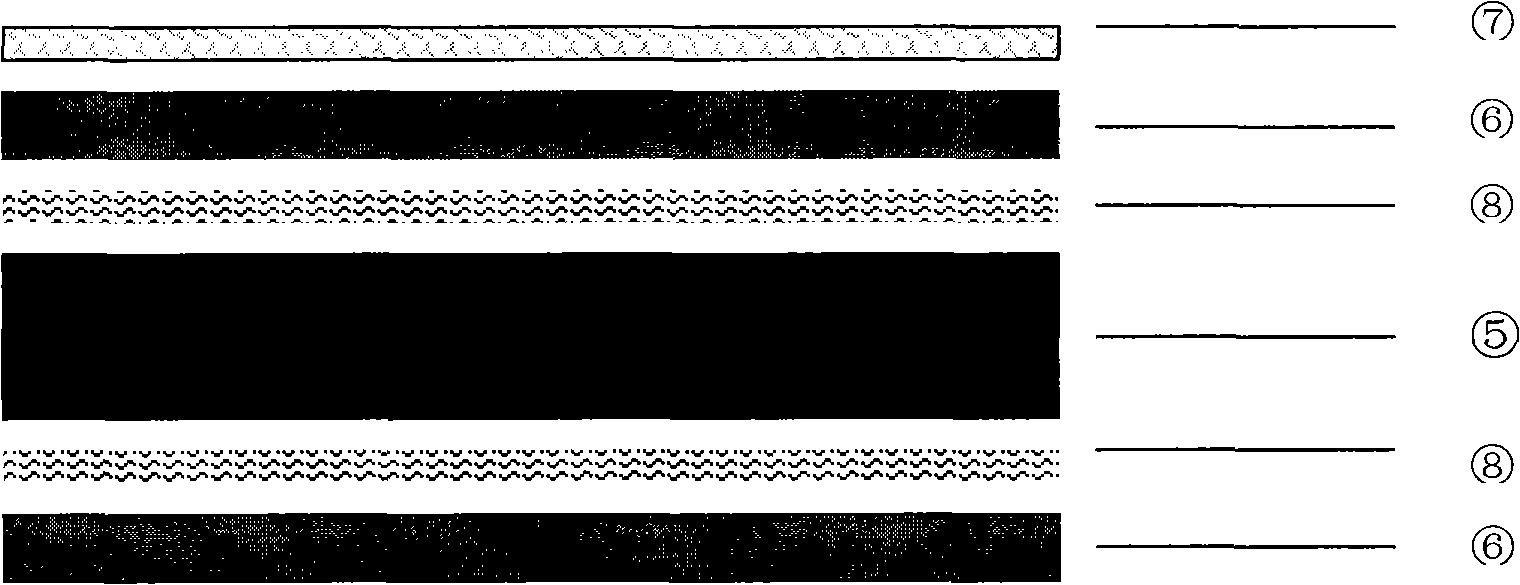

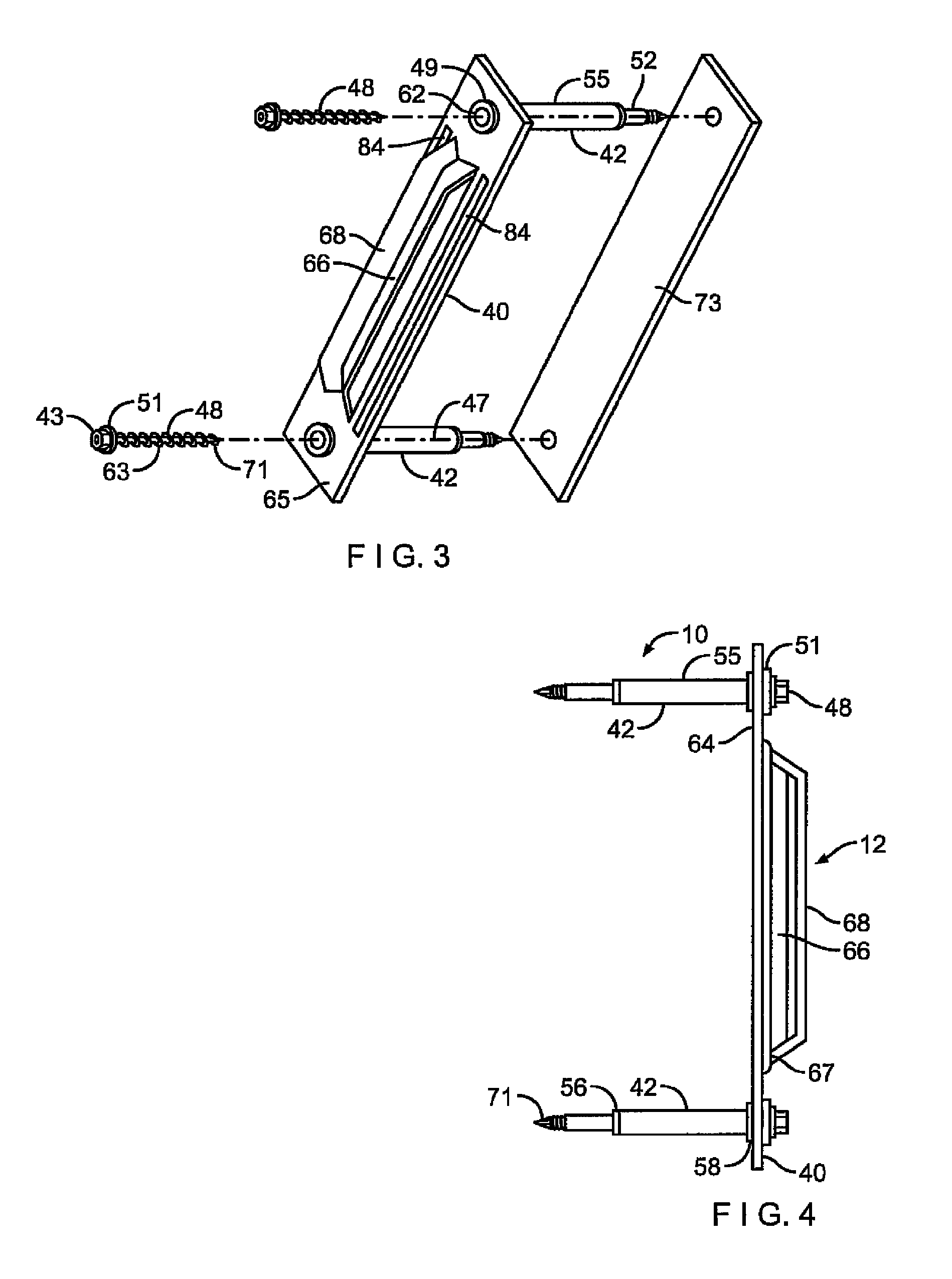

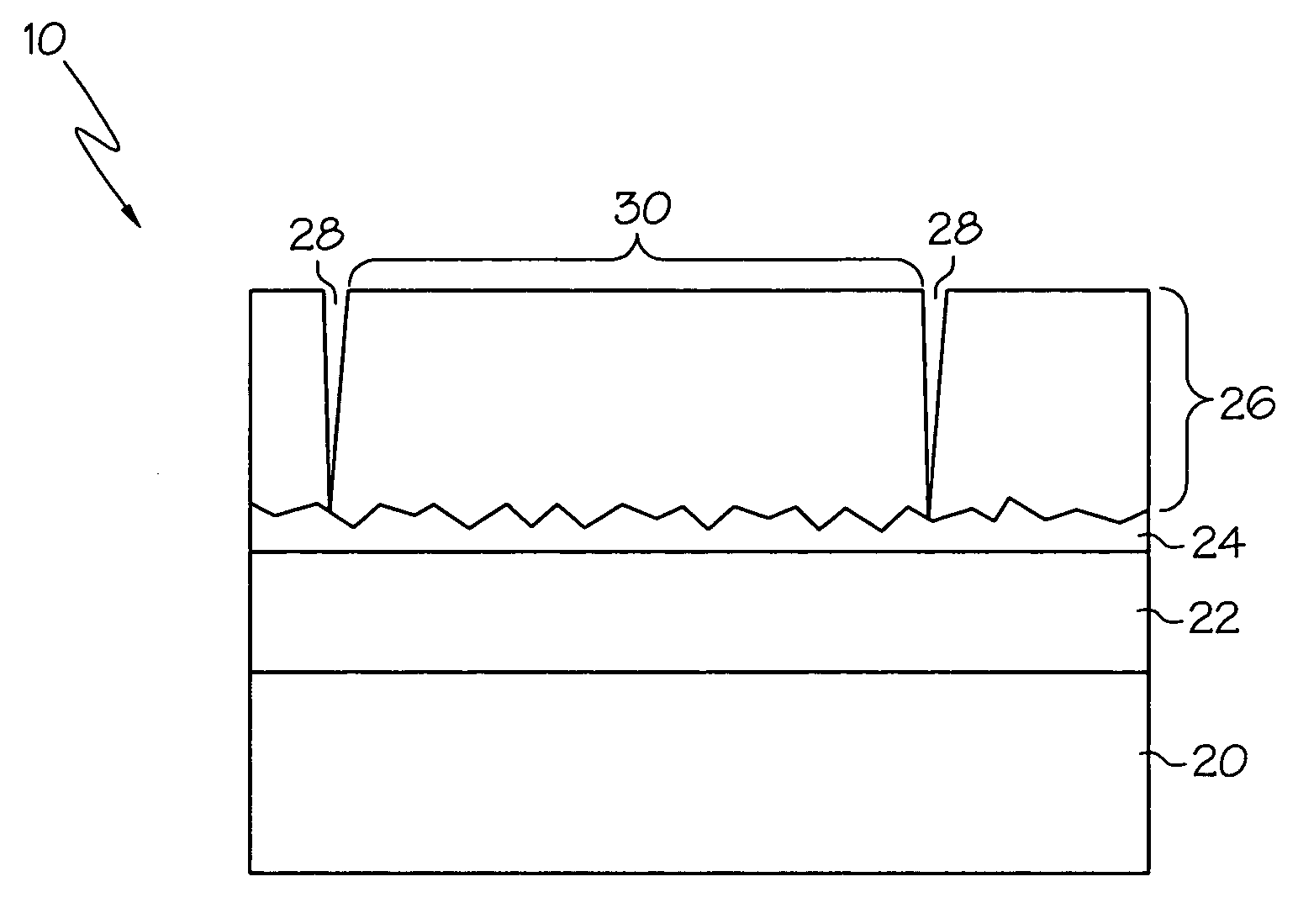

Protective coating for oxide ceramic based composites

InactiveUS20060024528A1Improve accommodationGlass/slag layered productsNatural mineral layered productsOxide ceramicPorosity

A layered structure includes a substrate comprising a layer of an oxide / oxide ceramic based composite material, a first oxide layer disposed directly on the substrate and formed from a material that has no greater than about 10% porosity and is substantially impermeable by water vapor, and a second oxide layer disposed directly on the first oxide layer and having a greater porosity than the first oxide layer. Either or both the first and second oxide layers of the coating system may be deposited using a plasma spraying process, a slurry deposition process which is followed by a sintering step, or an EB-PVD process.

Owner:HONEYWELL INT INC

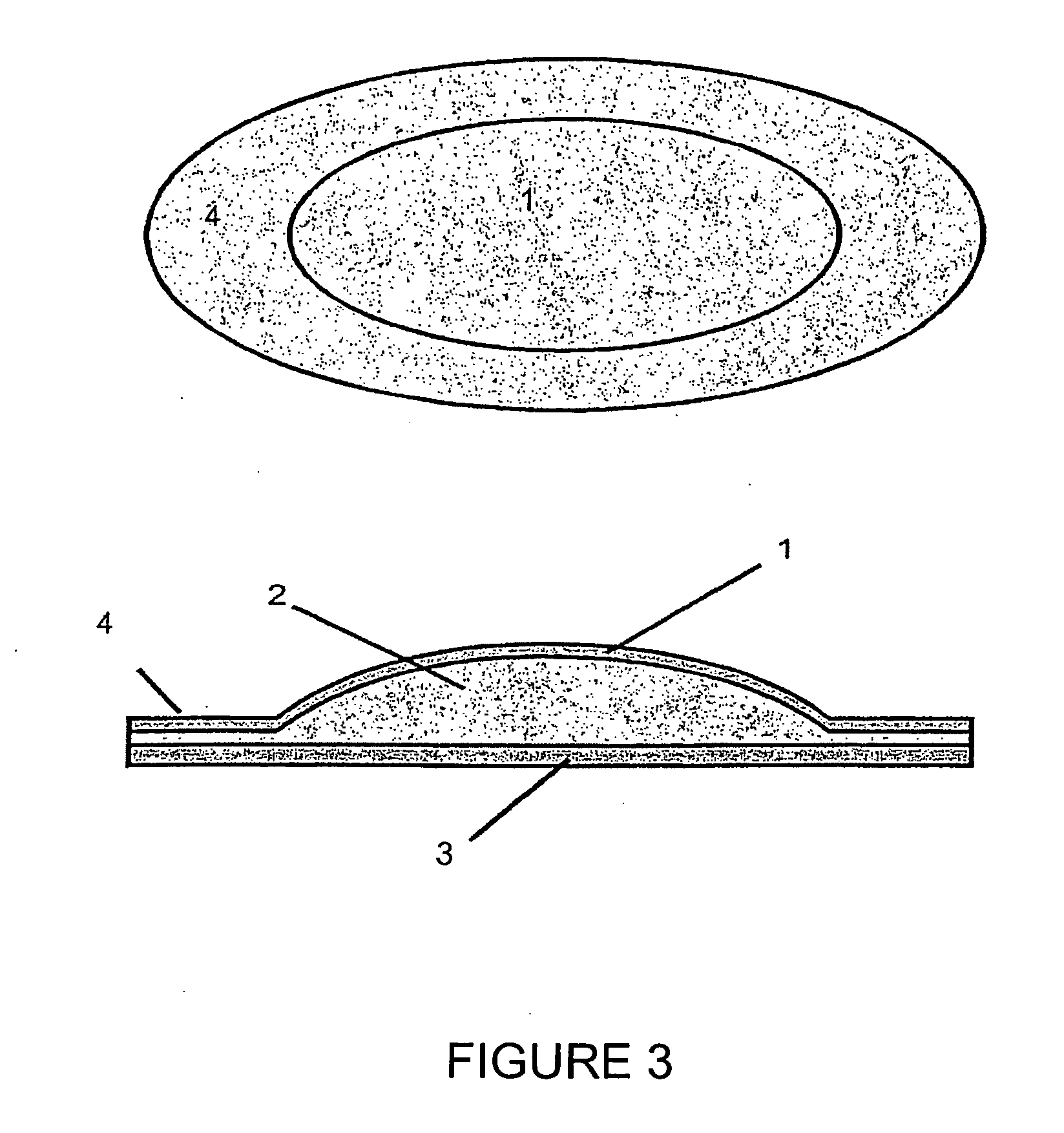

Scar-reducing plaster

The present invention is a scar-reducing plaster and a method for preparing scar-reducing plasters. The scar-reducing plasters comprise a backing film comprising an air- and water vapor-pervious and water-impervious polymer layer, and a breathable and adhesive polyurethane xerogel matrix layer that coats the backing film. The polyurethane xerogel matrix layer includes a central scar contact region and an edge region, wherein the scar contact region merges with the edge region and the thickness of the edge region decreases from the scar contact region to a thickness of from 5 to 150 μm at the edge of the polyurethane xerogel matrix layer. The scar-reducing plasters of the present invention have a reduced tendency to peel off during normal use.

Owner:BEIERSDORF AG

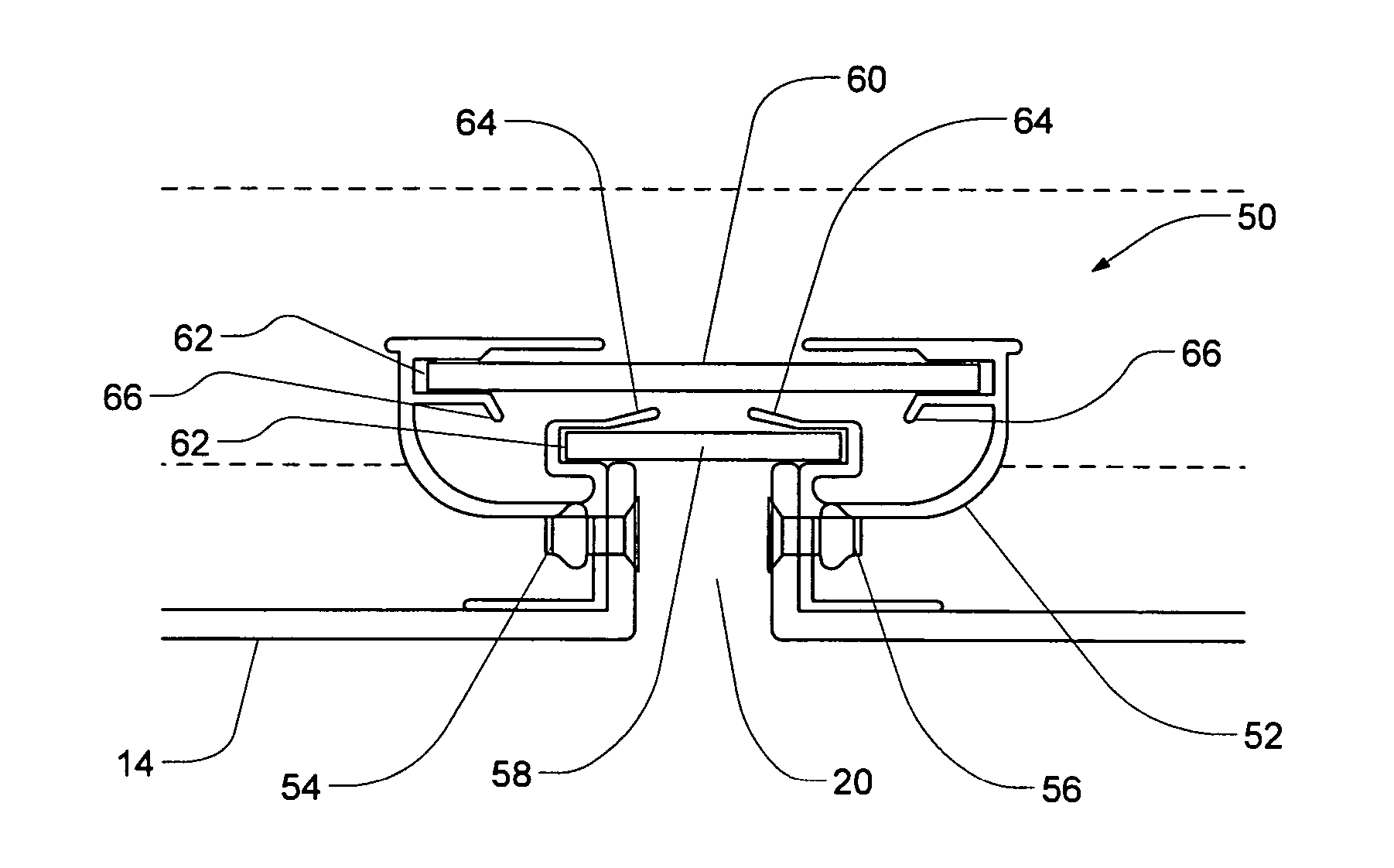

Thermally-isolated anchoring systems for cavity walls

InactiveUS20130247483A1Precludes pin-point loadingPrevent disengagementProtective buildings/sheltersBuilding reinforcementsWater vaporSurface mounting

A high-strength thermally-isolating surface-mounted anchoring system for a cavity wall is disclosed. The thermally-isolated anchoring system is adaptable to varied structures, including high-span applications, and for use with interlocking veneer ties and reinforcement wires. The anchoring system includes an anchor base and a stepped cylinder which sheaths the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The anchoring system is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings. Seals are formed which preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

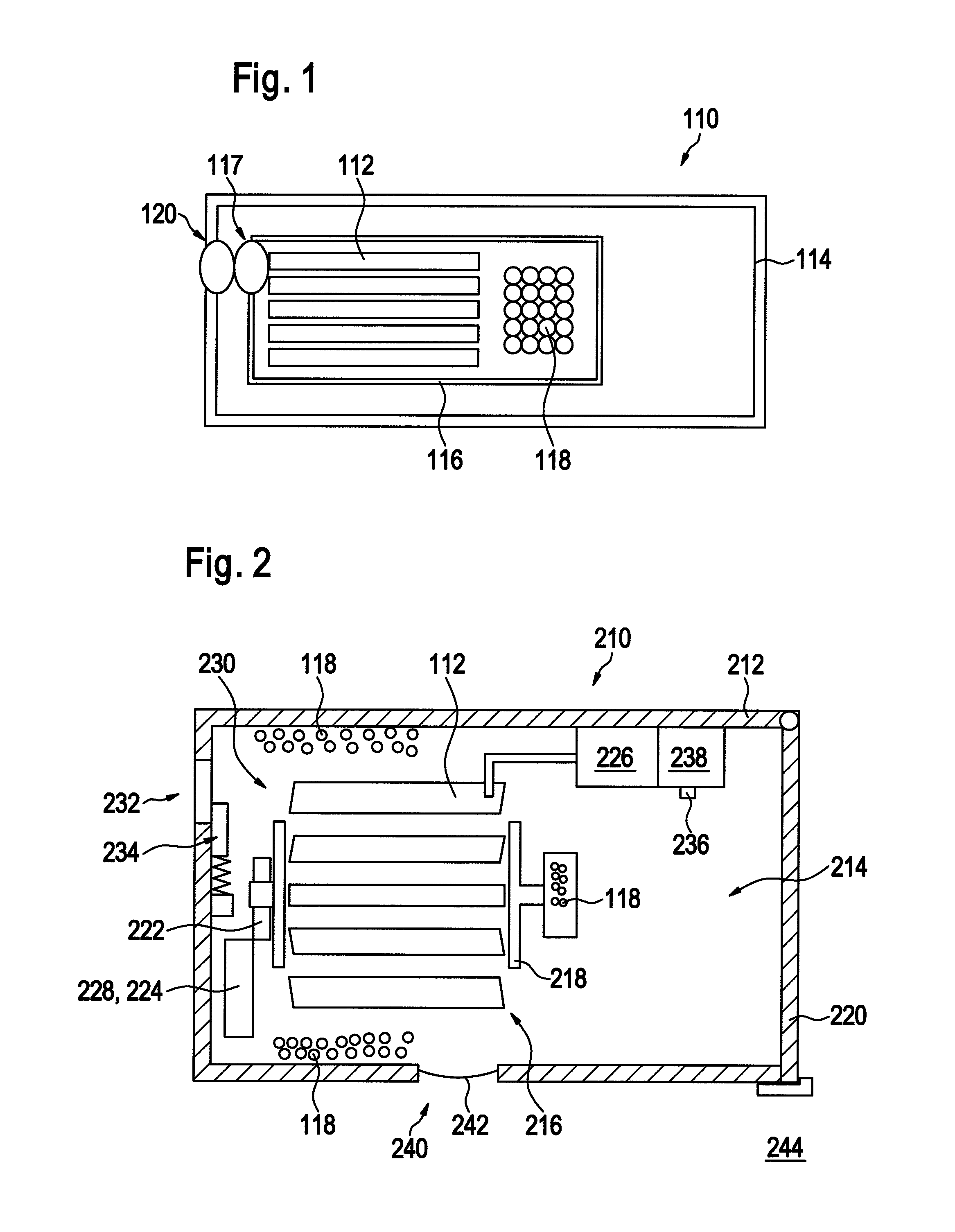

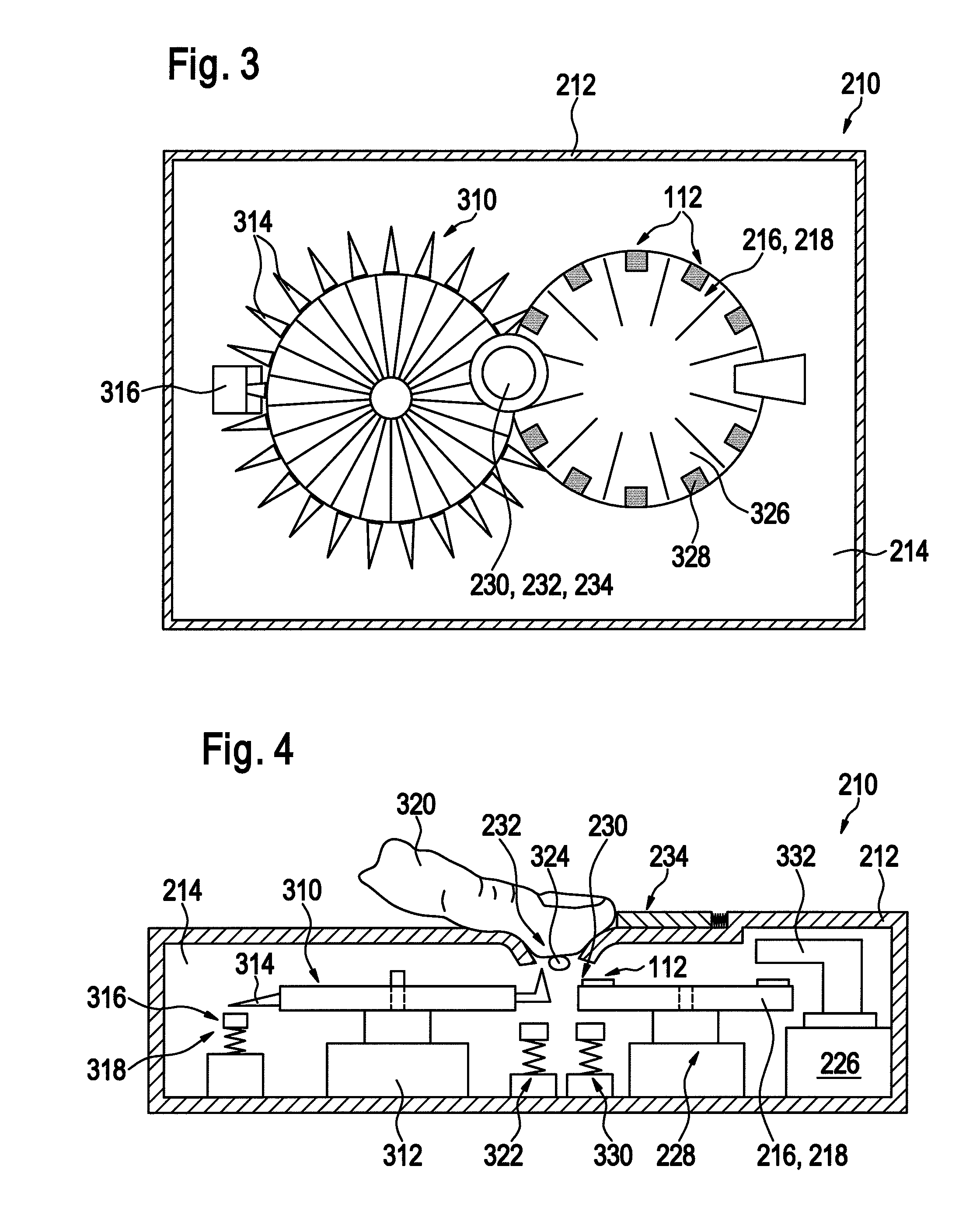

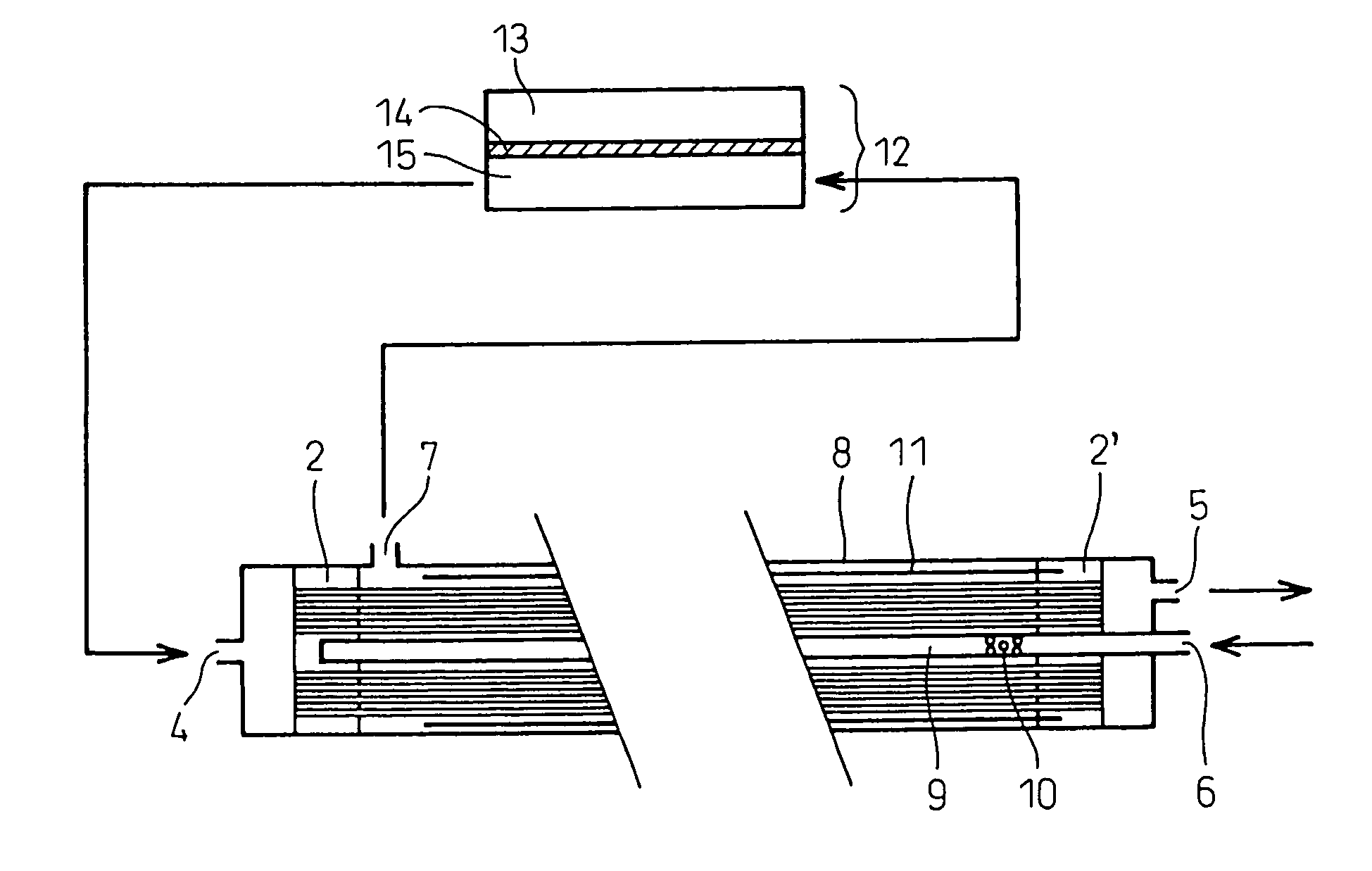

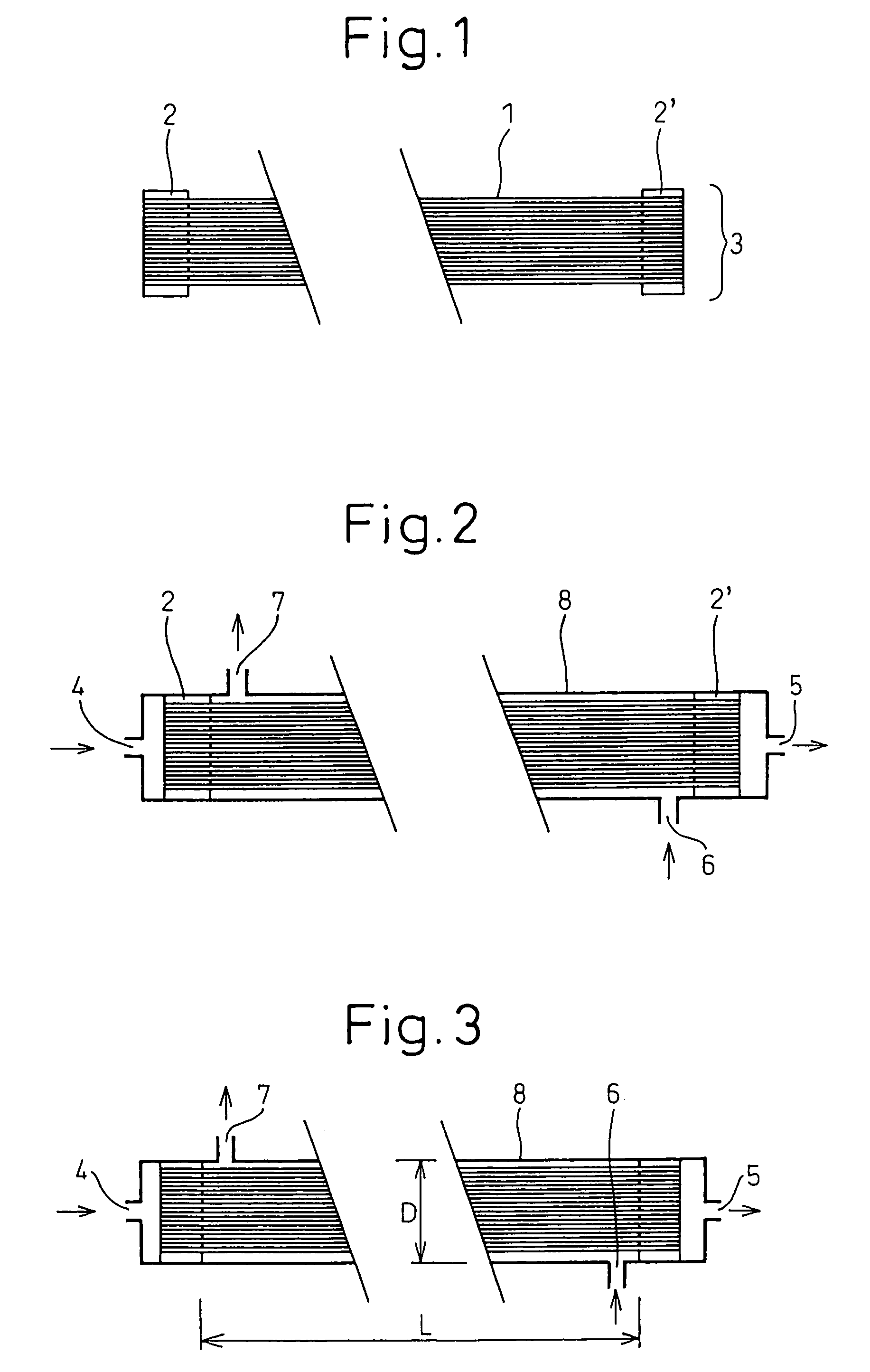

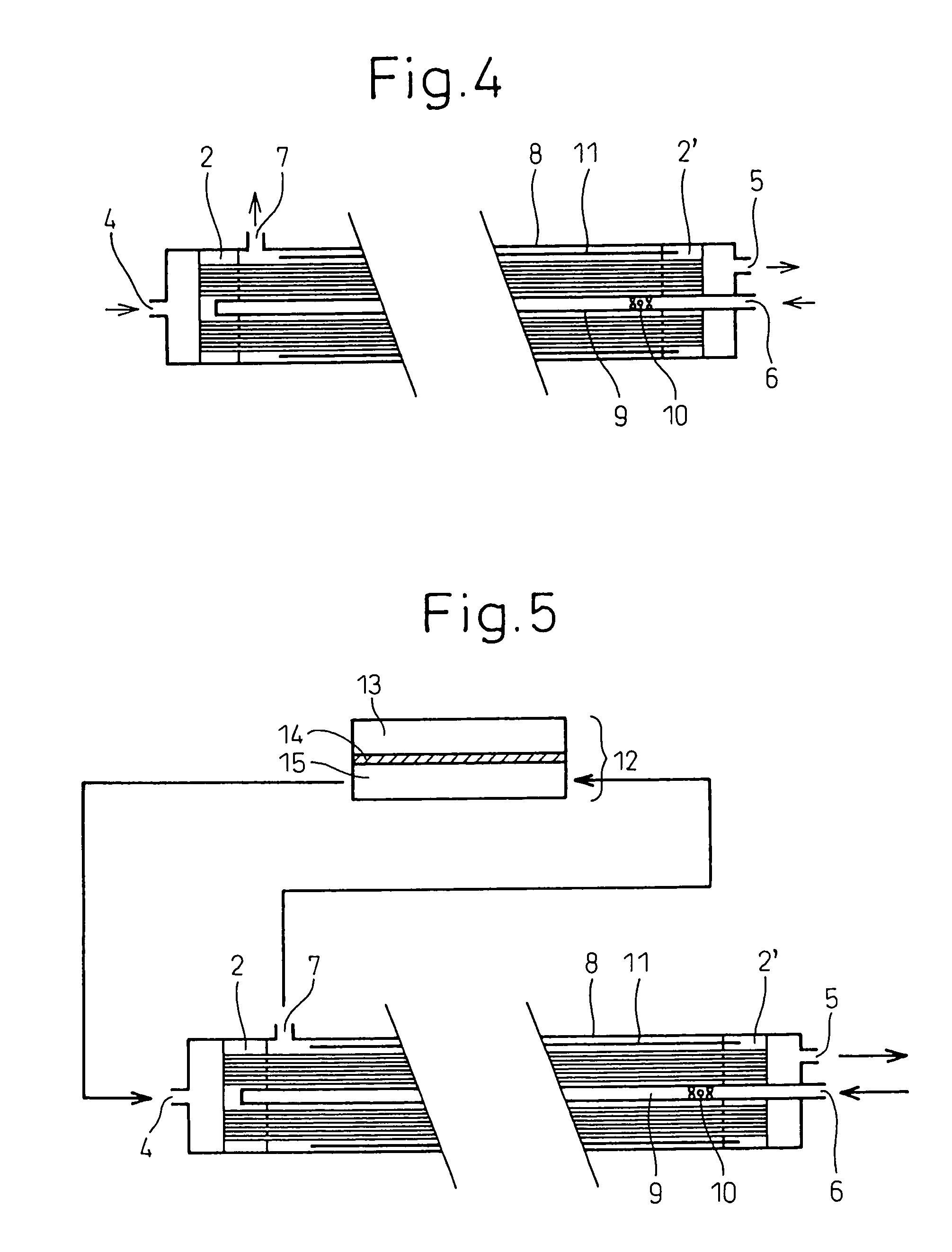

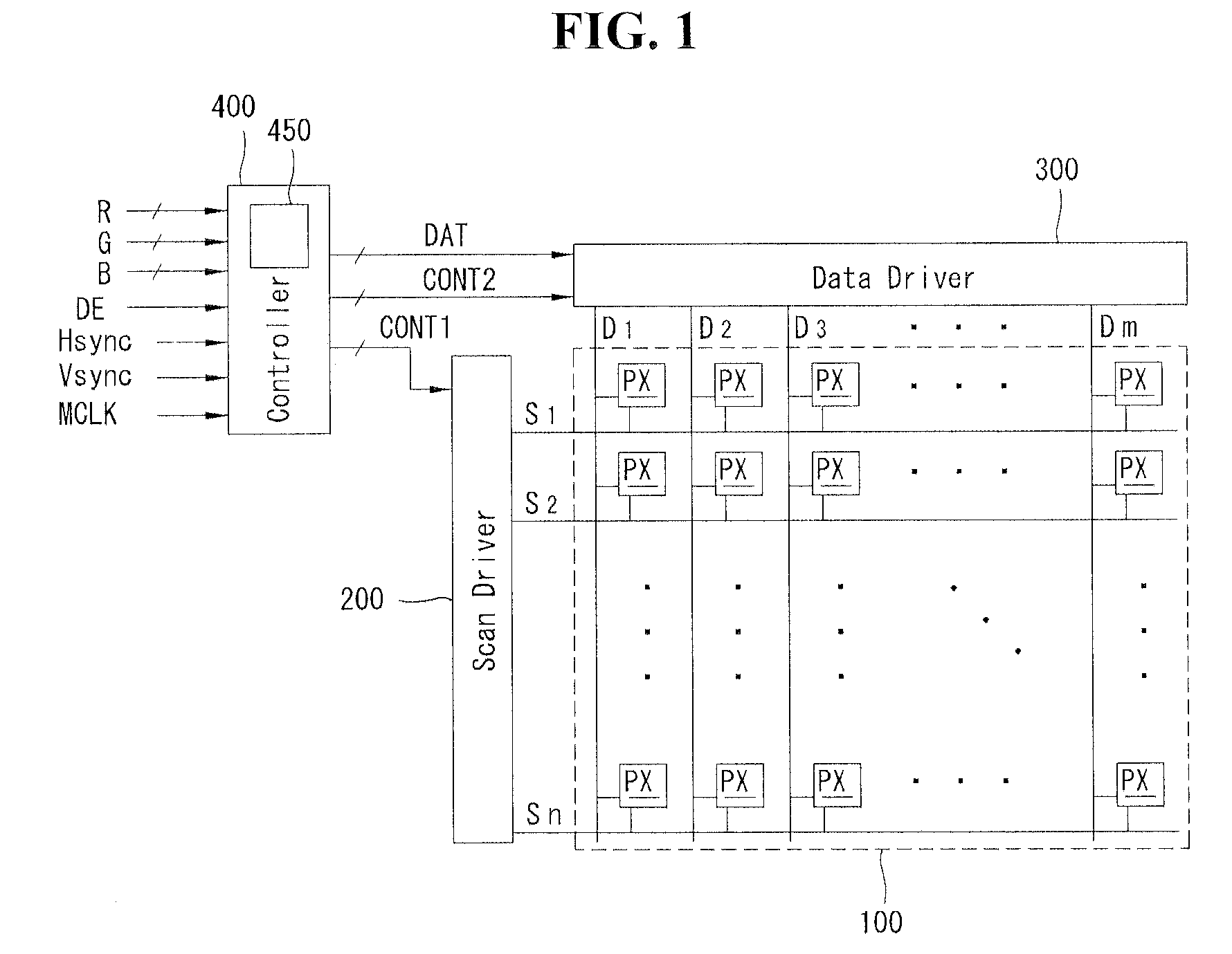

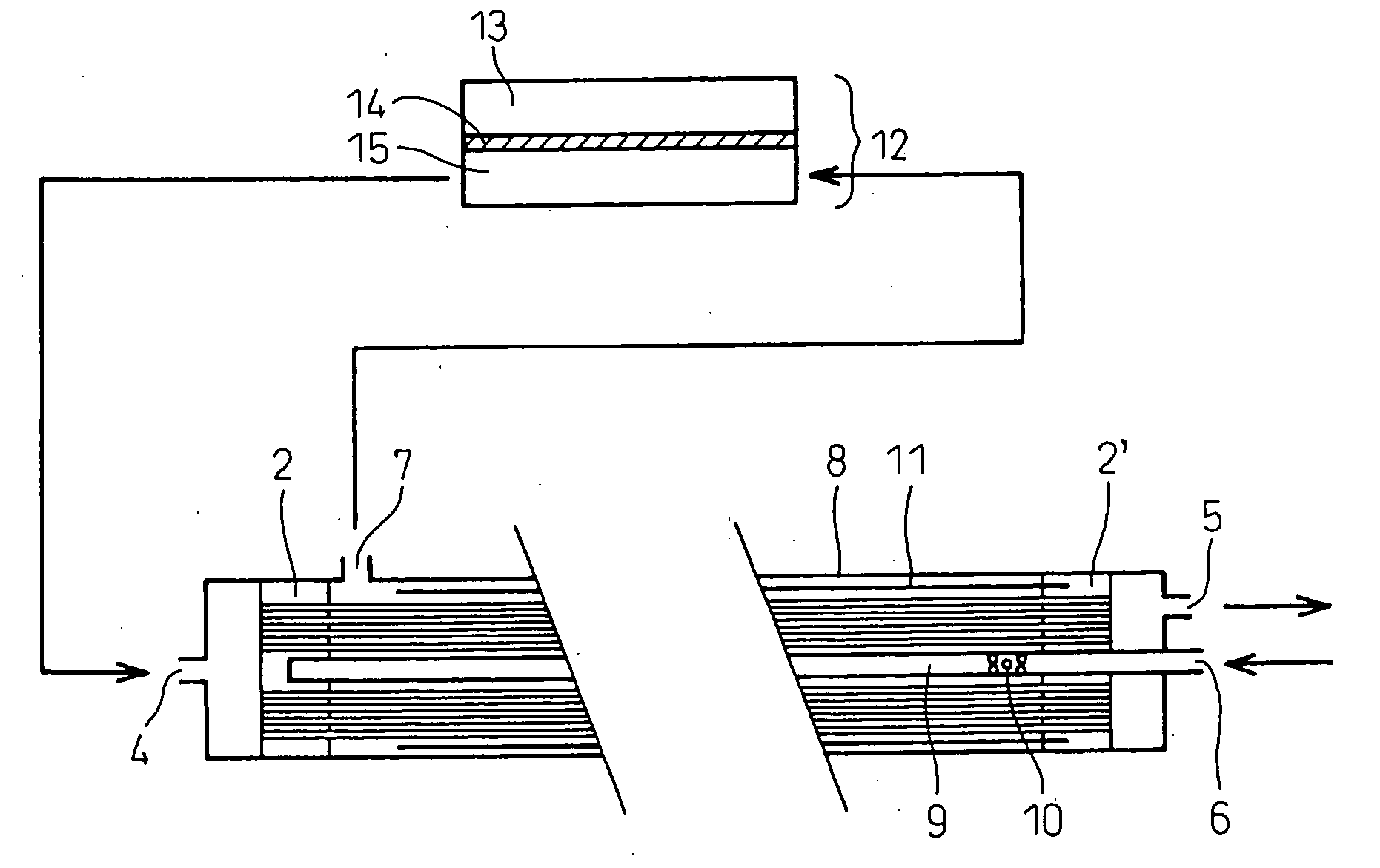

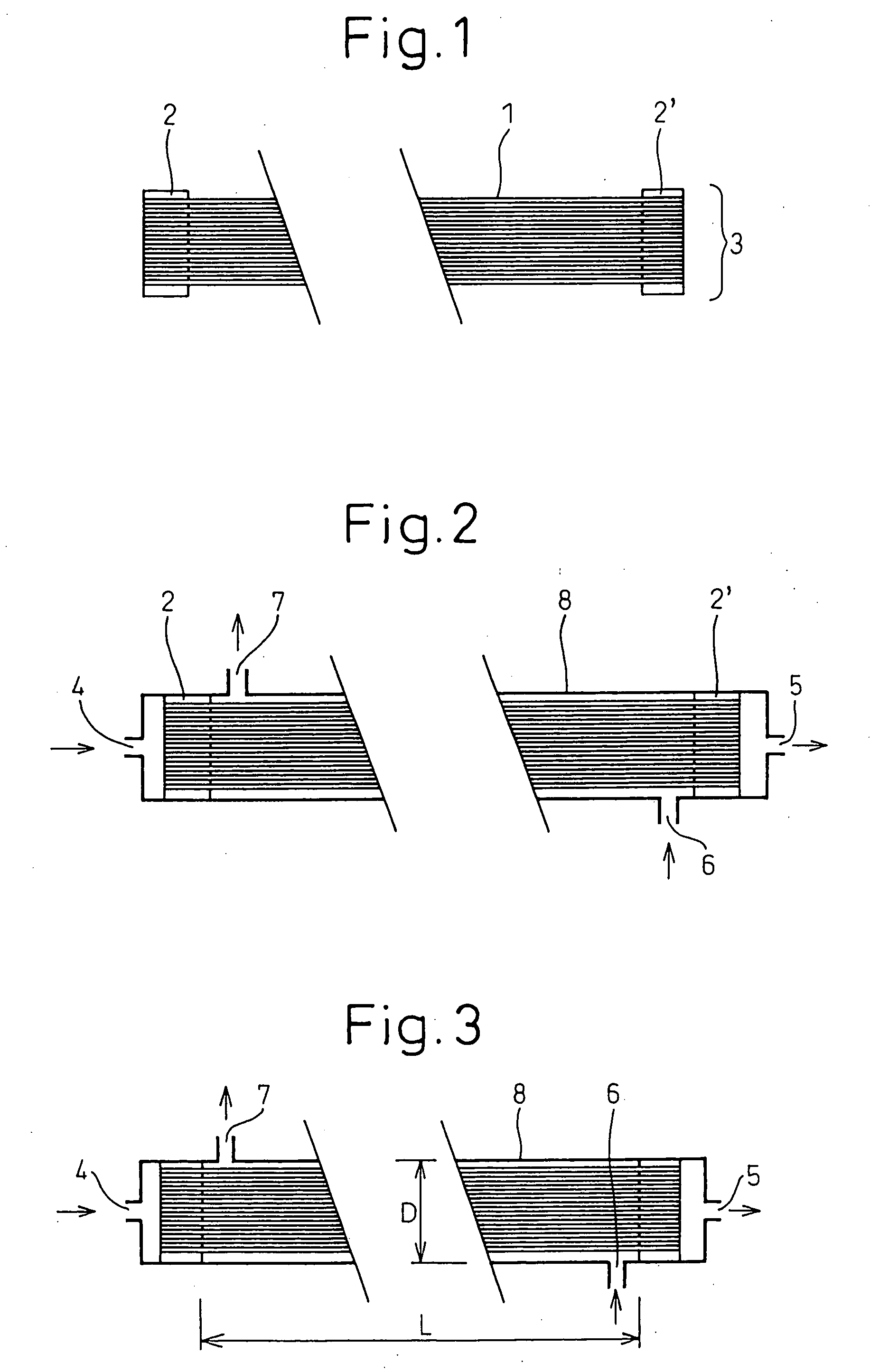

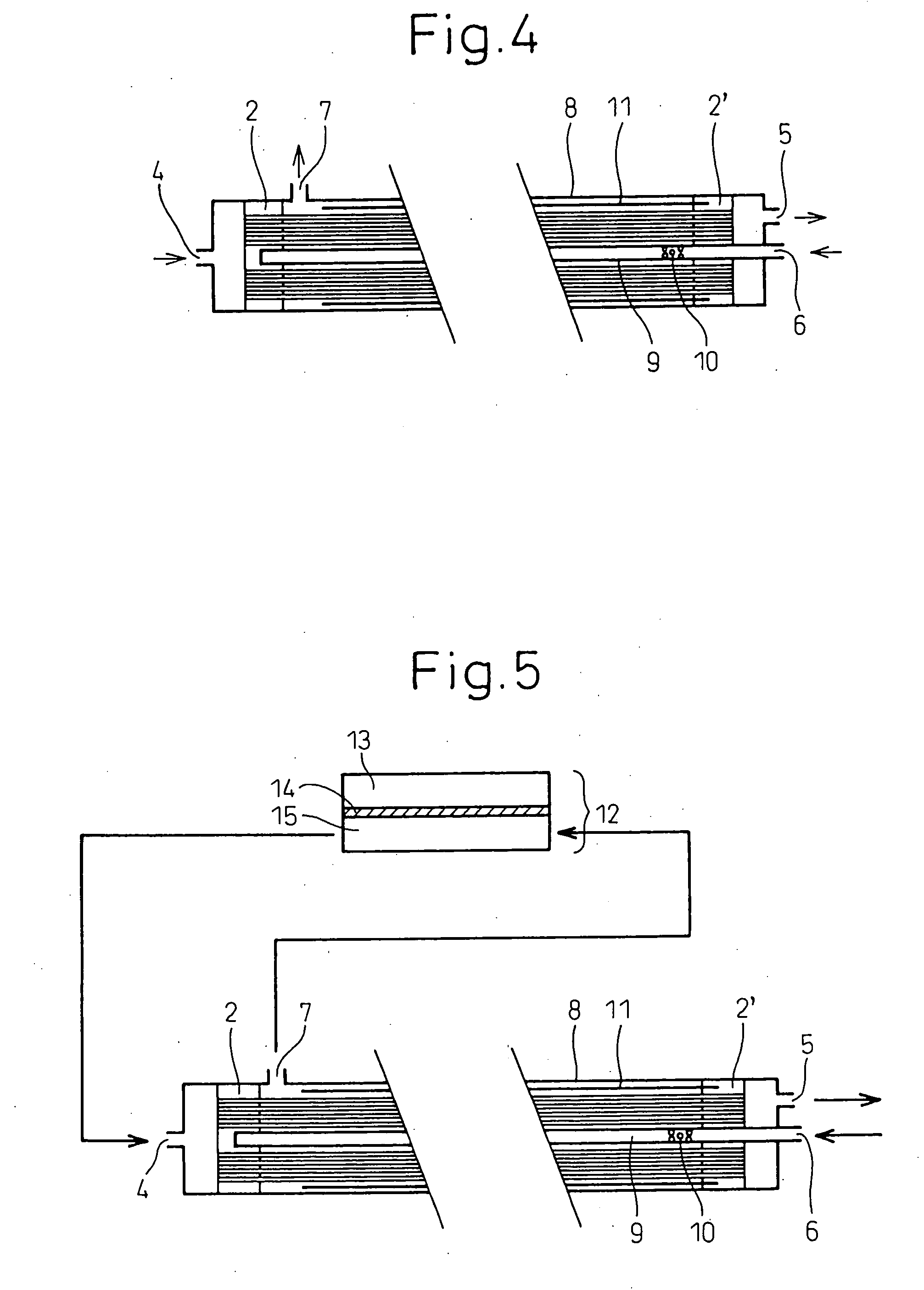

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

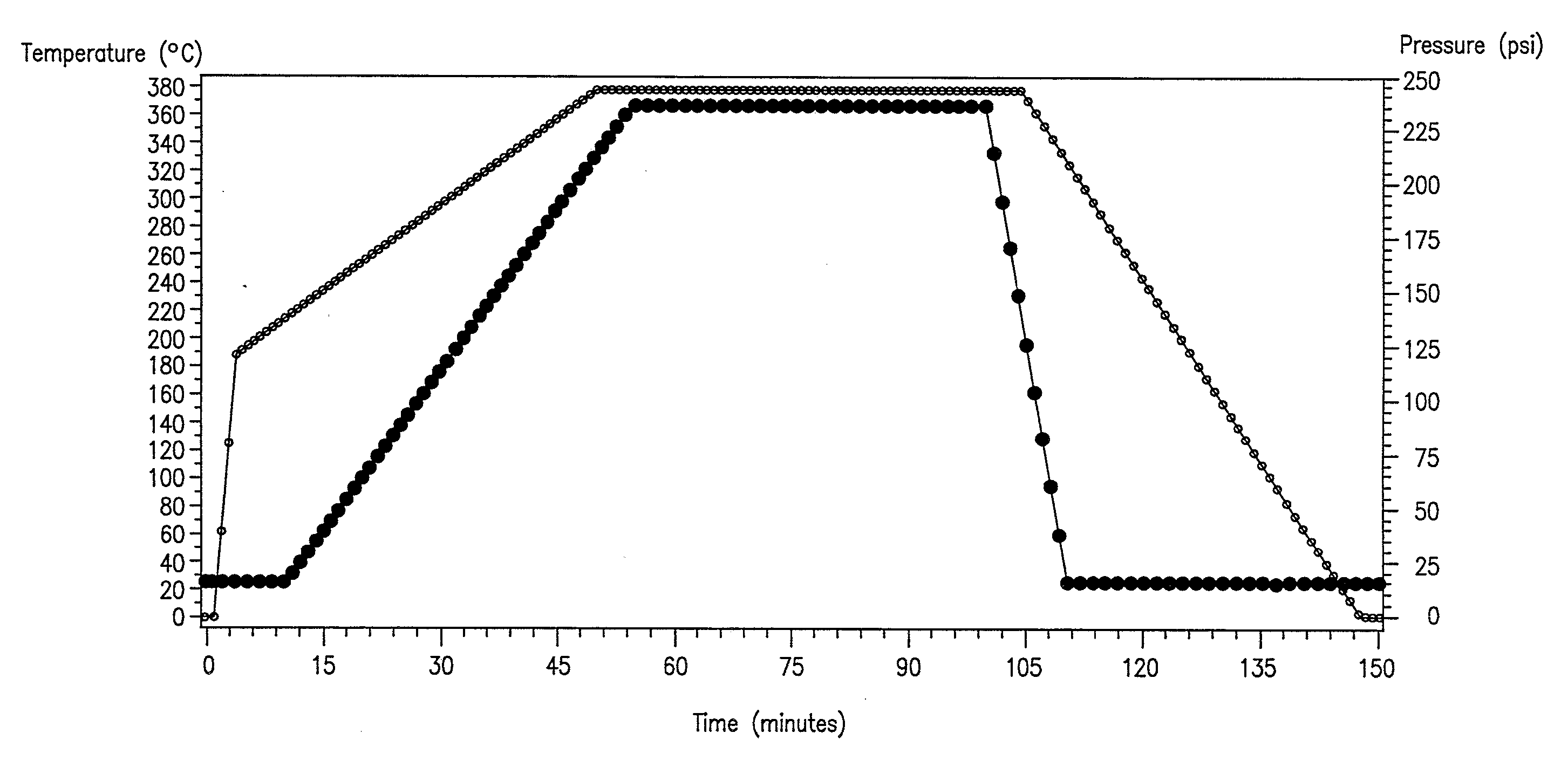

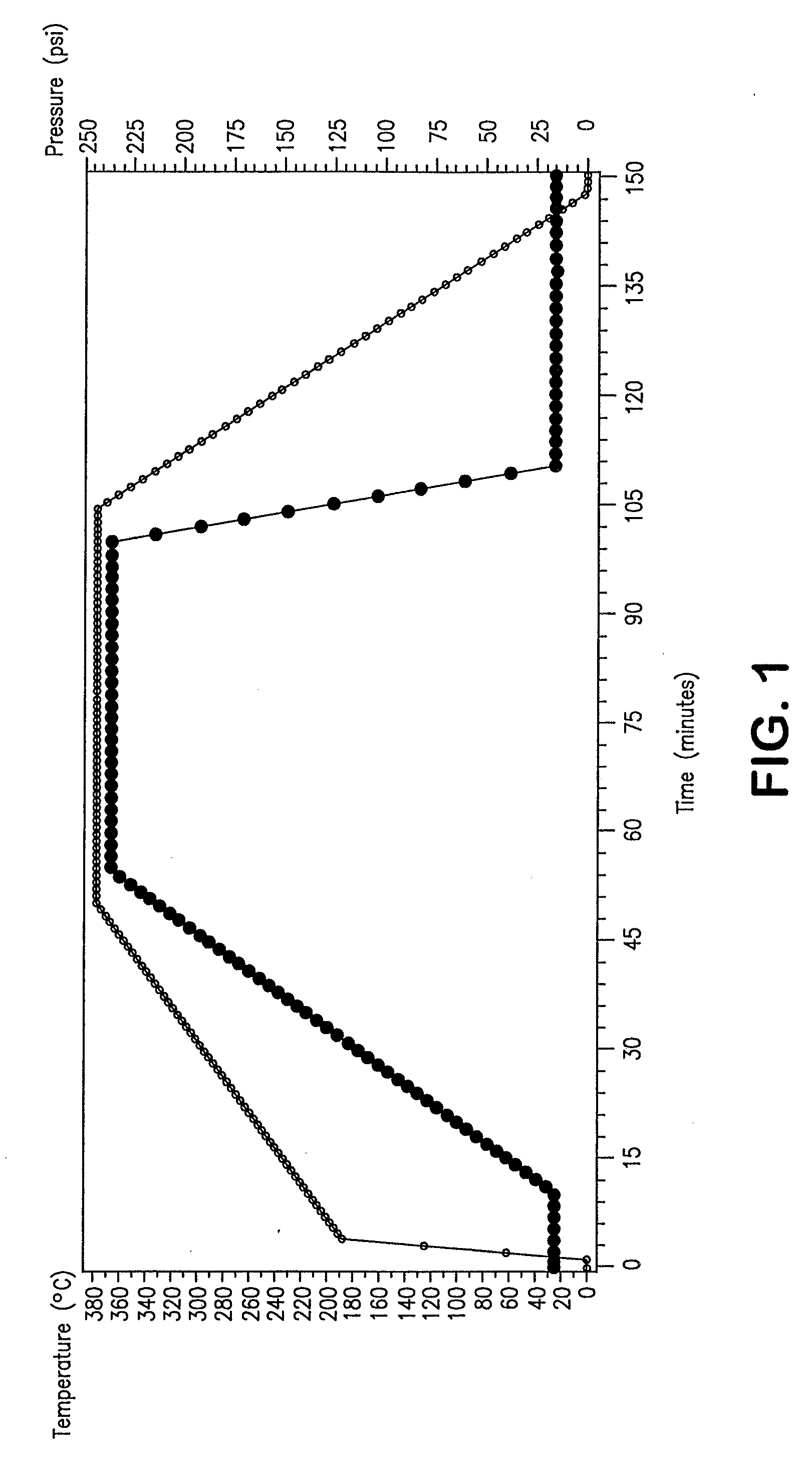

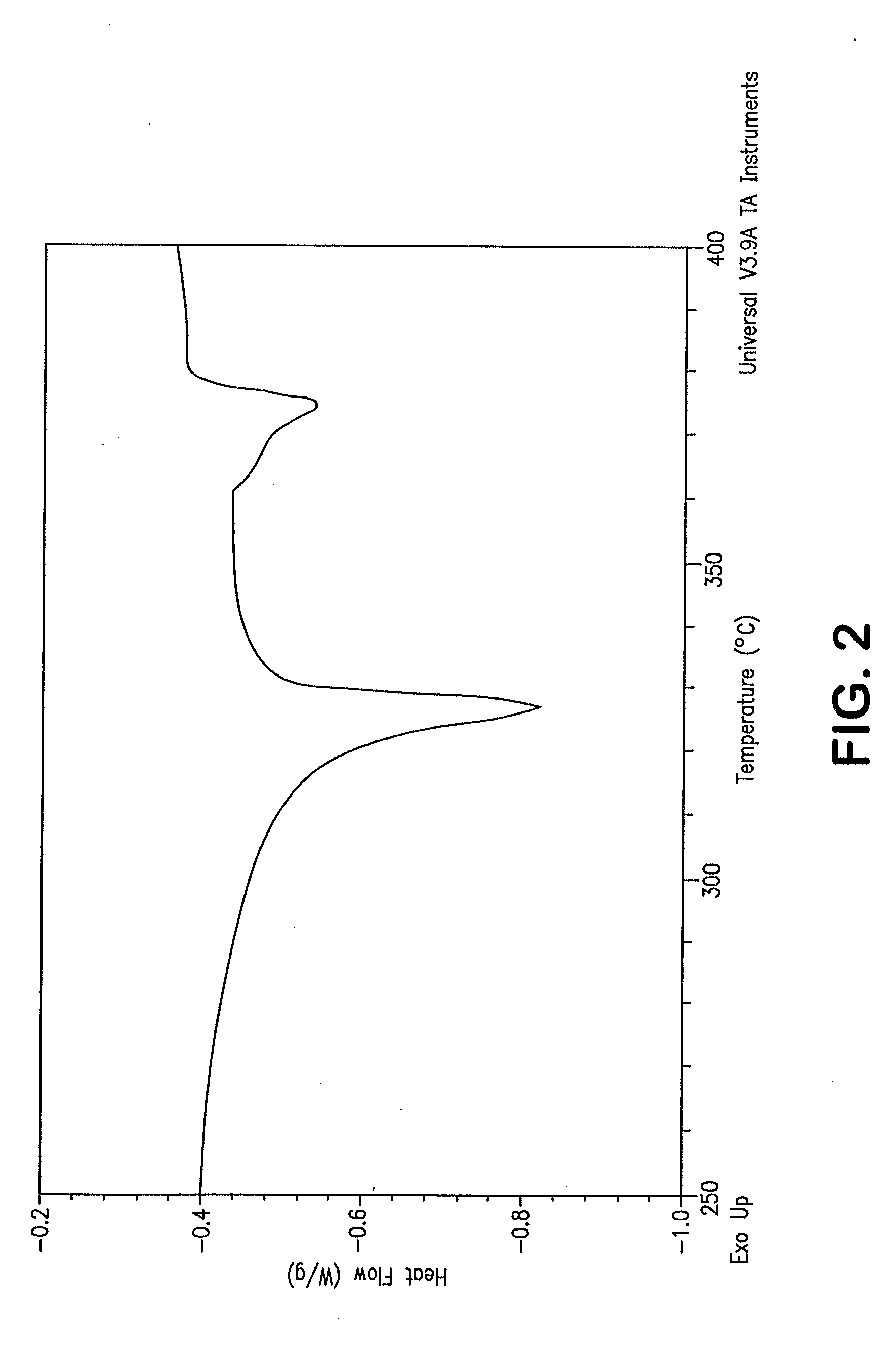

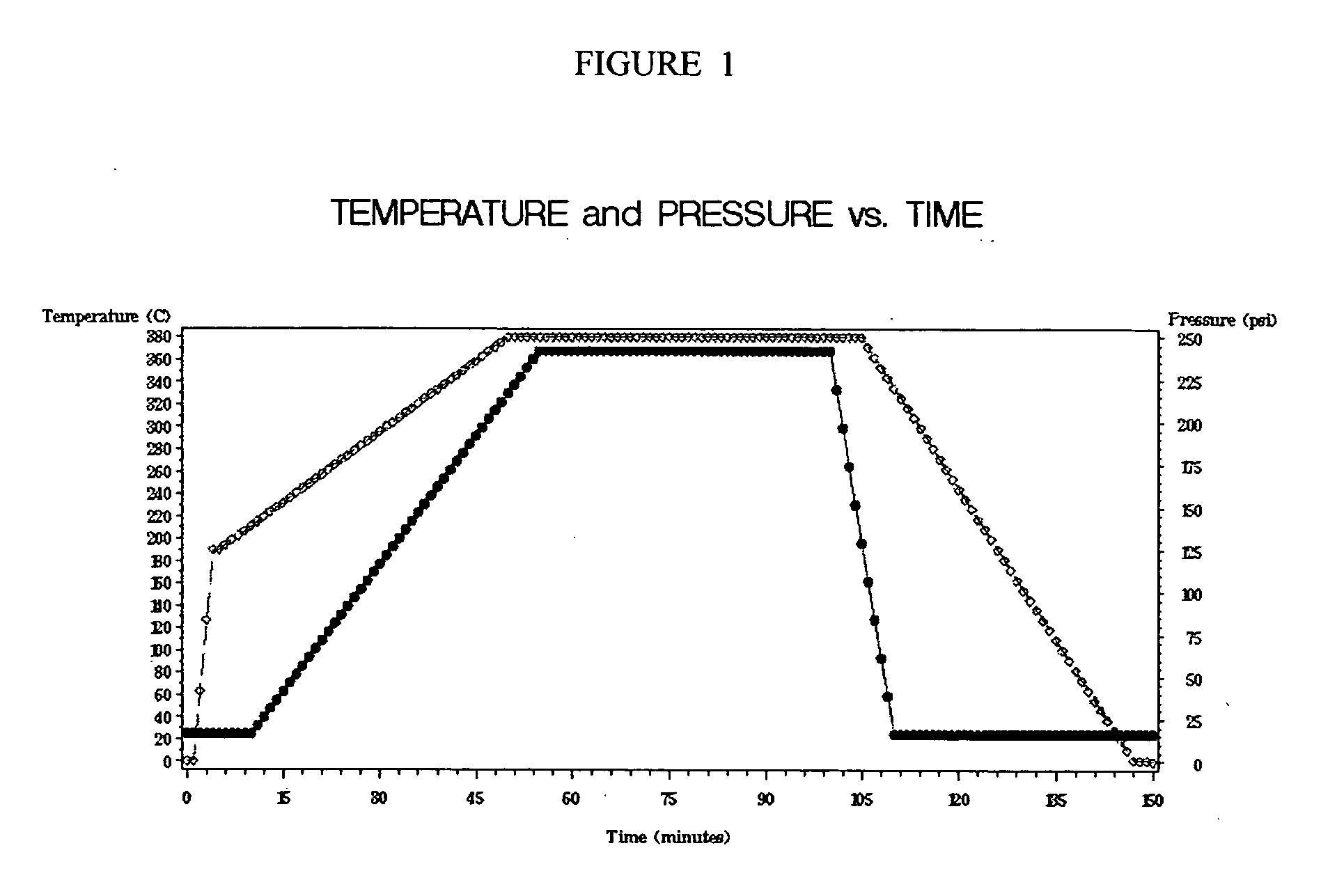

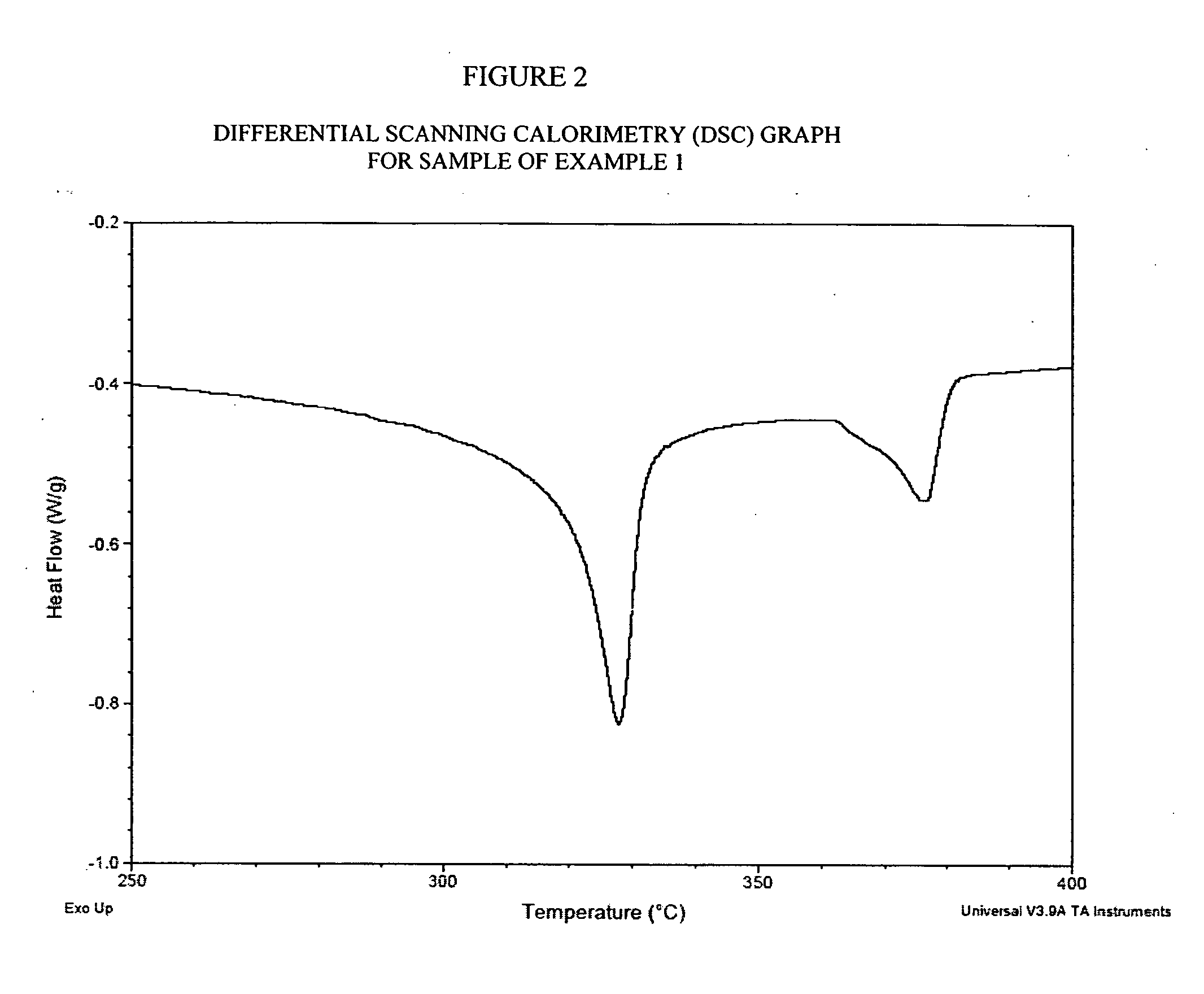

Fluoropolymer Barrier Material

ActiveUS20080061472A1Improve barrier propertiesImprove permeabilitySynthetic resin layered productsCeramic shaping apparatusPolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

Wall panel joint apparatus and system using same

A wall panel joint apparatus and a system using same is disclosed. The wall panel joint includes a perimeter joint body having a predetermined size and shape. The perimeter joint body floatably attaches to at least two wall panels. Embodiments include where the wall panel joint includes zero, one, two, three or more compartments. Also, some embodiments include a rainscreen clip that forms an additional compartment. The system includes at least two wall panel joints that attach the wall panels to an architectural wall. At the point of intersection of the joints, the joints are mitered. The system also includes a wall attachment device and a means for attaching the joint to the wall attachment device. The system is a liquid water impermeable, air permeable and water vapor permeable system, providing a ventilated, waterproof wall panel attachment joints for use in same.

Owner:LYMO CONSTR

Thermally isolating tubule for wall anchor

ActiveUS20120308330A1Prevent disengagementPrevent water penetrationConstruction materialWashersSurface mountingWater vapor

A tubule assembly for thermally isolating a surface-mounted wall anchor and an anchoring system employing the same are disclosed. The thermally-isolated tubule assembly is adaptable to varied anchor structures and for use with interlocking veneer ties and reinforcement wires to provide a high-strength surface mounted anchoring system for cavity walls. The stepped cylinders sheath the mounting hardware to limit insulation tearing and resultant loss of insulation integrity. The tubule assembly is thermally-isolated through the use of a series of strategically placed compressible nonconductive fittings and set within the perimeter of the anchor base. Seals are formed which preclude penetration of air, moisture, and water vapor into the wall structure.

Owner:HOHMANN & BARNARD INC

Fluoropolymer barrier material

InactiveUS20050238872A1Improve barrier propertiesImprove permeabilitySynthetic resin layered productsRecord information storagePolymer scienceWater vapor permeability

A novel densified fluoropolymer article is described which has a water vapor permeation of about 0.015 g-mm / m2 / day or less, and preferably has a matrix tensile strength of at least 10,000 psi in two orthogonal directions. The articles are made by compressing expanded porous PTFE at pressures, temperatures and times which result in elimination of the pores, and subsequent stretching above the crystalline melt temperature.

Owner:WL GORE & ASSOC INC

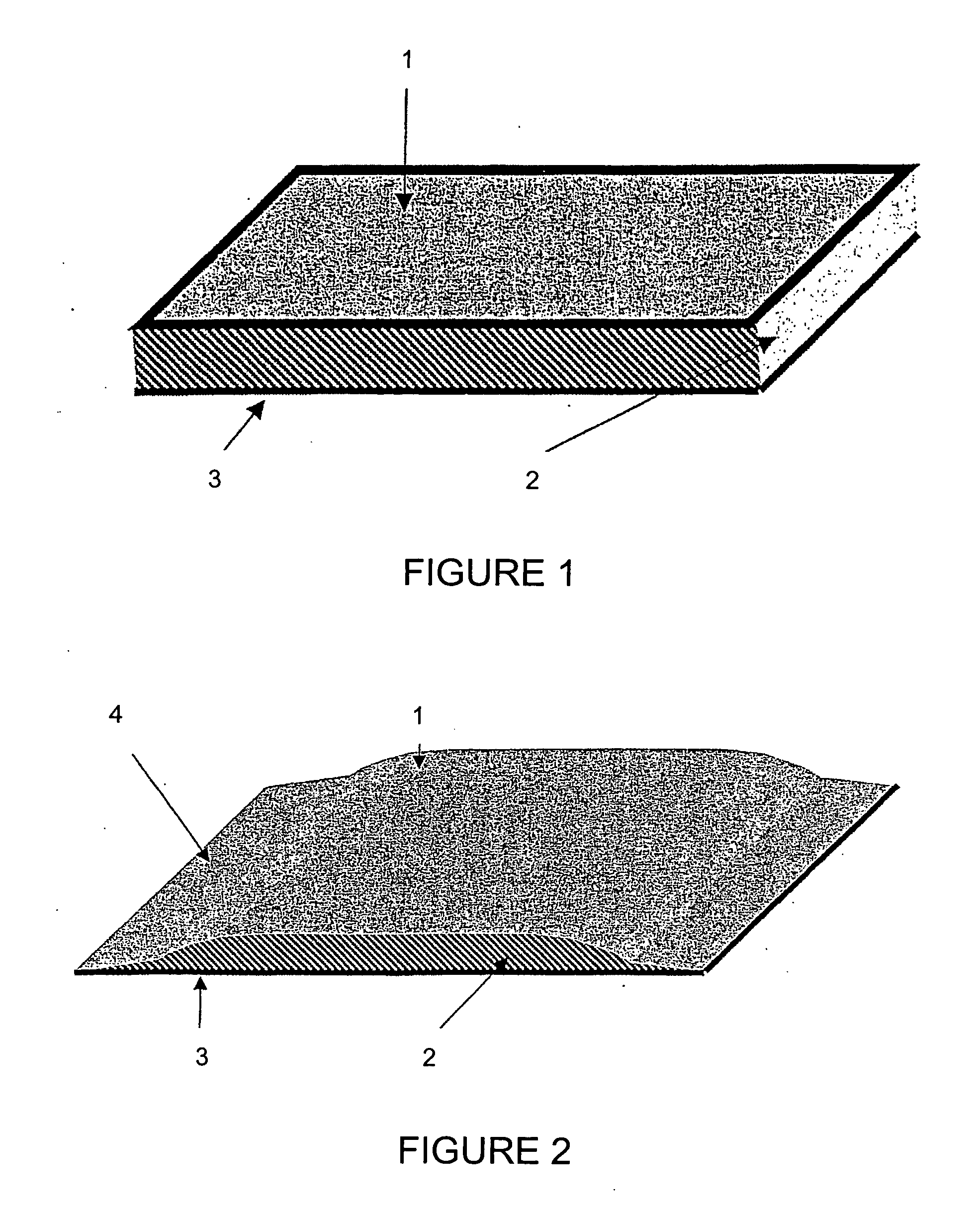

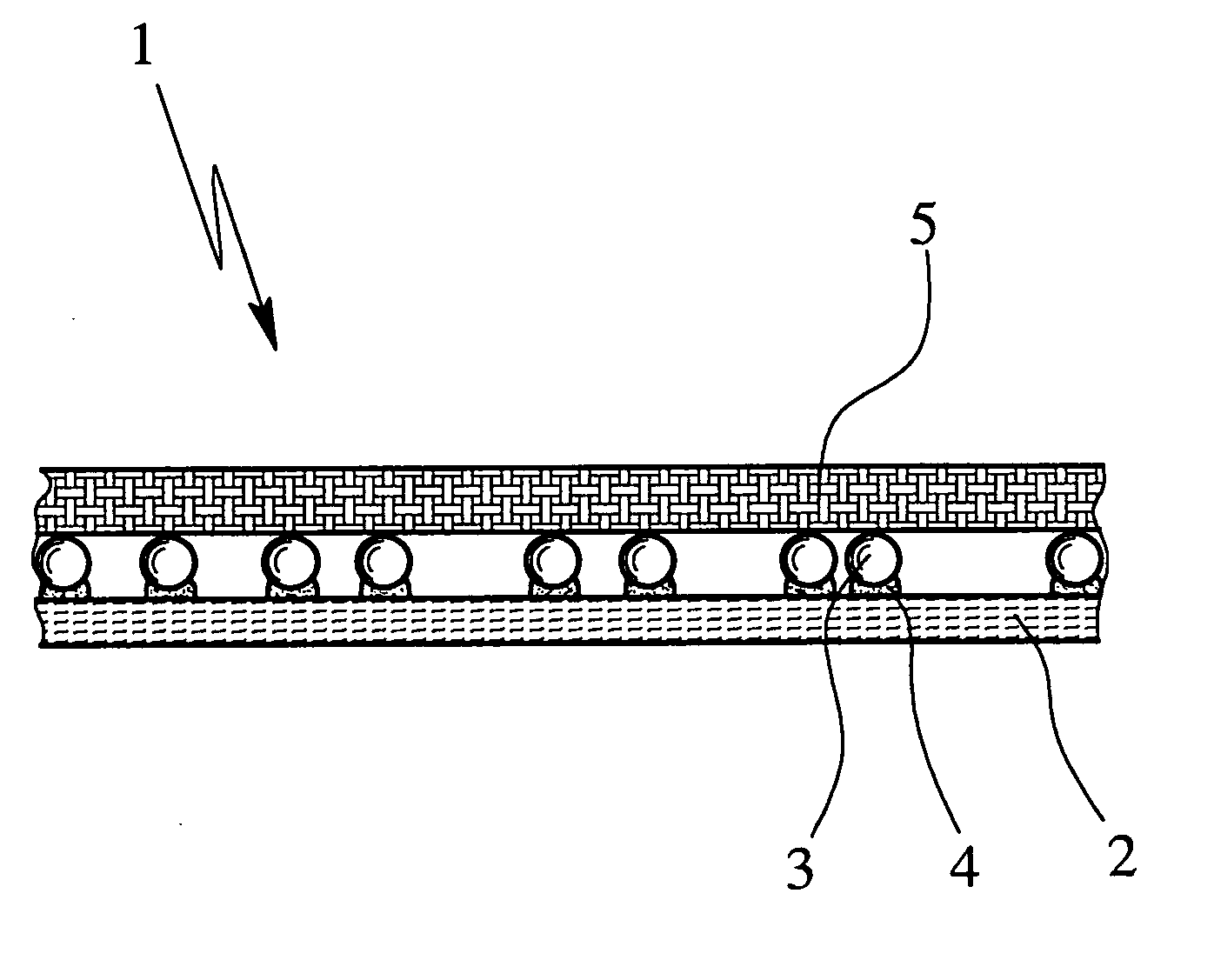

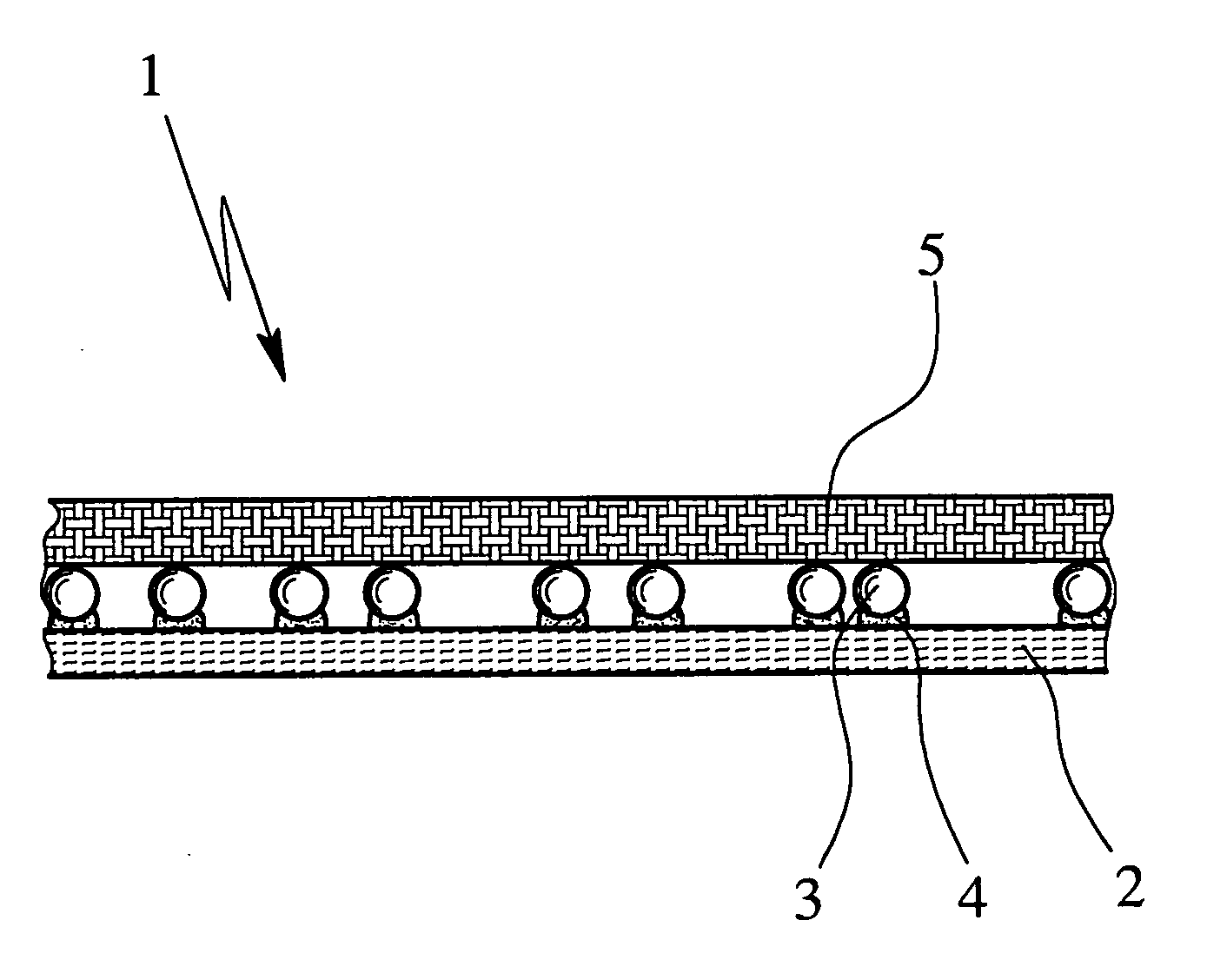

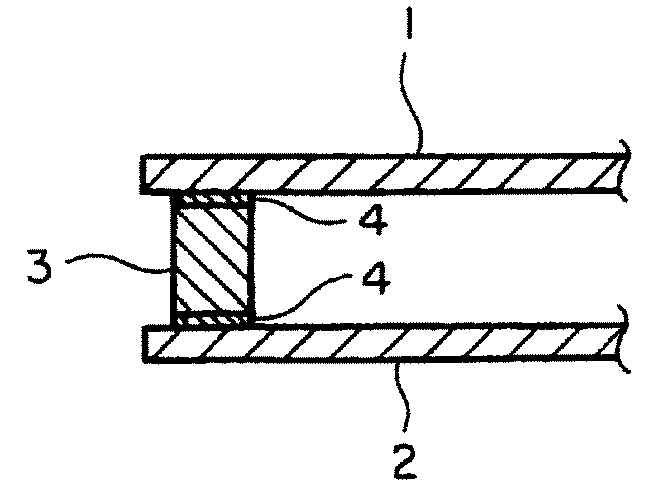

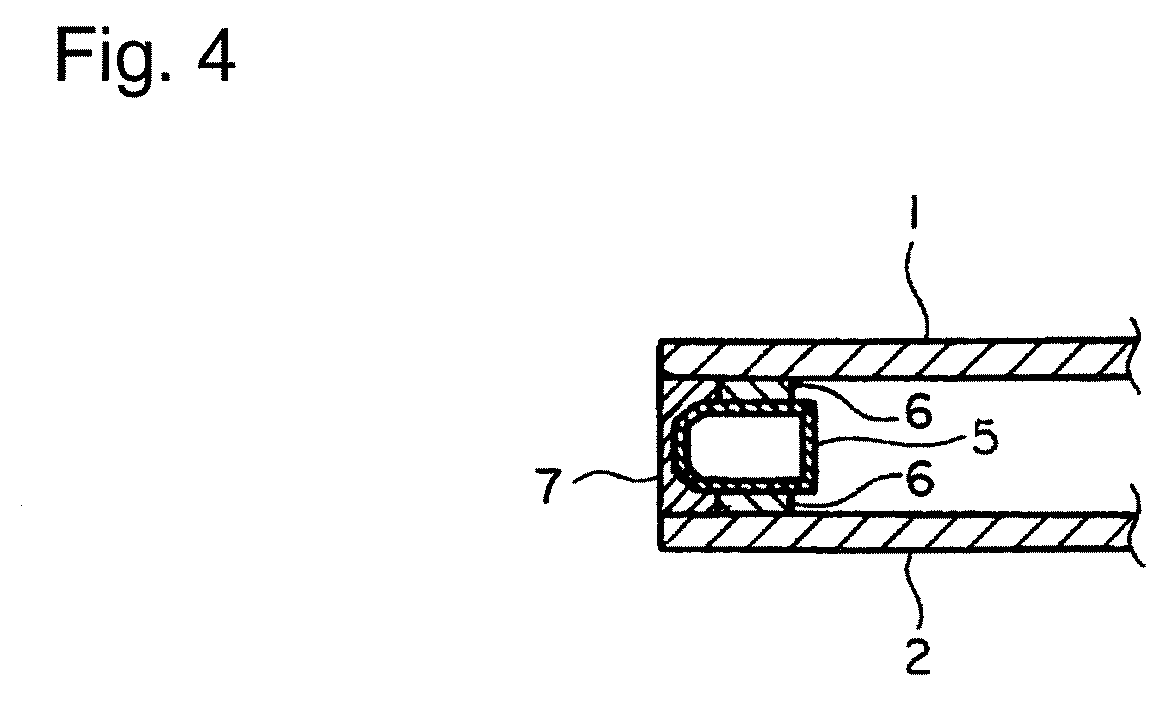

Functional textile material provided with microcapsules containing an active ingredient and use thereof

InactiveUS20070065658A1Reduce basis weightIncrease flexibilityMedical devicesDomestic netsAdhesiveWater vapor permeability

The subject of the invention is a functional textile material (1), wherein the functional textile material (1) comprises a textile backing (2) in the form of a two-dimensional textile formation, and the textile backing (2) is provided with microcapsules (3), which contain at least one active ingredient, and the microcapsules (3) are secured to the textile backing (2) by means of an adhesive (4) applied discontinuously to the textile backing (2). In this way, one obtains a functional textile material (1) with high air-permeability and high water vapor-permeability at reduced basis weight, which material can be used in particular for making functional clothing.

Owner:BLUCHER GMBH

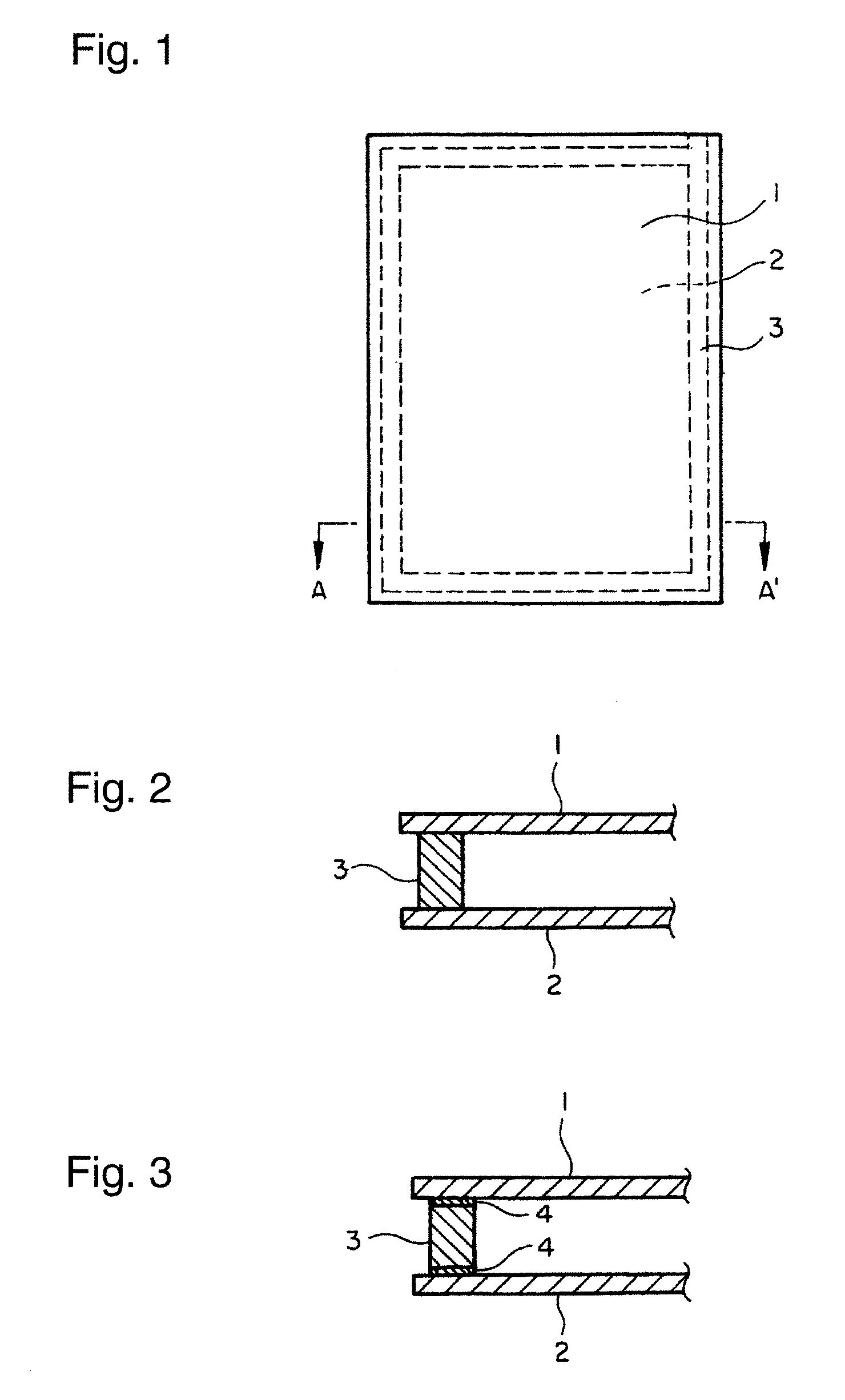

Single-sealed multilayer transparent unit

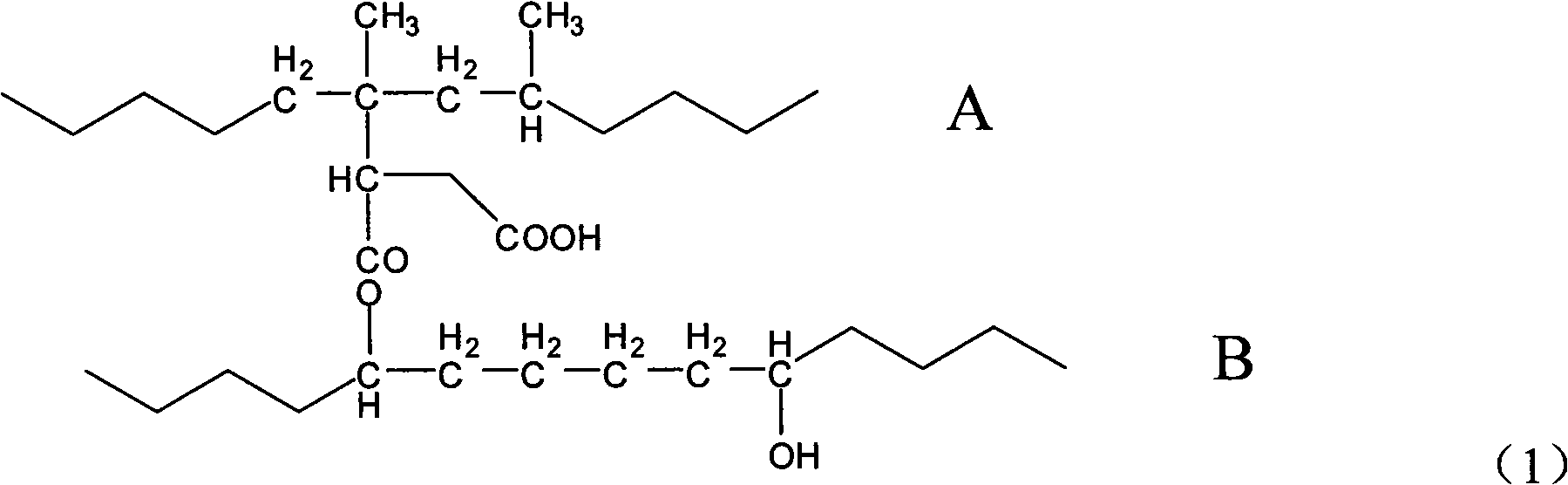

InactiveUS20070122572A1Reduce creepGood shape retentionDoors/windowsRubber layered productsElastomerPolyolefin

To provide a single-sealed multi-layer transparent unit, particularly a double-glazing unit, excellent in shape retention and water vapor permeation resistance. In a single-sealed multi-layer transparent unit, particularly a double-glazing unit, wherein only an elastomer spacer is used, said elastomer spacer contains, as the matrix component, at least one butyl elastomer component selected from the group consisting of polyisobutylene, butyl rubber and modified butyl rubber; Molecular Weight Index (MWI) of the butyl elastomer component represented by the following formula (1) is at least 400,000: MWI=Σ(Mw(i)×(mass % of the i-th butyl elastomer component based on the total amount of all butyl elastomer components / 100)) (1) (wherein i is an integer of at least 1 representing the number of types of butyl elastomer components contained as the matrix component in the elastomer spacer, and Mw(i) represents the viscosity-averaged molecular weight of the i-th butyl elastomer component); and the elastomer spacer contains no crystalline polyolefin or less than 2 mass % of crystalline polyolefin.

Owner:ASAHI GLASS CO LTD

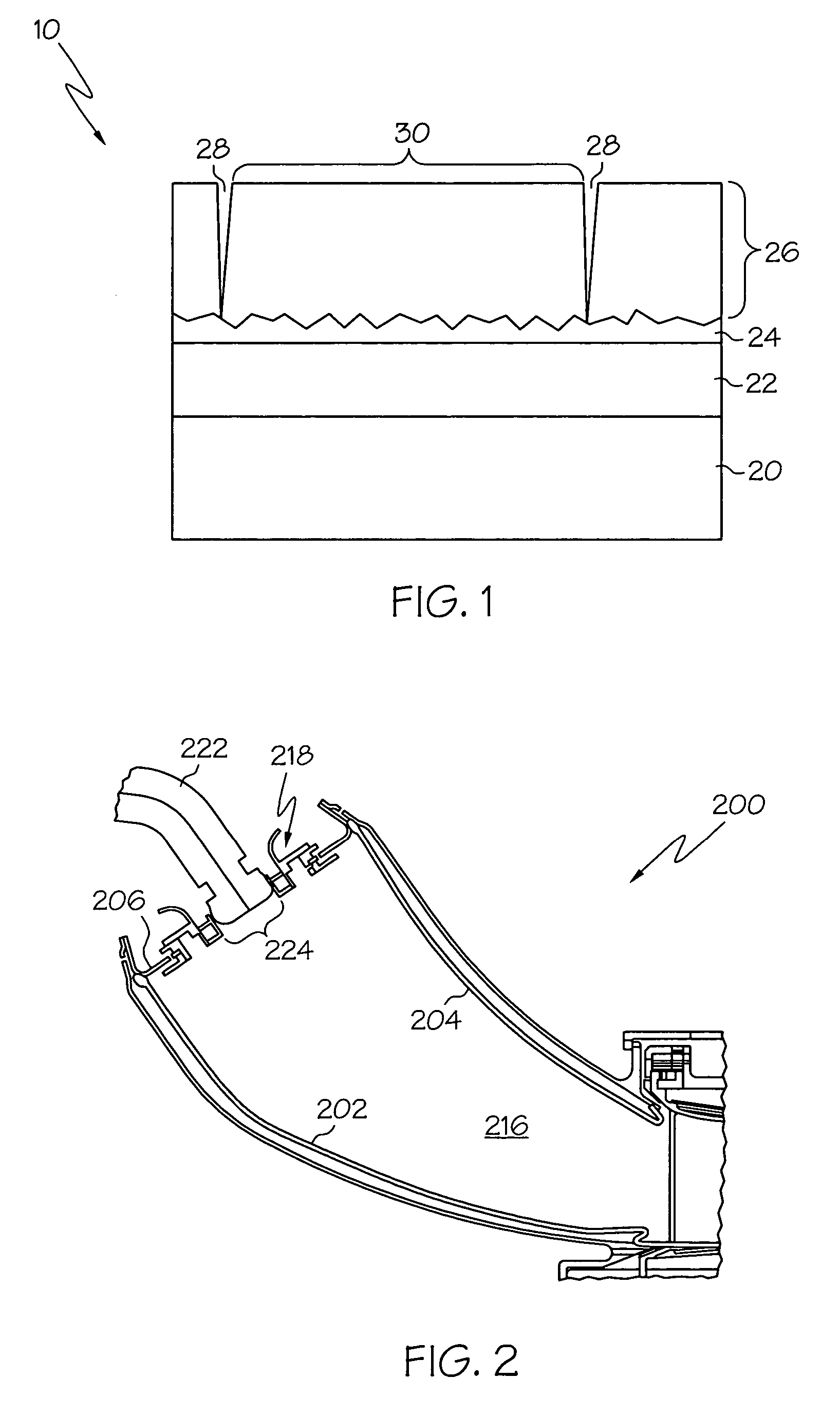

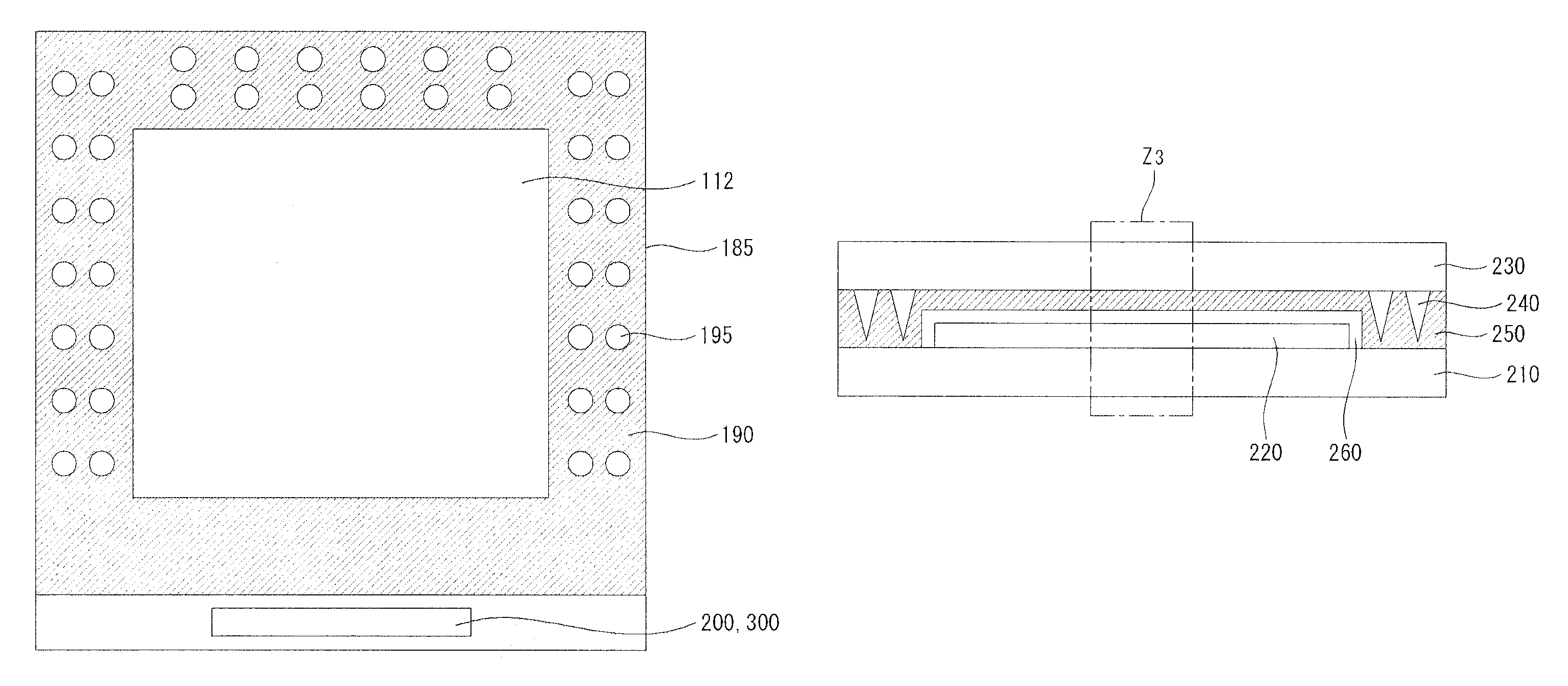

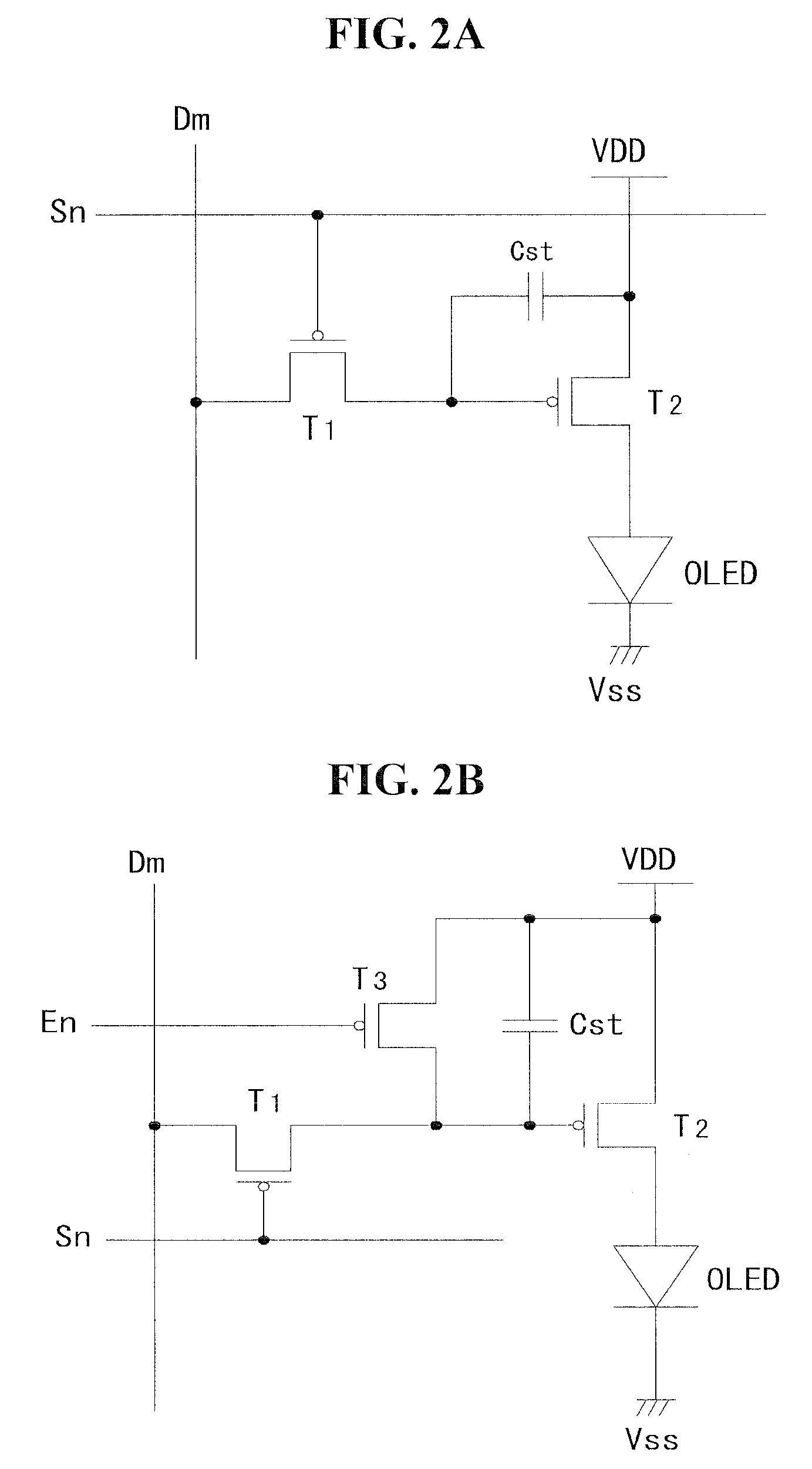

Organic light emitting device

ActiveUS7652424B2Increasing life-span and reliabilityDischarge tube luminescnet screensElectroluminescent light sourcesWater vapor permeabilityOrganic light emitting device

An organic light emitting device is disclosed. The organic light emitting device includes a first substrate, a display unit that is positioned on the first substrate and includes a plurality of subpixels, a second substrate facing the first substrate, a seal member attaching the first substrate to the second substrate, and at least one projection. The seal member substantially has a water vapor permeation rate of 100 g / m2 day to 103 g / m2 day. The projection is positioned at a location corresponding to a bezel area of at least one of the first and second substrates.

Owner:LG ELECTRONICS INC

Building structures containing external vapor permeable foam insulation

InactiveUS20100313507A1High standardAvoid dangerConstruction materialWallsWater vapor permeabilityWater vapor

Attach a thermoplastic polymeric foam to multiple spaced apart structural support members of a structure wherein the foam has a resistance to water vapor permeability (mu) that is less than 50, a thermal conductivity that is less than 40 milliwatts per meter*Kelvin, a compressive strength that is greater than 80 kilopascals, and a density of 48 kilograms per cubic meter or less to provide insulation while also providing water vapor-permeability and structural durability to the structure.

Owner:DOW GLOBAL TECH LLC

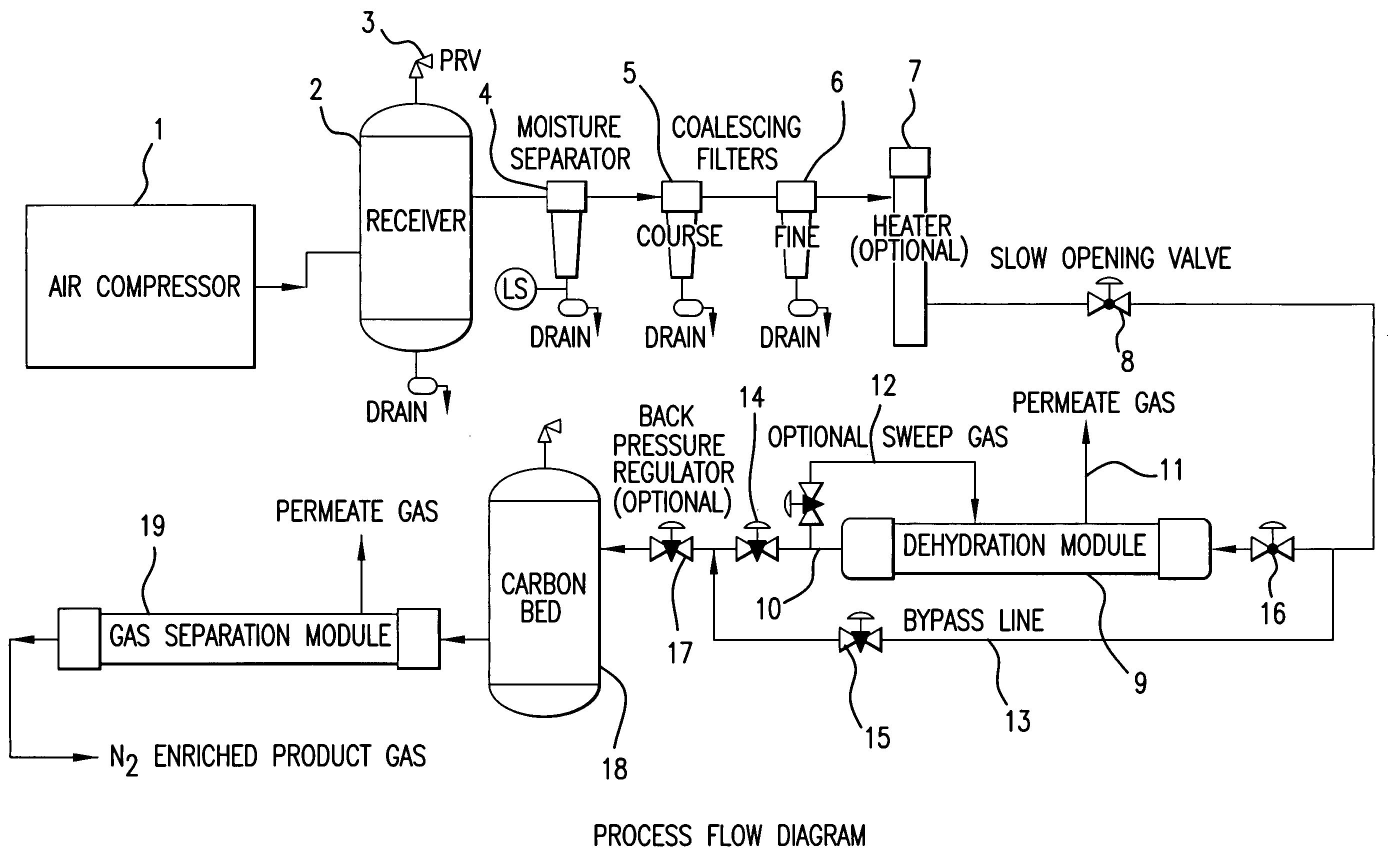

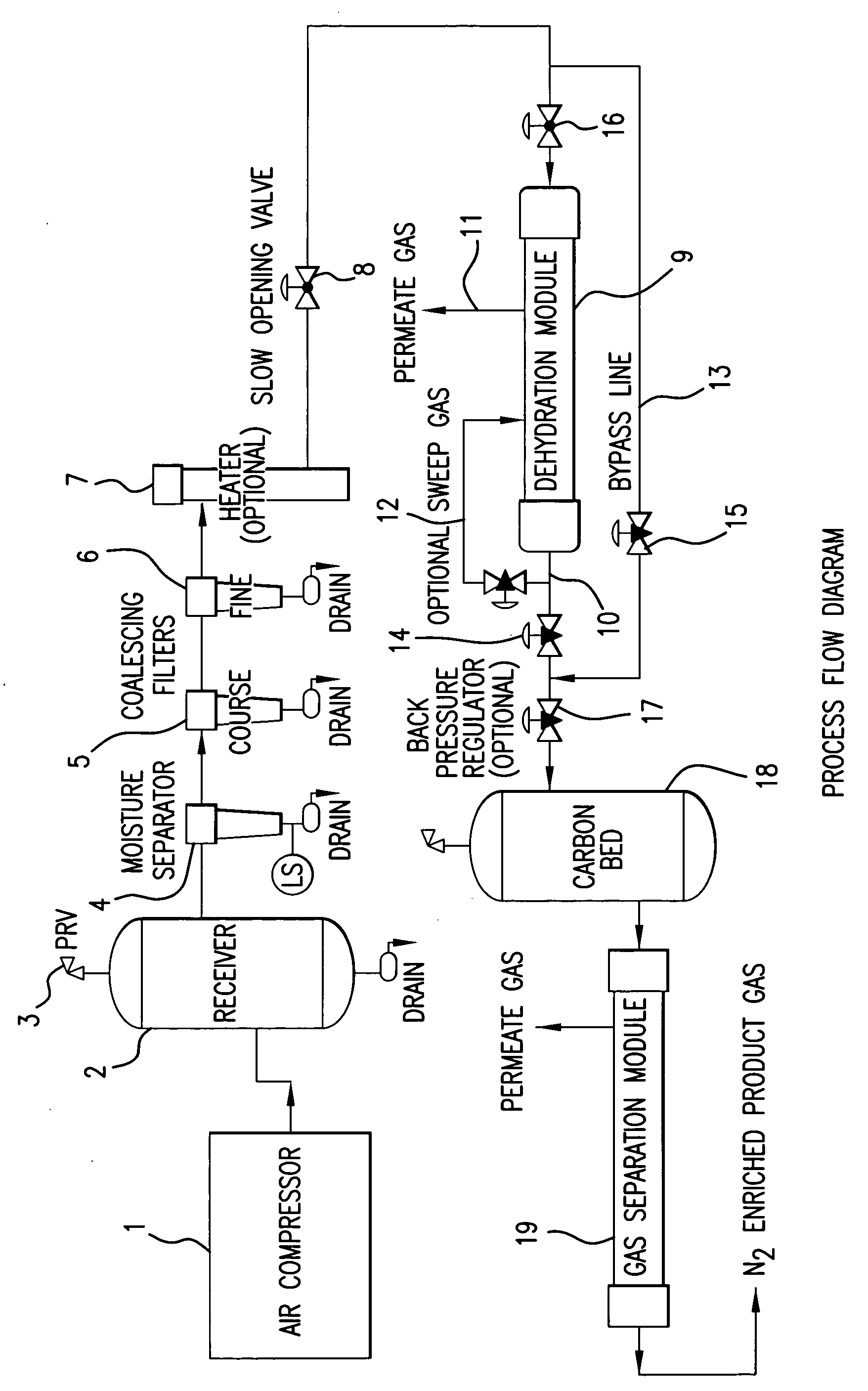

Air separation system using dehydration membrane for pretreatment of compressed air

Owner:GENERON IGS

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

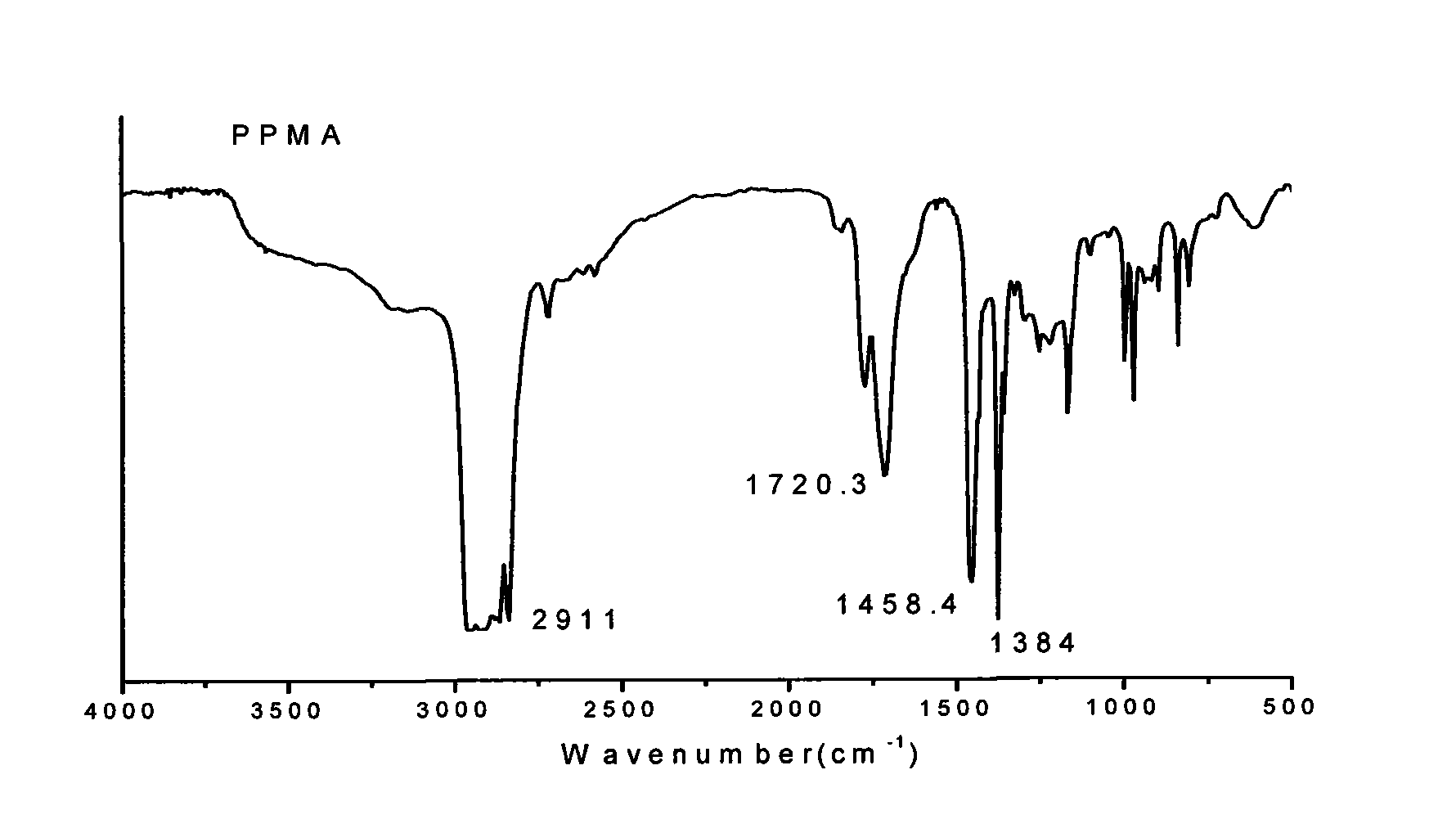

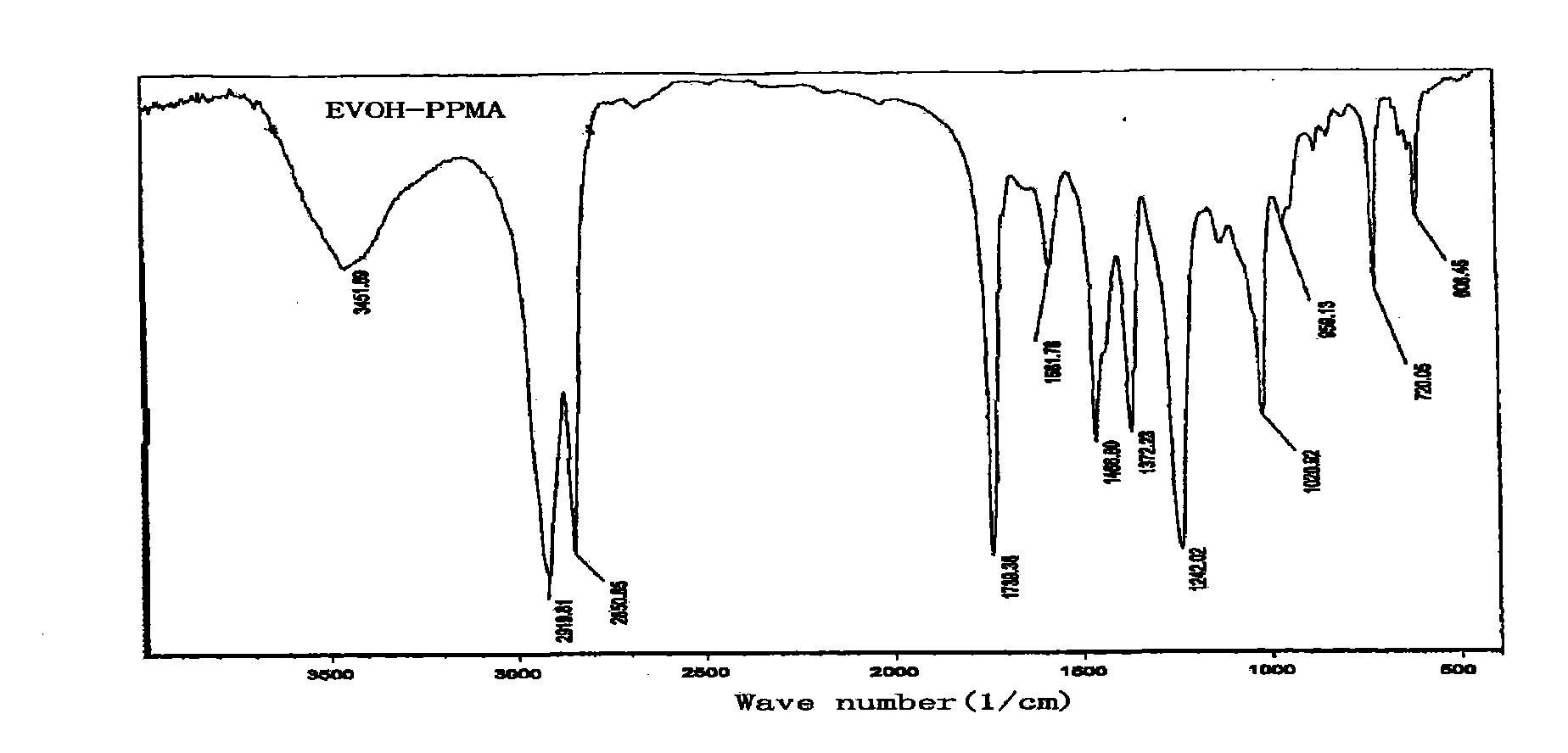

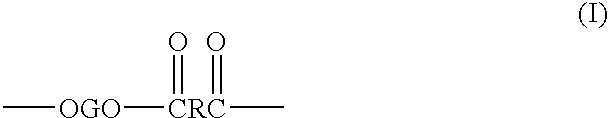

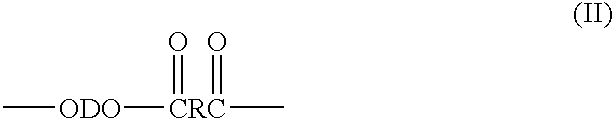

Isolating polypropylene composite material and preparation method thereof

InactiveCN101633761AImprove toughnessHigh gas barrierWater vapor permeationEthylene vinyl alcohol copolymer

The invention discloses an isolating polypropylene composite material which is prepared from the following components in terms of parts by weight: 60-80 parts of polypropylene, 20-40 parts of ethylene-vinyl alcohol copolymer and 1-10 parts of compatilizer. Meanwhile, the invention also discloses a preparation method of the isolating polypropylene composite material. The isolating polypropylene composite material has high tenacity, and the impact strength thereof is as high as 210 J / m or so. In addition, the isolating polypropylene composite material has high gas isolation capability, and water vapor permeation speed can be approximately 2000 g*um / (m<2>*24h). The isolating polypropylene composite material has both high gas isolation capability and high tenacity, therefore when the isolating polypropylene composite material is used for preparing an isolating film, a traditional film making process can be adopted, wherein the process is relatively simple and the production cost is relatively low. The isolating polypropylene composite material has a prospect for generalized application.

Owner:洛阳石化吉润化工有限责任公司

Internal wall anticorrosive coating for sea water evaporating installation

InactiveCN1709999AConducive to on-site constructionImprove water resistanceEpoxy resin coatingsEpoxySodium Bentonite

The invention relates to endophragm anticorrosion dope of carbon steel material vaporizing equipments in seawater desalting craft of low temperature and multiple effect distillation. It mainly comprises basic materials, pigment, padding, auxiliary agent and solvent. The basic materials are one or more than one kind of epoxy resin and painthydroxybenzene modified thermostable resins. The painthydroxybenzene modified thermostable resins are one or more than one kind of painthydroxybenzene silicon resin, painthydroxybenzene furol resin and painthydroxybenzene titanium resin got from chemical modification of painthydroxybenzene distilled from fresh paint; the color padding is one or more than one kind of titanium oxide powder, talcum powder, mica powder, mica ferric oxide, gas phase silicon dioxide, silica flour, porcelain powder and bentonite. The dope is solidified at room temperature. It has excellent permeability resistance of water, seawater and vapor at high temperature and is suitable to anticorrosion of low temperature.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

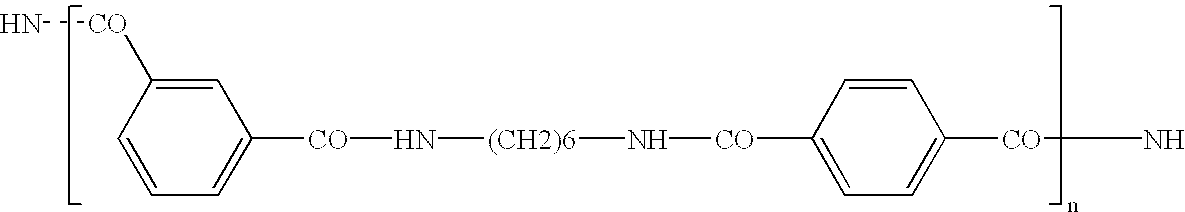

Smokable films comprising a polyamide and a copolyester elastomer

InactiveUS20030055181A1Hollow filament manufactureSynthetic resin layered productsElastomerPolymer science

Smokable films, in particular tubular films, comprising i) an aliphatic polyamide and ii) a block copolyetherester elastomer are provided. A process for manufacturing these films is also provided. The films of the invention show excellent water vapor permeability at high temperatures and barrier properties at room temperature. They are suitable for preparation of tubular casings, in particular smoked foodstuff casings.

Owner:DOW GLOBAL TECH LLC

Thermally-isolated anchoring systems for cavity walls

InactiveUS8904730B2High strengthMaintain structural integrityProtective buildings/sheltersBuilding reinforcementsSurface mountingWater vapor

Owner:HOHMANN & BARNARD INC

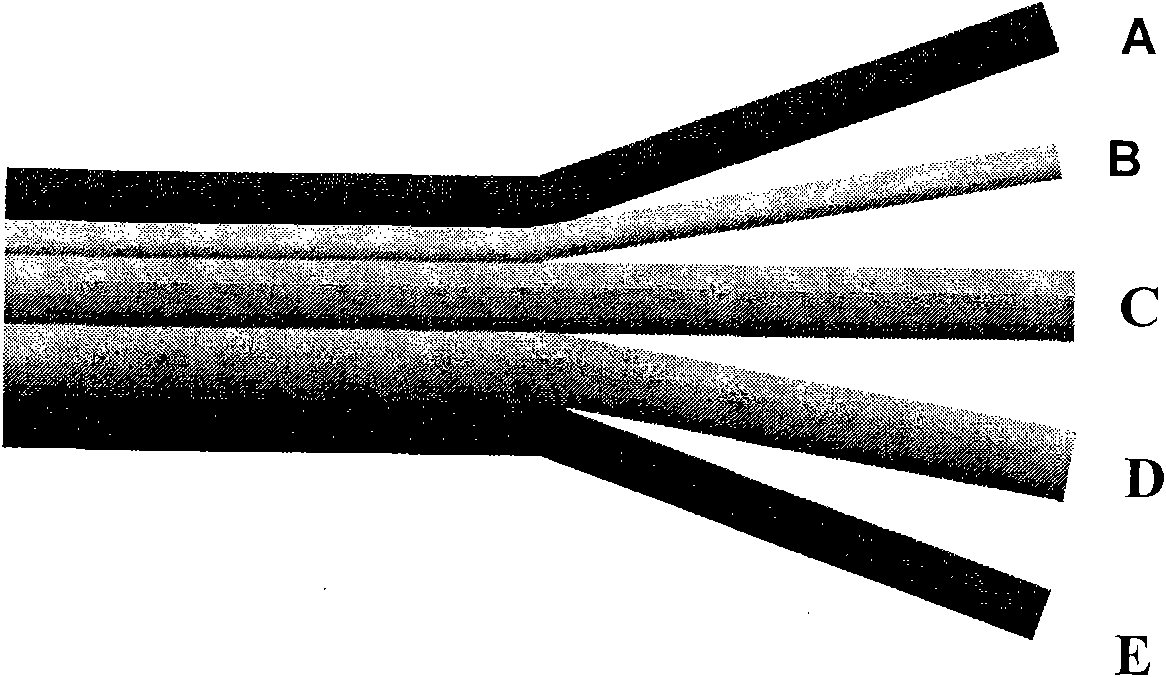

Five-layer coextrusion transfusion medicine packing film and manufacturing method thereof

The invention relates to a five-layer coextrusion transfusion medicine packing film. The five layers have the materials and the structure that the layer A is the outer layer of a product and is made of polyester or copolyester with the thickness of 10-30 Mum, the layer B is the secondary outer layer of the product and is made of acid modified polyolefin copolymer or the mixture thereof with the thickness of 3-15 Mum, the layer C is the middle layer of the product and is made of the mixture of polyethylene, polypropylene and SEBS with the thickness of 30-80 Mu m, the layer D is the secondary inner layer of the product and is made of the mixture of polyethylene, polypropylene and SEBS with the thickness of 40-110 Mu m, and the layer E is the inner layer of the product and is made of the mixture of co-polypropylene and SEBS with the thickness of 10-40 Mu m. The transfusion medicine packing film is transparent and highly flexible, can be sterilized at high temperature, the outer layer can be printed permanently with conventional pigments and has the functions of impact resistance and abrasion prevention. The inner layer can simply be bonded via heat seal without electron beam irradiation or any additives, and has lower water vapor permeability and oxygen and nitrogen penetration amount. The invention also discloses a manufacturing method of the film.

Owner:NANJING OTSUKA TECHBOND TECHNO

Portable measuring system having an optimized assembly space

ActiveUS20090182244A1Minimize timeSmall assembly spaceMaterial analysis by electric/magnetic meansCatheterWater vapor permeationEngineering

A portable measuring system which analyzes a liquid sample for at least one analyte. The portable measuring system has a substantially moisture-proof housing with an internal atmosphere. The housing prevents moisture from the air and water vapor from penetrating into the housing. The portable measuring system also has at least one test element support inserted into the internal atmosphere of the housing. The test element support is equipped with a retaining structure and a test element that is supported by the retaining structure. The test element support is designed such that, after insertion into the internal atmosphere, the test element is exposed to the internal atmosphere. A release mechanism is also provided which can convey at least one test element into an application position within the internal atmosphere of the housing. In this application position, the liquid sample can be applied to the test element.

Owner:ROCHE DIABETES CARE INC

Gas-phase rustproof packaging material and manufacturing method thereof

ActiveCN101717015AExpand processing methodsReduce permeationContainers preventing decayShock-sensitive articlesPolyolefinWater vapor

The invention relates to a gas-phase rustproof packaging material which comprises a rustproof membrane and a fabric layer. The gas-phase rustproof packaging material is characterized by comprising two layers or three layers of composite structures, wherein the three layers of composite structures sequentially comprise an inner-layer polyolefin rustproof membrane (2) with the thickness of 15Mum to 80 Mum; a middle high polymer fabric layer (1) with the quantitation of 20g / m2 to 80g / m2; and an outer-layer high polymer membrane (3) with the thickness of 15Mum to 80 Mum. The manufacturing method comprises the following steps of: compositing the outer-layer membrane (3) and the fabric layer (1) and then putting on two players, casting the rustproof membrane (2) at the other side of the fabric layer (1) through a membrane laminating machine, and then towing and coiling to finish three-layer coating. The invention has the advantages that: 1. the processing mode of the gas-phase rustproof membrane breaks through the limitation of blown processing under the temperature condition of less than or equal to 200 DEG C; 2. a processing mode of direct membrane-laminating by adopting a casting method is respectively adopted at both sides of a fabric enhancing layer, which reduces a working procedure and has low cost and stable quality; 3. nano-grade high-barrier ingredients are adopted for the outer-layer membrane (3), which ensures that the water vapor permeation amount of the product is reduced by 0.2g / m2*24h-0.4g / m2*24h compared with the traditional similar products; and 4. the spent packaging material can be recycled completely and accords with environment requirements.

Owner:上海一诺金属防护材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com