Hypereutectic cast aluminum-silicon alloy modification method

A technology for casting aluminum-silicon alloys and aluminum-silicon alloys, which is applied in the field of aluminum alloy smelting, can solve problems such as no research, no technical features provided, and limited application occasions, so as to improve metamorphic efficiency, reduce processing material costs and time costs, and reduce The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

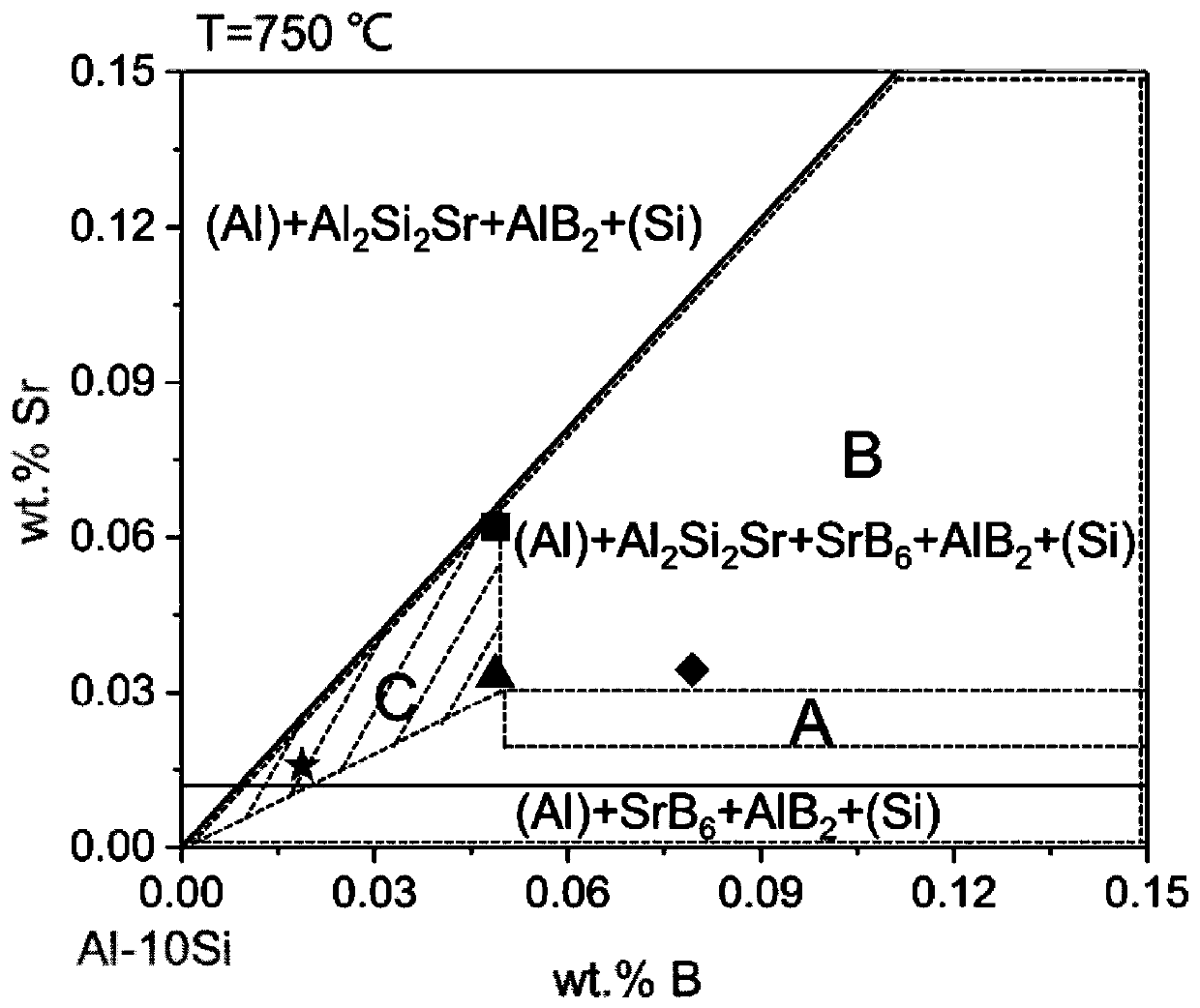

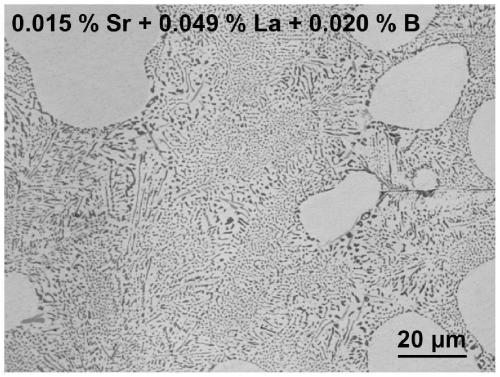

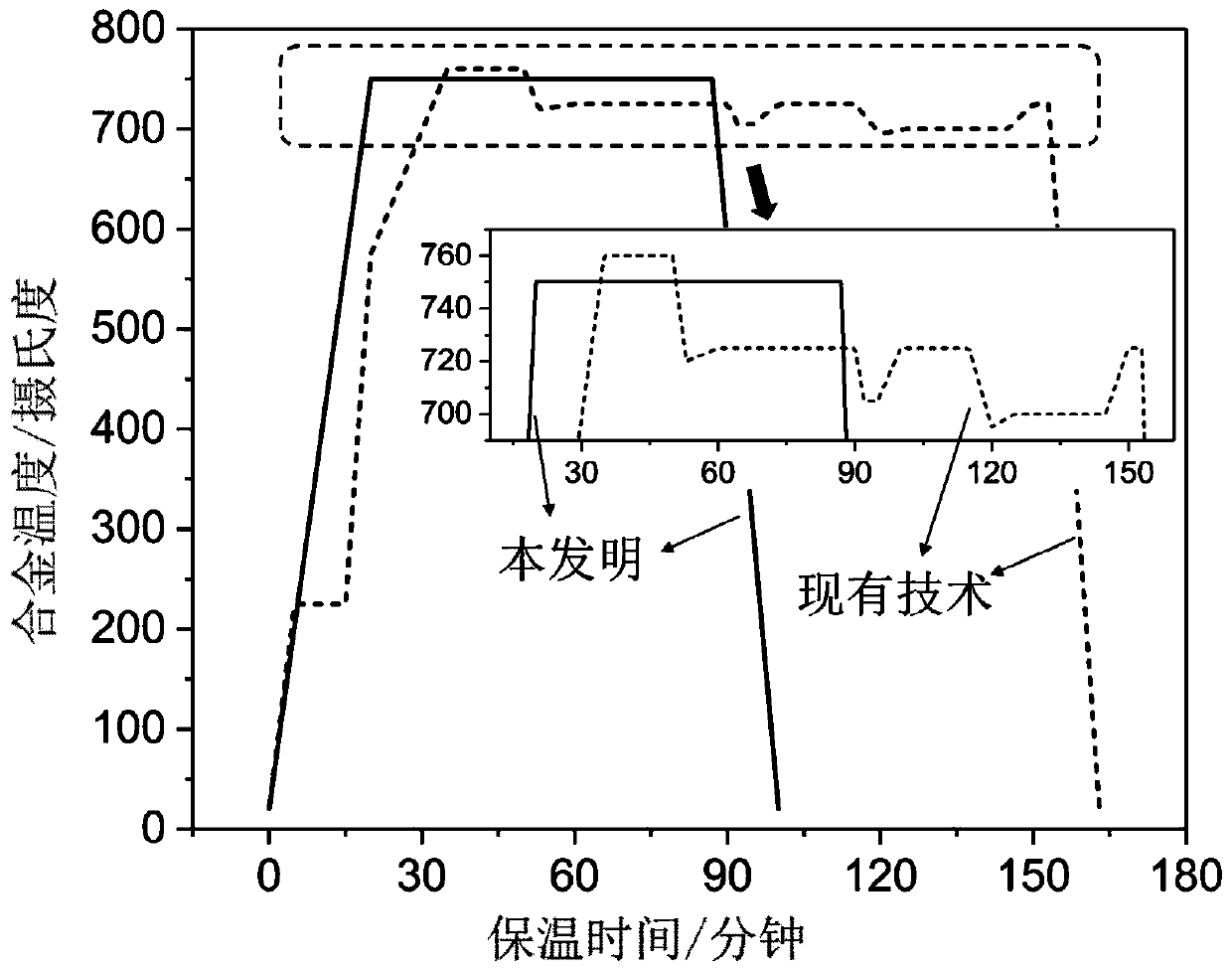

[0049] In this embodiment, a method for modifying a hypoeutectic cast aluminum-silicon alloy involves modifying an aluminum-silicon alloy with a silicon mass fraction of 10% to control the morphology and grain size of the eutectic silicon phase of a cast aluminum-silicon alloy , to obtain the hypoeutectic aluminum-silicon alloy structure; during the efficient modification of the hypoeutectic cast aluminum-silicon alloy, industrial silicon, industrial pure aluminum, Al-10Sr alloy, Al-10La alloy, and Al-3B alloy are used as raw materials. The mass percentage of elements is: Si: 10.000%, Sr: 0.015%, La: 0.049%, B: 0.020%, the balance is mainly Al, and the materials are prepared accordingly. Among them, Sr in the Al-10Sr alloy is Al 4 Exist in the form of Sr, La in Al-10La alloy as Al 11 La 3 、Al 4 La form exists, B in Al-3B alloy is AlB 2 The target hypoeutectic cast aluminum-silicon alloy is prepared according to the mass percentage requirements of the above elements, and the...

Embodiment 2

[0075] This embodiment is basically the same as Embodiment 1, and the special features are:

[0076] In this example,

[0077] The steps not specifically described are the same as those in Example 1, except that La is added at a mass percentage of 0.029%, and the mass ratio of La / B is 1.45 at this time.

Embodiment 3

[0079] The steps not specifically described are the same as those in Example 1, except that La is added at a mass percentage of 0.099% for feeding, and the La / B mass ratio is 4.95 at this time.

[0080] The changes in the modification effect and grain refinement effect of the cast aluminum-silicon alloy samples prepared in comparative example 2, embodiment 2, embodiment 1 and embodiment 3 are as follows Figure 5 As shown, when the La / B mass ratio is lower than 2.45, there is a critical value. When the La / B mass ratio is lower than this critical value, the alloy loses the modification effect and is in an unmodified state, but the primary aluminum grain size has no obvious Change; when the La / B mass ratio is greater than 2.45, the primary aluminum grain size tends to increase significantly, but the modification effect does not change significantly.

[0081] The results show that one of the decisive factors that really affects the modification effect of the hypoeutectic cast Al-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com