Bent glass adhesive pasting system, and method

A curved glass and adhesive technology, which is applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

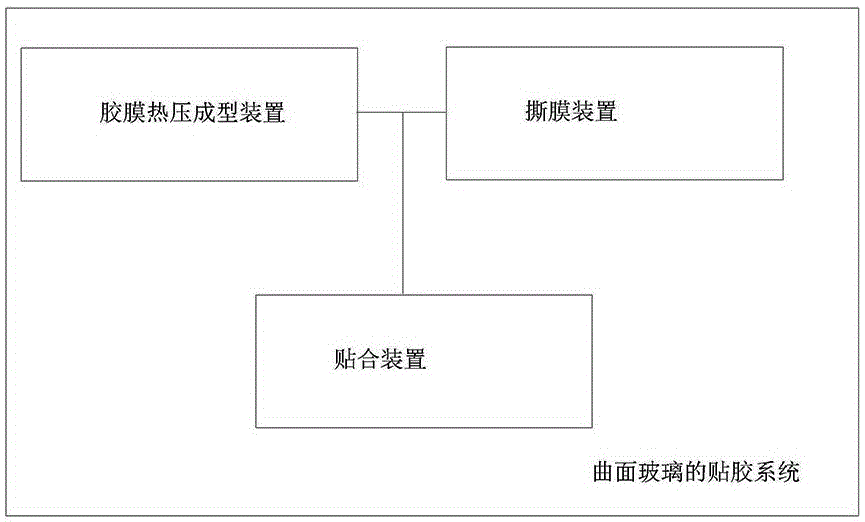

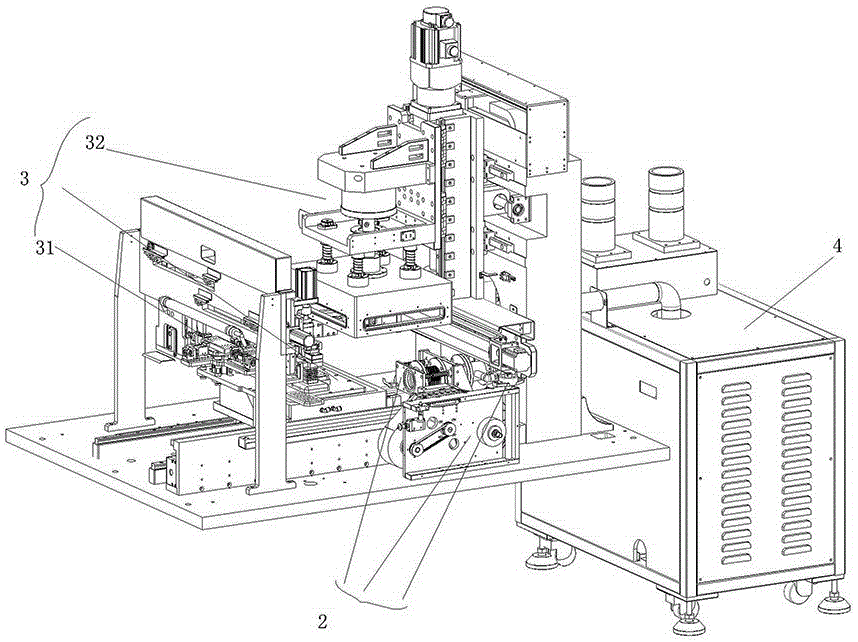

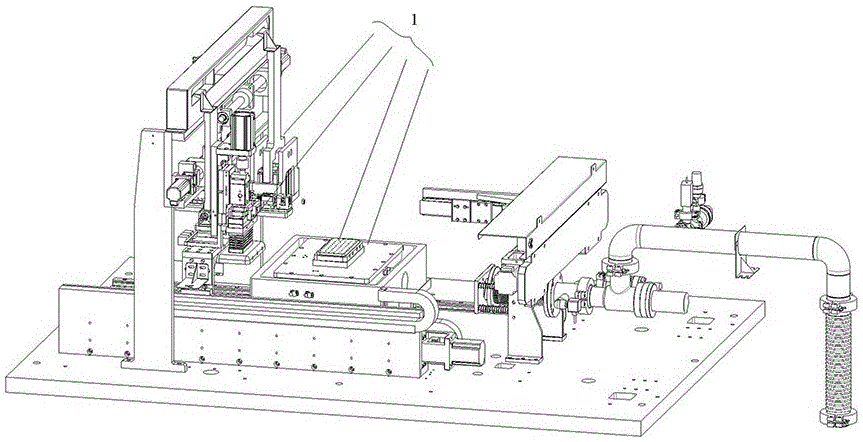

[0031] like Figures 1 to 3 As shown, the gluing system for curved glass in a certain embodiment includes three main parts: a film thermoforming device 1 , a film tearing device 2 , and a laminating device 3 . Among them, the adhesive film hot-press forming device 1 forms a curved adhesive film suitable for curved glass after vacuum adsorption, heating, pressing and shearing the flat adhesive film; the film tearing device 2 heats the adhesive film The release film on the upper surface of the formed curved surface adhesive film is peeled off; after the laminating device 3 absorbs the curved surface glass aligned by the center from its alignment module, it is driven by the mechanical arm to the adhesive film of the adhesive film hot pressing forming device 1 After the carrier platform 11 is above, it is pressed against the adhesive film carrier 11 so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com