Patents

Literature

166 results about "Ethyl caproate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

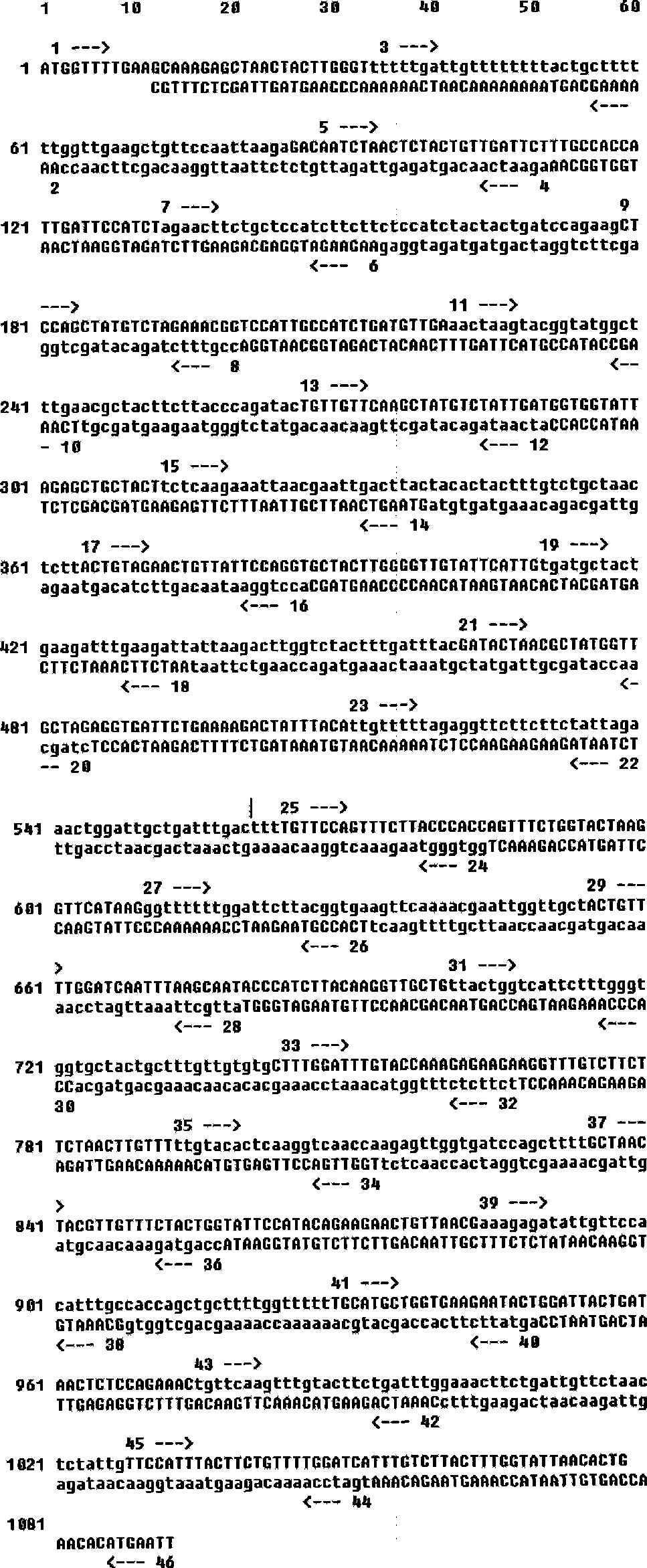

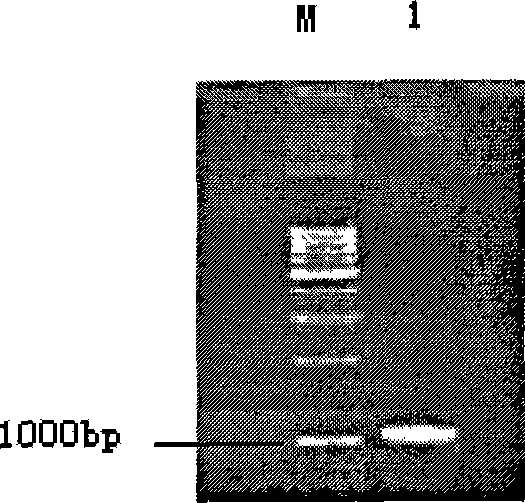

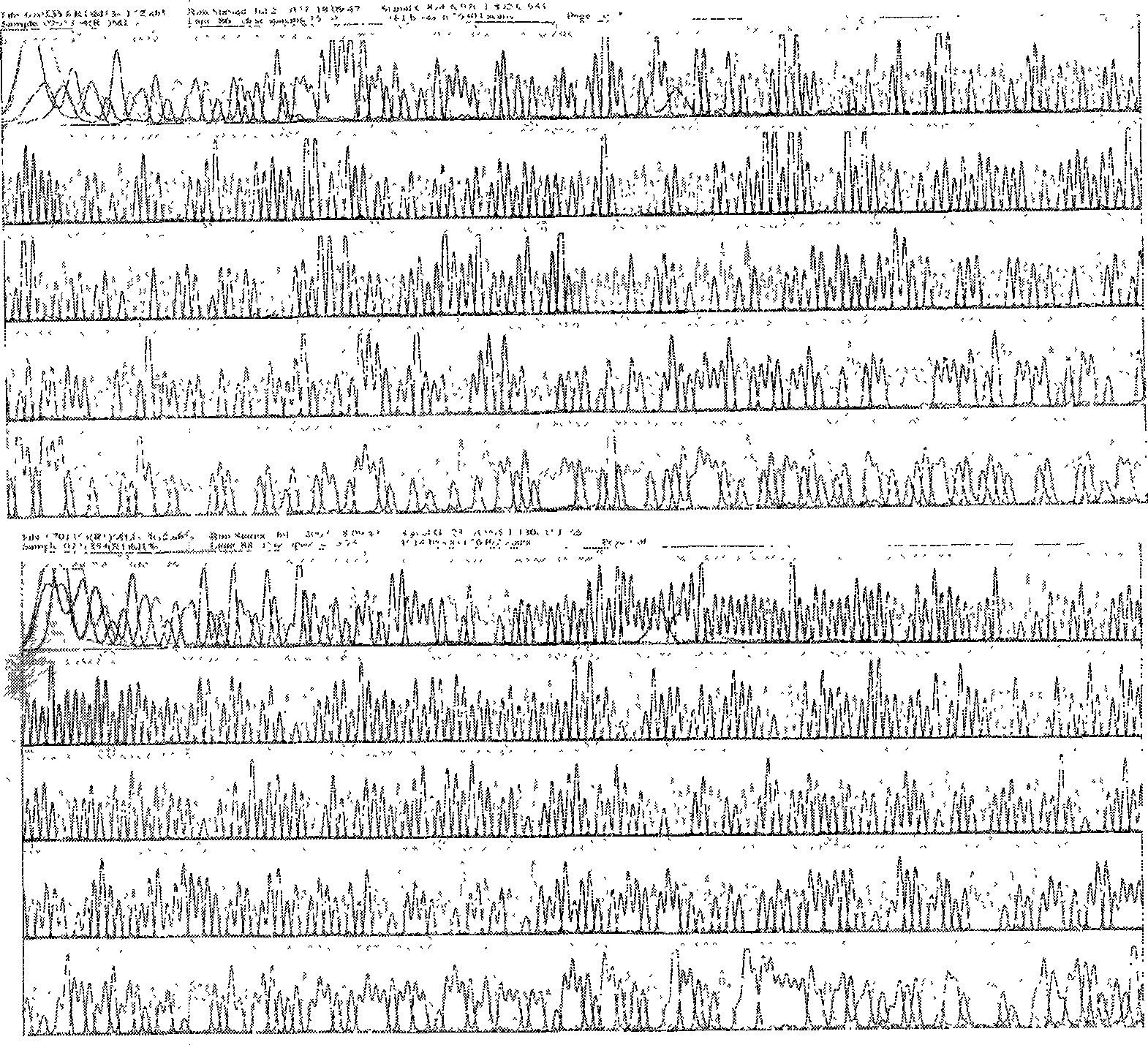

Candida Antarctica lipase B gene and applications thereof in yeast display

ActiveCN101565713AIncrease impressionImprove thermal stabilityFungiBiofuelsPichia pastorisNucleotide

The invention relates to candida Antarctica lipase B gene and applications thereof in yeast display. Coded protein of improved candida Antarctica B and wild type candida Antarctica lipase protein have the same function on the amino acid level; the heat resistance capacity of the enzyme is 50-80 DEG C, and the half-lift is 3-24 hours; a nucleotide sequence is hybridized with SEQ.ID.NO2 from 1st to 978th of nucleotide under the moderate precise condition; and a preservation number of colon bacillus DH5Alpha / Puc57-CALB (Escherichia coliDH5Alpha / pUC57-CALB) which carries the plasmids is CCTCC M 209081. The candida Antarctica lipase B gene is transferred into pichia pastoris host bacteria so as to realize the high-efficient display expression of the candida Antarctica lipase B in pichia pastoris; and the provided pichia pastoris bacteria can effectively display candida Antarctica lipase B, can be widely applied to the synthesis of ethyl caproate, has different melting points and does not contain triglyceride of various fatty acids, a plurality of structured lipids, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Improved Rhizomucor miehei lipase gene and use thereof in yeast display

ActiveCN101481695AIncrease vitalityImprove catalytic performanceFungiBacteriaBiotechnologyEscherichia coli

The invention relates to an improved rhizomucor miehei lipase gene and an application to yeast display. The sequence of the improved rhizomucor miehei lipase gene is SEQ.ID.No2, with respect to a recombinant vector pMD18-T-RML containing the gene, RML means lipase gene; and the collection number of a bacterial strain Escherichia coli TOP10 / pMD18-T-RML carrying the plasmid is CCTCC M 208136. In the invention, the gene is transferred into pichia stipitis host strain, so that the rhizomucor miehei lipase is displayed and expressed in the pichia stipitis. The provided pichia stipitis can effectively display the rhizomucor miehei lipase. The lipase can be widely applicable for producing fatty acid methyl ester, ethyl caproate, triglycerides which have different melting points but does not contain various types of fatty acid and a few 'reconstructed esters'.

Owner:DONGGUAN HUAQI BIOLOGICAL SCI & TECH +1

Ceramic product having alcoholic drink alcoholization function and preparation method thereof

InactiveCN102690102AGood colorSpicy and violent tasteAlcoholic beverage preparationClaywaresIsobutanolSilicic acid

The invention relates to an alcoholic drink storage utensil and a preparation method thereof. The alcoholic drink storage utensil is a ceramic product having an alcoholic drink alcoholization function and is composed of purple sand, an alcoholic drink purifying solvent, an energy activator and an environment-imitating solvent, wherein the purple sand accounts for 70-80% of the raw materials, the alcoholic drink purifying solvent accounts for 5-20% of the raw materials s, the energy activator accounts for 5-20% of the raw materials s, and the environment-imitating solvent accounts for 2-6% of the raw materials. The alcoholic drink purifying solvent contains major elements of potassium, sodium, calcium, magnesium and phosphorus and further contains zinc, iron, selenium, copper, strontium, iodine, fluorine and metasilicic acid; the energy activator can be tourmalinite or negative ion powder or a mixture of the tourmalinite and the negative ion powder; the environment-imitating solvent is diatomite. The function of the ceramic products is that parameters such as acetaldehyde, methanol, n-propanol, sec-butyl alcohol, isobutanol, n-butanol and isoamyl alcohol, and the like can be reduced to a different degree; parameters such as ethyl acetate, ethyl butyrate, ethyl lactate and ethyl caproate, and the like can be raised to different degrees. According to the invention, the alcoholic drink has good shade, virgin whiteness, no thickness, no pungent smell and no other off-flavors.

Owner:冯政

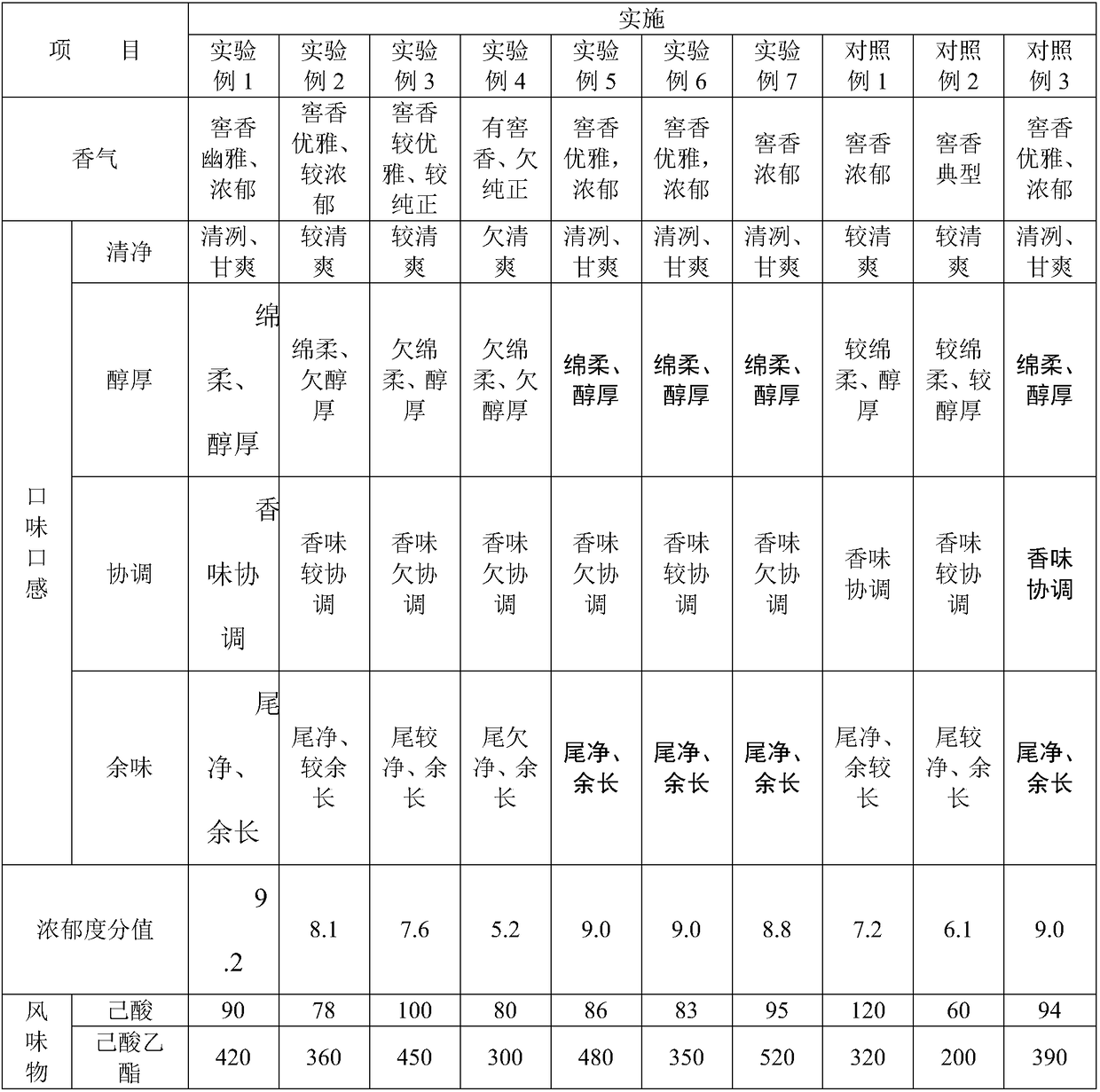

Functional pit mud for strong-flavor spirit, and manufacturing method thereof

InactiveCN102199505APrevent degradationIncrease contentMicroorganism based processesAlcoholic beverage preparationSodium acetatePhosphate

The invention discloses a functional pit mud for strong-flavor spirit. The pit mud comprises raw materials of, by weight: 70% to 75% of yellow mud, 12% to 14% of lotus pond mud, 1.2% to 1.5% of strong-flavor Daqu powder, 1% to 2% of bean cake powder, 0.05% of potassium dihydrogen phosphate, 0.8% of sodium acetate, 0.01% of magnesium sulfate, 4% to 5% of feints, and 5% to 6% of a functional bacilli liquid. The functional bacilli liquid is a mixed liquid of acetic bacilli, propionic bacilli and saccharomyces cerevisiae. The manufacturing method comprises steps of raw material preparating, mud mixing and in-pit cultivating. The functional pit mud for strong-flavor spirit provided by the present invention fundamentally prevents the pit from retrogression, and provides a good living environment for the microbes in the pit. With the functional pit mud, the flavoring components ethyl caproate and ethyl propanoate of the base spirit of the strong-flavor spirit can be increased, and the quality of the base spirit is improved.

Owner:SITIR LIQUOR

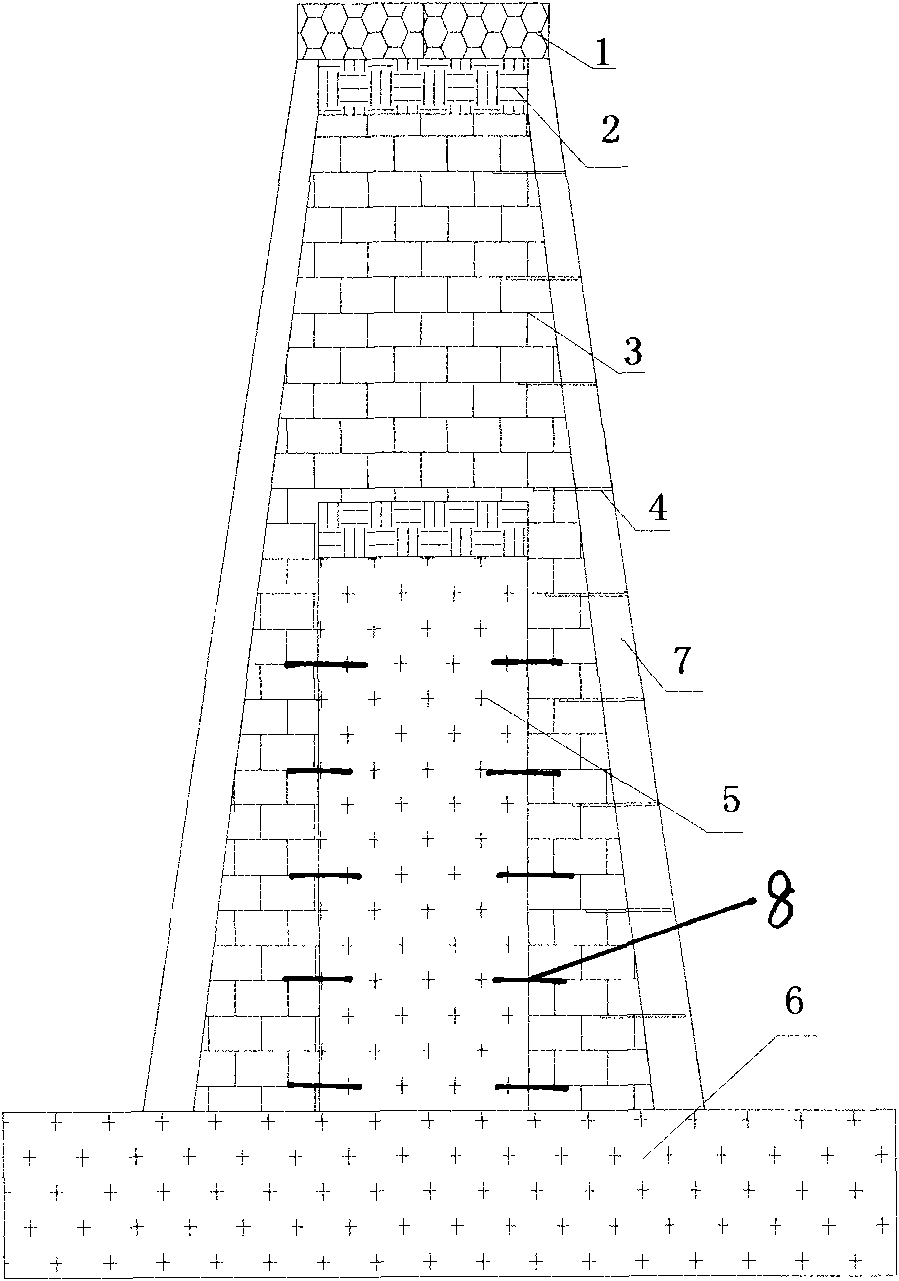

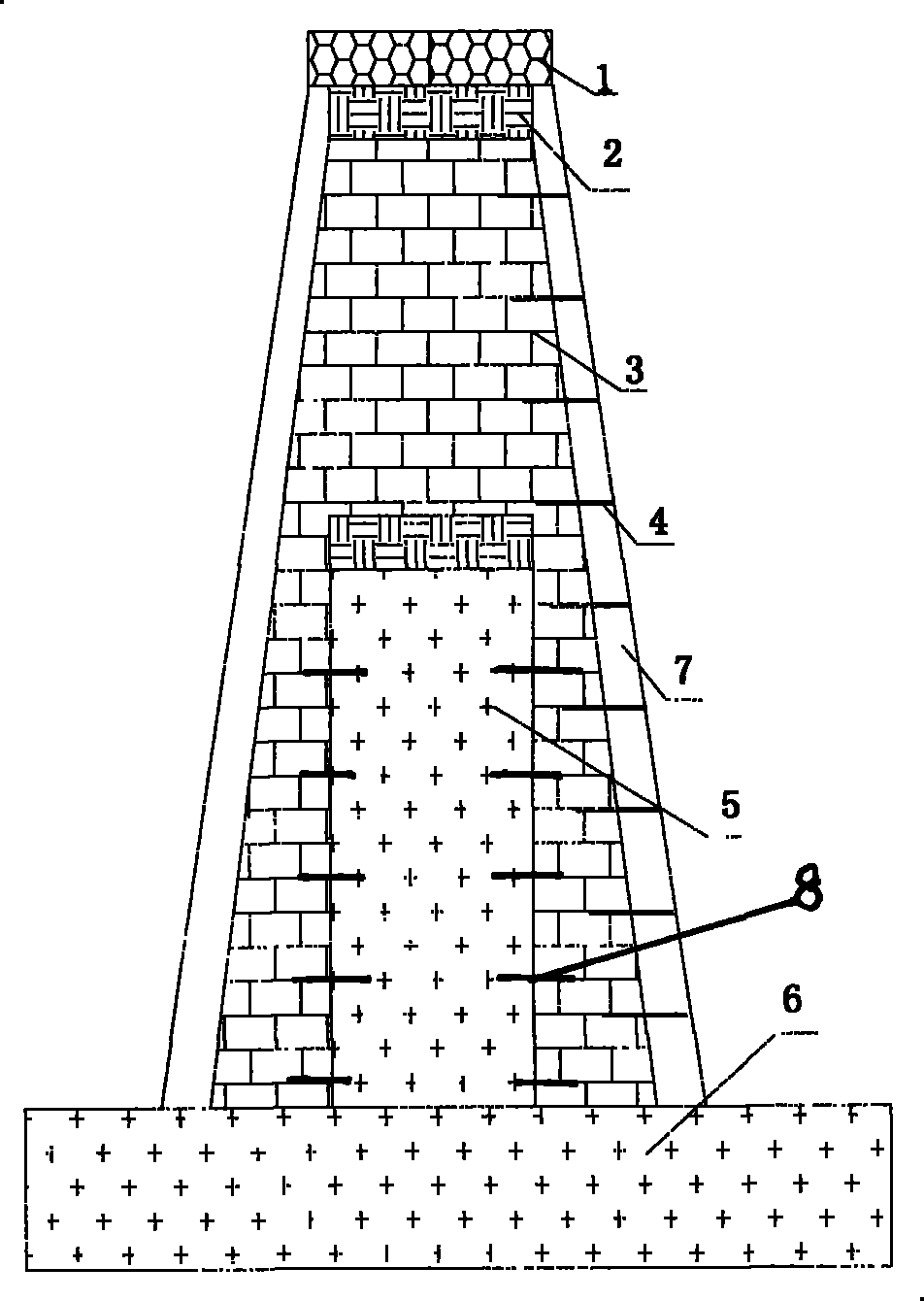

Soil-brick combined yeast wine cellar and construction method thereof

The invention relates to yeast wine fermentation, in particular to a soil-brick combined yeast wine cellar and a construction method thereof in the field of strong aromatic yeast wines. The yeast wine cellar of which not only the cellar moisture retention is good but also a wall body cannot collapse easily is provided by a method comprising the following steps of: culturing artificial aging cellar mud; building a two-component soil waterproof layer at the bottom of the cellar; ramming a two-component soil internal wall based on the waterproof layer at the bottom of the cellar; and building an inclining brick wall with a certain inclination angle by using red bricks on two sides next to the two-component soil internal wall respectively. The soil-brick combined yeast wine cellar overcomes the defects in the prior art, and can effectively improve the activity of cellar mud functional bacteria and accelerate the aging of artificially cultured cellar mud to ensure that the fragrance of a produced base liquor is a composite fragrance mainly comprising ethyl caproate, and the liquor body style is a typical concentrated fragrance type liquor style with 'a strong cellar fragrance, a sweet and clear taste, harmonious fragrances and long aftertastes'.

Owner:HUNAN XIANGJIAO WINE IND

Process for preparing fresh scent strong-flavor Chinese spirit

InactiveCN103666927AHas a strong fragrance styleOvercoming technical difficulties in anaerobic cultureAlcoholic beverage preparationAcetic acidYeast

The invention discloses a process for preparing fresh scent strong-flavor Chinese spirit. The process comprises distiller's yeast preparation, bacterial sludge preparation, construction of bacterial sludge pits and fermenting and distilling, wherein the step of bacterial sludge preparation comprises material pretreatment, culture of methane bacteria liquid and pit sludge fermentation and culture. Sludge pits in which methane bacteria serve as a primary flora and caproic acid bacteria serve as a secondary flora are constructed by adopting common conditions such as tile crocks and pits in common liquor factories, and conditions are created for producing fresh scent strong-flavor Chinese spirits. According to the process, the technical problem of factory-like methane bacteria anaerobic culture is overcome, and preparation of the sludge pits in which methane bacteria serve as the primary flora and caproic acid bacteria serve as the secondary flora is realized. The liquor is brewed by utilizing the prepared sludge pits and process thereof, and a fresh scent strong-flavor Chinese spirit with a primary component of ethyl acetate, a secondary component of ethyl caproate and an auxiliary material of 2,3-butanedione is formed. Partial characteristics of traditional daqu liquor and Xiaoqu wine processes are combined, and a process of the fresh scent strong-flavor Chinese spirit is formed.

Owner:DAZHOU CHUANHU FOOD

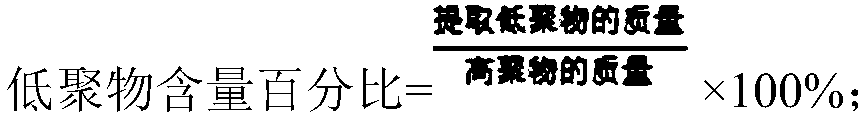

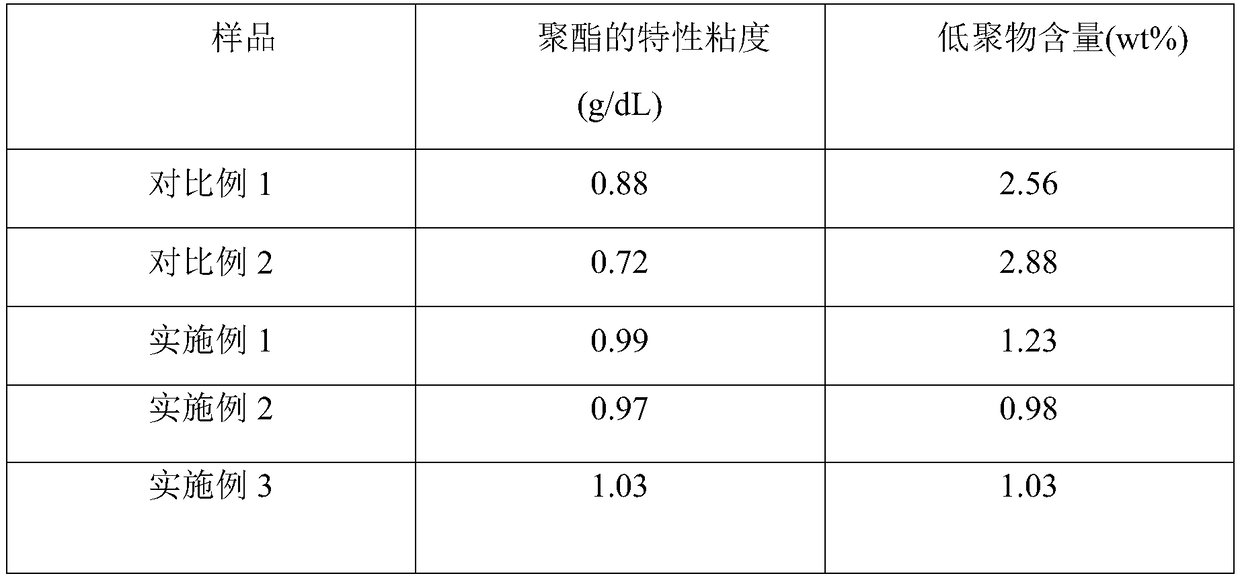

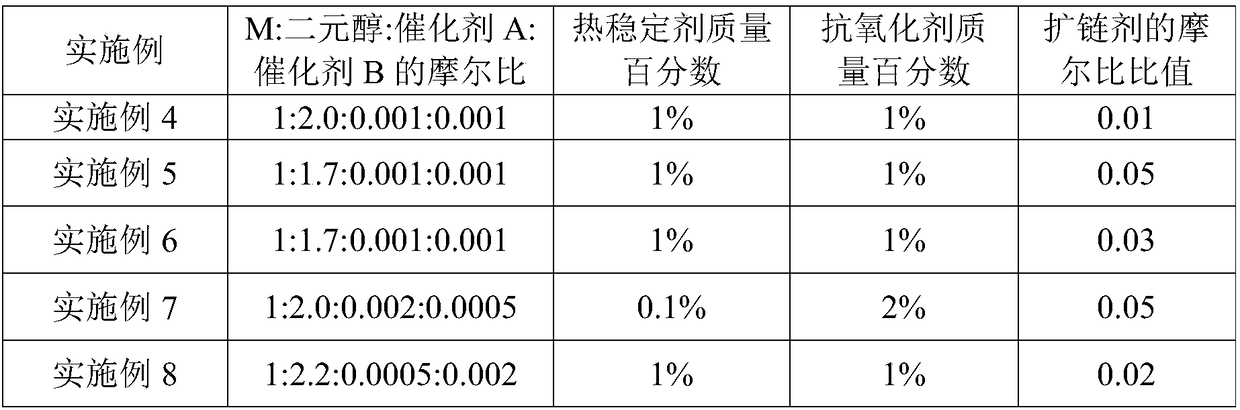

Polyester with low oligomer content and preparation method of polyester

The invention relates to a polyester with low oligomer content and a preparation method of the polyester. The method comprises the following steps: carrying out an esterification reaction and a first-stage condensation polymerization reaction on M and dihydric alcohol in the presence of a catalyst A; carrying out a second-stage condensation polymerization reaction; adding a catalyst B and carryingout a third-stage condensation polymerization reaction; and finally, adding a chain extender for carrying out a chain extension reaction, thereby obtaining the polyester with low oligomer content, wherein M is dicarboxylic acid or binary alkyl carboxylate; the catalyst A is a titanium catalyst, an antimony catalyst or metal acetate, the catalyst B is more than one of aluminum isopropoxide, dibutyl tin oxide, monobutyltin oxide, stannous octoate and stannous 2-ethyl caproate, and the oligomer content in the prepared polyester is less than 1.5wt%. The method disclosed by the invention is simplein operation, and the prepared product is low in oligomer content and has excellent popularization value.

Owner:DONGHUA UNIV

Process for producing lotus seed spirit

ActiveCN101831371AEthyl acetateIncrease ethyl caproate contentAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a process for producing lotus seed spirit. The process comprises the following steps of: selecting and crushing lotus seeds, moistening and stewing the crushed lotus seeds at the high temperature, adding water into the lotus seeds, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into a cylinder to perform large dreg fermentation, discharging fermented grains from the cylinder, distilling the lotus seeds to obtain first dreg spirit and rest secondary dreg yeast, and adding a stirring material into the secondary dreg yeast in a ratio of 1: 0.4-0.6, wherein the stirring material is prepared after the lotus seeds are selected, crushed, moistened at the high temperature and stewed; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform secondary dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain secondary dreg spirit or rest third dreg yeast; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform third dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain third dreg spirit; and blending the first dreg spirit and the second dreg spirit, or blending the first dreg spirit, the second dreg spirit and the third dreg spirit, and putting the blended spirit into storage and ageing the spirit. Therefore, the process can effectively control the acidity during fermentation, reasonably increase the activity of enzyme, reduce purification, effectively inhibit impurity bacteria, improve the content of ethyl acetate and ethyl caproate in the spirit, reduce the methanol in the spirit, enrich the mouthfeel, and keep the fragrance of the sprit thick.

Owner:浙江硒莲液富硒科技有限公司

Flavoring pear essence

ActiveCN102551022AImprove heat resistanceImprove aroma qualityFood preparationEthyl butyrateFood flavor

The invention relates to a favoring pear essence which consists of the following components in parts by weight: 0.1-100 parts of incense, 0-99.9 parts of solvent, 0-20 parts of surfactant, 0-20 parts of cosurfactant and 0-99.9 parts of carrier, wherein the incense consists of the following components in parts by weight: 5-20 parts of hexenyl acetate, 10-35 parts of ethyl butyrate, 6-15 parts of ethyl caproate, 10-30 parts of beta-carypohyllene, 0.5-5 parts of hexdecnoic cid, 3-20 parts of ethyl acetate, 6-15 parts of isoamyl acetate, 4-15 parts of hexyl acetate and 8-25 parts of 3-methylthiopropionate. The favoring pear essence formula disclosed by the invention has fresh pear flavor; and beverage in which the favoring pear essence is added has strong juice feeling as well as flavor and mouthfeel of the fresh pear.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

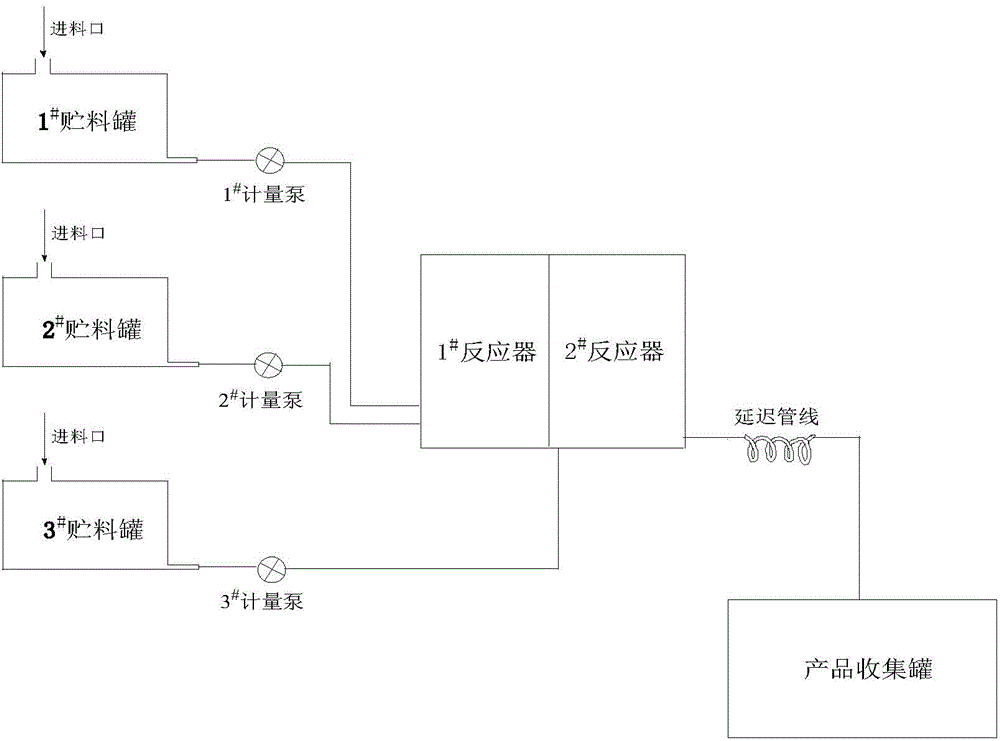

Method for preparing peroxidized dicarbonate (2-ethylhexyl) ester (EHP) by continuous flow

InactiveCN104370789AEmission reductionReduce labor intensityOrganic compound preparationPeroxy compound preparationDicarbonateEmulsion

The invention provides a method for preparing peroxidized dicarbonate (2-ethylhexyl) ester (EHP) by a continuous flow. The method comprises the following steps: preparing an alkaline aqueous liquid; carrying out reaction on the alkaline aqueous liquid and hydrogen peroxide in a reactor; adding a chloroformic acid-2-ethyl caproate liquid to react with a product of the alkaline aqueous liquid and hydrogen peroxide; and further carrying out full reaction on the product to obtain a product by virtue of a delayed pipeline, wherein the reaction process is carried out in a micro-reactor. The solvent or emulsion type peroxidized dicarbonate (2-ethylhexyl) ester (EHP) prepared by the method provided by the invention is stable in product quality and good in repeatability. As reaction is carried out in the micro-reactor, the process flow is simplified, so that the reaction is continuously carried out under mild, safe and environment-friendly conditions. Therefore, the product content and yield are greatly improved, and the yield can reach over 98%.

Owner:LINZIZHENGHUA ACCESSORY INGREDIENT ZIBO

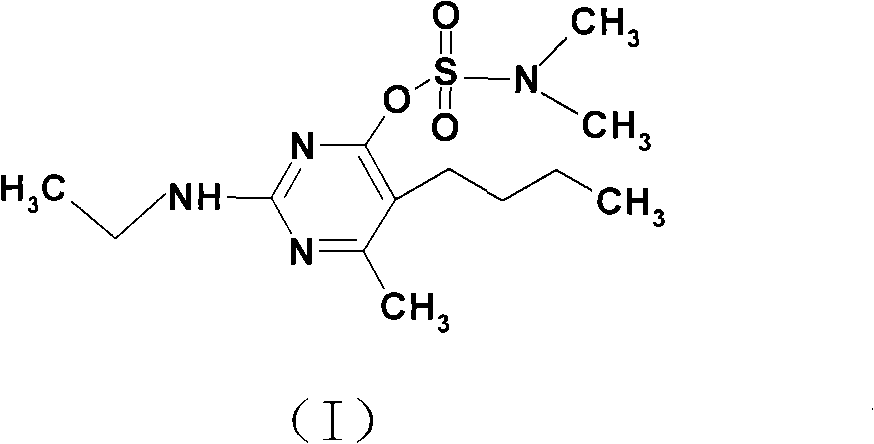

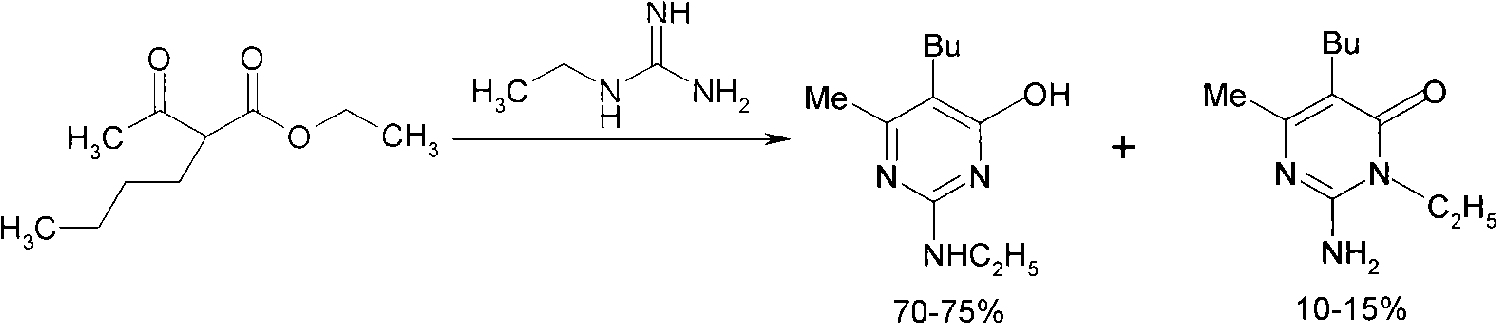

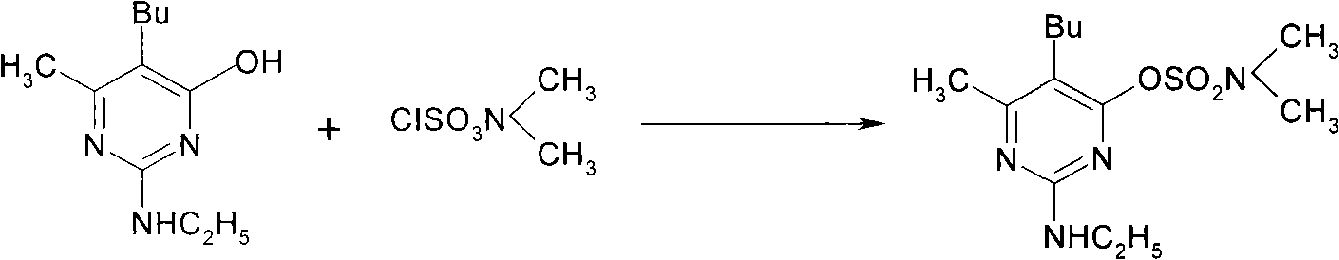

Method for synthesizing 5-nbutyl-2-ethylamido-6-methylpyrimidine-4-dimethyl amine sulfonic acid ester

The invention discloses a method for synthesizing 5- normal-butyl-2- ethide amid-6- methyl pyrimidine-4-based dimethyl amine group sulfonic ester (bupirimate). The method takes nitroguanidine and 2-acetyl group ethyl caproate as raw materials which react under the catalytic action of sodium alcoholate to generate 5- normal-butyl-2-nitryl amine-6- methyl pyrimidine-4- phenol which reacts with ethylamine under catalytic action of Glacial acetic acid; and bupirimate is obtained by the reaction of the 5- normal-butyl-2-nitryl amine-6- methyl pyrimidine-4- phenol and N, N-Dimethylsulfamoyl chloride in the presence of alkalescence. The bupirimate prepared by the synthesizing method has the purity quotient up to 95.4 percent, and the total yield coefficient up to 78.6 percent. The method is mainly used to prepare the bupirimate.

Owner:XIAN MODERN CHEM RES INST

Chinese chestnut rice wine and preparation method thereof

ActiveCN105296281ASweet and mellow tasteWith promoting blood circulation and removing blood stasisAlcoholic beverage preparationRed yeast riceDistillation

The invention relates to the technical field of nutritious and healthy wine processing, and especially relates to a Chinese chestnut rice wine and a preparation method thereof. The Chinese chestnut rice wine comprises the following raw materials in parts by weight: 30-50 parts of Chinese chestnut, 30-50 parts of glutinous rice, 8-14 parts of monocrystal rock sugar, 8-10 parts of red yeast rice, 1-5 parts of rice koji, and 1-5 parts of saccharomyces cerevisiae. The steps of crushing, saccharification, fermentation and distillation are carried out on raw materials of the provided Chinese chestnut rice wine, the Chinese chestnut rice wine is characterized in that the Chinese chestnut rice wine has crystal bright color, the color is orange red or bright red, nutrient composition is high, local flavor is unique, taste is sweet, obvious Chinese chestnut flavor and special ethyl caproate fragrance of the rice wine are provided; and the Chinese chestnut rice wine has the health caring functions of promoting blood circulation to remove blood stasis, invigorating spleen and promoting digestion, nourishing stomach and invigorating spleen, nourishing liver and tonifying kidney, delaying aging, treating beauty and skin, effectively adjusting human body, and reducing blood pressure and blood fat. The Chinese chestnut rice wine enables long-term preservation in a porcelain pot.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

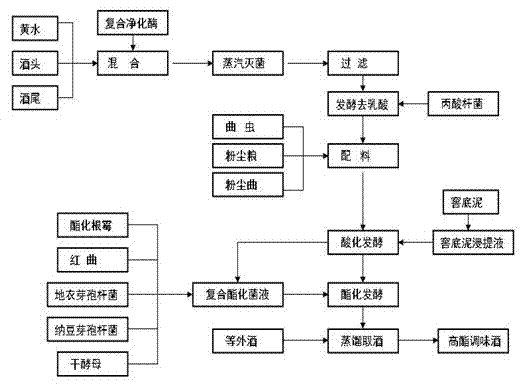

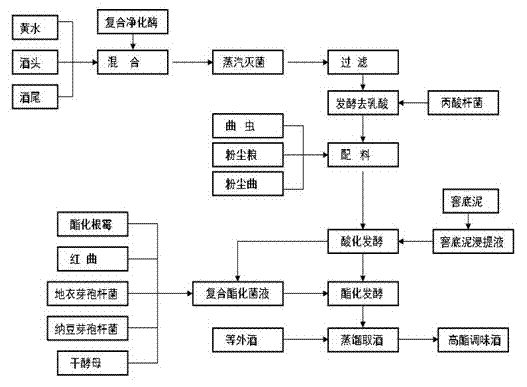

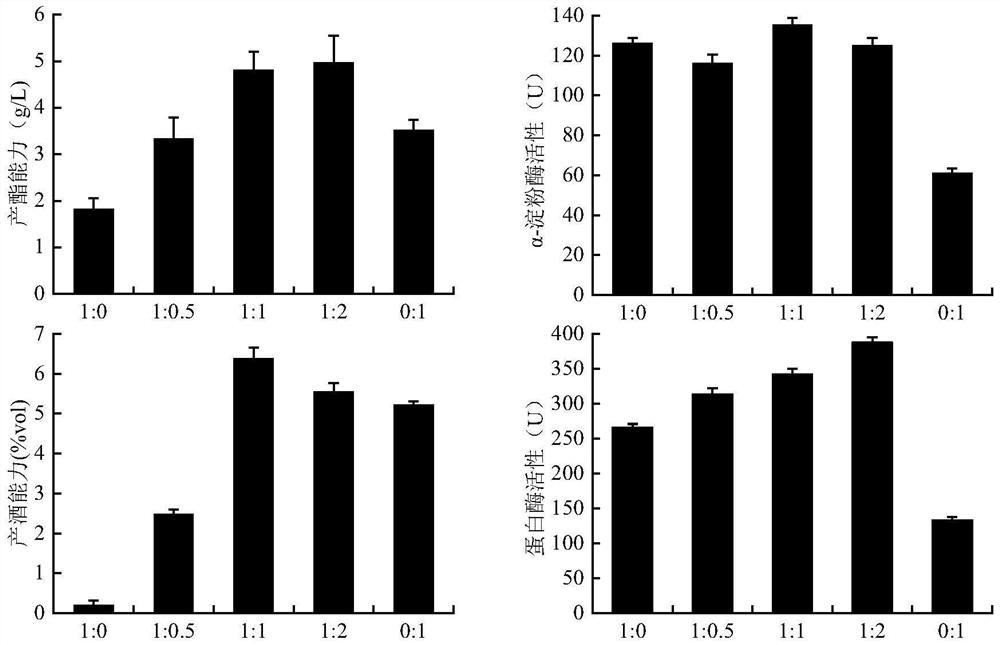

High-fat flavoring wine containing healthy flavor components and preparation method thereof

ActiveCN102408967ARemarkable fragrance functionTypical wine styleAlcoholic beverage preparationMicroorganism based processesBiotechnologyFuran

The invention discloses a high-fat flavoring wine containing healthy flavor components. The high-fat flavoring wine is prepared by a method comprising the following processes: pretreating raw materials; fermenting and removing lactic acid; burdening; acidifying and fermenting; and distilling and taking out wine. The preparation method comprises the following steps: mixing yellow water and foreshot with feint and then adding composite purification enzyme for sterilization and filtration to obtain a mixed liquor; inoculating propionibacterium in the mixed liquor for fermentation to remove lactic acid; adding powder starter, powder grain and starter pest powder; adding kiln bottom mud leach liquor for seal fermentation; preparing a composite esterified bacterium liquid with a fermented material; adding the composite esterified bacterium liquid in the remained fermented material for fermentation to obtain an esterified liquor; and preparing the high-fat seasoning wine by using overgauge wine and the esterified liquid, discarding stillage and distilling and taking out wine. Ethyl caproate, ethyl lactate, ethyl acetate, ethyl butyrate, Monacolin-K, tetramethylpyrazine, soy ketone, benzofuran, 5-hydroxymethyl-2-furfural and chitin are contained in distilled spirit with the alcohol strength of 50-68V / V%. After the flavoring wine is blended with the distilled spirit, the healthy flavorcomponents are duplicated. The high-fat flavoring wine in the invention can be used as a health distilled spirit.

Owner:SICHUAN TUOPAI SHEDE WINE

Thick film nanometer gold electrode slurry and preparation method thereof

InactiveCN101436441ASmall particle sizeChange the microstructureConductive materialNon-conductive material with dispersed conductive materialCelluloseSlurry

The invention relates to a lead-free thick film nanometer gold electrode slurry which selects nanometer gold powder as a main functional phase, in particular to a thick film nanometer gold electrode slurry and a method for preparing the same. The thick film nanometer gold electrode slurry is characterized by comprising the following components by weight portion: 60 to 90 portions of inorganic part and 40 to 10 portions of organic solvent, wherein the inorganic part comprises the following components by weight portion: 90 to 98 portions of noble metal nanometer gold powder, 2 to 10 portions of lead-free glass powder and 0 to 6 portions of inorganic additive; and the organic solvent comprises the following components by weight portion: 40 to 90 portions of terpineol, 4 to 10 portions of ethyl cellulose, 3 to 30 portions of ethyl caproate, 1 to 6 portions of nitro cellulose, 1 to 25 portions of triethanolamine, and 1 to 6 portions of sodium dodecylsulphonate. The invention changes the microstructure of the gold electrode slurry so as to change the conductivity, the printing performance and the connecting firmness of the slurry, thus the application of the gold electrode slurry to electronic parts and components, in particular high precision electronic parts and components is greatly expanded.

Owner:IRICO

Honey-sweet type cigarette paper essence and preparation method thereof

ActiveCN104830529AOutstanding fragranceImprove aroma harmonyTobacco preparationEssential-oils/perfumesEthyl phenylacetateCocoa Extract

The invention provides a honey-sweet type cigarette paper essence and a preparation method thereof. The cigarette paper essence comprises the components according to the total weight of 1000 parts: 1-4 parts of beeswax absolute oil, 2-5 parts of celery seed oil, 5-15 parts of ethyl vanillin, 30-50 parts of phenethyl phenylacetate, 0.5-2 parts of ethyl phenylacetate, 0.1-0.5 parts of ethyl caproate, 1-5 parts of delta-decalactone, 1-5 parts of gamma-nonanoic lactone, 5-15 parts of a cocoa extract, 5-15 parts of a coffee extract, 100-200 parts of propylene glycol, and the balance a 70% ethyl alcohol. The cigarette paper essence has the beneficial effects that: 1, the flavor is rich in hierarchy, can be coordinated with a tobacco original flavor, and can give cigarettes a unique style; 2, a small amount of addition of the essence can bring a prominent and lasting smell to the cigarettes; and 3, the loss of the aroma brought by reducing tar and harmful components is made up, a relatively good modification effect is played on the overall organoleptic characteristics of the cigarettes, and the quality of the cigarettes is facilitated to be improved.

Owner:HUBEI CHINA TOBACCO IND +2

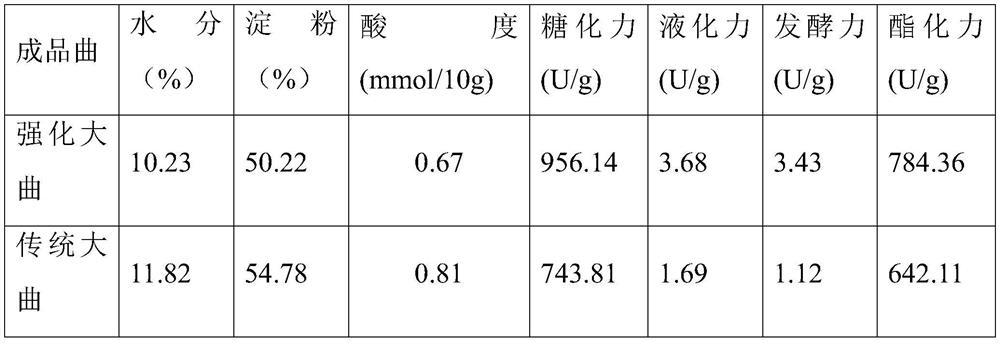

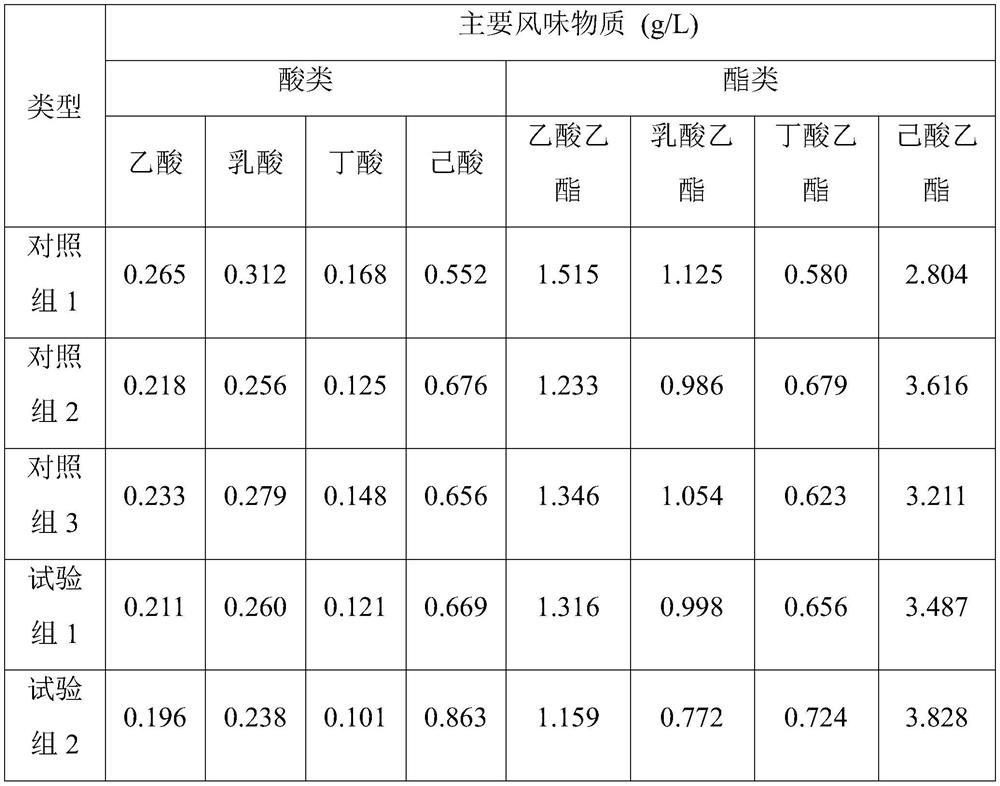

Method for increasing content of ethyl caproate in Luzhou-flavor liquor

ActiveCN112725114APromote growth and reproductionEasy to prepareMicroorganism based processesAlcoholic beverage preparationBiotechnologyMicroorganism

The invention discloses a method for increasing content of ethyl caproate in Luzhou-flavor liquor. The method comprises the following steps: preparing a bacterial solution A, preparing a bacterial solution B, and preparing a composite functional bacterial solution C; preparing reinforced Daqu D; and preparation of pit mud microorganism enrichment liquid E and fermentation in a pool. According to the method, bacillus siamensis and candida utilis are selected for culture and fermentation, reinforced yeast is prepared, and the content of an ethyl caproate precursor substrate in the pit is increased through the synergistic effect of the reinforced yeast and the pit mud microorganism enrichment liquid, so that synthesis of ethyl caproate is promoted. When the method is used for brewing the Luzhou-flavor liquor, the ethyl caproate content of the raw liquor produced by the new cellar and the aging cellar is obviously improved, the Luzhou-flavor style of the liquor body is prominent, and the aroma is mellow.

Owner:XIHUA UNIV +1

Orange essence

The invention provides an orange essence, consisting of the following components in parts by weight: 1-100 parts of an essence base, 10-50 parts of a solvent, 0-20 parts of a surfactant, 0-15 parts of a cosurfactant and 20-80 parts of a carrier, wherein the essence base consists of the following components in parts by weight: 10-40 parts of citral, 10-40 parts of linalool, 10-40 parts of terpineol, 0-10 parts of peach aldehyde, 5-10 parts of ethyl acetate, 1-30 parts of ethyl butyrate, 5-15 parts of dihydro jasmone, 5-20 parts of ethyl caproate, 5-20 parts of isobutyl acetate and 5-10 parts of lemon oil. The orange essence provided by the invention has a fresh fragrance of an orange juice, and enables consumers to feel the flavor of oranges.

Owner:顾明岐

Functional microbial agent for synthesizing caproic acid by degrading lactic acid and application thereof to pit mud curing

ActiveCN105385644AReduce accumulationLower lactic acid contentBacteriaMicroorganism based processesMicroorganismMicrobial agent

The invention relates to a functional microbial agent with the function of synthesizing caproic acid by degrading lactic acid. The microbial agent is prepared from viable bacteria of clostridium tyrobutyricum, clostridium sporogenes and clostridium kluyveri and can be used for curing pit mud in a baijiu cellar. The mixed floras can be used for curing pit mud, reducing lactic acid accumulation in the pit mud and preventing the pit mud from hardening, and can increase the content of important flavor substances including caproic acid and ethyl caproate in baijiu to produce the high-quality baijiu.

Owner:LUZHOU PINCHUANG TECH CO LTD +1

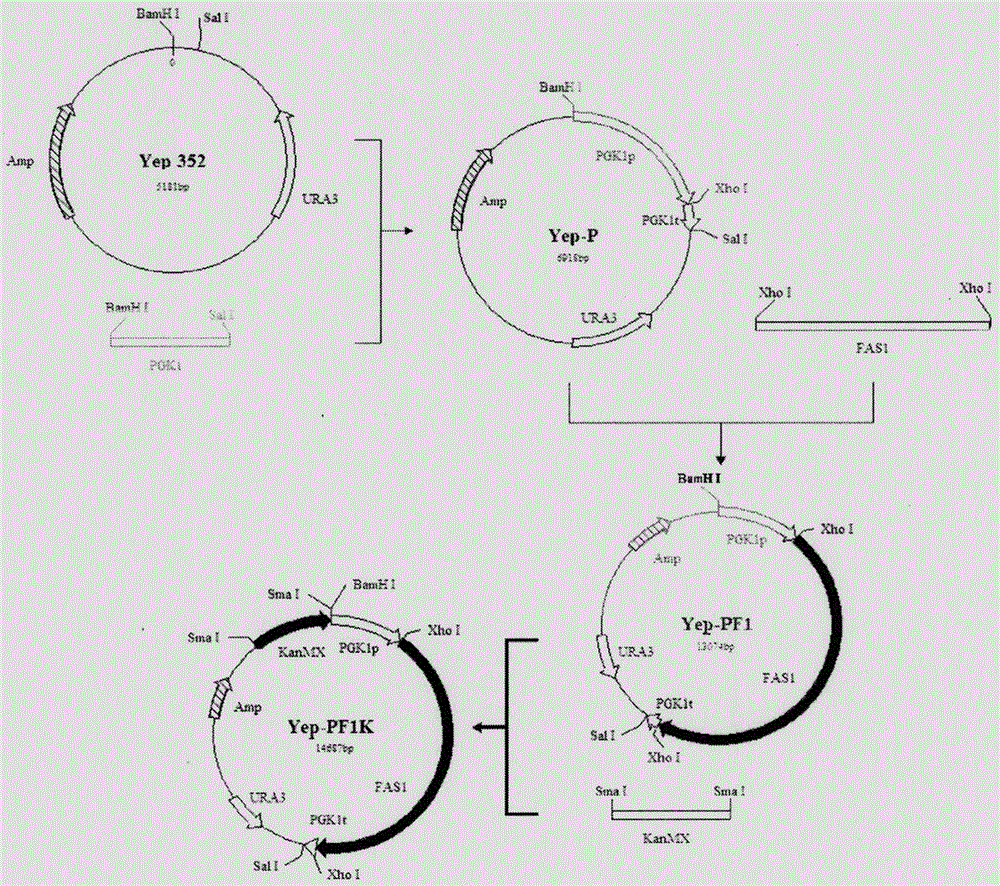

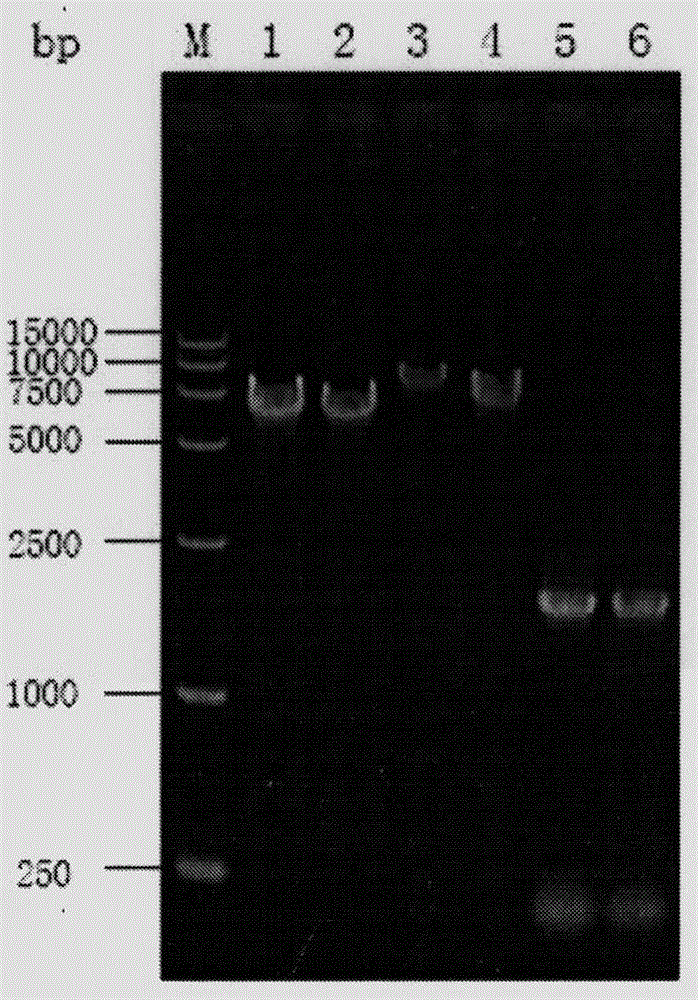

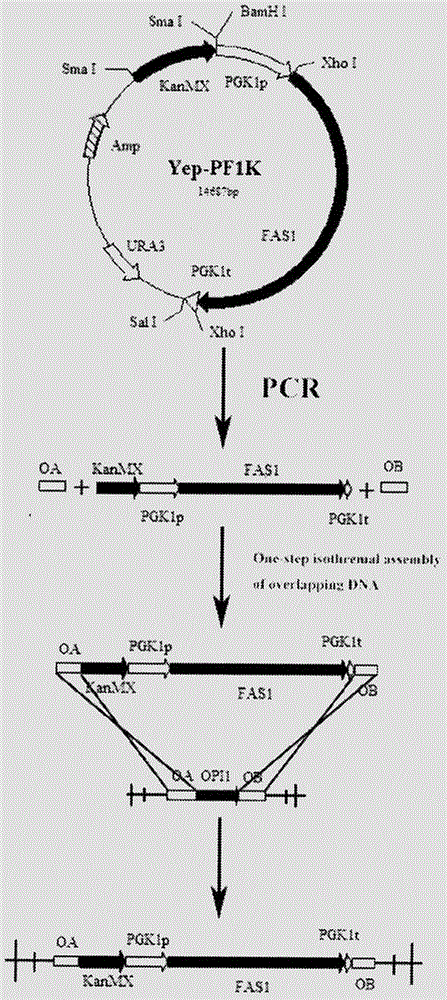

Saccharomyces cerevisiae strain with high yield of flavor ethyl ester and construction method of saccharomyces cerevisiae strain

The invention provides a saccharomyces cerevisiae strain with high yield of flavor ethyl ester and a construction method of the saccharomyces cerevisiae strain. An encoding gene FAS1 of a strong promoter PGK1 over-expressed fatty acid synthetase beta subunit is selected, an inositol-mediated controlling gene OPI1 is knocked out, and the saccharomyces cerevisiae strain with high yield of flavor ethyl ester is obtained. Compared with original strains, the strain has the following advantages under the condition that other fermentation performance of the strain is basically not affected: the content of ethyl acetate reaches 52.49 mg / L and is increased by 2.61 times than that of the original strains after 5 days of simulated liquid-state liquor fermentation of a corn material; the content of medium-chain fatty acid ethyl ester ethyl caproate, the content of ethyl caprylate, the content of ethyl caprate and the content of ethyl laurate are increased by 1.21 times, 2.66 times, 2.53 times and 1.27 times respectively than those of the original strains; the content of long-chain fatty acid ethyl ester ethyl myristate and the content of ethyl palmitate are increased by 1 time and 56.7% respectively.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

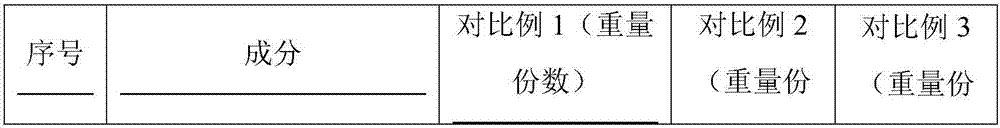

Pickled pod pepper flavor essence and production method of same

ActiveCN106912886AStrong sense of fermentationFull and lasting aromaFood ingredient as flavour affecting agentNatural extract food ingredients1-OcteneButyl caproate

The invention relates to a pickled pod pepper flavor essence, including: propylene glycol, alpha-pinene, butyl caproate, a pod pepper extract, beta-pinene, hexyl butyrate, acetic acid, 1-octene-3-ol, ethyl acetate, pentanal, 3-methylmercapto-propyl alcohol, alpha-terpineol, isopentyl alcohol, ethyl caproate, methyl salicylate, 2-methyl butanol, hexyl acetate, hexyl 2-methylbutyrate, ethyl 2-methylbutyrate, linalool, anisic aldehyde, allyl isothiocyanide, isopentyl isovalerate, mercaptan, 2-methyl butyric acid, 2-methoxy-3-isobutyl pyrazine and 3-methylthio propylaldehyde. The pickled pod pepper flavor essence has strong fermented sense and has a full and durable fragrance, is stable in quality and has pure and natural fragrance, which is approximate to the fragrance of naturally fermented pickled Capsicum frutescens (pod pepper). The pickled pod pepper flavor essence has better effects than other pod pepper flavor essences in meat products and spices, and is well received among customers in practical application and market promotion.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Esterification accelerant and method for preparing esterifying liquid by using same

InactiveCN101962607ASignificantly progressiveSolve the problem of hexanoylation inhibitionAlcoholic beverage preparationOrganic acidIsobutyl alcohol

The invention relates to an esterification accelerant consisting of alcohol substances and a method for preparing high-titer esterifying liquid by using the same. The esterification accelerant is one or more selected from n-propanol, isobutyl alcohol, butanol, hexanol and beta phenethanol. After the esterification accelerant of the invention is added during the preparation of the biological esterifying liquid, high-efficiency biological esterification synthesis can be performed on organic acids, such as caproic acid and the like, and simple raw materials, such as foreshot, feint and the like, so as to obtain flavor components, such as ethyl caproate and the like; and the accelerant and the method also have an obvious effect on the synthesis efficiency of esters in a kiln.

Owner:HUBEI UNIV OF TECH

Cave type pit, pit mud and method of brewing highly flavored type basic liquor by cave type pit and pit mud

ActiveCN105349400AIncrease aromaAvoid deathAlcoholic beverage preparationCellar toolsYeastEngineering

The invention discloses a cave type pit, pit mud and a method of brewing highly flavored type basic liquor by the cave type pit and the pit mud, relating to the field of wine brewing. The pit is located in a cave, wherein a plurality of pits are arranged in the cave; the top of the cave is covered with mud with the thickness of 4-12m; the height of the cave is 6-8m; the cave is provided with an entrance; the distance between the pits and the entrance of the cave is 15-25m, and the pit mud is smeared on the inner walls of the pits. The pit mud is prepared from 5-15 parts of yellow water, 20-35 parts of tail water, 50-80 parts of loess, 2-4 parts of powder of yeast for making hard liquor, 10-20 parts of saccharomycetes, 5-15 parts of ethyl caproate esterifying bacteria, 1-3 parts of aroma-producing yeast, 5-10 parts of distiller's grain, 5-20 parts of grain lees and 10-20 parts of chitin according to parts by mass. The problem that white spirit cannot be safely stored in summer is solved, so that the white spirit can be produced continuously in the season with higher temperature, and the basic liquor with higher quality can be obtained.

Owner:武汉雅仕博科技有限公司

Method for shortening period of Luzhou-flavor liquor fermentation by external esterification

InactiveCN108277132AIncrease the bodyShorten the fermentation cycleMicroorganism based processesAlcoholic beverage preparationAlcohol contentEthyl ester

The invention discloses a method for shortening the period of Luzhou-flavor liquor fermentation by external esterification. By culturing external caproic acid compound acid liquor, the compound acid liquor based on caproic acid is obtained; strong liquor is then used for regulating the alcohol content of the mixed liquid, yellow fermentation liquid and esterifying enzyme are added, and by externalnormal-temperature closed esterification, mature esterified liquid is obtained; and before being loaded into a steamer, the mature esterified liquid is added into a bottom pan to undergo the cross-steaming of liquor. Because of the optimized culture of the external liquor of caproic acid, the method realizes high caproic acid concentration, the formation of composite ester flavor based on ethyl caproate is accelerated by the esterifying effect of the external esterifying enzyme, the intensity of short-period Luzhou-flavor liquor is increased by the cross-steaming process, and thereby, while the concentration level of caproic acid and ethyl caproate in raw liquor is increased by two to three times, the intensity of the liquor body is greatly increased. The invention provides a basis for the controllable high-quality brewing of Luzhou-flavor liquor.

Owner:江苏汤沟两相和酒业有限公司 +1

Banana essence

The invention discloses a banana essence. The banana essence is characterized by being prepared from, by weight, 0.2-0.4% of vanillin, 8-10% of isoamyl acetate, 0.05-0.08% of linalyl acetate, 0.06-0.08% of linalool, 0.1-0.25% of benzyl acetate, 1.1-1.3% of ethyl butyrate, 2-2.5% of isoamyl butyrate, 0.3-0.4% of ethyl caproate, 0.05-0.1% of eugenol, 0.01-0.03% of citral, 5-7% of sweet orange base, 0.002-0.008% of furanone, 60-65% of ethyl alcohol and the balance distilled water. The banana essence has the advantages of being simple in formula, pure in fragrance, low in cost, especially suitable for being applied to frozen food, and capable of bringing a strong summer freshness sense to people.

Owner:SHANGHAI PEACOCK FLAVORS & FRAGRANCES TECH CO LTD

Essence made of orange juice

The invention discloses an orange water essence, formed by 1% butyl acetate at 0.18-0.26, 1% aldehyde group NO. 3 at 0.08-0.15, 1% alcohol at 0.01-0.02, 1% 3-hydroxy ethyl caproate at 0.015-0.023, 1% reverse-2-hexenol at 0.020-0.035, 1% ethyl caproate at 0.008-0.012, 1% fragrance at 0.016-0.025, 1% citral at 0.03-0.07, and the left is 10% orange oil. The invention can avoid the defects of present orange soluble essence as easy volatile and bad orange simulation, with natural feeling.

Owner:SHANGHAI INST OF TECH

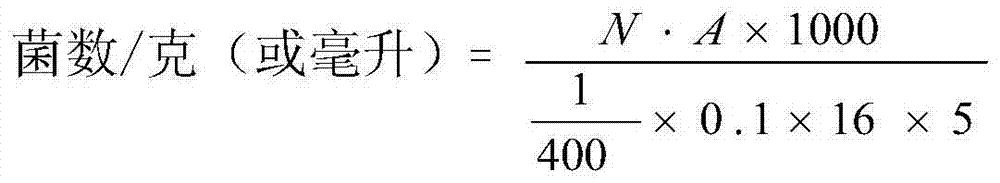

Dried pit mud functional bacteria protectant and application thereof

ActiveCN103497896AImprove antioxidant capacityNo side effectsFungiBacteriaMicroorganismSorbitan monostearate

The invention relates to a dried pit mud functional bacteria protectant. The dried pit mud functional bacteria protectant comprises sorbitan monostearate, trehalose, glycerin, D-sodium isoascorbiate and the balance water. The invention further provides a preparation method of the dried pit mud functional bacteria protectant and application of the dried pit mud functional bacteria protectant for preparing dried pit mud functional bacteria. Through proportioning of the sorbitan monostearate, trehalose, glycerin and the D-sodium isoascorbiate, cell viability of the dried active pit mud functional bacteria can be increased to 82-89%, survival rate of the dried active pit mud functional bacteria is increased to 80-85%, capability of the dried active pit mud functional bacteria for producing ethyl caproate is improved remarkably, and the shortcoming that existing microorganism protectants are not suitable for the functional bacteria in pit mud is solved.

Owner:JINAN RUIFENG BIO ENG

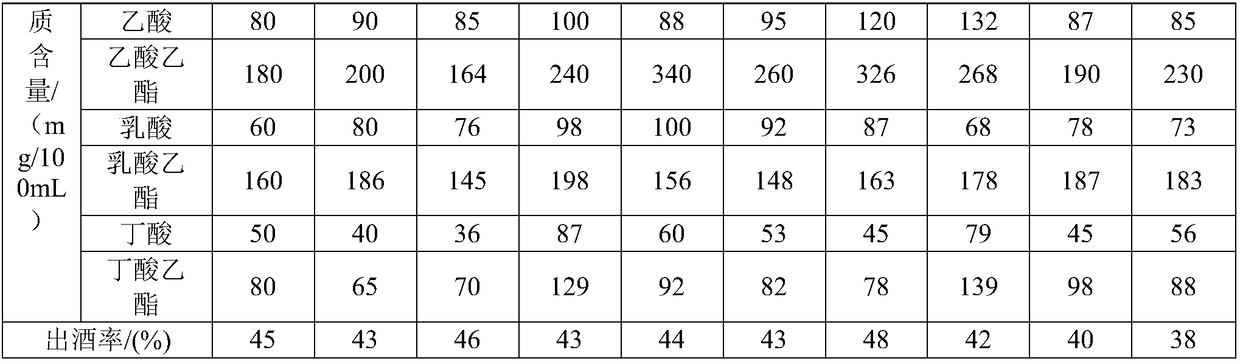

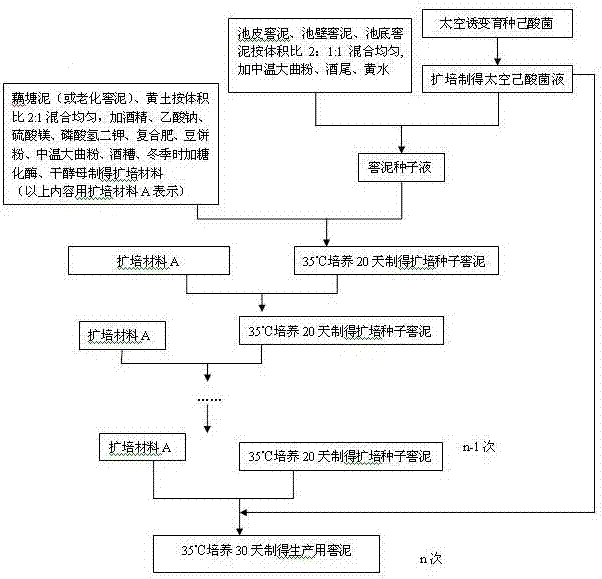

Preparation method of space caproic acid bacteria pit mud for brewing wine

ActiveCN103897920AStrong forceIncrease acidityAlcoholic beverage preparationMicroorganismEconomic benefits

The invention discloses a preparation method of space caproic acid bacteria pit mud for brewing wine. The method comprises the following steps: preparation of a space caproic acid bacteria liquid, preparation of pit mud seed liquor, seed pit mud propagation and production propagation. The pit mud which is vigorous and lasting in acting force of microorganisms, not easy to age is prepared and applied to brewing production of strong-flavor type and sesame-flavor type liquor; and the produced liquor is high in content of acid esters such as caproic acid, ethyl caproate, and the like, so that product quality is improved, and economic benefits are increased.

Owner:泰山酒业集团股份有限公司 +1

Method for preparing ethyl caproate by continuous esterification

InactiveCN101723828ATo avoidAvoid the defects of easy blackening and cokingOrganic compound preparationCarboxylic acid esters preparationAlcoholFixed bed

The invention discloses a method for preparing ethyl caproate by continuous esterification, which comprises the following steps of: mixing caproic acid and ethanol in the mol ratio of 1: (1-1.5), then preheating, esterifying by a fixed bed catalyst layer, then entering an ethanol fractionating tower, extracting 95%(V / V) alcohol obtained at the tower top, using the 95%(V / V) alcohol as a mixture and recycling; discharging the caproic acid and water from the tower bottom, separating out the caproic acid and recycling again; and leading out the total liquid phase from the position above a feed opening in the middle of the tower and naturally layering, wherein the upper layer is the water which reflows into the tower, and the lower layer is an ethyl caproate crude product which is extracted and refined separately. The method has the advantages that the method can operate within a wider esterification range without considering the conversion rate of the caproic acid; the unreacted caproic acid is separated from the water, thereby avoiding the defects of influencing the flavor of the ethyl caproate and reducing the yield caused by blackening and coking of the caproic acid due to heating when in conventional production and recovery; a neutralization washing work procedure is saved, and no neutralizing waste water exists; and the production efficiency is high.

Owner:河北科正化工有限公司

Flexible acrylic acid emulsion

A kind of soft propenoic acid latex is involved in this invention, whose formula has monomer with non saturated bond, emulsifying agent, and water. The said monomer contains methacrylate acetyl ether caproate whose content is 1.01-3.03% weight percentage in total latex besides propenoic acid and acrylate, methacrylate, styrene etc. contents. The invention acts methacrylate acetyl ethyl caproate as crosslinking agents which differs with other electriferous hydronium crosslinking agents because it produces short time polarity and produces crosslinking, and no confected latex has A-OK chemistry stability and can aggregate with cement as waterproof layer and tile putty having chapproof and alkaliproof capabilities, settless technical problem of properoic acid latex happening latex-broke when it meets strong electrolyte and not mixing with cement.

Owner:江苏日出化工有限公司

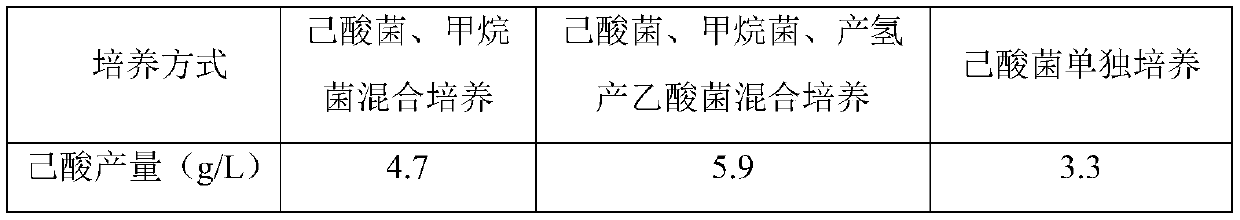

Composite caproic acid bacterium liquid for producing strength flavor type Baijiu and preparation method of composite caproic acid bacterium liquid

PendingCN110029076AThe taste of the wine is excellentIncrease contentBacteriaAlcoholic beverage preparationHydrogenEthyl ester

The invention discloses a preparation method of composite caproic acid bacterium liquid for producing strength flavor type Baijiu. The preparation method comprises the step of mixing enrichment liquidfor producing caproic acid bacteria through dulcitol, enrichment liquid for producing caproic acid bacteria through ethanol, enrichment liquid for producing caproic acid bacteria through lactic acid,enrichment liquid for producing hydrogen and producing caproic acid bacteria and enrichment liquid producing methane bacteria in the volume ratio being 2 to 1 to 1 to 1 to 1 to obtain the composite caproic acid bacterium liquid, wherein the enrichment liquid for producing caproic acid bacteria through dulsitol, the enrichment liquid for producing caproic acid bacteria through ethanol, the enrichment liquid for producing caproic acid bacteria through lactic acid, the enrichment liquid for producing hydrogen and producing caproic acid bacteria and the enrichment liquid producing methane bacteria are all bacterial liquid cultured to the log phase. The composite caproic acid bacterium liquid disclosed by the invention can be used for pit mud culture and pit mud conservation for production ofthe strength flavor type Baijiu, the contents of caproic acid and ethyl caproate as important flavor substances in the strength flavor type Baijiu can be increased, and the Baijiu quality is increased.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com