Patents

Literature

463results about How to "Avoid Bubble Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

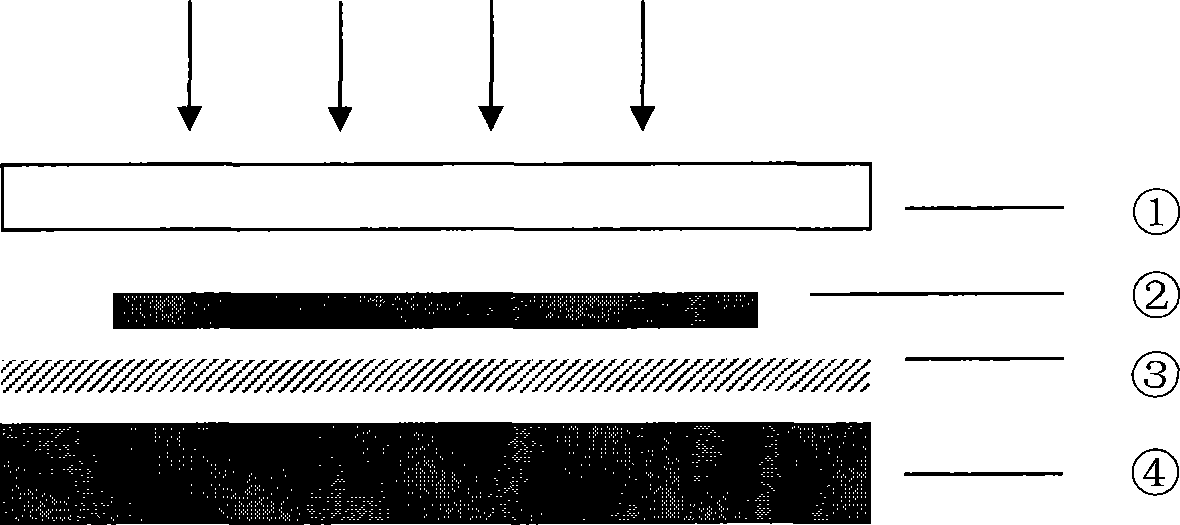

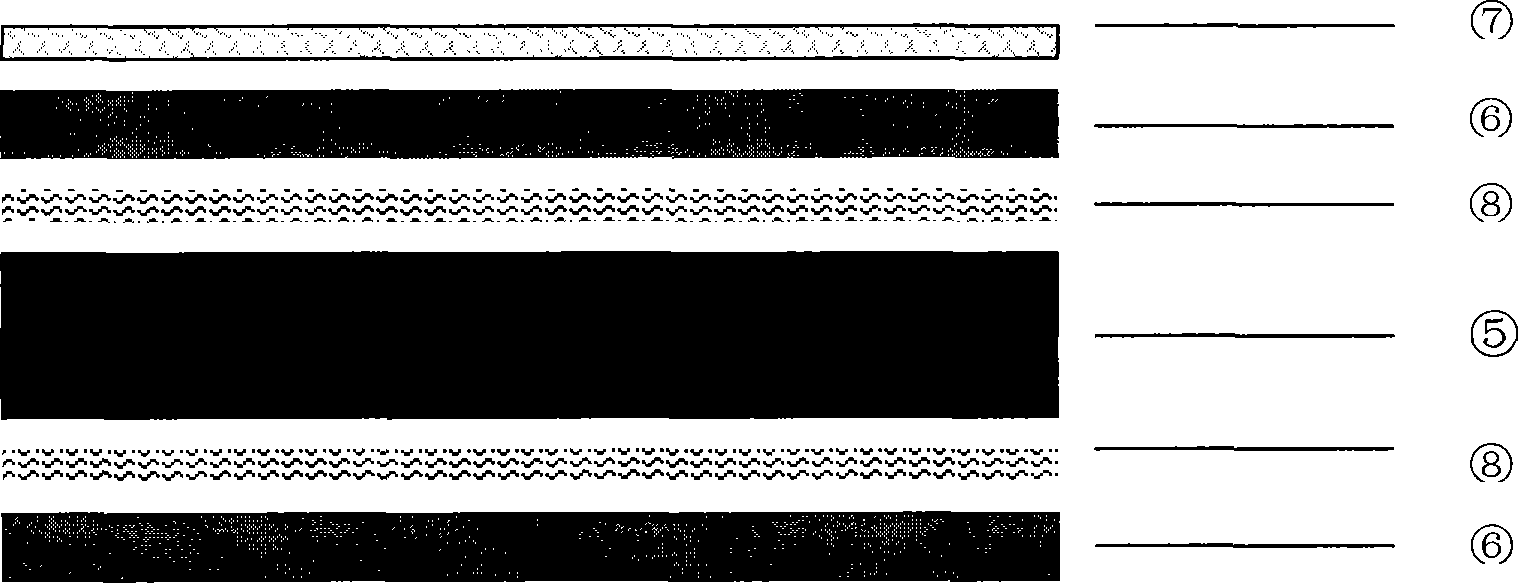

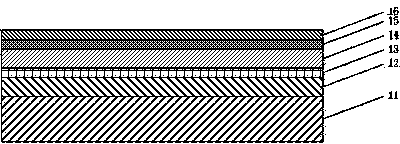

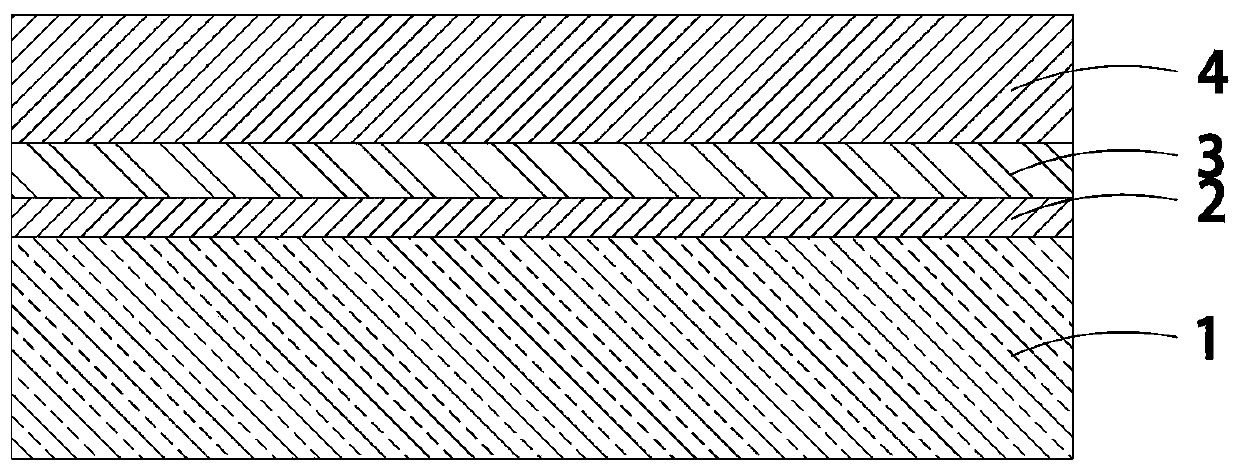

Back film of solar cell and preparing technique thereof

InactiveCN101290950AAvoid Bubble ProblemsAvoid stickingSynthetic resin layered productsPretreated surfacesWeather resistanceMass ratio

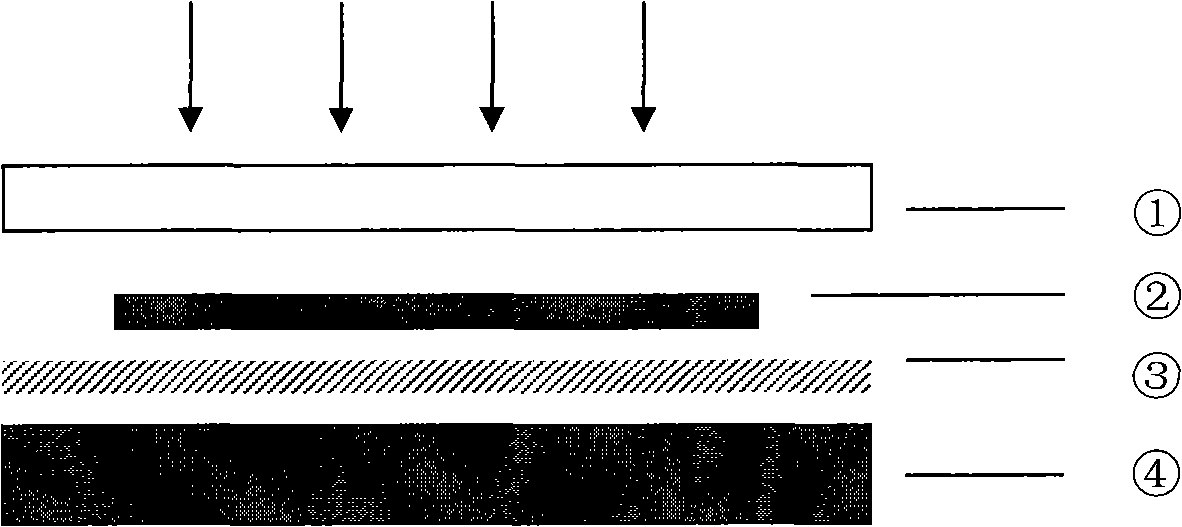

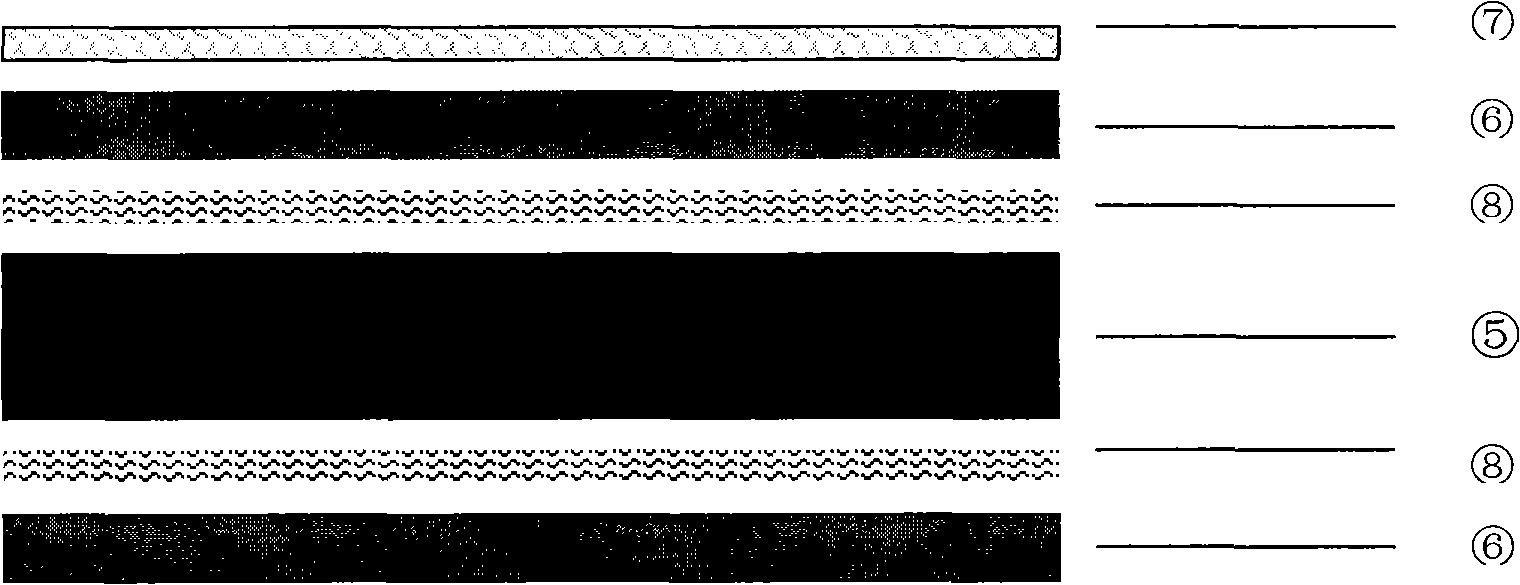

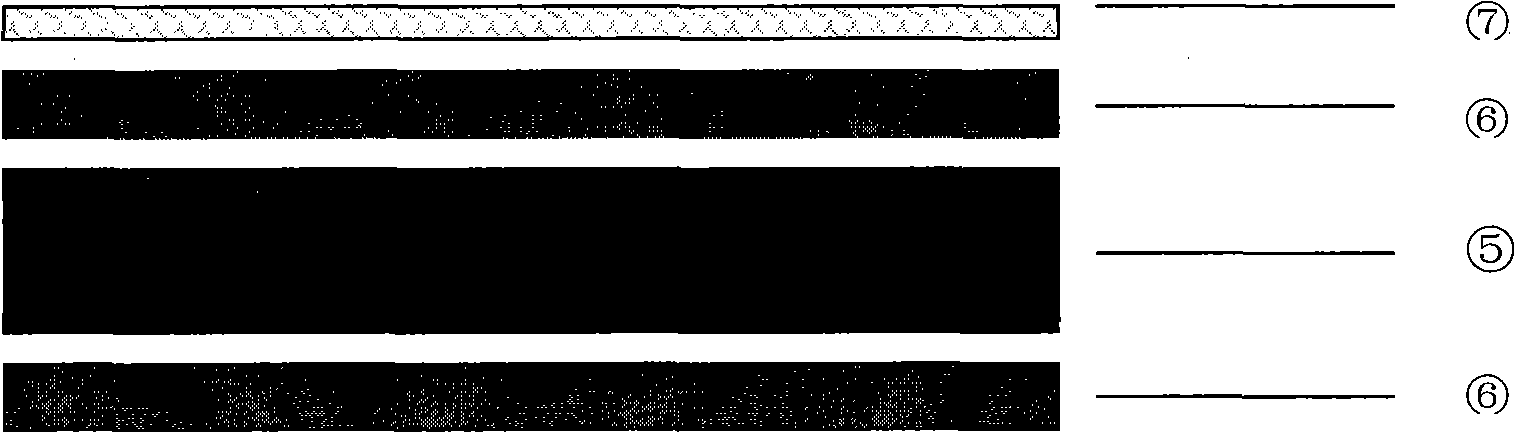

The invention discloses a solar panel back film and a technique for manufacturing the same. The back film comprises a PET film substrate with thickness of between 100 and 350 micrometers, wherein, fluoropolymer coatings with thickness of between 15 and 30 micrometers are coated on both sides of the substrate; an adhesive layer with thickness of between 0.5 and 5 micrometers is coated on the fluoropolymer coating on one side; the fluoropolymer coatings are obtained by direct coating of mixed latex which is obtained through mixture of various raw material compositions according to the mixture ratio and subsequent grinding treatment on the PET film substrate; the compositions by mass ratio of the raw materials of the fluoropolymer coatings are 30 to 55 percent of fluoride coating materials, 20 to 40 percent of solvent, 2 to 6 percent of cross-linking agent and curing agent and 15 to 40 percent of filling. The technique greatly improves the bonding strength between a back film layer and a layer, improves the ageing resistance, the weathering resistance of products, simultaneously improves the insulativity and the vapor permeability resistance due to the design of a multilayered structure and also can design and modify the performance and the appearance of the products as required.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS +2

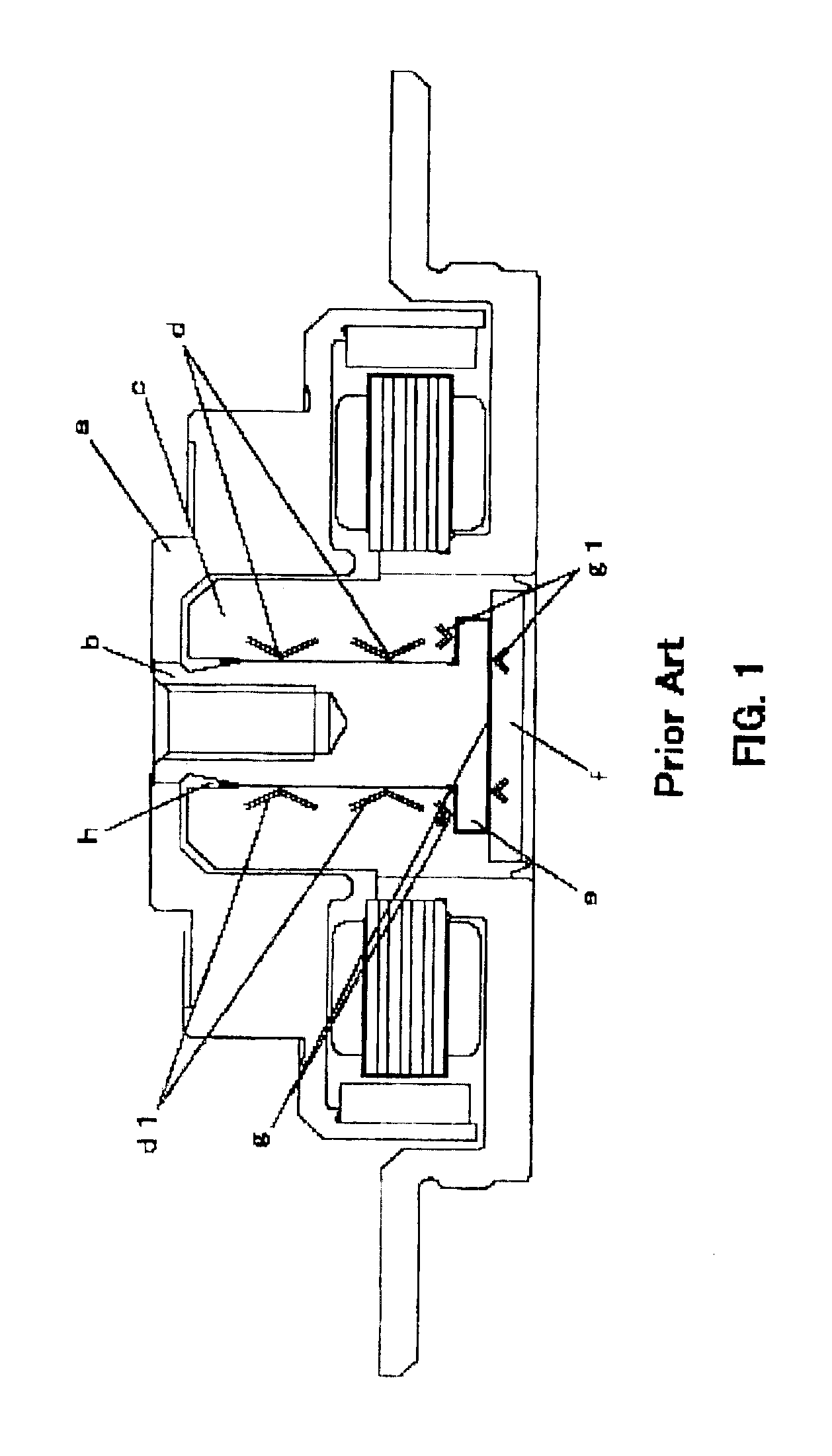

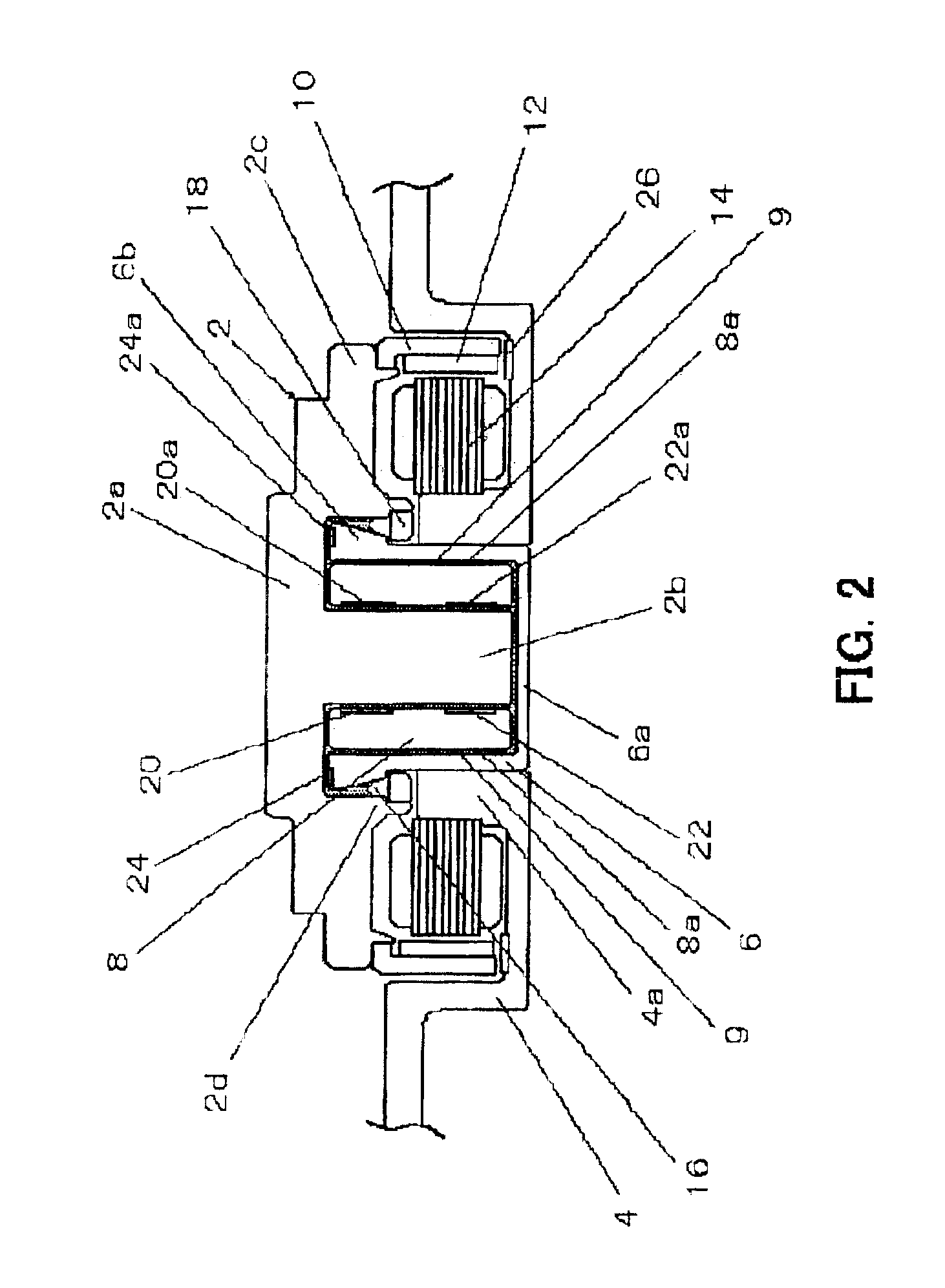

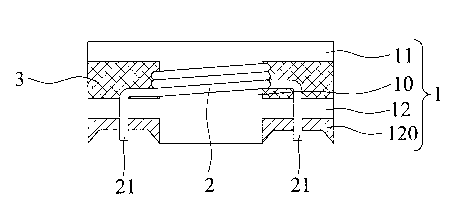

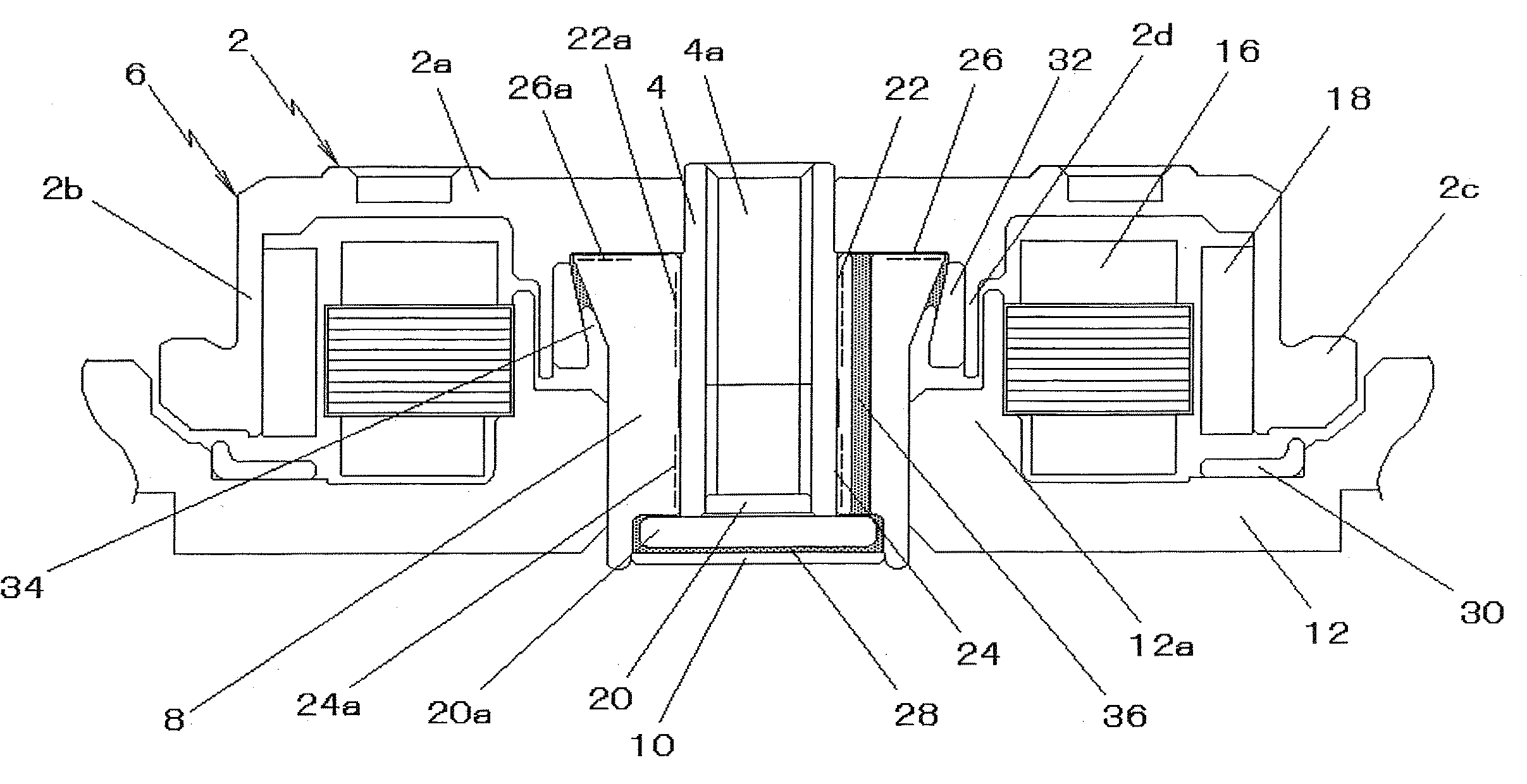

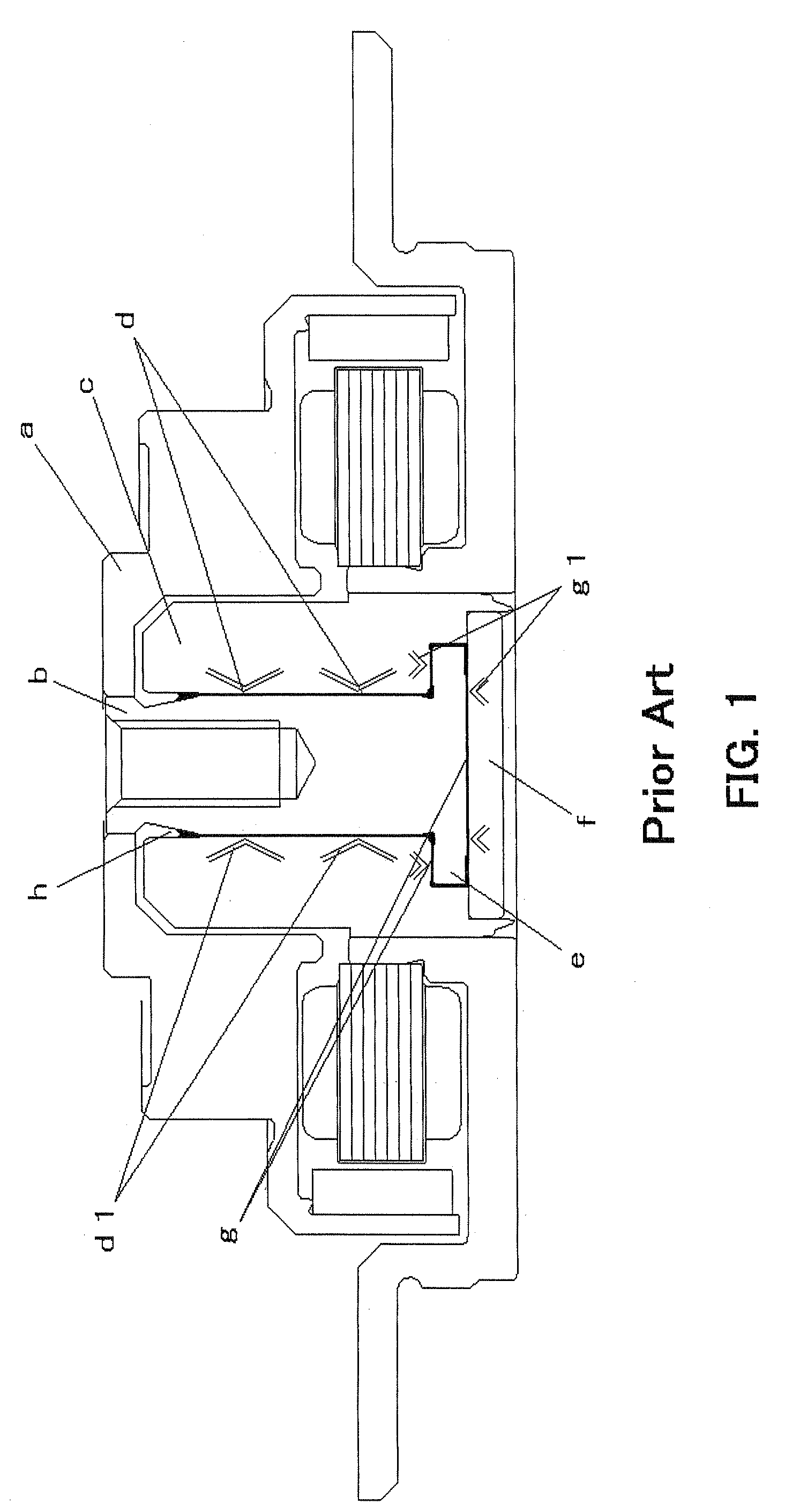

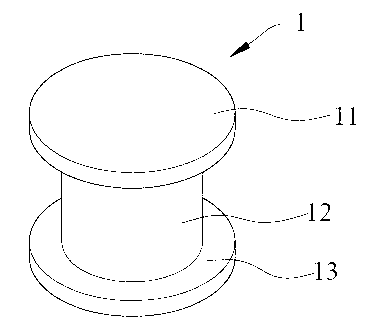

Spindle motor and disk drive furnished therewith

ActiveUS6914358B2Avoid Bubble ProblemsShaftsRecord information storageInternal pressureAtmospheric air

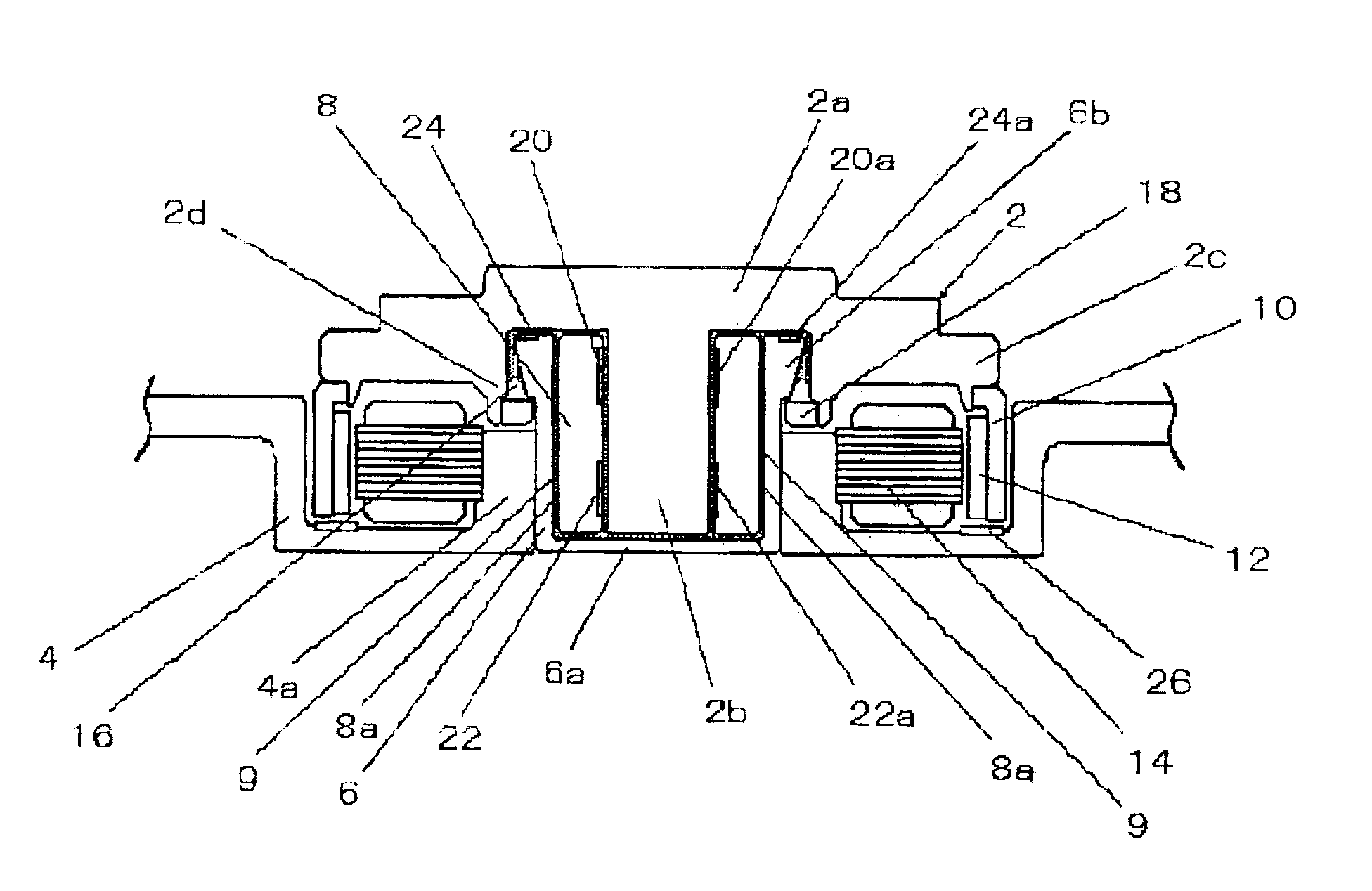

In a spindle motor utilizing dynamic-pressure bearings having a full-fill structure, a bearing configuration that balances and sustains at or above atmospheric pressure the internal pressure of the bearing oil. Thrust and radial bearing sections are configured within oil-filled bearing clearances in between the rotor, the shaft, and a shaft-encompassing hollow bearing member. A communicating passage one end of which opens on, radially inwardly along, the thrust bearing section is formed in the bearing member. Either axial ends of the bearing clearance in between the bearing member and shaft communicate through the passage. The communicating passage enables the oil to redistribute itself within the bearing clearances. Pressure difference between the axial upper and lower ends of the oil retained in between the bearing member and the shaft is compensated through the communicating passage, preventing incidents of negative pressure within the oil and of over-lift on the rotor.

Owner:NIPPON DENSAN CORP

Back film of solar cell and preparing technique thereof

InactiveCN101290950BAvoid Bubble ProblemsAvoid stickingSynthetic resin layered productsPretreated surfacesPolymer scienceWeather resistance

The invention discloses a solar panel back film and a technique for manufacturing the same. The back film comprises a PET film substrate with thickness of between 100 and 350 micrometers, wherein, fluoropolymer coatings with thickness of between 15 and 30 micrometers are coated on both sides of the substrate; an adhesive layer with thickness of between 0.5 and 5 micrometers is coated on the fluoropolymer coating on one side; the fluoropolymer coatings are obtained by direct coating of mixed latex which is obtained through mixture of various raw material compositions according to the mixture ratio and subsequent grinding treatment on the PET film substrate; the compositions by mass ratio of the raw materials of the fluoropolymer coatings are 30 to 55 percent of fluoride coating materials, 20 to 40 percent of solvent, 2 to 6 percent of cross-linking agent and curing agent and 15 to 40 percent of filling. The technique greatly improves the bonding strength between a back film layer and alayer, improves the ageing resistance, the weathering resistance of products, simultaneously improves the insulativity and the vapor permeability resistance due to the design of a multilayered structure and also can design and modify the performance and the appearance of the products as required.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS +2

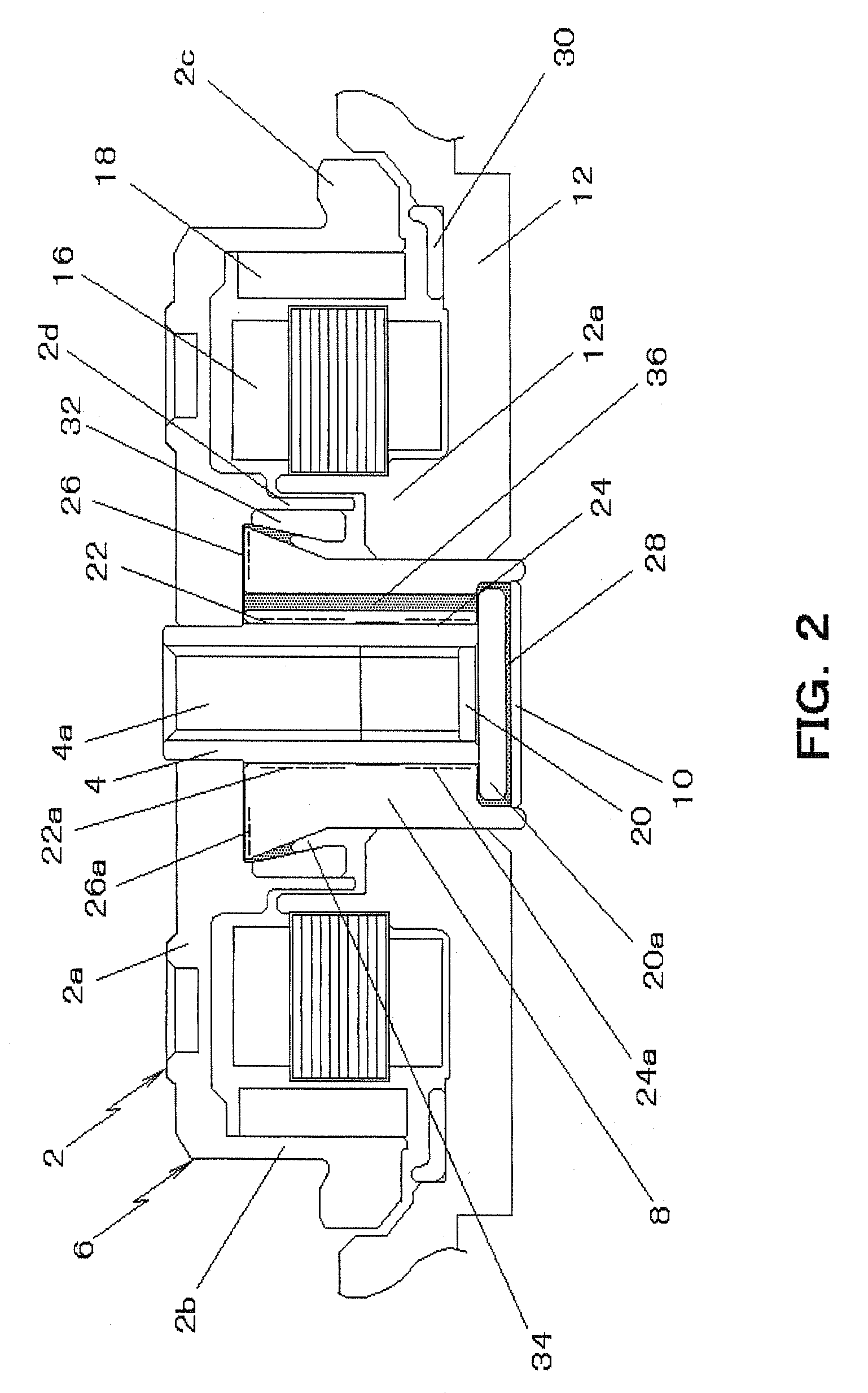

Disk drive spindle motor with radial inward thrust area annular protruding portion and bearing member communicating passage

InactiveUS6920013B2Avoid Bubble ProblemsFrictional torque and lossCarrier constructional parts dispositionApparatus for flat record carriersInternal pressureAtmospheric air

In a spindle motor utilizing dynamic-pressure bearings having a full-fill structure, a bearing configuration that balances and sustains at or above atmospheric pressure the internal pressure of the bearing oil. Thrust and radial bearing sections are configured within oil-filled bearing clearances in between the rotor, the shaft, and a shaft-encompassing hollow bearing member. A communicating passage one end of which opens on, radially inwardly along, the thrust bearing section is formed in the bearing member. Either axial ends of the bearing clearance in between the bearing member and shaft communicate through the passage. The communicating passage enables the oil to redistribute itself within the bearing clearances. Pressure difference between the axial upper and lower ends of the oil retained in between the bearing member and the shaft is compensated through the communicating passage, preventing incidents of negative pressure within the oil and of over-lift on the rotor.

Owner:NIDEC CORP

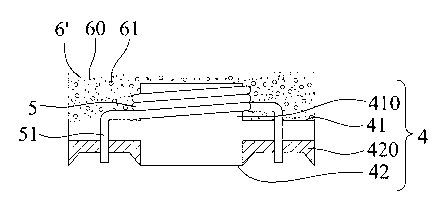

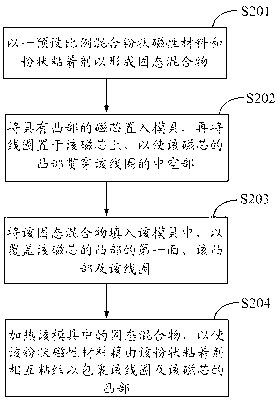

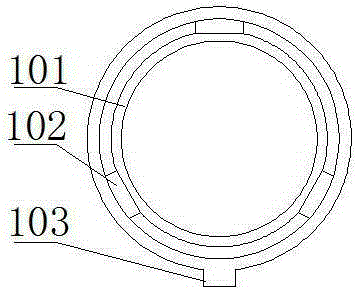

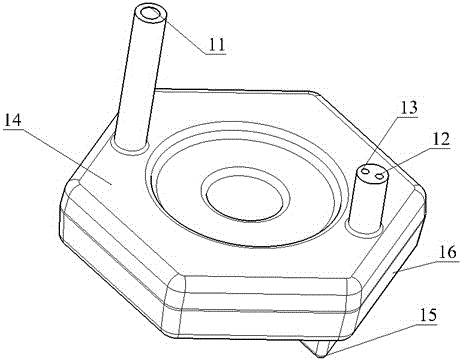

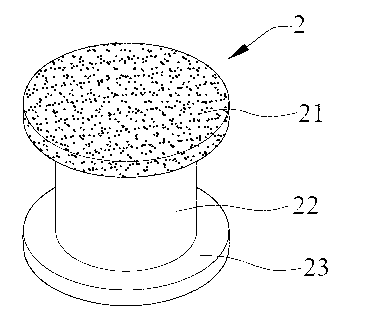

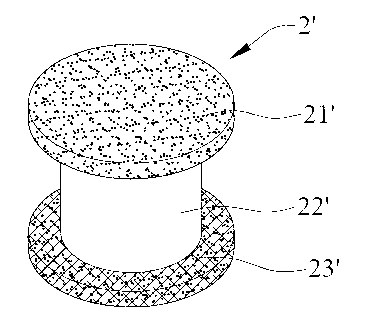

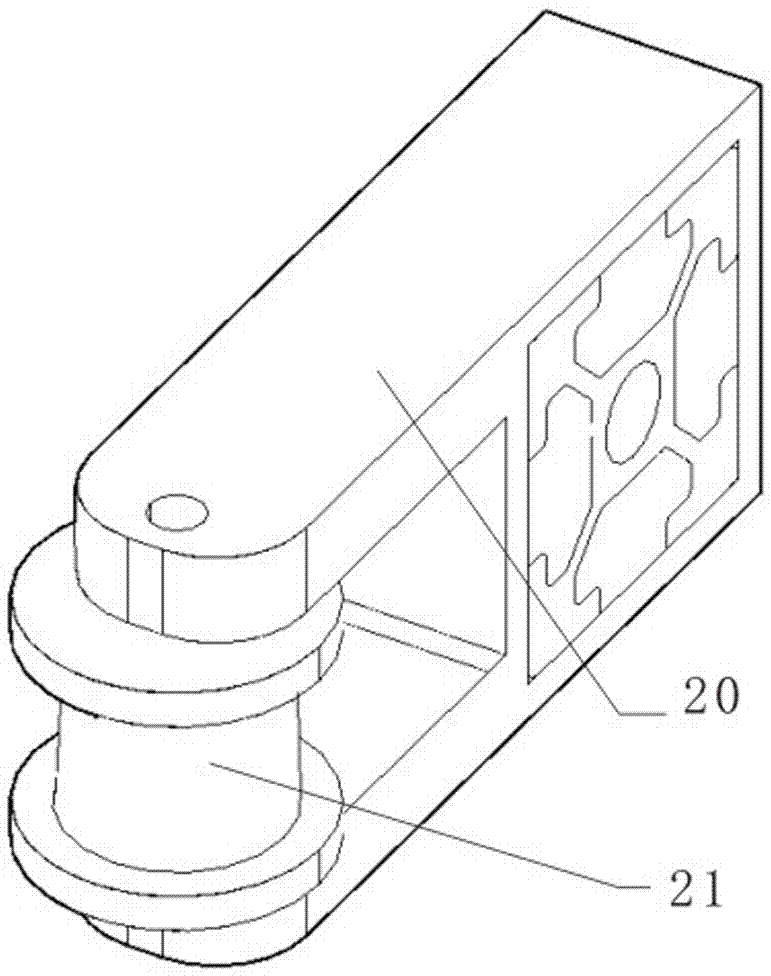

Thin closed magnetic circuit inductor and manufacturing method thereof

InactiveCN102810392AAvoid Bubble ProblemsAvoid powder settling phenomenonInductances/transformers/magnets manufactureInductance with magnetic coreAdhesiveInductor

The invention provides a thin closed magnetic circuit inductor and a manufacturing method thereof. The method comprises the following steps of: mixing a powdery magnetic material and a powdery adhesive to form a solid mixture according to a preset ratio; putting a magnetic core with a convex part into a mold in an upwards convex part mode; arranging a coil on the magnetic core, so that the convex part of the magnetic core penetrates through a hollow part of the coil; filling the solid mixture into the mold so as to cover the first surface of the convex part of the magnetic core, the convex part and the coil; and finally, heating the solid mixture in the mold, so that the powdery magnetic material is adhered through the powdery adhesive so as to coat the coil and the convex part of the magnetic core, and high-pressure forming is not required during heating. The manufacturing cost of the thin closed magnetic circuit inductor can be reduced, the production efficiency is improved, and the inductance of the inductor is improved.

Owner:重庆美桀电子科技有限公司

Disk drive spindle motor with radial inward thrust area annular prutruding portion and bearing member communicating passage

ActiveUS20050099722A1Prevent pressureHigh reliabilityCarrier constructional parts dispositionApparatus for flat record carriersEngineeringInternal pressure

In a spindle motor utilizing dynamic-pressure bearings having a full-fill structure, a bearing configuration that balances and sustains at or above atmospheric pressure the internal pressure of the bearing oil. Thrust and radial bearing sections are configured within oil-filled bearing clearances in between the rotor, the shaft, and a shaft-encompassing hollow bearing member. A communicating passage one end of which opens on, radially inwardly along, the thrust bearing section is formed in the bearing member. Either axial ends of the bearing clearance in between the bearing member and shaft communicate through the passage. The communicating passage enables the oil to redistribute itself within the bearing clearances. Pressure difference between the axial upper and lower ends of the oil retained in between the bearing member and the shaft is compensated through the communicating passage, preventing incidents of negative pressure within the oil and of over-lift on the rotor. And an annular protruding portion is formed on at least one of the end face of the bearing member and the flat face of the rotor at radially inward portion of the thrust bearing section.

Owner:NIDEC CORP

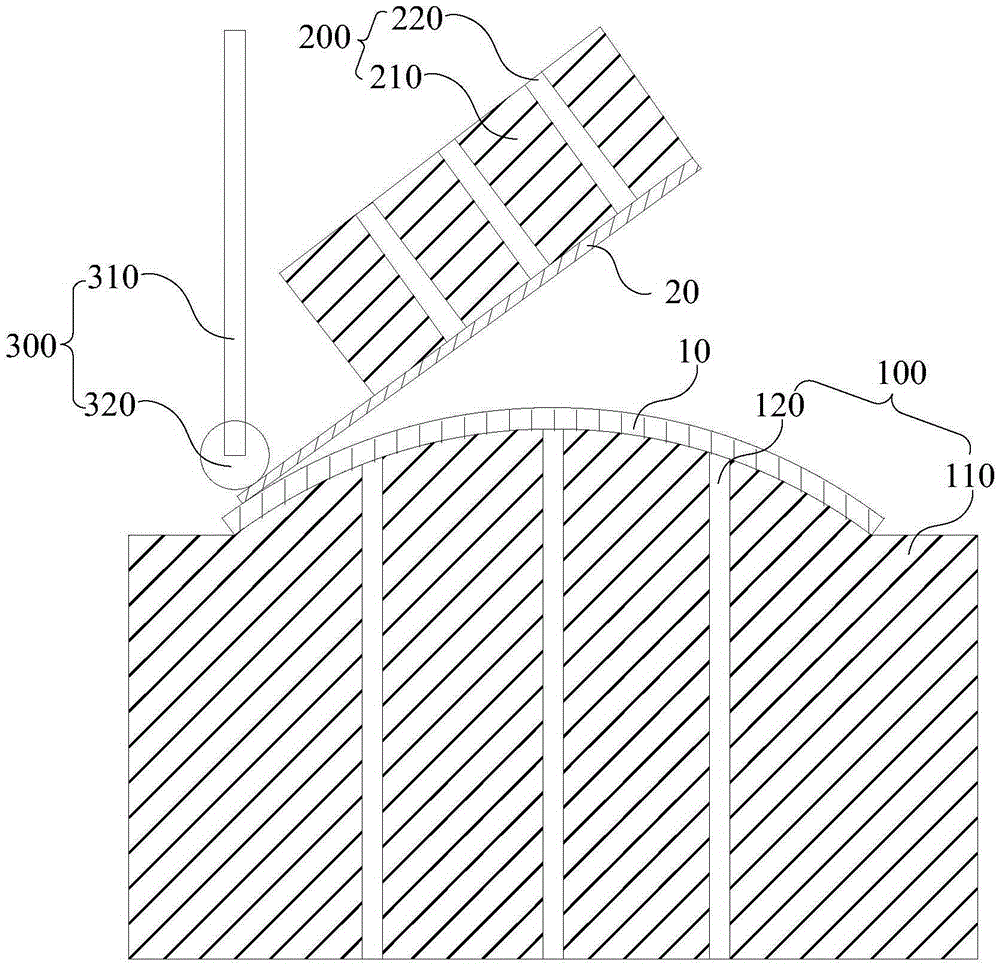

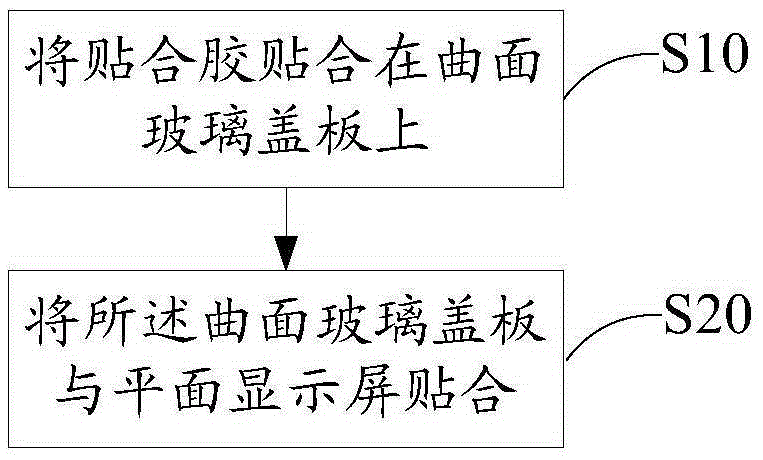

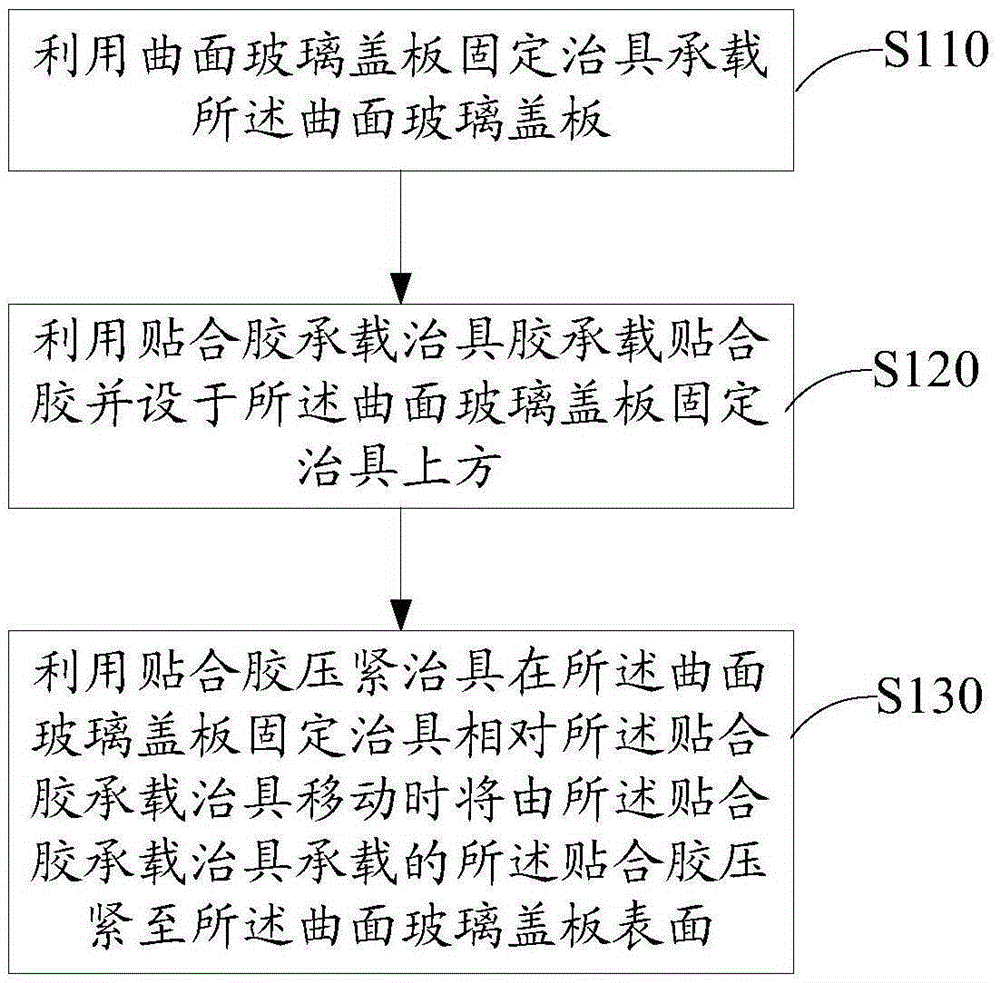

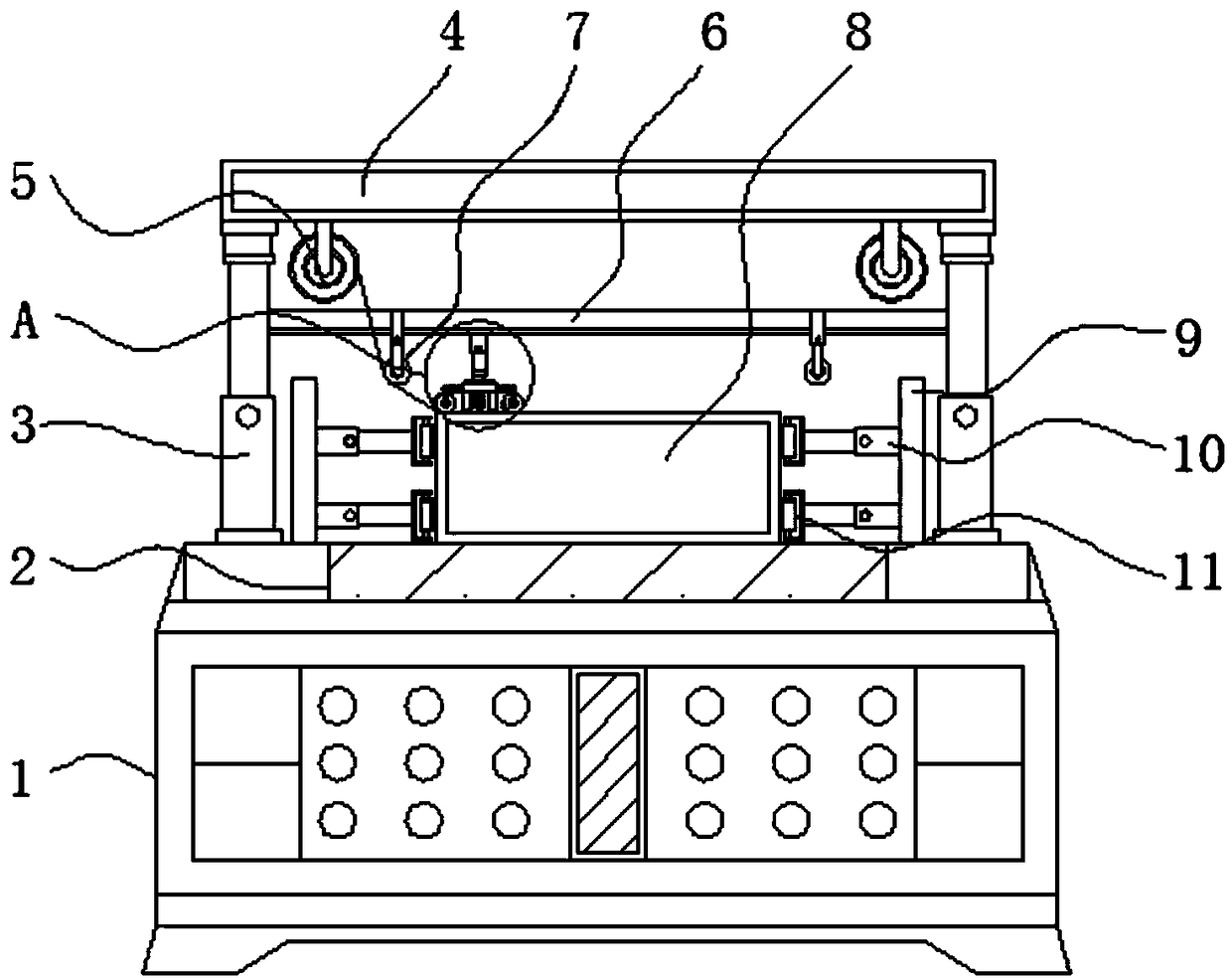

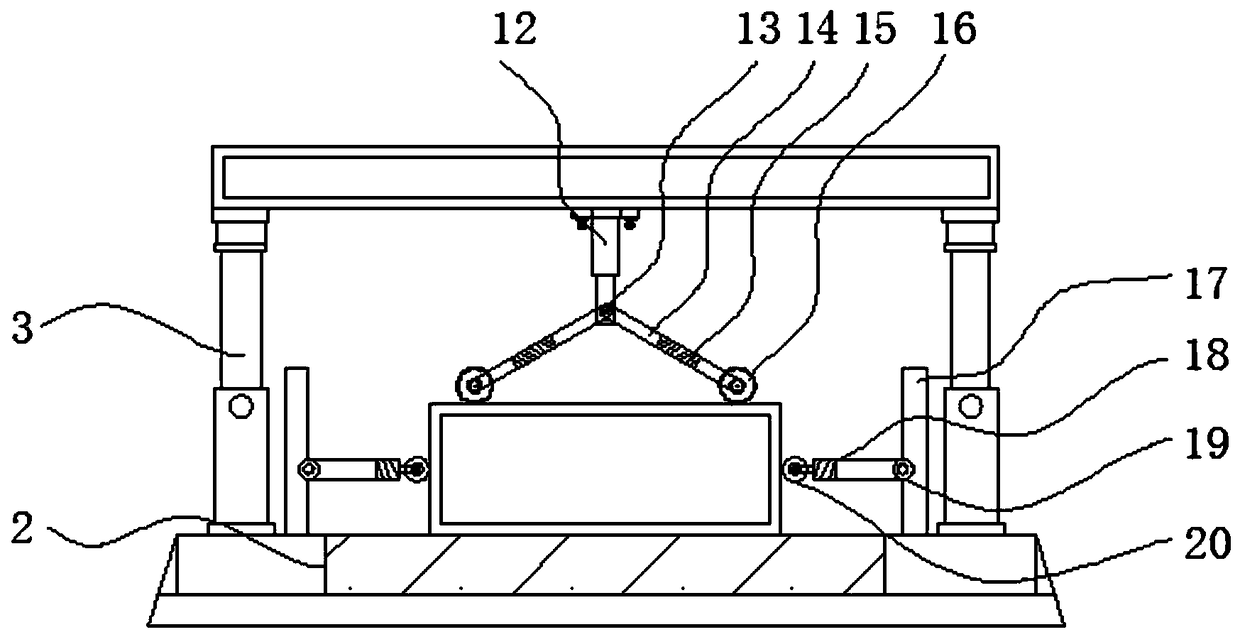

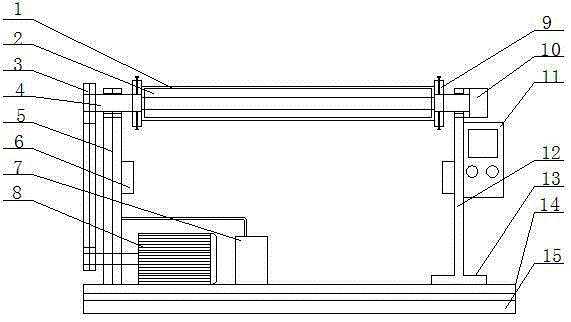

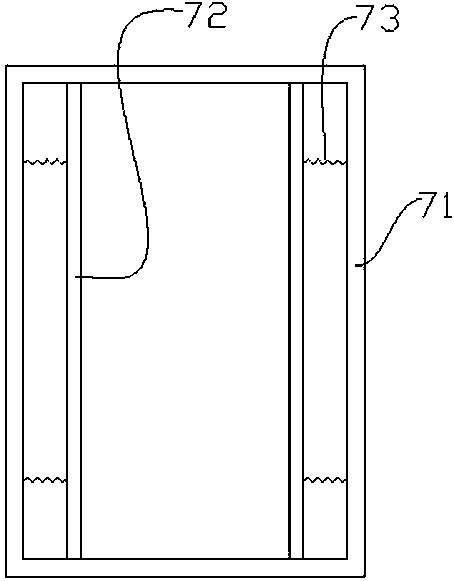

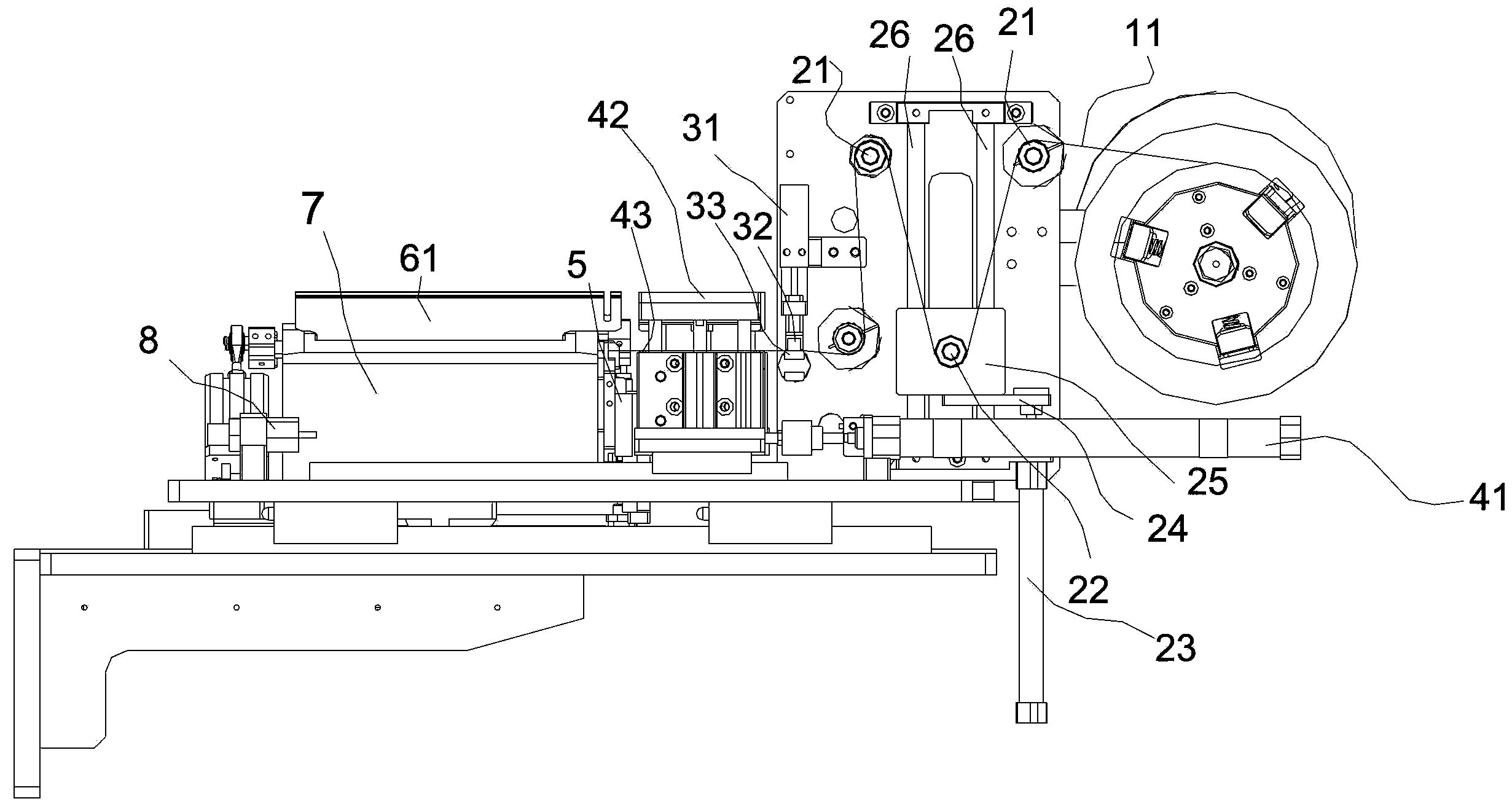

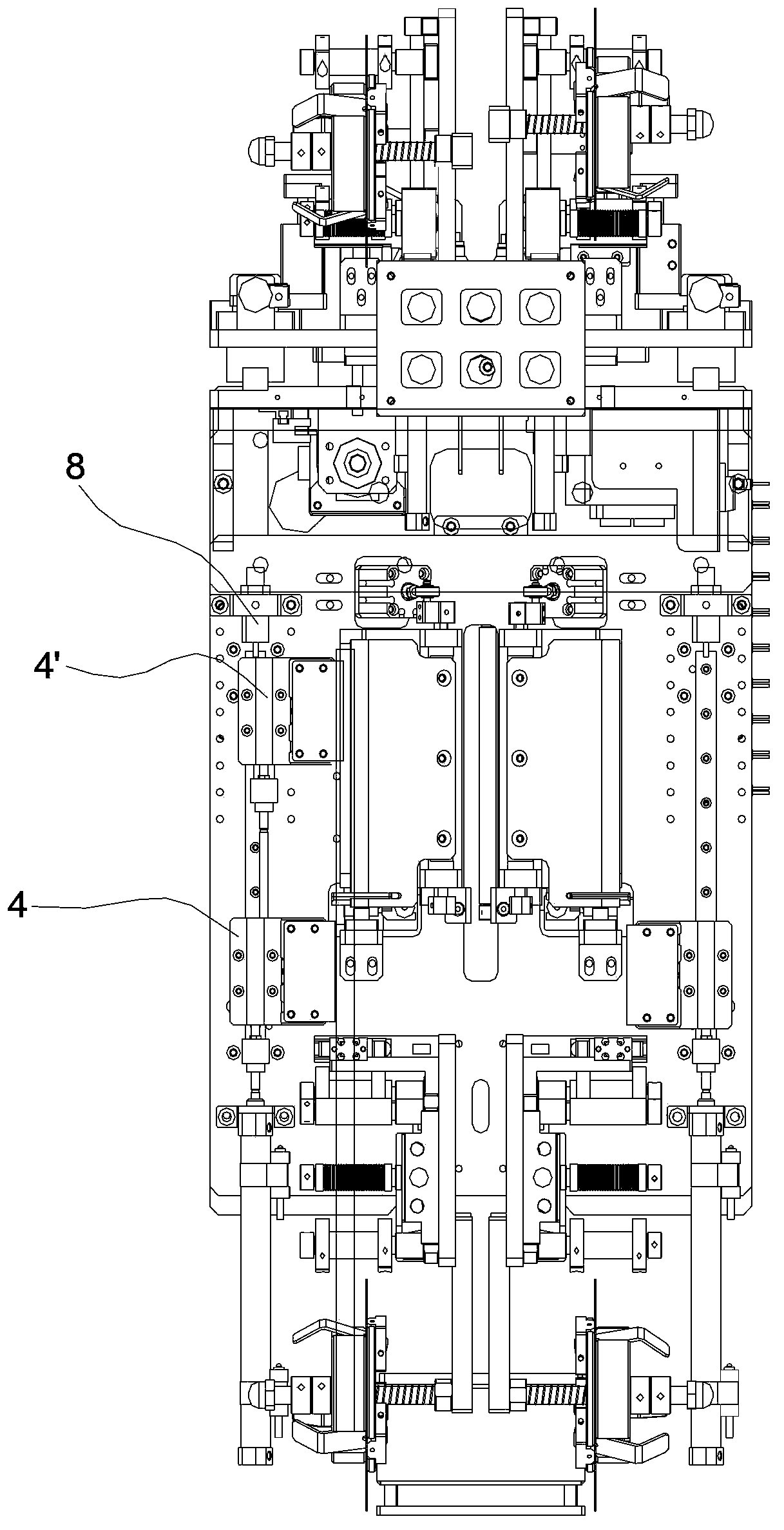

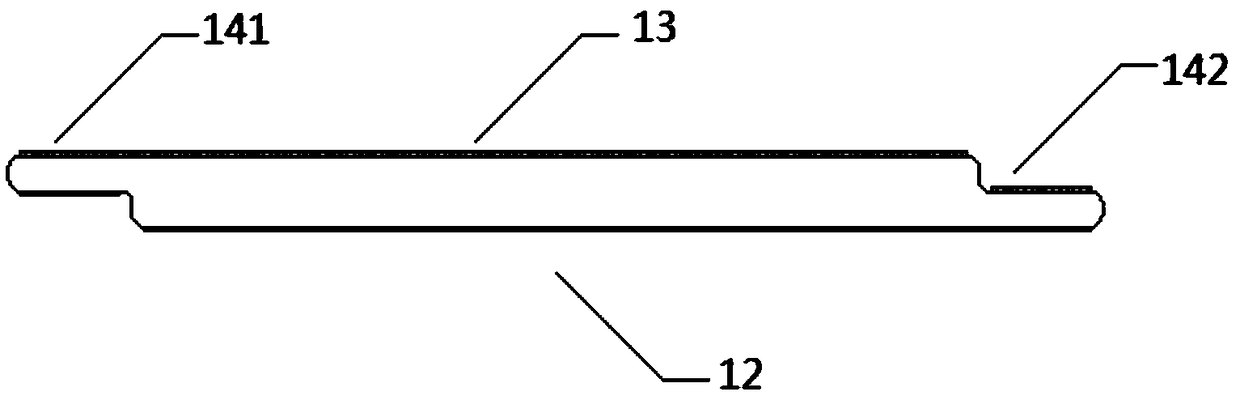

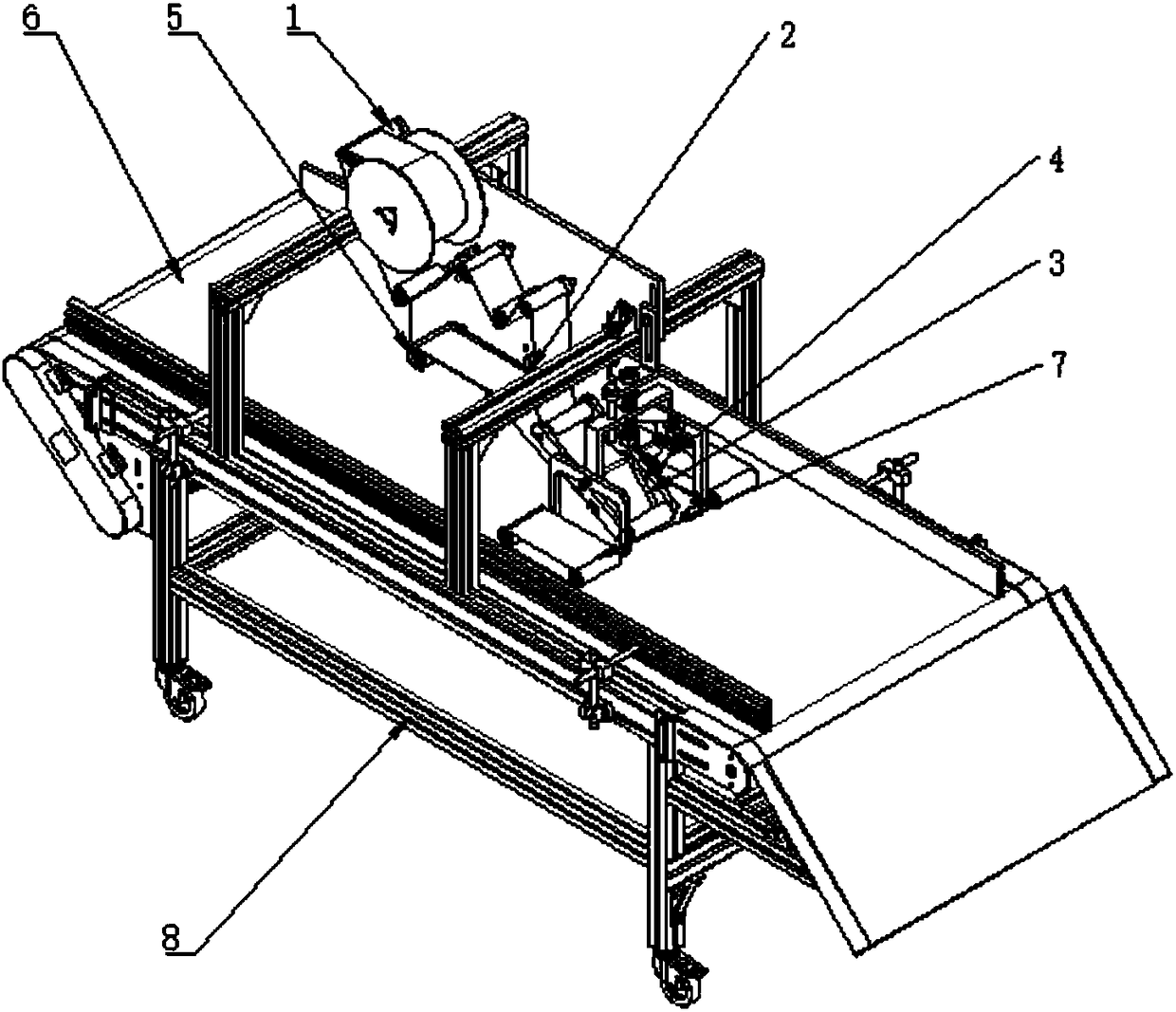

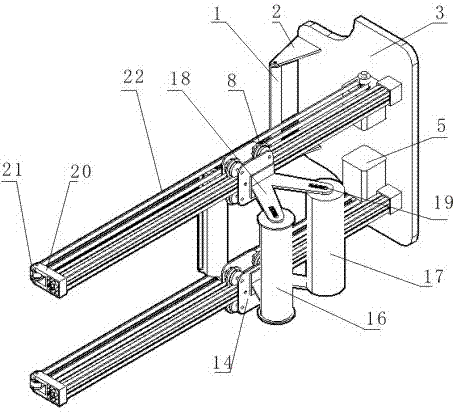

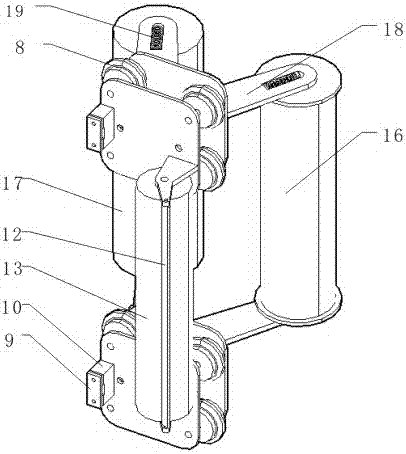

Lamination device for curved-surface glass cover plate and flat display panel and lamination method

ActiveCN105398181AInhibition thicknessAvoid Bubble ProblemsLaminationLamination apparatusGlass coverAdhesive

The invention provides a lamination device for a curved-surface glass cover plate and a flat display panel and a lamination method. The lamination device comprises a curved-surface glass cover plate fixing jig, a joint adhesive bearing jig and a joint adhesive compression jig, wherein the curved-surface glass cover plate fixing jig is provided with a curved surface of which the curvature is the same as that of the curved-surface glass cover plate so as to bear the curved-surface glass cover plate; the joint adhesive bearing jig is arranged above the curved-surface glass cover plate and used for bearing a joint adhesive; the joint adhesive compression jig is located at the side edge of the joint adhesive bearing jig and used for compressing the joint adhesion born by the joint adhesion bearing jig onto the surface of the curved-surface glass cover plate when the curved-surface glass cover plate fixing jig moves relative to the joint adhesive bearing jig. According to the lamination device for the curved-surface glass cover plate and the flat display panel and the lamination method, the joint adhesive is laminated with the curved-surface glass cover plate at first, then the curved-surface glass cover plate is laminated with the flat display panel, and non-uniform lamination thickness and bubbles of the joint adhesive, caused by gathering of the joint adhesive toward the middle, can be effectively avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

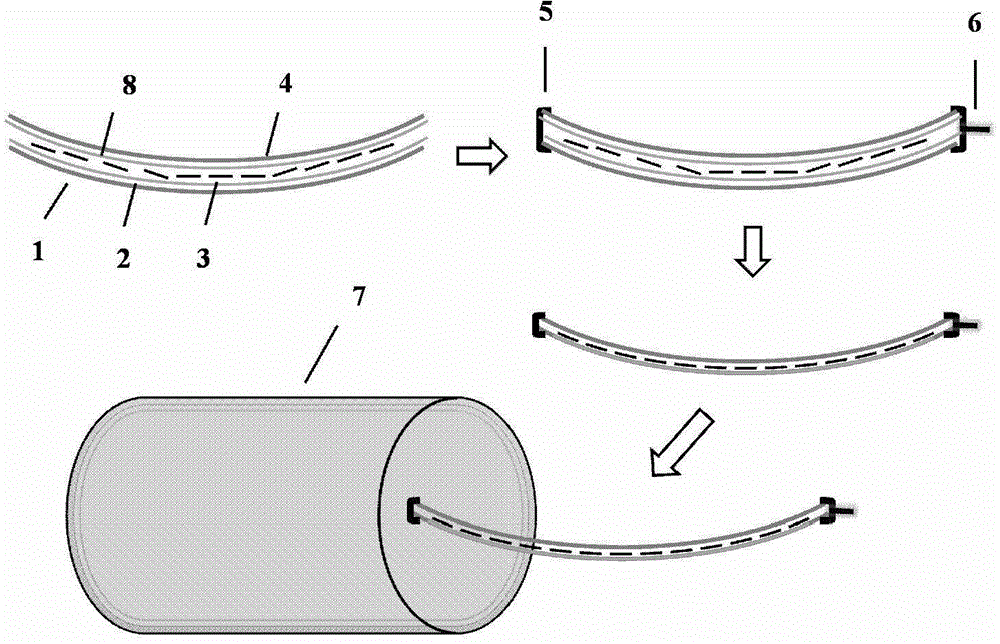

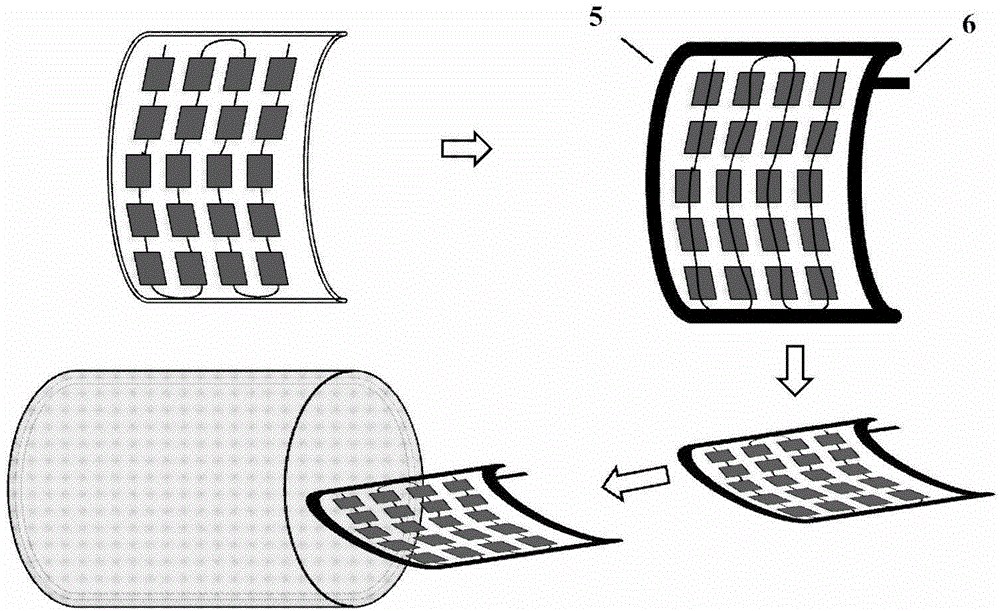

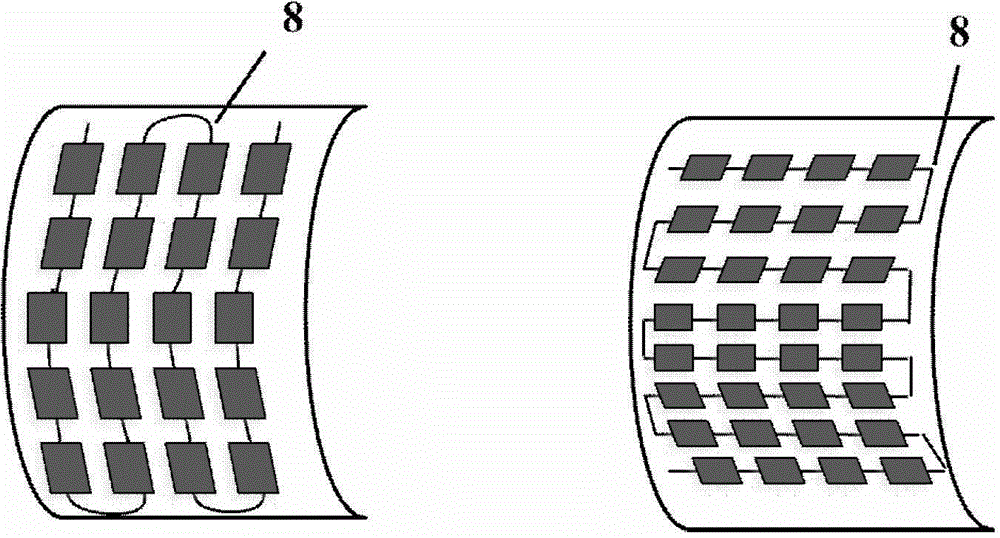

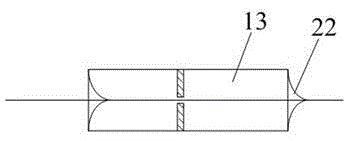

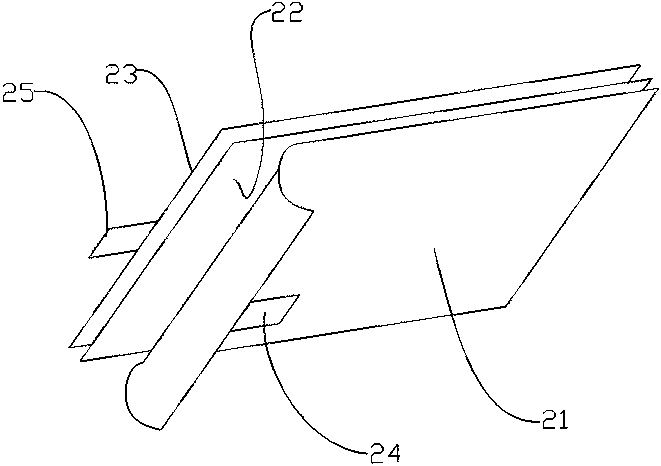

Lamination preparation process of curved-surface double-glass photovoltaic module

InactiveCN102983213AAchieve initial shapePrevent slidingFinal product manufactureLaminationRubber ringGlass cover

The invention discloses a lamination preparation process of a curved-surface double-glass photovoltaic module. Firstly, a layer of binding material covers face plate bent glass, a solar cell is arranged on the binding material, a layer of binding material covers the solar cell, and then rear plate bent glass covers on the binding material. After the panel bent glass is aligned to the rear plate bent glass, a vacuum rubber ring is sleeved on the periphery of the face plate bent glass and the rear plate bent glass, the solar cell and the two layers of binding materials are enabled to be in a closed space formed by the face plate bent glass, the rear plate bent glass and the vacuum rubber ring, the closed space is vacuumized then, the face plate bent glass and the rear plate bent glass compact the solar cell and the binding materials arranged between the face plate bent glass and the rear plate bent glass to prevent relative sliding, and an assembly to be packaged is obtained. The assembly to be packaged is placed into a high-pressure autoclave laminating machine to be carried out with lamination, and the vacuum rubber ring is removed and the curved-surface double-glass photovoltaic module is obtained after the lamination. The lamination preparation process of the curved-surface double-glass photovoltaic module can utilize one device to prepare photovoltaic modules with different radiuses of curvature.

Owner:CHINA SUNERGY CO LTD

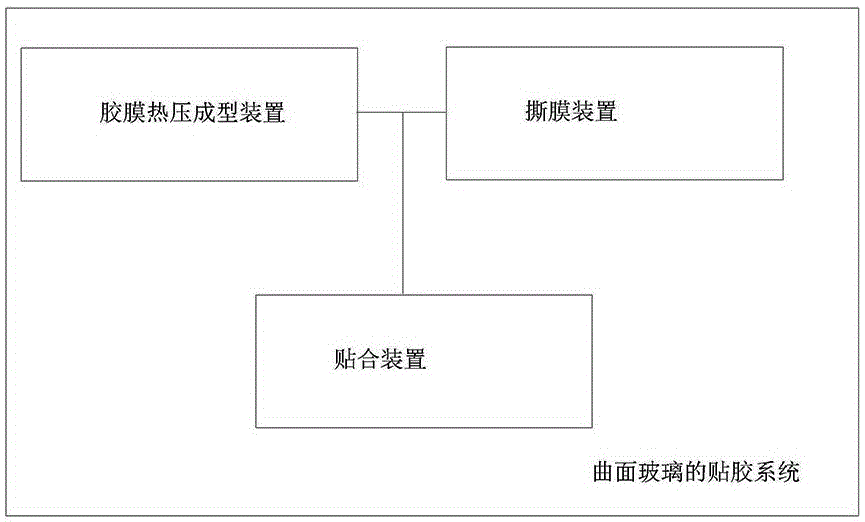

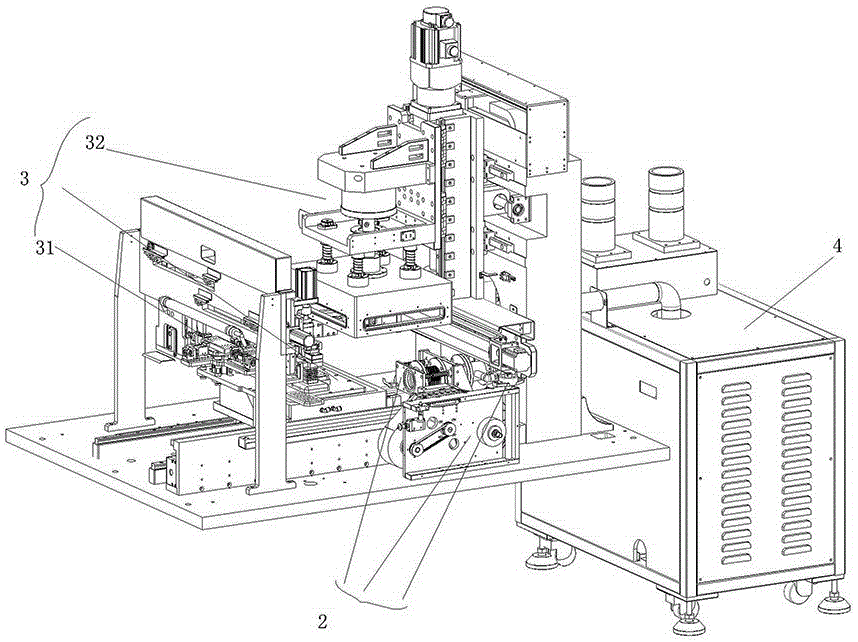

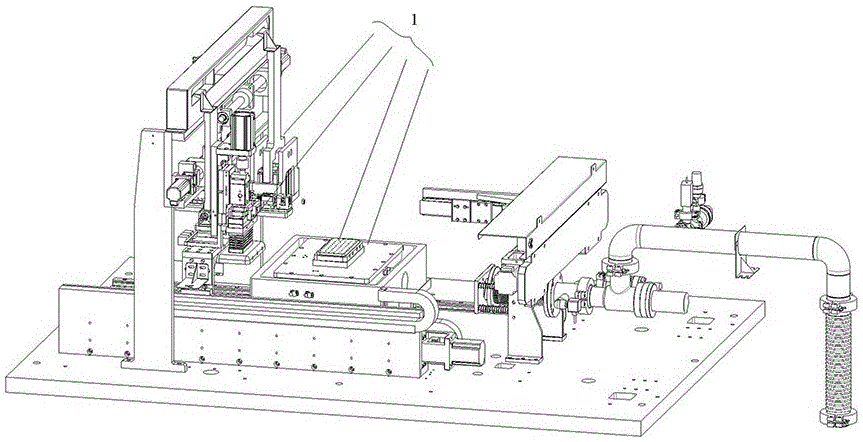

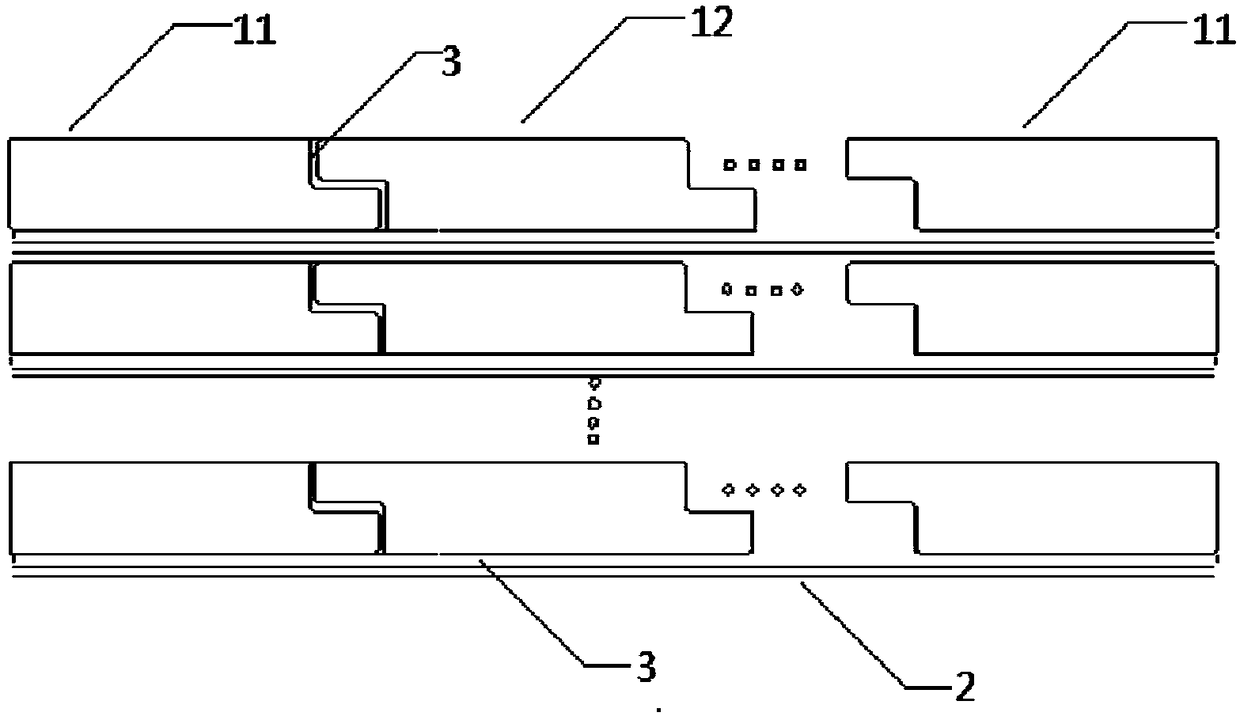

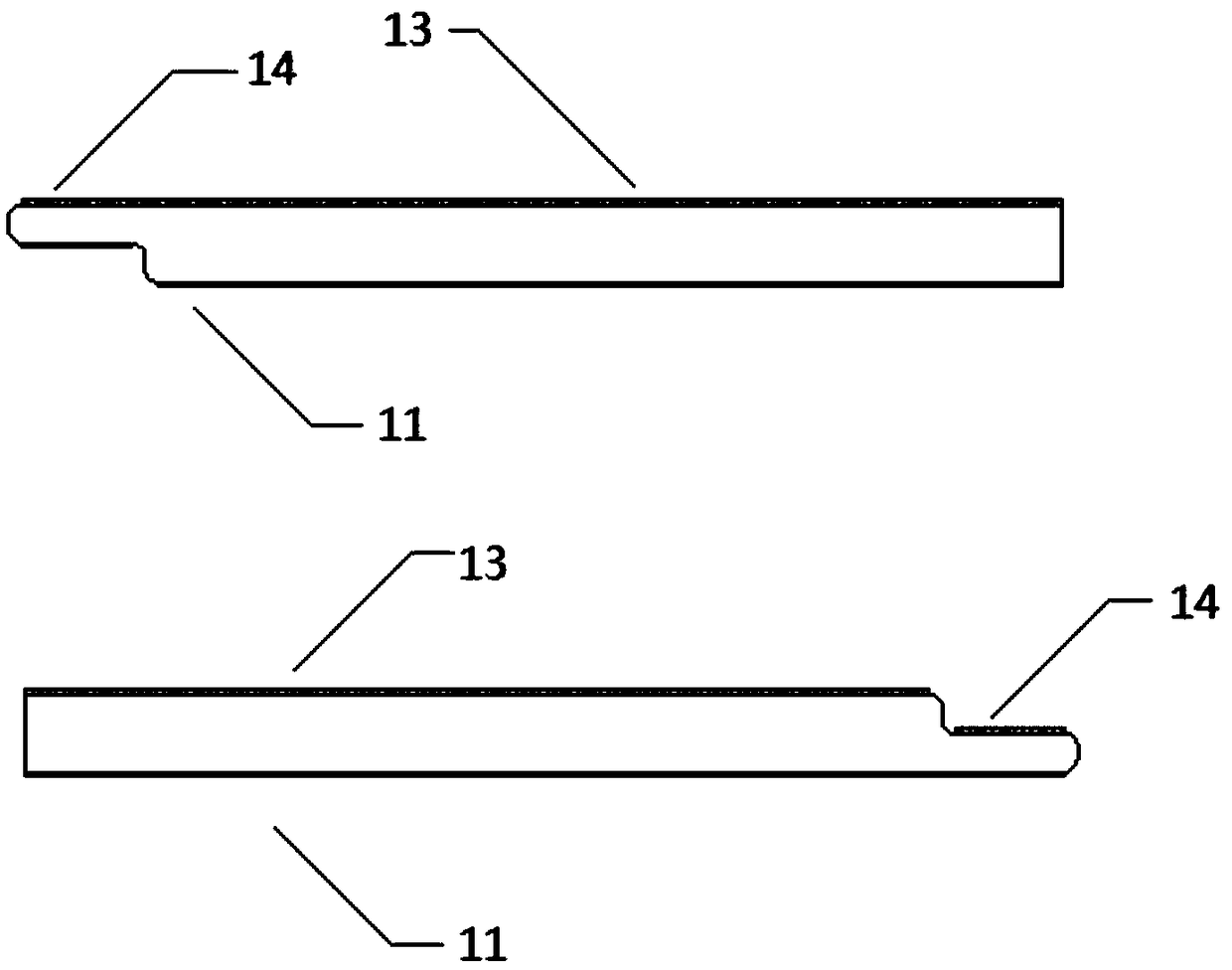

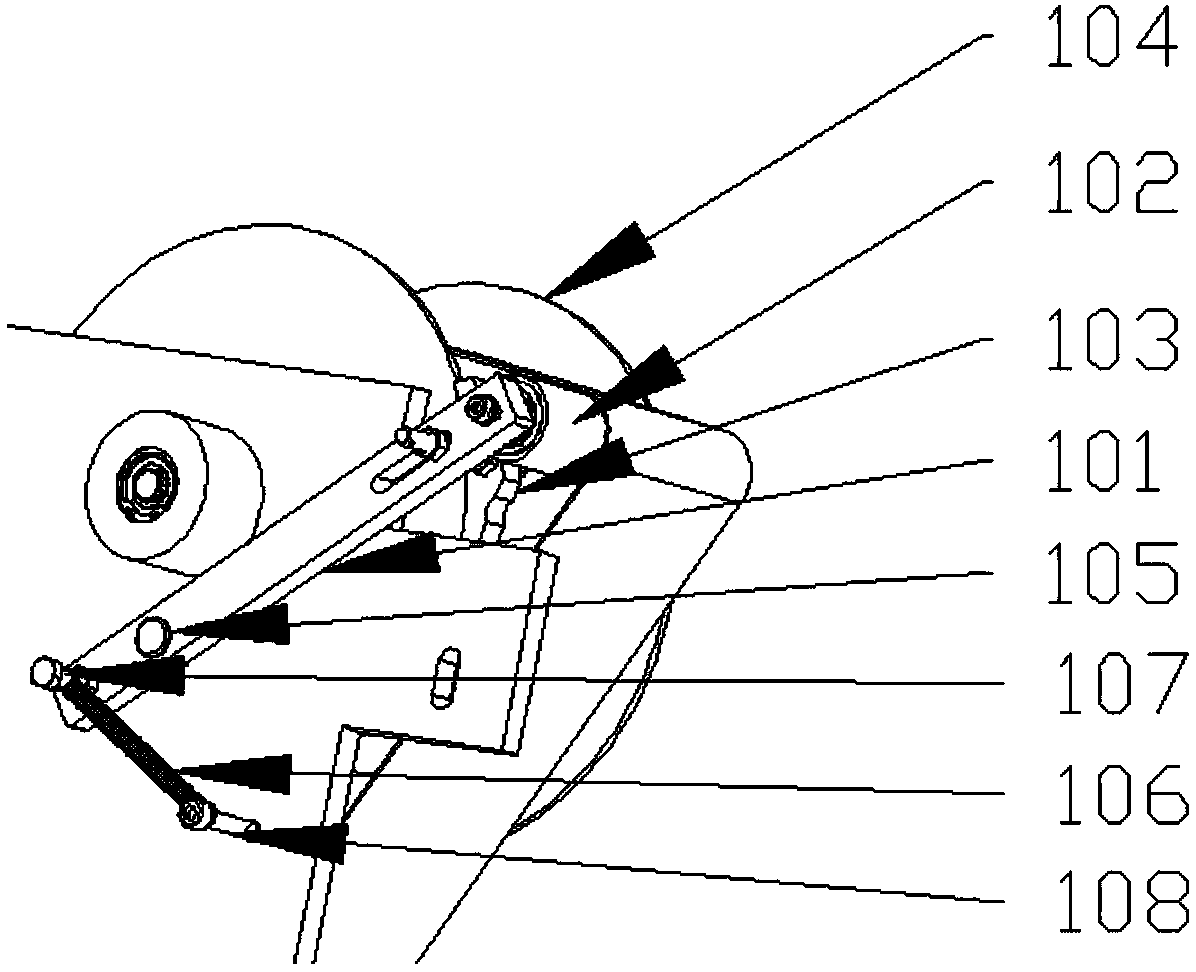

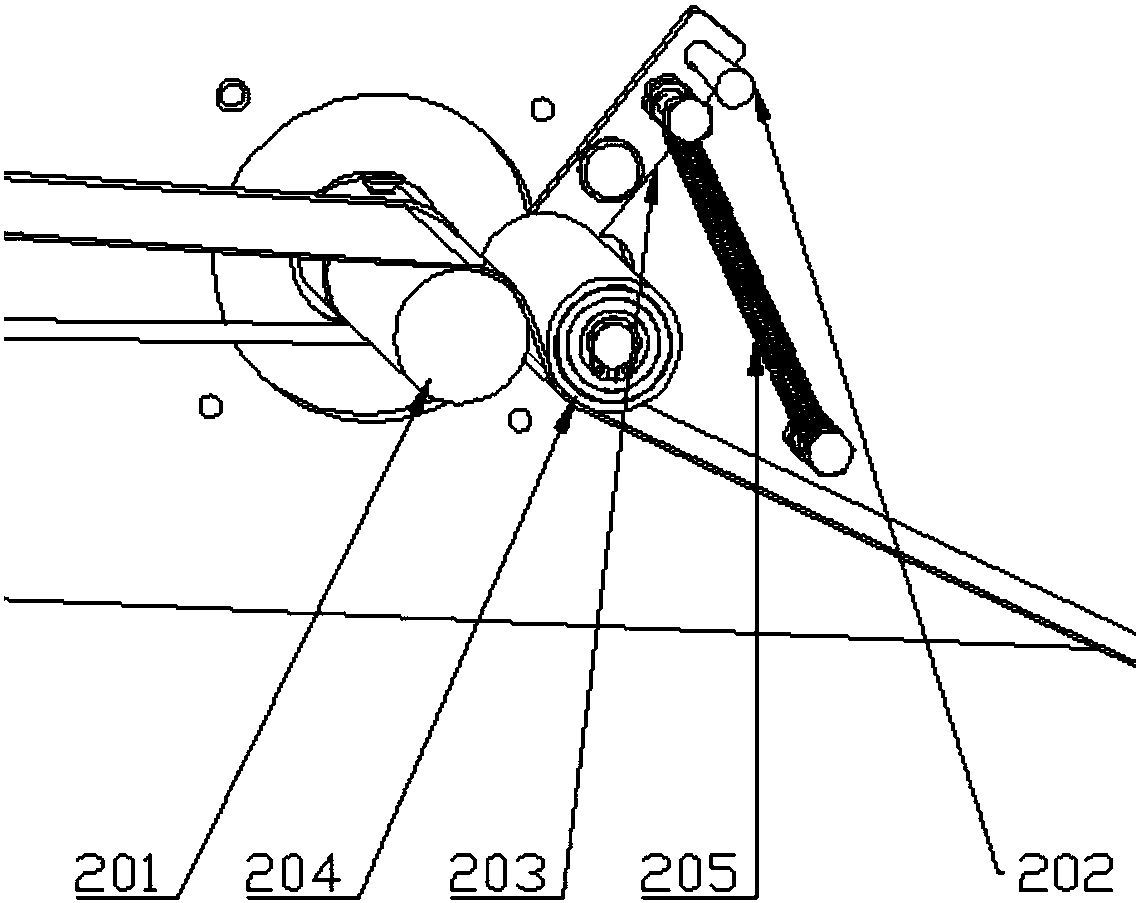

Bent glass adhesive pasting system, and method

InactiveCN106494053AOvercome the problem of sticking glueAvoid wrinklesLamination ancillary operationsLaminationAdhesiveThermal compression

The invention discloses a bent glass adhesive pasting system, and a method. The bent glass adhesive pasting system comprises an adhesive film hot press molding device (1), a dyestripping device (2), and a pasting device (3); the adhesive film hot press molding device (1) is used for obtaining a bent surface adhesive film fitting for bent glass via vacuum absorption, heating, pressing, and cutting of a flat surface adhesive film; the dyestripping device (2) is used for stripping a release film on the upper surface of the bent surface adhesive film prepared by the adhesive film hot press molding device (1); the pasting device (3) is used for adsorbing the bent glass processed via central aligning from an aligning module of the pasting device, is driven by a mechanical arm to move to be above an adhesive film platform (11) of the adhesive film hot press molding device (1), and then is pressed against the adhesive film platform (11) so as to paste the bent glass with the bent surface adhesive film. The bent glass adhesive pasting system is capable of solving problems of rapid automatic molding of bent surface OCA optical adhesive films, and automatic pasting of bent glass with the bent surface adhesive film, and perfect fitting of the bent surface adhesive film obtained via molding with bent glass is realized.

Owner:SHENZHEN CEWAY TECH

Anti-shift full-automatic box sealing machine with disinfecting function

InactiveCN109159995AAvoid position shiftDoes not affect transmissionWrapper twisting/gatheringCartonPaper adhesive tape

The invention relates to an anti-shift full-automatic box sealing machine with a disinfecting function. The anti-shift full-automatic box sealing machine with the disinfecting function comprises a machine body and a steering plate, the left side of the machine body is provided with roller shafts, the steering plate is arranged in the middles of the roller shafts, a conveyor belt is arranged abovethe machine body, and first hydraulic rods are fixedly connected above the machine body; a top plate is arranged above the first hydraulic rods, moreover, paper adhesive tape is arranged on the lowerside of the top plate, a fixing plate is fixed below the paper adhesive tape, and adhesive tape tensioning rollers are arranged on two sides below the fixing plate; and a paper box is arranged on theconveyor belt, moreover, first fixing rods are fixed to the two sides of the paper box, electric push rods are arranged on the inner sides of the first fixing rods, and rolling wheels are arranged onthe inner sides of the electric push rods. According to the anti-shift full-automatic box sealing machine with the disinfecting function, the rolling wheels are arranged so that the position shiftingof the paper box can be prevented, and meanwhile, the rolling wheels can roll along with the movement of the paper box, so that conveying of the paper box is not influenced.

Owner:广东全过程工程咨询有限公司

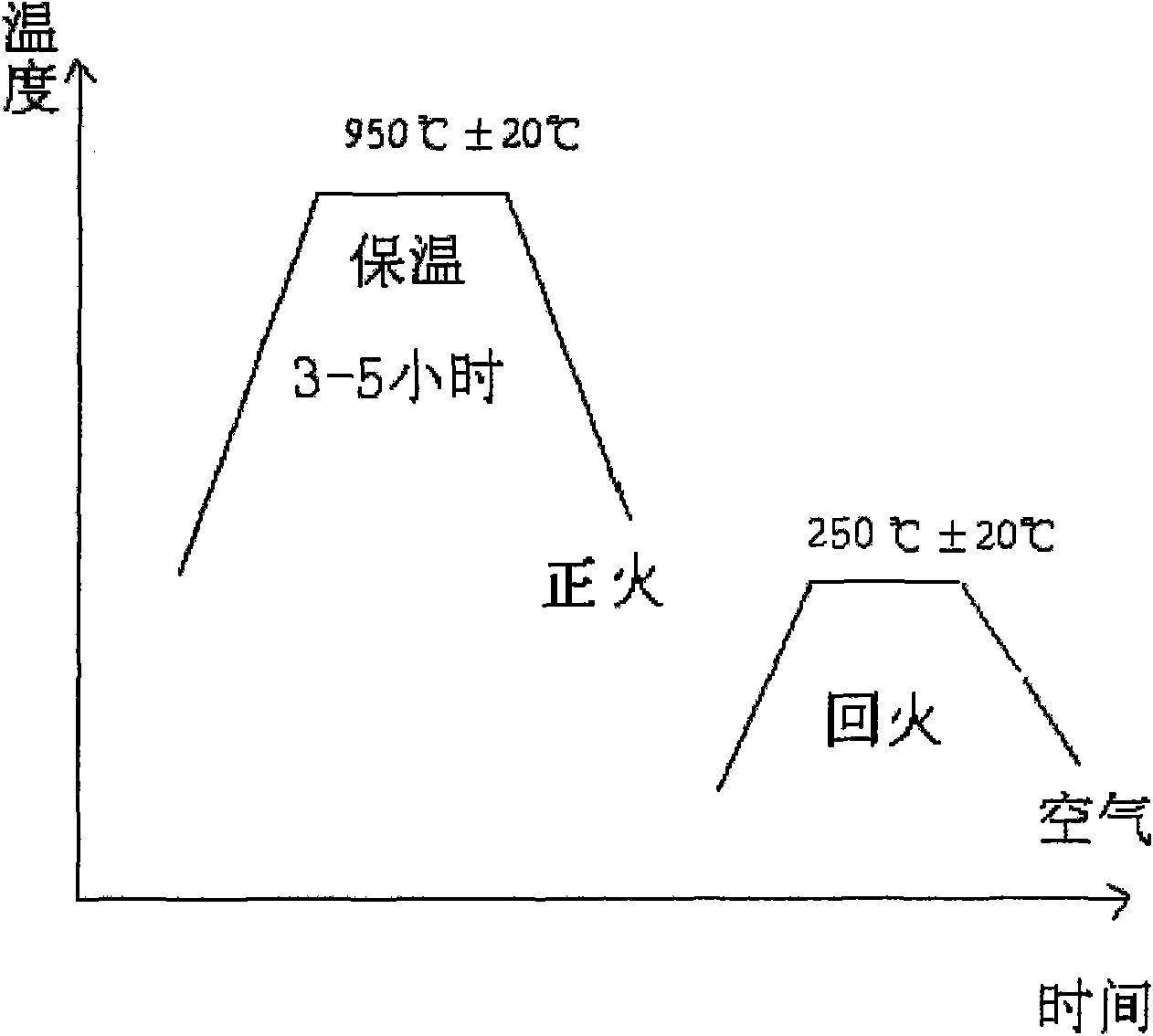

Liquid-state bimetal composite hammer for crusher and manufacturing method thereof

InactiveCN101905184AReasonable operation of deoxygenation and degassingAvoid Bubble ProblemsGrain treatmentsAlloyCrusher

The invention discloses a liquid-state bimetal composite hammer. The hammer comprises a head and a handle, wherein the head is made of an alloying high-chromium cast iron containing 15 to 17 weight percent of Cr, and the handle is made of carbon steel containing no more than 5 weight percent of Cr; after the liquid-state bimetal composite hammer is cast, the hammer is subjected to heat preservation at the temperature of 950+ / -20 DEG C in a thermal treatment furnace for 3 to 5 hours, is subjected to air cooling and normalizing, and is tempered in the air at the temperature of between 250+ / -20 DEG C for 3 to 5 hours. Furthermore, the invention also discloses a method for manufacturing the liquid-state bimetal composite hammer. Two kinds of steel can be metallurgically combined excellently by effectively controlling the pouring temperatures, pouring speeds and intervals of two kinds of molten steel; the molten steel is subjected to reasonable deoxidizing and degassing operation, and bubbles and impurities of joint parts are avoided, so the strength and toughness of the joint parts are improved; a phenomenon that the handle and the head are separated or destroyed cannot occur, and the service life of the hammer is remarkably prolonged by 200 to 400 percent compared with that of the conventional hammer.

Owner:朝阳力宝重工集团有限公司

Silicon PU court and manufacturing method thereof

The invention provides a silicon PU court and a manufacturing method thereof. The court comprises a base plane, a primer layer coated on the base plane, an elastic layer positioned on the primer layer, a reinforcing layer coated on the elastic layer, a surface layer coated on the reinforcing layer, and at least one primer reinforcing layer arranged between the primer layer and the elastic layer. According to the invention, the reinforcing layer is added on the primer layer. With the cooperation of glass fiber mesh cloth and primer PU glue, the mesh cloth is applied on the surface of the base plane; with the high-strength tensile force of the fiber, the elastic layer bottom layer is not swelled due to water vapor rising of the base plane. Therefore, a base bubble problem of the silicon PU court is solved.

Owner:ZHEJIANG WIN SPORTS PRODS

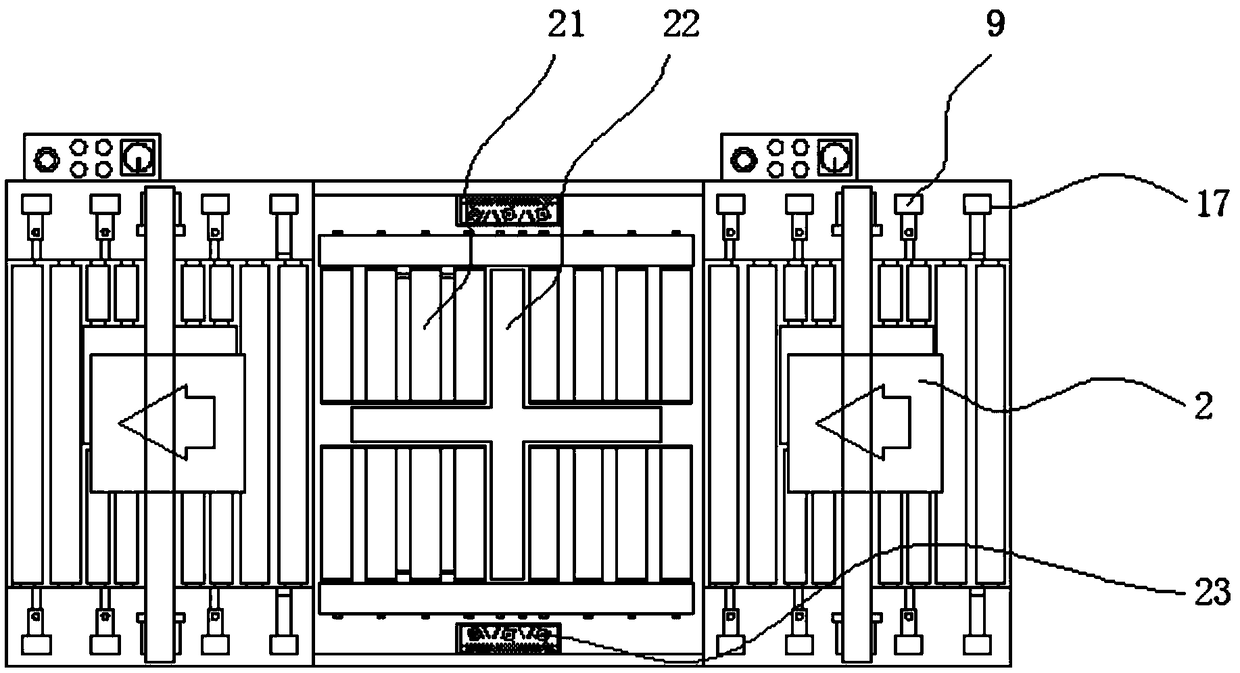

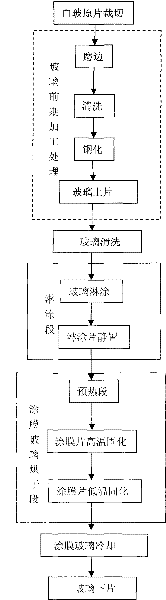

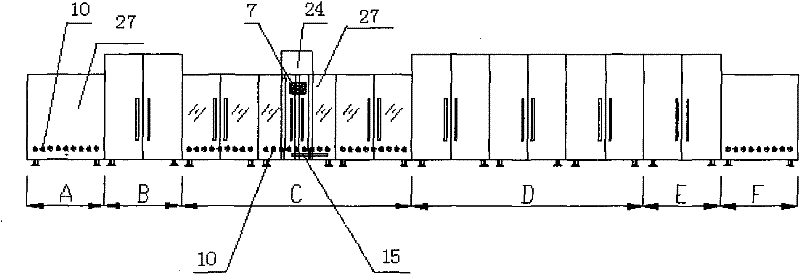

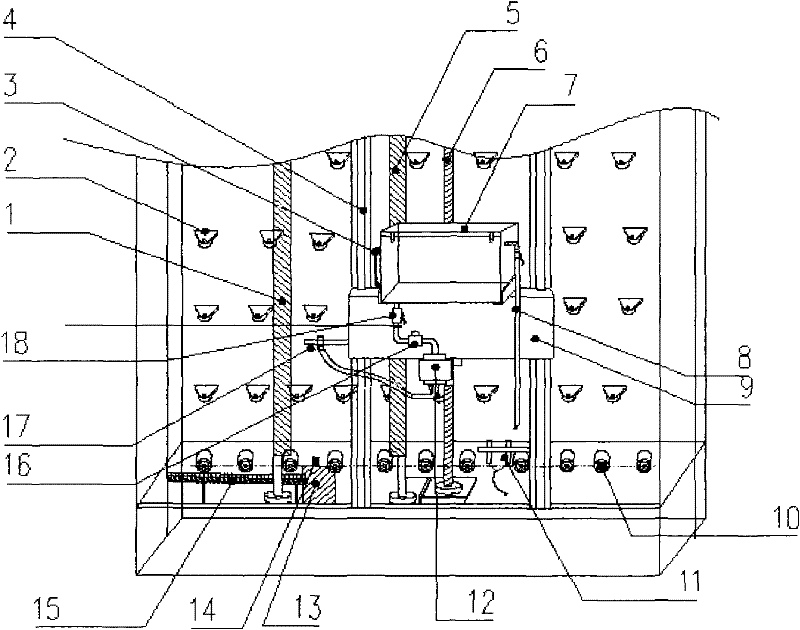

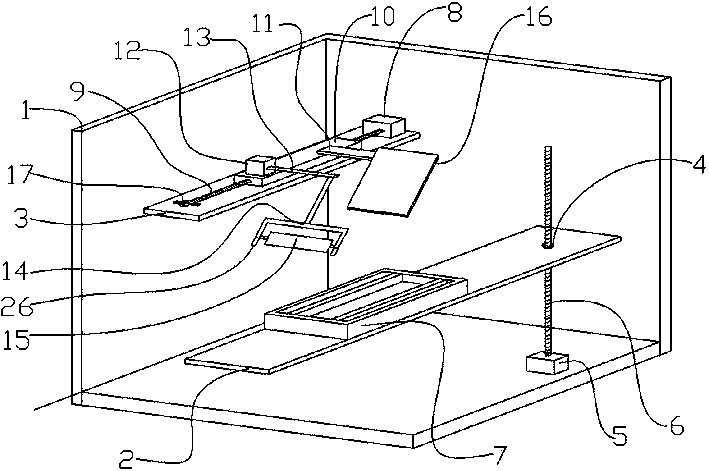

Process and device for coating film on glass

The invention discloses a process and device for coating a film on glass. Glass film coating processing process flow steps include an earlier stage glass treatment procedure, a glass sheet loading procedure, a glass cleaning procedure, a spraying section procedure, a film-coated glass drying section procedure, a film-coated glass cooling procedure and a glass sheet unloading procedure. The entire glass film coating processing device designed by the invention consists of a sheet loading section (A), a cleaning section (B), spraying section (C), a drying section (D), a cooling section (E) and a sheet unloading section (F), wherein the bottom end of a glass support frame (27) is provided with a plurality of drying wheels (10) which are driven to bear and move glass sheets by using a controlled servo motor (23); and a spraying device in the spraying section (C) mainly comprises the glass support frame (27), a front storage box (7), an upper sealing cover at the spraying position of a coating recovering groove (15), and the like. Due to the adoption of the process and the device, the glass film coating quality is ensured, and the problem that the treatment requirement of surface coating on glass with a low-viscosity coating is difficult to meet is solved.

Owner:BEIJING BUILDING TECH DEV +1

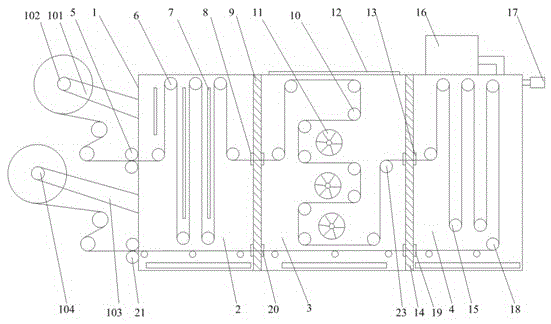

Lithium ion battery pole piece drying device

InactiveCN105486059AEasy to assembleEasy to moveDrying gas arrangementsDrying machines with progressive movementsElectrical batterySmall footprint

The invention relates to the technical field of lithium batteries and in particular to a lithium ion battery pole piece drying device. The lithium ion battery pole piece drying device comprises a cabinet. The cabinet is sequentially divided into a heating chamber I, a heating chamber II and a heating chamber III. Turning rolls I and infrared heaters are arranged in the heating chamber I. A first transmission port is formed in the upper end of the heating chamber I and formed in a heat insulation board I. Turning rolls II and fans are arranged in the heating chamber II. Turning rolls III are arranged in the heating chamber III and a vacuum pump and a vent valve are arranged at the upper end of the heating chamber III. A rotary roll is arranged at the lower end of the heating chamber III. The lithium ion battery pole piece drying device is safe, reliable, convenient to assemble and move, small in occupied area, high in drying speed and capable of solving the problem that bubbles, needle holes and chaps are generated and greatly improving production efficiency.

Owner:SHANDONG PEARSON POWER NEW ENERGY

Film winding mechanism for biodegradable film

The invention discloses a film winding mechanism for a biodegradable film. The film winding mechanism comprises a pneumatic supporting rod, a belt wheel, rotary shafts, infrared detectors, an air pump, a right end cover, a controller and a telescopic bottom plate. The pneumatic supporting rod is arranged on the surface of a roller. The two rotary shafts are arranged at the left end and the right end of the roller respectively. The rotary shafts are arranged on a fixed support and a movable support through rotary bearing sets. The belt wheel is arranged on the left rotary shaft and connected with a drive motor through a belt. The infrared detectors are arranged in the middle of the fixed support. The fixed support is arranged on a platform, and the fixed support and the platform are fixed through bolts. The telescopic bottom plate is arranged below the platform. The rotary shafts are provided with chucks, and the right end cover is arranged at the right end of the right rotary shaft. The film winding mechanism is reasonable in structure and safe and convenient to use, and by means of the telescopic bottom plate and a rotating speed controller, it is guaranteed that in the film winding process, no bubble exists, and flatness of finished products is achieved.

Owner:HUNAN KELAIBAO BIO ENERGY TECH CO LTD

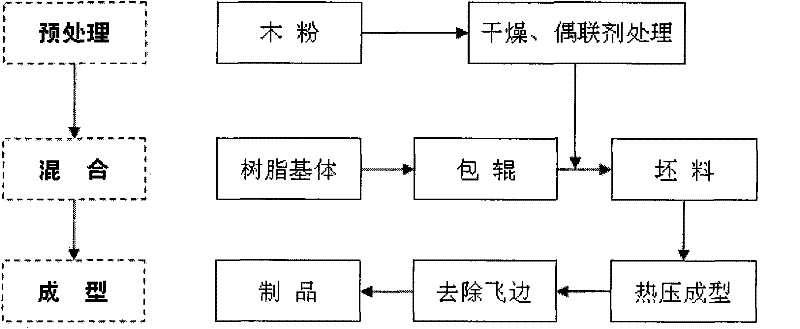

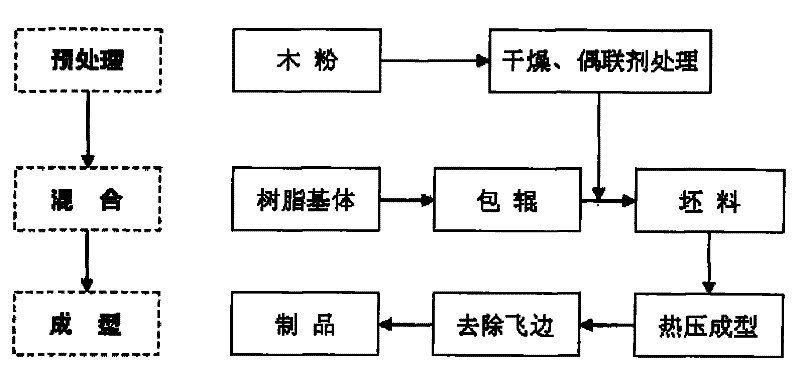

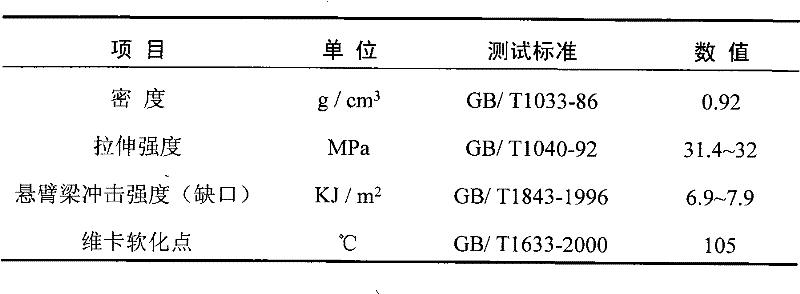

Preparation method of wood plastic material

The invention discloses a preparation method of wood plastic material, which comprises the following raw materials according to parts by weight: 100 parts of thermoplastic plastic, 20-50 parts of wood powder or vegetable fibre, 0.4-0.9 part of silane or aluminate coupling agent, 4-15 parts of ethylene-vinylacetate and 0.8-1.5 parts of paraffin. The above materials are mixed at a high speed and are milled on an open mill, a blank is prepared, and the prepared blank is shaped by hot pressing by a vulcanizer. The invention has simple operation, needs less equipment, correspondingly lowers operation difficulty and equipment investment, can lower cost, has strong competitive power, especially can substantially lower and put an ends to air bubbles in products, improves the quality of a product and improves the rank; the product has the advantages of high strength, light weight, worm damage prevention, low cost, no toxin, environment protection and reuse.

Owner:CHONGQING UNIV OF TECH

Laminator

InactiveCN104369900AAutomatic fast filmAvoid Bubble ProblemsPackagingElectric machineMembrane bodies

The invention discloses a laminator. The laminator comprises a lamination device and a special membrane; the lamination device comprises a shell; a first layer board and a second layer board are arranged in the shell; the bottom of the shell is provided with a first stepping motor and a first lead screw vertically coupled to the first stepping motor; the first layer board is connected to the first lead screw through a nut in a sleeving mode and provided with a fixing groove; the second layer board is provided with a second stepping motor, a second lead screw horizontally coupled to the second stepping motor and a sliding board connected to the second lead screw through threads in a sleeving mode; the sliding board is provided with a telescopic board and a third stepping motor; a membrane clamping board is arranged at the tail end of the telescopic board; the third stepping motor is coupled with a rotary rod; the tail end of the rotary rod is connected with a shifting fork; the shifting fork is provided with an idler wheel; the special membrane comprises a screen protection membrane body in the middle, an auxiliary membrane body at the bottom layer and a protection membrane body at the top layer; double-faced adhesive tape is arranged on the outer side of the front end of the auxiliary membrane body; single-faced adhesive tape is arranged on the outer side of the front end of the protection membrane body. The laminator can automatically and rapidly paste the screen protection membrane body.

Owner:刘哲 +10

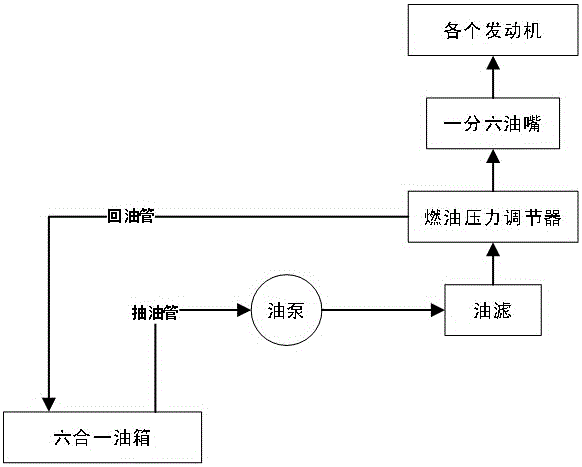

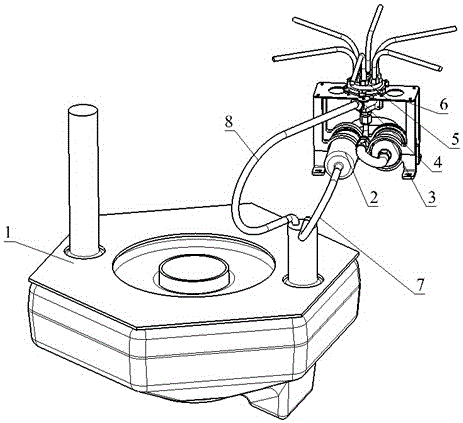

Fuel-powered multi-rotor unmanned plane fuel supply scheme

ActiveCN106081132AReduce weightLow costPower plant fuel tanksFuel injection apparatusFuel tankFuel supply

The invention relates to a fuel-powered multi-rotor unmanned plane fuel supply scheme. An all-in-one fuel tank, a fuel pump, a fuel strainer, a fuel pressure regulator, a one-to-more nipple and a fixed support constitute a whole fuel supply system. The central idea of the scheme is all-in-one one-to-more combined design. The fuel tank adopts the all-in-one design: a plurality of partitions with smaller height than the fuel tank are arranged inside the fuel tank, and the upper and lower ends of each partition do not contact the upper and lower surfaces of the fuel tank, so that the whole fuel tank is divided into a plurality of independent small fuel tanks which communicate with each other. The nipple adopts the one-to-more design: one fuel inlet is divided into a plurality of fuel outlets. The fuel pressure regulator and the one-to-more nipple form an integral body, and do not need special arrangement. The scheme solves the following problems: fuel shortage of a certain engine can easily occurs when the fuel-powered multi-rotor unmanned plane is inclined, each engine of the fuel-powered multi-rotor unmanned plane needs one fuel supply system, bubbles can easily appear in the fuel supply system, and the fuel pressure regulator needs to be independently arranged.

Owner:辽宁大壮无人机科技有限公司

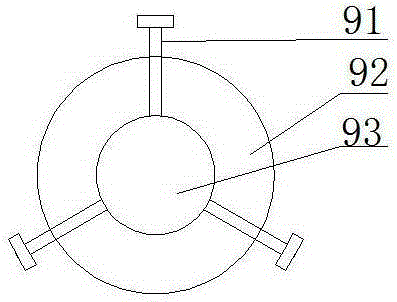

Combined type magnetic core and preparation method thereof

InactiveCN102810386AResolve fragmentationAvoid Bubble ProblemsInorganic material magnetismTransformers/inductances detailsNanotechnologyMagnetic core

The invention provides a combined type magnetic core and a preparation method thereof. The method comprises the following steps: firstly, mixing powdery magnetic materials and a powdery adhesive agent in a presetting proportion so as to form a solid mixture; secondly, putting a column-shaped core material into a column-shaped holding mold of a mould; filling the mixture into the upper and the lower ends of the mould respectively so as to form a mold, or putting the mixture, an annular core material and the mixture into another mould in sequence; and subsequently, heating the mould or the solid mixture in another mould to enable the powdery magnetic materials to be mutually bonded through the powdery adhesive agent so as to be shaped at two ends of the column-shaped core material, or enable the powdery magnetic materials to be mutually bonded through the powdery adhesive agent so as to be wrapped outside the whole annular core material coaxially and form a through holes around the axis of the annular core material. Therefore, with the adoption of the preparation method, the magnetic cores containing more than two materials can be produced.

Owner:美桀电子科技(深圳)有限公司

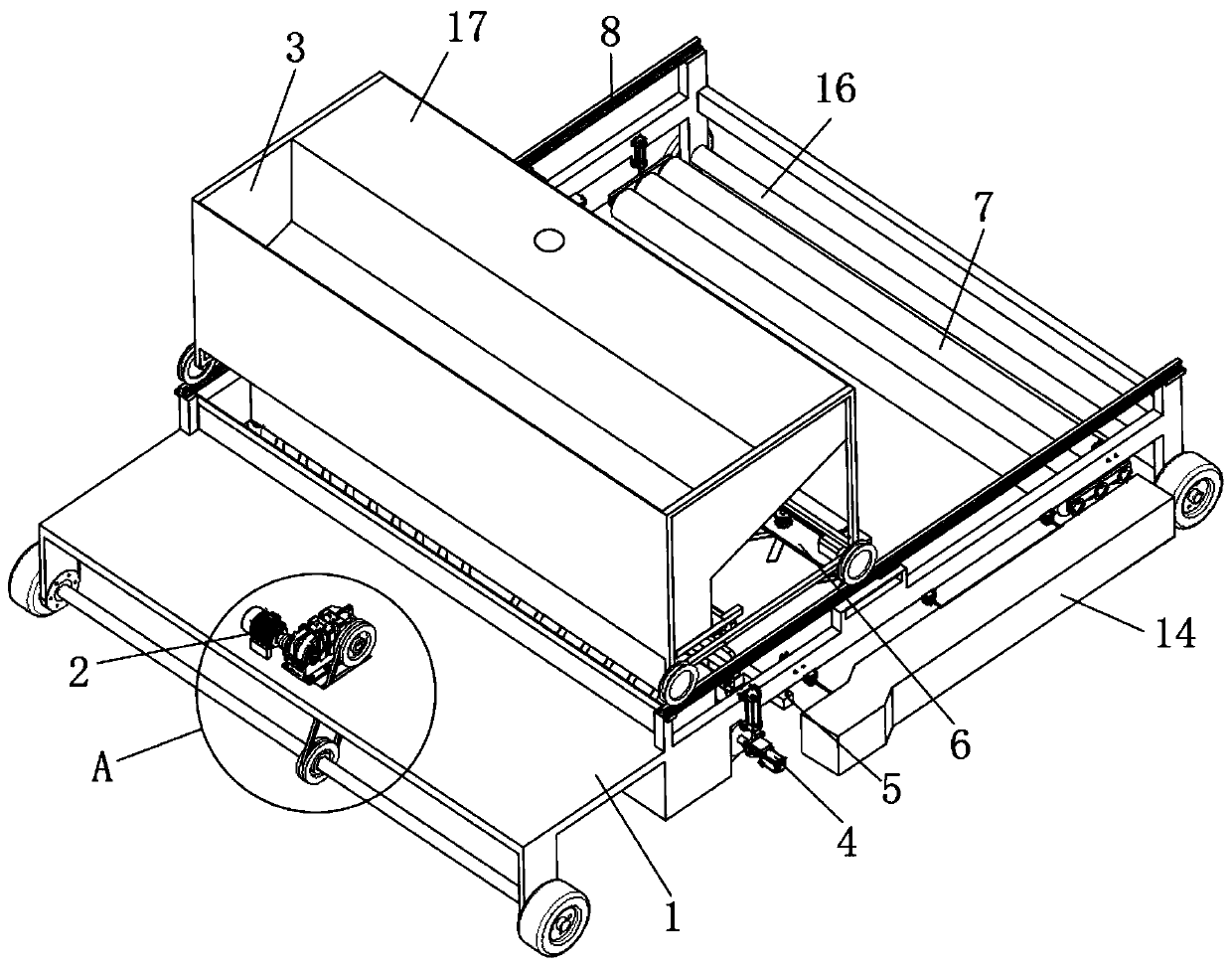

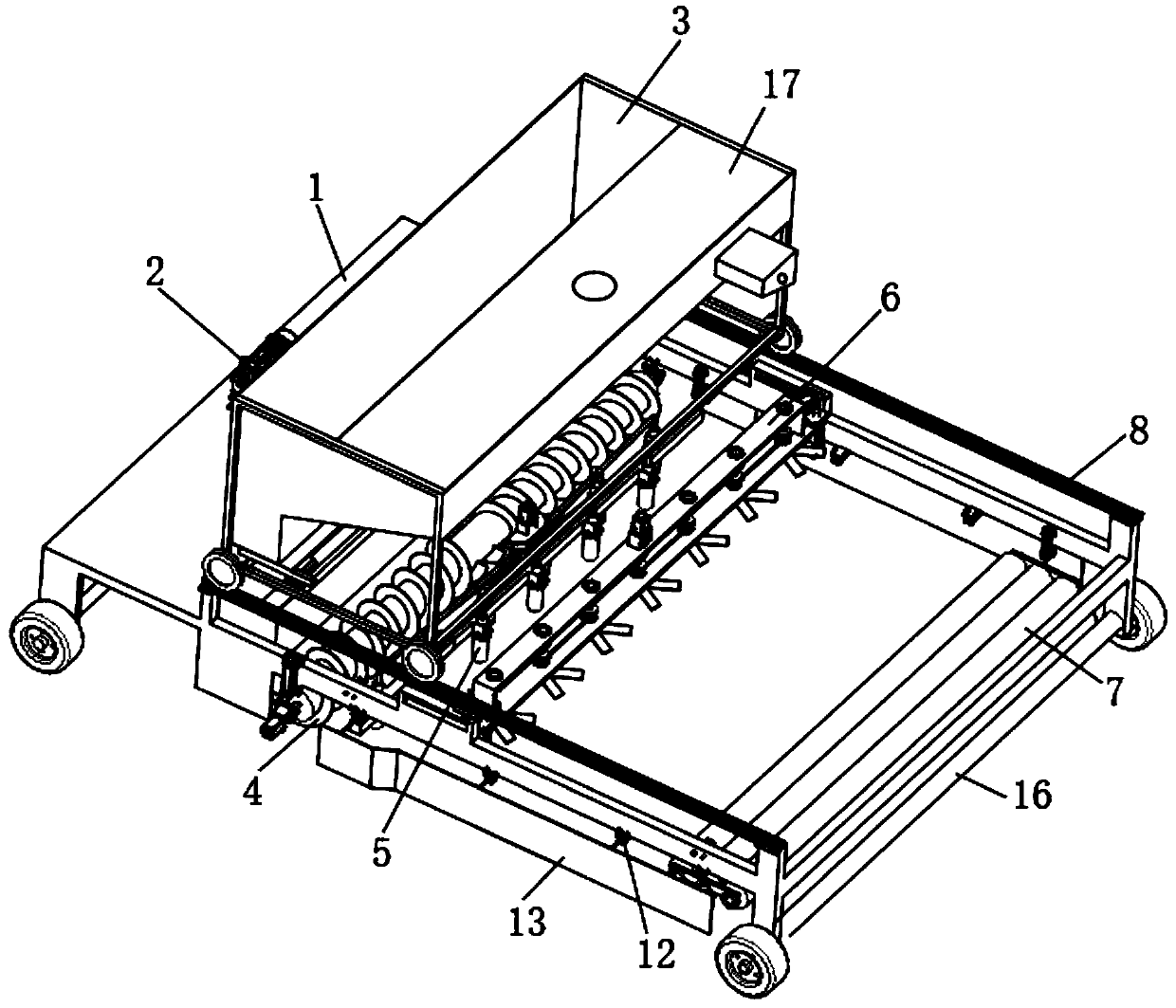

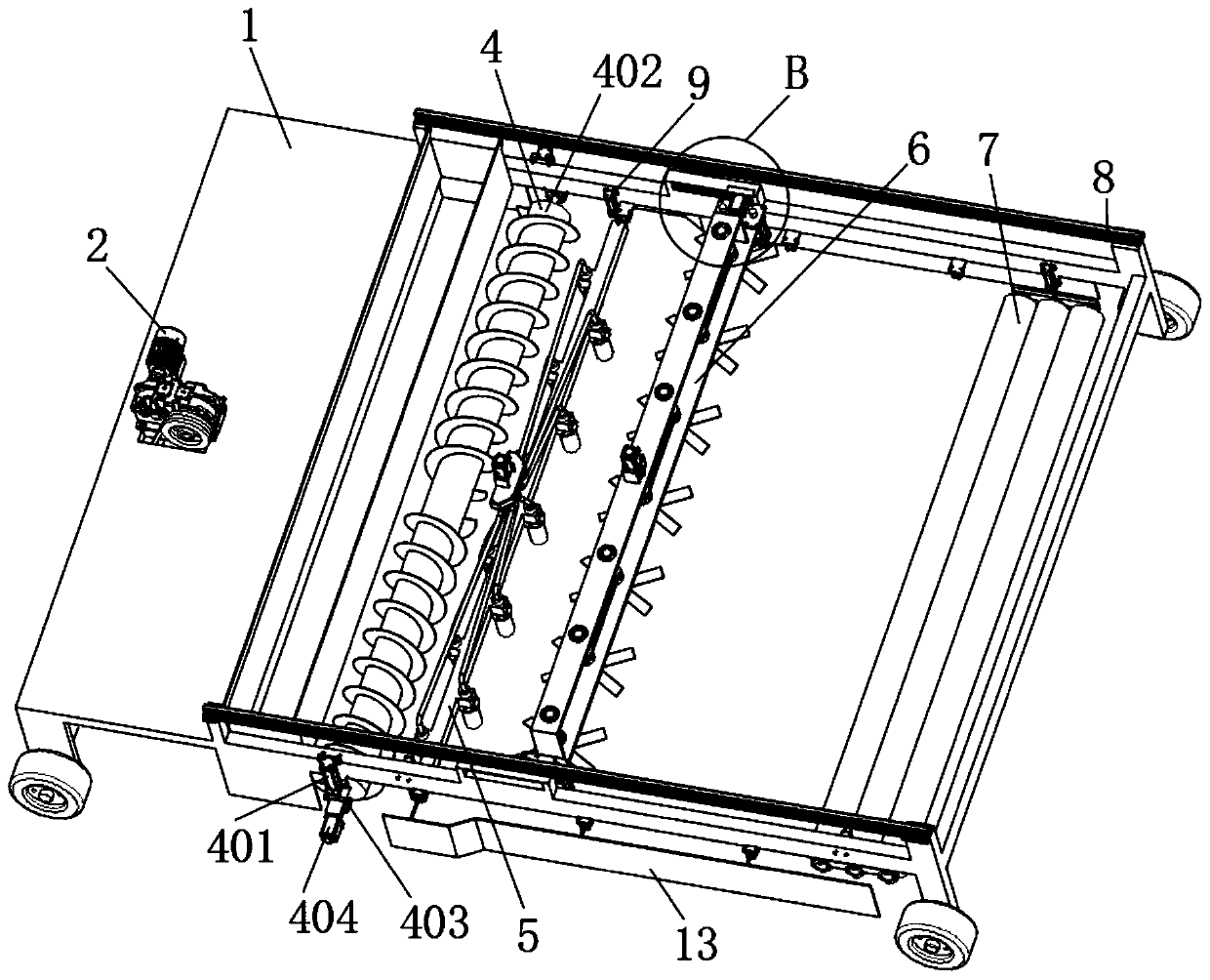

Cement pavement paving and maintaining all-in-one machine for road construction

ActiveCN111379209ATo achieve the purpose of maintenanceEfficient pavingRoads maintainenceHydraulic cylinderArchitectural engineering

The invention discloses a cement pavement paving and maintaining all-in-one machine for road construction, and belongs to the field of road construction. A striker plate storage box is arranged on a vehicle body, the striker plate is pushed to an outlet of the striker plate storage box through the hydraulic cylinder c, the vacuum sucker sucks the striker plate, the cement material can be discharged to the position between the material blocking plates, the paving training is further improved, a film roller and a water tank are also arranged, and then, after the cement laying is completed, the cement pavement is subjected to water spraying and film covering operation, so the goal of maintaining the cement pavement is further achieved; and meanwhile, the cement discharging mechanism, the cement paving mechanism, the cement vibrating mechanism, the grinding mechanism and the leveling mechanism are matched for use, the device can automatically pave, gather, grind and flatten cement on a pavement, the purpose of efficiently and conveniently paving the cement is achieved, the structural design is simple and reasonable, the device has the advantage of quickly paving and maintaining the cement pavement, and the device is convenient and quick to use and suitable for application and popularization.

Owner:杨明 +4

Glue spreading device and glue spreading equipment

ActiveCN103354282AAvoid Bubble ProblemsAvoid wrinklesElectrode manufacturing processesWrinkle skinReciprocating motion

The invention a glue spreading device and glue spreading equipment. A pressing adhesive tape piece is driven to perform a reciprocating motion between the position of a pressing adhesive tape and an initial position through a glue spreading power assembly; the pressing adhesive tape piece is contacted with a pole piece and an adhesive tape wire to be subjected to glue spread, at least partially of which is attached on the pole piece, at the position of the pressing adhesive tape; the pressing adhesive tape piece presses one end of the adhesive tape wire to be subjected to glue spread, and gradually moves to the other end of the adhesive tape wire to be subjected to glue spread at an extrusion state along with the movement of the pole piece; air between the glue tape and the pole piece is extruded out, so that air bubbles and wrinkles can be effectively prevented.

Owner:GEESUN AUTOMATION TECH

Wind power blade main beam or subsidiary beam structure and fabrication method thereof

InactiveCN109372708AAvoid Bubble ProblemsImprove bindingMachines/enginesWind energy generationElectricityEngineering

The invention discloses a wind power blade main beam or subsidiary beam structure. The wind power blade main beam or subsidiary beam structure comprises plate materials, low-surface-density fabric andresin, wherein the plate materials are superimposed in both the chord direction and the longitudinal direction and comprise main plates and side plates arranged at the end portions of the main plates, the thickness of the side plates is less than that of the main plates, the superimposed parts of the adjacent plate materials in the chord direction are superimposed through the side plates of the adjacent plate materials, and the thickness of the superimposed parts of the side plates is not more than that of the main plates, the low-surface-density fabric is arranged between the adjacent platematerials in the longitudinal direction, and the positions between the plate materials as well as the positions between the plate materials and the low-surface-density fabric are filled with the resin. By means of the plate materials and a fabrication method, the resin passage length and the number of corners are effectively increased, excessive penetration of the molten lower-layer resin towardsupper layers is prevented, the flowing speed of the resin can be effectively controlled, the situation that the interlamination resin content is low to cause defects is prevented, the use ratio of theresin is increased, and the quality of wind power blades obtained finally is good.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

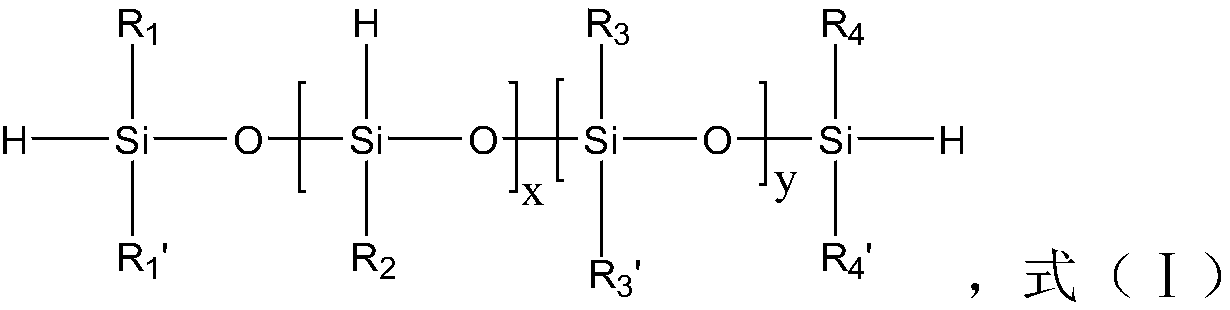

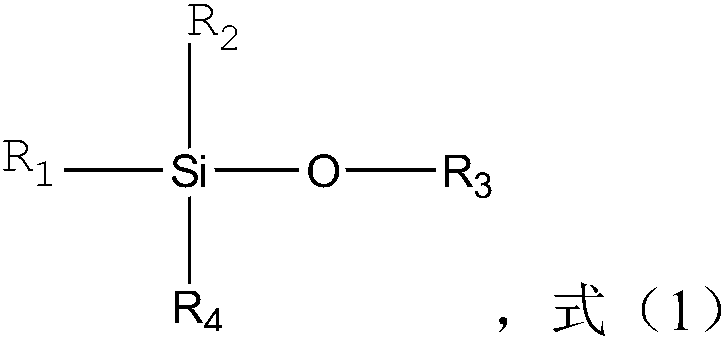

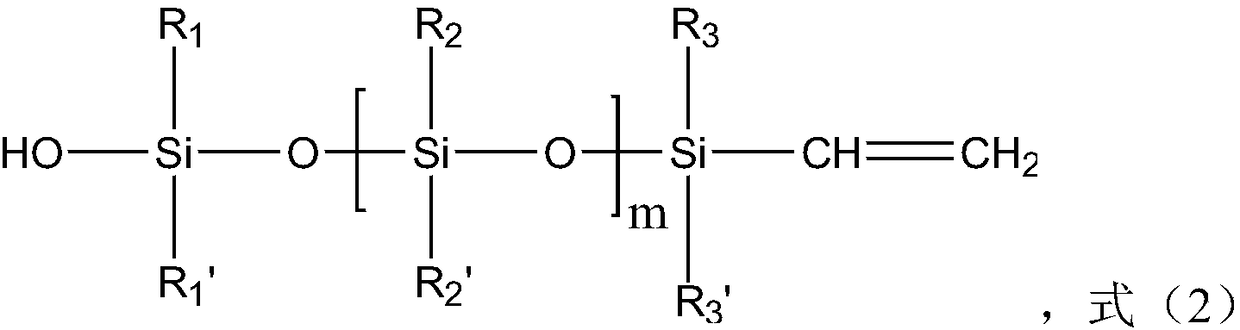

Low-viscosity optical adhesive composition, a preparation method thereof and application thereof to perfusion of touch screen to realize full lamination

ActiveCN108384509AReduce light transmittanceLow refractive indexNon-macromolecular adhesive additivesHydrogenPhotoinitiator

The invention provides a low-viscosity optical adhesive composition, which is prepared from the following components with contents in percentage by mass: 60 to 80 percent of vinyl silicone oil, 5 to 15 percent of hydrogen-containing polysiloxane, 1 to 3 percent of coupling agent, 3 to 15 percent of viscosity modifier, 1 to 3 percent of construction additive, 0 to 4 percent of photoinitiator, 0.001to 0.05 percent of catalyst and 0.001 to 0.05 percent of inhibitor. The low-viscosity optical adhesive composition can be used for quickly completing the full lamination of a super-large-size multipoint touch screen, moreover, cannot generate gas-bubble and adhesive-overflow phenomena, and meanwhile, has favorable bonding performance, temperature-resistant and damp-resistant reliability and coldand hot impact stability. The invention also provides a preparation method of the low-viscosity optical adhesive composition. The preparation method comprises the steps of proportioning, blending preparation, debubbling and subpackaging, and the like. The low-viscosity optical adhesive composition is simple in process and is safe and environment-friendly, and the industrialization is easily realized.

Owner:新纶光电材料(深圳)有限公司

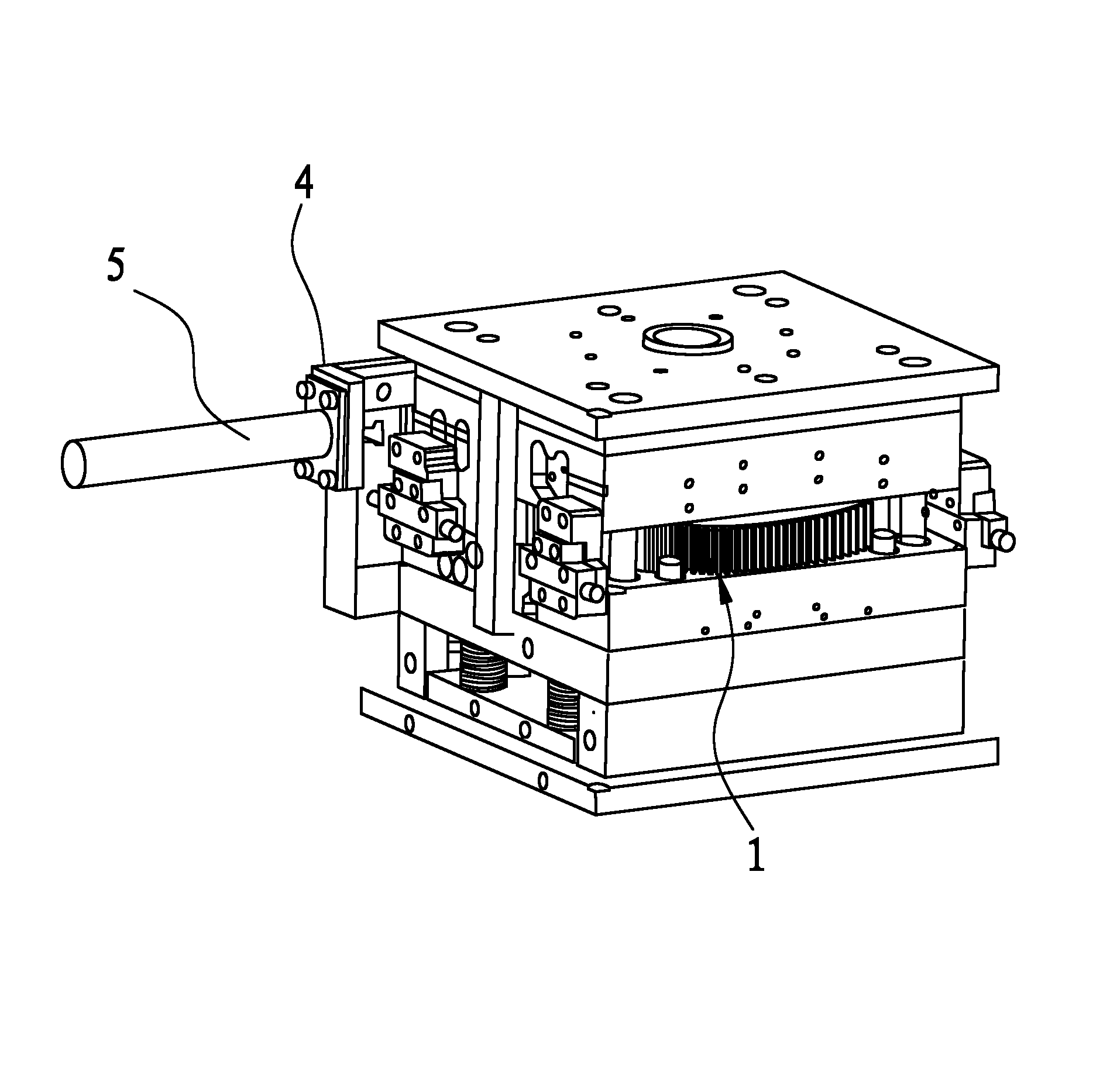

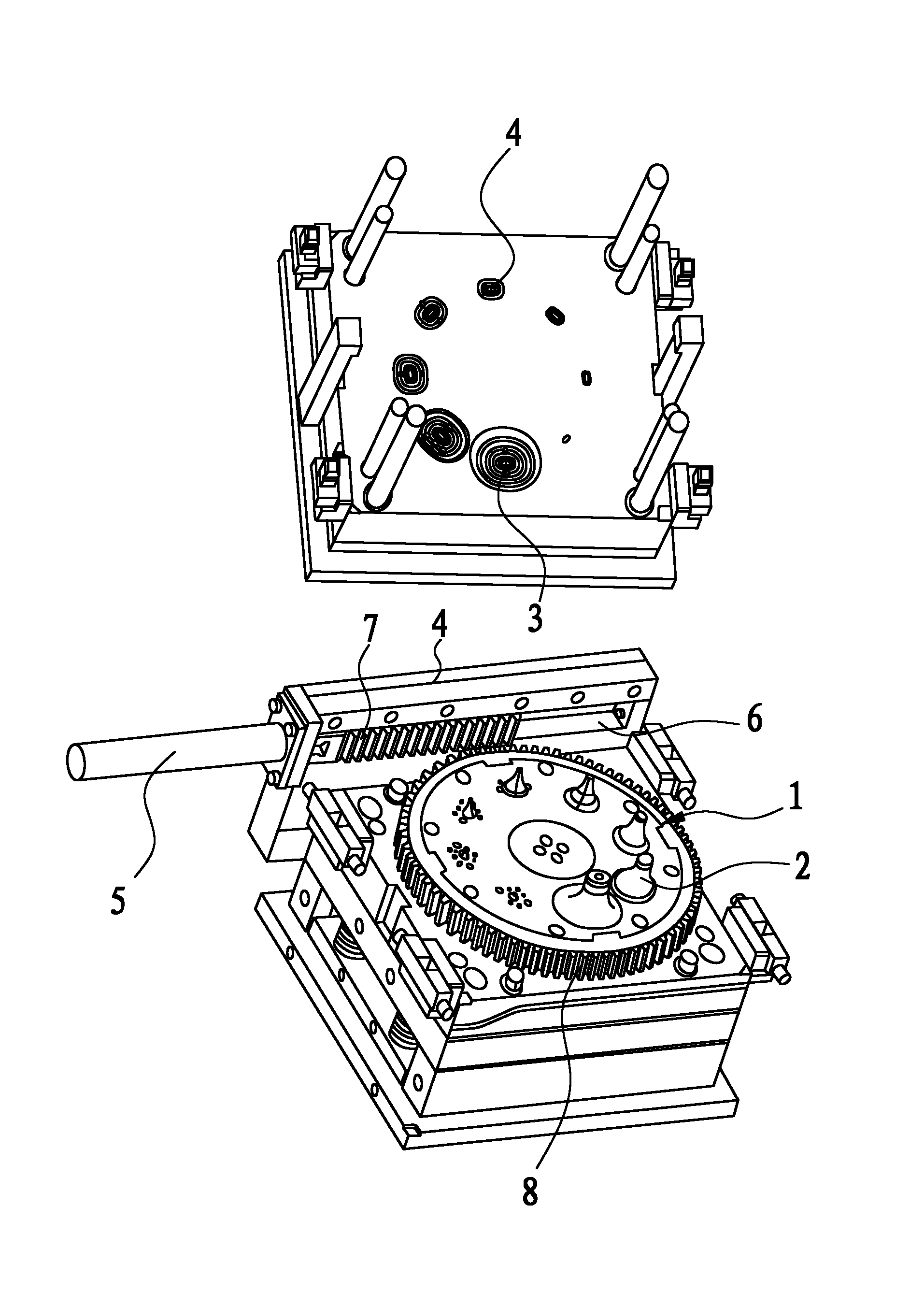

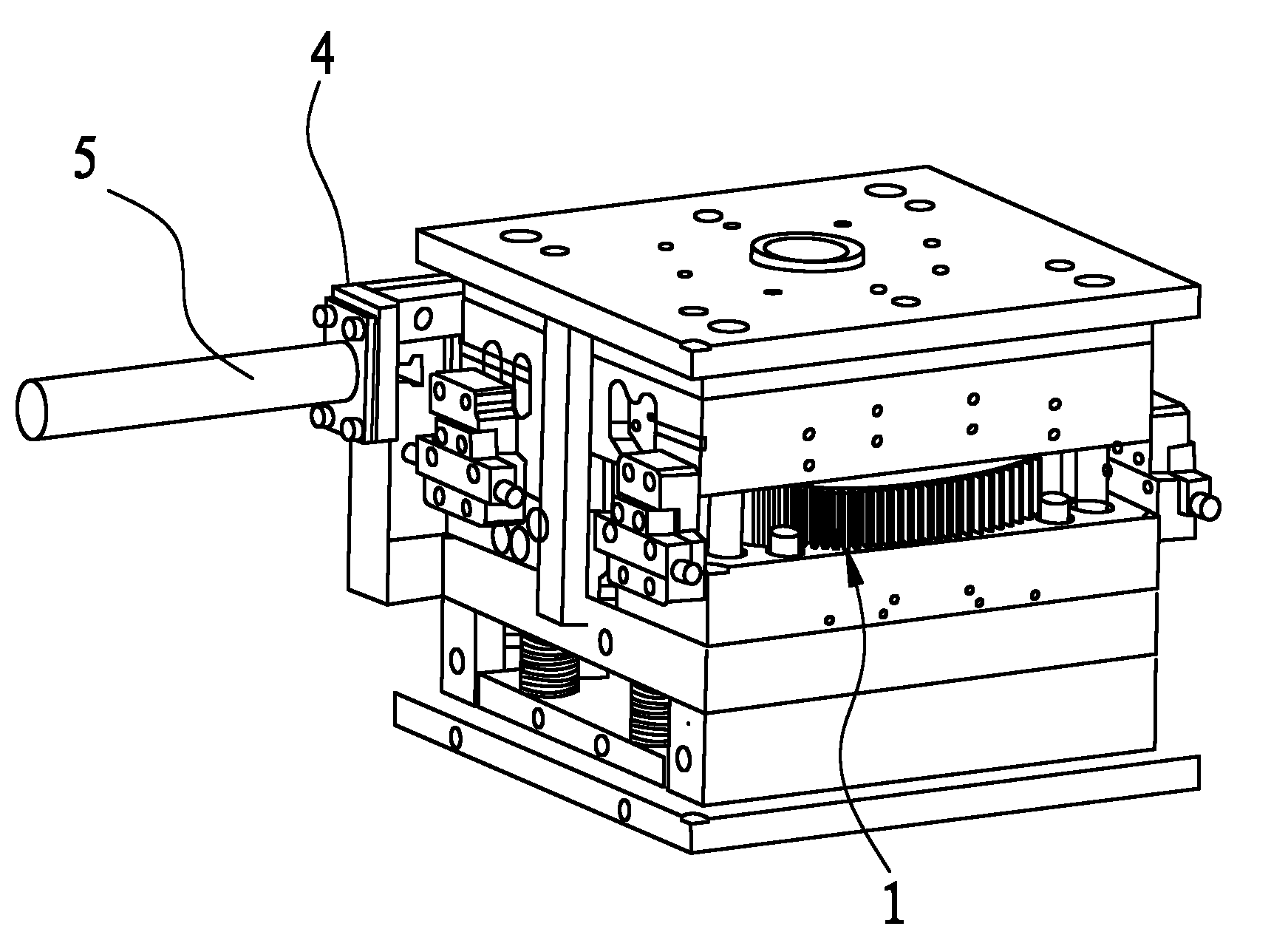

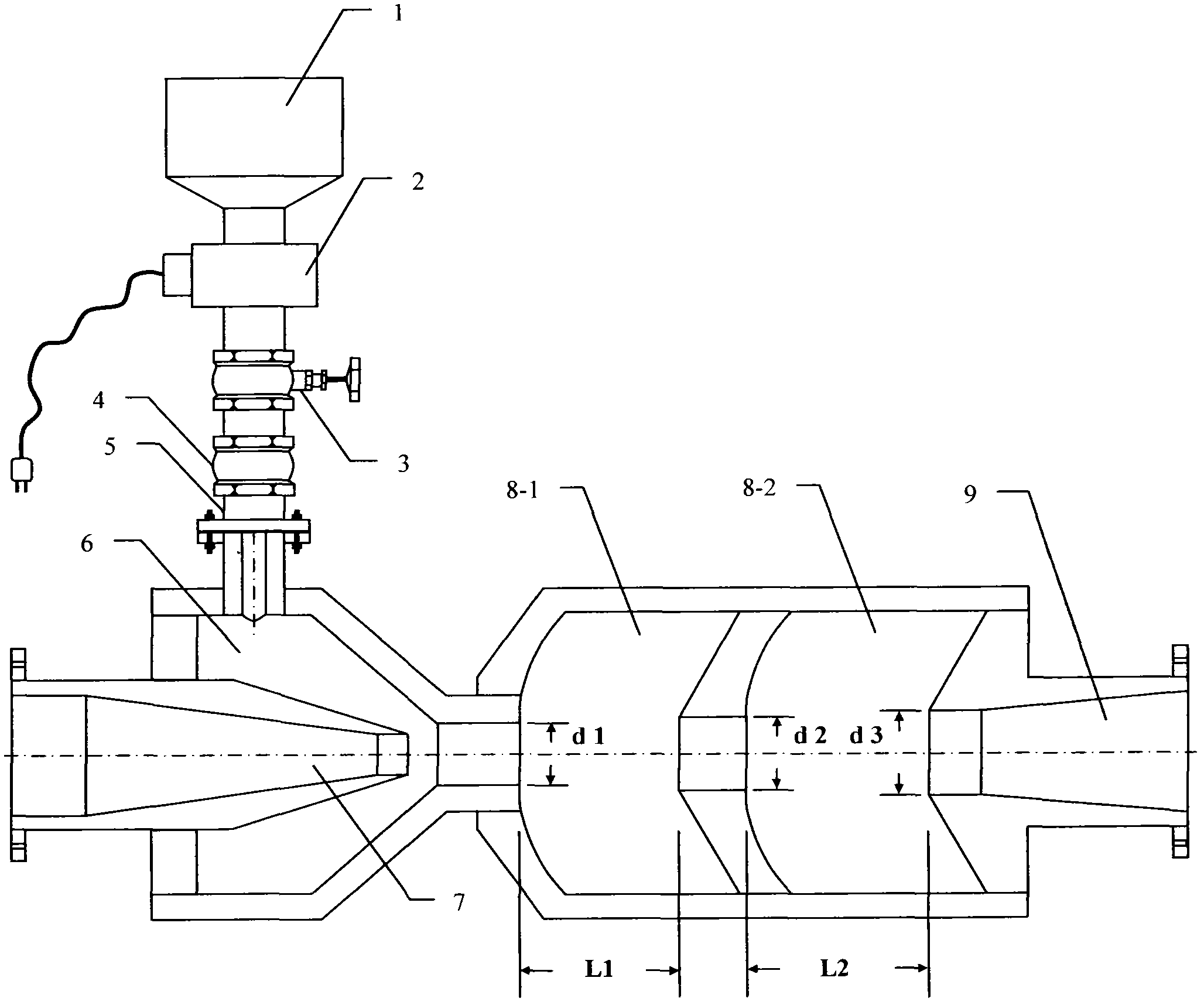

Rotating laminated type injection mould and injection method using same

The invention relates to the technical field of an injection mould, and in particular relates to a rotating laminated type injection mould and an injection method using the same. The mould comprises a fixed mould main body and a movable mould main body, wherein the fixed mould main body comprises a fixed mould plate and a fixed mould chamber, the movable mould main body comprises a movable mould plate, an ejection mechanism and a movable mould chamber, the movable mould chamber is coupled with a rotating disk, one side of the mould is provided with a driving device which drives the rotating disk to rotate, the rotating disk is annularly provided with at least two embedding pieces which are set according to the thickness of a product, and the fixed mould chamber is provided with cavities which are matched with the embedding pieces. As the rotating disk rotates, the embedding pieces arranged at the rotating disk and the cavities arranged at the fixed mould chamber are closed, glued and cooled to be formed and opened, and the transparent product with the special thickness is divided to be subjected to alternated type or laminated type injection at least twice. The invention is reasonable in structure, the size of a mould blank is reduced, the indentation on the surface of the transparent product with the special thickness is controlled, the easily generated air bubble of an inner core is avoided, the injection period is shortened, and the production cost is reduced.

Owner:毅昌金型(东莞)五金制品有限公司

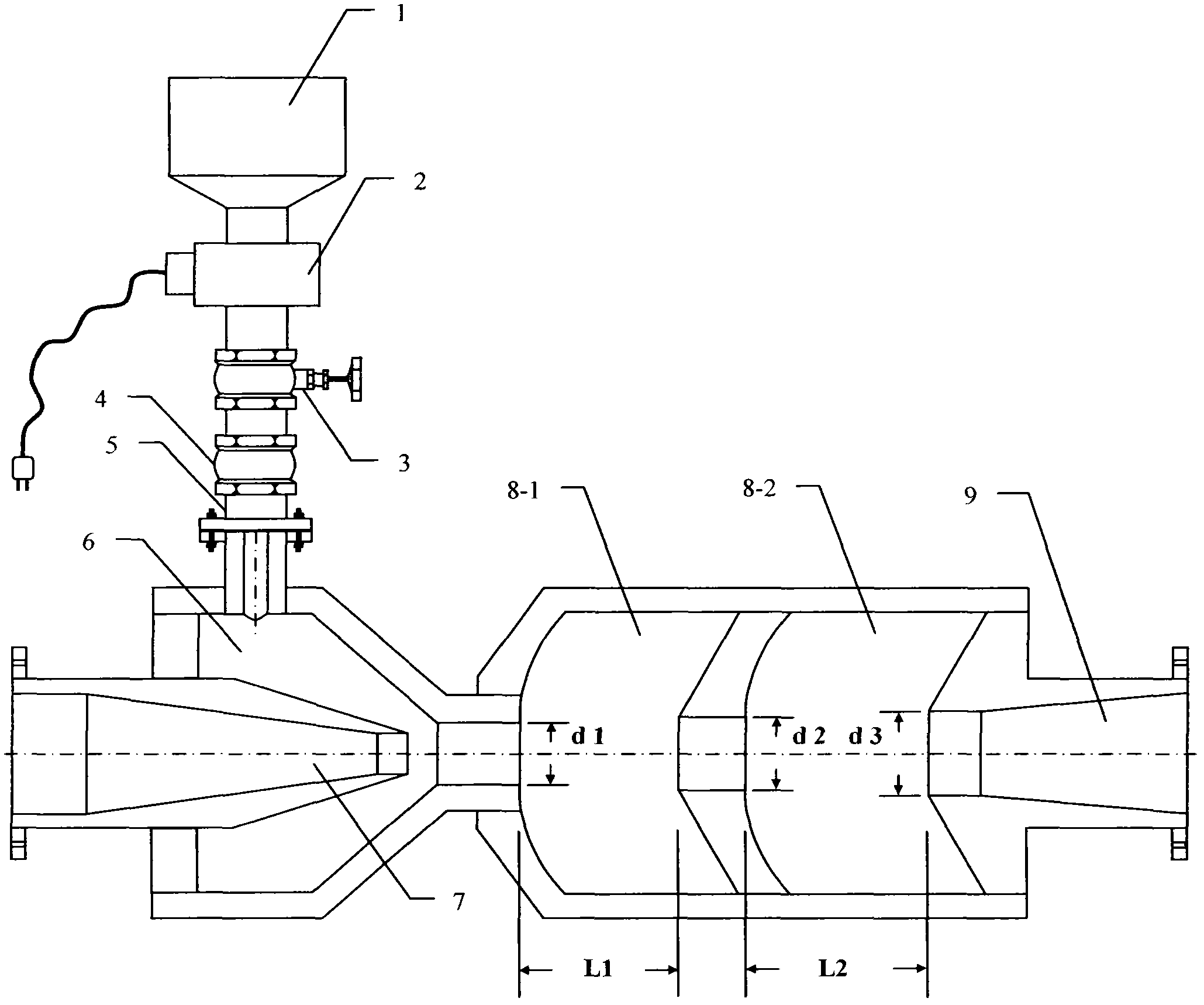

Anti-biological blocking device for drip irrigation system

InactiveCN102283080ANo residueNo troubleClimate change adaptationWatering devicesAir filterHazardous substance

The invention relates to an anti-biological clogging device for a drip-irrigation system. The drip-irrigation system is started, an air intake brake valve is opened, an ozone generator is started, and compressed water which comes from the head part of the drip-irrigation system is sprayed at high speed from a jet orifice of a jet nozzle so as to form the negative pressure in a gas injection cavity; and under the action of the negative pressure, the ozone generator ensures that ozone generated through air ionization enters the gas injection cavity through the air intake brake valve, a check valve and an air inlet pipe along with the air filtered by an air filter, and enters an oscillating cavity for vortex oscillation, stirring and aerification along with the high-speed water flow sprayed by the jet nozzle so as to form 'ozone water' of which gas and liquid are distributed uniformly, and the 'ozone water' enters the drip-irrigation system to kill microorganisms in flow channels and cansynchronously inhibit crop root systems from growing toward the direction of a water outlet of a drip irrigation emitter in an underground drip-irrigation system, so that the aim of biological clogging resistance of the drip-irrigation system is fulfilled. Compared with a method of injecting a chemical agent into irrigation water, the invention has the advantages that: the residue of harmful substances which can pollute the environment is not produced, and the risk of using dangerous chemical agents is avoided.

Owner:FARMLAND IRRIGATION RES INST CHINESE ACAD OF AGRI SCI

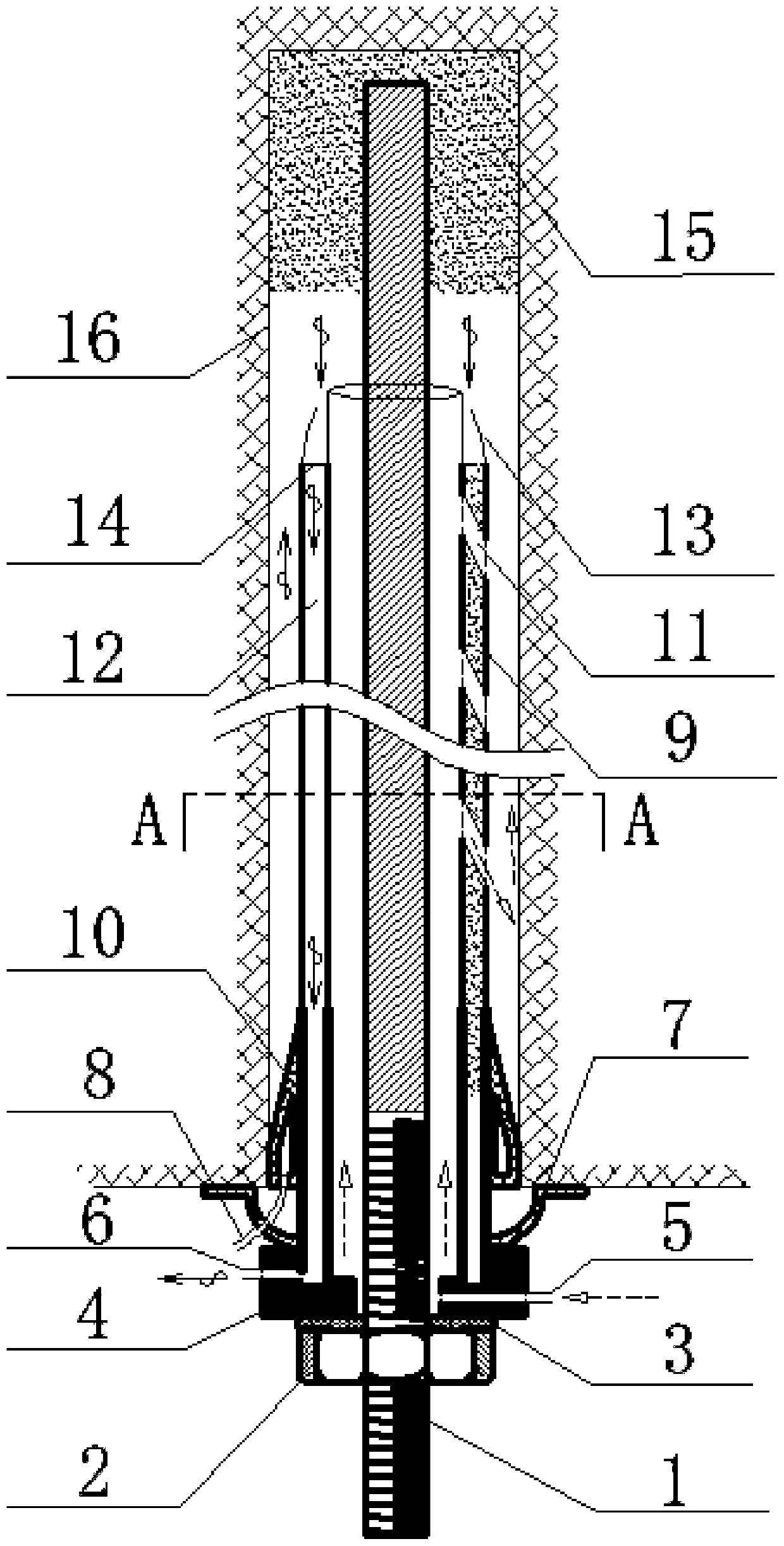

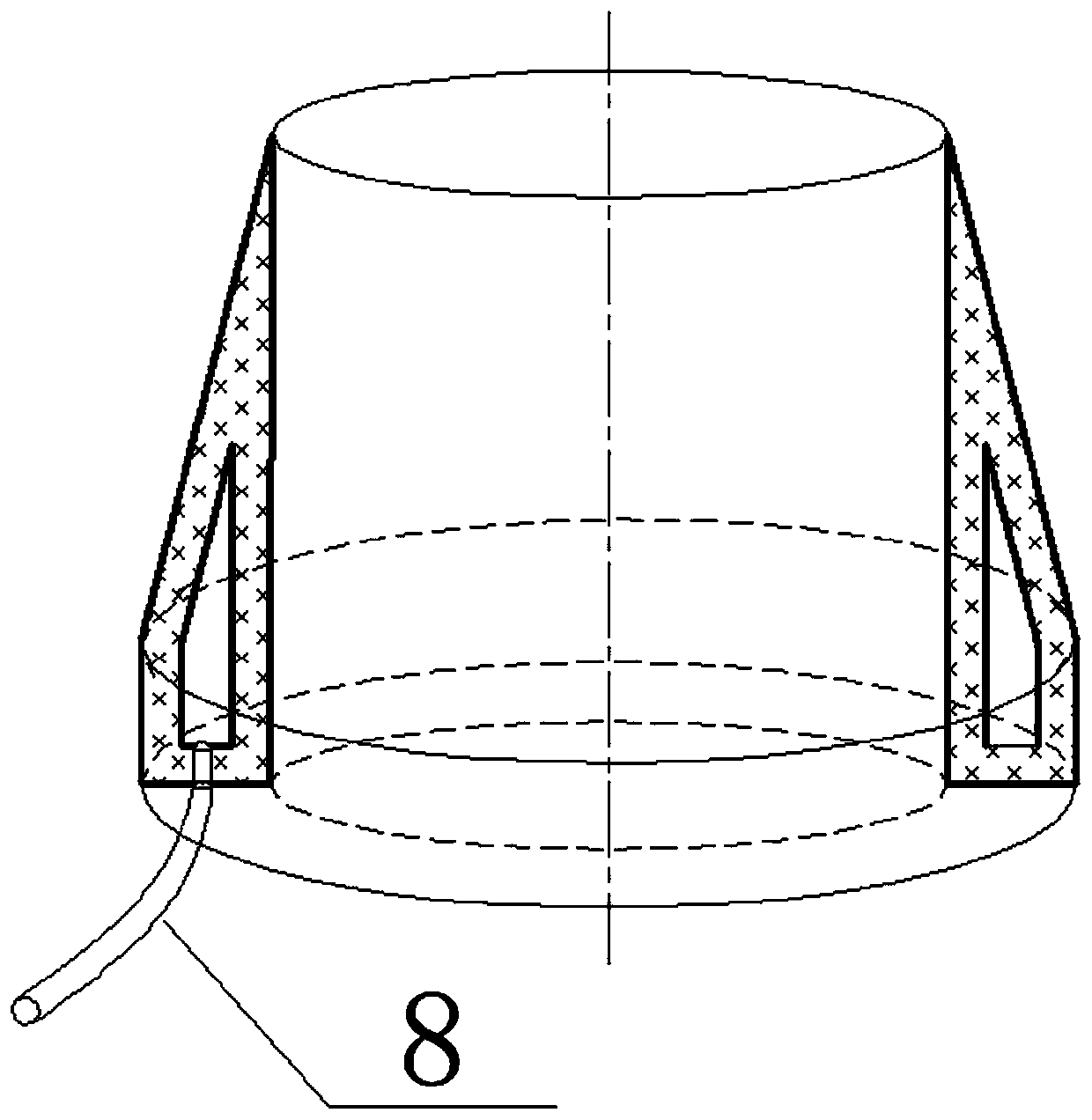

Vented anchoring and grouting device for common anchor rod and using method thereof

ActiveCN110230511ADoes not affect the support effectGood support effectAnchoring boltsEngineeringBuilding construction

The invention discloses a vented anchoring and grouting device for a common anchor rod and a using method thereof. The vented anchoring and grouting device includes an anchor rod, fastening nuts, a sealing washer, a venting grouting composite end socket, a tray, a venting grouting integrated pipe, an inflatable elastic grouting-stop plug, a guide protection cover, a sealing dustproof film, and ananchoring agent. According to the vented anchoring and grouting device for the common anchor rod, a venting passage and a grouting passage are separately arranged, and the venting grouting composite end socket is fixed in a borehole through the inflatable elastic grouting-stop plug; and according to the vented anchoring and grouting device for the common anchor rod and the using method thereof, inthe process of mounting the common anchor rod, by adding the device, a mounting hole can be directly used as a grouting hole for grouting without affecting normal pre-tightening force reinforcement of the common anchor rod, while a rock mass is reinforced, a common end socket anchoring anchor rod is changed to full length anchoring, the vented anchoring and grouting device solves the problems ofventing and plugging in the processes of anchoring and grouting support and grouting, the grouting effect is improved, and construction workload and the support cost of anchoring and grouting are reduced.

Owner:ANHUI UNIV OF SCI & TECH

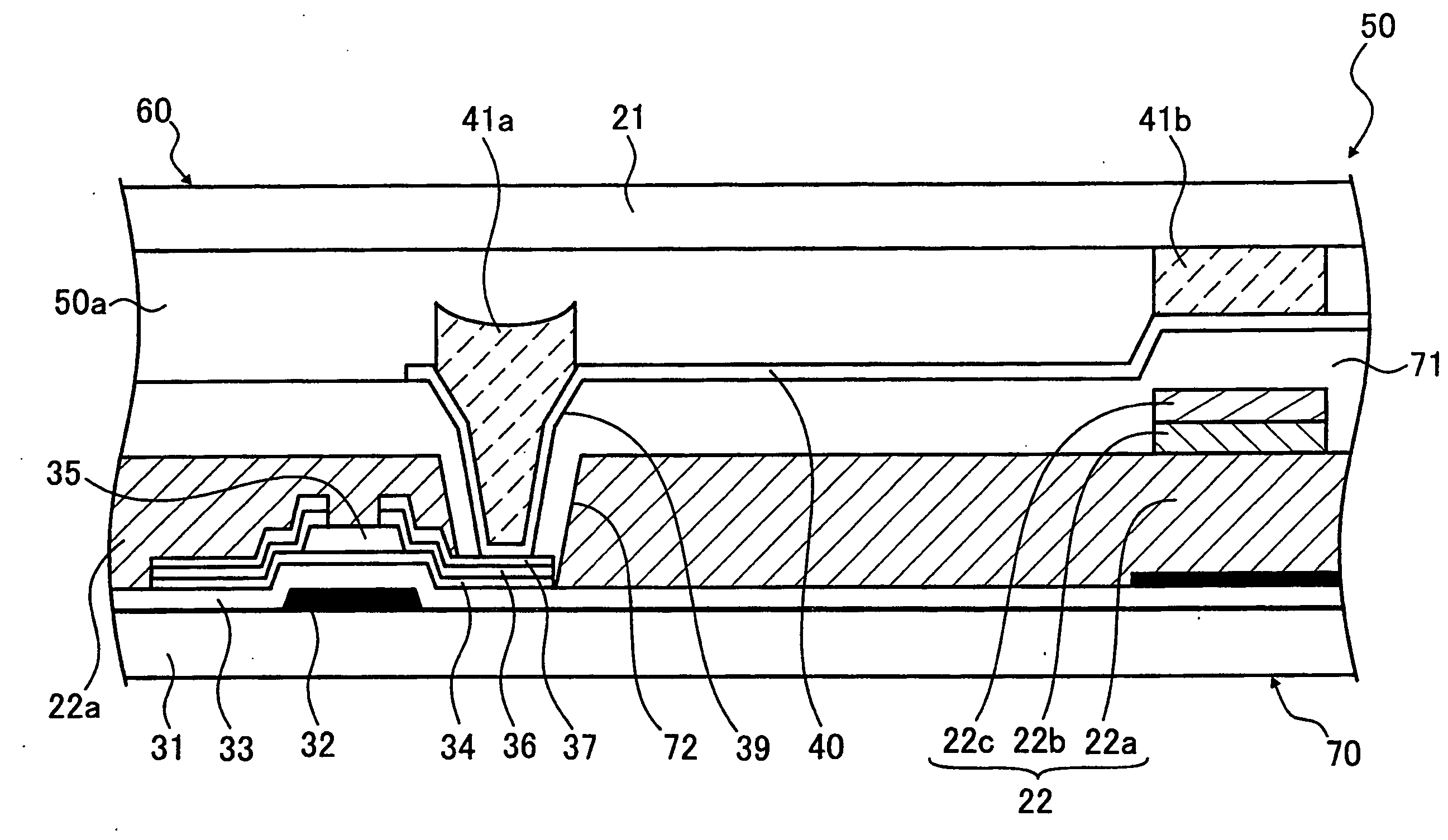

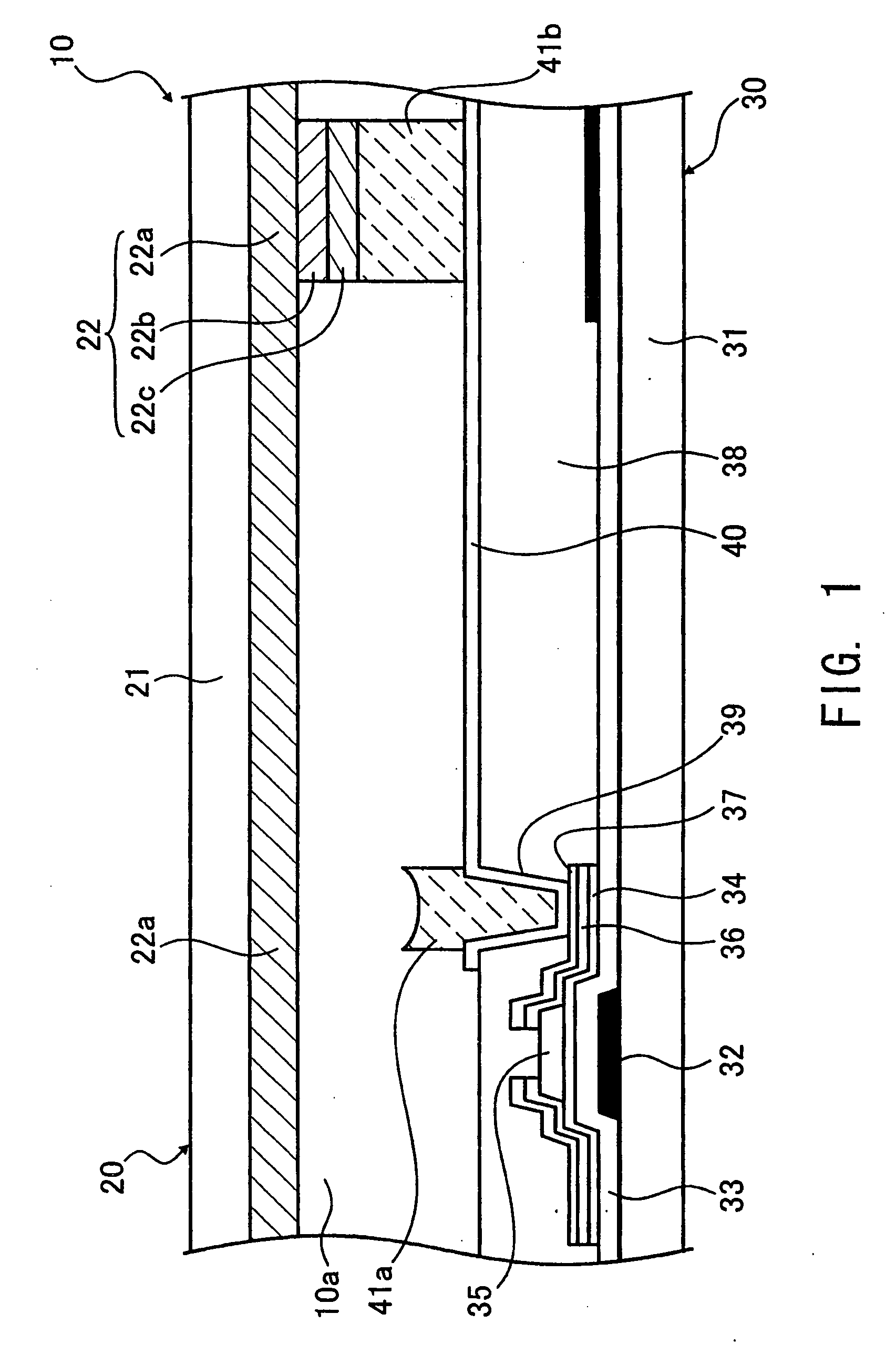

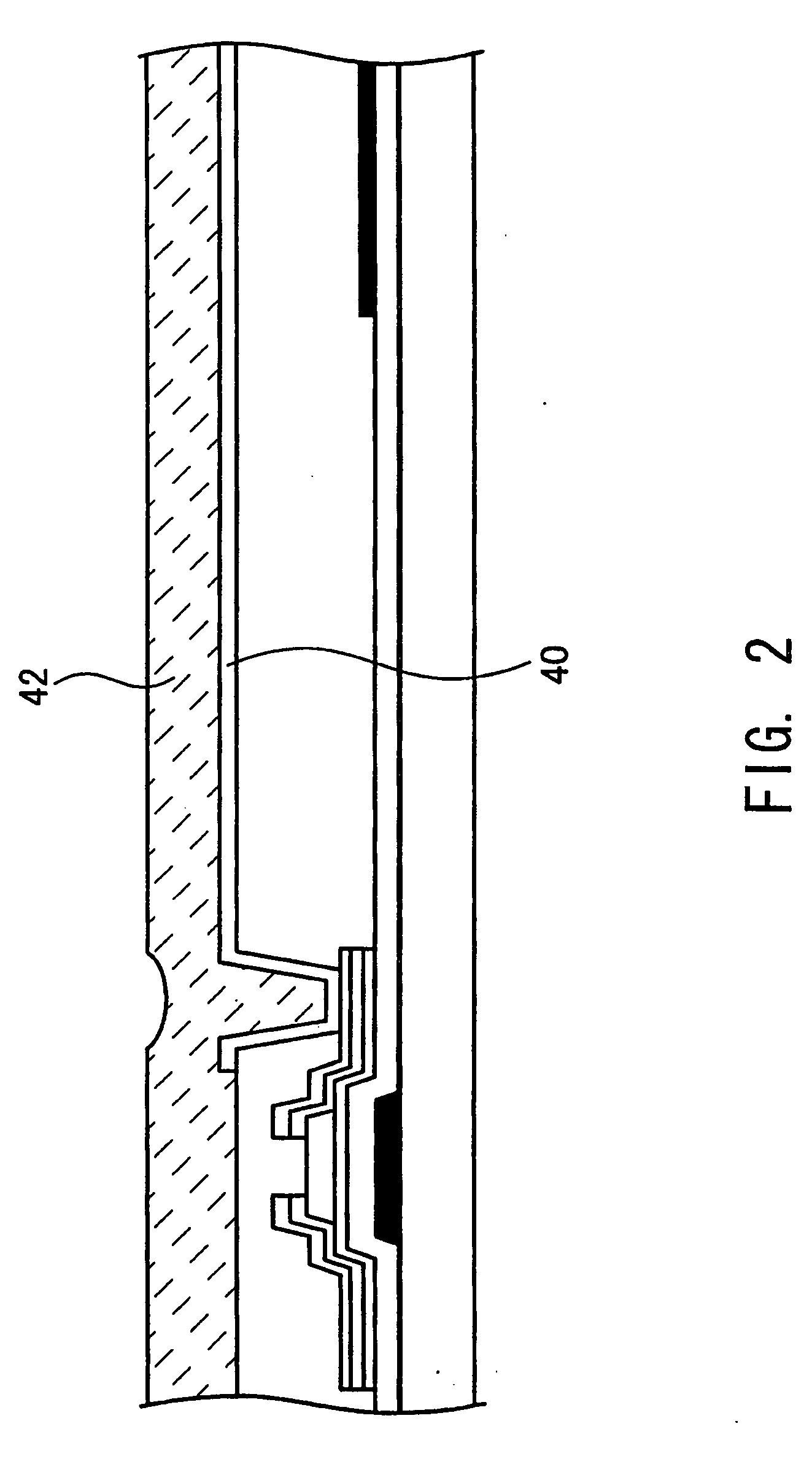

Liquid crystal panel and method of manufacturing the same

InactiveUS20060215070A1Effective maintenanceAvoid problemsNon-linear opticsProduction rateEngineering

There is provided a liquid crystal panel capable of maintaining a cell gap and preventing generation of air bubbles. In the liquid crystal panel having a liquid crystal layer sandwiched between a color filter (CF) substrate and a thin film transistor (TFT) substrate, recesses formed at respective locations of contact holes each for connecting a drain metal layer and a pixel electrode to each other are filled with respective hole-filling columnar layers. At the same time, the cell gap between the CF substrate and the TFT substrate is maintained by cell gap-maintaining columnar layers. The columnar layers are simultaneously formed by subjecting a photosensitive resin to exposure and development. As a result, a reliable liquid crystal panel which does not suffer from air bubbles remaining in the recesses formed at the locations of the contact holes, and capable of effectively maintaining the cell gap with high productivity at low costs.

Owner:SHARP KK

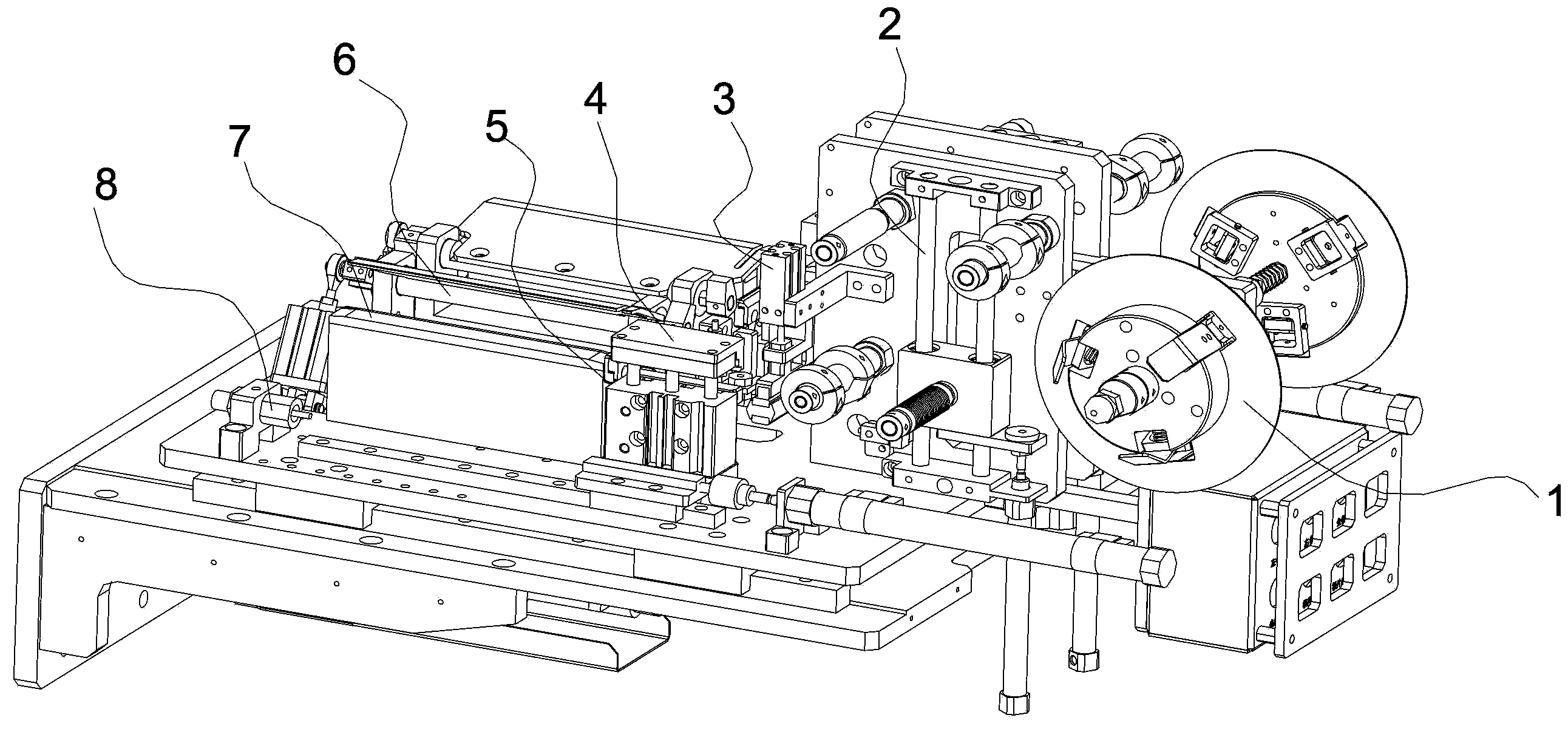

Souvenir bag labeling machine

ActiveCN108190164AAdapt to market demandEasy to installLabelling machinesWebs handlingPaper recyclingEngineering

The invention relates to a souvenir bag labeling machine. A souvenir bag conveying device is mounted on a rack and provided with a photoelectric sensor. A braking mechanism is mounted on the souvenirbag conveying device, and a drawing mechanism is mounted blow the front portion of the braking mechanism. A label peeling mechanism and a pneumatic label covering mechanism are mounted below the frontportion of the drawing mechanism, and a label flattening roller is mounted at the front end of the pneumatic label covering mechanism. A souvenir bag compressing device is mounted between the label peeling mechanism and the souvenir bag conveying device, and a wax paper recycling mechanism is mounted below the drawing mechanism. Wax paper separated from a label is recycled and wound around a label rolling device of the wax paper recycling mechanism through a drawing shaft and a pressing roll of the drawing mechanism. According to the souvenir bag labeling machine, the labeling work of souvenir bags can be automatically completed, and a synchronous contact pasting method of a brush-pasting method is adopted for achieving the aim of reliable and efficient labeling; and the whole mechanism is high in movement speed, simple in structure and convenient to operate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of wet-process dry-grain polished crystal brick and polished crystal brick

ActiveCN110981197AEasy to recycleEasy to adjust the glaze amountCeramic shaping apparatusTextile printerProduction line

The invention discloses a preparation method of a wet-process dry-grain polished crystal brick and the polished crystal brick. The preparation method comprises the following steps: preparing a green brick; performing drying for the first time; applying surface glaze; performing ink-jet printing; applying dry particle protective glaze; performing drying for the second time; and performing firing and molding. The wet-process dry-grain polished crystal brick sequentially comprises a green brick layer, a cover glaze layer, a printing layer and a dry-grain protective glaze layer from bottom to top.The polished crystal brick with excellent performance is prepared by controlling production process parameters and the setting of proper components and proportion of dry particles and dry particle protective glaze. The method is suitable for existing production equipment, and a production line does not need to be modified; a glaze spraying process is adopted, a glaze layer is more uniform, and abell jar is adopted for glaze spraying, so that the glaze amount is more convenient to adjust, and the recycle is easy; the required glaze layer is thinner and is only 1 / 5 of the dosage of dry-processdry particles, so that the dosage is lower, the firing period is shorter, the production cost is reduced, and the production efficiency is improved; meanwhile, compared with a dry method, the defectsof bubbles, pinholes and the like of the glaze layer are fewer, and color development is finer and richer.

Owner:FOSHAN OCEANO CERAMICS

Semi-automatic pasting machine for wallpaper pasting

InactiveCN106985597AGuaranteed linear flatnessAvoid the problems of unstable quality, time-consuming and labor-intensive manual pastingPaperhangingSemi automaticDrive motor

The invention discloses a semi-automatic pasting machine for wallpaper pasting. The semi-automatic pasting machine comprises a bottom plate which is flattened against the ground and the wall surface for positioning, and an installation seat fixedly connected to the bottom plate; the installation seat is provided with a wallpaper winding shaft around which wallpaper is wound, the bottom plate is furthermore fixedly provided with two parallel sliding rails perpendicular to the bottom plate, and a wallpaper pasting mechanism is slidably connected between the sliding rails; the end heads of the ends, away from the bottom plate, of the sliding rails are provided with synchronous wheels, the synchronous wheels are sleeved with belts, and the belts are driven by a drive motor installed on the bottom plate; and the belts are detachably and fixedly connected with the wallpaper pasting mechanism. Through the arrangement of the sliding rails and a tackle matched with the sliding rails, the wallpaper is pasted through relatively linear sliding, and linear flatness of wallpaper pasting can be guaranteed; and the drive motor is utilized to drive the tackle, so that the problems that quality is unstable through fully manual pasting, and time and labor are consumed are solved.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com