Coal gasification wastewater treatment process

A technology for coal gasification wastewater and treatment process, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. Improved effect, avoidance of water quality effects, effect of increased treatment steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

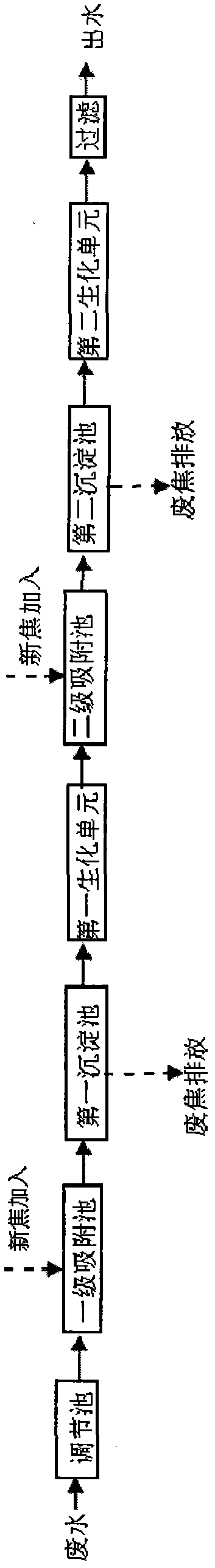

[0036] figure 1 The flow chart of the coal gasification wastewater treatment process and its system according to the present invention is given. The system includes a regulating tank for wastewater inflow, a primary adsorption tank, a first sedimentation tank, a first biochemical unit, a secondary adsorption tank, The second settling tank, the second biochemical unit and filtering equipment, the above-mentioned equipment and structures are connected in sequence through pipelines. The coal gasification wastewater treatment process described in this system is as follows:

[0037] (1) Adsorption treatment in the primary adsorption pool: the coal gasification wastewater in the wastewater regulating pool is passed into the primary adsorption pool, and the adsorption material is continuously added in the primary adsorption pool, and the adsorption material has a good effect on the coal gasification wastewater. Adsorption treatment of macromolecular refractory organic pollutants;

...

Embodiment 2

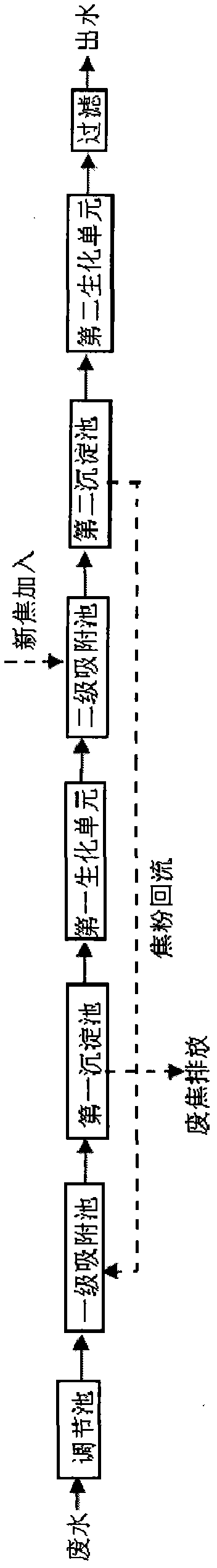

[0047] On the basis of the above-mentioned Example 1, the activated coke discharged from the bottom of the second sedimentation tank in the step (5) is returned to the primary adsorption tank for reuse, and the primary adsorption tank does not need to add new active coke. Such as figure 2 As shown, in this embodiment, the mass ratio of the active coke solution that flows back to the primary adsorption pool to the influent of the primary adsorption pool is 50:100, and it can also be determined according to the concentration of wastewater and the utilization rate of active coke. This reflux ratio is selected within the range of 5:100-200:100. During this process, the coke powder discharged from the bottom of the second sedimentation tank is refluxed to the primary adsorption tank through the pump, and the coke powder discharged here is refluxed in the form of coke aqueous solution. In the returned coke aqueous solution, the content of coke Around 30%.

[0048] In this embodim...

Embodiment 3

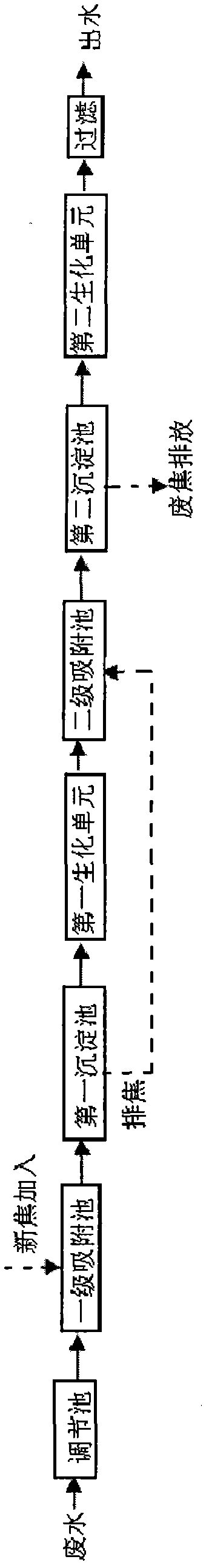

[0050] On the basis of the above-mentioned Example 1, the activated coke discharged through the first sedimentation tank in the step (2) is returned to the secondary adsorption tank in the step (4), such as image 3 As shown, the mass ratio of the refluxing coke aqueous solution to the water inflow of the secondary adsorption tank is 200:100. Recycling of the active coke can also be realized through such a cycle, and its use efficiency can be improved.

[0051] In this embodiment, active semi-coke is continuously added in the primary adsorption pool; in the primary adsorption pool, the mass ratio of water to active coke is 50:1; in the step (3), the biochemical The dwell time of processing is 10 hours in the present embodiment, generally selects about 10-60 hour according to the organic pollutant concentration of waste water; In described step (6), the dwell time of described biochemical treatment is selected 5 hours here, here The time is generally selected for 5-30 hours ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com