Patents

Literature

146results about "Cellar tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

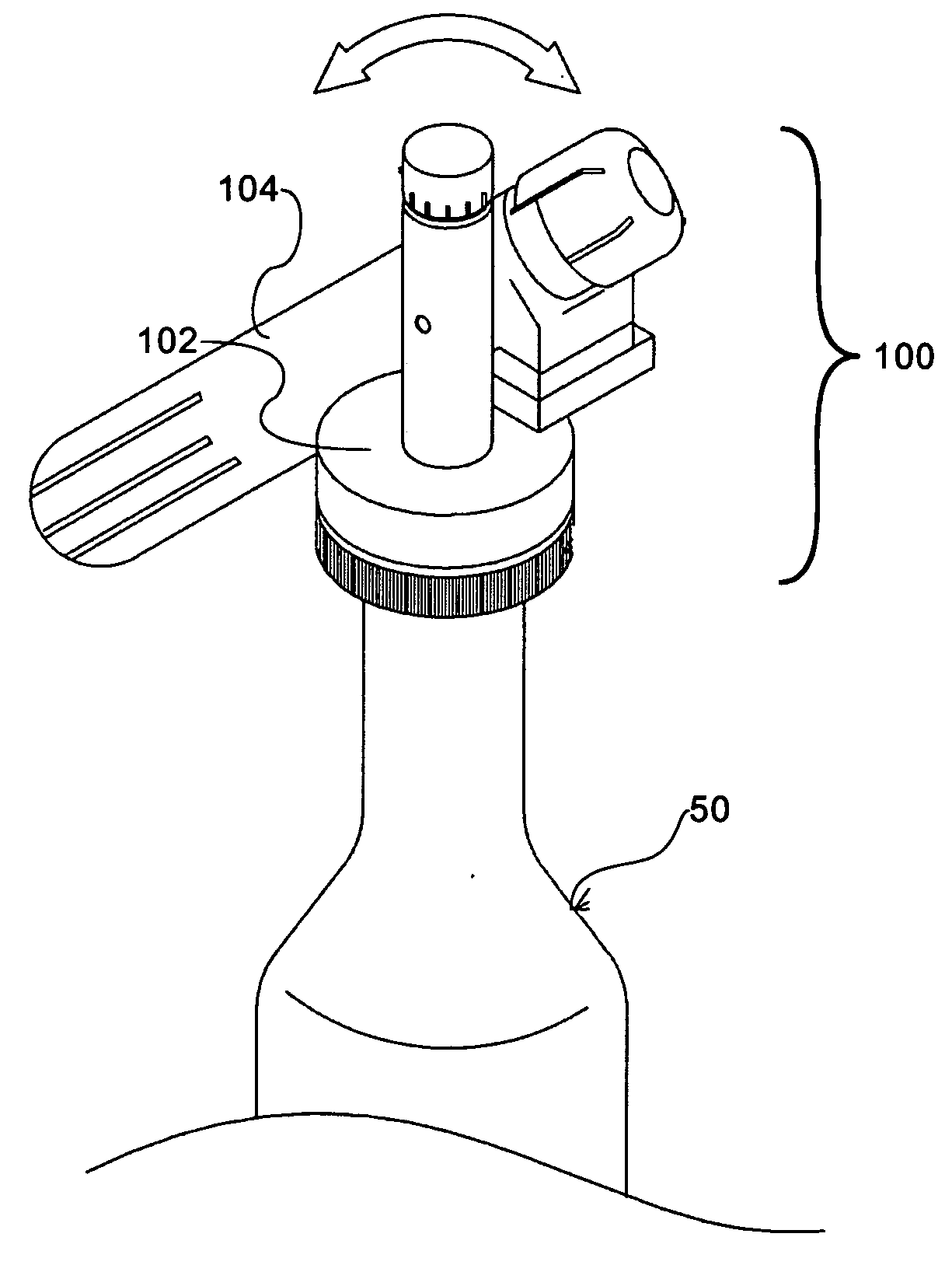

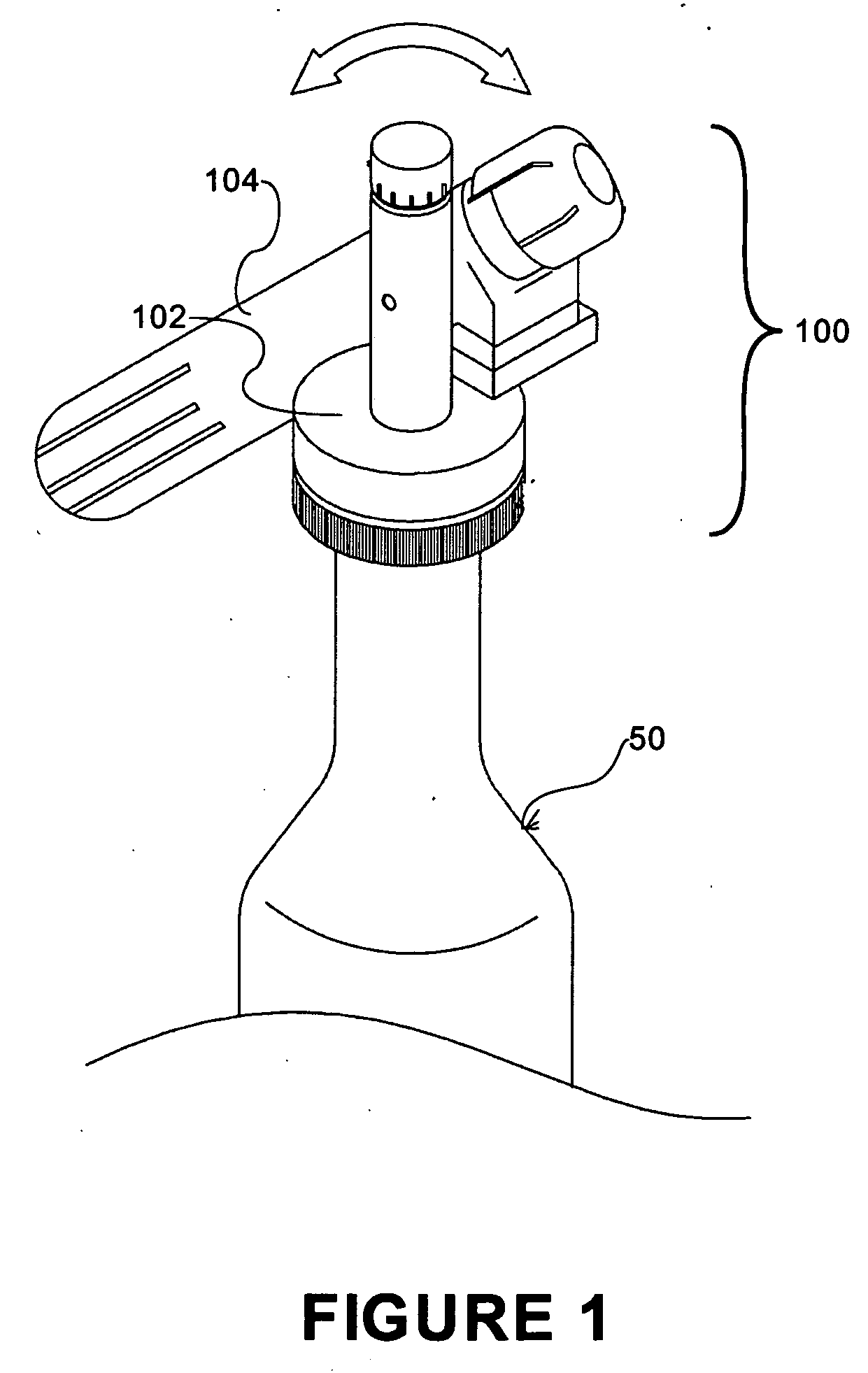

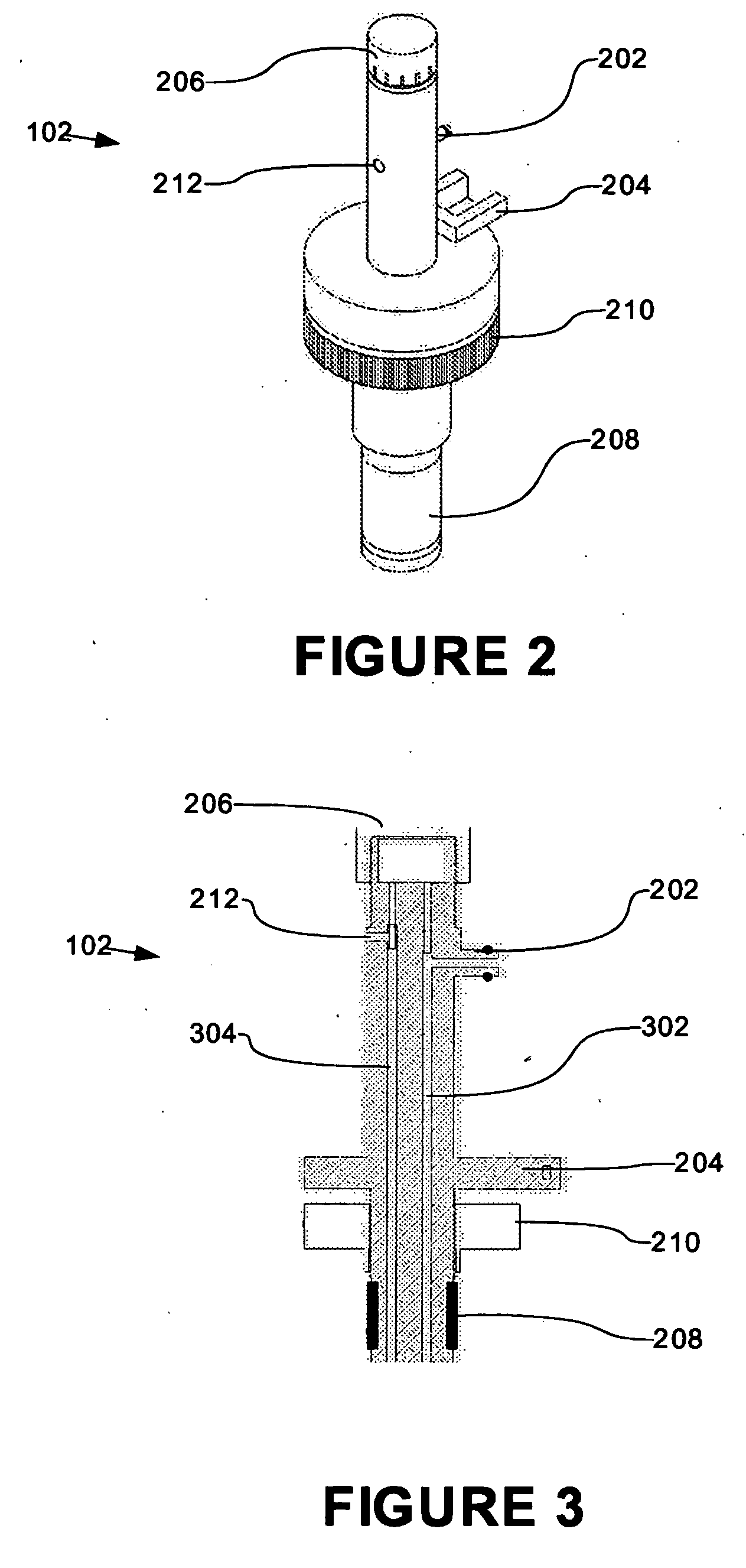

Wine preservation system

InactiveUS20050142260A1Reliable deliveryReduce wasteClosure with auxillary devicesAlcoholic beverage preparationWine bottleEngineering

Wine within an opened bottle is preserved by introducing an inert gas through a seal which seals the previously opened bottle. An adapter seals the bottle and the inert gas is injected into the bottle through the seal from a removable gas supply. The gas supply attaches to the adapter in an airtight manner while the adapter seals the wine bottle in an airtight manner. The gas supply can be removed from the adapter and used with other adapters to preserve other bottles of wine while each adapter seals the inert gas within a respective bottle of wine until consumption of the wine in a particular bottle is to resume.

Owner:WINE INNOVATIONS

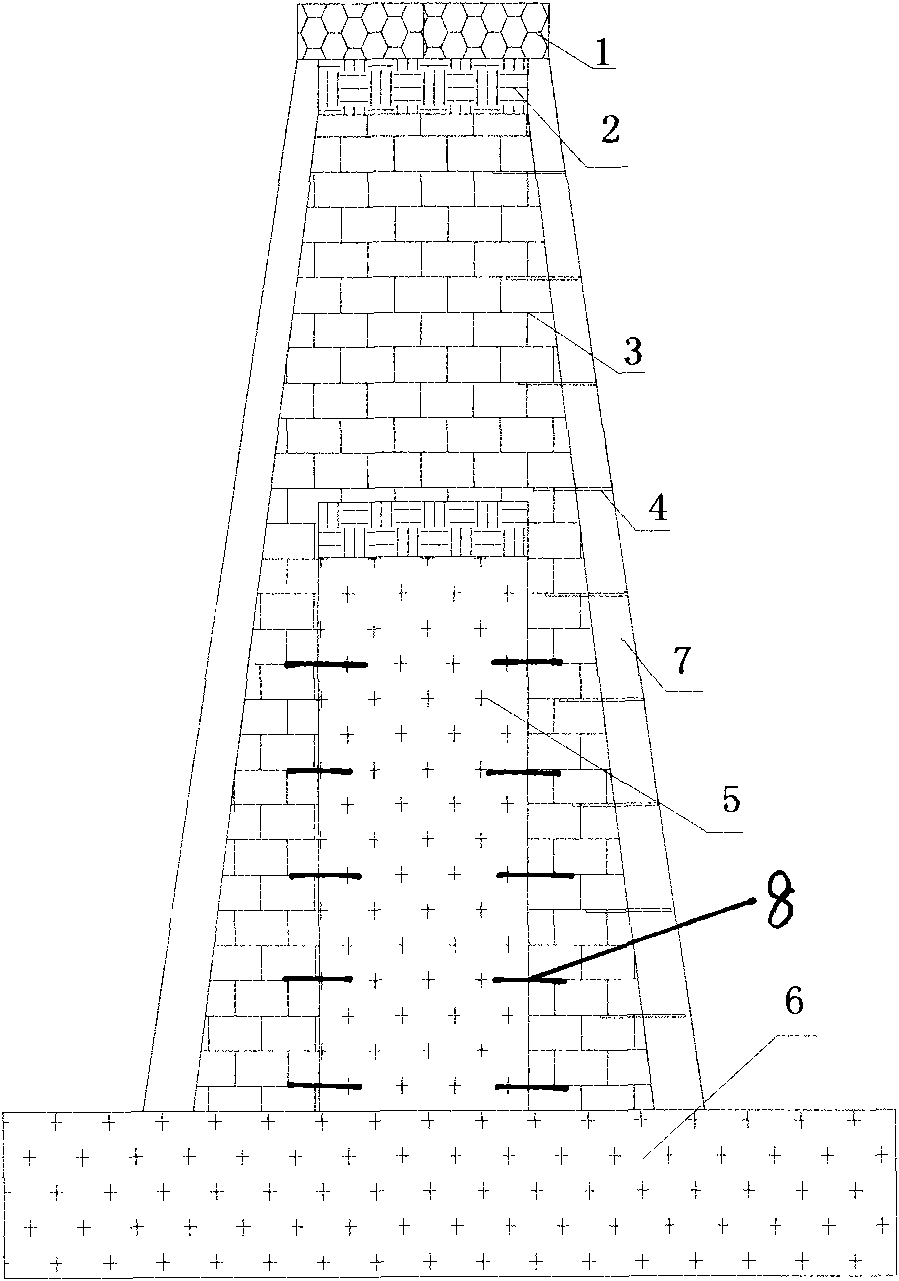

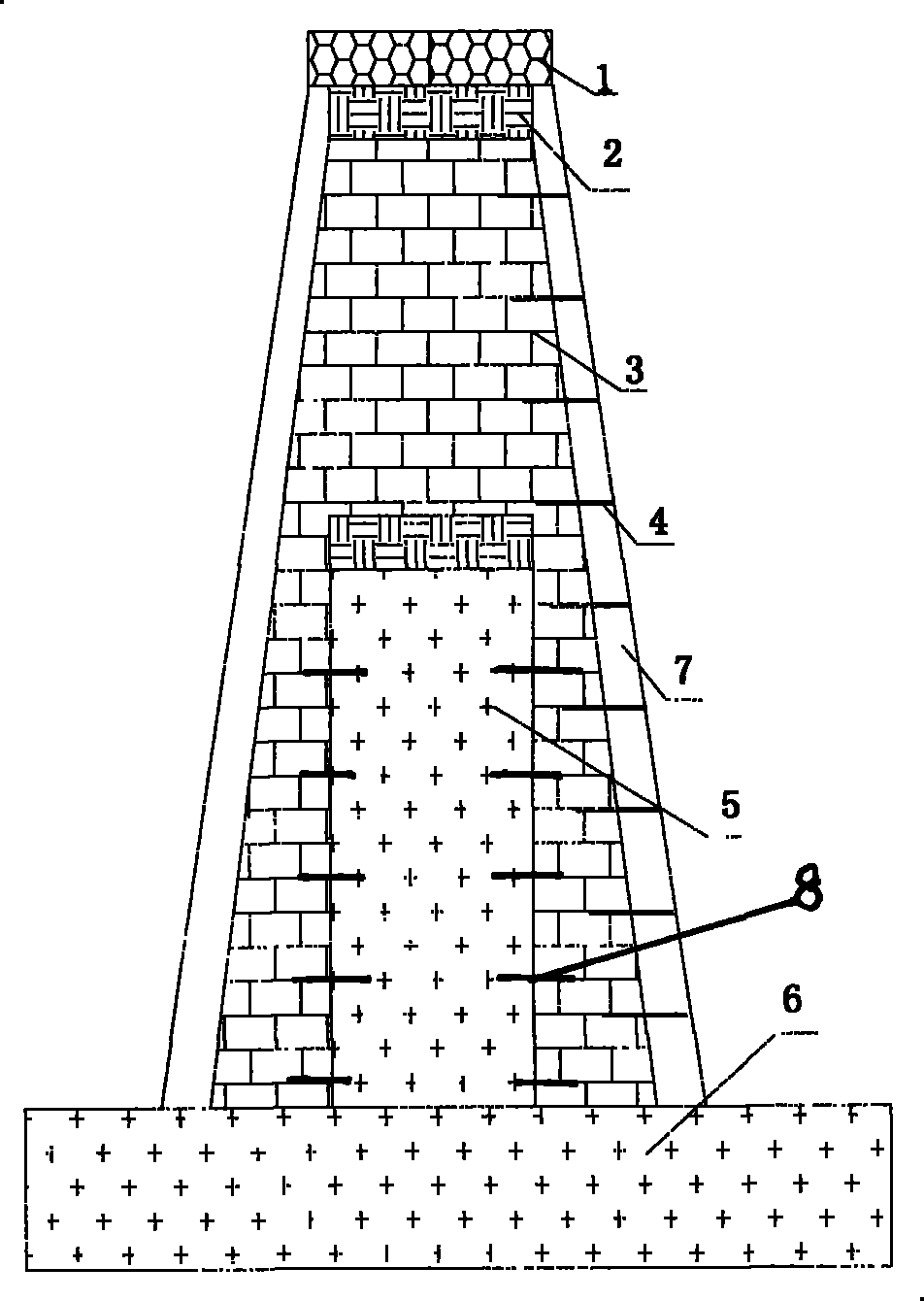

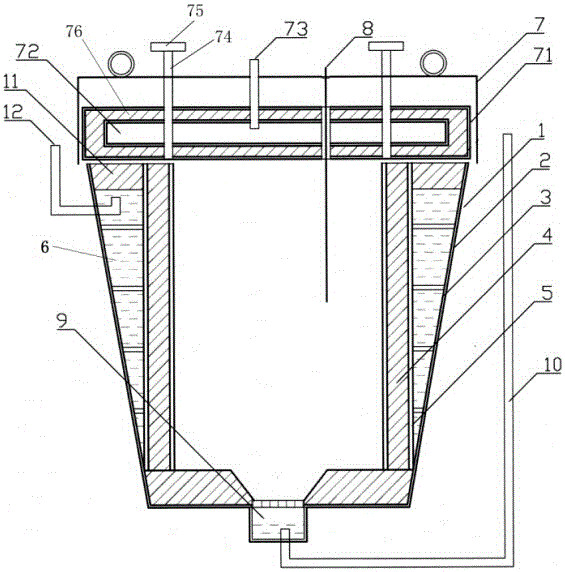

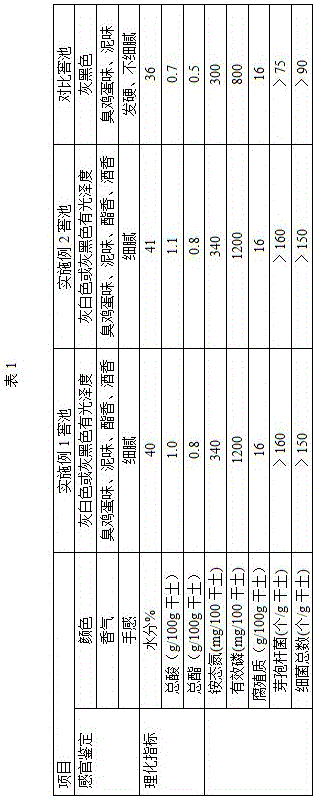

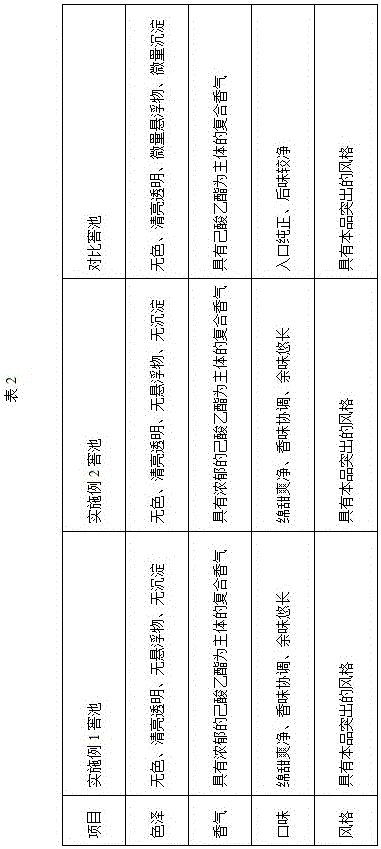

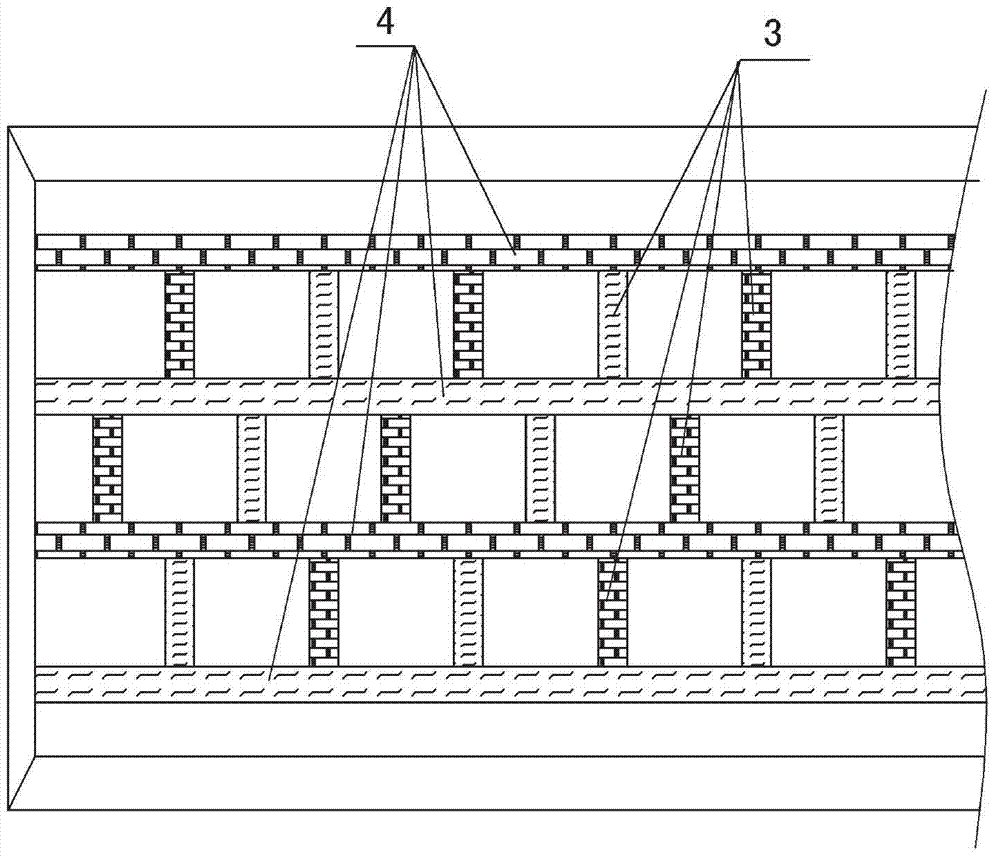

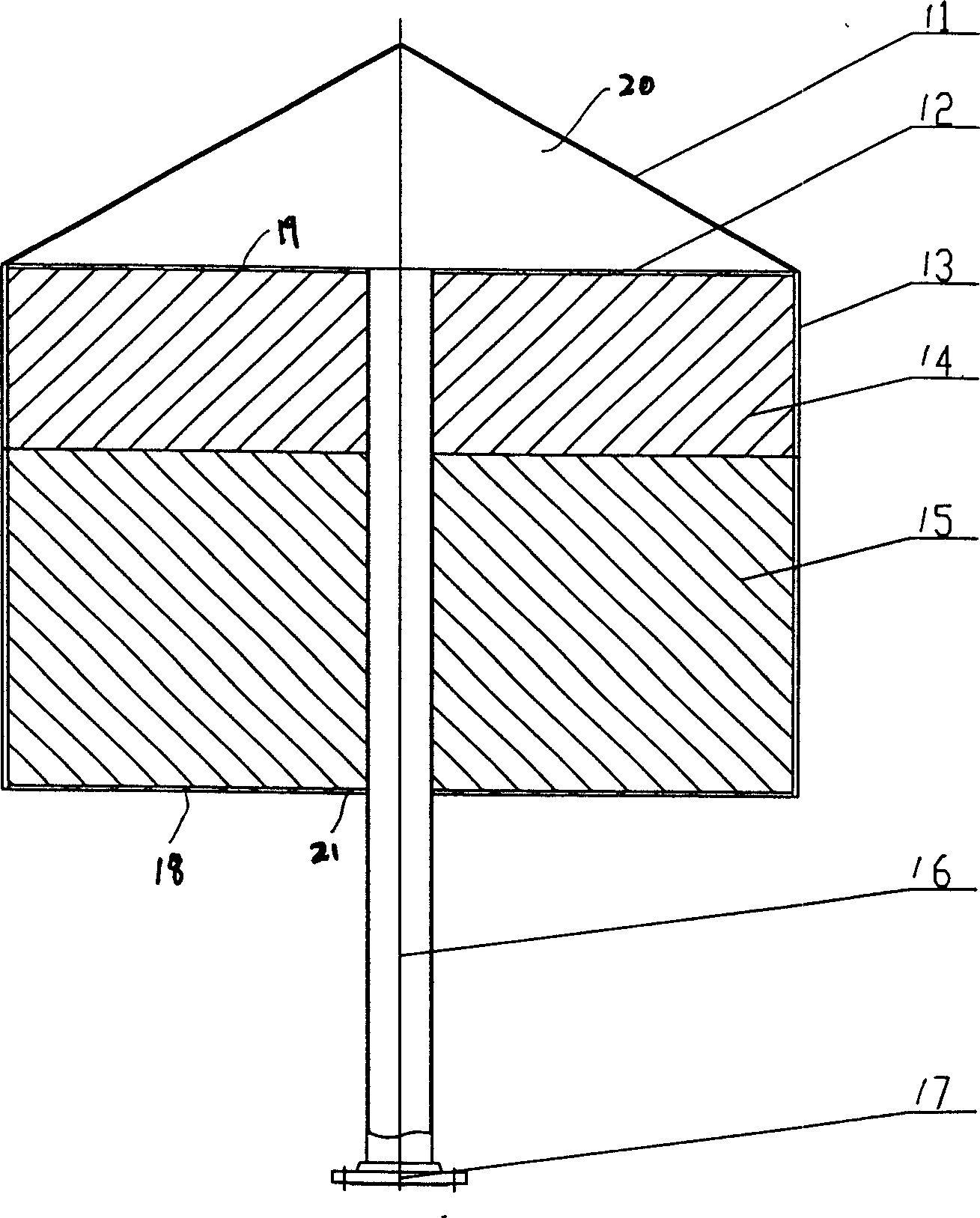

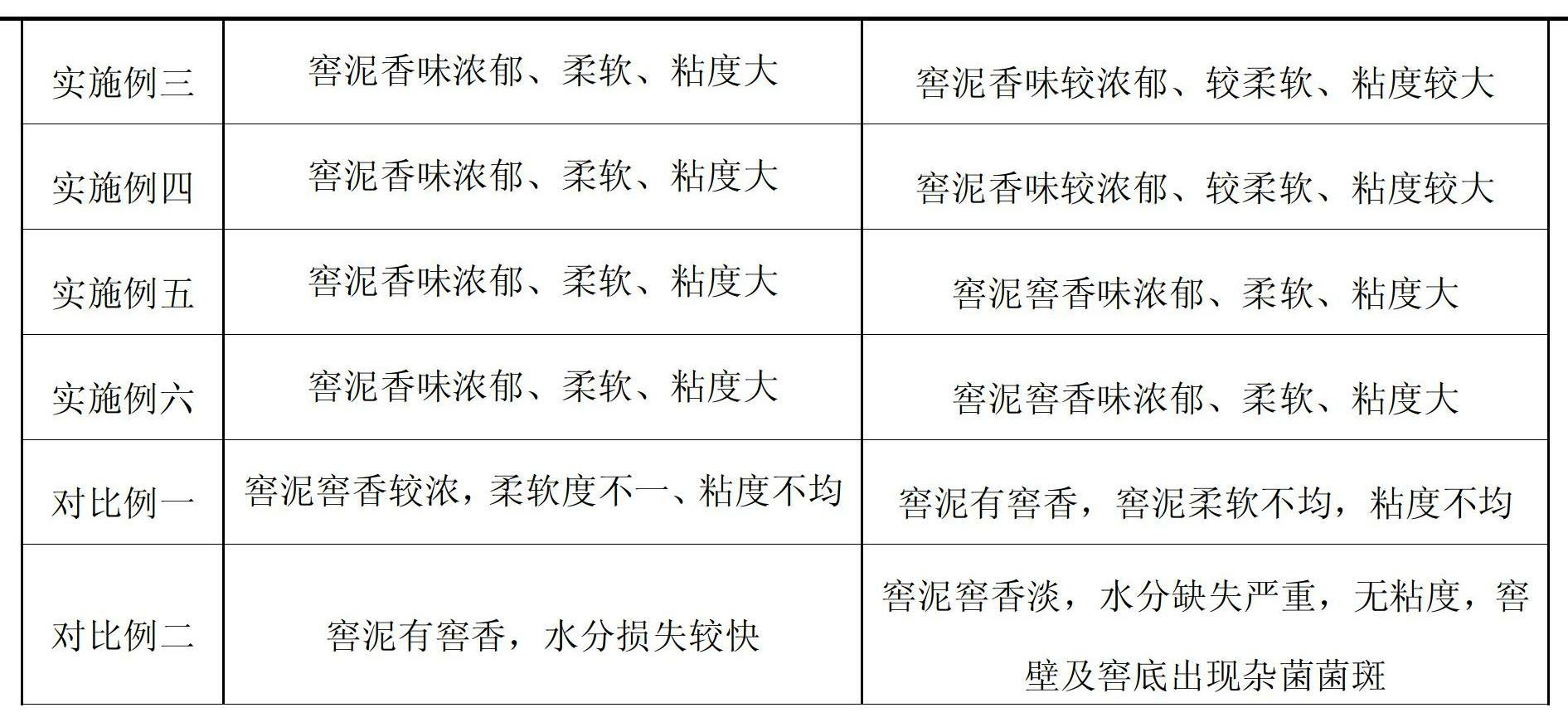

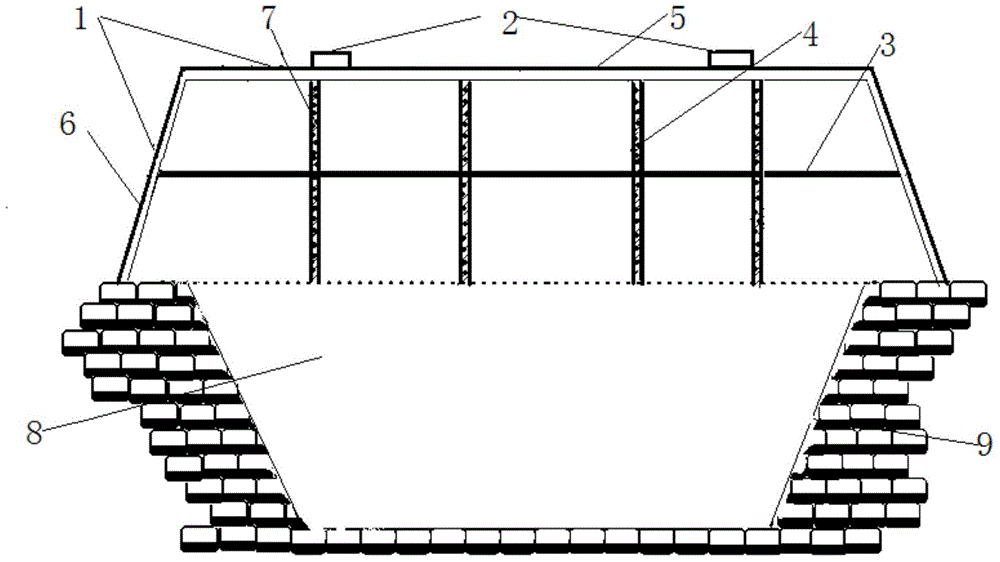

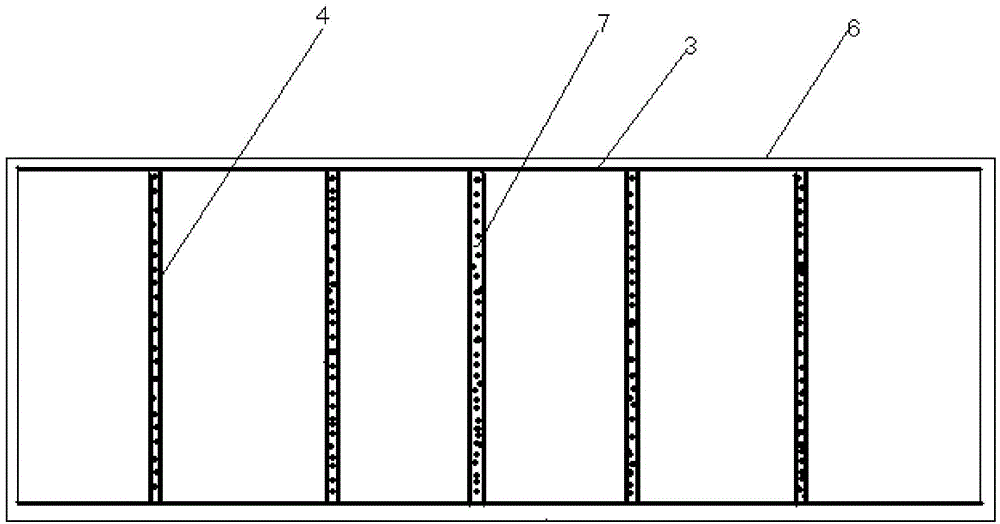

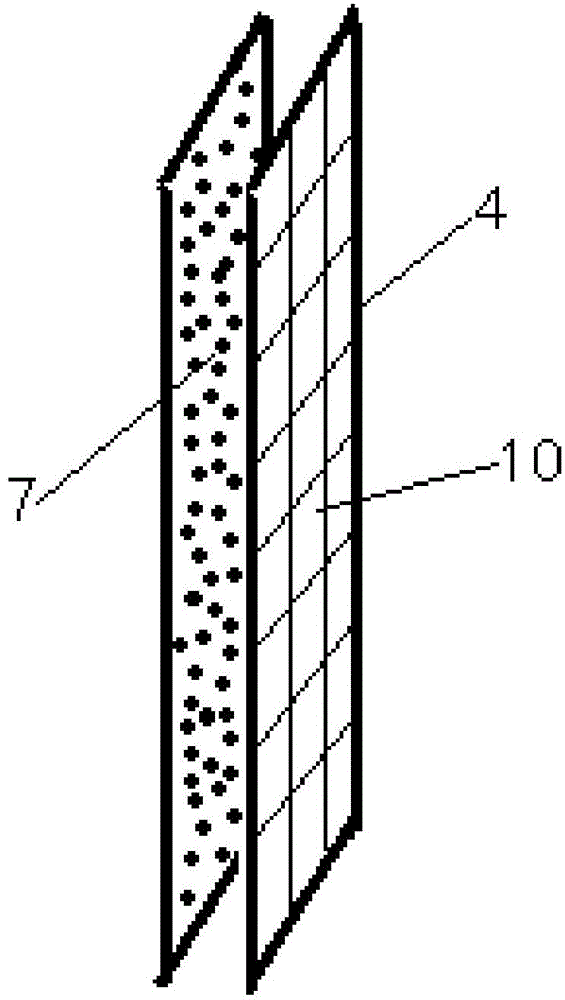

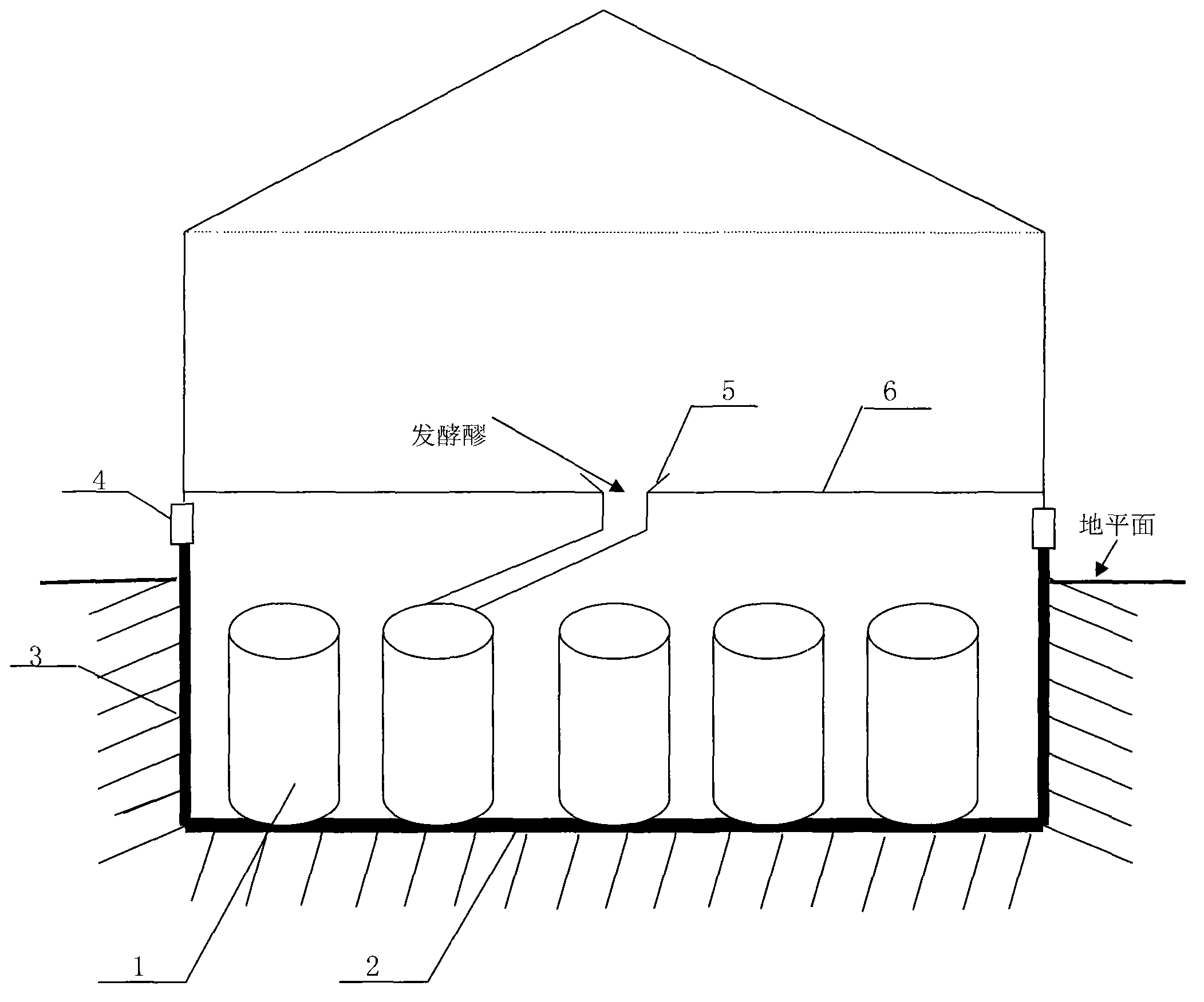

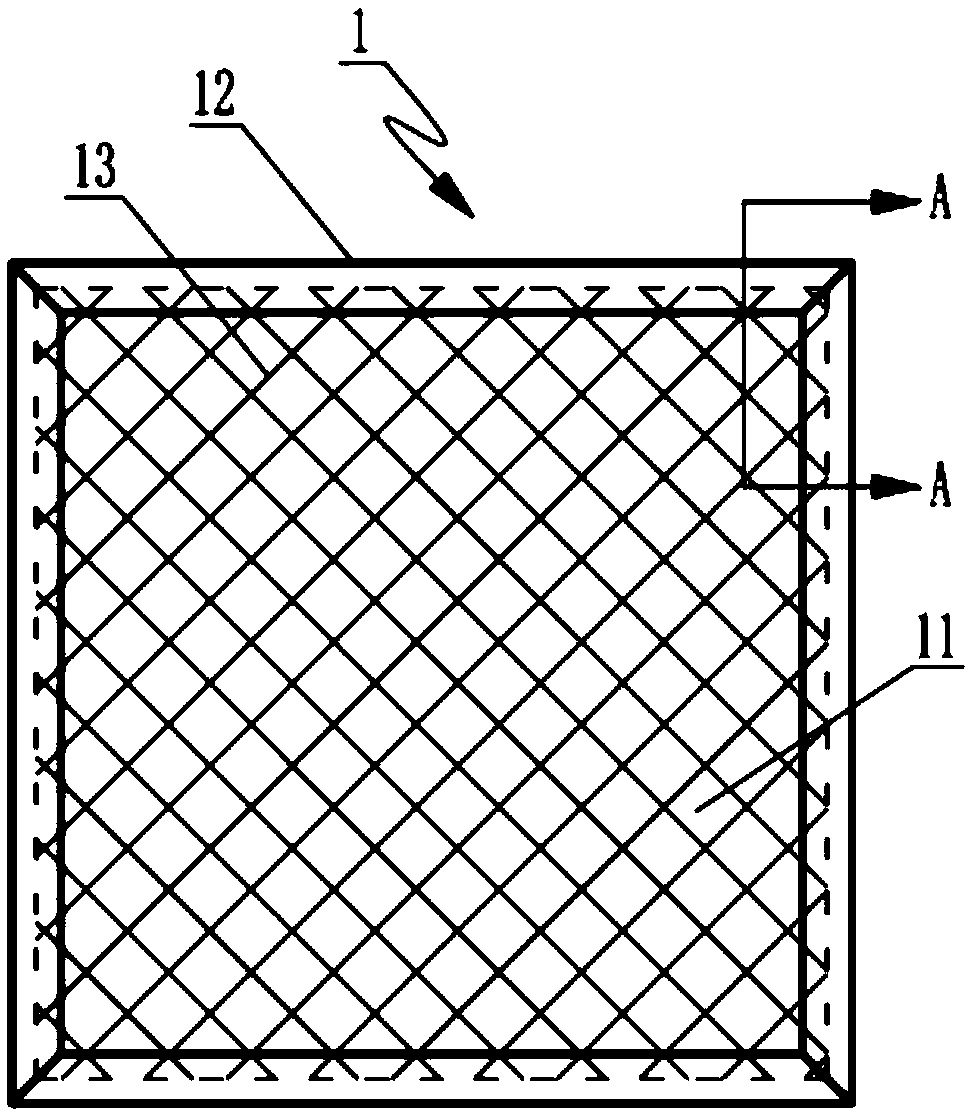

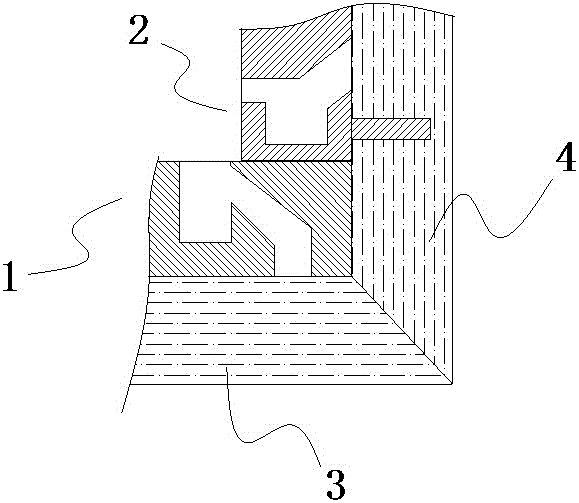

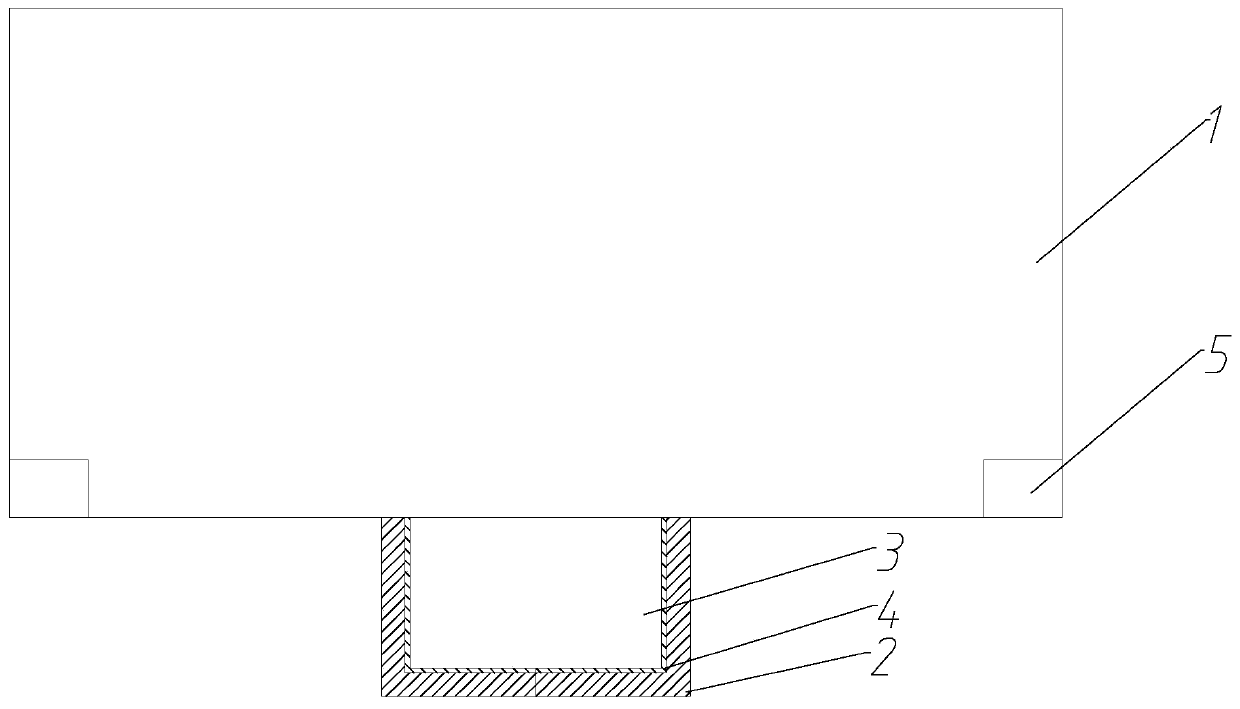

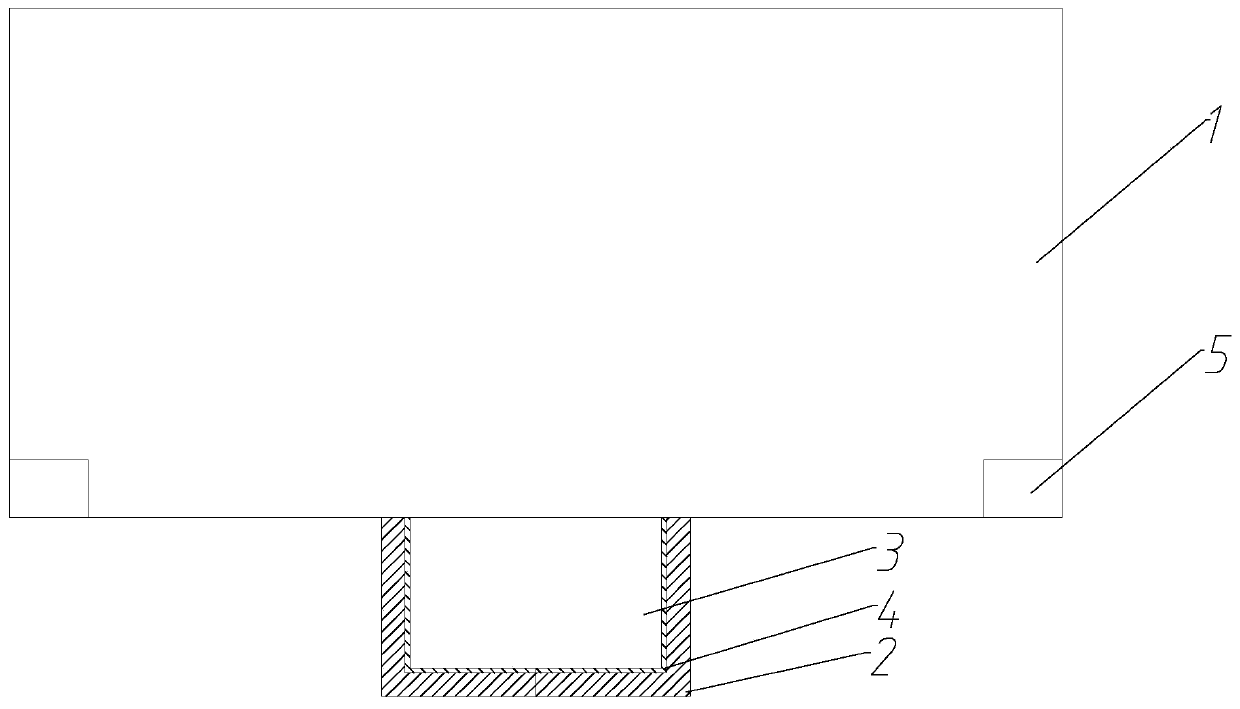

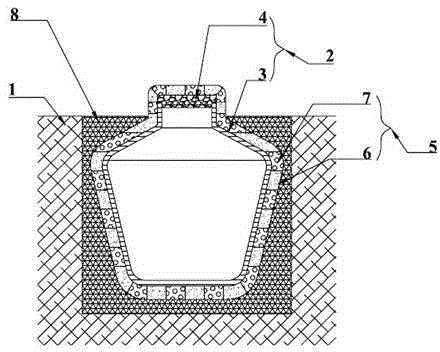

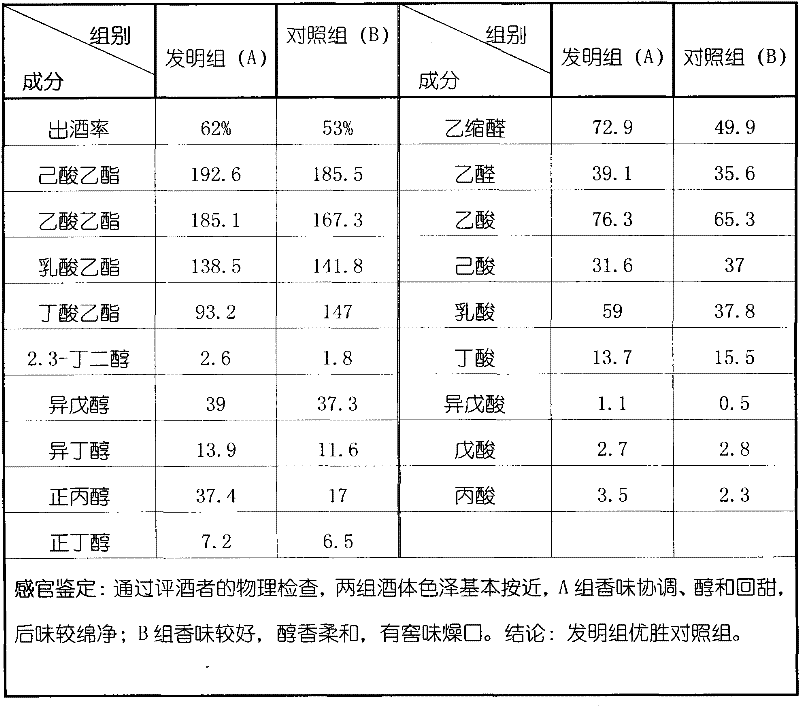

Soil-brick combined yeast wine cellar and construction method thereof

The invention relates to yeast wine fermentation, in particular to a soil-brick combined yeast wine cellar and a construction method thereof in the field of strong aromatic yeast wines. The yeast wine cellar of which not only the cellar moisture retention is good but also a wall body cannot collapse easily is provided by a method comprising the following steps of: culturing artificial aging cellar mud; building a two-component soil waterproof layer at the bottom of the cellar; ramming a two-component soil internal wall based on the waterproof layer at the bottom of the cellar; and building an inclining brick wall with a certain inclination angle by using red bricks on two sides next to the two-component soil internal wall respectively. The soil-brick combined yeast wine cellar overcomes the defects in the prior art, and can effectively improve the activity of cellar mud functional bacteria and accelerate the aging of artificially cultured cellar mud to ensure that the fragrance of a produced base liquor is a composite fragrance mainly comprising ethyl caproate, and the liquor body style is a typical concentrated fragrance type liquor style with 'a strong cellar fragrance, a sweet and clear taste, harmonious fragrances and long aftertastes'.

Owner:HUNAN XIANGJIAO WINE IND

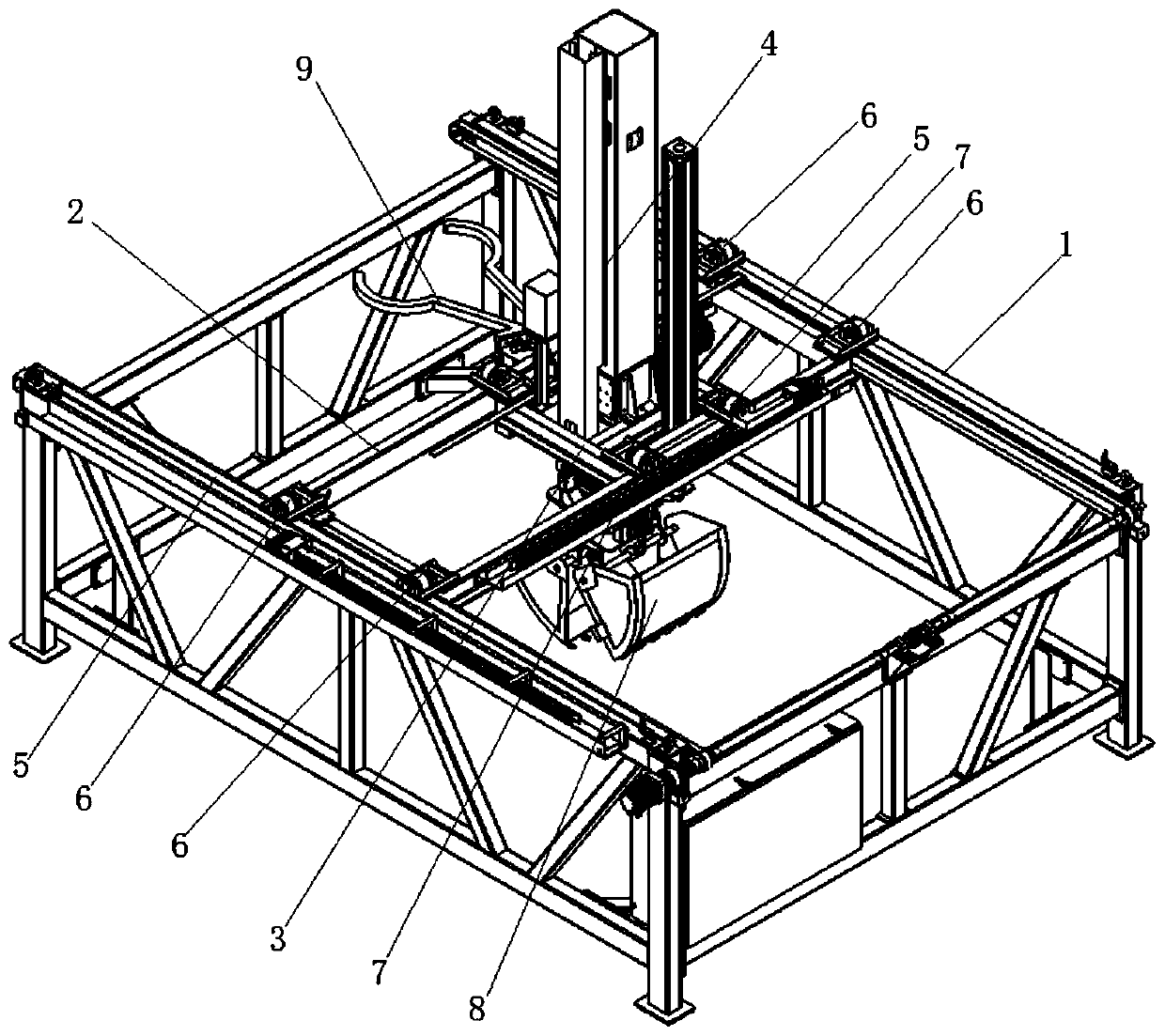

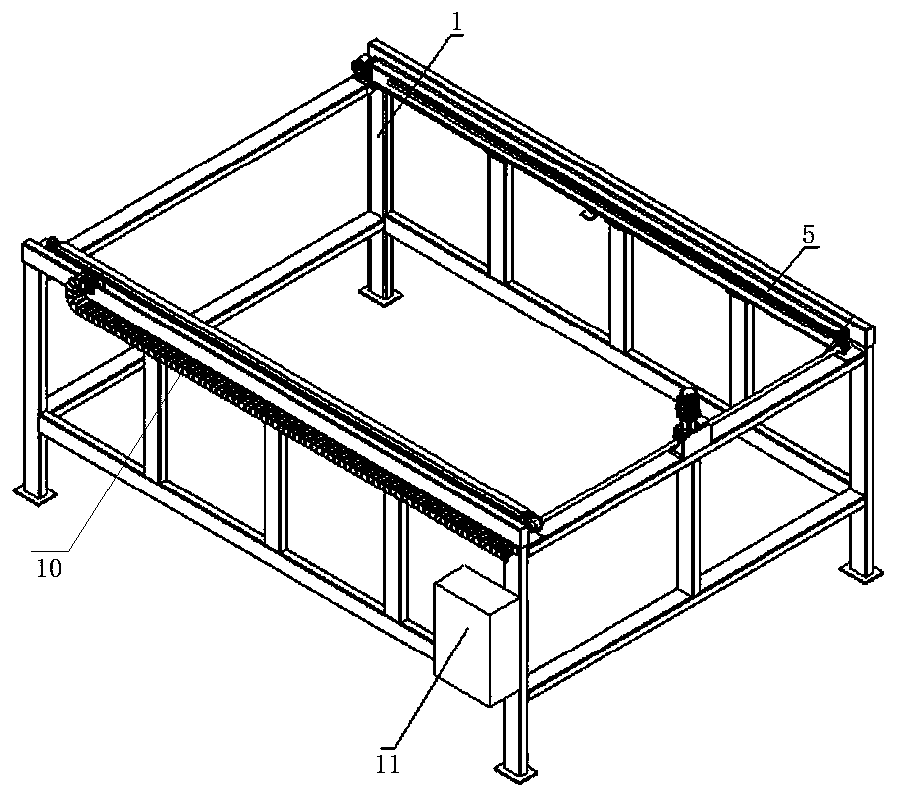

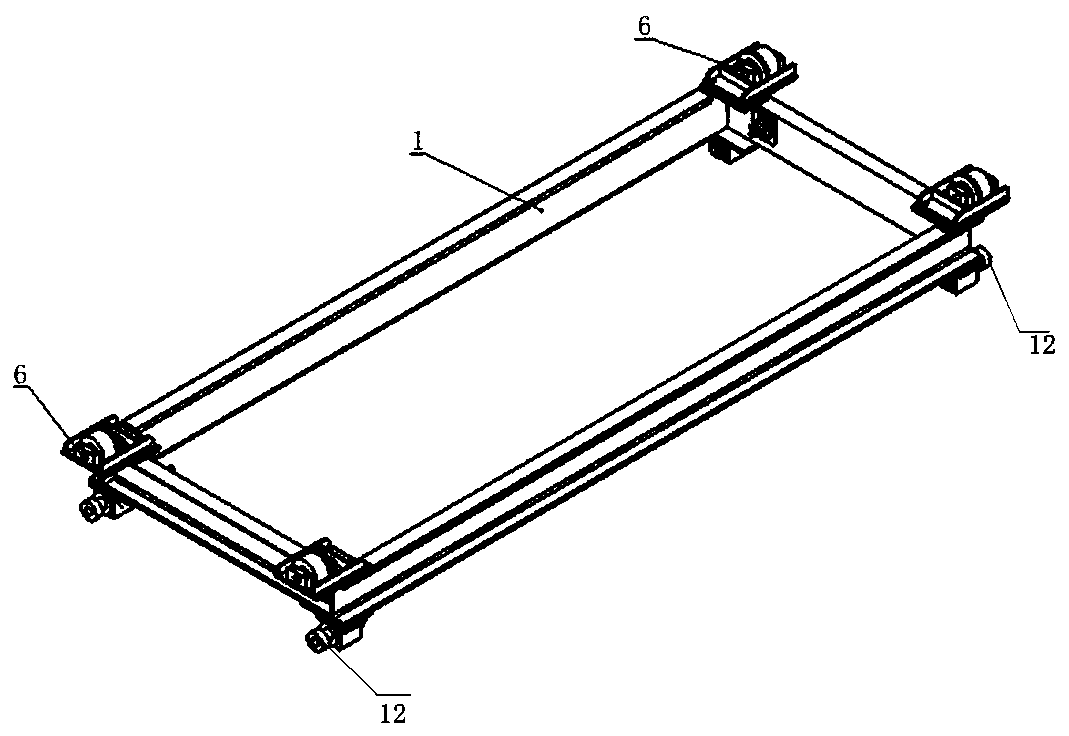

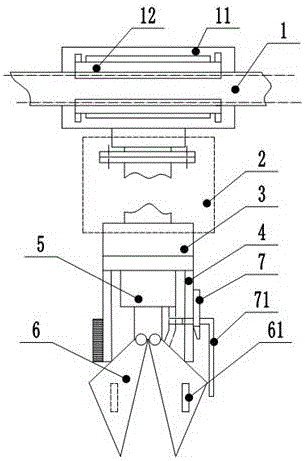

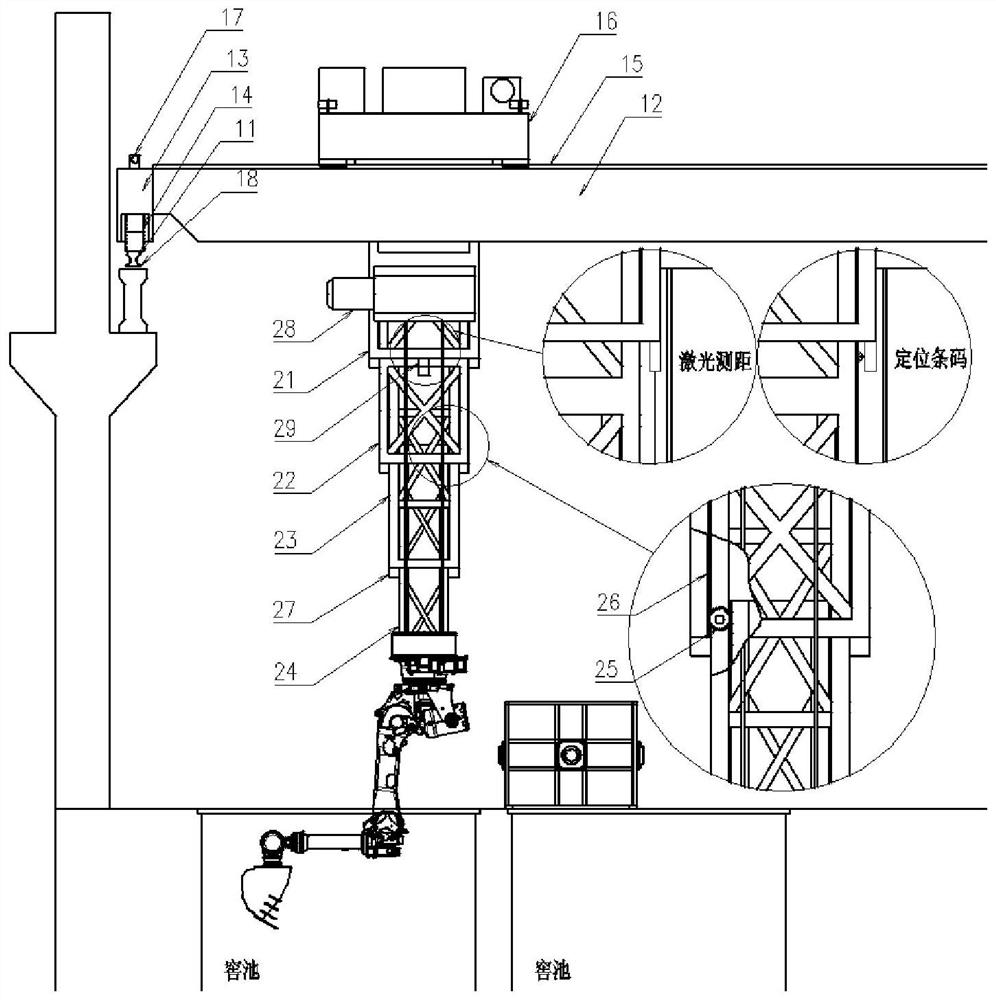

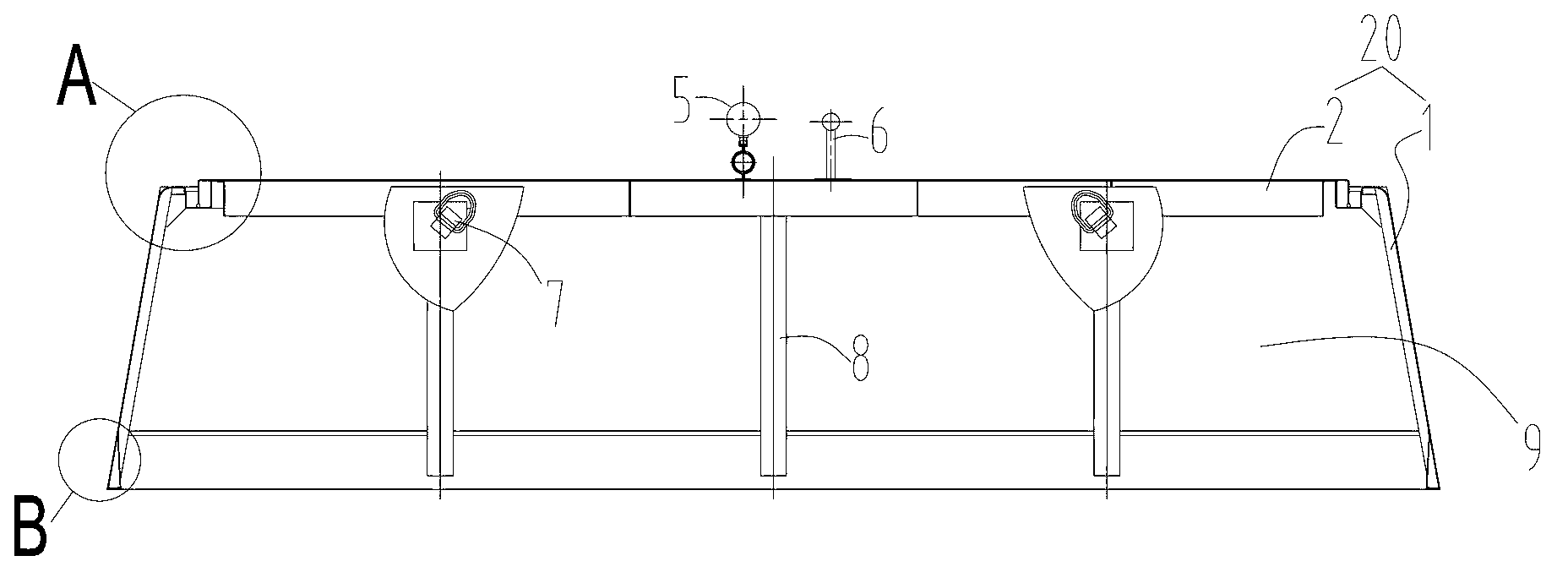

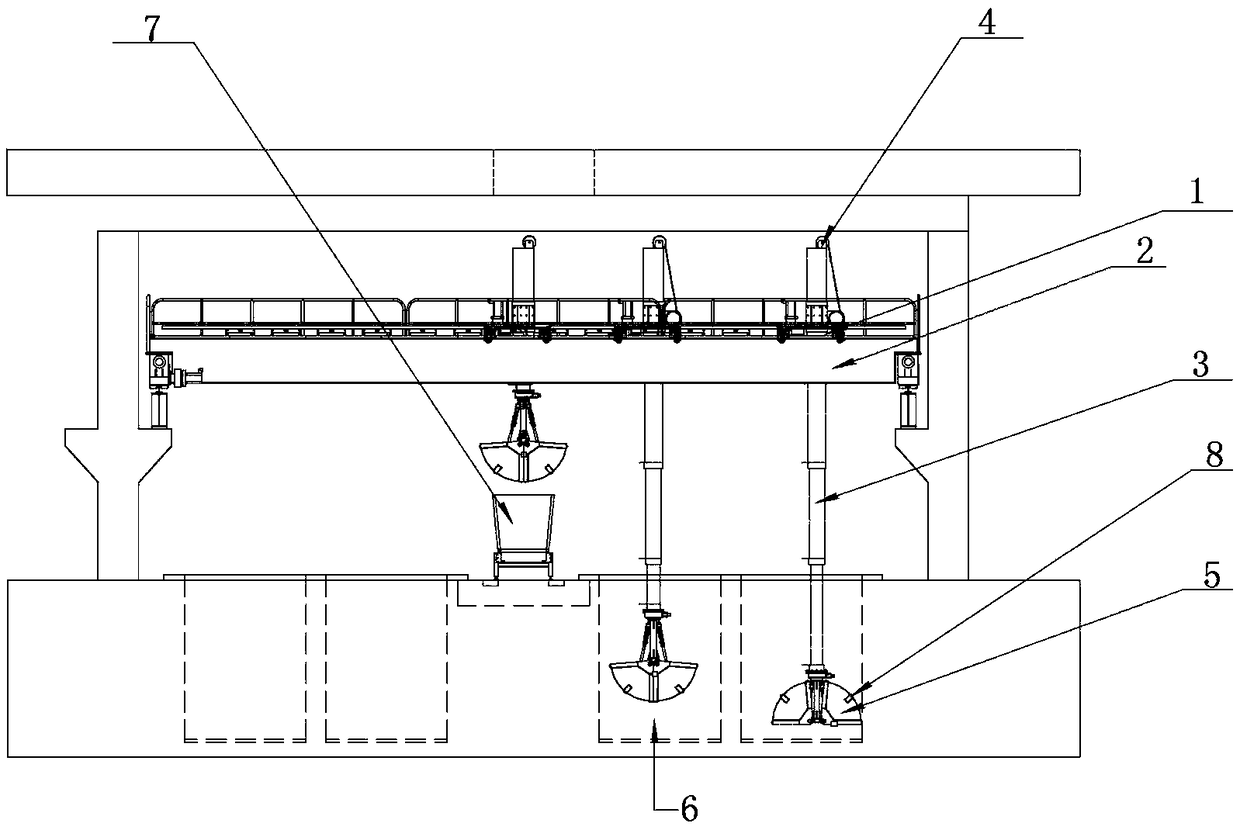

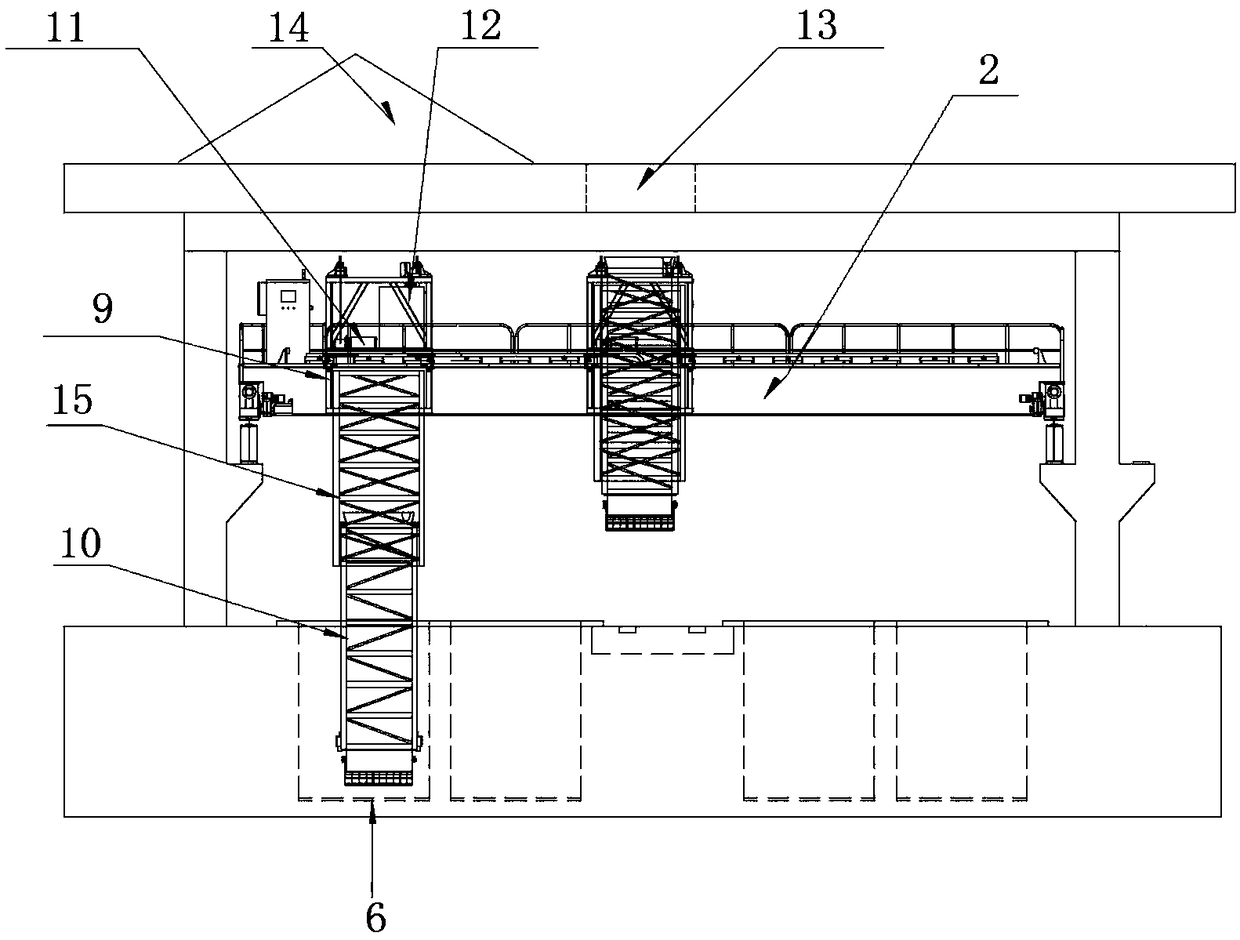

System and method for discharging fermented grains out of fermentation pit

PendingCN110562729ALeaving the cellar is beneficialAvoid damageCellar toolsConveyor partsEngineeringBrewing

The invention relates to the technical field of liquor brewing, and discloses a system and method for discharging fermented grains out of a fermentation pit. The system comprises a collaborative robot. The collaborative robot comprises a support, an X-axis moving trolley, a Y-axis moving trolley and a telescopic mechanism, wherein the X-axis moving trolley is movably arranged on the support in theX-axis direction, the Y-axis moving trolley is movably arranged on the X-axial moving trolley in the Y-axis direction, the telescopic mechanism is vertically arranged on the Y-axis moving trolley, acollaborative grab bucket is connected to the bottom end of the telescopic mechanism, and the support is detachably fixed to the periphery of an opening of the fermentation pit, so that the collaborative grab bucket is located above the fermentation pit and is used for transferring fermented grains at the corners and on the wall of the fermentation pit to a preset position. According to the systemand method for discharging the fermented grains out of the fermentation pit, with the assistance of the collaborative robot, the fermented grains at the corners of the fermentation pit can be smoothly grabbed, the fermented grains can be completely discharged of the fermentation pit, and the fermented grains on the wall of the fermentation pit are grabbed through the collaborative grab bucket instead of a main working grab bucket, so that the wall of the fermentation pit is prevented from being damaged by the main grab bucket.

Owner:WUHAN FENJIN INTELLIGENT MACHINE CO LTD

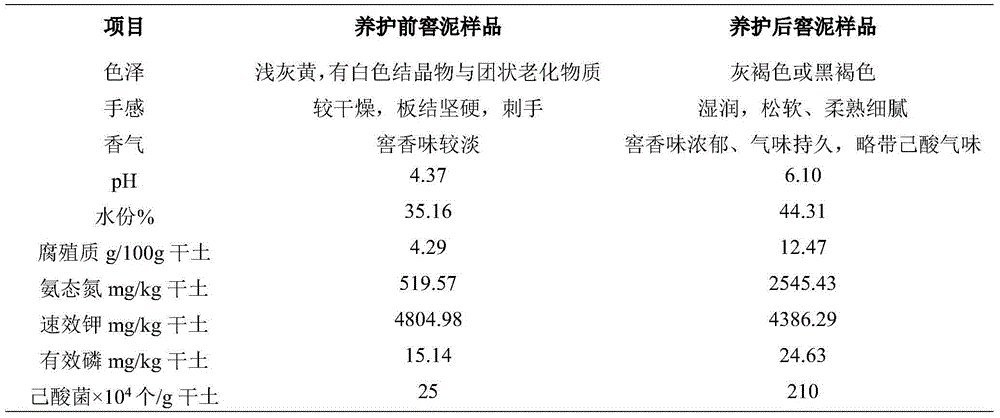

Method for maintaining cellar by washing with hot water

The invention discloses a method for maintaining a cellar by washing with hot water, belonging to the technical field of brewage. The method comprises the following steps: cleaning the cellar wall and cellar bottom, spraying hot water to white crystals and bulky aged substances, and finally, supplementing water, mild wine and yeast powder; and after finishing supplementing the nutrients, covering with a PVDC (polyvinyl dichloride) fabric to moisturize the cellar, and arranging special people to stamp the sides of the cylinder and three barrels. The method for maintaining cellar by washing with hot water effectively enhances the cellar quality; and after the cellar is maintained according to the maintenance procedure for 2-3 rows, the calcification phenomenon of the cellar disappears, and the cellar looks moist, feels delicate and has thick cellar aroma, thereby prolonging the cellar sludge replacement period and greatly saving the production input cost for fermentation sludge.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

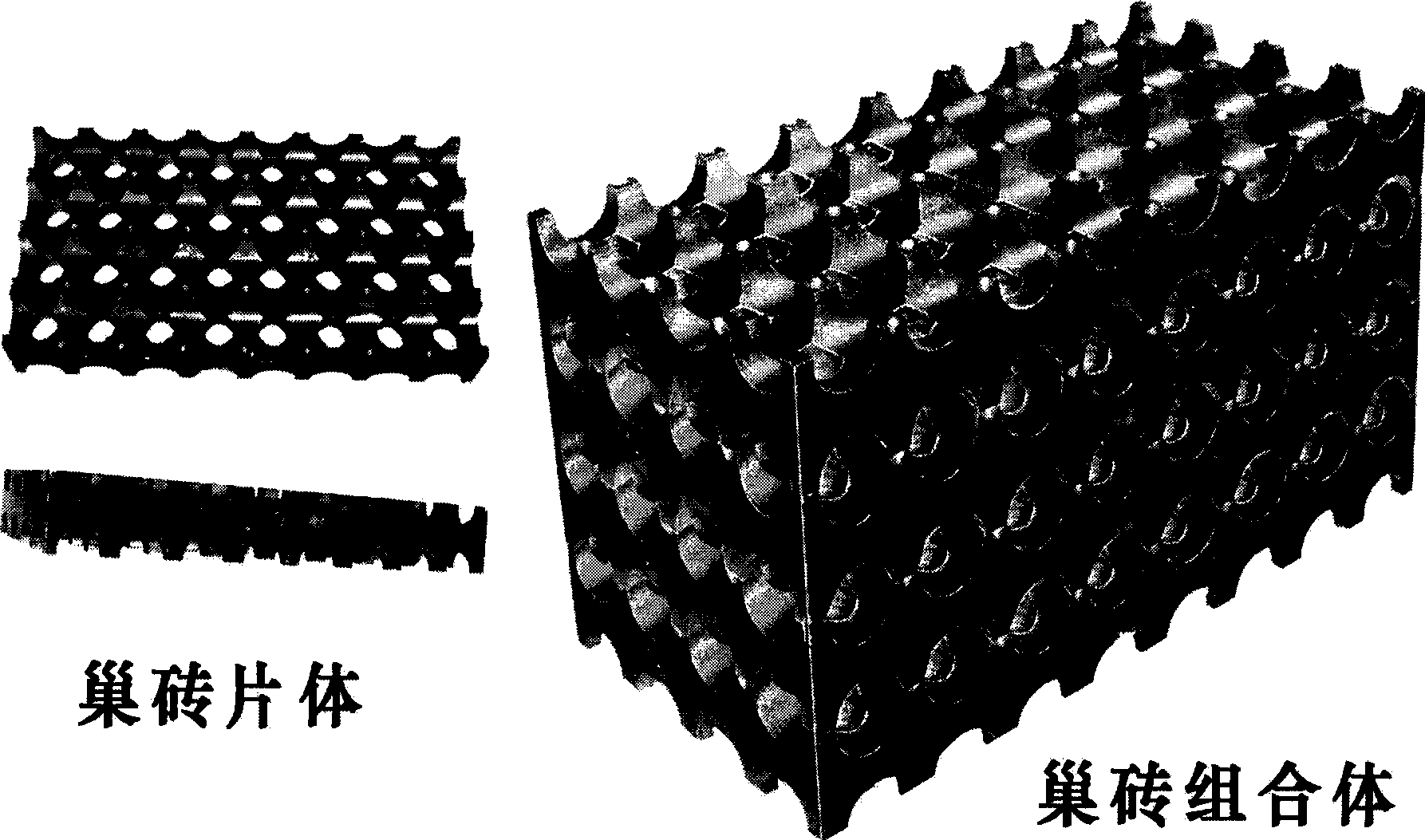

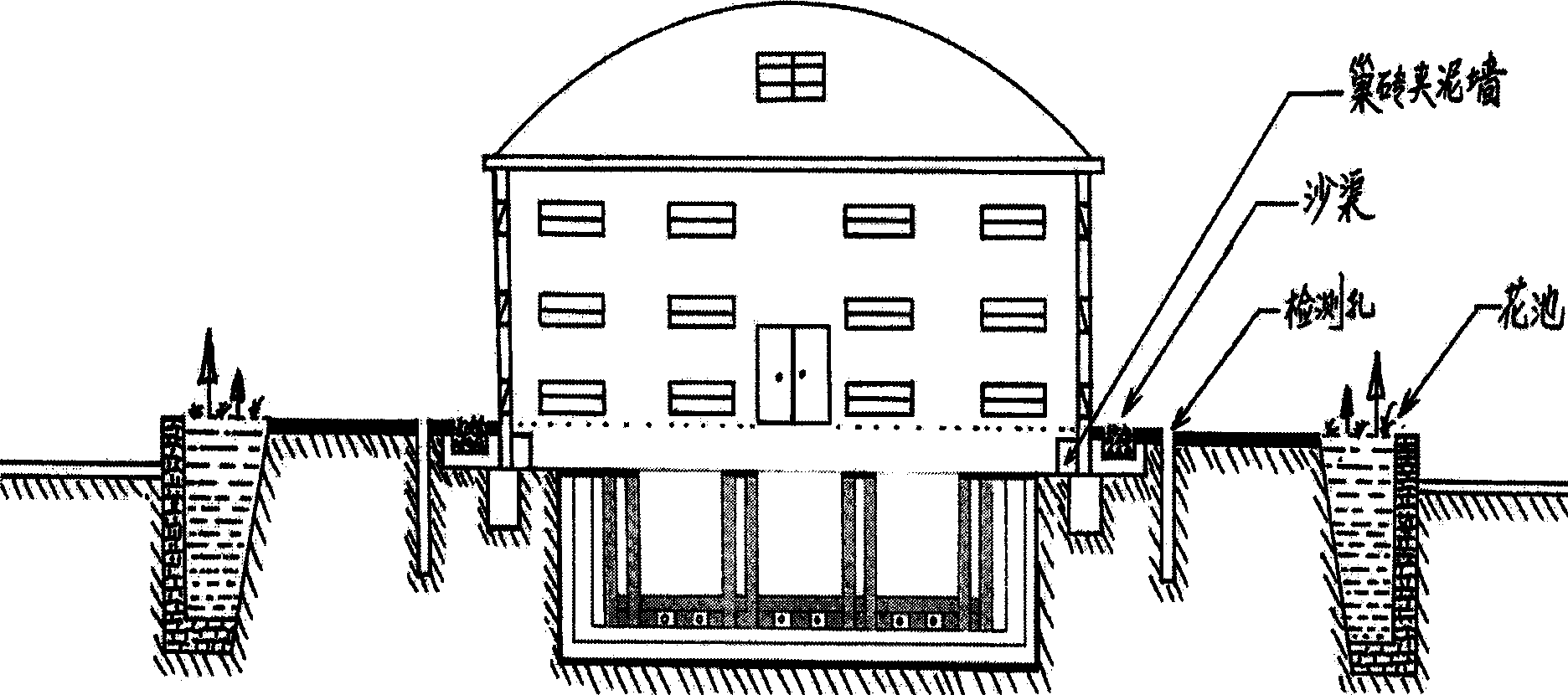

Wine brewing cellar building technology

The invention relates to a wine-making bodega-building technology which comprises a brick combination body, a bodega workshop auxiliary facility, bodega workshop venting hole reconstruction, a multilayer bodega structure method, a cultivation way of bodega mud, and a bodega body microcirculation compensating system. On the base of the traditional bodega process, the technology creates the bodega-building process, develops the technical measures of brick mud clamping and building, multilayer bodega body structure, external remote assistance, bodega body internal compensation, venting hole reconstruction, bodega soil adulterating and bacteria grafting, and the like, can effectively release the harmful influence on the bodega wine production by natural factors, has obvious promotion function to achieve the purpose of quick bodega mellowing, easy maintenance, aging resistance, interference resistance and stable wine quality, develops a new way of operability of the bodega wine flavor, accords with the principles of physical science and bodega wine process, develops and creates the bodega-building process, is suitable for bodega wine companies with different processes and flavors in different areas, and plays a positive role in improving the product quality and increasing the economic benefit.

Owner:山东省古窖藏酒与酒文化研究发展中心 +1

Baijiu fermenting tank and building method

ActiveCN105779266ASolve lifetime maintenanceSolve problemsCellar toolsBuilding material handlingFlavorAlcohol

The invention discloses a baijiu fermenting tank and a building method. The problems that for a general fermentation pit, pit mud is prone to aging, and for a returned mud fermentation method, due to the fact that the mud quantity in fermented grains is too large, distillation is affected are solved. The baijiu fermenting tank comprises a fermentation pit, a pit cover, a pit cavity, a waterproof layer, a fermentation pit liquid containing interlayer, a yellow water tank and a U-shaped tube, the fermentation pit is internally provided with a pit mud permeable barrier, the portion between the pit mud permeable barrier and the inner wall of the fermentation pit is the fermentation pit liquid containing interlayer which is shaped like an inverted truncated triangular pyramid, and a pit edge seal ring is arranged on the top of the fermentation pit liquid containing interlayer. According to the fermenting tank, the pit mud is rich in a large amount of beneficial microbiota, and generation of aroma-producing substances of distiller's grains is increased; a functional bacteria culture solution is added into a pit cover liquid containing cavity and the fermentation pit liquid containing interlayer, after a main fermentation period is completed, the functional bacteria culture solution permeates the distiller's grains through the permeable barrier, a biochemical reaction of generating ester from acid and alcohol is completed, the content of aroma-producing ingredients of strong-flavor baijiu is further increased, and a baijiu body style is highlighted.

Owner:SHANDAN LANCHI FOOD CO LTD

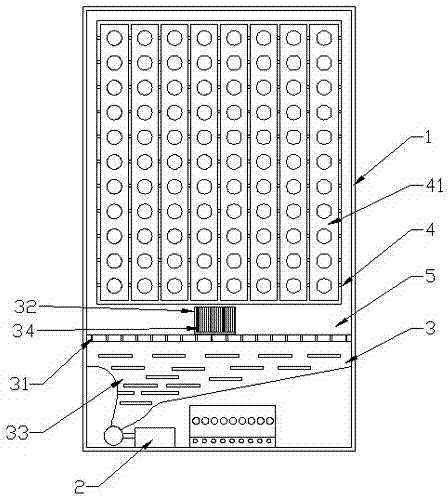

All-directional constant-temperature wine cellar with sub-control adjustment function

An all-directional constant-temperature wine cellar with the sub-control adjustment function comprises a wine cellar body, a temperature and humidity control device, an air disperse device and a wine rack, wherein the temperature and humidity control device, the air disperse device and the wine rack are arranged in the wine cellar body, the wine rack is located in a wine storage space on the upper portion of the interior of the wine cellar body, an airflow circulating space is arranged in the wine storage space and between the wine rack and the inner wall of the wine cellar body, a plurality of partition plates are arranged inside the wine rack so that the interior of the wine rack is divided into a plurality of vertical wine storage channels, air holes for air circulation are formed in the walls of the wine rack and the partition plates, the air disperse device is arranged below the wine rack and is connected with the temperature and humidity control device, a plurality of air disperse holes are evenly distributed in the top surface of the air disperse device, and the air disperse device is further provided with an air disperse window which is arranged at the bottom of the wine storage space. According to the all-directional constant-temperature wine cellar with the sub-control adjustment function, constant-temperature and constant-humidity airflow circulation is formed in the wine storage space, so that it is guaranteed that the temperature and the humidity at any position in the wine storage space are the same.

Owner:况维义

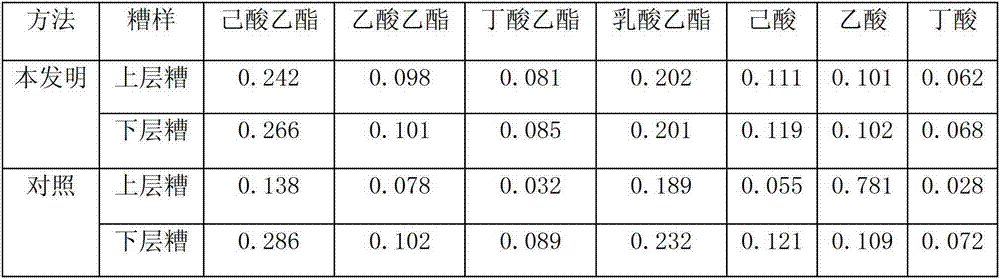

Cave type pit, pit mud and method of brewing highly flavored type basic liquor by cave type pit and pit mud

ActiveCN105349400AIncrease aromaAvoid deathAlcoholic beverage preparationCellar toolsYeastEngineering

The invention discloses a cave type pit, pit mud and a method of brewing highly flavored type basic liquor by the cave type pit and the pit mud, relating to the field of wine brewing. The pit is located in a cave, wherein a plurality of pits are arranged in the cave; the top of the cave is covered with mud with the thickness of 4-12m; the height of the cave is 6-8m; the cave is provided with an entrance; the distance between the pits and the entrance of the cave is 15-25m, and the pit mud is smeared on the inner walls of the pits. The pit mud is prepared from 5-15 parts of yellow water, 20-35 parts of tail water, 50-80 parts of loess, 2-4 parts of powder of yeast for making hard liquor, 10-20 parts of saccharomycetes, 5-15 parts of ethyl caproate esterifying bacteria, 1-3 parts of aroma-producing yeast, 5-10 parts of distiller's grain, 5-20 parts of grain lees and 10-20 parts of chitin according to parts by mass. The problem that white spirit cannot be safely stored in summer is solved, so that the white spirit can be produced continuously in the season with higher temperature, and the basic liquor with higher quality can be obtained.

Owner:武汉雅仕博科技有限公司

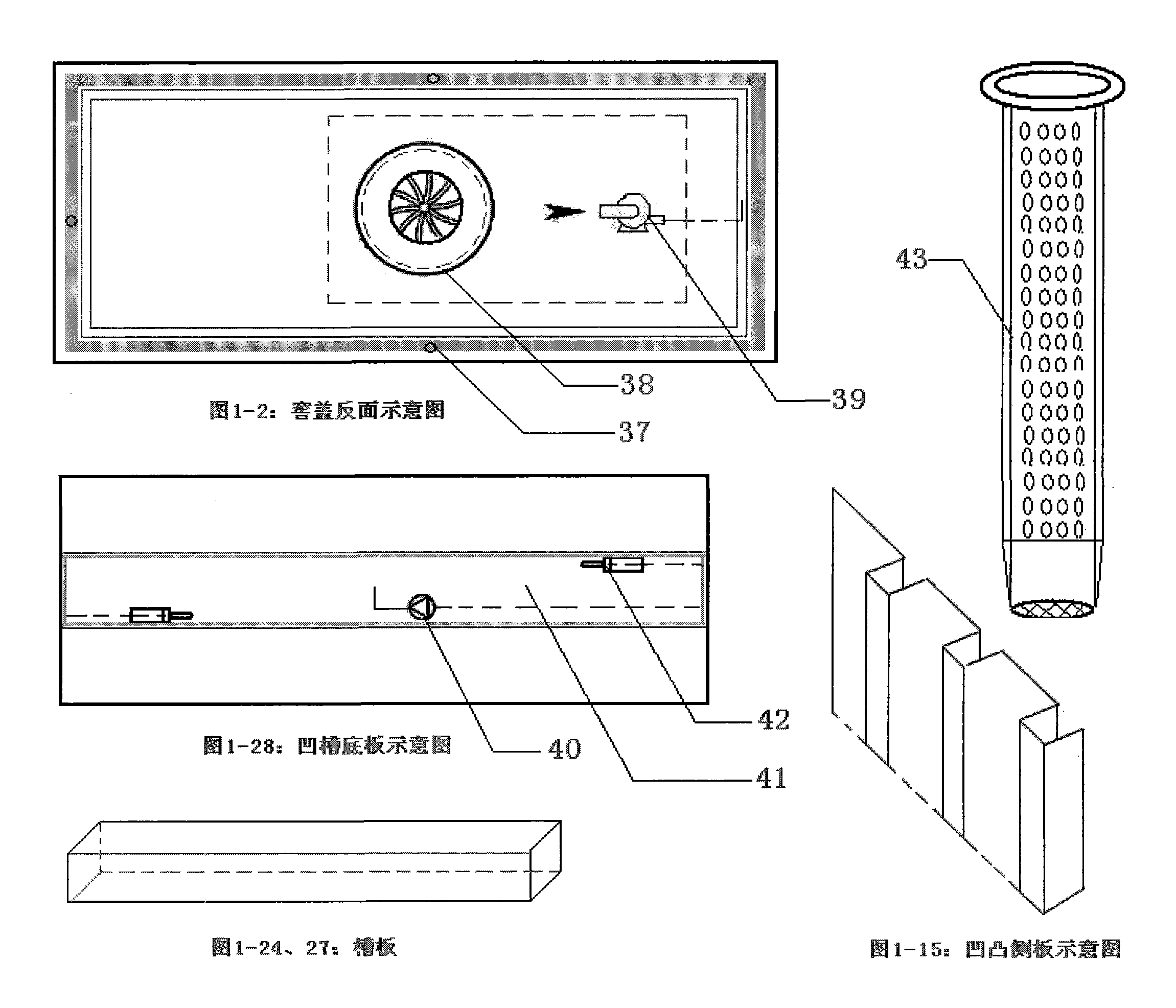

Wine produced from sun-scorched grains, alpinia katsumadai and areca catechu and thermostatic wine cellar

InactiveCN103361229AImprove bad tasteSuitable for long-term drinkingAlcoholic beverage preparationCellar toolsAreca palmAbdomen diseases

The invention discloses a wine produced from sun-scorched grains, alpinia katsumadai and areca catechu and a thermostatic wine cellar. The wine is characterized by being produced from sun-scorched grain extracts, a variety of wines with different aromas and medicinal and edible functional herbs by adopting the modern enzymic preparation production technology through the processes of compounding, blending and ageing, wherein the sun-scorched grain extracts are produced in the thermostatic wine cellar. The wine has unique, natural and pure aroma, has the efficacy of conditioning the stomach and treating stomach diseases and is suitable for people to drink for a long time. The thermostatic wine cellar takes various wood plates as the inner walls, can artificially provide nutrient mixtures needed for microorganisms to grow and is made by combing industrial materials. By detecting the nutrients, temperature and process data needed for the microorganisms to grow and scientifically designing the industrial mechanical brewing operation of the thermostatic wine cellar, the influence of the geographical environment to wine brewing can be overcome, and the effective rate of the components of the raw materials can be improved by more than 16%. The thermostatic wine cellar is suitable for brewing various wines and is very important to the popularization of industrial and domestic brewing of wine.

Owner:邓柏福

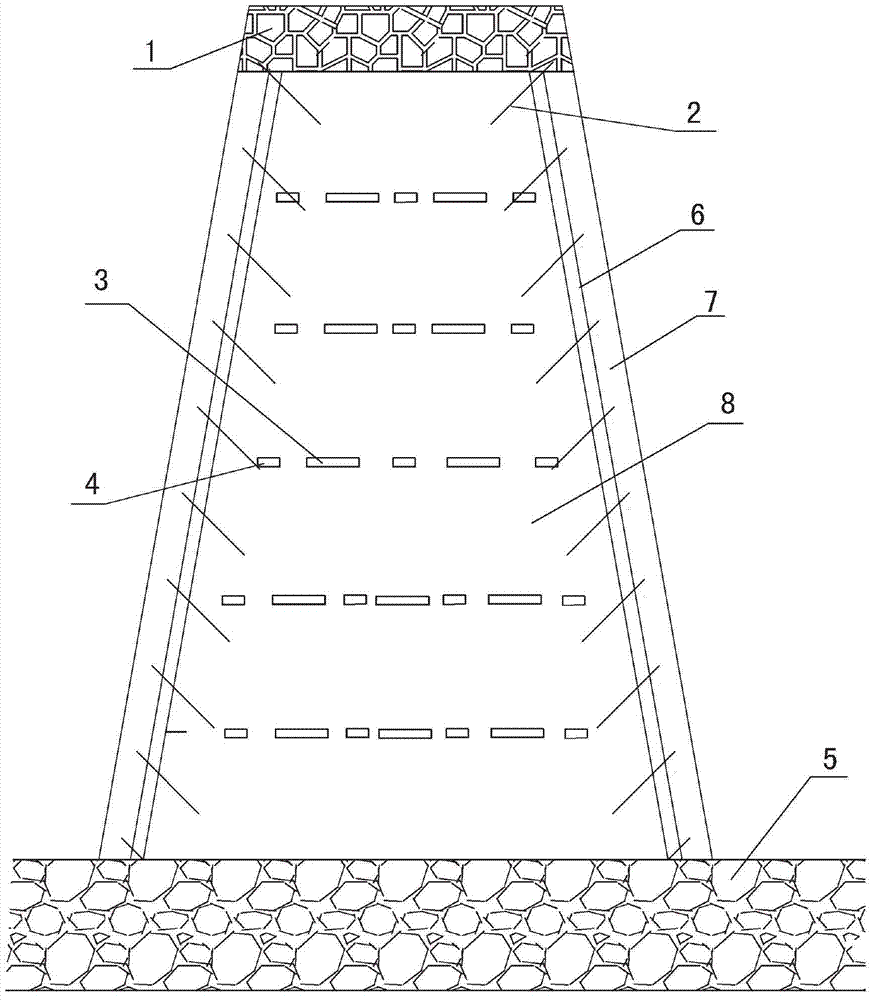

Ecologically-brewing fragrant Daqu liquor cellar

The invention discloses an ecologically-brewing fragrant Daqu liquor cellar, which is characterized in that a vertical surface of a pool of the cellar is of an inverted trapezoid shape, the width of the vertical surface is gradually reduced from top to bottom, the gradient of the wall of the pool is 70 to 120, and the cross section of the cellar pool is of a rectangular shape; one layer of bamboosheet layers which are formed by distributing bamboo bars is paved at an interval of every 25 to 35 cm from bottom to top of the cellar, and the bamboo sheet layer is used as interlayer pull bars of the cellar wall. The bamboo is selected as the pull bar of the cellar wall, so that environmental friendliness, safety and corrosion resistance are achieved, the cellar wall is not easy to fall down, and the growth of microorganisms of cellar mud and the ageing of the cellar mud can be favored.

Owner:ANHUI GUJING DISTILLERY

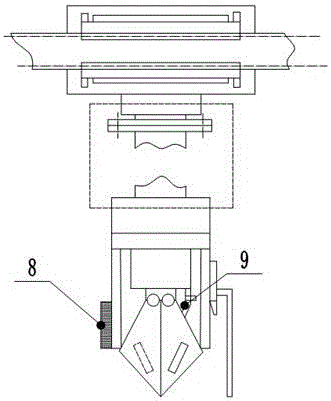

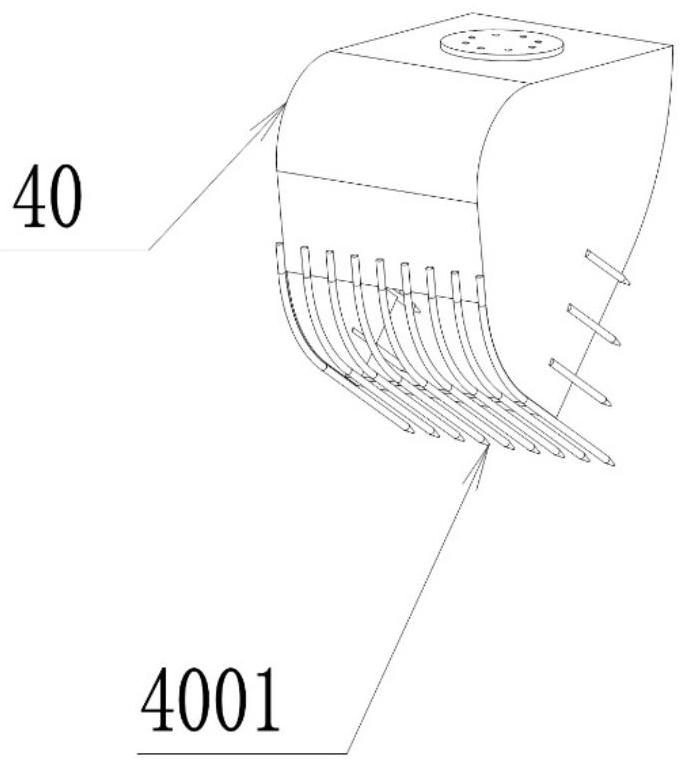

Device for rotationally discharging fermented grains out of cellar

The invention relates to mechanical cellar material output equipment in a baijiu production process, in particular to a device for rotationally discharging fermented grains out of a cellar. The device comprises a translation mechanism and a working mechanism, wherein the translation mechanism comprises an overhead travelling crane and a lifting mechanism, the upper part of the lifting mechanism is fixed on the overhead travelling crane, and the lower part of the lifting mechanism is connected with the working mechanism; the working mechanism comprises a rotary driving device, a rotary cover, a telescoping mechanism and claws, the lower end of the rotary driving device is connected with the rotary cover, and the telescoping mechanism is connected inside the rotary cover; the two claws are oppositely arranged and hinged to the lower end of the telescoping mechanism, and torsional springs for enabling the claws to be opened automatically are connected with hinged parts of the claws and the telescoping mechanism. According to the structure, one-time grabbing is adopted and assisted by rotary feeding, so that the collection efficiency of the fermented grains is greatly improved, and unloading is more convenient and faster; due to the fact that the open type claws are adopted at the collecting parts, residual fermented grains are not accumulated in the claws easily, and the cleaning is easier.

Owner:贵州古酿坊酒业(集团)有限公司

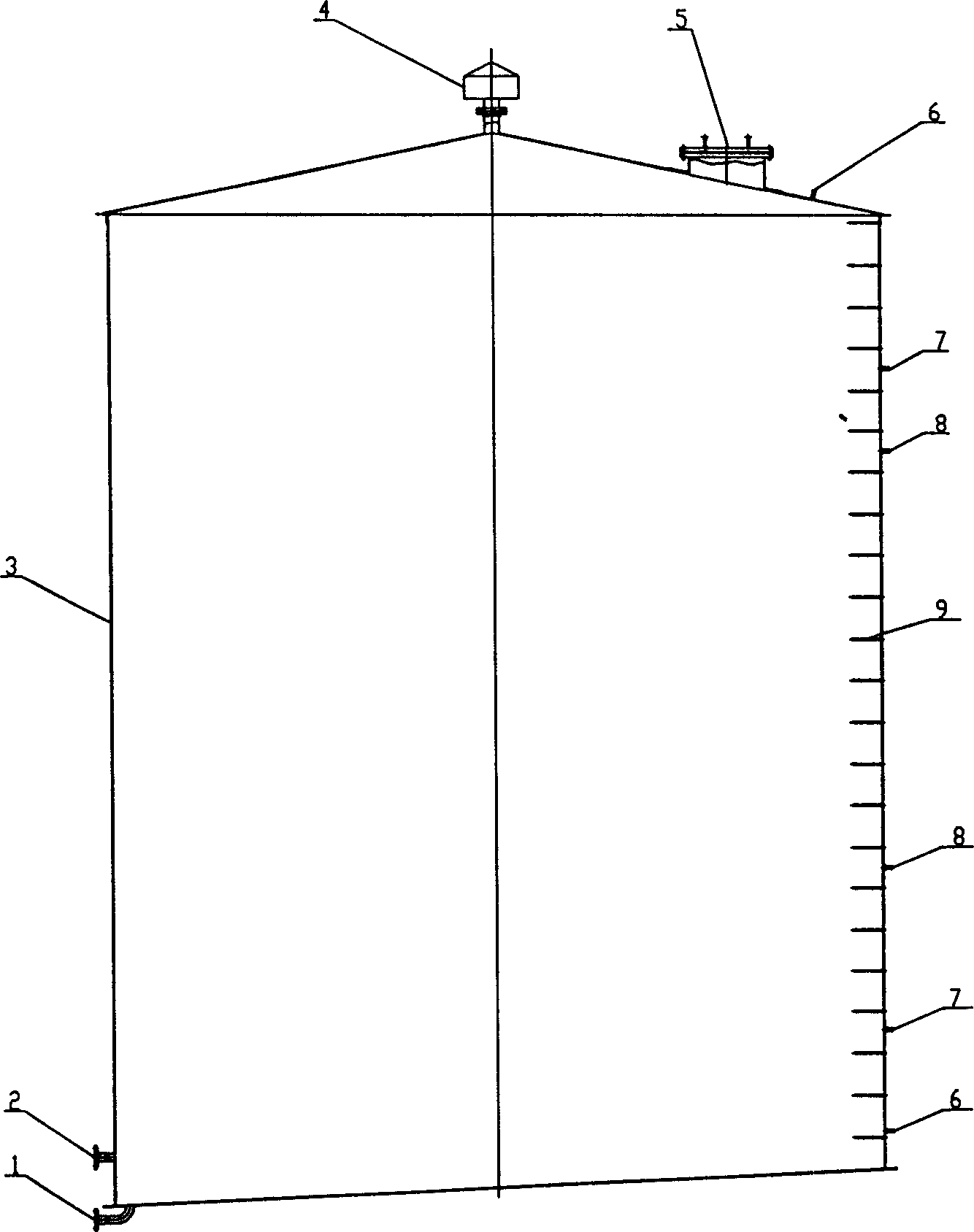

Yellow rice wine jar storage method and storage apparatus thereof

The invention is a kind of big pot storing method for rice wine and the storing devce, which refers to brewing technology of rice wine, especially refers to a kind of storing technology. The scheme of the invention is: a. processes the big pot container: cleans the pot with water and carries on sterilization and seals the apertures; at the same time carries on b. wine processing: the rice wine is carried on sterilization under 80-85 deg.C and the wine are put into container to thermal retardation for 20-30 minutes, them it is cooled to normal temperature; c. packaging: the processed wine are packaged with the big pot; d. the wine are aged: opens the ventilation value on the pot after the wine is poured into the pot, thus the air can enters the pot after it is sterilized by the filtering materials in the valve. By using the method, it can solves the problem such as large labour intensity, high consumption, high debasement rate and big occupied storage premises.

Owner:李永炎

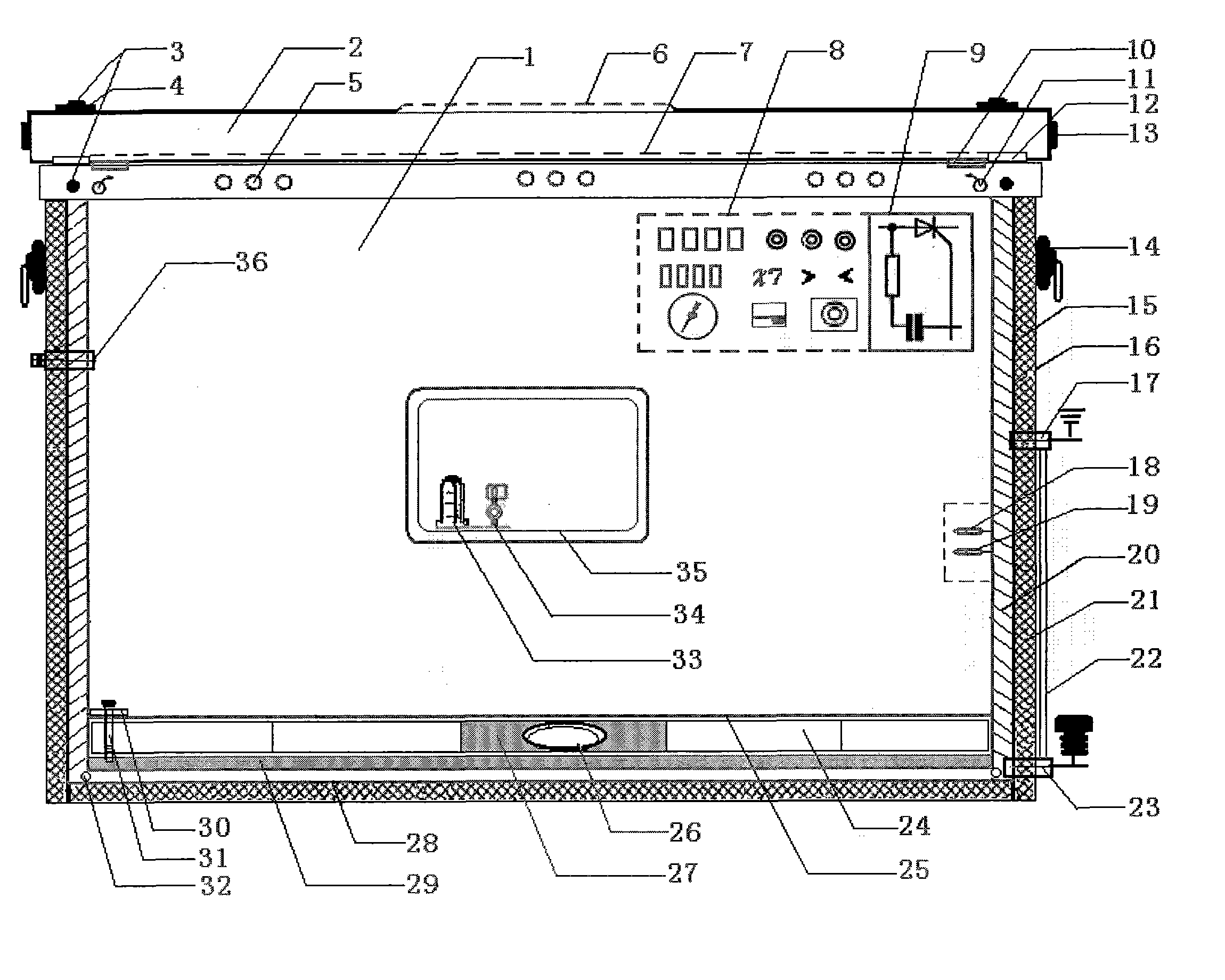

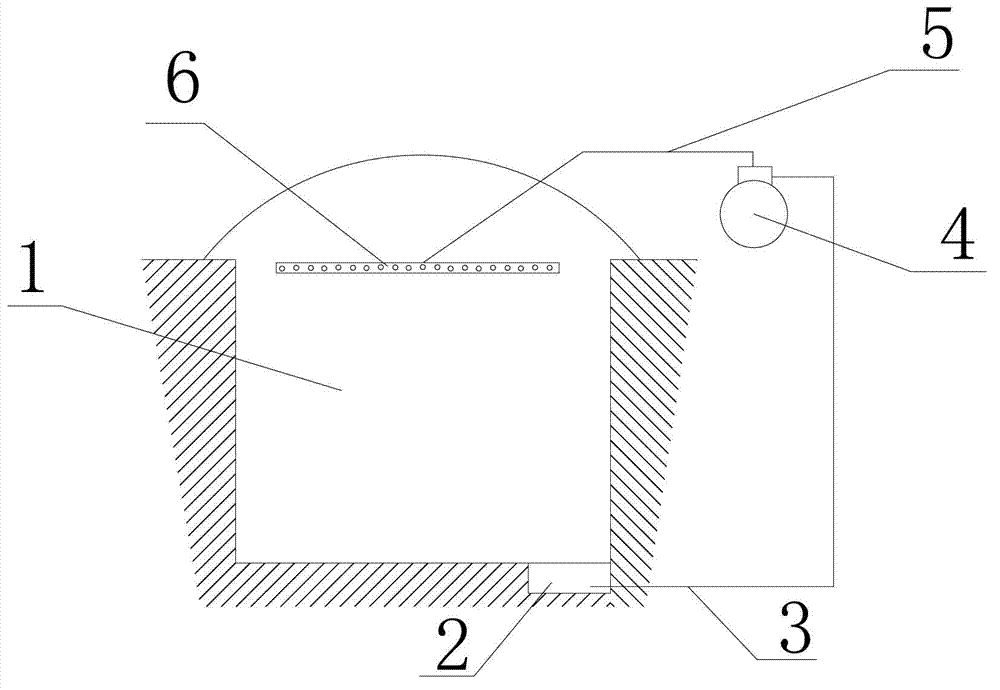

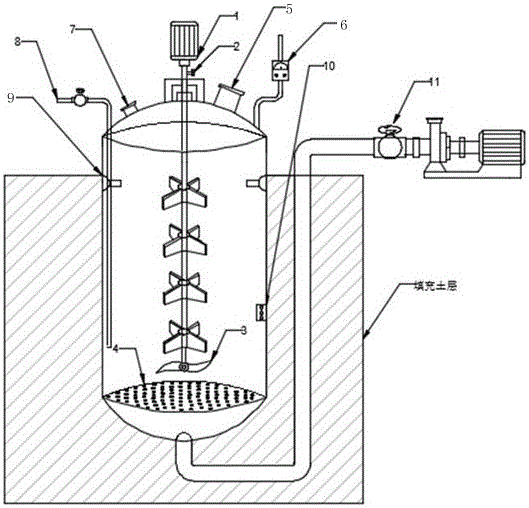

Solid fermentation device and method for white liquor

InactiveCN102776115ASolve the problem of long-term sedimentation pit bottomImprove wine qualityAlcoholic beverage preparationCellar toolsWhite liquorWater flow

The invention discloses a white liquor making device, in particular to a solid fermentation device for white liquor. The solid fermentation device for white liquor keeps quality of fermented grains at all positions in a cellar uniform and comprises a cellar, a water pump, a dropper drainer, a water inlet guide pipe and a water outlet guide pipe. A yellow water pit is arranged at the bottom of the cellar. The dropper drainer is disposed at the top of the cellar. Two ends of the water inlet guide pipe are communicated with the yellow water pit and an inlet of the water pump respectively. Two ends of the water outlet guide pipe are communicated with the dropper drainer and an outlet of the water pump respectively. In late fermentation of the fermented grains, the yellow water pit is used to collect yellow water generated in fermentation, the water pump is used to continuously pump the yellow water in the cellar from the bottom to the top, the problem that the yellow water accumulates at the bottom of the cellar for a long period of time is solved, the yellow water flows cyclically and dynamically, quality difference of the fermented grains above and below the level of the yellow water in the cellar is avoided effectively, and the quality of the whole fermented grains in the cellar is uniformized.

Owner:LUZHOU PINCHUANG TECH CO LTD

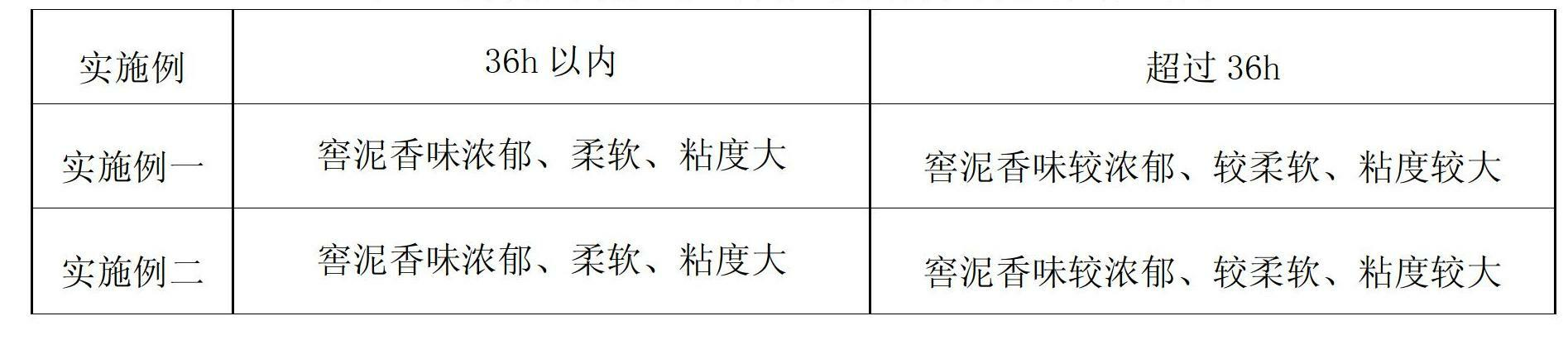

Method for curing after opening of thick white liquor pit

The invention discloses a method for curing after opening of a thick white liquor pit, belonging to the technical field of brewing. Due to the adoption of the method, mixed bacteria can be prevented from polluting the pit, and the quality of the pit can be kept effectively. The method comprises the following steps of: a, curing by adopting the following measure within 36 hours after pit opening: opening the pit, and covering the pit with a material with sealing performance in time; and uniformly spraying tail water of 20-35 DEG C onto pit walls and the pit bottom every 1-6 hours, wherein the using amount of tail water applied to the pit walls and pit bottom in every square meter is 2-4 kilograms; and b, curing by adopting the following measure within 36 hours after pit opening: uniformly spraying tail water of 20-35 DEG C onto pit walls and the pit bottom every 1-6 hours, wherein the using amount of tail water applied to the pit walls and pit bottom in every square meter is 2-4 kilograms; and uniformly spraying daqu-containing tail water of 20-35 DEG C onto pit walls and the pit bottom every 8-12 hours, wherein the using amount of tail water applied to the pit walls and pit bottomin every square meter is 2-4 kilograms; and the using amount of the daqu is 0.1-0.3 kilogram. The method can be used for effectively curing a thick white liquor pit.

Owner:LUZHOU PINCHUANG TECH CO LTD

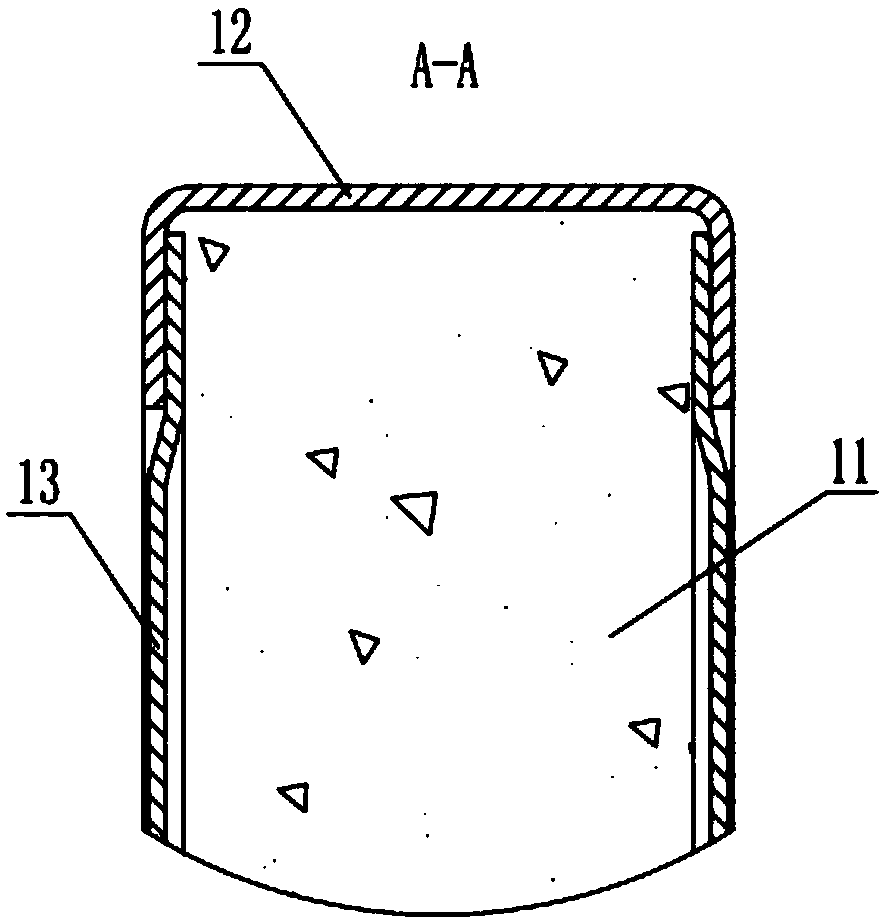

Three-dimensional fermentation pit sealed fermentation device and pit sealing method

ActiveCN104877863AIncrease heightGuaranteed contact areaAlcoholic beverage preparationCellar toolsAgricultural engineeringFermentation

The invention discloses a wine making device and particular provides a three-dimensional fermentation pit sealed fermentation device for improving the utilization rate of a white spirit fermentation pit. The three-dimensional fermentation pit sealed fermentation device comprises a fermentation pit cover, wherein the fermentation pit cover comprises a cover top and a lower box body provided with an inner cavity, the cover top is arranged on a top opening of the lower box body. The three-dimensional fermentation pit sealed fermentation device further comprises a fermentation mud plate, wherein the fermentation mud plate is arranged in the lower box body and is hollow, the hollow portion of the fermentation mud plate is a fermentation mud storage space, and through holes communicated with the fermentation mud storage space are formed in the outer wall of the fermentation mud plate. The three-dimensional fermentation pit sealed fermentation device adopts the fermentation mud plate, and the fermentation mud storage space of the fermentation mud plate can be filled with fermentation mud, so that upper-layer fermented grains located in the fermentation pit cover can be in contact with fermentation mud in the fermentation mud plate so as to obtain the fermentation effect the same as the effect of lower-layer fermented grains, the contact area of the upper-layer fermented grains and the fermentation mud and the sealing performance of fermentation are ensured while the height of the fermentation pit cover is increased, and accordingly normal fermentation is ensured.

Owner:LUZHOU PINCHUANG TECH CO LTD

Method for fermenting rice wine with cellar

InactiveCN103849546AIncrease production capacityReduce energy consumptionCellar toolsAir exchangeBiology

The invention provides a method for fermenting rice wine with a cellar. According to the method, an underground cellar, ventilating windows and a feed opening are provided. The method is characterized in that the cellar is about 300cm in depth underground and 100cm in depth aboveground; a capping is of a plane concrete pouring structure; the feed opening being 30cm in diameter is preset in the middle; 50*100 (cm) air exchange windows are arranged at every 150cm about the aboveground part; the windows are 20cm away from the ground; the aboveground part of the cellar is subjected to waterproof treatment in 10cm; the walls of the cellar, below the windows, are also subjected to waterproof treatment. When in use, a fermenting vat or tank is positioned in the underground fermenting cellar, then fermented mash is added to ferment, and thus the production can be carried out at all seasons. With the adoption of the method, the problem that, the fermenting of a rice enterprise is difficult to control due to the weather influence in winter, and the rice enterprise cannot do any production, can be solved; the rice wine can be fermented all the year round, and thus at least 30% of output of rice wine can be raised; in addition, the energy consumptions due to lowering down the temperature in summary and raising temperature in winter is saved, and 10% energy can be saved from this part each year.

Owner:青岛九盛酒业有限公司

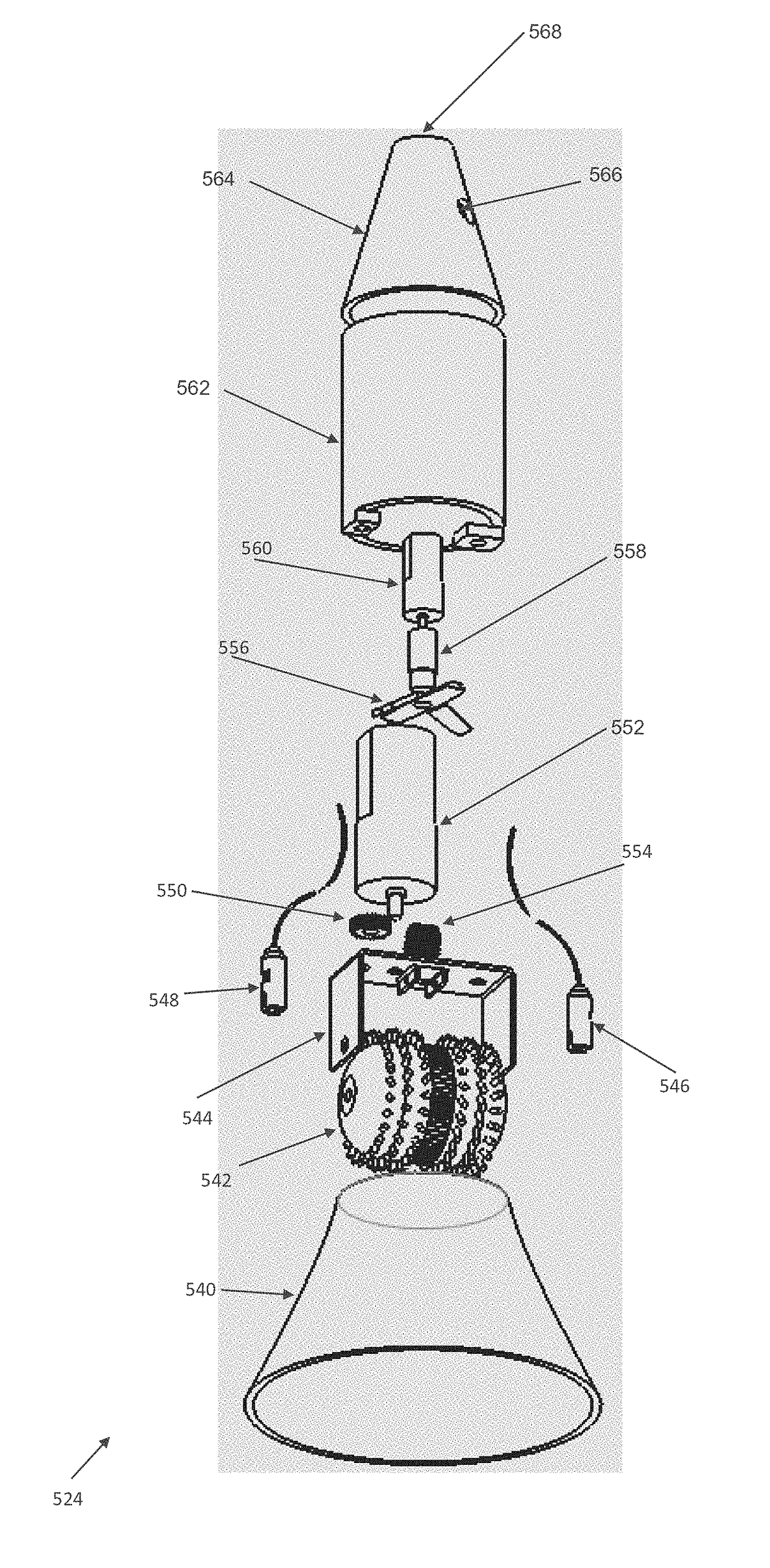

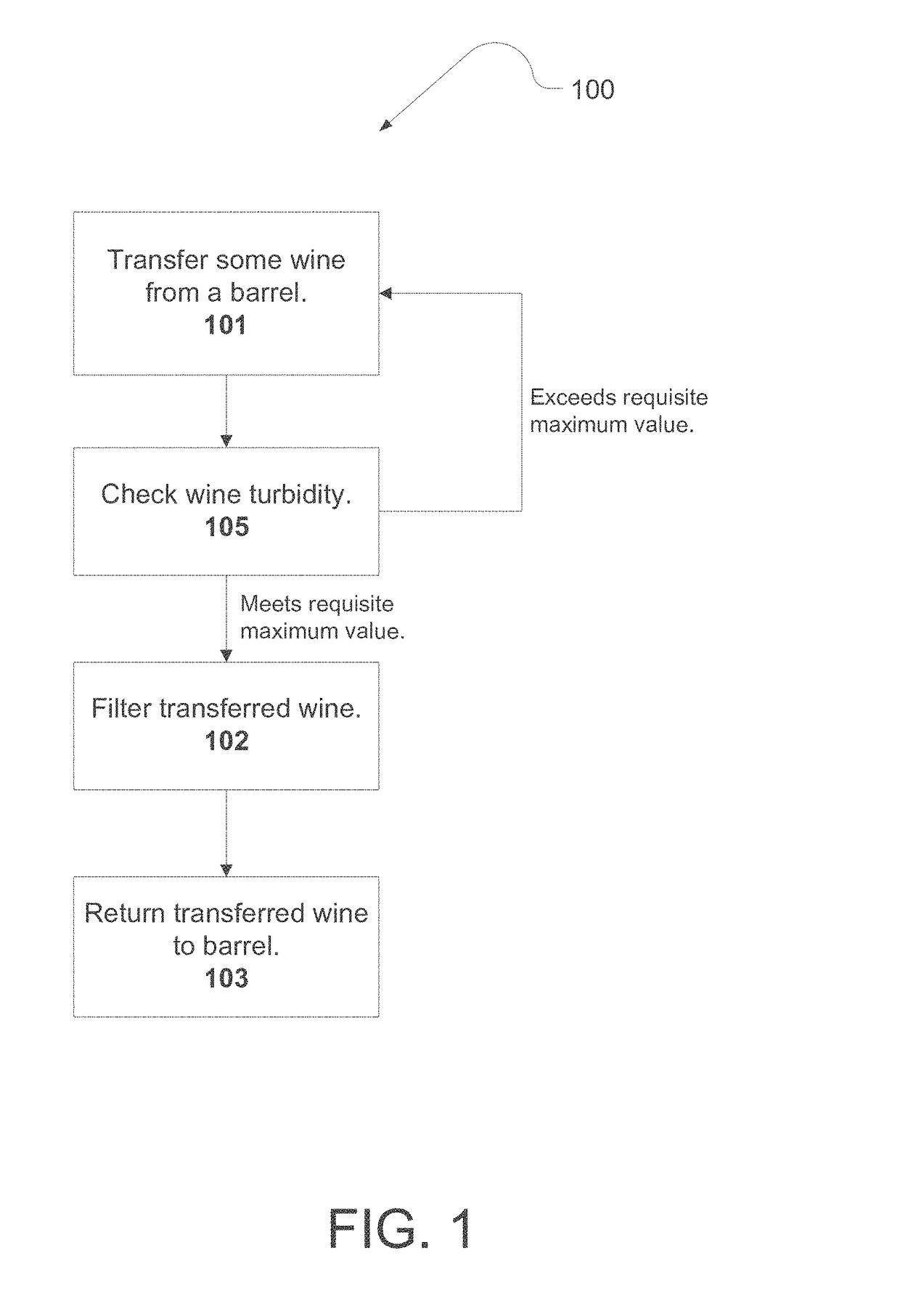

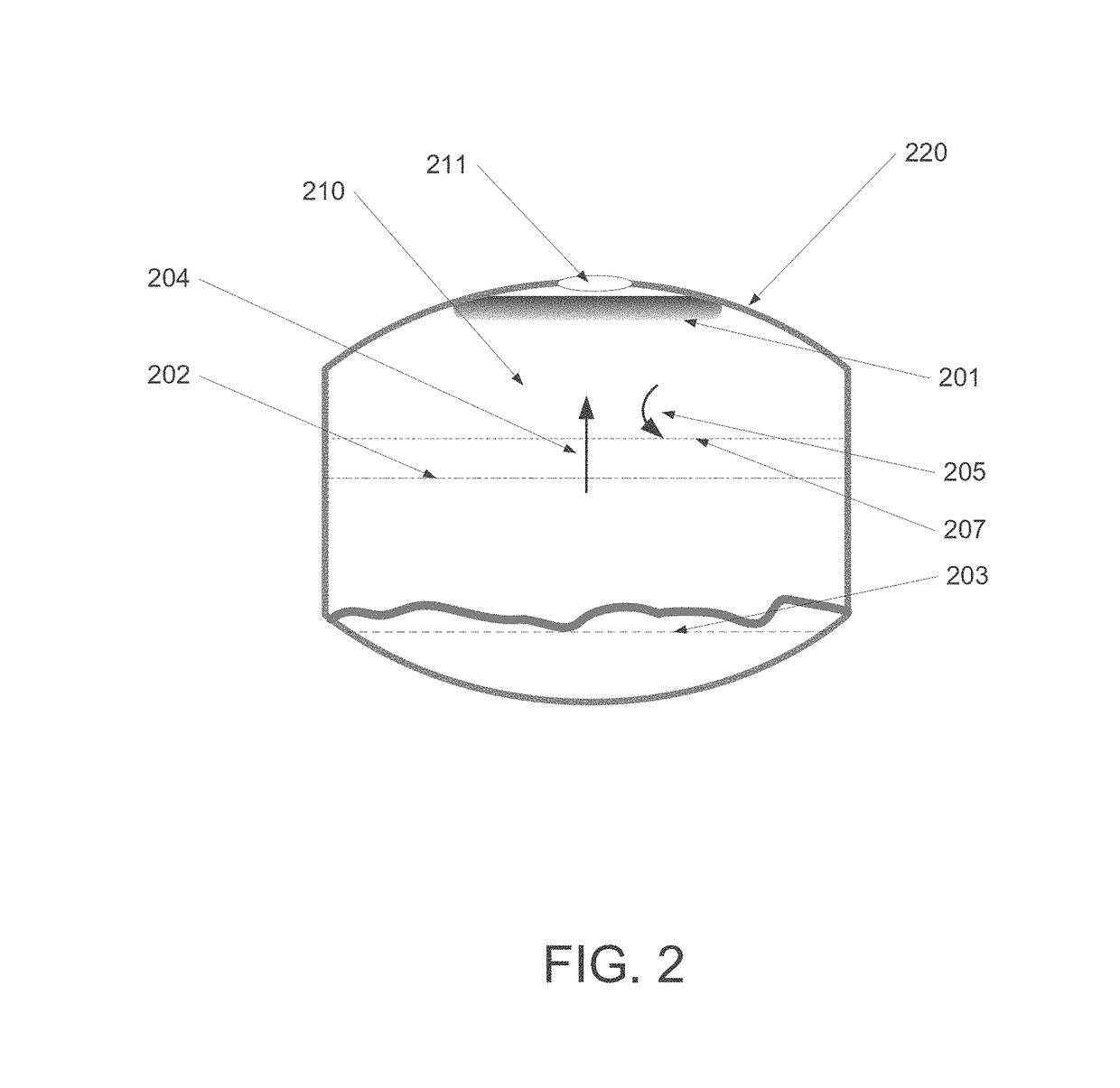

System and method for cleaning wine and/or a barrel containing wine

There is disclosed a system and method for processing wine and / or a containing barrel, while keeping a volume of most of the wine in the barrel. The disclosed system and method can provide reduced mixing of different layers of wine in the barrel. An optional scrubbing mechanism cleans an interior surface of the barrel from encrusted matter, and an optional UV sterilization light source sanitizes an interior surface of the barrel that is alongside a cavity in the barrel empty of wine. In some embodiments a pumping and filtering system preserves non-mixing flow of wine in the barrel while effectively filtering wine optionally without the use of a filter cartridge or other interposing medium.

Owner:ARIEL UNIV RES & DEV

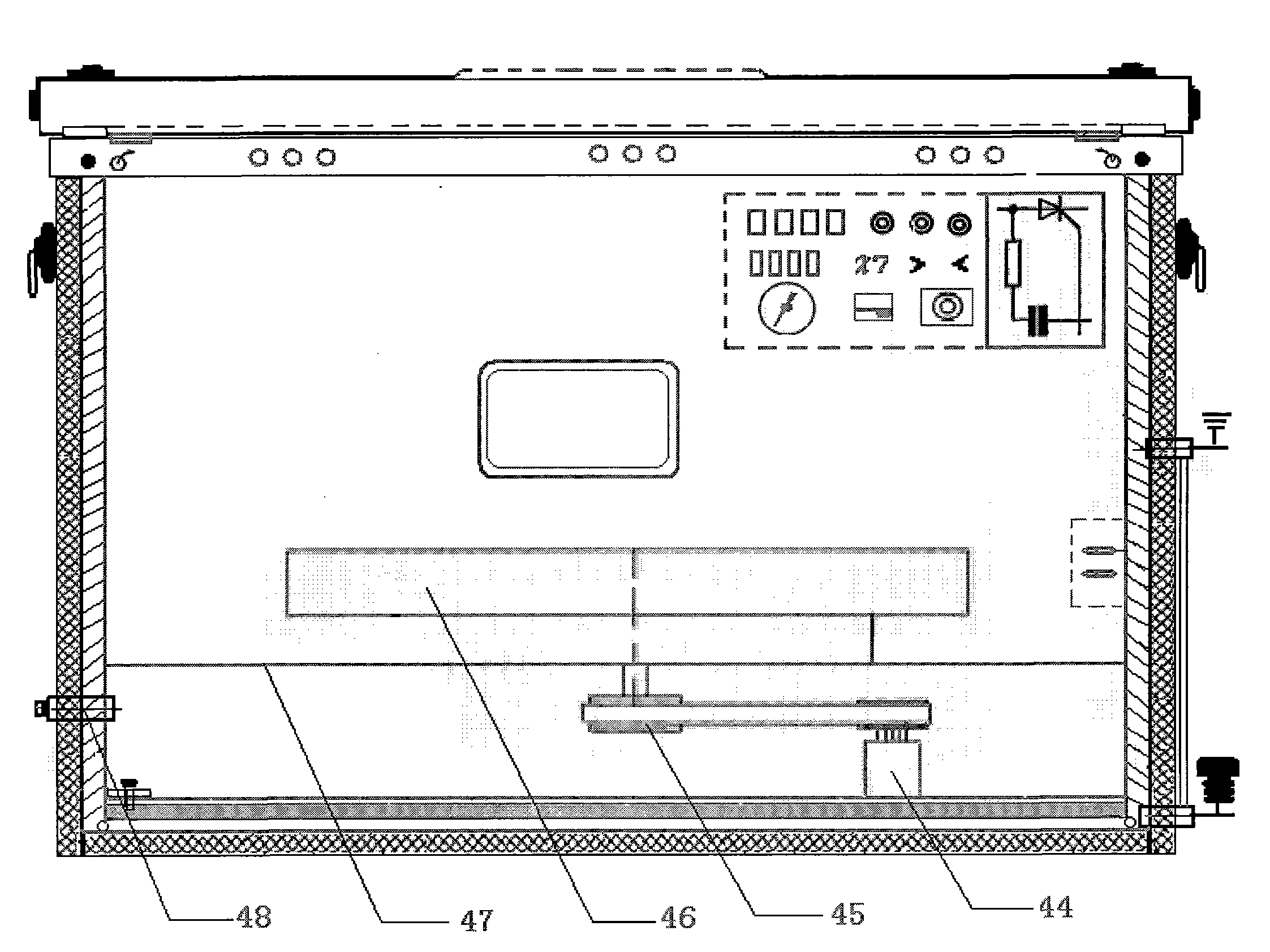

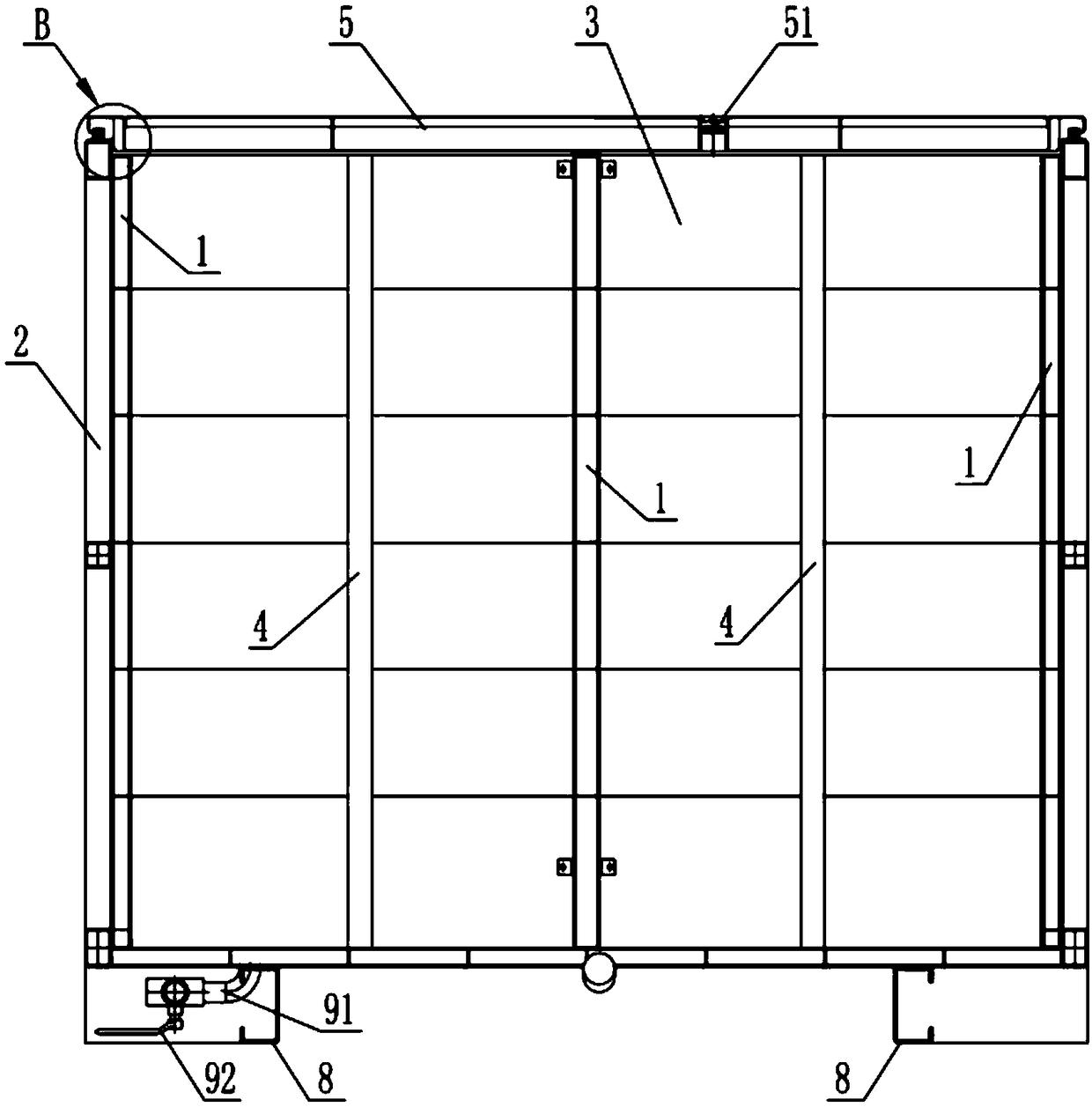

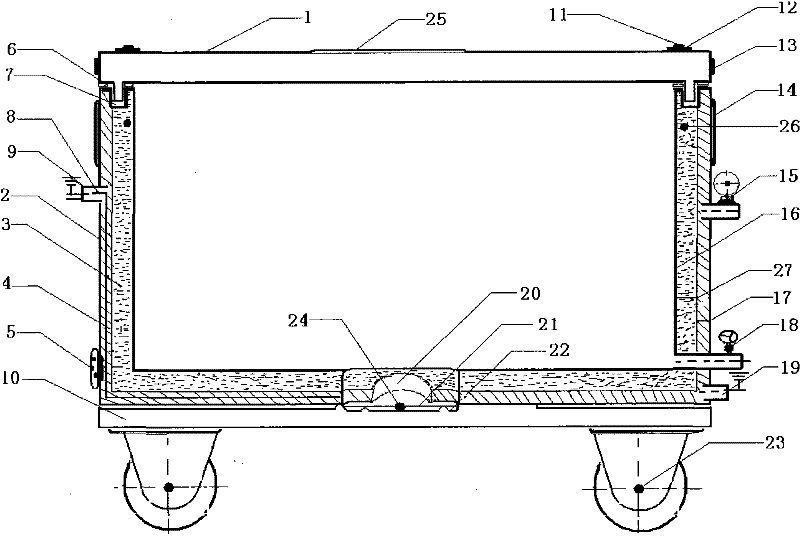

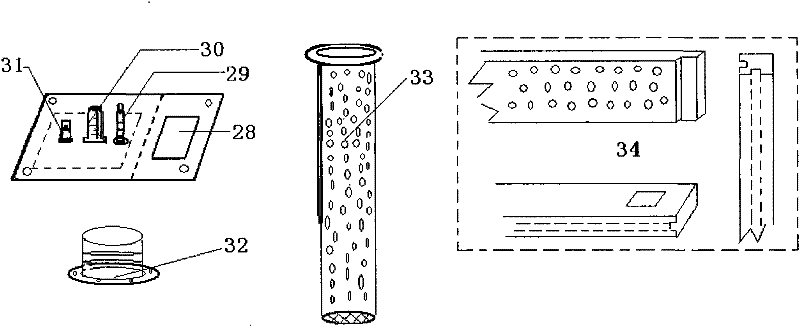

Movable cellar for making baijiu and cellar clay plate components

The invention discloses a movable cellar for making baijiu, belongs to the field of wine making equipment, and provides an independent movable cellar and cellar clay plate components applied to the independent movable cellar. The movable cellar comprises the detachable cellar clay plate components which can be used for making strong-flavor baijiu and aromatic-flavor baijiu respectively. The movable cellar has the advantages that the movable cellar can move integrally, so that baijiu can be put into the cellar, taken out from the cellar and fermenting tanks can be transferred and the like in amanner of mechanized operation, and the movable cellar is suitable for mass production; multiple movable cellars can be stacked layer by layer, the floor space of the movable cellar can be reduced effectively, the limitation of conventional workshop space can be broken through, and the three-dimensional layout of cellars in workshops can be realized; in addition, the cellar clay plate components can be mounted selectively according to different production needs of the strong-flavor baijiu and the aromatic-flavor baijiu to achieve switching, different container devices are not needed, and the equipment costs for producing the strong-flavor baijiu and the aromatic-flavor baijiu are reduced effectively.

Owner:LUZHOU PINCHUANG TECH CO LTD

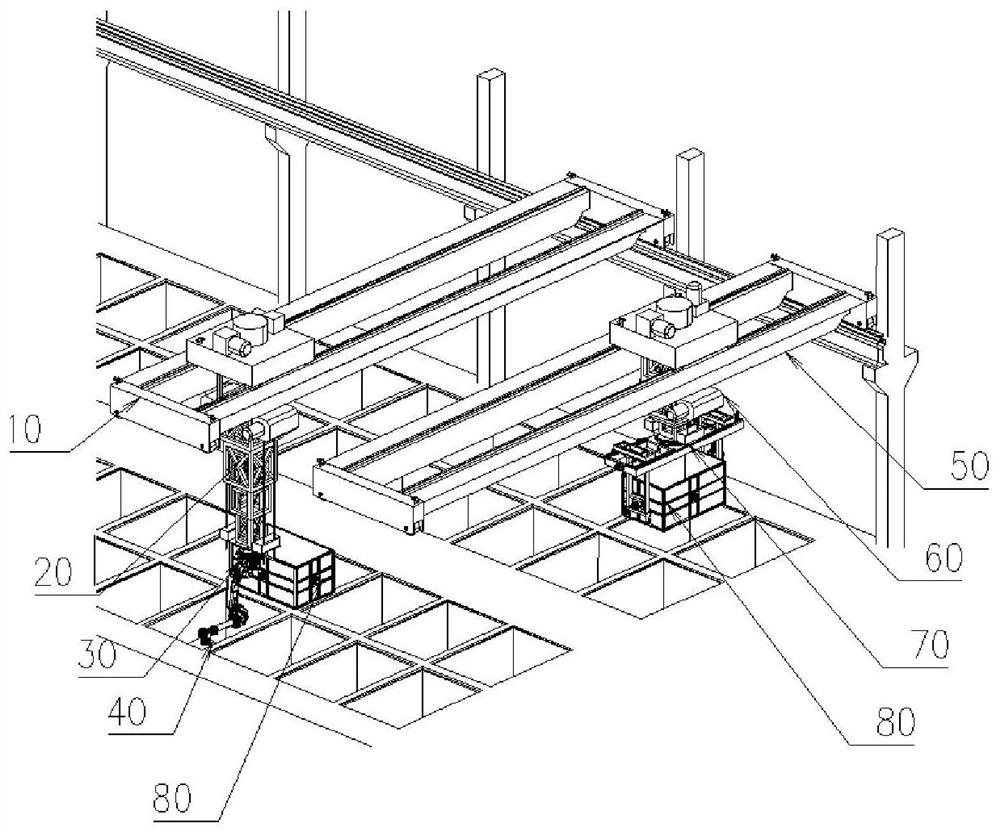

Automatic vinasse pit discharging and feeding device

PendingCN111620233AReduce resistanceEasy to cleanCellar toolsTravelling cranesControl engineeringVinasse

The invention provides an automatic vinasse pit discharging and feeding device. The device comprises a first crane and a second crane arranged on a pit, wherein a first lifting mechanism and a secondlifting mechanism are separately arranged on the first crane and the second crane. A bucket controlled by a robot is arranged at the tail end of the first lifting mechanism, an automatic overturning and hoisting device is arranged at the tail end of the second lifting mechanism, stroke positioning mechanisms are further arranged on the first crane and the second crane, height positioning mechanisms are further arranged on the first lifting mechanism and the second lifting mechanism, and an anti-falling mechanism matched with a stock bin is arranged on the automatic overturning and hoisting device. The device can achieve automatic pit discharging and feeding without artificial operations, and can be controlled automatically, so that the labor cost is saved and the production efficiency is improved. The automatic vinasse pit discharging and feeding device can achieve unmanned pit discharging and feeding operations.

Owner:百特(福建)智能装备科技有限公司

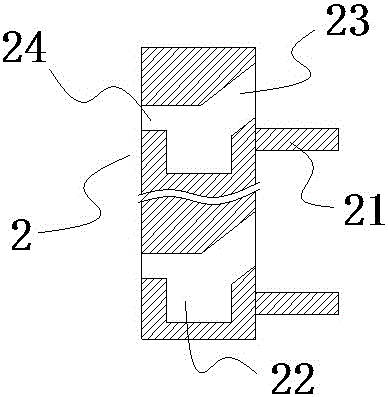

Luzhou-flavor baijiu fermentation pit and building method thereof

InactiveCN105695299AImprove qualityGuaranteed qualityCellar toolsBuilding material handlingBrickStructural engineering

The invention aims at providing a Luzhou-flavor baijiu fermentation pit and a building method thereof. The Luzhou-flavor baijiu fermentation pit can reduce damage to pit mud in vinasse discharging, and thus the stability of the brewing function of the pit and the quality of base liquor can be improved. According to the specific structure of the Luzhou-flavor baijiu fermentation pit, hard ground bricks are laid at the pit bottom of the pit, hard wall bricks are fixed to the pit wall of the pit, and both the ground bricks and the wall bricks are fried with pit mud; the ground bricks are evenly provided with top-open dents; cavities are formed in the wall bricks, and the upper portions of the cavities are provided with openings facing the middle of the pit; pit mud is contained in the dents and the cavities; the portions, beside the dents, of the ground bricks are provided with ground brick air holes communicated with the pit bottom; the portions, above the cavities, of the wall bricks are provided with wall brick air holes communicated with the pit wall, the bottom ends of the wall brick air holes are communicated with the tops of the cavities, and the wall brick air holes incline towards the pit wall gradually from bottom to top.

Owner:周琦

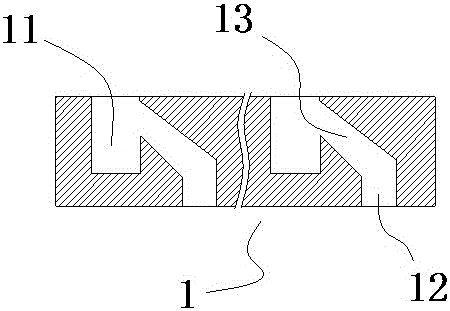

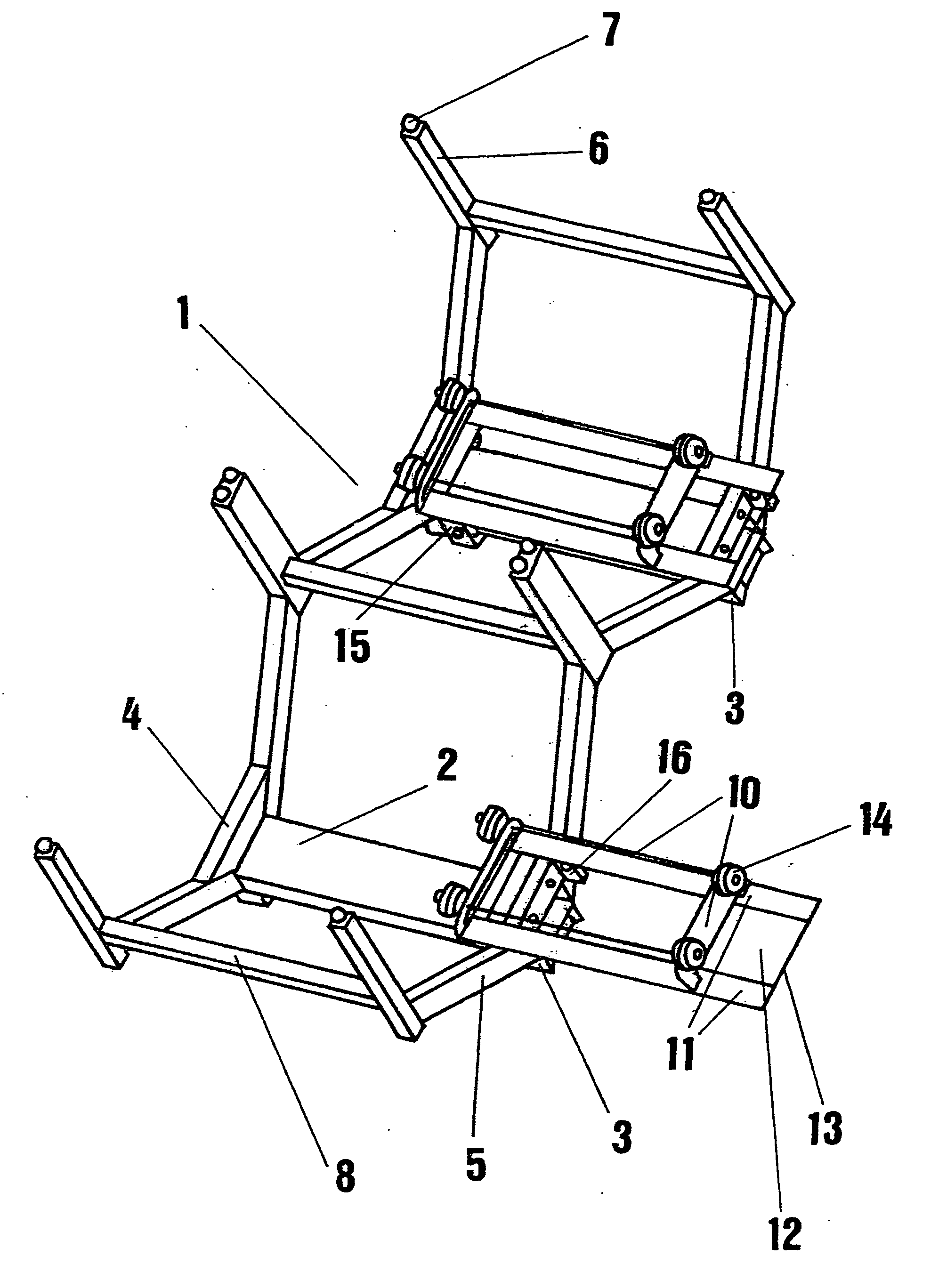

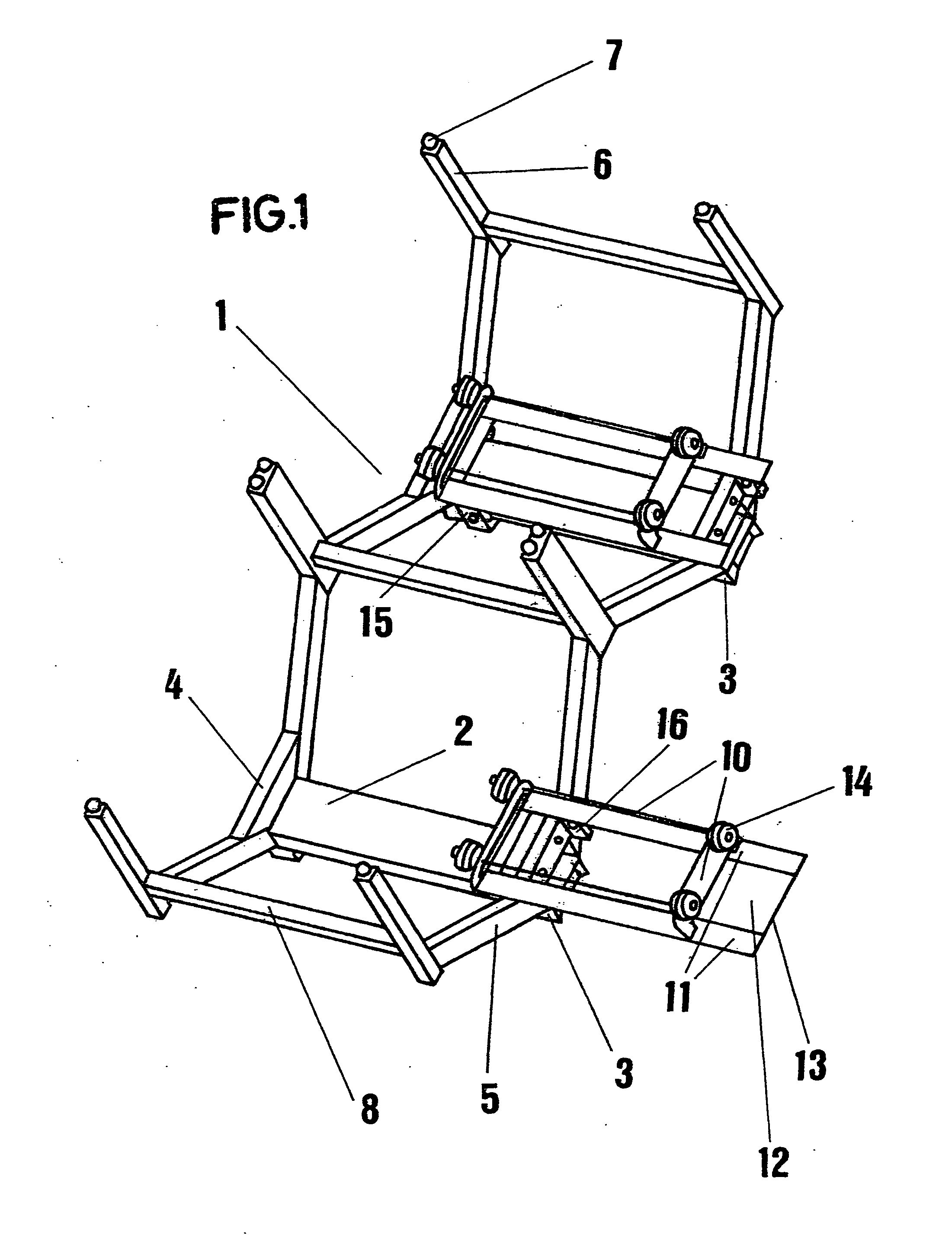

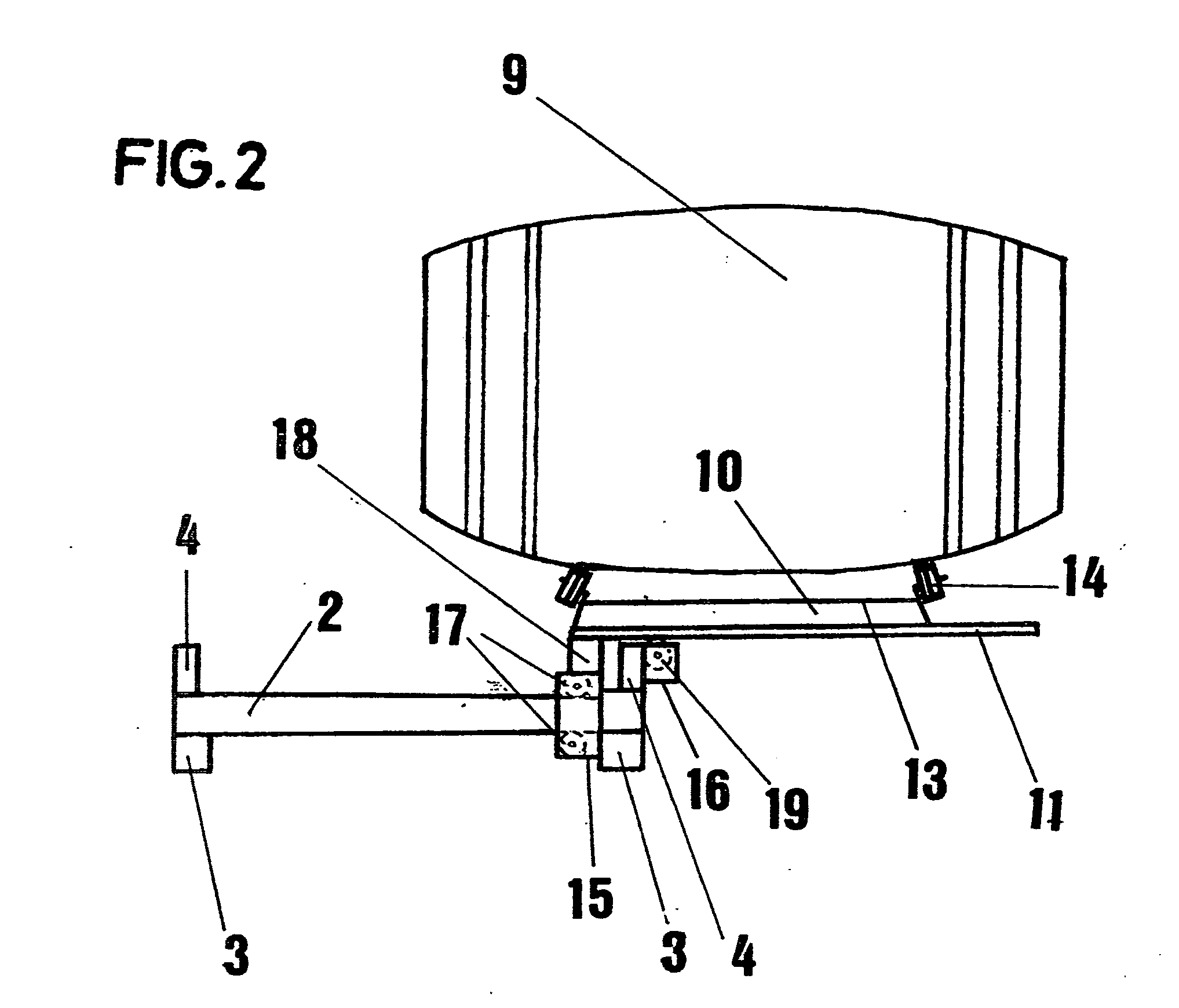

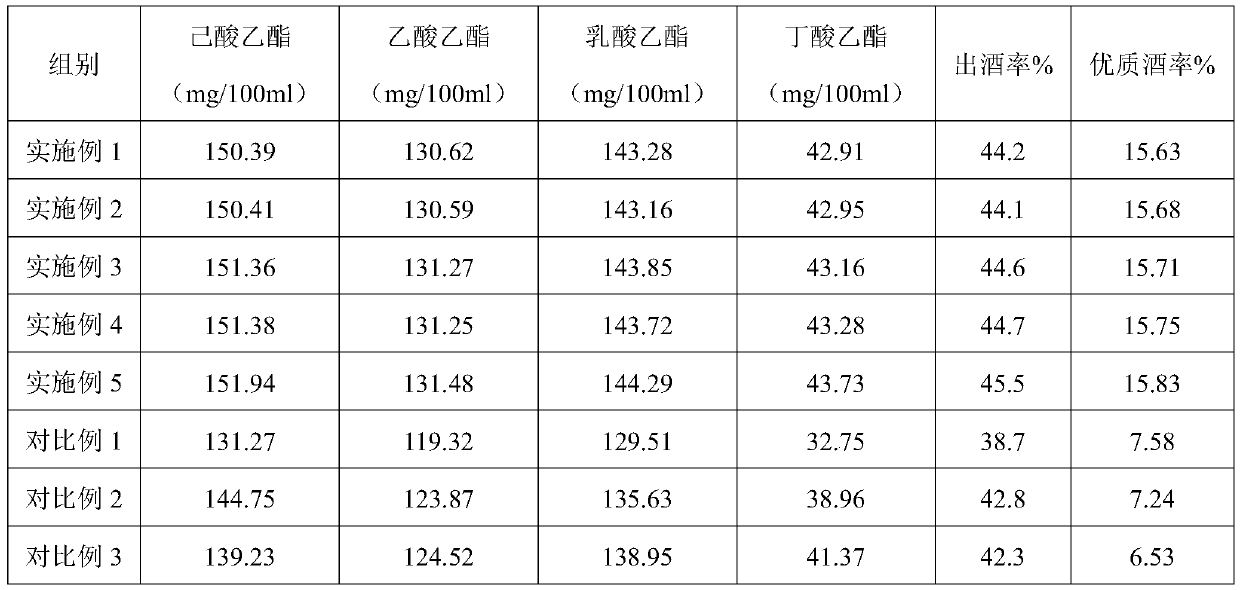

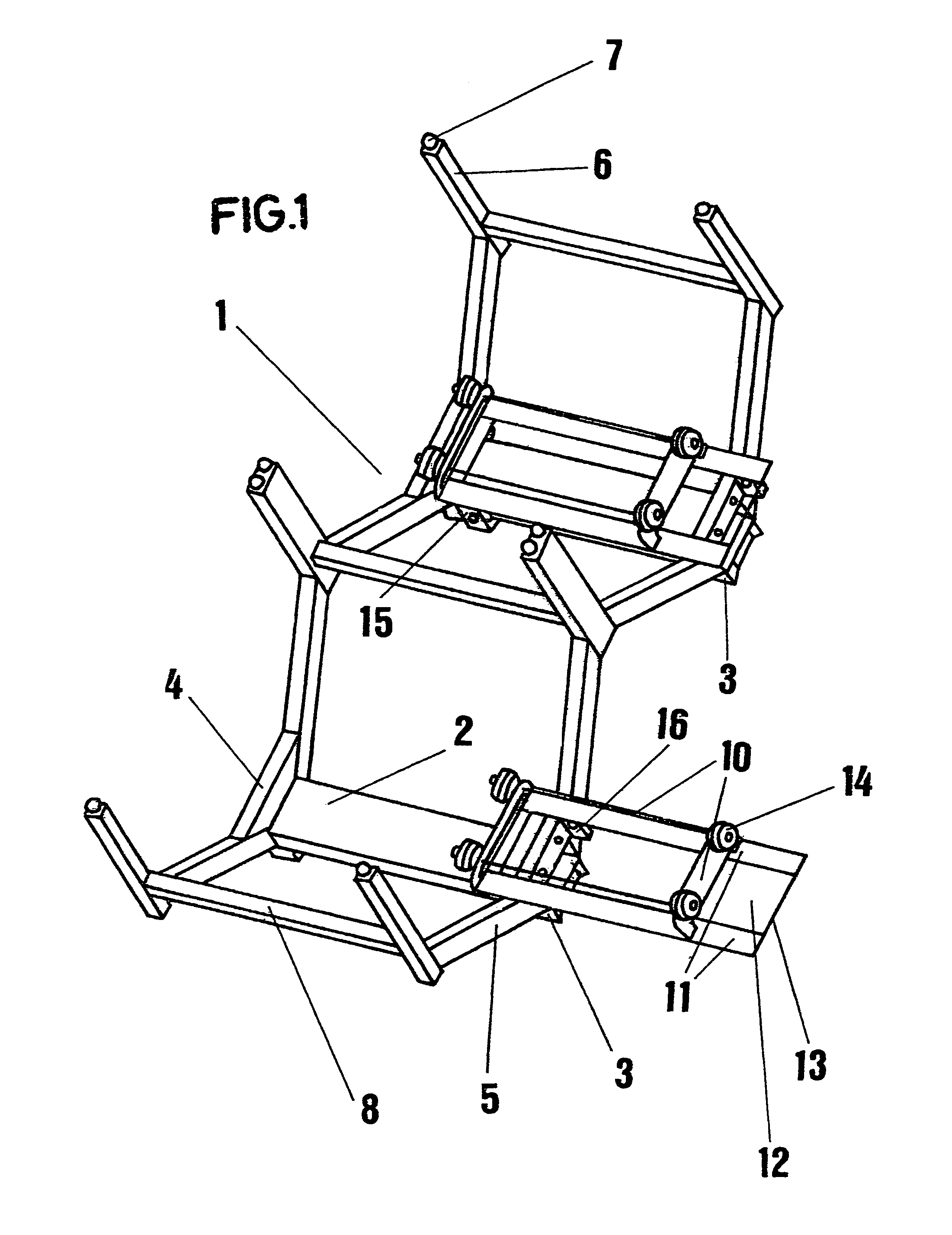

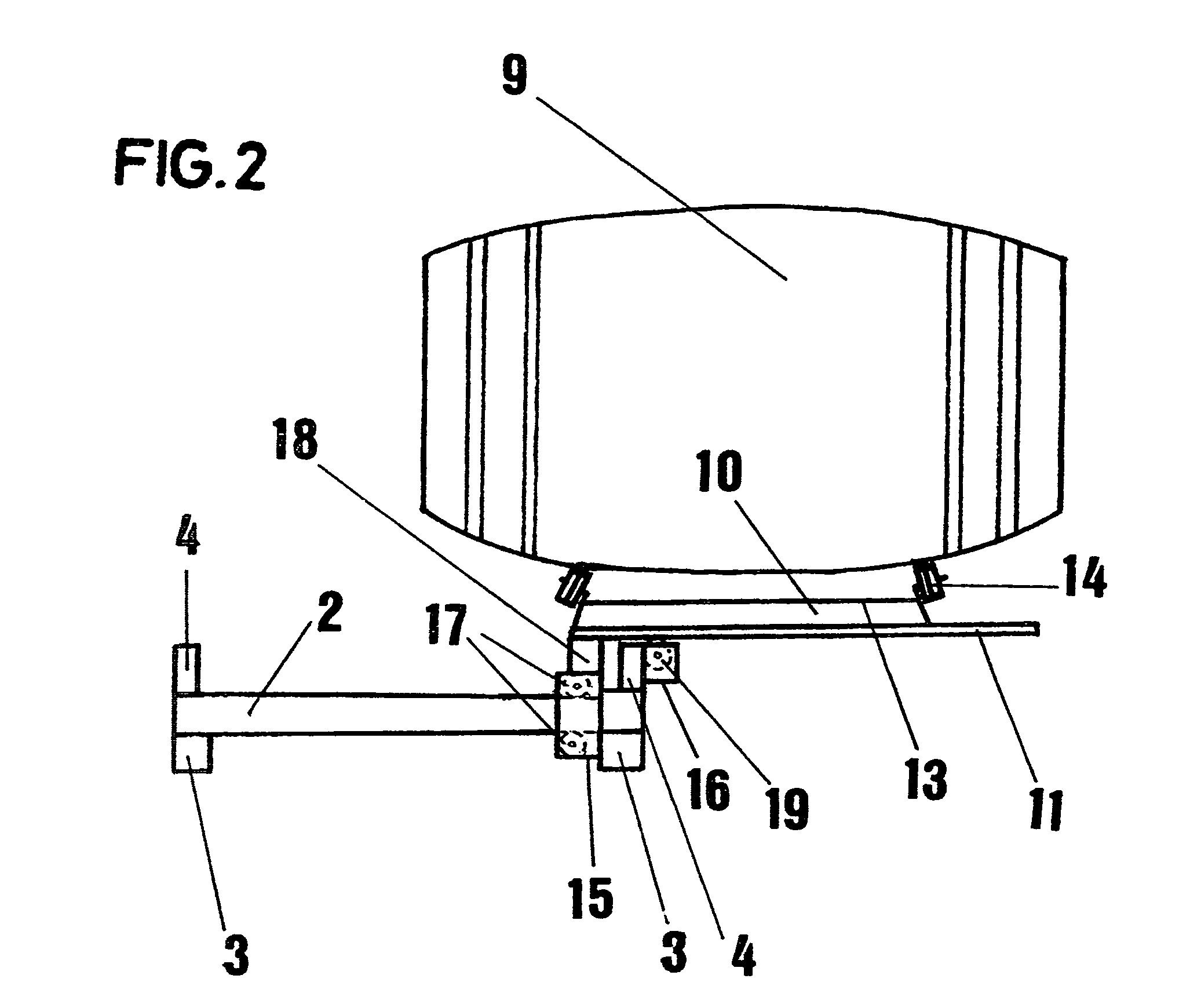

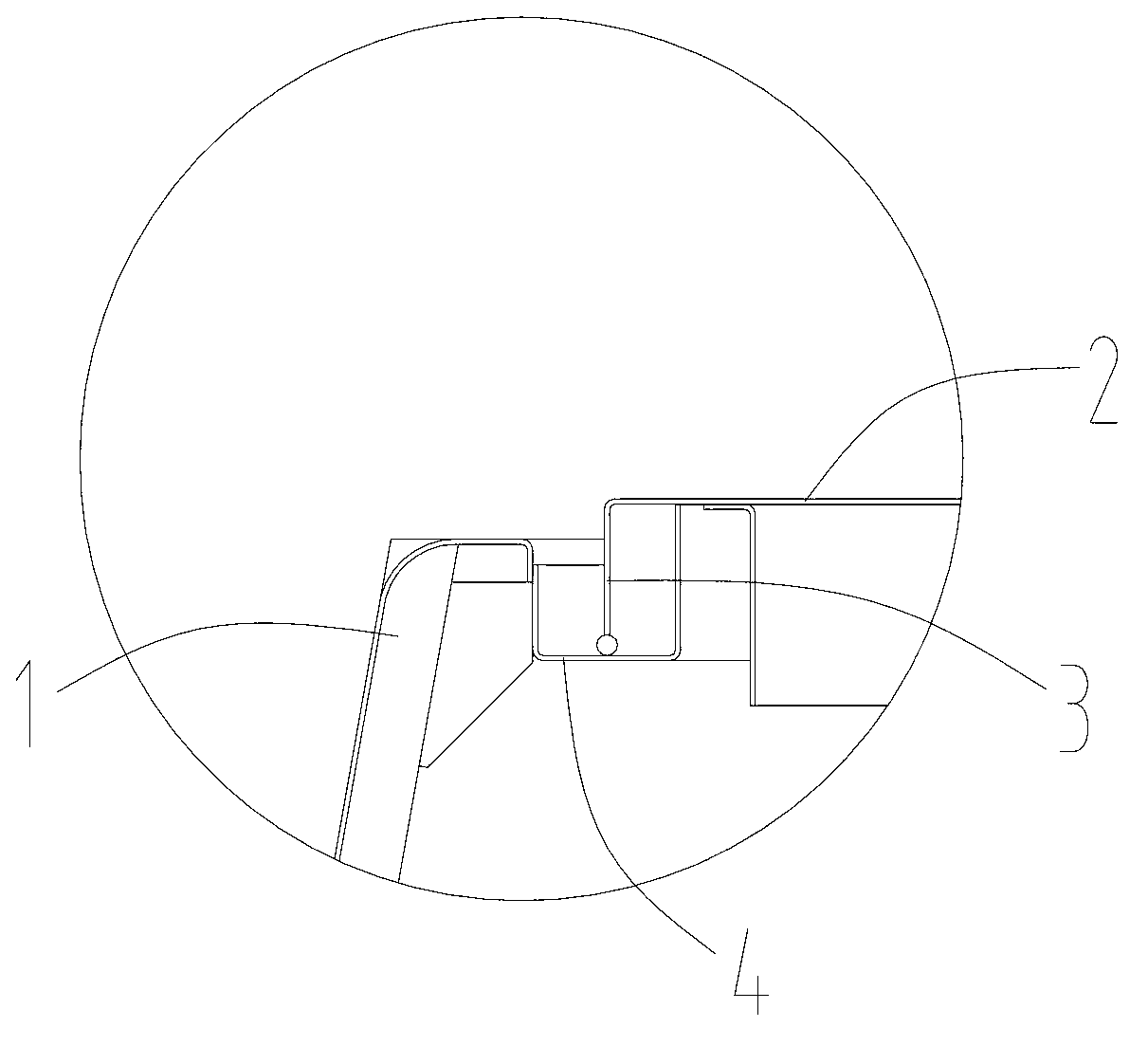

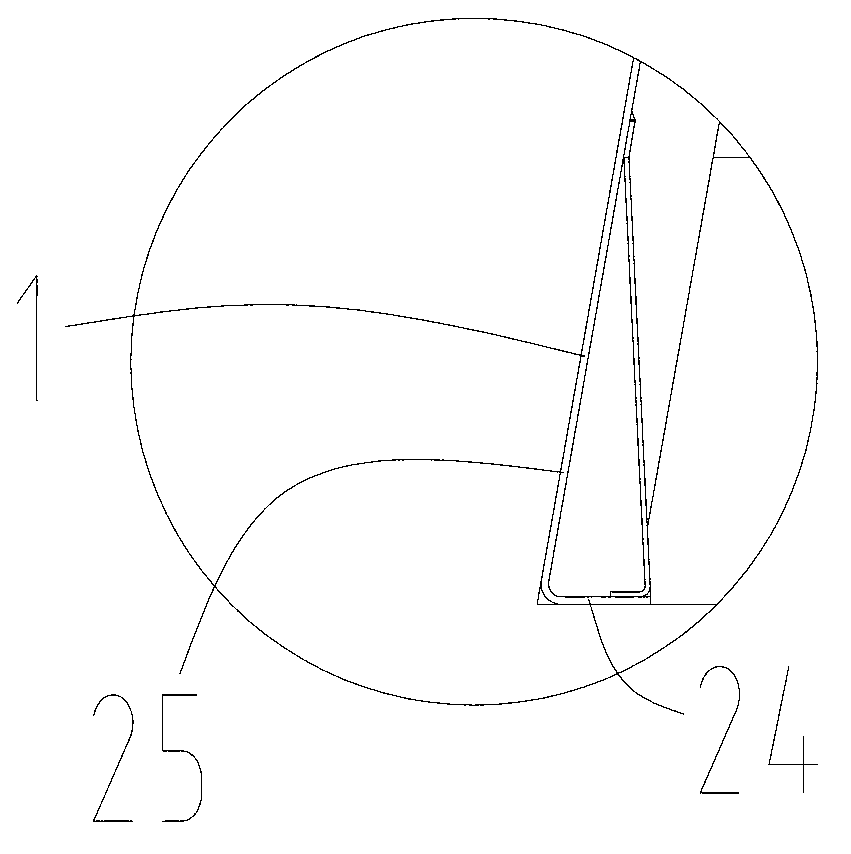

Cask support

A cask support allows housing two casks (9) therein (1), such that the casks (9) will be arranged in a staggered manner when multiple supports are stacked together. Each support (1) includes two bedplates (2) with a seating for housing a cask (9). A carriage (10) formed by a rectangular platform is mounted to the framework of the support (1) with two brackets (15) with wheels (17) fixed to the carriage (10) which can move along each bedplate (2), and two other brackets (16) with wheels (19) fixed to the support and on which the platform of the carriage (10) slides. The carriage (10) has freedom of movement parallel to the bedplate (2). Each cask (9) rests on four rotating wheels (14) which are disposed on the vertices of the framework of the carriage (10). The cask support is especially applicable in large wine aging cellars.

Owner:SAGARTE

Method for maintaining pit of highly flavored type yeast wine

The invention discloses a method for maintaining a pit of highly flavored type yeast wine. The method is characterized in that after fermented grain fermentation is finished and pit discharging is finished, medium-high temperature yeast, high-temperature pit mud and after-run are laid at the bottom of a pit after being fermented according to the situation of the pit in a sealed mode, and large cultivation on the bottom of the pit is finished; or the bottom of the pit is drilled through a fork, high-temperature yeast powder is evenly scattered in holes, and small cultivation on the bottom of the pit is finished; during large cultivation or small cultivation, the after-run is sprayed to the wall of the pit, and the wall of the pit is maintained. According to the method, the physicochemical property of the pit mud can be improved, and the phenomena of hardening and crystallizing between the wall of the pit and a pit floor of the pit disappear after cultivation; the pit mud is soft, fine, smooth, blue dark and glossy, the fragrance is strong and pure, and ammoniacal odor and other foreign flavor are avoided.

Owner:ANHUI GUJING DISTILLERY +1

Method for manufacturing baijiu by cellar-in-cellar fermentation

InactiveCN110042026AReduce the amount of feedPure bouquetAlcoholic beverage preparationCellar toolsPolygonum fagopyrumSorghum

The present invention belongs to the technical field of baijiu brewing and provides a method for manufacturing baijiu by cellar-in-cellar fermentation. The method comprises the following steps: S1, raw materials are pretreated: raw materials are weighed, the weighed raw materials are mixed, a mixture is crushed, water is added for soaking to obtain a wet mixture, the wet mixture is boiled, and cooling and air-drying are conducted to obtain brewed grains; and the raw materials are composed of the following components in parts by weight: 23-50 parts of sorghum, 16-35 parts of polished round-grained rice, 8-26 parts of tartary buckwheat, 5-16 parts of corns, 2-13 parts of sophora flowers and 2-6 parts of lotus flowers; S2, fermentation materials are prepared: koji block powder is added into the brewed grains obtained in the S1 and the materials are mixed evenly to obtain fermented materials; S3, fermentation is conducted: a cellar-in-cellar fermentation is used, a layer of corn cob is first sprinkled in a pool bottom of a cellar pool of a cellar-in-cellar, then a layer of the fermentation materials is added, then a layer of lotus receptacles is then sprinkled, then a layer of the fermented materials is added, cellar mud is used to seal a top, fermentation is conducted for 3 months and fermented grains are obtained after being taken out from the cellar; and S4, the fermented grainsare distilled to obtain the baijiu. The above technical solution solves problems that in the prior art, koji adding amount is low and pool entering temperature is low, thereby affecting yield and fragrance of the baijiu.

Owner:河北乾隆御酒业有限公司

Cask support

A cask support allows housing two casks (9) therein (1), such that the casks (9) will be arranged in a staggered manner when multiple supports are stacked together. Each support (1) includes two bedplates (2) with a seating for housing a cask (9). A carriage (10) formed by a rectangular platform is mounted to the framework of the support (1) with two brackets (15) with wheels (17) fixed to the carriage (10) which can move along each bedplate (2), and two other brackets (16) with wheels (19) fixed to the support and on which the platform of the carriage (10) slides. The carriage (10) has freedom of movement parallel to the bedplate (2). Each cask (9) rests on four rotating wheels (14) which are disposed on the vertices of the framework of the carriage (10). The cask support is especially applicable in large wine aging cellars.

Owner:SAGARTE

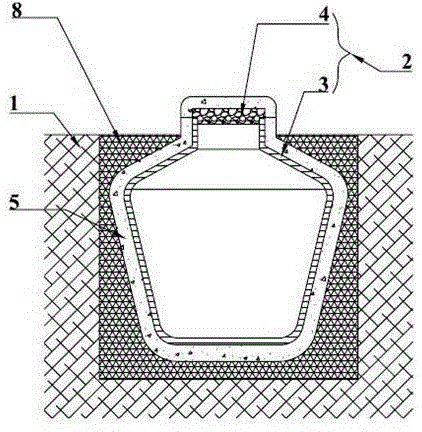

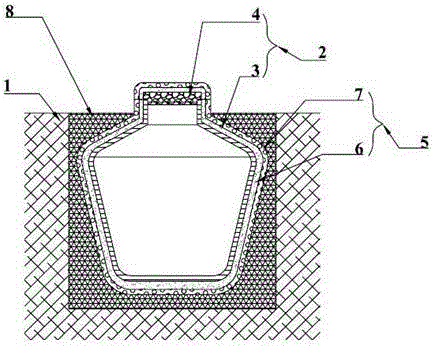

Wine cellar for health care wine cellaring

The invention relates to a wine cellar for health care wine cellaring. According to a traditional cellaring method, a pottery clay wine jar is directly stored in a cellar or buried in soil after wine is contained in the pottery clay wine jar. Nutritional ingredients in the wine after cellaring and health efficacy are neither ideal, and color and taste of the wine are not remarkably changed. The wine cellar for health care wine cellaring in the invention comprises pits and wine jars. Each wine jar contains a pottery clay jar body and a slabstone cover. The jar outer-wall of the pottery clay jar body and the jar bottom are both coated with a sophora flavescens fermentation layer and a radix astragali fermentation layer. The upper surface and side edge of the slabstone cover are both coated with a sophora flavescens fermentation layer and a radix astragali fermentation layer. The upper opening of the pottery clay jar body strictly matches the side edge of the slabstone cover in size and shape. The wine cellar for health care wine cellaring has advantages of simple structure, convenient operation, low cost and obvious effect. By the use of the wine cellar for health care wine cellaring, nutrient content of a wine which undergoes cellaring is high, the wine has high health care and medicinal value, and the wine is endowed with ideal color and taste.

Owner:王锦超

Pit sealing method

The invention discloses a pit sealing method which is beneficial for maintaining an anaerobic environment for distilled grains in the fermentation process. The method comprises sealing the pit by using a sealing cover; and an air discharge device for discharging the air inside the sealing cover is arranged on the sealing cover. By utilizing the method, the defect that dry crack happens in a pit mud sealing method is avoided, and the anaerobic environment is maintained for the distilled grains in the fermentation process; and moreover due to the air discharging device, the surplus air inside the sealing cover can be discharged in time, so as to prevent the sealing cover from being jacked to lose the sealing effect.

Owner:LUZHOU PINCHUANG TECH CO LTD

Five grain mixed liquor and moveable starter liquor cellar

InactiveCN102268339AImprove bad tasteSuitable for long-term drinkingAlcoholic beverage preparationCellar toolsFlavorAlcohol

The invention discloses a five grain mixed liquor and a movable starter liquor cellar. The five grain mixed liquor is characterized in that: a five grain spirit prepared by the movable starter liquor cellar is taken as a base, nine natural plants are taken as aromatic raw materials, and an acid alcohol flavoring wine and a compound flavoring lotion are prepared, blended and aged. The five grain mixed liquor is prepared from various functional raw materials, microbes and enzyme preparation products are applied, and the five grain mixed liquor has unique mellow flavor and medical care effect, and is suitable for long-term use. The movable starter liquor cellar comprises a forest material, a nutrition mixture, an organic industrial material, instruments and the like; and by scientific designs of microbe growth nutrients, process data detection and mechanical operation, the influence of geographic environment is avoided, the effective rate of raw material components is improved by over 15 percent, and the movable starter liquor cellar is suitable for producing various starter liquors and has important significance for popularizing industrialization and home brewing.

Owner:邓柏福

Fermented grain cellar feeding and discharging conveying system

The invention relates to the technical field of Baijiu brewing, and discloses a fermented grain cellar feeding and discharging conveying system. The fermented grain cellar feeding and discharging conveying system comprises a cellar discharging system, wherein the cellar discharging system comprises a first moving trolley, a telescopic arm, a first vertical ascending and descending mechanism and agrab bucket; a girder vehicle is arranged at the upper side inside a cellar pool chamber; the first moving trolley is movably connected with the girder vehicle; the first vertical ascending and descending mechanism is fixed through the first moving trolley; the telescopic arm is in vertical arrangement and is connected with the first vertical ascending and descending mechanism; and the bottom of the telescopic arm is connected with the grab bucket. The fermented grain cellar feeding and discharging conveying system provided by the invention has the advantages that through the arrangement of the girder vehicle and the first moving trolley, material transfer can be conveniently performed on each cellar pool in the cellar pool chamber; through the arrangement of the first vertical ascending and descending mechanism, the telescopic arm can be driven to ascend or descend; the grasping lifting and transfer of the materials can be realized; the system is simple; the operation is easy; the control is convenient; the cost is low; the labor can be replaced to realize the automatic cellar discharging of fermented grain materials; the work intensity of workers can be greatly reduced; and the production efficiency is improved.

Owner:WUHAN FENJIN INTELLIGENT MACHINE CO LTD

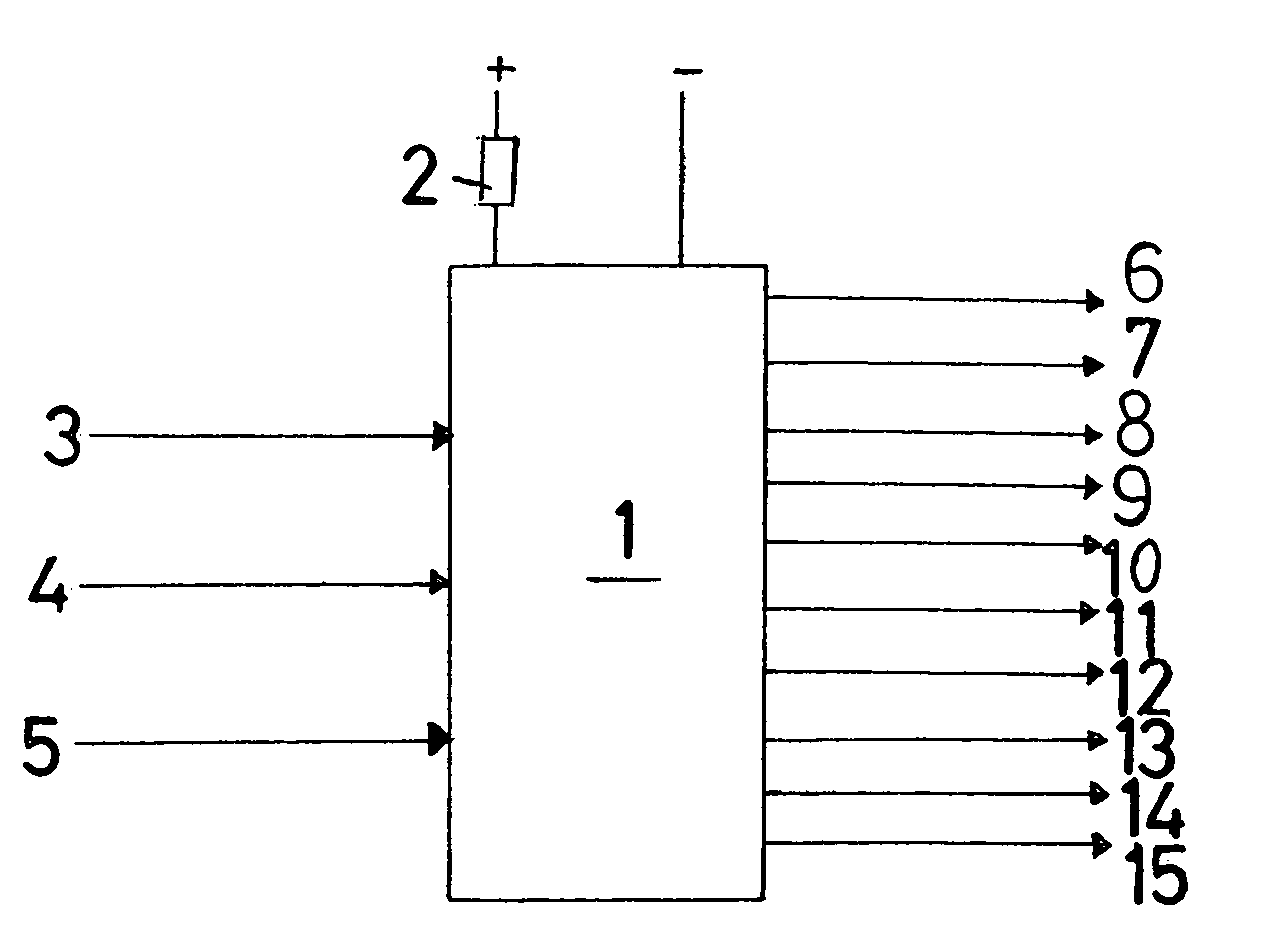

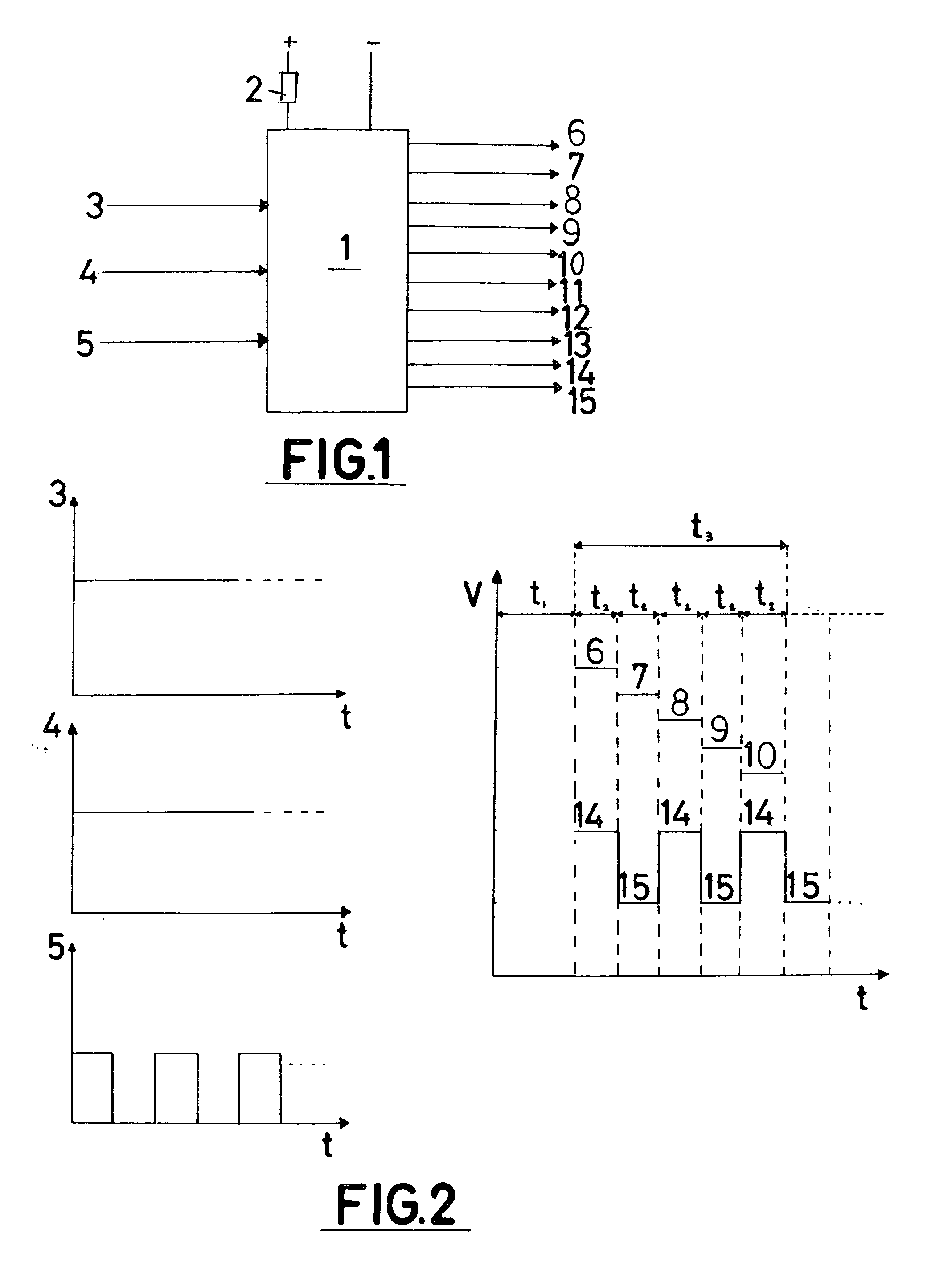

Automatic signaling device for automobiles

InactiveUS7342487B2Avoid confusionAvoid errorsPedestrian/occupant safety arrangementHollow article cleaningContinuous signalEmergency light

The device automatically actuates the vehicle emergency lights when the brake pedal and one of the turn signals are simultaneously used. To do so it uses an integrated circuit that actuates a periodic pulsating signal in its outputs when a continuous signal is received in its inputs that comes from the brake pedal switch, and, at the same time, a pulsating signal from one of the turn signals. The device is especially indicated for warning that a dangerous maneuver with left or right turns is going to be performed on two-way highways, for example.

Owner:DEL ESTAL VILLAR JOSE MARIA

Method for brewing kiwi fruit wine through cellar fermentation tank

ActiveCN105969573AIncrease productionLess consumablesAlcoholic beverage preparationCellar toolsBiotechnologyPectinase

The invention belongs to the technical field of fruit wine brewing and particularly provides a method for brewing kiwi fruit wine by means of cellar fermentation. The method specifically comprises the following steps of 1, fruit selecting, cleaning and crushing; 2, ingredient adjustment, wherein firstly, pectinase is added for enzyme treatment, saccharomyces cerevisiae TP6 is added through inoculation after enzyme treatment, then SO2 is added, sugar is added for the first time, and then CaCO3 and citric acid are used for adjusting the pH value of kiwi fruit pulp in a fermentation tank; 3, primary fermentation and after fermentation; 4, clarification and aging; 5, bottling and clarification. By the adoption of the method for brewing the kiwi fruit wine through the cellar fermentation tank and new bacteria, the quality of the fruit wine is improved, and the fruit wine has the highest ester content and the most varieties and the highest total content of volatile and fragrant substances. Therefore, the kiwi fruit wine brewed through the cellar fermentation tank in cooperation with the saccharomyces cerevisiae TP6 has a unique flavor, the taste of the kiwi fruit wine can be better, and the fragrance of the kiwi fruit wine can be stronger.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com