Device for rotationally discharging fermented grains out of cellar

A rotary drive device and technology of wine grains, applied in wine cellar appliances, biochemical equipment and methods, etc., can solve the problems of affecting the speed of lees, easy accumulation of wine grains, troublesome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

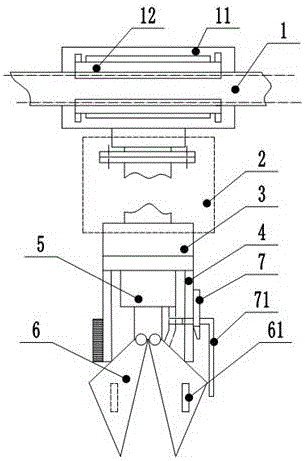

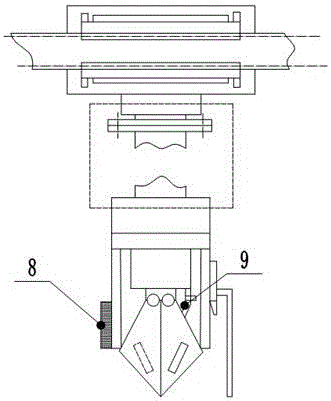

[0017] The reference signs in the drawings of the description include: screw rod 1, car body 11, threaded sleeve 12, lifting mechanism 2, rotating cylinder 3, rotating cover 4, telescopic mechanism 5, material claw 6, feeding port 61, plow shovel 7, Suction pipe 71, hairbrush 8, ventilation pipe 9.

[0018] The embodiment is basically as attached figure 1 And attached figure 2 Shown: the rotating wine cellar unloading device in this scheme includes a translation mechanism and a working mechanism. The translation mechanism consists of a crane and a lifting mechanism 2. The upper part of the lifting mechanism 2 is fixed on the crane, and the lower part of the lifting mechanism 2 is connected to the working mechanism. The crown block is composed of a car body 11, a screw 1 and a threaded sleeve 12. The car body 11 is sheathed and slidably connected to the screw 1. The thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com