Lurgi furnace coal gasification wastewater treatment and reuse technology

A technology of coal gasification sewage and Lurgi furnace, which is applied in the directions of degassed water/sewage treatment, oxidized water/sewage treatment, biological water/sewage treatment, etc. It can solve the difficulties in discharge standards and high pollution load treatment process design and promotion restrictions and other issues, to achieve the effect of saving energy and degrading COD without aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those of ordinary skill in the art to clearly understand the technical scheme of the present invention, it is now described in further detail with specific examples:

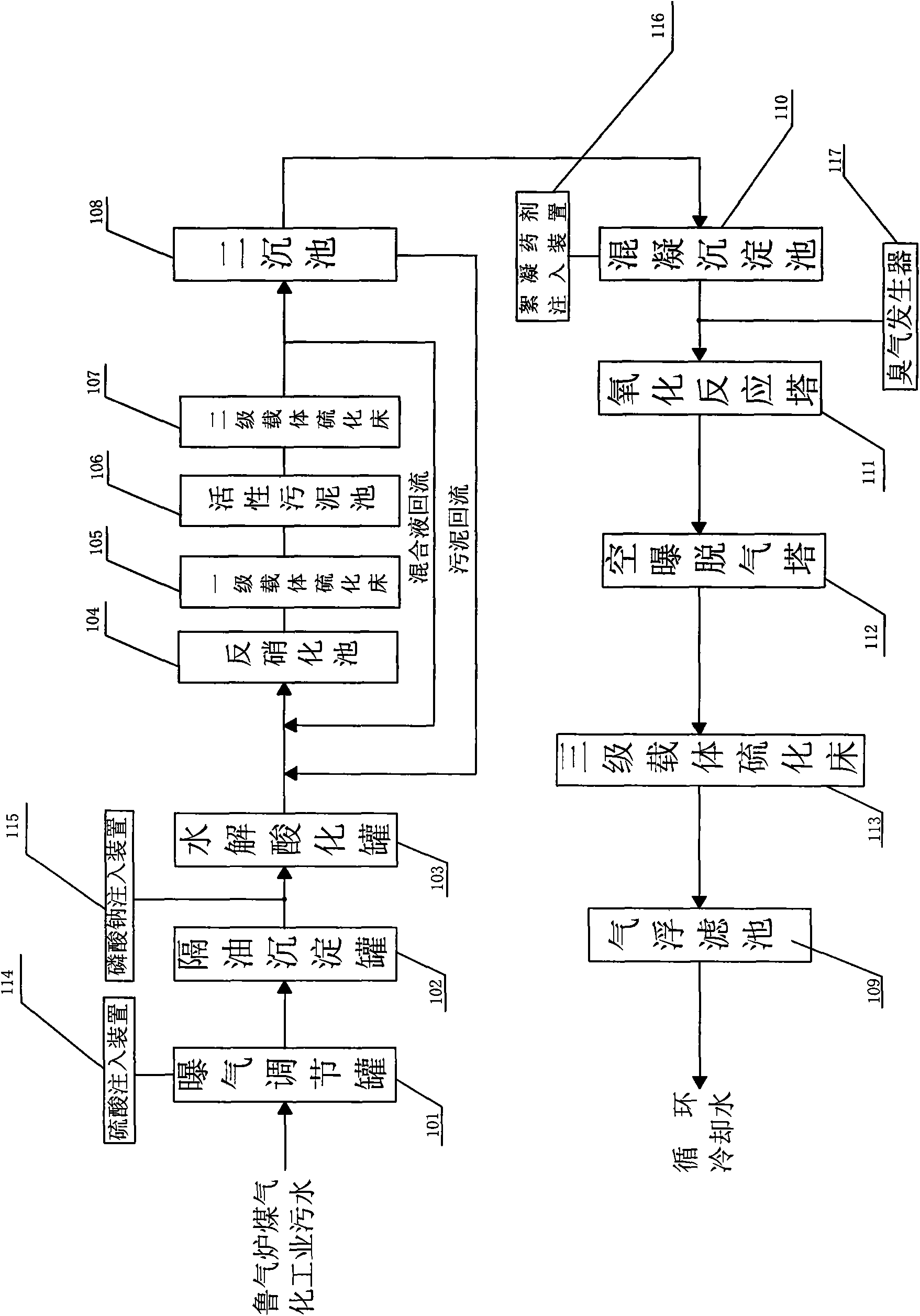

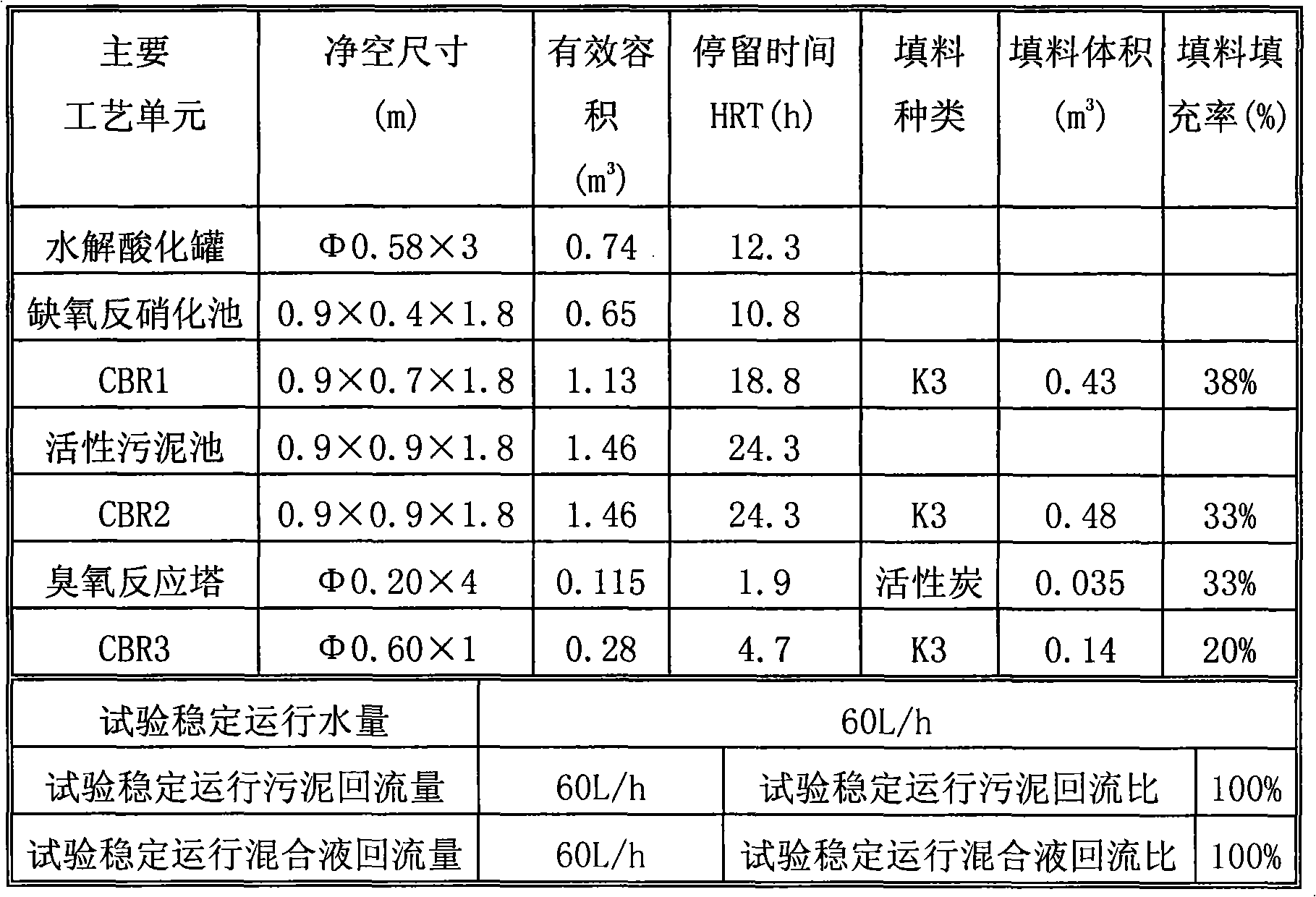

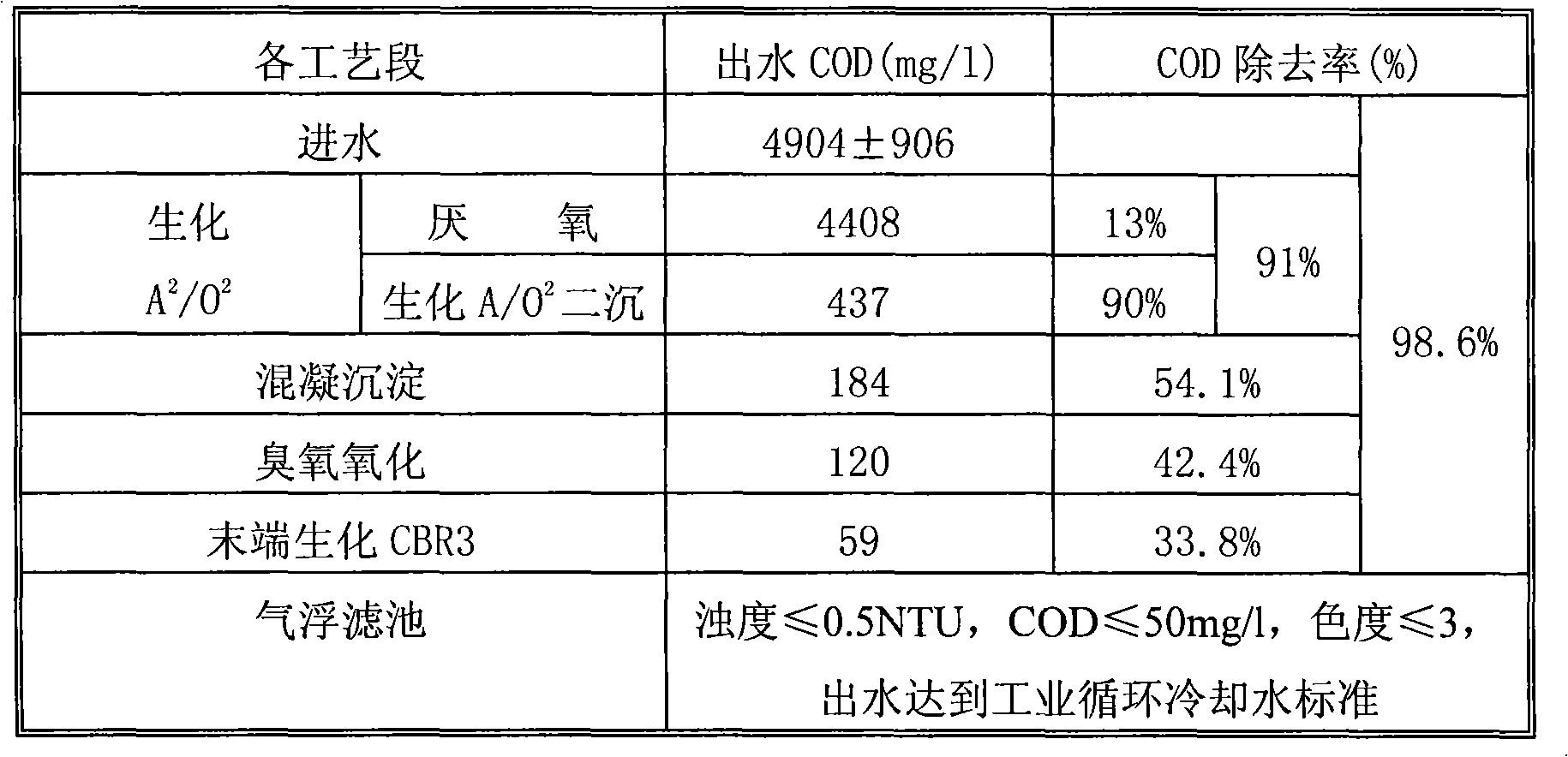

[0052] The method of the present invention involves the following devices connected sequentially through the sewage output pipeline: as figure 1 As shown, the aeration adjustment tank 101, the oil separation sedimentation tank 102, the hydrolysis acidification tank 103, the denitrification tank 104, the primary carrier fluidized bed pool 105 (CBR1), the activated sludge pool 106, and the secondary carrier fluidized bed pool 107 (CBR2), secondary settling tank 108, coagulation sedimentation tank 110, oxidation reaction tower 111, air aeration degassing tower 112, post carrier fluidized bed pool 113 (CBR3), air flotation filter 109. Wherein, a sulfuric acid injection device 114 is set above the aeration adjustment tank 101, a sodium phosphate injection device 115 is set on the sewage outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com