Patents

Literature

707 results about "Polyaluminium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyaluminium chloride (PAC) is manufactured in both liquid and powder form. The product is used in deodorants and antiperspirants, as a flocculant in water purification, in treatment of drinking / potable water, wastewater treatment and paper sizing.

Method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution

The invention discloses a method of preparing high-purity vanadium pentoxide from roasting-method vanadium solution. The method comprises the following steps: adding a purifying agent into the roasting-method vanadium solution, wherein the purifying agent is polyaluminium chloride, magnesium chloride or calcium chloride, or the purifying agent is polyaluminium chloride and magnesium chloride, or polyaluminium chloride and calcium chloride; uniformly stirring the roasting-method vanadium solution containing the purifying agent, standing for settling, then filtering, and adding ammonium salt into the filtrate to precipitate vanadium; and finally, calcining meta-ammonium and deaminizing to prepare vanadium pentoxide with the purity being higher than 99.5%. Polyaluminium chloride serving as the purifying agent can be used for polymerizing jellies with several molecules into large particles with several tens of thousands of molecules, even hundreds of thousands of molecules. The large-particle molecular polymer is easy to settle in the vanadium solution and can be separated from the solution. The method provided by the invention has the advantages that the consumption of polyaluminium chloride is low, the flocculation process is simple, the flocculation capacity is strong, the flocculation speed is high, pollution is hardly caused and the cost is low.

Owner:贵州义信矿业有限公司

Antimicrobial agents

InactiveUS6726936B1Wide disinfecting spectrumAvoid problemsInorganic/elemental detergent compounding agentsBiocideMicrobial agentSolvent

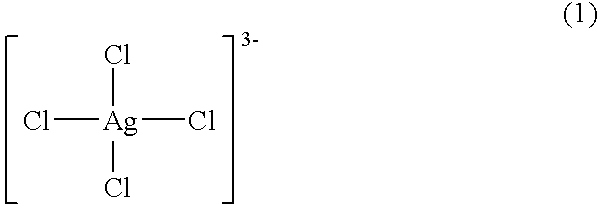

An antimicrobial agent includes silver-chloro complex salts and chloride, and further oxidizing agents such as sodium hypochlorite or sodium chlorite. As a result, it is possible to provide the antimicrobial agent having immediate and residual disinfecting and antimicrobial effects on bacteria and molds of a wide variety of species and capable of demonstrating instantaneous deodorizing effect. The antimicrobial agent includes the silver-chloro complex salts and chloride, and further a compound, for example, such as alcohols or surfactants, which has compatibility with a solvent such as water which dissolves the chloride. As a result, it is possible to provide the antimicrobial agent which can be used conveniently at the stored concentration, and which has immediate effect and cleansing ability without causing rust or deposition of salts in use. Further, the antimicrobial agent includes the silver-chloro complex salts, and chloride, for example, such as polyaluminium chloride or benzalkonium chloride, which has at least (I) a property capable of existing as a supersaturated aqueous solution in the presence of a crystal nucleus at least at room temperature for 24 hours or longer and (II) a property capable of being decomposed when dissolved in water.

Owner:YOKOSAWA METAL

Flocculating agent for sludge dewatering and sludge dewatering method

InactiveCN101367597AImprove rigidityImprove toughnessSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateSewage

is the invention discloses a flocculating agent for filthy mud dehydration, which is composed of polyaluminium chloride and polyacrylamide. The flocculating agent addition is 4.92 percent to 10.18 percent by weight of the solid content of the filthy mud; and the polyaluminium is 4.38 percent to 5.33 percent by weight of the flocculating agent. The flocculating agent has the advantages of low specific impedance value of the filthy mud and high solid content of filter mass after dehydration. The method of filthy mud dehydration and the method of flocculating agent adding are as follows: polyaluminium chloride is added first, then is fast stirred at the speed of 32.0 r / m for two minutes and slowly stirred at the speed of 10.0 r / m for three minutes, and the pH value of sewage mud is regulated to 6 to 8; and the polyacrylamide is added, is fast stirred at the speed of 32.0 r / m for three minutes and then is slowly stirred at the speed of 10.0 r / m for seven minutes. The methods have the advantages that the flocculating agent can fully contact solid grains to facilitate the flocculating agent to trap colloid grains, so that the concentration distribution of the flocculating agent is uniform; large grains can not be stirred into small grains, precipitated grains can not be stirred into non-precipitated grains, so that the flocculation effect is improved.

Owner:广州中滔绿由环保科技有限公司

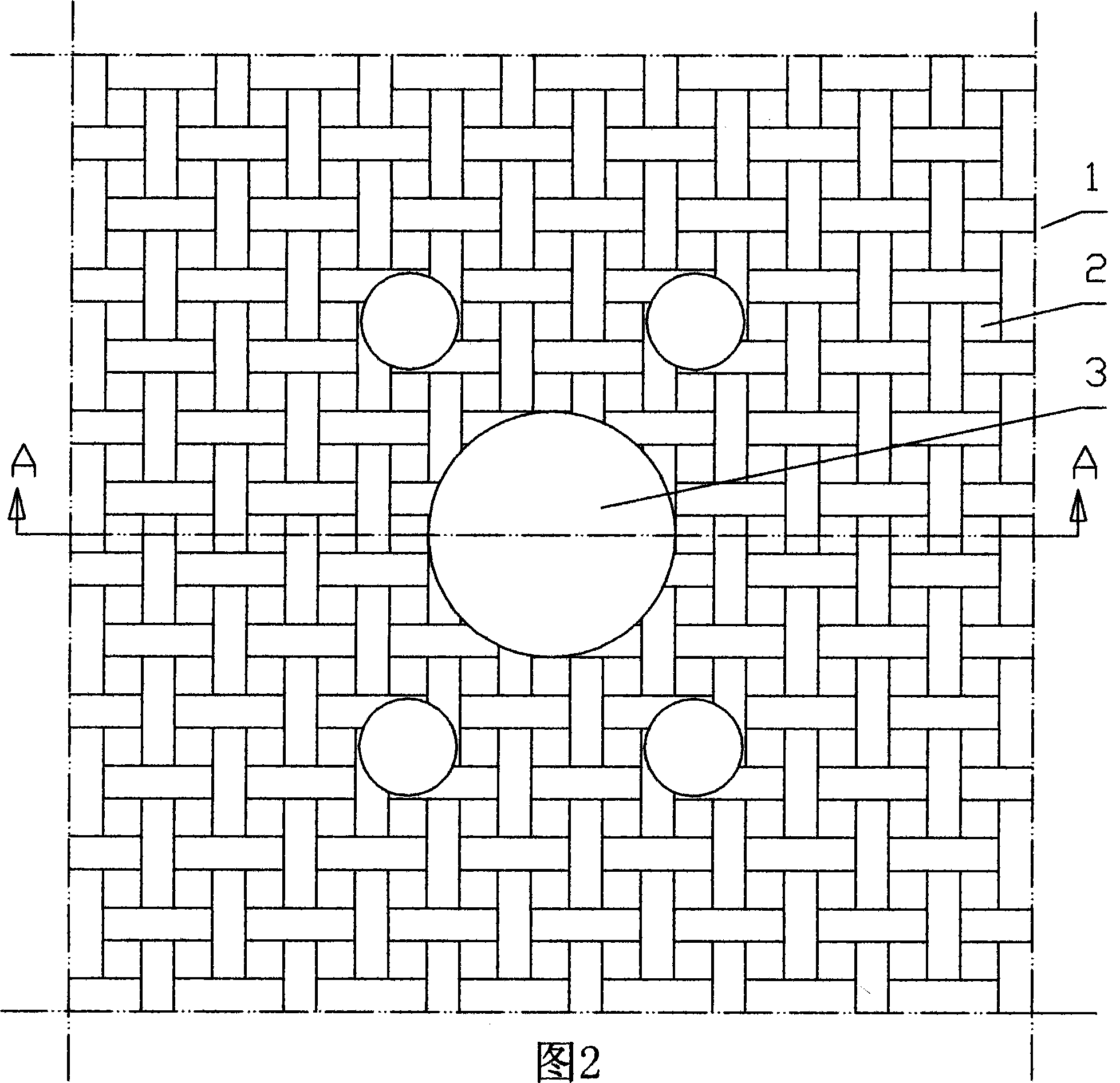

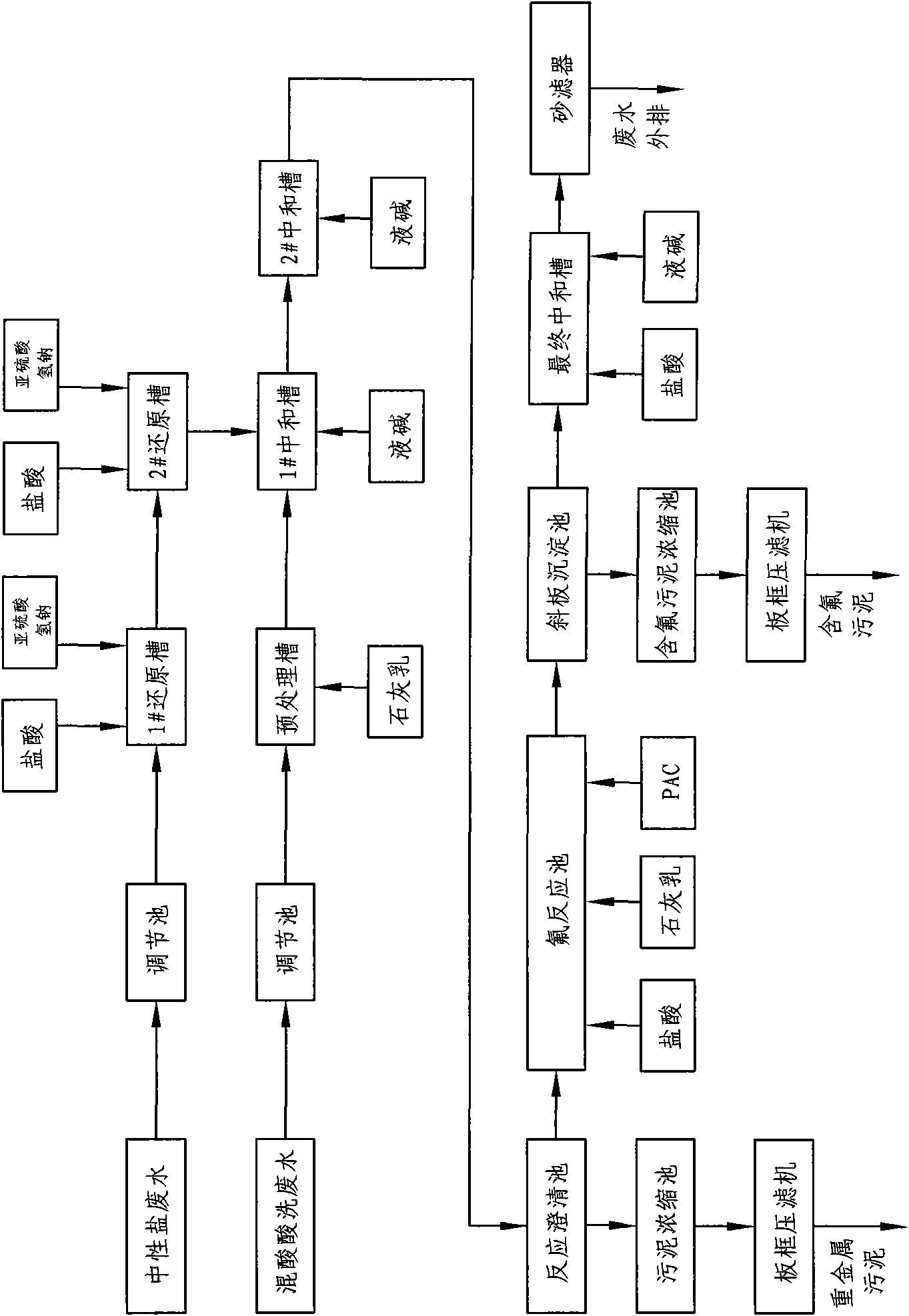

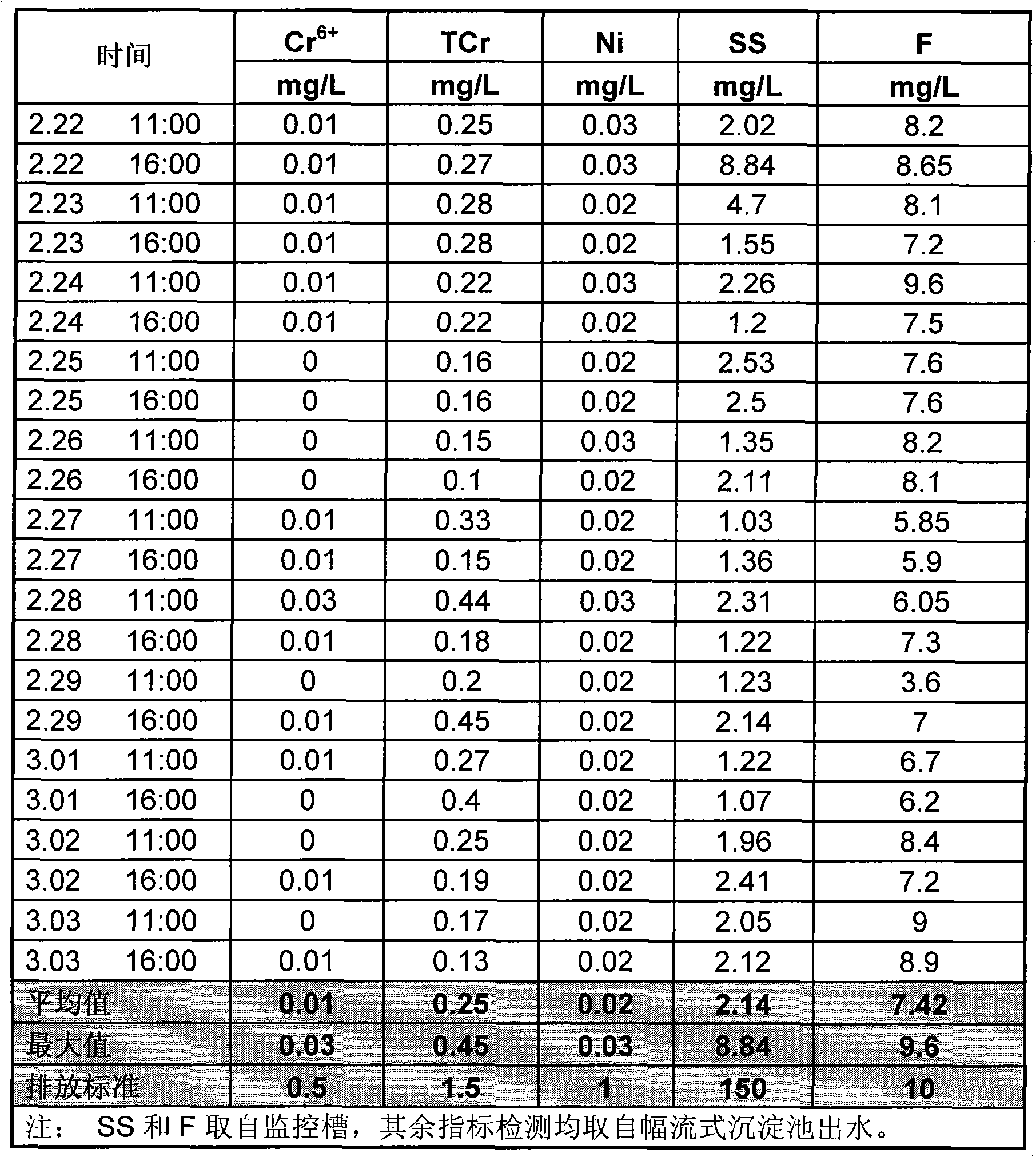

Method for treating stainless steel cold rolling pickling waste water

InactiveCN101993158AReduce consumptionStable fluoride ion concentrationIron oxides/hydroxidesWater contaminantsAluminium chlorohydrateSludge

The invention discloses a method for treating stainless steel cold rolling pickling waste water, which adopts a lime milk pretreatment process and a waste water segmental treatment process and comprises the following steps of: firstly, performing lime milk pretreatment on the waste water to control the pH value between 5 and 6; secondly, adding liquid caustic soda to remove heavy metal ions in the waste water so as to form a metal oxide precipitate; and finally, treating fluorine ions, namely adding polyaluminium chloride and lime milk to remove the fluorine ions, and filtering and discharging the waste water after adjusting the pH. The treatment method has good using effect, the waste water reaches the required standard and is stable, the sludge quantity is small, and the cost is low.

Owner:NINGBO BAOXIN STAINLESS STEEL

Chemical fertilizer waste water treatment method

ActiveCN101723554AEasy to waterReduce processing costsTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandSludge

The invention provides a chemical fertilizer waste water treatment process control method. The process comprises the following steps of: homogenizing chemical fertilizer waste water through a regulating pool; then pumping the waste water in the regulating pool into a primary aeration tank by utilizing a sewage pump so as to primarily remove COD (chemical oxygen demand) and relieve toxic and side effects for a subsequent biological and chemical system; after the waste water is treated by a primary sedimentation tank, ensuring that the waste water enters an A / O (anacrobic / oxic) biological denitrification system and a subsequent materialization deep treatment system; keeping DO (dissolved oxygen) of a pool A (anoxia pool) being below 0.5mg / L and the water flow of nitration liquid refluxing from a pool O (oxic pool) being 3-5 times of that of inlet water; maintaining the pH of the pool O to be 6.5-8.5 and the DO to be 2-3mg / L; and regulating to a proper mud reflux ratio so as to ensure that the biological and chemical system can be efficiently and stably operated. The materialization deep treatment system is used for adding flocculating agents PAC (polyaluminium chloride) and PAM (polyacrylamide), and after reaction and precipitation, outlet water can reach the national first-level discharge standard.

Owner:SOUTH CHINA UNIV OF TECH

Recovery processing process for fracturing return liquid

ActiveCN101475290AAchieving zero emissionsNo pollutionMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEmulsionAluminium chlorohydrate

The invention relates to a process for reclaiming and treating fracturing backflow fluid. The process comprises the following steps: a, feeding the fracturing backflow fluid into a dirty oil reclaiming pool, and reclaiming dirty oil; b, after natural degradation, adding gel breaker active polyaluminium chloride into sewage, and pumping the sewage into an electric flocculator; c, further breaking gel and emulsion in the sewage through the electric flocculator; and d, after electric flocculation treatment, feeding water purifying agent nano-scale clay and flocculating agent polyaluminium chloride into the sewage, adding coagulant aid polyacrylamide after the sewage is pumped by the pump, feeding the sewage into a suspended silt filter and then conveying the sewage into an oilfield sewage treatment station to be treated and recycled. The process for treating the fracturing backflow fluid has the advantages of low cost, safe production and stable treating effect, and is not limited by environmental conditions.

Owner:DAQING OILFIELD CO LTD +1

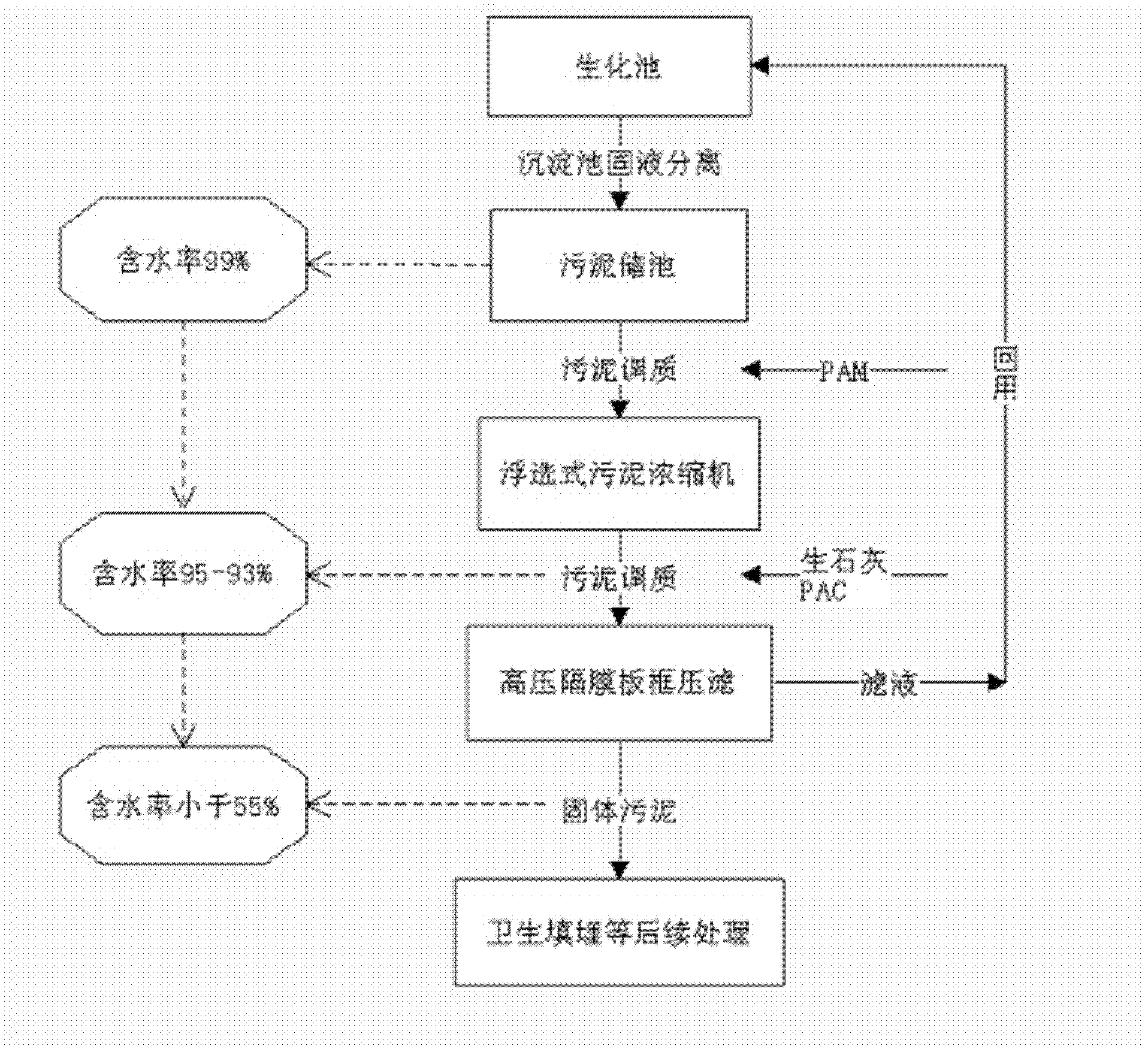

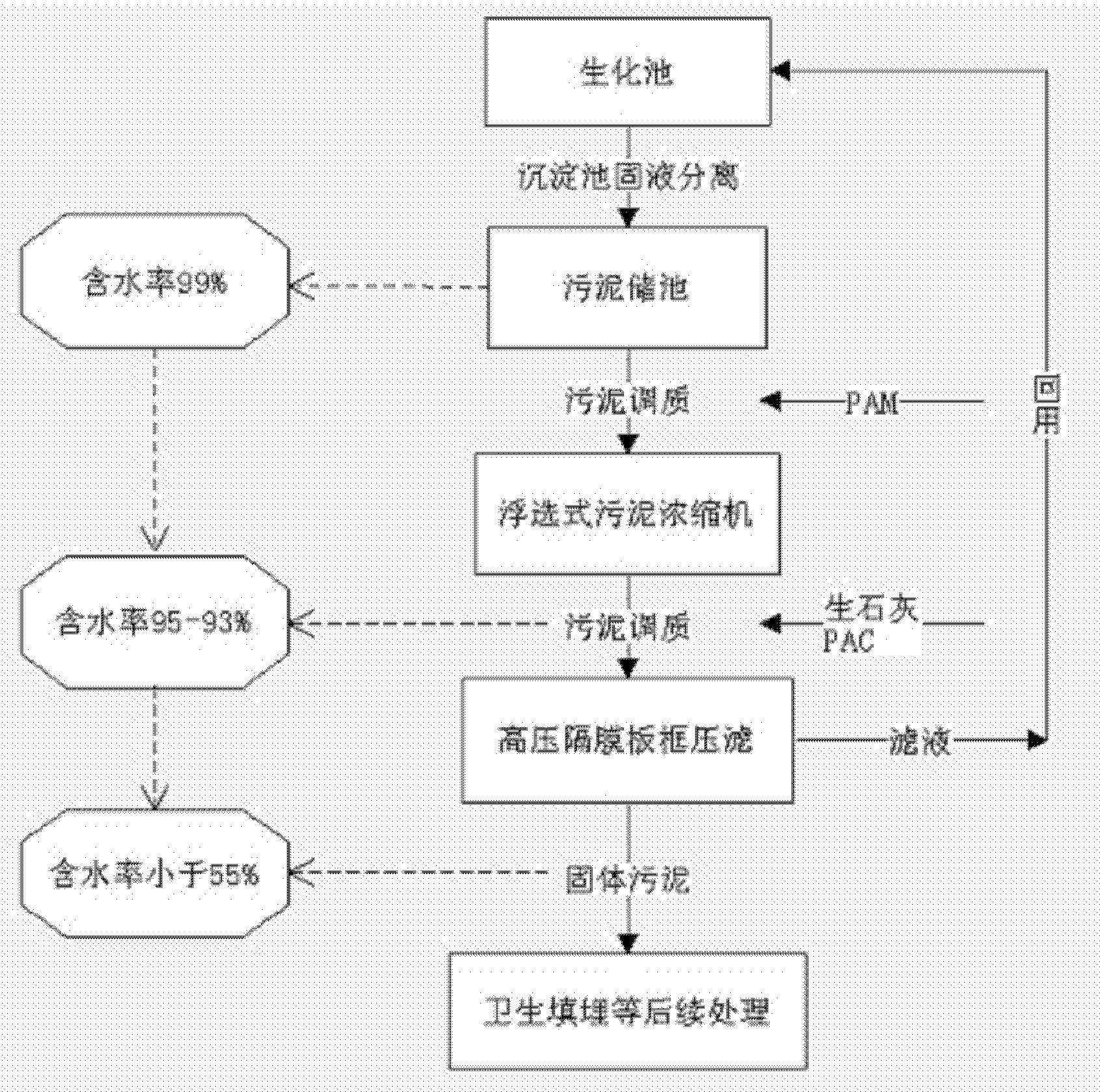

Method for concentrating and dehydrating sludge

InactiveCN102617013AReduce moisture contentHigh degree of automationSludge treatment by de-watering/drying/thickeningFiltration separationHigh concentrationAluminium chlorohydrate

The invention discloses a method for concentrating and dehydrating sludge. The method is characterized by comprising the following steps of: adding polyacrylamide into residual sludge of which the moisture content is 99 percent in an amount of 0.3 percent based on the mass of absolutely dry sludge for hardening and tempering the sludge; feeding the hardened and tempered sludge of which the moisture content is 99 percent into a flotation sludge concentrator through a pump for concentrating; feeding the concentrated sludge into a sludge hardening and tempering tank through a pump, adding caustic lime in an amount of 15 percent based on the mass of the absolutely dry sludge and polyaluminium chloride in an amount of 5 percent of based on mass of the absolutely dry sludge for further hardening and tempering; and performing filter pressing on the further hardened and tempered sludge by adopting a high-pressure diaphragm plate filter press. The method has the advantages of high system automatic degree, high concentration efficiency, low energy consumption, low mud moisture content and capability of making obtained sludge directly meet a filling requirement.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

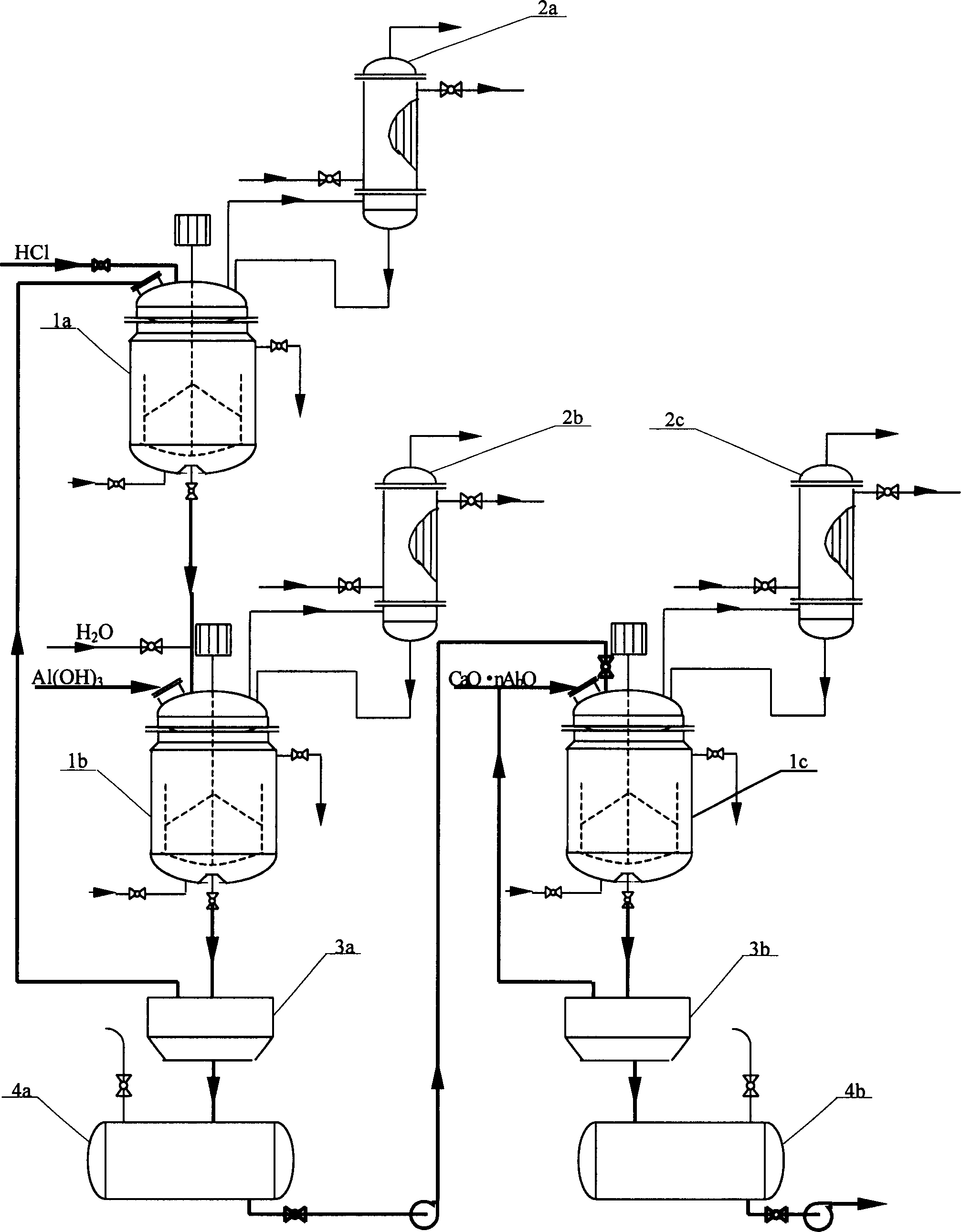

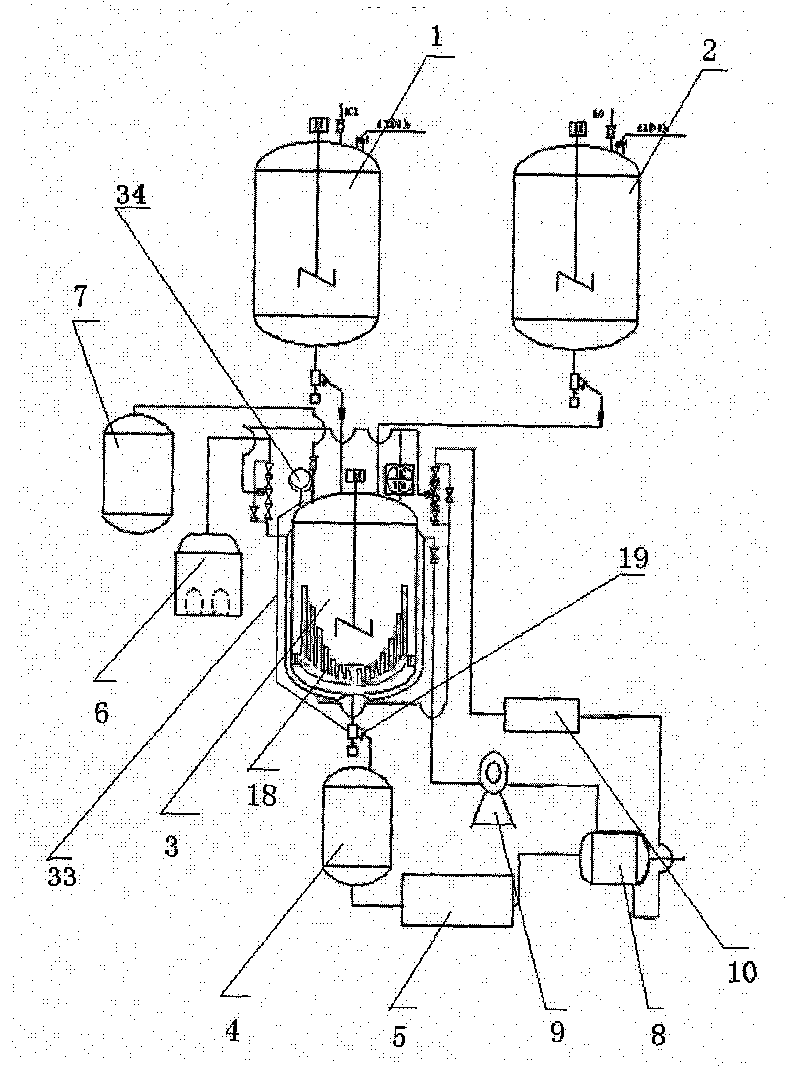

Recycling process of polyaluminium chloride filter residue

ActiveCN104402031AReduce manufacturing costReduce the dosing ratioAluminium chloridesLiquid densityProcess equipment

The invention discloses a recycling process of polyaluminium chloride filter residue; the process is as follows: adding water and hydrochloric acid into a first reaction kettle to prepare a 22-28% hydrochloric acid solution, adding the filter residue, stirring until the filter residue is dissolved; heating to 55 to 85 DEG C, adding aluminium-containing waste slag, after the addition, controlling the material liquid system temperature to be 92 to 118 DEG C for reacting for 2.5-5h; controlling the basicity of the material liquid after the reaction to be 27% + / -11% by adjustment of weight parts of the hydrochloric acid and the filter residue; separating the residue from the material liquid after the reaction, taking mother liquor, adding calcium aluminate powder; adjusting the material liquid density to be greater than or equal to 1.20g / ml, adding a synergist solution, reacting at 85-125 DEG C for 2.5-5h to obtain liquid polyaluminium chloride; and collecting and recycling the produced filter residue for reusing in production system to continue participating into the reaction. The recycling process achieves reuse of the filter residue in the polyaluminium chloride production system without addition of process equipment and other materials, greatly reduces the polyaluminium chloride production cost, reduces filter residue emissions, and conforms to environmental protection concepts of circular economy, energy saving and emission reduction.

Owner:蓝保(厦门)水处理科技有限公司

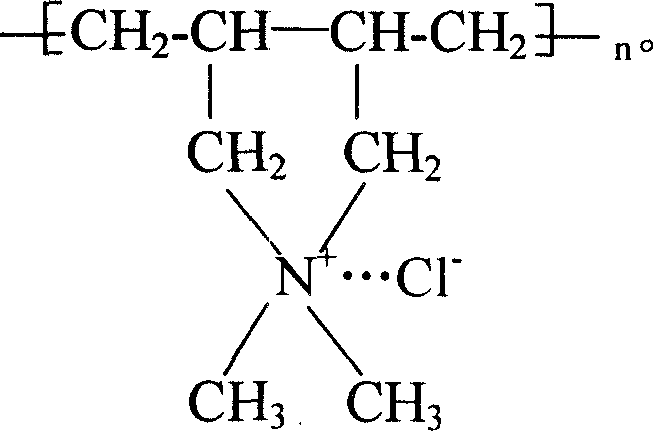

Polyaluminium chloride e-poly-dimethyl-diallyl-ammonium chloride composite flocculent, preparation and use method thereof

InactiveCN101323473AGuaranteed performanceGuaranteed stabilityWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateWater quality

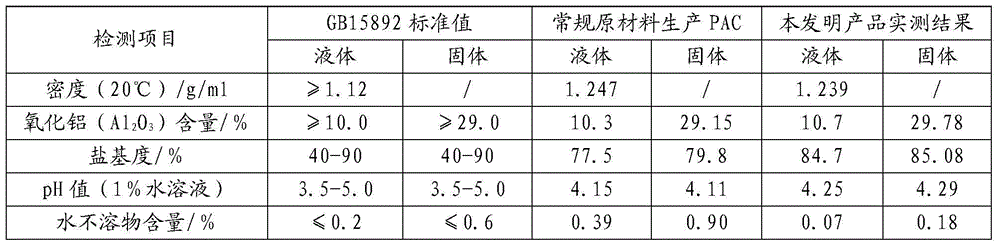

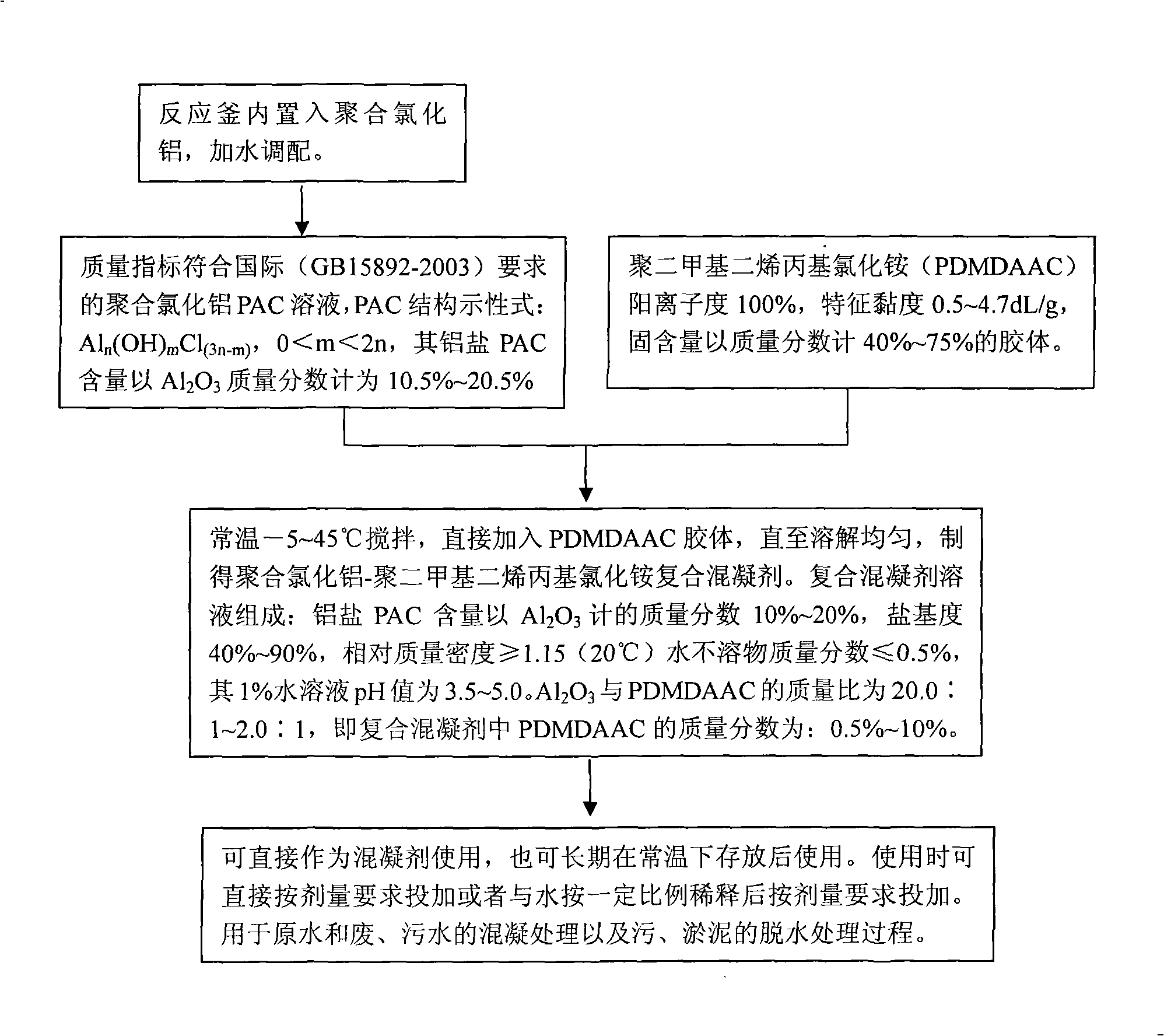

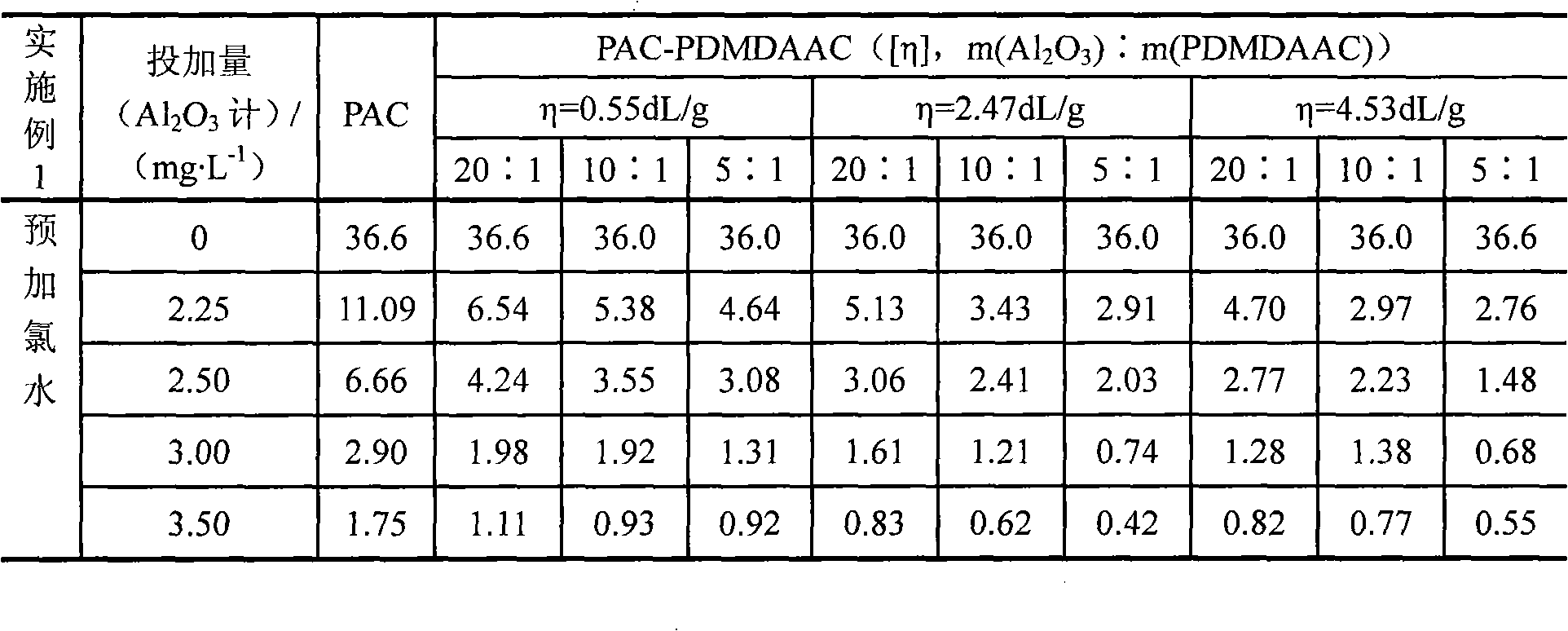

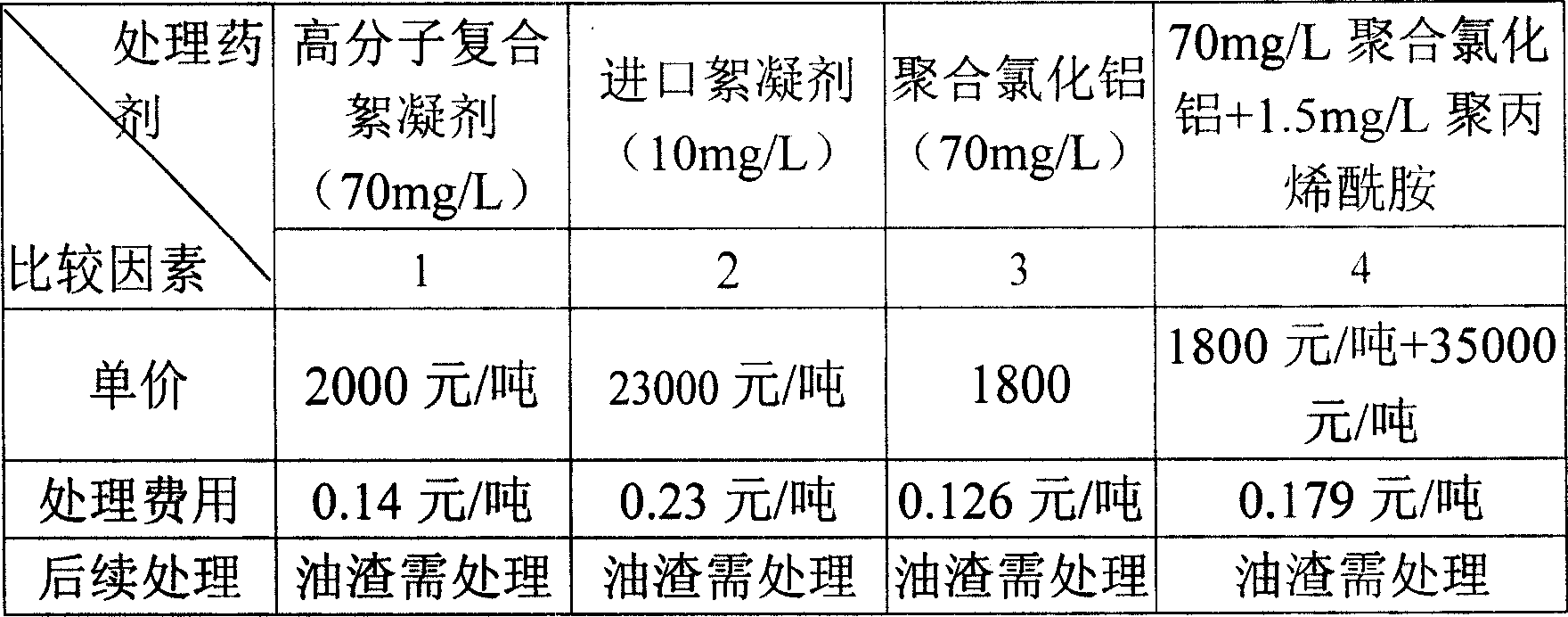

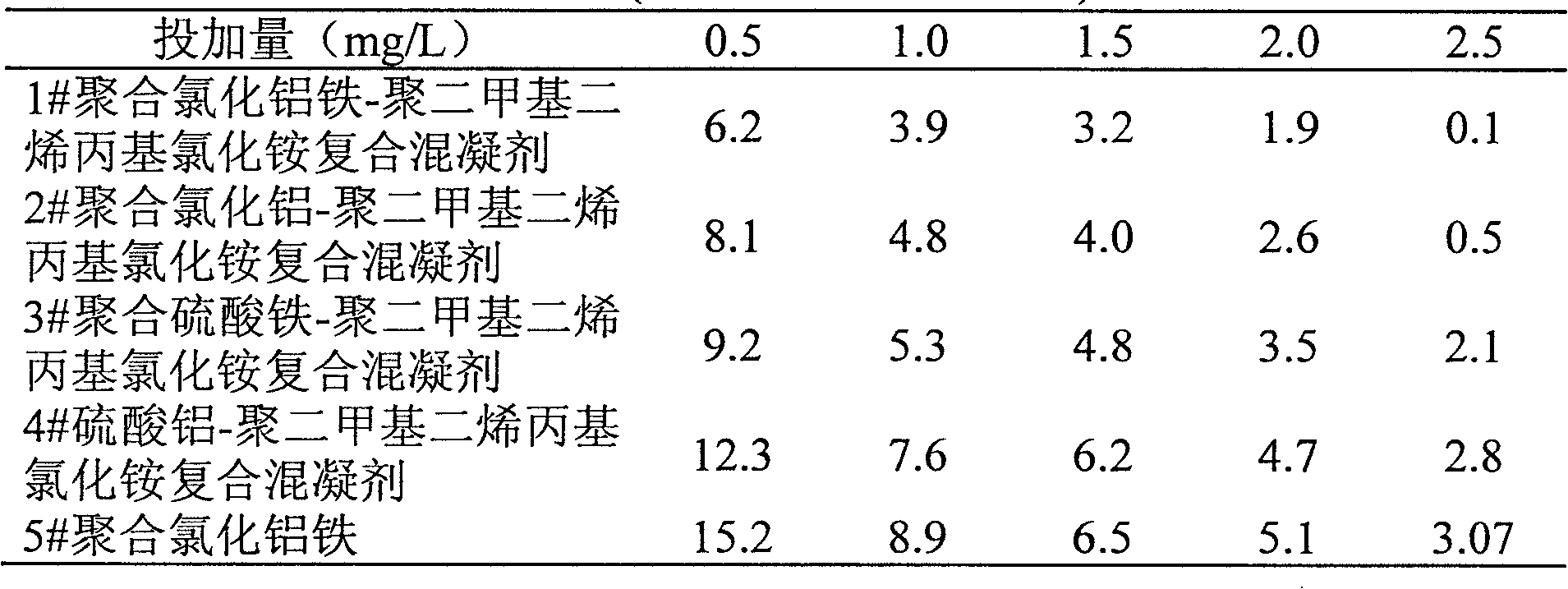

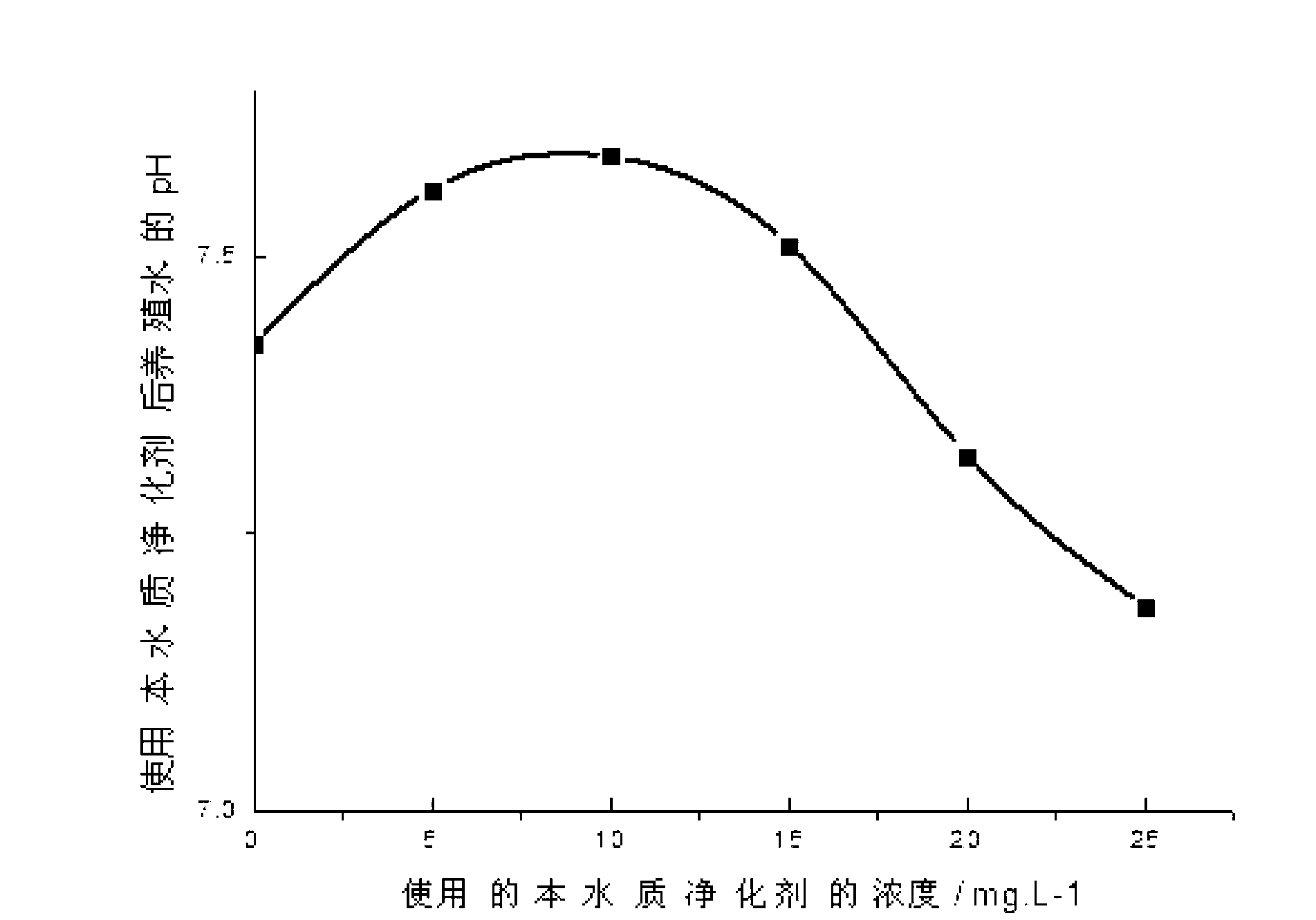

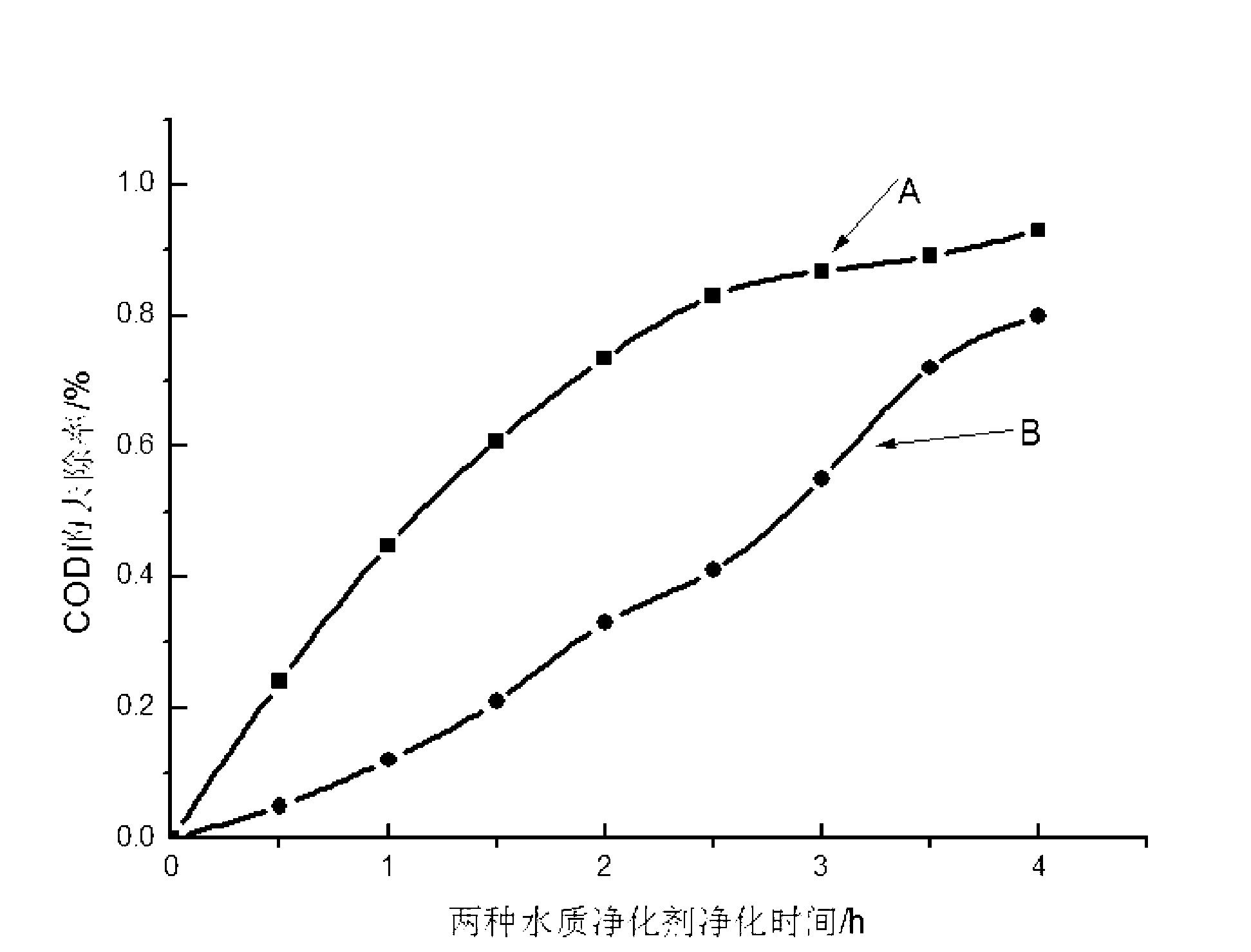

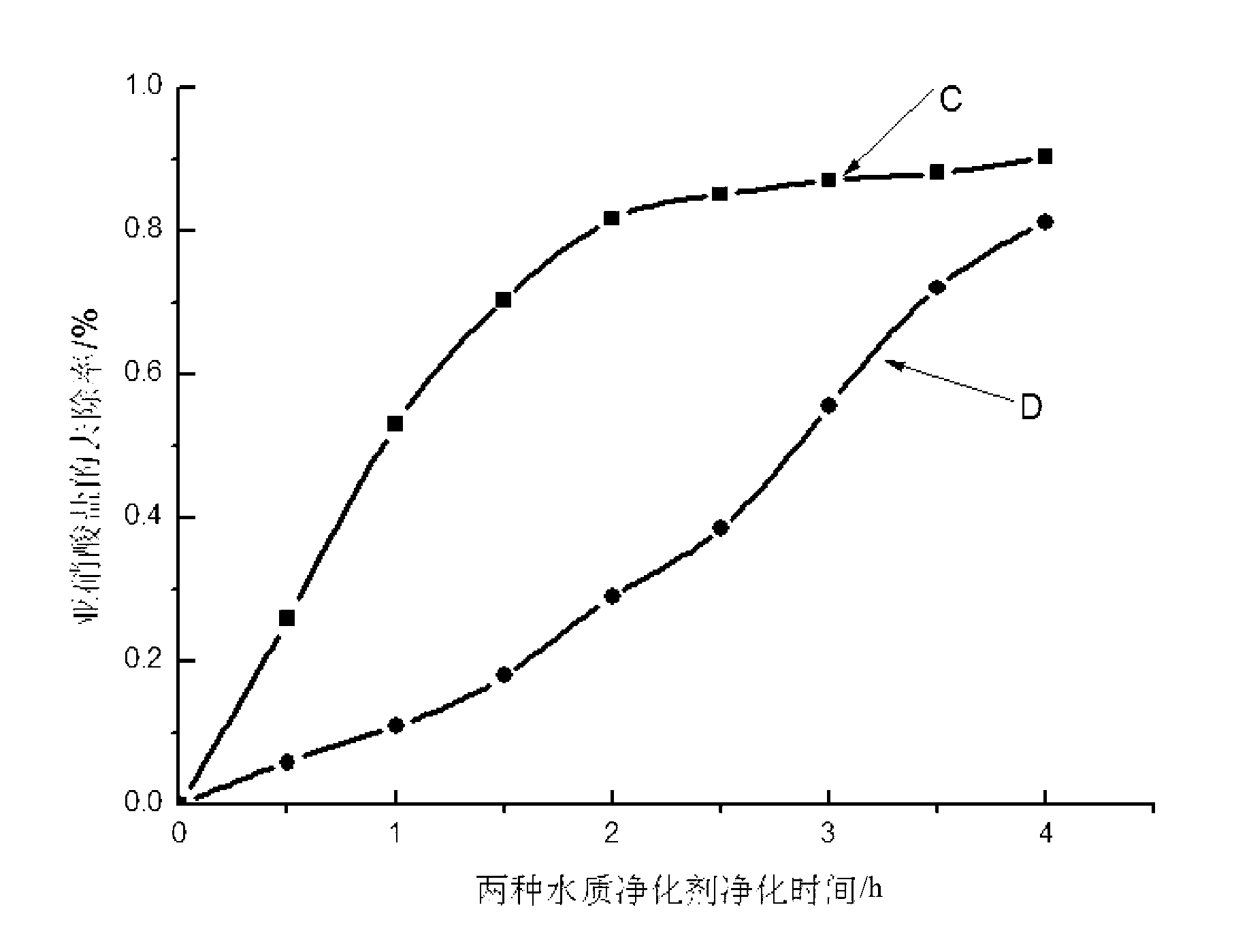

The invention discloses a PAC-PDMDAAC compound coagulant, a corresponding preparation method and an application method. The PAC-PDMDAAC compound coagulant is prepared as the following steps: the PAC dry powder or solution is arranged in a mixing reactor, and water is added to obtain a PAC solution which is stirred under normal temperature and a PDMDAAC colloid is added into the solution; the mixed solution is stirred under normal temperature till the PDMDAAC colloid is completely dissolved to obtain a stable PAC-PDMDAAC. The application of the PAC-PDMDAAC compound coagulant is to adopt the PAC-PDMDAAC compound coagulant for the coagulation treatment to raw water and waste water and sewage and the dehydration treatment to sludge or silt directly or after dilution with water by any proportion. The component structure and content scope of the invention are distinct to guarantee the capability and stability of the obtained PAC-PDMDAAC compound coagulant, and the materials on industrial manufacturing are available. The various functions of the PAC-PDMDAAC compound coagulant can be adjusted during water treatment with high adaptability so as to reduce cost, reinforce coagulation effect and dramatically enhance the quality of obtained water.

Owner:NANJING UNIV OF SCI & TECH

Composite flocculating agent for printing and dyeing waste water treatment

InactiveCN1654348AImprove decolorization efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSludge

The composite flocculant for treating printing and dyeing effluent consists of natural high molecular water soluble chitosan and polyaluminium chloride. The usage of the composite flocculant in treating printing and dyeing effluent includes regulating effluent to pH 6-8, and throwing composite flocculant in the amount of chitosan in 1-2 ppm and polyaluminium chloride in 100-250 ppm to result in printing and dyeing effluent decolorizing rate up to 91 %. The composite flocculant of the present invention has simple compounding process, easy use, low cost, small thrown amount, excellent decolorizing performance, fast deposition, small sludge amount, easy biodegradation, less secondary pollution of water and thus wide application foreground.

Owner:SHANGHAI NORMAL UNIVERSITY

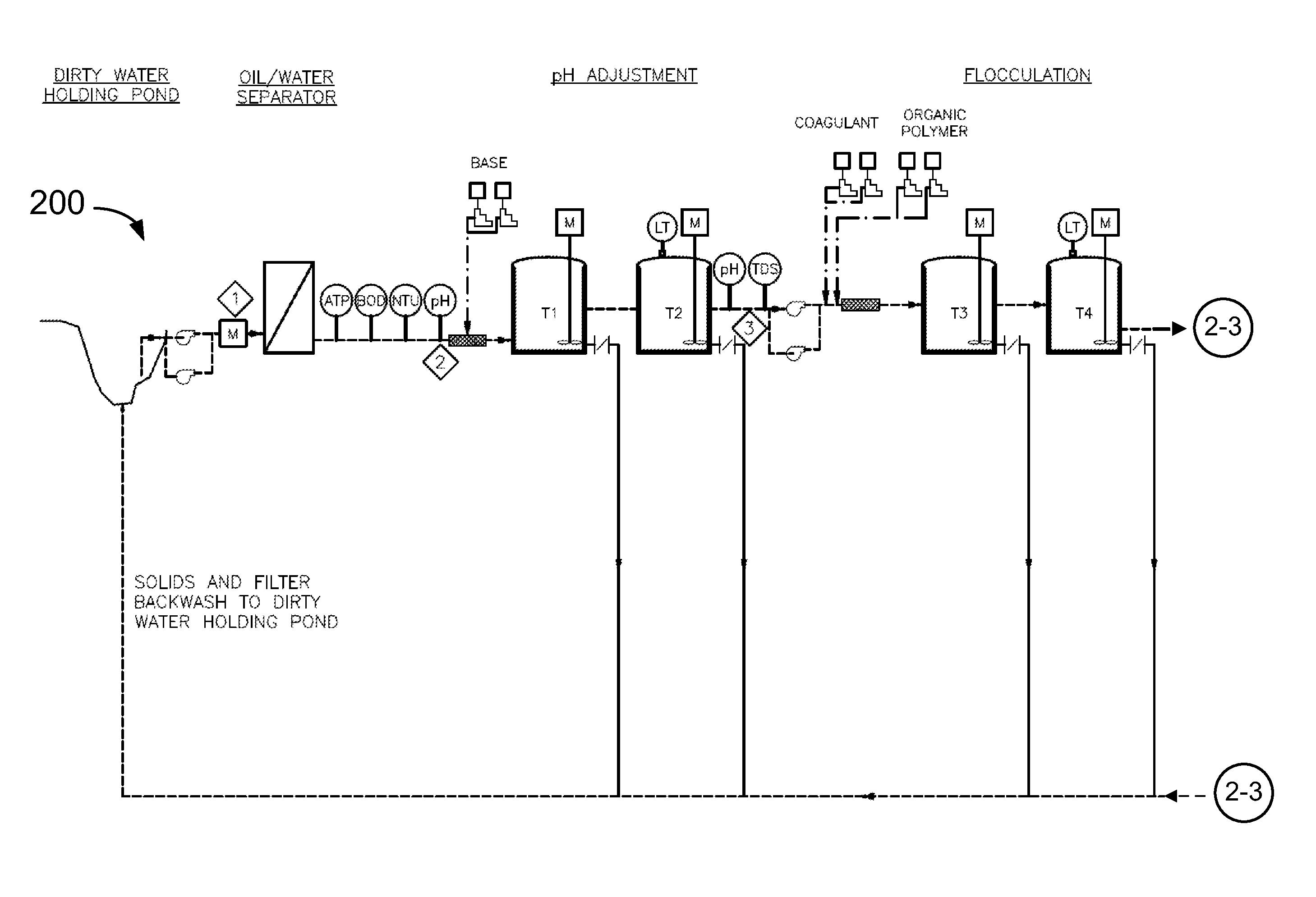

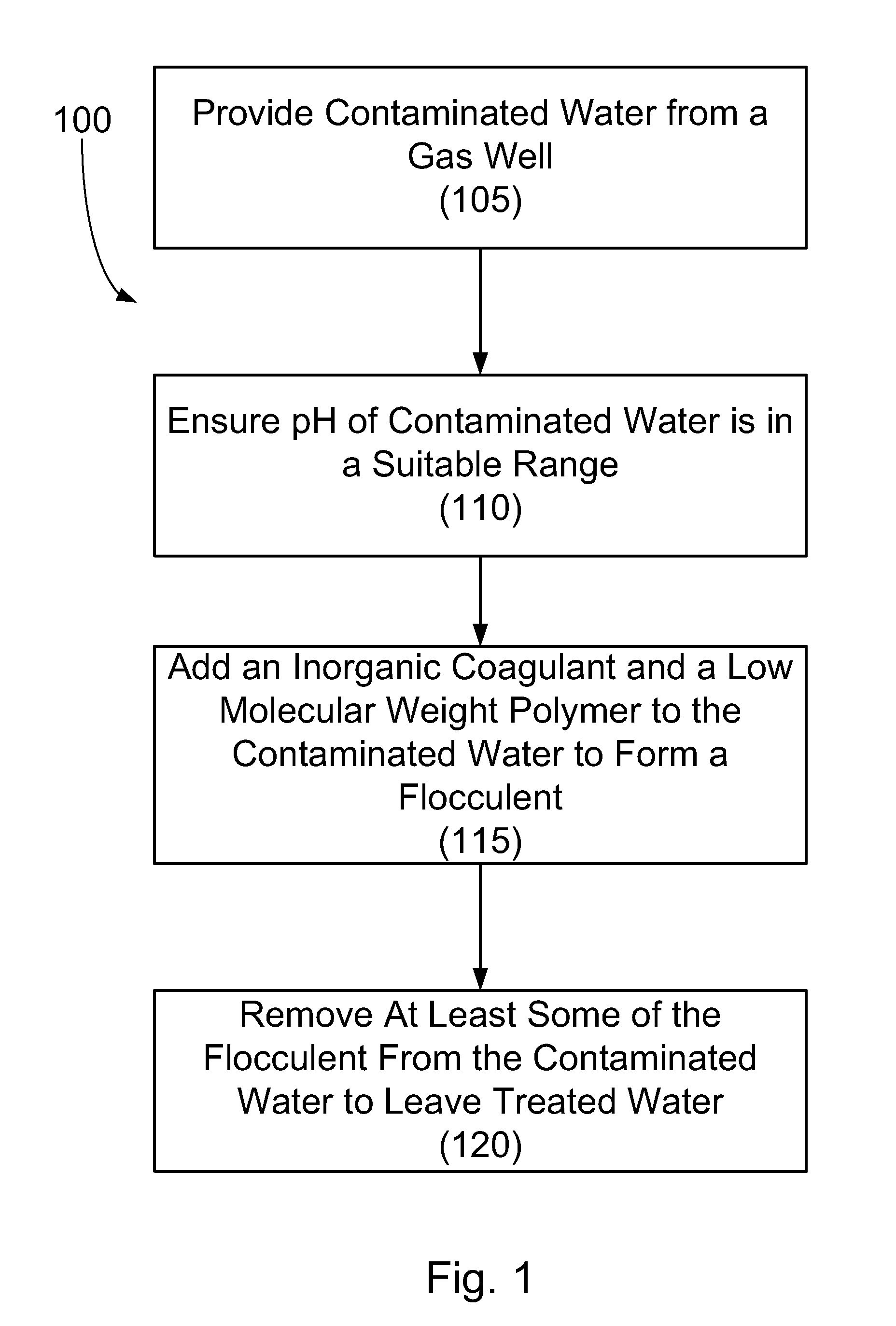

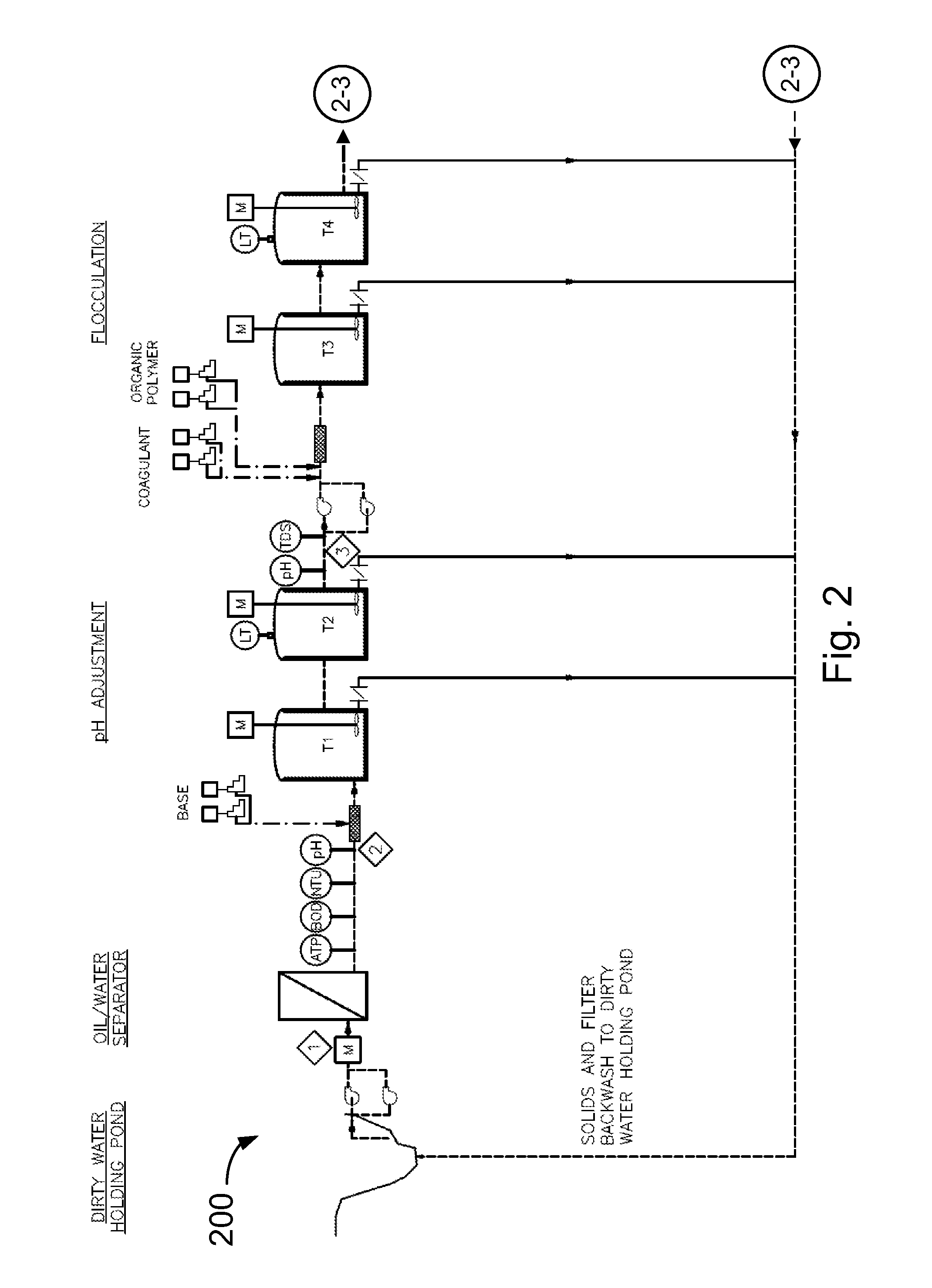

Treatment of contaminated water from gas wells

ActiveUS20110042320A1Increase in sizeWaste water treatment from quariesWater treatment parameter controlParticulatesDistillation

Systems and methods for treating contaminated water from gas wells by adding an inorganic coagulant and a low molecular weight polymer to the contaminated water to increase the size of solid particulates in the water and to thereby allow the solid particulates to be filtered or to otherwise be removed from the water are disclosed herein. While the inorganic coagulant can be any suitable coagulant, in some cases the coagulant is selected from aluminum chlorohydrate, polyaluminum chloride, aluminum sulfate, and ferric sulfate. Similarly, the polymer can comprise any suitable polymer, such as epi / dma, a condensation product of epichlorohydrin and dimethyl amine. The described systems and methods can clean the contaminated water so that the water can then be treated in a variety of other manners, which may include reverse osmosis, deionization, treatment with mixed bed deionizers, electro-separation, fraction distillation, distillation, and other suitable water cleansing processes.

Owner:WATER SOLUTIONS TECH LLC

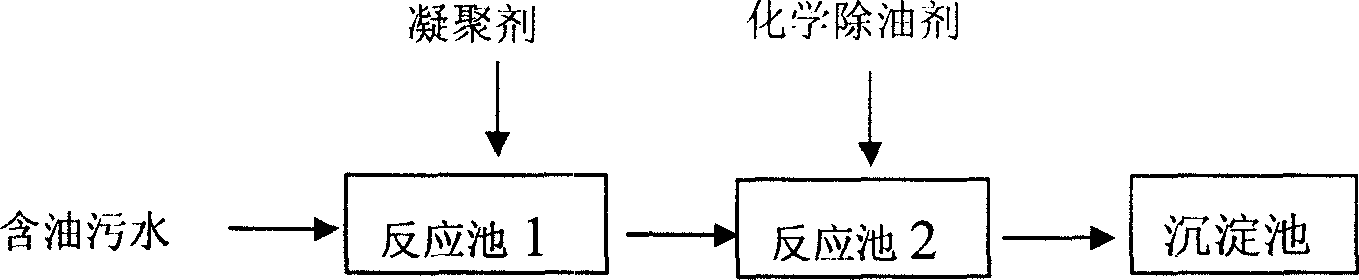

High polymer composite coagulant for treatment of oily waste water and making method thereof

InactiveCN101041495AEasy to handleLess one-time investmentWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chloridePolymer science

The invention discloses a high polymer composite coagulant for disposing oily wastewater and preparing method, which comprises the following steps: setting ingredient and weight ratio of high polymer composite coagulant with polymeric aluminium chloride : polymeric ferric sulfate : soluble glass : polydiene propyl dimethyl amchlor : water = 39.00:(1.90-2.10):(0.26-0.31):(1.04-1.52):(57.80-57.10); setting 0.02% basic ion polyacrylamide in polydiene propyl dimethyl amchlor; preparing finite density water solution with raw material as first step; preparing flocculant intermediate with polyaluminium chloride, polymeric ferric persulfate and sodium silicate as second step; proceeding mixed reaction with flocculating agent intermediate of the second step and polydiene propyl dimethyl amchlor of 0.02% positive ion polyacrylamide; controlling condition as temperature at 70-90 deg.c, pH value at 4-7; stirring intensity at 50-70r / min and ripening time at 6-24h.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

Polymeric aluminum ferric chloride-polydimethyldiallylammonium chloride composite coagulant and preparation method thereof

InactiveCN101628746AAdvanced technologyEasy to manageSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateRoom temperature

The invention discloses a polymeric aluminum ferric chloride-polydimethyldiallylammonium chloride composite coagulant and a preparation method and an application thereof. The method comprises the following steps: heating polyaluminium chloride solution to 40-90 DEG C while stirring the solution, adding polyferric chloride, heating and stirring the solution to perform copolymerization between polyaluminium chloride and polyferric chloride for 0.5-2.0h, obtaining polymeric aluminum ferric chloride solution; adding polydimethyldiallylammonium chloride colloid at room temperature while stirring to obtain a mixed liquor of the two products; stirring at room temperature to ensure that the polydimethyldiallylammonium chloride colloid and polymeric aluminum ferric chloride are completely mutually soluble and obtaining the polymeric aluminum ferric chloride-polydimethyldiallylammonium chloride composite coagulant.

Owner:JINAN UNIVERSITY

Aquaculture water purification agent and preparation method thereof

ActiveCN103214074AQuick purificationReduced duration of actionWater/sewage treatment by flocculation/precipitationWater qualityPotassium ferrate

The invention relates to an aquaculture water purification agent. The purification agent comprises the following components in parts by weight: 200-300 parts of polyaluminium chloride, 200-300 parts of potassium ferrate, 0.1-20 parts of cationoid polyacrylamide, 1-20 parts of powdered sulfur, 10-100 parts of activated carbon, 2-40 parts of calcium oxide, 100-300 parts of zeolite powder, 100-300 parts of kieselguhr and 0.1-5 parts of copper sulphate. The invention further relates to a preparation method of the aquaculture water purification agent. The aquaculture water purification agent is ingenious in design, has a physical purification and chemical agent synergistic effect and an obvious coagulation effect, quickly and thoroughly purifies and is suitable for large-scale popularization and application.

Owner:SHANGHAI YUKING WATER SOLUBLE MATERIAL TECH

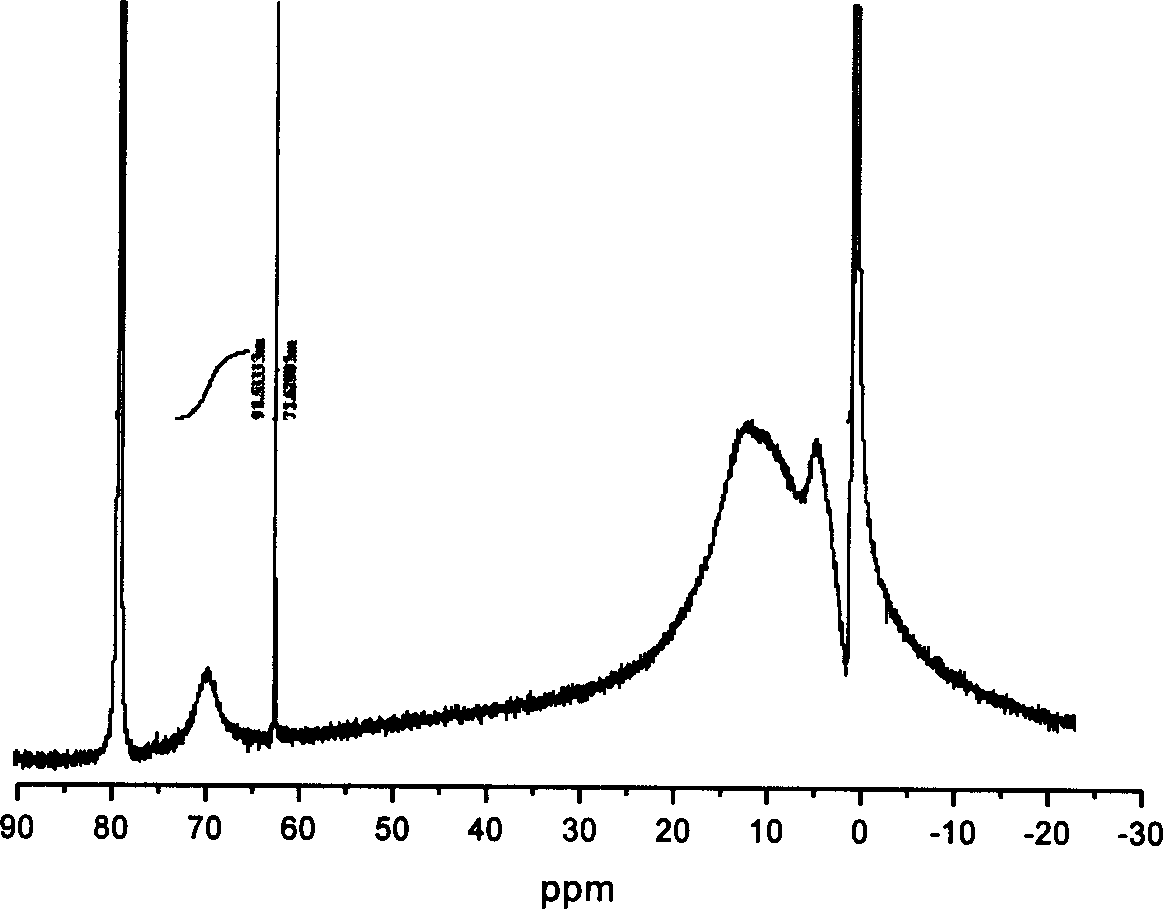

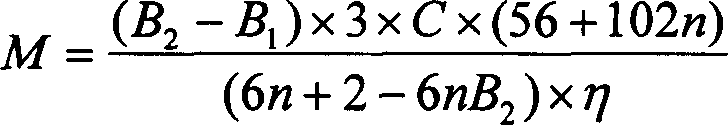

Method and technique for preparing Nano type sol of polyaluminium chloride in high purity

This invention describes a process for preparing high-purity nanoscale polyalumina sols. This invention uses active aluminum hydroxide and industrial hydrochloric acid as raw materials, and adopts a two-stage reverse stripping process to produce a solution of polyaluminum chloride with an alkalinity higher than 50%, which is then increased to 70% or higher using high-purity calcium aluminate as the alkalizer. The process ensures complete stripping of the aluminum hydroxide raw material at normal atmosphere and a low temperature, thus obtaining a high-purity product. In addition, in the produced polyaluminum chloride sols the total content of nanoscale Al13 and Al30 having Keggin structure is higher than 70%, the alkalinity is 70-85% and the aluminum concentration is 10-19% (measured as Al2O3). The product is widely used as raw material for modern fine chemical binders, gluing agent for neutral paper manufacturing, intermediate or additive for modern pharmaceutical technology, coupling agent and catalyst for chemical production and flocculant for water treatment, and has potential applications in such emerging fields as inorganic nanocomposites and inorganic membrane materials.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

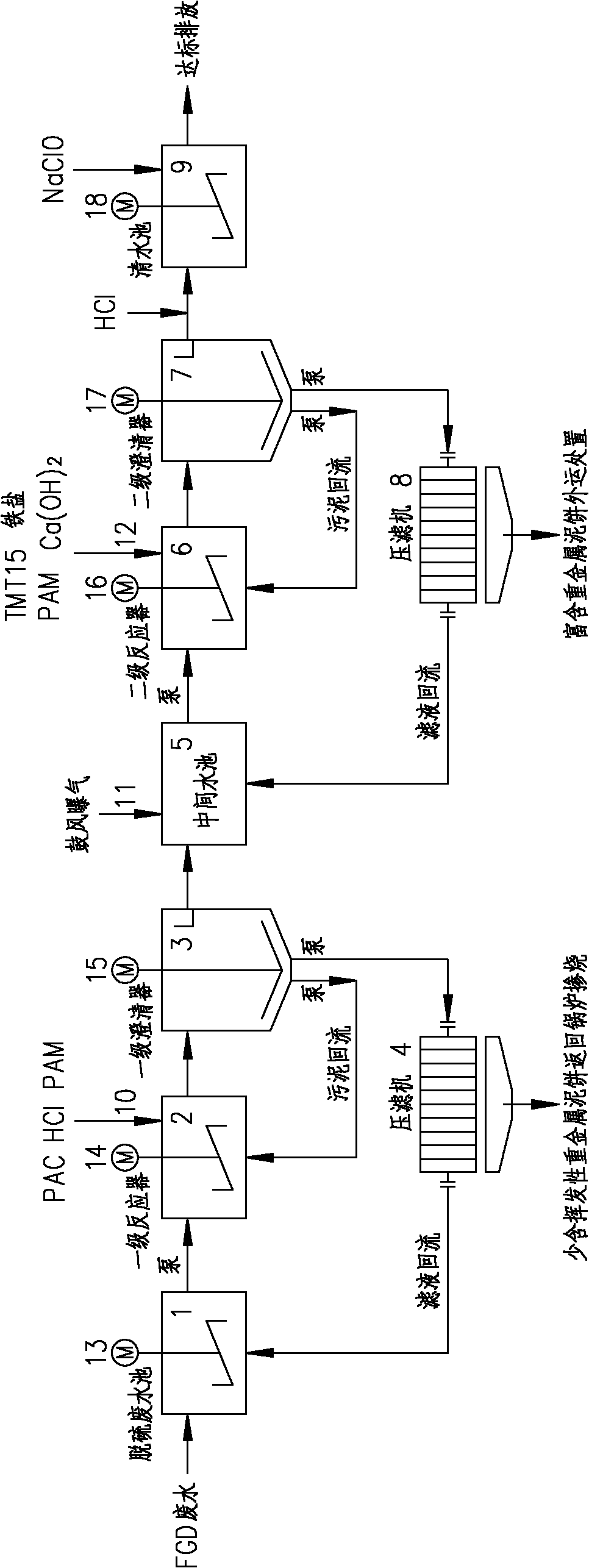

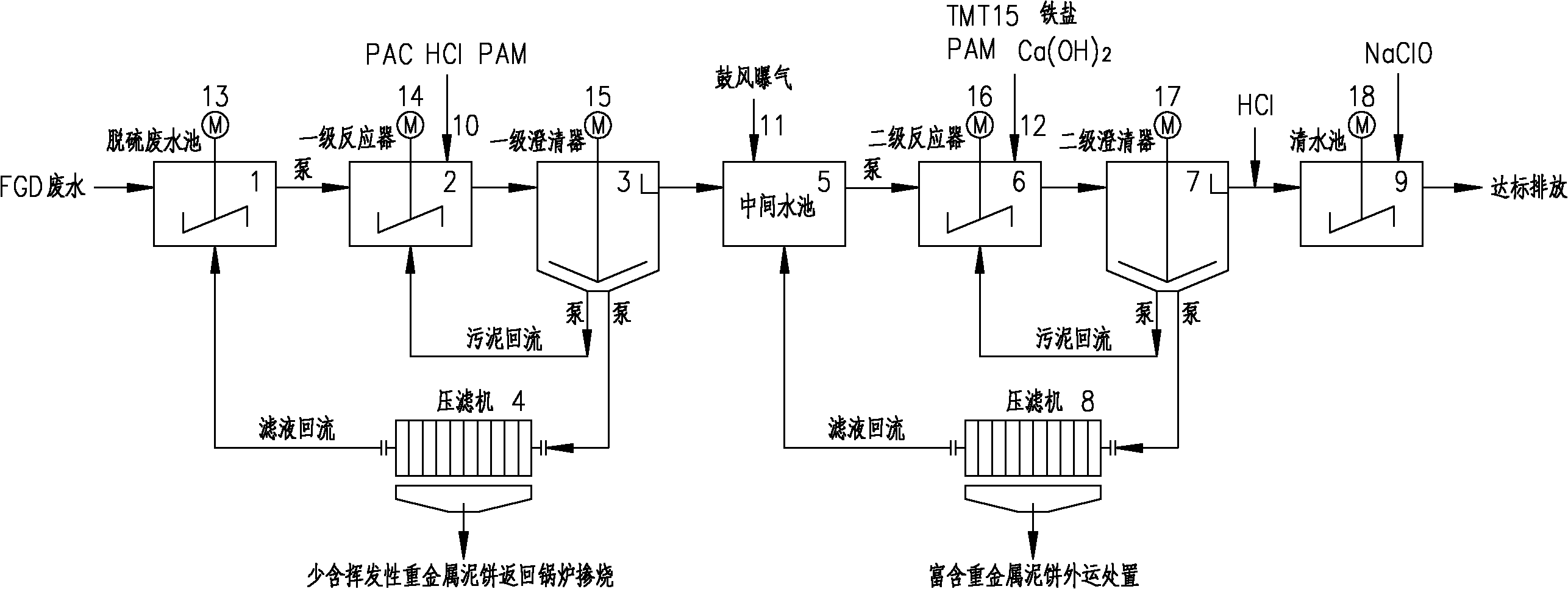

Treatment system and treatment method for reducing amount of volatile heavy metal sludge in desulfurization wastewater

ActiveCN101838072AContains less volatile heavy metalsLarge amount of sludgeSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentSludgeChelation

The invention relates to a treatment system and a treatment method for reducing the amount of volatile heavy metal sludge in desulfurization wastewater. A two-stage chemical precipitation technique is adopted to treat desulfurization wastewater, hydrochloric acid is added to regulate the wastewater in the first stage of chemical precipitation, so that the wastewater becomes acidic, polyaluminium chloride as polycoagulant and polyacrylamide as coagulant aid are added for flocculation reaction, consequently, the content of the volatile heavy metal in the sludge in the first stage of chemical precipitation is greatly reduced, while the amount of the sludge is increased, and thereby the sludge can be added into a boiler and burnt; calcium hydroxide is added to regulate the wastewater in the second stage of chemical precipitation, so that the wastewater becomes alkaline, heavy metal precipitator-organic sulfur (TMT15) is added to combined with the heavy metal in the wastewater to form highly stable chelate, molysite as polycoagulant and polyacrylamide as coagulant aid are added, so that the sludge in the second stage of precipitation is rich in the heavy metal, while the amount of the sludge is little, and thereby the sludge can be buried alone. Hydrochloric acid and sodium hypochlorite are added into clean water, so that the treated discharged water can meet the requirements of GB8978-1996 and DL / T 997-2006 standards.

Owner:XIAN TPRI WATER & ENVIRONMENTAL PROTECTION

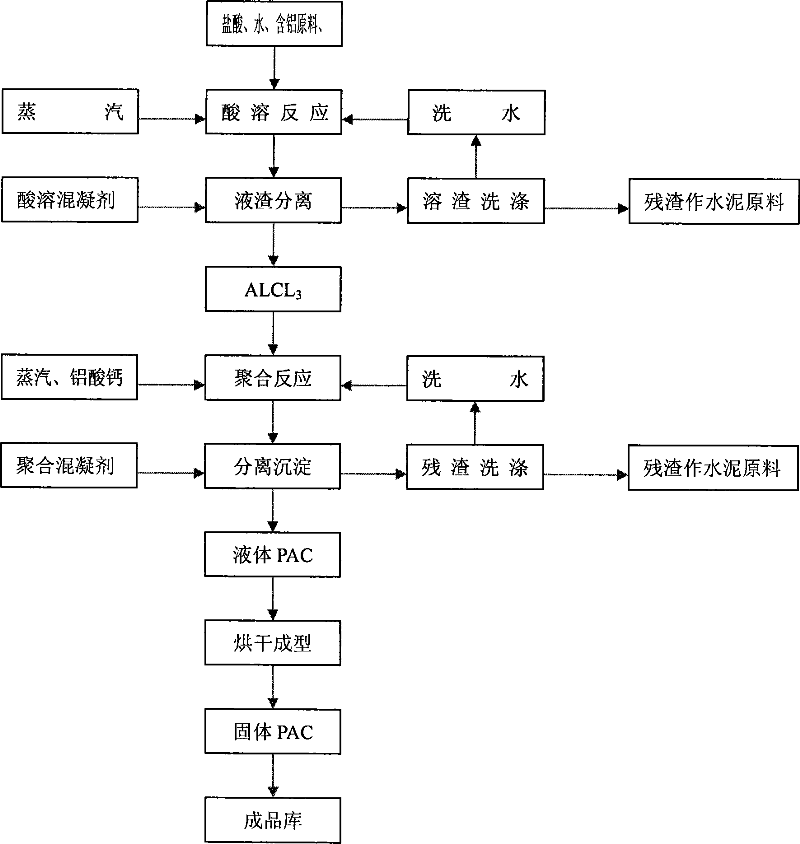

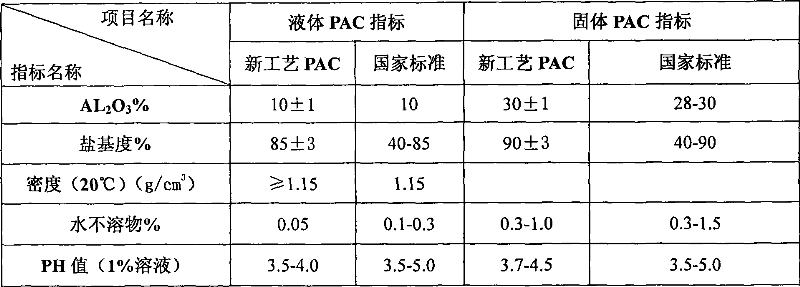

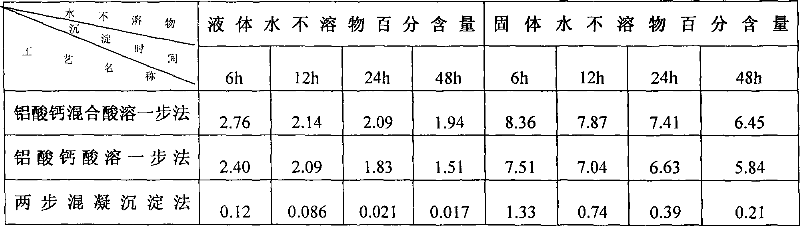

Technical process for producing chloride aluminum

InactiveCN101037212AIncrease productionNatural settling time shortenedAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminateWater insoluble

A technique for preparing polyaluminium chloride is characterized in that: the technique controls the water insoluble substances by a two-step coagulating sedimentation method and comprises the steps of: (1)generating aluminic acid solution by the reaction of aluminium-containing raw material and hydrochloric acid in an acid-proof vessel, adding acid soluble coagulant to execute coagulating sedimentation, and then picking up the supernatant as mother liquor; (2)adding water into the mother liquor obtained in step (1), and heating up in an acid-proof vessel, and then adding calcium aluminate to react in atmospheric pressure, finally adding polymerization coagulant; (3)precipitating to obtain the supernatant which is liquid PAC, obtaining solid PAC by means of drying. The present invention has the advantages of that: the two-step coagulating sedimentation method can overcome the problem of that the control and reduction of the water insoluble substances in PAC preparing process, which uses calcium aluminate as raw material, is hard, the operation is simple, the cost is lower, the settling time can be reduced at 10~20 times, the operability is better, the economic benefit is obviously and each index of the PAC product can satisfy the national standard.

Owner:王军 +1

Metal salt-converting method for treating high concentration phosphor-containing wastewater

InactiveCN101439901AGood removal effectReduce processing operating costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationHigh concentrationSludge

The invention relates to a treatment method for chemical gold high concentration P-contained wastewater. The method is characterized in that the method comprises the following steps: lifting the wastewater from a collecting tank to an oxidation precipitation tank, opening the oxidation precipitation tank for aeration, adding steam, calcium hydroxide, ferrous sulfate and hydrogen peroxide solution into the wastewater for reaction, leading the supernatant into a subsequent physiochemical system for treatment, and pumping the precipitant into a sludge concentration tank for treatment through a sludge pump; after the catalytic oxidation reaction is completed, leading the supernatant into a physiochemical treatment neutralization tank, adding calcium hydroxide into the neutralization tank, leading the supernatant into a flocculating tank after a polyaluminium chloride reaction, adding polyacrylamide into the flocculating tank for intensive agitation, mixing and reaction, then leading the supernatant into a precipitation tank for solid-liquid separation, discharging the supernatant into the next flow, and pumping the sludge to the sludge concentration tank for treatment. A catalytic oxidation method is used to oxidize the stable hypophosphorous acid radical into the phosphate radical capable of easily reacting with metallic salts and producing precipitant; and then a physiochemical method is used to precipitate and remove the phosphate radical, thereby enabling the P content in the outputted water to reach the state emission standard.

Owner:TRIPOD WUXI ELECTRONICS

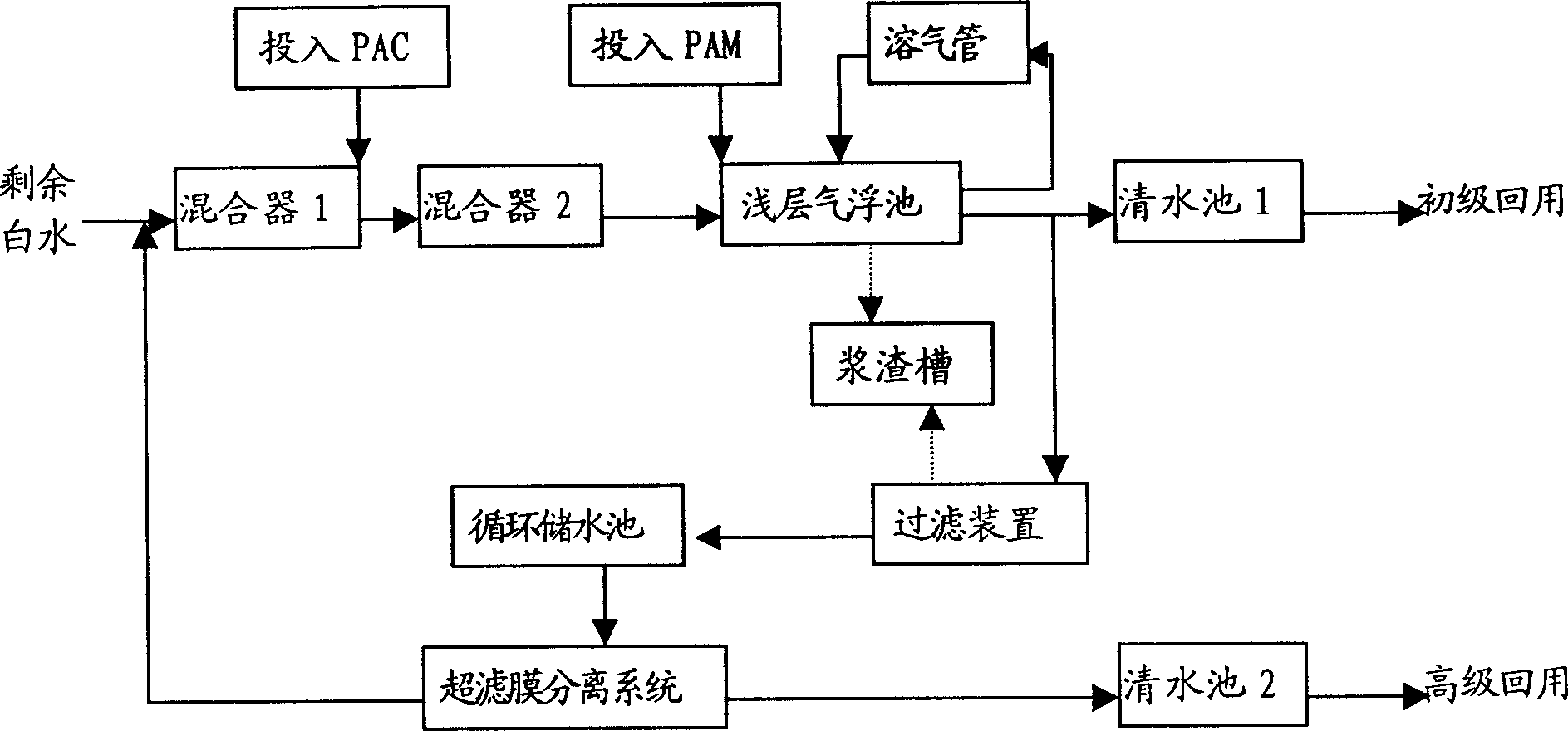

Processing mthod of white water from paper making

ActiveCN1766227AReduce turbidityMeet the requirements of advanced circulating waterPulp liquor regenerationMultistage water/sewage treatmentAluminium chlorohydrateUltrafiltration

The invention relates to a treatment method for paper-making white water, which comprises: treating residual white water with superficial air-float technique and with polyaluminium chloride and strong-cation polyacrylamide as flocculant and coagulant by special proportion to make SS of out water about 10mg / L and turbidity not larger than 15NTU and become primary recycling water, ultrafiltrating to remove all SS with turbidity not larger than 1NTU, and obtaining super recycling water. This invention can realize zero-discharge of paper-making white water in deed.

Owner:BAODING BANKNOTE PAPER CO LTD +1

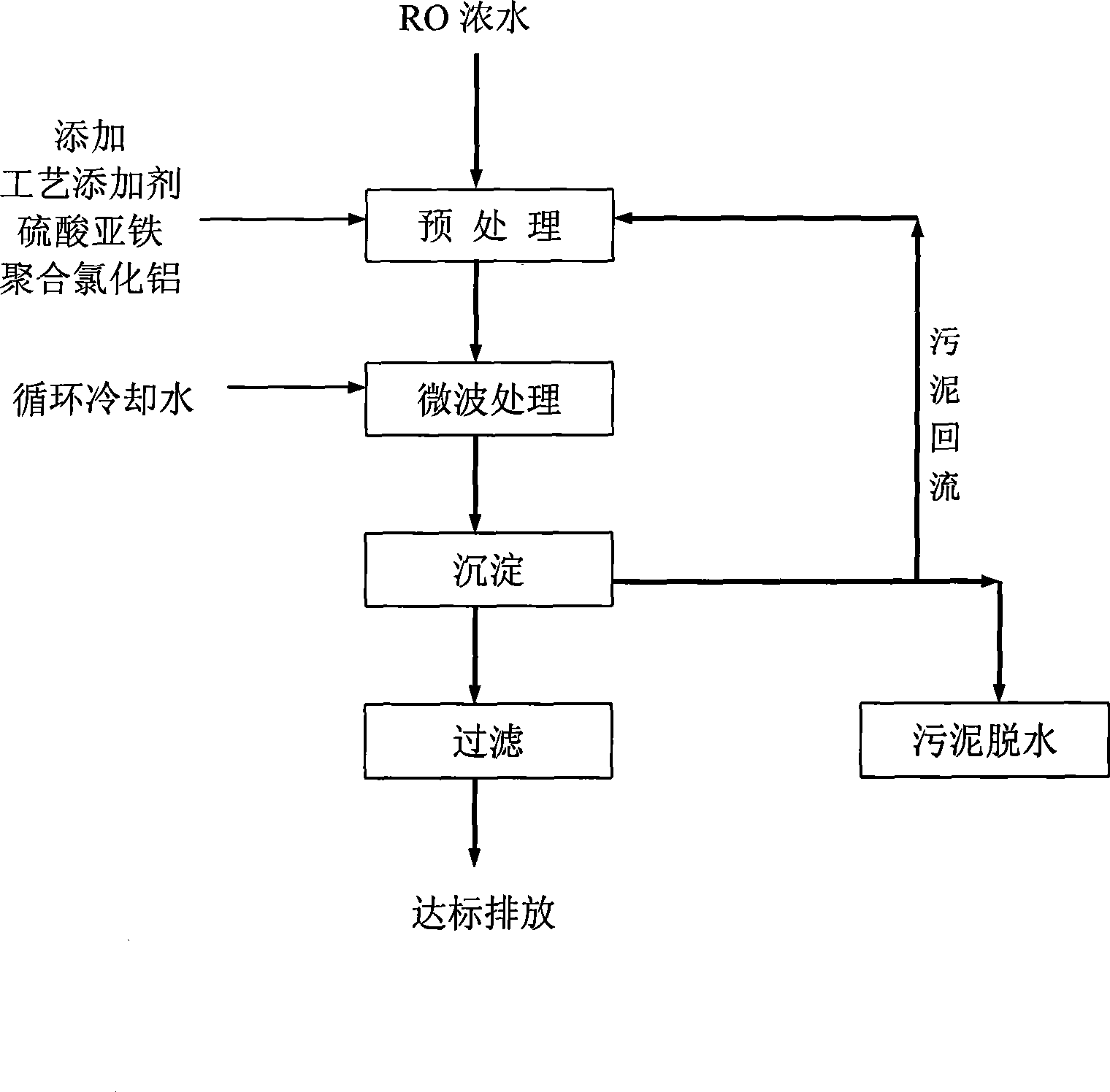

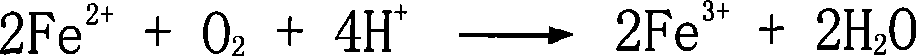

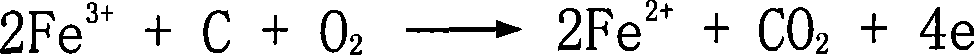

Microwave method for processing reverse osmosis concentrated water

InactiveCN101381120AStrong targetingGood processing effectSludge treatment by de-watering/drying/thickeningWater/sewage treatment by irradiationMicrowave methodChemical reaction

The invention relates to a method for reverse osmosis enriched water by microwave treatment. The method comprises the following steps: adding a process additive, ferrous sulfate and polyaluminium chloride into the reverse osmosis enriched water to perform the pretreatment; putting the pretreated enriched water into a microwave processor from the lower part of the microwave processor and taking out the pretreated enriched water from the middle and upper part of the microwave processor so as to ensure that the process additive, the ferrous sulfate and the polyaluminium chloride perform adequate physical and chemical reactions with the enriched water; guaranteeing that the yielding water of the microwave processor flows into a precipitation filtering unit automatically to realize stable drainage reaching the standards; and branching sludge to cause part of the precipitated sludge to be pumped back to the pretreatment reaction for recycling, and dehydrating the ineffective or residual sludge into dry sludge. The method is applicable to processing various organic waste water or mixed waste water which takes COD and heavy metal as the main pollutant and is hard to biodegrade; the method has the advantages of simple technical processes, convenient control, low treatment cost and less occupied space; in addition, the method fills in the domestic gap of the method for processing the new reverse osmosis enriched water generated in the recycling process of reclaimed water, and has good popularization value.

Owner:深圳市弘玮环境技术有限公司

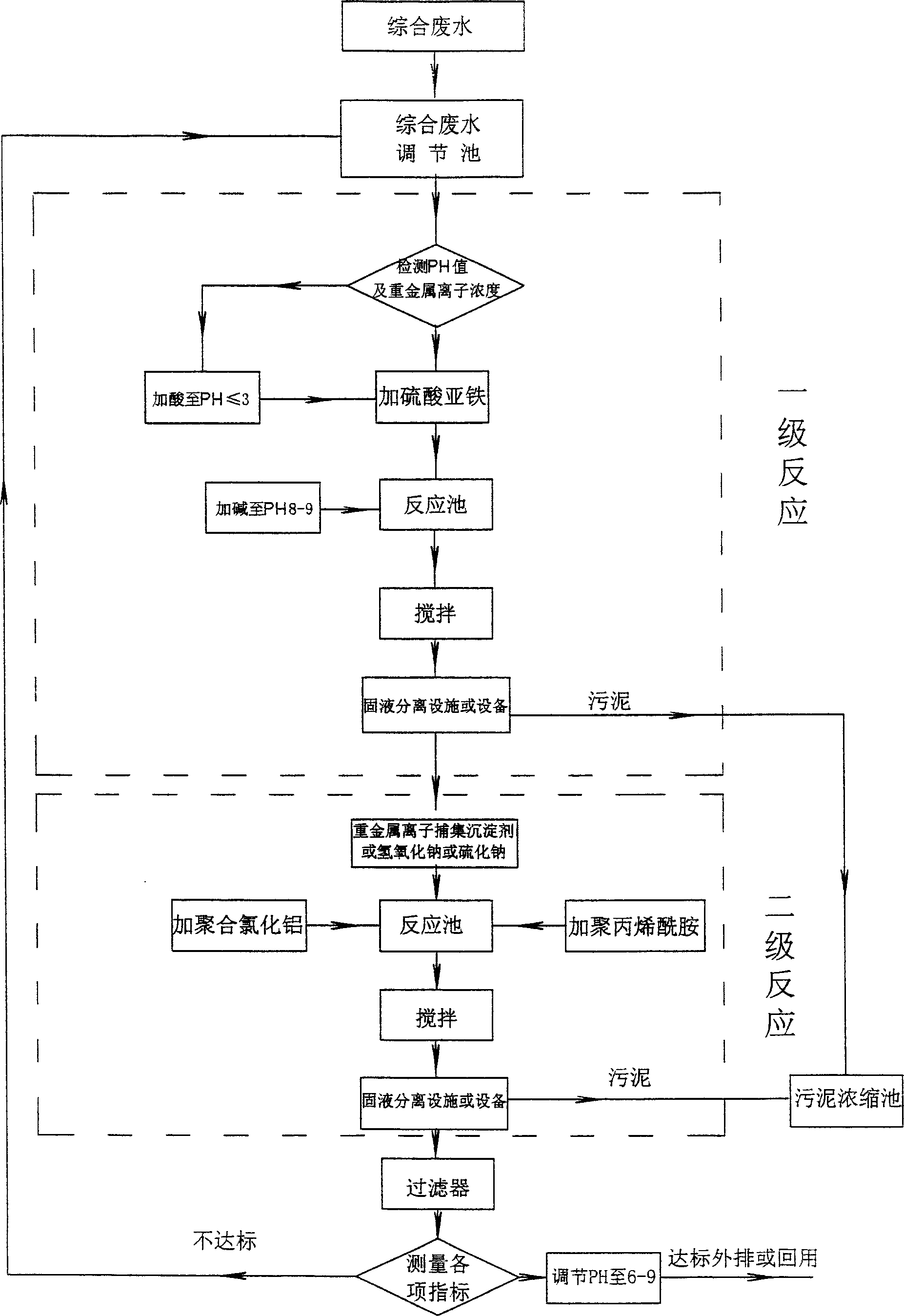

Multi-stage treatment process for electroplating wastewater of centralized park zone

InactiveCN1803659AGuarantee complianceGuaranteed compliance rateWaste water treatment from metallurgical processWater/sewage treatment by neutralisationAluminium chlorohydrateWater quality

The invention relates to a multistep treatment technique for electroplated sewage in centralized park. Wherein, adjusting the sewage and leading into reaction pond to stir and react; in solid-liquid separator, taking the first-step reaction and forcing the supernatant into the second-step reaction pond; adding catching and precipitating agent for heavy metal ion or NaOH or Na2S as well as polyaluminium chloride and polyacrylamide to stir evenly and solid-liquid separate; using quartz sand to filter minim suspension, then discharging or recovering. This invention can ensure the sewage come up to the standard at maximum limit.

Owner:JIANGSU GOLDEN KYLIN ENVIRONMENTAL TECH

Treatment agent of steelmaking waste water

The invention belongs to the technical field of a sewage treatment agent, in particular to a treatment agent of steelmaking waste water. The treatment agent comprises the following raw materials in parts by weight: 25 to 45 parts of polyacrylamide, 5 to 15 parts of sodium hydroxide, 2 to 5 parts of sodium carbonate, 5 to 15 parts of magnesium oxide powder, 10 to 20 parts of polysilicon ferric sulfate, 10 to 20 parts of quaternary ammonium salt lignin flocculant, 20 to 30 parts of sodium base bentonite, 0.5 to 2 parts of amino trimethylene phosphonic acid, 5 to 15 parts of pentasodium diethylenetriaminepentaacetate, 10 to 20 parts of polyaspartic acid, and 12 to 25 parts of polyaluminium chloride. The treatment agent of steelmaking waste water disclosed by the invention is good in treatment effect, obvious in corrosion and scale inhibiting effect, capable of reducing scaling and corrosion effectively, lowering the production cost, high in purity, free of toxicity, and has no influence on operating workers and problems such as secondary pollution after treatment.

Owner:HEBEI UNIV OF ENG

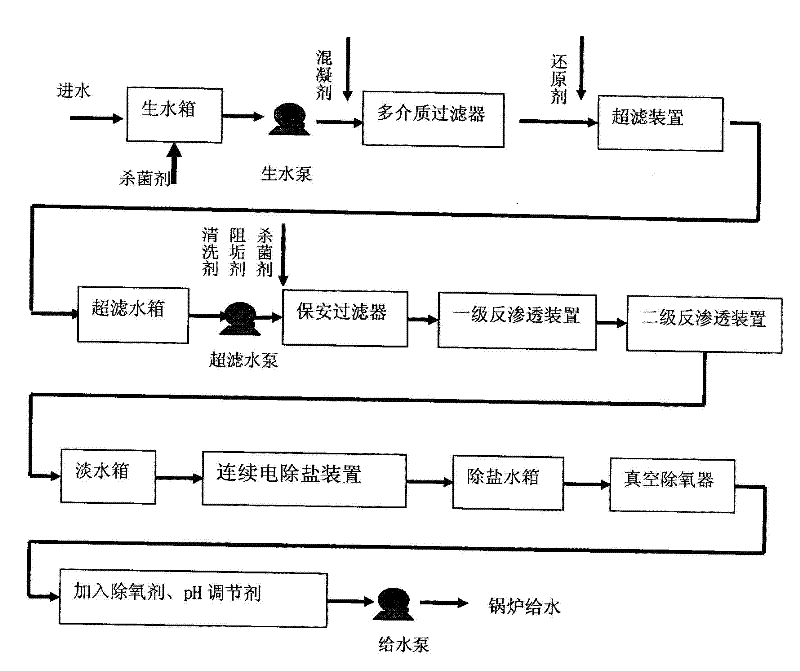

Novel water treatment method for boiler feedwater

ActiveCN102344215AAvoid breedingDecreased water conductivityGeneral water supply conservationMultistage water/sewage treatmentChlorine dioxideUltrafiltration

A novel water treatment method for boiler feedwater of the invention comprises the following steps: sterilization, that is adding liquid chlorine, sodium hypochlorite or stabilized chlorine dioxide into a raw water tank, controlling the residual chlorine amount in water to be 0.2-0.5 mg / L; filtration, that is adding a polyaluminium chloride coagulant before a multimedium filter with an amount of 10-20 mg / L, controlling the water turbidity of the ultrafiltration feedwater to be not more than 0.1 NTU and the SDI to be not more than 3; adding a reducing agent of sodium bisulfite before ultrafiltration with an adding amount of 3-5 mg / L; reverse osmosis, that is performing desalination treatment by a reverse osmosis membrane device, continuously adding a PTP-0100 scale inhibitor before a security filter with an adding amount of 3-5 mg / L; continuously adding a Micro Treat BIO bactericide with an adding amount of 3-5 mg / L; additionally adding cleaning agents of Dimamite and High Flux once a month with an amount of 3-5% of the water amount to be produced; desalination, that is performing desalination by an electrical desalination system (EDI); deoxygenation, that is performing deoxygenation by a vacuum deoxygenator, adding 10-20 microgram / L of deoxidants, controlling the agent residual amount to be 5-20 microgram / L, adding a corrosion-inhibiting pH regulator to control the pH value to be 8.8-9.3.

Owner:XINJIANG DELAND

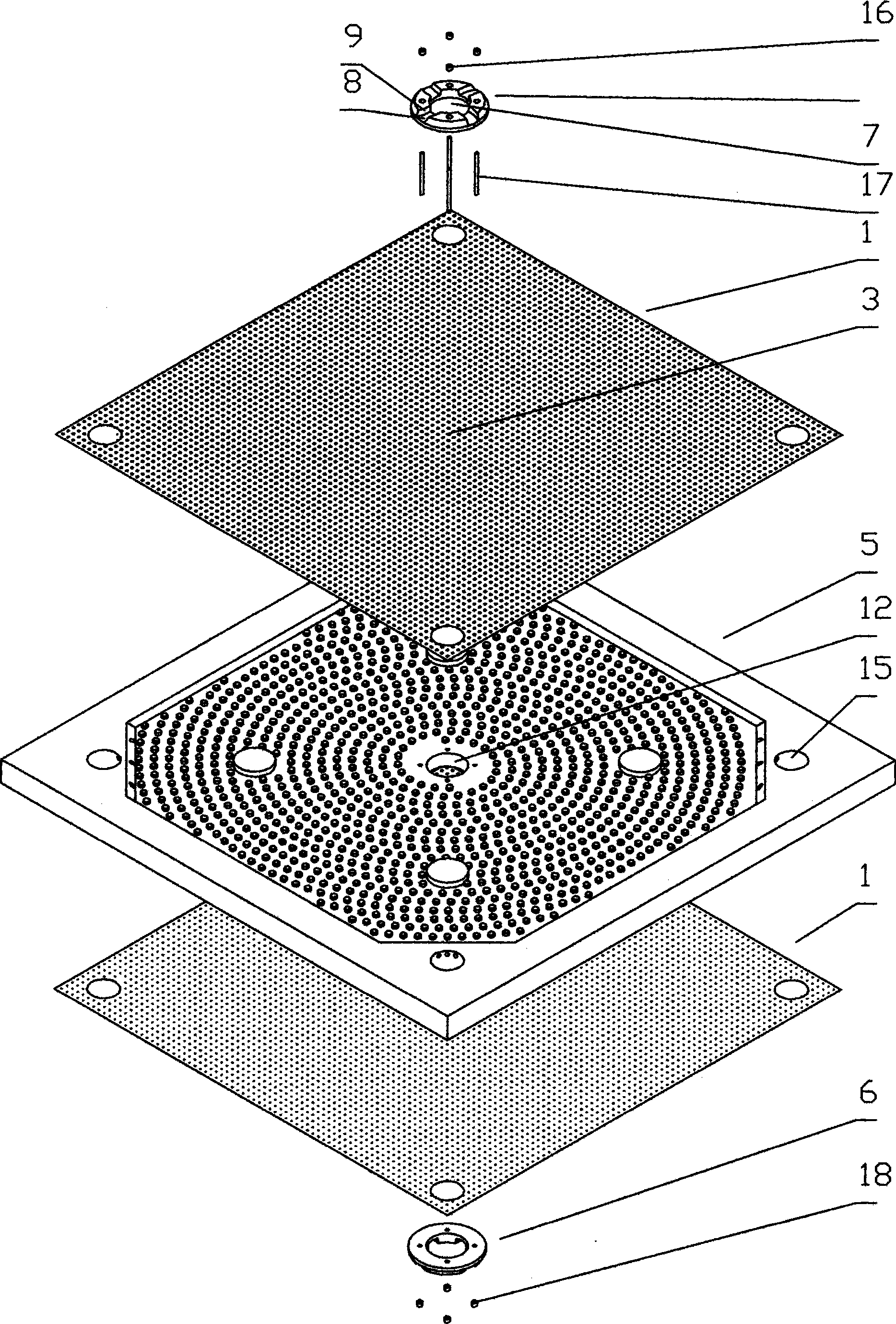

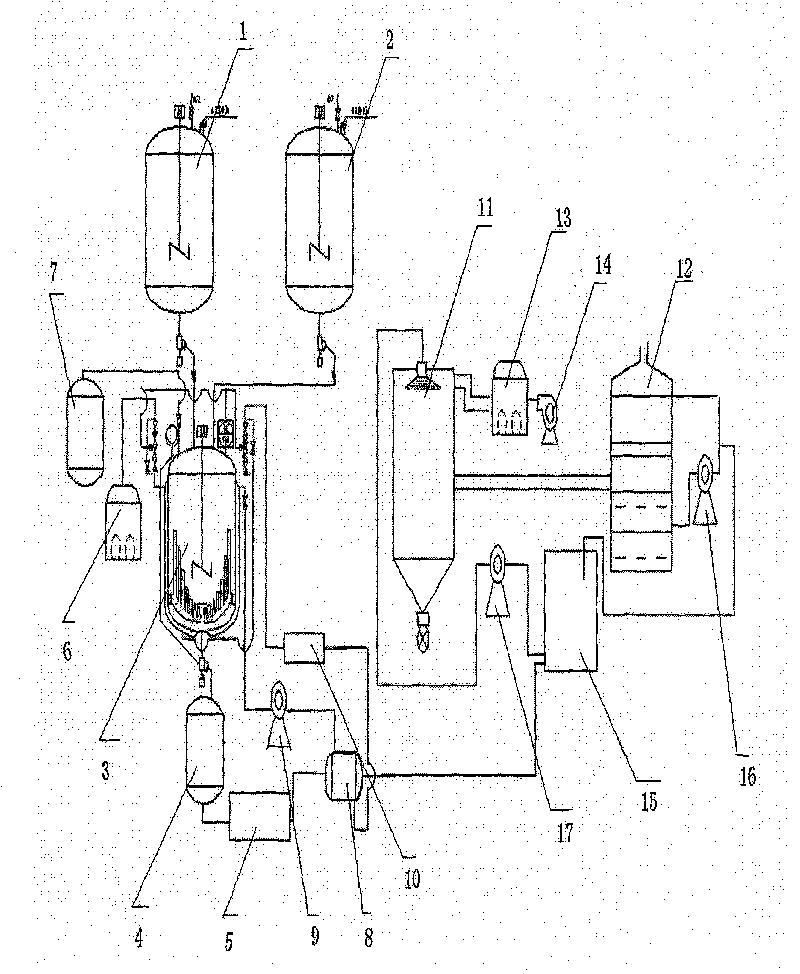

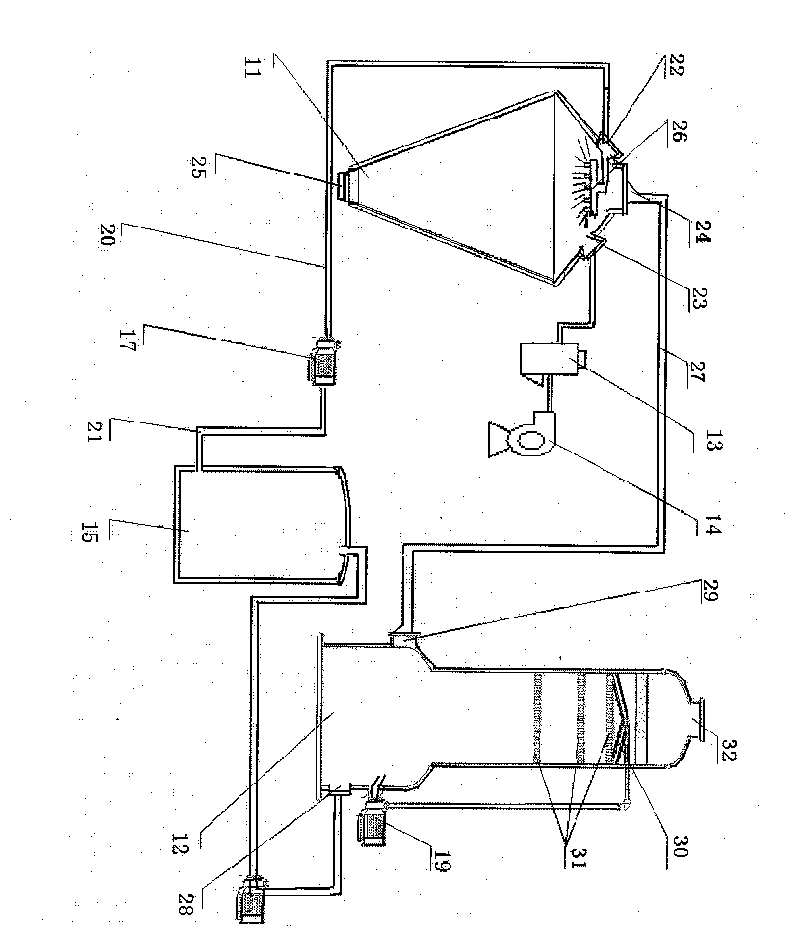

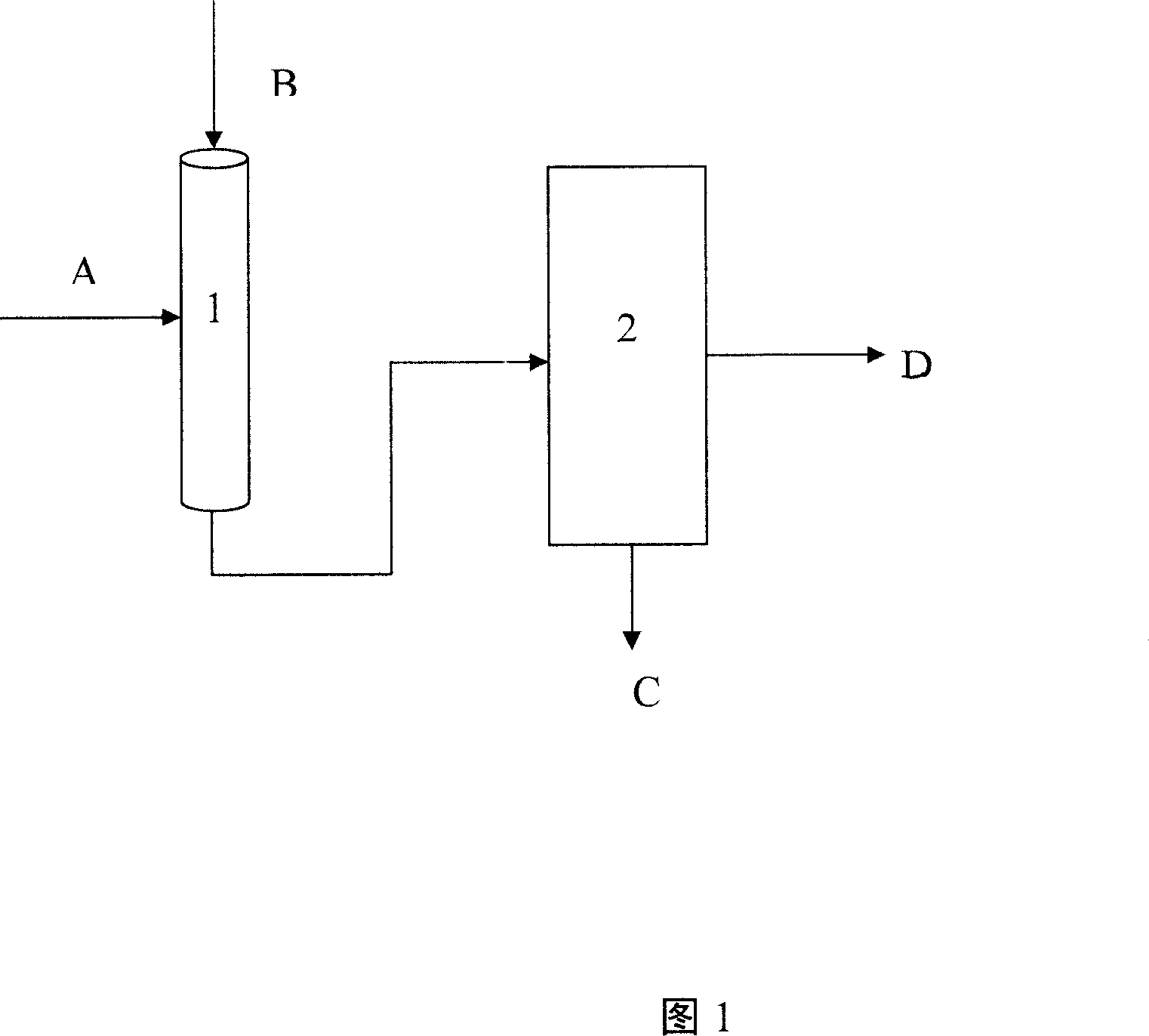

Device and method for preparing high-purity nano polyaluminium chloride with high efficiency, energy saving and environmental protection

InactiveCN101734703AEasy dischargeEfficient heat dissipationEnergy inputAluminium chloridesAluminium chlorohydrateProcess engineering

The invention relates to a device for utilizing the residual heat of tail gas in the production of polyaluminium chloride, which comprises a drying part of the liquid material of the polyaluminium chloride. The device is characterized in that the drying part of the liquid material of the polyaluminium chloride is provided with a drying tower 1 and a tail gas absorption tower 2, wherein a device for recovering the residual material of the tail gas and recycling the residual heat is arranged in the tail gas absorption tower 2; the utilization method of the device comprises a drying technology and a tail gas absorption technology. The method is characterized in that part of the liquid material is still in an atomization state after the liquid material is dried, and enters the tail gas absorption tower 2 along with the tail gas together, the circulation of the liquid material is carried out in the tail gas absorption tower 2 at any moment by a circulation pump 18, and the liquid material is heated and concentrated by the residual heat of the tail gas. The invention has the advantages that the liquid material is concentrated by utilizing the tail gas, the residual material and the residual heat of the tail gas are fully utilized, energy resources are saved, the mass output rate is enhanced, the discharge of the waste gas and the waste heat is reduced, the pollution is reduced, and the cost is lowered.

Owner:TIANJIN RUNWO WATER SUPPLY INSTALLATION ENG

Method for producing water treatment agent polyaluminium chloride from industrial waste residues

ActiveCN101445286AWide range of raw materialsSimple processWater/sewage treatment by flocculation/precipitationSlagProduced water

A method for producing water treatment agent polyaluminium chloride from industrial waste residues comprises the following steps: (1) calcining the admixture of bauxite, kaoline and coal slack for 2 to 4 hours; (2) crushing and screening; (3) adding 10 to 25 portions of screenings by weight into a reaction vessel and adding 15 to 25 portions of mixed waste acid liquor by weight; (4) agitating and heating to 100 to 150 DEG C for 2 to 5 hours; (5) adding 10 to 25 portions of the admixture of sulfur-iron slag, fly ashes and aluminum ashes by weight and simultaneously adding 20 to 35 portions of mixed waste acid liquid or 1 to 5 portions of sodium hypochlorite by weight; (6) heating to 80 to 130 DEG C for 2 to 4 hours; (7) heating 3 to 10 portions of calcium oxide saturated solution by weight, agitating and heating to 70 to 100 DEG C, and polymerizing for 1 to 3 hours; and (8) evaporating and filtering, and obtaining the water treatment agent polyaluminium chloride with the pH value of 3.0 to 5.5. The invention has the advantages of wide raw material source, simple process and lower cost.

Owner:常熟紫金知识产权服务有限公司

Method for reproduction by using polyaluminium chloride residue

InactiveCN101671047ACreate pollutionEmission reductionSolid waste disposalAluminium chloridesAluminium chlorohydratePolyaluminium chloride

The invention relates to a method for reproduction by using polyaluminium chloride residue, belonging to a chemical engineering method. The method comprises the following steps: a great amount of residue, generated in the production of polyaluminium chloride which is obtained by the reaction of bauxite or calcium aluminate powder with acid liquor, reacts with alkali liquor to extract the polyaluminium chloride. The method has the advantages of being reasonable in design, and capable of effectively recycling aluminium ion in residue, effectively lightening environmental pollution and saving theproduction cost.

Owner:倪明锋

Efficient environment-friendly flocculant for treatment of black-odor river

ActiveCN103922449AOdorlessRich sourcesWater/sewage treatment by flocculation/precipitationNeutral proteaseSludge

The invention discloses a novel efficient environment-friendly flocculant for the treatment of black-odor river. The flocculant comprises the following components in percentage by weight: 20-60% of PAC (Polyaluminium Chloride), 5-10% of unslaked lime, 5-10% of sodium carbonate, 10-30% of diatomaceous earth, 1-3% of chitosan, 2-5% of carboxymethyl starch (CMS), 1-3% of neutral protease and 10-25% of cement. the components of the flocculant disclosed by the invention are abundant, inexpensive, economical and environment-friendly; all the components are used together, the addition of the flocculant is small, the flocculant hardly affects the pH of the water and the original performances of the sludge in water are not changed; partially active heavy metals are cured, which is beneficial to increase of the activity of the sludge so that the self cleaning capacity of water bodies is greatly improved. The multiple functions such as adsorption, aggregation, chelation, curing and catalytic degradation are integrated into a whole to achieve a good treatment effect. The flocculated and settled water body is clear, transparent and odorless.

Owner:张爱均

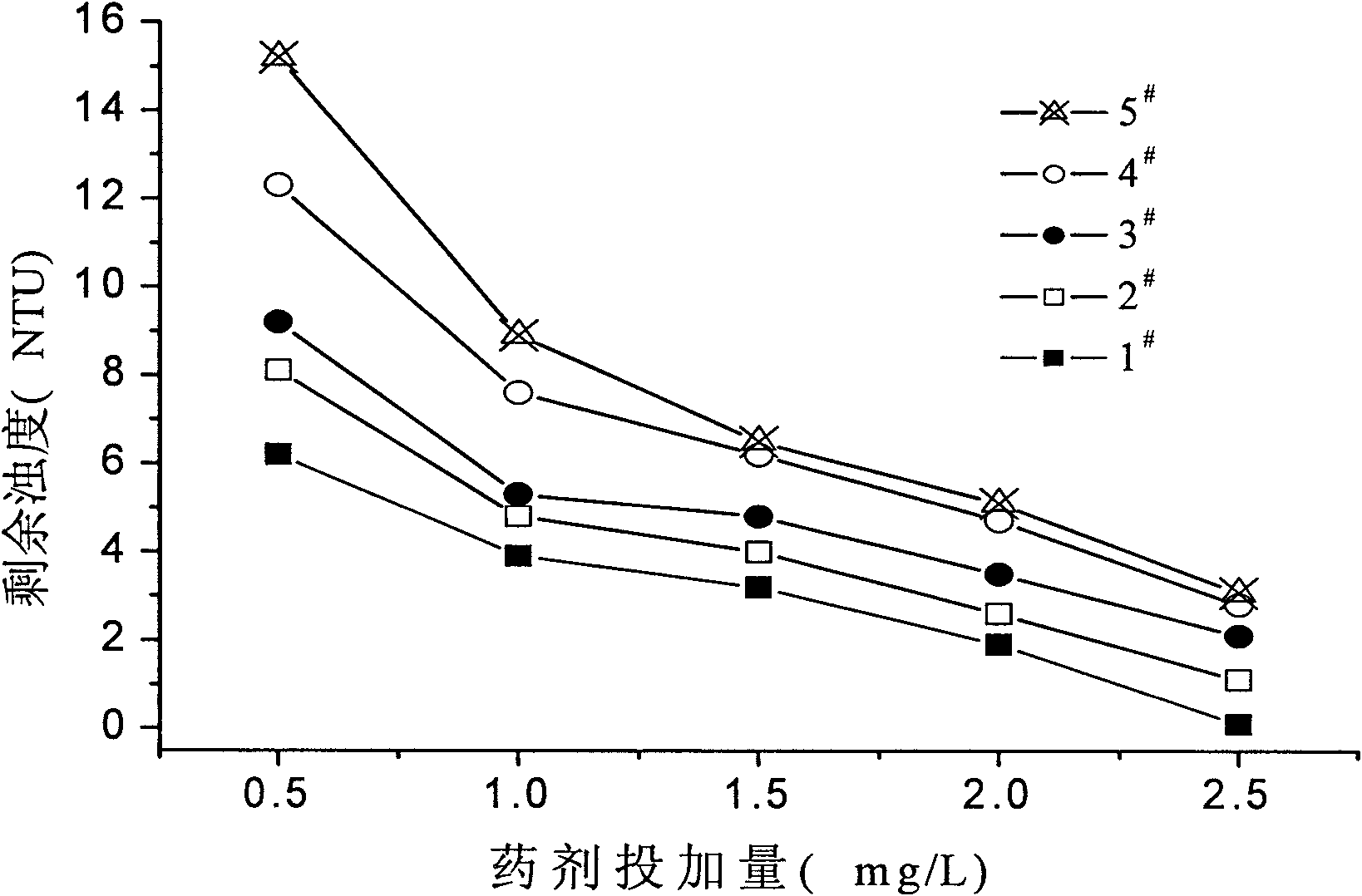

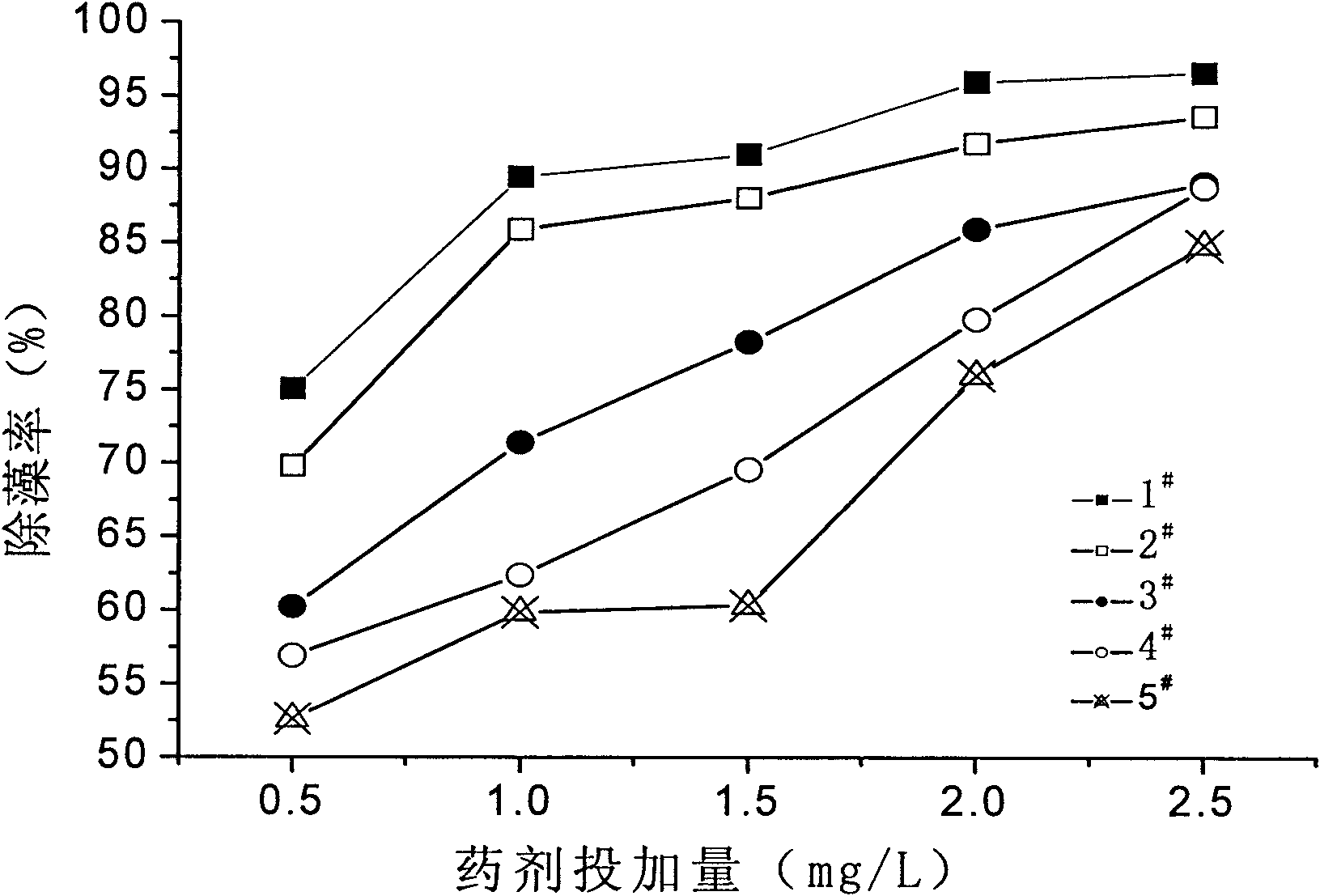

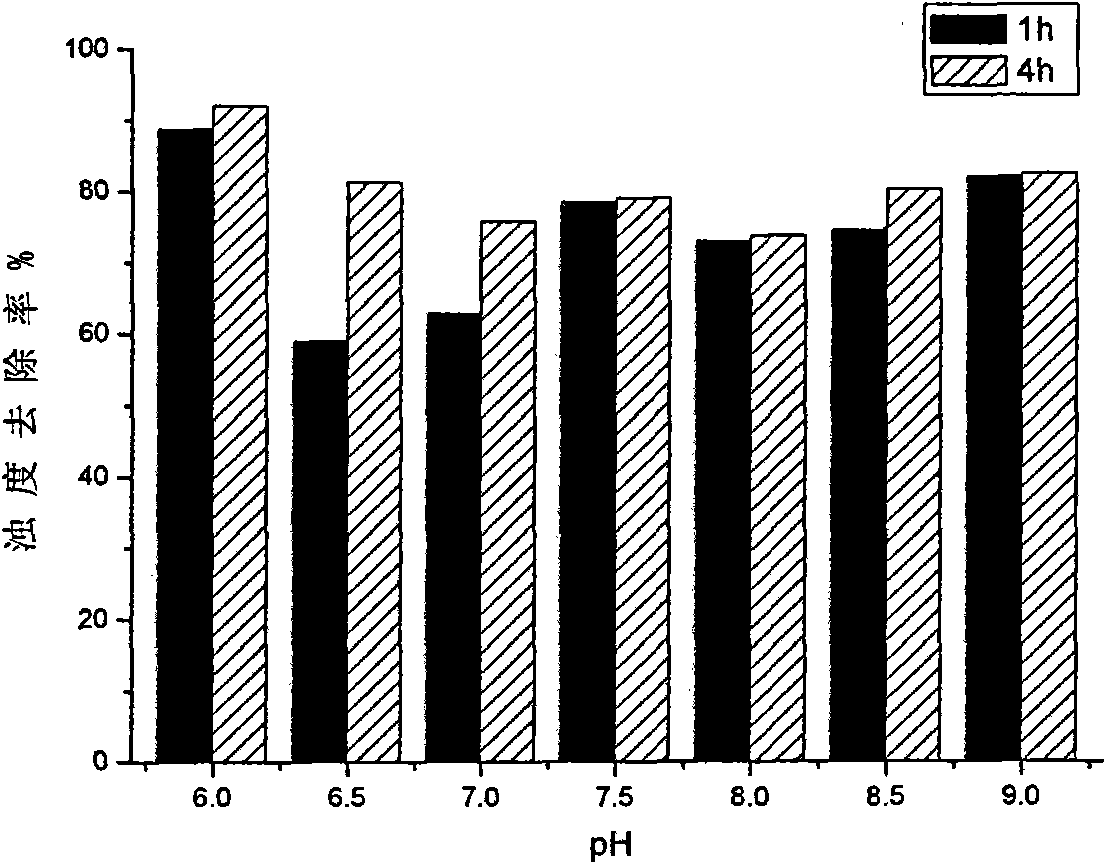

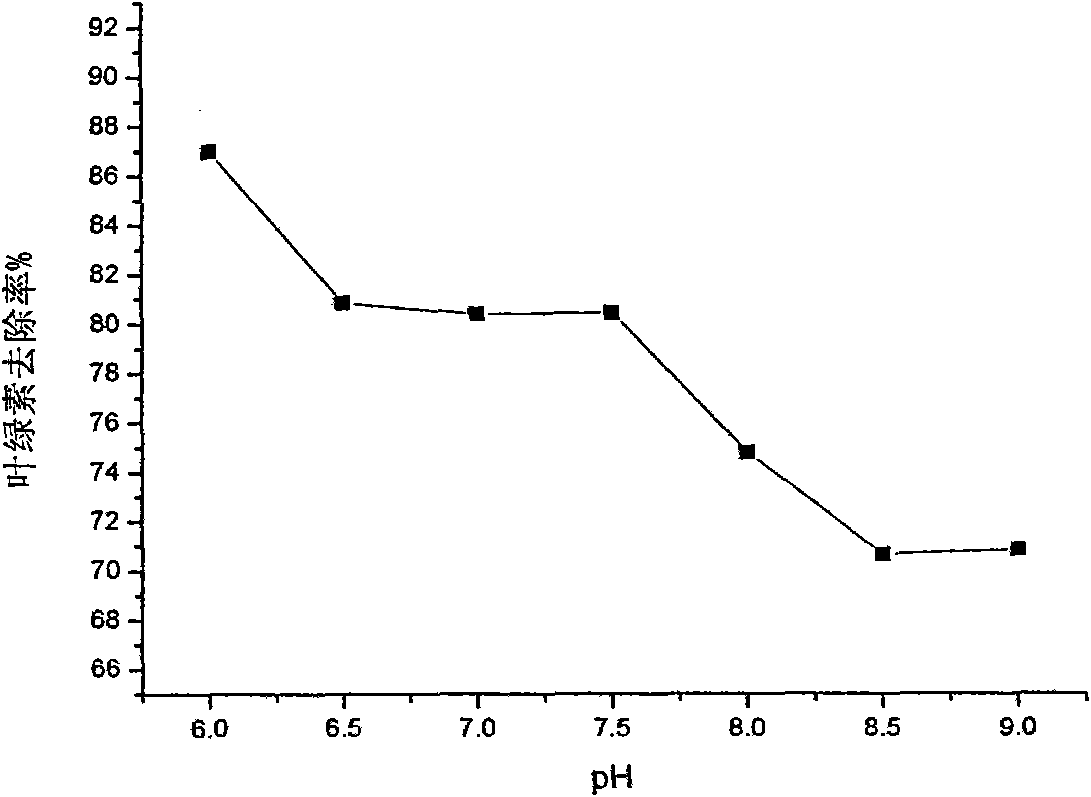

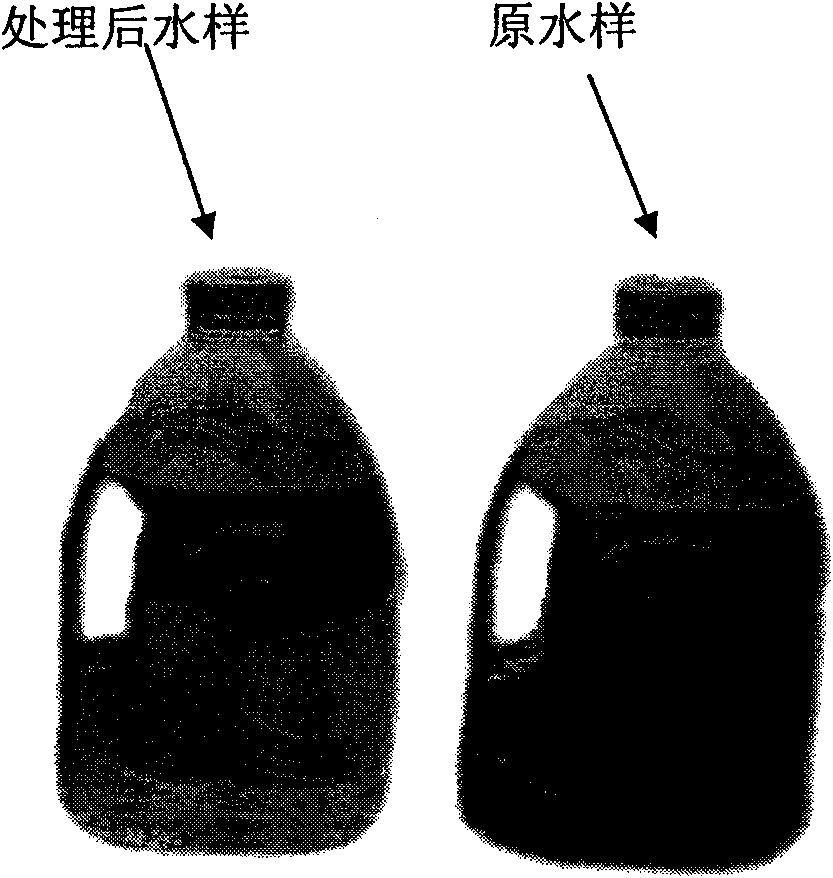

Algae-controlling laterite compound flocculant as well as preparation method and applications thereof

ActiveCN101643261ASimple structureChange single force modeWater/sewage treatment by flocculation/precipitationAluminium chlorideChlorophyll a

The invention discloses an algae-controlling laterite compound flocculant as well as a preparation method and applications thereof. The method comprises the following steps: mixing 64.52-86.42% of laterite, 7.41-19.35% of polyaluminium chloride and 6.17-16.13% of ferric trichloride, and then milling to obtain the algae-controlling laterite compound flocculant. Compared with the methods by independently adding ferric trichloride or polyaluminium chloride, the algae-controlling laterite compound flocculant can obtain higher turbidity and higher chlorophyll a clearance rate, i.e. favorable effects for clearing algae and purifying water. Furthermore, with similar turbidity and chlorophyll a clearance rate, the quantities of the polyaluminium chloride and the ferric trichloride contained in thealgae-controlling laterite compound flocculant are lower than those of the polyaluminium chloride and the ferric trichloride which are independently used so as to save the cost and enhance the safetyof the flocculant in utilization. The algae-controlling laterite compound flocculant has the advantages of simple preparation procedure, moderate cost and favorable effects for clearing algae and purifying water, and is especially suitable for water bloom emergency treatment.

Owner:JINAN UNIVERSITY

Preprocessing method for coking wax oil used as hydrocracking raw material

ActiveCN101144031ATo achieve the processing effectReduce the temperatureRefining with acid-containing liquidsHydrocarbon oil crackingPhosphorous acidPretreatment method

The invention relates to a pretreatment method for hydrocracking raw material to improve the processing property of coker gas oil to be equivalent with straight-run refining wax oil through remove polar impurities, such as coke powder, colloid, heterocyclic benzenoid, and basic nitrogen compound, from coker gas oil, which includes the following steps: the pretreatment agent and the coker gas oil are mixed under 20-120 DEG C according to 0.1-10 percent by weight proportion; the pretreatment agent includes 49-89 percent of active components, such as hydrochloric acid, nitric acid, perchloric acid, sulfuric acid, phosphorous acid or phosphorous anhydride; 10-50 percent of cosolvents, such as ferric chloride, glycerol, ethylene glycol or DMF; and 0.1-10 percent one or more of polyacrylamide, polyaluminium chloride, polymeric aluminum ferric chloride, sodium meta-aluminate, sodium sulfate, sulfuric acidaluminum, aluminum potassium sulfate, and sodium silicate; the mixed materials are gravity settled in a settling tank, the sedimentation temperature is 60-150 DEG C, and the time is 30-120min, refined coker gas oil can be directly blended into hydrocracking device to decrease the initial temperature of hydrocracking prerefining section by more than 10 DEG C or improve the device processing capacity by more than 30 percent.

Owner:PETROCHINA CO LTD +1

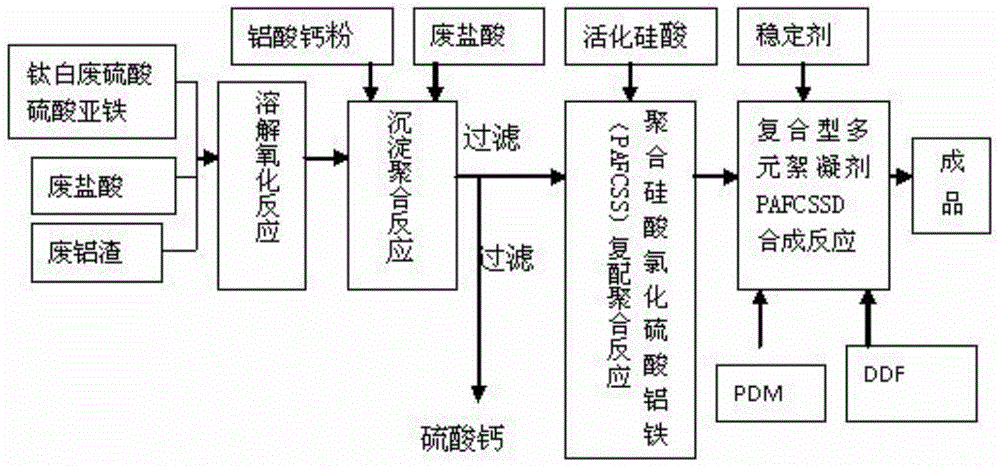

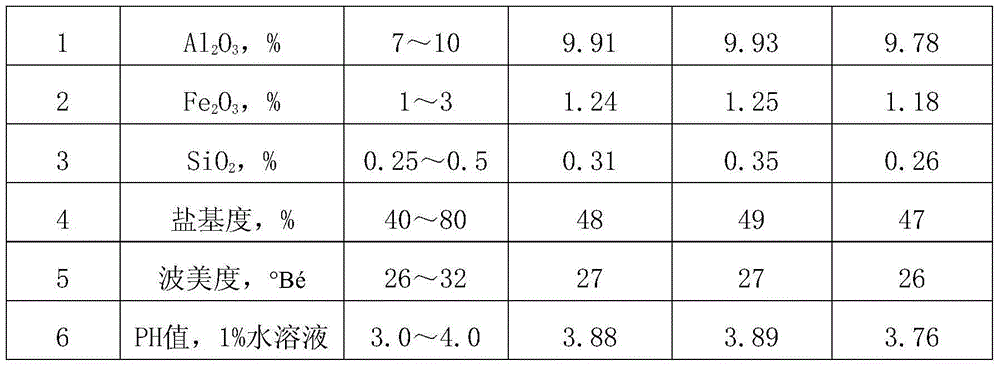

Method for preparing compound type multi-element flocculating agent aluminum ferric sulfate chloride polysilicate by utilizing waste acid

ActiveCN104085969AReduce moisture contentEasy to chargeWater/sewage treatment by flocculation/precipitationTreatment effectSlag

The invention relates to a method for preparing a compound type multi-element flocculating agent aluminum ferric sulfate chloride polysilicate. The method comprises the following 4 steps of: dissolving and oxidizing; precipitation polymerization and filtering; compound polymerization; synthesis of the aluminum ferric sulfate chloride polysilicate. The method disclosed by the invention can be used for producing the compound type multi-element flocculating agent aluminum ferric polysilicate by integrally utilizing the waste sulfuric acid liquor, ferrous sulfate heptahydrate, waste aluminum slag and waste hydrochloric acid liquor of a titanium dioxide plant, a chemical plant and a steel and ion plant in a recycling way. The prepared flocculating agent can be widely applied to the treatment of domestic sewage and industrial wastewater, has higher turbidity, color and COD removing capacity compared with the treatment effect of polyaluminium chloride and polyaluminum ferric chloride and has the advantages of high floc forming velocity, large and compact floc, high sedimentation velocity and small sedimentary sludge size.

Owner:GUANGXI PINGGUO FENGHUA TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com