Patents

Literature

7559 results about "Water cooled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water cooling is sometimes referred to as liquid cooling, because various other substances are sometimes used instead of, or in addition to, water.

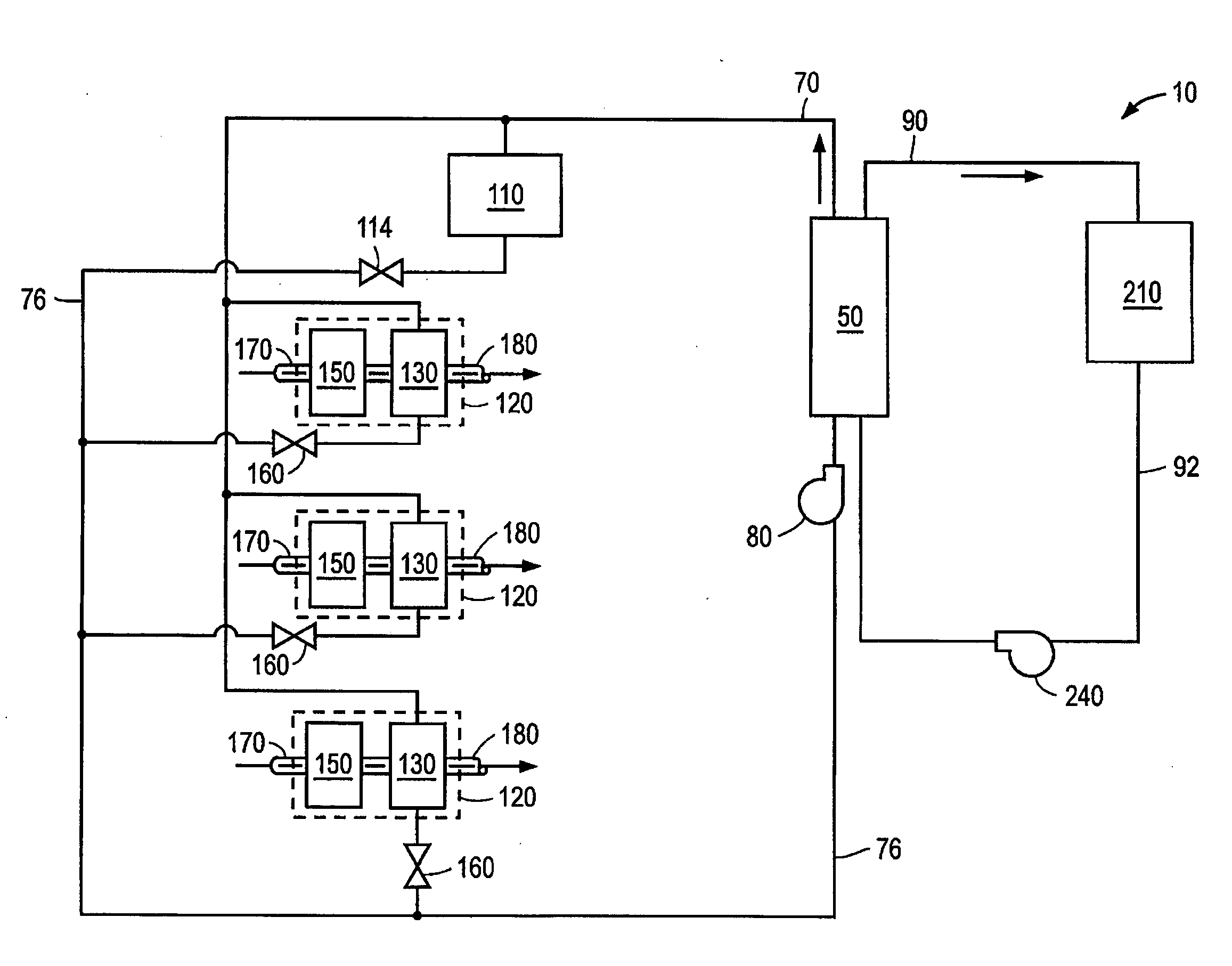

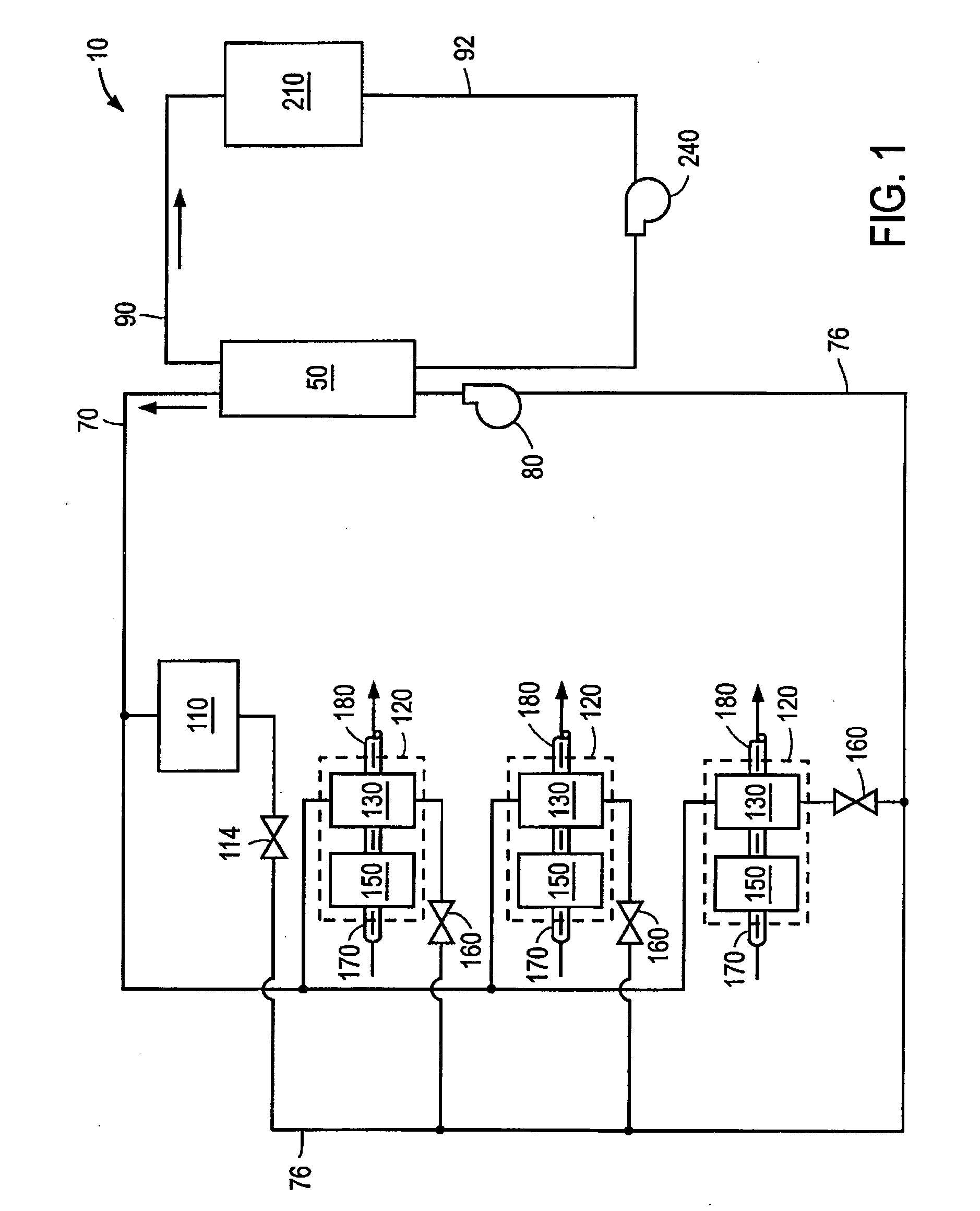

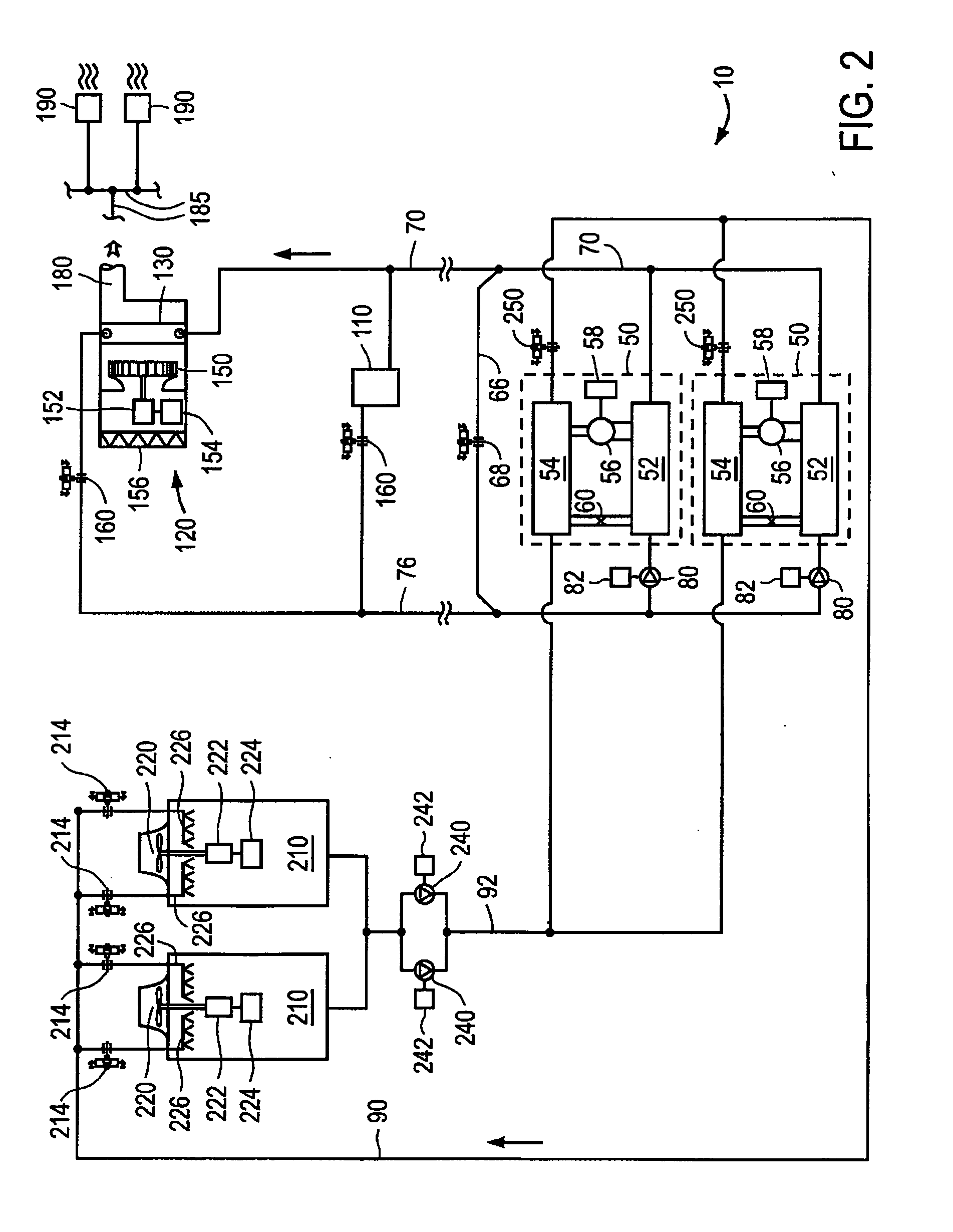

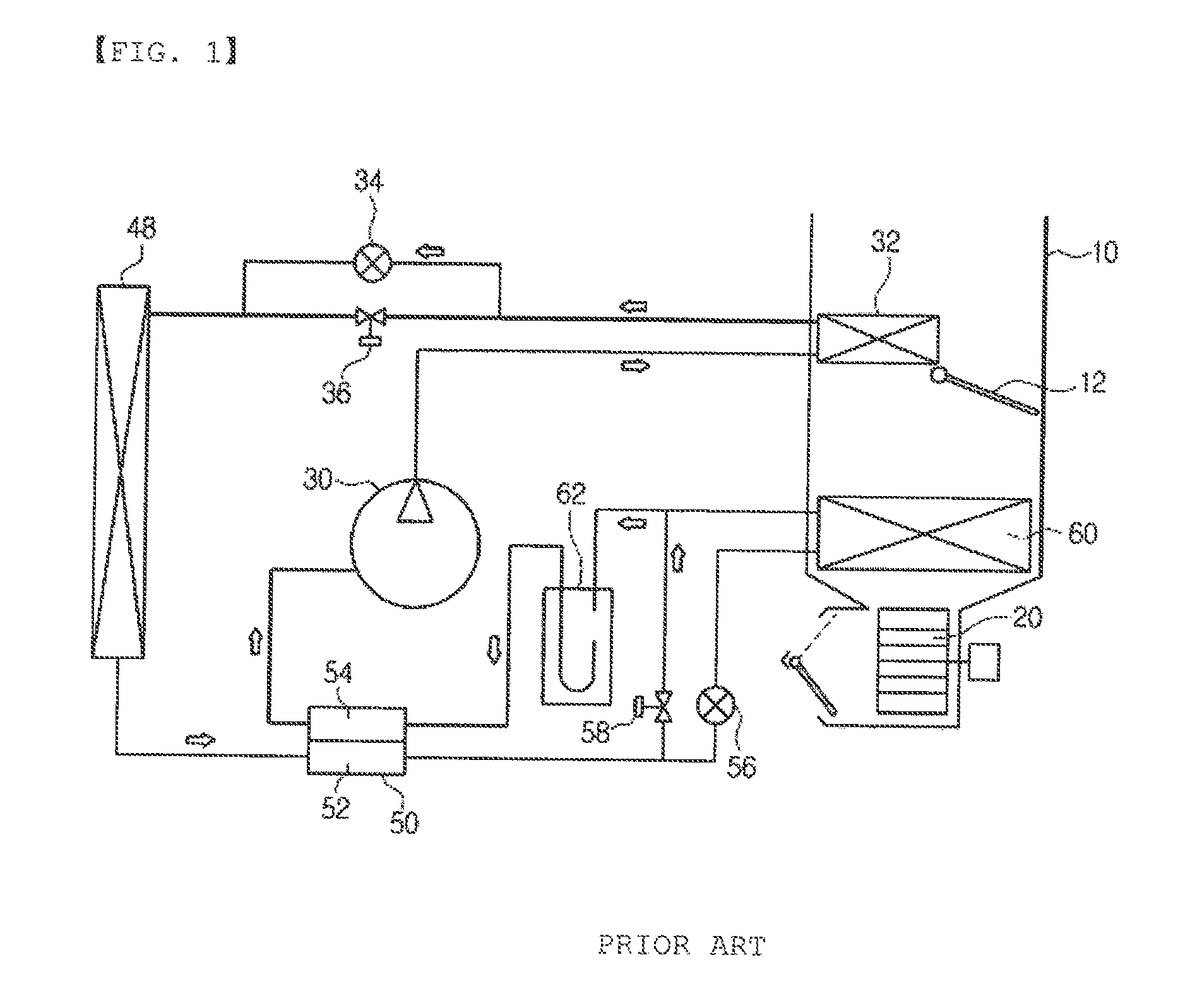

Optimized Control System For Cooling Systems

ActiveUS20090171512A1Reduce energy consumptionImprove energy efficiencySampled-variable control systemsMechanical apparatusCooling towerControl system

A cooling system for providing conditioned air to a facility includes a chiller or other cooling subsystem, a cooling tower subsystem and one or more air handling units or process cooling units. The cooling subsystem may advantageously include one or more chillers (e.g., variable speed chillers, constant speed chillers, absorption chillers, etc.) and chilled fluid pumps. The cooling tower subsystem includes one or more cooling tower units and condenser fluid pumps. In some implementations, the air handling unit has a cooling coil and a variable volume fan. In some implementations, direct expansion (DX) cooling systems comprise compressors, evaporators and air-cooled, water-cooled or evaporatively-cooled condensing systems. Such systems can be controlled to reduce energy waste, improve occupant comfort and / or improve the thermal characteristics of the process cooling unit. The cooling system further comprises a control system which is configured to evaluate a cooling load value at the air handling unit and use the cooling load value to calculate at least one operational setpoint. The operational setpoint may advantageously be selected to improve the energy efficiency of the overall cooling system.

Owner:YARDI SYST

Production of potable water and freshwater needs for human, animal and plants from hot and humid air

InactiveUS6868690B2Reduces cargo spaceMinimize any benefitGeneral water supply conservationSeawater treatmentParticulatesFresh water organism

Systems and methods are disclosed for extracting freshwater from atmospheric humidity in extremely hot and humid climates and supplying freshwater to a small group of people, a building, a farm, or forestation area. The freshwater is treated to provide drinking water by disinfecting to eliminate microorganisms and filtration to remove suspended particulates from air, erosion or corrosion products, and disinfected waste. Compact units provide drinking water for individuals, passengers in cars, vans, trucks, or recreational boats, or crewmembers on a seagoing cargo ship whether from atmospheric humidity or from moisture-laden gases. Furthermore, systems are disclosed for the ample supply of freshwater with minimal treatment for small- to large-sized buildings in a manner that alleviates the heat load on buildings. Collection of freshwater from hot humid ambient air is also provided for other uses, such as irrigation and farm animal drinking. Various methods are used for condensation of water vapor suspended in the air as alternative to conventional refrigeration cycles using CFC refrigerants. Devices are disclosed using naturally occurring brackish cold water, circulation of cooling water cooled by thermoelectric cooling or thermoacoustic refrigeration as well as evaporative cooling and transpiration cooling. Water produced by the systems may flow under gravitational forces entirely or with the assistance of boasting pumps.

Owner:FAKIEH RES & DEV CENT

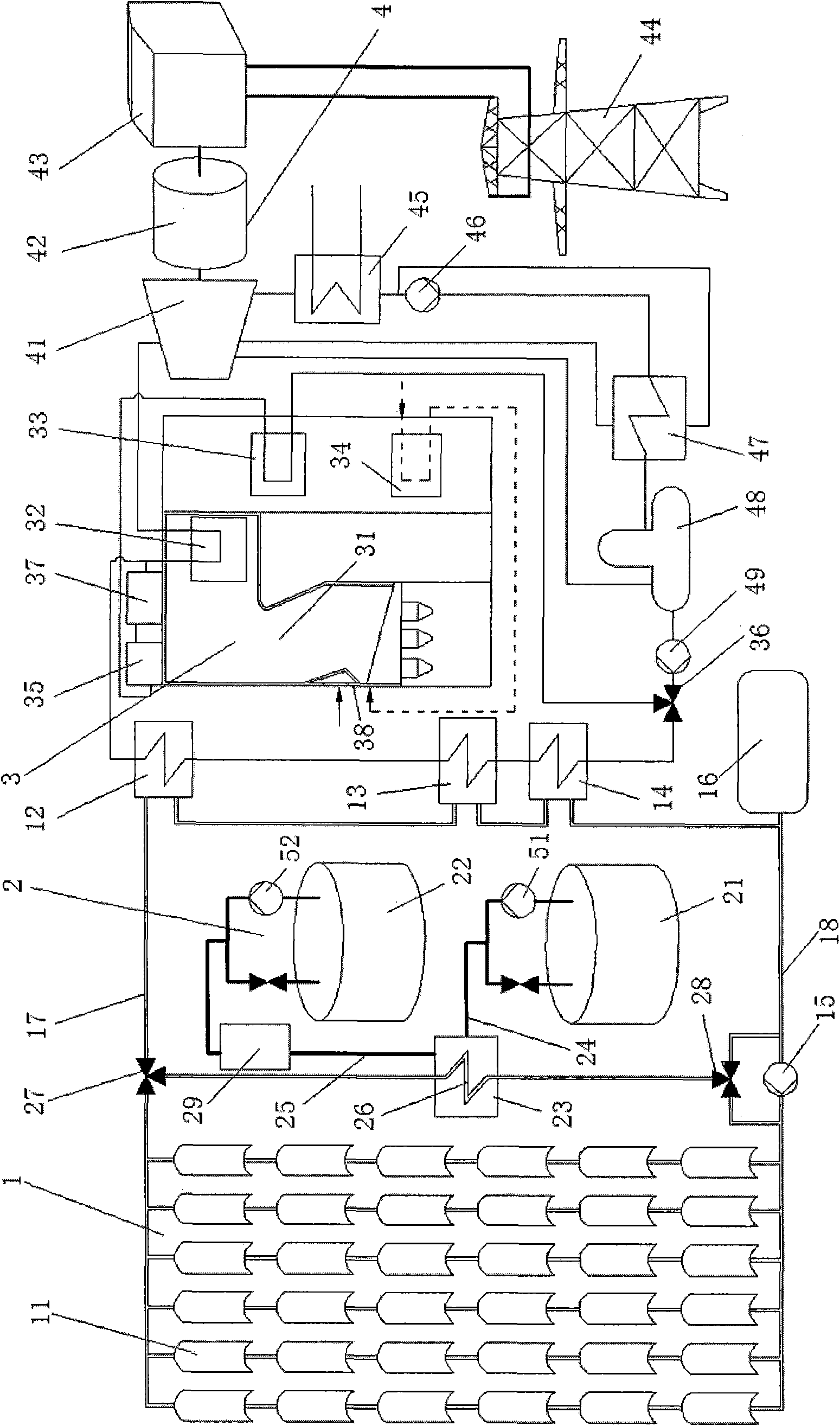

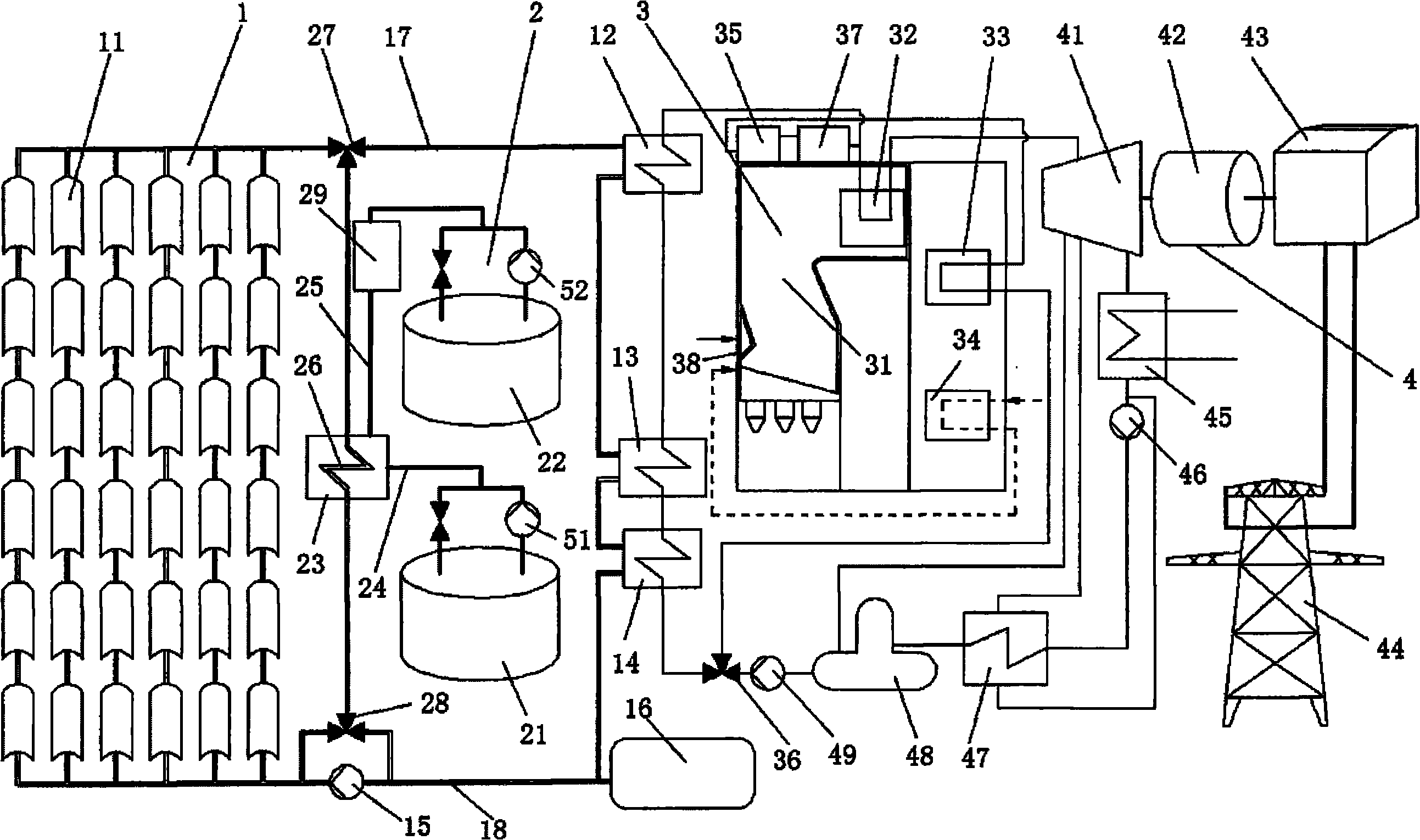

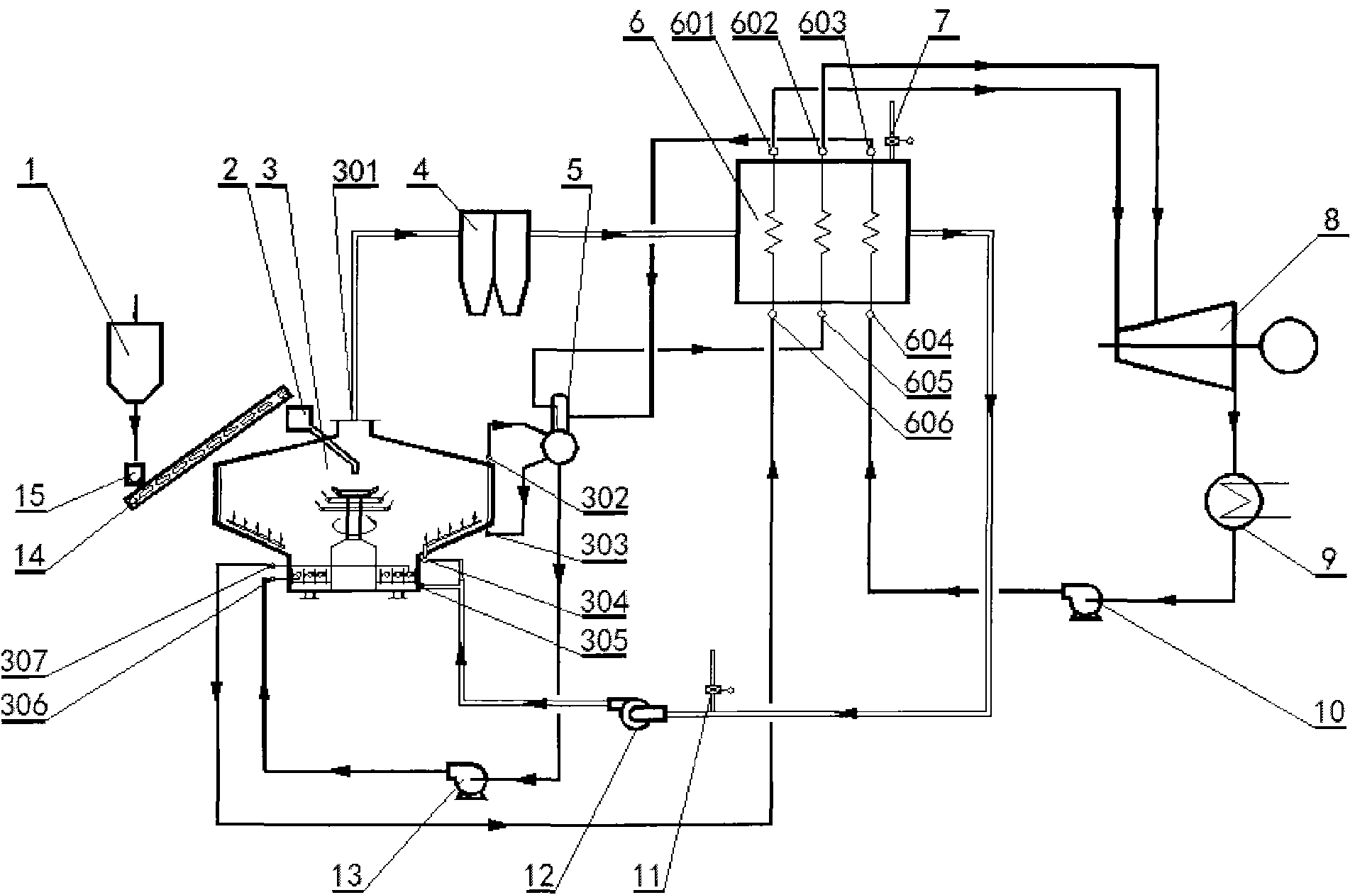

Method and system for combing solar energy thermal power generation with biomass power generation

ActiveCN101876299AReduce dosageReduce procurement costsSteam generation heating methodsFrom solar energyThermal energyCounter flow

The invention relates to a method and a system for combining solar energy thermal power generation with biomass power generation. When the method is used for generating electricity in the daytime (a fine day), one path of heat transfer oil heated in a heat collection field passes through a heat exchanger to ensure that counter-flow water is heated up into superheated steam at the temperature of between 360 and 380 DEG C; and the other path of the heat transfer oil heated in the heat collection field passes through the heat exchanger to heat up a fused salt so as to perform energy storage. The water heated in a water cooled wall of a biomass boiler is changed into steam which enters a steam header and a steam-water separator, then is heated to the temperature of between 535 and 545 DDEG C after being sent into a super-heater of the boiler together with the steam at the temperature of between 360 and 380 DEG C, and then is supplied to a steam turbine to drive a generator to finish the power generation process. During receiving electric valley adjustment, the biomass boiler maintains the minimum stable combustion state. The self power generation of the method and the system can be used for supplying electricity to an electric heater in a fused salt heat storage system to heat the fused salt and perform secondary energy storage for a fused salt heat tank. During the night, or when a solar energy condition is not good, the heat energy stored in the fused salt is released by the heat exchanger to generate electricity.

Owner:北京京仪集团有限公司

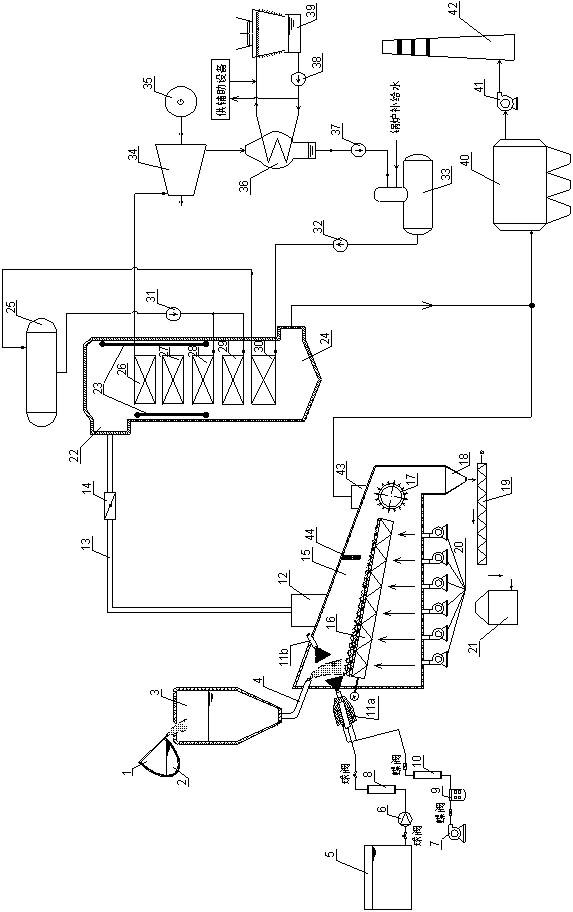

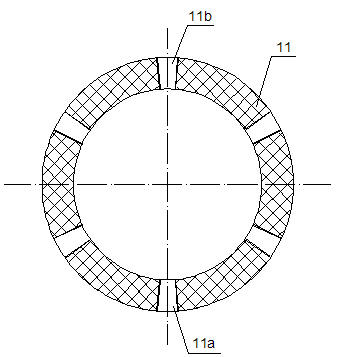

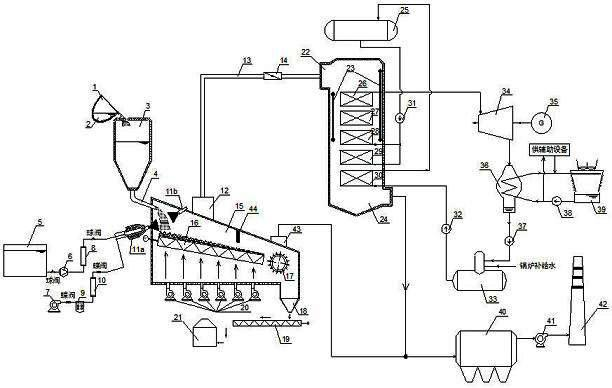

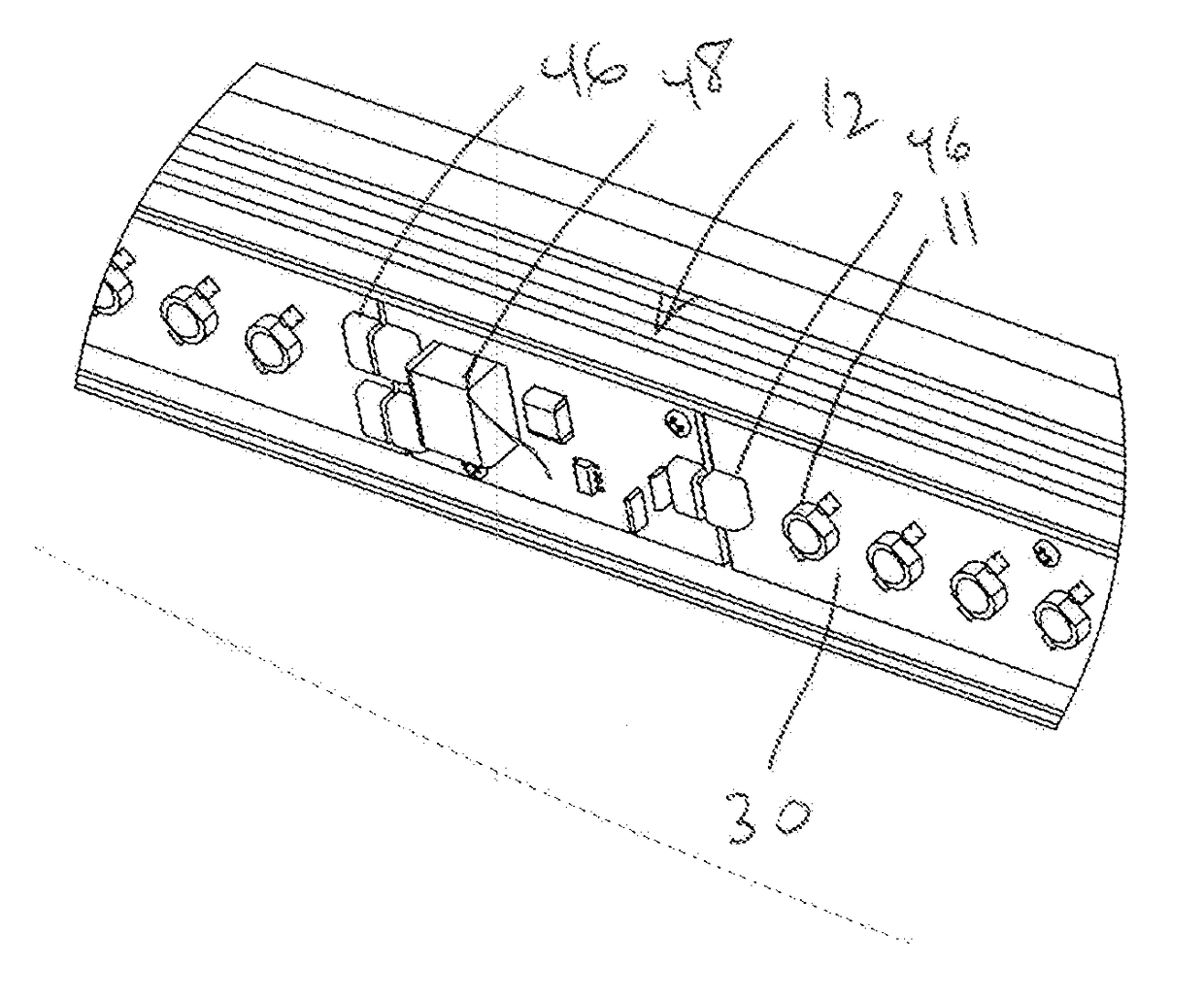

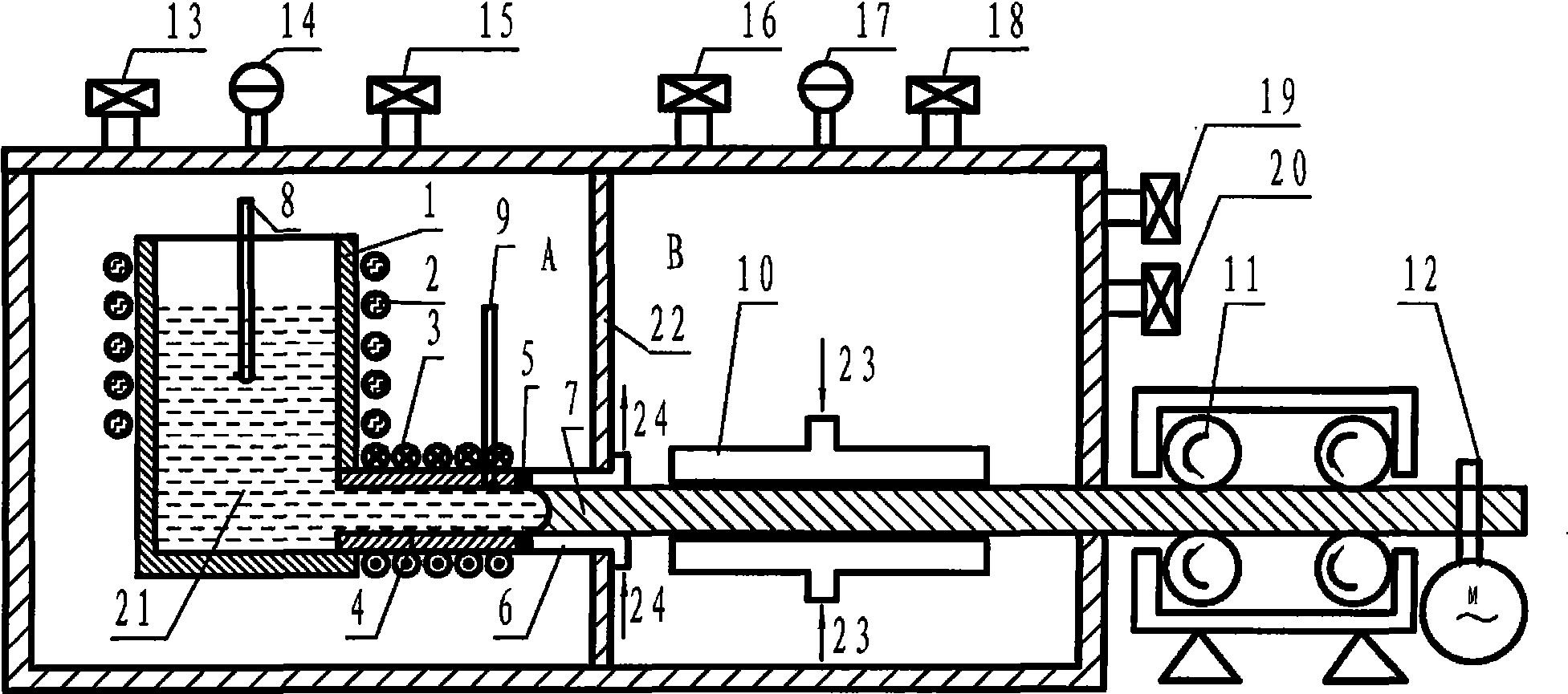

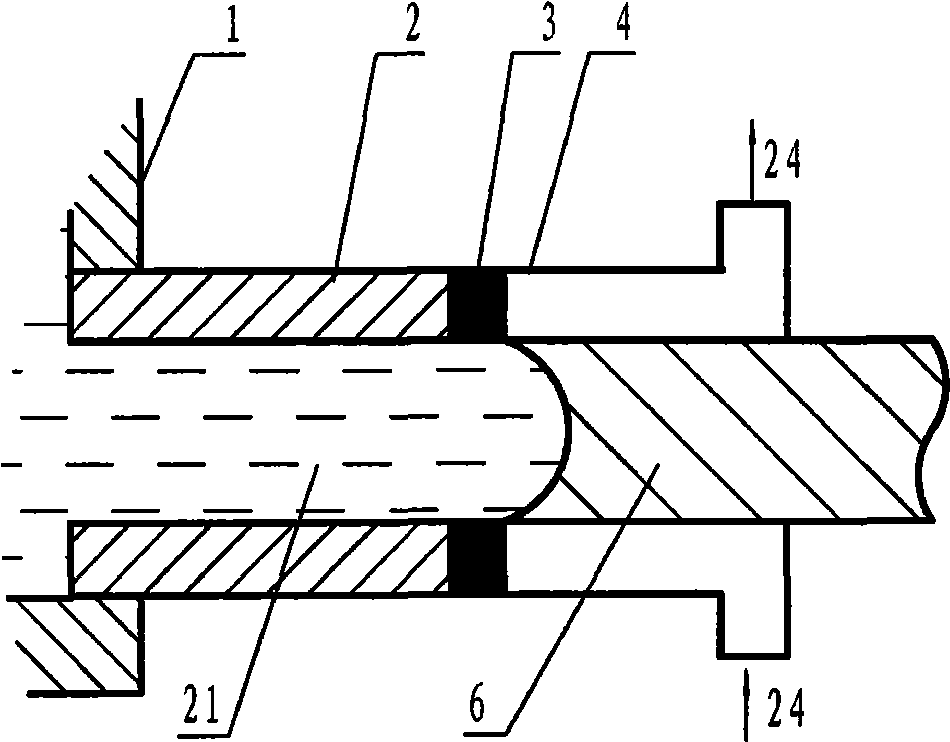

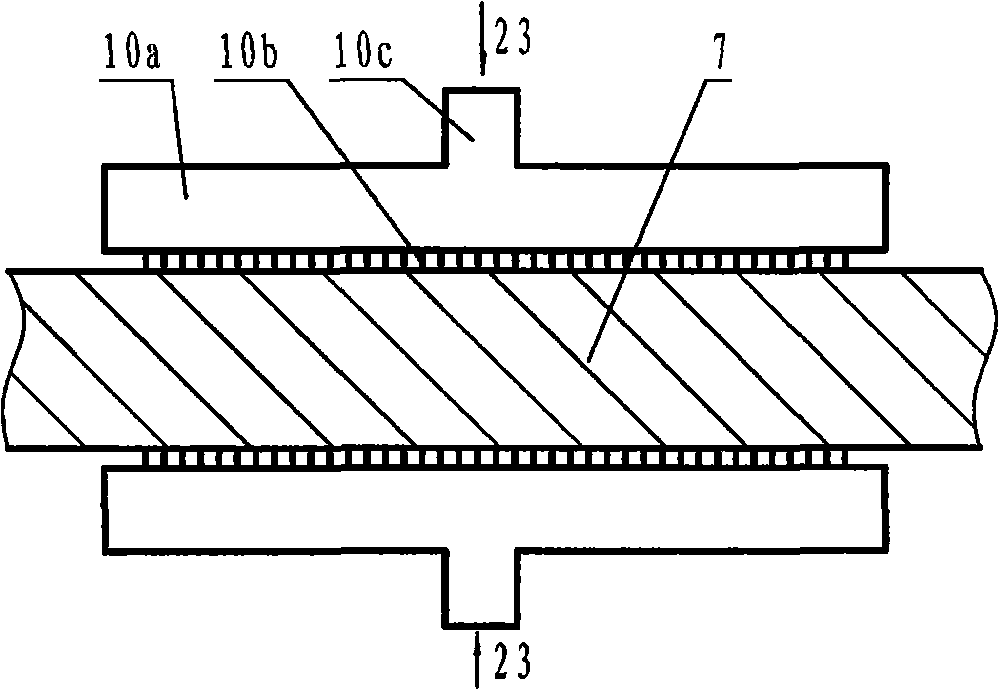

Melting furnace slag quenching dry type granulation and sensible heat recovery generating system and method using same

ActiveCN102433401AReduce cooling air volumeReduce power consumptionIncreasing energy efficiencyRecycling and recovery technologiesSlagHigh pressure water

The invention provides a melting furnace slag quenching dry type granulation and sensible heat recovery generating system and a method using the same and belongs to the technical field of steel metallurgy furnace slag treatment and complementary energy recovery. The melting furnace slag quenching dry type granulation and sensible heat recovery generating system provided by the invention comprisesa slag-receiving device, a high-pressure water-air pulverization furnace slag quenching and granulating device, a furnace slag slow-cooling device, a sensible heat recovery generating device and a waste gas purification treatment device. According to the invention, the melting furnace slag is quenched and granulated by utilizing the high-pressure water-air pulverization device, so that the melting furnace slag is rapidly cooled to be in a glassy state; and then through a water-cooled type vibration grid plate, the melting furnace slag in the glassy state is further subjected to heat exchange with cold air so as to facilitate the subsequent recovery of the sensible heat. By the system provided by the invention, the melting furnace slag is quenched and granulated, and the high-temperature sensible heat resource of the furnace slag is sufficiently recovered and is used for generation on the basis that the water activity quality of the furnace slag is not influenced.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

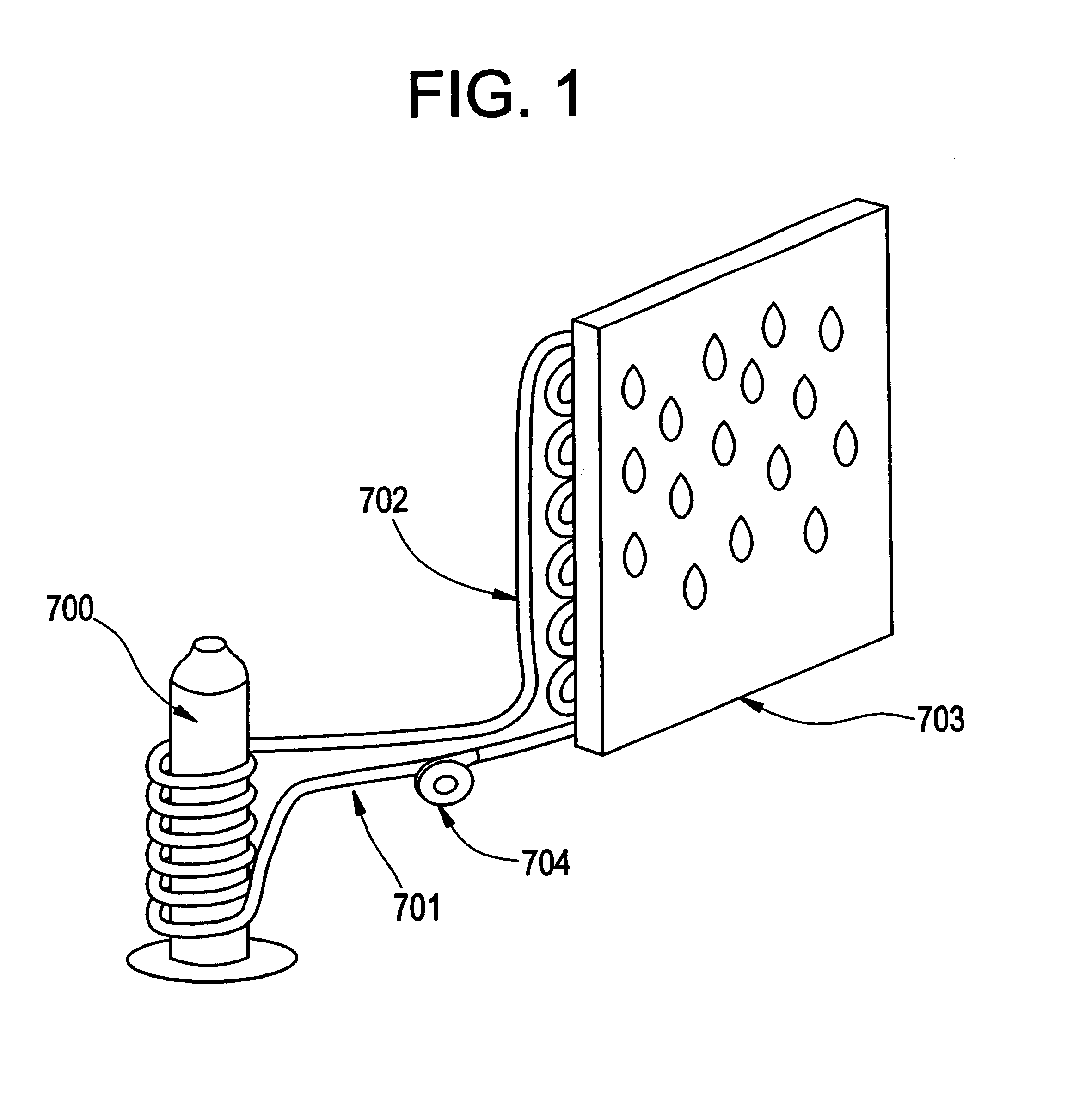

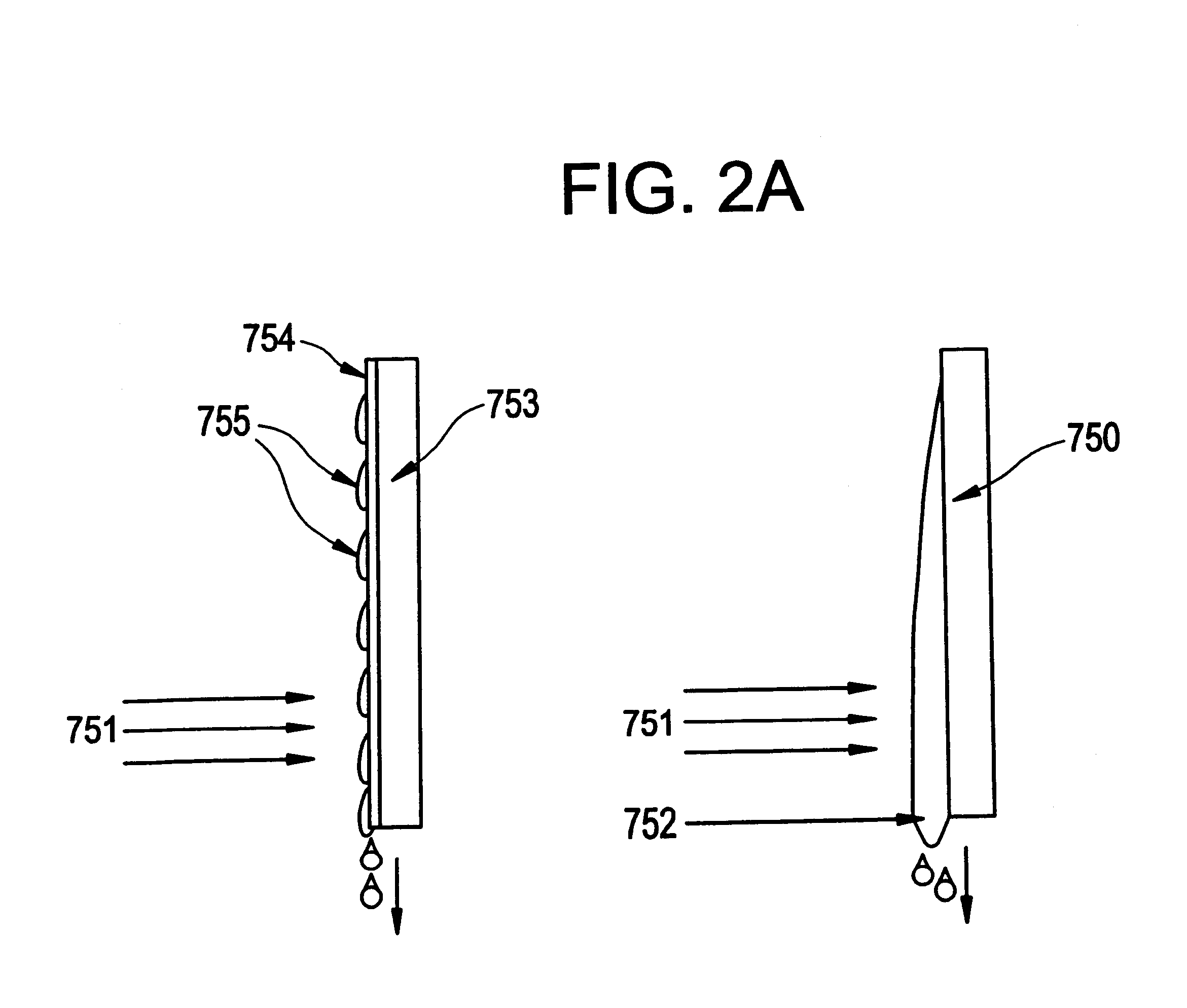

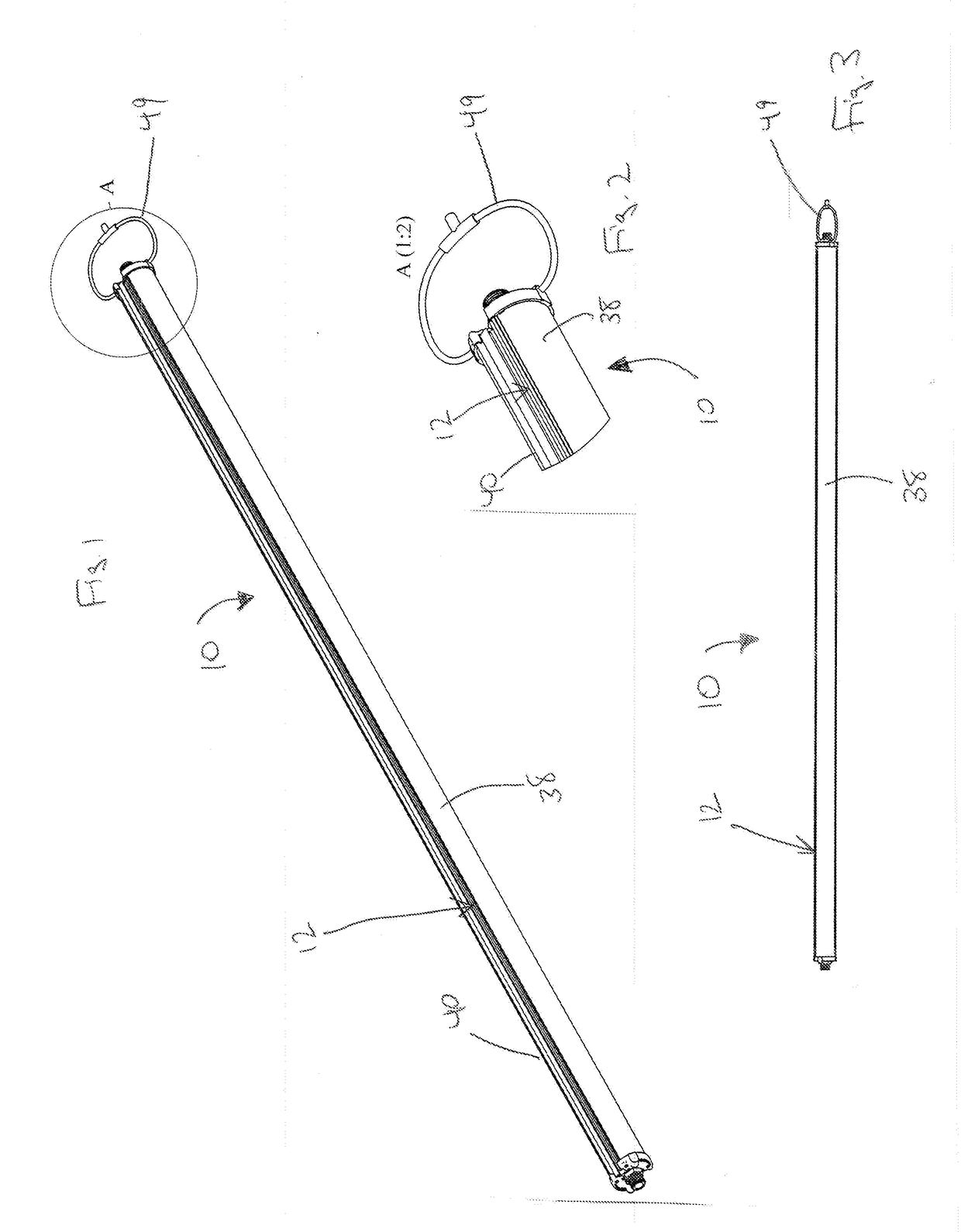

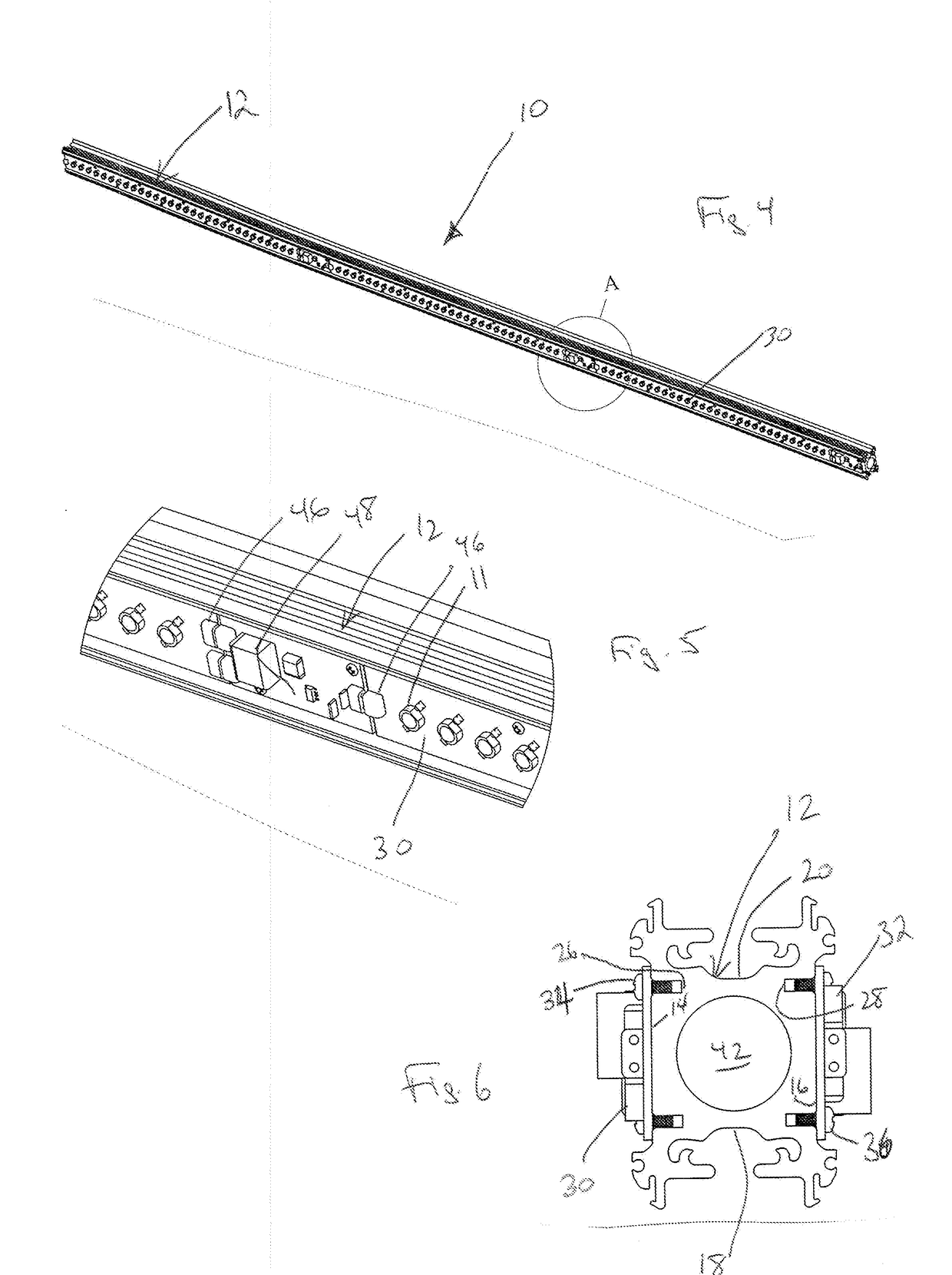

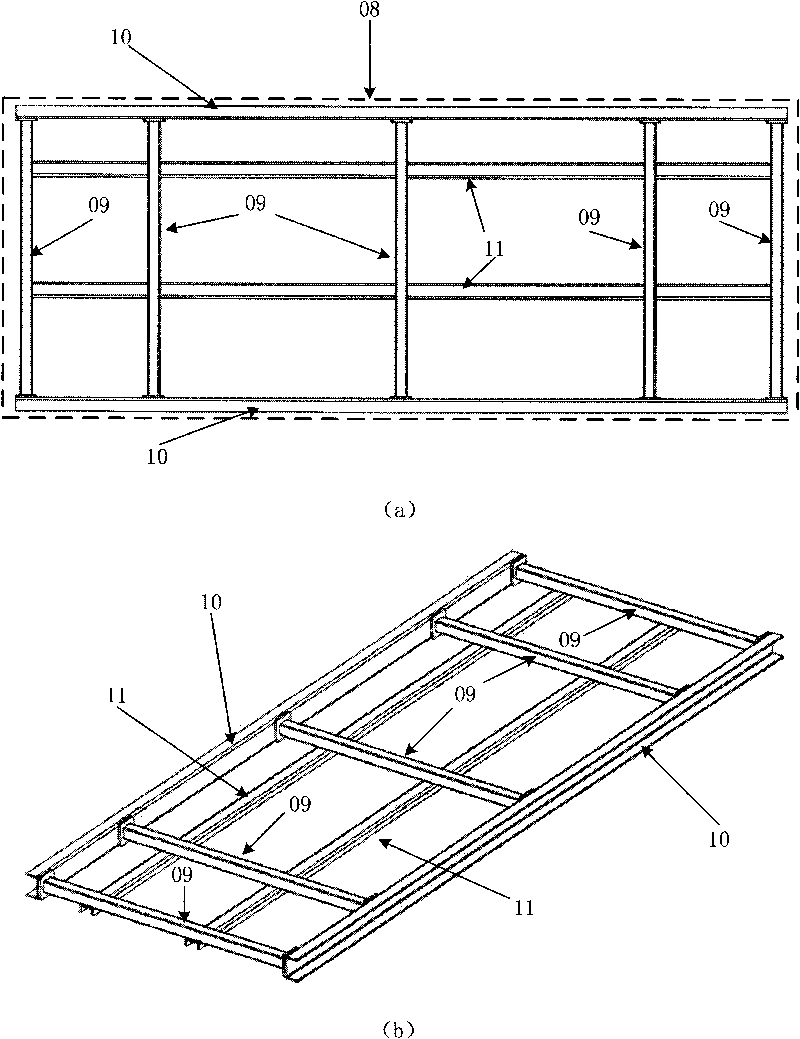

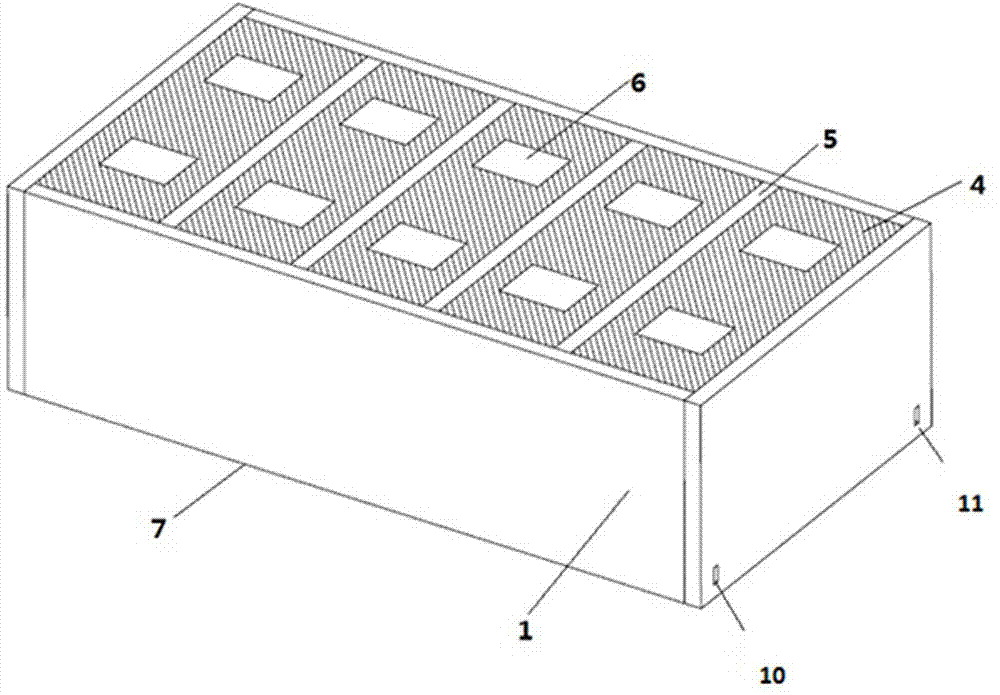

Water-Cooled LED Lighting System for Indoor Farming

ActiveUS20170146226A1High intensity lightReducing and eliminating heat loadElongate light sourcesClimate change adaptationActive coolingEffect light

A lighting system for indoor farming for delivering high intensity light while reducing or eliminating heat loads in a growing environment is provided. The lighting system comprises a lighting housing having a first end, a second end, a first side, a second side opposite the first side, a third side between the first side and the second side, and a fourth side opposite the third side. A first LED board is mounted to the first side and a second LED board is mounted to the second side. A first shroud covers the first LED board and a second shroud covers the second LED board. A coolant passage is formed completely through the lighting housing. A coolant liquid is receivable through the coolant passage. The coolant liquid provides active cooling, of the lighting housing from heat created by the first and second LED boards.

Owner:MJNN LLC

Method for manufacturing pure titanium seamless tubes

ActiveCN101708511ASimple processImprove efficiencyMetal rolling arrangementsRoll speed control devicePunchingTitanium

The invention relates to a method for manufacturing pure titanium seamless tubes. The method is characterized by comprising the following steps of: preparing tube blank bars; machining the tube blank bars; diagonally rolling and punching holes: heating blank to 700 to 980 DEG C, punching holes once or twice by utilizing a two-roll diagonally rolling mill group, wherein molybdenum mandrels or water-cooled mandrels are utilized, the inclined angle of punching roll is 8 degrees, the number of revolutions of the roll is 40 to 90 basic speed to 195 r / min; preparing the pierced billet after punching hole, wherein the specifications of the pierced billet are that the outside diameter is phi 72 to phi 125mm,the wall thickness is 5 to 20mm, and the length is; carrying out cold rolling; and carrying out heat treatment on finished product, detecting performance and entering warehouse. The invention has the characteristics of high production efficiency, low production cost, high material yield, short production period, low device investment, better product quality, and the like. The produced pure titanium seamless tubes have good quality, the mechanical properties accord with state requirements, and the pure titanium seamless tubes can meet the need for large-scale industrial production.

Owner:PANGANG GROUP SICHUAN CHANGCHENG SPECIAL STEEL

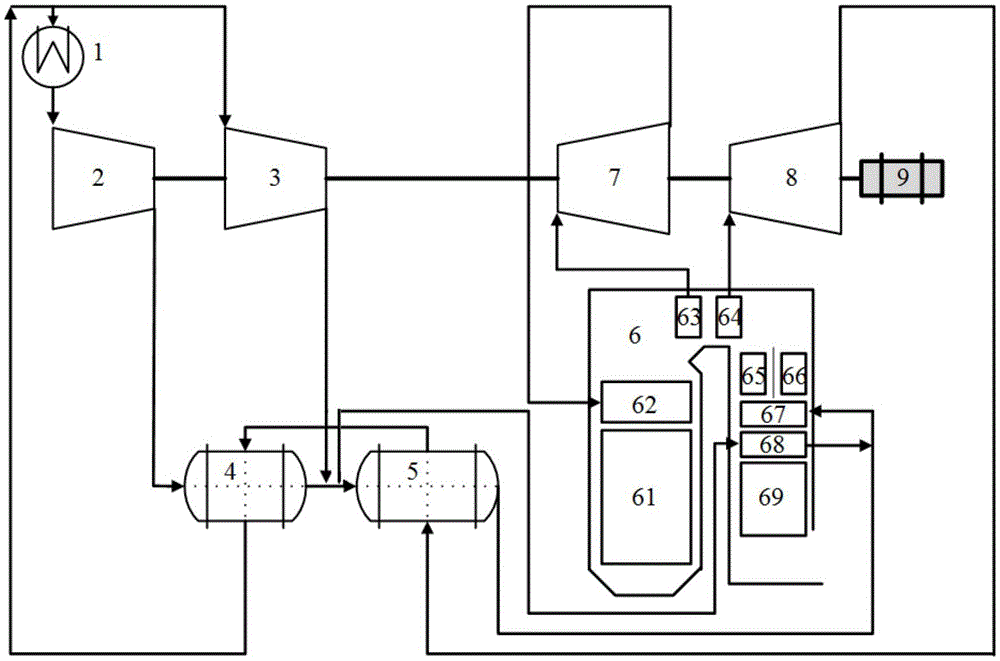

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

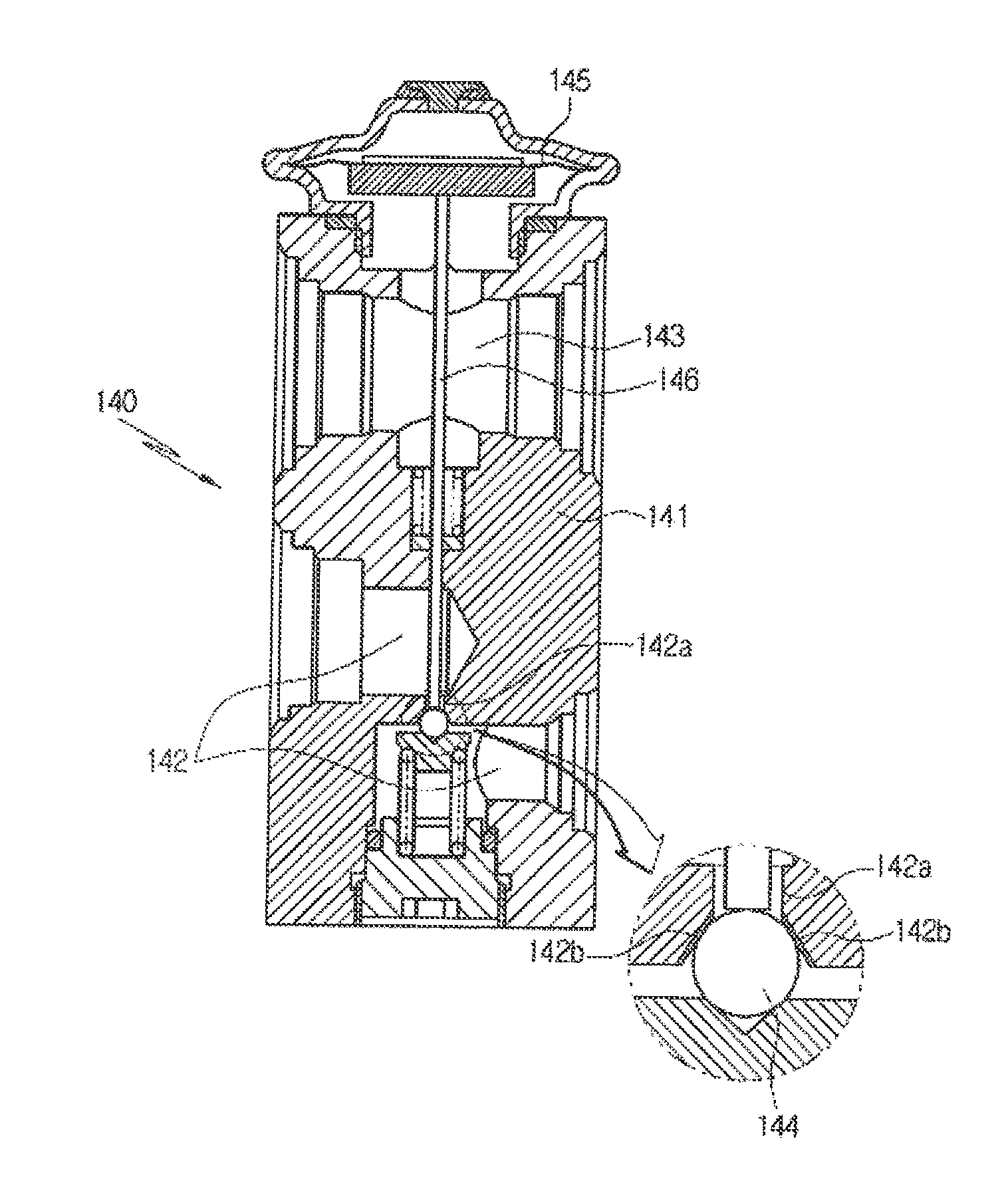

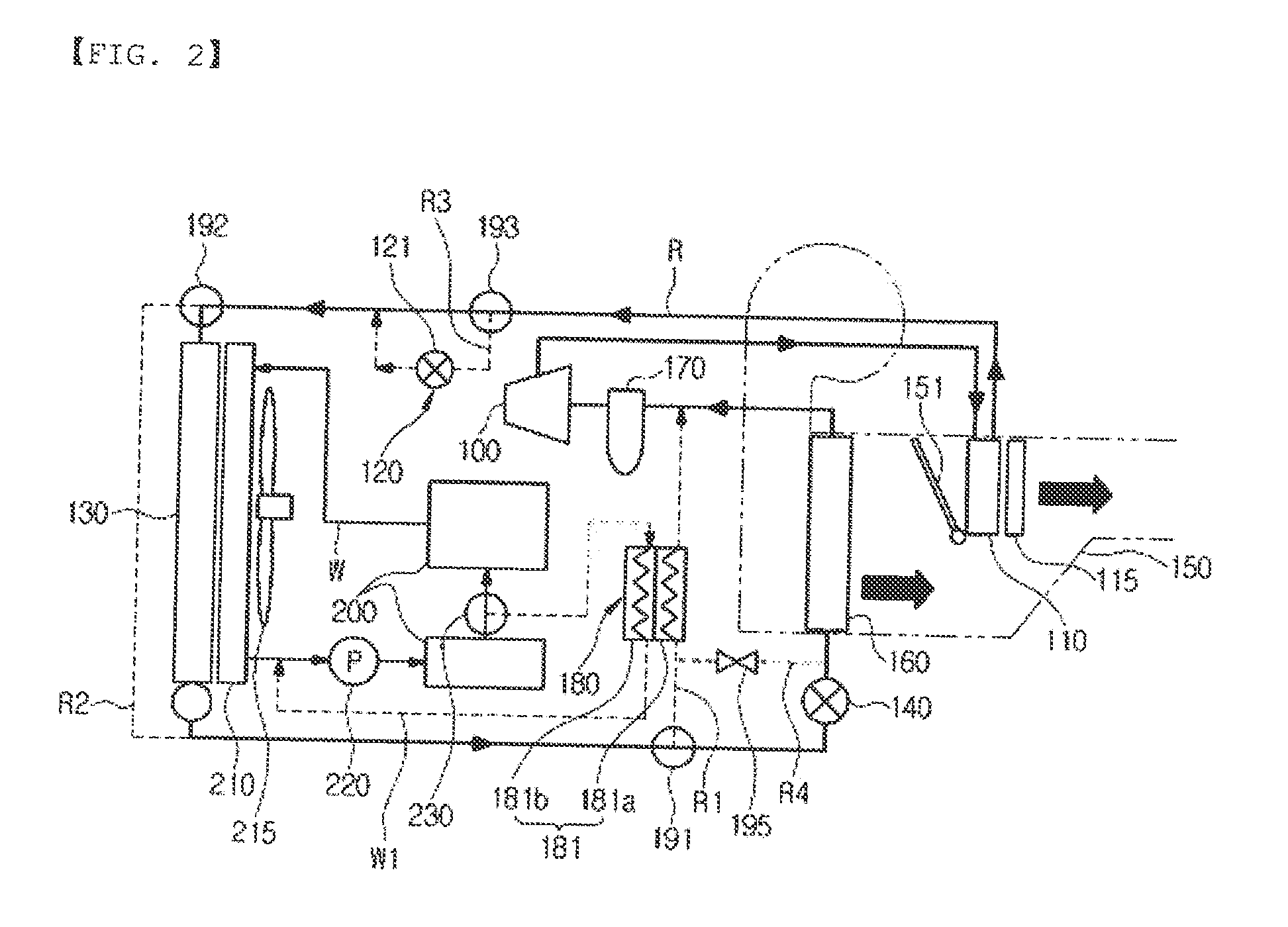

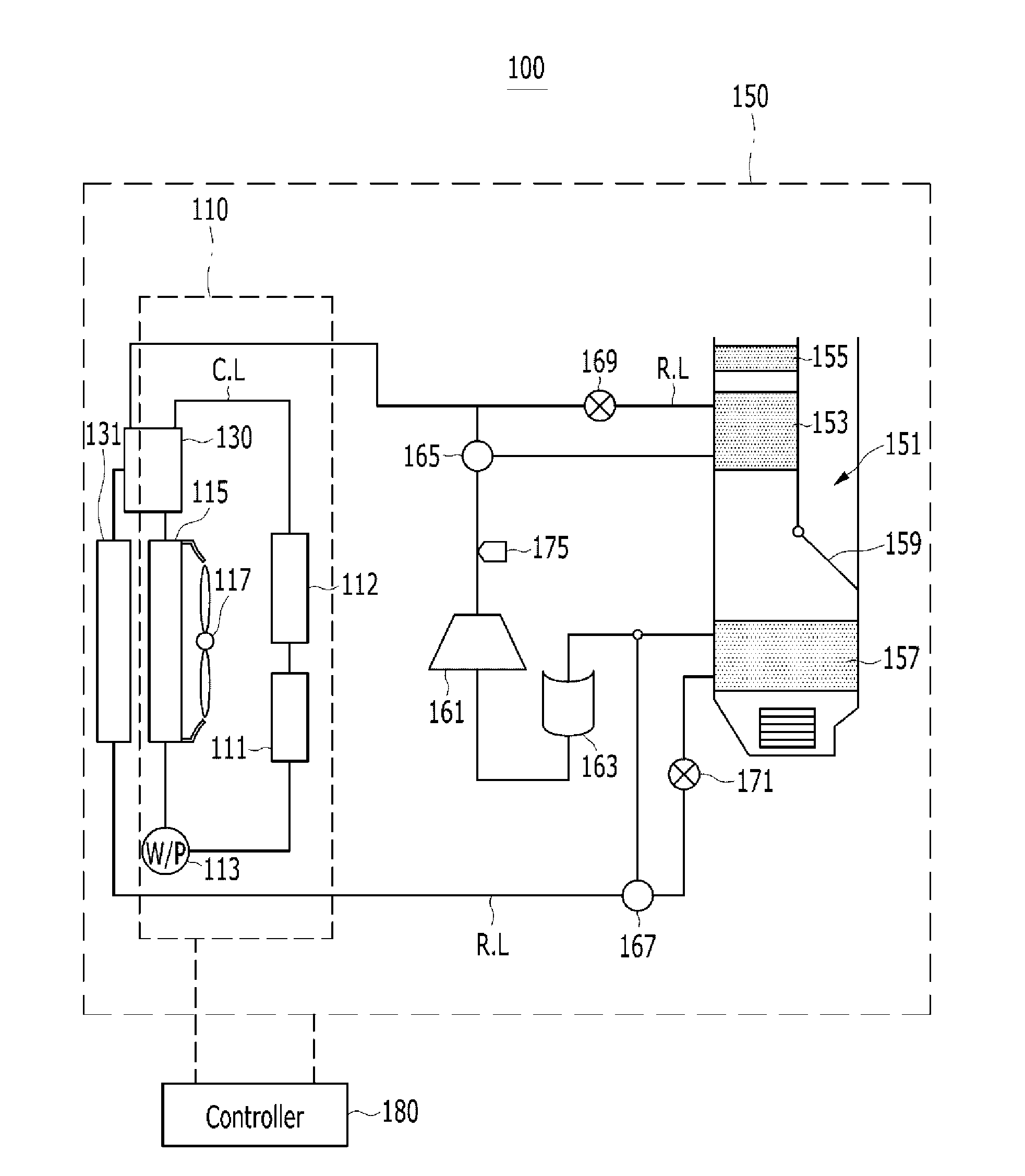

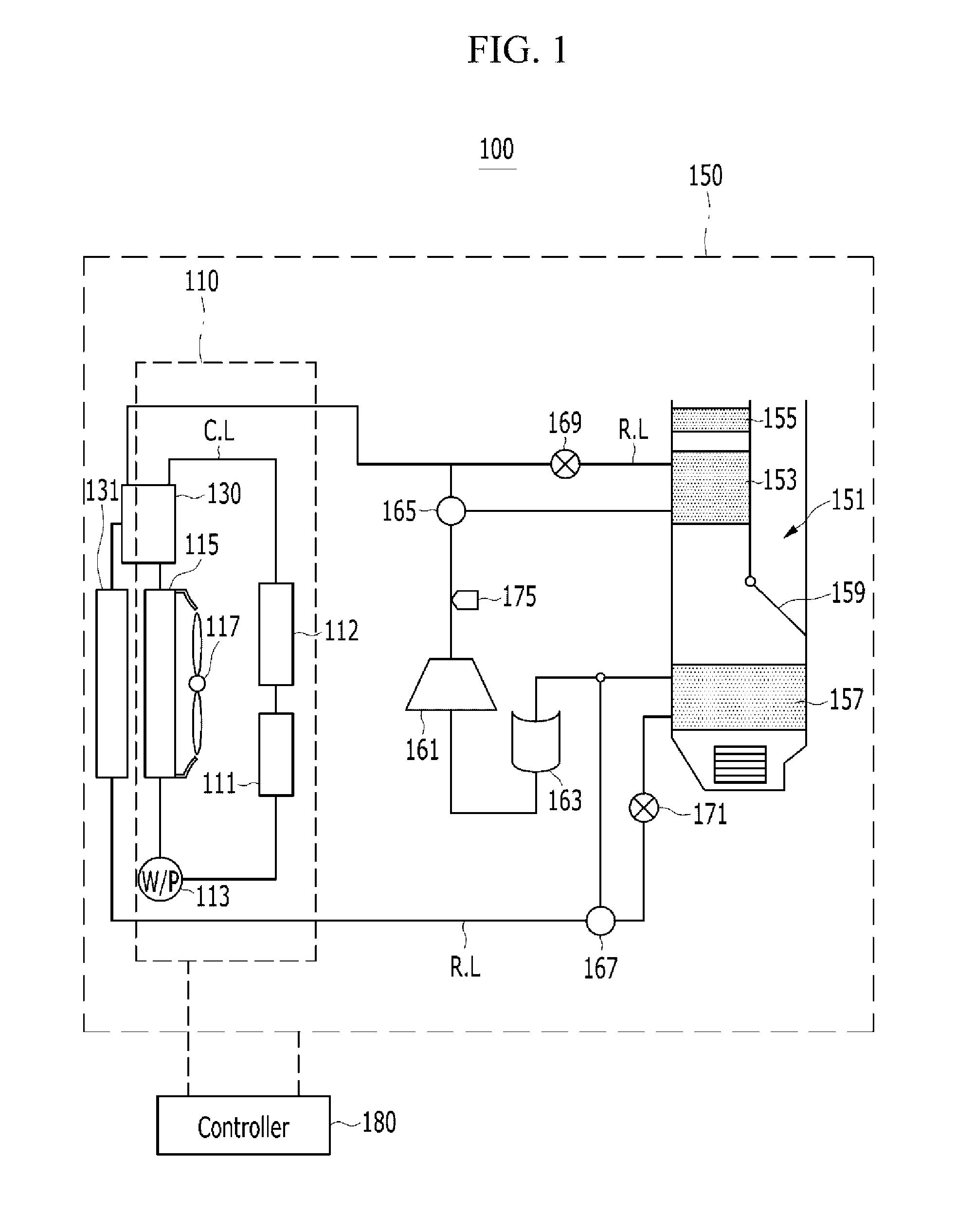

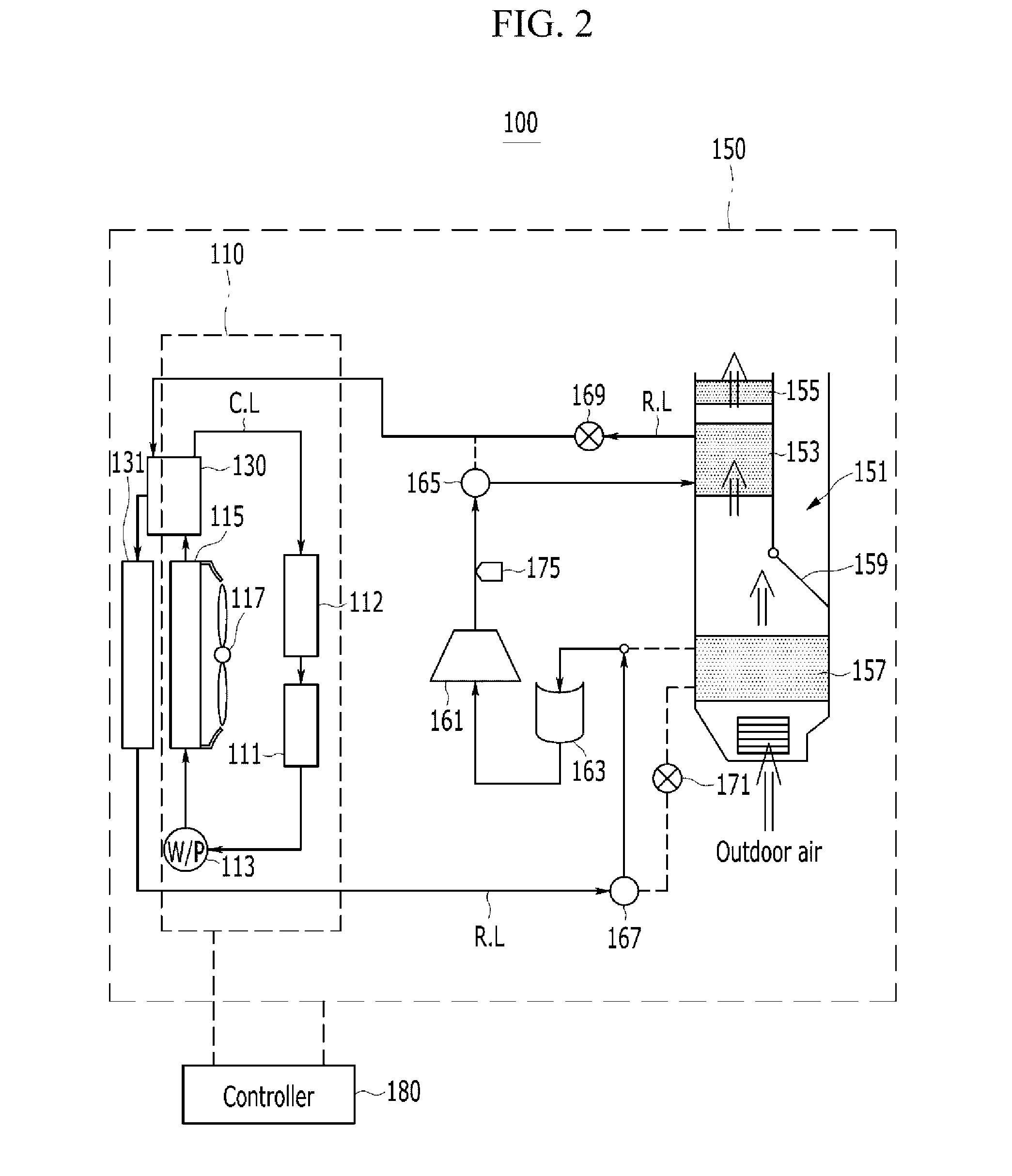

Heat pump system for vehicle

ActiveUS20120227431A1Minimize impactImprove heating performanceHeat pumpsCorrosion preventionElectricityEngineering

A heat pump system including a water-cooled type heat exchanger, which is a heat supply means, mounted on a first bypass line bypassing a second indoor heat exchanger to collect waste heat of vehicle electric devices to thereby enhance a heating efficiency of the heat pump system. The heat pump system for a vehicle includes: a branch line for connecting a refrigerant circulation line of the second indoor heat exchanger and the first bypass line with each other; a second bypass line, which bypasses an outdoor heat exchanger; and a control part that controls a flow of the indoor air to be introduced into an air-conditioning case, whereby the heat pump system can minimize influences of the outdoor air of low temperature even when the outdoor temperature is below zero, enhance the operation and the heating performance of the heat pump system by collecting waste heat of the vehicle electric devices and heat sources of the indoor air, and increase the mileage of the vehicle by minimizing operation of an electric heater.

Owner:HANON SYST

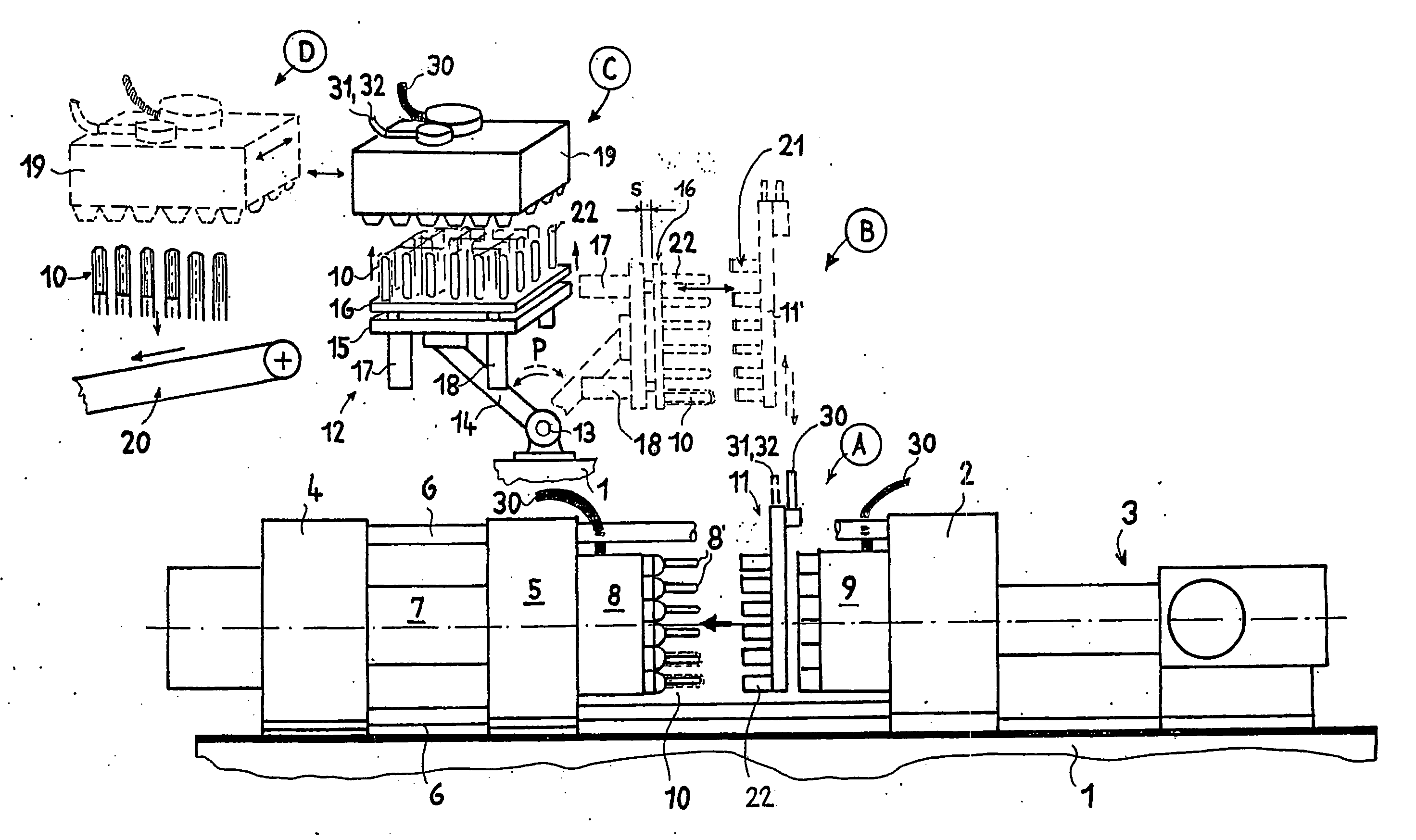

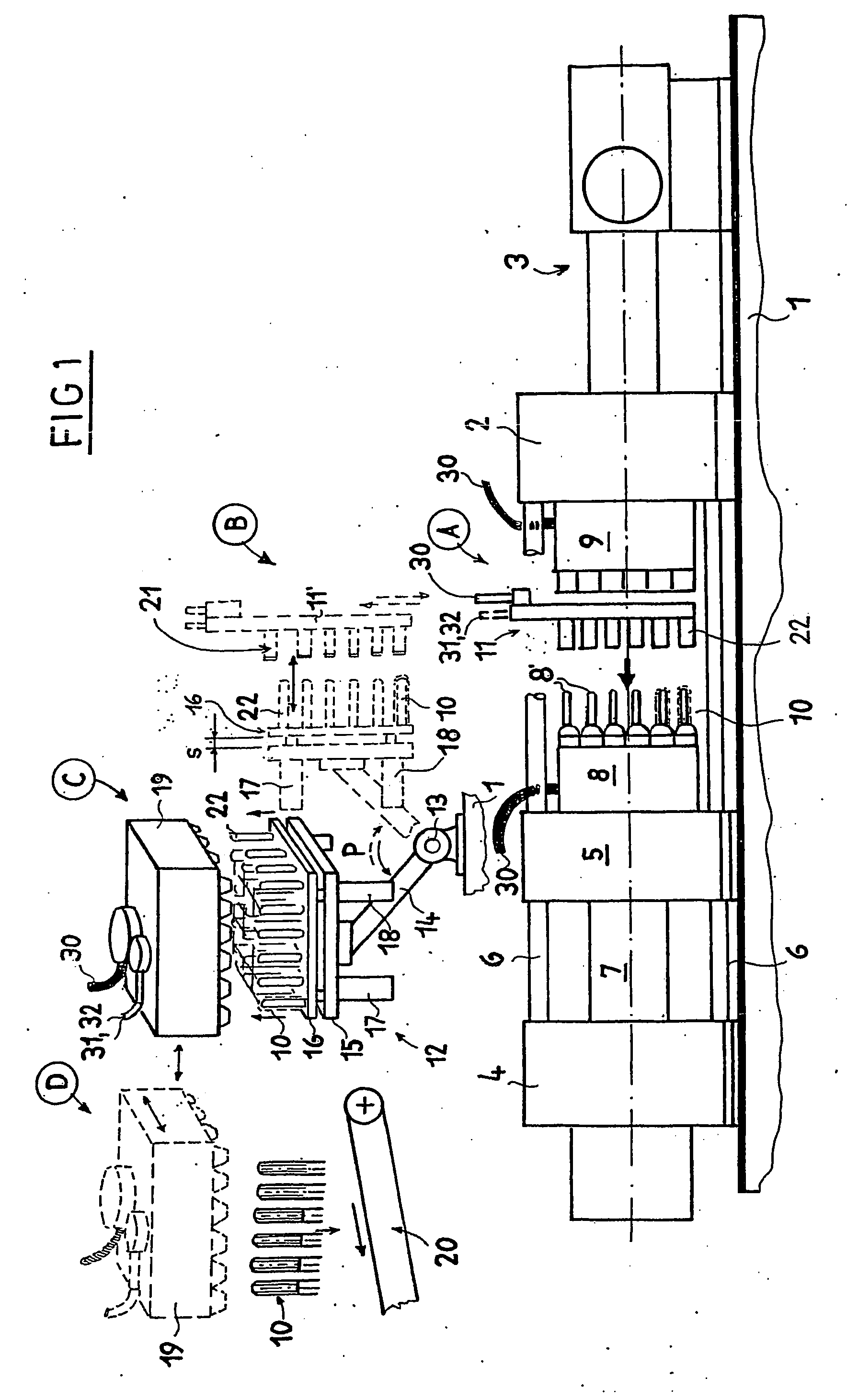

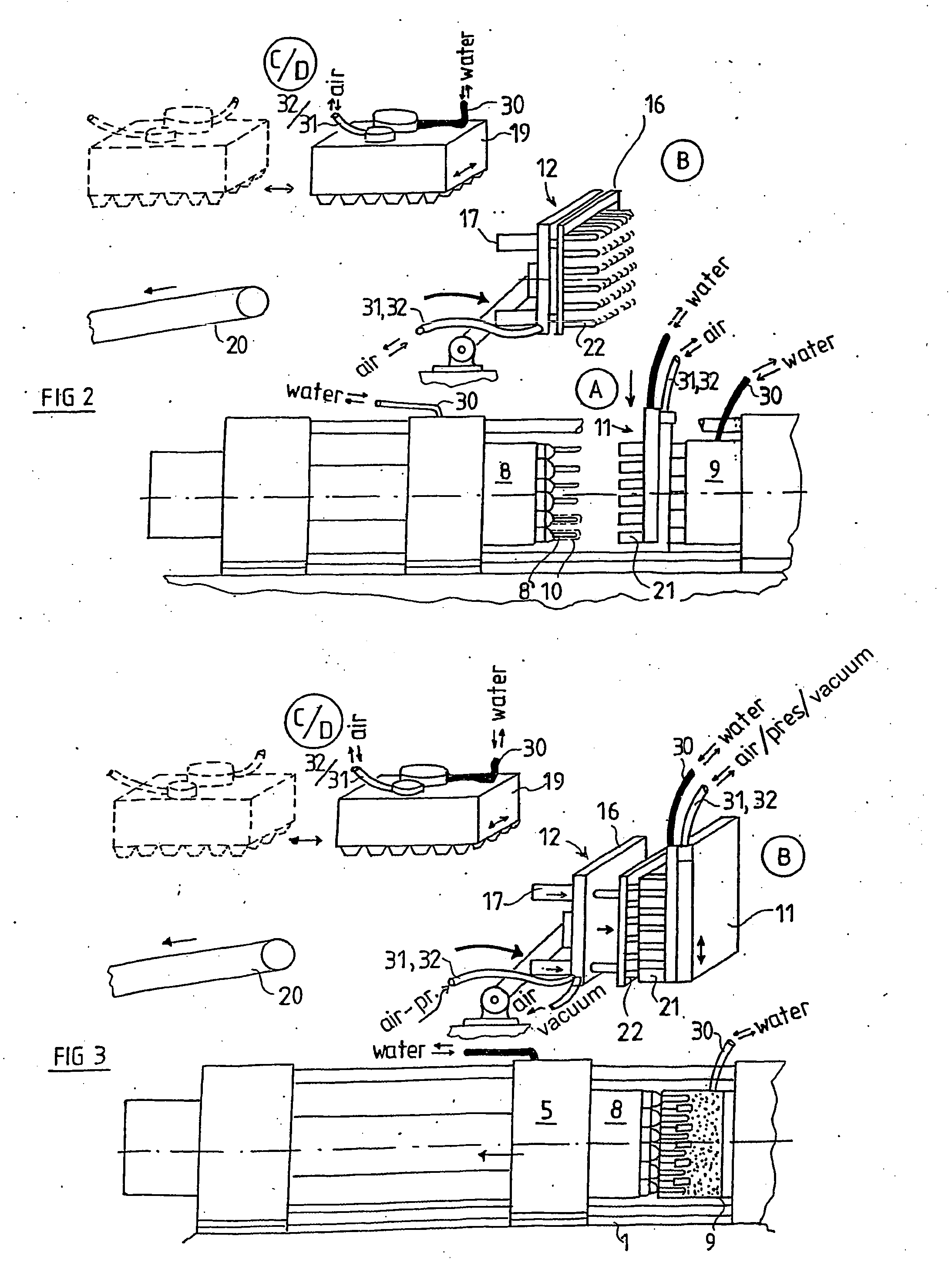

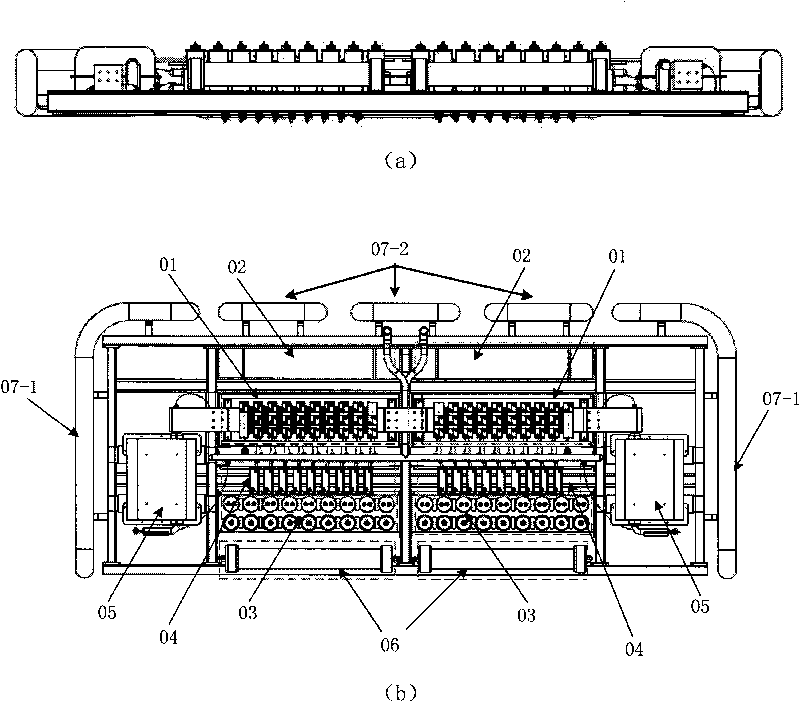

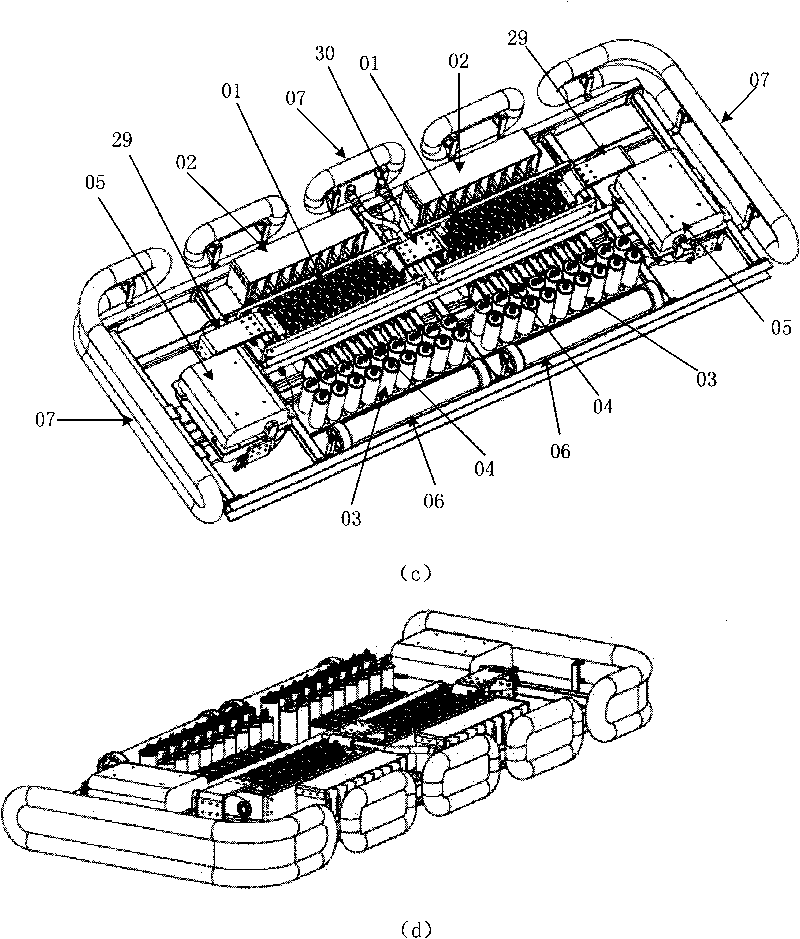

Method and device for the secondary treatment and the cooling of preforms

InactiveUS20060138696A1The temperature drops quicklyShort injection cycleDischarging arrangementMouldsTime delaysEngineering

The invention relates to a method and a device for the secondary treatment and the cooling of preforms (10) once they have been removed from the open mould halves (18, 9) of an injection moulding machine. The preforms are removed from the open moulds (18, 9) while still hot, by means of water-cooled cooling sleeves (21) of a removal device (11), and are subjected to intensive cooling during the duration of an injection moulding cycle. Both the entire inner side and the entire outer side of the blow-moulded part (10) are subjected to intensive cooling. Secondary cooling is then carried out, the duration thereof being equal to a multiple of the duration of an injection moulding cycle. After being removed from the casting moulds, the preforms are dynamically introduced into the cooling sleeves (21) until they fully touch the walls thereof. The inner cooling is carried out in a time-delayed manner.

Owner:NETABTAL MASCHEN

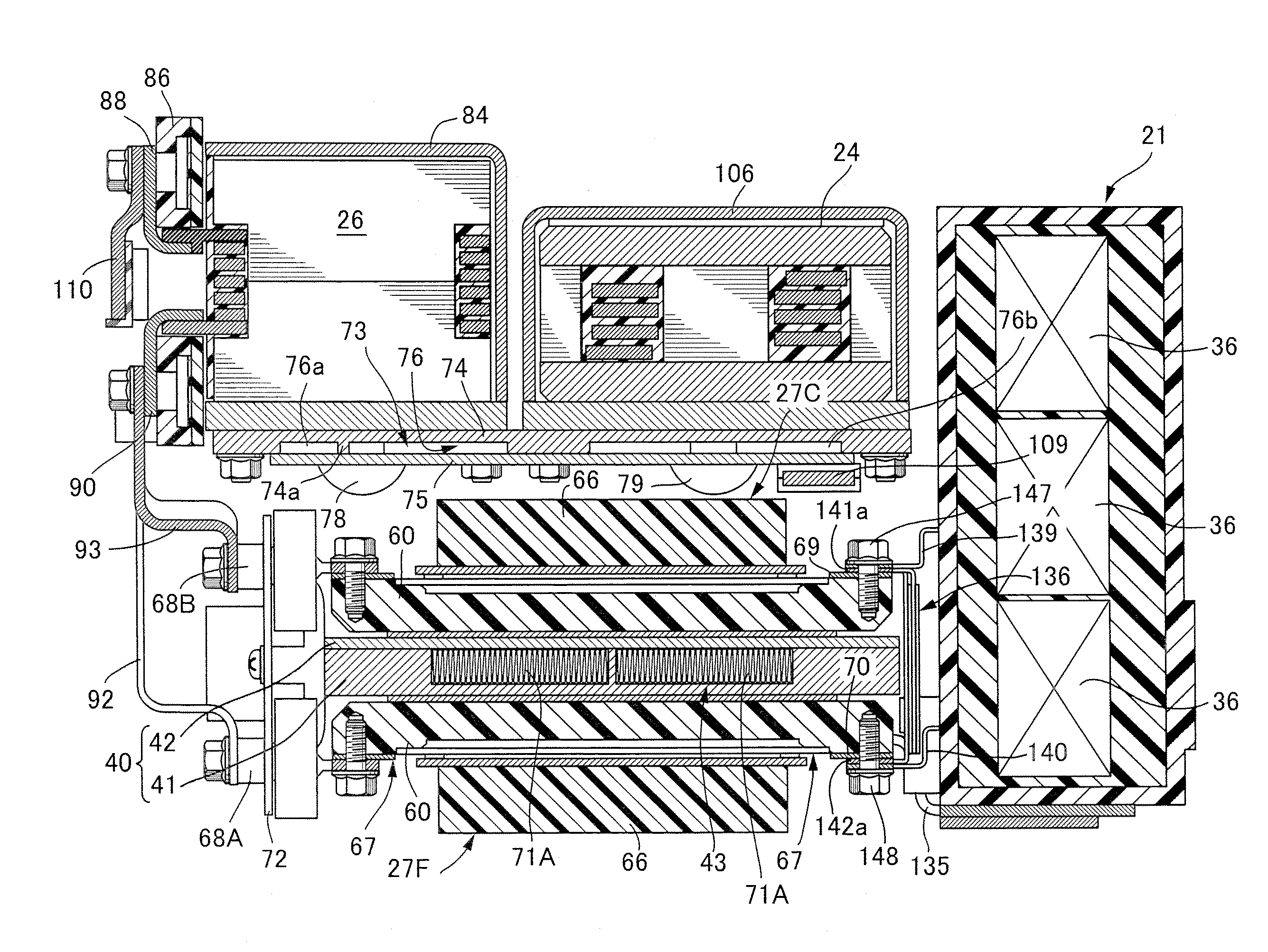

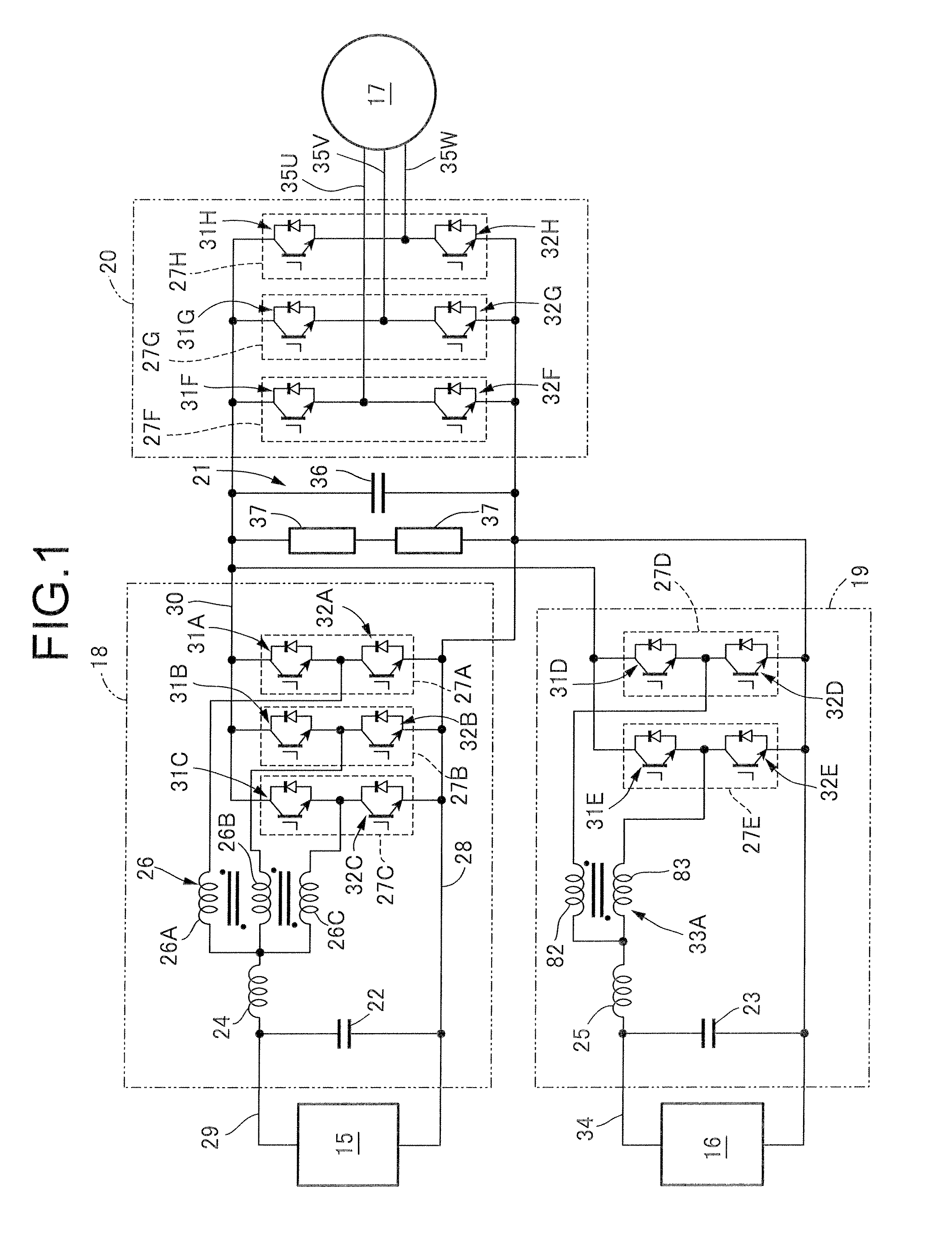

Novel thyristor converter valve module

ActiveCN101719719AReduce weightSmall geometryConversion constructional detailsElectric power transfer ac networkCapacitanceMechanical engineering

The invention provides electronic equipment with high voltage and high power, which is used for converting alternating current (AC) voltage into direct current (DC) voltage or converting DC voltage into AC voltage, in particular a thyristor converter valve module. A whole valve module is divided into two same segments, and each segment comprises a saturable reactor, a thyristor, a DC equalizing resistor unit, an energy-extracting resistor unit, a damping resistor unit, a damping capacitor unit, a gate electrode unit and a water cooling system, wherein the reactors of the electronic equipment are connected in series to meet the requirements on different transmission powers and different power voltage grades. The equipment is core equipment for high-voltage DC power transmission and can be applied to a DC-AC converting system, meet the requirements of different voltage grades and for the DC converting system with different voltage grades, including the super high voltage of 800 kV or above.

Owner:CHINA ELECTRIC POWER RES INST

Heat pump system for vehicle and method of controlling the same

InactiveUS20140069123A1Improve heating performanceImproving performance dehumidificationMechanical apparatusHeat pumpsEngineeringRefrigerant

A heat pump system for a vehicle may include a cooling apparatus that supplies and circulates coolant to a motor and an electrical equipment through a cooling line, wherein the cooling apparatus includes a radiator, a cooling fan that ventilates wind to the radiator, and a water pump connected to the cooling line, and an air conditioner apparatus connected through a refrigerant line, wherein the air conditioner apparatus includes a water-cooled condenser connected to the cooling line to change a temperature of the coolant using a waste heat that has occurred in the motor and the electrical equipment according to each mode of the vehicle and that is connected to the refrigerant line to enable an injected refrigerant in the refrigerant line to exchange a heat with the coolant at the inside thereof, and an air-cooled condenser connected in series to the water-cooled condenser through the refrigerant line.

Owner:HYUNDAI MOTOR CO LTD

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

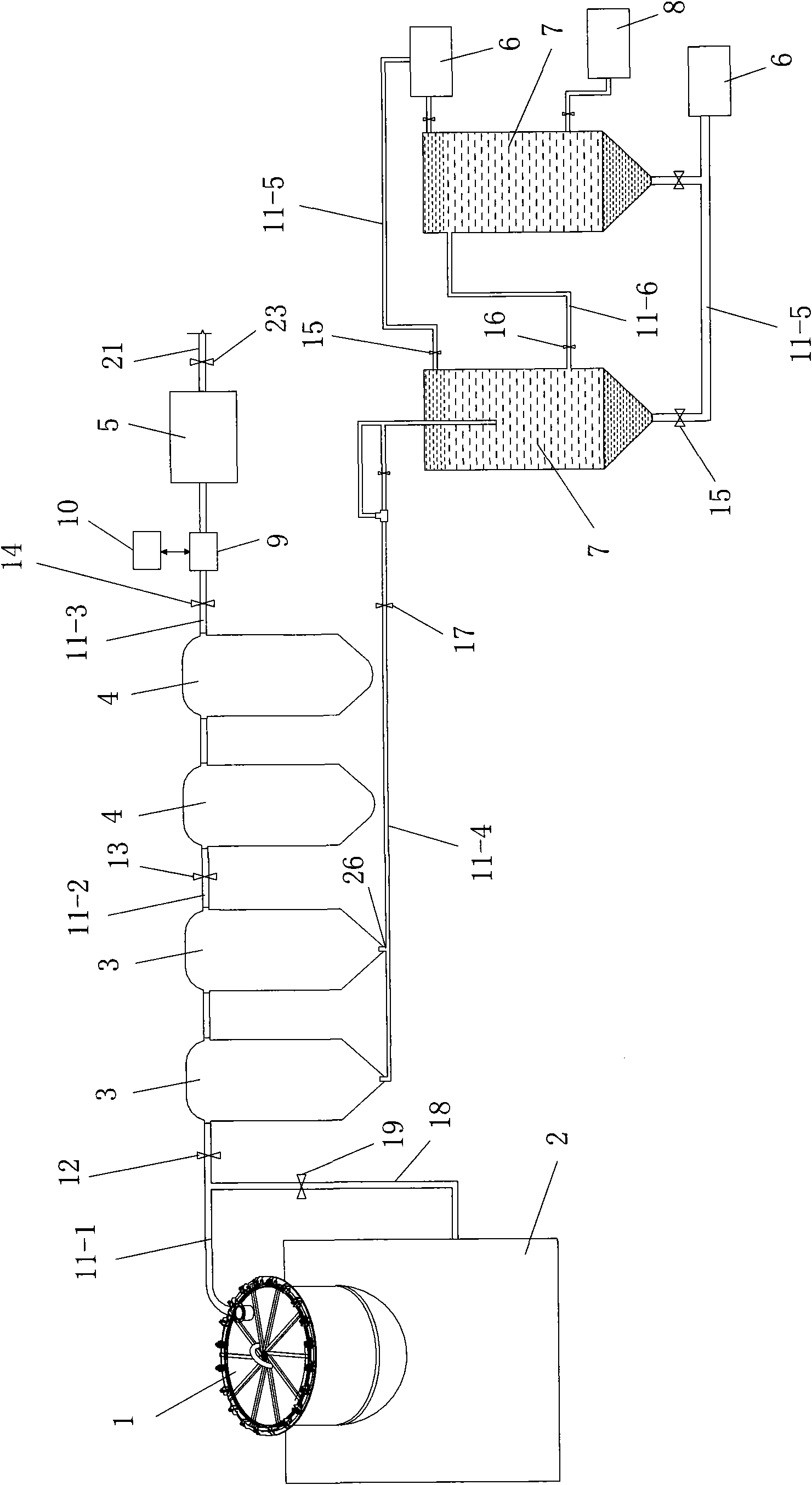

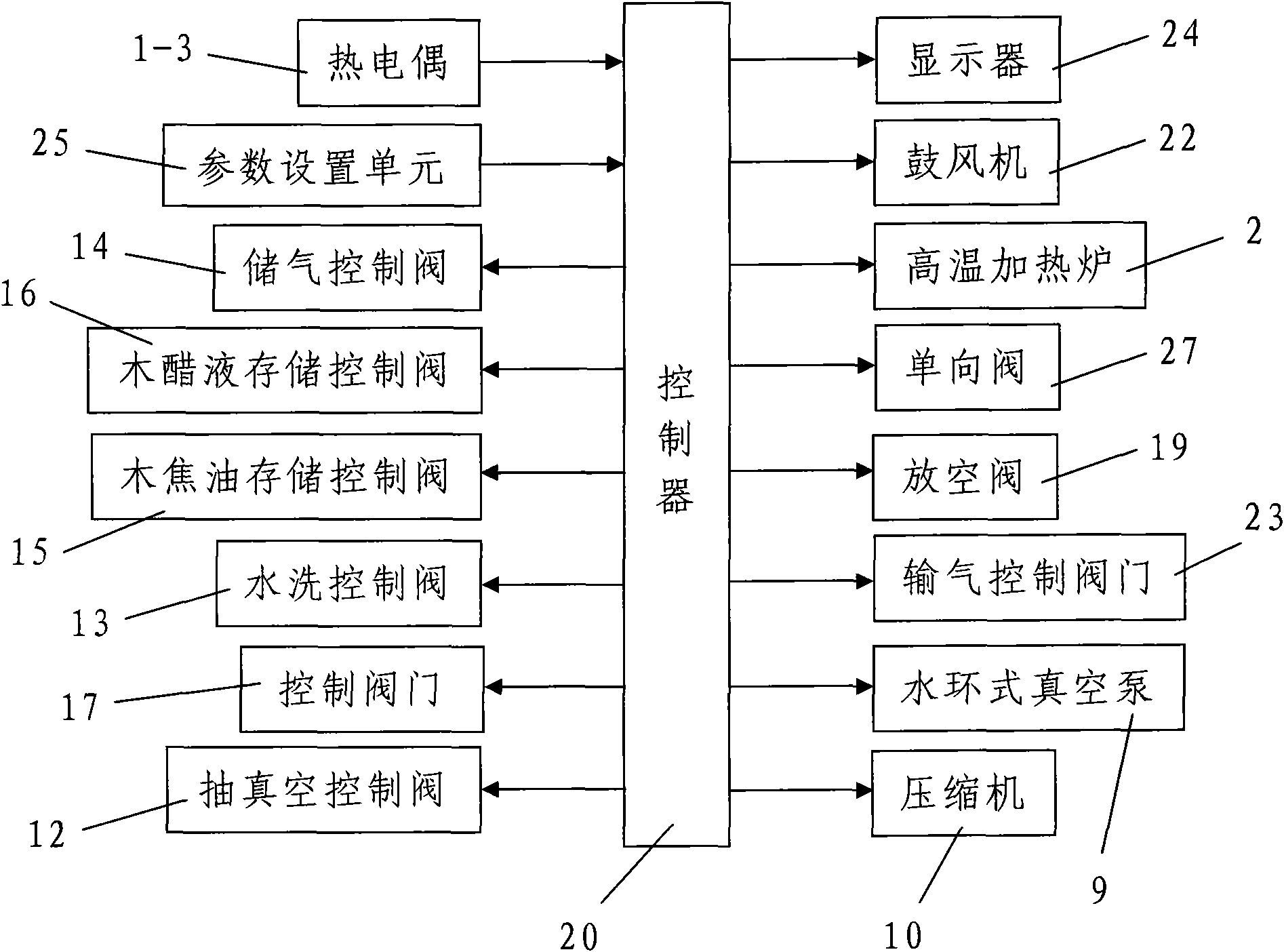

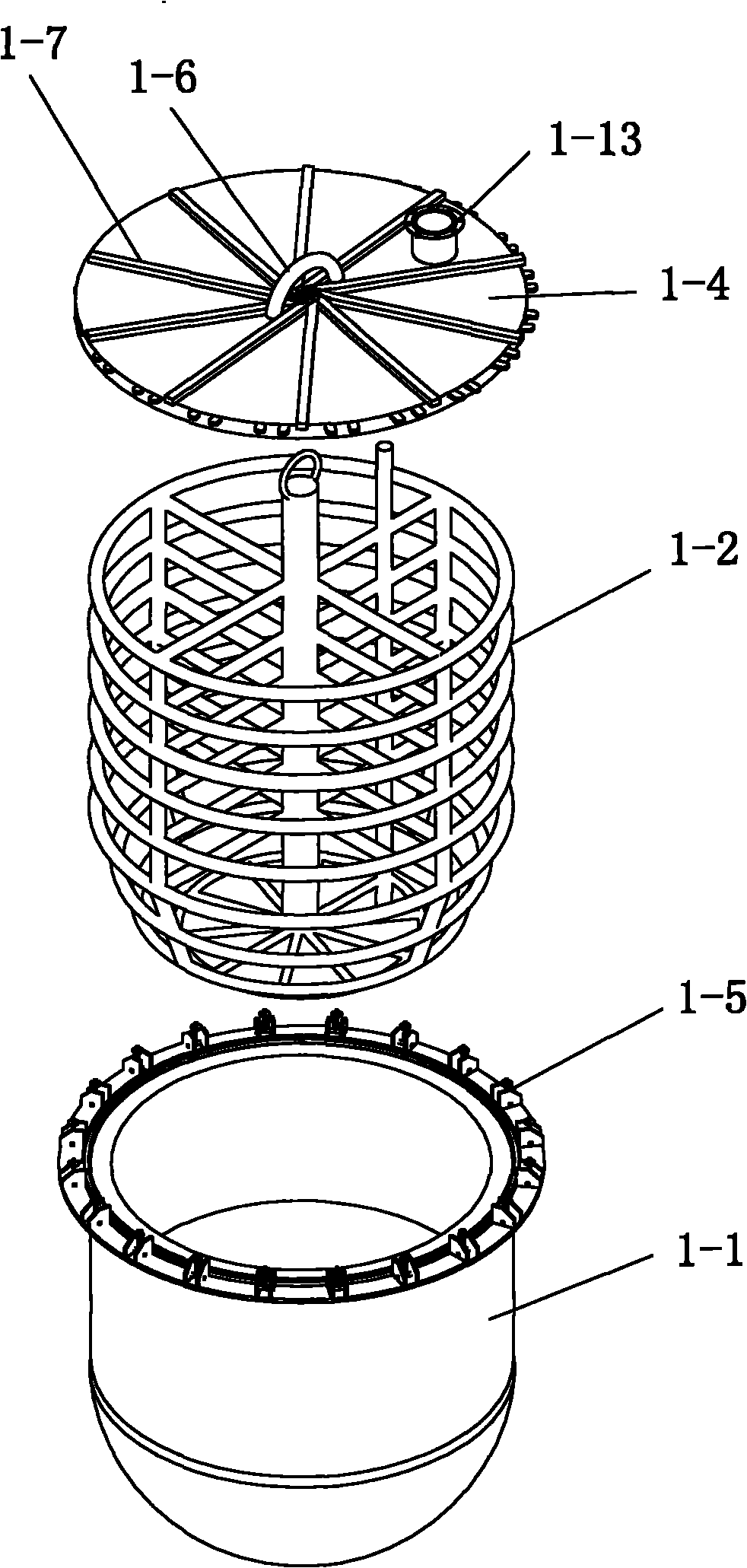

Co-production system and co-production method for biomass carbon, gas, wood tar and wood vinegar

InactiveCN101955780AFirmly connectedReasonable designBiofuelsPyroligneous acid productionSocial benefitsBiomass carbon

The invention discloses a co-production system and a co-production method for biomass carbon, gas, wood tar and wood vinegar. The co-production system comprises a biomass dry distillation kettle, a high-temperature heating furnace, a water cooling device, a washing device, a liquid separation device, a gas storage tank, a water-ring vacuum pump, a compressor, wood tar storage tank and a wood vinegar storage tank, wherein the liquid separation device separates wood vinegar and wood tar in the mixed liquid obtained by gas-liquid separation of the water cooling device; the co-production method comprises the following steps: 1, charging; 2, high-temperature carbonization: water cooling and gas-liquid separation, washing, gas storage and separation and storage of liquid matters; and 3, obtaining of the biomass carbon after the high-temperature carbonization. The co-production system for the biomass carbon, gas, wood tar and wood vinegar has the advantages of reasonable design, convenient processing, simple mounting arrangement, easy operation and good effect; and the co-production method has the advantages of convenient realization, high yield, low cost, fast co-production and relatively high production purity and has obvious economic and social benefits and wide popularization and application prospect.

Owner:陕西亿鑫生物能源科技开发有限公司

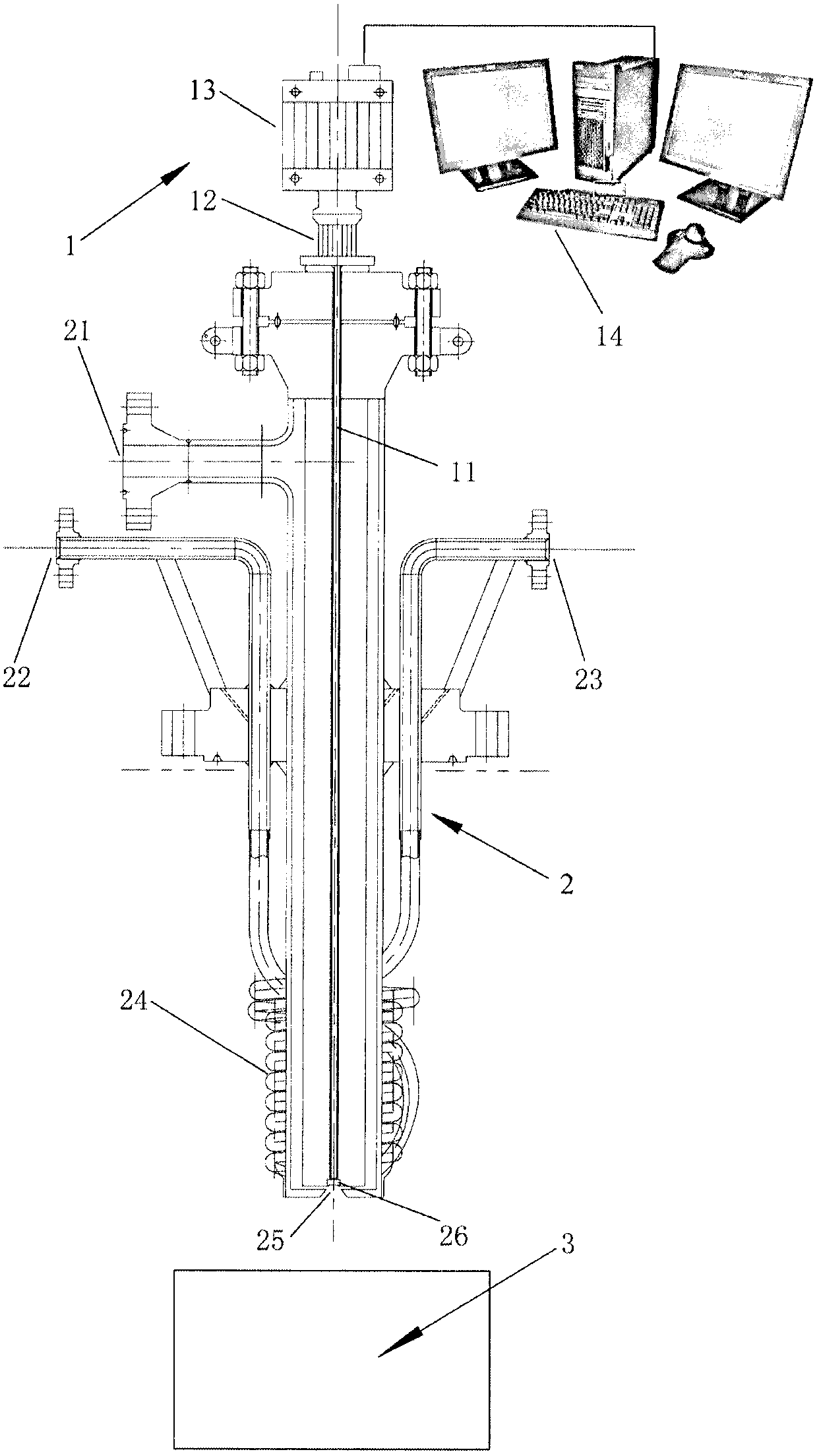

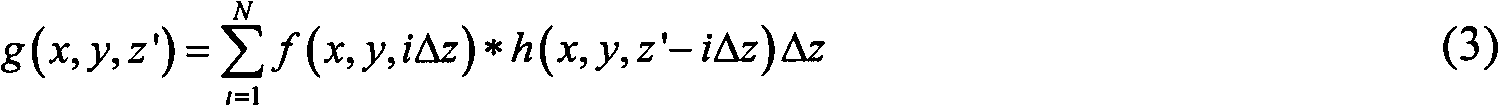

Detection device and method for three-dimensional temperature field in combustion chamber of single-CCD imaging system

The invention relates to a detection device for a three-dimensional temperature field in a combustion chamber of a single-CCD imaging system. The detection device comprises a high-temperature and high-pressure resistant water cooling jacket, an endoscope, a color industrial plane array CCD camera and a data acquisition and analysis unit, wherein the water cooling jacket is used for forming an embedded type protective housing in equipment, the light path of the endoscope is cooled through a water coil and the blowing of an inert gas, and a pressure resistant lens at the front end the jacket is protected so as to maintain the normal operation of the endoscope; the endoscope is used for leading radiating images out of a high-temperature and high-pressure furnace through the light path; the color industrial plane array CCD camera is used for imaging the radiating images of visible light wave band; and the data acquisition and analysis unit is used for acquiring the radiating images of different focal planes and measuring the three-dimensional temperature field by an optical stratified imaging method and a colorimetric temperature measurement method. The invention also relates to a detection method for the three-dimensional temperature field. Due to the adoption of the technical scheme, the three-dimensional temperature field detection on the baisi of the single-CCD camera can be realized, the technical scheme is realized simply, and the device and the method can be applied to harsh environments, such as high temperature, high pressure and the like, and are easy to popularize in the industrial production field.

Owner:EAST CHINA UNIV OF SCI & TECH

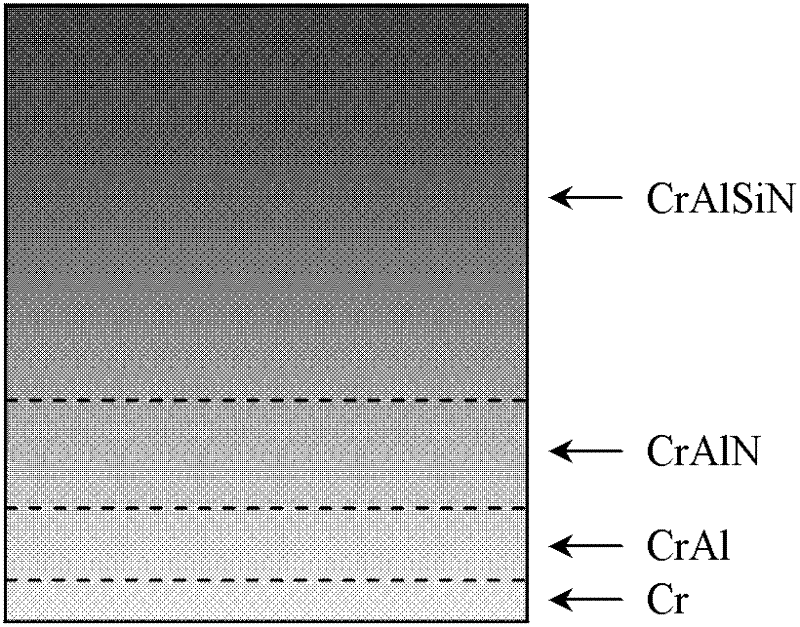

Technology for preparing nuclear fission reactor fuel clad surface CrAlSiN gradient coating

InactiveCN102400099ABeneficial technical effectExcellent resistance to high temperature oxidation and corrosionFuel elementsNuclear energy generationNuclear fissionOxidation resistant

The invention relates to a new technology for depositing a CrAlSiN gradient coating with high-temperature oxidation corrosion resistance and excellent mechanical properties on a supercritical water-cooled reactor fuel clad surface in a nuclear fission reactor. The CrAlSiN gradient coating is deposited on the surface of a base material by adopting a multi-target reaction magnetron sputtering method, and the technology comprises the following four continuous stages of: 1, preparing a Cr gradient coating; 2, preparing a CrAl gradient coating; 3, preparing a CrAlN gradient coating; and preparing the CrAlSiN gradient coating, and annealing. By reasonably designing the gradient variable microstructure of each element, the anti-oxidation temperature of the coating reaches 950 DEG C, the hardnessof the coating reaches over 37GPa, and the adhesive force of the coating adhered to the base material reaches 34N; the coating also has excellent thermal shock resistance, abrasion resistance and thelike; and the service property of the supercritical water-cooled reactor fuel clad part can be greatly improved, and the service life of the clad part can be greatly prolonged.

Owner:SICHUAN UNIV

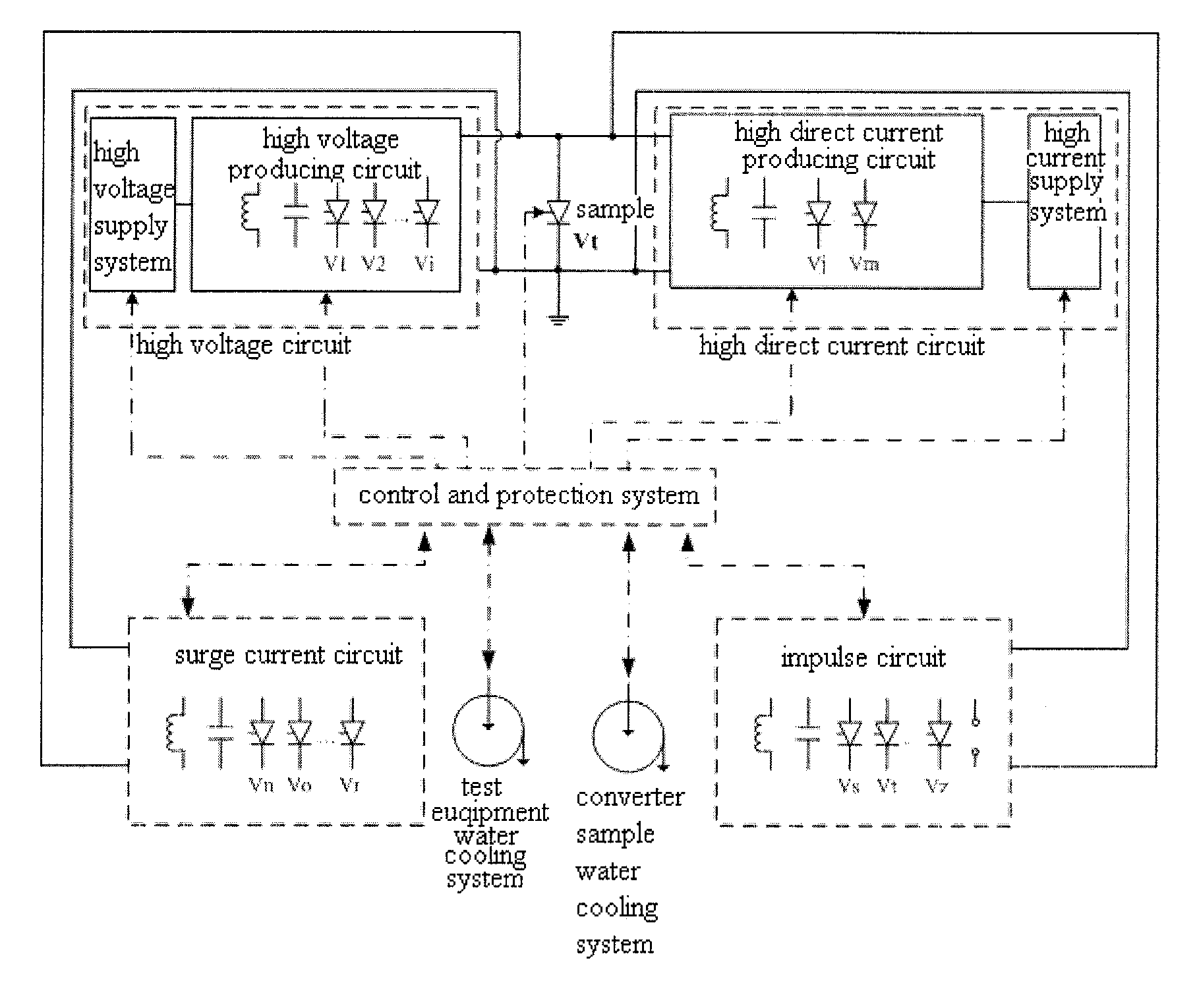

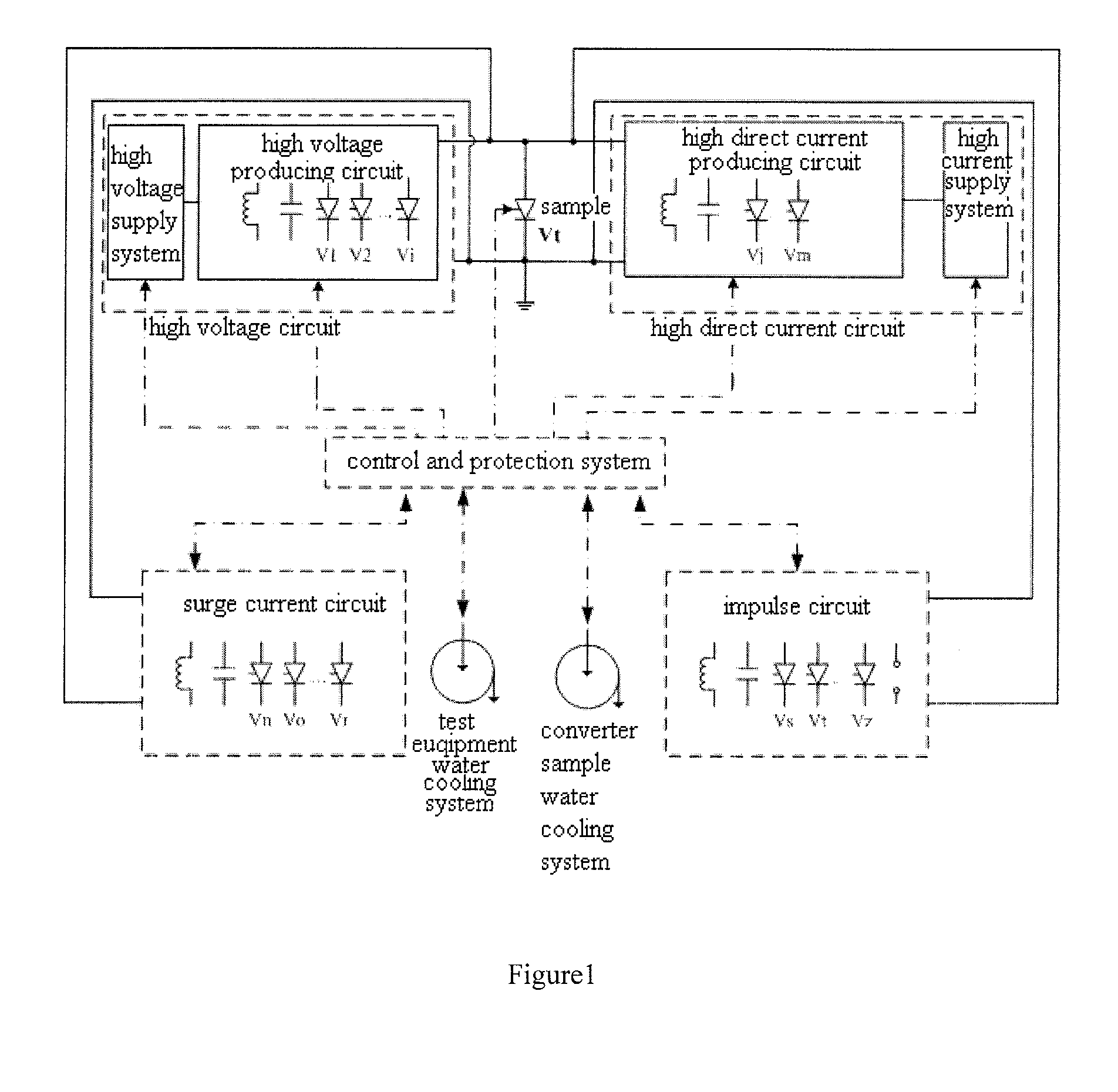

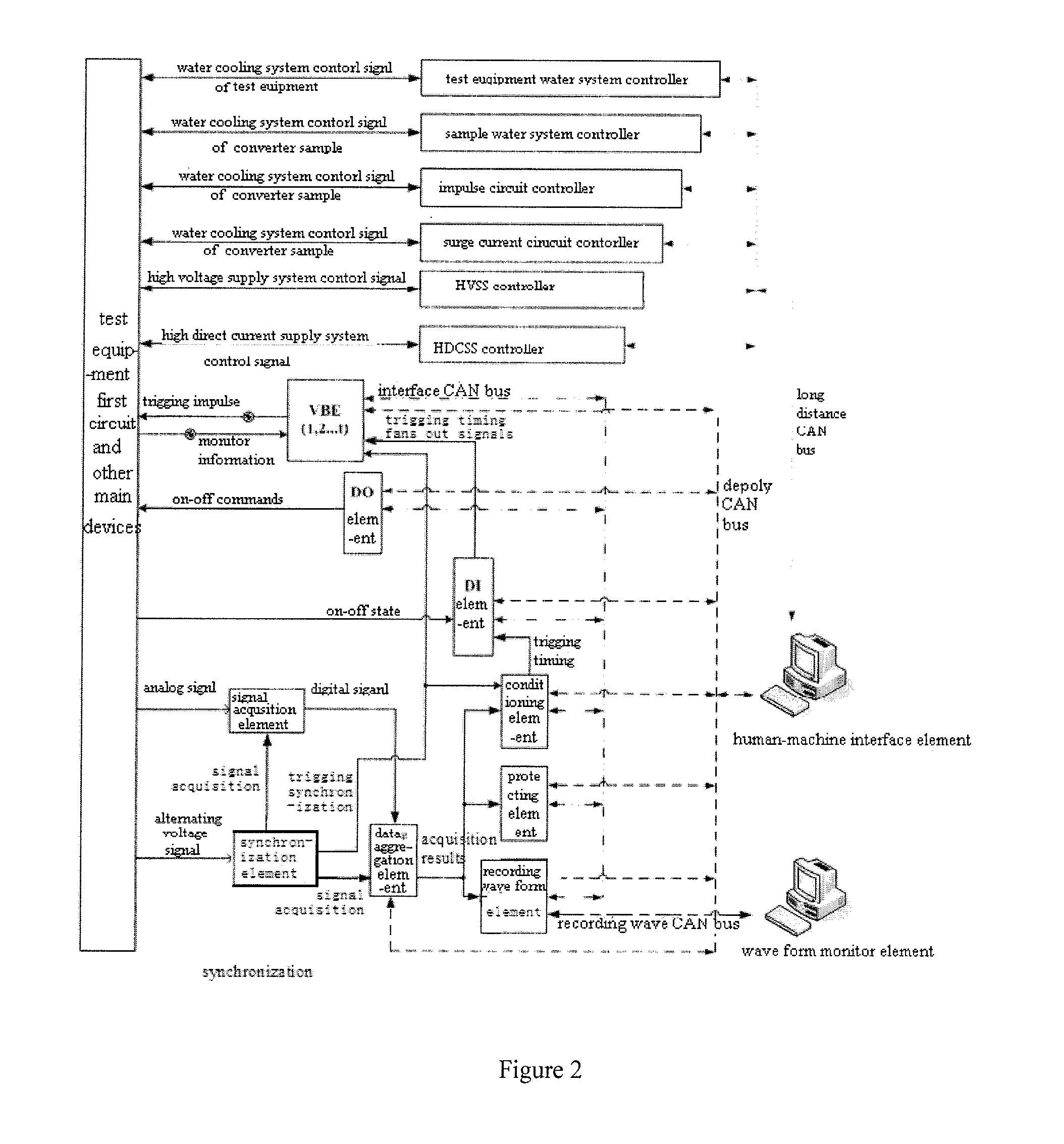

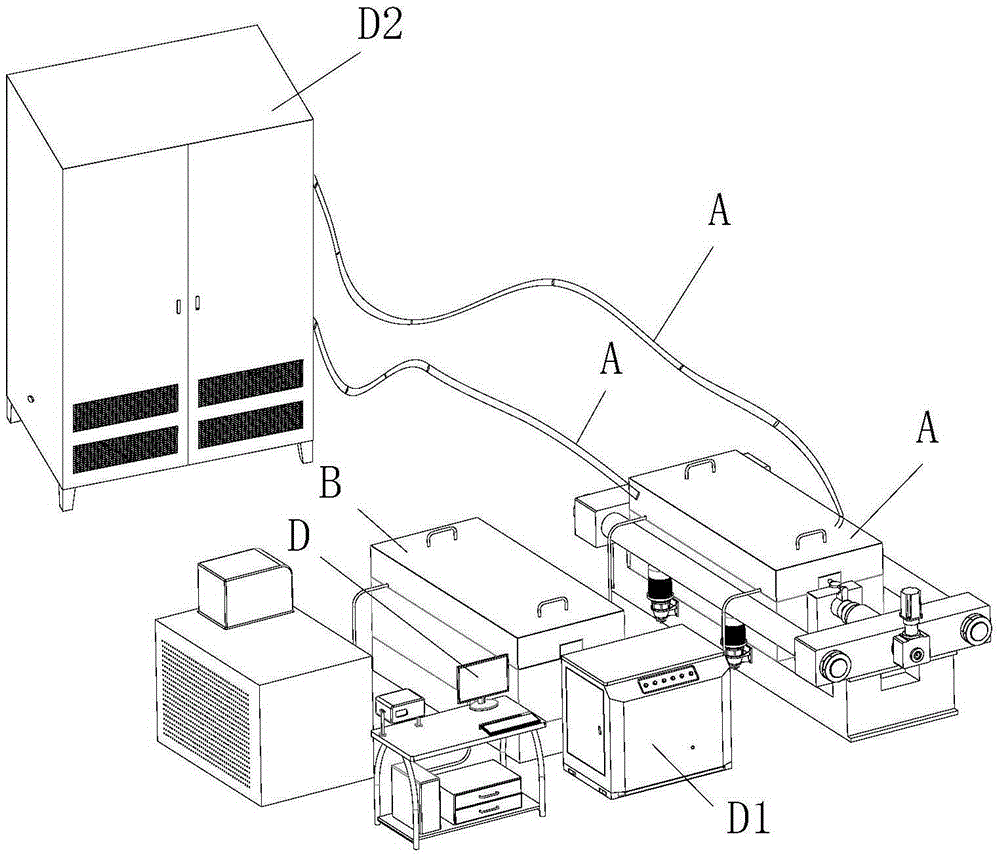

Control and Protection System of Converter Valve Operation Test Equipment

ActiveUS20110276189A1Compact structureReduce hardware investment costsLevel controlFrequency-division multiplex detailsHuman–machine interfaceData aggregator

This present provides a control and protection equipment system suitable for synthesis converter operation test, relates to power system automation equipment field. This system includes human-machine interface element, synchronization element, signal acquisition element, data aggregation element, conditioning element, protecting element, wave form recording element, wave form monitor element, on-off input element, on-off output element, vale based element (VBE), high direct current supply power system controller, high voltage supply system controller, current surge circuit controller, impulse circuit controller, test converter valve water cooling controller and test equipment water cooling system controller. This system can control converter samples and auxiliary valves on set trigging timing, produce various operation tests need heat, voltage and current of the converter samples and carry through operation tests. This system can also monitor on-off condition and important analog parameters condition of main circuit immediately, when abnormal condition takes place, the suitable protective measures will be made immediately.

Owner:CHINA ELECTRIC POWER RES INST

Preparation method for wear resistant fire-retardant coating

ActiveCN101570650AImprove working environmentImprove work efficiencyFireproof paintsO-Phosphoric AcidSodium phosphates

The invention provides a preparation method for wear resistant fire-retardant coating with simple construction process, good wear resistance and relatively low cost. The raw material of the wear resistant fire-retardant coating selects plate-shaped tabular alumina, brown alumina and high-quality bauxite chamotte as aggregate, selects plate-shaped tabular alumina powder, flint clay powder, alpha-Al2O3 micropowder and ceramic powder as fine powder, selects 42.5 mass percent industrial phosphoric acid solution, solid aluminium dihydrogen phosphate and clay powder as bonding agents, selects fused magnesite as a curing agent and selects sodium borate and sodium hexametahposphate as sintering aids. The wear resistant fire-retardant coating can be directly smeared on the surfaces of a wear resistant fire-retardant material liner and a water cooling wall pipe, fills up technical blank of resisting the wear on metal by using a non metal coating at a high temperature of 900 DEG C, provides a new repairing method for a non metal wear resistant fire-retardant material liner, has simple construction process, can obviously improve working environment of workers, reduce the labor intensity and improve the working efficiency of maintaining a circulating fluid bed boiler heated surface metal pipe wall and the wear resistant fire-retardant material liner.

Owner:TONGDA REFRACTORY TECH CO LTD

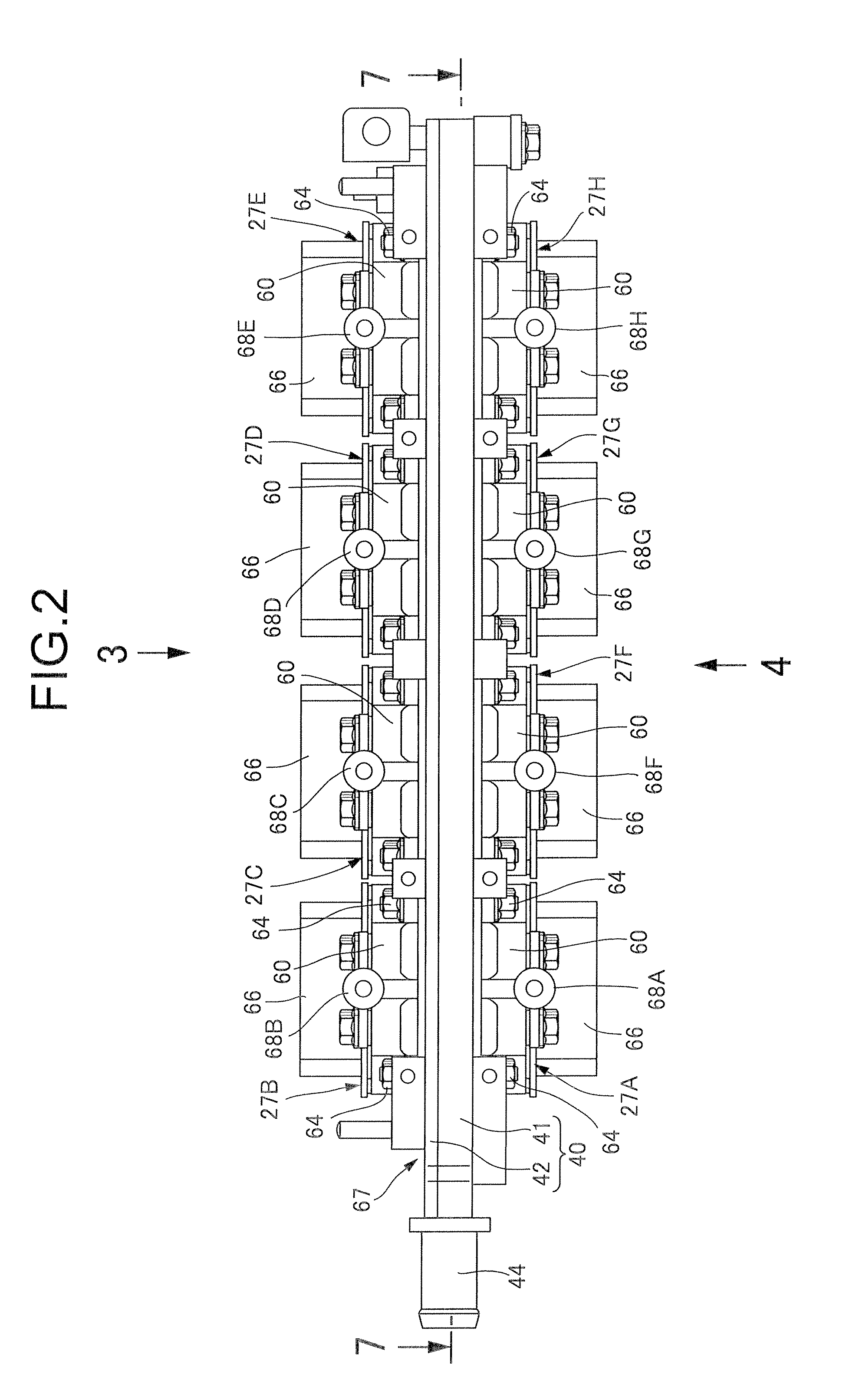

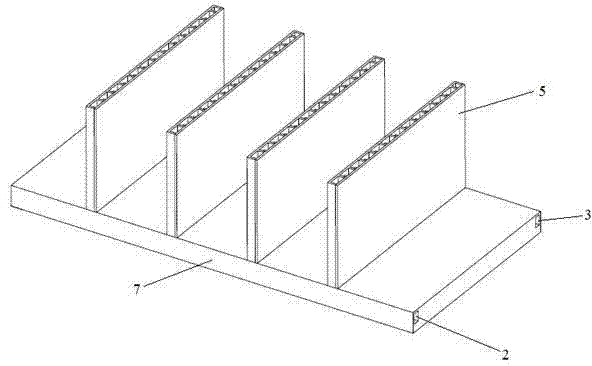

Cooling device for semiconductor element module and magnetic part

ActiveUS8064198B2Improve heating efficiencyElectric signal transmission systemsAc-dc conversion without reversalEngineeringCooling efficiency

A cooling device for a semiconductor element module and a magnetic part, includes: a water-cooled type heat sink having a cooling water passage; a semiconductor element module including a plurality of chips arranged side by side in a circulation direction in the cooling water passage, the semiconductor element module being mounted on the heat sink; and a magnetic part including a core and a winding portion mounted on the core, the magnetic part being mounted on the heat sink or another heat sink. In the cooling device, a plurality of cooling fins is disposed to extend along the circulation direction in the cooling water passage in a manner that the plurality of cooling fins are separated into groups for the respective chips arranged side by side in the circulation direction, and that the groups of the cooling fins are offset from each other in a direction perpendicular to the circulation direction. Accordingly, it is possible to have improved cooling efficiency of a heat sink with cooling fins.

Owner:HONDA MOTOR CO LTD

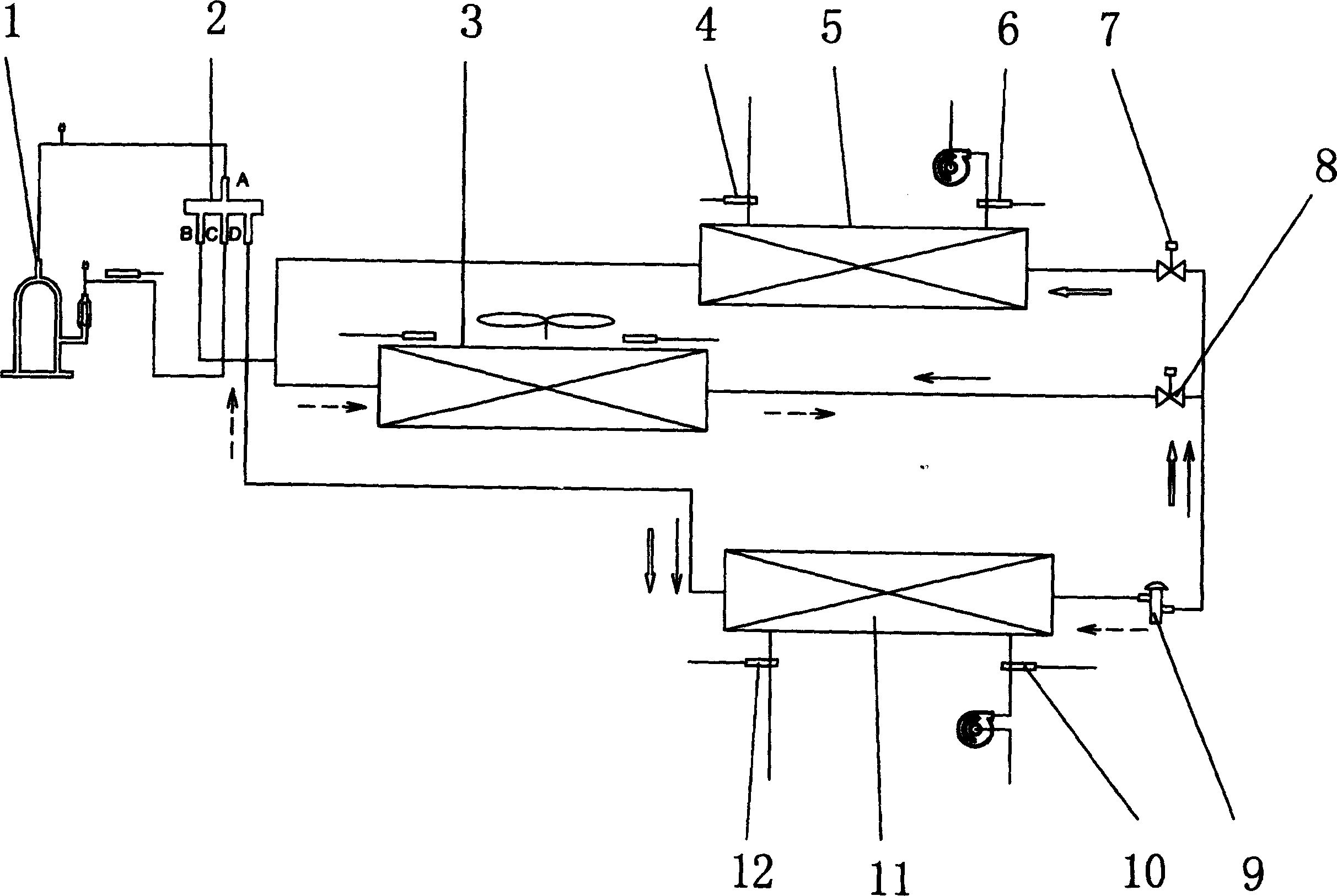

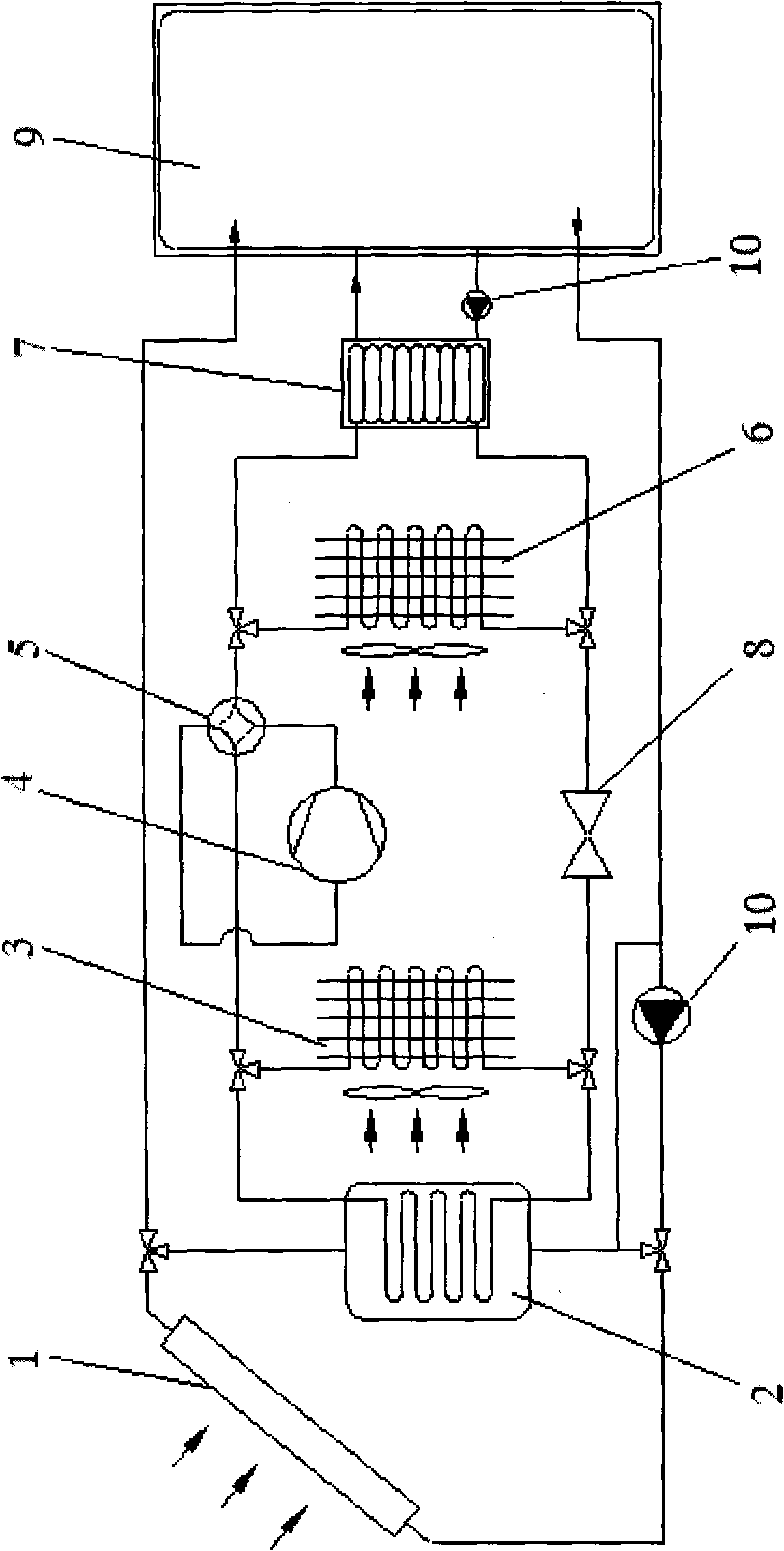

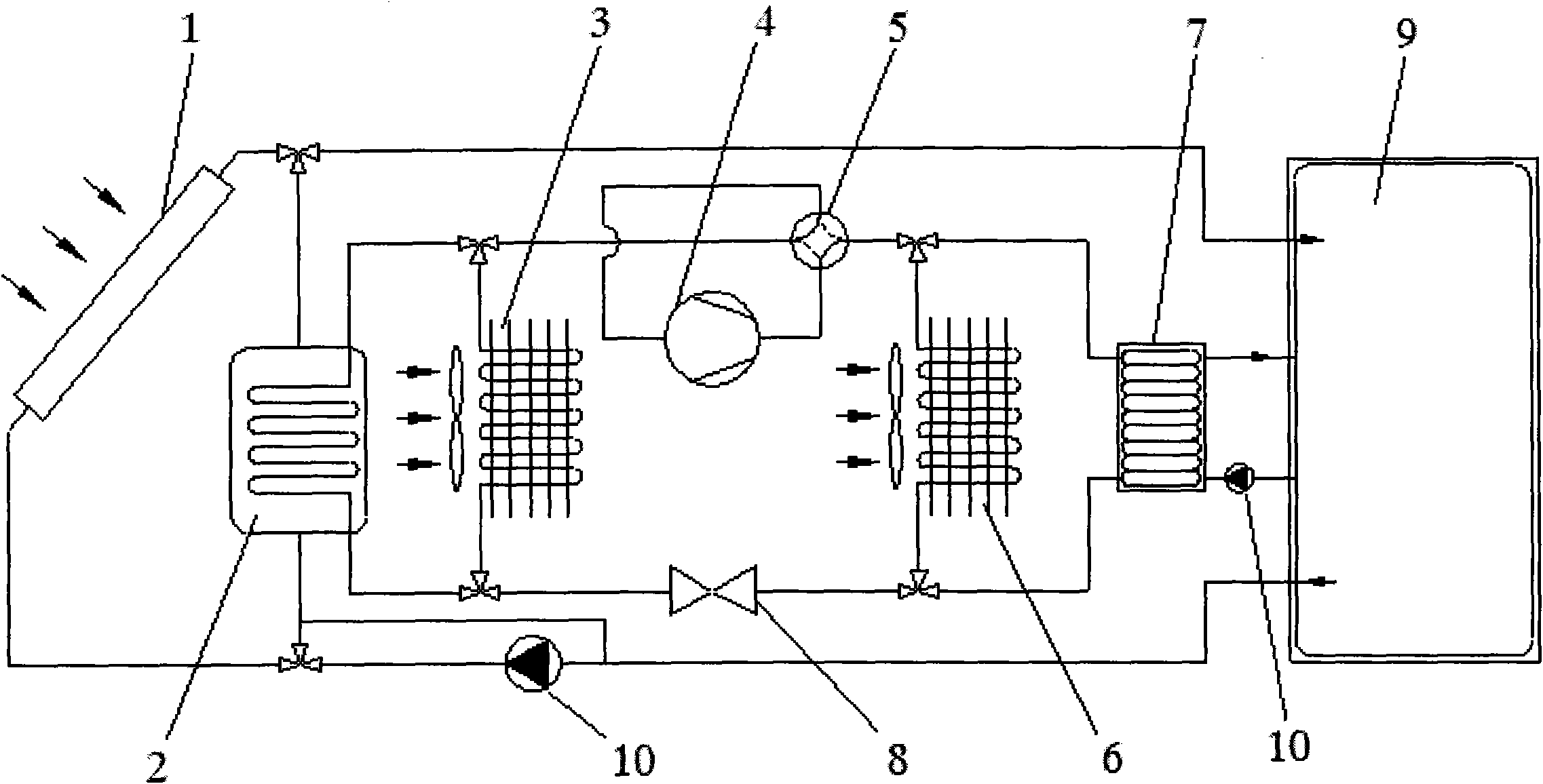

Air-cooled water-cooled two-evaporimeter hot-water machine set

InactiveCN101089518AIncrease heating capacityTo achieve the purpose of supplying domestic hot waterCompression machines with several evaporatorsEnergy industryWater sourcePulp and paper industry

The present invention relates to a kind of air-cooled water-cooled double-evaporator hot-water machine unit for recovering after heat of waste water. It is characterized by that it has a refrigeration circulating loop composed of compressor, water-cooled condenser, air-cooled evaporator and water-cooled evaporator. On said loop a controller is set. Said invention also provides the working principle of said air-cooled water-cooled double-evaporator hot-water machine unit and its concrete operation method.

Owner:扬州辛普森中央空调制造有限公司

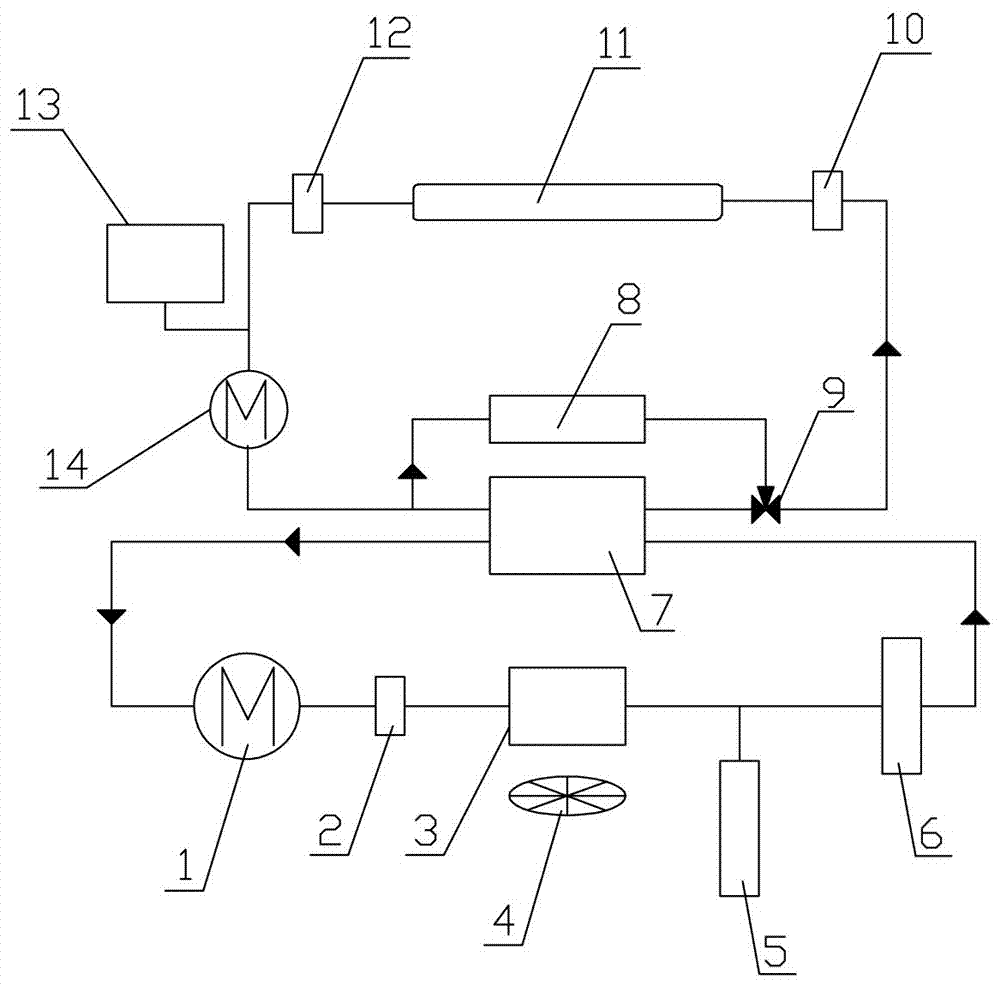

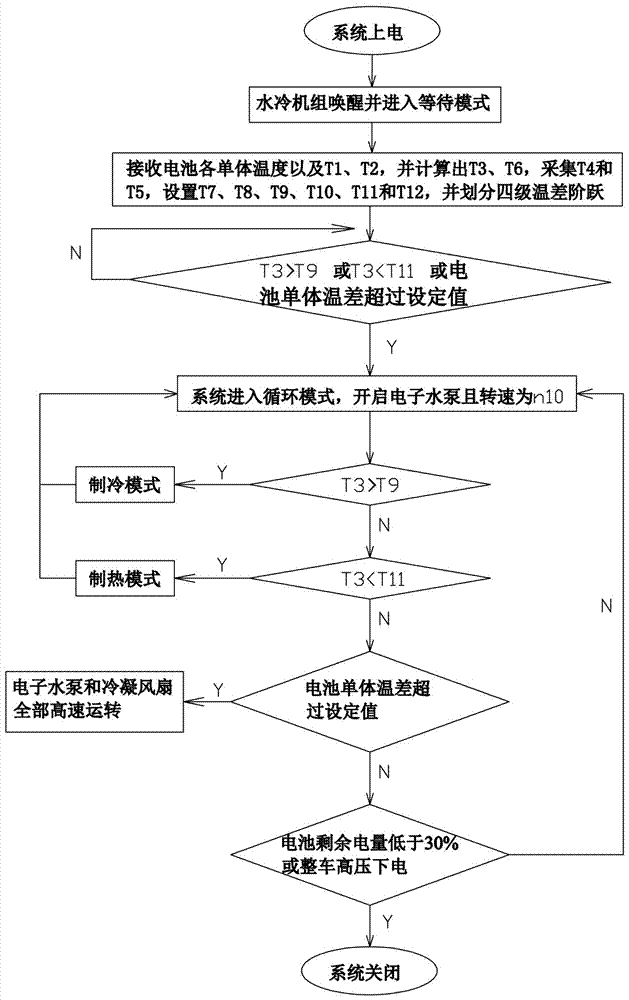

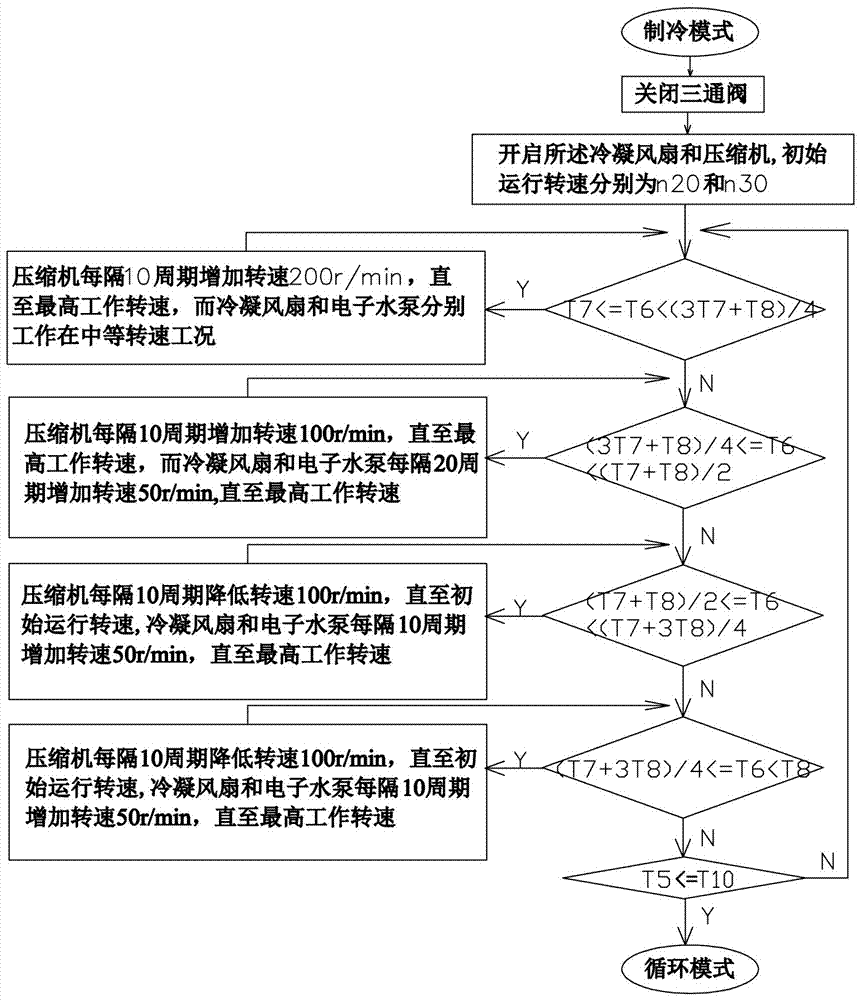

Power battery water-cooling unit system and intelligent temperature difference control method thereof

ActiveCN106953138AHigh degree of automationEffective control of temperature balanceSecondary cellsRefrigeration safety arrangementPower batteryControl system

The invention discloses a power battery water-cooling unit system and an intelligent temperature difference control method thereof. The power battery water-cooling unit system comprises a water cooling unit and a water cooling unit controller, wherein the water cooling unit comprises a compressor, a pressure switch, a condenser, a condensation fan, a liquid storing and drying tank, an expansion valve, a plate type exchanger, a PTC heater, a three-way valve, an inlet water temperature sensor, a power battery box, an outlet water temperature sensor, a water tank and an electronic water pump, wherein the compressor, the pressure switch, the condenser, the condensation fan, the liquid storing and drying tank, the expansion valve and the plate type exchanger are connected with each other in series. Through the power battery water-cooling unit system, the automation degree of the control of the power battery water-cooling unit is improved; the control system is capable of judging the difference between the battery average temperature and the outlet water temperature of the water cooling unit, adaptively adjusting operation rotation rate of the compressor, the electronic water pump and the condensation fan in real time through an intelligent control algorithm, indirectly controlling a battery to operate in the optimal temperature range and the optimal temperature difference range and predicting the battery temperature trend in advance through ampere-hour integral.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

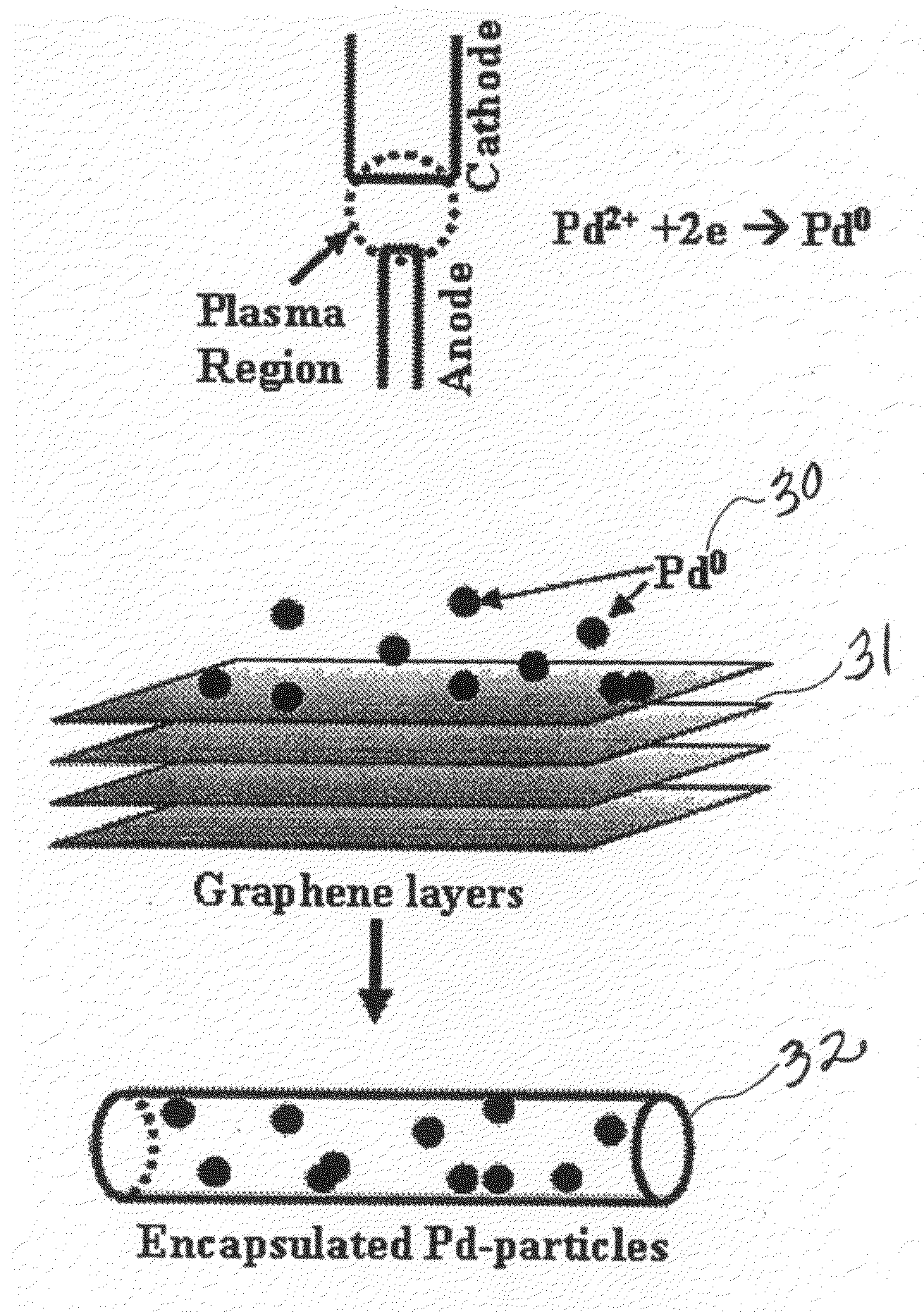

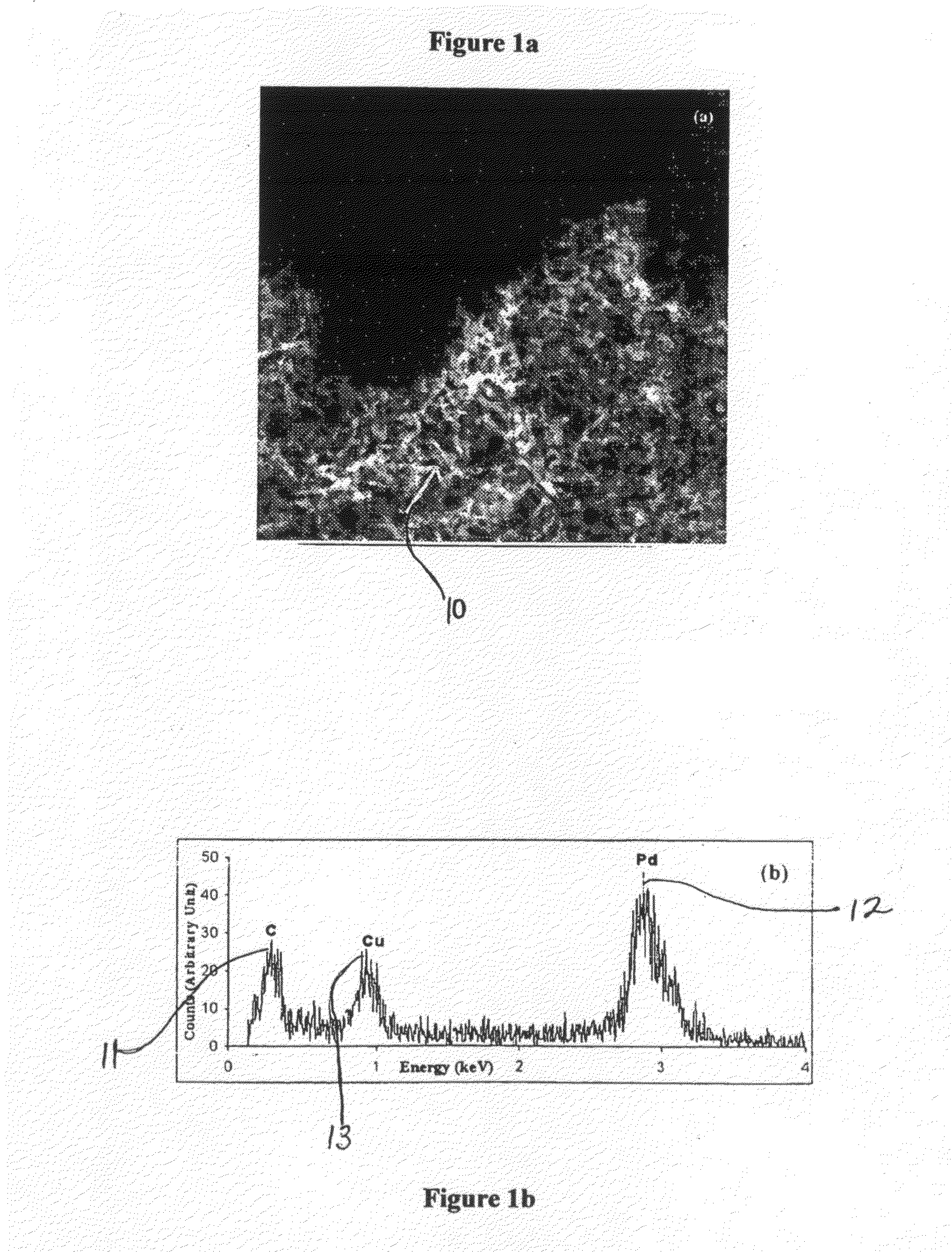

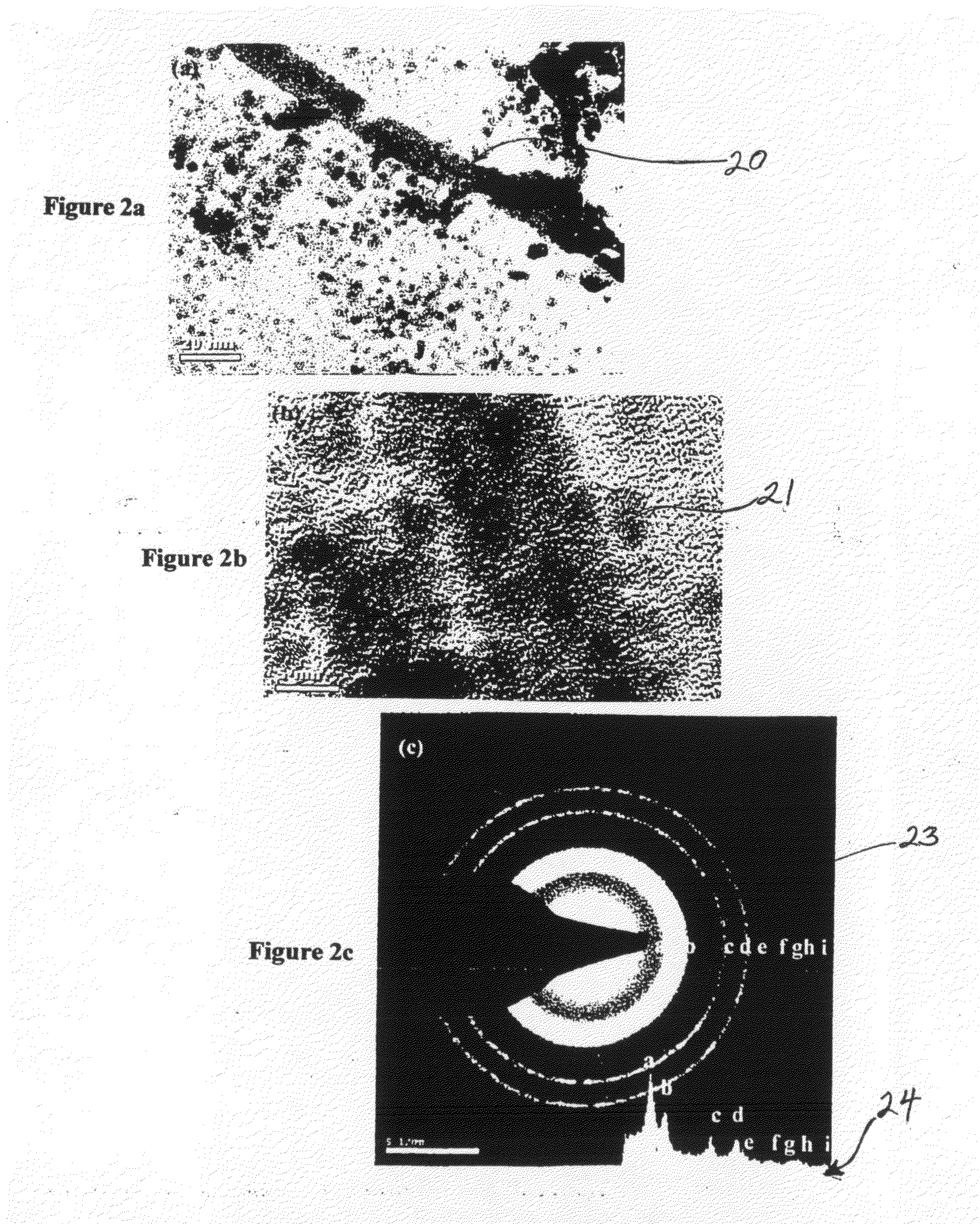

Synthesis of carbon nanotubes filled with palladium nanoparticles using arc discharge in solution

InactiveUS20090072192A1Improve abilitiesMaterial nanotechnologyOther chemical processesNanotubeMaterials science

Owner:UNIV OF CENT FLORIDA RES FOUND INC

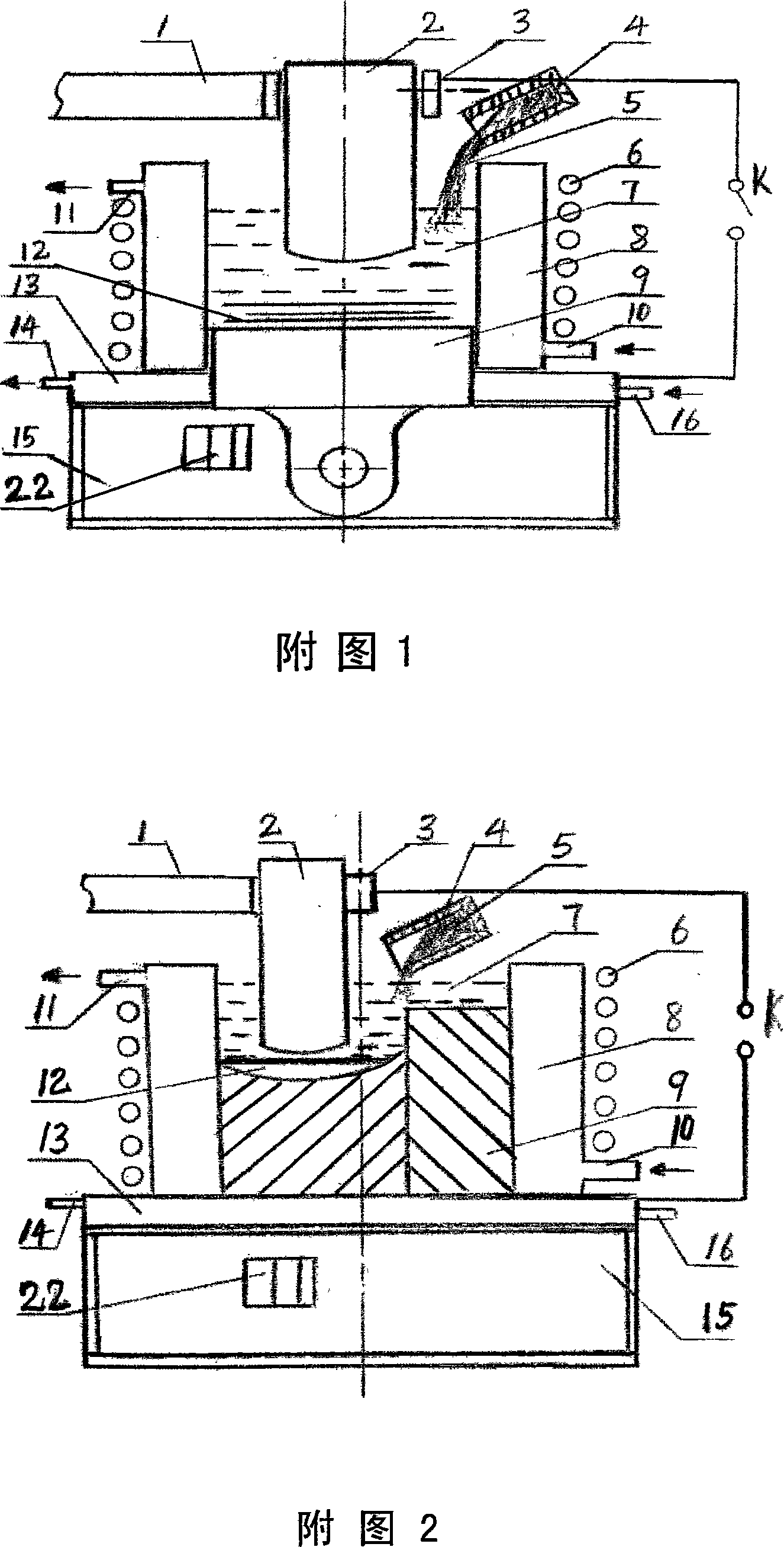

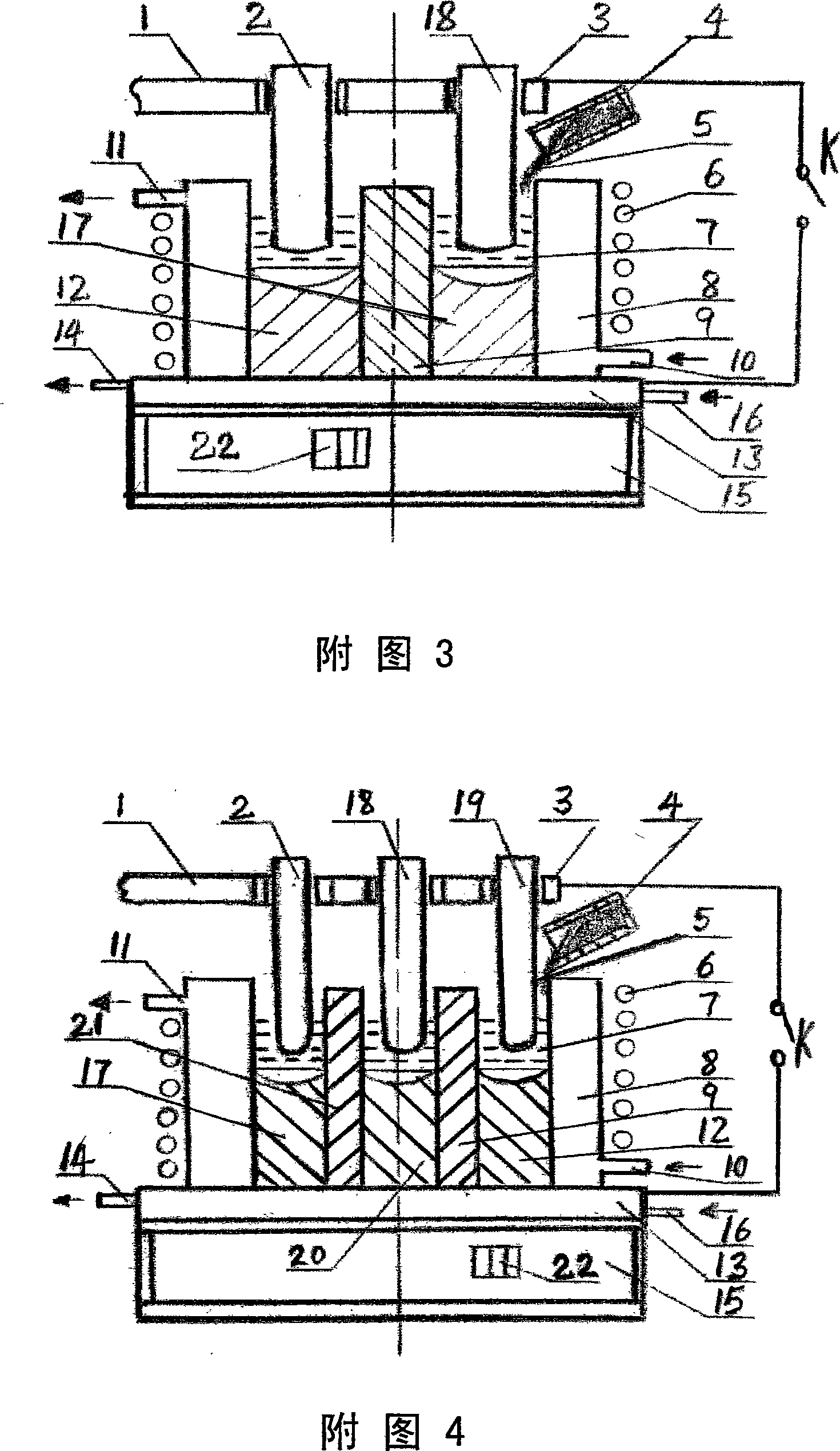

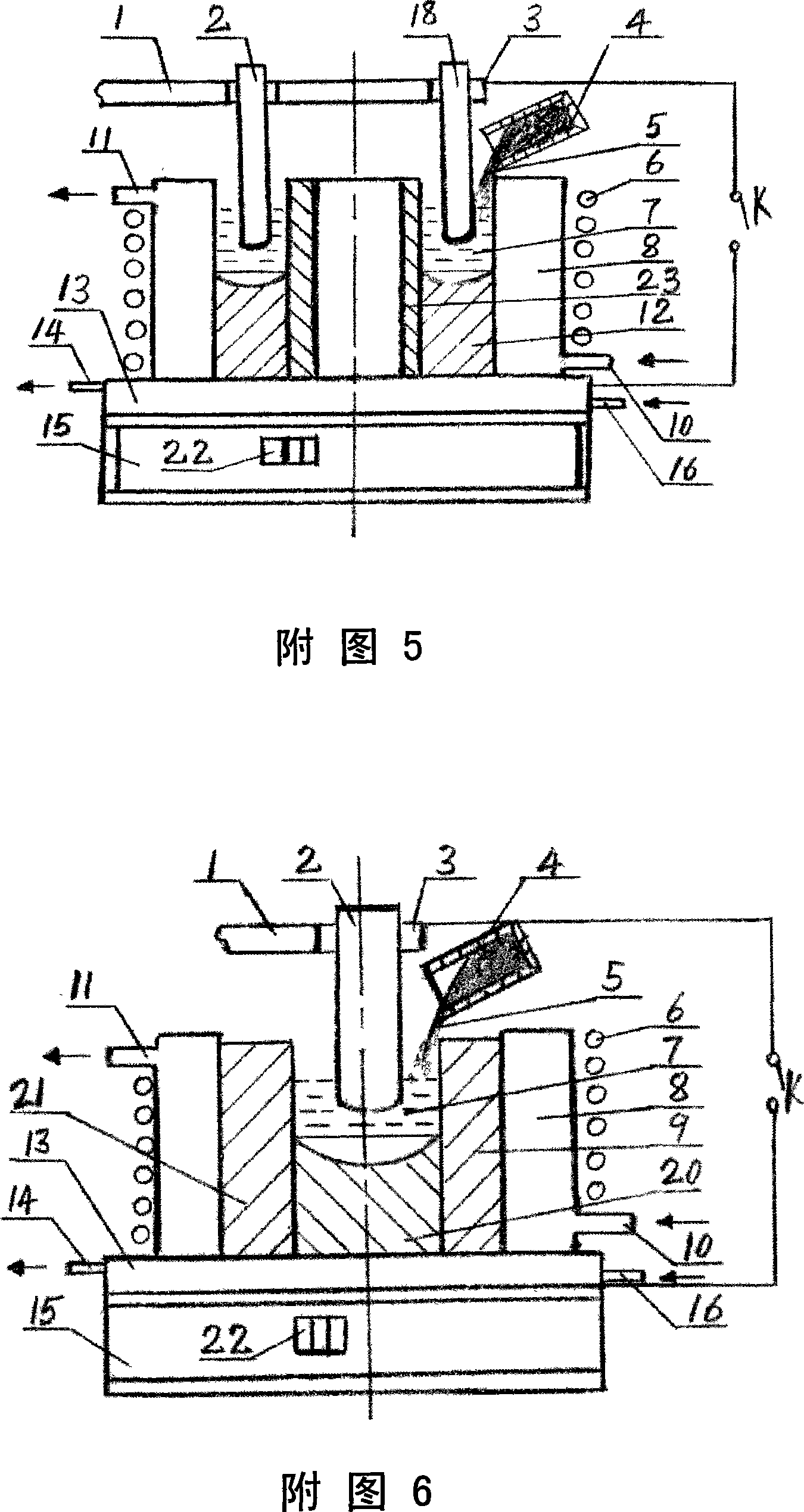

Casting method for manufacturing layered metal composite material technology and equipment

The present invention discloses a technique and relative equipment for casting laminated and composite metal material. Target material is heated to 300 DEG C to 1200 DEG C by an electromagnetic induction heater installed on exterior of a casting die or a water cooling crystallizer. Molten electroslag liquid is poured in the casting die or the water cooling crystallizer, and an electrode is inserted in for heating. The metal liquid is poured in the casting die or the water cooling crystallizer by top casting mode or bottom casting mode. After casting, the induction heater and the electrode conduct continuous heating for 3 to 20 minutes, then heating is stopped, and layered composite material with plane gradient, laminated composite material and coated composite material of all geometric shapes can be produced. The present invention can simplify production procedures of composite material and can realize the dynamic regulation of all technical parameters during composition. The interface of the composite layer is under eay control so as to achieve excelllent metallurgical combination. The present invention has wide optional range about materal of the composite layer, high productivity, simple production technique and low cost.

Owner:丁家伟 +1

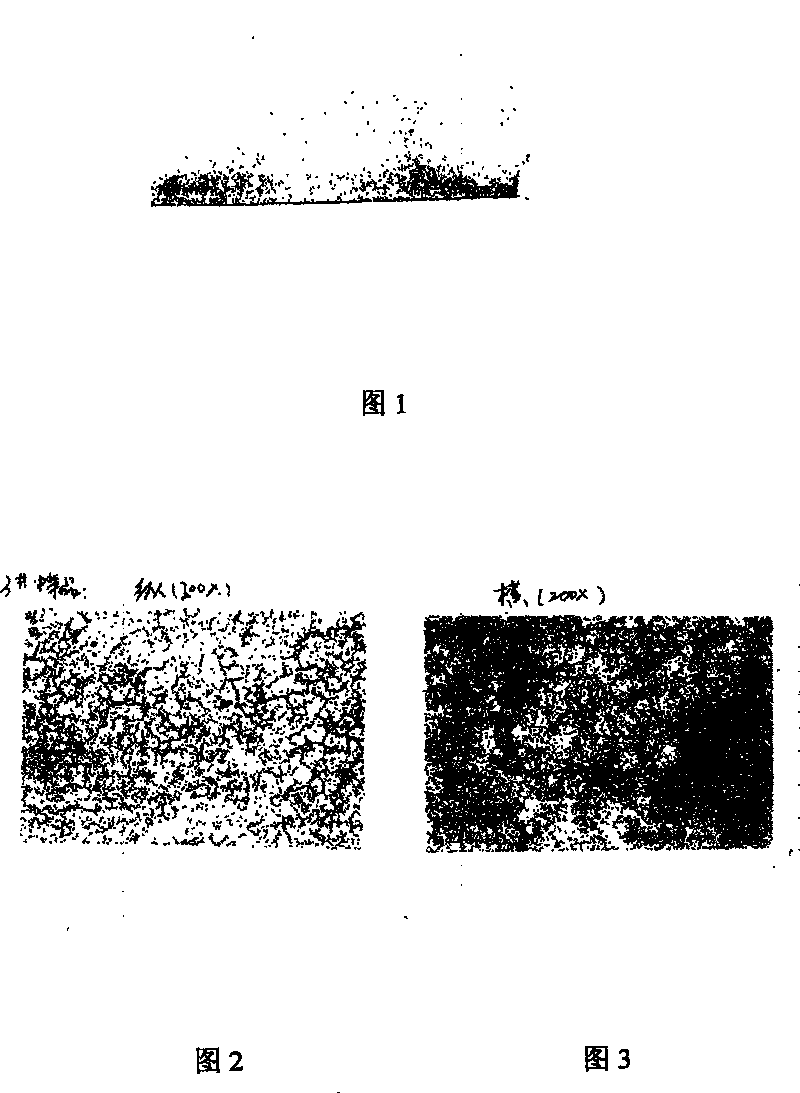

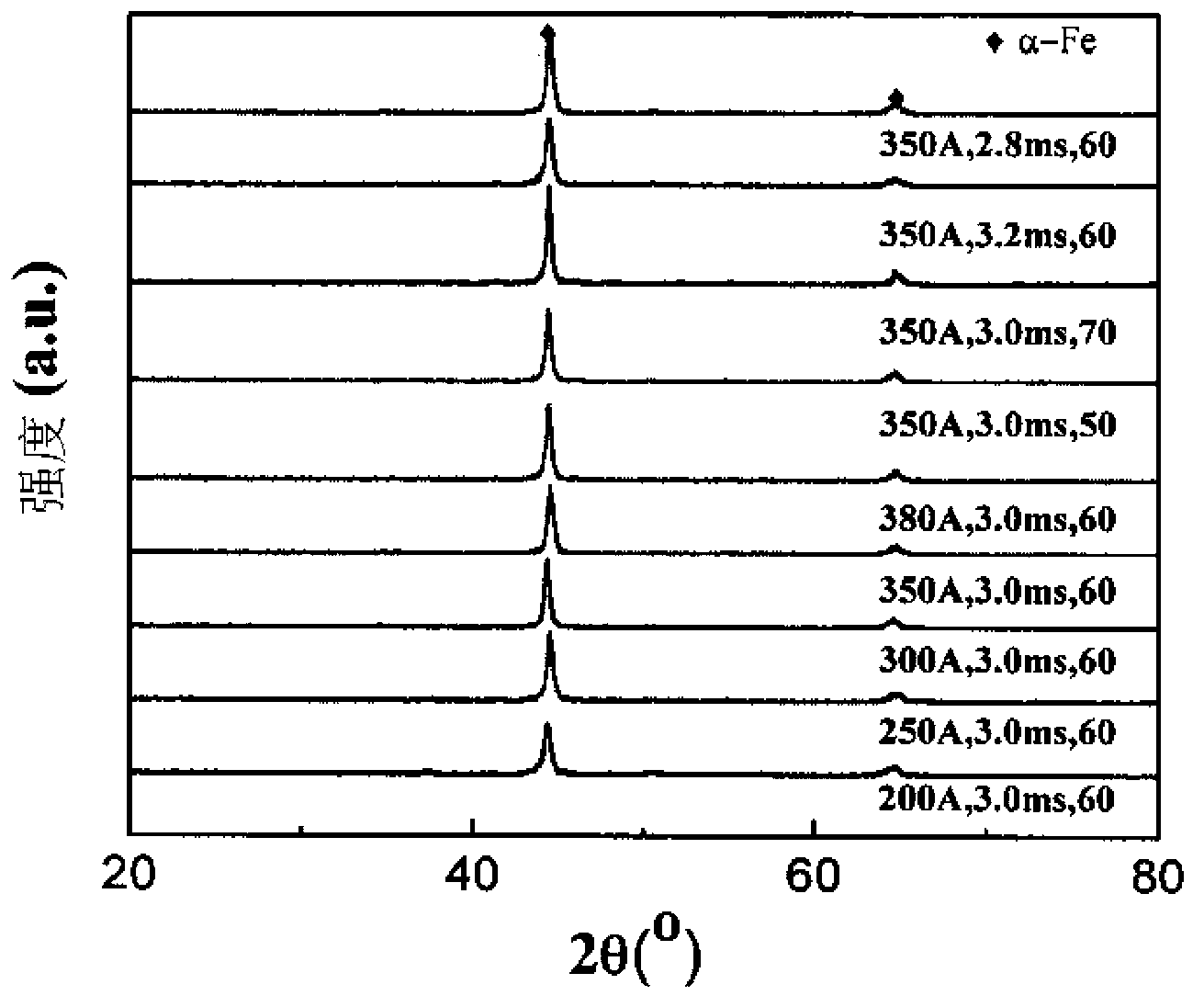

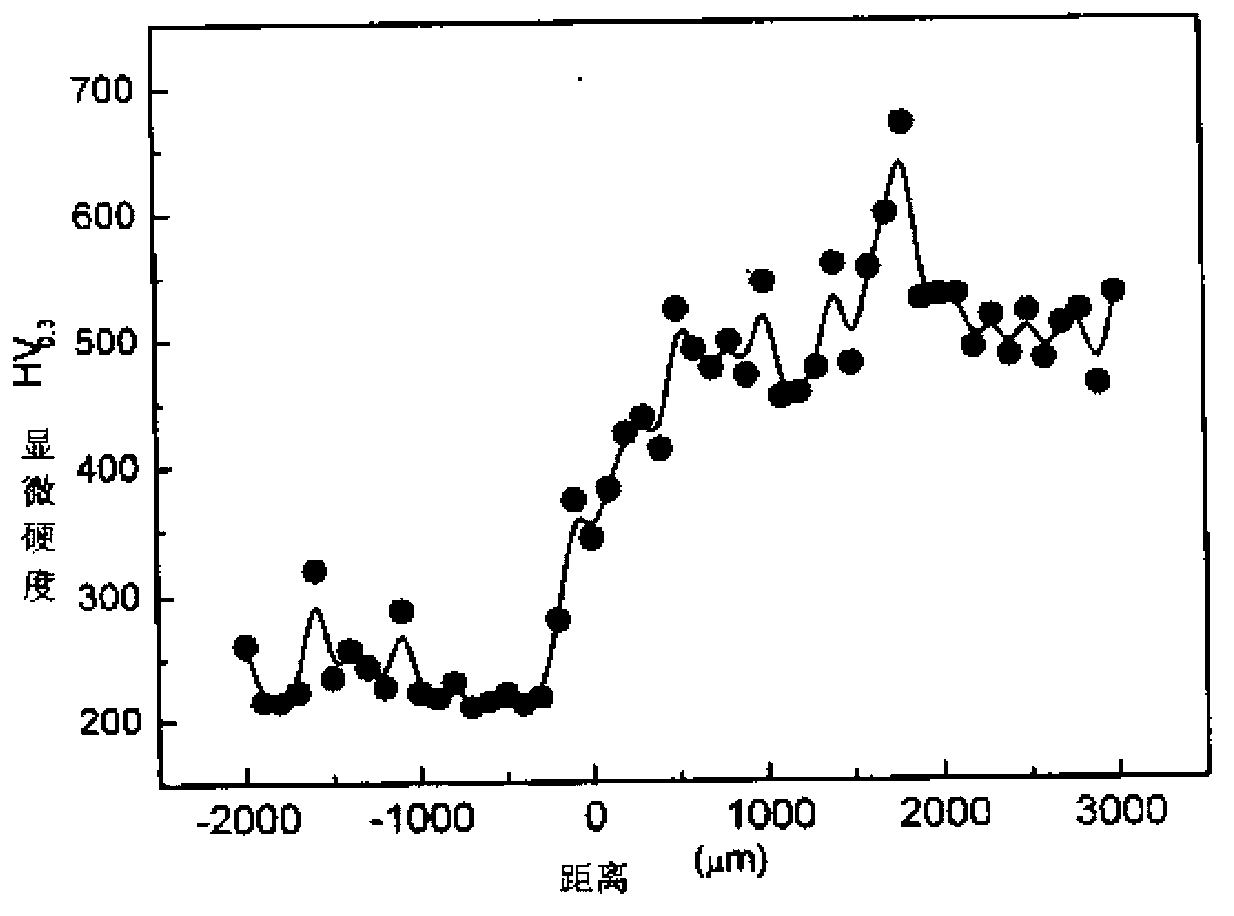

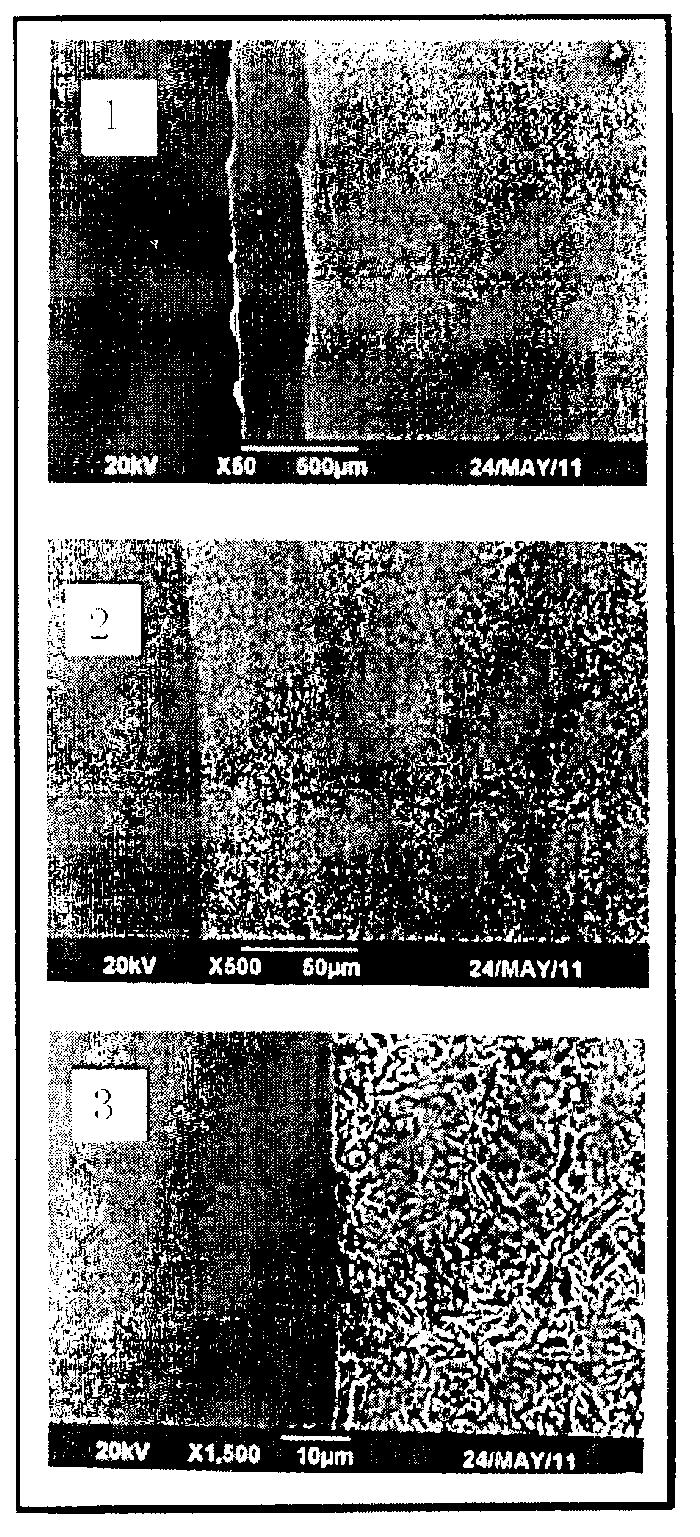

Iron-based amorphous powder for wear-resisting and corrosion-resisting coating and preparation method thereof

InactiveCN103302287AImprove wear and corrosion resistanceWear and corrosion resistance and long service lifeMetallic material coating processesSurface engineeringThermal spraying

The invention discloses iron-based amorphous powder for wear-resisting and corrosion-resisting coating and a preparation method thereof, and belongs to the technical field of surface engineering. Iron-based amorphous alloy coating adopts iron as a main component, and also comprises amorphous phase (in at least 30 percent by volume), and the representation formula of all elements in percentage by weight is FeaCrbNicSidBeMnfCgMohNbiCujCokRel. The powder is prepared through direct ball-milling mixing in proportion of all components according to the required weight ratio. The powder can be used for not only laser cladding but also thermal spraying technology, mixed powder is melt by high-energy density laser beams, an iron-based amorphous or amorphous composite cladding layer is formed on the outer surface of a matrix, the cladding layer has the characteristics of higher wear and collision resistance, the dilution rate is low, the wear-resisting and collision-resisting service lives of a petroleum drill rod, an air compressor screw rod, a roller, a water-cooled wall pipe and an economizer pipe are remarkably prolonged, the process is simpler, and the manufacturing cost is low.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

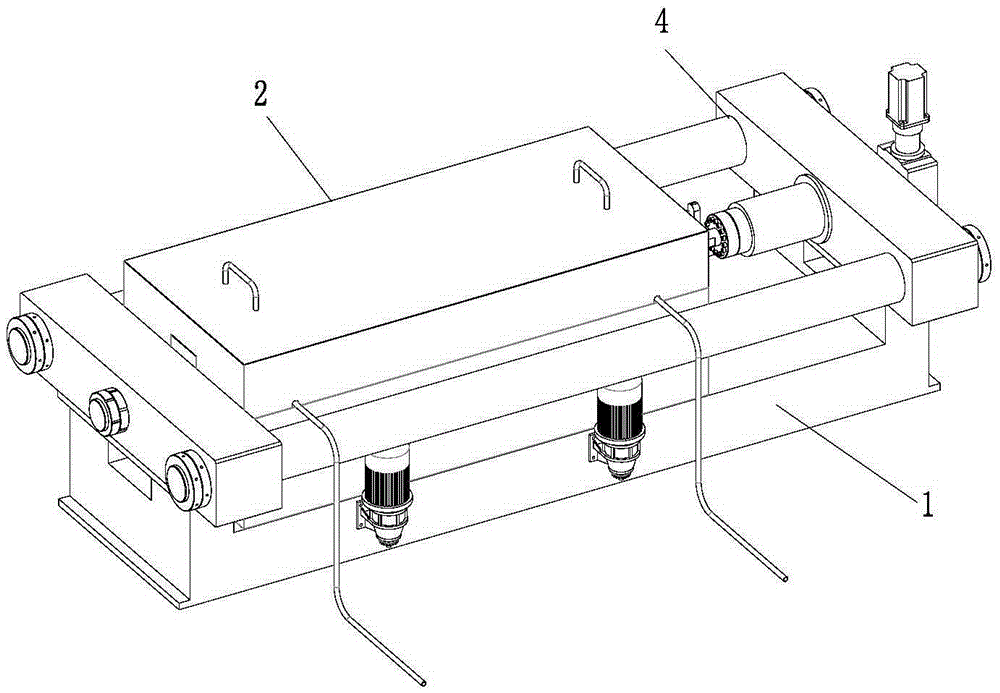

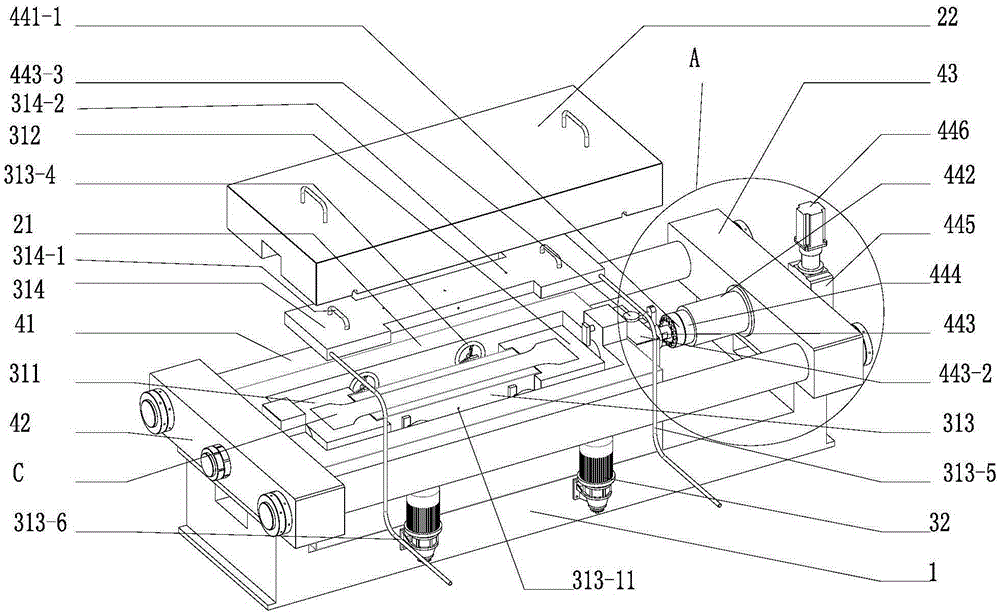

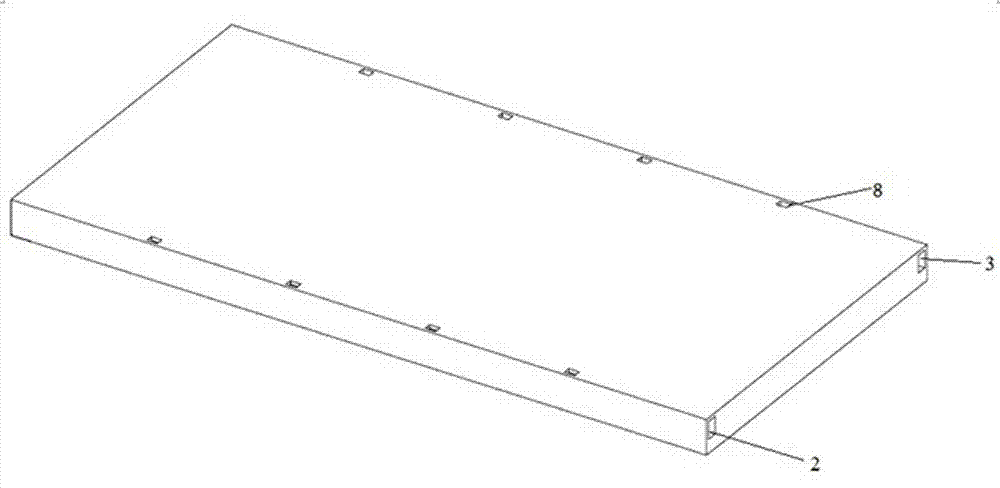

Concrete water cooling overall process testing device and method

ActiveCN105424494AStable structureEvaluation of Crack ResistanceWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesCrack resistanceEngineering

The invention provides a concrete water cooling overall process testing device and method. A main testing machine comprises a concrete test sample containing device, and a test sample is placed in the concrete test sample containing device; a loading system is connected with a movable clamping chuck arranged on the concrete test sample containing device, a water cooling simulation system is arranged in a concrete test sample containing space and comprises a water pipe, the water pipe is provided with a water inlet and outlet connecting pipe which penetrates through the containing space to be connected with a water supplying device to form a loop, and the loop is provided with two executing mechanisms, that is, the cooling device and the circulating power device; a flowmeter and a water temperature sensor are arranged in the loop. According to the concrete water cooling overall process testing device and method, the self temperature stress developing process including the developing process of parameters such as adiabatic temperature rise, a thermal expansion coefficient, elasticity modulus and creep along with time of concrete in the overall process from pouring to hardening can be tested under the condition of multiple temperature control measures, and a true meteorological environment can be also simulated to simulate the temperature stress and the cracking mechanism which are influenced by natural factors. The device can set different temperature and constraint degree conditions including insulation, constant temperature, temperature rising and lowering process setting and the like as needed. The crack resistance of the concrete is evaluated through a concrete cracking overall process simulation test.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

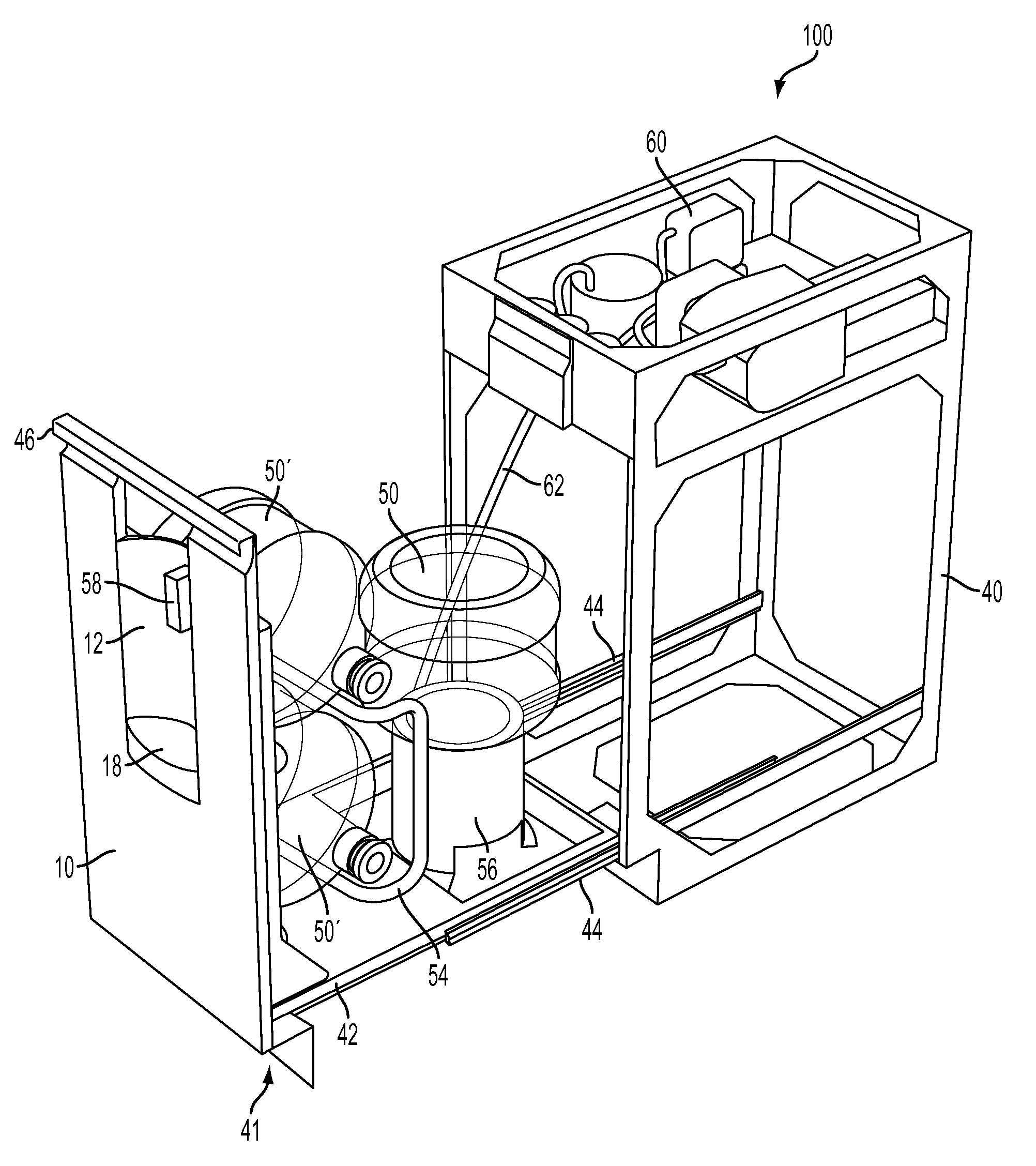

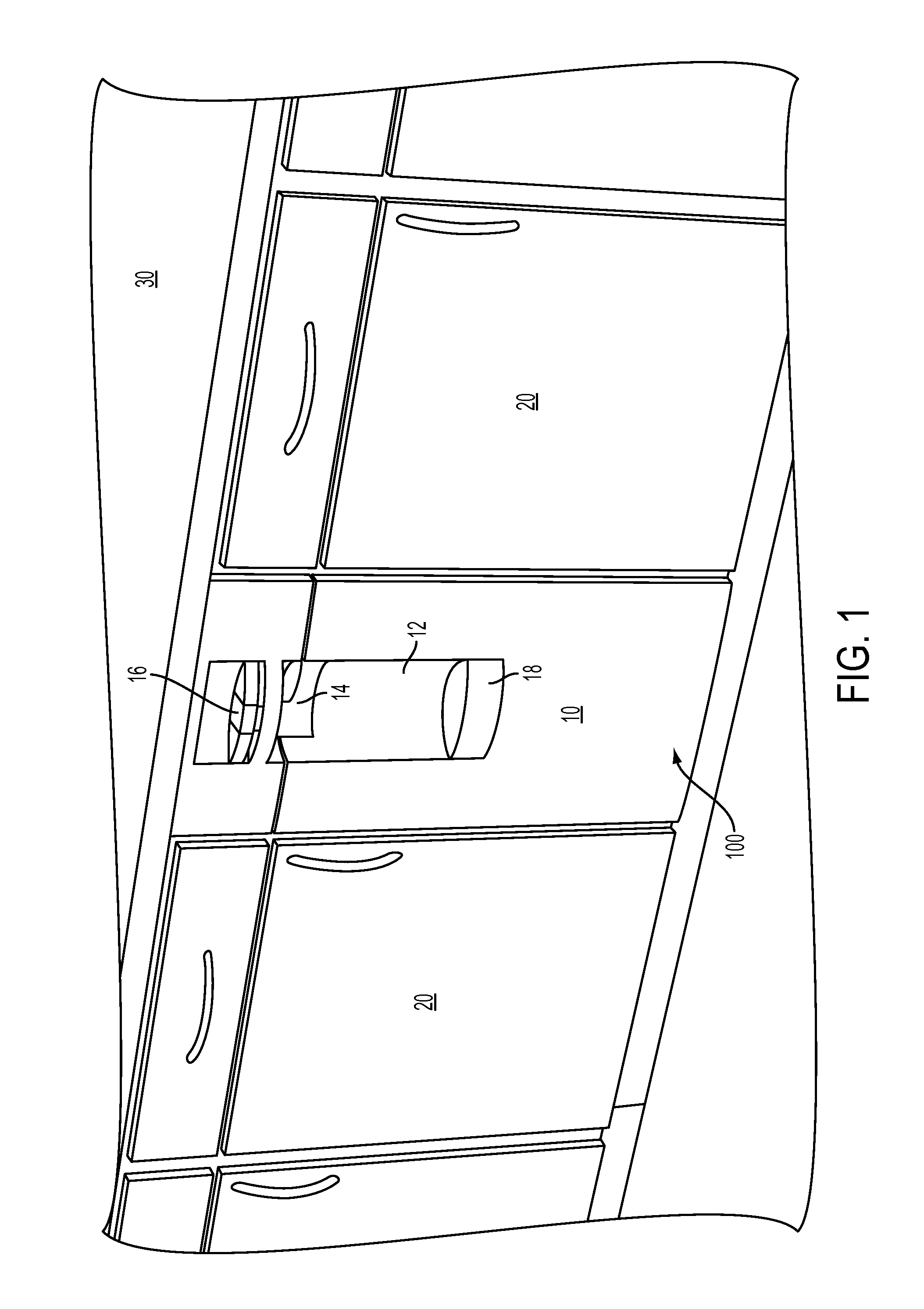

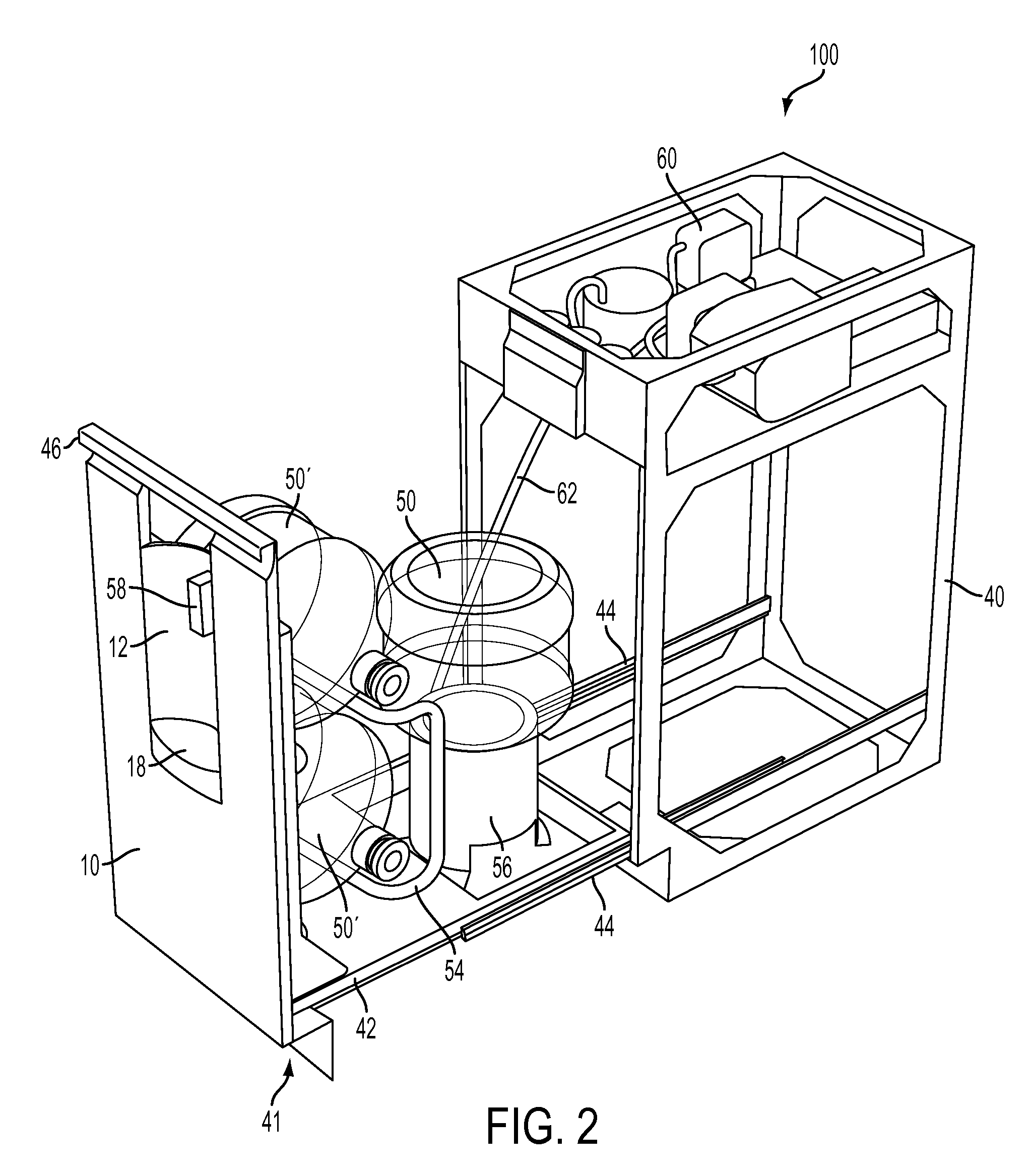

Under-counter water cooler appliance

InactiveUS20100116847A1Liquid flow controllersLiquid transferring devicesLiquid storage tankEngineering

An appliance for dispensing a liquid to a user, including an appliance base cabinet comprising an enclosure positioned under a counter that is fixed to a wall. The appliance base cabinet having a support member that is moveable relative to the counter. At least one dispenser spigot is coupled to the appliance base cabinet at a suitable distance below the counter to allow a user dispense water via the at least one dispenser spigot. At least one liquid storage tank is supported by the support member having an opening for out-flow of the liquid. The at least one liquid storage tank is accessible for removal or installation when the support member is moved away from the kitchen counter. The appliance further includes an intermediate reservoir within the appliance base cabinet under the kitchen counter coupled to the opening of the at least one liquid storage tank through which the liquid out of the at least one liquid storage tank is channeled to the at least one dispenser spigot.

Owner:DESIGN BY PARI

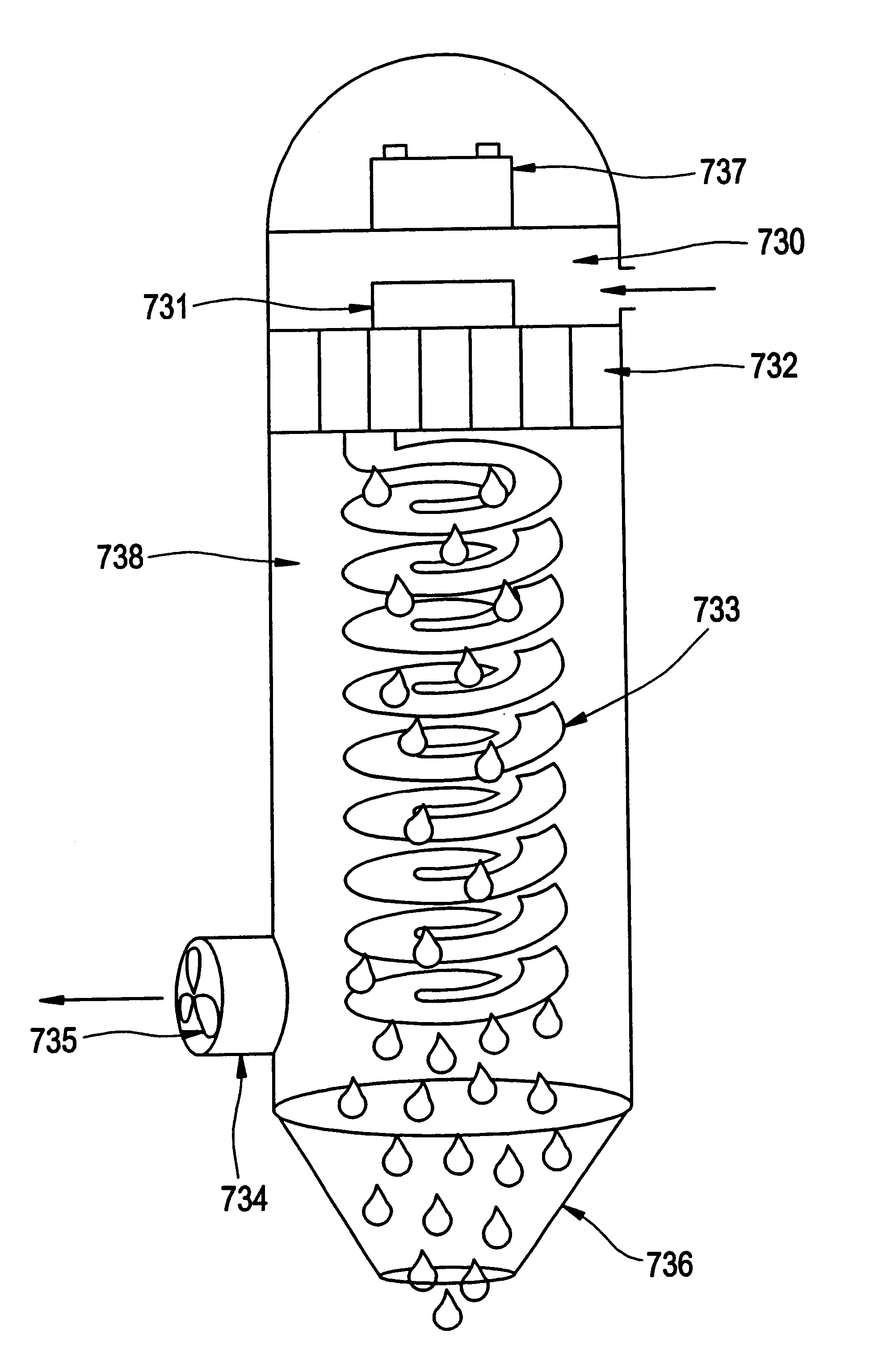

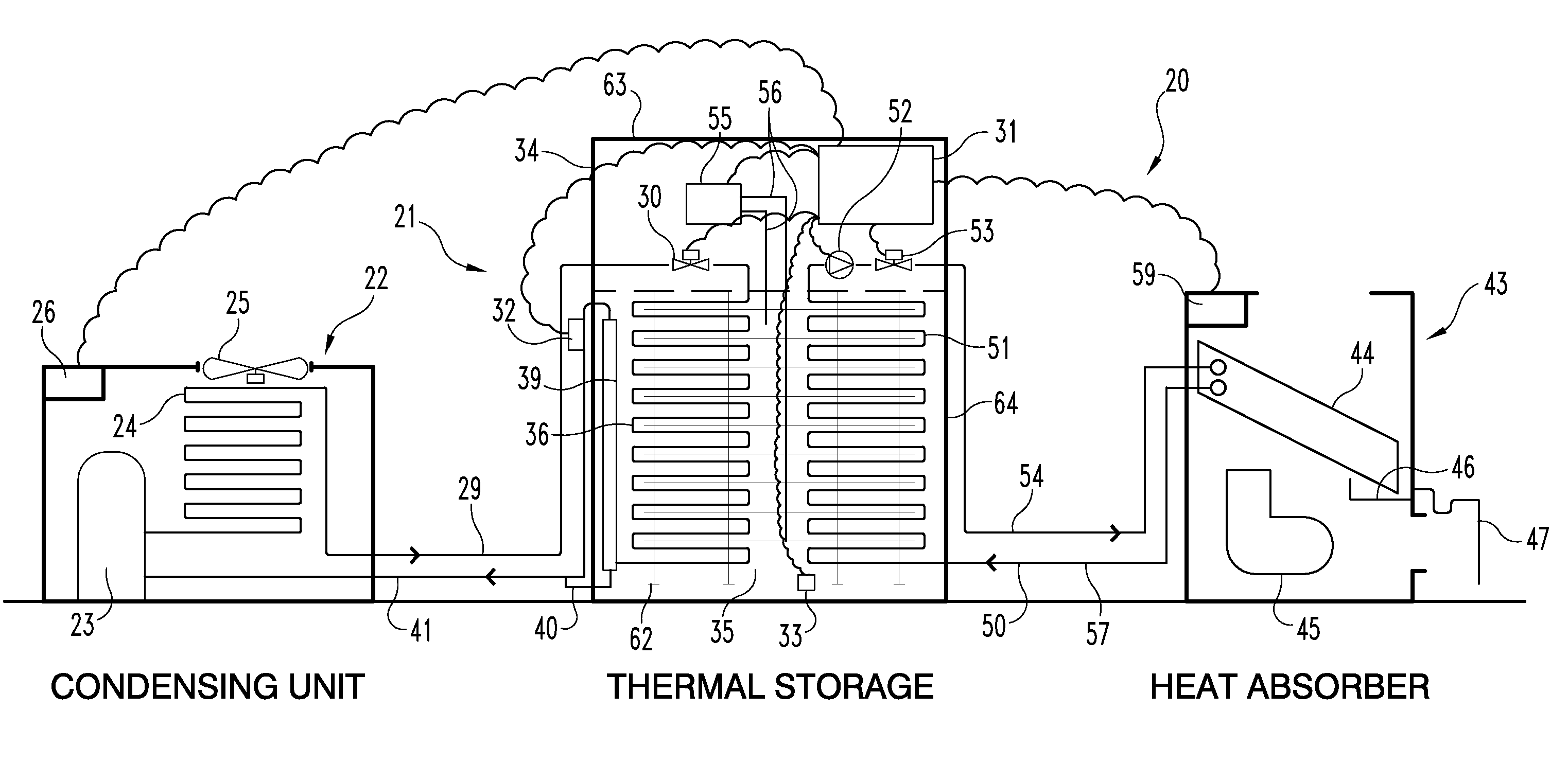

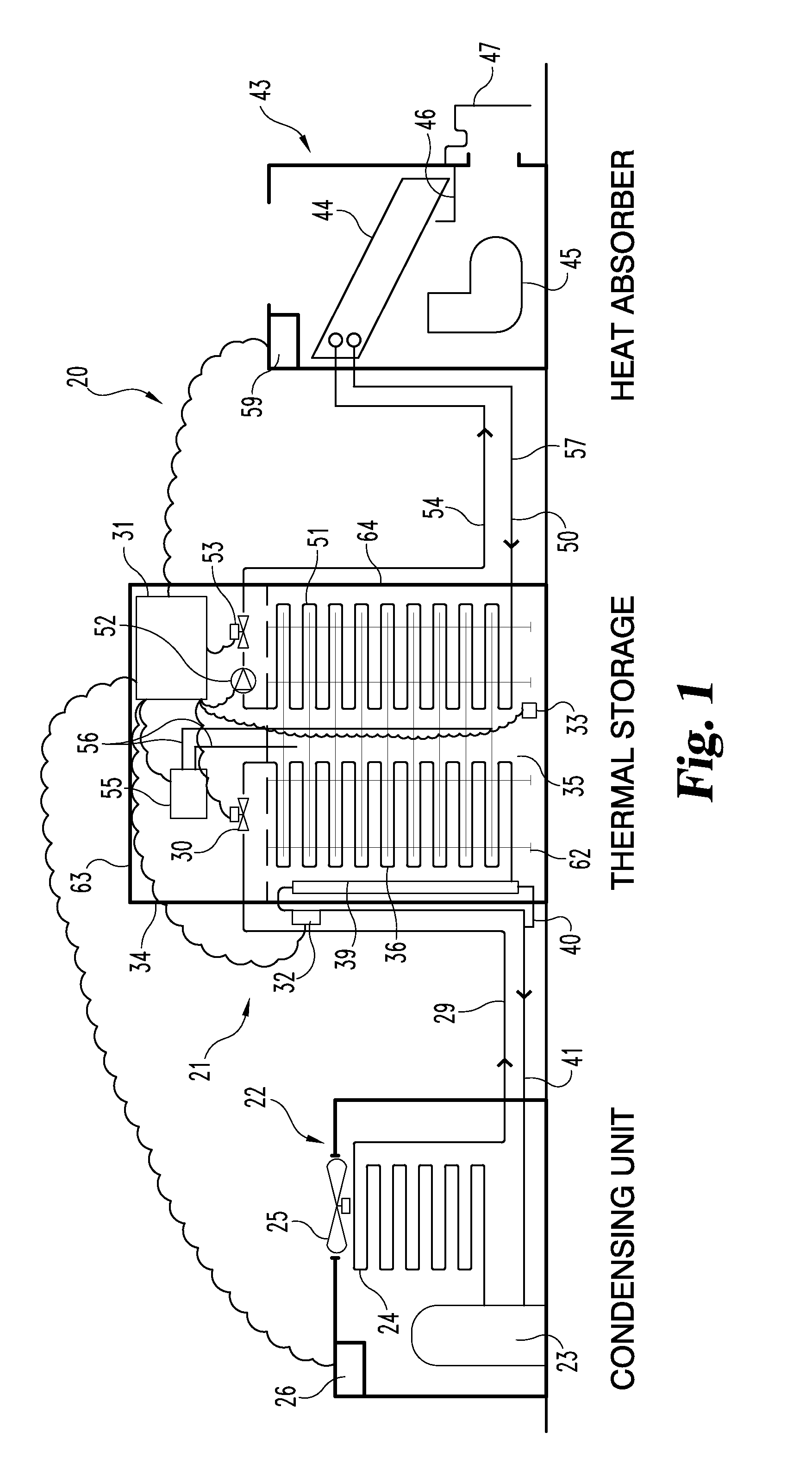

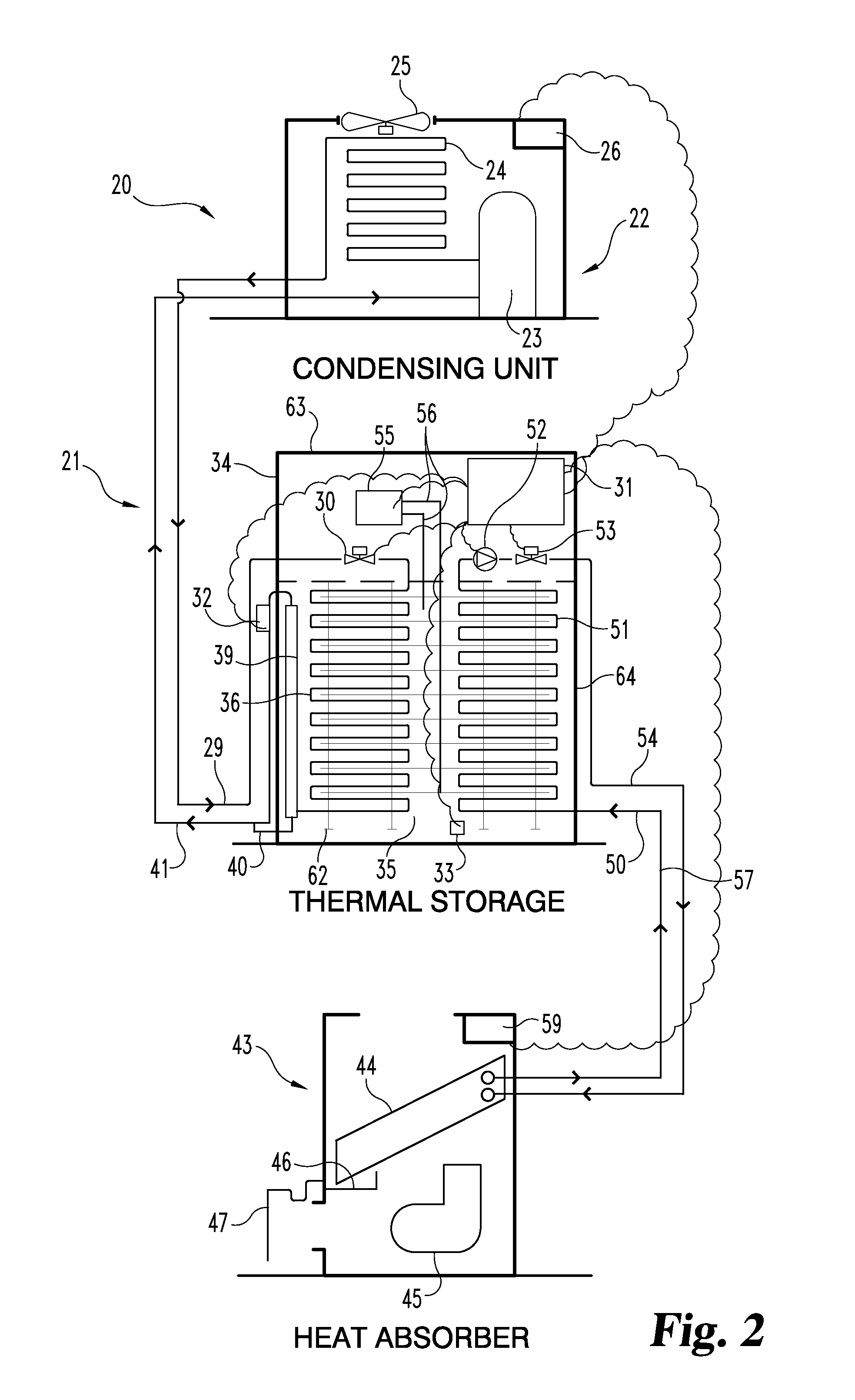

Thermal storage unit for air conditioning applications

ActiveUS20080022713A1Heat storage plantsStationary tubular conduit assembliesThermal energyThermal energy storage

Disclosed is a demand shifting thermal storage system employing a heat transfer / thermal energy storage vessel to produce and hold a phase change fluid using an air cooled / water cooled / ground coupled or evaporative condensing unit to generate the cold fluid with a separate and dependent circuit coupled to the indoor cooling load to remove heat from the HVAC or process cooling load using one or multiple indoor coils to absorb heat returning the heat to the thermal energy storage vessel to reject the space heat, cool the space and continue the cycle.

Owner:JACOBI ROBERT W

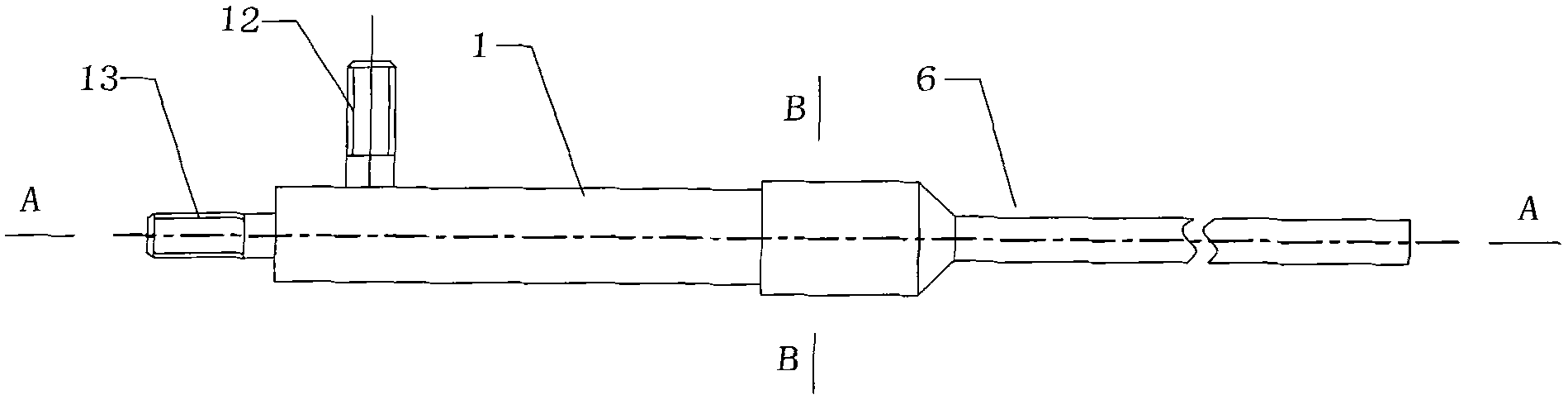

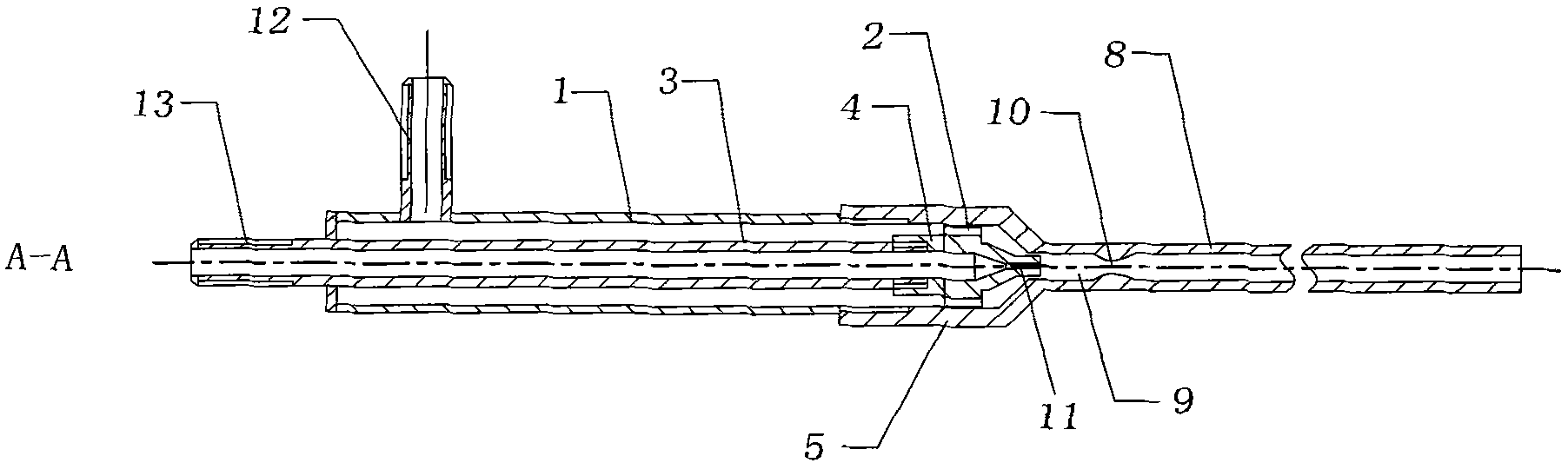

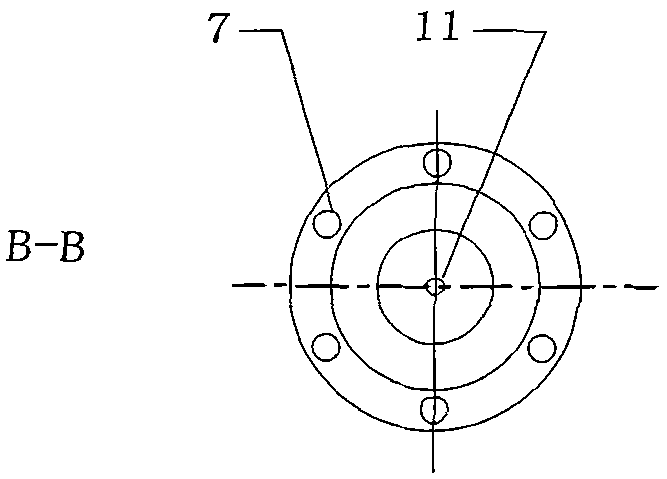

Reducing agent atomization spray gun for selective non-catalytic reduction denitration process

InactiveCN102085452ASimple structureLow costDispersed particle separationLiquid spraying apparatusInjection portSpray nozzle

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Phase change thermal storage type auxiliary solar hot-water device of air source heat pump

InactiveCN101943481AReduce energy consumptionReduce lossFluid heatersSolar heating energyThermal energy storageEngineering

The invention discloses a phase change thermal storage type auxiliary solar hot-water device of an air source heat pump, comprising an indoor air cooled heat exchanger, an outdoor air cooled heat exchanger and a rotator compressor, wherein the outdoor air cooled heat exchanger is connected with the indoor air cooled heat exchanger respectively through a four-way reversing valve and an expansion valve; the rotator compressor is connected with the four-way reversing valve in parallel; the indoor air cooled heat exchanger is connected with a water cool tube heat exchanger; and the outdoor air cooled heat exchanger is connected with a phase change thermal accumulator in parallel. The device of the invention can carry out phase change energy storage when solar radiation is overmuch in summer, thereby avoiding over high water temperature to exceed use requirement, sever water tank heat dissipation and other drawbacks, and when the solar radiation is in short, heat supplement is carried out through phase change to release energy, and an air source heat pump is used to assist heating in necessity.

Owner:SOUTHEAST UNIV

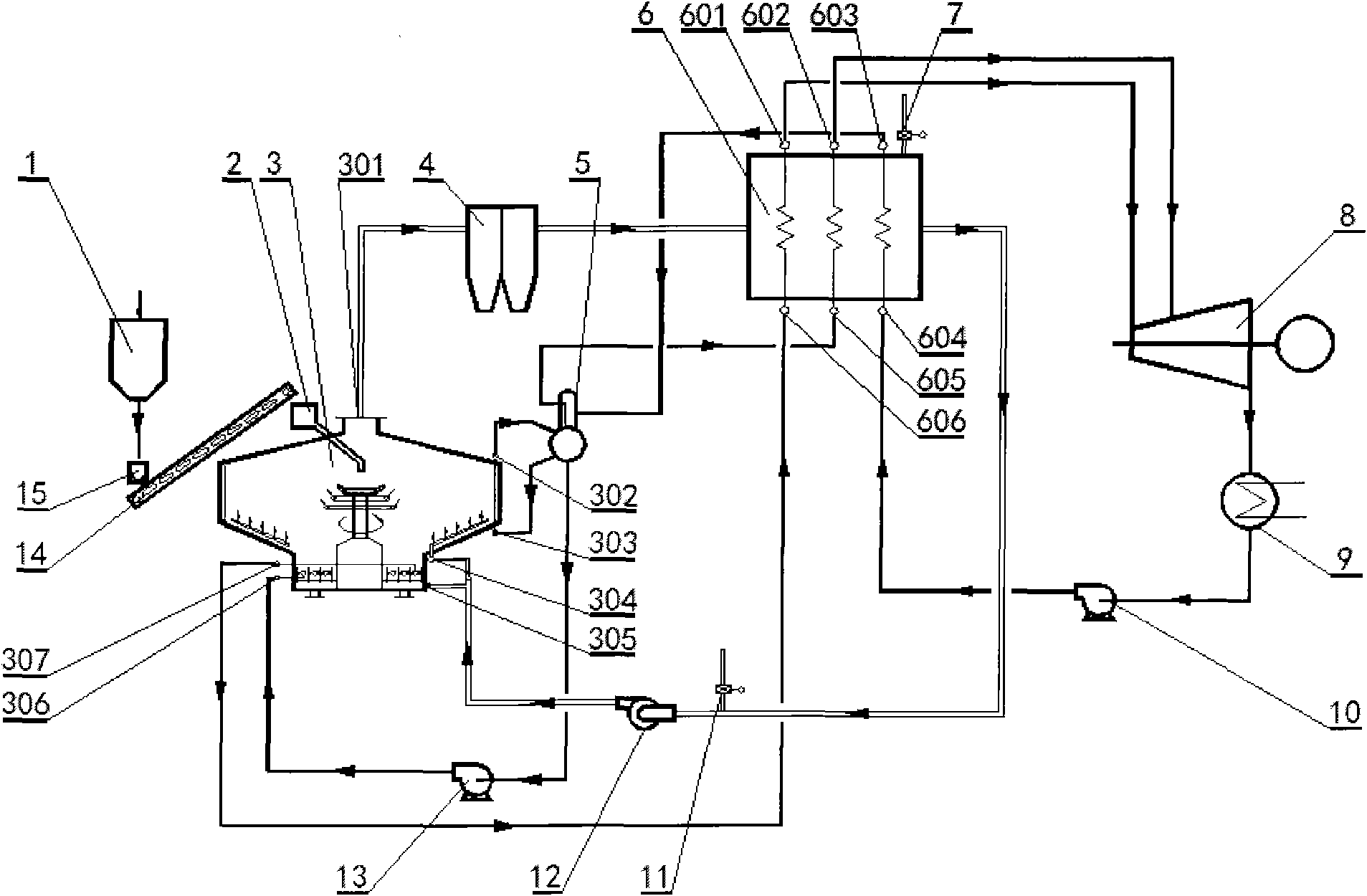

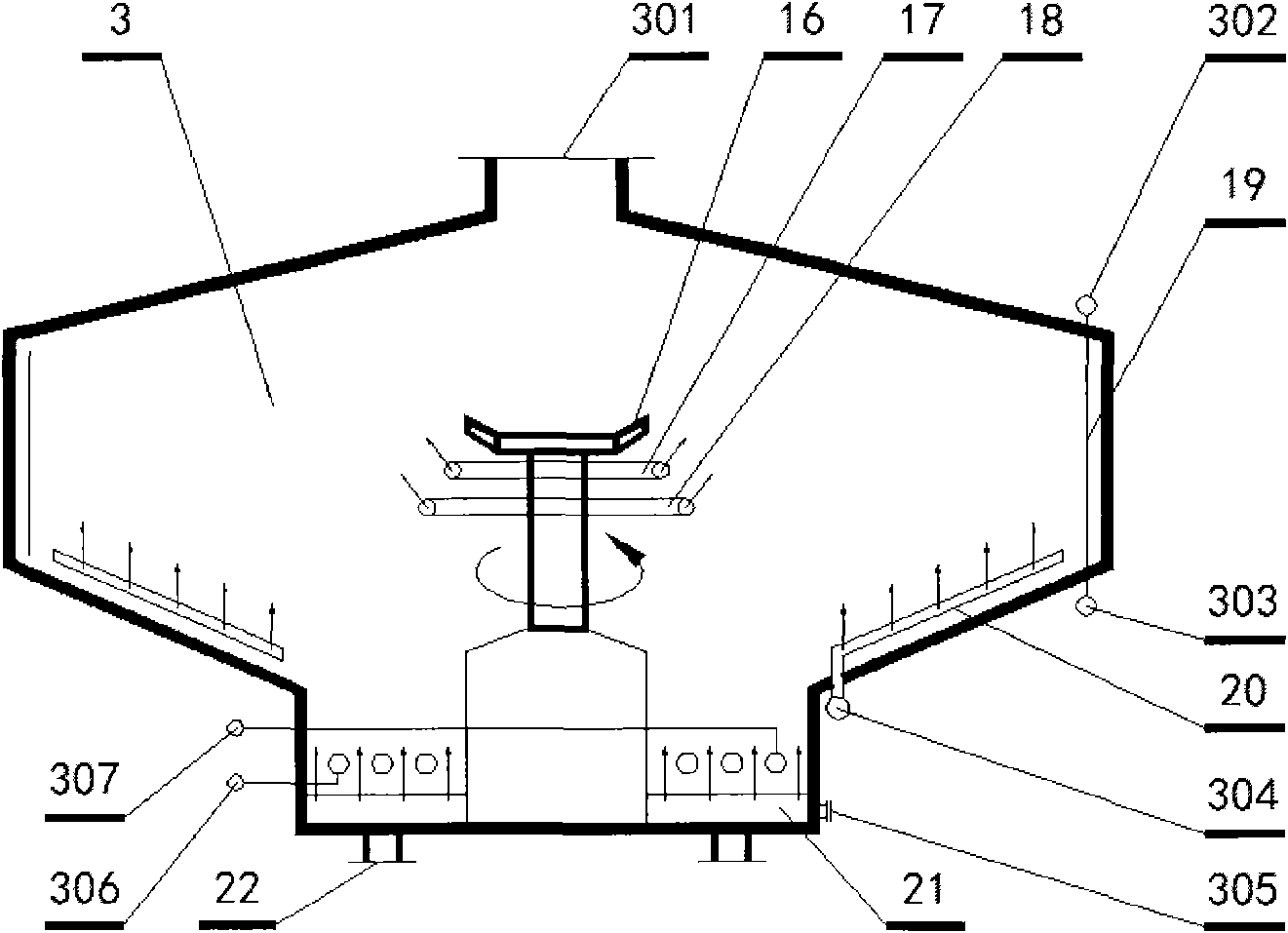

Metallurgical molten slag dry granulating and heat recovering system

ActiveCN101993964AAvoid wastingReduce consumptionRecycling and recovery technologiesThermal energyVitrification

The invention relates to a metallurgical molten slag dry granulating and heat recovering system and belongs to mechanical equipment. The metallurgical molten slag dry granulating and heat recovering system consists of a feeding system, a dry granulating device and a heat recovering system. Liquid molten slag is subjected to dry granulation in a way of centrifugal rotation and air flow pulse; and the molten slag is cooled and solidified after exchanging heat with a water cooled wall and fluidization gas. In the whole granulating process, water is not consumed or only a small amount of water is consumed, and a large quantity of waste water and harmful gases such as H2S and SOx and the like are not generated; sensible heat in the molten slag is fully recycled while the granulated slag with high vitrification rate is formed; waste of high-grade heat is effectively avoided; and energy consumption of metallurgical enterprises is saved. The granulated slag is subsequently used without being additionally dried; and the energy consumption in a subsequent using process is saved.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

Water cooling and composite phase change material combined power battery heat dissipating device

ActiveCN104241729AImprove thermal conductivityIncrease heat storageSecondary cellsBatteriesPower batteryProcess engineering

The invention discloses a water cooling and composite phase change material combined power battery heat dissipating device which comprises a box body and a base plate arranged at the bottom of the box body, wherein a water inflow channel and a water outflow channel which are used for accommodating cooling water are respectively arranged inside the base plate and along two long edges, aperture passages communicated with the water inflow channel and the water outflow channel respectively are arranged on the upper surface of the base plate and along the two long edges, tabular micro-channel heat exchangers are arranged on the base plate at certain intervals in the length direction, micropore flow passages are arranged inside the tabular micro-channel heat exchangers, the two end ports of each micropore flow passage are respectively connected with an aperture passage I communicated with the water inflow channel and an aperture passage II communicated with the water outflow channel, and spaces formed by the tabular micro-channel heat exchangers, the base plate and the box body are filled with a composite phase change material. The water cooling and composite phase change material combined power battery heat dissipating device provided by the invention has the advantages of high heat accumulation and heat dissipation rates, convenience in operation and maintenance, low cost and the like, can be used for heat dissipation of high-power and quick charge-discharge power batteries, and can improve the working performance and the reliability of batteries.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com