Patents

Literature

54results about How to "Oligomer content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst composition with mixed selectivity control agent and polymerisation method using it

ActiveCN102186889AImproved aggregation methodIncrease stiffnessOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen concentrationZiegler–Natta catalyst

The present disclosure provides a Ziegler-Natta catalyst composition comprising a procatalyst, a cocatalyst and a mixed external electron donor comprising a first selectivity control agent, a second selectivity control agent and an activity limiting agent. A polymerization process incorporating the present catalyst composition produces a high-stiffness propylene-based polymer with a melt flow rate greater than about 50 g / 10 min. The polymerization process occurs in a single reactor, utilizing standard hydrogen concentration with no visbreaking.

Owner:WR GRACE & CO CONN

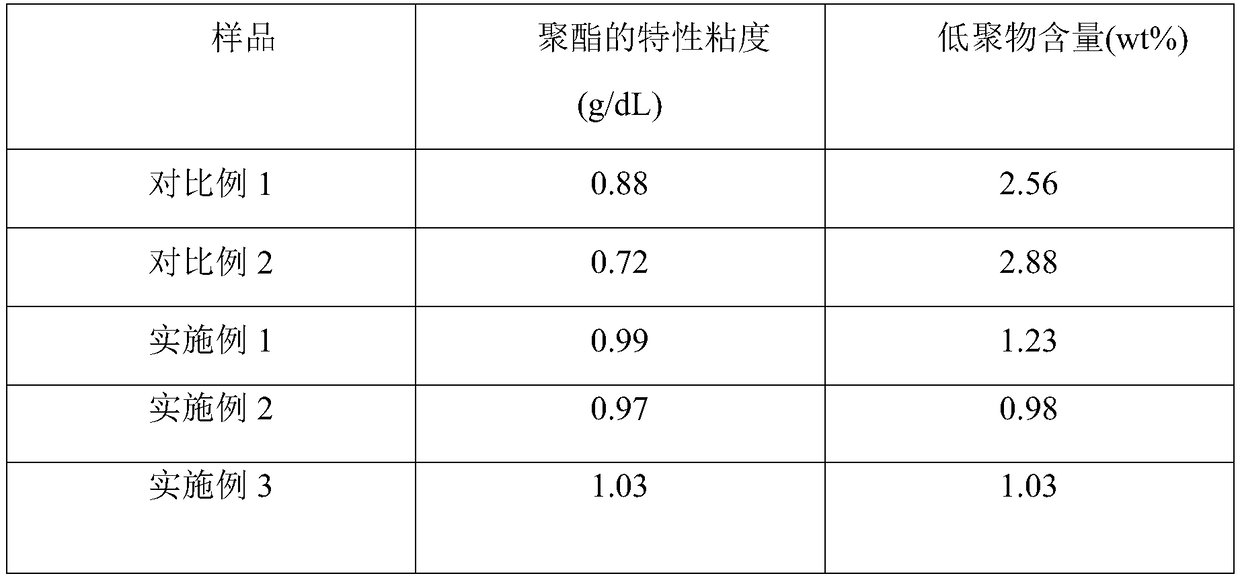

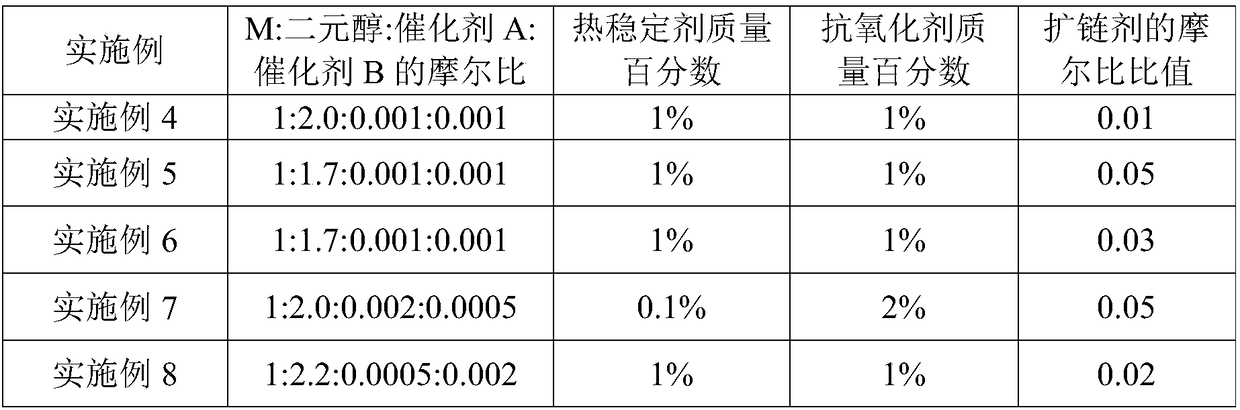

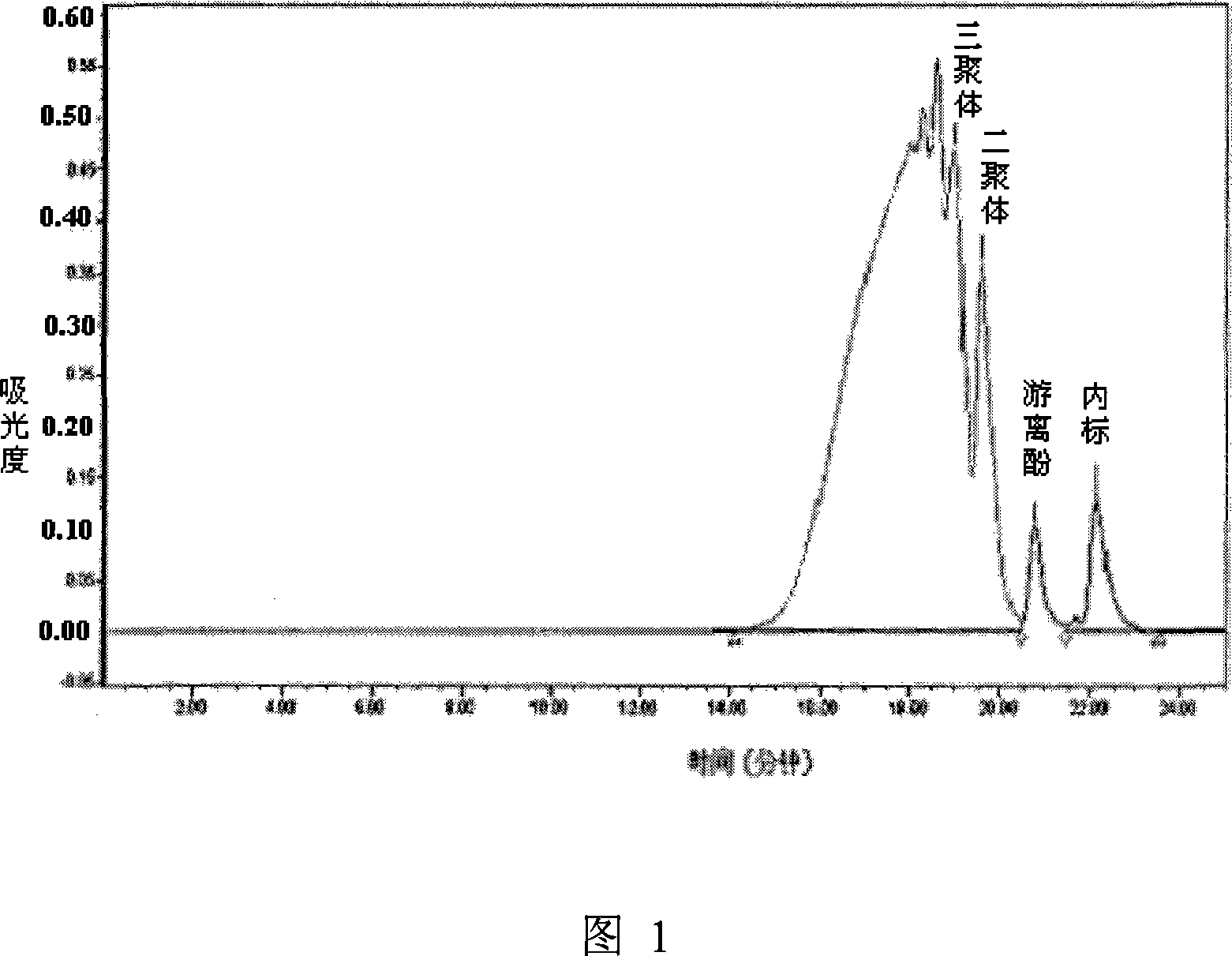

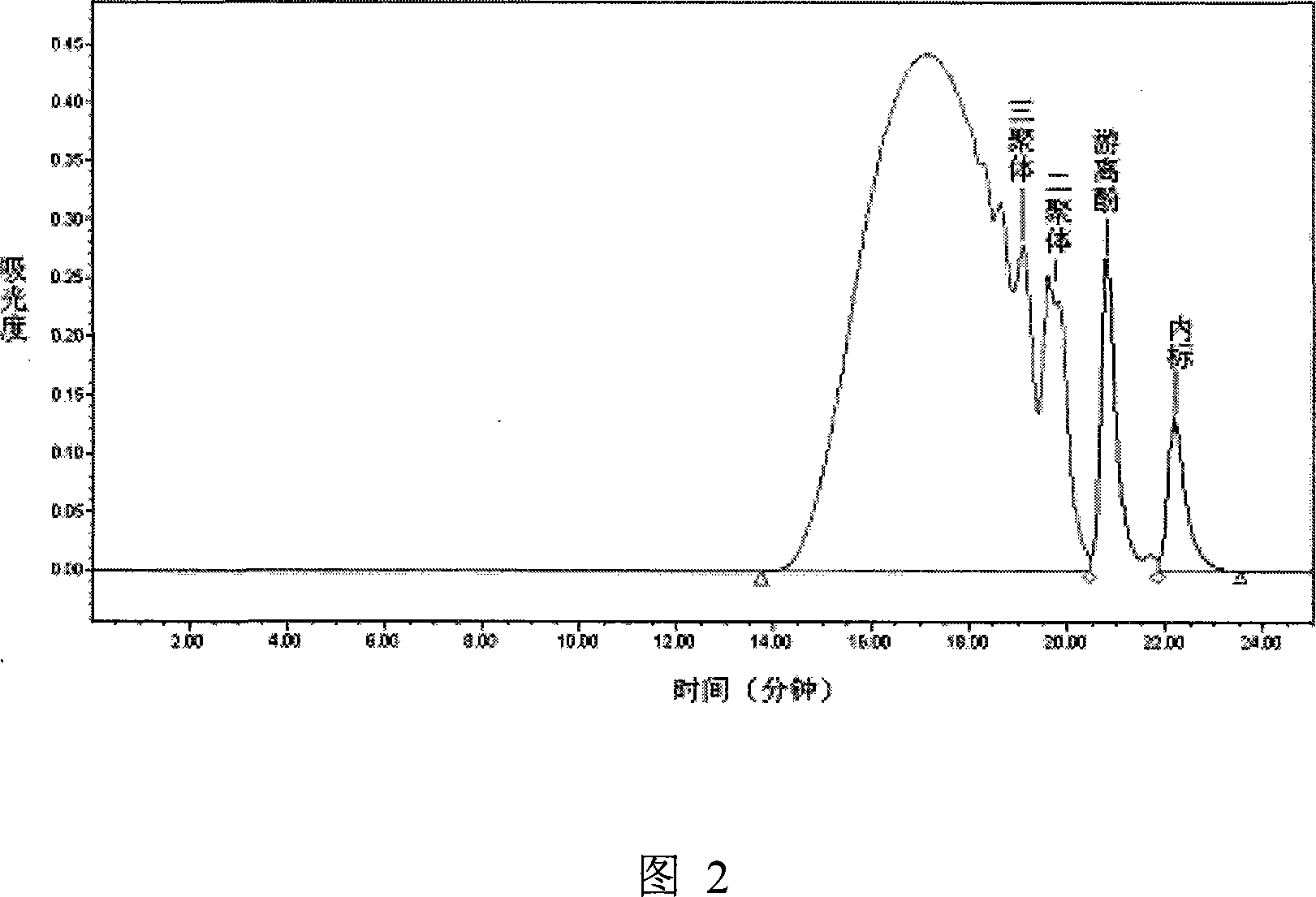

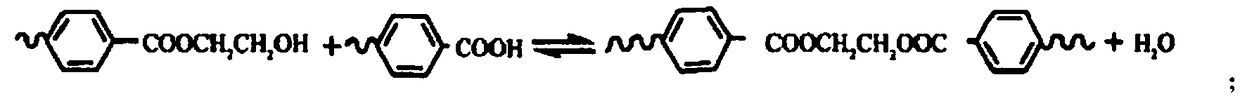

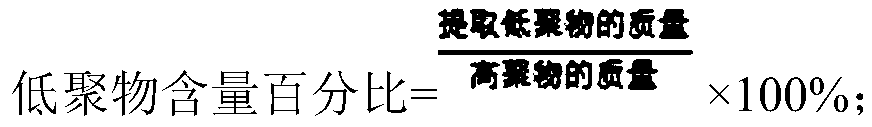

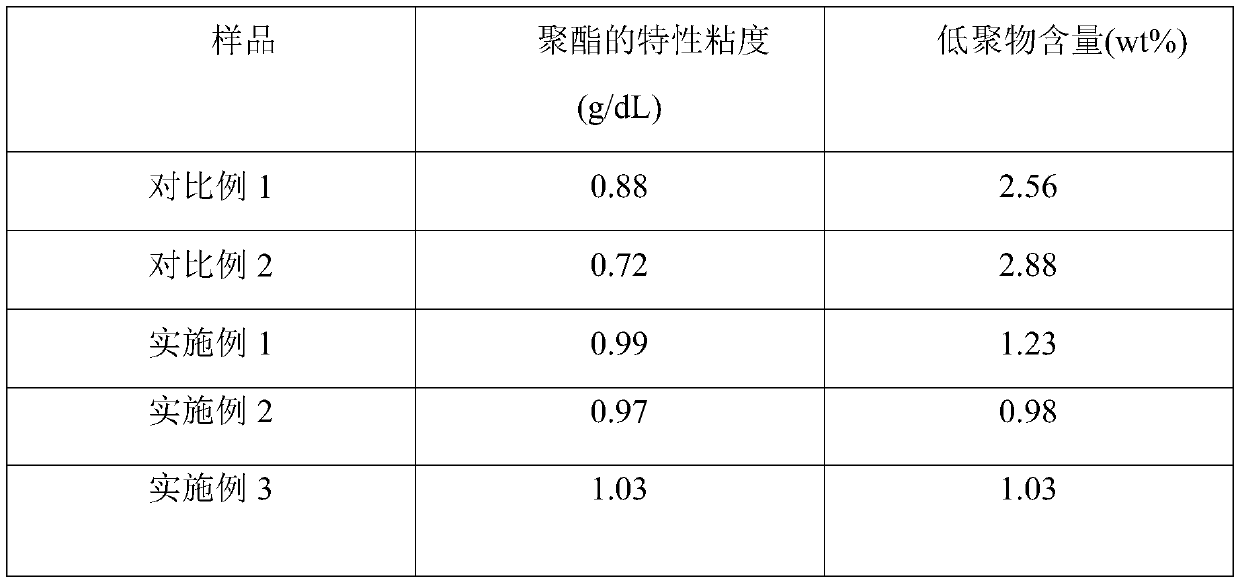

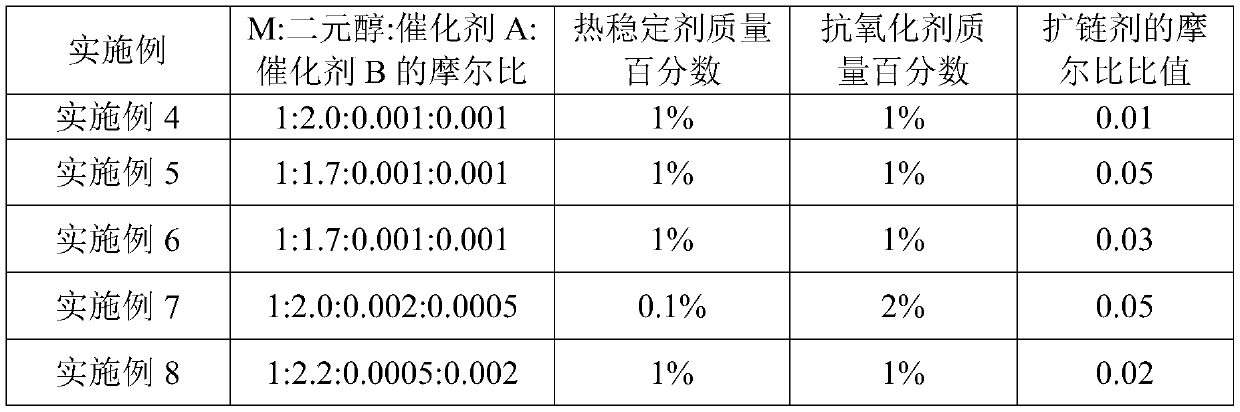

Polyester with low oligomer content and preparation method of polyester

The invention relates to a polyester with low oligomer content and a preparation method of the polyester. The method comprises the following steps: carrying out an esterification reaction and a first-stage condensation polymerization reaction on M and dihydric alcohol in the presence of a catalyst A; carrying out a second-stage condensation polymerization reaction; adding a catalyst B and carryingout a third-stage condensation polymerization reaction; and finally, adding a chain extender for carrying out a chain extension reaction, thereby obtaining the polyester with low oligomer content, wherein M is dicarboxylic acid or binary alkyl carboxylate; the catalyst A is a titanium catalyst, an antimony catalyst or metal acetate, the catalyst B is more than one of aluminum isopropoxide, dibutyl tin oxide, monobutyltin oxide, stannous octoate and stannous 2-ethyl caproate, and the oligomer content in the prepared polyester is less than 1.5wt%. The method disclosed by the invention is simplein operation, and the prepared product is low in oligomer content and has excellent popularization value.

Owner:DONGHUA UNIV

Narrow distribution linear phenolic resins and preparation method thereof

The present invention discloses one kind of linear phenolic resin with narrow molecular weight distribution and its preparation process. The linear phenolic resin is prepared with phenols and aldehydes under the action of composite catalyst including acid and layer silicate. It has the features of low oligomer content and narrow molecular weight distribution, and may be applied as the adhesive for Bakelite, friction material, grinding tool, etc.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

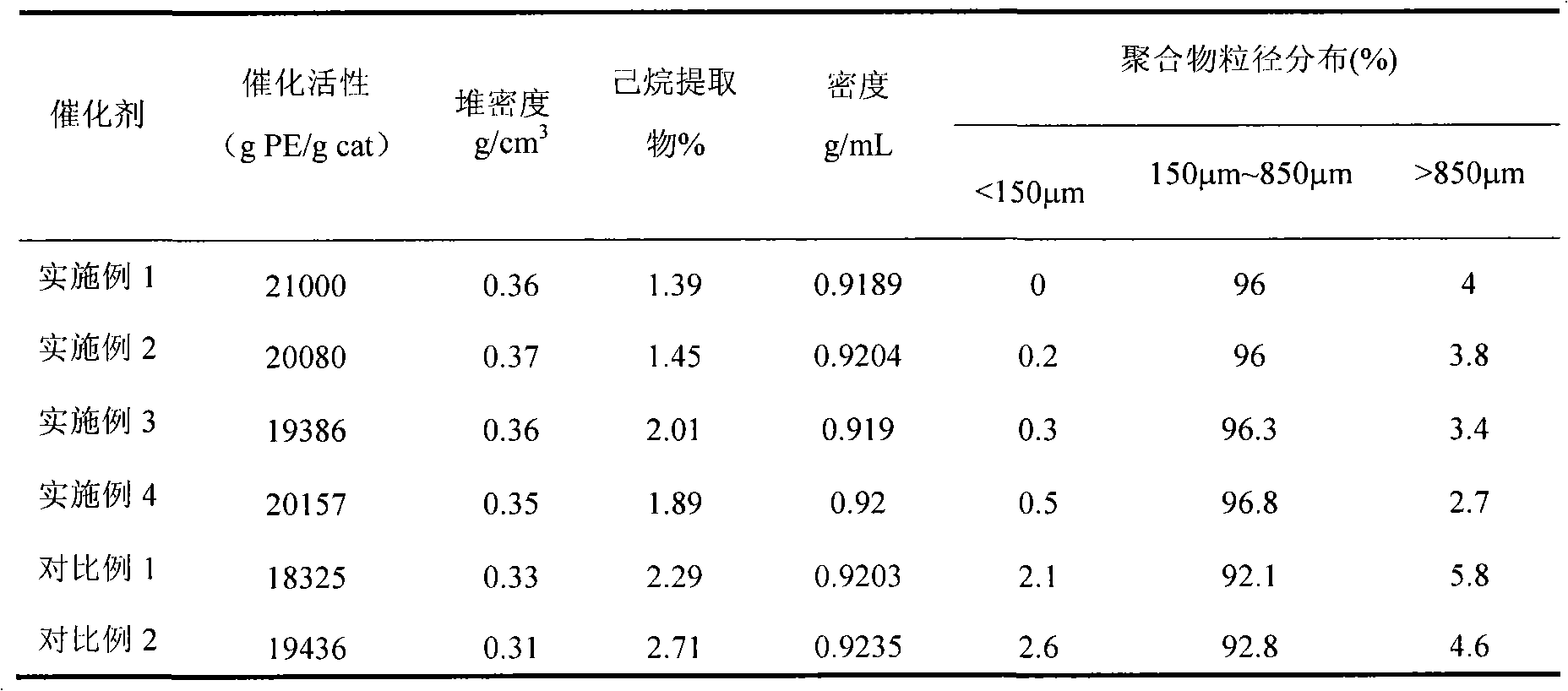

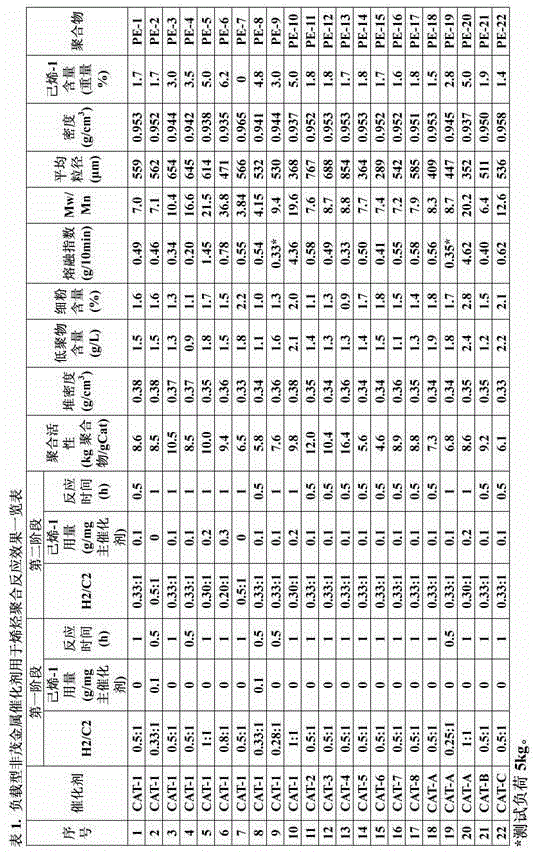

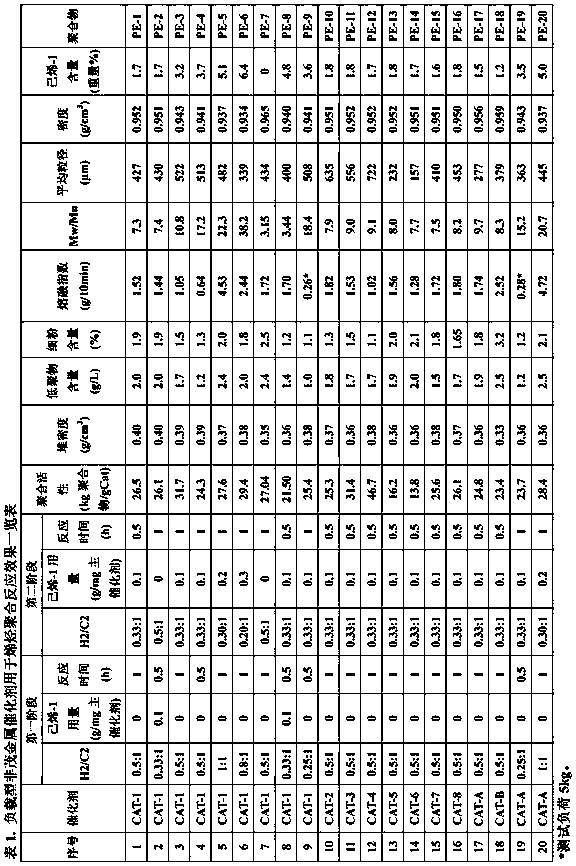

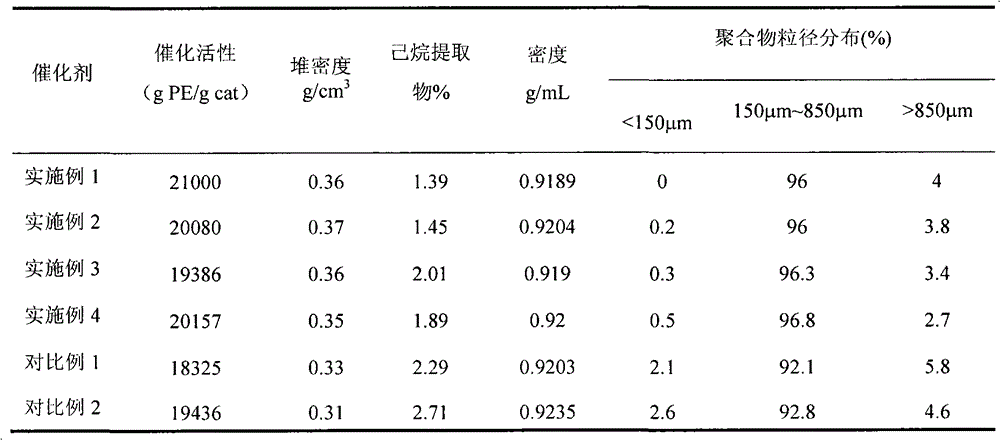

Catalyst for gas-phase polymerization or copolymerization of ethylene and preparation method thereof

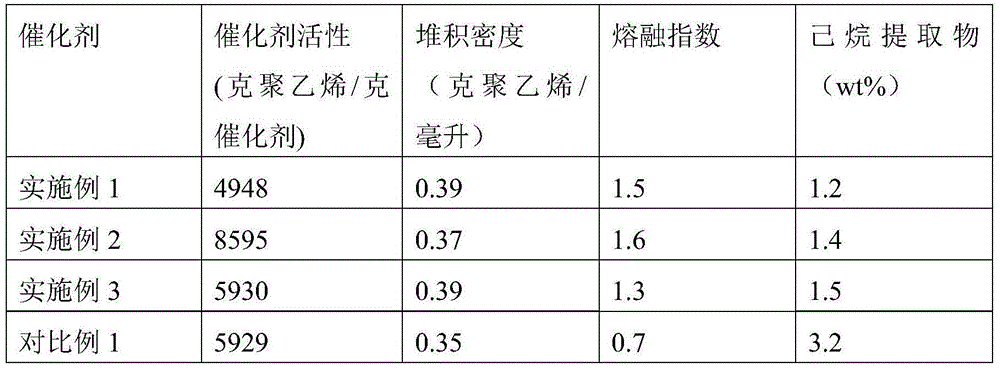

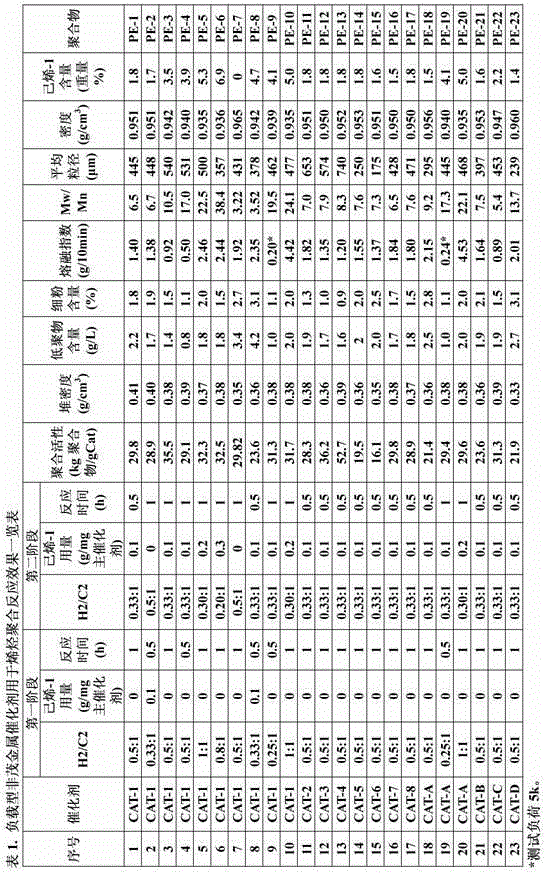

InactiveCN101864013AParticles in good shapeFlat surfaceBulk chemical productionChemistryActive agent

The invention relates to a catalyst for the gas-phase polymerization or copolymerization of ethylene and a preparation method thereof. The catalyst consists of a titanium-containing active ingredient and an active agent, wherein the titanium-containing active ingredient is formed by loading at least one kind of halogenated titanium, at least one kind of electron donor compound and a surfactant ona halogenated magnesium / silicon dioxide double carrier; the electron donor compound may be an alcohol or an ether; and the surfactant may be an anionic surfactant, a cationic surfactant or a nonionicsurfactant. A surfactant is added into the mother liquor of the active ingredient of the catalyst, so when the components of the catalyst are used for the polymerization or copolymerization reaction of ethylene together with an organic aluminum auxiliary catalyst, the obtained product of the polymerization of ethylene has low hexane-extractable material content, the catalytic activity of the catalyst is improved obviously, the grain shape and grain size distribution of polyethylene are improved obviously.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparation method of oligomer grape seed procyanidin

The invention relates to a preparation method of oligomer grape seed procyanidin. The preparation method comprises the following steps that: firstly, after grape seeds are washed and cleaned by clear water, the grape seeds are added into an ethanol solution, leached, filtered and removed, and an extracting solution is collected; secondly, the extracting solution is regulated by an NaOH solution, slightly stirred to separate out a brick-red procyanidin coarse sediment, and the sediment is filtered and collected; thirdly, the sediment is put into the ethanol solution and dissolved, and filter liquor containing dissolved procyanidin is collected; and finally, the filter liquor is filtered by a nano filter film, oligomer procyanidin intercepted and deposited on the filter film is collected, the sediment is respectively washed by acetone and ethanol, and an oligomer procyanidin product is obtained after the sediment is put into a drying oven and dried.

Owner:QINGDAO UNIV +1

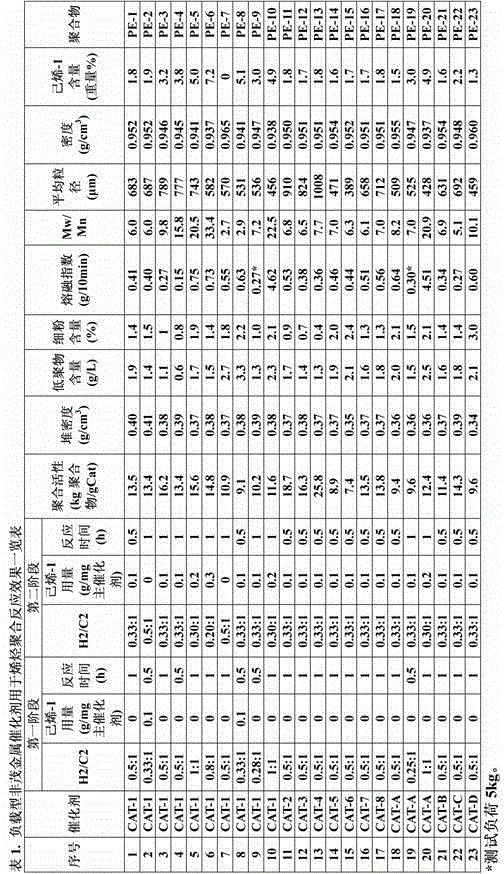

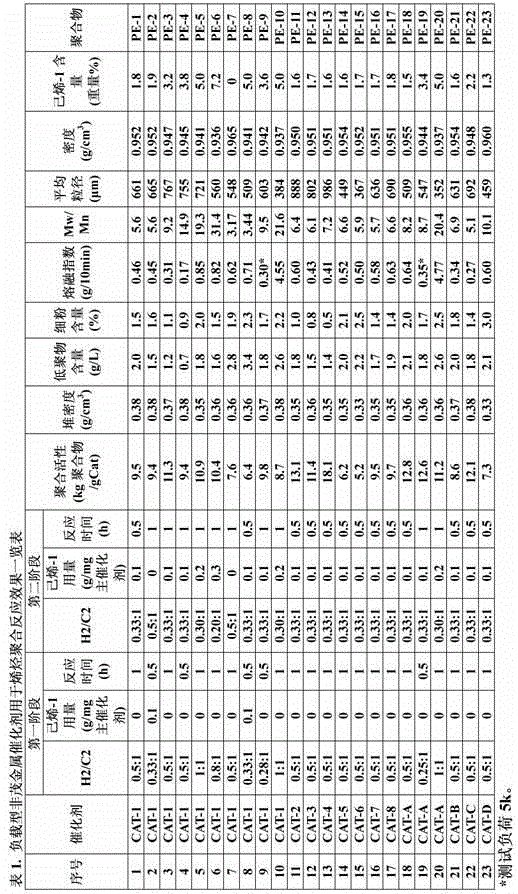

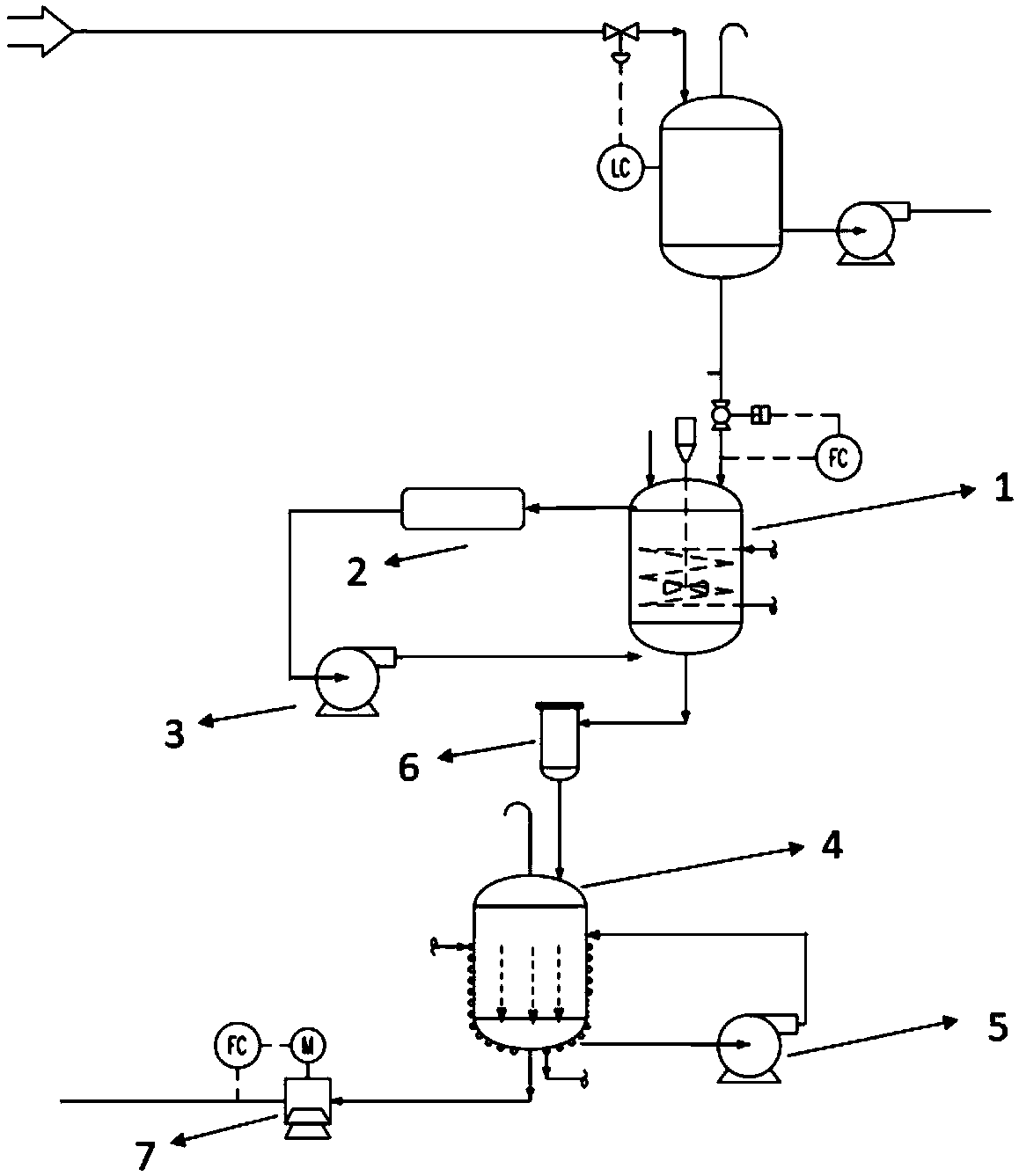

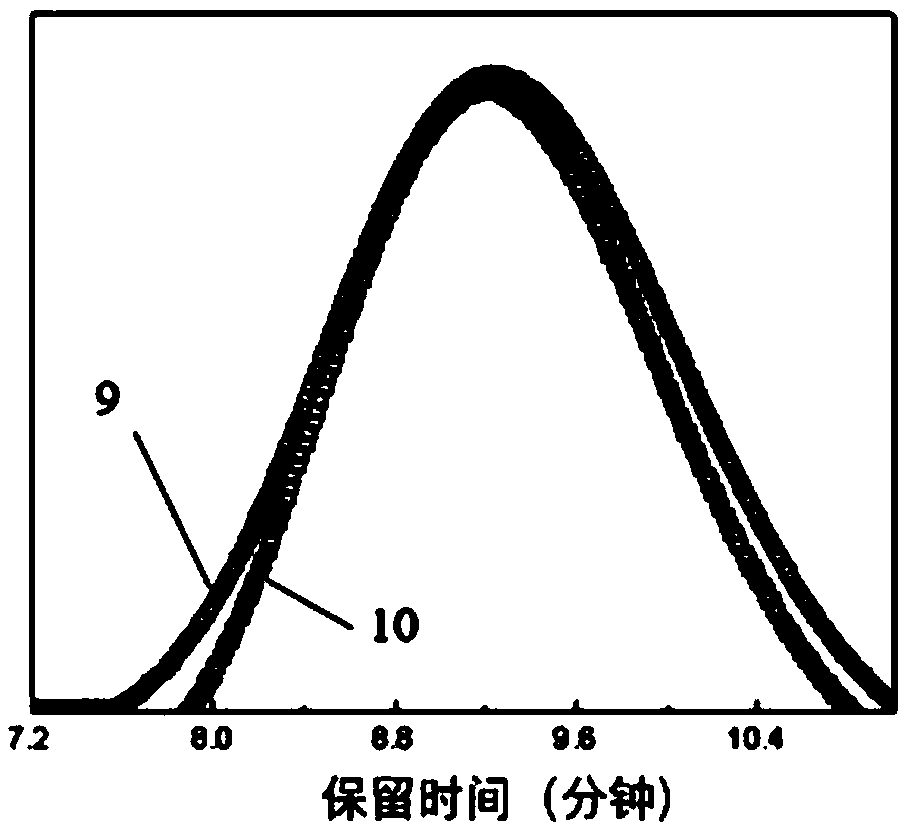

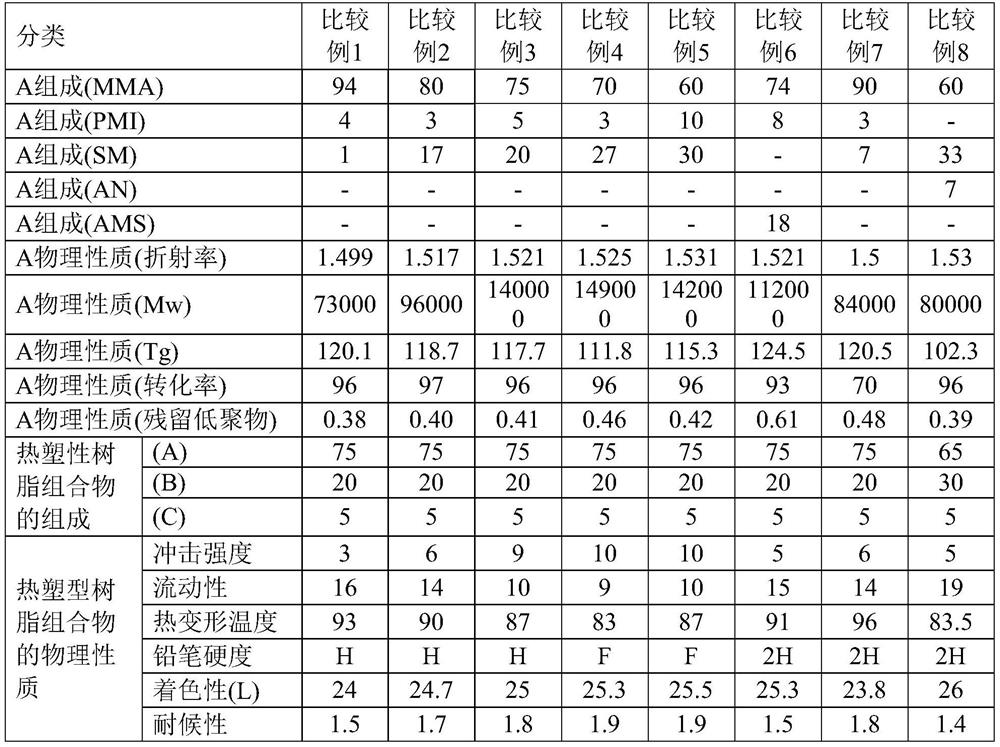

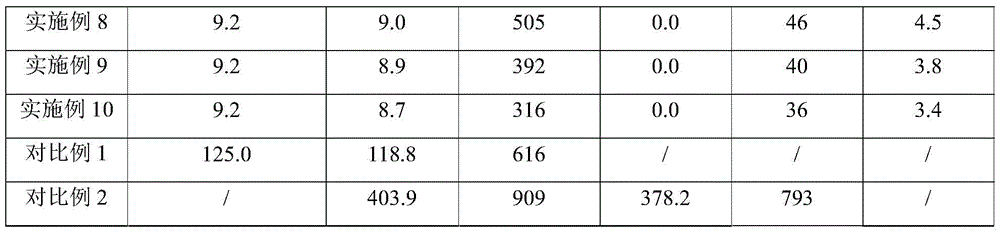

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

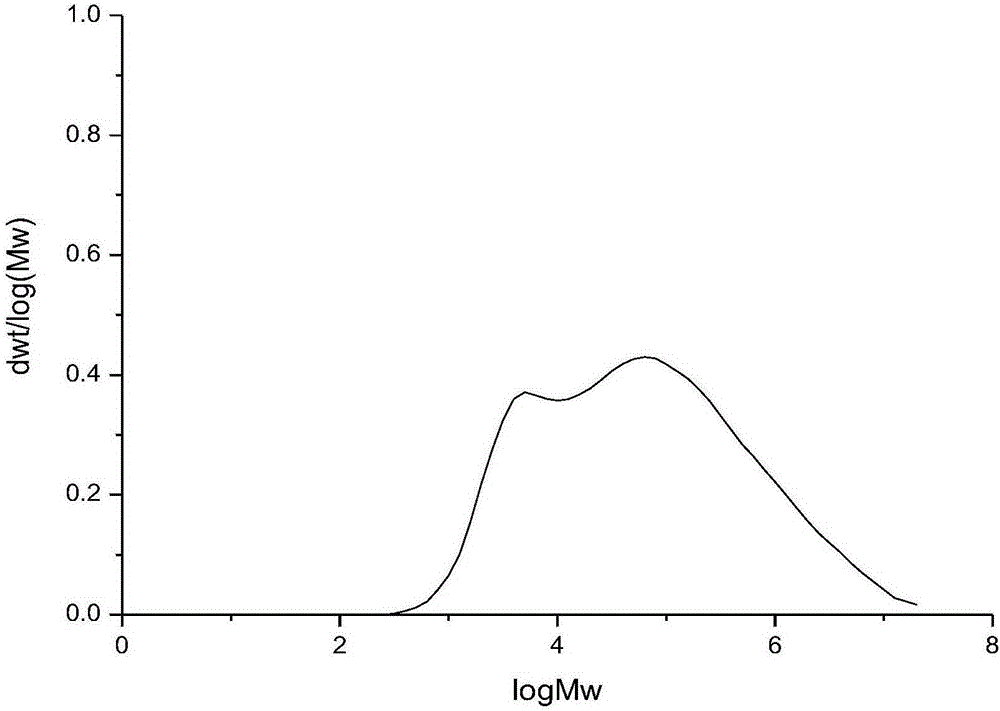

ActiveCN105001360AUniform particle sizeAppropriate molecular weight distributionComposite materialAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molded product manufacturing. According to the present invention, the ethylene-alpha-olefin copolymer has advantages of balanced and excellent processability and mechanical property compared with the product in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

Method for preparing partially crosslinked hydroexpansivity acrylate-acrylic acid copolymer

The invention relates to the process for preparing a partial cross bonding type water expanding acrylate- acrylic acid copolymer, characterized in that ultraviolet light is applied to initiate monomer polymerization, and the raw materials and their proportion are, 23.7-36.5 wt. portions of acrylic acid, 9.4-21.2 wt. portions of alkali metal hydroxide, and 44.1-66.2 wt. portions of water. The preparation method comprises the steps of, (1) charging in acrylic acid, (2) dropping alkali metal hydroxide into acrylic acid, controlling the temperature below 30 deg. C, (3) letting nitrogen into the feed liquid, (4) light lamination for 3-24 hours, subjecting material to polymerization reaction so as to obtain polymer gel, (5) subjecting the gel to granulation, drying, and disintegrating.

Owner:英德市安信保水有限公司

Catalyst component and catalyst for olefin polymerization, and preparation methods thereof

The invention relates to a catalyst component and catalyst for olefin polymerization, and preparation methods thereof. The catalyst component comprises 1) an ultrafine inorganic oxide carrier and 2) a reaction product of magnesium halide, halogenated hydrocarbon, titanium halide and an electron donor compound. The catalyst comprises a reaction product of the following components: (A) the catalyst component provided by the invention, and (B) an organo-aluminum compound with a general formula of AlR<n>X<3-n>, wherein in the formula, R is an alkyl group with a hydrogen or carbon atom number of 1 to 20, X is halogen, preferably chlorine, bromine or iodine, and n is more than 0 and no more than 3. The catalyst has high activity; and a polymer prepared by using the catalyst has higher bulk density and a higher melt index.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017456AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

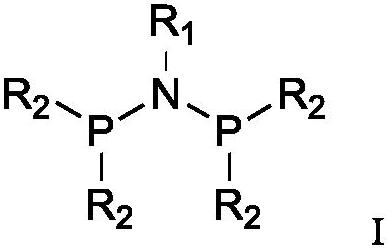

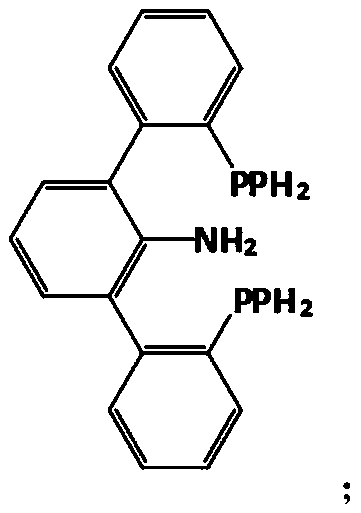

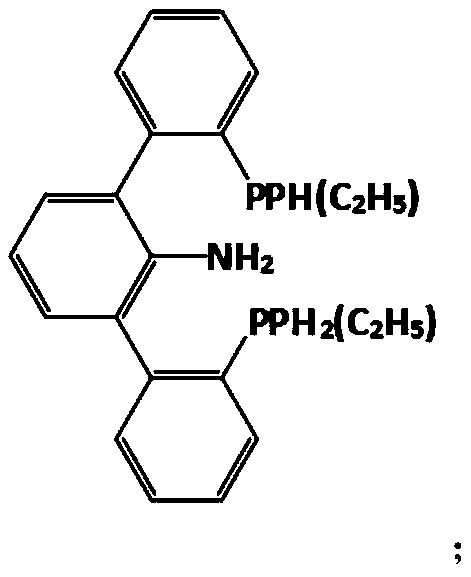

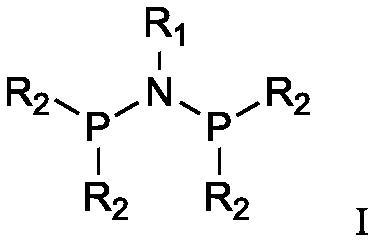

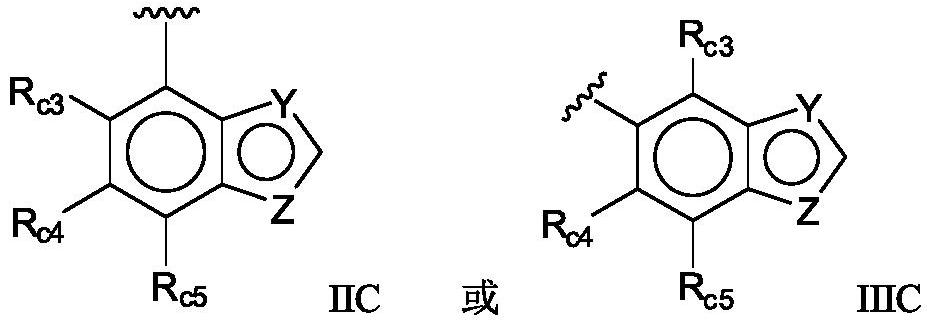

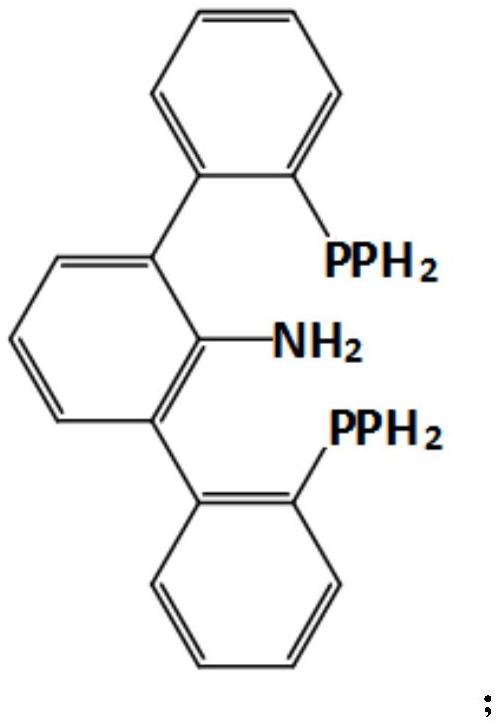

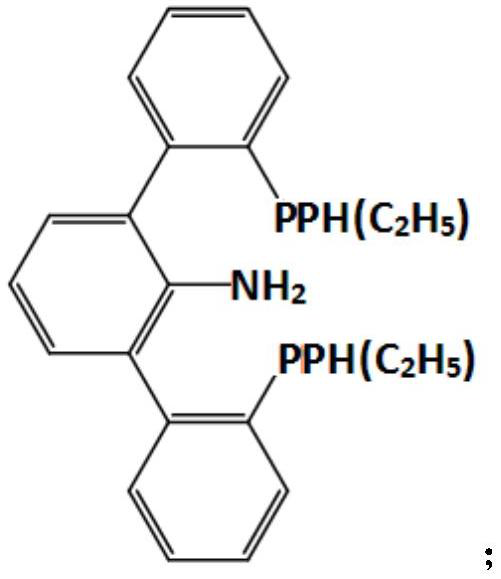

Ethylene oligomerization catalyst system as well as preparation method and application thereof

PendingCN112387311AHigh activitySolution to short lifeOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPtru catalystOctene

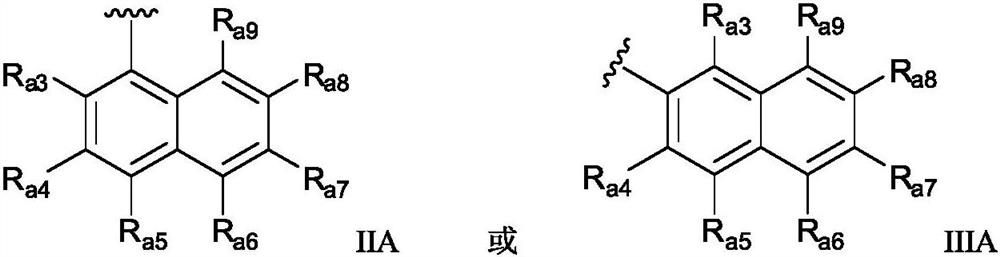

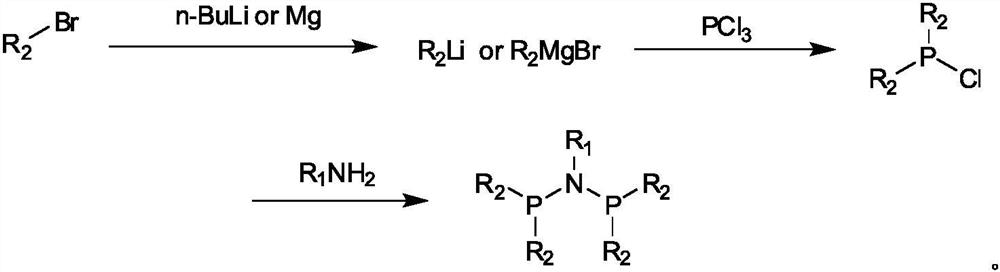

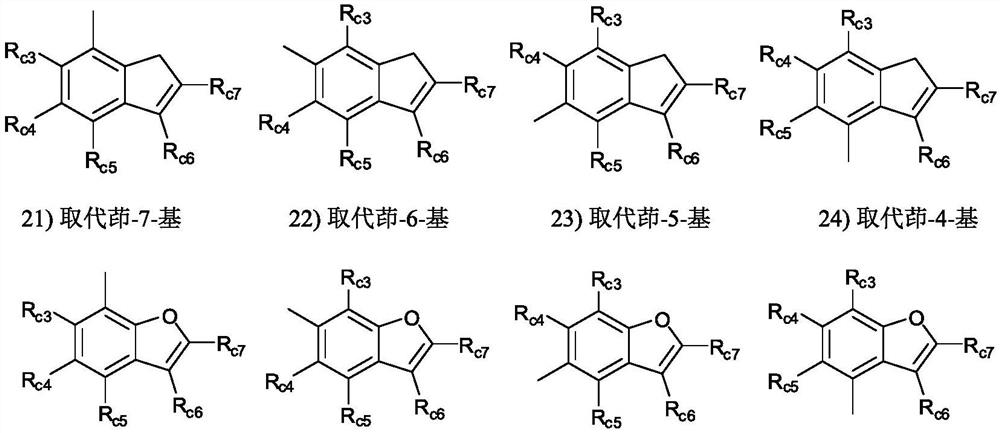

The invention discloses a novel ethylene oligomerization catalyst system with high activity and high selectivity as well as a preparation method and application thereof. The catalyst system comprisesa novel PNP ligand, a transition metal compound and a cocatalyst, according to the PNP ligand, a binary ring-fused aromatic group is used for replacing phenyl in a conventional PNP ligand, and the binary ring-fused aromatic substituent has more substitution positions, richer aromatic ring electron cloud distribution modes and larger space volume than a benzene ring, so that more and stronger influences can be provided for a donor part of the ligand, and therefore, the catalyst shows more excellent linear alpha-olefin (LAO) selectivity in an ethylene oligomerization reaction, and 1-hexene or 1-octene can be prepared with high selectivity.

Owner:XLINK TECH CO LTD HANGZHOU

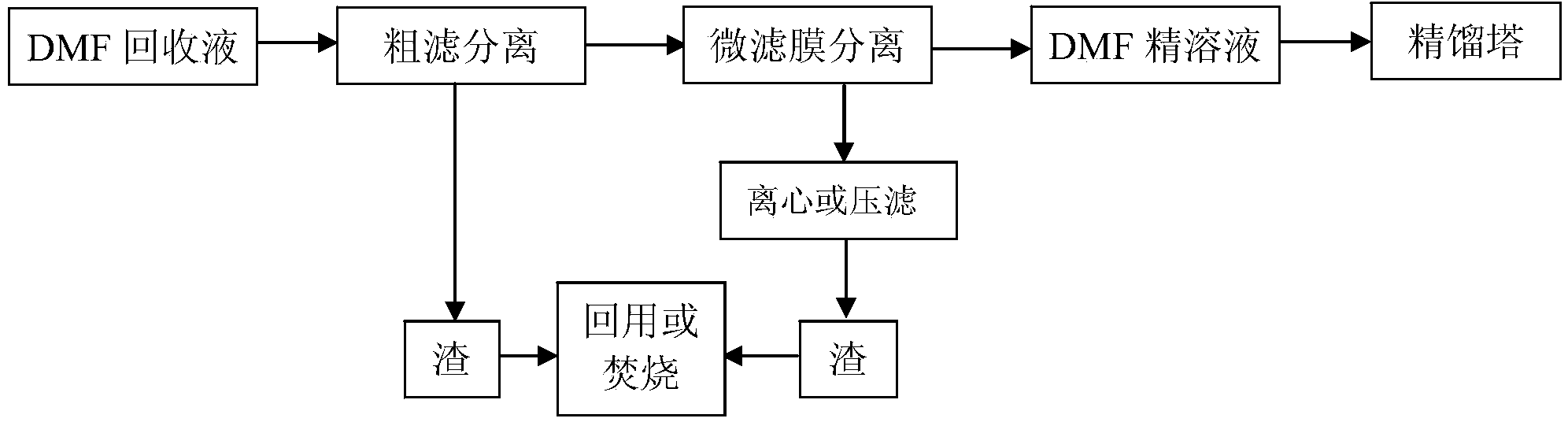

Pretreatment method for rectifying and recovering dimethyl formamide (DMF) waste liquid of polyurethane (PU) synthetic leather

InactiveCN103623605AReduce turbidityOligomer contentFractional distillationLeather industryPretreatment method

The invention discloses a pretreatment method for rectifying and recovering dimethyl formamide (DMF) waste liquid of polyurethane (PU) synthetic leather. The pretreatment method comprises the following steps: (1) pumping the DMF waste liquid from a waste water storage tank of a PU synthetic leather production line into a coarse filter consisting of a stainless steel filter screen by using an infusion pump and performing first-stage separation to obtain coarse filtration DMF waste liquid; and (2) allowing the coarse filtration DMF waste liquid obtained by first-stage separation to enter a microfiltration hollow fiber membrane separation device and performing second-stage separation to obtain a DMF fine solution for rectification and recovery. By the pretreatment method for rectifying and recovering the DMF waste liquid of the PU synthetic leather provided by the invention, the problems of high pollution and high energy consumption of rectification and recovery of the DMF waste liquid in the PU synthetic leather industry are solved; the aims of energy saving and emission reduction in the production process of the PU synthetic leather are fulfilled, and economic benefit, social benefit and environmental benefit are organically unified.

Owner:ZHEJIANG UNIV OF TECH

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017625AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

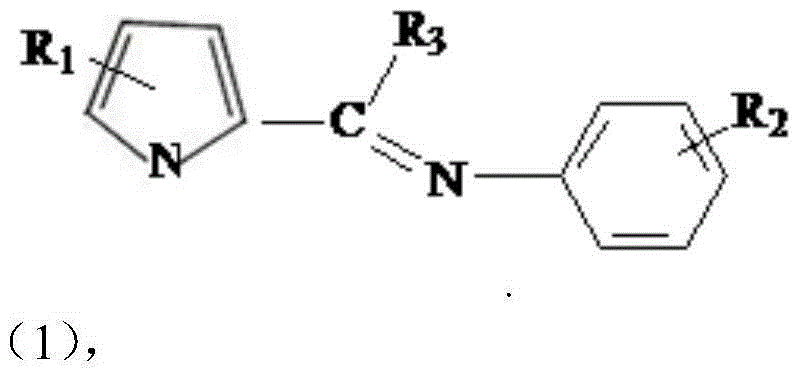

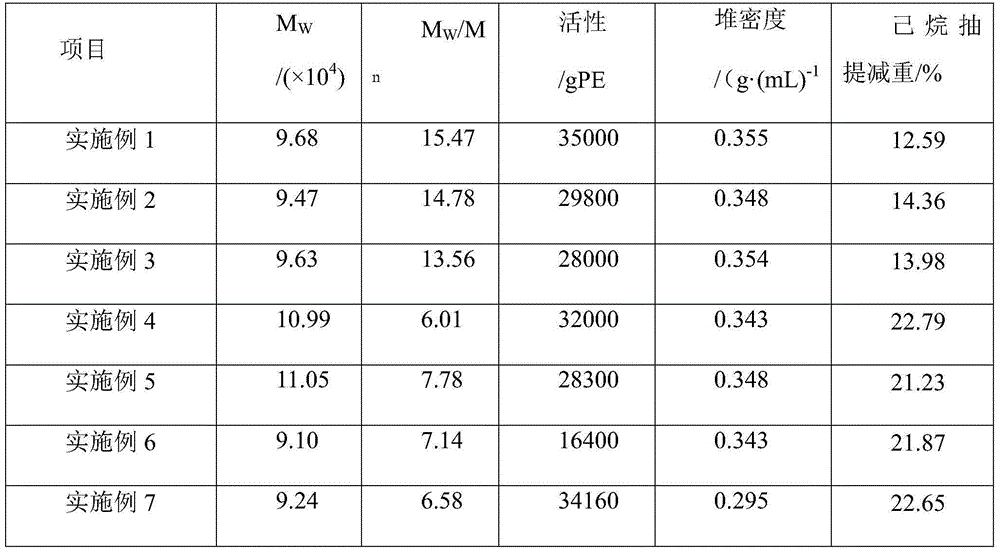

Olefin polymerization catalyst with double active components and preparation method

ActiveCN105218711AImprove material performanceHigh strengthBulk chemical productionDrop impactPolymer science

The present application provides a novel catalyst for olefin polymerization. The catalyst comprises a magnesium-containing composite carrier, a dispersant Ti(OBu)4, a pyrrole ring-containing electron donor compound and active components VCl4 and TiCl4. The magnesium-containing composite carrier of the the catalyst is obtained by spray-drying, has a preferable shape and high ethylene polymerization activity, and is suitable for being used in a gas-phase fluidized bed polymerization process, and is further suitable for being used in a slurry polymerization process; linear polyethylene containing relatively few oligomers with bimodal or wide relative molecular weight distribution can be prepared, and the obtained linear polyethylene has a good material property. The polyethylene resin prepared by using the catalyst has bimodal or broad relative molecular mass distribution, polyethylene resin containing relatively few oligomers can be obtained when polymerization of ethylene and comonomer is catalyzed, a film material blown by the resin has a preferable material property, a good strength and a high dart drop impact quality.

Owner:ZIBO XINSU CHEM

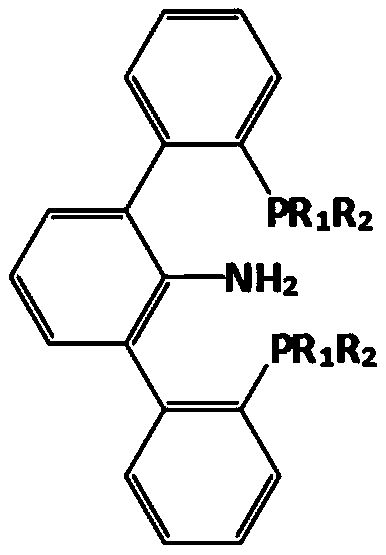

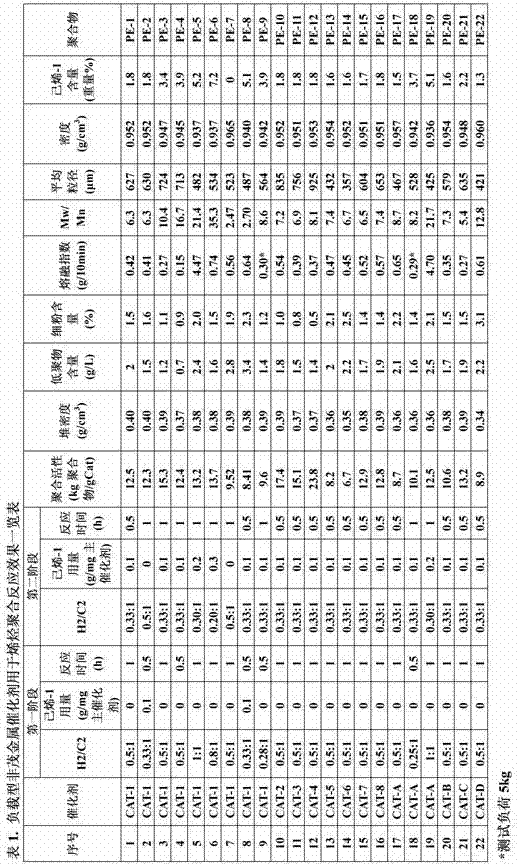

Catalyst system for preparing 1-octene through ethylene selective oligomerization and preparation method and application thereof

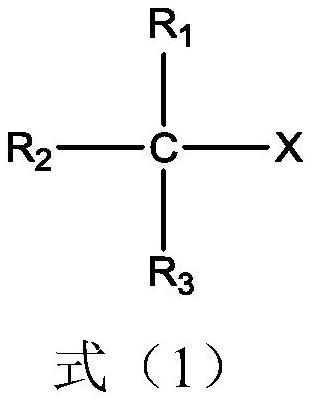

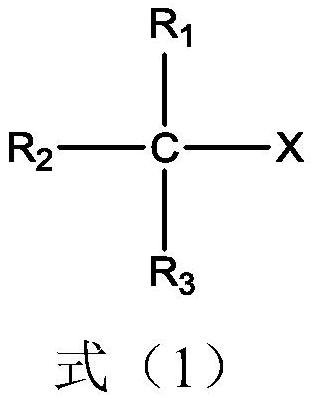

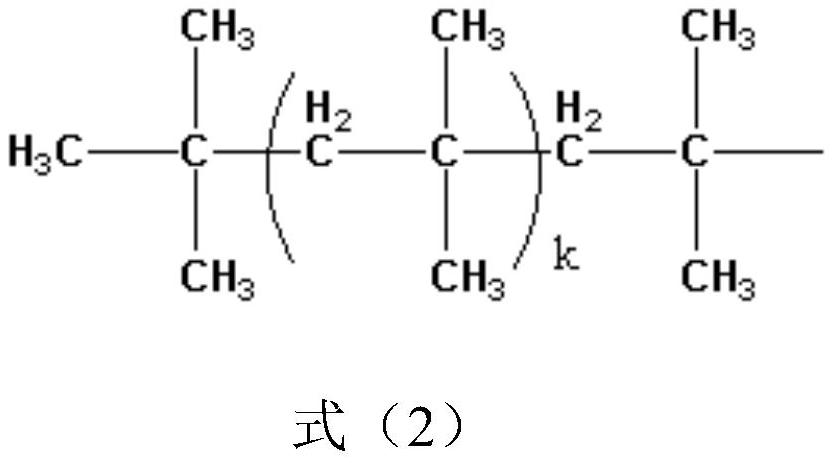

ActiveCN110479382AHigh selectivityOligomer contentGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOligomer1-Octene

The invention provides a catalyst system for preparing 1-octene from ethylene, which comprises three components: a ligand A, a transition metal compound B and an activating agent C, wherein the structural formula of the ligand A is shown in the specification, and the transition metal compound B is a group IVB-VIII metal compound; and the activating agent C is selected from an organic aluminum compound or an organic boron compound. When the catalyst system is used for ethylene oligomerization, the catalyst system has excellent selectivity for preparing 1-octene through ethylene tetramerizationand relatively low oligomer generation amount, and has relatively clear application prospect in the technical field of preparation of 1-octene through ethylene oligomerization.

Owner:迈瑞尔实验设备(上海)有限公司

Catalyst system for ethylene oligomerization as well as preparation method and application thereof

PendingCN112473738AHigh activitySolution to short lifeOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPhenyl groupHigh selectivity

The invention discloses a novel catalyst system with high activity and high selectivity for ethylene oligomerization as well as a preparation method and application thereof. The catalyst system comprises a novel PNP ligand, a transition metal compound and a cocatalyst. According to the PNP ligand, a binary ring-fused aromatic group is used for replacing a phenyl group in a conventional PNP ligand,and a binary ring-fused aromatic substituent has more substitution positions, richer aromatic ring electron cloud distribution modes and larger space volume than a benzene ring, so more and strongerinfluences can be provided for a donor part of the ligand; and therefore, the catalyst shows more excellent linear alpha-olefin (LAO) selectivity in an ethylene oligomerization reaction, and 1-hexeneor 1-octene can be prepared with high selectivity.

Owner:XLINK TECH CO LTD HANGZHOU

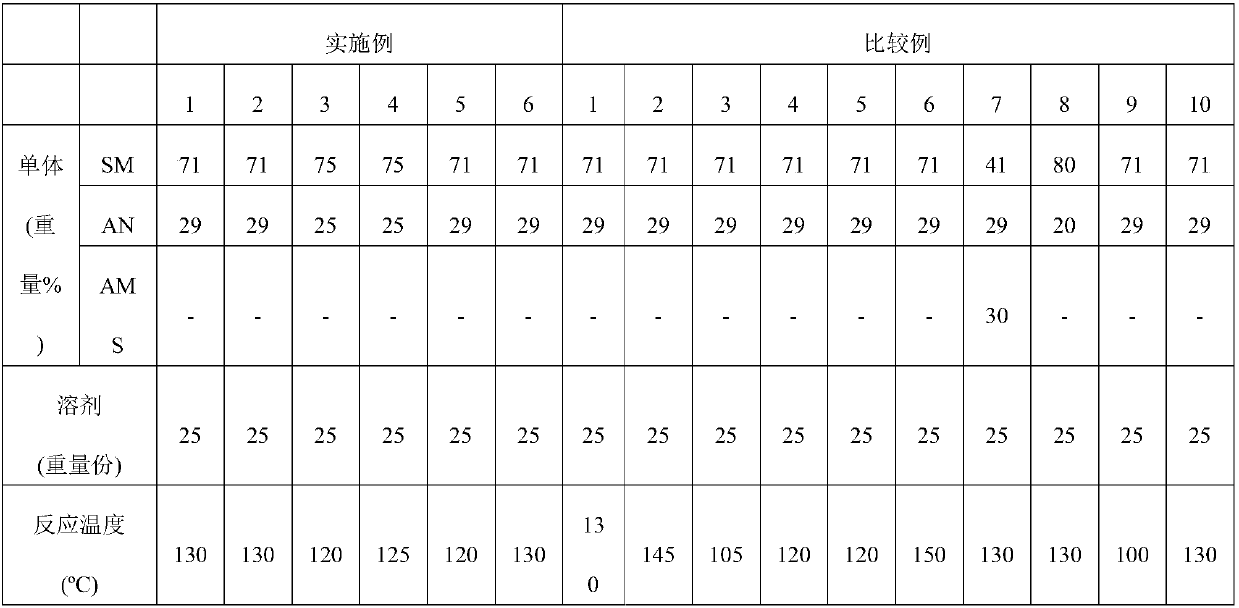

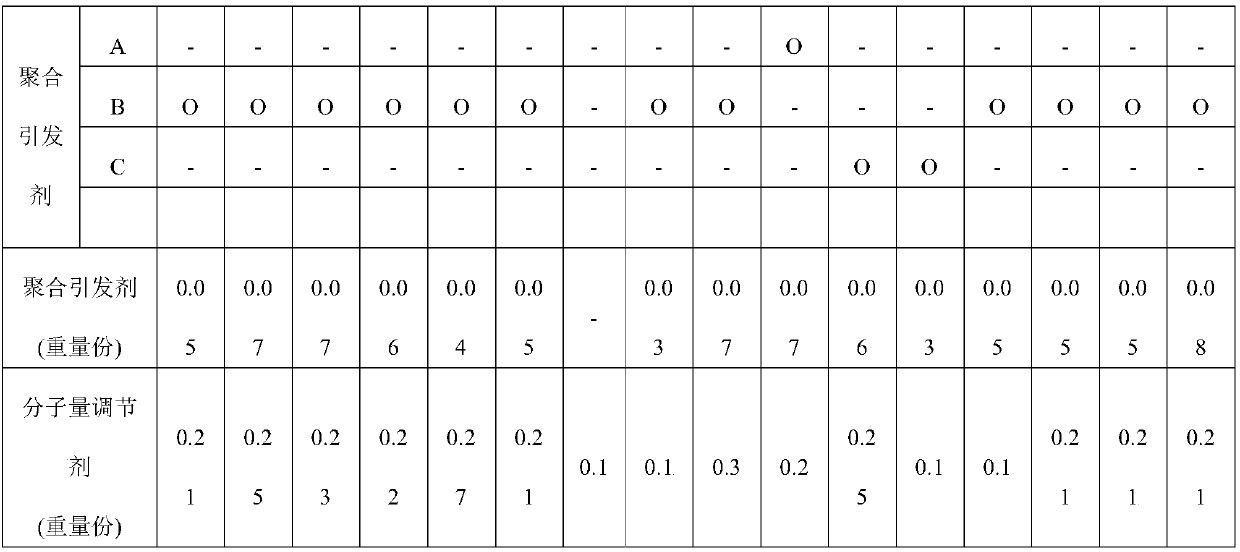

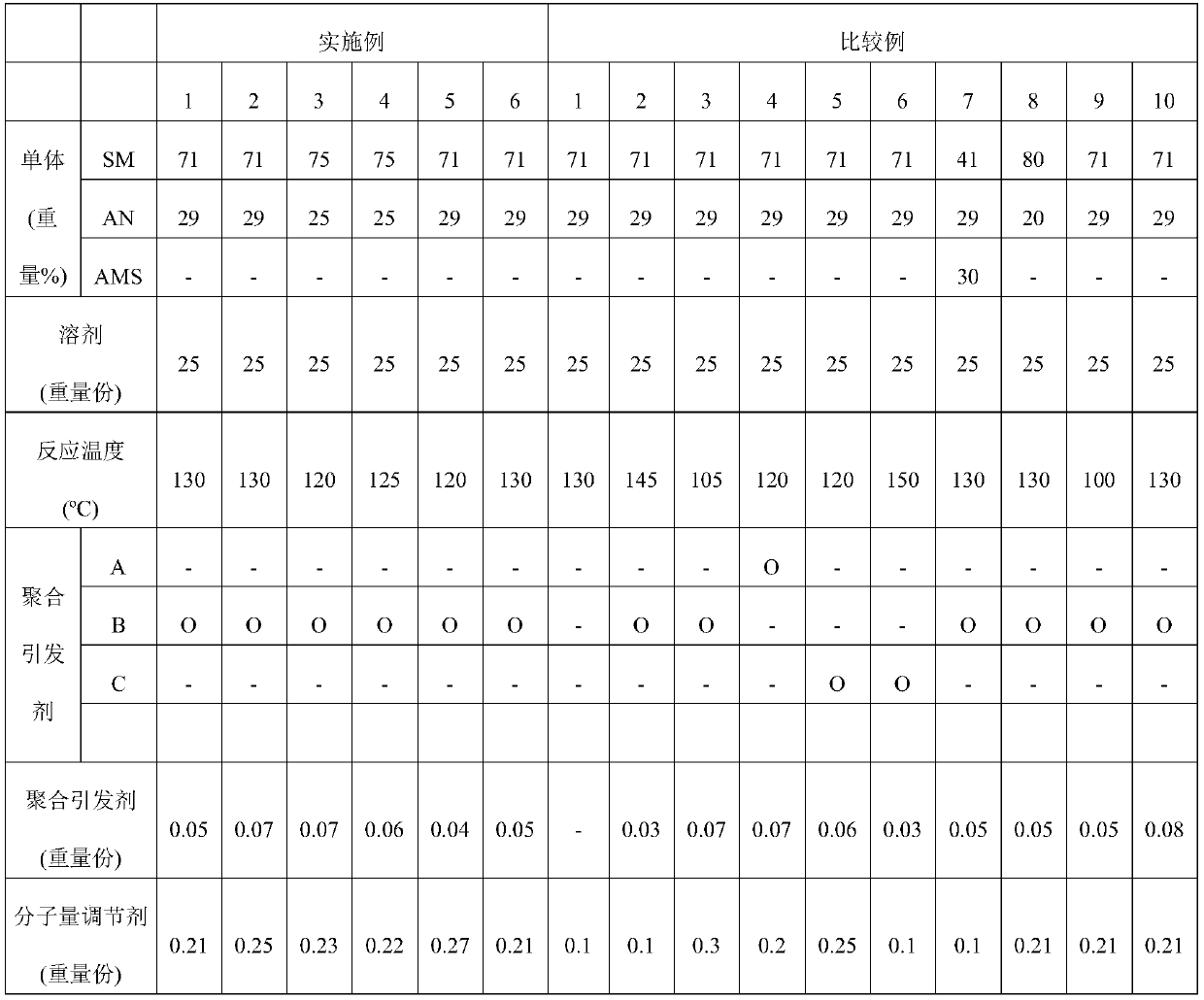

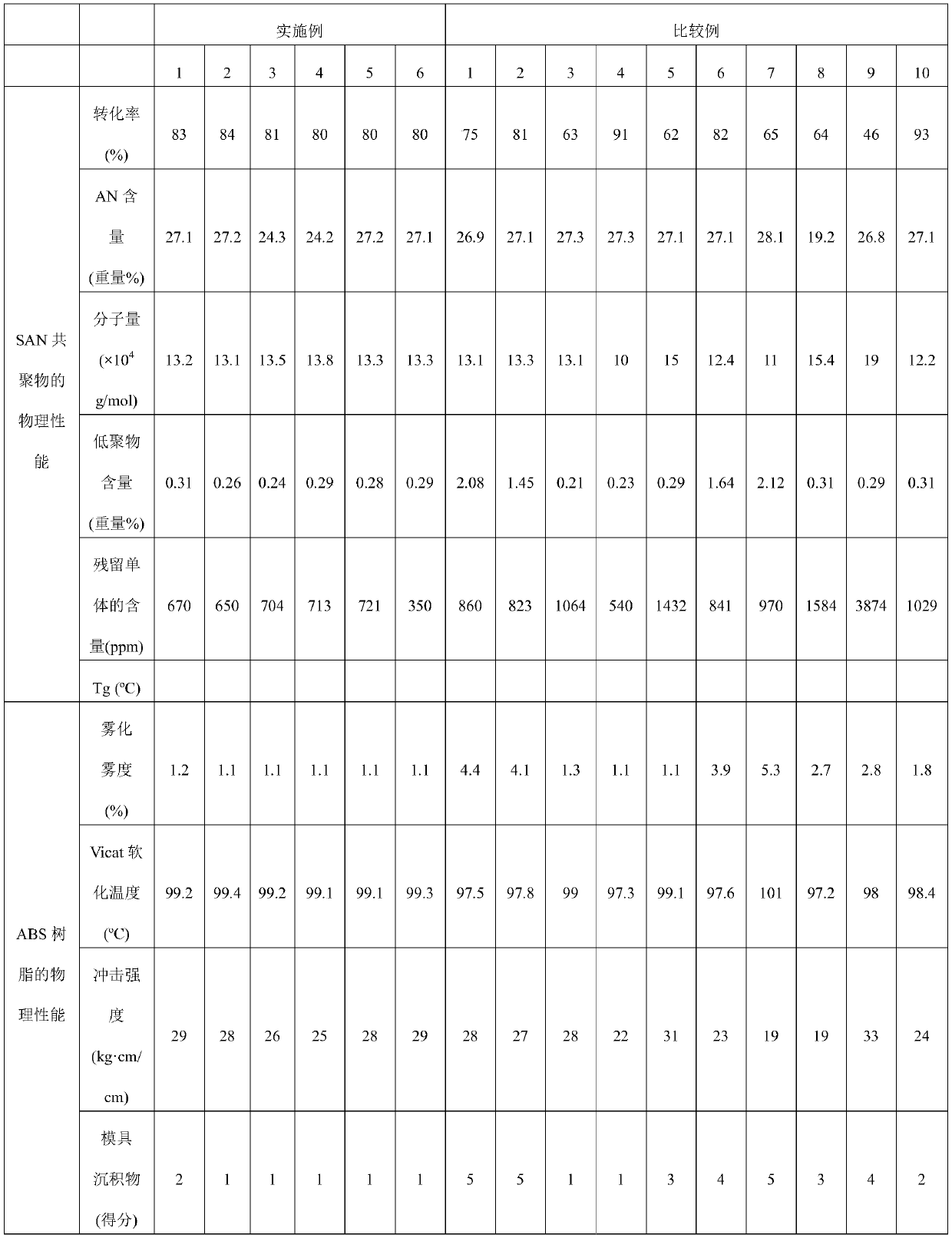

Method for preparing aromatic vinyl-unsaturated nitrile-based copolymer and aromatic vinyl-unsaturated nitrile-based copolymer prepared thereby

The present invention provides a method for preparing an aromatic vinyl-unsaturated nitrile-based copolymer and an aromatic vinyl-unsaturated nitrile-based copolymer prepared using the method, wherein, in the preparation of an aromatic vinyl-unsaturated nitrile-based copolymer, of which the content of unsaturated nitrile-based monomer-derived structural units in a copolymer is 22-30 wt%, the contents of oligomers and unreacted monomers are decreased, and as a result, excellent heat resistance and remarkably improved surface quality can be obtained, and particularly, when a product is used in aclosed high-temperature environment, the residues generated on a surface of the product and the mold deposits generated during injection molding can be reduced.

Owner:LG CHEM LTD

Ethylene-alpha-olefin copolymer, manufacturing method and applications thereof

ActiveCN105017457AUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceAlkene

The present invention relates to an ethylene-alpha-olefin copolymer and a manufacturing method thereof, and applications of the ethylene-alpha-olefin copolymer in molding product manufacturing, wherein the ethylene-alpha-olefin copolymer exhibits balanced and excellent processability and mechanical properties compared with the ethylene-alpha-olefin copolymer in the prior art.

Owner:SINOPEC YANGZI PETROCHEM +1

Homogeneous hyper-viscous polyester and preparation method thereof

The invention relates to homogeneous hyper-viscous polyester and a preparation method thereof. The method comprises the following steps of: controlling the mechanism of adding a catalyst during a synthesis process to obtain low-viscous polyester with an intrinsic viscosity of 0.300-0.500 dL / g, and then performing solid phase thickening on the low-viscous polyester to obtain the homogeneous hyper-viscous polyester with an intrinsic viscosity of 0.85-1. 15dL / g, an intrinsic viscosity deviation less than or equal to 0.02dL / g and a molecular weight distribution index of 2.5, wherein the catalyst is added when the average polymerization degree of an intermediate product in a polymerization reaction reaches 8-17; the pre-reaction of the solid-phase thickening is divided into four stages which are a first stage, a second stage, a third stage, and a fourth stage, the corresponding temperatures are 190-195 DEG C,195-210 DEG C, 210-220 DEG C and 220-230 DEG C respectively. The preparation methodof the homogeneous hyper-viscous polyester obviously reduces the content of oligomer in a product, and the prepared polyester has high quality and excellent popularization value.

Owner:ZHEJIANG UNIFULL IND FIBER +1

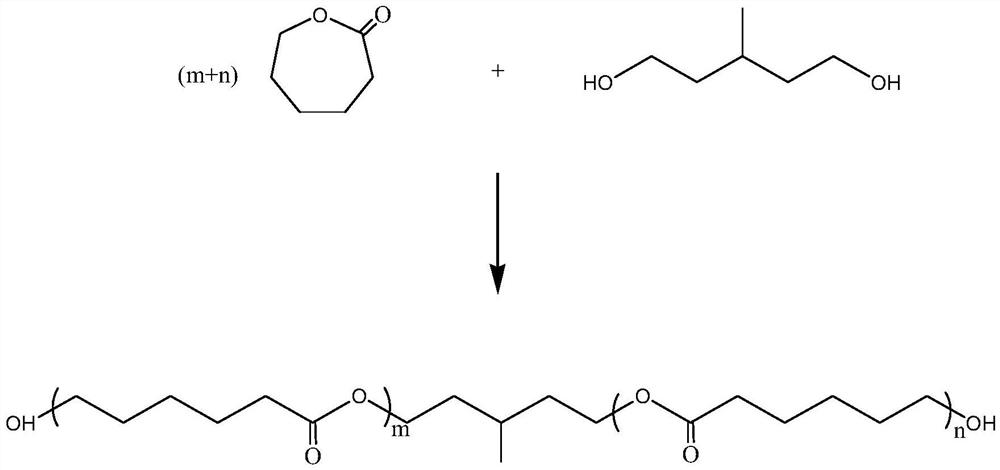

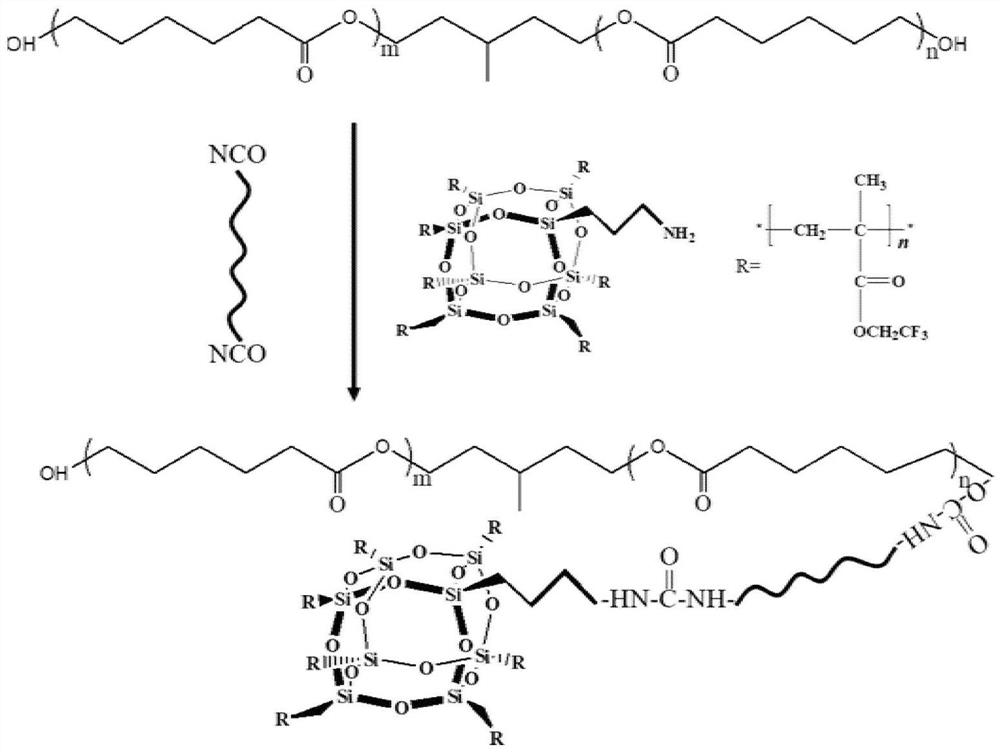

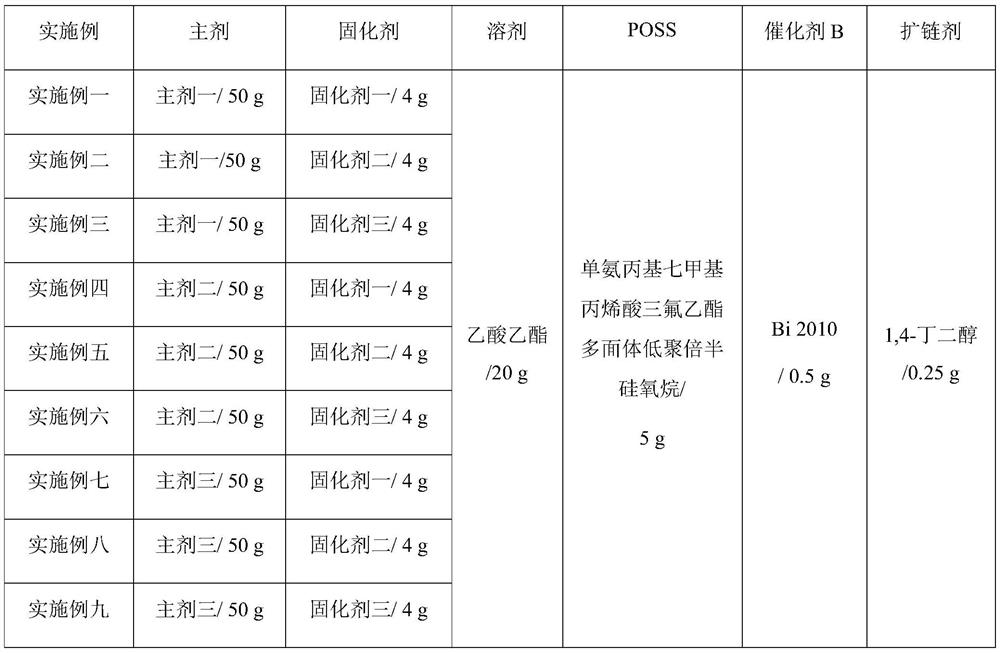

Preparation method of polyurethane adhesive

PendingCN112358845AImprove hydrolytic stabilityImprove performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a polyurethane adhesive with low stripping force, the polyurethane adhesive comprises a polyurethane adhesive main agent, a curing agent and an auxiliary additive, the polyurethane adhesive main agent is a hydroxyl (-OH) terminated prepolymer obtained by monomer modified polyol; the curing agent is an isocyanate group (-NCO) terminated prepolymer obtained by reacting diisocyanate with polyhydric alcohol; monoamino fluorine-containing polyhedral oligomeric silsesquioxane (POSS) is introduced, and POSS is used for reducing the stripping force of the polyurethane adhesive;the auxiliary additive is composed of a catalyst, an antifoaming agent, an antistatic agent, an antioxidant and a chain extender; the polyurethane adhesive main agent, the curing agent and the auxiliary additive are mixed according to a certain ratio and uniformly stirred and then the mixture is used for coating to form a film; and the prepared adhesive film has the advantages of high exhaust speed, small stripping force, no bubbles after aging, no white spots, high temperature resistance, no residual adhesive and yellowing resistance, and good antistatic performance and the like.

Owner:ICLOUD ADVANCED MATERIAL TECH CO LTD

A kind of ethylene-alpha-olefin copolymer, its manufacture method and its application

ActiveCN105017626BUniform particle sizeReasonable distribution and flexible adjustmentPolymer scienceMechanical property

Owner:SINOPEC YANGZI PETROCHEM +1

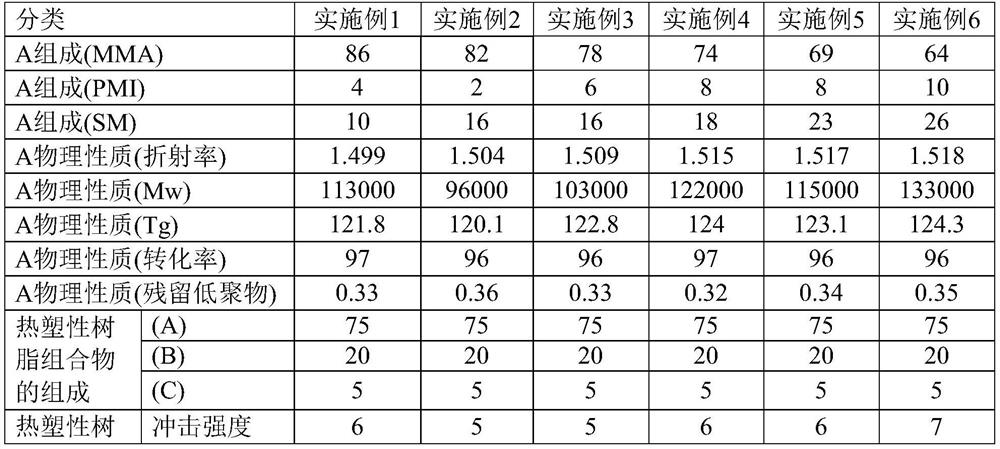

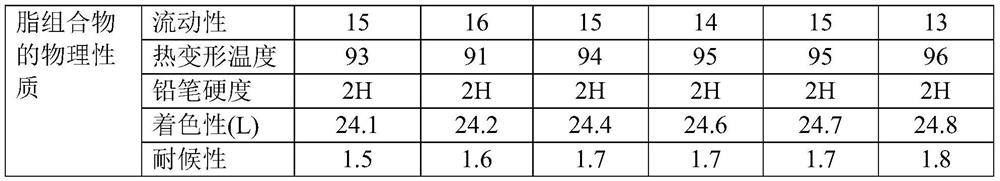

Thermoplastic resin composition, method for producing same, and molded article produced using same

The present invention has the effects of providing a thermoplastic resin composition, a method for preparing the thermoplastic resin composition, and a molded article comprising the thermoplastic resin composition, the thermoplastic resin composition comprising: a styrene-based copolymer containing a (meth) acrylate-based monomer, an aromatic vinyl-based monomer, and a maleimide-based monomer; a first graft copolymer comprising an acrylic rubber polymer, an aromatic vinyl-based monomer, and a vinyl nitrile-based monomer; and a second graft copolymer containing an acrylic rubber polymer, an aromatic vinyl monomer, and a vinyl nitrile monomer, in which the content of residual oligomers in the styrene copolymer is 0.37 wt% or less, and the content of residual oligomers in the styrene copolymer is 0.37 wt% or less. The acrylic rubber polymer of the first graft copolymer and the acrylic rubber polymer of the second graft copolymer have different average particle sizes.

Owner:LG CHEM LTD

A kind of preparation method of oligomer grape seed proanthocyanidin

A method for preparing oligomeric grape seed proanthocyanidins. After the grape seeds are rinsed with clean water, they are added to an ethanol solution for leaching, the grape seeds are removed by filtration, and an extract is collected; Brick red procyanidin crude precipitate, suction filtration and collect the precipitate; dissolve the precipitate in ethanol solution, collect the filtrate containing dissolved procyanidin; then filter the filtrate with nanofiltration membrane to collect the oligomers that are trapped and precipitated on the filter membrane The oligomeric proanthocyanidins are obtained by washing the precipitates with acetone and ethanol respectively, and drying them in a drying oven.

Owner:QINGDAO UNIV +1

A kind of ethylene-alpha-olefin copolymer, its manufacture method and its application

ActiveCN105017625BUniform particle sizeReasonable distribution and flexible adjustmentAlpha-olefinMechanical property

Owner:SINOPEC YANGZI PETROCHEM +1

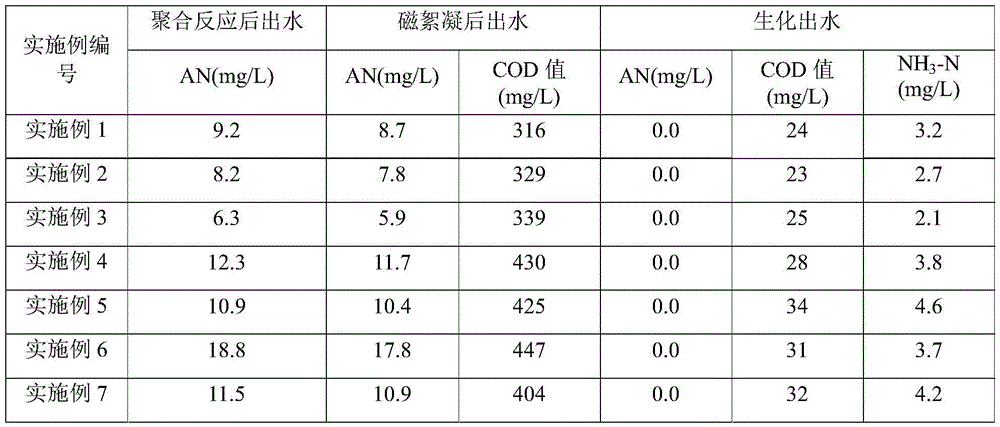

A kind of treatment method of nitrile rubber production wastewater

ActiveCN104556538BOligomer contentImprove effluent qualityMultistage water/sewage treatmentNature of treatment waterFlocculationActivated sludge

The invention discloses a treatment method for nitrile rubber production wastewater. The method comprises the following steps: a, mixing the nitrile rubber production wastewater and a polymerization initiator under the conditions of polyreaction; b, performing magnetic flocculation on the wastewater which is subjected to the polyreaction; c, mixing the wastewater which is subjected to the polyreaction and activated sludge. In the water treated by the method disclosed by the method, acrylonitrile does not residue basically, the COD value is smaller than 50 mg / L, and the ammonia-nitrogen content is smaller than 5 mg / L; the water quality of outlet water is high; the treatment effect is remarkable. Moreover, the method disclosed by the invention is also particularly suitable for the treatment of the nitrile rubber production wastewater with low-content acrylonitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ethylene-α-olefin copolymer, its manufacture method and its application

ActiveCN105017455BUniform particle sizeReasonable distribution and flexible adjustmentAlpha-olefinMechanical property

Owner:SINOPEC YANGZI PETROCHEM +1

A kind of catalyst system for the selective oligomerization of ethylene to prepare 1-octene, its preparation method and application

ActiveCN110479382BHigh selectivityOligomer contentOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsOligomerPtru catalyst

The present invention provides a catalyst system for producing 1-octene from ethylene, which includes three components: ligand A, transition metal compound B, and activator C: the ligand A, whose structural formula is: The transition metal compound B is a metal compound of groups IVB-VIII; the activator C is selected from organoaluminum compounds or organoboron compounds. When the catalyst system of the present invention is used for ethylene oligomerization, it has excellent selectivity of ethylene tetramerization to 1-octene, lower oligomer generation, and has a clearer technical field of ethylene oligomerization to 1-octene application prospects.

Owner:迈瑞尔实验设备(上海)有限公司

A kind of polyester with low oligomer content and preparation method thereof

The invention relates to a polyester with low oligomer content and a preparation method of the polyester. The method comprises the following steps: carrying out an esterification reaction and a first-stage condensation polymerization reaction on M and dihydric alcohol in the presence of a catalyst A; carrying out a second-stage condensation polymerization reaction; adding a catalyst B and carryingout a third-stage condensation polymerization reaction; and finally, adding a chain extender for carrying out a chain extension reaction, thereby obtaining the polyester with low oligomer content, wherein M is dicarboxylic acid or binary alkyl carboxylate; the catalyst A is a titanium catalyst, an antimony catalyst or metal acetate, the catalyst B is more than one of aluminum isopropoxide, dibutyl tin oxide, monobutyltin oxide, stannous octoate and stannous 2-ethyl caproate, and the oligomer content in the prepared polyester is less than 1.5wt%. The method disclosed by the invention is simplein operation, and the prepared product is low in oligomer content and has excellent popularization value.

Owner:DONGHUA UNIV

Catalyst for gas-phase polymerization or copolymerization of ethylene and preparation method thereof

InactiveCN101864013BFlat surfaceParticles in good shapeBulk chemical productionElectron donorActive agent

The invention relates to a catalyst for the gas-phase polymerization or copolymerization of ethylene and a preparation method thereof. The catalyst consists of a titanium-containing active ingredient and an active agent, wherein the titanium-containing active ingredient is formed by loading at least one kind of halogenated titanium, at least one kind of electron donor compound and a surfactant ona halogenated magnesium / silicon dioxide double carrier; the electron donor compound may be an alcohol or an ether; and the surfactant may be an anionic surfactant, a cationic surfactant or a nonionicsurfactant. A surfactant is added into the mother liquor of the active ingredient of the catalyst, so when the components of the catalyst are used for the polymerization or copolymerization reaction of ethylene together with an organic aluminum auxiliary catalyst, the obtained product of the polymerization of ethylene has low hexane-extractable material content, the catalytic activity of the catalyst is improved obviously, the grain shape and grain size distribution of polyethylene are improved obviously.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparation method of aromatic vinyl-unsaturated nitrile copolymer and prepared aromatic vinyl-unsaturated nitrile copolymer

The present invention provides a method of preparing an aromatic vinyl-unsaturated nitrile-based copolymer in which, when an aromatic vinyl-unsaturated nitrile-based copolymer in which a content of a structural unit derived from unsaturated nitrile monomers in the copolymer is in the range of 22 to 30 wt% is prepared, oligomer content and unreacted monomer content are decreased, resulting in excellent heat resistance, significantly improved surface quality, and particularly, reduced generation of residue on a product surface when used in a closed high temperature environment and reduced occurrence of mold deposits during injection molding, and an aromatic vinyl-unsaturated nitrile-based copolymer prepared using the method.

Owner:LG CHEM LTD

A kind of medical rubber and its preparation method and application

Owner:NOVASHIN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com