Device and method for continuous block metal glass shaping

A block metal and forming device technology, applied in the continuous forming device of block metallic glass, continuous preparation of block metallic glass and non-equilibrium solidified materials, can solve the problem of reducing the forming ability of alloy glass, reducing the vacuum degree of vacuum system, The problems such as the increase of the frictional resistance between the casting slab and the casting mold can reduce the defects such as cold shut, increase the contact pressure, and improve the cooling strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

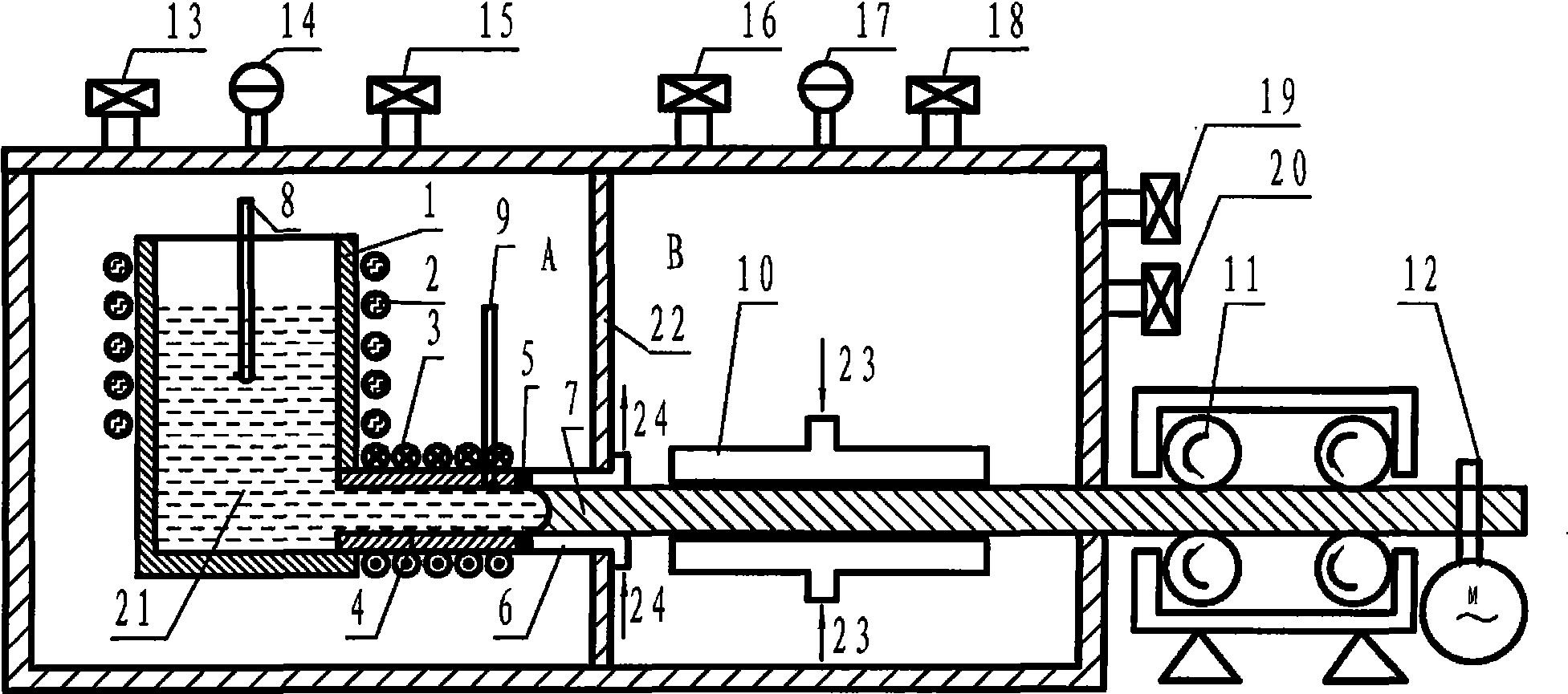

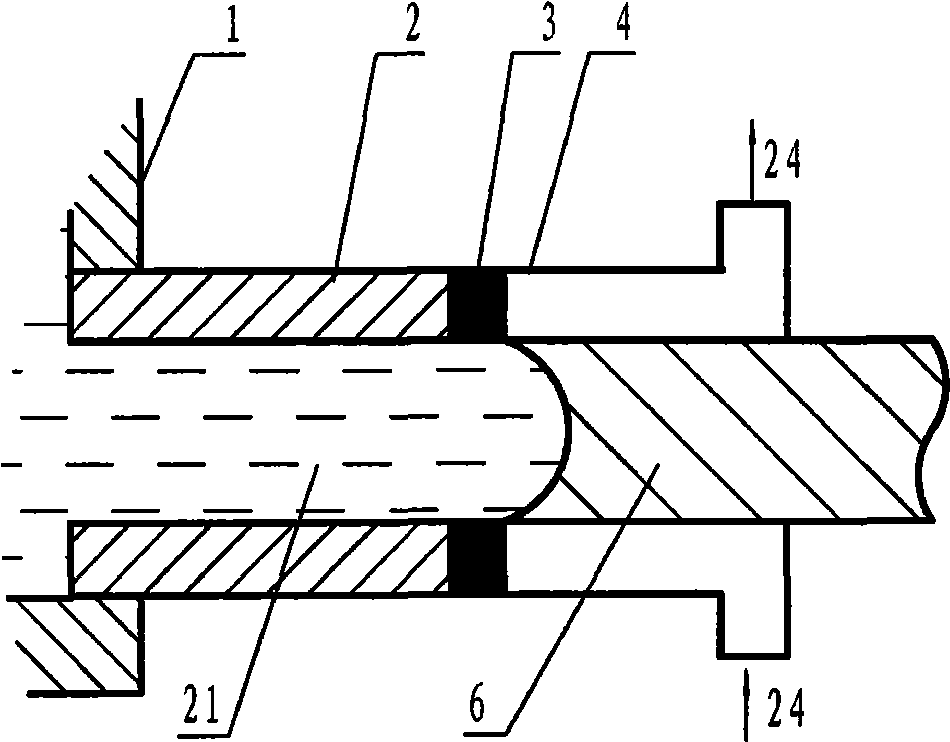

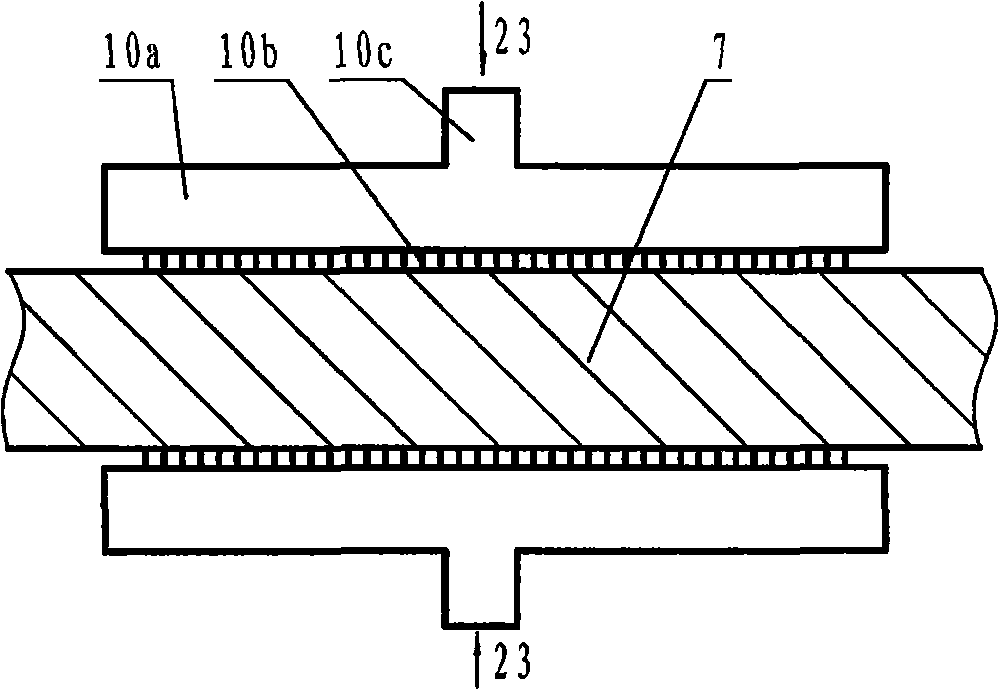

[0025] figure 1 It shows a device for continuous casting of bulk metallic glass material. It mainly includes a first vacuum chamber A and a second vacuum chamber B. The two vacuum chambers are separated by a partition plate 22; the graphite crucible 1 is placed in the first vacuum chamber A, and the melting and heat preservation device 2 heats the graphite crucible 1 and Insulation, the thermocouple 8 is used to measure the temperature of the molten metal 21 in the graphite crucible 1; the graphite mold 4 and the heat insulation ring 5 in the composite mold are also located in the first vacuum chamber A, and the graphite mold 4 and The graphite crucible 1 is connected and heated by the heating device 3 of the graphite mold 4. The thermocouple 9 is used to measure the temperature of the graphite mold 4; the front end of the water-cooled copper mold 6 is connected to the graphite mold 4 through the heat insulation ring 5, The water-cooled copper mold 6 is installed on the partitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com