Method for manufacturing baijiu by cellar-in-cellar fermentation

A technology of liquor and fermented materials, applied in biochemical equipment and methods, wine cellar utensils, preparation of alcoholic beverages, etc., can solve problems such as low temperature in the pool, low amount of added koji, affecting the yield and aroma of the wine, etc. Achieve the effect of more aroma, coordination of wine body and guaranteed yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

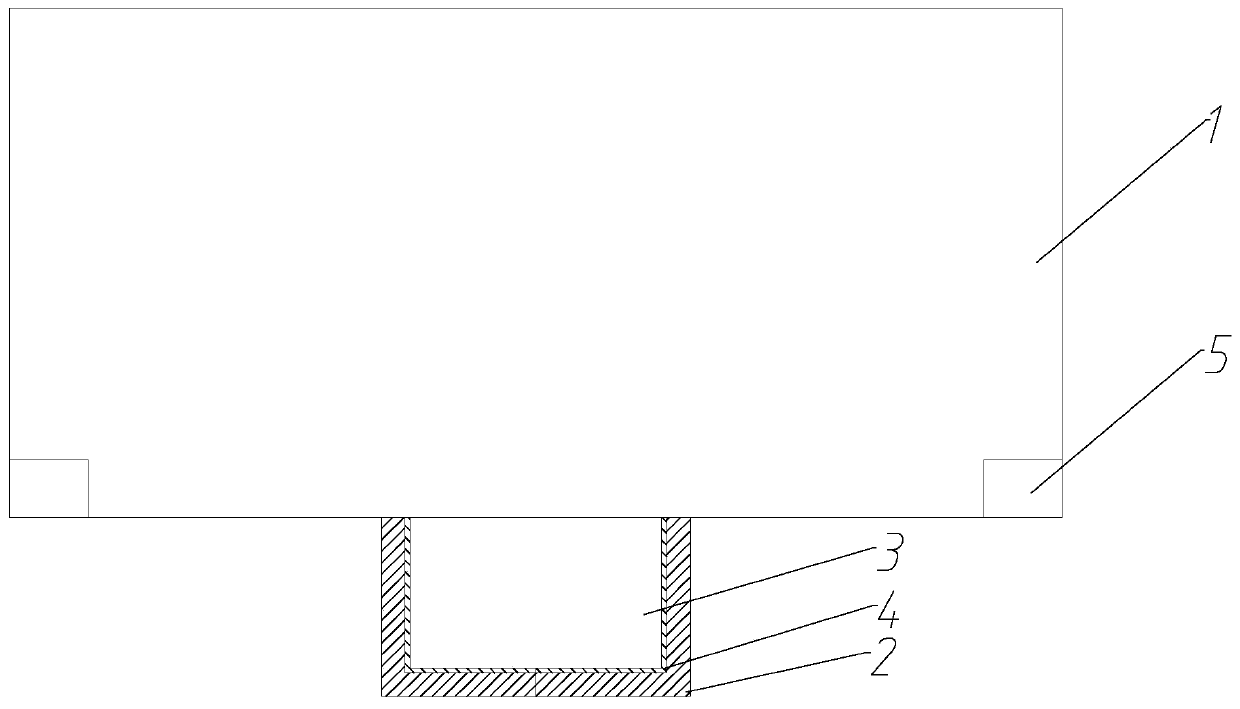

Image

Examples

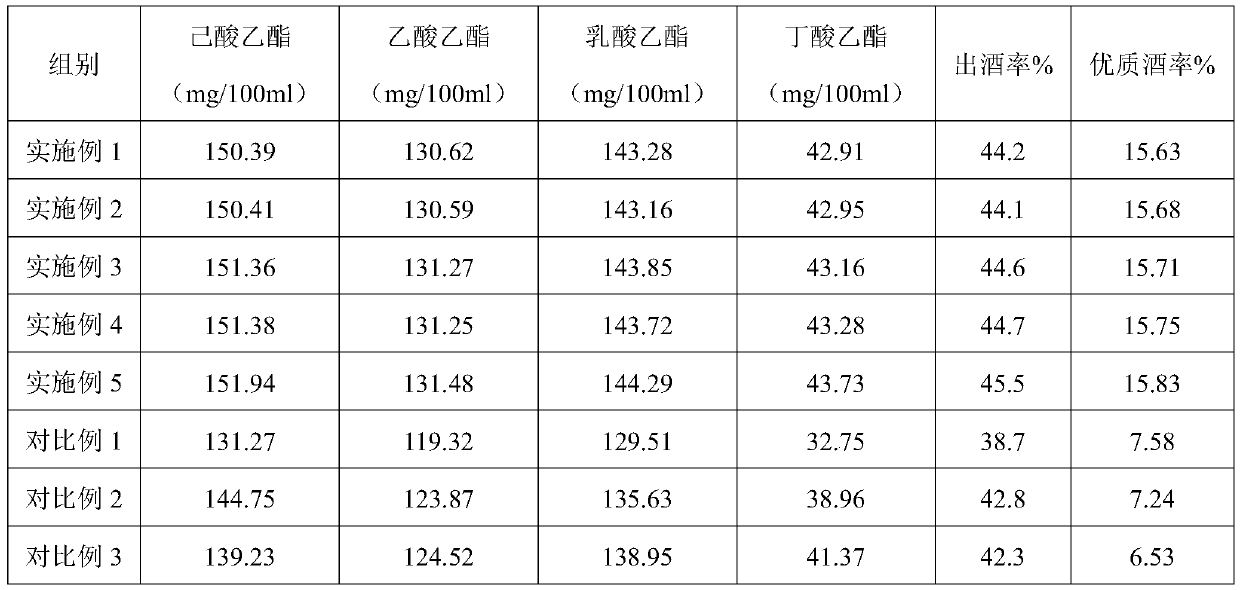

Embodiment 1

[0031] A method for making liquor by cellar-in-cellar fermentation, comprising the following steps:

[0032] S1. Raw material pretreatment: Weigh the raw materials, mix them and crush them through a 20-mesh sieve to obtain a mixture, add 3 times the mass of water to the mixture and soak it at room temperature for 5-6 hours to obtain a wet mixture, and mix the wet mixture Add water and cook at 95-100°C for 12 hours, cool and dry to obtain brewed grain;

[0033] The raw material is composed of the following components by weight: 23 parts of sorghum, 16 parts of japonica rice, 8 parts of tartary buckwheat, 5 parts of corn, 2 parts of Sophora japonica, 2 parts of lotus,

[0034] S2. Preparation of fermented material: add Daqu powder to the fermented grain obtained in step S1, and mix uniformly to obtain fermented material, wherein the mass ratio of Daqu powder to fermented grain is 31:100;

[0035] S3. Fermentation: ferment in a cellar in a cellar, first sprinkle a layer of corn ...

Embodiment 2

[0038] A method for making liquor by cellar-in-cellar fermentation, comprising the following steps:

[0039] S1. Raw material pretreatment: Weigh the raw materials, mix them and crush them through a 20-mesh sieve to obtain a mixture, add 3 times the mass of water to the mixture and soak it at room temperature for 5-6 hours to obtain a wet mixture, and mix the wet mixture Add water and cook at 95-100°C for 12 hours, cool and dry to obtain brewed grain;

[0040] The raw material is composed of the following components by weight: 50 parts of sorghum, 35 parts of japonica rice, 26 parts of tartary buckwheat, 16 parts of corn, 13 parts of Sophora japonica, 6 parts of lotus,

[0041] S2. Preparation of fermented material: add Daqu powder to the fermented grain obtained in step S1, and mix uniformly to obtain fermented material, wherein the mass ratio of Daqu powder to fermented grain is 31:100;

[0042] S3. Fermentation: ferment in a cellar in a cellar, first sprinkle a layer of co...

Embodiment 3

[0045] A method for making liquor by cellar-in-cellar fermentation, comprising the following steps:

[0046]S1. Raw material pretreatment: Weigh the raw materials, mix them and crush them through a 20-mesh sieve to obtain a mixture, add 3 times the mass of water to the mixture and soak it at room temperature for 5-6 hours to obtain a wet mixture, and mix the wet mixture Add water and cook at 95-100°C for 12 hours, cool and dry to obtain brewed grain;

[0047] The raw material consists of the following components by weight: 32 parts of sorghum, 21 parts of japonica rice, 15 parts of tartary buckwheat, 9 parts of corn, 6 parts of Sophora japonica, 3 parts of lotus,

[0048] S2. Preparation of fermented material: add Daqu powder to the brewed grain obtained in step S1, and mix evenly to obtain fermented material, wherein the mass ratio of Daqu powder to brewed grain is 31:100;

[0049] S3. Fermentation: ferment in a cellar in a cellar, first sprinkle a layer of corn cobs on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com