Processing mthod of white water from paper making

A technology for papermaking white water and treatment method, which is applied in papermaking, processing wastewater treatment, water/sewage multi-stage treatment, etc. Strong ability, good hydrophilicity, and the effect of reducing white water turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

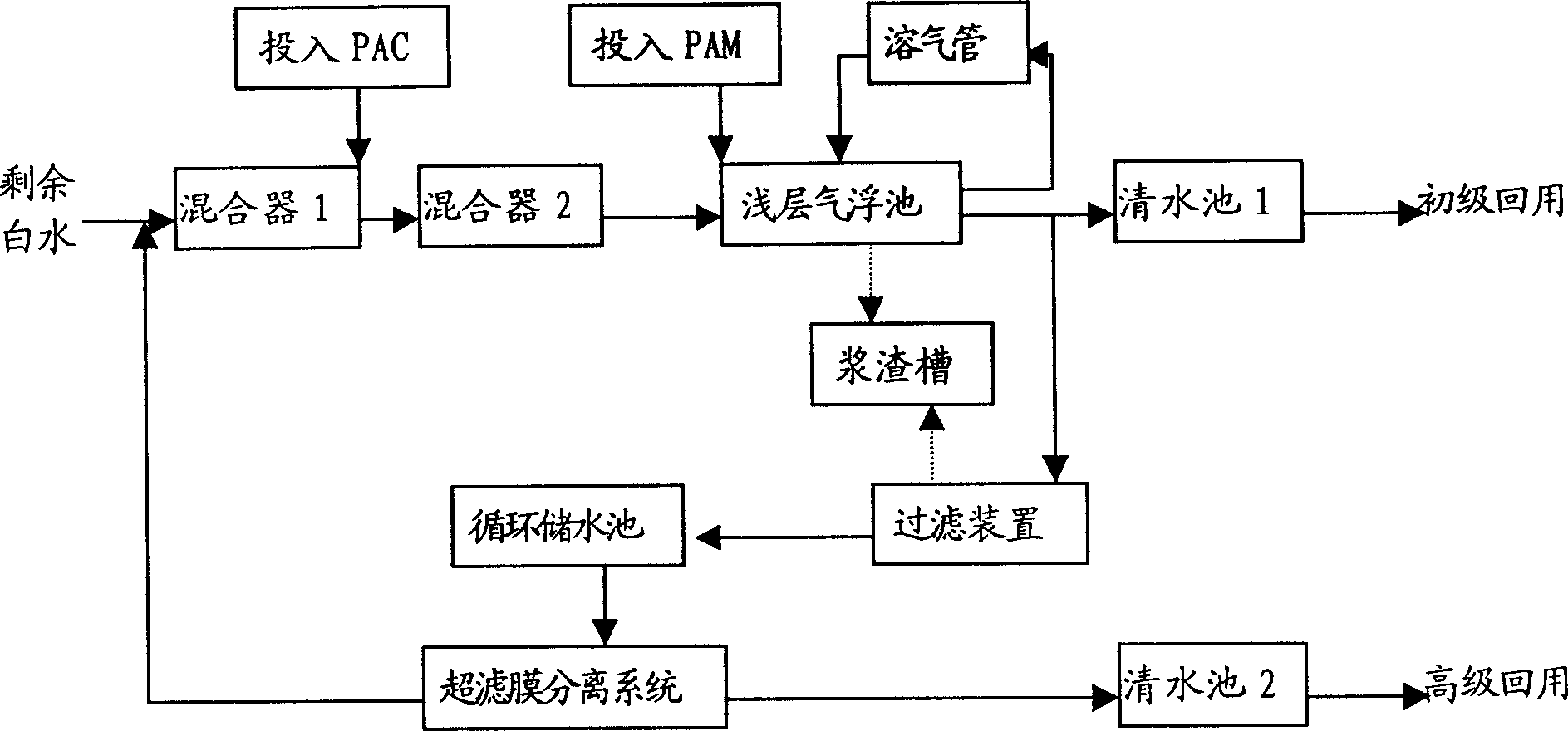

Method used

Image

Examples

Embodiment 1

[0032] The treated white water comes from the secondary recycled white water of a banknote paper mill.

[0033] 1. Treated water volume and water quality

[0034] ①Treated water volume: 3000m 3 / d;

[0035] ②Influent water quality: SS40~150mg / L, COD50~200mg / L, pH value around 7.0, turbidity 200~1000NTU.

[0036] 2. Main equipment configuration and process parameters

[0037] ①First and second mixer: φ300mm, length 500mm;

[0038] ② Shallow air flotation water purifier: CQJ-6 type (Wuxi Jiangchuan Engineering Complete Equipment Co., Ltd.), φ6m;

[0039] ③ Clean water pump: 150FR-35 type, power 30KW, head 35m, maximum flow 200m 3 / h;

[0040] ④White water pump: 100WD type, power 15KW, head 15m, maximum flow 140m 3 / h;

[0041] ⑤ Dissolved air water return pump: IS80-50-250A type, power 18.5KW / 22KW, head 64.5m / 80m, maximum flow 45m 3 / h;

[0042] ⑥ Cationic PAM dispensing device: power 2.2KW, speed 1420r / min, transmission ratio 1:11, PAM from Mitsubishi, Japan, molecula...

Embodiment 2

[0052] The air flotation effluent that embodiment 1 obtains is implemented advanced treatment:

[0053] 1. Capacity: 25m 3 / d.

[0054] 2. Main equipment

[0055] ①Water storage tank (circulating storage tank)∮600mm*1000mm;

[0056] ②Circulation pump (stainless steel centrifugal pump), Q60~260L / min;

[0057] ③Ultrafiltration membrane module: PS-PEK hollow fiber ultrafiltration membrane with single skin structure, packing area 4m 2 , the membrane pore size is 0.01-0.1 μm, that is, the molecular weight of the intercepted substance is 60000-70000;

[0058] ④ One set of control system and one set of water inlet and outlet rotameters.

[0059]3. Process

[0060] The effluent treated by air flotation (such as the effluent of Example 1) passes through the filtrate after the rotary filter device, with a certain speed and pressure (inlet pressure 0.13 ~ 0.15Mpa, outlet pressure is 0.10 ~ 0.12Mpa) from the ultrafiltration membrane One end of the separator enters, and water and sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com