Cold rolled dual-phase sheet steel with 1000MPa grade tensile strength and preparation method thereof

A technology for tensile strength and steel plates, which is applied in the field of cold-rolled ferrite/martensitic dual-phase steel plates for automobiles, can solve the problems of decreased elongation, poor stamping and formability of steel plates, etc., and achieves yield elongation avoidance, The effect of high tensile strength and low yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

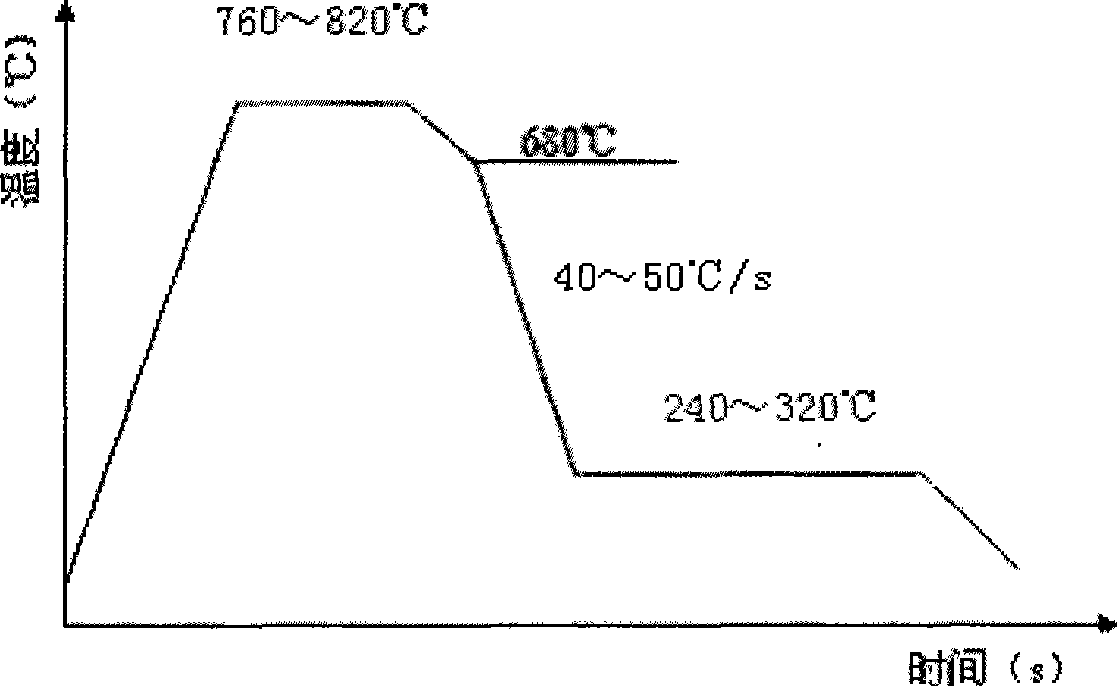

[0018] The chemical compositions of the examples of the present invention are shown in Table 1. After smelting, the cast billets are forged into billets with a size of 40 mm (thickness) × 80 mm (width) × 100 mm (length). After forging, the billet was soaked at 1250 °C for 1 hour, hot rolled into a 3.5mm thick steel plate, the final rolling temperature was controlled at 830 °C, water cooled to 650 °C, placed in a holding furnace for heat preservation and then cooled with the furnace to simulate the coiling process. The hot-rolled sheet is cold-rolled to 1mm after pickling, and the cold-rolling reduction rate is about 70%. The continuous annealing of dual-phase steel generally adopts dual-phase zone heat preservation and two-stage cooling process, such as figure 1 shown.

[0019] holding the cold-rolled steel sheet at 780 and 820° C. for 100 s;

[0020] After slow cooling to 680°C, the cold-rolled steel sheet is cooled to 280°C at a cooling rate greater than 45°C / s, the cold-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com