Pretreatment method for rectifying and recovering dimethyl formamide (DMF) waste liquid of polyurethane (PU) synthetic leather

A synthetic leather and pretreatment technology, applied in fractionation and other directions, can solve the problems of large and high-concentration wastewater, increased energy consumption, DMF loss, etc., to achieve good results, reduce production costs and energy consumption, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

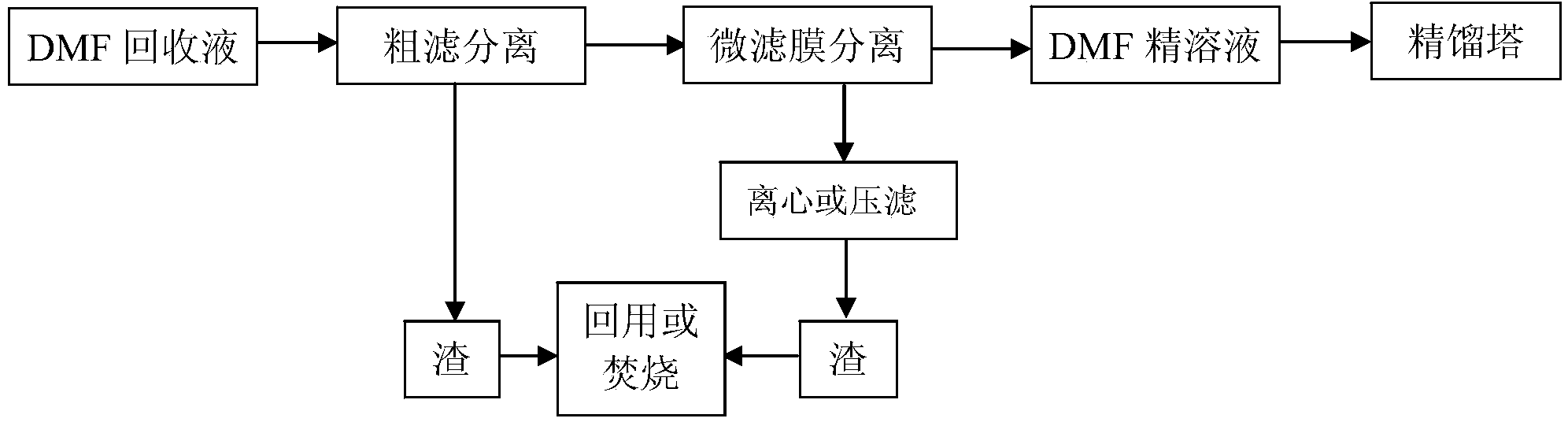

[0022] Since many processes in the production of PU synthetic leather will generate DMF waste liquid, it is necessary to collect the DMF waste liquid discharged from each process uniformly. 10 tons of DMF waste liquid from the waste water storage tank of the PU synthetic leather production line is sent through the infusion pump into the coarse filter made of 100-mesh stainless steel mesh for primary separation, and the particles with a particle size ≥ 154 μm are removed to ensure the quality of the subsequent sedimentation separator. Safe operation and improved operation capacity; the DMF waste liquid after primary separation enters the microfiltration membrane separation device for secondary separation to remove sol-like solid suspended particles with a particle size ≥ 1 μm, and basically removes particles with a particle size of 1~ Particles of 154 μm; the self-priming pump of the membrane separation device adopts intermittent working mode: work for 5 hours, pause for 5 minut...

Embodiment 2

[0025] 15 tons of DMF waste liquid from the waste water storage tank of the PU synthetic leather production line is sent through the infusion pump into the coarse filter made of 150-mesh stainless steel mesh for primary separation, and the particles with a particle size ≥ 100 μm are removed to ensure the quality of the subsequent sedimentation separator. Safe operation and improved operation capacity; the DMF waste liquid after primary separation enters the microfiltration membrane separation device for secondary separation to remove sol-like solid suspended particles with a particle size ≥ 1 μm, and basically removes particles with a particle size of 1~ Particles of 100 μm; the self-priming pump of the membrane separation device adopts intermittent working mode: work for 7 hours, pause for 10 minutes, and cycle repeatedly. During the suspension period of the self-priming pump, backwash with DMF waste liquid after microfiltration, the backwash pressure is about 0.1MPa, and the ...

Embodiment 3

[0028] 15 tons of DMF waste liquid from the waste water storage tank of the PU synthetic leather production line is sent through the infusion pump into the coarse filter made of 200-mesh stainless steel mesh for primary separation, and the particles with a particle size ≥ 74 μm are removed to ensure the quality of the subsequent sedimentation separator. Safe operation and improved operation capacity; the DMF waste liquid after primary separation enters the microfiltration membrane separation device for secondary separation to remove sol-like solid suspended particles with a particle size ≥ 1 μm, and basically removes particles with a particle size of 1~ Particles of 74 μm; the self-priming pump of the membrane separation device adopts intermittent working mode: work for 8 hours, pause for 20 minutes, and cycle repeatedly. During the suspension period of the self-priming pump, backwash with the clean liquid after microfiltration, the backwash pressure is about 0.2MPa, and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com