Physicochemical and biochemical combined treatment method of fracturing backflow liquid

A technology for fracturing flowback fluid and treatment methods, which is applied in the fields of chemical instruments and methods, mining wastewater treatment, water/sewage multi-stage treatment, etc. It can solve the problem that the effluent is difficult to achieve the required pollutant removal effect, and the investment and operation costs are high , Unable to achieve engineering applications and other problems, to achieve the effects of shortening processing time, easy operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

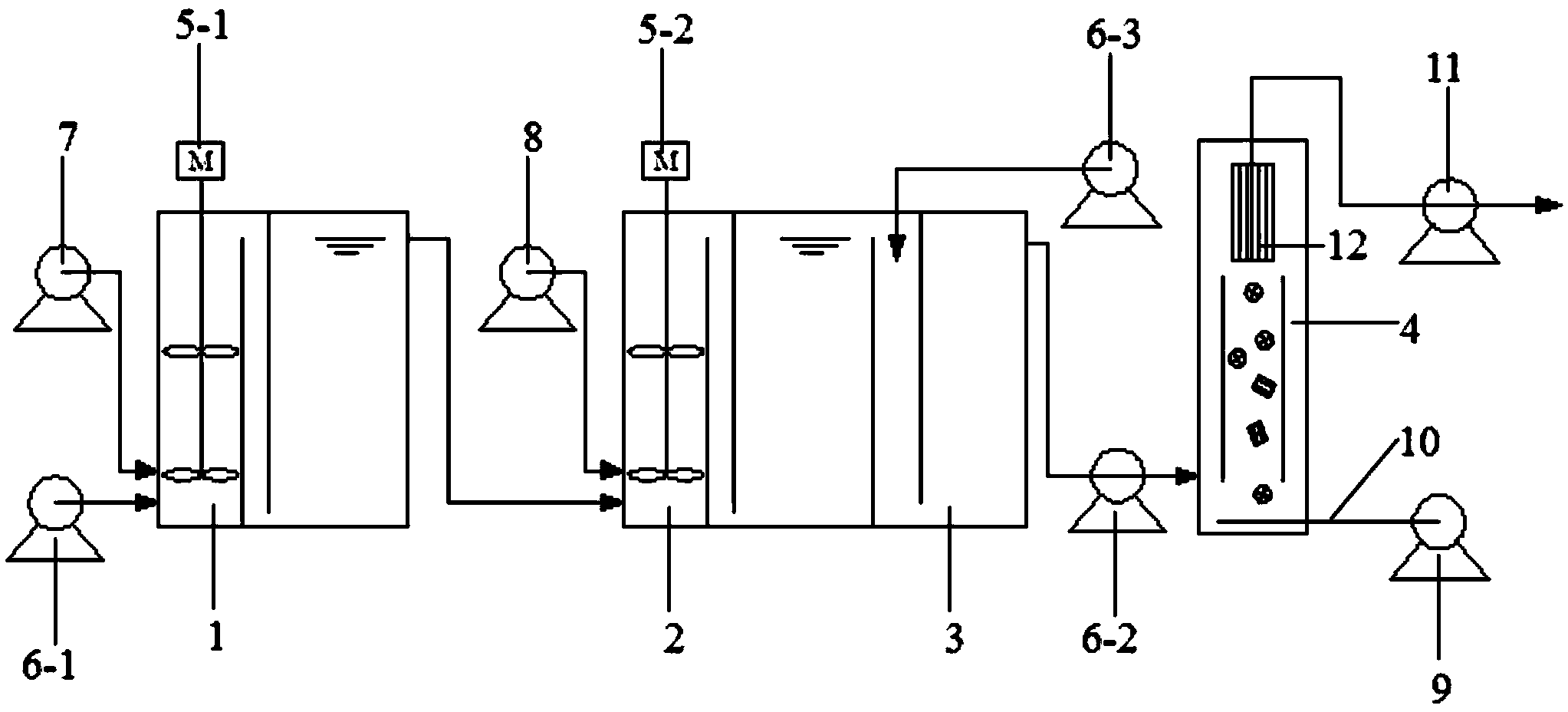

[0027] In this embodiment, the COD concentration of the fracturing flowback fluid is about 27,000 mg / L, the ammonia nitrogen concentration is about 150 mg / L, and the pH value is about 11. The process of using the method of the present invention to treat the above-mentioned fracturing flowback fluid is as follows: figure 1 shown, the steps are as follows:

[0028] (1) Under the stirring of the first agitator 5-1, the fracturing flowback liquid is passed into the adjustment sedimentation tank 1 from the first inlet pump 6-1, and is added into the adjustment sedimentation tank through the acid-base dosing pump 7 The pH value of the fracturing flowback fluid was adjusted to 7 with sulfuric acid, and the hydraulic residence time of the fracturing flowback fluid in the adjustment sedimentation tank was controlled to 2h.

[0029](2) Adjust the supernatant in the sedimentation tank 1 to enter the coagulation sedimentation tank from the water inlet at the bottom of the coagulation sedi...

Embodiment 2

[0033] In this embodiment, the COD concentration of the fracturing flowback fluid is about 27,000 mg / L, the ammonia nitrogen concentration is about 150 mg / L, and the pH value is about 11. The process of using the method of the present invention to treat the above-mentioned fracturing flowback fluid is as follows: figure 1 shown, the steps are as follows:

[0034] (1) Under the stirring of the first agitator 5-1, the fracturing flowback liquid is passed into the adjustment sedimentation tank 1 from the first inlet pump 6-1, and is added into the adjustment sedimentation tank through the acid-base dosing pump 7 The pH value of the fracturing flowback fluid was adjusted to 8 with sulfuric acid, and the hydraulic residence time of the fracturing flowback fluid in the adjustment sedimentation tank was controlled to 4h.

[0035] (2) Adjust the supernatant in the sedimentation tank to pass into the coagulation sedimentation tank through the water inlet at the bottom of the coagulatio...

Embodiment 3

[0039] In this embodiment, the COD concentration of the fracturing flowback fluid is about 27,000 mg / L, the ammonia nitrogen concentration is about 150 mg / L, and the pH value is about 11. The process of using the method of the present invention to treat the above-mentioned fracturing flowback fluid is as follows: figure 1 shown, the steps are as follows:

[0040] (1) Under the stirring of the first agitator 5-1, the fracturing flowback liquid is passed into the adjustment sedimentation tank 1 from the first inlet pump 6-1, and is added into the adjustment sedimentation tank through the acid-base dosing pump 7 The pH value of the fracturing flowback fluid was adjusted to 6 with sulfuric acid, and the hydraulic residence time of the fracturing flowback fluid in the adjustment sedimentation tank was controlled to 3h.

[0041] (2) Adjust the supernatant in the sedimentation tank to pass into the coagulation sedimentation tank through the water inlet at the bottom of the coagulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com