Patents

Literature

96results about How to "Improve biochemical treatment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

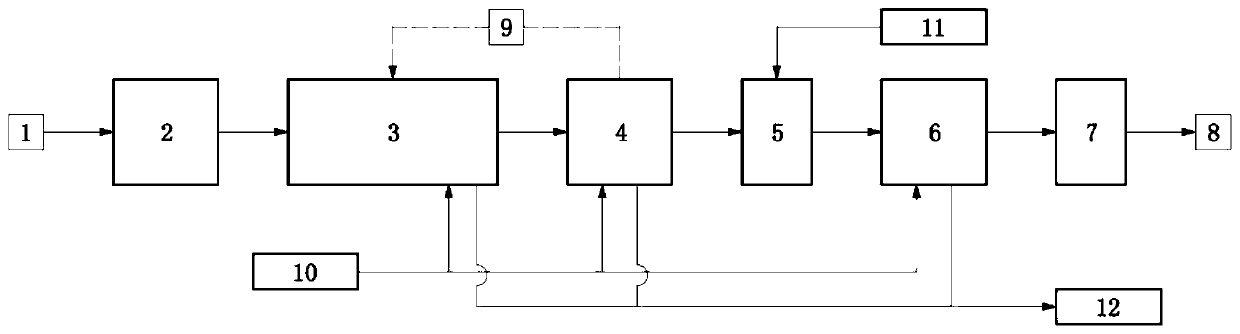

Coal gasification wastewater treatment process

InactiveCN102070277AImprove utilization efficiencyReduce dosageMultistage water/sewage treatmentCoal gasification wastewaterSalt content

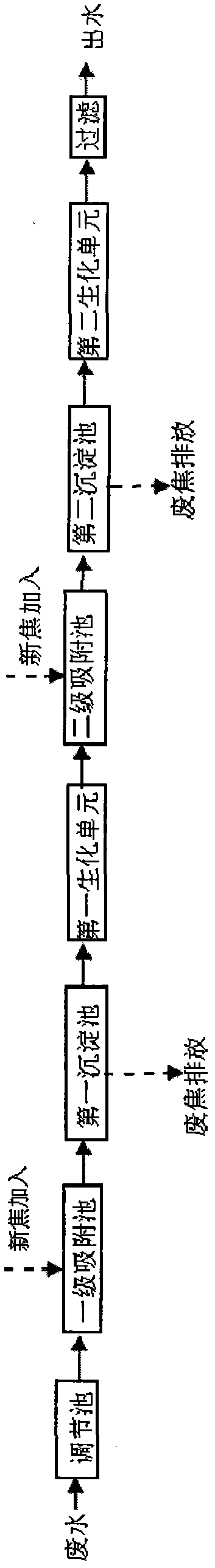

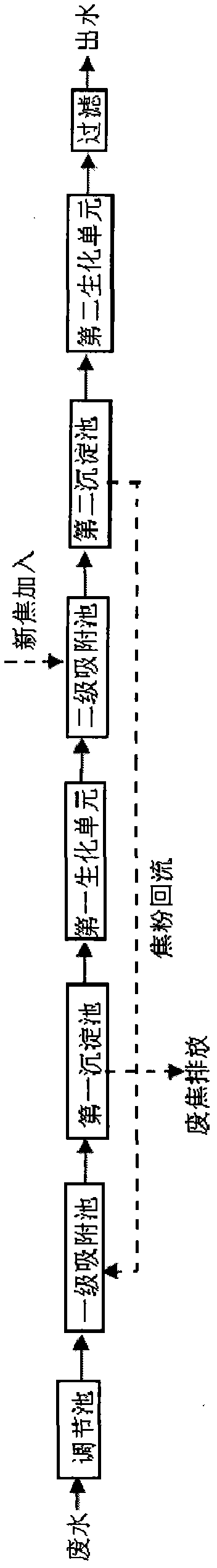

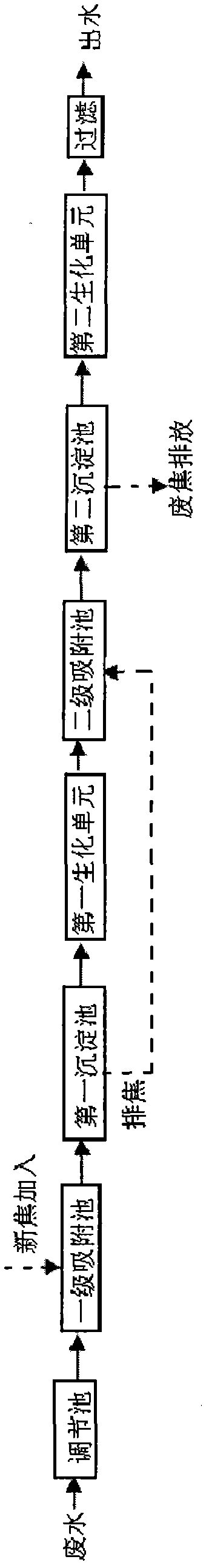

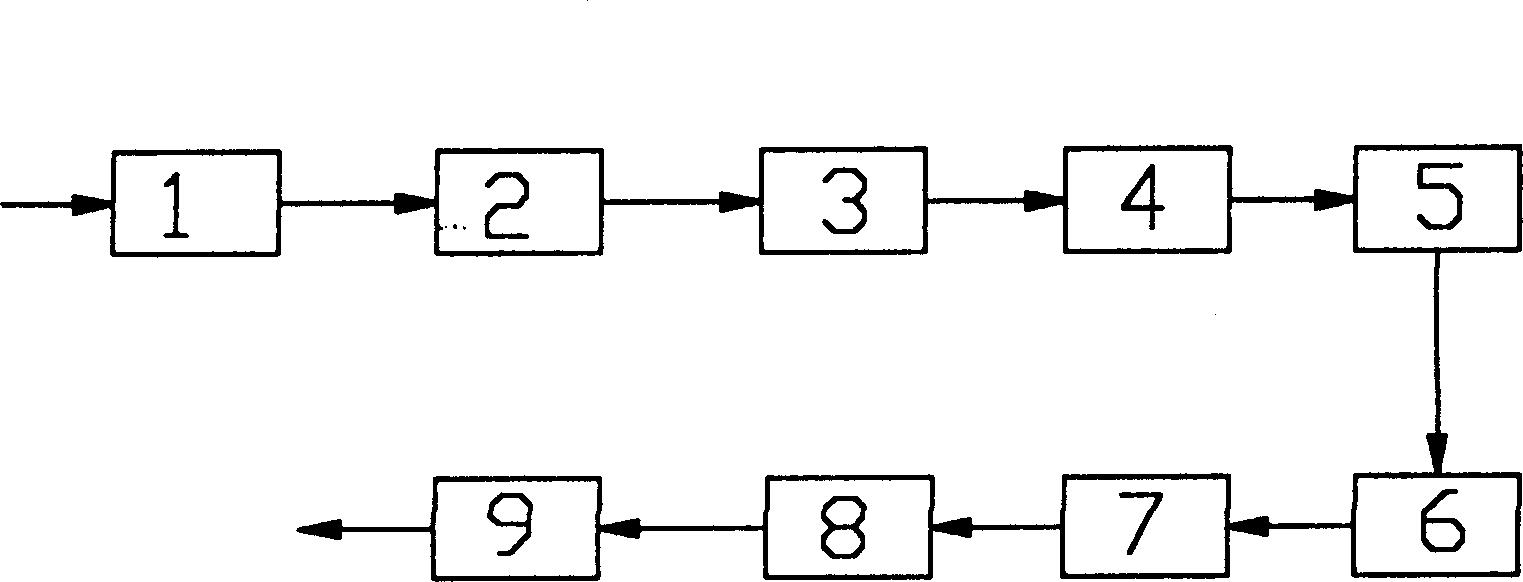

The invention discloses a coal gasification wastewater treatment process, which comprises the following steps of: performing adsorption treatment in a primary adsorption tank; performing sedimentation treatment in a first sedimentation tank; performing biochemical treatment in a first biochemical unit; performing adsorption treatment in a secondary adsorption tank; performing sedimentation treatment in a second sedimentation tank; performing biochemical treatment in a second biochemical unit; and filtering and discharging. The coal gasification wastewater treatment process solves the technical problem that active carbon is added into an active sludge aeration tank to influence the effects of the biochemical treatment and the adsorption treatment in the conventional coal gasification wastewater treatment process, has the advantages of independent adsorption and biochemical treatment, combined arrangement, concise process, high treatment efficiency, no increase of salt content and stable operation, and is particularly suitable for treating coal gasification wastewater.

Owner:北京国能普华环保工程技术有限公司 +1

Deep purification and reclaiming device and method for dyeing waste water

InactiveCN1569694AImprove biochemical treatment efficiencyMeet process water requirementsMultistage water/sewage treatmentFiberChlorine dioxide

The invention discloses a deep purification and reclaiming device and method for dyeing waste water, wherein the device comprises a regulating reservoir, an naerobic tank, an aerobic aeration tank, a sedimentation tank, a chlorine peroxide oxidation tank, a medicament administration and coagulation tank, a biologically active charcoal tank and a fiber ball filter. The waste water treatment method integrates a biochemical treatment process and a physical-chemical treatment method.

Owner:东莞市天虹实业投资有限公司

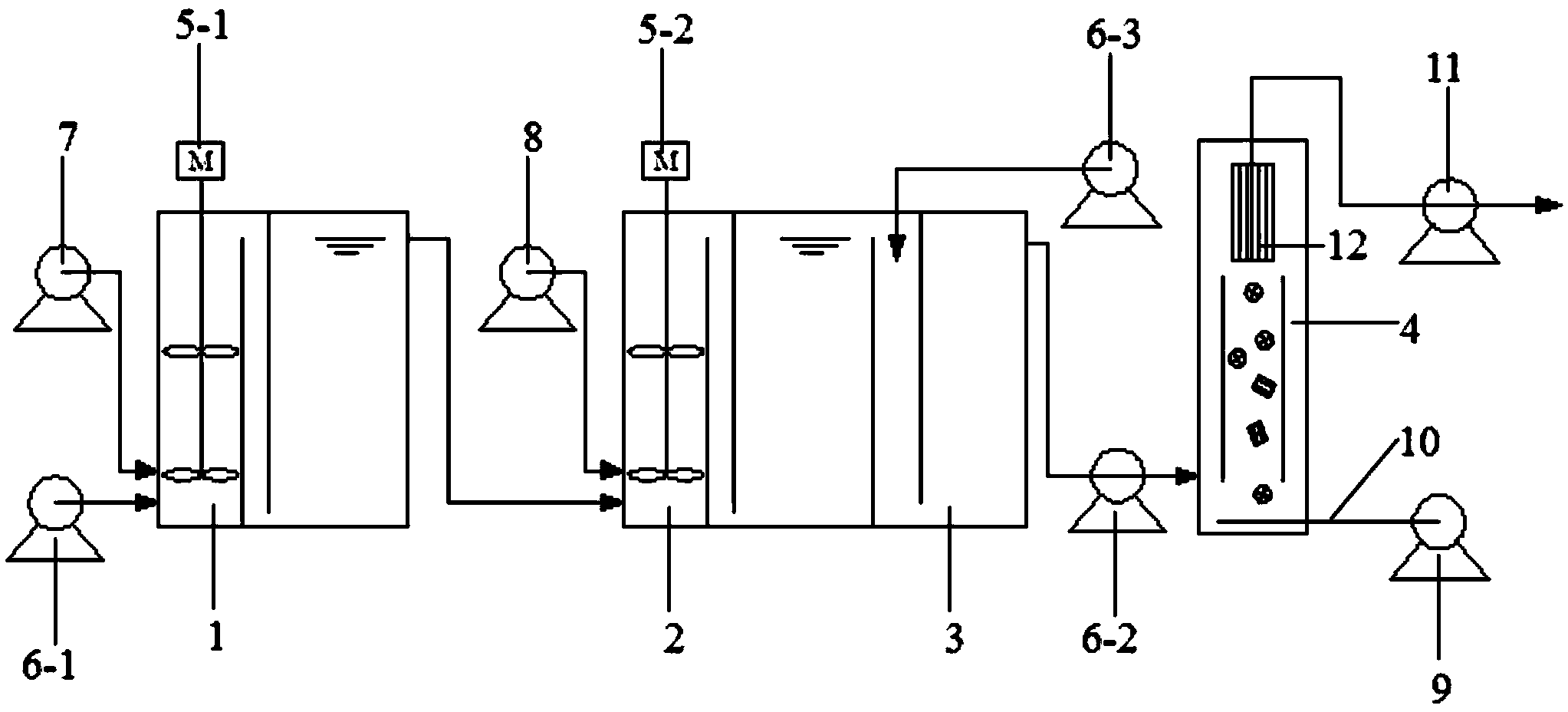

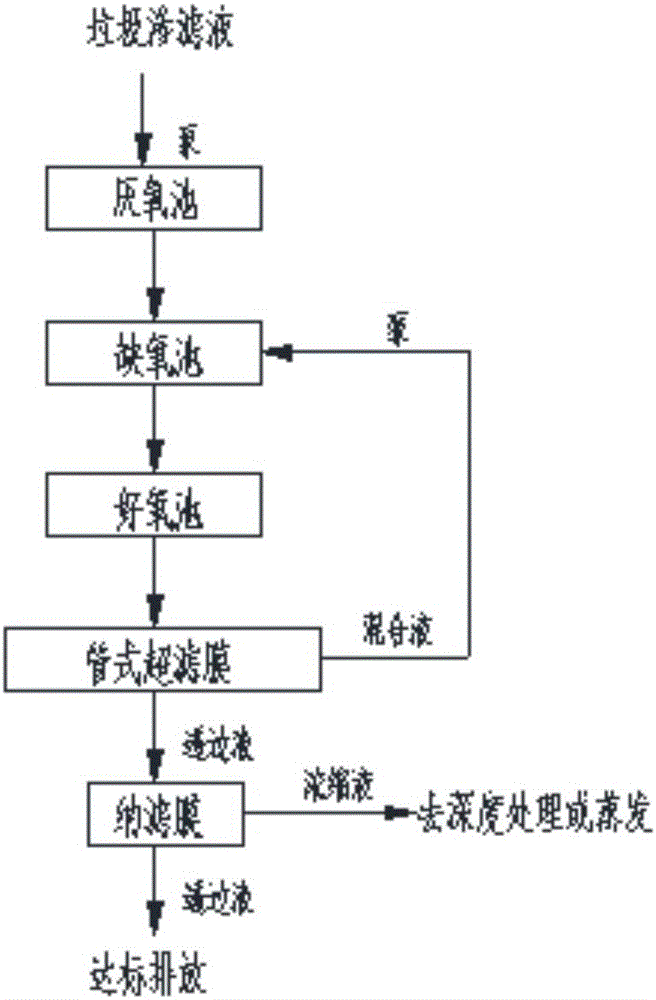

Technology for treating garbage leachate

InactiveCN101928094AIncrease concentrationSmall footprintDispersed particle separationTreatment with aerobic and anaerobic processesUltrafiltrationDistillation

The invention relates to technology for urban environmental hygiene treatment, in particular to technology for treating leachate of municipal refuse landfills and garbage burning plants. The technology comprises the following steps of: nitrifying garbage leachate, and performing polymeric membrane treatment which comprises treatment of an ultrafiltration membrane, a nanofiltration membrane and a reverse osmosis membrane, and selecting a specific operating environment in each step; performing electroosmosis treatment on the treated concentrated water; and finally, performing distillation and other treatment on the concentrated feed liquid subjected to electroosmosis, and exhausting waste materials in the garbage leachate for purification. The technology for treating the garbage leachate has the advantages of complete treatment of wastewater, relative economy, convenient installation, high efficiency, no secondary pollution and the like, and can be widely applied to treating household garbage, industrial production garbage and the like.

Owner:杭州深瑞环境有限公司

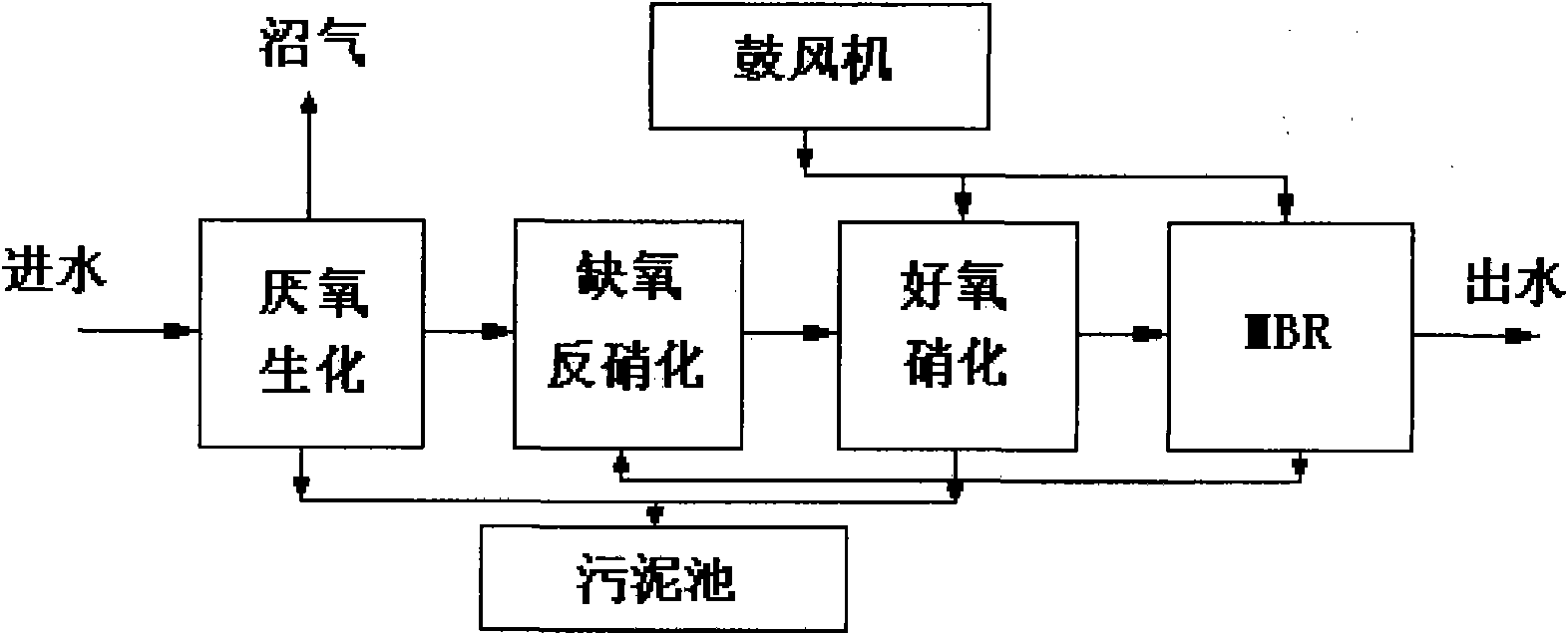

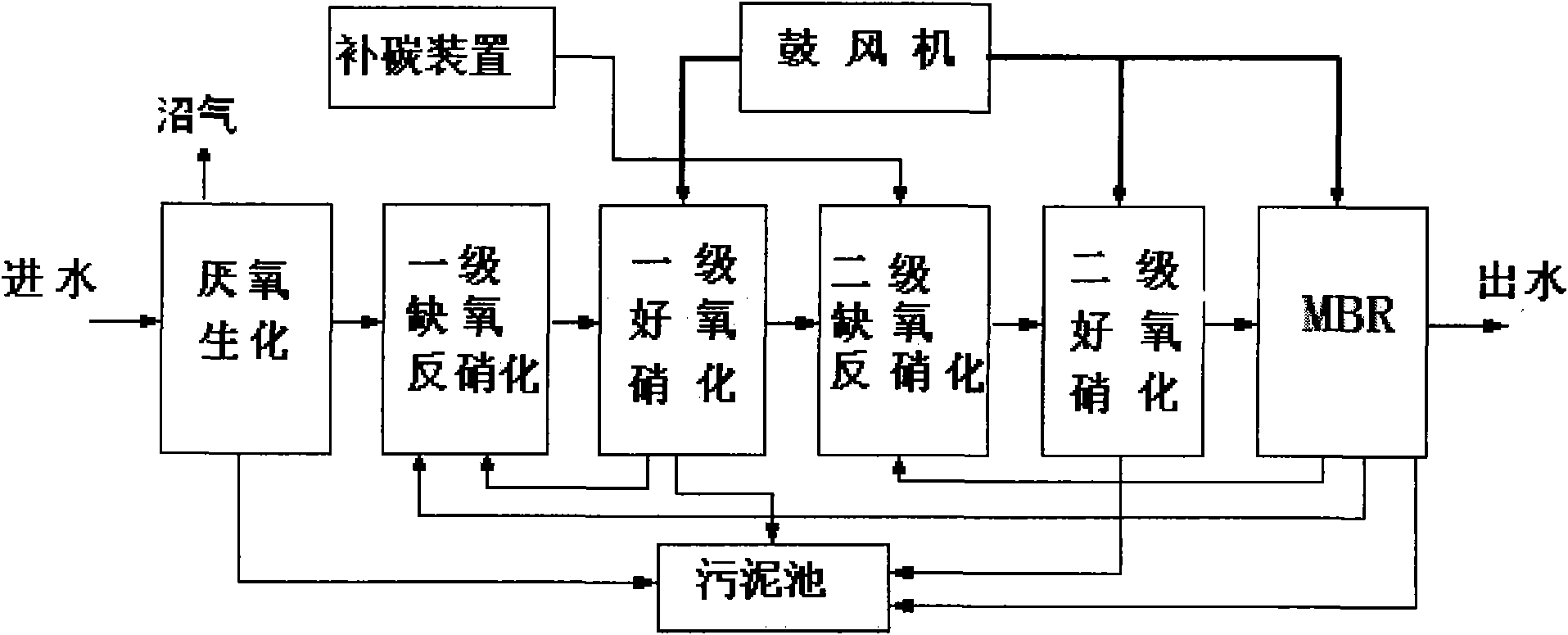

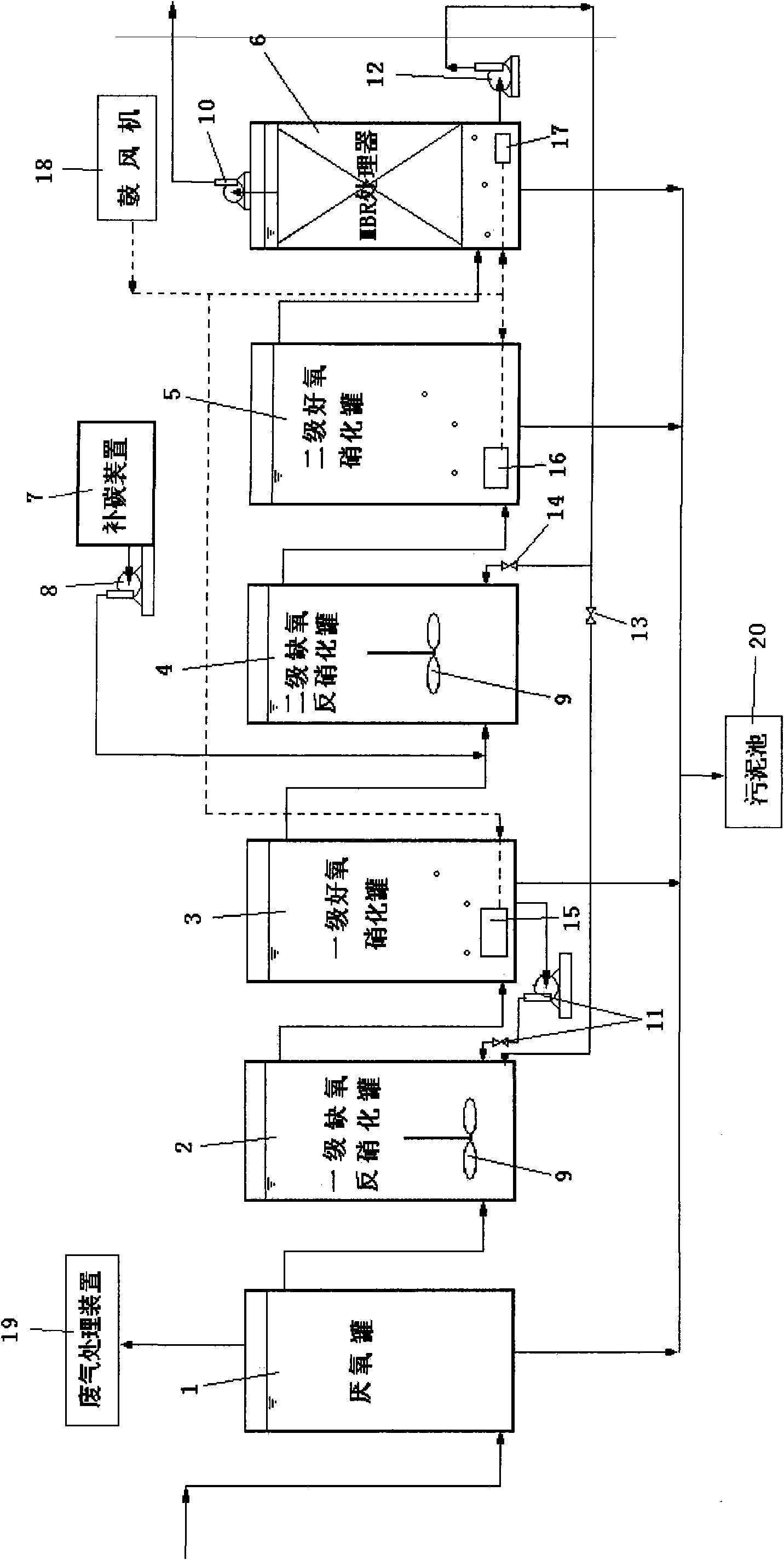

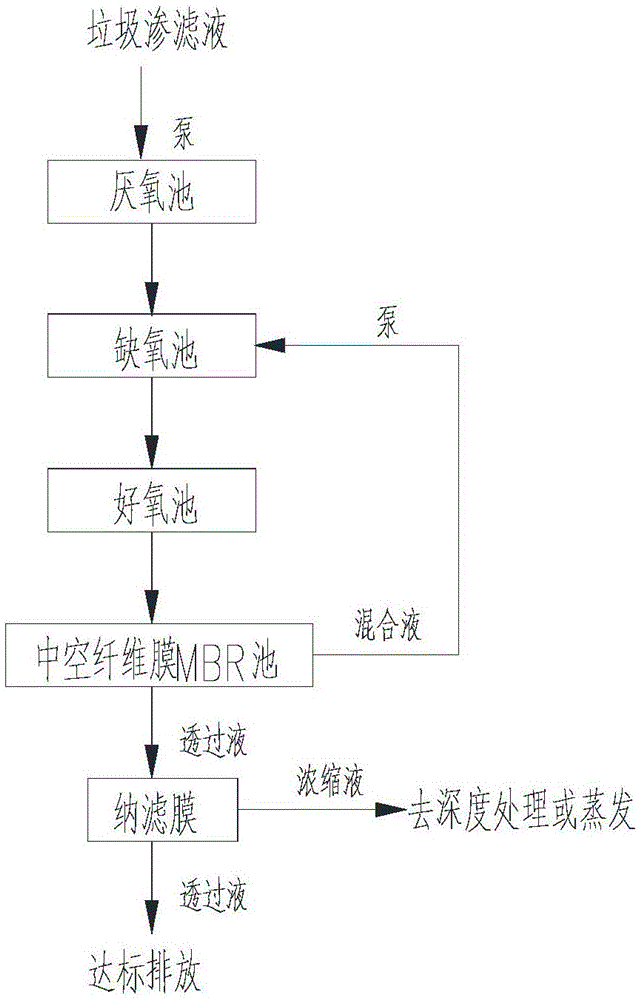

Rubbish leachate biological nitrogen removal process and device

InactiveCN101811803AImprove nitrogen removal efficiencyIncrease concentrationWater contaminantsWater/sewage treatment bu osmosis/dialysisNitrogen removalReflux

The invention relates to a rubbish leachate biological nitrogen removal process and a rubbish leachate biological nitrogen removal device. The process comprises the steps of water feeding, anaerobic biochemical treatment, primary anoxic denitrification, primary aerobic nitrification, secondary anoxic denitrification, secondary aerobic nitrification, MBR treatment and subsequent treatment. The device comprises an anaerobic tank, a primary anoxic denitrification tank, a primary aerobic nitrification tank, a secondary anoxic denitrification tank, a secondary aerobic nitrification tank and an MBR treatment device which are connected in turn through a water through pipeline, wherein a reflux pipe is led out from the primary aerobic nitrification tank to the primary anoxic denitrification tank; two reflux pipes led out from the MBR treatment device are connected to the primary and secondary anoxic denitrification tanks respectively; the anaerobic tank, the primary and secondary aerobic nitrification tanks and the MBR treatment device are connected with a sludge pipe respectively; the anaerobic tank is connected with a waste gas treatment device; the secondary anoxic denitrification tank is connected with a carbon supply device; and an aerating device is arranged in the primary and secondary aerobic nitrification tanks and the MBR treatment device respectively. The process can meet the requirement of GB16889-2008 'Domestic Rubbish Percolate (Leachate) Emission Limit' on nitrogen.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

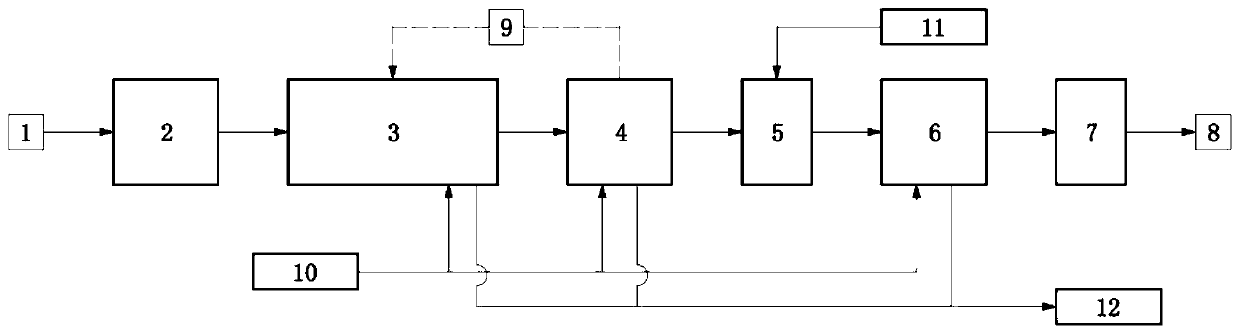

Physicochemical and biochemical combined treatment method of fracturing backflow liquid

ActiveCN104108833AReduce processing costsSimple processWaste water treatment from quariesMultistage water/sewage treatmentSuspended particlesAluminium chlorohydrate

The invention provides a physicochemical and biochemical combined treatment method of fracturing backflow liquid. The physicochemical and biochemical combined treatment method comprises the following steps of: (1) introducing the fracturing backflow liquid into a regulating sedimentation tank, and controlling the pH value of the fracturing backflow liquid to 6-8, wherein the hydraulic retention time of the fracturing backflow liquid is 2-4 hours in the regulating sedimentation tank; (2) introducing a supernatant from the regulating sedimentation tank into a coagulation sedimentation tank, adding a polyaluminium chloride water solution and a polyacrylamide water solution to the coagulation sedimentation tank, depositing to remove suspended particles out of waste water inside the coagulation sedimentation tank, introducing the supernatant from the coagulation sedimentation tank into an intermediate tank, and regulating the CODconcentration of the waste water inside the intermediate tank to 800-1200mg / L; (3) treating the waste water from the intermediate tank into an aerobic fluidized bed membrane bioreactor in which biological membrane culture is completed, wherein the aerobic fluidized bed membrane bioreactor operates in a way of a continuous water feeding and continuous drainage under the condition of aeration, and the treated waste water is discharged after passing through the membrane assembly of the aerobic fluidized bed membrane bioreactor.

Owner:SICHUAN UNIV

Biological accelerator for sewage treatment, preparation method and feeding method thereof

ActiveCN106830358AImprove biological activityStrong ability to resist BOD load impactWater treatment compoundsBiological water/sewage treatmentBiologyAmino acid

The present invention discloses a biological accelerator for sewage treatment. The biological accelerator comprises, by weight, 40-60% of carbohydrate, 10-30% of amino acid, 5-15% of vitamin, 2-8% of an inorganic salt, 0.1-1% of a surfactant, 0.1-2% of a growth promotion factor, and 10-20% of a powder carrier. Accordingly the present invention further provides a preparation method and a feeding method for the biological accelerator for sewage treatment. The biological accelerator of the present invention has advantages of low raw material cost, easy raw material purchasing, long storage time and convenient and rapid feeding, can increase the sewage biomass within a short time, can improve the system stability and the sewage treatment capacity, and does not damage the system ecology.

Owner:碧沃丰生物科技(广东)股份有限公司 +2

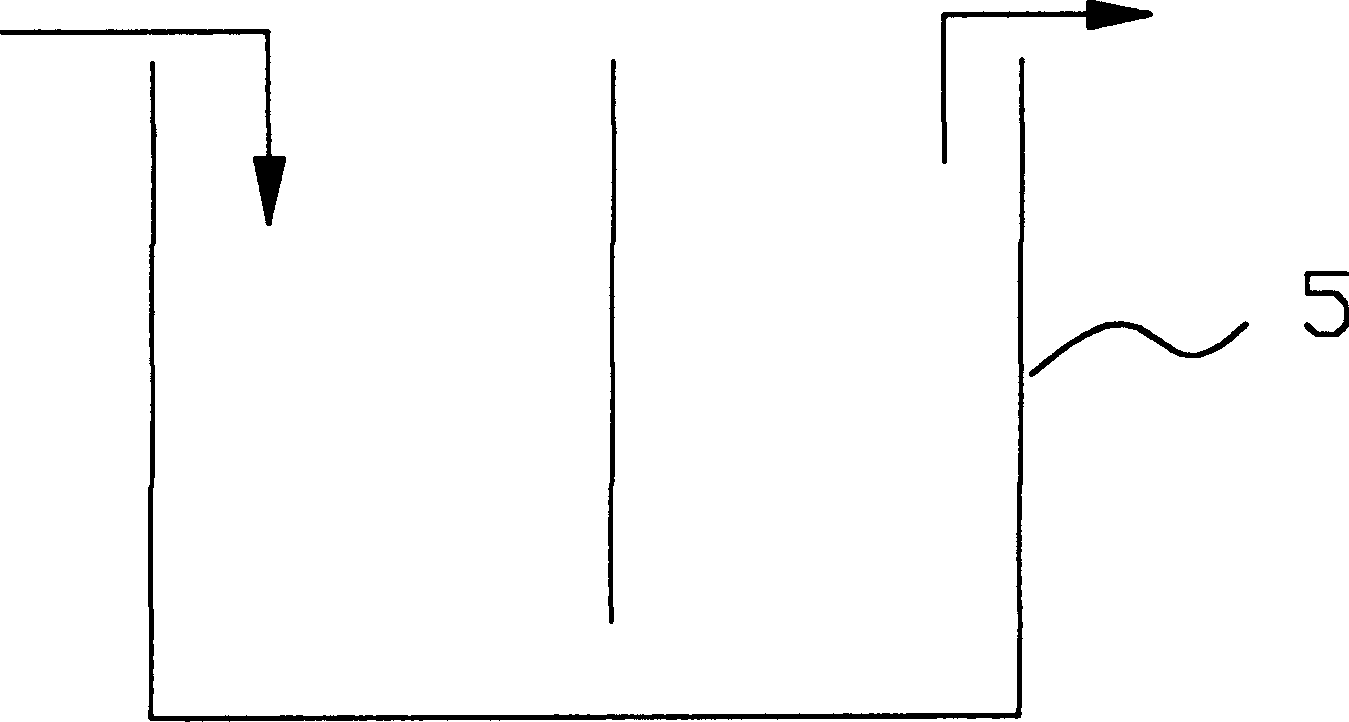

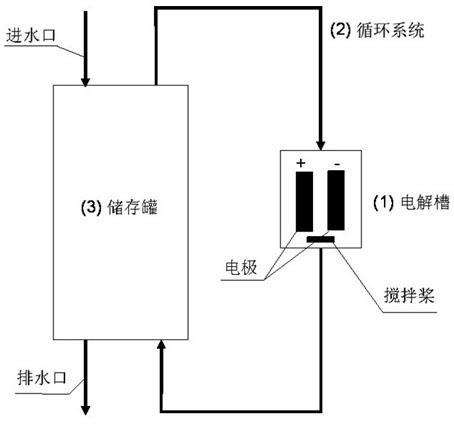

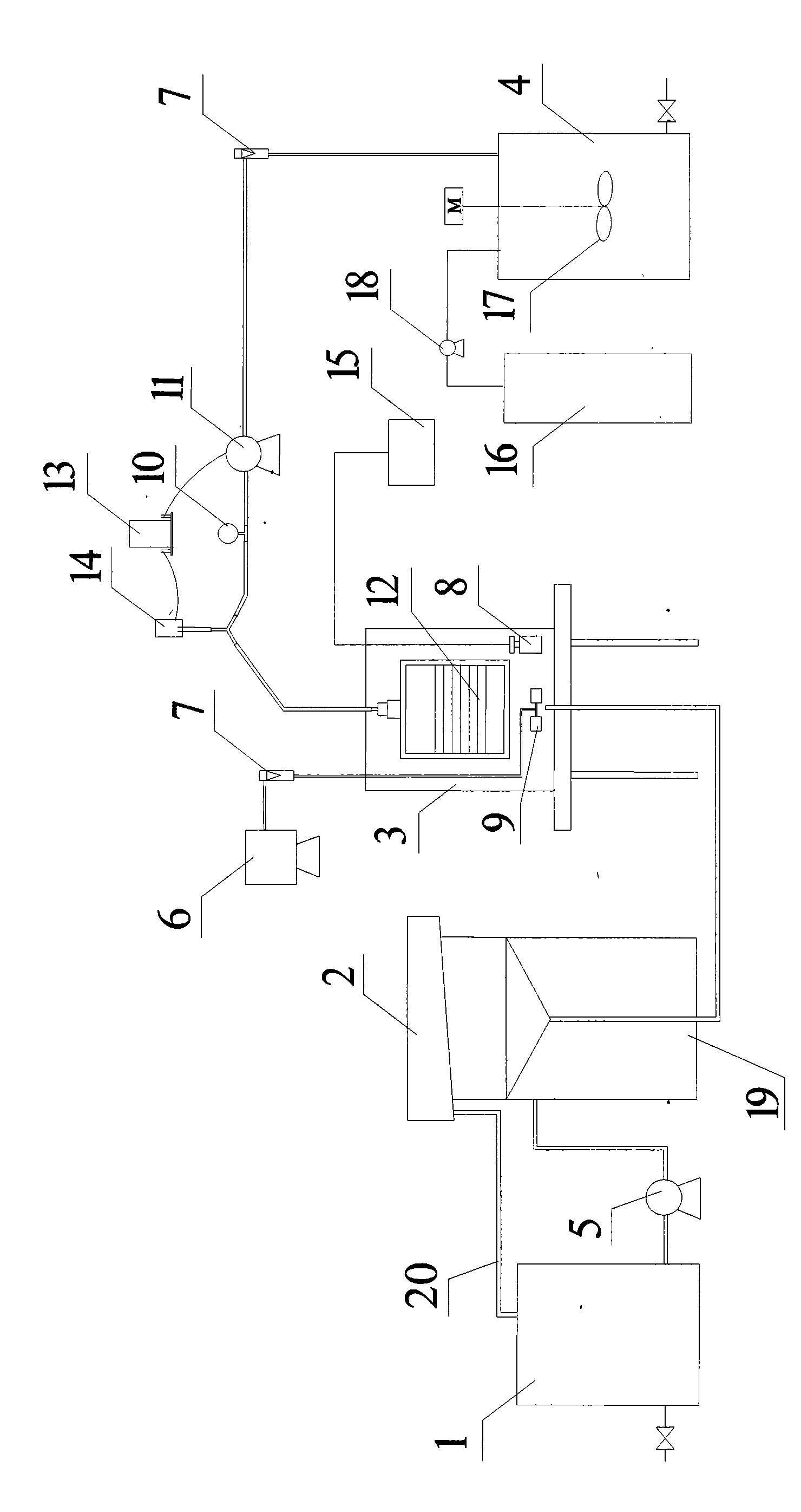

Equipment for treating organic wastewater through joint of electrolyzation and oxidant

InactiveCN102381791ASmall volumeHigh space-time efficiencyWater contaminantsMultistage water/sewage treatmentElectrolysisDC - Direct current

The invention discloses equipment for treating organic wastewater through the joint of electrolyzation and oxidants. The equipment comprises an electrolysis bath, a circulating system and a storage tank, wherein a water inlet and a drainage outlet are formed on the storage tank, one end of the electrolysis bath is connected with the storage tank through the circulating system, the other end of the electrolysis bath is directly connected with the storage tank, the circulating system comprises a circulating pump and a pipeline, and the equipment is characterized in that the oxidants are added into the electrolysis bath, an electrode is arranged in the electrolysis bath, and the electrode is connected with direct current; during operation, waste water firstly enters into the storage tank and then flows into the electrolysis bath from one end of the electrolysis bath through the circulating pump, in case of making current, electrolytic reaction and oxygenolysis reaction occur in the electrolysis bath, waste water flowing through the electrolysis bath flows out from the other end of the electrolysis bath and then returns to the storage tank; and the process is repeated until organic matters in waste water are degraded to meet the required level.

Owner:刘伟

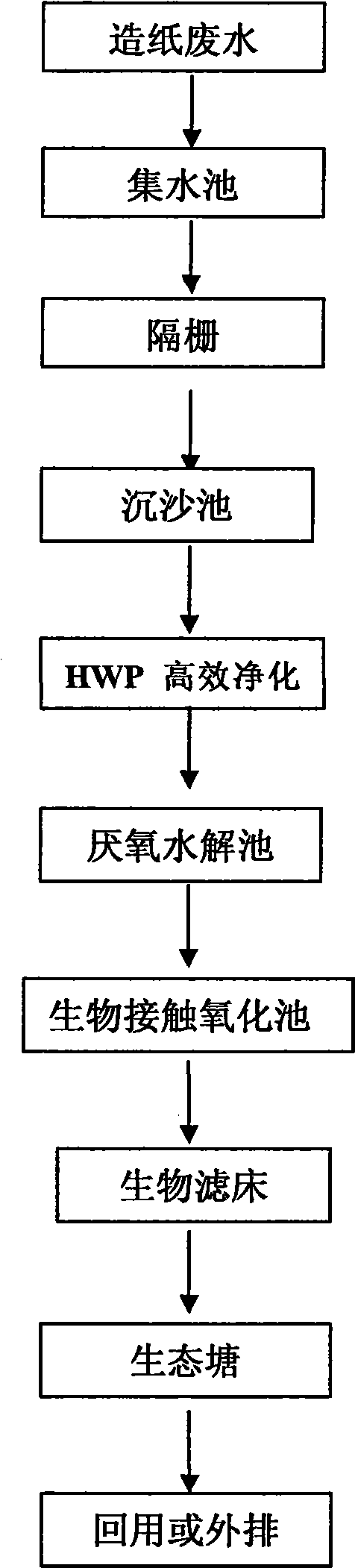

A method for restoring microorganism ecology of paper making waste water and a device

ActiveCN101544445AIncrease diversityHigh selectivityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentMicroorganismWastewater

Owner:GUANGZHOU SCUT TECH

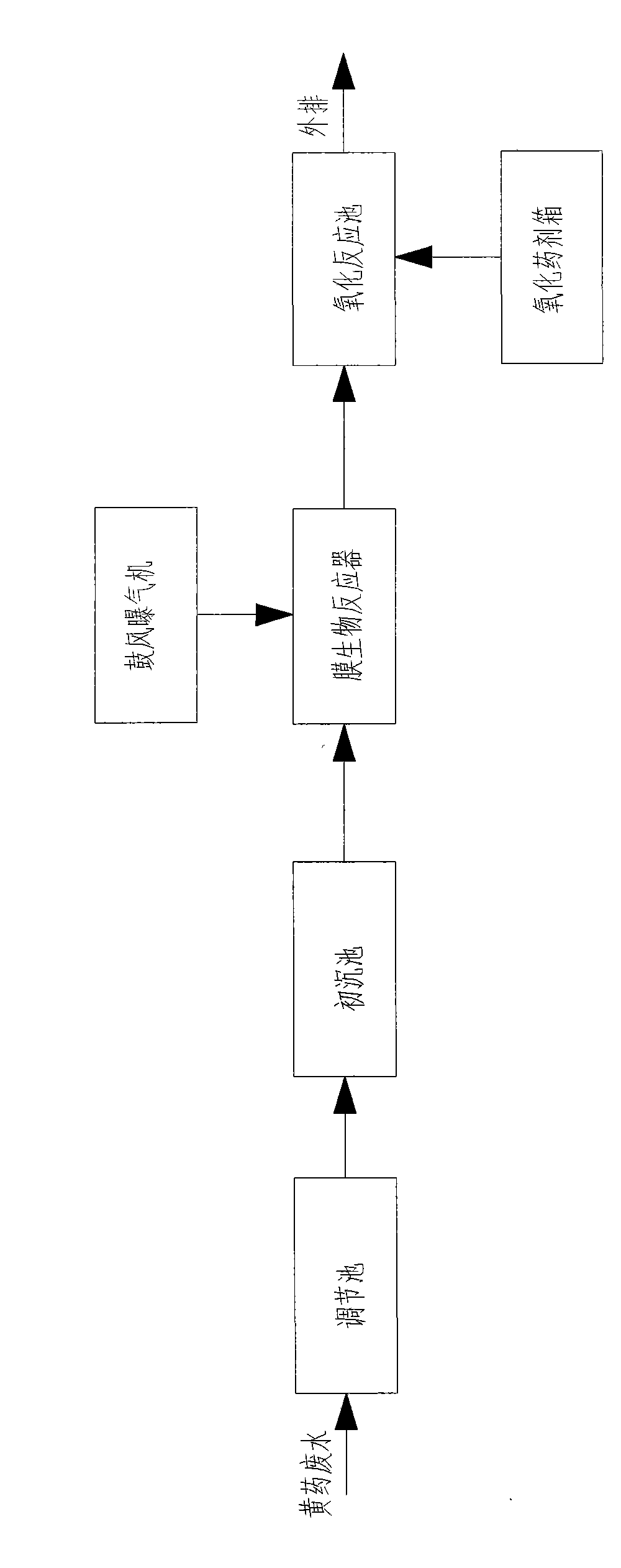

Method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation

InactiveCN101591121AFully degradedAvoid the danger of cloggingWater contaminantsWater/sewage treatment bu osmosis/dialysisOxygenOxidative treatment

The invention relates to a method for treating xanthate wastewater through combination of film biodegradation and hydrogen peroxide oxidation, which belongs to the technical field of sewage treatment. The method comprises two sections of treatment processes, namely the film biodegradation and the hydrogen peroxide oxidation. The method comprises the following steps: controlling the volume loading of a film bioreactor to between 3.0 and 5.0 kgCOD / (m.d), controlling the hydraulic power residence time in the reactor to between 18 and 36 hours and the sludge residence time to between 75 and 150 days, controlling the dissolved oxygen concentration to between 2.5 and 4.0 milligrams per liter, controlling the temperature in the reactor to between 20 and 35 DEG C and the active sludge concentration to between 10,000 and 15,000 milligrams per liter, and controlling the sludge loading to between 0.11 and 0.17 kgCOD / (kgMLSS.d); and adjusting the pH value of the sewage in a reaction tank to between 3 and 5, adding 5 to 10 mg / L H2O2 to perform oxidation treatment for 30 to 60 minutes, and after the oxidation treatment, discharging the purified water. Through the treatment by the method, the removal rate of the COD and the xanthate reaches more than 90 percent and more than 99 percent respectively.

Owner:NORTHEASTERN UNIV

Preparation method of microbial nutrition agent for wastewater biochemical treatment

ActiveCN103224887ADosage is smallImprove microbial activityMicroorganismsBiological water/sewage treatmentChemistryFish meal

The invention relates to a preparation method of a microbial nutrition agent for wastewater biochemical treatment, comprising the following steps: Mixing fish meal and distilled water to prepare a slurry with the mass concentration of 5-30%; (2) heating the slurry to 45-55 DEG C, adjusting pH to 7.2-8.5, adding protease and alkaline lipase, stirring and reacting for 4-6h to prepare an enzymolysis slurry; and (3) adjusting pH of the enzymolysis slurry to 1.0-1.5, stirring and carrying out an acidolysis reaction for 1-2h to prepare the acidolysis slurry, adding alcohol slops of 1-2 times the weight of the acidolysis slurry into the acidolysis slurry, and adjusting pH to 1.5-2.0 to prepare the microbial nutrition agent for wastewater biochemical treatment. The nutrition agent prepared by the preparation method of the microbial nutrition agent for wastewater biochemical treatment is used for industrial wastewater biochemical treatment. Additive dosage of the nutrition agent is little. Microbial activity is remarkably raised. Biochemical treatment efficiency is raised. And handling expense is low.

Owner:SHANDONG ACAD OF ENVIRONMENTAL SCI CO LTD

Biological product containing aerobe combined bacteria and preparation method and application thereof

InactiveCN104419699AProlong survival timeKeep aliveBacteriaWaste water treatment from animal husbandryMicroorganismSludge

The invention discloses a biological product containing aerobe combined bacteria and a preparation method and application thereof. The biological product includes aerobe combined bacteria loaded on a porous carrier; and the aerobe combined bacteria includes bacillus and pseudomonas putida. The preparation method includes the steps of: 1) soaking the porous carrier with acid or alkali and rinsing the porous carrier with water to a neutral state to obtain pretreated porous carrier; and 2) loading the aerobe combined bacteria liquid on the porous carrier. The biological product can be used in sewage treatment, and significantly improve the efficiency of biochemical treatment, efficiently remove COD and ammonia nitrogen, improve the outlet water quality and reduced the sludge yield by more than 80%.

Owner:房来喜 +3

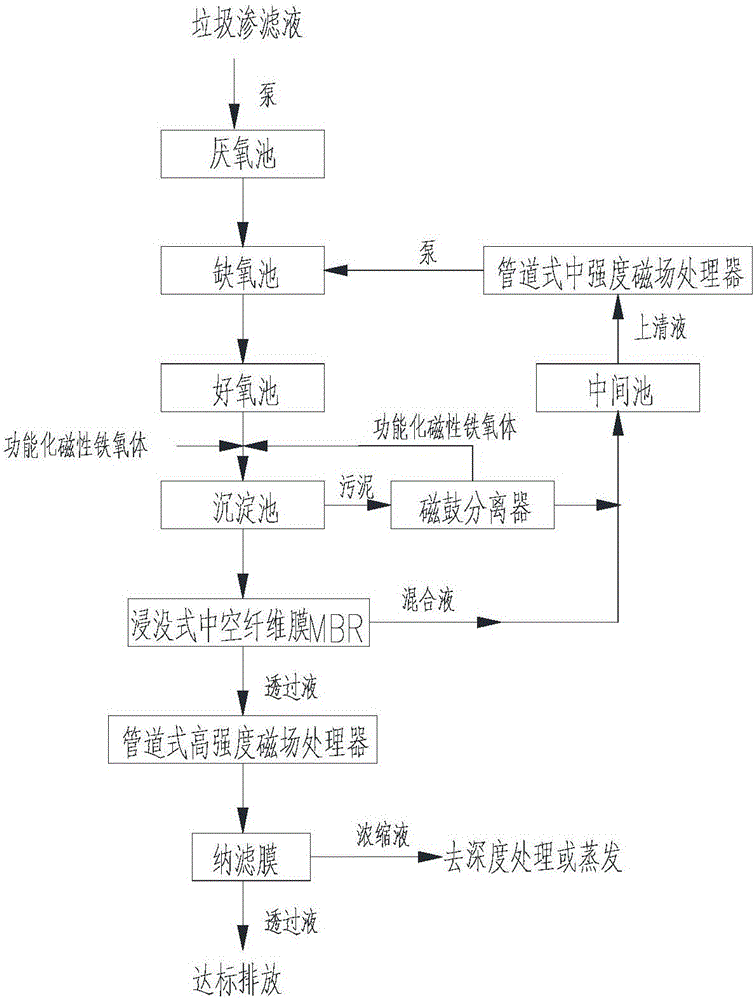

Landfill leachate multi-membrane treatment process

ActiveCN106219752AReduce concentrationEffective solid-liquid separationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment bu osmosis/dialysisReverse osmosisSlurry

The invention discloses a landfill leachate multi-membrane treatment process. Landfill leachate is pumped into an anaerobic tank, an anoxic tank and an aerobic tank in sequence for treatment, functional magnetic ferrite is put into effluent of the aerobic tank, and the effluent enters a sedimentation tank for solid-liquid separation; supernatant obtained from the sedimentation tank enters an immersed membrane reactor for secondary solid-liquid separation; sludge obtained from the sedimentation tank enters a magnetic drum separator for separation, and slurry containing the magnetic ferrite and returned sludge are obtained, wherein the slurry containing the magnetic ferrite flows back to enter the water outlet portion of the aerobic tank, and the returned sludge enters a middle tank; immersed membrane reactor permeate enters a tubular high-intensity magnetic field processor for magnetizing sterilization and then enters a nanofiltration or reverse osmosis system to be treated, and the treated immersed membrane reactor permeate is discharged up to standard; immersed membrane reactor concentrated mixed liquid is mixed with the returned sludge through the middle tank, and the supernatant is pressurized through a water pump and subjected to magnetic activation through a tubular medium-intensity magnetic field processor and then flows back to enter the anoxic tank.

Owner:江苏环保产业技术研究院股份公司

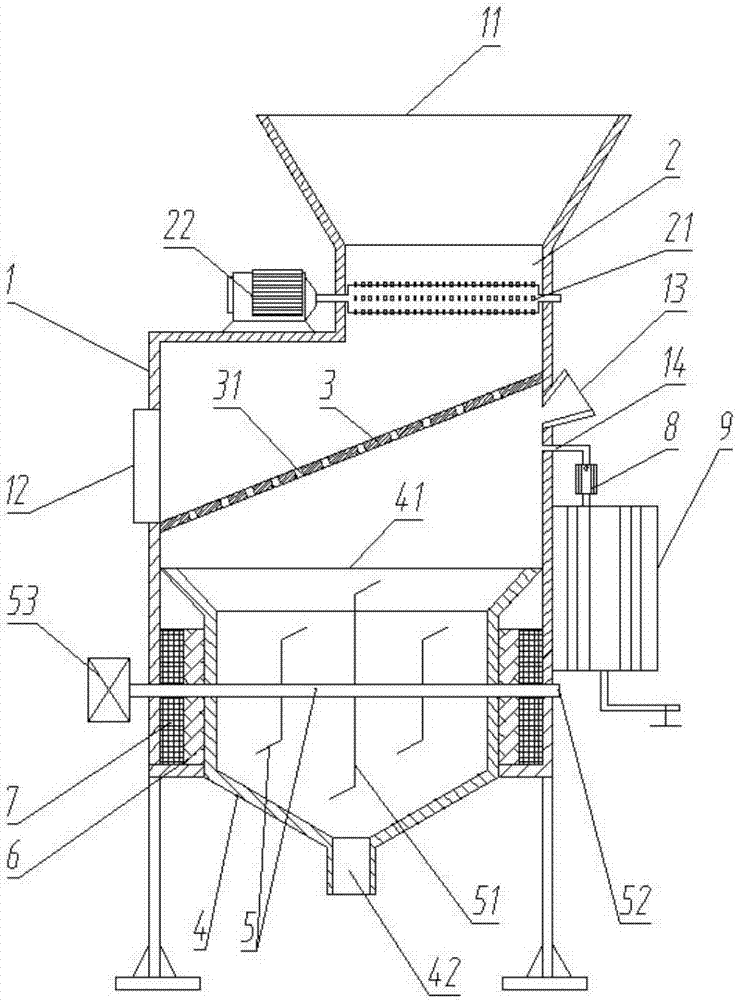

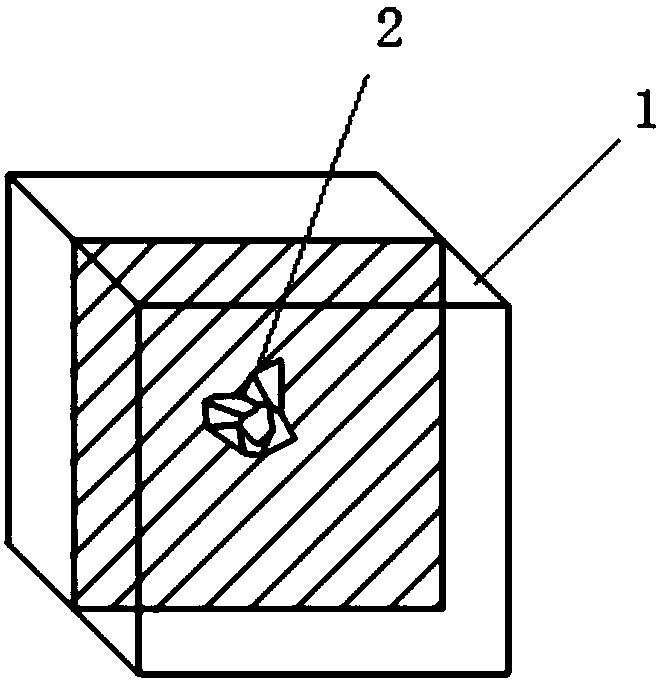

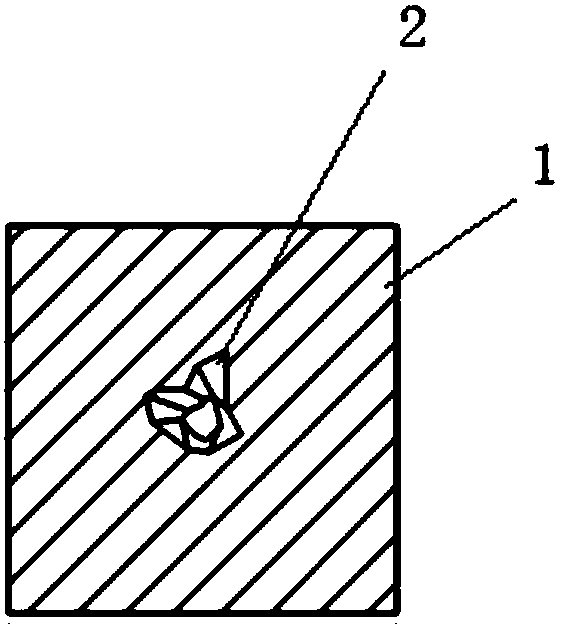

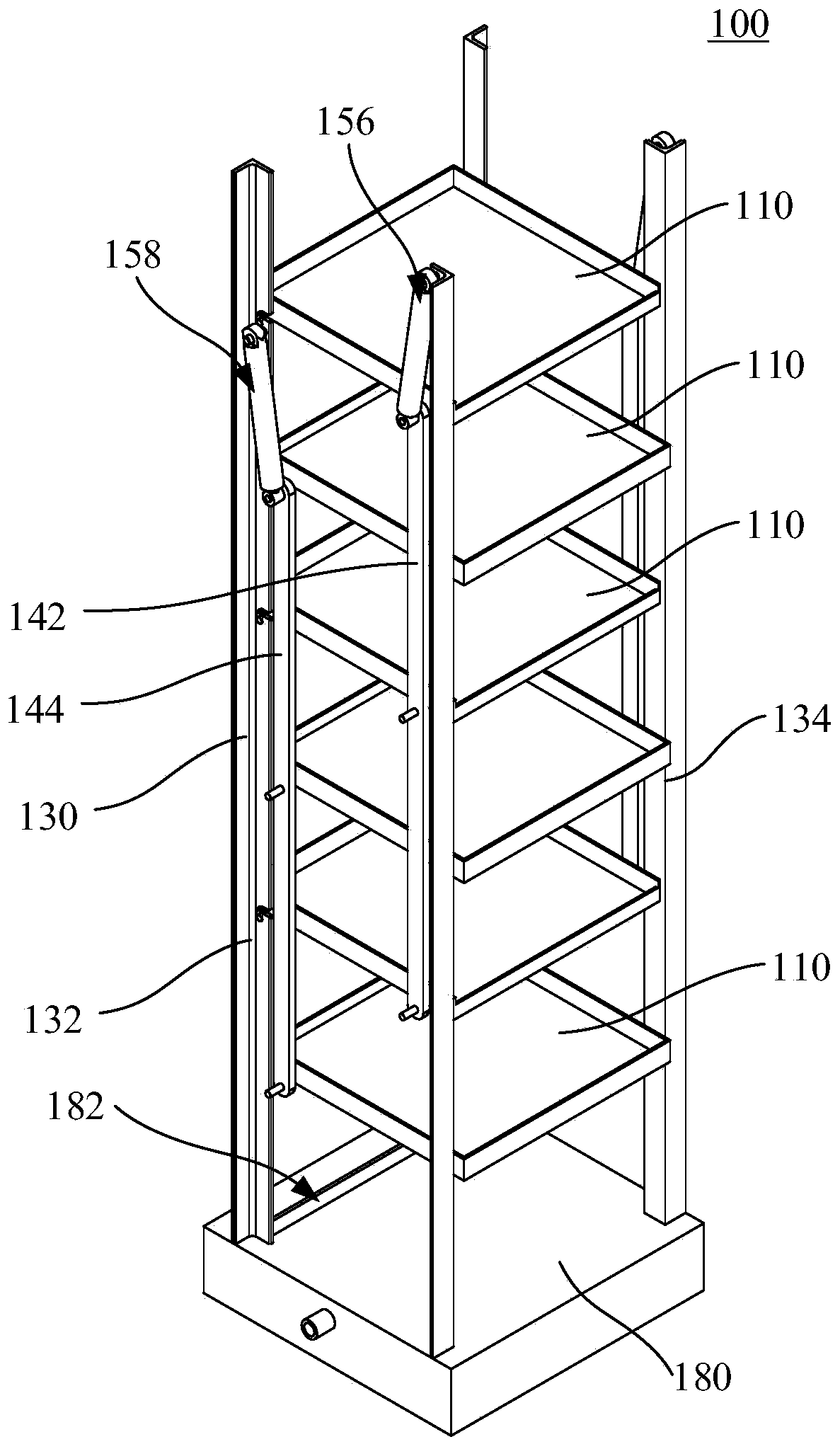

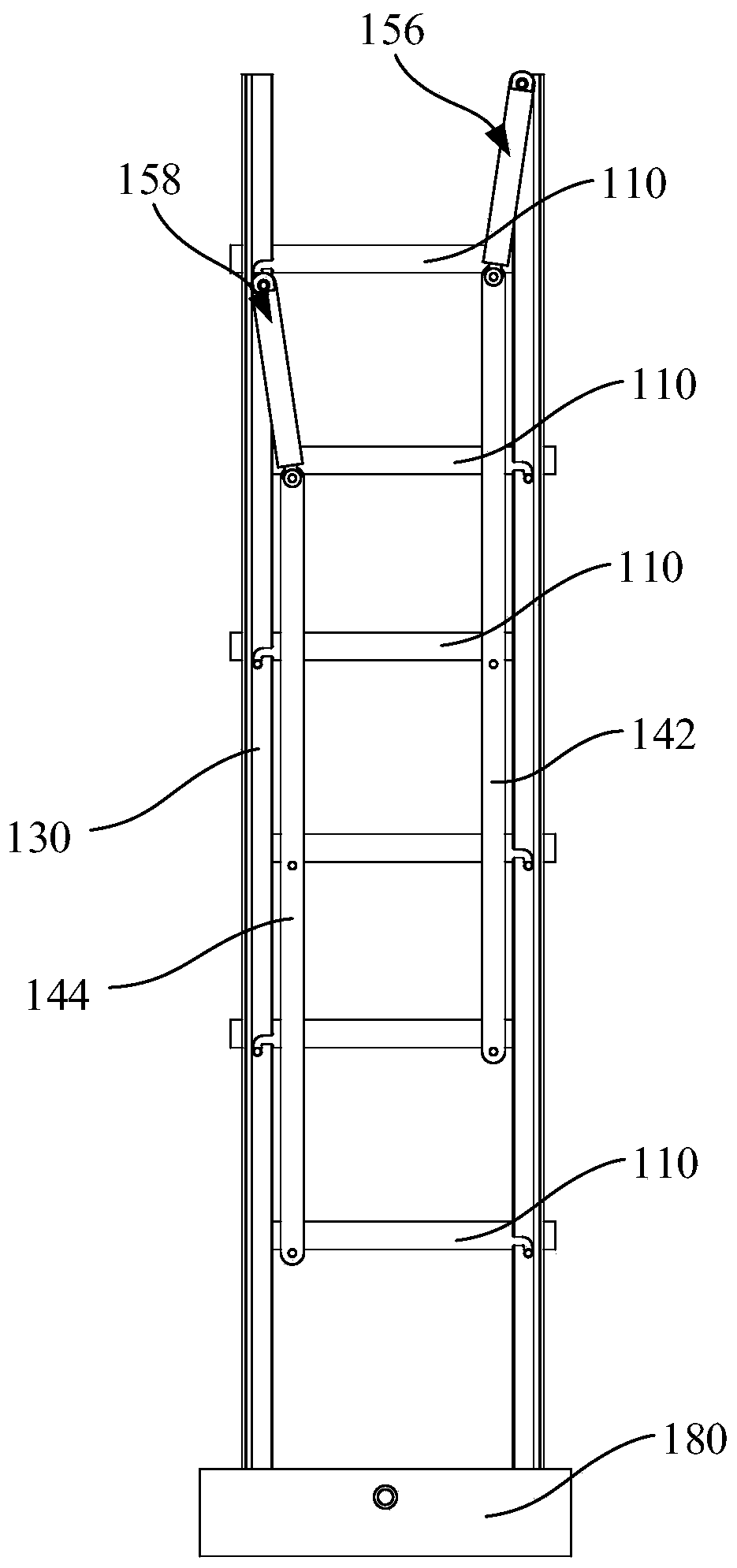

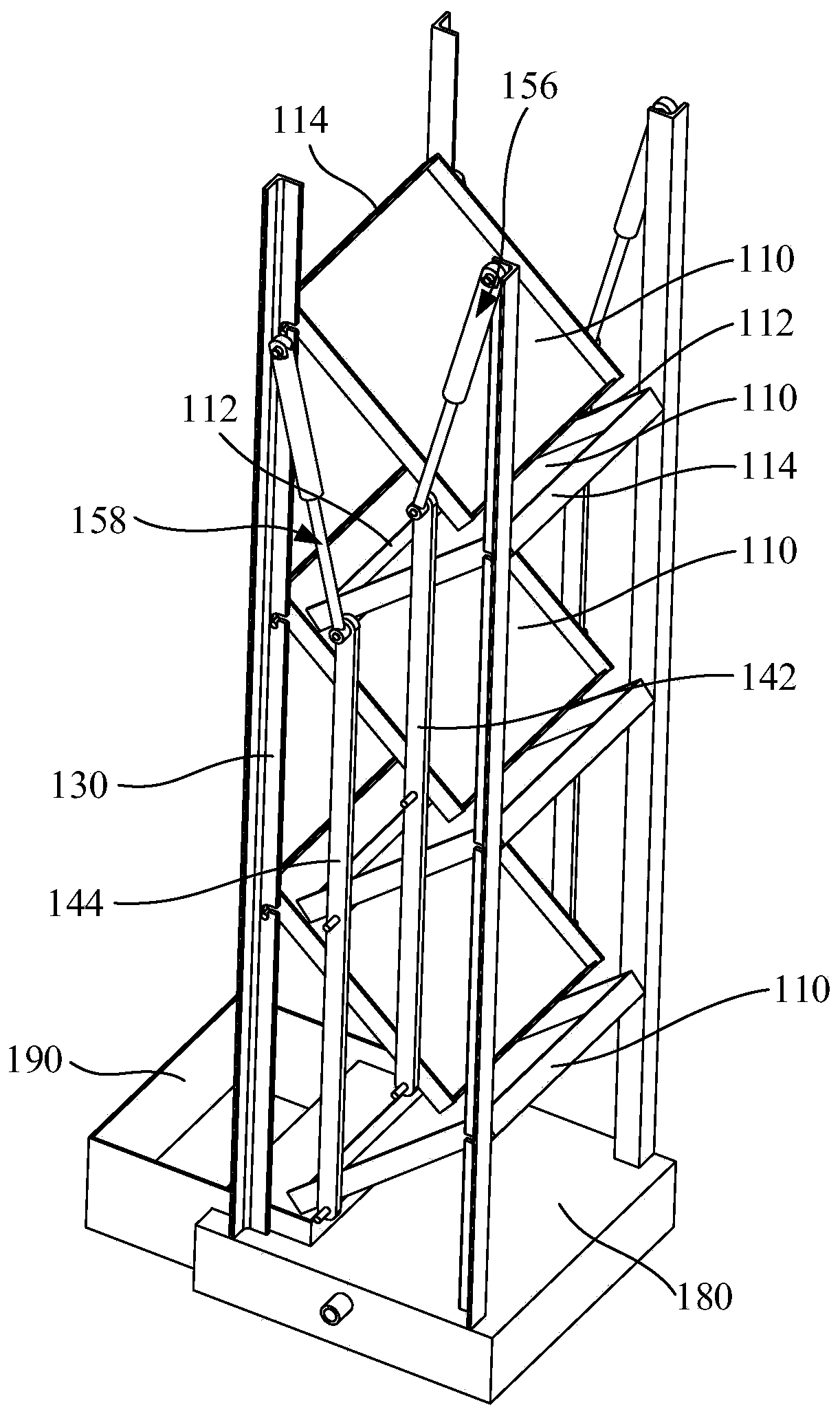

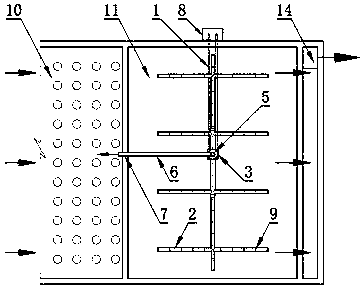

Biochemical treatment device of kitchen wastes

InactiveCN107962060AImprove biochemical treatment efficiencyImprove the effect of biochemical treatmentRotary stirring mixersSolid waste disposalWater vaporFiltration

The invention discloses a biochemical treatment device of kitchen wastes. The biochemical treatment device comprises a box body, wherein a feeding opening is formed in the upper part of the box body;a discharging opening I is formed in the side wall of the box body; a crushing chamber is formed between the feeding opening and the box body; a crushing mechanism is arranged in the crushing chamber;a partition plate and a material receiving cylinder are arranged in the box body; the partition plate is tilted; filtration through holes are formed in the partition plate; the discharging opening Iis located above one side of the down-tilted end of the partition plate; the material receiving cylinder is located under the partition plate; a stirring device is arranged in the material receiving cylinder; an interlayer is formed between the outer wall of the material receiving cylinder and the inner wall of the box body; a heating device and a heat insulation material are successively arrangedin the interlayer from inside to outside. According to the biochemical treatment device of kitchen wastes, the stirring device and the heating device are adopted; the biochemical treatment efficiencyand effect of the waste are improved; the tilted partition plate is arranged; the large crushed wastes or the difficultly-crushed waste sundries can be sorted and reused; the odor can be effectivelyremoved by the water vapor generated in the processes of recycling and treating; the secondary pollution to the environment can be avoided.

Owner:SUZHOU MEIJIESHENG ENVIRONMENTAL PROTECTION ENG CO LTD

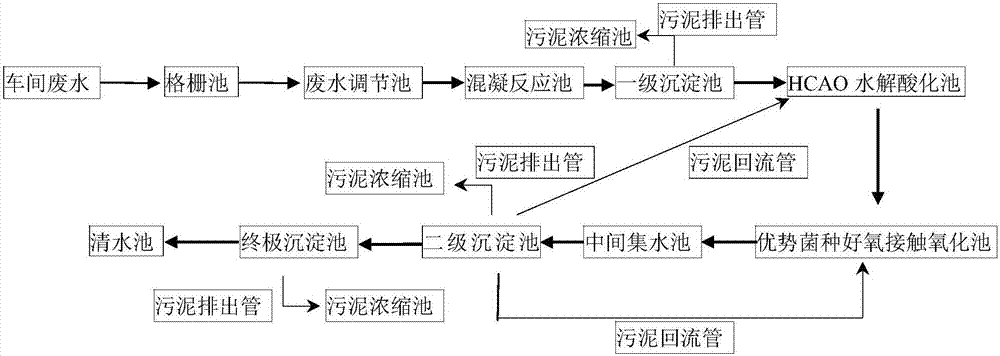

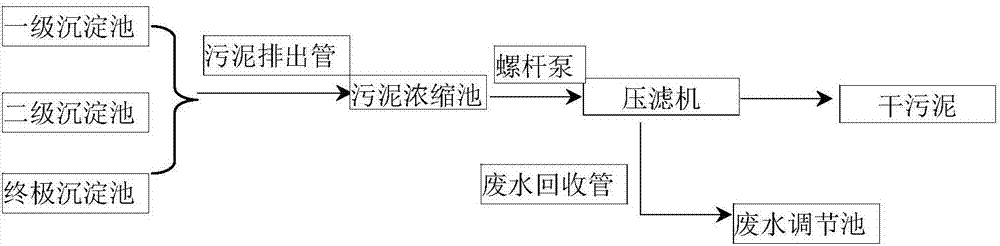

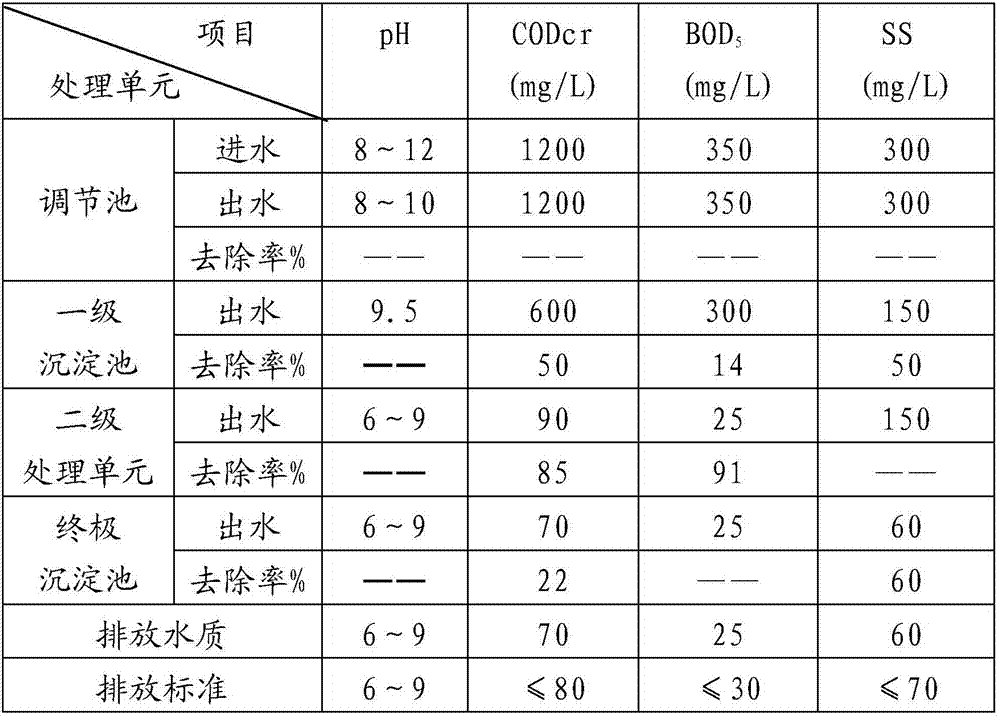

Printing and dyeing wastewater treatment system and technology

PendingCN107512833AFully removeAvoid cloggingSludge treatment by de-watering/drying/thickeningTreatment using aerobic processesHigh concentrationSludge

The invention discloses a printing and dyeing wastewater treatment system and technology. An HCAO (hydrolytic acidification dominant bacterial strain aerobic contact oxidation) system which is summarized and developed by the applicant according to many years of practical experience in the printing and dyeing wastewater engineering is used for treating high-concentration printing and dyeing wastewater, the content of SS (suspended solids) and BOD in recycled water can meet discharge requirement, sludge activity is good, and settling property is good. The printing and dyeing wastewater treatment technology disclosed by the invention has the advantages that the printing and dyeing wastewater can be deeply treated, and the standards of recycled water are met, so that pure investment on wastewater treatment is changed into investment with output, the multiple effects of reducing discharge amount of wastewater, saving water resource and protecting the environment are achieved, and the market demand of the spinning, dyeing and finishing industry can be met.

Owner:福建省万德环境工程有限公司

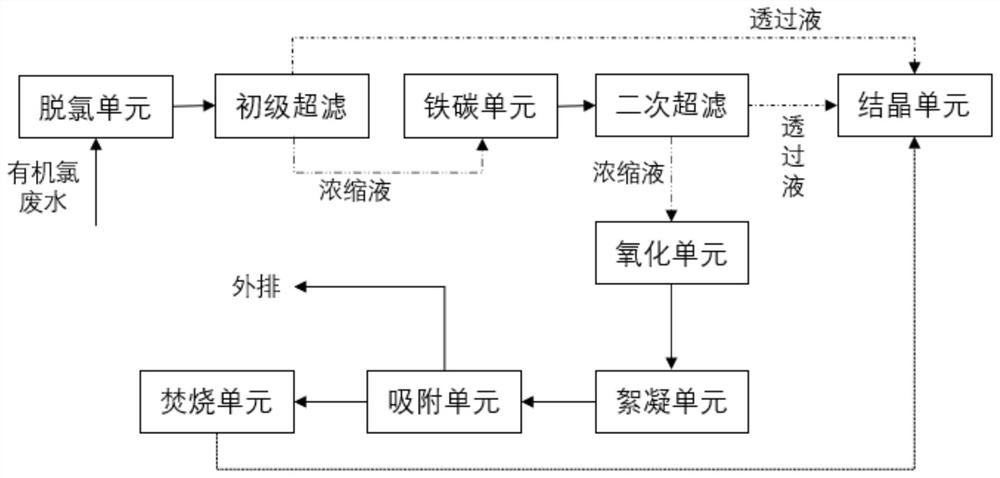

Combined treatment process for non-biodegradable organic wastewater

InactiveCN105152471AHigh removal rateWide range of adaptationMultistage water/sewage treatmentChemistryCarbon dioxide

The invention discloses a combined treatment process for non-biodegradable organic wastewater. The combined treatment process includes: removing suspended substances in water via a coagulation precipitation process; performing efficient muddy water separation via a coarse filtering process; subjecting the wastewater to treatment on the basis of combined action of electrochemistry, oxidation-reduction, physical absorption and flocculent precipitation by the aid of the iron-copper and iron-carbon galvanic cell principle, degrading organic pollutants and improving biodegradability of the wastewater; finally degrading organics into carbon dioxide and water via the anaerobic-aerobic biochemical reaction process; further filtering the suspended substances via the fine filtration process to enable the produced water to reach the wastewater discharge standard. Double electrolytic reaction is applied, so that organics removal effect is higher, biodegradability of the wastewater is further improved, and the combined treatment process has the advantages of being good in treatment effect, low in operation cost, convenient to operate and maintain and the like.

Owner:HUZHOU DEXIANG ENVIRONMENTAL PROTECTION ENG

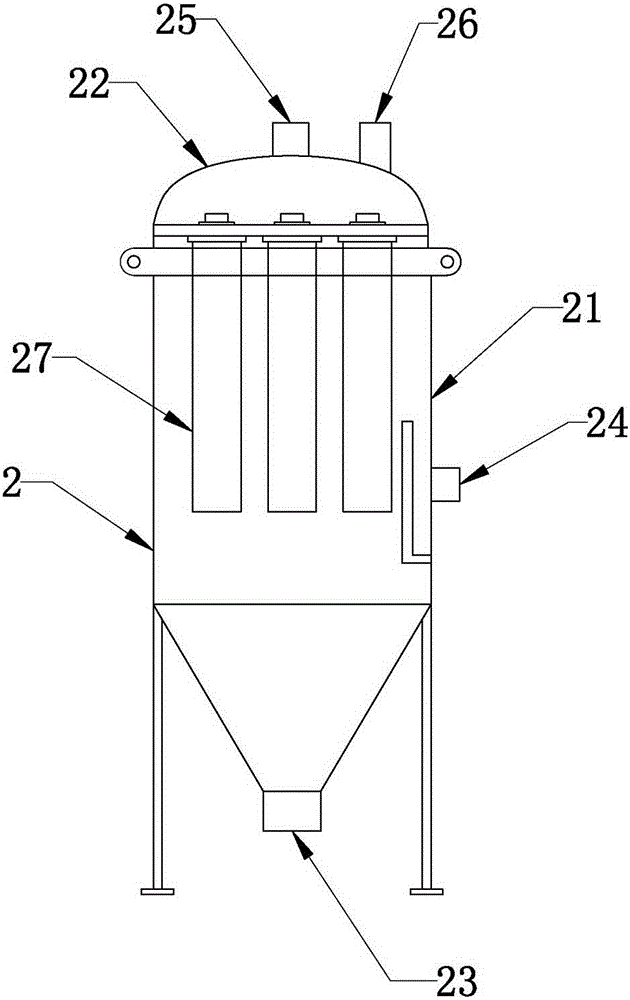

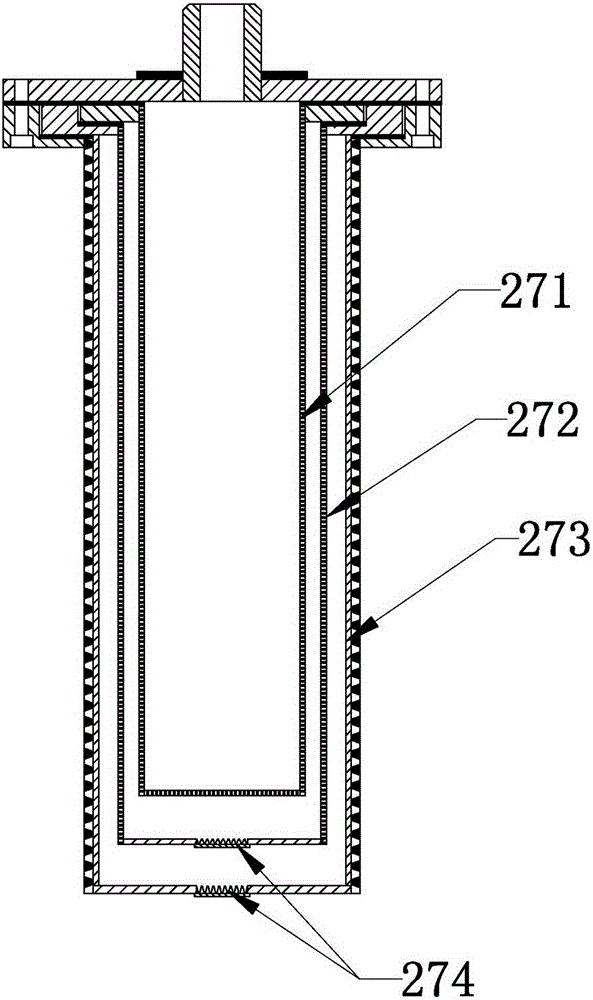

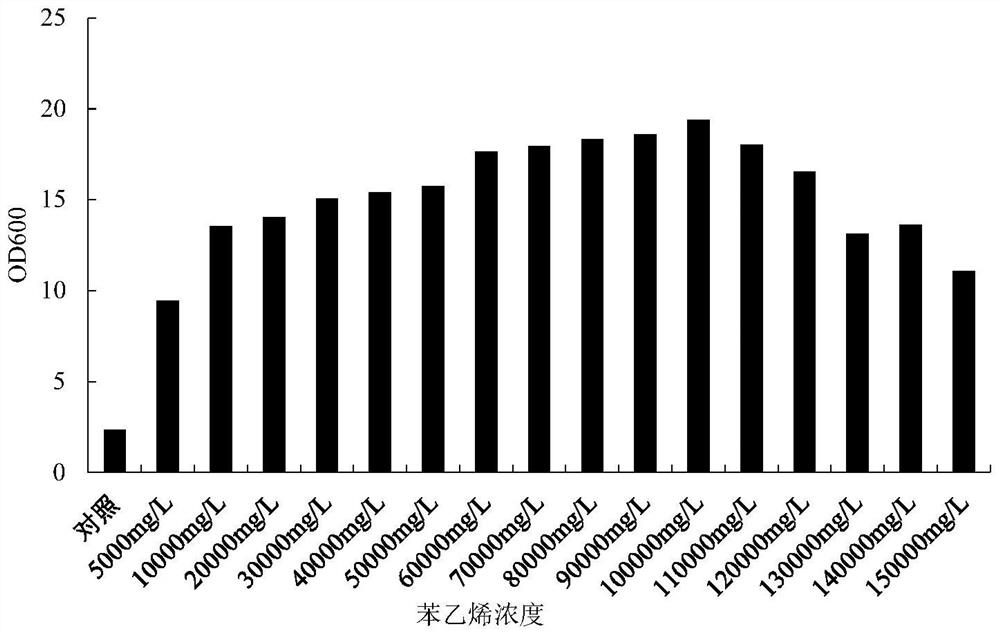

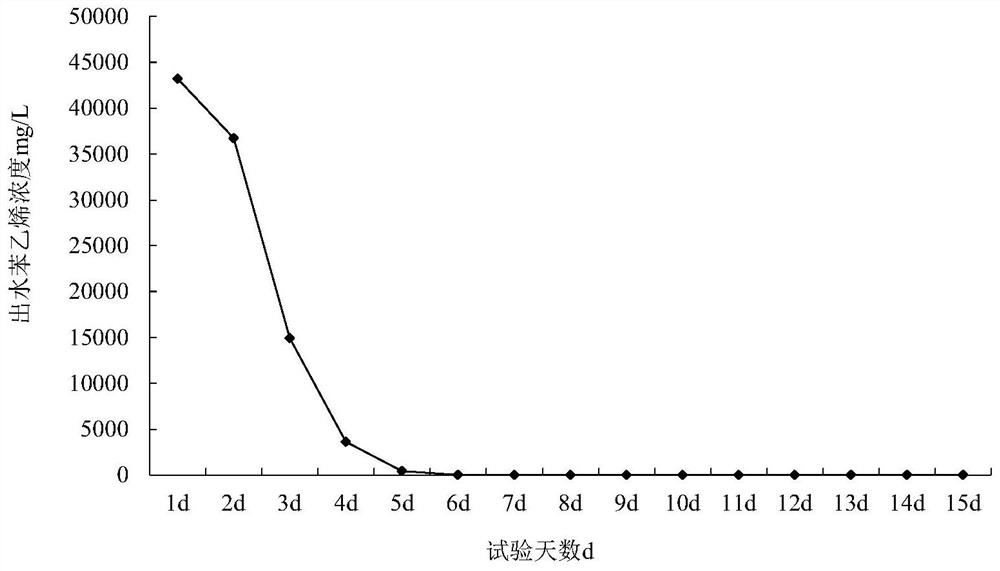

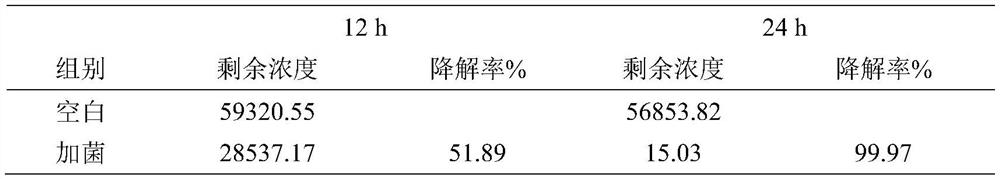

Styrene degrading bacterium and application thereof

ActiveCN114214233ASolving Governance ChallengesImprove biochemical treatment efficiencyBacteriaWater contaminantsStyrene degradationEngineering

The invention belongs to the technical field of bioengineering, and provides a styrene degrading bacterium and application thereof. According to the present invention, the styrene degrading bacterial agent is identified as Pseudomonas plecoglossa through 16S rDNA identification, the bacterial strain has been preserved in the China General Microbiological Culture Collection Center (CGMCC) in June 2021, and the preservation number is CGMCC No.22757. The invention further provides a preparation method of the styrene degrading bacterial agent, under the optimal condition, the degradation rate of the microbial inoculum to styrene with the initial concentration of 60000mg / L for 24h is 99.97%, and the maximum tolerance concentration to styrene reaches 100000mg / L. The styrene degrading bacterial agent provided by the invention can reduce the impact of styrene on a biochemical treatment system, improves the treatment efficiency of styrene-containing wastewater, and has remarkable economic and environment-friendly benefits. Meanwhile, the strain can be applied to the field of treatment of styrene polluted wastewater and soil or styrene-containing organic waste gas.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

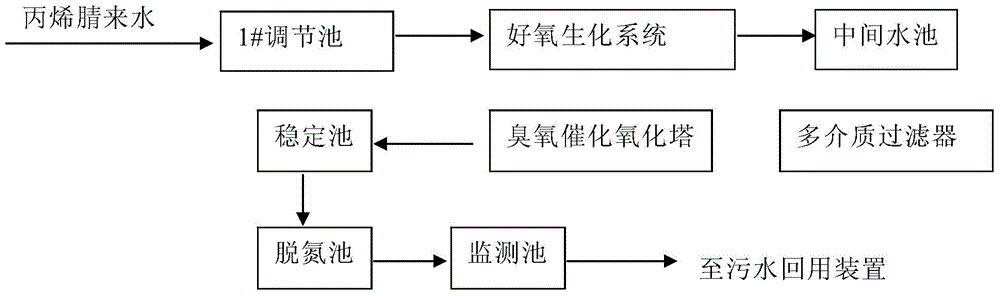

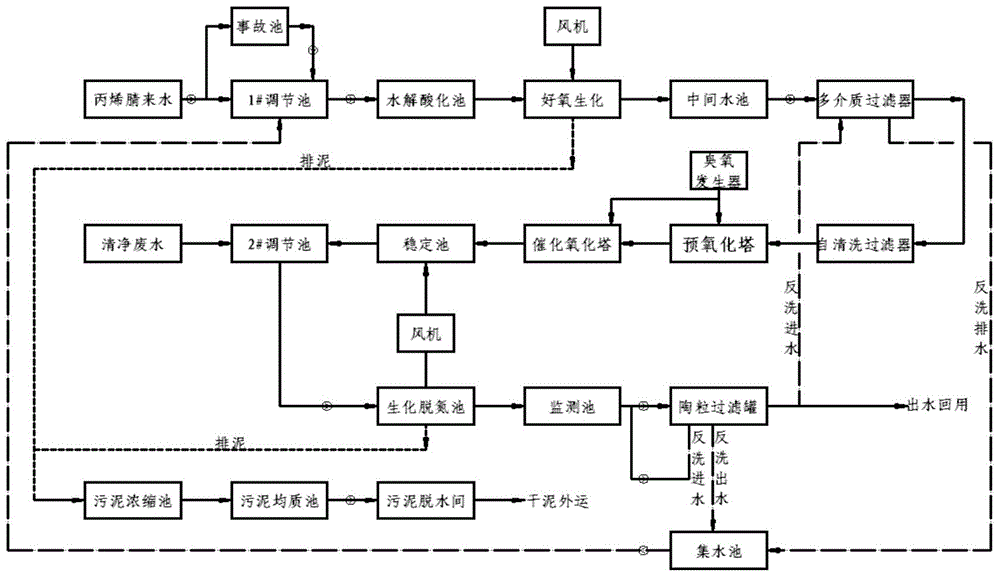

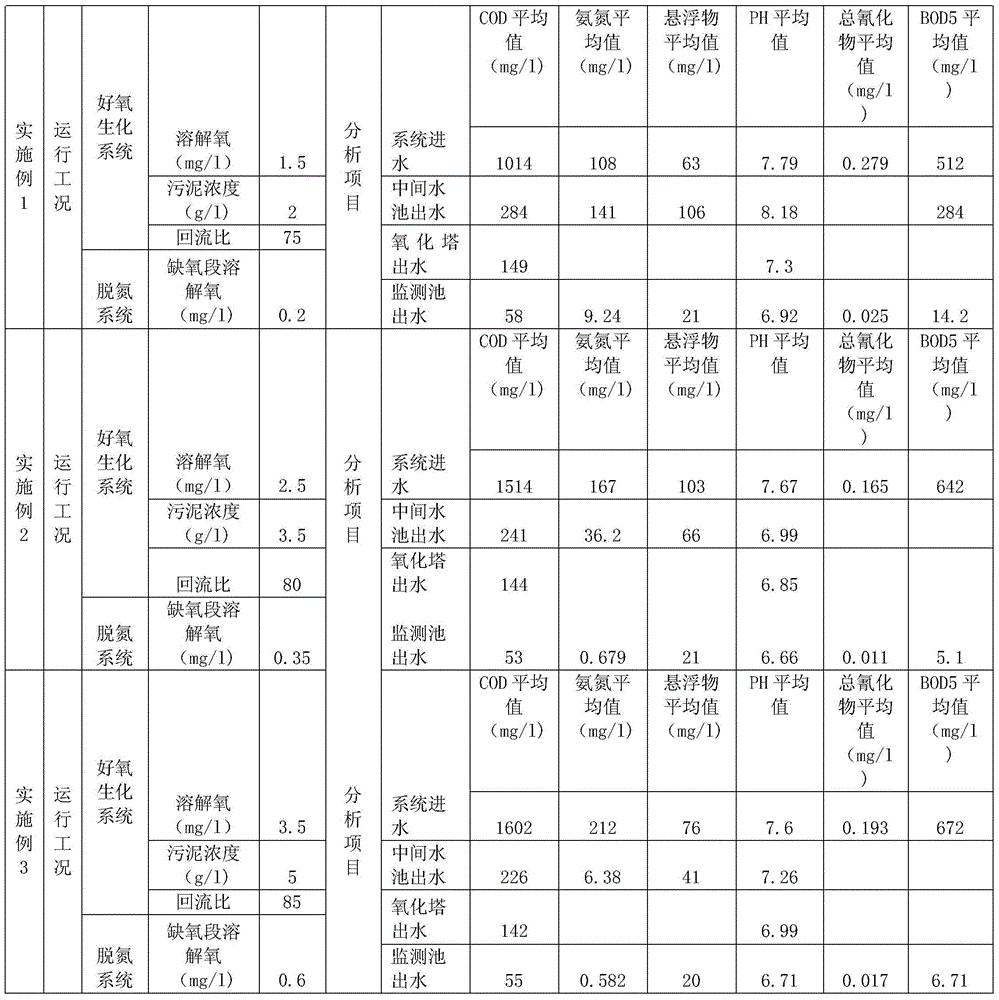

A combined process coupling aerobic biochemical treatment, ozone catalytic oxidation and biological denitrogenation for acrylonitrile wastewater

InactiveCN105693006AImprove biodegradabilityIncrease alkalinityMultistage water/sewage treatmentNature of treatment waterNitrogenWastewater

A combined process coupling aerobic biochemical treatment, ozone catalytic oxidation and biological denitrogenation for acrylonitrile wastewater is disclosed. The combined process comprises an aerobic biochemical process, an ozone catalytic oxidation process and a biological denitrogenation process. Discharged water subjected to aerobic biochemical process treatment in an aerobic biochemical unit is led into an ozone catalytic oxidation unit. Ozone catalytic oxidation process treatment is performed in the ozone catalytic oxidation unit, and discharged water after the ozone catalytic oxidation process treatment is led into a biological denitrogenation system and subjected to biological denitrogenation process treatment.

Owner:PETROCHINA CO LTD

Double-MBR-method sewage treatment process combined with ozone oxidation

InactiveCN111115950AReduce load/consumptionLow running costTreatment involving filtrationMultistage water/sewage treatmentSludgeFiltration

The invention provides a double-MBR- method sewage treatment process combined with ozone oxidation. The process comprises the steps of pretreatment, biochemical treatment, primary MBR method treatment, ozone oxidation treatment, secondary MBR method treatment and filtration to obtain water meeting the emission standard, the process can reduce the addition amount of conventional ozone, reduce the generation of sludge, improve the degradation rate of degradation-resistant substances, has a wide application range and has process practicability.

Owner:SHANGHAI SUPRATEC MEMBRANE TECH CO LTD +1

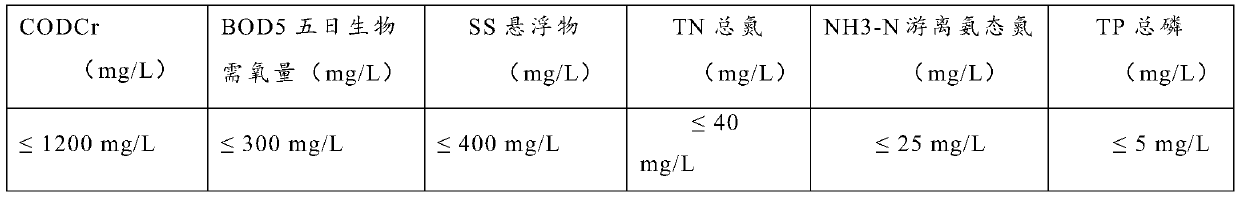

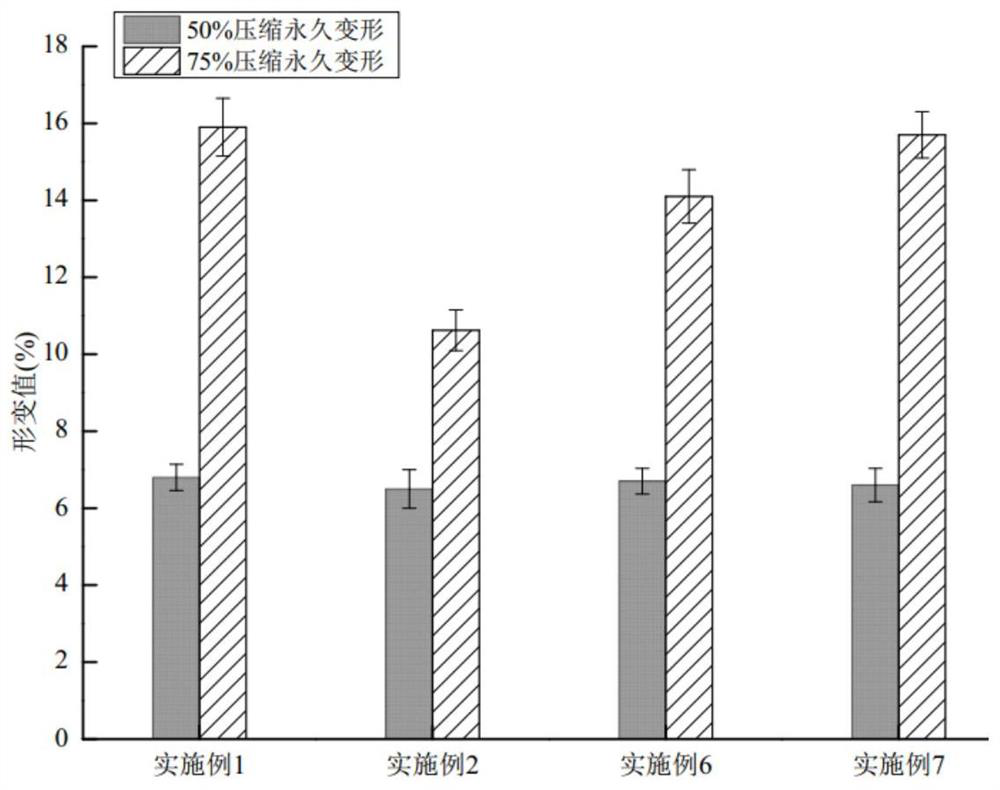

Aerobic biological membrane material, preparation method and application of aerobic biological membrane material in sewage treatment technology

ActiveCN112960766AImprove hydrophilicityGood biocompatibilityWater contaminantsSustainable biological treatmentActivated sludgeMicrobial agent

The invention provides an aerobic biological membrane material, a preparation method and application of the aerobic biological membrane material in a sewage treatment technology, and relates to the technical field of sewage treatment. The biological membrane material comprises a biological carrier material and a microbial agent or activated sludge fixed inside or on the surface of the carrier material; the biological carrier material comprises a polyurethane foam filler and porous spheres; and microorganisms fixed on the biological carrier material are aerobic bacteria. The biological membrane material provided by the invention has the advantages of high membrane forming speed, high efficiency, short time consumption, large microorganism loading capacity and adsorption capacity, good microorganism adhesive force, short starting time of a biological membrane reactor, high sewage biochemical treatment efficiency and good decontamination and decontamination effects, and can be applied to biochemical treatment technologies of garbage treatment sewage, high-ammonia-nitrogen sewage, high-phosphorus sewage and breeding sewage; and the preparation method can accelerate the biofilm formation speed of the biofilm, prolong the service life of the biofilm, realize sewage reduction and reduce the operation cost of a biological reaction system.

Owner:HANGZHOU NAXI ECOLOGICAL TECH CO LTD

Pretreatment device for removing nitrobenzene in waste water by potassium ferrate and method

InactiveCN101575137AIncrease agitationShort reaction timeWater contaminantsWater/sewage treatment by flocculation/precipitationNitrobenzeneChemistry

The invention relates to a pretreatment device for removing nitrobenzene in waste water by potassium ferrate and a method. By adopting the device, the waste water containing nitrobenzene is mixed fully with potassium ferrate by a tube-type mixer, and then the mixture passes through a one-piece device for coagulation and precipitation to carry out degradation to the nitrobenzene in the waste water by the synergy of oxidization, coagulation, absorption and the like of potassium ferrate, wherein part of nitrobenzene is removed, and the rest part thereof can be converted into a series of aliphatic hydrocarbon, which can be further degraded completely by the subsequent biological treatment of waste water. The invention solves problem of secondary pollution commonly existing in the conventional nitrobenzene waste water treatment process; a gridding frame plate is added in the coagulating area so as to increase the stirring strength to waste water, strengthen the mass transferring action of substances in waste water, shorten the reaction time, and improve reaction efficiency; and a transitional area is added between the coagulating area and a precipitating area and a gridding-shaped clapboard is additionally arranged so as to improve the precipitating effect.

Owner:DONGHUA UNIV

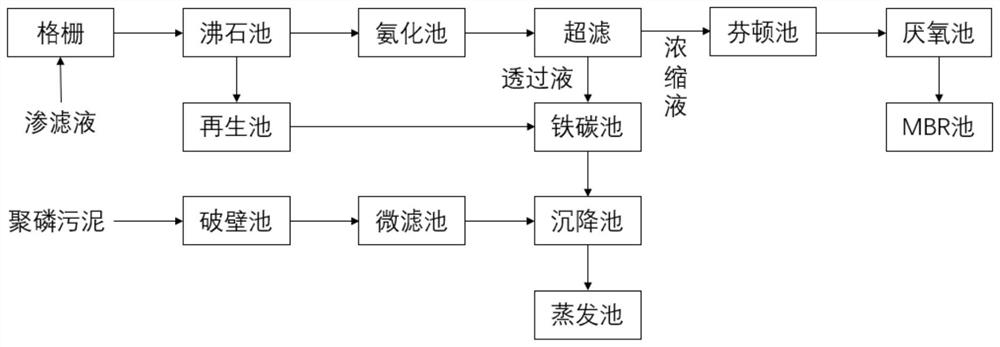

Landfill leachate treatment system

ActiveCN113443794AImprove biochemical treatment efficiencyReduce ammonia nitrogenWater contaminantsMultistage water/sewage treatmentZeoliteSludge

The invention relates to a landfill leachate treatment system which is sequentially provided with a zeolite tank, an ammoniation tank, an ultrafiltration tank, an iron-carbon tank, a sedimentation tank and an evaporation tank, a water outlet of the zeolite tank is connected with the ammoniation tank, the ammoniation tank is connected with the ultrafiltration tank, a concentrated solution of the ultrafiltration tank is conveyed to a Fenton tank, and the Fenton tank is communicated with a biochemical tank; ultrafiltration permeate is conveyed to the iron-carbon tank, and iron-carbon tank effluent is conveyed to the sedimentation tank. The landfill leachate treatment system is further provided with a wall breaking tank and a microfiltration tank, polyphosphate sludge is added into the wall breaking tank for wall breaking treatment, effluent of the wall breaking tank is conveyed to the microfiltration tank, effluent of the microfiltration tank is conveyed to the sedimentation tank, the sedimentation tank is further provided with a sedimentation agent inlet, and effluent of the sedimentation tank is conveyed to the evaporation tank for evaporation treatment. The landfill leachate treatment system can improve the biochemical treatment efficiency.

Owner:江苏御镐智能制造有限公司

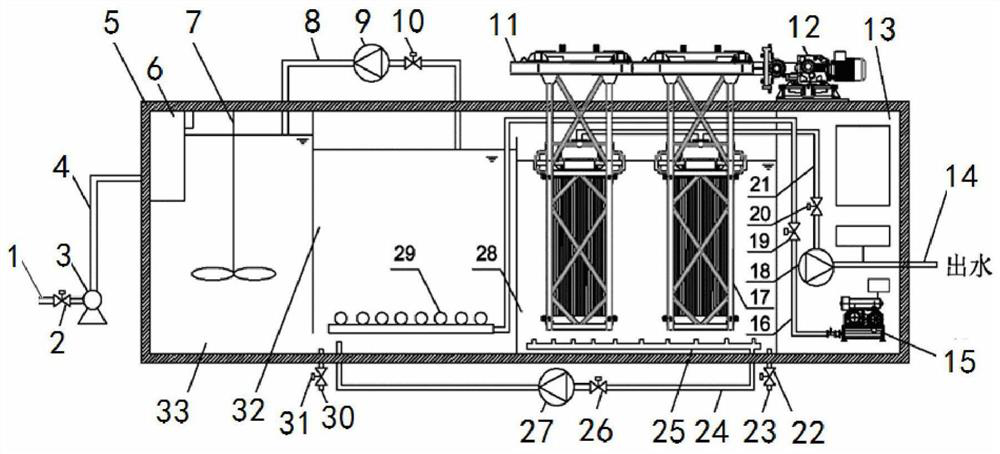

Integrated sewage treatment device and method

PendingCN112759078ASolve pollutionEnhanced denitrification and denitrificationWater contaminantsBiological treatment apparatusActivated sludgeAmmoniacal nitrogen

The invention discloses an integrated sewage treatment device and method and belongs to the technical field of sewage treatment. The sewage treatment process comprises the following steps: ammonia nitrogen is converted into nitrate nitrogen through a nitration reaction in an aerobic environment, the nitrate nitrogen is converted into nitrogen through a denitrification reaction in an anoxic environment, and denitrification is realized; and meanwhile, activated sludge is left in the system by utilizing the membrane separation performance of the MBR, so that the yield of residual sludge is reduced, and meanwhile, the high-concentration microbial biomass of the system is kept. Periodic in-situ membrane cleaning is performed through reciprocating motion of a membrane module device, and sludge adsorbed on the surfaces of membrane filaments is desorbed through mutual collision and friction between the membrane filaments and water, so that the use frequency and concentration of chemical liquid medicine are reduced, the damage of the chemical liquid medicine to the membrane filament state is reduced, the service life of the membrane module is prolonged, and the operation and maintenance cost of equipment is reduced; and meanwhile, the resistance of water flowing through the membrane is reduced, the permeability of micropores on the surface of membrane filaments is maintained, the MBR running flux is improved, and the running stability of equipment is enhanced.

Owner:北京华特源科技有限公司

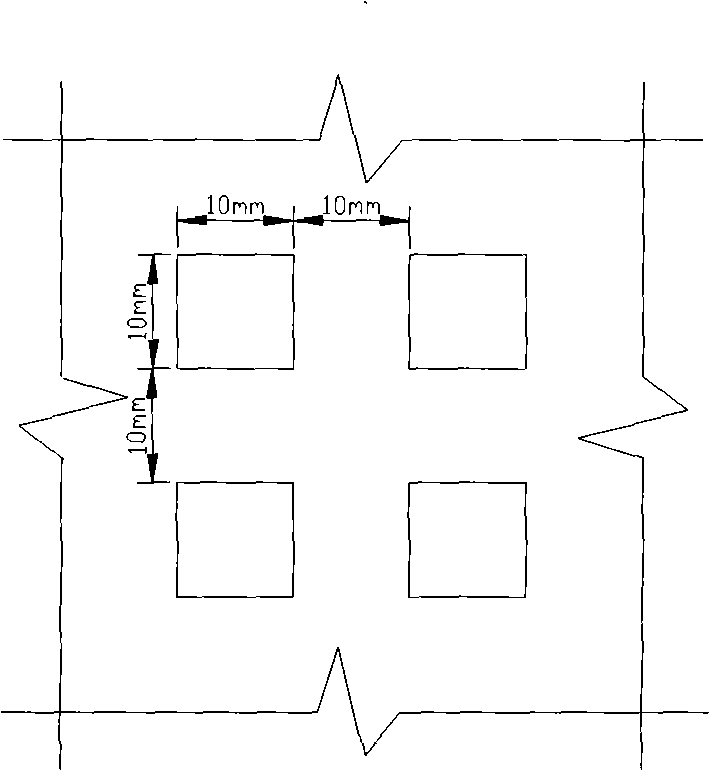

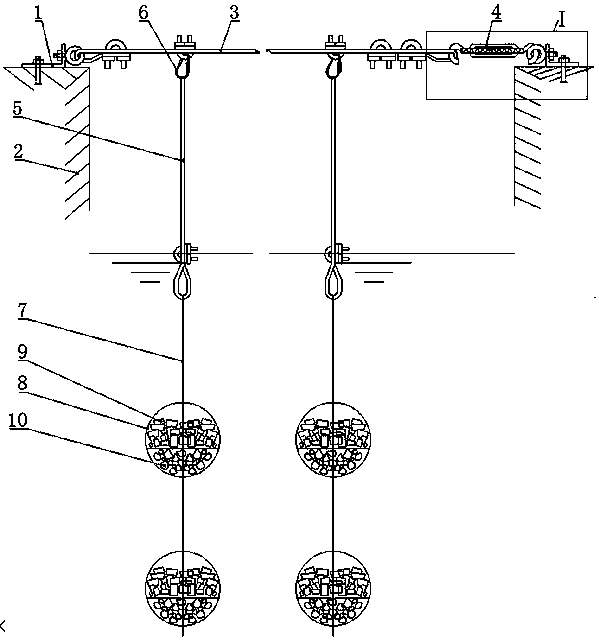

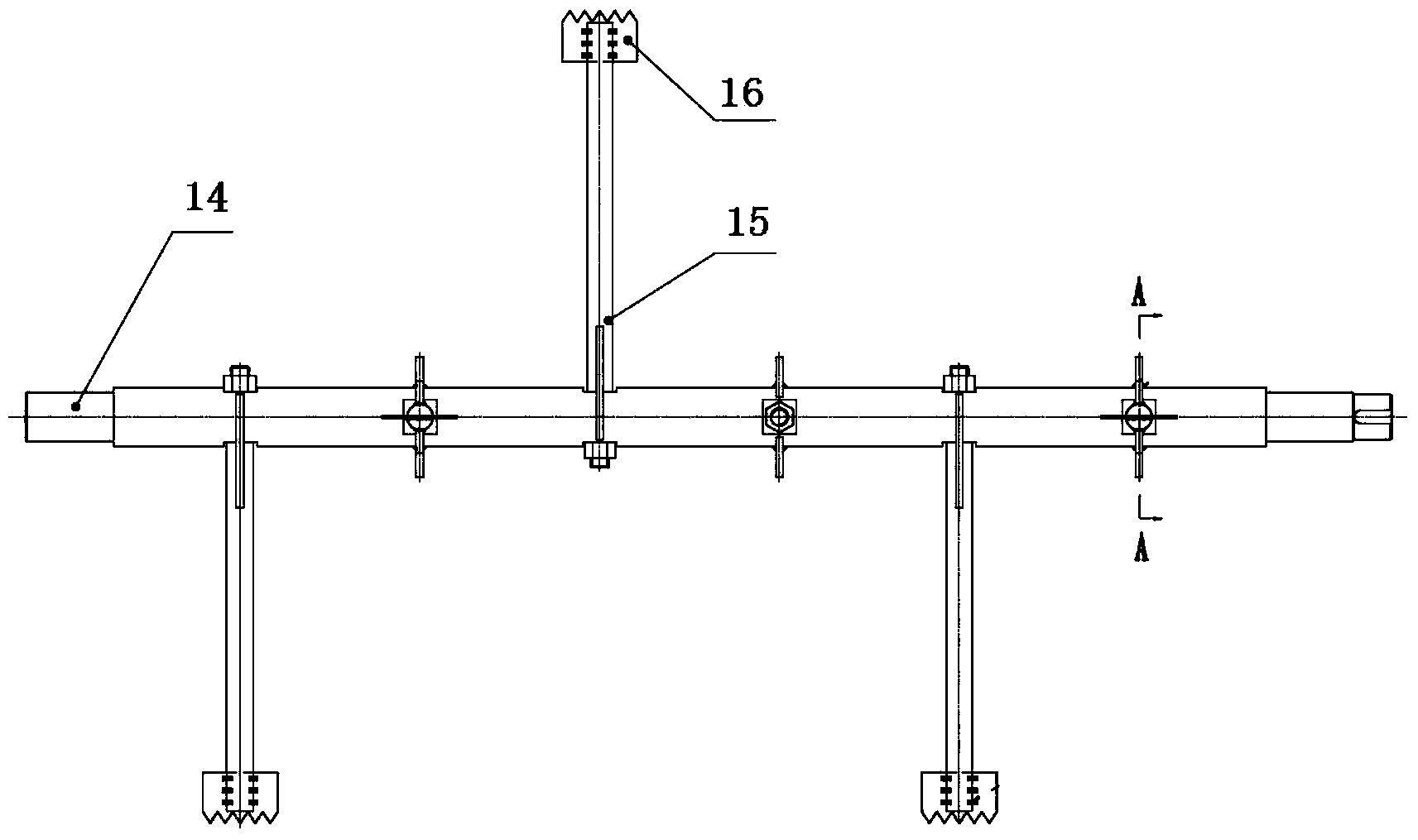

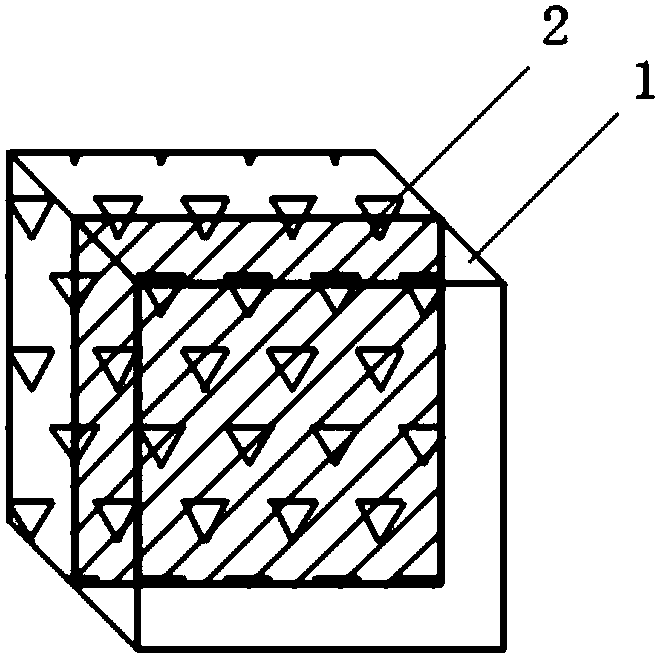

Suspended packing device of wastewater treatment pond

PendingCN107698039AEvenly distributedImprove biochemical treatment efficiencySpecific water treatment objectivesBiological treatment apparatusTreatment pondEngineering

The invention discloses a suspended packing device of a wastewater treatment pond and solves the problems of non-uniform packing distribution and low biochemical treatment efficiency due to direct addition of the conventional packing. The suspended packing device comprises at least two fixing seats, at least one fixing cable as well as a plurality of suspension cables, packing cables, packing balls and counterweights, wherein the fixing seats are fixed at tops of two opposite pond walls of the treatment pond correspondingly and respectively; one end of each fixing cable is fixedly connected toone fixing seat, and the other end of the fixing cable is fixed on the other fixing seat through a tension device; connecting ends of the suspension cables are arranged on the corresponding fixing cables through lock catches at intervals respectively; the packing balls penetrate and are fixed on the packing cables at intervals, and one end of each packing cable is fixed at a suspension end of thecorresponding suspension cable; through holes are formed in walls of the packing balls, and the packing balls are filled with packing and the counterweights. The suspended packing device is reasonable in structure and convenient to use, the packing is suspended in water at intervals and uniformly distributed, and the biochemical treatment efficiency is high.

Owner:山东赛恩环保设备有限公司

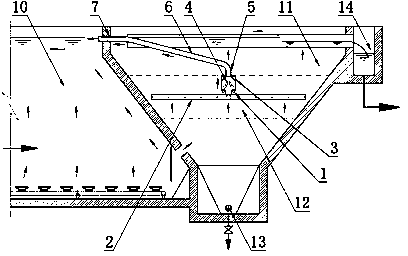

Photo-catalytic/biochemical integrated reactor

InactiveCN105130098AImprove the efficiency and effect of water biochemical treatmentImprove the efficiency and effect of water biochemical treatment in anoxic zoneWater/sewage treatment by irradiationTreatment with anaerobic digestion processesToxic materialHydroxyl radical

The invention discloses a photo-catalytic / biochemical integrated reactor, which includes a reactor body. An upper part of the reactor body is a photo-catalytic zone and a lower part of the reactor body is an anoxic zone. At least one high-pressure mercury lamp tube is arranged in the photo-catalytic zone, wherein a photo-catalyst layer is formed on inner wall of each high-pressure mercury lamp tube. A filling material is arranged in the anoxic zone. The photo-catalytic / biochemical integrated reactor has the following significant effect: in the photo-catalytic zone, hydrogen peroxide and high-active hydroxyl free radicals are generated and are used for degrading organic substances, dyes and a part of toxic substances, which are difficult to degrade biologically and is slow in biological degradation, in waste water, thereby providing an excellent input condition to the anoxic zone at the lower part and further improving water bio-chemical treatment efficiency and water bio-chemical treatment effect in the anoxic zone.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

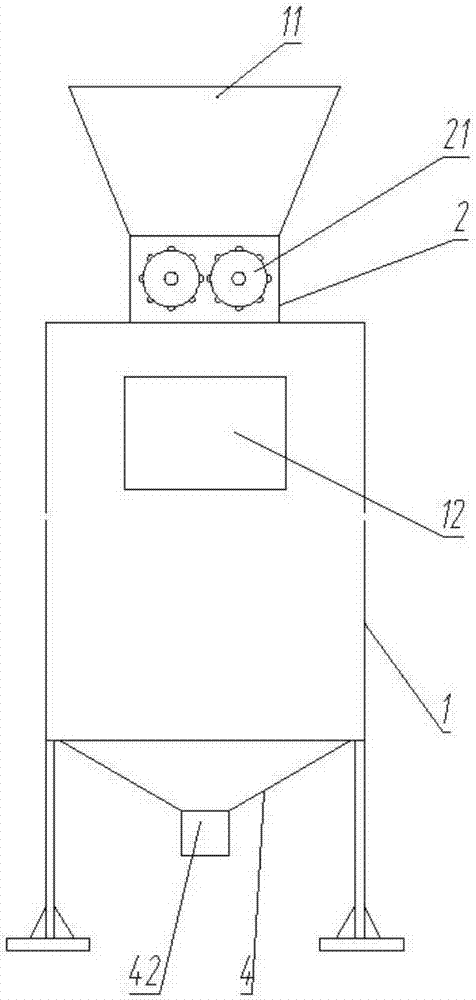

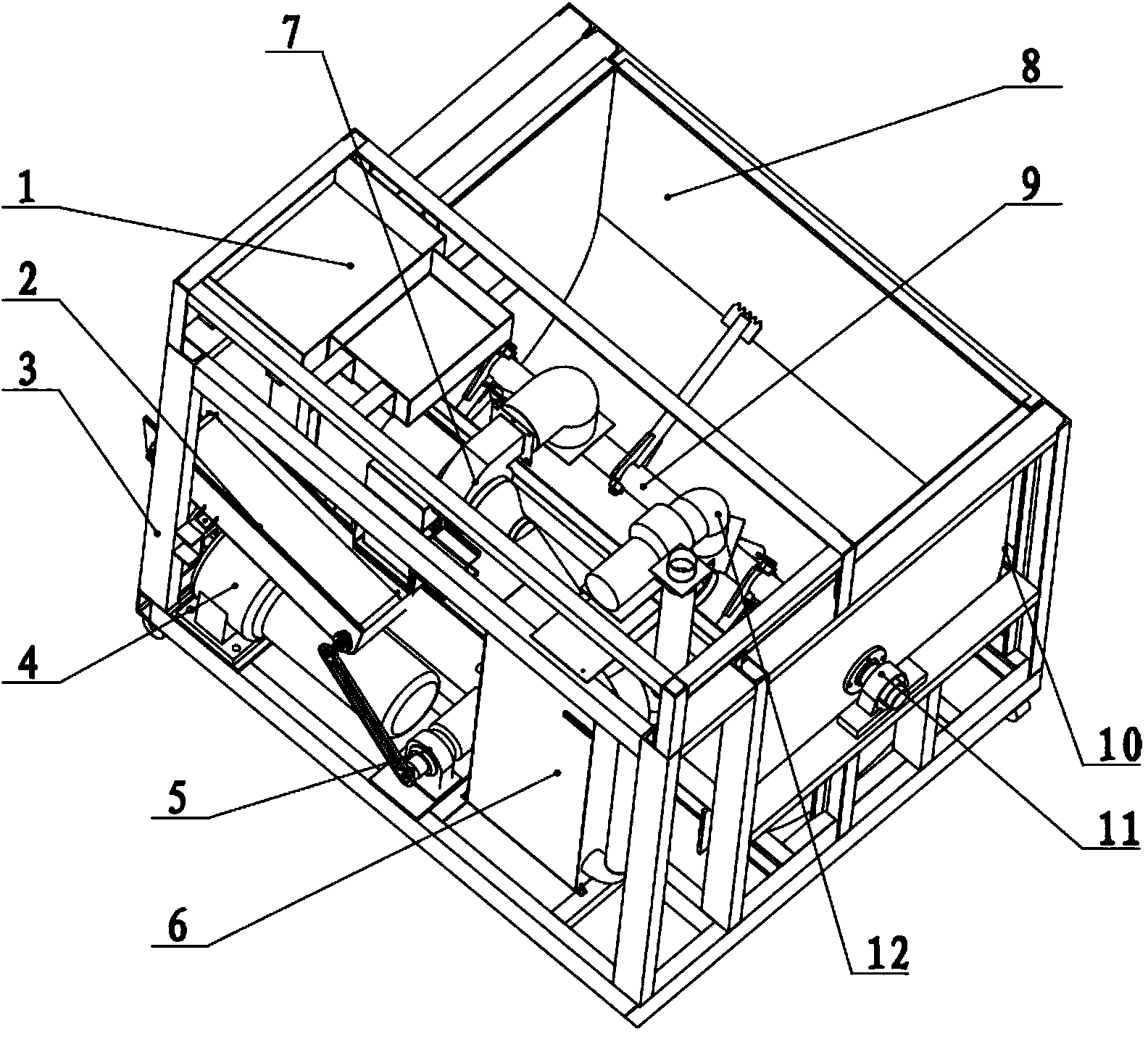

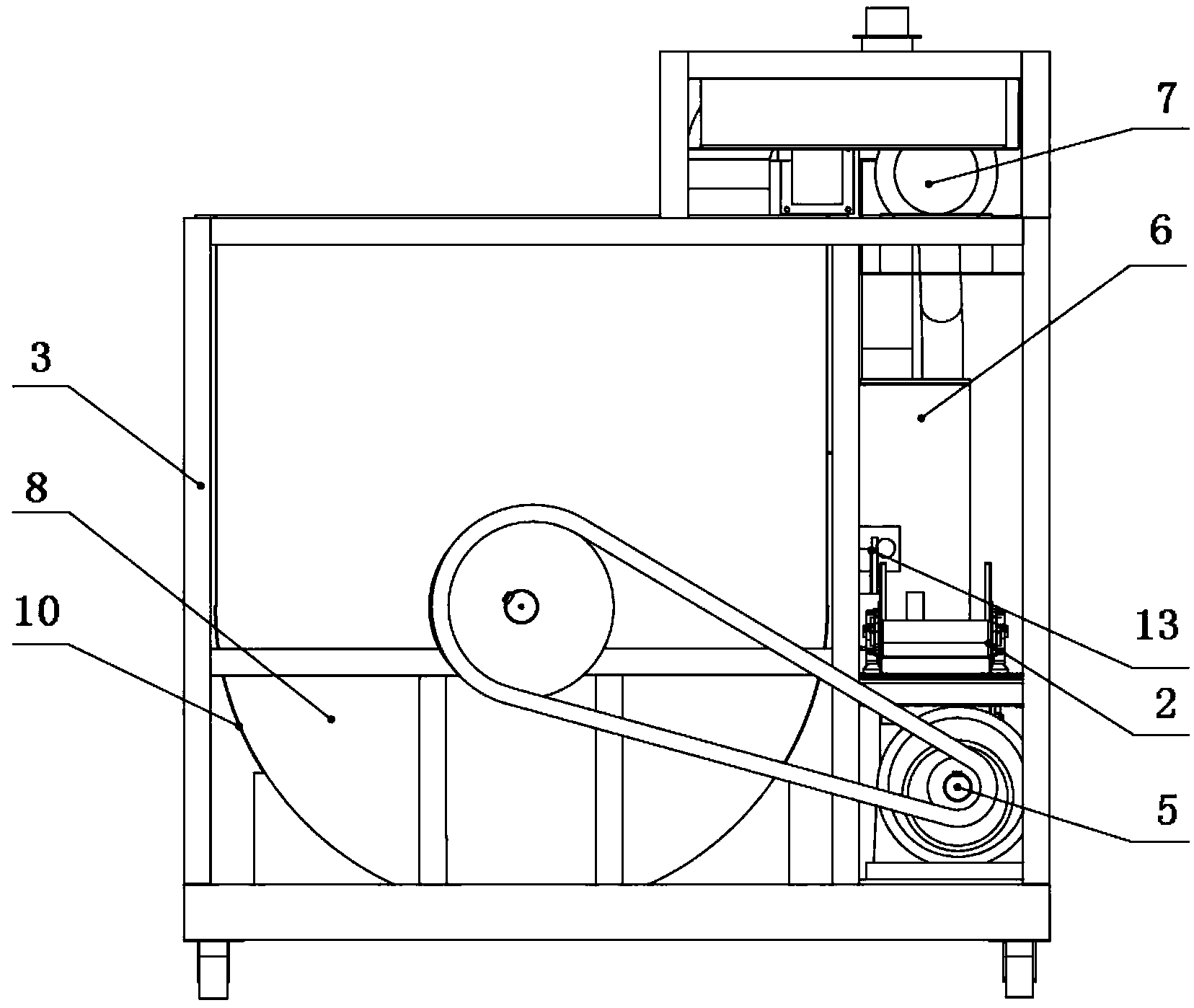

Biochemical treatment equipment for kitchen waste

ActiveCN104001710AImprove biochemical treatment efficiencyWell mixedSolid waste disposalMicroorganismFixed bearing

The invention discloses biochemical treatment equipment for kitchen waste. The biochemical treatment equipment comprises a framework (3), a liner (8), an agitating mechanism (9), a discharging mechanism (2), a deodorization tower (6) and an electric control box (1), wherein the liner is arranged at the lower middle part of the framework and is fixedly connected with the framework (3); the agitating mechanism (9) is connected with the framework (3) through a fixed bearing seat (11); the discharging mechanism (2), the deodorization tower (6) and the electric control box (1) are respectively and fixedly mounted on the framework (3); the liner (8) is internally further provided with a heating device. The biochemical treatment equipment is mainly used for resourceful treatment of the kitchen waste. The heating device designed by the invention is used for heating the liner (8) and keeping the temperatures of the kitchen waste and strains in the liner (8); the designed agitating mechanism (9) is used for sufficiently mixing the kitchen waste and the microorganism strains; the biochemical treatment efficiency of the kitchen waste is improved and the water content of the treated kitchen waste is reduced to be less than 10% from 30% previously.

Owner:ZUNYI FENGHUA ELECTROMECHANICAL FITTINGS CO LTD

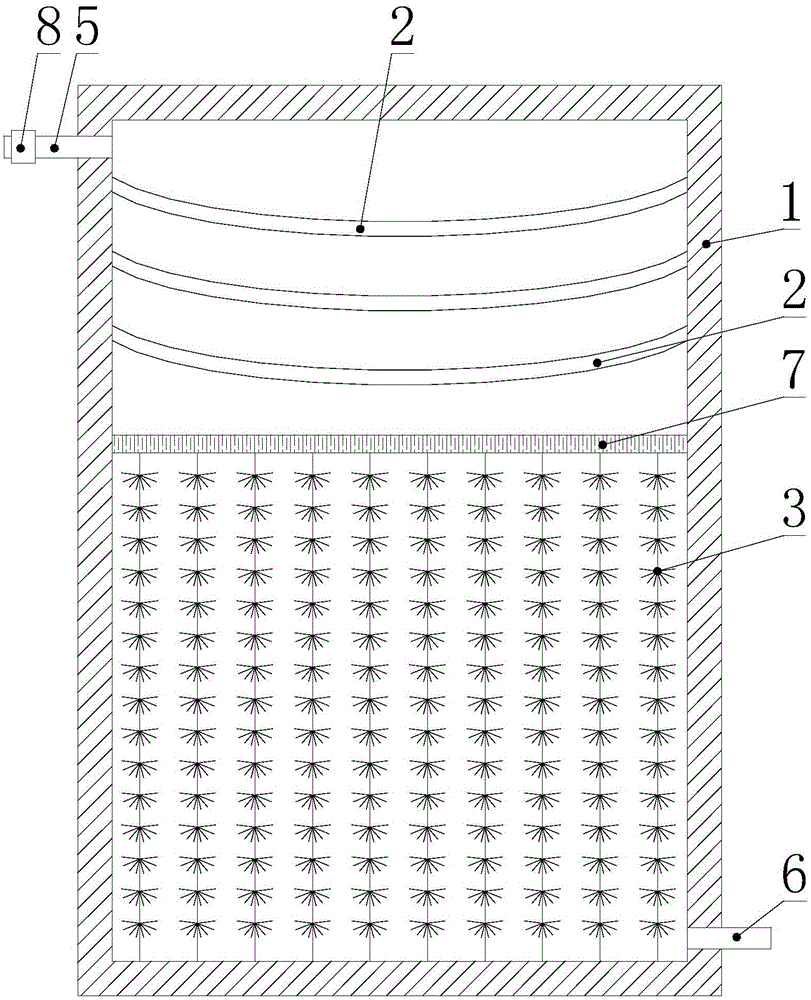

Suspending filter material having trace element self-release function

PendingCN108423801ARoughEasy to interceptTreatment using aerobic processesWater treatment compoundsBiochemical engineeringTrace element

The invention discloses a suspending filter material having a trace element self-release function. The suspending filter material comprises polyurethane sponge, and a trace element releaser is embedded in the polyurethane sponge. The filter material is suitable for a biochemical function of a suspending rapid filter, has good intercepting and adsorbing effect on suspending pollutants and has goodmicrobial adhesion, bio-film formation and bio-film protection effect, thereby being capable of better playing a role in quick filtering and biochemical treating; the trace element releaser can provide needed trace elements for microorganisms to grow, so that microbial adhesion and bio-film formation are better facilitated.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

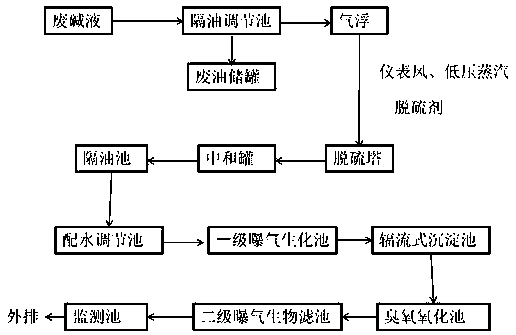

Standard treatment method for high sulfur containing waste alkali liquor in petroleum and coal chemical industry

PendingCN109052850AImprove biodegradabilityImprove removal efficiencyTreatment using aerobic processesWater contaminantsReaction temperatureTherapeutic effect

The invention relates to a standard treatment method for high sulfur containing waste alkali liquor in the petroleum and coal chemical industry and belongs to the technical field of sewage treatment.The standard treatment method comprises the steps: firstly, sending waste alkali liquor into an oil separation adjusting tank to remove oil and suspended matters, mixing the waste alkali liquor with aliquid-state desulfurization catalyst, sending into a desulfurization tower, fixing a solid-state desulfurization catalyst in the desulfurization tower, staying the waste alkali liquor in the desulfurization tower for 20 to 25 h, then sending into a pH adjusting tank to adjust a pH to 6 to 10, then sending into an oil separator to remove impurities of emulsified oil, sending into a water distribution adjusting tank, diluting reaction liquid to 10 to 15 times, controlling sewage COD to be below 2000 mg / L, adding N and P compound and an osmotic pressure regulator, then sending into a primary aerating biochemical tank, staying for 40 to 50 h, then sending into a radial sedimentation tank, sending liquid supernatant into an ozone contact oxidation tank, then flowing into a secondary aeratingbiofilter, staying for 5 to 15 h, finally sending into a monitoring tank and draining out after indexes are detected and can reach the standard. The standard treatment method disclosed by the invention has the advantages of lower reaction temperature, low operation cost, stable treatment effect and the like.

Owner:河南省众和环保科技有限公司

Sewage treatment device

PendingCN111573855ARealize denitrificationImprove denitrification effectSpecific water treatment objectivesWater contaminantsBiofilmEngineering

The invention relates to a sewage treatment device which comprises a plurality of packing cups and packing, and the packing cups are sequentially stacked in the vertical direction. The packing is arranged in the packing cups and is used for the growth of biofilms. The packing cups can be rotationally switched between a first position and a second position. When each packing cup is positioned at the first position, the inclination angle of each packing cup is a first angle, the sewage can flow through the plurality of packing cups in sequence from top to bottom by virtue of gravity, and can bein full contact with the biofilms grown on the corresponding packing in the process of flowing through the packing cups and form water films on the surfaces of the biofilms, so that the biofilms grownon the packing in the plurality of packing cups perform biochemical treatment on the sewage in sequence; and when each packing cup is located at the second position, the inclination angle of each packing cup is a second angle, and the second angle is larger than the first angle, so that aged biofilms and dirt attached to the packing in the packing cups are separated from the packing by virtue ofgravity and are discharged from the corresponding packing cups.

Owner:SHENZHEN UNIVERSILICON ENVIRONMENTAL SCI & TECH CO LTD

Horizontal suspension sludge air-lift backflow method

ActiveCN103435148AEnsure consistencyNo hardening depositsBiological water/sewage treatmentAir volumeEngineering

The invention provides a horizontal suspension sludge air-lift backflow method. The method mainly comprises the following steps: sludge is sucked completely and in equilibrium and lifted to a biochemical reaction tank for recycling by arranging a horizontal plane-type air-lift micro-power backflow device in a suspension thick activated sludge layer and utilizing sludge suction pipes of the backflow device, which are horizontally arranged in the vertical and horizontal directions, and a compressed air control device outside the tank adjusts the air volume to control the quantity of backflow. Compared with the conventional sludge backflow method, the horizontal suspension sludge air-lift backflow method provided in the invention has a high backflow efficiency, there is no dead area or dead angle of sludge return in the large-area suspension sludge layer, and the backflow is in equilibrium; and besides, the activated sludge floc structure is not damaged, the control of backflow quantity is flexible, rapid and visual, no moving part or electrical equipment is used under water, and the backflow reliability is extremely high. Furthermore, an aeration blower of a sewage treatment plant is adopted for air supply, the corrected energy consumption for air-lift backflow is extremely low, and the energy-saving effect is obvious.

Owner:CENT & SOUTHERN CHINA MUNICIPAL ENG DESIGN & RES INST

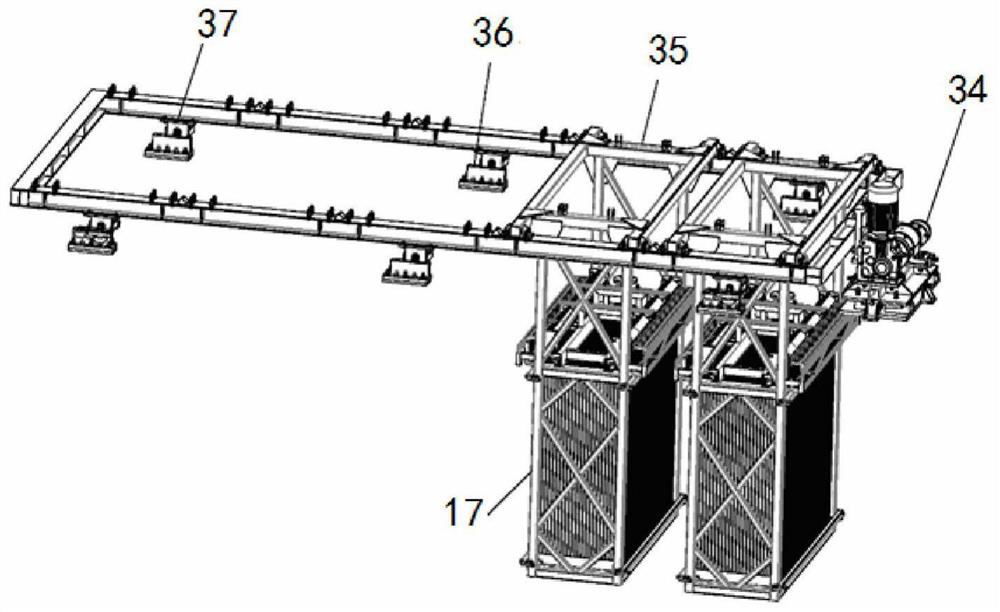

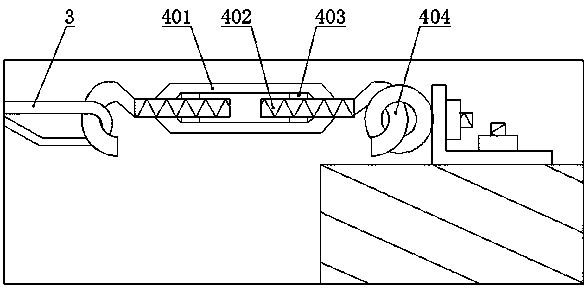

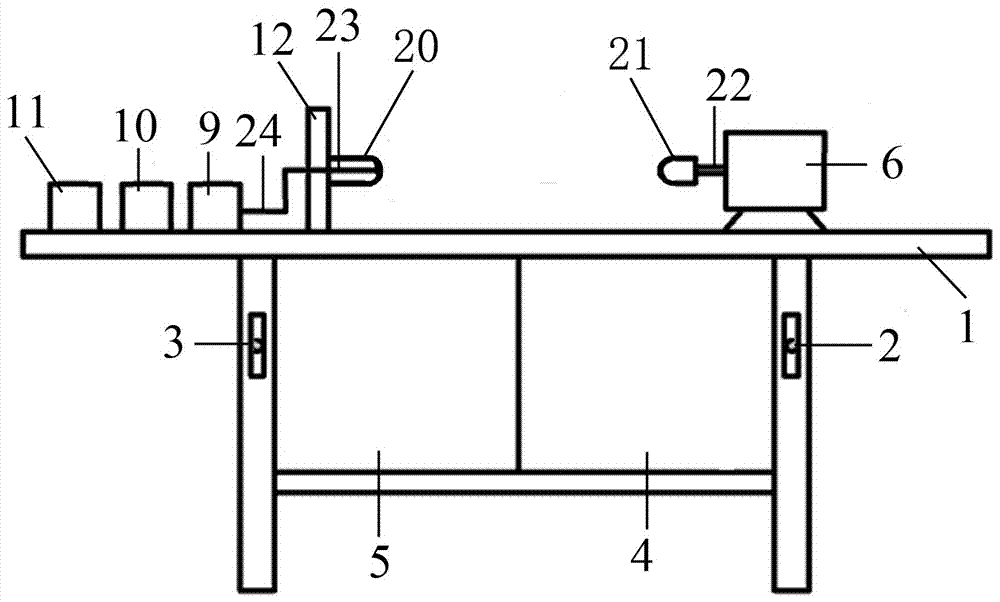

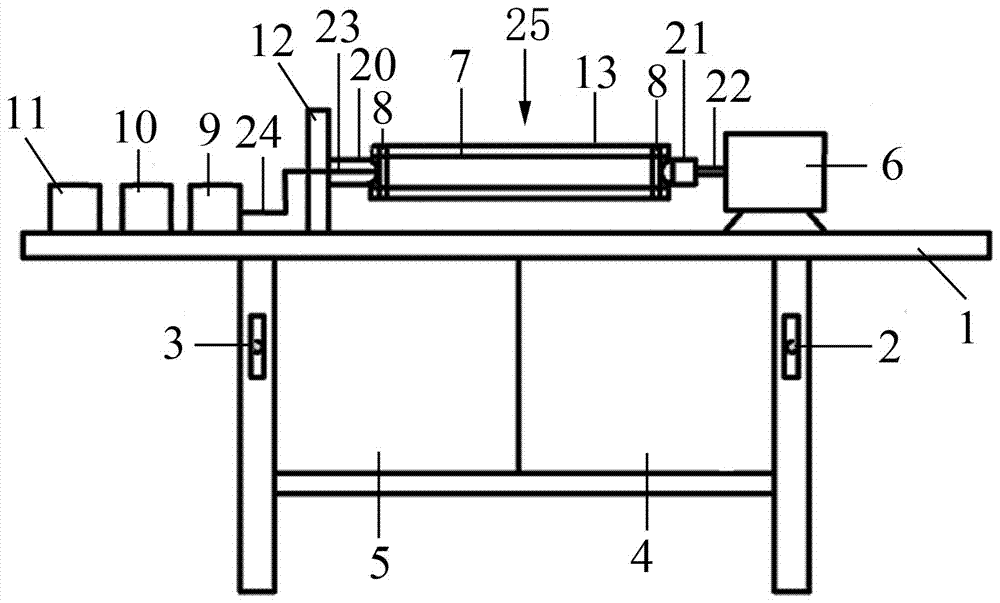

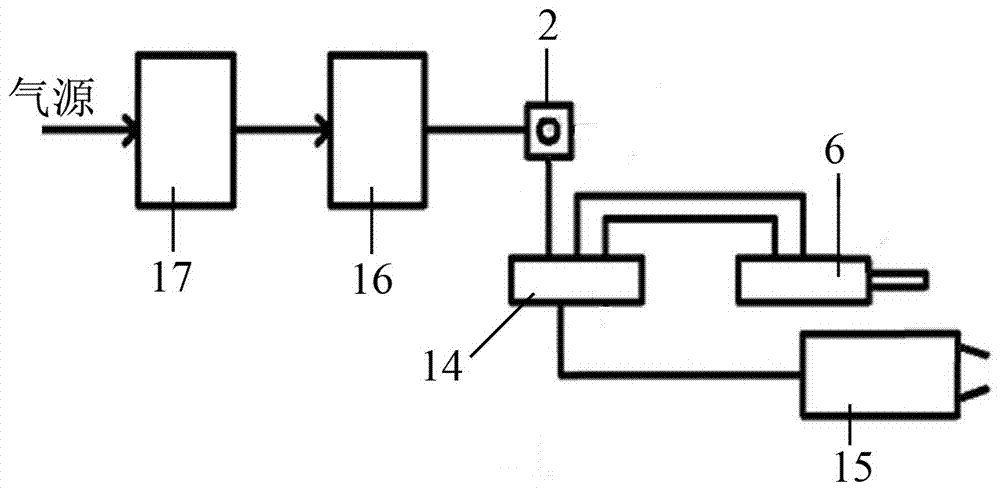

Precision tubular microporous aerator mounting and detecting system and method

ActiveCN107117723AConsistent tighteningSame degree of tighteningMachine part testingWater aerationData informationEngineering

The invention discloses a precision tubular microporous aerator mounting and detecting system and a precision tubular microporous aerator mounting and detecting method. The precision tubular microporous aerator mounting and detecting system consists of a workbench, a mounting facility and a detecting facility, wherein the mounting facility and the detecting facility are arranged on the workbench; through a mounting pneumatic switch and a detection switch, mounting and detection of tubular microporous aerators are switched; through an air compressor or an air blower, an air source is generated; the air source is connected with a pressure reducing valve through a pipeline; a filter is connected to a pneumatic valve; the mounting pneumatic switch is mounted between the filter and the pneumatic valve; the mounting pneumatic switch controls the air source entering the pneumatic valve; the mounting facility and the detecting facility are connected with a main controller; and the main controller collects, stores, sorts and analyzes data information of each tubular microporous aerator. The precision tubular microporous aerator mounting and detecting system is scientific in structure, reliable in performance, easy to manufacture, convenient to use, easy to operate and precision in mounting, and is especially applicable to urban sewage treatment, new construction and expansion of a large factory and reconstruction of an old aeration tank.

Owner:葛洲坝水务投资有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com