Patents

Literature

141 results about "Coal gasification wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

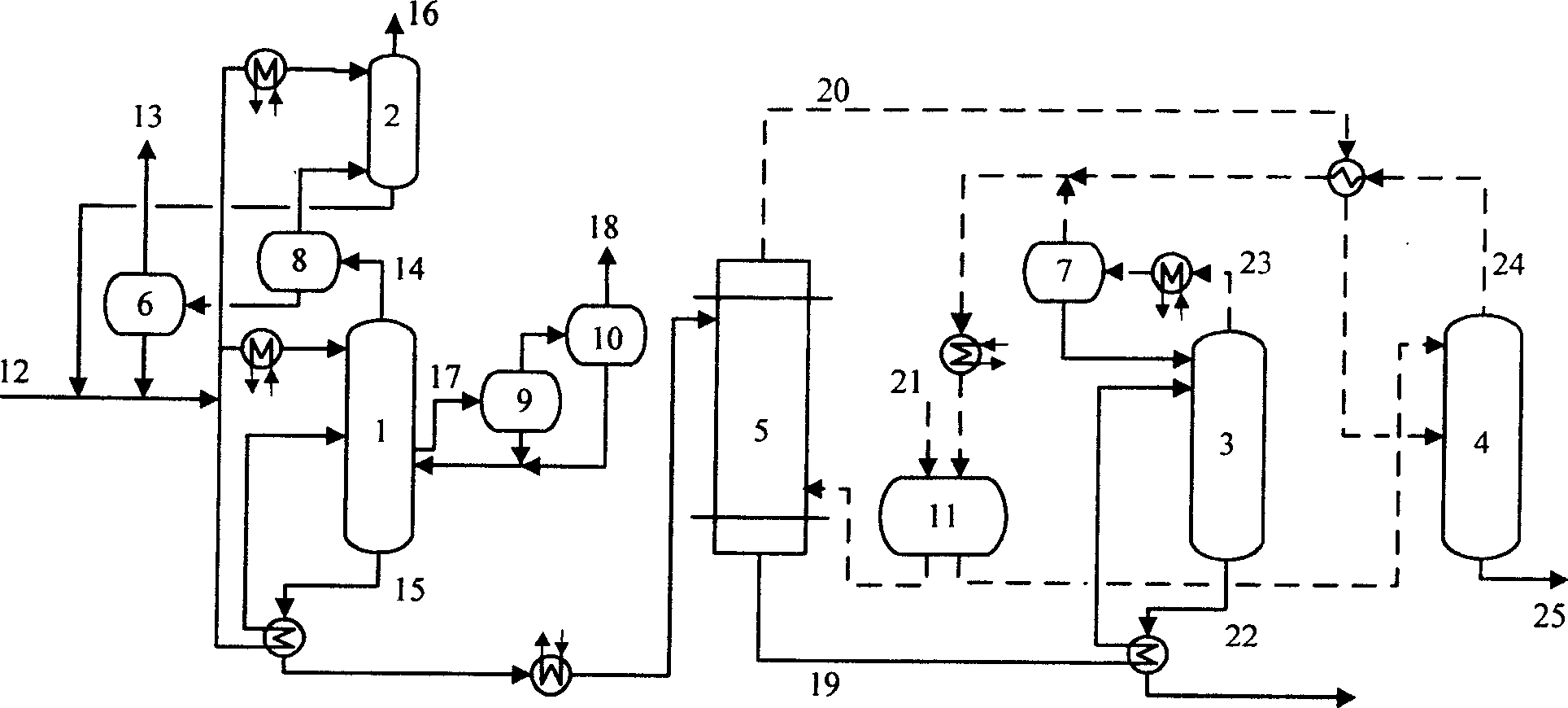

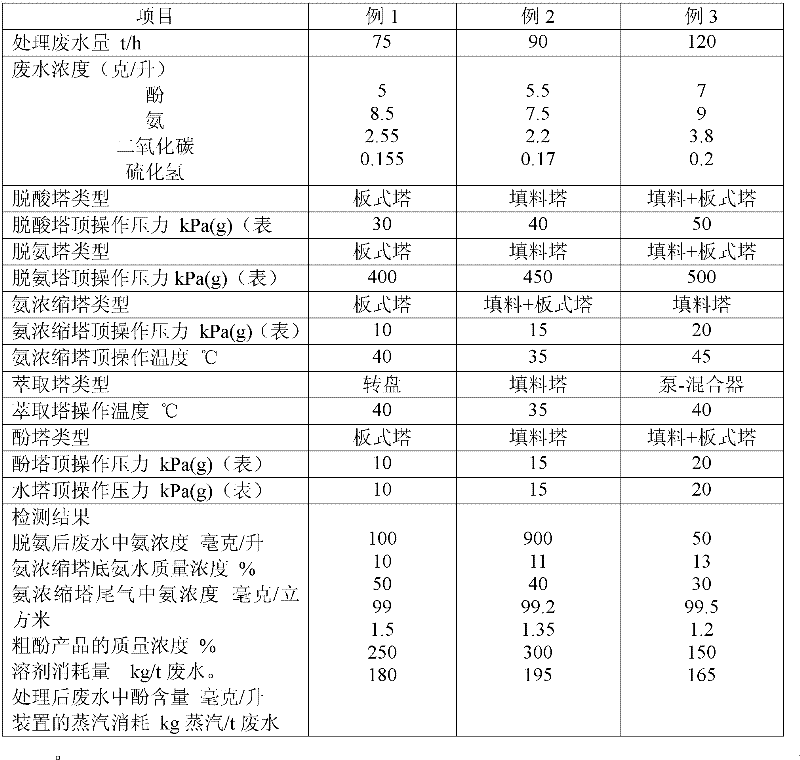

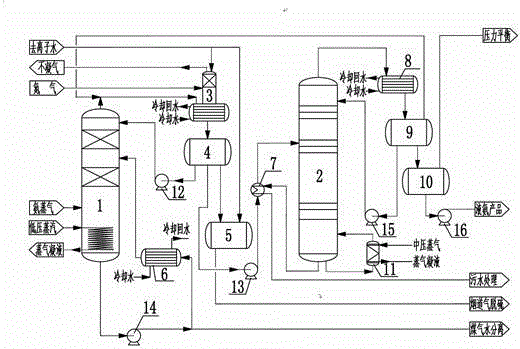

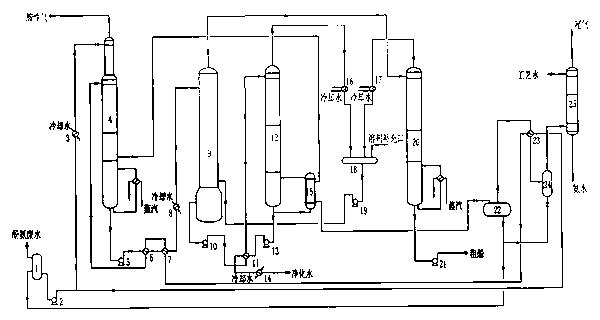

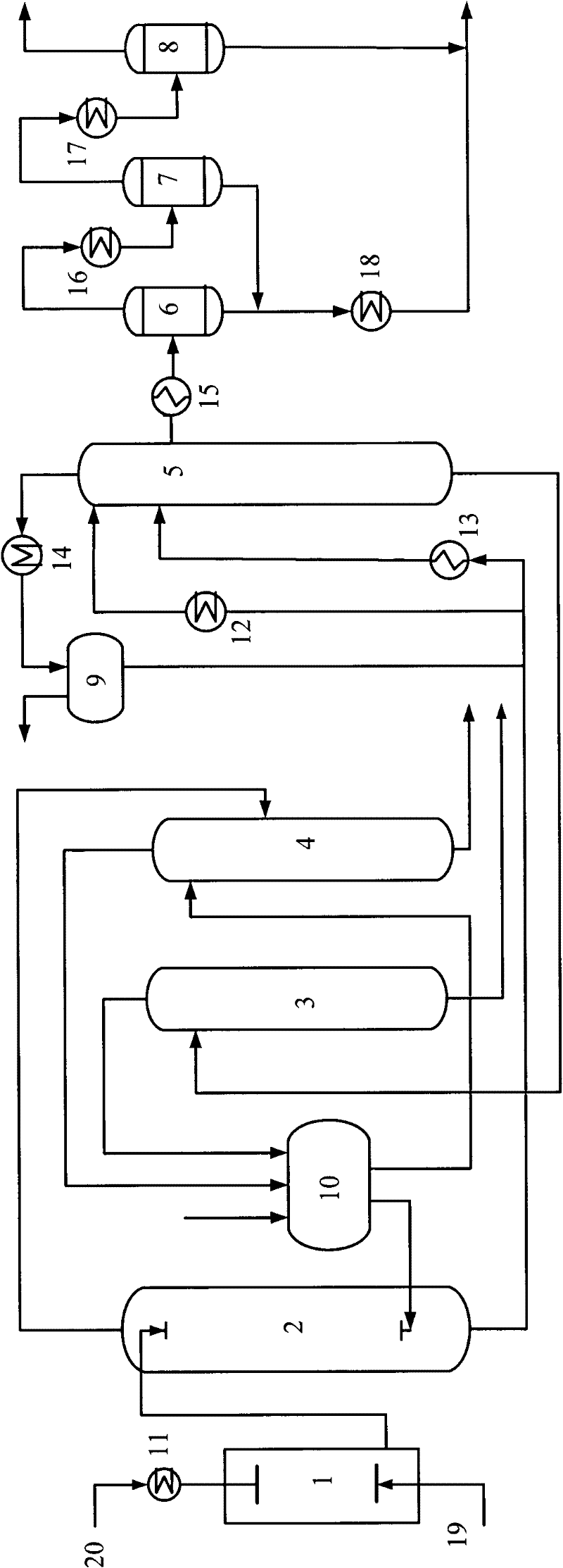

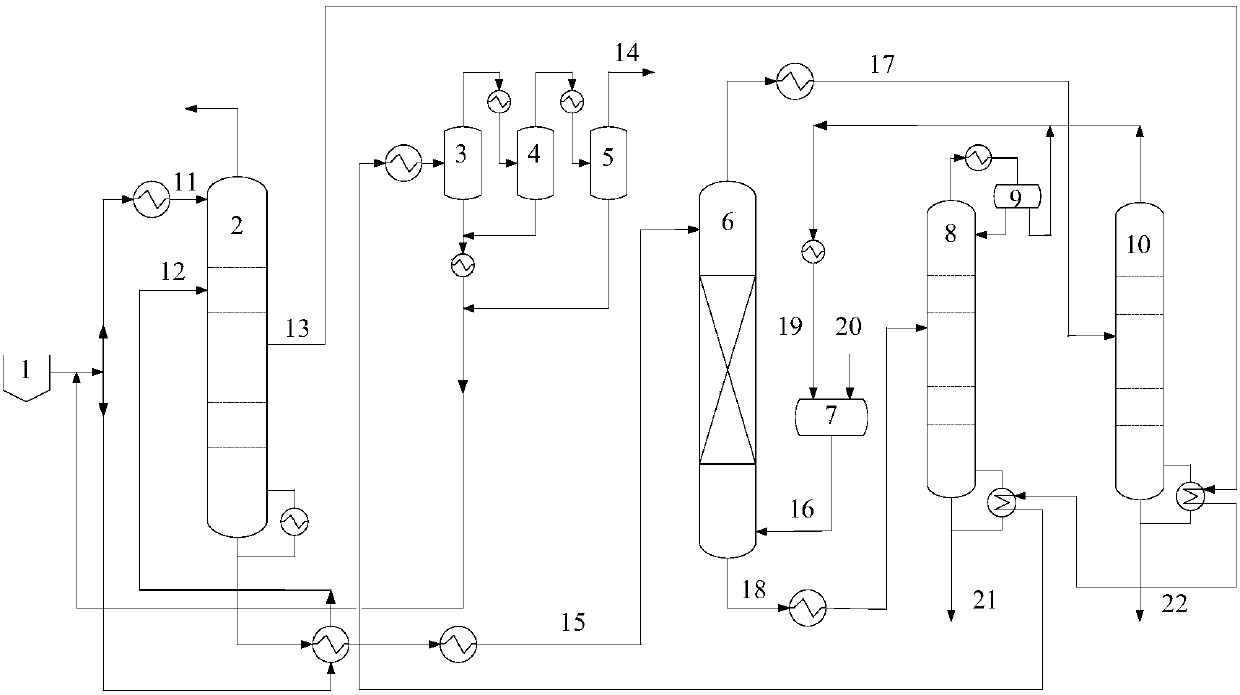

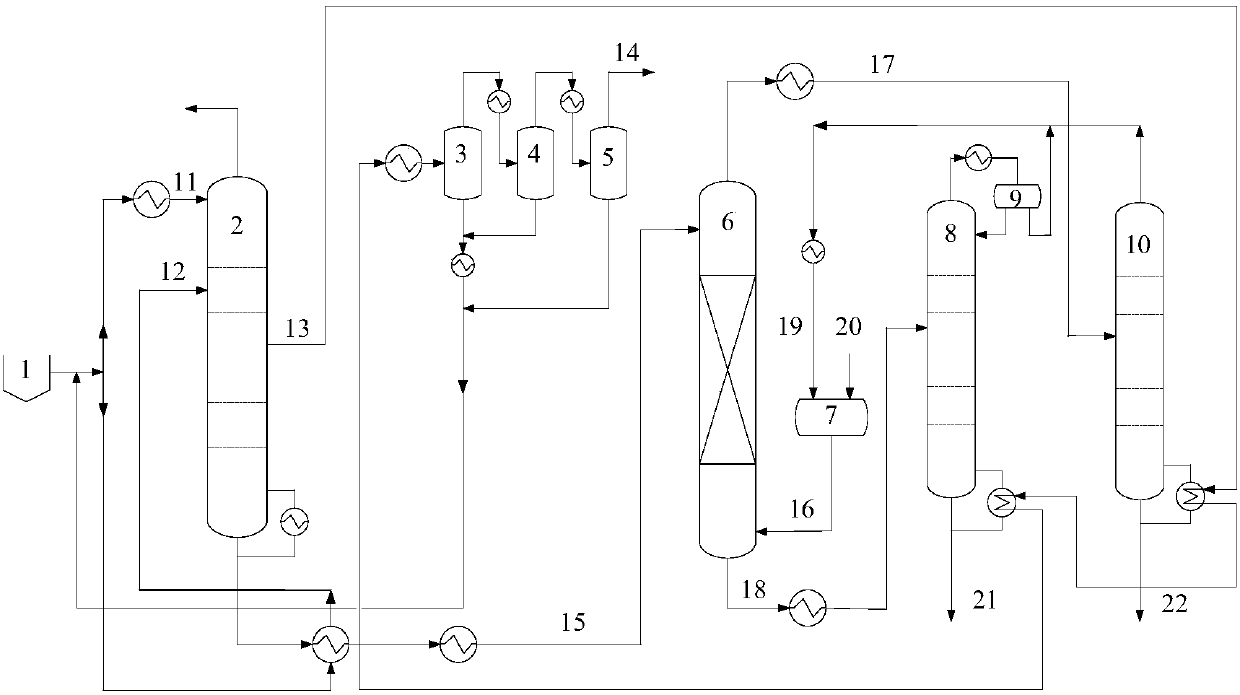

Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

InactiveCN1884150AHigh removal rateReduce crystallizationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCoal gasification wastewaterOrganic solvent

The invention discloses a gasification wastewater disposing method and device through single-tower pressurizing stripping, which comprises the following steps: entering the extracted of acid gas or ammonia gas of cold and hot coal gasification wastewater from band lateral line in the stripping tower from top and upper top; blending gas; dividing phases; washing; separating light oil and acid gas; preparing liquid ammonia through two-grade concreting and refining; separating crude phenol and organic solvent from bottom of tower through inversed-extracting autoclave liquid and organic solvent; recycling organic solvent through stripping. The gasification disposing device contains oil acid gas / ammonia stripping tower, extracting tower, acid gas washing tower, solvent stripping tower, solvent recycling tower, oil-water separator, dephlegmator, pump and reservoir.

Owner:SOUTH CHINA UNIV OF TECH

Treatment and reclaimation method of coal gasification wastewater contg. phenol

InactiveCN1834039AEfficient extractionHigh partition coefficientMultistage water/sewage treatmentWater/sewage treatment by extractionHigh concentrationCoal gasification wastewater

This invention relates to a method to dispose and recycle coal-gasification sewage containing high-concentration hydroxybenzenes, which includes following steps: a) acid removal; b) hydroxybenzene removal by extraction; c) regeneration of extraction solvent; d) ammonia recycling and rudimental extraction solvent recycling. The extraction solvent is isobutyl methyl ketone. After disposal with this method, more than 92% hydroxybenzenes and 99.5% ammonia can be recycled from the sewage. The extractant can be regenerated by distillation separation. The regenerated extractant is high purified and can meet the requirement of circulative extraction. Besides, while hydroxybenzenes, especially polyphenols are effectively recycled, CODCr of the sewage is also greatly lowered, which is benefic to sewage biochemical standardization.

Owner:SOUTH CHINA UNIV OF TECH

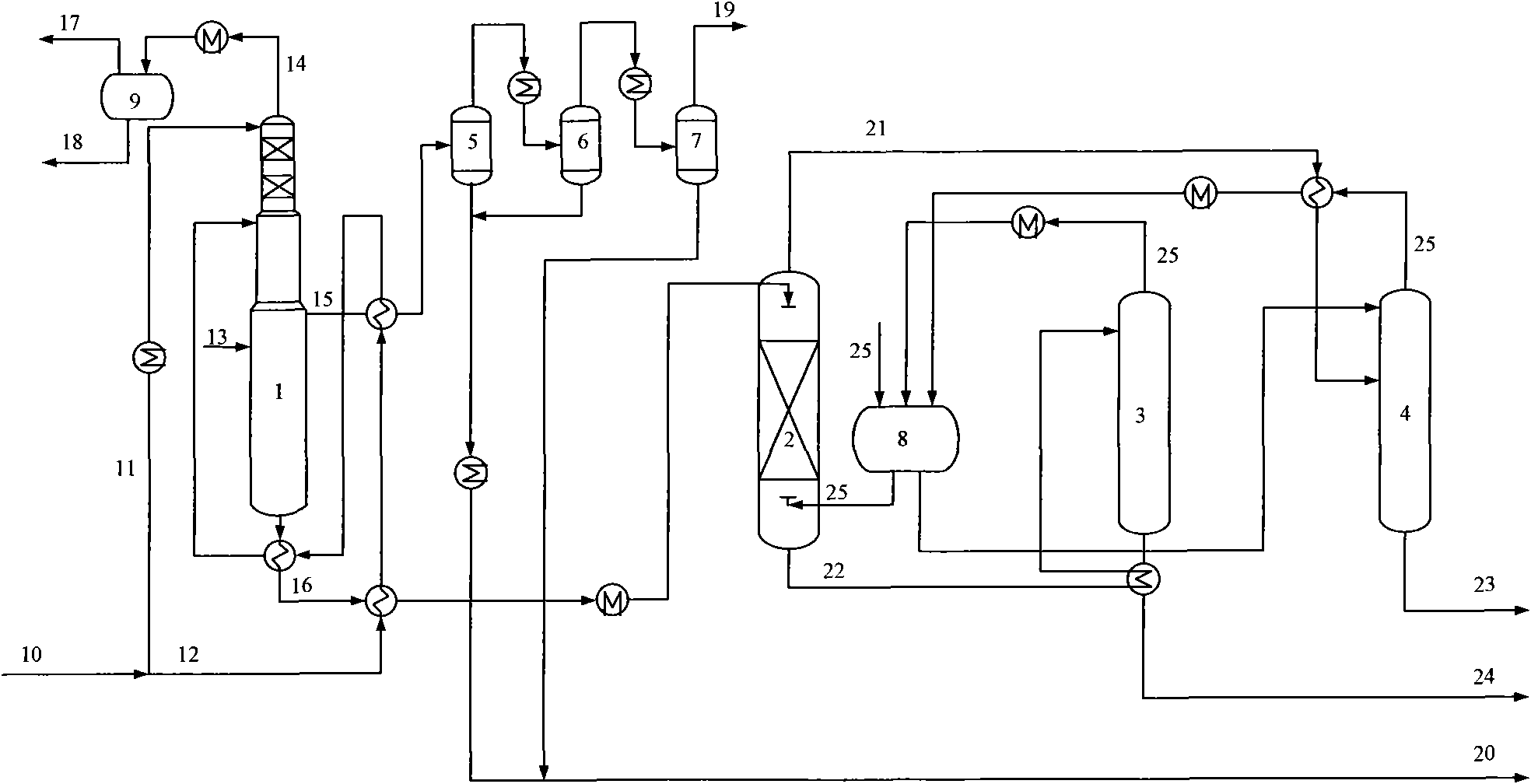

Method for treating coal gasification wastewater containing phenol and ammonia

InactiveCN101597124AEffective removal of fixed ammonia contentMeet the requirements of subsequent biochemical treatmentMultistage water/sewage treatmentWater/sewage treatment by degassingCoal gasification wastewaterHigh concentration

The invention relates to a method for treating coal gasification wastewater containing phenol and ammonia. The method comprises the following steps: single tower alkali injection and pressurization steam stripping removal of acidic gas and ammonia, three-level dephlegmation of lateral line tapped gas, extraction of phenol by diisopropyl ether and solvent recovery. The cold and hot coal gasification wastewater, according to a certain proportion, respectively enters a pressurization single tower from the upper part and middle upper part of a wastewater steam stripping tower, and acid gas is discharged from the tower top; the lateral line withdrawal mixed gas goes through three-level dephlegmation to obtain high-concentration ammonia, alkali is injected at the position below the lateral line to transform fixed ammonia into free ammonia which is to be removed; counter-current extraction is carried out on removed ammonia, residue of acid gas and diisopropyl ether to dephenolize; extraction solvent is recovered by a solvent recovery tower and a solvent steam stripping tower to obtain the byproduct, namely crude phenol. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, and the purified coal gasification wastewater meets the requirement of follow-up biochemical treatment.

Owner:SOUTH CHINA UNIV OF TECH +2

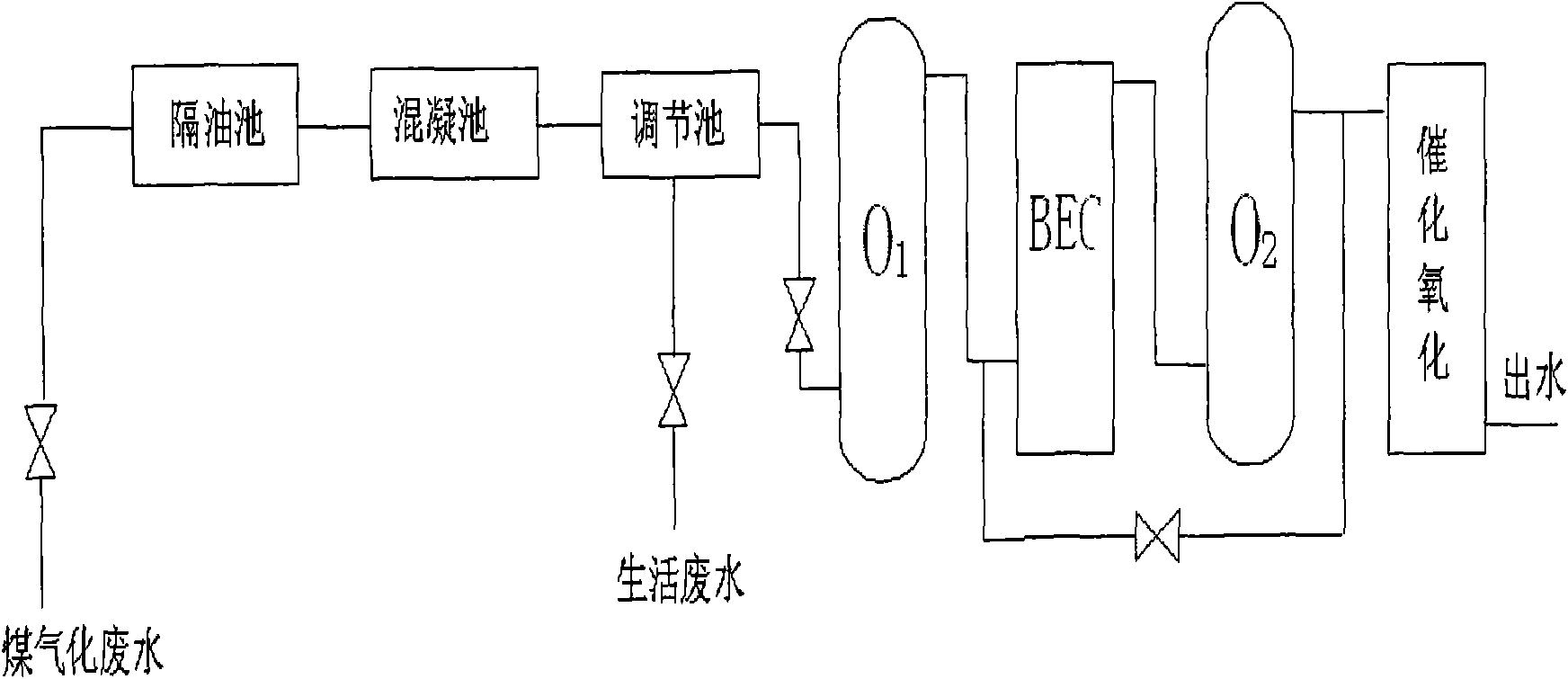

Method for processing coal gasification wastewater

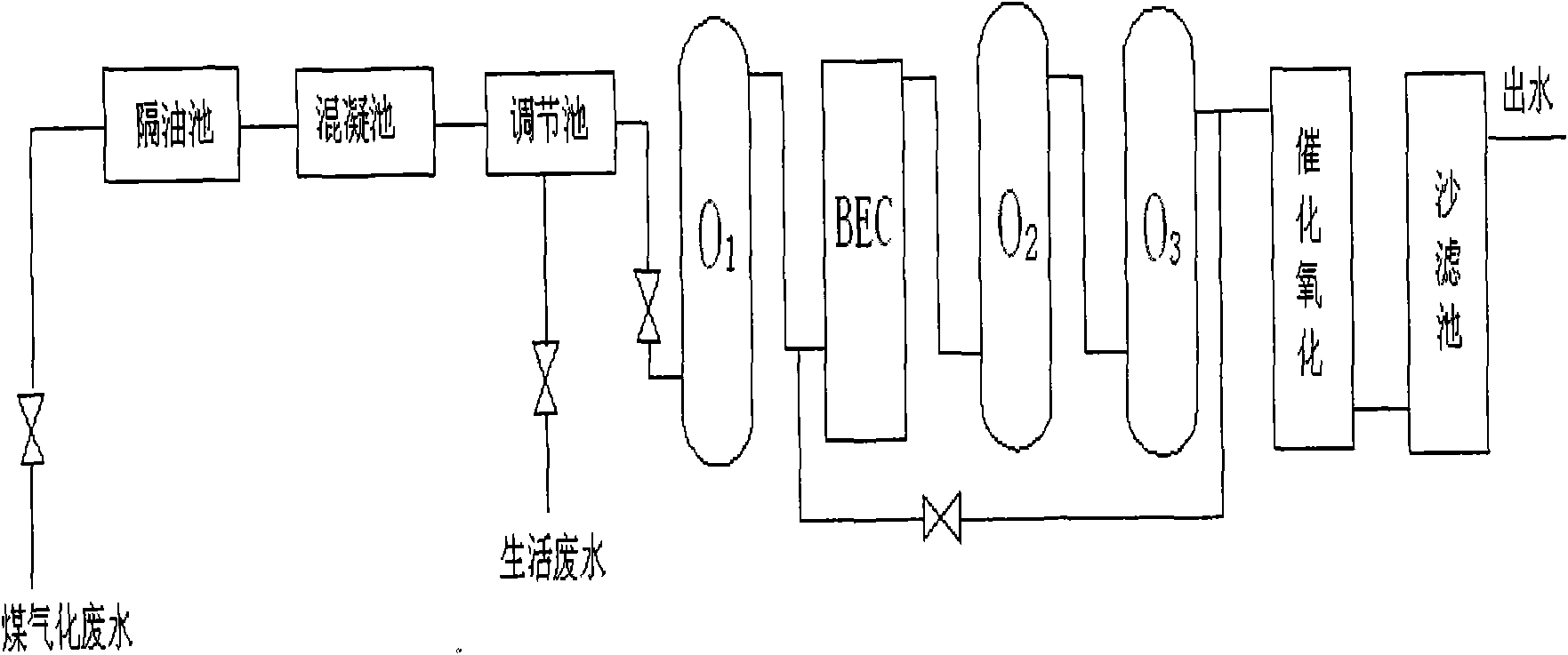

ActiveCN101654316APromote degradationImprove nitrogen removal efficiencyWaste water treatment from gaseous effluentsMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention discloses a method for processing coal gasification wastewater. The method sequentially comprises the following steps: a. carrying out preprocessing on the coal gasification wastewater in a preprocessing step comprising oil removal processing, coagulation processing and optional adjustment processing; then b. leading the preprocessed coal gasification wastewater to sequentially flowthrough a first-class bio-contact oxidation reactor, a biological electrochemical reactor, a second-class bio-contact oxidation reactor and an optional third-class or multi-class bio-contact reactor to carry out biological processing; and c. leading the biologically processed coal gasification wastewater to carry out catalytic oxidation processing in a catalytic oxidation reactor.

Owner:ENN ENVIROTECH CO LTD

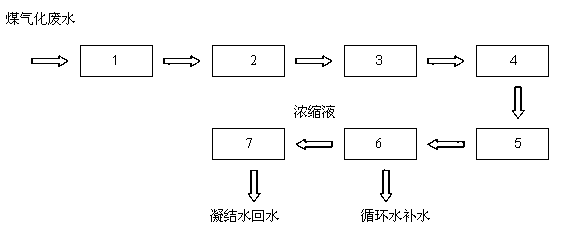

Coal gasification wastewater zero-emission treatment method, treatment system and application thereof

InactiveCN103288309AAchieving zero emissionsSave waterGeneral water supply conservationMultistage water/sewage treatmentCoal gasification wastewaterSlag

The invention provides a coal gasification wastewater zero-emission treatment method, a treatment system and an application thereof. The treatment system provided by the invention can respectively perform biochemical treatment, desalting and concentrated saline treatment on coal gasification wastewater through a biochemical treatment unit, a desalting unit and a concentrated saline treatment unit, clear water produced by each step can be reused, the produced high-salinity concentrated water can enter the next step for treatment, evaporation is finally performed through an evaporation unit, the clear water produced after evaporation can be used for water supply of a boiler, and the produced concentrated water can be used for flushing ash and slag. The treatment system provided by the invention can realize wastewater zero-emission treatment so as to achieve the purpose of saving water resources.

Owner:DATANG INT CHEM TECH RESINST

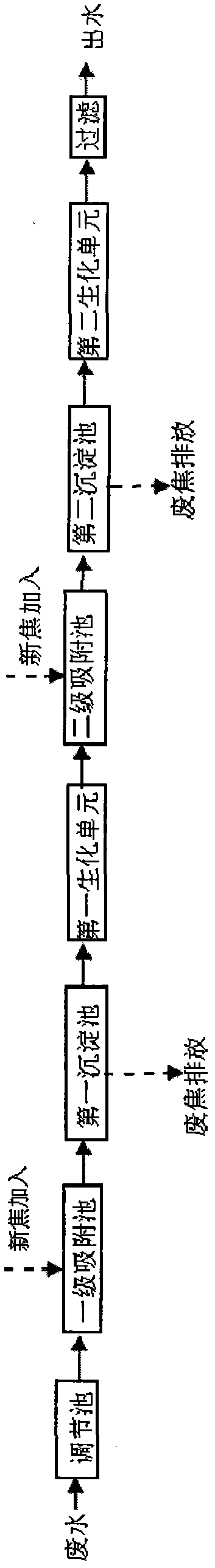

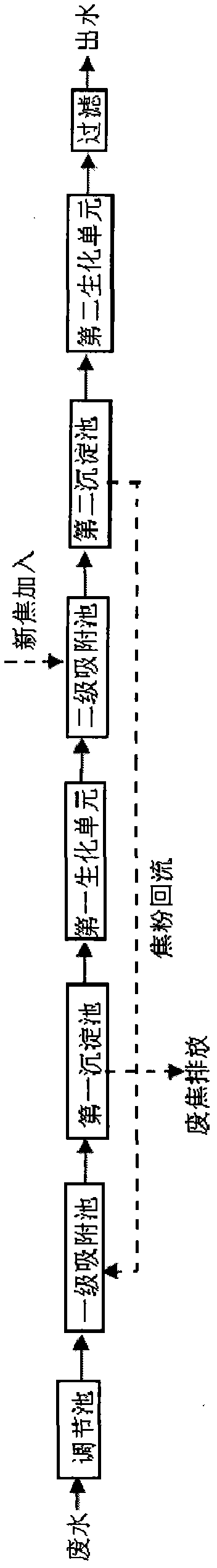

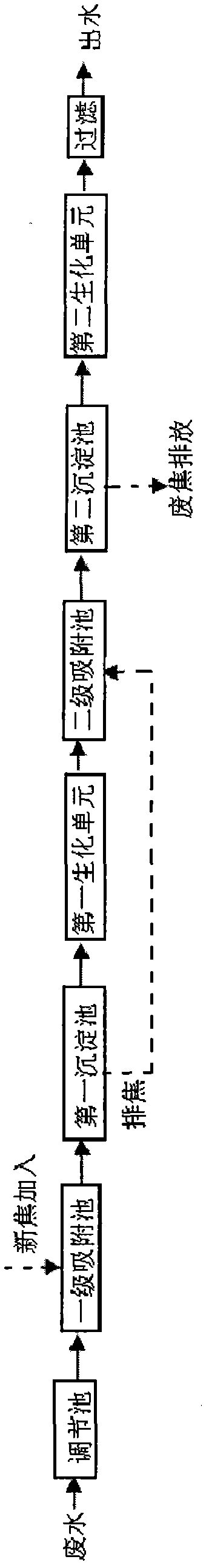

Coal gasification wastewater treatment process

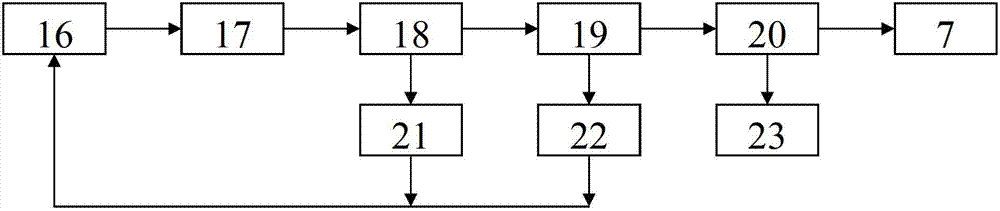

InactiveCN102070277AImprove utilization efficiencyReduce dosageMultistage water/sewage treatmentCoal gasification wastewaterSalt content

The invention discloses a coal gasification wastewater treatment process, which comprises the following steps of: performing adsorption treatment in a primary adsorption tank; performing sedimentation treatment in a first sedimentation tank; performing biochemical treatment in a first biochemical unit; performing adsorption treatment in a secondary adsorption tank; performing sedimentation treatment in a second sedimentation tank; performing biochemical treatment in a second biochemical unit; and filtering and discharging. The coal gasification wastewater treatment process solves the technical problem that active carbon is added into an active sludge aeration tank to influence the effects of the biochemical treatment and the adsorption treatment in the conventional coal gasification wastewater treatment process, has the advantages of independent adsorption and biochemical treatment, combined arrangement, concise process, high treatment efficiency, no increase of salt content and stable operation, and is particularly suitable for treating coal gasification wastewater.

Owner:北京国能普华环保工程技术有限公司 +1

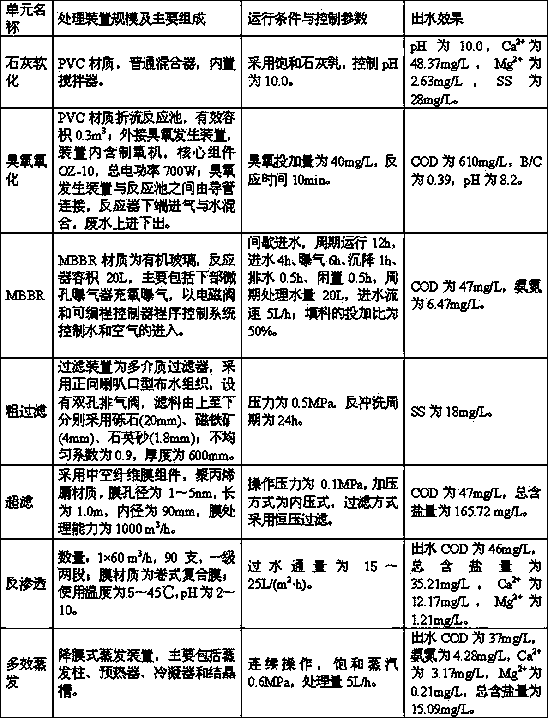

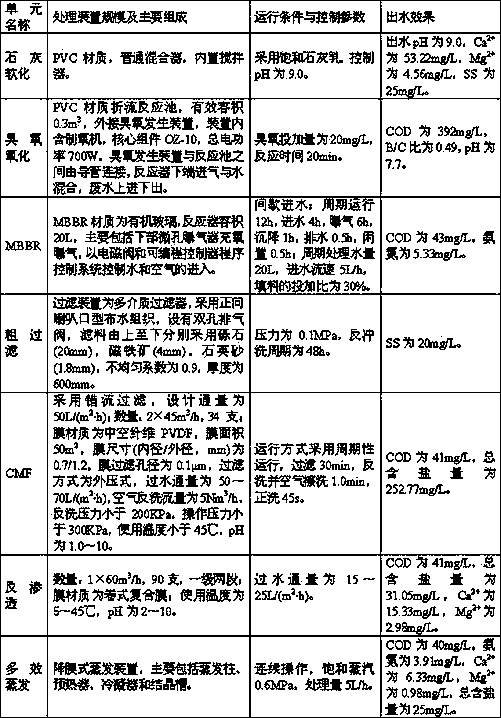

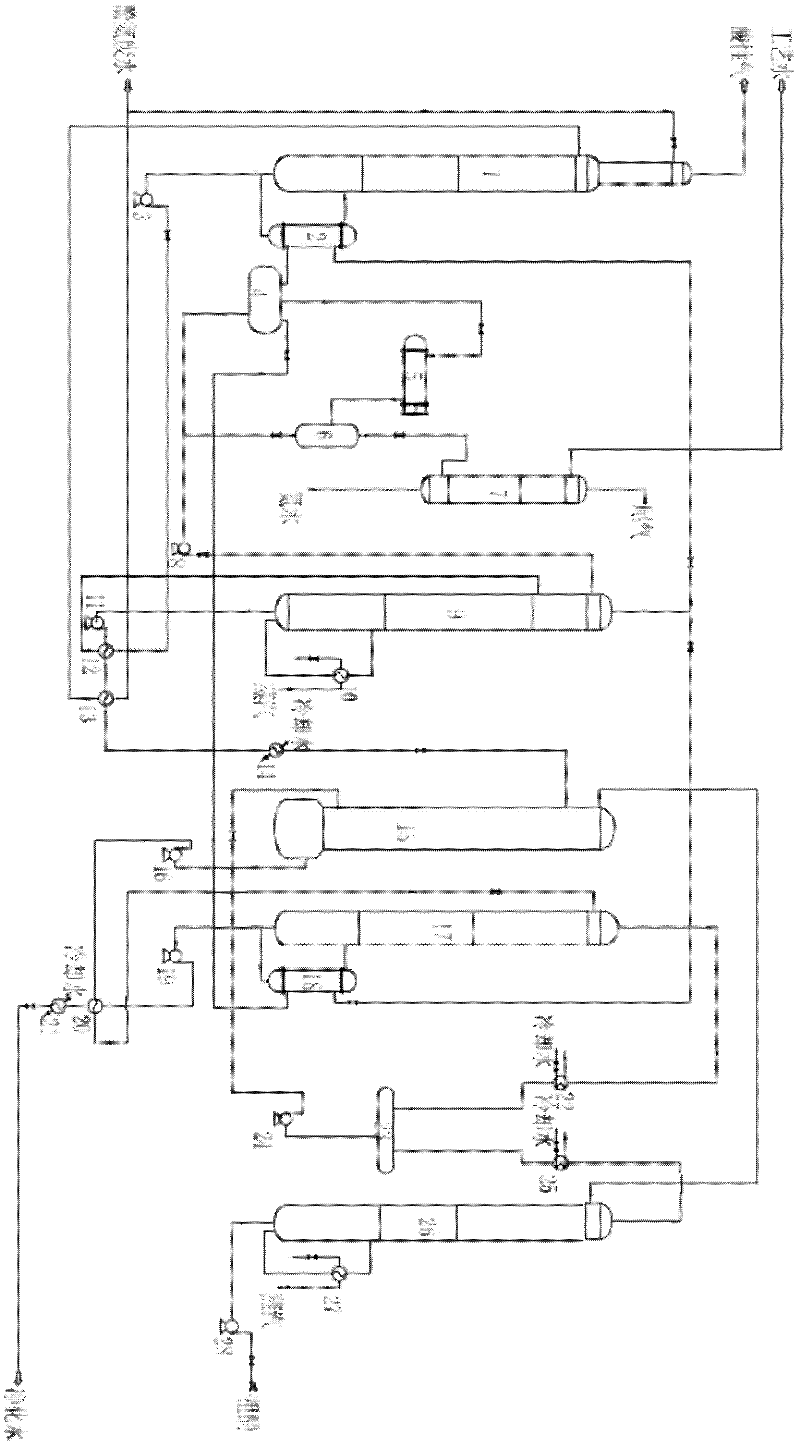

Method for treating coal gasification wastewater

ActiveCN103771650AReduce hardnessHigh removal rateWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentCoal gasification wastewaterFiltration

The invention discloses a method for treating coal gasification wastewater. The method comprises steps of: (1) lime softening by first adding lime milk to the coal gasification wastewater to conduct chemical precipitation on calcium salt and magnesium salt with the lime milk, standing the precipitation and filtering an supernatant; (2) ozone oxidation by sending the wastewater filtered in the step (1) into an ozone oxidation device for treatment; (3) MBBR treatment by sending the wastewater subjected to ozone oxidation into an MBBR for treatment; (4) coarse filtration; (5) continuous membrane filtration or ultrafiltration; (6) reverse osmosis; and (7) multi-effect evaporation by conducting multi-effect evaporation on the concentrate obtained by reverse osmosis treatment, and further crystallizing the concentrate obtained by multi-effect evaporation. The method of the invention can effectively remove the main pollutants such as COD, ammonia nitrogen and chroma in coal gasification wastewater, can also greatly reduce the salt content of the wastewater, ensure the efficient and long-term running of the double membranes, and achieve zero discharge of coal gasification wastewater.

Owner:CHINA PETROLEUM & CHEM CORP +1

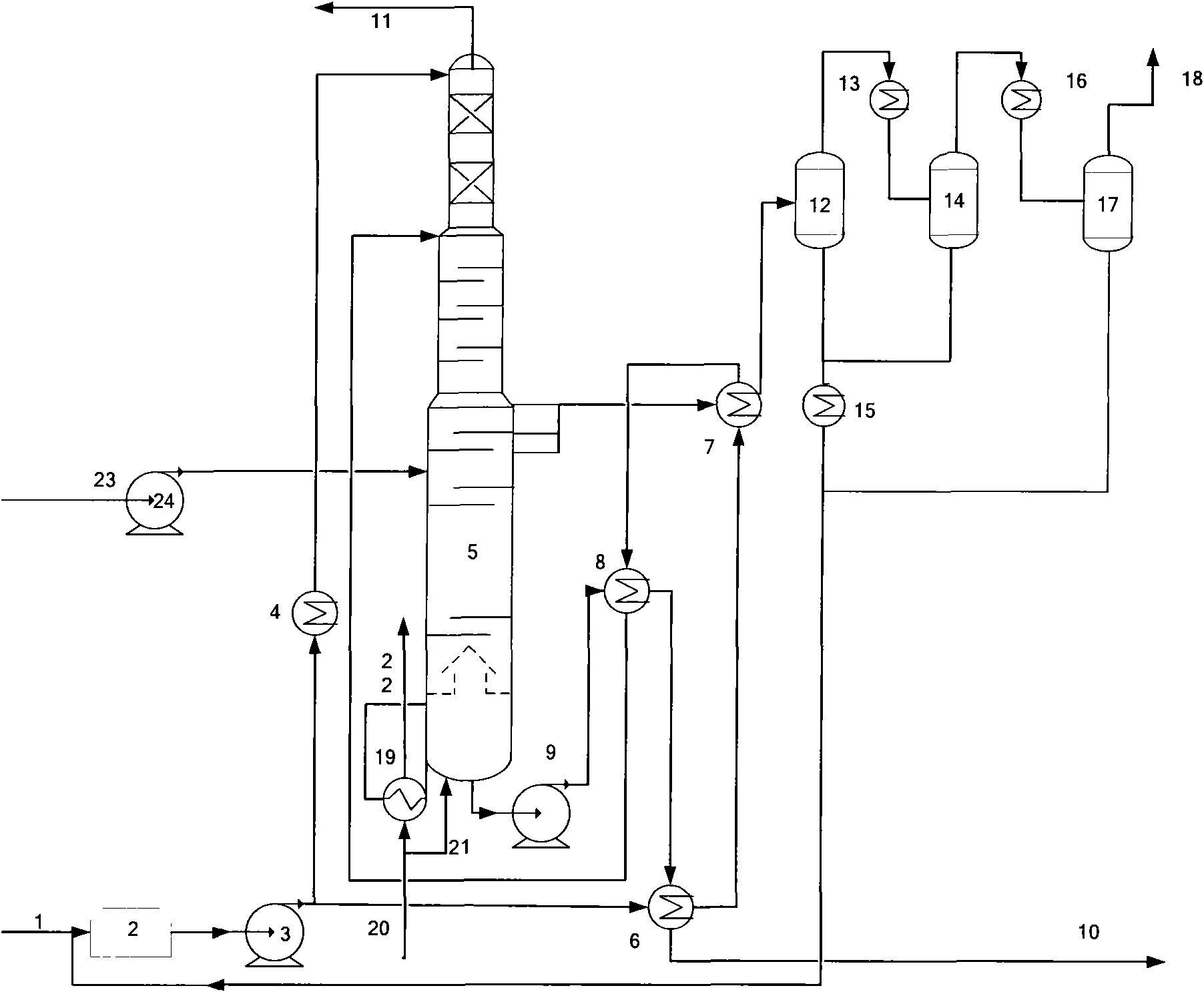

A kind of energy-saving method for recovery and treatment of phenol ammonia wastewater

InactiveCN102259943AEfficient recyclingSolve the technical problems of high energy consumptionChemical industryWater/sewage treatment by heatingCoal gasification wastewaterDifferential pressure

The invention relates to a method for treating wastewater containing phenol and ammonia, in particular to an energy-saving process for recycling the wastewater containing the phenol and the ammonia. Equipment among an acid removing tower, an ammonia removing tower and a water tower is coupled, namely a crude ammonia condenser on the top of the ammonia removing tower is taken as a reboiler of the acid removing tower and the water tower; and a differential pressure rectification technology is utilized, so that the step comprehensive utilization of a heat resource is realized, the energy consumption of wastewater treatment is reduced, and the using amount of steam and circulating water is greatly saved; particularly the equipment is coupled, the differential pressure rectification technologyis utilized and the ammonia and the phenol in the coal gasification wastewater are recycled simultaneously, so that the aims of saving energy and reducing emission in the wastewater treatment and recycling process are fulfilled. The technical problem that the energy consumption is high when the wastewater containing the phenol and the ammonia is recycled in the coal gasification process is solved; and the comprehensive utilization of energy is realized, and the method is high in social value and economic value.

Owner:TIANJIN HAOYONG CHEM TECH

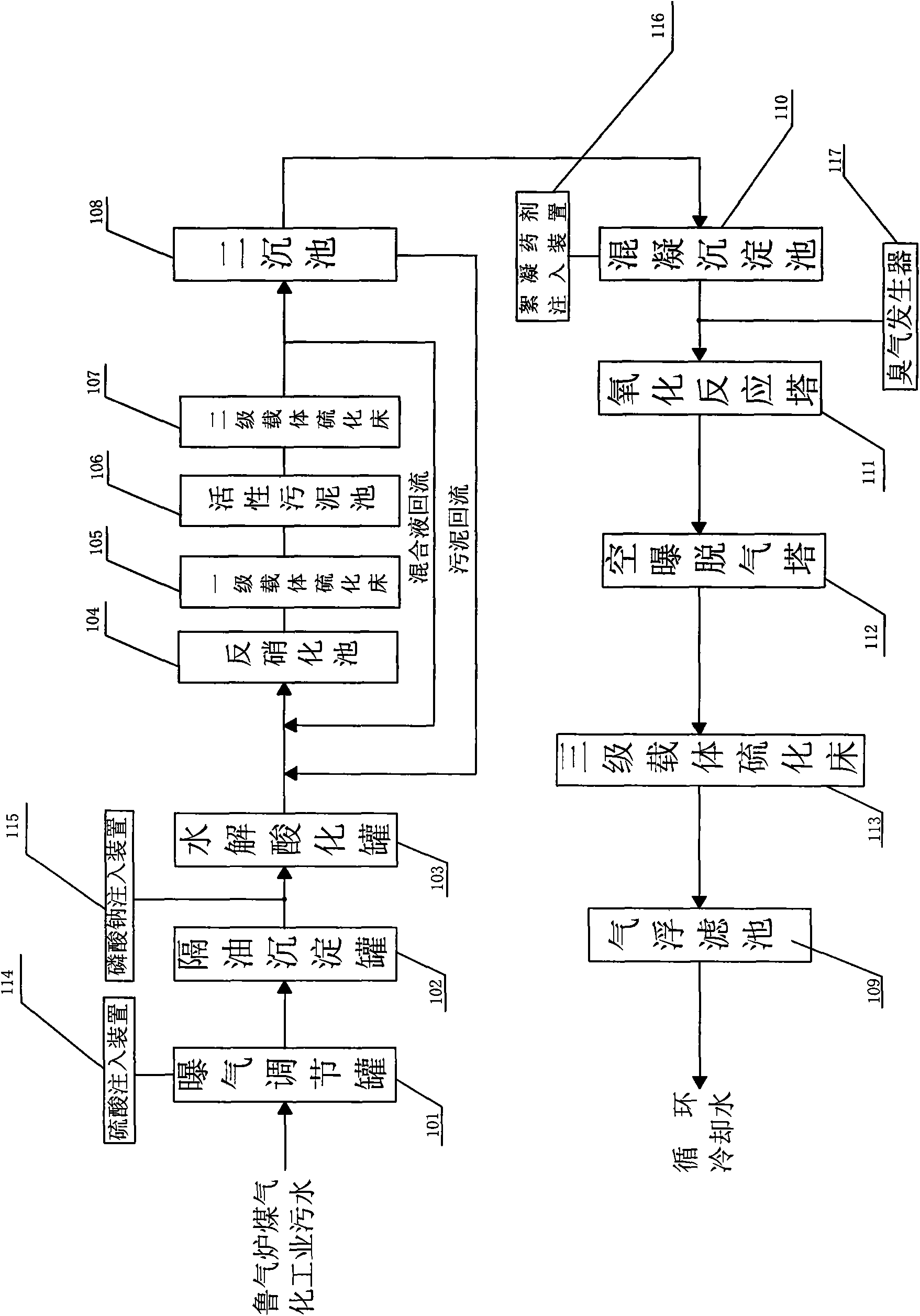

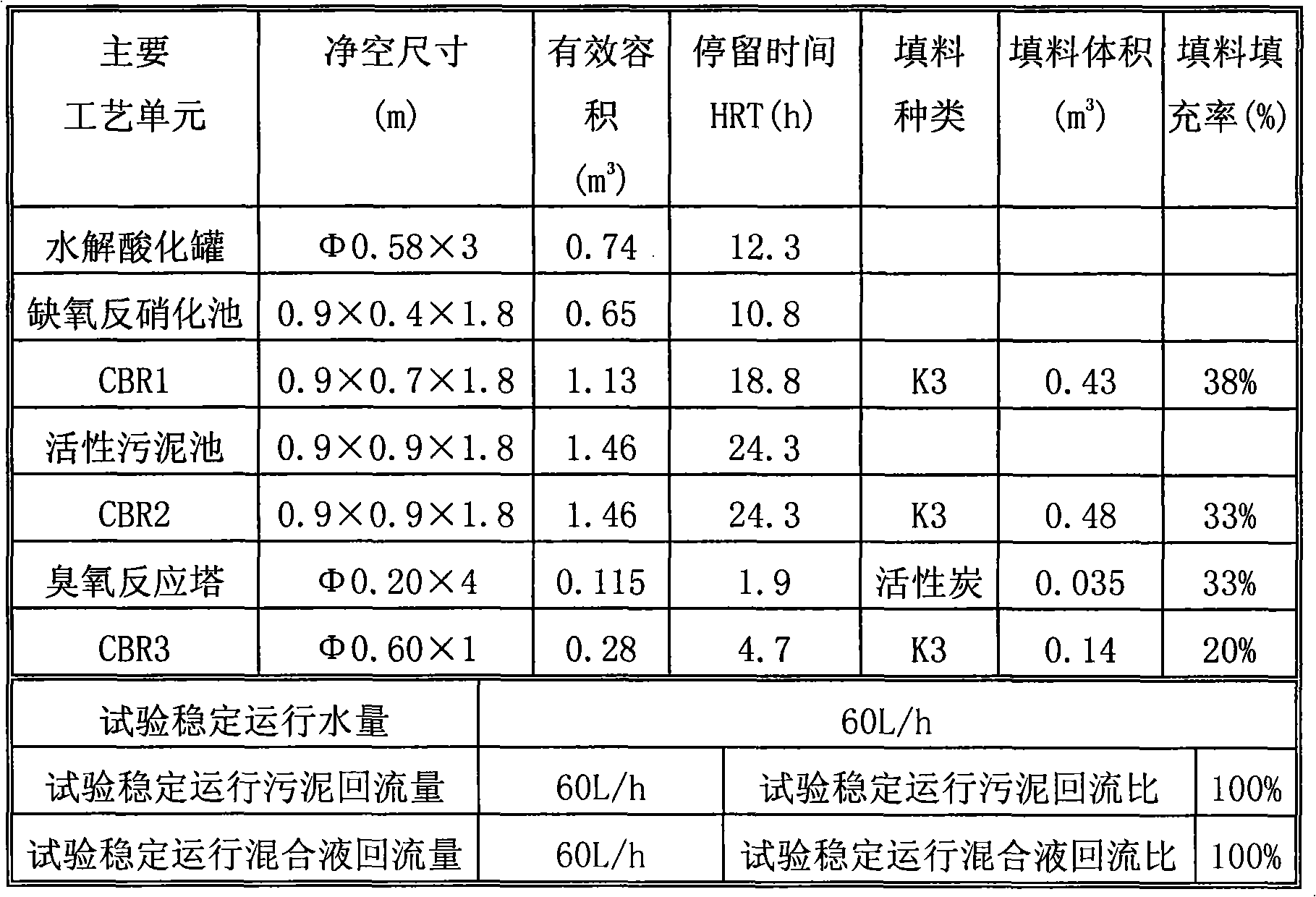

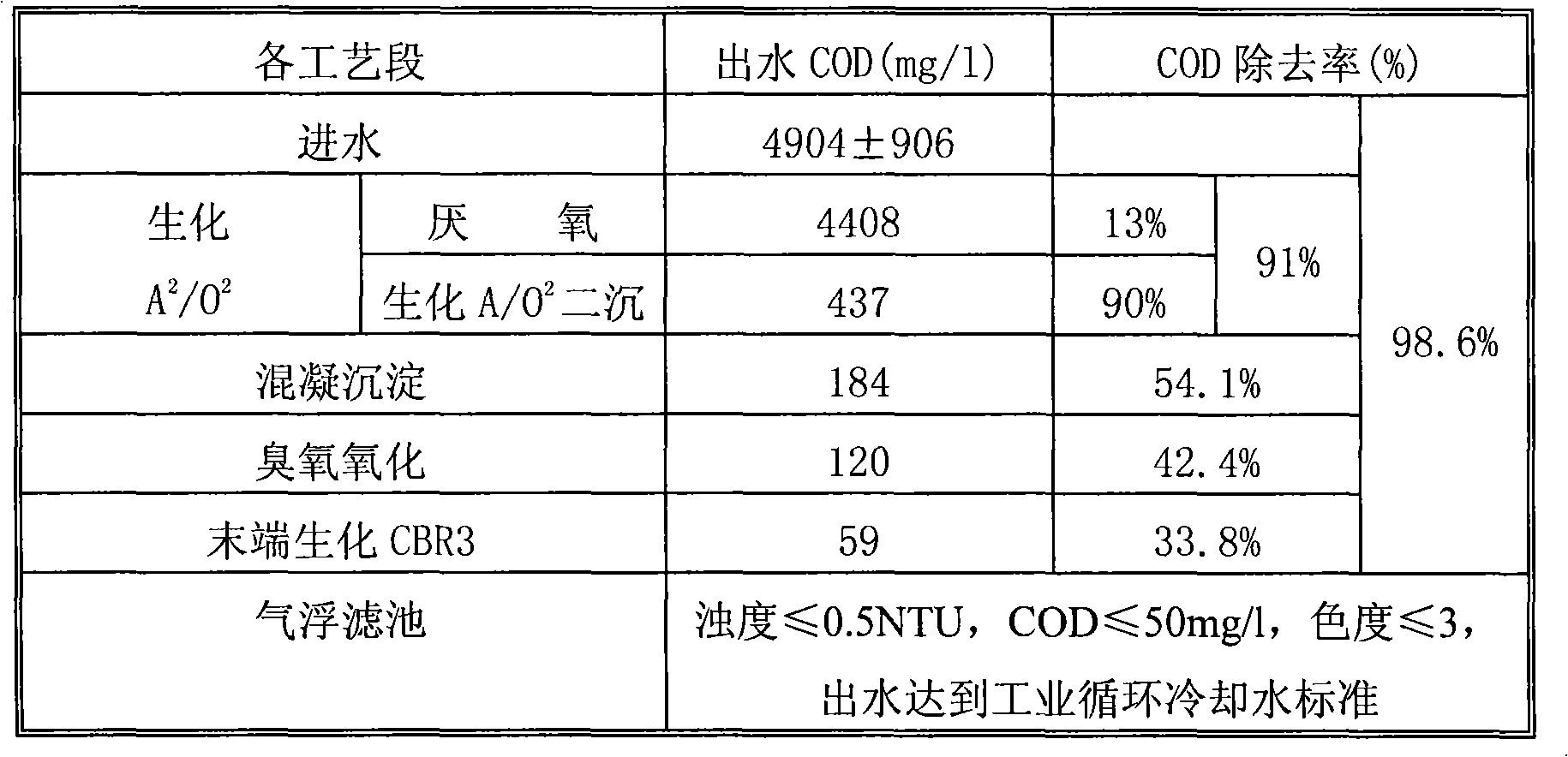

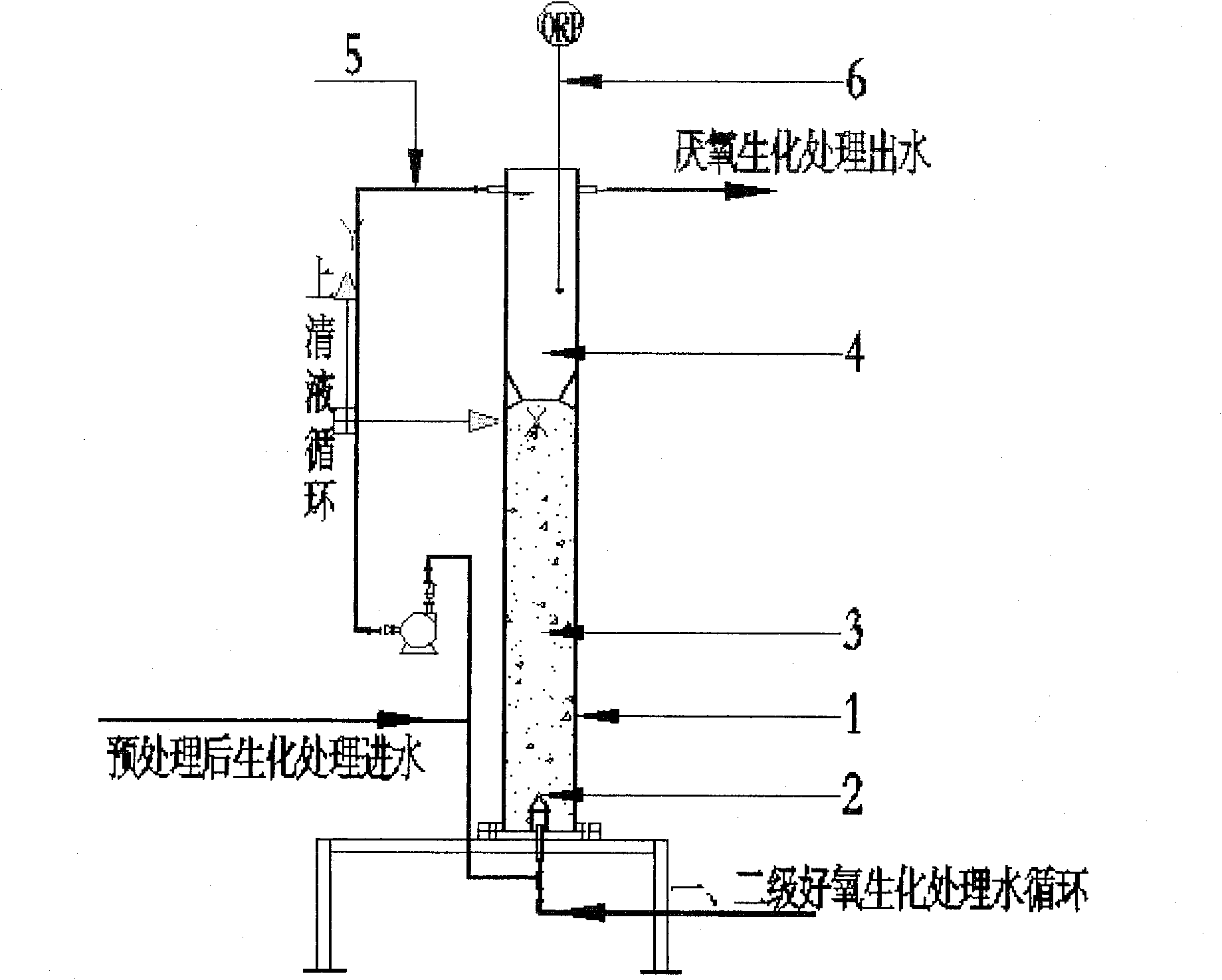

Lurgi furnace coal gasification wastewater treatment and reuse technology

ActiveCN101607777AImprove impact resistanceGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterActivated sludge

The invention discloses a Lurgi furnace coal gasification wastewater treatment and reuse technology, comprising the steps of adopting aeration adjustment, oil separation and sedimentation, hydrolysis acidification, denitrification treatment, first order carrier fluidized bed decarburization, residual COD removement with activated sludge, second order carrier fluidized bed ammonia / nitrogen removement, sludge-water separation, precipitation, oxidation reaction, residual ozone removement, organic waste removement and floating filter treatment to treat the coal gasification wastewater of a Lurgi furnace coal gasification factory and obtaining water which can be reused. The invention has simple operation and low process cost and the treated effluent can be used as the cooling water of boiler furnaces, thus fully recycling the treated Lurgi furnace coal gasification wastewater.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

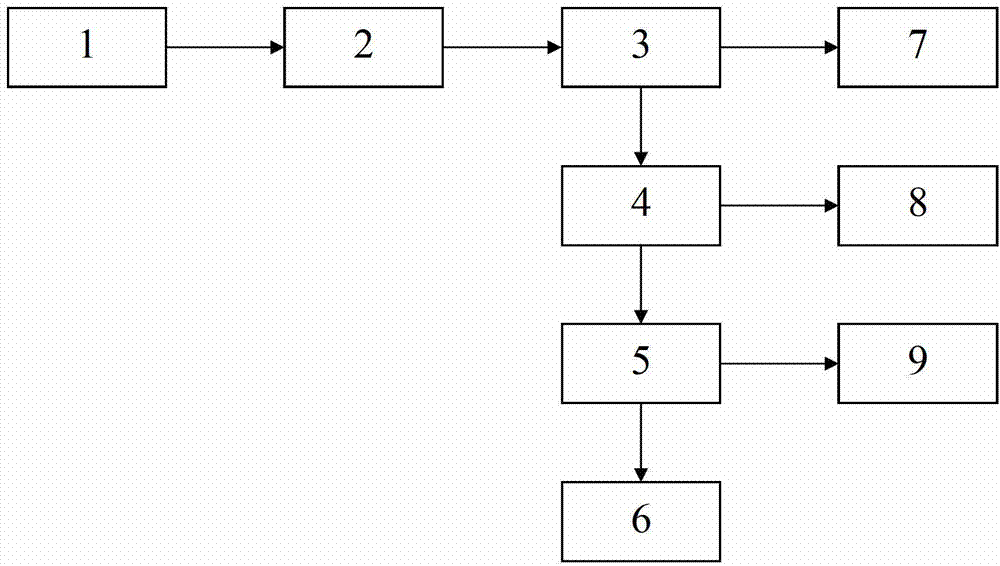

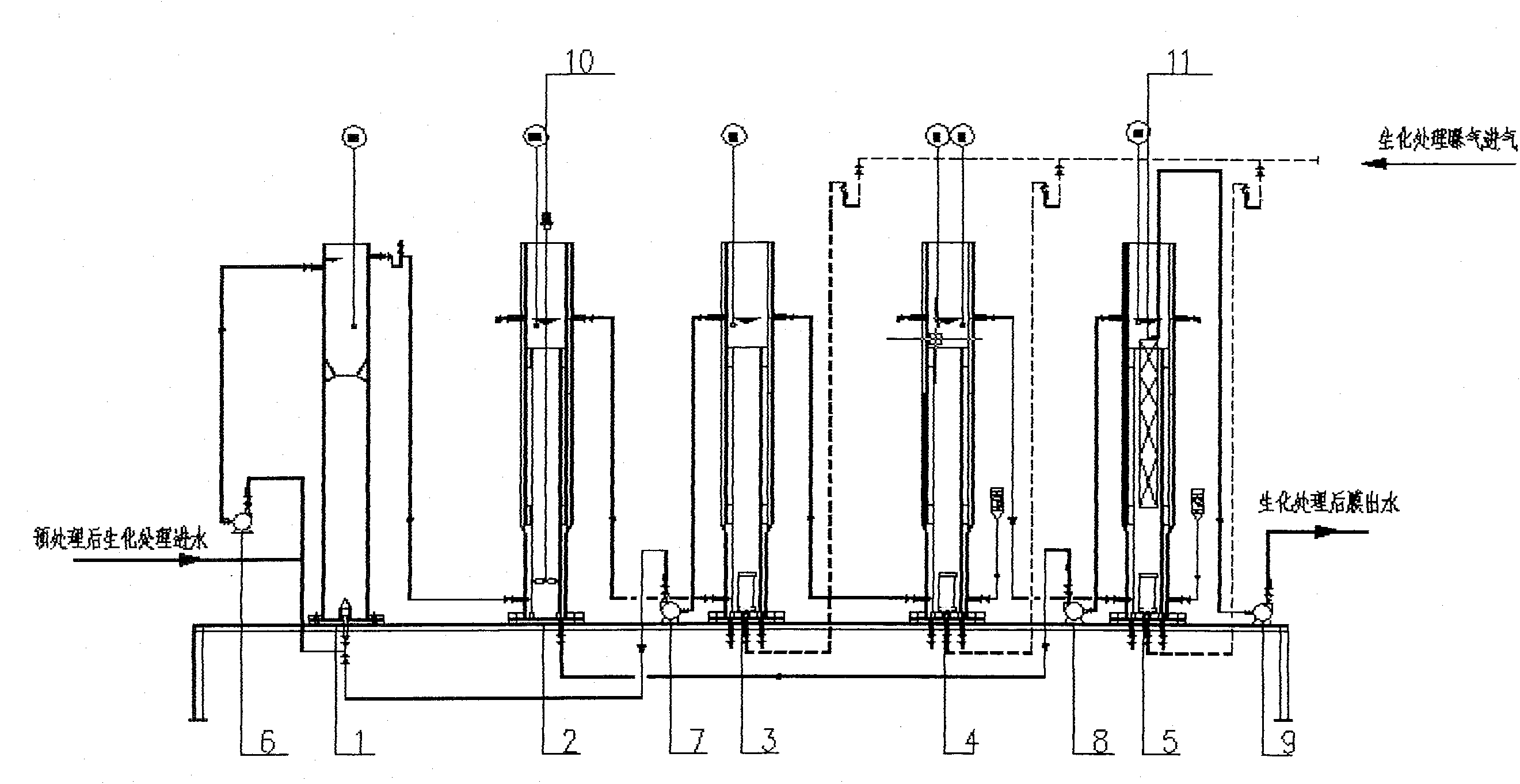

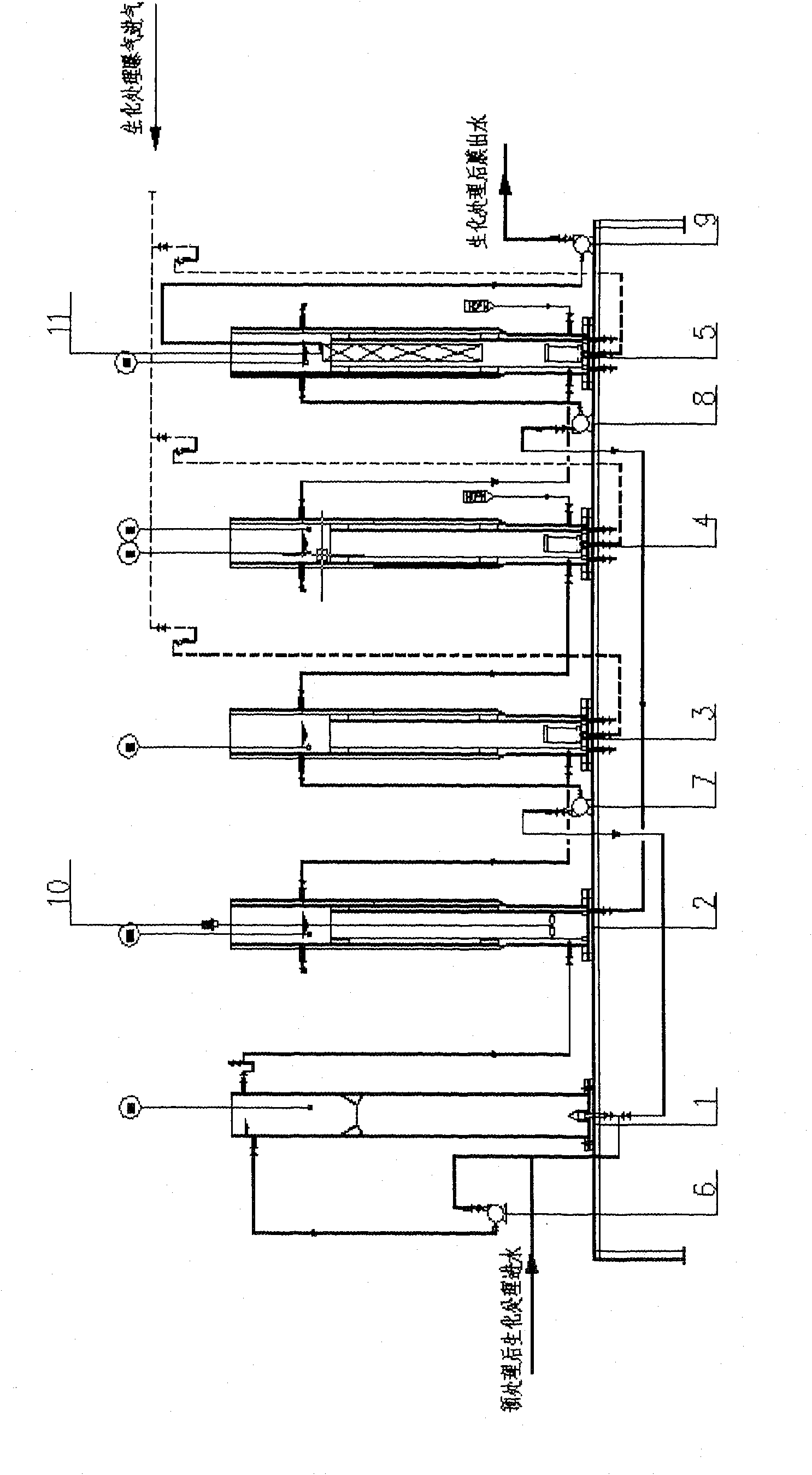

Coal gasification waste water biochemical treatment equipment and method

ActiveCN101811797AIncrease concentrationPollution suppressionTreatment with aerobic and anaerobic processesWater/sewage treatment bu osmosis/dialysisCoal gasification wastewaterBiochemical engineering

The invention provides coal gasification waste water biochemical treatment equipment and a method. The equipment comprises an anaerobic biochemical treatment unit, an anoxic biochemical treatment unit, a one-grade or multiple-grade aerobic biochemical treatment unit and a membrane biological response unit which are communicated in sequence. In addition, the aerobic biochemical treatment unit is also communicated with the anoxic biochemical treatment unit, and the membrane biological response unit is communicated with the anoxic biochemical treatment unit; each biochemical treatment unit has the characteristics of biochemistry and slurry and water separation integration. The coal gasification waste water biochemical treatment equipment and the method have high COD load and high ammonia nitrogen load and can realize high COD removal rate and high ammonia nitrogen removal rate.

Owner:ENN ENVIROTECH CO LTD

Method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping

InactiveCN101597092ALow investment costLow running costWater/sewage treatment by degassingAmmonia preparation/separationHigh concentrationCoal gasification wastewater

The invention discloses a method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping, comprising the following steps: the cold and hot coal gasification wastewater respectively enters a single tower from the upper part and middle upper part of a wastewater steam stripping tower, gas ammonia is extracted from the lateral line of the single tower which goes through three-level dephlegmation to obtain high-concentration ammonia, condensate returns to a stock tank; alkali is injected at the position below the lateral line to transform fixed ammonia into ammonia which is to be removed; the mass percentage concentration of alkali liquor is 20-40%, the use level of the alkali liquor is not more than that of mol number of fixed ammonia in the wastewater, and residue is extracted from the tower bottom and is subjected to follow-up extraction and dephenolizing process of coal gasification wastewater. In the method of the invention, the process removing acid gas, free ammonia and fixed ammonia is carried out simultaneously on the coal gasification wastewater in the wastewater steam stripping single tower, as a result, high-concentration ammonia is obtained, the content of carbon dioxide, sulfureted hydrogen, free ammonia and fixed ammonia in tower kettle purified water is extremely low, encrustment is not prone to take place, pH value is reduced to around 6, as a result, fine extraction conditions are created for the follow-up solvent extraction dephenolizing of the coal gasification wastewater. The method of the invention is suitable for the coal gasification wastewater and overall treatment process thereof.

Owner:SOUTH CHINA UNIV OF TECH +2

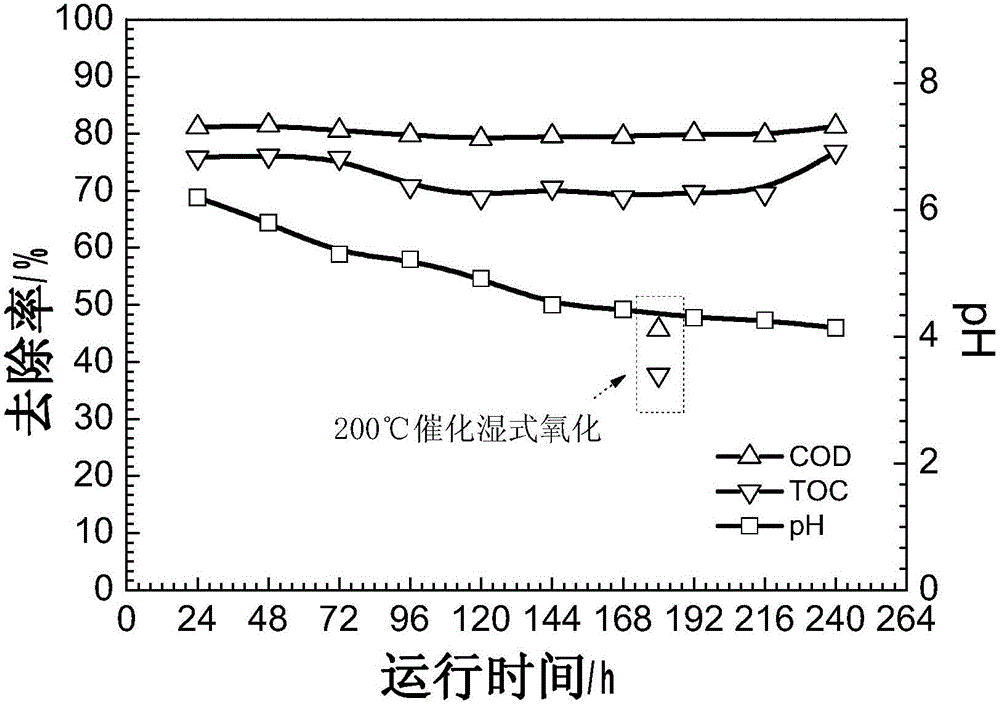

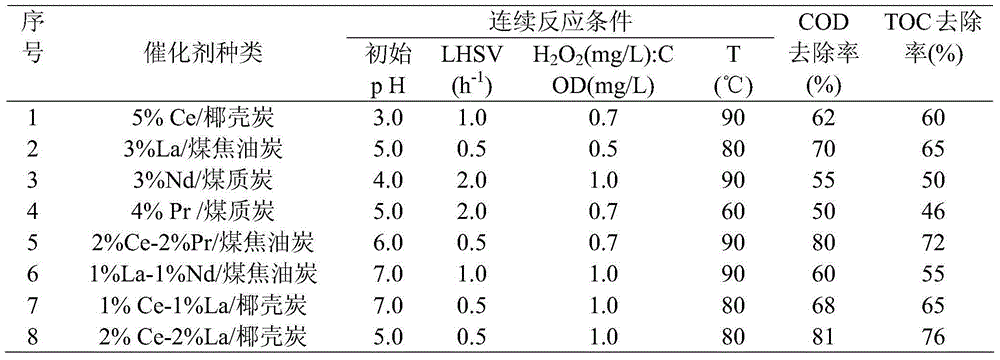

Modified active carbon catalyst, and preparation and application thereof

ActiveCN105268425ALarge specific surface areaHigh activityMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationHigh concentrationCoal gasification wastewater

The invention discloses a modified active carbon catalyst, and preparation and an application thereof, particularly discloses the catalyst for treatment of coal gasification wastewater through a catalytic wet hydrogen peroxide oxidation technology, and the preparation and the application thereof, and belongs to the fields of water treatment technology and environmental functional materials. The coal gasification wastewater is a by-product generated in a coal gasification process, contains a variety of high-concentration pollutants including a large amount of phenols, ammonia, sulfides, cyanides, tar and the like, and has poor biodegradability. Activated carbon as a carrier is loaded with rare earth metals La, Ce, Pr and Nd at low temperature to improve the activity, and the active carbon-based catalyst having larger specific surface area, high activity and high stability is prepared; after the catalyst is used for 240 h in a 80 DEG C atmospheric pressure system, the activity of the catalyst can still basically remain unchanged. Studies on harmless and resourceful treatment and reuse of the coal gasification wastewater are facilitated, and an important scientific and application significance is provided for establishment of corresponding demonstration projects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

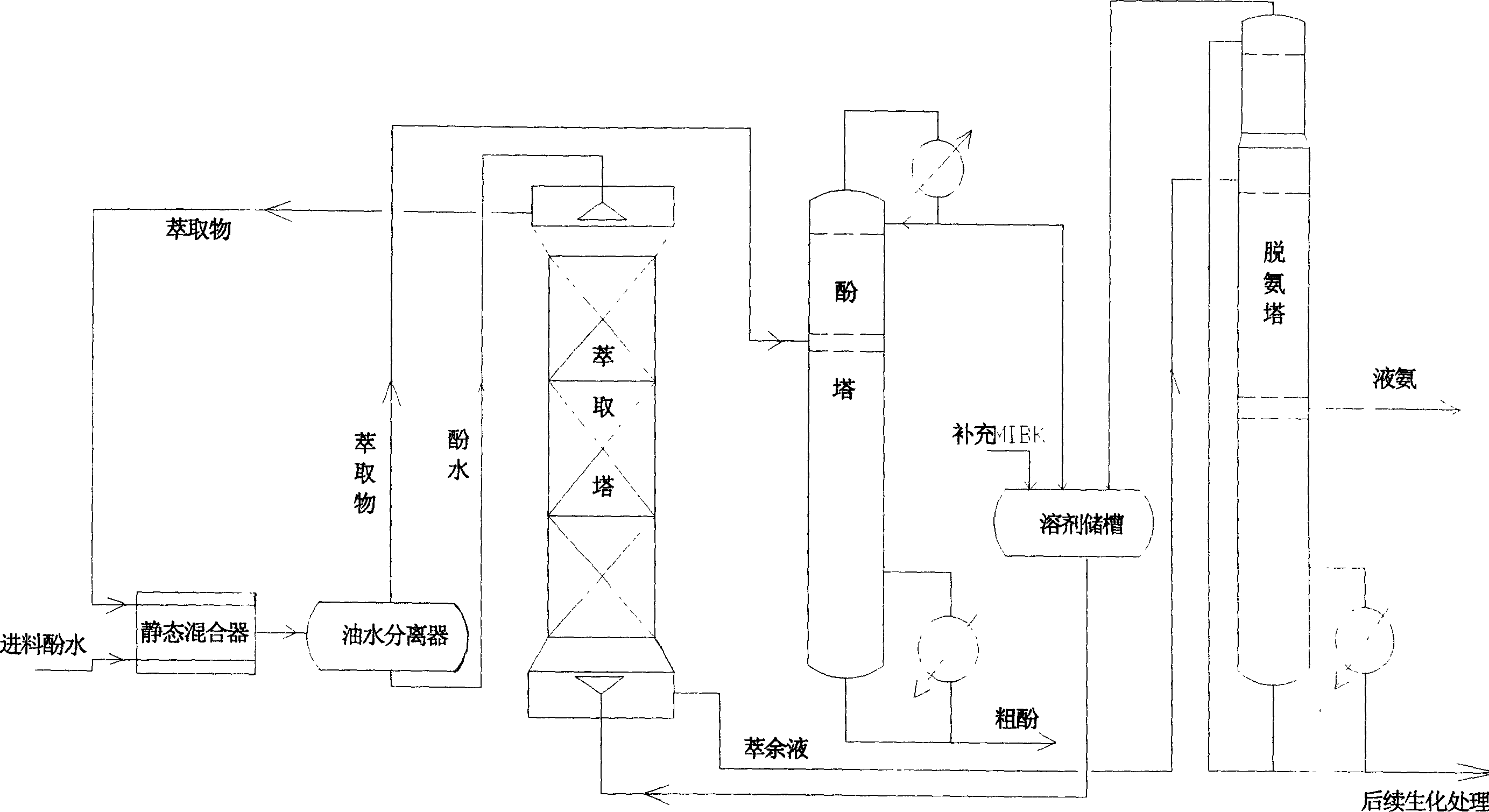

Extraction and dephenolization process of coal gasification wastewater

InactiveCN1834040AHigh partition coefficientSolve the problem of ineffective extraction of polyphenolsMultistage water/sewage treatmentWater/sewage treatment by extractionCoal gasification wastewaterHigh concentration

This invention discloses a method to remove high-concentration hydroxybenzenes from coal-gasification sewage, that is, coal-gasification sewage containing hydroxybenzenes and isobutyl methyl ketone as extracting solvent are mixed and separated so as to obtain solvent phase and remnant aqueous phase liquid. Solvent and crude hydroxybenzene are extracted from the solvent phase by distillation. Multiple-class reflux extraction is carried out towards remnant aqueous phase liquid and rudimental solvent is further extracted from the extract. Facilities involved in this method include a static mixer, an oil-water separator, a hydroxybenzene distillation tower and an extraction tower. Extracting coal-gasification sewage containing high-concentration hydroxybenzenes with the method provided by this invention, total hydroxybenzene extraction ratio can be as high as 92%. Besides, it also has the advantages of simple technique, soft conditions and recyclable extraction solution.

Owner:SOUTH CHINA UNIV OF TECH

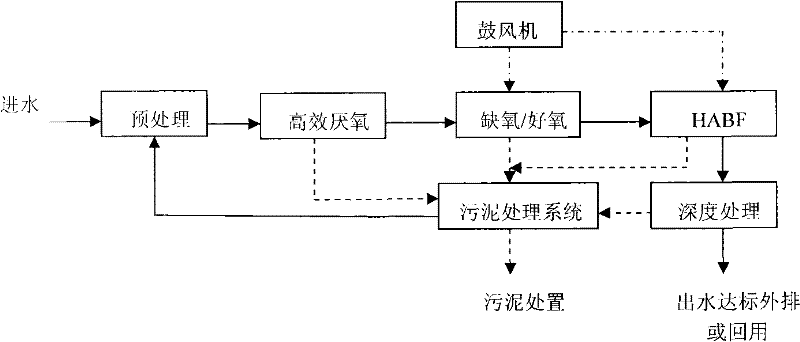

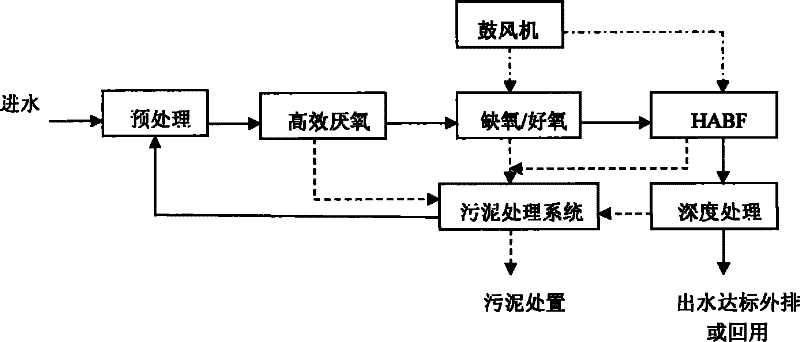

Treatment or recycling method and purpose for coal gasification and coal carbonization waste water

InactiveCN102344223AAchieve recyclingAchieving "Zero Emissions"Multistage water/sewage treatmentCoal gasification wastewaterCarbonization

The invention provides a treatment or recycling method and purpose for coal gasification and coal carbonization waste water. The method employs a combined technology of '' pretreatment + efficient + anoxic / aerobic treatment + efficient aeration biofilter + advanced treatment '' with details seen in a specification. The invention has advantages that efficient anoxic treatment not only eliminates organic pollutants in the waste water to reduce post treatment process load but also enhances waste water biodegradability; the efficient aeration biofilter efficiently gathers microbes growing slow, so as to improve processing effect on difficultly degraded organic matters and ammonia nitrogen in the waste water, guarantee stable operation of the integral combined technology and effectively mitigate process operating difficulty of the subsequent advanced treatment. The invention is suitable for standard reached discharging or recycling and present engineering reconstruction and upgrade of gasification and coal carbonization waste water, as well as standard reached discharging or recycling and present engineering reconstruction and upgrade of similar coal chemical industry waste water and waste water containing high density difficultly degraded organic matter.

Owner:曾明

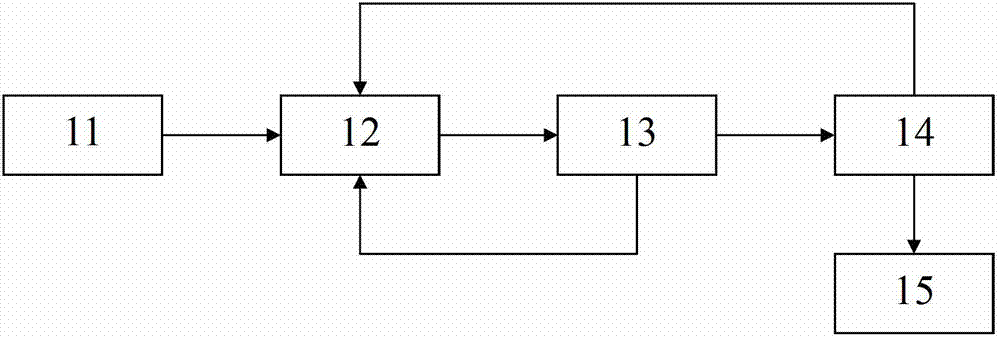

Coal gasification wastewater processing method

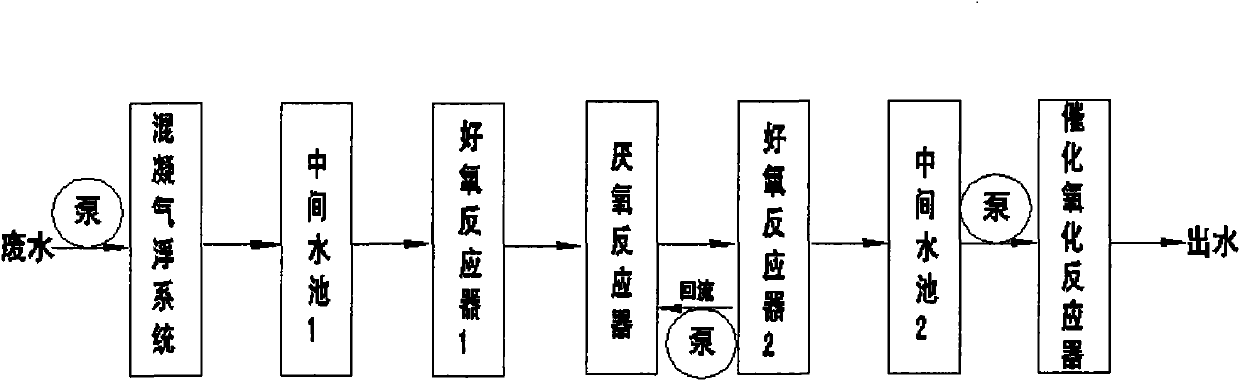

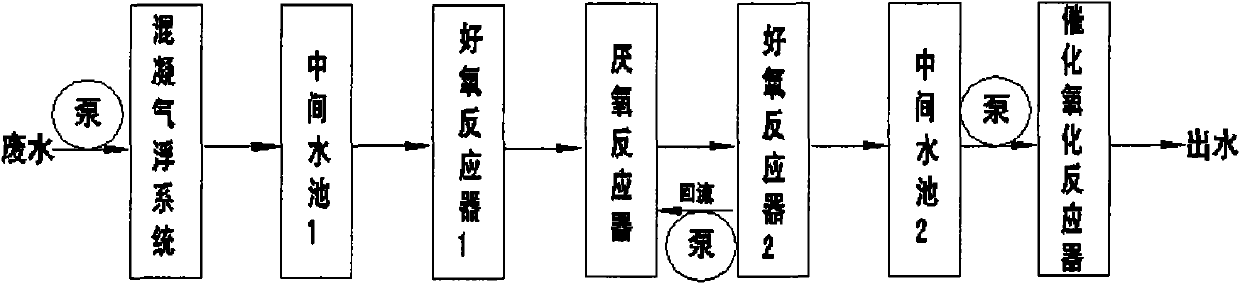

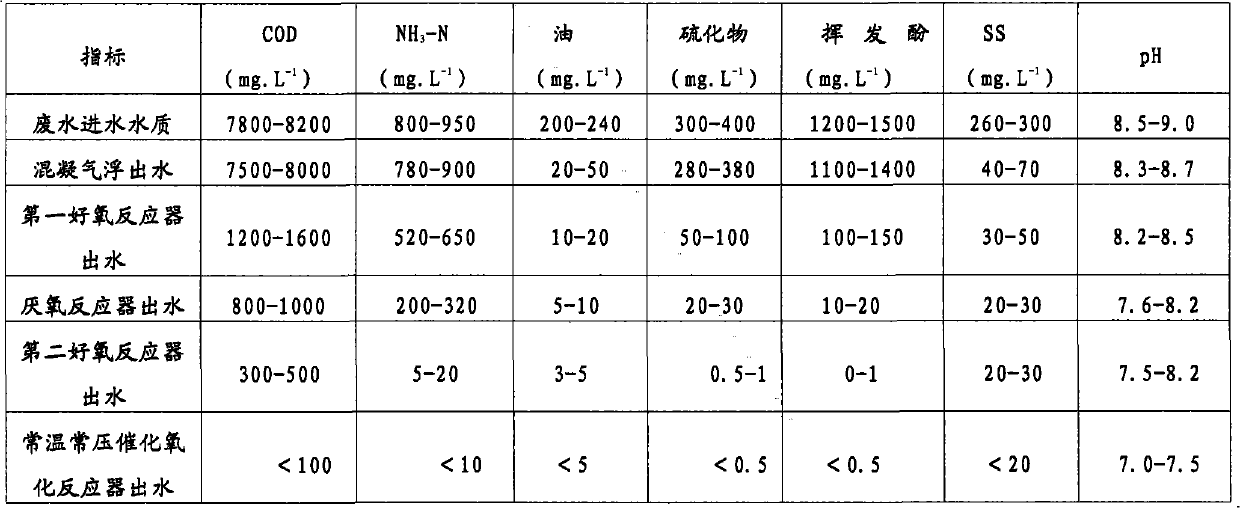

ActiveCN102557328ATreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterCatalytic oxidation

The invention relates to a coal gasification wastewater processing method. The method comprises the following steps: carrying out coagulation processing and air floatation processing on coal gasification wastewater, sequentially carrying out aerobic biological processing, anaerobic biological processing and the aerobic biological processing by allowing the wastewater to flow through a first aerobic reactor, an anaerobic reactor and a second aerobic reactor, allowing parts of water discharged from the second aerobic reactor to return to the anaerobic reactor, and carrying out normal-temperature normal-pressure catalytic oxidation or carrying out Fenton oxidation and normal-temperature normal-pressure catalytic oxidation on the residual water.

Owner:ENN ENVIROTECH CO LTD

Advanced treatment process for coal gasification wastewater

ActiveCN102464415AMultistage water/sewage treatmentWater/sewage treatment by neutralisationCoal gasification wastewaterFerrous salts

The invention relates to an advanced treatment process for coal gasification wastewater, which comprises the following steps of: after regulating the pH value of the wastewater with acid, adding ferrous salt and hydrogen peroxide to oxidize organisms in the wastewater; then sequentially adding a first coagulant and a second coagulant to carry out coagulation after adding alkali to regulate the pH value; after precipitating to separate out coagulation substances, oxidizing the wastewater with oxygen-containing gas under the action of a catalyst at normal temperature and under normal pressure; and optionally carrying out sand filtration.

Owner:ENN ENVIROTECH CO LTD

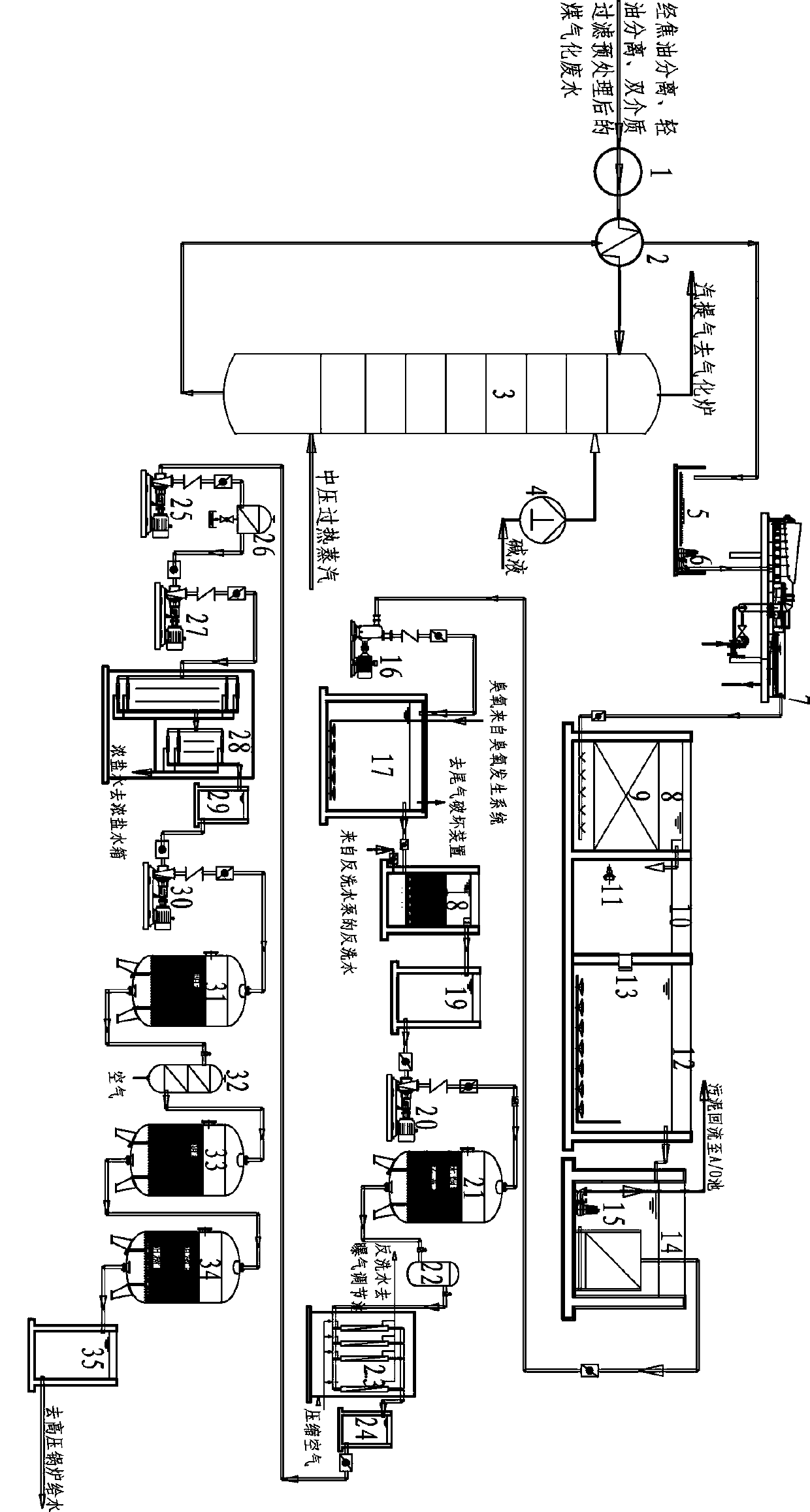

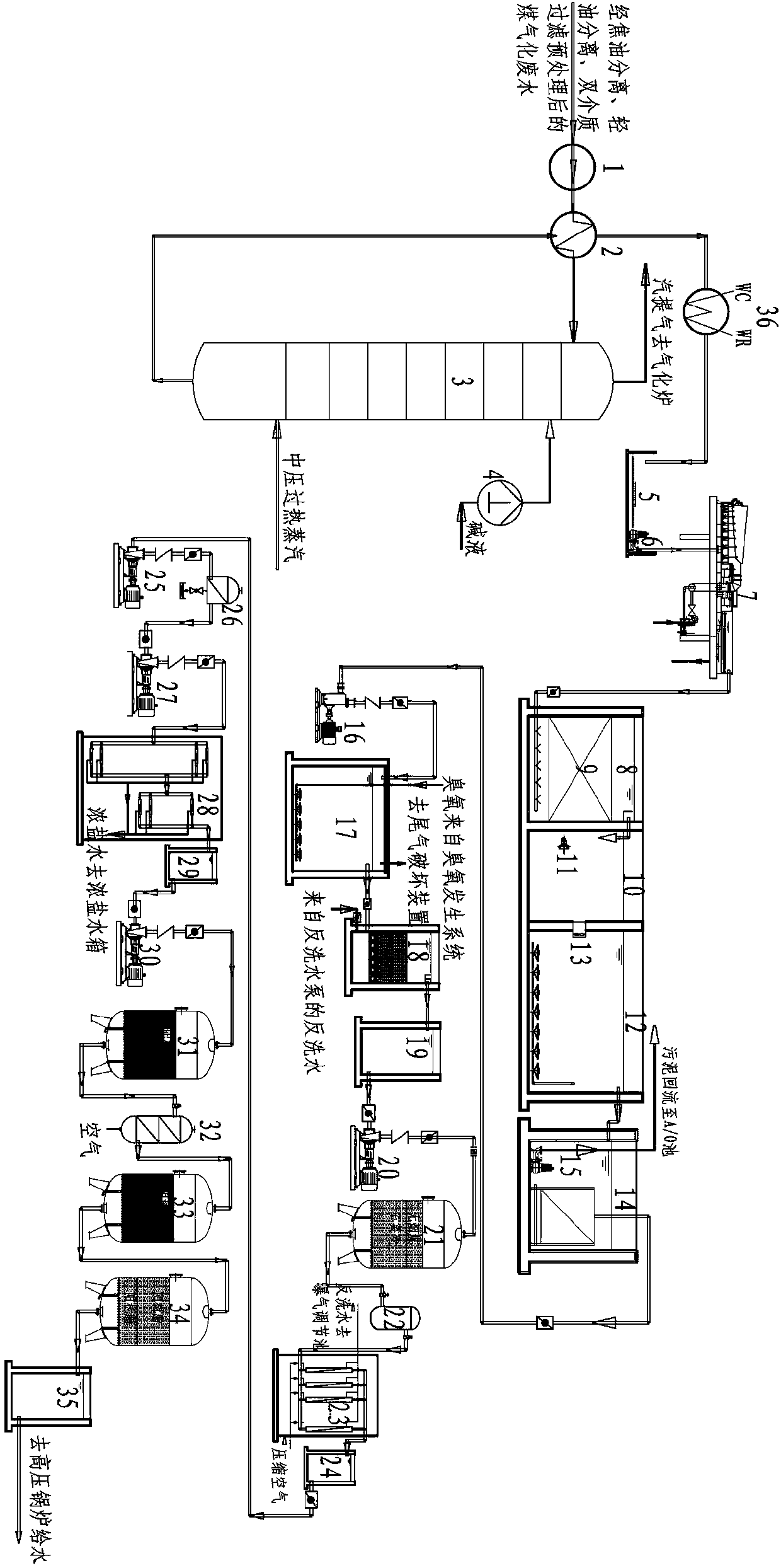

Coal gasification wastewater treating and recycling method and device

ActiveCN103922549AEasy to handleSmall footprintMultistage water/sewage treatmentCoal gasification wastewaterFiltration

The invention relates to a coal gasification wastewater treating and recycling method and device. The coal gasification wastewater treating and recycling method comprises the following steps: carrying out medium-pressure steam stripping on coal gasification wastewater generated by coal pressure gasification, exchanging heat, preheating / cooling, sequentially carrying out shallow air-floatation, hydrolytic acidification, anaerobic-aerobic biological treatment, membrane biological reaction and ozone oxidation, adsorbing matters by using carbon, filtering by using multiple mediums, sequentially carrying out self-cleaning filtration, ultrafiltration, cartridge filtration, reverse osmosis and ion exchange adsorption, and feeding into a water feeding system of a high pressure boiler. The coal gasification wastewater treating and recycling method optimally combines various wastewater treatment methods and is used for solving the problems that after being treated, the coal gasification wastewater is difficult to reach the discharge standard, and the realization of zero discharge by recycling is difficult.

Owner:TIANJI COAL CHEM IND GROUP

Purification technology for ammonia recycled from wastewater from coal gasification

ActiveCN104355343AWith characteristicsHave made significant progressWater contaminantsWater/sewage treatment by heatingCoal gasification wastewaterSulfur

The invention discloses a purification technology for ammonia recycled from wastewater from coal gasification. According to the purification technology, coarse ammonia from a deamination tower is firstly washed by a purification tower to remove impurities such as partial phenols, H2S, organic sulfur, CO2 and oil and then is discharged from the top of the purification tower; after being condensed, ammonia is refined to obtain liquid nitrogen. The purification technology has the advantages of high efficiency, energy conservation, good purification effect and high recycled ammonia purity.

Owner:SEDIN ENG +1

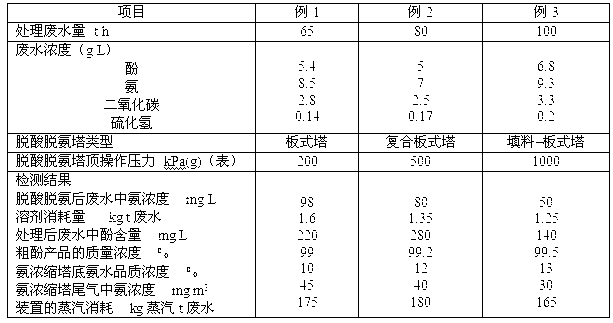

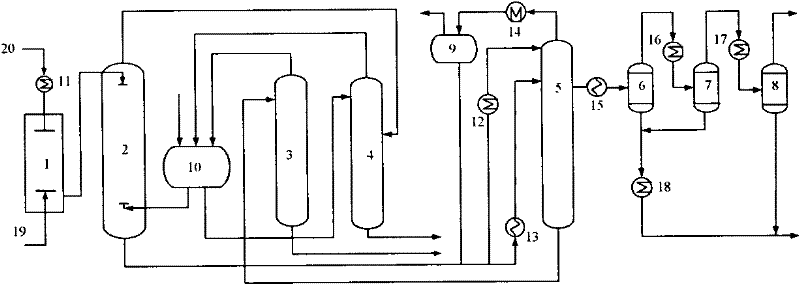

Phenol and ammonia wastewater recycling treatment method by using single tower for performing de-acidification and de-amination simultaneously

InactiveCN102863112ASmall investmentSolve the technical problems of high energy consumptionMultistage water/sewage treatmentWater/sewage treatment by heatingChemical industryCoal gasification wastewater

The invention relates to a treatment method for wastewater containing phenol and dissoluble amine salts produced in chemical industry production, and particularly relates to a phenol and ammonia wastewater recycling treatment method by using a single tower for performing de-acidification and de-amination simultaneously. By means of an energy-saving technology which uses a single device for decomposing amine salts and achieving separation and purification, the device investment is reduced; and the energy recycling is achieved by using a differential pressure rectification technology, so that the energy consumption is reduced. Specifically, a de-acidification and de-amination coupling tower is used, and side withdrawing and differential pressure rectification technologies are utilized for achieving a simultaneous de-acidification and de-amination process and recycling ammonia and phenol in coal gasification wastewater, and accordingly, the method is energy saving and emission reducing, the technological process is simplified simultaneously, and the operation difficulty is reduced. According to the phenol and ammonia wastewater recycling treatment method by using the single tower for performing de-acidification and de-amination simultaneously, technical problems of large device investment and high energy consumption in phenol and ammonia wastewater recycling in a coal gasification process are solved, the technological process is simplified through the coupling of devices, and high economic and social values are provided.

Owner:TIANJIN HAOYONG CHEM TECH

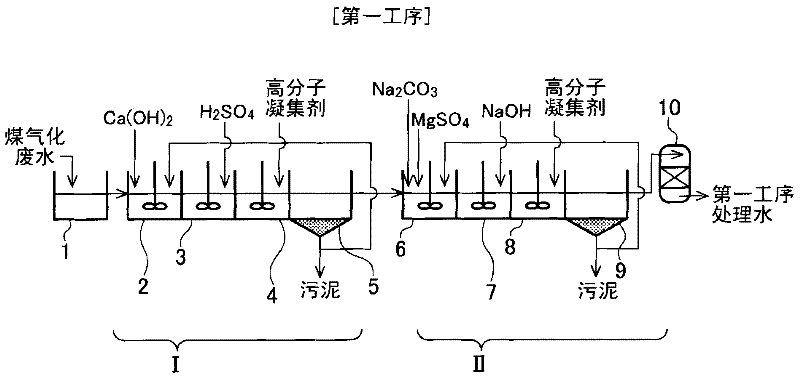

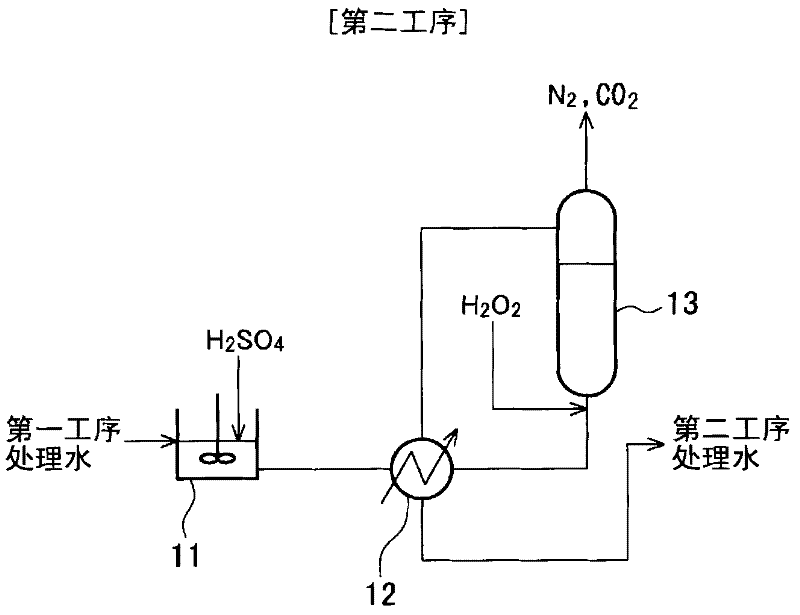

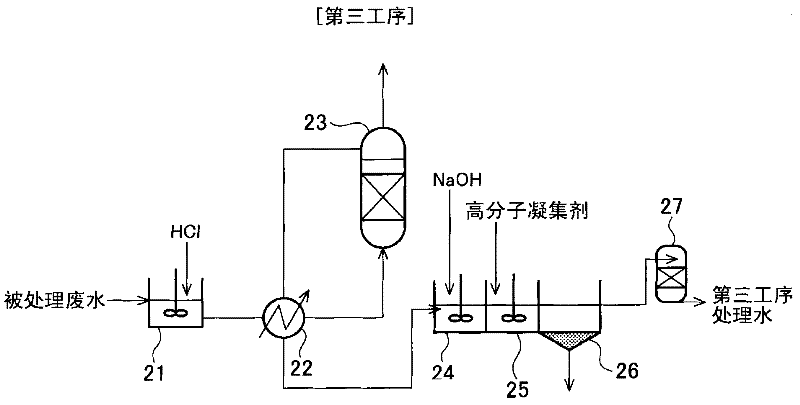

Method of treating coal gasification wastewater

InactiveCN102348648AImprove water qualitySludge treatment by oxidationWater contaminantsCoal gasification wastewaterReduction treatment

Owner:KURITA WATER INDUSTRIES LTD

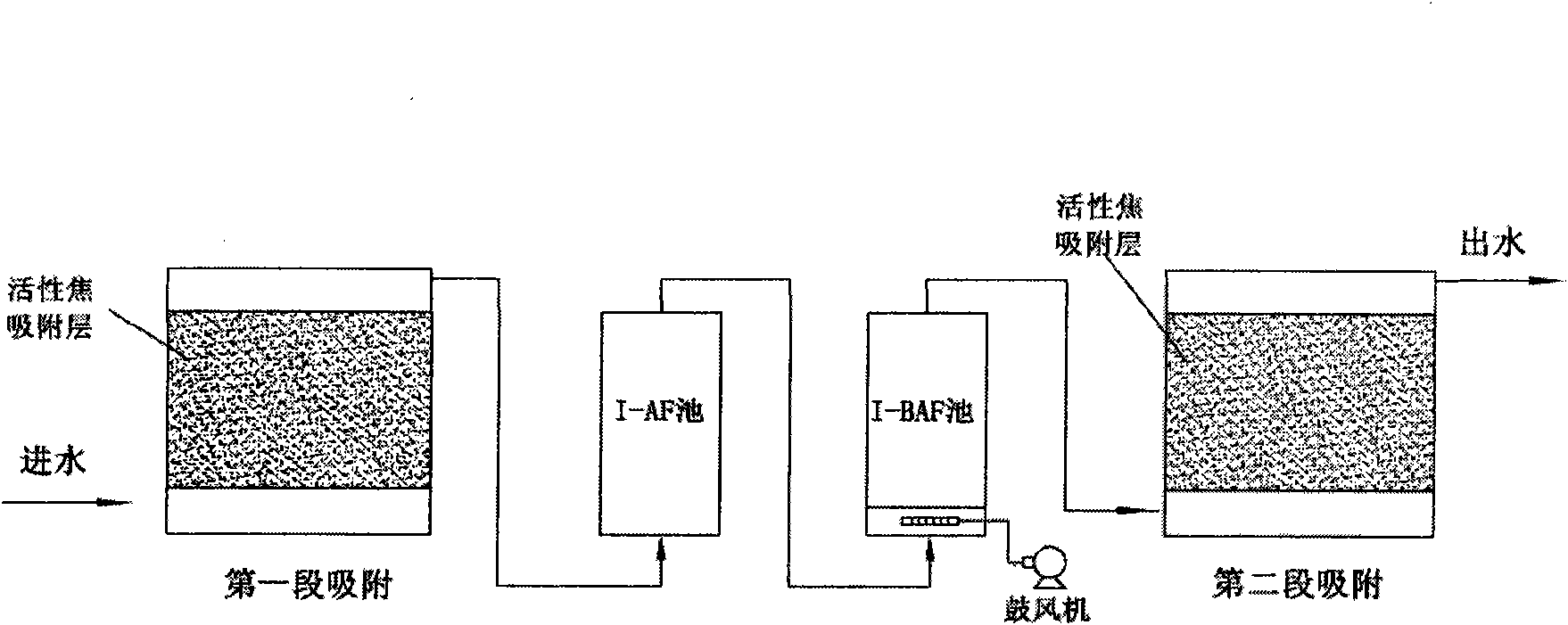

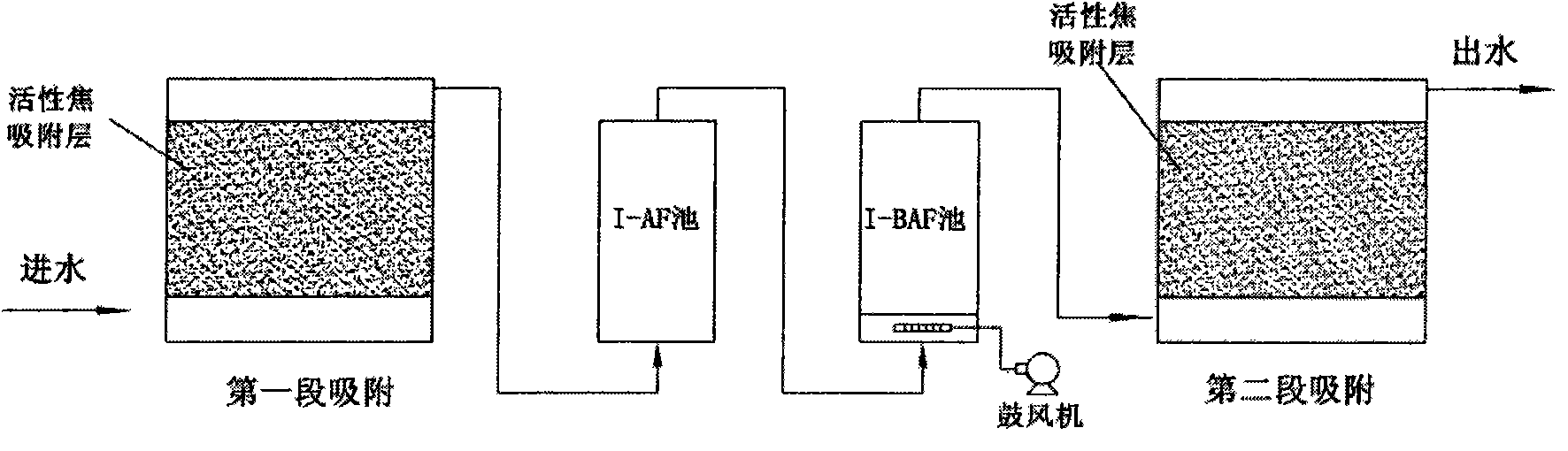

New process for treating coal gasification wastewater with active coke

InactiveCN101921046AEfficient removalGood removal effectMultistage water/sewage treatmentWater/sewage treatment by sorptionHigh concentrationCoal gasification wastewater

The invention relates to a new process for treating coal gasification wastewater with active coke, which comprises the following steps: first-stage absorption is carried out on coal gasification wastewater by directly using active coke to remove most of COD, suspended matters and chroma; after the absorption treatment, the outlet water enters an immobilized microbe-anaerobe filter chamber (hereinafter referred to as I-AF) and immobilized microbe-aerobe aeration biological filter (hereinafter referred to as I-BAF) system to be biologically treated, thereby removing most of ammonia nitrogen and COD in the wastewater; second-stage deep absorption is carried out on the outlet water performed by I-AF+I-BAF processing by using active coke; and the outlet water satisfies Grade 1 in Sewage Comprehensive Emission Standard GB8978-96. Compared with the traditional treatment process, the invention has the advantages of simple technical process, low treatment cost, favorable COD and ammonia nitrogen removal effect, small occupation area of facilities, and convenient operational management. In addition, the saturated active coke can be recycled by heating in the anaerobic atmosphere, and the phenols in the saturated active coke can be recycled or the saturated active coke can be directly used as fuel. The invention can be used for treating coal gasification wastewater, coked wastewater and the like at low cost, and has unique effects for treating various high-concentration industrial wastewaters and modifying the prior processes.

Owner:PEKING UNIV

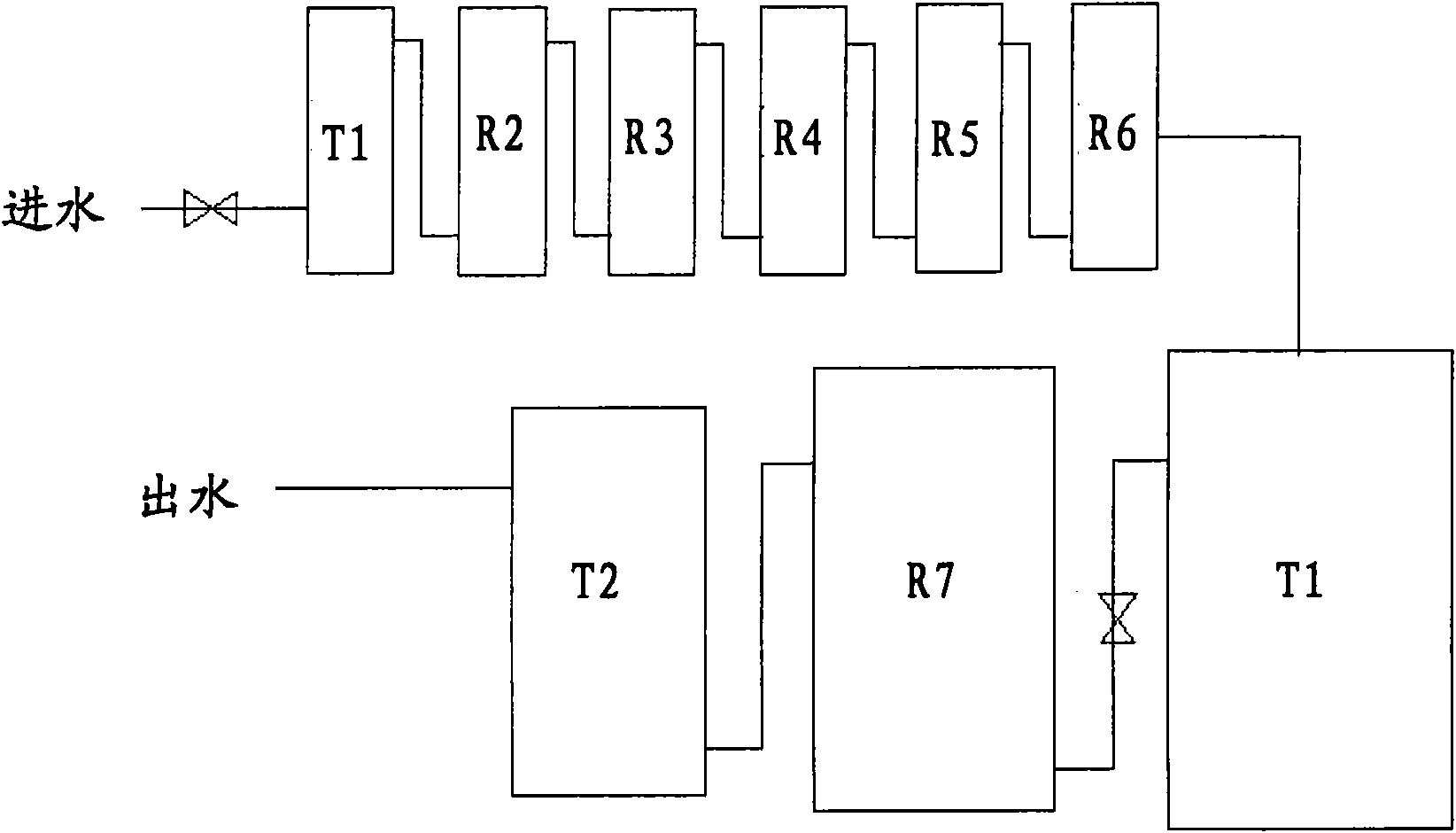

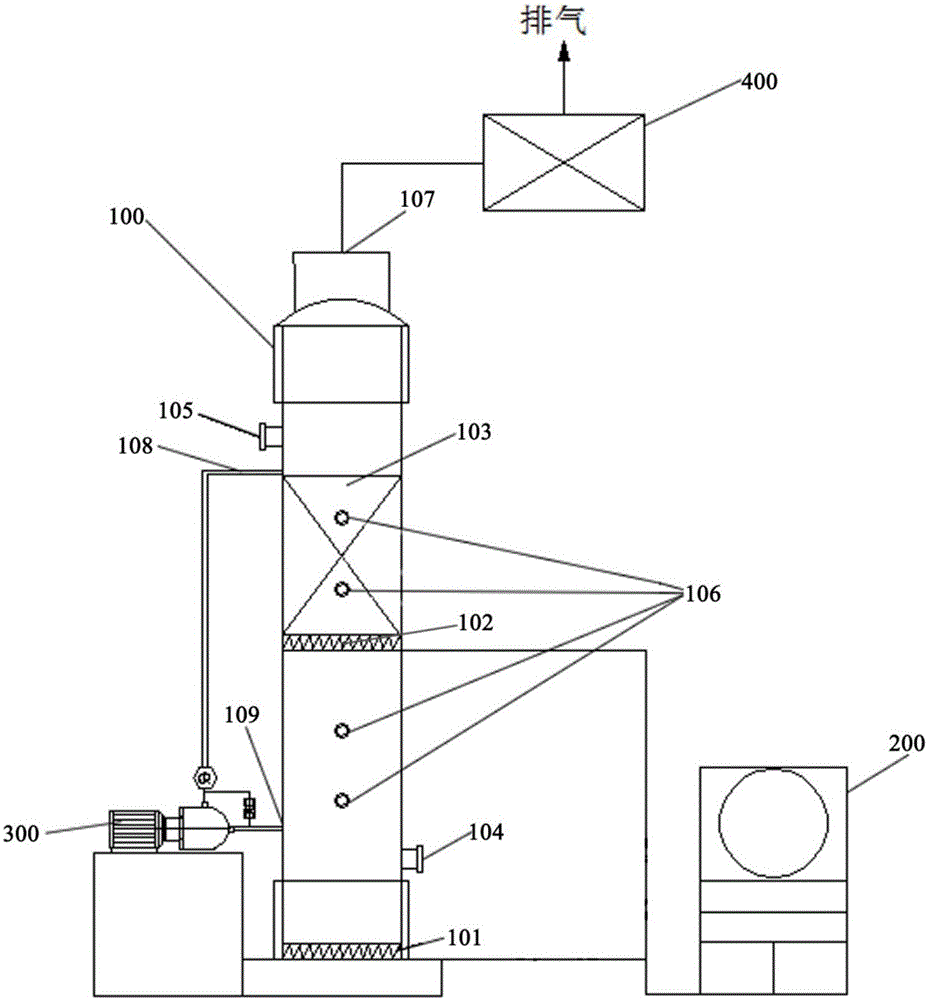

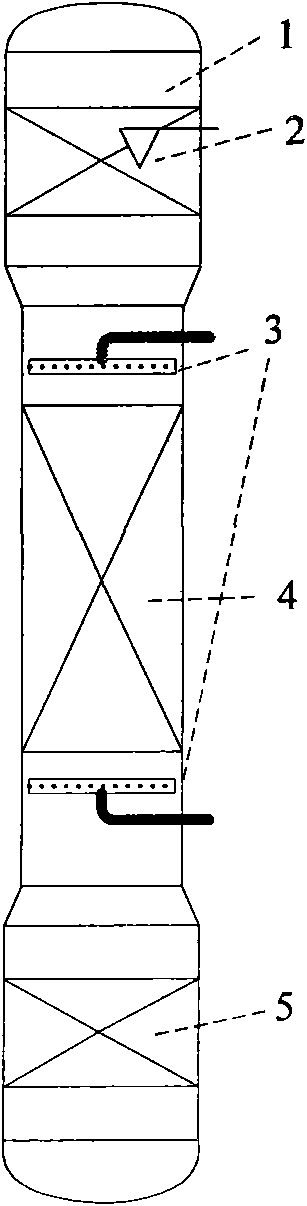

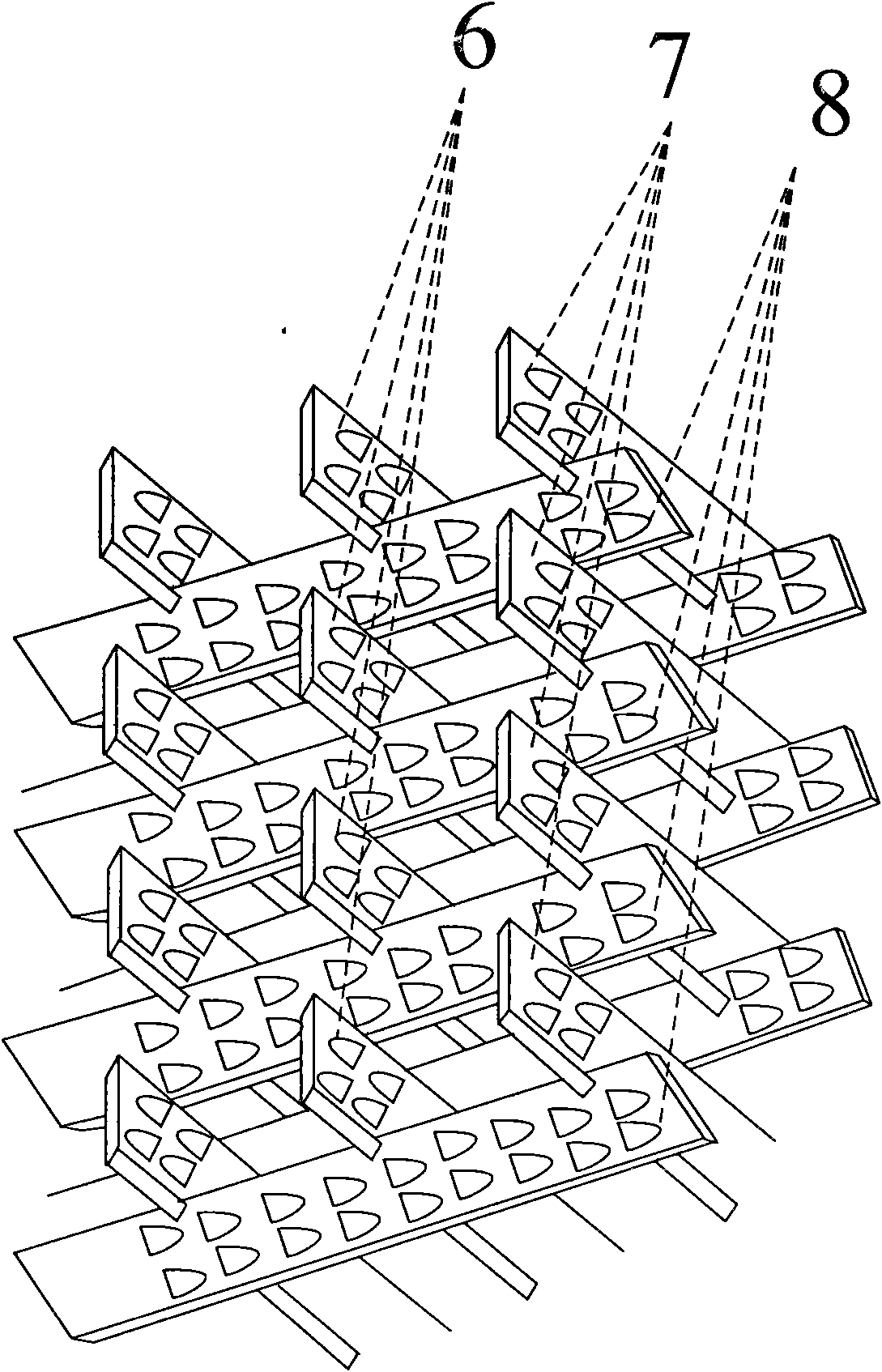

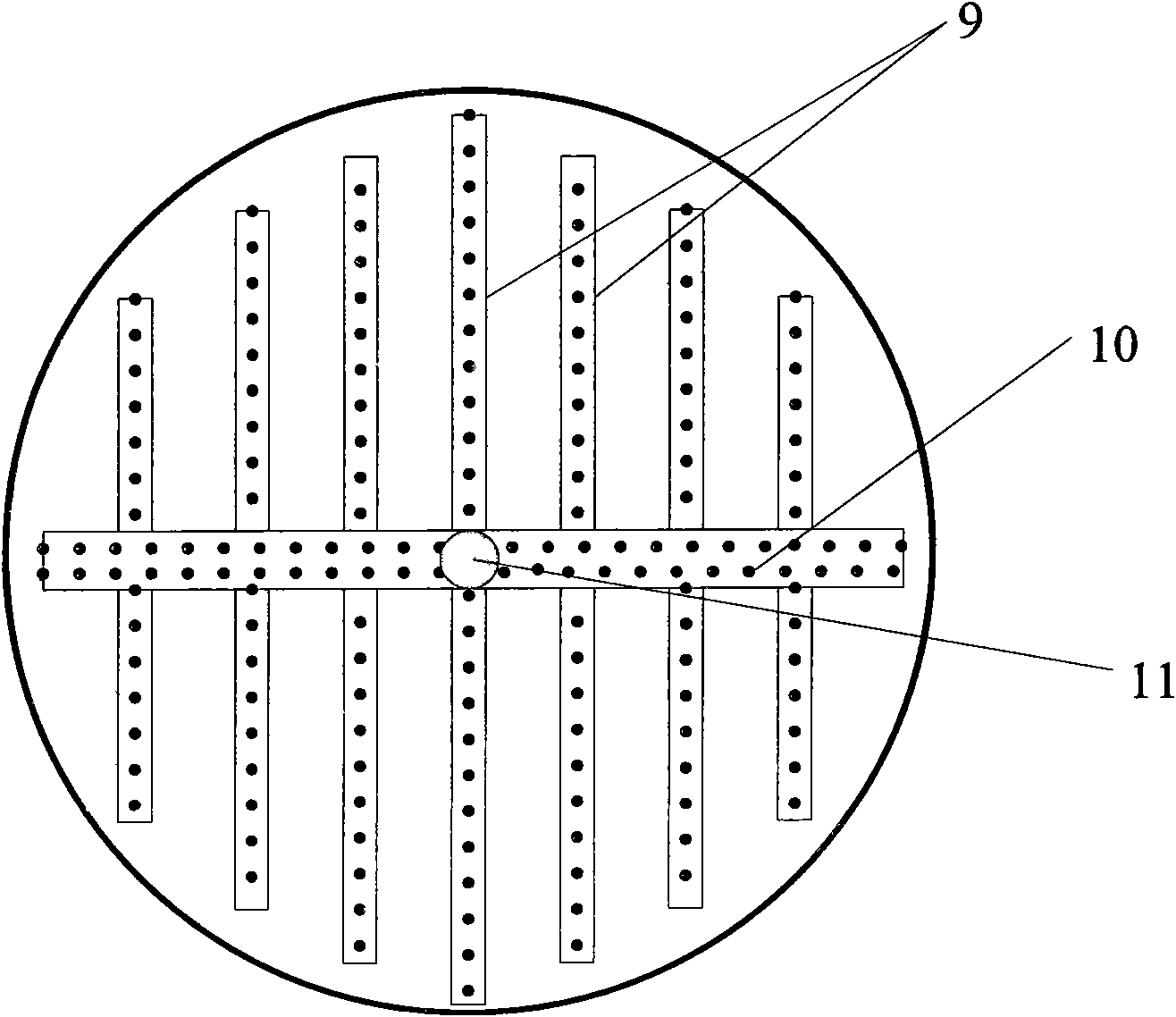

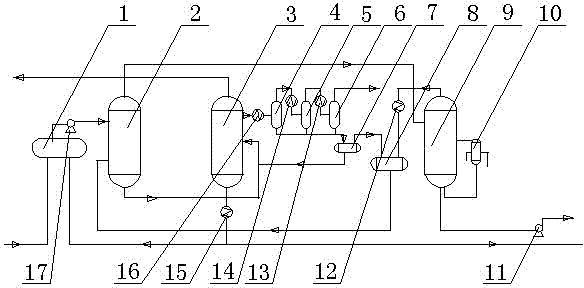

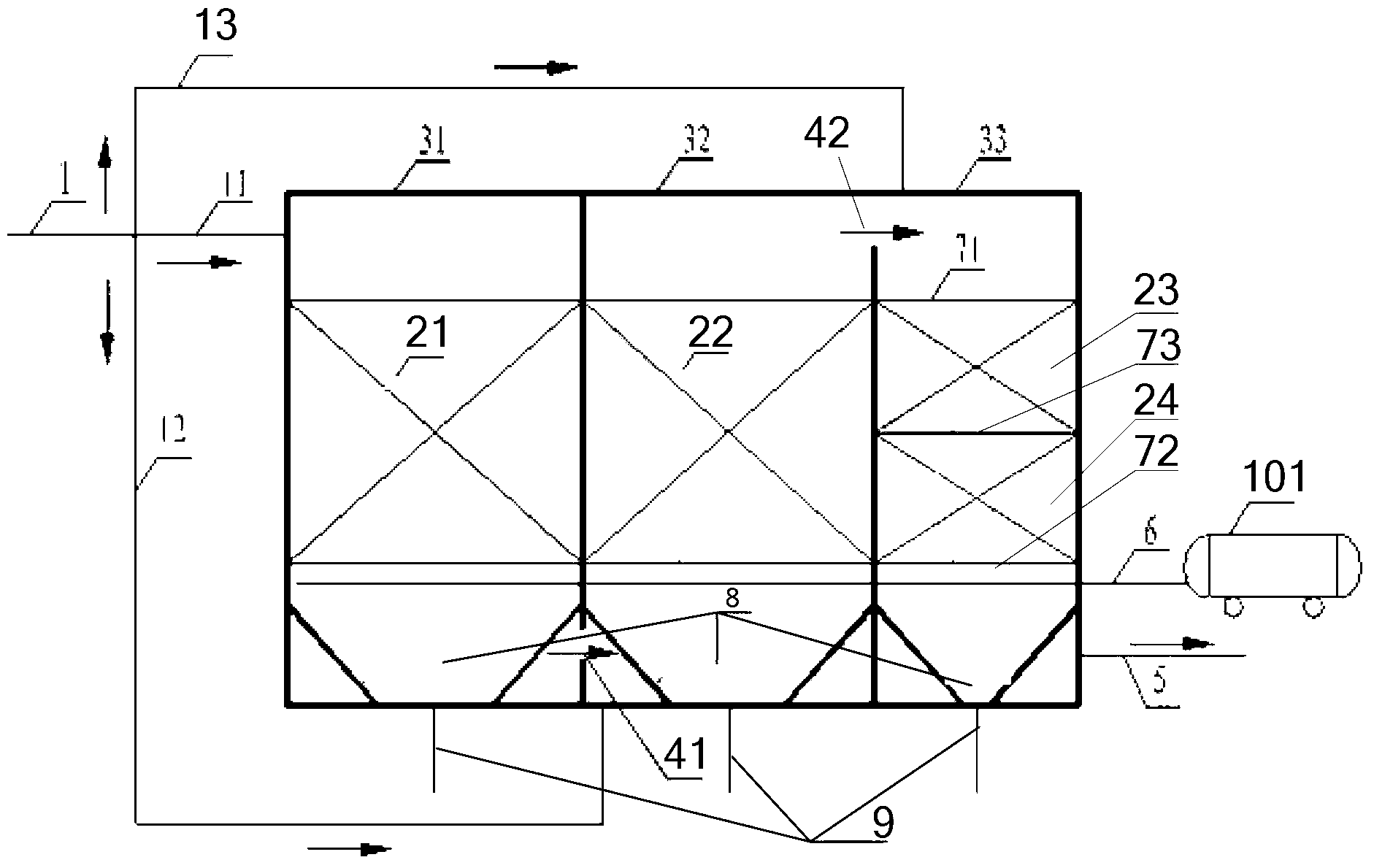

Ozone catalytic ozonation tower and gasified waste water treatment method utilizing same

ActiveCN105753133AEfficient removalReduce dosageMolecular sieve catalystsHeterogenous catalyst chemical elementsCoal gasification wastewaterOzone generator

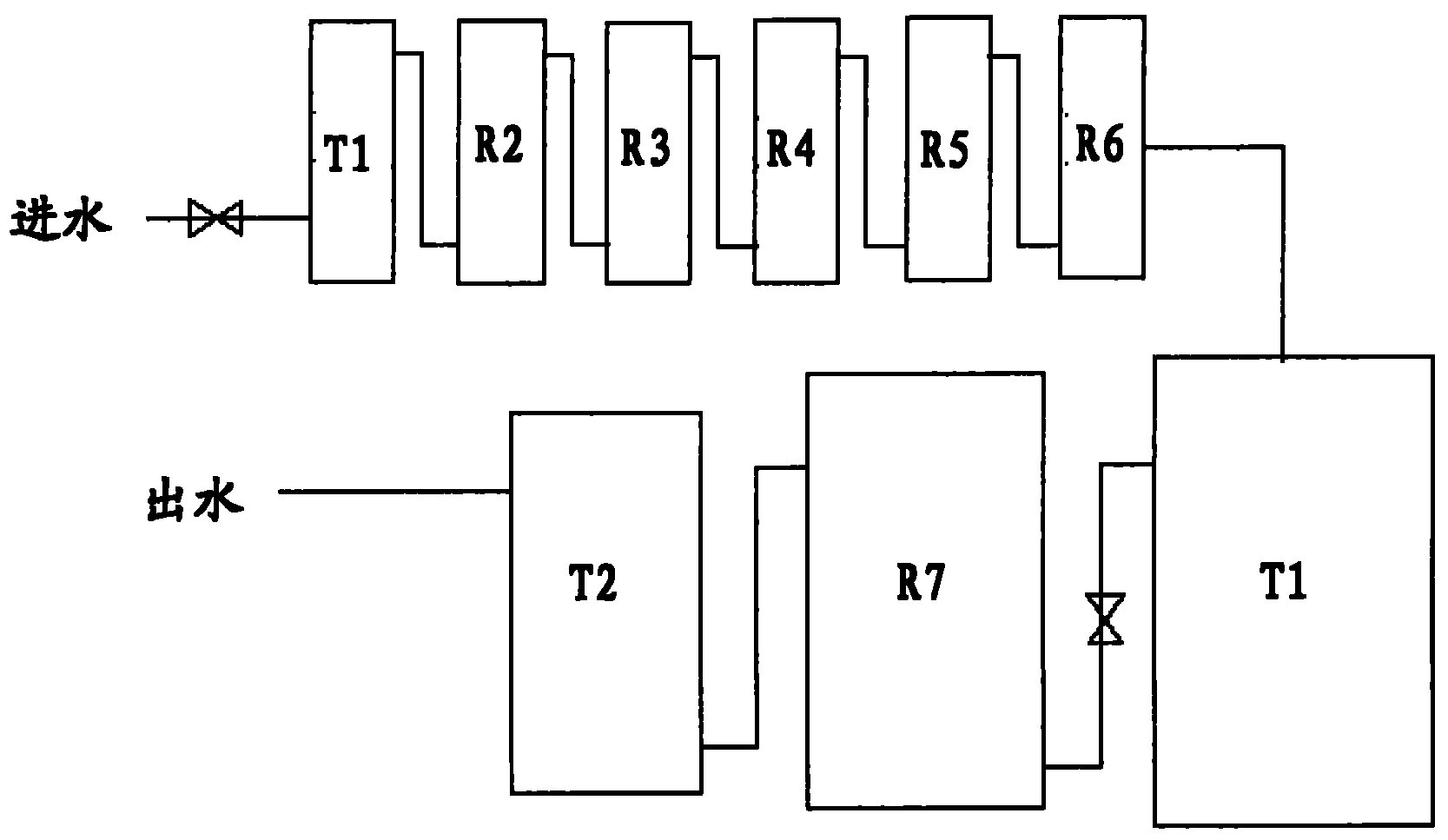

The embodiment of the invention discloses an ozone catalytic ozonation tower which comprises an oxidation tower body, an ozone generator, a circulating pump and a tail gas damage device, wherein the oxidation tower body comprises a first micro-porous aeration diffuser, a second micro-porous aeration diffuser, a catalyst layer, a water inlet, a water outlet, at least one oxidizing agent feeding hole, an exhaust port, a circulating water inlet and a circulating water outlet; the first micro-porous aeration diffuser is positioned at the bottom of the oxidation tower body; the second micro-porous aeration diffuser is positioned above the first micro-porous aeration diffuser; the catalyst layer is positioned above the second micro-porous aeration diffuser; the side wall of the oxidation tower body between the first micro-porous aeration diffuser and the second micro-porous aeration diffuser is sequentially provided with the water inlet and the circulating water inlet from bottom to top; the side wall of the oxidation tower body above the catalyst layer is sequentially provided with the circulating water outlet and the water outlet from bottom to top; the side wall of the oxidation tower body between the water inlet and the circulating water outlet is provided with at least one oxidizing agent feeding hole. The ozone catalytic ozonation tower is capable of reducing the dwell time of ozone in the tower and improving the ozone utilization rate.

Owner:POTEN ENVIRONMENT GRP

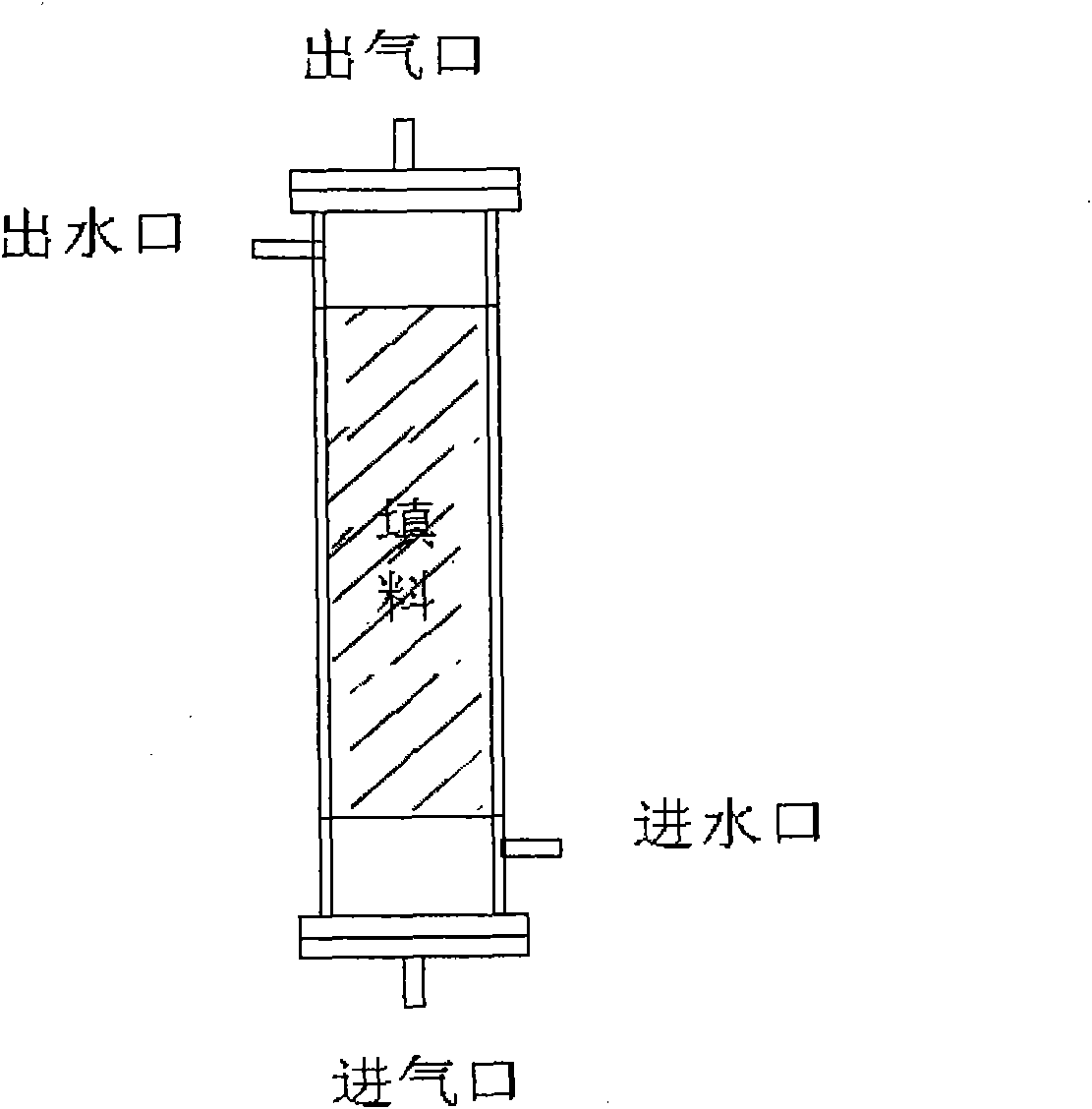

Filler extraction tower for dephenolizing coal gasification wastewater and extraction dephenolizing processing method

InactiveCN101659453ASmall pressure dropLarge packing porosityWater/sewage treatment by extractionHigh concentrationCoal gasification wastewater

Owner:SOUTH CHINA UNIV OF TECH +1

Method for treating high-concentration phenol-ammonia wastewater

InactiveCN103496812AShort process flowImprove processing efficiencyWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterButyl acetate

The invention relates to a method for treating high-concentration phenol-ammonia coal gasification wastewater. The method takes butyl acetate as an extraction agent and comprises the steps of firstly extracting by use of a phenol extraction tower to remove phenols contained in the wastewater, removing the acid gas and ammonia in the wastewater by use of an acid and ammonia removal tower, and recovering the extraction agent in the extraction phase by use of a solvent stripping tower so as to obtain a crude phenol product from the bottom of the tower. The method provided by the invention realizes high-purity removal of the phenols, acid gas, free ammonia and solid ammonia in the coal gasification wastewater so as to meet the requirement of biochemical treatment on the inflow water quality, and obtains the crude phenol product and high-concentration ammonia gas. Compared with the prior art, the method provided by the invention has the advantages of good extraction effect, high phenol removal efficiency, short process flow and low treatment cost; the method is simple and convenient to operate, and the treatment quality is reliable.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

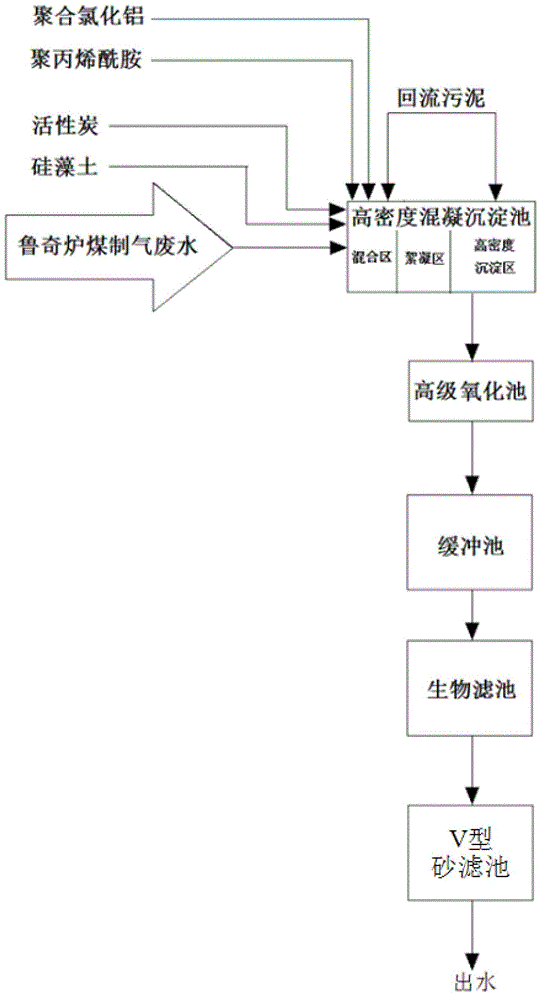

Advanced treatment method for Lurgi coal gasification wastewater

ActiveCN103145299AImprove biodegradabilitySmall footprintMultistage water/sewage treatmentCoal gasification wastewaterHigh density

The invention discloses an advanced treatment method for Lurgi coal gasification wastewater, relates to a sewage treatment method and aims to solve the problems that the discharged Lurgi coal gasification wastewater after being subjected to advanced treatment by using the traditional biochemical method still cannot meet the standard and a physic-chemical method is high in cost when being used for carrying out advanced treatment on the Lurgi coal gasification wastewater. The method comprises the following steps of: firstly, coagulation and absorption treatment; secondly, high-density sedimentation treatment; thirdly, advanced oxidation treatment; fourthly, continuous aeration and batch stirring treatment; fifthly, batch aeration biotreatment; and sixthly, V-shaped sand filter treatment to finish advanced wastewater treatment. The advanced treatment method has the advantage that the final effluent obtained through treating the Lurgi coal gasification wastewater by using the method provided by the invention can meet the recycling standard. The advanced treatment method is mainly used for advanced treatment of the Lurgi coal gasification wastewater.

Owner:哈尔滨工创环保科技有限公司

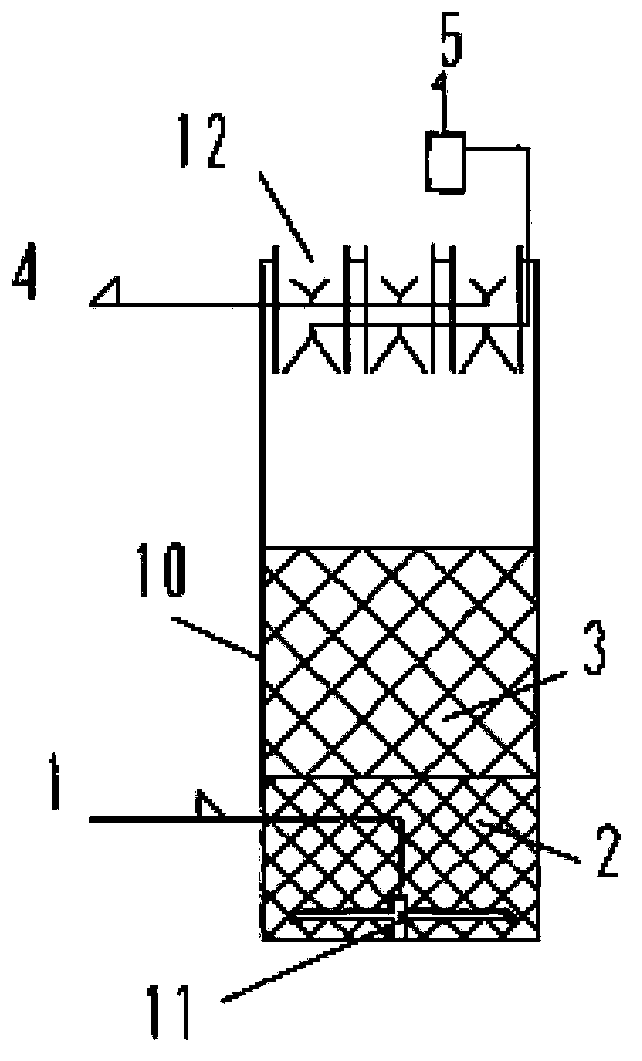

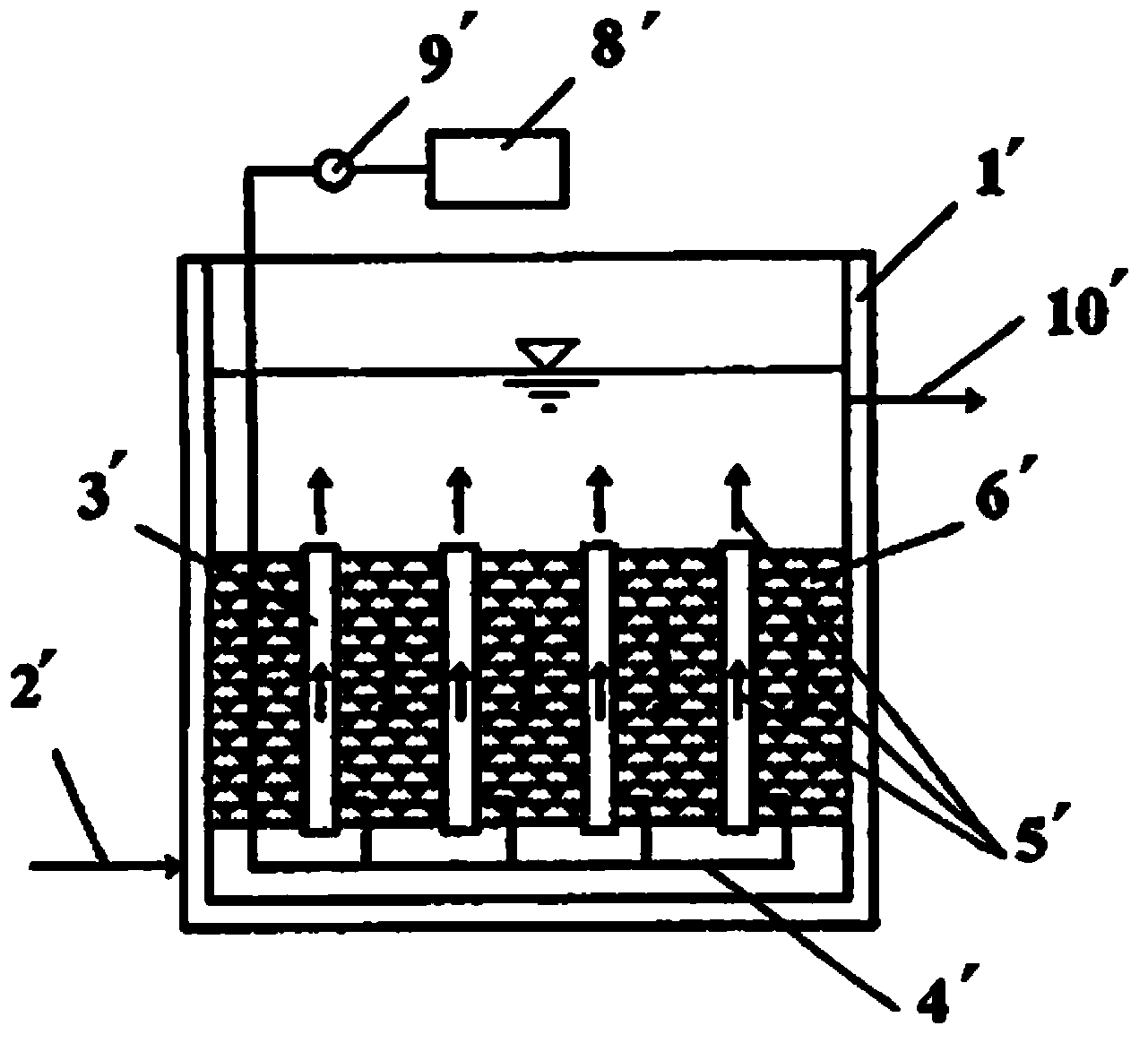

Coal gasification wastewater treatment device and treatment method thereof

ActiveCN103253835AReduce consumptionEfficient removalMultistage water/sewage treatmentCoal gasification wastewaterAlkalinity

The invention discloses a coal gasification wastewater treatment device. When the treatment device is used, the coal gasification wastewater of which partial suspended matters are removed by a regulating pool and a physical and chemical sedimentation pool enters a first biological oxidation pool from a first water inlet; after a short-range nitrification and denitrification reaction is performed on the coal gasification wastewater through a first carrier for the first time, the coal gasification wastewater flows into a second biological oxidation pool from a first channel; after the secondary short-range nitrification and denitrification reaction is performed on the coal gasification wastewater through a second carrier, the coal gasification wastewater flows into a third biological oxidation pool from a second channel; a denitrification reaction is performed through a third carrier and then a nitrification reaction is performed through a fourth carrier; and the coal gasification wastewater is discharged from a water pipe after the treatment process is finished, wherein the nitrification reaction is controlled at the nitrite stage during the short-range nitrification and denitrification reaction, so that the denitrification reaction is performed directly under the condition that nitrite is not further oxidized into nitrate; and thus the wastewater denitrification process is shortened. A supplementing device is used for supplementing a carbon source and alkalinity. The invention further provides a coal gasification wastewater treatment method.

Owner:YANKUANG GRP CO LTD +2

Treatment method for coal gasification wastewater containing phenol and ammonia

InactiveCN102241453AOvercome churnOvercoming pollutionMultistage water/sewage treatmentWater/sewage treatment by extractionCoal gasification wastewaterSolvent

The invention discloses a treatment method for coal gasification wastewater containing phenol and ammonia, which comprises the following steps: 1, introducing CO2 to regulate the pH value of the waste water; 2, extracting and removing phenol; 3, pressurizing and stripping to remove acidic gases and ammonia; 4, concentrating ammonia; and 5, recovering solvent. In the invention, the drawbacks of stripping phenol loss, pollution of phenol to ammonia product, high extraction temperature and the like of a process in which extraction is performed after stripping by cooling raw material waste water to 30 to 60 DEG C first, absorbing CO2 to regulating the pH value of the waste water to 7 to 8 and advancing a phenol extracting and removing process. Meanwhile, the treatment method has the advantages that: the system can be modified to an optimal extraction environment easily; heating is required once; carbon dioxide can be recovered and recycled; and the like. The coal gasification wastewater purified by the method meets the requirements of subsequent biological treatment completely.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Coal gasification wastewater phenol and ammonia recovery process

ActiveCN106698785ADoes not affect the processing effectLow operating pressureWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterTreatment effect

The invention relates to the technical field of wastewater treatment, in particular to a coal gasification wastewater phenol and ammonia recovery process. The process comprises the following steps that feeding wastewater is divided into cold feeding materials and hot feeding materials to respectively enter an acid water stripping tower from the tower top and the tower middle upper part; the tower top pressure is set to be 0.9 to 1.2MPa; the tower top temperature is 50 to 80 DEG C; the tower kettle pressure is set to be 0.92 to 1.25 MPa; the tower kettle temperature is 178 to 188 DEG C; acid gas is produced at the tower top; ammonia water vapor is produced at the lateral line; the ammonia water vapor is sequentially used as a heat source of a phenol tower and a solvent stripping tower, and then enters a three-stage segregated system to be concentrated into crude ammonia gas; kettle liquid of the acid water stripping tower enters an extraction device to be subjected to phenol removal; an extraction phase enters the phenol tower; an extracting agent and crude phenol are separated through rectification; a raffinate phrase enters a solvent steam extraction tower; the extracting agent dissolved in the wastewater is stripped out and returns to an extraction tower. By using the process provided by the invention, the steam consumption can be greatly reduced; in addition, the good treatment effect can be ensured.

Owner:QINGDAO JUNYANG CHEM TECH

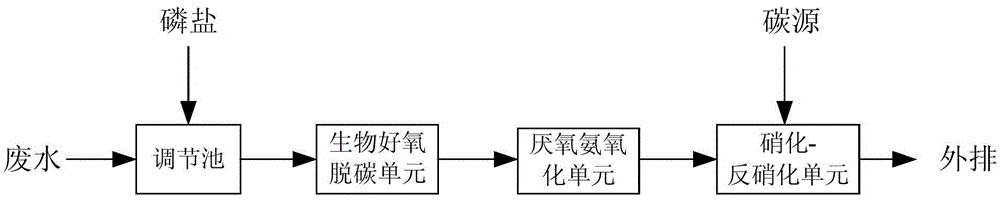

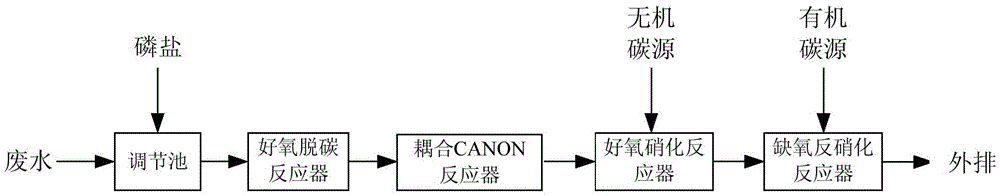

Degradation-resistant ammonia-nitrogen wastewater treatment system and method

InactiveCN106746152AWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterHigh concentration

The invention relates to a degradation-resistant ammonia-nitrogen wastewater treatment system. The system comprises a biological aerobic decarburization unit, an anaerobic ammonium oxidation unit and a nitrification-denitrification unit and the above units are orderly connected. The method is suitable for treatment on degradation-resistant high-concentration ammonia-nitrogen wastewater such as coking wastewater, coal gasification wastewater, pharmaceutical wastewater, fermentation wastewater and food enterprise wastewater and can also be used for municipal wastewater and domestic sewage treatment. Through the system, the total nitrogen content of the treated degradation-resistant ammonia-nitrogen wastewater is controlled to 15 mg / L or less so that the national first-level emission standard is satisfied.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Treatment method of coal gasification wastewater

InactiveCN103508623ATreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterEutrophication

The invention provides a treatment method of coal gasification wastewater, which comprises the following steps: the coal gasification wastewater is sequentially subjected to anaerobic biological treatment, aerobic biological treatment and denitrification treatment; by using the methods and conditions of the anaerobic biological treatment and aerobic biological treatment, the COD (chemical oxygen demand) value of the coal gasification wastewater after the aerobic treatment and before the denitrification treatment is 350-500 mg / L, the total phenol content is 60-100 mg / L, the BOD (biochemical oxygen demand) value is 35-50 mg / L, and the total nitrogen content is 200-400 mg / L; and by using the conditions of the denitrification treatment, the COD (chemical oxygen demand) value of the coal gasification wastewater is lower than 350 mg / L, and the total nitrogen content is not higher than 60 mg / L. The method for treating coal gasification wastewater has the advantages of simple procedures, short treatment time and high efficiency, and can effectively remove total nitrogen in the wastewater to avoid eutrophication of the water body.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com